Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

561results about "Electrostatic transducer loudspeakers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroactive polymer generators

InactiveUS7034432B1Speed up the conversion processImprove responseTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesPre strainActive polymer

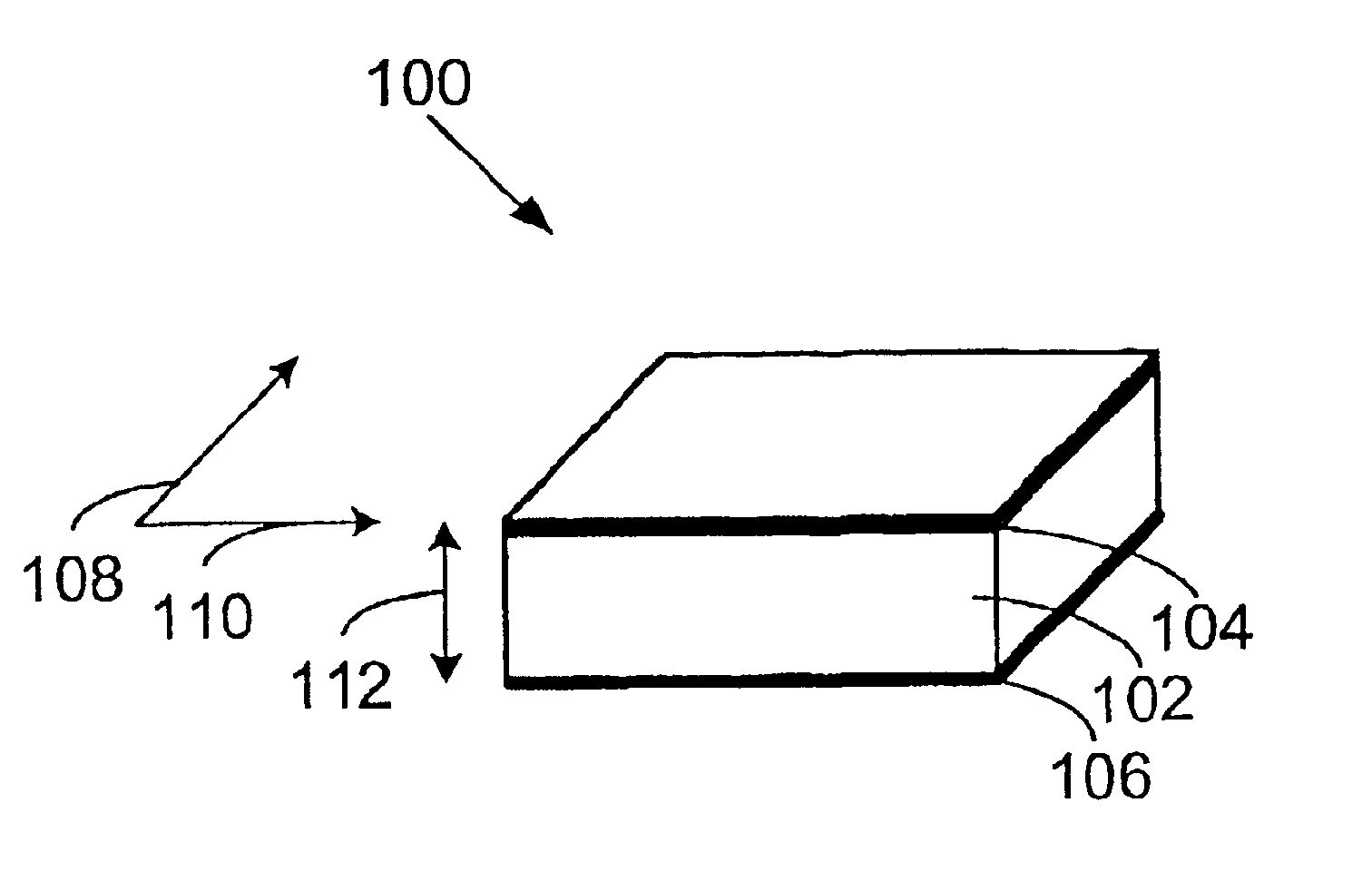

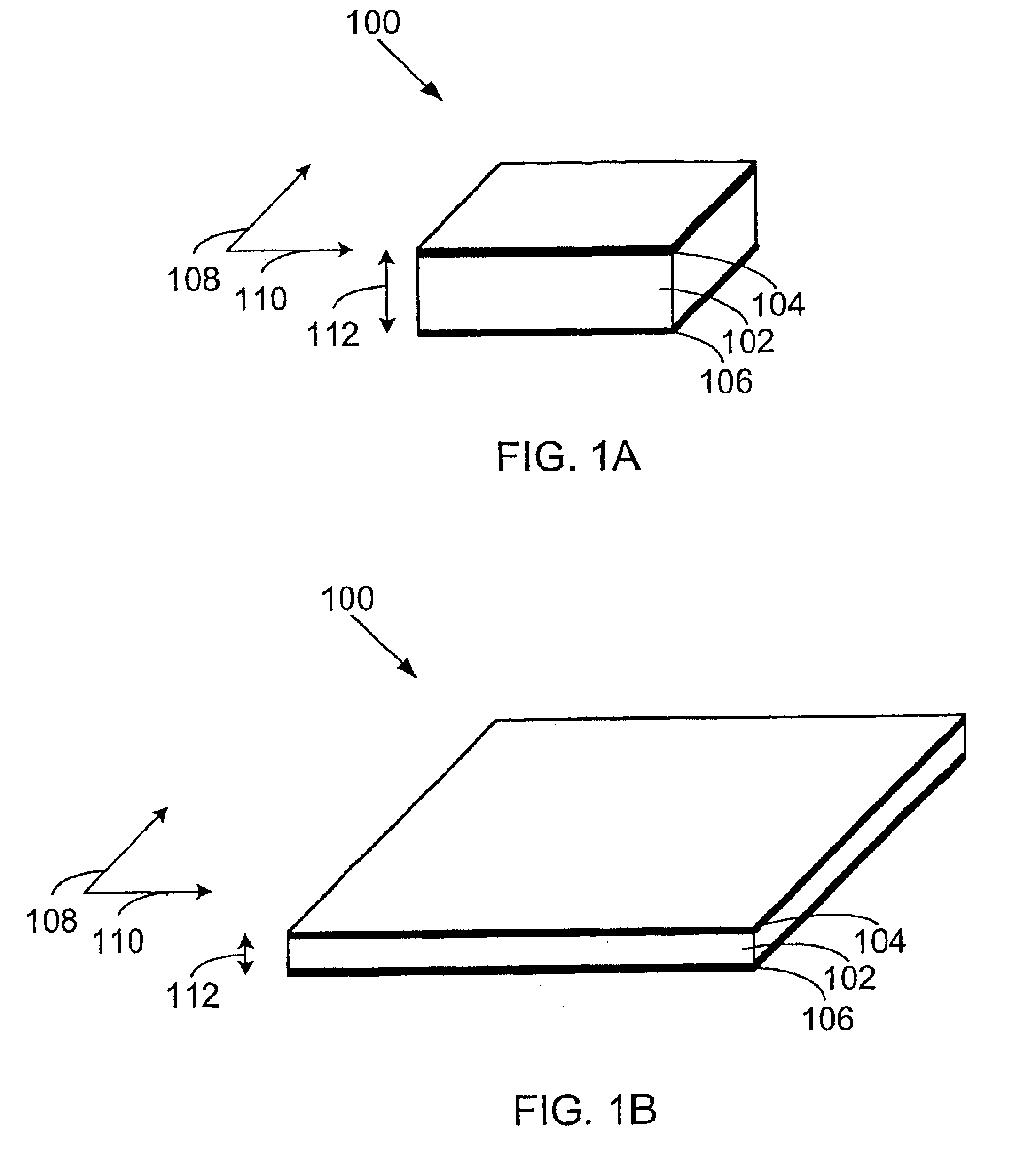

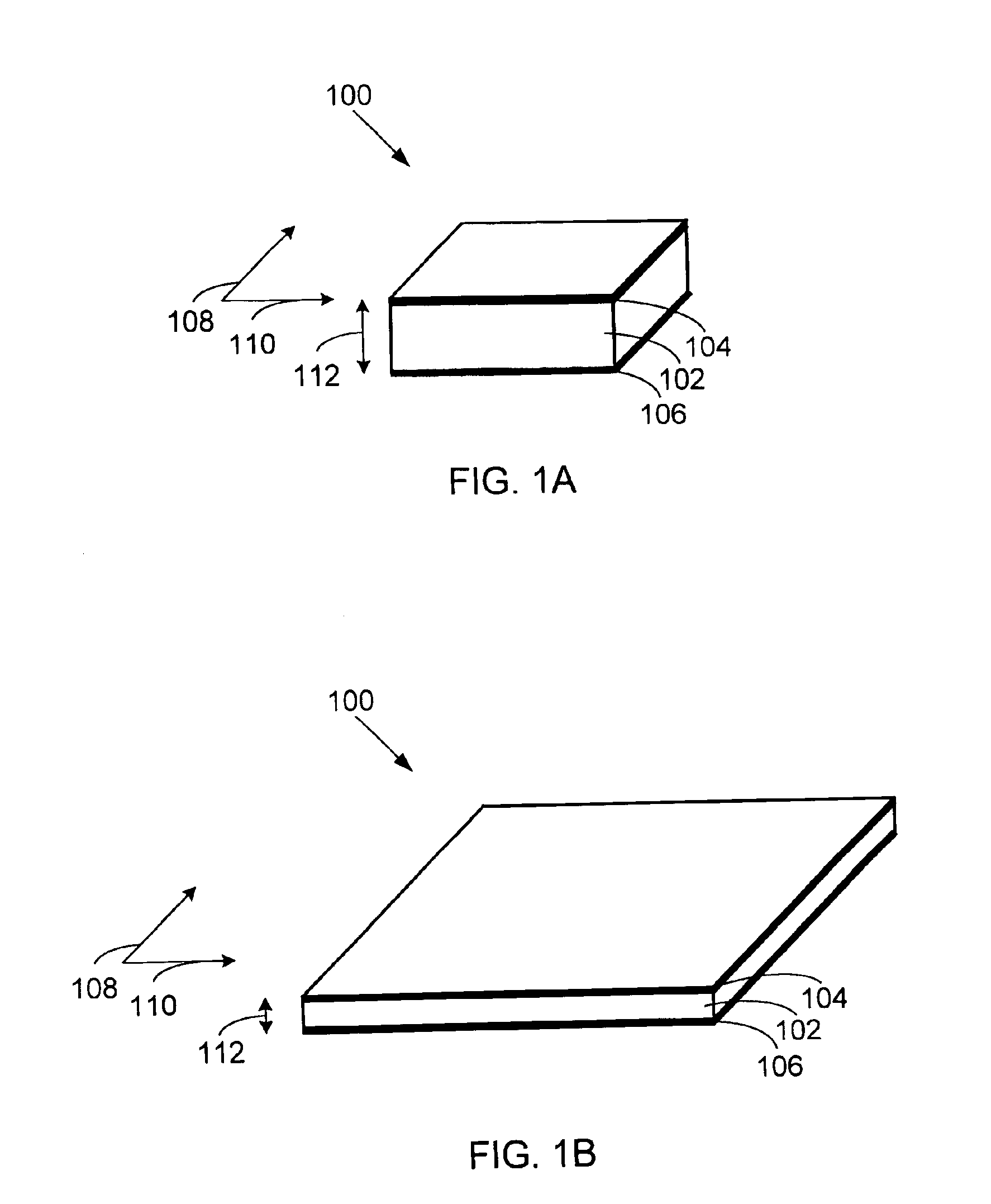

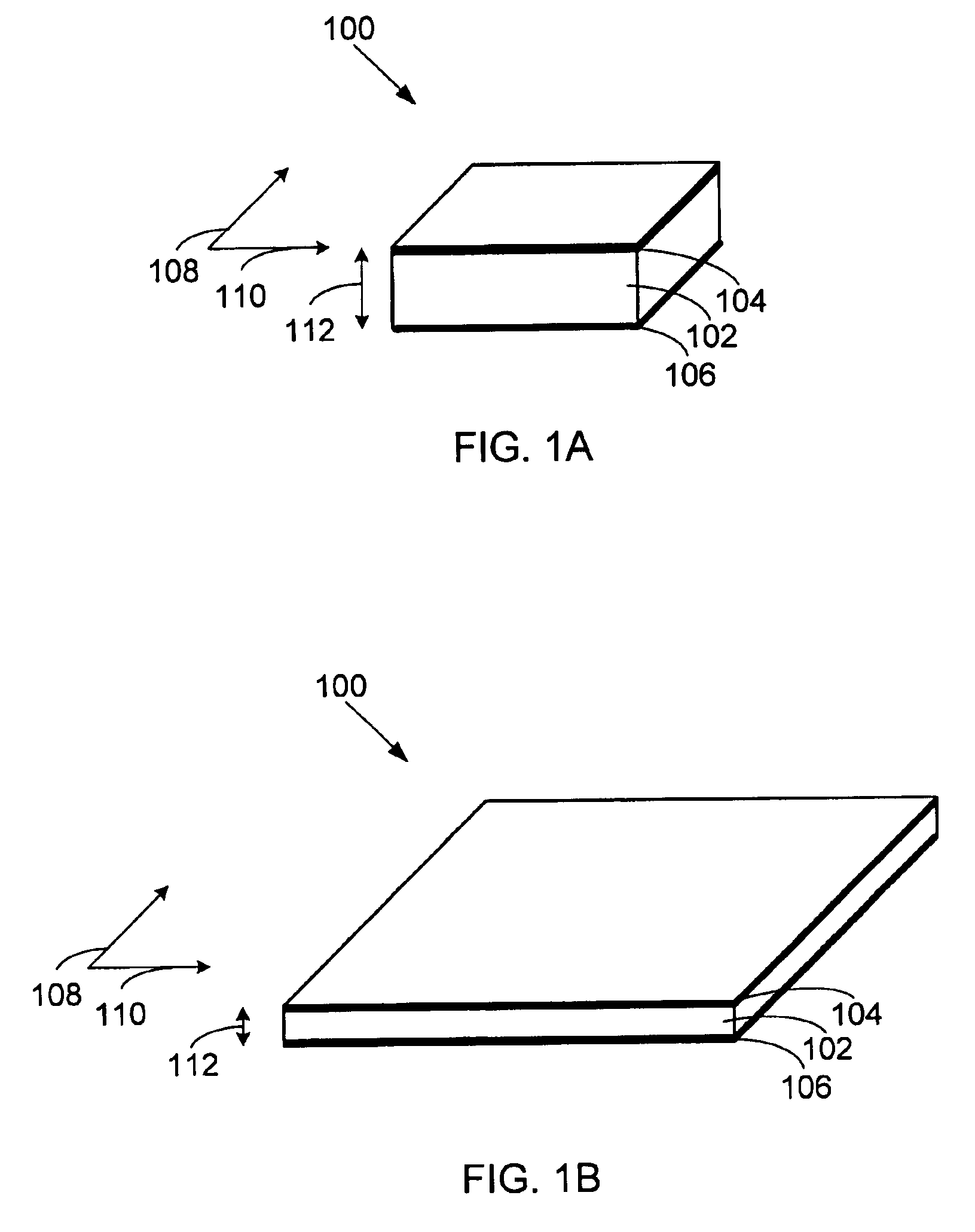

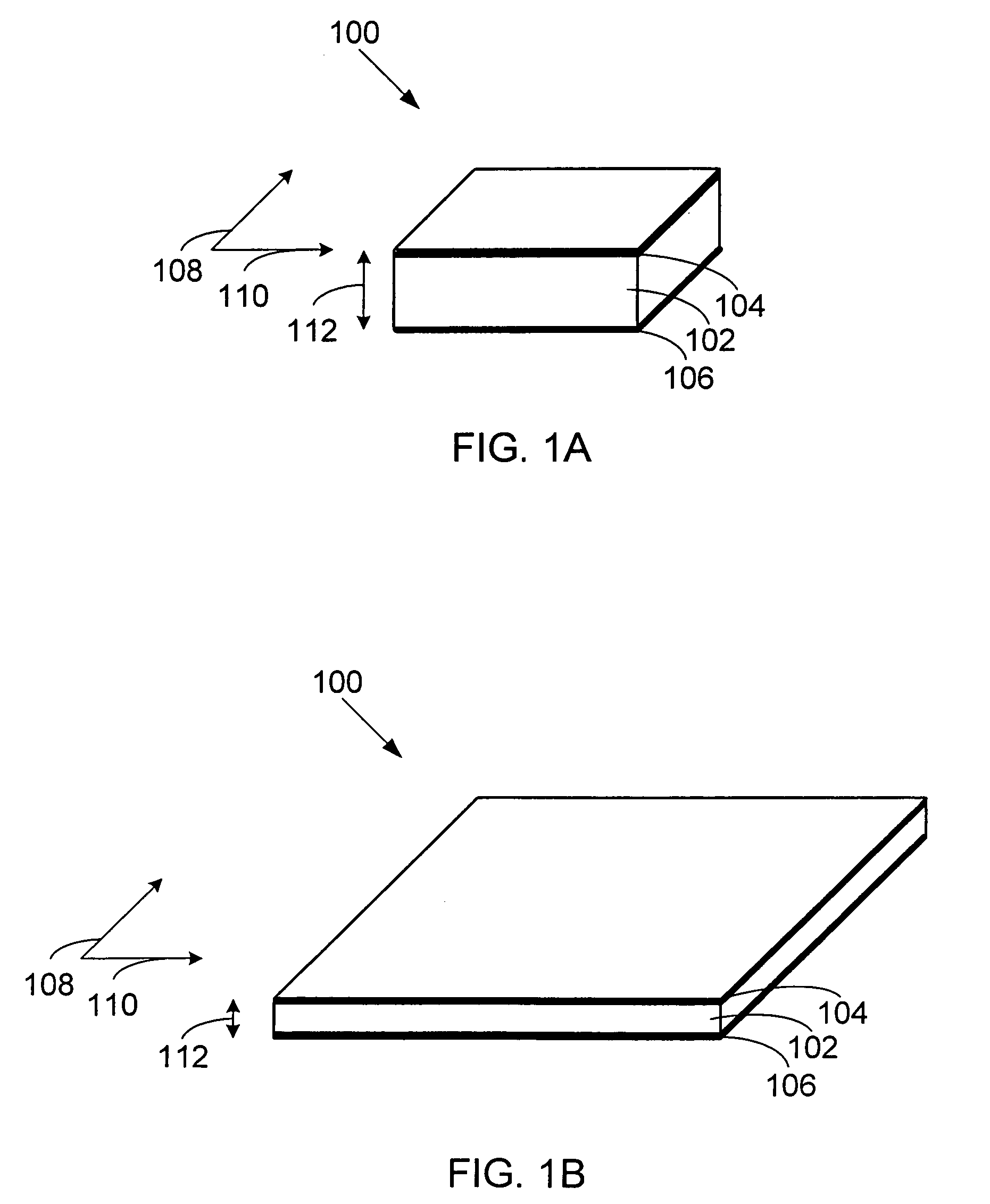

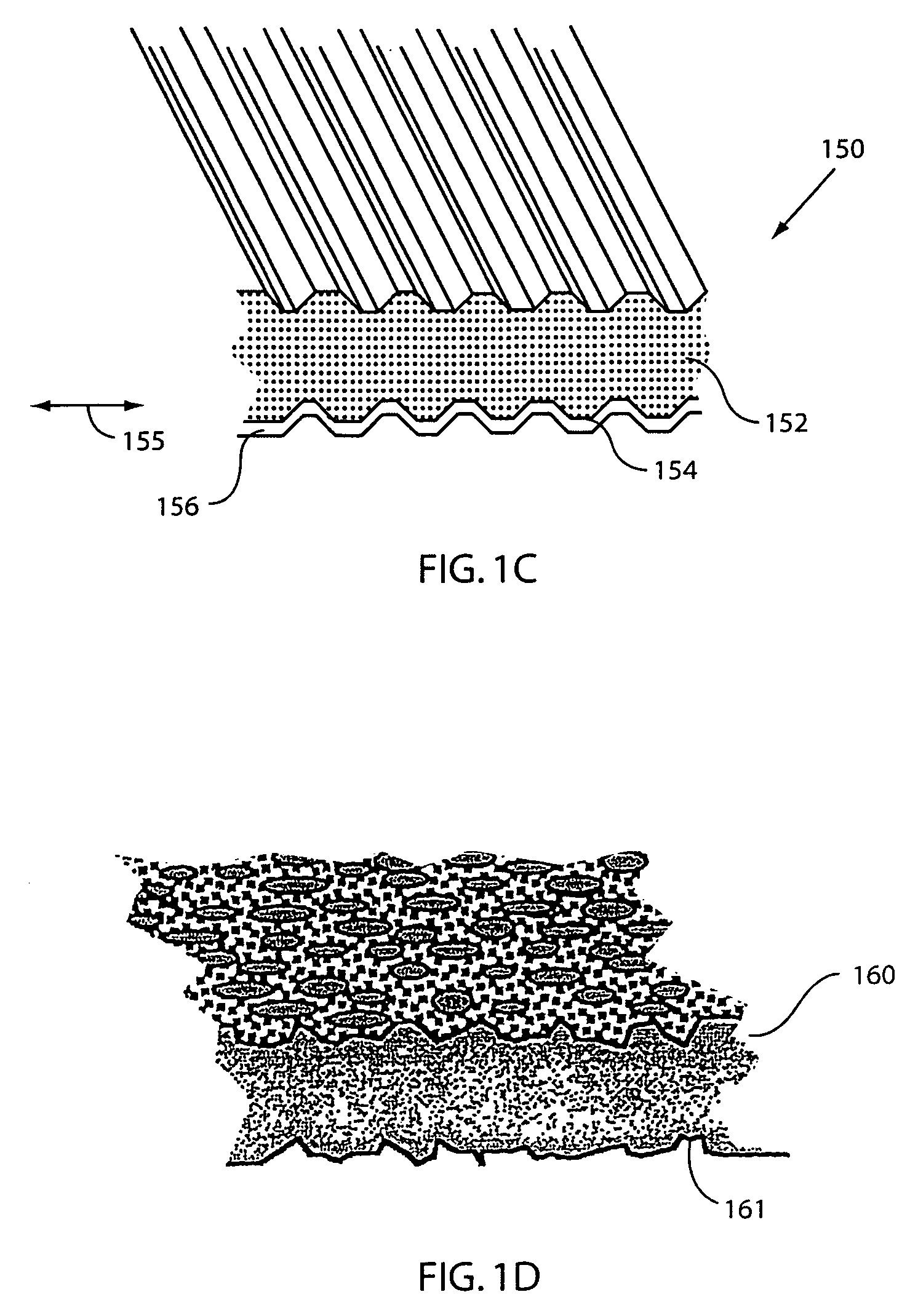

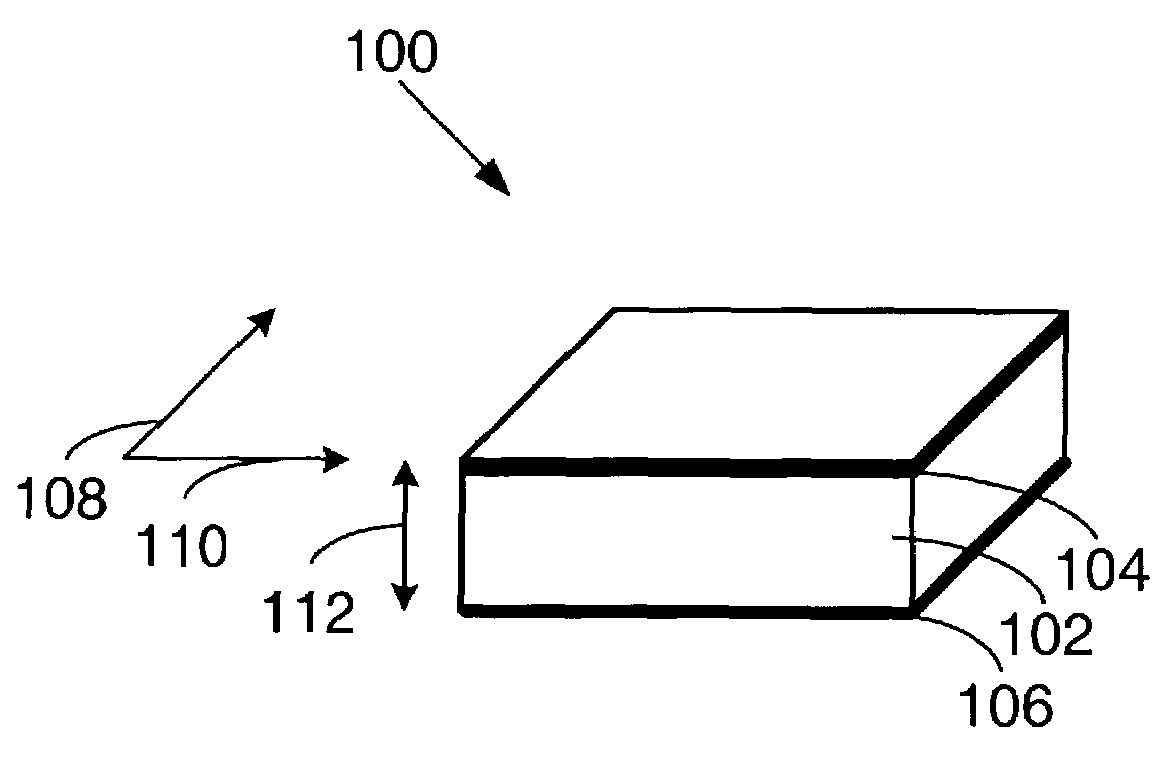

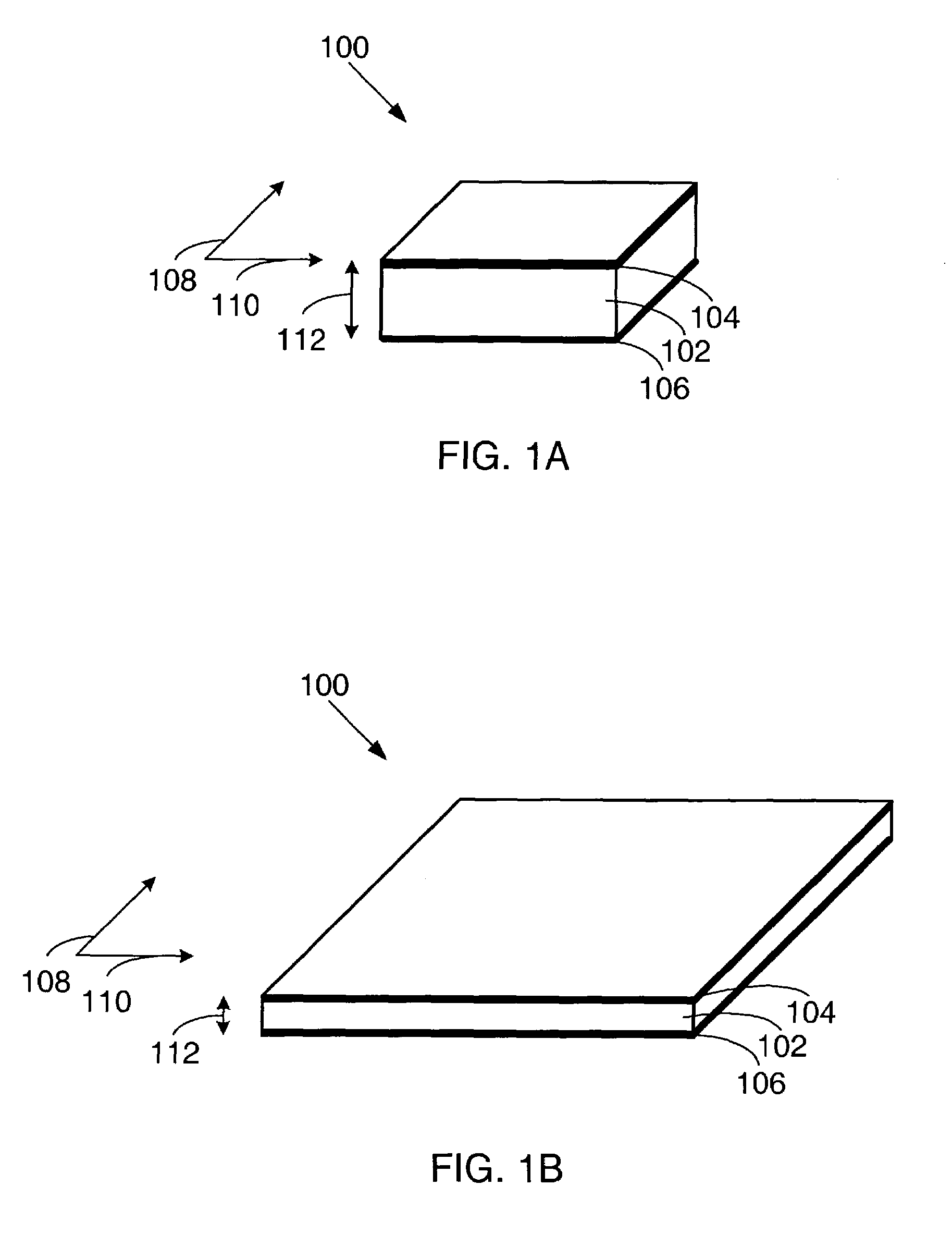

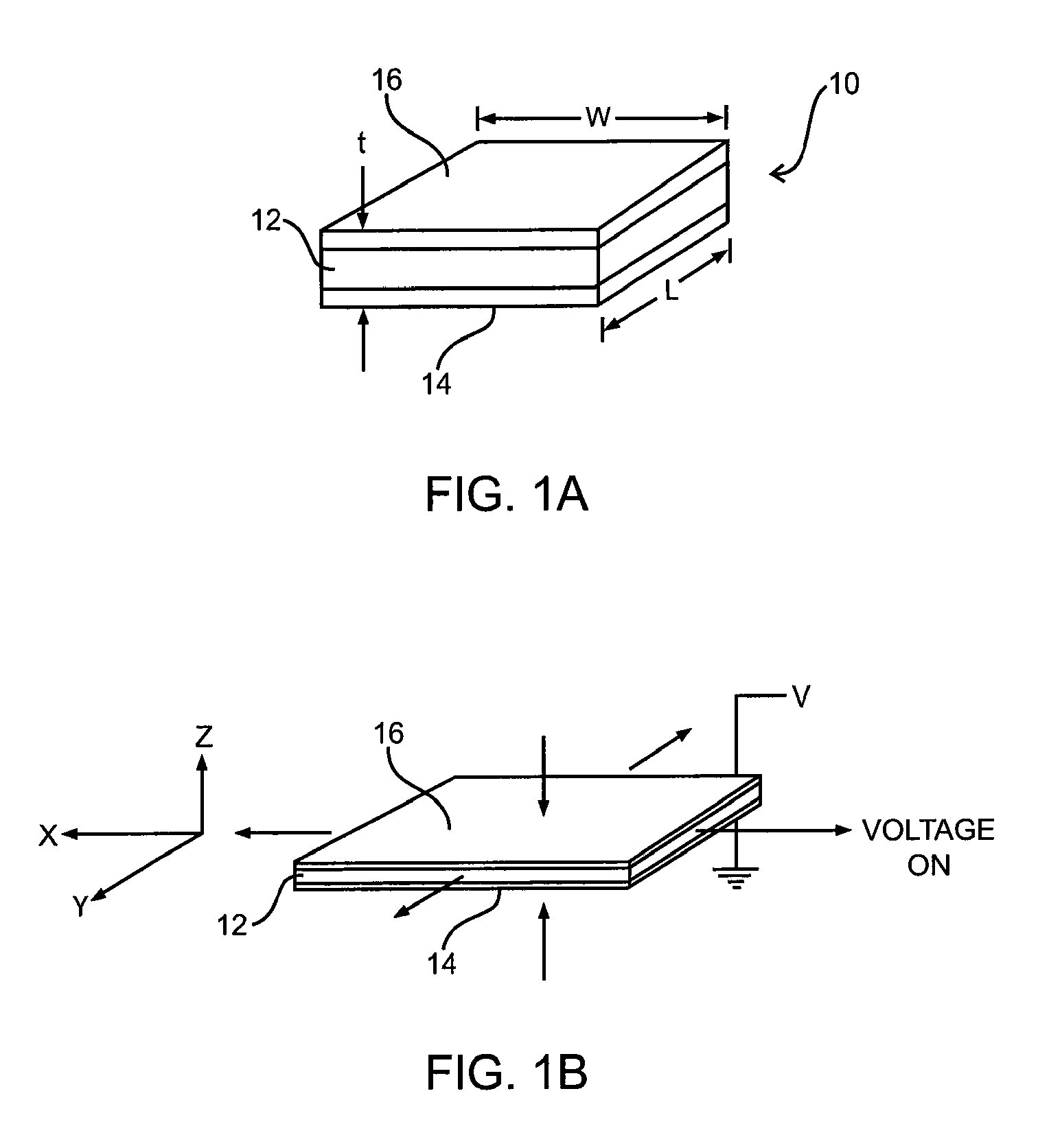

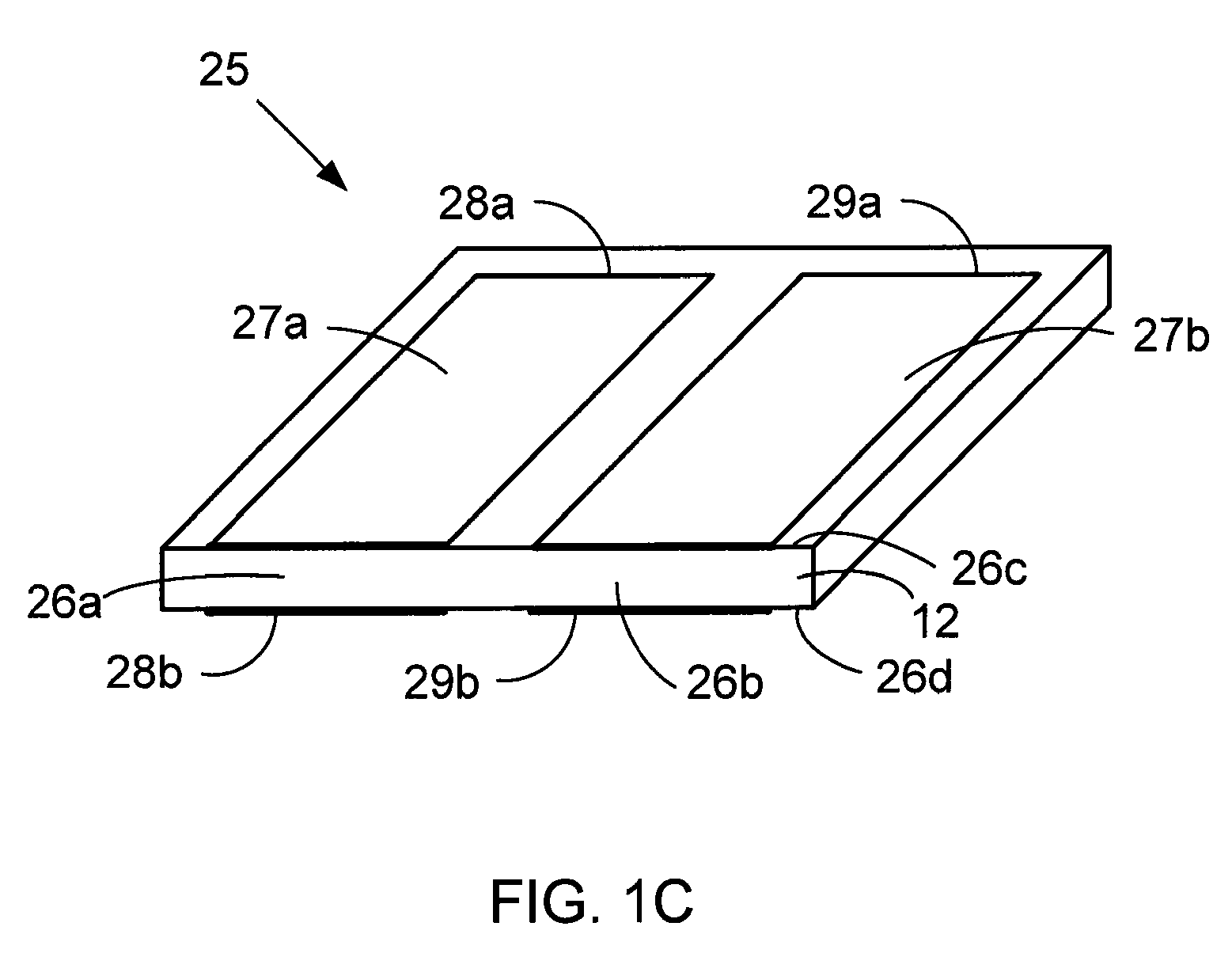

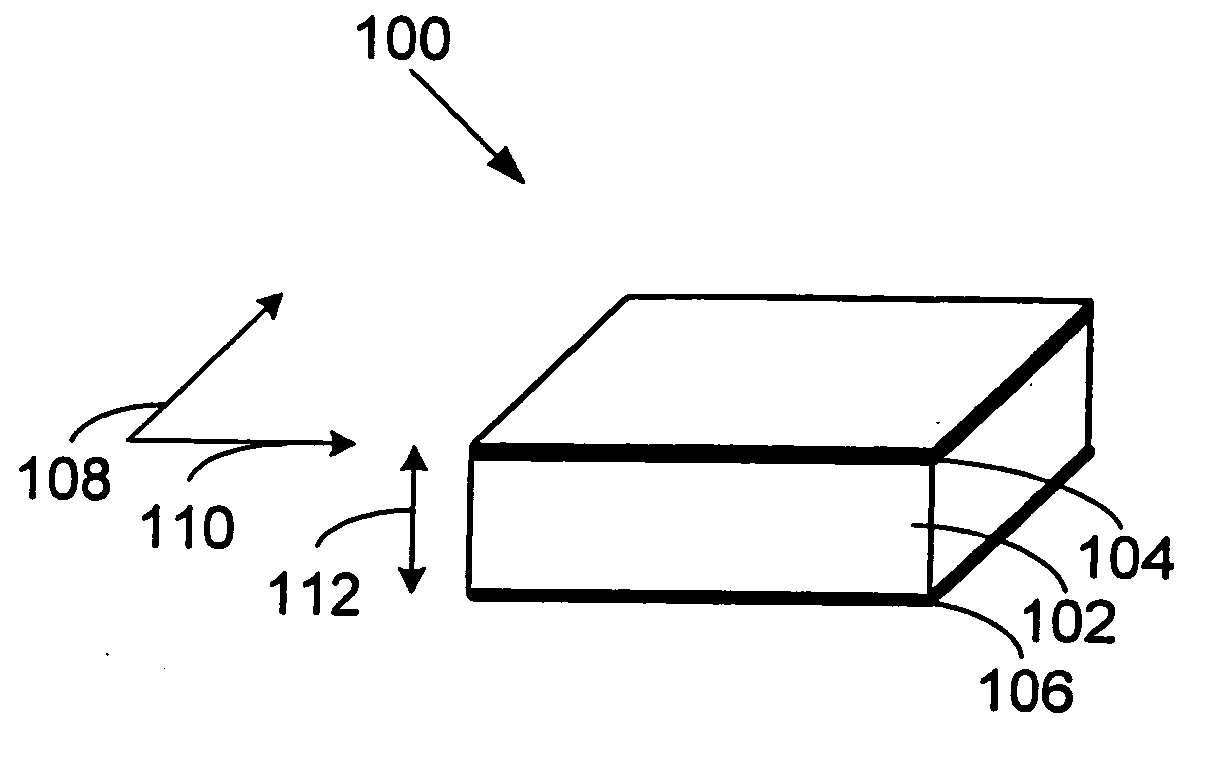

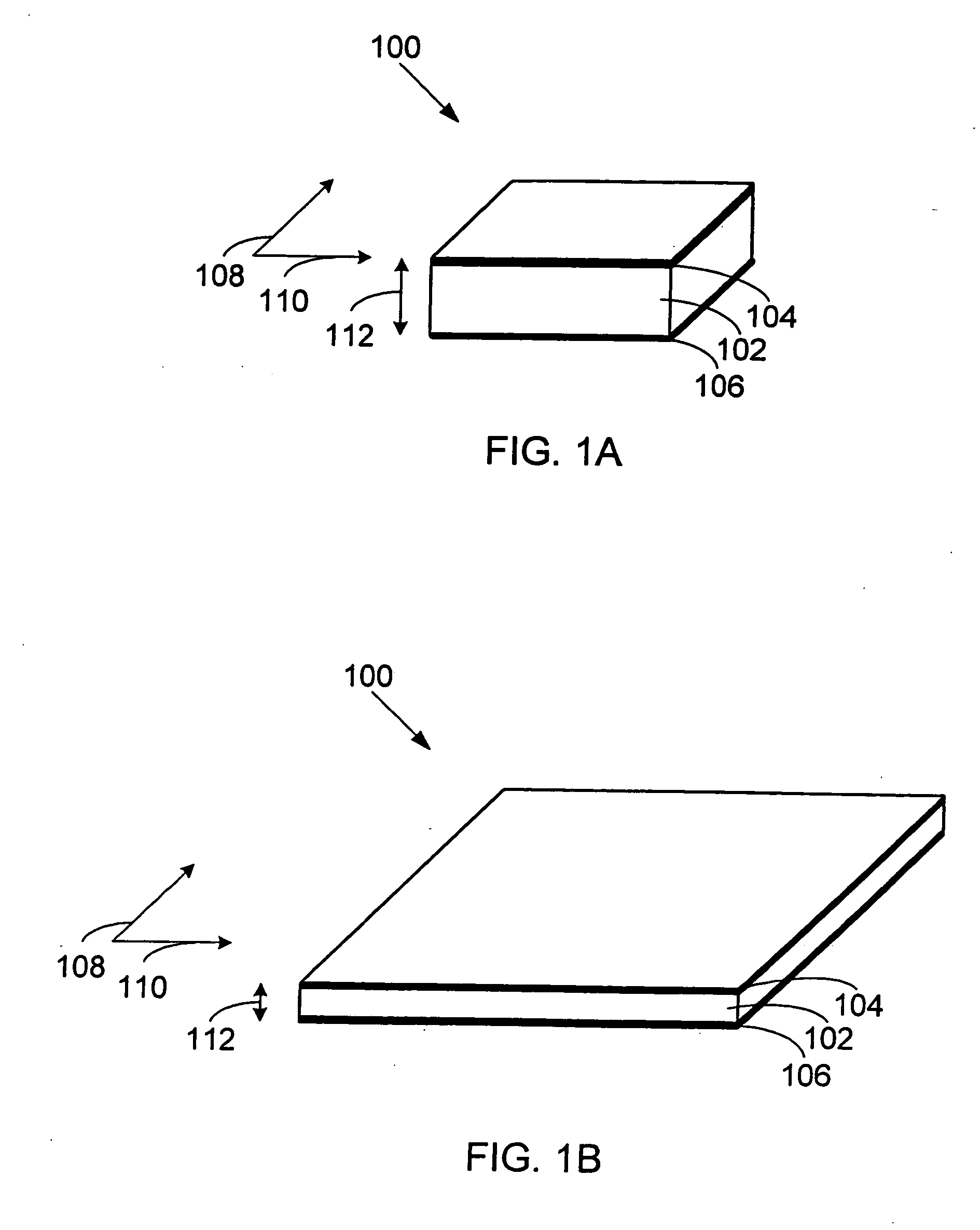

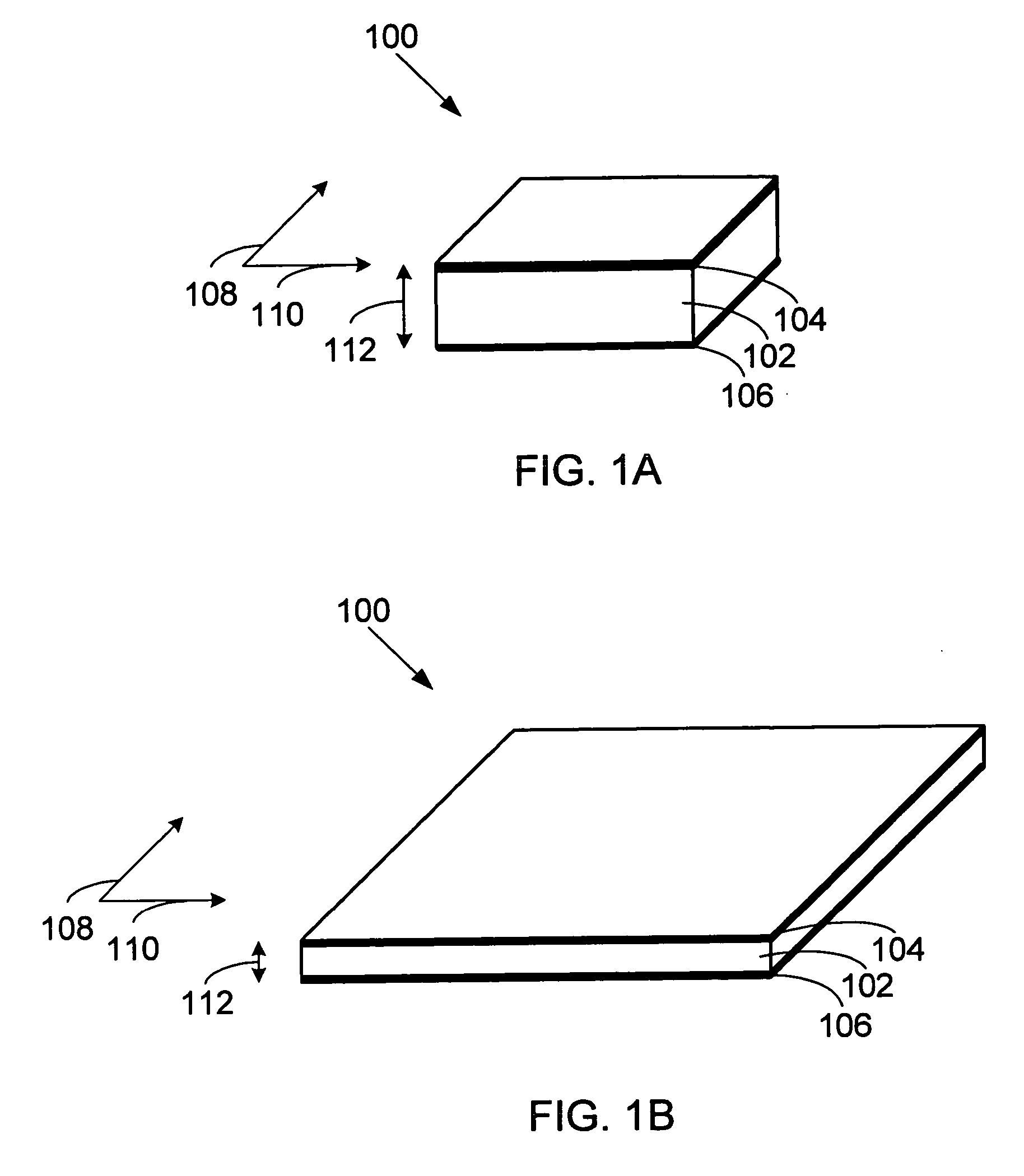

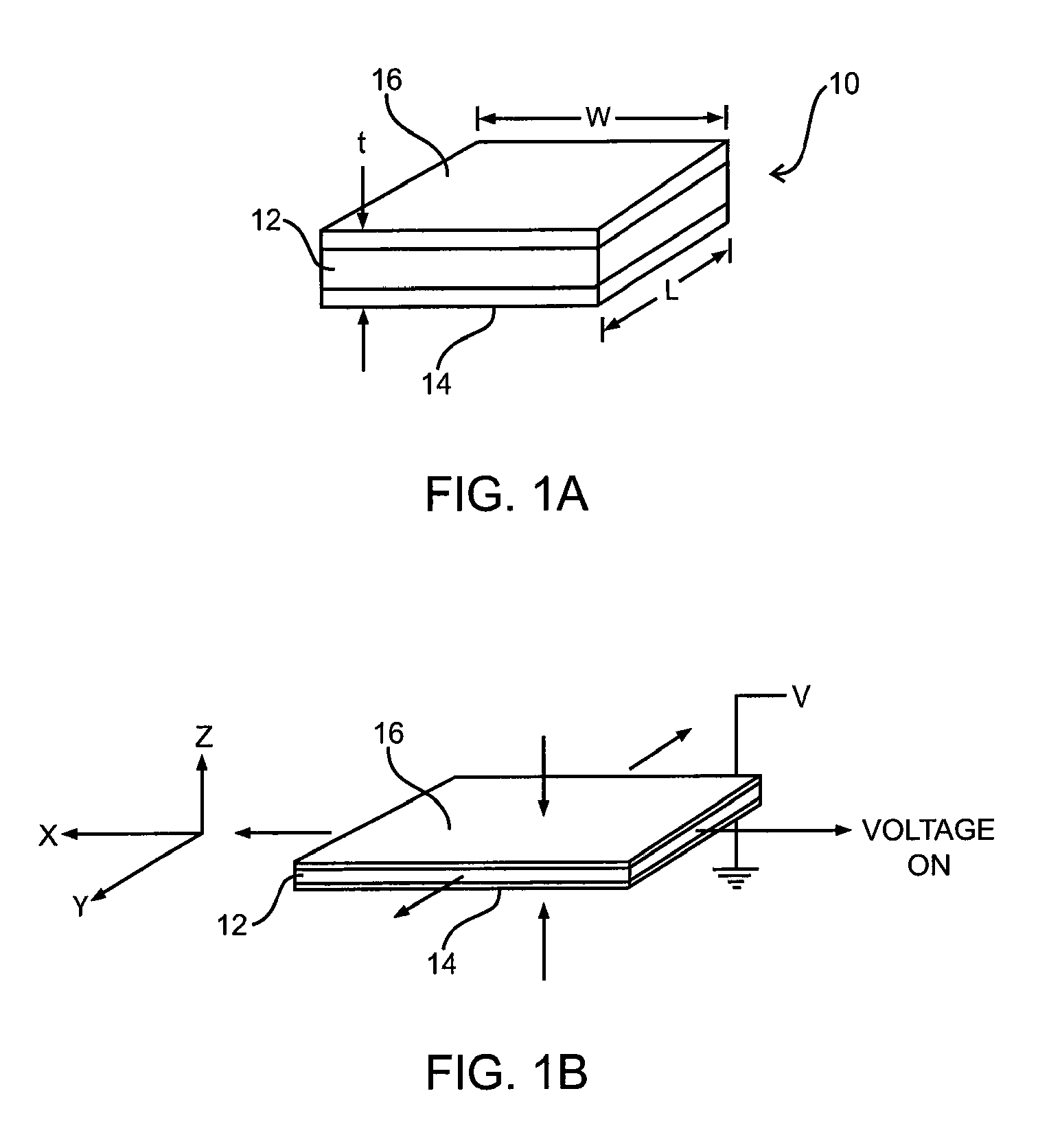

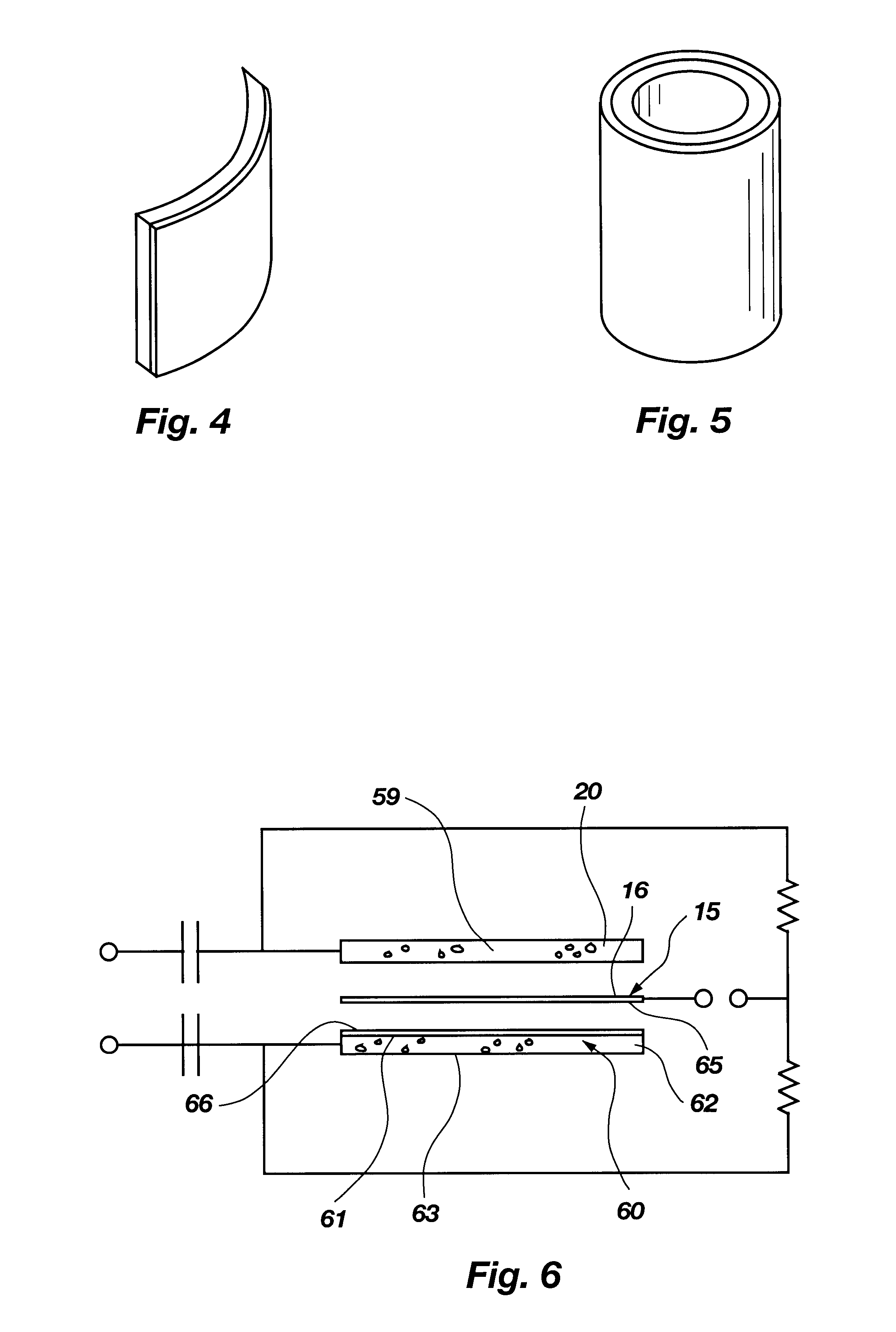

The present invention relates to transducers, their use and fabrication. The transducers convert between mechanical and electrical energy. Some transducers of the present invention include a pre-strained polymer. The pre-strain improves the conversion between electrical and mechanical energy. The present invention also relates to devices including an electroactive polymer to convert between electrical and mechanical energy. The present invention further relates to compliant electrodes that conform to the shape of a polymer included in a transducer. The present invention provides methods for fabricating electromechanical devices including one or more electroactive polymers.

Owner:SRI INTERNATIONAL

Energy efficient electroactive polymers and electroactive polymer devices

InactiveUS6911764B2Increase deflectionImprove energy conversion efficiencyTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesActive polymerMechanical energy

Owner:SRI INTERNATIONAL

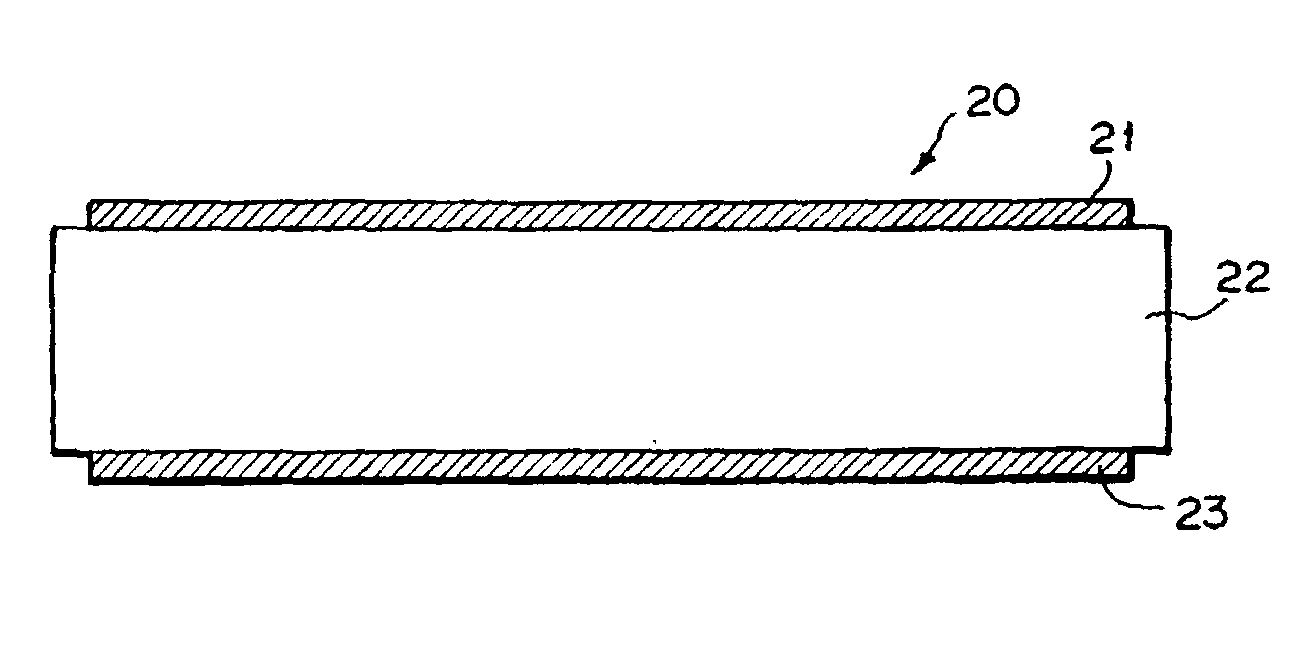

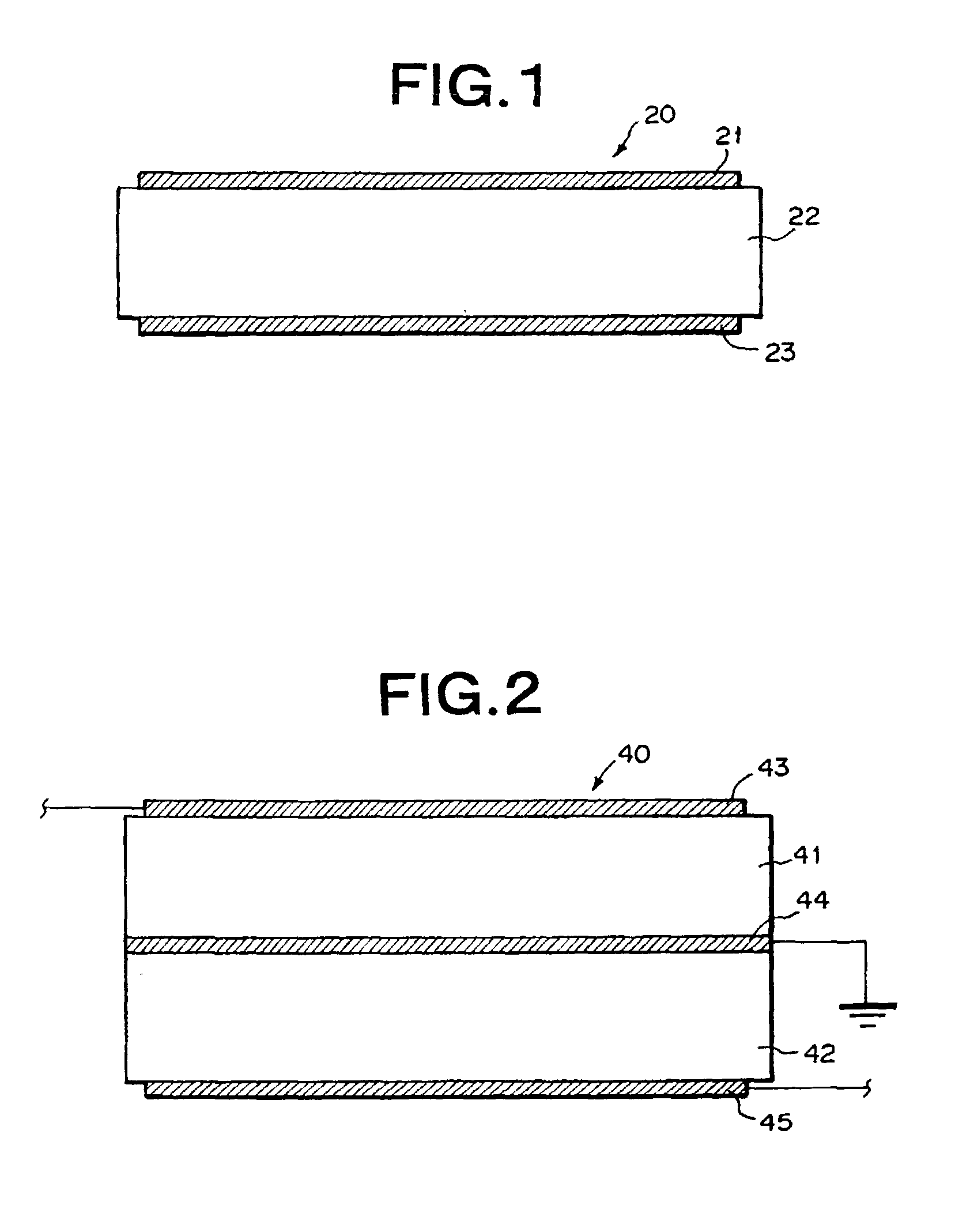

Thin film acoustic resonator and method of producing the same

InactiveUS6842088B2Improve temperature stabilityImprovement factorNanotechPiezoelectric/electrostrictive device manufacture/assemblyThin-film bulk acoustic resonatorElectromechanical coupling coefficient

Owner:MEMS SOLUTIONS INC

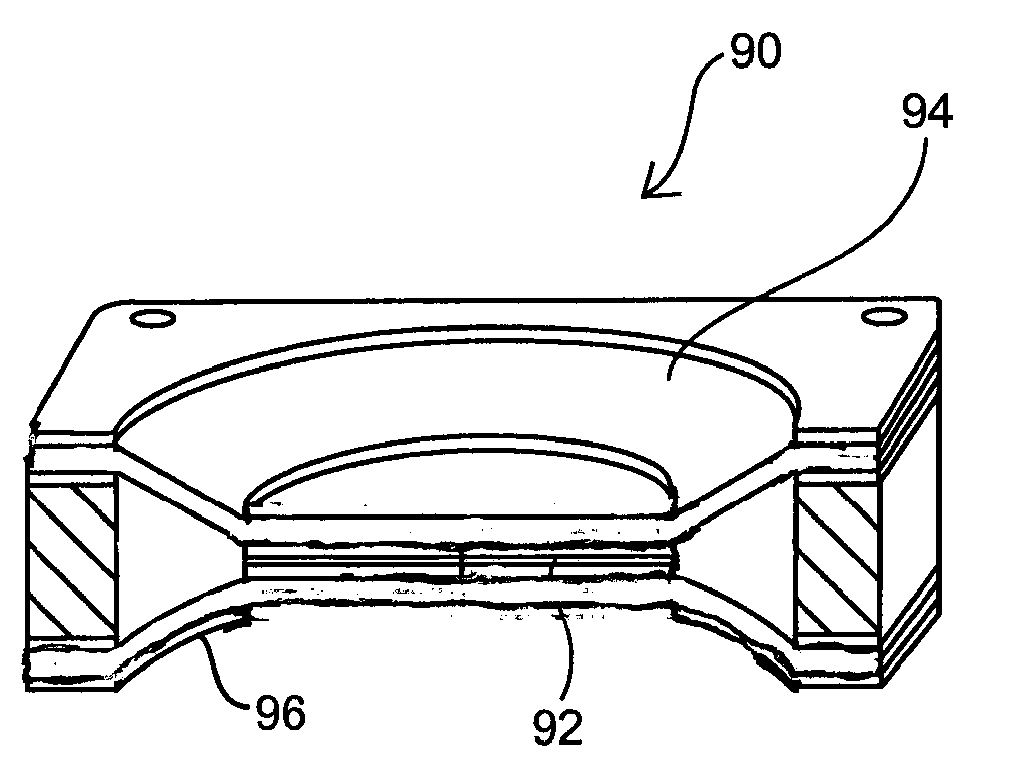

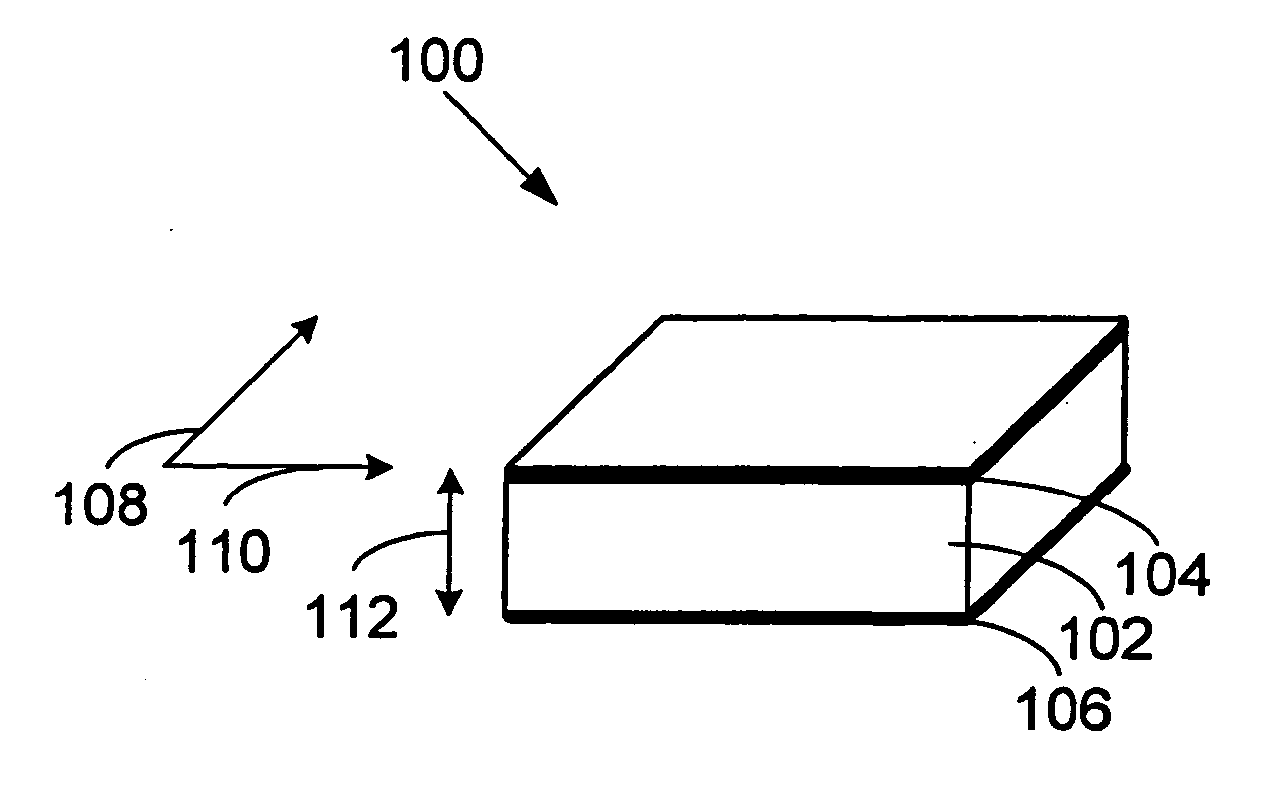

Electroactive polymers transducers and actuators

InactiveUS6940211B2Speed up the conversion processImprove mechanical responseTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesPre strainActive polymer

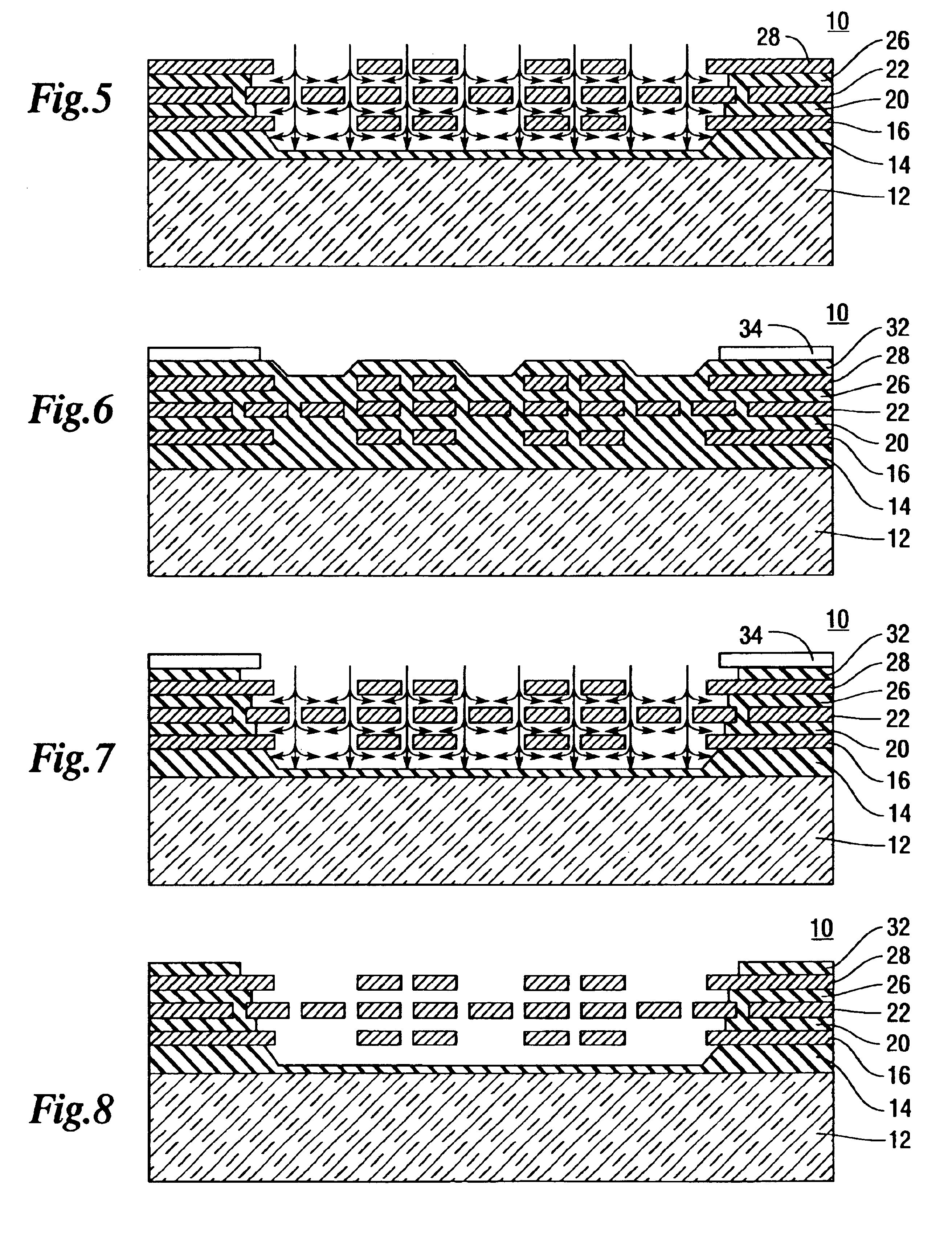

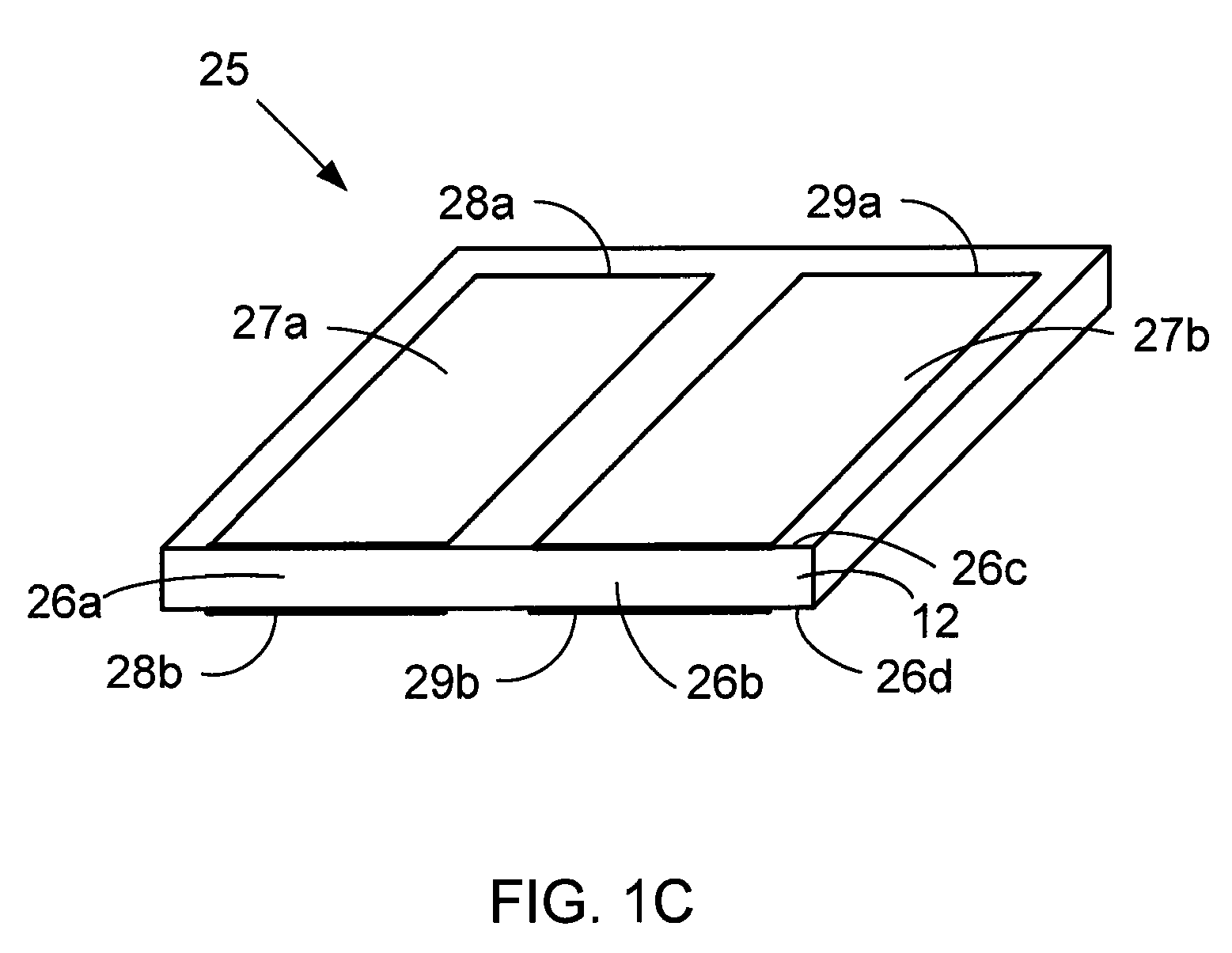

The present invention relates to electroactive polymers that are pre-strained to improve conversion from electrical to mechanical energy. When a voltage is applied to electrodes contacting a pre-strained polymer, the polymer deflects. This deflection may be used to do mechanical work. The pre-strain improves the mechanical response of an electroactive polymer. The present invention also relates to actuators including an electroactive polymer and mechanical coupling to convert deflection of the polymer into mechanical work. The present invention further relates to compliant electrodes that conform to the shape of a polymer. The present invention provides methods for fabricating electromechanical devices including one or more electroactive polymers.

Owner:SRI INTERNATIONAL

Electroactive polymers

InactiveUS7049732B2Speed up the conversion processImprove responseTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesPolymer sciencePolymer chemistry

The present invention relates to transducers, their use and fabrication. The transducers convert between mechanical and electrical energy. Some transducers of the present invention include a pre-strained polymer. The pre-strain improves the conversion between electrical and mechanical energy. The present invention also relates to devices including an electroactive polymer to convert between electrical and mechanical energy. The present invention further relates to compliant electrodes that conform to the shape of a polymer included in a transducer. The present invention provides methods for fabricating electromechanical devices including one or more electroactive polymers.

Owner:SRI INTERNATIONAL

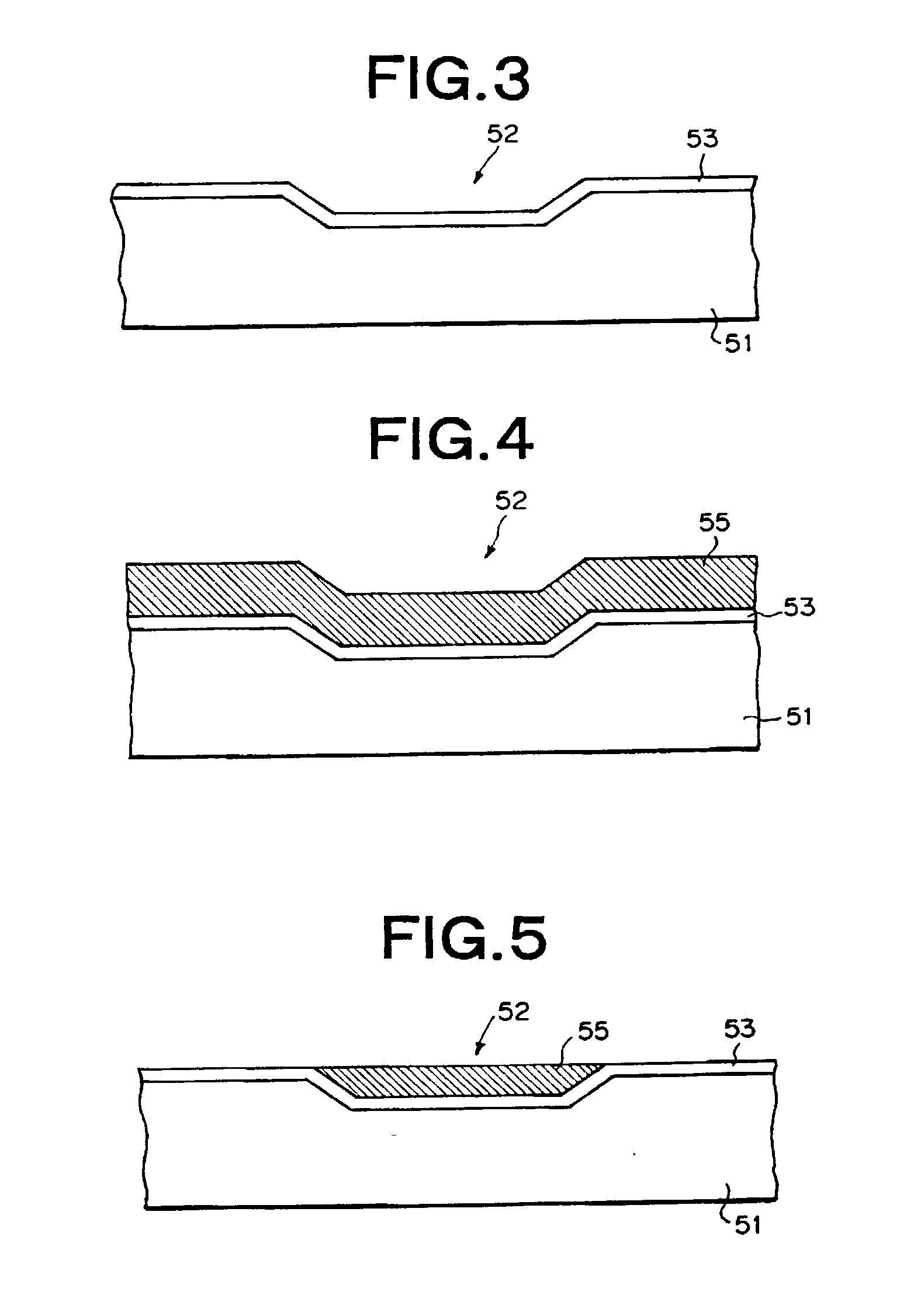

Thin film bulk acoustic resonator and method of producing the same

InactiveUS20020190814A1Improve featuresPiezoelectric/electrostrictive device manufacture/assemblyNanotechThin-film bulk acoustic resonatorElectromechanical coupling coefficient

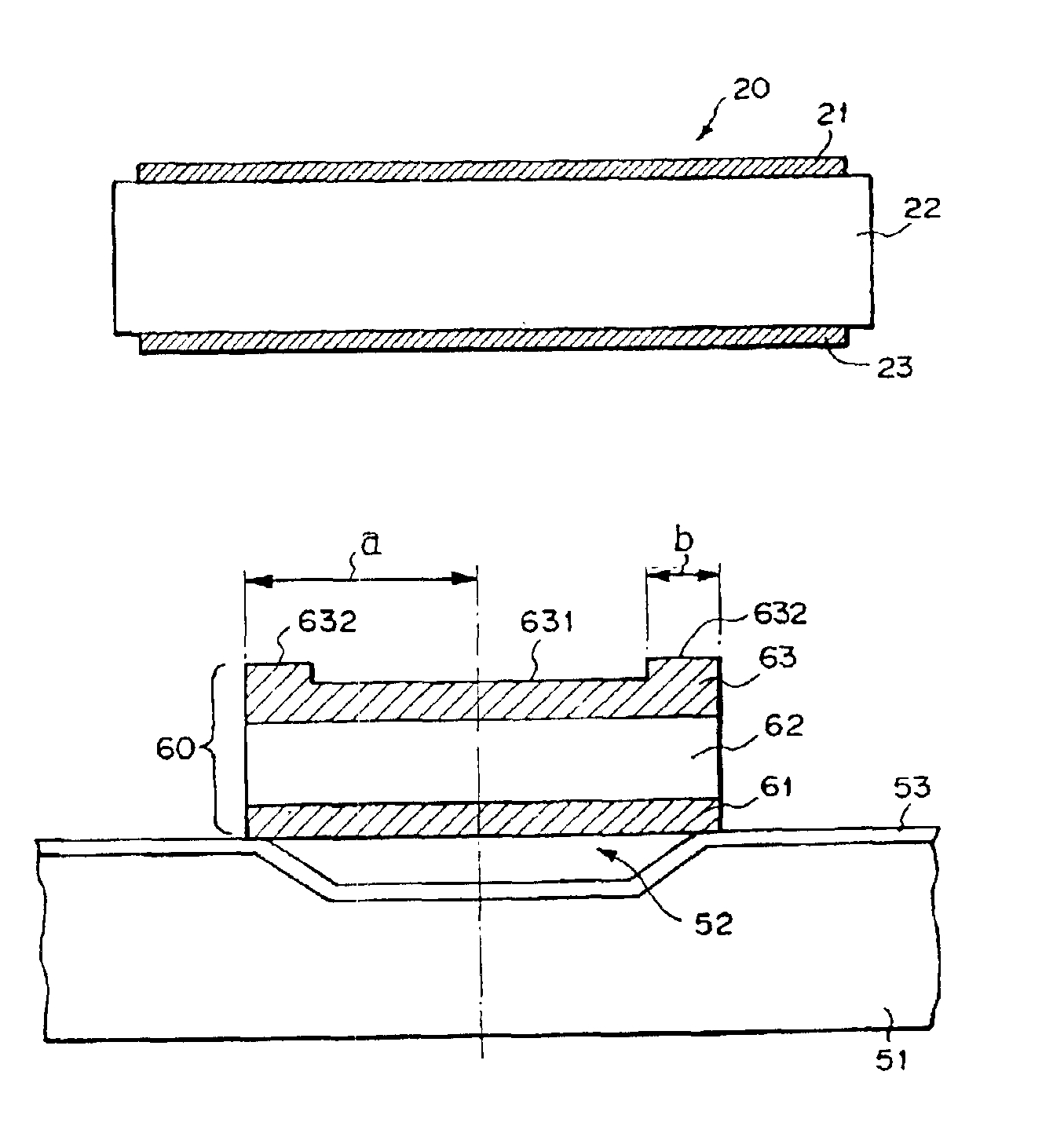

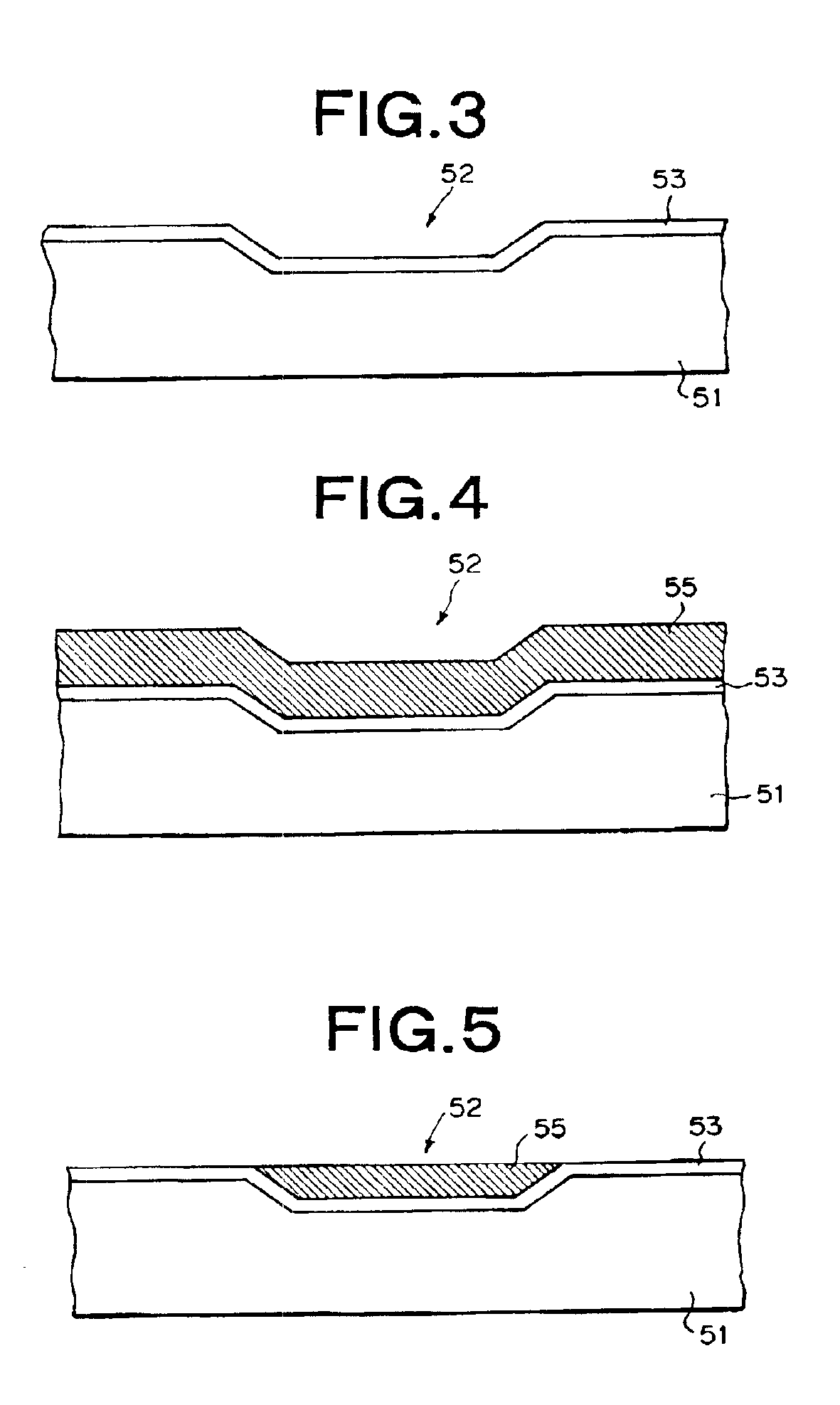

A pit (52) is formed in a substrate comprising a silicon wafer (51) on a surface of which a silicon oxide thin layer (53) is formed. A sandwich structure (60) comprising a piezoelectric layer (62) and lower and upper electrodes (61, 63) joined to both surfaces of the piezoelectric layer is disposed so as to stride over the pit (52). The upper surface of the lower electrode (61) and the lower surface of the piezoelectric layer (62) joined to the upper surface of the lower electrode are treated so that the RMS variation of the height thereof is equal to 25 nm or less. The thickness of the lower electrode (61) is set to 150 nm or less. According to such a structure, there is provided a high-performance thin film bulk acoustic resonator which are excellent in electromechanical coupling coefficient and acoustic quality factor.

Owner:MEMS SOLUTIONS INC

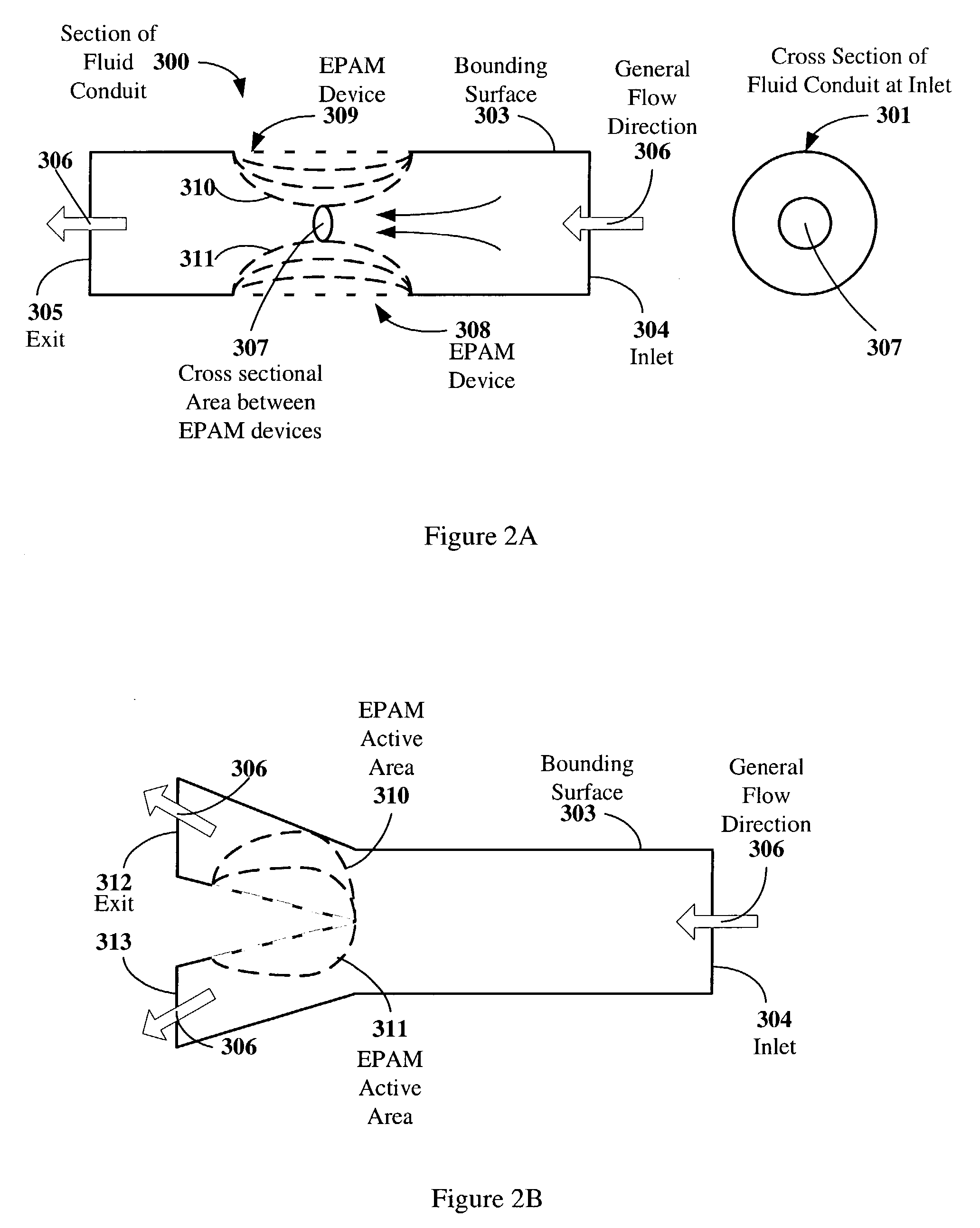

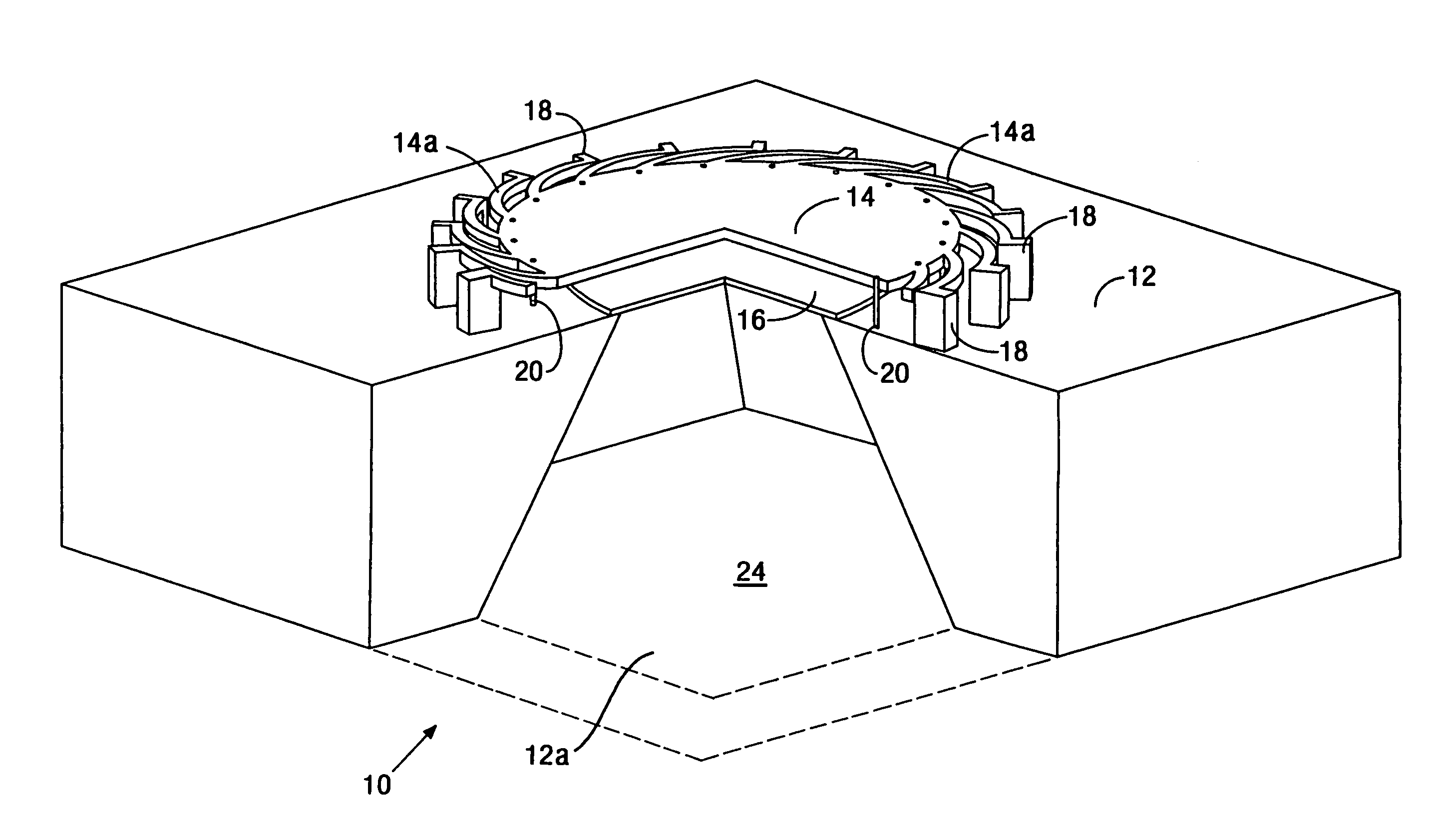

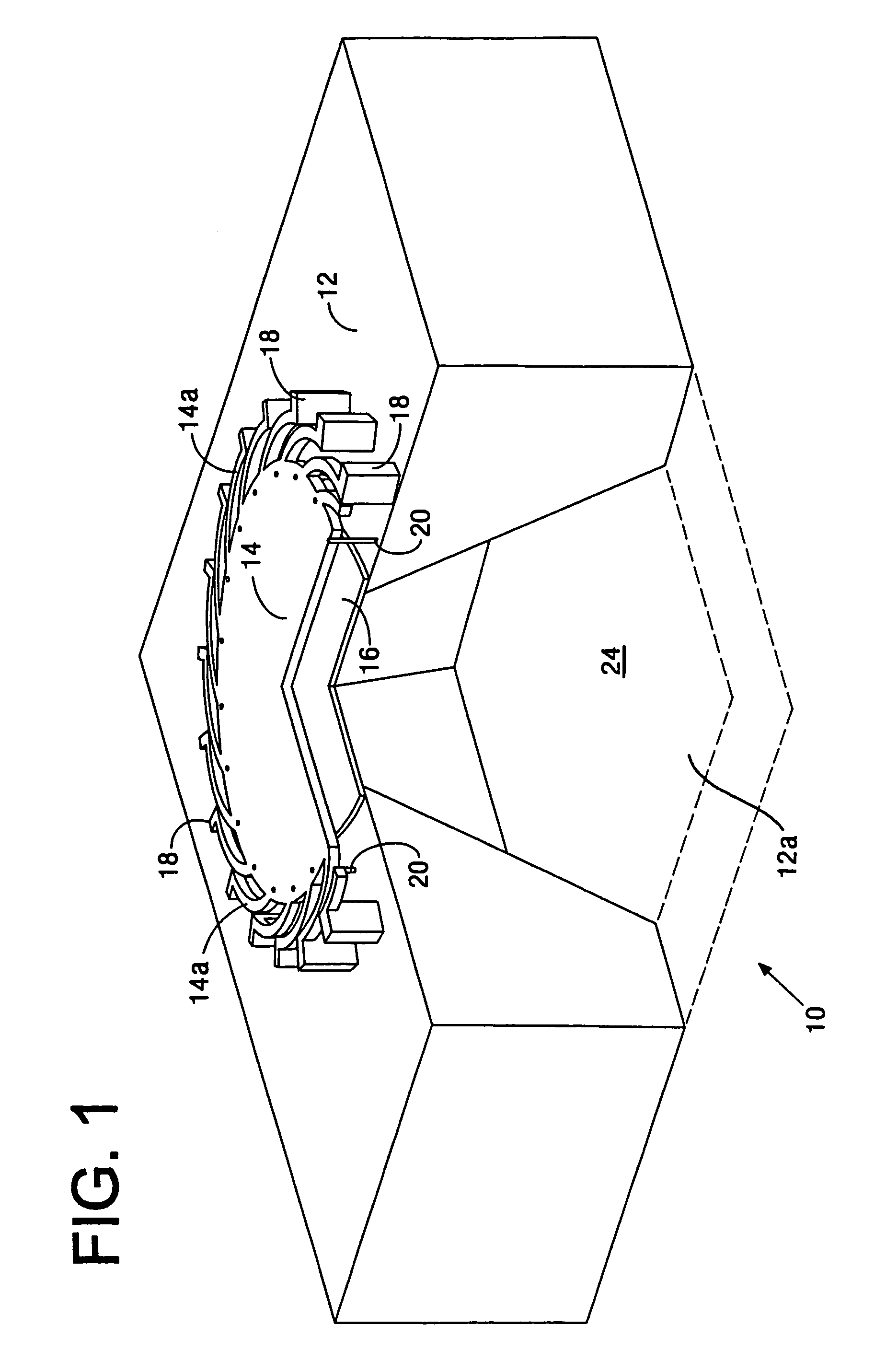

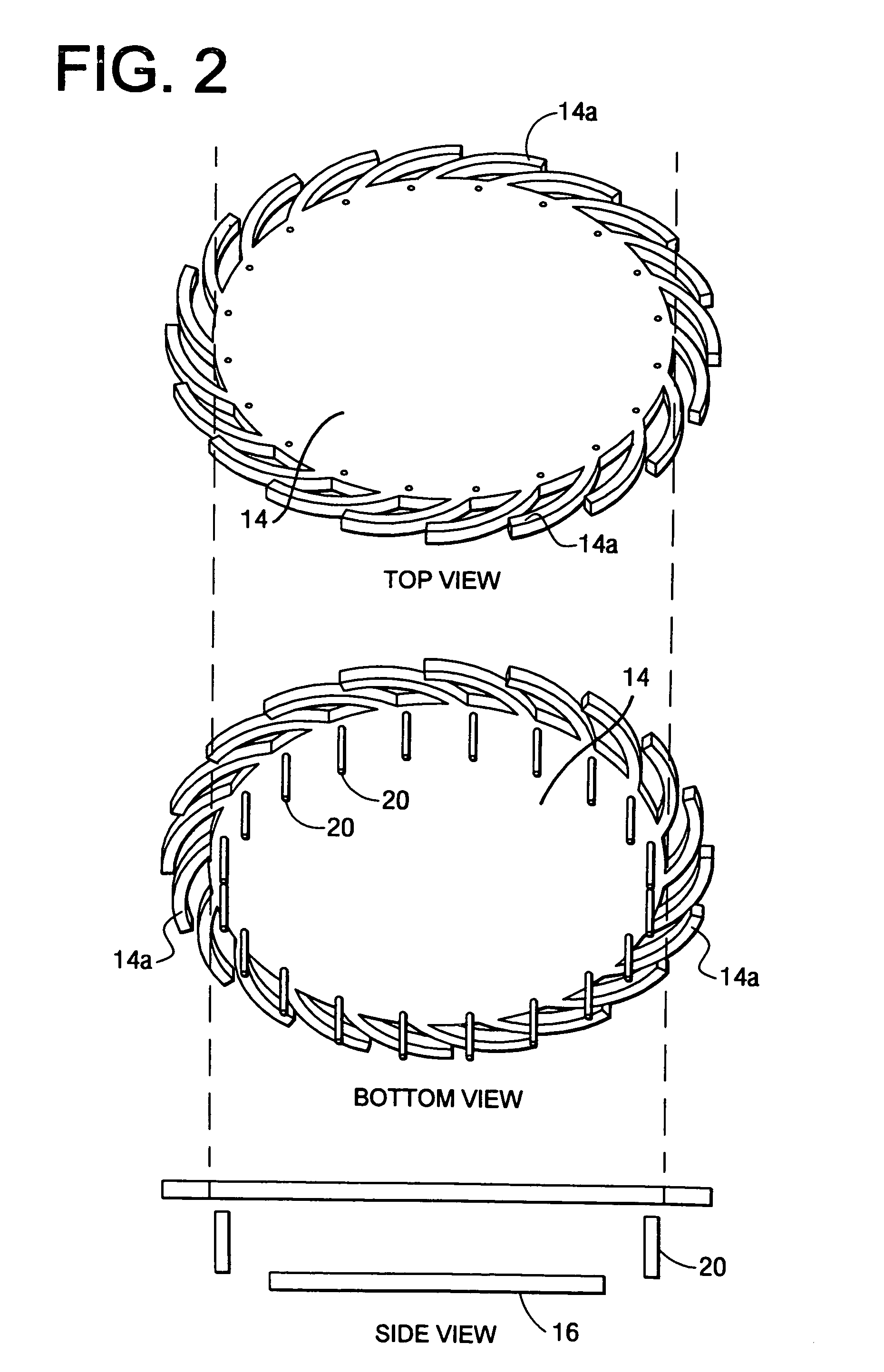

Electroactive polymer devices for controlling fluid flow

InactiveUS7320457B2Improve mechanical responseImprove responsePiezoelectric/electrostrictive gramophone pickupsTransducer detailsMomentumTransducer

The invention describes devices for controlling fluid flow, such as valves. The devices may include one or more electroactive polymer transducers with an electroactive polymer that deflects in response to an application of an electric field. The electroactive polymer may be in contact with a fluid where the deflection of the electroactive polymer may be used to change a characteristic of the fluid. Some of the characteristic of the fluid that may be changed include but are not limited to 1) a flow rate, 2) a flow direction, 3) a flow vorticity, 4) a flow momentum, 5) a flow mixing rate, 6) a flow turbulence rate, 7) a flow energy, 8) a flow thermodynamic property. The electroactive polymer may be a portion of a surface of a structure that is immersed in an external fluid flow, such as the surface of an airplane wing or the electroactive polymer may be a portion of a surface of a structure used in an internal flow, such as a bounding surface of a fluid conduit.

Owner:SRI INTERNATIONAL

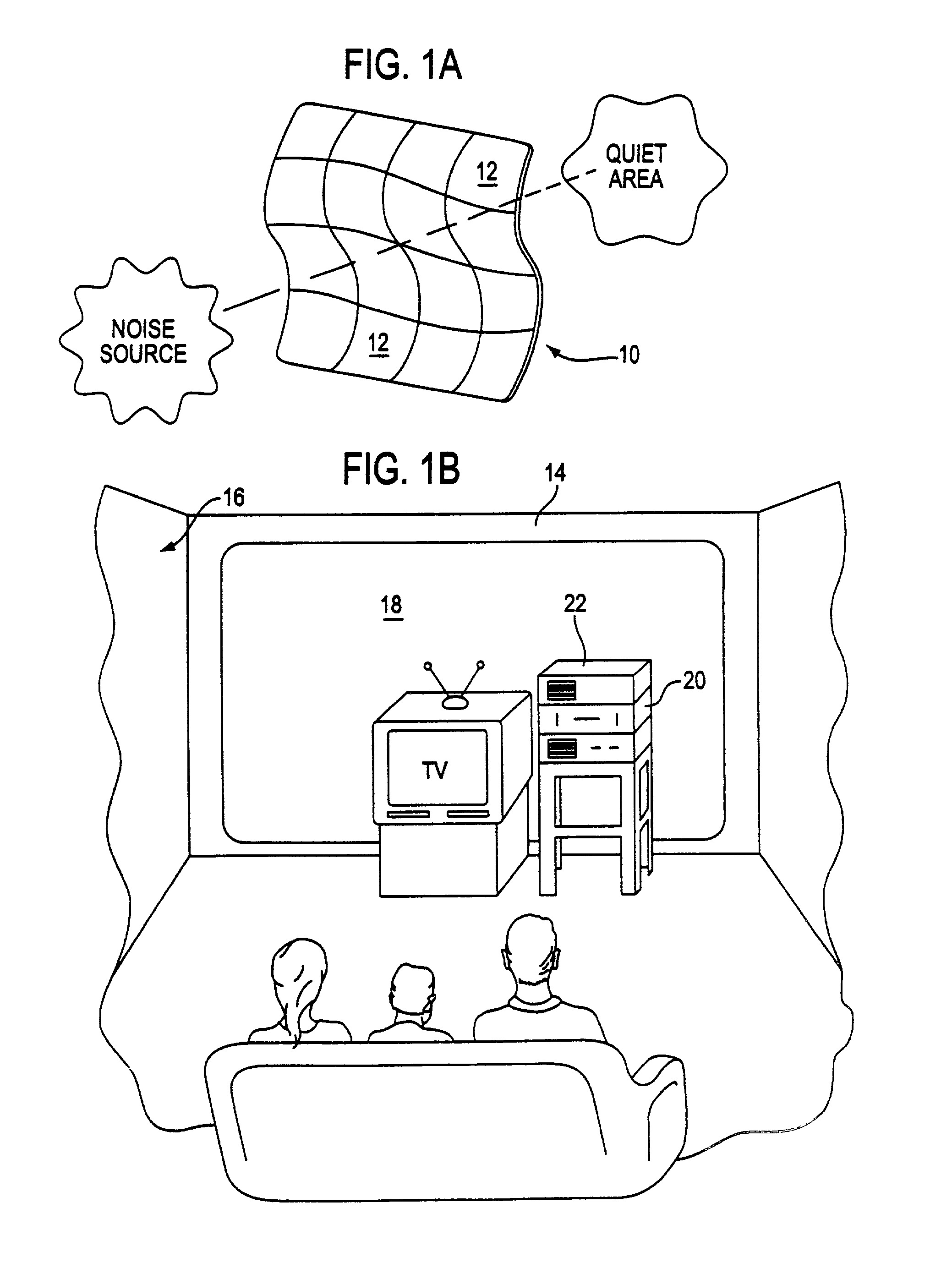

Compliant electroactive polymer transducers for sonic applications

InactiveUS20070200467A1Avoid excessive elastic modulusPiezoelectric/electrostriction/magnetostriction machinesElectrostatic transducer loudspeakersActive polymerTransducer

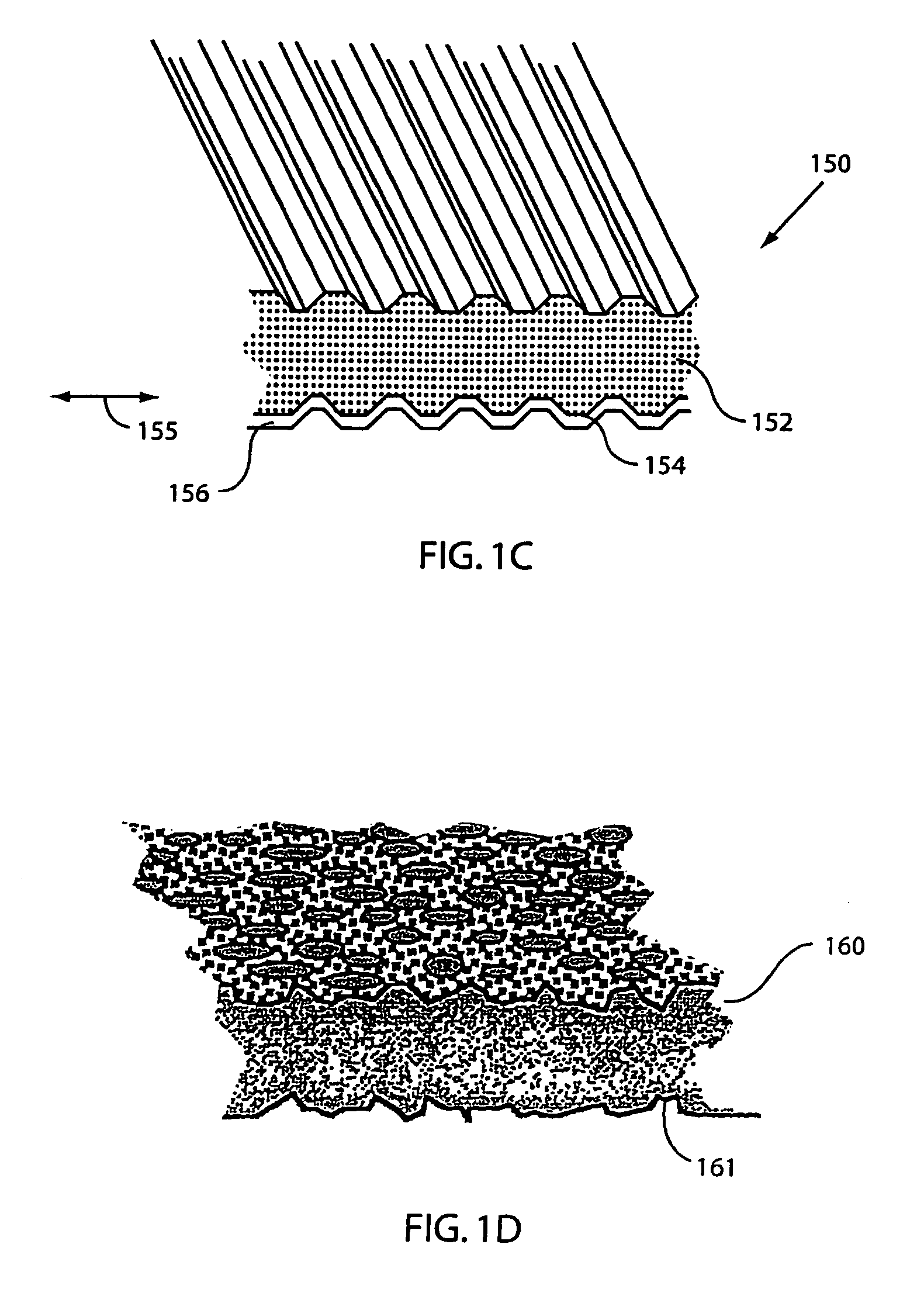

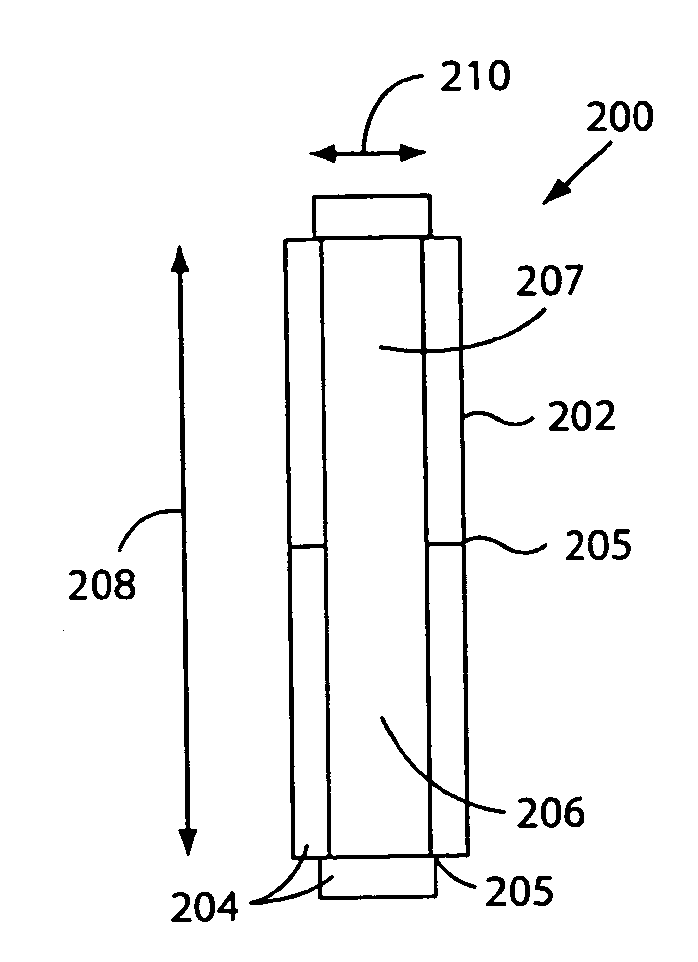

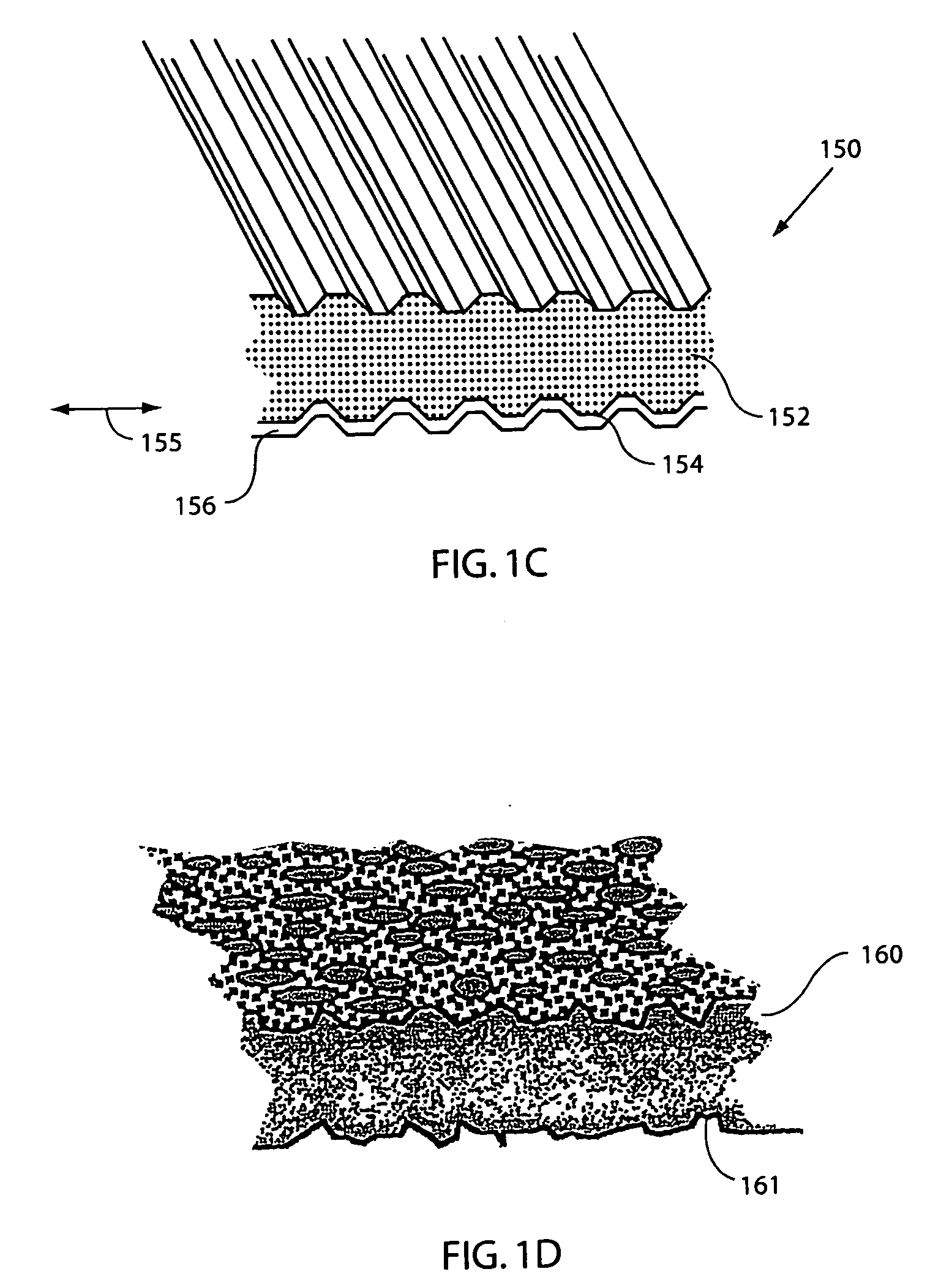

Described herein are compliant electroactive polymer transducers for use in acoustic applications. A compliant electroactive polymer transducer includes a compliant electroactive polymer at least two electrodes. For sound production, circuitry in electrical communication with the transducer electrodes is configured to apply a driving signal that causes the electroactive polymer to deflect in the acoustic range.

Owner:SRI INTERNATIONAL

Electroactive polymers

InactiveUS20060113878A1Speed up the conversion processImprove responseTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesPre strainActive polymer

Owner:SRI INTERNATIONAL

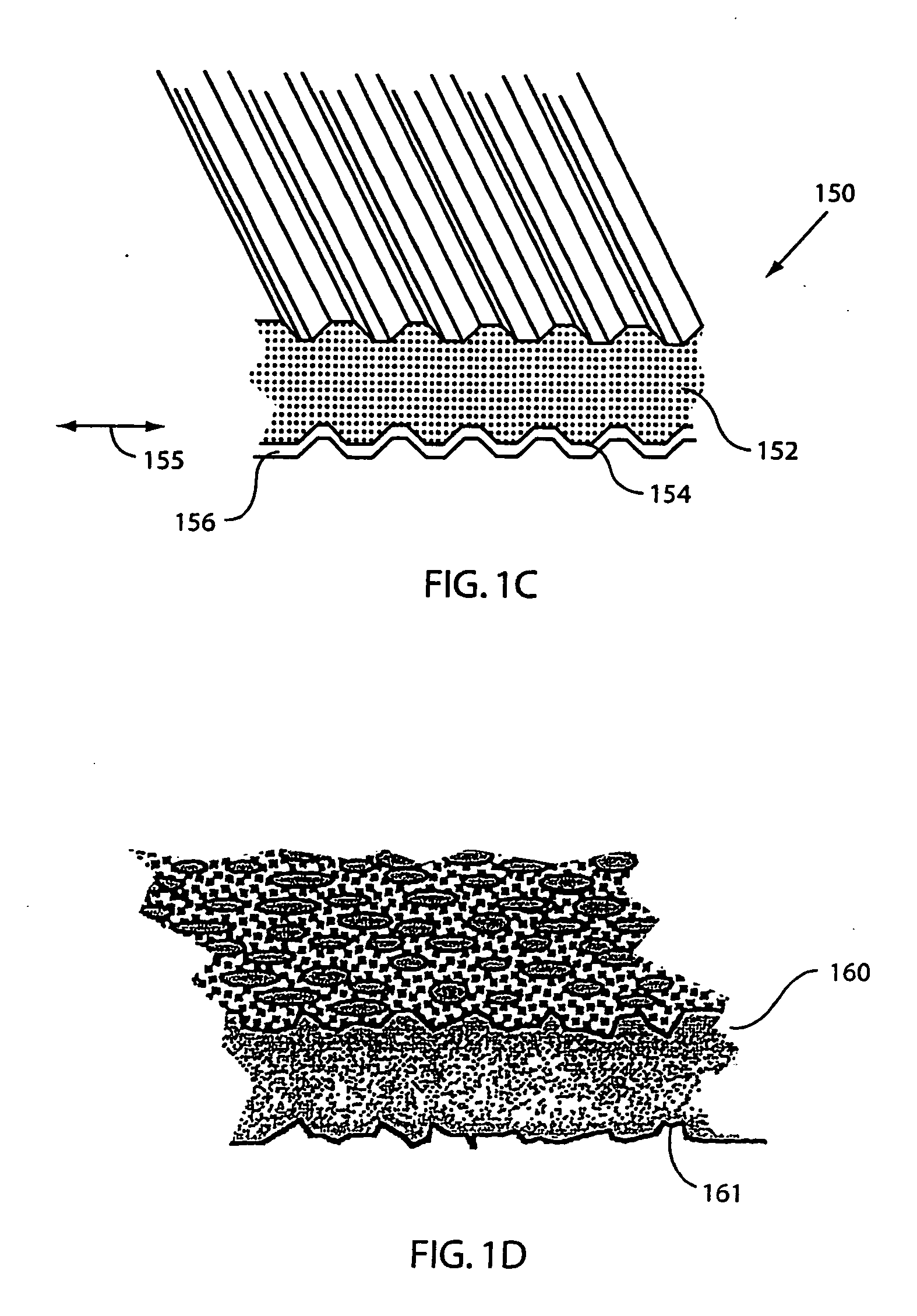

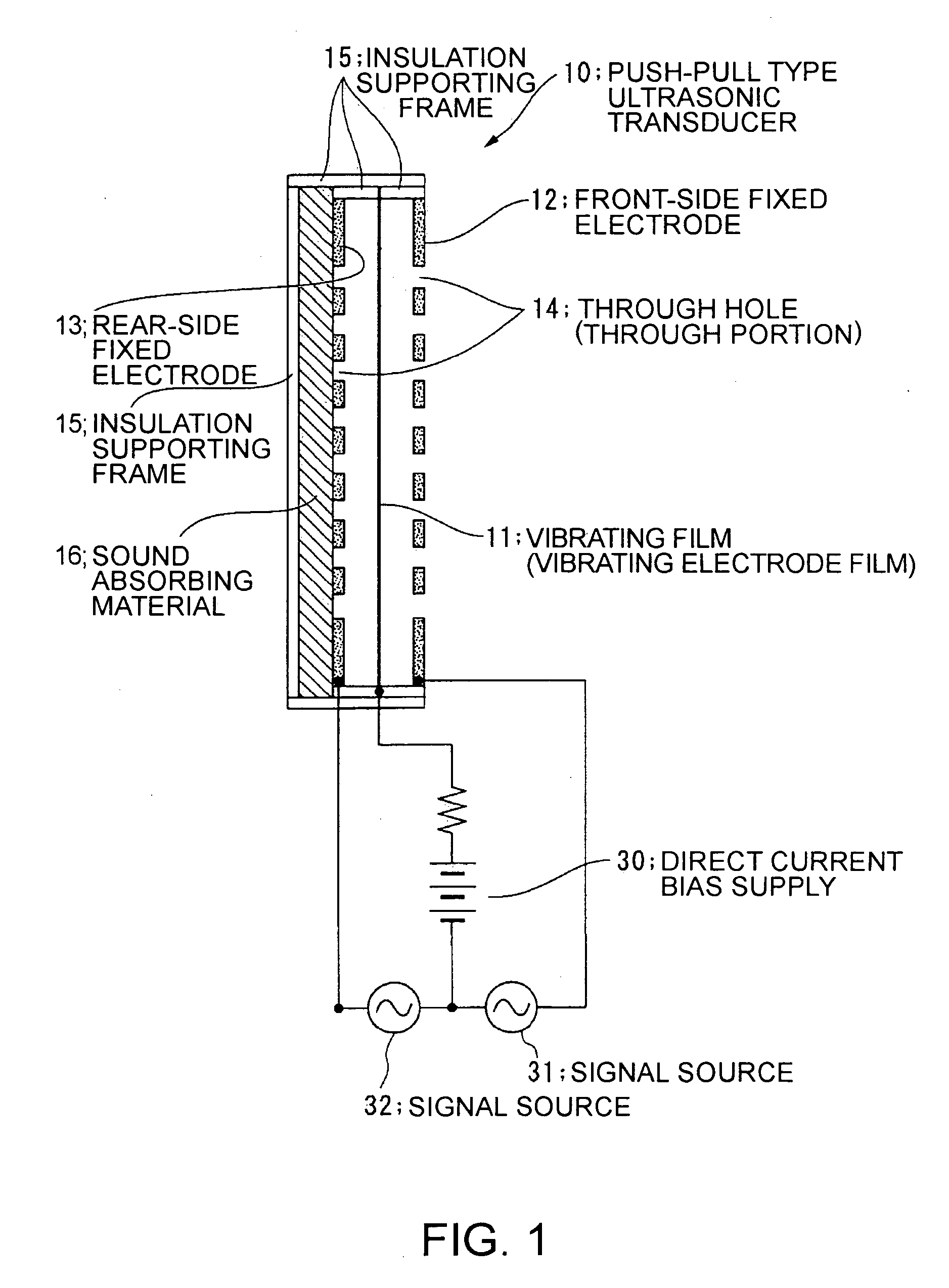

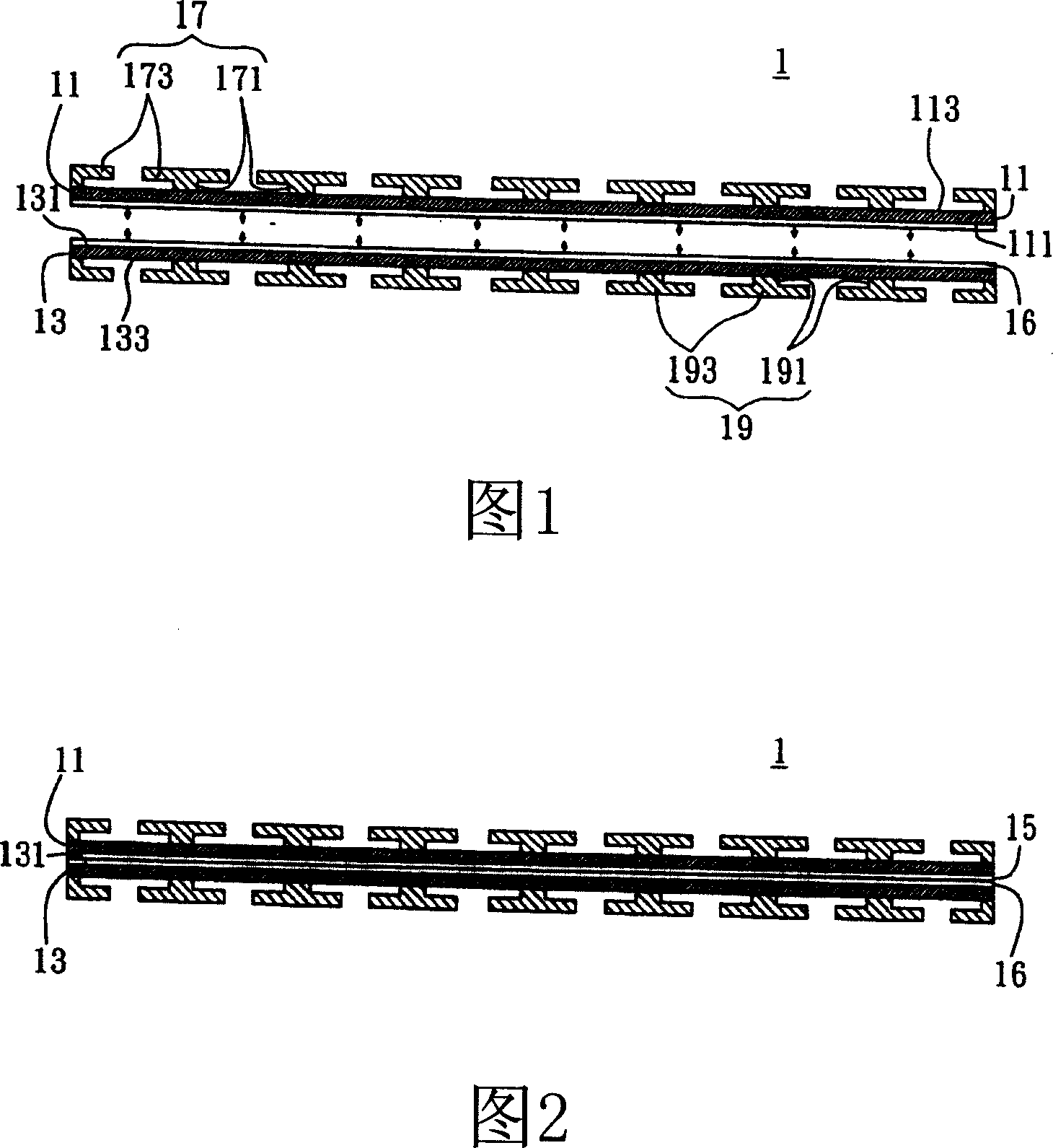

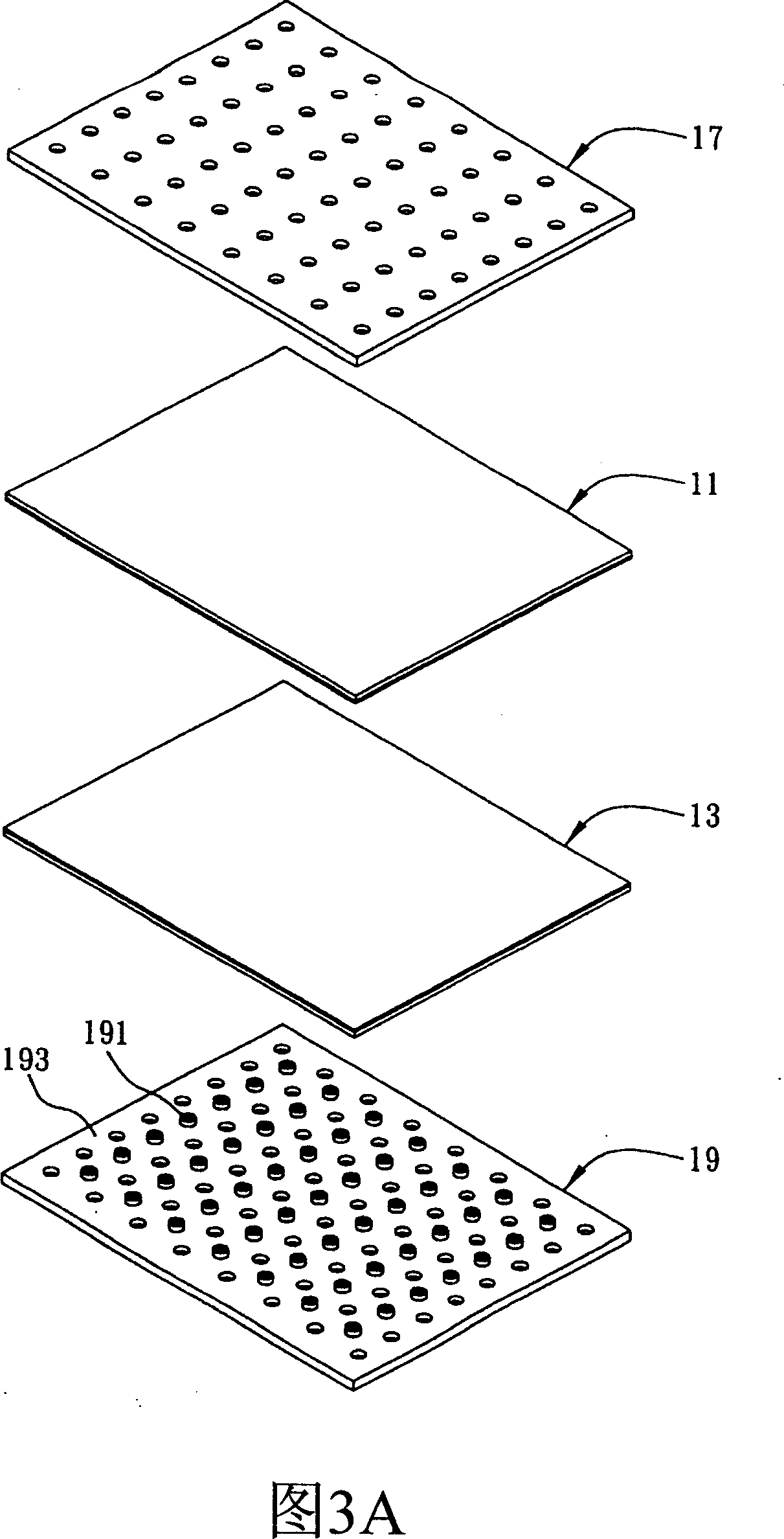

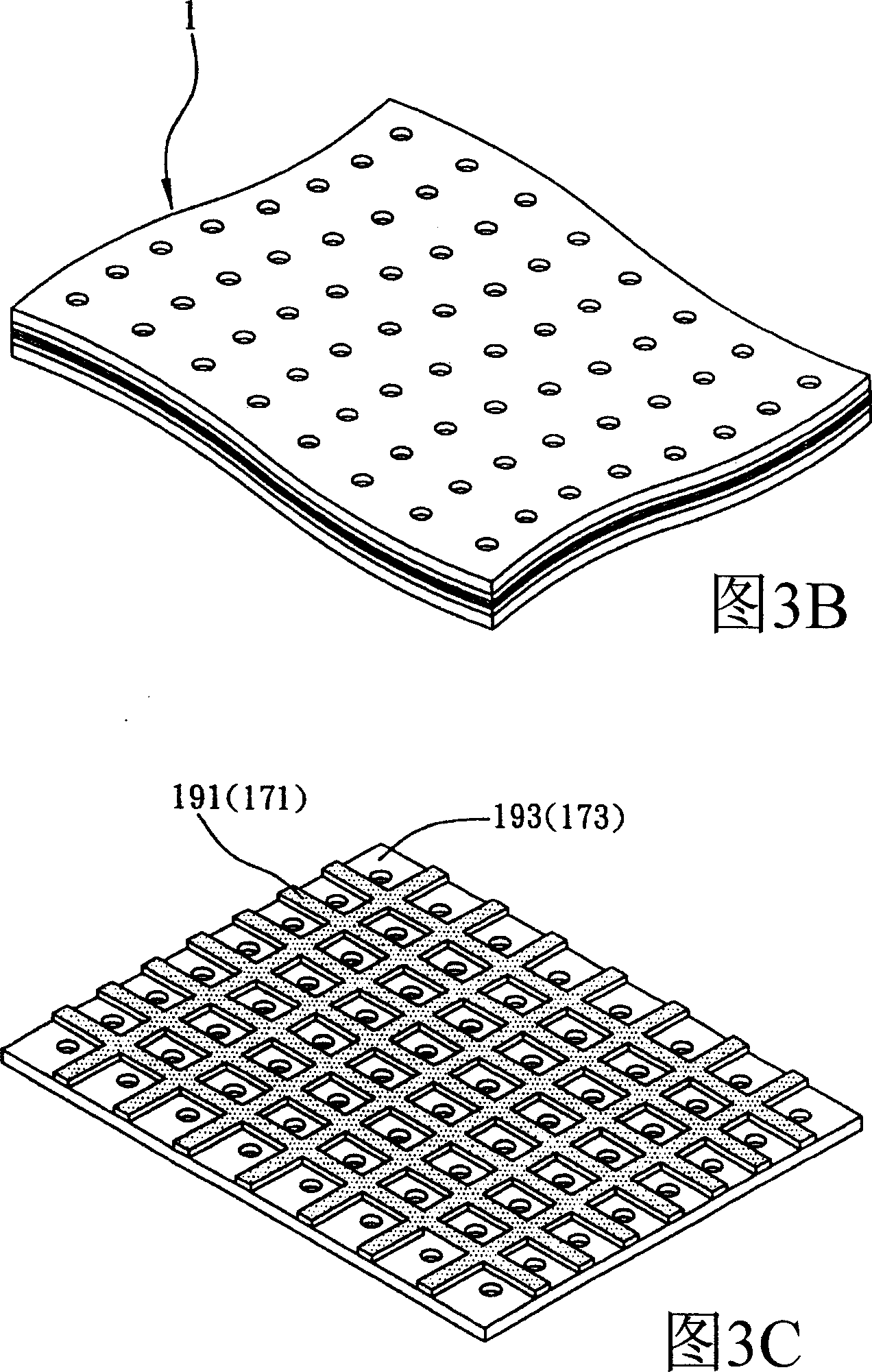

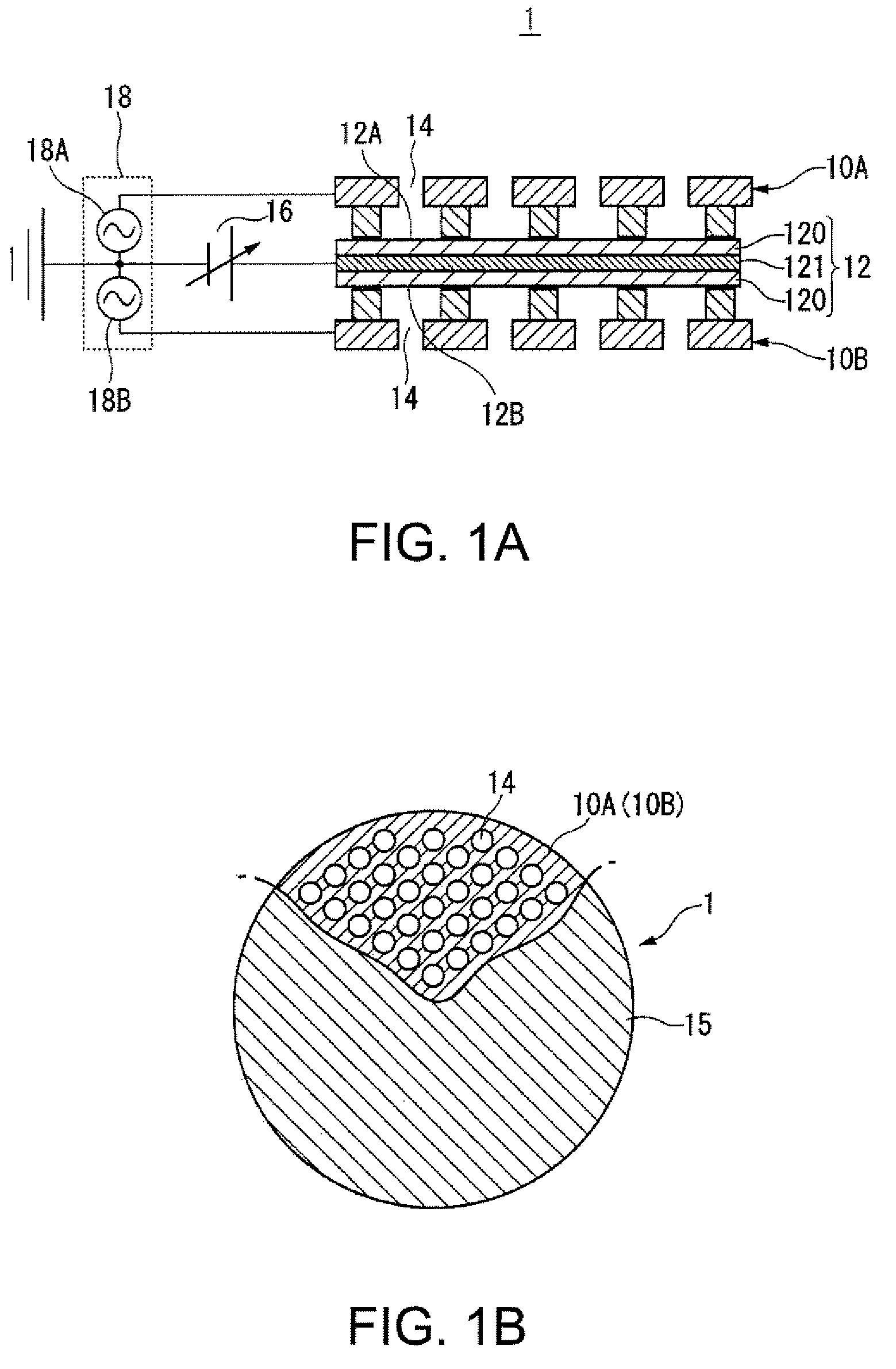

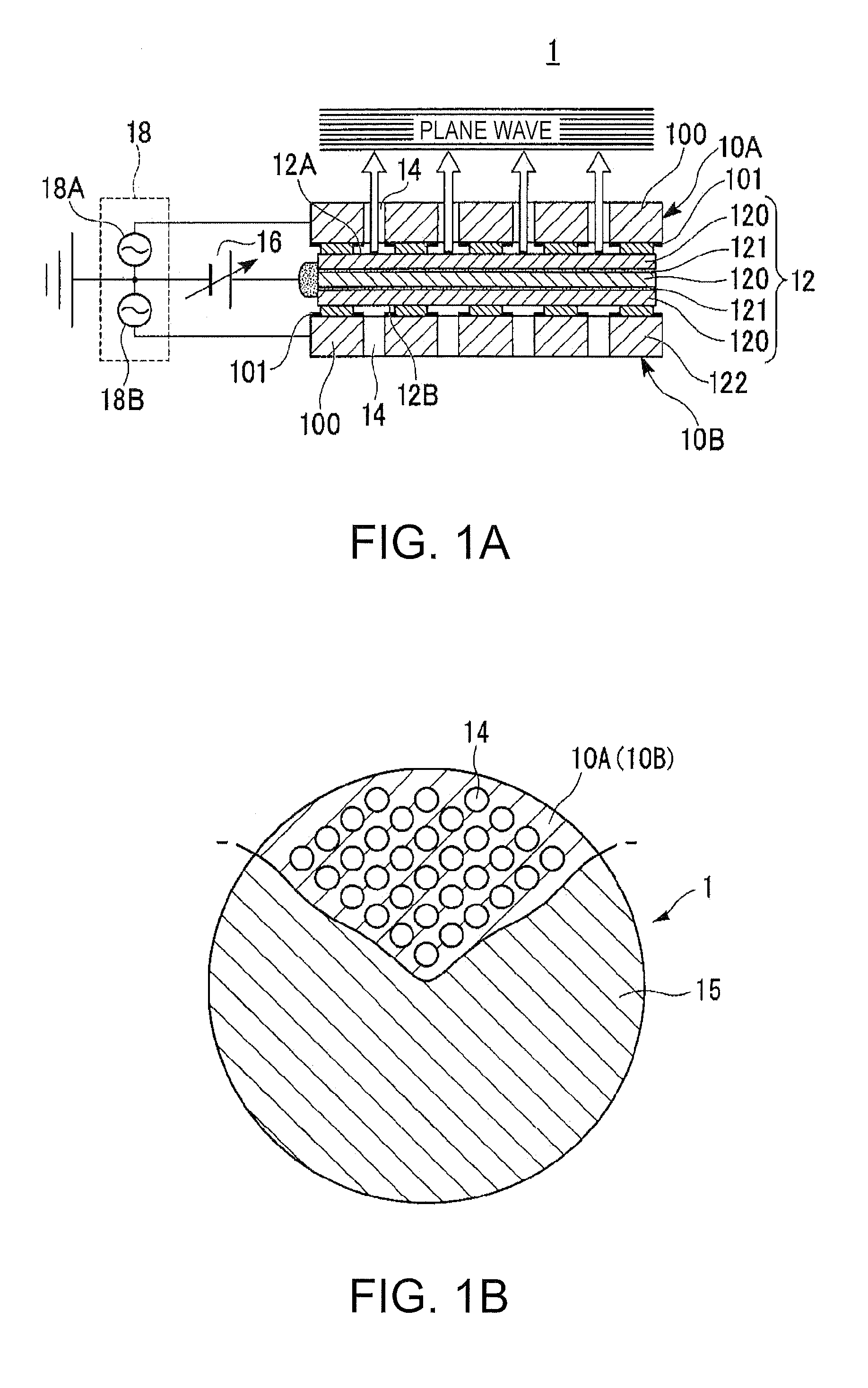

Electrostatic ultrasonic transducer and ultrasonic speaker

InactiveUS20060072770A1Small distortionImprove directionalityPiezoelectric/electrostrictive transducersElectrostatic transducer loudspeakersUltrasonic sensorSonification

To provide an electrostatic ultrasonic transducer arranged so that sound wave is not radiated from the rear surface while utilizing advantages of a push-pull type electrostatic ultrasonic transducer. A push-pull type electrostatic ultrasonic transducer includes a vibrating film 11 having a conductive layer and a pair of fixed electrodes 12, 13 provided facing respective surfaces of the vibrating film, and applies a direct current bias voltage to the conductive layer of the vibrating film and applies an alternating current signal between the pair of fixed electrodes so as to allow the vibrating film to generate sound wave and outputting the sound wave generated from the vibrating film from two sound wave output surfaces via through holes provided in the respective pair of fixed electrodes. Plural through holes are provided in the front-side fixed electrode that sandwiches the vibrating film and through holes having the same shapes are provided in the rear-side fixed electrode in positions opposed to the respective through holes provided in the front-side fixed electrode, and a sound absorbing material 16 is provided facing the rear-side fixed electrode.

Owner:SEIKO EPSON CORP

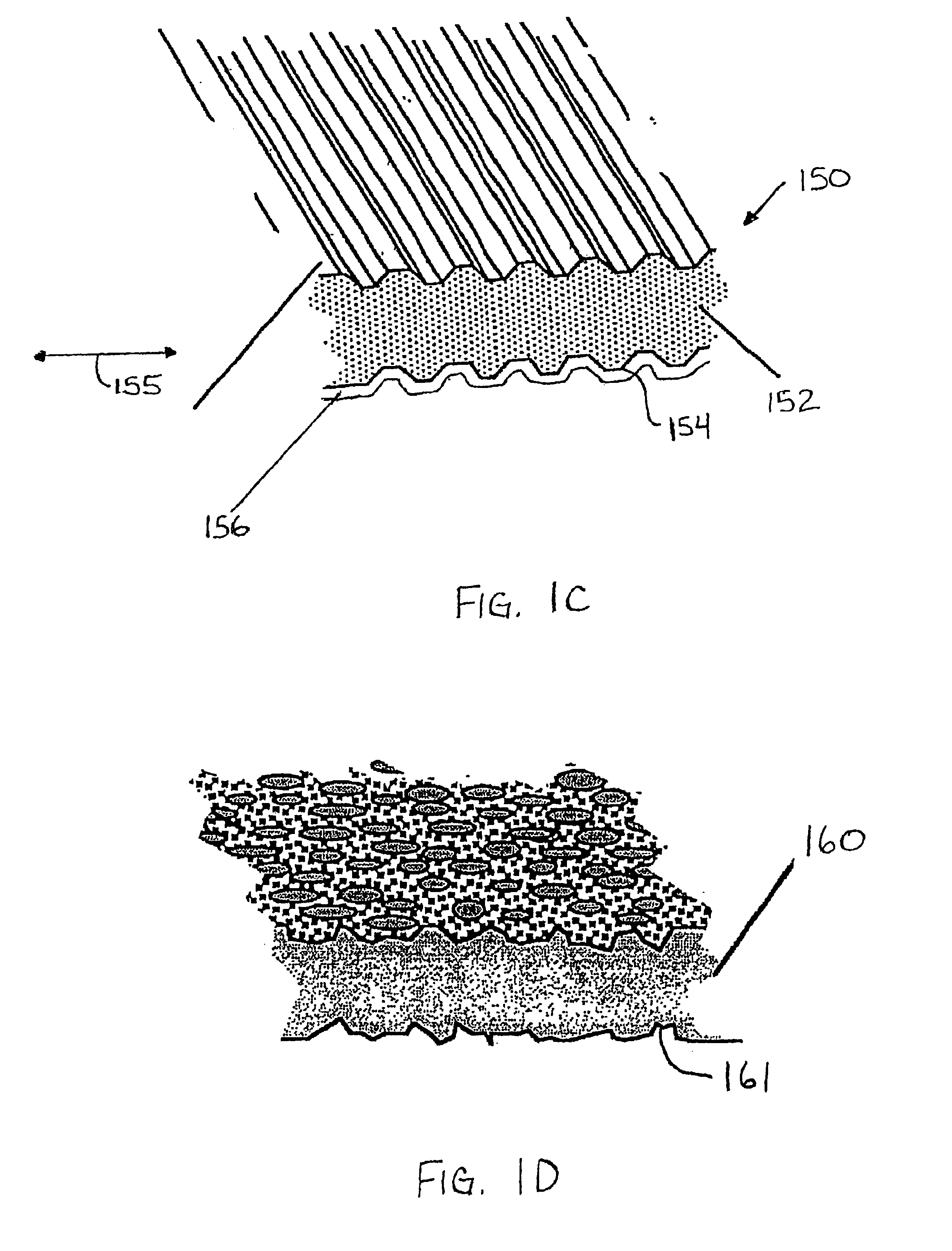

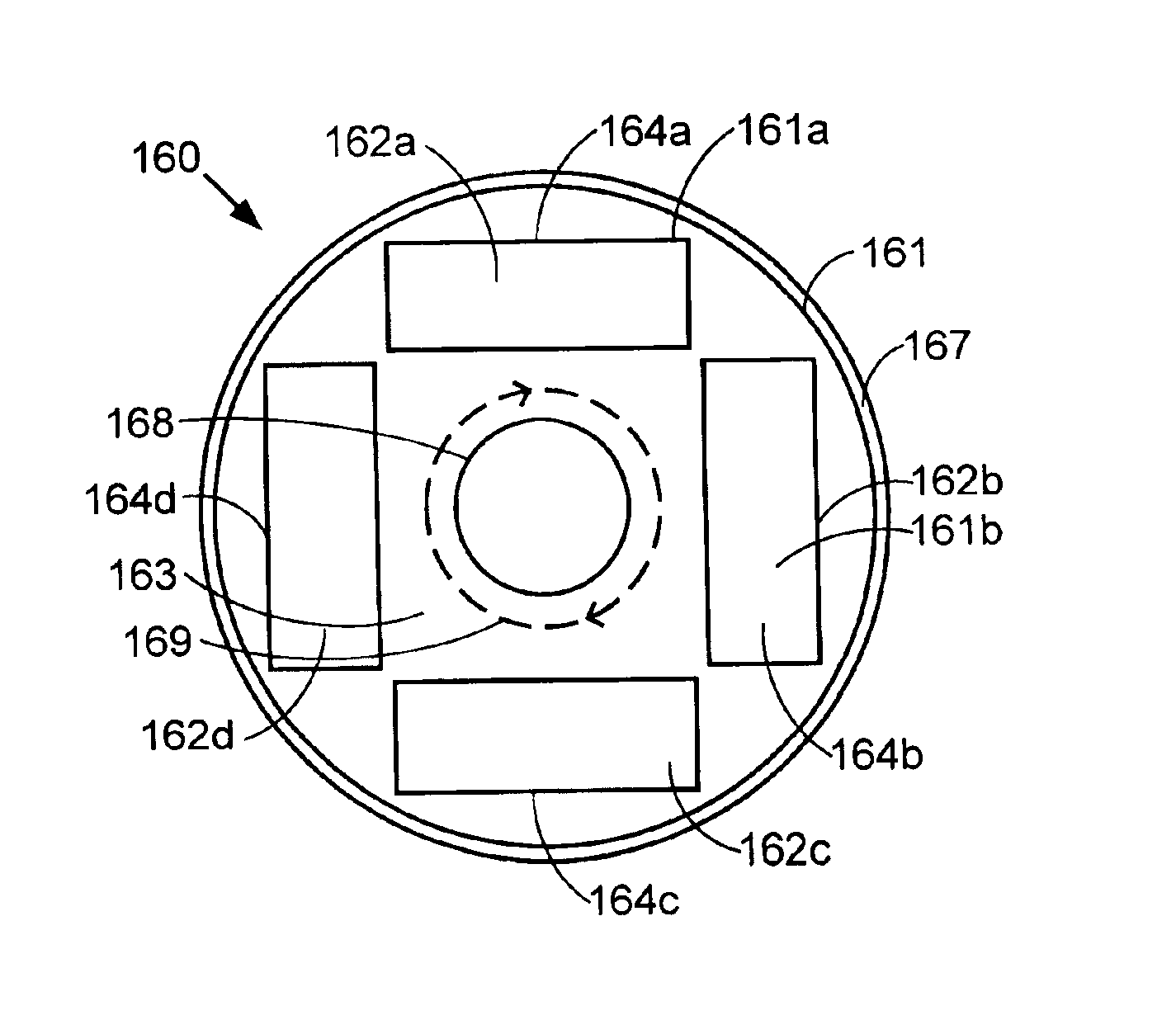

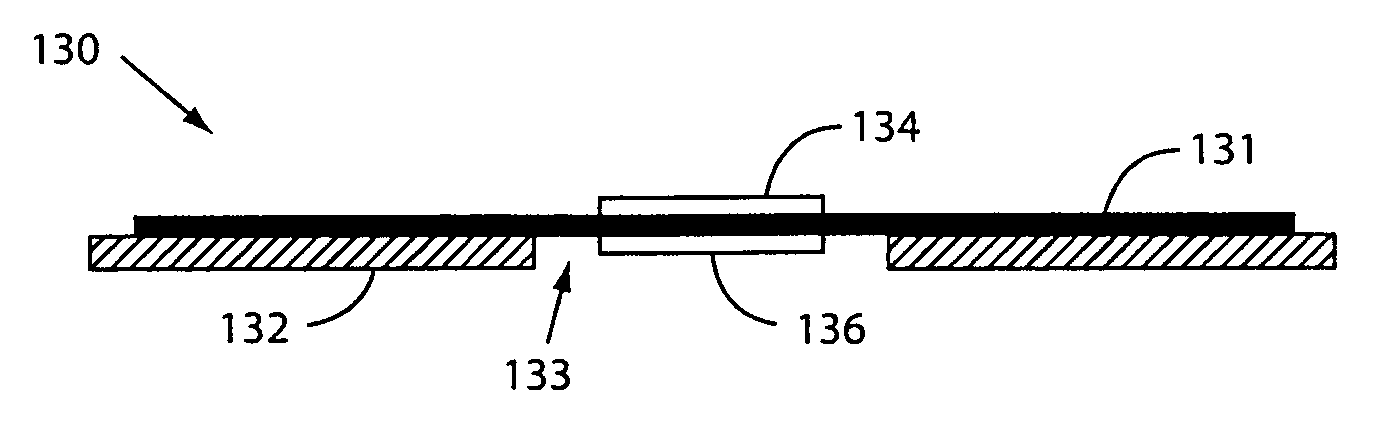

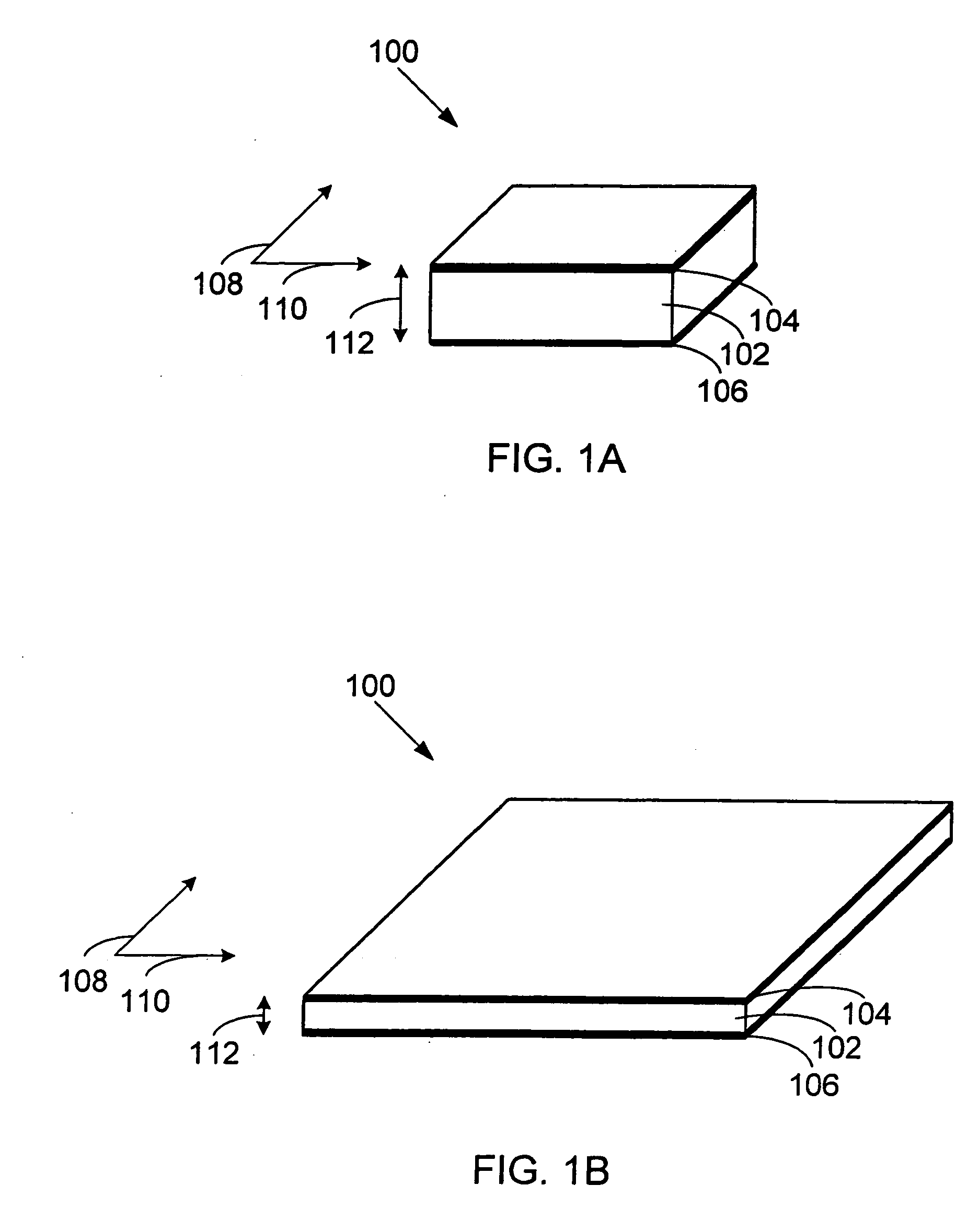

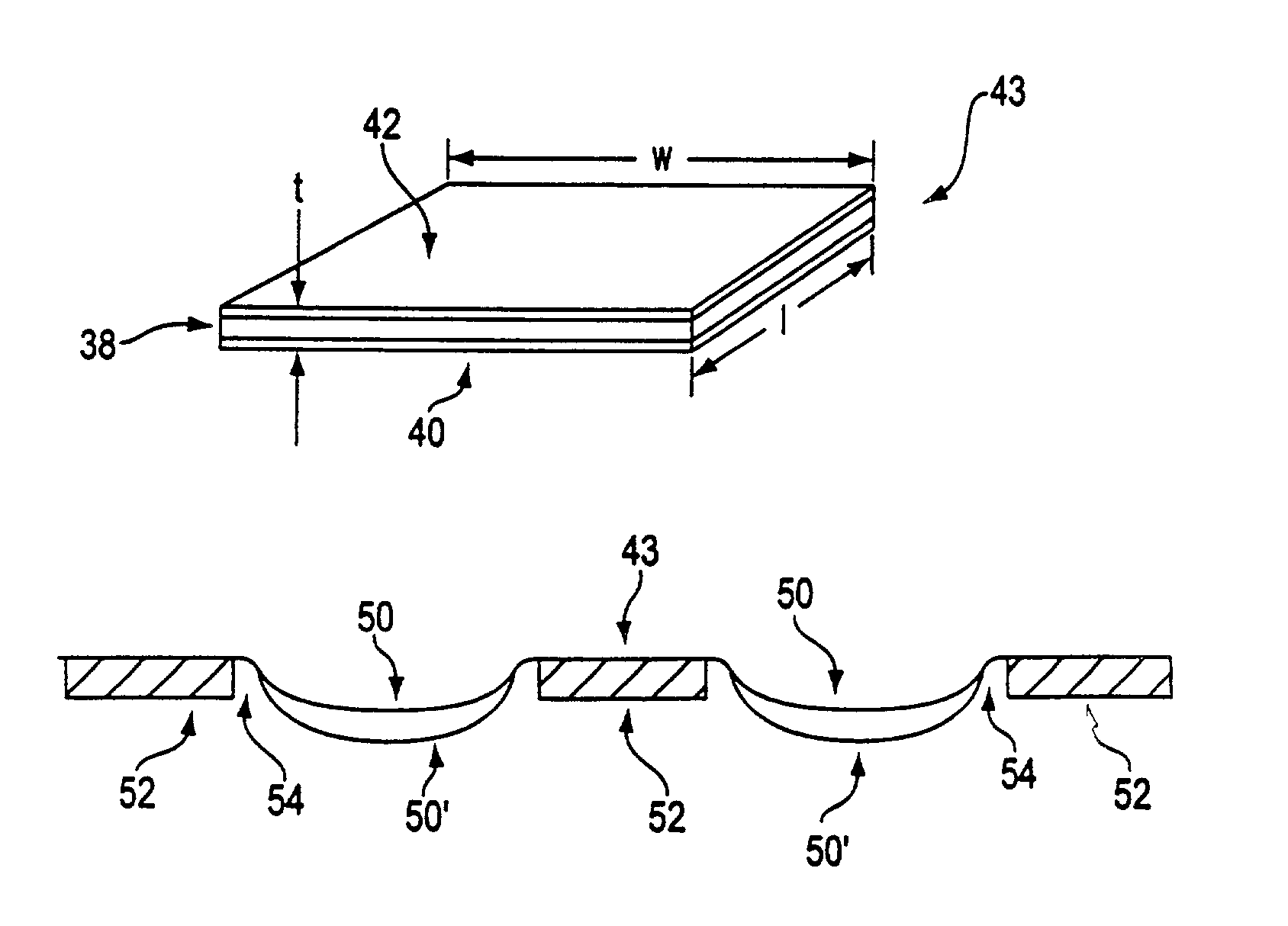

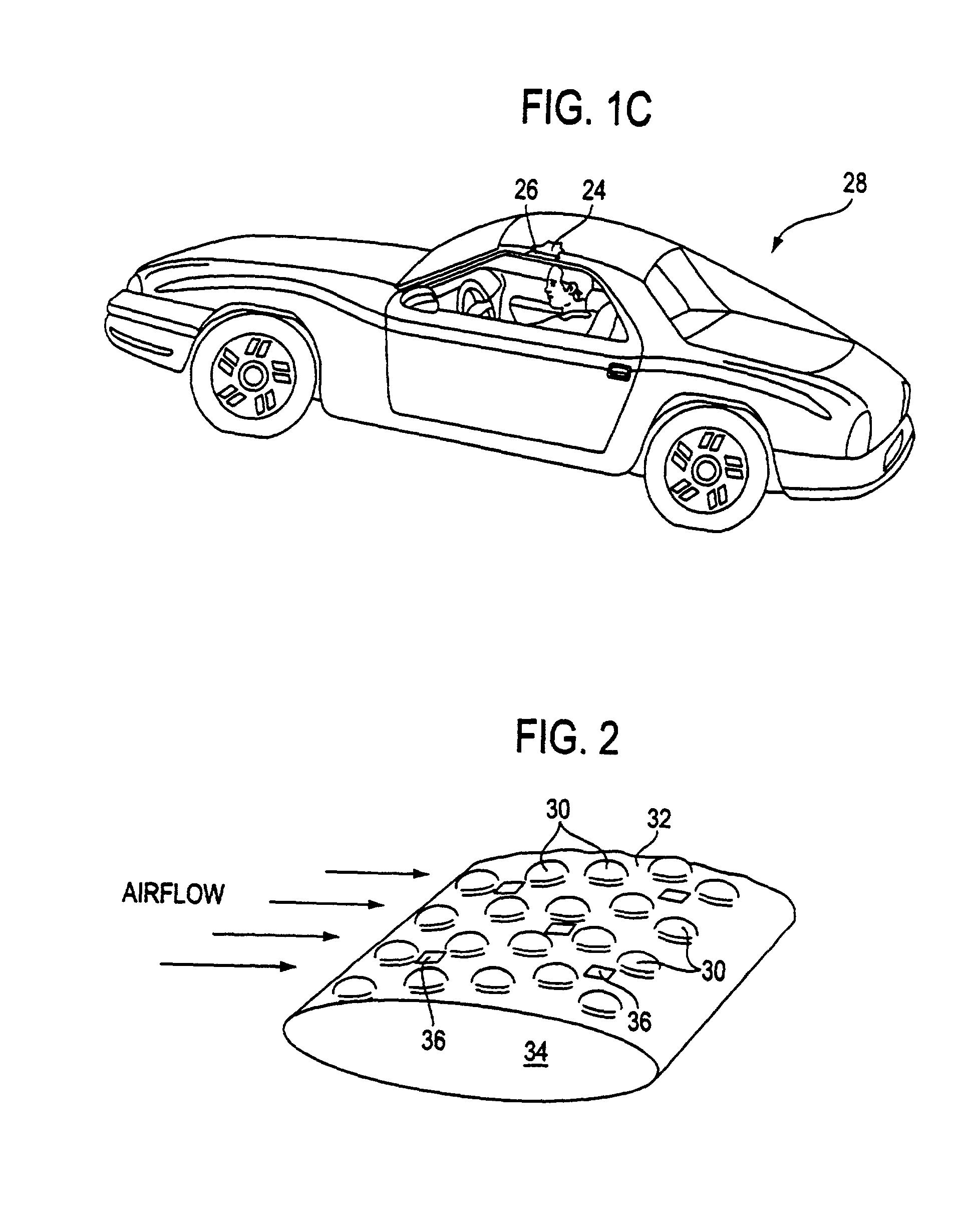

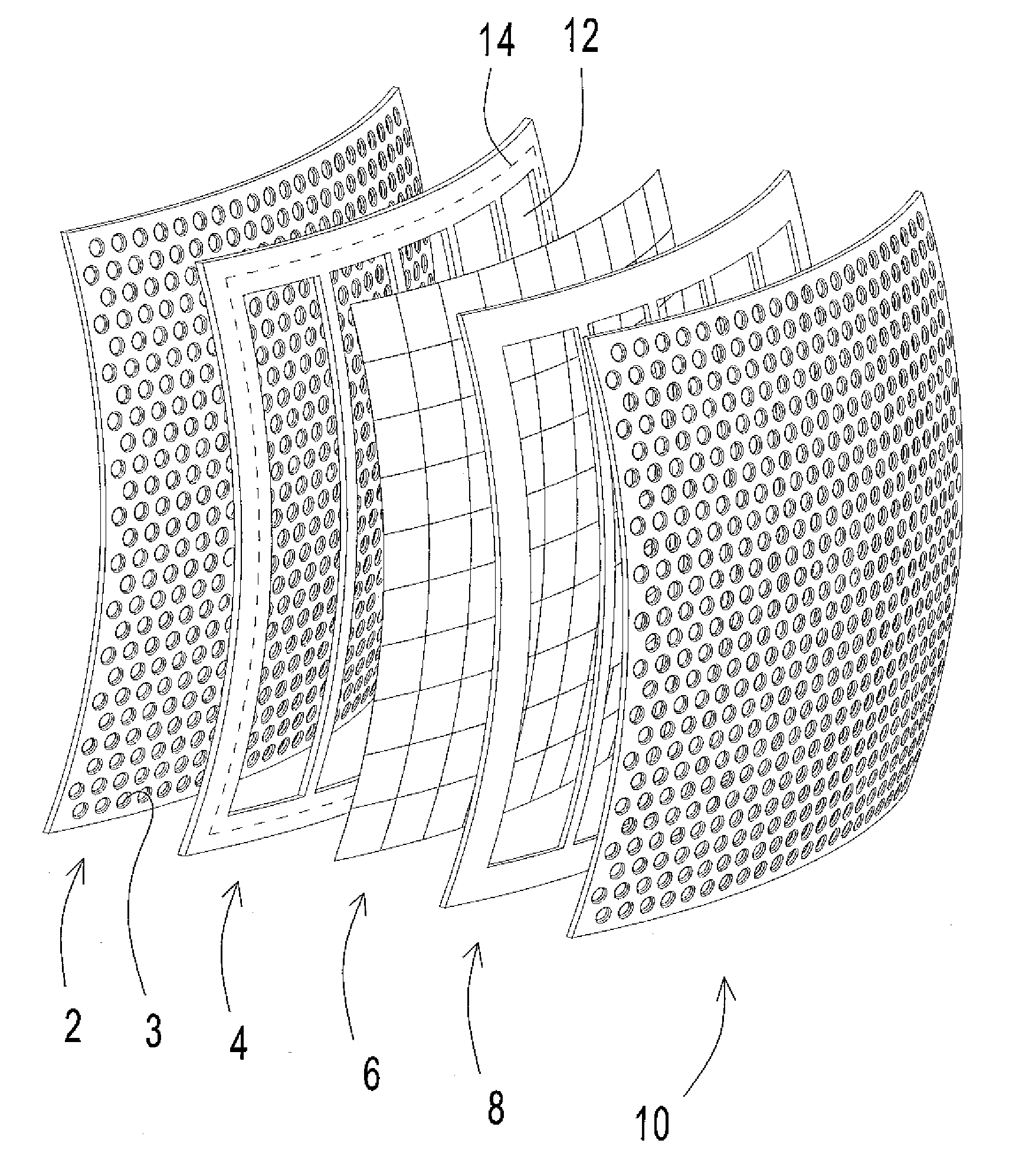

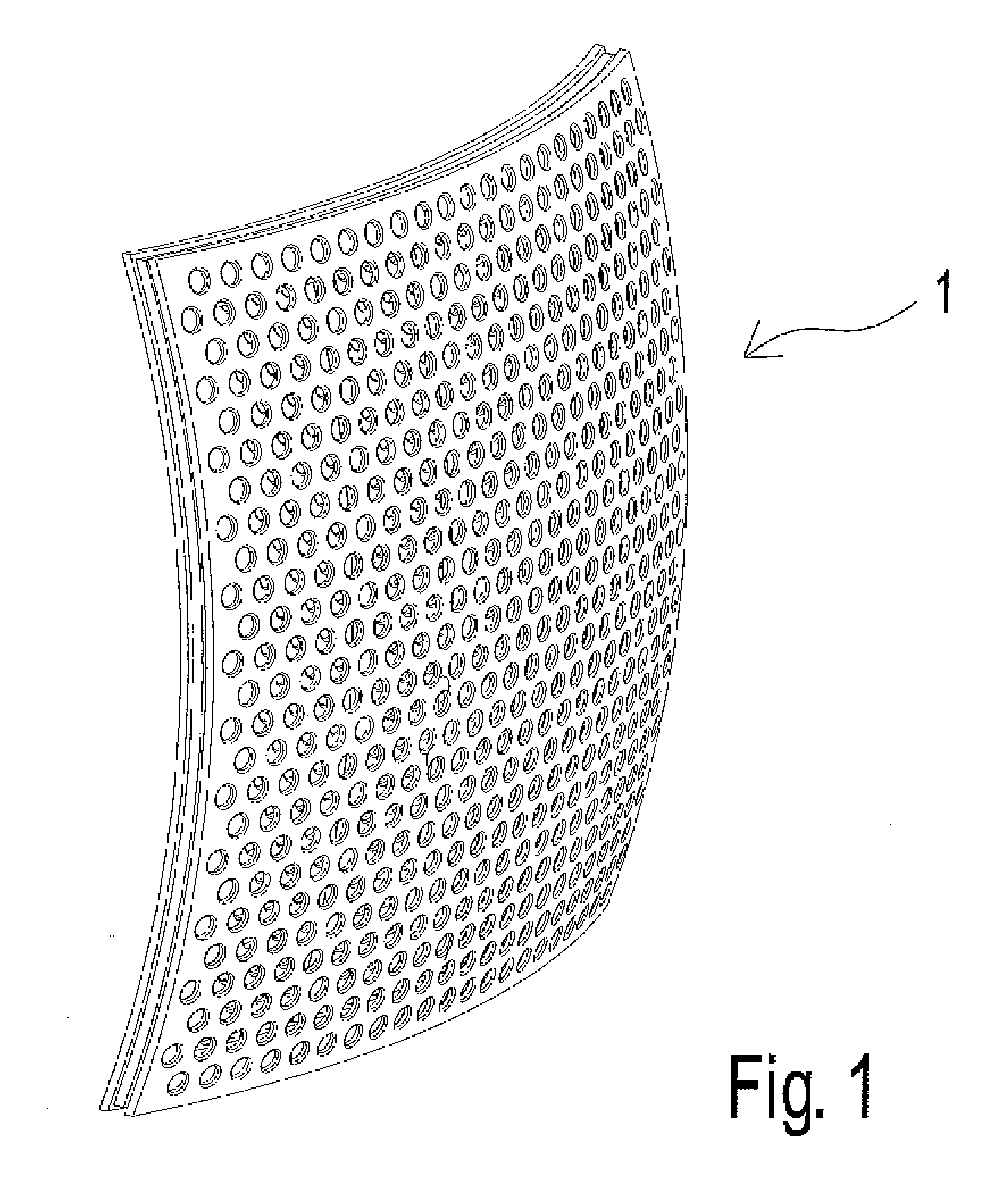

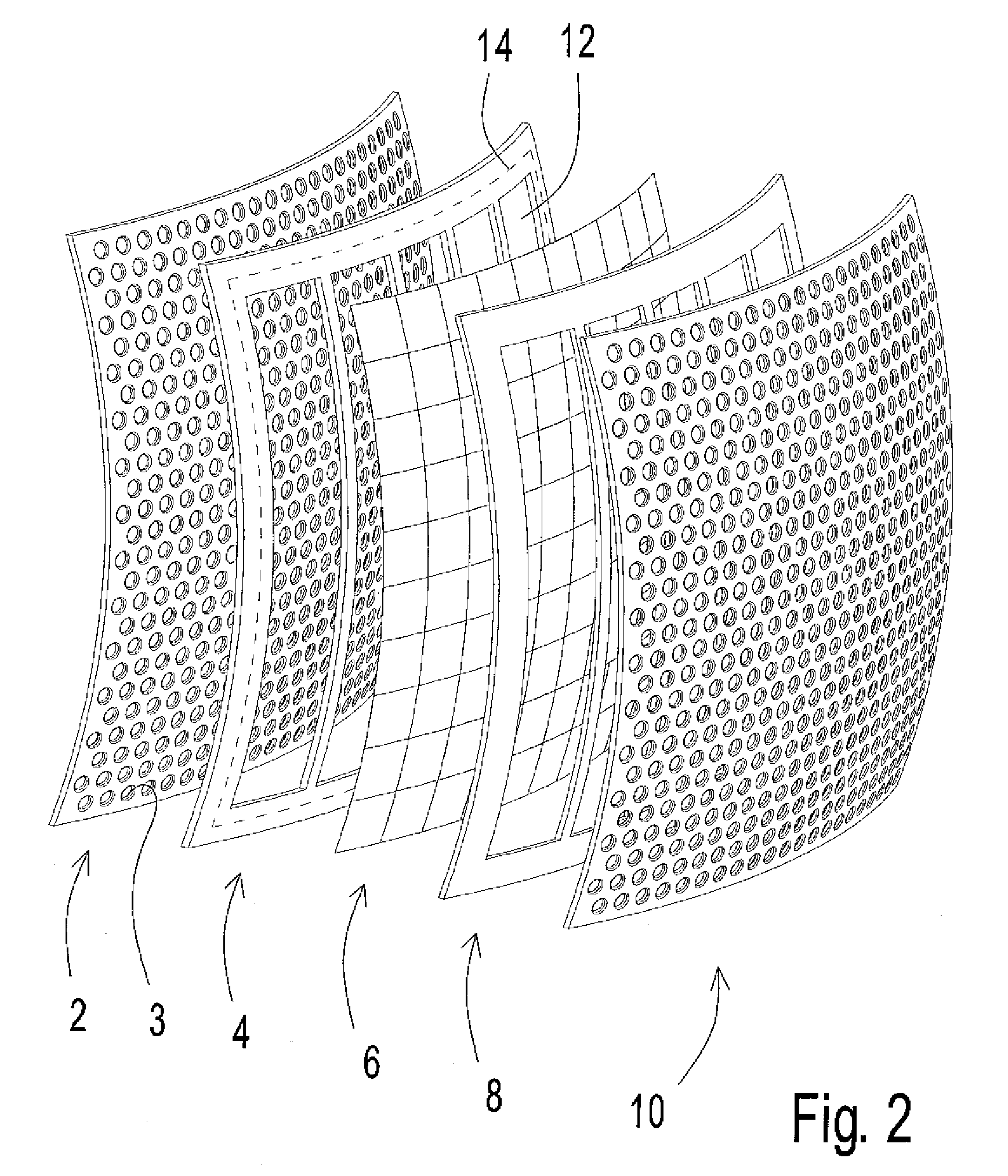

Elastomeric dielectric polymer film sonic actuator

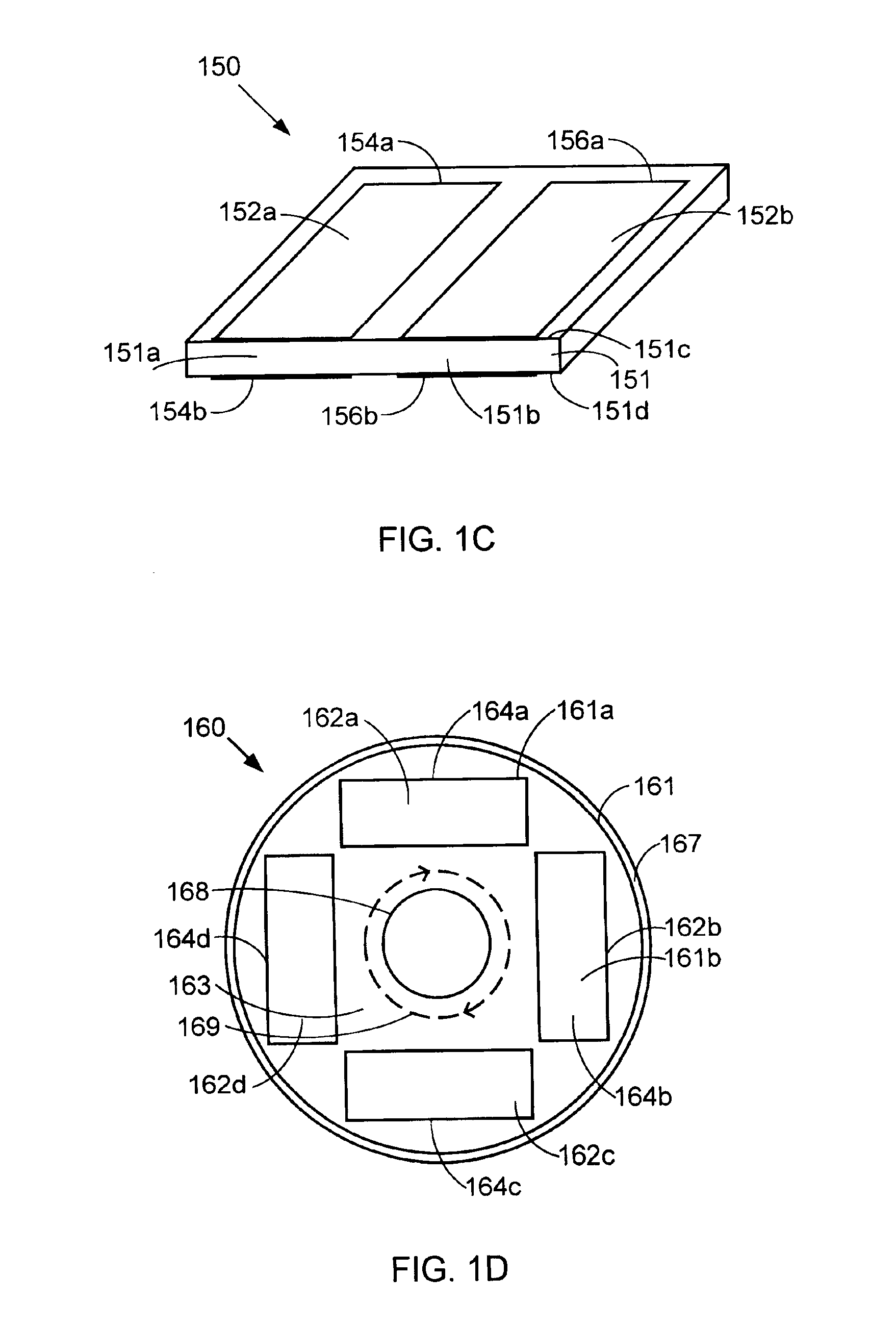

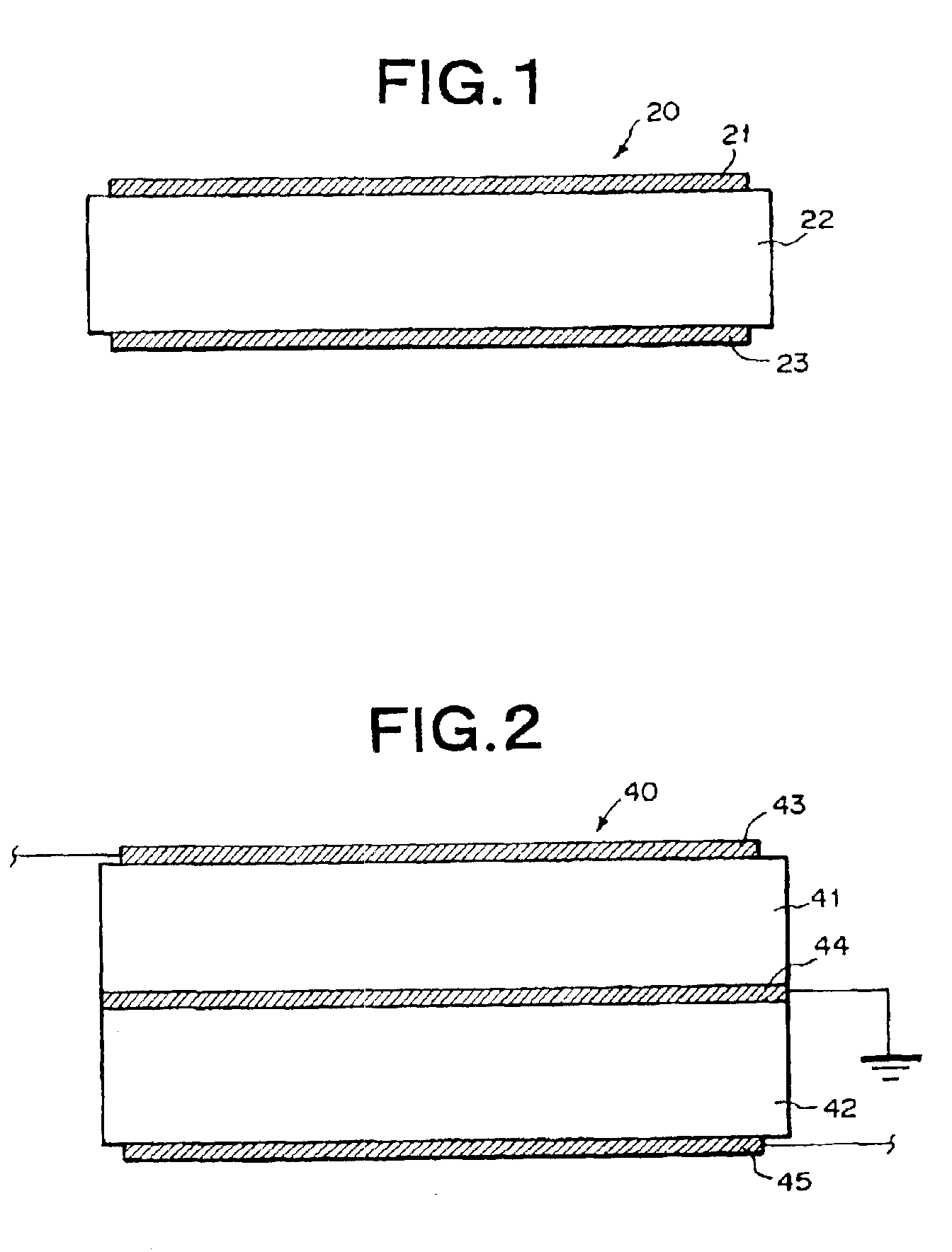

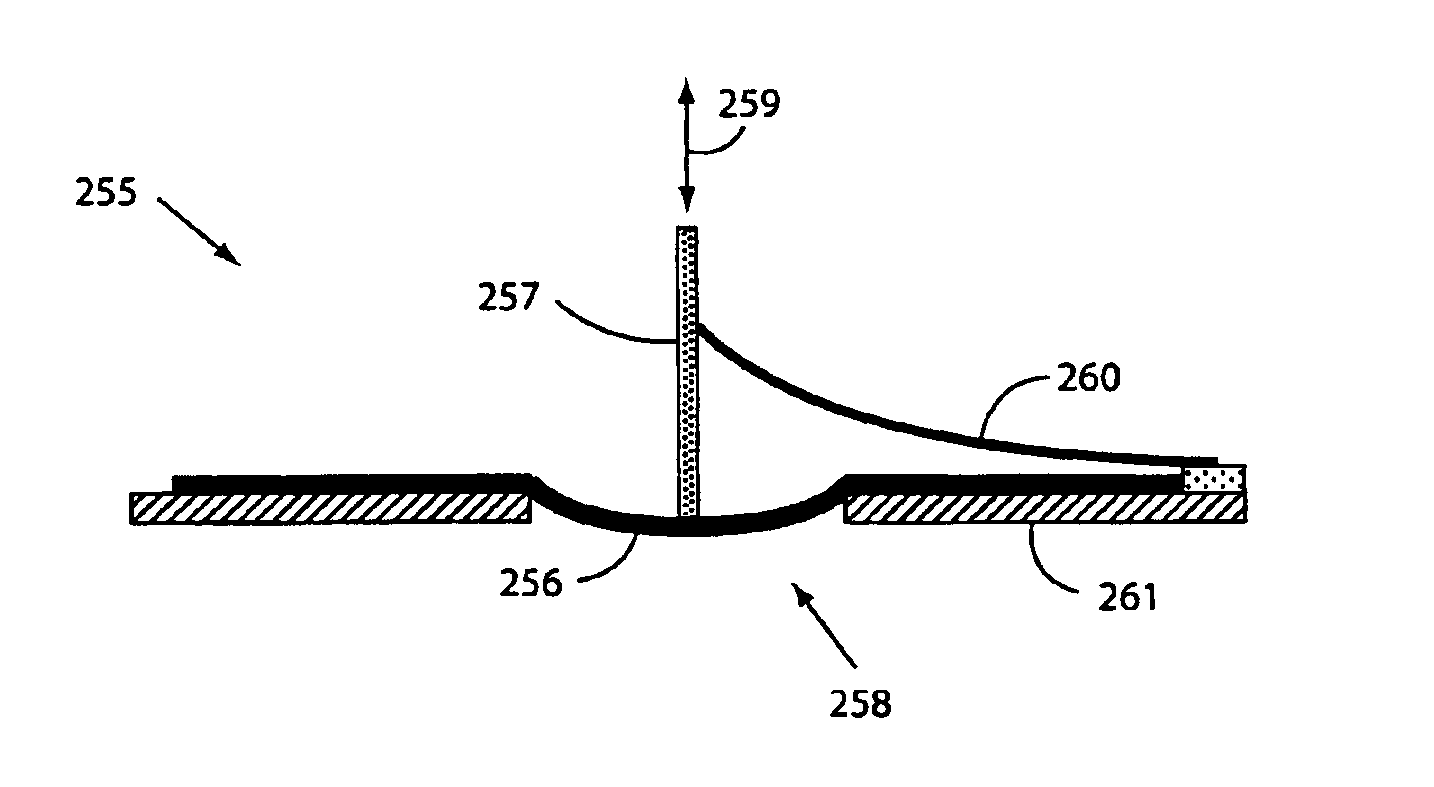

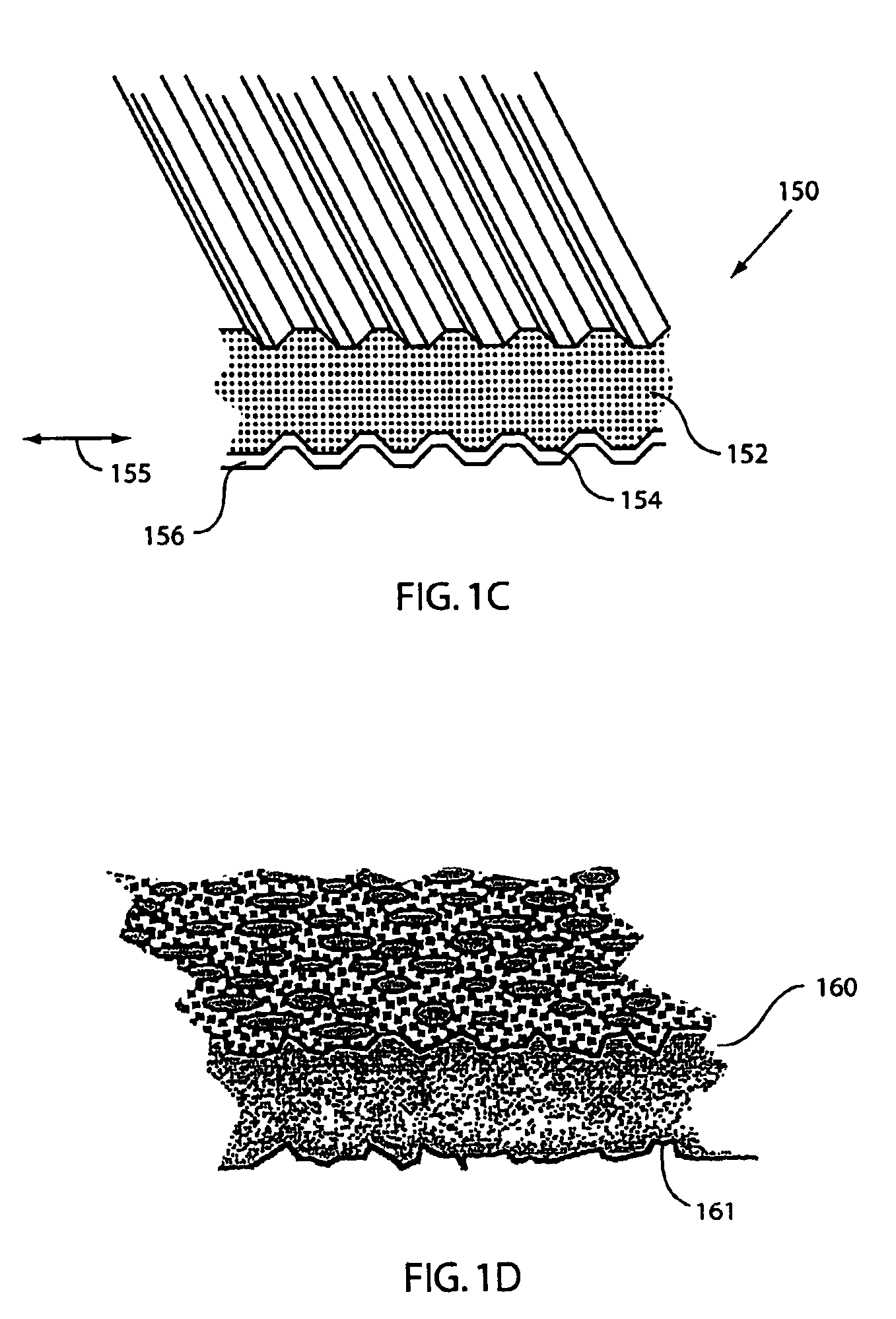

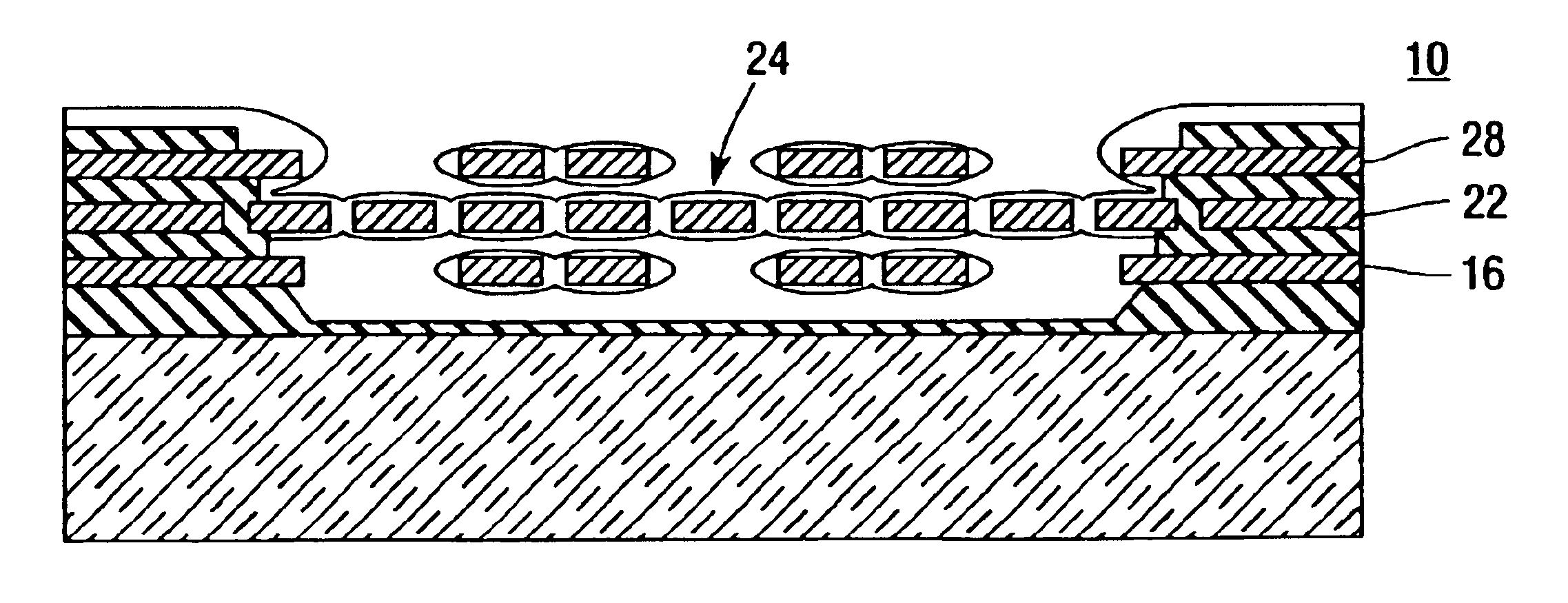

InactiveUS7062055B2Optimize power outputLow working voltagePiezoelectric/electrostrictive gramophone pickupsStirling type enginesDielectricConductive polymer

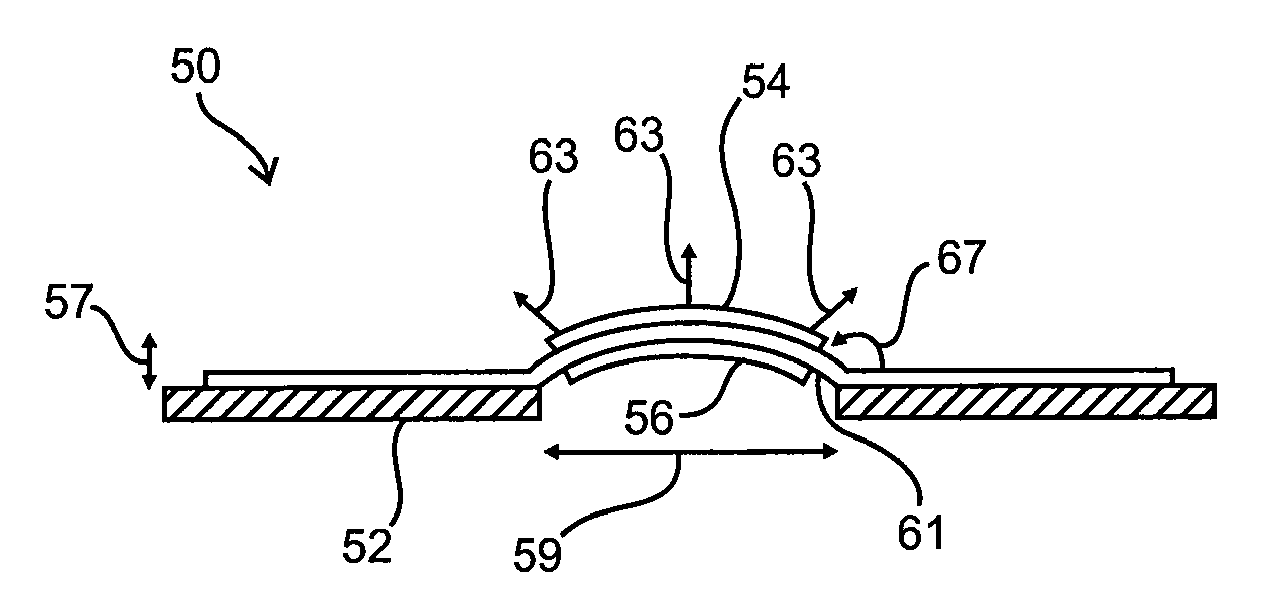

A sonic actuator including a multi-layer membrane having a non-metallic elastomeric dielectric polymer layer with a first surface and a second surface, a first compliant electrode layer contacting the first surface of the polymer layer, and a second compliant electrode layer contacting the second surface of the polymer layer. The actuator further includes a support structure in contact with the sonic actuator film. Preferably, the non-metallic dielectric polymer is selected from the group consisting essentially of silicone, fluorosilicone, fluoroelastomer, natural rubber, polybutadiene, nitrile rubber, isoprene, and ethylene propylene diene. Also preferably, the compliant electrode layer is made from the group consisting essentially of graphite, carbon, and conductive polymers. The support structure can take the form of grid having a number of circular apertures. When a voltage is applied to the electrodes, portions of the film held at the aperture of the support structure can bulge due to the electrostriction phenomenon. The resultant “bubbles” can be modulated to generate sonic vibrations, or can be used to create a variable surface for airflow control.

Owner:SRI INTERNATIONAL

Silicon microphone

InactiveUS7023066B2Simplify the manufacturing processMinimizes parasitic capacitanceSemiconductor electrostatic transducersSemiconductor/solid-state device manufacturingEngineeringSound pressure

A solid-state transducer is disclosed. The transducer comprises a semi-conductor substrate forming a support structure and having an opening. A thin-film structure forming a diaphragm responsive to fluid-transmitted acoustic pressure is disposed over the opening. The transducer further includes a plurality of semi-conductor supports and tangential arms extending from the diaphragm edge for connecting the periphery of the diaphragm to the supports. The tangential arms permit the diaphragm to rotate relative to the supports to relieve film stress in the diaphragm. The transducer still further includes a plurality of stop bumps disposed between the substrate and the diaphragm. The stop bumps determine the separation of the diaphragm from the substrate when the transducer is biased.

Owner:KNOWLES ELECTRONICS INC

Electroactive polymers

InactiveUS20060113880A1Speed up the conversion processImprove responseTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesPre strainActive polymer

The present invention relates to transducers, their use and fabrication. The transducers convert between mechanical and electrical energy. Some transducers of the present invention include a pre-strained polymer. The pre-strain improves the conversion between electrical and mechanical energy. The present invention also relates to devices including an electroactive polymer to convert between electrical and mechanical energy. The present invention further relates to compliant electrodes that conform to the shape of a polymer included in a transducer. The present invention provides methods for fabricating electromechanical devices including one or more electroactive polymers.

Owner:SRI INTERNATIONAL

Electroactive polymer generators

InactiveUS20060238066A1Speed up the conversion processImprove responseTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesPre strainActive polymer

The present invention relates to transducers, their use and fabrication. The transducers convert between mechanical and electrical energy. Some transducers of the present invention include a pre-strained polymer. The pre-strain improves the conversion between electrical and mechanical energy. The present invention also relates to devices including an electroactive polymer to convert between electrical and mechanical energy. The present invention further relates to compliant electrodes that conform to the shape of a polymer included in a transducer. The present invention provides methods for fabricating electromechanical devices including one or more electroactive polymers.

Owner:SRI INTERNATIONAL

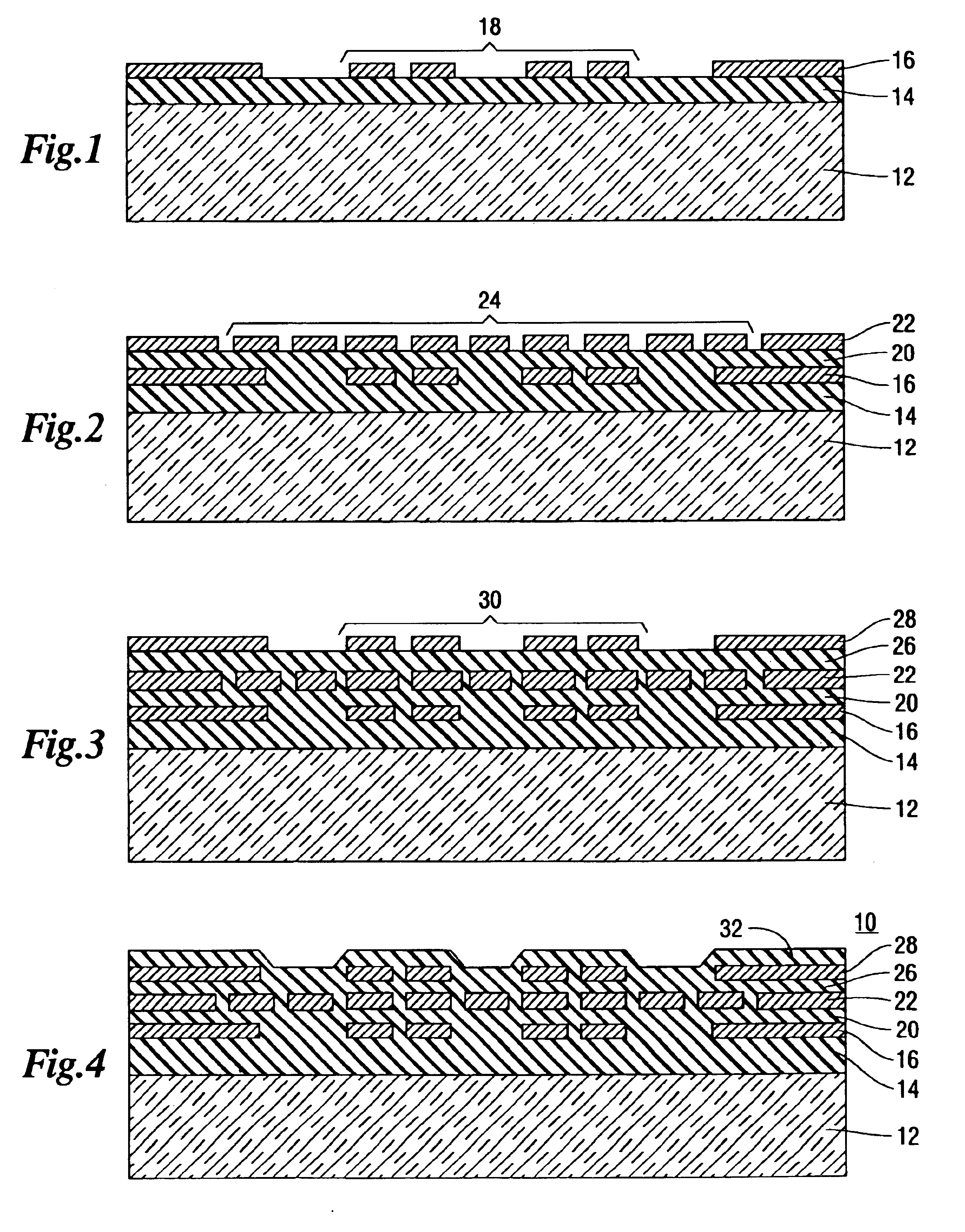

Multi-metal layer MEMS structure and process for making the same

The present invention is directed to a structure comprised of alternating layers of metal and sacrificial material built up using standard CMOS processing techniques, a process for building such a structure, a process for fabricating devices from such a structure, and the devices fabricated from such a structure. In one embodiment, a first metal layer is carried by a substrate. A first sacrificial layer is carried by the first metal layer. A second metal layer is carried by the sacrificial layer. The second metal layer has a portion forming a micro-machined metal mesh. When the portion of the first sacrificial layer in the area of the micro-machined metal mesh is removed, the micro-machined metal mesh is released and suspended above the first metal layer a height determined by the thickness of the first sacrificial layer. The structure may be varied by providing a base layer of sacrificial material between the surface of the substrate and the first metal layer. In that manner, a portion of the first metal layer may form a micro-machined mesh which is released when a portion of the base sacrificial layer in the area of the micro-machined mesh is removed. Additionally, a second layer of sacrificial material and a third metal layer may be provided. A micro-machined mesh may be formed in a portion of the third metal layer. The structure of the present invention may be used to construct variable capacitors, switches and, when certain of the meshes are sealed, microspeakers and microphones.

Owner:AKUSTICA

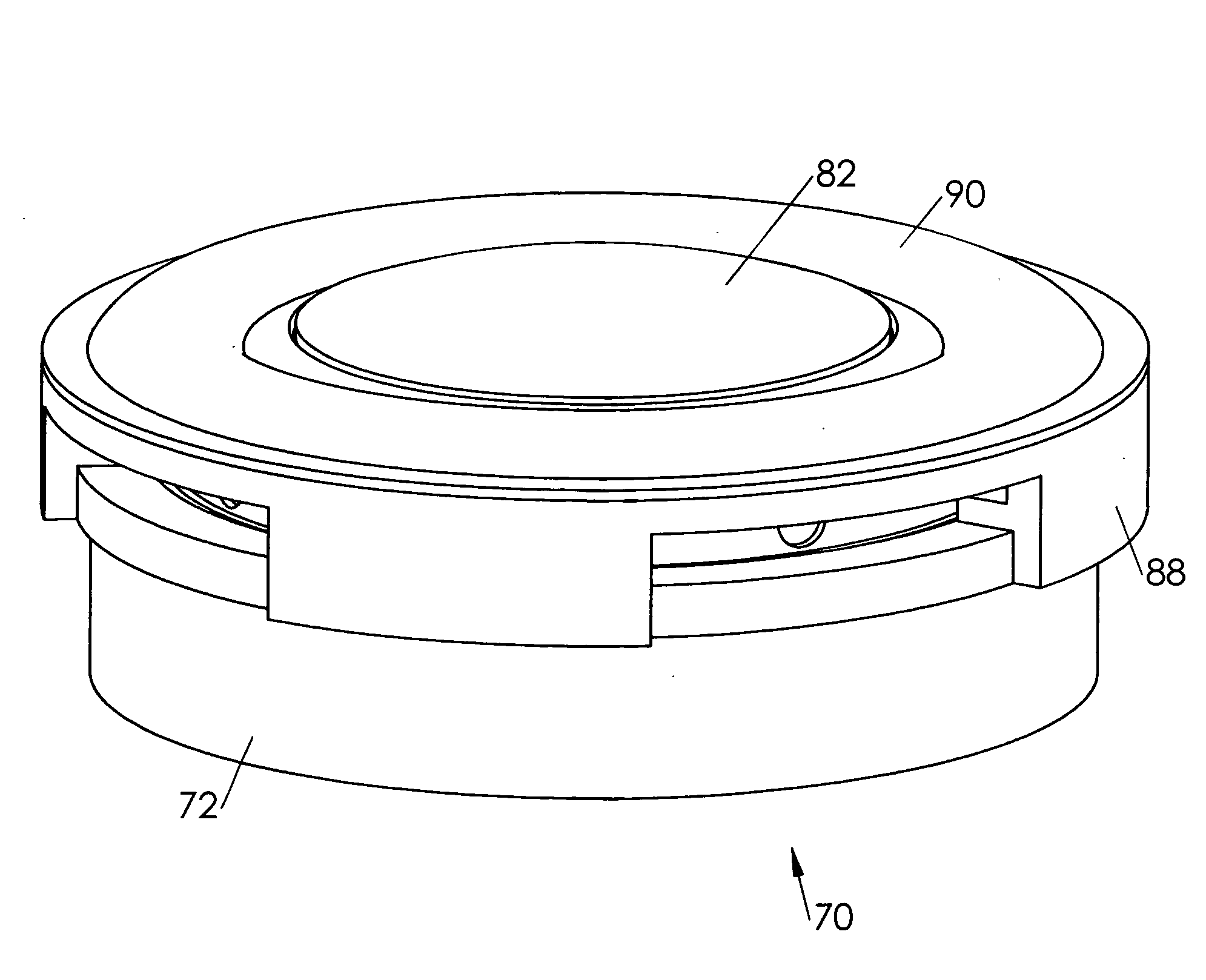

Compliant electroactive polymer transducers for sonic applications

InactiveUS7608989B2Piezoelectric/electrostriction/magnetostriction machinesElectrostatic transducer loudspeakersPolymer scienceSound generation

Described herein are compliant electroactive polymer transducers for use in acoustic applications. A compliant electroactive polymer transducer includes a compliant electroactive polymer at least two electrodes. For sound production, circuitry in electrical communication with the transducer electrodes is configured to apply a driving signal that causes the electroactive polymer to deflect in the acoustic range.

Owner:SRI INTERNATIONAL

Pliable loudspeaker and its making method

InactiveCN1997243ASolve the tight diaphragmSolve functionElectrets selectrostatic transducerElectrostatic transducer loudspeakersEngineeringLoudspeaker

This invention relates to one flexible microphone and its process method, which forms sound to same direction with flexible piezoelectricity materials property by flexible driver parts, vibration film, and vibration electrode to overcome traditional technique defaults.

Owner:VERISONIX

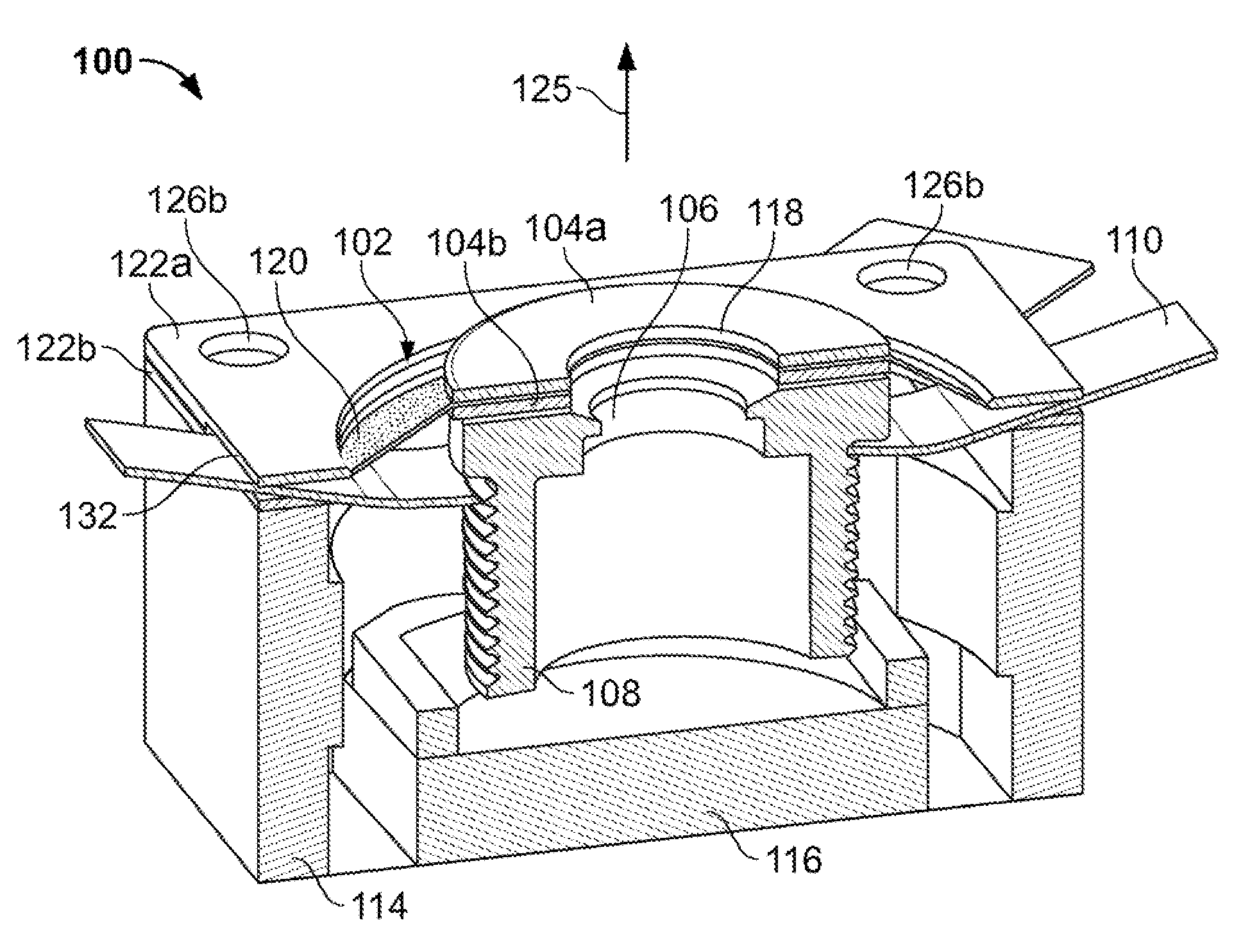

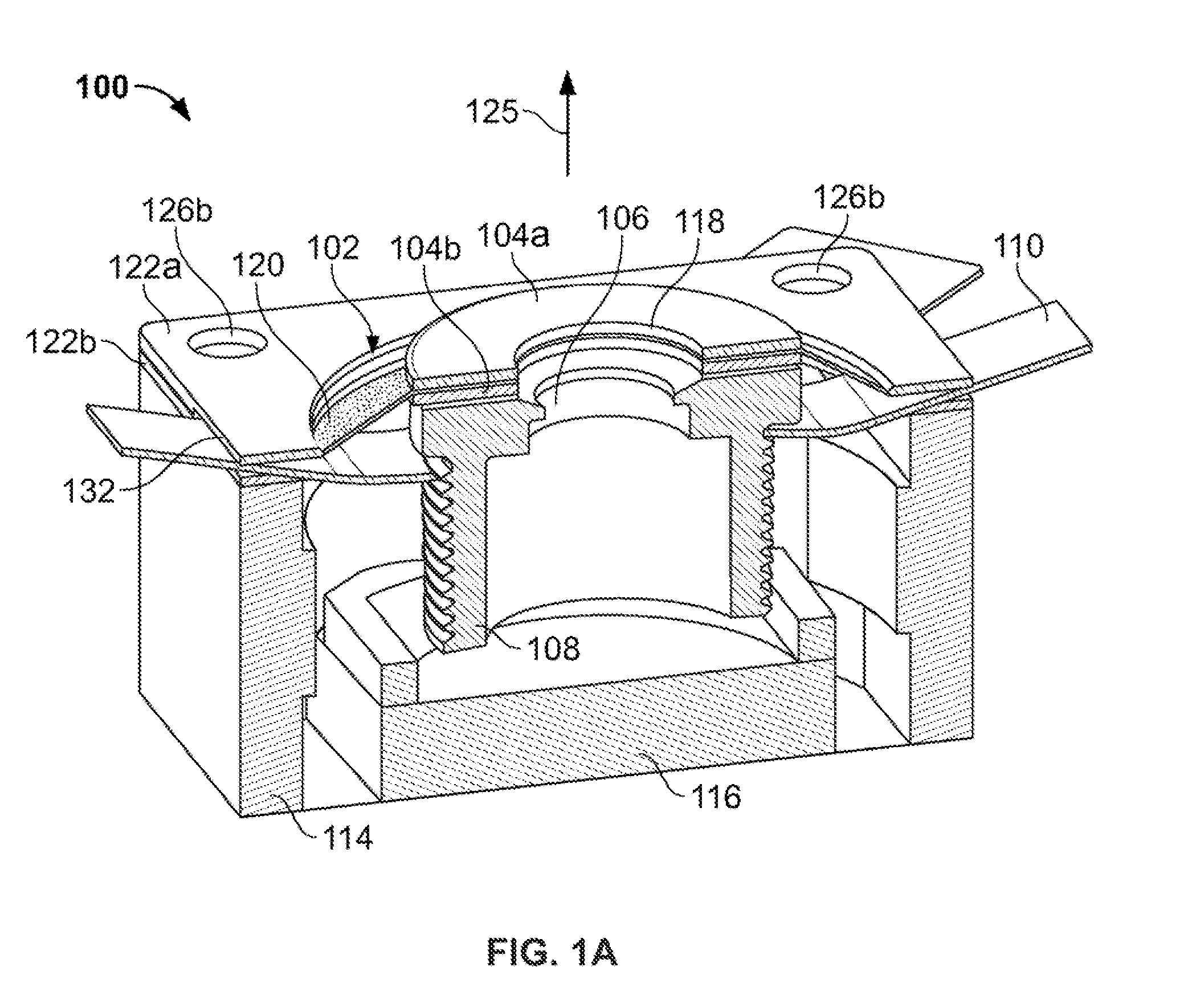

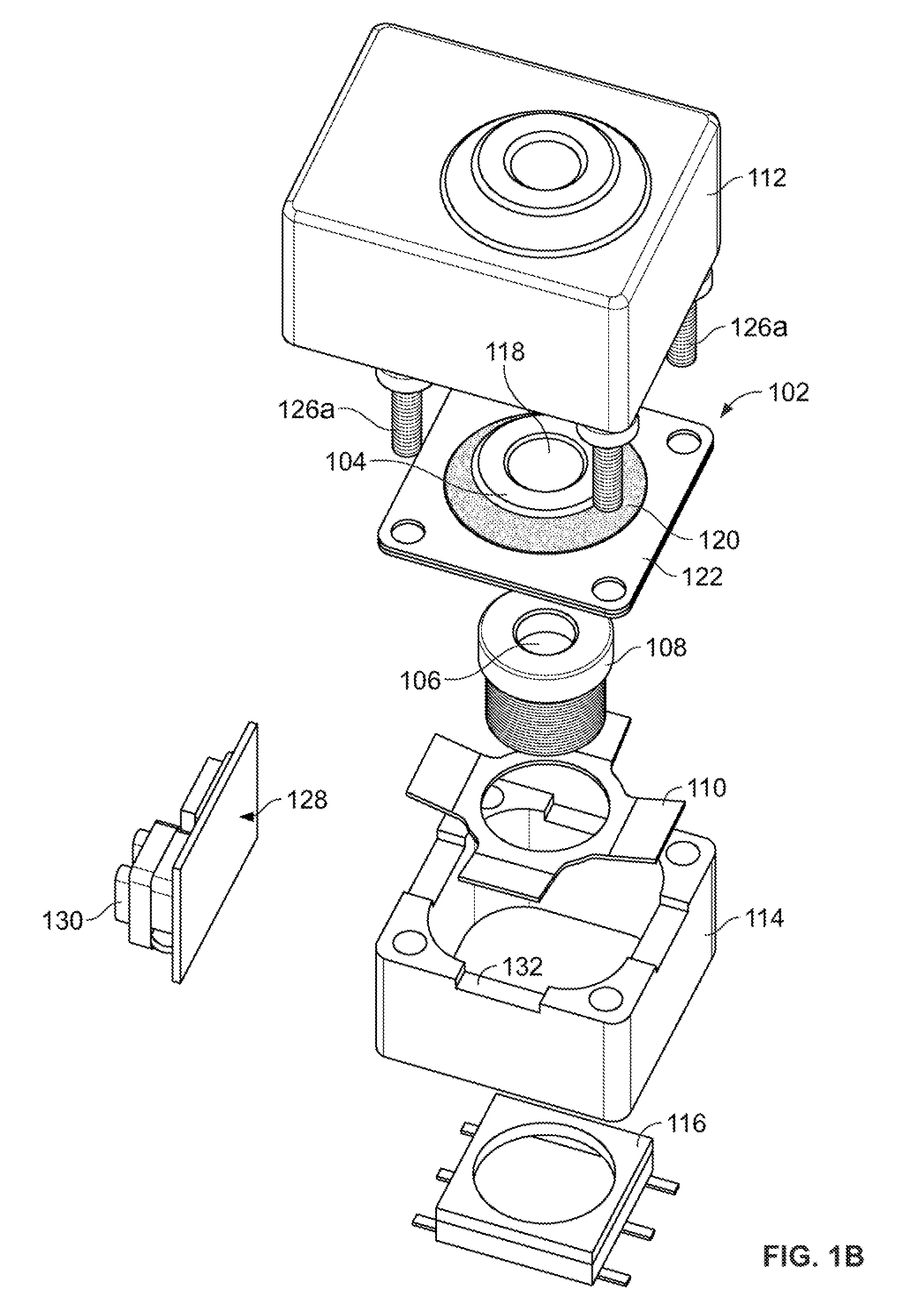

Optical lens displacement systems

ActiveUS20100033835A1Flexible member pumpsElectrostatic transducer loudspeakersElectroactive polymer actuatorsEngineering

The present invention provides optical systems, devices and methods which utilize one or more electroactive polymer actuators to adjust an optical parameter of the optical device or system.

Owner:BAYER MATERIALSCIENCE AG

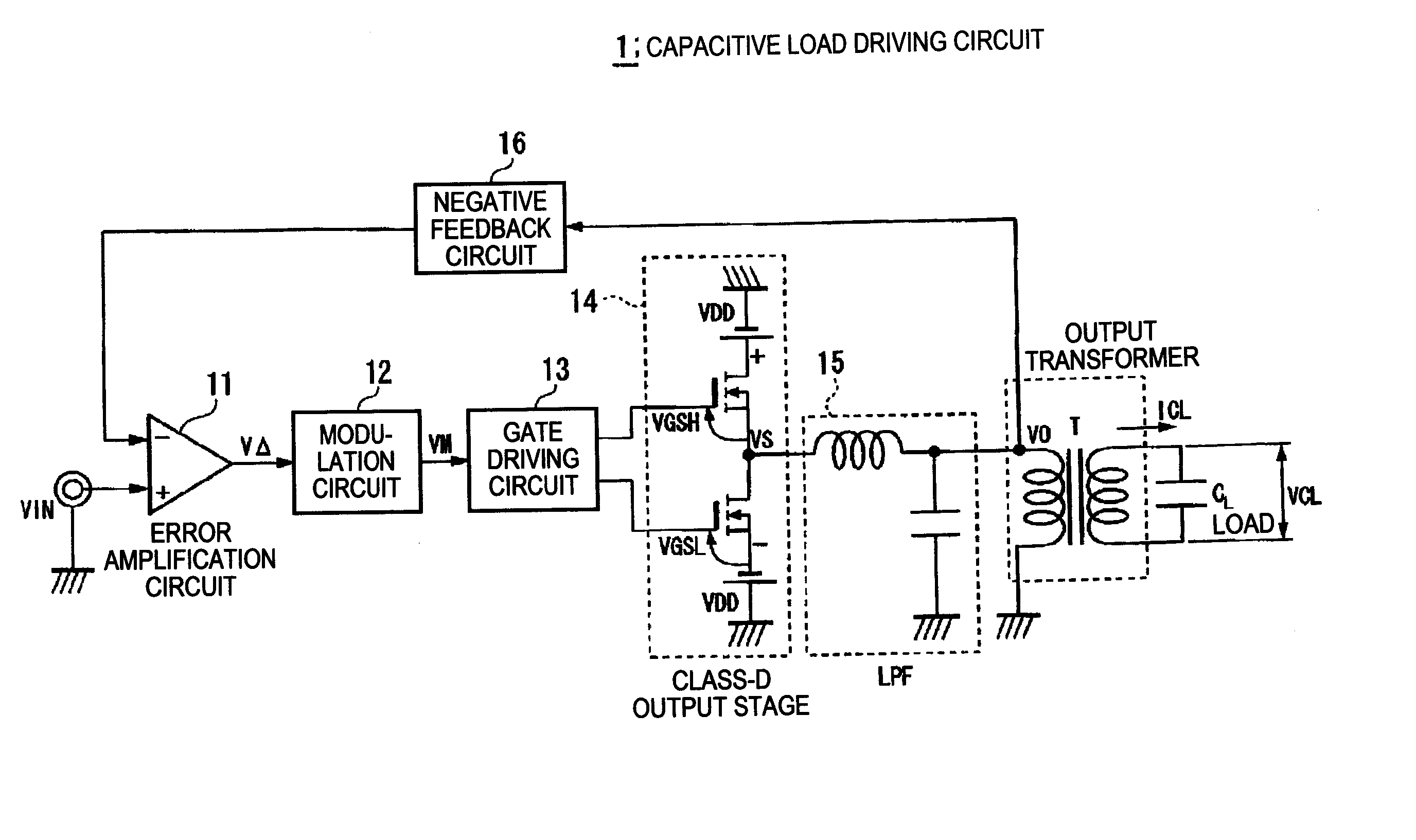

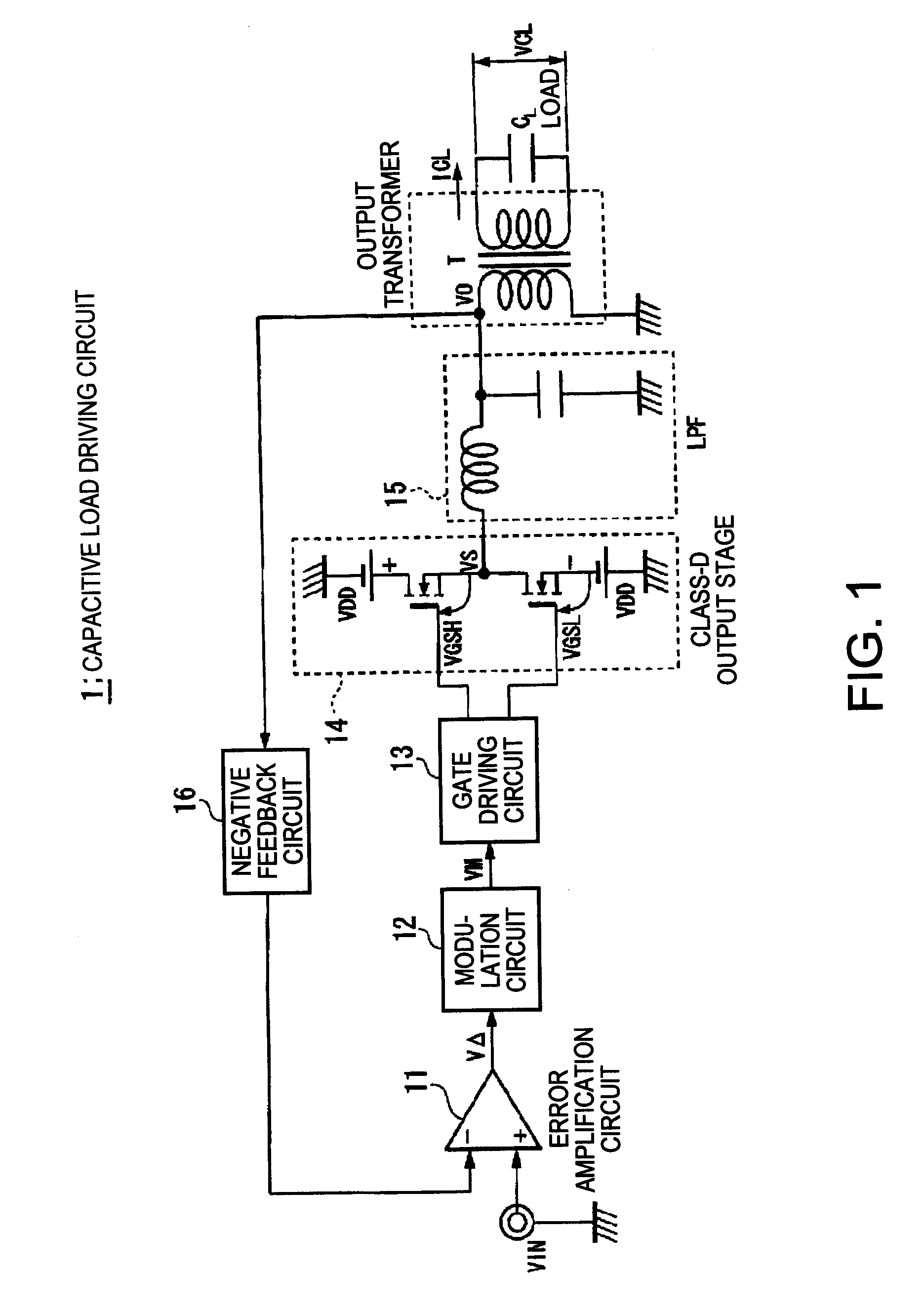

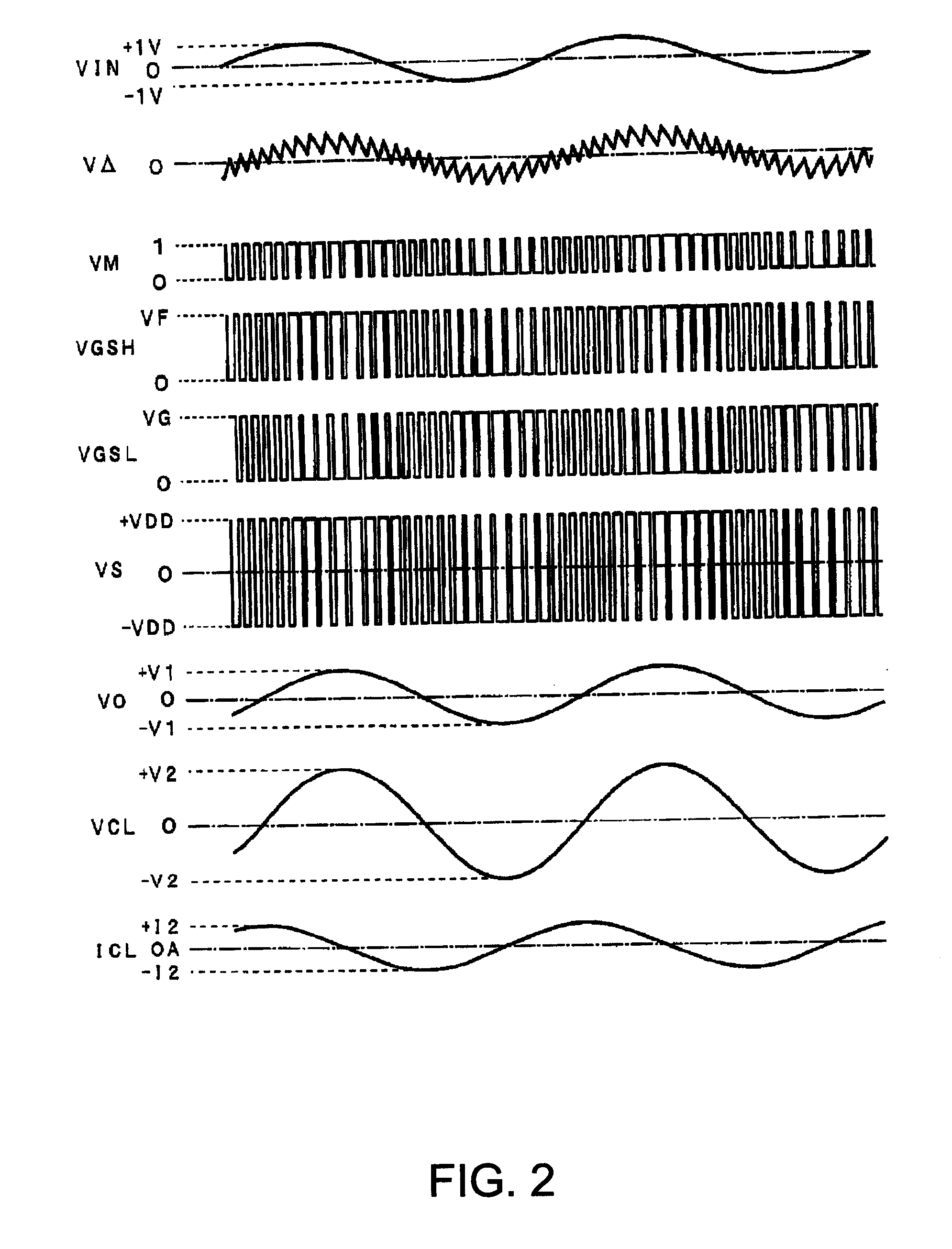

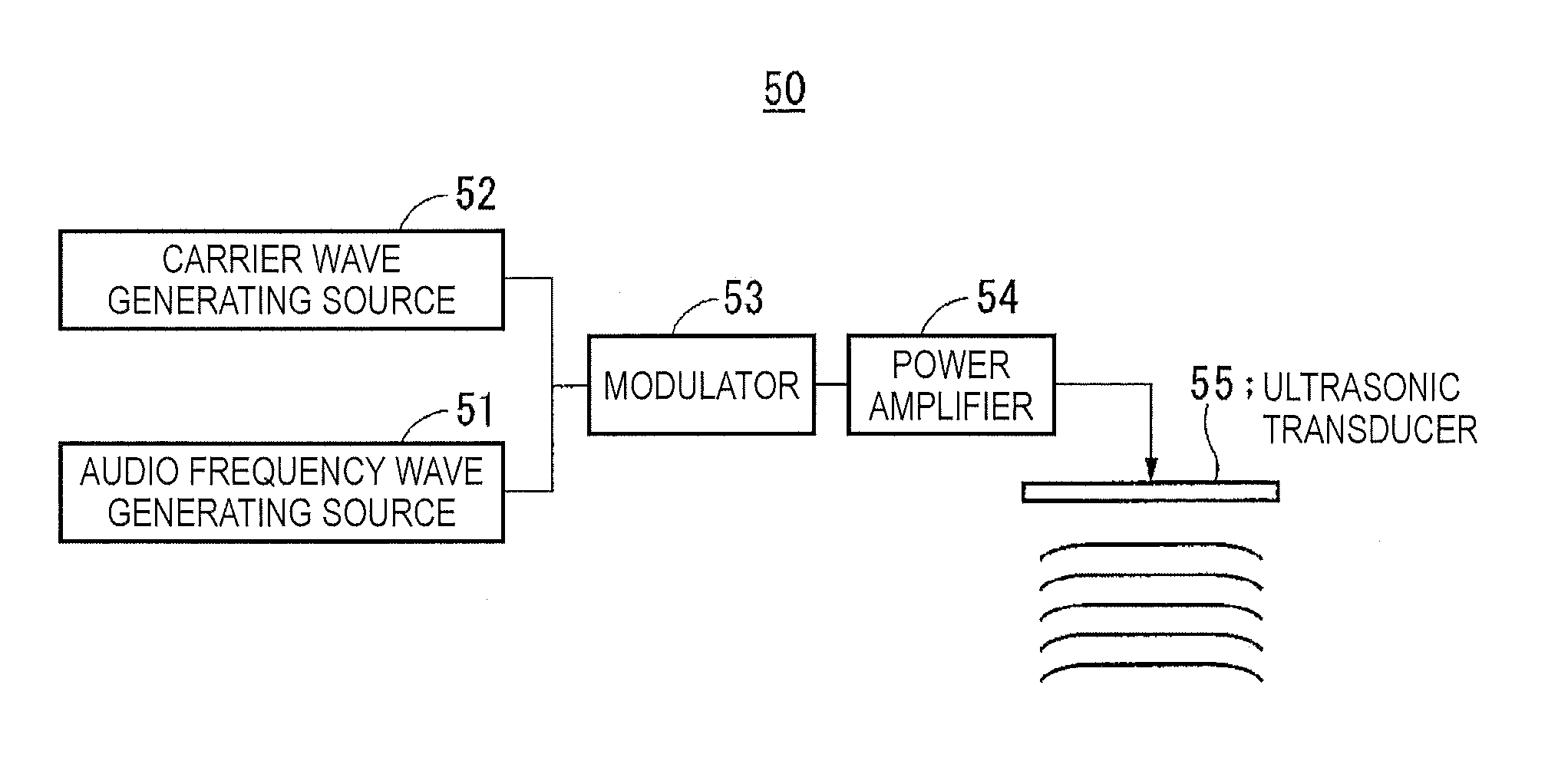

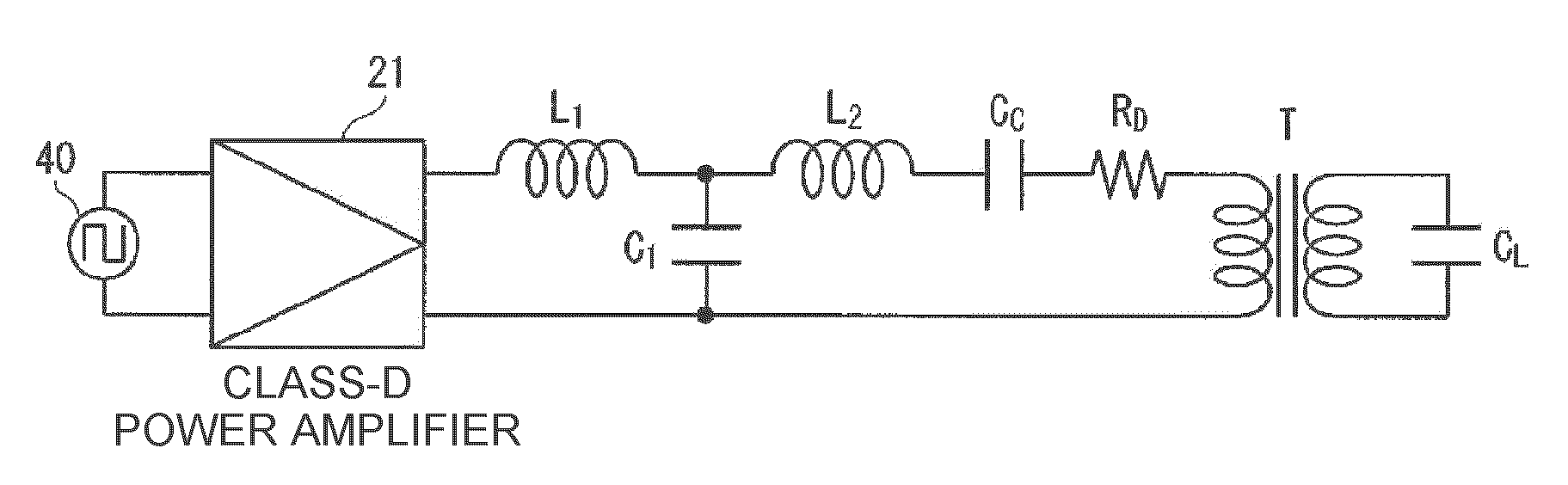

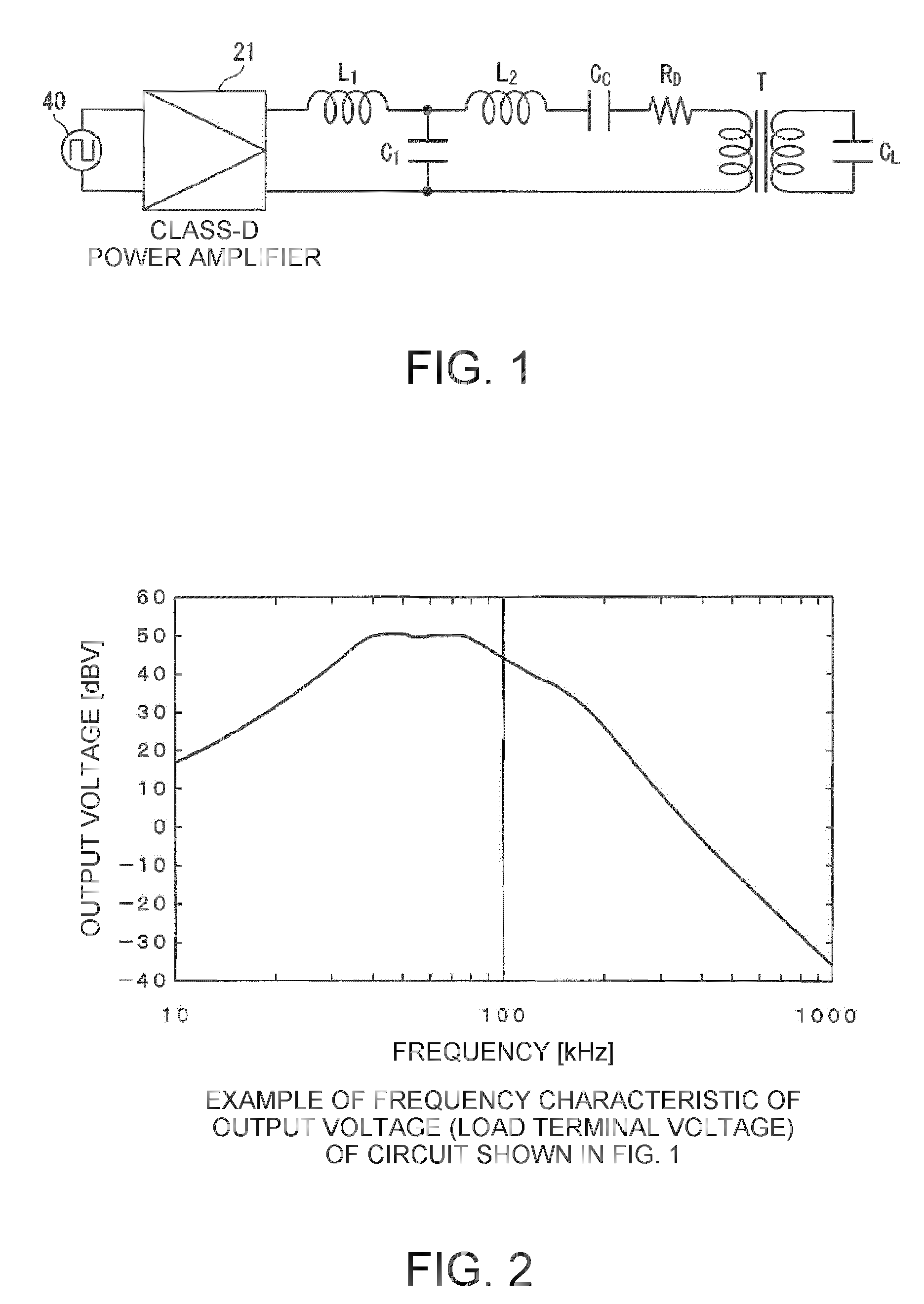

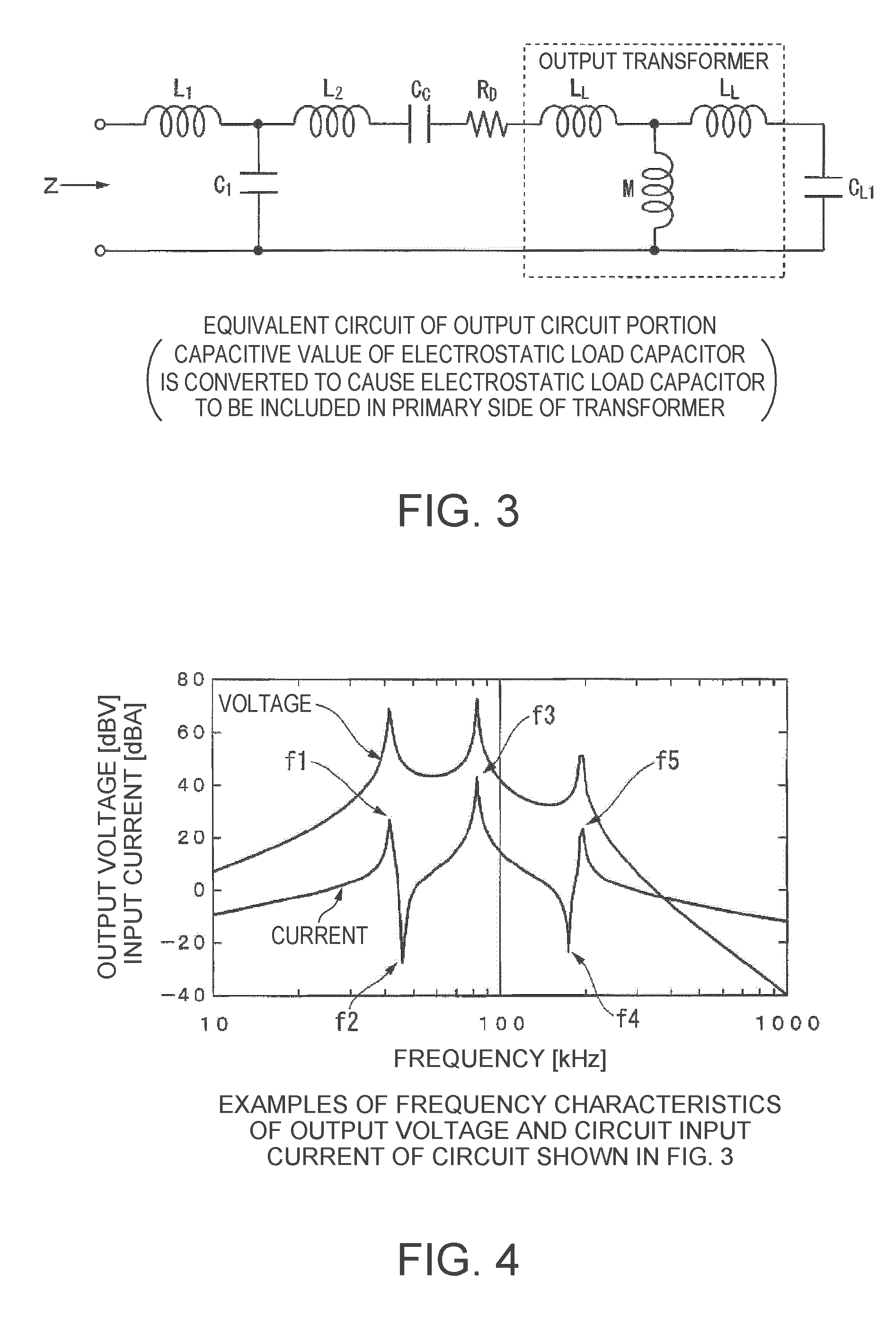

Capacitive load driving circuit, electrostatic transducer, method of setting circuit constant, ultrasonic speaker, display device, and directional acoustic system

InactiveUS20070124620A1Reduce lossImproved sound presenceNegative-feedback-circuit arrangementsDigital data processing detailsCapacitanceOutput transformer

A capacitive load driving circuit includes an error amplification circuit that amplifies a difference between an external input signal provided to one input terminal and a negative feedback signal provided from the following negative feed back circuit to the other input terminal; a modulation circuit that pulse-modulates the signal outputted from the error amplification circuit; a power switching circuit that switches between a power supply voltage and a ground potential or between a positive power supply voltage and a negative power supply voltage; a gate driving circuit that generates a gate driving signal for switching-controlling a switching element configuring the power switching circuit, from a modulated signal outputted from the modulation circuit; a low-pass filter that is connected to an output side of the power switching circuit and removes switching carrier components included in an output signal of the power switching circuit; an output transformer that boosts an output signal of the low-pass filter and has a primary winding connected to an output terminal of the low-pass filter; a capacitive load that is connected in parallel with a secondary winding of the output transformer; and a negative feedback circuit that performs a negative feedback from the output terminal of the low-pass filter to an input side of the error amplification circuit.

Owner:SEIKO EPSON CORP

Electrostatic loudspeaker capable of dispersing sound both horizontally and vertically

ActiveUS20070242844A1Improved dispersion of soundIncreased angular dispersion of soundElectrostatic transducer loudspeakersFrequency/directions obtaining arrangementsEffect lightEngineering

Owner:LUMINOS INDS

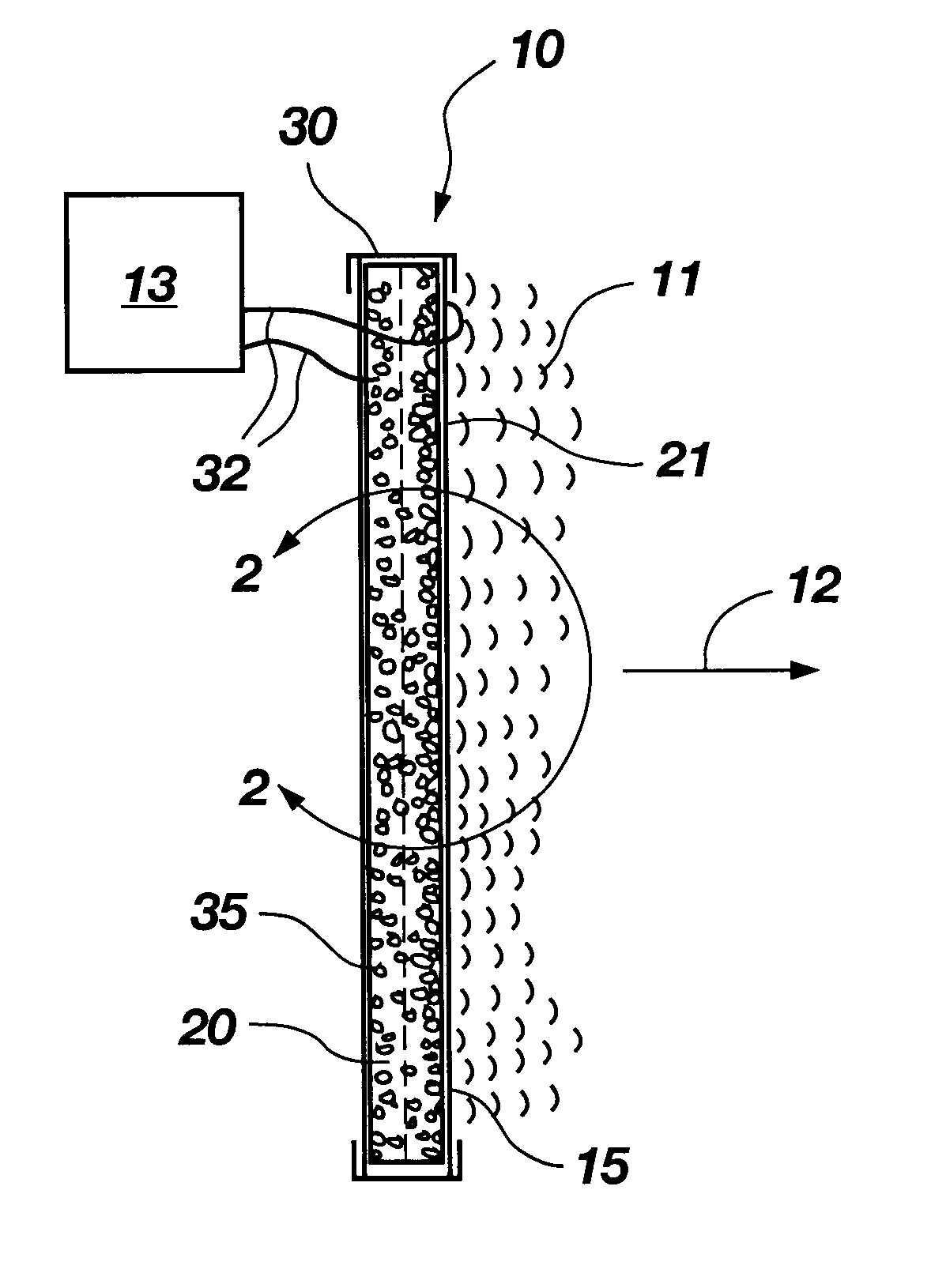

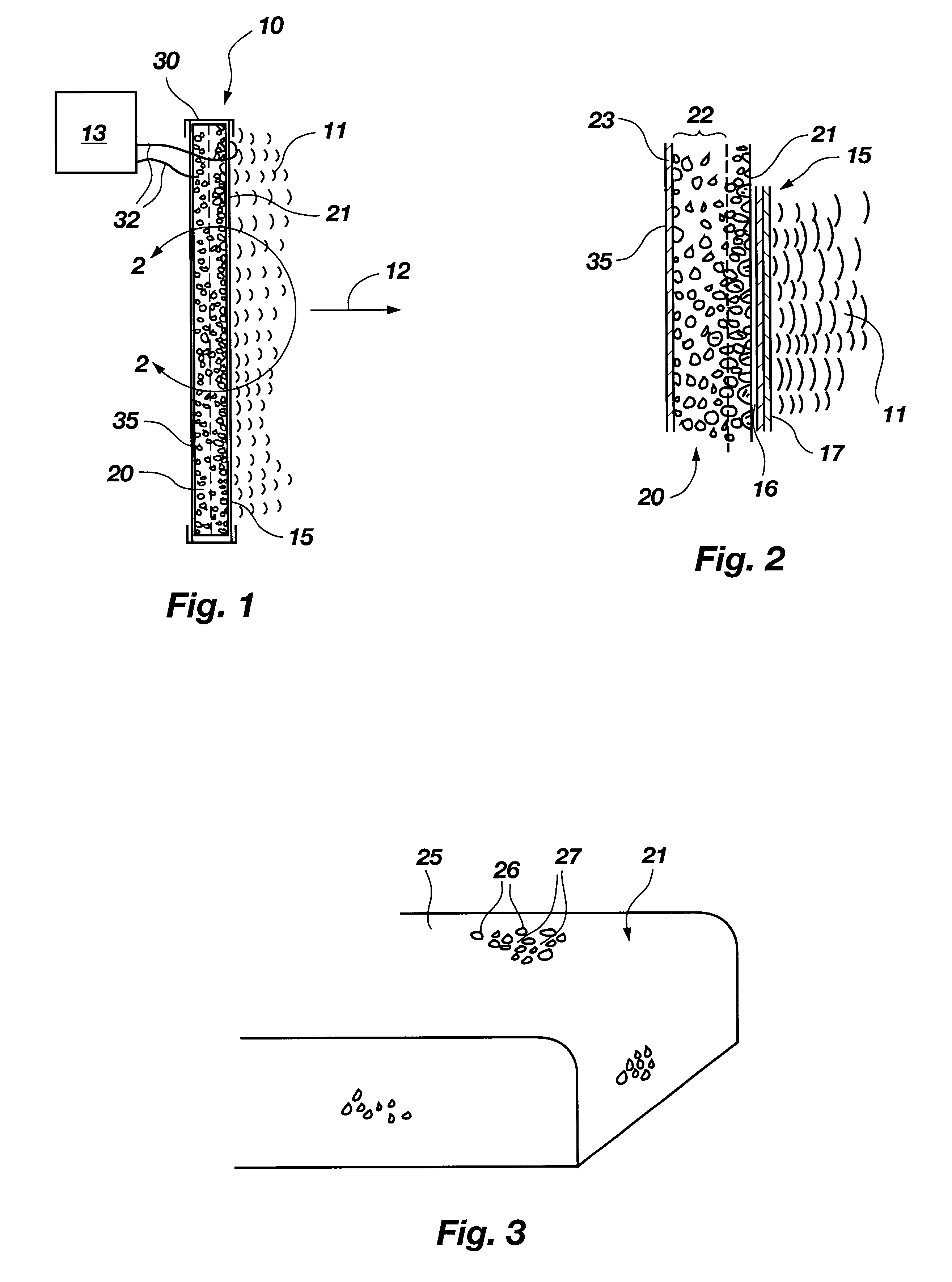

Sound Producing Device

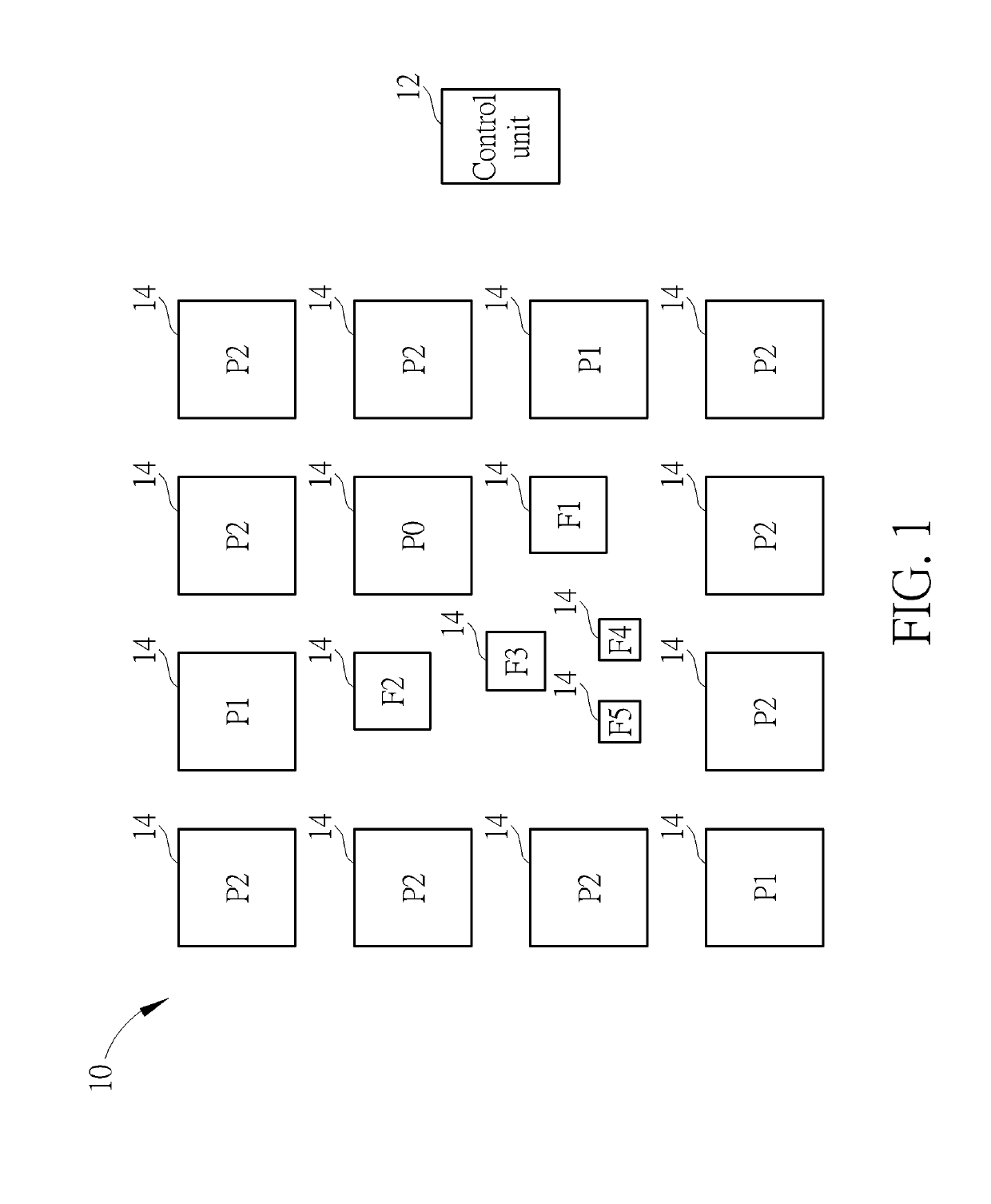

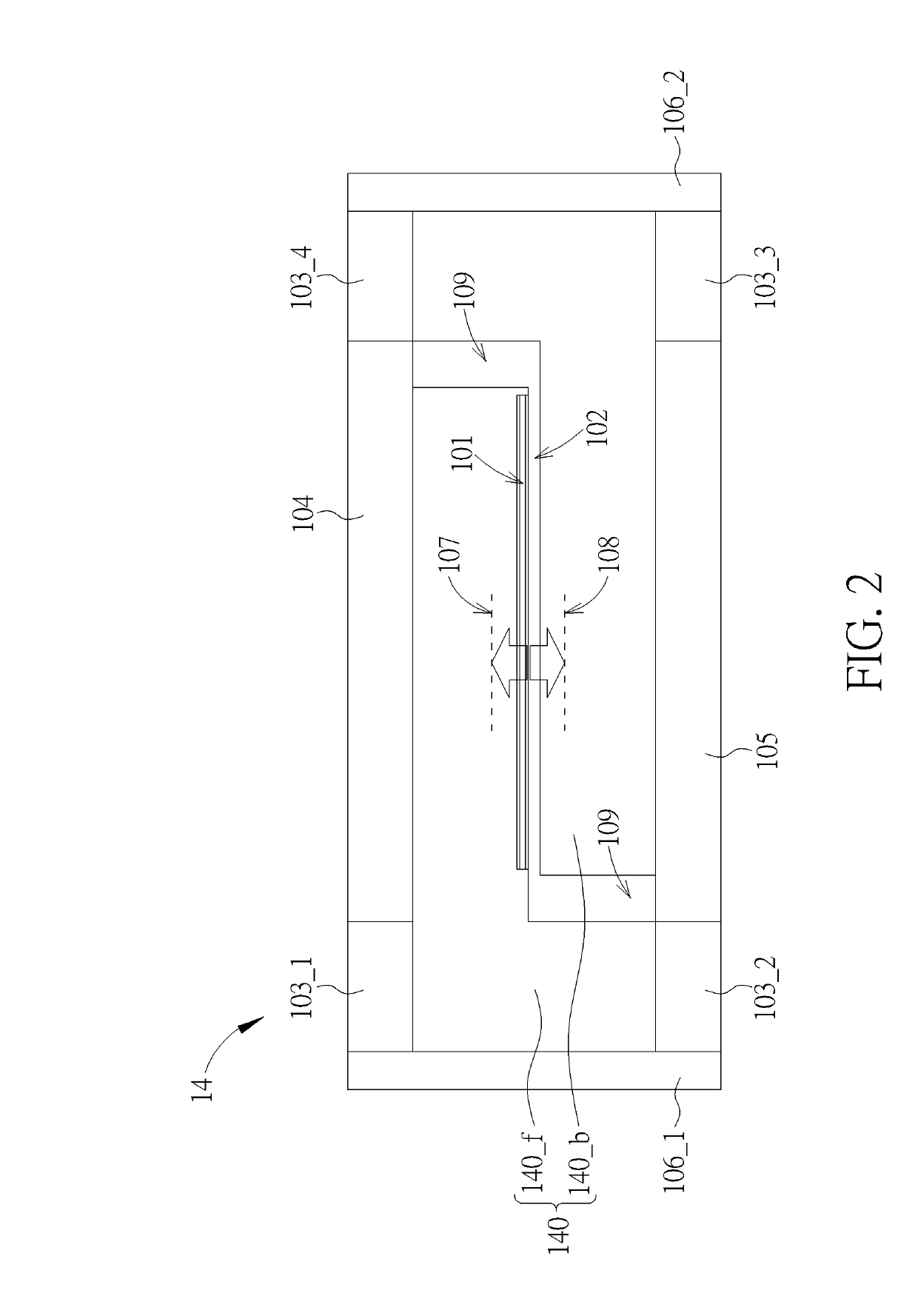

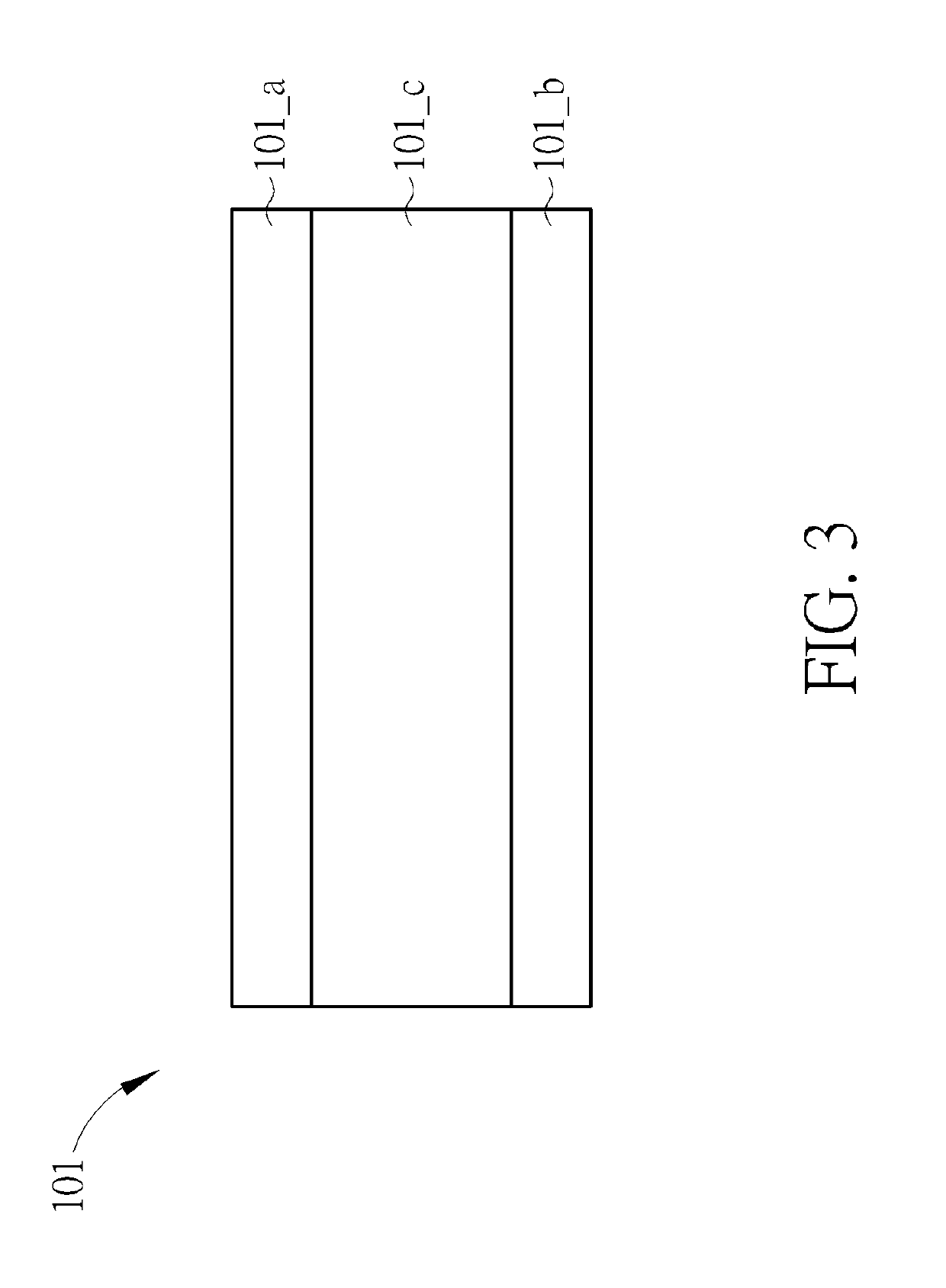

ActiveUS20190313189A1Improve fidelitySmall sizeMicrophonesLoudspeaker transducer fixingPulse rateSound production

The present invention provides a sound producing device comprising: an air pulse generating element and a control unit. The air pulse generating element comprises an air chamber and an actuator. The control unit, configured to generate a driving voltage applied to the actuator of the air pulse generating element, such that the air pulse generating element generates a plurality of air pulses in response to the driving voltage. The plurality of air pulses are at a pulse rate, and the pulse rate of the plurality of air pulses is higher than a maximum audible frequency.

Owner:XMEMS LABS INC

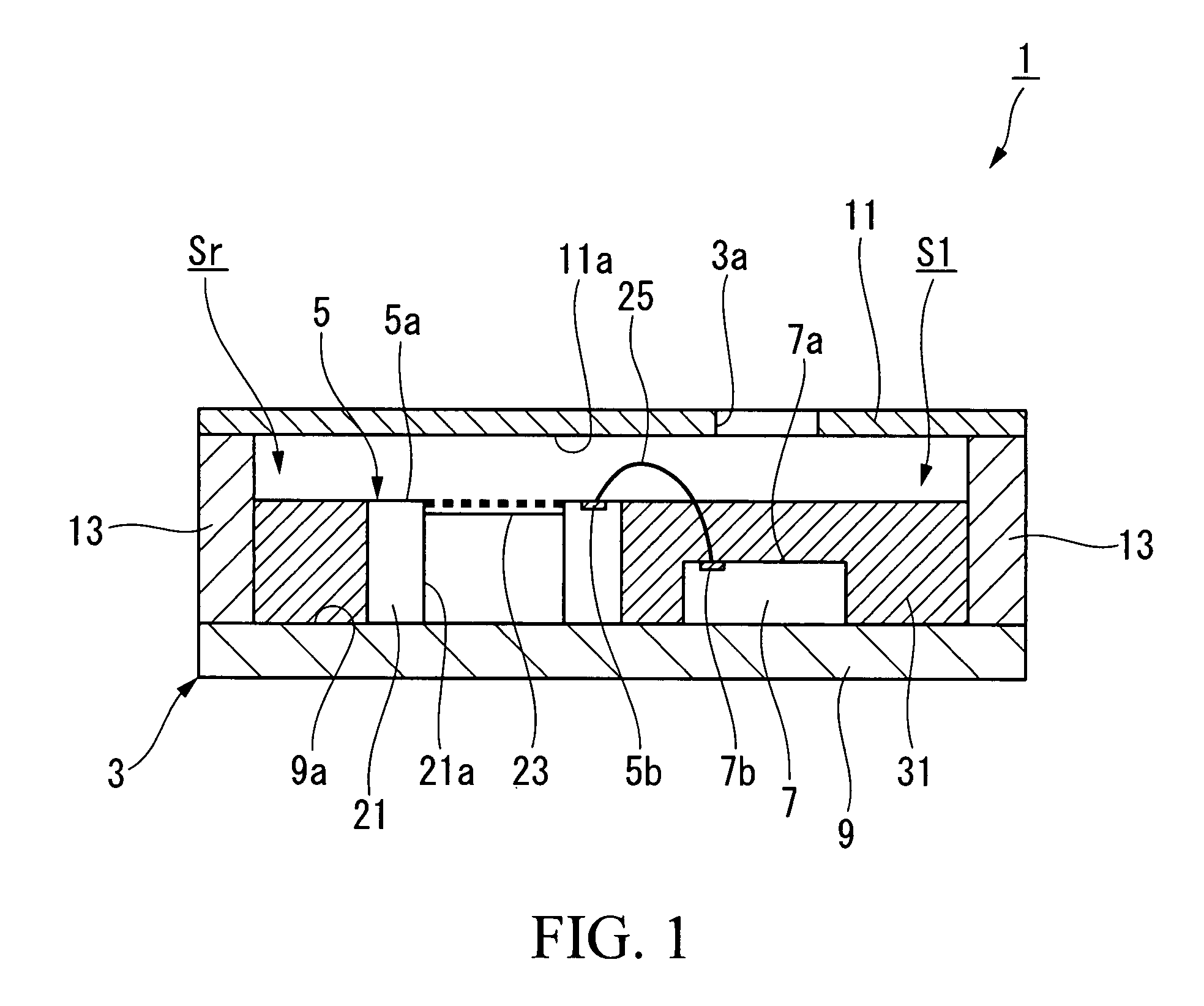

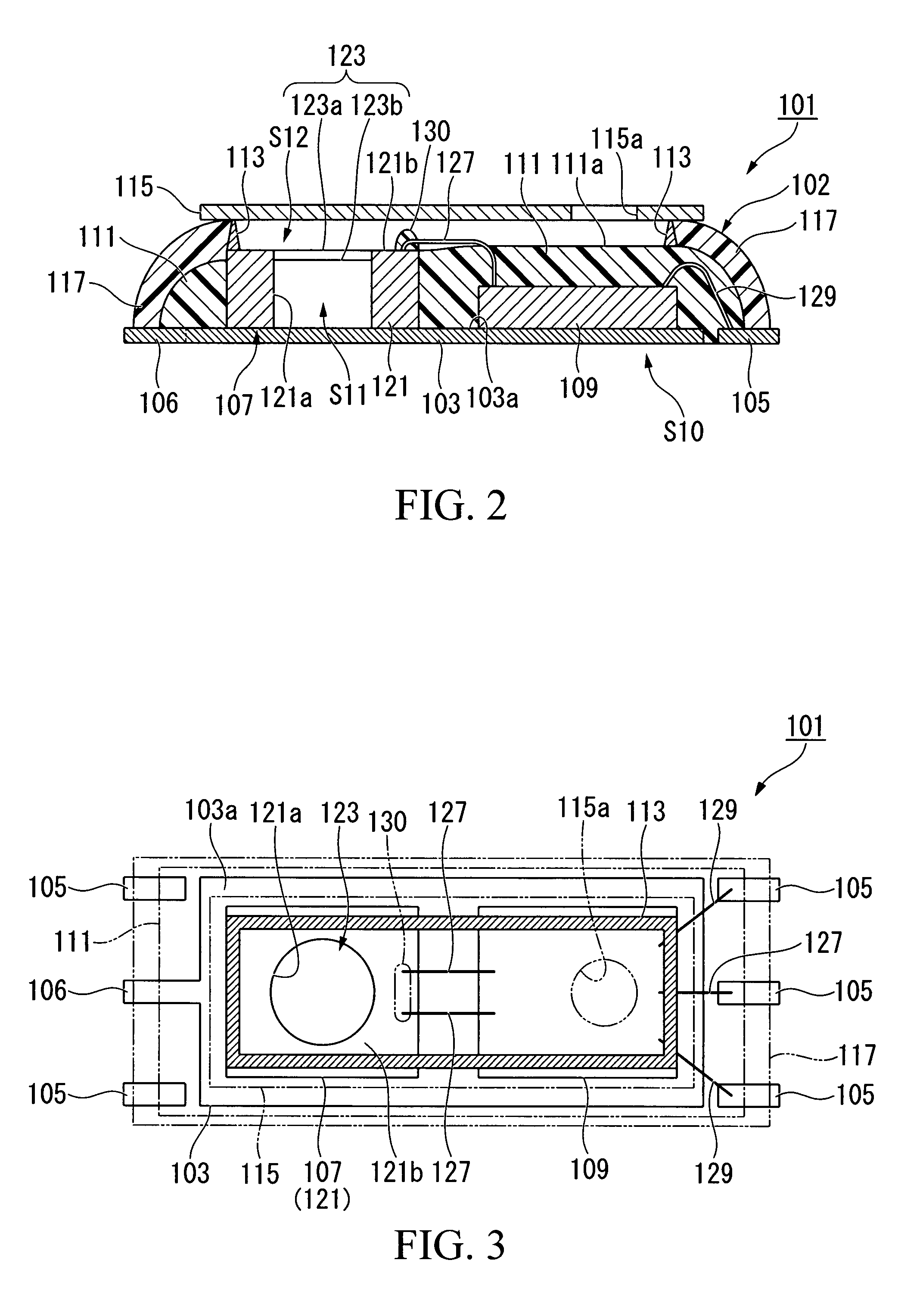

Microphone package

InactiveUS20080130935A1Quality improvementSmall sizePiezoelectric/electrostrictive microphonesTransducer detailsEngineeringSemiconductor sensor

Owner:YAMAHA CORP

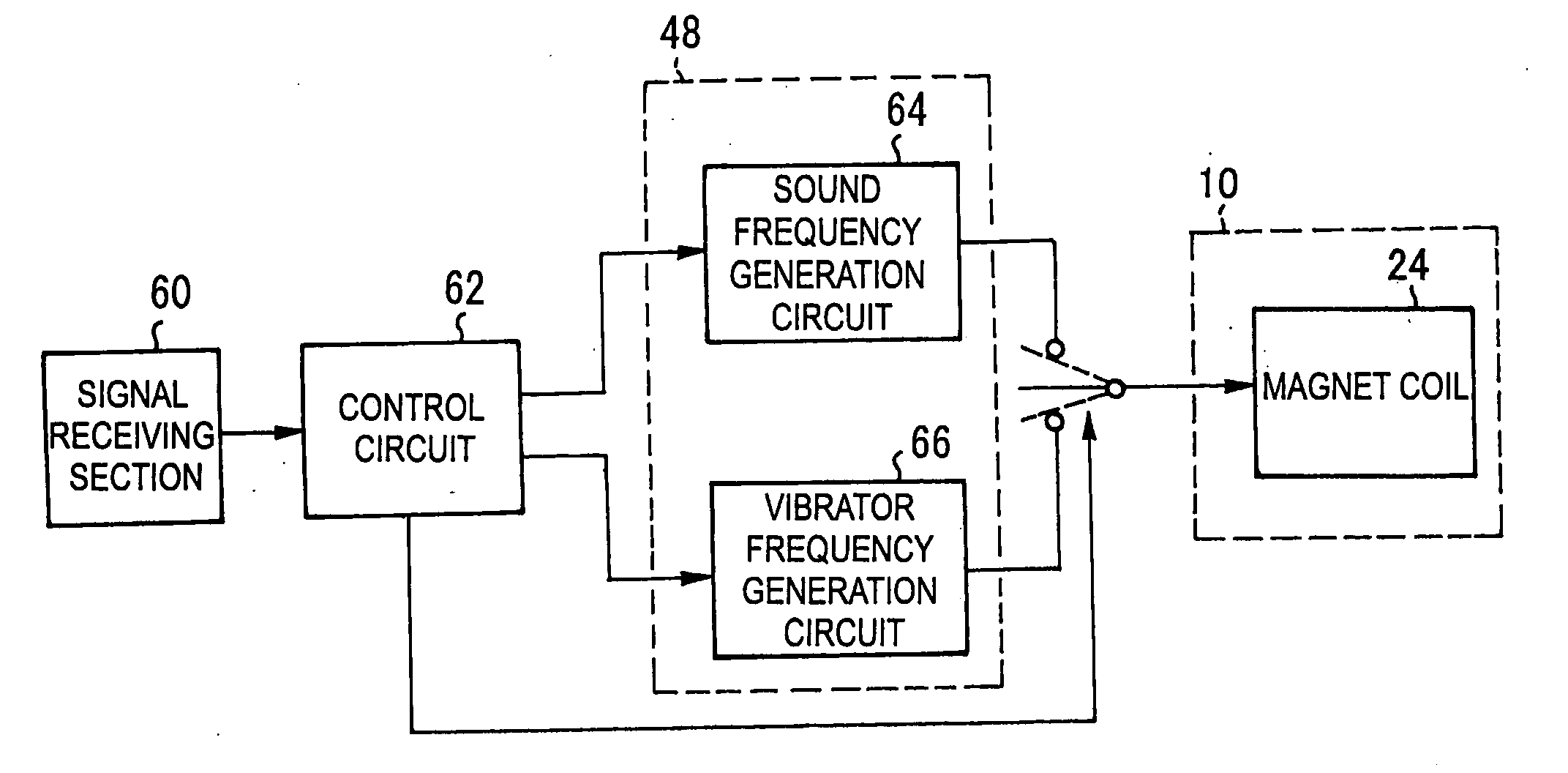

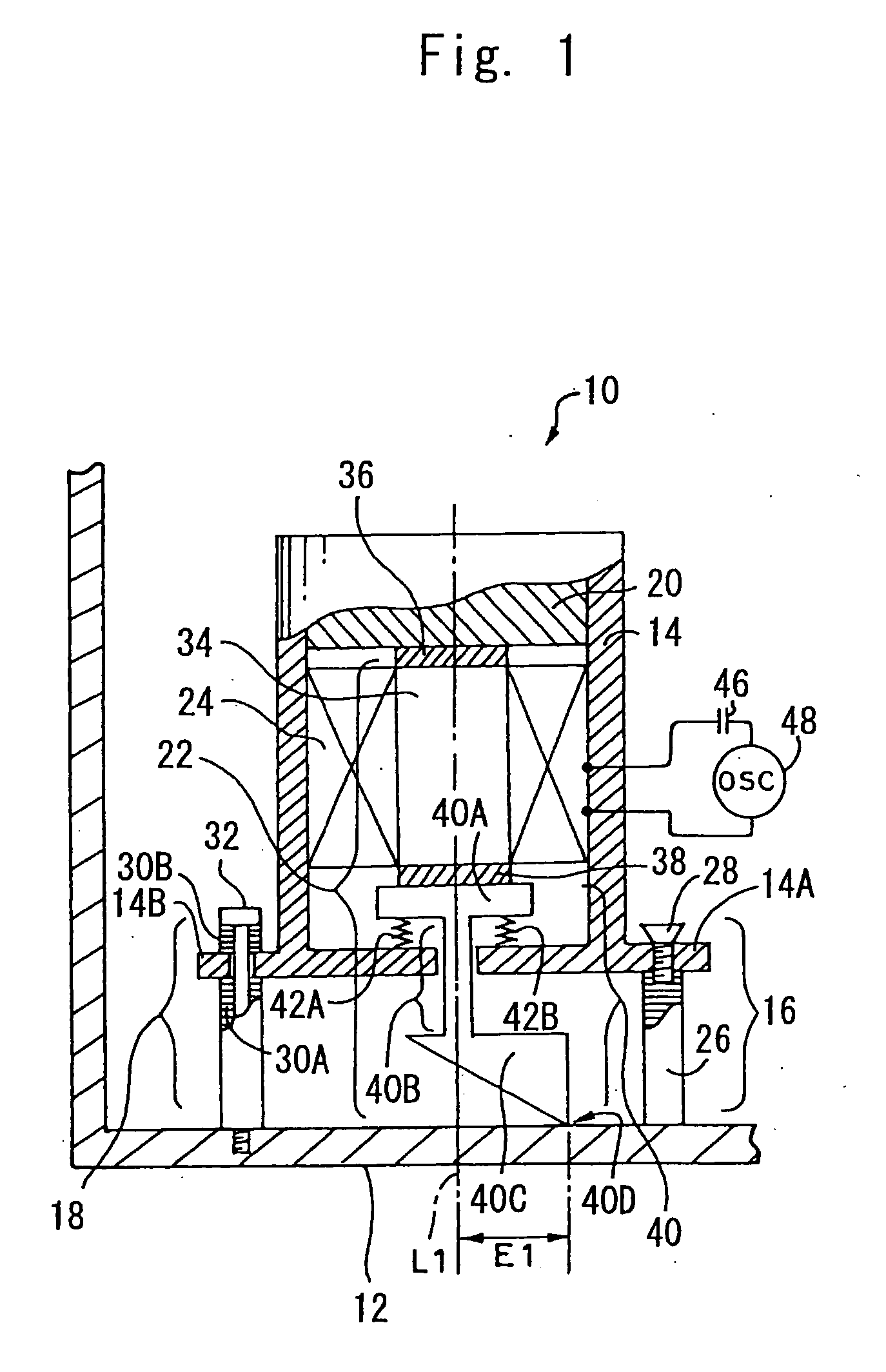

Vibrator unit and portable telephone employing it

InactiveUS20060113932A1Low costSmall sizeMotor/generator/converter stoppersDC motor speed/torque controlMiniaturizationEngineering

A vibrating device that can be applied to various purposes other than as a vibrator and that can achieve cost reduction, size reduction, and space saving by a reduction in the number of components, and a mobile phone using this vibrating device are provided. The vibrating device has a housing supported by a base and capable of oscillating in a vibration frequency range of a vibrator, and an expandable rod that can expand and contract, one end of which is fixed to the housing, and the other end of which is a free end contacting the base. The base is resonated by oscillation of the housing in the vibration frequency range of a vibrator, while the base is vibrated by expansion and contraction of the expandable rod in a sound frequency range other than the vibration frequency range of a vibrator.

Owner:TDK CORPARATION

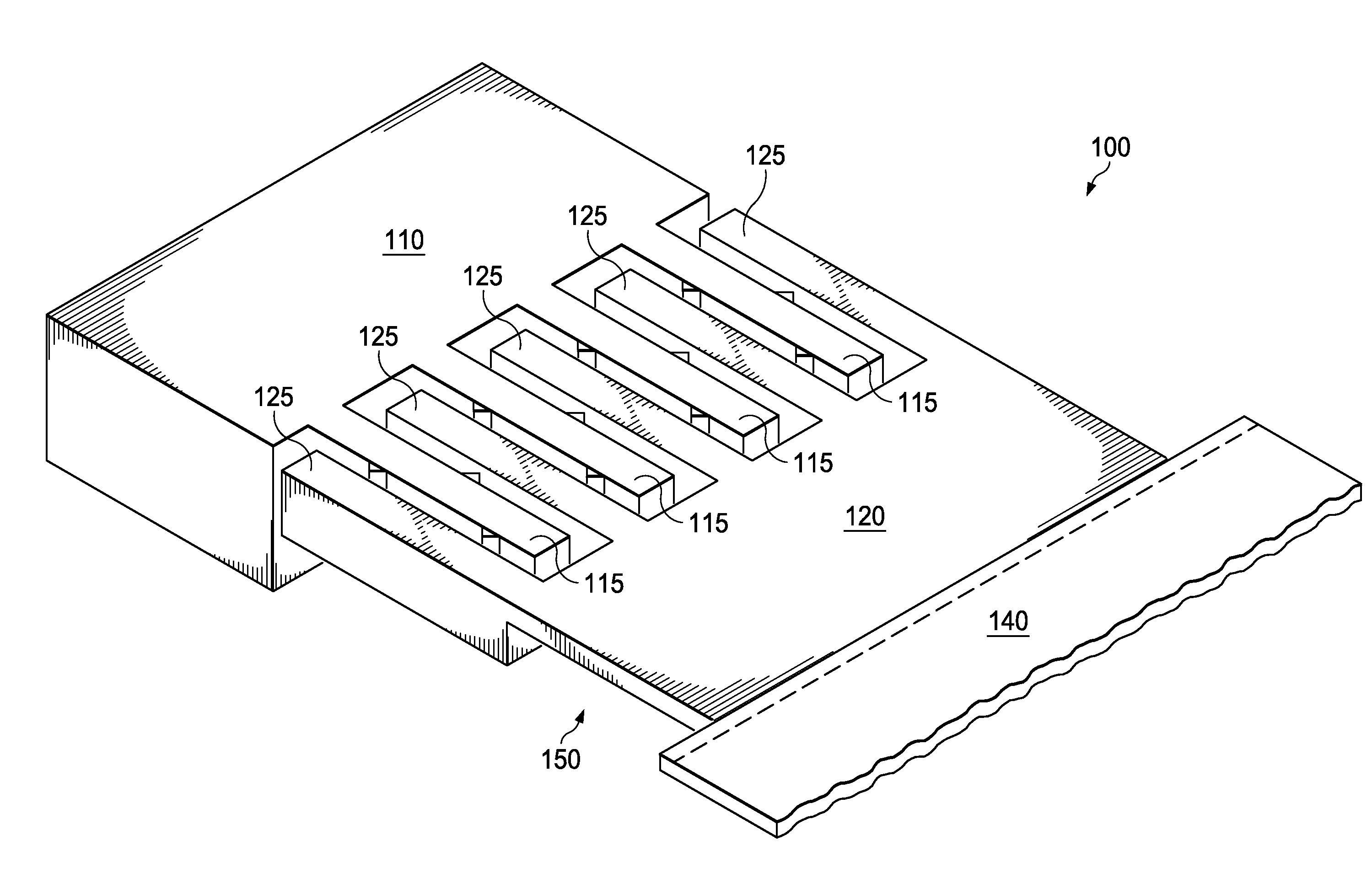

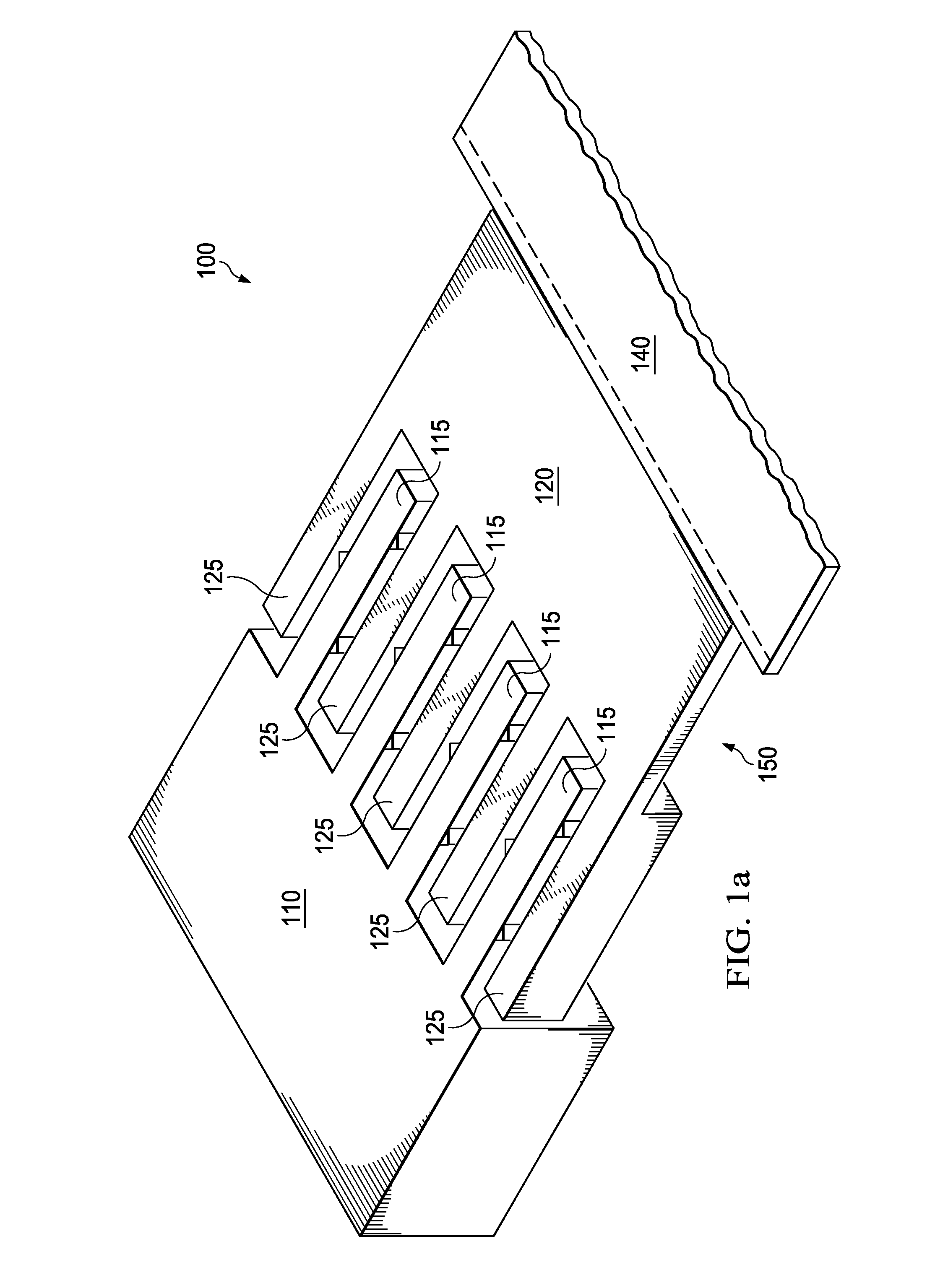

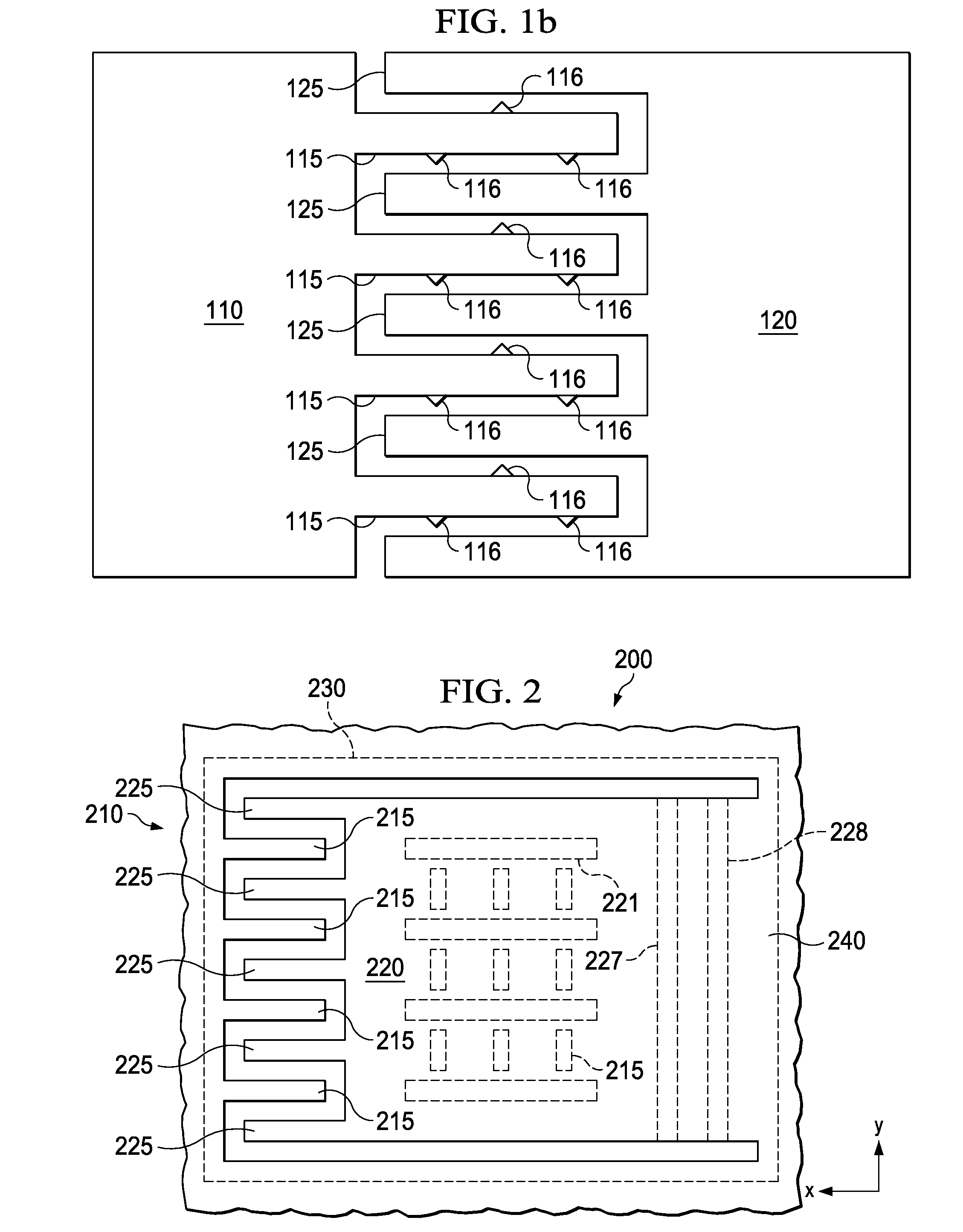

Comb MEMS Device and Method of Making a Comb MEMS Device

InactiveUS20140197502A1Decorative surface effectsSemiconductor/solid-state device manufacturingEngineeringConductive materials

Owner:INFINEON TECH AG

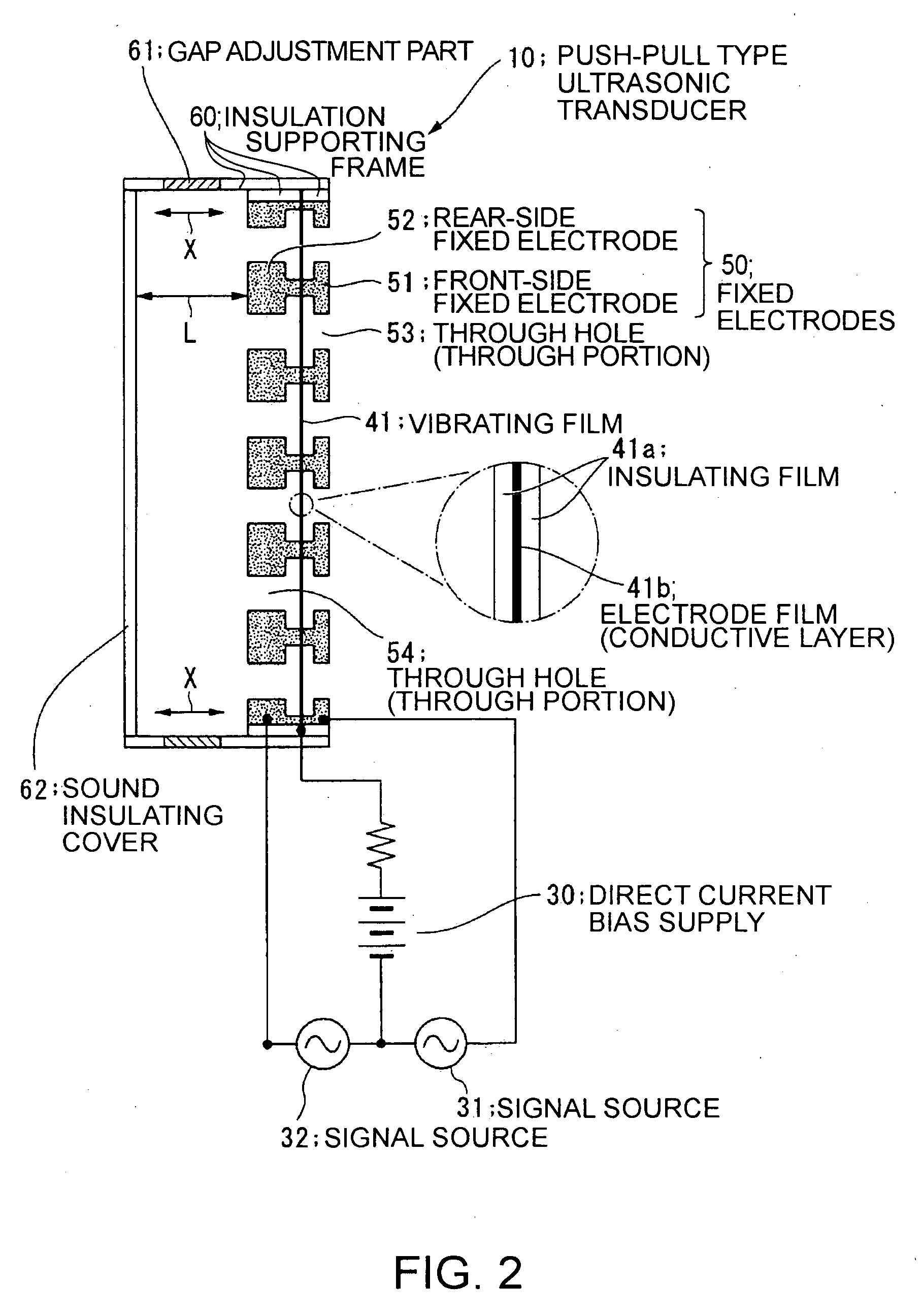

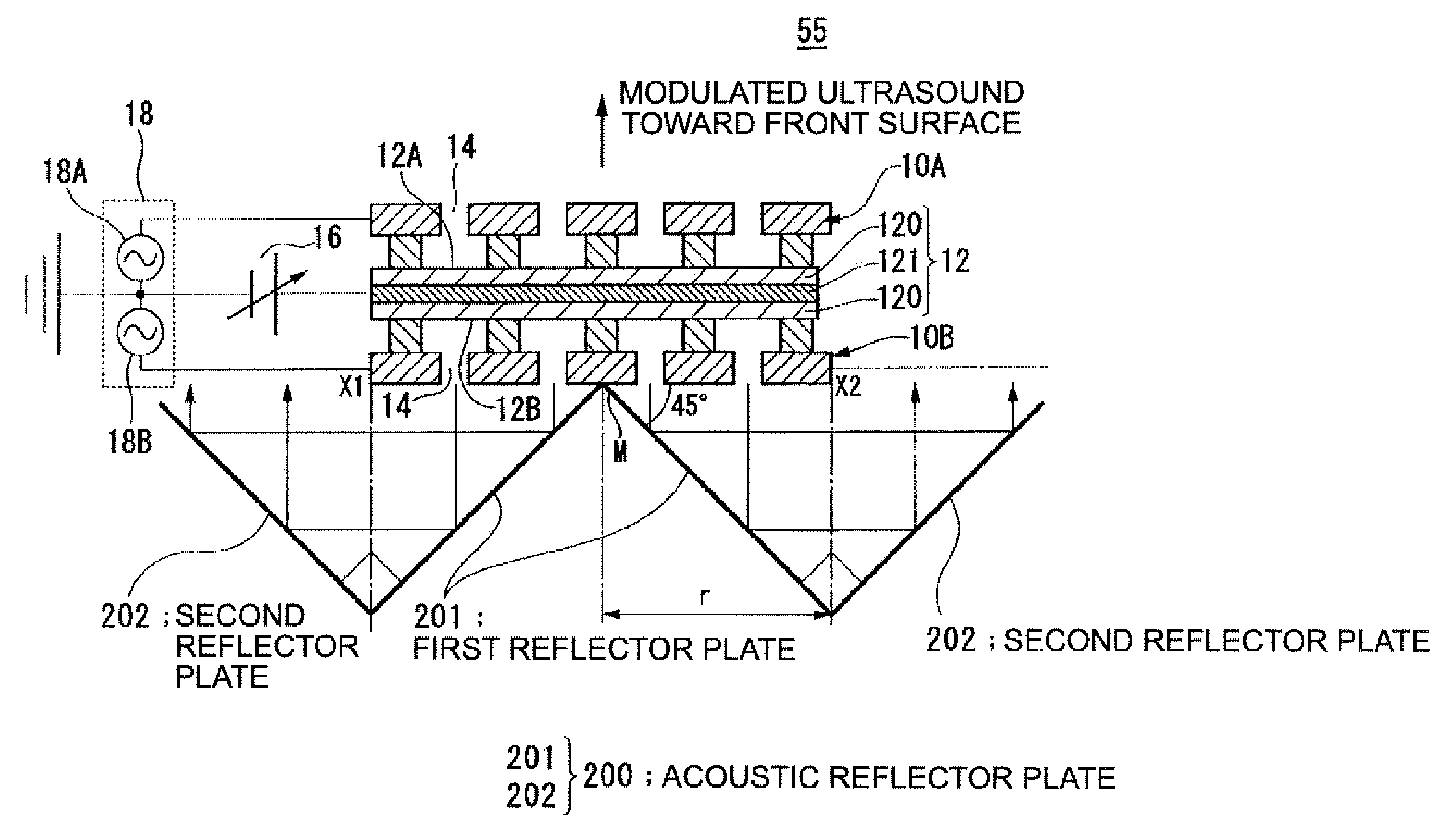

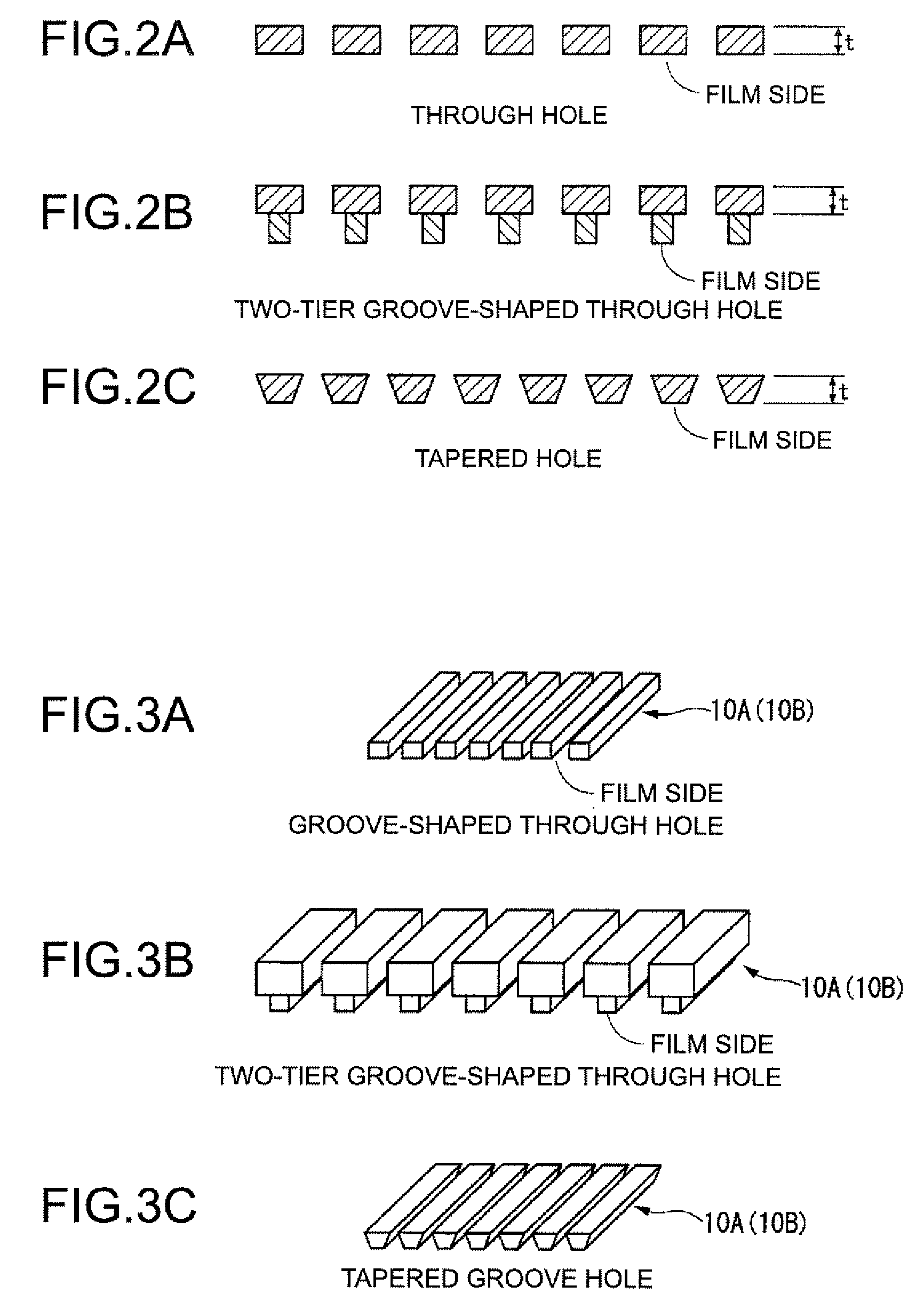

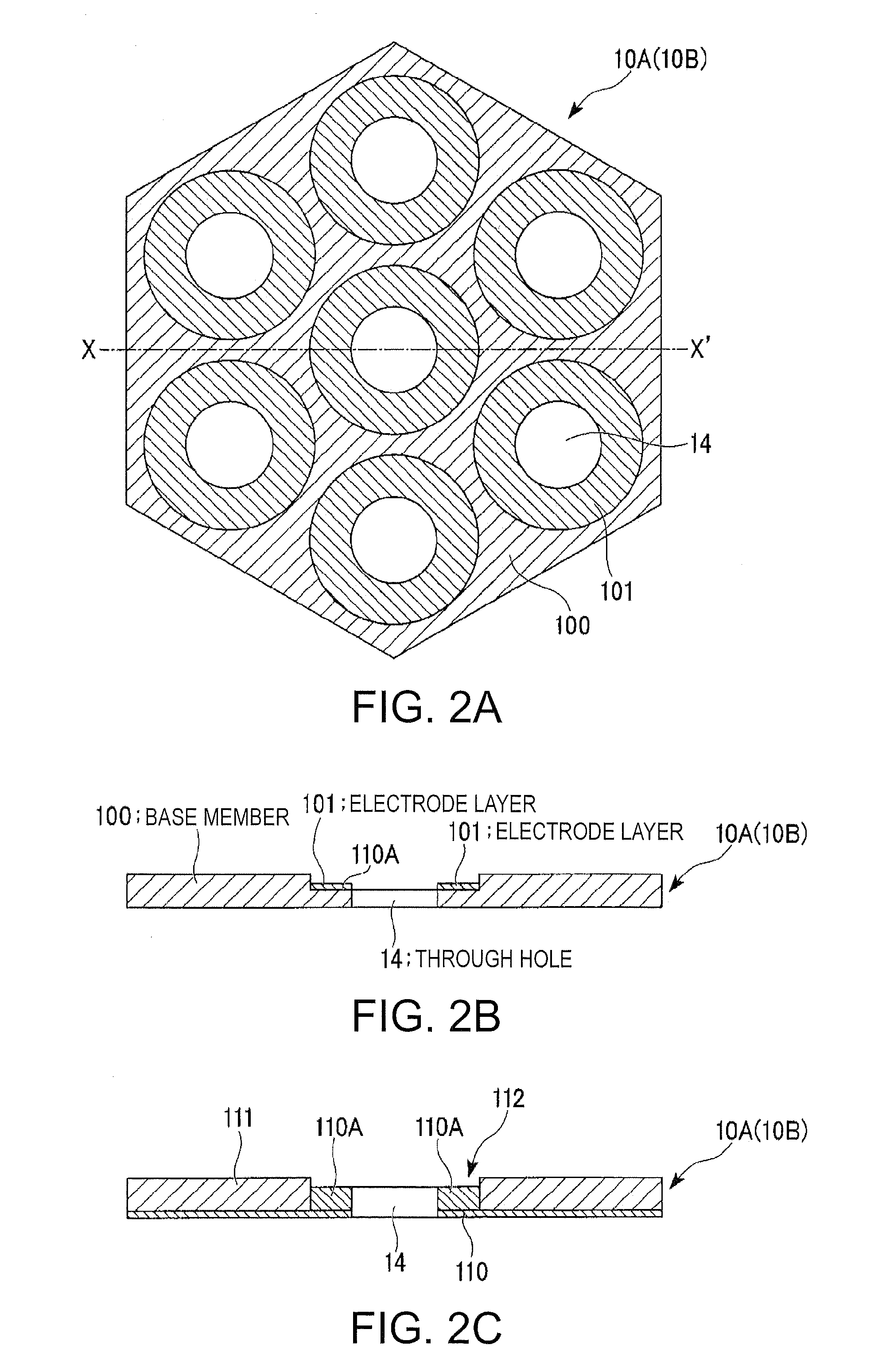

Electrostatic ultrasonic transducer, ultrasonic speaker, audio signal reproduction method, electrode manufacturing method for use in ultrasonic transducer, ultrasonic transducer manufacturing method, superdirective acoustic system, and display device

InactiveUS20070029899A1Easy to controlSufficient sound pressurePiezoelectric/electrostriction/magnetostriction machinesElectrostatic transducer loudspeakersUltrasonic sensorElectrical conductor

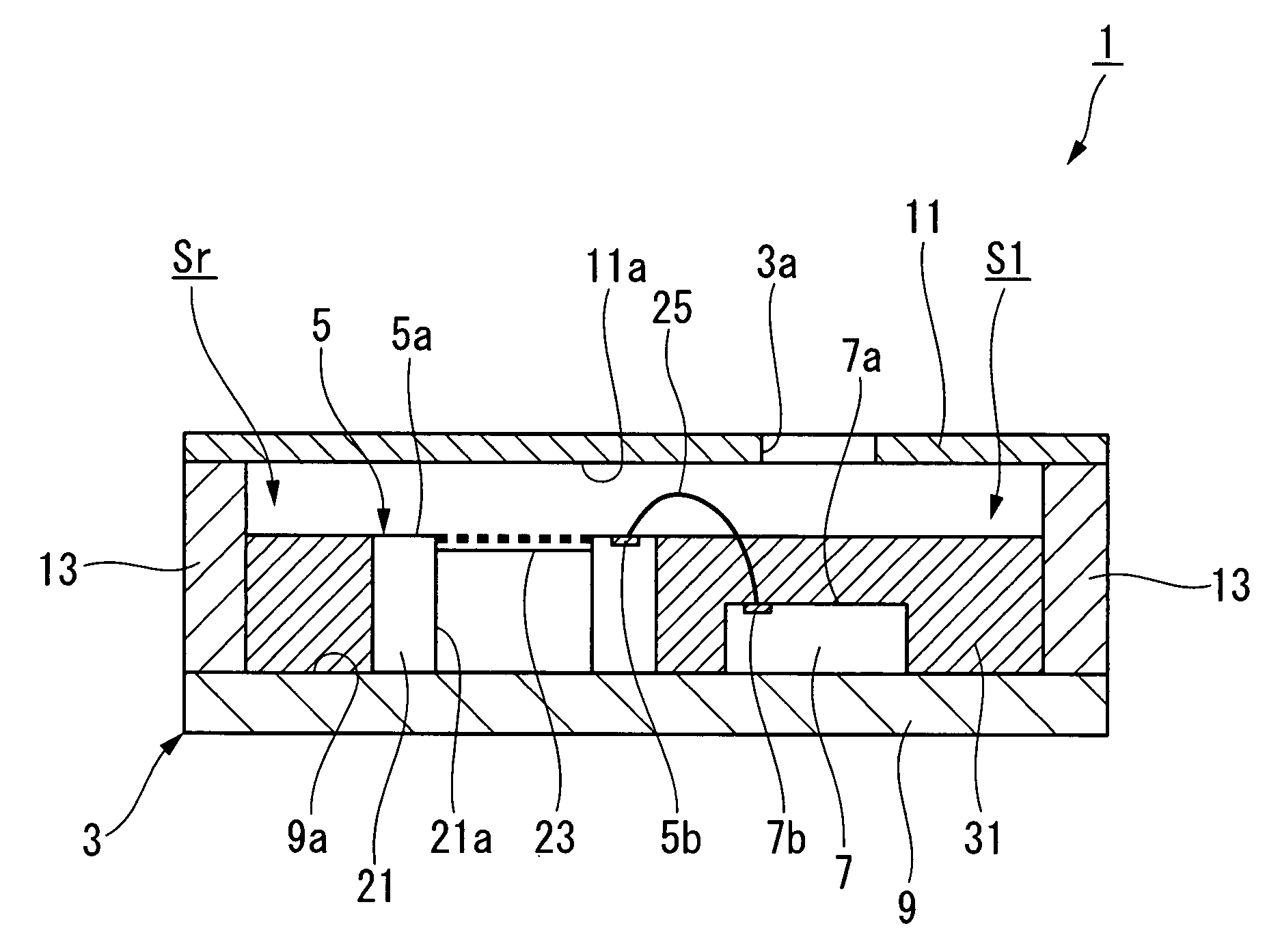

An electrostatic ultrasonic transducer that includes: a first electrode that is formed with a plurality of holes; a second electrode that is formed with a plurality of holes, and is used in pair with the first electrode; an oscillation film formed with a conductor layer that is sandwiched between the pair of electrodes, and the conductor layer is applied with a direct-current (DC) bias voltage; and a retention member that keeps hold of the pair of electrodes and the oscillation film. In the transducer, an alternating signal is applied between the pair of electrodes, and the pair of electrodes each have a thickness t of about (λ / 4)·n (where k denotes a wavelength of ultrasound, and n denotes a positive odd number).

Owner:SEIKO EPSON CORP

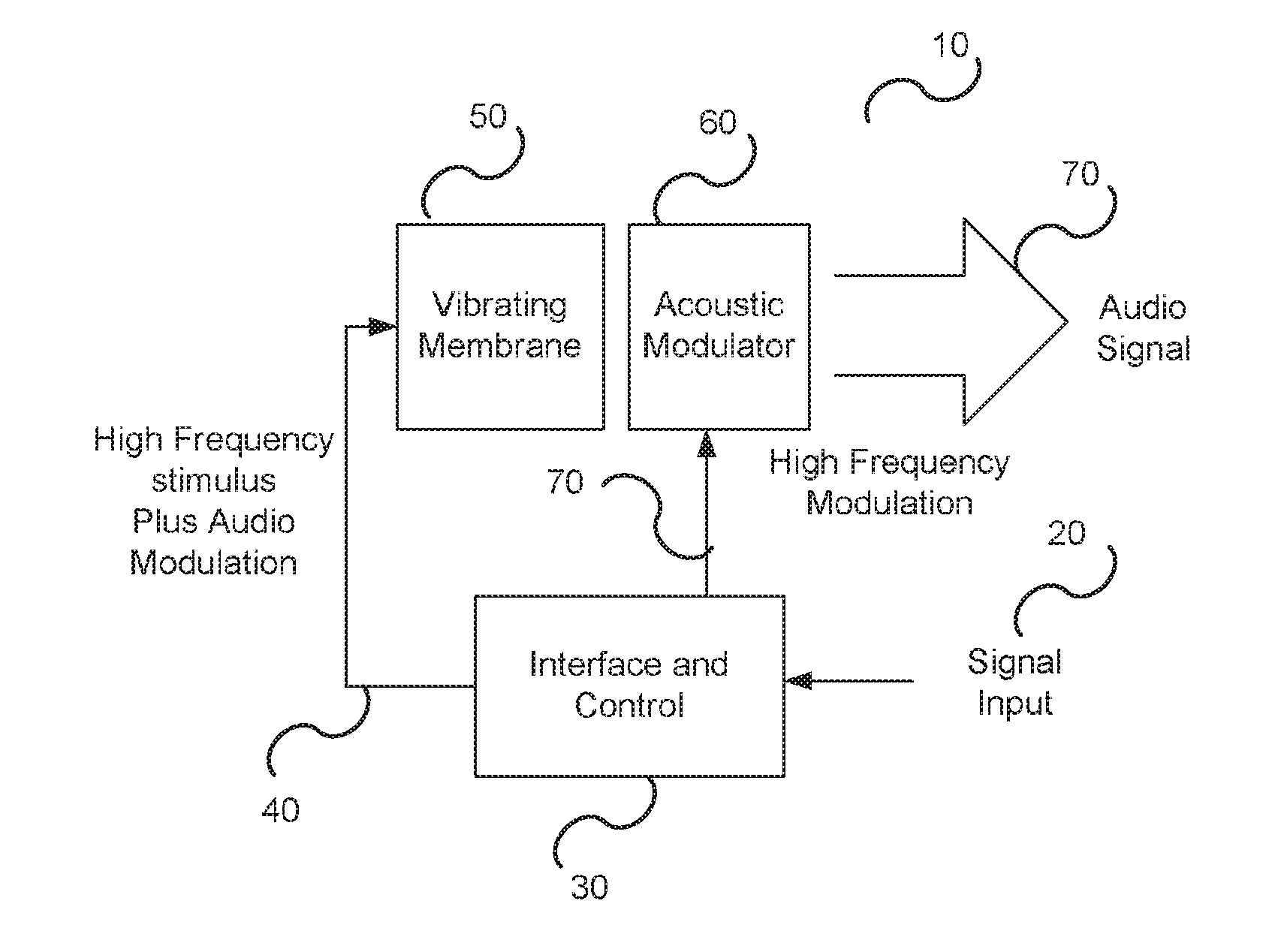

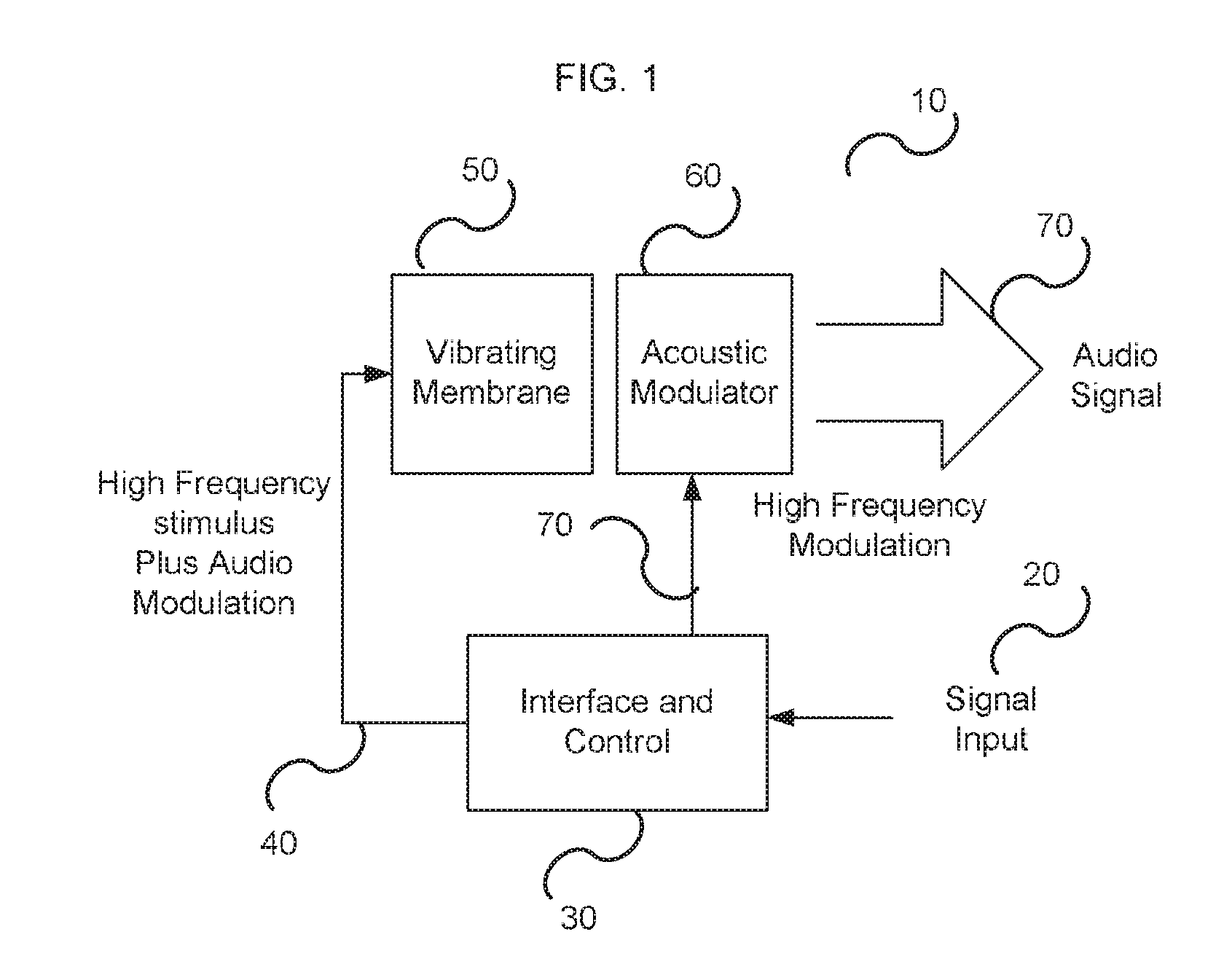

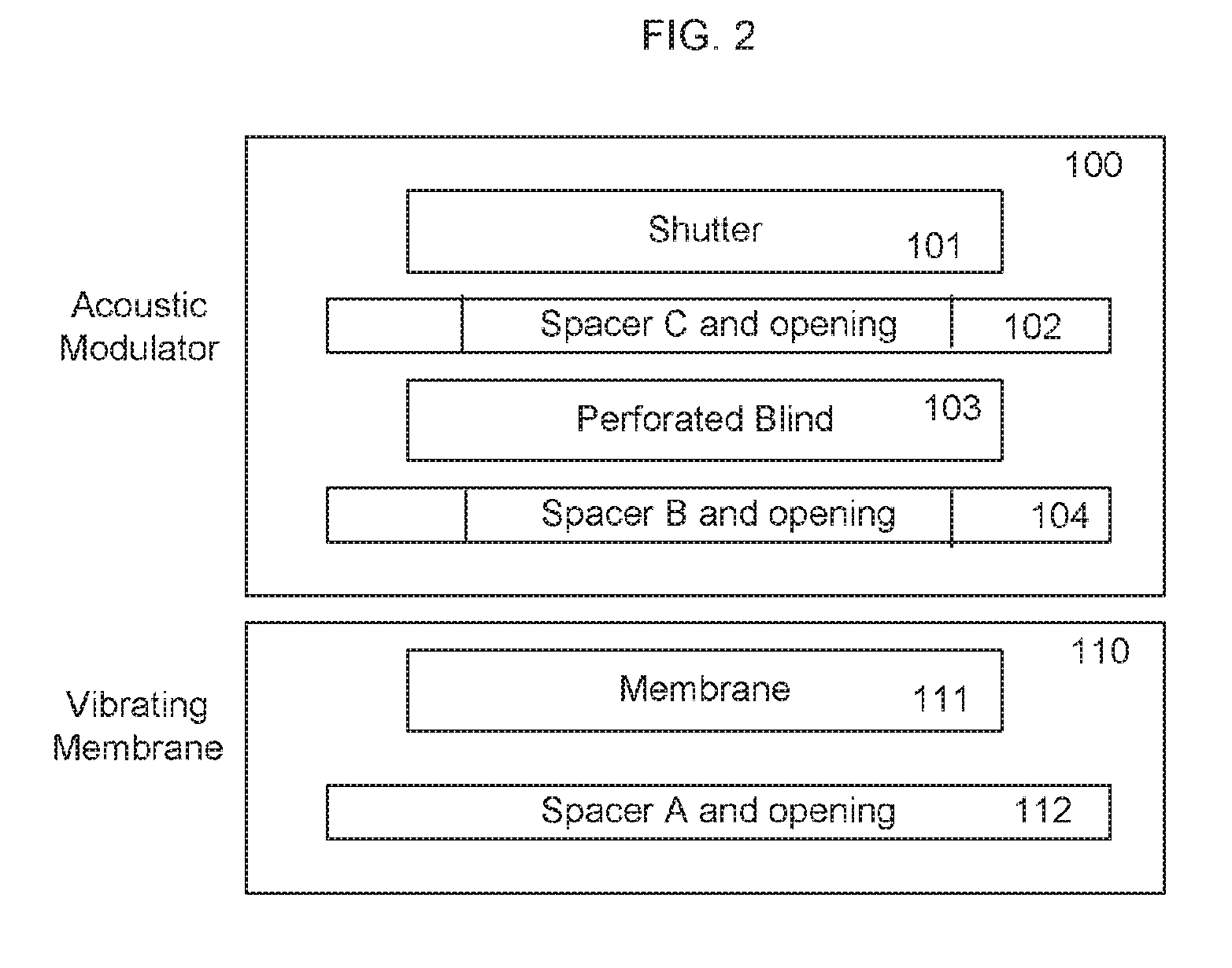

Two port speaker acoustic modulator

InactiveUS20160381464A1Piezoelectric/electrostrictive transducersElectrostatic transducer loudspeakersSonificationLow distortion

A two-port air pump speaker that includes at least two active, phase-modulated, bi-directional shutters and an ultrasonic pumping chamber having at least two ports; a first port facing towards the listener, the forward port, and a second port facing another direction, the backward port which may be behind an acoustic baffle or inside a speaker enclosure. A two-port speaker with two active steering shutters can create continuous bi-directional airflow which leads to low distortion reproduction of low audio frequencies. The same improved design can be used also for other applications where acoustic modulation is required, especially in ultrasonic frequencies.

Owner:DSP GROUP

Sonic emitter with foam stator

InactiveUS6304662B1Reduce stiffnessReduce weightElectrostatic transducer loudspeakersDeaf-aid setsAcoustic waveEngineering

A speaker device comprising an electrostatic emitter film which is responsive to an applied variable voltage to emit sonic output based on a desired sonic signal, used in combination with at least a first foam member having a forward face, an intermediate core section and a rear face. The forward face is composed of a composition having sufficient stiffness to support the electrostatic film and includes conductive properties which enable application of a variable voltage to supply the desired sonic signal. The surface of the forward face includes small cavities having surrounding wall structure defining each cavity which terminates at contacting edges approximately coincident with the forward face of the foam member. The film is applied to the forward face of the foam member and biased in direct contact with the contacting edges of the forward face.

Owner:TURTLE BEACH

Electrostatic ultrasonic transducer, and ultrasonic speaker, audio signal reproduction method, ultra-directive sound system, and display apparatus using electrostatic ultrasonic transducer

InactiveUS20080152172A1Sufficient sound pressureSound pressure characteristic can be enhancedElectrostatic transducer loudspeakersMechanical vibrations separationUltrasonic sensorAlternating current

An electrostatic ultrasonic transducer includes a first electrode having a through hole, a second electrode having a through hole, and an oscillation film disposed such that the through hole of the first electrode can be paired with the through hole of the second electrode and sandwiched between the pair of the first electrode and second electrode. The oscillation film has an electrode layer to which direct current bias voltage is applied. Each of the pair of the electrodes has an electrode portion at a position in the periphery of the through hole. An alternating current signal is applied between the pair of the electrodes and the electrode layer of the oscillation film.

Owner:SEIKO EPSON CORP

Electrostatic transducer, ultrasonic speaker, driving circuit of capacitive load, method of setting circuit constant, display device, and directional sound system

InactiveUS20070121970A1Reduce lossSufficient sound pressurePiezoelectric/electrostrictive transducersElectrostatic transducer loudspeakersCapacitanceOutput transformer

An electrostatic transducer includes: a class-D power amplifier that amplifies an input signal; and a low pass filter that has a plurality of pairs of inductors and capacitors, is connected to an output side of the class-D power amplifier, and serves to eliminate switching carrier components included in an output of the class-D power amplifier. An electrostatic load capacitor of the electrostatic transducer serving as a driving load is disposed at a capacitor, which is closest to the output side of the class-D power amplifier, of circuit elements forming the low pass filter, an electrostatic coupling capacitor and an output transformer are interposed between the electrostatic load capacitor of the electrostatic transducer and an inductor closest to the output side of the class-D power amplifier of the low pass filter, and a damping resistor is connected in series to a primary coil of the output transformer.

Owner:SEIKO EPSON CORP

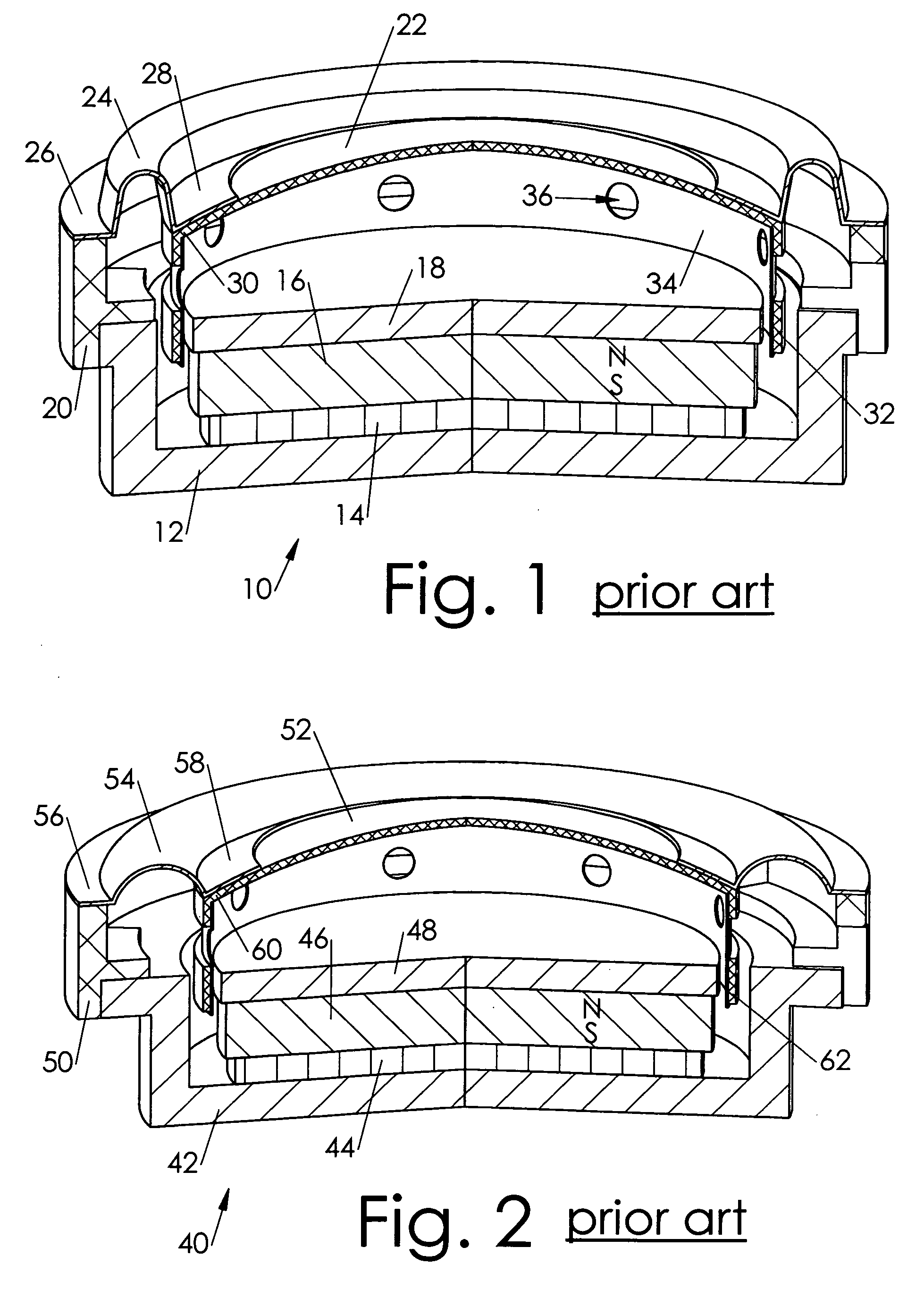

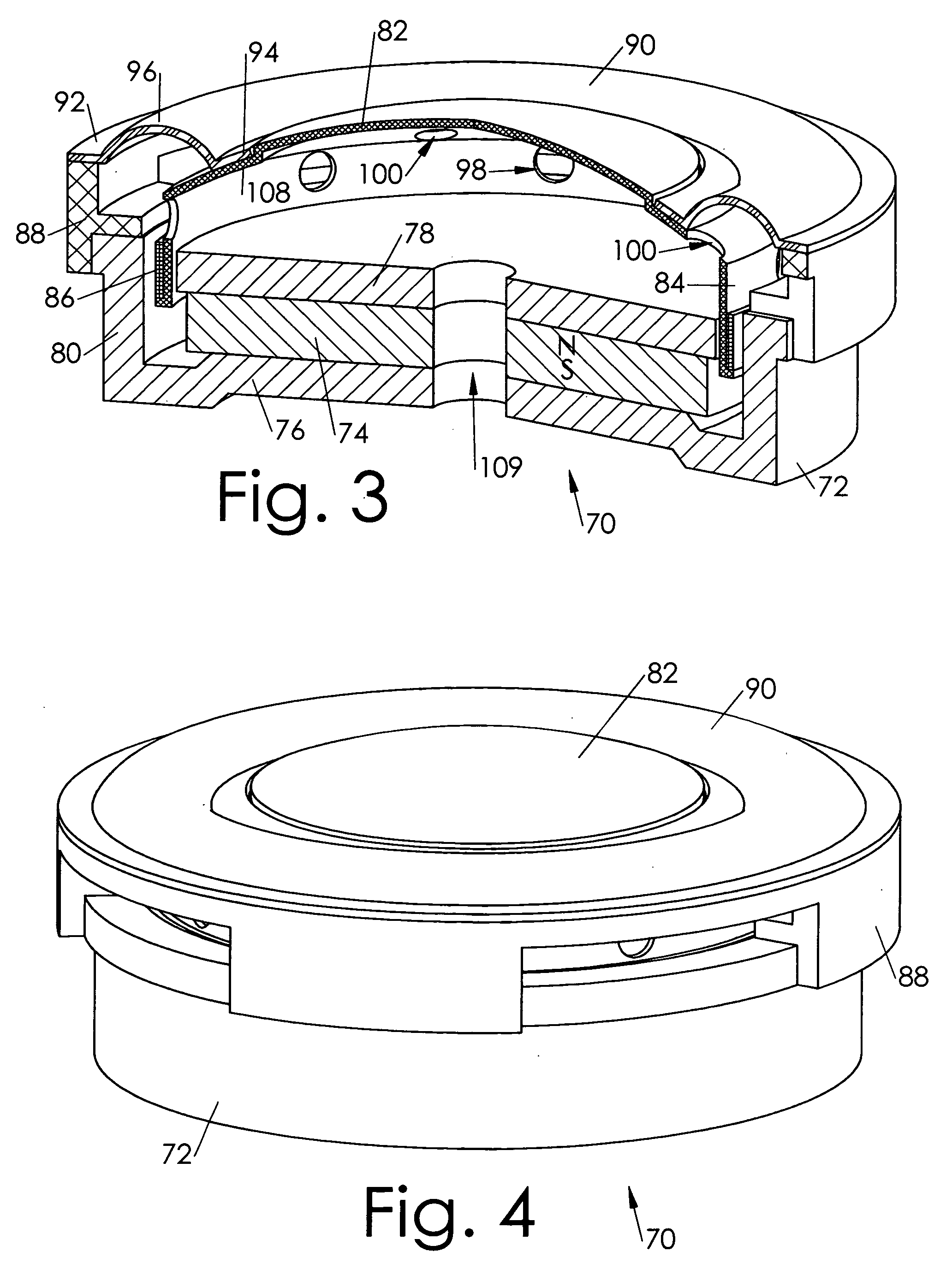

Overlapping surround roll for loudspeaker

InactiveUS20080166010A1Electrostatic transducer loudspeakersTransducer casings/cabinets/supportsBobbinTransducer

A loudspeaker in which the voice coil diameter is so large that the voice coil is axially beneath the suspension roll of the surround. The surround has an overlapping suspension roll such that the inner portion of the surround is coupled to the diaphragm well inward of the bobbin. Such a transducer having greatly extended low frequency abilities by virtue of its wider, softer suspension roll enabling a much lower resonant frequency, and by virtue of its maximum sized magnet and voice coil yielding increased motor strength and power handling. Additionally, the dome diaphragm can now be vented through the portion of the dome that is beneath the surround roll, releasing the trapped back pressure below the diaphragm, thereby further lowering the resonant frequency.

Owner:STILES ENRIQUE M +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com