Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1181results about How to "Reduce package size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

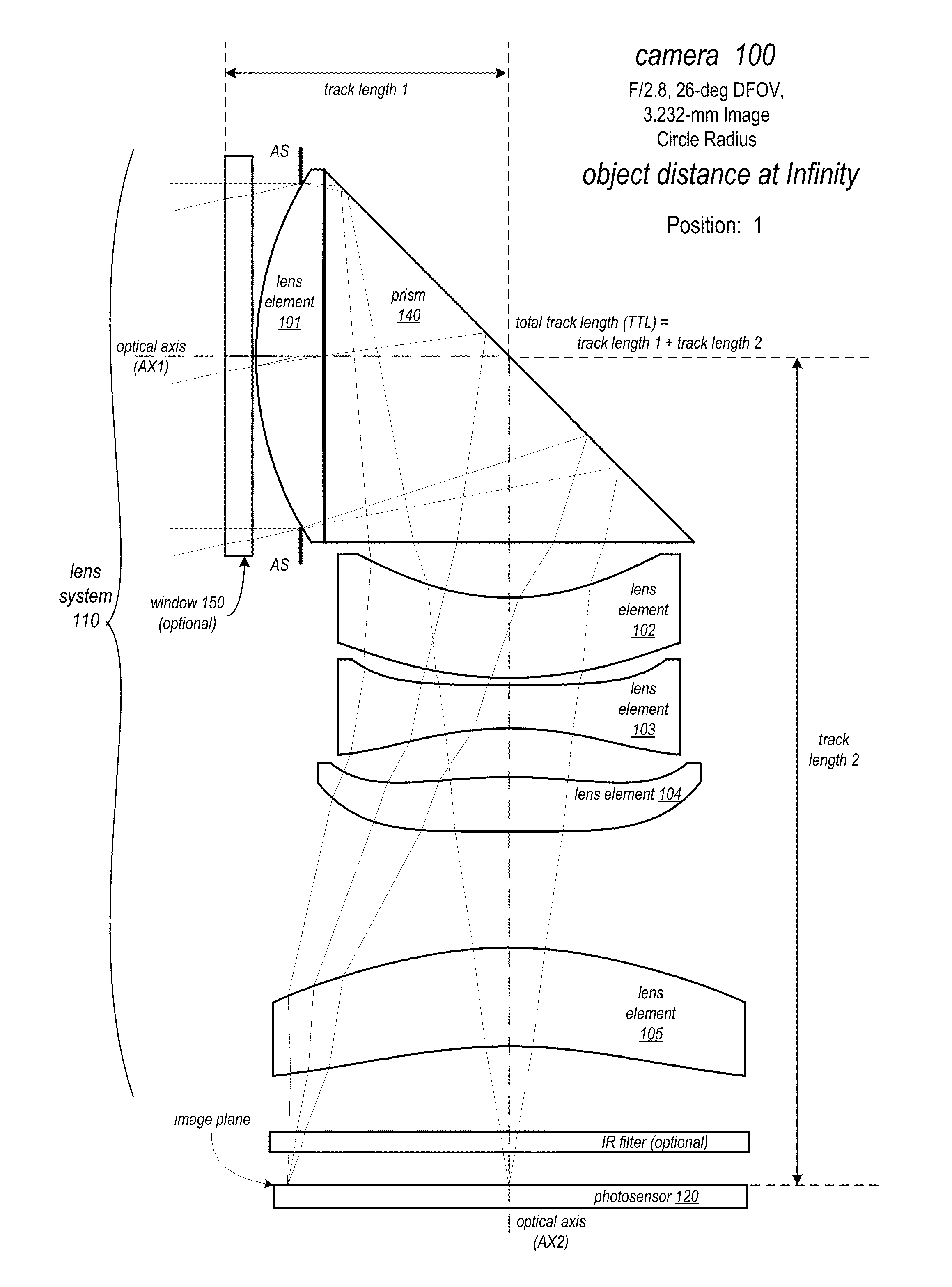

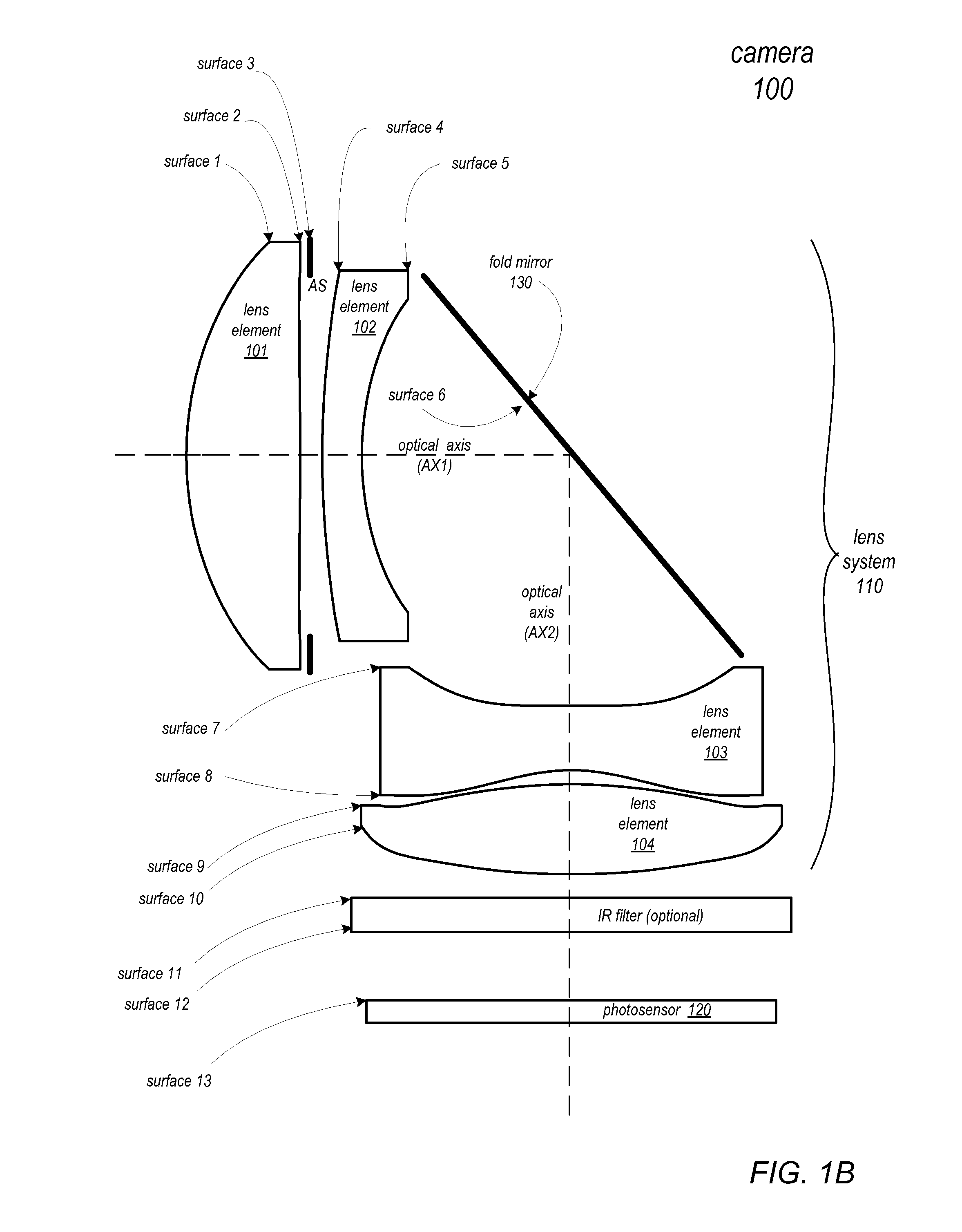

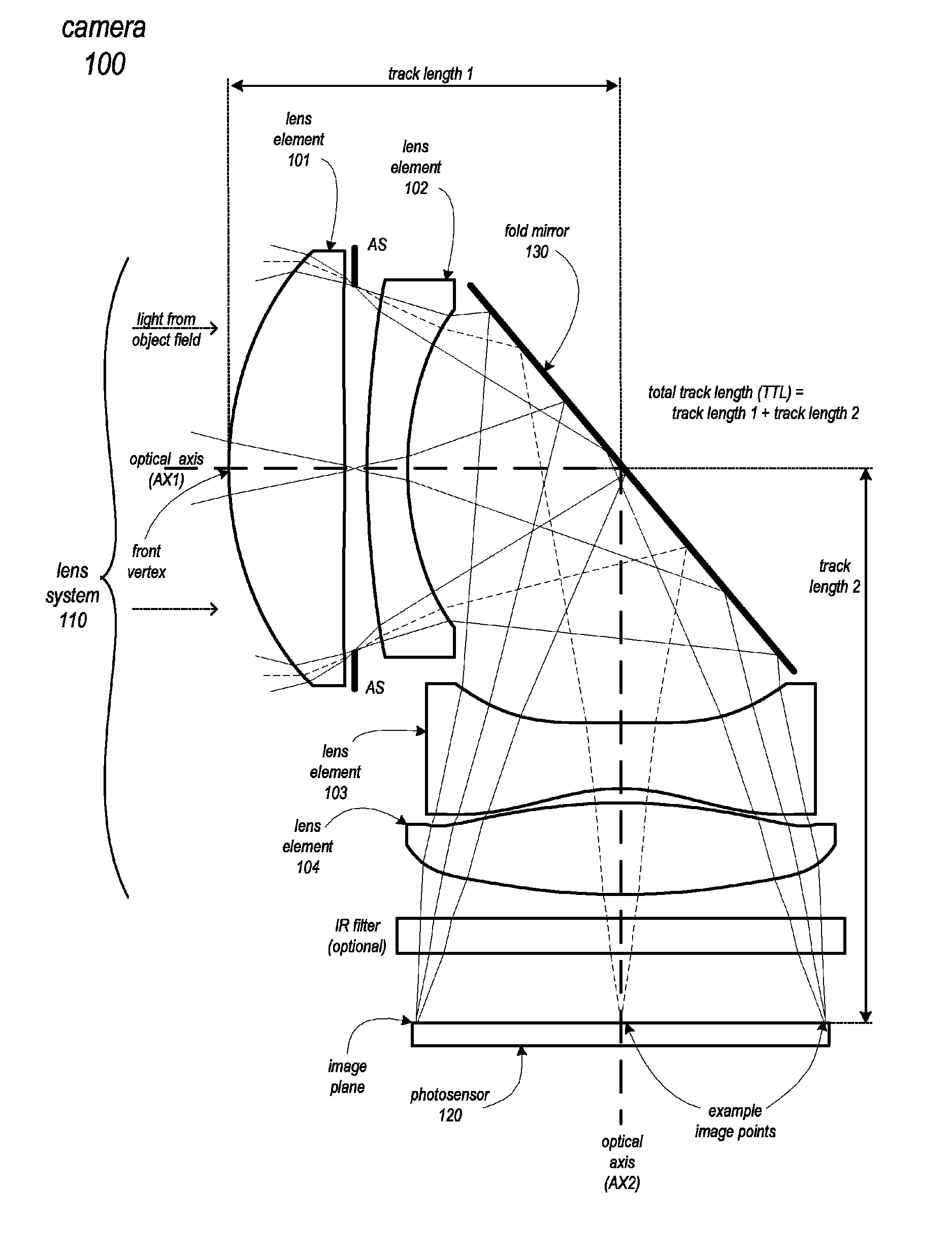

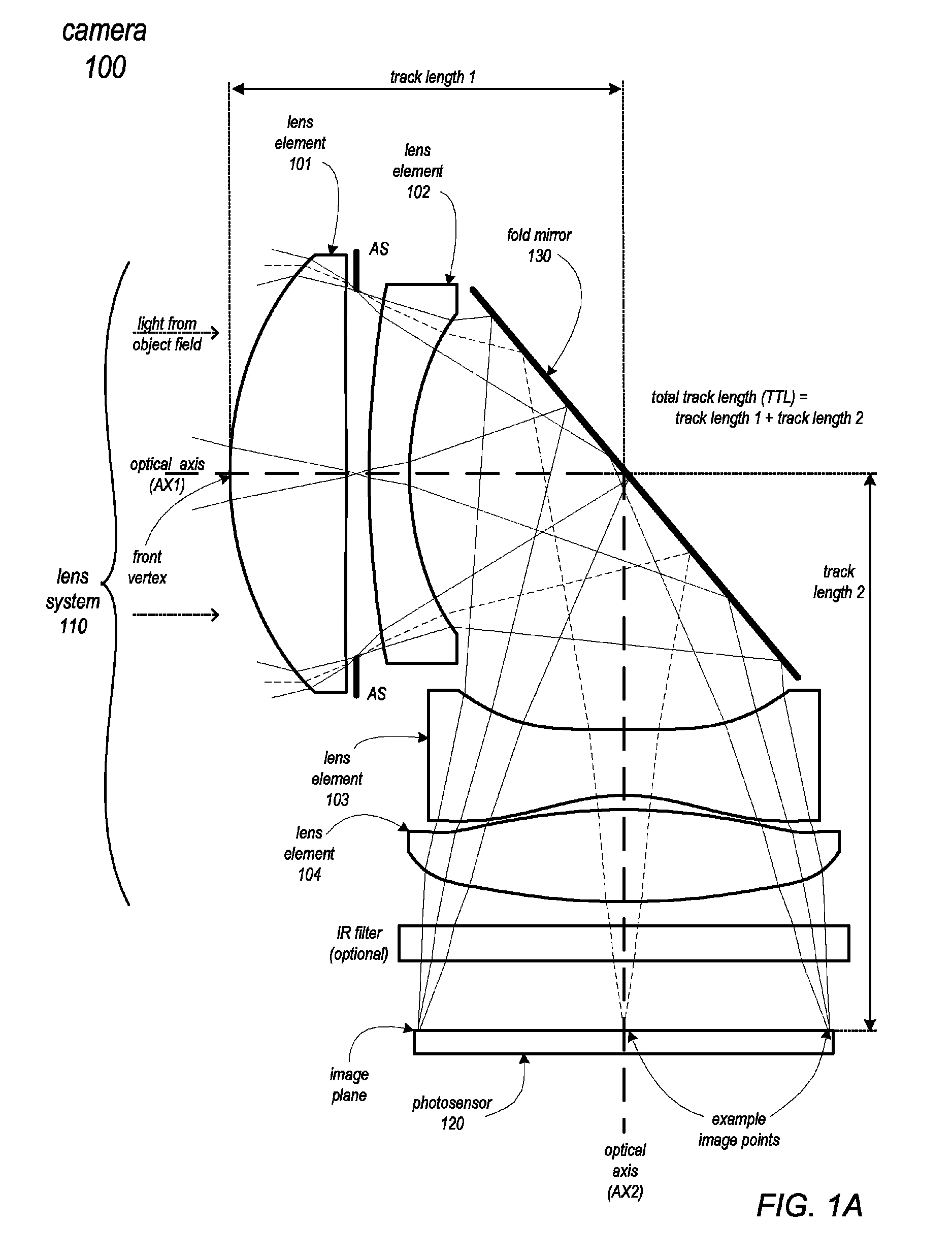

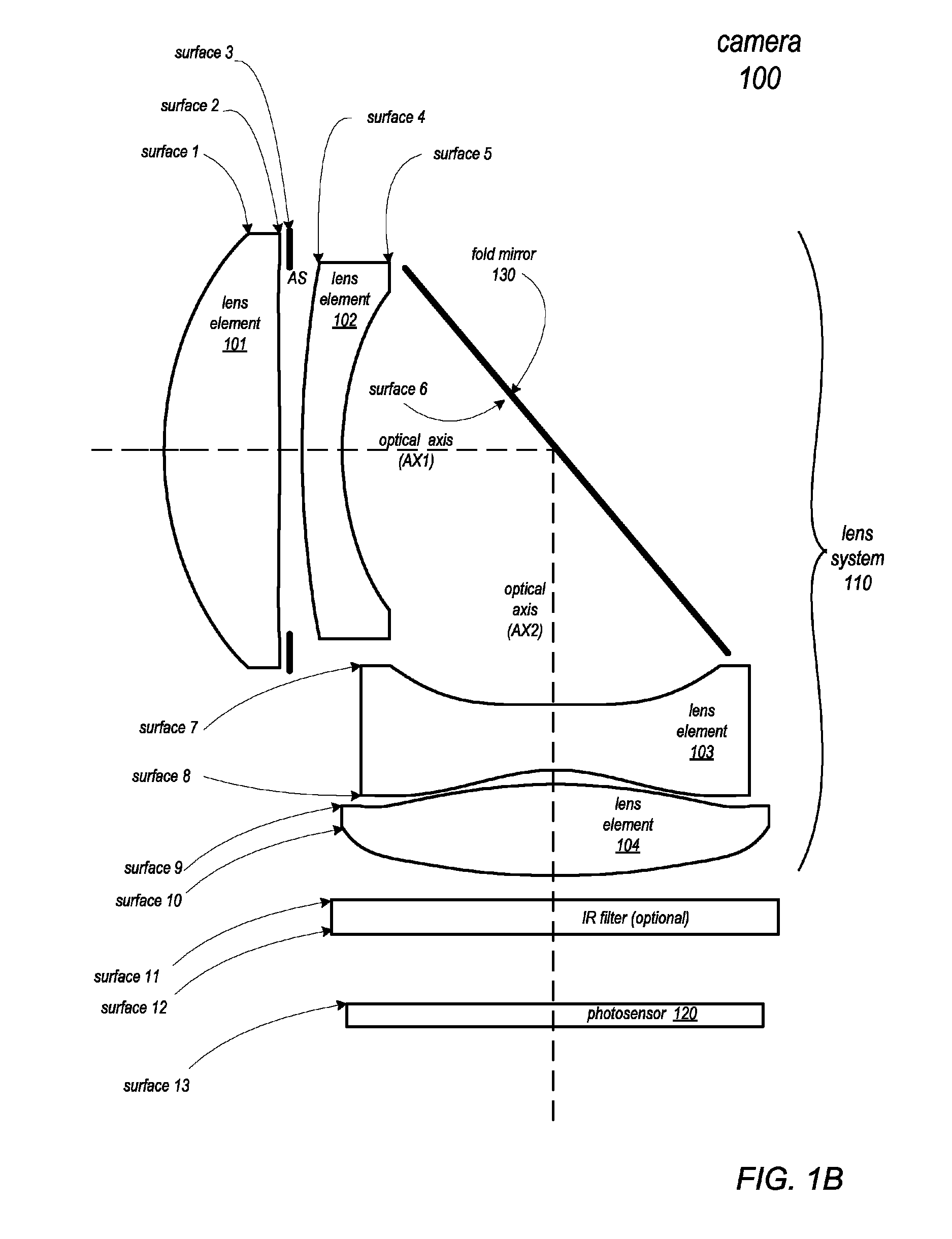

Folded camera lens systems

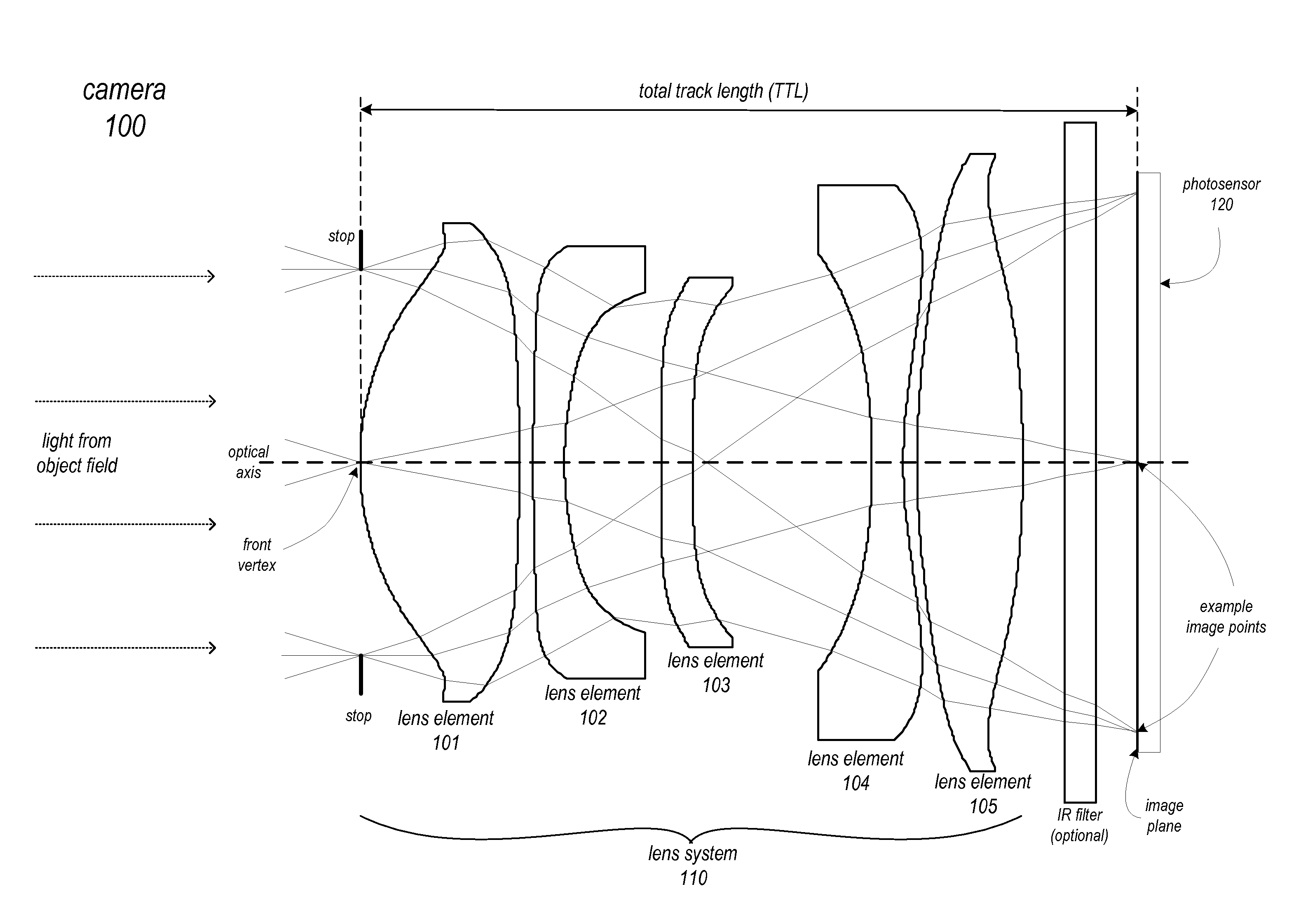

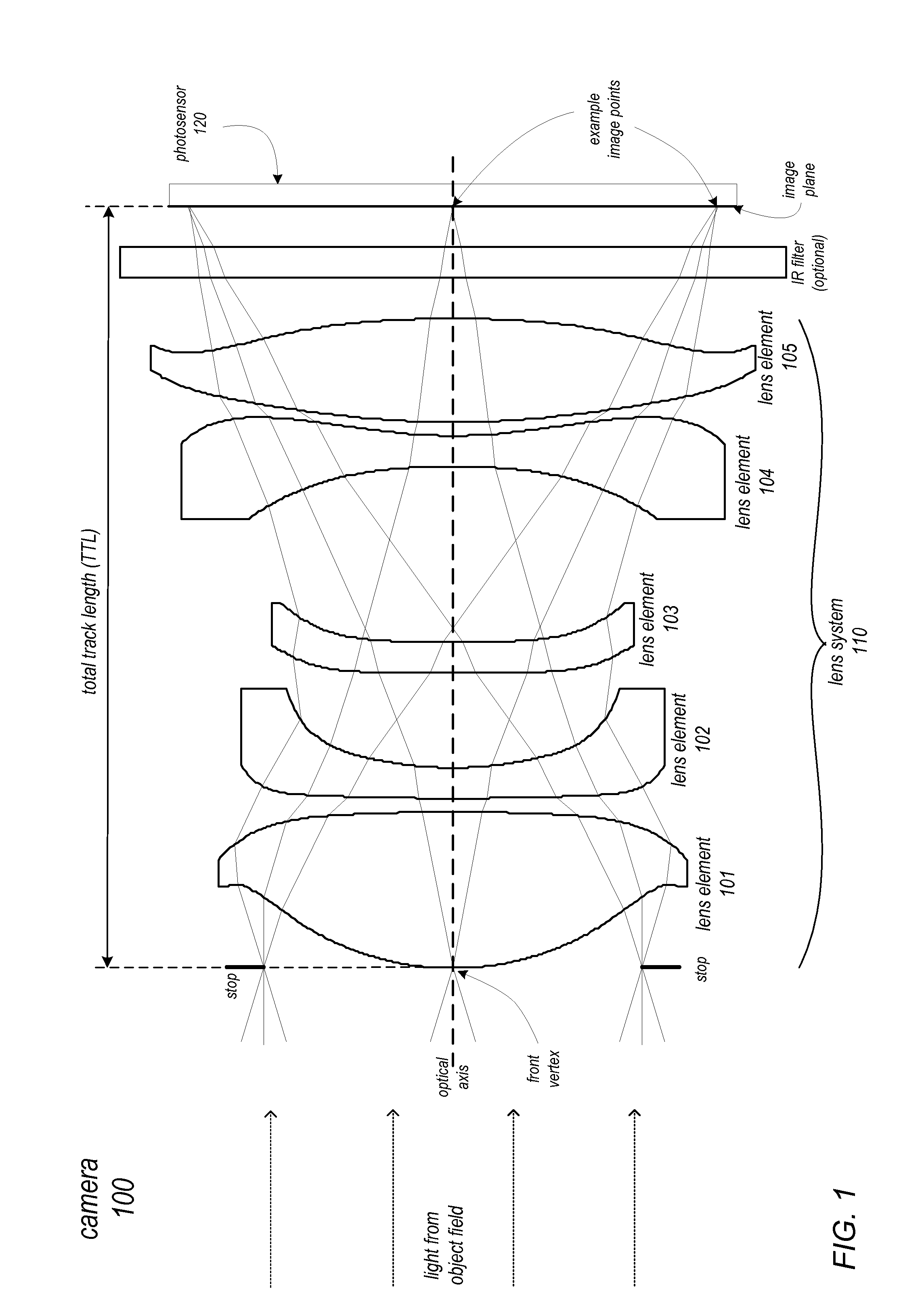

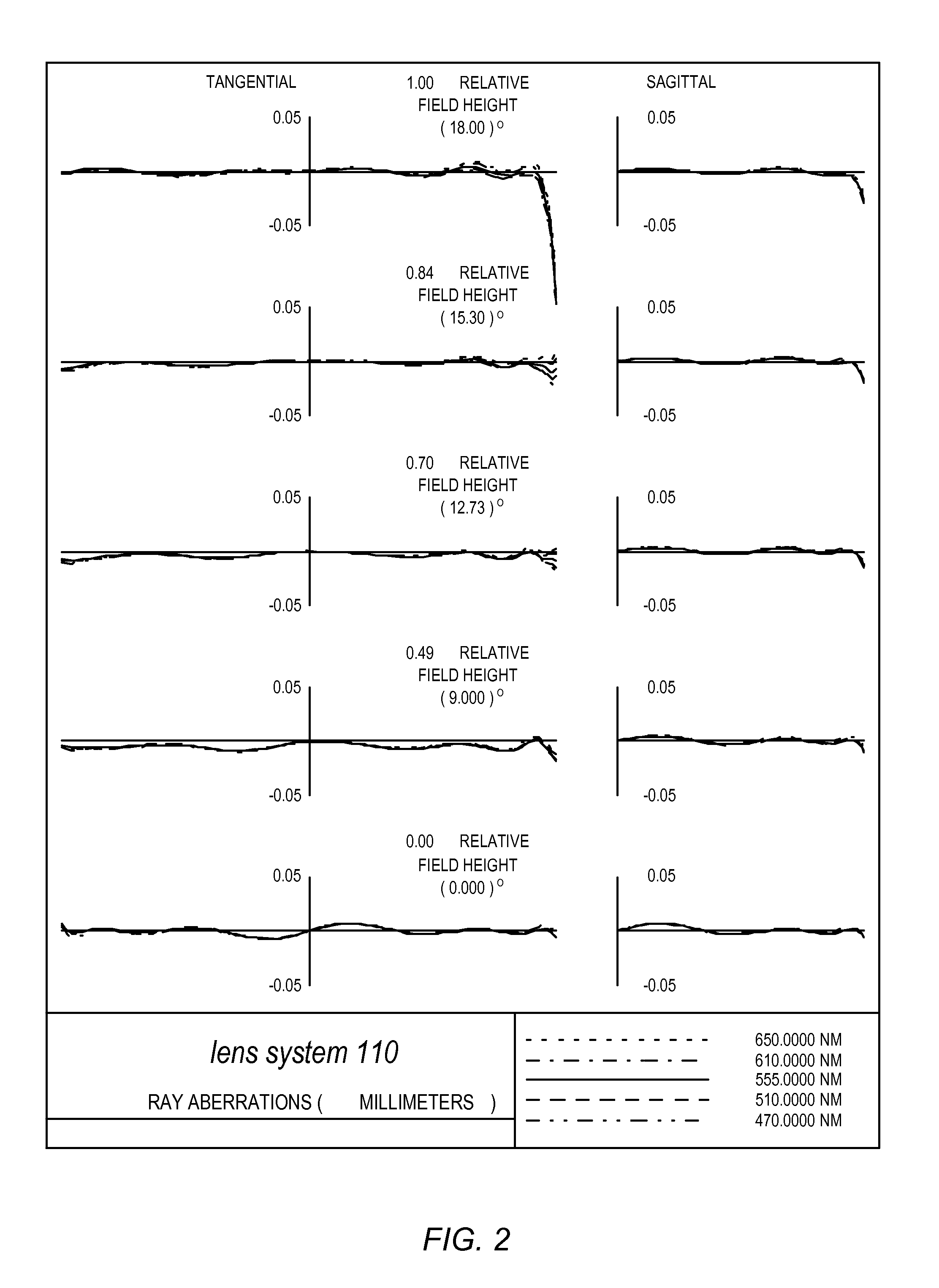

ActiveUS20150253647A1Well-corrected and balanced minimal residual aberrationReduce track lengthTelevision system detailsColor television detailsCamera lensImage resolution

A folded lens system may include multiple lenses with refractive power and a light path folding element. Light entering the camera through lens(es) on a first optical path or axis is refracted to the folding element, which changes direction of the light onto a second optical path or axis with lens(es) that refract the light to form an image plane at a photosensor. At least one of the object side and image side surfaces of at least one of the lens elements may be aspheric. Total track length (TTL) of the lens system may be 16.0 mm or less. The lens system may be configured so that the telephoto ration |TTL / f| is greater than 1.0. Materials, radii of curvature, shapes, sizes, spacing, and aspheric coefficients of the optical elements may be selected to achieve quality optical performance and high image resolution in a small form factor camera.

Owner:APPLE INC

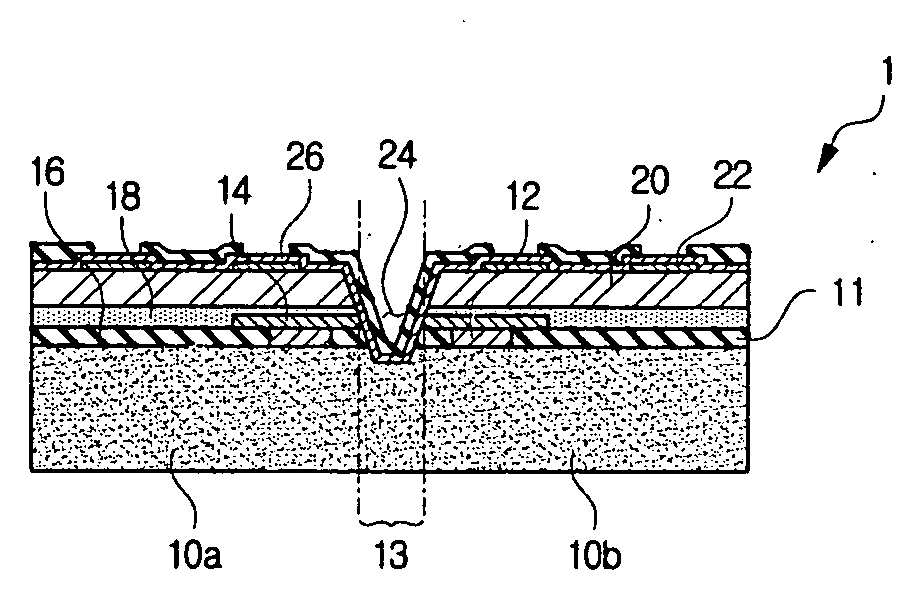

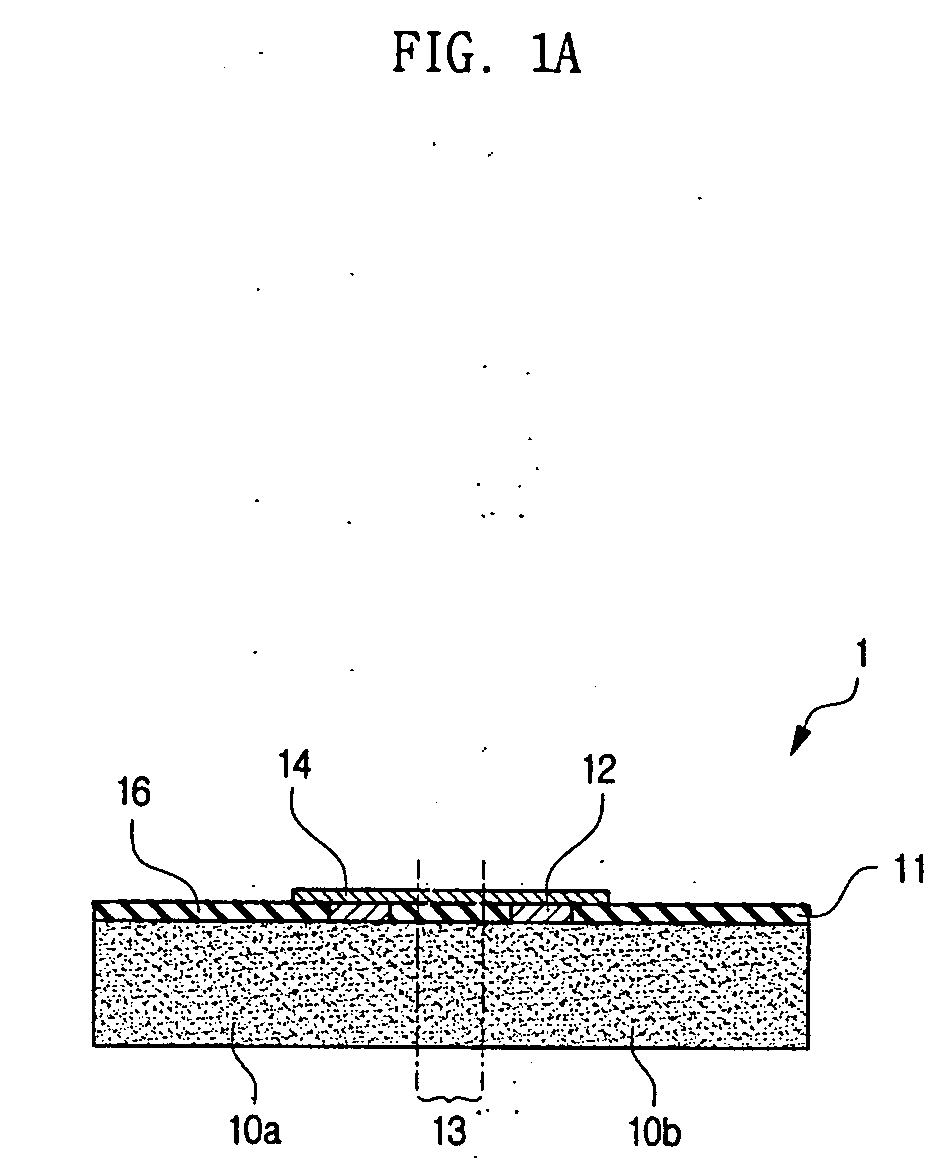

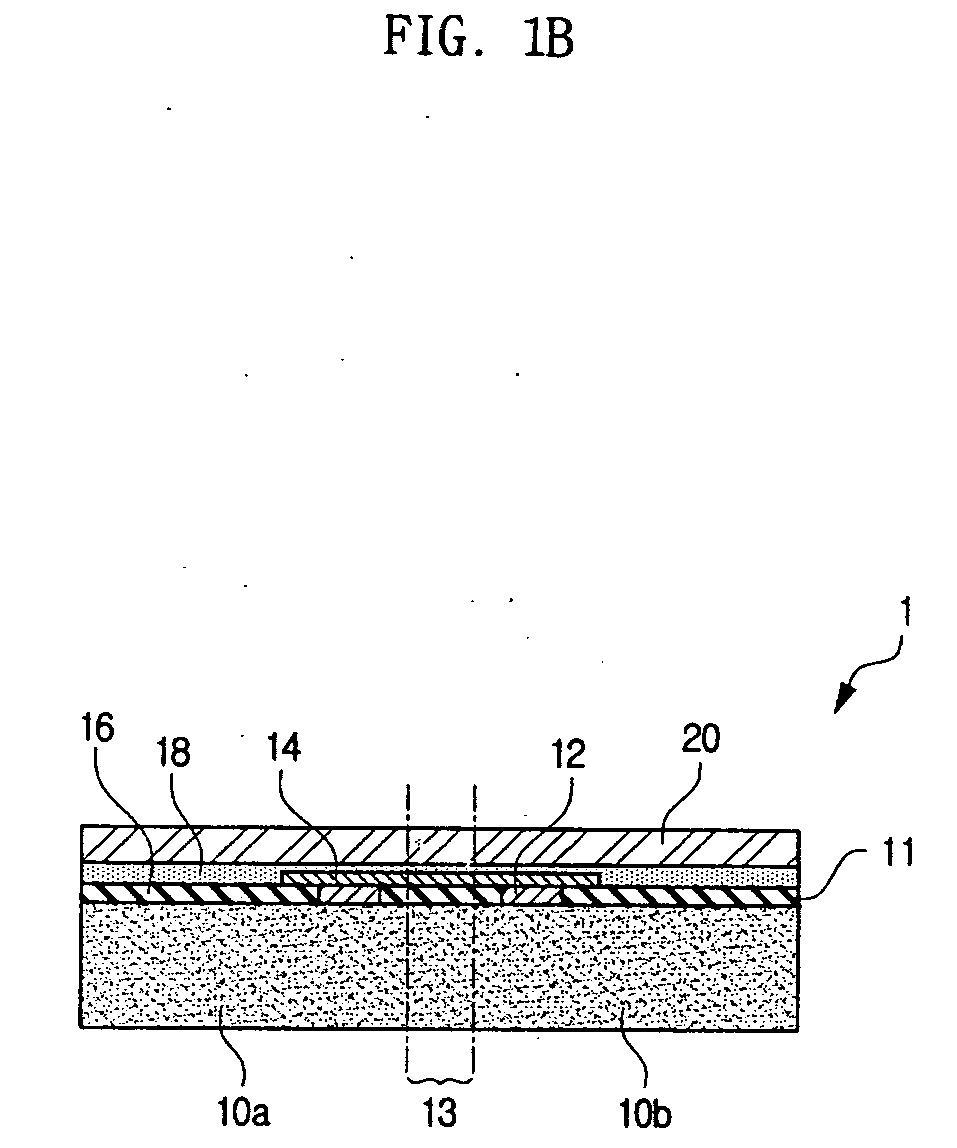

Method for manufacturing wafer level chip scale package using redistribution substrate

InactiveUS20060079019A1Increase widthIncrease flexibilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringChip-scale package

The present invention provides a method for manufacturing a wafer level chip scale package using a redistribution substrate, which has patterned bump pairs connected by redistribution lines and formed on a transparent insulating substrate. The redistribution substrate is produced separately from a wafer and then bonded to the wafer. One part of each bump pair is in contact with a chip pad on the active surface of the wafer, and the other part coincides with one of holes formed in the wafer. Conductive lines are formed in the holes and on the non-active surface of the wafer. External connection terminals are formed on the conductive lines at the non-active surface.

Owner:EPWORKS

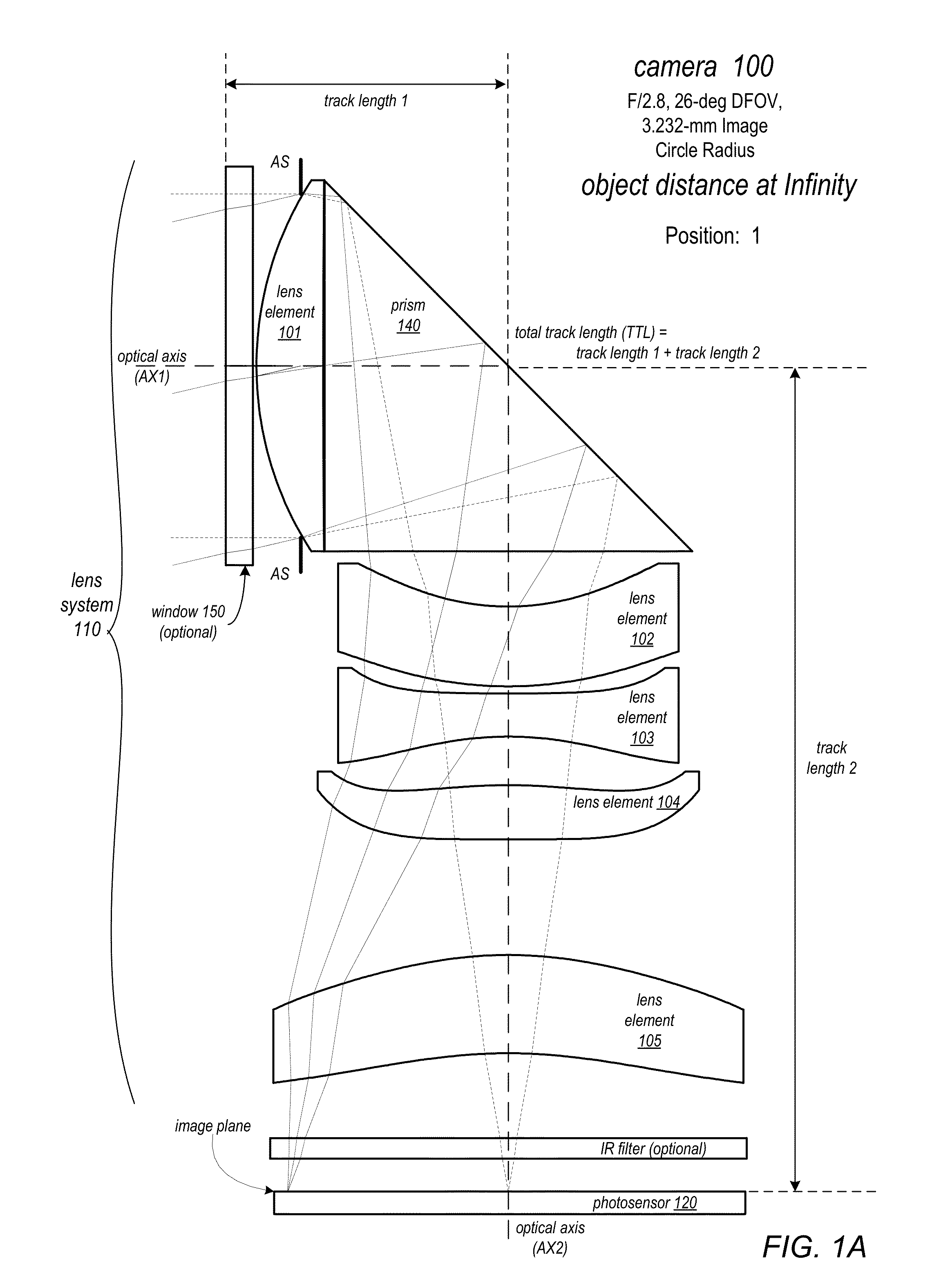

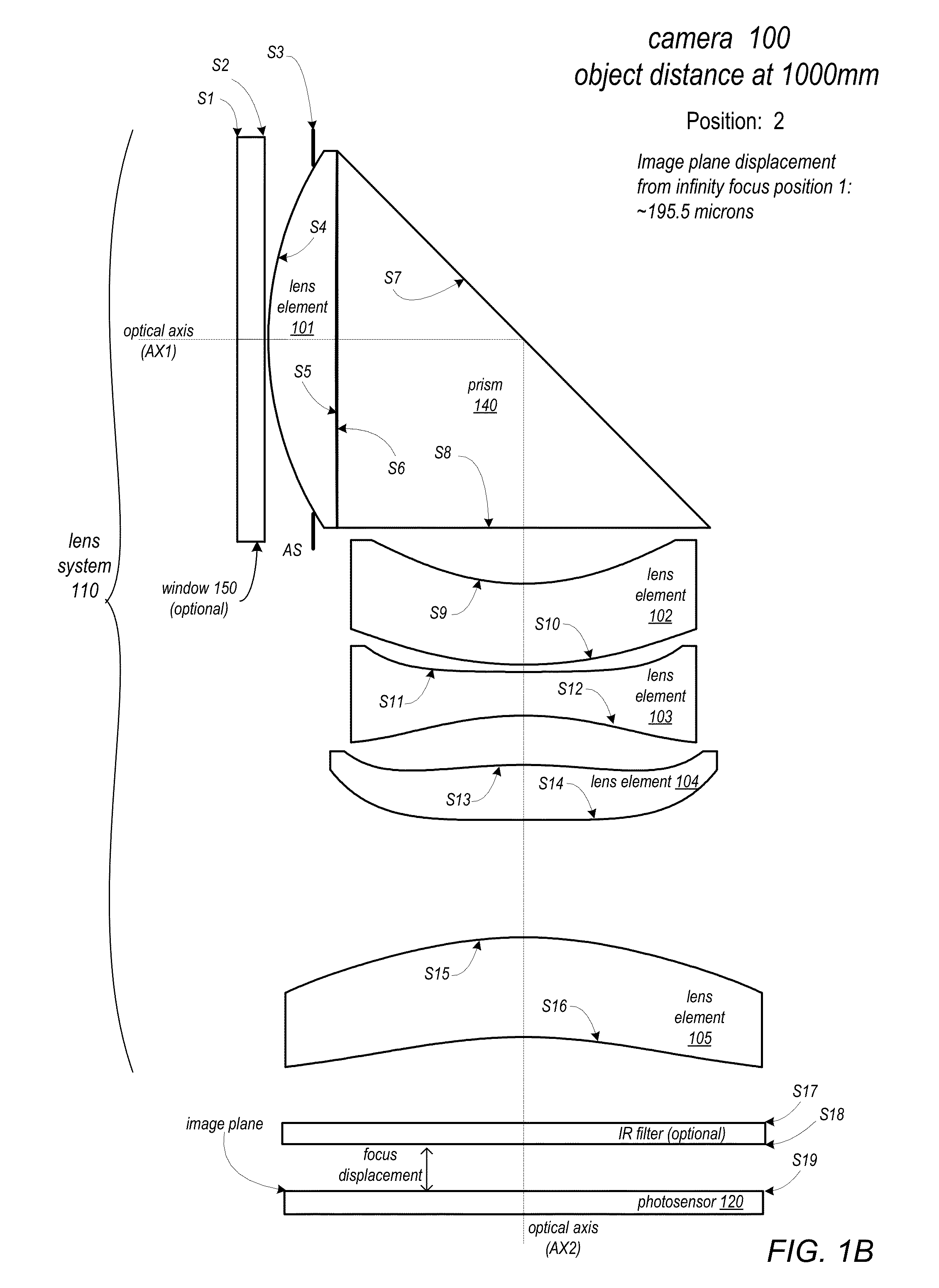

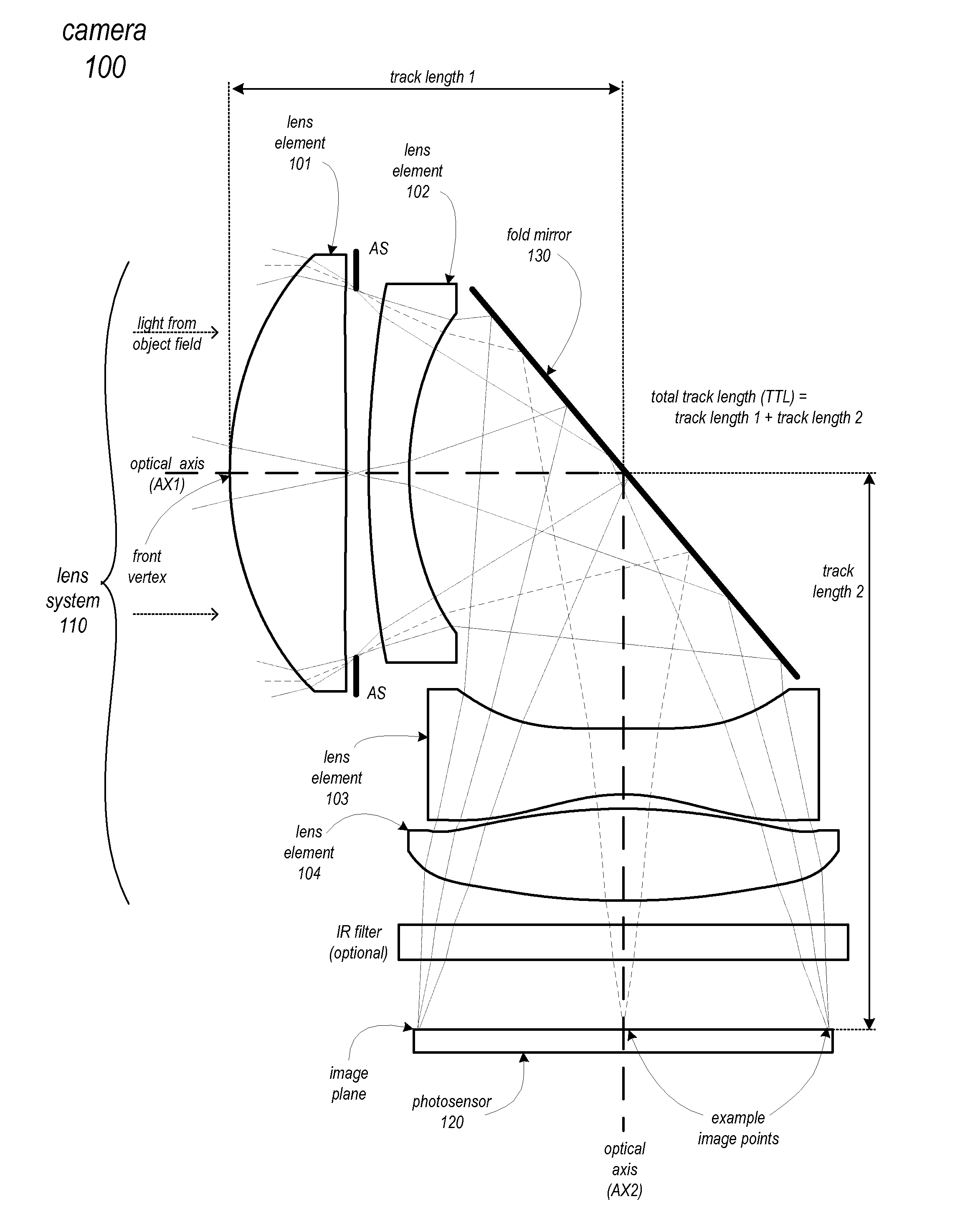

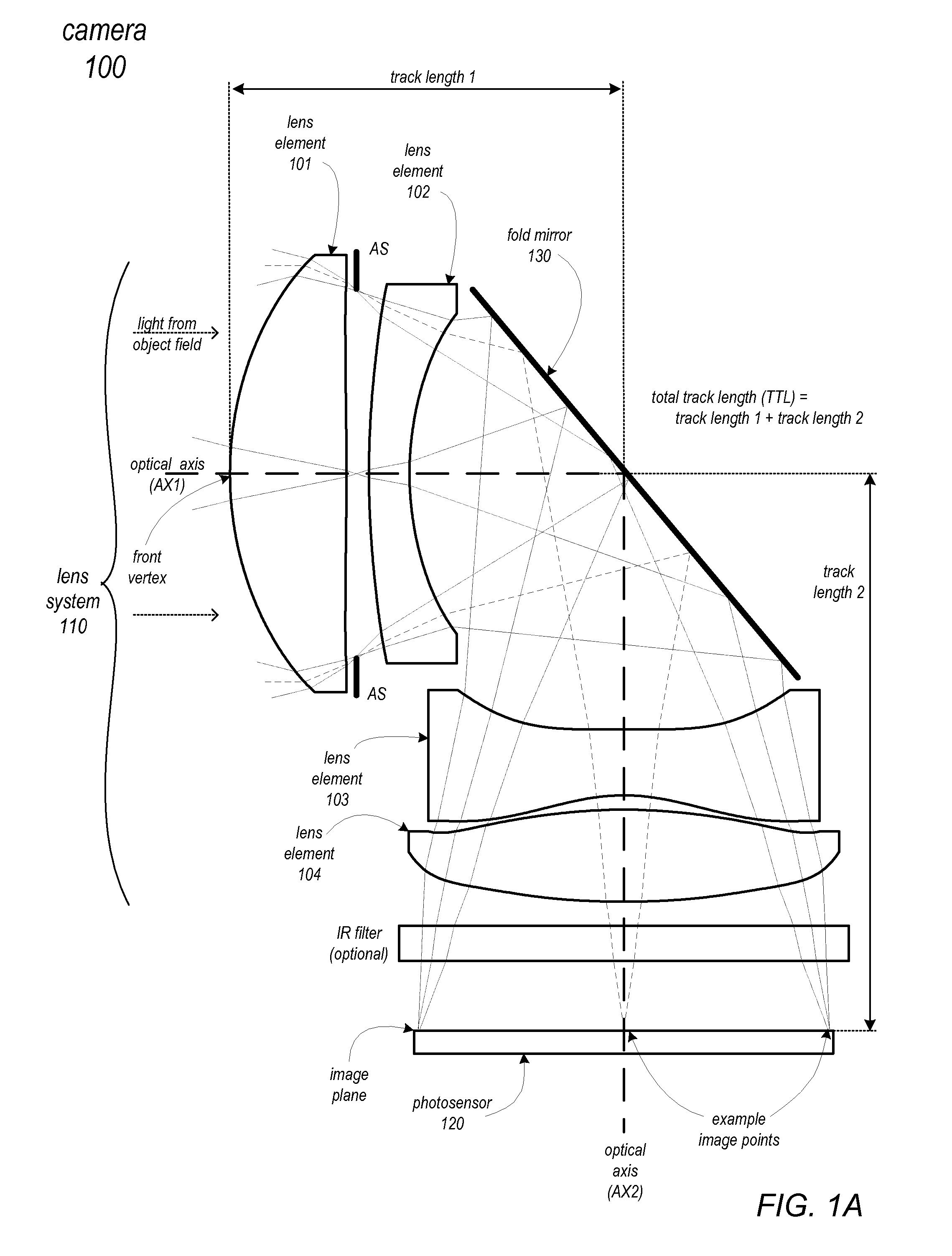

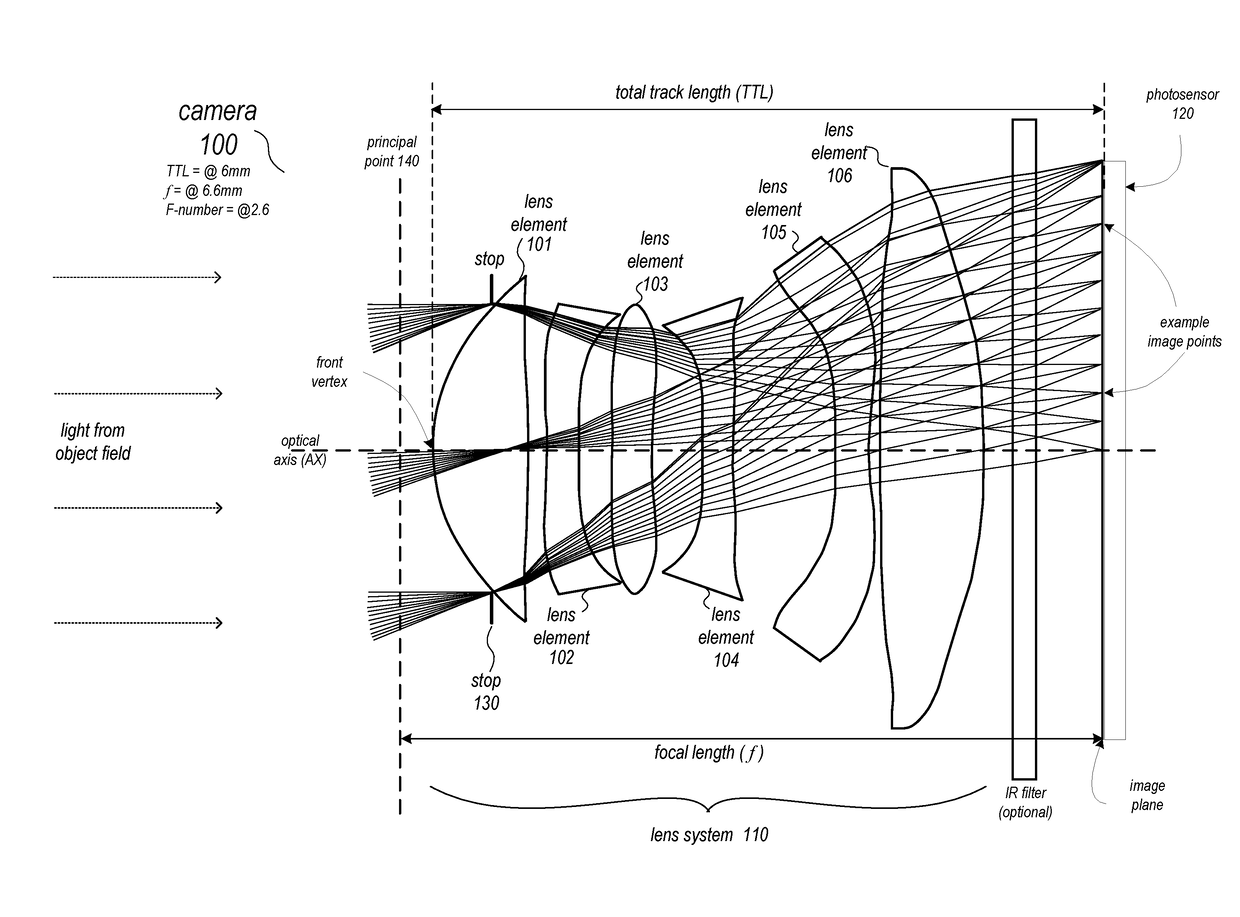

Folded telephoto camera lens system

ActiveUS20150253543A1Reduce total track lengthMinimum aberrationTelevision system detailsColor television detailsOptical pathCamera lens

A folded telephoto lens system may include multiple lenses with refractive power and a light path folding element. Light entering the camera through lens(es) on a first path is refracted to the folding element, which changes direction of the light on to a second path with lens(es) that refract the light to form an image plane at a photosensor. At least one of the object side and image side surfaces of at least one of the lens elements may be aspheric. Total track length (TTL) of the lens system may be 14.0 mm or less. The lens system may be configured so that the telephoto ration (TTL / f) is less than or equal to 1.0. Materials, radii of curvature, shapes, sizes, spacing, and aspheric coefficients of the optical elements may be selected to achieve quality optical performance and high image resolution in a small form factor camera.

Owner:APPLE INC

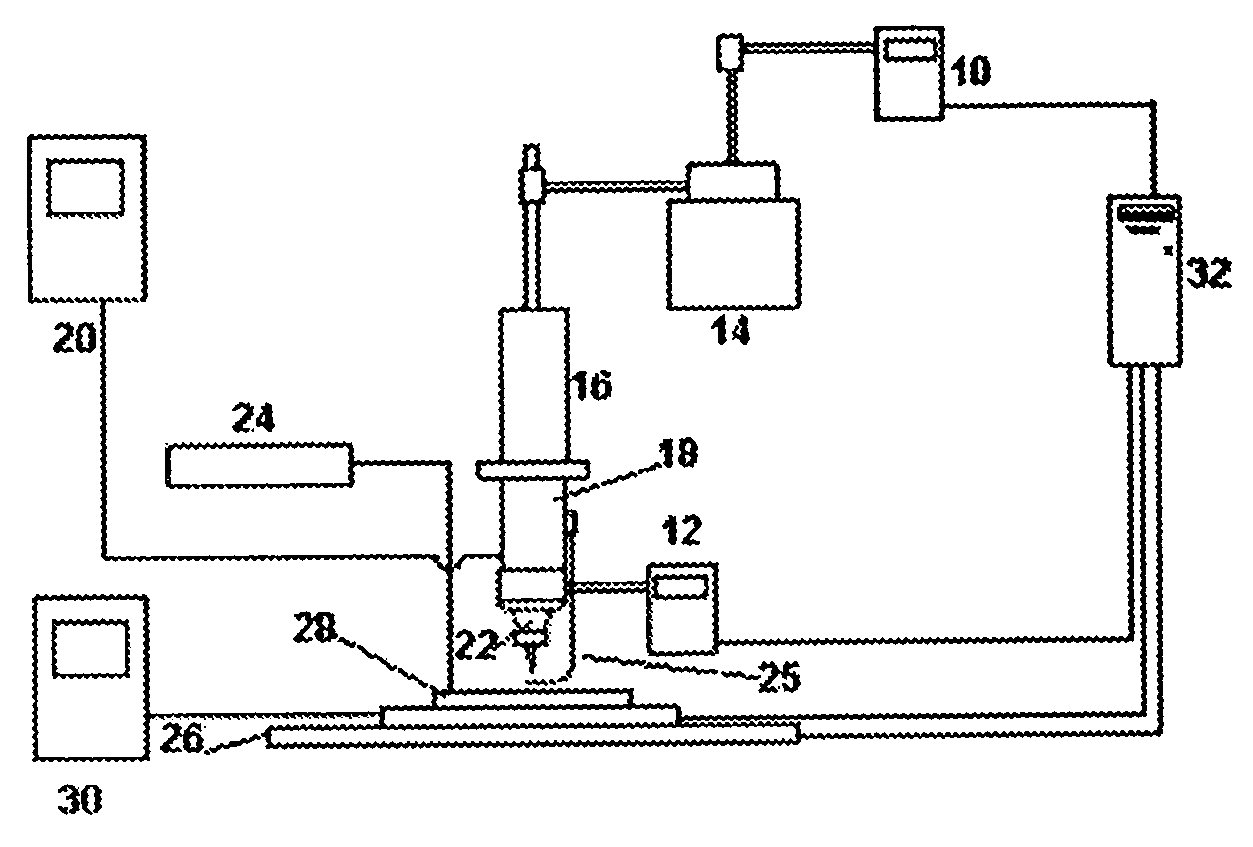

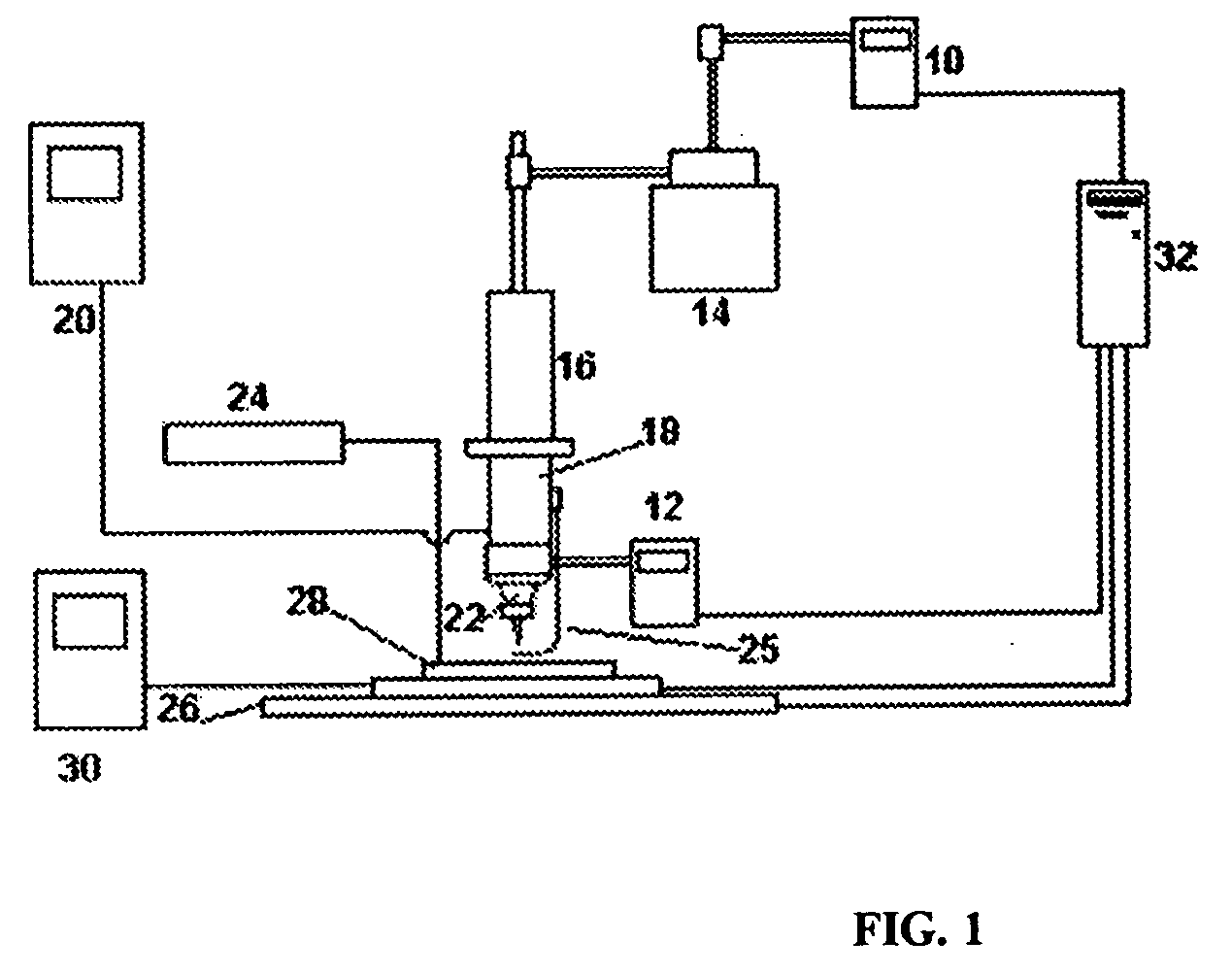

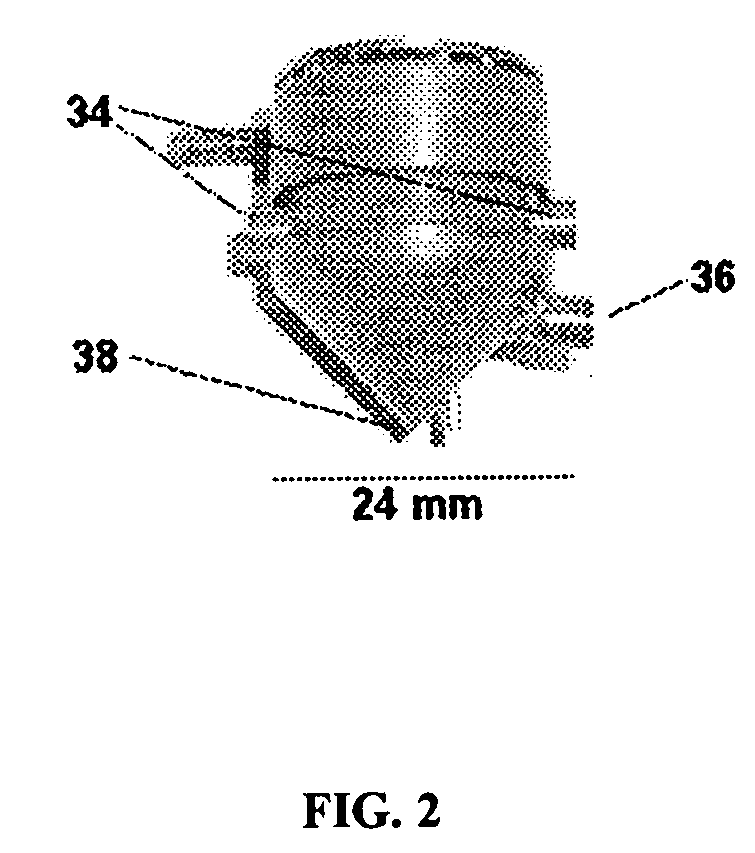

Apparatus, methods and precision spray processes for direct write and maskless mesoscale material deposition

InactiveUS20040197493A1Reduce package sizeElectric discharge heatingVacuum evaporation coatingOptoelectronicsBiological materials

Apparatuses and processes for maskless deposition of electronic and biological materials. The process is capable of direct deposition of features with linewidths varying from the micron range up to a fraction of a millimeter, and may be used to deposit features on substrates with damage thresholds near 100° C. Deposition and subsequent processing may be carried out under ambient conditions, eliminating the need for a vacuum atmosphere. The process may also be performed in an inert gas environment. Deposition of and subsequent laser post processing produces linewidths as low as 1 micron, with sub-micron edge definition. The apparatus nozzle has a large working distance-the orifice to substrate distance may be several millimeters-and direct write onto non-planar surfaces is possible. This invention is also of combinations of precision spray processes with in-flight laser treatment in order to produce direct write electronic components, and additionally lines of conductive, inductive, and resistive materials. This development has the potential to change the approach to electronics packaging in that components can be directly produced on small structures, thus removing the need for printed circuit boards.

Owner:OPTOMEC DESIGN CO

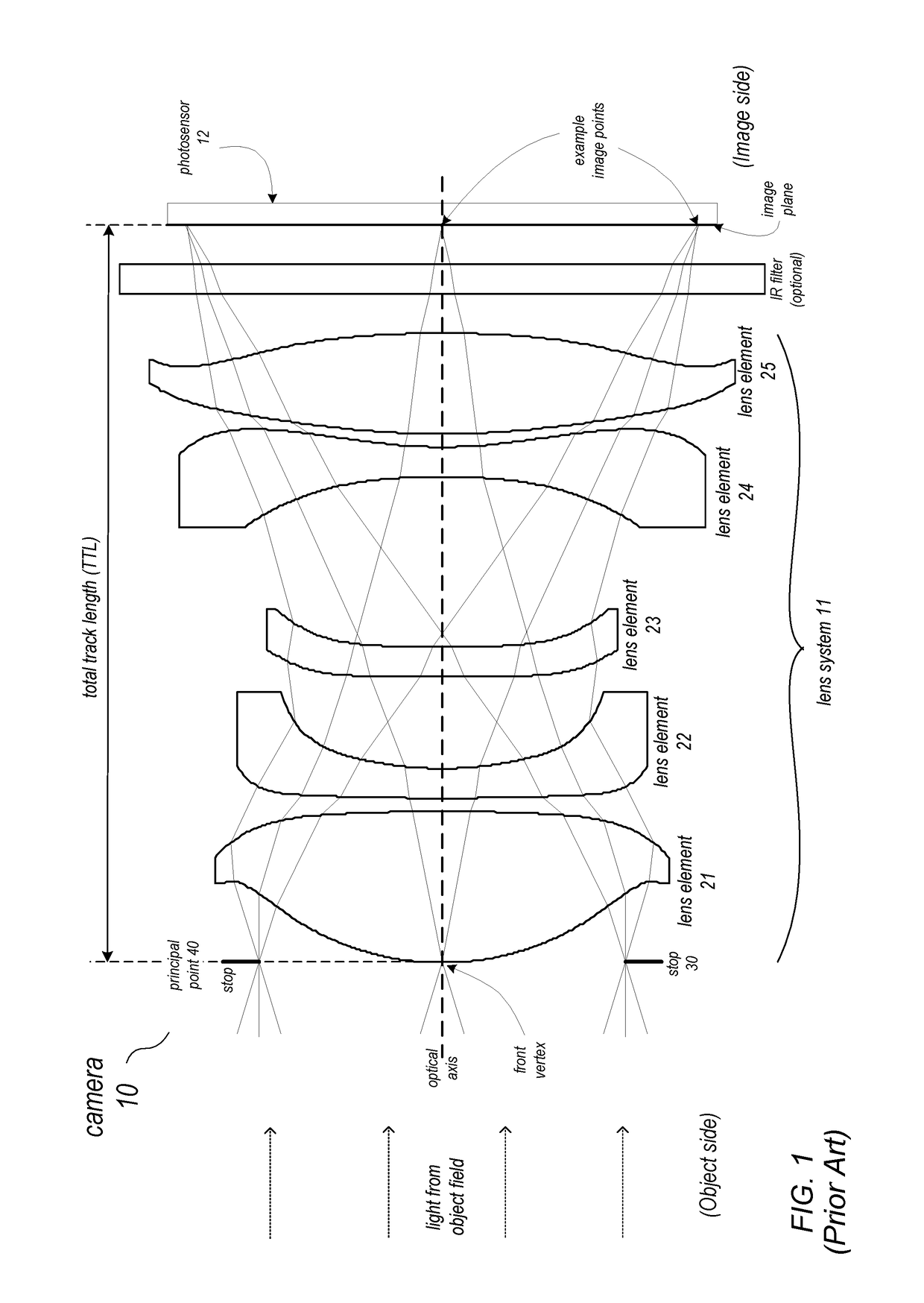

Small form factor telephoto camera

ActiveUS20150116569A1Well-corrected and balanced minimal residual aberrationReduce track lengthTelevision system detailsColor television detailsImage resolutionTelephoto lens

A compact telephoto lens system that may be used in a small form factor cameras. The lens system may include five lens elements with refractive power. Alternatively, the lens system may include four lens elements with refractive power. At least one of the object side and image side surfaces of at least one of the lens elements is aspheric. Total track length (TTL) of the lens system may be 6.0 mm or less. Focal length f of the lens system may be at or about 7.0 mm (for example, within a range of 6.5-7.5 mm). Lens elements are selected and configured so that the telephoto ratio (TTL / f) satisfies the relation 0.74<TTL / f<1.0. Materials, radii of curvature, shapes, sizes, spacing, and aspheric coefficients of the lens elements may be selected to achieve quality optical performance and high image resolution in a small form factor telephoto camera.

Owner:APPLE INC

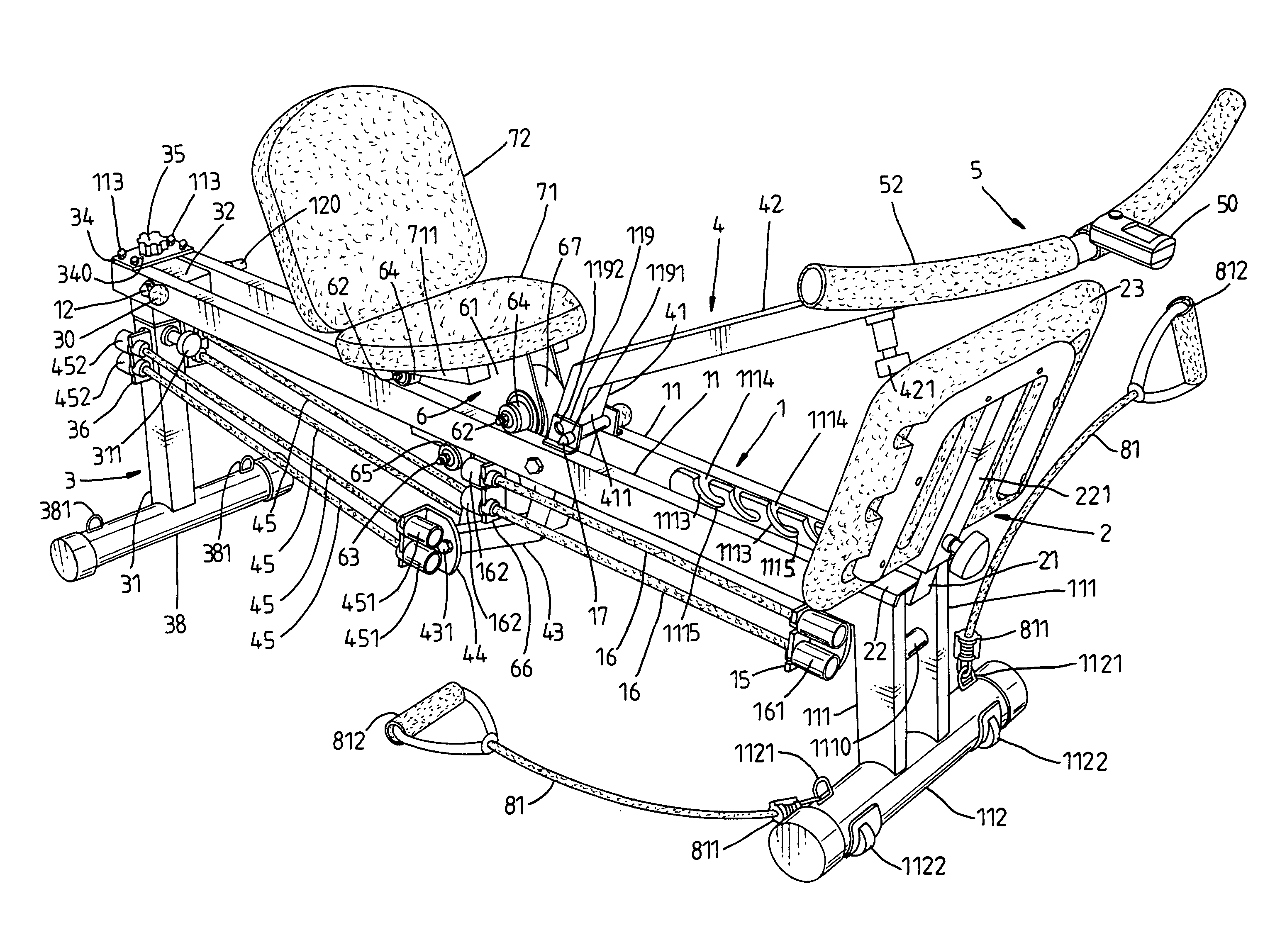

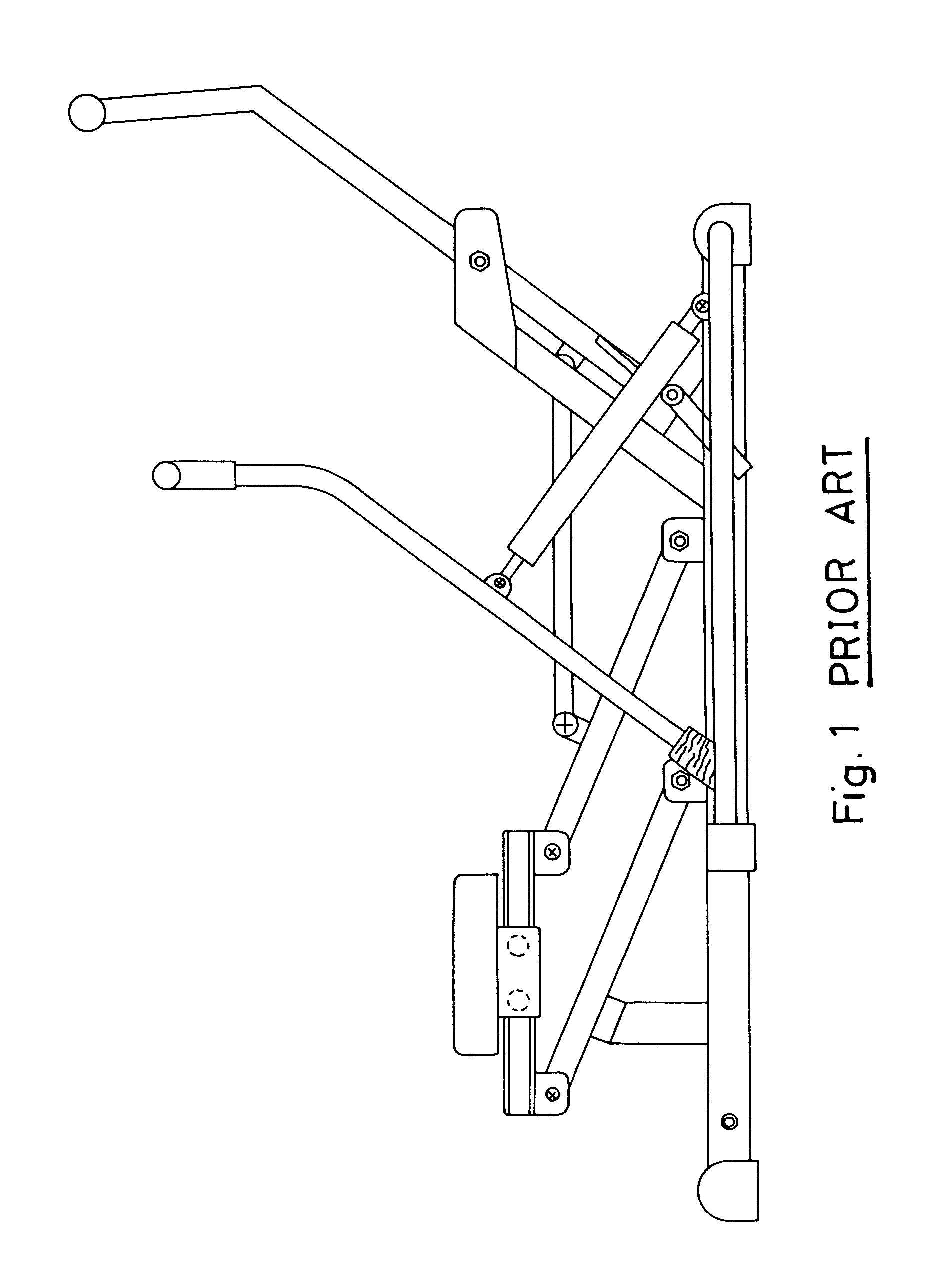

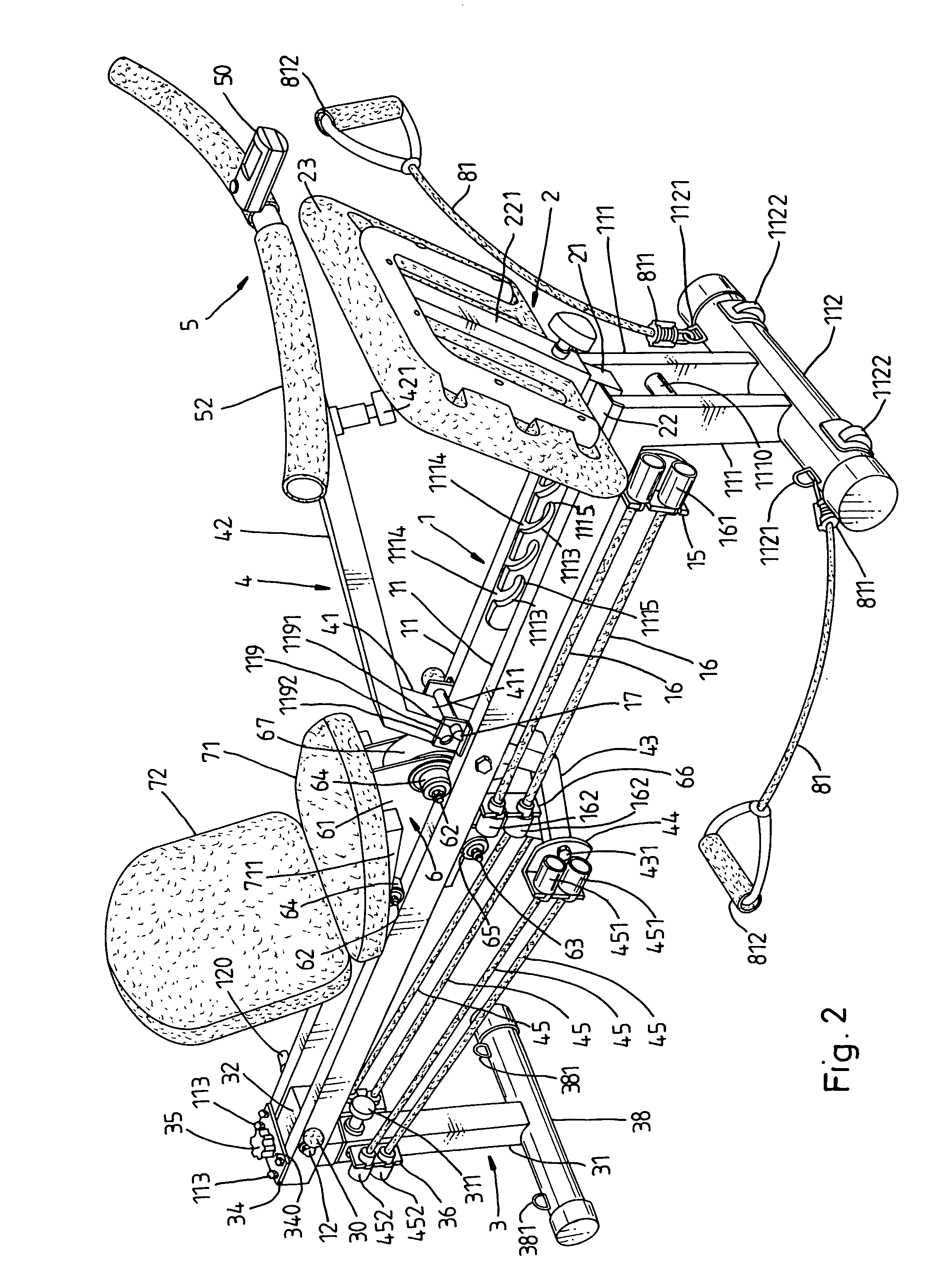

Rowing machine

InactiveUS6981932B1Reduce package sizeResilient force resistorsSpace saving gamesSlope angleEngineering

A rowing machine is constructed to include a sloping angle-adjustable base frame, a foot rack selectively and pivotally mounted on the base frame at the front side, a rocker arm coupled with a detachable handlebar for rowing exercise to stretch elastic cord members, a slide slidably mounted on two parallel rails of the base frame to support a seat and a collapsible back, and two elastic pull cords detachably fastened to the base frame for pulling by the user sitting on the seat.

Owner:KUO JOHNSON

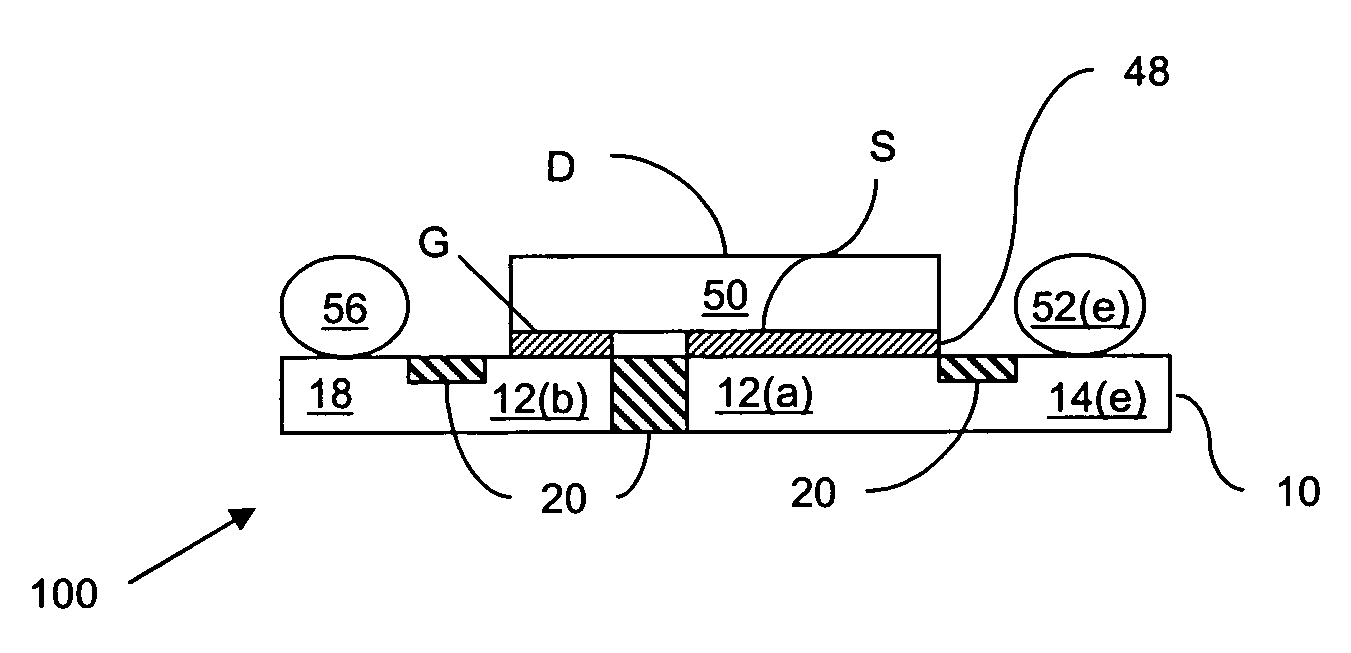

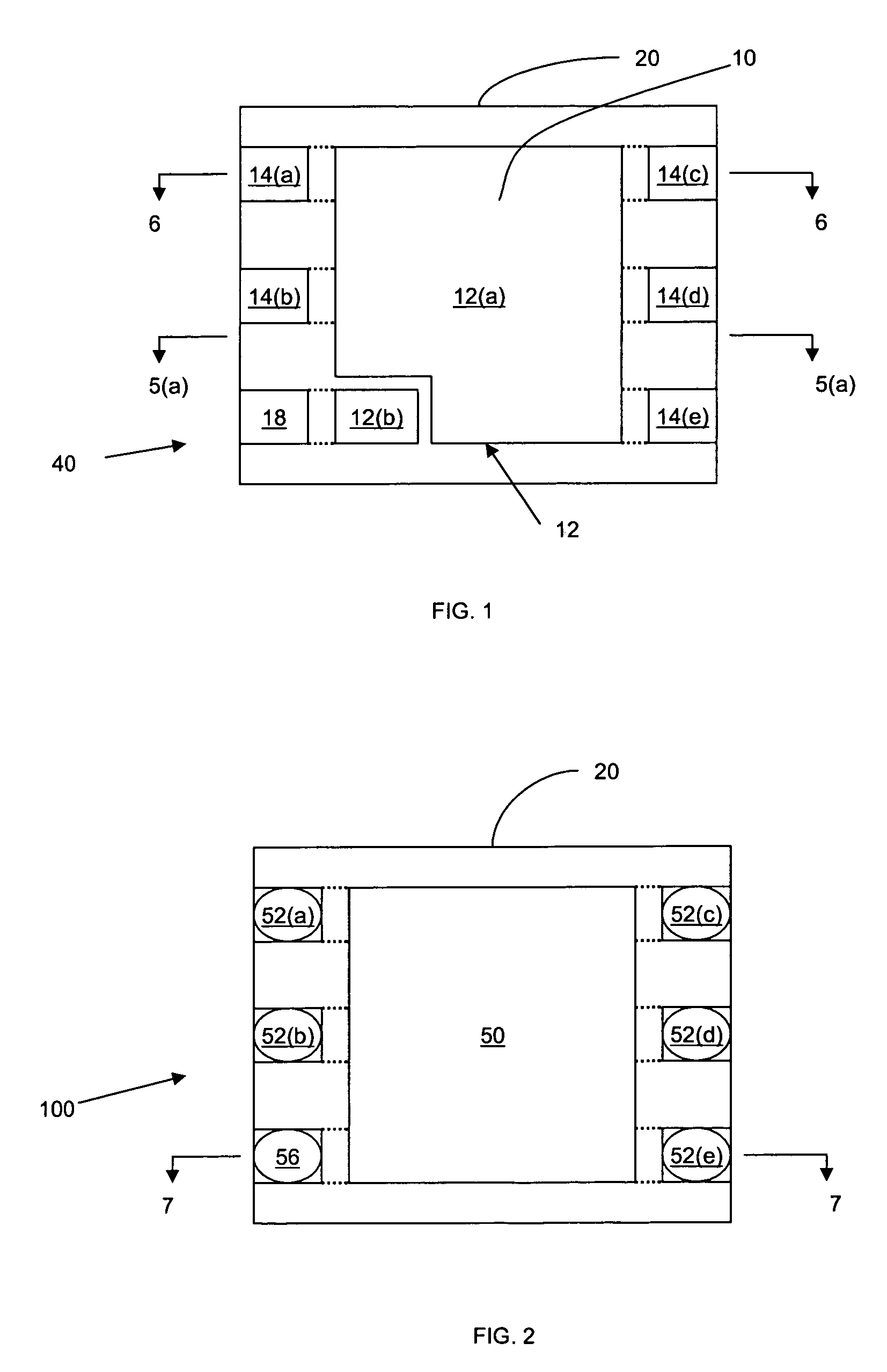

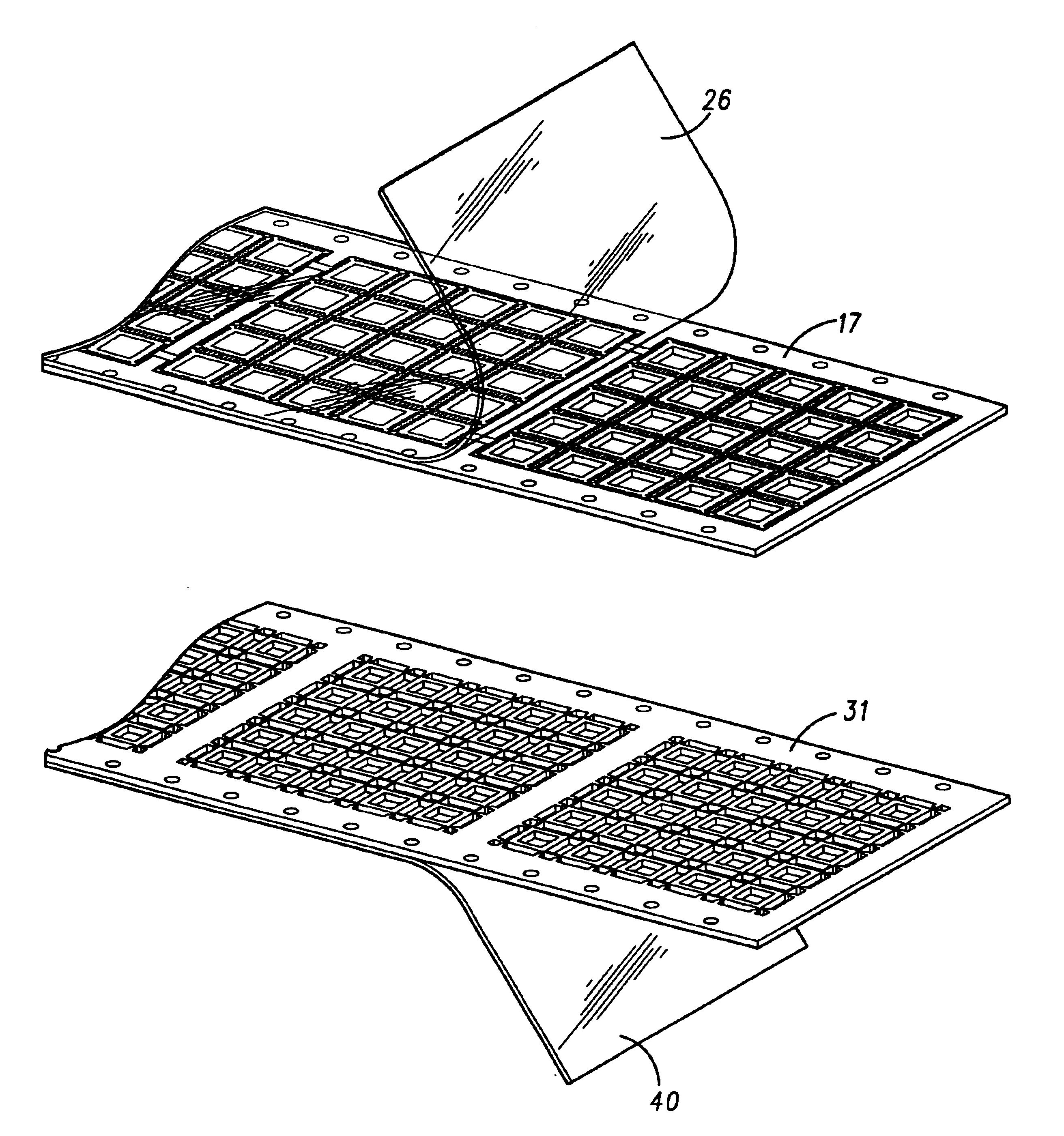

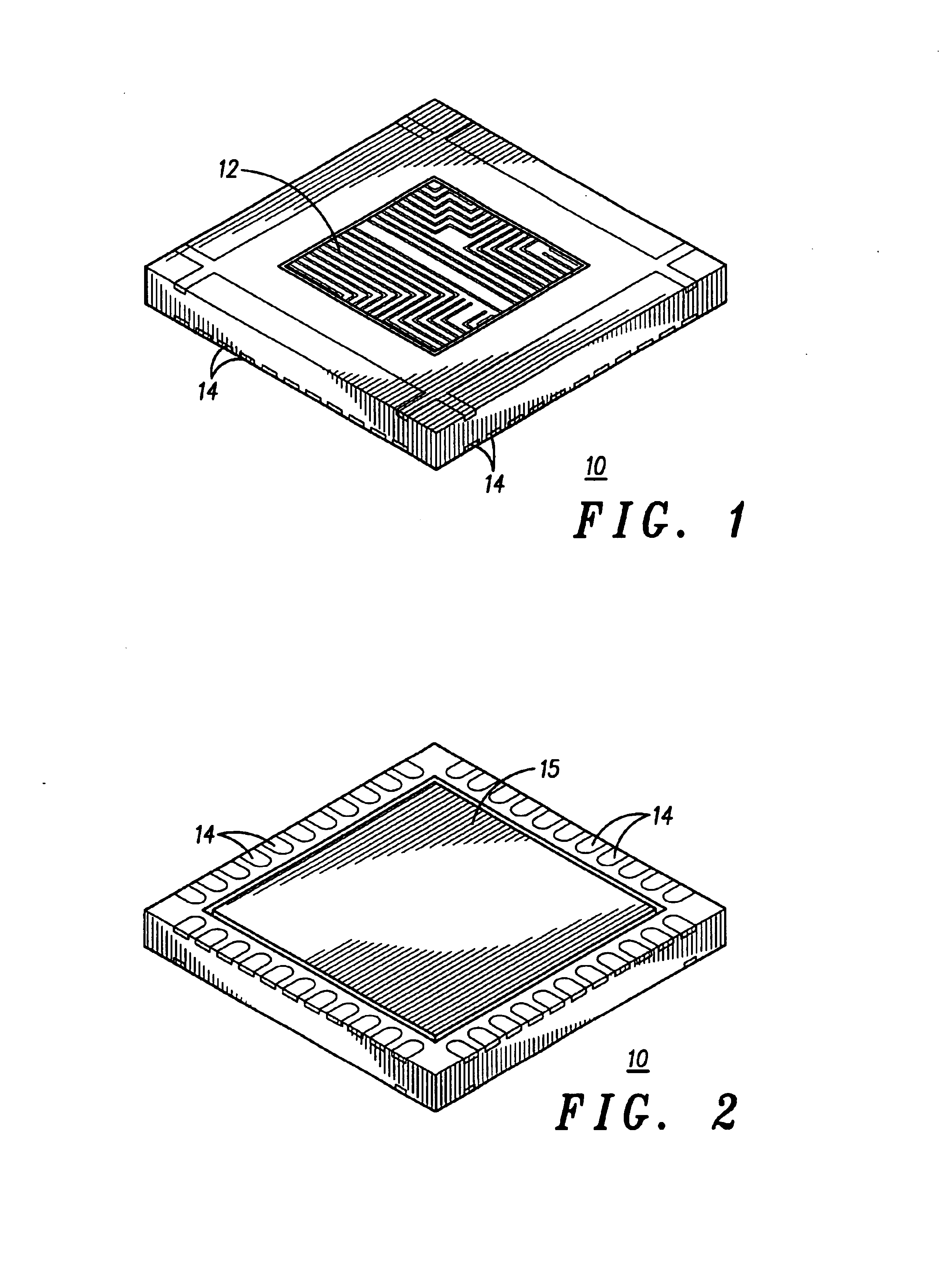

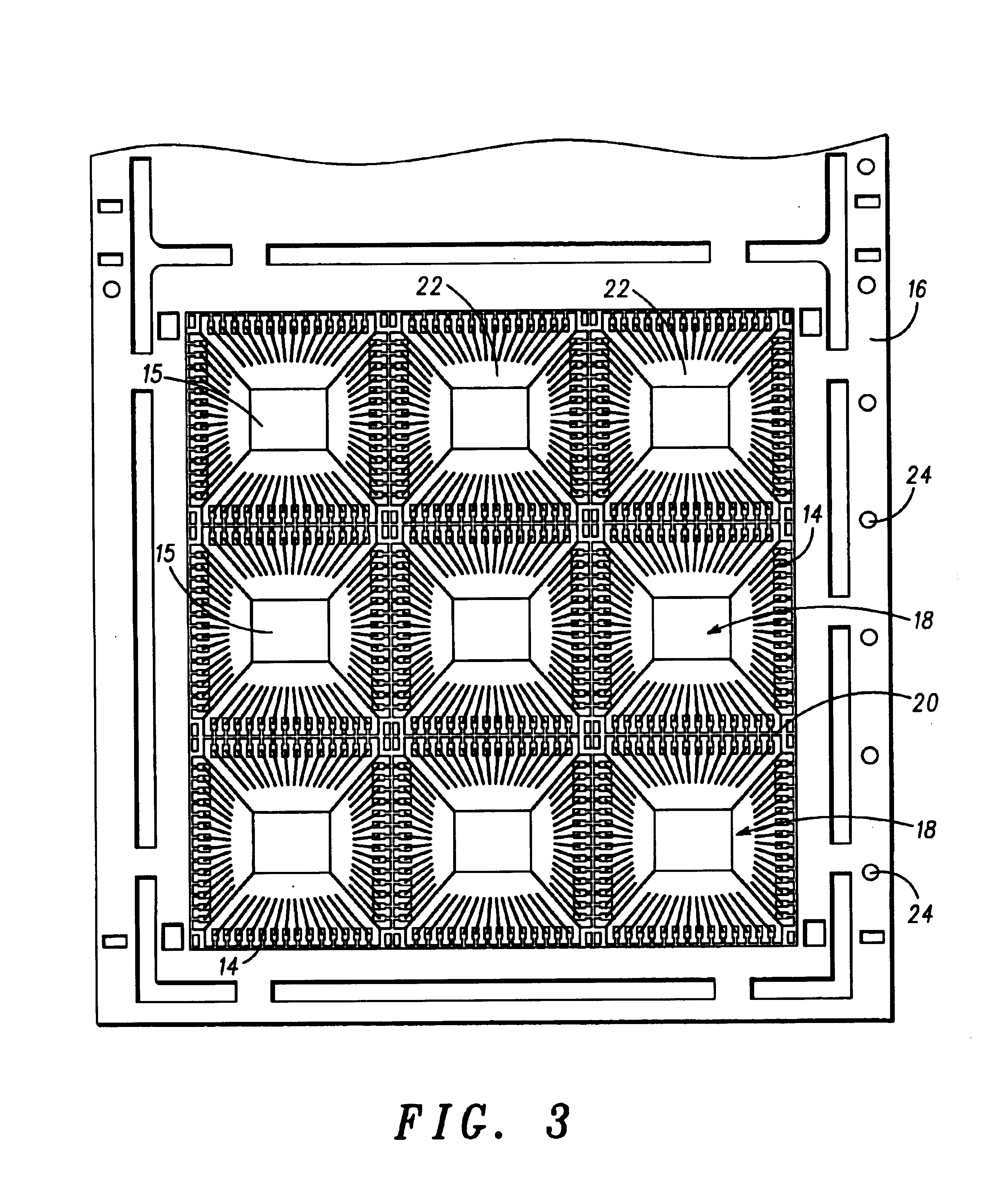

Substrate based unmolded package including lead frame structure and semiconductor die

InactiveUS7061077B2Easy to makeIncrease contrastSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A semiconductor die package is disclosed. In one embodiment, the semiconductor die package has a substrate. It includes (i) a lead frame structure including a die attach region with a die attach surface and a lead having a lead surface, and (ii) a molding material. The die attach surface and the lead surface are exposed through the molding material. A semiconductor die is on the die attach region, and the semiconductor die is electrically coupled to the lead.

Owner:SEMICON COMPONENTS IND LLC

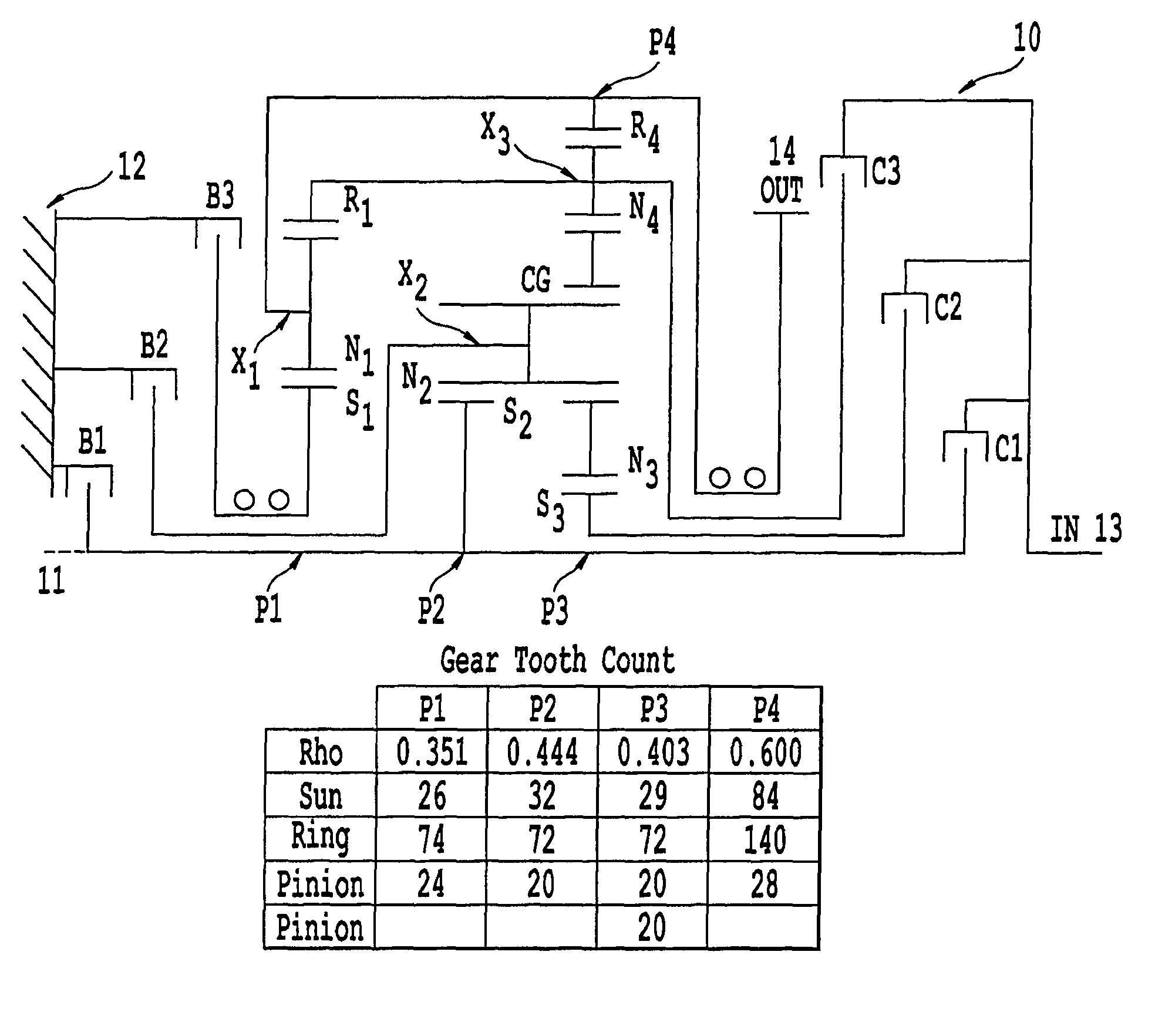

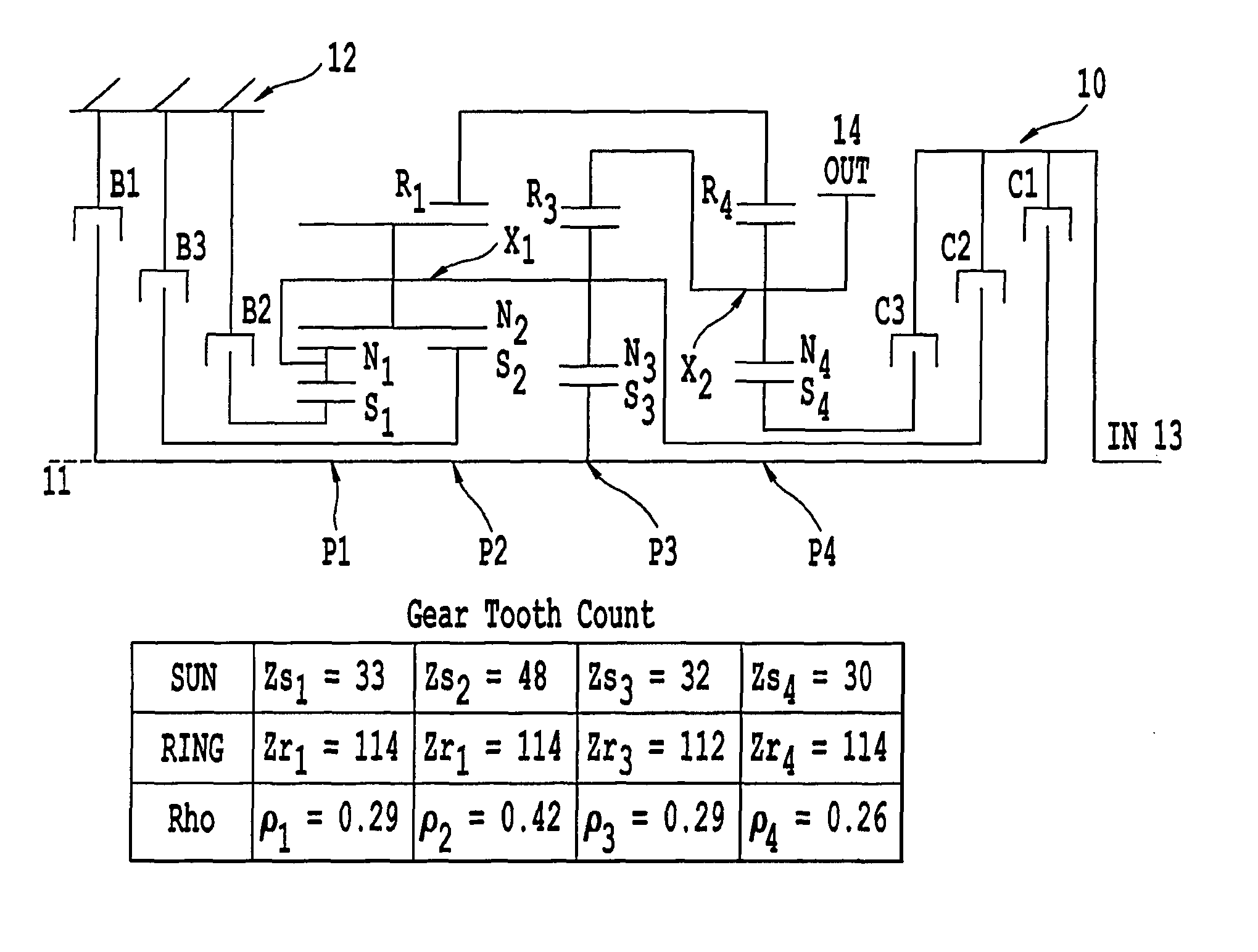

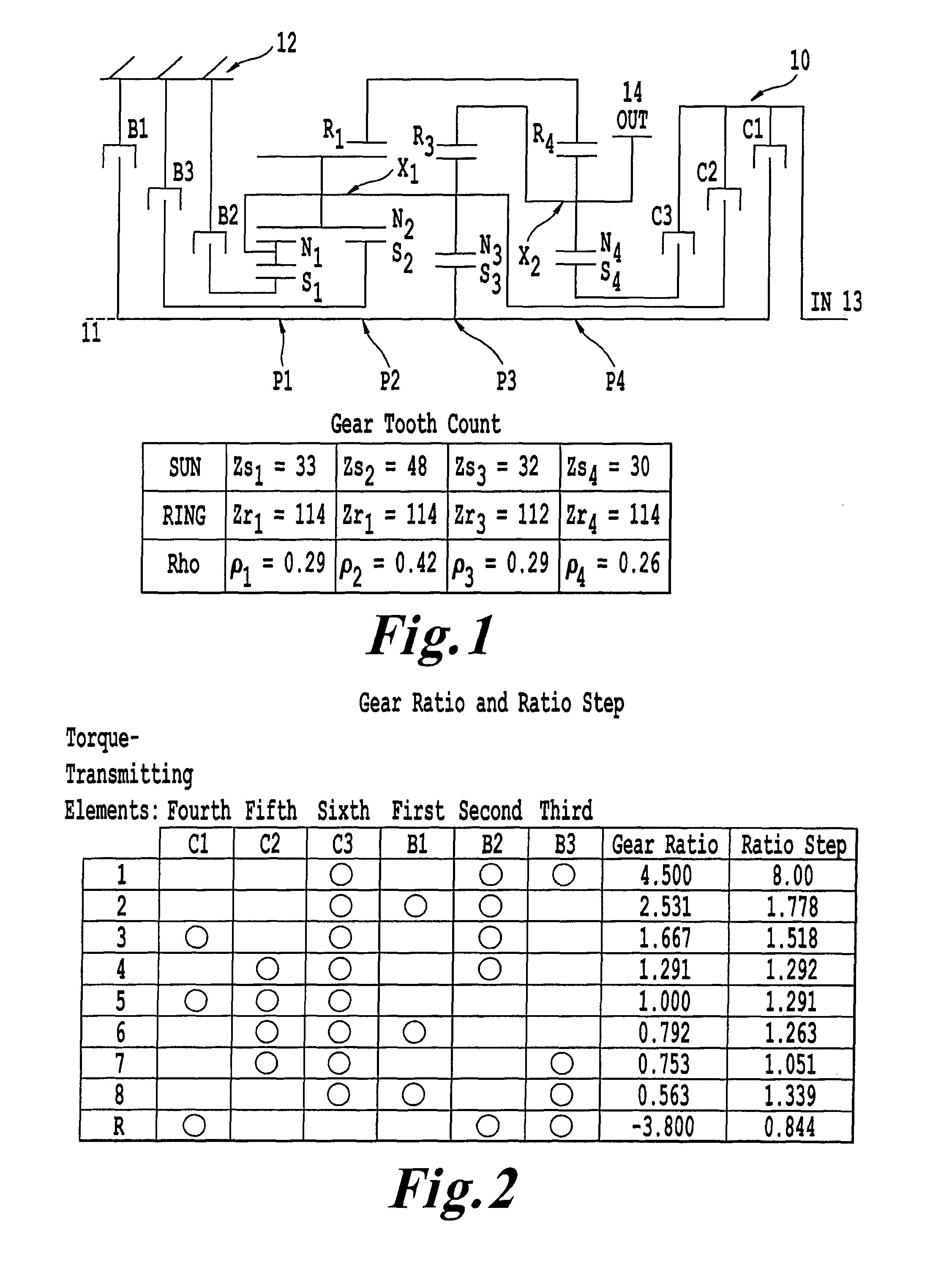

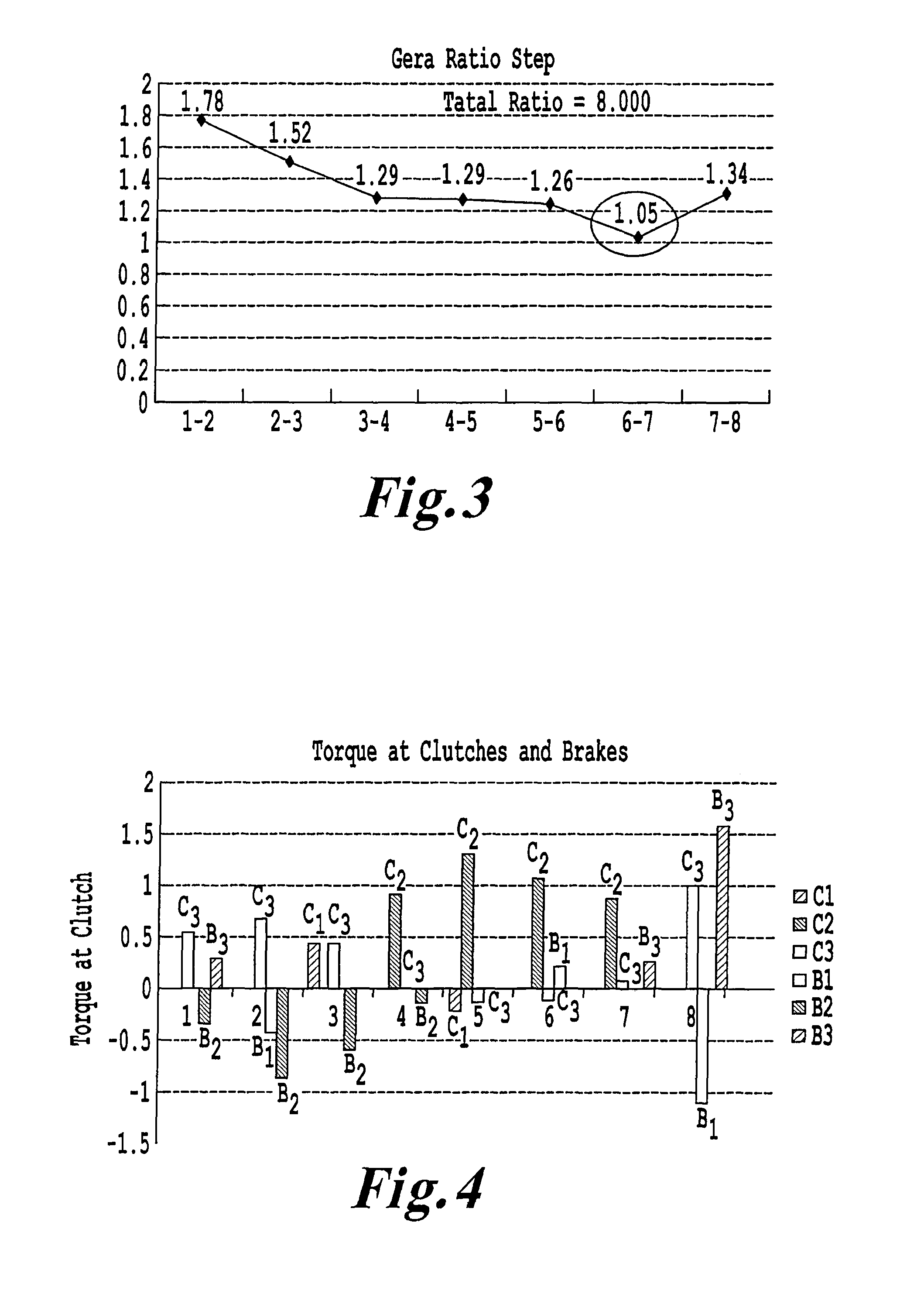

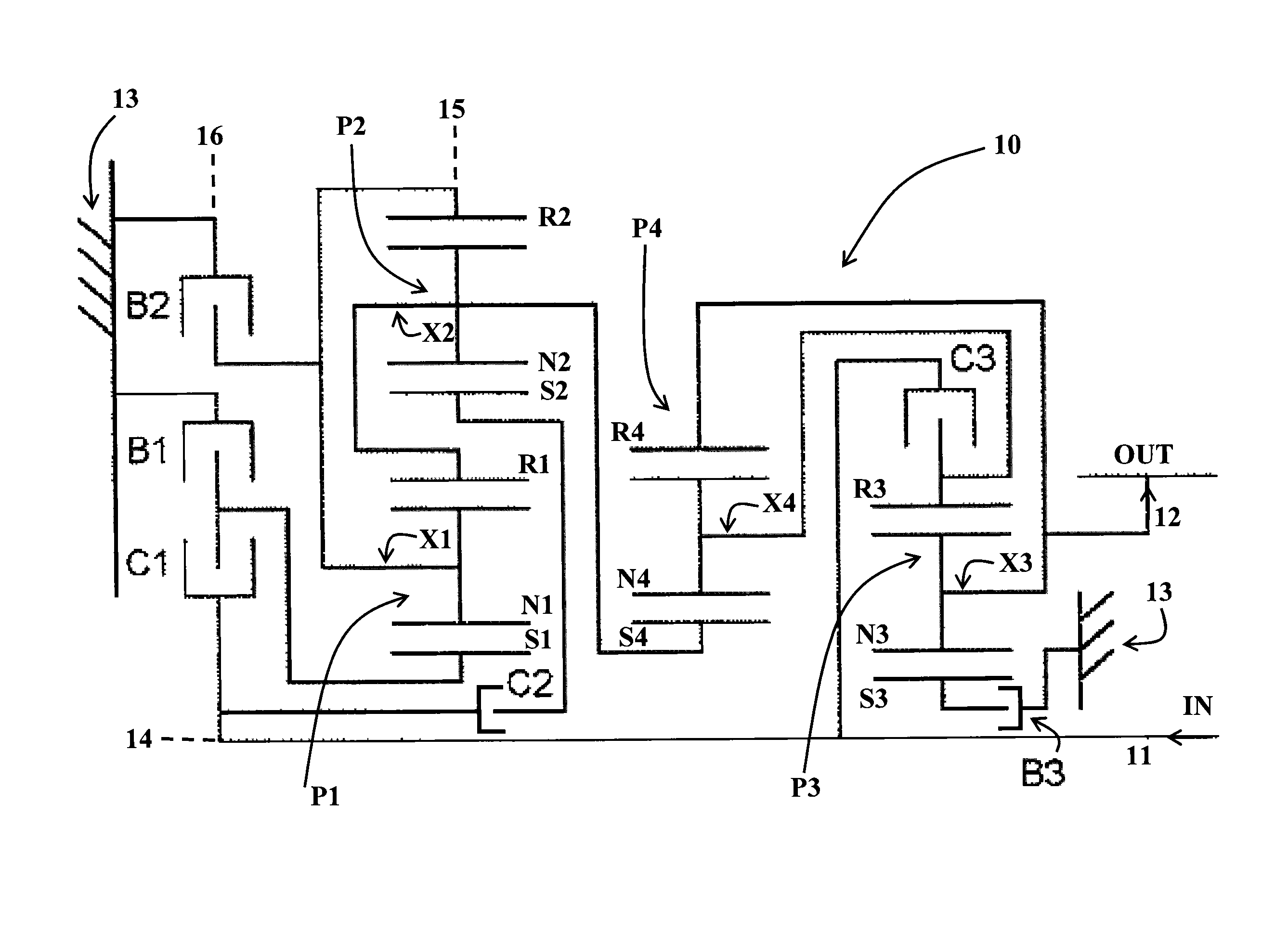

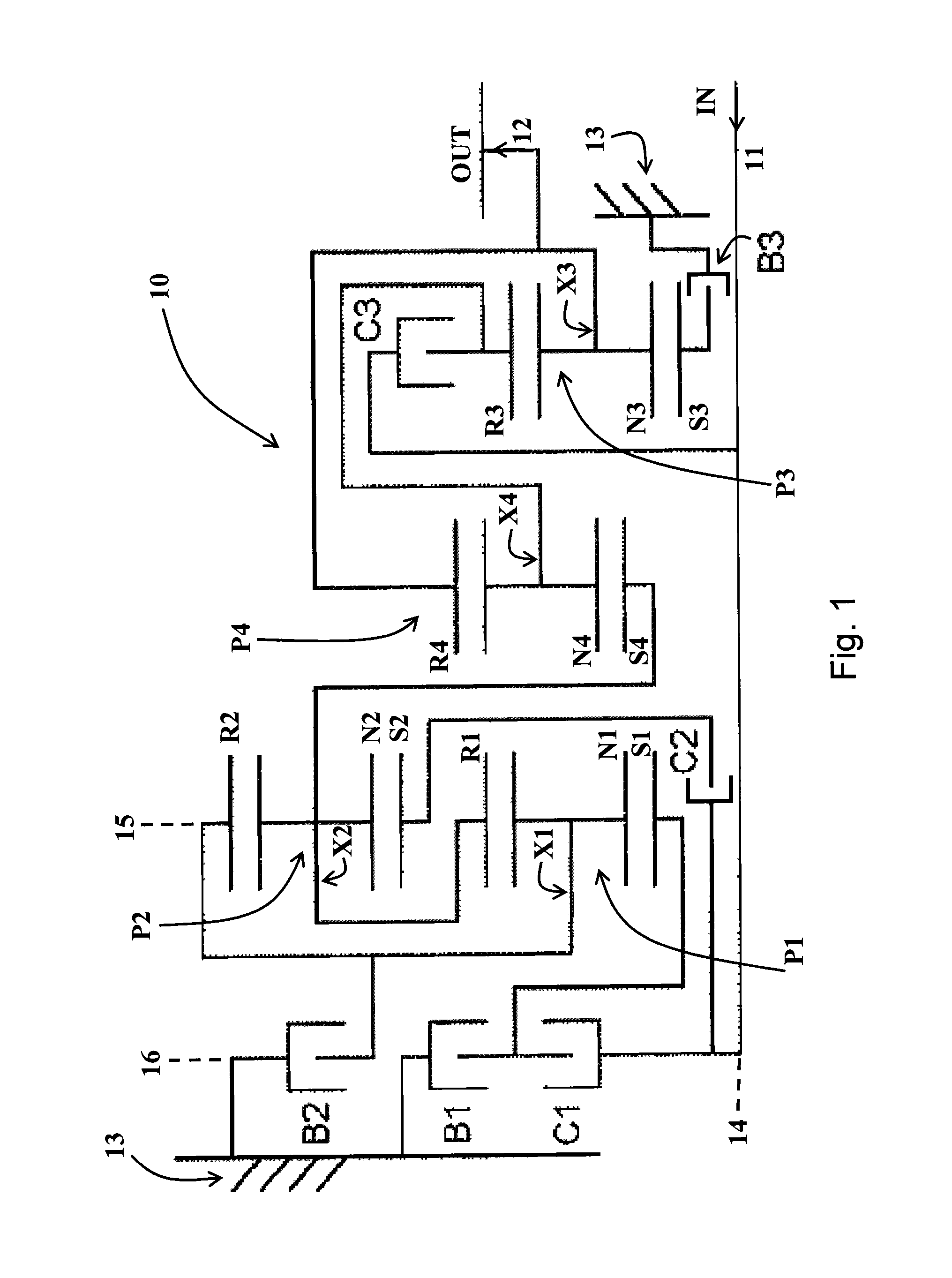

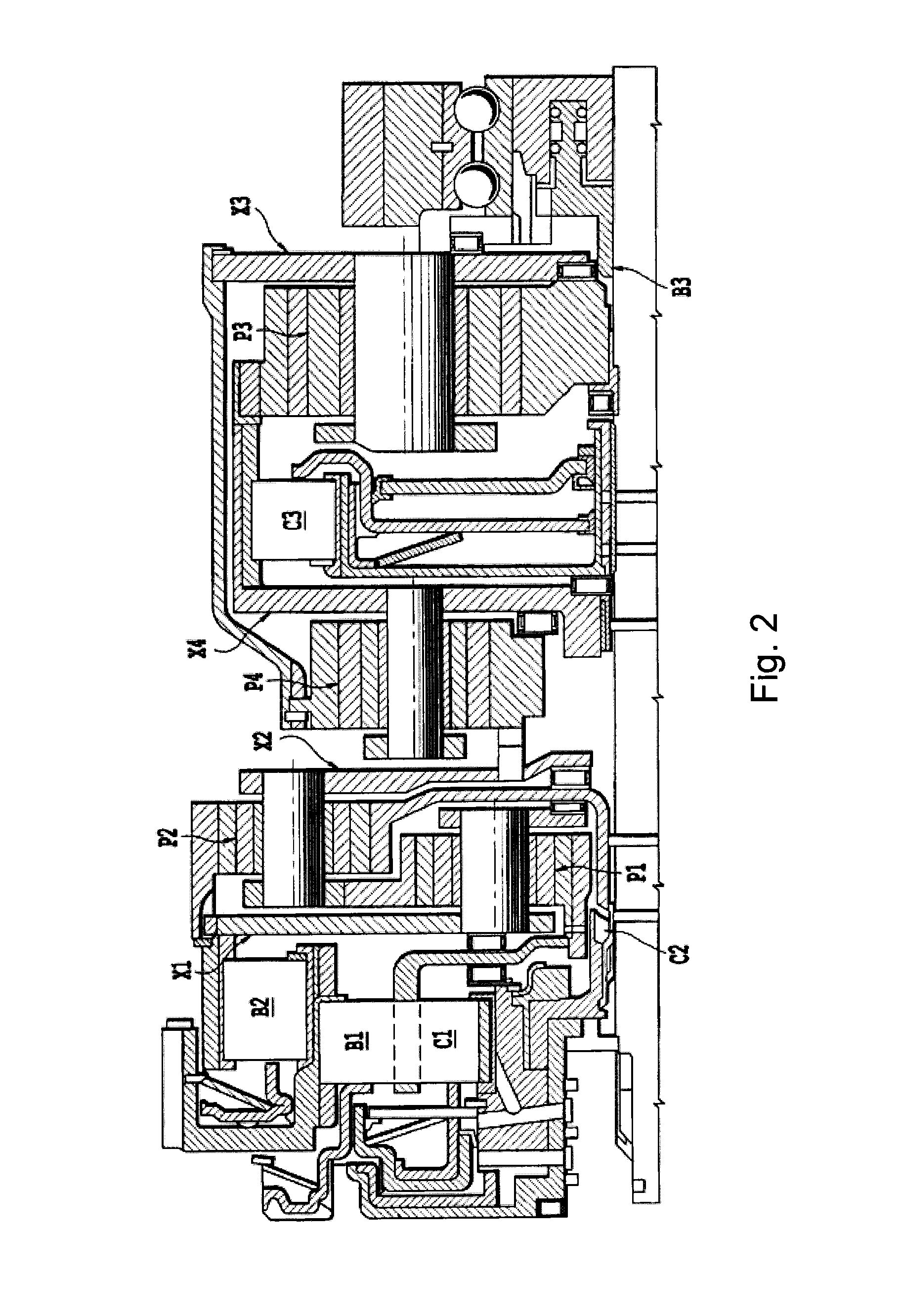

Multi-speed automatic transmission

InactiveUS8617022B1Guaranteed normal transmissionReduce package sizeToothed gearingsTransmission elementsAutomatic transmissionSpur gear

An automatic transmission includes a first planetary gear set including a first sun gear, a first pinion, and a ring gear of the first planetary gear set. The transmission includes a second planetary gear set including a second sun gear, a second pinion, and a common gear. The transmission includes a third planetary gear set including a third sun gear, the second pinion, a third pinion, and the common gear. The transmission also includes a fourth planetary gear set including the common gear, a fourth pinion, and a ring gear of the fourth planetary gear set. The second planetary gear set and the third planetary gear set form a Ravigneaux gear set. The fourth planetary gear set is concentrically arranged with the second planetary gear set or the third planetary gear set, and the second and third planetary gear sets are radially inward of the fourth planetary gear set.

Owner:TOYOTA JIDOSHA KK

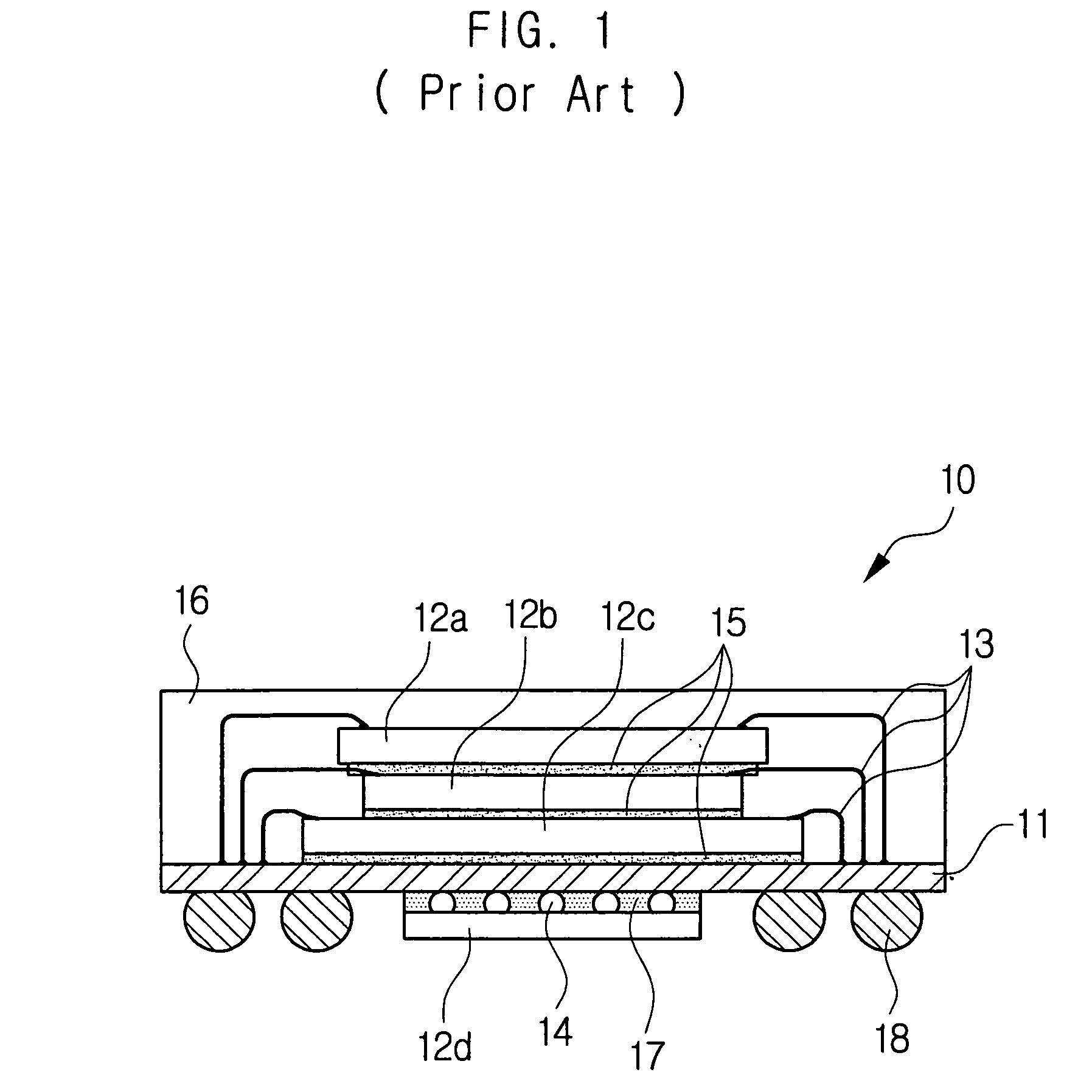

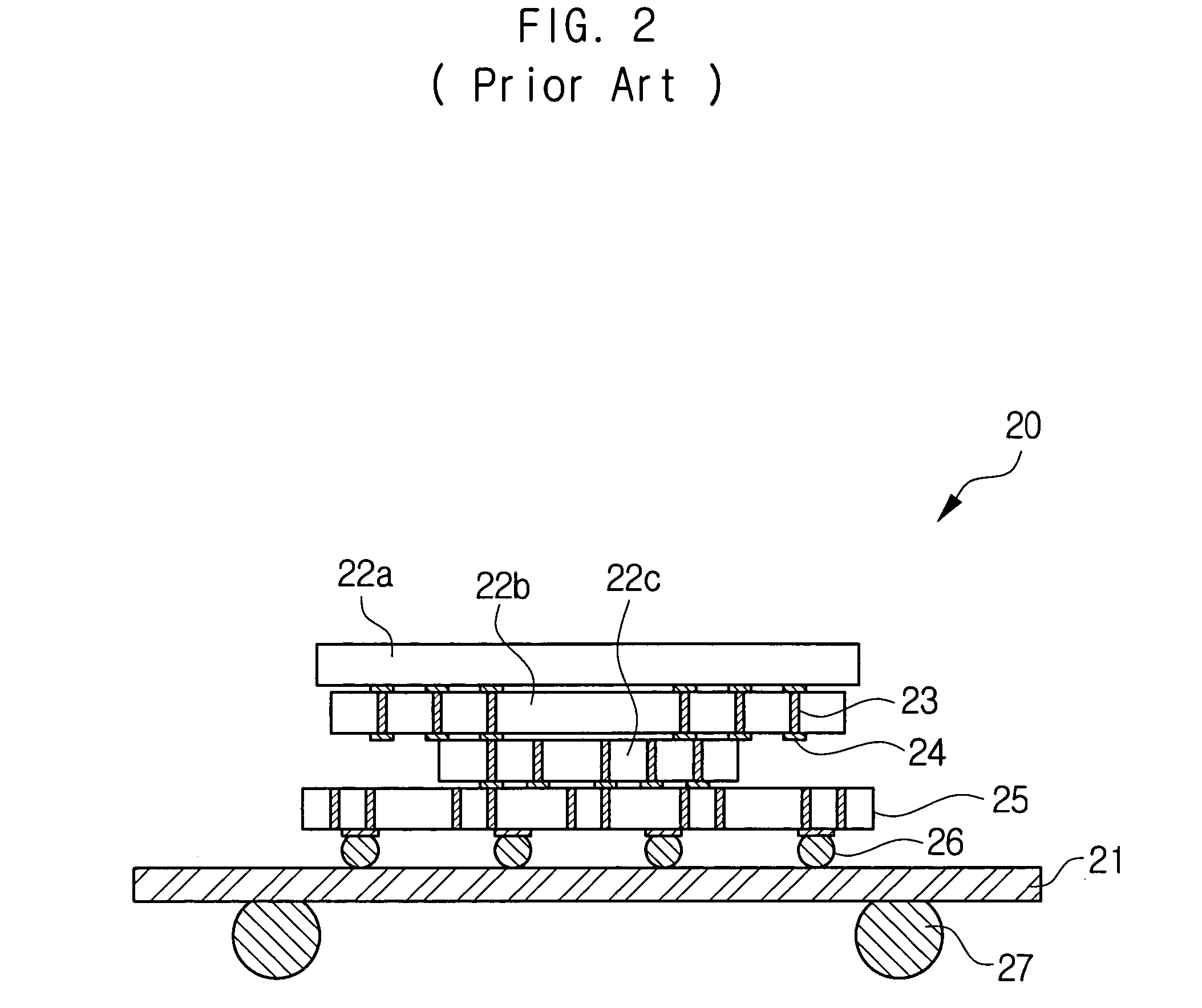

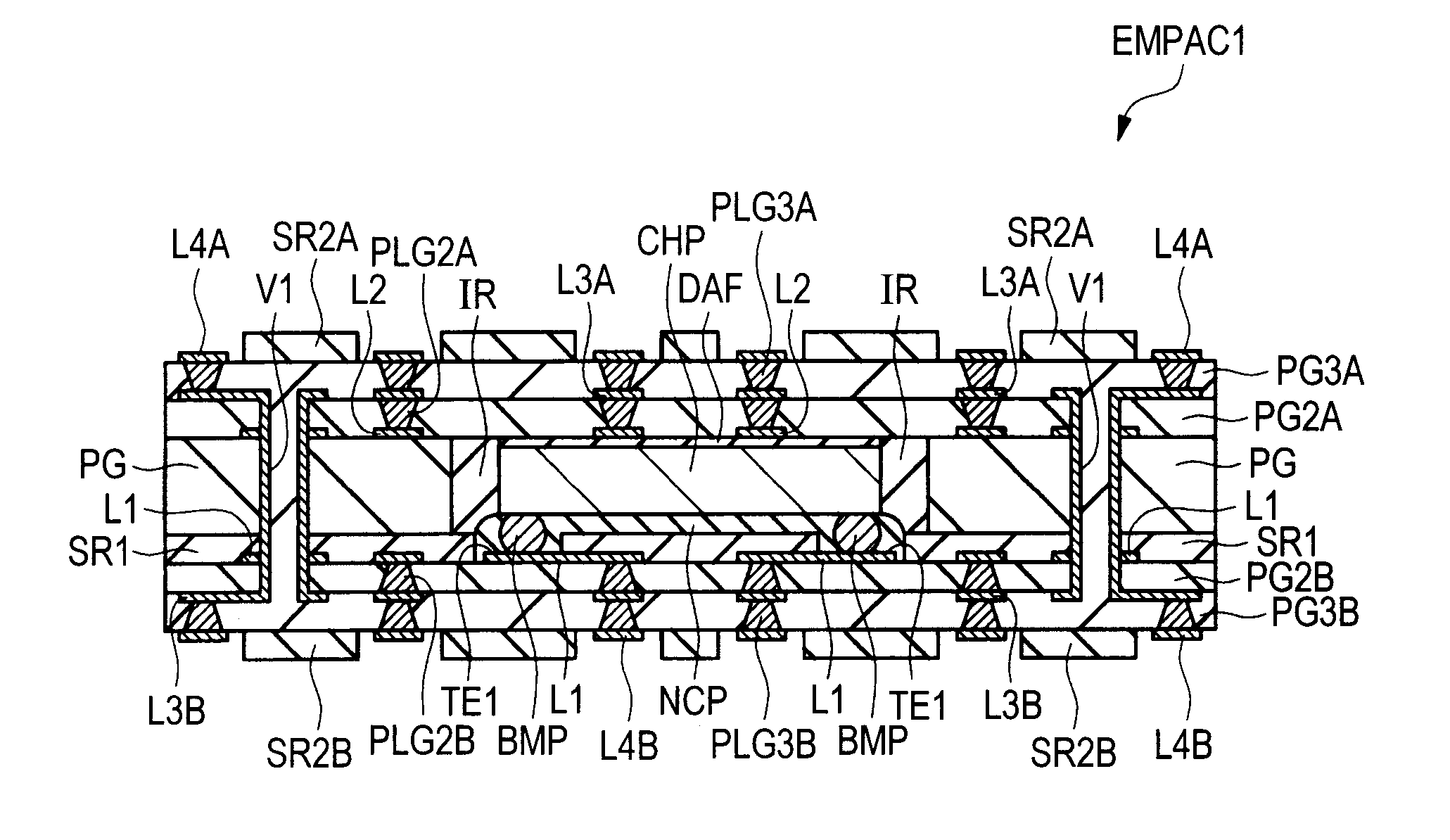

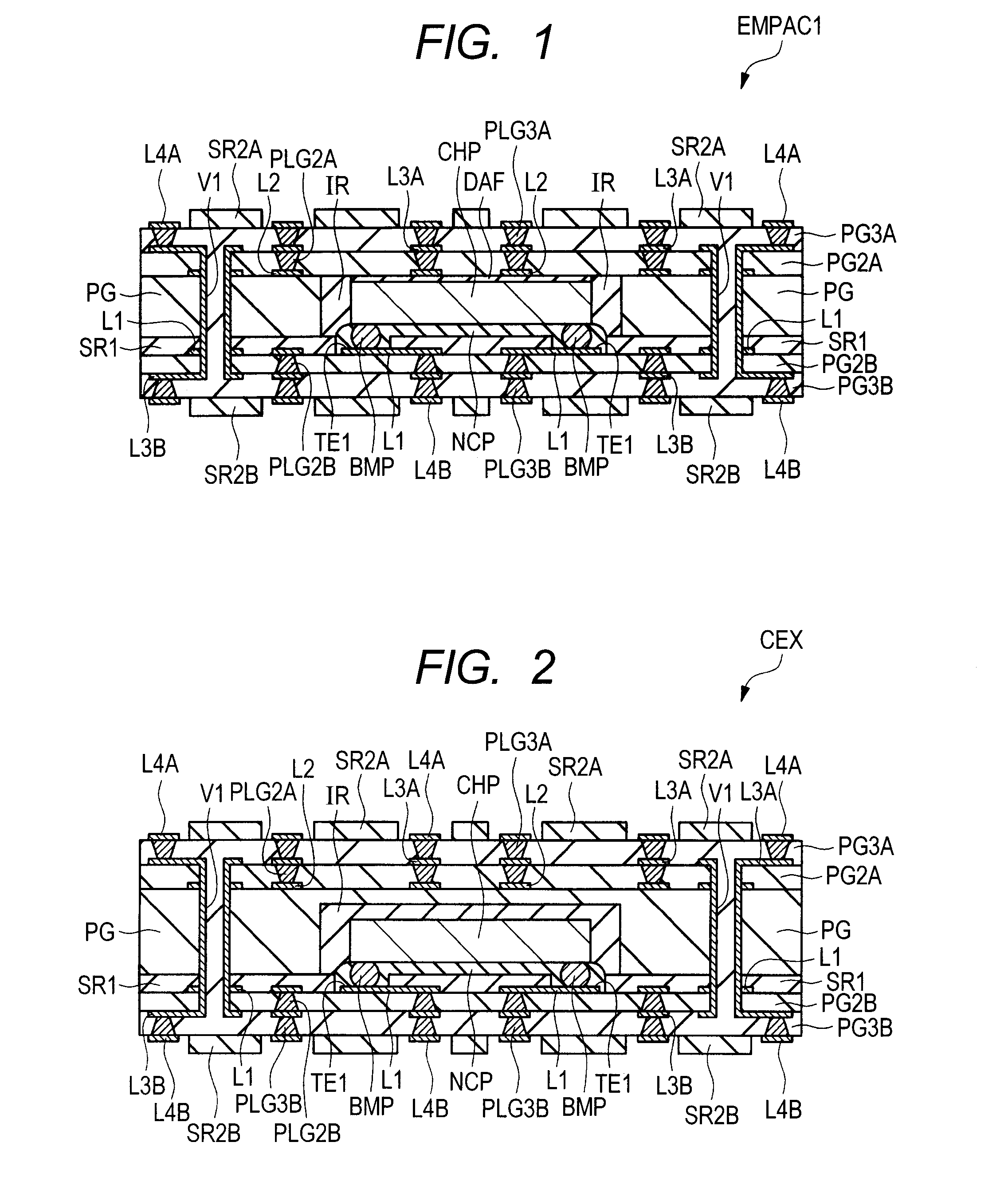

Chip-embedded interposer structure and fabrication method thereof, wafer level stack structure and resultant package structure

InactiveUS20070007641A1Improve system performanceReduce package sizeSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorInterposer

A method for fabricating a chip-embedded interposer may comprise forming at least one cavity on a silicon substrate, forming a plurality of through vias penetrating the silicon substrate, providing an integrated circuit chip having a plurality of I / O pads, and forming rerouting conductors connected to the I / O pads and the through vias. A stack structure having different kinds of chips may be incorporated at wafer level using the described interposer.

Owner:SAMSUNG ELECTRONICS CO LTD

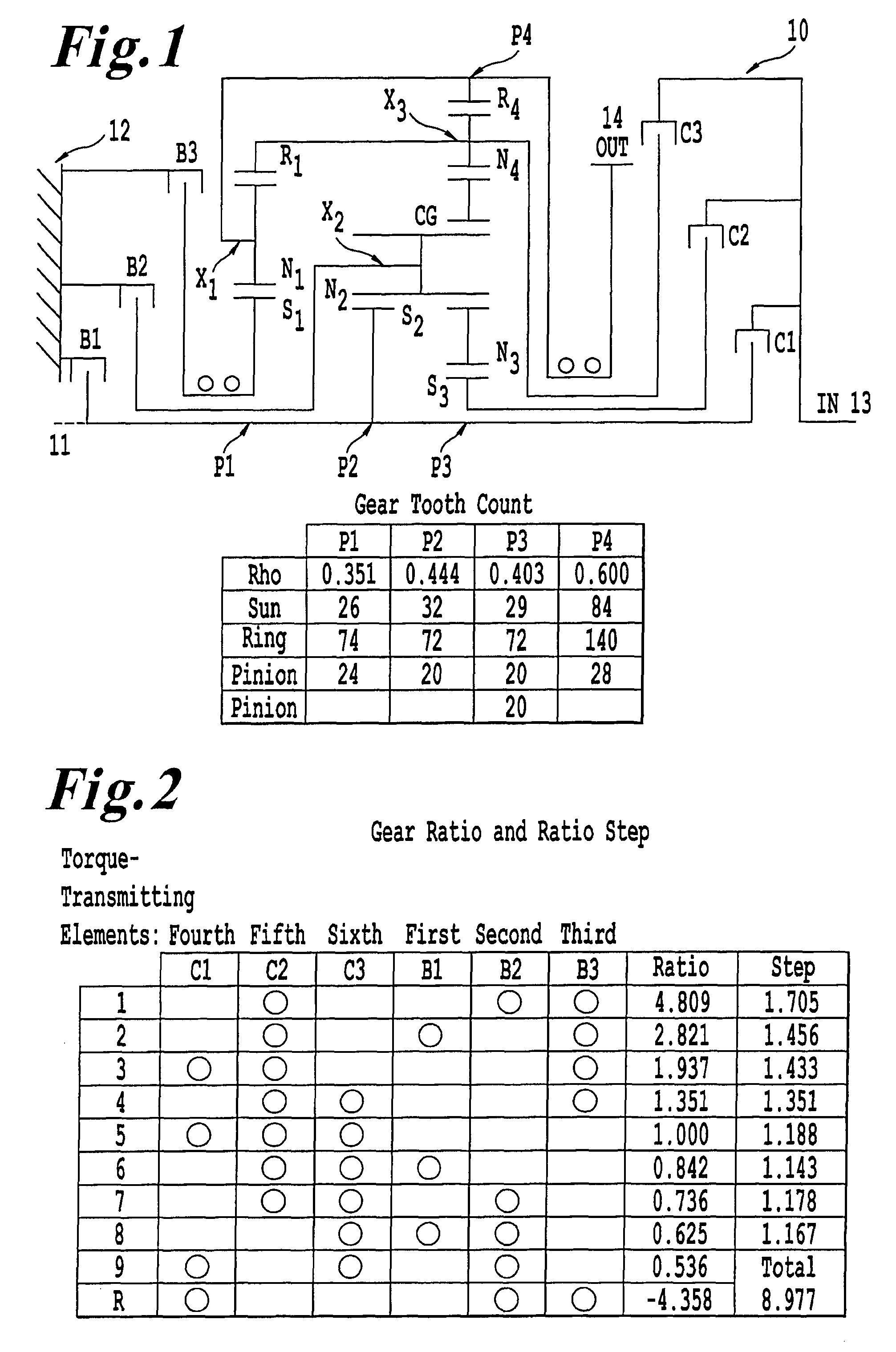

Multi-speed automatic transmission

InactiveUS8529396B1Guaranteed normal transmissionReduce package sizeToothed gearingsTransmission elementsAutomatic transmissionMechanical engineering

An automatic transmission includes a first planetary gear set including a first sun gear, a first pinion, a second pinion, and a common ring gear, and includes a second planetary gear set including a second sun gear, the second pinion, and the common ring gear. The transmission includes a third planetary gear set including a third sun gear, a third pinion, and a ring gear of the third set, and includes a fourth planetary gear set including a fourth sun gear, a fourth pinion, and a ring gear of the fourth set. The transmission also includes a first planetary carrier rotatably supporting the first pinion, the second pinion, and the third pinion. The common ring gear is directly connected to the ring gear of the fourth set, and a second planetary carrier rotatably supports the fourth pinion and is directly connected to the ring gear of the third set.

Owner:TOYOTA MOTOR CO LTD

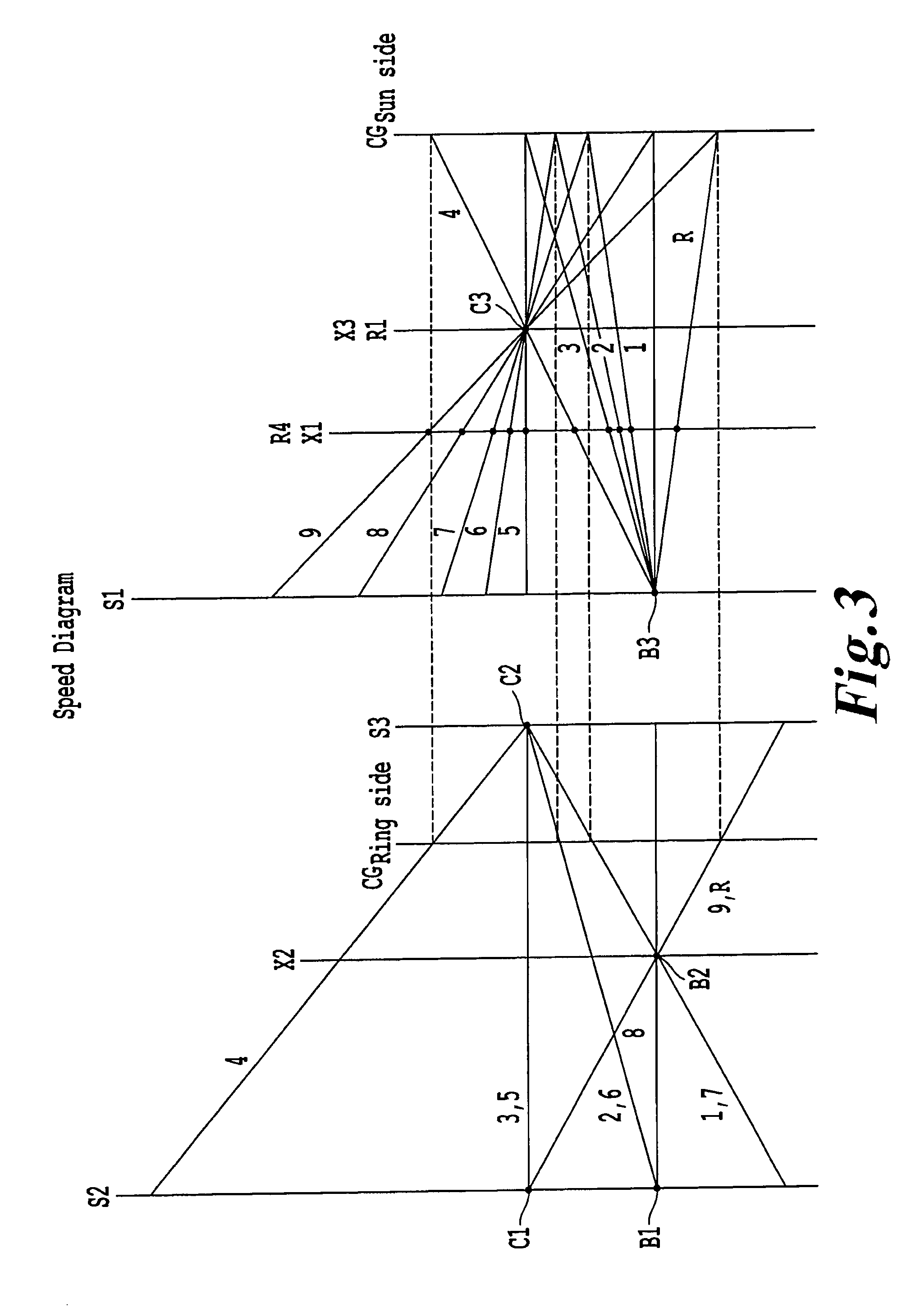

Multi-speed automatic transmission

InactiveUS8951160B2Reduce the difficulty of packagingImprove drivabilityToothed gearingsTransmission elementsAutomatic transmissionEngineering

An multi-speed automatic transmission providing at least nine forward speeds and one reverse speed, includes four planetary gear sets, six shift control elements, an input shaft, an output shaft, and a transmission case. Each planetary gear set includes a sun gear, a pinion gear set, a carrier that rotatably supports the pinion gear set, and a ring gear. A carrier of a first planetary gear set is connected to the ring gear of a second planetary gear set and a carrier of the second planetary gear set is connected to the ring gear of the first planetary gear set. The first and second planetary gear sets are concentrically arranged in a common plane.

Owner:TOYOTA JIDOSHA KK

DC-DC converter implemented in a land grid array package

InactiveUS6940724B2Improve heat dissipation characteristicsHigh densityEfficient power electronics conversionSemiconductor/solid-state device detailsMOSFETSemiconductor chip

A semiconductor chip package that includes a DC—DC converter implemented with a land grid array (LGA) package for interconnection and surface mounting to a printed circuit board. The LGA package integrates all required active components of the DC—DC power converter, including a synchronous buck PWM controller, driver circuits, and MOSFET devices. In particular, the LGA package comprises a substrate having a top surface and a bottom surface, with a DC—DC converter provided on the substrate. The DC—DC converter including at least one power silicon die disposed on the top surface of the substrate. A plurality of electrically and thermally conductive pads are provided on the bottom surface of the substrate in electrical communication with the DC—DC converter through respective conductive vias. The plurality of pads include first pads having a first surface area and second pads having a second surface area, the second surface area being substantially larger than the first surface area. Heat generated by the DC—DC converter is conducted out of the LGA package through the plurality of pads.

Owner:PWER BRIDGE

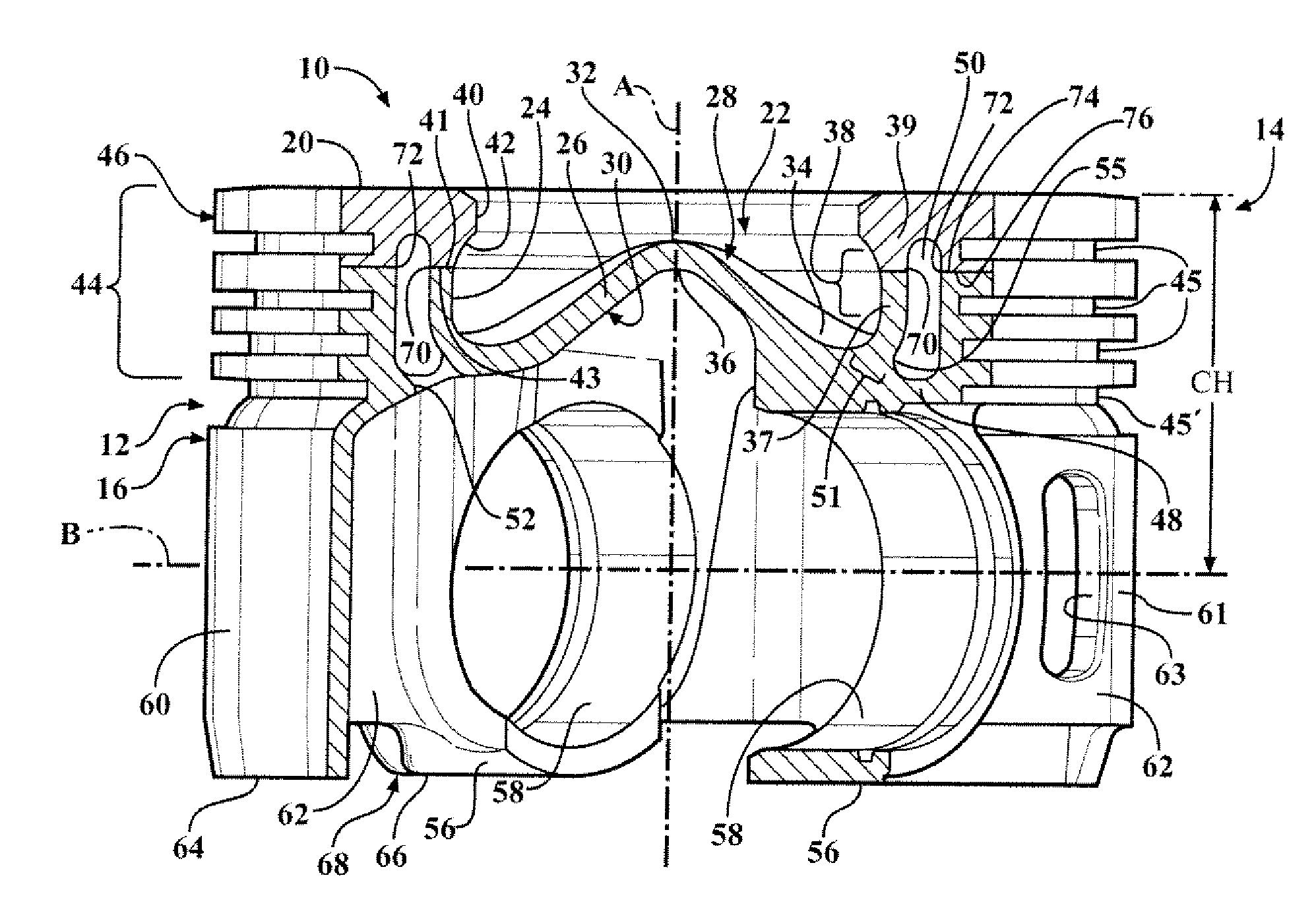

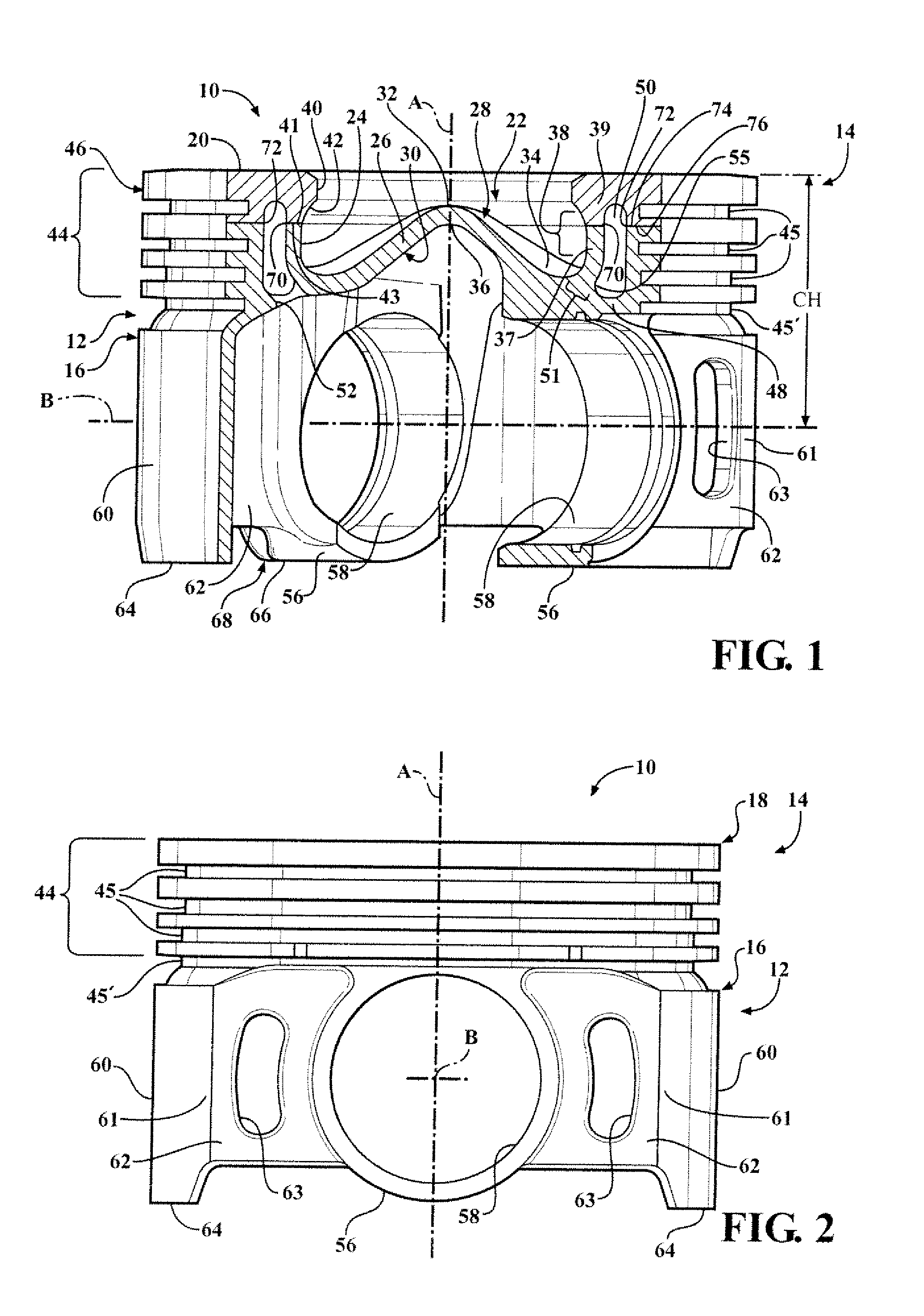

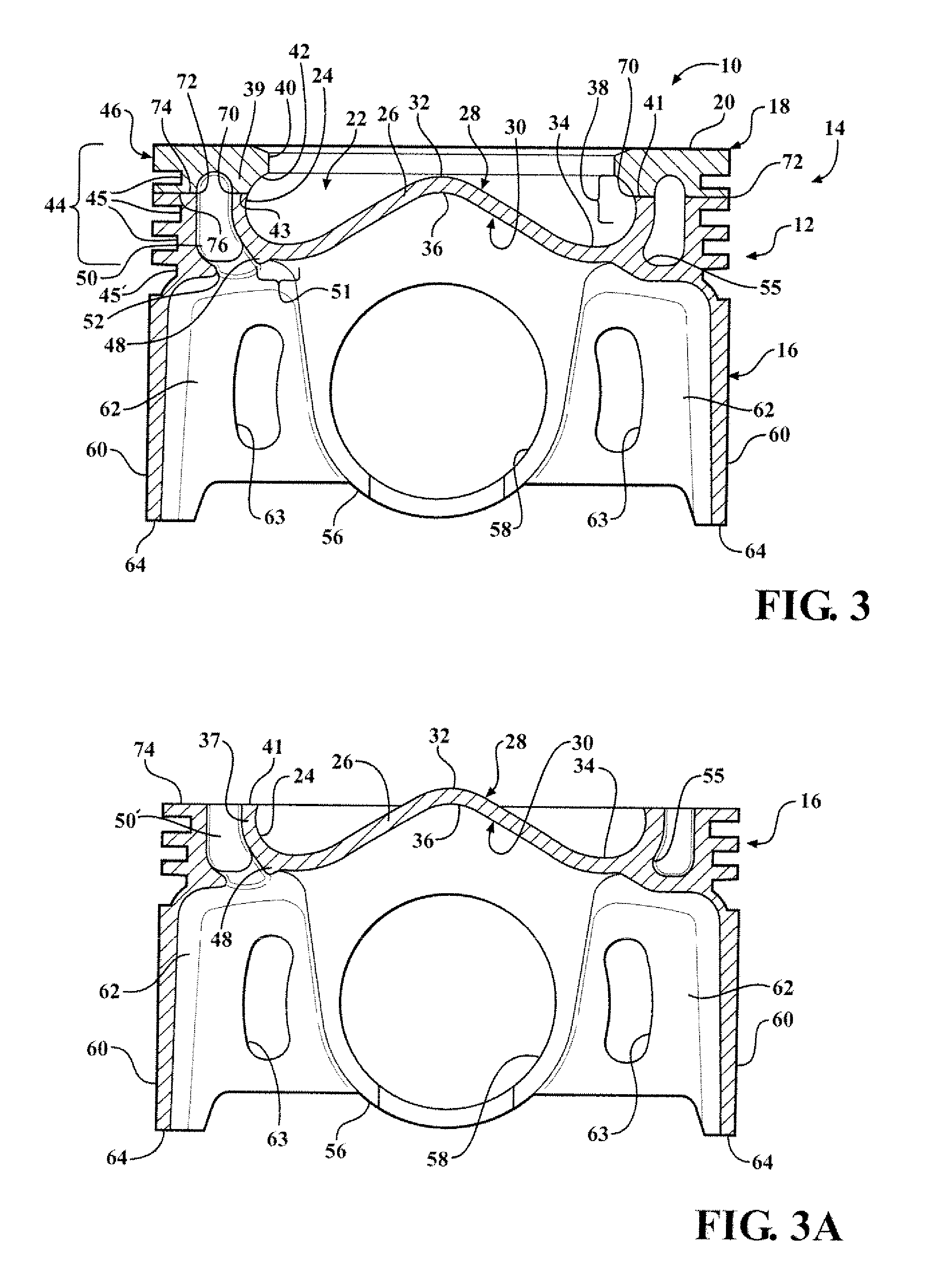

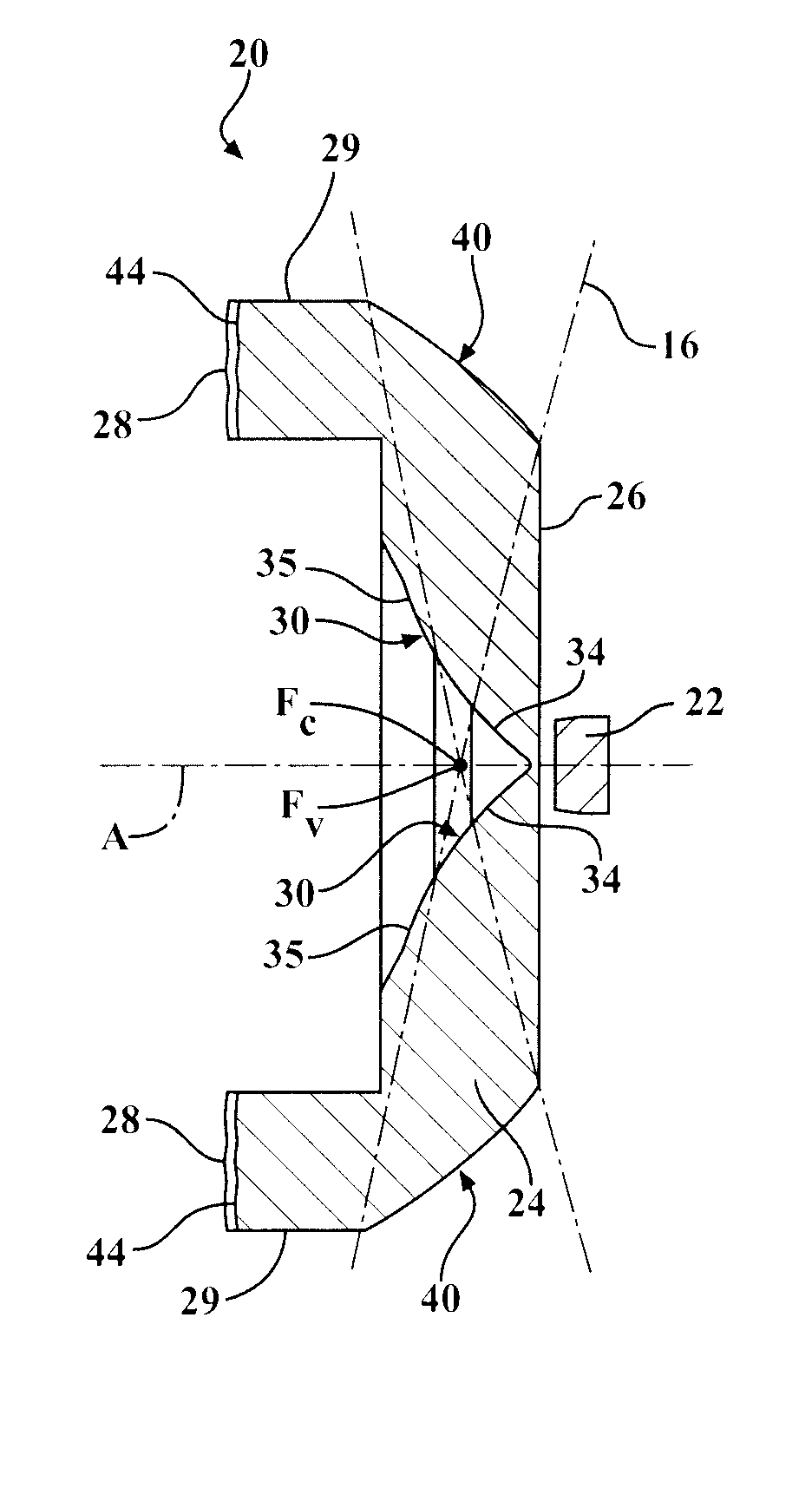

Steel piston with cooling gallery and method of construction thereof

ActiveUS20120037112A1High strengthIncreased durabilityInternal combustion piston enginesPistonsCombustionEngineering

A piston and method of construction is provided. The piston includes a top part fixed to a bottom part. The top part has an uppermost surface with annular inner and outer upper joining surfaces depending therefrom. The bottom part has a pair of pin bosses with pin bores aligned with one another along a pin bore axis; a pair of upwardly extending annular inner and outer lower joining surfaces and a combustion bowl wall. Inner and outer weld joints fix the inner and outer upper and lower joining surfaces to one another. An annular cooling gallery is formed laterally between the upper and lower joining surfaces. The inner weld joint joining the top part to the bottom part is located within the combustion bowl wall and configured to minimized the compression height of the piston.

Owner:TENNECO INC

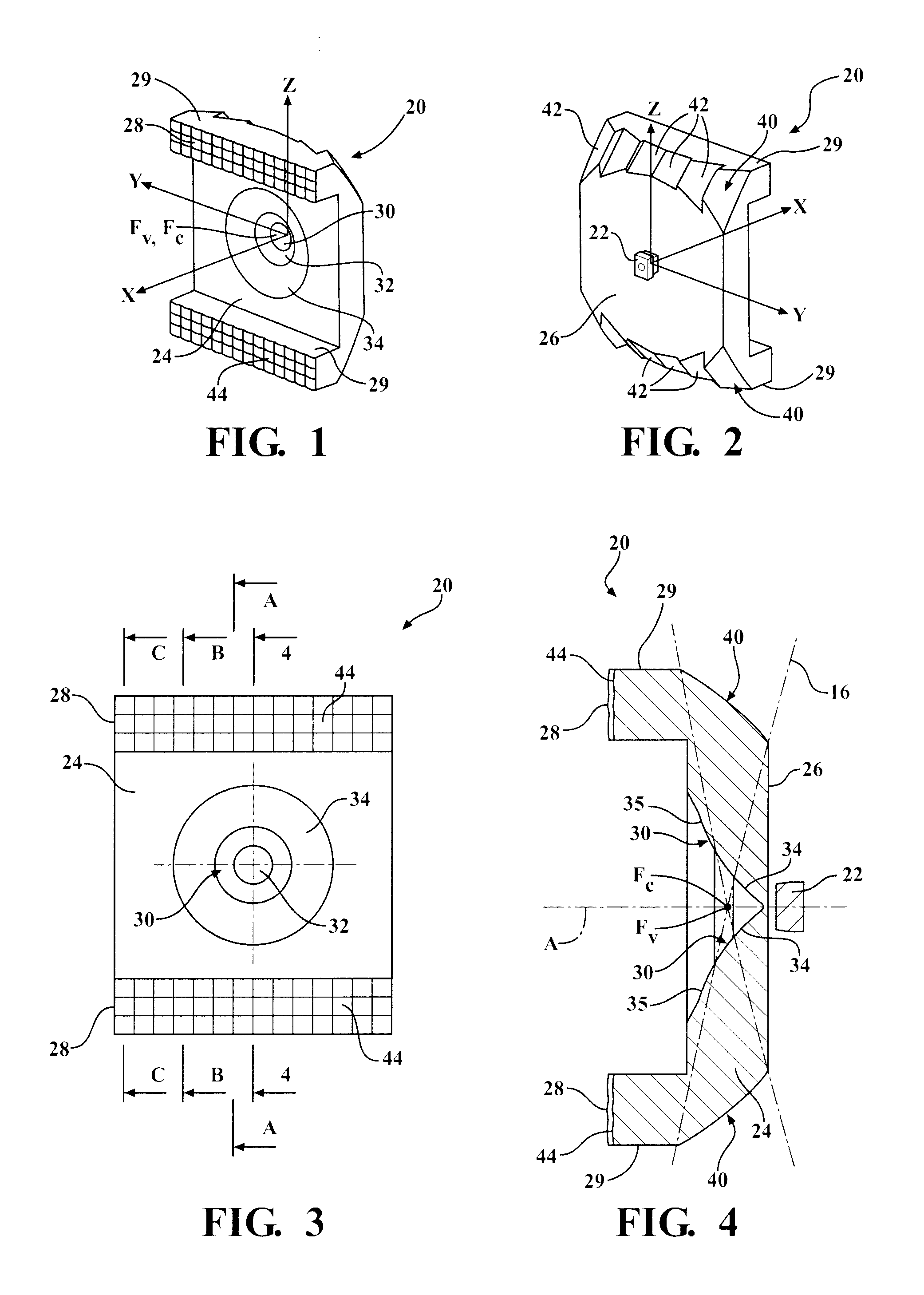

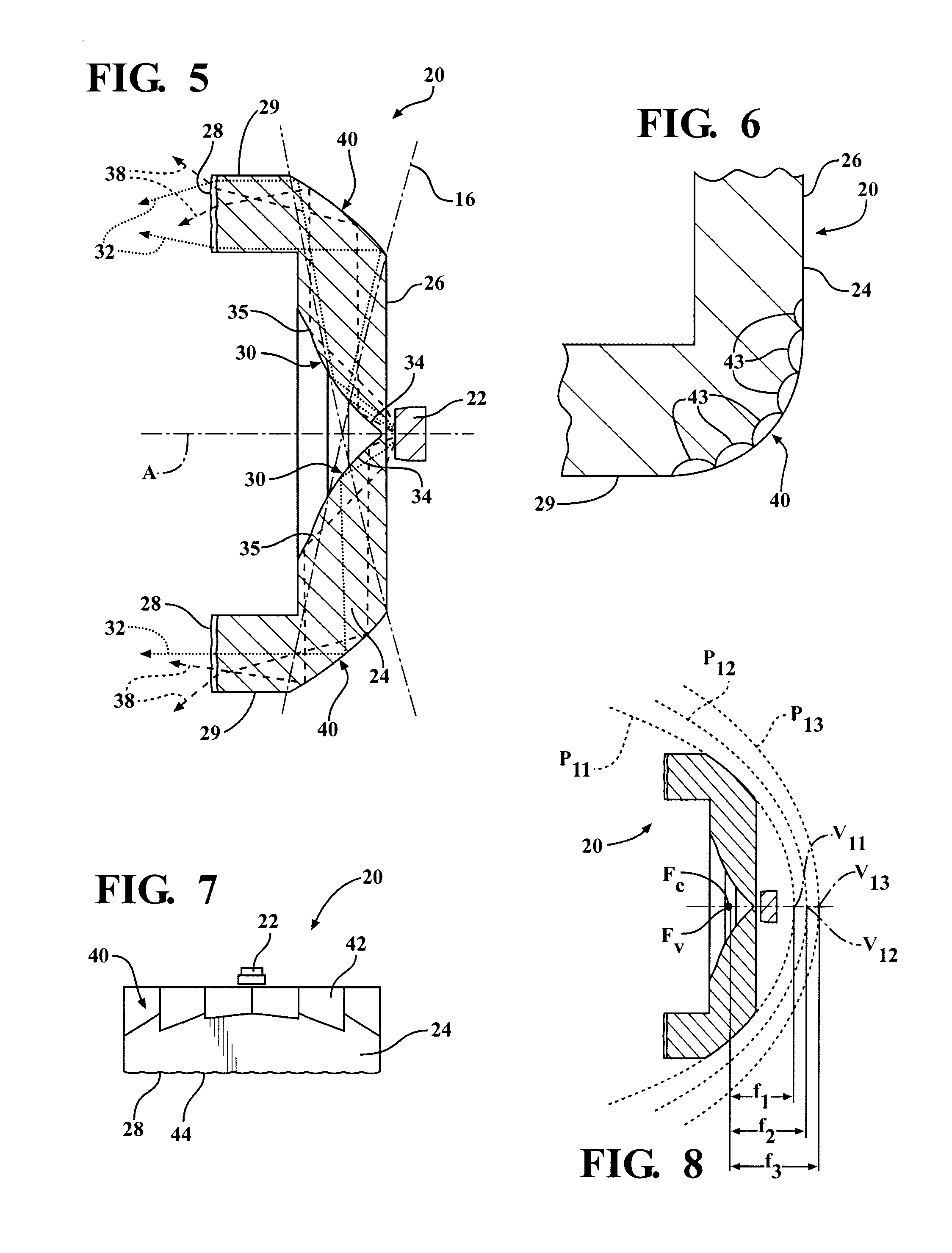

Collimator assembly

InactiveUS8434892B2Increase awarenessEasy to placeNon-electric lightingPoint-like light sourceLight guideOptoelectronics

A flat refractive collimator assembly including a light guide and a light source, for example, an LED. The sides of the light guide defines a collimating reflective surface having a paraboloidal shape with a collimating focal point placed on the axis of the light guide. The central portion of the light guide defines a main reflective surface having a virtual focal point, which is substantially similar to the collimating focal point. The collimating reflective surface is a paraboloidal surface or is formed as a plurality of paraboloidal segments having various focal lengths and having a common collimating focal point. The collimating reflective surface can also include spread optics.

Owner:VARROC LIGHTING SYST SRO

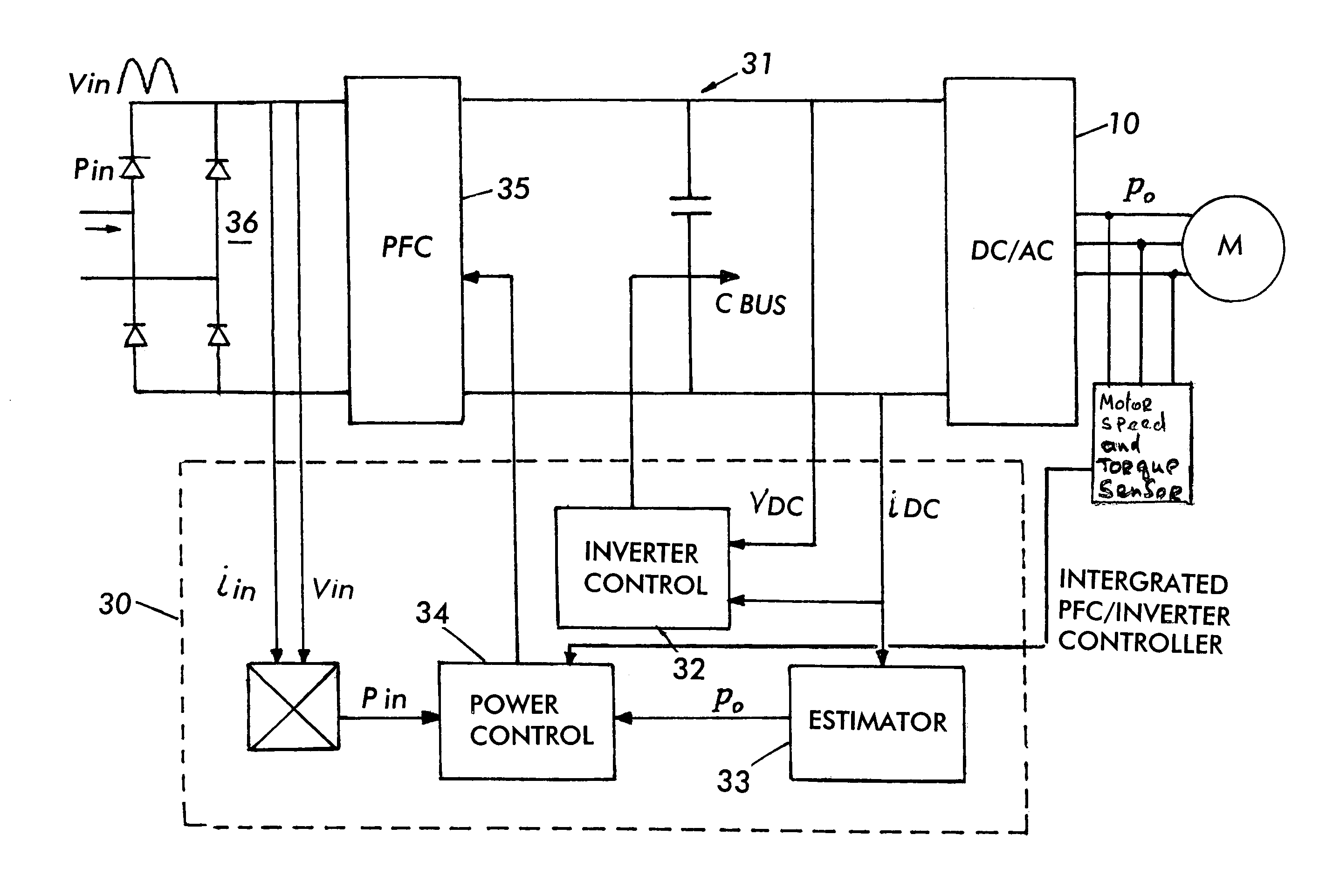

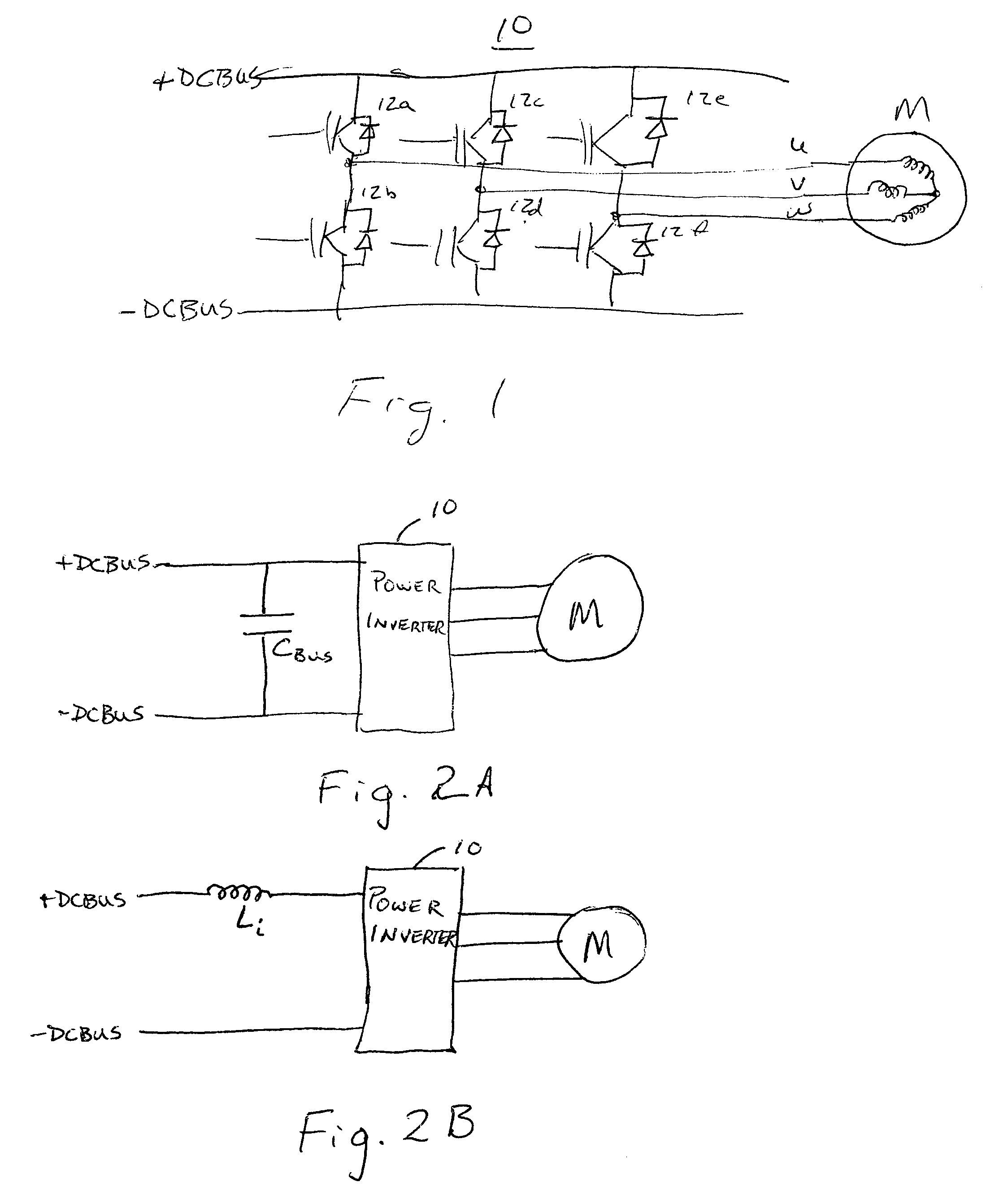

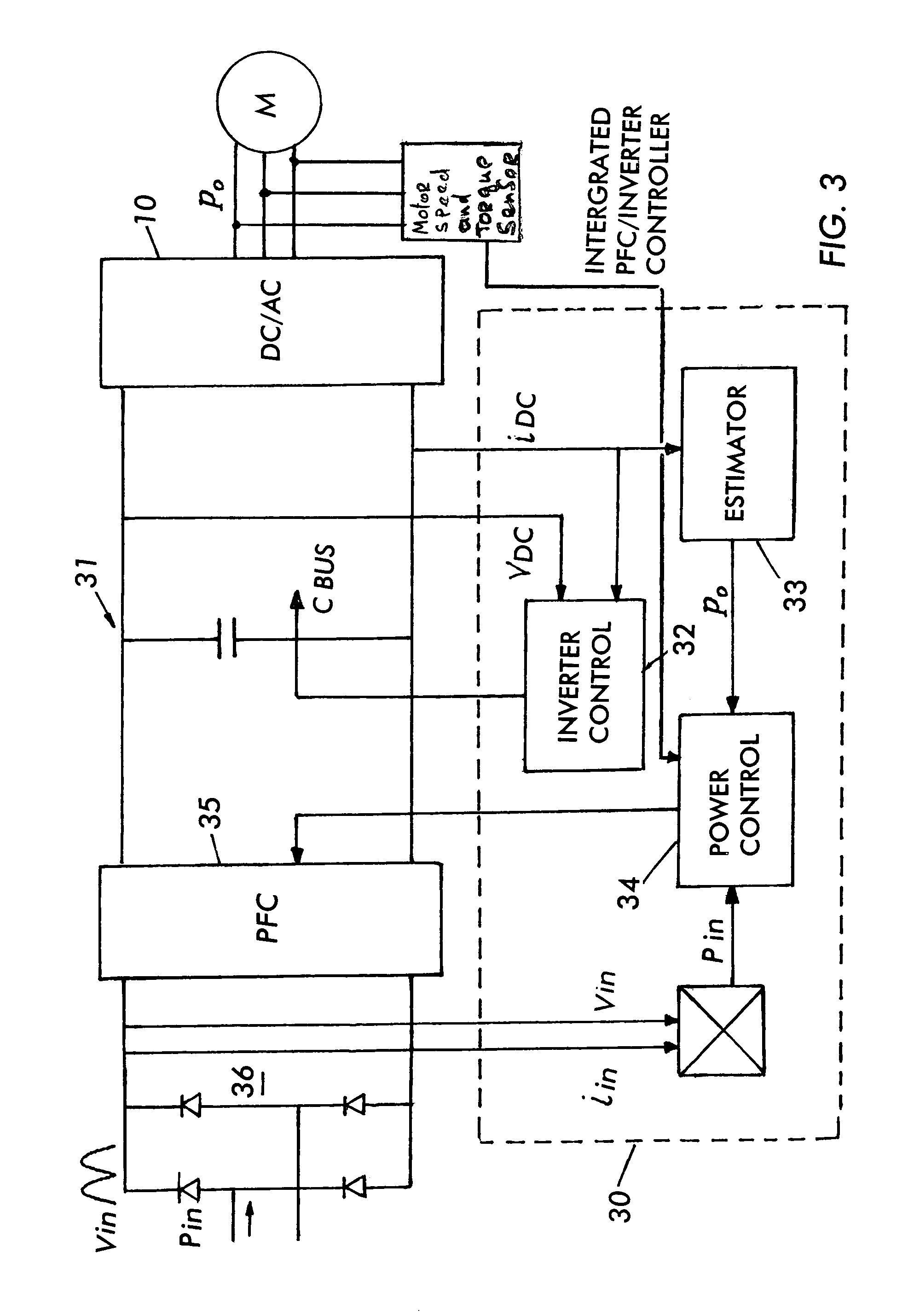

Power transfer system with reduced component ratings

InactiveUS7164590B2Ripple voltage can be minimizedMinimize the differenceAc-dc conversion without reversalConversion with intermediate conversion to dcElectric power transmissionPower inverter

A power inverter control adjusts input power to track with output power to reduce energy handling requirements for an inverter DC bus. Input power to the power inverter circuit is measured and compared with a measurement of inverter output power. The comparison result is applied to a power factor correction circuit to adjust input power to track with output power, while obtaining a good power factor for the power inverter circuit. The energy requirements and ripple voltages or ripple currents on the DC bus are reduced, leading to a reduction in rating specifications for passive energy storage elements on the DC bus.

Owner:INFINEON TECH AMERICAS CORP

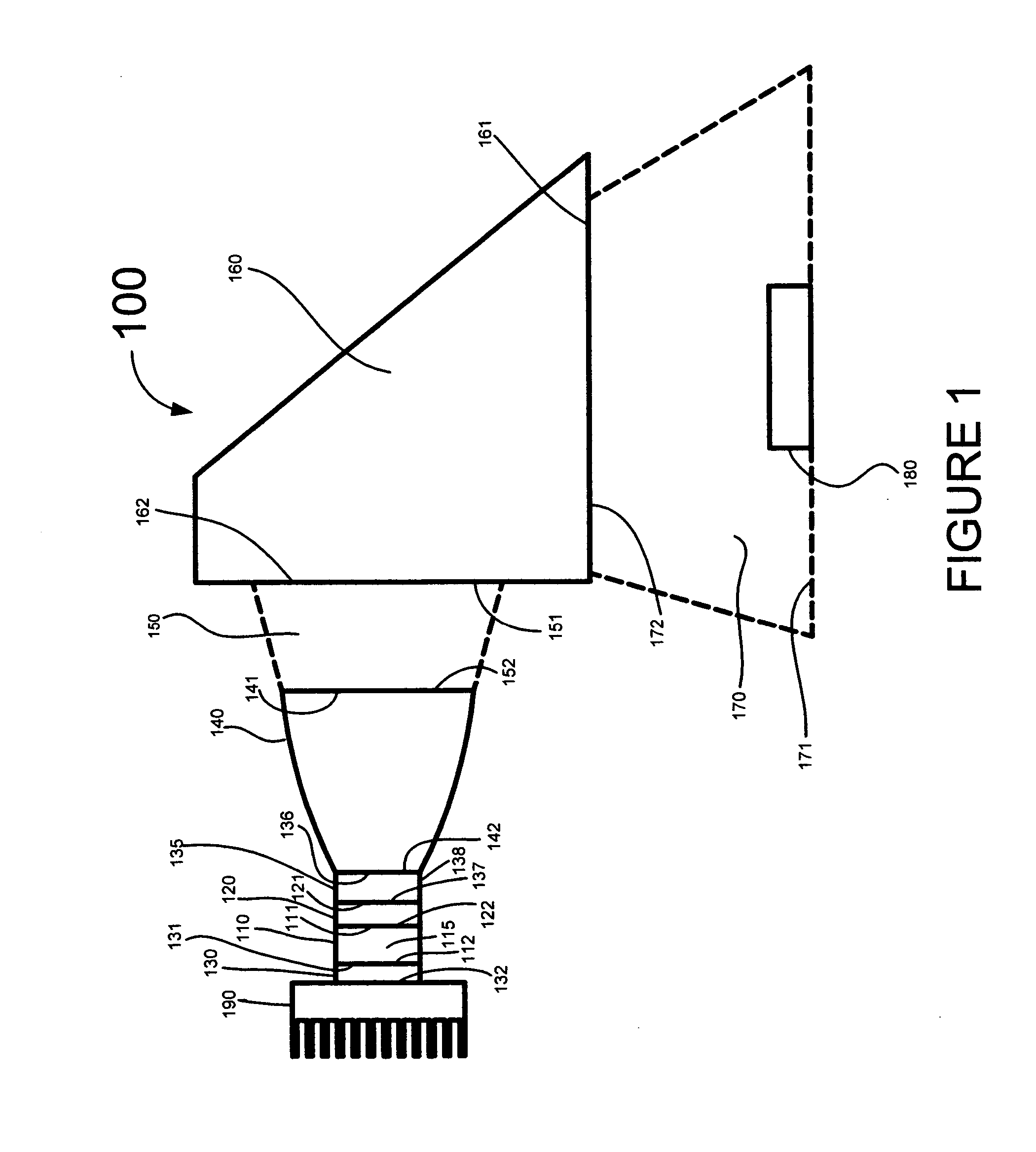

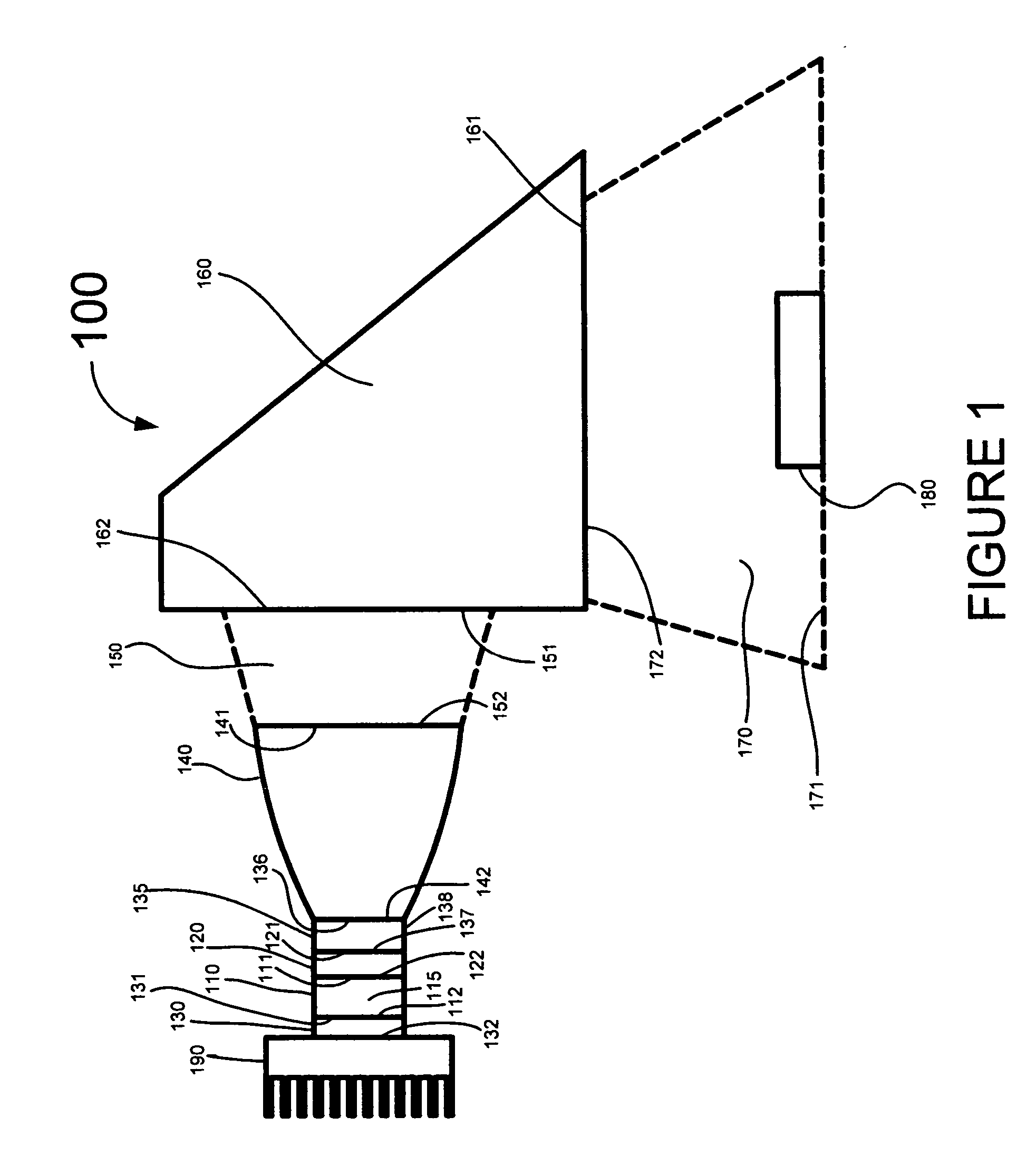

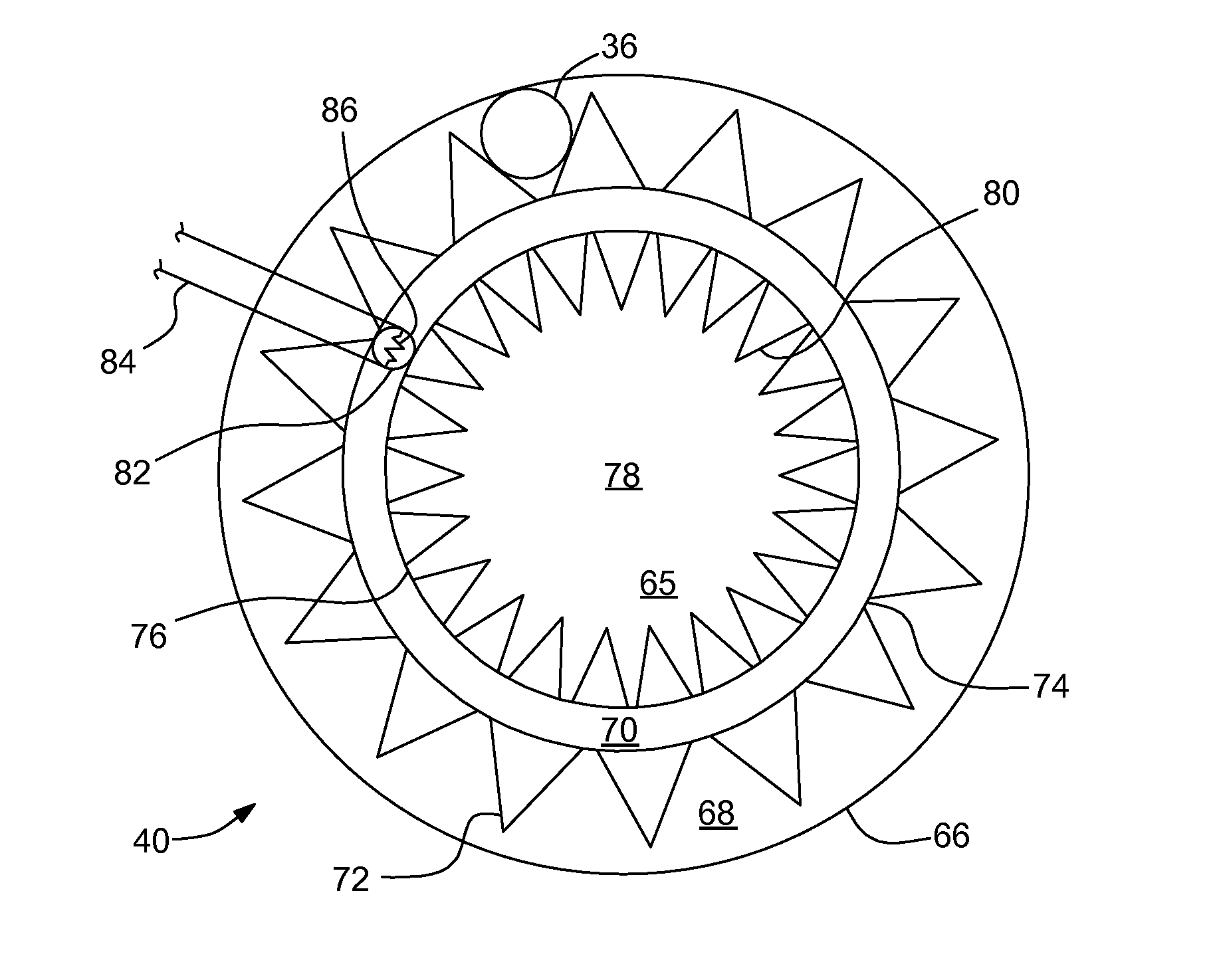

High intensity LED array illuminator

InactiveUS20070053200A1High strengthReduce package sizeLighting heating/cooling arrangementsLight therapyIntegratorLed array

A high intensity mutli-wavelength illumination apparatus comprising an array of LEDs each of which has a predetermined spectral output that is emitted over a predetermined solid angle, an array of non-imaging concentrators the individual non-imaging concentrators of which are optically coupled in one-to-one correspondence with the LEDs, each non-imaging concentrator in the array of non-imaging concentrators operating to collect radiation emitted by each of the LEDs and to re-emit substantially all the collected radiation as a beam having a diverging solid angle smaller than said predetermined solid angle over which radiation is emitted by each of the LEDs, the non-imaging concentrators each having an entrance aperture for receiving radiation emitted by a corresponding one of the LEDs and an exit aperture from which the LEDs output emerges spatially and spectrally uniform in the near field of the exit aperture, and a light integrator having an entrance facet optically coupled to each of the exit apertures of the non-imaging concentrators for receiving radiation there through and conducting it to an exit facet thereof from which radiation is emitted for a downstream application, the light integrator being structured and arranged to substantially uniformly mix the individual beams emitted by each concentrator so that radiation emitted from its exit facet is uniformly colored.

Owner:INNOVATIONS & OPTICS

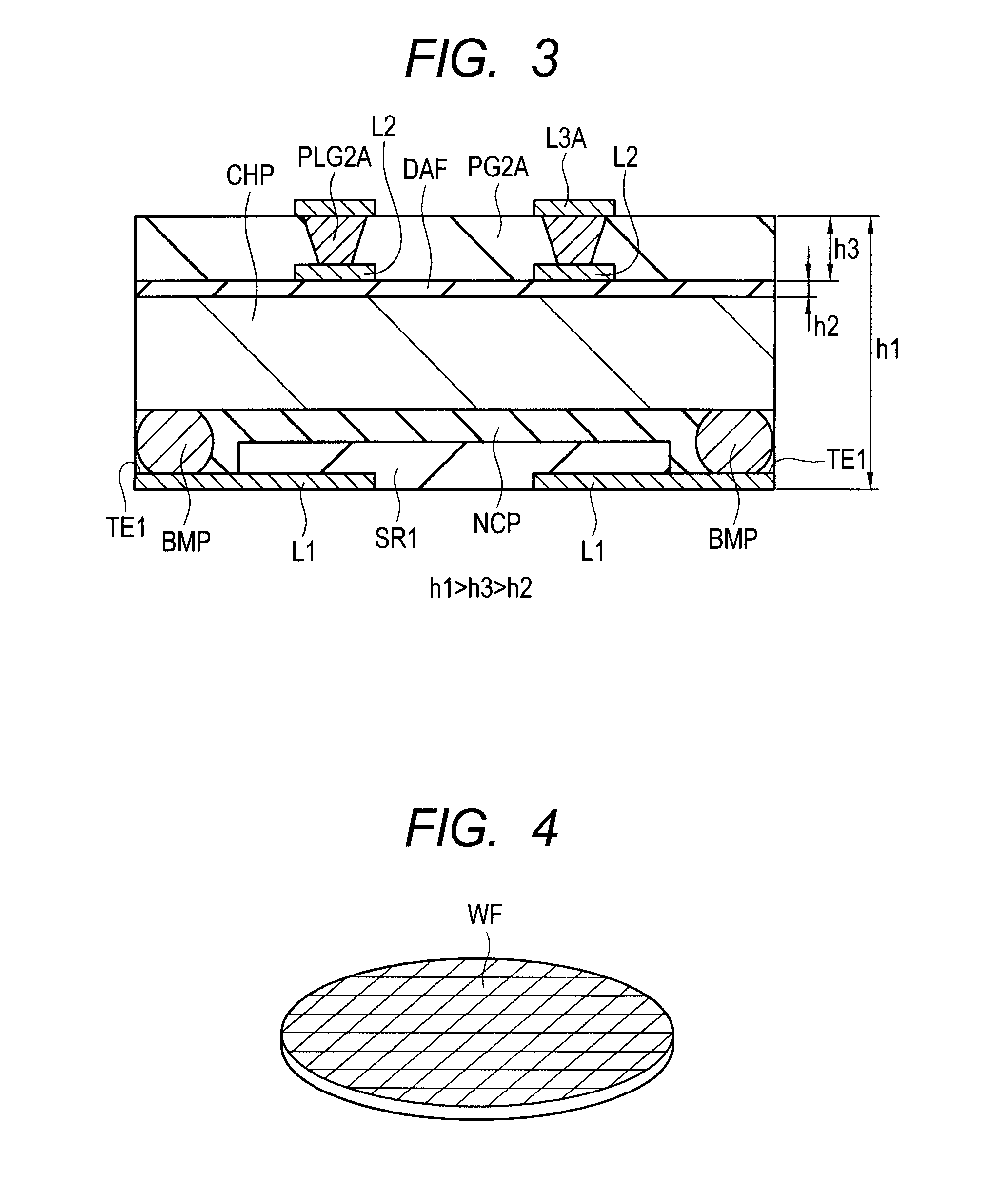

Semiconductor device and method of manufacturing the same

InactiveUS20110193203A1Preventing the semiconductor chip from being brokenEasy to operateSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

In regard to a semiconductor device having a multilayered wiring board where a semiconductor chip is embedded inside, a technology which allows the multilayered wiring board to be made thinner is provided. A feature of the present invention is that, in a semiconductor device where bump electrodes are formed over a main surface (element forming surface) of a semiconductor chip embedded in a chip-embedded wiring board, an insulating film is formed over a back surface (a surface on the side opposite to the main surface) of the semiconductor chip. As a result, it becomes unnecessary to form a prepreg over the back surface of the semiconductor chip. Therefore, an effect of thinning the chip-embedded wiring board in which the semiconductor chip is embedded is obtained.

Owner:RENESAS ELECTRONICS CORP

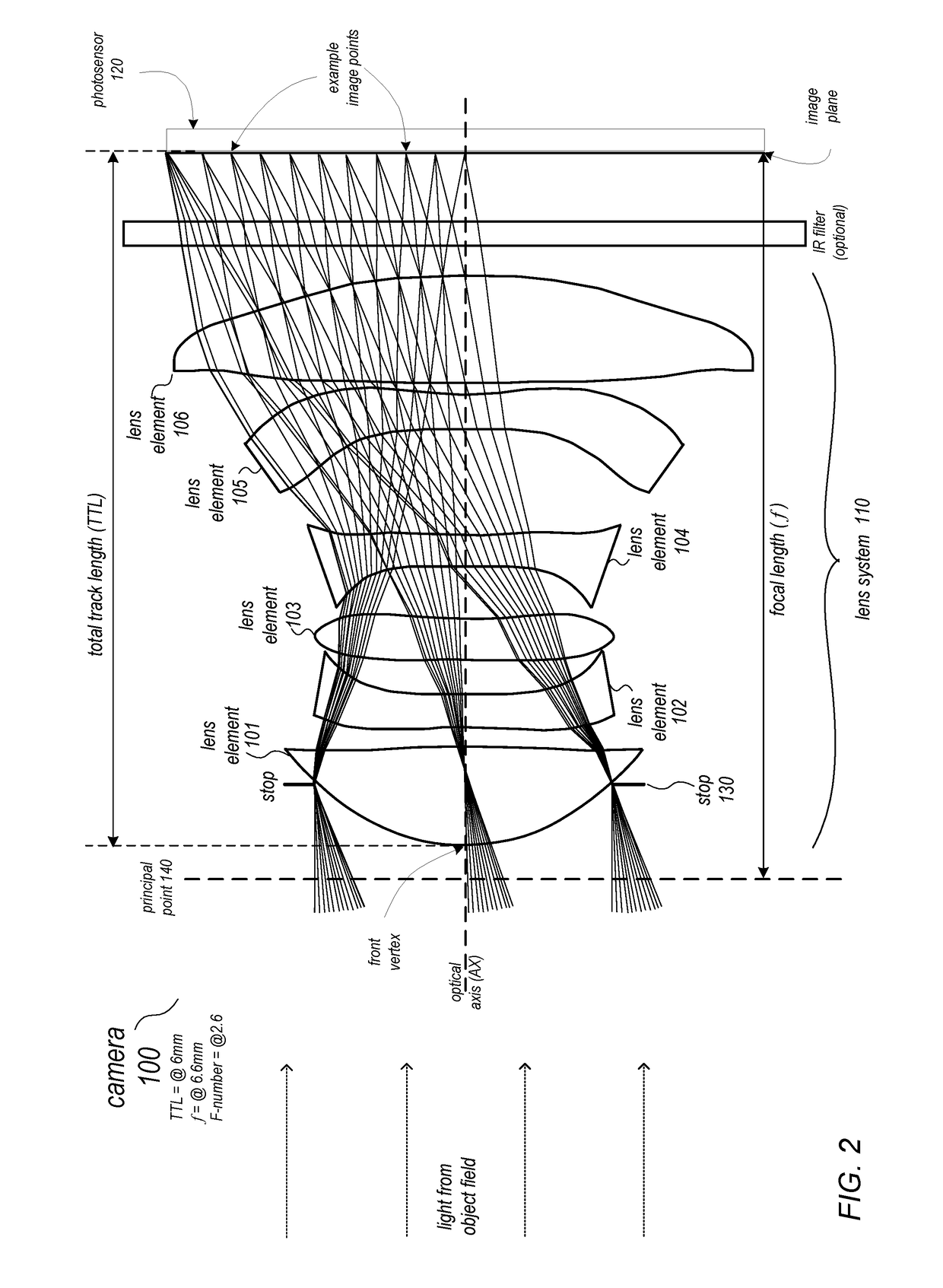

Lens system

ActiveUS20170115471A1Big imageLong effective focal lengthProjector focusing arrangementCamera focusing arrangementCamera lensImaging quality

Compact narrow angle lens systems that may be used in small form factor cameras. The lens system may include six lens elements with refractive power, and may provide lower F-numbers while maintaining or improving imaging quality and package size when compared to other compact lens systems. Total track length of the lens system may be 6.5 millimeters or less, for example 5.9 or 6 millimeters. Focal length of the lens system may be 7.0 millimeters or less, for example 6.6 millimeters. The lens system may include an aperture stop located behind the front vertex of the lens system, for example between the first and second lens elements, that effectively moves the ideal principal point of the camera to in front of the front vertex. The lens system may provide a focal ratio of 2.8 or less, for example 2.6 or 2.4.

Owner:APPLE INC

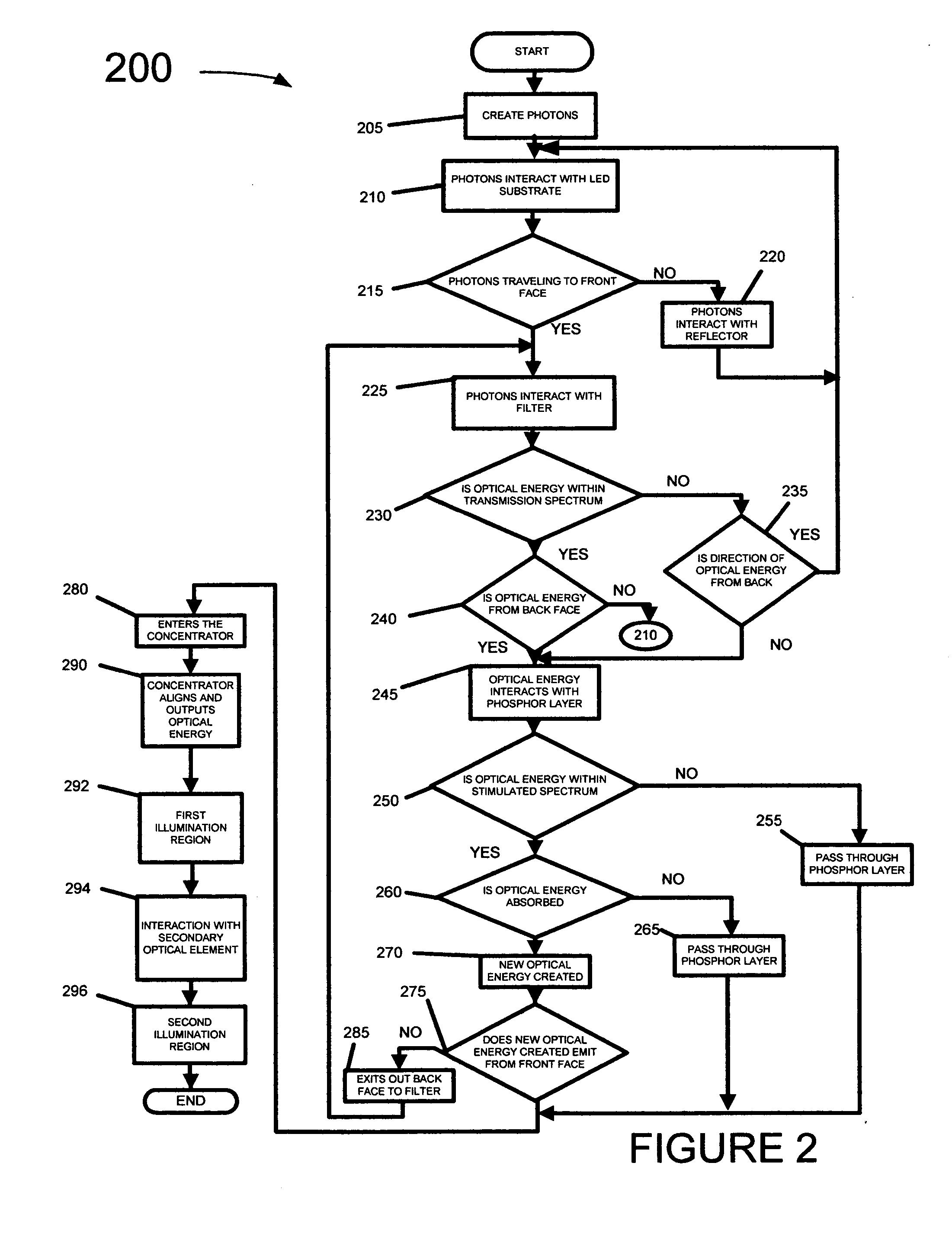

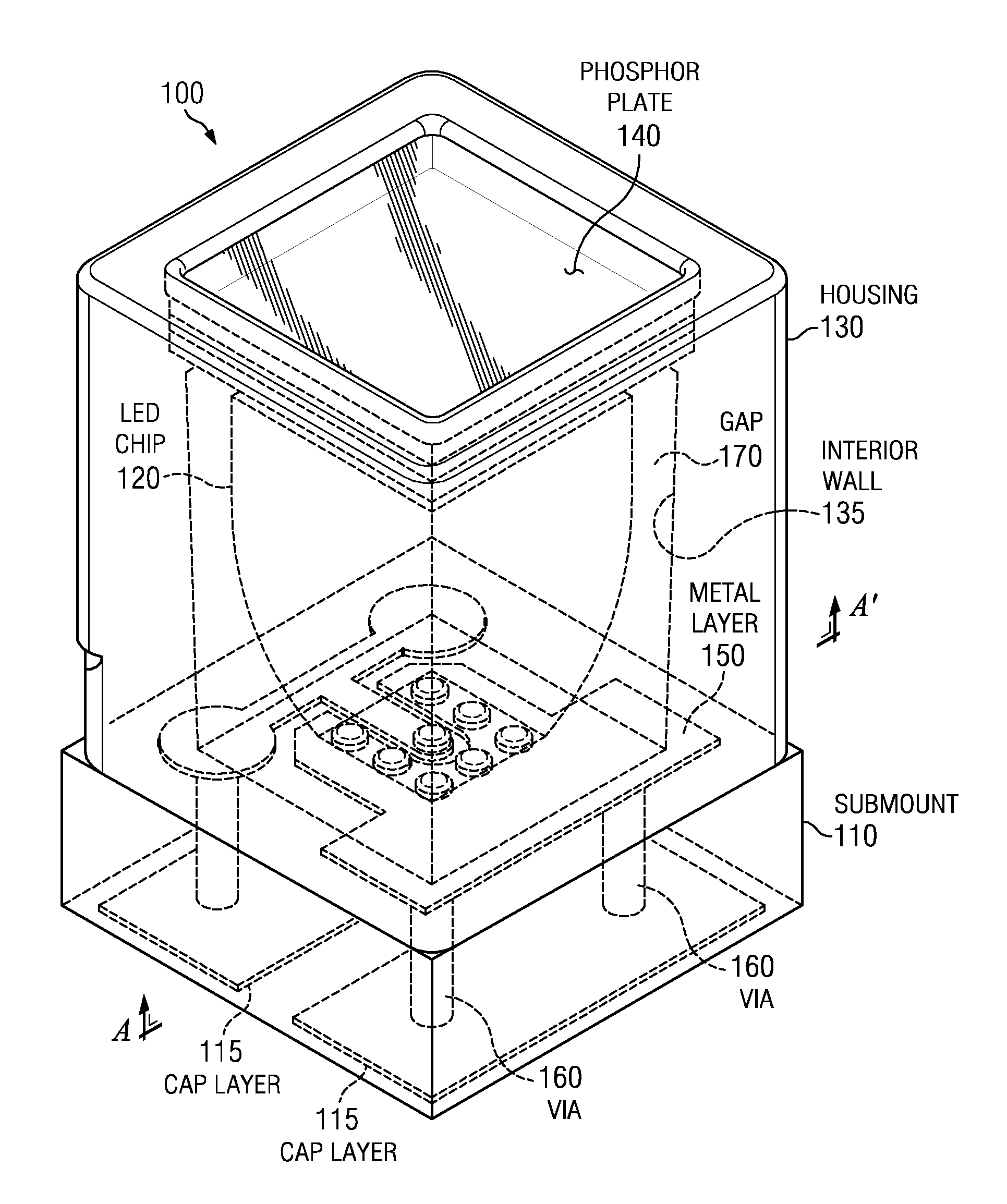

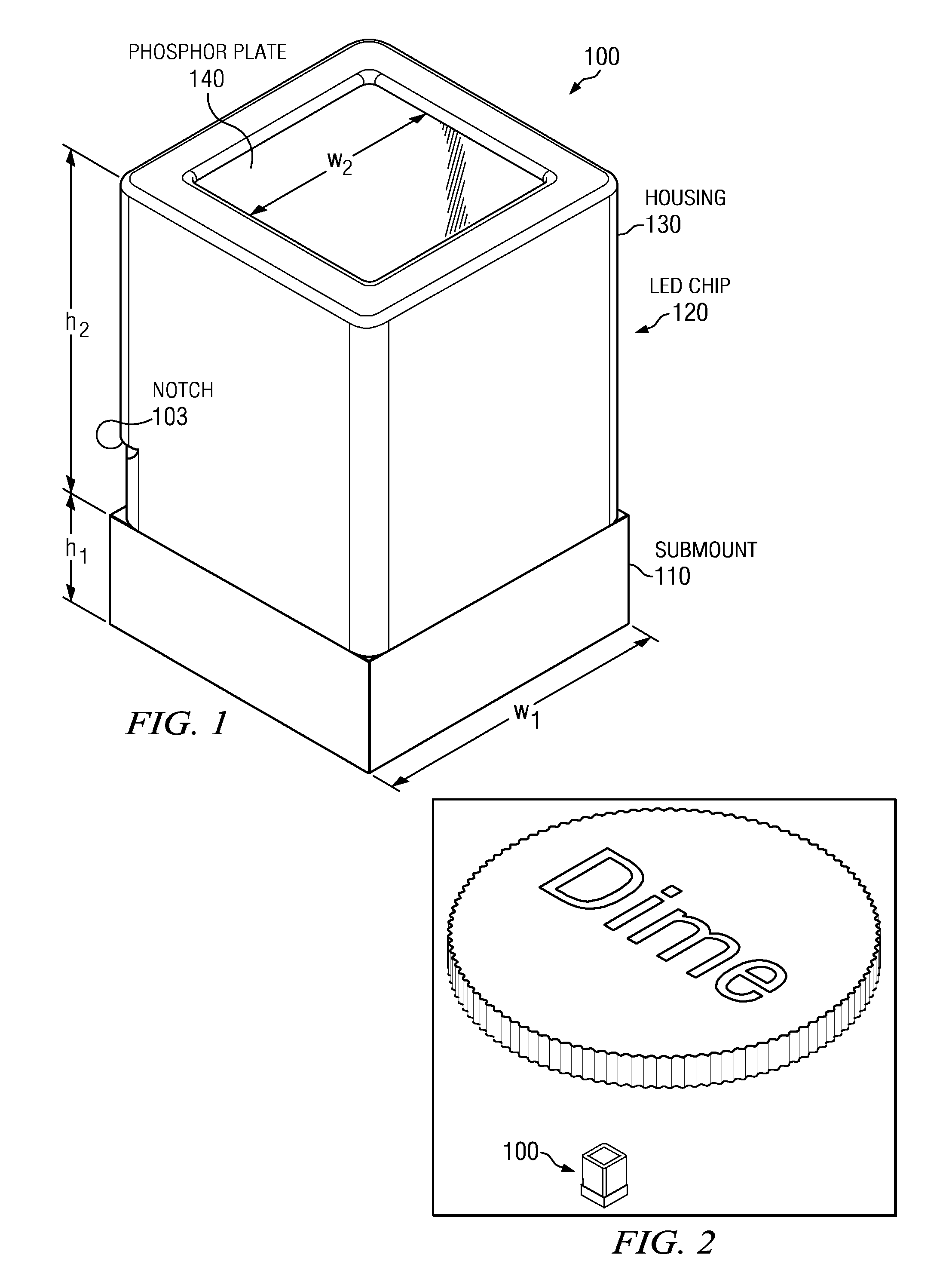

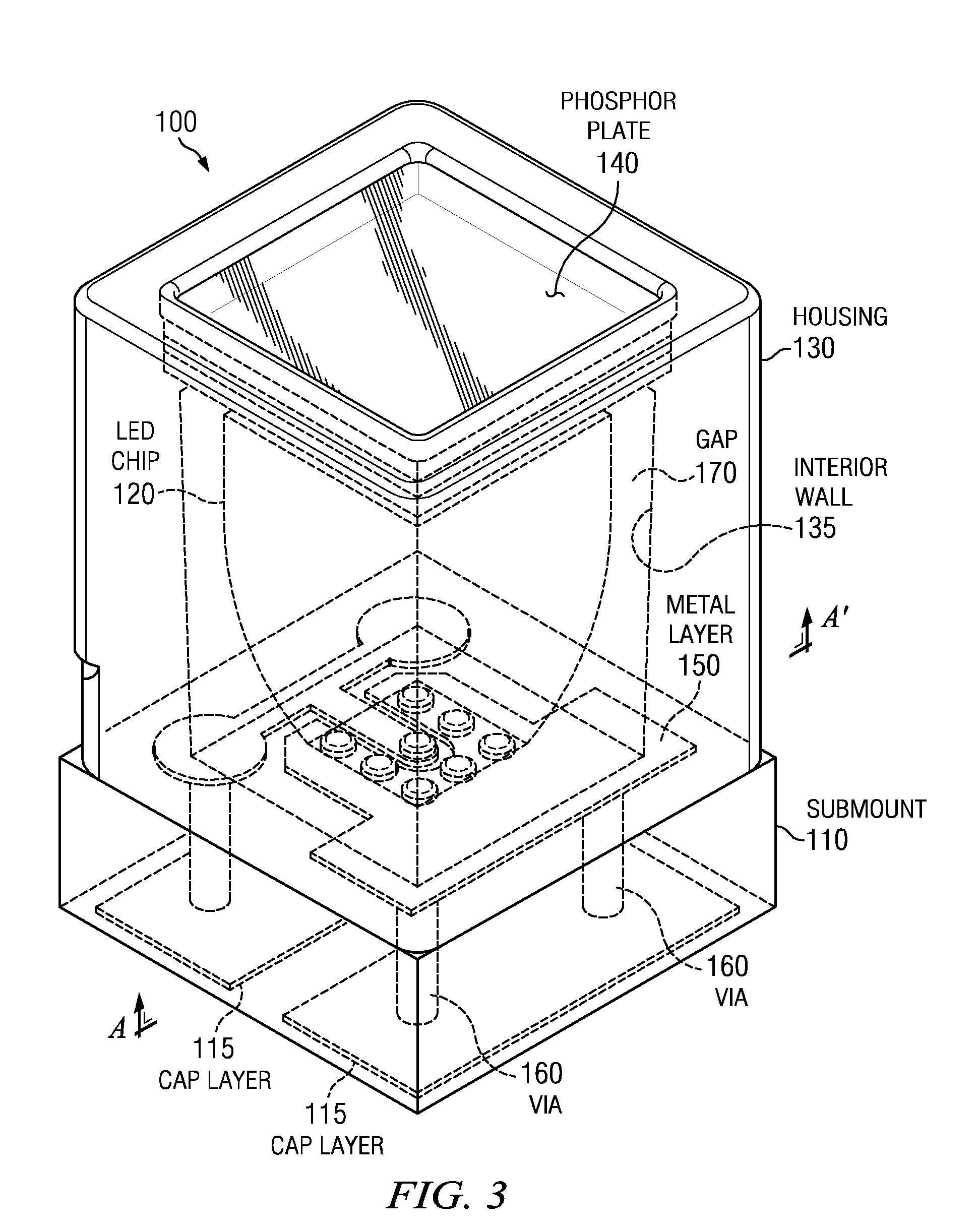

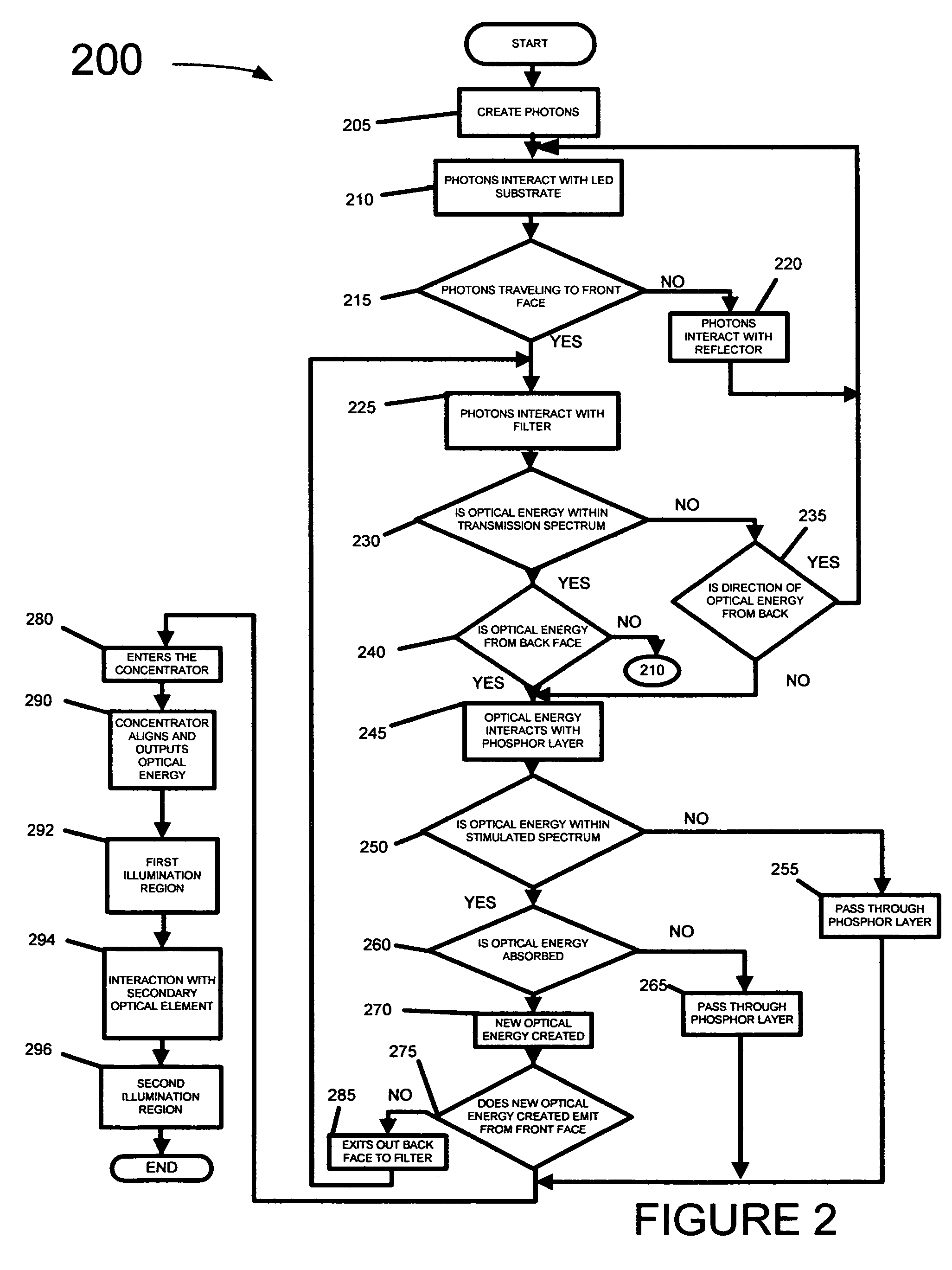

Systems and methods for packaging light-emitting diode devices

InactiveUS8115217B2Simple processReduce package sizeSolid-state devicesSemiconductor/solid-state device manufacturingEpoxyComing out

Embodiments disclosed herein provide packaged LED devices in which the majority of the emitted light comes out the top of each LED chip with very little side emissions. Because light only comes out from the top, phosphor deposition and color temperature control can be significantly simplified. A package LED may include a housing positioned on a supporting submount, sized and dimensioned to accommodate a single LED chip or an array of LED chips. The LED chip(s) may be attached to the submount utilizing the Gold-to-Gold Interconnect (GGI) process or solder-based approaches. In some embodiments, phosphor may be deposited on top of the LED chip(s) or sandwiched between glass plates on top of the LED chip(s). The phosphor layer may be inside or on top of the housing and be secured to the housing utilizing an adhesive. The housing may be adhered to the submount utilizing a thermal epoxy.

Owner:ILLUMITEX INC

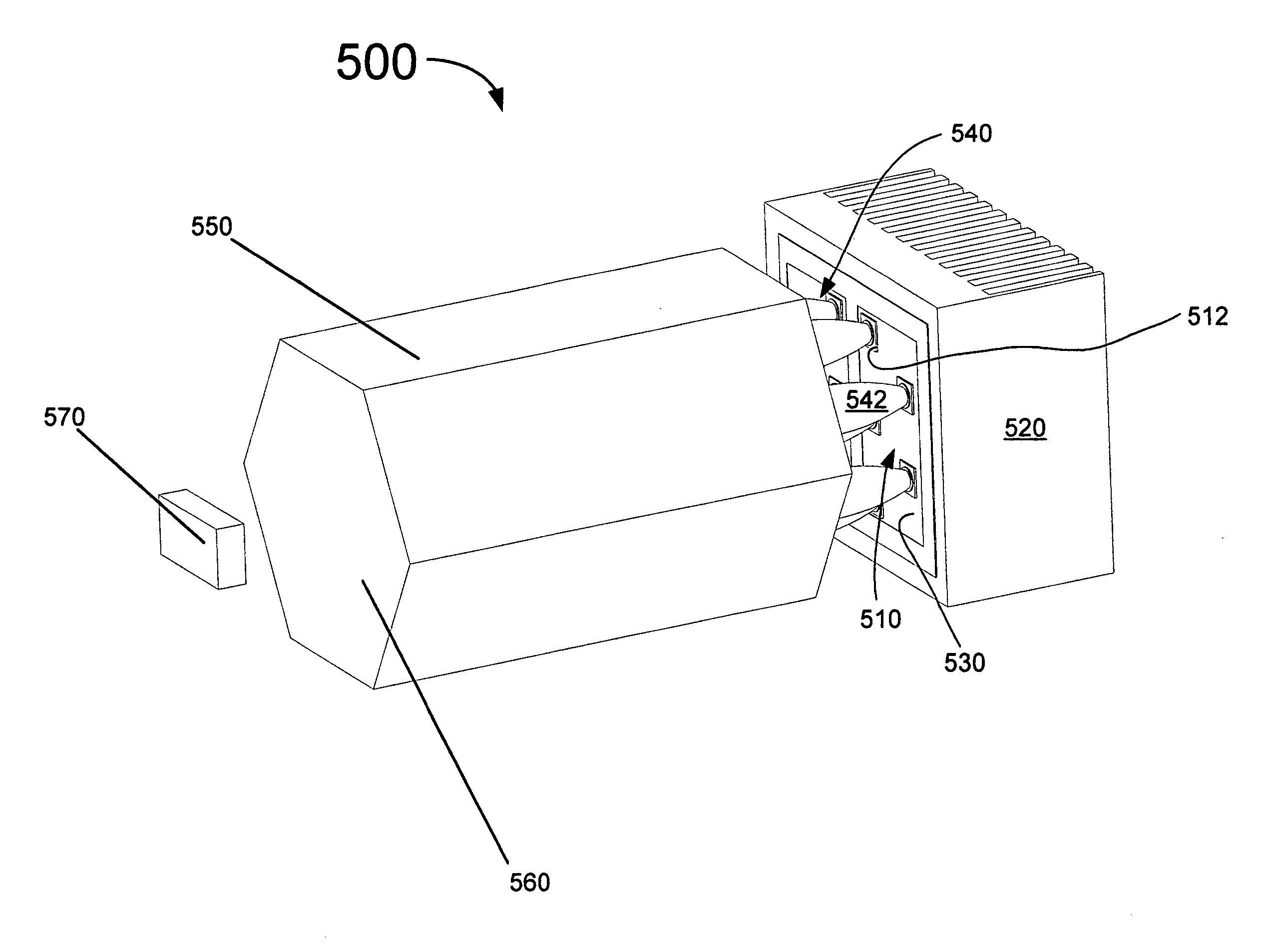

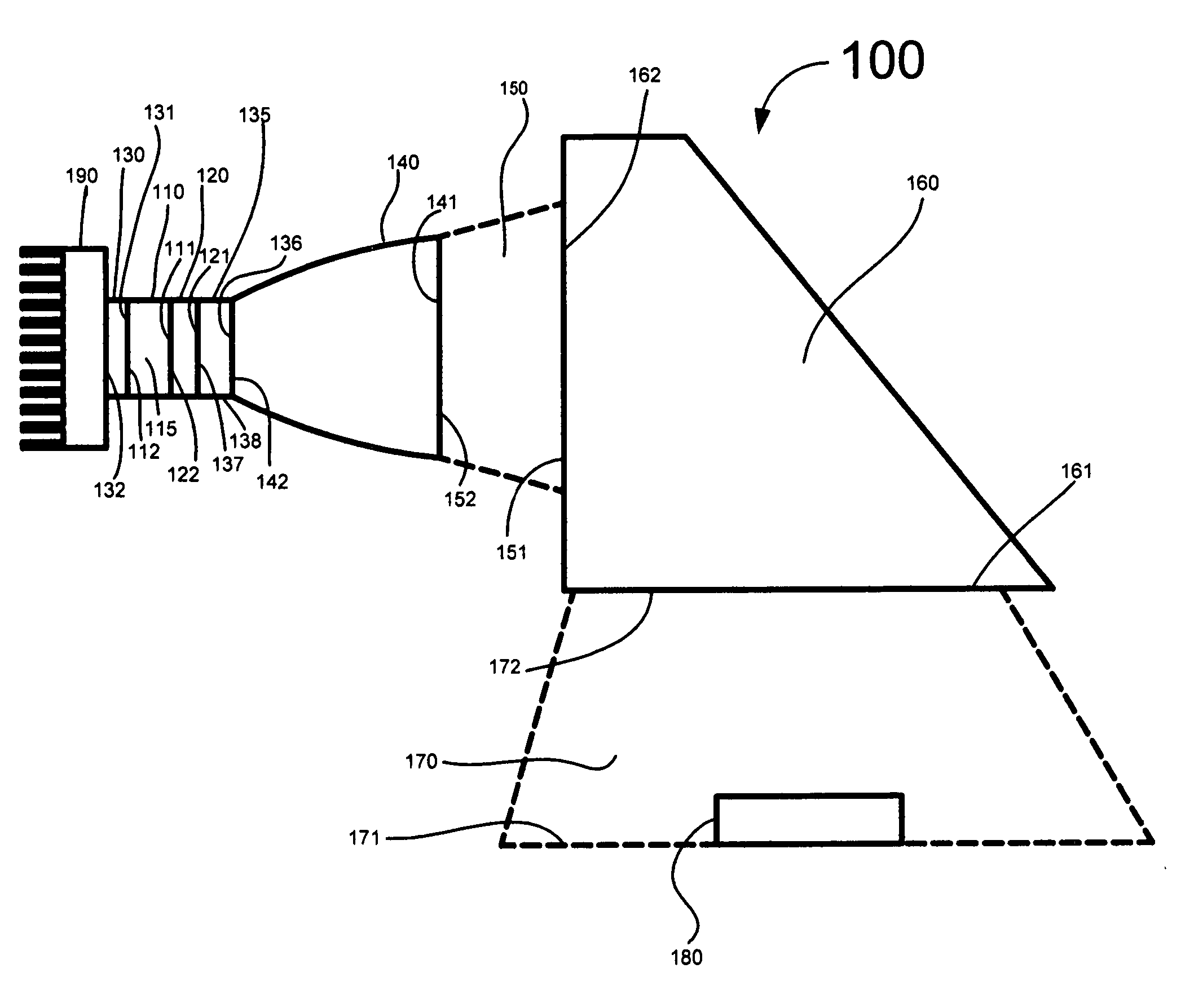

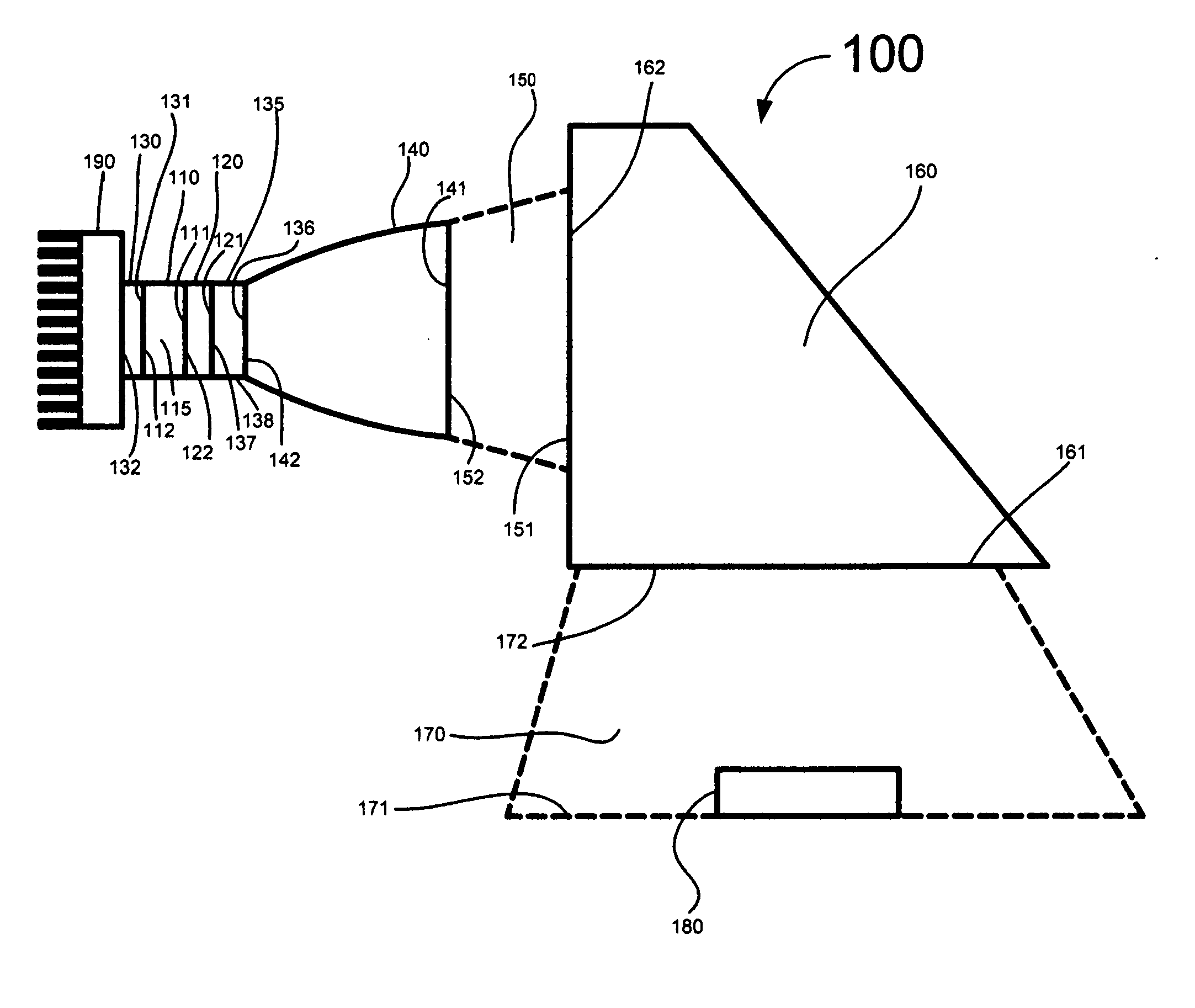

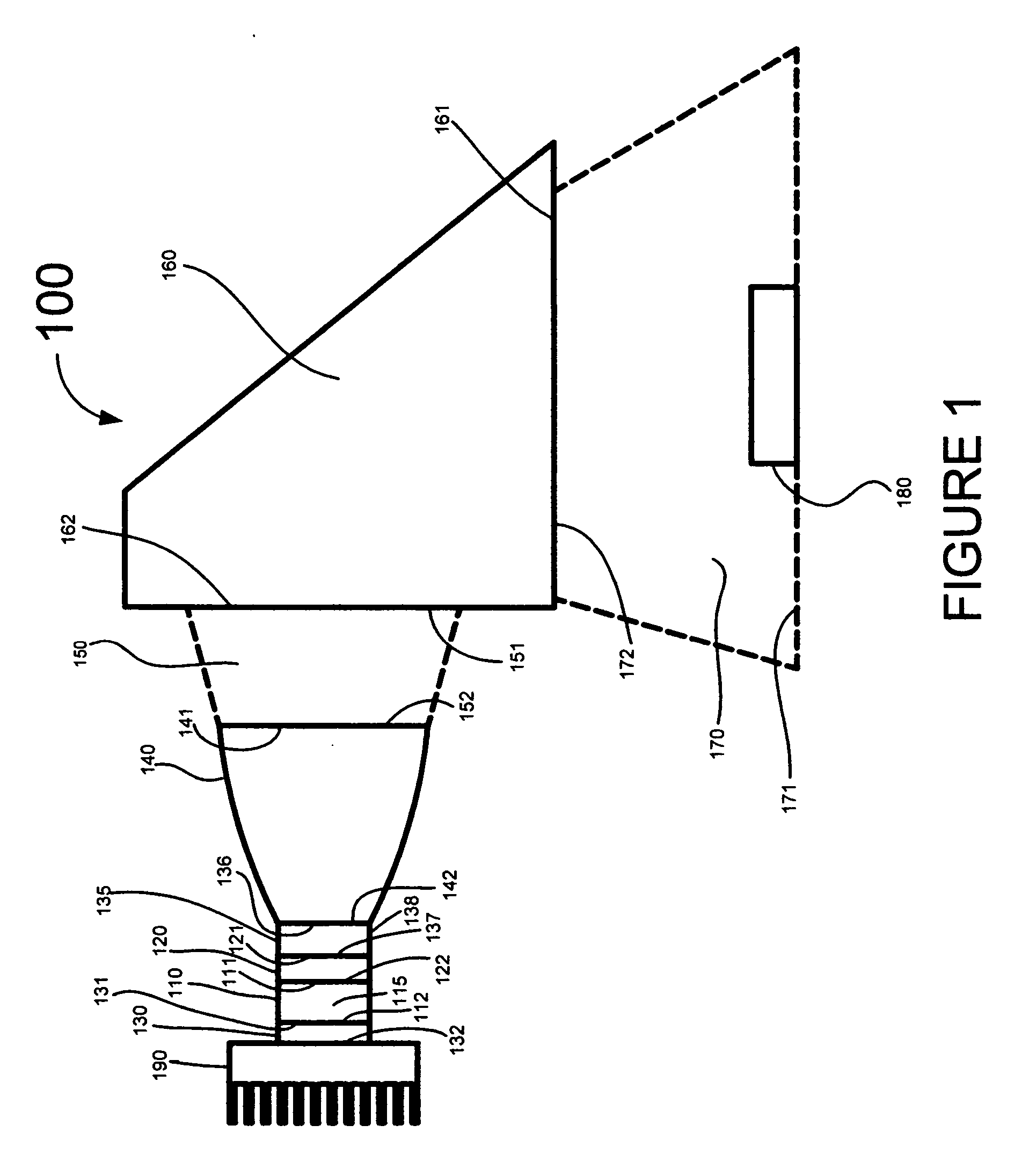

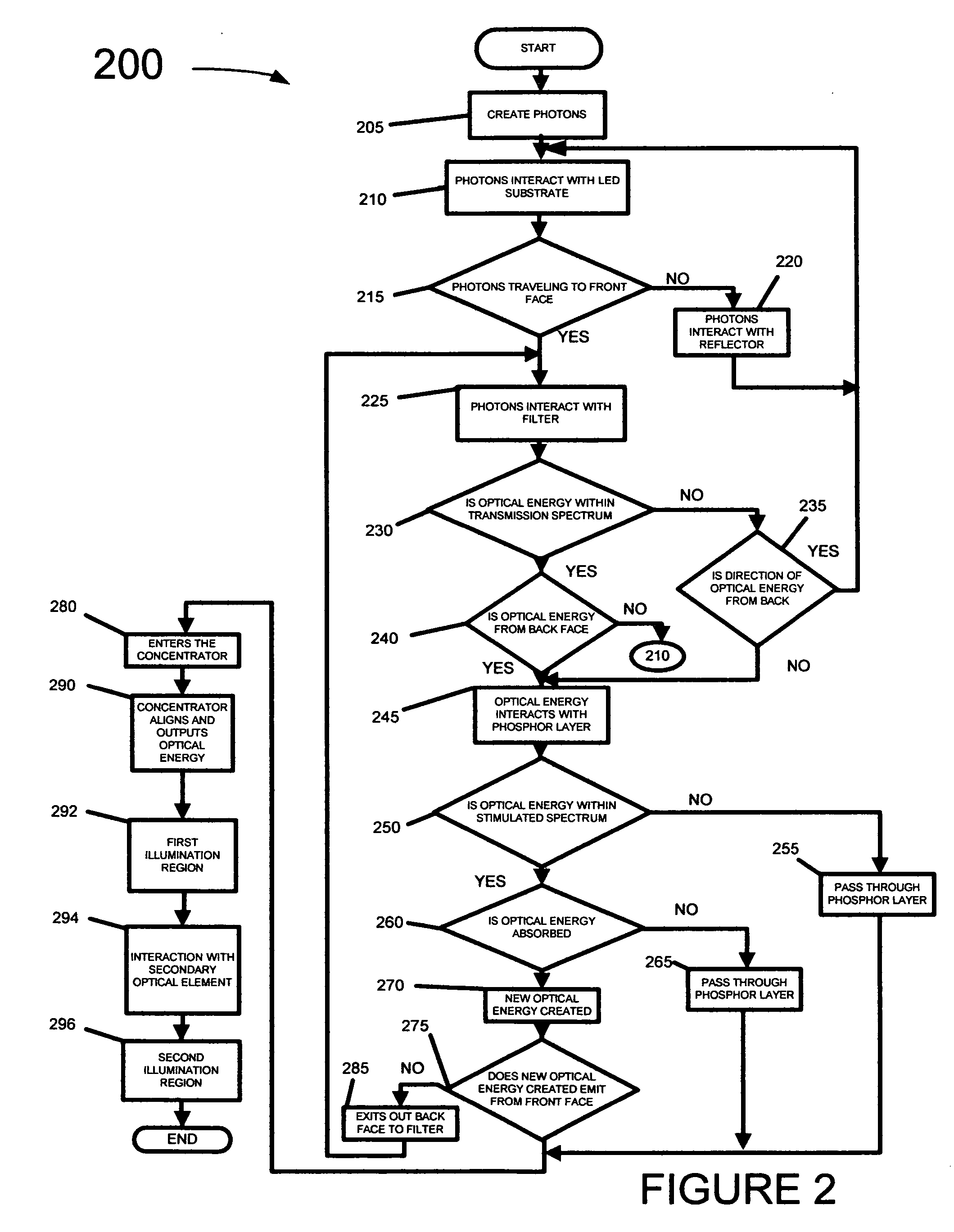

LED illuminator with retro reflector

InactiveUS20070053184A1High strengthReduce package sizeLight therapyOptical light guidesPhosphorLight beam

An illuminator with blue and red LEDs, a reflector upstream of the LEDs for capturing upstream light emitted out of the back surfaces of the LEDs and redirecting downstream as useful illumination, a band pass filter for conditioning the downstream light, a phosphor layer for changing the spectral properties of light from the LEDs, and a non-imaging concentrator for creating a beam of illumination over a predetermined solid angle, uniformity, and spectral content.

Owner:INNOVATIONS & OPTICS

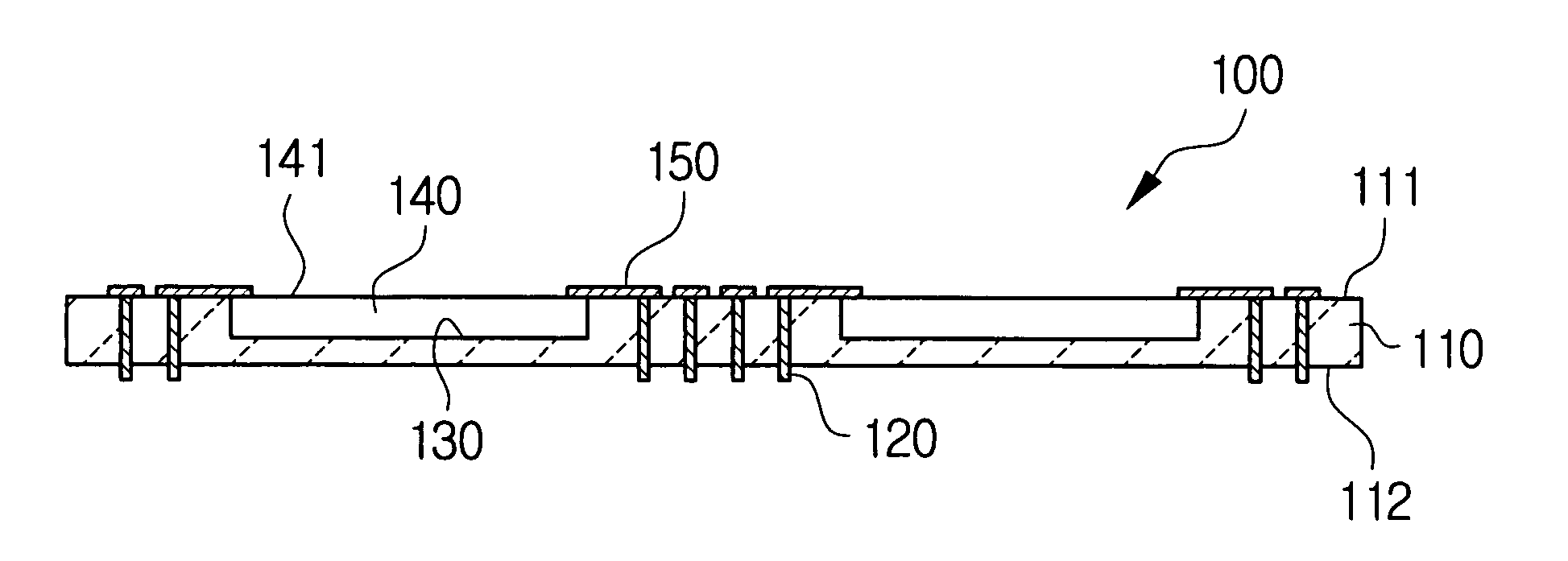

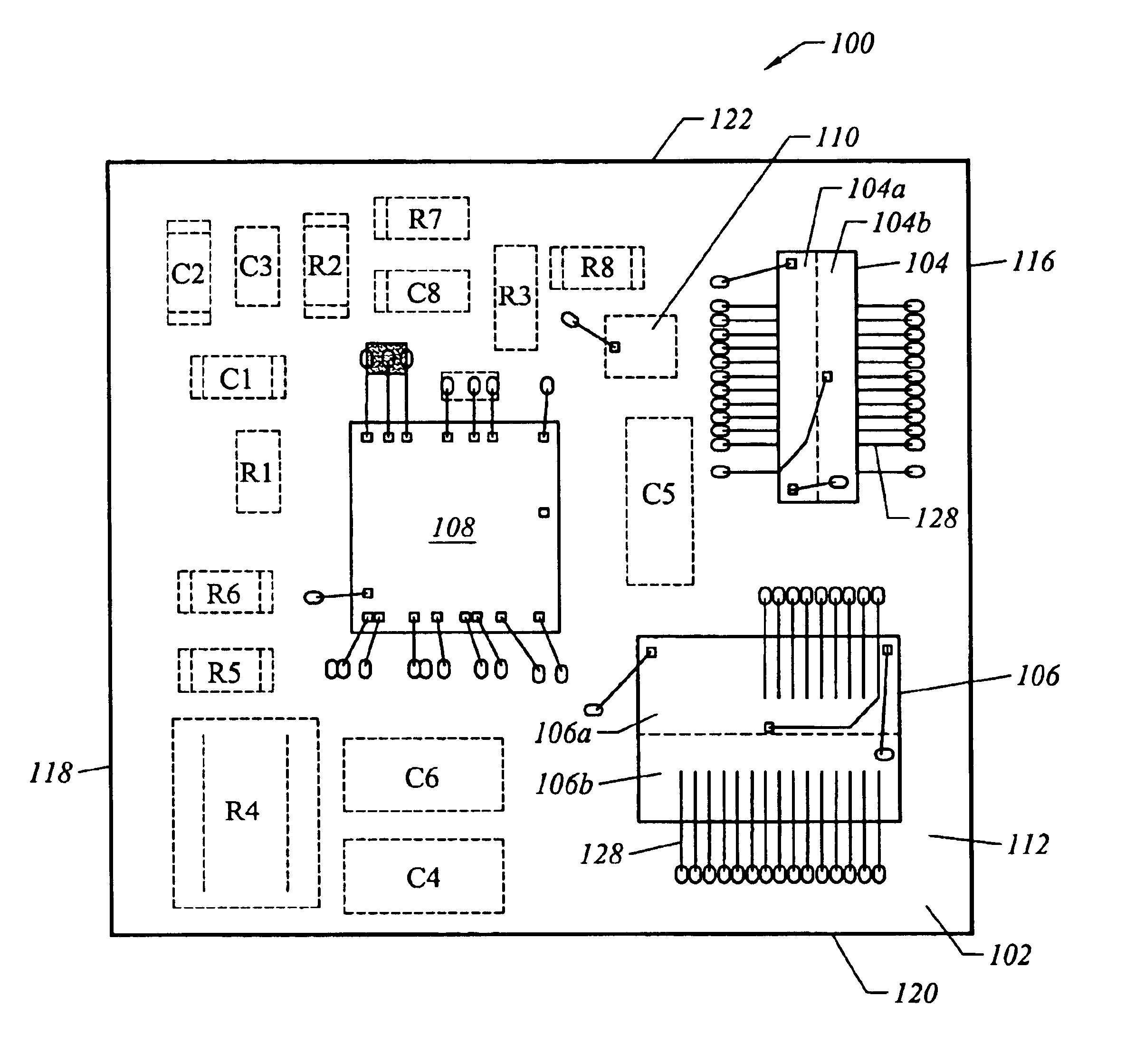

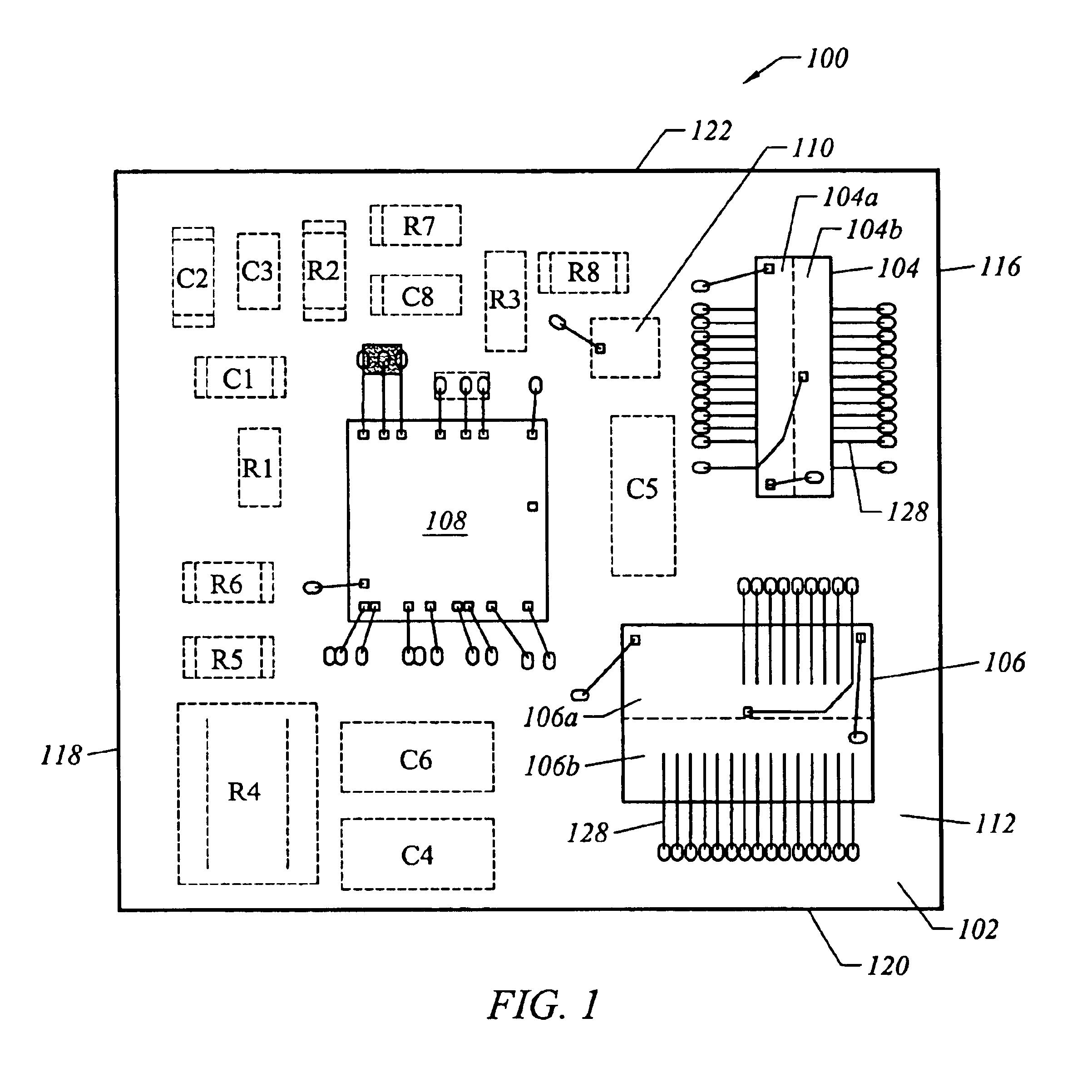

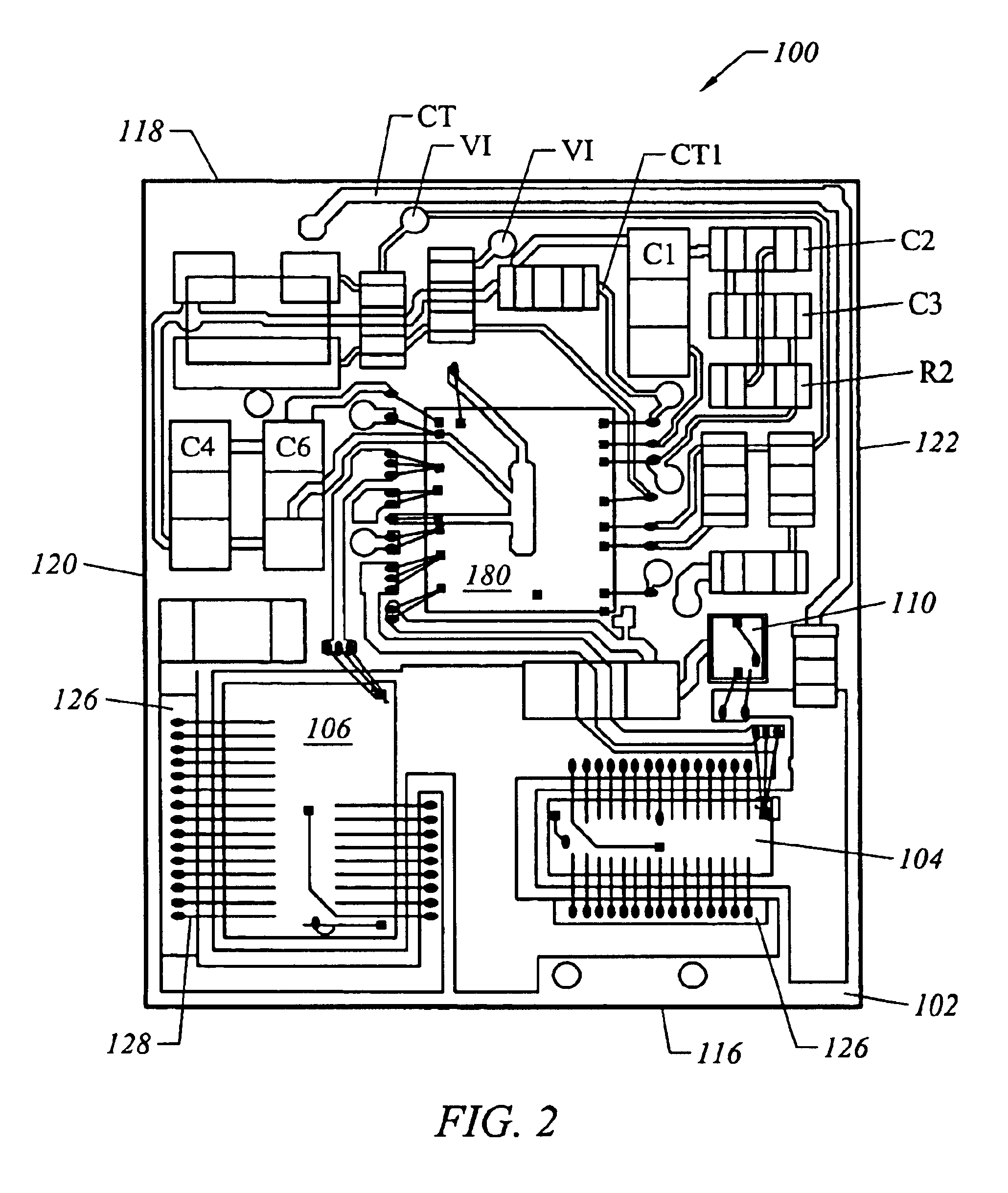

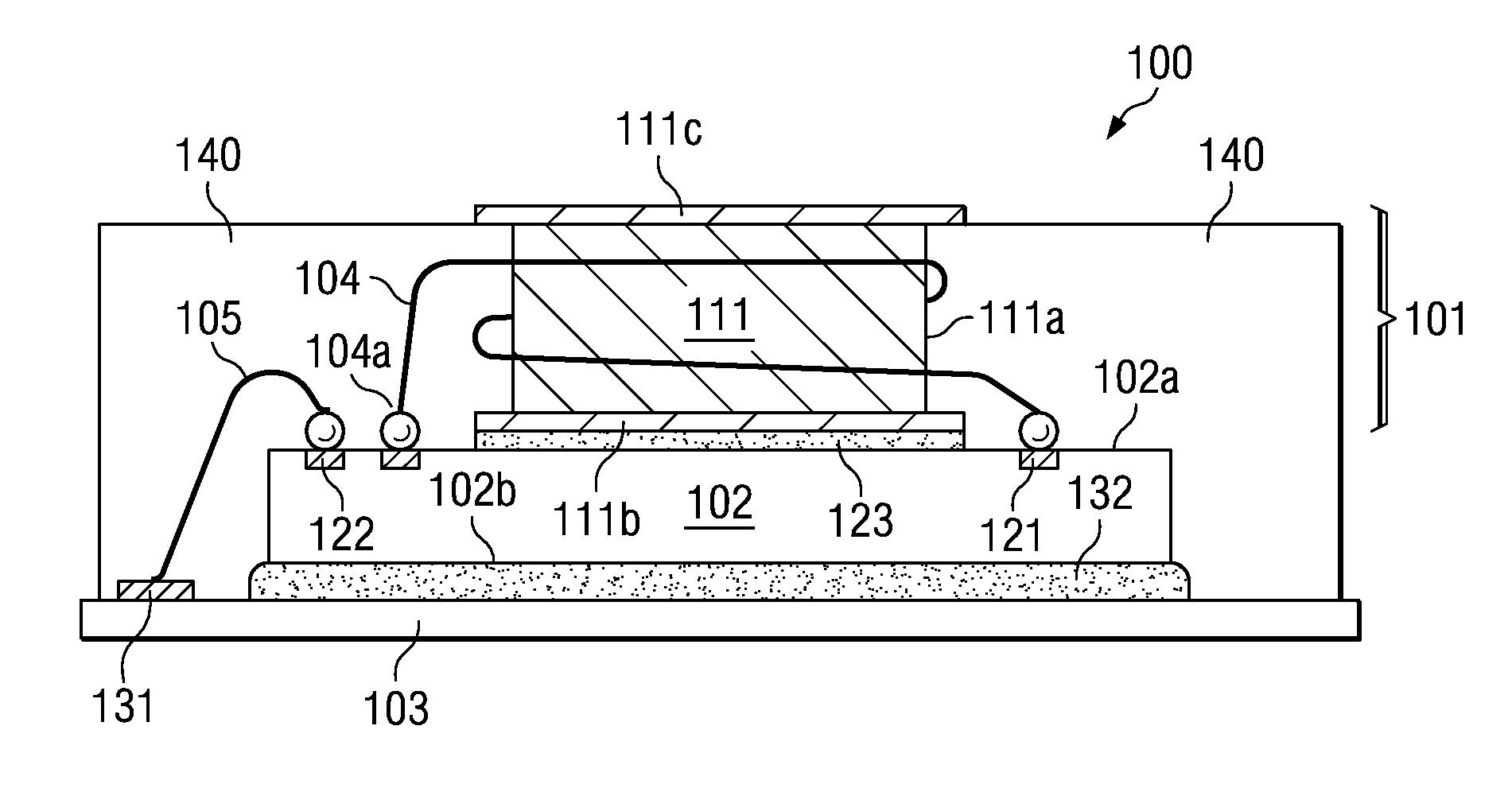

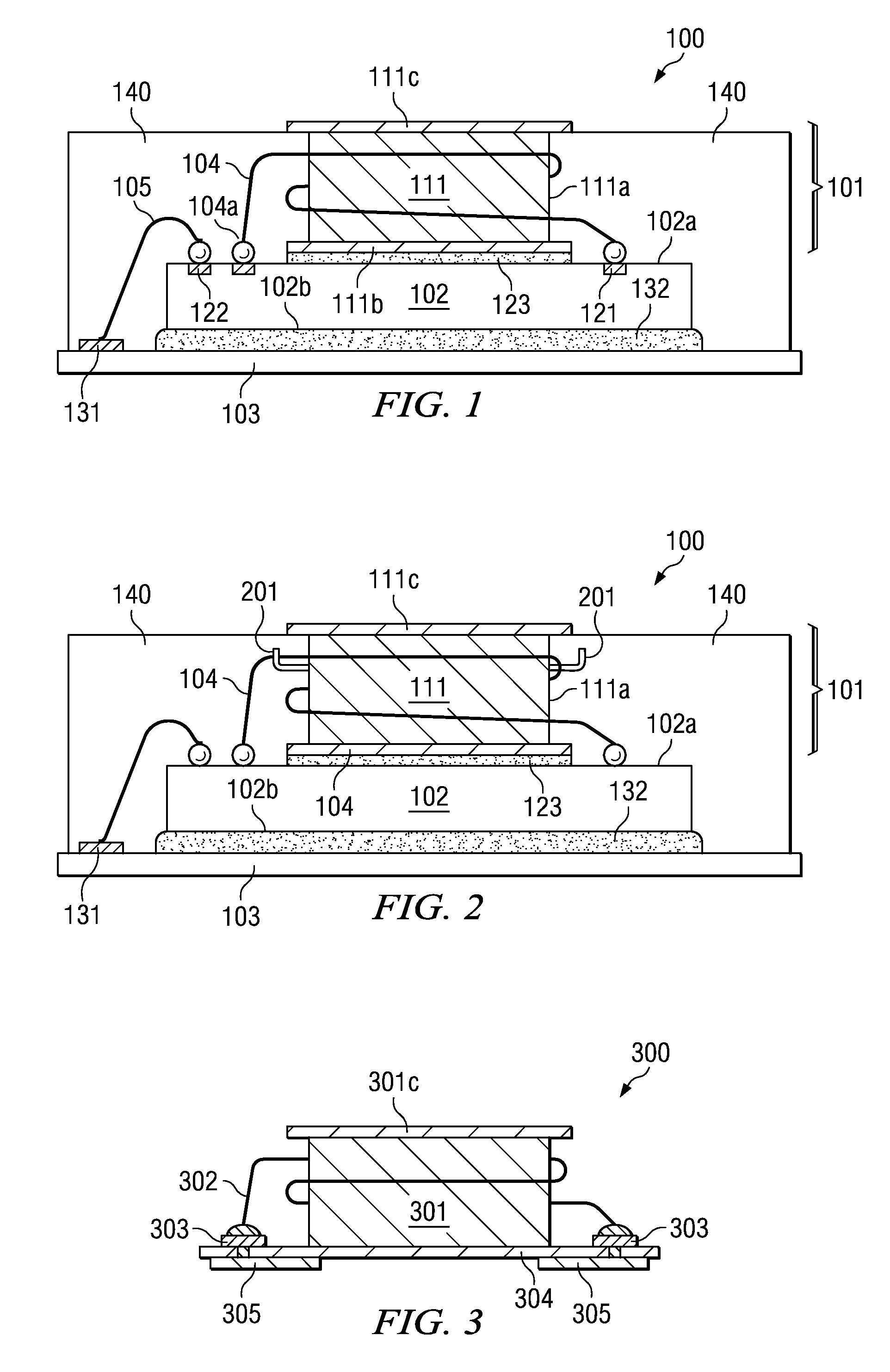

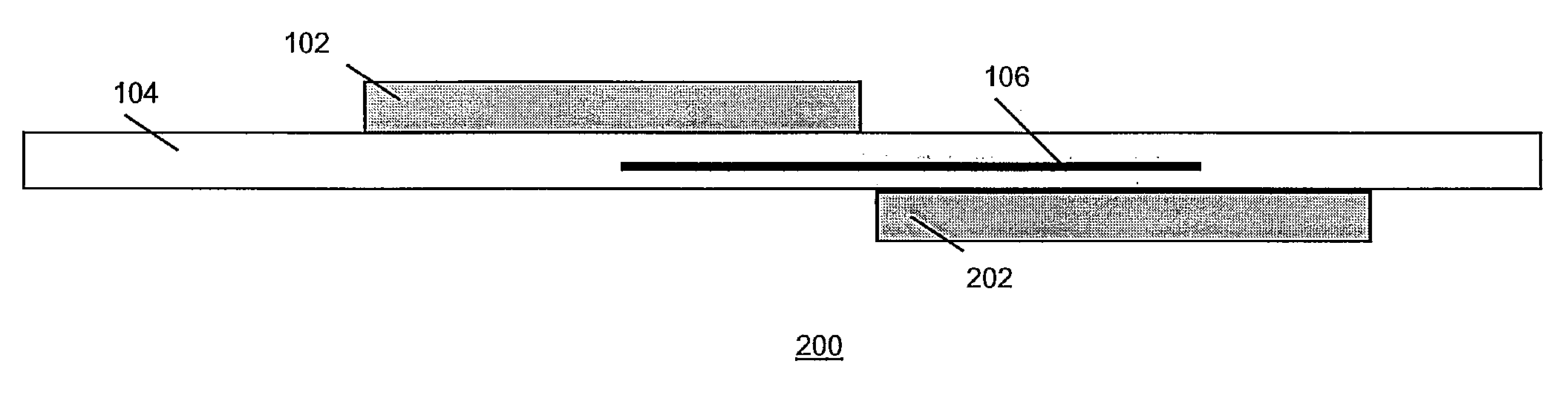

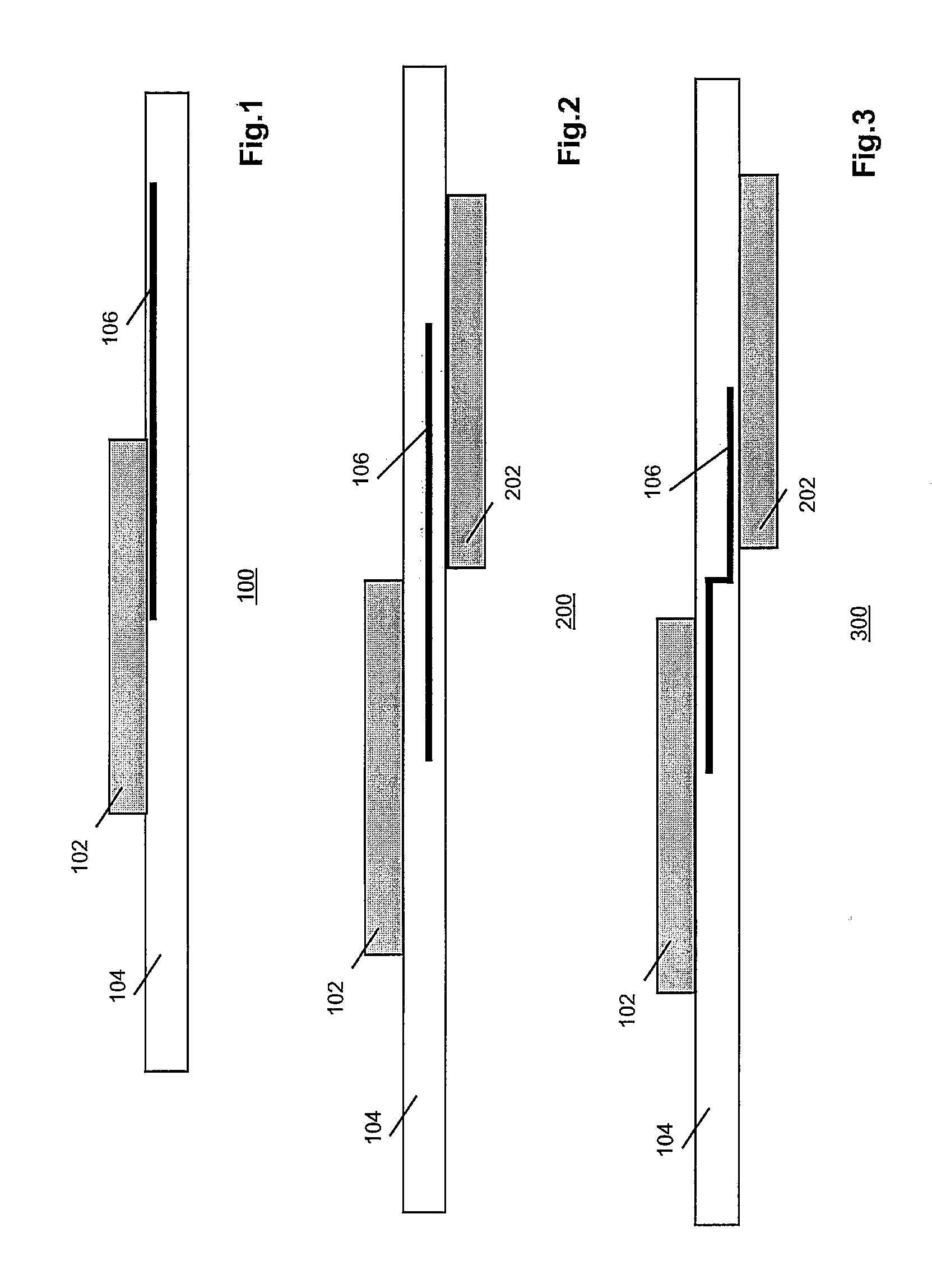

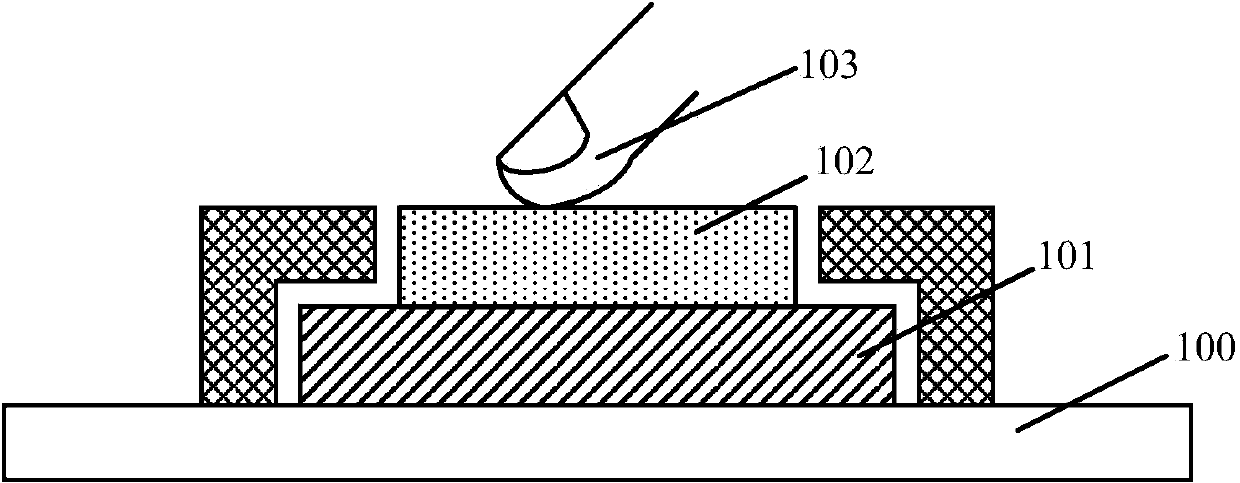

Power Semiconductor Devices Having Integrated Inductor

ActiveUS20080029907A1Improve thermal device performanceShorten the time to marketSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceSemiconductor chip

An electronic device (100) with one or more semiconductor chips (102) has an inductor (101) assembled on or under the chips. The inductor includes a ferromagnetic body (111) and a wire (104) wrapped around the body to form at least a portion of a loop; the wire ends (104a) are connected to the chips. The assembly is attached to a substrate (103), which may be a leadframe. The device may be encapsulated in molding compound (140) so that the inductor can double as a heat spreader (111c), enhancing the thermal device characteristics.

Owner:TEXAS INSTR INC

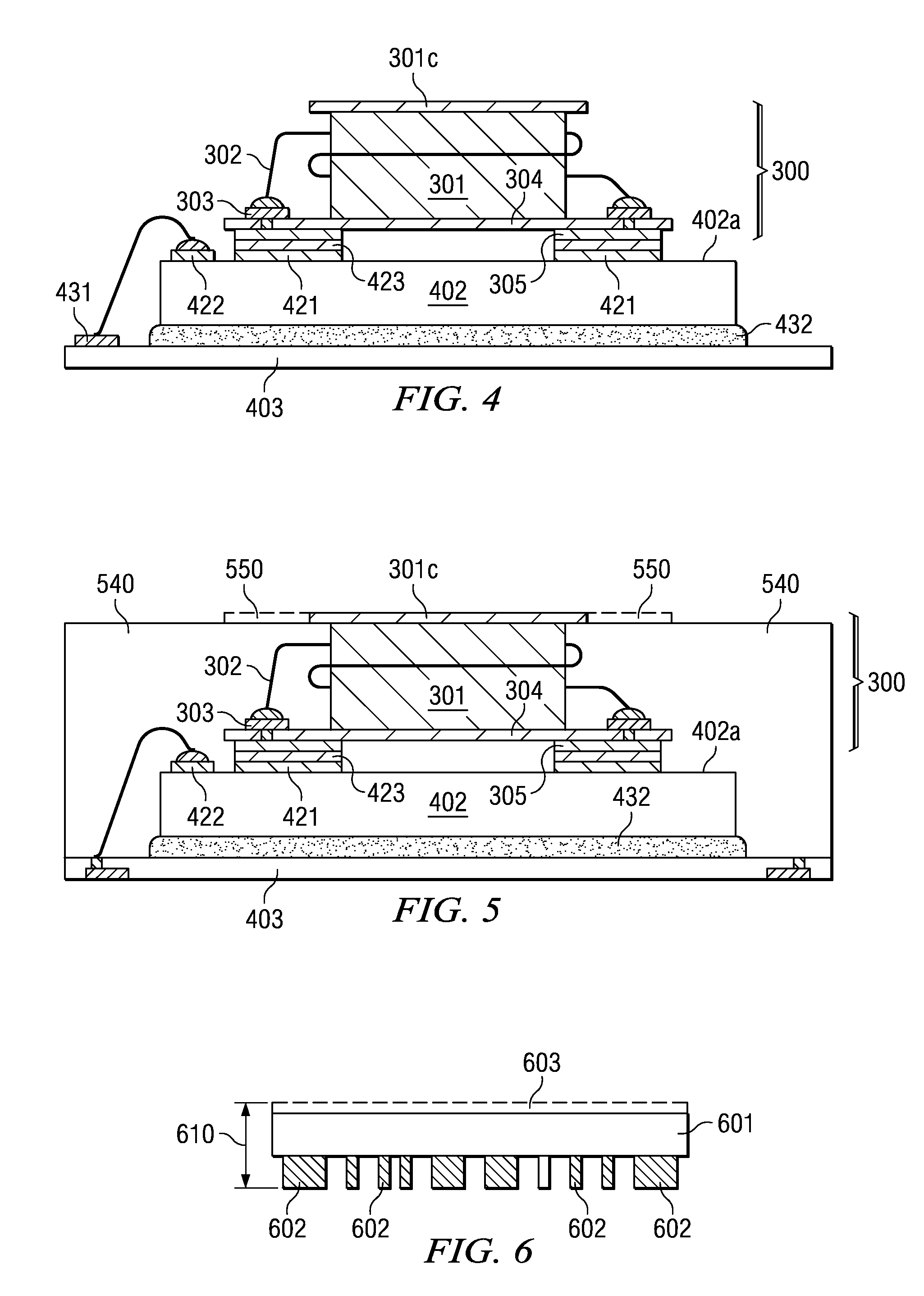

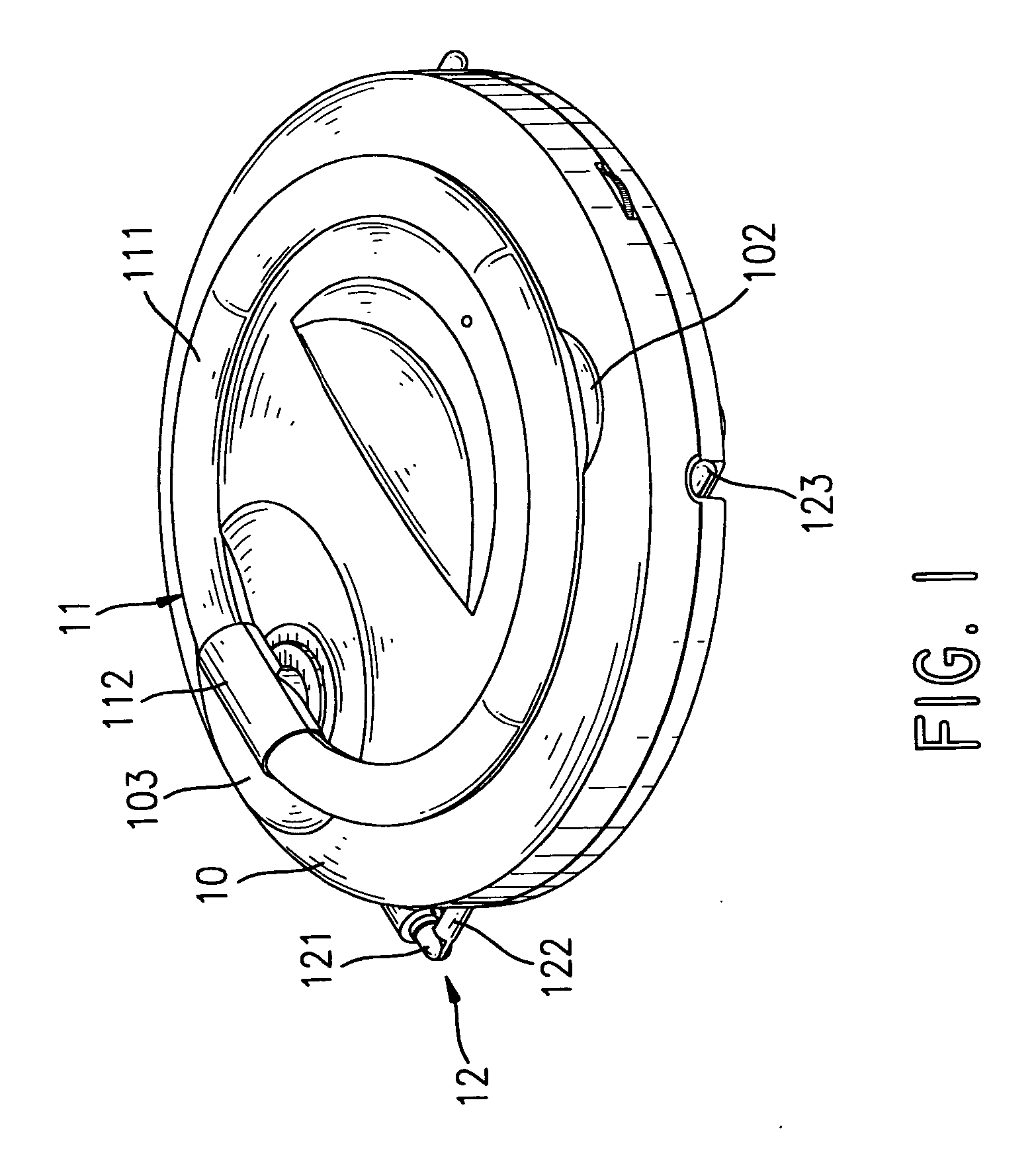

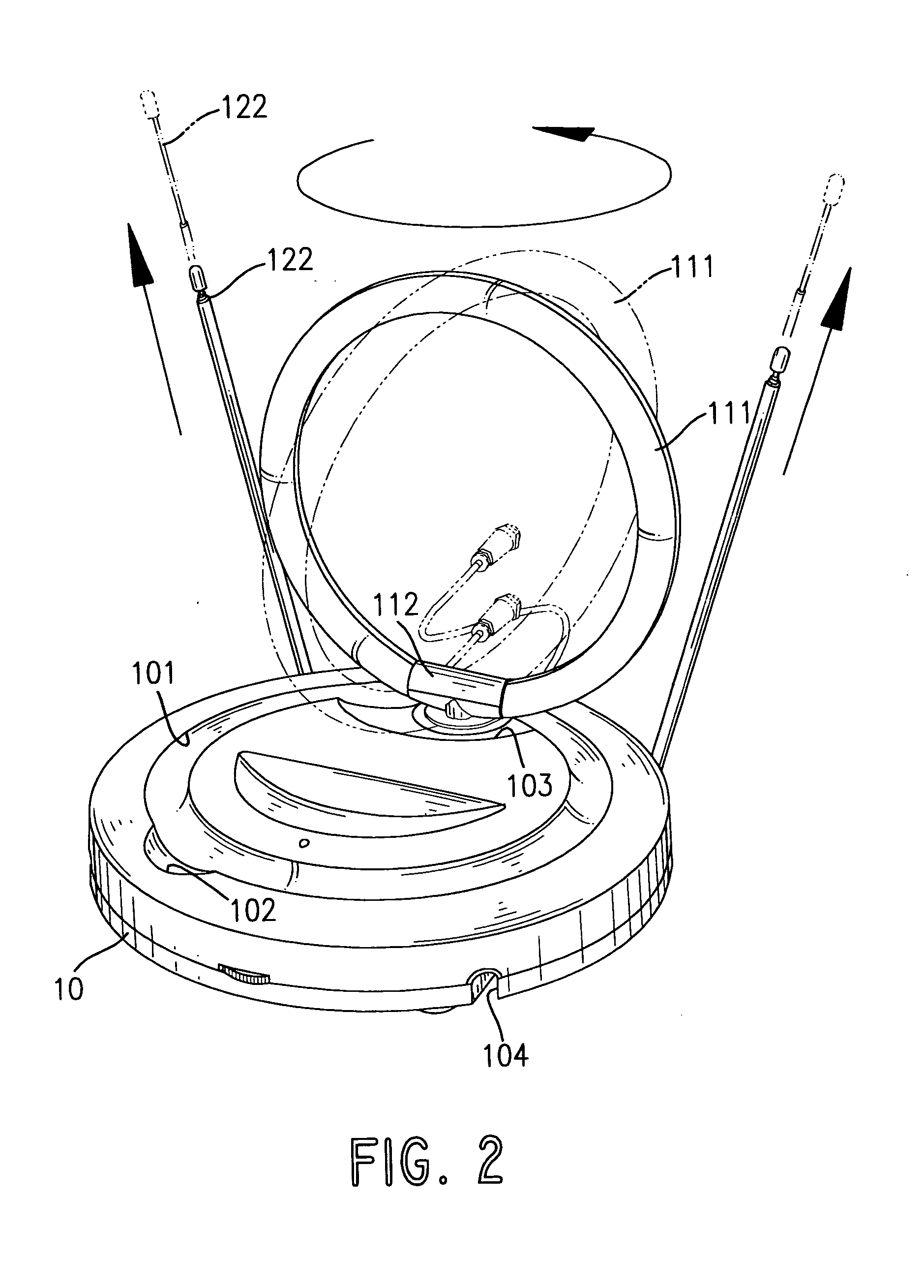

Collapsible indoor television antenna assembly

InactiveUS20050259023A1Save on packaging materialsSave storage spaceLoop antennasAntenna feed intermediatesDipole antennaLoop antenna

An indoor television antenna assembly includes a base, a UHF antenna and a VHF antenna. The base has a top, a bottom, an annular groove defined in the top and two elongated straight slots defined in the bottom alongside the base. The UHF antenna is adjustably mounted on the top of the base and includes a ring seat rotatably mounted in the rotation recess and a ring antenna pivotally mounted on the ring seat. The VHF antenna is pivotally mounted in the base and includes an inner shaft pivotally mounted in the base and two dipole antennas pivotally respectively mounted on the inner shaft and held respectively in the elongated straight slots. Consequently, the foldable UHF and VHF antennas make the entire indoor television antenna assembly compact to save packaging materials and storage space.

Owner:TRANS ELECTRIC

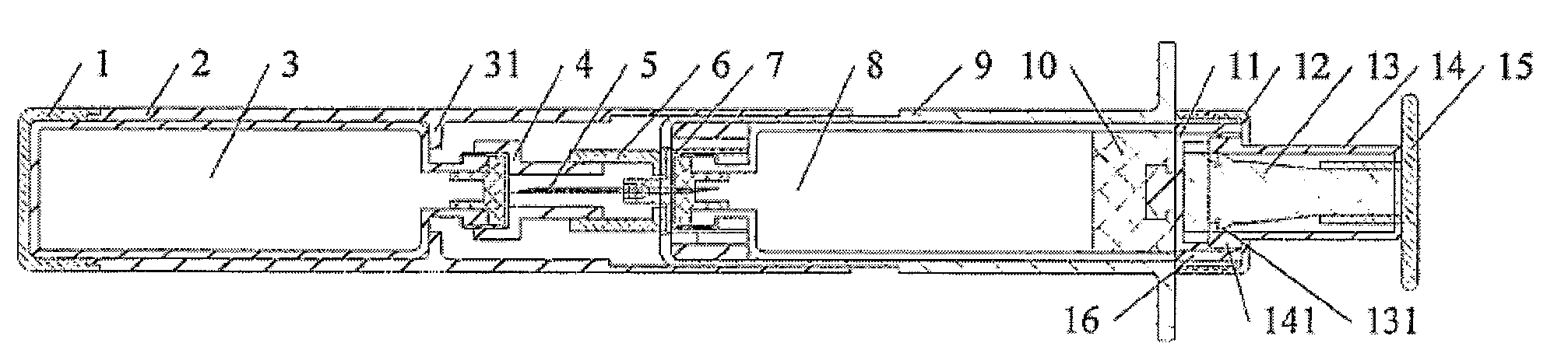

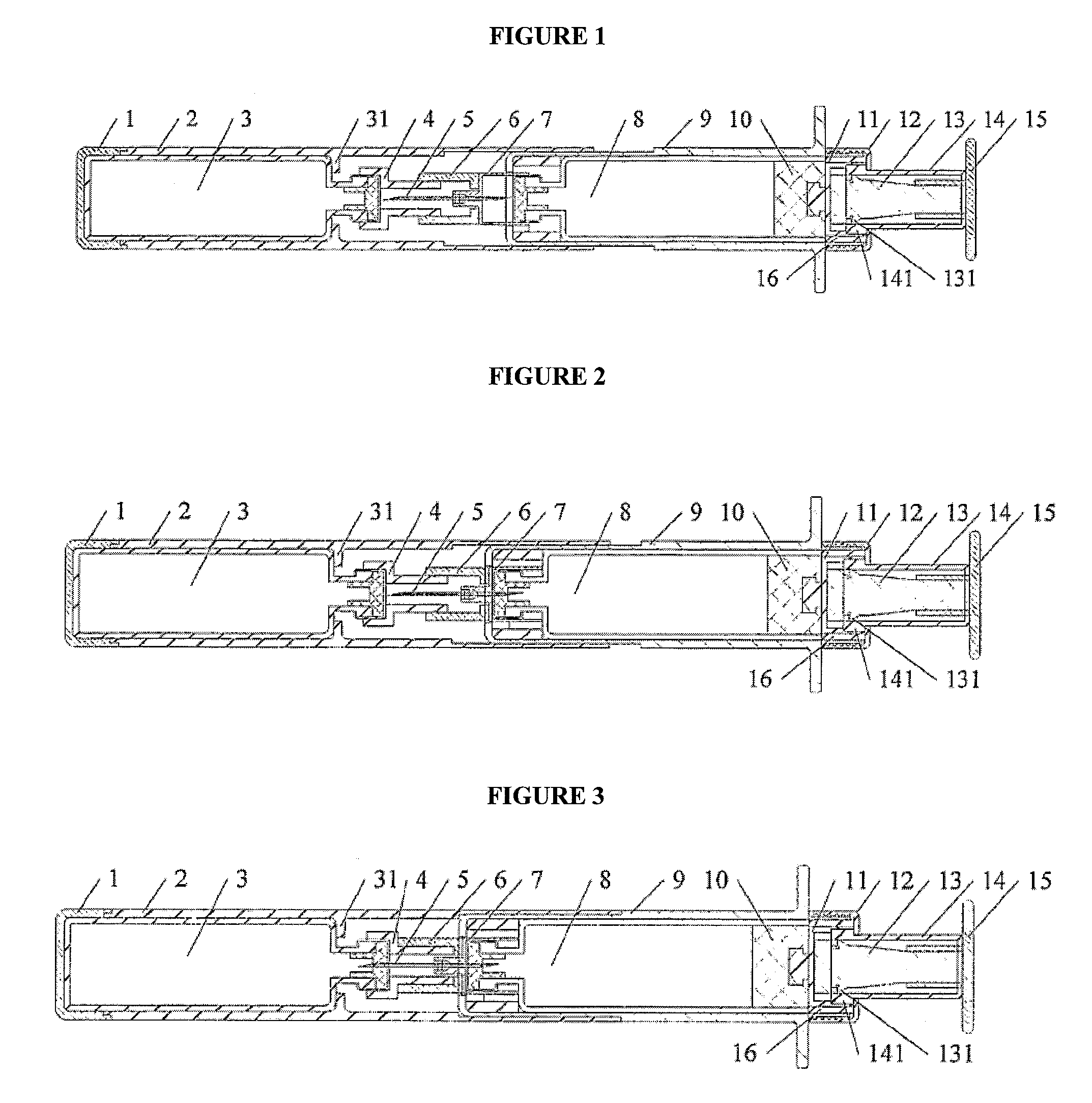

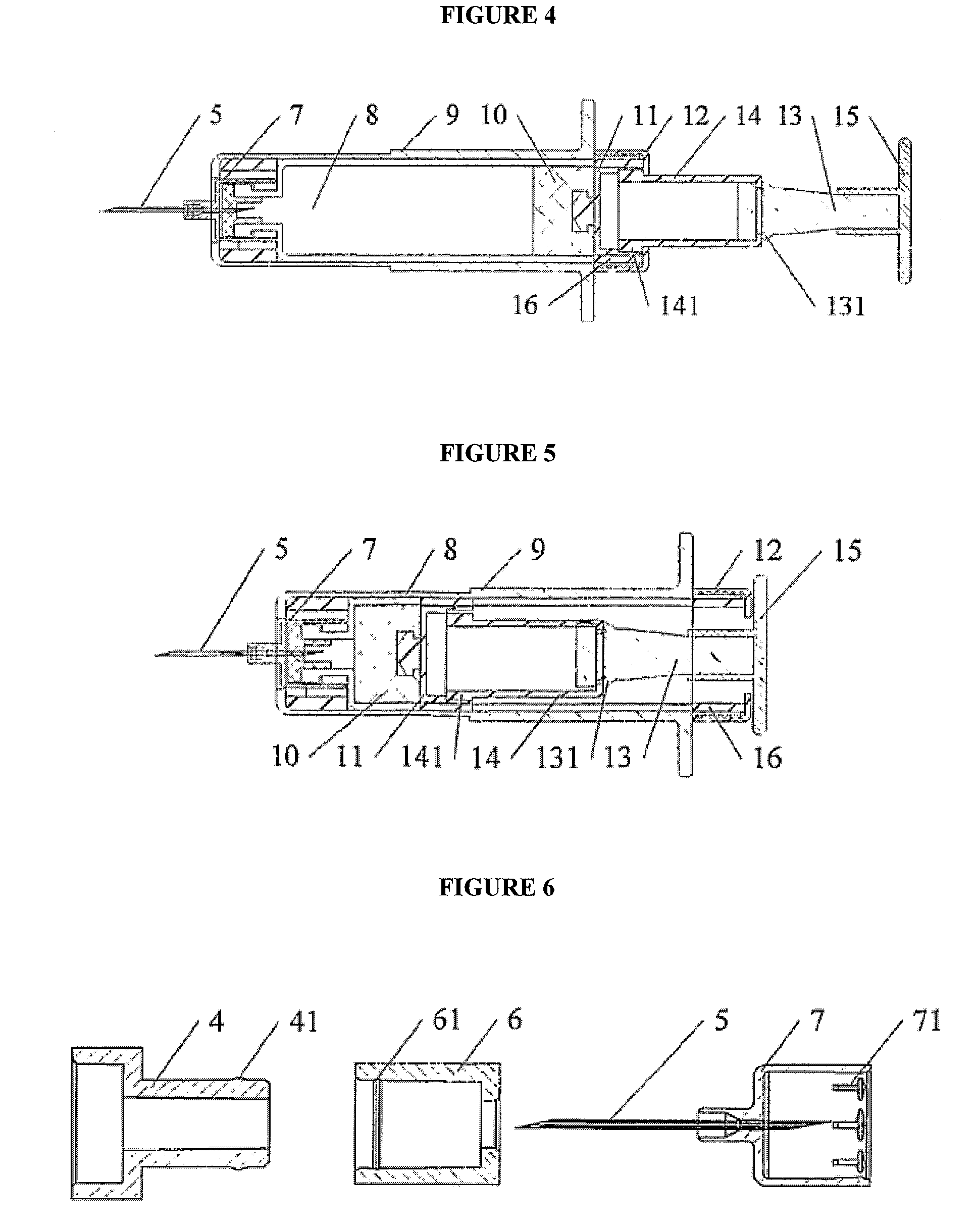

Sterile Drug-Mixing Syringe

InactiveUS20090326448A1Easy to operateInjection is simpleDiagnosticsInfusion syringesNeedle puncturePush pull

The invention is directed to a menstruum prepositioned type sterile drug-mixing syringe and a menstruum separately positioned type sterile drug-mixing syringe including a shell, a needle, a piston and a push-pull rod assembly. The syringe further includes a menstruum bottle, a solute bottle, a sliding sleeve and a needle loading assembly. The menstruum bottle may be fixed to the inner wall of a sliding sheath, and the solute bottle may be fixed to the inner of the shell. Piston may be disposed within the solute bottle. The sliding sleeve may be socketed to the front end of the shell in advance or disposed by other ways. The mouth of the menstruum bottle may be opposite to the mouth of the solute bottle and may be connected by a needle, which has two piercing tips, wherein the needle punctures and is securely connected to the needle loading assembly.

Owner:HUO PINGAN +5

Folded telephoto camera lens system

ActiveUS9316810B2Small sizeEasy to implementTelevision system detailsColor television detailsCamera lensTelephoto lens

Owner:APPLE INC

Led white light illuminator

InactiveUS20070058389A1High strengthReduce package sizeLighting heating/cooling arrangementsLight therapyEffect lightHigh intensity

Owner:INNOVATIONS & OPTICS

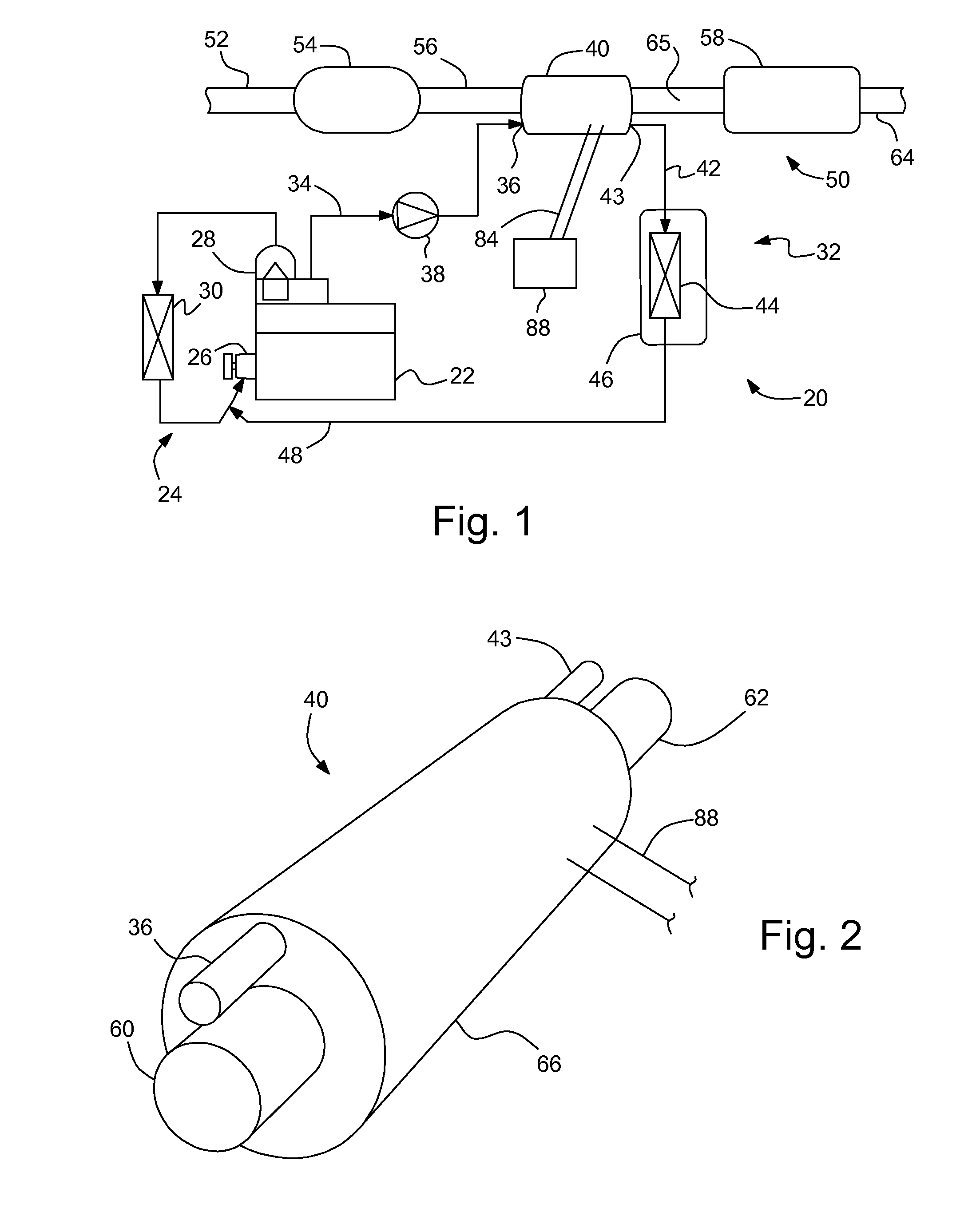

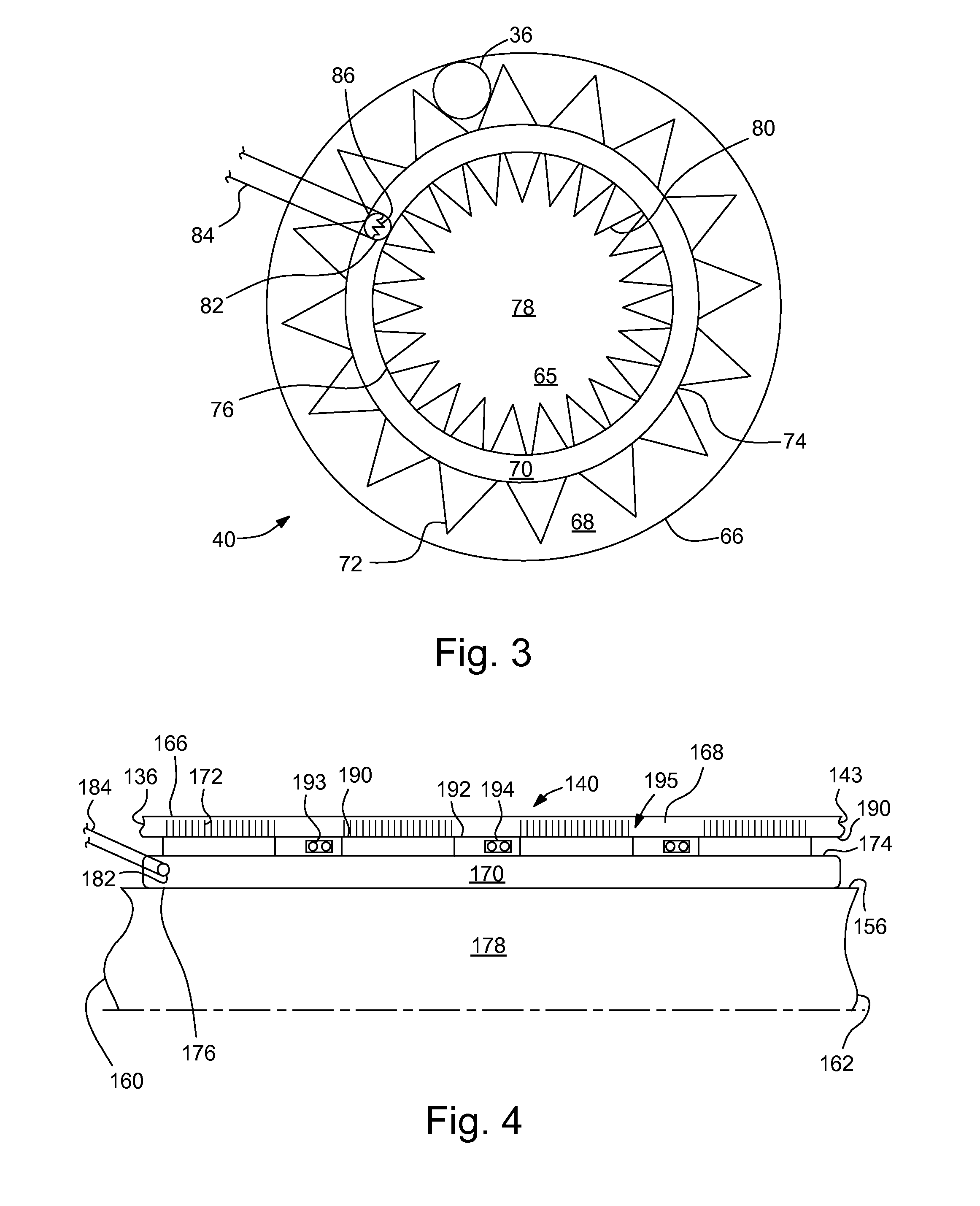

Exhaust gas waste heat recovery

InactiveUS7921640B2Faster engine warm upImprove economyInternal combustion piston enginesExhaust apparatusPower flowEngineering

Owner:GM GLOBAL TECH OPERATIONS LLC

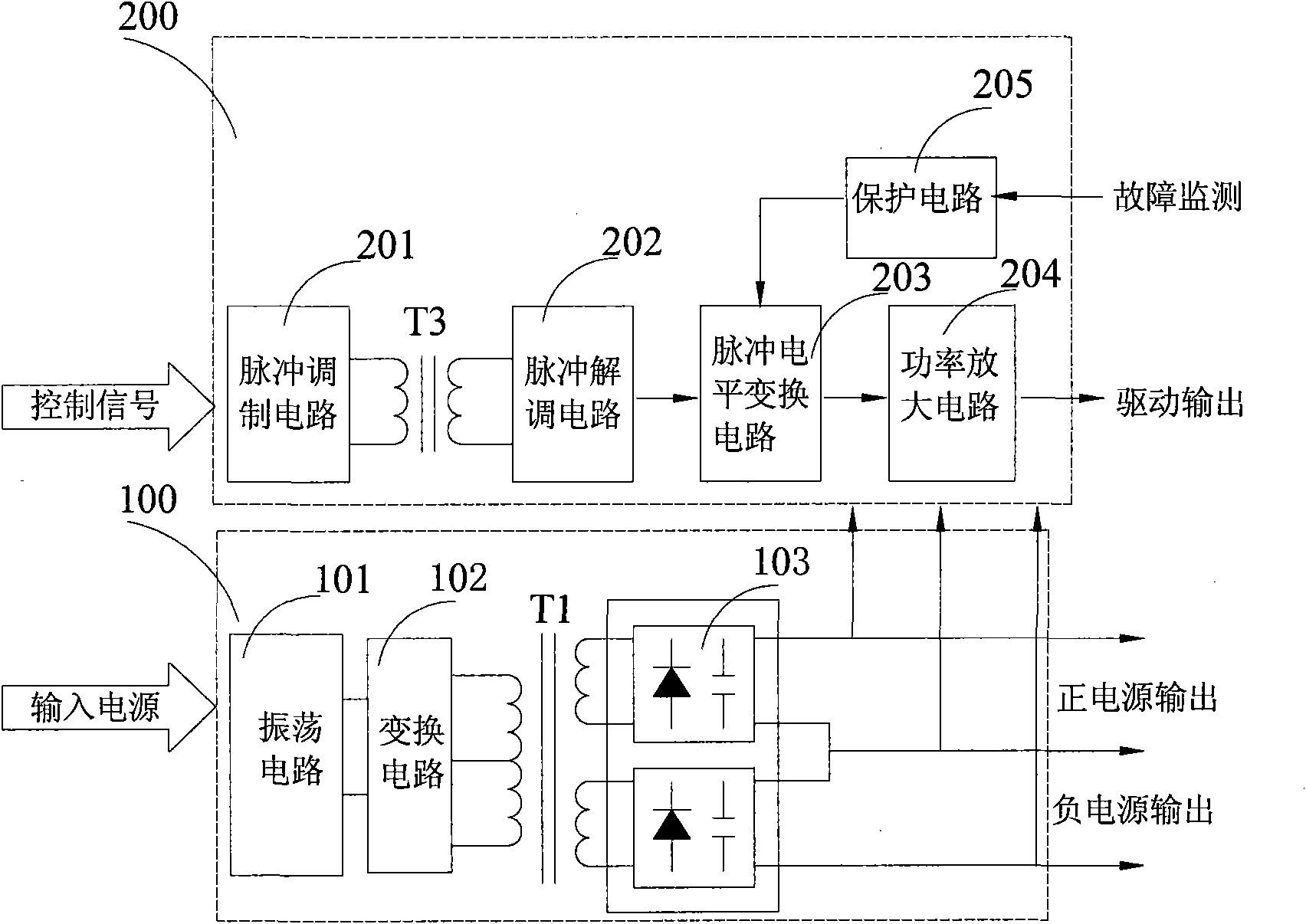

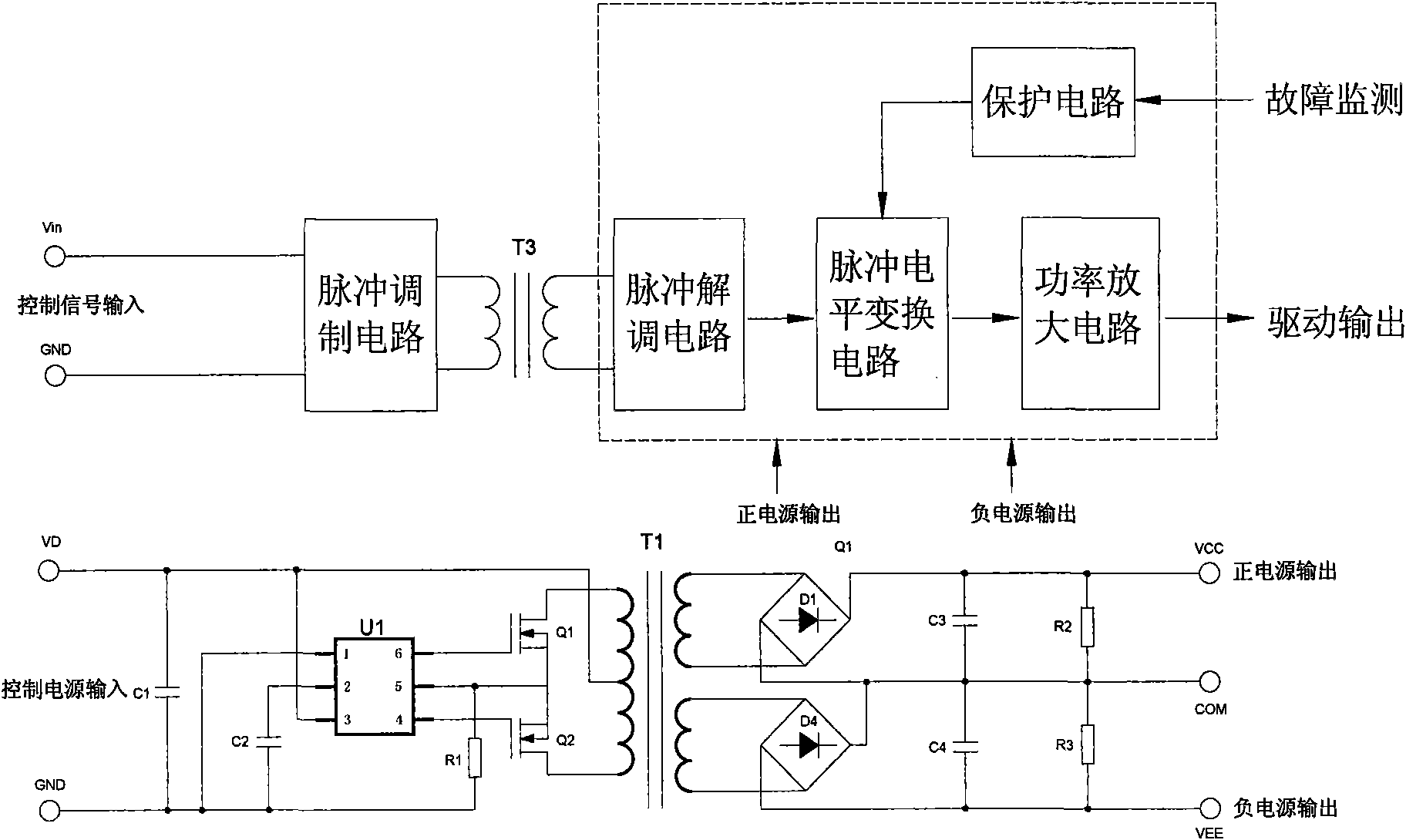

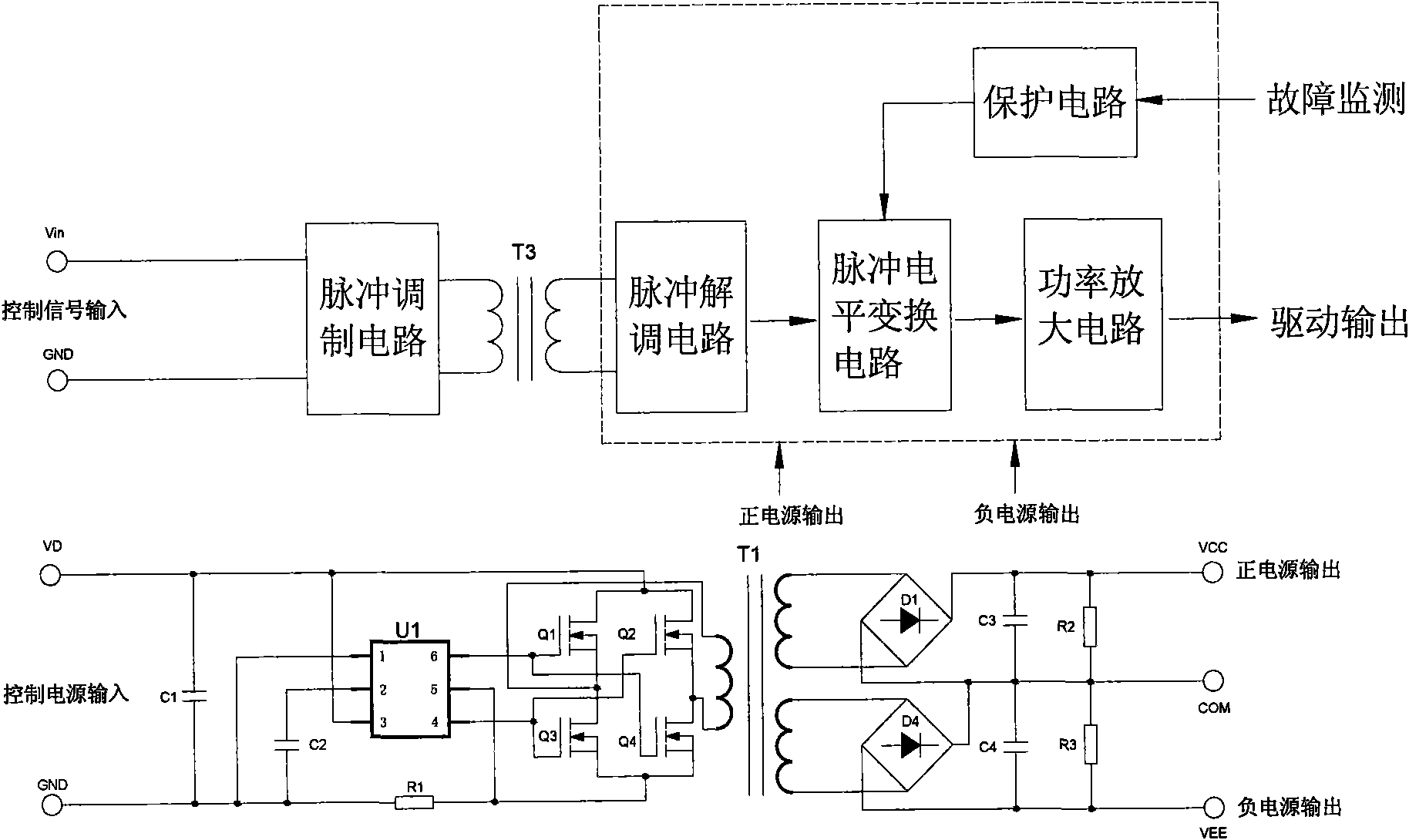

IGBT driving circuit embedded with isolating source

ActiveCN101640526AReduce stray inductanceImprove reliabilityElectronic switchingApparatus with intermediate ac conversionTransformerPush pull

The invention discloses an IGBT driving circuit embedded with an isolating source, comprising a power supply circuit and a driving circuit; wherein the power supply circuit sequentially comprises an oscillating circuit in charge of producing a push-pull driving signal, a transforming circuit which comprises at least one pair of switch tube and realizes energy transformation by alternate on / off according to the push-pull driving signal, a power transformer in charge of transmitting energy from the primary winding thereof to the secondary winding and a rectifying filtering circuit in charge of independent rectifying filtering on the secondary winding of the power transformer in two paths, wherein a common terminal is led out to realize positive and negative power supply output, so as to supply power to the driving circuit. A high-efficiency DC / DC isolating converter and the IGBT driving circuit are integrated, thus saving an outdoor isolating source and being convenient for application of a driver; and the invention is easy to be realized by adopting hybrid integrated thick film circuit, thus being beneficial to adopting SIP encapsulation and saving PCB area.

Owner:MORNSUN GUANGZHOU SCI & TECH

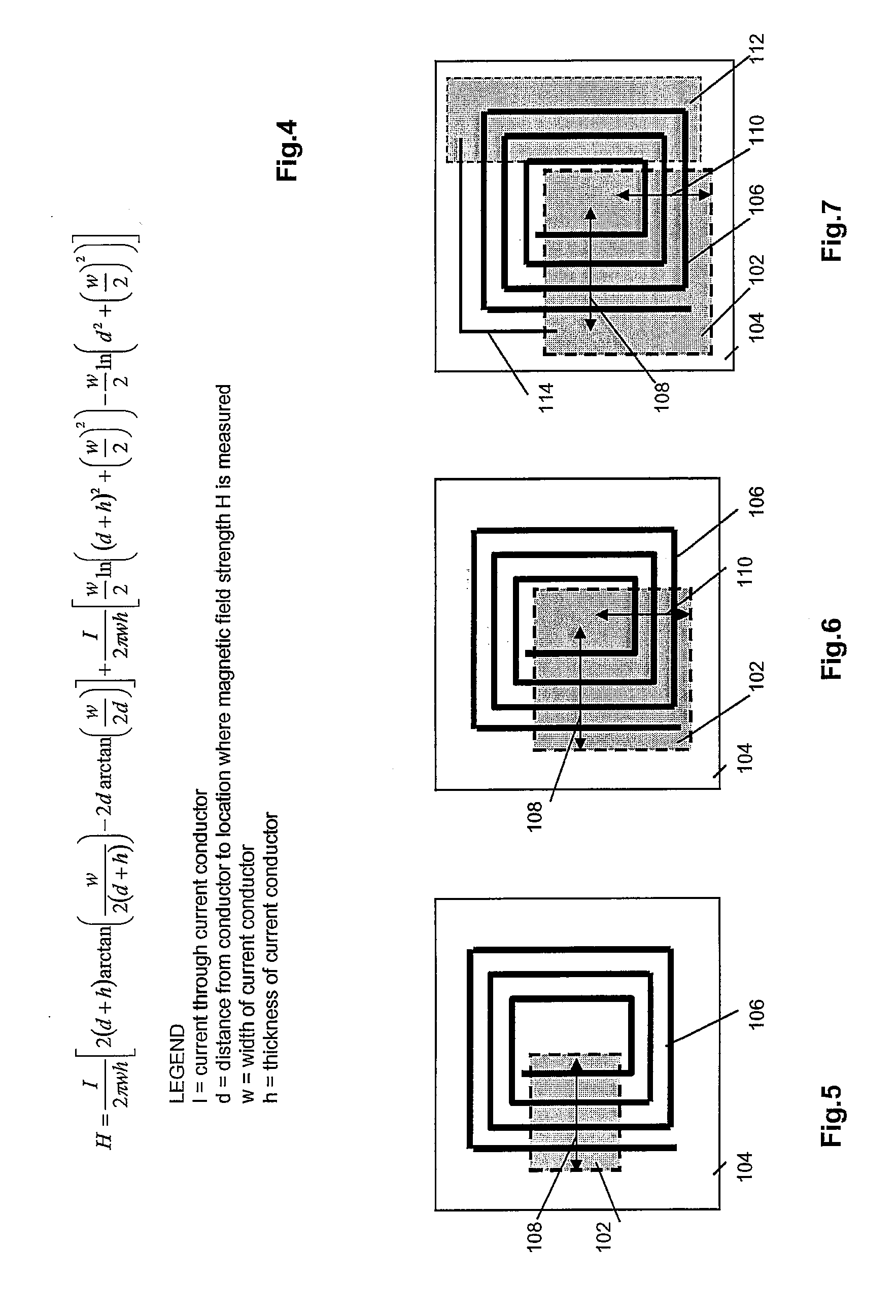

Magneto-resistive sensor

InactiveUS20100033175A1Low costReduce package sizeNanomagnetismMagnetic-field-controlled resistorsMagnetoEngineering

A high-performance, integrated AMR sensor has compensation and flipping coils for signal conditioning of the sensor output. At least one of the coils is formed in the laminate that connects the AMR sensor with its IC within a single package. As a result, the dimensions of the die area of the AMR sensor and the package size can be kept small.

Owner:NXP BV

Flipchip QFN package and method therefor

ActiveUS6867072B1Reduce package sizeLess costlySemiconductor/solid-state device detailsSolid-state devicesLead frameSemiconductor

A semiconductor device (10) includes a first leadframe (18) having a perimeter (20) that defines a cavity (22) and leads (14) extending inwardly from the perimeter, and a second leadframe (32) having top and bottom surfaces and a die paddle surrounding a die receiving area (36). An integrated circuit (12) is placed within the die receiving area of the second leadframe. The IC has bonding pads (44) located on a peripheral portion of its top surface. The second leadframe and the IC are in facing relation with the first leadframe such that the leads of the first leadframe are electrically connected to respective ones of the bonding pads. A mold compound (50) is injected between the first and second leadframes and covers the second leadframe top surface and a central area of the first surface of the IC. At least the bottom surfaces of the leads are exposed.

Owner:NORTH STAR INNOVATIONS

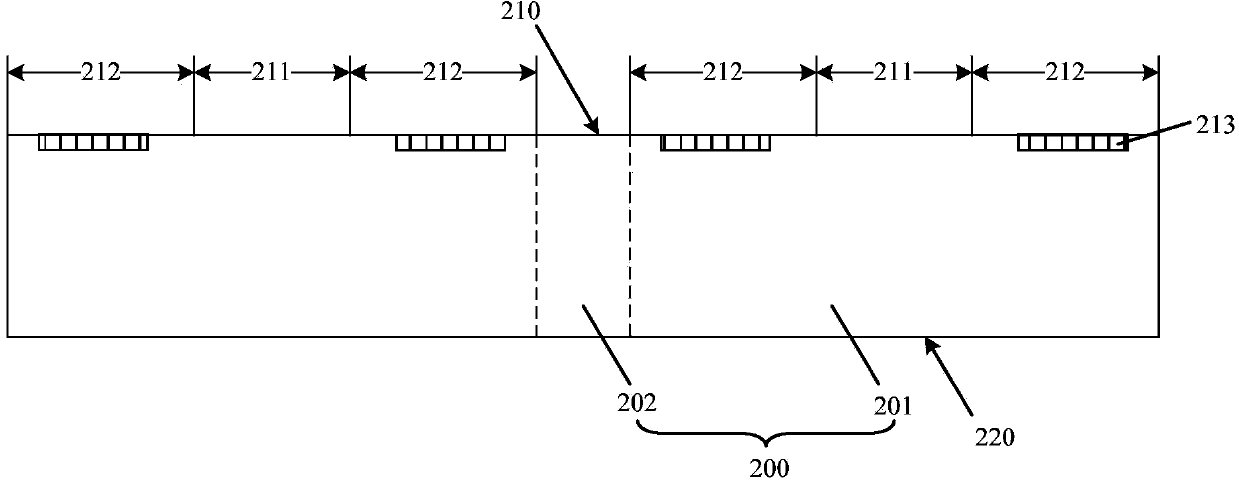

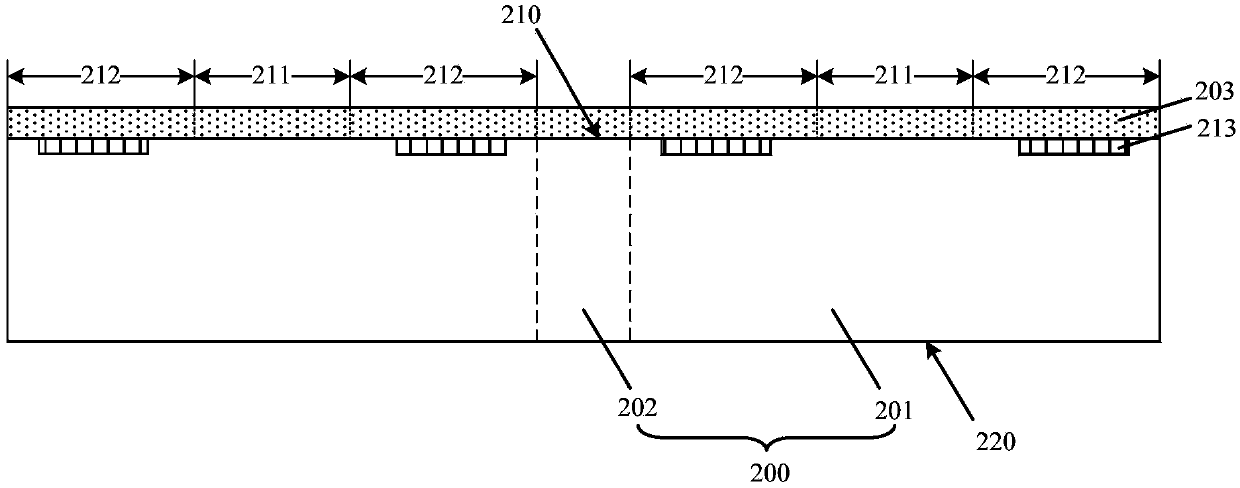

Wafer-level fingerprint recognition chip packaging structure and method

InactiveCN104201115ASimplify the packaging processReduce damageMeasurement apparatus componentsSemiconductor/solid-state device detailsFingerprintComputer science

Disclosed is a wafer-level fingerprint recognition chip packaging structure and method. The method includes: providing a substrate which comprises a plurality of induction chip areas and is provided with a first surface and a second surface opposite to the first surface, wherein a first surface of each induction chip area comprises an induction area; forming a covering layer on the first surface of the substrate; forming a plug structure in each induction chip area of the substrate, wherein one end of each plug structure is electrically connected with the corresponding induction area, and the other end of each plug structure is exposed out of the second surface of the substrate. By the forming method, the packaging process of a fingerprint recognition chip can be simplified, the requirement on sensitivity of the induction chip is lowered, and the packaging method is wider in application.

Owner:CHINA WAFER LEVEL CSP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com