Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

235results about "Loudspeaker diaphragm shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

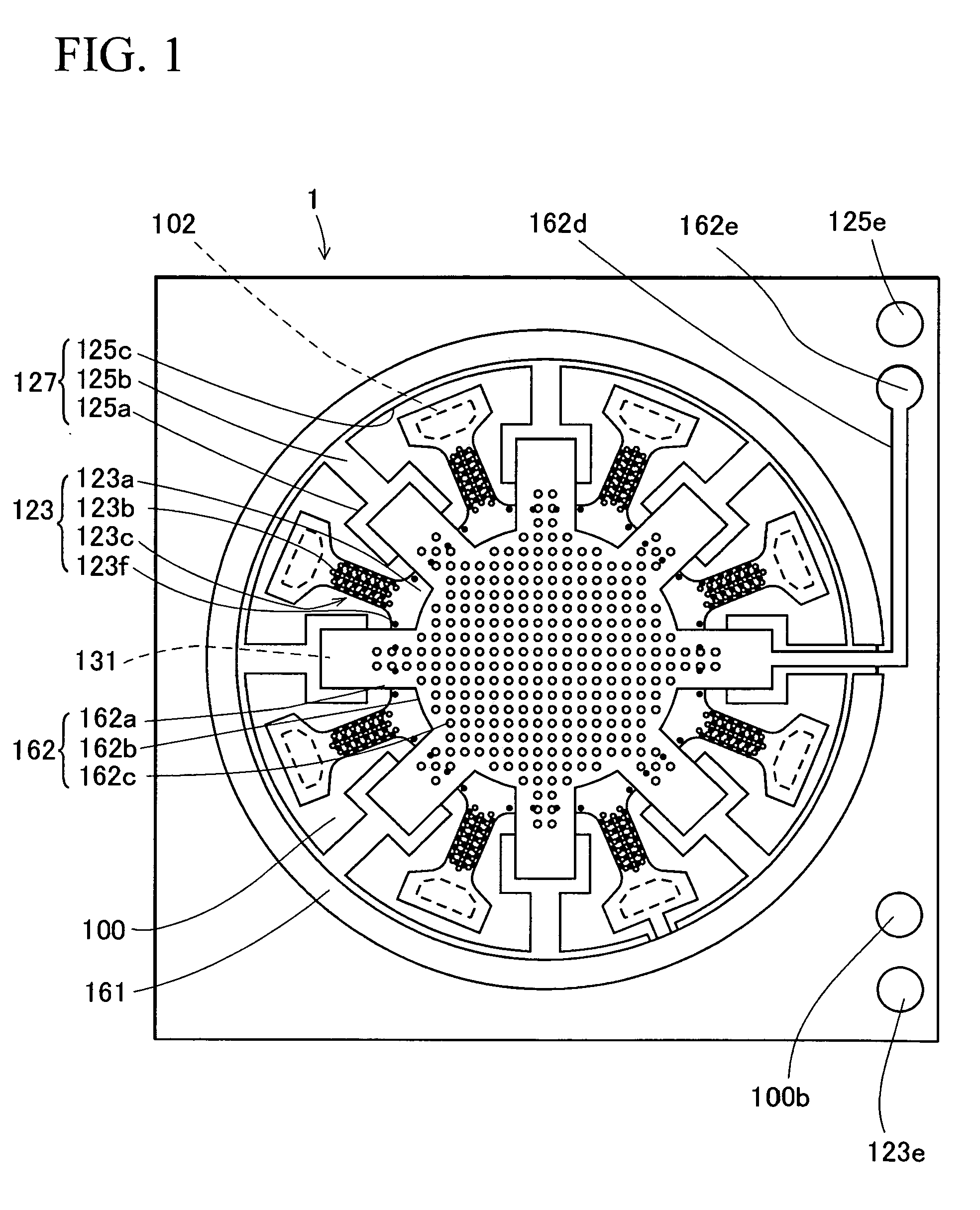

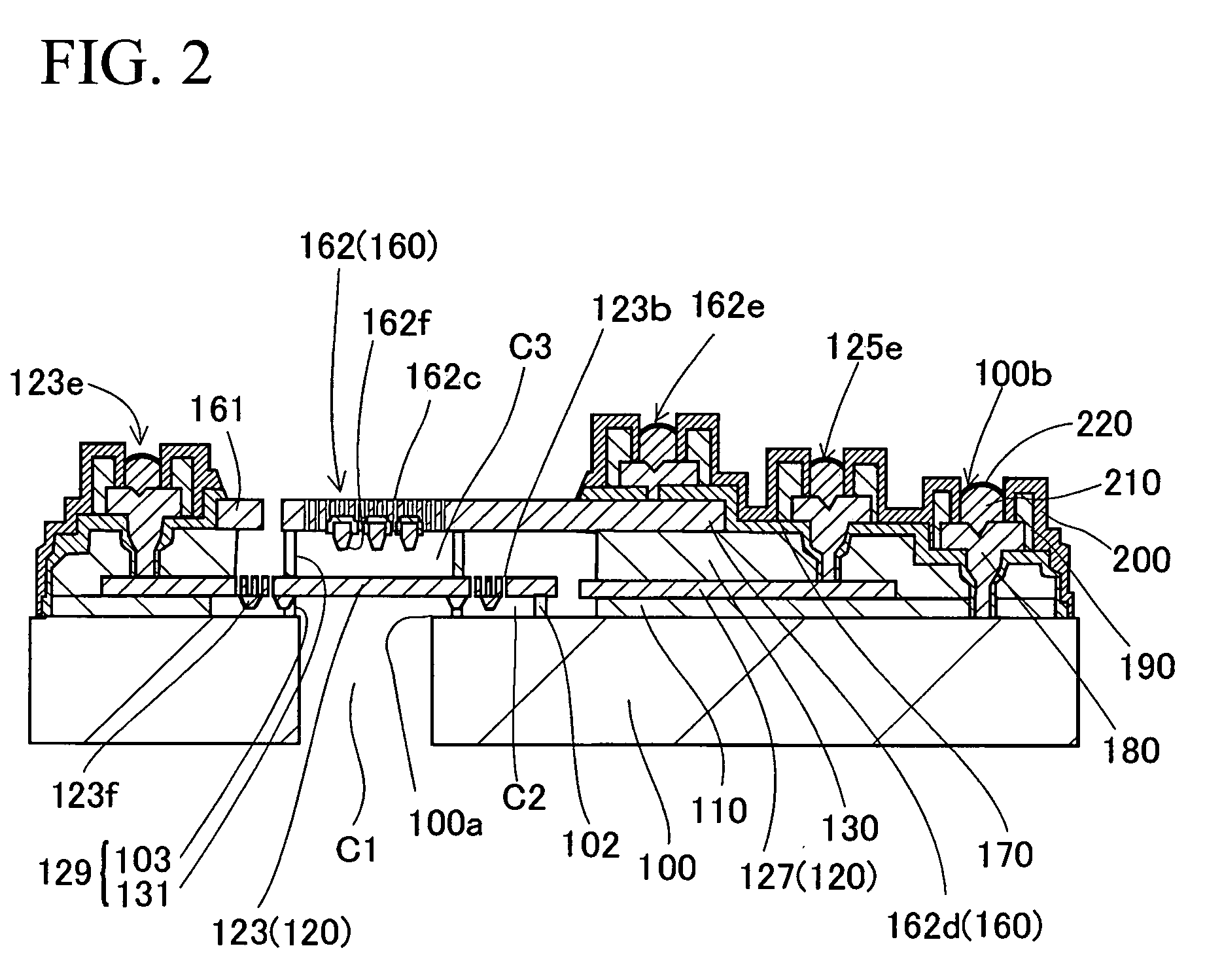

MEMS process and device

InactiveUS7781249B2NanotechSemiconductor/solid-state device testing/measurementEngineeringAcoustic wave

Owner:CIRRUS LOGIC INC

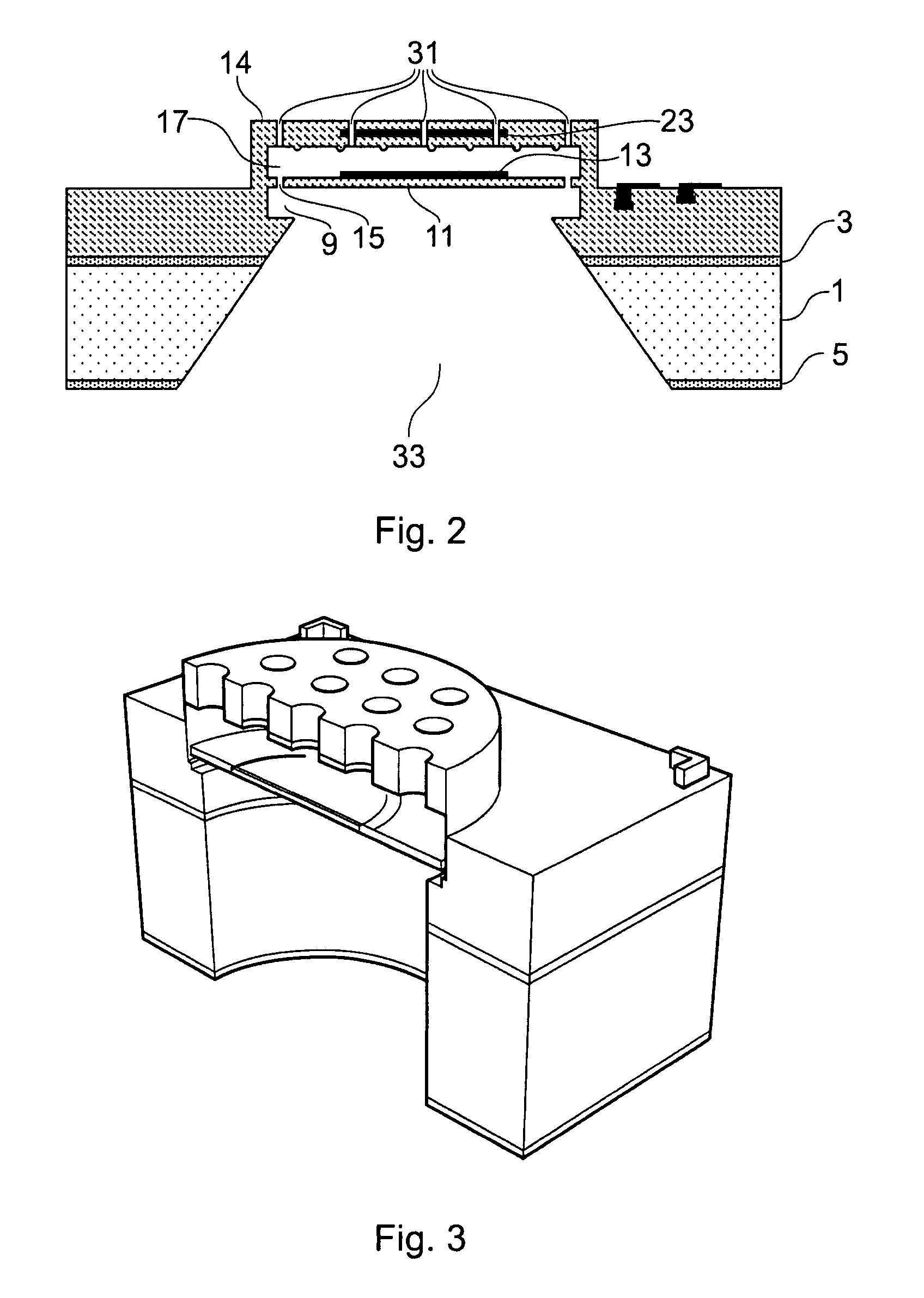

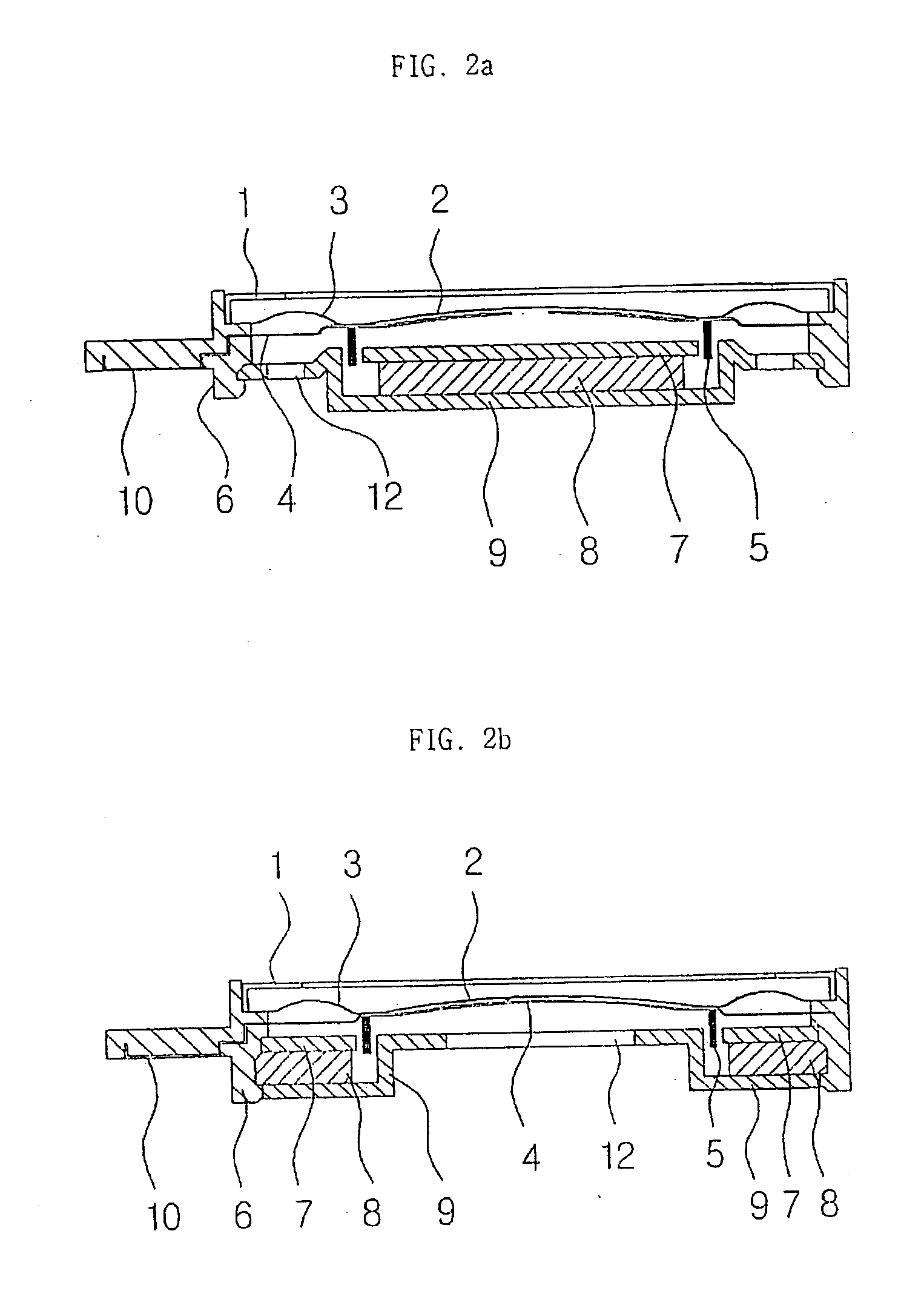

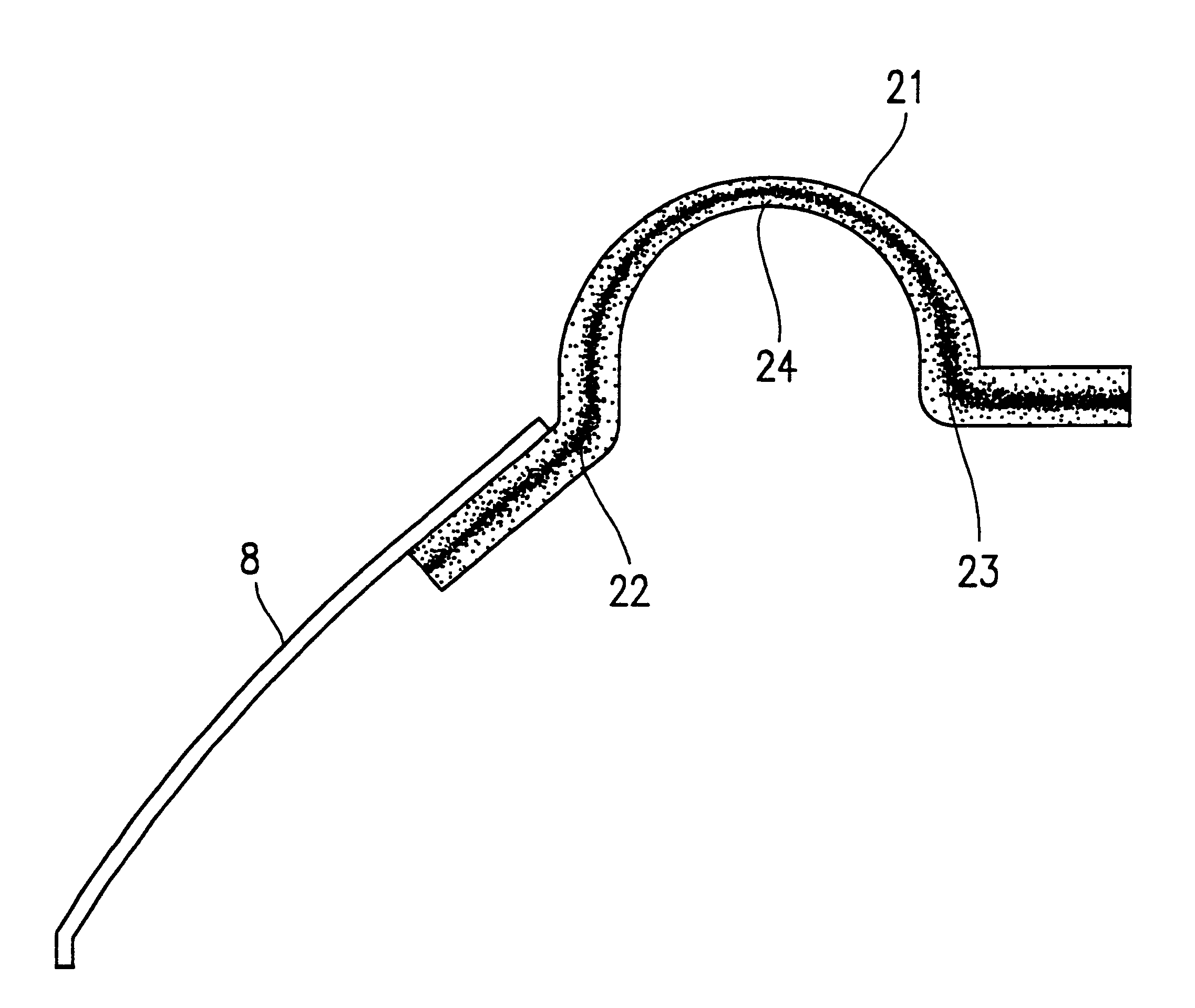

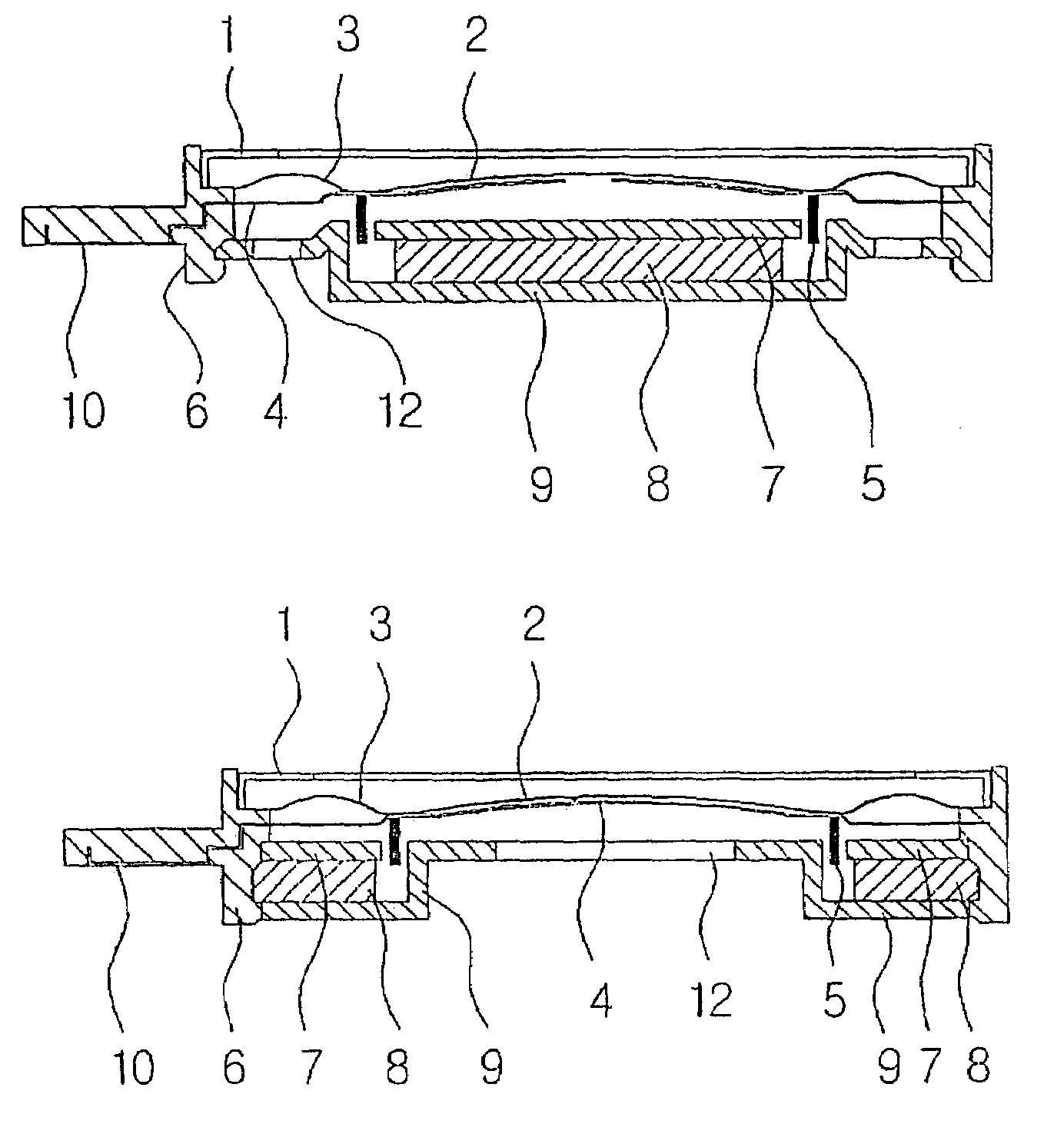

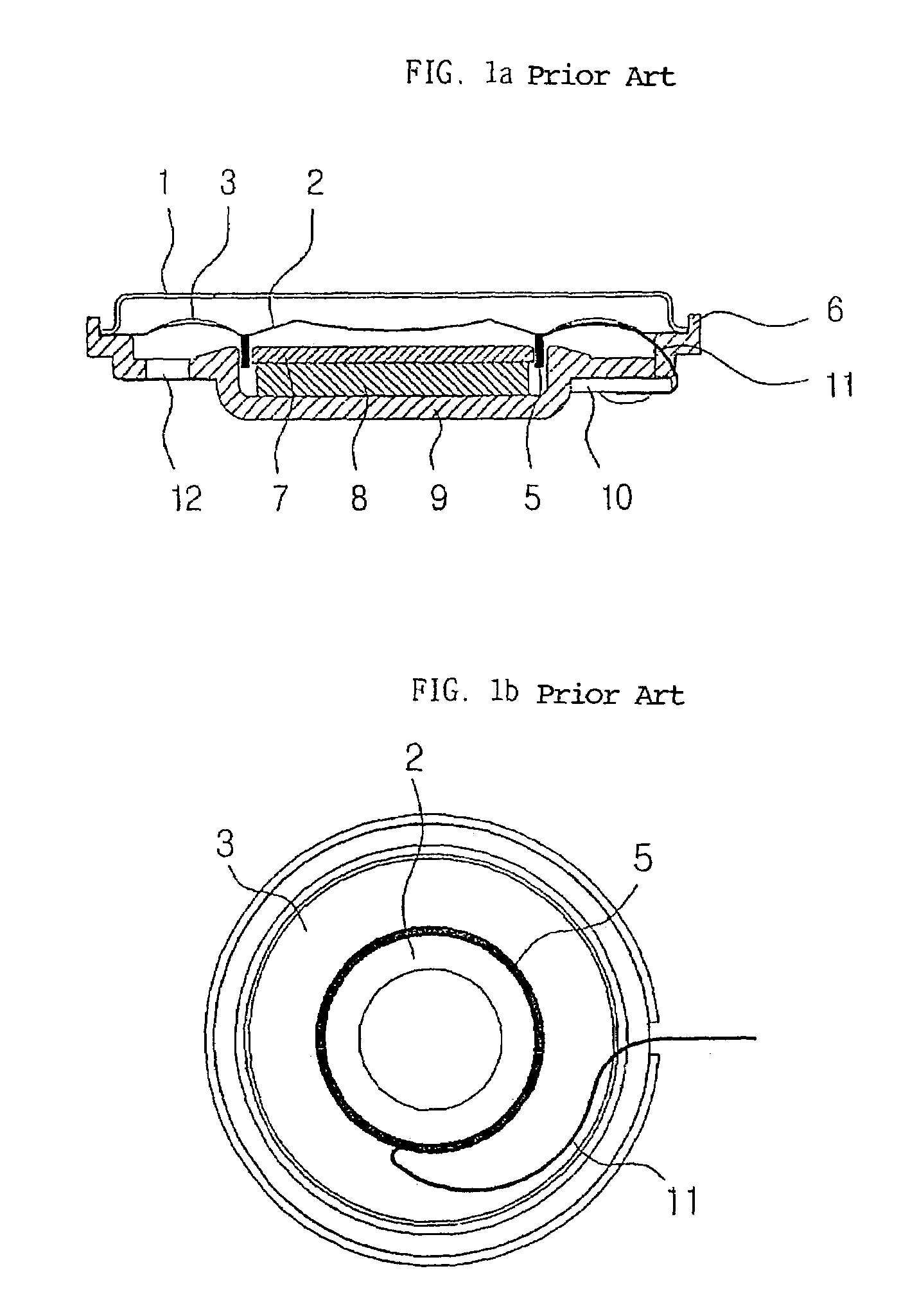

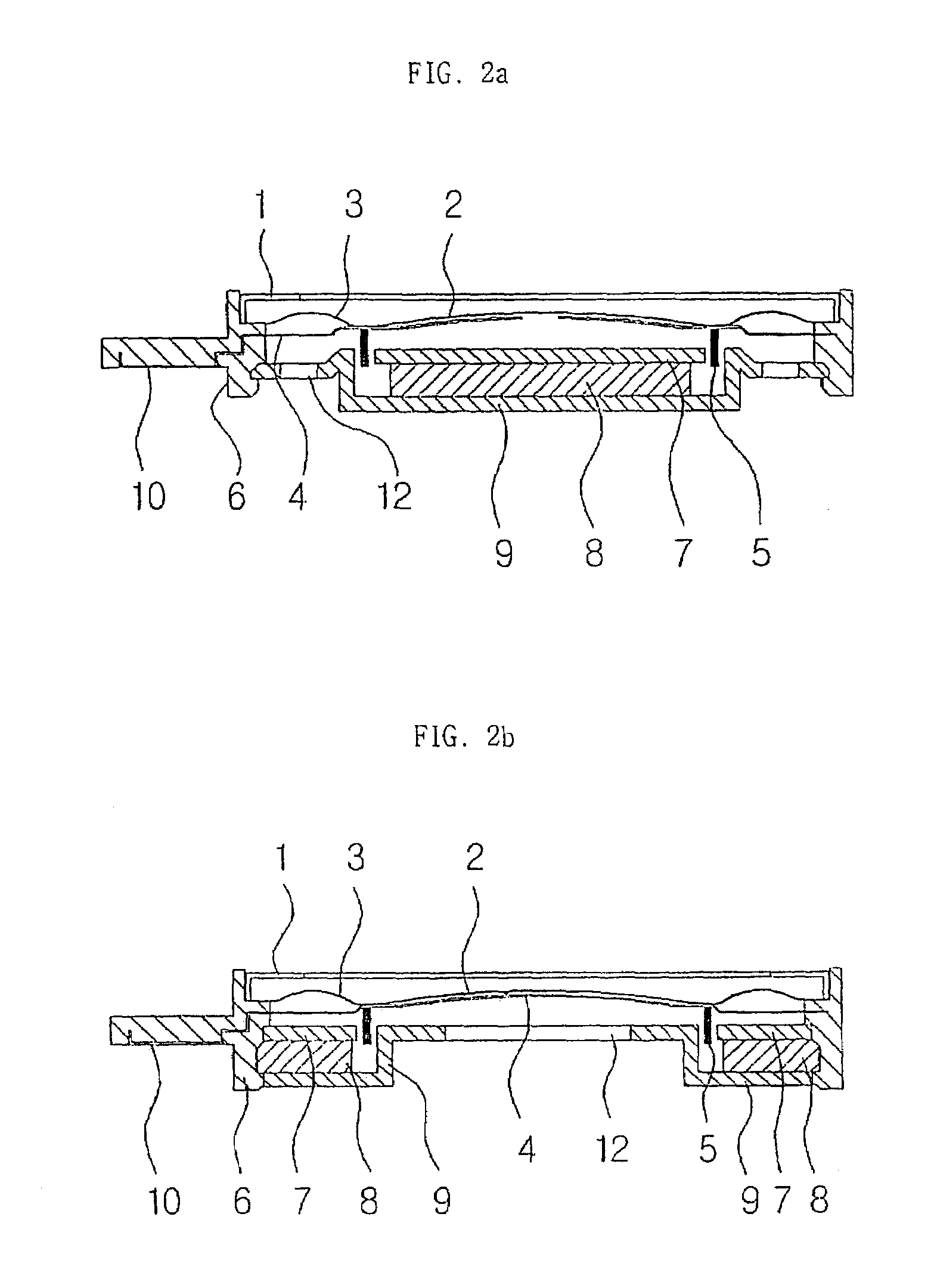

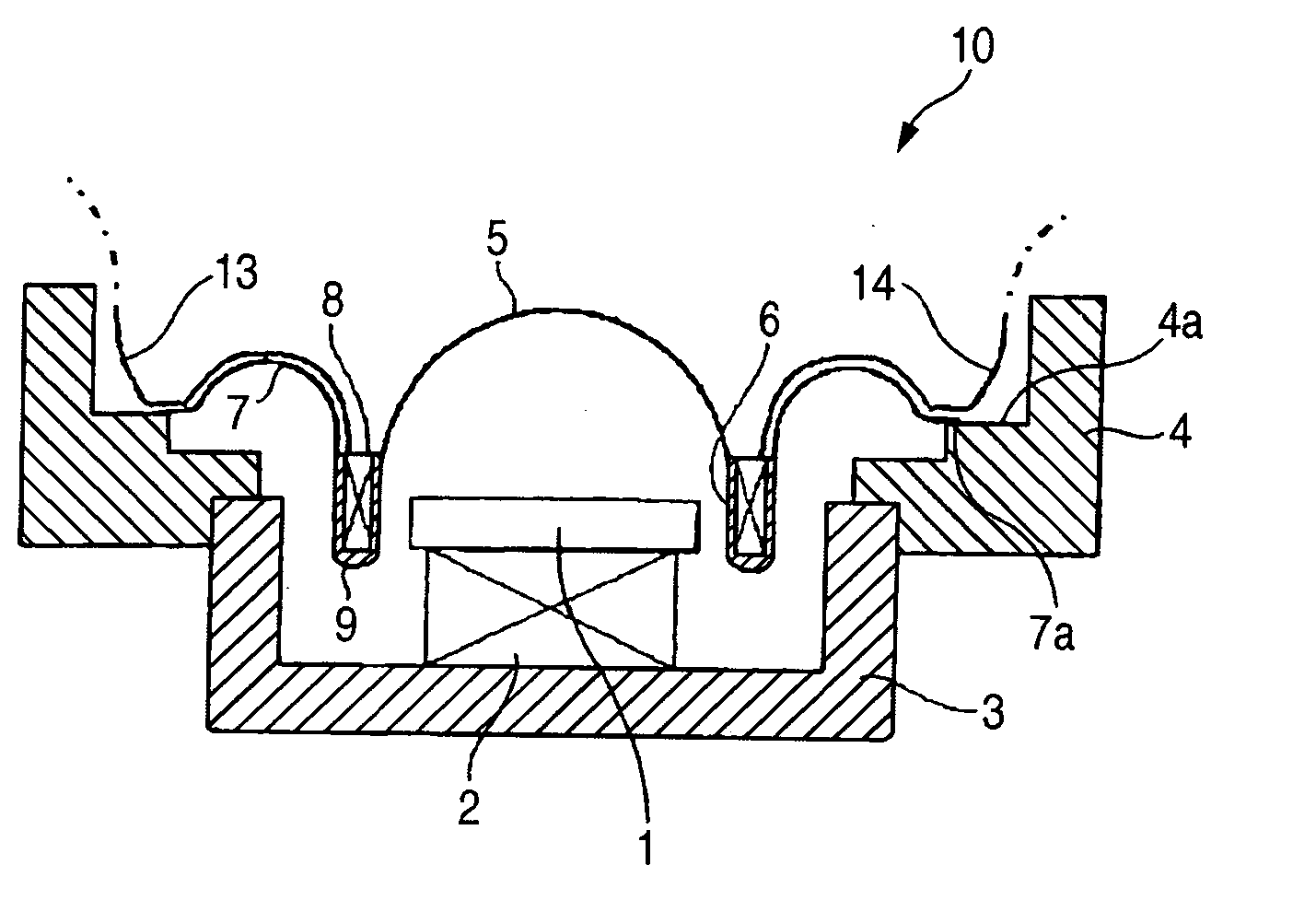

Dynamic micro speaker with dual suspension

InactiveUS20060098838A1Reduce distortion problemsAvoid disconnectionLoudspeaker diaphragm dampingLoudspeaker transducer fixingLow distortionEngineering

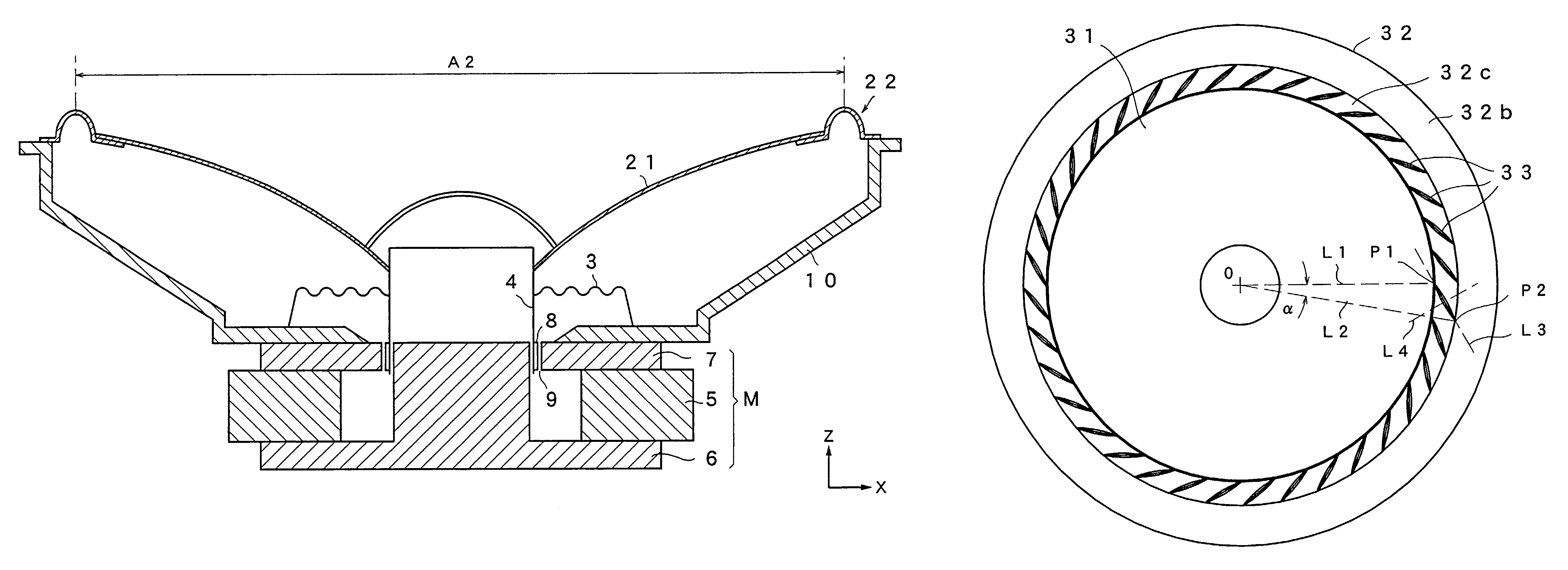

The invention relates to a micro-speaker with a second suspension made of highly resilient material installed inside of the speaker. The speaker is able to provide high level acoustic output with low distortion rate in a wide frequency range with a very small and slim structure and it may prevent a disconnection of a lead connecting the voice coil and the electrode. The speaker includes a yoke, a permanent magnet, a plate, a vibration plate integrated with a first suspension, a voice coil, a frame and a protector. The speaker further comprises a second suspension made of highly resilient material installed between the plate and the vibration plate, and is characterized in that the voice coil is attached to the lower surface of the second suspension and the vibration plate is attached to the upper surface of the second suspension and the vibration plate is attached to the upper surface of the second suspension and the outer periphery of the second suspension is fixed to the frame.

Owner:JY CUSTOM CO LTD

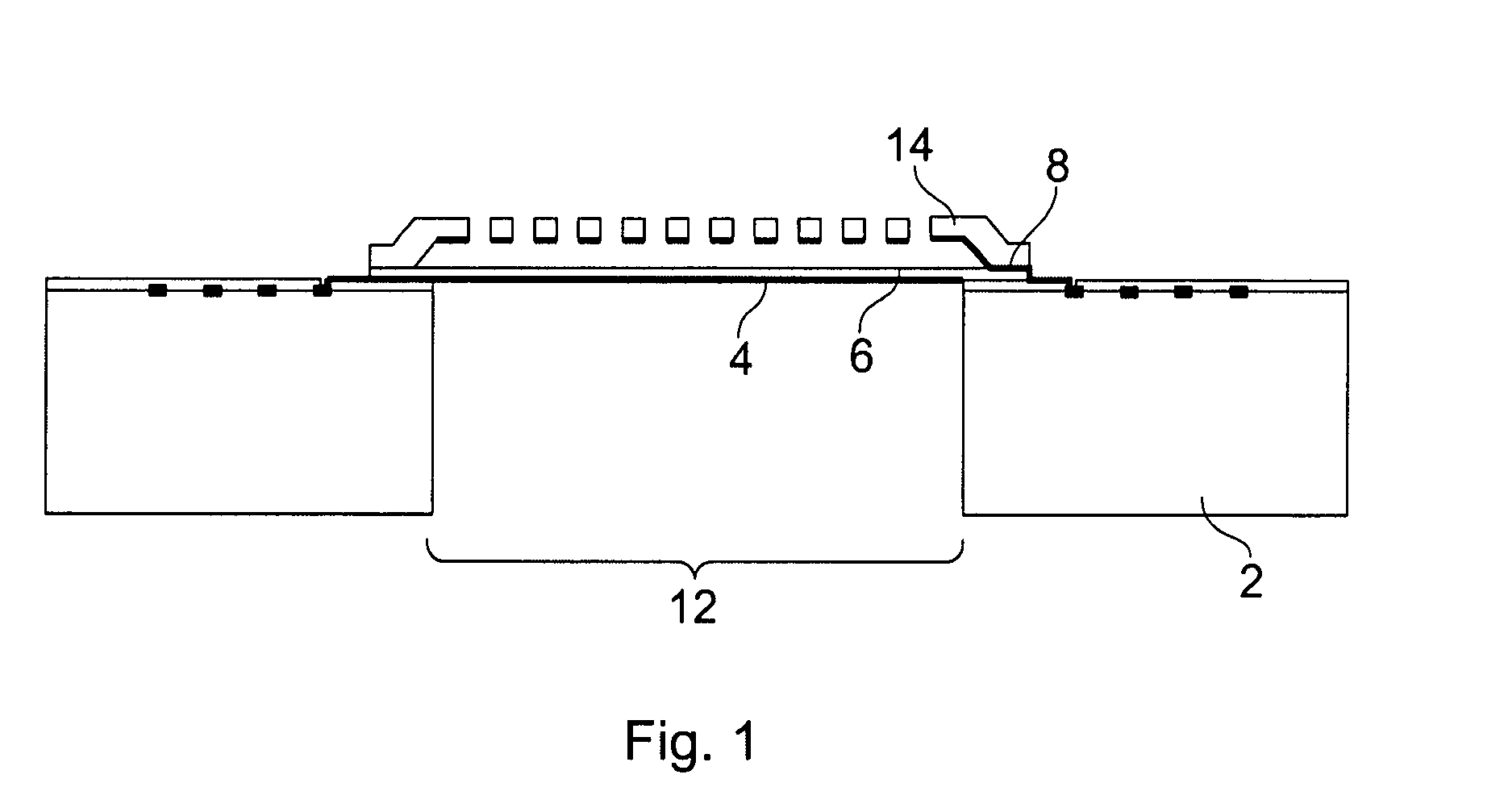

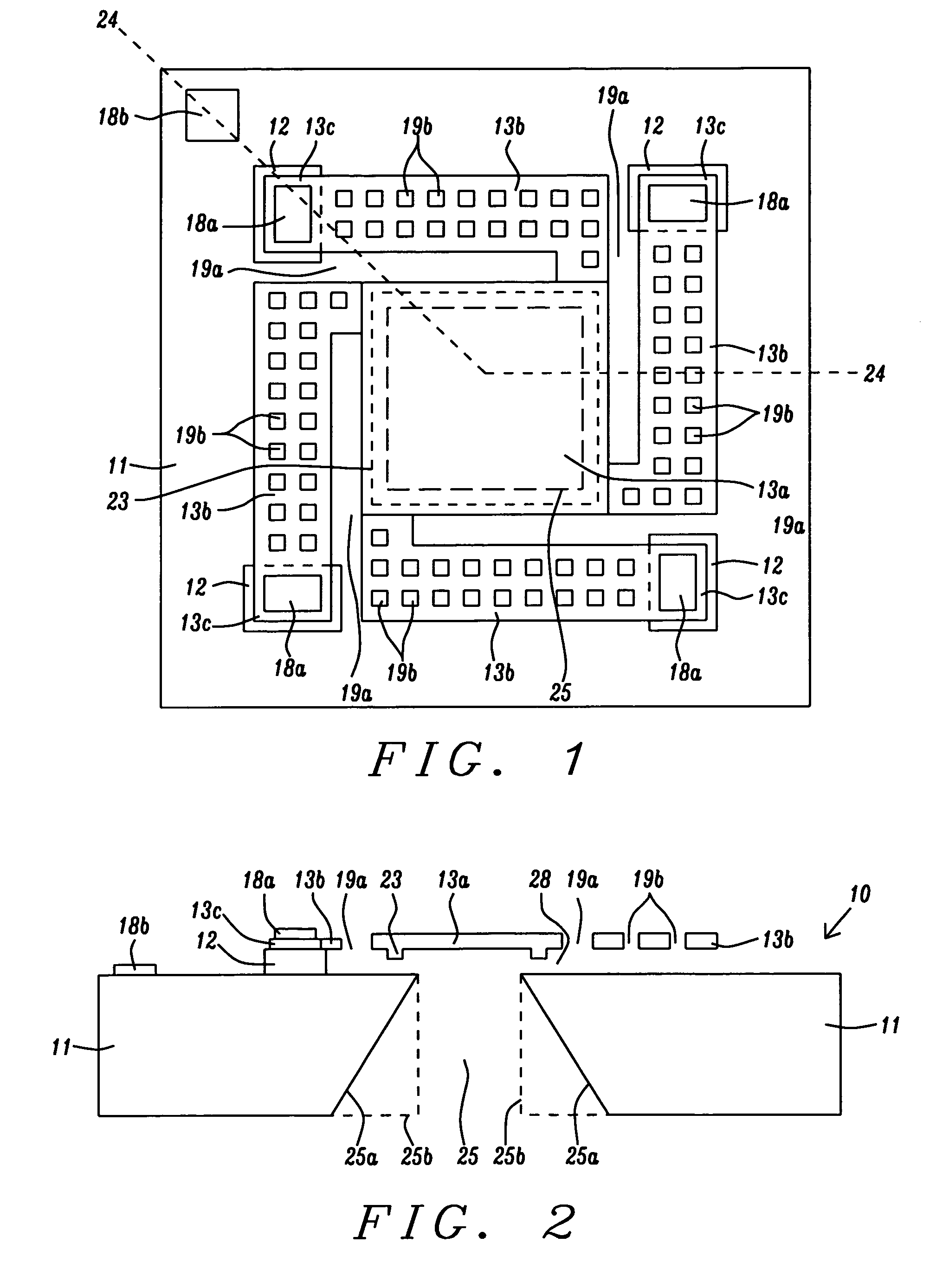

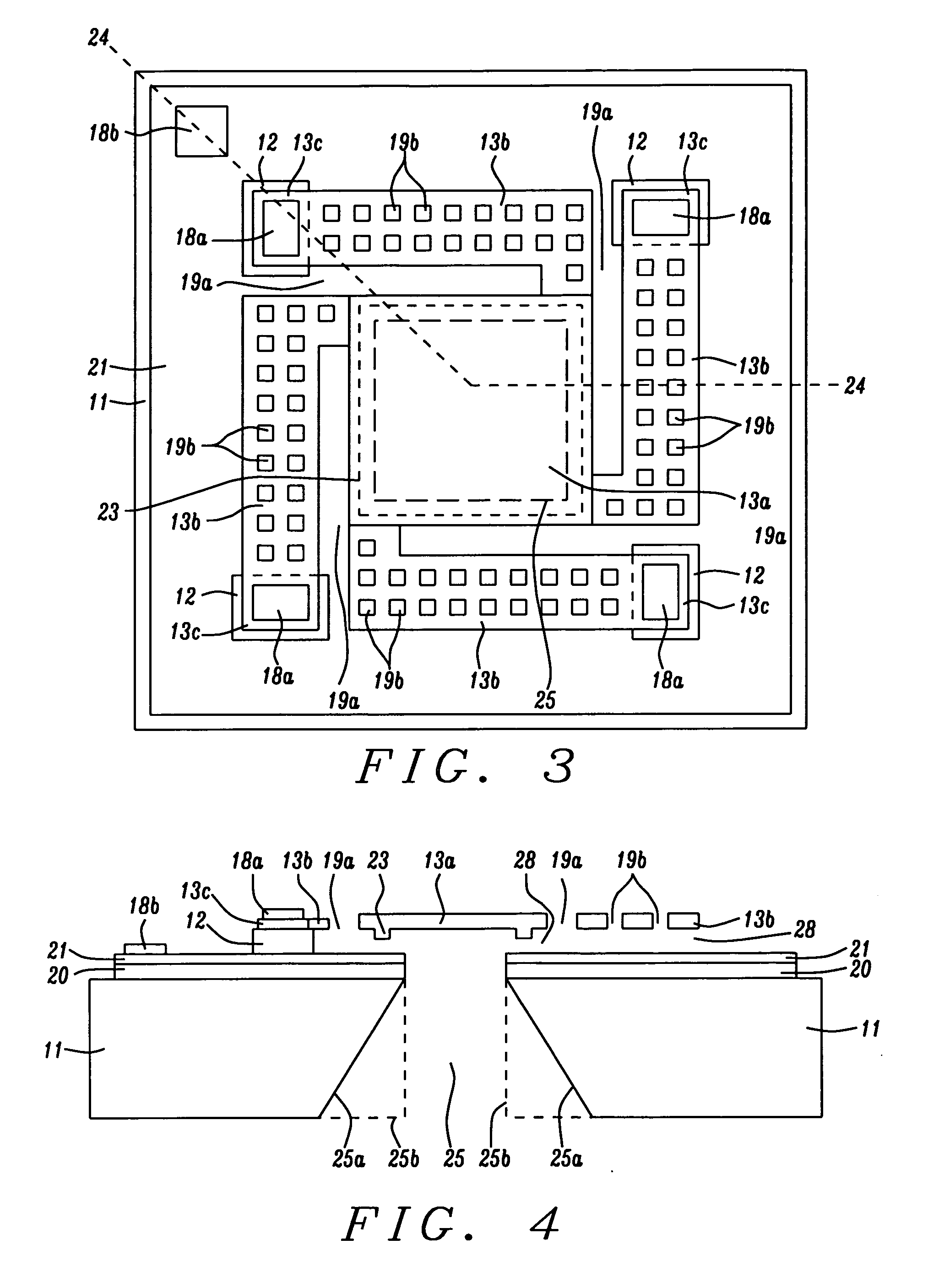

Silicon microphone without dedicated backplate

ActiveUS20090208037A1Piezoelectric/electrostrictive microphonesLoudspeaker diaphragm dampingCMOSEngineering

Various embodiments of a silicon microphone sensing element without dedicated backplate are disclosed. The microphone sensing element has a circular or polygonal diaphragm with a plurality of perforated springs suspended above the front side of a conductive substrate. The diaphragm is aligned above one or more back holes in the substrate having a front opening smaller than the diaphragm. In one embodiment, a continuous perforated spring surrounds the diaphragm and has a shape that conforms to the diaphragm. A plurality of perforated beams connects the spring to rigid pads that anchor the movable diaphragm and spring. In another embodiment, there is a plurality of perforated springs having double or triple folding configurations and a plurality of perforated beams connecting the diaphragm to rigid pads. Also disclosed is a scheme to integrate the silicon microphone sensing element with CMOS devices on a single chip.

Owner:SHANDONG GETTOP ACOUSTIC

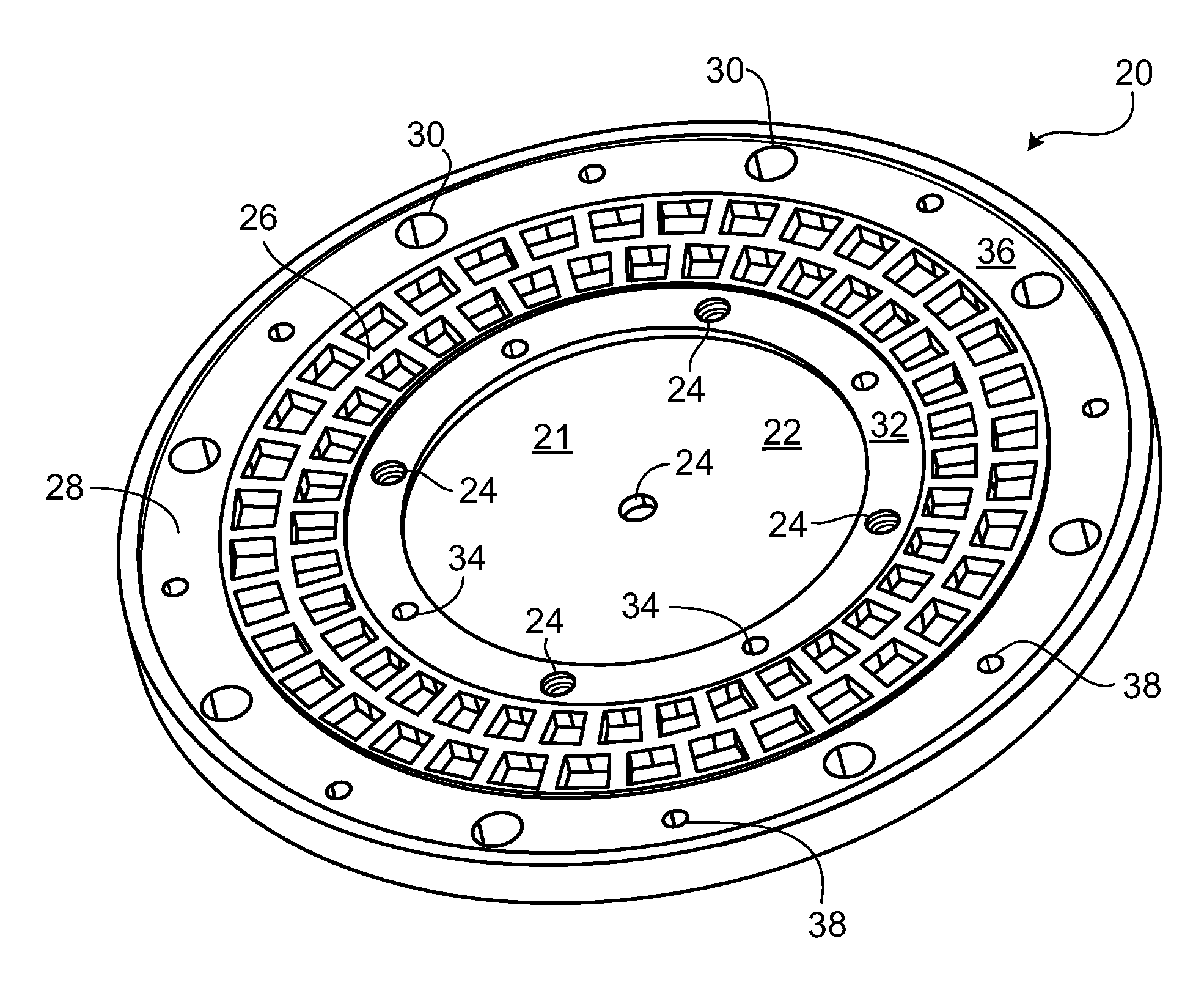

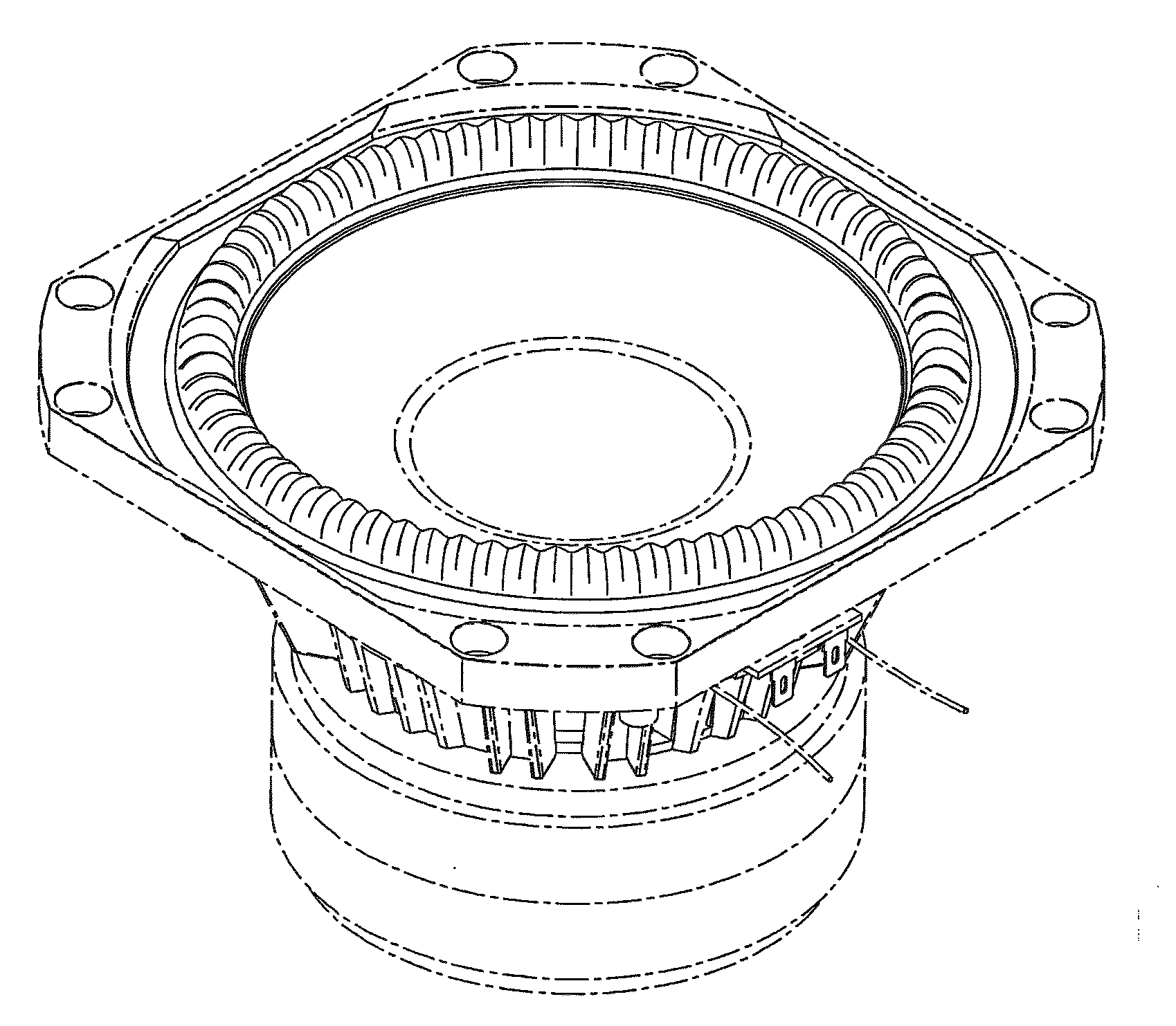

Square speaker

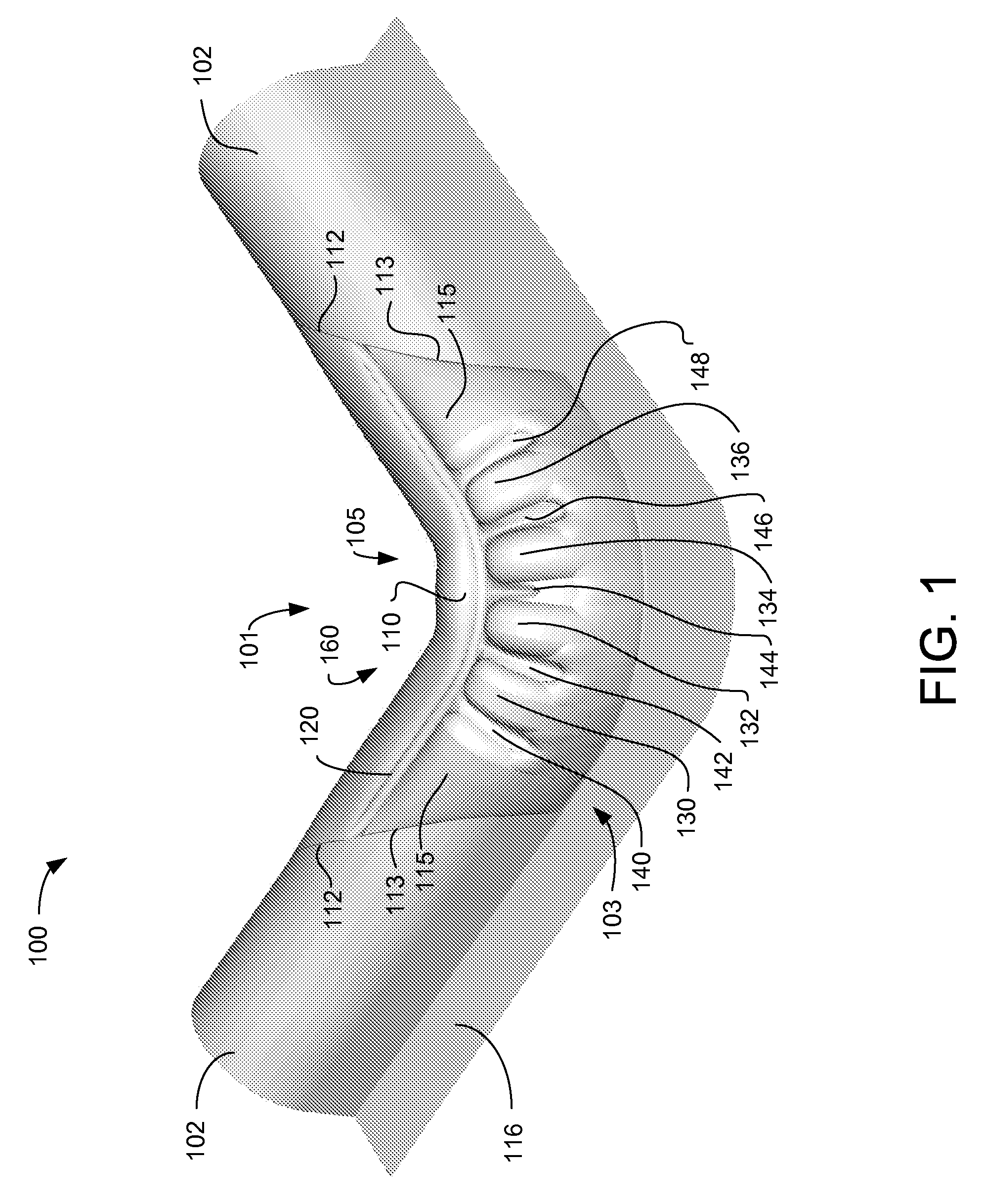

ActiveUS7275620B1Increase amplitudeLoudspeaker diaphragm materialsLoudspeaker diaphragm shapeEngineeringVolume displacement

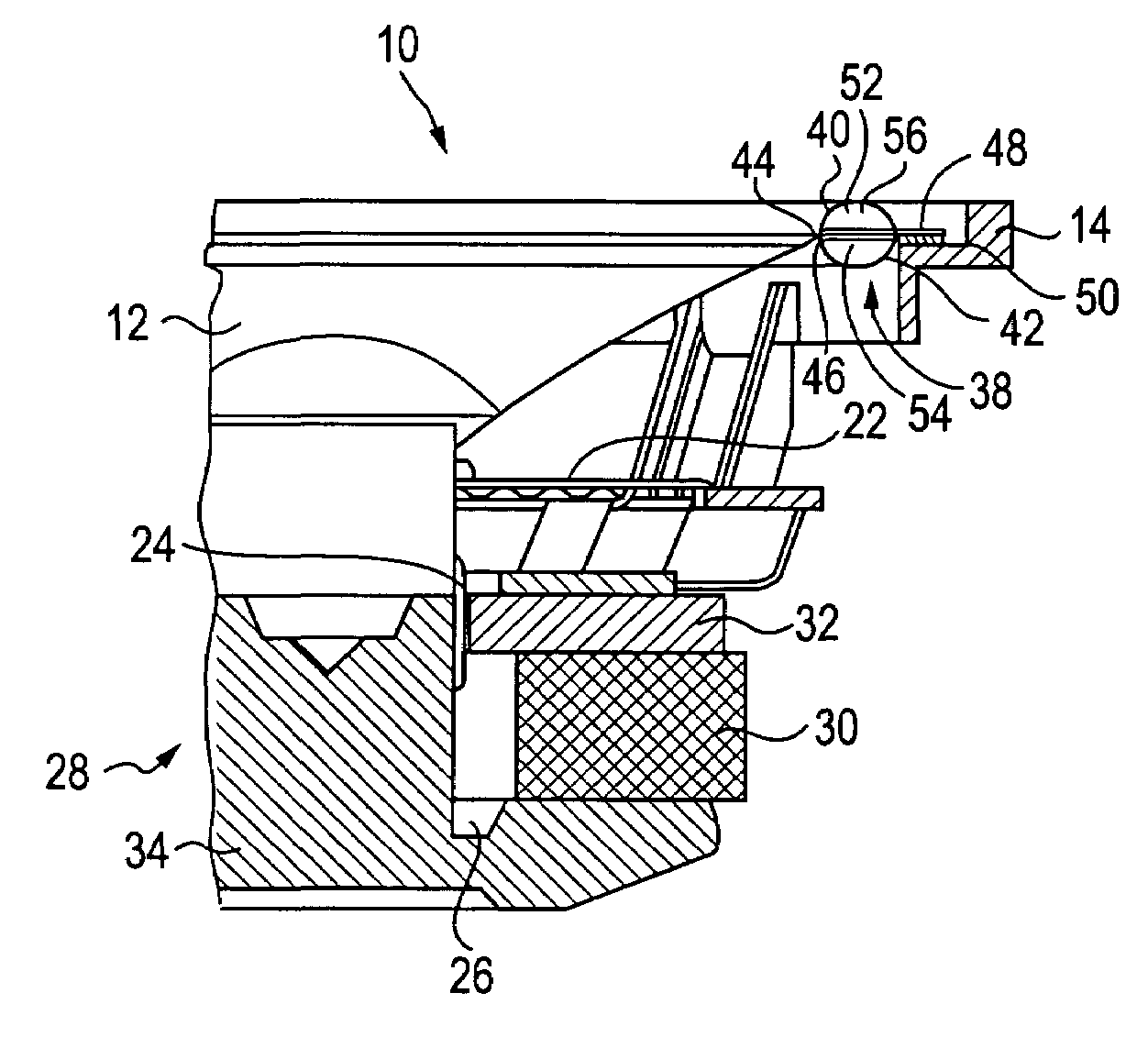

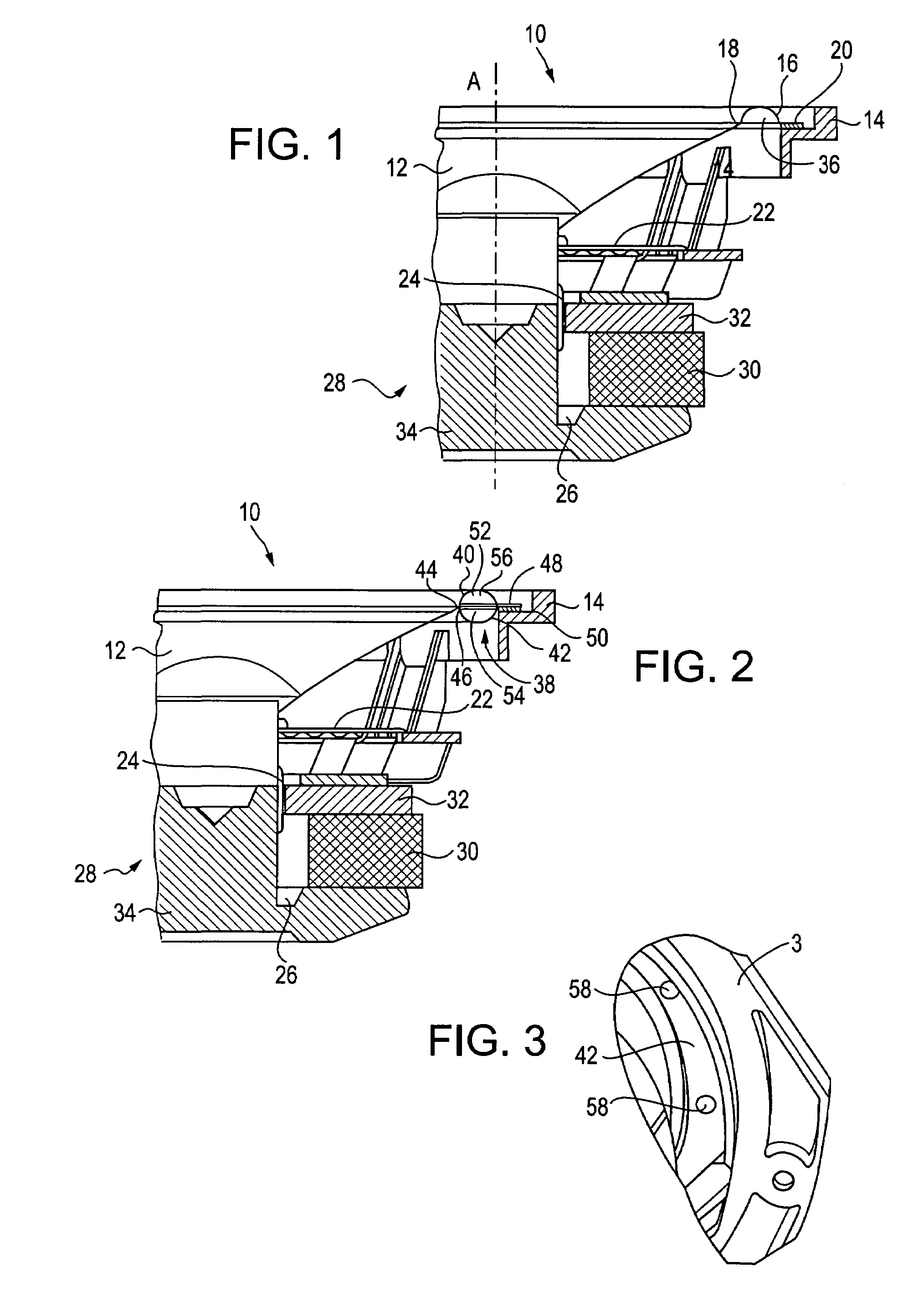

A square speaker is disclosed having a novel surround with a novel rounded corner design and with a magnet assembly and former sized, shaped, and arranged to exploit the increased excursions enabled by the novel surround. The arcuate portion of the rounded corner features smoothed trapezoidal circumferential undulations of the radially outer portion and an extension pad forms the arcuate portion of the radially inner portion of the rounded corner. An apex groove separates the inner portion from the outer portion. Tapered protrusions of the outer portion flank the smoothed trapezoidal circumferential undulations. The rounded corner is bounded by edges making angles of between 20 degrees and 40 degrees (preferably about 35 degrees) with straight sides of the square surround. Most of the outer perimeter of the entire inner flange adjoins the inner portions of the rounded corners. Significant increases in volume displacement per speaker size are achieved.

Owner:MITEK

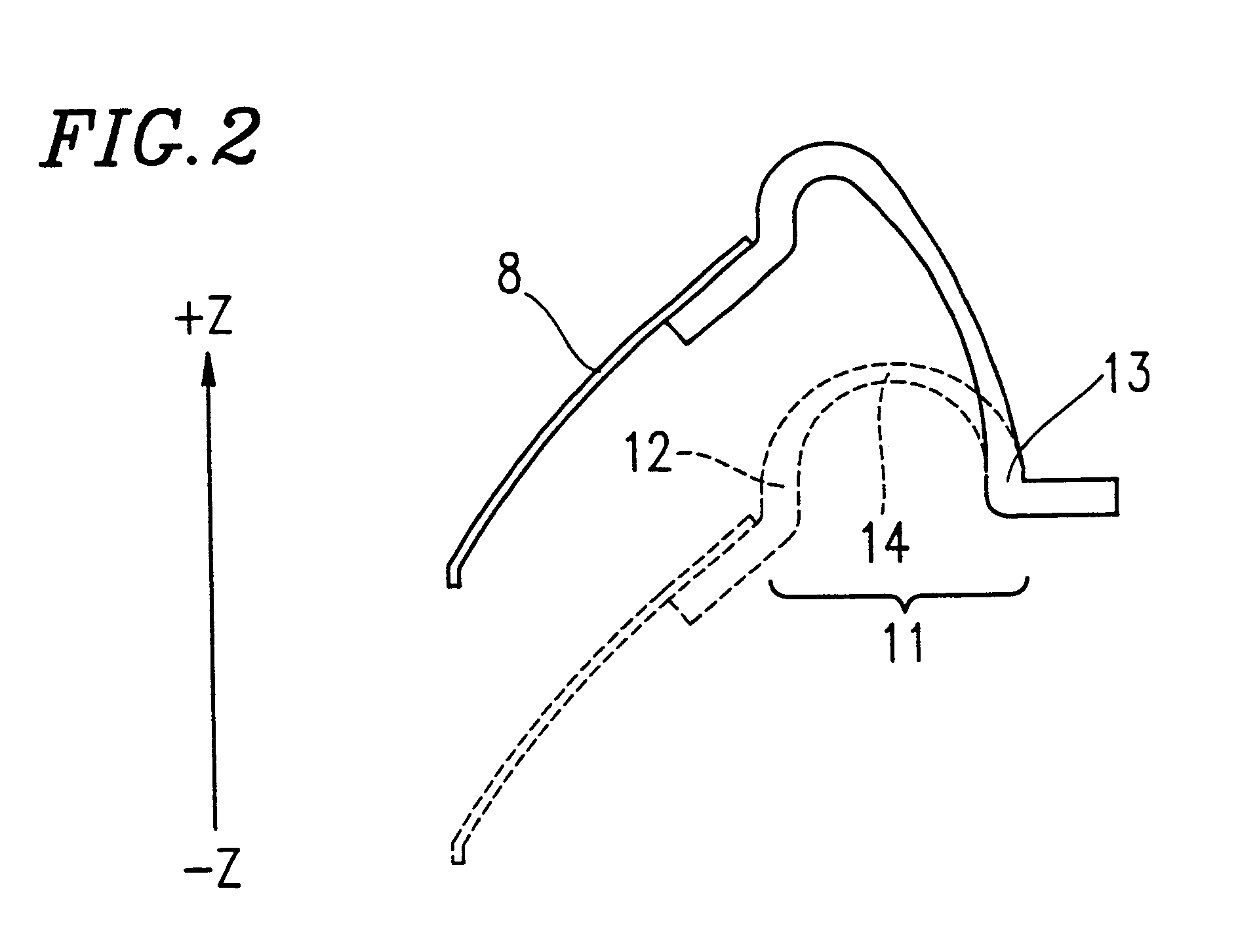

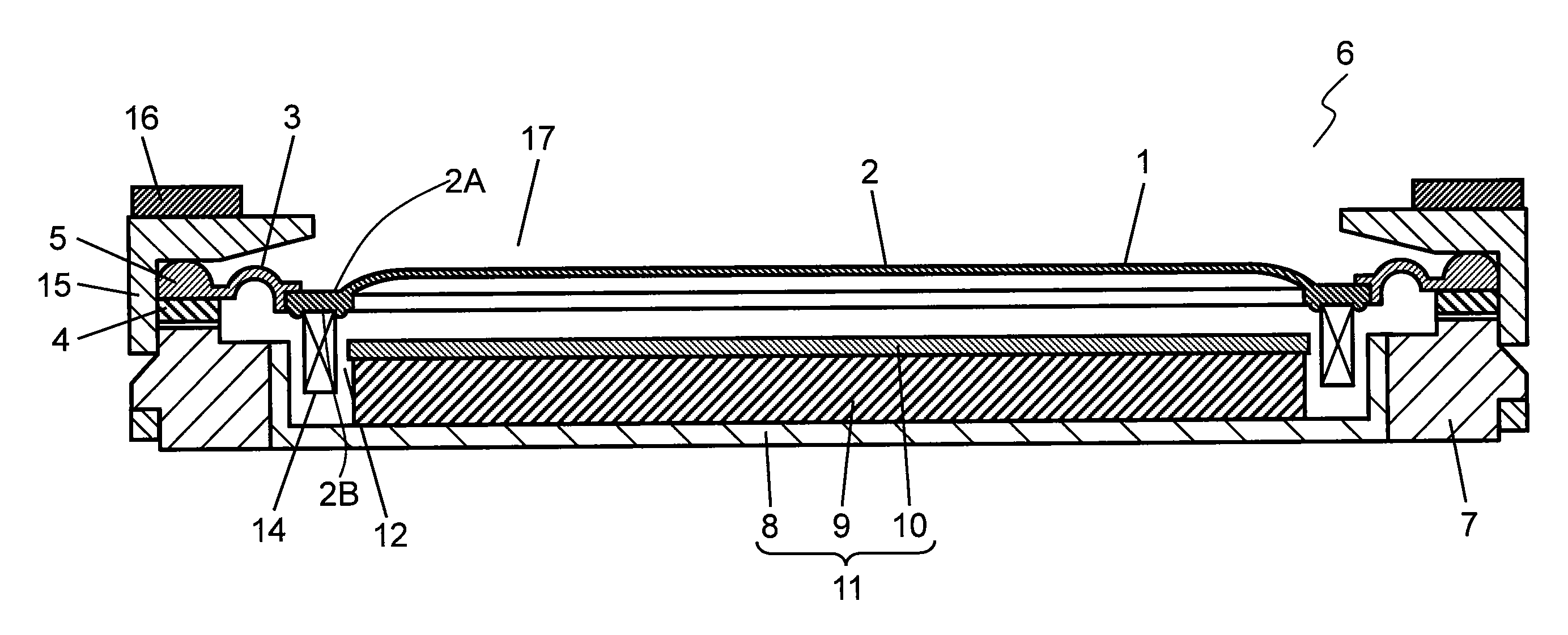

MEMS process and device

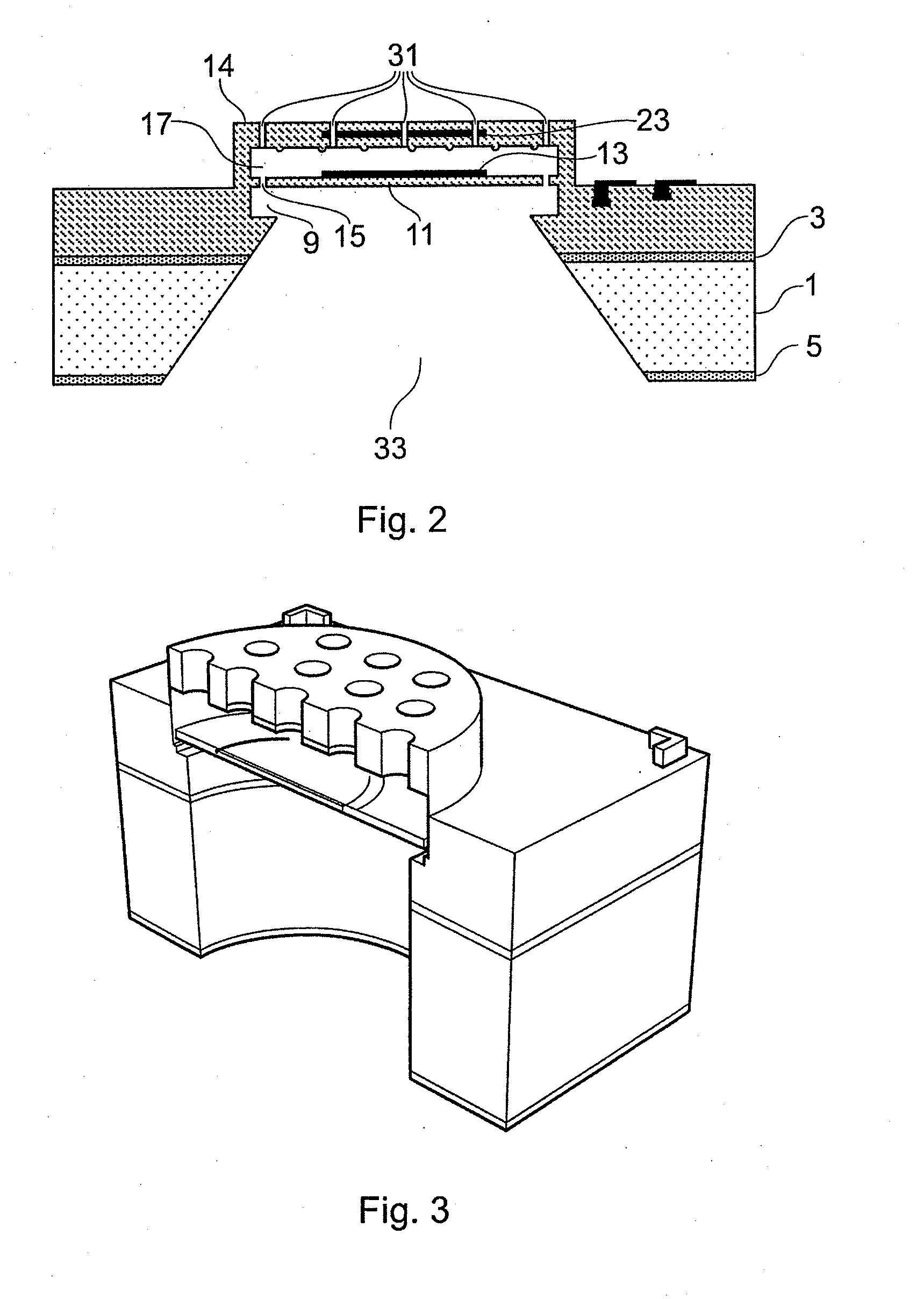

A MEMS device, for example a capacitive microphone, comprises a flexible membrane 11 that is free to move in response to pressure differences generated by sound waves. A first electrode 13 is mechanically coupled to the flexible membrane 11, and together form a first capacitive plate of the capacitive microphone device. A second electrode 23 is mechanically coupled to a generally rigid structural layer or back-plate 14, which together form a second capacitive plate of the capacitive microphone device. The capacitive microphone is formed on a substrate 1, for example a silicon wafer. A back-volume 33 is provided below the membrane 11, and is formed using a “back-etch” through the substrate 1. A first cavity 9 is located directly below the membrane 11, and is formed using a first sacrificial layer during the fabrication process. Interposed between the first and second electrodes 13 and 23 is a second cavity 17, which is formed using a second sacrificial layer during the fabrication process. A plurality of bleed holes 15 connect the first cavity 9 and the second cavity 17. Acoustic holes 31 are arranged in the back-plate 14 so as to allow free movement of air molecules, such that the sound waves can enter the second cavity 17. The first and second cavities 9 and 17 in association with the back-volume 33 allow the membrane 11 to move in response to the sound waves entering via the acoustic holes 31 in the back-plate 14. The provision of first and second sacrificial layers has the advantage of protecting the membrane during manufacture, and disassociating the back etch process from the definition of the membrane. The bleed holes 15 aid with the removal of the first and second sacrificial layers. The bleed holes 15 also contribute to the operating characteristics of the microphone.

Owner:CIRRUS LOGIC INC

Surrounding structure of a loudspeaker

The surrounding structure of the loudspeaker forms an annular structure, including attaching parts and curved part. The cross section of the curved part is in a hollow and approximately elliptical form. The height along the major axis of the ellipse is made parallel to the center axis of the vibrating diaphragm of the loudspeaker while the width along the major axis of the ellipse is set in the direction orthogonal to the center axis of the vibrating diaphragm. In the elliptical surrounding structure having such a structure, the width in the cross section of the surrounding structure of the loudspeaker can be made narrow in comparison with a semi-circular surround, whereby the linearity of the amplitude and the maximum displacement are increased.

Owner:PANASONIC CORP

Diaphragm Surrounding

Owner:BOSE CORP

Speaker and speaker diaphragm

InactiveUS6957714B2Improve flexural strengthImprove performanceLoudspeaker diaphragm dampingLoudspeaker diaphragm shapeFlexural strengthEngineering

The speaker has a diaphragm main body 30 supported resiliently on a frame 23 via an edge portion 31 around its outer circumference, and the groove ribs 35 integrally formed in the edge portion 31, wherein a regulation member 37 for partially improving a flexural strength of the edge portion 31 is provided on a part of the front or back face of the edge portion 31.

Owner:PIONEER CORP +1

Speaker

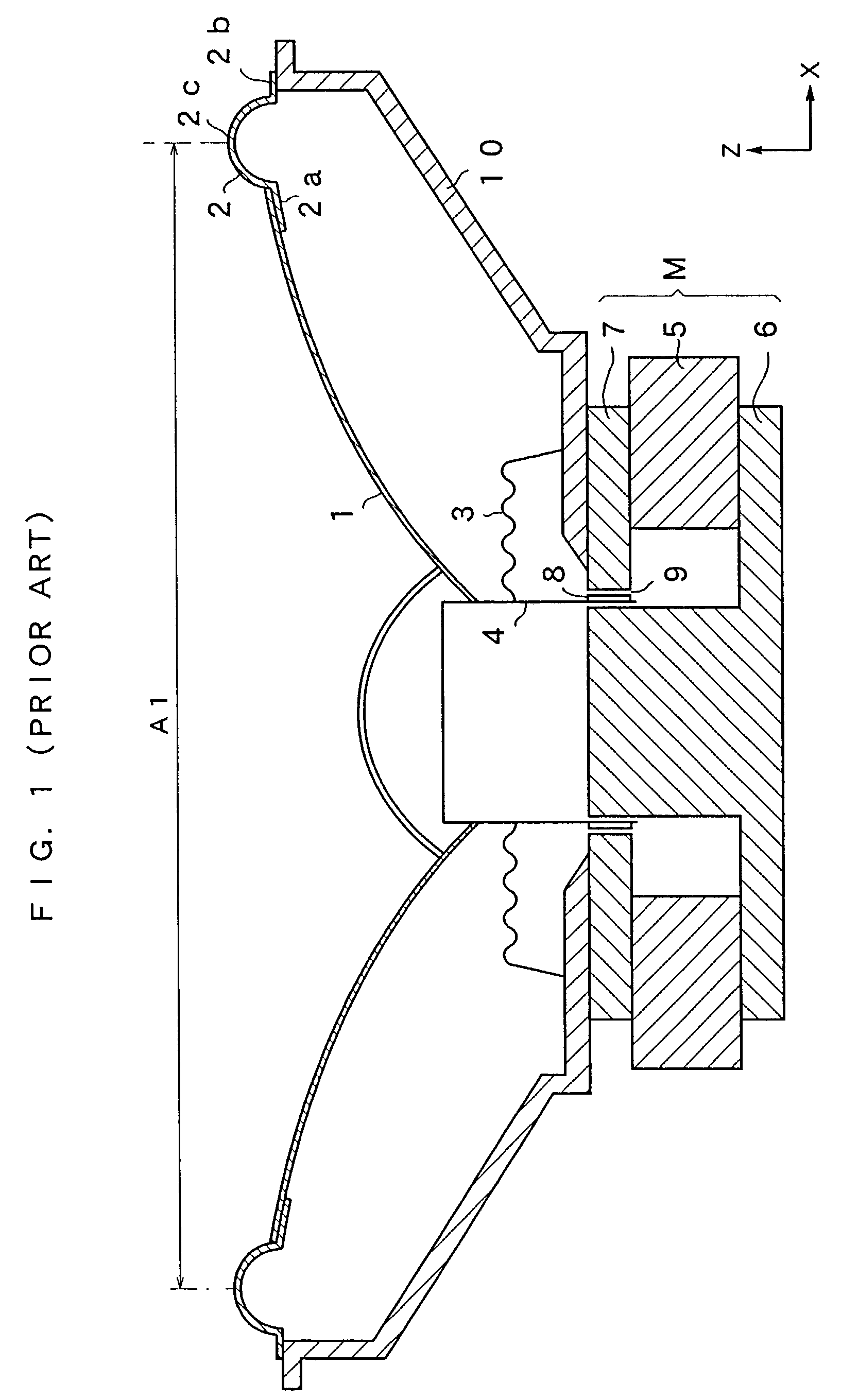

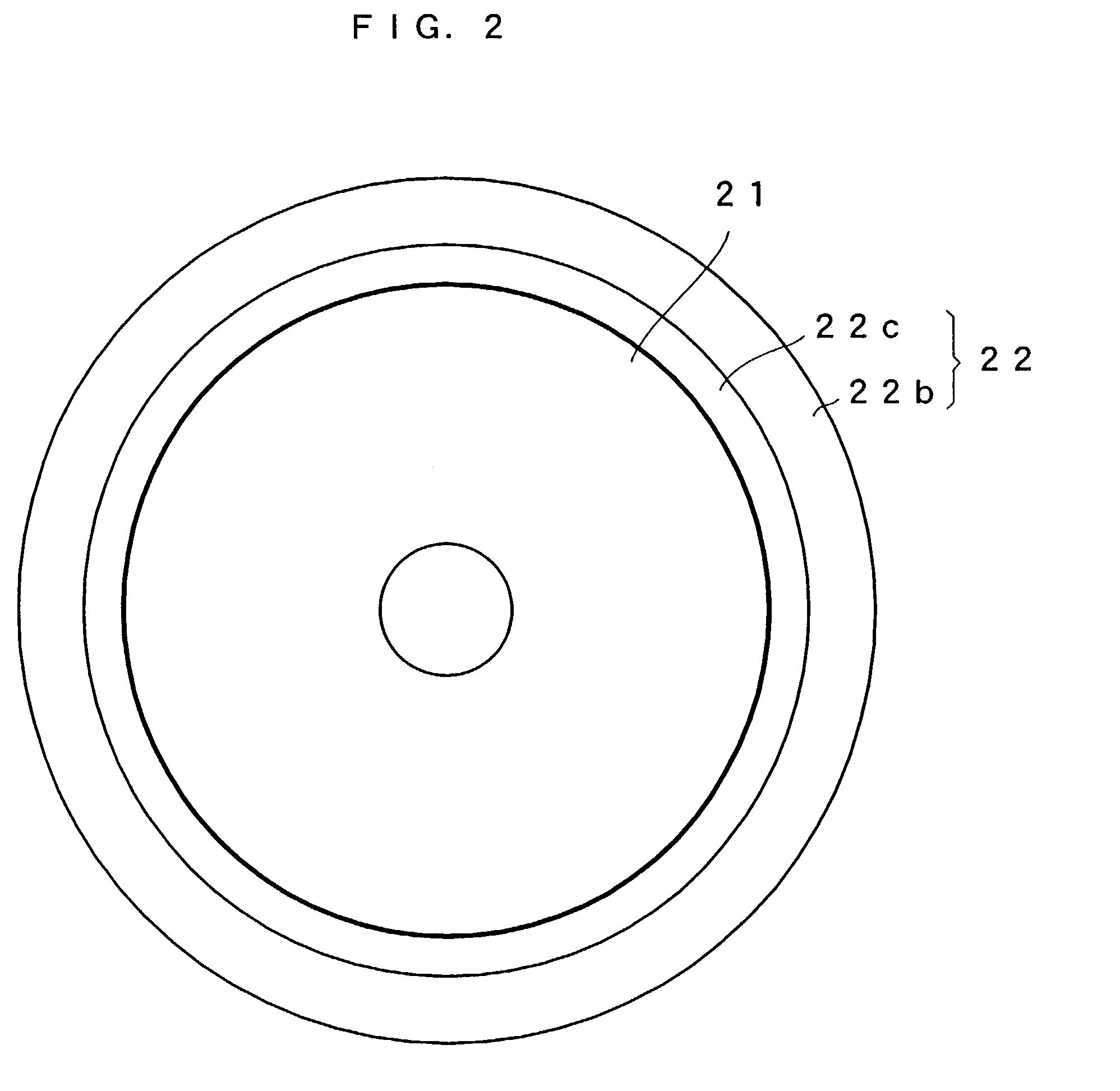

InactiveUS6305491B2Avoid it happening againLoudspeaker diaphragm shapeSound producing devicesEngineeringLoudspeaker

Owner:PANASONIC CORP

Insert moulded surround with integrated lead-out wires

InactiveUS20070071274A1Lower resonance frequencyFlat Frequency ResponseLoudspeaker diaphragm materialsLoudspeaker diaphragm shapeTransducerEngineering

The present invention relates to a suspension member for a diaphragm and to an electro-acoustic transducer applying such suspension member. The suspension member comprises an inner portion being adapted to be attached to a piston, an outer portion being adapted to be coupled to a substantially stationary portion of an associated electro-acoustic transducer, and a flexible member connecting the inner and outer portions. The flexible member comprises at least one electrically conducting element adapted to transport electrical signals across the suspension member.

Owner:SONION HORSENS

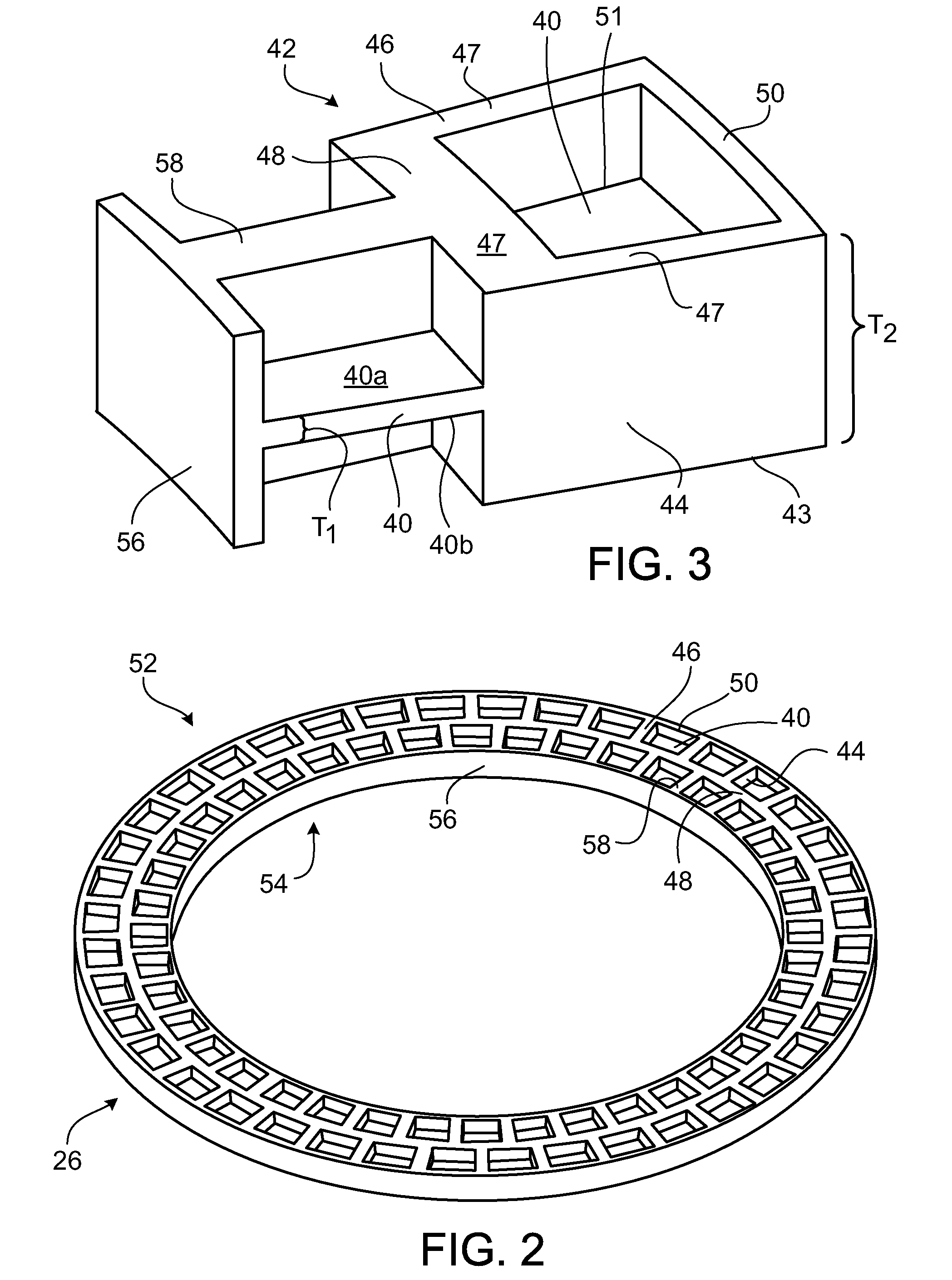

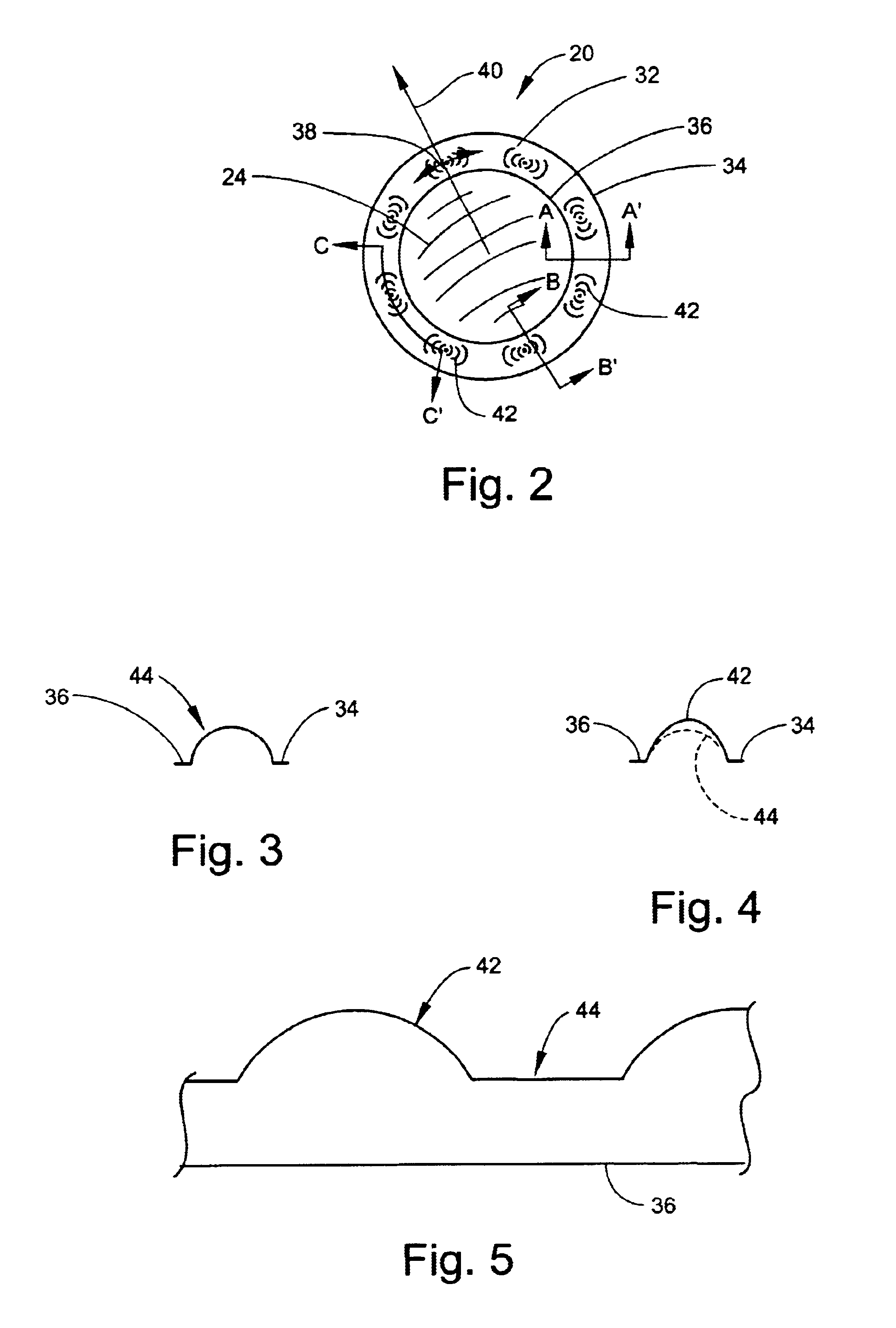

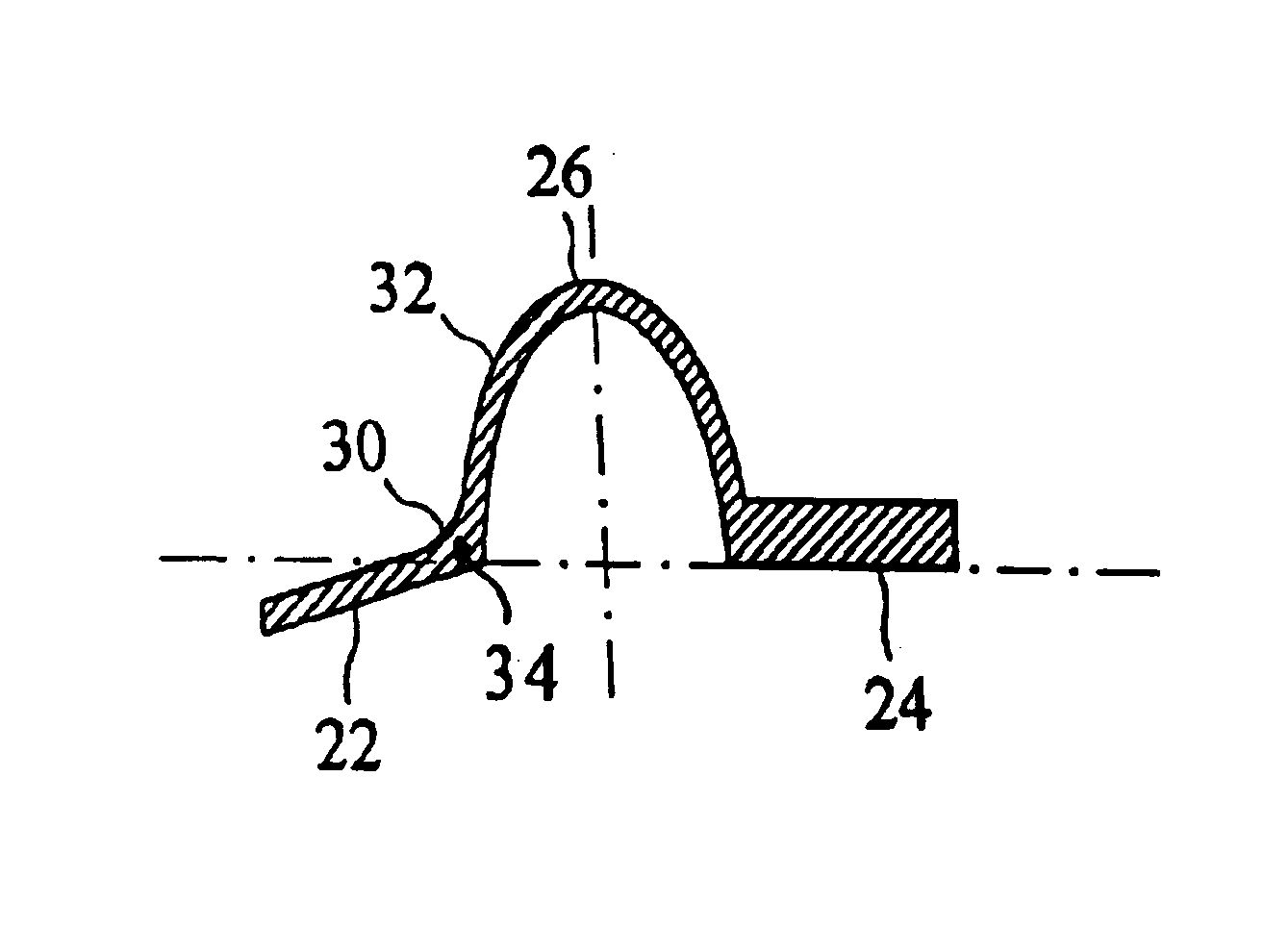

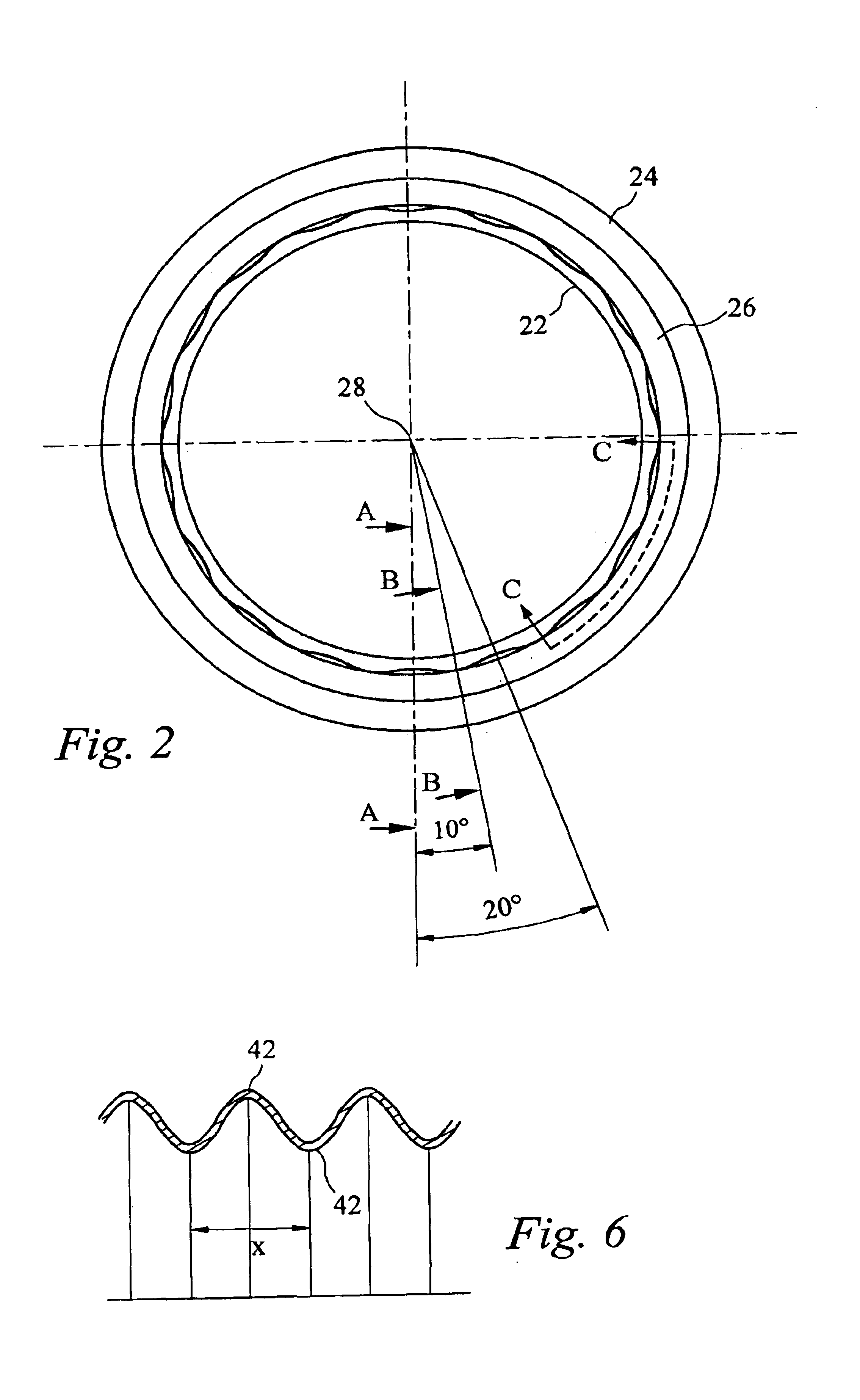

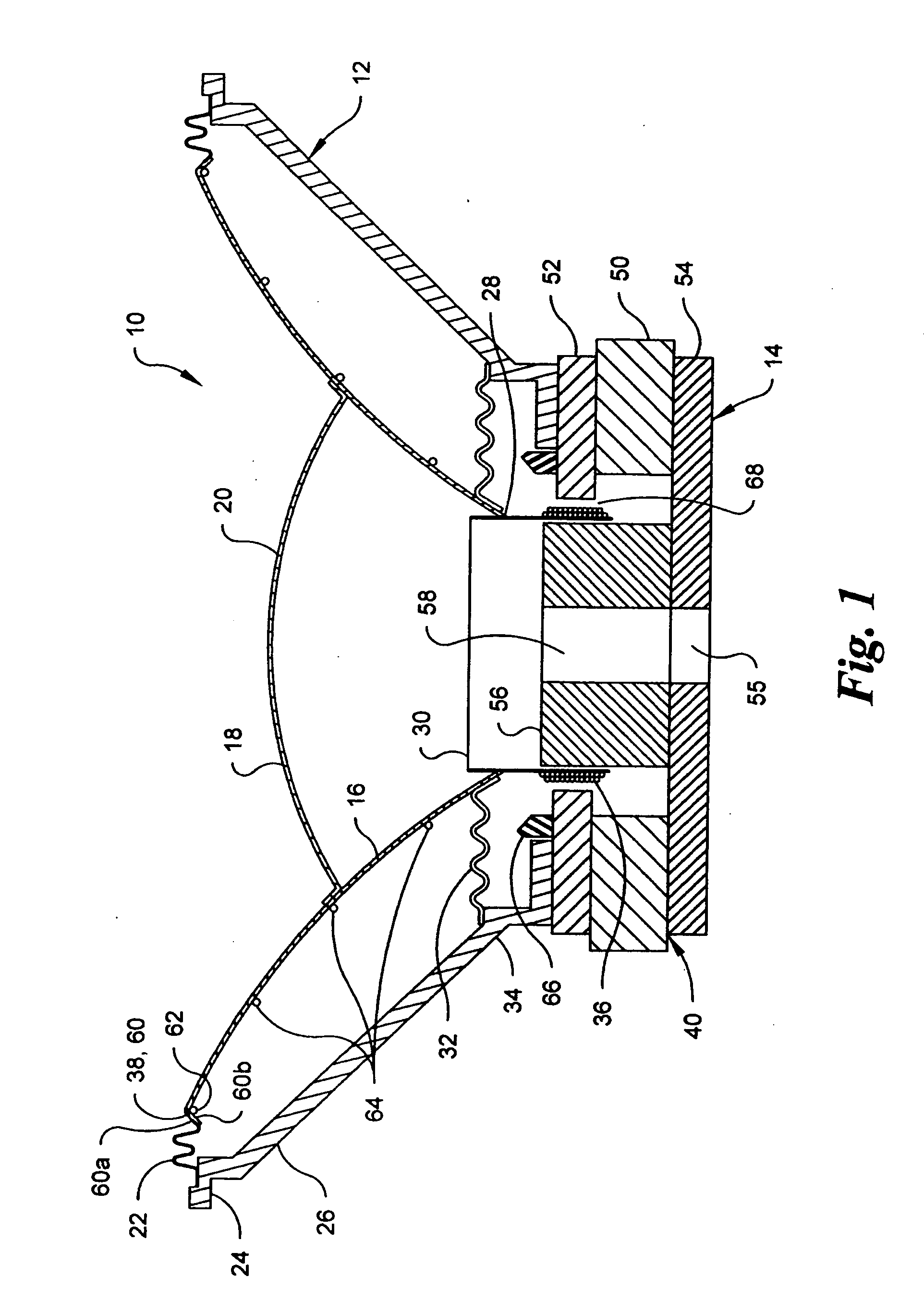

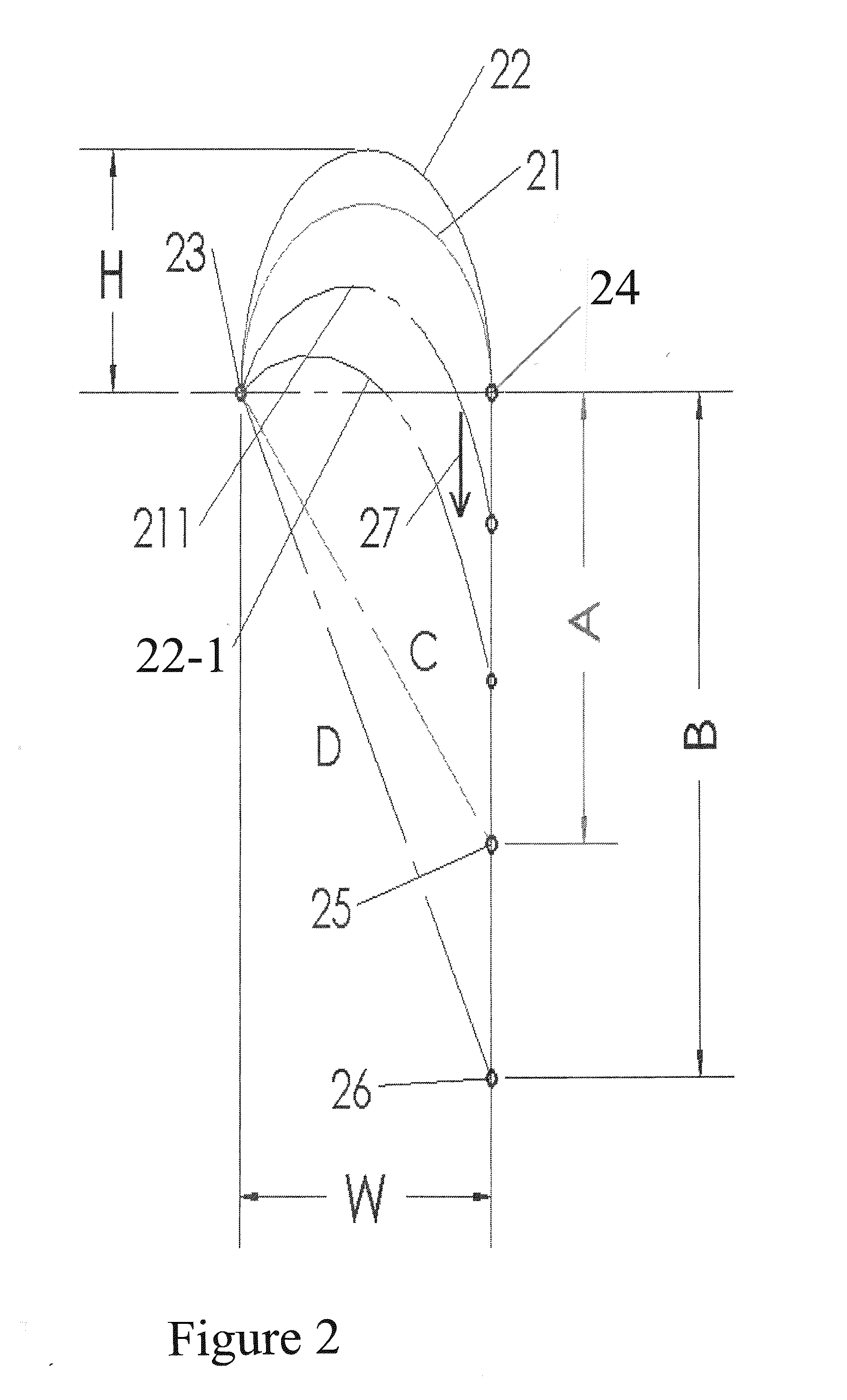

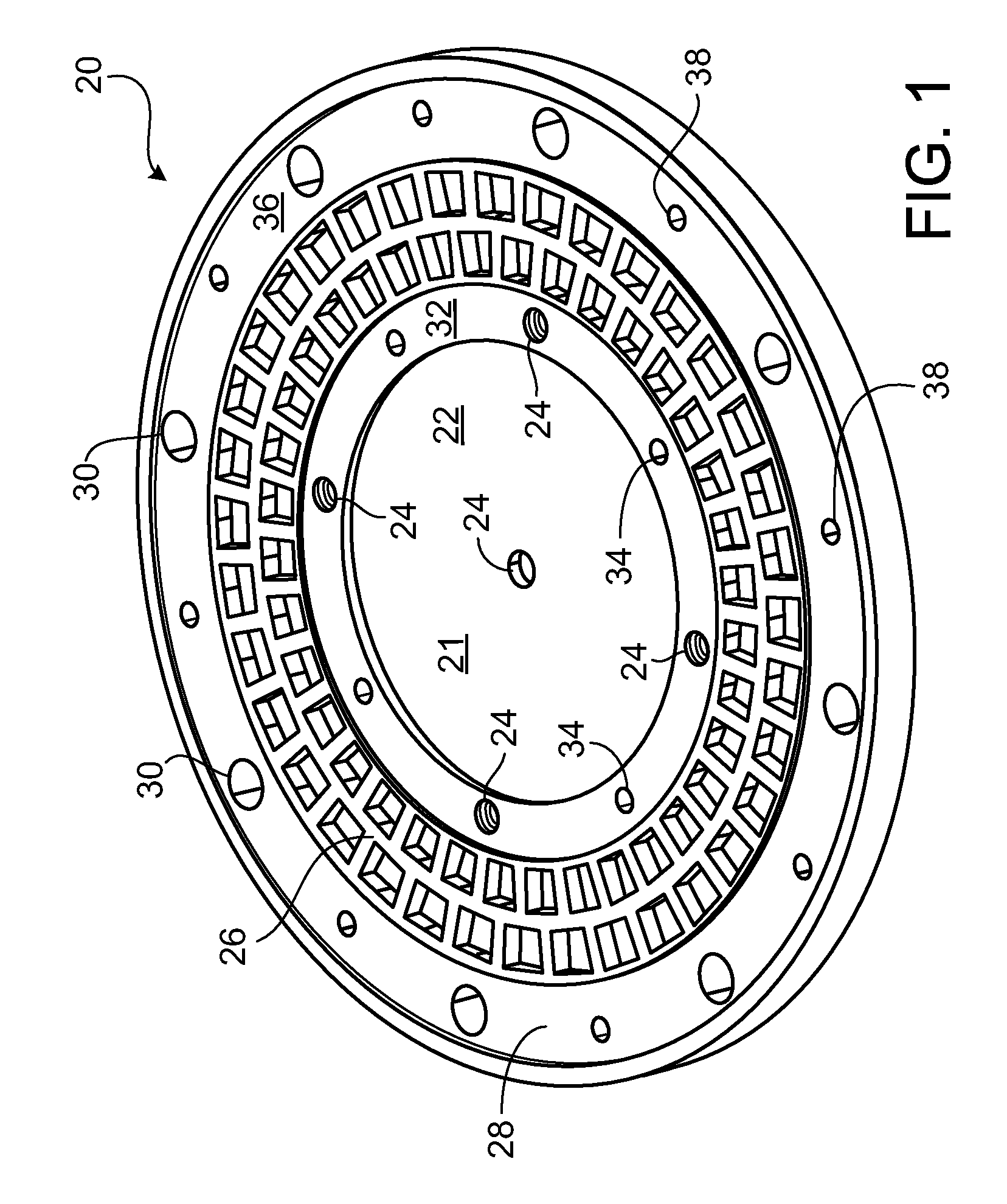

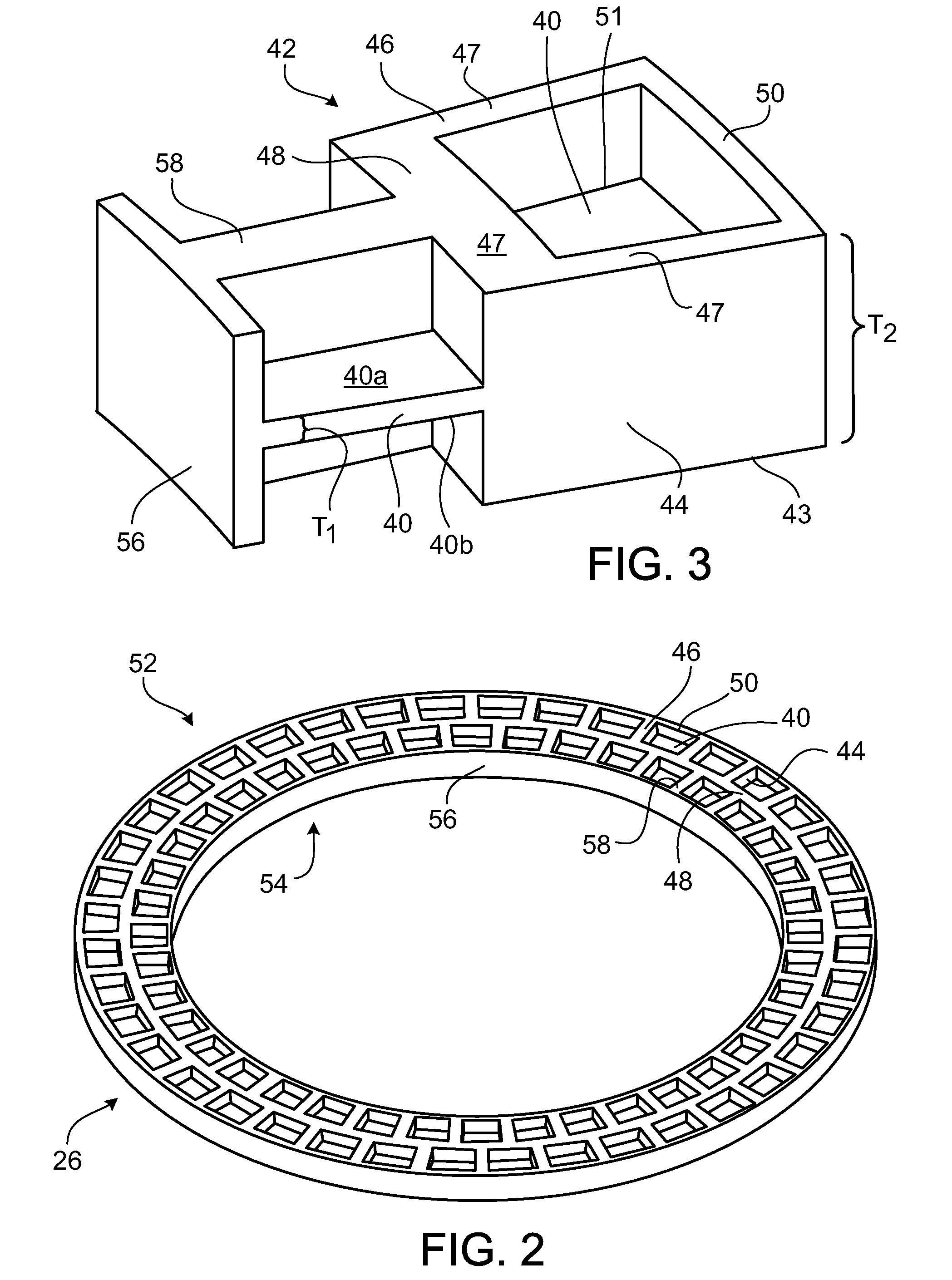

Tangential stress reduction system in a loudspeaker suspension

InactiveUS6851513B2Improve linearityImproved speaker performanceTransducer detailsLoudspeaker diaphragm shapeTangential stressEngineering

The invention is a suspension element having an outer edge and an inner edge. The suspension element, such as a spider or surround, varies in shape along at least a portion of the suspension element to help relieve both the radial and tangential stress placed on the suspension element when it is stretched. The shape employed in the suspension element allows the suspension element to stretch more easily, creating a higher performance speaker of the same size by increasing the diaphragm excursion and voice coil movement.

Owner:HARMAN INT IND INC

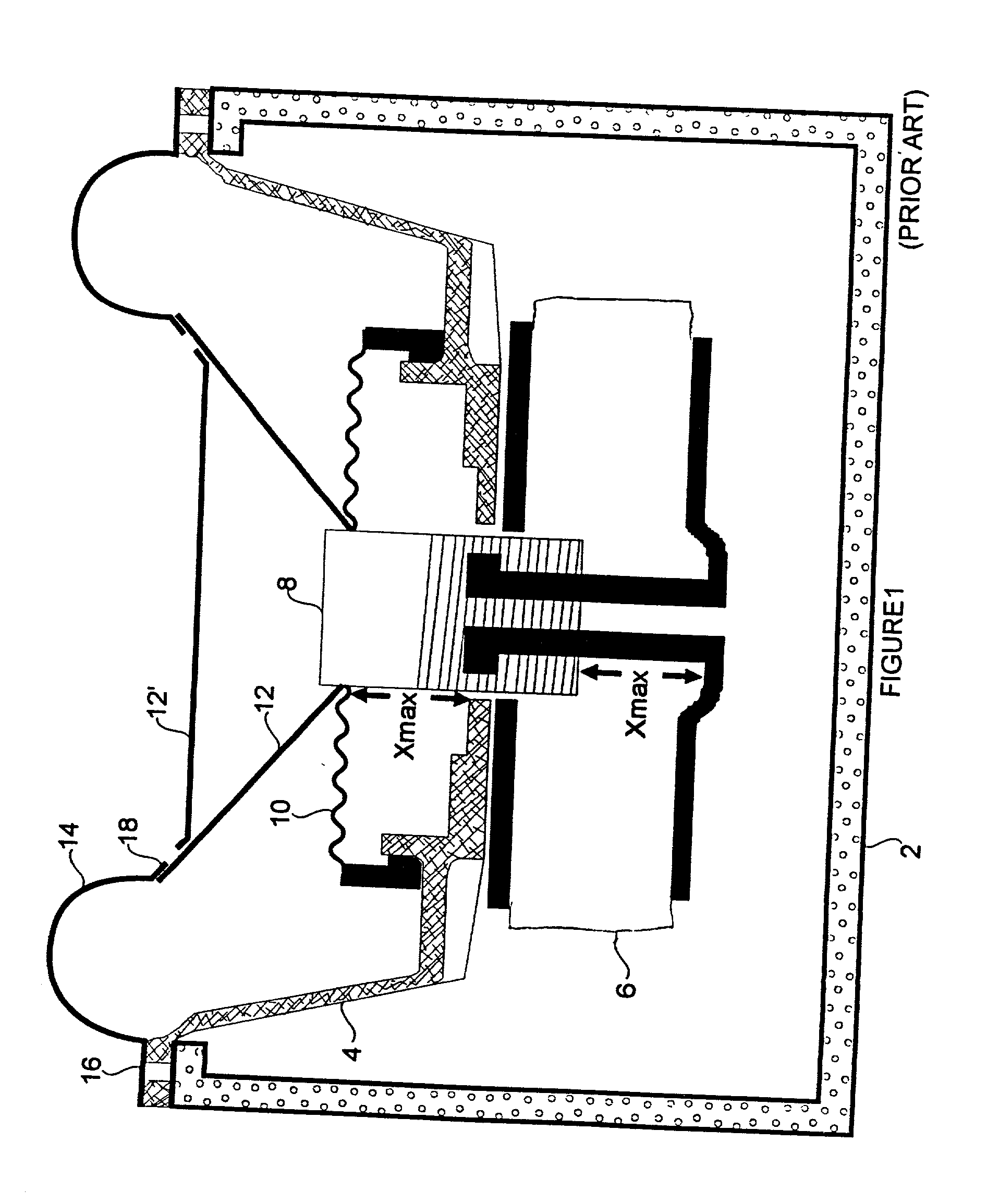

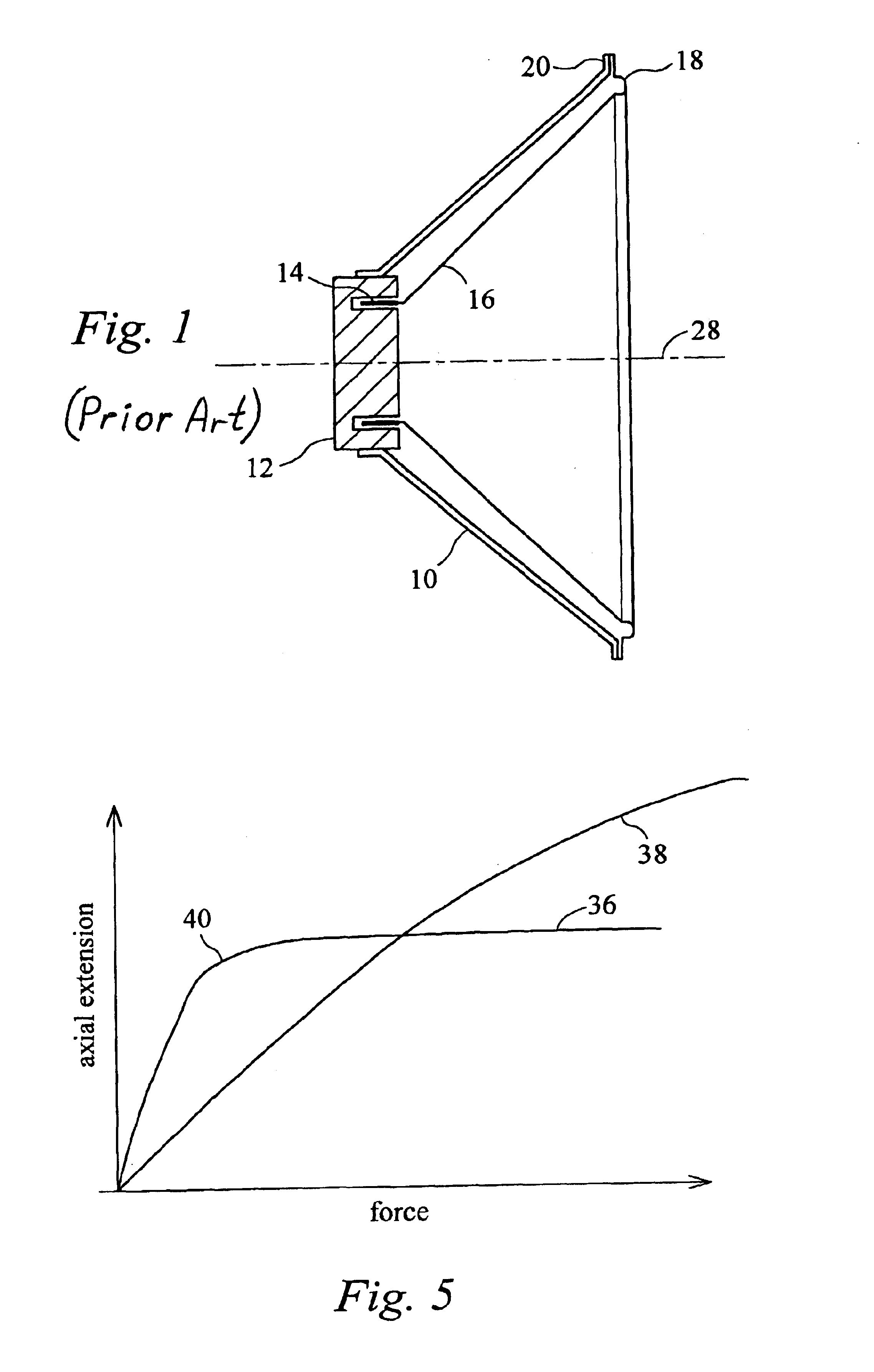

Acoustic radiator with a baffle of a diameter at least as large as the opening of the speaker enclosure to which it is mounted

InactiveUS20020148678A1Loudspeaker diaphragm shapeSound producing devicesPassive radiatorEngineering

Several different acoustic radiator designs improve performance over the prior art while providing a larger baffle (cone), a lesser volume of air displaced than by the smaller prior art speaker design, while maintaining the same enclosure mouth diameter and allowing the use of a shallower enclosure. These advantageous are achieved in a variety of ways with several configurations that include: a substantially vertically oriented resilient mount for the baffle (cone) where that resilient mount is entirely beneath the outer edge of the baffle (cone), between the outer rim of the baffle (cone) and the outer flange of the basket; a resilient mount that resembles prior art surround rotated outward by 45° to 70° extending the outer edge of the baffle (cone) outward allowing the use of a larger diameter speaker baffle (cone); and surround mounted to the outer flange of the basket beneath the dome of the surround moving the surround outward from the center of the enclosure allowing for a larger diameter baffle (cone) in an enclosure with the same mouth size than provided by prior art speakers and passive radiators.

Owner:EARTHQUAKE SOUND

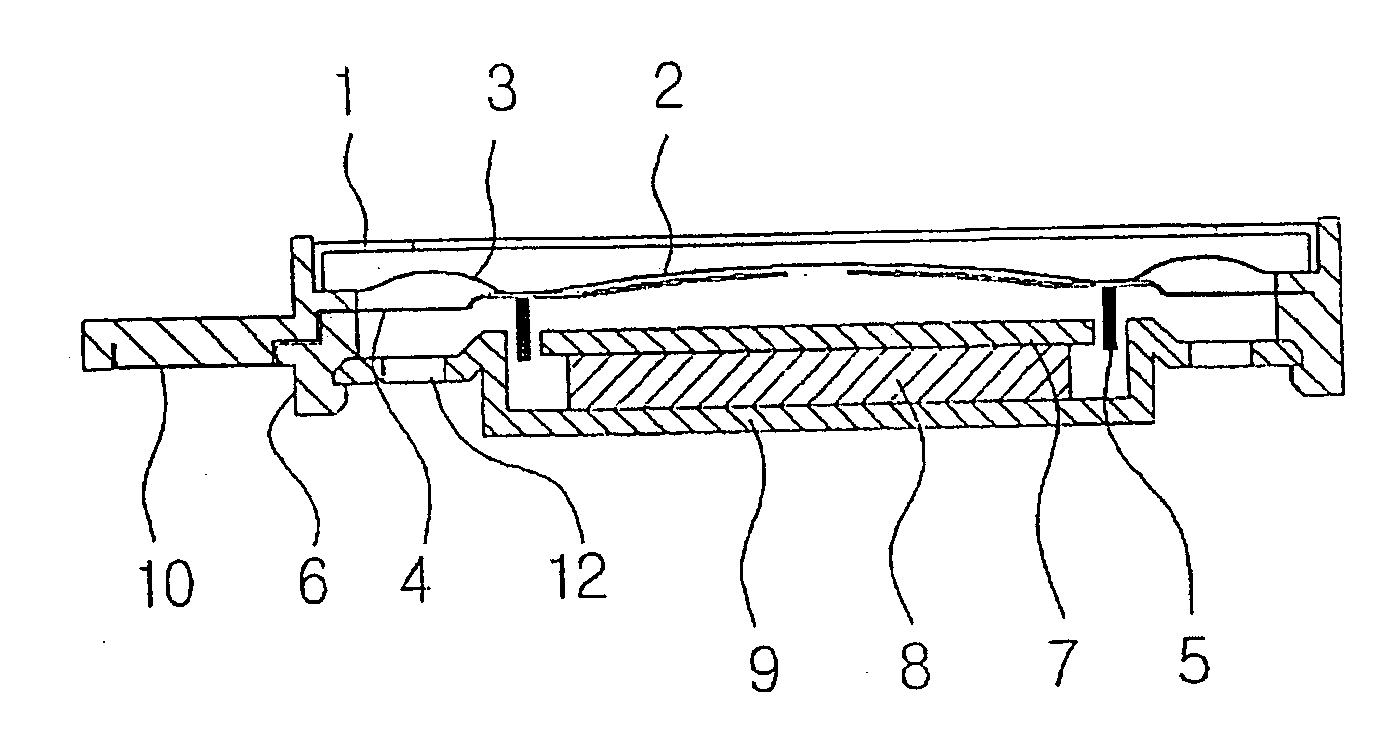

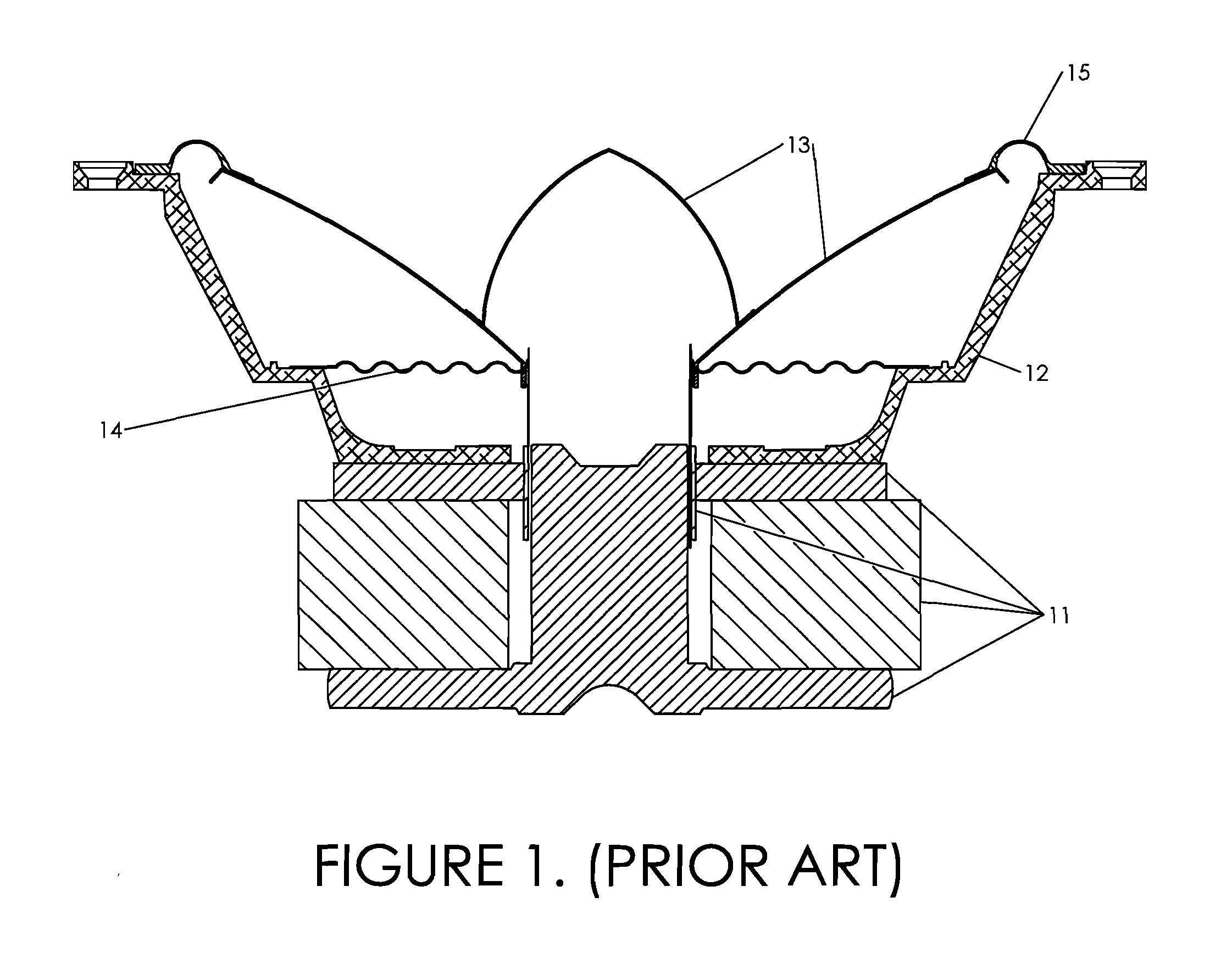

Dynamic micro speaker with dual suspension

InactiveUS7505603B2Reduce distortion problemsAvoid disconnectionLoudspeaker diaphragm dampingLoudspeaker transducer fixingLow distortionEngineering

The invention relates to a micro-speaker with a second suspension made of highly resilient material installed inside of the speaker. The speaker is able to provide high level acoustic output with low distortion rate in a wide frequency range with a very small and slim structure and it may prevent a disconnection of a lead connecting the voice coil and the electrode. The speaker includes a yoke, a permanent magnet, a plate, a vibration plate integrated with a first suspension, a voice coil, a frame and a protector. The speaker further comprises a second suspension made of highly resilient material installed between the plate and the vibration plate, and is characterized in that the voice coil is attached to the lower surface of the second suspension and the vibration plate is attached to the upper surface of the second suspension and the vibration plate is attached to the upper surface of the second suspension and the outer periphery of the second suspension is fixed to the frame.

Owner:JY CUSTOM CO LTD

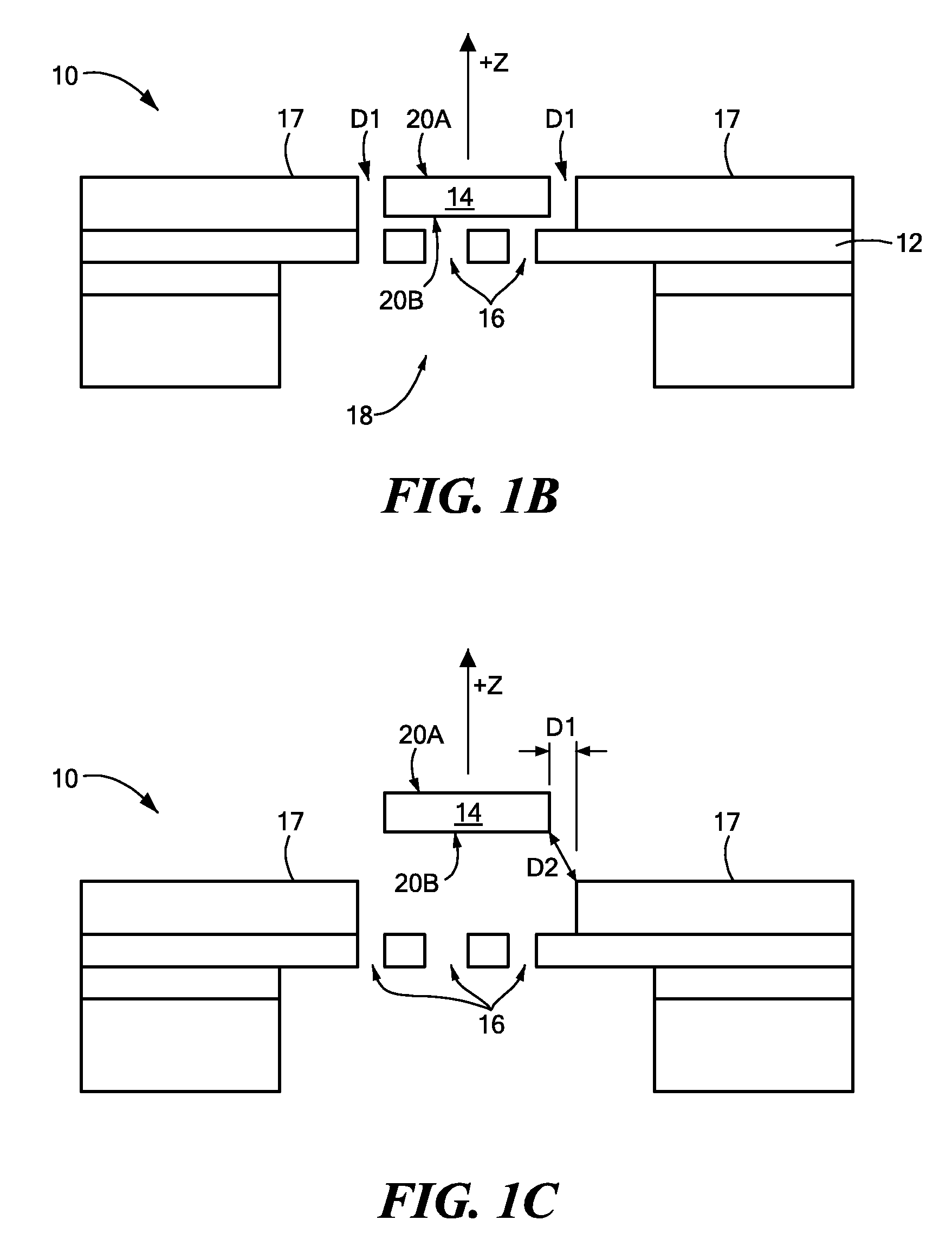

Microphone with pressure relief

ActiveUS8111871B2Add dimensionTransducer detailsSemiconductor electrostatic transducersRest positionEngineering

A microphone has a movable diaphragm having a rest position, a stationary portion, and a set of springs movably coupling the diaphragm and the stationary portion. The diaphragm and stationary portion are spaced a first distance when the diaphragm is in the rest position. When not in the rest position, however, the diaphragm and stationary portion are capable of being spaced a second distance, which is greater than the first distance. Despite the change in distance, the diaphragm still is capable of returning the space from the second distance to the first distance when the diaphragm returns to the rest position.

Owner:INVENSENSE

Speaker diaphragm, and speaker and handheld terminal device using said speaker diaphragm

InactiveUS20120237076A1Loudspeaker diaphragm materialsLoudspeaker diaphragm shapeTerminal equipmentEngineering

A speaker diaphragm includes a body vibrating to generate a sound, an edge fusion-bonded to an outer circumference portion of the body, a projection provided on an upper surface of the edge, and a gasket provided on a lower surface of the edge. The edge is made of material different from that of the body. The projection is made of material identical to that of the edge. The gasket is made of material identical to that of the body. A speaker including the diaphragm has waterproof property by itself.

Owner:PANASONIC CORP

Loudspeaker suspension

InactiveUS6889796B2Reduce complianceCompromise abilityLoudspeaker diaphragm shapeSound producing devicesEngineeringLoudspeaker

An annular surround for a loudspeaker cone wherein a radial cross-section of the surround varies around the circumferential extent of the surround, so as to accommodate peripheral expansion or contraction of the surround by bending. Thus a trough shaped cross-section of the surround may vary sinusoidally with angle around the polar axis of the surround between a semicircular and semielliptical cross-section. The trough section may bland to an adjacent portion of the surround by a fillet which also varies sinusoidally in cross-section in phase with the variation of the trough.

Owner:HARMAN INT IND INC

Acoustic device and method of manufacturing same

ActiveUS8233646B2Quality improvementLoudspeaker diaphragm dampingPiezoelectric/electrostrictive transducersEngineeringTranslational motion

Owner:SOUND SOLUTIONS INTERNATIONAL COMPANY LTD

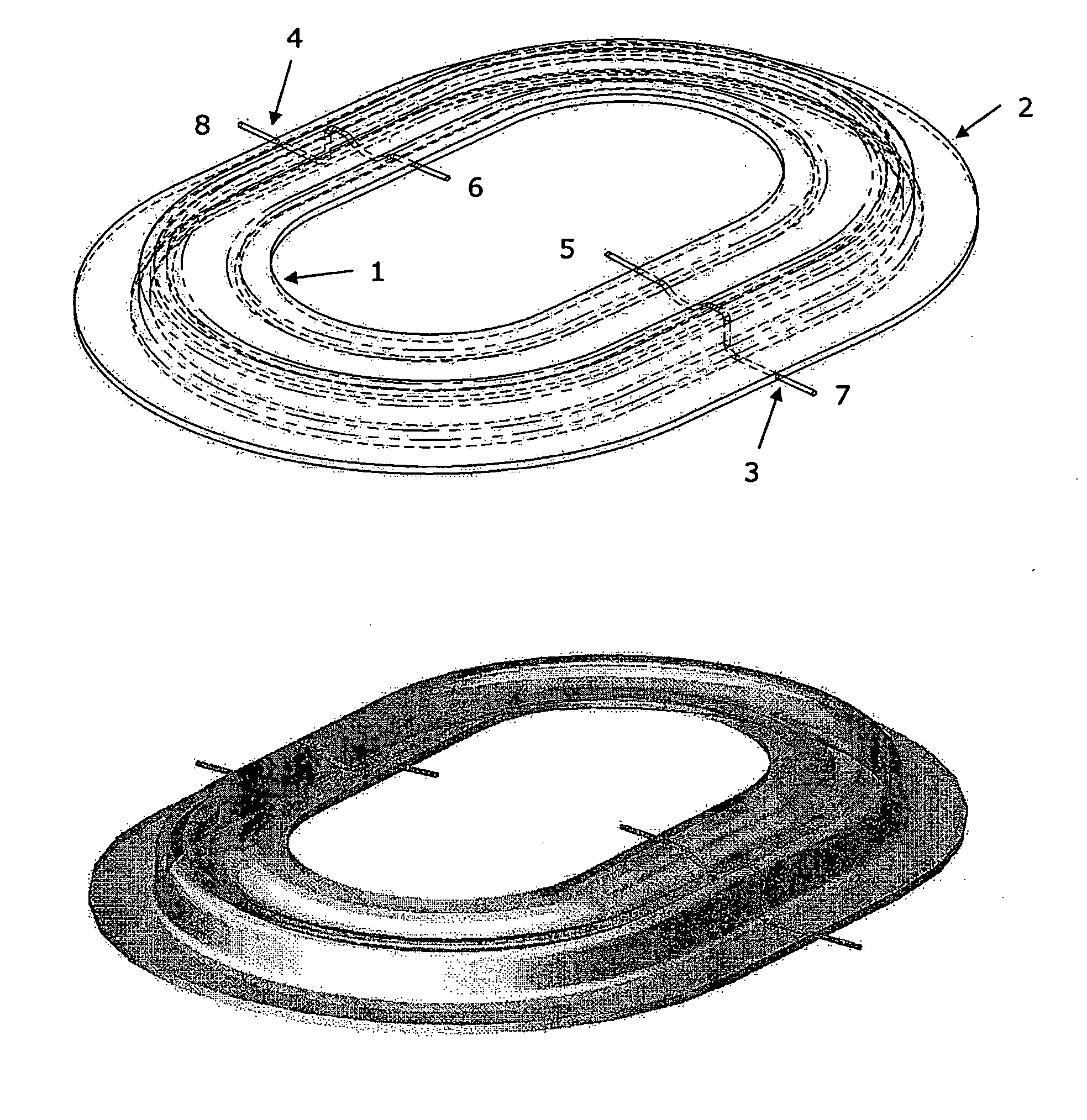

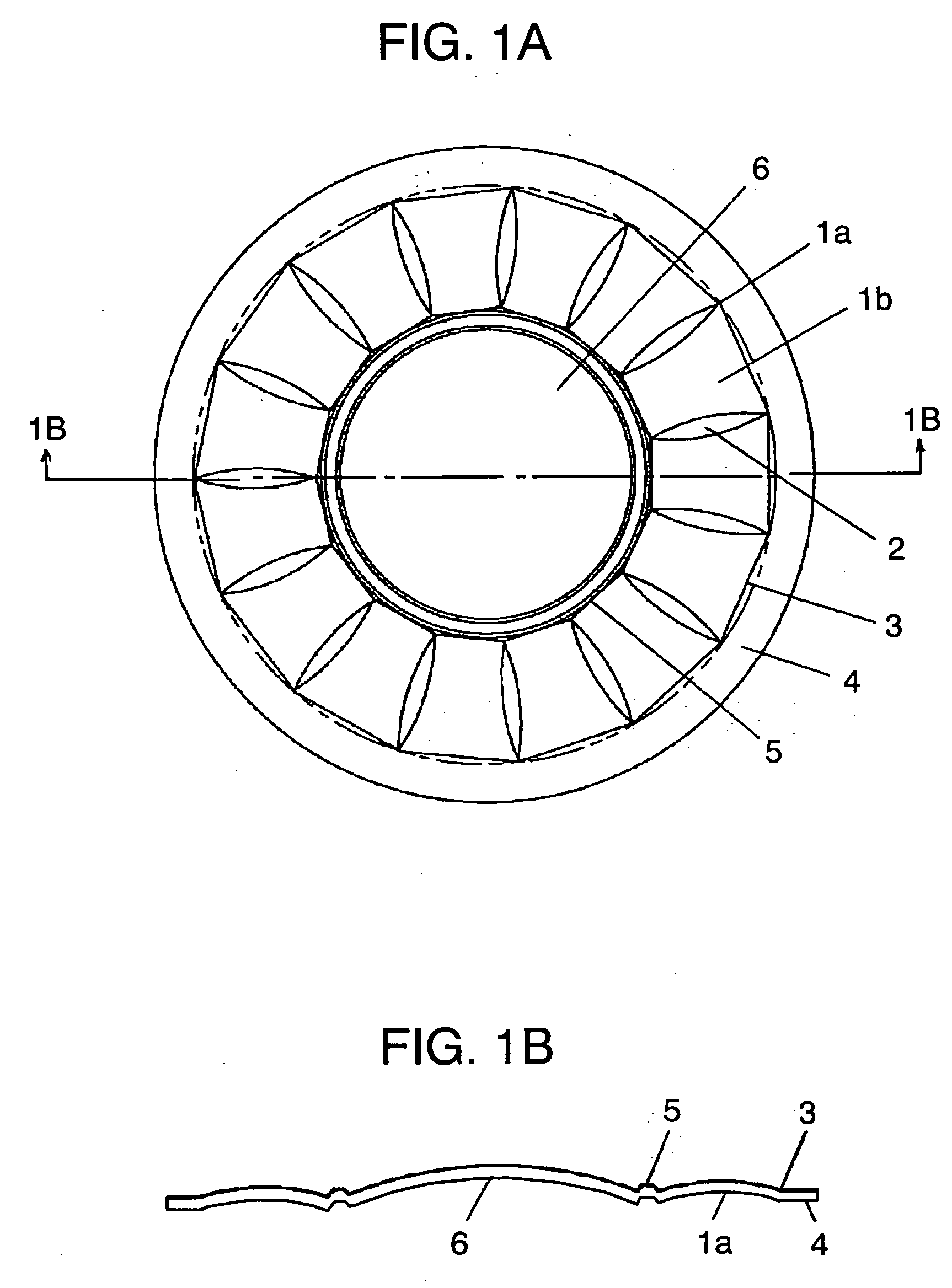

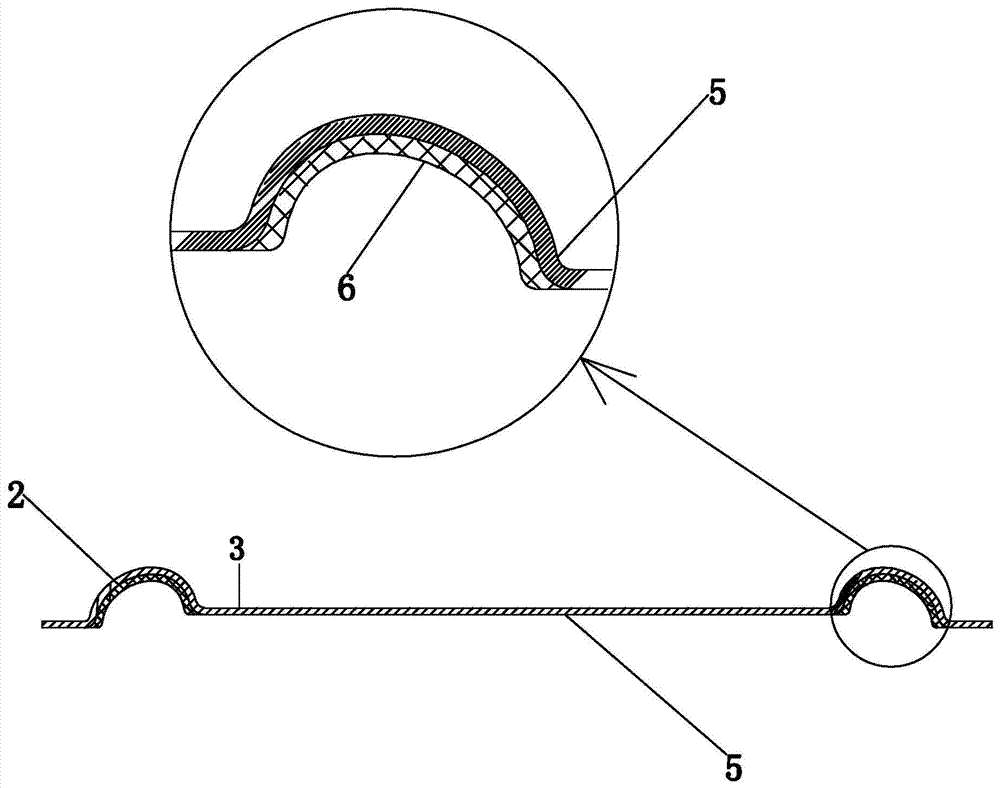

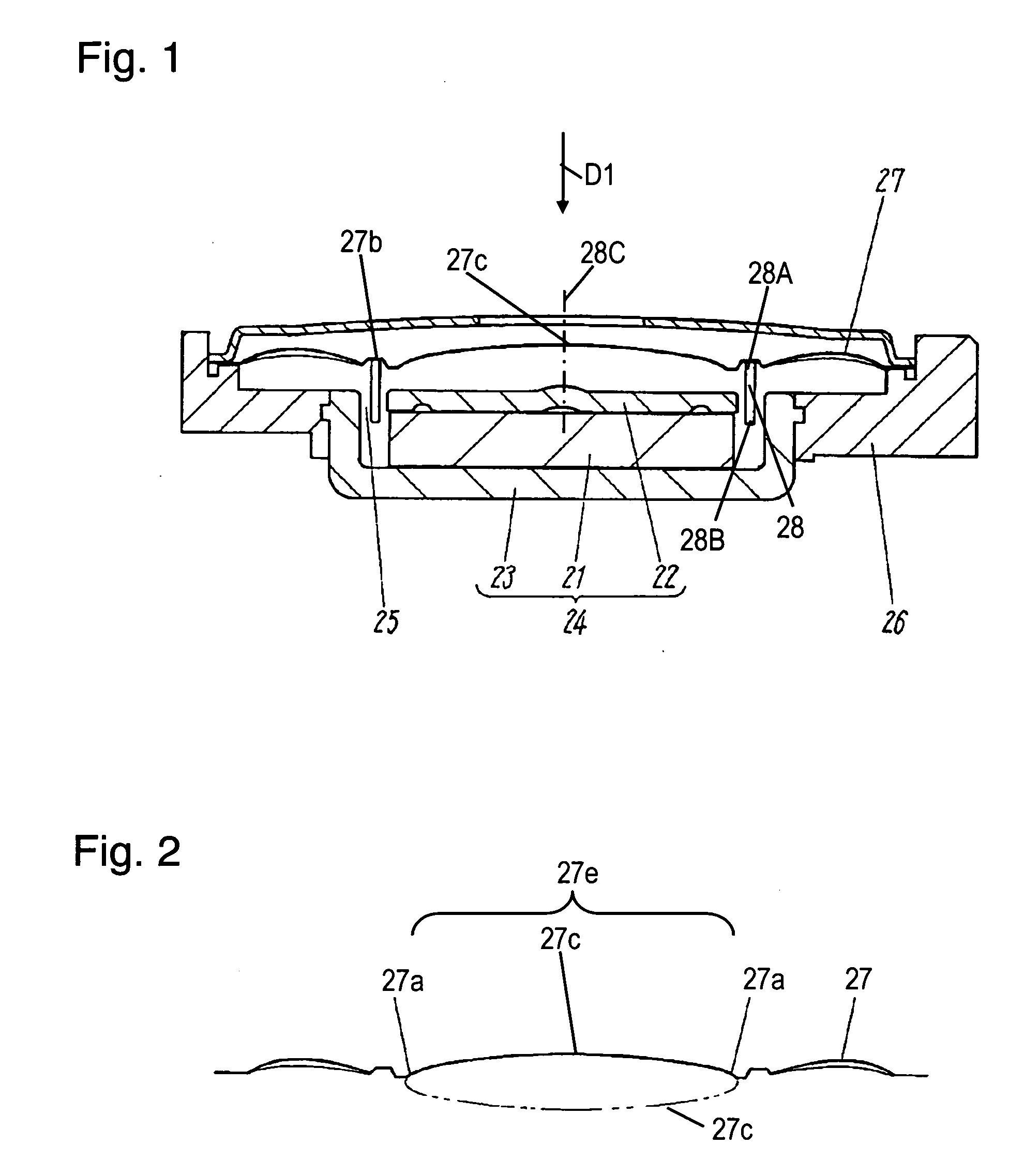

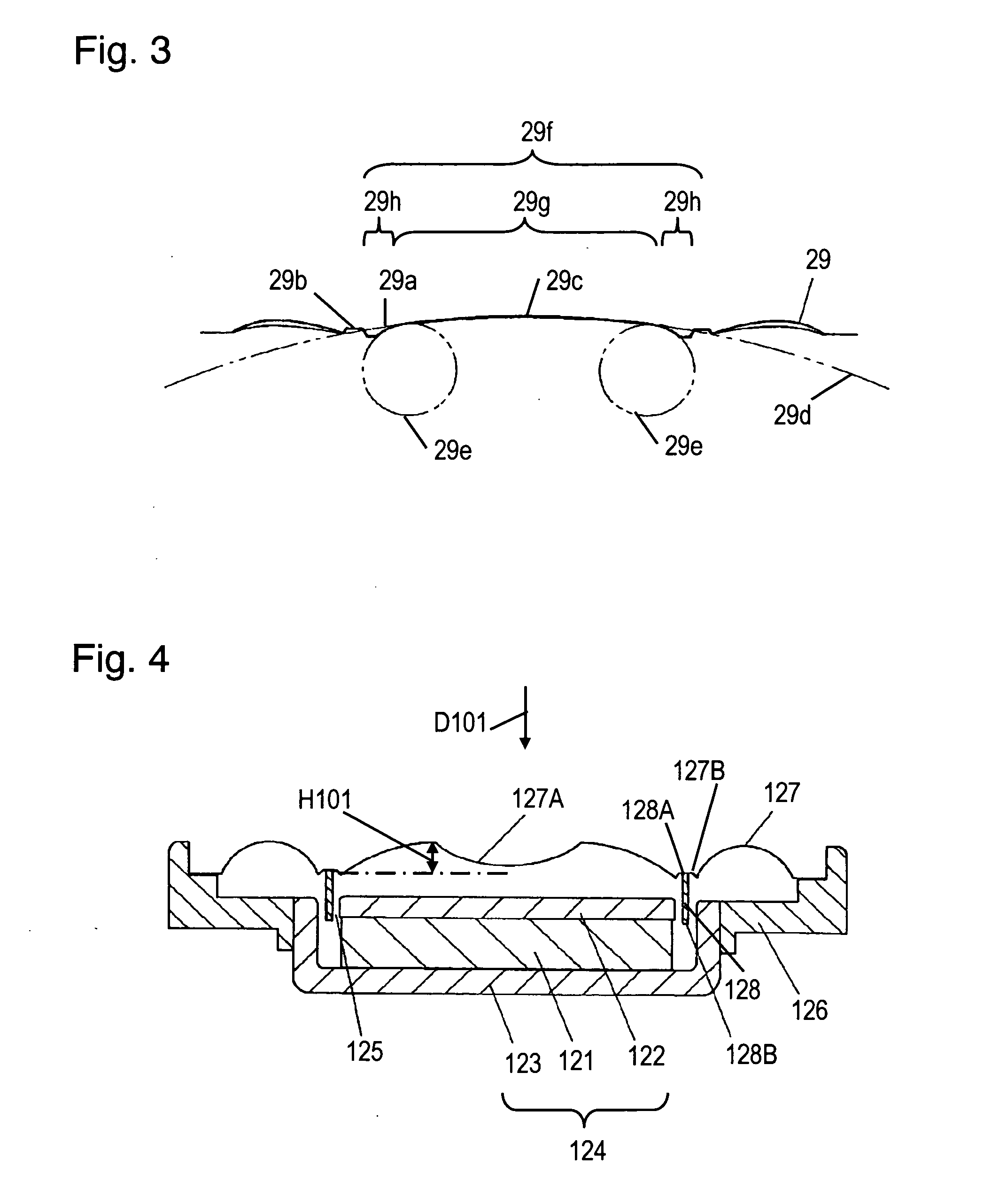

Suspension and electro-acoustic transducer using the suspension

A suspension with a plurality of roll sections each of which has a semi-cylindrical shape from a cross-section view. The roll sections are disposed side by side based on a straight line connecting two points on an inner periphery or an outer periphery. The roll sections form a closed loop in a manner that a roll section of the roll sections being disposed first adjoins a roll section of the roll sections being disposed last. Adjacent roll sections are coupled with each other through a boundary section forming a continuous three dimensional curved surface. A linearity of compliance improves, and generation of distortion or rolling is restricted using the suspension.

Owner:PANASONIC CORP

Vibration transducer

InactiveUS20090190782A1Increase sound resistanceImproved acoustic resistanceLoudspeaker diaphragm dampingSemiconductor electrostatic transducersCapacitanceTransducer

A vibration transducer includes a substrate, a diaphragm formed using deposited films having conductive property, which has a plurality of arms extended from the center portion in a radial direction, a plate formed using deposited films having conductive property, and a plurality of diaphragm supports formed using deposited films, which join the arms so as to support the diaphragm above the substrate with a prescribed gap therebetween. A plurality of bumps is formed in the arms of the diaphragm so as to prevent the diaphragm from being attached to the substrate or the plate. When the diaphragm vibrates relative to the plate, an electrostatic capacitance therebetween is varied so as to detect variations of pressure applied thereto. In addition, a plurality of diaphragm holes is appropriately aligned in the arms of the diaphragm so as to improve the sensitivity while avoiding the occurrence of adherence.

Owner:YAMAHA CORP

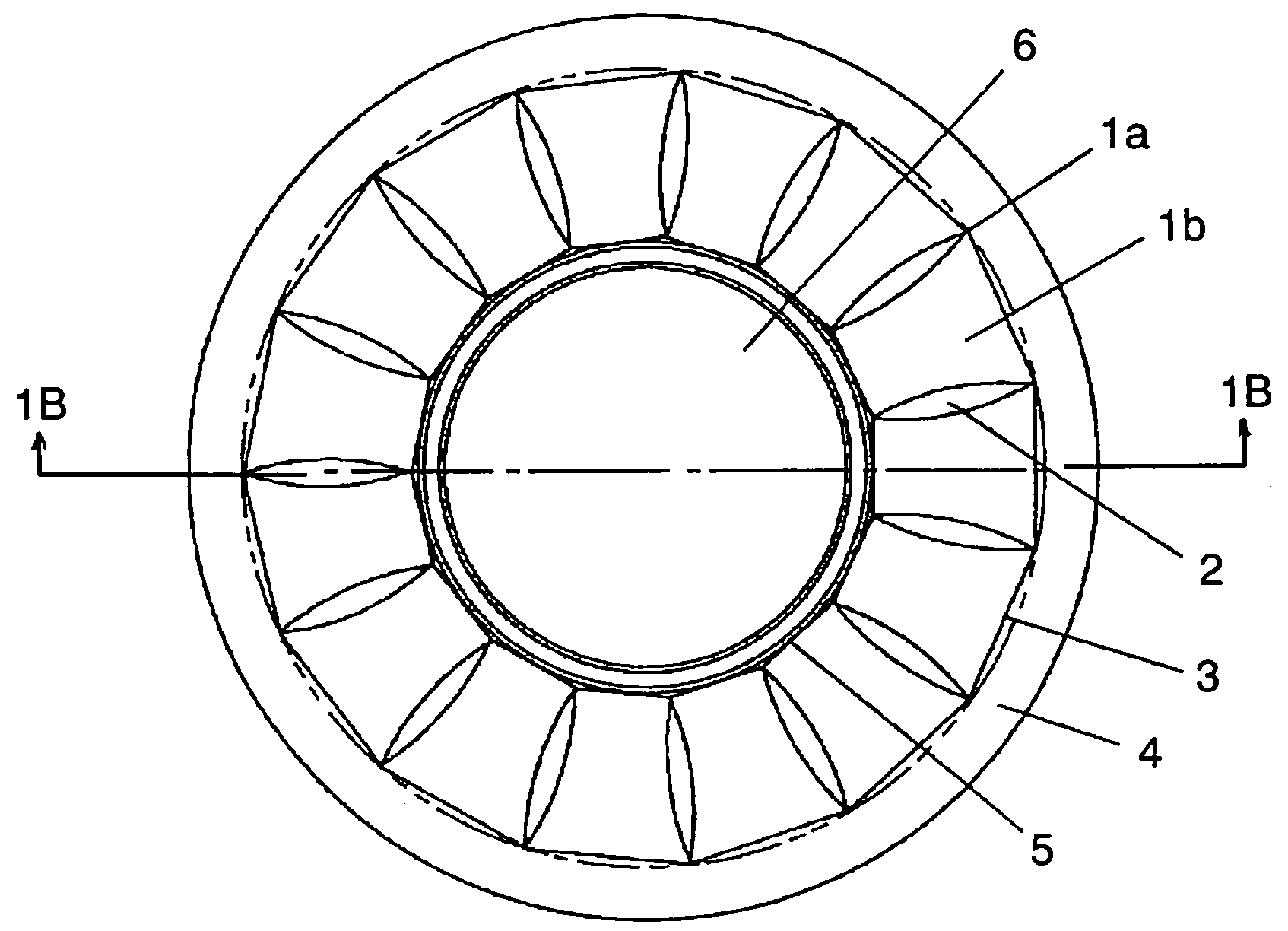

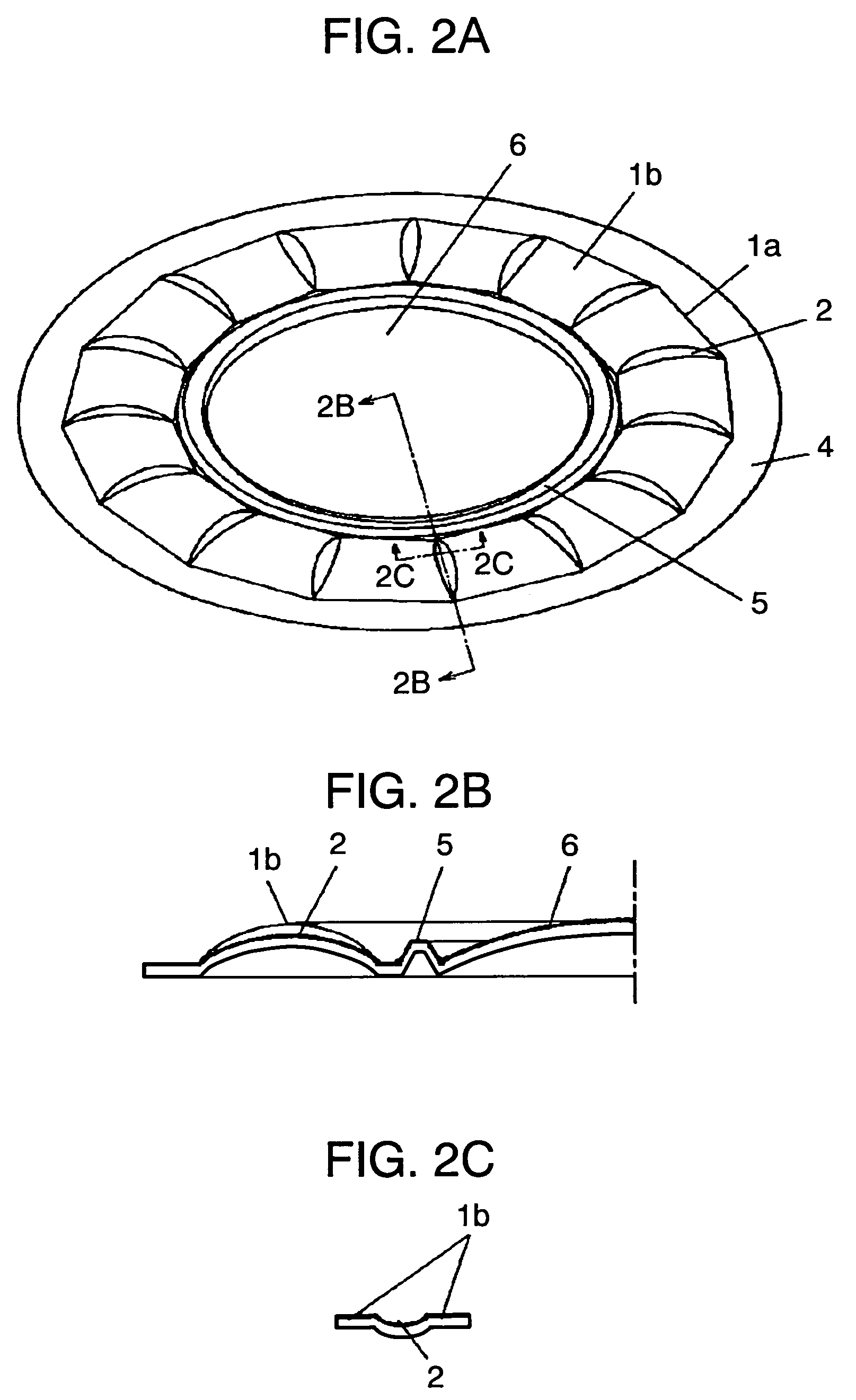

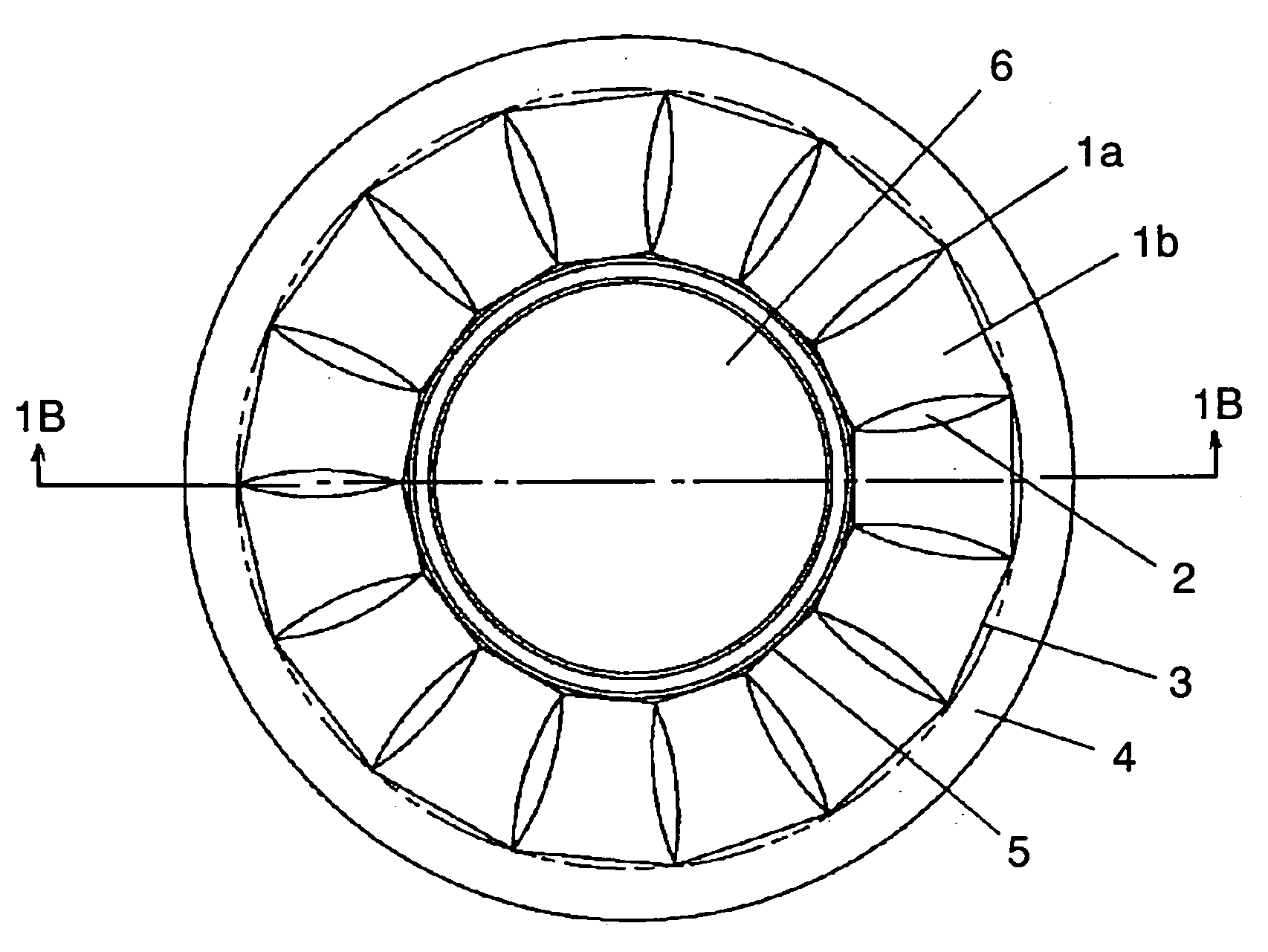

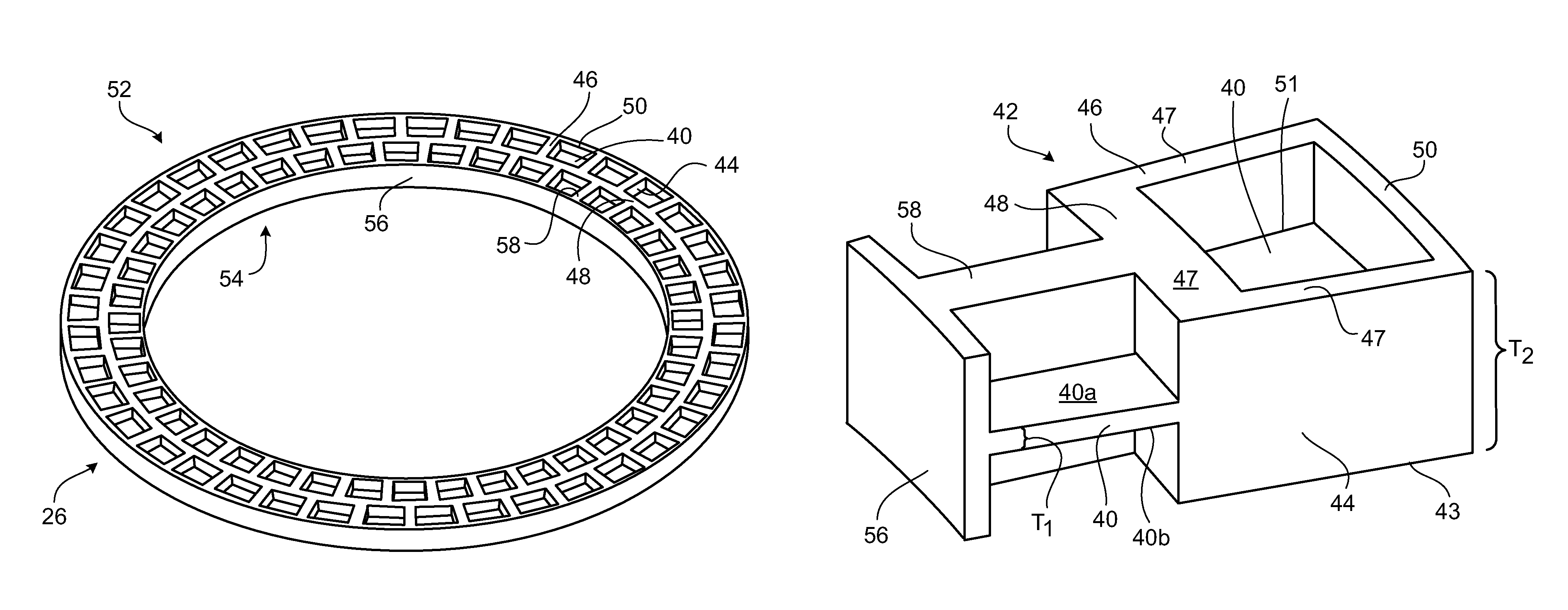

Suspension and electro-acoustic transducer using the suspension

A suspension (1a) includes a plurality of roll sections (1b) each of which has a semicylindrical shape in a cross section. The roll sections (1b) are disposed side by side based on a straight line connecting two points on an inner periphery or an outer periphery. The roll sections (1b) form a closed loop in a manner that a roll section (1b) of the roll sections (1b) being disposed first adjoins a roll section (1b) of the roll sections (1b) being disposed last. Adjacent roll sections (1b) are coupled with each other through a boundary section (2) forming a continuous three dimensional curved surface. A linearity of compliance improves, and generation of distortion or rolling is restricted using the suspension (1a).

Owner:PANASONIC CORP

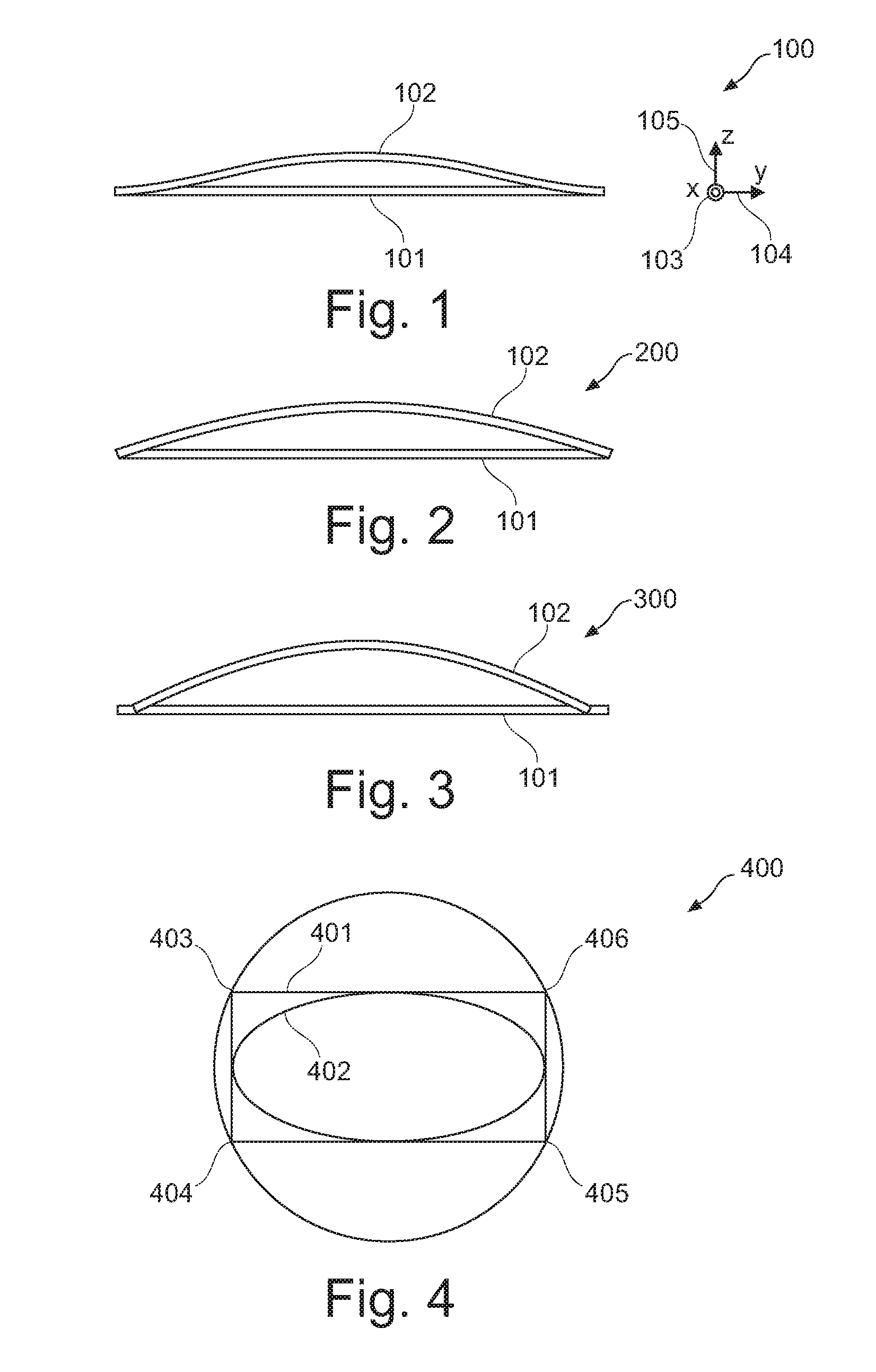

Speaker diaphragm, speaker, device, and method for manufacturing speaker diaphragm

ActiveUS20160014522A1Reduce supportImprove linearityRecord carriersTransducer detailsEngineeringLoudspeaker

A speaker diaphragm includes: a vibrator; and a suspension adhered to an outer peripheral part of the vibrator and supporting the vibrator so that the vibrator can vibrate, at least part of the suspension including a top surface member constituting a top surface part of the suspension, a rear surface member constituting a rear surface part of the suspension, and an intermediate member between the top surface member and the rear surface member, these members being stacked, the intermediate member having a rigidity lower than that of at least one of the top surface member and the rear surface member, the top surface member having one or more first holes, the rear surface member having one or more second holes, and at least some of the first holes and second holes being dispose so as to overlap across the intermediate member in a direction in which the members are stacked.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

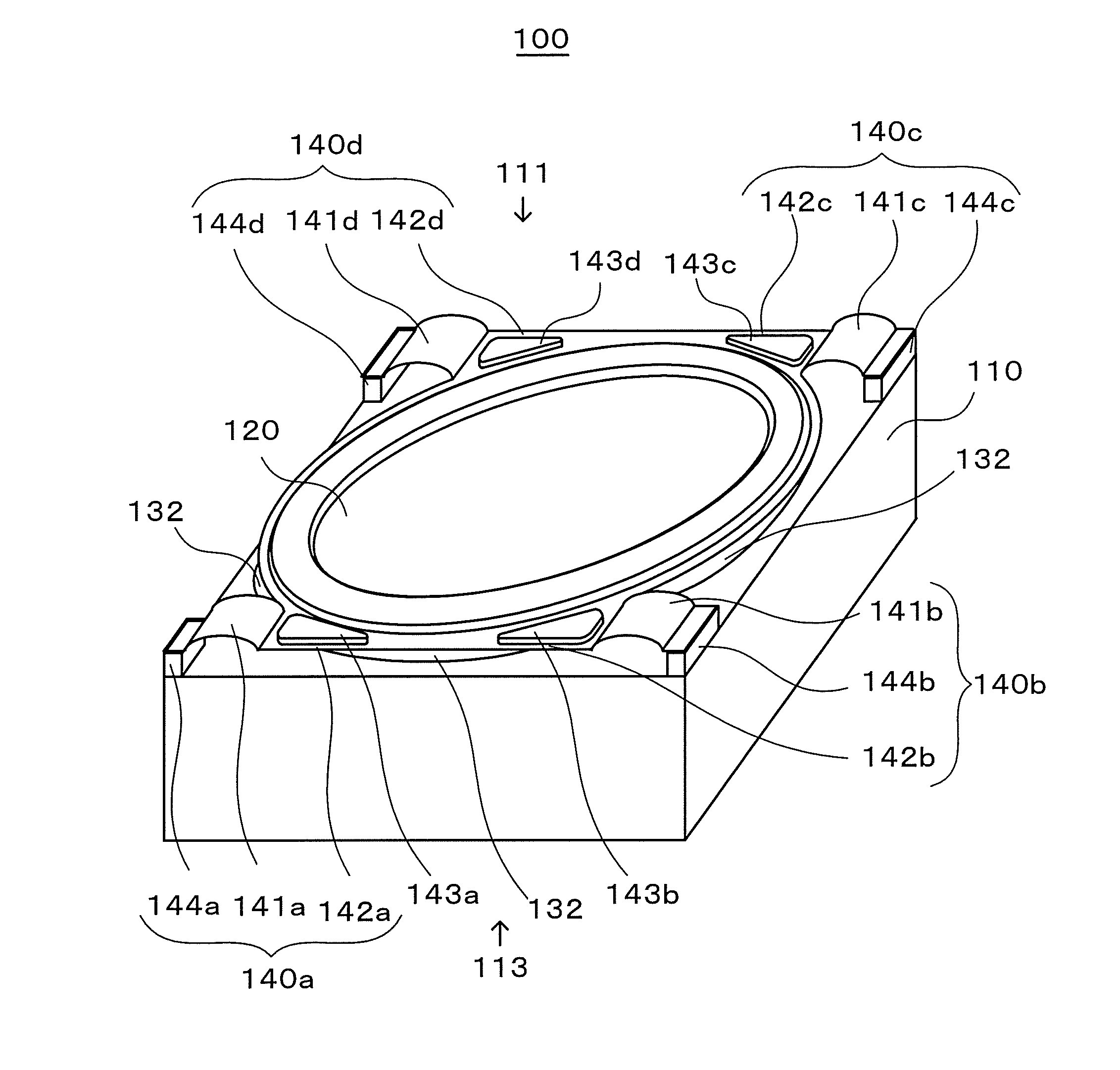

Speaker, and mobile electronic device

ActiveUS20120106774A1Improving bass characteristicAdd supportSingle transducer incorporationPolymeric diaphragmsEngineeringLoudspeaker

A speaker and the like, which is capable of wideband reproduction by improving the bass characteristic, and which is suitable for size reduction, is provided.A housing (110) includes one main surface (111) having a polygonal shape, and an opening portion (112) in the one main surface. A diaphragm (120) is disposed in the opening portion so as to cover the one main surface, except for corner regions (115a, 115b, 115c, and 115d) which are areas in the vicinity of respective vertices of a polygonal shape of the one main surface. A driving unit (130) causes the diaphragm to vibrate so as to generate a sound corresponding to a signal inputted from an outside. A plurality of movable supports (140a, 140b, 140c, and 140d) is disposed in the respective corner regions, for supporting the diaphragm by joining the housing and the diaphragm such that the diaphragm is vibratable.

Owner:PANASONIC CORP

Loudspeaker including a cone circumscribed by a stiffener

The present invention is a loudspeaker. The loudspeaker includes a frame, a cone having an outer edge in a shape of a reverse angle flange, and a reinforcing ring bonded to a back side of the flange.

Owner:COMMUNITY LIGHT & SOUND

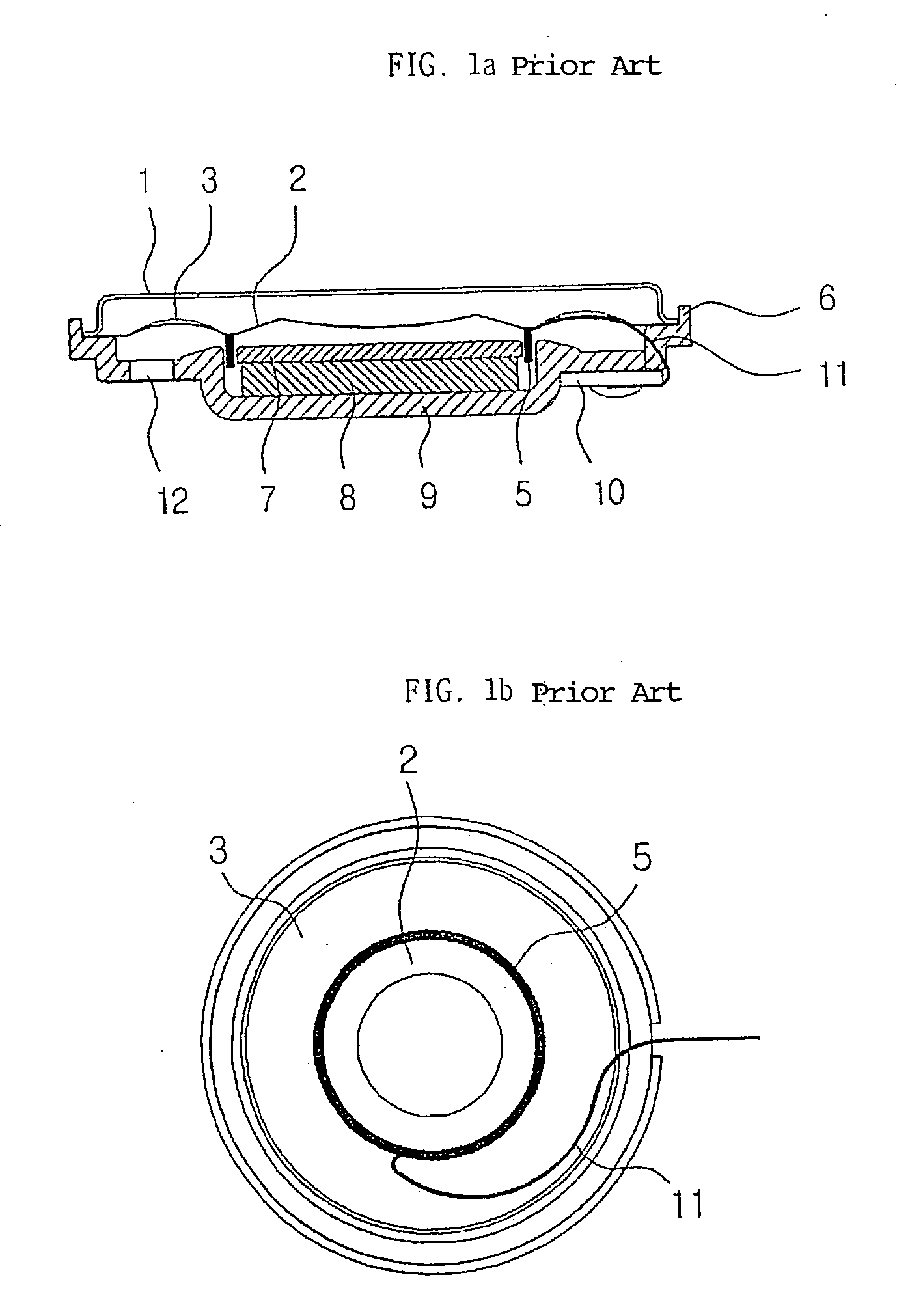

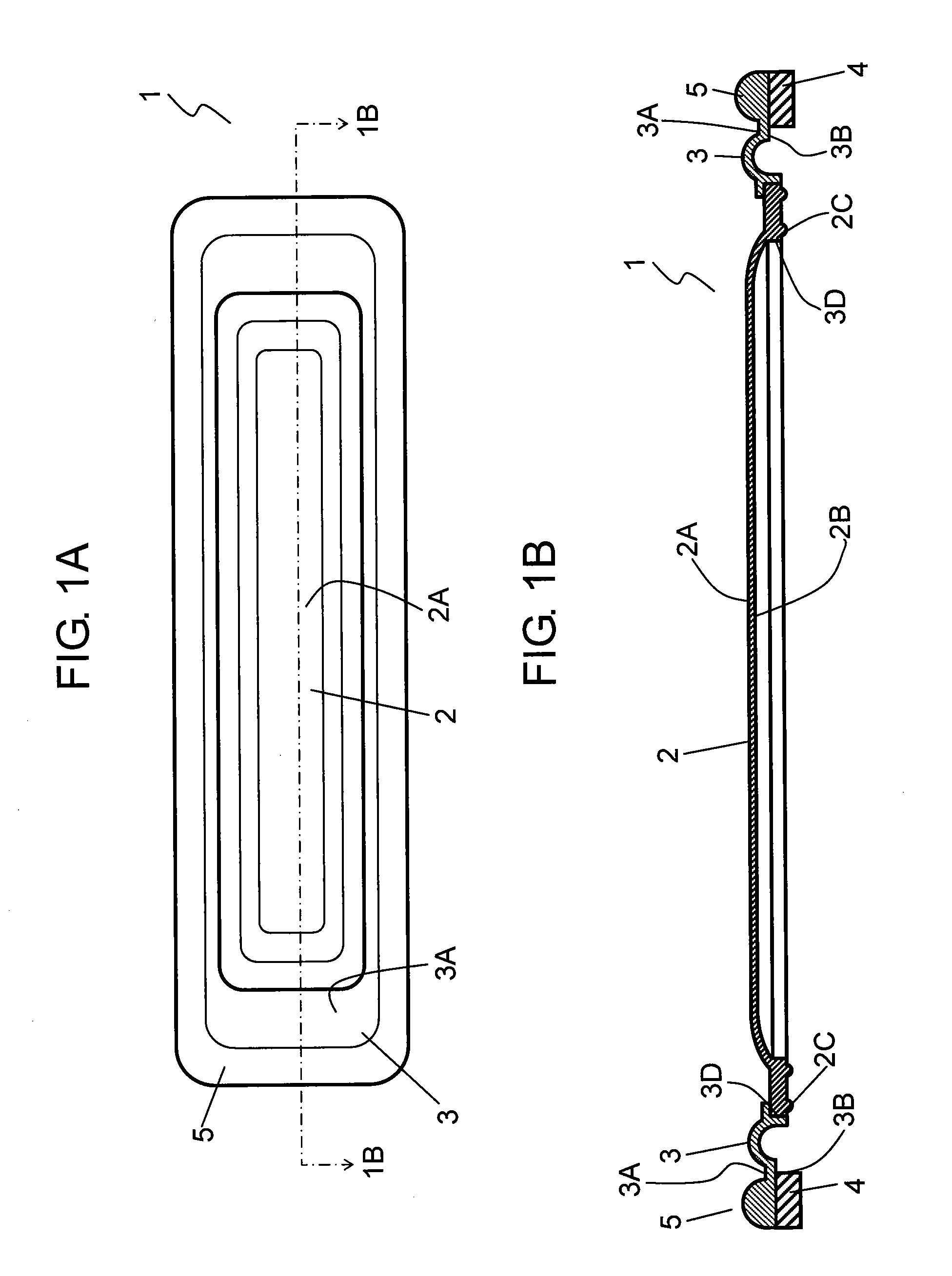

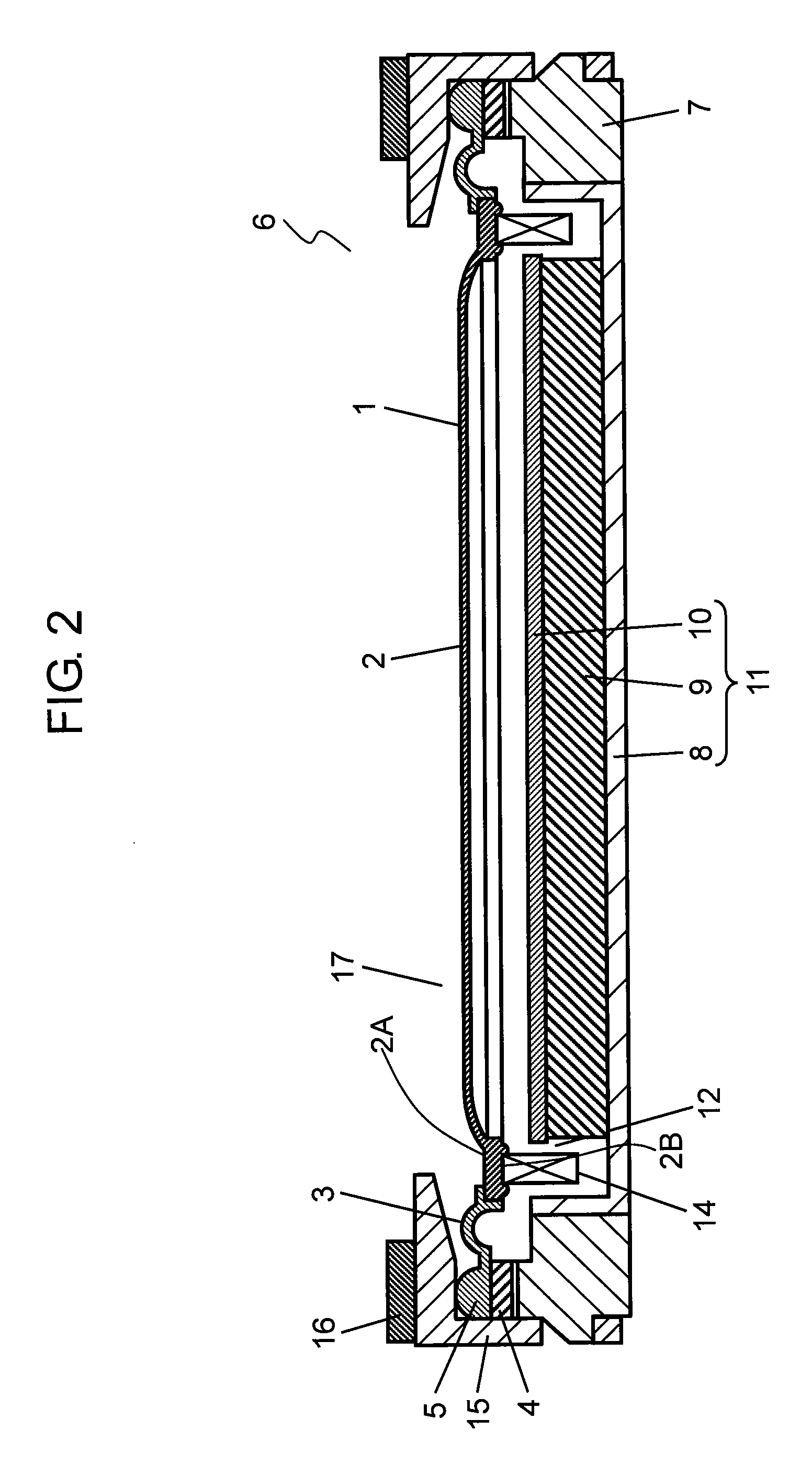

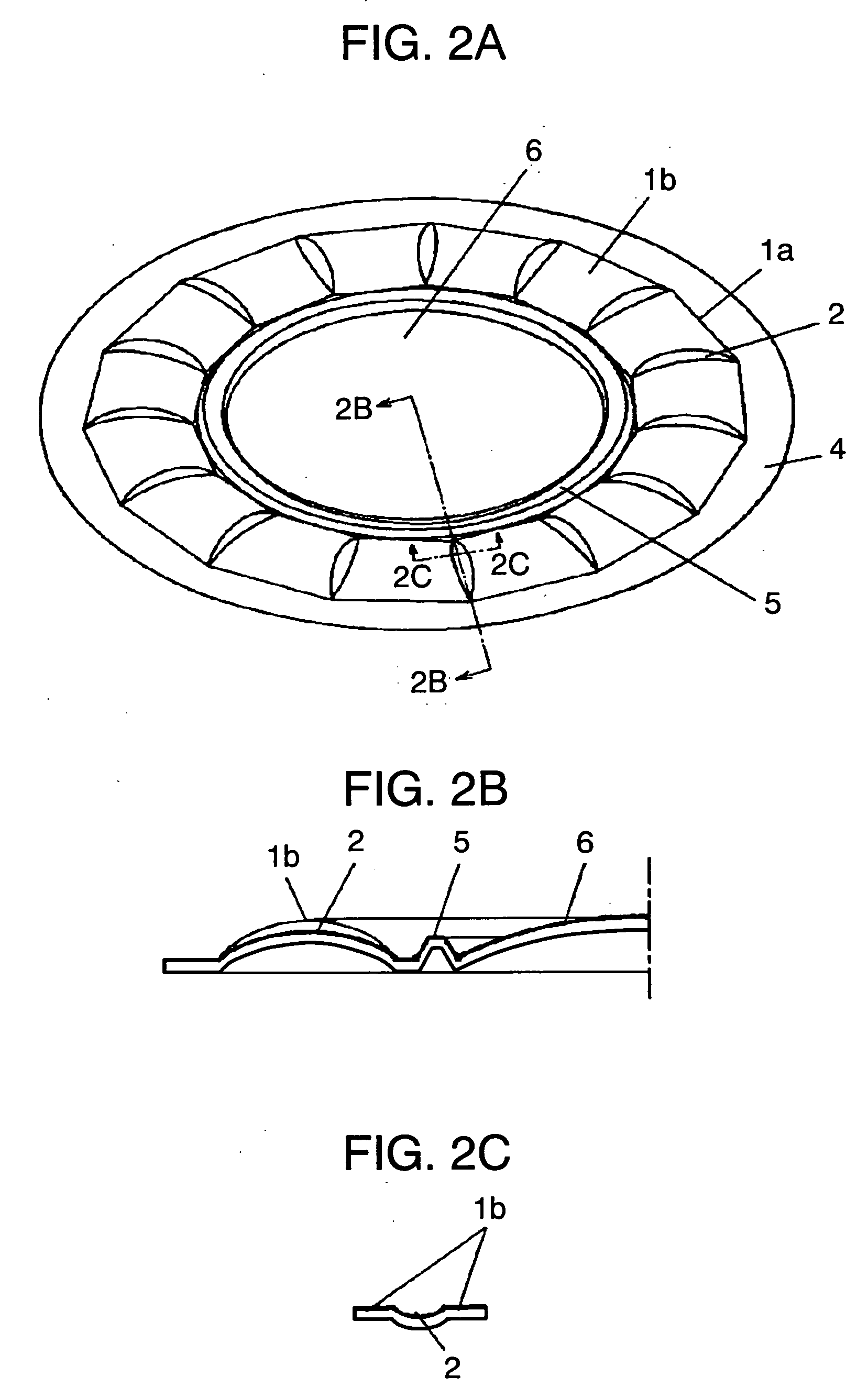

Oval speaker apparatus and method of manufacturing the same

InactiveUS20050175205A1Increase flexibilityEasy to bend and deformLoudspeaker diaphragm shapeNon-planar diaphragms/conesEngineeringLoudspeaker

An oval speaker apparatus includes a diaphragm whose outer peripheral shape in a plan view is oval or elliptical; an oval or elliptical voice coil for driving the diaphragm; an edge which is joined to an outer periphery of the diaphragm; and a frame to which an outer peripheral edge of the edge is fixed. Further, lead wire which is led out from the voice coil is wired so as to traverse the surface of the edge along the minor-axis direction of the diaphragm, and is provided with slack.

Owner:PIONEER CORP +1

Vibration film component

InactiveCN104754472AStrong mechanical propertiesIncrease vibration amplitudePolymeric diaphragmsSynthetic resin layered productsFilm baseInjection moulding

The invention discloses a vibration film component, and relates to the technical field of electro acoustical products. The vibration film component comprises a vibration film, wherein the vibration film comprises a middle portion and a fold ring portion which wraps around the periphery of the middle portion. The vibration film furthermore comprises a vibration film base layer and a silica gel layer, wherein the silica gel layer is integrated in the vibration film base layer at least partially, the vibration film base layer is a polymer material layer, the silica gel layer is integrated in the surface of the fold ring portion, and the silica gel layer and the polymer material layer are injection molded. The vibrating film component achieves recombination of the silica gel layer and the polymer material layer by arranging the silica gel layer in the surface of the fold ring portion, and thereby improves compliance of the vibration film, enhances chemical stability and adaptability to temperature of the vibration film, optimizes acoustic performances, and improves products yield rate.

Owner:GOERTEK INC

Loudspeaker driver suspension

ActiveUS20110164782A1Reduce deficiencyMinimize undesirable compressive buckling loadTransducer detailsLoudspeaker diaphragm shapeEngineeringLoudspeaker

A loudspeaker driver has a diaphragm connected to a surrounding frame by a roll suspension which extends around the diaphragm and within the frame. The roll suspension connects the outer edge of the diaphragm to the inner edge of the frame and flexes as the diaphragm is displaced to and fro axially relative to the frame. In order to provide for better integrity of the roll suspension during its displacement, and reduce unwanted deformation and concomitant distortion, the suspension roll is provided with pleats extending across the roll suspension transversely to the direction of axial movement of the diaphragm to create a series of undulations (peaks and troughs) around the perimeter of the roll suspension. In transverse cross-section, the roll suspension is parabolic. The roll suspension varies continuously between each peak and adjacent trough. Preferably, outer surfaces of each peak and adjacent trough merge to a common point on the outer edge of the roll, while their inner surfaces merge to a common point on the outer edge of the roll, such that the peaks and troughs effectively disappear.

Owner:PARADIGM ELECTRONICS

Diaphragm surrounding

Owner:BOSE CORP

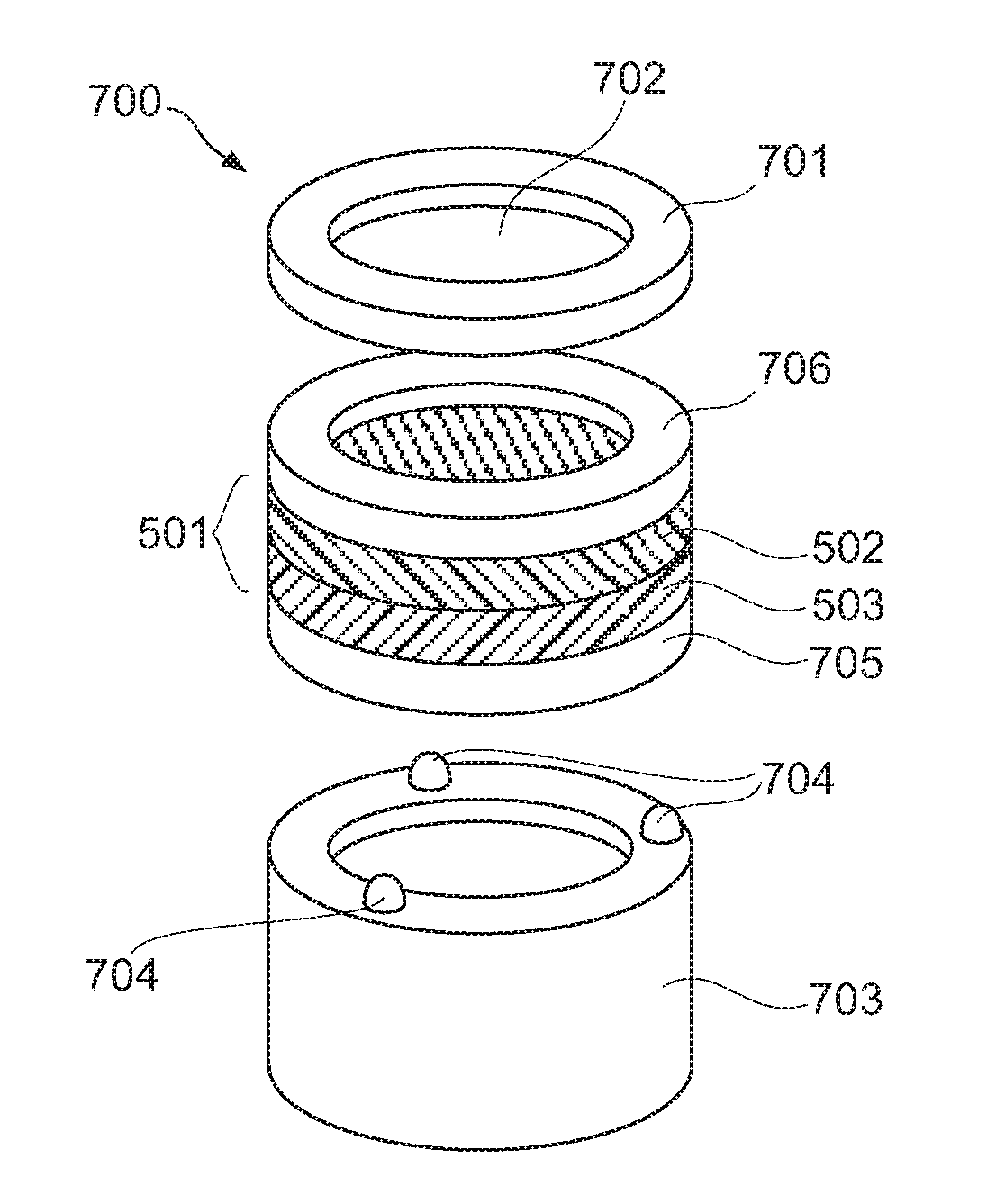

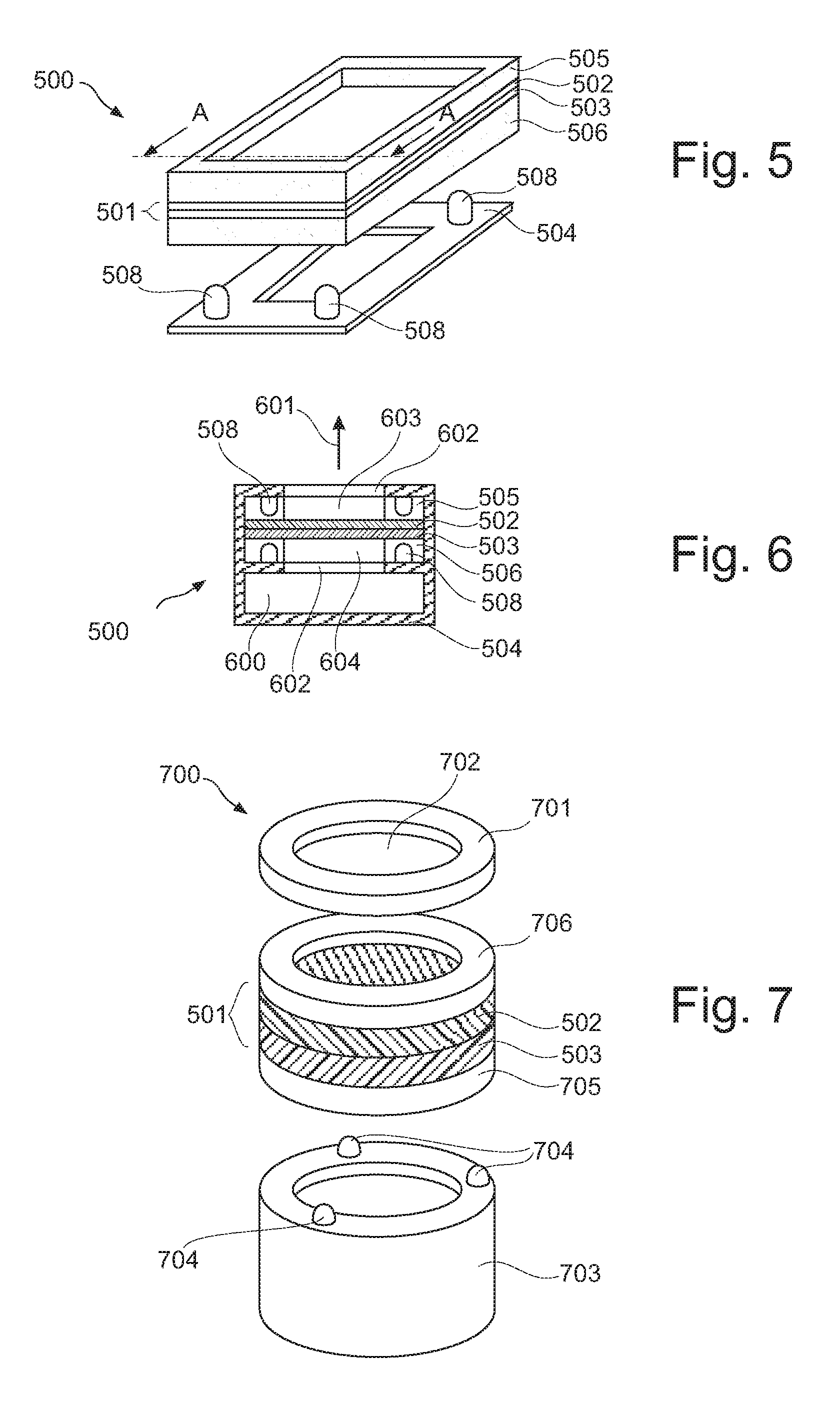

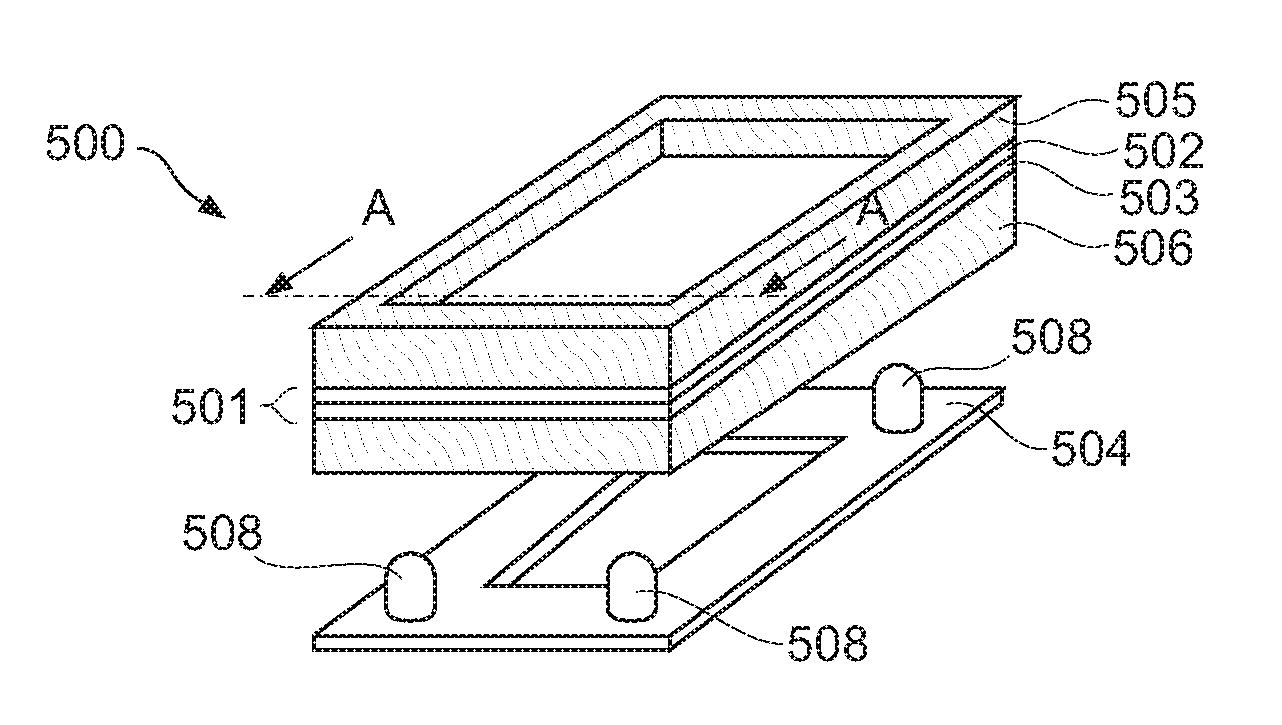

Acoustic device and method of manufacturing same

ActiveUS20100239109A1Ensure correct executionQuality improvementLoudspeaker diaphragm dampingPiezoelectric/electrostrictive transducersEngineeringTranslational motion

An acoustic device (500), comprising an oscillatory membrane (501) which comprises a transducing element (503) and a frame (504) adapted for accommodating the membrane (501) in an accommodation plane, wherein the membrane (501) is accommodated in the frame (504) in such a manner that a translational motion of the membrane (501) in at least one direction of the accommodation plane is made possible.

Owner:SOUND SOLUTIONS INTERNATIONAL COMPANY LTD

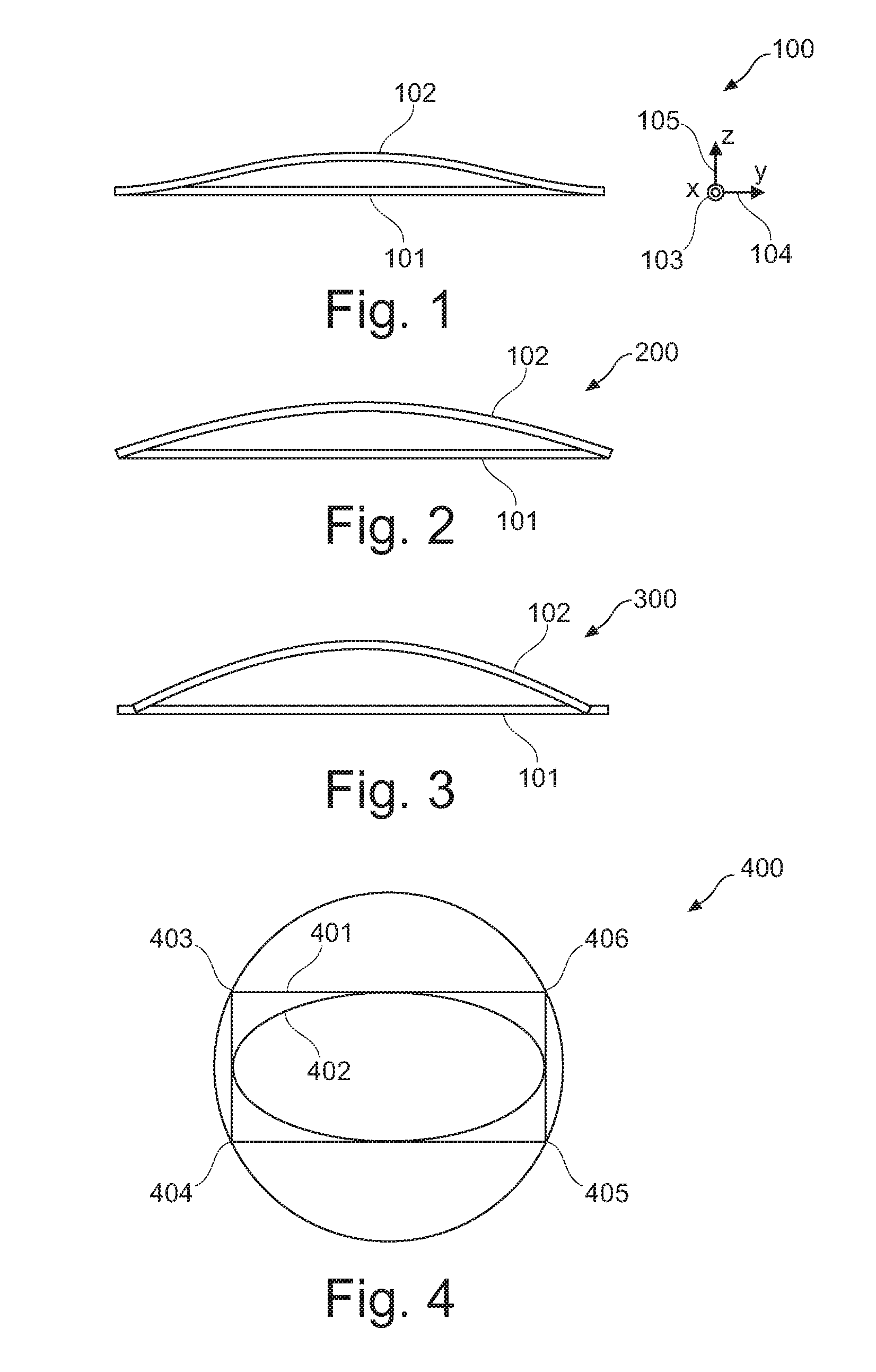

Speaker and device using the same

ActiveUS20060153420A1Small thicknessIncrease the sound pressure levelLoudspeaker diaphragm shapeNon-planar diaphragms/conesEngineeringLoudspeaker

A loudspeaker includes a magnetic circuit having a magnetic gap, a frame coupled to the magnetic circuit, a voice coil having a first end positioned in the magnetic gap and a second end opposite to the first end, and a diaphragm coupled to the second end of the voice coil and the frame. The voice coil has a center axis provided through the first end and the second end. The diaphragm has a first portion in which the center axis of the voice coil is provided. The first portion of the diaphragm is provided inside the voice coil. The diaphragm further has a second portion outside the voice coil. One of the first portion and the second portion of the diaphragm has a cross section in a plane including the center axis, and the cross section of the one of the first portion and the second portion of the diaphragm has an elliptic-arc shape. This loudspeaker has a small thickness, has a high sound pressure level in a high frequency range, and secures a wide reproduction range in high frequencies.

Owner:PANASONIC CORP

Loudspeaker

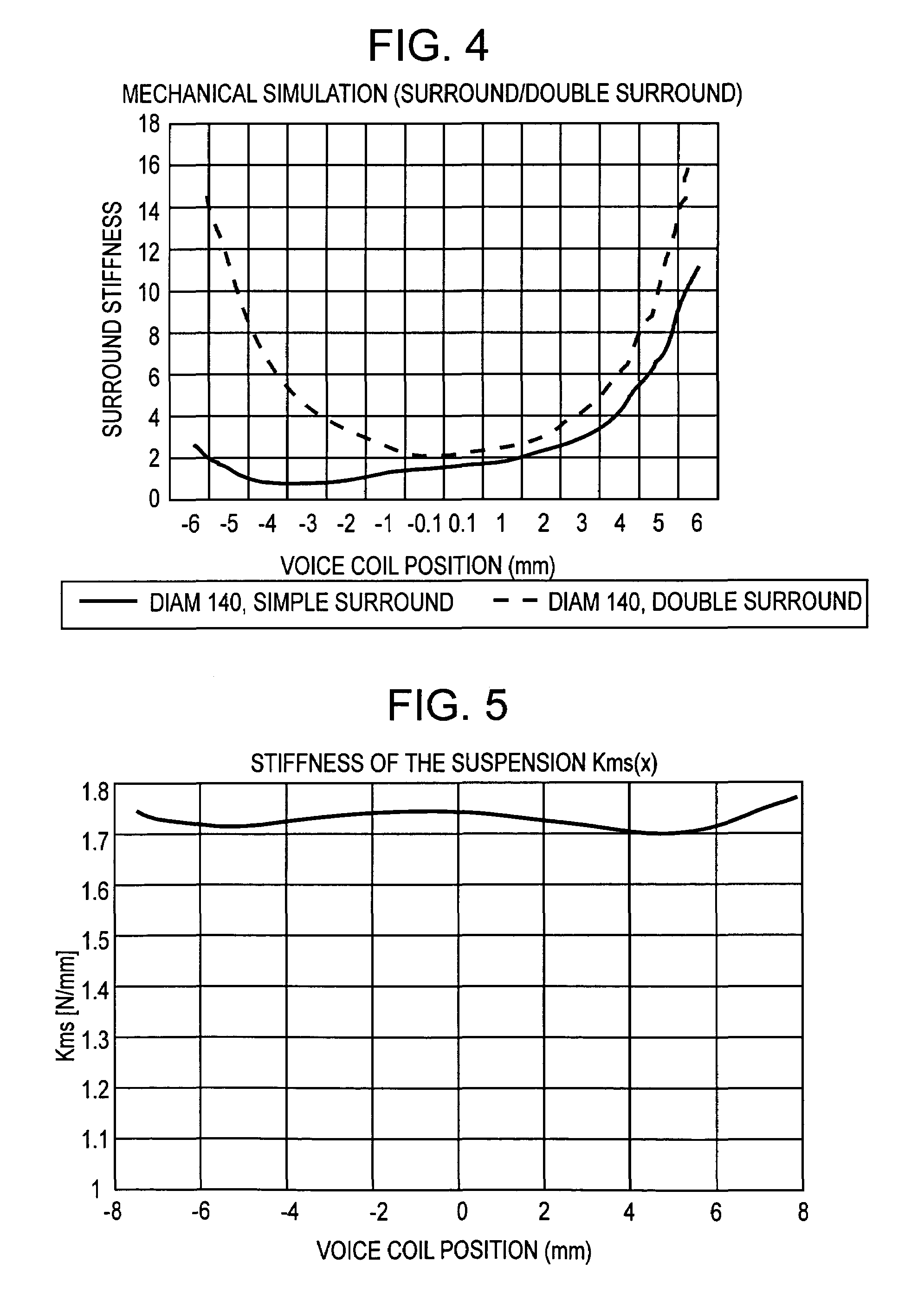

ActiveUS7418107B2Reduce stiffnessImproved linearity and symmetryLoudspeaker diaphragm shapeSound producing devicesEngineeringLoudspeaker

Owner:HARMAN BECKER AUTOMOTIVE SYST

Popular searches

Semiconductor/solid-state device manufacturing Electrostatic transducer microphones Flexible microstructural devices Microstructural device manufacture Semiconductor devices Individual semiconductor device testing Microelectromechanical systems Plane diaphragms Circuit lead arrangements/relief Clamped/spring connections

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com