Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

480 results about "Capacitive microphone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon capacitive microphone

InactiveUS6847090B2Transducer detailsSemiconductor electrostatic transducersSemiconductor materialsEngineering

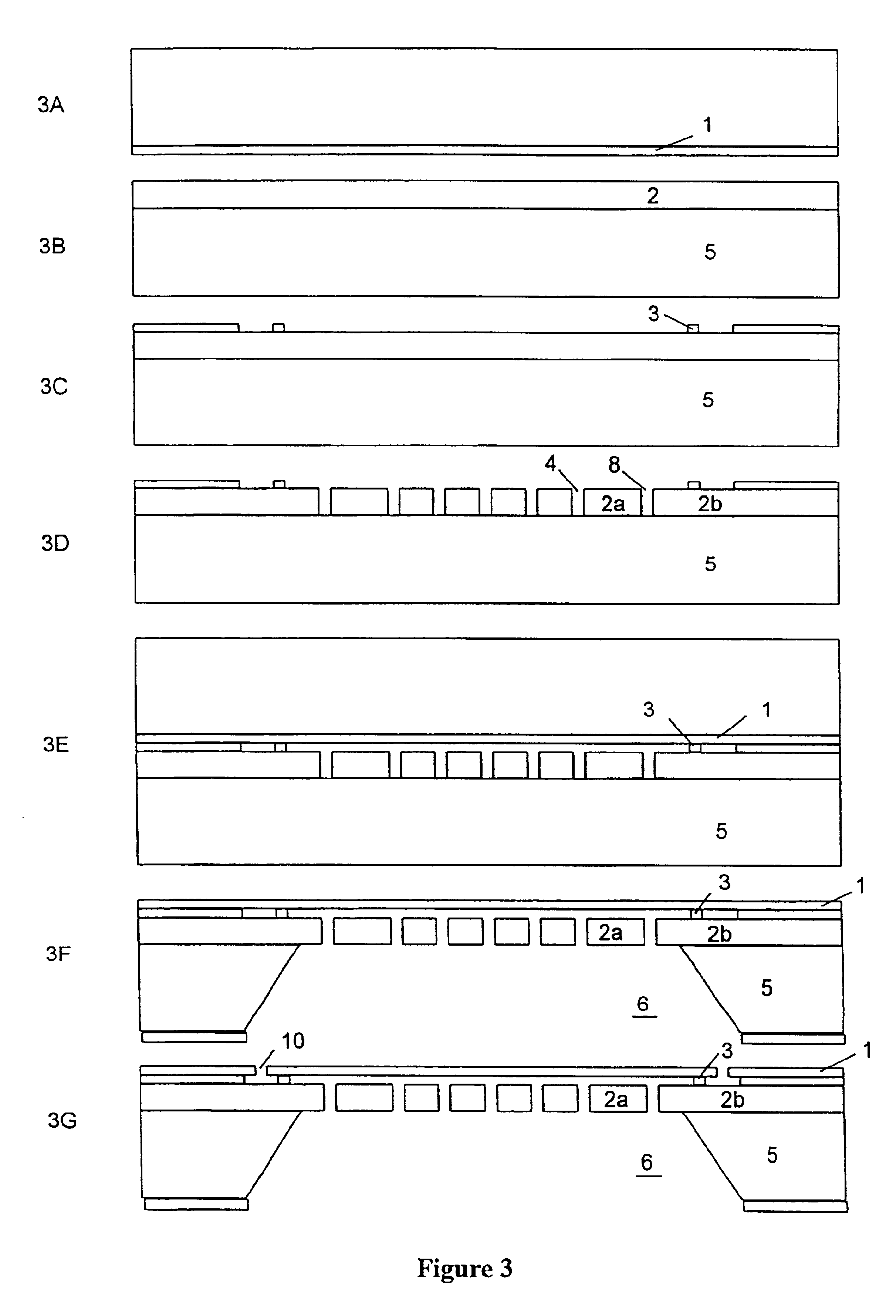

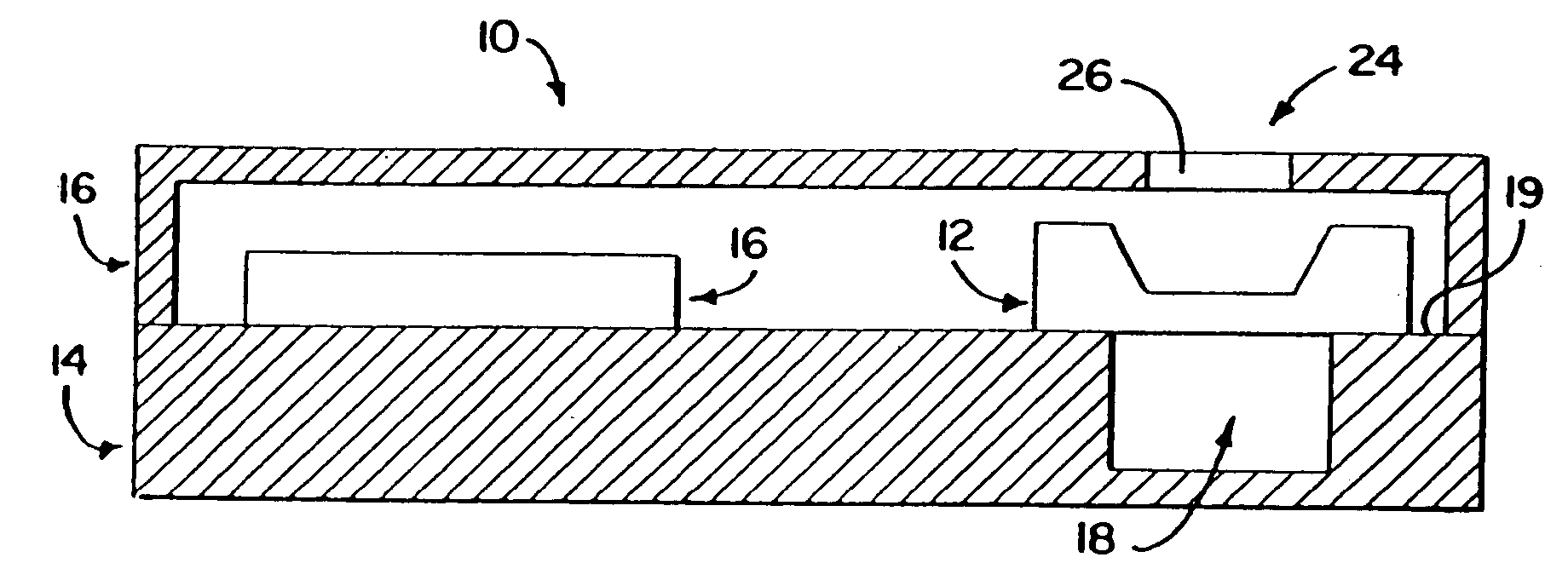

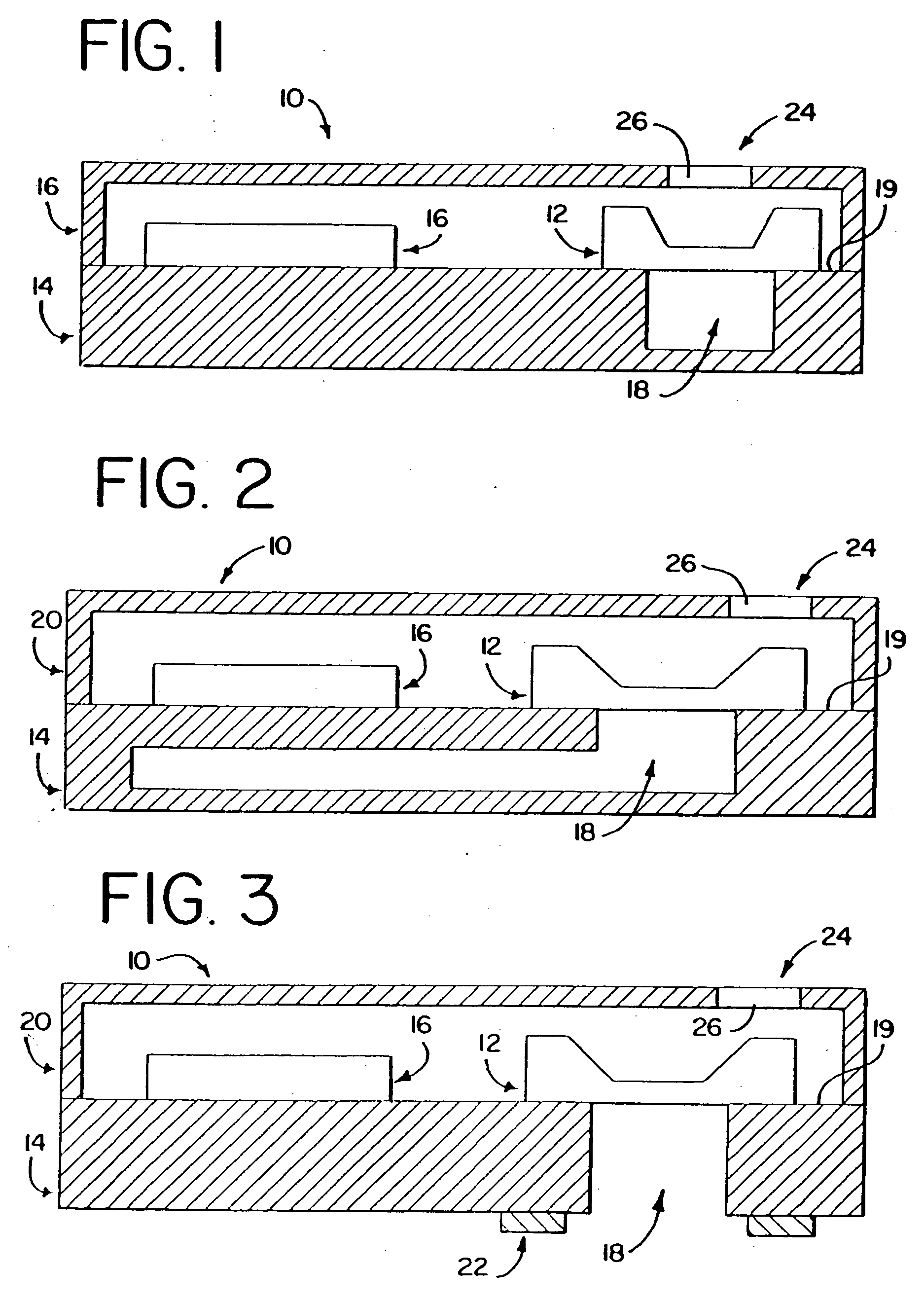

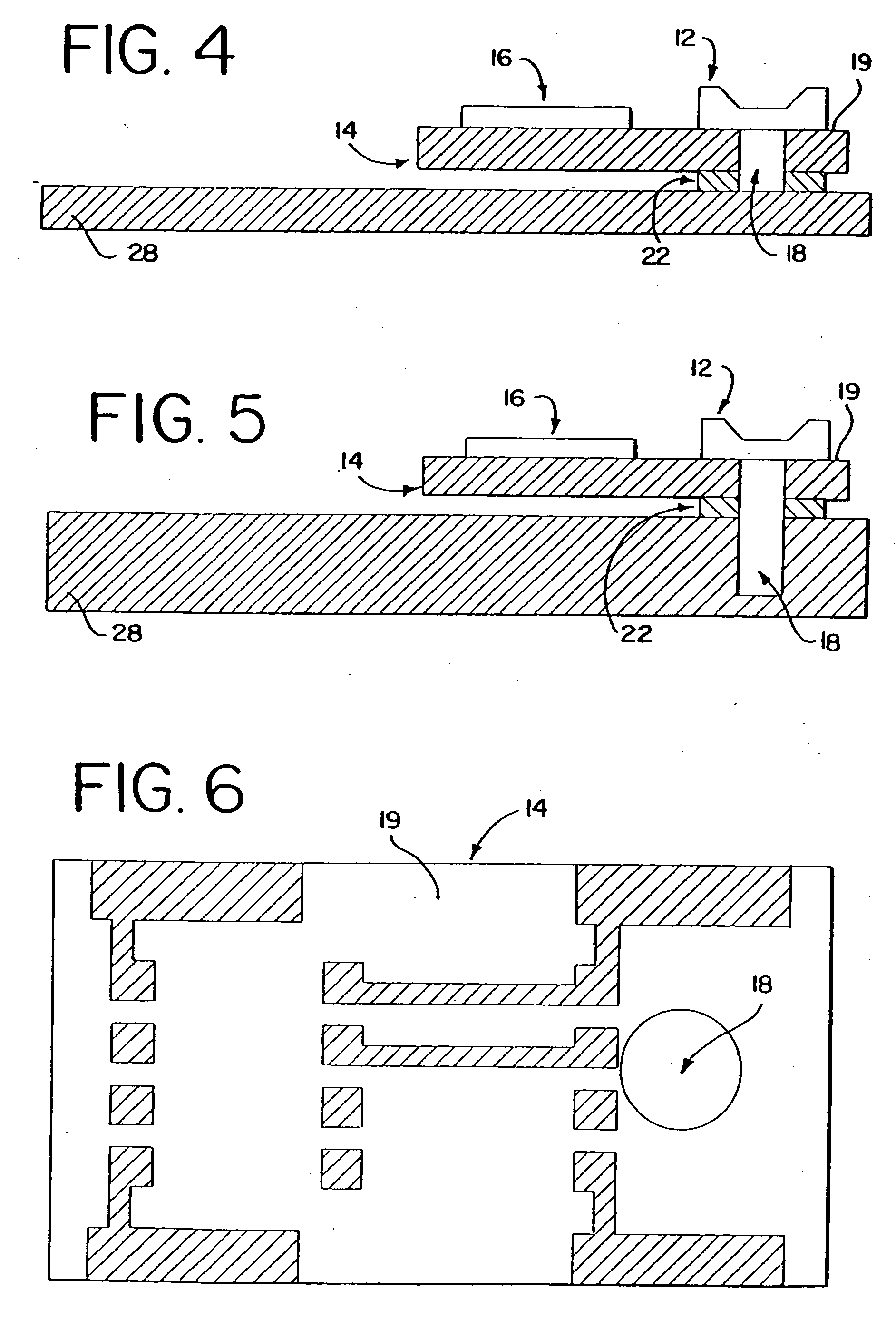

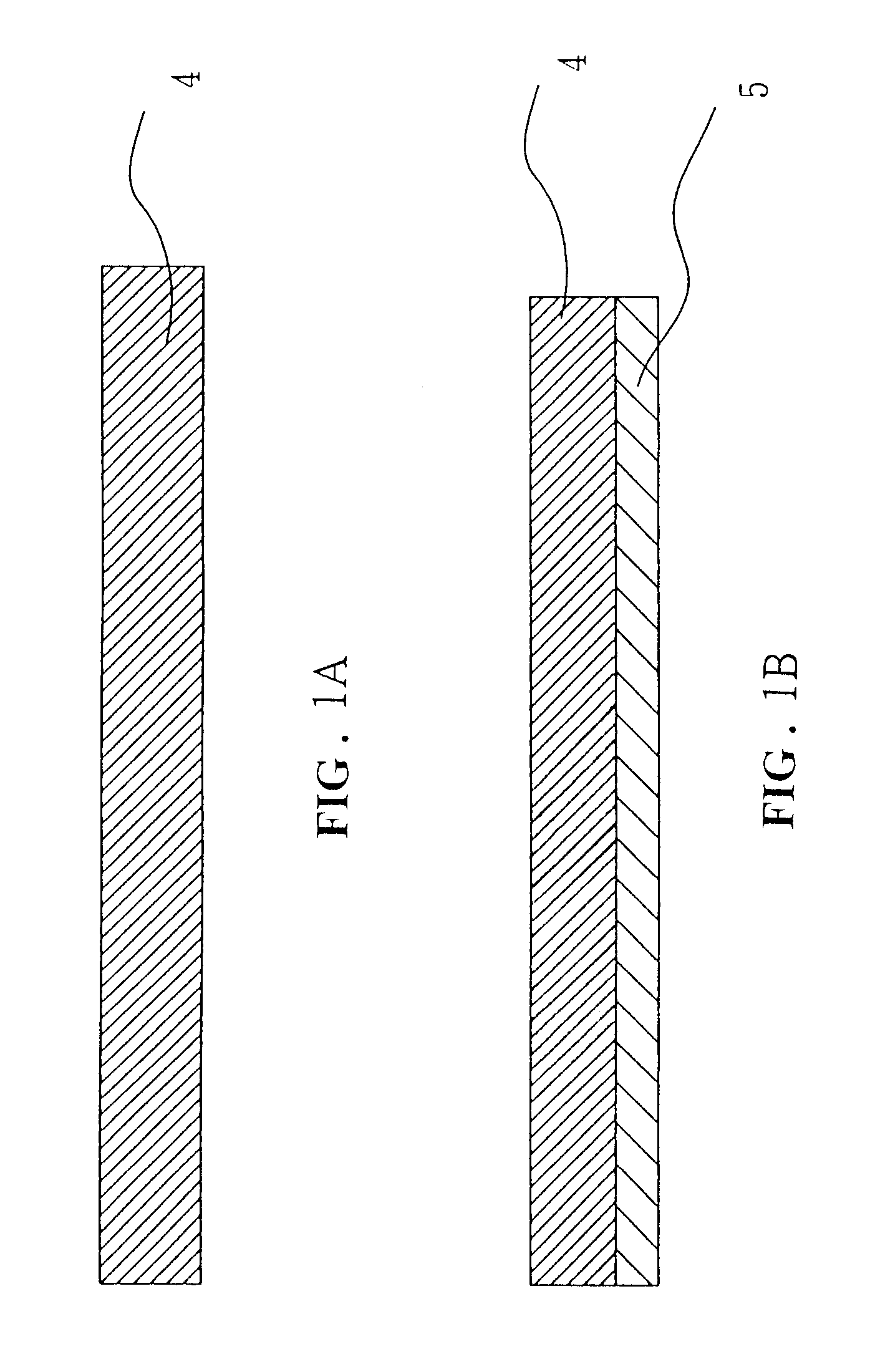

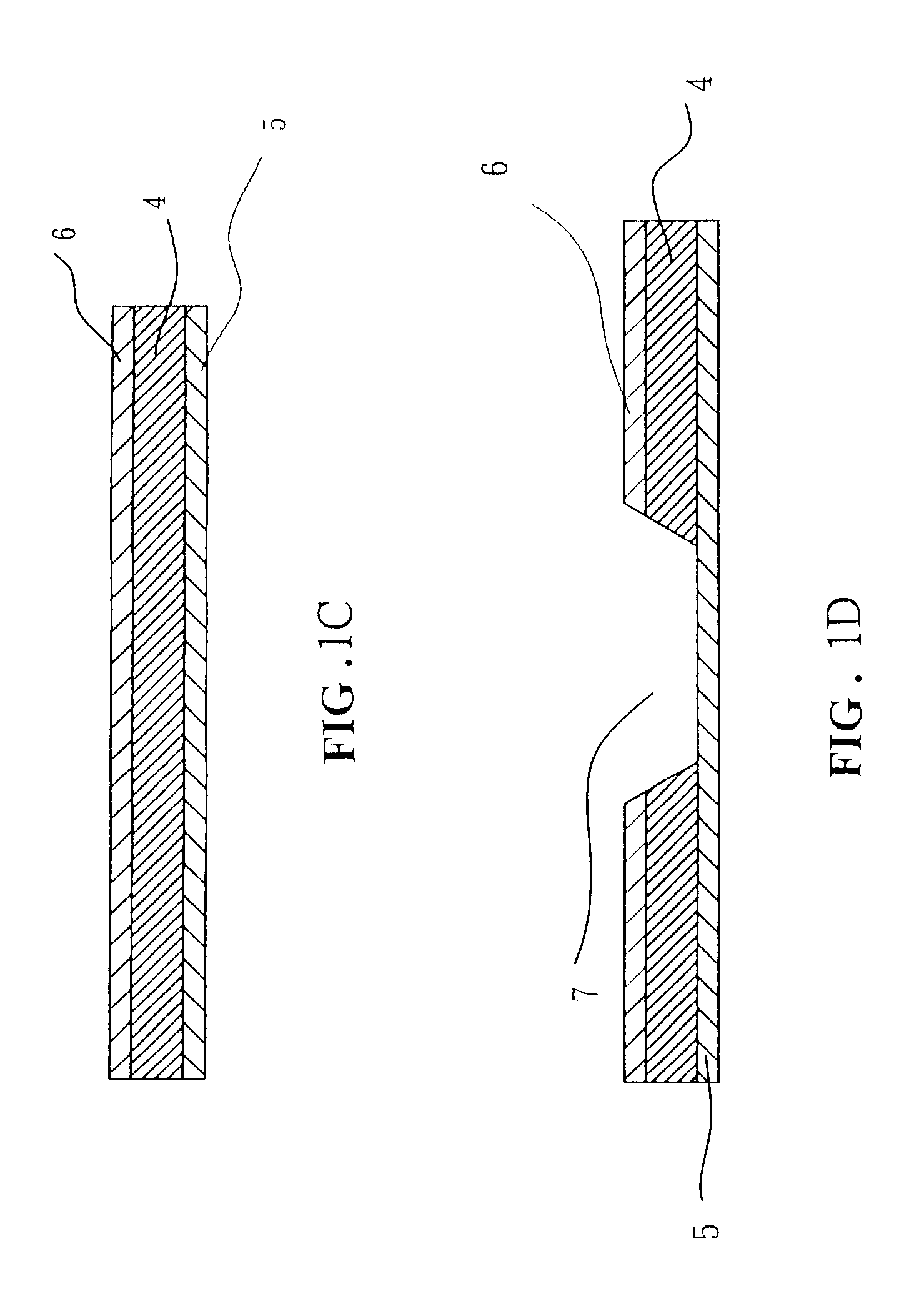

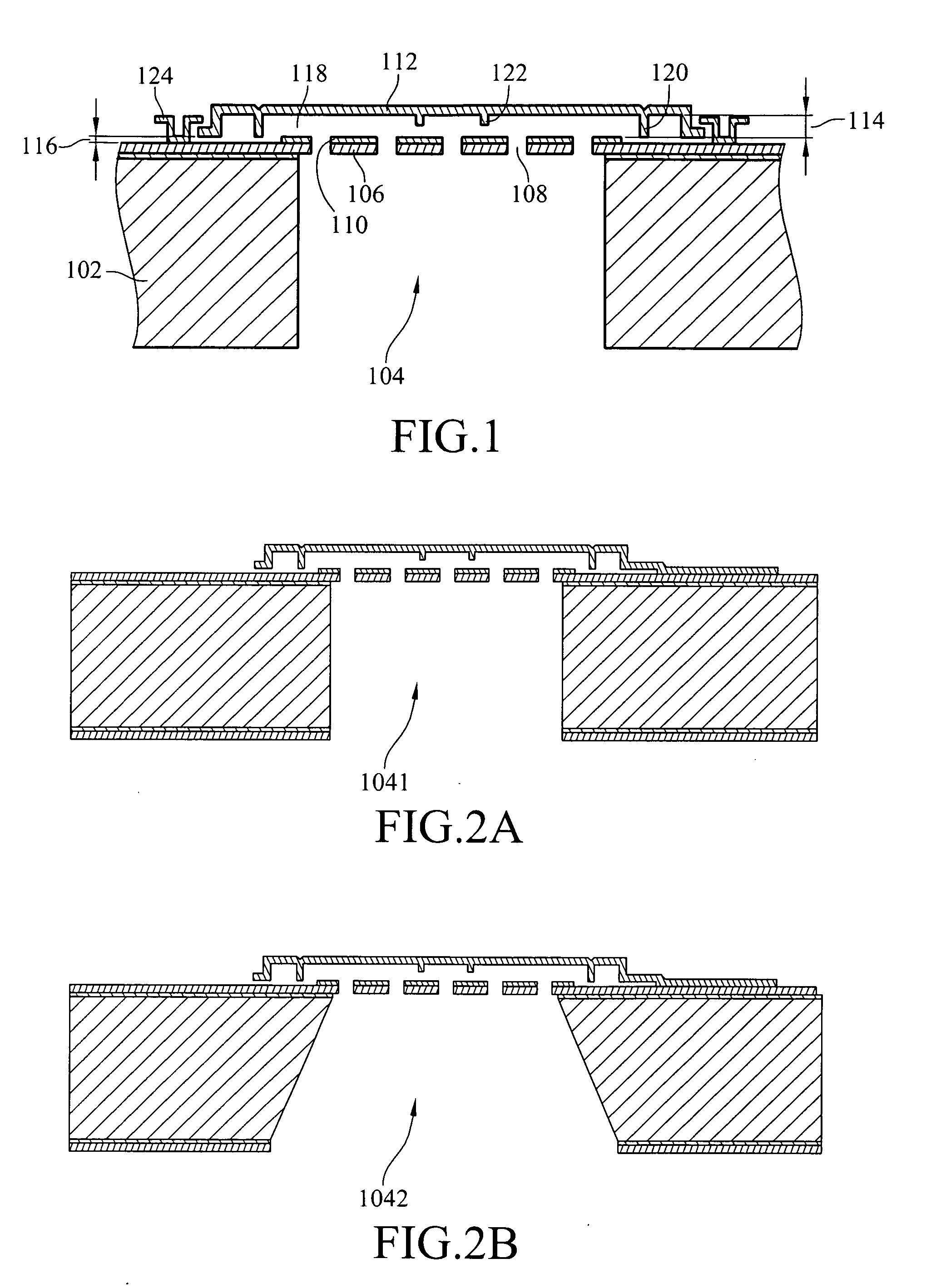

The present invention is directed to a process for the manufacture of a plurality of integrated capacitive transducers. The process comprises the steps of supplying a first substrate of a semiconductor material having first and second faces, supplying a second substrate of a semiconductor material having first and second faces, forming a diaphragm layer on the first face of the first substrate, forming a backplate layer on the first face of the other of the second substrate, forming a support layer on the backplate layer, etching a plurality of supports from the support layer, for each of the capacitive transducers, etching a plurality of vents from the backplate layer, for each of the capacitive transducers, positioning the diaphragm layer of the first substrate adjacent with the support layer of the second substrate, and welding the diaphragm layer and the support layer together, removing at least a portion of the first substrate to expose the diaphragm layer, for each of the capacitive transducers, removing a portion of the second substrate to expose the vents, for each of the capacitive transducers, and, etching a portion of the diaphragm layer, for each of the capacitive transducers.

Owner:KNOWLES ELECTRONICS INC

Condenser microphone

InactiveUS20070201710A1High sensitivityReduce tensile stressMicrophonesLoudspeakersCapacitanceEngineering

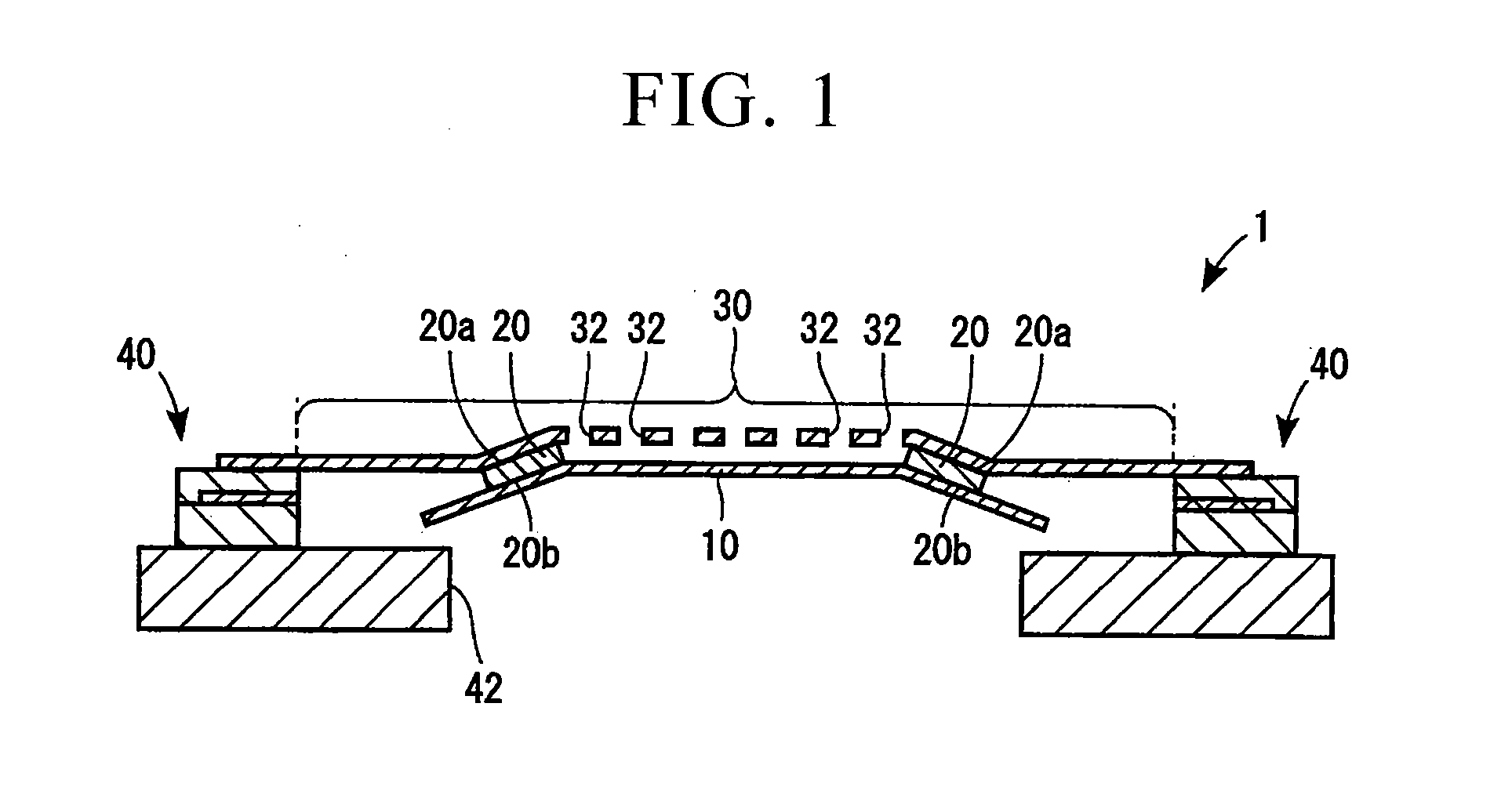

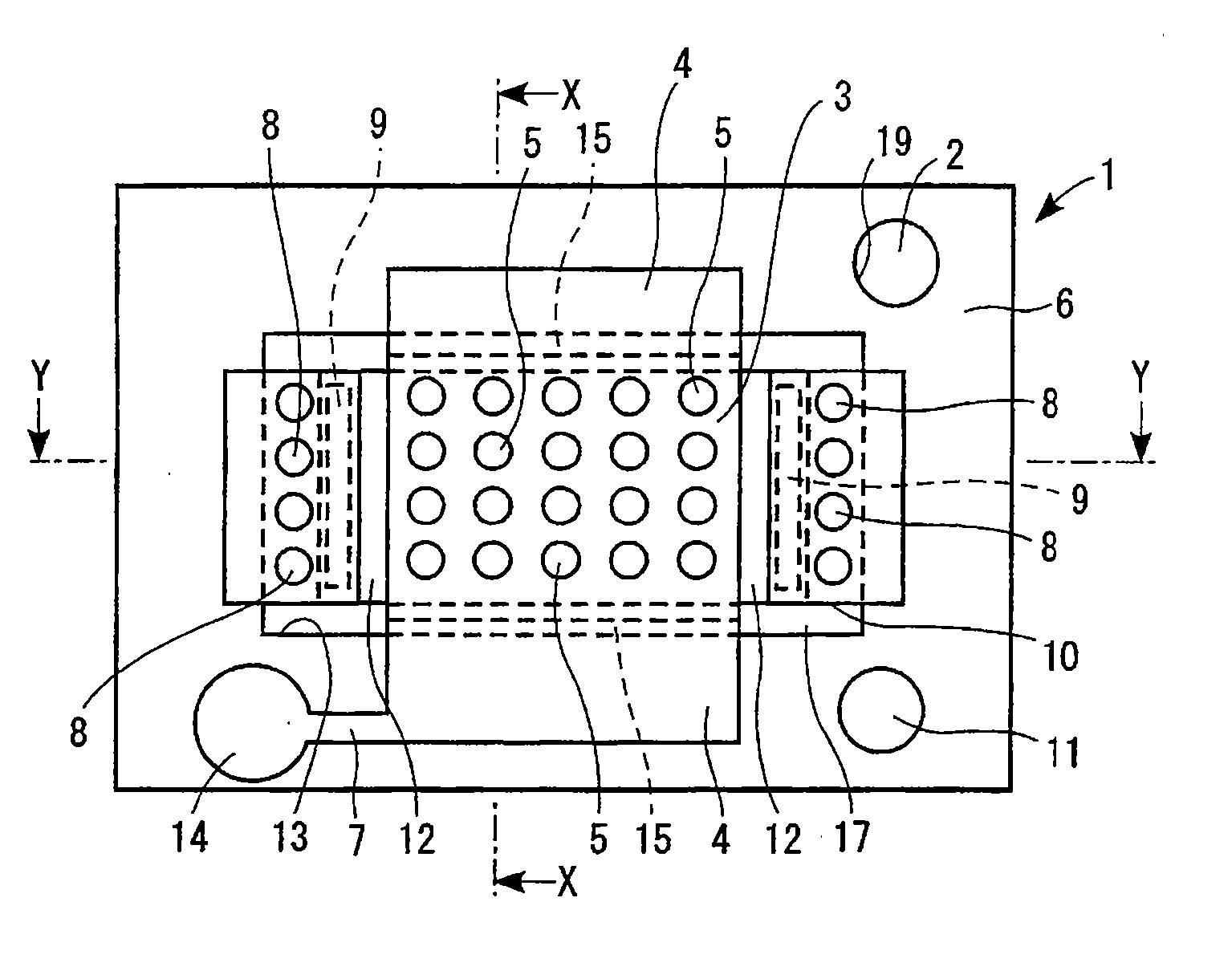

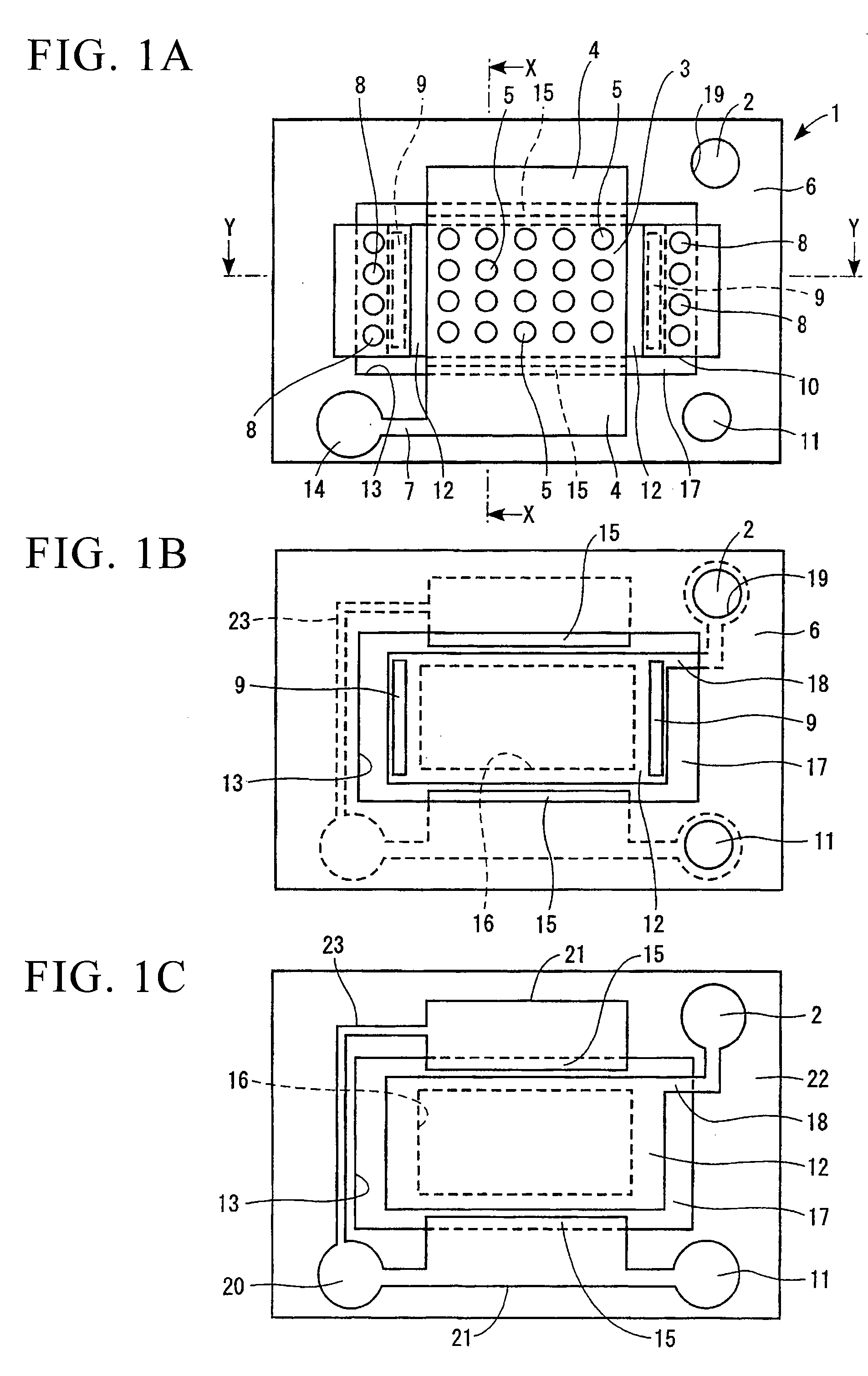

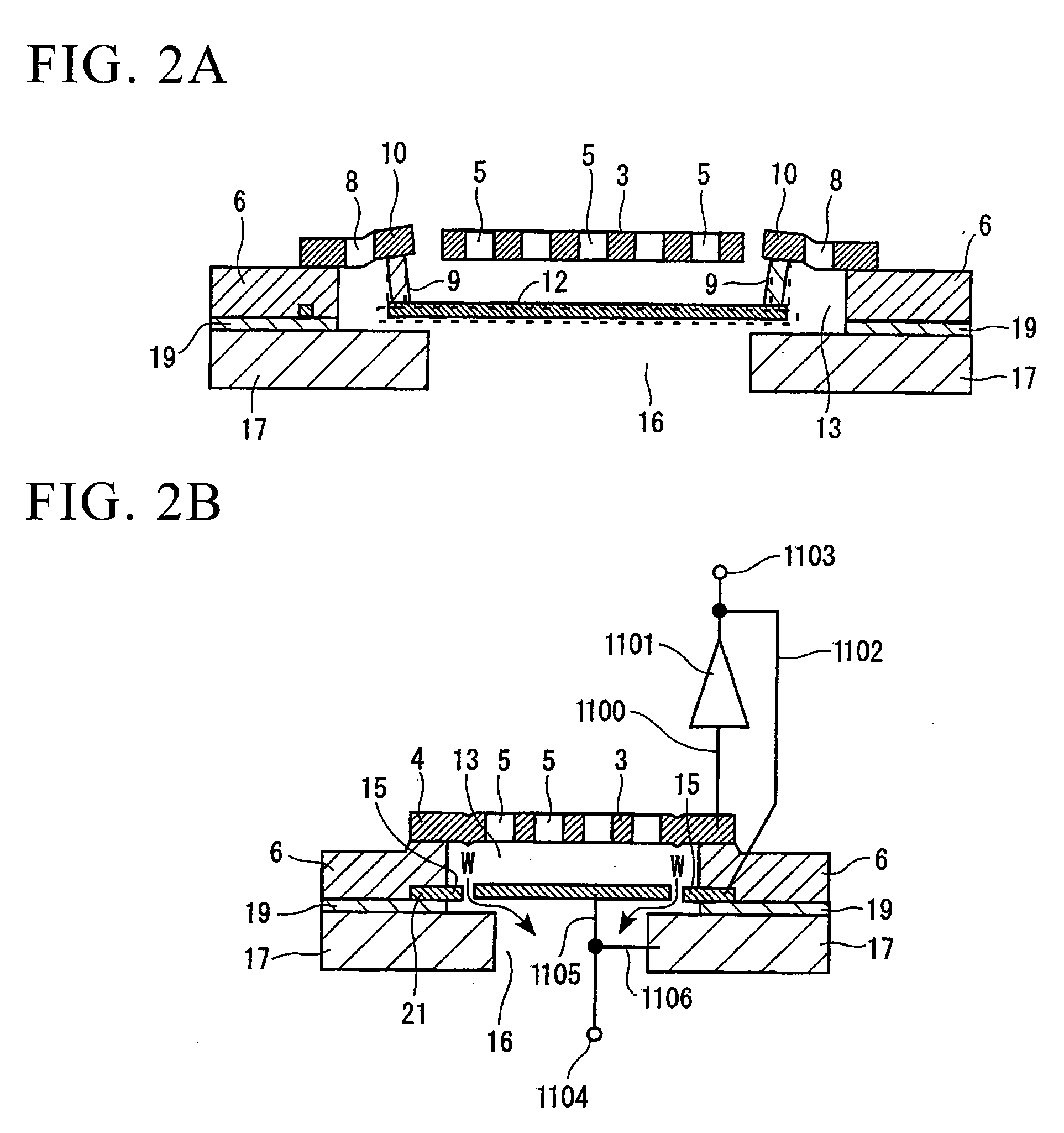

A condenser microphone includes a support, a plate having a fixed electrode bridged across the supports, a diaphragm, which has a moving electrode at a center portion thereof and which vibrates due to sound waves applied thereto, and a spacer, in which a first end is fixed to the plate, and a second end is fixed to the near-end portion of the diaphragm so as to surround the center portion of the diaphragm, wherein an air gap is formed between the plate and the diaphragm. This reduces the tensile stress of the diaphragm so as to increase the amplitude of vibration of the diaphragm. Hence, it is possible to increase the sensitivity of the condenser microphone. A structure constituted of the plate, the diaphragm, and the spacer is bridged across the support by means of the bridges, which absorb the residual stress of the diaphragm due to the deformation thereof.

Owner:YAMAHA CORP

Miniature silicon condenser microphone and method for producing the same

InactiveUS20050185812A1Piezoelectric/electrostrictive microphonesSemiconductor/solid-state device detailsTransducerEngineering

A silicon condenser microphone package includes a transducer unit, a substrate, and a cover. The substrate includes an upper surface transducer unit is attached to the upper surface of the substrate and overlaps at least a portion of the recess wherein a back volume of the transducer unit is formed between the transducer unit and the substrate. The cover is placed over the transducer unit and either the cover or the substrate includes an aperture.

Owner:KNOWLES ELECTRONICS INC

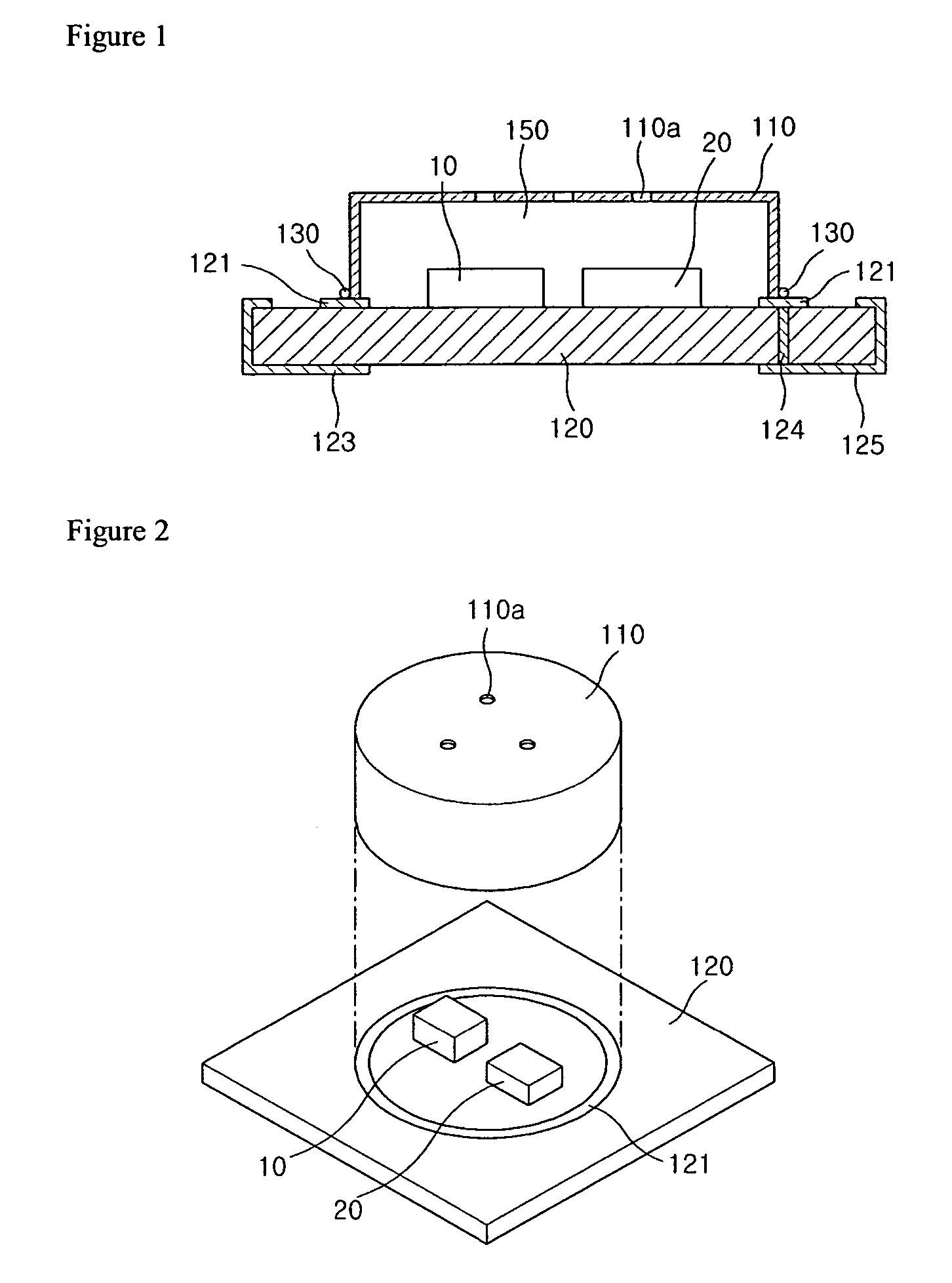

Silicon based condenser microphone and packaging method for the same

InactiveUS7903831B2High bonding strengthIncrease resistanceSolid-state devicesElectrostatic transducer microphonesMems microphoneCondenser microphone

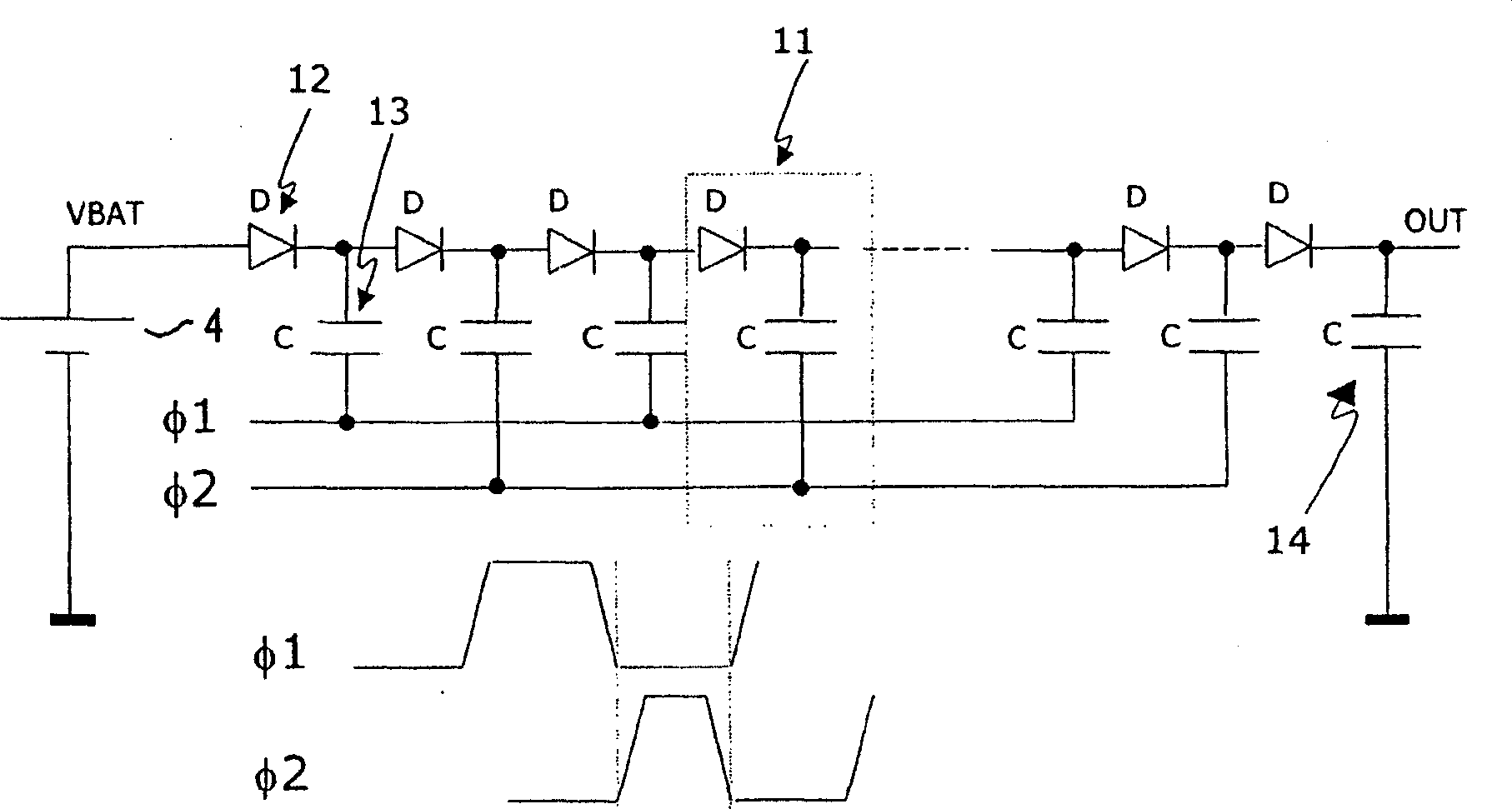

Disclosed are a silicon based condenser microphone and a packaging method for the silicon based condenser microphone. The silicon based condenser microphone comprises a metal case, and a board which is mounted with a MEMS microphone chip and an ASIC chip having an electric voltage pump and a buffer IC and is formed with a connecting pattern for bonding with the metal case, wherein the connecting pattern is welded to the metal case. The method for packaging a silicon based condenser microphone includes the steps of inputting a board which is mounted with a MEMS chip and an ASIC chip and is formed with a connecting pattern; inputting a metal case, aligning the metal case on the connecting pattern of the board, and welding an opened end of the metal case to the connecting pattern of the board. Thus, the metal case is welded to the board by the laser.

Owner:BSE CO LTD

Micromachined Capacitive Microphone

InactiveUS20060280319A1Wide and flat frequency responseHigh sensitivitySemiconductor electrostatic transducersDeaf-aid setsElectrical conductorEngineering

This invention relates to a micromachined capacitive microphone having a shallowly corrugated diaphragm that is anchored at one or more locations on the support has a plurality of dimples to support itself and rest freely on the perforated backplate. The diaphragm whose ends are not anchored is bounded by the taps of edge rail. Also disclosed includes: a fixed perforated backplate having one or more regions; an adjustable cantilever formed by the diaphragm, the support and the backplate; a plurality of dimples maintaining vertical separation between diaphragm and backplate; and the patterning of conductor electrodes carried by diaphragm and backplate.

Owner:GENERAL MEMS CORP

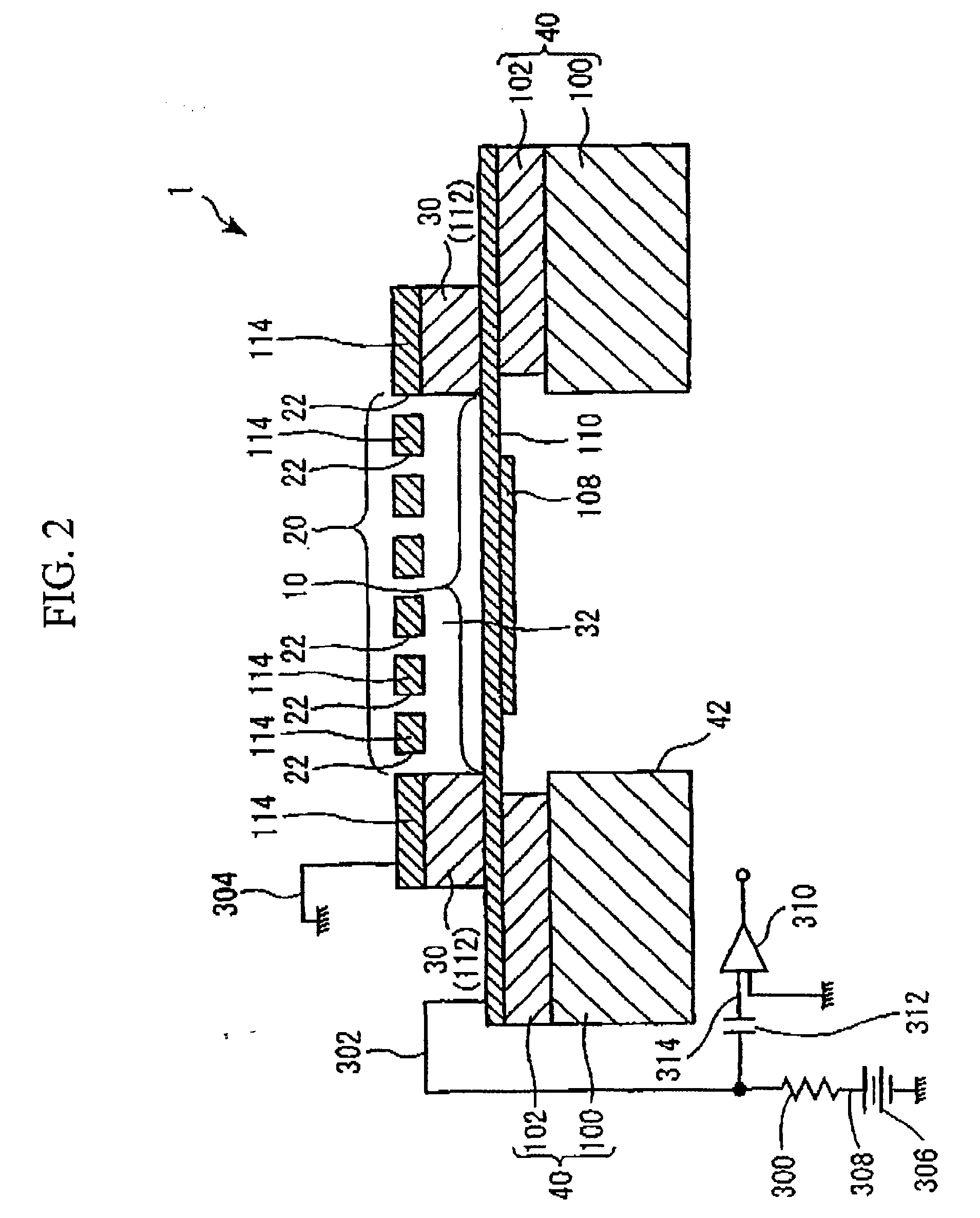

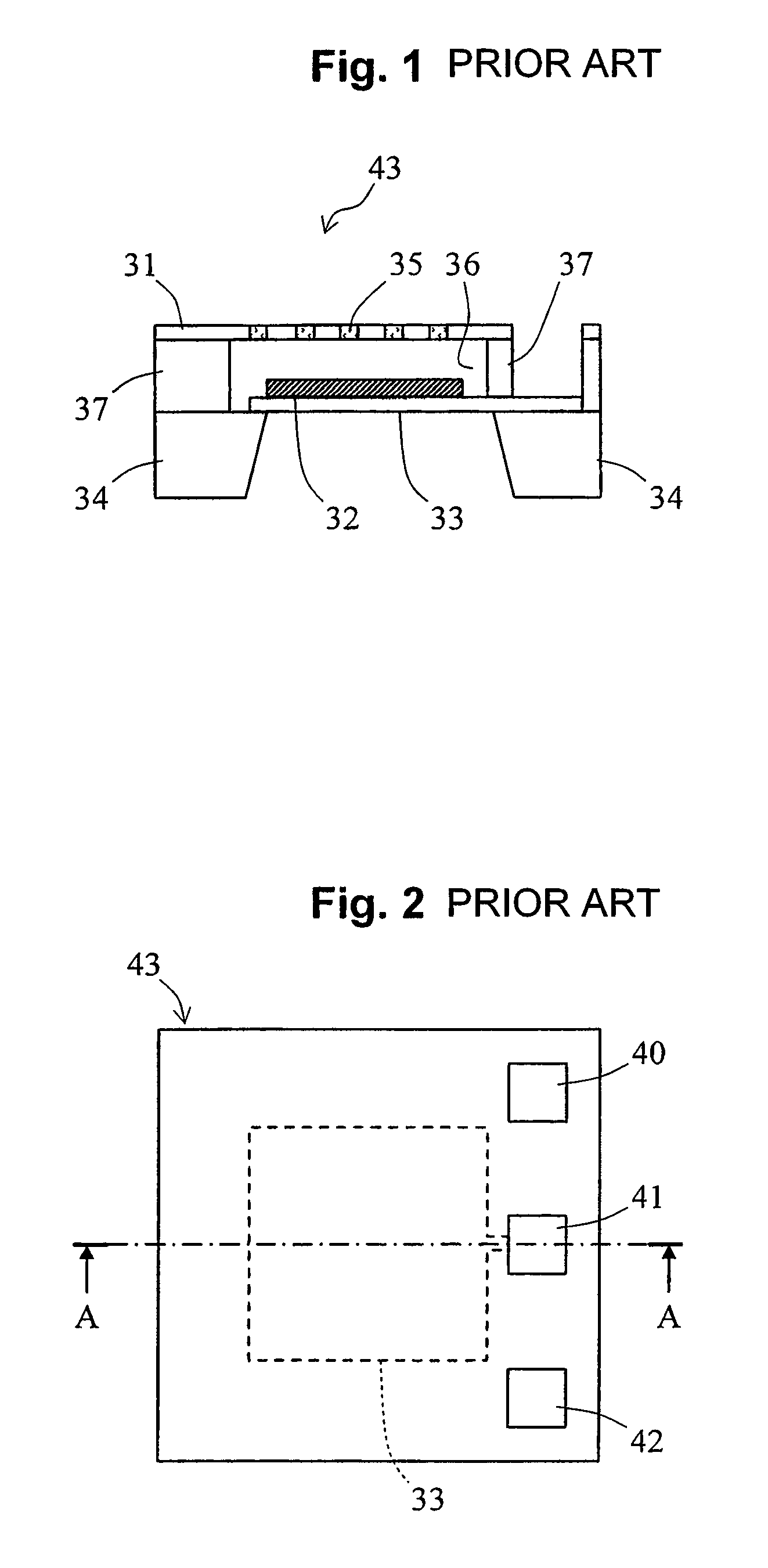

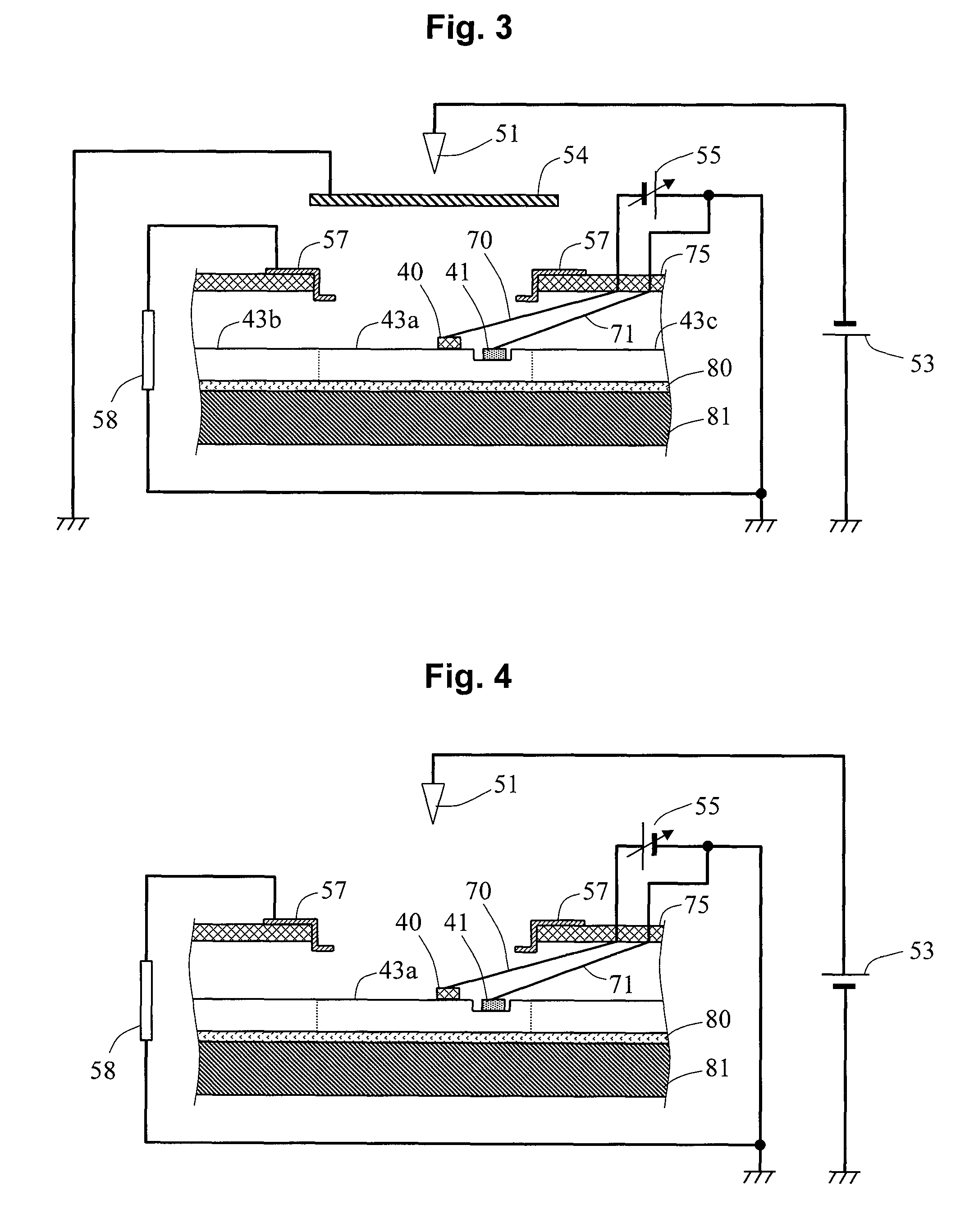

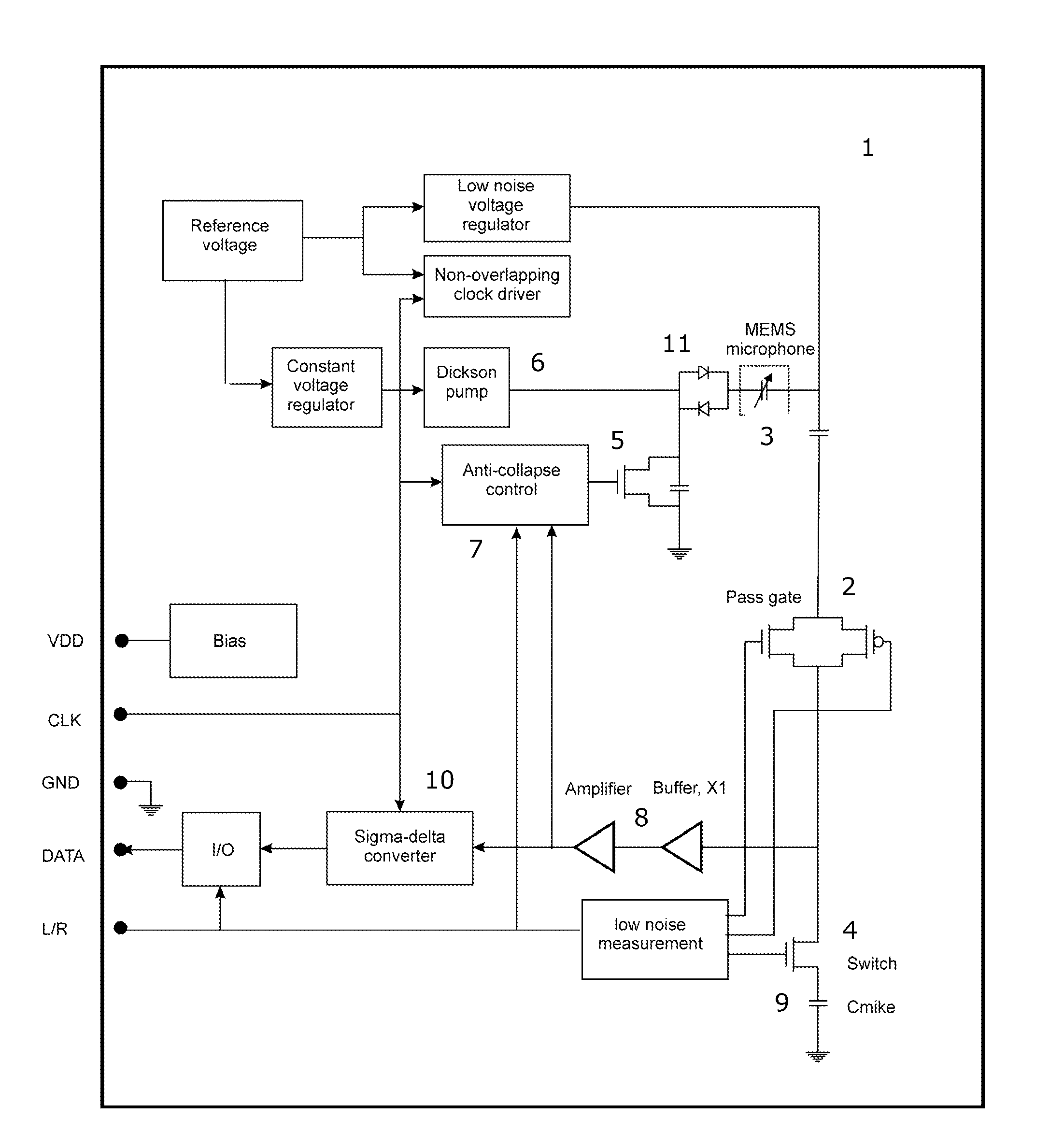

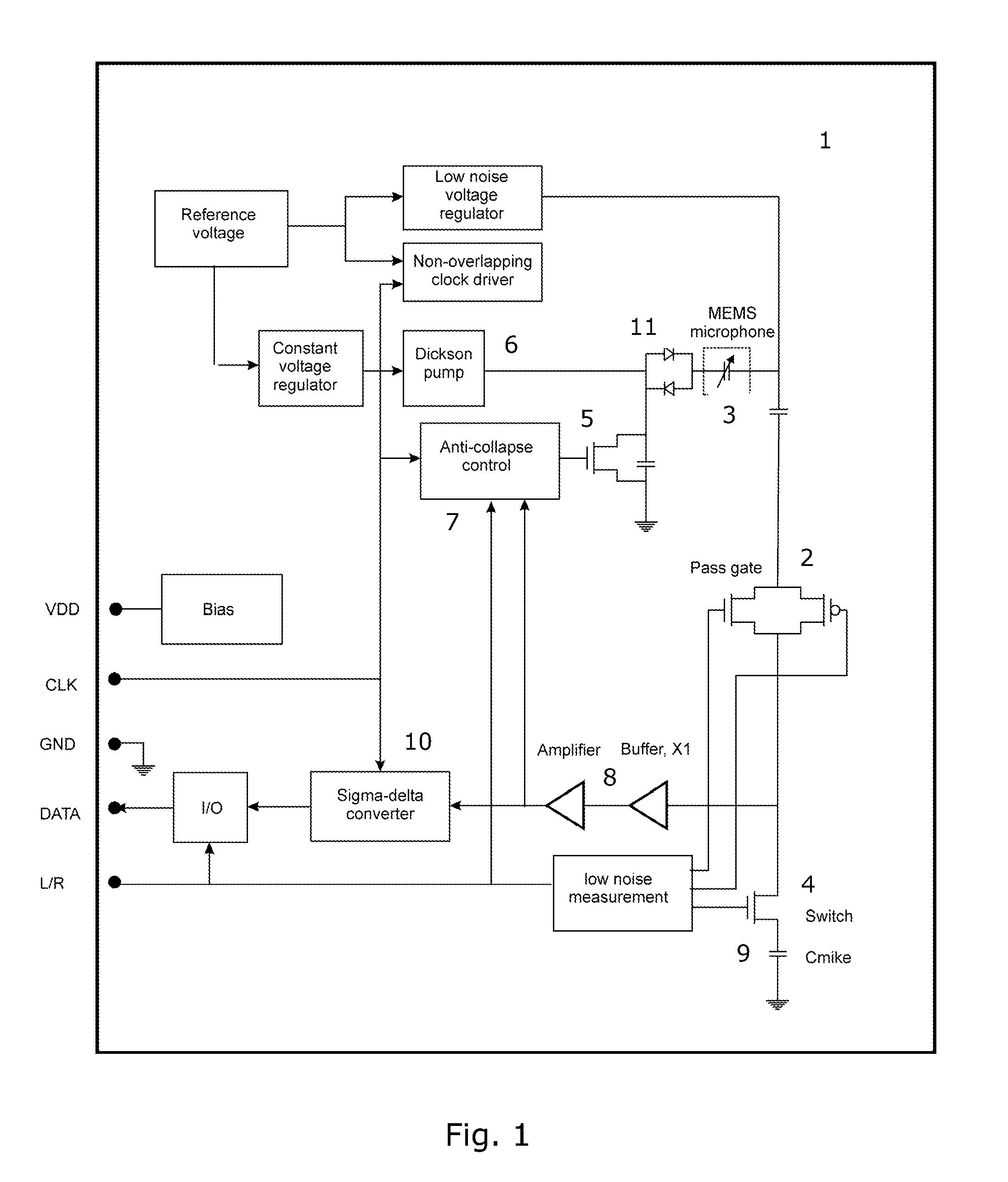

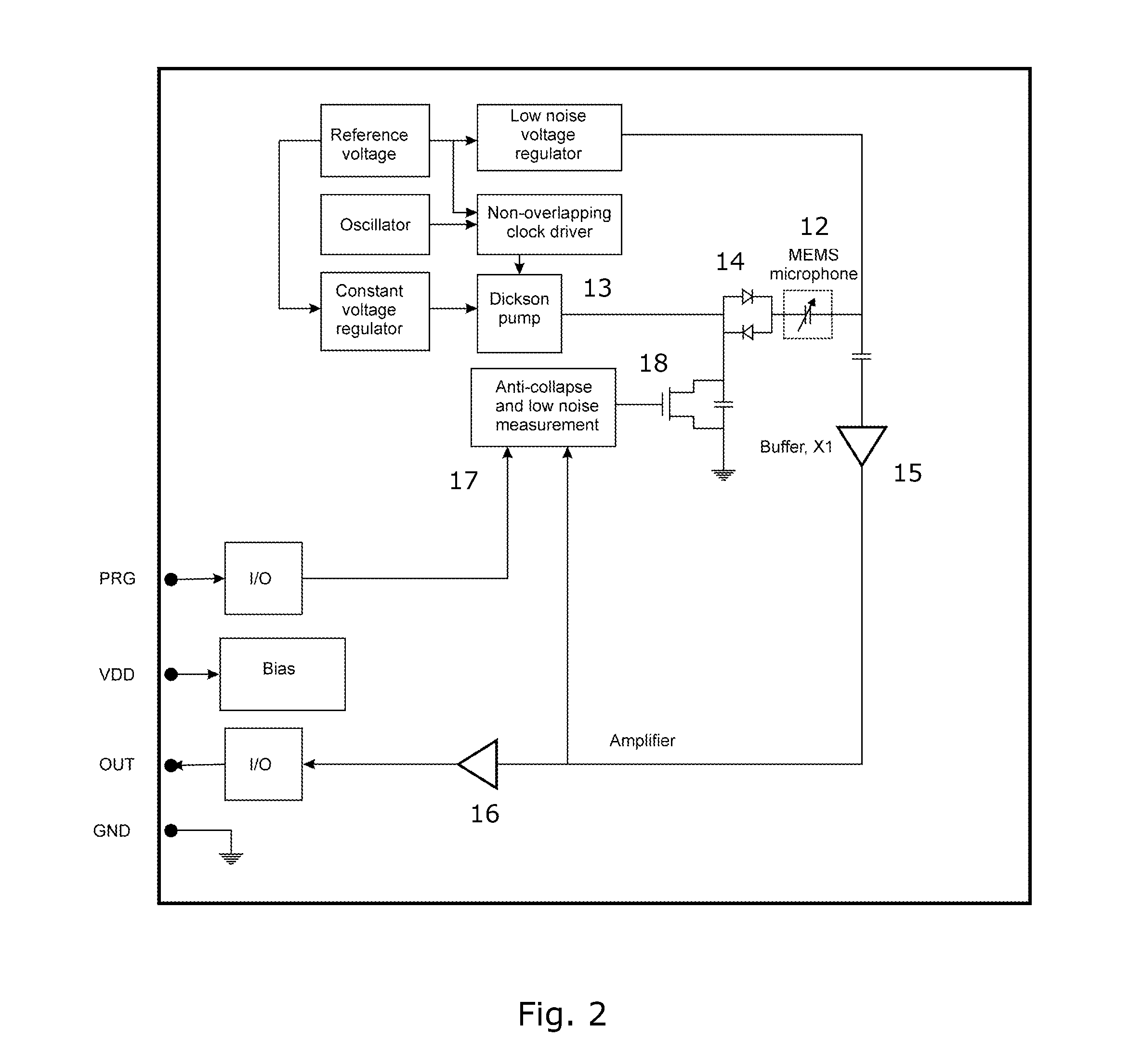

Detection and control of diaphragm collapse in condenser microphones

ActiveUS7548626B2Increase freedomMaximum flexibilityElectrostatic transducer microphonesTransducer protection circuitsTransducerEngineering

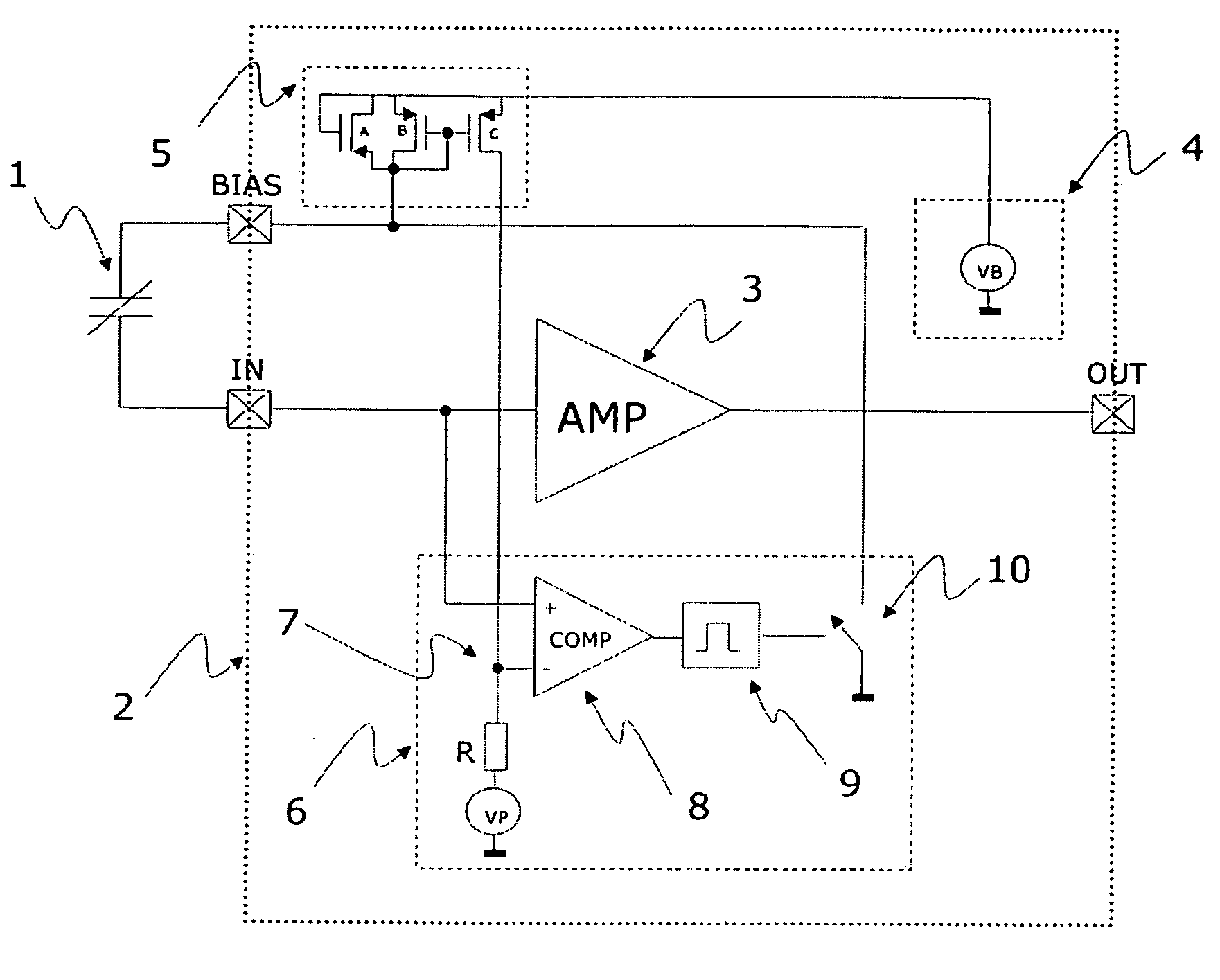

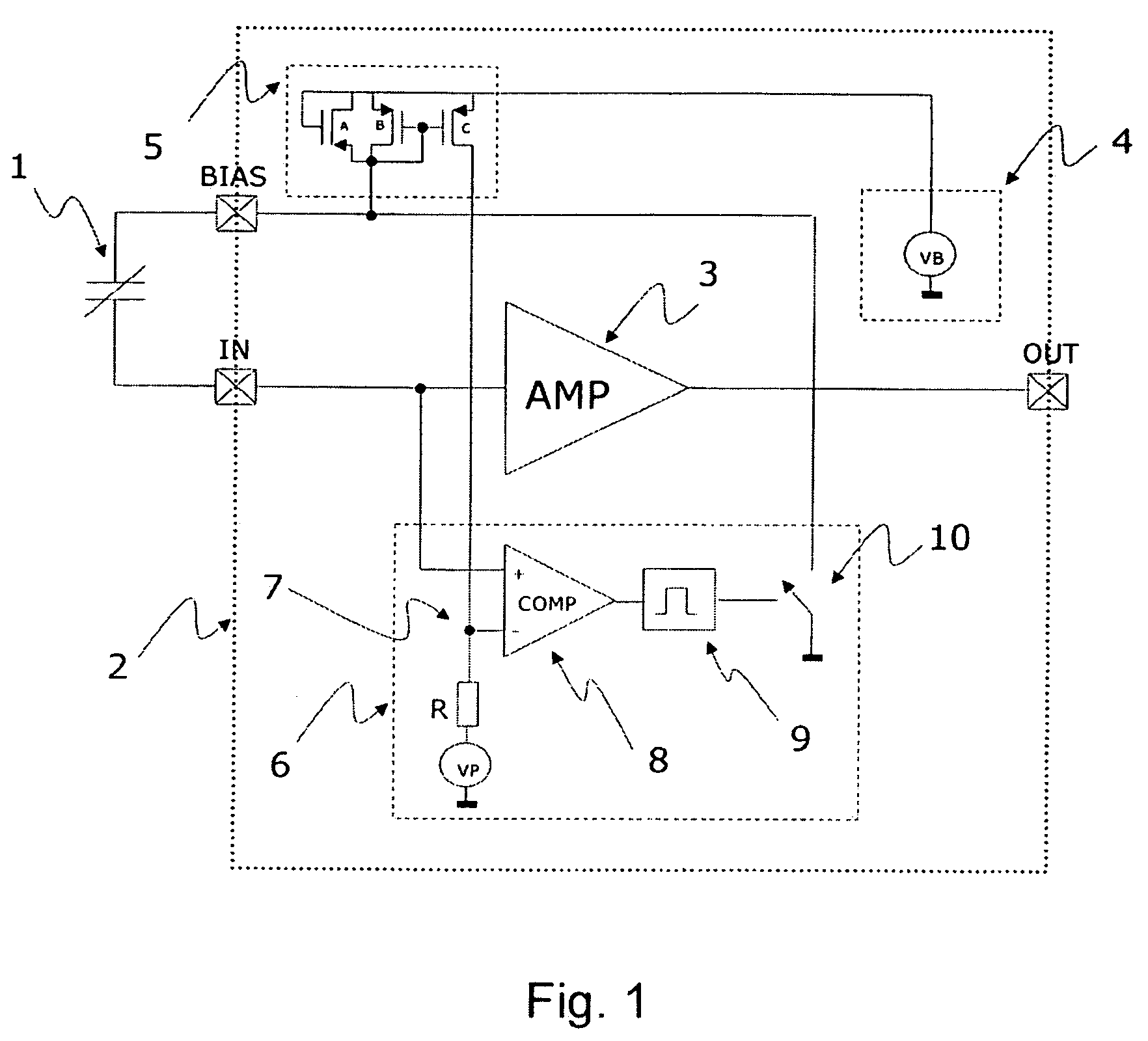

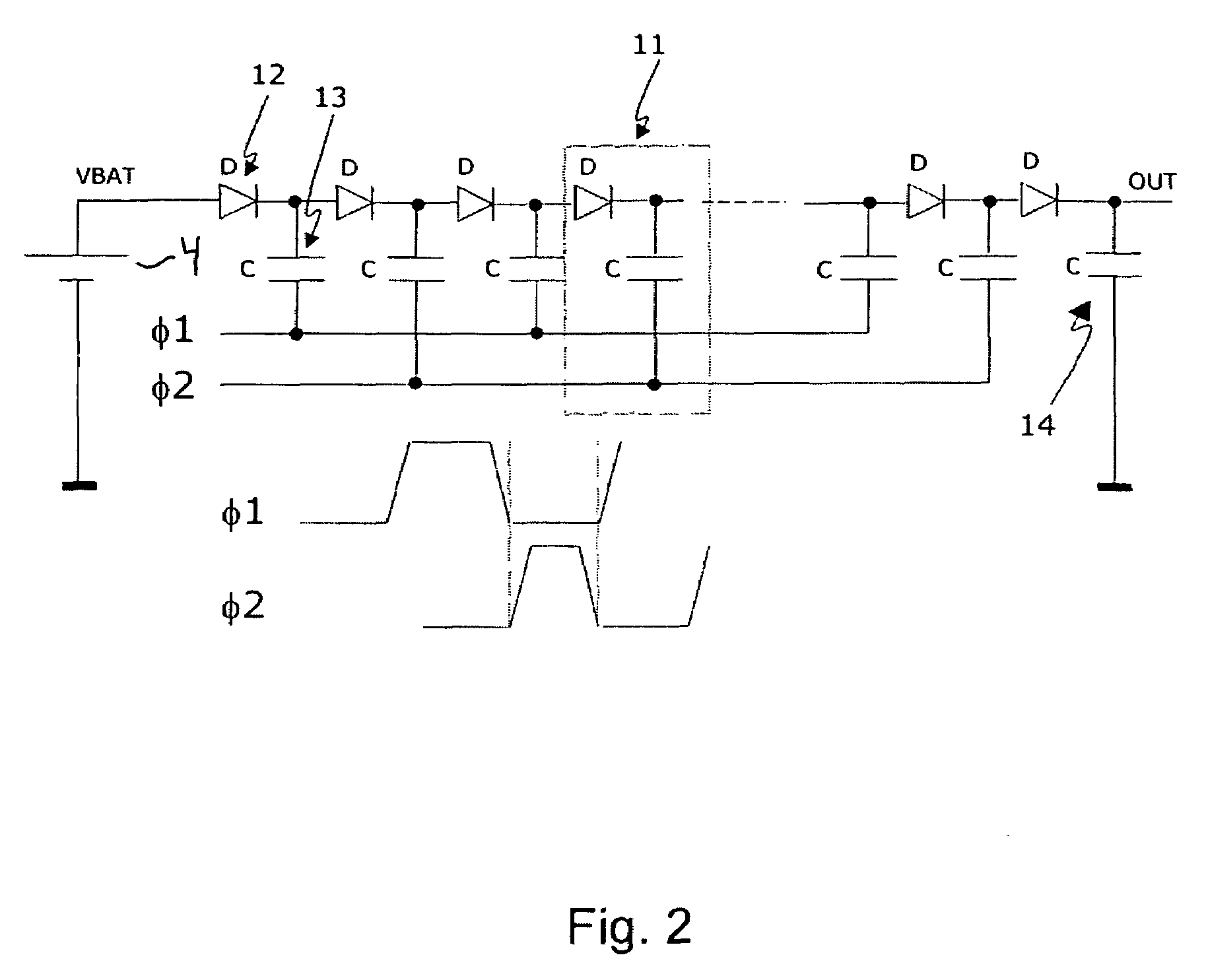

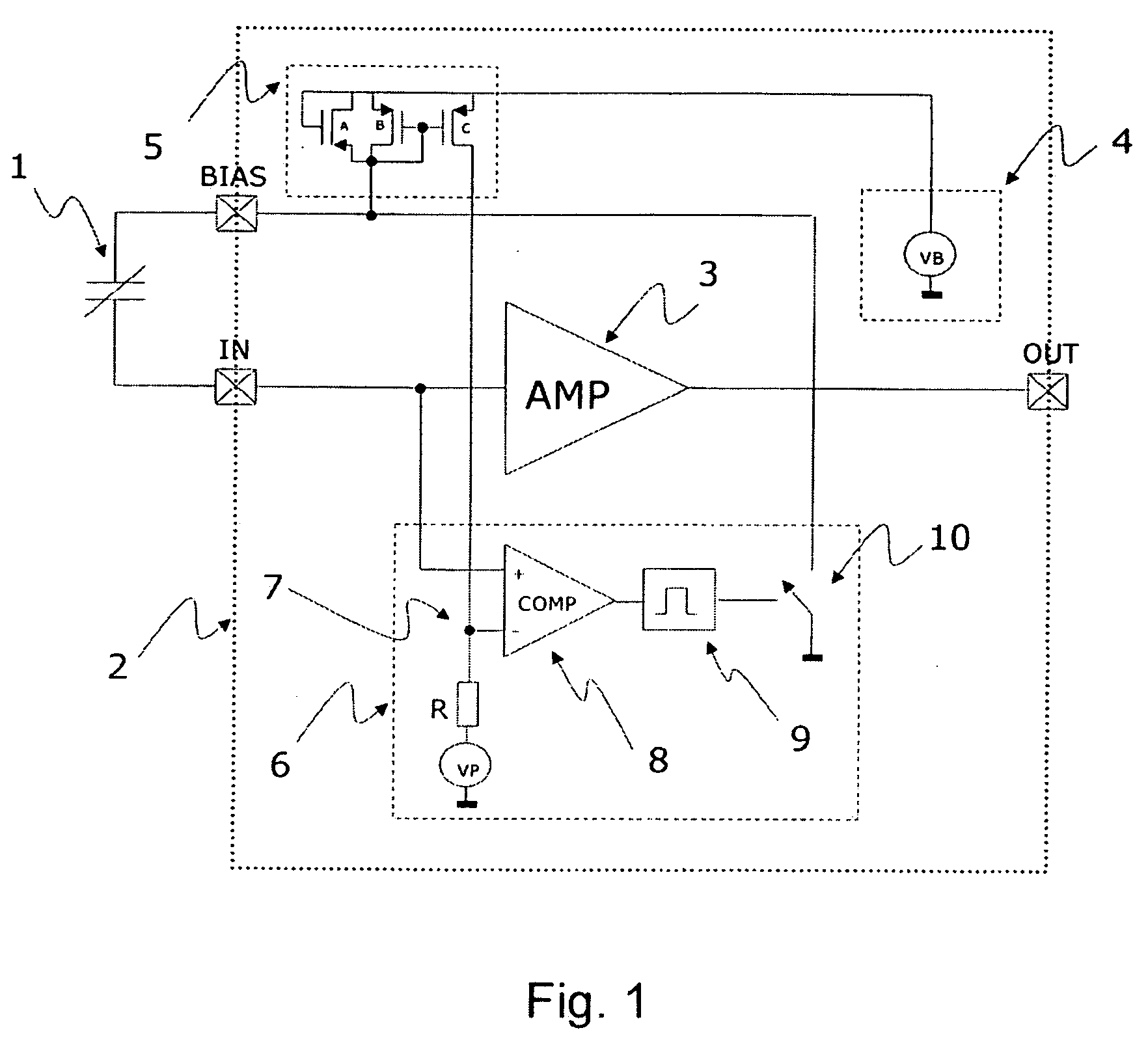

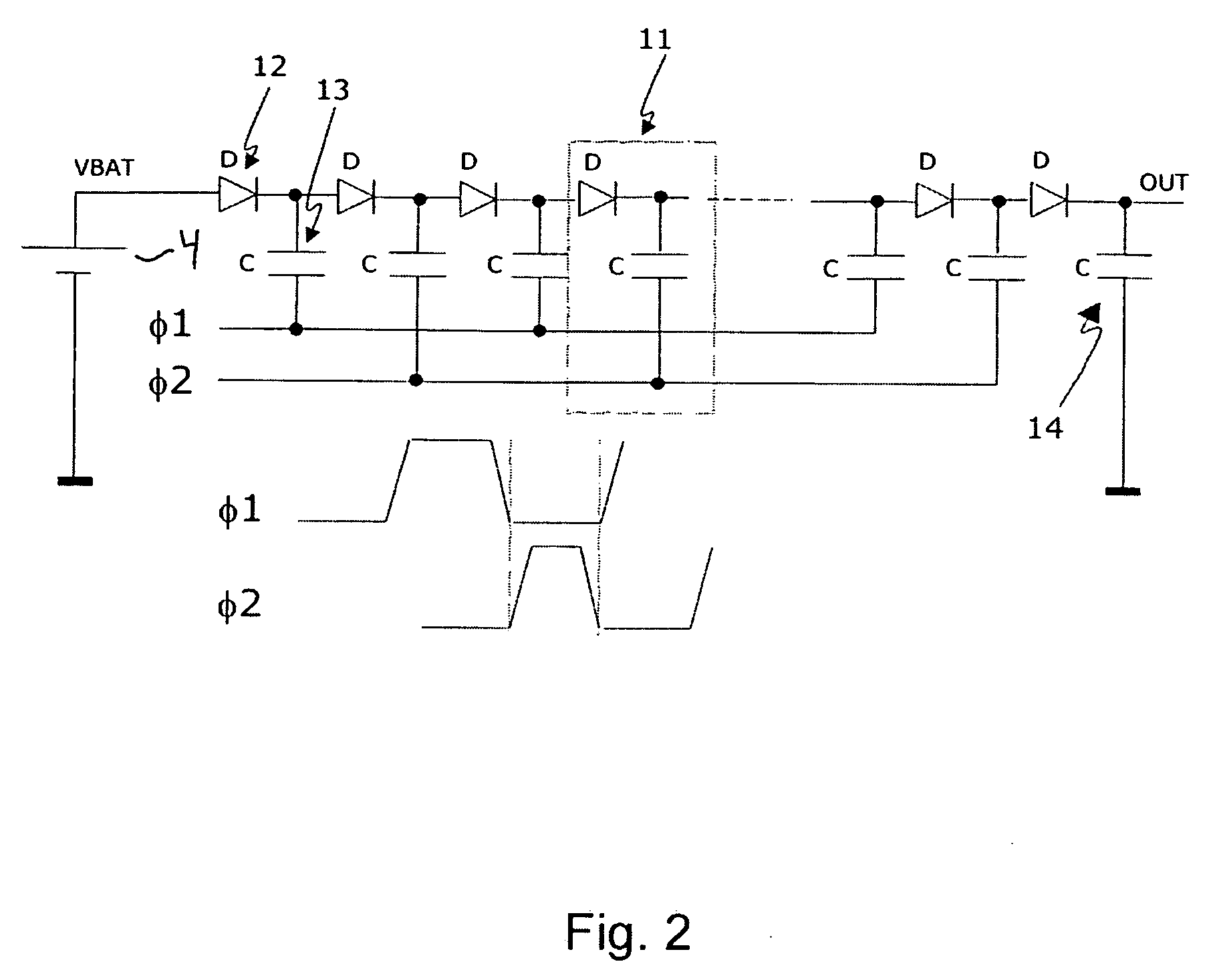

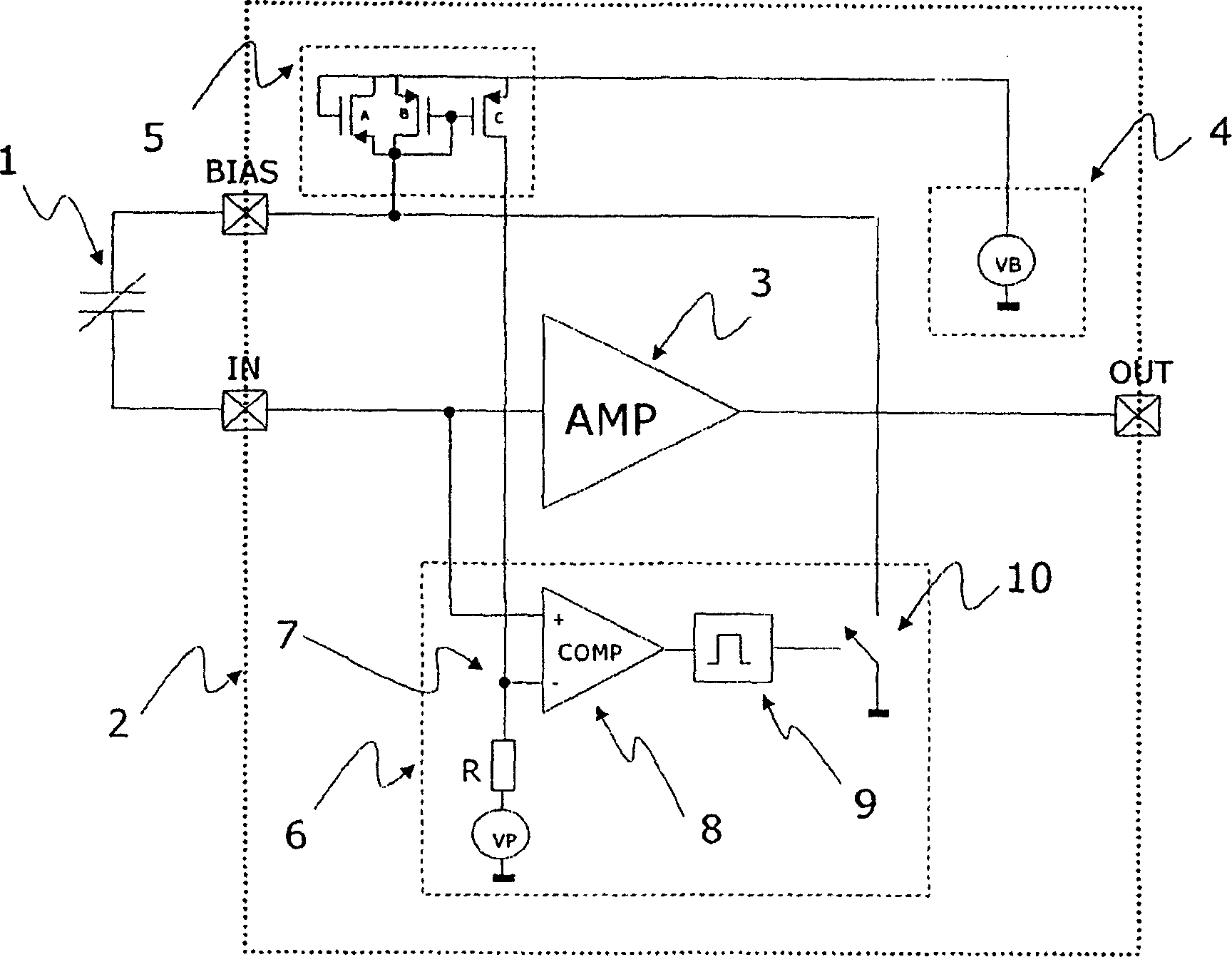

A condenser microphone is provided having a transducer element. A diaphragm has an electrically conductive portion. A back-plate has an electrically conductive portion. A DC bias voltage element is operatively coupled to the diaphragm and the back-plate. A collapse detection element is adapted to determine a physical parameter value related to a separation between the diaphragm and the back-plate. A collapse control element is adapted to control the DC bias voltage element based on the determined physical parameter value.

Owner:TDK CORPARATION

Detection and control of diaphragm collapse in condenser microphones

ActiveUS20060008097A1Increase freedomMaximum flexibilityElectrostatic transducer microphonesTransducer protection circuitsTransducerEngineering

A condenser microphone is provided having a transducer element. A diaphragm has an electrically conductive portion. A back-plate has an electrically conductive portion. A DC bias voltage element is operatively coupled to the diaphragm and the back-plate. A collapse detection element is adapted to determine a physical parameter value related to a separation between the diaphragm and the back-plate. A collapse control element is adapted to control the DC bias voltage element based on the determined physical parameter value.

Owner:TDK CORPARATION

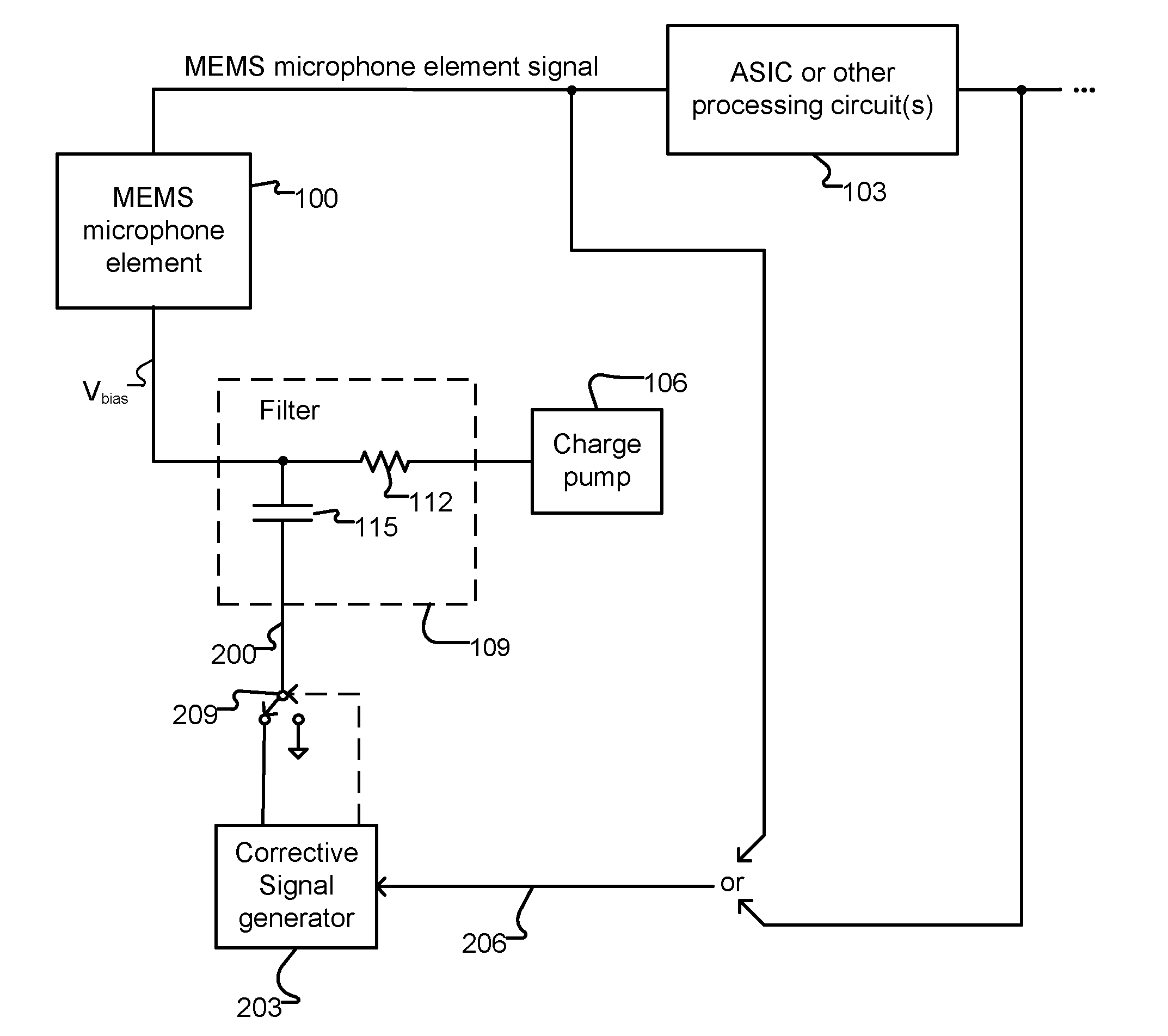

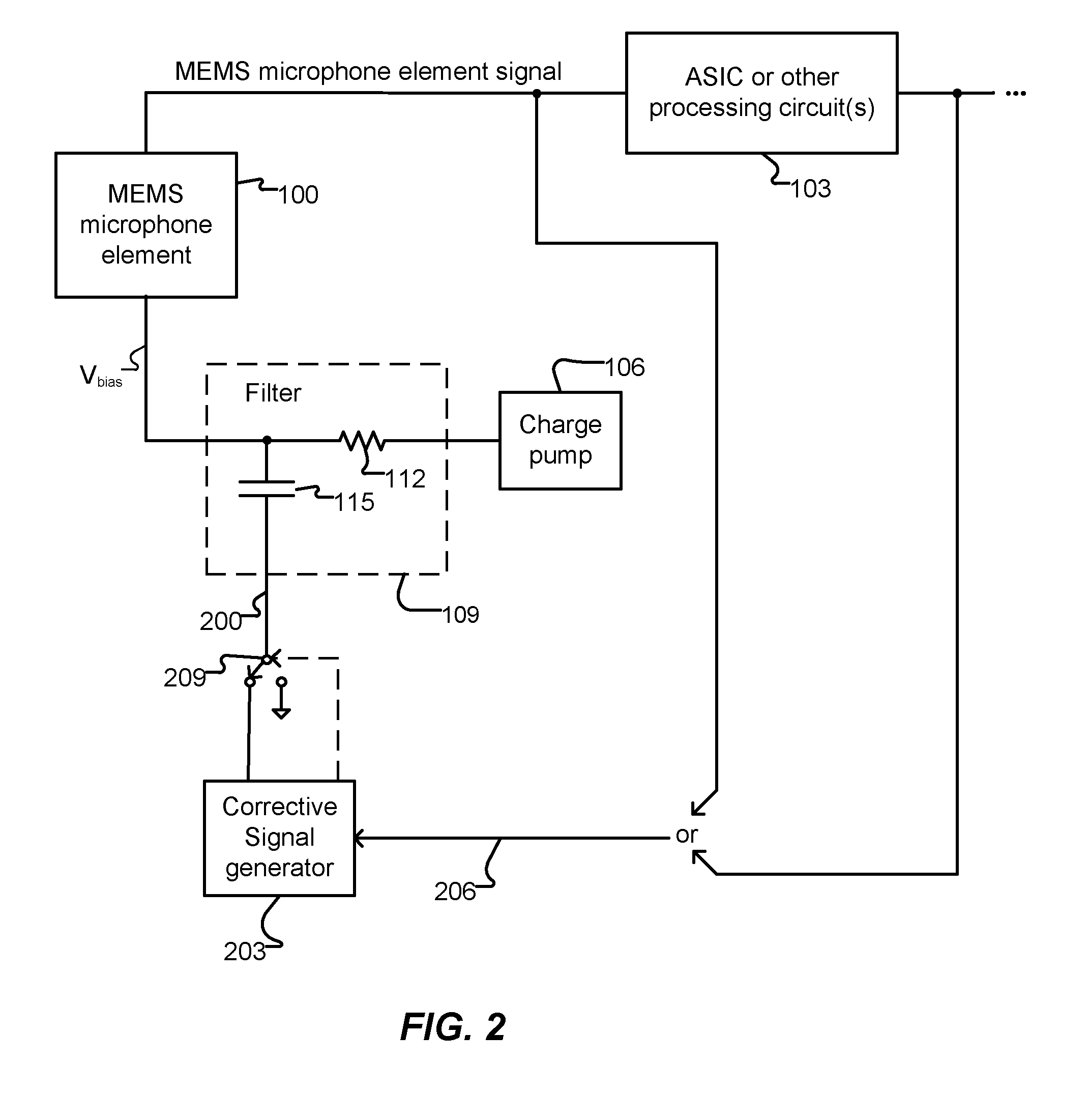

Microphone with Programmable Frequency Response

ActiveUS20140086433A1Efficient removalEffectively couple impedanceMicrophonesLoudspeakersMems microphoneCondenser microphone

Methods and apparatus automatically cancel or attenuate an unwanted signal (such as low frequencies from wind buffets) from, and / or control frequency response of, a condenser microphone, or control the effective condenser microphone sensitivity before the signal reaches an ASIC or other processing circuit. As a result, the maximum amplitude signal seen by the processing circuit is limited, thereby preventing overloading the input of the processing circuit. Remaining (wanted) frequencies can be appropriately amplified to reduce the noise burden on further processing circuits. A corrective signal is applied to a bias terminal of the condenser microphone to cancel the unwanted signal. Optionally or alternatively, a controllable impedance is connected to a line that carries the signal generated by the MEMS microphone, so as to attenuate unwanted portions of the signal.

Owner:INVENSENSE

Condenser microphone

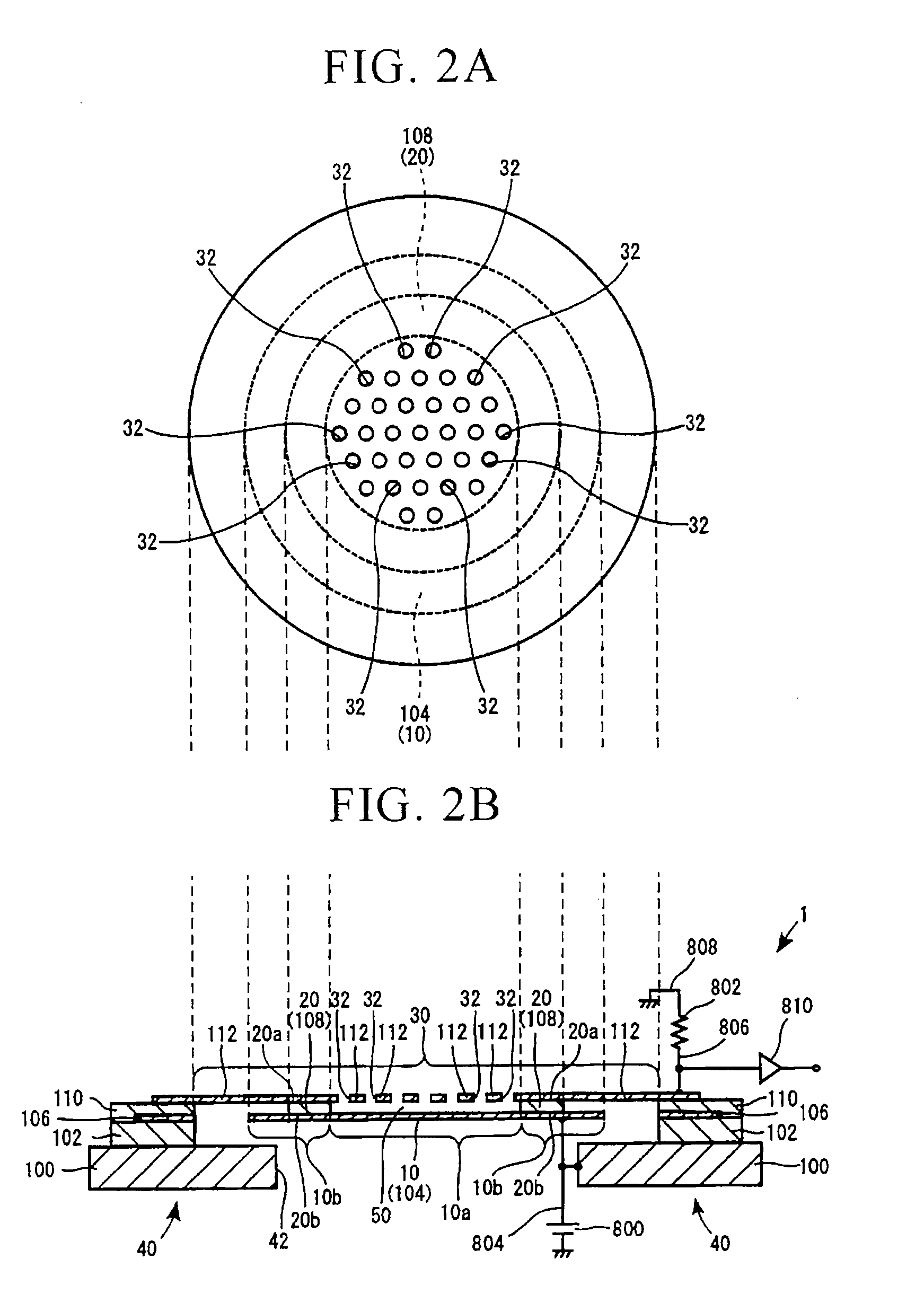

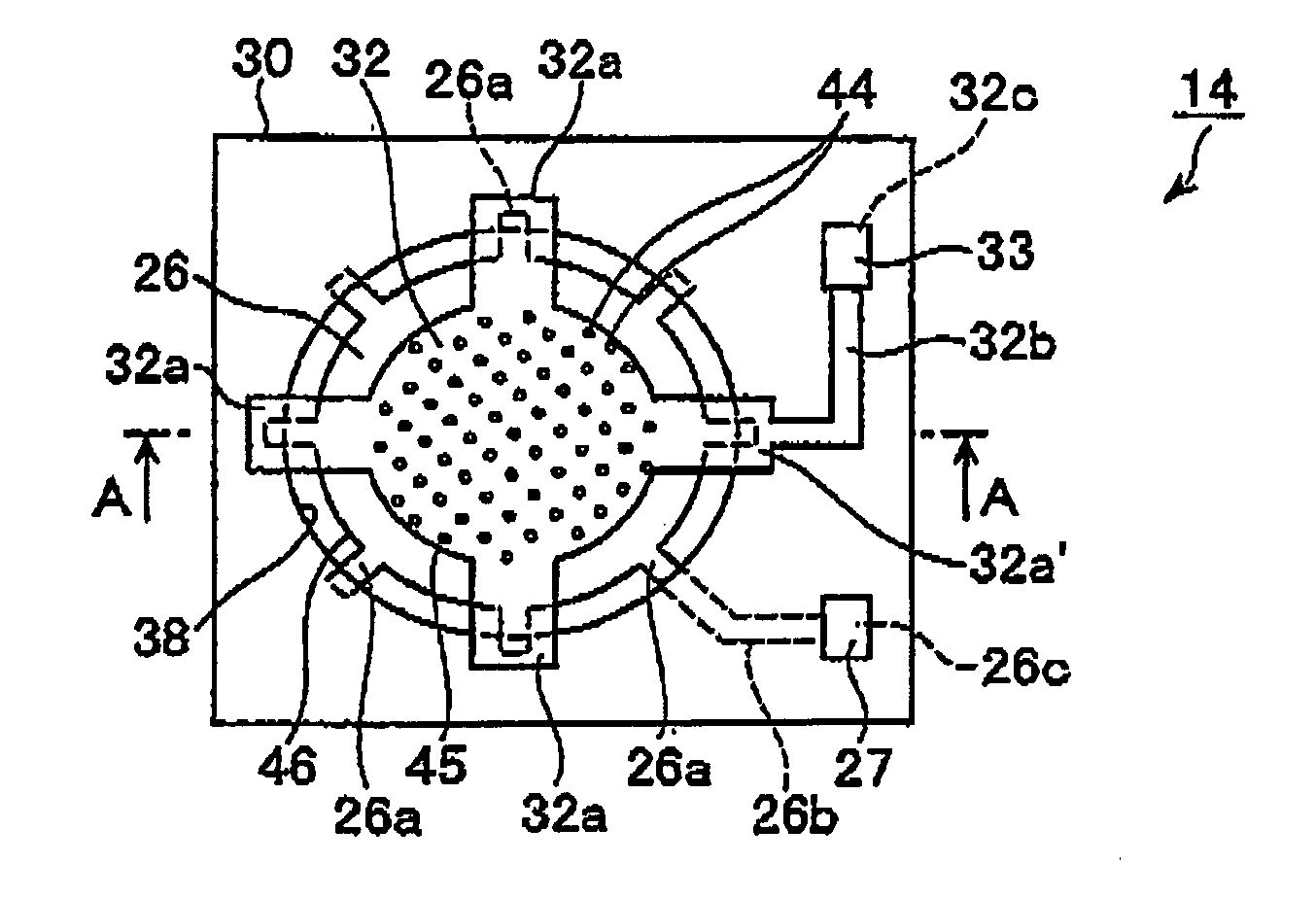

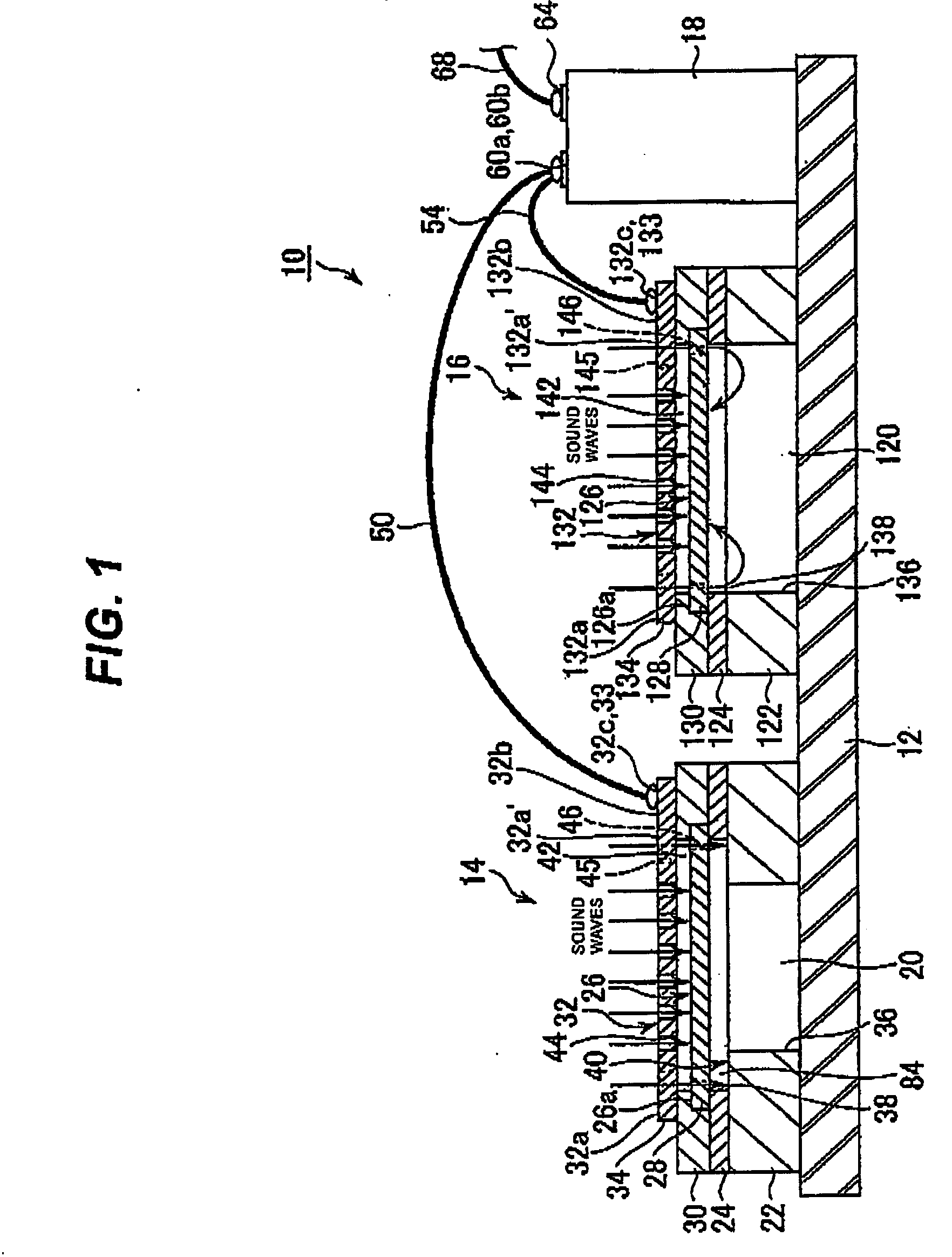

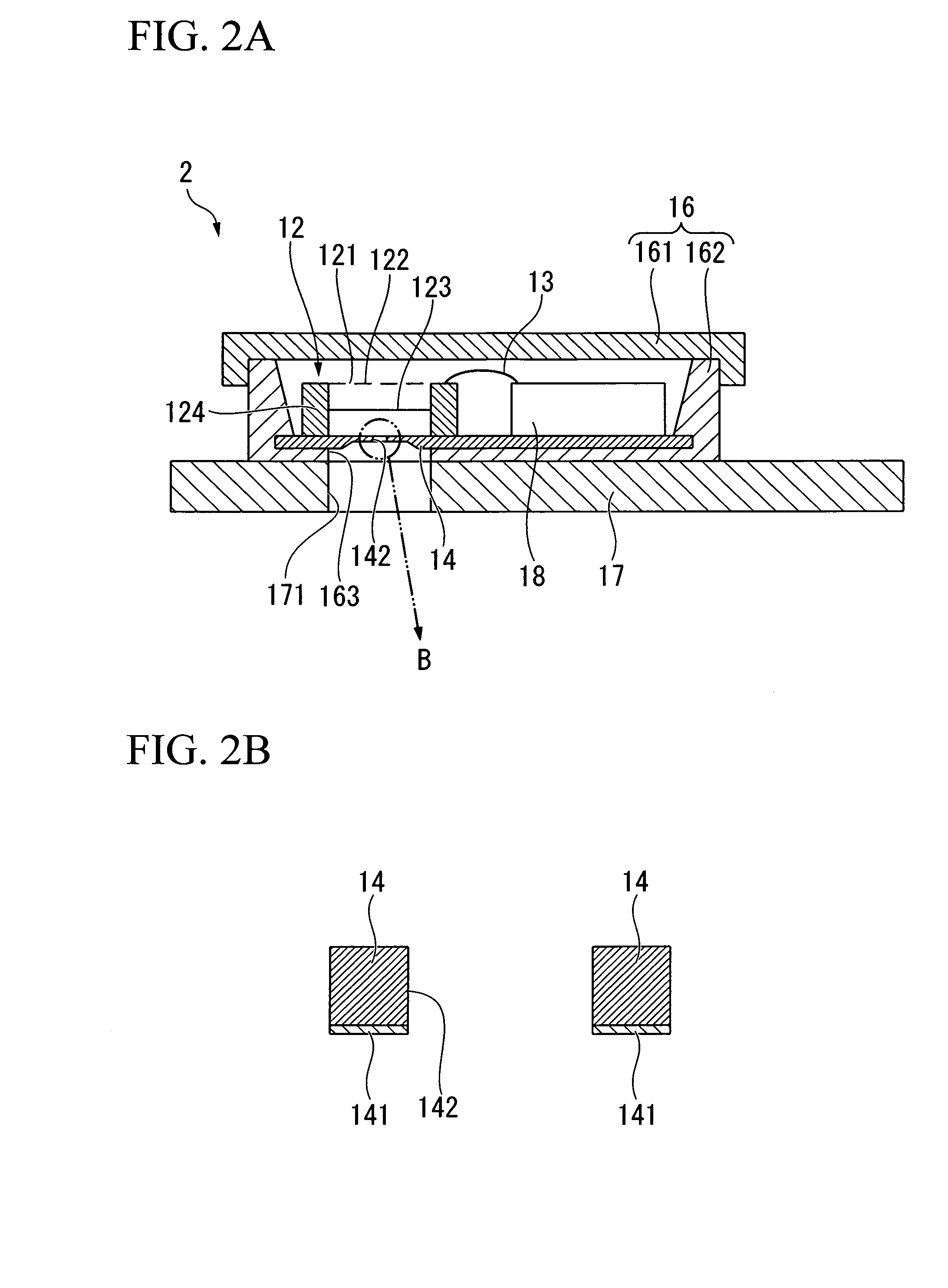

InactiveUS20080192963A1Prevent impact soundSemiconductor electrostatic transducersSolid-state devicesCapacitanceAccelerometer

A condenser microphone 14 and an accelerometer 16 are placed on a device substrate 12 with arranging same sides in a same direction. Both condenser microphone 14 and accelerometer 16 are formed of condenser microphones. Sizes of the condenser microphone 14 and accelerometer 16 are same other than diameters of back cavities 20 and 120. A step 40 that decreases an inner diameter of the back cavity 20 is formed inside the back cavity 20 to function as an audio resistance, whereas the back cavity 120 of the accelerometer 16 has no step (audio resistance). A microphone output is obtained by subtracting a terminal voltage of the condenser microphone 14 by a terminal voltage of the accelerometer 16.

Owner:YAMAHA CORP

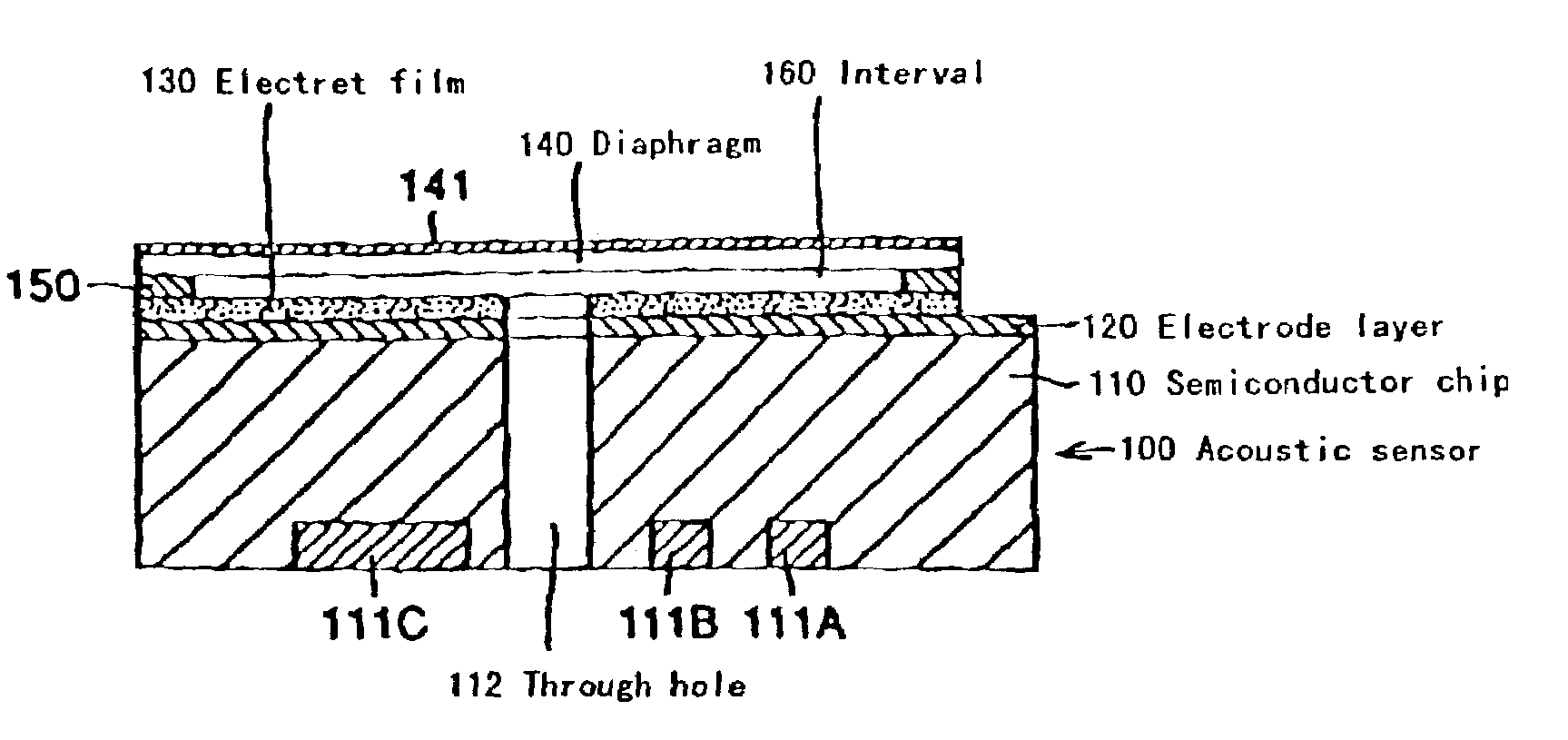

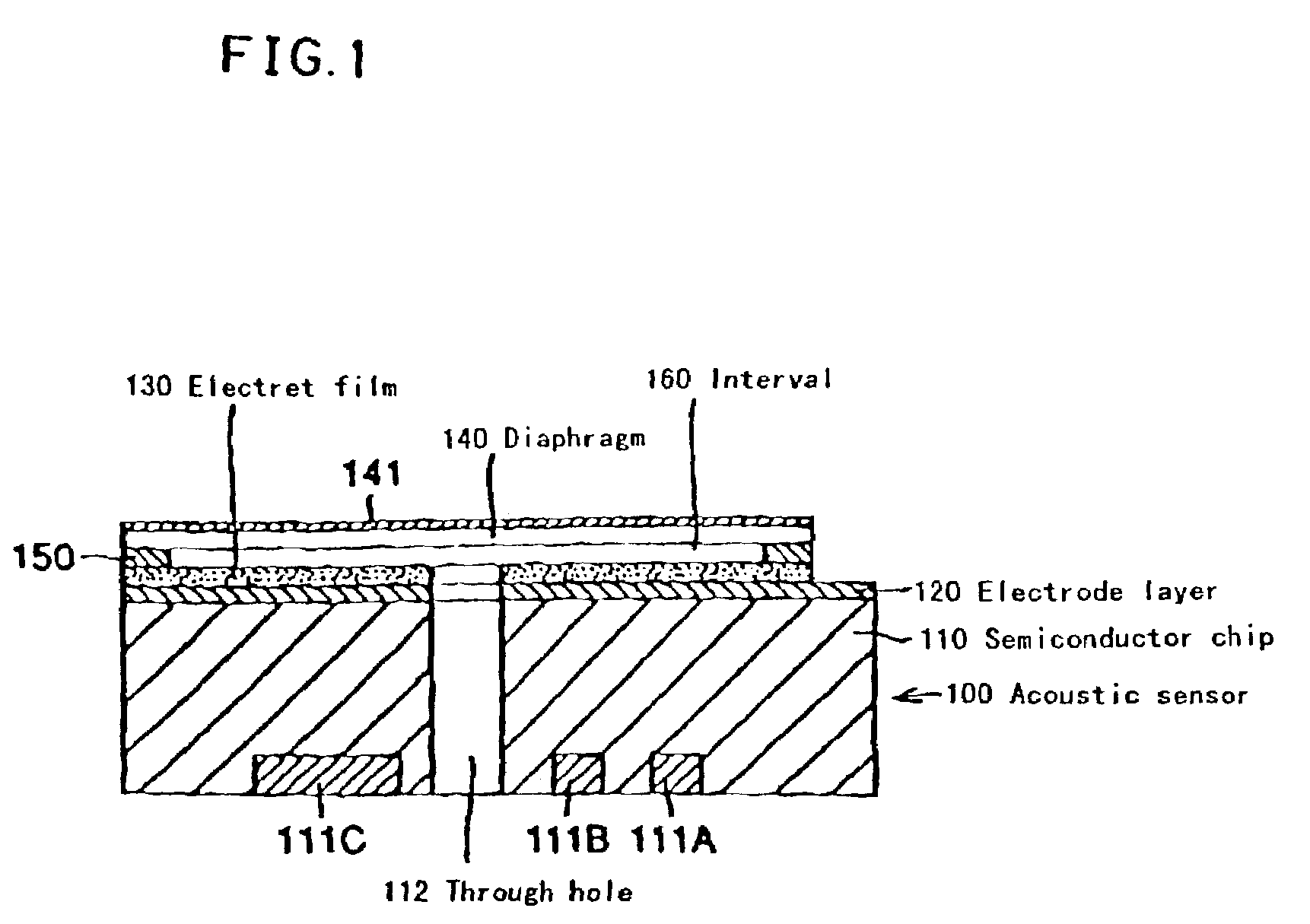

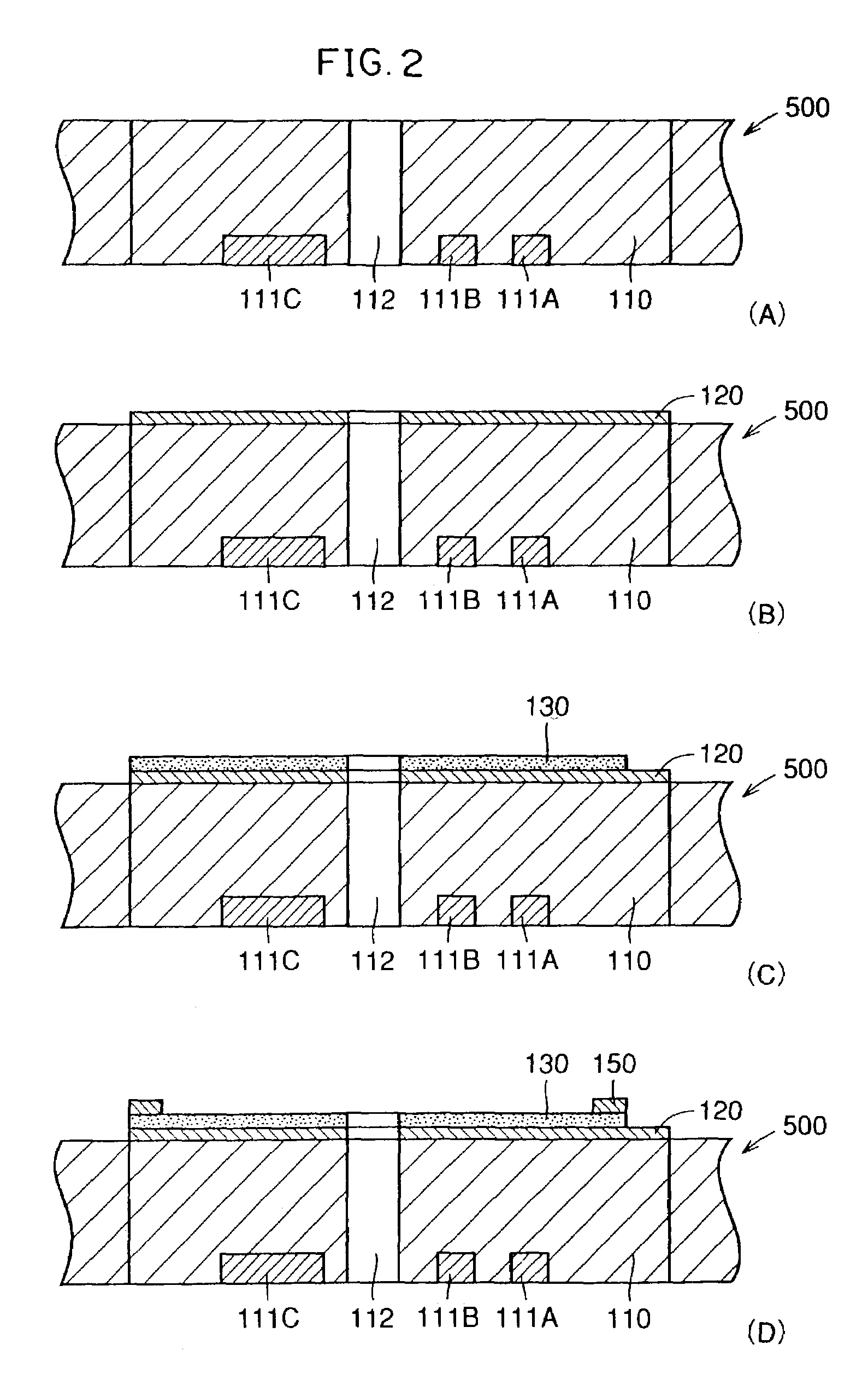

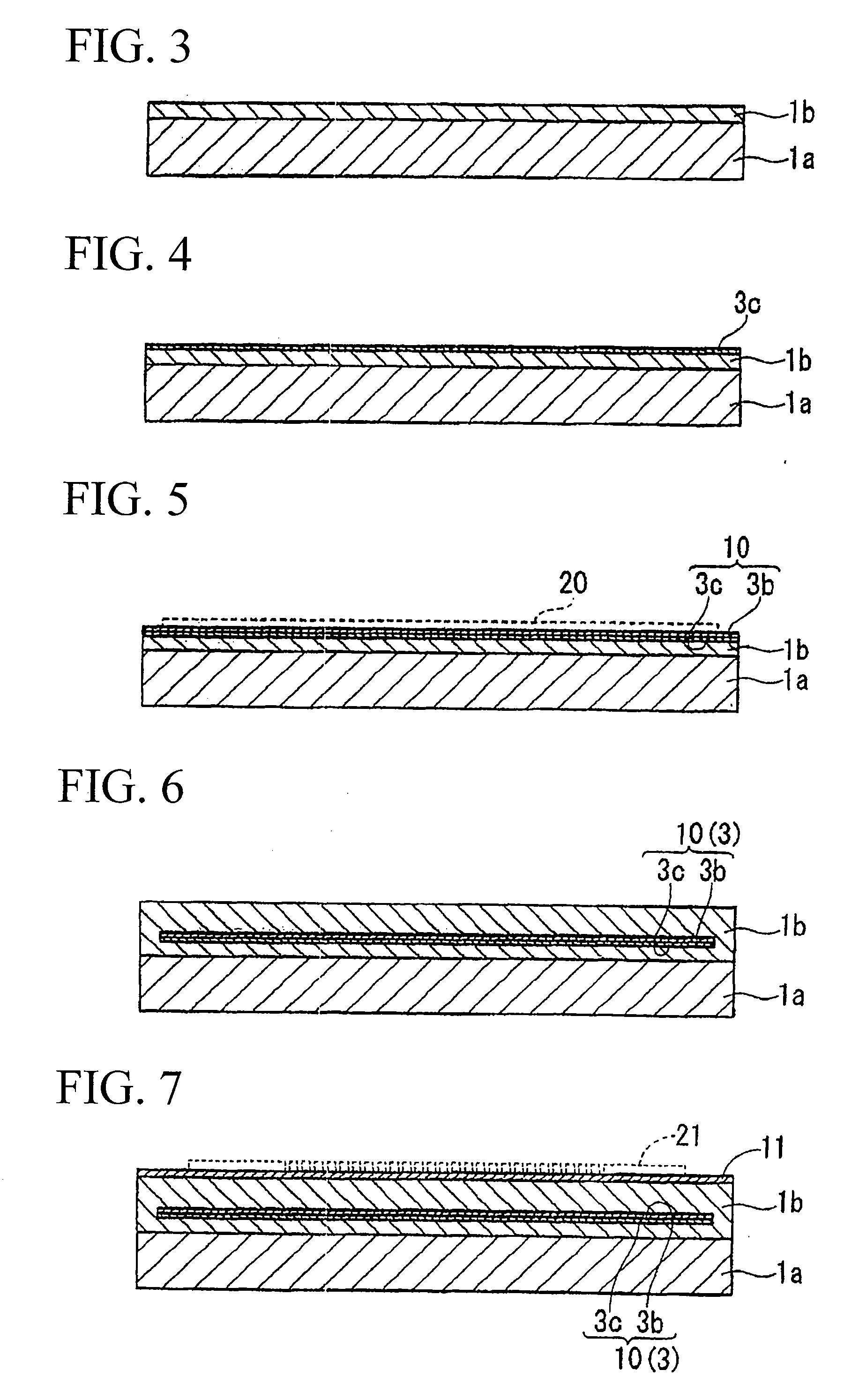

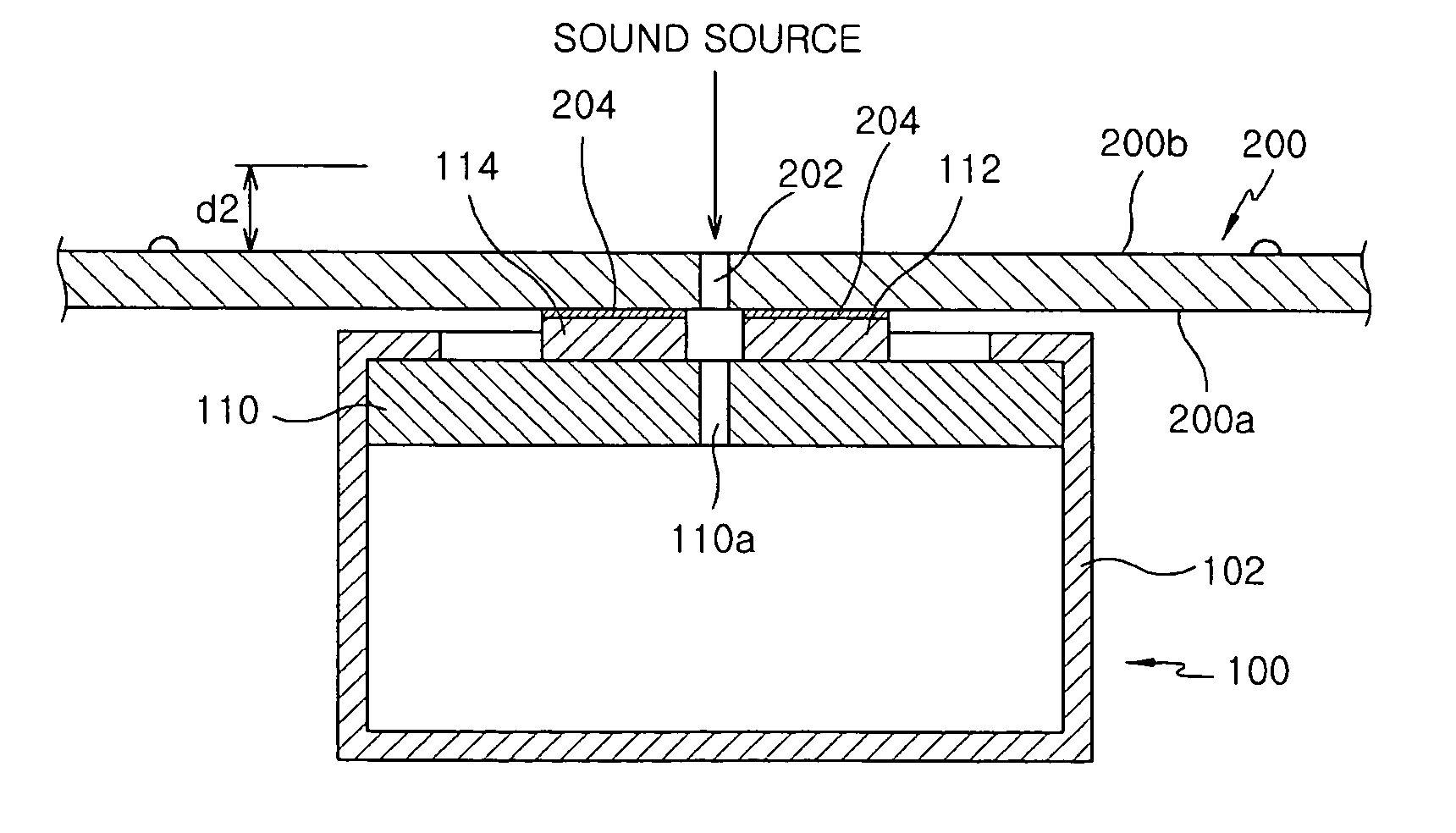

Manufacturing method of acoustic sensor

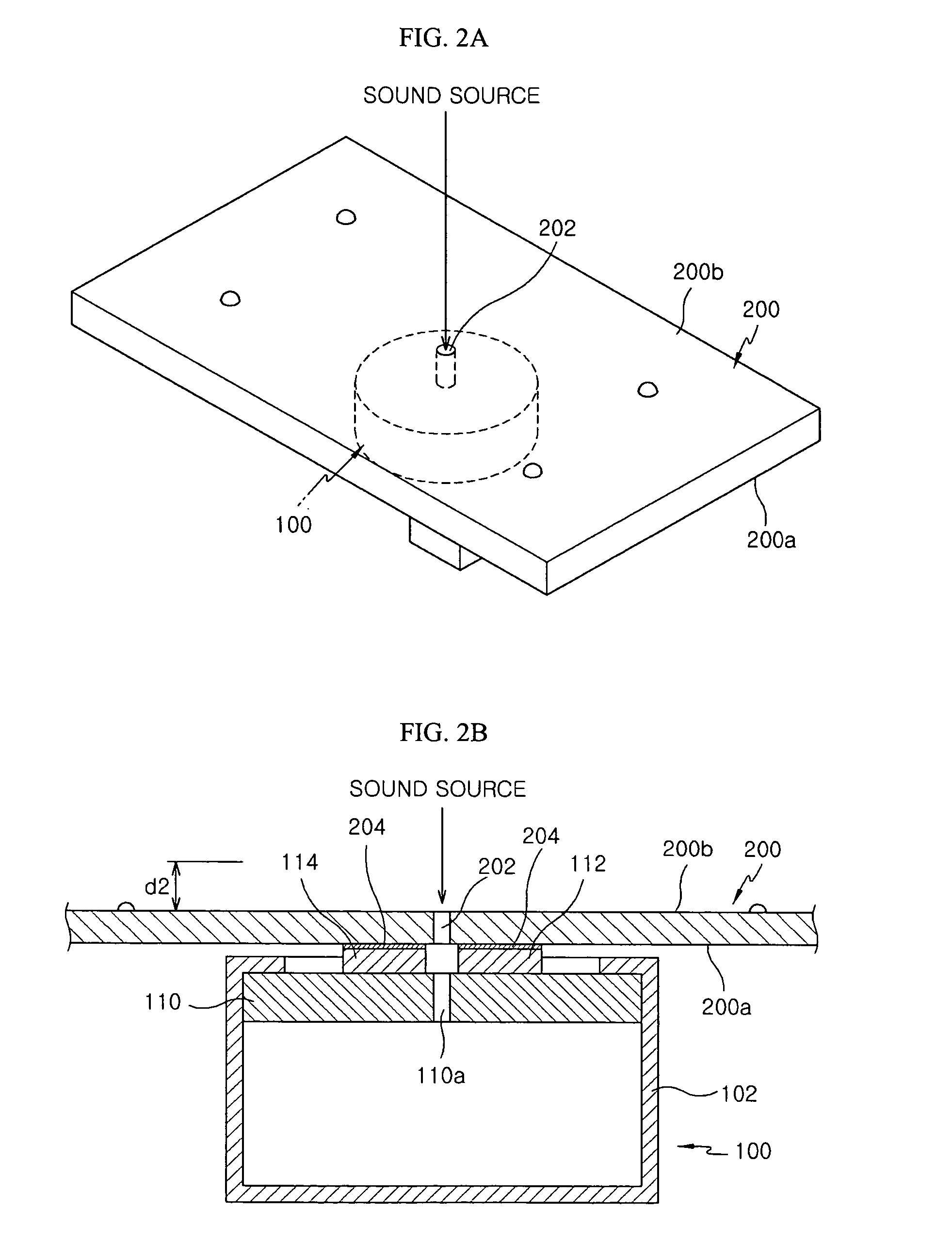

The present invention relates to a semiconductor electret condenser microphone capable of being reduced in size and including an acoustic sensor 100 and a case 200 for accommodating the acoustic sensor 100, the acoustic sensor 100 has a semiconductor chip 110 forming necessary electronic circuits 111A to 111C, and opening a through hole 112 away from the electronic circuits 111A to 111C, an electrode layer 120 formed on the surface of the semiconductor chip 110 away from the through hole 112, an electret member 130 laminated away from part of the electrode layer 120 and through hole 112, and a diaphragm 140 provided with a spacing 160 to the electret member 130, in which the electrode layer 120 exposed from the electret member 130 is connected to the electrode 111a of the electronic circuit 111A through the case 200 (FIG. 6).

Owner:HOSHIDEN ELECTRONICS CO LTD

Capacitor microphone

InactiveUS20070058825A1Uniform stress distributionDegree of improvementPiezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersCapacitanceEngineering

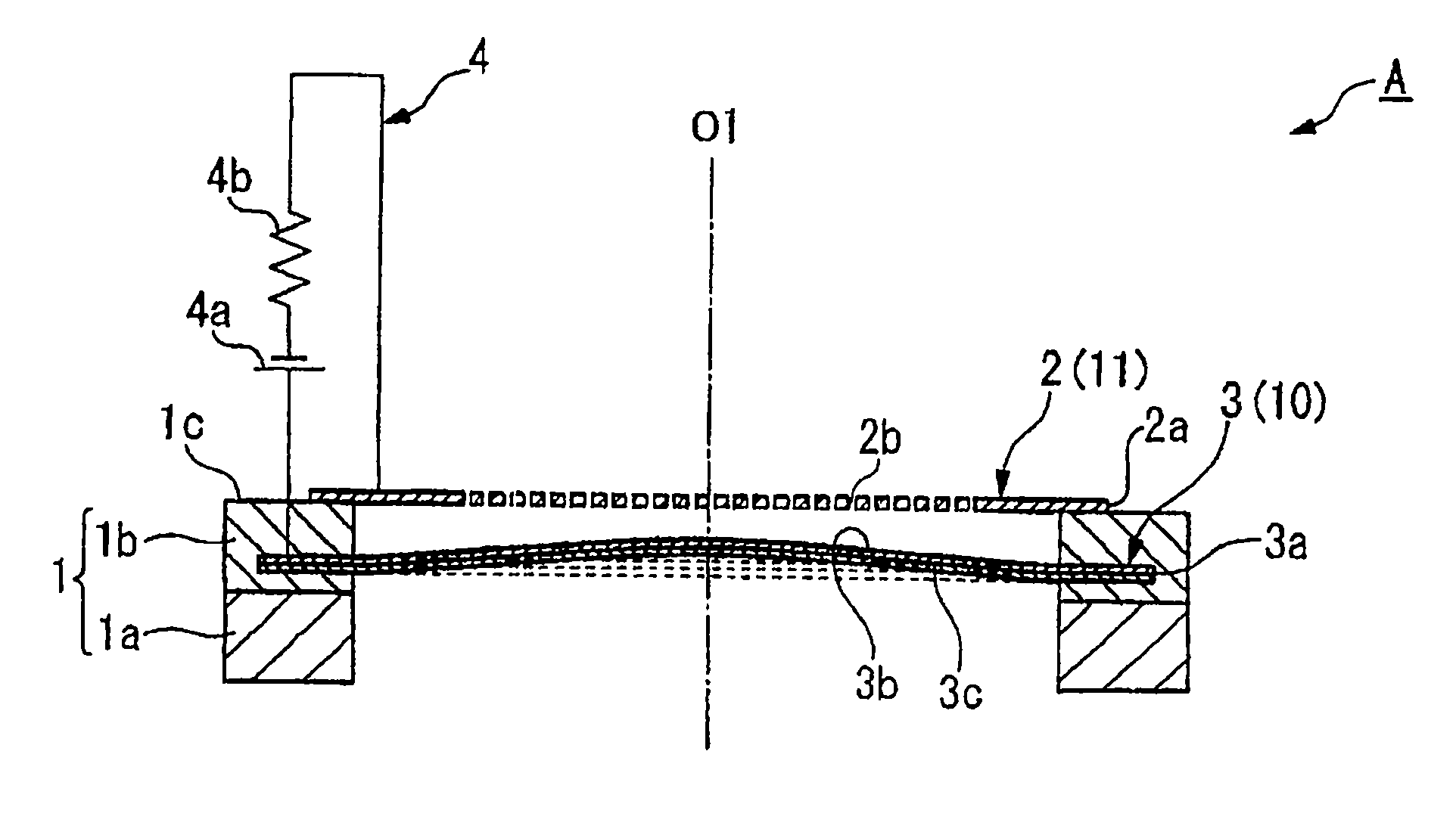

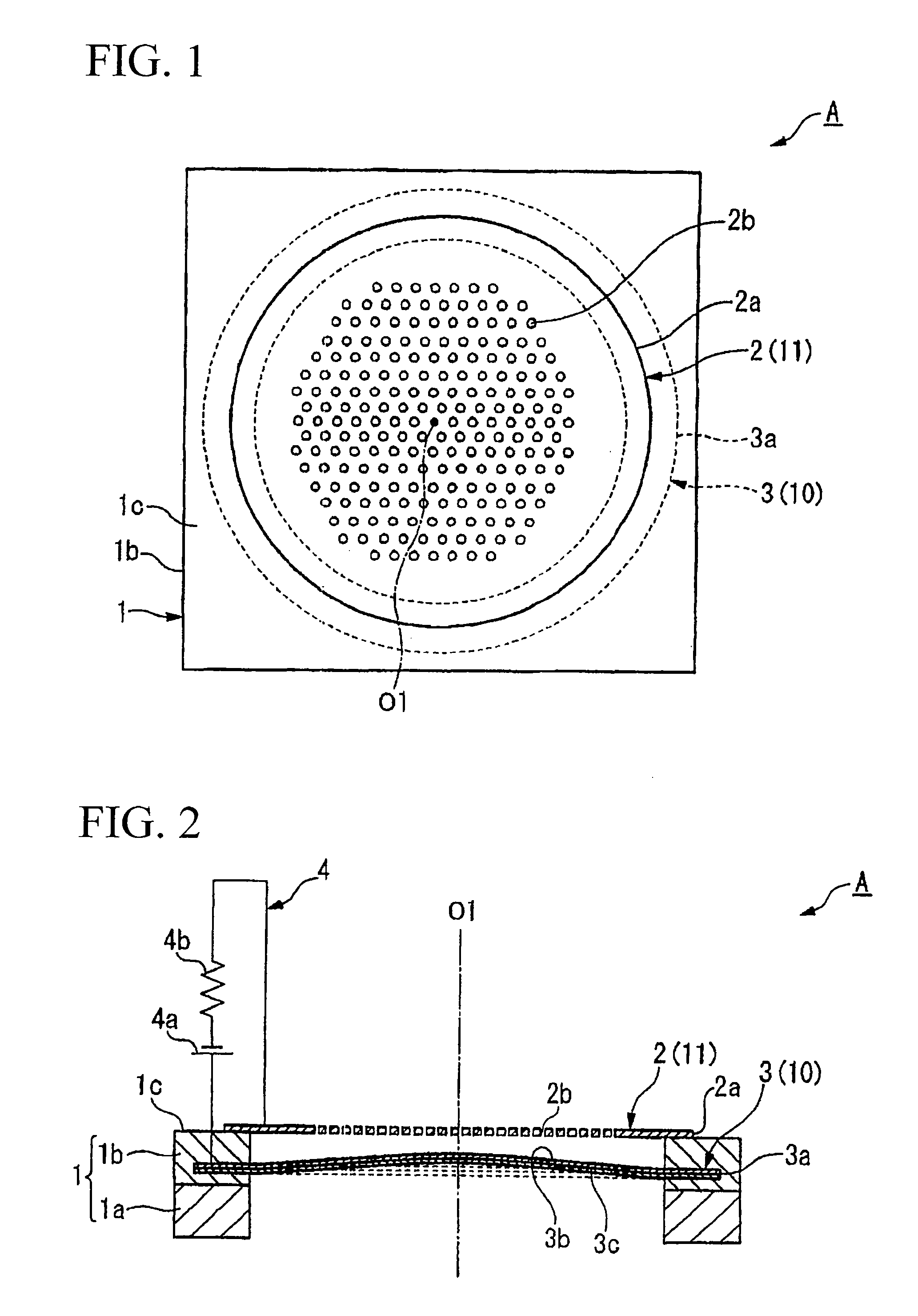

A capacitor microphone is constituted by a plate having a fixed electrode, a diaphragm including a center portion and at least one near-end portion that is fixed to the outer periphery, in which the center portion having a vibrating electrode, which is positioned relative to the fixed electrode and which vibrates in response to sound waves, is increased in rigidity in comparison with the near-end portion; and a spacer that is fixed to the plate and the near-end portion of the diaphragm and that has an air gap formed between the plate and the diaphragm. Alternatively, a diaphragm electrode is horizontally supported by extension arms extended from a circular plate thereof and is vertically held in a hanging state being apart from a fixed electrode with a controlled distance therebetween.

Owner:YAMAHA CORP

Method of fabricating an ultra-small condenser microphone

ActiveUS7855095B2Improve accuracyShort timeSemiconductor electrostatic transducersSemiconductor/solid-state device manufacturingProduction ratePotential difference

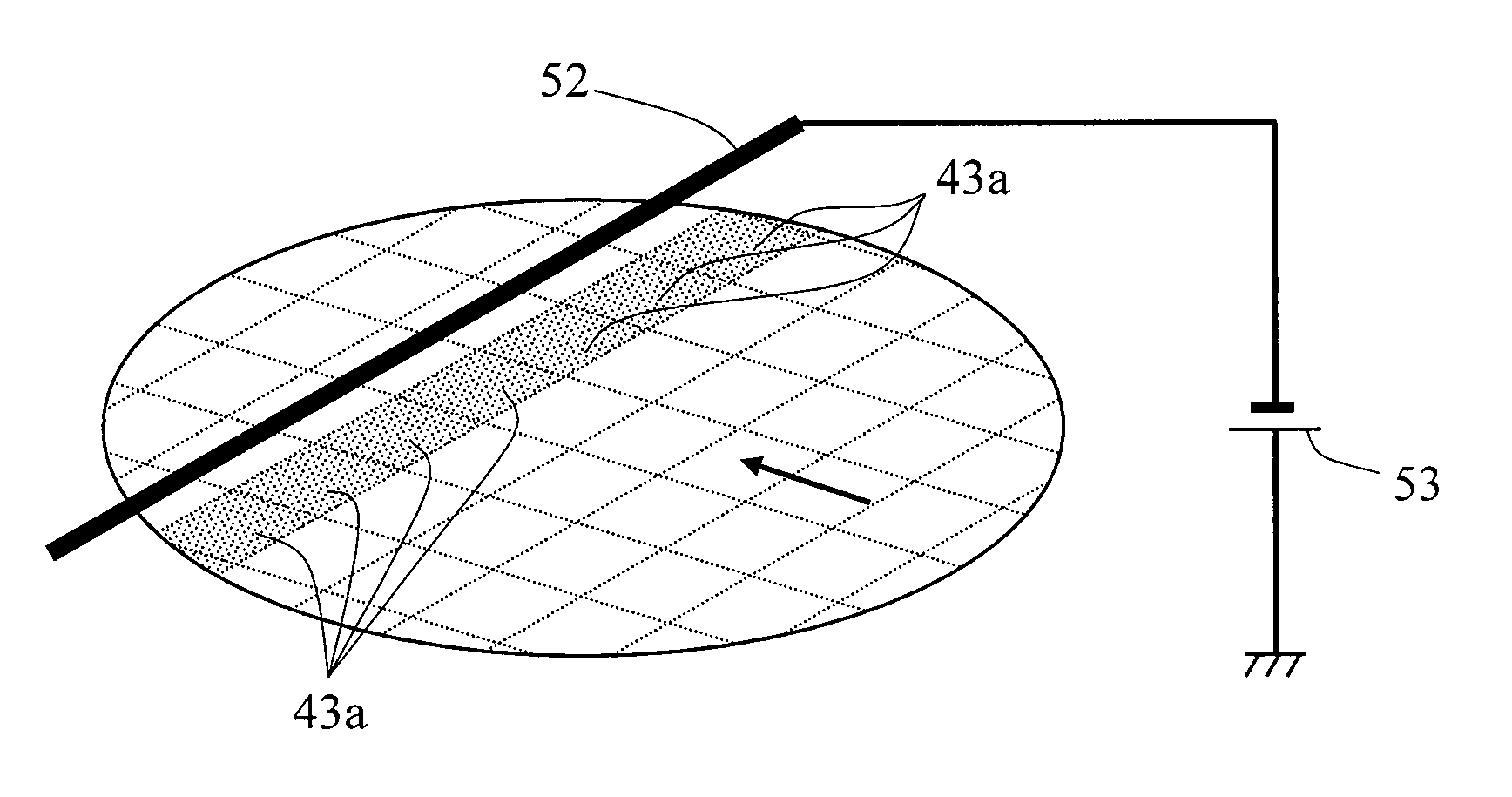

In the present invention, a semiconductor substrate wherein a plurality of MEMS microphones is formed is disposed opposed to a discharge electrode in a state of being stuck on a sheet. Electretization of a dielectric film provided in the MEMS microphone is performed by irradiating the dielectric film between a fixed electrode and a vibration film provided in the MEMS microphone with ions resulting from a corona discharge of the discharge electrode in a state that a predetermined potential difference is applied to the fixed electrode and the vibration film and fixing charges based on the ions to the dielectric film. The electretization is successively performed to each MEMS microphone on the semiconductor substrate by relatively moving the semiconductor substrate and the discharge electrode. Therefore, electretization of the dielectric film in the MEMS microphone chip is realized using a low-cost and simple fabricating equipment and productivity can be enhanced.

Owner:TDK CORPARATION

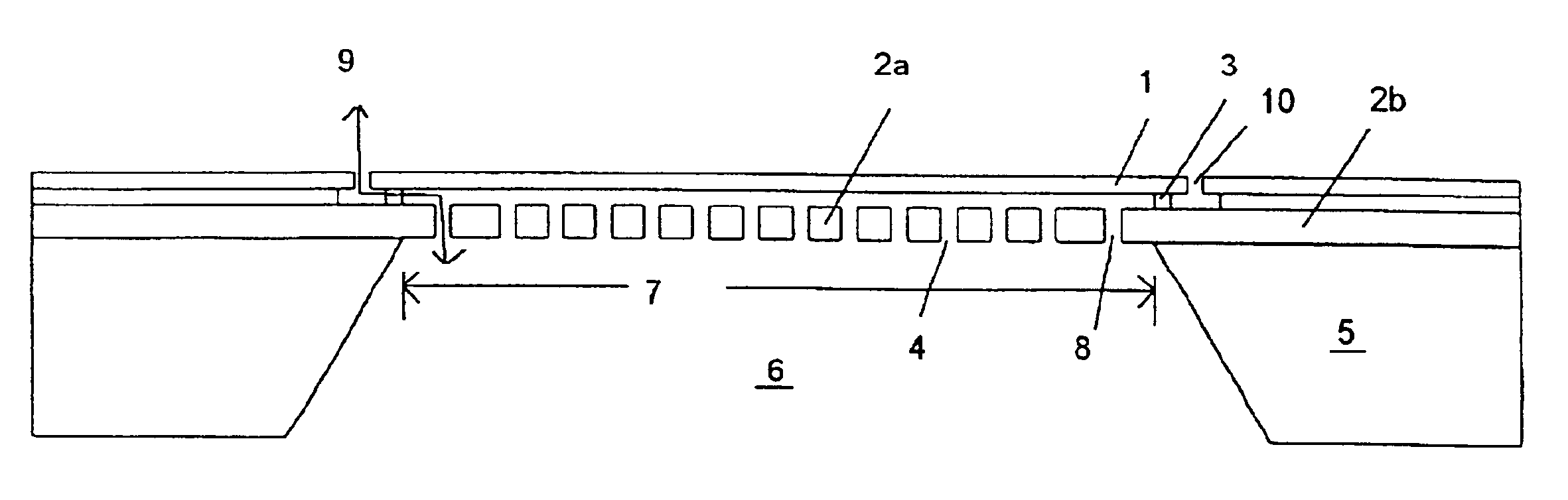

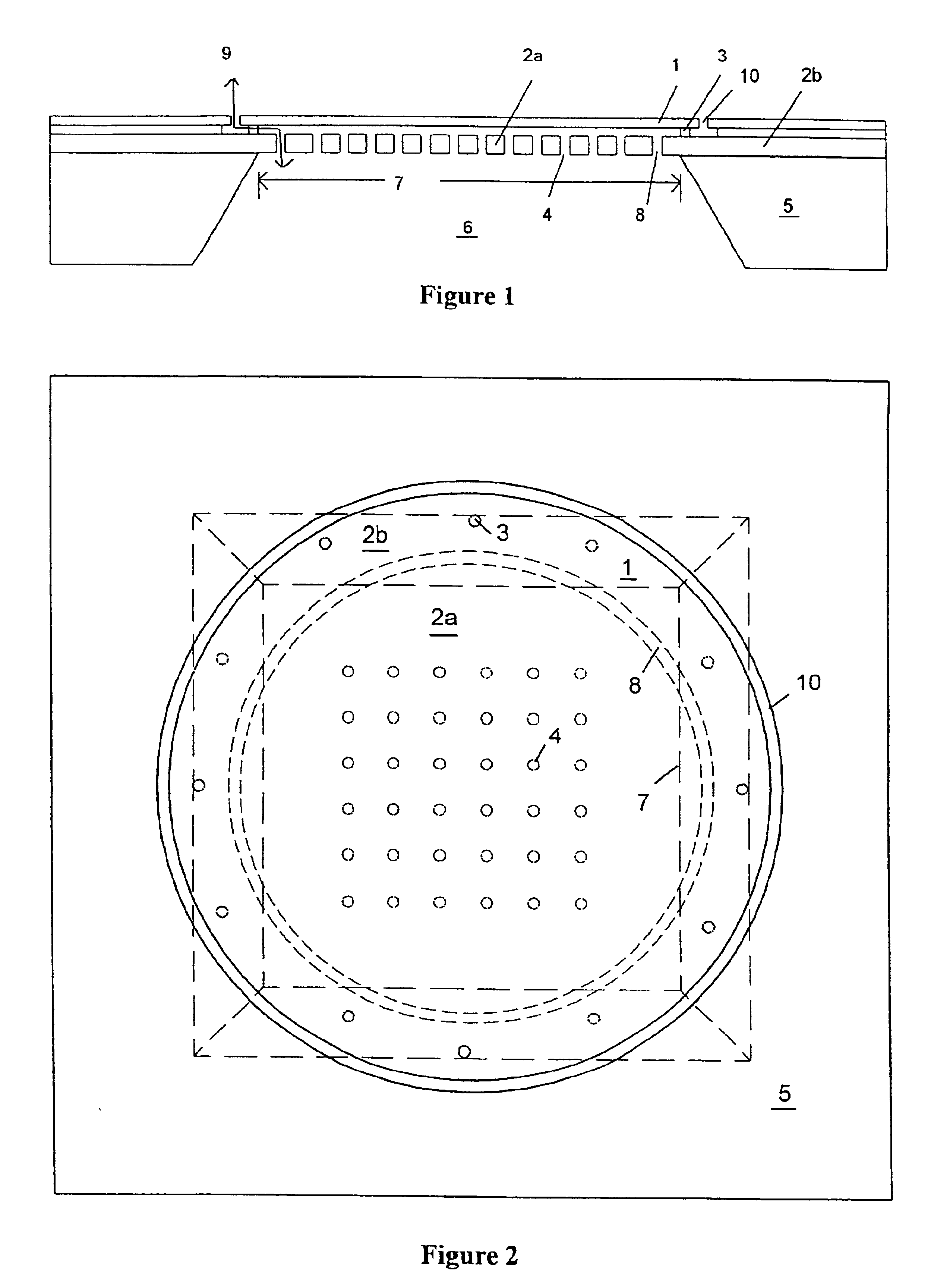

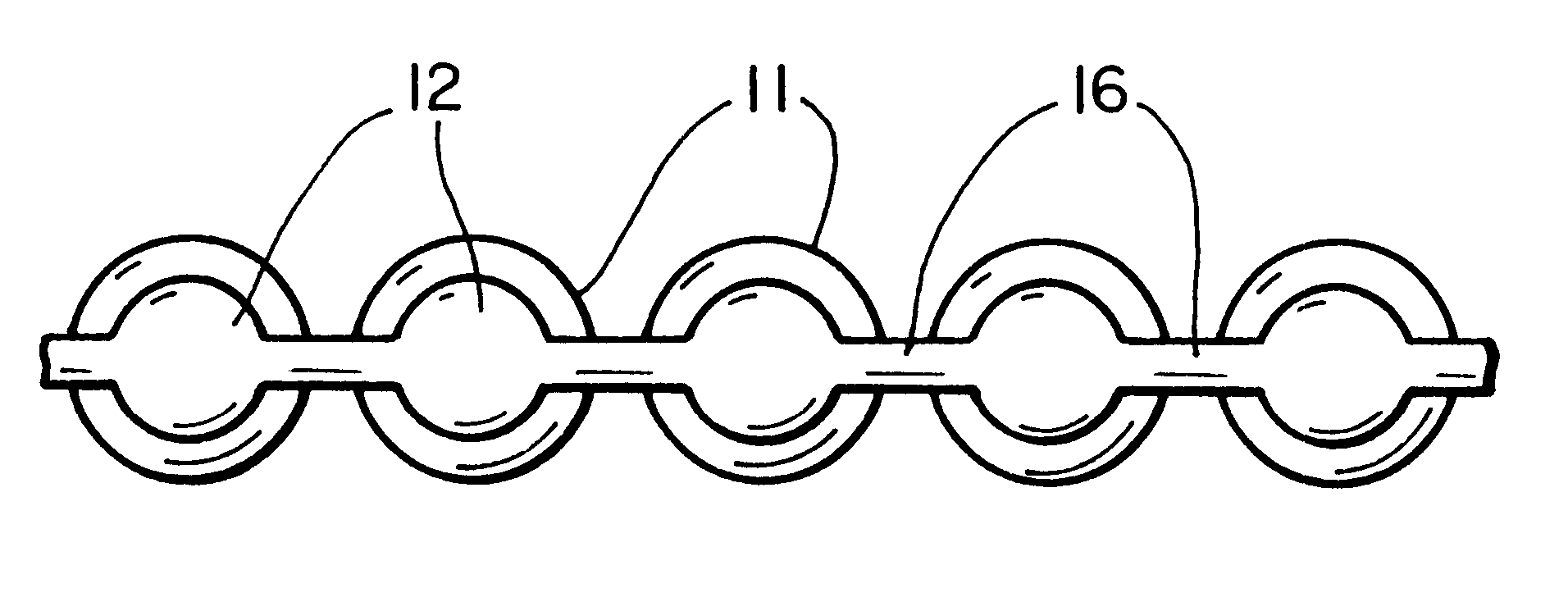

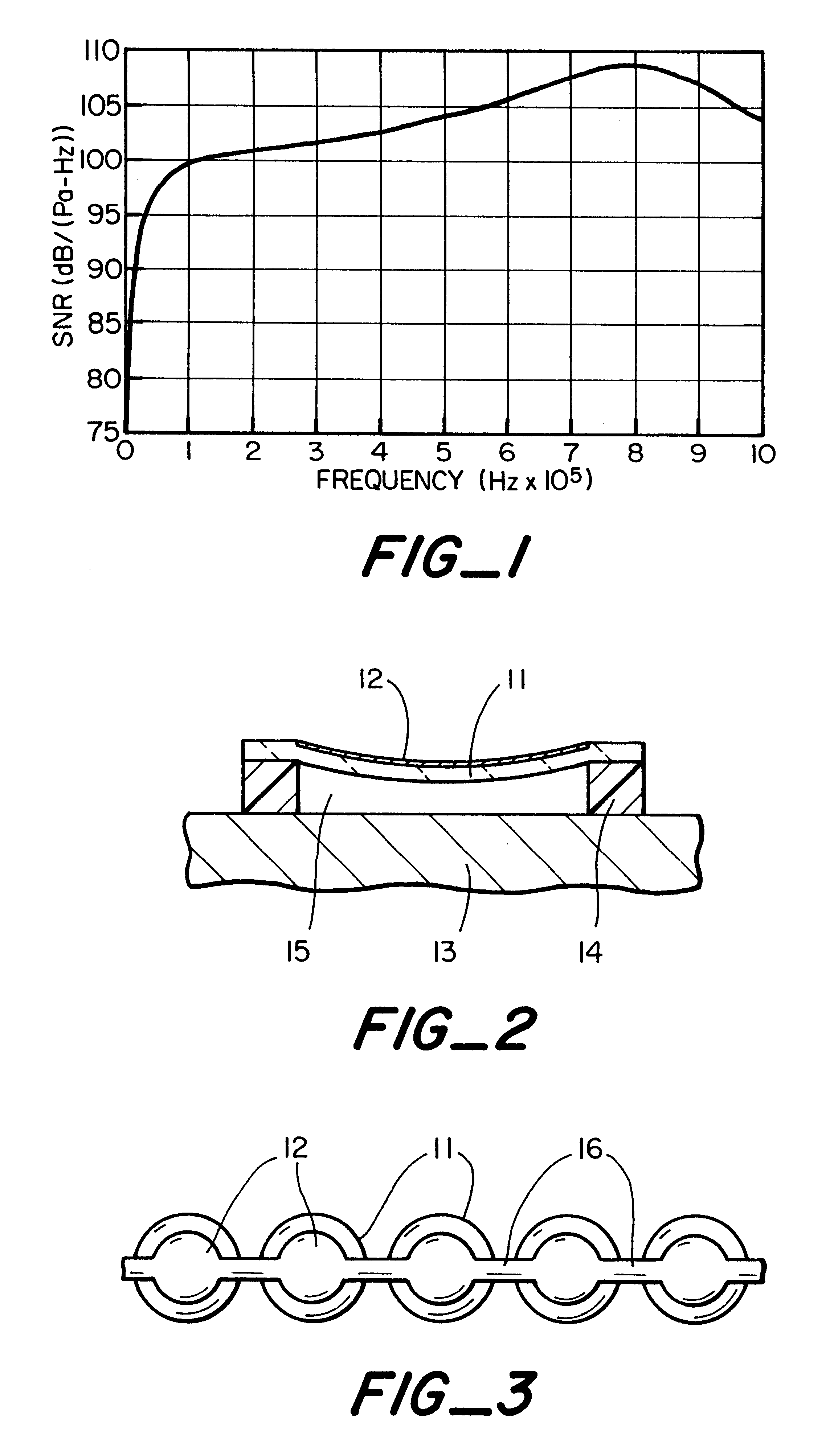

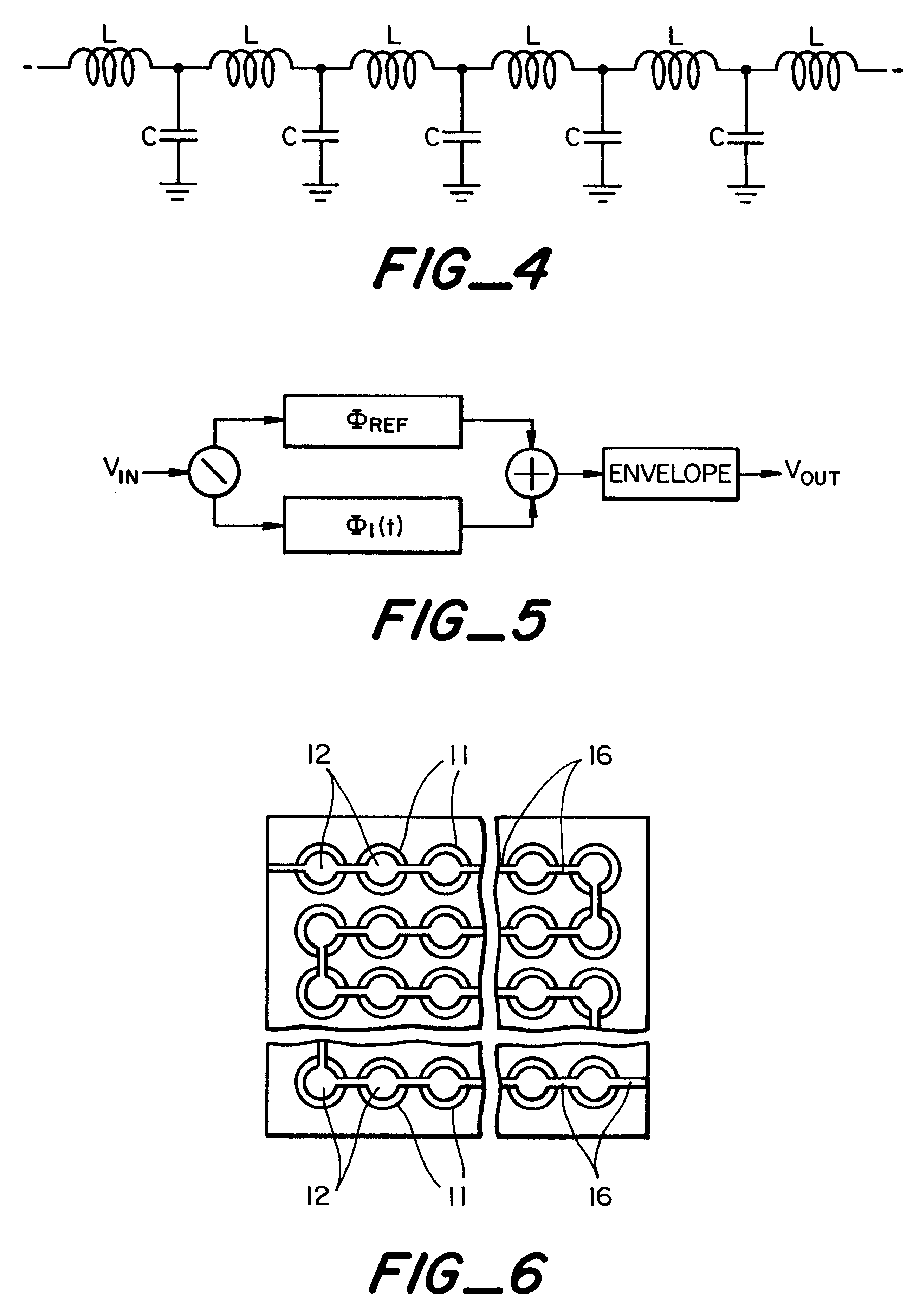

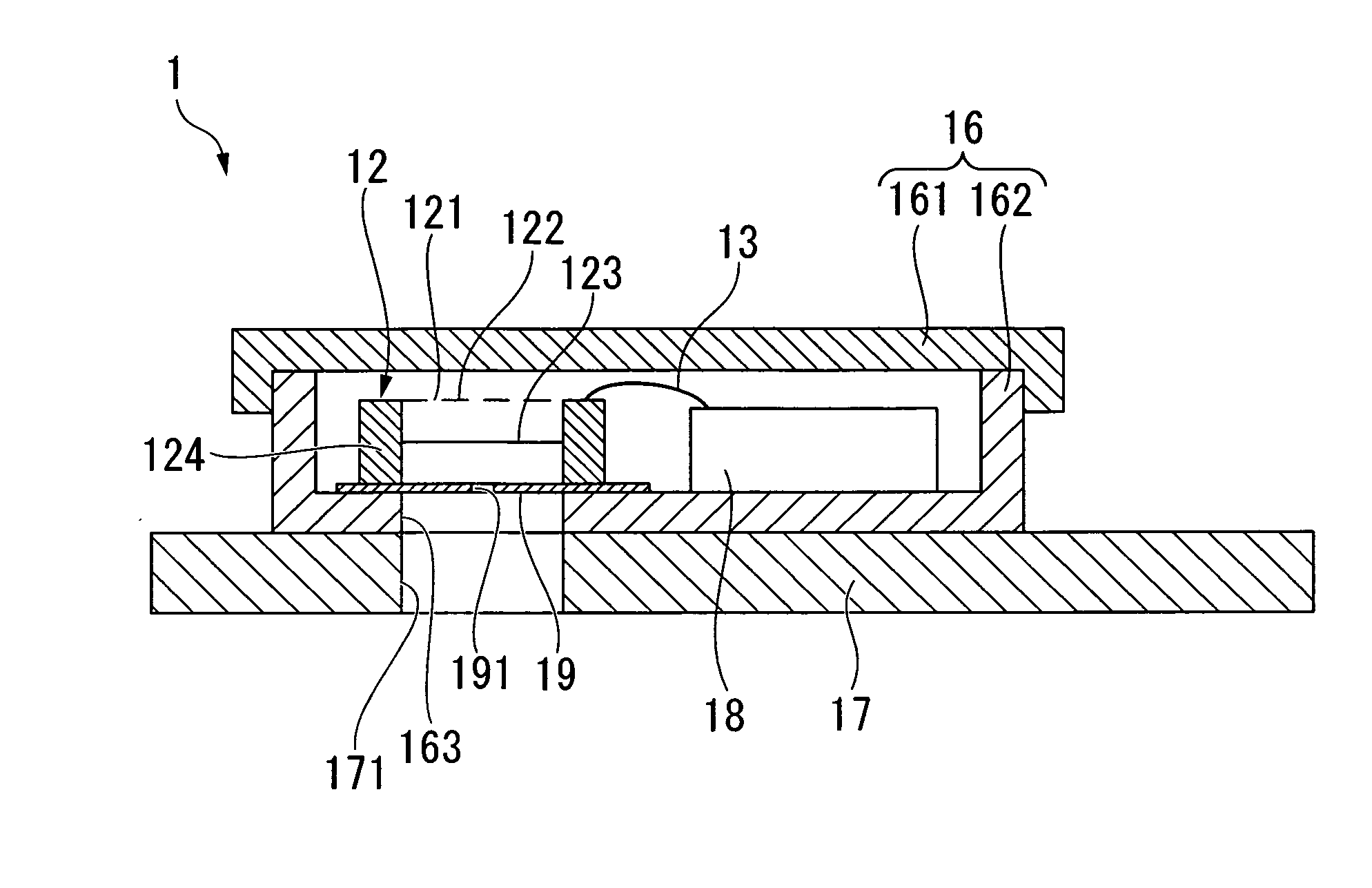

Wide frequency band micromachined capacitive microphone/hydrophone and method

InactiveUS6493288B2Subsonic/sonic/ultrasonic wave measurementUsing electrical meansHydrophoneEngineering

A wide frequency band micromachined microphone including a plurality of micromachined cells of the type including electrodes carried by a membrane supported above a common electrode with conductive lines interconnecting the electrodes is described. A method of operating a microphone array is also described.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Condenser microphone

InactiveUS20080219482A1Improve environmental adaptabilityImprove abilitiesSolid-state devicesElectrostatic transducer microphonesCapacitanceResonance

An electroacoustic transducer includes a condenser microphone, which includes a package having a cavity and a through-hole, a plate whose thickness is thinner than the length of the through-hole and which has a sound hole overlapping with the through-hole in plan view, and an electroacoustic transducer die, which is stored in the cavity of the package. The electroacoustic transducer die includes a fixed electrode and a diaphragm electrode, which are positioned opposite to each other and which are supported by and enclosed inside of a support. The sound hole of the plate is reduced in dimensions realizing a small sectional area and a small depth, thus realizing a high resonance frequency higher than the audio frequency range.

Owner:YAMAHA CORP

Condenser microphone chip

ActiveUS20080232615A1Reduce decreaseRelease residual stressSemiconductor electrostatic transducersElectrostatic transducer microphonesCapacitanceEngineering

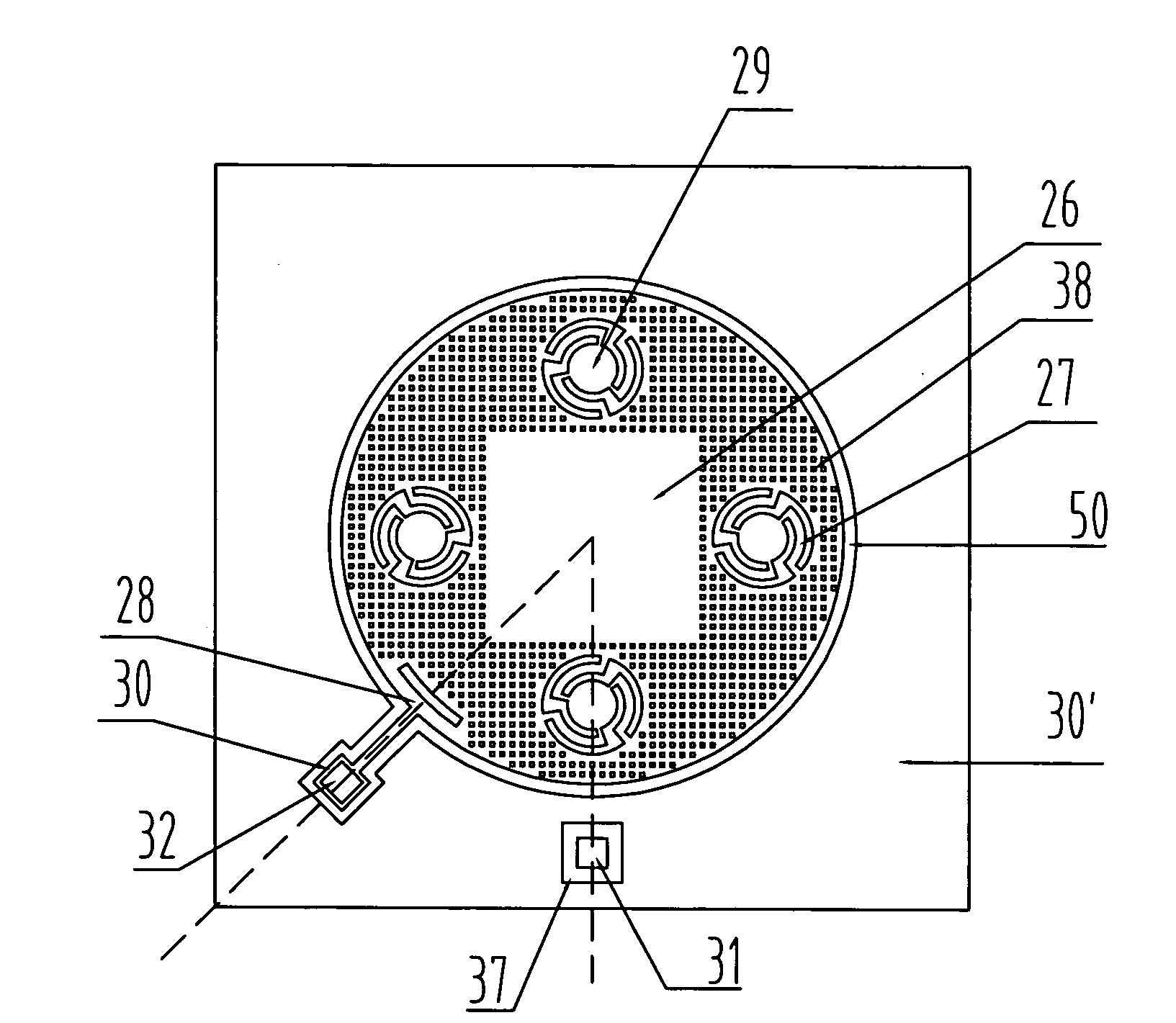

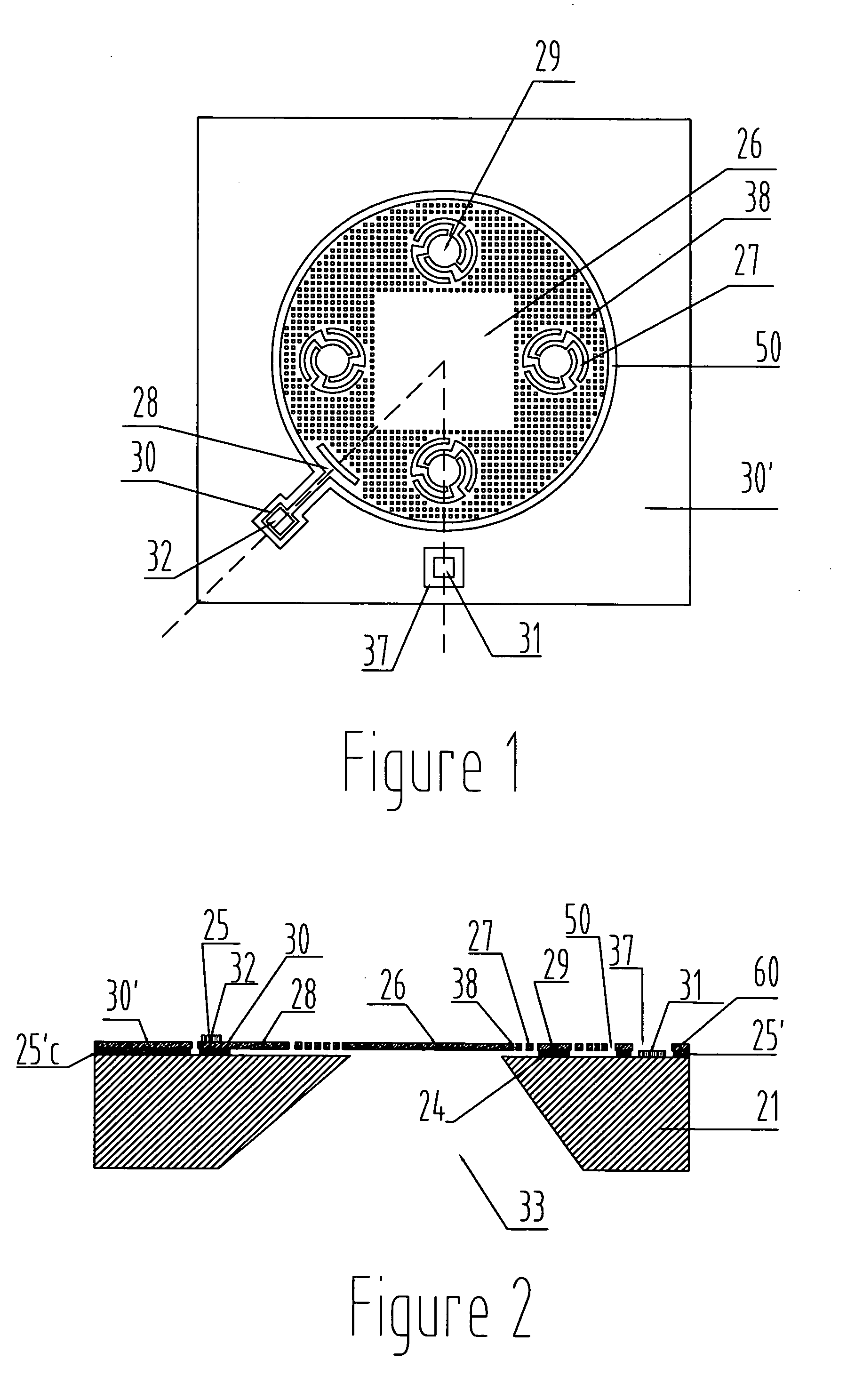

Disclosed is a condenser microphone chip, comprising: a substrate (21); a diaphragm (26) spaced from the substrate; a curved beam (27) connected with the diaphragm (26) to anchor the diaphragm (26) to the substrate (21); a curved beam connecting part (29) having a shape of a substantially circular plate. The curved beam (27) is arranged in the diaphragm (26). The curved beam (27) includes a plurality of sub beams, each of the plurality of sub beams including a first sub beam portion extending in a substantially radial direction from a circumference of the curved beam connecting part (29); a second sub beam portion extending in a substantially circumferential direction from an end of the first sub beam portion away from the circumference of the curved beam connecting part (29) and having a shape of a substantial arc; and a third sub beam portion extending in the radial direction from an end of the second sub beam portion away from the first sub beam portion and connected to the diaphragm (26). The condenser microphone chip according to the present invention is high in sensitivity, low in noise, wide in frequency band, simple in manufacturing process, and high in reliability. In addition, the condenser microphone chip can be easily manufactured in mass production.

Owner:GOERTEK MICROELECTRONICS CO LTD

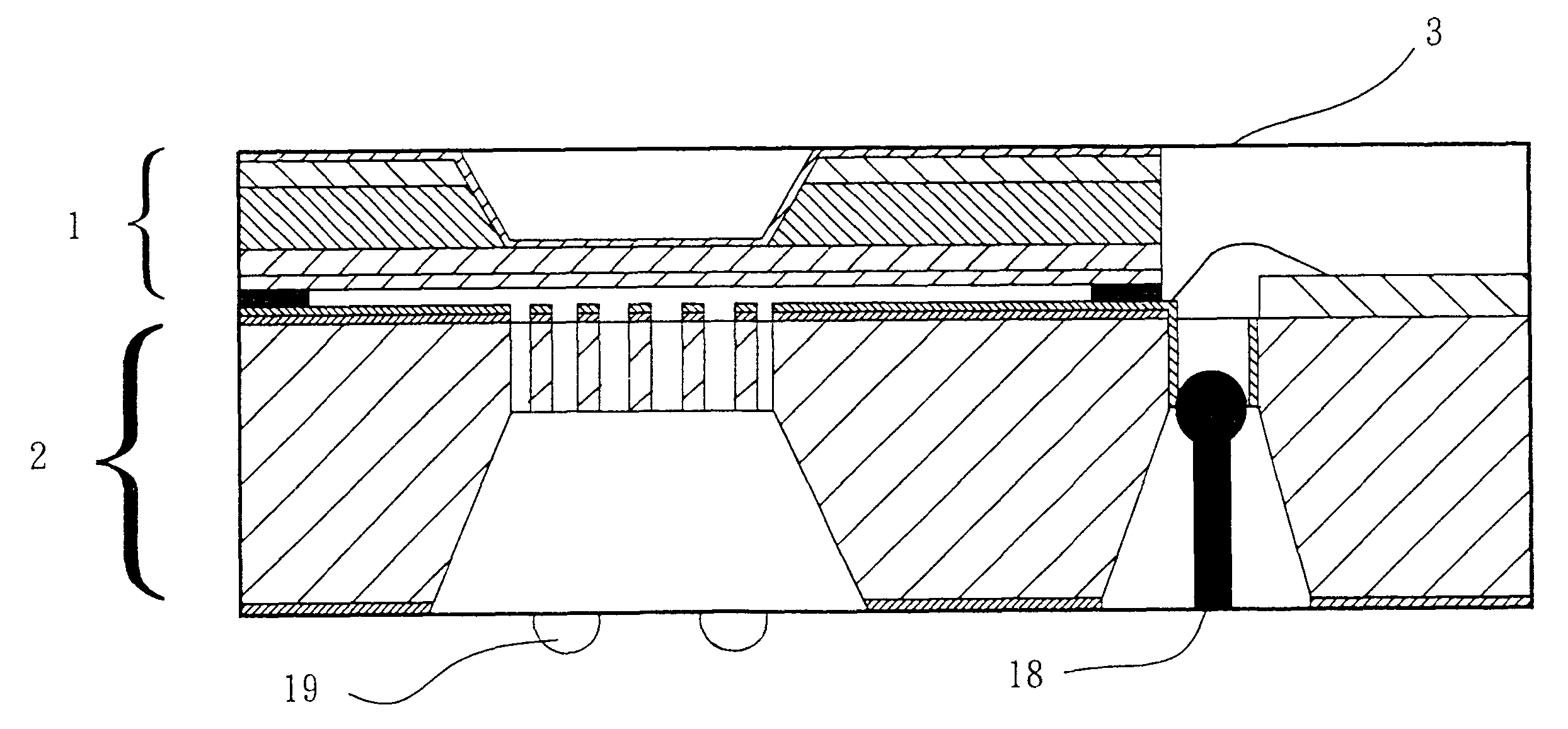

SMT-type structure of the silicon-based electret condenser microphone

InactiveUS6870939B2Reduce Harmonic DistortionStructure miniaturizationPiezoelectric/electrostrictive microphonesElectrets selectrostatic transducerCapacitanceDielectric

This invention mainly provides a SMT-type structure of the minimized and low-power silicon-based electret condenser microphone. Primarily integrates with the electret, silicon-based, MEMS and microphone techniques to implement the minimized and low-power silicon-based electret condenser microphone. The Silicon-based bi-diaphragm of the composite diaphragm-chip was coated with the low-dielectric macromolecule material to allow the microphone acquires the sufficient electrical charges. Moreover, the impedance matching element of the microphone that MOSFET was implemented by the MEMS technology. Conclusively, this silicon-based electret condenser microphone gains several achievements as the smallest volume, a lower bias voltage, a SMT-type structure, a lower residue stress and a lower assembly cost.

Owner:IND TECH RES INST

Capacitive microphone and method for making the same

ActiveUS20070154040A1Avoid static frictionAvoid driftingElectrostatic transducer microphonesDeaf-aid setsEngineeringStiction

A capacitive microphone and method for making the same are provided. A backplate with a plurality of holes is formed on a substrate with at least one cavity, and a diaphragm is formed above the backplate. There is an air gap between the backplate and the diaphragm. The air gap and the cavity communicate with each other by each hole. The diaphragm and the backplate are separated by a first distance and a second distance which is smaller than the first distance, such that the difference is formed on the diaphragm. The second distance area is fastened through surface stiction produced by mist or other fluids.

Owner:IND TECH RES INST

Silicon based condenser microphone and packaging method for the same

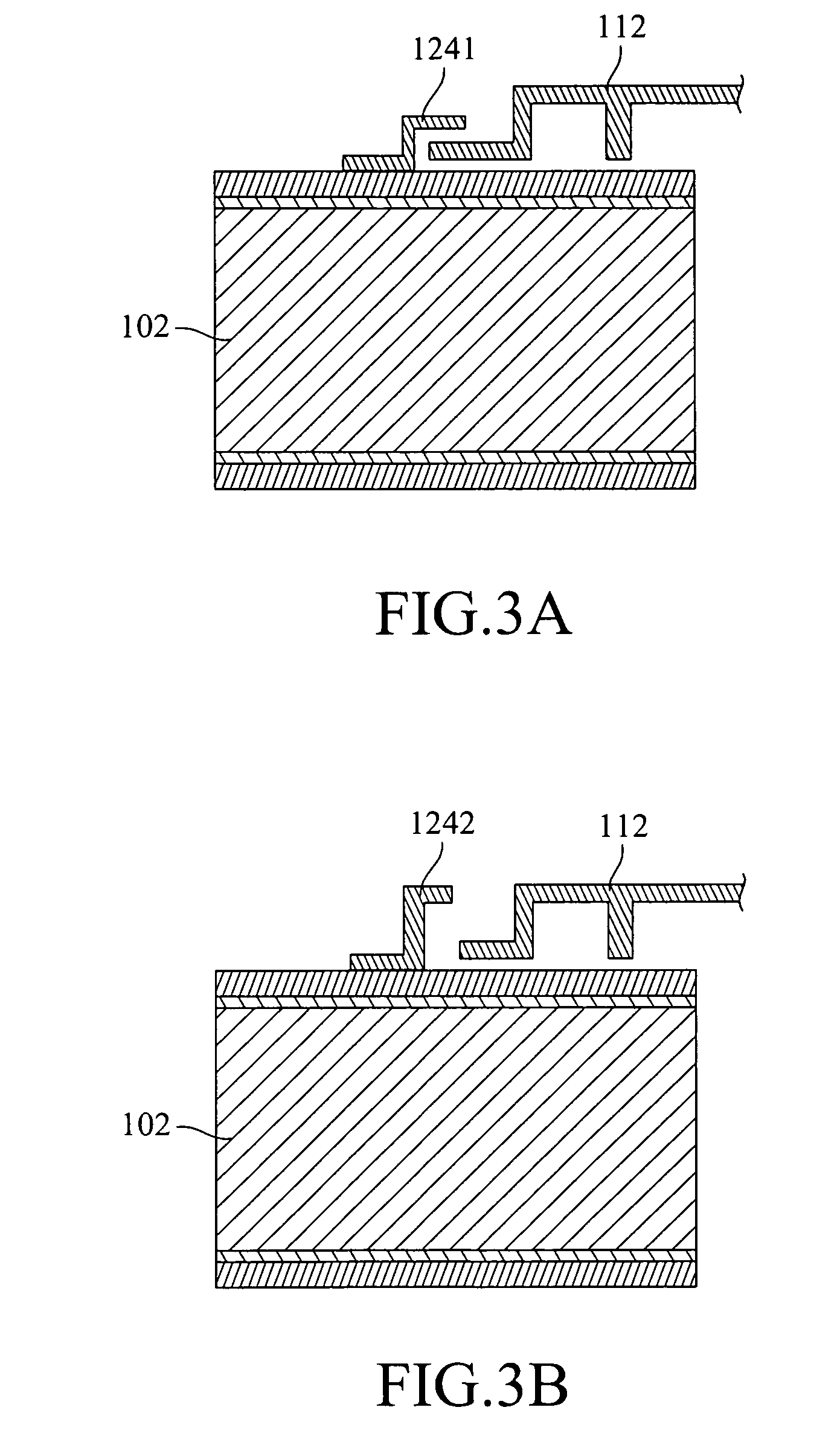

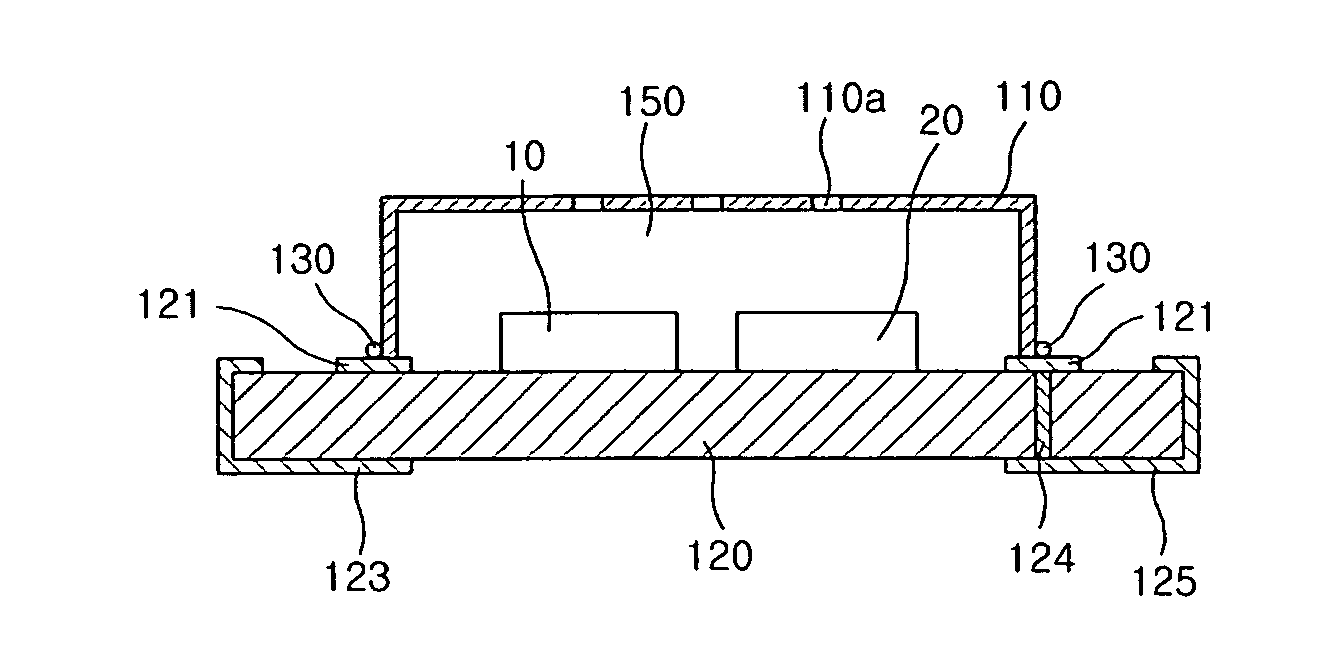

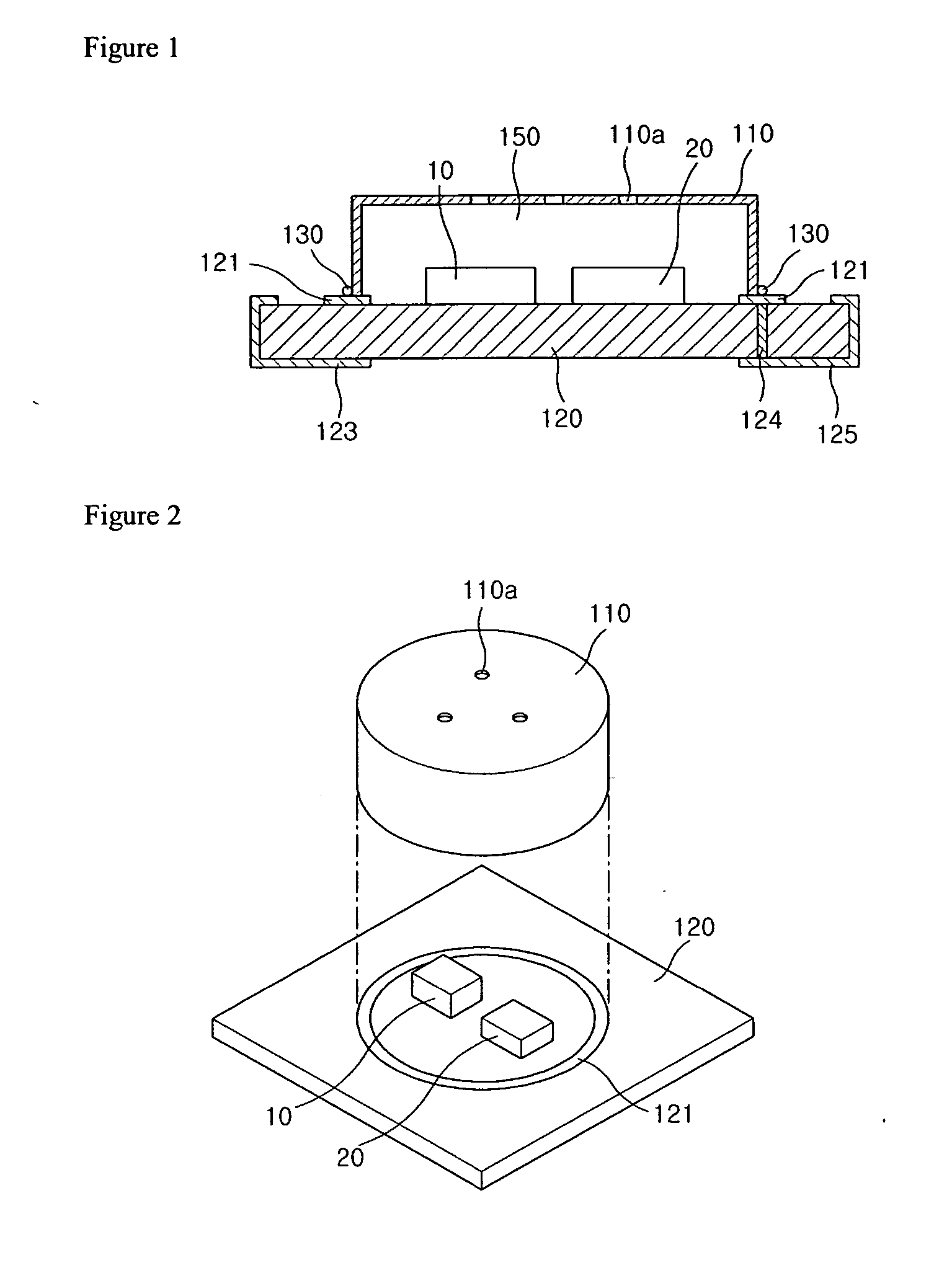

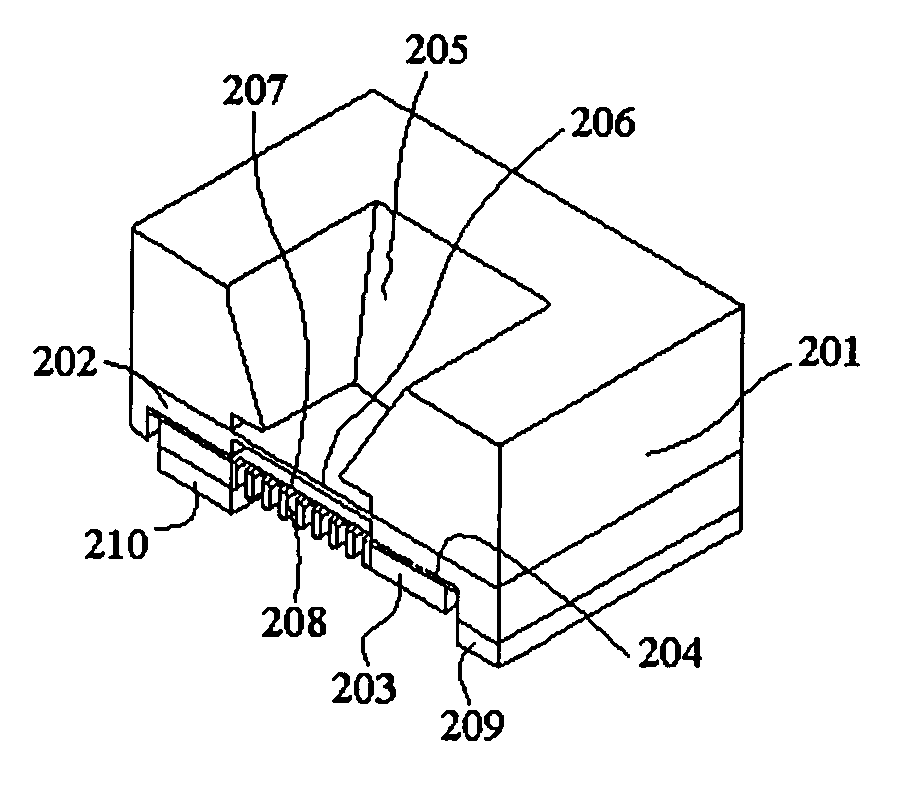

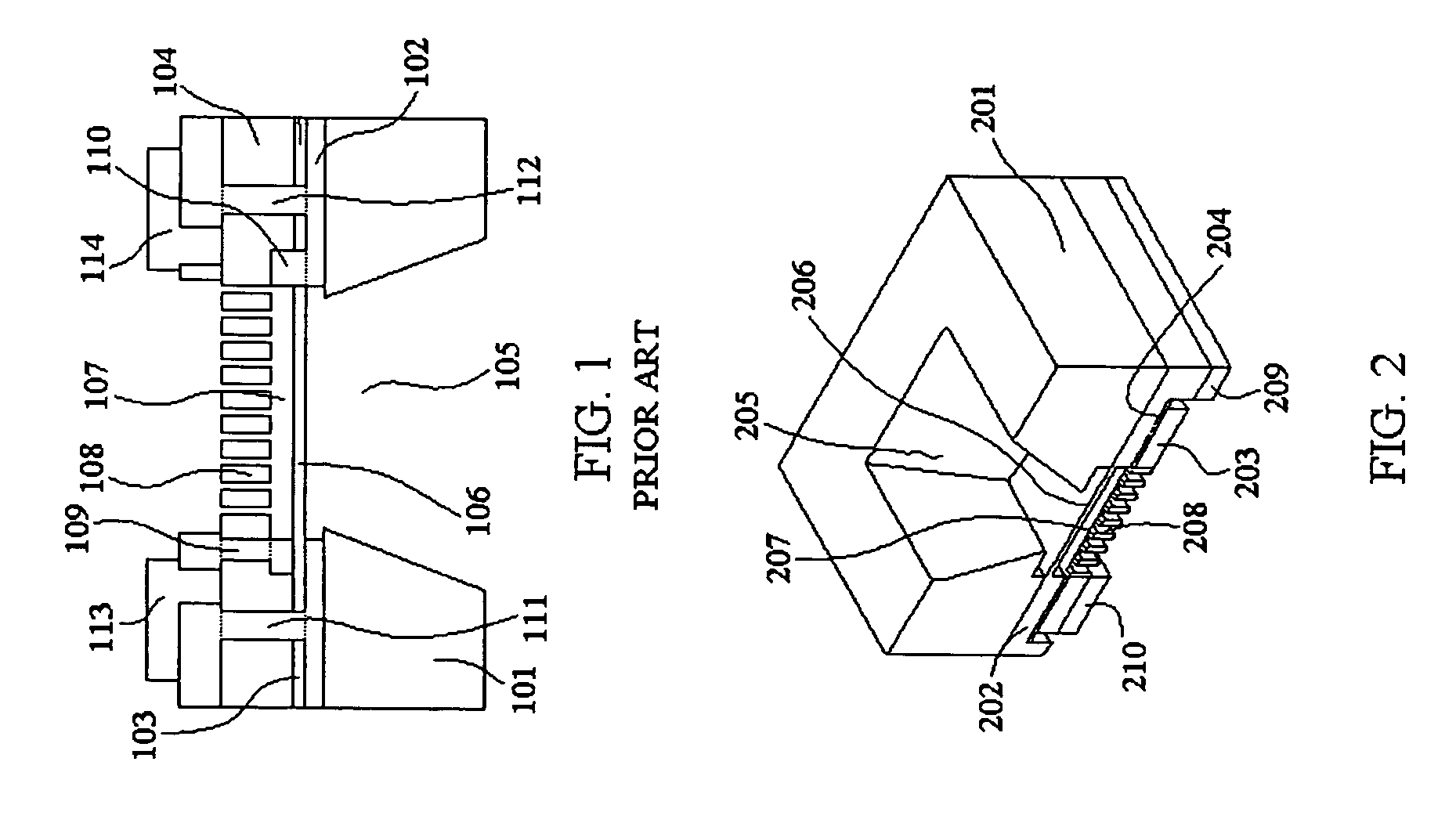

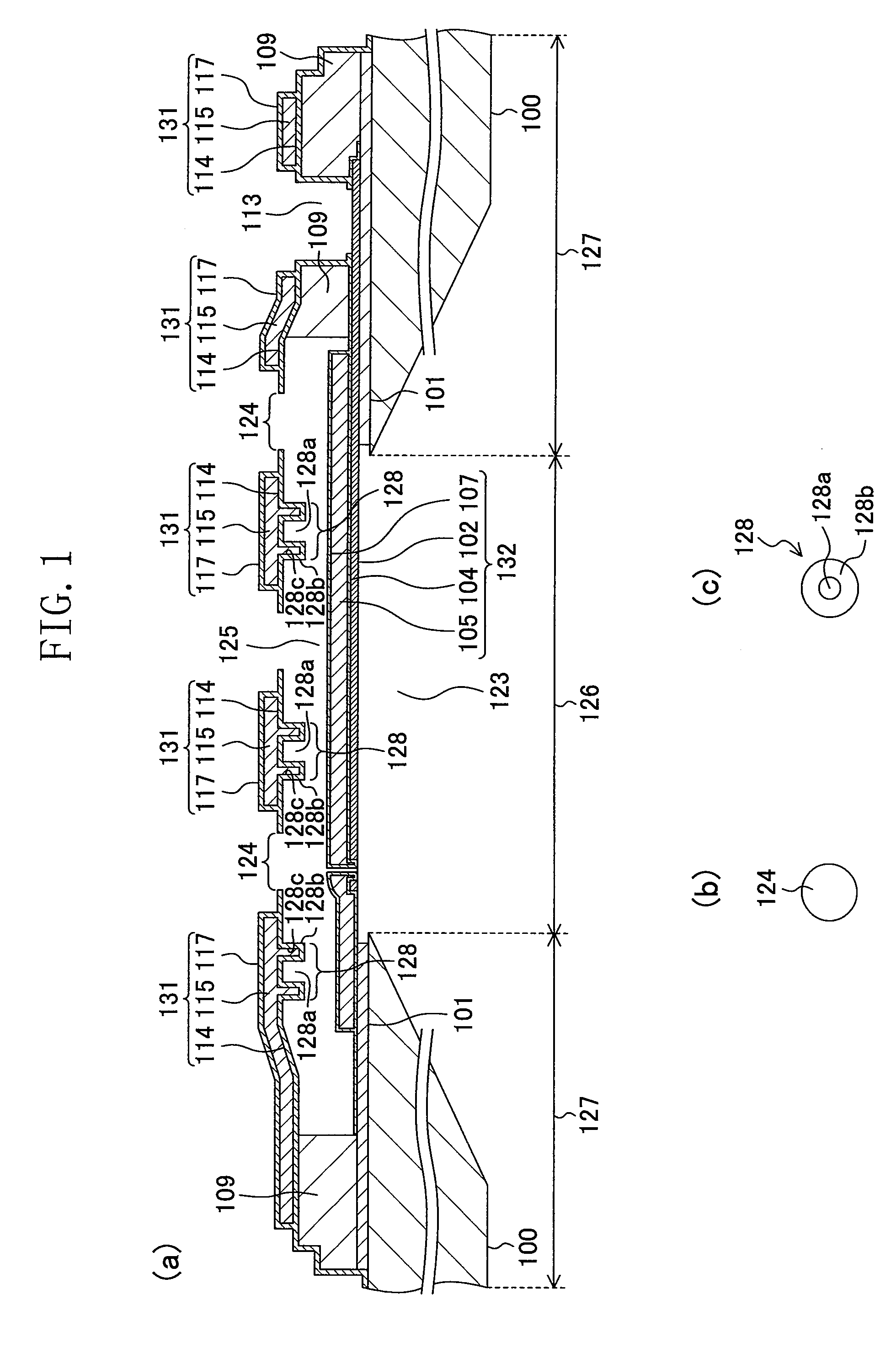

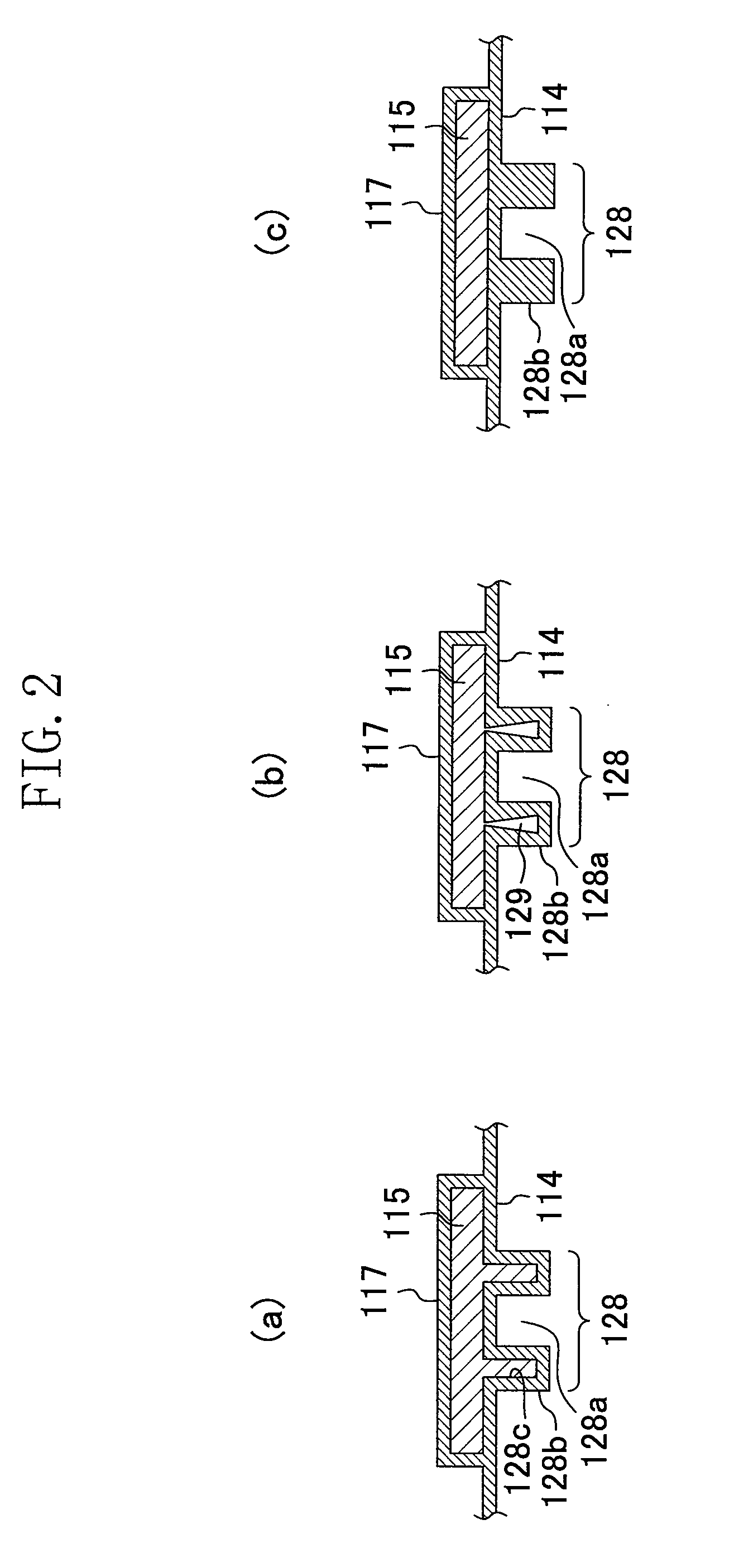

InactiveUS20070041597A1High bonding strengthIncrease resistancePiezoelectric/electrostrictive microphonesSolid-state devicesMems microphoneCondenser microphone

Disclosed are a silicon based condenser microphone and a packaging method for the silicon based condenser microphone. The silicon based condenser microphone comprises a metal case, and a board which is mounted with a MEMS microphone chip and an ASIC chip having an electric voltage pump and a buffer IC and is formed with a connecting pattern for bonding with the metal case, wherein the connecting pattern is welded to the metal case. The method for packaging a silicon based condenser microphone includes the steps of inputting a board which is mounted with a MEMS chip and an ASIC chip and is formed with a connecting pattern; inputting a metal case, aligning the metal case on the connecting pattern of the board, and welding an opened end of the metal case to the connecting pattern of the board. Thus, the metal case is welded to the board by the laser.

Owner:BSE CO LTD

Single crystal silicon micromachined capacitive microphone

InactiveUS20060008098A1Mismatch problemPrecise definitionPiezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersEtchingLateral overgrowth

A single crystal silicon micromachined capacitive microphone is disclosed. The microphone comprises a flexible plate made from a bottom layer of a first epitaxial single crystal silicon layer, a stiff and perforated plate made from a portion of a second epitaxial single crystal silicon layer, a supporting frame is made from a combination of lateral overgrowth of the first epitaxial single crystal silicon layer and a polysilicon layer grown or deposited on the surface of an insulating layer, and an air gap is formed by etching a portion of the first epitaxial single crystal silicon layer. Both the first epitaxial single crystal silicon layer and the second epitaxial single crystal silicon layer are developed from a single crystal silicon substrate. A micromaching technology based on selective formation and etching of porous single crystal silicon layers is used to make the microphone structure.

Owner:TU XIANG ZHENG

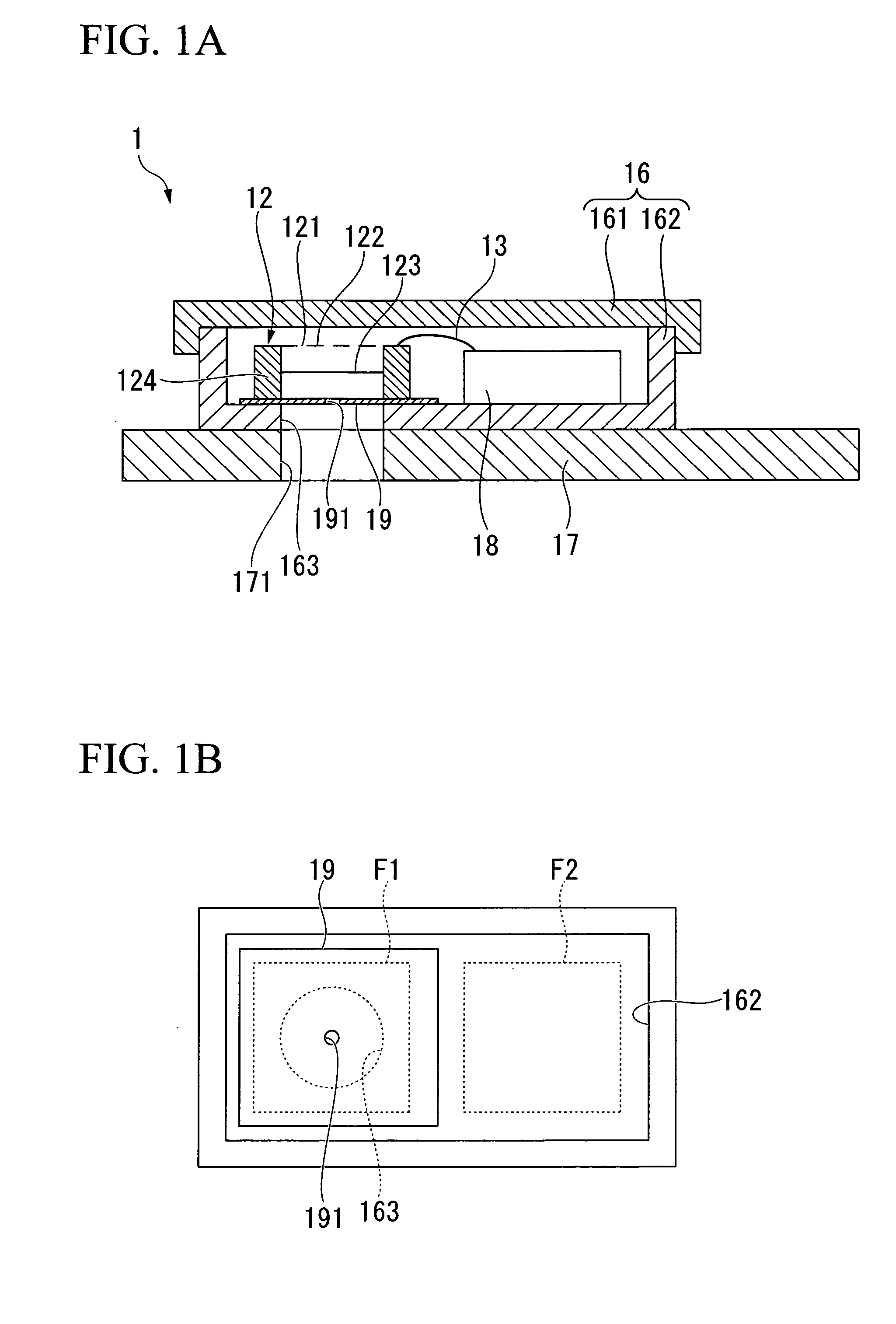

Condenser microphone and MEMS device

InactiveUS20100002895A1Excellent in sticking resistanceReduce contact areaElectretsElectrostatic transducersCondenser microphoneCapacitive microphone

Owner:PANASONIC CORP

Capacitor microphone and diaphragm therefor

InactiveUS20070121972A1Improved vibration characteristicsHigh sensitivitySemiconductor electrostatic transducersDeaf-aid setsHydrofluoric acidEngineering

In a capacitor microphone, a diaphragm is positioned opposite to a fixed electrode for covering inner holes of a ring-shaped support, wherein when the diaphragm is deflected to approach the fixed electrode due to electrostatic attraction upon application of a bias voltage, internal stress that occurs on the diaphragm is canceled by compressive stress that is applied to the diaphragm in advance. The diaphragm is formed using a multilayered structure including a first thin film and a second thin film whose internal stress differs from the internal stress of the first thin film, thus adjusting the total internal stress thereof. The diaphragm can be formed in such a way that a center layer having a single-layered structure is sandwiched between first and second coating layers having controlled residual tensions and resistance against hydrofluoric acid.

Owner:YAMAHA CORP

Microphone Assembly with Integrated Self-Test Circuitry

ActiveUS20110110536A1Accurate and fast measurementFast and cost-effectiveSemiconductor electrostatic transducersElectrostatic transducer microphonesSignal processing circuitsTransducer

The present invention relates to a condenser microphone assembly comprising an electro-acoustic transducer element comprising a diaphragm and a back plate, signal processing circuitry operatively connected to the transducer element so as to process signals generated by the transducer element, and a mode-setting circuitry for selectively setting the condenser microphone assembly in a test mode or an operational mode. The electro-acoustic sensitivity of the condenser microphone assembly, when operated in the test mode, is at least 40 dB lower than the corresponding electro-acoustic sensitivity of the assembly when operated in the operational mode. The present invention further relates to a method for determining a performance parameter of a signal processing circuitry mounted inside a housing of an assembled condenser microphone assembly.

Owner:TDK CORPARATION

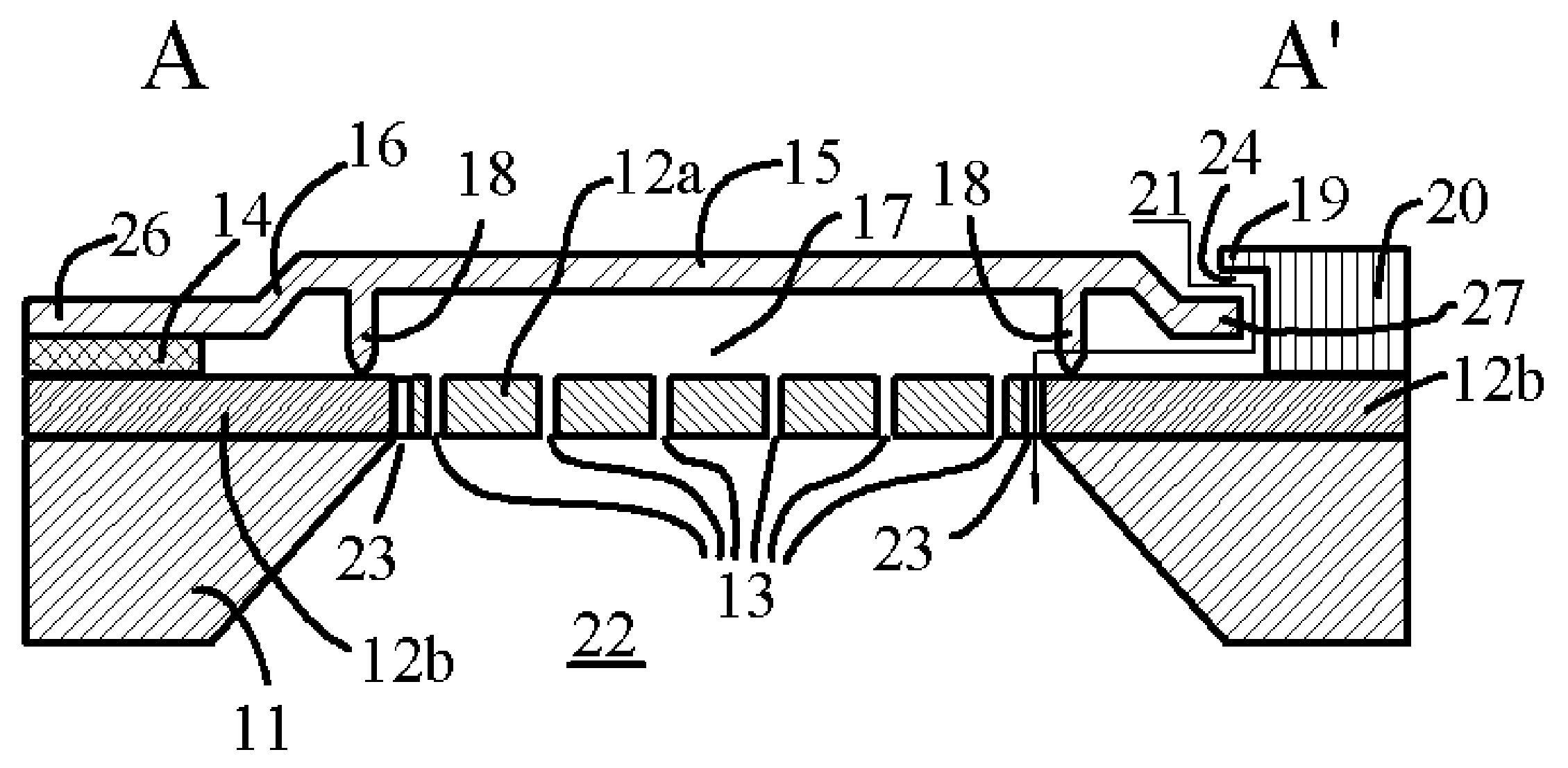

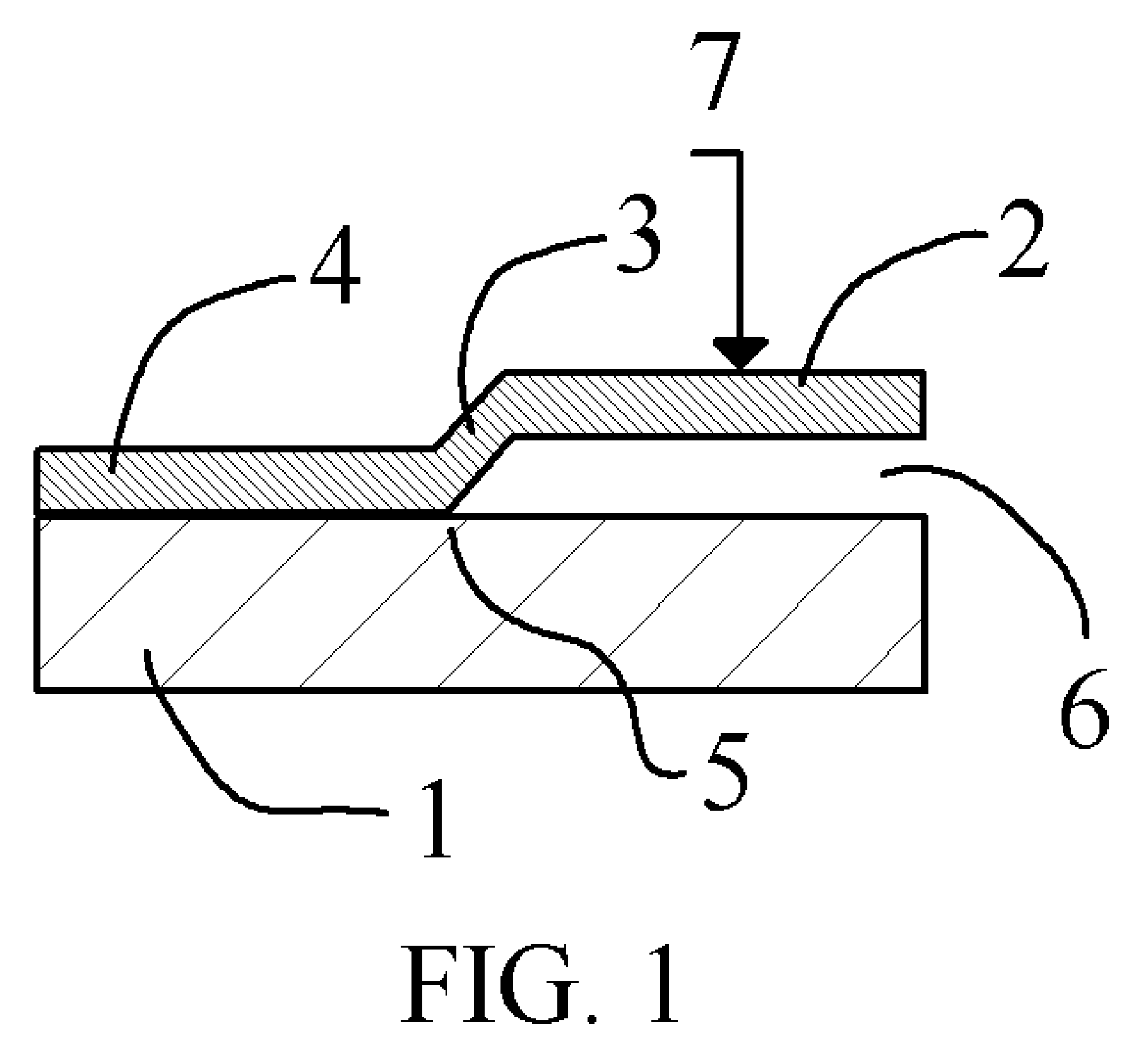

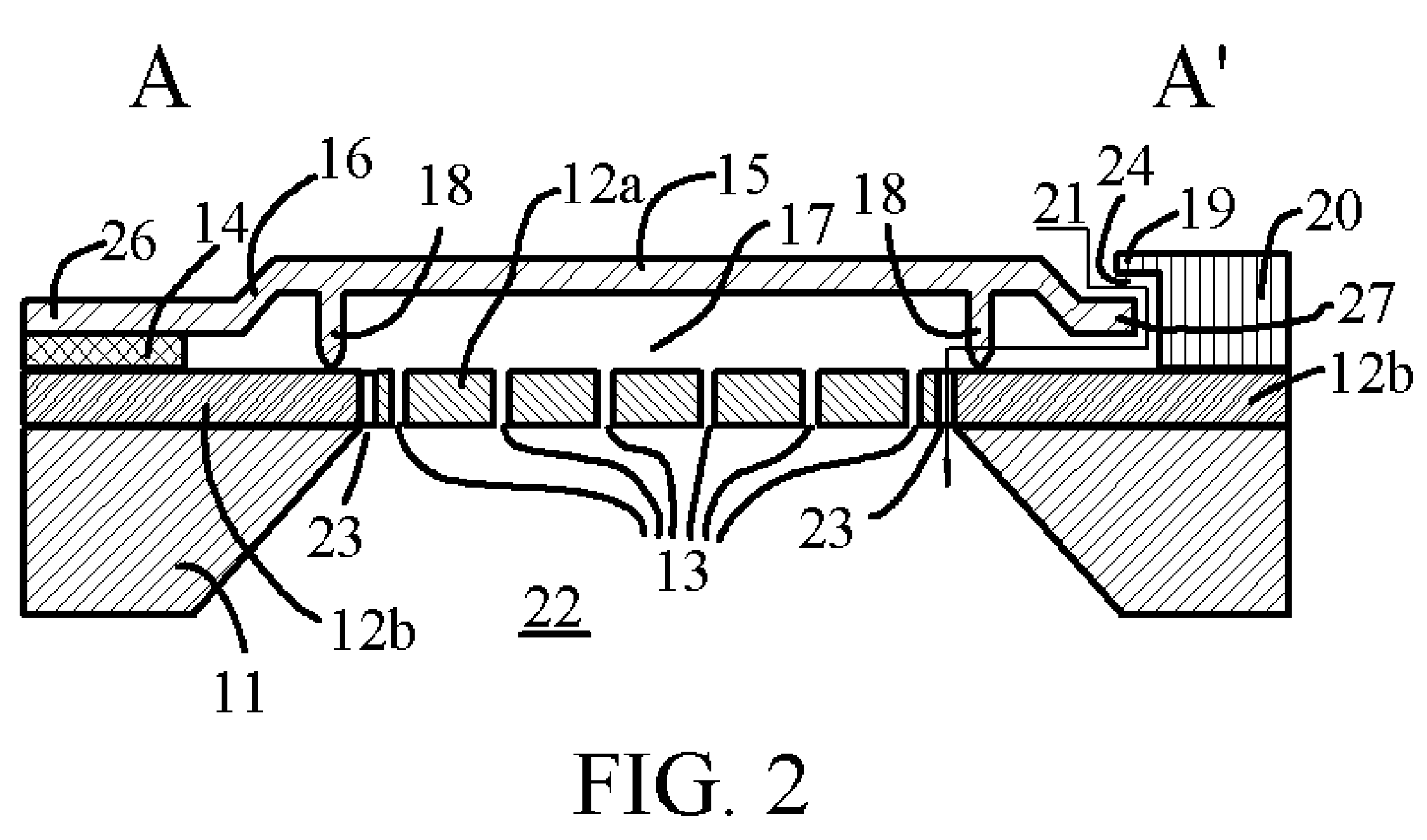

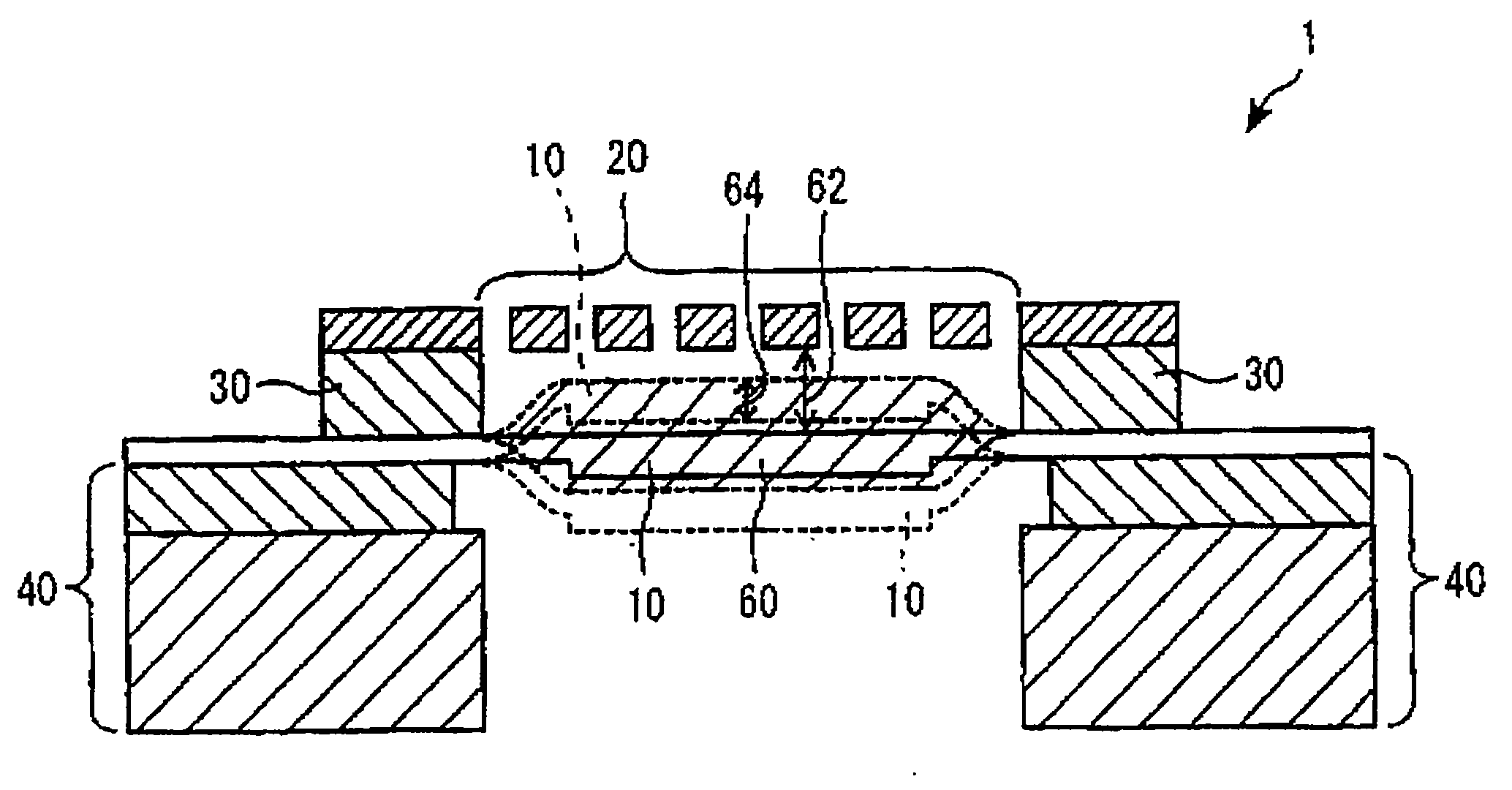

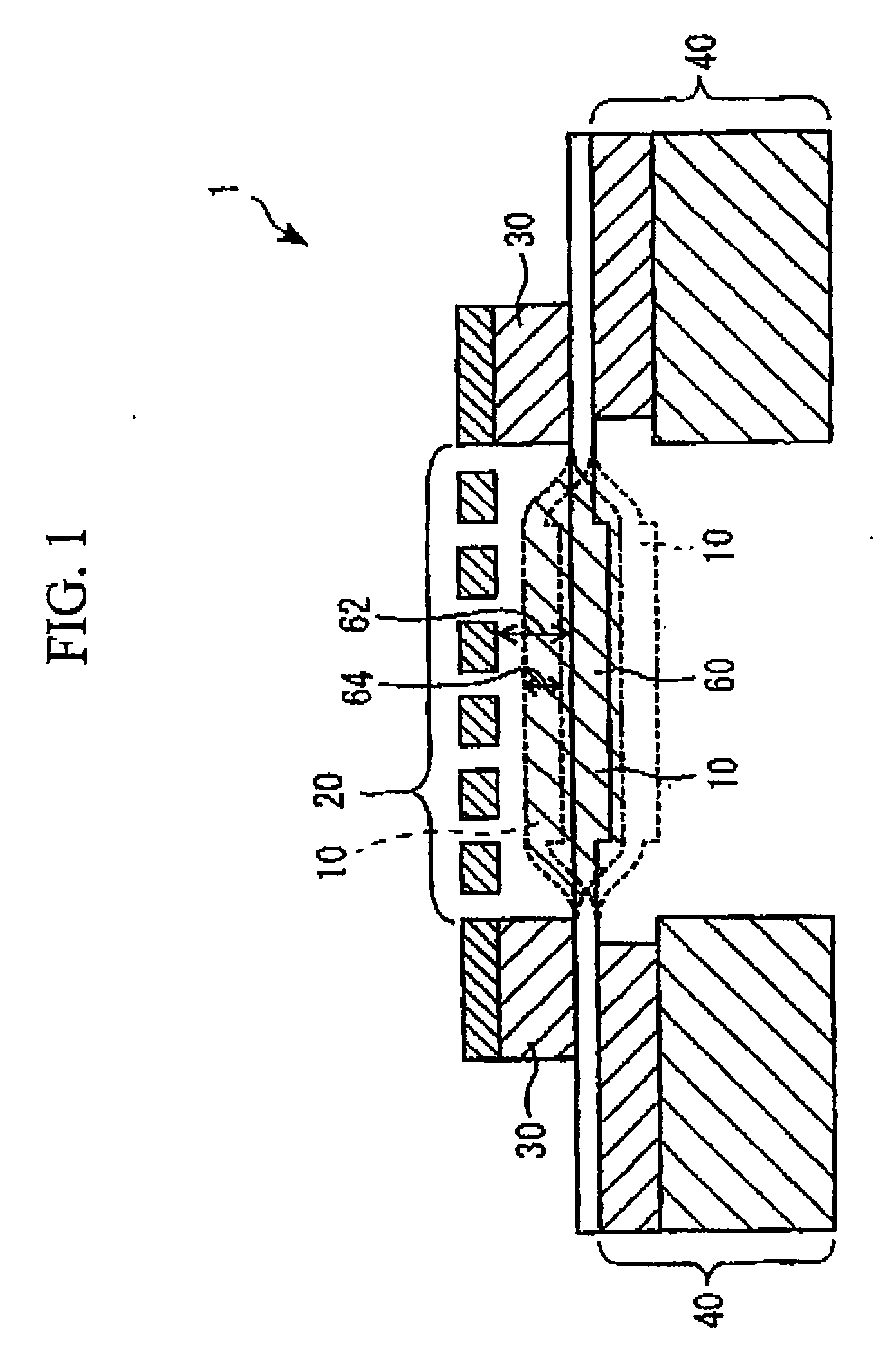

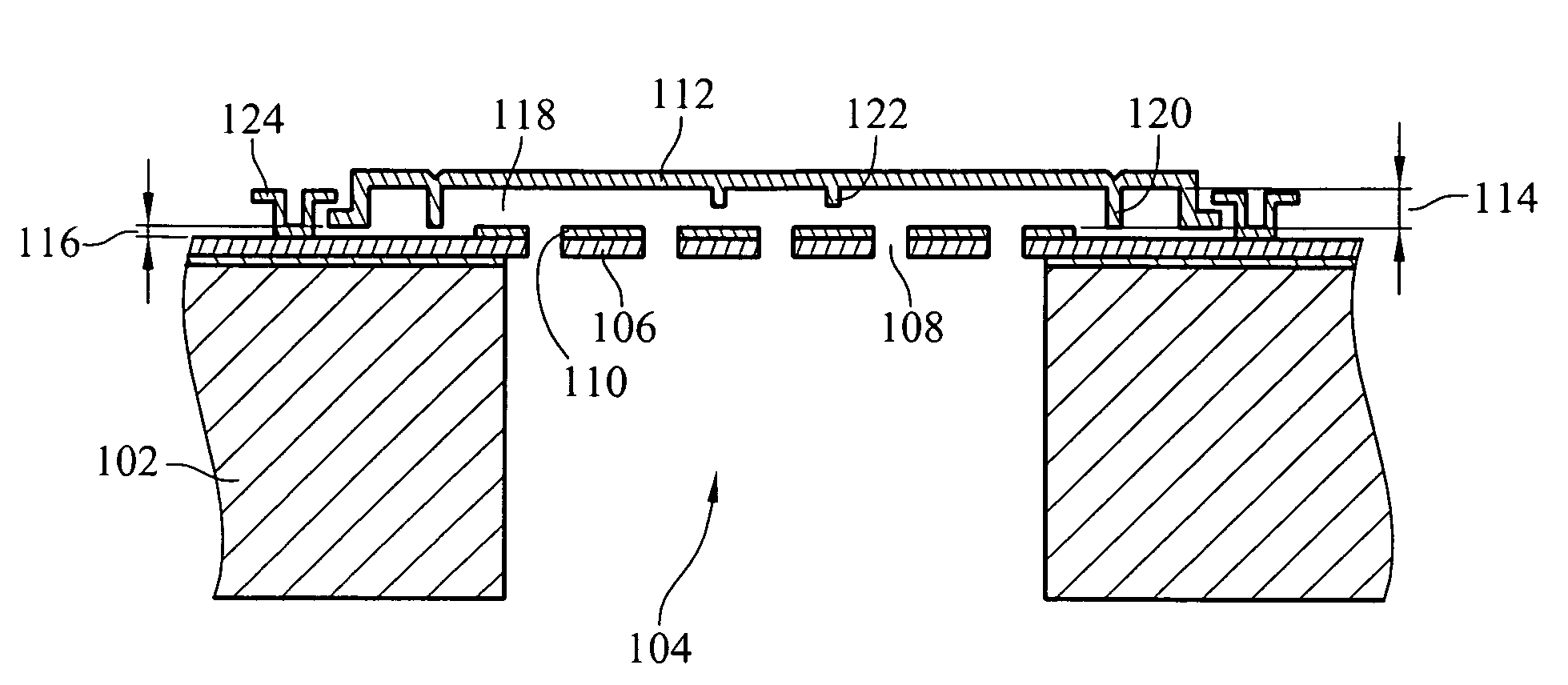

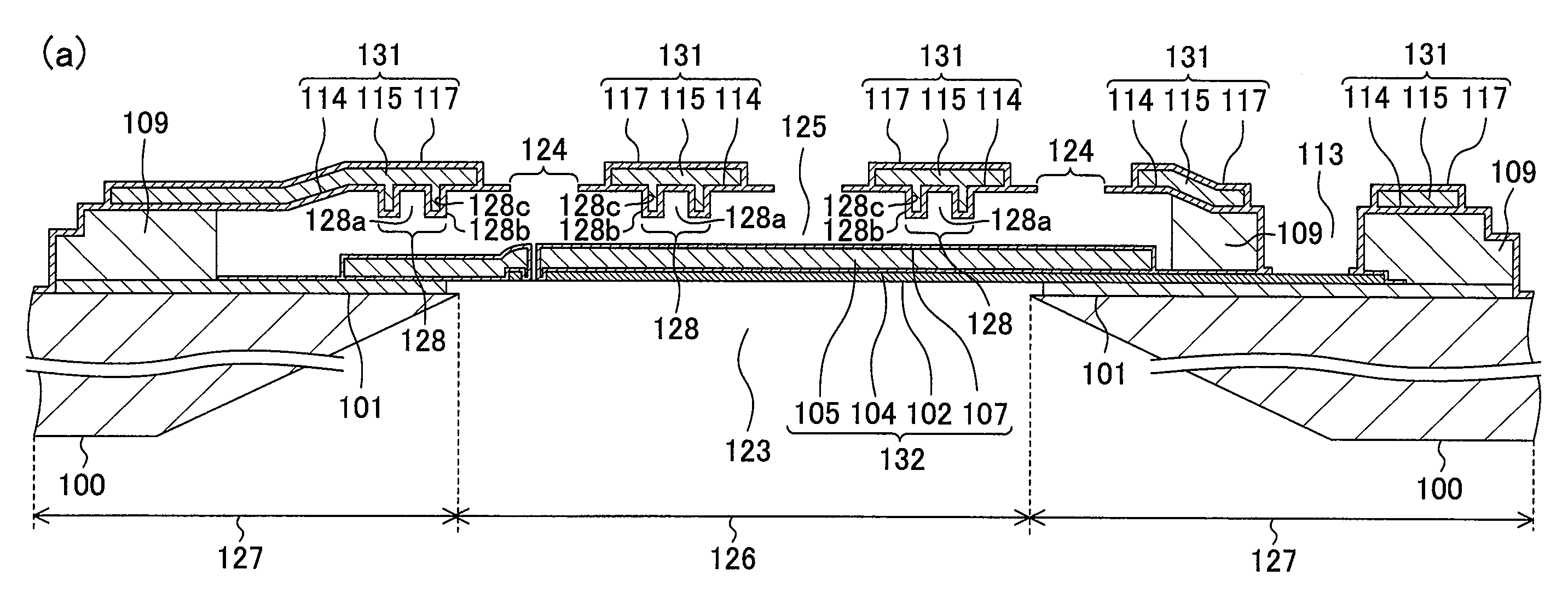

MEMS process and device

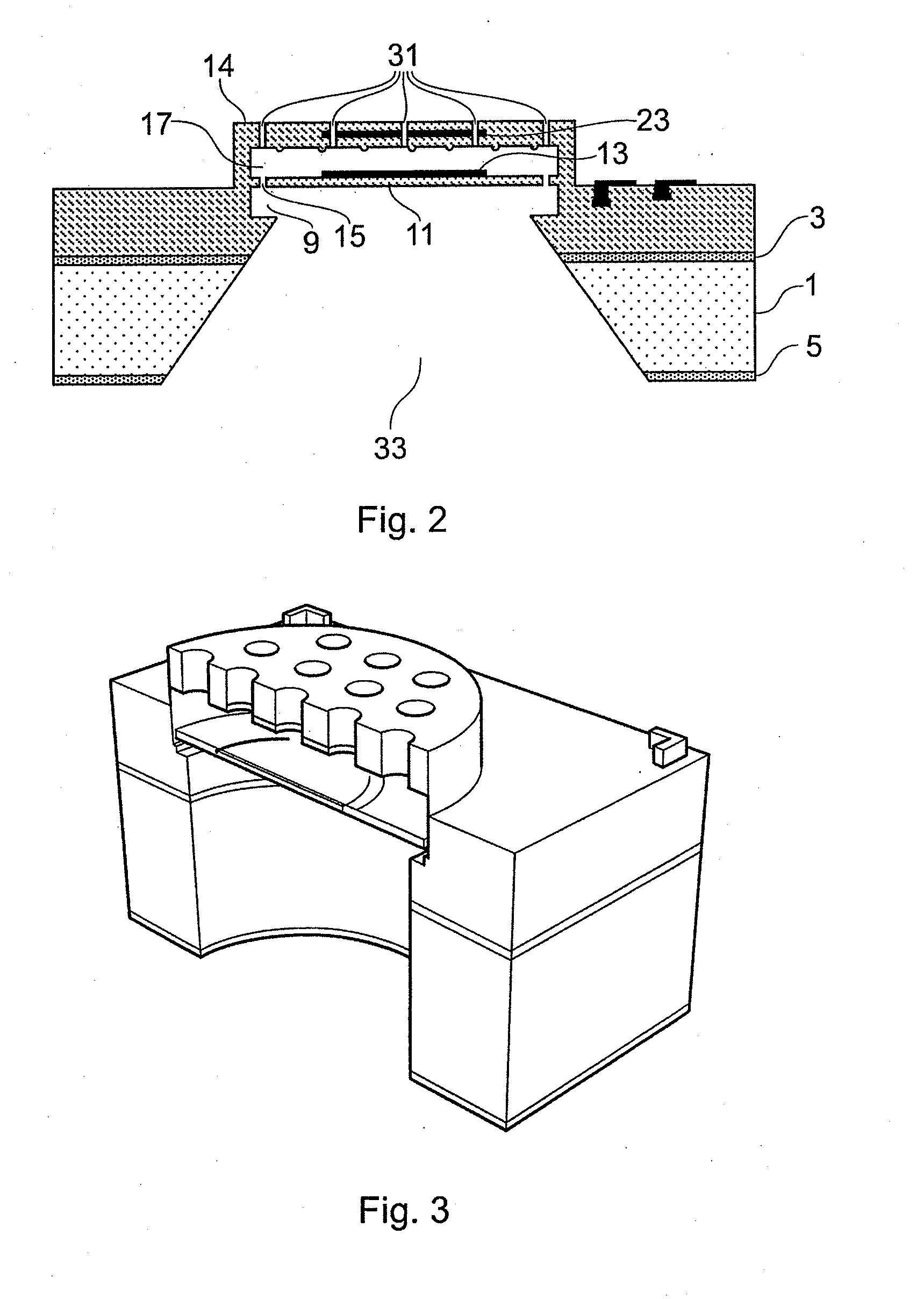

A MEMS device, for example a capacitive microphone, comprises a flexible membrane 11 that is free to move in response to pressure differences generated by sound waves. A first electrode 13 is mechanically coupled to the flexible membrane 11, and together form a first capacitive plate of the capacitive microphone device. A second electrode 23 is mechanically coupled to a generally rigid structural layer or back-plate 14, which together form a second capacitive plate of the capacitive microphone device. The capacitive microphone is formed on a substrate 1, for example a silicon wafer. A back-volume 33 is provided below the membrane 11, and is formed using a “back-etch” through the substrate 1. A first cavity 9 is located directly below the membrane 11, and is formed using a first sacrificial layer during the fabrication process. Interposed between the first and second electrodes 13 and 23 is a second cavity 17, which is formed using a second sacrificial layer during the fabrication process. A plurality of bleed holes 15 connect the first cavity 9 and the second cavity 17. Acoustic holes 31 are arranged in the back-plate 14 so as to allow free movement of air molecules, such that the sound waves can enter the second cavity 17. The first and second cavities 9 and 17 in association with the back-volume 33 allow the membrane 11 to move in response to the sound waves entering via the acoustic holes 31 in the back-plate 14. The provision of first and second sacrificial layers has the advantage of protecting the membrane during manufacture, and disassociating the back etch process from the definition of the membrane. The bleed holes 15 aid with the removal of the first and second sacrificial layers. The bleed holes 15 also contribute to the operating characteristics of the microphone.

Owner:CIRRUS LOGIC INC

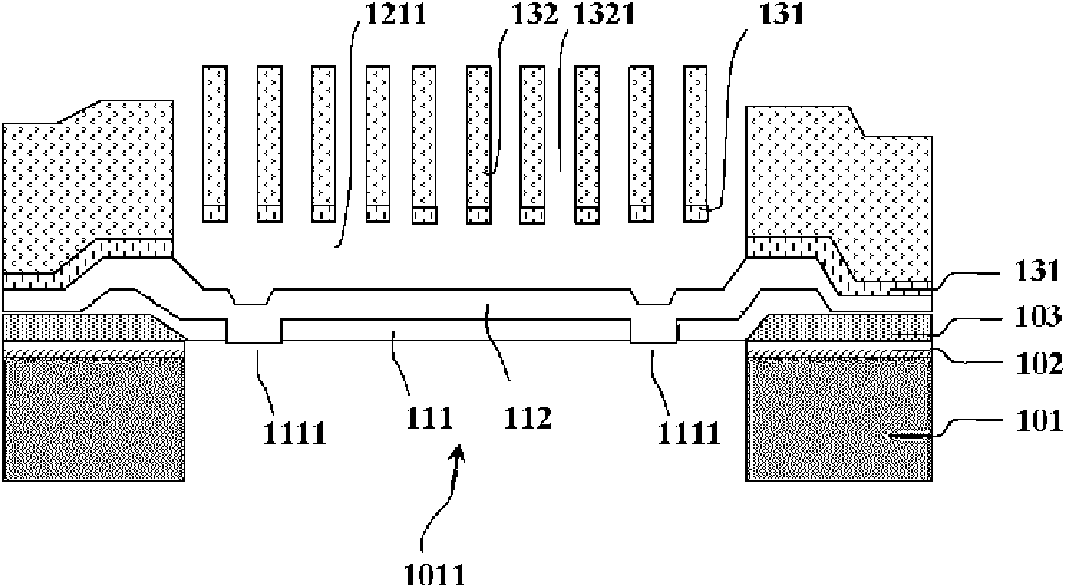

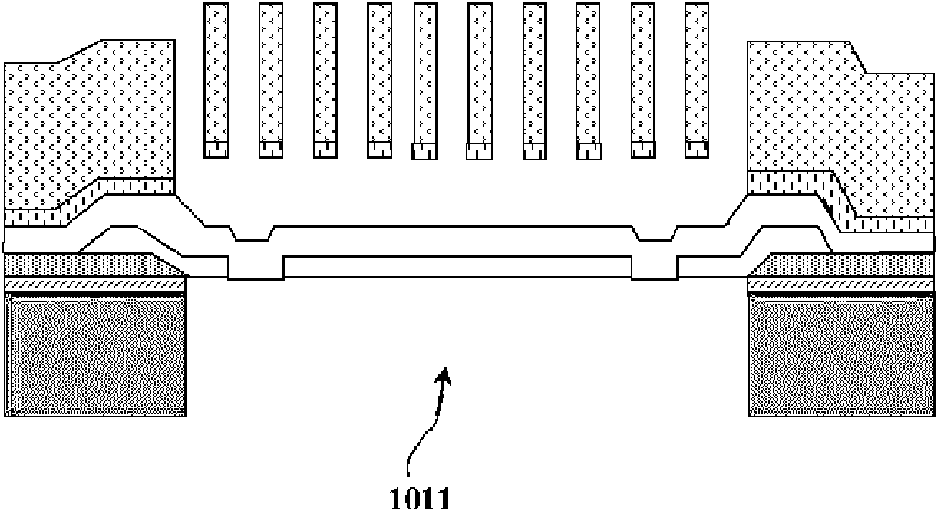

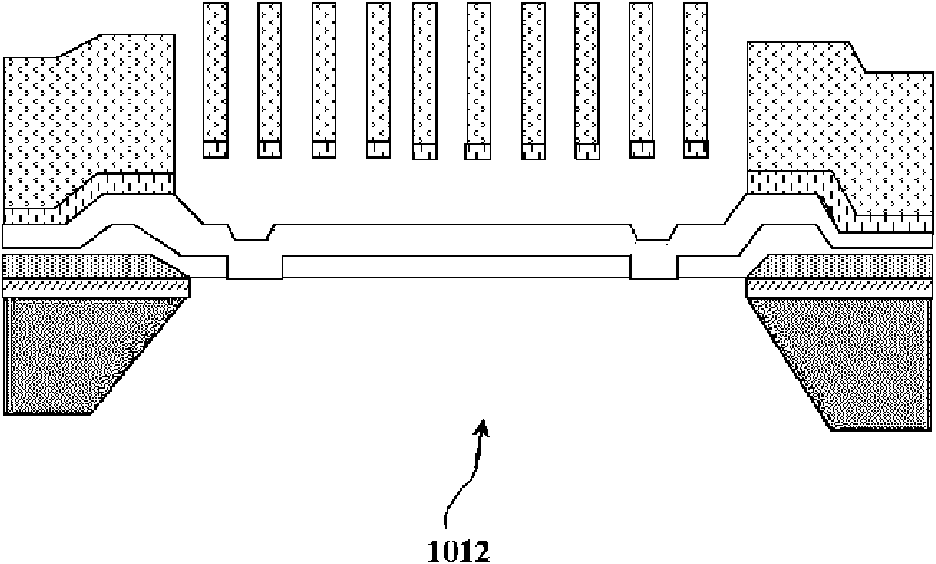

Capacitance type microphone with stress release membrane prepared at a low temperature and preparation method thereof

InactiveCN101572850AHigh sensitivityReduce parasitic capacitanceElectrostatic transducer microphonesResonant cavityParasitic capacitance

A capacitance type microphone with a stress release membrane prepared at a low temperature and a preparation method thereof. The capacitance type microphone includes a substrate having at least a resonant cavity; a septum, arranged on the top of the resonant cavity and connected with the substrate for implementing a mechanical vibration when being excitated by an acoustic pressure wave; a back board, arranged on the top of the septum and having a plurality of perforations; an air gap is provided the back board and the septum; a capacitor is composed of the septum, the air gap and the back board. The method includes steps: forming the resonant cavity on the substrate; forming the septum on the top of the resonant cavity, wherein the septum is connected with the substrate; setting the back board on the top of the septum, wherein the back board has a plurality of perforations; forming the air gap between the back board and the septum. The invention is a MEMS capacitance type microphone processed by a completely low-temperature technique. It is capable of being used as a post IC circuit processing technique being compatible thereof. The structure of the vibration diaphragm of the capacitance type microphone is a stress-releasing structure, and is capable of reducing a parasitic capacitance. Comparing with the traditional initial stress release membrane, the invention improves the sensitivity of the microphone more effectively.

Owner:王文 +1

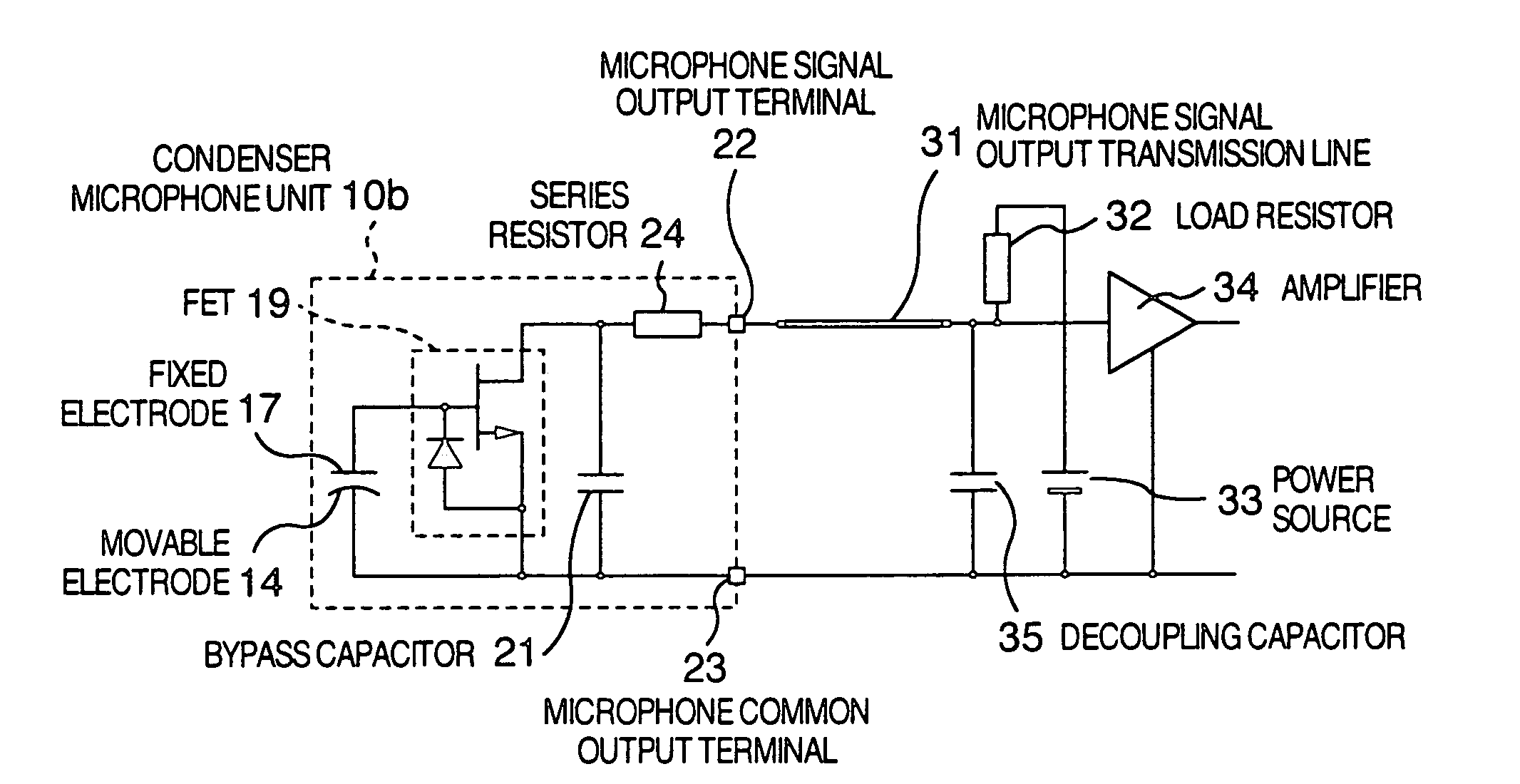

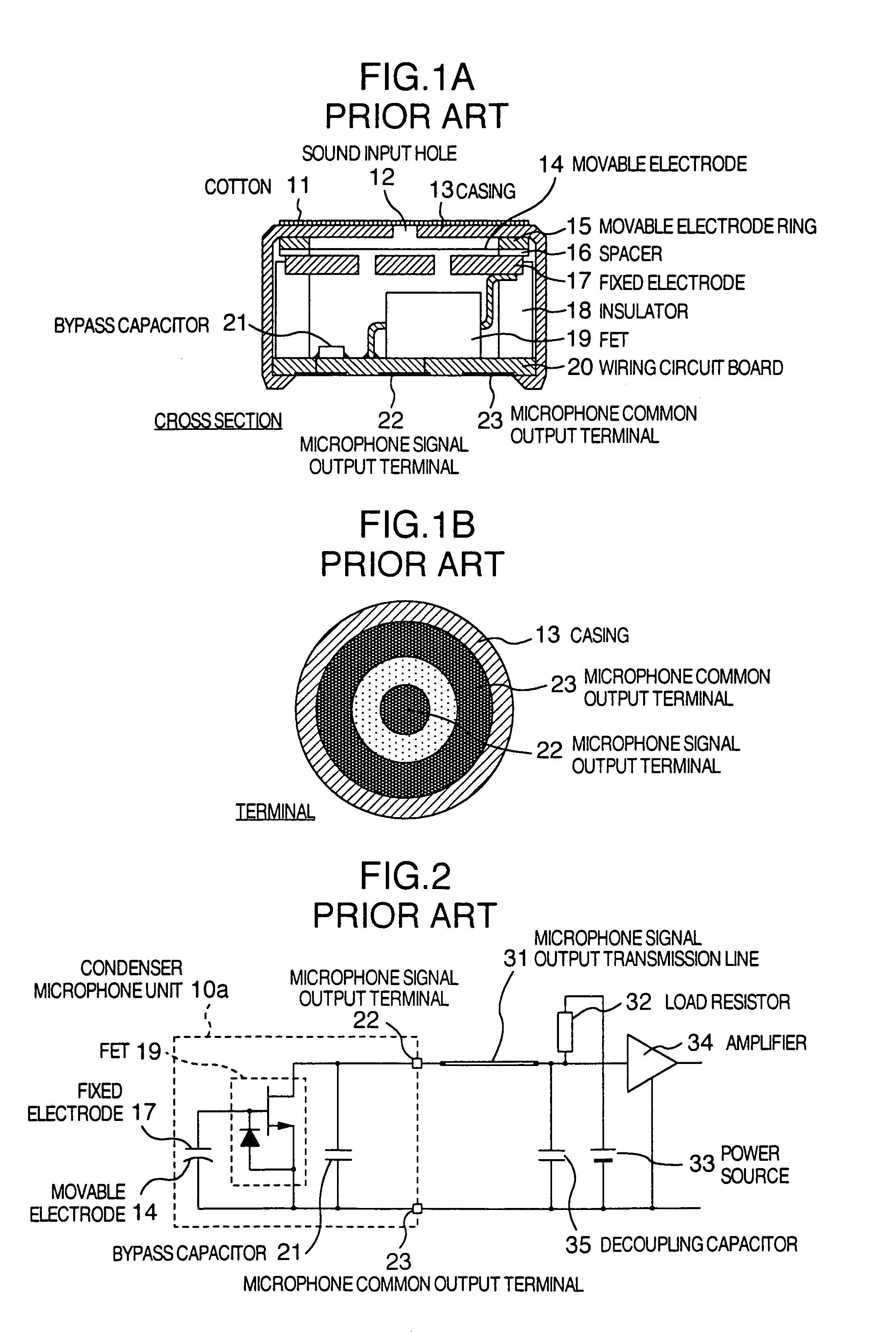

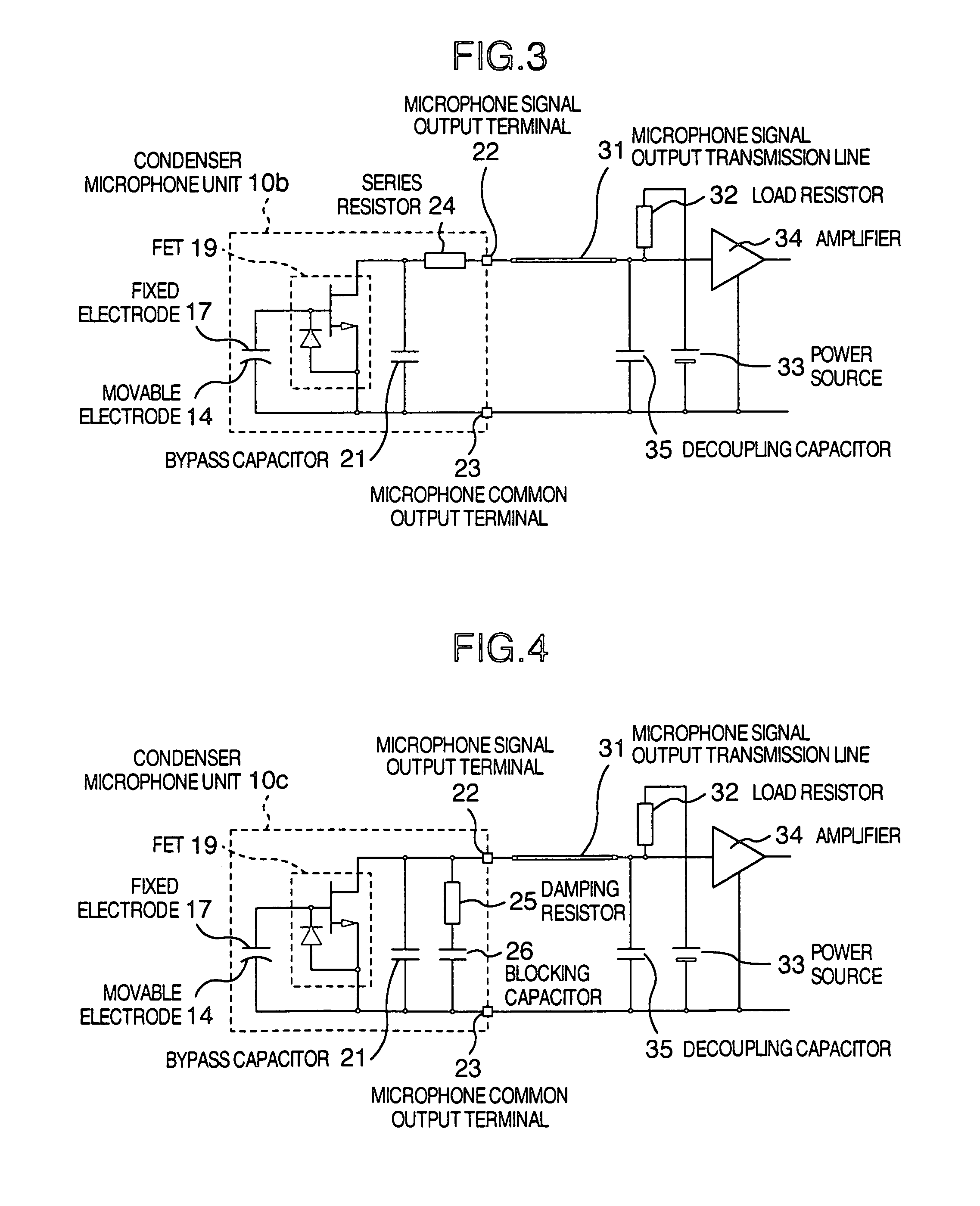

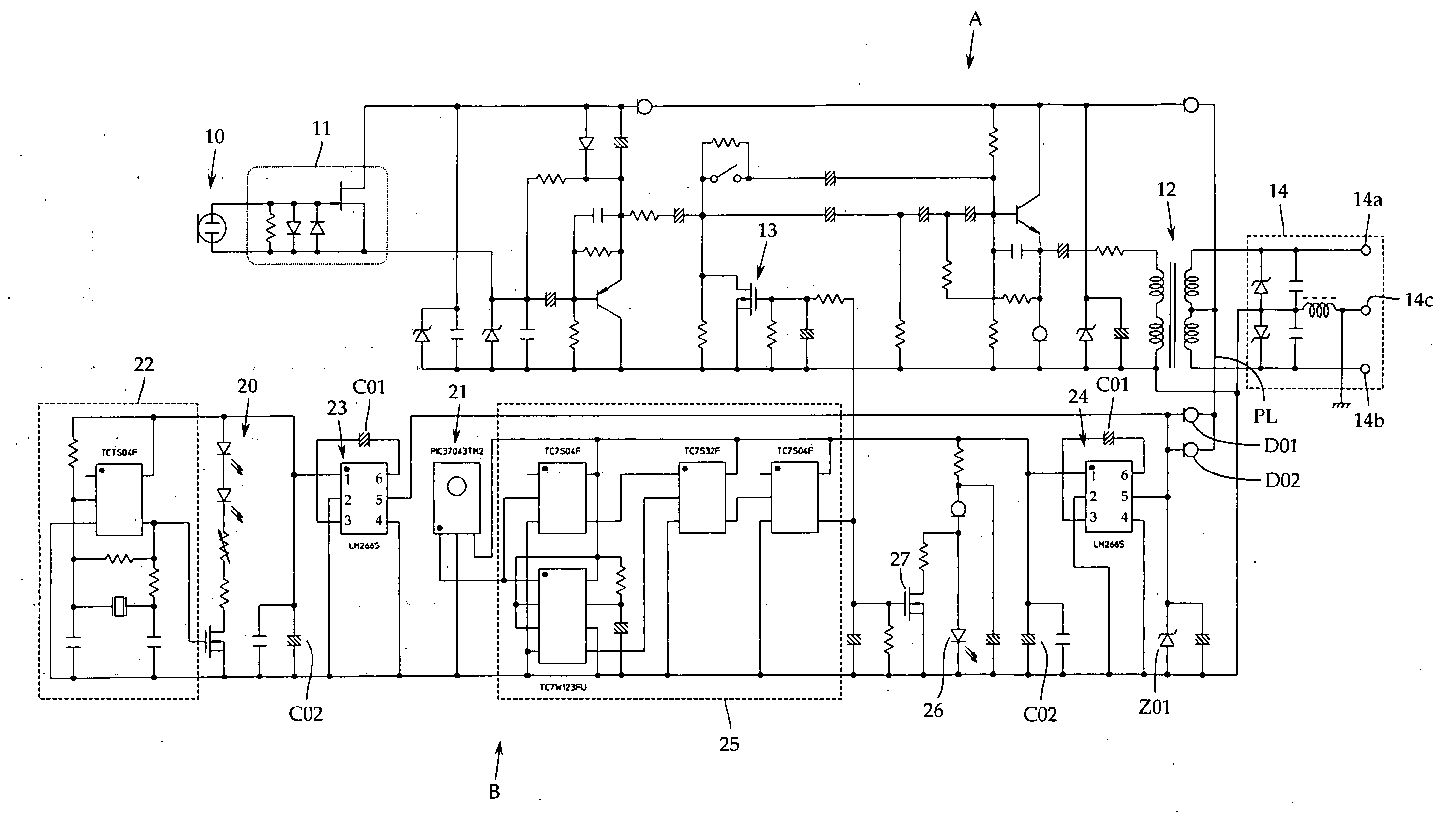

Condenser microphone apparatus and its connecting apparatus

InactiveUS6978029B1Reduce noise outputNoise outputElectrostatic transducer microphonesTransducer protection circuitsResonanceEngineering

A condenser microphone apparatus which is used for a radio apparatus in order to reduce noises generated due to radiation of a high frequency signal of a transmitting unit. A series resistor is provided between a bypass capacitor provided between a drain and a source of an FET and a microphone signal output transmission line in order to prevent a high frequency voltage from being increased due to a resonance of the bypass capacitor and microphone signal output transmission line. Thus, the noises due to the radiation of the high frequency signal can be reduced.

Owner:PANASONIC CORP

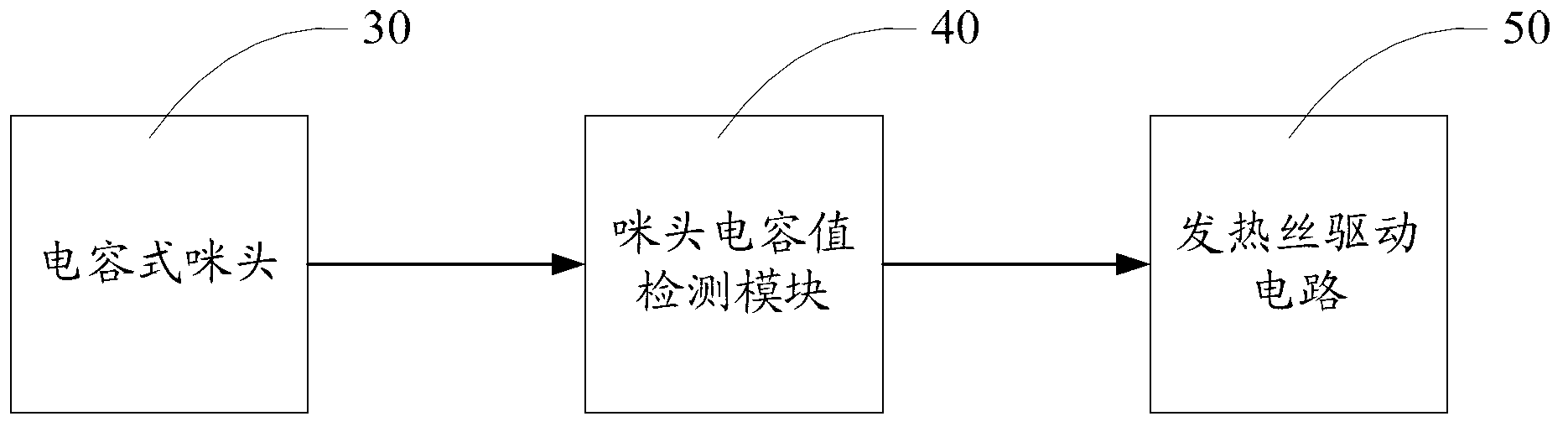

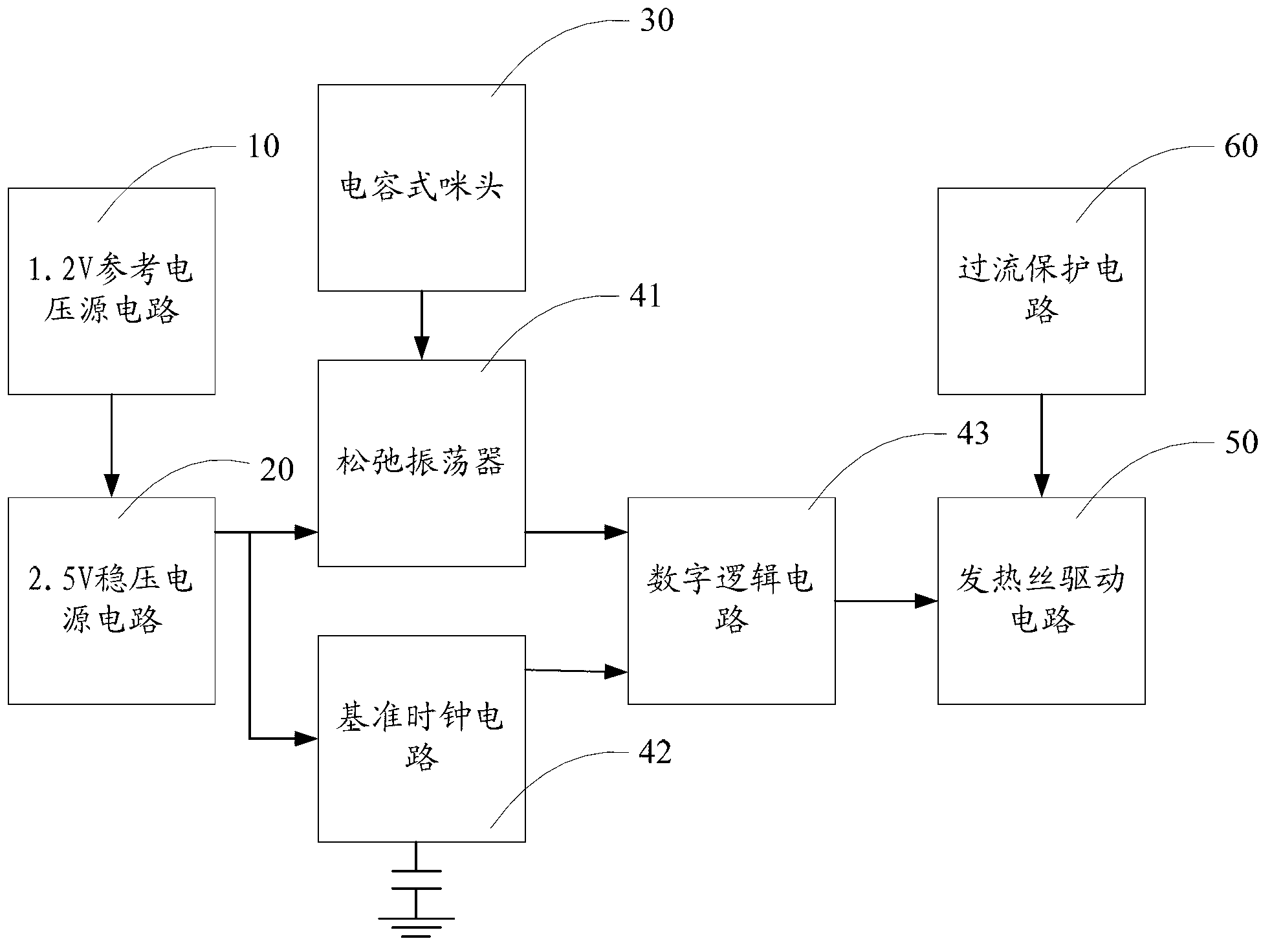

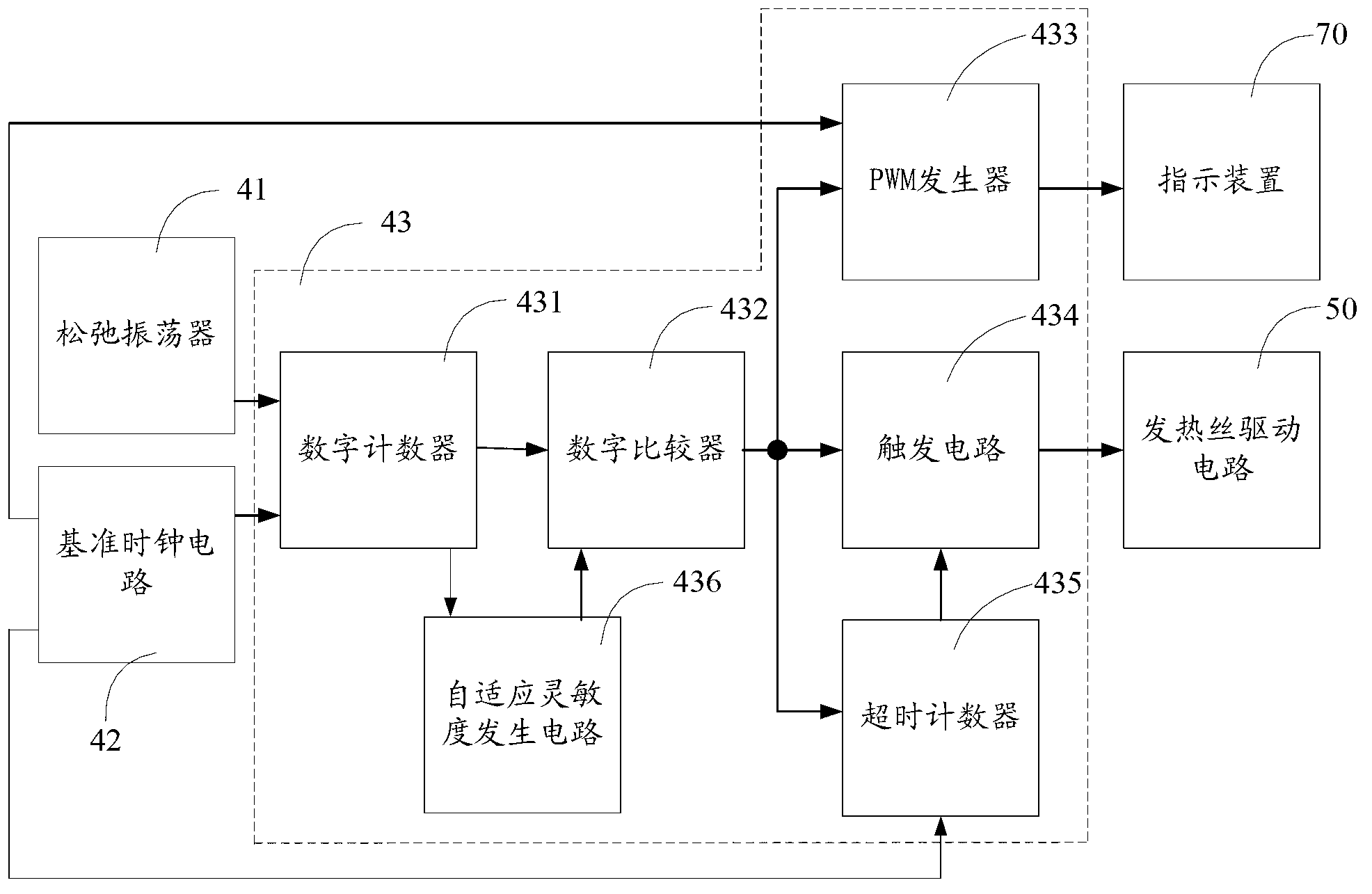

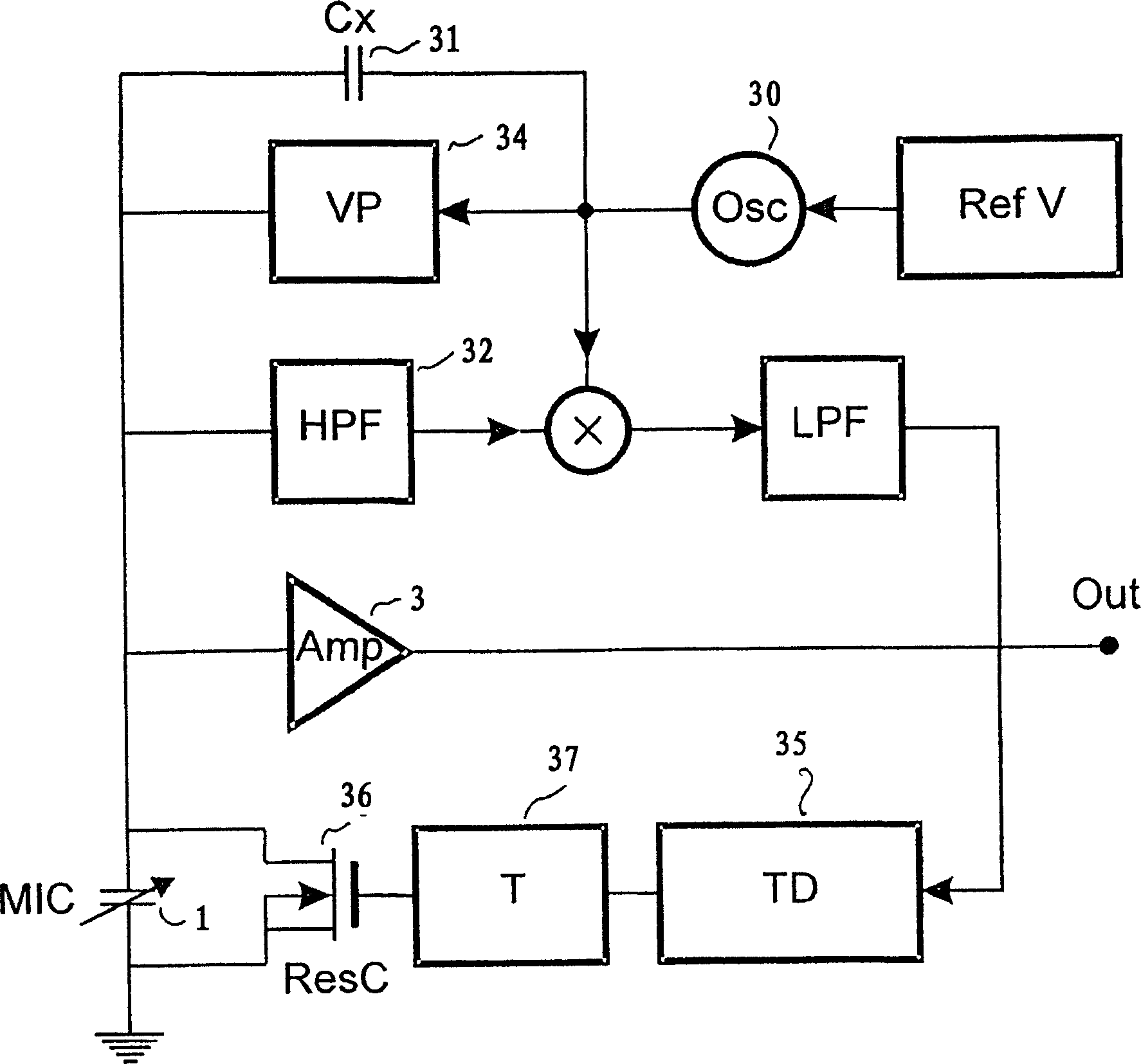

Electronic cigarette chip and electronic cigarette

The invention relates to an electronic cigarette chip which is used for controlling the switching on and off of an electronic cigarette adopting a capacitive microphone according to capacitance change of the capacitive microphone. The electronic cigarette chip comprises a microphone capacitance detecting module and a heating wire driving circuit which are connected with each other, wherein the microphone capacitance detecting module is used for detecting the capacitance of the capacitive microphone, converting the capacitance of the capacitive microphone into a comparison signal, comparing the comparison signal with a smoking threshold value, and controlling the open and close of the heating wire driving circuit according to the comparing result. As the sensibility and reliability of the electronic cigarette chip are effectively improved, the electronic cigarette can generate smoke even under little sucking force, the phenomenon of smoking by false triggering is avoided, and the electronic cigarette chip solves a series of problems that the electronic cigarette is heated excessively, a plastic shell of the electronic cigarette is burnt, the service life of the electronic cigarette is shortened, the yield is low and the like caused by the long-time continuous false triggering smoking action of the conventional electronic cigarette chip.

Owner:胡朝群

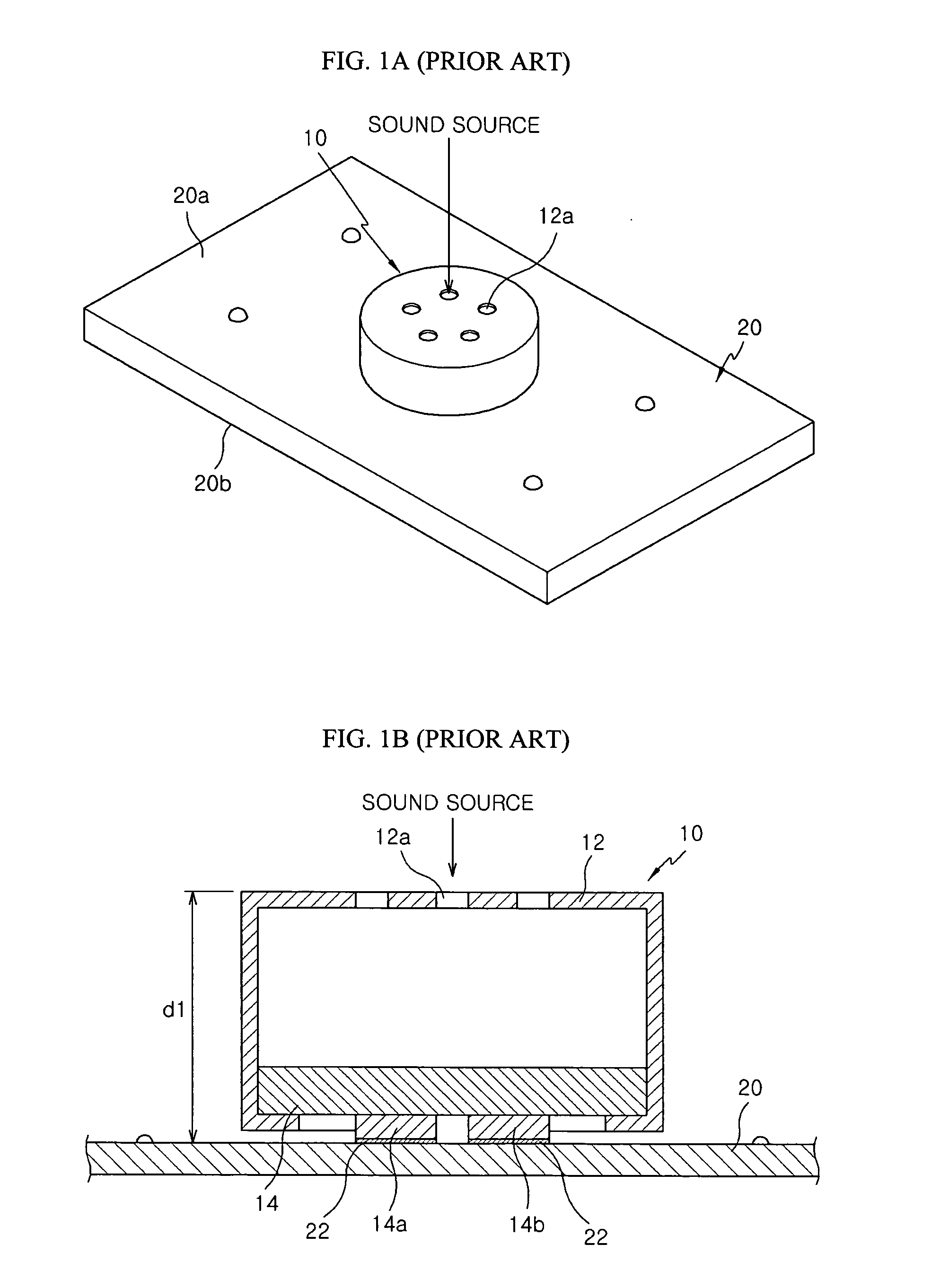

Method of mounting condenser microphone on main PCB and condenser microphone adapted for the same

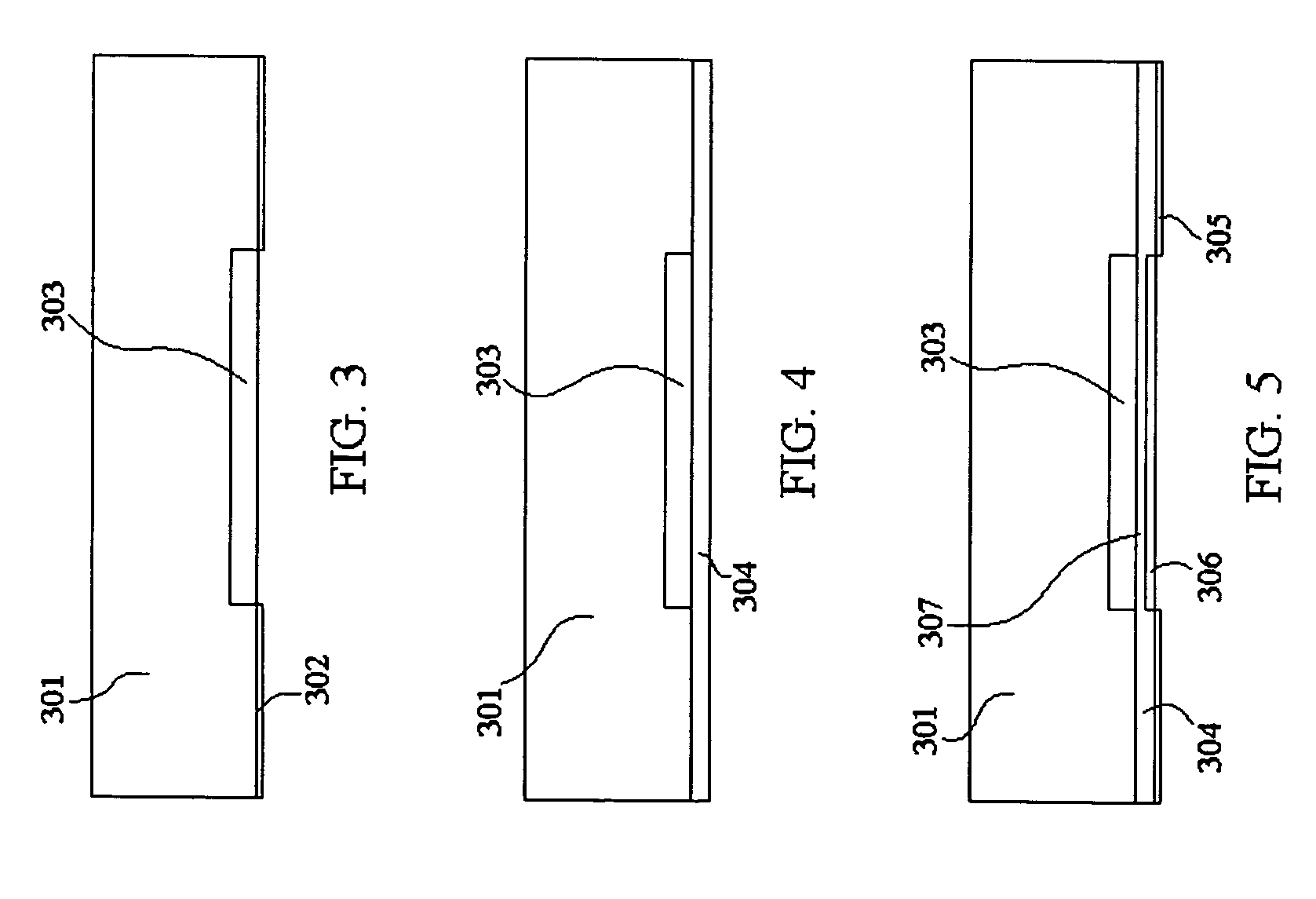

InactiveUS20050094832A1Piezoelectric/electrostrictive microphonesFinal product manufactureEngineeringAcoustic wave

A condenser microphone and a method of mounting a condenser microphone on a main PCB are provided. The method includes assembling the condenser microphone by assembling elements of the condenser microphone such that a vibration plate including a diaphragm and a backplate is directed toward an opened surface of a casing of the condenser microphone. The casing has a closed bottom surface and an opened surface opposite to the closed bottom surface. A PCB includes a sound hole. The assembled condenser microphone is positioned on a main PCB such that the sound hole of the PCB is aligned in accordance with a through hole formed in the main PCB. According to the present invention, if necessary, the main PCB can be mounted such that its elements surface is directed toward an inside of an electronic product, thereby maintaining good sound quality due to a short delivery path of sound waves.

Owner:BSE CO LTD

Detection and control of diaphragm collapse in condenser microphones

InactiveCN1741685AIncrease freedomIncrease flexibilityElectrostatic transducer microphonesTransducer protection circuitsTransducerEngineering

The invention relates to a condenser microphone comprising detection means adapted to determine the value of a physical parameter with respect to the spacing or distance between the diaphragm of the transducer element and the rear plate, and adapted to control the transducer based on the determined value of the physical parameter. Burst control device for DC biasing of energy element.

Owner:TDK CORPARATION

Condenser microphone

ActiveUS20070201709A1High sensitivityEasy to produceTransducer detailsSemiconductor electrostatic transducersCapacitanceEngineering

A condenser microphone includes a substrate having a cavity, first and second spacers defining an opening, a diaphragm having a rectangular shape positioned inside of the opening, and a plate having a rectangular shape positioned just above the diaphragm. Plate joint portions integrally interconnected with two sides of the plate are directly attached onto the second spacer. Supports, which are attached onto the second spacer across the opening and project inwardly of the opening, are connected to the prescribed portions of the diaphragm via third spacers relatively to the other two sides of the plate. The center portion of the diaphragm can be designed in a multilayered structure, and the peripheral portion can be bent outwardly. In addition, both ends of the diaphragm are fixed in position, while free ends of the diaphragm vibrate due to sound waves.

Owner:INFINEON TECH AG

Condenser microphone

InactiveUS20060083392A1Cut in halfPower supply voltage can be preventedMicrophone structural associationElectrostatic transducer microphonesCapacitanceProximity sensor

The present invention provides a condenser microphone having a proximity sensor consisting of an infrared light emitting diode and an infrared photodetector, the condenser microphone preventing the occurrence of noise and the malfunctioning of the infrared photodetector when the infrared light emitting diode is lighted using an AC component. Specifically, the present invention provides a condenser microphone operated using a predetermined DC power source; an infrared light emitting diode 20 is lighted at a predetermined frequency by an oscillation circuit 22 using an AC component, and a microphone output is turned on and off by an output signal from the infrared photodetector 21 which is tuned to the predetermined frequency. The condenser microphone further includes two DC-DC converters 23 and 24 connected in parallel with the DC power source. One 23 of the DC-DC converters 23 supplies power to the infrared light emitting diode 20 and the oscillation circuit 22. The other DC-DC converter 24 supplies power to the infrared photodetector 21.

Owner:AUDIO-TECHNICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com