Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

972 results about "Mems microphone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

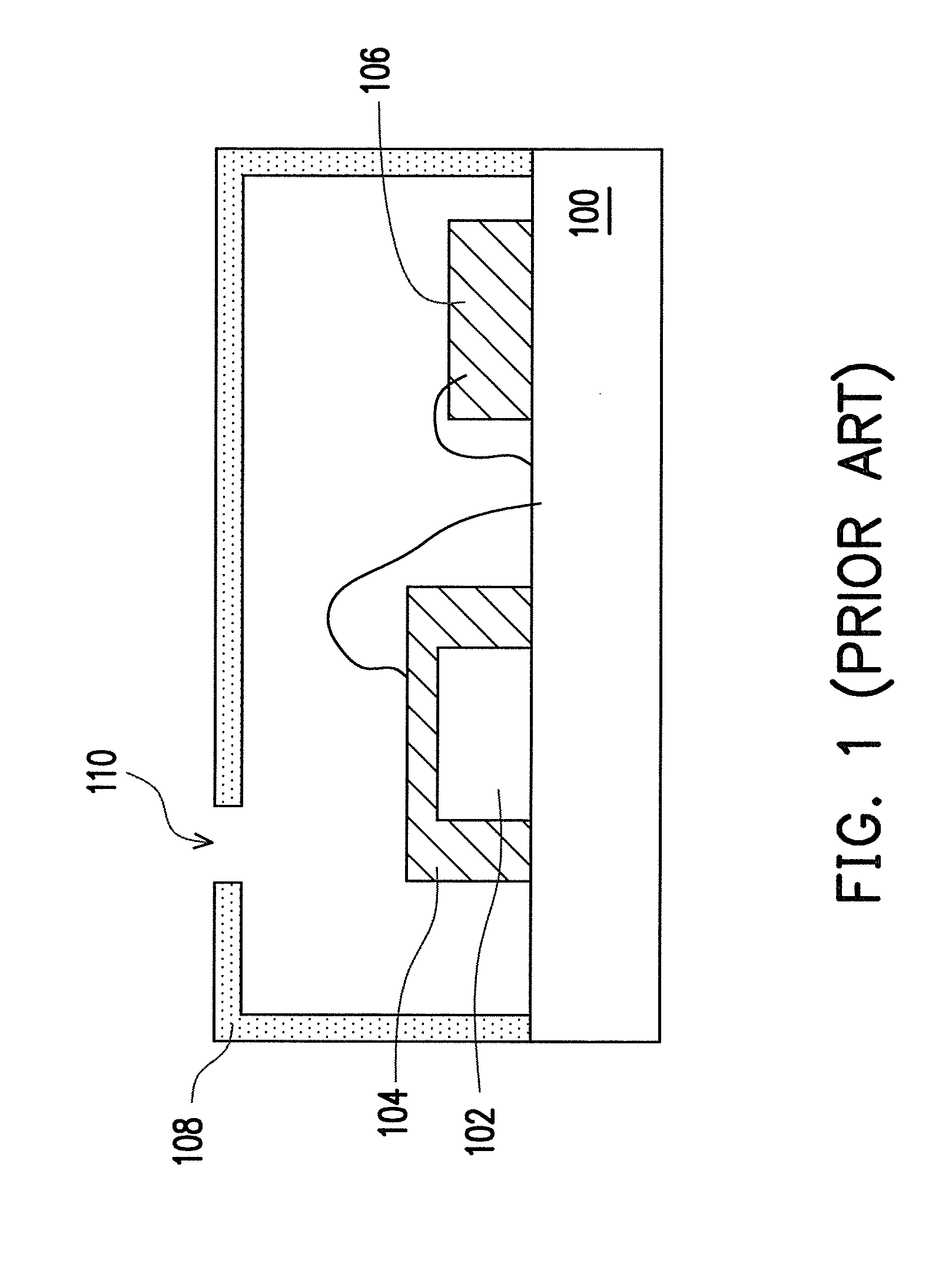

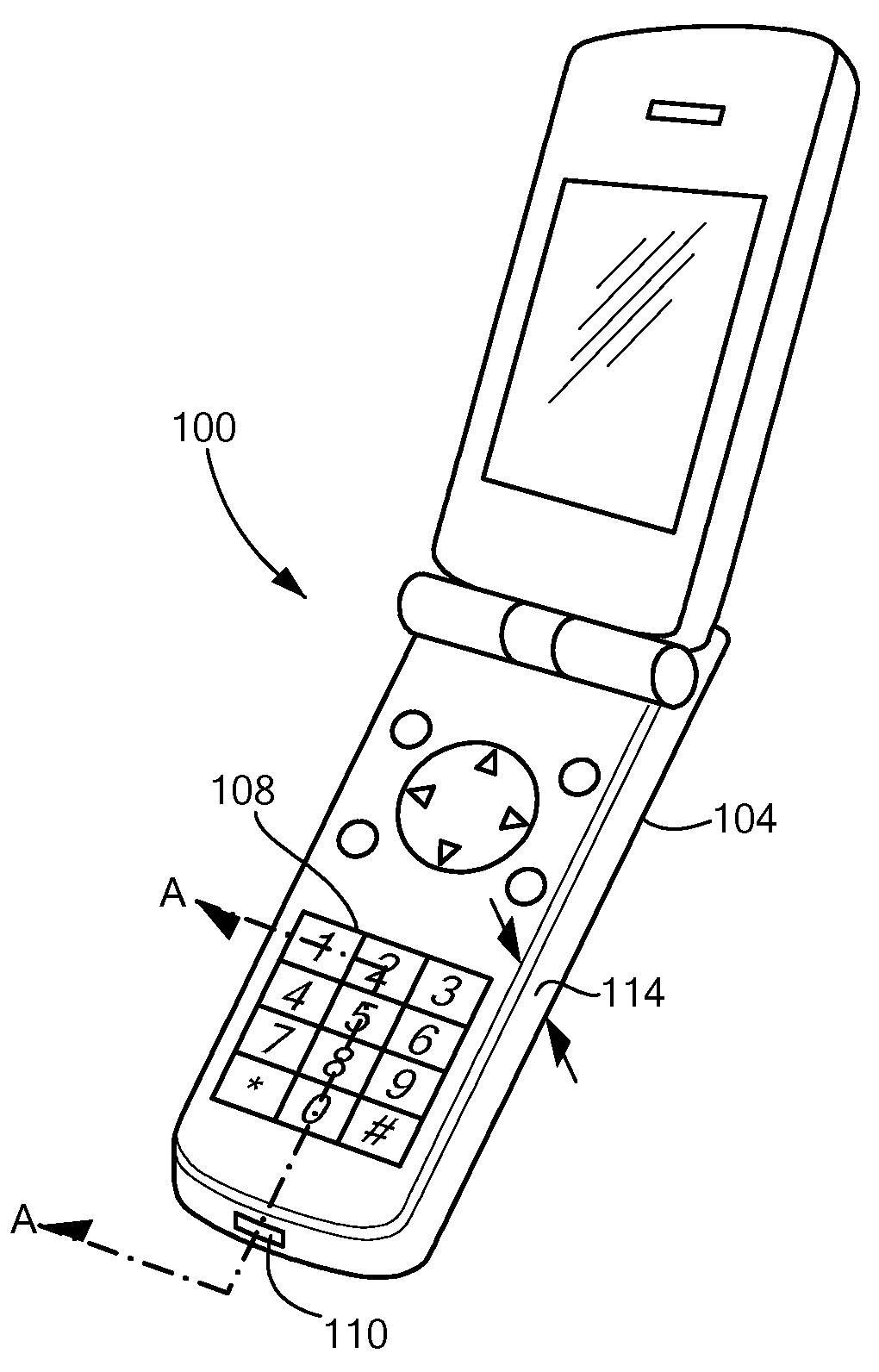

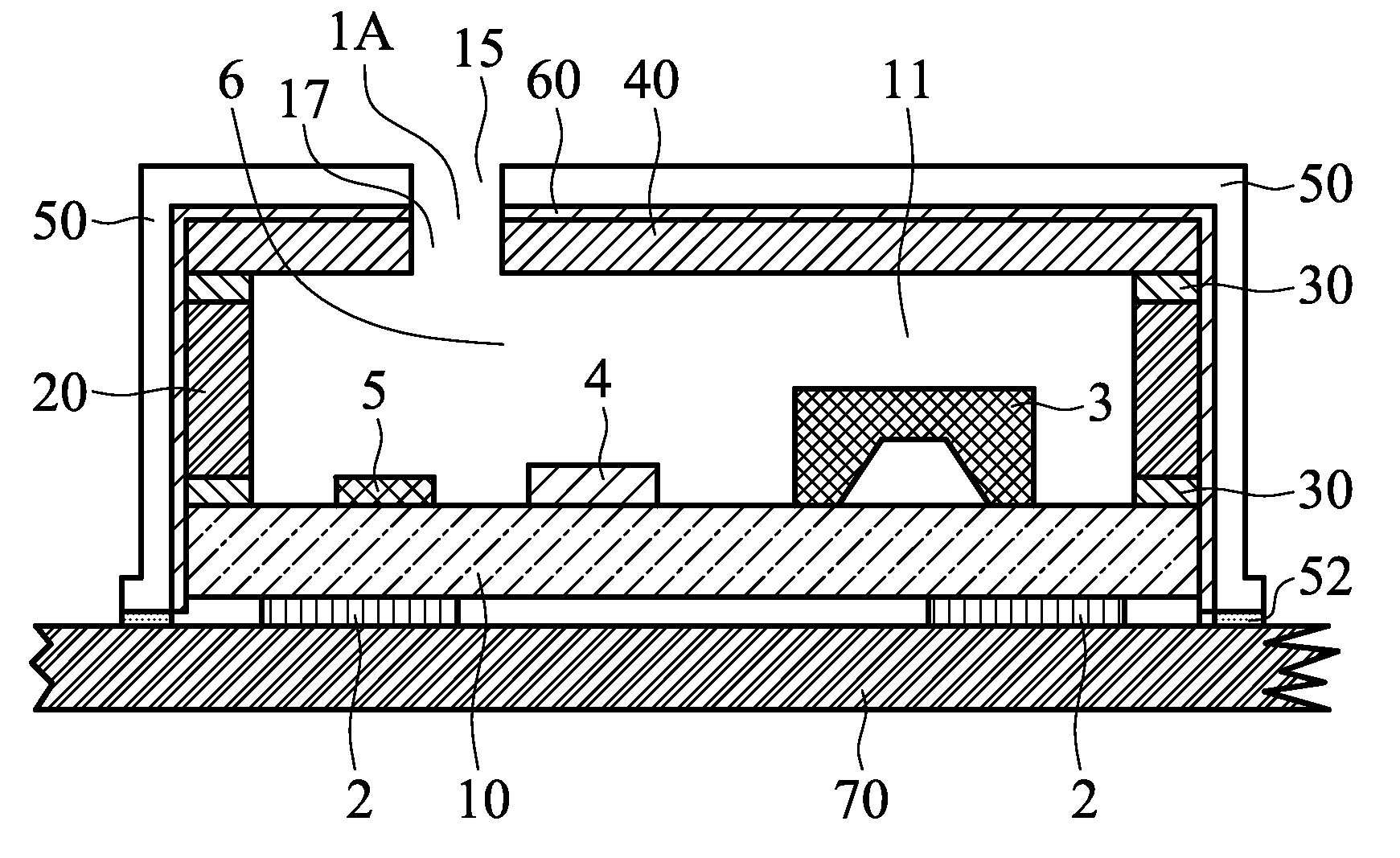

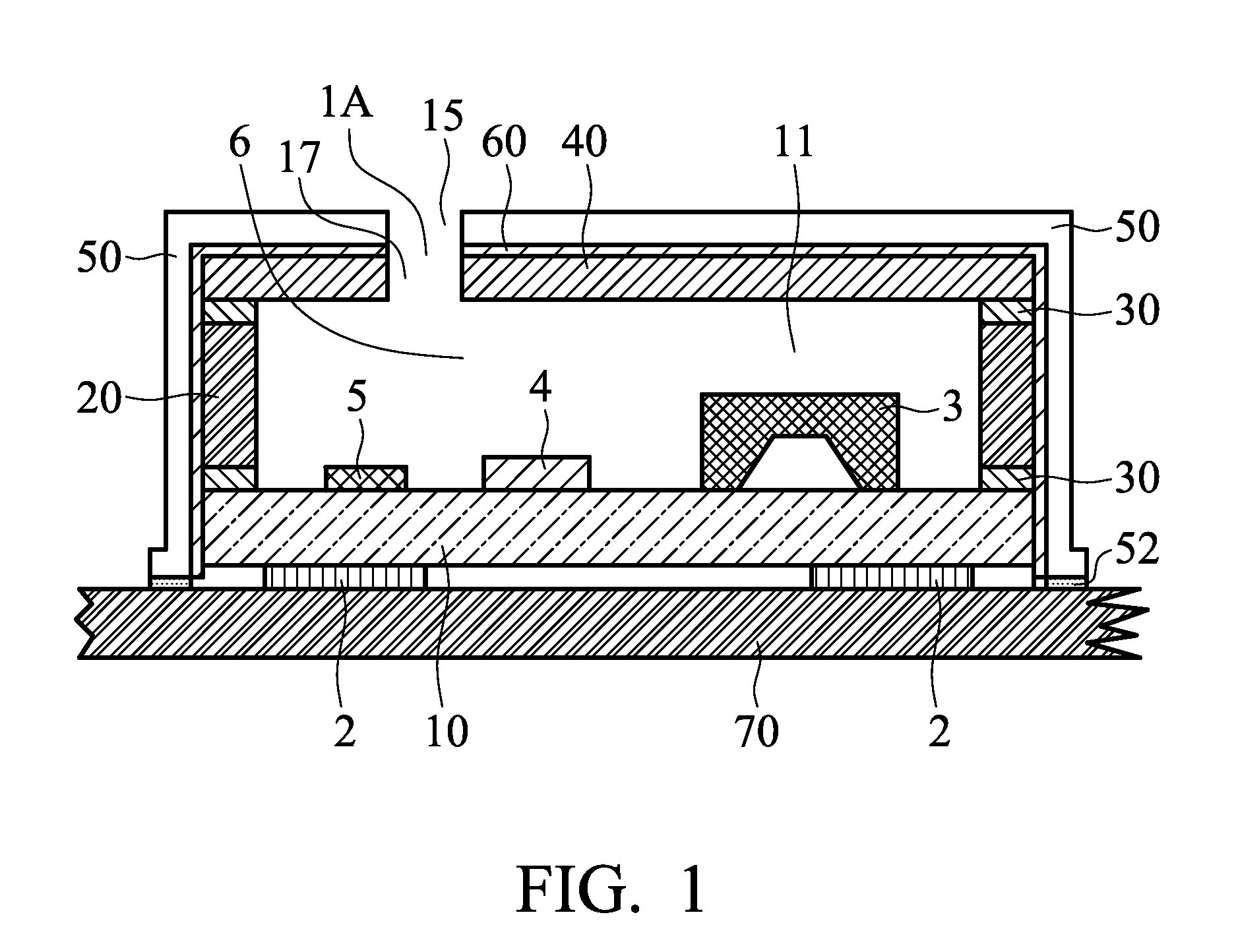

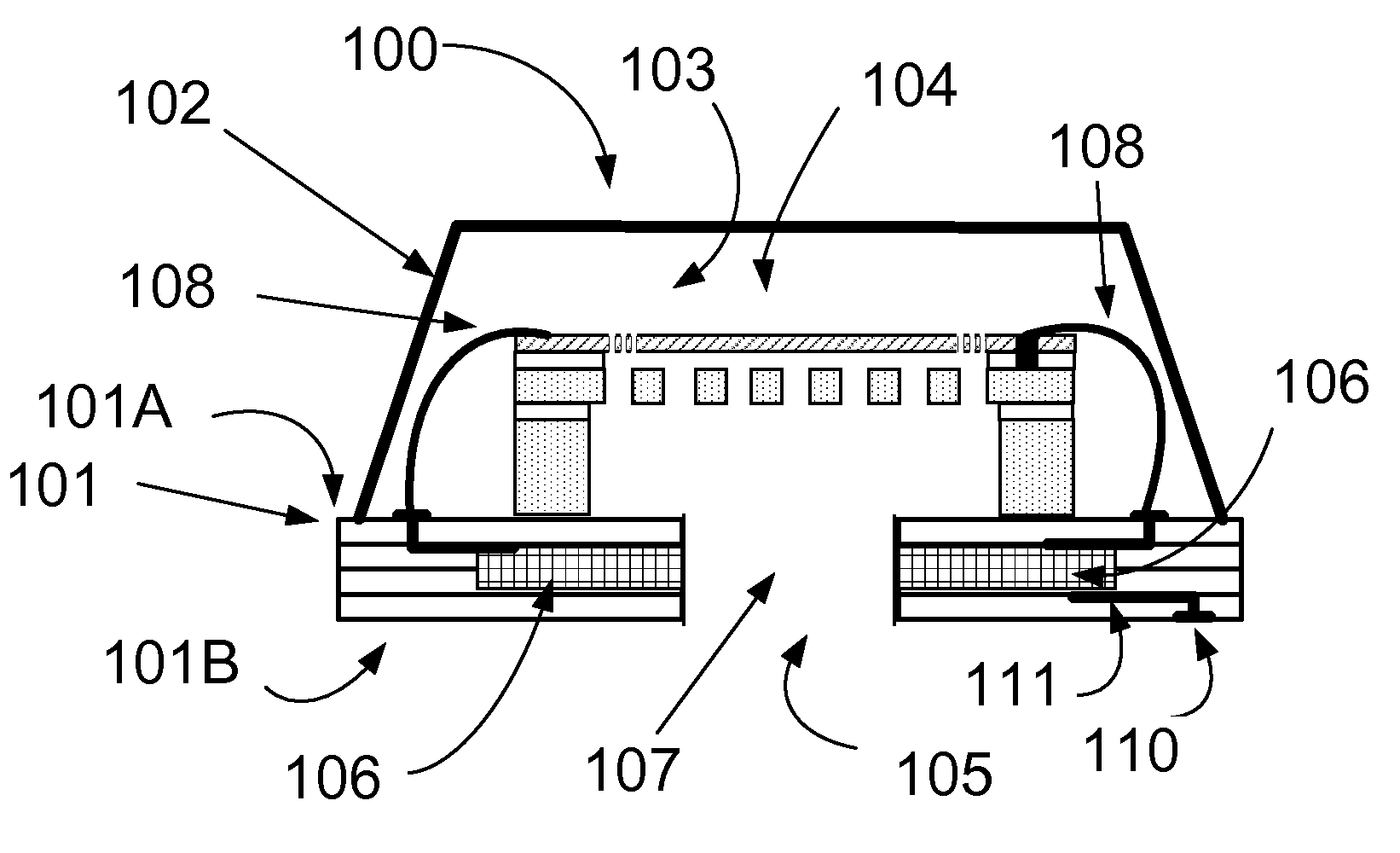

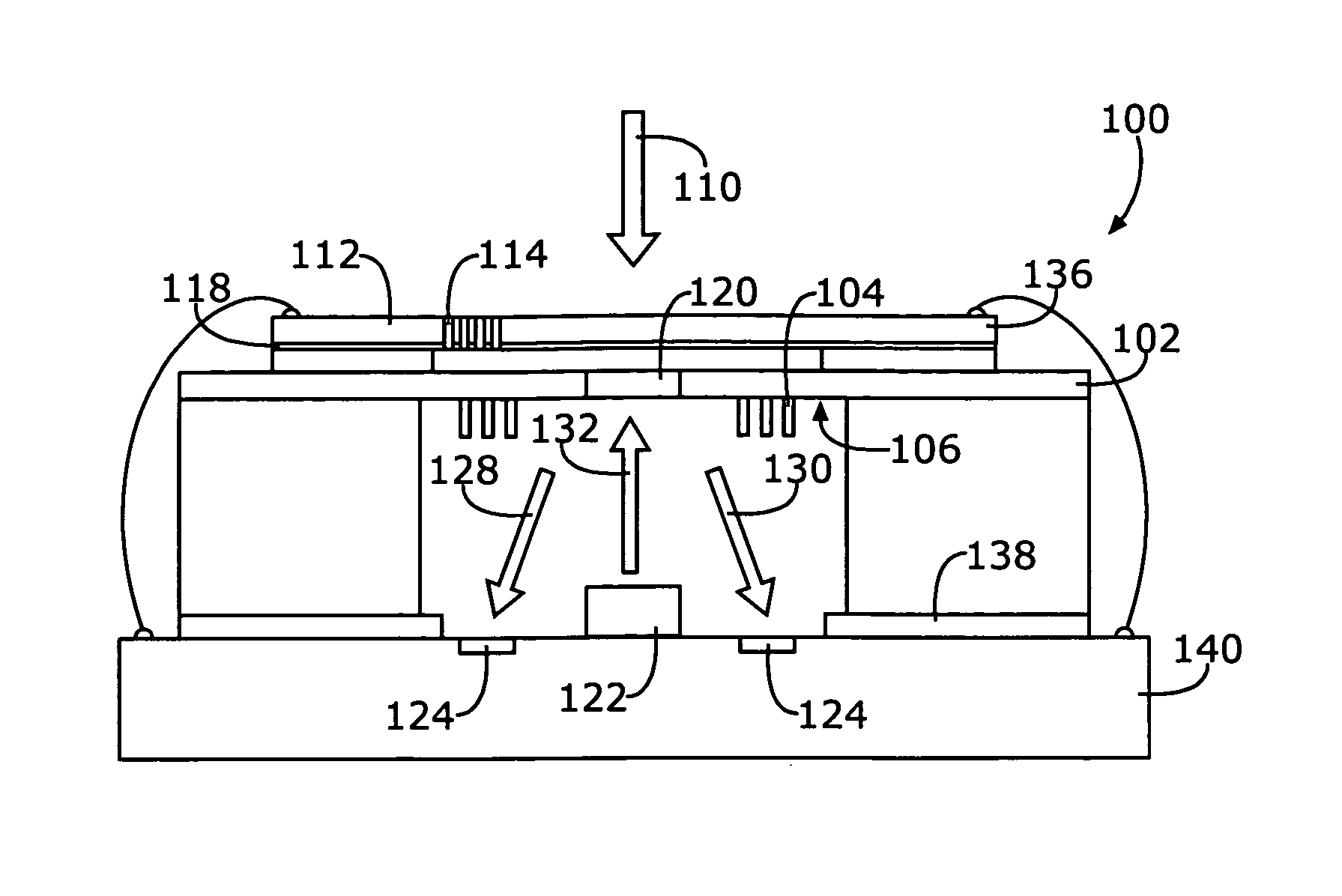

Micro-electro-mechanical systems (MEMS) package and method for forming the MEMS package

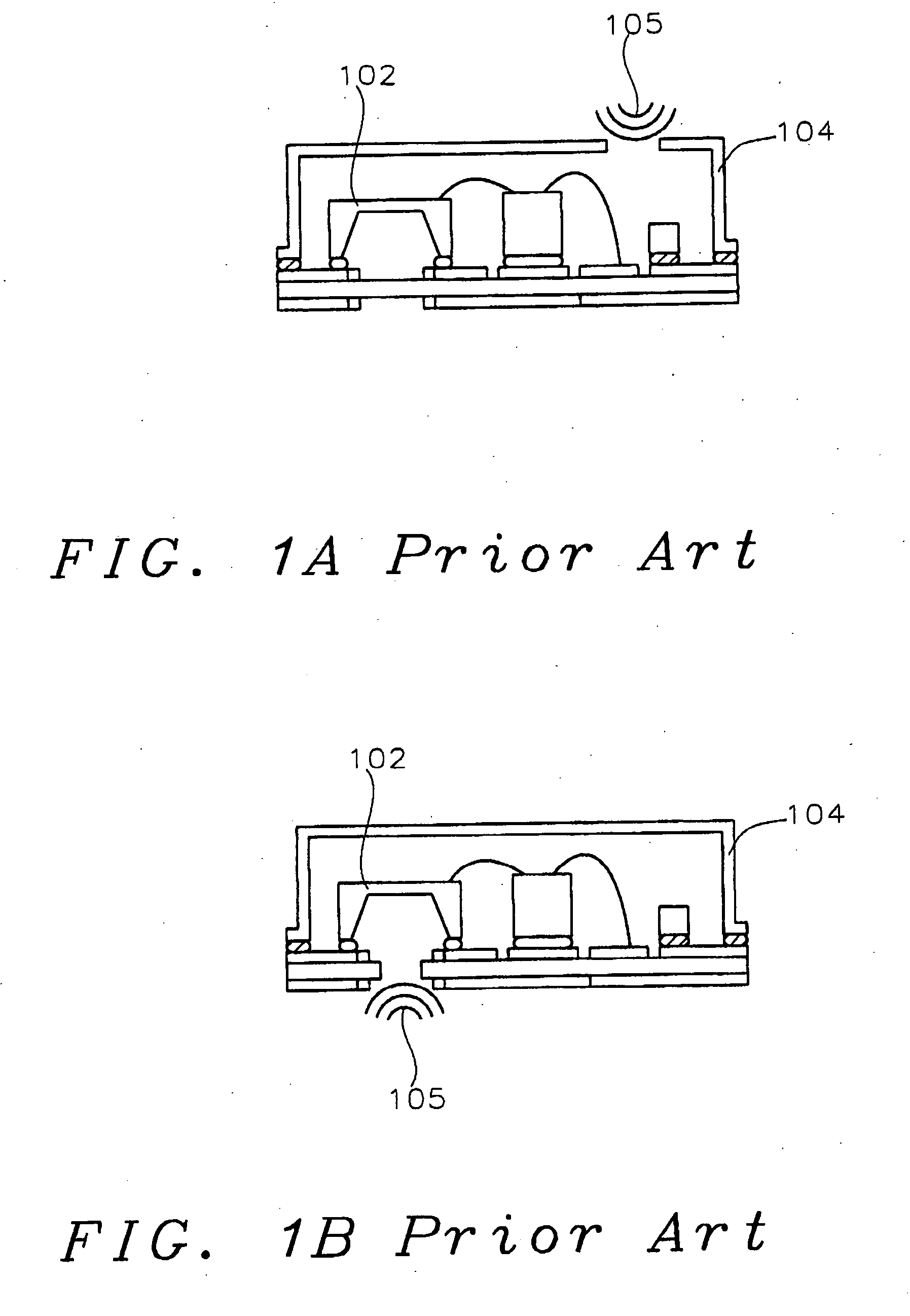

ActiveUS20100052082A1High sensitivitySmall sizeSolid-state devicesSemiconductor/solid-state device manufacturingMems microphoneMechanical system

A micro-electro-mechanical systems (MEMS) package includes a MEMS microphone device. The MEMS microphone device has a first substrate and at least a sensing element on the first substrate wherein a first chamber in the MEMS microphone device is connected to the sensing element. A second substrate is disposed over the MEMS microphone device to provide a second chamber in the second substrate over the sensing element opposite to the first chamber.

Owner:SOLID STATE SYST

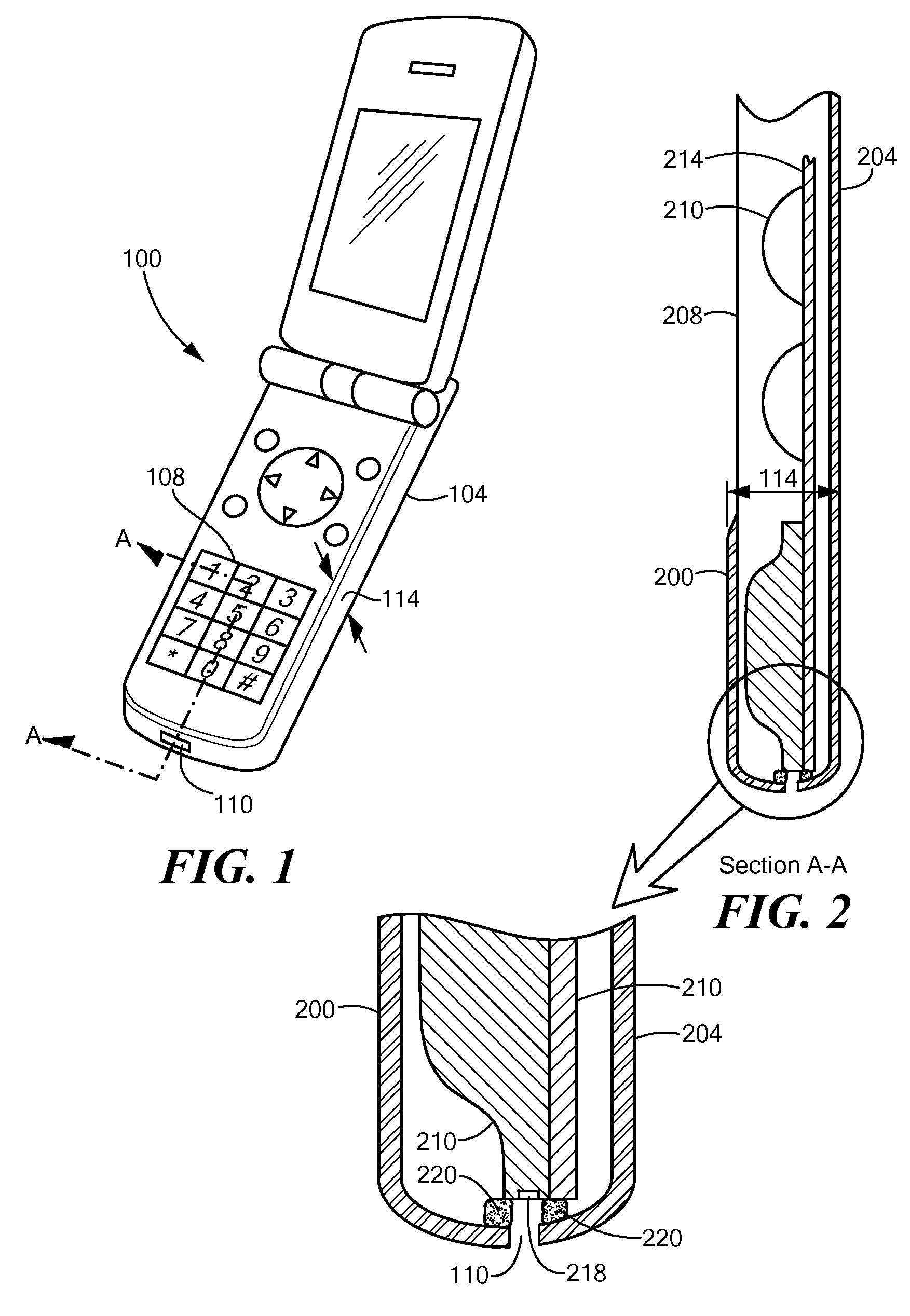

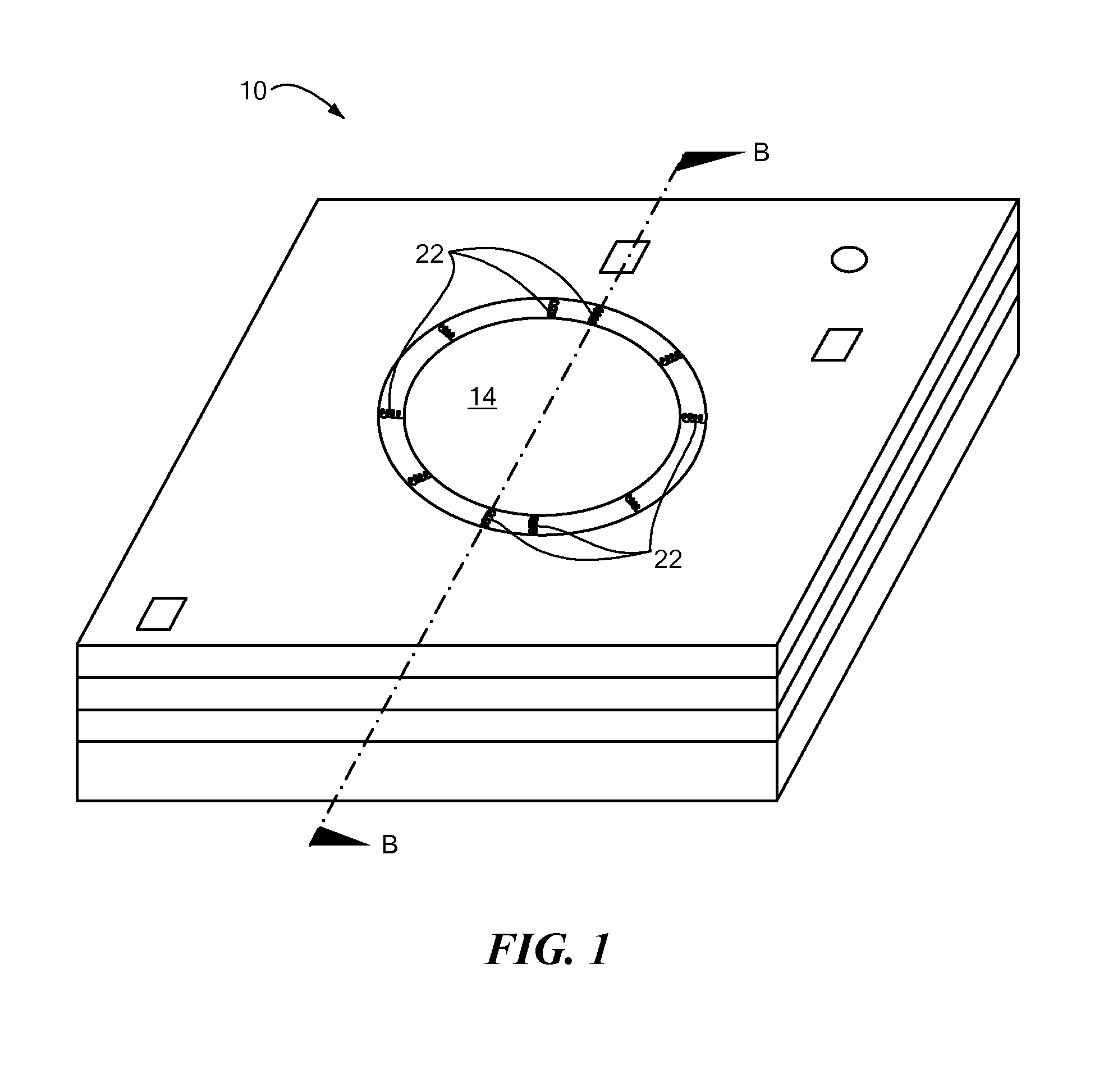

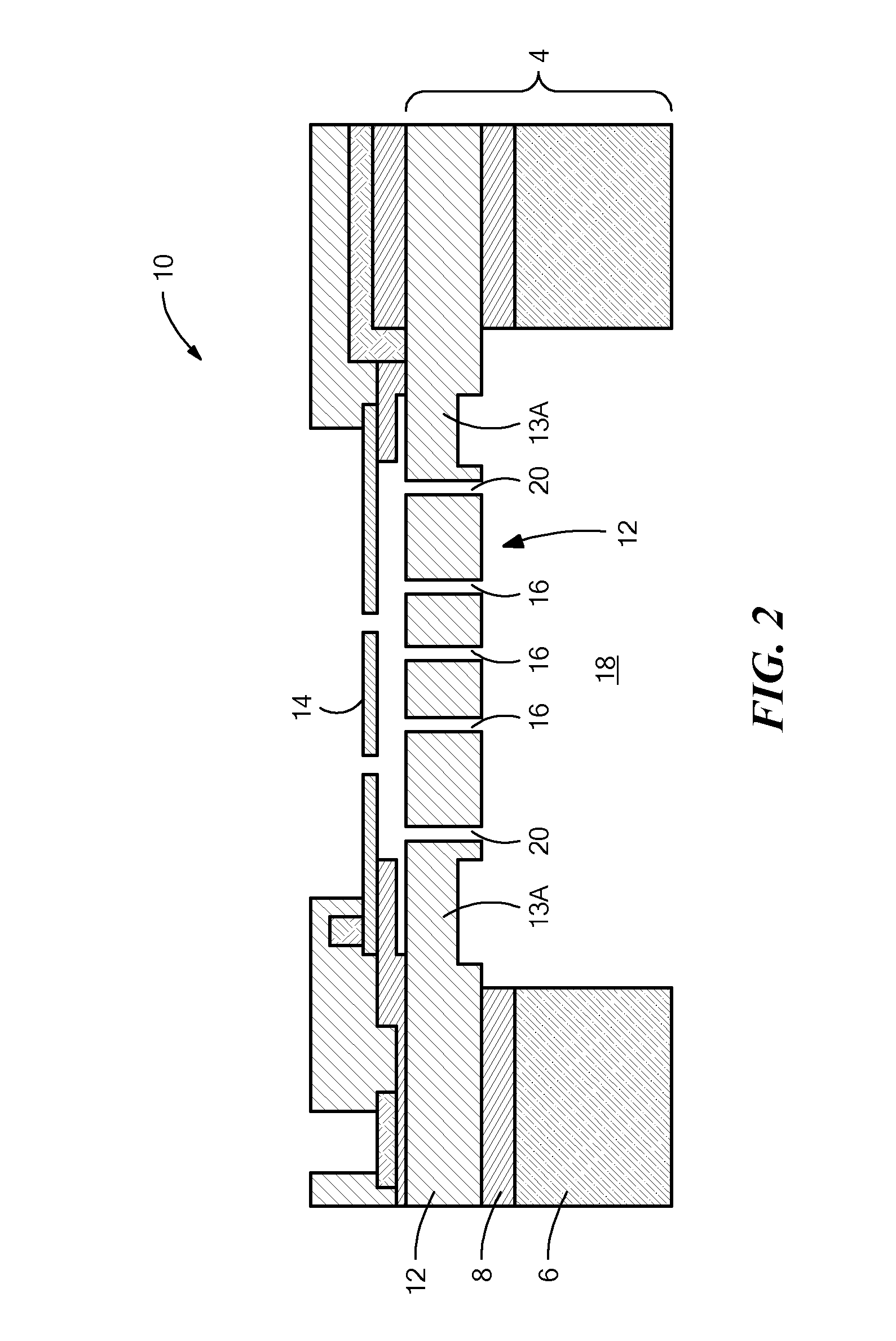

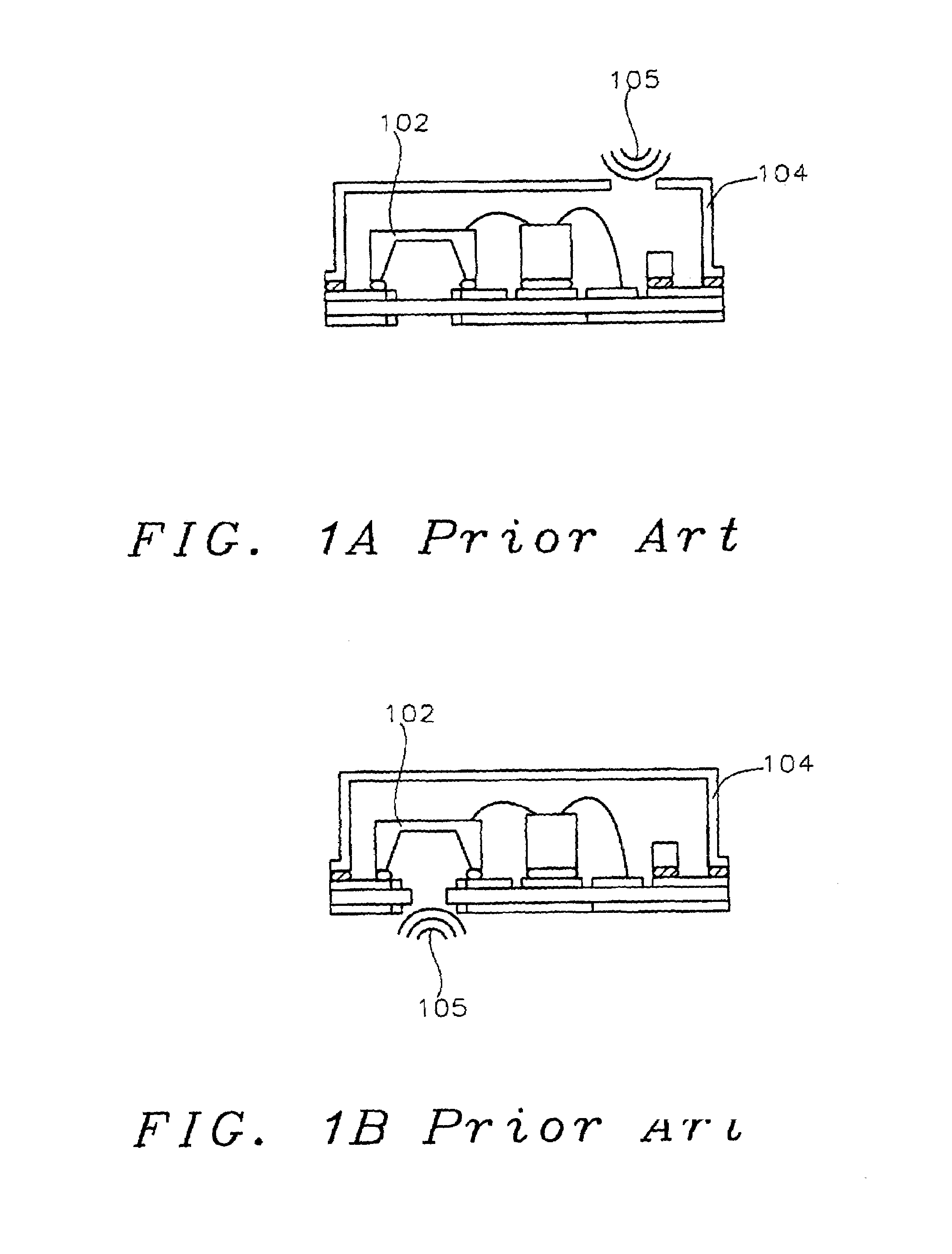

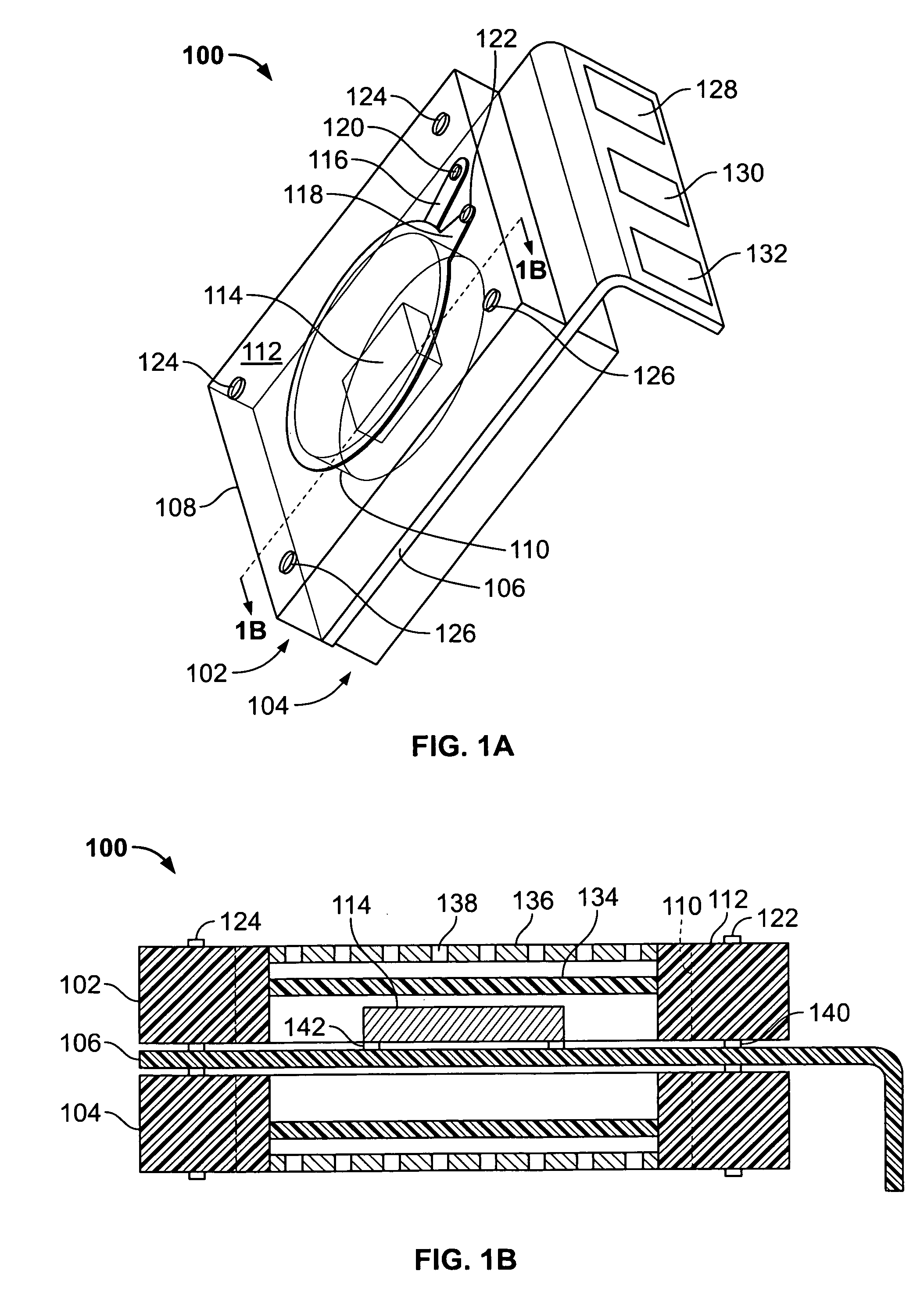

Side-ported MEMS microphone assembly

ActiveUS20100128914A1Piezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersMems microphone

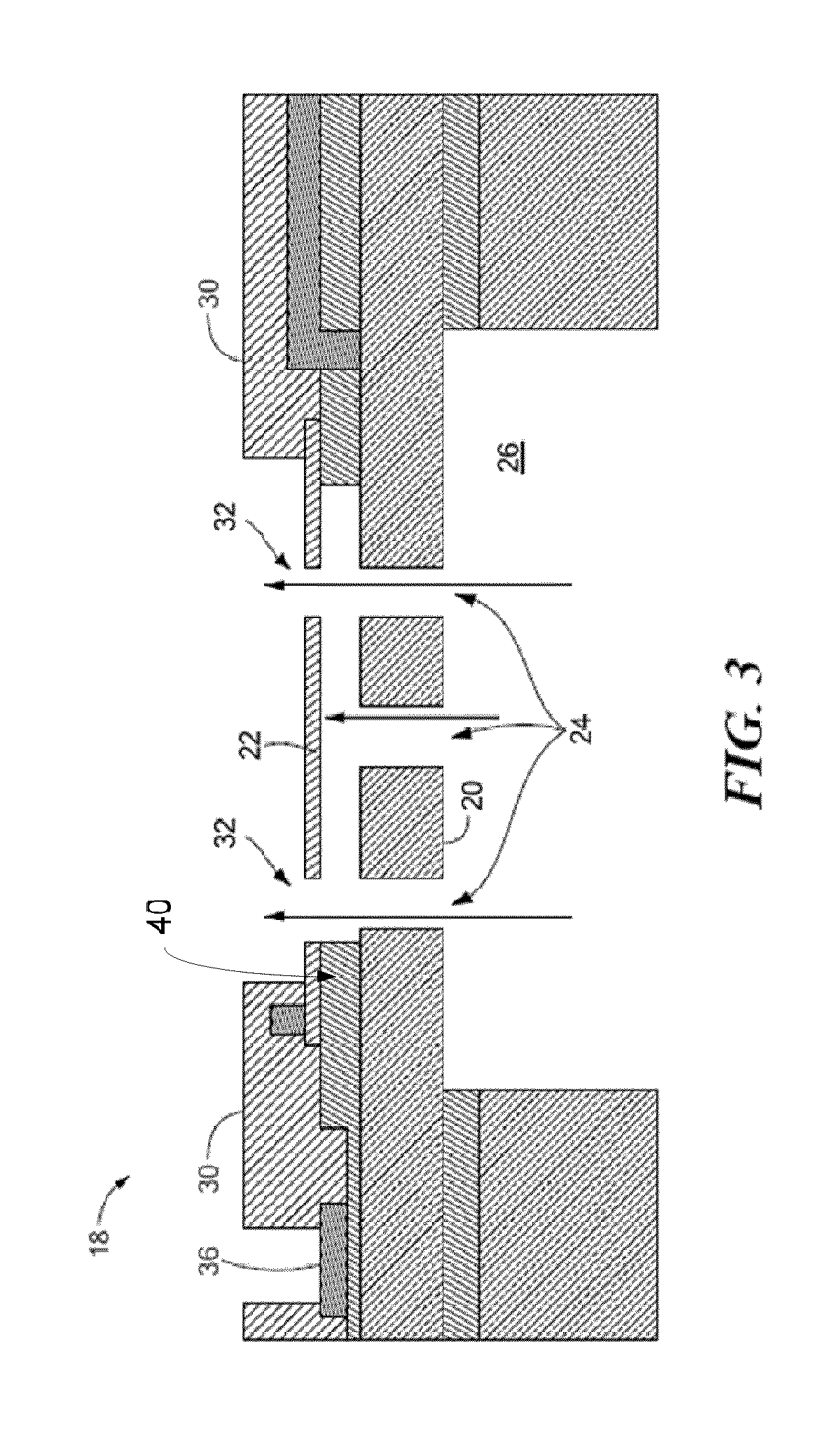

A side-ported MEMS microphone package defines an acoustic path from a side of the package substrate to a microphone die disposed within a chamber defined by the substrate and a lid attached to the substrate. Optionally or alternatively, a circuit board, to which the microphone package is mounted, may define an acoustic path from an edge of the circuit board to a location under the microphone package, adjacent a bottom port on the microphone package. In either case, the acoustic path may be a hollow passage through at least a portion of the substrate or the circuit board. The passage may be defined by holes, channels, notches, etc. defined in each of several layers of a laminated substrate or circuit board, or the passage may be defined by holes drilled, molded or otherwise formed in a solid or laminated substrate or circuit board.

Owner:INVENSENSE

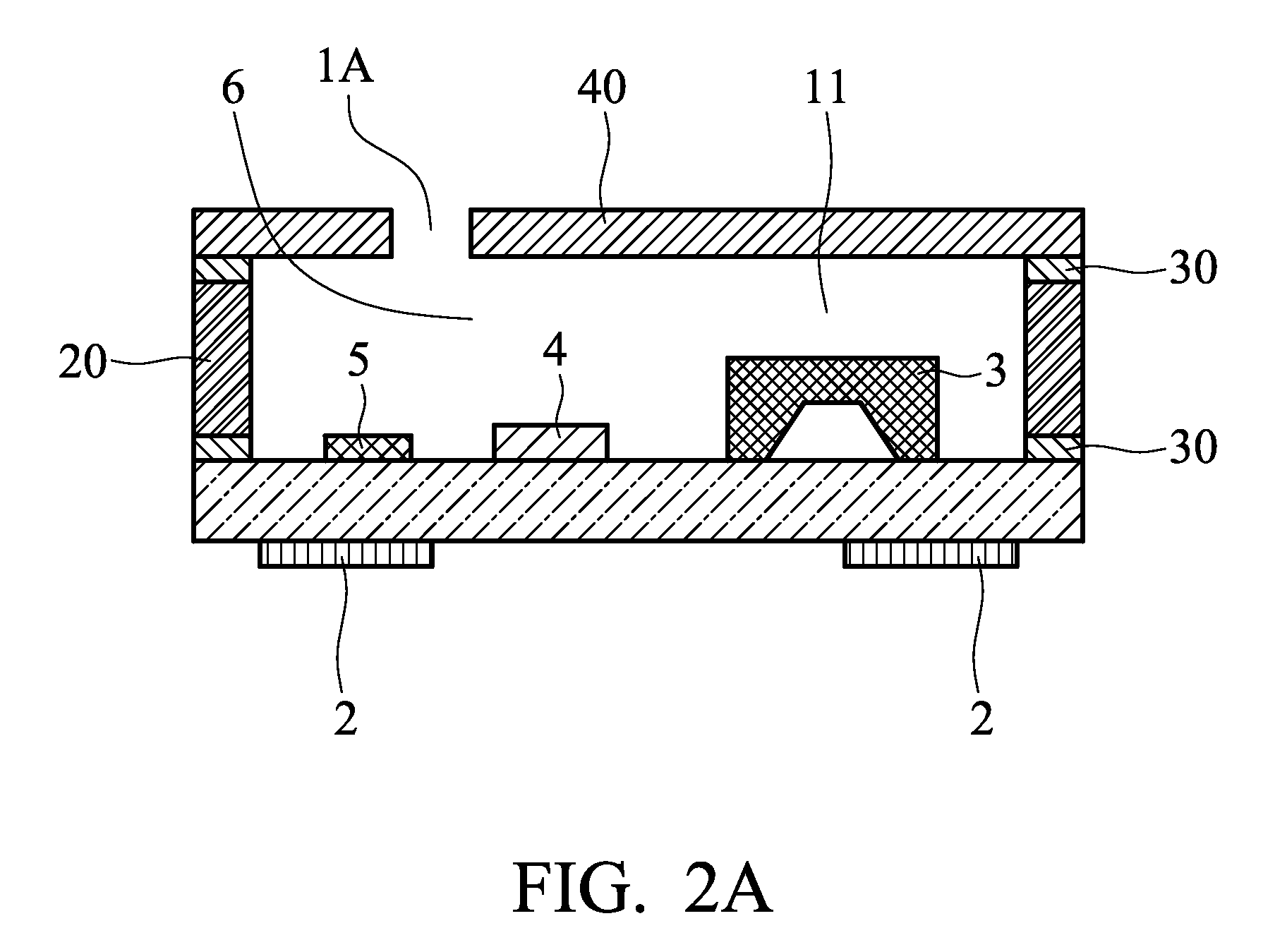

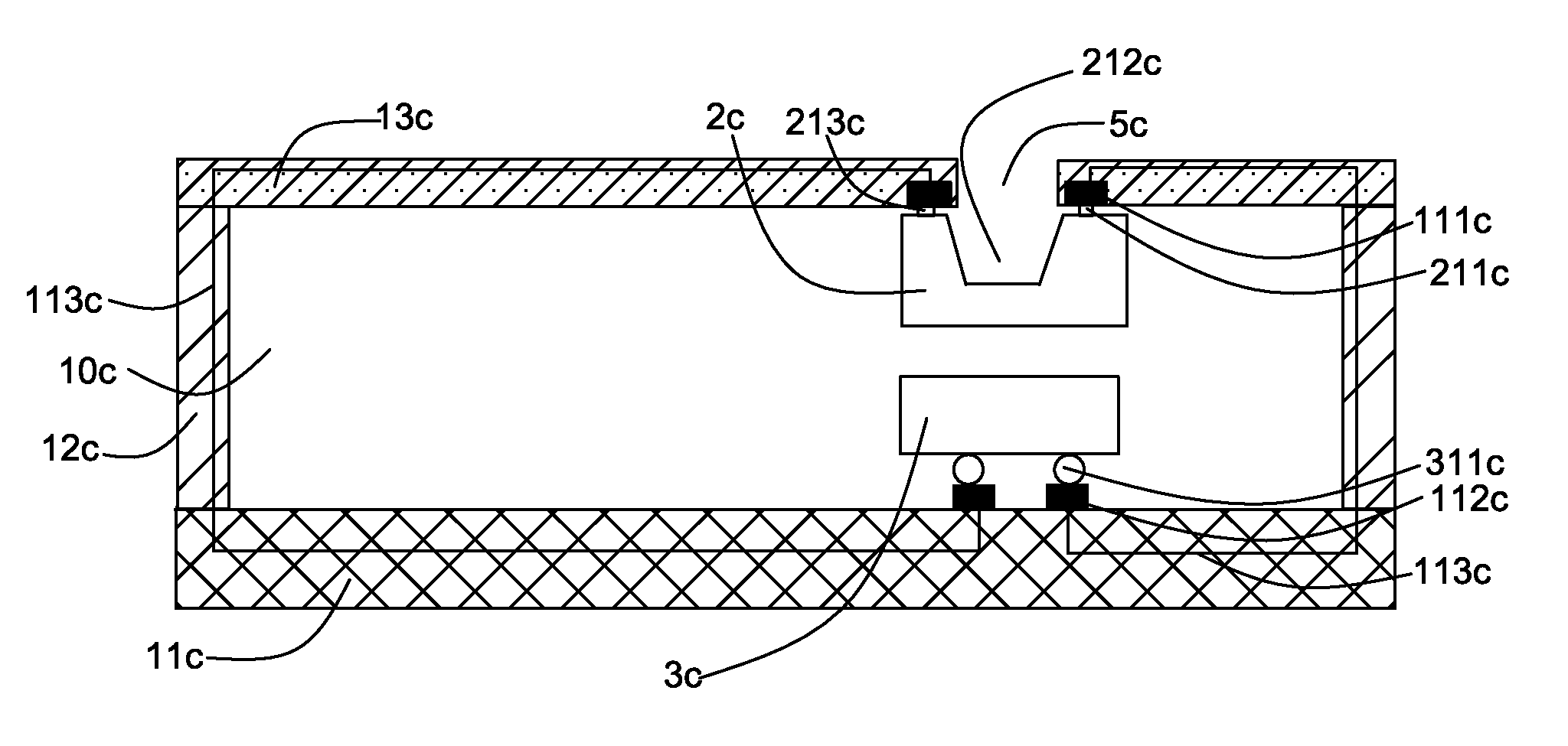

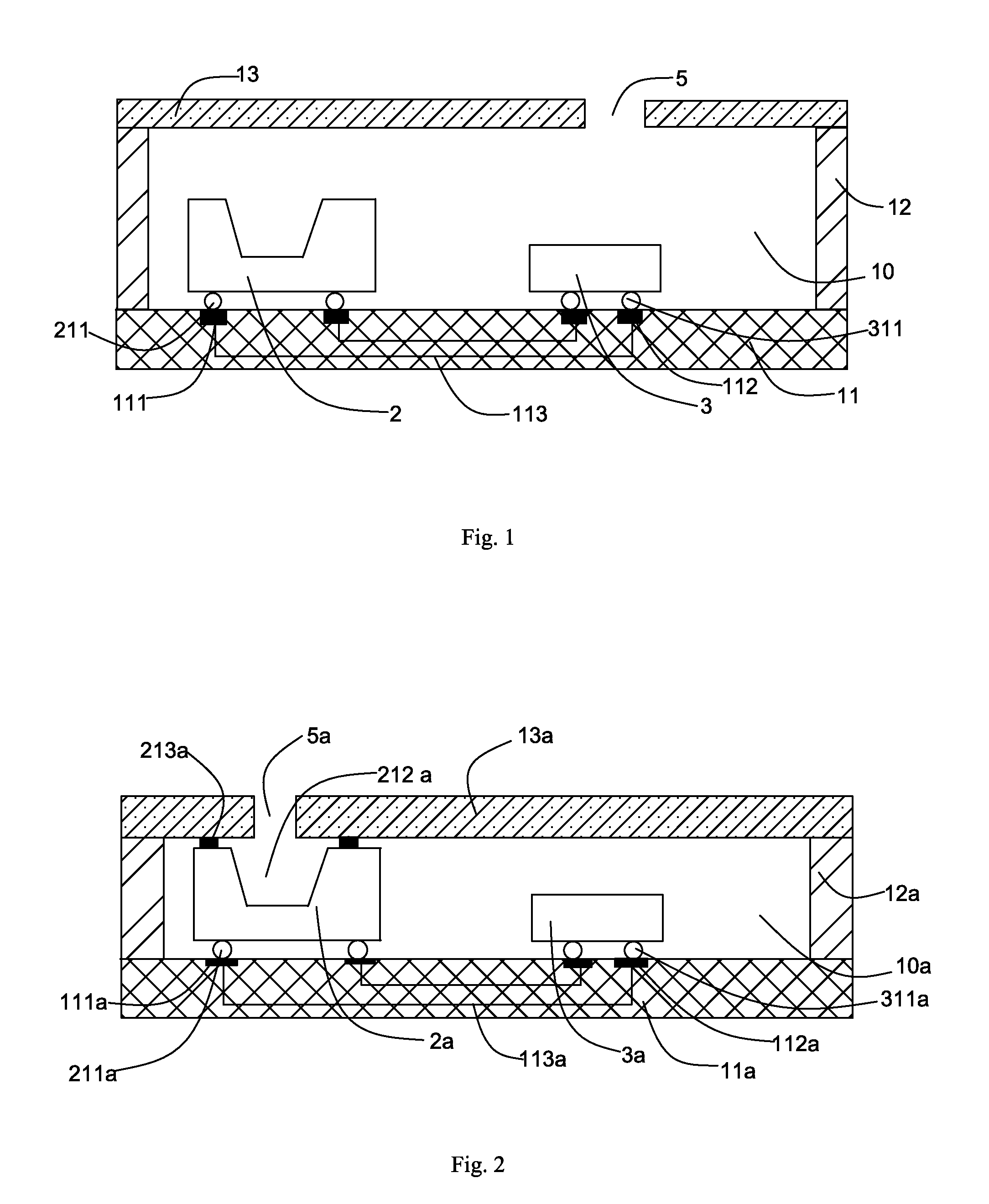

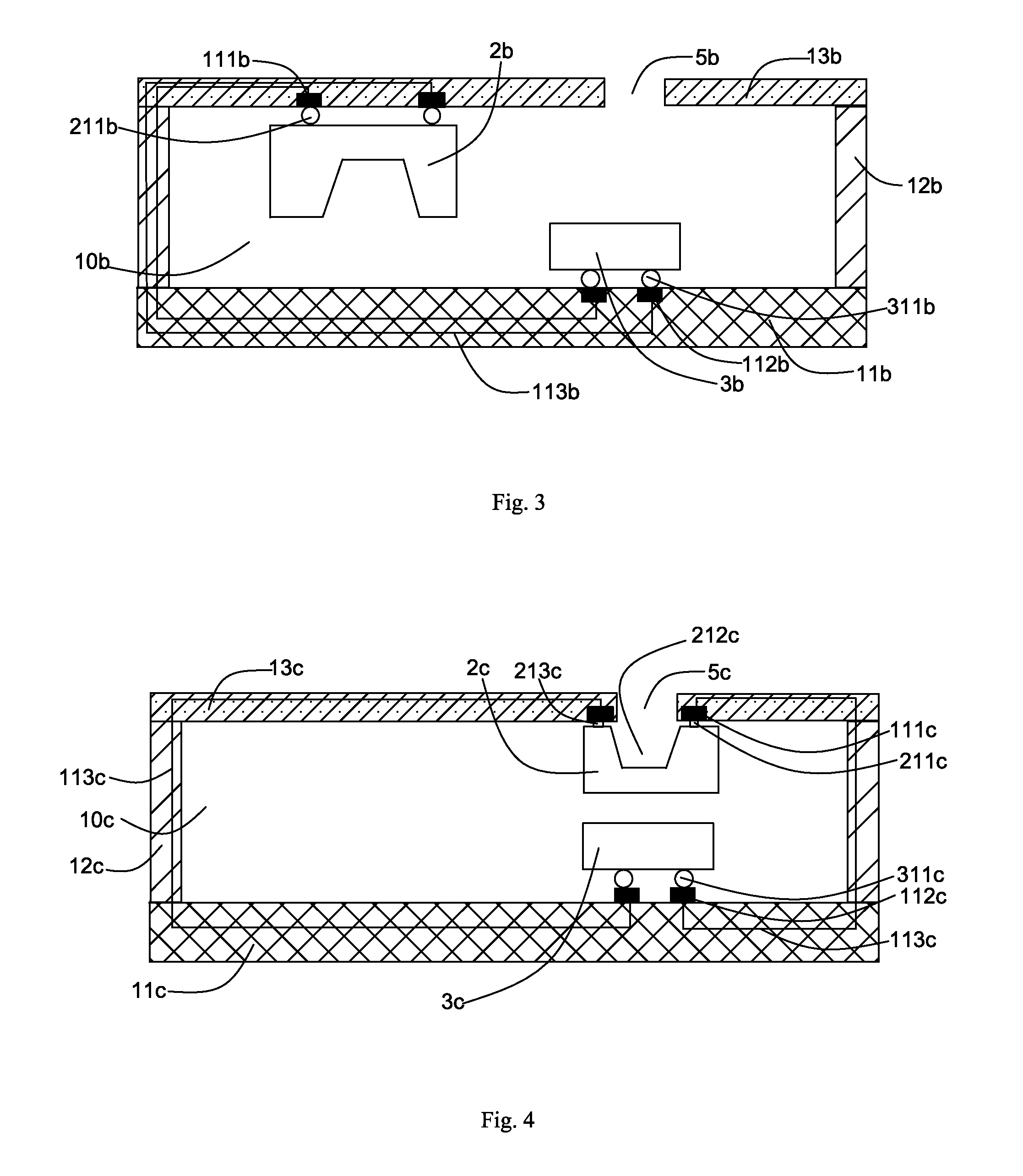

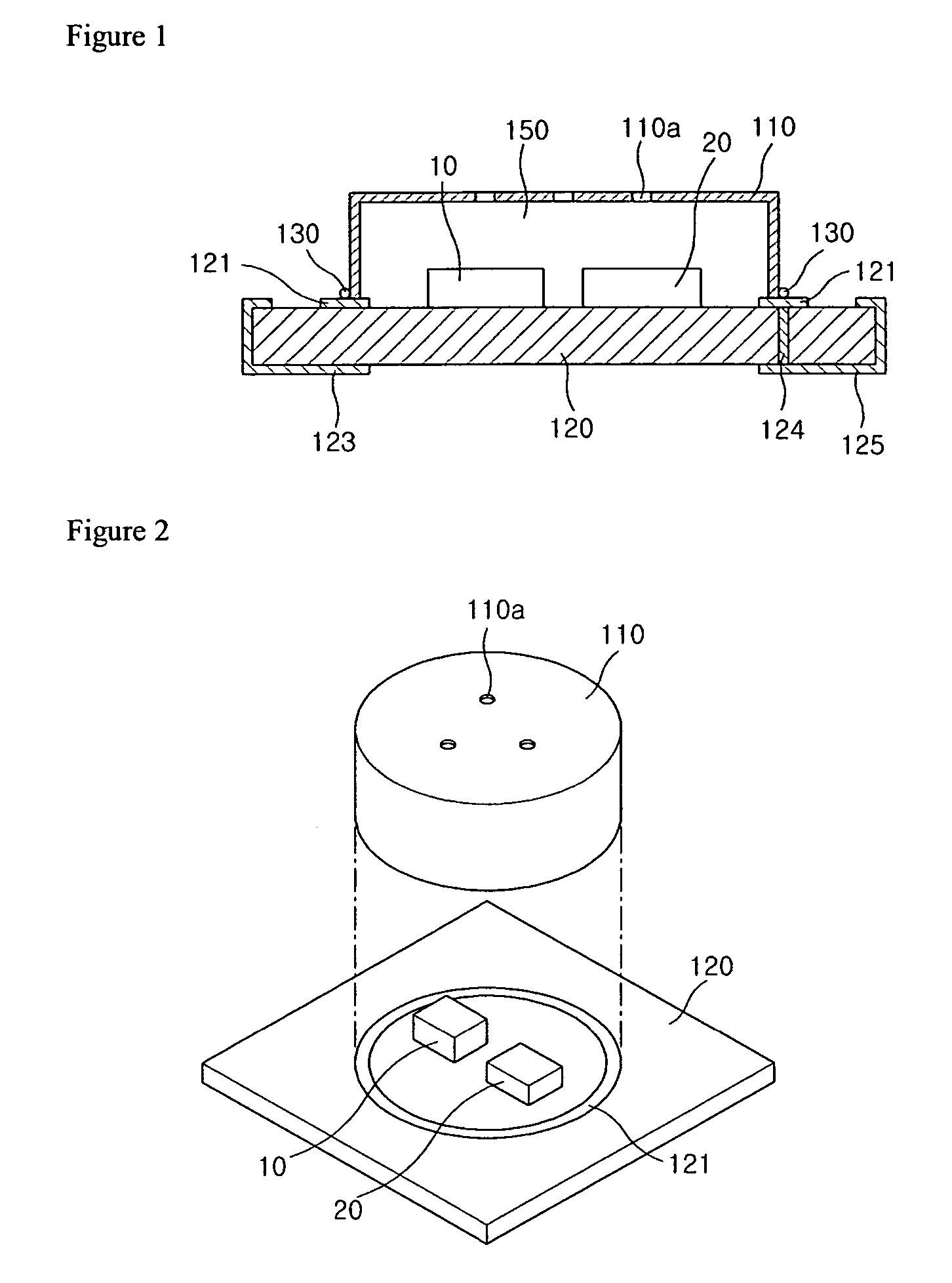

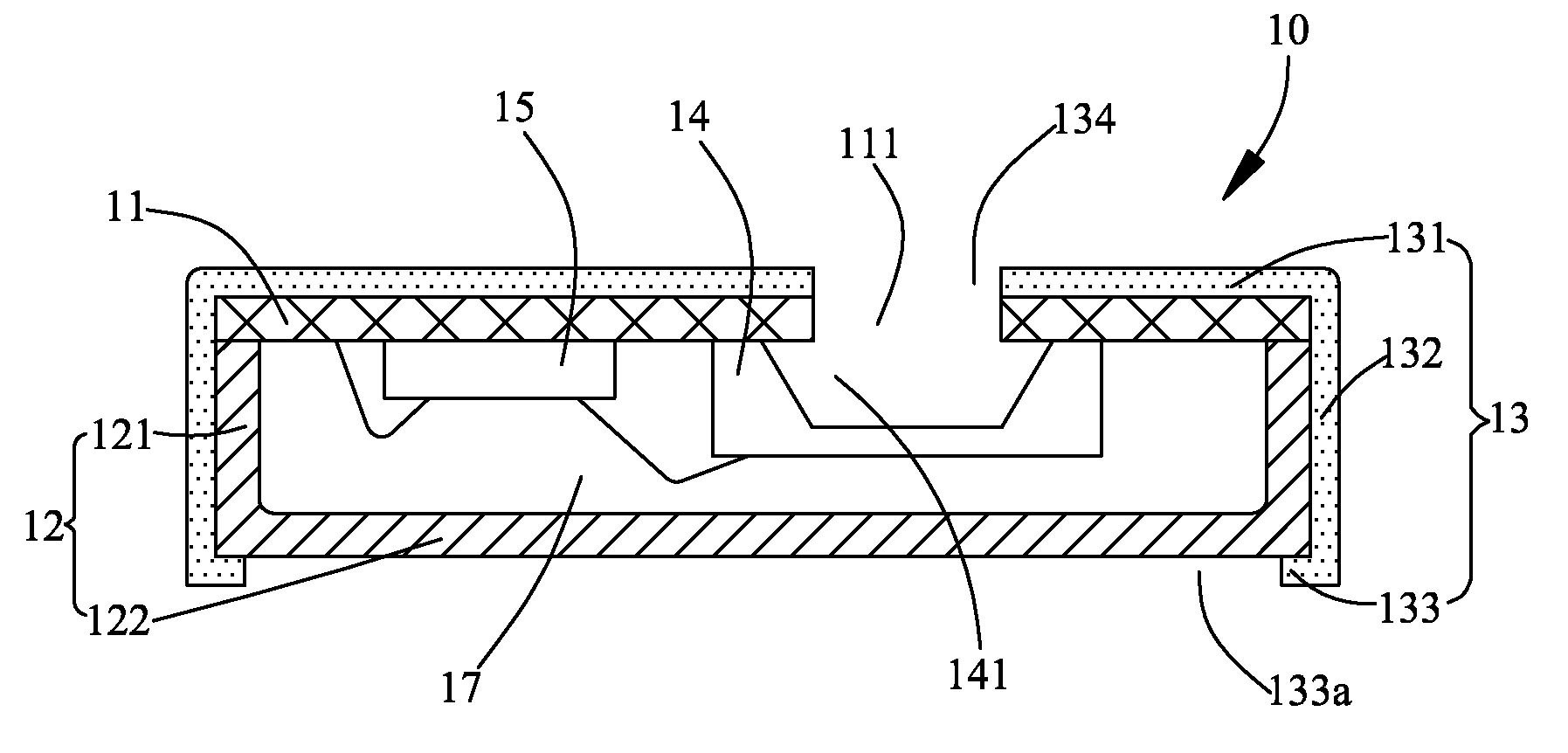

Miniature MEMS condenser microphone packages and fabrication method thereof

ActiveUS20100183181A1Piezoelectric/electrostrictive microphonesLine/current collector detailsAcoustic absorptionMems microphone

MEMS microphone packages and fabrication methods thereof are disclosed. A MEMS microphone package includes a cavity that houses a MEMS sensing element, an IC chip and other passive elements supported by a common substrate. The cavity is formed by a top cover member, a housing wall surrounds and supports the top cover member and the common substrate supports the housing wall. A conductive casing encloses and surrounds the cavity, and is electrically connected to a common analog ground lead on a PCB board. The top cover member and the housing wall are non-conductive. And the conductive casing is not connected directly to the ground leads of the package. An acoustic absorption layer is sandwiched between the conductive casing and the cavity which is formed by the top cover member, the housing wall and the substrate.

Owner:NEOMEMS TECH INC WUXI CHINA

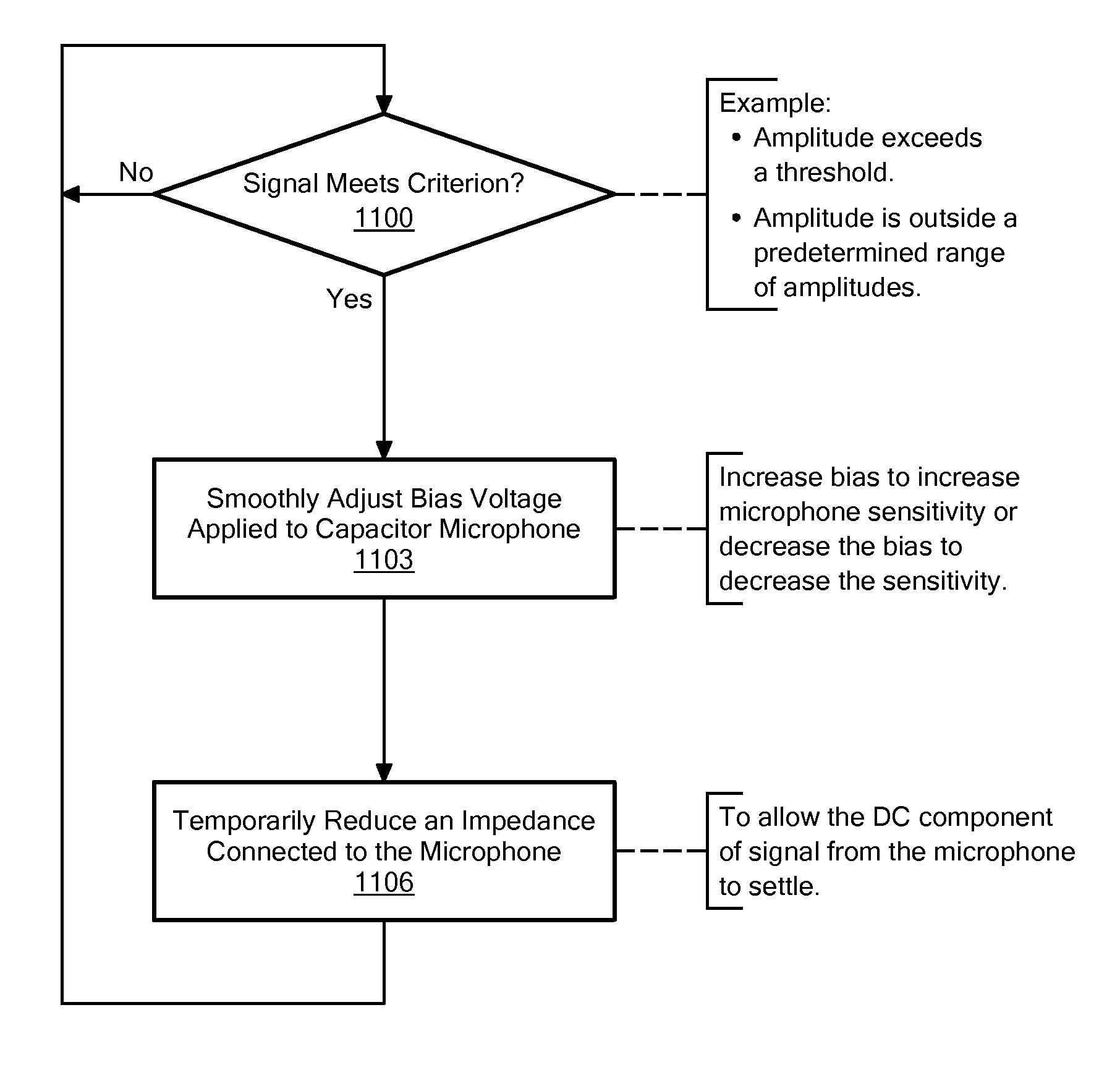

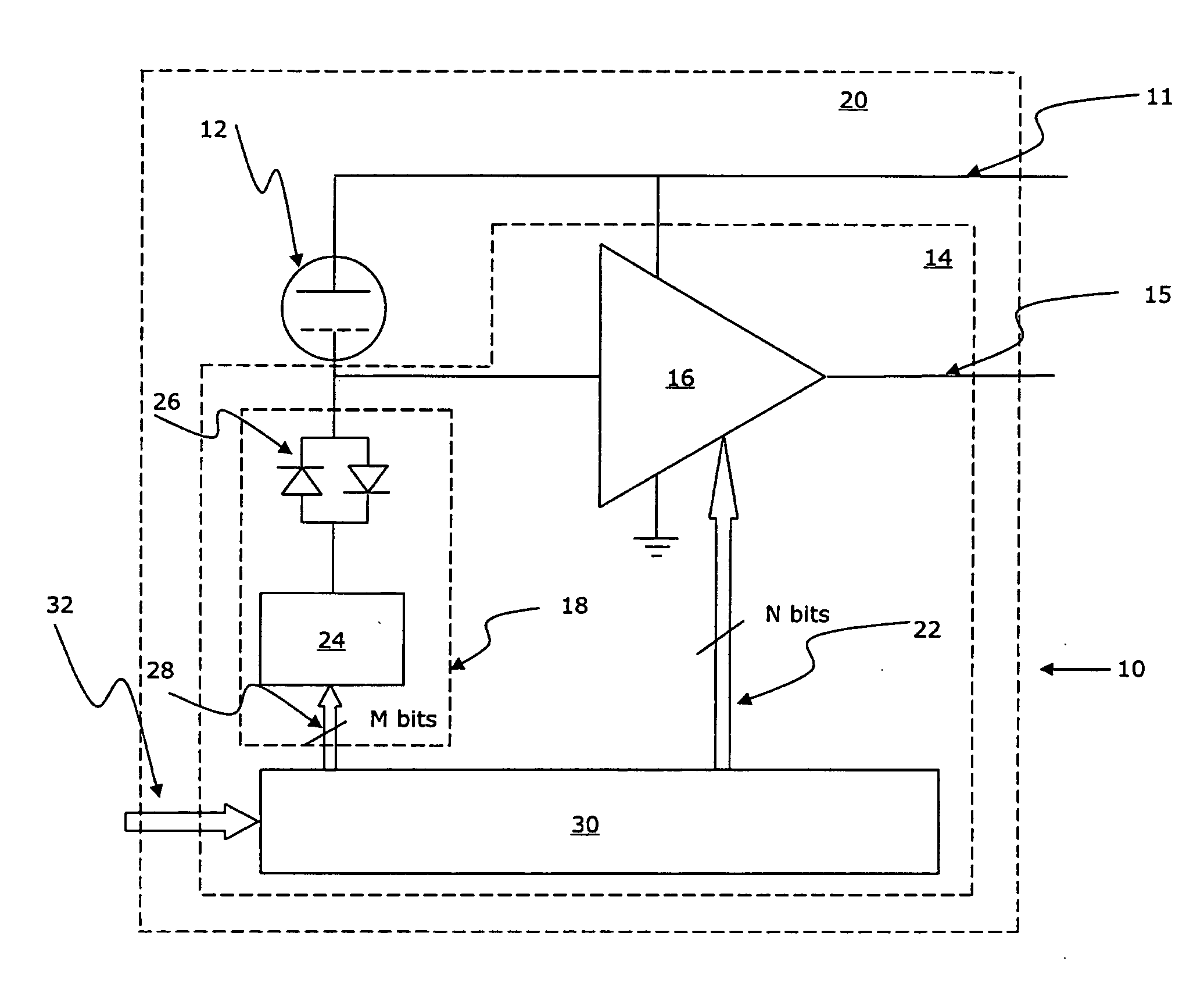

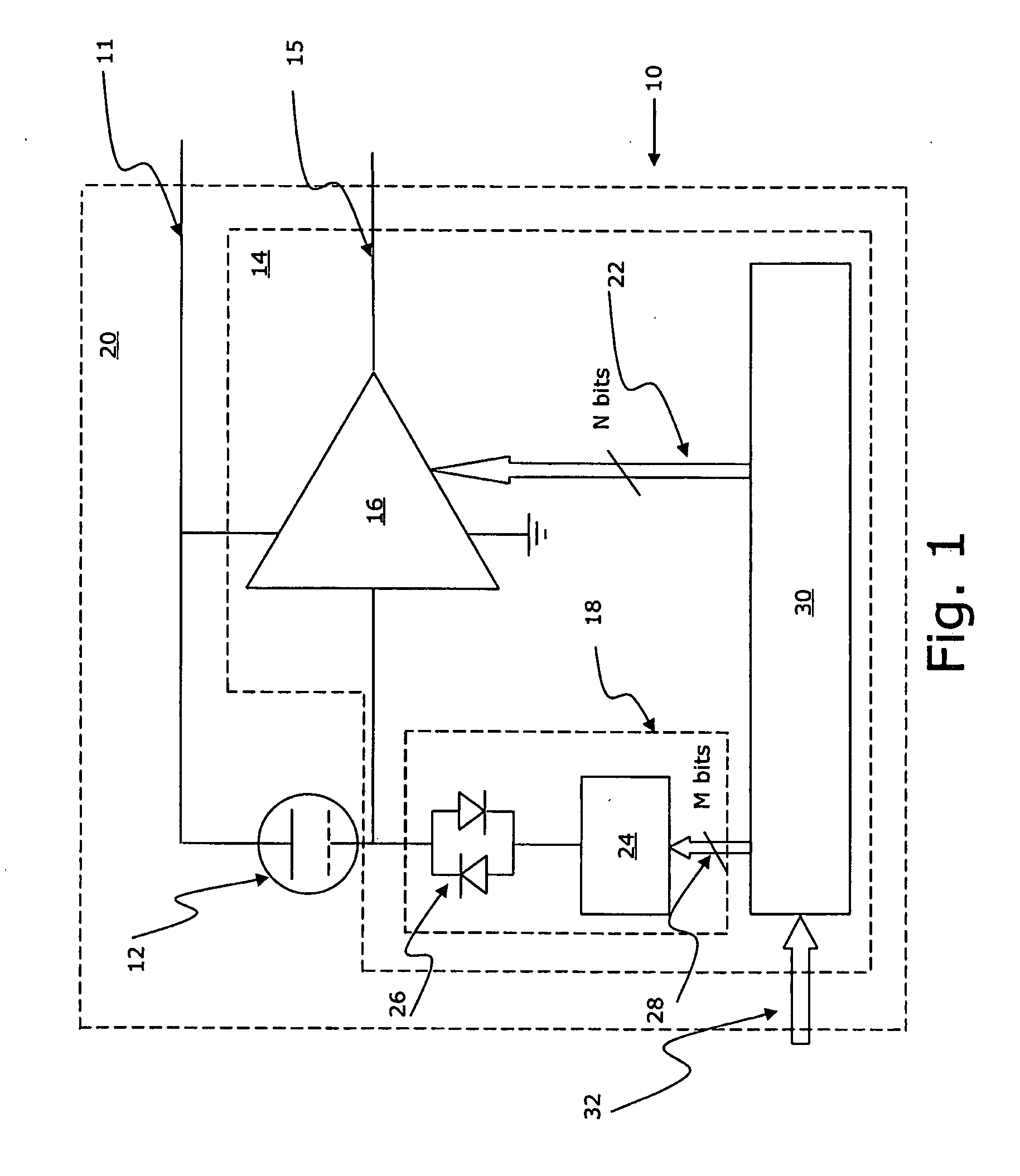

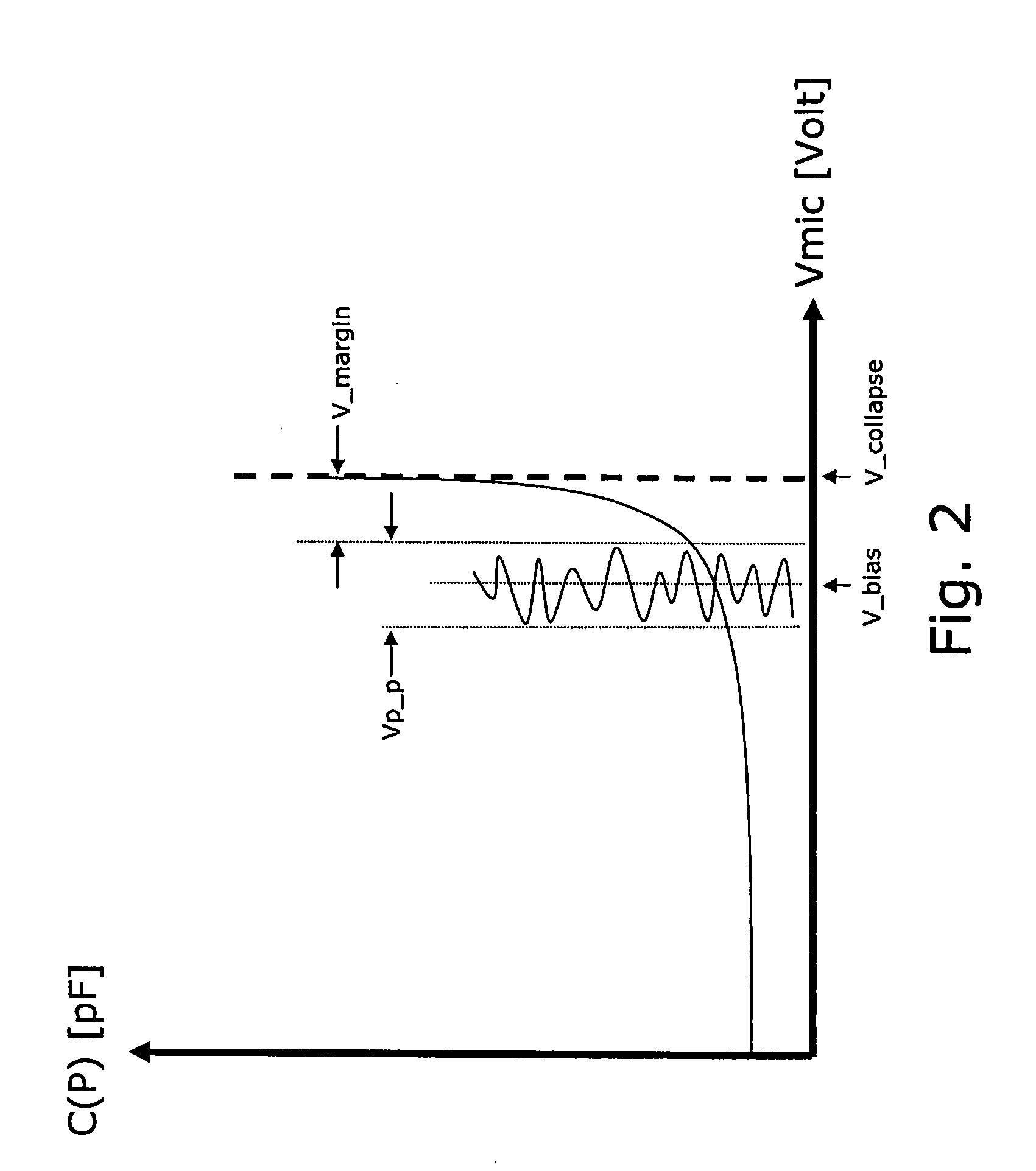

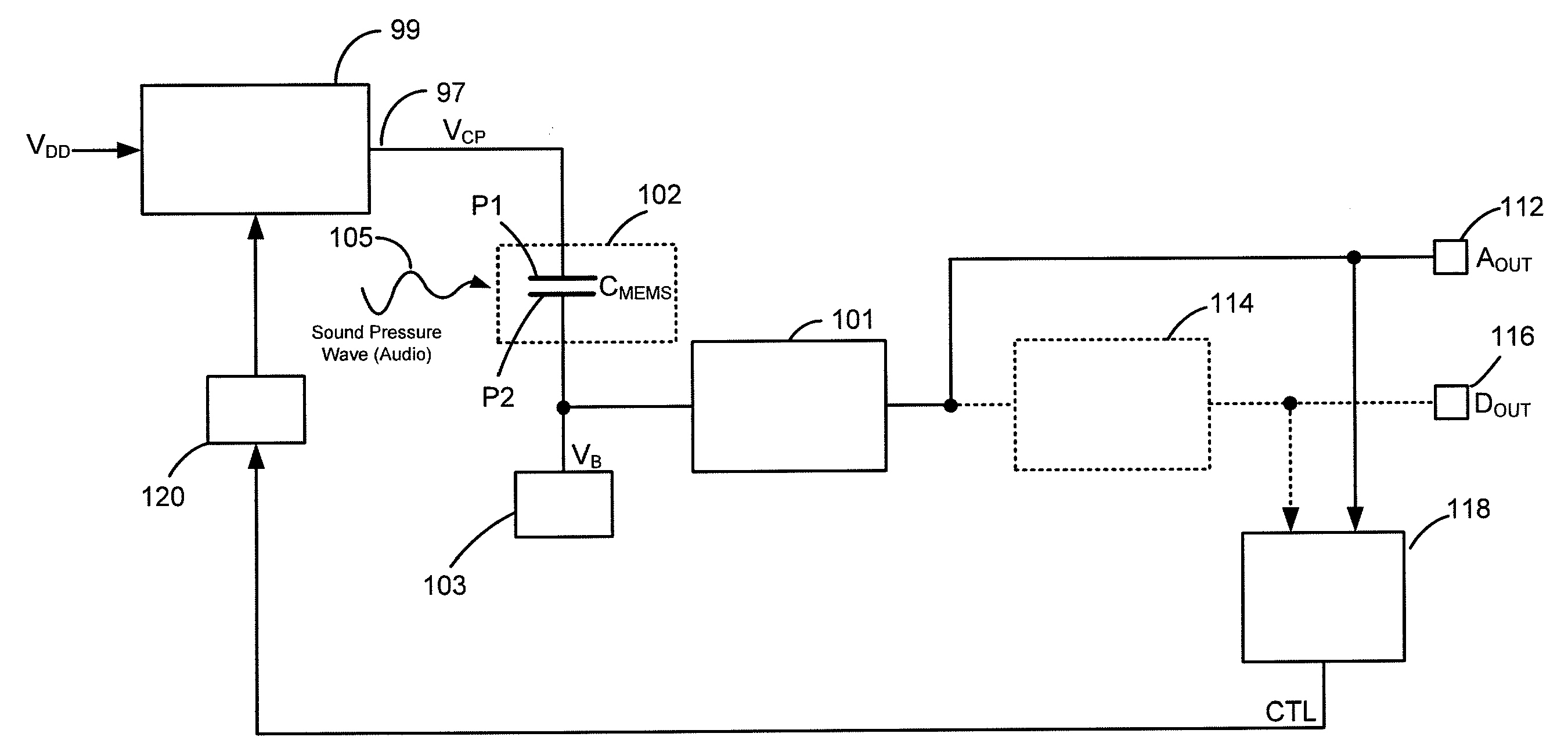

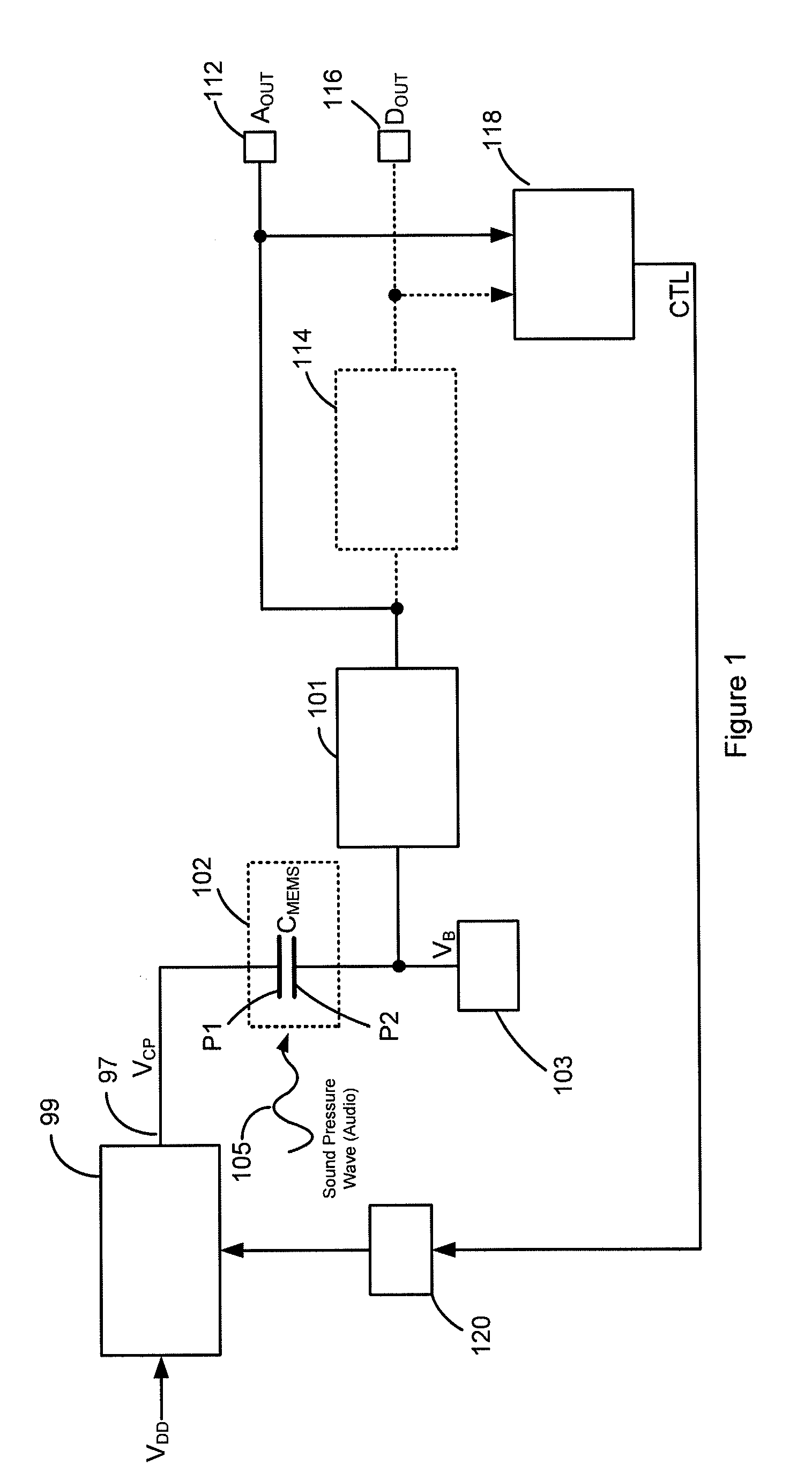

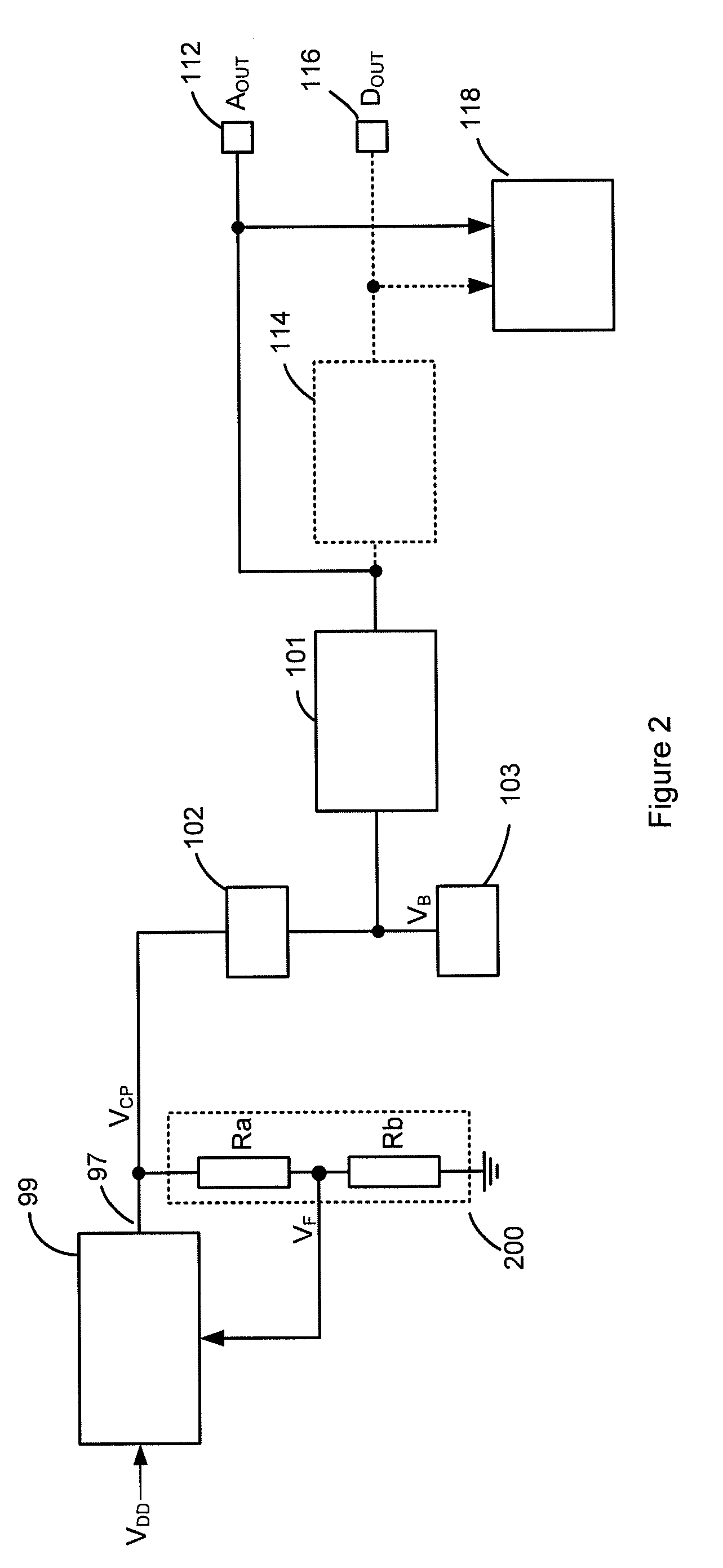

MEMS Microphone with Programmable Sensitivity

A control circuit monitors a signal produced by a MEMS or other capacitor microphone. When a criterion is met, for example when the amplitude of the monitored signal exceeds a threshold or the monitored signal has been clipped or analysis of the monitored signal indicates clipping is imminent or likely, the control circuit automatically adjusts a bias voltage applied to the capacitor microphone, thereby adjusting sensitivity of the capacitor microphone.

Owner:INVENSENSE

MEMS microphone package

InactiveUS20110075875A1Piezoelectric/electrostrictive microphonesSemiconductor/solid-state device manufacturingMems microphoneEngineering

A MEMS microphone package is disclosed. The MEMS microphone package comprises a housing, a MEMS die and an ASIC chip. The housing includes a base, a sidewall extending from the base, and a cover supported by the sidewall for forming a receiving space. The housing defines an acoustic hole for receiving external sound waves. The MEMS die is accommodated in the housing and the MEMS die defines a plurality of first conductive pads. The ASIC chip is accommodated in the housing and the ASIC chip defines a plurality of second conductive pads.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD +1

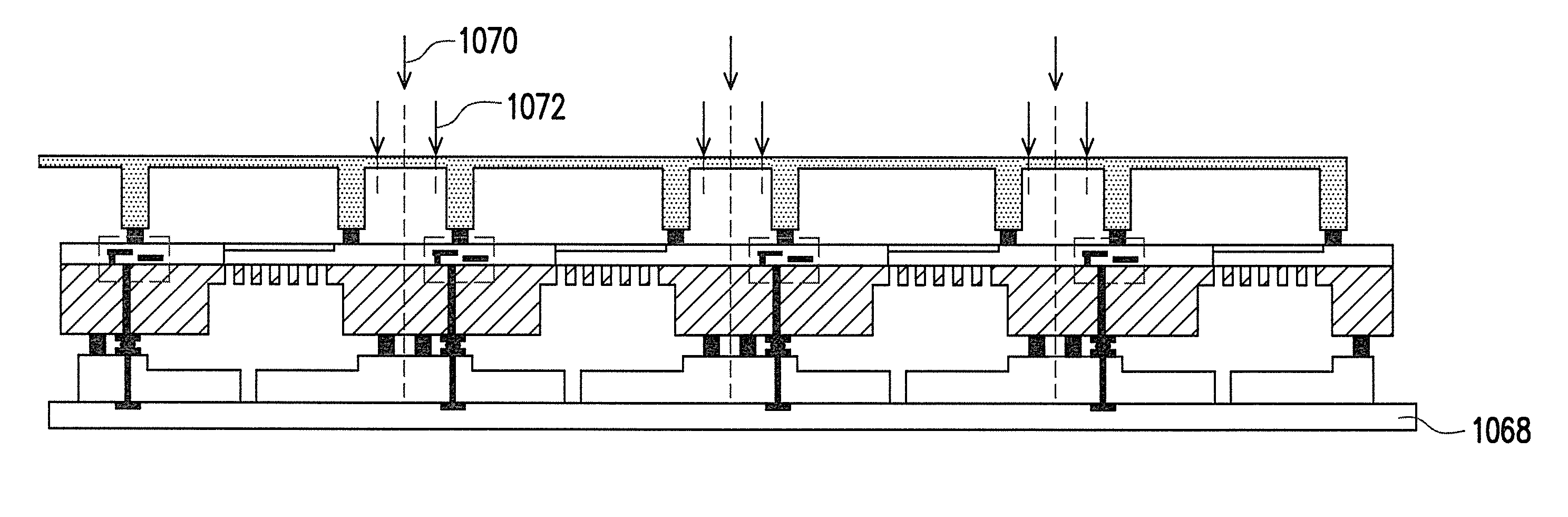

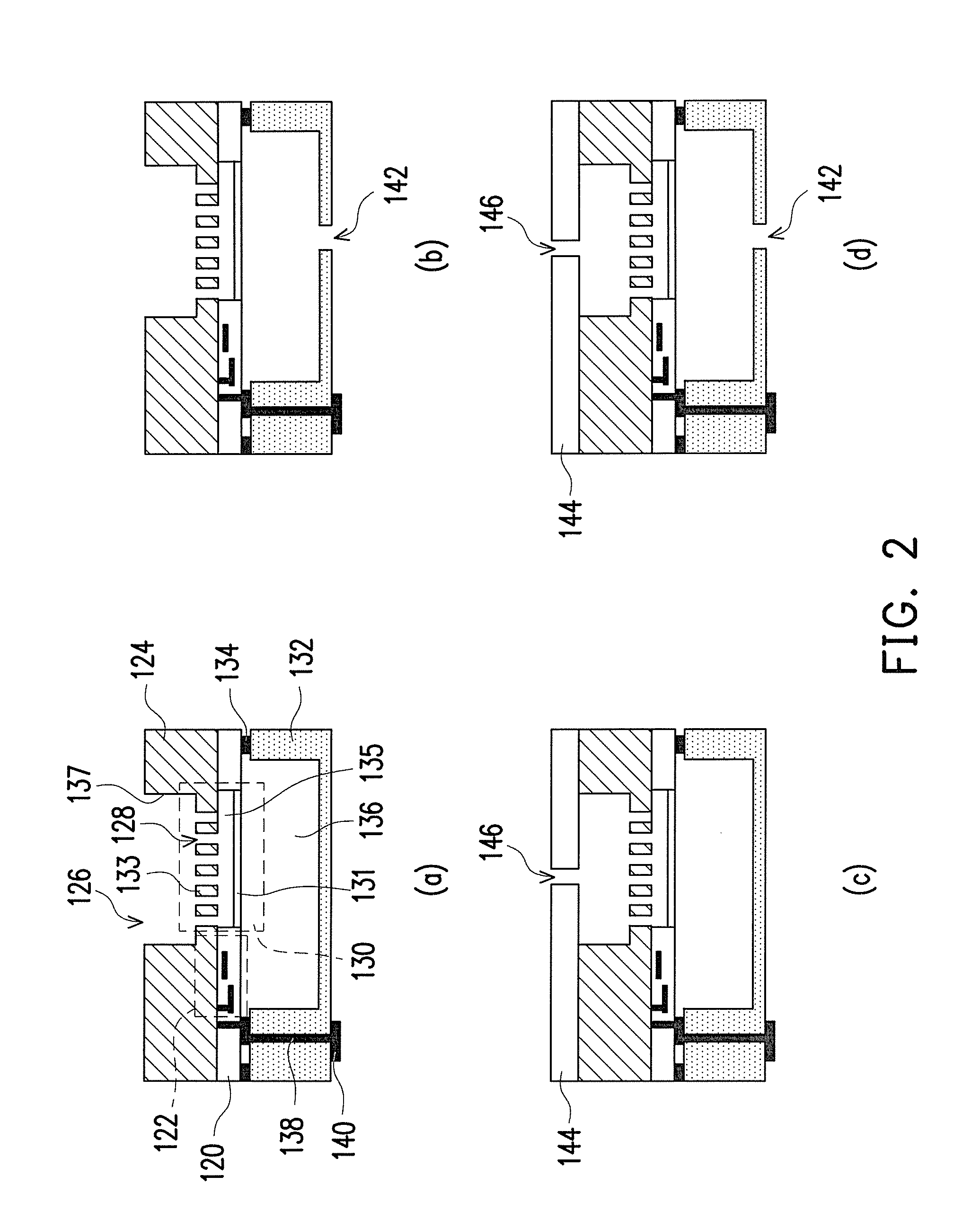

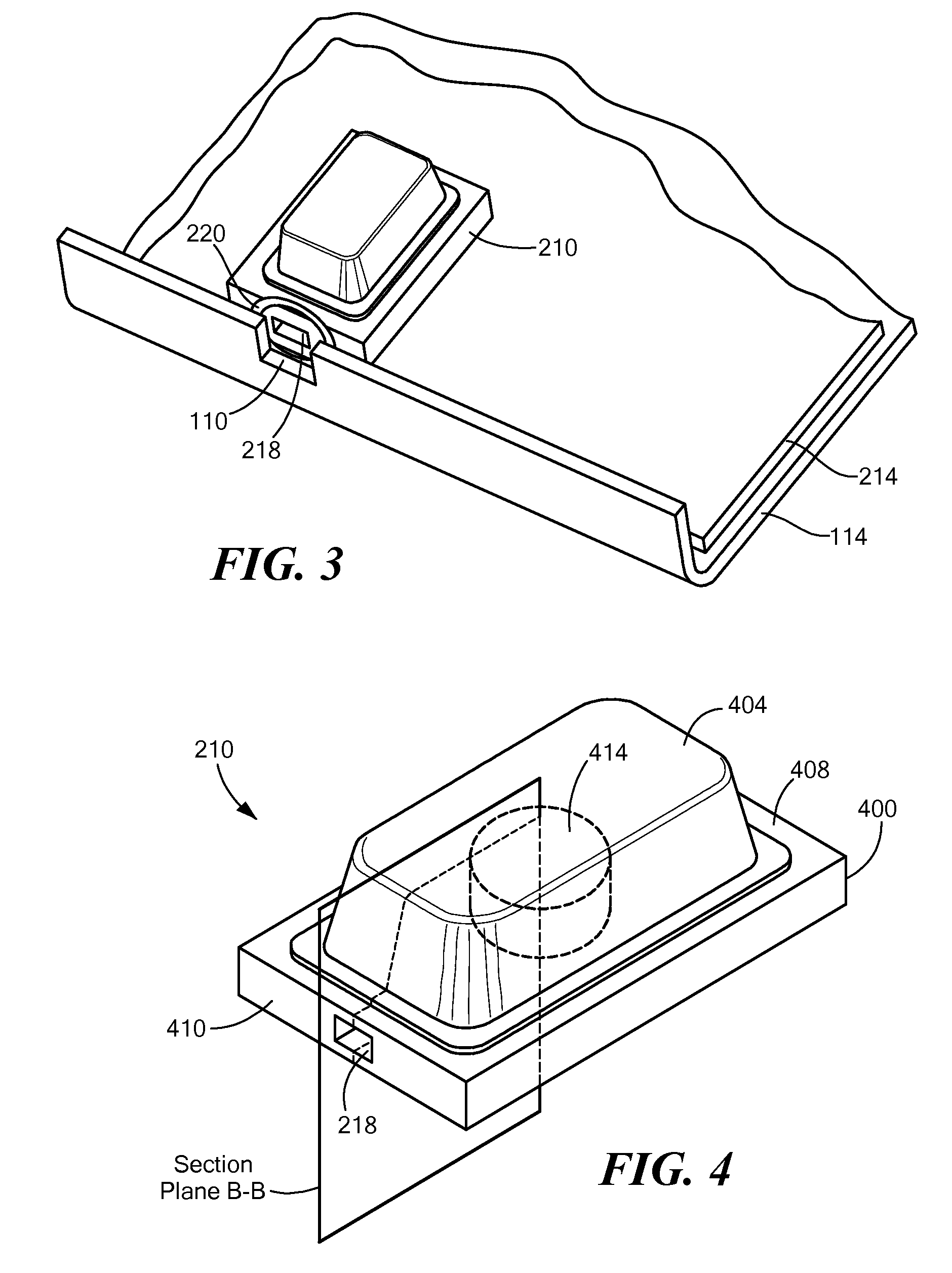

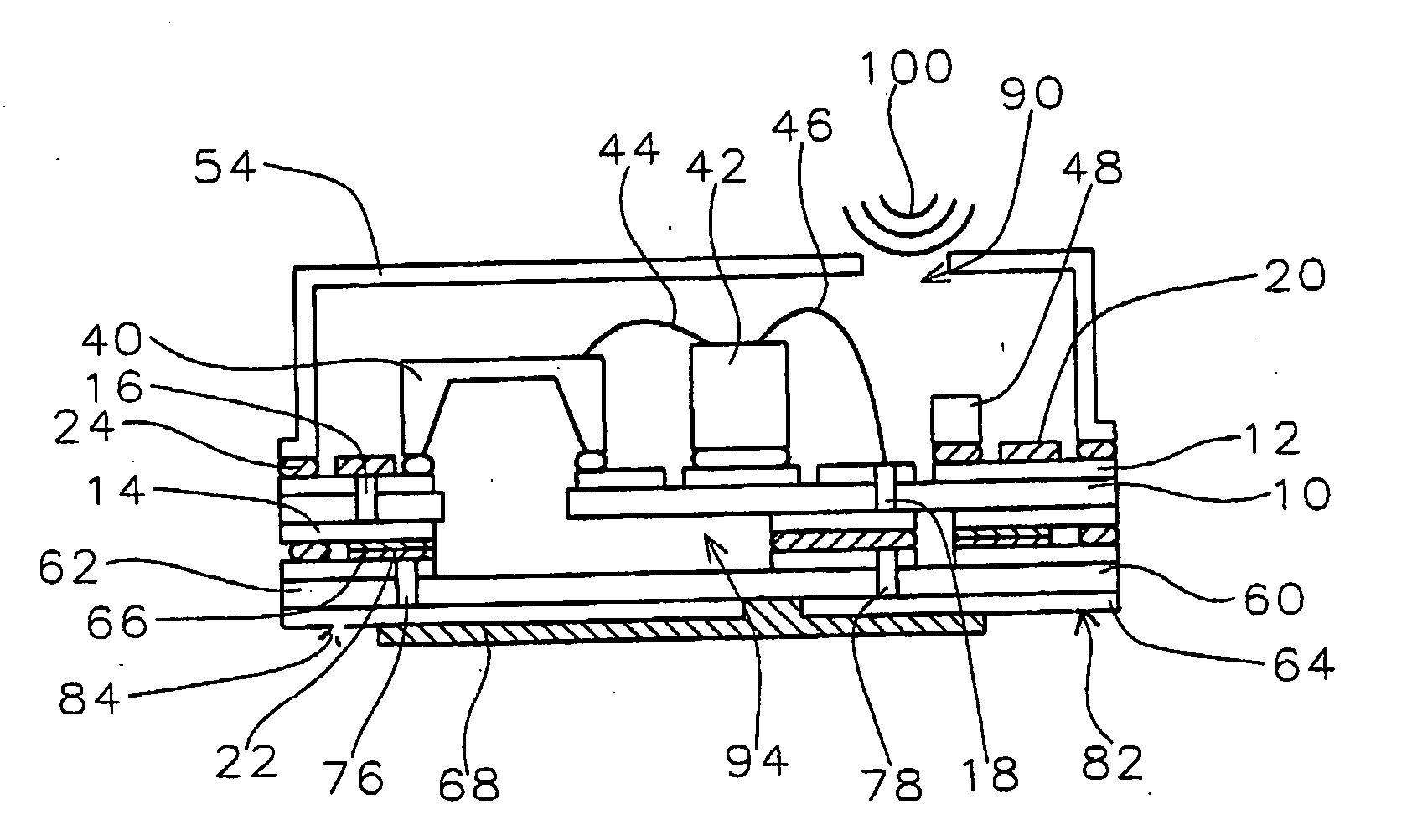

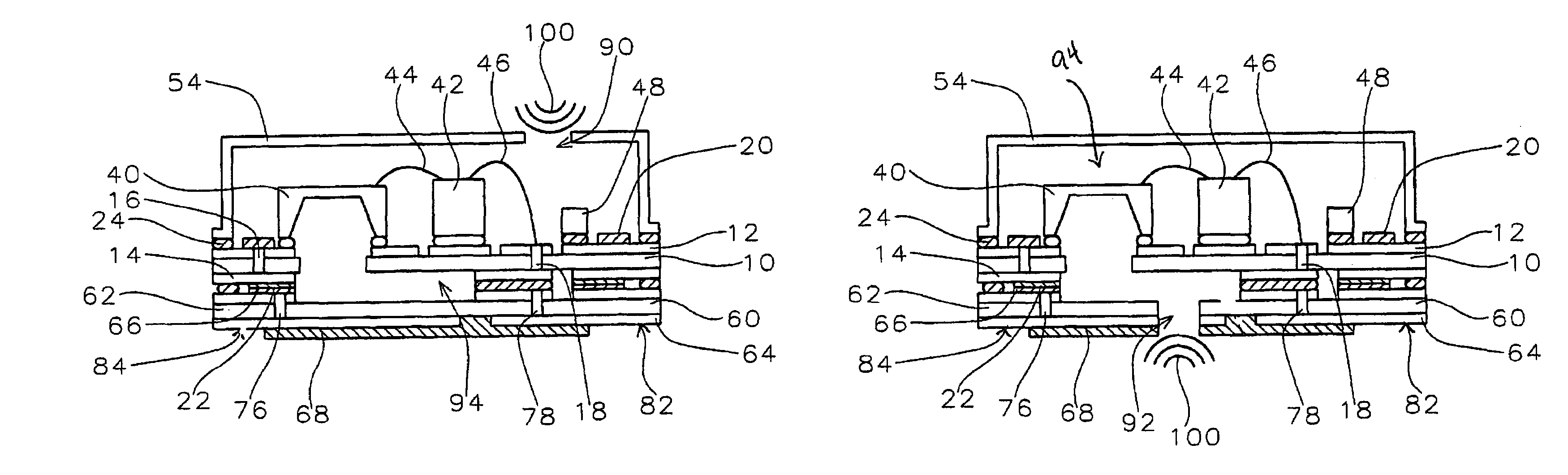

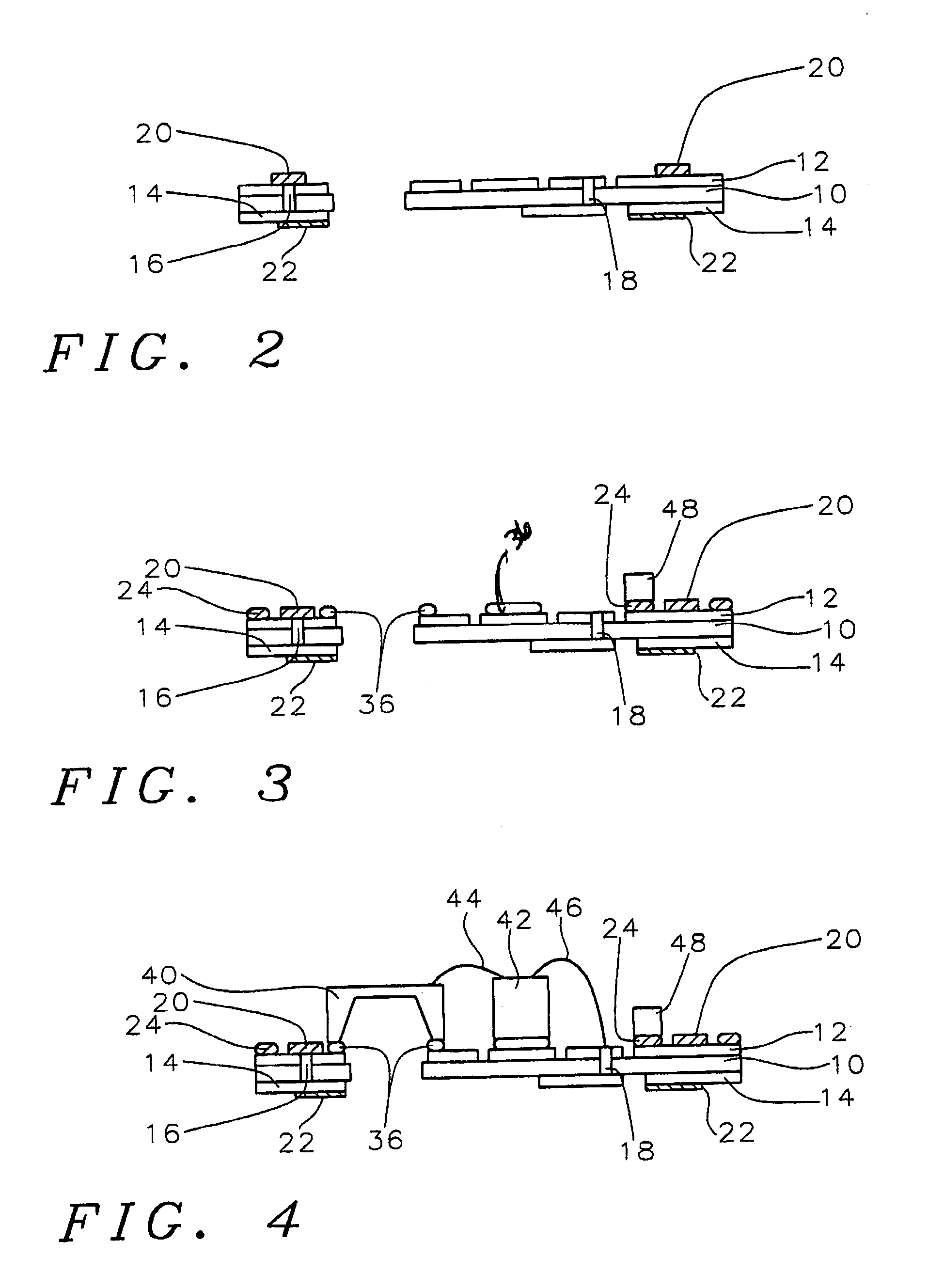

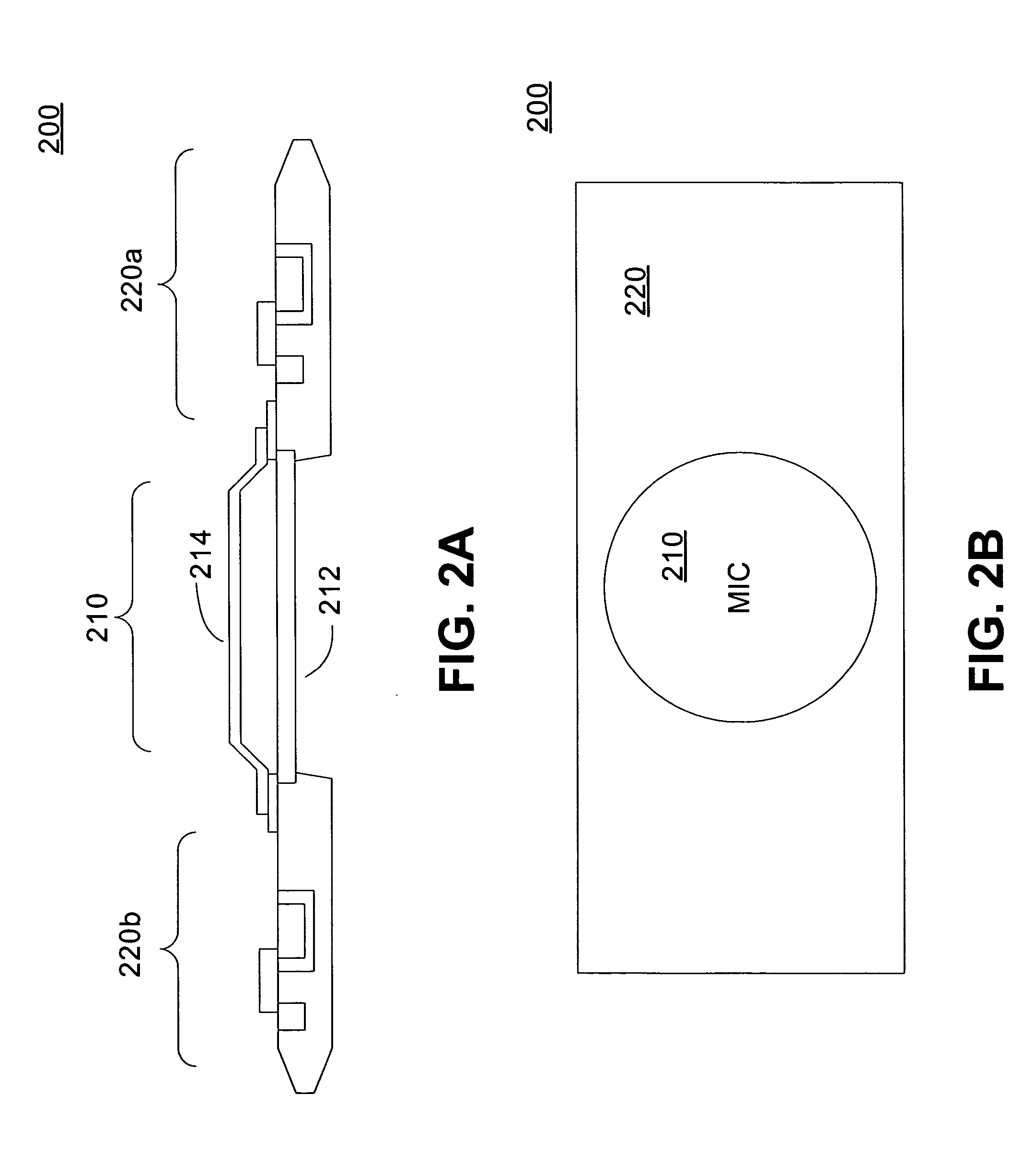

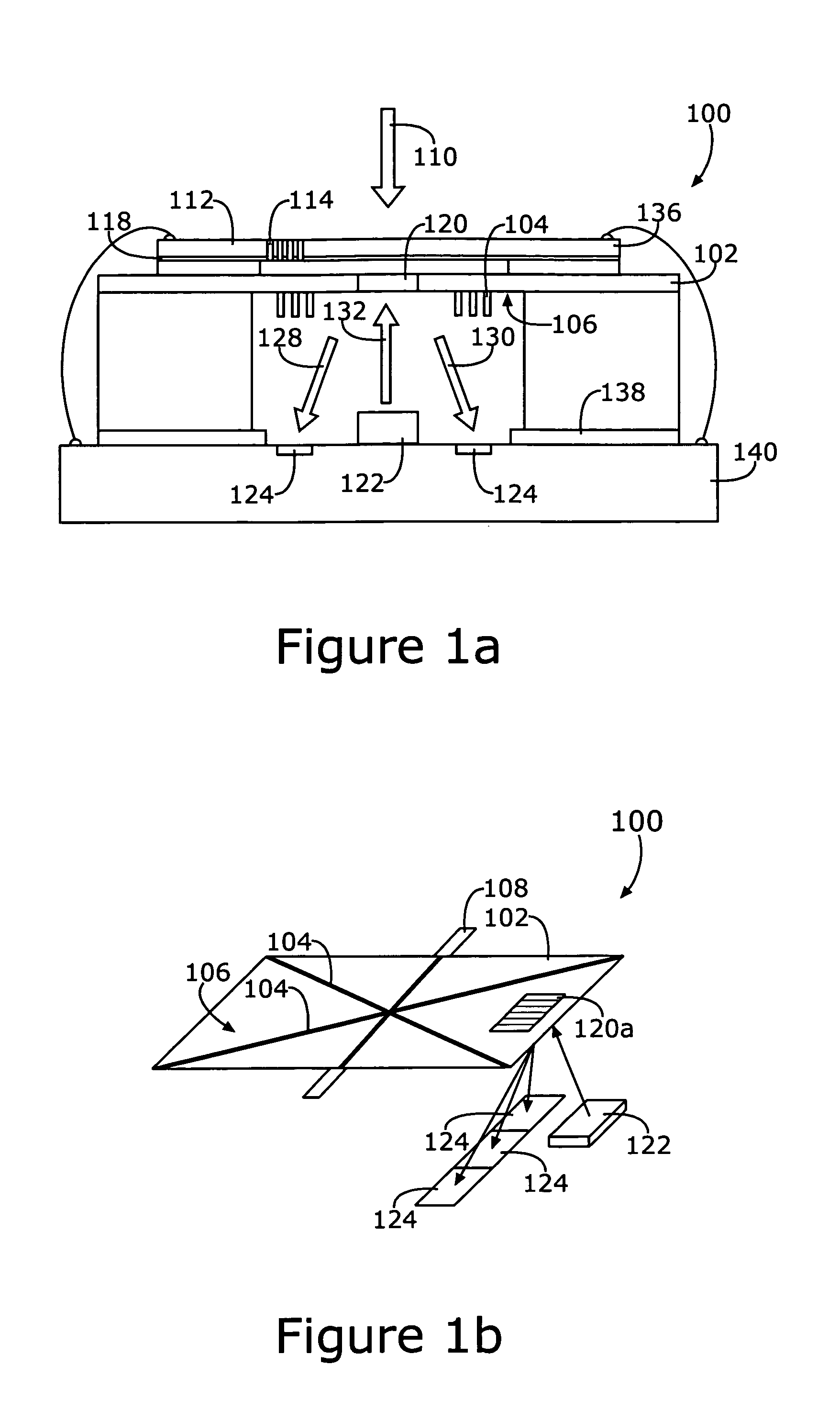

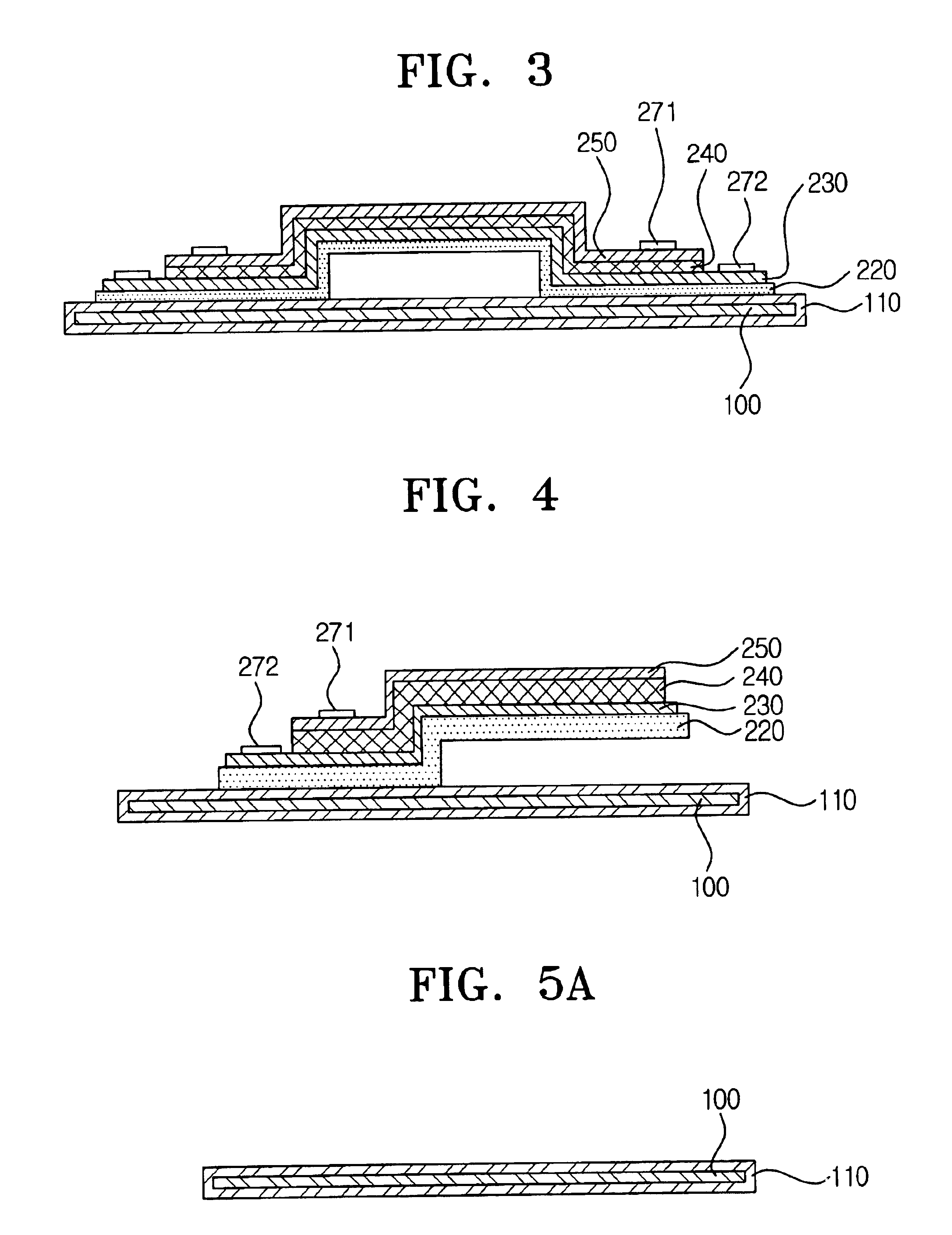

MEMS microphone with a stacked PCB package and method of producing the same

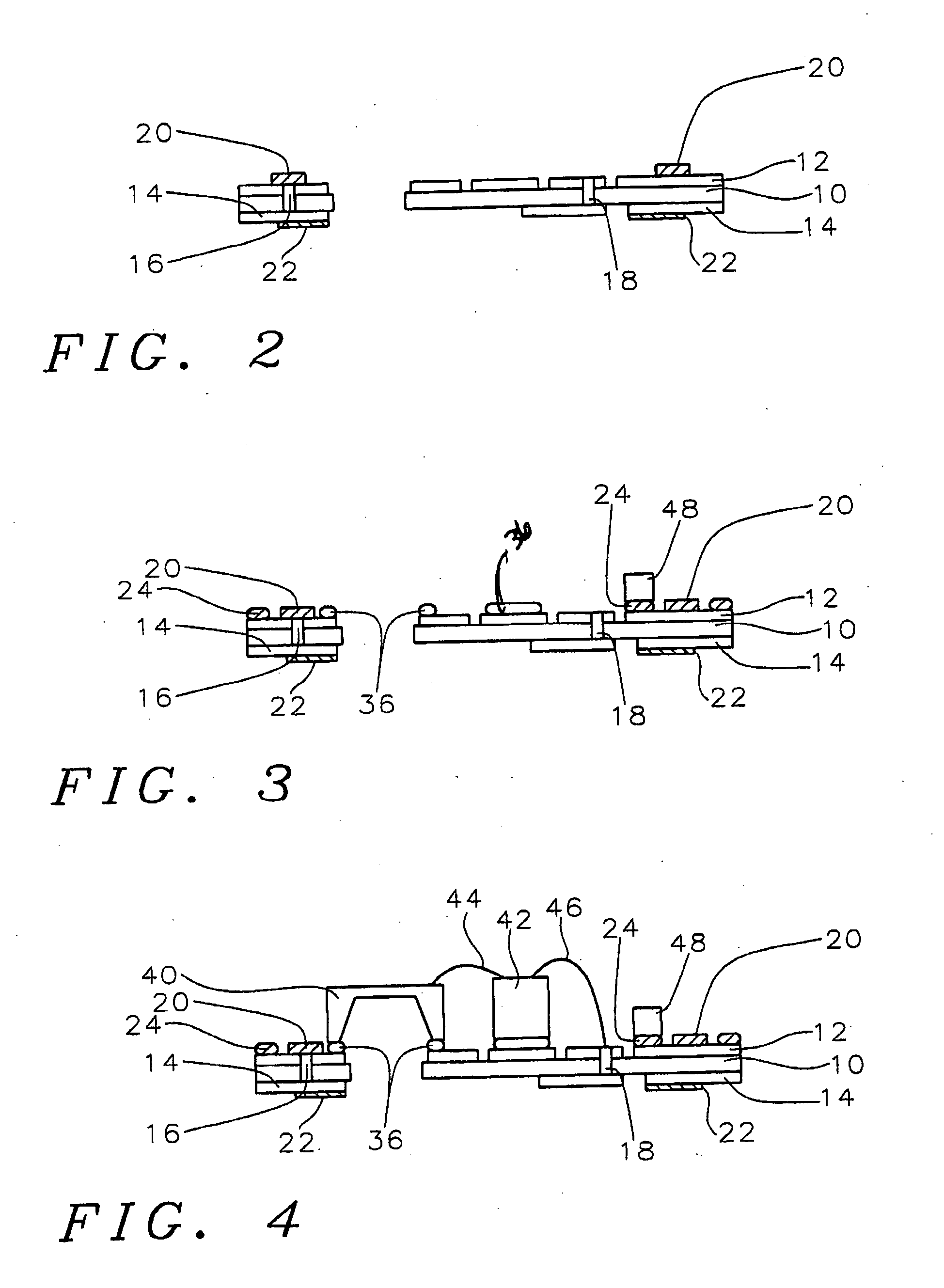

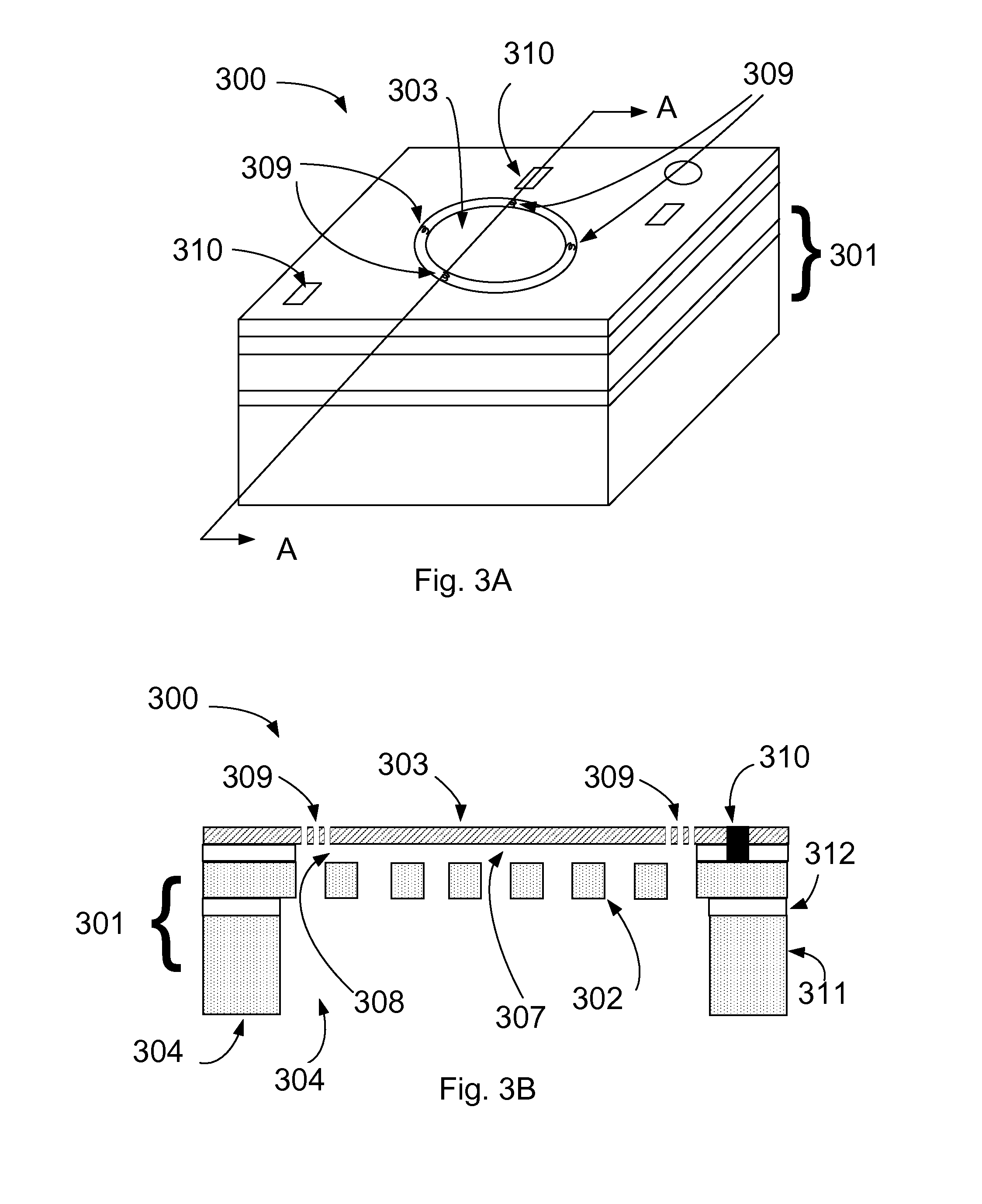

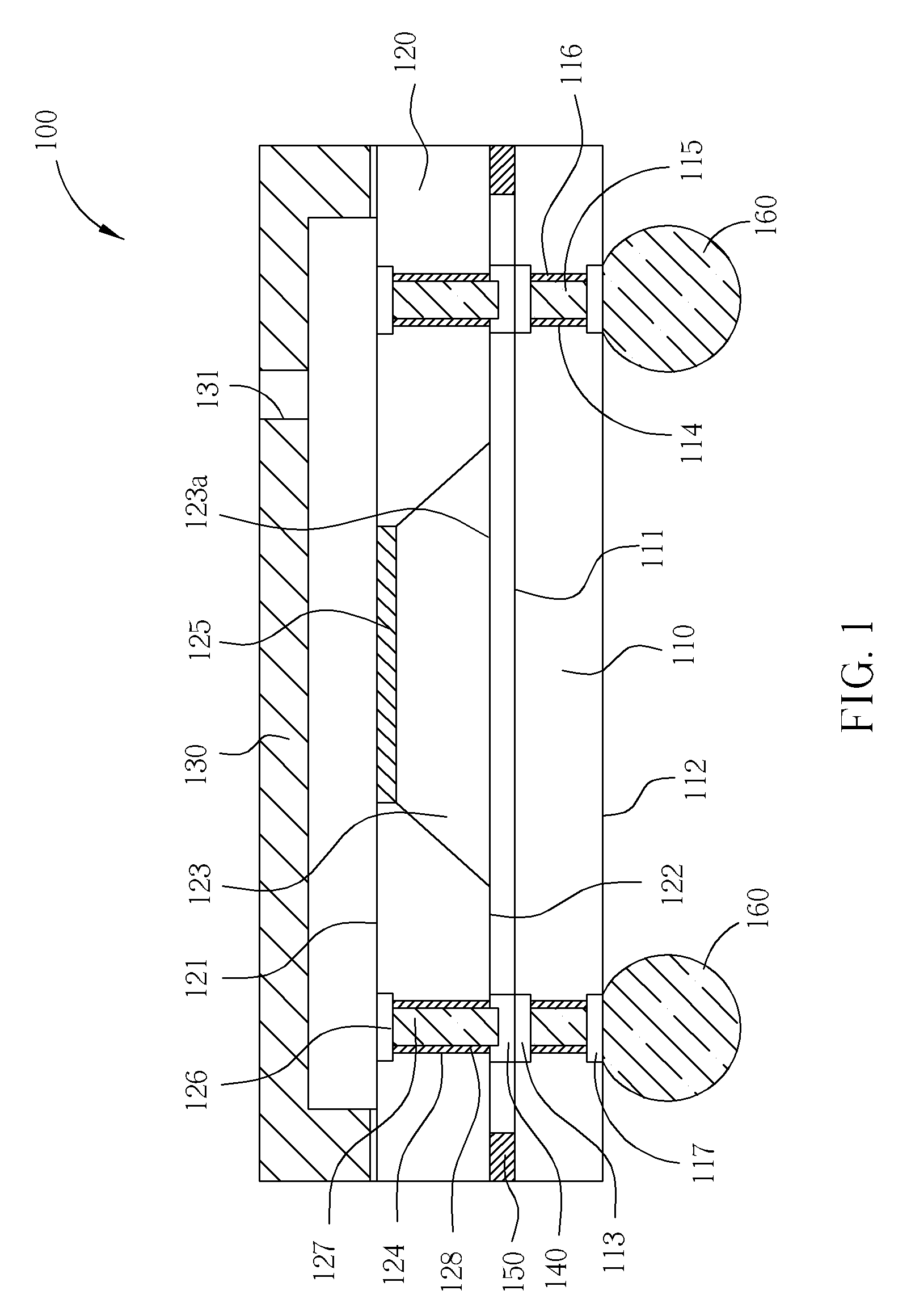

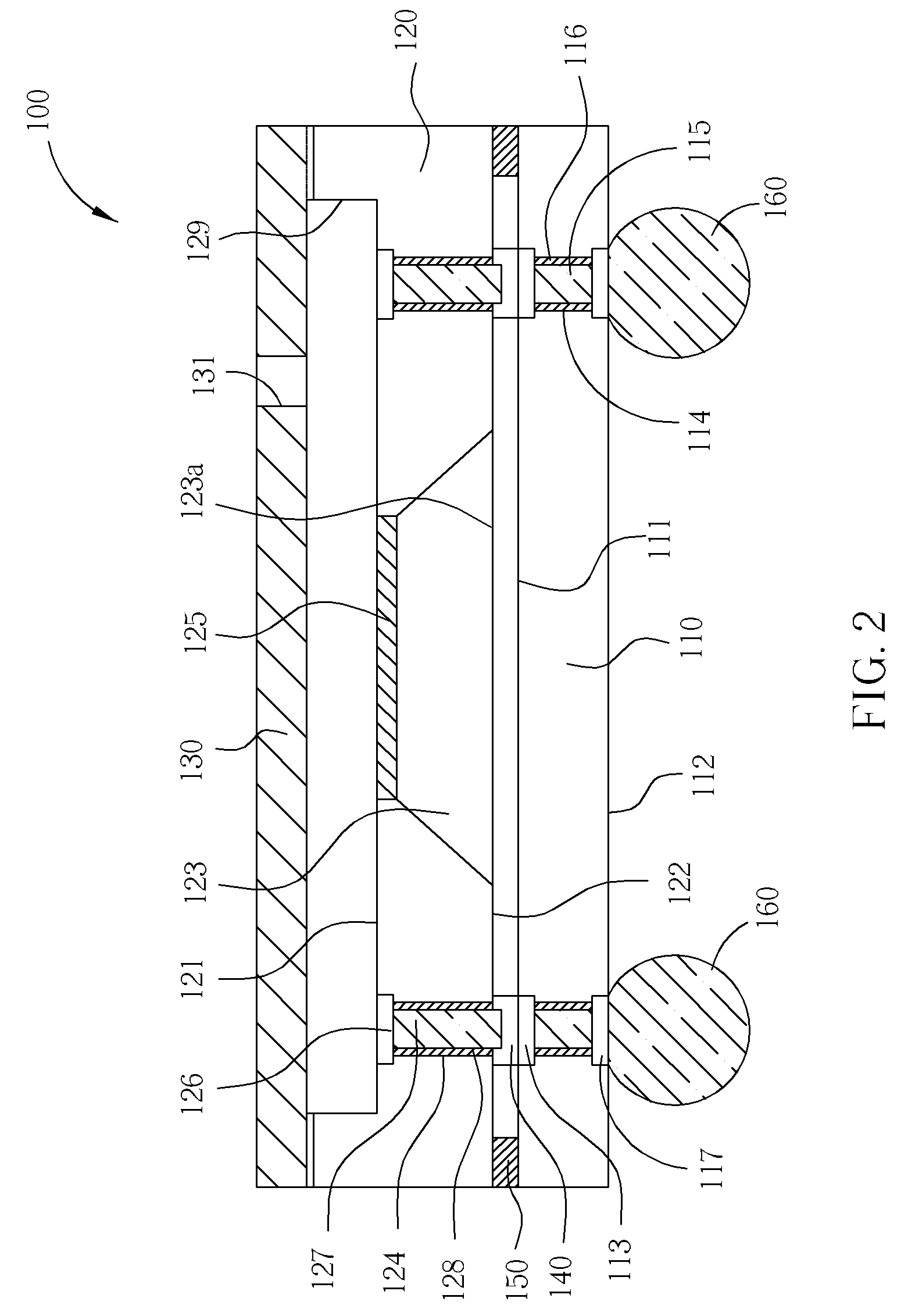

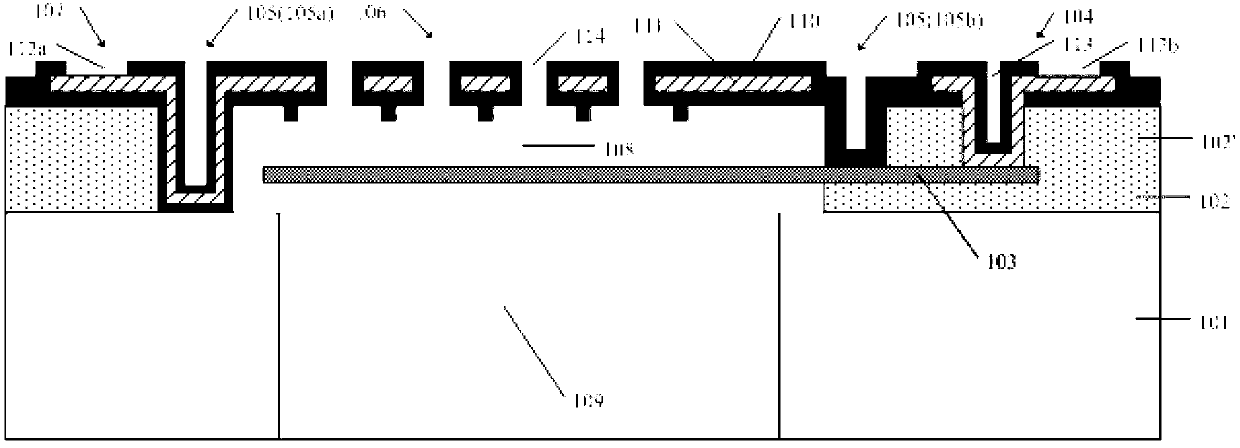

ActiveUS20070205492A1Cost-effectiveSemiconductor/solid-state device detailsSolid-state devicesEdge surfaceAcoustic energy

A MEMS microphone with a stacked PCB package is described. The MEMS package has at least one MEMS acoustic sensor device located on a PCB stack. A metal cap structure surrounds the at least one MEMS acoustic sensor device wherein an edge surface of the metal cap structure is attached and electrically connected to the PCB stack. In a first embodiment, a back chamber is formed underlying the at least one MEMS acoustic sensor device and within the PCB stack wherein an opening underlying the at least one MEMS acoustic sensor device accesses the back chamber. An opening in the metal cap structure not aligned with the at least one MEMS acoustic sensor device allows external fluid, acoustic energy or pressure to enter the at least one MEMS acoustic sensor device. In a second embodiment, a back chamber is formed in the space under the metal cap and over the first PCB. A hollow chamber is formed between the first PCB and the second PCB wherein an opening under the at least one MEMS acoustic sensor device accesses the hollow chamber. An opening in a bottom surface of the PCB stack not aligned with the at least one MEMS acoustic sensor device also accesses the hollow chamber and allows external fluid, acoustic energy or pressure to enter the at least one MEMS acoustic sensor device.

Owner:SHANDONG GETTOP ACOUSTIC

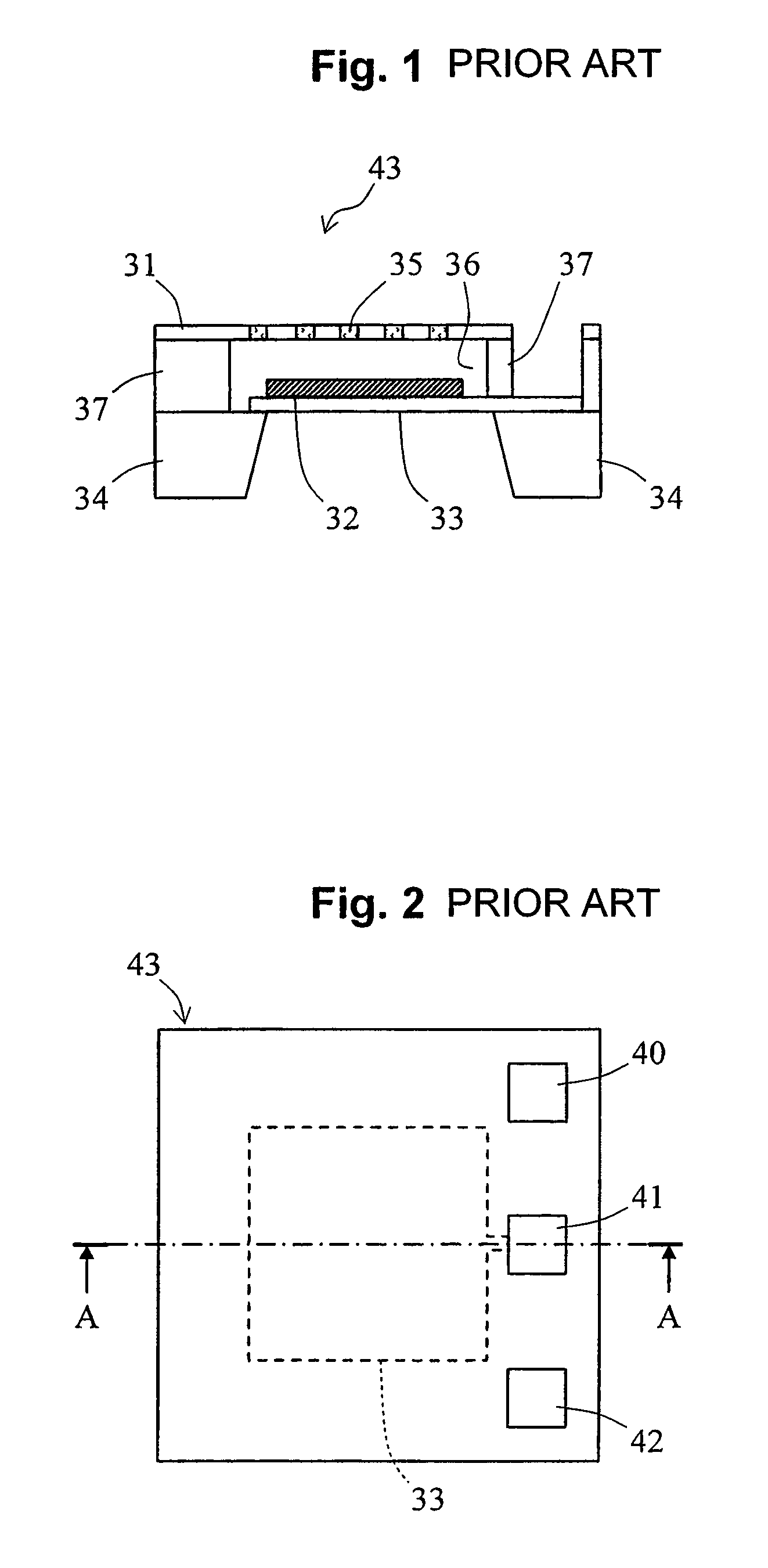

Silicon based condenser microphone and packaging method for the same

InactiveUS7903831B2High bonding strengthIncrease resistanceSolid-state devicesElectrostatic transducer microphonesMems microphoneCondenser microphone

Disclosed are a silicon based condenser microphone and a packaging method for the silicon based condenser microphone. The silicon based condenser microphone comprises a metal case, and a board which is mounted with a MEMS microphone chip and an ASIC chip having an electric voltage pump and a buffer IC and is formed with a connecting pattern for bonding with the metal case, wherein the connecting pattern is welded to the metal case. The method for packaging a silicon based condenser microphone includes the steps of inputting a board which is mounted with a MEMS chip and an ASIC chip and is formed with a connecting pattern; inputting a metal case, aligning the metal case on the connecting pattern of the board, and welding an opened end of the metal case to the connecting pattern of the board. Thus, the metal case is welded to the board by the laser.

Owner:BSE CO LTD

MEMS microphone with a stacked PCB package and method of producing the same

ActiveUS7436054B2Cost-effectiveSemiconductor/solid-state device detailsSolid-state devicesEdge surfaceAcoustic energy

Owner:SHANDONG GETTOP ACOUSTIC

Microphone Package with Embedded ASIC

ActiveUS20120087521A1Transducer detailsSemiconductor electrostatic transducersEngineeringMems microphone

A packaged microphone has a base, a lid coupled to the base forming an interior, a MEMS microphone secured to the base within the interior, and an integrated circuit embedded in the base. Apertures in the base and integrated circuit are aligned to form an aperture from the exterior of the package to the interior.

Owner:INVENSENSE

Calibrated microelectromechanical microphone

ActiveUS20080075306A1Improve production yieldMaximize sensitivitySemiconductor electrostatic transducersElectrostatic transducer microphonesVoltage generatorAudio power amplifier

A MEMS microphone comprising a MEMS transducer having a back plate and a diaphragm as well as controllable bias voltage generator providing a DC bias voltage between the back plate and the diaphragm. The microphone also has an amplifier with a controllable gain, and a memory for storing information for determining a bias voltage to be provided by the bias voltage generator and the gain of the amplifier.

Owner:TDK CORPARATION

MEMS microphone

A MEMS microphone includes a cover, a housing engaging with the cover for forming a cavity, at least one transducer accommodated in the cavity, and a conductive case covering the cover and the sidewall of the housing. The housing includes a cover and a sidewall extending from the base. The conductive case defines a first part covering the cover, a second part extending from the first part for covering the sidewall and a third part perpendicularly extending from the second part for covering a periphery part of the base, the third part forming an opening.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD +1

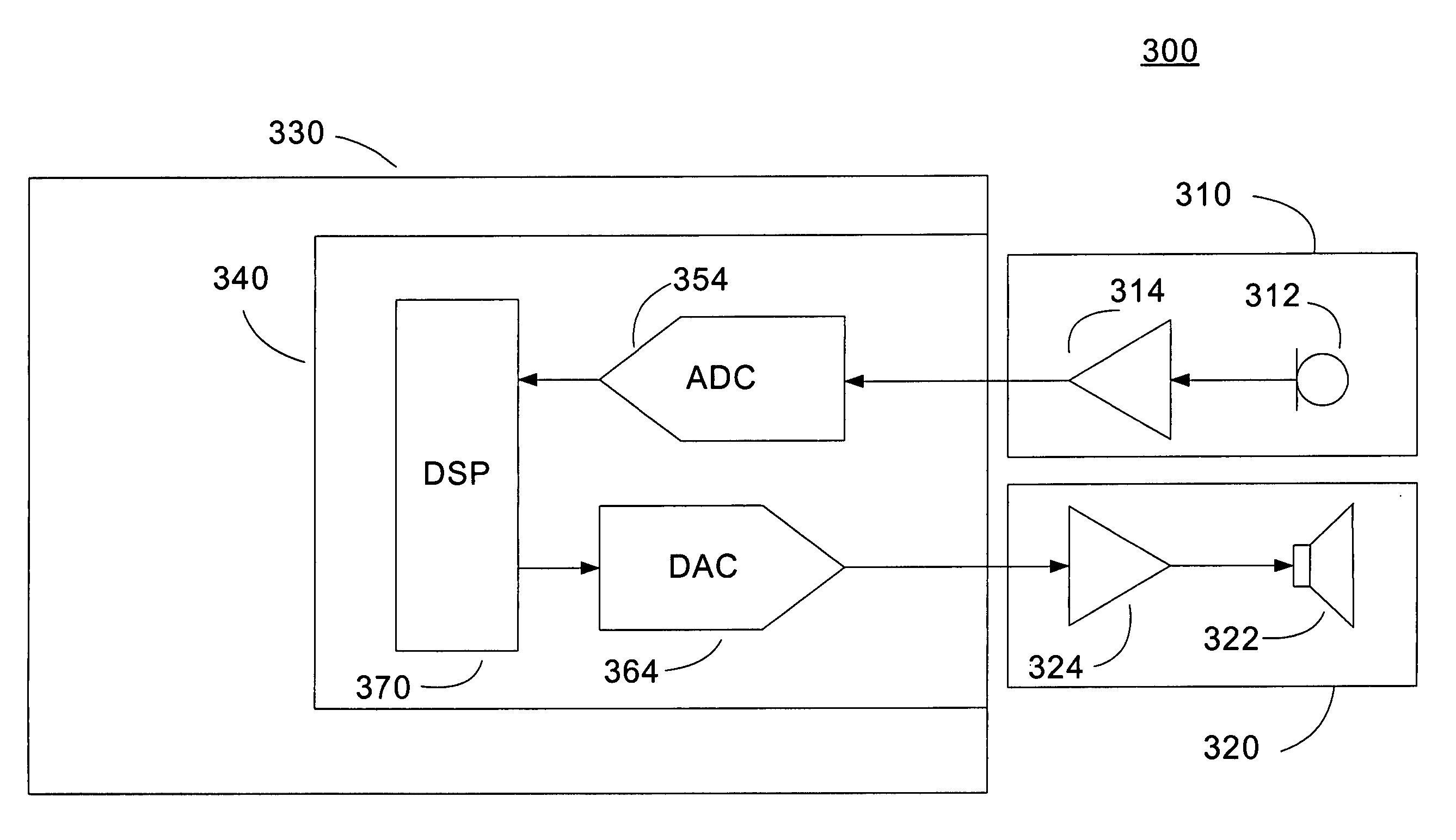

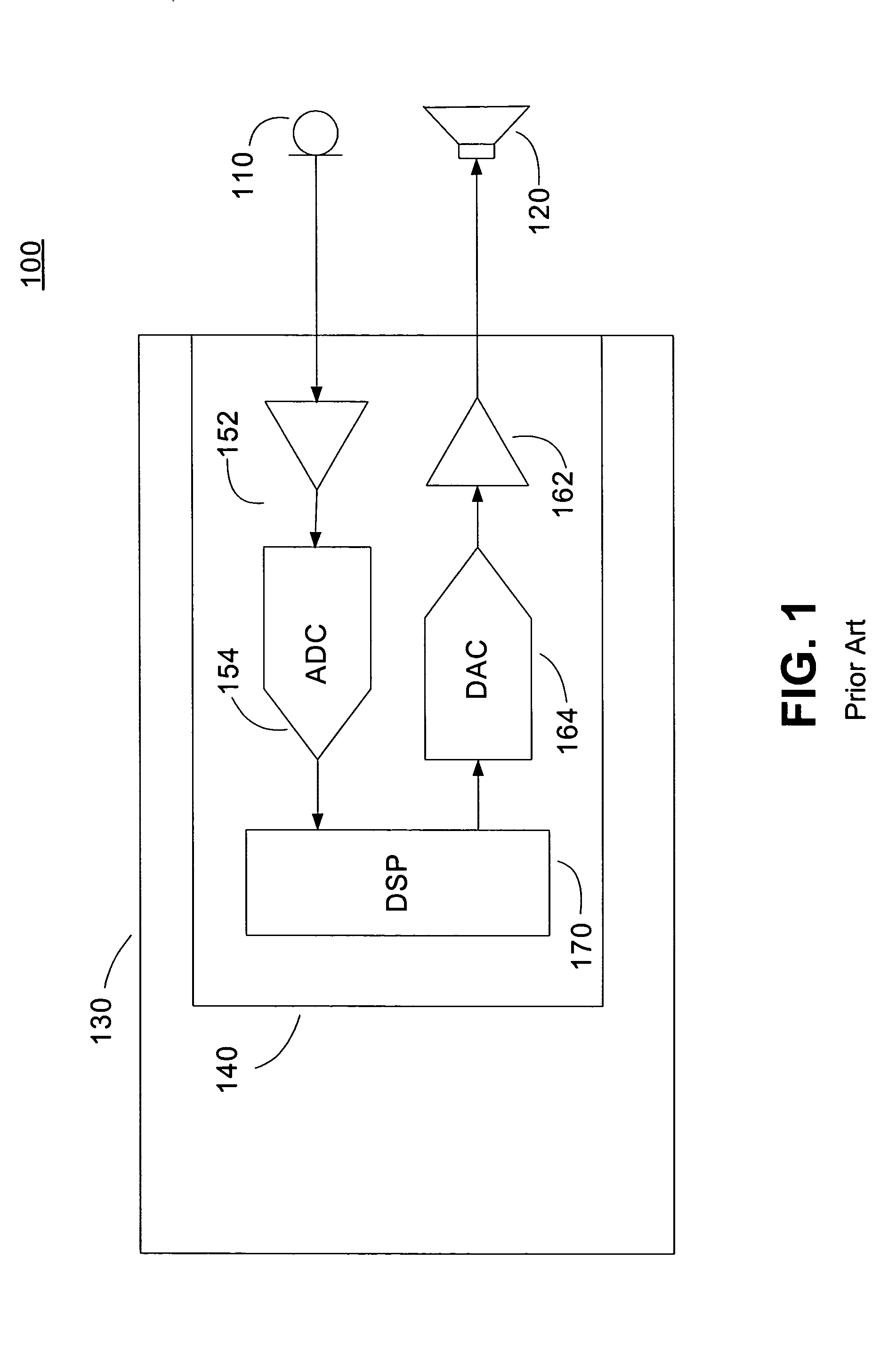

Integrated audio codec with silicon audio transducer

ActiveUS20060034472A1Gain controlSemiconductor electrostatic transducersControl signalMems microphone

An integrated audio transducer with associated signal processing electronics is disclosed. A silicon audio transducer, such as a MEMS microphone or speaker, can be integrated with audio processing electronics in a single package. The audio processing electronics can be configured using control signals. The audio processing electronics can provide a single line serial data interface and a single line control interface. The audio transducers can be integrated with associated processing electronics. A silicon microphone can be integrated with an Analog to Digital Converter (ADC). The ADC output can be a single line serial interface. The ADC can be configured using a single line serial control interface. A speaker may be integrated with a Digital to Analog Converter (DAC). Audio transducers can also be integrated with more complex processing electronics. Audio processing parameters such as gain, dynamic range, and filter characteristics may be configured using the serial interface.

Owner:QUALCOMM INC

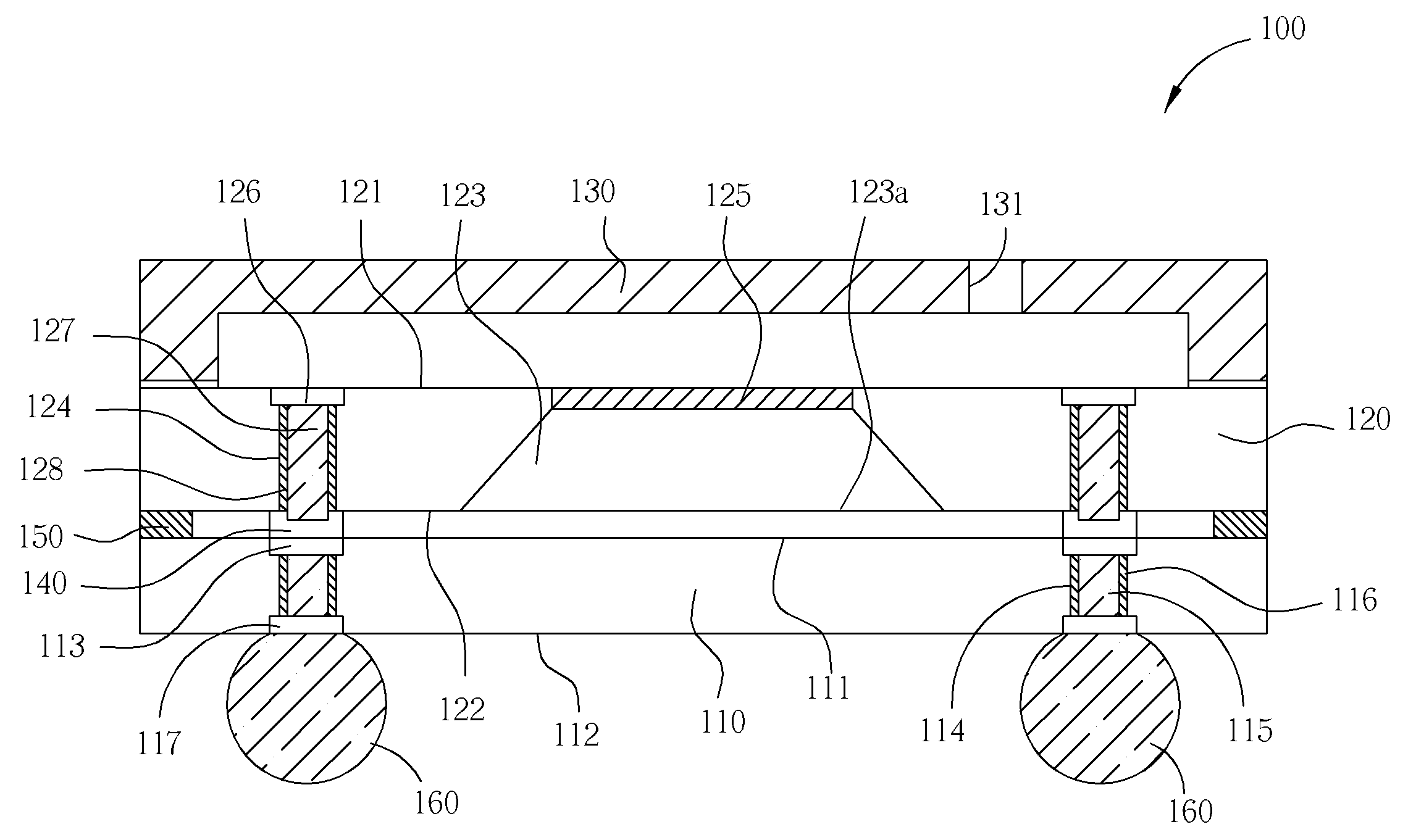

MEMS microphone package and mehtod for making same

InactiveUS20110013787A1Semiconductor electrostatic transducersSemiconductor/solid-state device manufacturingContact padConductive materials

An exemplary micro-electro-mechanical systems (MEMS) microphone package includes a first substrate, a second substrate opposite to the first substrate, and a microphone chip disposed on the second substrate. First through holes are defined in the first substrate. Conductive material is disposed in each first through hole. A through hole is defined in the second substrate. Contact pads are disposed on the second substrate. Each contact pad connects the corresponding electrically conductive material in each first through hole. The microphone chip is surrounded by the contact pads. When sound waves transmit through the through hole in the second substrate to the microphone chip, the microphone chip converts sound into an electrical signal.

Owner:HON HAI PRECISION IND CO LTD

Apparatus and method for biasing a transducer

ActiveUS20100166228A1No unnecessary loadingLimiting stepSemiconductor electrostatic transducersApparatus without intermediate ac conversionVoltage generatorMems microphone

An apparatus comprising a capacitive transducer, for example a MEMS microphone. A first voltage generator is connected to receive a first voltage (VDD*) and generate a second voltage (VCP) for biasing the capacitive transducer. A control circuit is adapted to, in use, control the first voltage (VDD*) based on a calibration value, wherein a different calibration value would lead to a different first voltage level and the calibration value is set such that an input signal of known amplitude produces an output signal of predetermined amplitude.

Owner:CIRRUS LOGIC INC

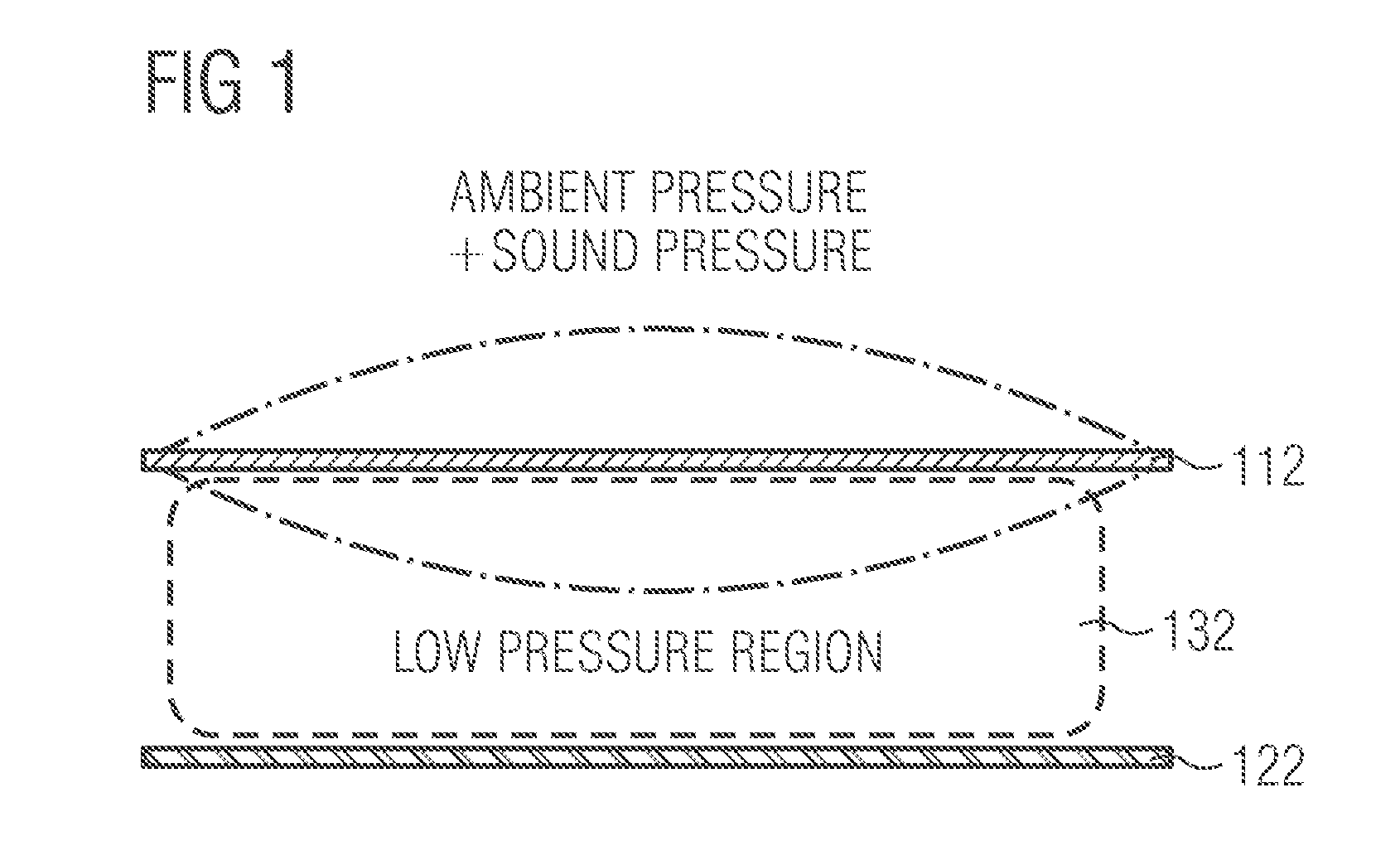

MEMS Microphone with Low Pressure Region Between Diaphragm and Counter Electrode

ActiveUS20150001647A1Avoid enteringSolid state device transducersDecorative surface effectsAmbient pressureMems microphone

A MEMS microphone includes a first diaphragm element, a counter electrode element, and a low pressure region between the first diaphragm element and the counter electrode element. The low pressure region has a pressure less than an ambient pressure.

Owner:INFINEON TECH AG

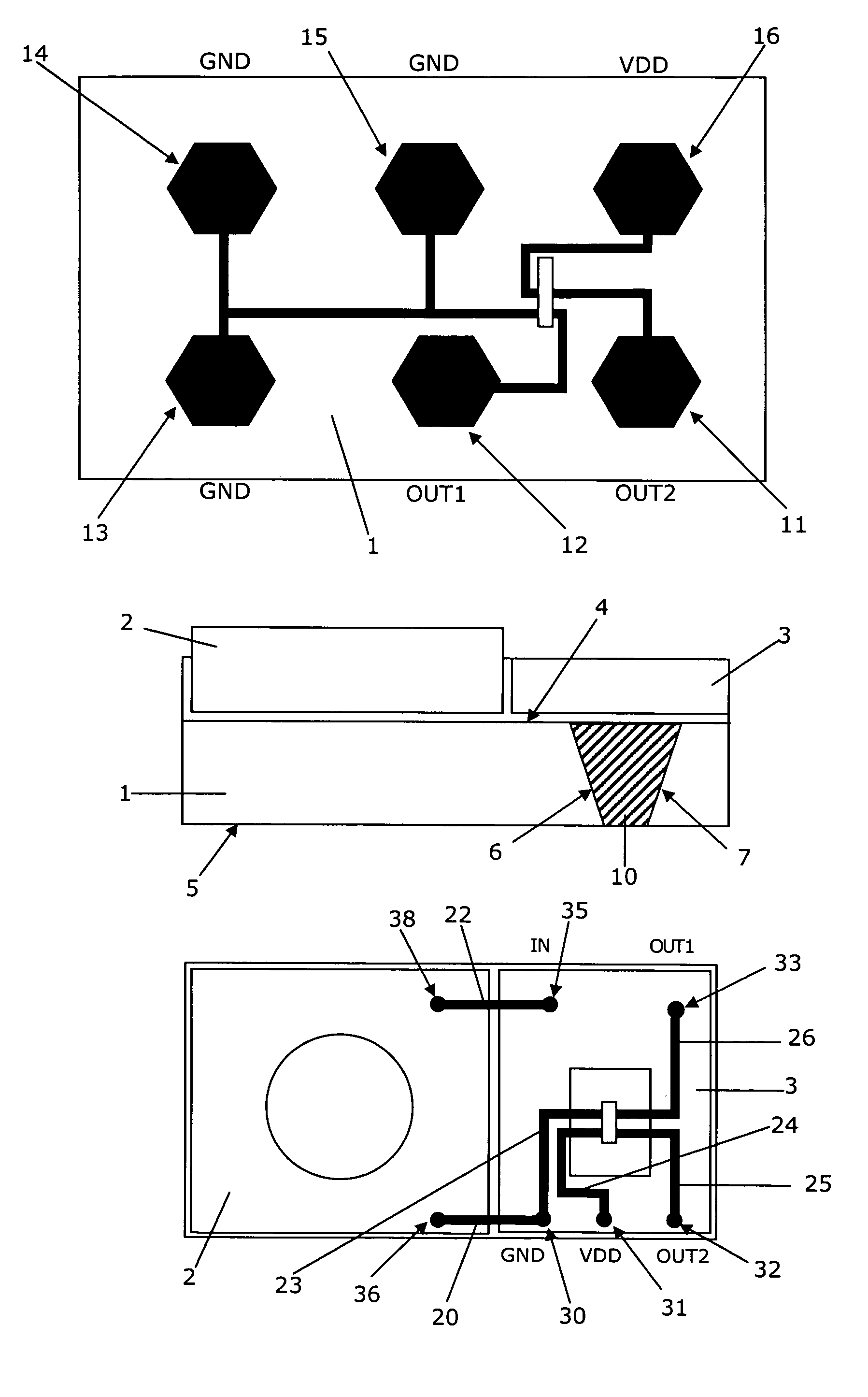

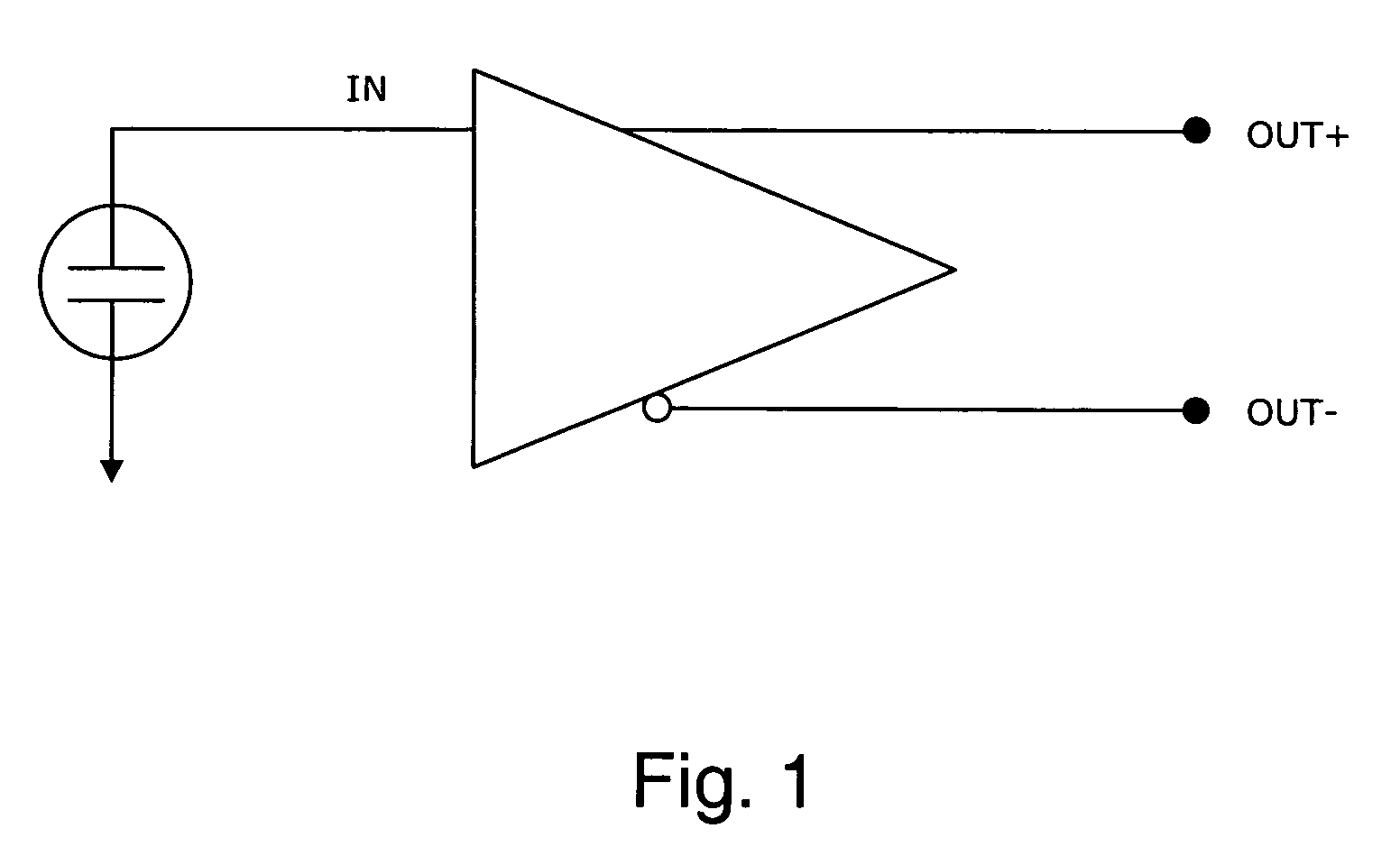

Miniature microphone with balanced termination

ActiveUS7466835B2Improve dynamic rangeLess susceptible to EMIPiezoelectric/electrostrictive microphonesSignal processingAudio power amplifierSurface mounting

The present invention provides a miniature MEMS microphone comprising a single-ended transducer element connected to an amplifier providing a differential electrical output at terminals arranged at a substantially plane exterior surface. The differential or balanced output signal provides a miniature microphone exhibiting a high dynamic range and a reduced susceptibility to EMI. The microphone is adapted for surface mounting thus the extra output terminal required is still suitable for low cost mass production. In preferred embodiments the transducer element and amplifier are silicon-based. The microphone may have a plurality of separate single-ended transducer elements connected to separate amplifiers providing separate differential outputs. The microphones according to the invention are advantageous for applications within for example hearing aids and mobile equipment.

Owner:TDK CORPARATION

Optical sensing in a directional MEMS microphone

InactiveUS20070165896A1Bulky and heavyReduce external noiseVibration measurement in solidsSolid state device transducersEngineeringMems microphone

A microphone having an optical component for converting the sound-induced motion of the diaphragm into an electronic signal using a diffraction grating. The microphone with inter-digitated fingers is fabricated on a silicon substrate using a combination of surface and bulk micromachining techniques. A 1 mm×2 mm microphone diaphragm, made of polysilicon, has stiffeners and hinge supports to ensure that it responds like a rigid body on flexible hinges. The diaphragm is designed to respond to pressure gradients, giving it a first order directional response to incident sound. This mechanical structure is integrated with a compact optoelectronic readout system that displays results based on optical interferometry.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK +1

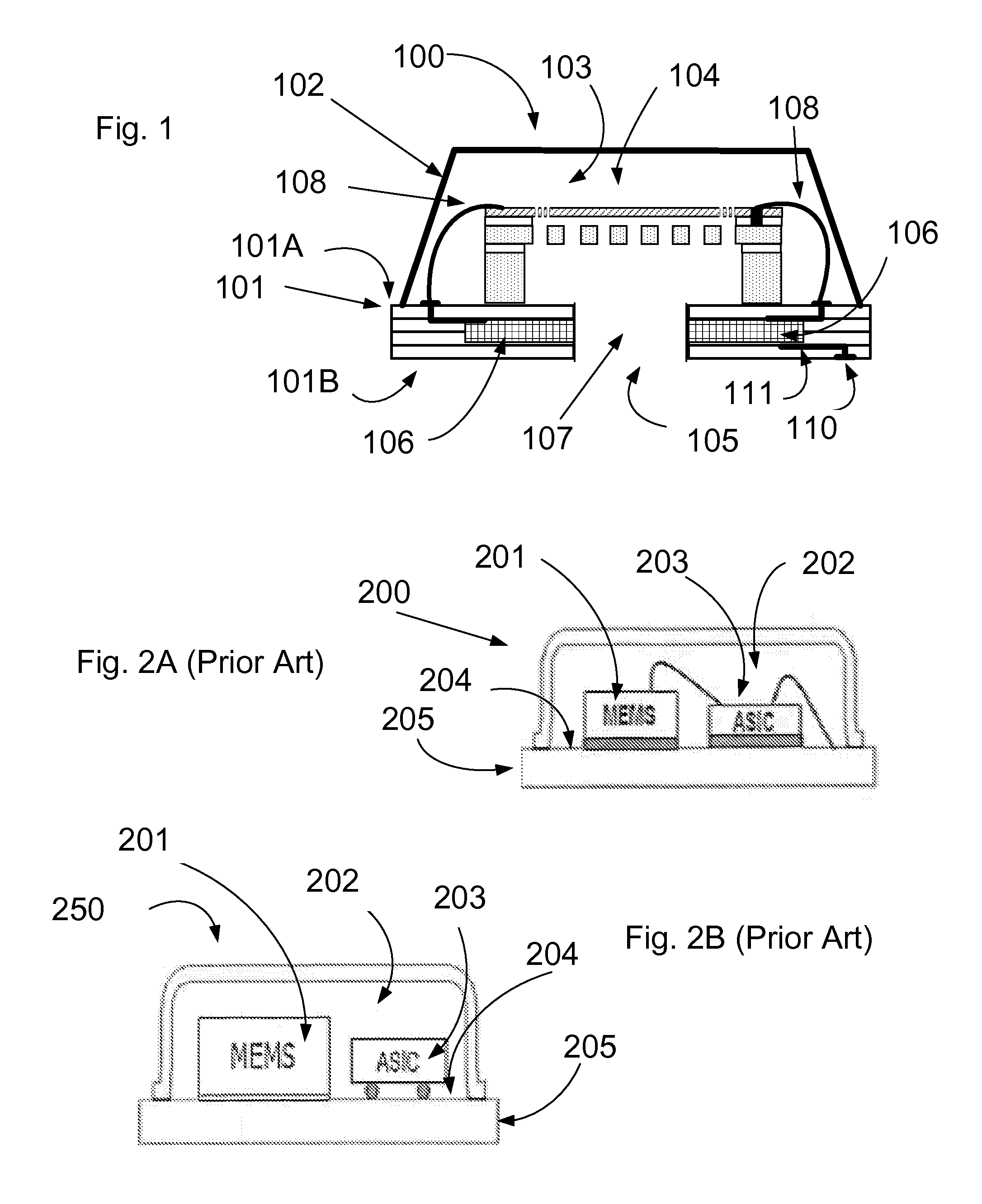

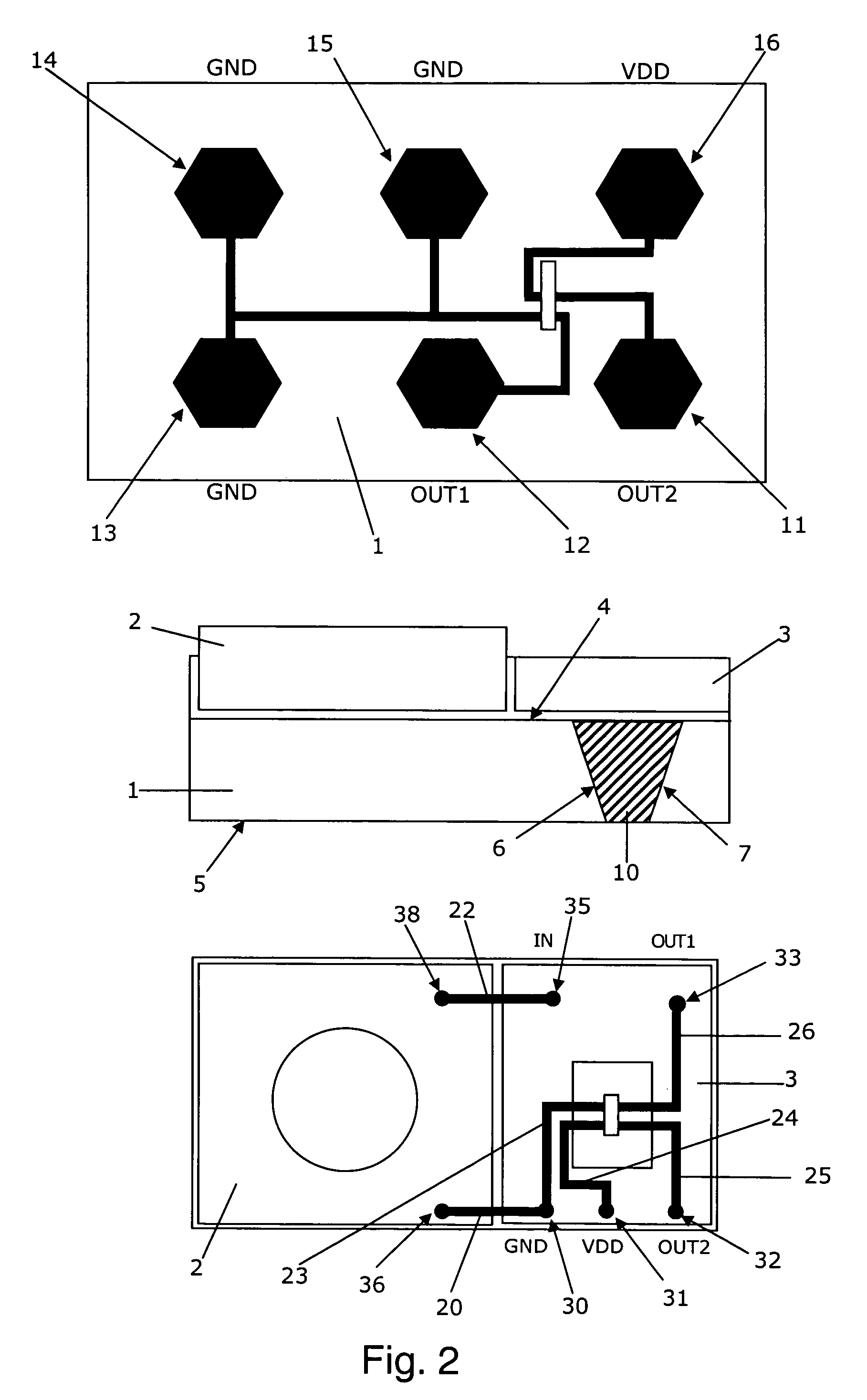

MEMS microphone module and method thereof

ActiveUS20080157238A1Reduce package sizeImprove package reliabilitySemiconductor/solid-state device detailsSolid-state devicesResonant cavityMems microphone

A MEMS microphone module having an application specific IC and a microphone chip is disclosed. The application specific IC has a plurality of first vias and a plurality of first pads, and the first vias are connected to the first pads. The microphone chip has a resonant cavity, a plurality of second vias and a plurality of second pads, and the second vias are connected to the second pads. The microphone chip is disposed on a first surface of the application specific IC with an opening of the resonant cavity facing toward a first surface of the application specific IC. The second conductive vias of the microphone chip are also electrically connected to the first vias of the application specific IC. By placing the microphone chip on the first surface of the application specific IC, the present invention could reduce the package size and increase the reliability of the package.

Owner:ADVANCED SEMICON ENG INC

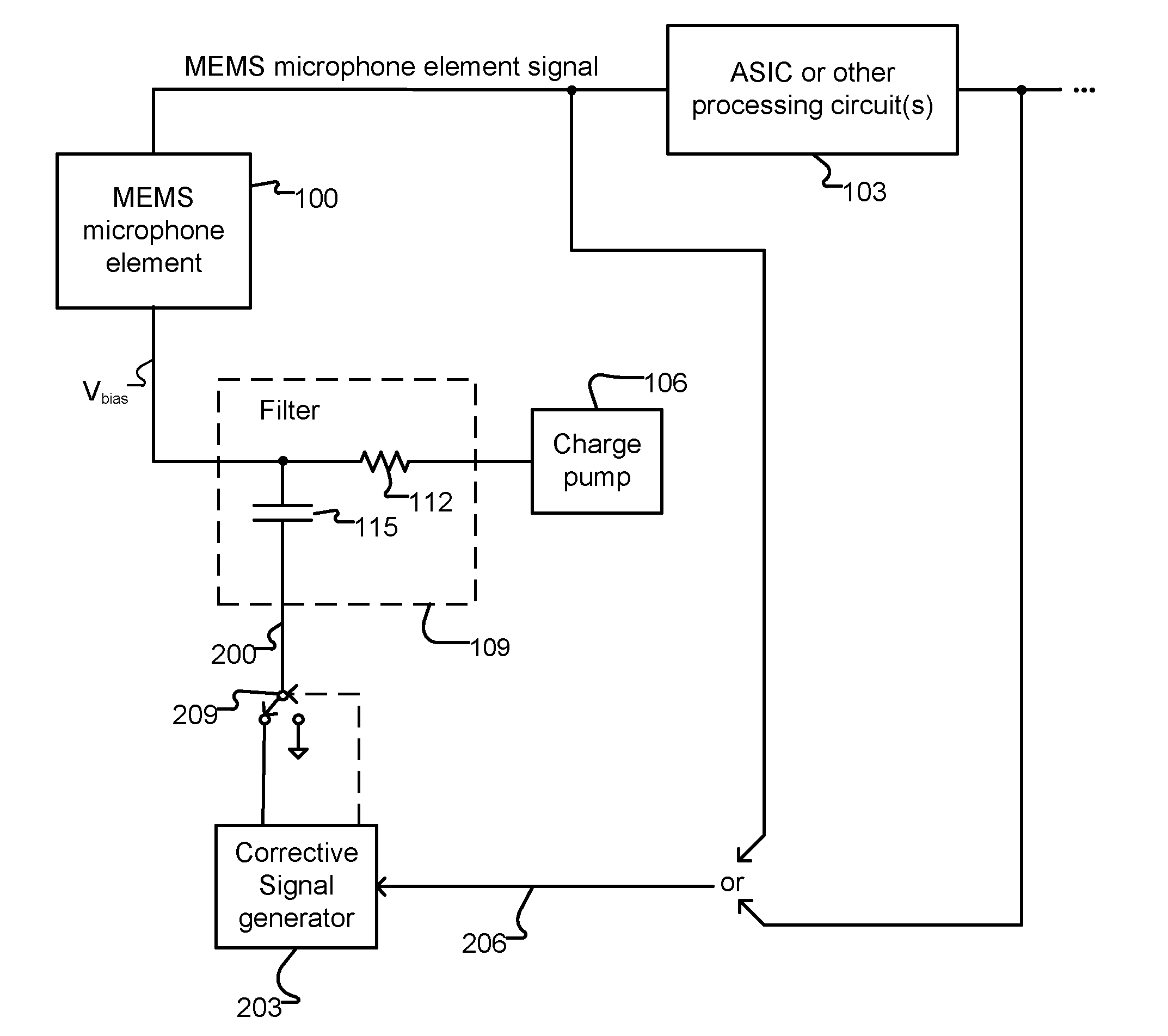

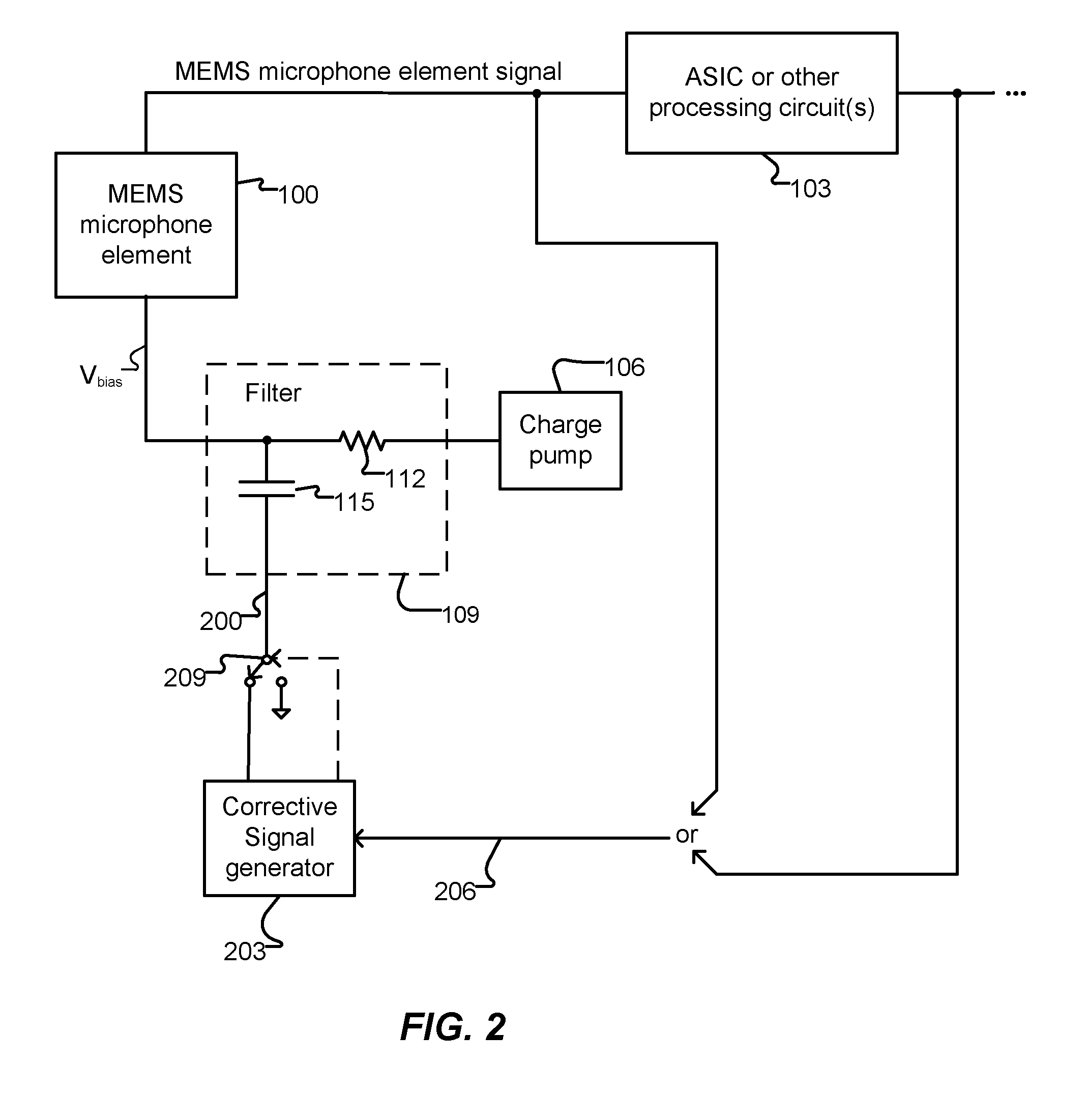

Microphone with Programmable Frequency Response

ActiveUS20140086433A1Efficient removalEffectively couple impedanceMicrophonesLoudspeakersMems microphoneCondenser microphone

Methods and apparatus automatically cancel or attenuate an unwanted signal (such as low frequencies from wind buffets) from, and / or control frequency response of, a condenser microphone, or control the effective condenser microphone sensitivity before the signal reaches an ASIC or other processing circuit. As a result, the maximum amplitude signal seen by the processing circuit is limited, thereby preventing overloading the input of the processing circuit. Remaining (wanted) frequencies can be appropriately amplified to reduce the noise burden on further processing circuits. A corrective signal is applied to a bias terminal of the condenser microphone to cancel the unwanted signal. Optionally or alternatively, a controllable impedance is connected to a line that carries the signal generated by the MEMS microphone, so as to attenuate unwanted portions of the signal.

Owner:INVENSENSE

Microphone with dual transducers

InactiveUS20080192962A1Transducer detailsSemiconductor electrostatic transducersTransducerPeak value

Microphone is disclosed having unmatched electroacoustic transducers. The microphone may be a traditional ECM microphone, or it may be a MEMS microphone. Each of the unmatched electroacoustic transducers may have its own peak frequency selected so that the electroacoustic transducers together produce a desirable resultant peak frequency. The unmatched electroacoustic transducers may have different package sizes, front volumes, back volumes, and / or diaphragm tensions, thicknesses, lengths, widths, and / or diameters. In some embodiments, the microphone may have different backplate charging and / or output signal amplification schemes for the electroacoustic transducers. Where the microphone is a MEMS microphone, voltage generation and output signal amplification are provided by an integrated circuit that may be mounted either within a front volume of one of the electroacoustic transducers or adjacent to one of the electroacoustic transducers.

Owner:SONION NEDERLAND

Microphone with Aligned Apertures

A MEMS microphone has a backplate with a given backplate aperture, and a diaphragm having a diaphragm aperture. The given backplate aperture is substantially aligned with the diaphragm aperture.

Owner:INVENSENSE

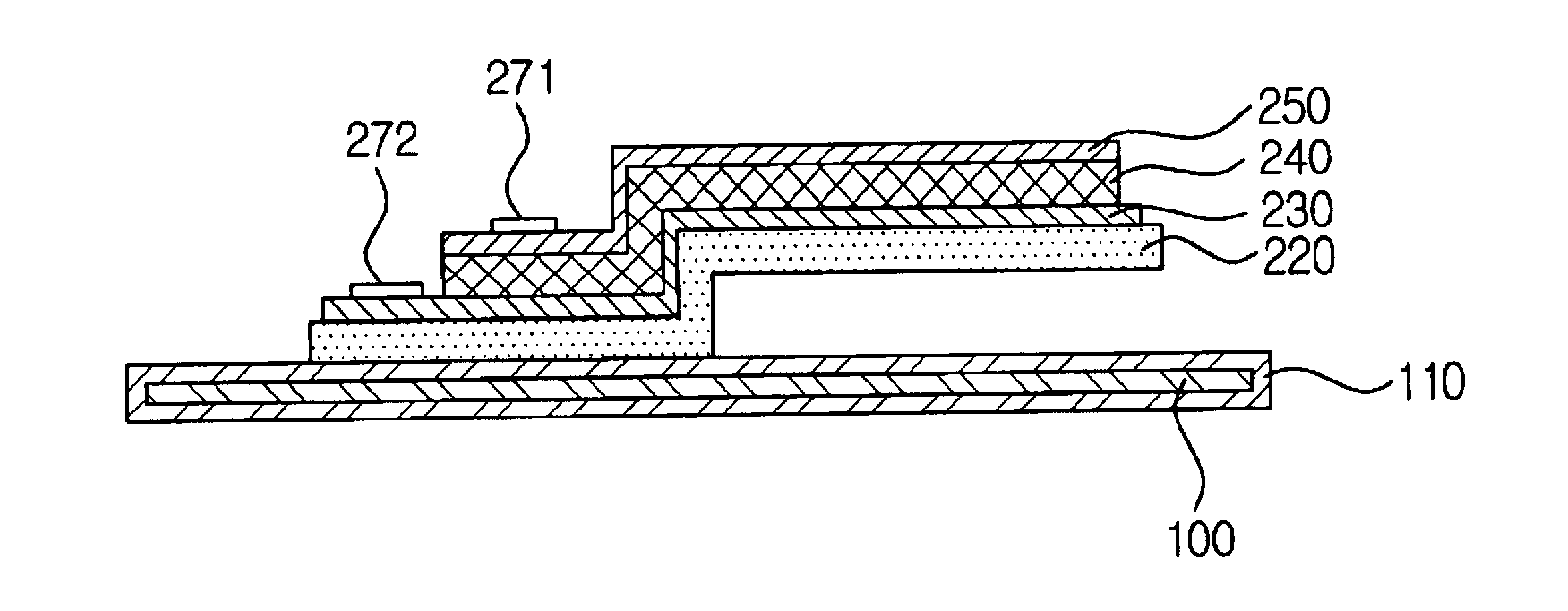

Flexible MEMS transducer and manufacturing method thereof, and flexible MEMS wireless microphone

InactiveUS6967362B2Increase depositionPiezoelectric/electrostrictive microphonesPiezoelectric/electrostrictive device manufacture/assemblyWireless microphoneTransducer

A flexible wireless MEMS microphone includes a substrate of a flexible polymeric material, a flexible MEMS transducer structure formed on the substrate by PECVD, an antenna printed on the substrate for communicating with an outside source, a wire and interface circuit embedded in the substrate to electrically connect the flexible MEMS transducer and the antenna, a flexible battery layer electrically connected to the substrate for supplying power to the MEMS transducer, and a flexible bluetooth module layer electrically connected to the battery layer. The flexible MEMS transducer includes a flexible substrate, a membrane layer deposited on the substrate, a lower electrode layer formed on the membrane layer, an active layer formed by depositing a piezopolymer on the lower electrode layer, an upper electrode layer formed on the active layer, and a first and a second connecting pad electrically connected to the lower and upper electrode layers, respectively.

Owner:SAMSUNG ELECTRONICS CO LTD

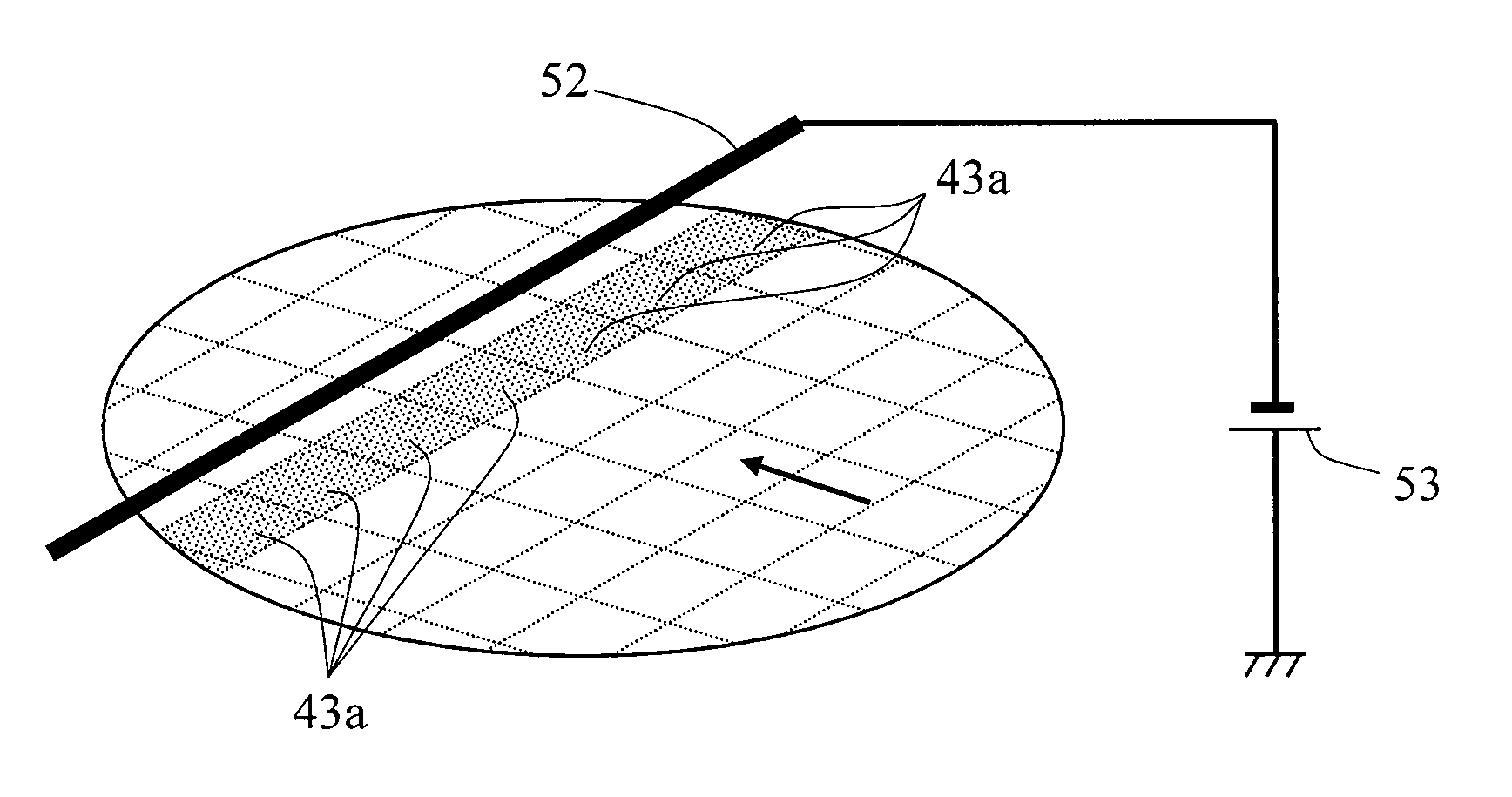

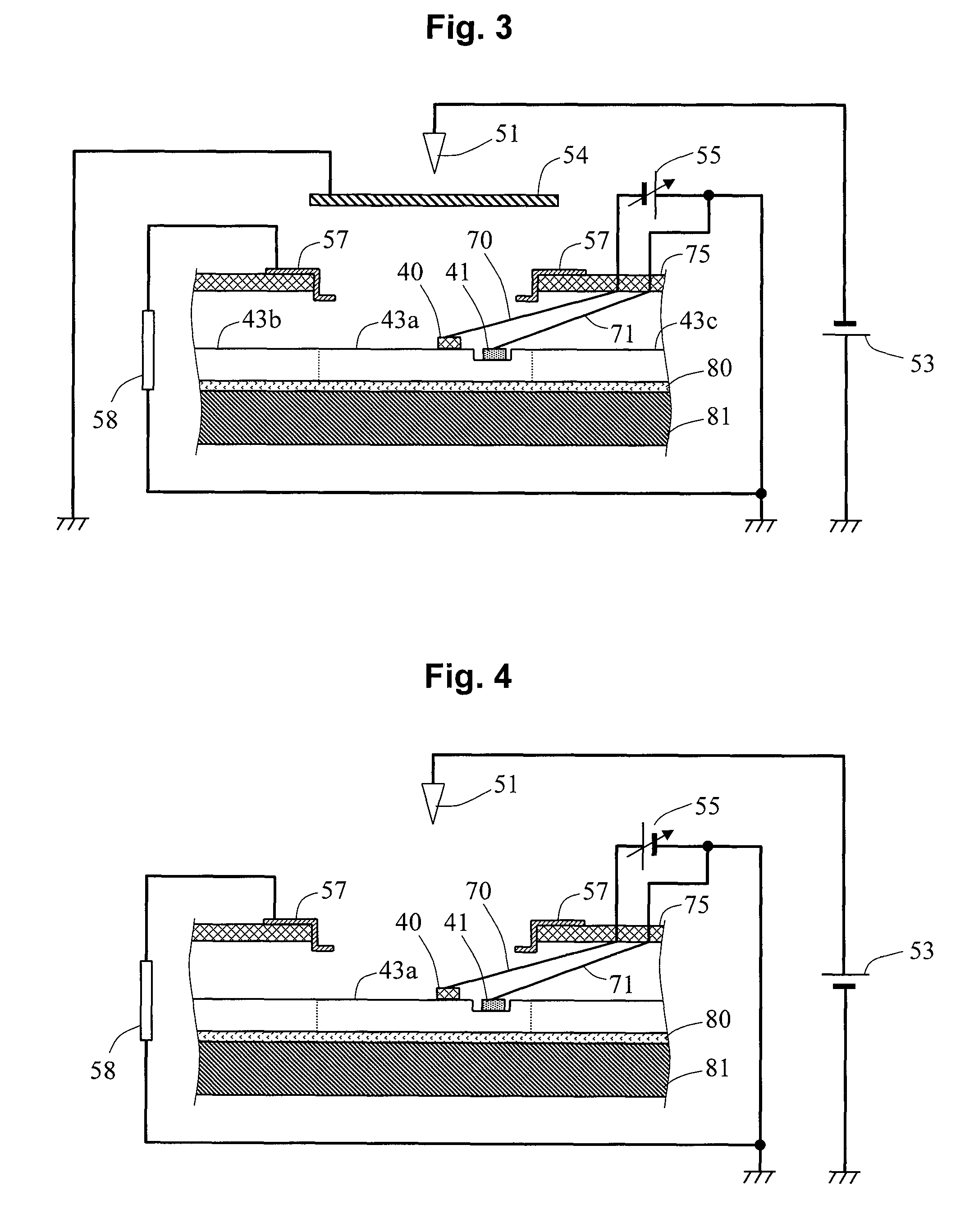

Method of fabricating an ultra-small condenser microphone

ActiveUS7855095B2Improve accuracyShort timeSemiconductor electrostatic transducersSemiconductor/solid-state device manufacturingProduction ratePotential difference

In the present invention, a semiconductor substrate wherein a plurality of MEMS microphones is formed is disposed opposed to a discharge electrode in a state of being stuck on a sheet. Electretization of a dielectric film provided in the MEMS microphone is performed by irradiating the dielectric film between a fixed electrode and a vibration film provided in the MEMS microphone with ions resulting from a corona discharge of the discharge electrode in a state that a predetermined potential difference is applied to the fixed electrode and the vibration film and fixing charges based on the ions to the dielectric film. The electretization is successively performed to each MEMS microphone on the semiconductor substrate by relatively moving the semiconductor substrate and the discharge electrode. Therefore, electretization of the dielectric film in the MEMS microphone chip is realized using a low-cost and simple fabricating equipment and productivity can be enhanced.

Owner:TDK CORPARATION

Package structure and packaging method of MEMS microphone

ActiveUS20080083960A1Improve throughputPrevent steppingPiezoelectric/electrostriction/magnetostriction machinesSemiconductor electrostatic transducersEngineeringMems microphone

A package structure of a micro-electromechanical system (MEMS) type microphone is disclosed. The MEMS microphone comprises a substrate, a MEMS chip, an acoustic wave cover, and an encapsulant. The substrate has connection pads. The MEMS chip is electrically coupled to the connection pads. The MEMS chip includes an acoustic wave sensing portion. The acoustic wave cover is fixed on the MEMS chip for covering without contacting the acoustic wave sensing portion and defining an acoustic wave cavity space. The acoustic wave cover has an opening for allowing an acoustic wave to enter or exit out of the acoustic cavity space. The encapsulant encapsulates the substrate, the MEMS chip, and the acoustic wave cover, wherein a surface of the acoustic wave cover is exposed. The exposed surface of the acoustic wave cover is along the same level as the surface of the encapsulant.

Owner:IND TECH RES INST

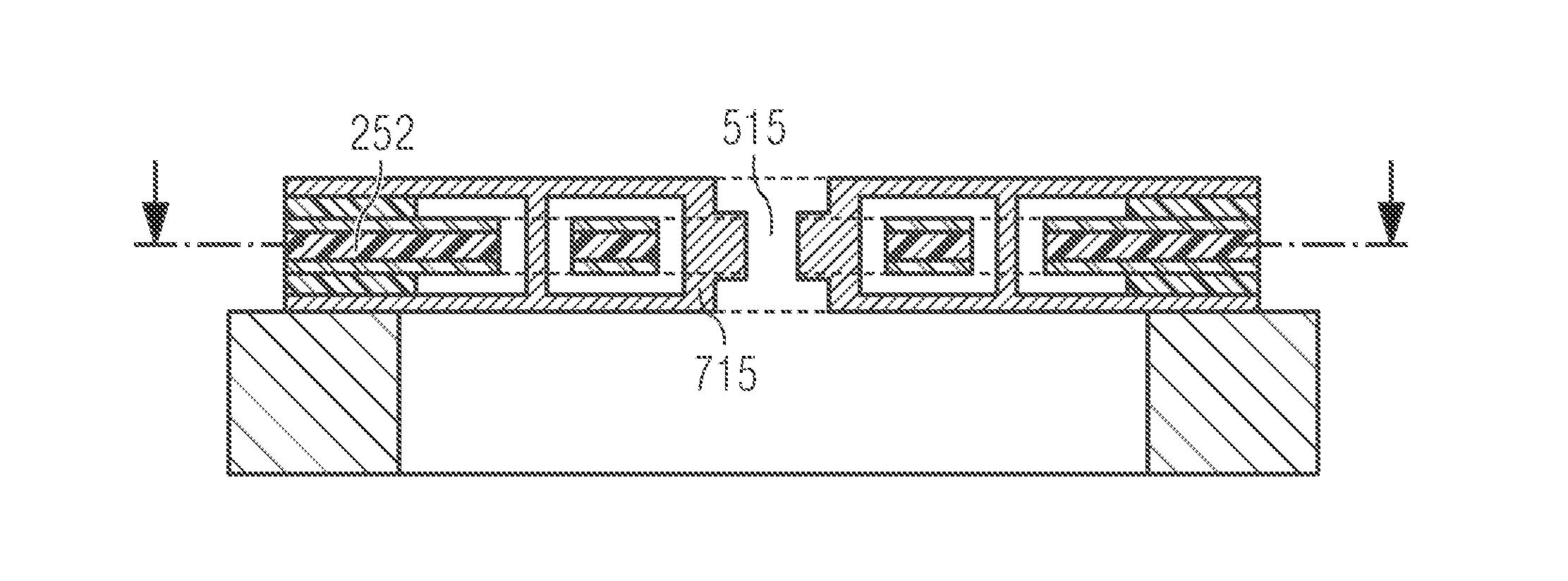

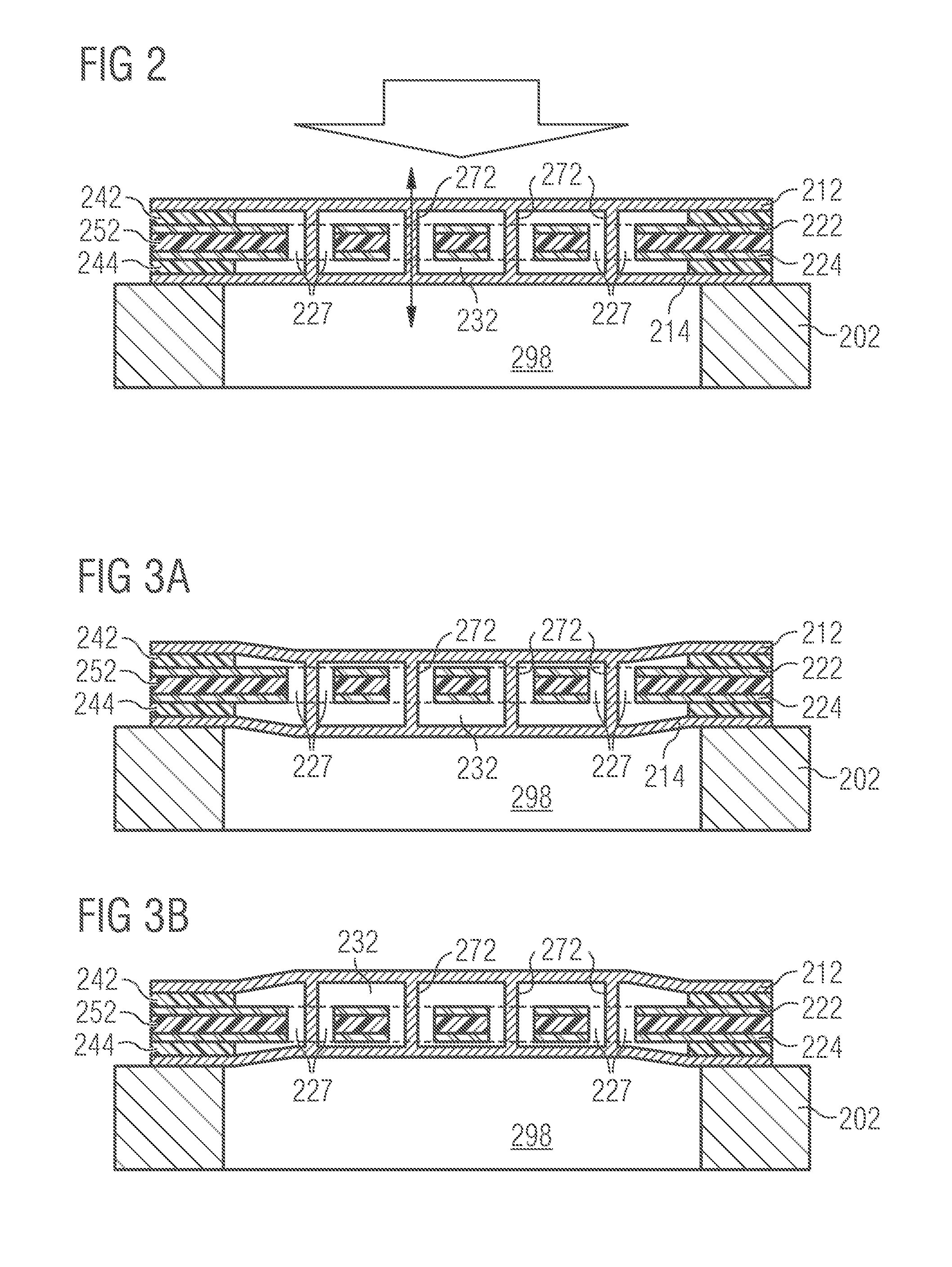

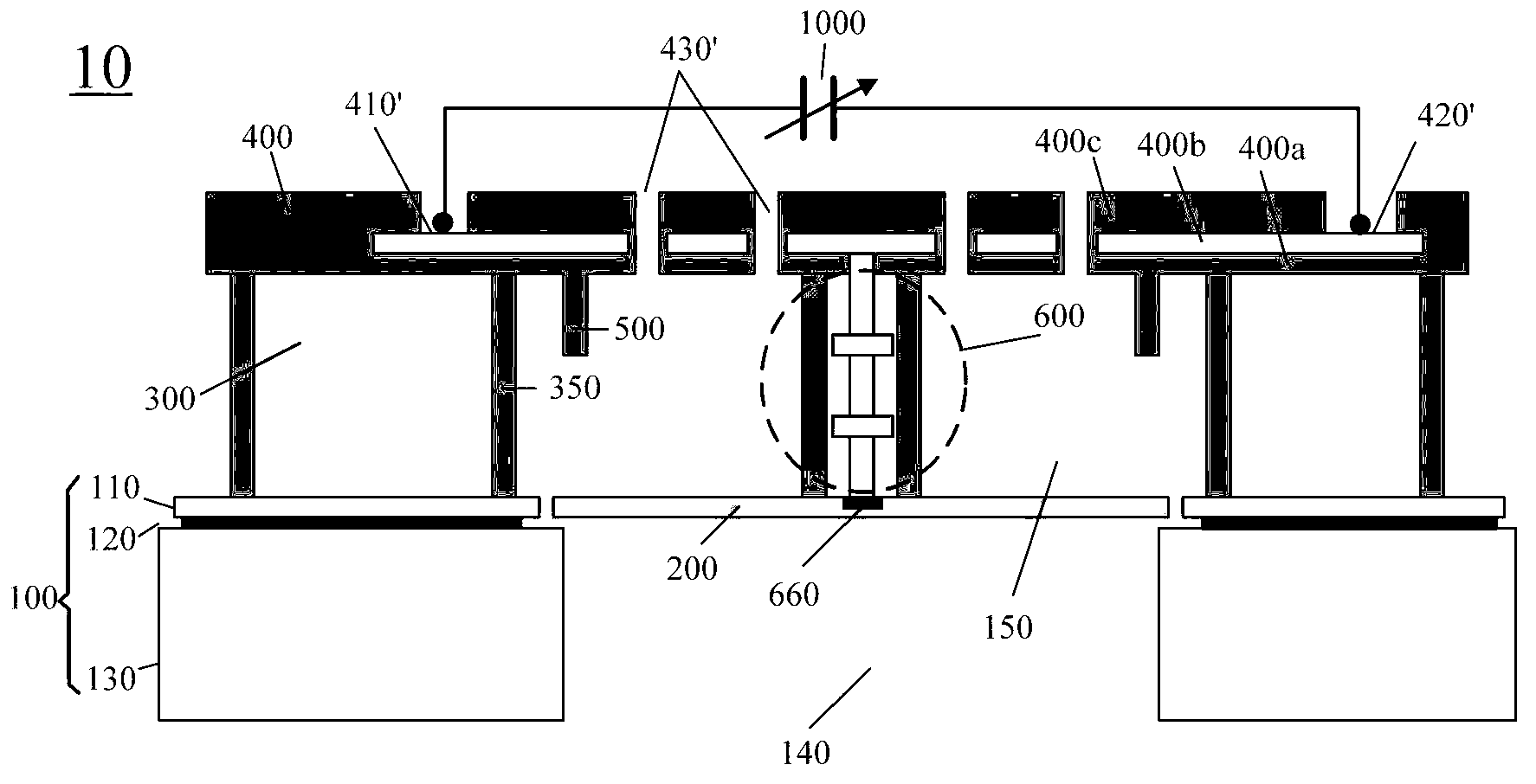

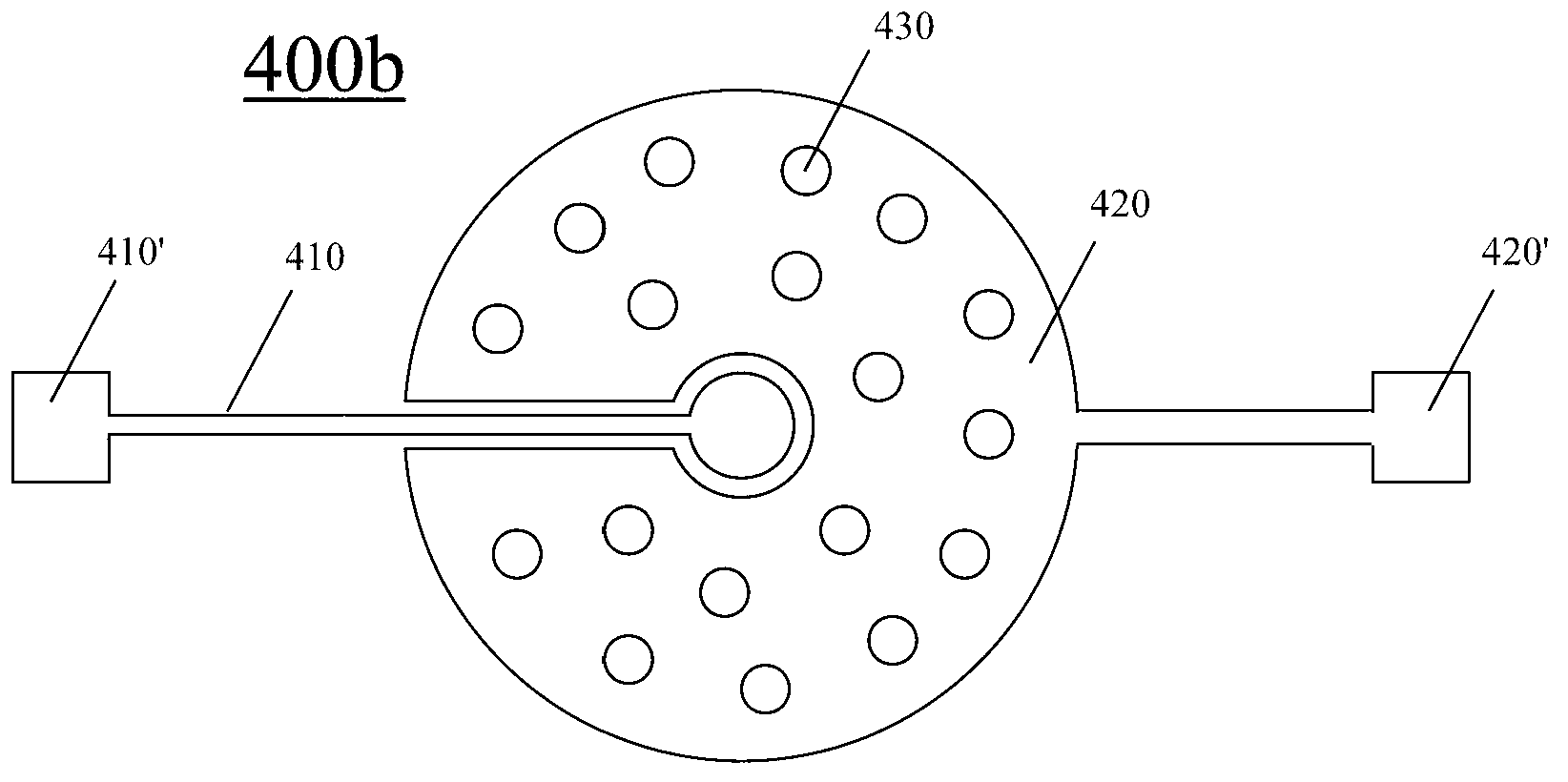

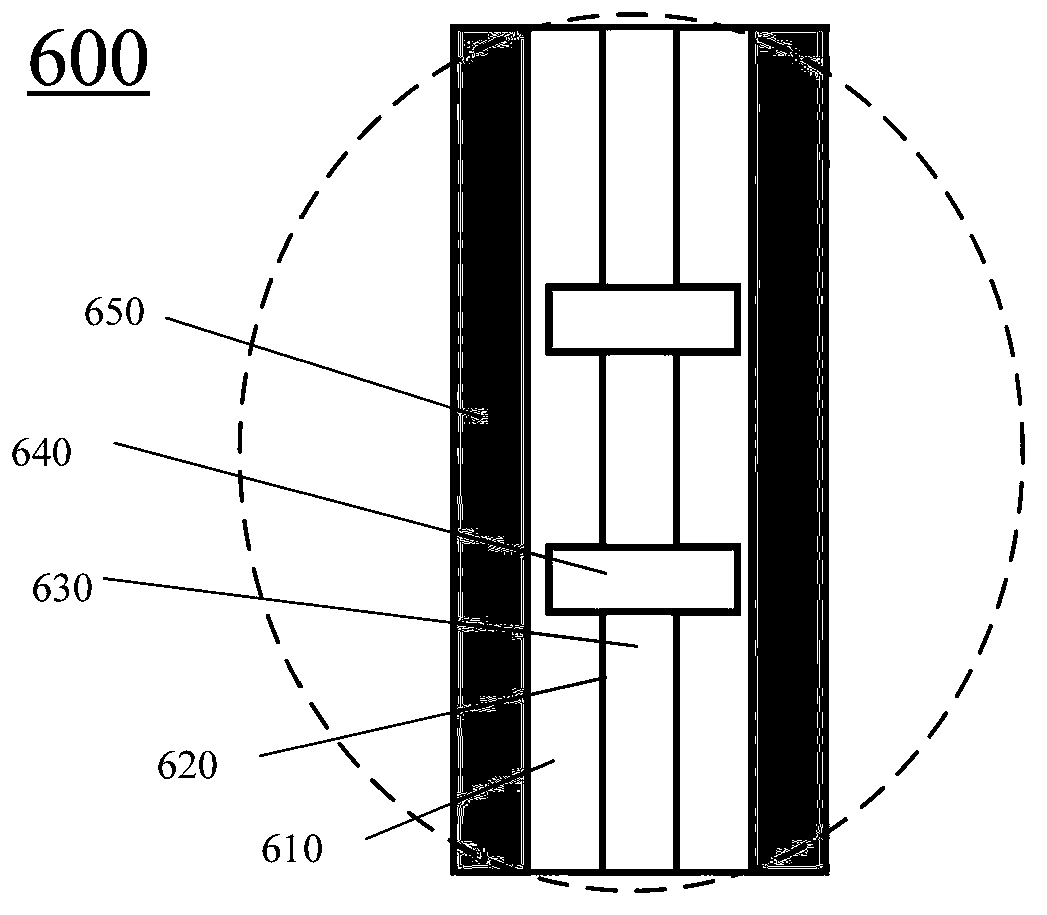

Dual Single-Crystal Backplate Microphone System and Method Of Fabricating Same

ActiveUS20110075865A1Reliable electrical connectionWave amplification devicesSemiconductor/solid-state device detailsEngineeringMems microphone

A dual backplate MEMS microphone system includes a flexible diaphragm sandwiched between two single-crystal silicon backplates. Such a MEMS microphone system may be formed by fabricating each backplate in a separate wafer, and then transferring one backplate from its wafer to the other wafer, to form two separate capacitors with the diaphragm.

Owner:INVENSENSE

Chip-scaled MEMS microphone package

An MEMS microphone package includes a circuit board and an MEMS microphone chip. The MEMS microphone chip, mounted on the circuit board, includes a substrate, an MEMS transducer formed on the substrate, and a readout circuit also formed on the substrate. The MEMS transducer generates a sound signal according to sound pressure variations. The readout circuit reads the sound signal from the MEMS transducer.

Owner:FORTEMEDIA

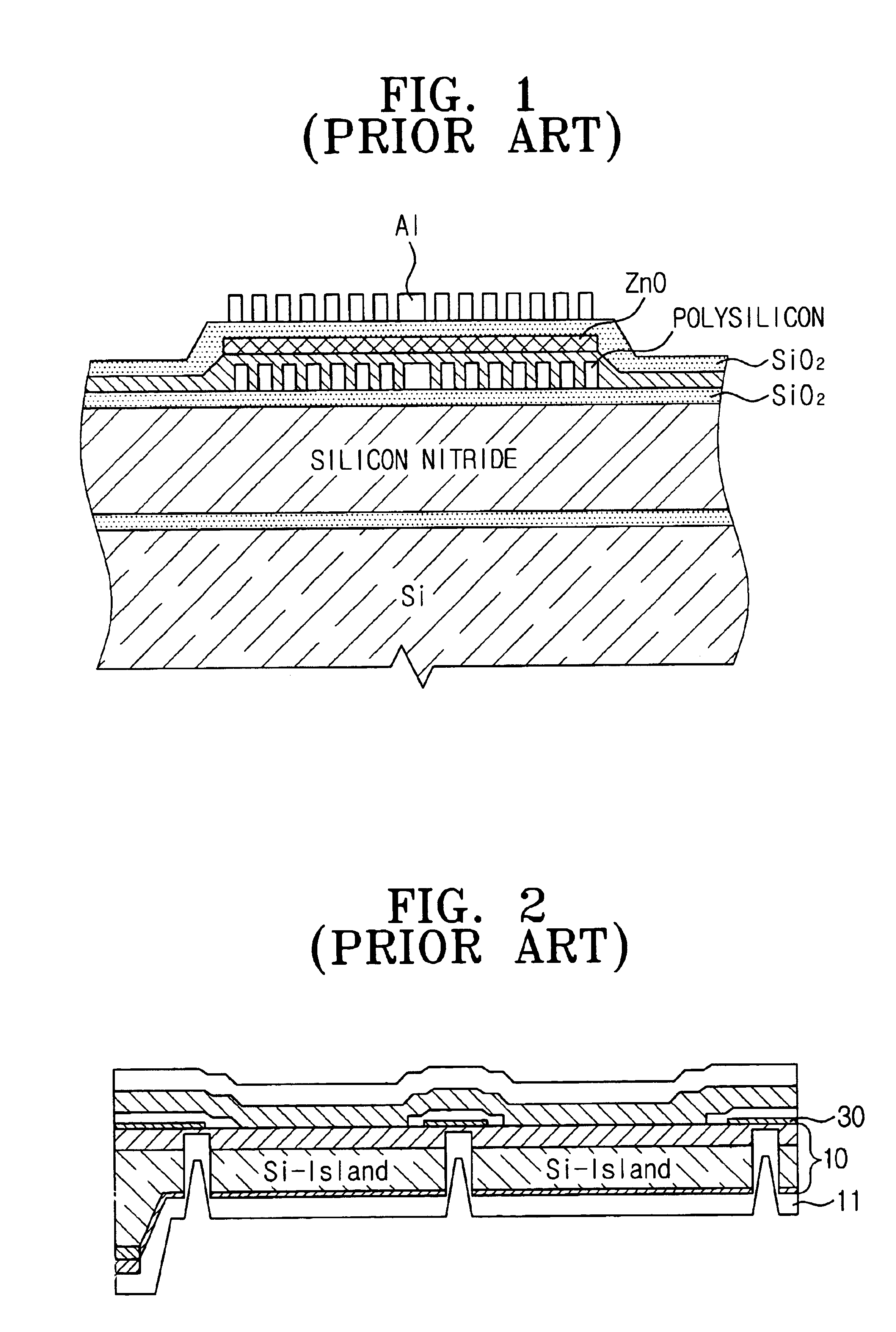

CMOS compatible MEMS microphone and method for manufacturing the same

The present invention relates to a CMOS compatible MEMS microphone, comprising: an SOI substrate, wherein a CMOS circuitry is accommodated on its silicon device layer; a microphone diaphragm formed with a part of the silicon device layer, wherein the microphone diaphragm is doped to become conductive; a microphone backplate including CMOS passivation layers with a metal layer sandwiched and a plurality of through holes, provided above the silicon device layer, wherein the plurality of through holes are formed in the portions thereof opposite to the microphone diaphragm, and the metal layer forms an electrode plate of the backplate; a plurality of dimples protruding from the lower surface of the microphone backplate opposite to the diaphragm; and an air gap, provided between the diaphragm and the microphone backplate, wherein a spacer forming a boundary of the air gap is provided outside of the diaphragm or on the edge of the diaphragm; wherein a back hole is formed to be open in substrate underneath the diaphragm so as to allow sound pass through, and the microphone diaphragm is used as an electrode plate to form a variable capacitive sensing element with the electrode plate of the microphone backplate.

Owner:GOERTEK MICROELECTRONICS CO LTD

MEMS (micro electro mechanical system) microphone structure and manufacturing method of MEMS microphone structure

ActiveCN103281661AAvoiding Shedding DefectsNot easy to damageSemiconductor electrostatic transducersElectrostatic transducer microphonesVibrating membraneMems microphone

The invention discloses an MEMS (micro electro mechanical system) microphone structure, which comprises a semiconductor substrate, a first dielectric layer, a lower electrode vibrating membrane and an upper electrode structure, wherein the semiconductor substrate is provided with a cavity, the first dielectric layer is provided with a through hole communicated with the cavity, the lower electrode vibrating membrane is positioned above the through hole, in addition, at least one part of the lower electrode vibrating membrane is in contact with the upper surface of the first dielectric layer, the lower electrode vibrating membrane is led out from a lower electrode connecting part, the upper electrode structure is provided with an insulating layer and comprises an annular support structure, a backboard and an upper electrode connecting part, the backboard is provided with a plurality of through holes, at least one part of the annular support structure downwards extends to the lower electrode vibrating membrane, the rest parts of the annular support structure downwards extend to the substrate, the backboard is hung above the lower electrode vibrating membrane through the annular support structure, in addition, an air gap is formed between the backboard and the lower electrode vibrating membrane, and an upper electrode is embedded in the insulating layer of the backboard and is led out from the upper electrode connecting part. The MEMS microphone structure has the advantage that the damage or the falling of the upper electrode and the vibrating membrane in the release process can be avoided.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

Microphone with Reduced Parasitic Capacitance

ActiveUS20090202089A1Transducer detailsSemiconductor electrostatic transducersParasitic capacitanceEngineering

A MEMS microphone has an SOI wafer, a backplate formed in a portion of the SOI wafer, and a diaphragm adjacent to and movable relative to the backplate. The backplate has at least one trench that substantially circumscribes a central portion of the backplate.

Owner:INVENSENSE

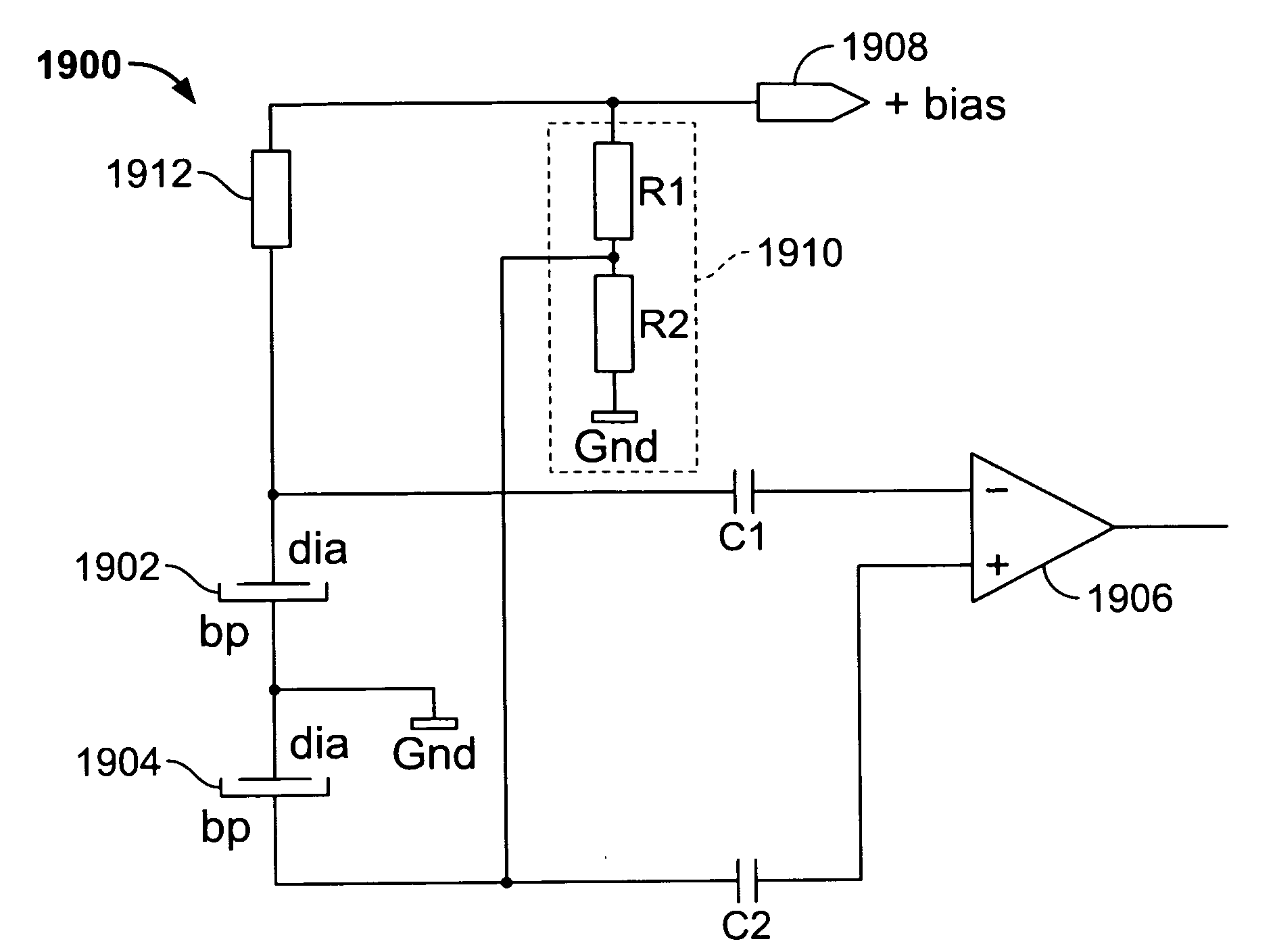

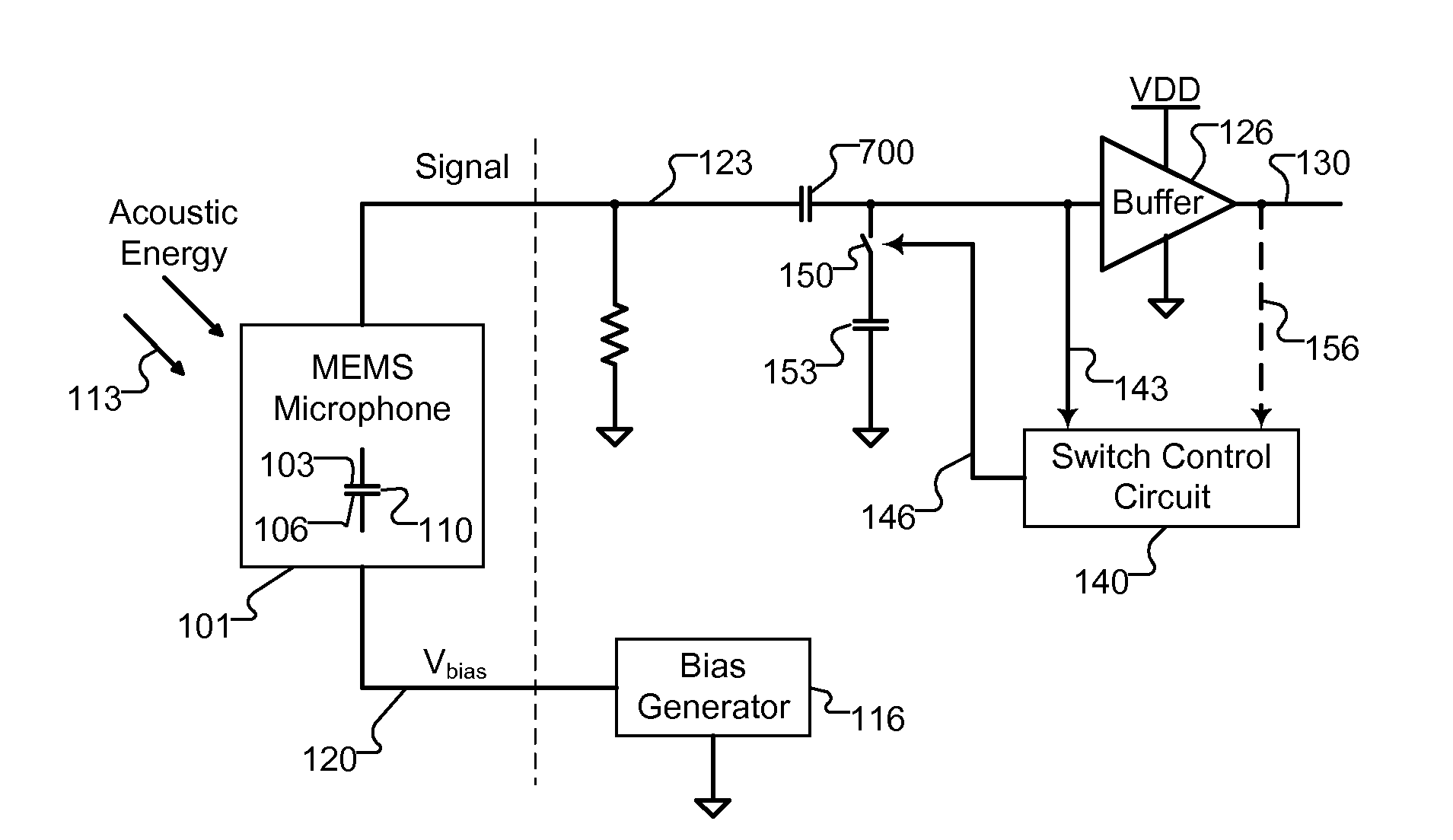

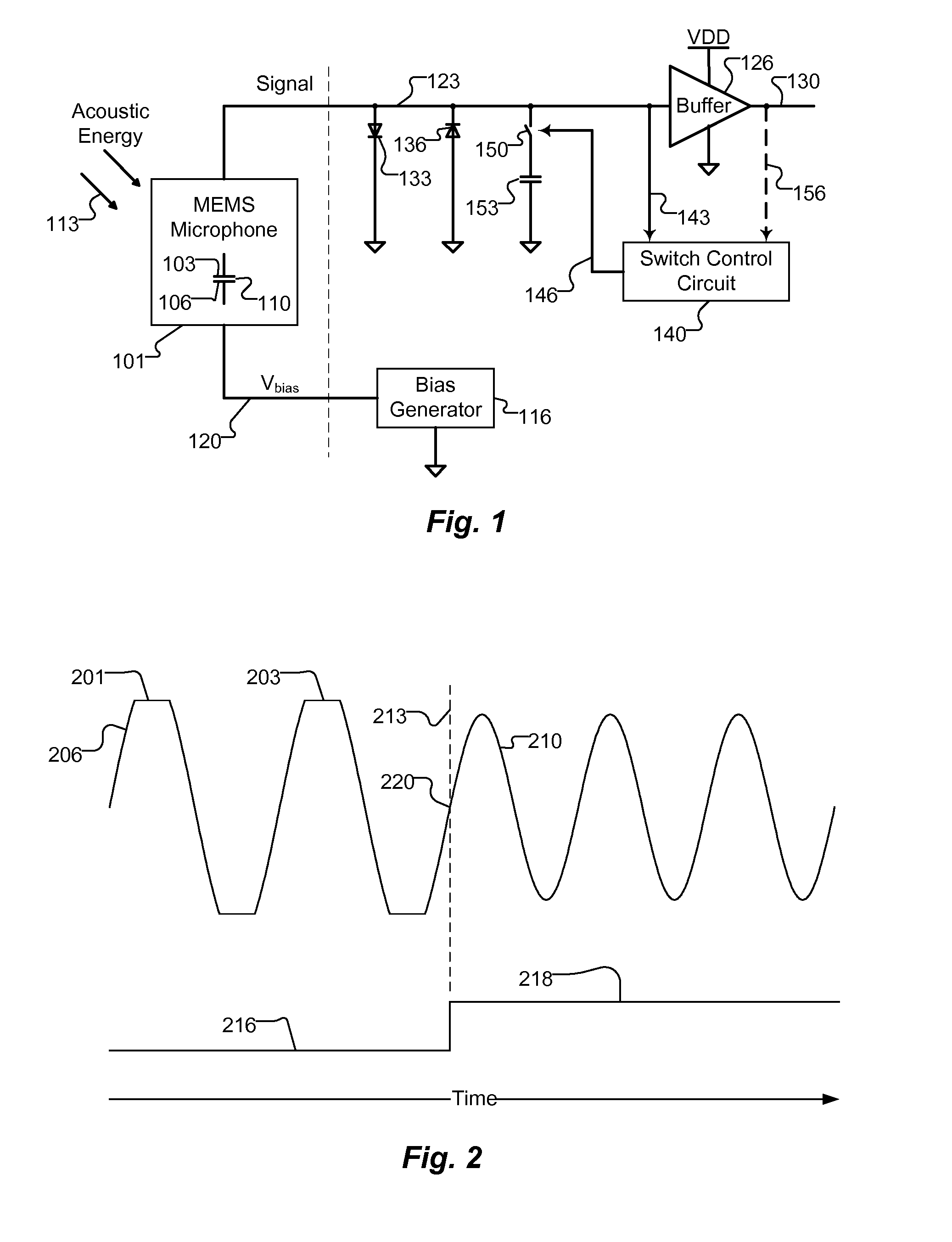

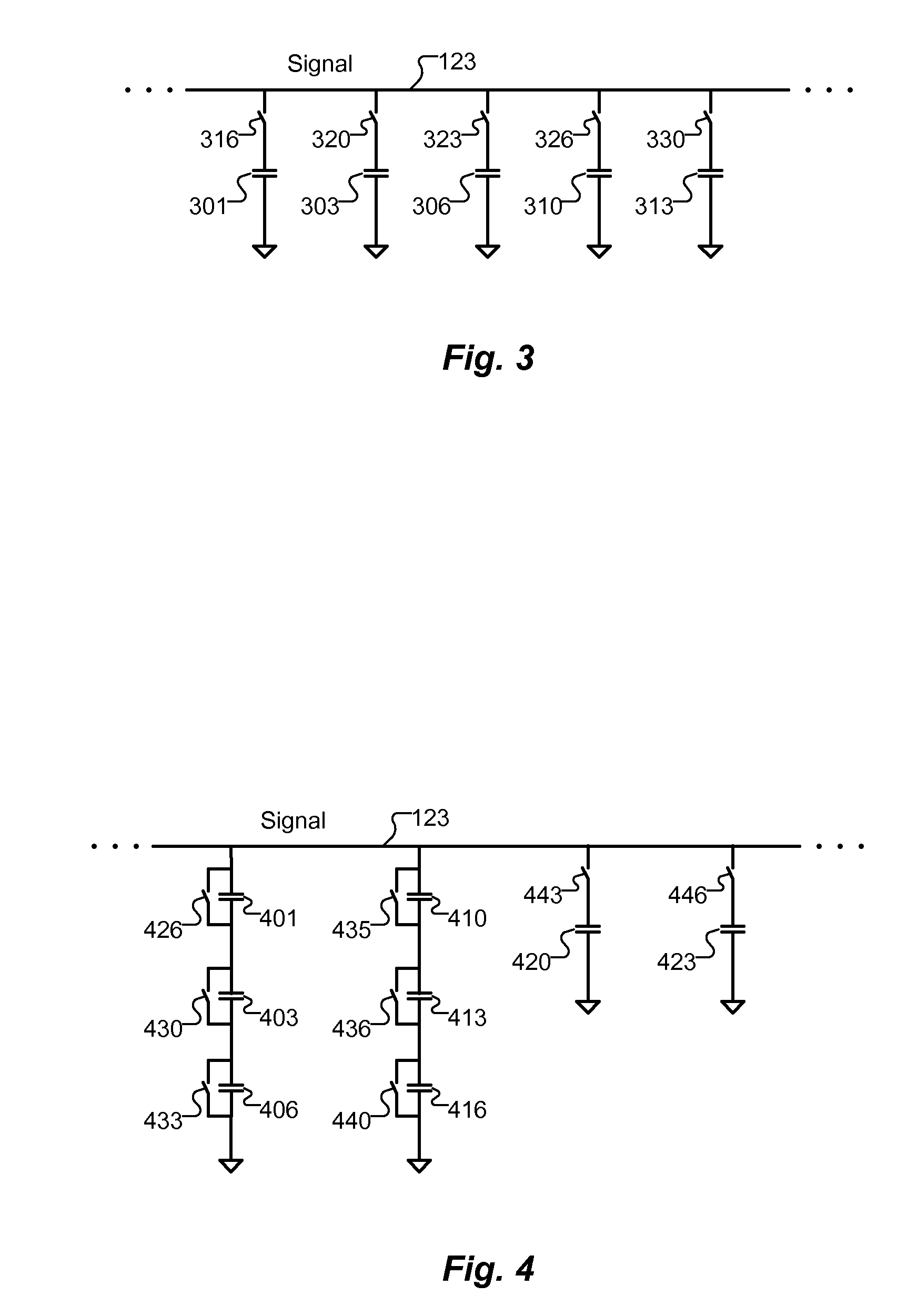

Switchable Attenuation Circuit for MEMS Microphone Systems

ActiveUS20100310096A1Avoid and reduce clippingSemiconductor electrostatic transducersElectrostatic transducer microphonesCapacitanceUltrasound attenuation

A switch control circuit monitors a signal produced by a MEMS or other capacitor microphone. When a criterion is met, for example when the amplitude of the monitored signal exceeds a threshold or the monitored signal has been clipped or analysis of the monitored signal indicates clipping is imminent or likely, the switch control circuit operates one or more switches so as to selectively connect one or more capacitors to a signal line from the microphone, i.e., so as to connect a selected capacitance to the signal line to attenuate the signal from the microphone and, therefore, avoid clipping. The switches may be MOSFET, MEMS or other types of switches co-located with the microphone in a common semiconductor package. Similarly, the capacitors, a circuit that processes the signals from the microphone and / or the switch control circuit may be co-located with the microphone in a common semiconductor package.

Owner:INVENSENSE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com