Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2008results about "Diaphragm mounting/tensioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

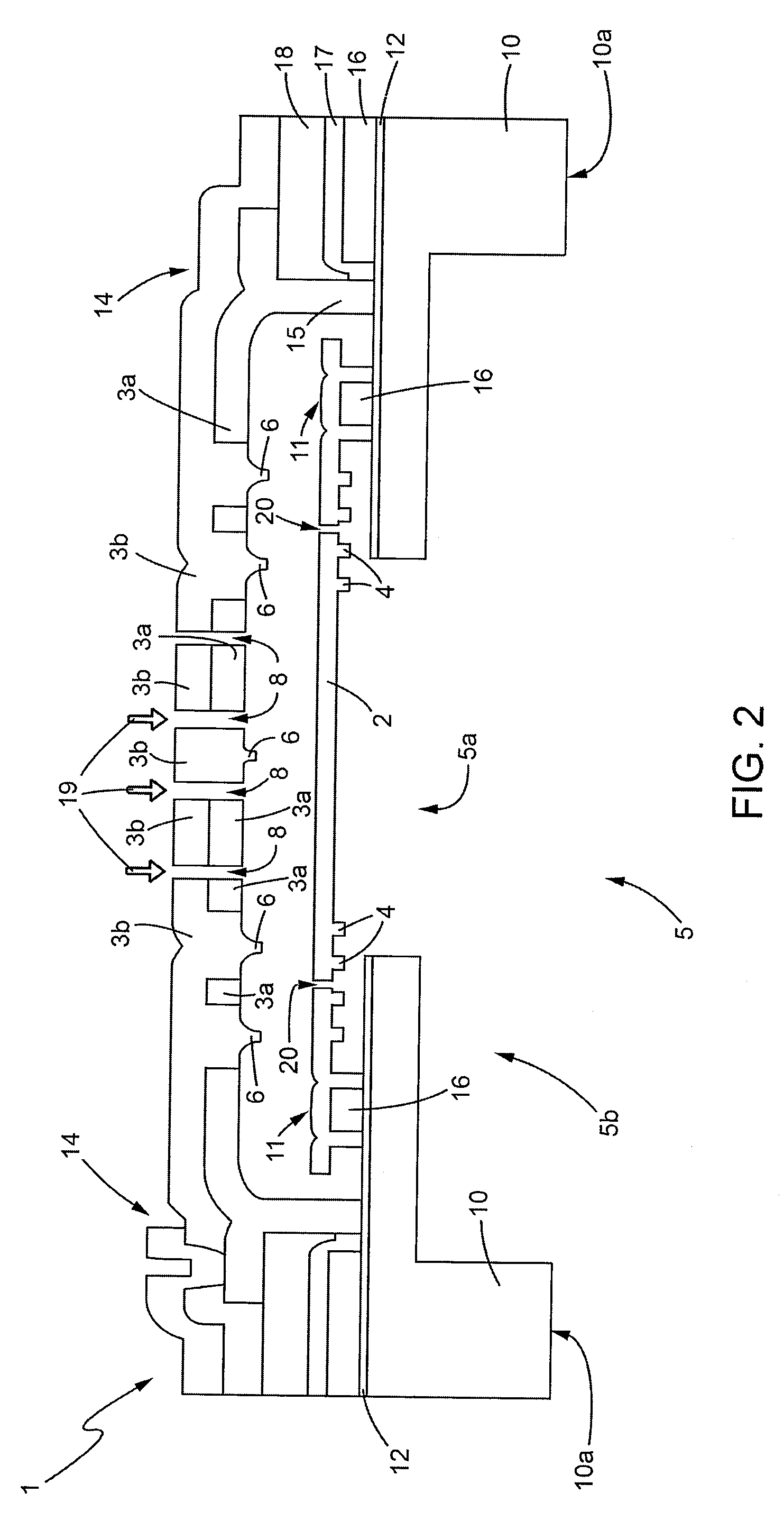

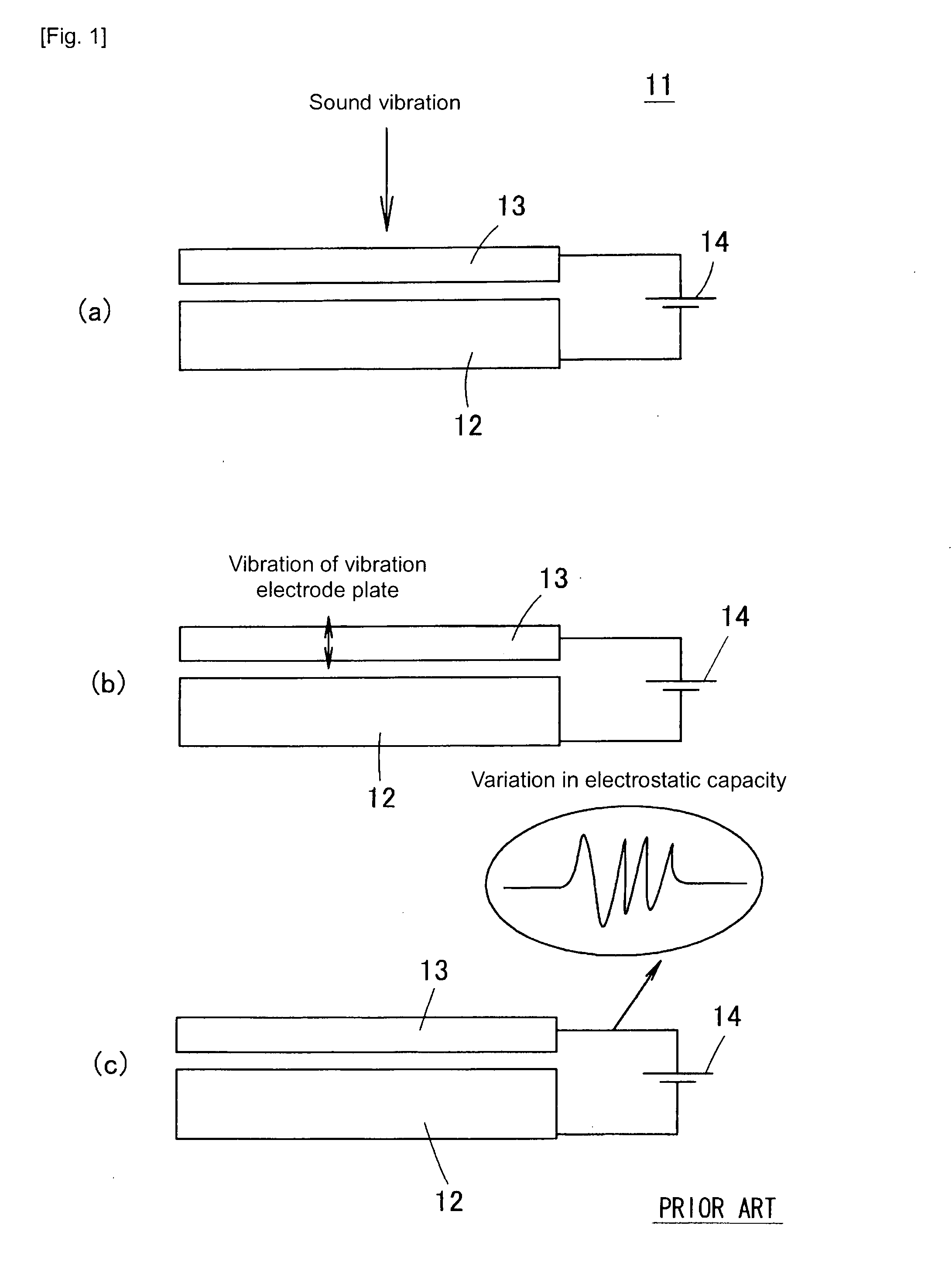

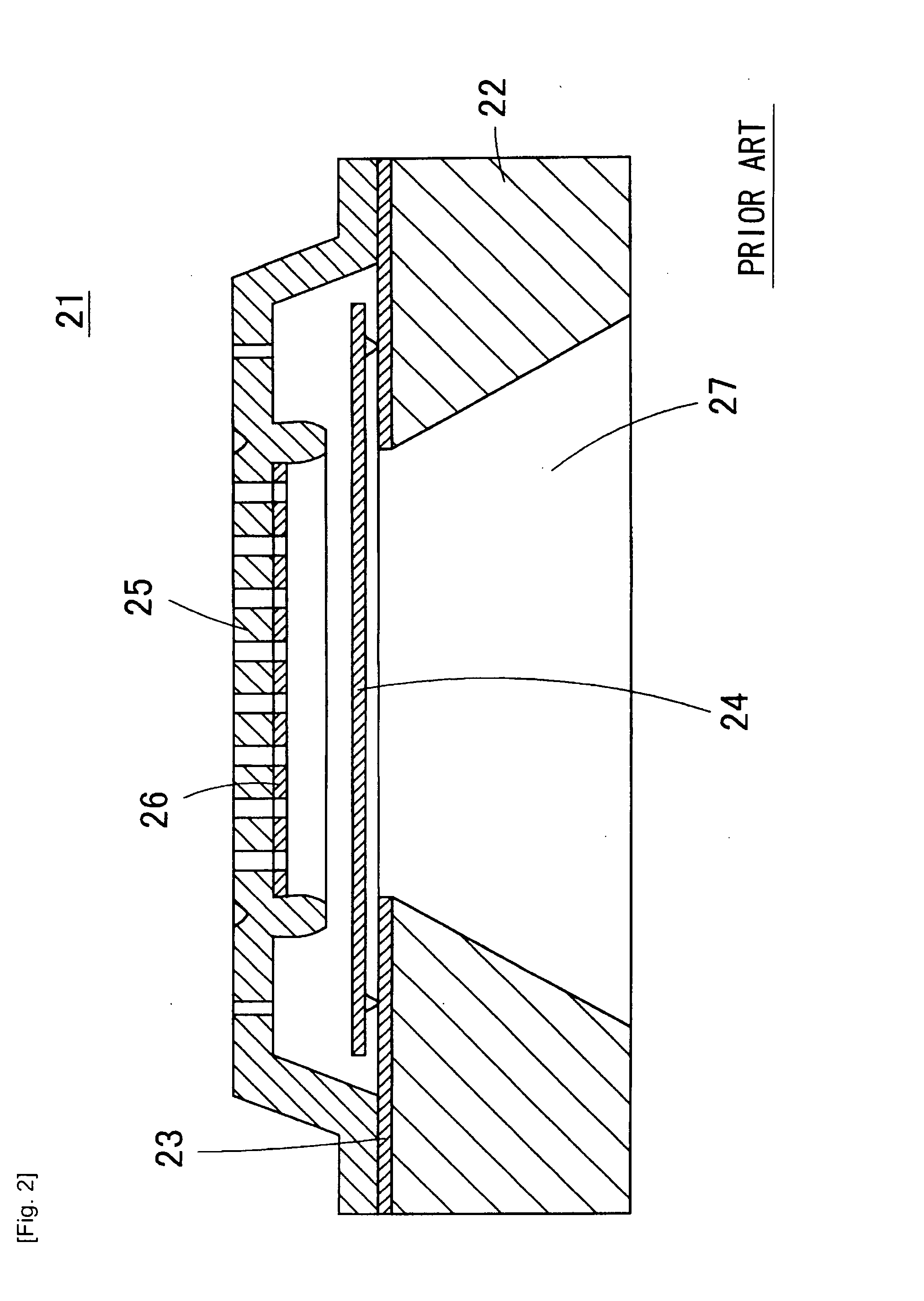

MEMS process and device

InactiveUS7781249B2NanotechSemiconductor/solid-state device testing/measurementEngineeringAcoustic wave

Owner:CIRRUS LOGIC INC

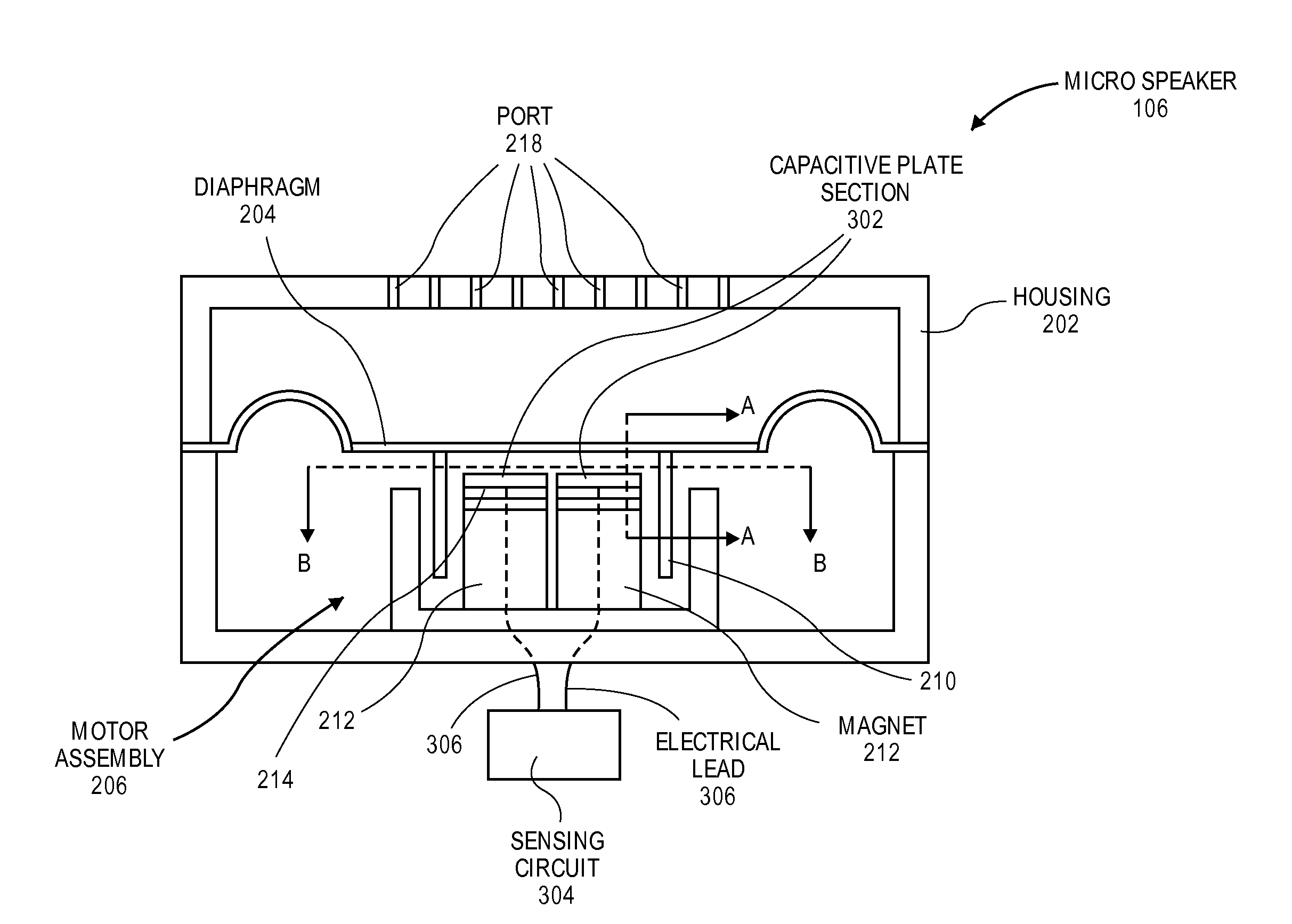

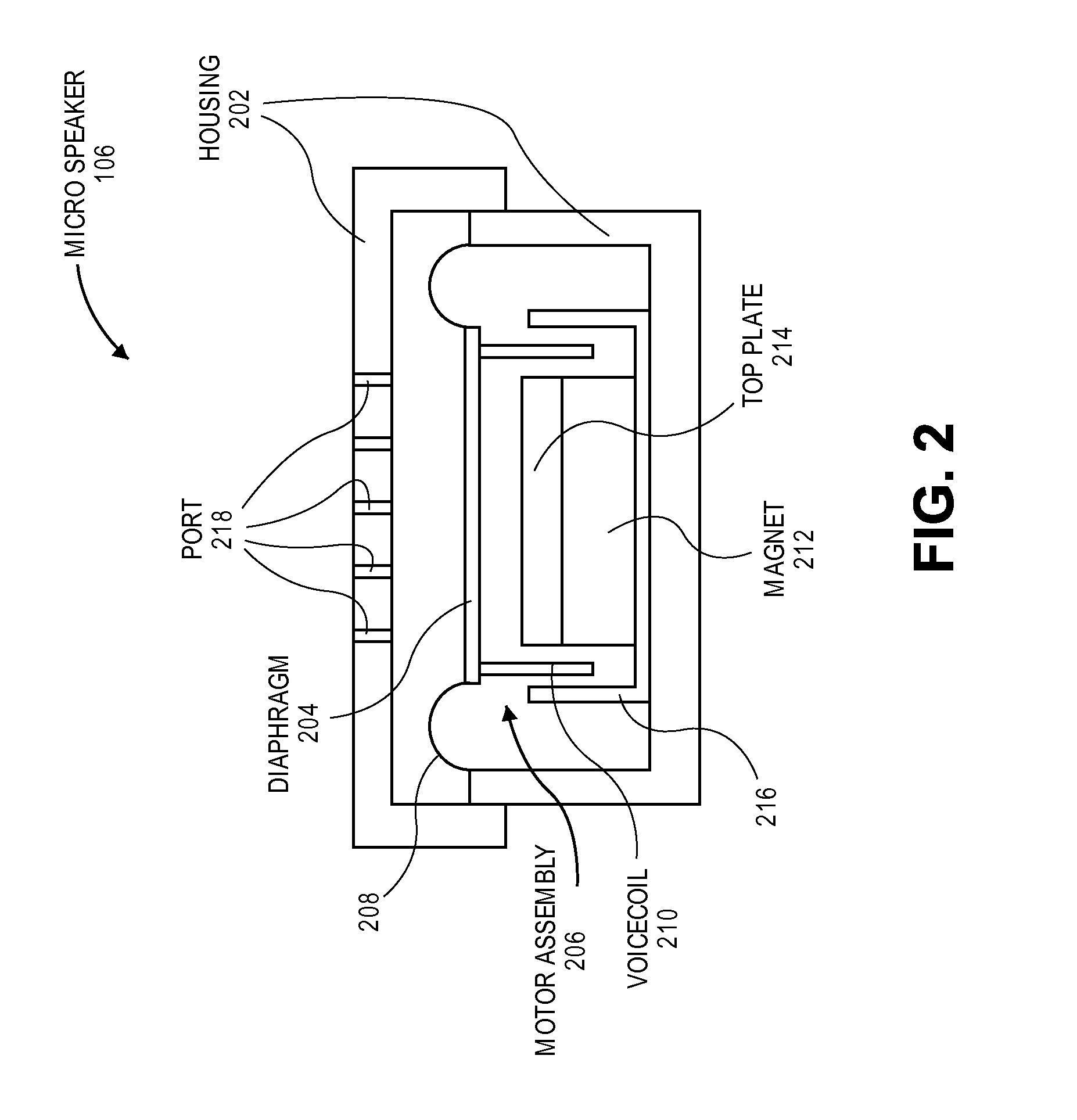

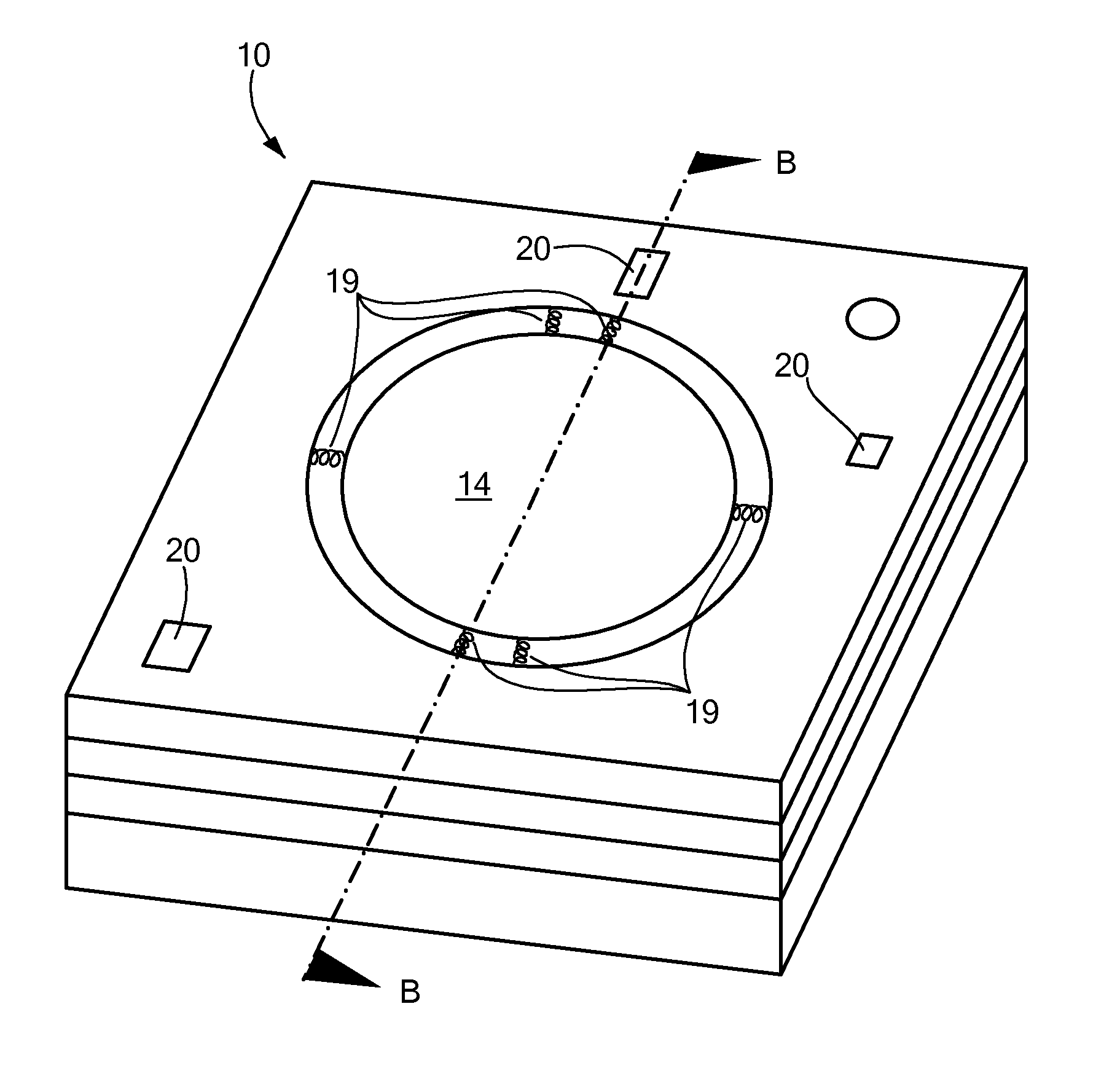

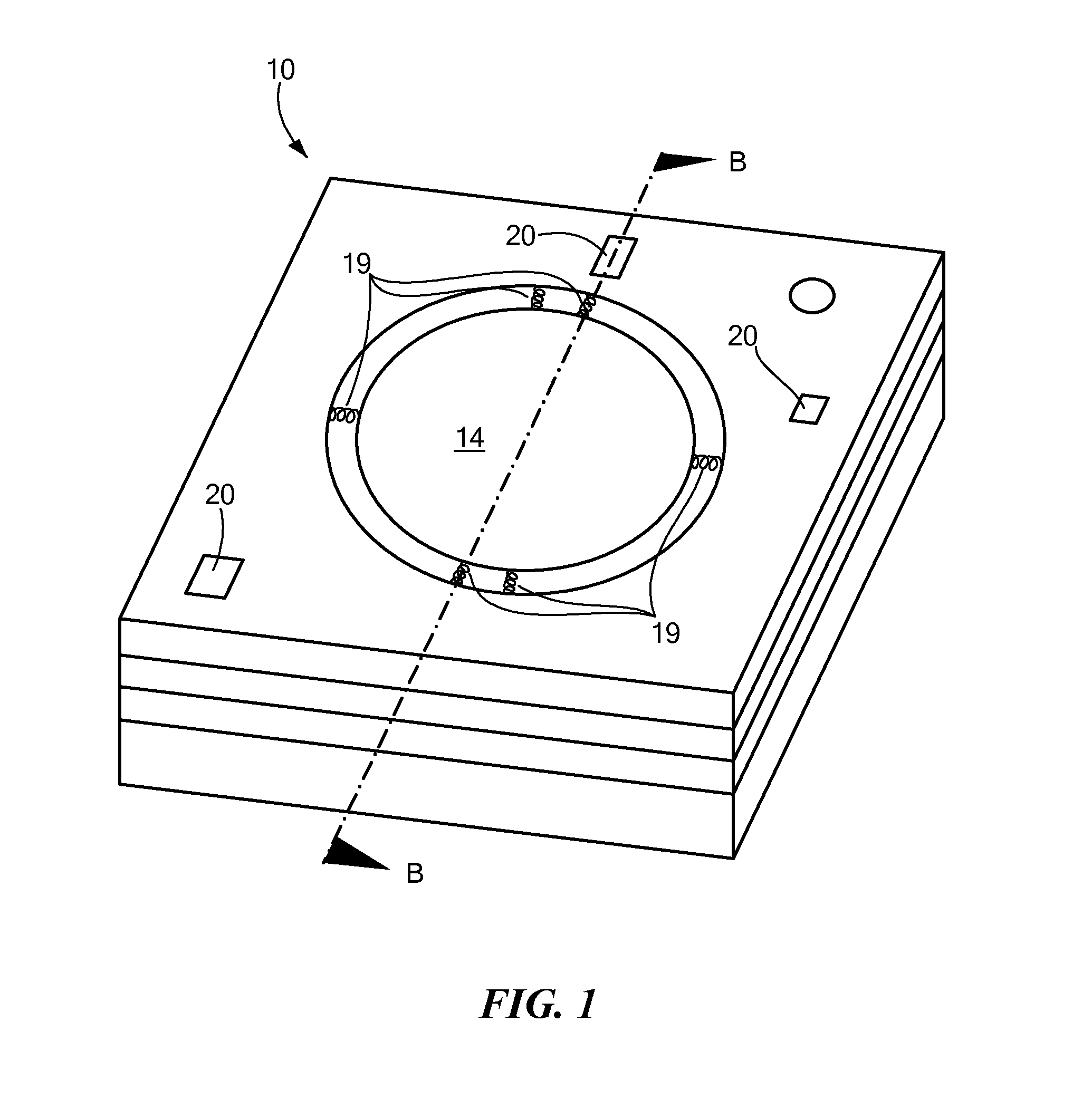

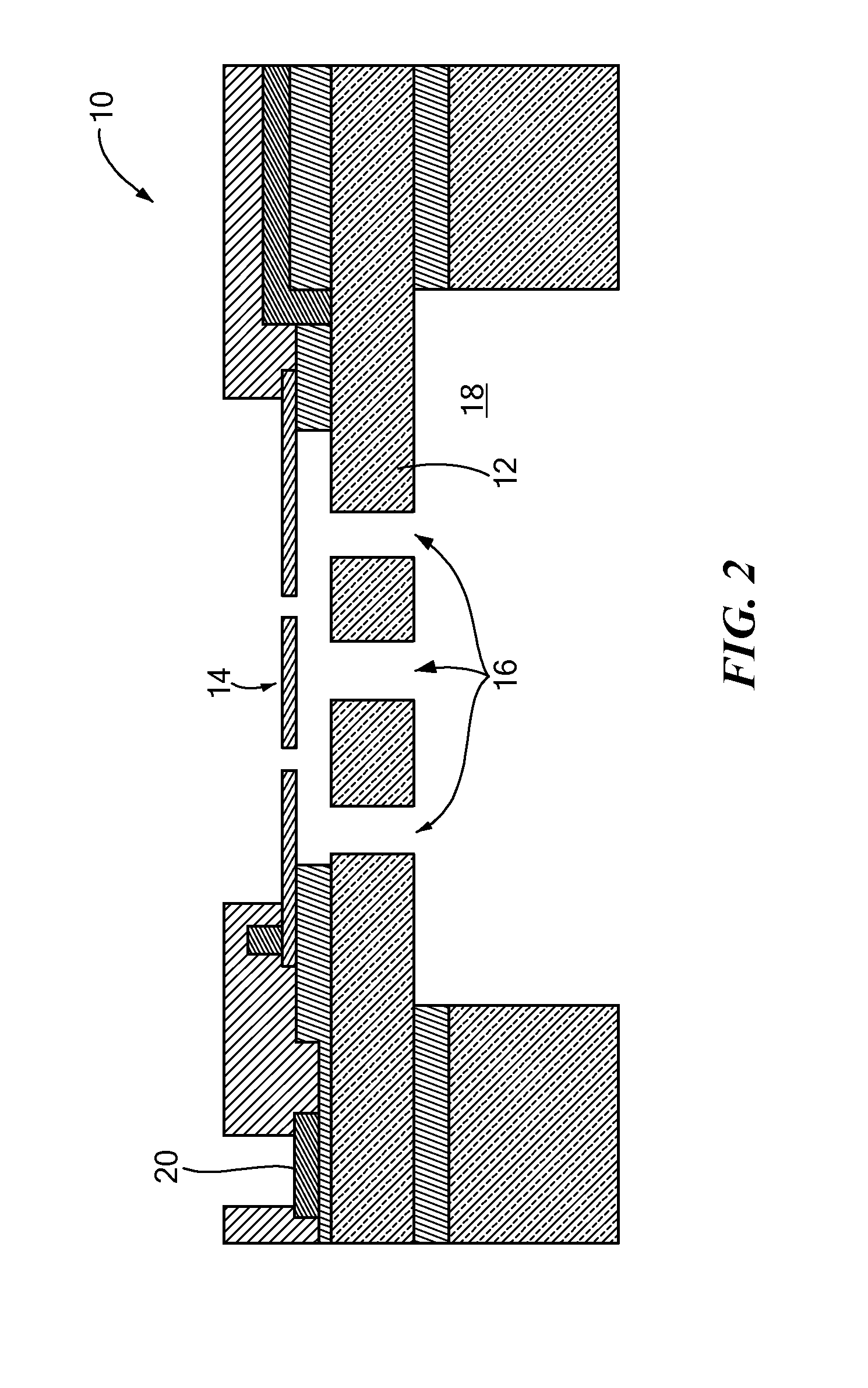

Capacitive position sensing for transducers

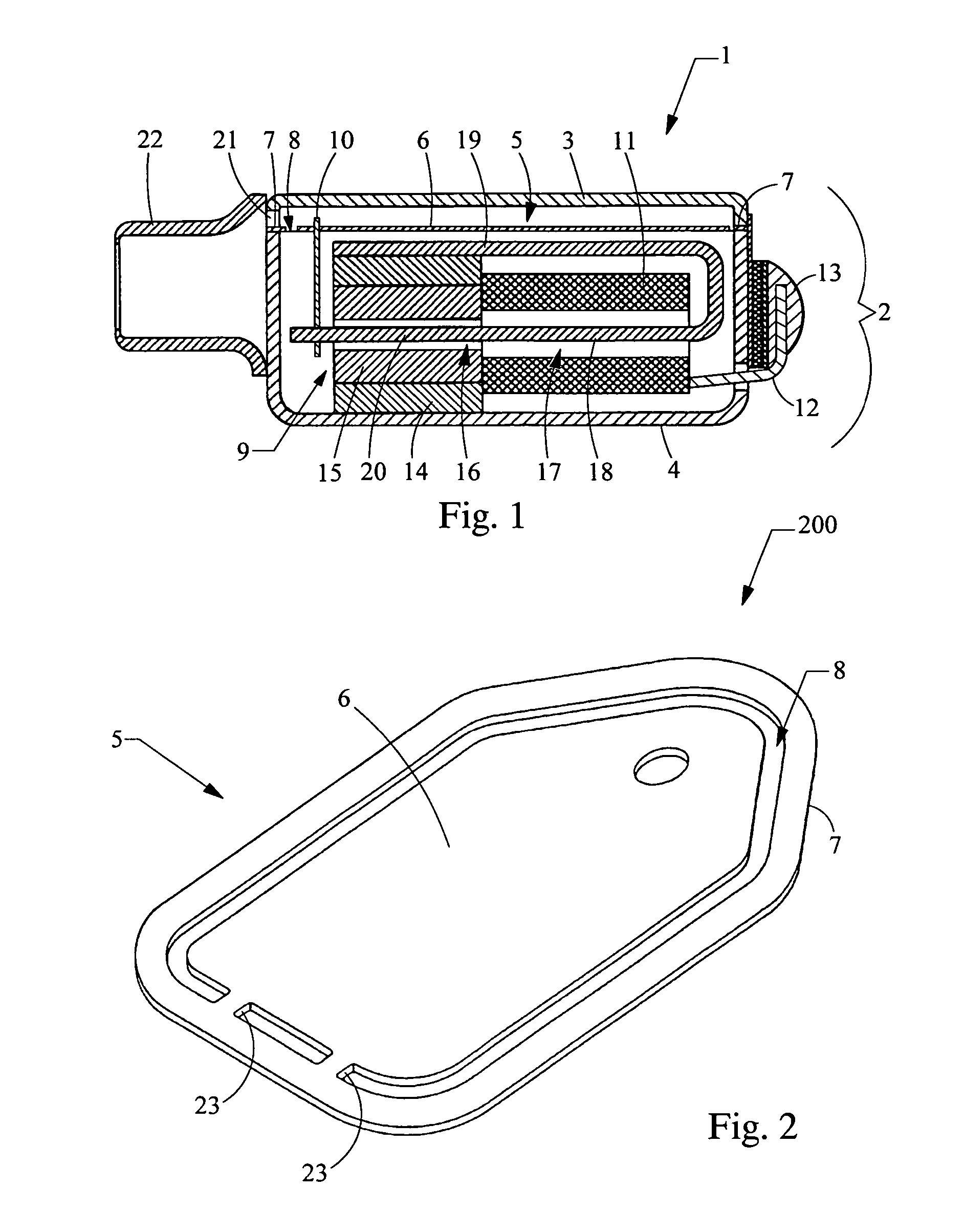

ActiveUS20160094917A1Avoid speaker damageReduce and eliminate non-axial rocking motionTransducer protection circuitsDiaphragm mounting/tensioningEngineeringLoudspeaker

A micro speaker having a capacitive sensor to sense a motion of a speaker diaphragm, is disclosed. More particularly, embodiments of the micro speaker include a conductive surface of a diaphragm facing conductive surfaces of several capacitive plate sections across a gap. The diaphragm may be configured to emit sound forward away from a magnet of the micro speaker, and the capacitive plate sections may be supported on the magnet behind the diaphragm. In an embodiment, the gap provides an available travel for the diaphragm, which may be only a few millimeters. A sensing circuit may sense capacitances of the conductive surfaces to limit displacement of the diaphragm to within the available travel.

Owner:APPLE INC

Integrated acoustic transducer obtained using MEMS technology, and corresponding manufacturing process

ActiveUS20100158279A1Semiconductor electrostatic transducersElectrostatic transducer microphonesTransducerEngineering

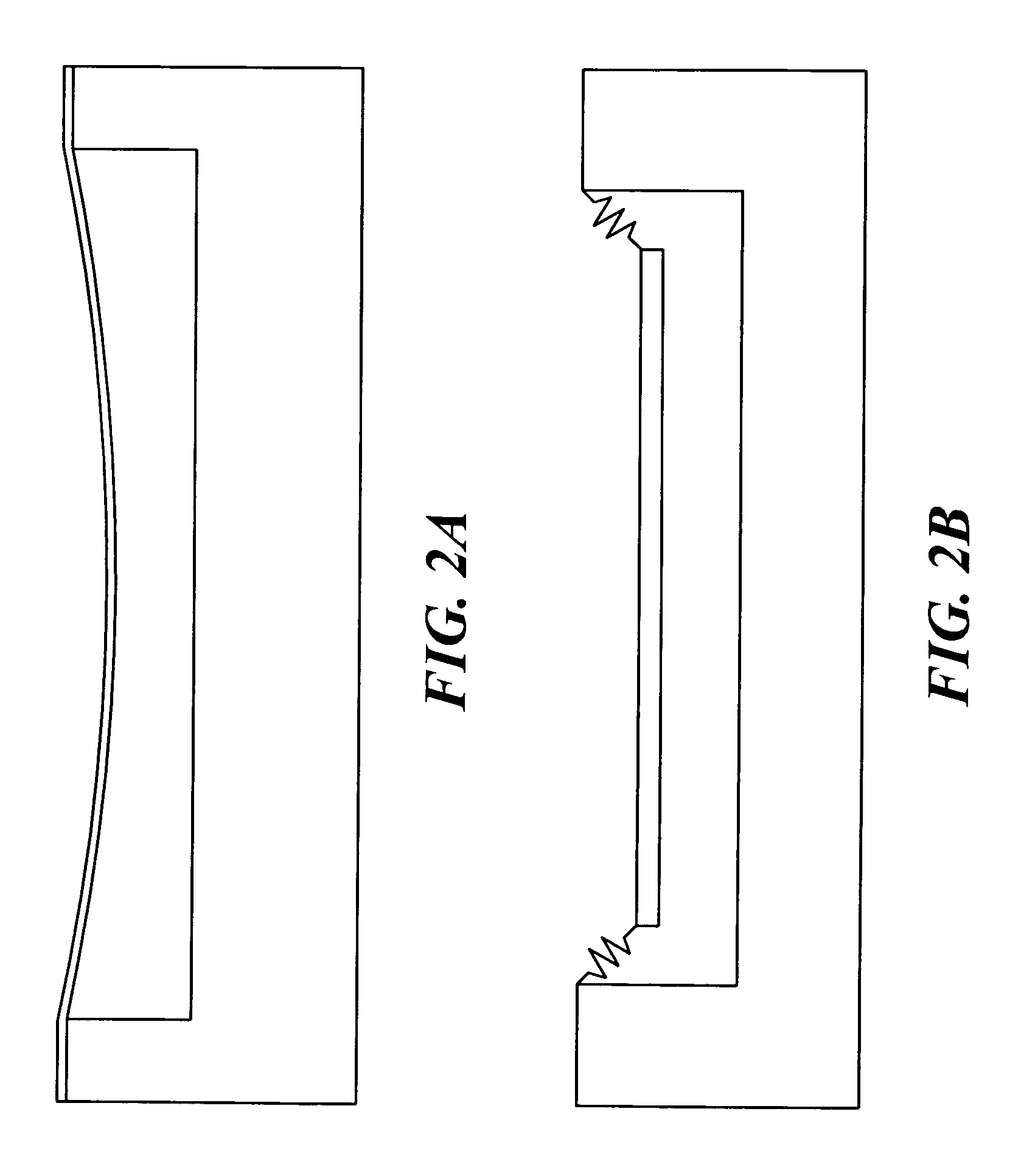

A MEMS acoustic transducer provided with a substrate having cavity, and a membrane suspended above the cavity and fixed peripherally to the substrate, with the possibility of oscillation, through at least one membrane anchorage. The membrane comprises at least one spring arranged in the proximity of the anchorage and facing it, and is designed to act in tension or compression in a direction lying in the same plane as said membrane.

Owner:STMICROELECTRONICS SRL

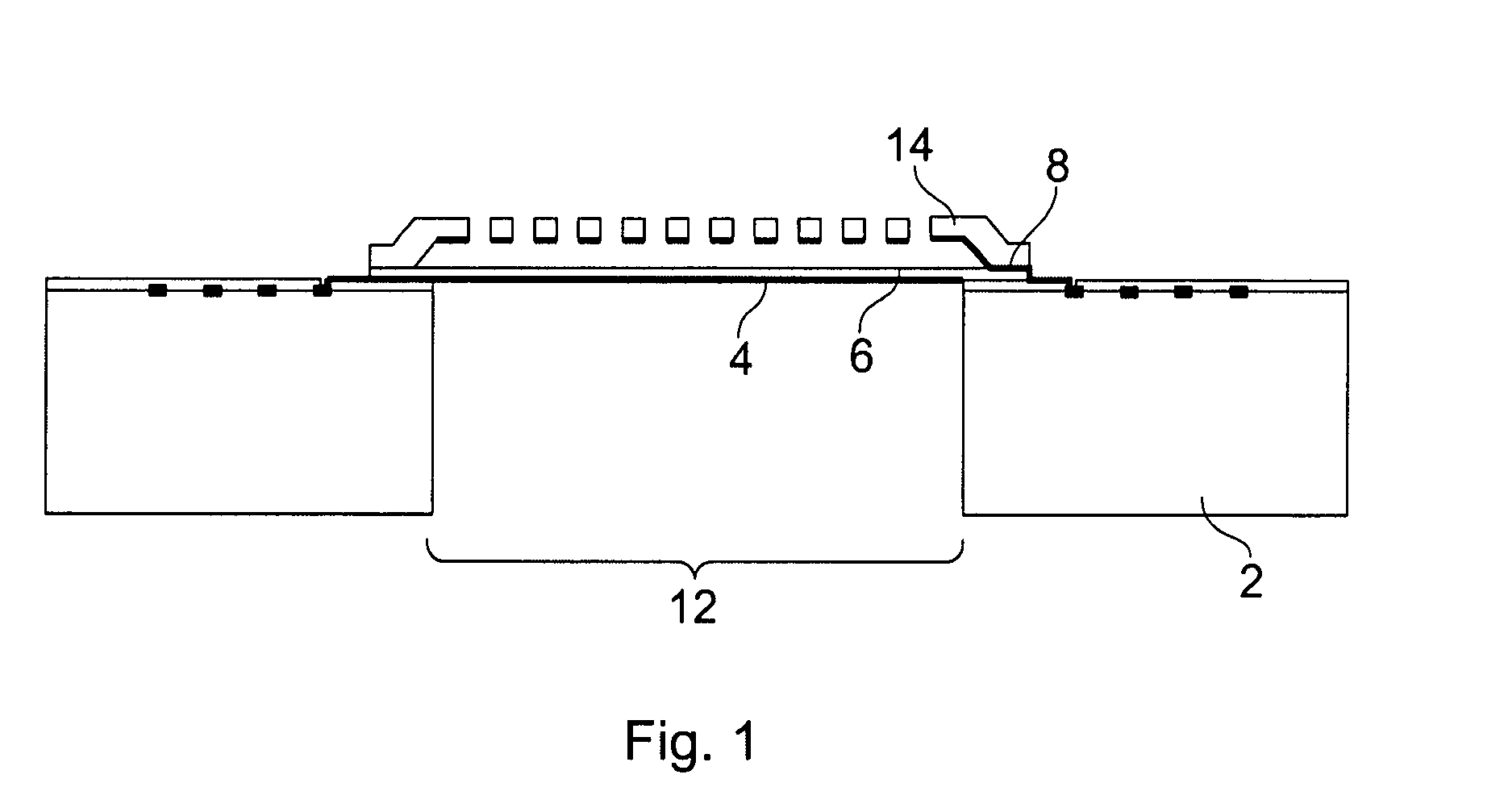

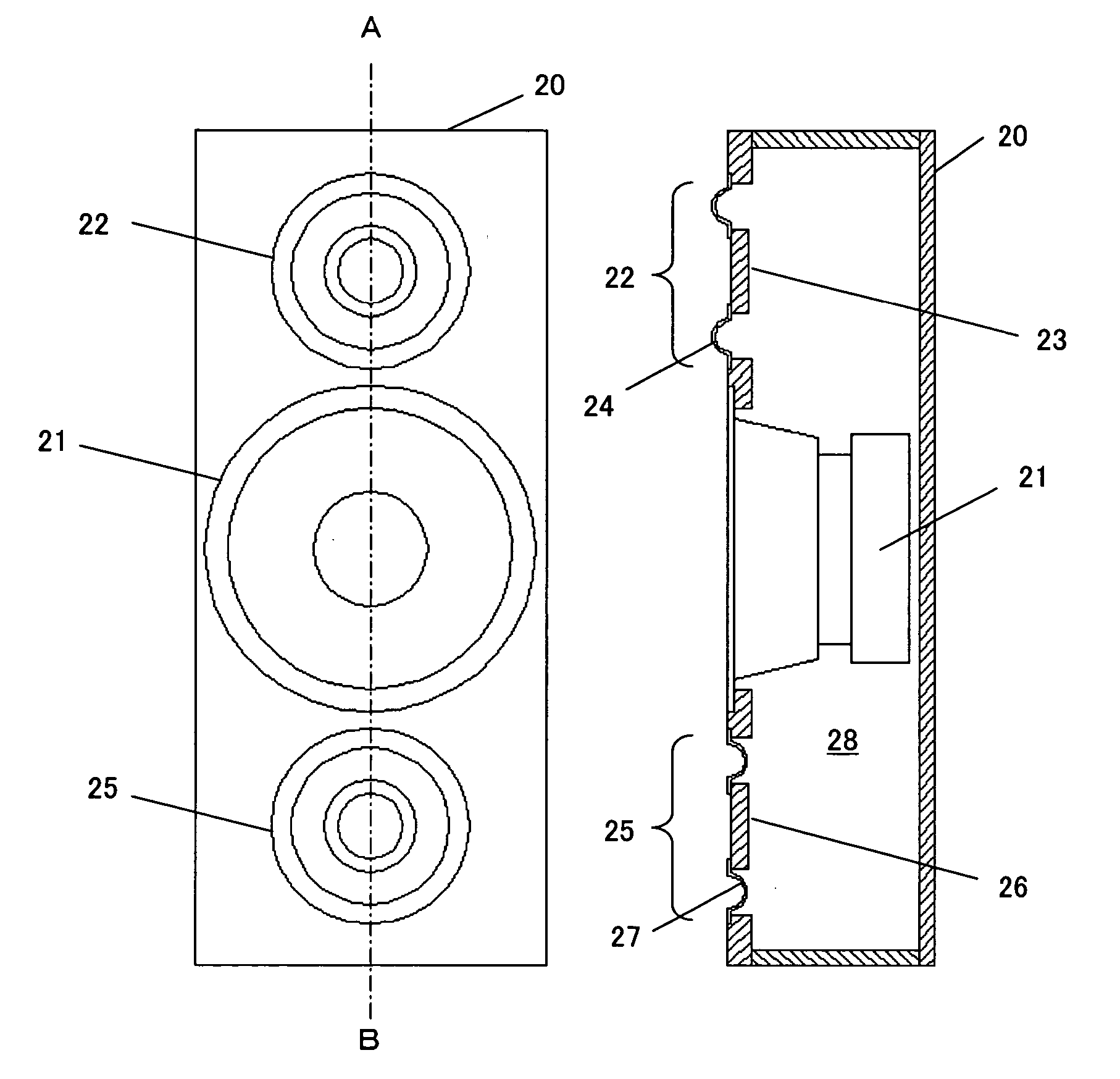

Electroacoustic transducer with a diaphragm and method for fixing a diaphragm in such transducer

InactiveUS7706561B2Improve acoustic propertiesImprove deformationTransducer detailsDeaf-aid setsTransducerEngineering

Apparatus and method for manufacturing an electroacoustic transducer for, for instance, a hearing aid, with a diaphragm arranged in a housing. The diaphragm is attached onto a film or punched from a sheet of material, such that along the circumferential edge of the diaphragm, a free strip of film or a strip of material remains present, in a capillary space between the circumferential edge of the film and the inner wall of the housing, or in a capillary space between the diaphragm and the strip of material, a polymer of a low viscosity is provided to connect to diaphragm with the housing wall. Through the method, the production of the transducer is greatly simplified.

Owner:SONION NEDERLAND

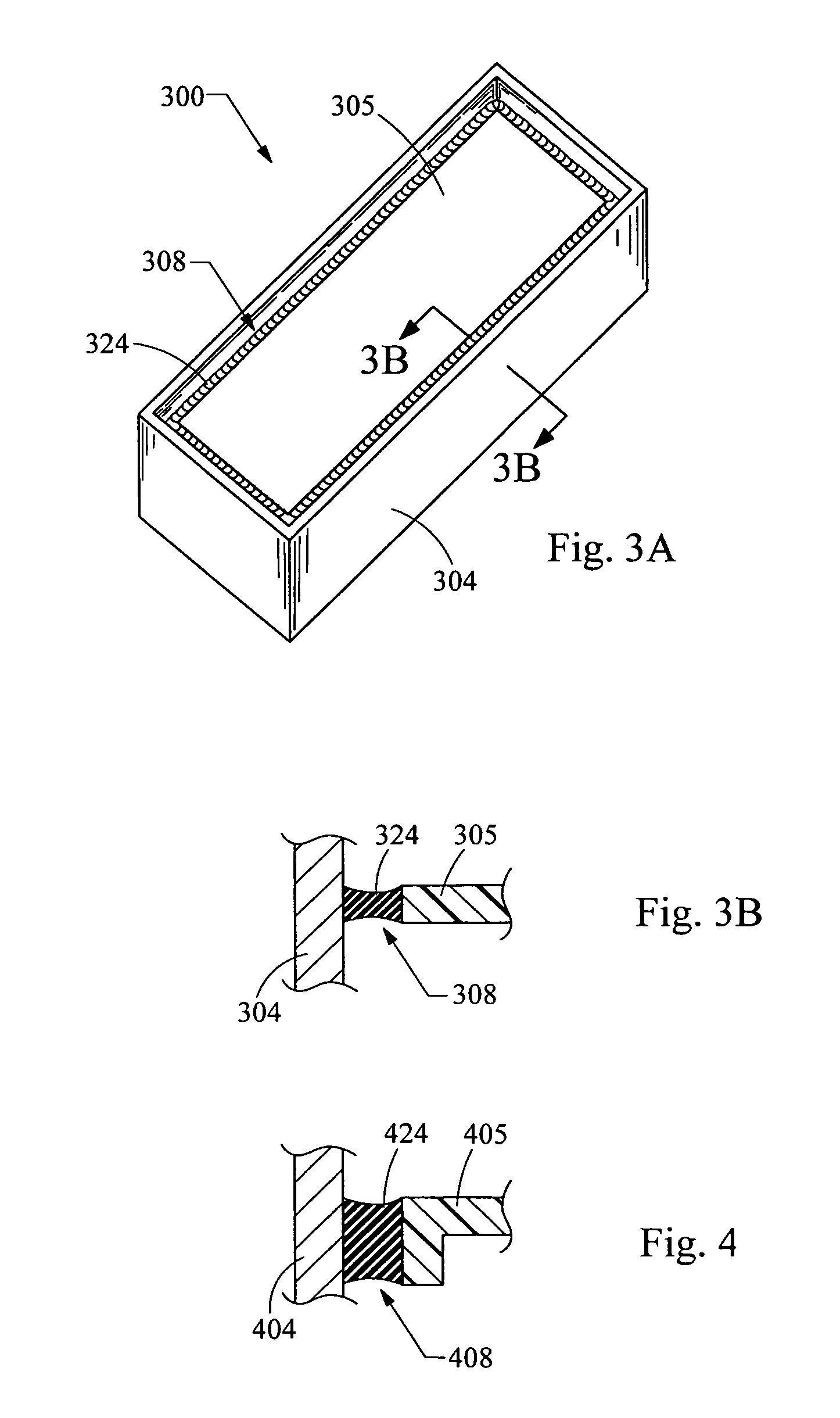

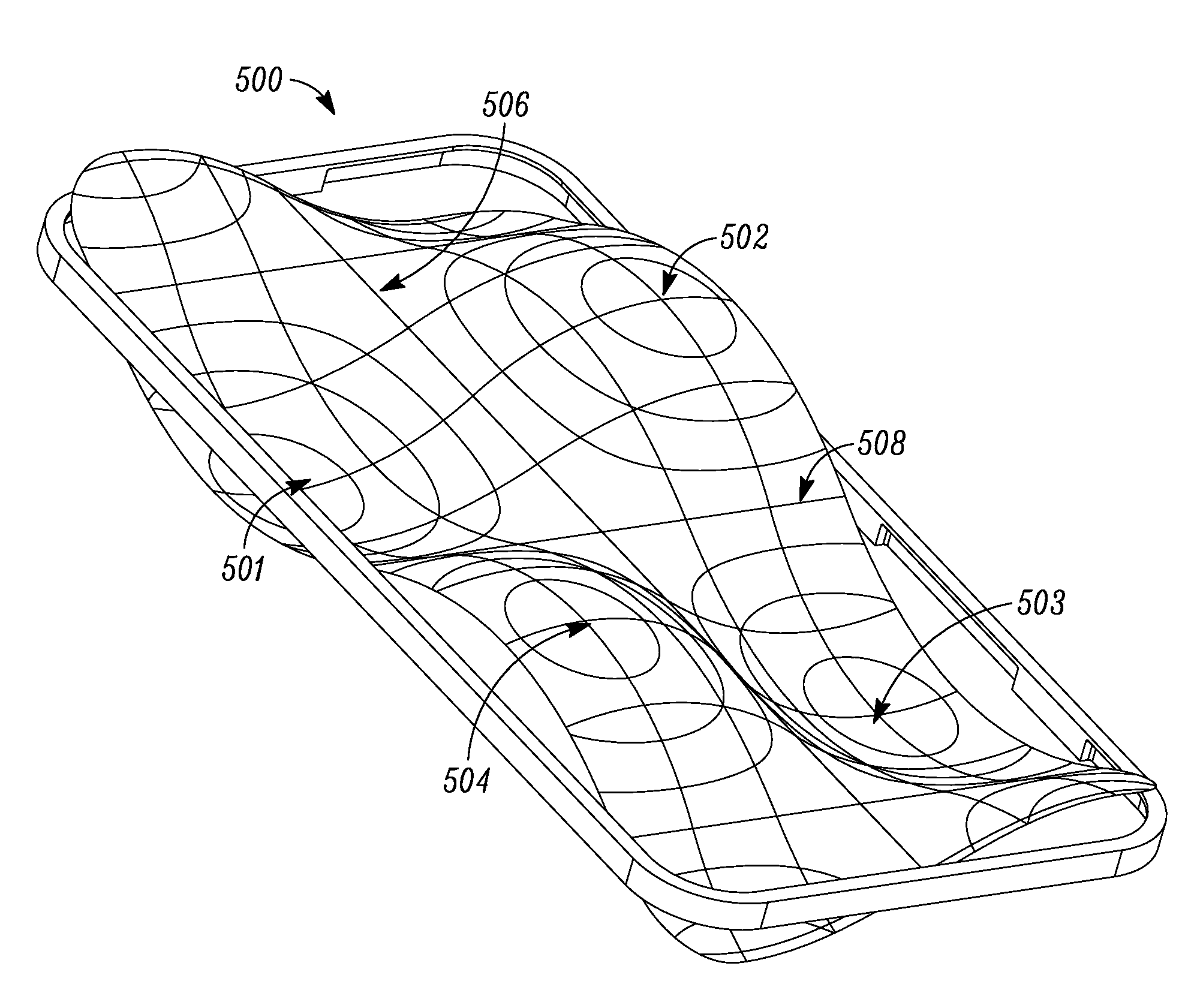

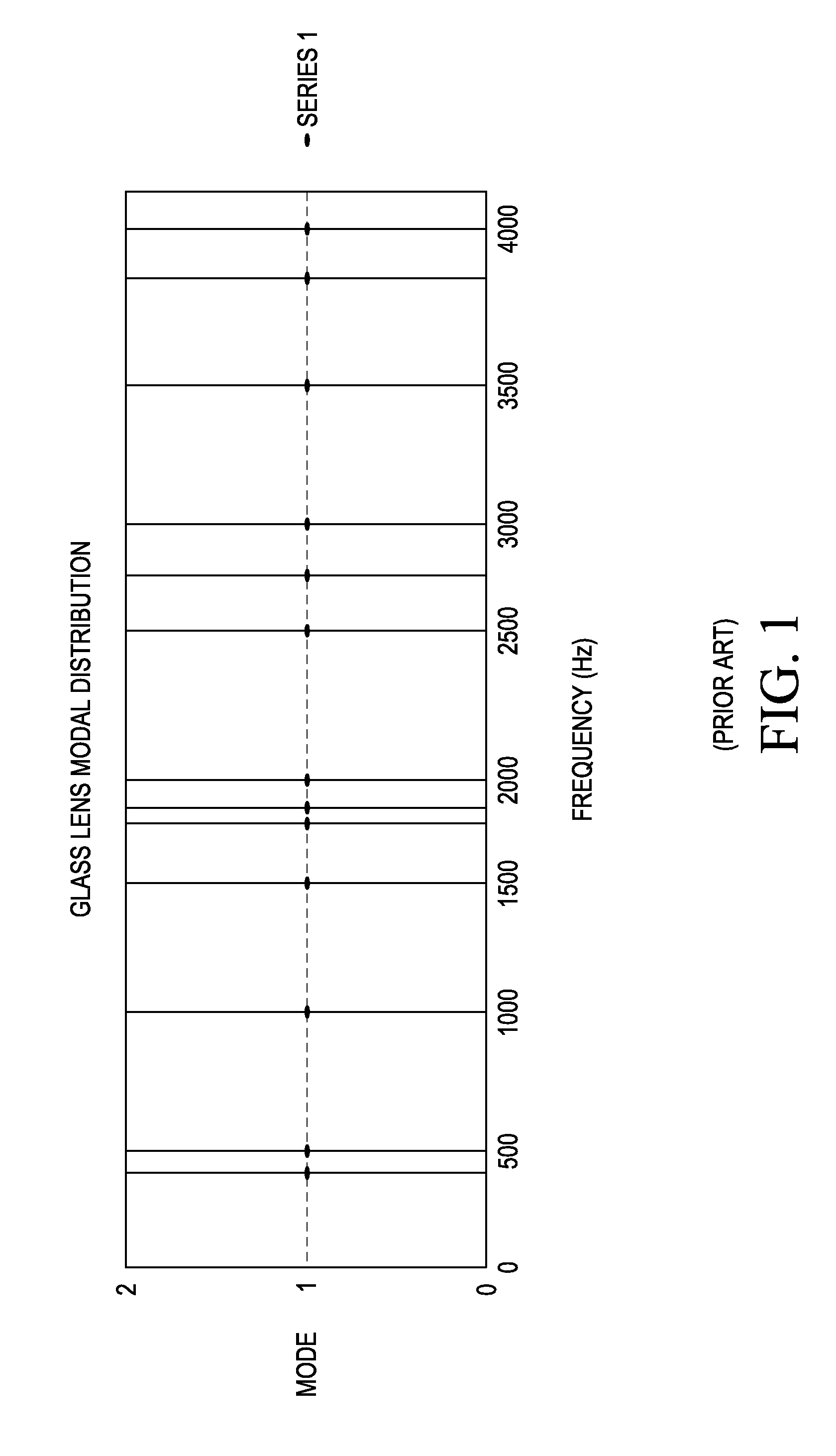

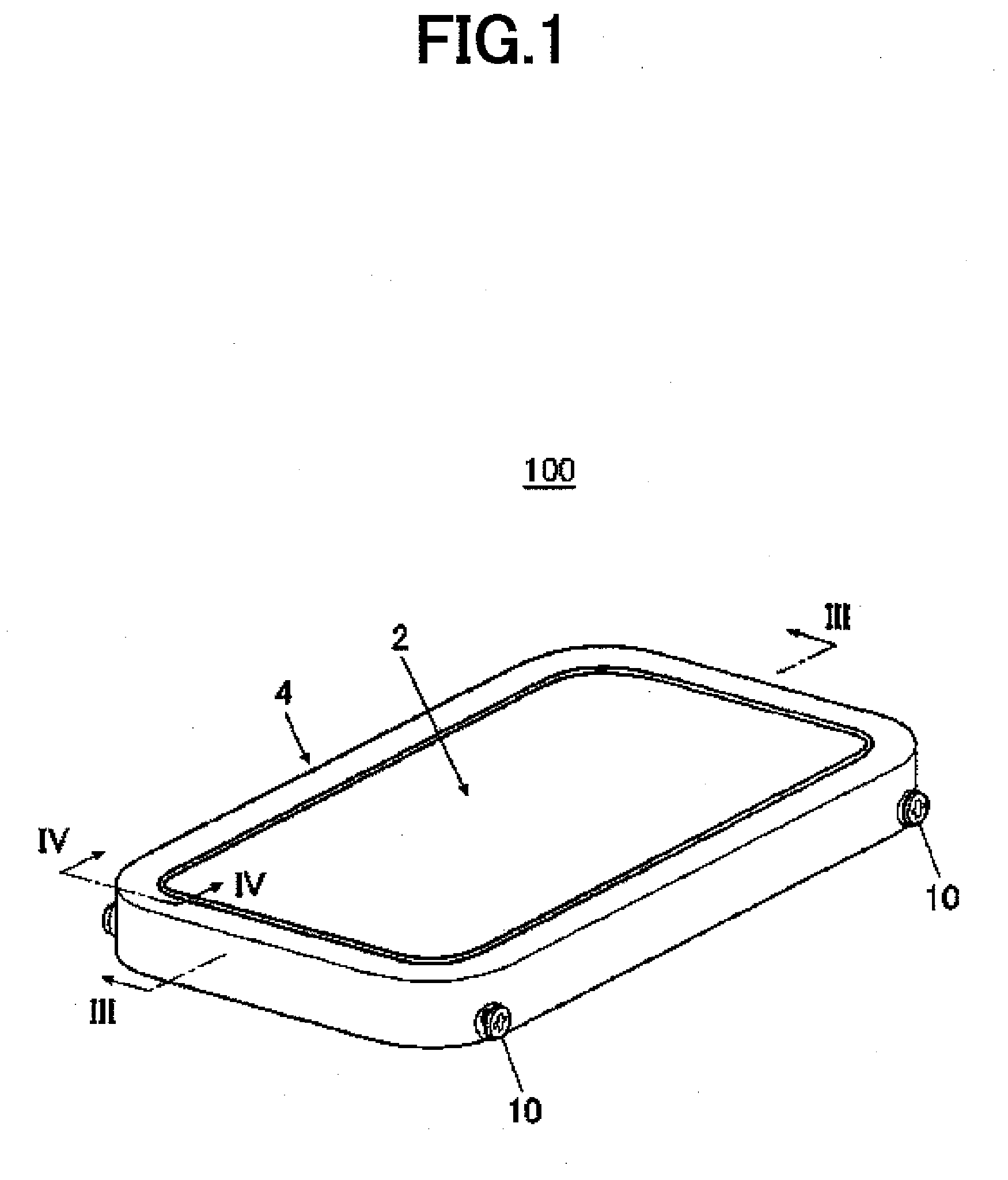

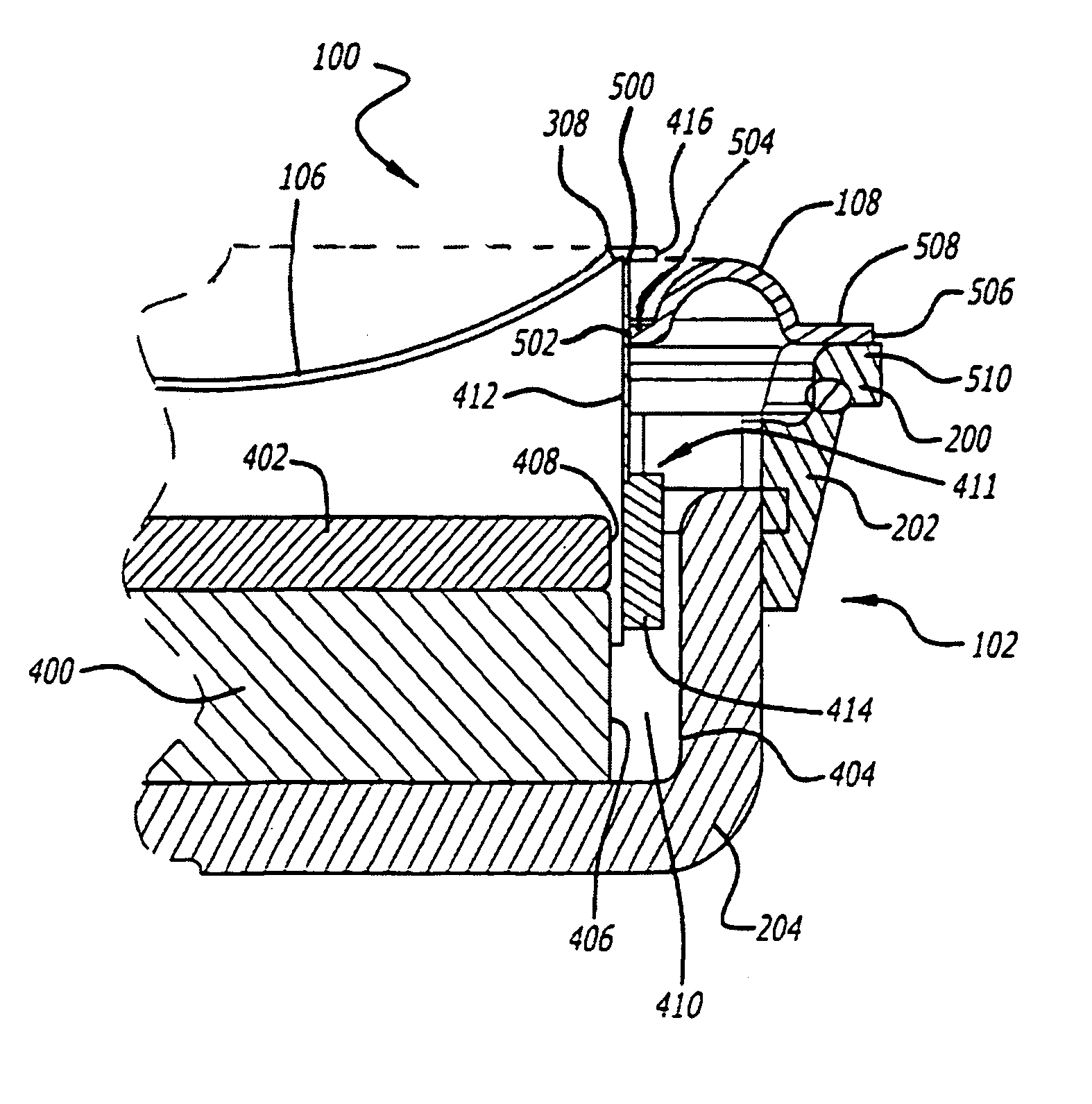

Portable electronic device

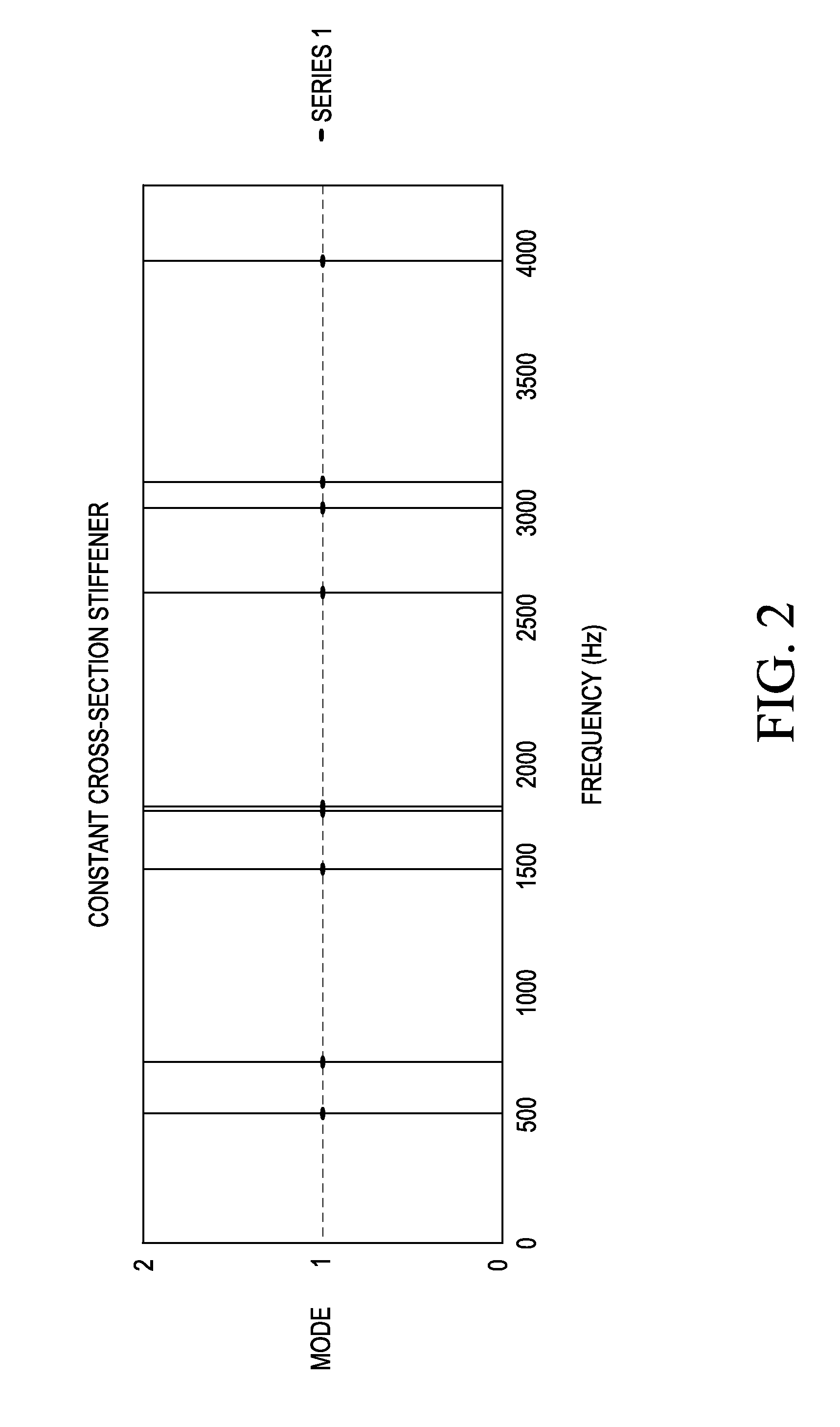

A portable electronic device includes a free floating display lens having a stiffener ring mounted on a peripheral region or edge of the free floating display lens to affect modal density and modal distribution of the free floating display lens. Additionally, a piezoelectric supporting structure is attached to the stiffener ring, while surrounding a display, wherein the piezoelectric supporting structure is electrically driven to produce an acoustic signal in one mode and a vibratory haptic signal in another mode.

Owner:GOOGLE TECH HLDG LLC

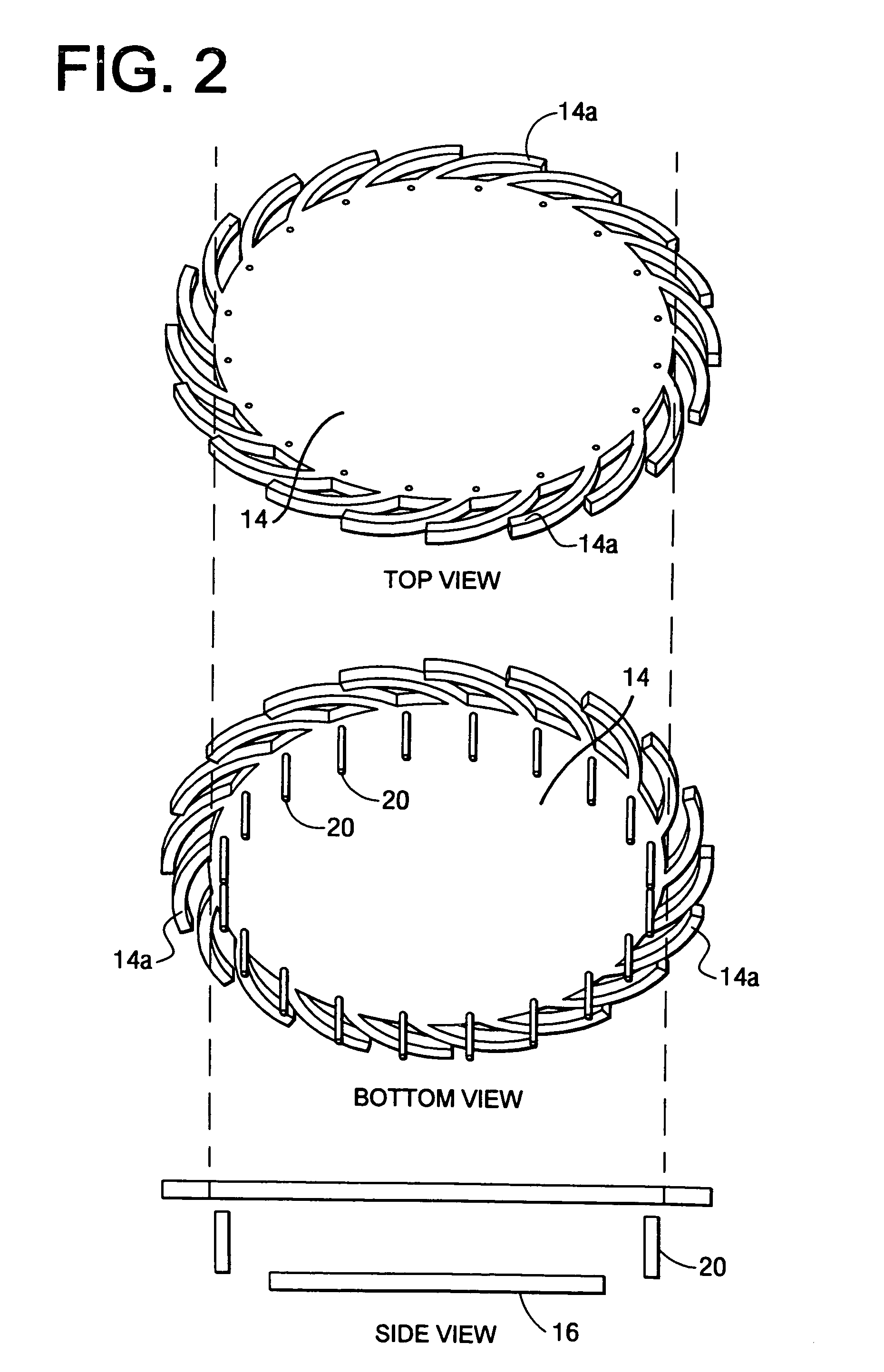

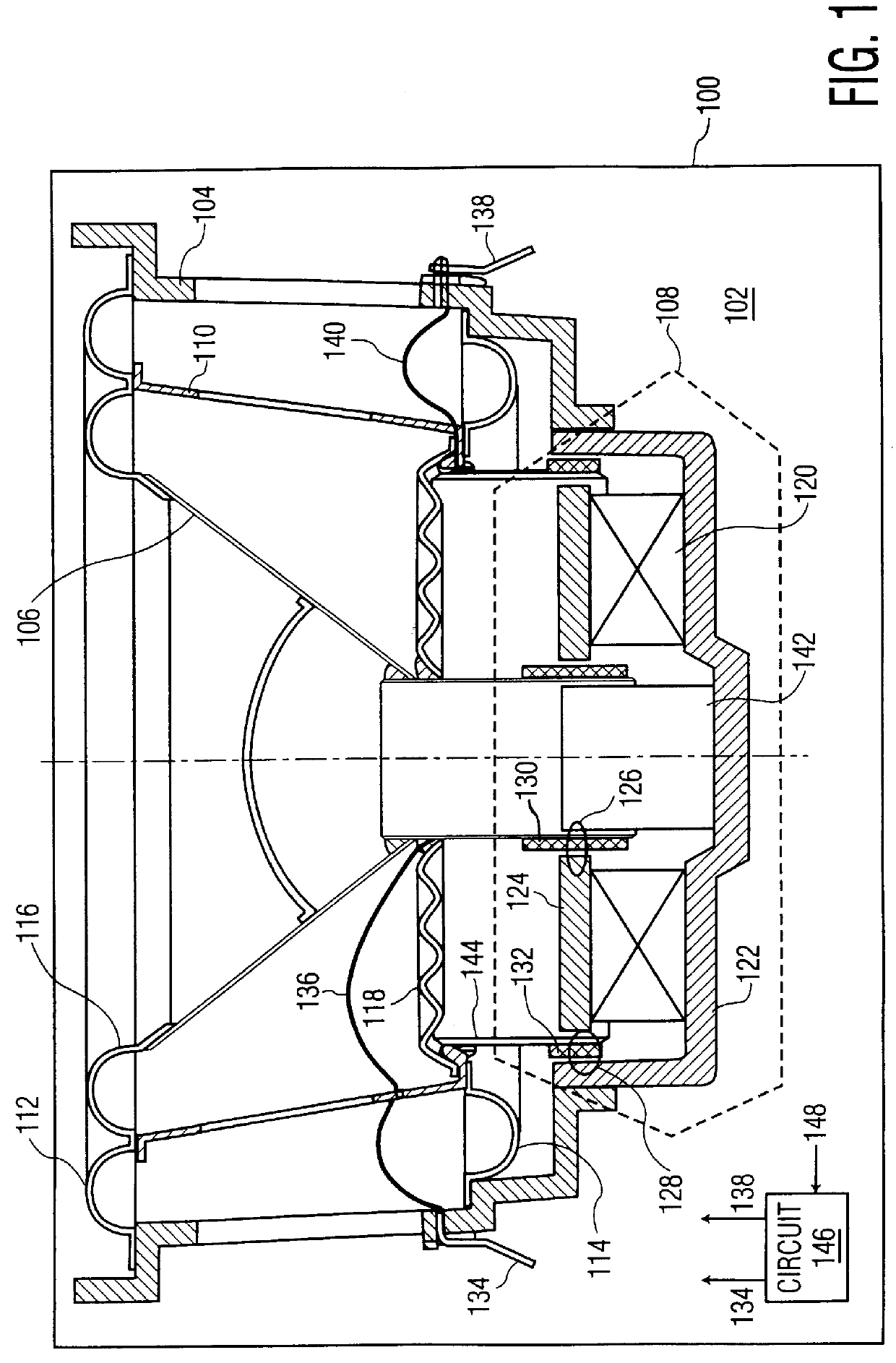

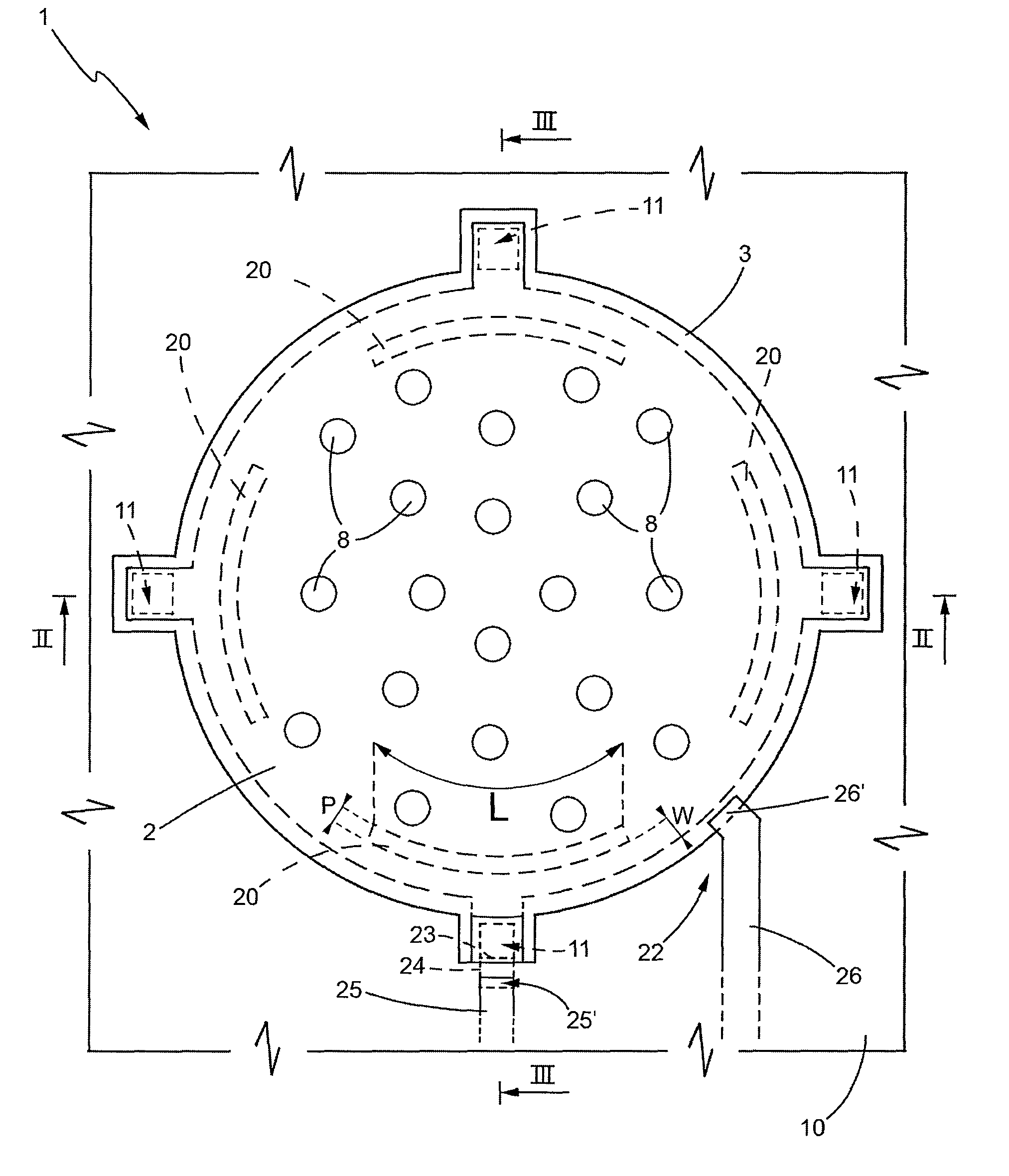

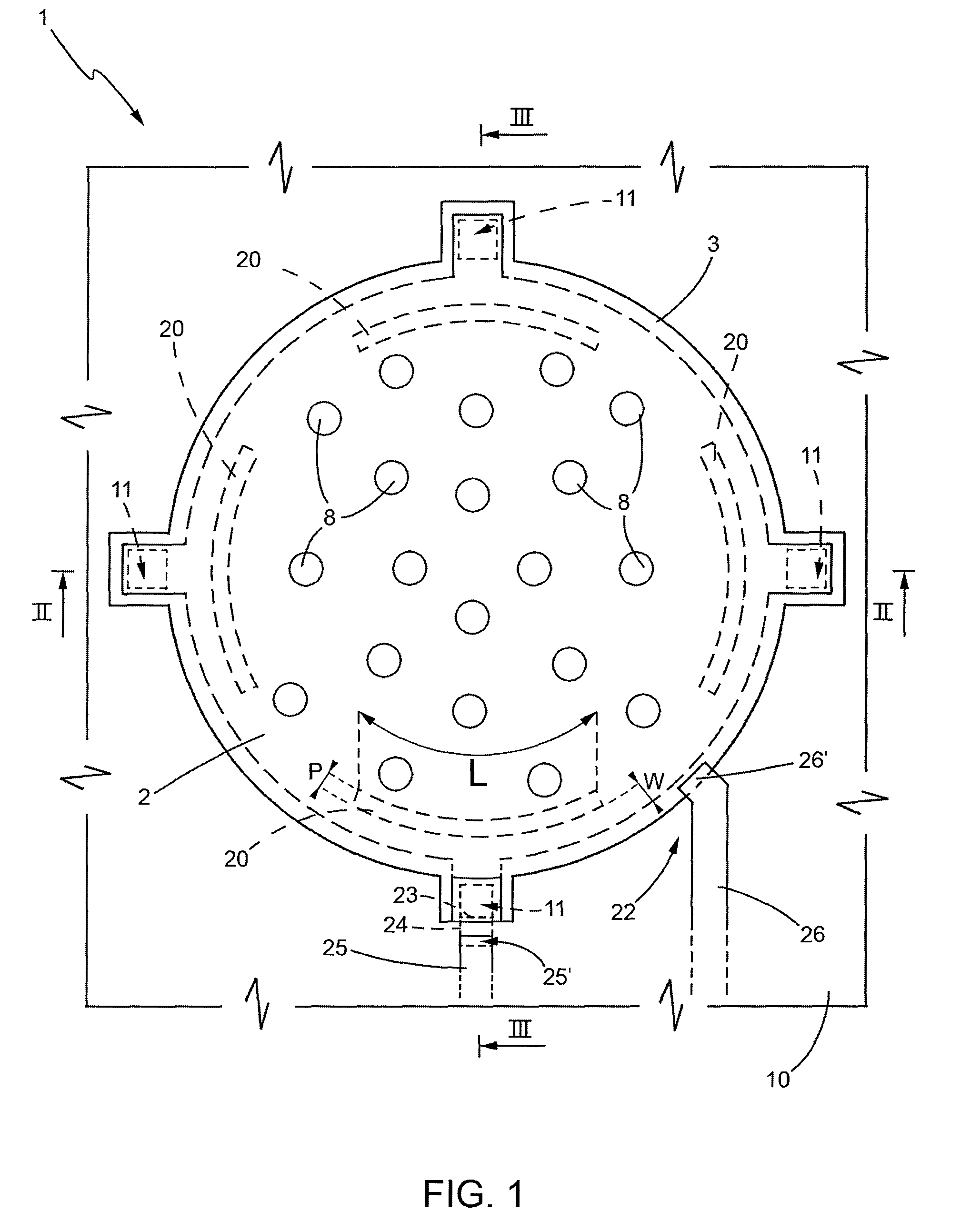

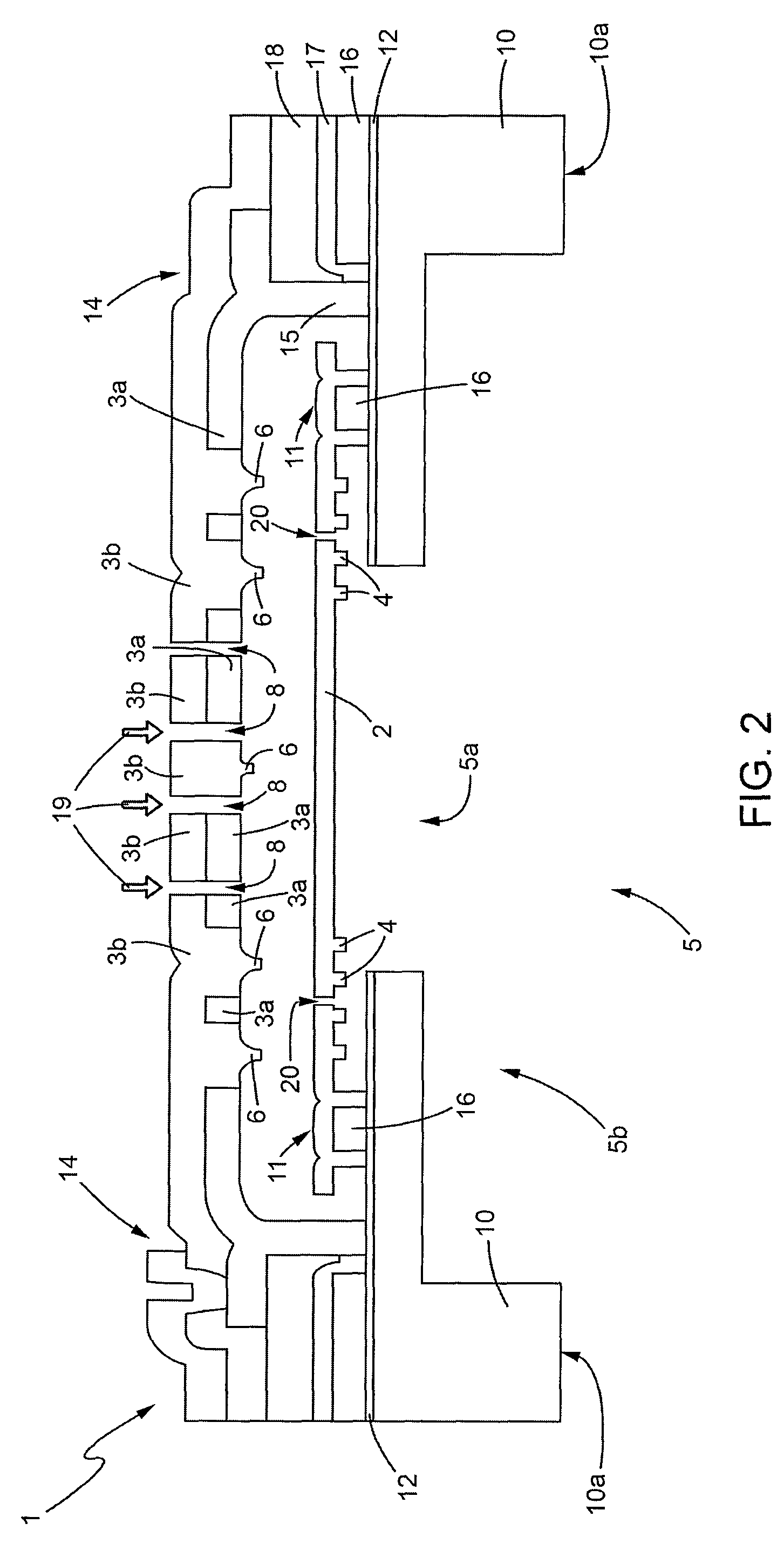

Vibration actuator having magnetic circuit elastically supported by a spiral damper with increased compliance

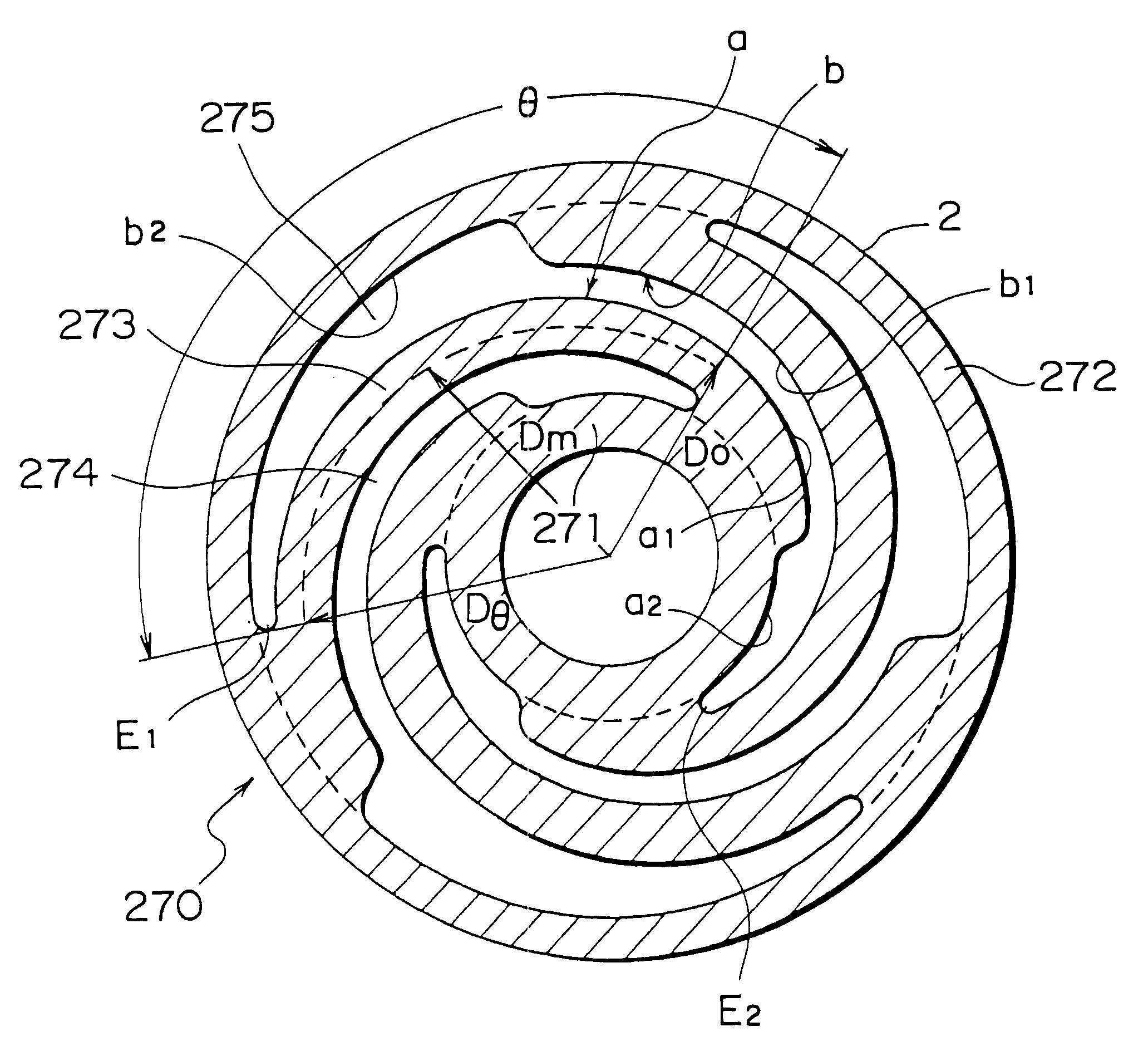

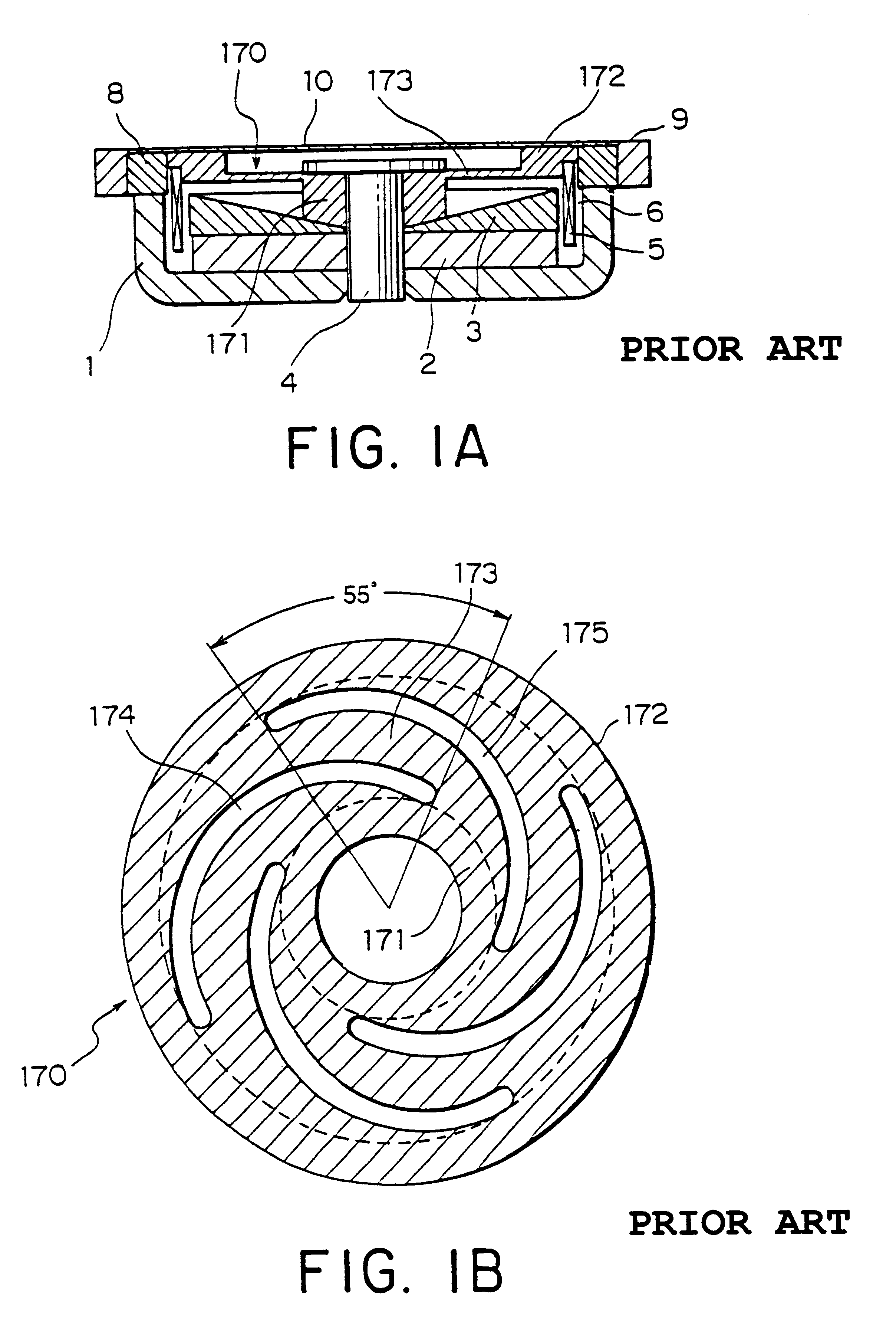

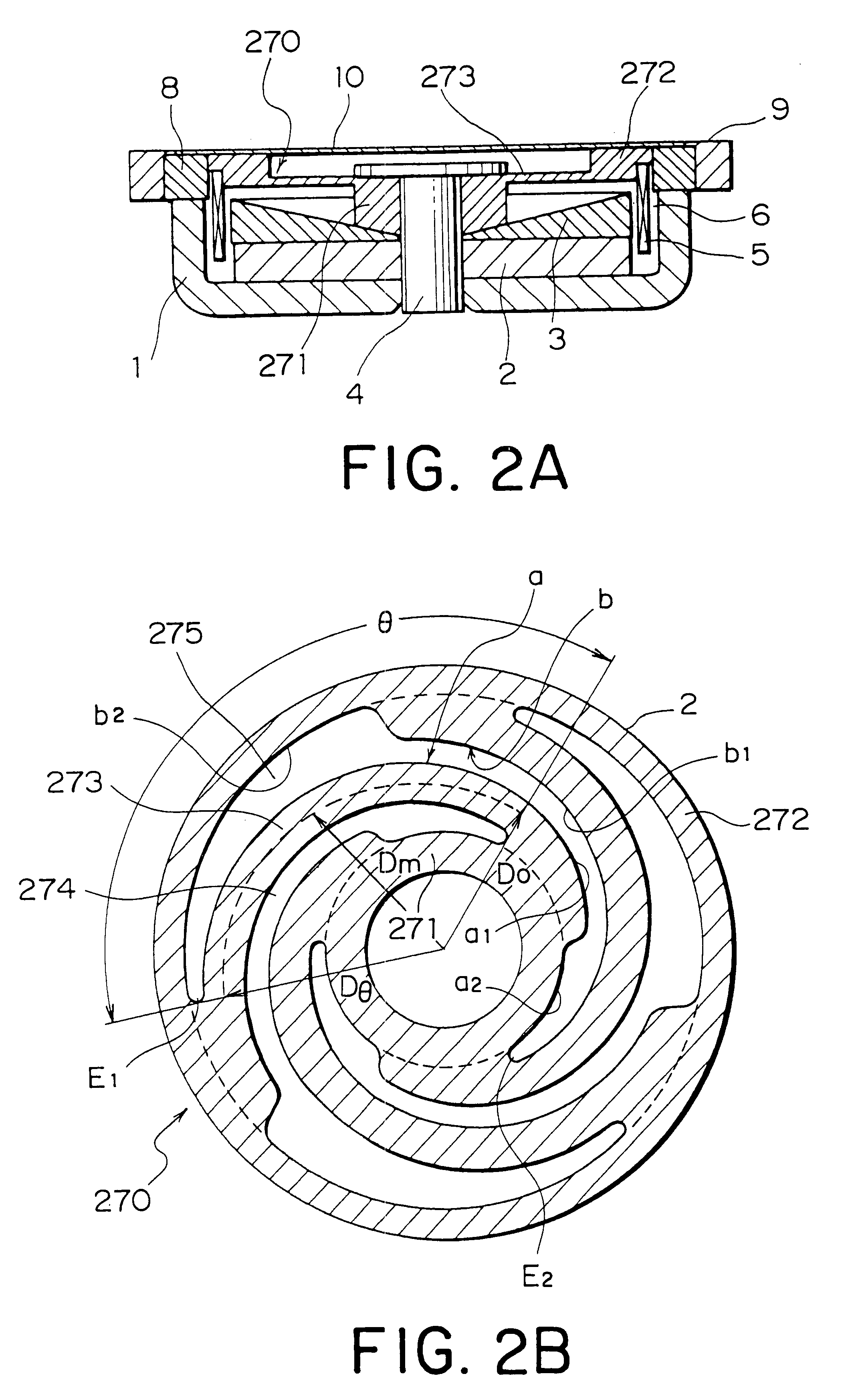

InactiveUS6377145B1Improve seismic performanceStable characteristicsTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesAngular degreesCoil spring

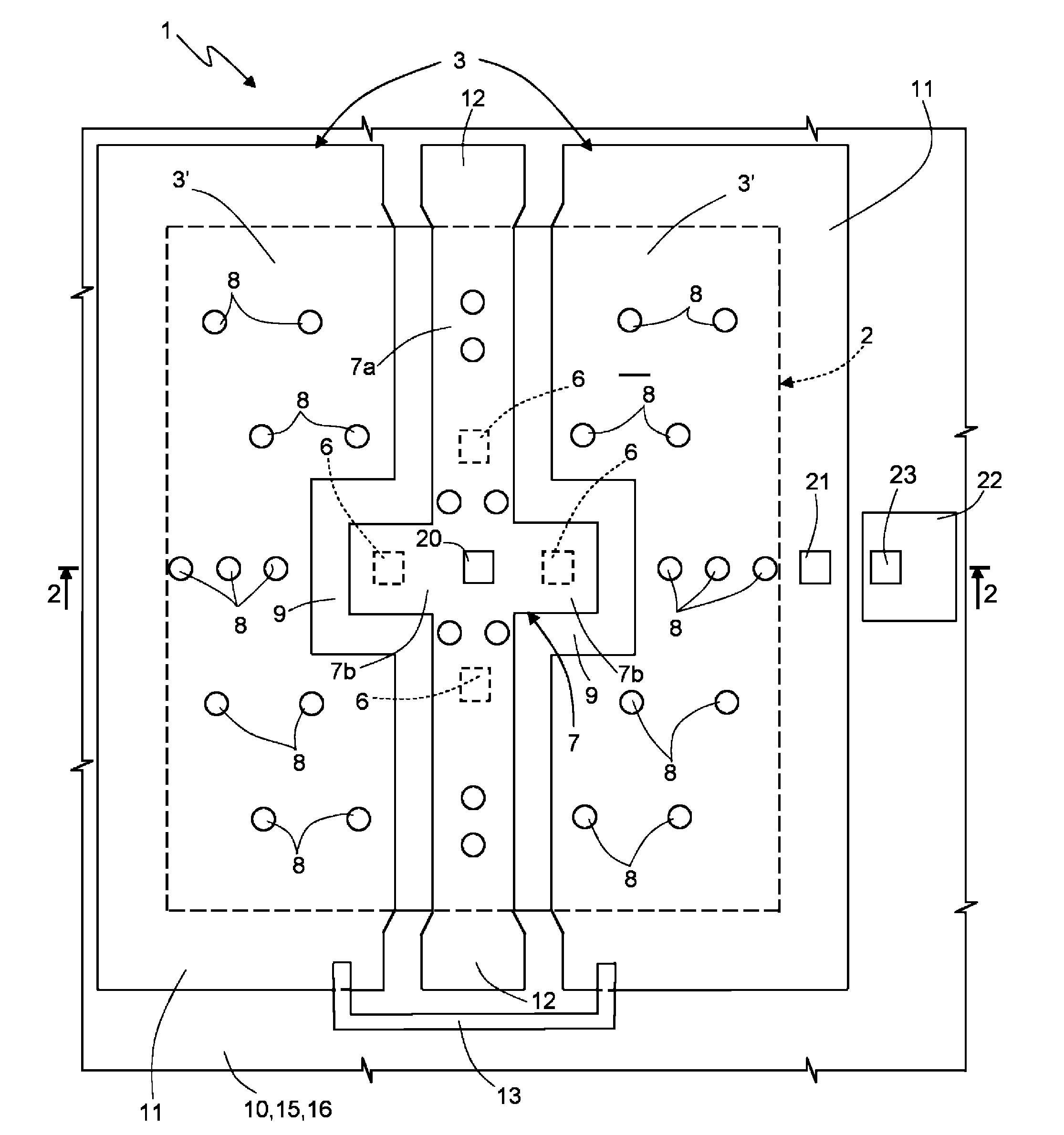

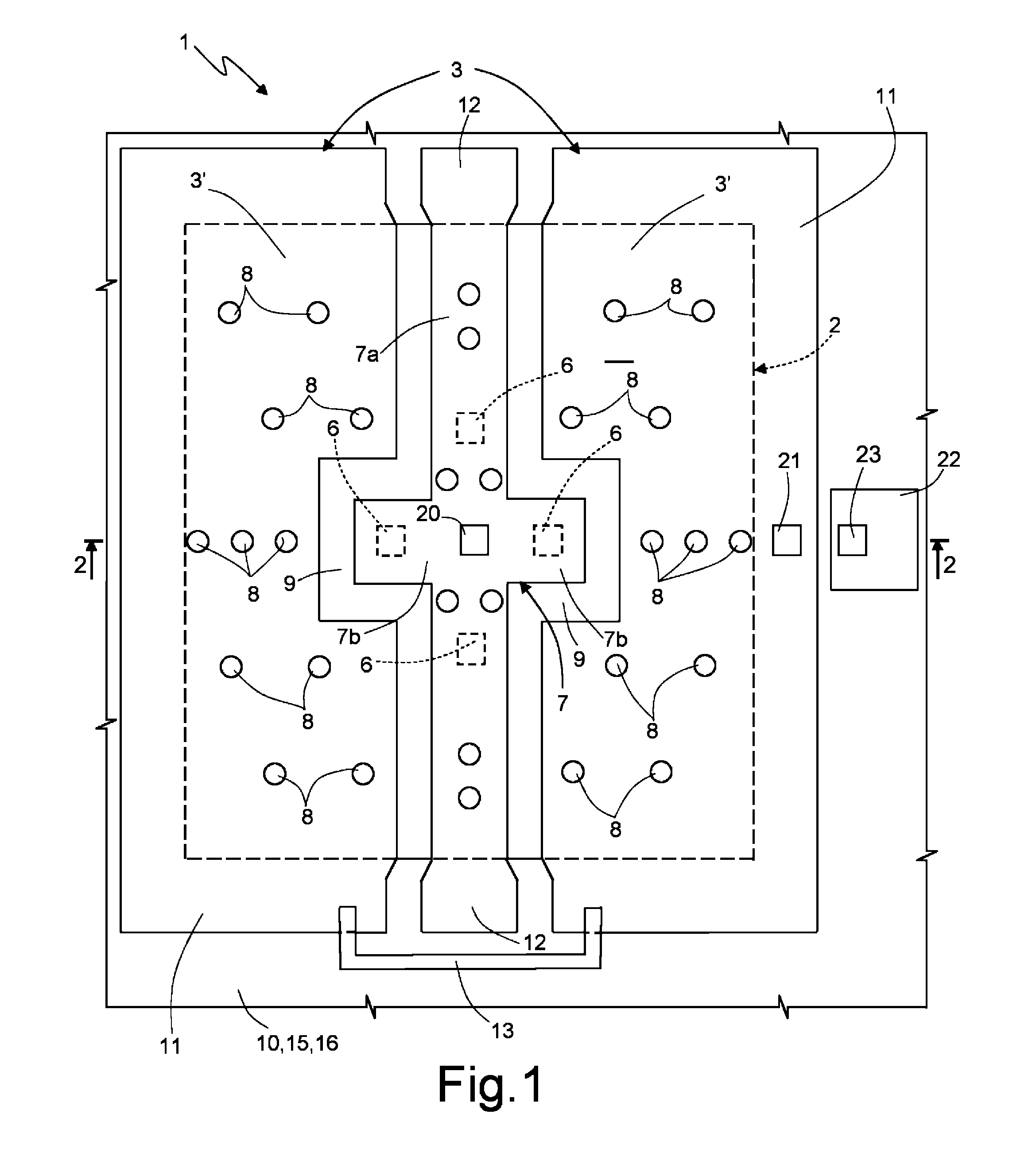

A vibration actuator includes an electromechanical transducer having a magnetic circuit (1-4) and a driving coil (5), a support frame (9), and a damper (270) elastically supporting the magnetic circuit onto the support frame to flexibly damp the vibration of the magnetic circuit when a driving AC current is supplied to the coil (5). The damper (270) comprises inner and outer ring portions (271, 272) and a plurality of spiral spring portions (273) determined by a plurality of spiral slits (274, 275) formed in the damper. In order to reduce the spiral spring portion determined by the adjacent two spiral slits in its compliance, each of the spiral spring portions has an effective spring length determined by an effective angle (theta) which is determined as an angle (by angular degree) from an inner end of the inner spiral slit to an outer end of the outer spiral slit defining each respective spiral spring portion around a center of the damper. The effective angle is 55 angular degree or more. In a preferable example, the effective spring length is determined by a product (r.theta) of an average radius (r) value by the unit of "mm" and the effective angle (theta) value by unit of the angular degree. The effective spring length is selected to 320 or more, and preferably 400 or more.

Owner:TOKIN CORP

Silicon microphone

InactiveUS7023066B2Simplify the manufacturing processMinimizes parasitic capacitanceSemiconductor electrostatic transducersSemiconductor/solid-state device manufacturingEngineeringSound pressure

A solid-state transducer is disclosed. The transducer comprises a semi-conductor substrate forming a support structure and having an opening. A thin-film structure forming a diaphragm responsive to fluid-transmitted acoustic pressure is disposed over the opening. The transducer further includes a plurality of semi-conductor supports and tangential arms extending from the diaphragm edge for connecting the periphery of the diaphragm to the supports. The tangential arms permit the diaphragm to rotate relative to the supports to relieve film stress in the diaphragm. The transducer still further includes a plurality of stop bumps disposed between the substrate and the diaphragm. The stop bumps determine the separation of the diaphragm from the substrate when the transducer is biased.

Owner:KNOWLES ELECTRONICS INC

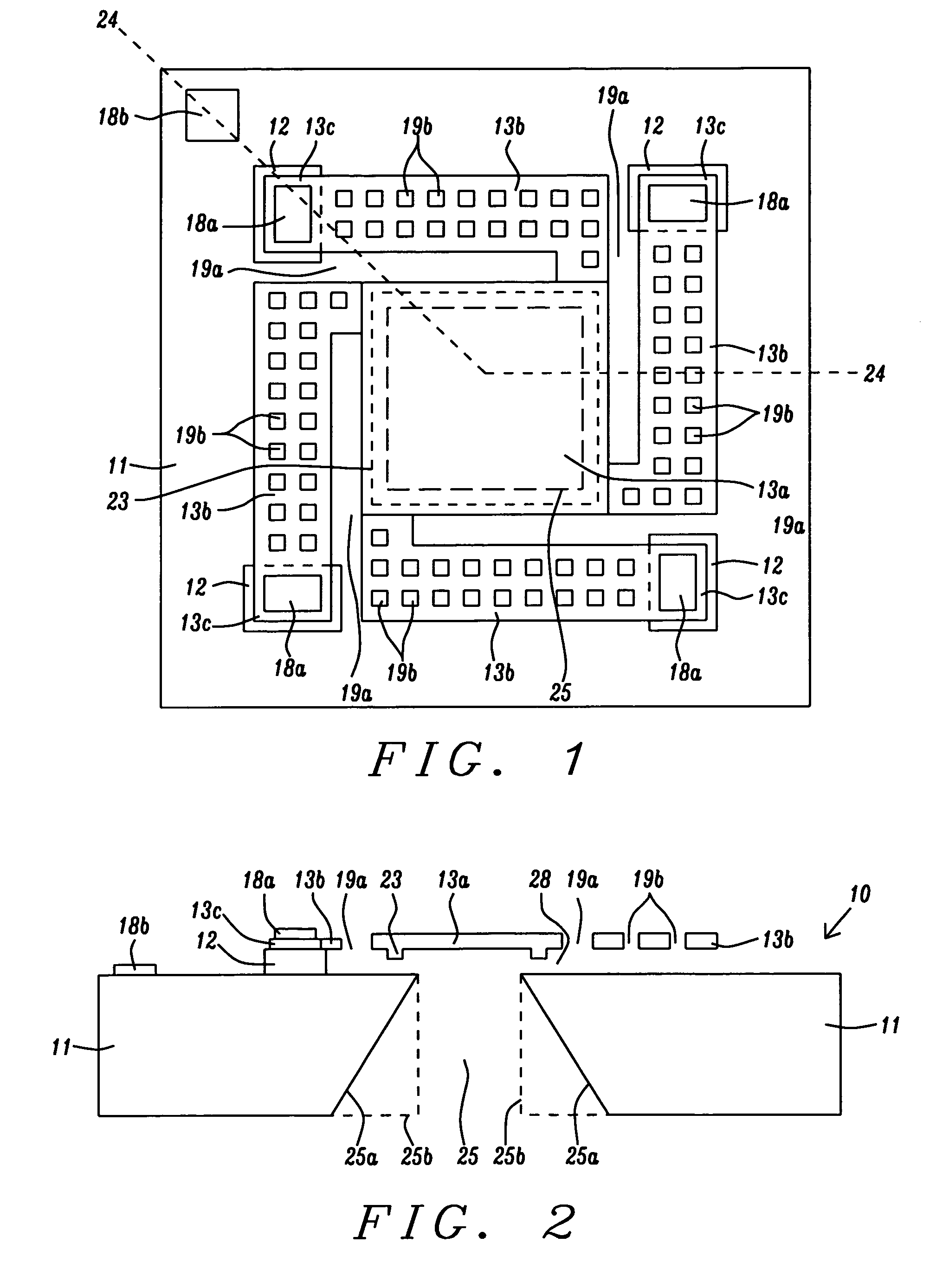

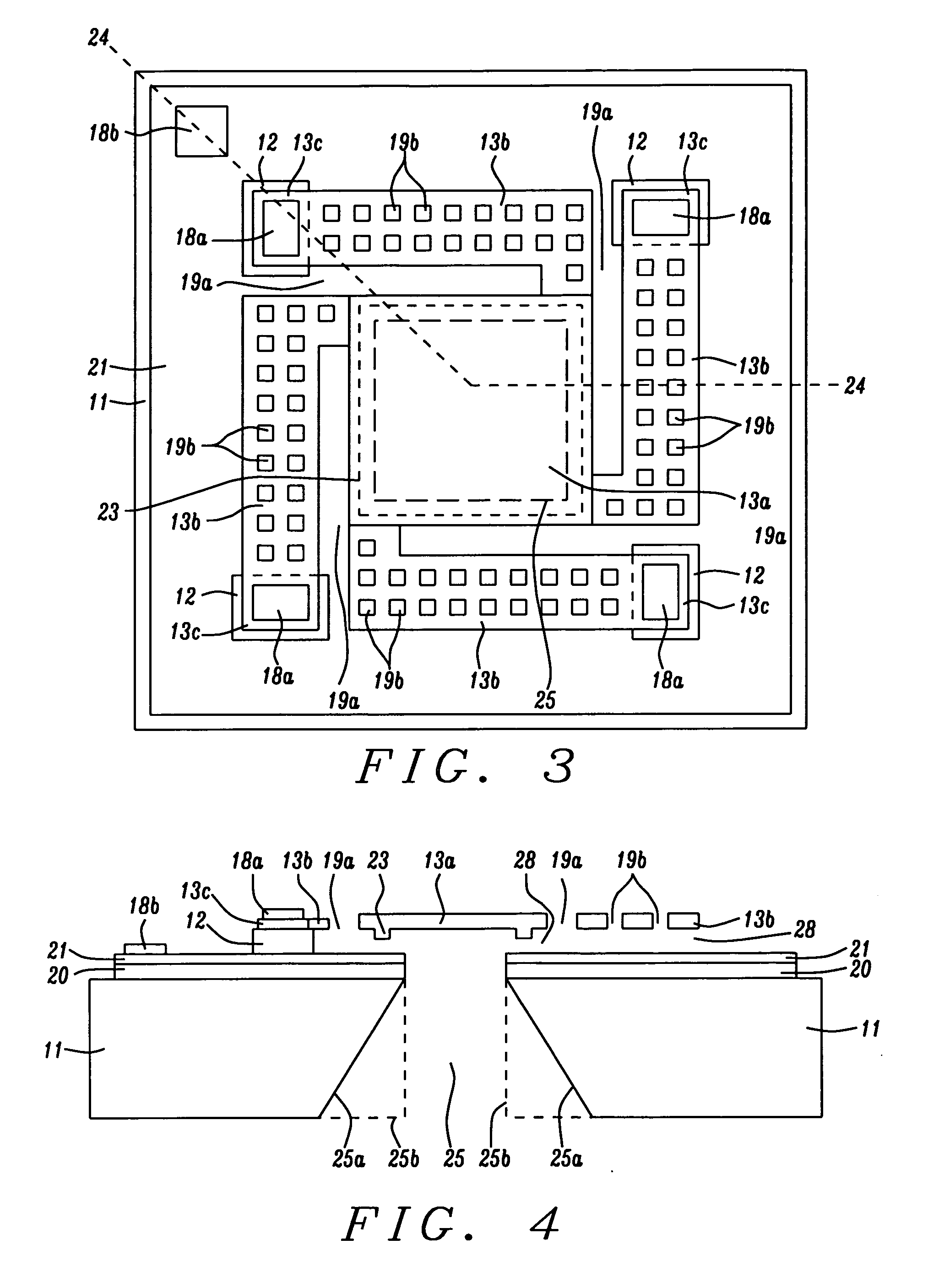

Support Apparatus for Microphone Diaphragm

A microphone includes a diaphragm assembly supported by a substrate. The diaphragm assembly includes at least one carrier, a diaphragm, and at least one spring coupling the diaphragm to the at least one carrier such that the diaphragm is spaced from the at least one carrier. An insulator (or separate insulators) between the substrate and the at least one carrier electrically isolates the diaphragm and the substrate.

Owner:INVENSENSE

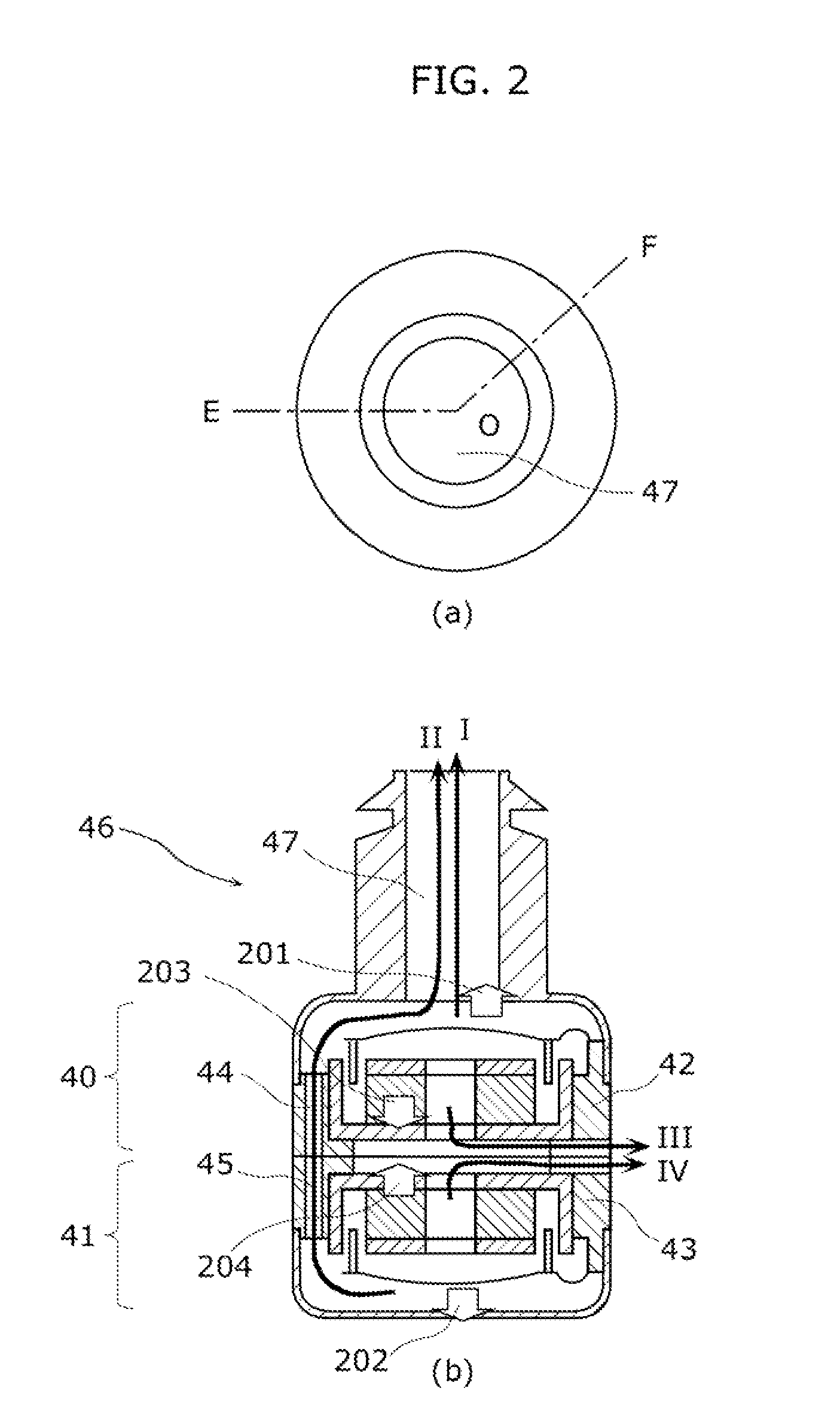

Integrated acoustic transducer in MEMS technology, and manufacturing process thereof

ActiveUS20100158280A1Piezoelectric/electrostrictive microphonesTransducer detailsTransducerEngineering

A MEMS acoustic transducer, for example, a microphone, includes a substrate provided with a cavity, a supporting structure, fixed to the substrate, a membrane having a perimetral edge and a centroid, suspended above the cavity and fixed to the substrate the membrane configured to oscillate via the supporting structure. The supporting structure includes a plurality of anchorage elements fixed to the membrane, and each anchorage element is coupled to a respective portion of the membrane between the centroid and the perimetral edge of the membrane.

Owner:STMICROELECTRONICS SRL

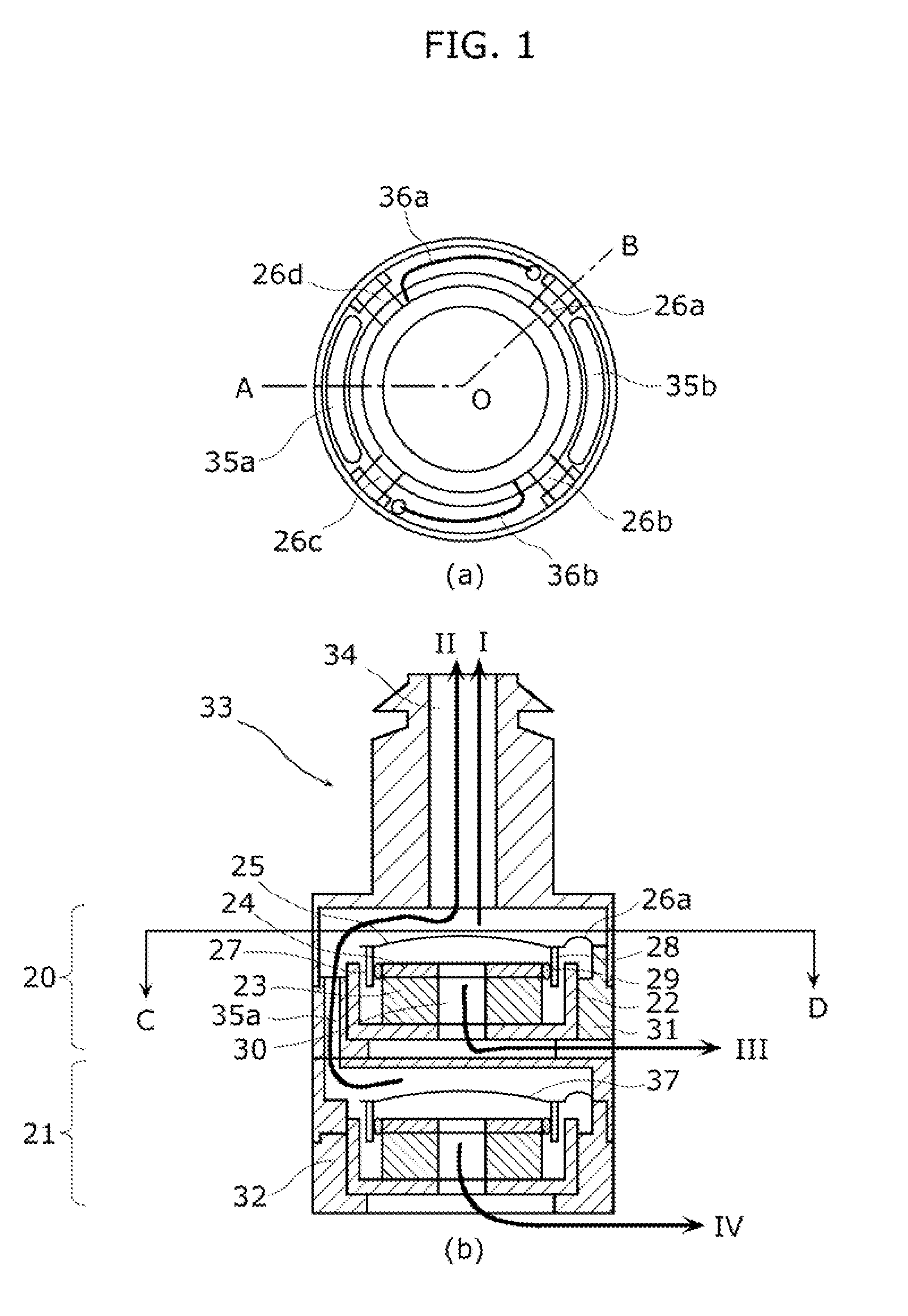

Speaker, hearing aid, earphone, and portable terminal device

ActiveUS20120070022A1Eliminate needHigh-efficiency speaker including plural units can be miniaturizedIntra aural earpiecesFrequency/directions obtaining arrangementsTerminal equipmentMiniaturization

A speaker capable of suppressing deterioration of acoustic efficiency while allowing miniaturization of the speaker includes a first unit (20) and a second unit (21) each of which outputs sound. The first unit (20) includes: a diaphragm (25) which vibrates back and forth to radiate sound; and plural suspensions (26a, 26b, 26c, 26d) which support, at different positions, an outer periphery of the diaphragm (25). At least one of air passages (35a, 35b) for channeling sound from the second unit (21) to the outside is provided between the plural suspensions (26a, 26b, 26c, 26d).

Owner:PANASONIC CORP

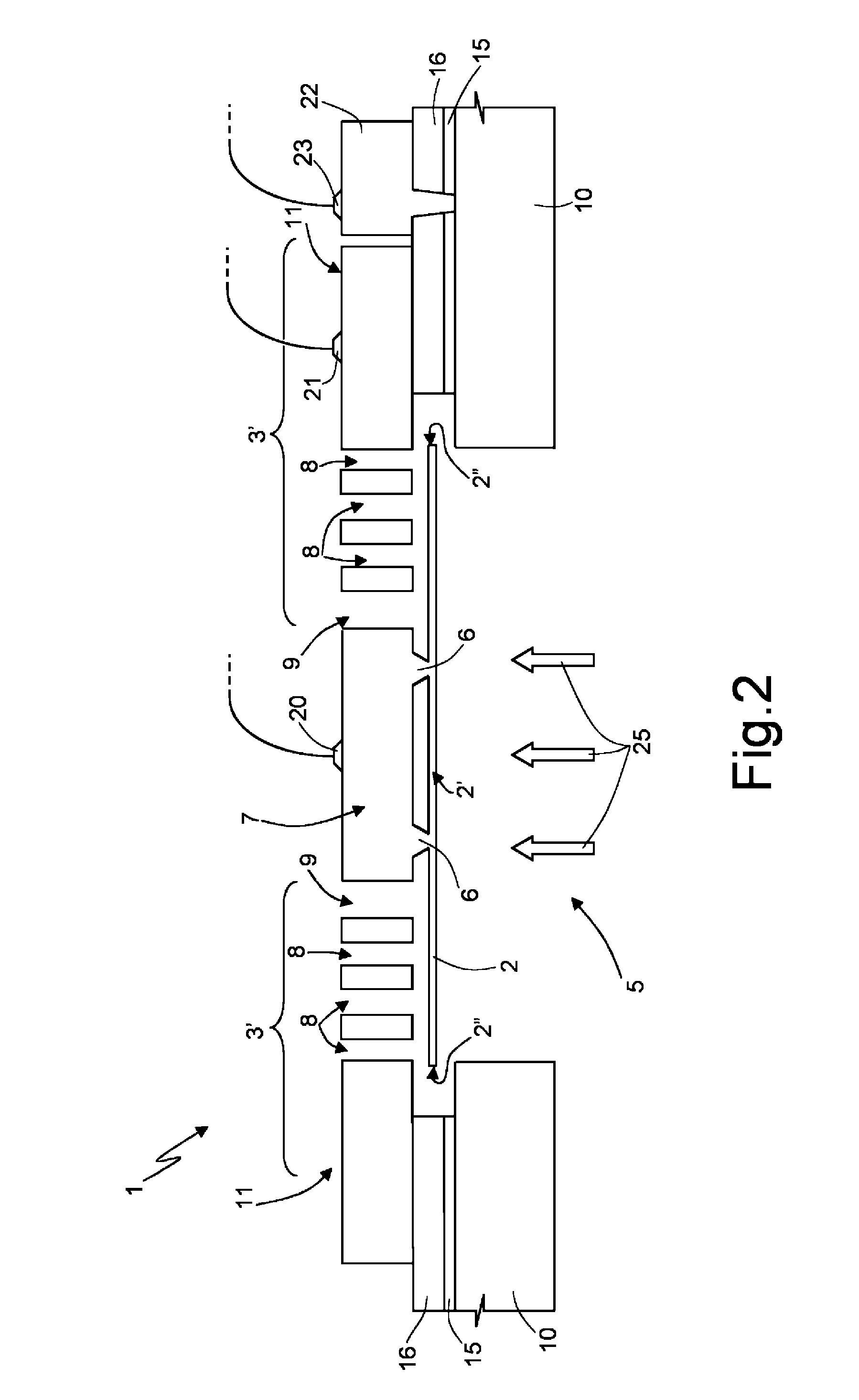

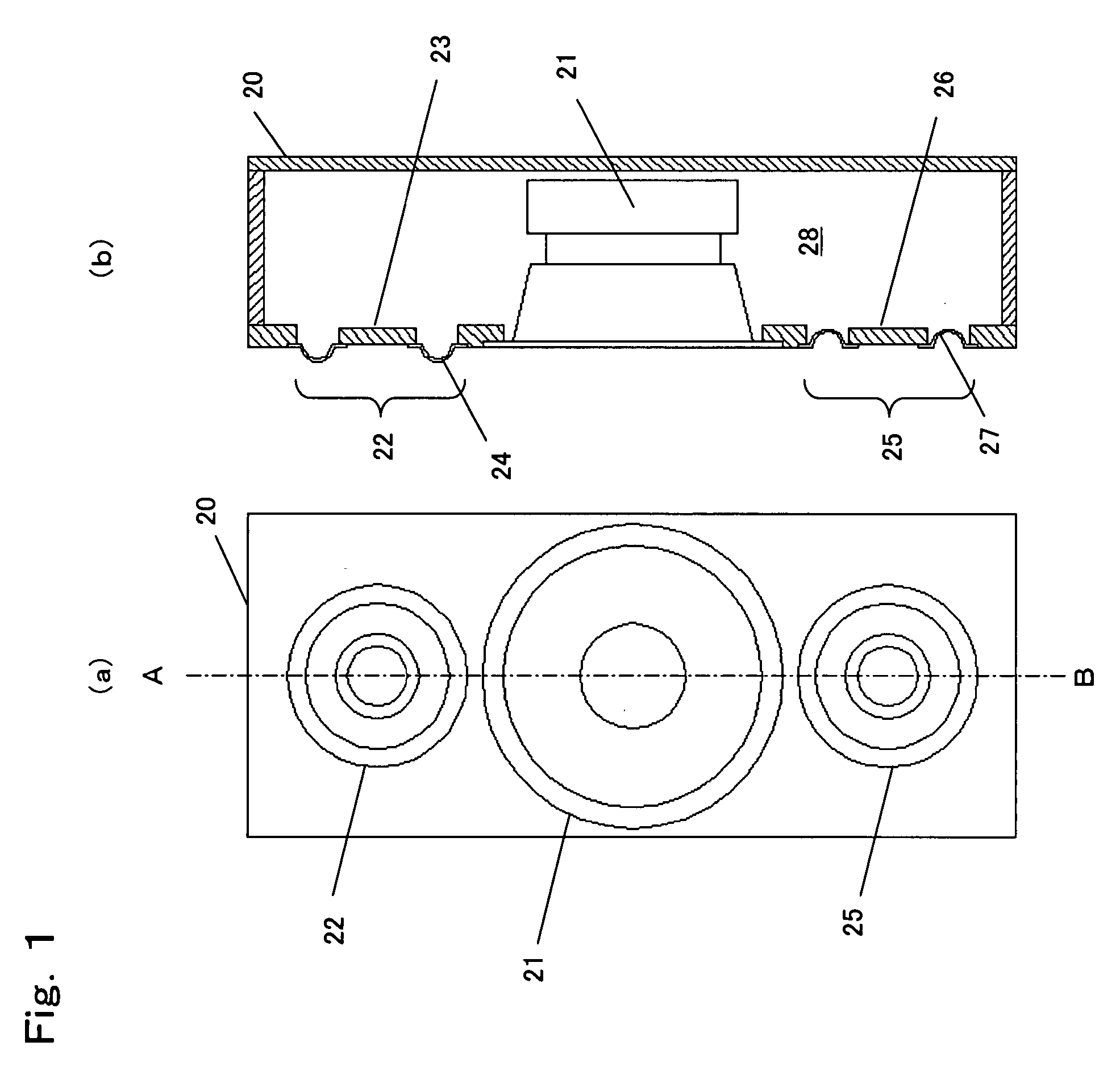

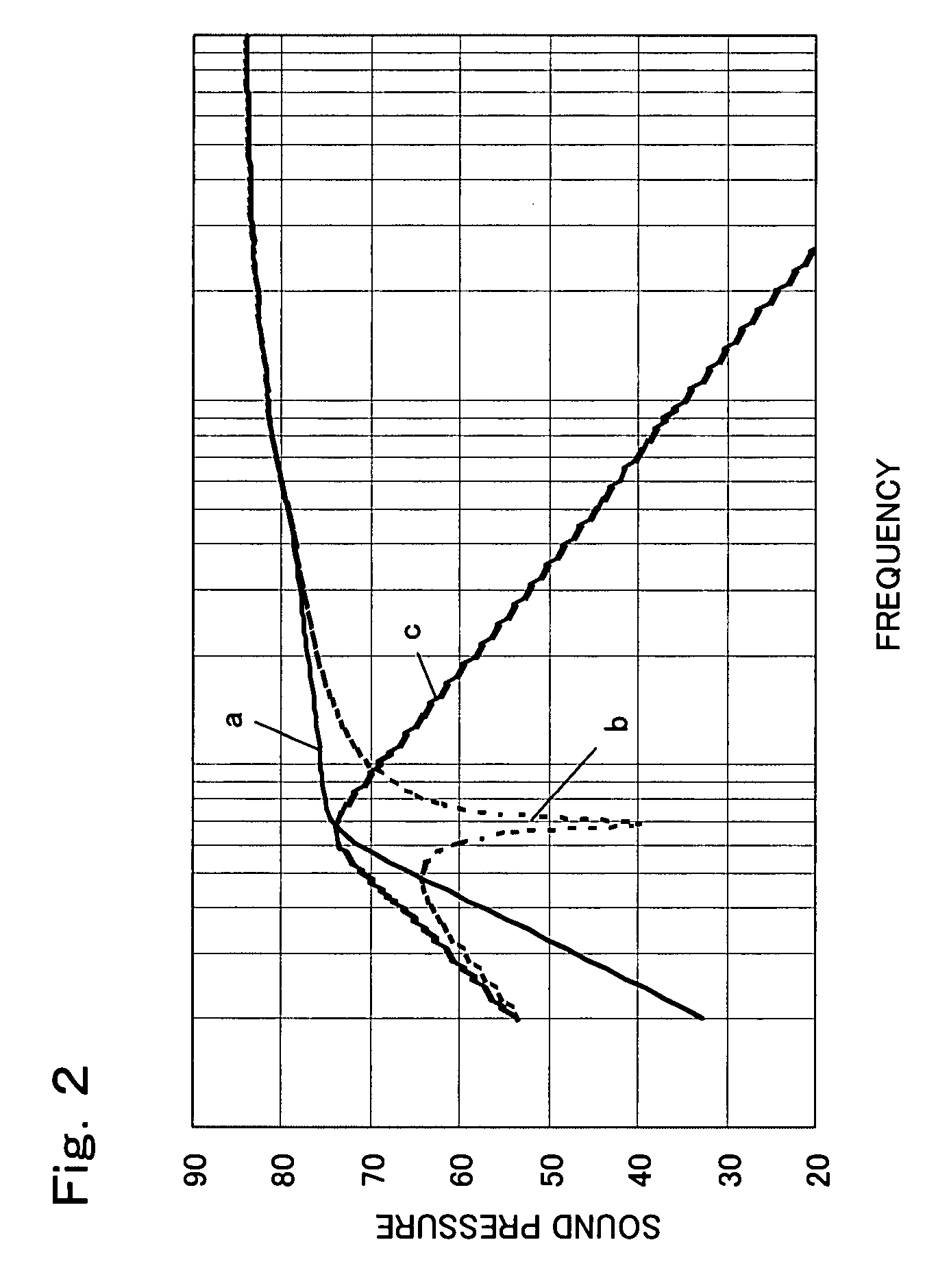

Speaker System

ActiveUS20070201712A1Reduce distortion problemsFrequency/directions obtaining arrangementsTransducer casings/cabinets/supportsSupporting systemPassive radiator

A speaker system of the present invention comprises a cabinet, at least one speaker unit attached to the cabinet, and a plurality of passive radiators attached to the cabinet and each including a diaphragm and a supporting system supporting the diaphragm. The speaker system of the present invention is configured so that distortion components of sound pressures radiated from the supporting systems of the plurality of passive radiators are canceled with each other, and sounds radiated by the plurality of passive radiators are radiated in substantially the same direction from the cabinet.

Owner:SOVEREIGN PEAK VENTURES LLC

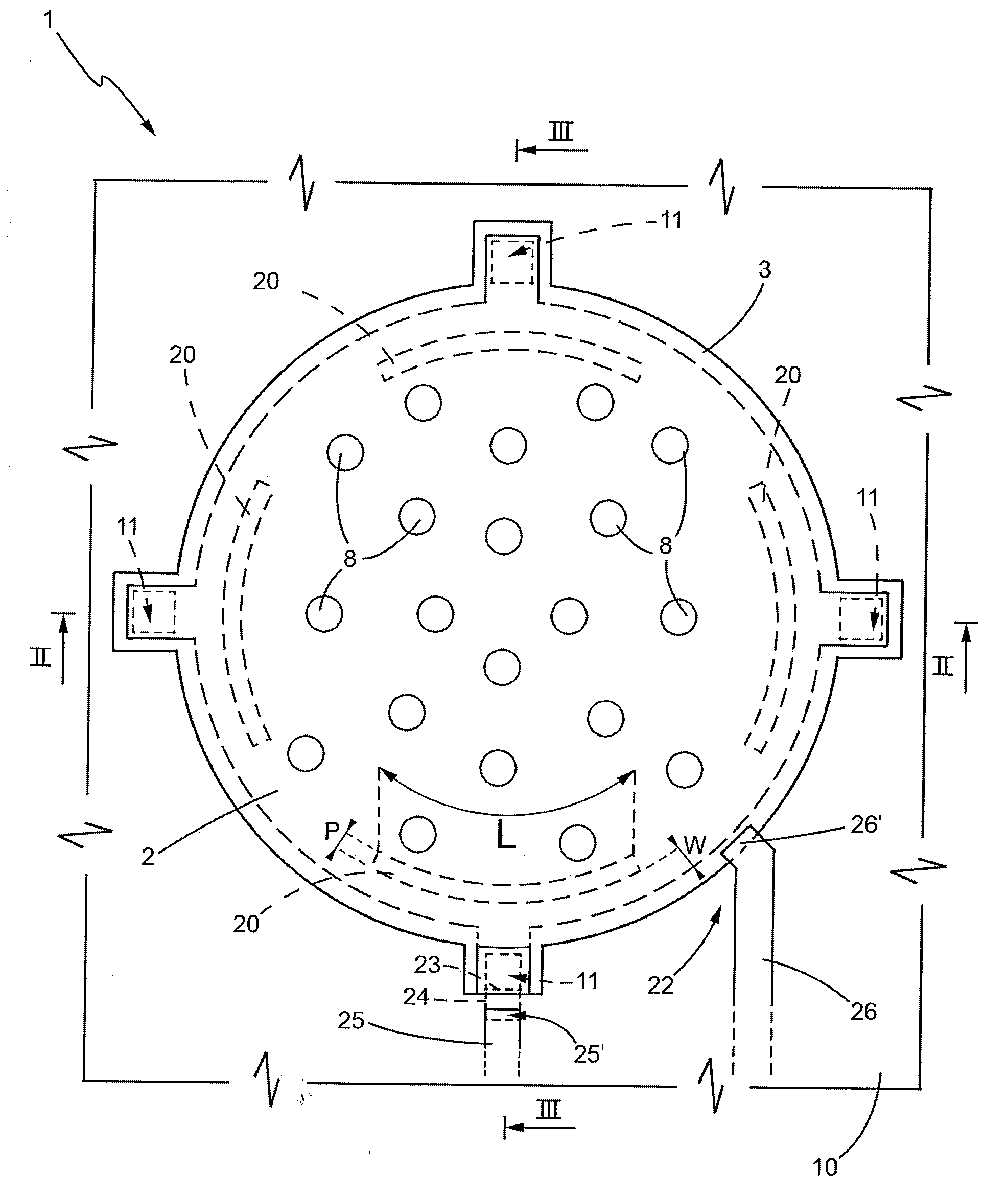

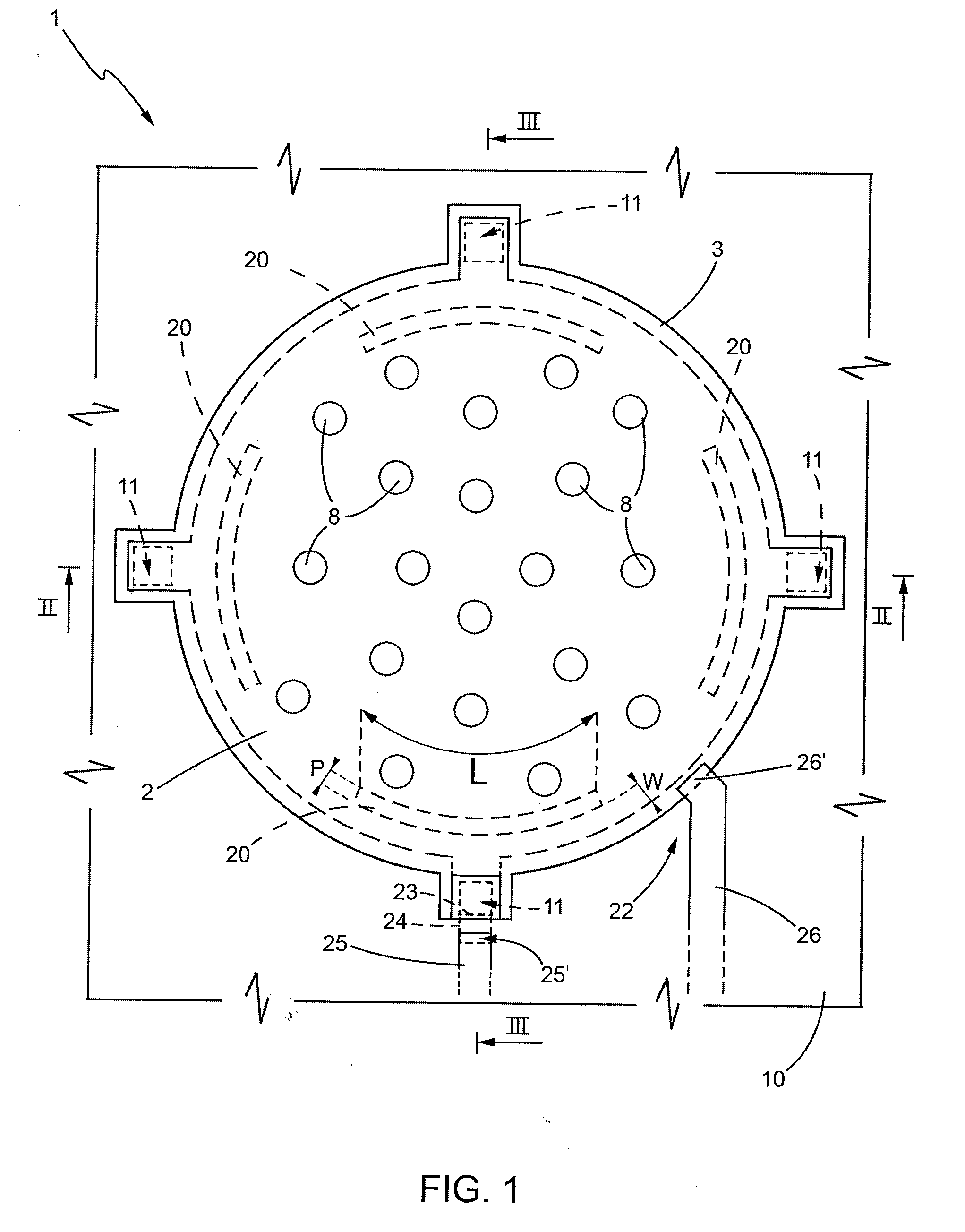

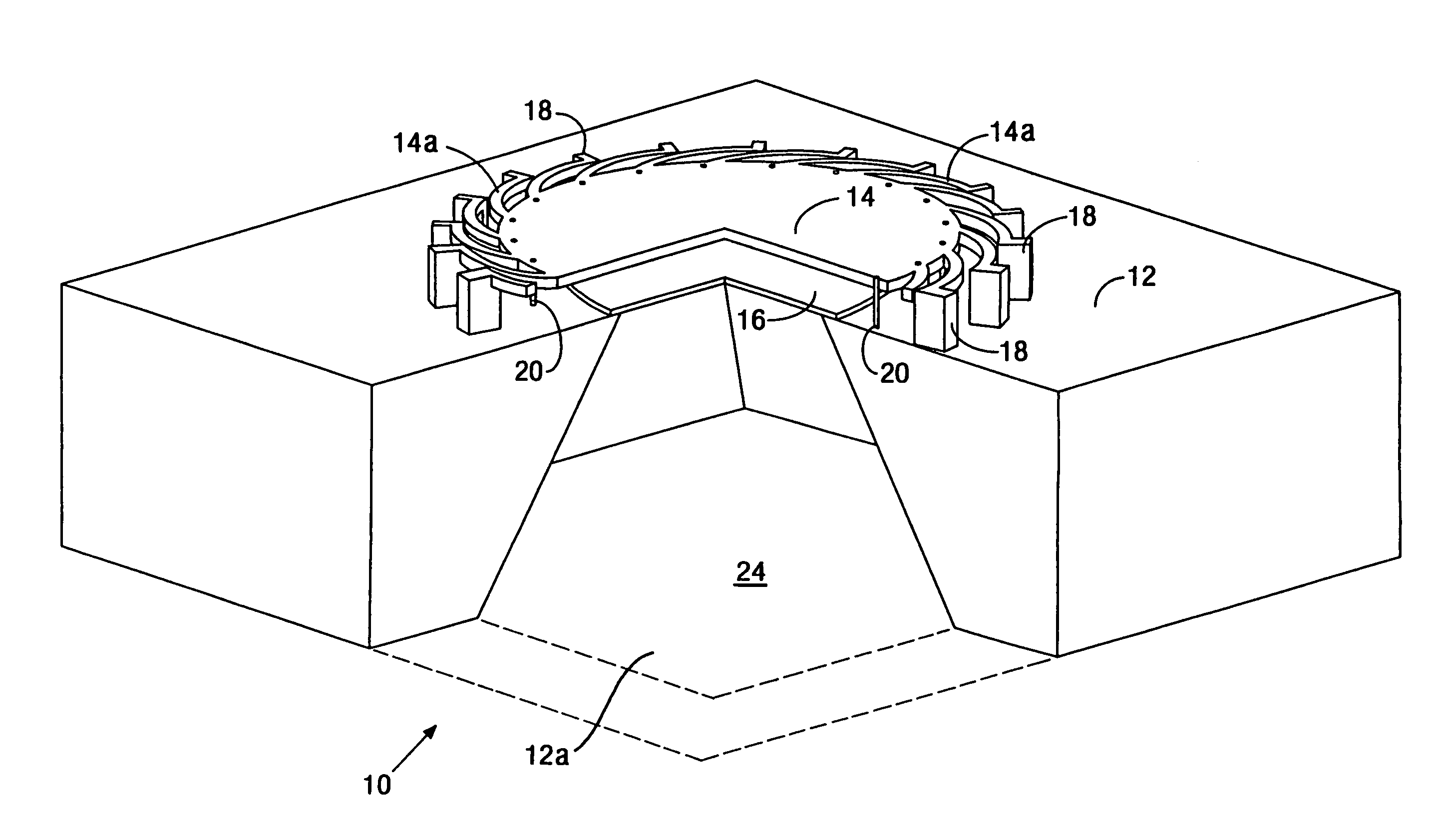

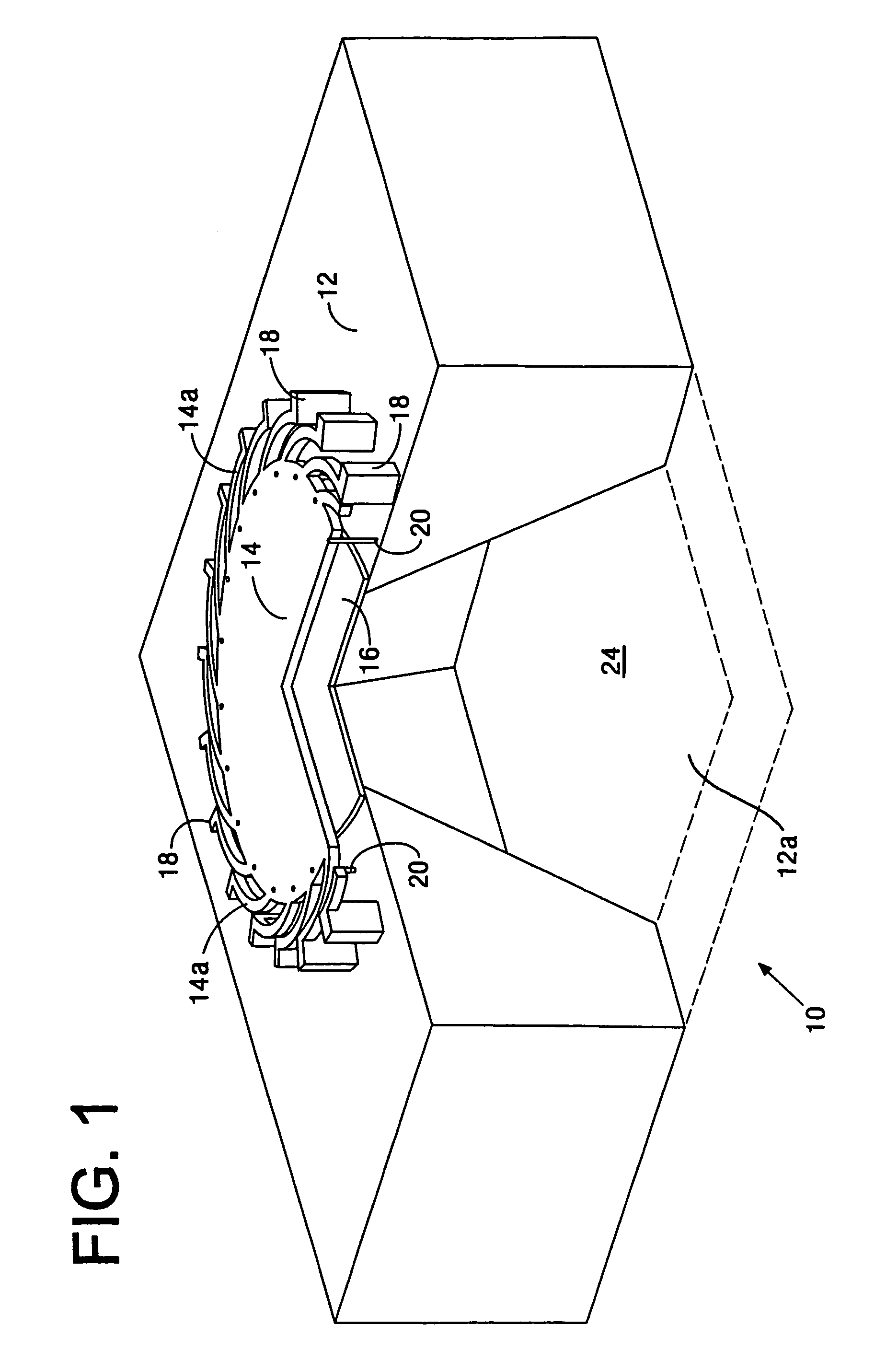

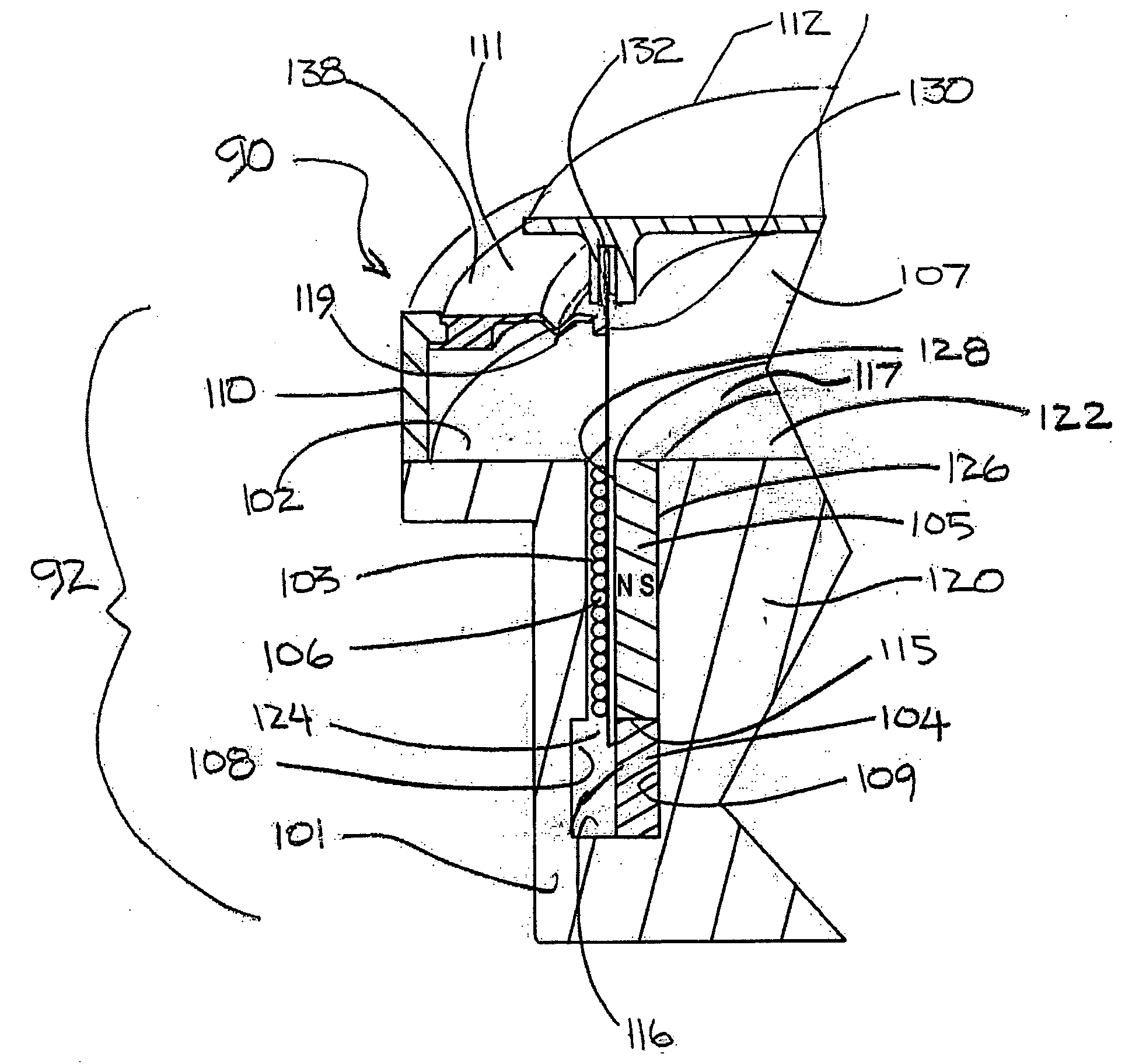

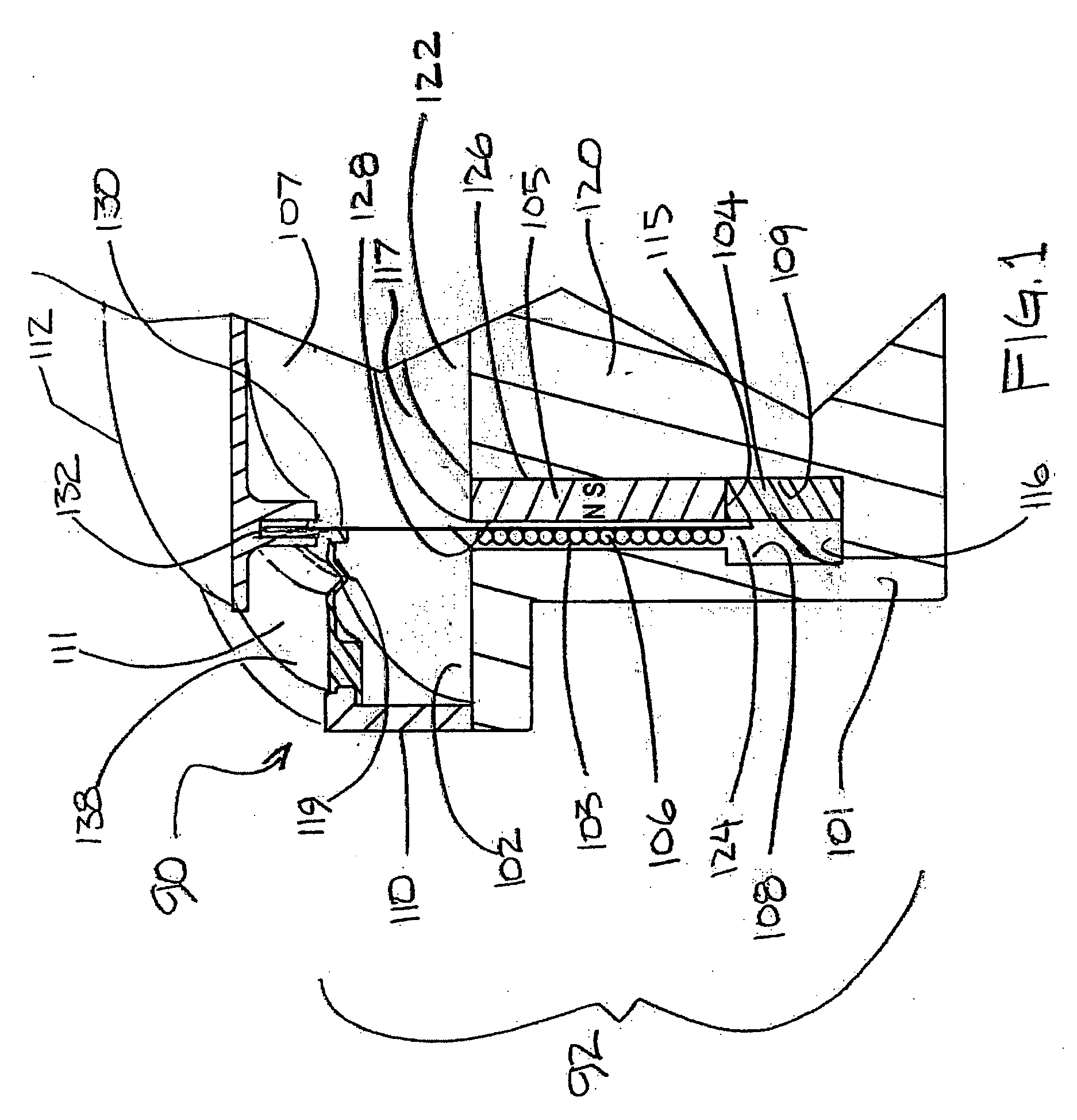

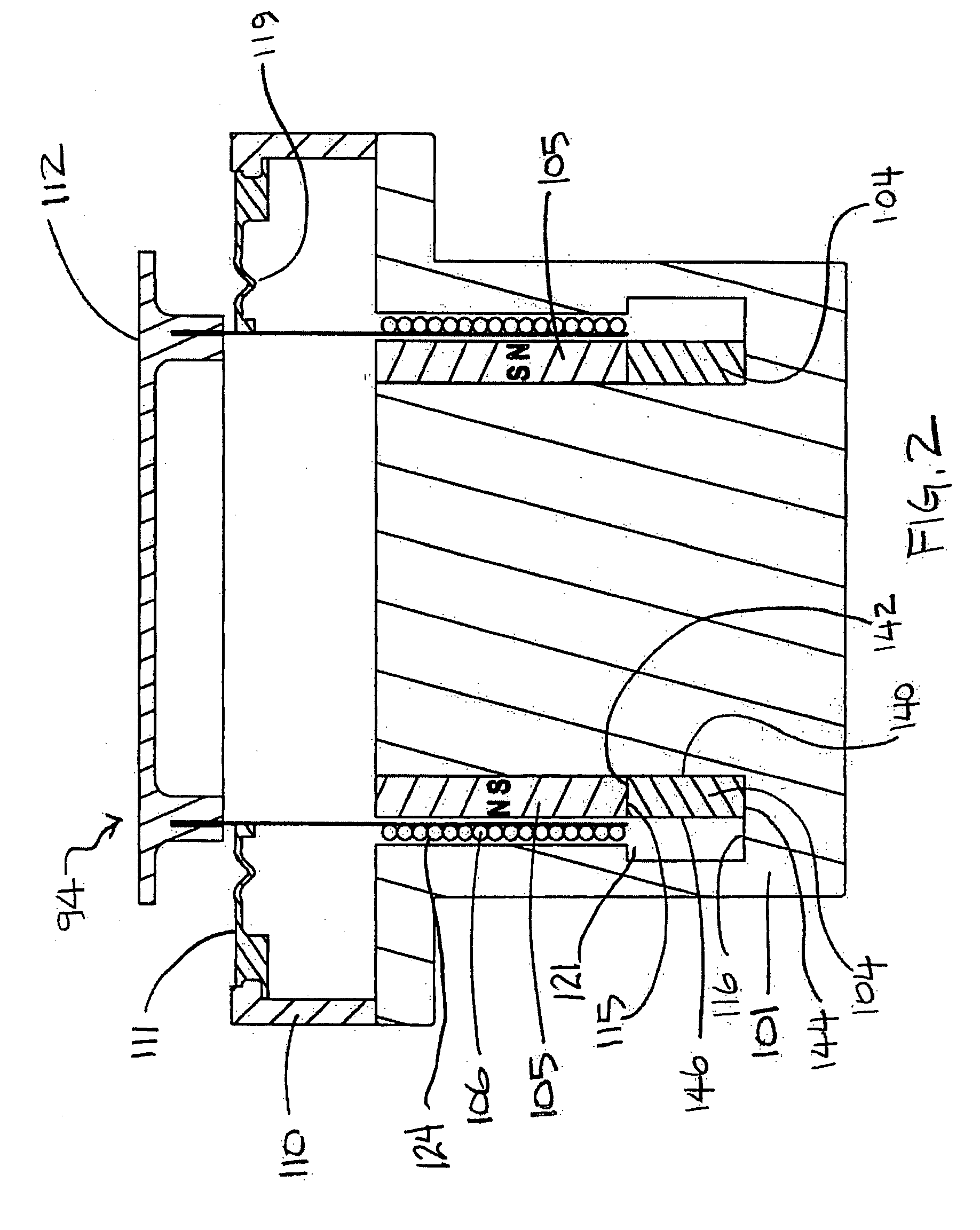

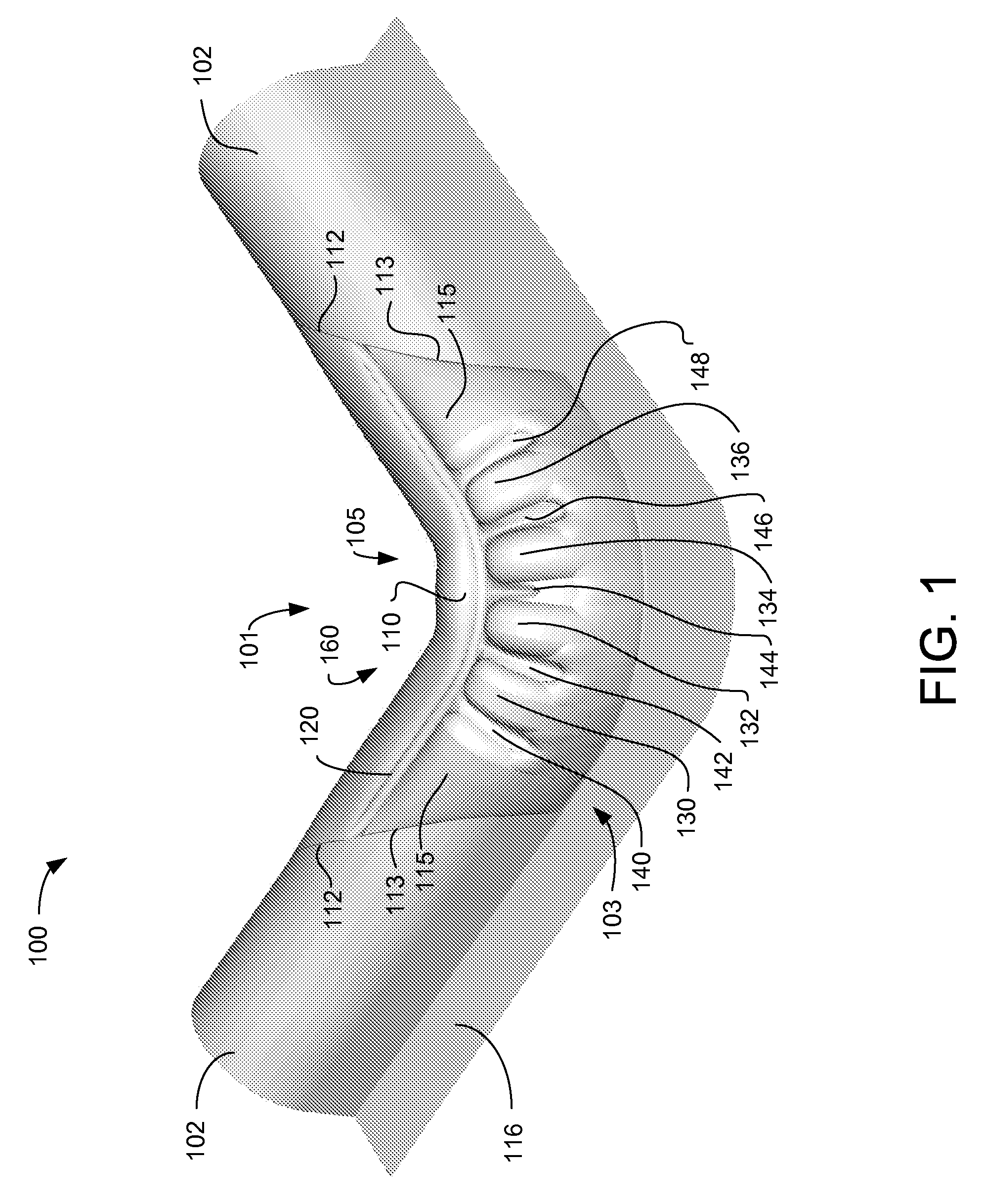

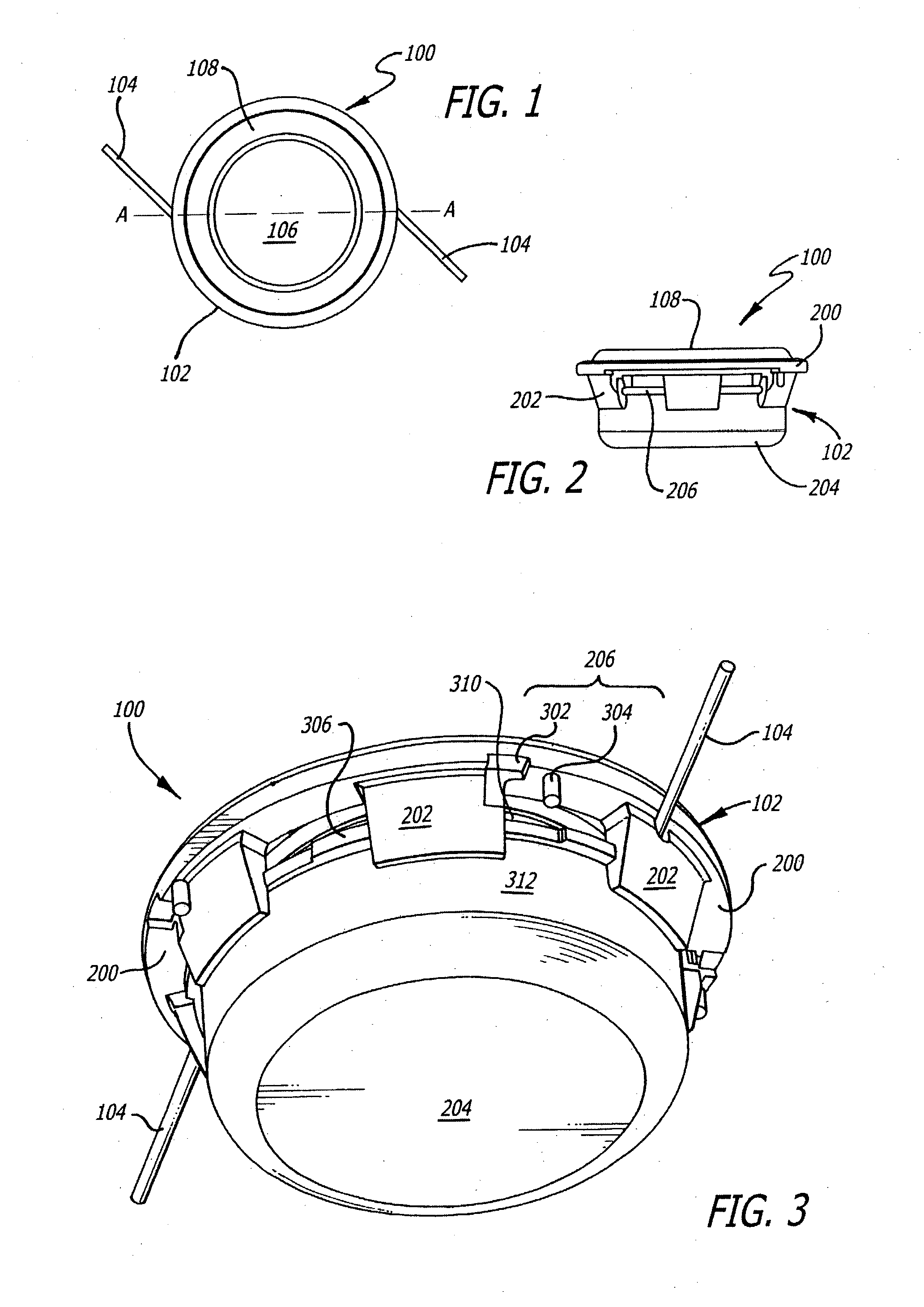

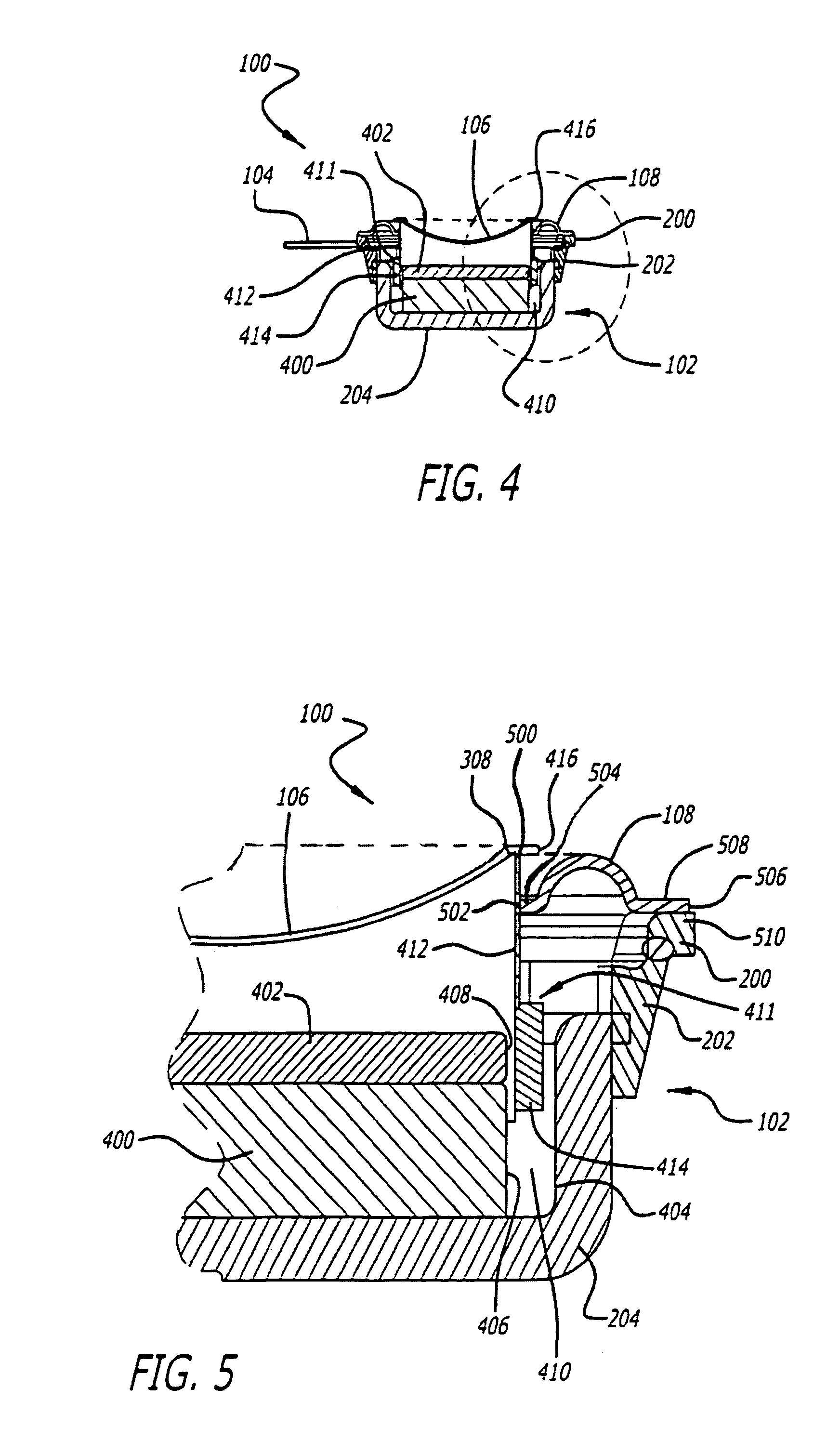

Inertial voice type coil actuator

InactiveUS20060115107A1Minimizing assembly timeMinimizing repair timeTransducer detailsDiaphragm mounting/tensioningConductive materialsActuator

The present invention provides an intertial-type voice actuator that includes a magnetic flux conductive material core with a continuous channel. The channel has antifringing groove. The actuator employs a radially polarized cylindrical magnet spaced in the channel to form a magnetic gap and a conductive coil positioned at least partially in the gap. A multi-component suspension system provides high quality sound using an antifriction bearing, a viscous magnetic fluid, and a spider suspension. The inertial-type actuator is completed by an integrated mounting apparatus. In one embodiment, a receiver and an output disk are interlocked by helical wedges and the actuator is mounted on a soundboard. In another embodiment, a special receiving cavity is attached to a wall stud for intrawall installation. The cavity is equipped with longitudinal electrical contacts so that the actuator can move and still be connected. After the actuator is inserted, the wall covering is installed.

Owner:REVOLUTION ACOUSTICS

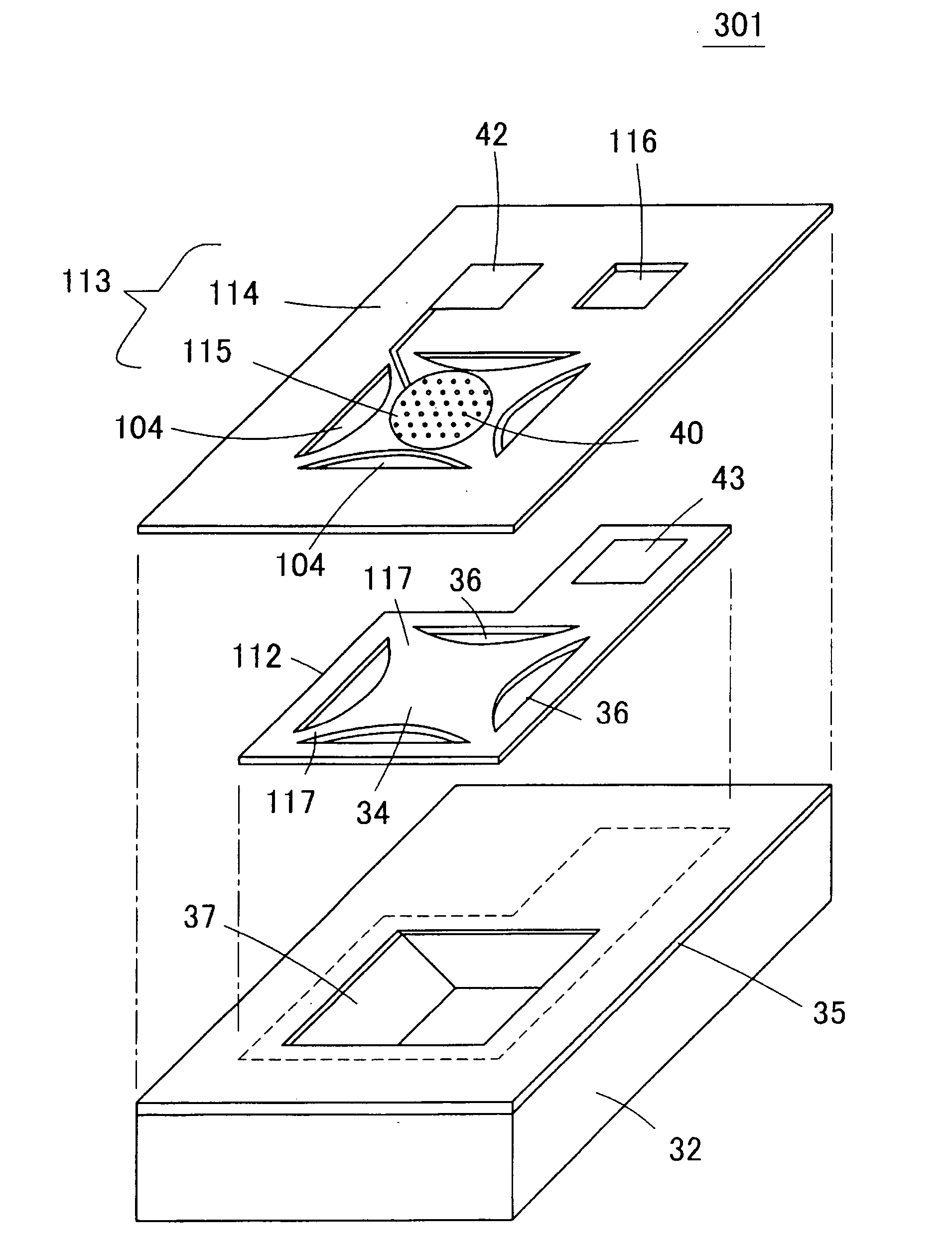

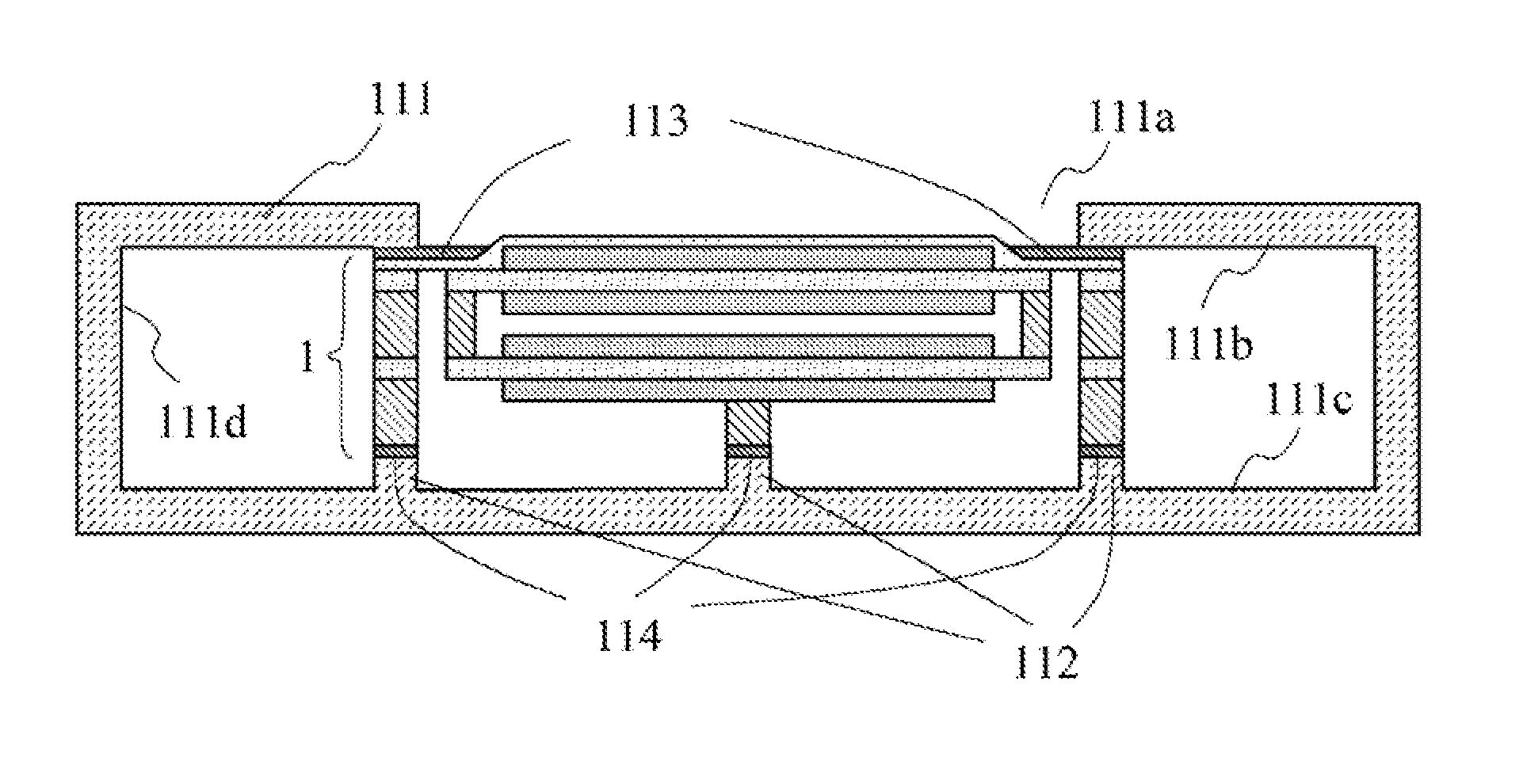

Capacitive Vibration Sensor and Method for Manufacturing Same

ActiveUS20070261910A1MiniaturizeSuppress mutationSubsonic/sonic/ultrasonic wave measurementDecorative surface effectsSiliconVibration sensor

A vibration electrode plate 112 is formed on the upper face of a silicon substrate 32 with an insulating coat film 35 interposed in between. An opposing electrode plate 113 is placed on the vibration electrode plate 112 with an insulating coat film interposed in between, and acoustic holes 40 are opened through the opposing electrode plate 113. Etching holes 36 and 104, each having a semi-elliptical shape, are opened through the vibration electrode plate 112 and the opposing electrode plate 113 so as to face each other longitudinally. A concave section 37 having a truncated pyramid shape is formed in the upper face of the silicon substrate 32, by carrying out an etching process through the etching holes 36 and 104. The vibration electrode plate 112 is held in the silicon substrate 32 by a holding portion 112 placed between the etching holes 36.

Owner:MMI SEMICON CO LTD

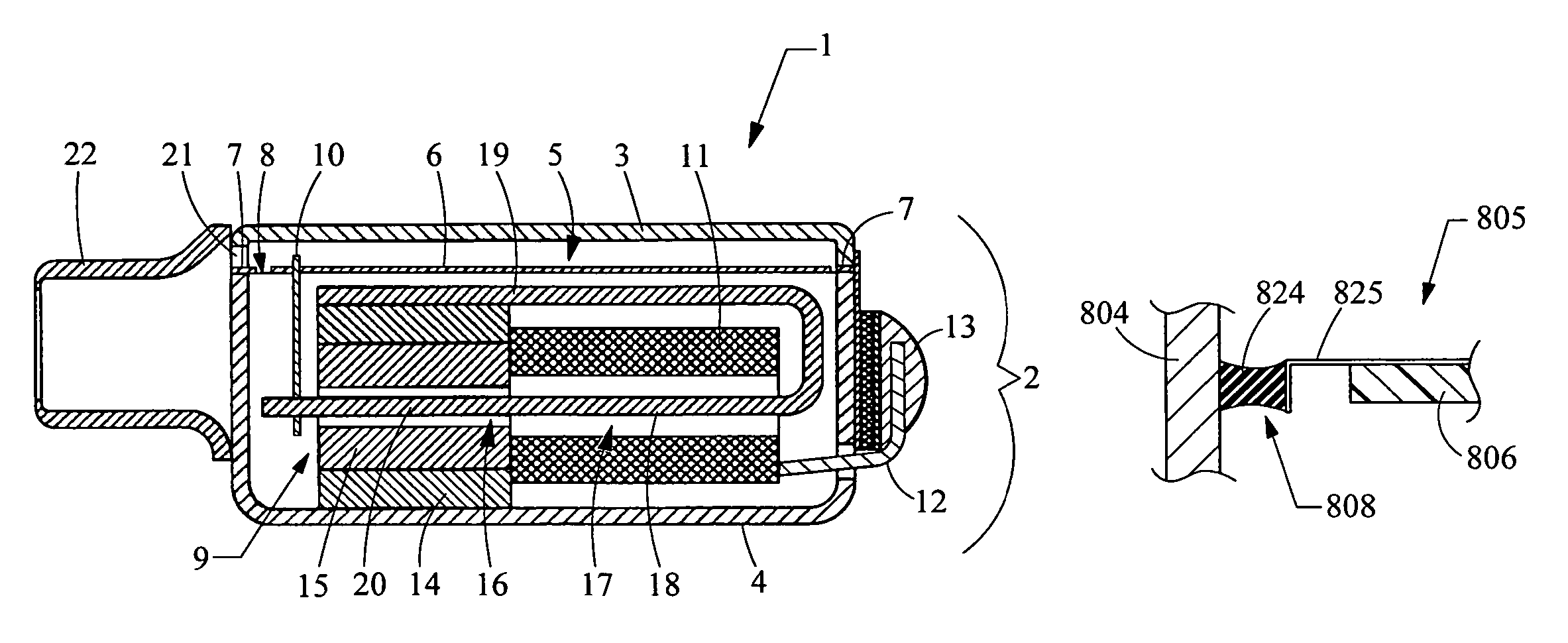

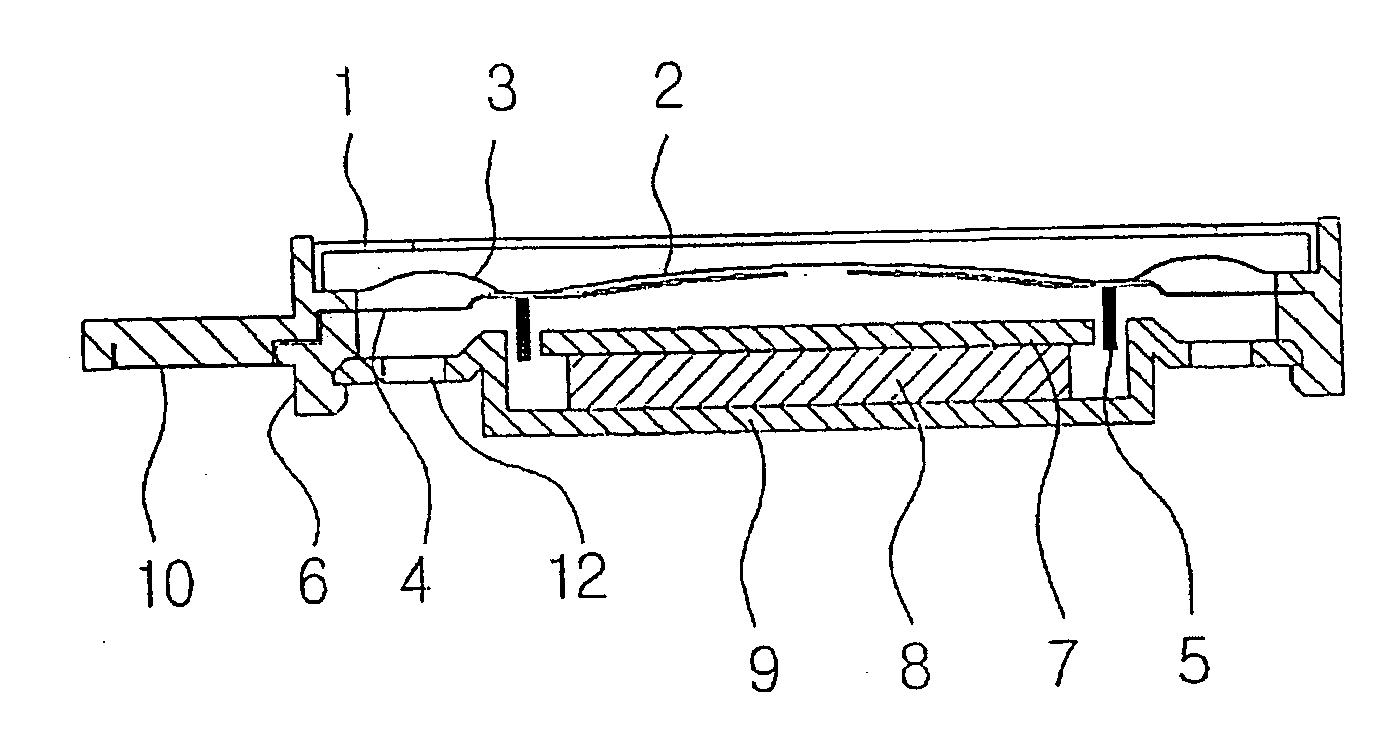

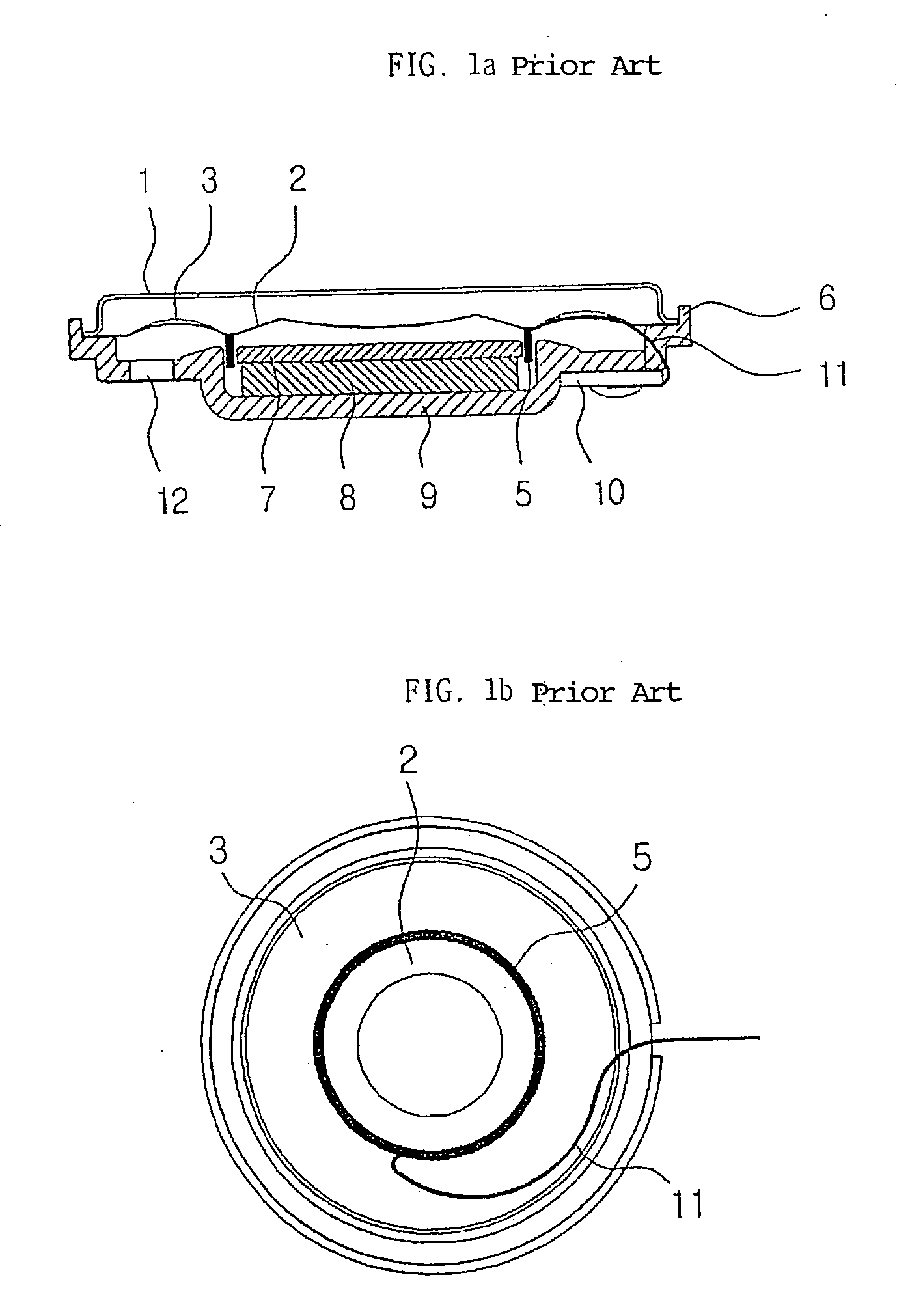

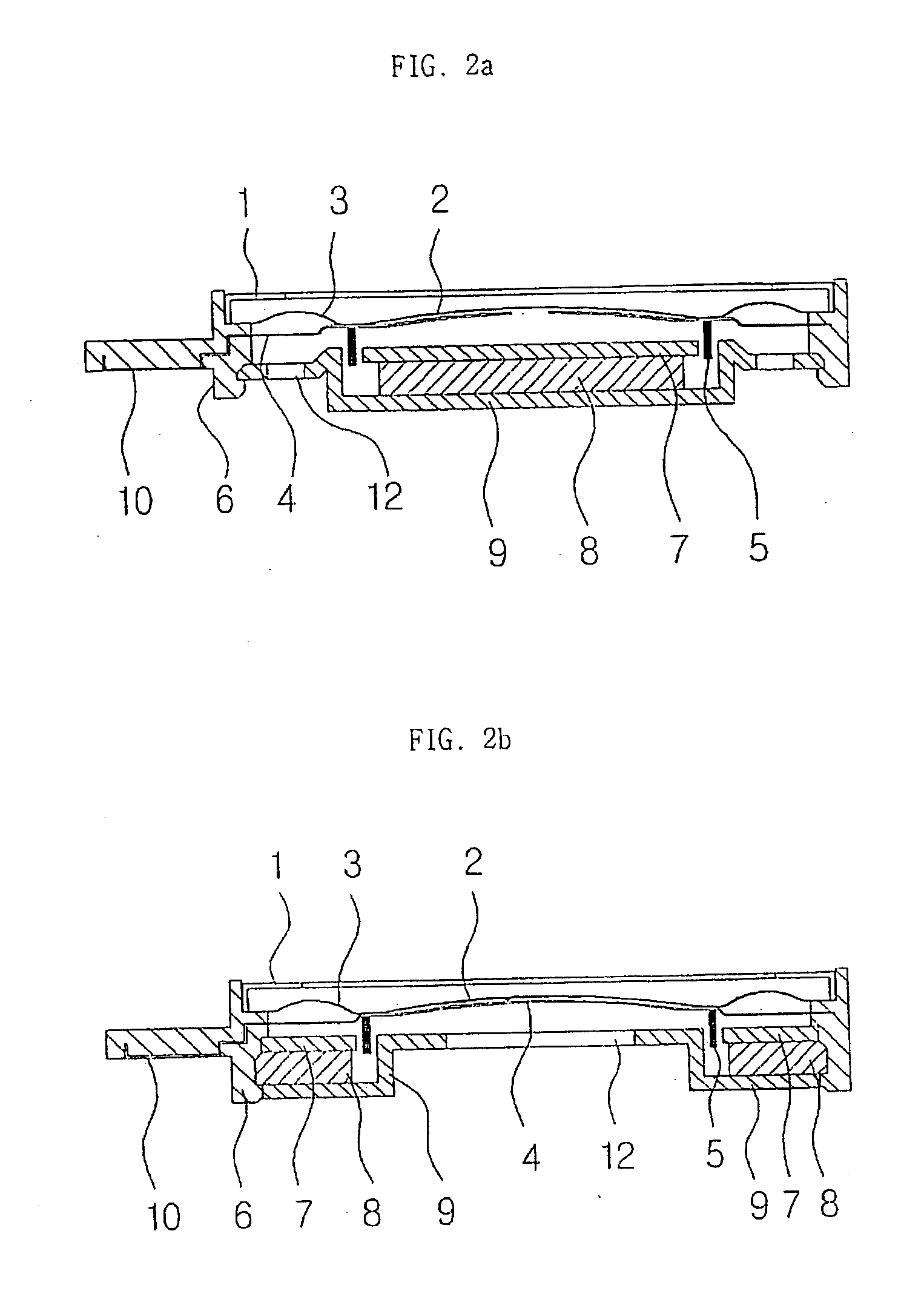

Dynamic micro speaker with dual suspension

InactiveUS20060098838A1Reduce distortion problemsAvoid disconnectionLoudspeaker diaphragm dampingLoudspeaker transducer fixingLow distortionEngineering

The invention relates to a micro-speaker with a second suspension made of highly resilient material installed inside of the speaker. The speaker is able to provide high level acoustic output with low distortion rate in a wide frequency range with a very small and slim structure and it may prevent a disconnection of a lead connecting the voice coil and the electrode. The speaker includes a yoke, a permanent magnet, a plate, a vibration plate integrated with a first suspension, a voice coil, a frame and a protector. The speaker further comprises a second suspension made of highly resilient material installed between the plate and the vibration plate, and is characterized in that the voice coil is attached to the lower surface of the second suspension and the vibration plate is attached to the upper surface of the second suspension and the vibration plate is attached to the upper surface of the second suspension and the outer periphery of the second suspension is fixed to the frame.

Owner:JY CUSTOM CO LTD

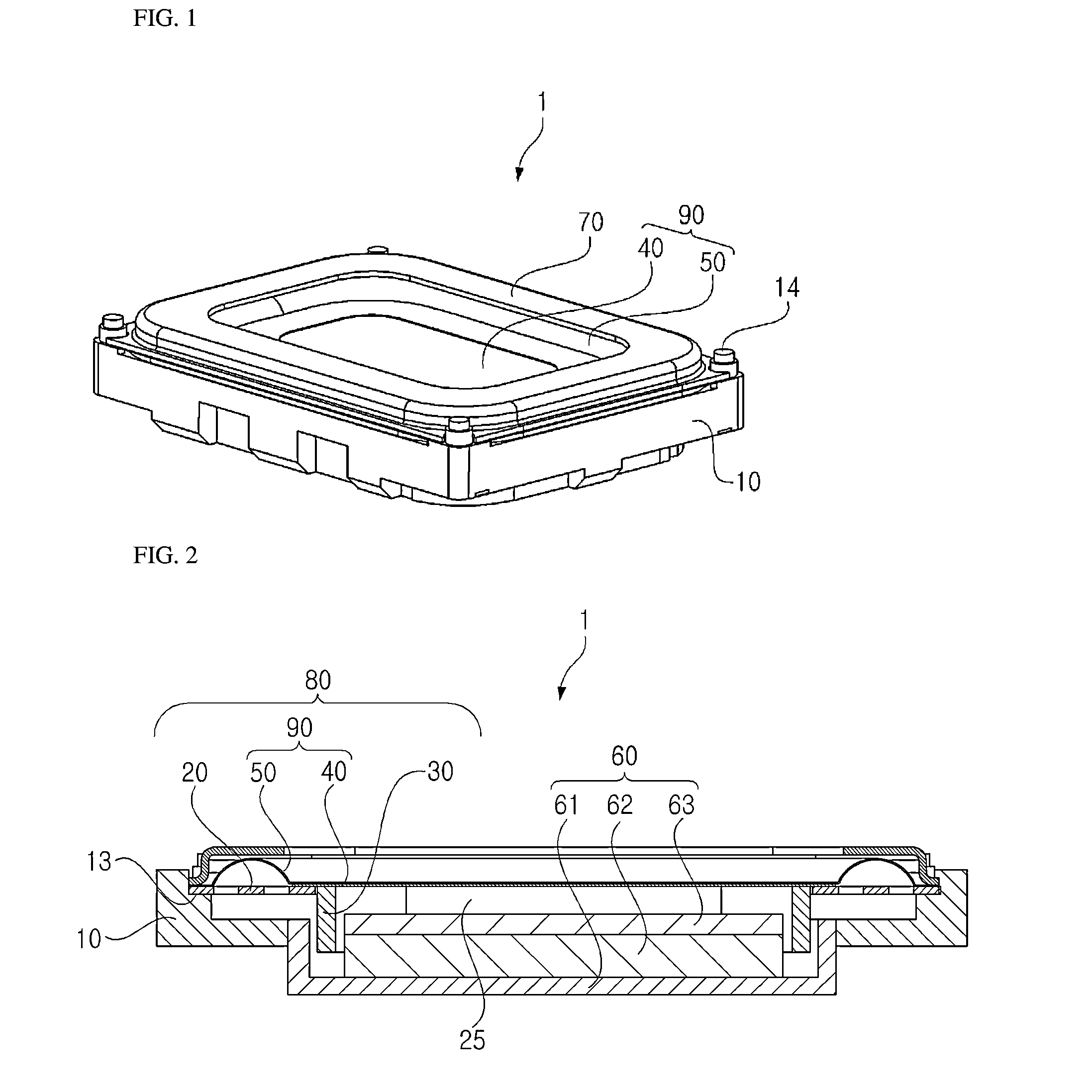

Piezoelectric acoustic transducer

ActiveUS20120057730A1Large displacementImprove voltage sensitivityTransducer detailsPiezoelectric/electrostrictive transducersTransducerEngineering

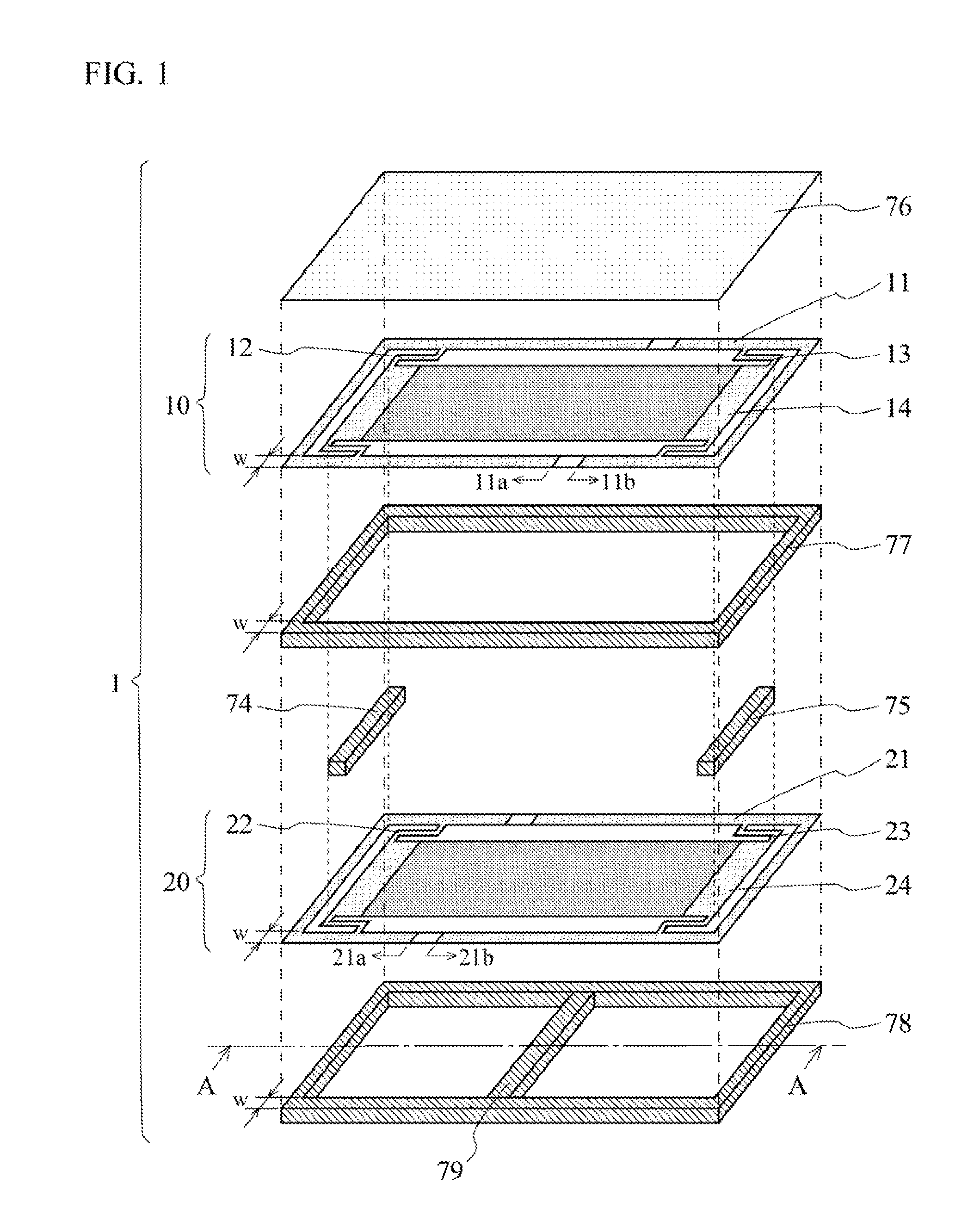

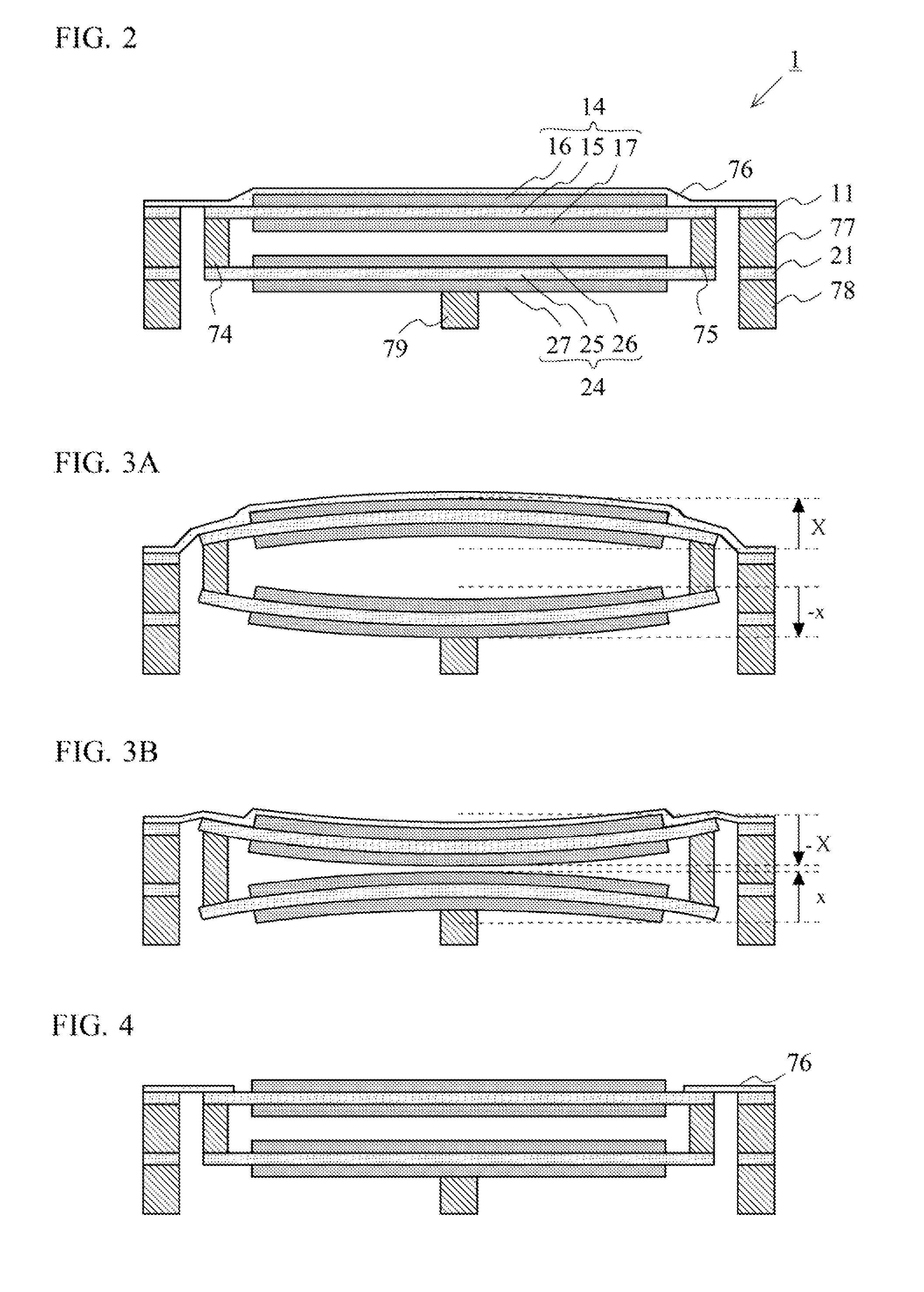

A piezoelectric acoustic transducer (1) of the present invention includes a lower frame (78), a lower speaker circuit (20), an upper frame (77), an upper speaker circuit (10), and a surround (76). The upper speaker circuit (10) has a piezoelectric diaphragm (14) in which piezoelectric elements (16, 17), each having a structure that flat plate electrodes are disposed on top and bottom of a piezoelectric member, are mounted on top and bottom surfaces of a board (15). The lower speaker circuit (20) has a piezoelectric diaphragm (24) in which piezoelectric elements (26, 27), each having the same structure, are mounted on a top surface and a bottom surface of a board (25). The piezoelectric diaphragms (14, 24) are coupled to each other via coupling members (74, 75). At an application of a voltage, the piezoelectric diaphragms (14, 24) are caused to curve in directions opposite to each other. Having this structure, the piezoelectric acoustic transducer (1) has an increased displacement in a thickness direction thereof, and thereby achieving high quality sound with space-saving.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

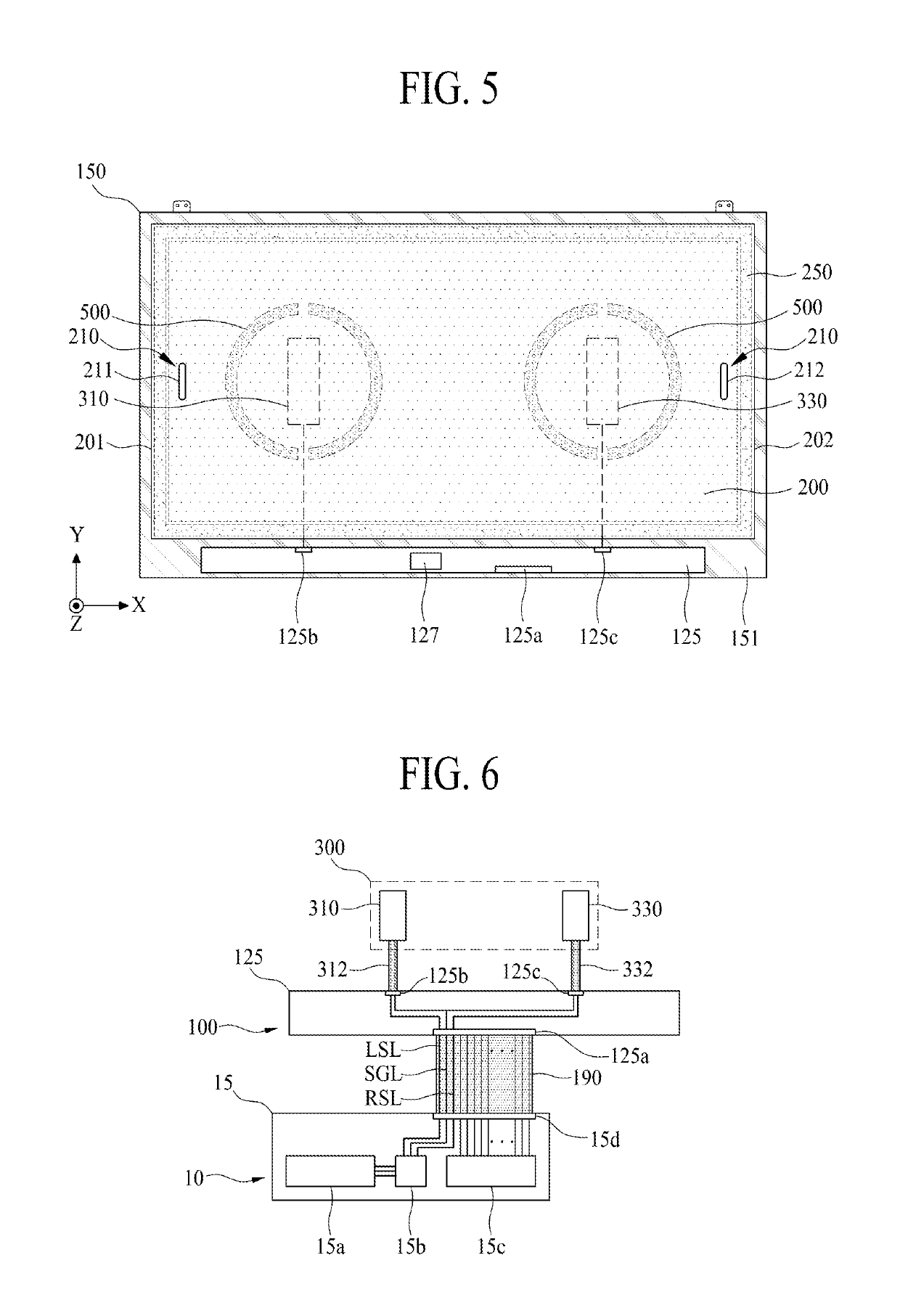

Panel vibration type sound generating actuator and double-faced display device including same

ActiveUS20170289694A1Minimum footprintReduce pressureTelevision system detailsStatic indicating devicesDisplay deviceEngineering

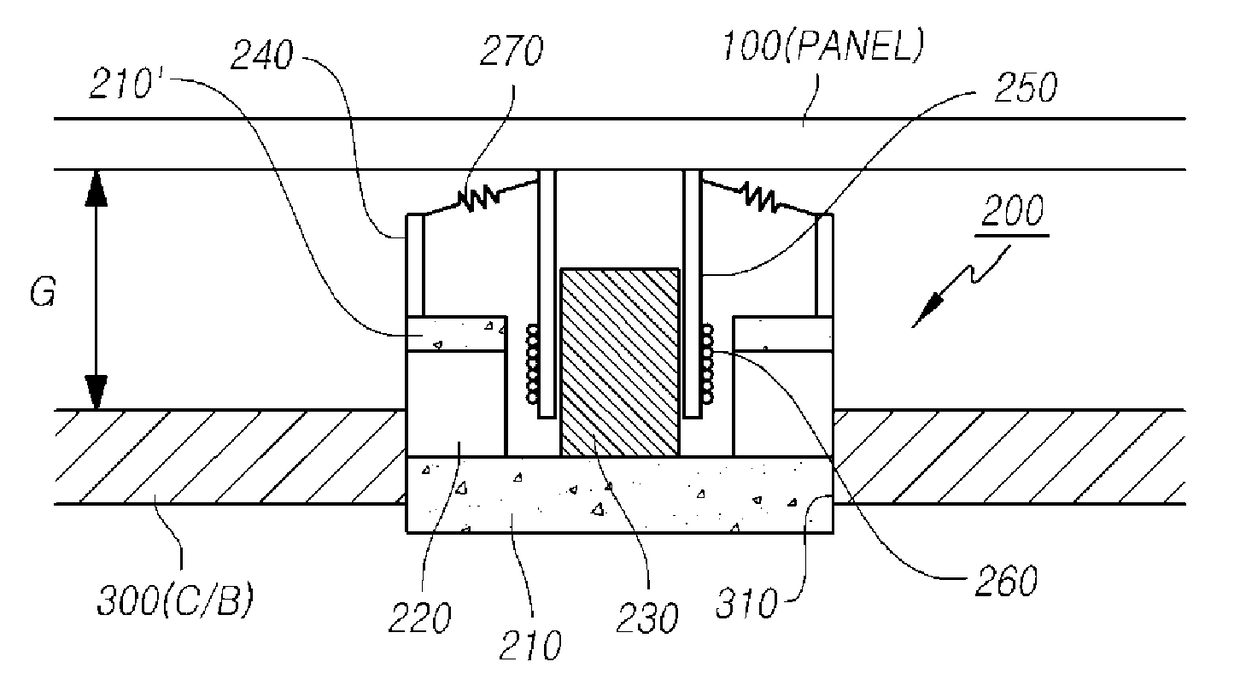

The present embodiment relates to a double-faced display device generating sound by directly vibrating a display panel and includes: a first display panel and a second display panel disposed at the front and rear surface thereof, respectively; a single sound generating actuator connected to the first display panel and the second display panel to simultaneously vibrate the first display panel and the second display panel and thus generate sound; and a support part configured to support the sound generating actuator, the first display panel, and the second display panel. The present embodiment does not require a separate speaker and thus can achieve a thin or slim display device, and can improve the localization or the quality of sound output in opposite directions in the double-faced display device.

Owner:LG DISPLAY CO LTD

Telescoping loudspeaker has multiple voice coils

InactiveUS6031925AImprove performanceSmall sizeTransducer detailsSound producing devicesActuatorControl theory

A loudspeaker has a chassis, a cone, an actuator and a sub-frame. The actuator is coupled between the chassis and the diaphragm. The sub-frame is flexibly coupled to the chassis and the diaphragm. The diaphragm is flexibly suspended from the chassis. The actuator directly drives both the diaphragm and the sub-frame through coils attached to the cone and to the sub-frame.

Owner:U S PHILIPS CORP

Silicon microphone without dedicated backplate

ActiveUS20090208037A1Piezoelectric/electrostrictive microphonesLoudspeaker diaphragm dampingCMOSEngineering

Various embodiments of a silicon microphone sensing element without dedicated backplate are disclosed. The microphone sensing element has a circular or polygonal diaphragm with a plurality of perforated springs suspended above the front side of a conductive substrate. The diaphragm is aligned above one or more back holes in the substrate having a front opening smaller than the diaphragm. In one embodiment, a continuous perforated spring surrounds the diaphragm and has a shape that conforms to the diaphragm. A plurality of perforated beams connects the spring to rigid pads that anchor the movable diaphragm and spring. In another embodiment, there is a plurality of perforated springs having double or triple folding configurations and a plurality of perforated beams connecting the diaphragm to rigid pads. Also disclosed is a scheme to integrate the silicon microphone sensing element with CMOS devices on a single chip.

Owner:SHANDONG GETTOP ACOUSTIC

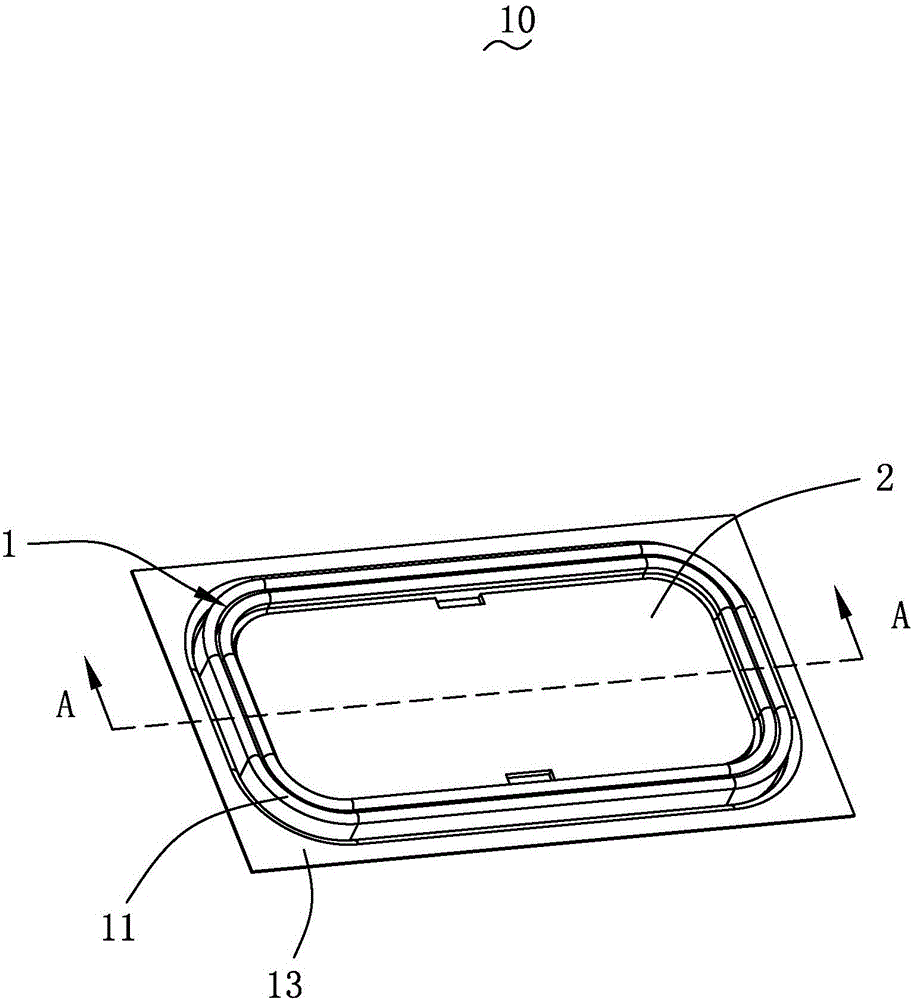

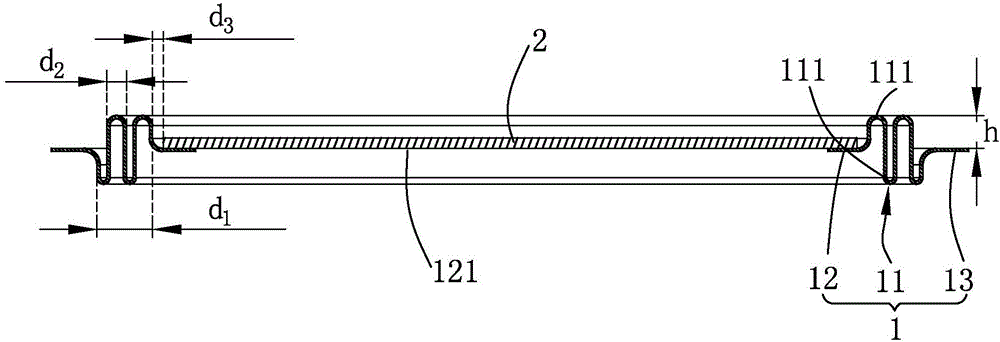

Diaphragm and sounding device

InactiveCN106817658ASimple processImprove consistencyPolymeric diaphragmsNon-planar diaphragms/conesEngineeringSounds device

A diaphragm provided by the present invention comprises a vibration part and a spherical top part fixed on the vibration part, and the vibration part is made of a rubber compound and comprises a folding ring part, a first fixing part extending from the inner side of the folding ring part and a second fixing part extending from the outer side of the folding ring part. The spherical top part is fixed at the first fixing part, and the folding ring part comprises a plurality of arc-shaped folding ring units which recess along the vibration direction of the diaphragm, wherein the recessing directions of the two adjacent folding ring units are reverse. The present invention also provides a sounding device which comprises a basin stand and the above diaphragm provided by the present invention and fixedly supporting the basin stand. Compared with the prior art, the diaphragm of the present invention is good in consistency, small in distortion and high in stability, and the sounding device applying the diaphragm is good in acoustic performance.

Owner:AAC TECH SHUYANG +1

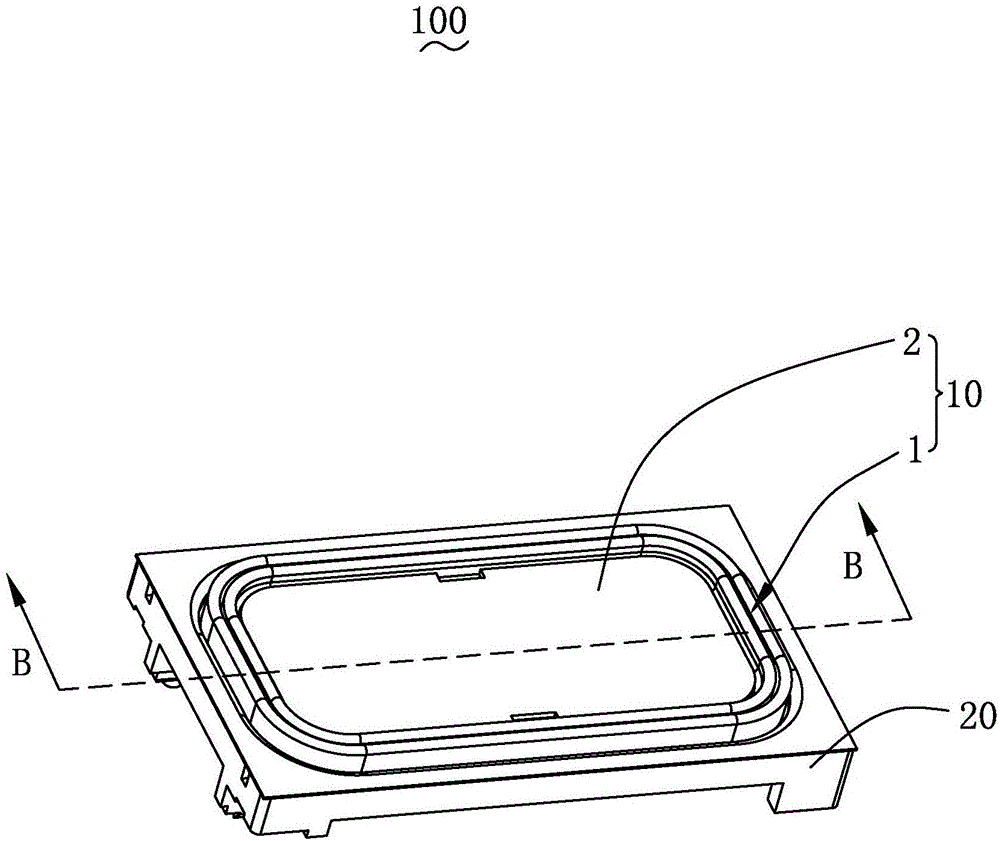

Square speaker

ActiveUS7275620B1Increase amplitudeLoudspeaker diaphragm materialsLoudspeaker diaphragm shapeEngineeringVolume displacement

A square speaker is disclosed having a novel surround with a novel rounded corner design and with a magnet assembly and former sized, shaped, and arranged to exploit the increased excursions enabled by the novel surround. The arcuate portion of the rounded corner features smoothed trapezoidal circumferential undulations of the radially outer portion and an extension pad forms the arcuate portion of the radially inner portion of the rounded corner. An apex groove separates the inner portion from the outer portion. Tapered protrusions of the outer portion flank the smoothed trapezoidal circumferential undulations. The rounded corner is bounded by edges making angles of between 20 degrees and 40 degrees (preferably about 35 degrees) with straight sides of the square surround. Most of the outer perimeter of the entire inner flange adjoins the inner portions of the rounded corners. Significant increases in volume displacement per speaker size are achieved.

Owner:MITEK

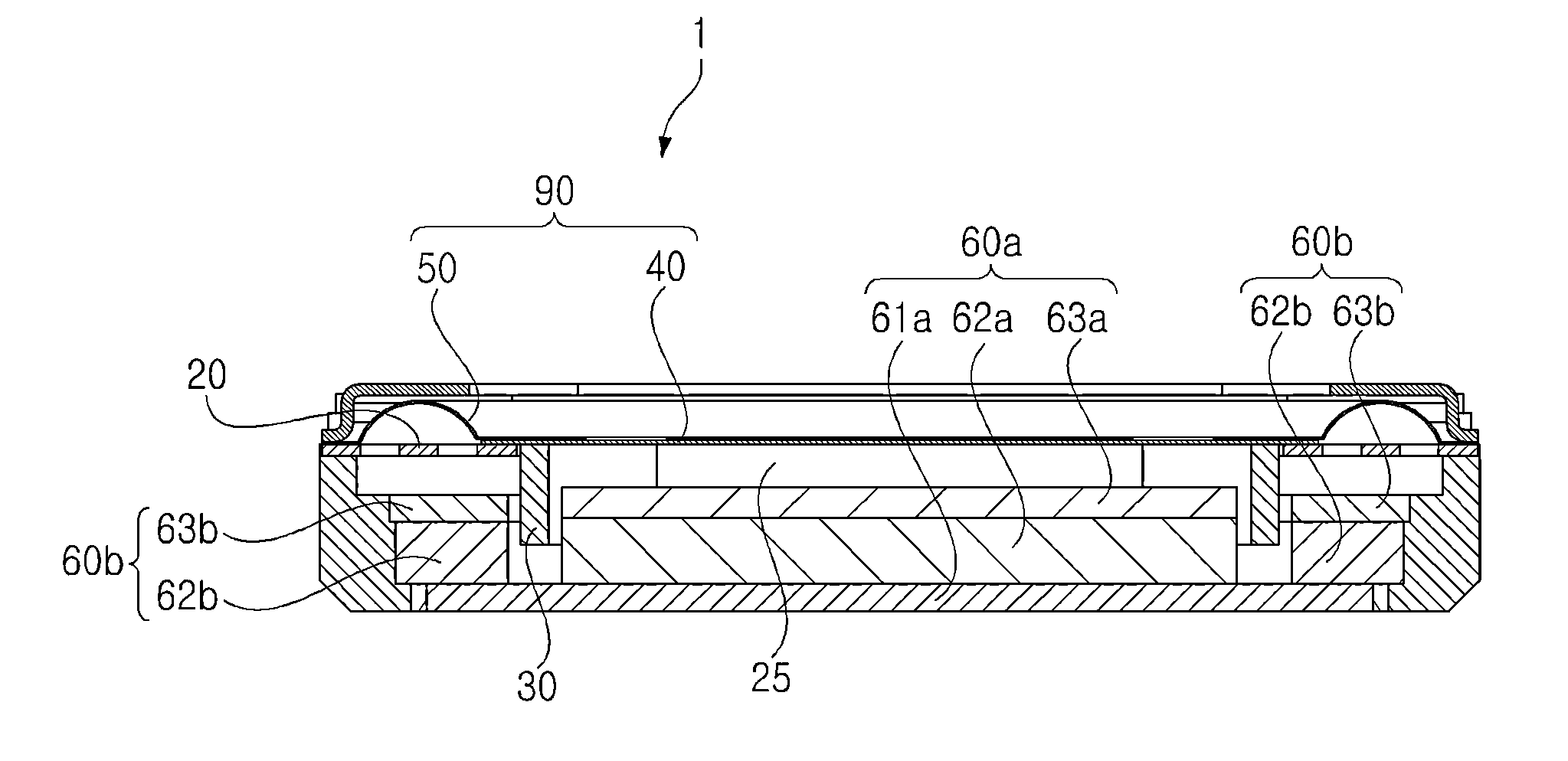

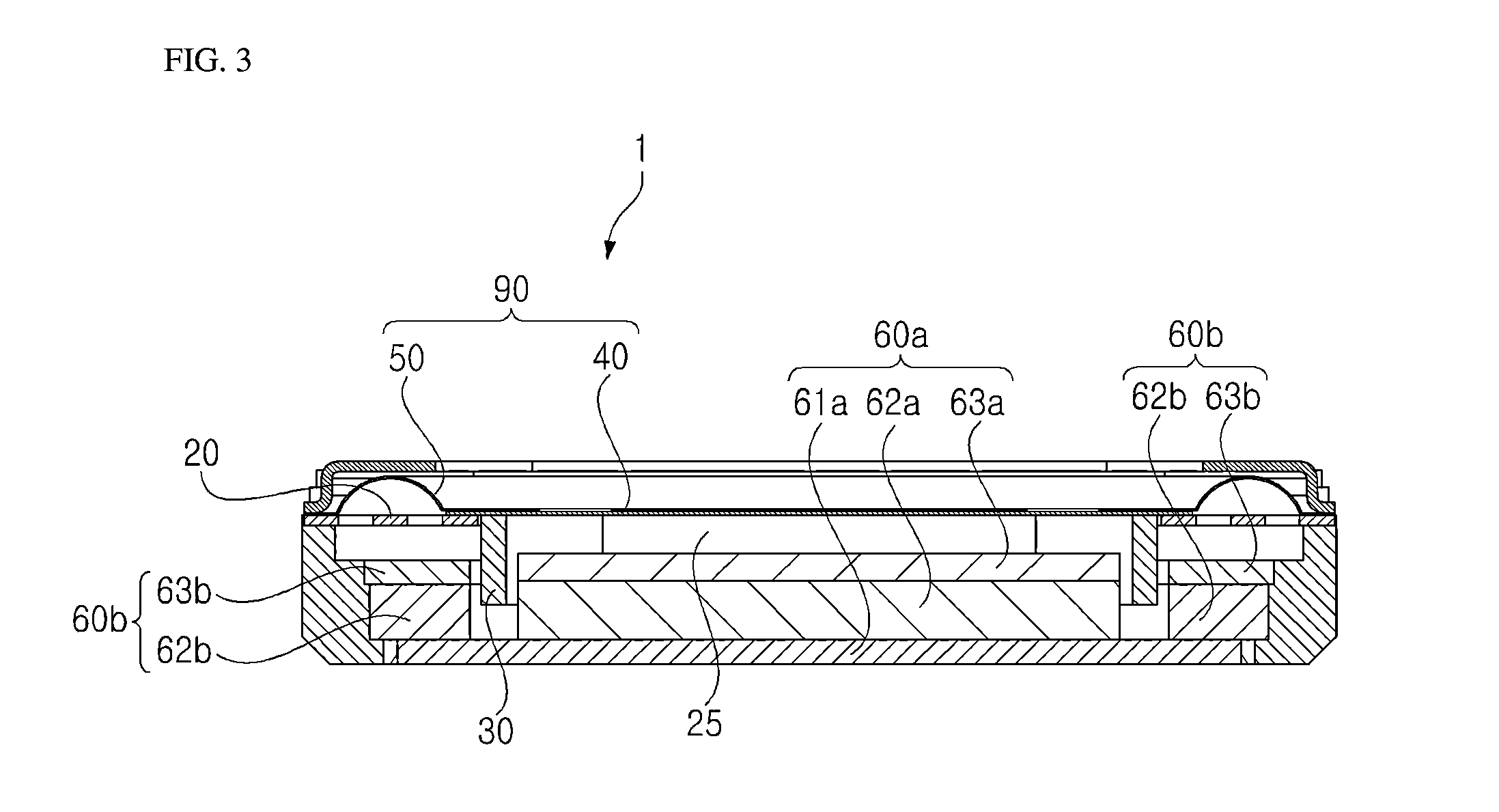

High power micro-speaker

InactiveUS20130156237A1Simple processImprove automationTransducer circuit dampingDeaf-aid setsEngineeringLoudspeaker

Disclosed is a high power micro-speaker having a damper plate. More particularly, disclosed is a high power micro-speaker in which a damper plate has an opening through which a voice coil can pass, and the voice coil having passed through the opening is attached to a lower surface of a vibrating plate that is located above the damper plate, which provides an increased vibrating region. As such, enhanced output power of the micro-speaker is accomplished by increasing a height of the voice coil, or a slimmer design of the micro-speaker is accomplished by reducing a height of a frame.

Owner:BUJEON

Integrated acoustic transducer obtained using MEMS technology, and corresponding manufacturing process

ActiveUS8942394B2Semiconductor electrostatic transducersElectrostatic transducer microphonesTransducerEngineering

A MEMS acoustic transducer provided with a substrate having cavity, and a membrane suspended above the cavity and fixed peripherally to the substrate, with the possibility of oscillation, through at least one membrane anchorage. The membrane comprises at least one spring arranged in the proximity of the anchorage and facing it, and is designed to act in tension or compression in a direction lying in the same plane as said membrane.

Owner:STMICROELECTRONICS SRL

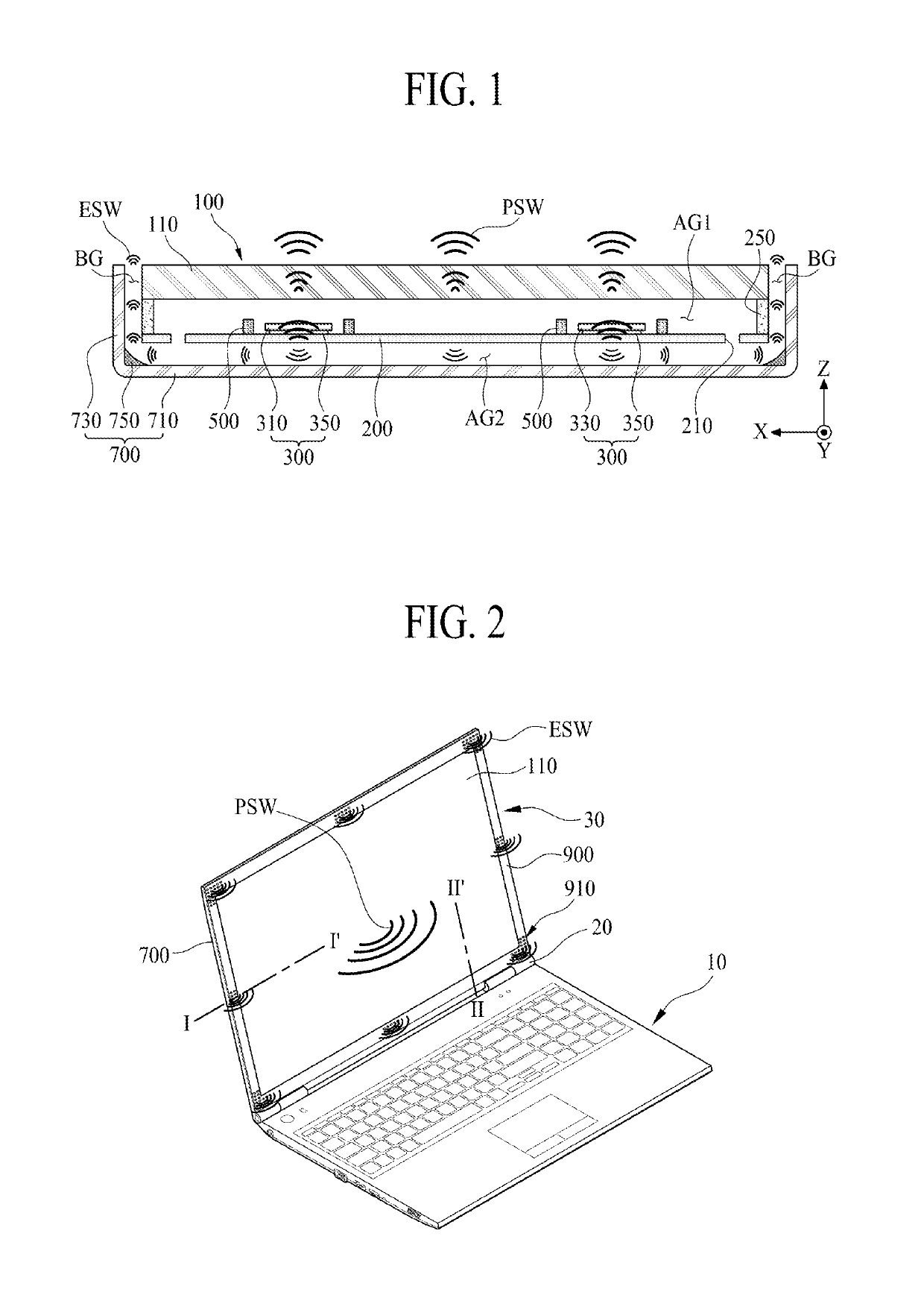

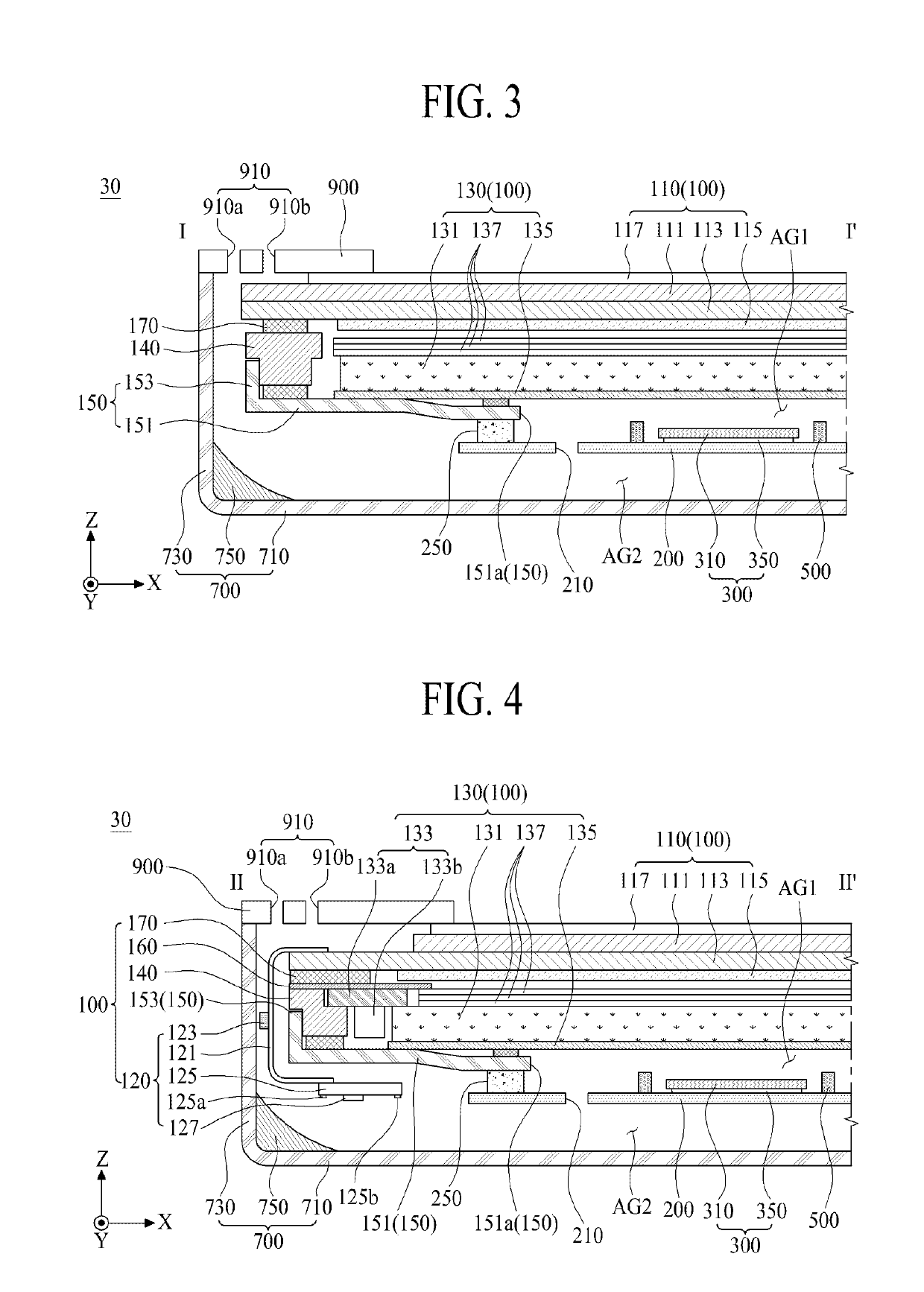

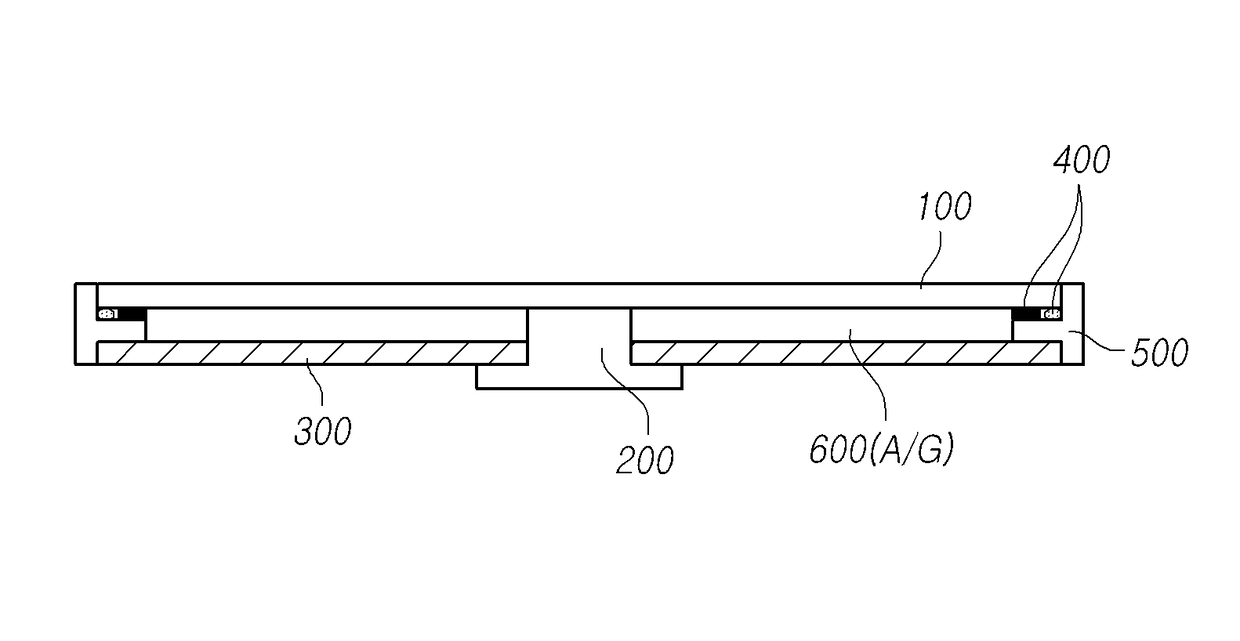

Display apparatus and computing apparatus including the same

ActiveUS20190182573A1Excellent characteristicsImprove featuresPiezoelectric/electrostrictive transducersDetails for portable computersEngineeringComputer science

Provided are a display apparatus and a computing apparatus including the same. A display apparatus includes: a display module including a display panel configured to display an image, a vibration plate on the display module, a first air gap between the vibration plate and the rear surface of the display module, a vibration module on the vibration plate, and a system rear cover on the vibration plate, a second air gap between the system rear cover and the vibration plate, wherein the vibration plate includes a communication part configured to allow air to flow between the first air gap and the second air gap.

Owner:LG DISPLAY CO LTD

Organic light emitting display device including a sound generating apparatus

ActiveUS9818805B2Convenient ArrangementImprove sealingBending wave transducersSolid-state devicesSound generationDisplay device

Embodiments of the present disclosure relate to an organic light emitting display device which directly vibrates an organic light emitting display panel to generate sound, and includes: an organic light emitting display panel including a light emitting layer including an organic light emitting material layer and an encapsulation layer disposed at one side of the light emitting layer; and a sound generating actuator in direct contact with the organic light emitting display panel to vibrate the organic light emitting display panel to generate sound. Especially, the organic light emitting display panel is a bottom emission type device, and thus can prevent generation of a weighted color mixing phenomenon in a wide viewing angle at the time of panel vibration and reduce the thickness or weight of the panel to thereby enhance the sound generation characteristic.

Owner:LG DISPLAY CO LTD

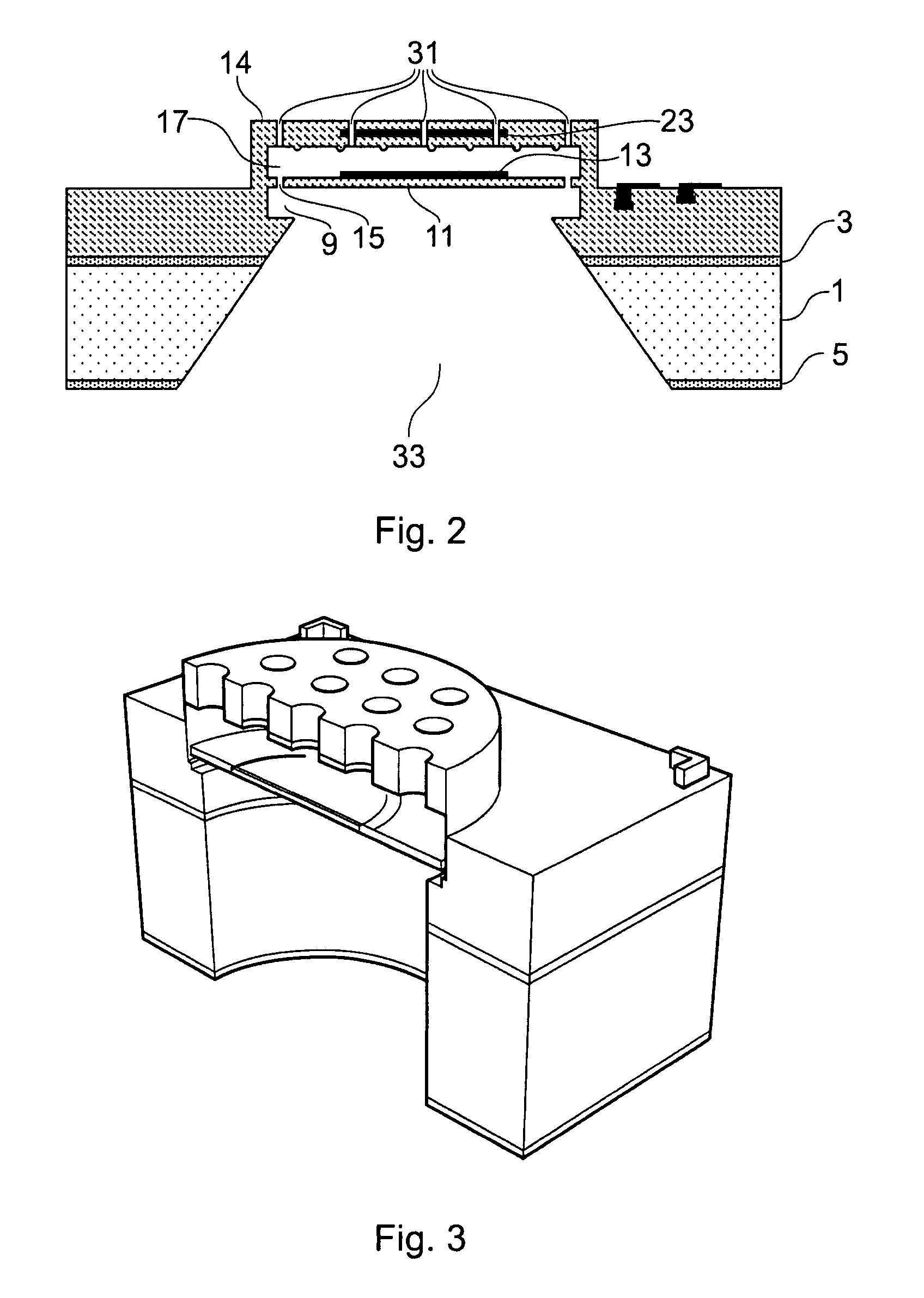

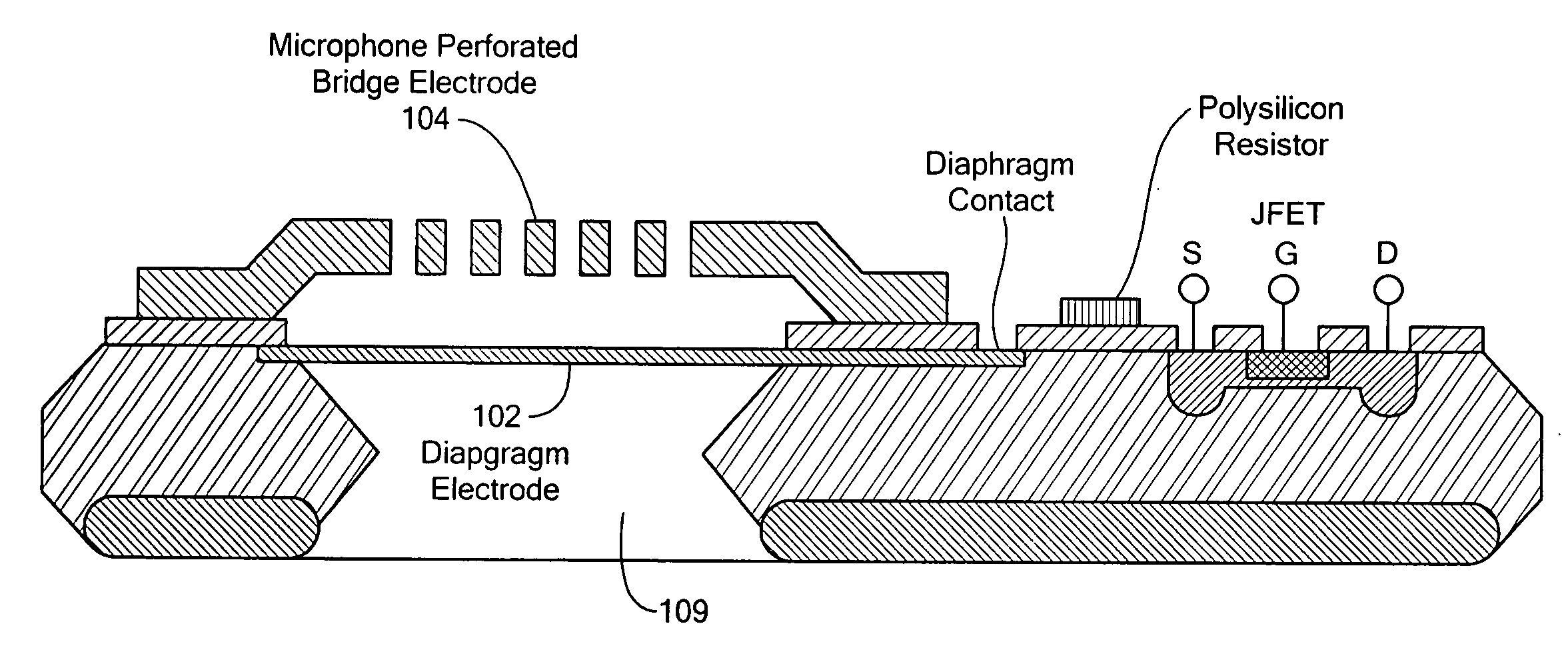

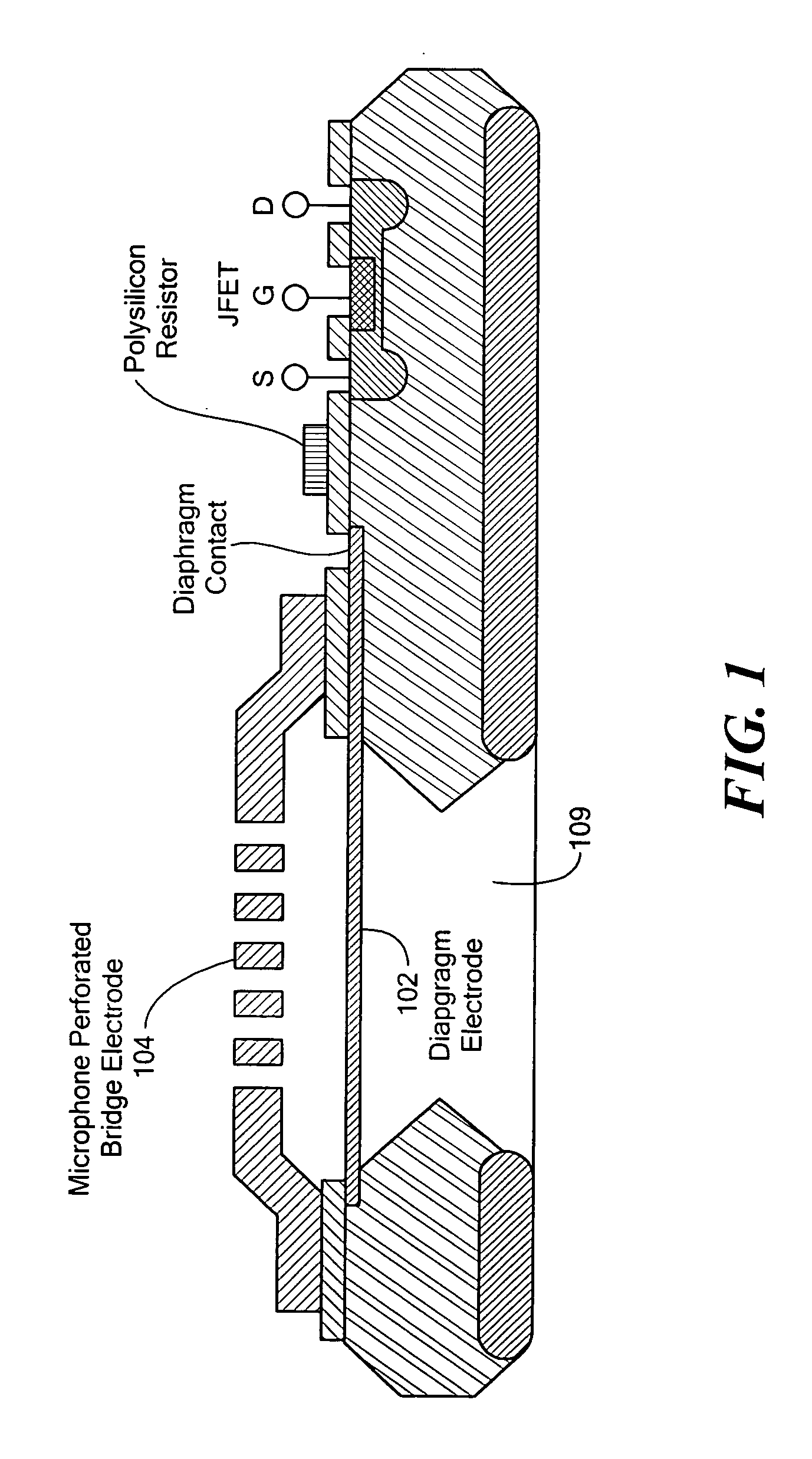

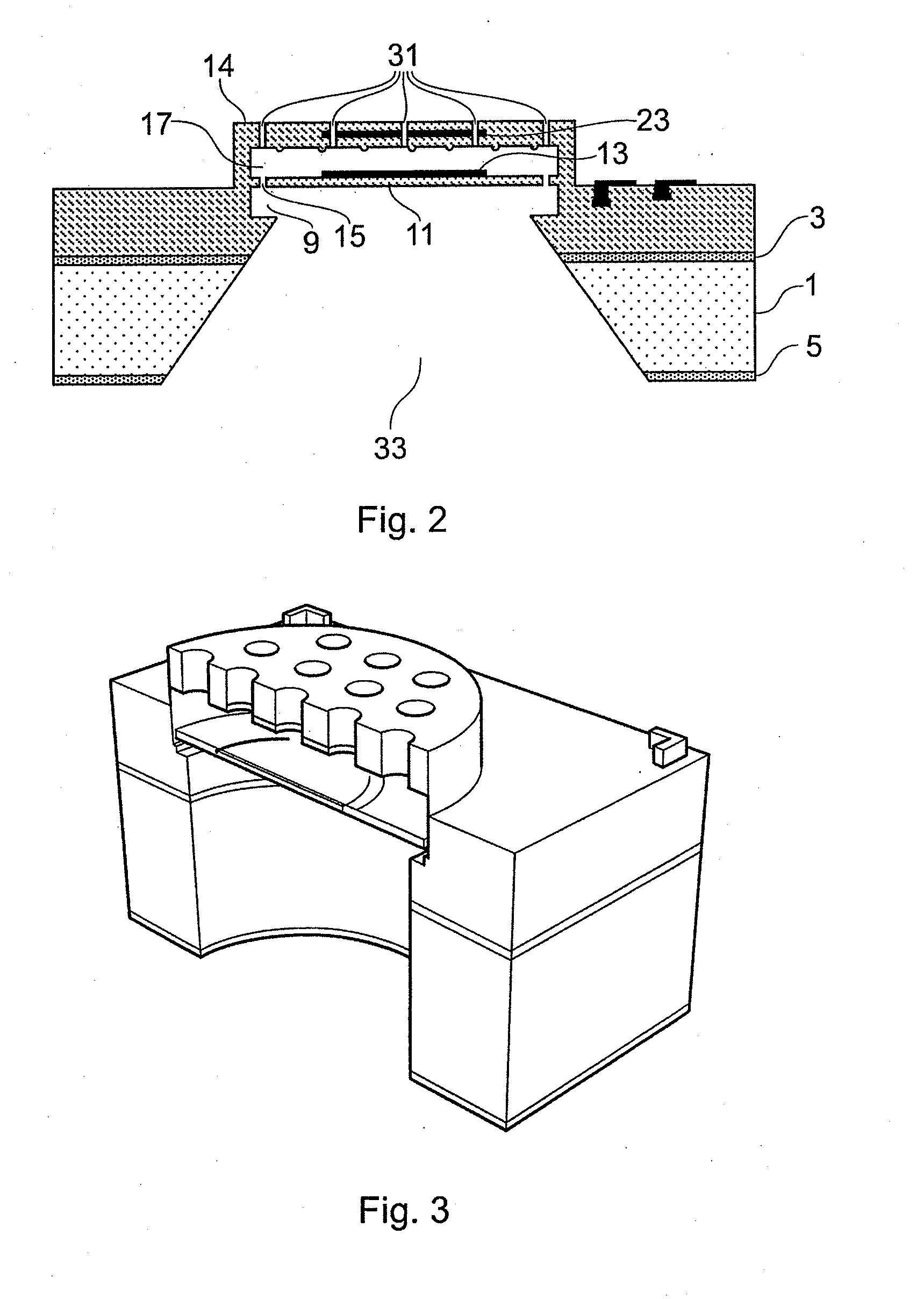

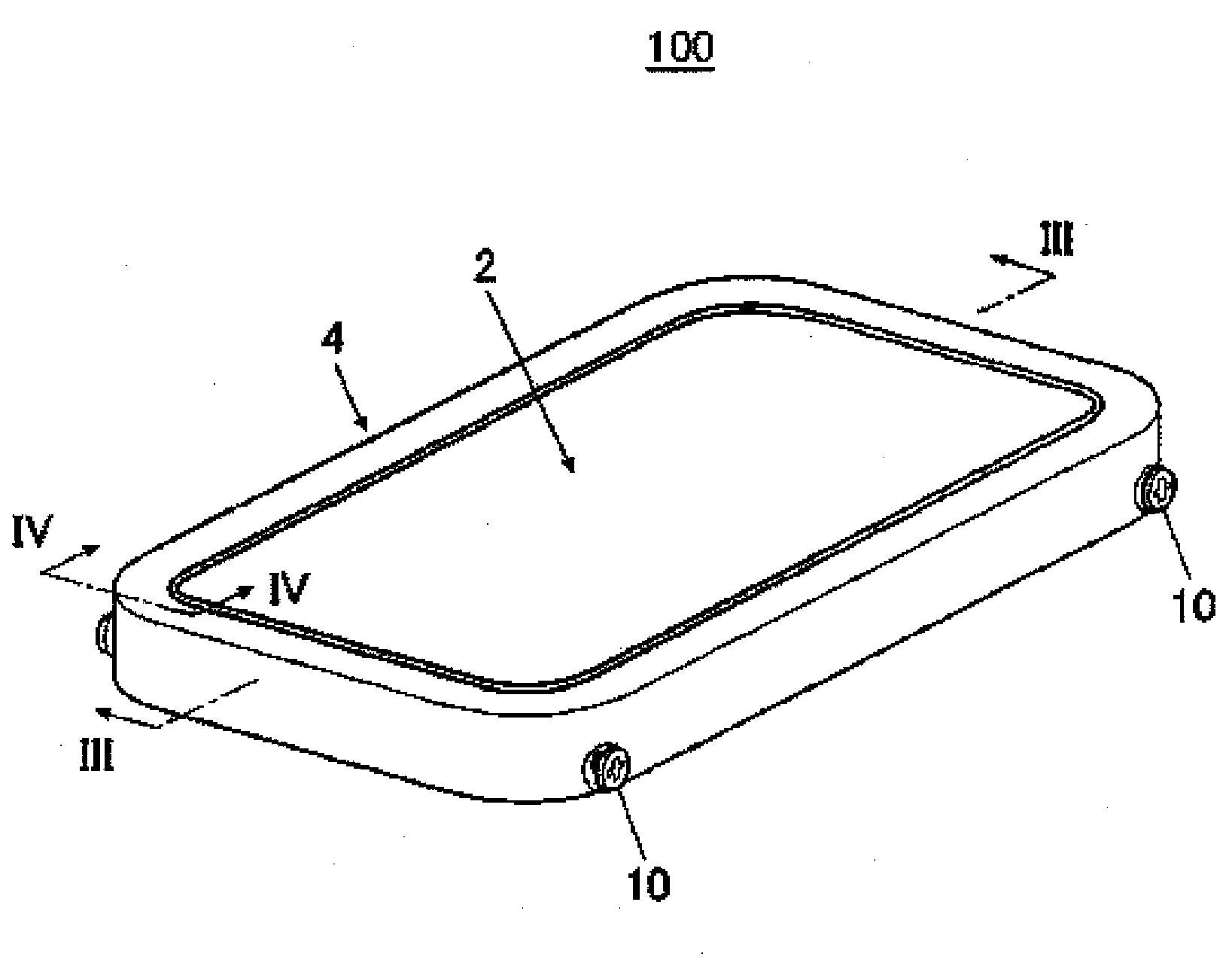

MEMS process and device

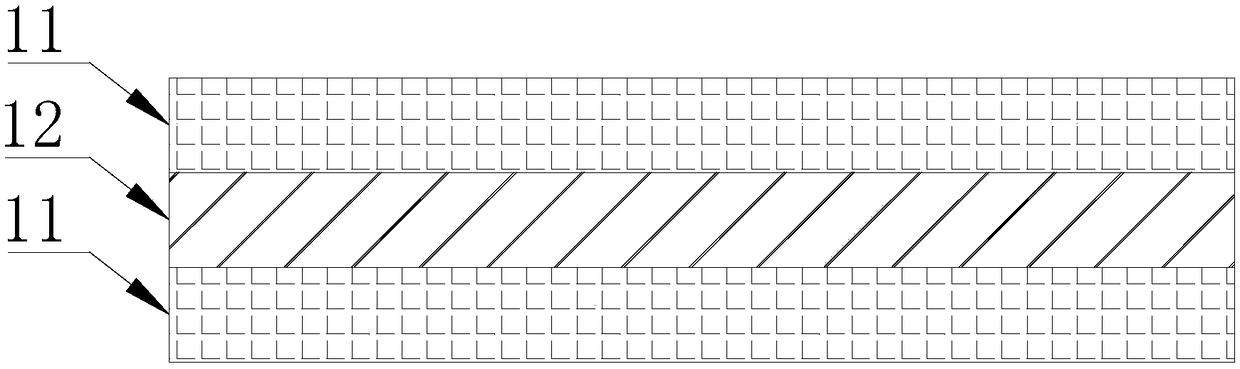

A MEMS device, for example a capacitive microphone, comprises a flexible membrane 11 that is free to move in response to pressure differences generated by sound waves. A first electrode 13 is mechanically coupled to the flexible membrane 11, and together form a first capacitive plate of the capacitive microphone device. A second electrode 23 is mechanically coupled to a generally rigid structural layer or back-plate 14, which together form a second capacitive plate of the capacitive microphone device. The capacitive microphone is formed on a substrate 1, for example a silicon wafer. A back-volume 33 is provided below the membrane 11, and is formed using a “back-etch” through the substrate 1. A first cavity 9 is located directly below the membrane 11, and is formed using a first sacrificial layer during the fabrication process. Interposed between the first and second electrodes 13 and 23 is a second cavity 17, which is formed using a second sacrificial layer during the fabrication process. A plurality of bleed holes 15 connect the first cavity 9 and the second cavity 17. Acoustic holes 31 are arranged in the back-plate 14 so as to allow free movement of air molecules, such that the sound waves can enter the second cavity 17. The first and second cavities 9 and 17 in association with the back-volume 33 allow the membrane 11 to move in response to the sound waves entering via the acoustic holes 31 in the back-plate 14. The provision of first and second sacrificial layers has the advantage of protecting the membrane during manufacture, and disassociating the back etch process from the definition of the membrane. The bleed holes 15 aid with the removal of the first and second sacrificial layers. The bleed holes 15 also contribute to the operating characteristics of the microphone.

Owner:CIRRUS LOGIC INC

Waterproof Structure and Electronic Equipment

InactiveUS20090101384A1Improve waterproof performanceReduce in quantityHermetically-sealed casingsPlane diaphragmsEngineeringElectronic equipment

Owner:LENOVO INNOVATIONS LTD HONG KONG

Full range loudspeaker

InactiveUS7167573B2Improve performancePrecise alignmentFrequency/directions obtaining arrangementsDiaphragm mounting/tensioningEngineeringLoudspeaker

An edge-driven diaphragm loudspeaker driver is configured such that the suspension system of the driver is connected to the voice coil rather than to the diaphragm. Thus, the diaphragm in the loudspeaker is free of suspension systems connected to or extending from the diaphragm. By attaching the surround suspension to the voice coil rather than to the diaphragm, the diaphragm is isolated from the influence of spurious high frequency vibrations in the suspension system, thereby increasing the performance of the loudspeaker at high frequencies. The loudspeaker driver configuration also provides for a longer excursion range for the voice coil / diaphragm assembly, which allows for the driver components to be more accurately aligned during manufacturing, thereby enabling the loudspeaker driver to operate as a full range unit by producing low output frequencies.

Owner:HARMAN INT IND INC

Loudspeaker diaphragm and loudspeaker

ActiveCN108551640AIncrease stiffnessIncrease dampingPolymeric diaphragmsLoudspeakersPolyesterElastomer

The invention discloses a loudspeaker diaphragm and a loudspeaker. The diaphragm comprises a thermoplastic polyester elastomer film layer, wherein the thermoplastic polyester elastomer is a copolymerformed by a polyester hard segment A and a polyether or aliphatic polyester soft segment B, the Young modulus of the thermoplastic polyester elastomer film layer is 1-1000MPa, and after 10% of strain,the elastic recovery rate is larger than or equal to 80%. The loudspeaker diaphragm has excellent rigidity, good damping performance, resilience and the like.

Owner:GOERTEK INC

Microphone with Backplate Having Specially Shaped Through-Holes

A MEMS microphone has 1) a backplate with a backplate interior surface and a plurality of through-holes, and 2) a diaphragm spaced from the backplate. The diaphragm is movably coupled with the backplate to form a variable capacitor. At least two of the through-holes have an inner dimensional shape (on the backplate interior surface) with a plurality of convex portions and a plurality of concave portions.

Owner:INVENSENSE

Speaker

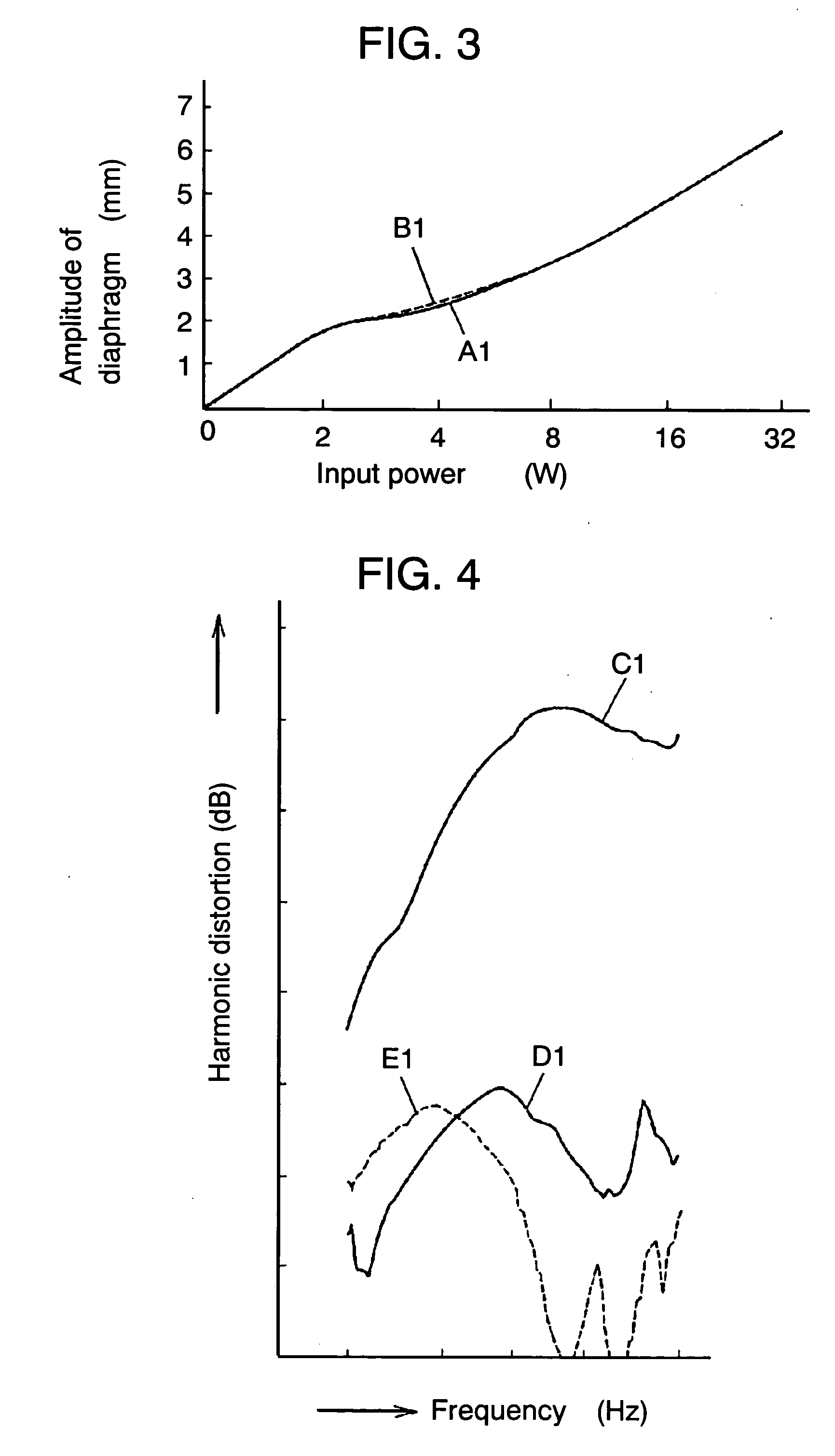

ActiveUS20050201588A1Reduce Harmonic DistortionImprove power linearityTransducer detailsNon-planar diaphragms/conesMiniaturizationEngineering

A speaker has diaphragm (16) and suspension holder (19) disposed on the back surface of the diaphragm. In the diaphragm, the part from a bent section (21) disposed between the outer periphery and the inner periphery to the outer periphery is formed in a conical shape. The diaphragm is coupled to the suspension holder through the bent section of the diaphragm. This configuration can omit a damper causing the nonlinearity and asymmetry of suspension, reduce the harmonic distortion of the speaker, improve the power linearity, and improve the performance of the speaker. Even a flat shape can secure sufficient rigidity, so that securing the rigidity of the diaphragm does not require large thickness of the diaphragm and downsizing and low profile can be realized.

Owner:PANASONIC CORP

Popular searches

Flexible microstructural devices Microstructural device manufacture Semiconductor devices Individual semiconductor device testing Microelectromechanical systems Mechanical energy handling Piezoelectric/electrostrictive/magnetostrictive devices Electromagnets with armatures Electrostatic transducer loudspeakers Variable resistance transducer microphones

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com