A kind of iron-based porous adsorption material and its preparation method and application in wastewater treatment

A porous adsorption material and wastewater treatment technology, applied in the field of materials, can solve the problems of difficult regeneration and high cost of chemicals, and achieve the effects of sustainable operation, easy operation and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

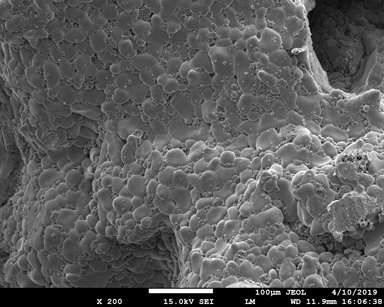

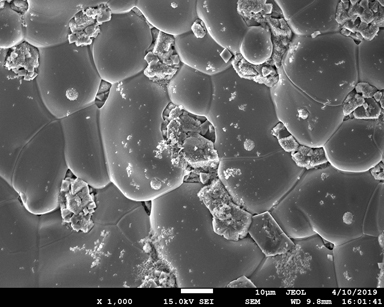

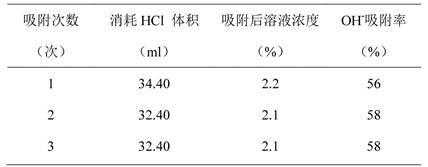

Image

Examples

Embodiment 1

[0026] A kind of iron-based porous adsorption material of the present embodiment is mainly composed of Fe 2 o 3 and carbon black as raw materials, the content of elemental iron in the iron-based porous adsorption material is 62%, Fe 2+ with Fe 3+ The content of carbon is 34%, and the content of elemental carbon is 4%.

[0027] A kind of preparation method of iron-based porous adsorption material of the present embodiment, comprises the following steps:

[0028] (1) Material preparation: Fe 2 o 3 Weigh the two raw materials according to the molar ratio of 1:0.3 with carbon black, and add the pore-forming agent CaCl to the above-mentioned raw materials 2 , the mass of the pore-forming agent is Fe 2 o 3 1 / 26 of the total weight of carbon black; then add steel balls to the ball mill tank according to the material-ball ratio of 5:1, set the running time to 5h, and the rotating speed to 400r / h, and start the planetary ball mill for grinding;

[0029] (2) Sample preparation: ...

Embodiment 2

[0042] A kind of iron-based porous adsorption material of the present embodiment is mainly composed of Fe 2 o 3 and carbon black as raw materials, the content of elemental iron in the iron-based porous adsorption material is 51%, Fe 2+ with Fe 3+ The content of carbon is 48%, and the content of elemental carbon is 1%.

[0043] A kind of preparation method of iron-based porous adsorption material of the present embodiment, comprises the following steps:

[0044] (1) Material preparation: Fe 2 o 3 Take two kinds of raw materials according to the molar ratio of 1:0.225 with carbon black, add pore-forming agent CaCl to the above-mentioned raw materials 2 , the mass of the pore-forming agent is Fe 2 o 3 1 / 30 of the total weight of carbon black; then add steel balls to the ball mill tank according to the material-ball ratio of 4:1, set the running time to 4h, and the rotating speed to 500r / h, and start the planetary ball mill for grinding;

[0045] (2) Sample preparation: pa...

Embodiment 3

[0049] A kind of iron-based porous adsorption material of the present embodiment is mainly composed of Fe 2 o 3 and carbon black as raw materials, the content of elemental iron in the iron-based porous adsorption material is 68%, Fe 2+ with Fe 3+ The content of carbon is 25%, and the content of elemental carbon is 7%.

[0050] A kind of preparation method of iron-based porous adsorption material of the present embodiment, comprises the following steps:

[0051] (1) Material preparation: Fe 2 o 3 Take two kinds of raw materials according to the molar ratio of 1: 0.325 with carbon black, add pore-forming agent CaCl in the above-mentioned raw materials 2 , the mass of the pore-forming agent is Fe 2 o 3 1 / 20 of the total weight of carbon black; then add steel balls to the ball mill tank according to the material-ball ratio of 4:1, set the running time to 5h, and the rotating speed to 500r / h, and start the planetary ball mill for grinding;

[0052] (2) Sample preparation: p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com