Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2174results about How to "Reduce shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

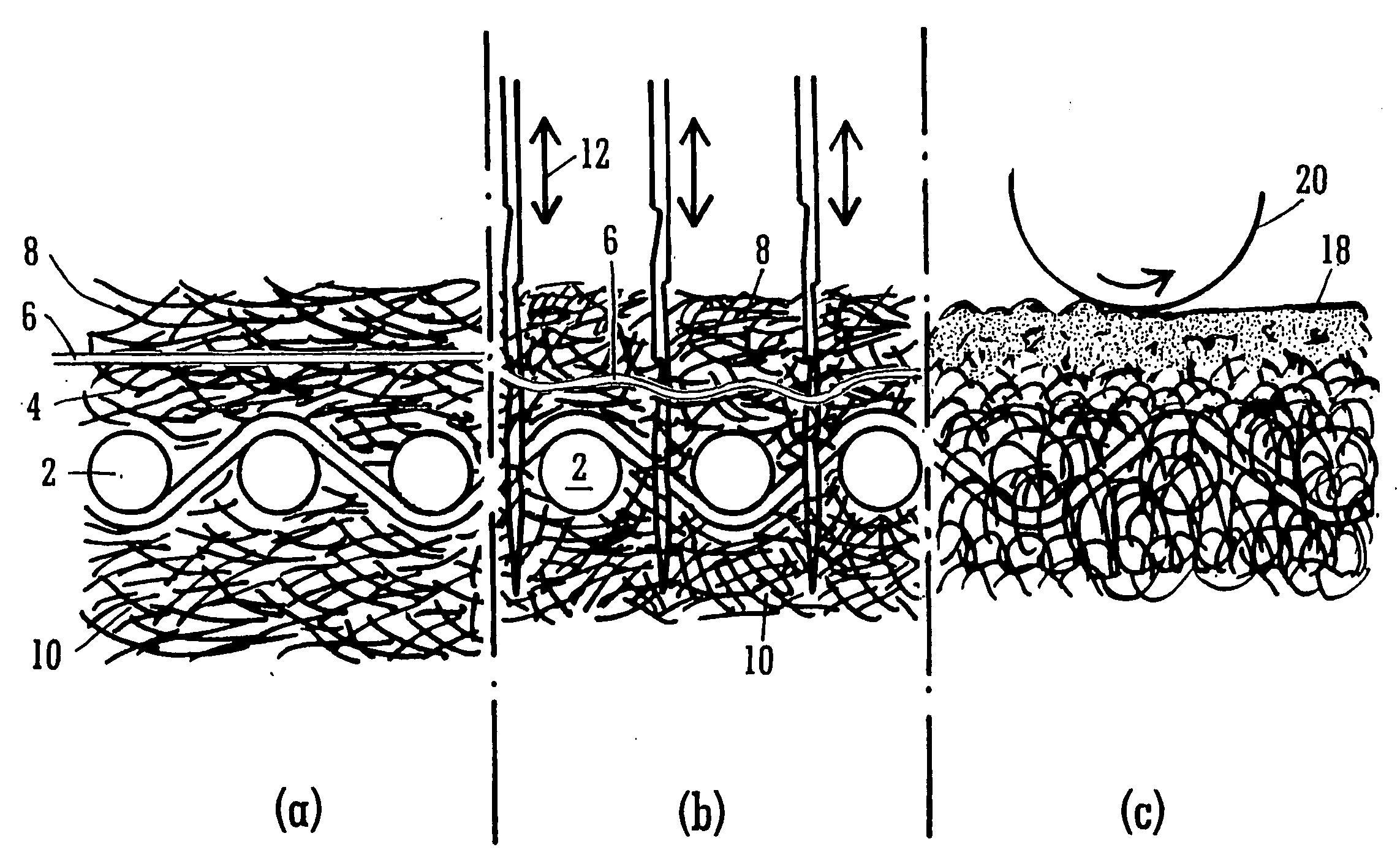

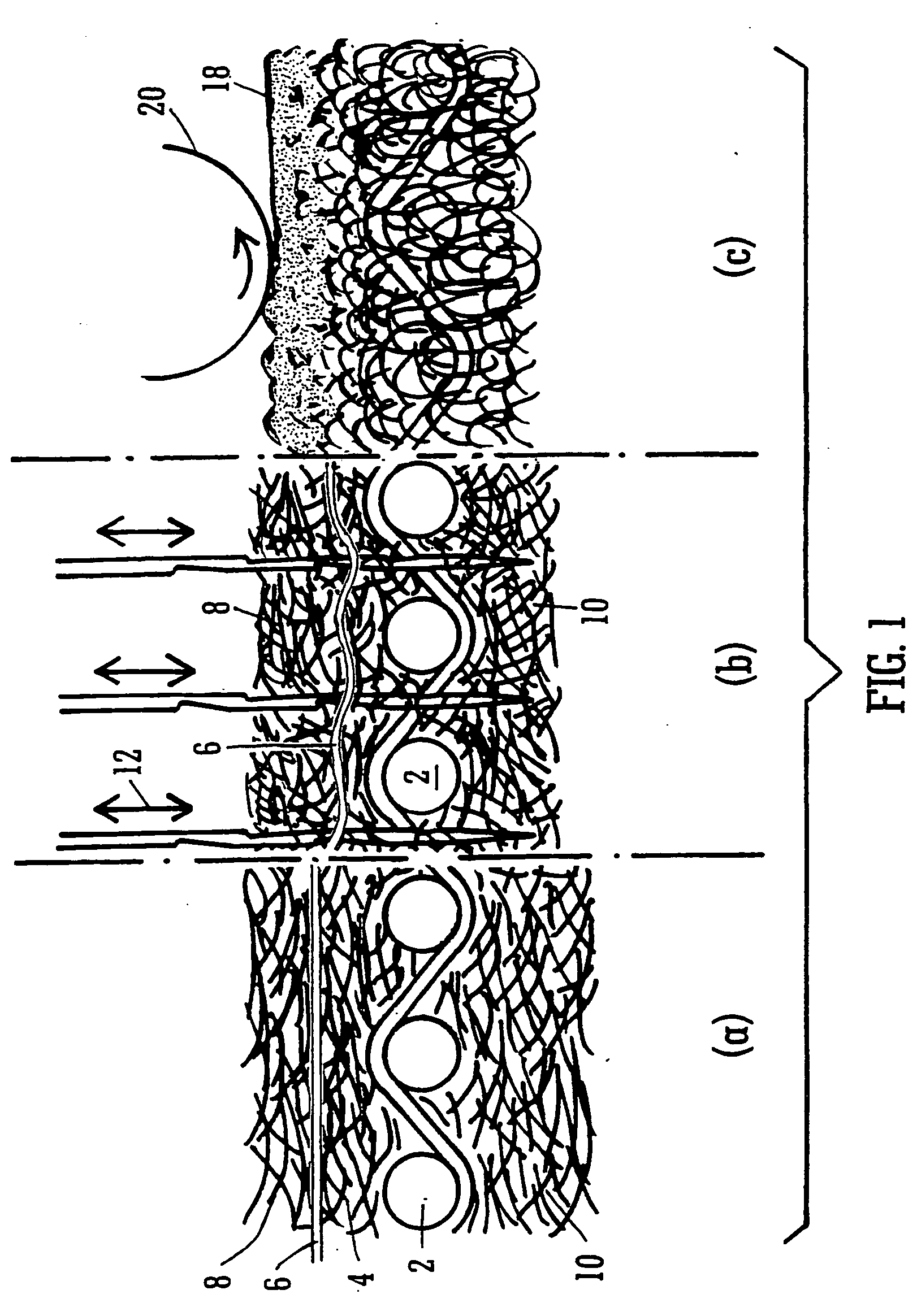

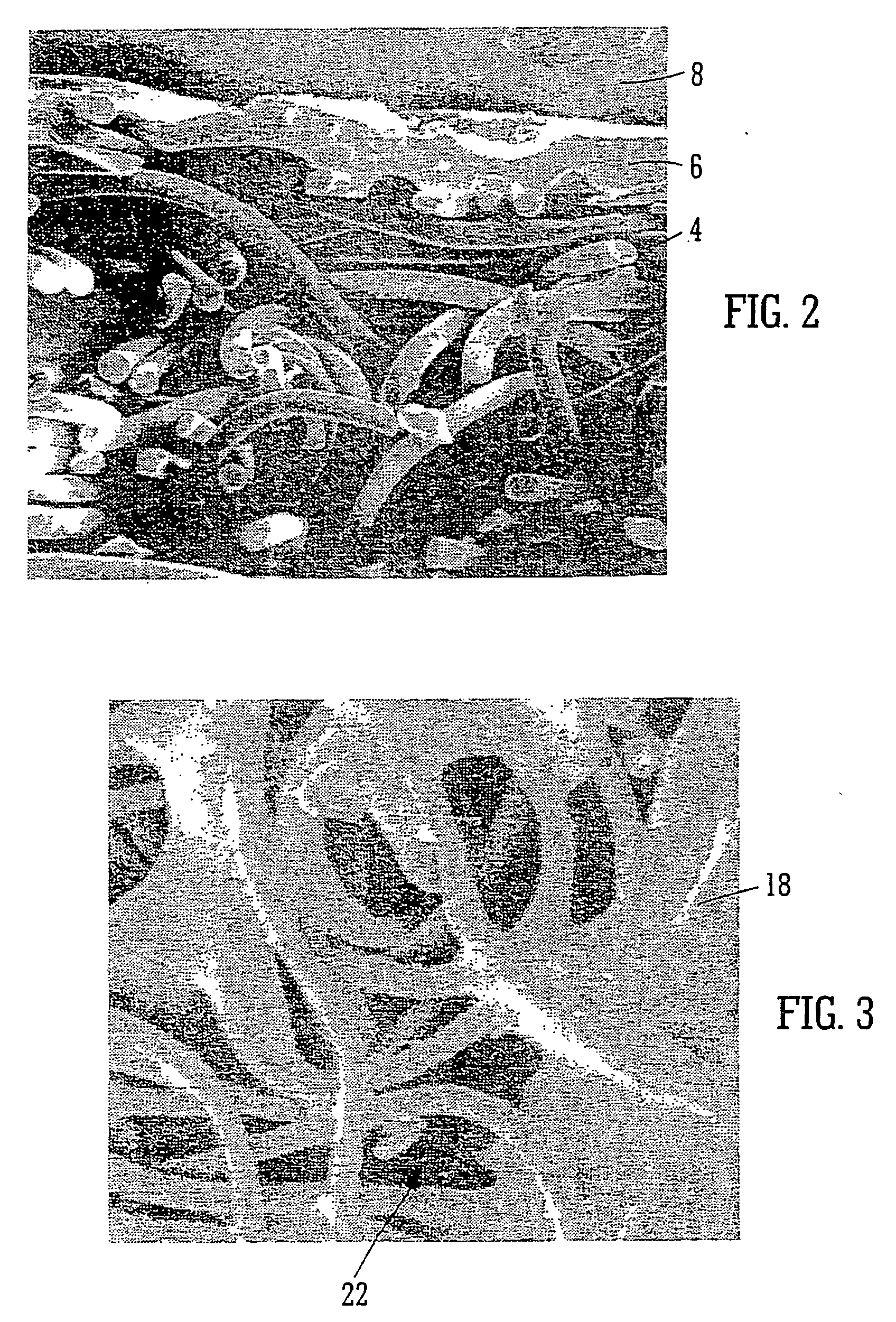

Nonwoven webs having reduced lint and slough

InactiveUS20050148261A1Reduce coefficient of frictionReduce sheddingCosmetic preparationsPersonal careFiberPolymer science

Nonwoven webs having reduced levels of lint and slough are disclosed. In accordance with the present invention, the nonwoven webs are treated on at least one surface with a small amount of a polymeric component. The polymeric component may be present, for instance, in the form of meltblown fibers. The meltblown fibers are made from a polymer that is compatible with the nonwoven web. By adding relatively small amounts of meltblown fibers to at least one side of the nonwoven material, lint and slough levels have been found to be significantly reduced. The nonwoven web may be any web containing pulp fibers, such as a tissue web or a coform web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Nutritional conjunctive support therapy for recovery in animals following stress or illness

ActiveUS20070009502A1Good treatment effectRapid preventionBiocideBacteria material medical ingredientsHeifer calfFluid replacement

A composition of probiotics, vitamins and minerals, electrolytes with glutamine and glucose along with medium chain triglycerides are provided as a supplement to animals. This is administered to cattle, calves, sheep, pigs, horses, dogs, and cats that are experiencing stress and or are undergoing medical drug therapy to treat conditions of diseases along with pre and post operative surgical conditions. The composition helps correct imbalances in beneficial bacteria, provides energy and helps in rehydration to reduce recovery time from stress or in disease treatment in these animals.

Owner:VETAB PLUS

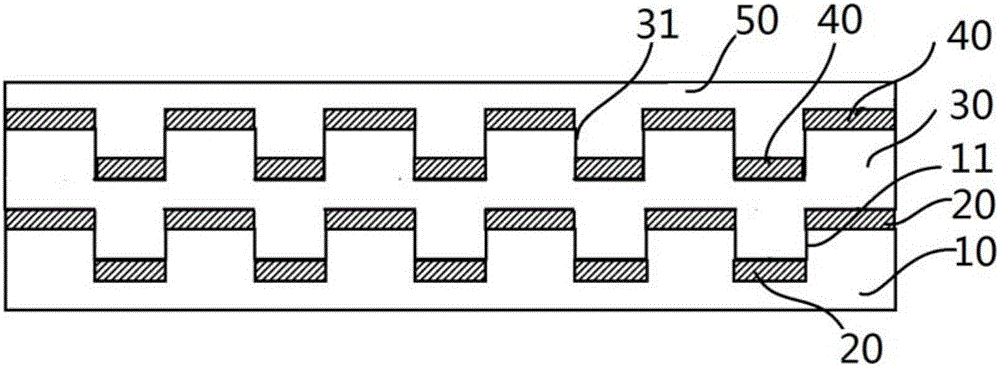

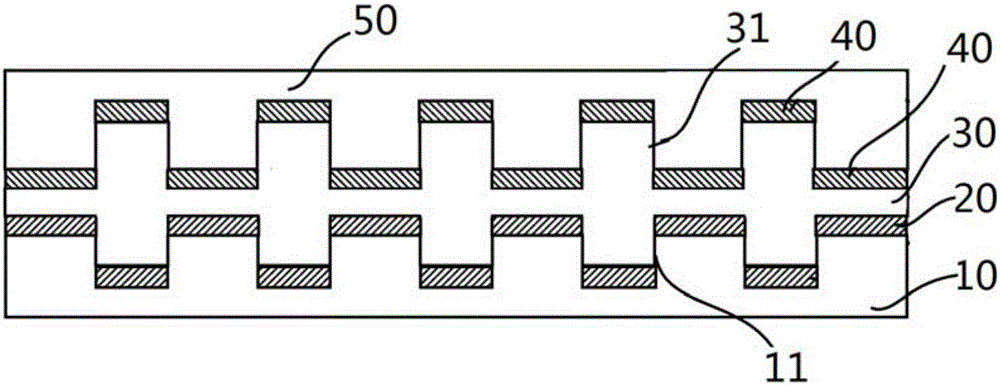

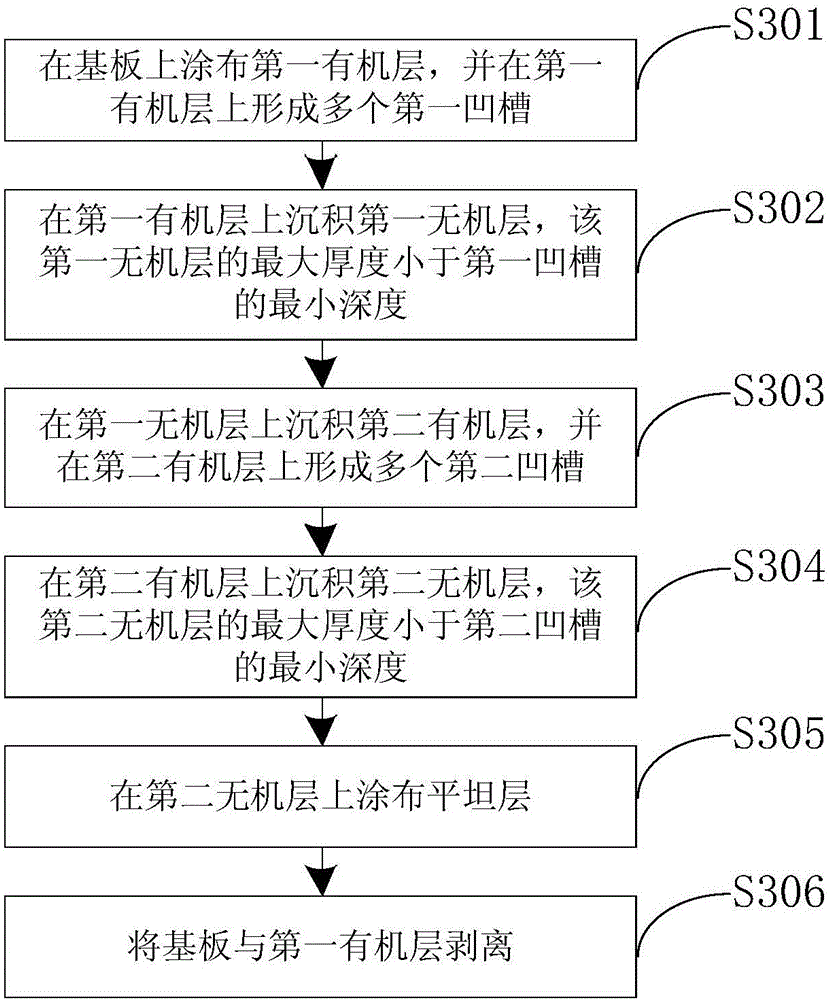

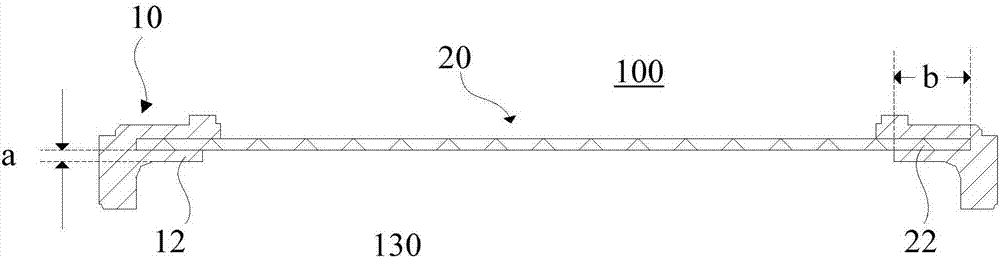

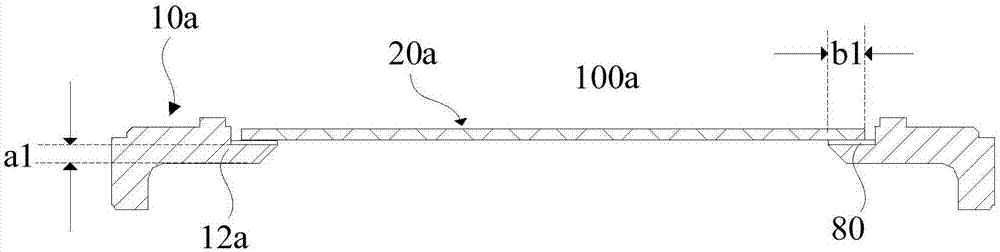

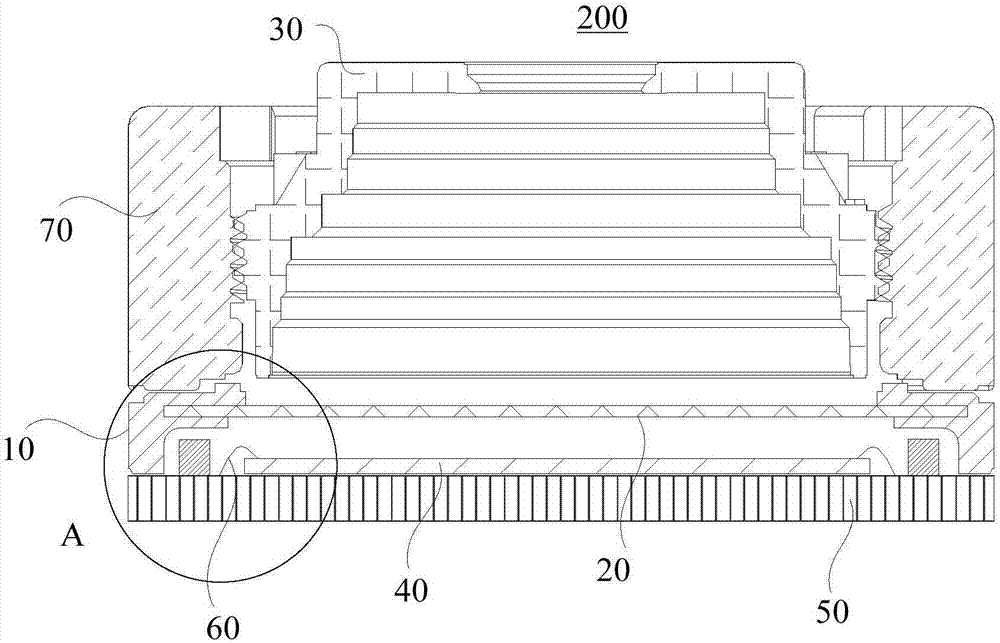

Laminated flexible substrate and production method

InactiveCN105702624AGood flexibilityImprove adhesionFinal product manufactureSynthetic resin layered productsOptoelectronicsInorganic layer

The invention provides a laminated flexible substrate and a production method. The production method comprises the following steps of coating a first organic layer on a substrate, and forming a plurality of first grooves on the first organic layer; depositing a first inorganic layer on the first organic layer, wherein the maximum thickness of the first inorganic layer is smaller than the minimum depth of the first grooves; depositing a second organic layer on the first inorganic layer, and forming a plurality of second grooves on the second organic layer; depositing a second inorganic layer on the second organic layer, wherein the maximum thickness of the second inorganic layer is smaller than the minimum depth of the second grooves; coating a flat bed on the second inorganic layer; and stripping the substrate from the first organic layer. According to the laminated flexible substrate and the production method which are provided by the invention, an adhesive force between the organic layers is increased, the possibility that a film surface falls off in the subsequent product process is reduced, and the probability that stresses are accumulated when the laminated flexible substrate is bent is reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Hair conditioner capable of nourishing hair and repairing damage

ActiveCN104095792AFast actingGood responsivenessCosmetic preparationsHair cosmeticsHair conditionerHumectant

The invention relates to a hair conditioner capable of nourishing hair and repairing damage. The hair conditioner comprises three categories, namely rinsing type, washing-free type and foam type, wherein the rinsing type hair conditioner comprises the following components in percentage by mass: 0.5-5% of a medicinal plant extract, 0.1-2% of keratin, 4-20% of a hair care conditioner, 0.5-6% of an emulsification thickener and 70-90% of deionized water; the washing-free type hair conditioner comprises the following components in percentage by mass: 0.5-5% of a medicinal plant extract, 0.1-2% of keratin, 1-15% of a hair care conditioner, 0.5-2% of an emulsification thickener, 0.05-5% of a humectant and 75-95% of deionized water; the foam type hair conditioner comprises the following components in percentage by mass: 0.5-5% of a medicinal plant extract, 0.1-2% of keratin, 0.5-3% of a foaming agent, 0.5-5% of a hair care conditioner, 0.2-3% of a solubilizer and 83-94% of deionized water. The hair conditioner can more rapidly and efficiently repair damaged hair and nourish hair.

Owner:广州好迪集团有限公司

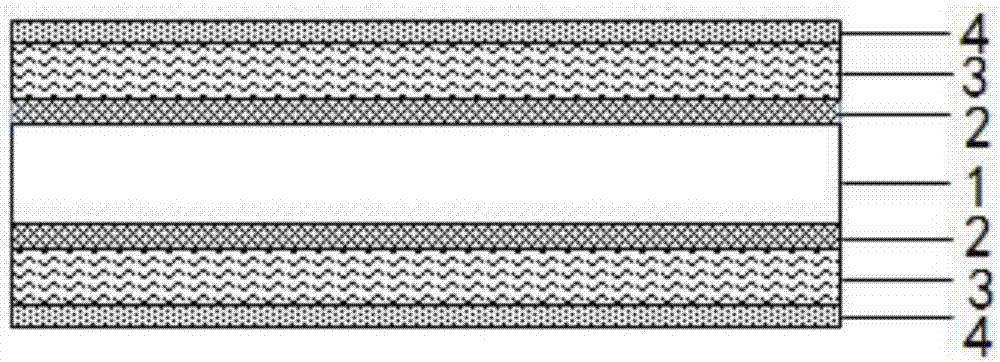

Positive electrode current collector and preparation method and application thereof

ActiveCN107123812AIncrease energy densityReduce thicknessFinal product manufactureElectrode carriers/collectorsEvaporationAluminum metal

The invention discloses a positive electrode current collector and a preparation method and an application thereof. The positive electrode current collector is of a multilayered structure and comprises a plastic thin film, wherein the upper and lower surfaces of the plastic thin film are coated with a bonding force enhancement layer, an aluminum metal coating layer and an anti-oxidization layer in sequence. The preparation method comprises the steps of coating the bonding force enhancement layer, the aluminum metal coating layer and the anti-oxidization layer through an evaporation film-coating process in sequence. The application of the positive electrode current collector mainly refers to an application in a lithium ion battery. By virtue of the positive electrode current collector, light weight of the battery can be realized, energy density can be improved, the aluminum coating layer does not fall off easily, and easy oxidization can be avoided.

Owner:CONTEMPORARY AMPEREX TECH CO +1

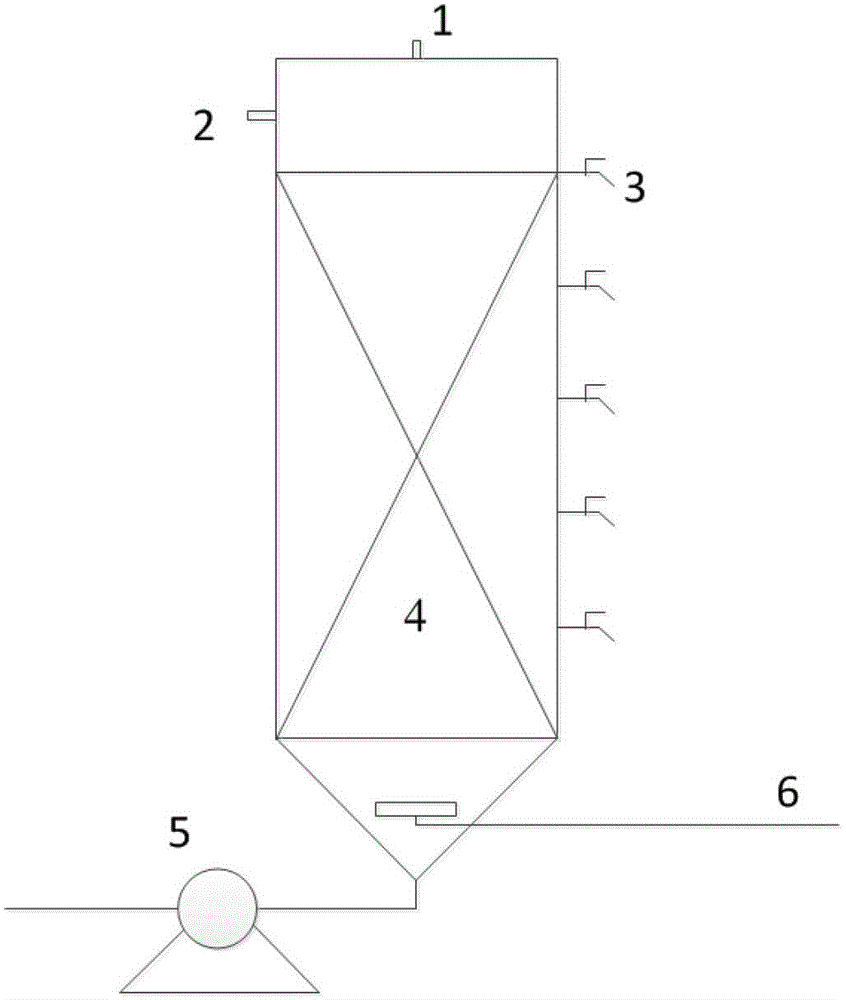

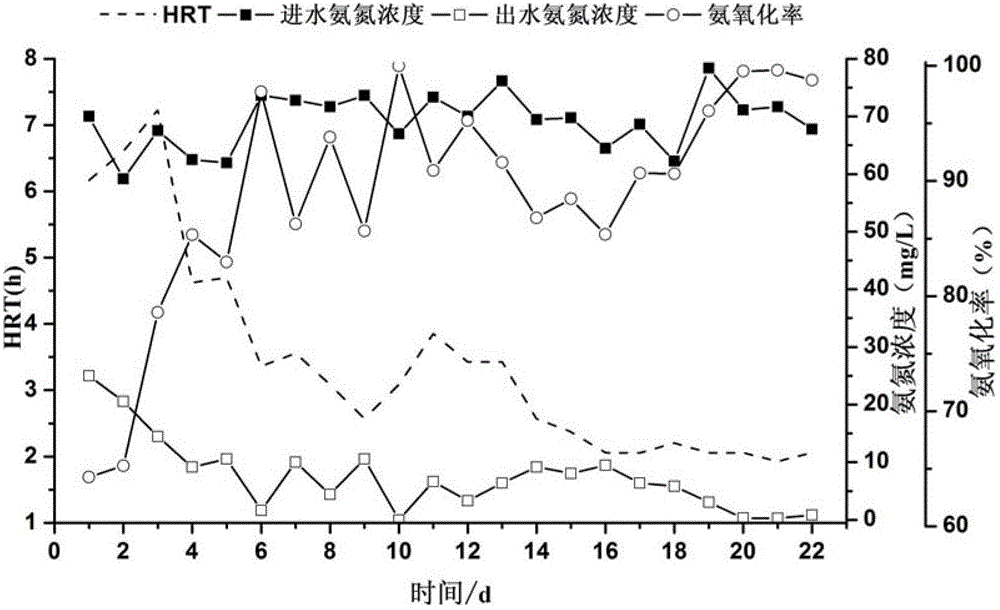

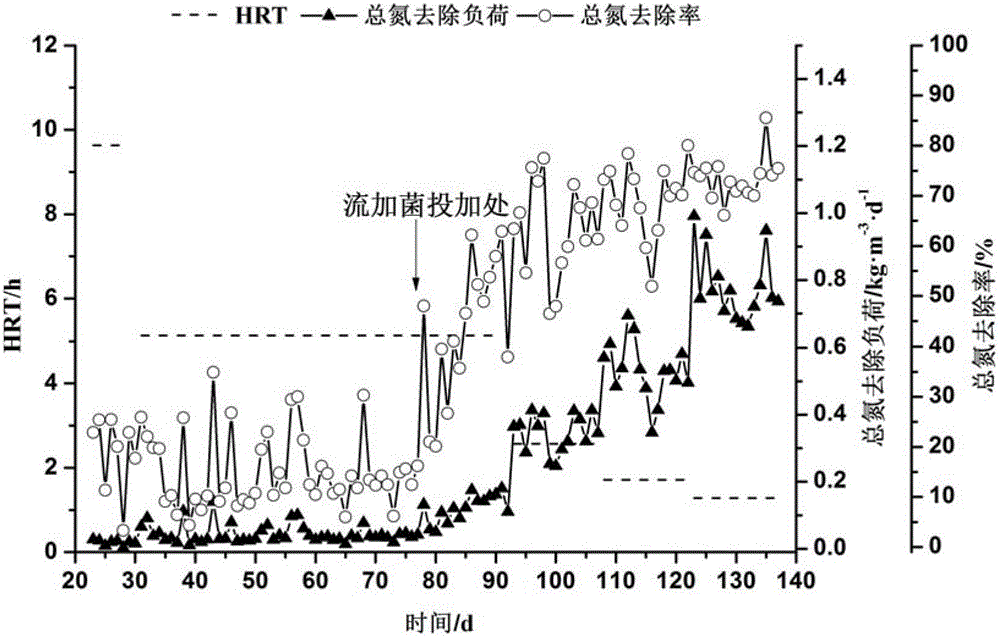

Method for quick starting of anaerobic ammonium oxidation technology at room temperature in low matrix

ActiveCN102718314AReduce sheddingAvoid deathTreatment with aerobic and anaerobic processesStart timeSludge

A method especially for quick starting of anaerobic ammonium oxidation technology at room temperature in low matrix belongs to the field of urban domestic sewage treatment and regeneration. The method comprises firstly inoculating nitrified sludge having certain nitration function into an upward-flow biology filtering tank using volcanic rocks as filtering materials, and employing a method of continuous aeration and dissolved oxygen concentration control so as to cultivate nitrified biomembrane; secondly, employing a intermittent aeration / anaerobic way to screen and concentrate anaerobic ammonium oxidation (ANAMMOX) bacterium; and lastly adding a certain amount of ANAMMOX bacterium into the reactor after the reactor fully enter into an anaerobic situation to perform rapid induction, andthus reducing starting time. On the basis of appearance of anaerobic ammonium oxidation characteristics, HRT continues to be reduced, water inflow load is raised, and finally starting of ANAMMOX technology at room temperature in low-matrix sewage can be realized. The invention provides a method for quick starting of the anaerobic ammonium oxidation technology at room temperature in low matrix.

Owner:BEIJING UNIV OF TECH

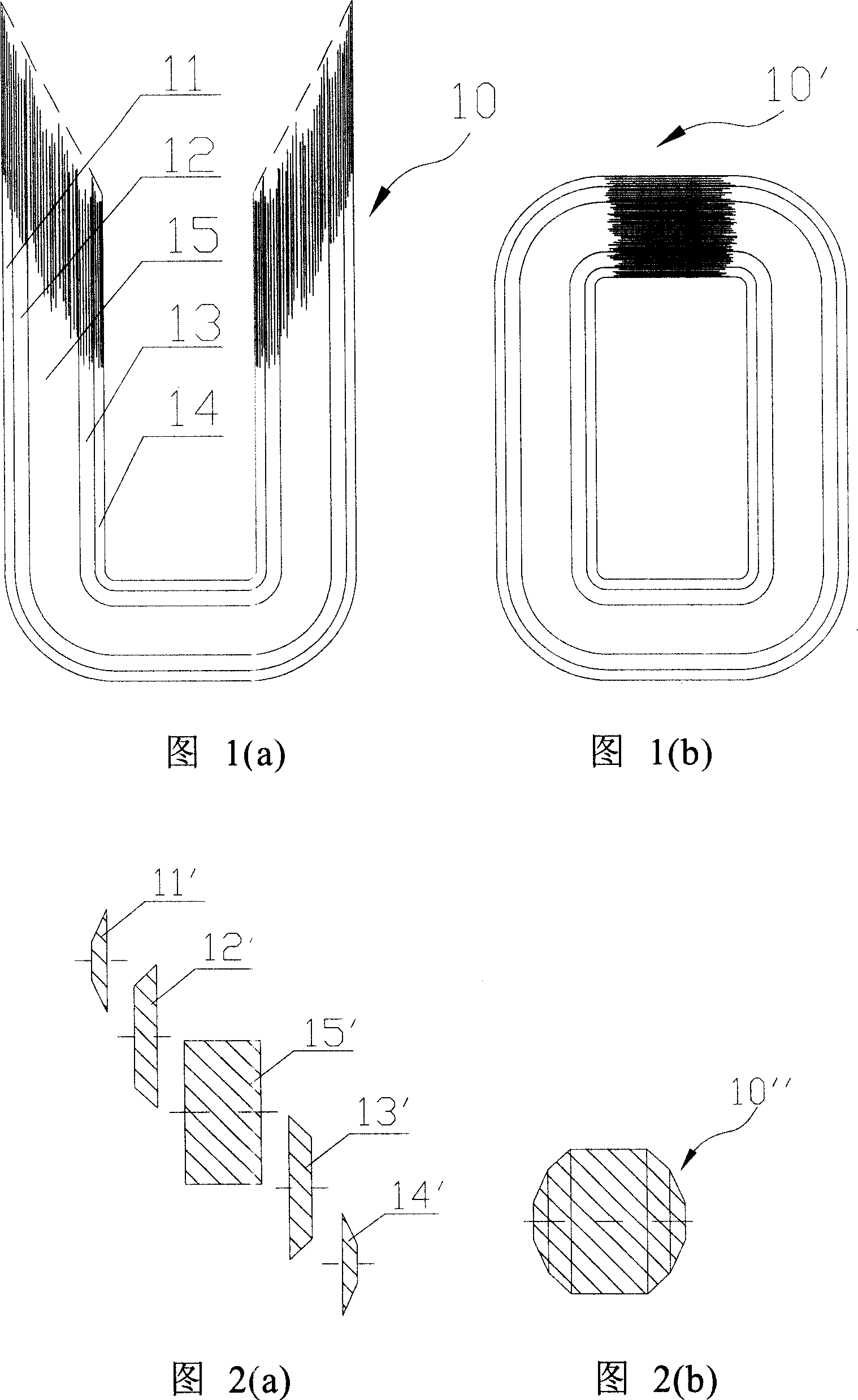

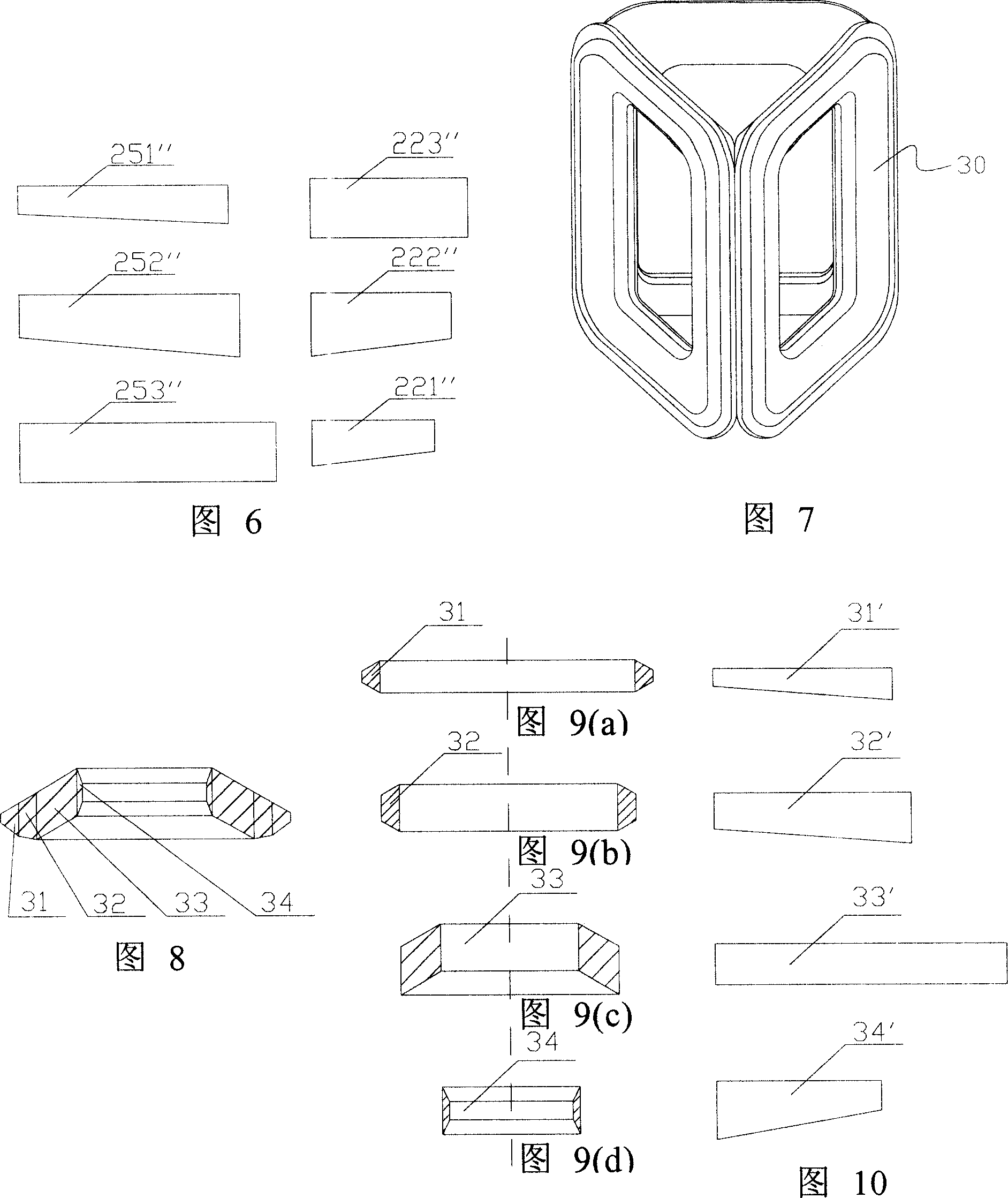

Amorphous alloy roll-core and its production method

ActiveCN101150006AReduce turn lengthSave copperTransformers/inductances magnetic coresInductances/transformers/magnets manufactureButt jointTransformer

This invention relates to a non-crystal alloy rolled iron-core and its manufacturing method, in which, the iron-core is formed by several single frames winded in different sections and the section shape of the butt-joint iron-core is in a pre-designed Quasi-circular, quasi-polygon or a complex shape made of non-crystal alloy material or non-crystal alloy and silicon steel ribbon, in which, the one with the largest section is taken as the master frame rolled continuously with the straight non-crystal alloy ribbon and other single frames are formed by rolling different shapes of silicon steel ribbons, besides, the butt-joint core can be either close one or an open one, can be either single phase iron-core, three phase three posts planar core or a three phase five posts planar core or a three phase solid core.

Owner:NEWONDER SPECIAL ELECTRIC

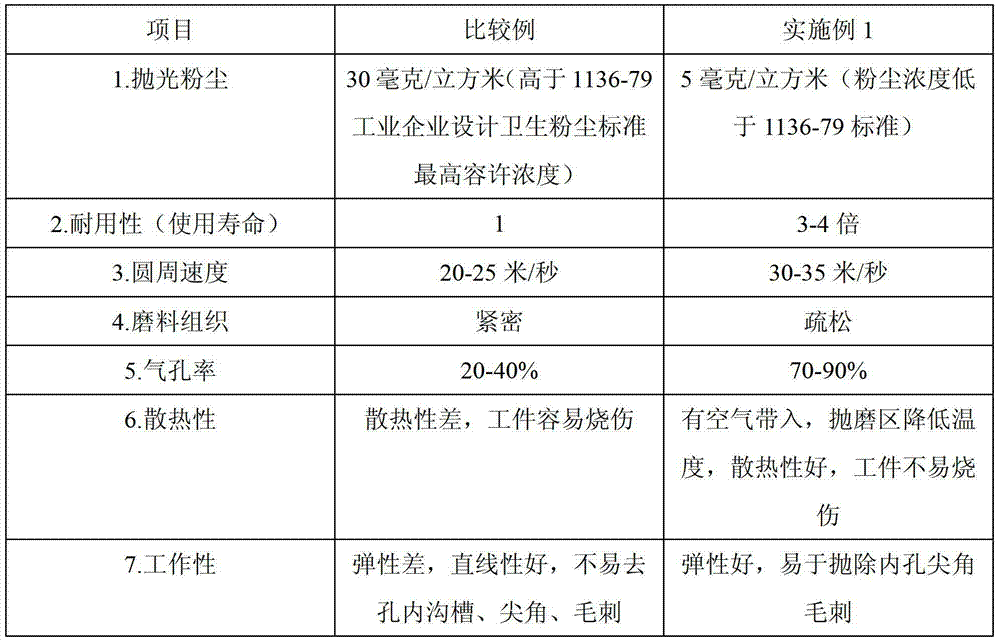

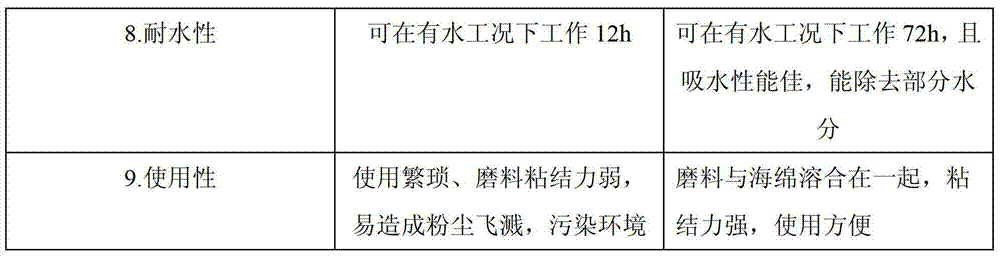

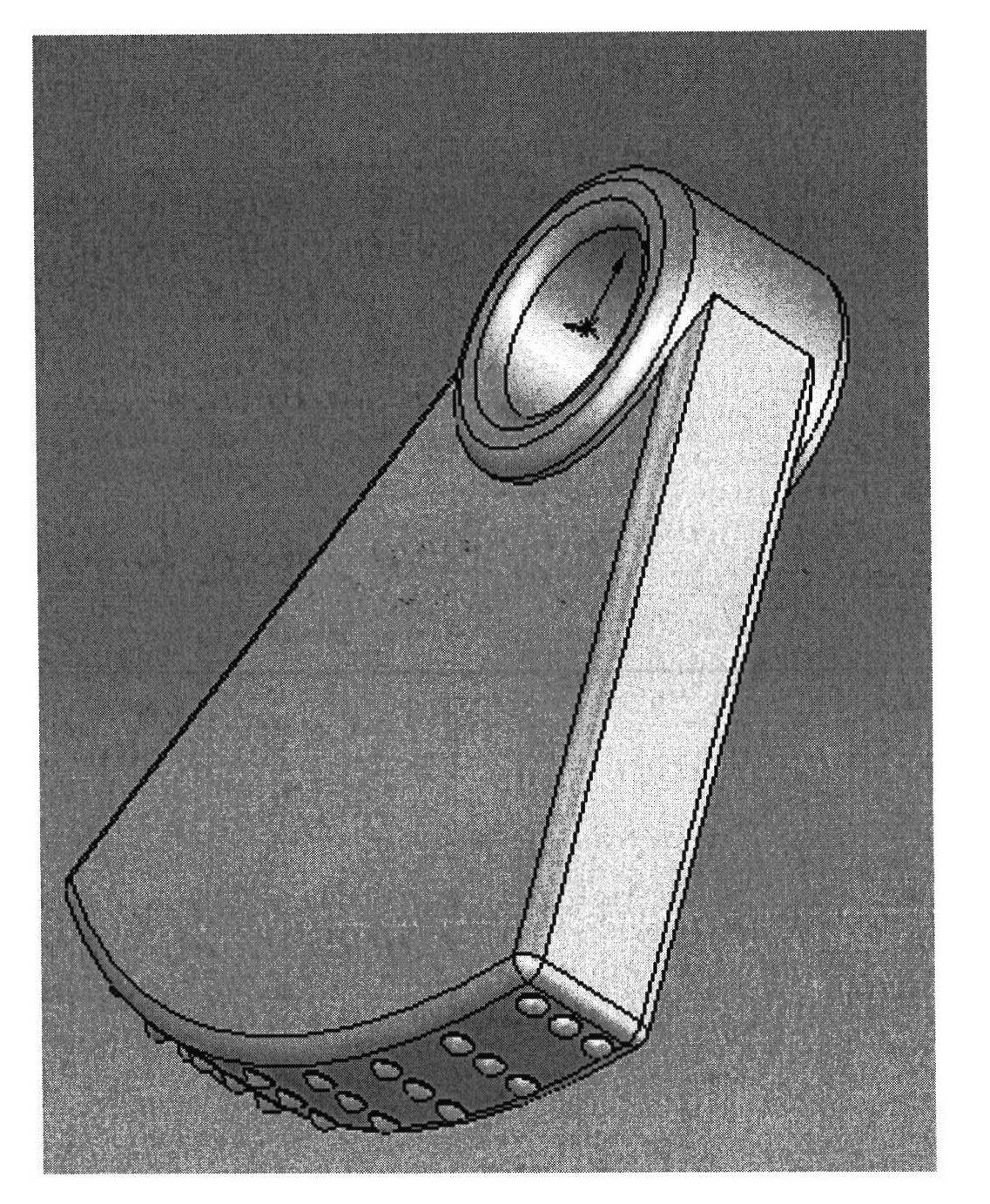

Polyvinyl alcohol-polyurethane elastic buffing wheel and preparation method thereof

InactiveCN103395011AUniform cellsNo stuffingAbrasion apparatusGrinding devicesWater bathsDistilled water

The invention discloses a polyvinyl alcohol-polyurethane elastic buffing wheel and a preparation method of the polyvinyl alcohol-polyurethane elastic buffing wheel. The preparation method comprises the steps that firstly, polyvinyl alcohol is mixed with distilled water, and the mixture is dissolved for 20-30 minutes under the condition of 50-95 DEG C water bath and at the rotation speed of 400-600r / min to obtain a polyvinyl alcohol aqueous solution; then, the polyvinyl alcohol aqueous solution is heated up to 30-100 DEG C, grinding materials are firstly added into the polyvinyl alcohol aqueous solution, after the mixture of the grinding materials and the polyvinyl alcohol aqueous solution is stirred and mixed evenly at the rotation speed of 400-600r / min, polyurethane pre-polymers, catalysts and air hole generating agents are added, and all the components are stirred and mixed evenly at the rotation speed of 400-600r / min and react for 5-10min; solidification is conducted for 2-4h under the condition of 30-100 DEG C, and then the buffing wheel which is good in elasticity, good in water resistance, good in heat-dissipating performance and high in mechanical strength is obtained. The elastic buffing wheel is even in foam hole, good in abrasion resistance and grinding force, not prone to deforming or curling in humid environment and applicable to long-time grinding work.

Owner:SOUTH CHINA UNIV OF TECH

Inserted tooth hammer of crushing machine and preparation method thereof

The invention relates to an inserted tooth hammer of a crushing machine and a preparation method thereof and belongs to the fields of high technology engineering materials and application thereof. The inserted tooth hammer of the crushing machine consists of ball teeth and a hammer base body and is formed by virtue of high temperature imbedding, wherein the ball teeth are novel high-hardness high-strength anti-abrasive composite metal ceramic comprising one or more of WC, TiN or TiC based composite metal ceramic; the hammer base body is middle-low carbon steel or alloy steel with high hardness and strength and good toughness; the inserted tooth hammer of the crushing machine structurally comprises multiple cylindrical ball teeth with spherical crowns, the multiple cylindrical ball teeth are imbedded at the front end of the hammer base body, a cylinder is buried in a steel body, the spherical crowns are exposed out of the steel body, and a distance is reserved between the ball teeth. The preparation method of the inserted tooth hammer of the crushing machine successively comprises the following steps of: pre-preparing composite metal ceramic ball teeth; smelting hammer base body alloy steel; imbedding the ball teeth; and demoulding. The inserted tooth hammer of the crushing machine has the characteristics of good abrasive resistance, long service life, raw material economization and low cost.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Cathode current collector, and preparation method and application of cathode current collector

ActiveCN107369810AIncrease energy densityHigh tensile strengthNitrogen-metal/silicon/boron binary compoundsElectrode carriers/collectorsCopper platingEvaporation

The invention discloses a cathode current collector, and a preparation method and an application of the cathode current collector. The cathode current collector is in a multilayer structure, and comprises a plastic film, wherein the upper and lower surfaces of the plastic film are sequentially coated with bonding force reinforcement layers, copper coating layers and antioxidation layers. The preparation method comprises the steps of coating the bonding force reinforcement layers on the plastic film by utilizing a magnetron sputtering coating technology, coating the copper coating layers by utilizing an evaporation coating technology, and coating the antioxidation layers by utilizing an electron beam evaporation coating technology or the magnetron sputtering coating technology. The application of the cathode current collector is mainly in a lithium ion battery. The cathode current collector can realize lightweighting of the battery, improves the energy density, lowers the cost, and can reduce the possibility of falling and oxidation of the copper coating layers.

Owner:CONTEMPORARY AMPEREX TECH CO

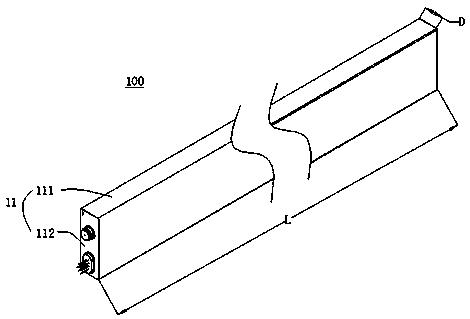

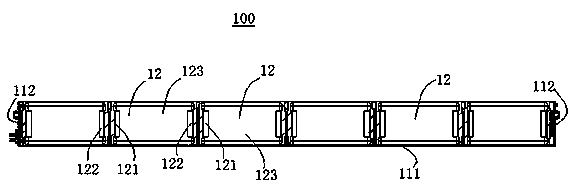

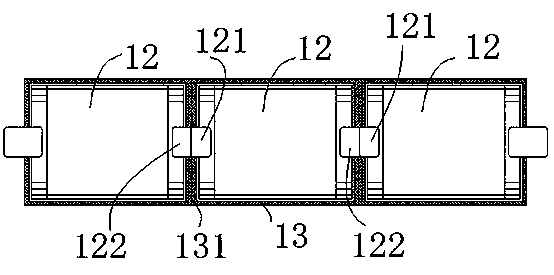

Battery, battery module, battery pack and electric vehicle

ActiveCN110828717AHigh mechanical strengthExtended service lifeVent arrangementsElectrolyte accumulators manufactureElectric carsElectric vehicle

The invention provides a battery, a battery module, a battery pack and an electric vehicle. The battery comprises a metal casing body and a plurality of pole core strings packaged in the metal casingbody. The plurality of pole core strings are arranged along a second direction and connected in series with one another. Each pole core string comprises a plurality of pole core groups which are arranged along a first direction and connected in series with one another. Each pole core group comprises at least one pole core. Each pole core group is packaged in a packaging film. The air pressure between the metal casing body and packaging films is lower than the air pressure outside the metal casing body. According to the invention, the sealing effect and the strength of the battery are improved.

Owner:BYD CO LTD

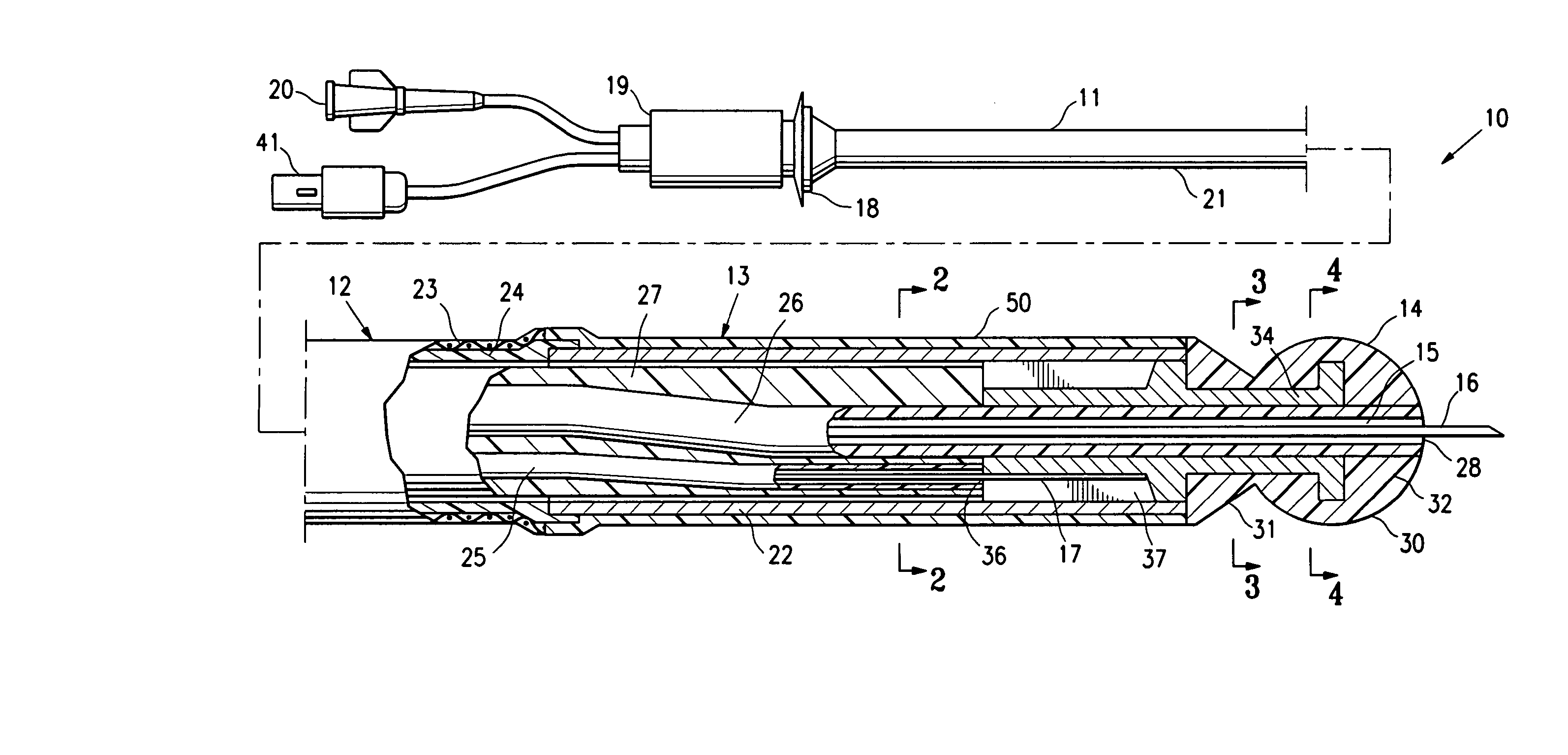

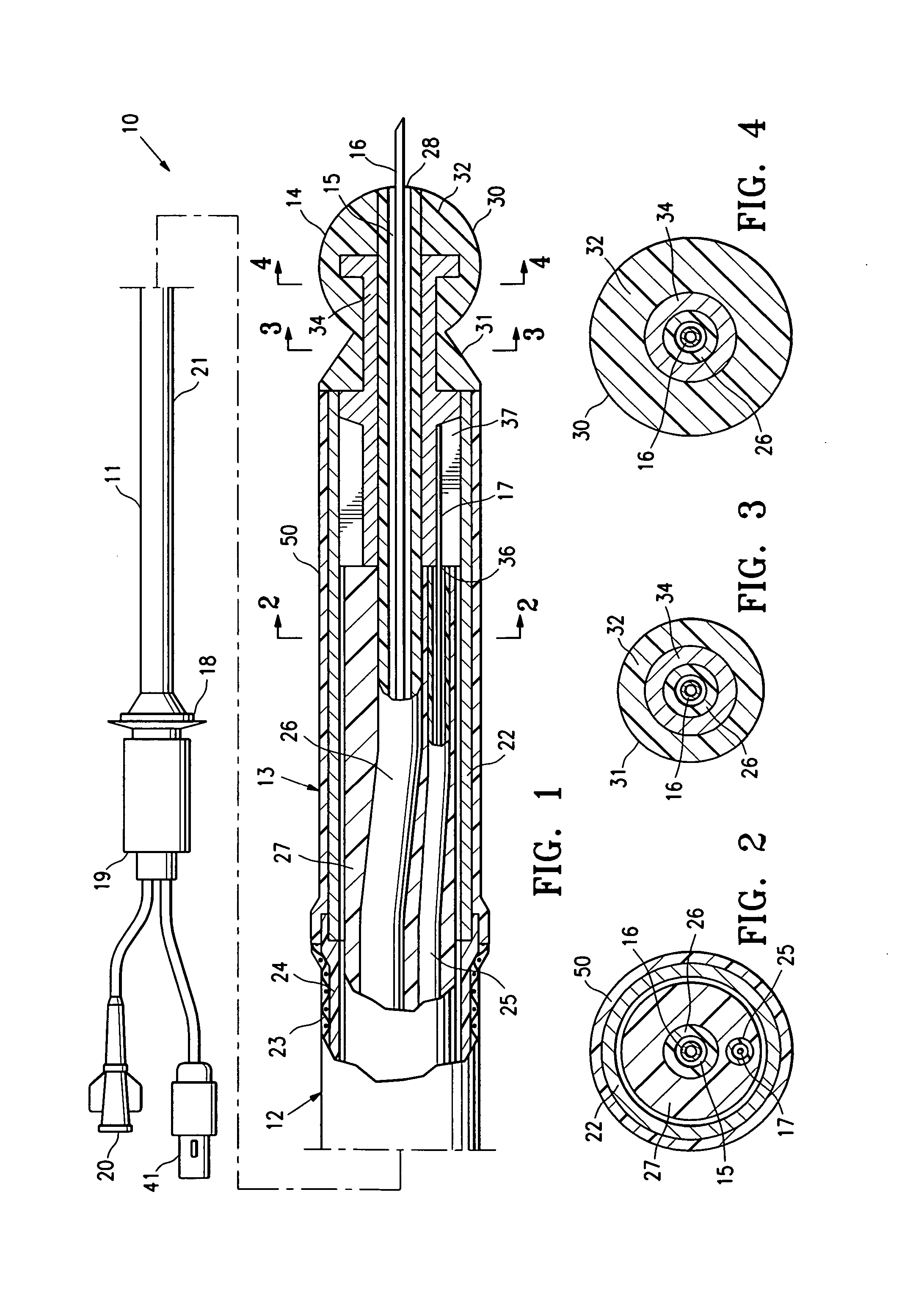

Echogenic needle catheter configured to produce an improved ultrasound image

InactiveUS20070265516A1Minimize amount of metalReduces and eliminates artifactElectrocardiographyBlood flow measurement devicesUltrasound imagingNeedle catheter

An echogenic catheter, such as a needle catheter, formed at least in part of an intrinsically conductive organic polymer for providing a highly conductive surface in combination with an improved ability to ultrasonically image the catheter, and a method of performing a medical procedure using a catheter of the invention.

Owner:ABBOTT CARDIOVASCULAR

Coating and suspending chocolate with sweet potato powder added

The invention relates to a coating chocolate, wherein, every 1000 weight portions of chocolate comprises raw materials of 220 to 250 weight portions of sugar, 30 to 80 weight portions of sweet potato powder, 180 to 280 weight portions of milk solid, 340 to 430 weight portions of oil, 70 to 110 weight portions of cocoa powder and 0.5 to 1 weight portion of emulsifier. The sweet potato powder is cheap, full of nutriments, rich in cellulose, pectin and protein and relatively expensive raw materials such as milk powder, whey powder, etc., are replaced in the current coating chocolate, thus guaranteeing the quality of the coating chocolate and greatly saving cost. The coating chocolate provided by the invention can be applied to producing ice cream with surface coated with particles, can improve the adhesive capacity of particles by 5 to 10 percent, thereby not only improving the flavor and taste of ice cream, but also reducing the waste of particles.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

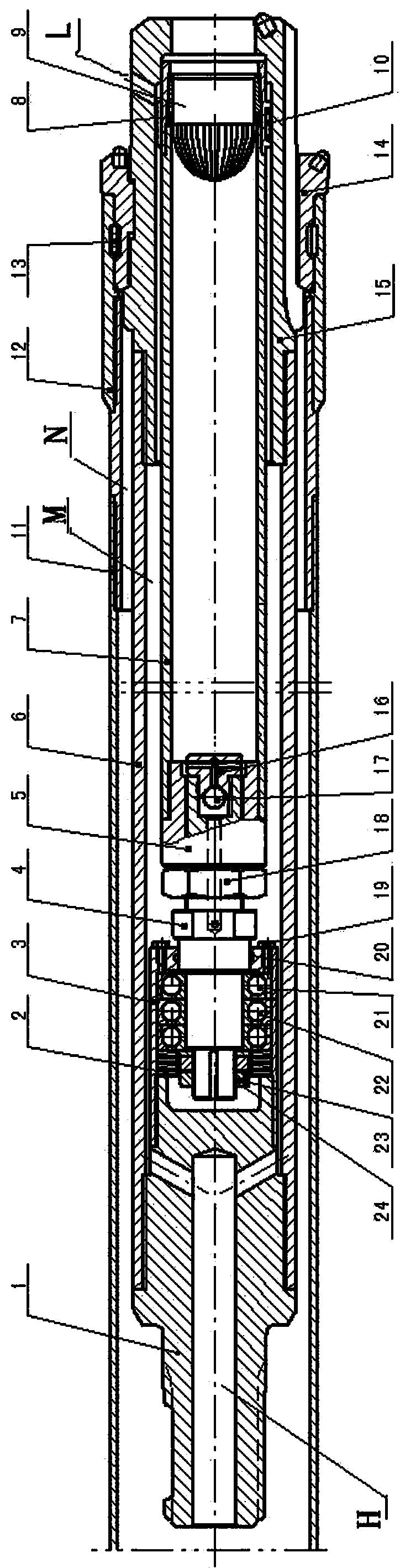

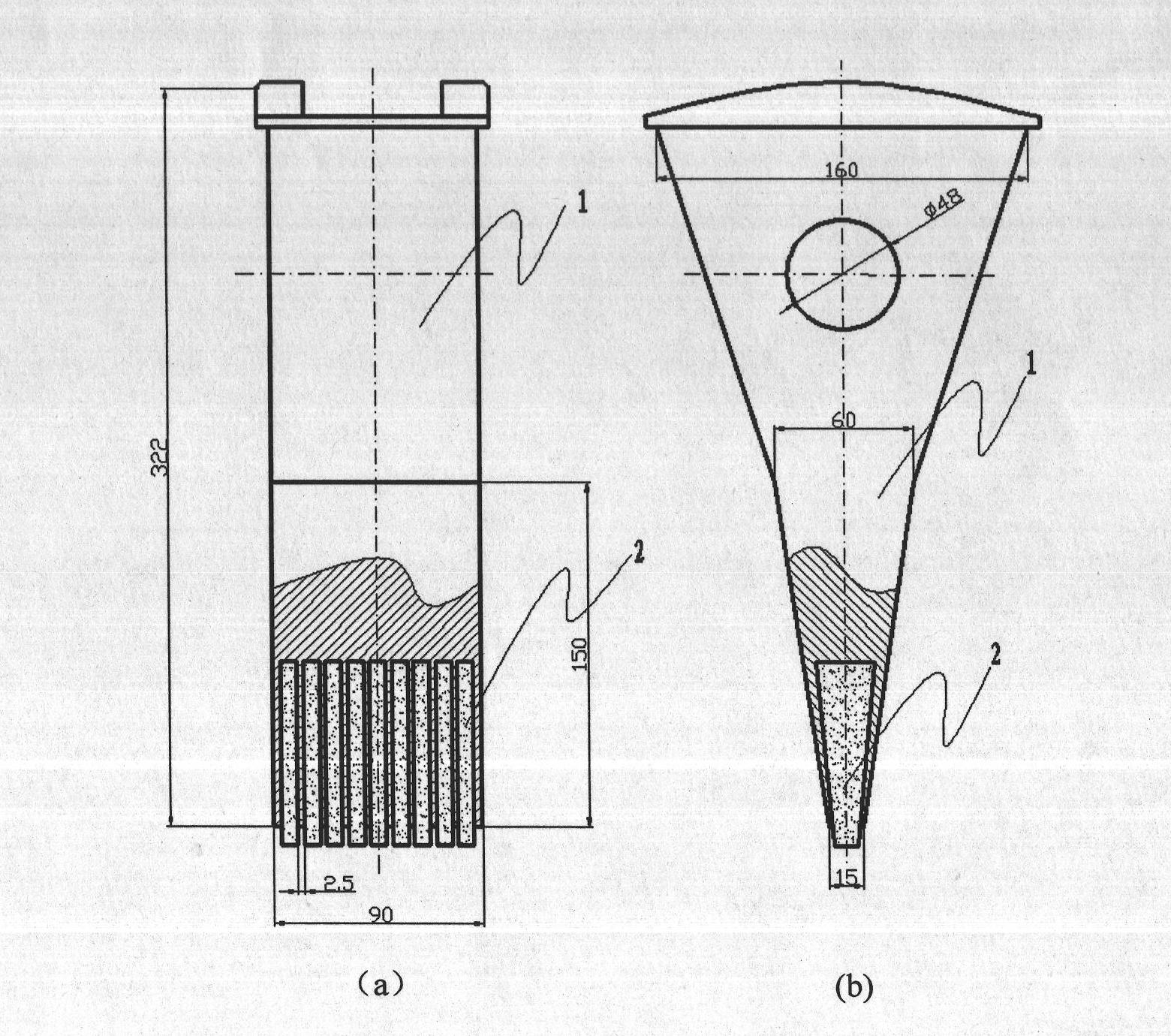

Single-action double-pipe coring overburden drill tool for air down-the-hole hammer

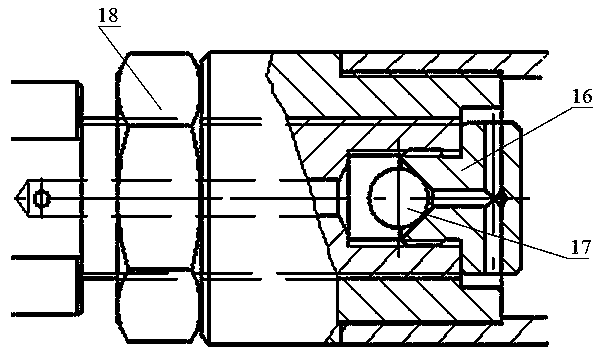

InactiveCN104295232AEliminate disadvantagesReduce frictional resistanceBorehole drivesCore removalBall bearingGeological survey

The invention relates to a single-action double-pipe coring overburden drill tool for an air down-the-hole hammer. The single-action double-pipe coring overburden drill tool comprises a central coring drill tool and an overburden drill tool. The central coring drill tool is a single-action double-pipe coring drill tool and comprises a single-action vibration reduction mechanism, an inner pipe adjusting mechanism and a coring mechanism with a bayonet device; the single-action vibration reduction mechanism comprises an impact connector, a disc spring, a bearing block, a connecting shaft, a thrust ball bearing and a radial ball bearing; the inner pipe adjusting mechanism comprises a connecting shaft, a core pipe connector, an inner pipe and a nut; the coring mechanism with the bayonet device comprises an outer pipe, an inner pipe, a connecting shaft, a core pipe connector, a coring drill bit, a rolling needle, a pawl spring seat and a pawl spring; the overburden drill tool comprises a casing, a casing connector, a casing shoe, a clamp ring and a casing drill bit. The single-action double-pipe coring overburden drill tool for the air down-the-hole hammer is applicable to relevant fields such as geological mineral exploration and engineering geological survey for complex formation with loose sand, cobbles, gravel, fracture, breakage and the like.

Owner:江苏省南京工程高等职业学校

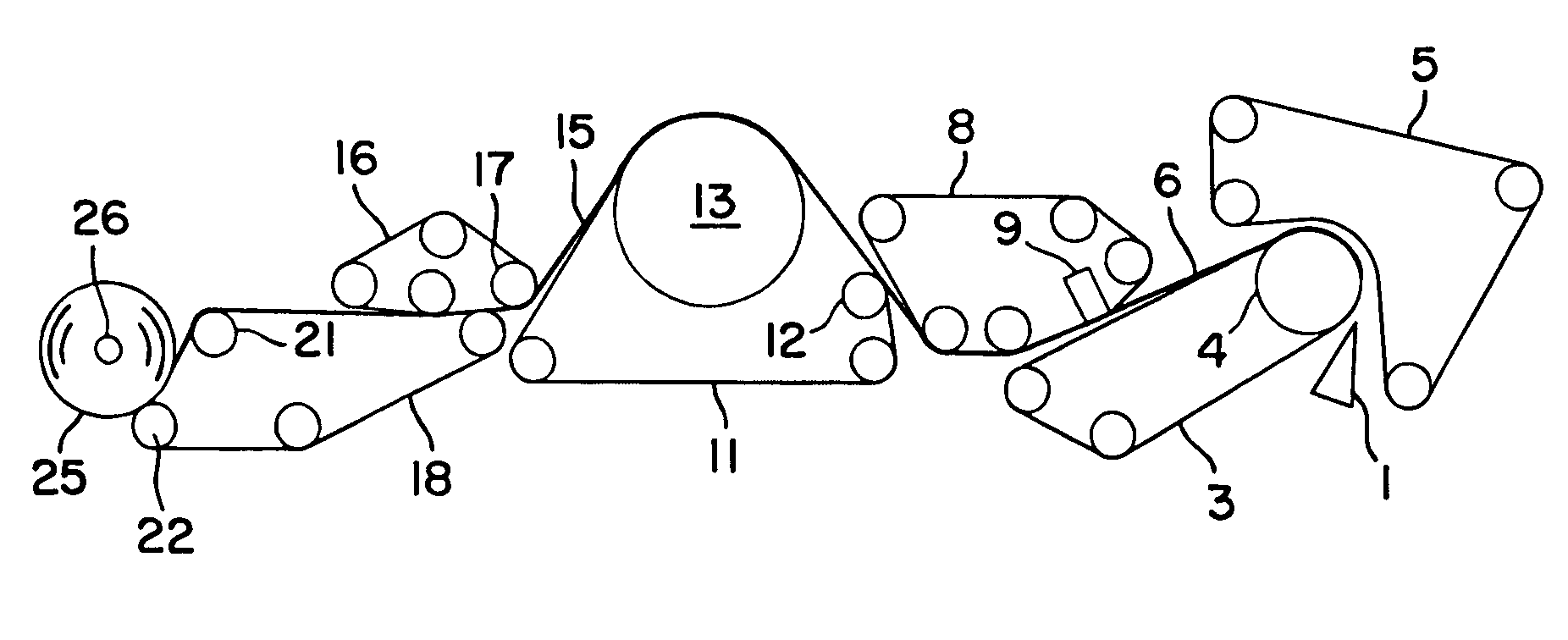

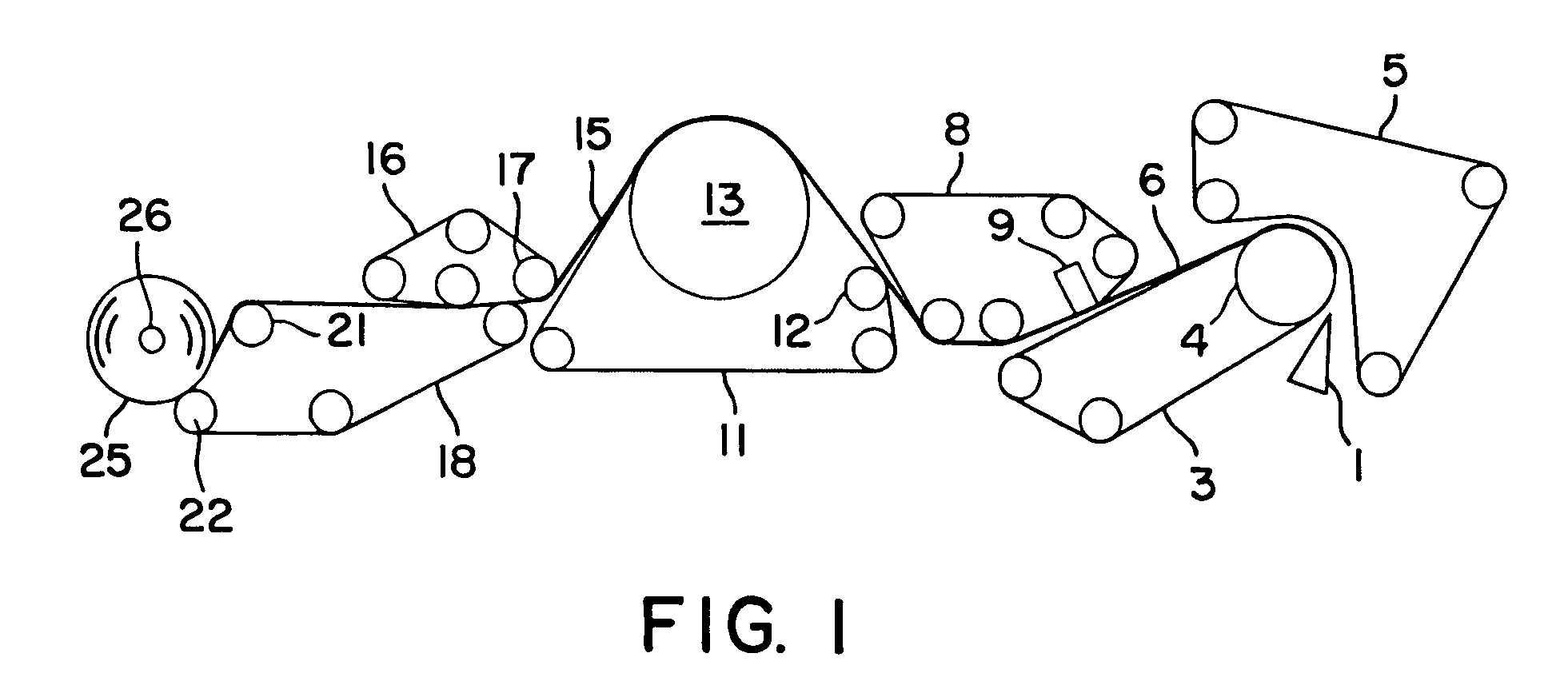

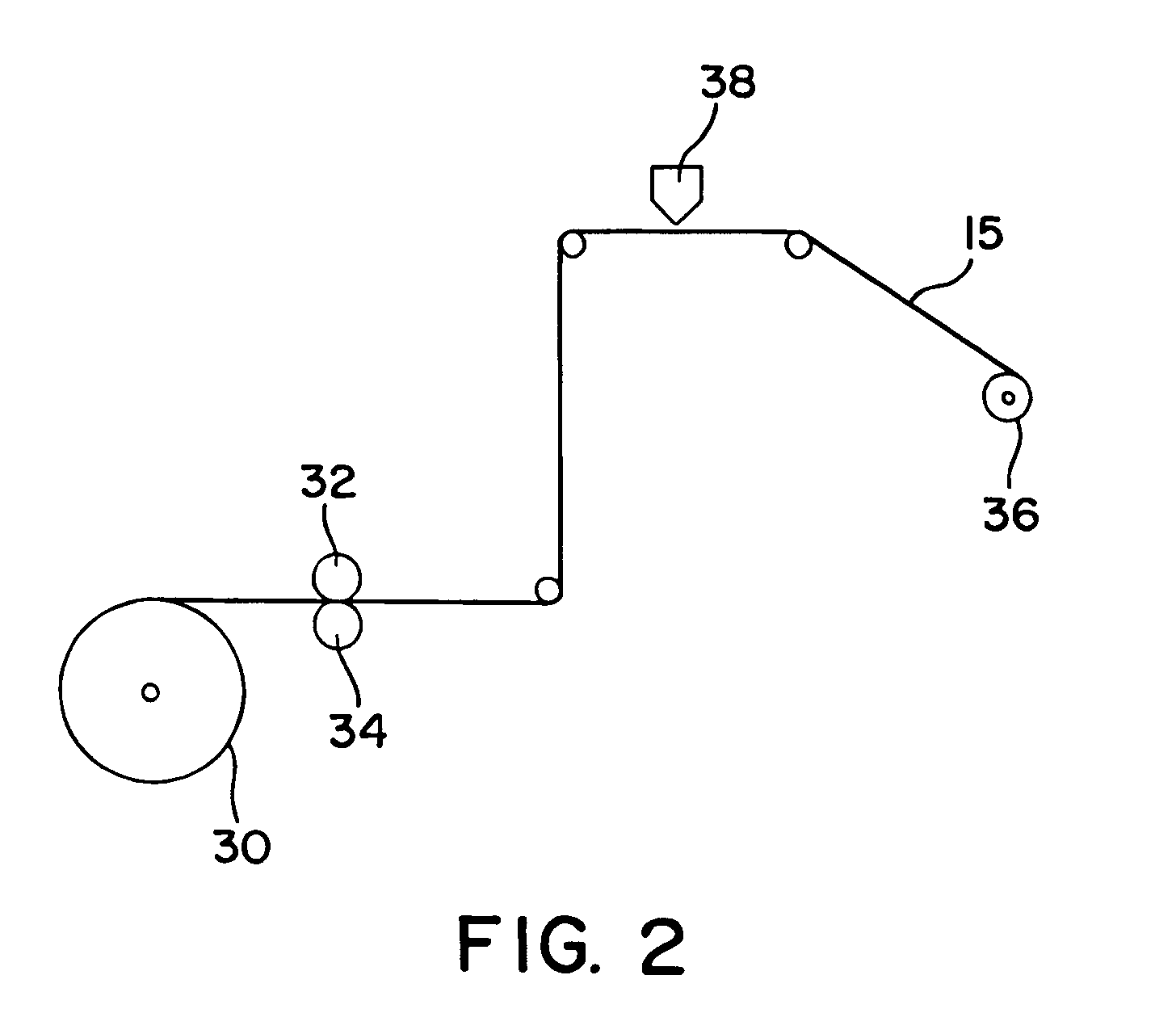

Industrial fabrics

InactiveUS20050181694A1Improve the immunitySuperior macroSynthetic resin layered productsWoven fabricsFiberBiochemical engineering

Owner:VOTH FABRICS PATENT GMBH

Silver-knit material

InactiveUS6993941B2Less deformationReduce fatigueLiquid surface applicatorsCircular knitting machinesFiberComposite material

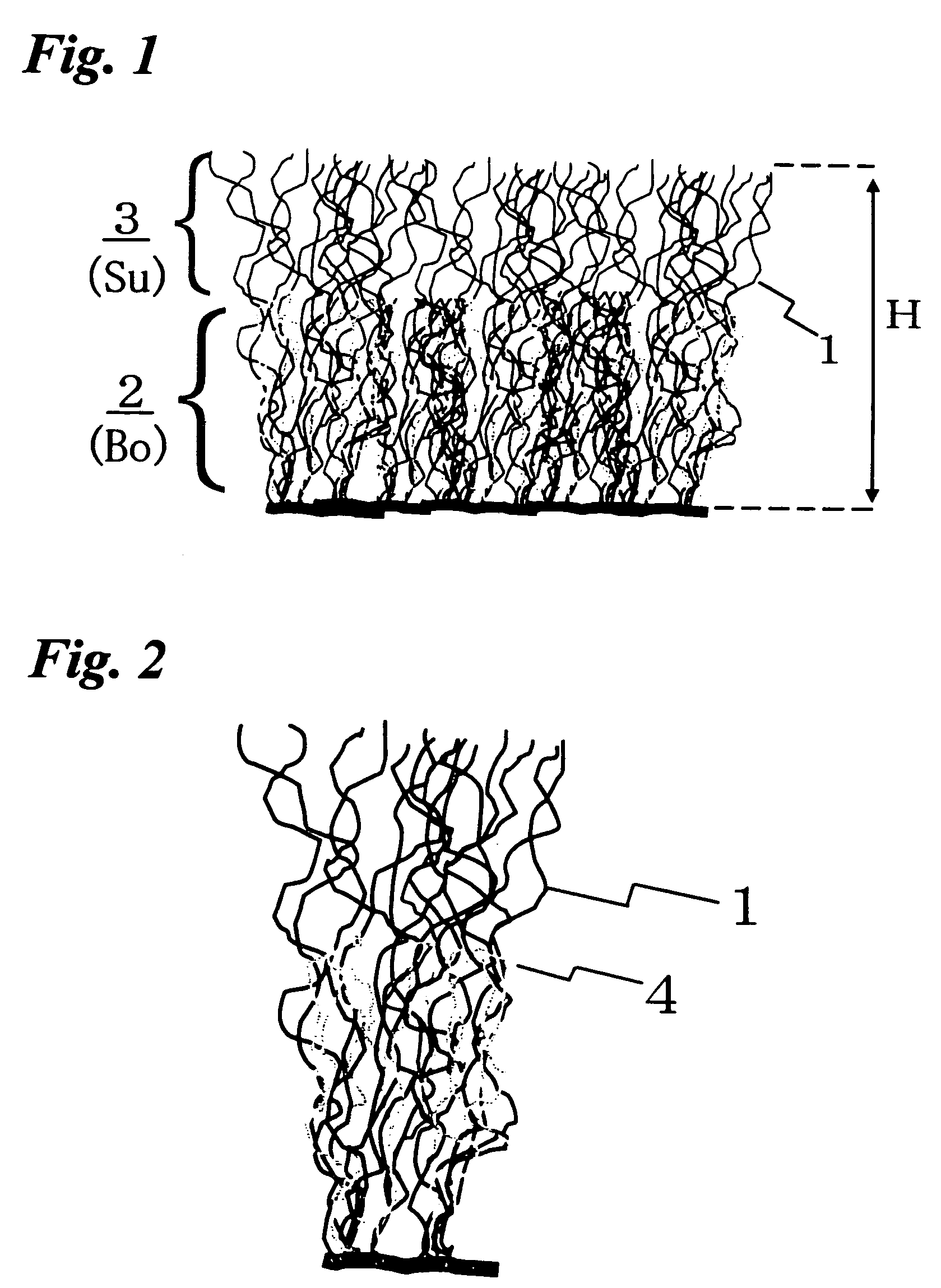

A sliver-knit material causing less buckling fatigue or deformation during compression and improved with shedding, in which a pile thread contains 30% or more of staple fibers having steric crimps, and a dense layer (Bo) and a bulky layer (Su) on the side of the upper layer in contact with the dense layer (Bo) are formed, where the ratio of height between the dense layer (Bo) and the bulky layer (Su) in the sliver-knit material is from 2:5 to 1:1, and at least a portion of fibers present in the dense layer (Bo) are folded back.

Owner:KURARAY CO LTD

Loudspeaker module and manufacturing method thereof

ActiveCN103618984AReduce sheddingGuaranteed firmnessElectrical transducersDomestic articlesEngineeringSoft materials

The invention relates to the electroacoustic technical field, and provides a loudspeaker module and a manufacturing method thereof. The loudspeaker module comprises a case and a single loudspeaker body combined inside the case. The single loudspeaker body comprises a vibrating diaphragm assembly and a magnetic circuit assembly. A front sound cavity and a rear sound cavity are formed between the single loudspeaker body and the case. The case is provided with an elastic part, the elastic part is combined with the end surface of the opening end of the front sound cavity or the rear sound cavity, and the elastic part and the case are of an integrated structure formed in an injection molding mode. By adopting the structure in the loudspeaker module, the process of attaching the elastic part manually is eliminated, the accuracy and the stability of combination of the elastic part are guaranteed, the elastic part does not fall easily, the sealing property between a sound outlet hole of the loudspeaker module and a sound hole of a mobile phone after the loudspeaker module and a terminal electronic product are assembled can be effectively guaranteed, and the acoustic performance is improved. The manufacturing method for the loudspeaker module can solve the technical problems effectively and can be popularized to production for other structures with soft materials or hard materials needing to be injected into other materials.

Owner:GOERTEK INC

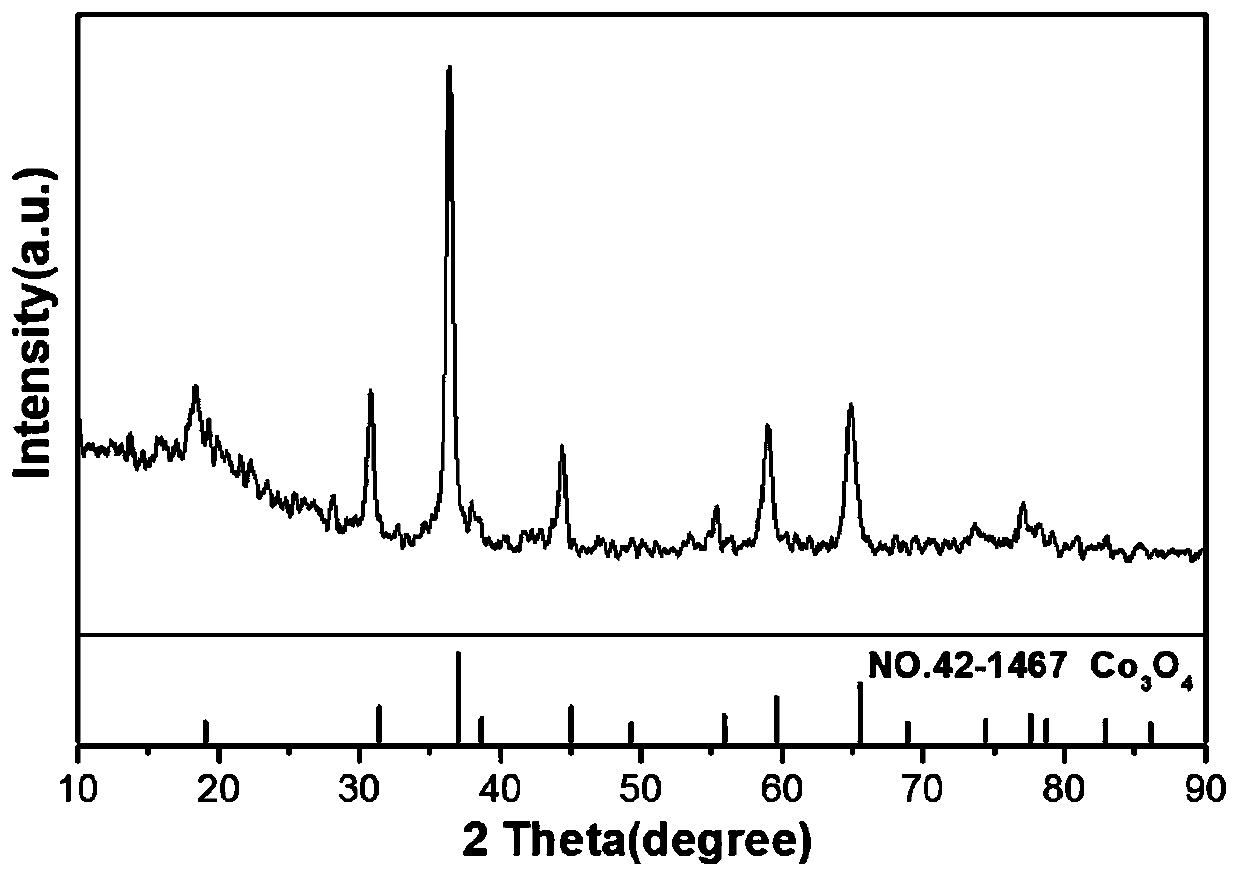

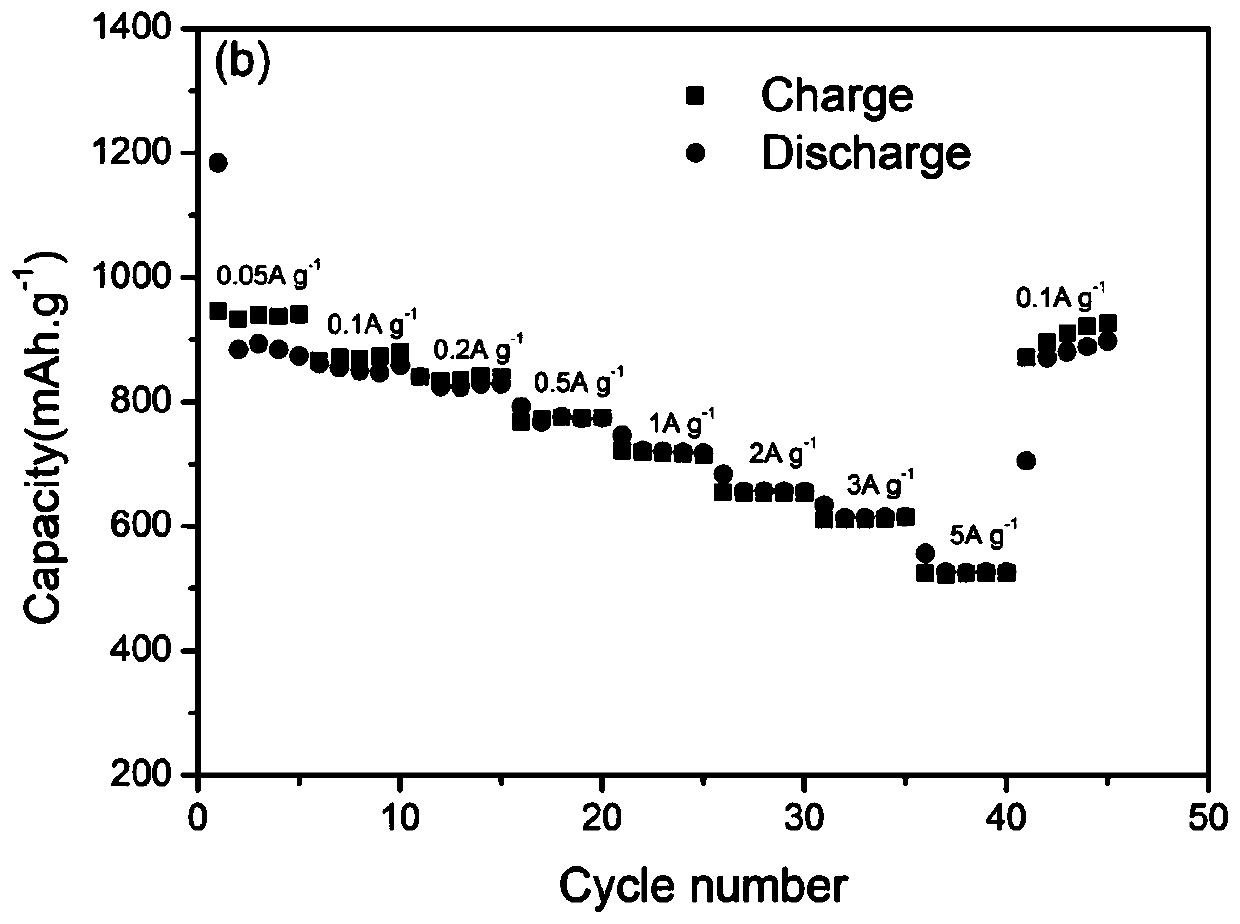

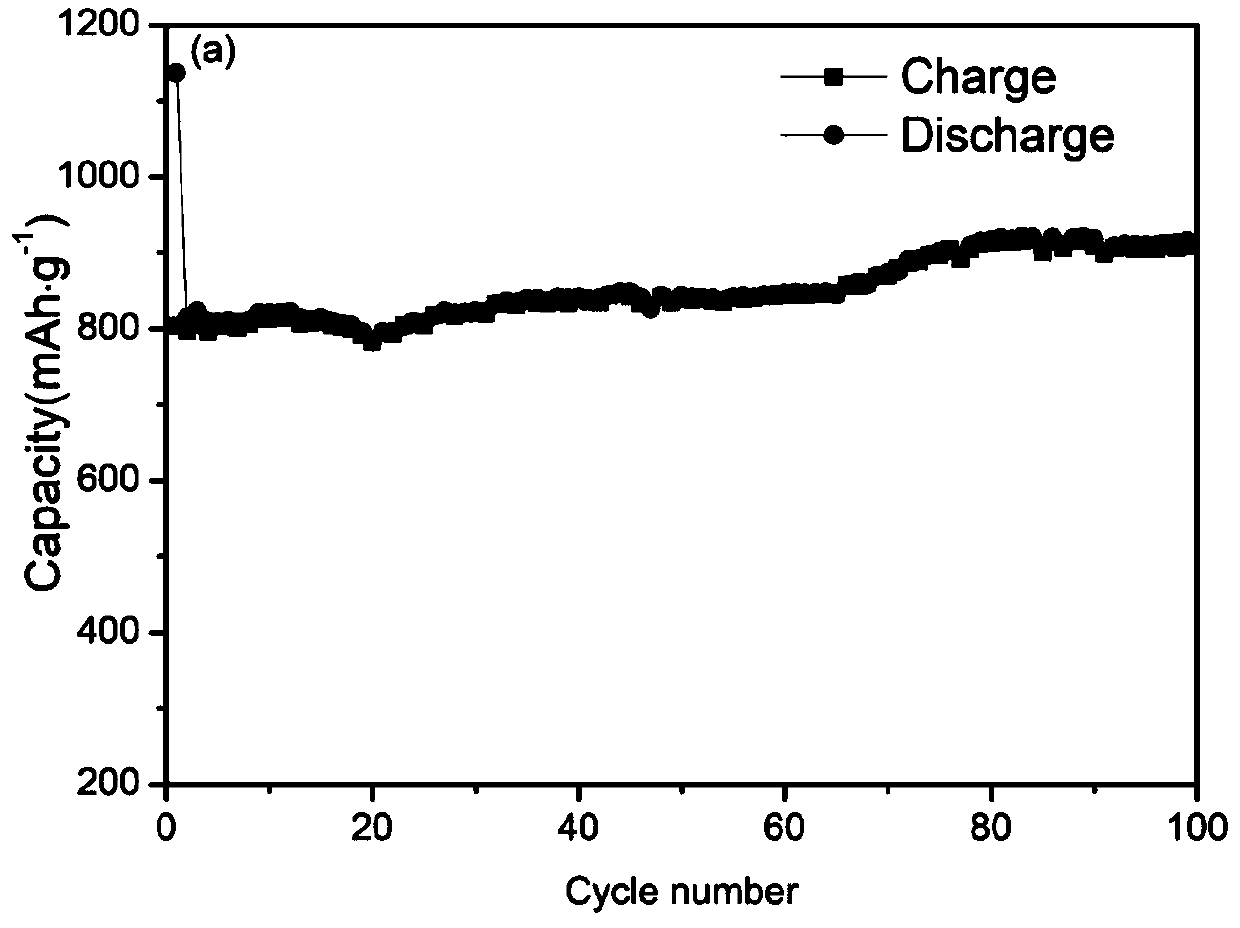

Cobalt oxide carbon nanofiber flexible electrode material derived from MOF for lithium ion batteries and preparation method thereof

InactiveCN110137461AImprove flexibilityImprove cycle stabilityMaterial nanotechnologyFilament/thread formingCarbonizationCarbon nanofiber

The invention provides a cobalt oxide carbon nanofiber flexible electrode material derived from MOF for lithium ion batteries and a preparation method thereof. Carbon nanofibers containing ZIF-67 areobtained by electrospinning with a mixture of polyacrylonitrile and a metal organic frame material ZIF-67 as a precursor solution, and then, a Co3O4 carbon nanofiber flexible electrode material is synthesized through pre-oxidation, carbonization and oxidation heat treatment of electrospun fibers. The flexible electrode material prepared in the invention not only has good conductivity and cyclic stability of carbon materials (900mAh g<-1> after 100 cycles at the current density of 200mA g<-1>, but also has good rate performance (a capacity of 550mA g<-1> can still be maintained at the current density of 5000mA g<-1>) and the characteristics of high specific capacity of Co3O4.

Owner:SHAANXI UNIV OF SCI & TECH

Cotton seedling raising transplantation method

InactiveCN101379919ALow costImprove structural performanceCultivating equipmentsSoilless cultivationFungicideAntitranspirant

The invention relates to a method for transplanting cotton seedlings. The method comprises three steps of preparation of a matrix, sowing and transplanting sequentially. Step 1, cotton stalks, rape stalks, corn stalks, soybean stalks or wheat straws are crushed, added with a nitrogenous fertilizer, and mixed with human excrement or livestock and poultry manure bio-fertilizer or other fertilizers to obtain a mixture which is treated to obtain a prepared material, then the prepared material is sun-dried or baked, added with a fungicide and bagged for spare use; step 2, the prepared cotton stalk matrix or the matrixes prepared from other stalks are filled in a seedling raising aperture disk or flatly spread on a plastic film laid on the ground as a seedbed, seeds are sown, watered and covered with an agricultural film, and seedlings are raised under heat insulation condition; step 3, an antitranspirant and a rooting agent are applied before transplanting; the taken seedlings are bound, put in the watered rooting agent solution for root soaking, and then taken out and put in a watered gel containing a water retention agent to dip the roots; when in transplantation, the water retention agent is applied to planting furrows; after transplantation, the seedlings are covered with soil, and irrigated with adequate water for fixing the roots. The method is characterized by high seedling survival rate, stable effect, short rejuvenation period, low cost and environmental protection.

Owner:操宇琳

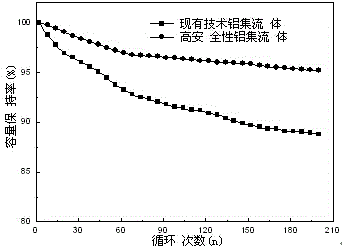

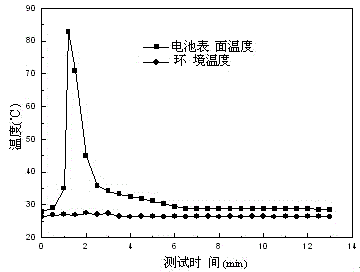

Lithium ion battery positive current collector high in safety performance, preparing method thereof and lithium ion battery

InactiveCN104966840AAdd resistanceReduce the current valueElectrode carriers/collectorsSecondary cellsPhysicsComposite material

The invention provides a lithium ion battery positive current collector high in safety performance, a preparing method thereof and a lithium ion battery. The positive current collector comprises an aluminum layer and a porous anodic alumina resistive layer which covers the surface of the aluminum layer. The thickness of the porous anodic alumina resistive layer is 10-100 nm. The porous structure of the porous anodic alumina resistive layer is a blind hole structure. The diameter of blind holes is 0.01-5 microns. The porous anodic alumina resistive layer can effectively increase the resistance of the positive current collector so that the current value generated when a short circuit happens to the battery can be lowered, and accordingly the temperature is decreased when the short circuit happens to the battery and the dangers of firing and exploding caused by heat generated by the battery is avoided. In addition, the adhesive strength of the positive current collector and positive active substances can be improved through the blind hole structure of the positive current collector, so that the probability of falling of the positive active substances during charging and discharging is lowered, and accordingly the cycle life of the lithium ion battery is prolonged.

Owner:GUANGZHOU GREAT POWER ENERGY & TECH CO LTD

Deep-cycle-resistant lead-acid storage battery anode lead paste formula and preparation process thereof

The invention relates to a deep-cycle-resistant lead-acid storage battery anode lead paste formula which comprises the following components by the weight percentage: 70-90% of a lead powder, 3-15% of sulfuric acid, 3.9-10% of water, 0.05-2% of short fibers, 0.1-0.4% of colloidal graphite, 0.1-0.5% of tetra-basic lead sulfate, 0.1-1.5% of a silica emulsion, and 0.1-5% of a polytetrafluoroethylene emulsion, wherein the particle size of tetra-basic lead sulfate particles is 10-120 nm. A structure of active substances in charge and discharge processes is ensured by adding the polytetrafluoroethylene emulsion; through adding the silica emulsion in a lead paste, silica forms a network structure on the surface of the lead paste, so that lead paste crystals are protected, and the active substance softening and shedding caused by volume expansion and contraction in the charge and discharge processes are reduced; and through adding 4BS in the lead paste, 4BS plays a seed crystal role in the lead paste, and at the same time, with use of the processes of high temperature and paste, a large amount of 4BS crystals are promoted to exist in the lead paste, so as to increase the battery cycle service life.

Owner:CHAOWEI POWER CO LTD

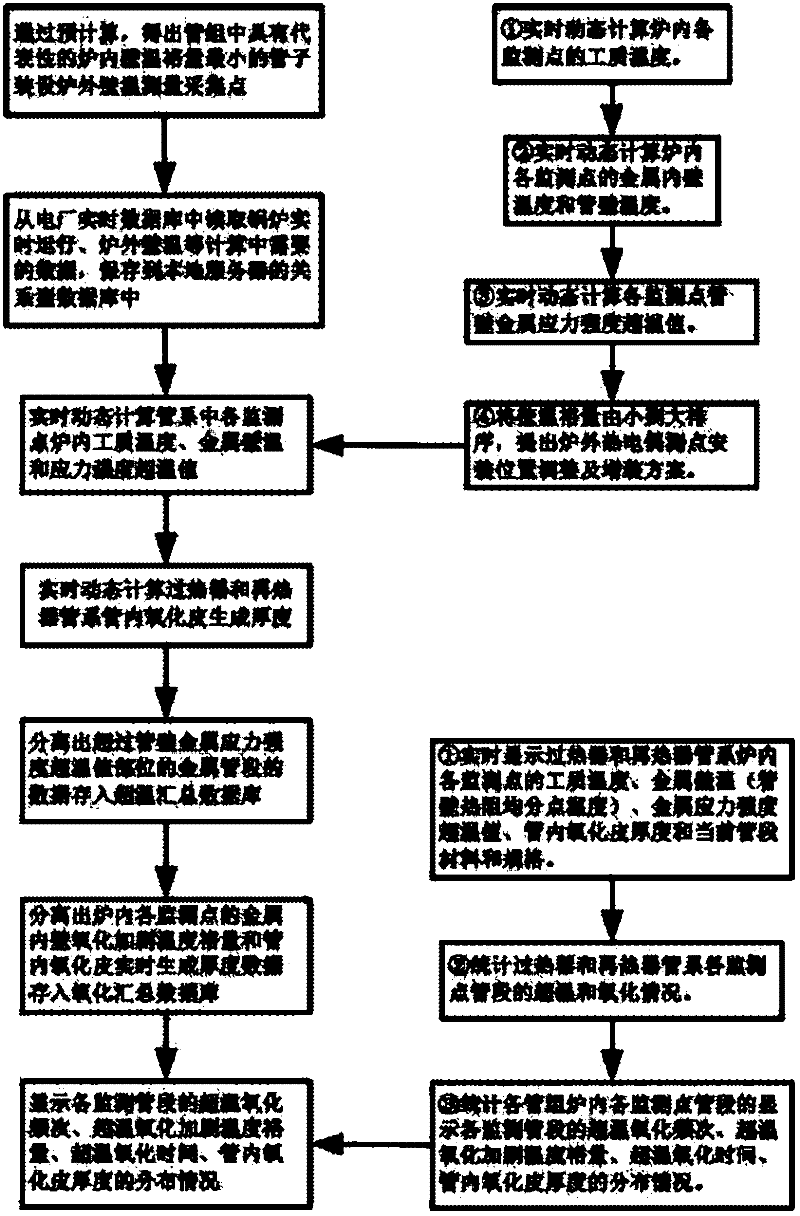

Method for avoiding overheat tube burst in tubular boiler of power station boiler

ActiveCN102444885AExtended service lifeEliminate squibBoiler indication operationsBoiler controlPower stationRelational database

The invention relates to a method for avoiding overheat tube burst in a tubular boiler of a power station boiler, belonging to the technical field of power station boilers. The method comprises the following steps: selecting representative tubes from a nest of tubes to install measurement acquisition points of temperature of an outer wall of the boiler; reading data from a power plant real-time database, and storing the data in a relational database of a local server; dynamically calculating the generation thicknesses of scale cinder in tubes of overheater and reheater in real time; separating out data of metal tube sections of parts exceeding metal stress strength overtemperature values of tube walls from calculated results and storing the data in an overtemperature summarizing database; and according to calculated inner wall working medium boundary layer temperature, metal inner wall oxidation aggravation temperature margin and real-time generation thickness of scale cinder in the tubes, automatically generating a visual distribution graph according to sequence. The method provided by the invention can accurately give out a tube burst early warning of the power station boiler, and preset measurements can be taken to avoid great direct financial losses to enterprises and nation caused by tube burst of the power station boiler.

Owner:SHANGHAI WANGTE ENERGY RESOURCE SICENCE & TECH

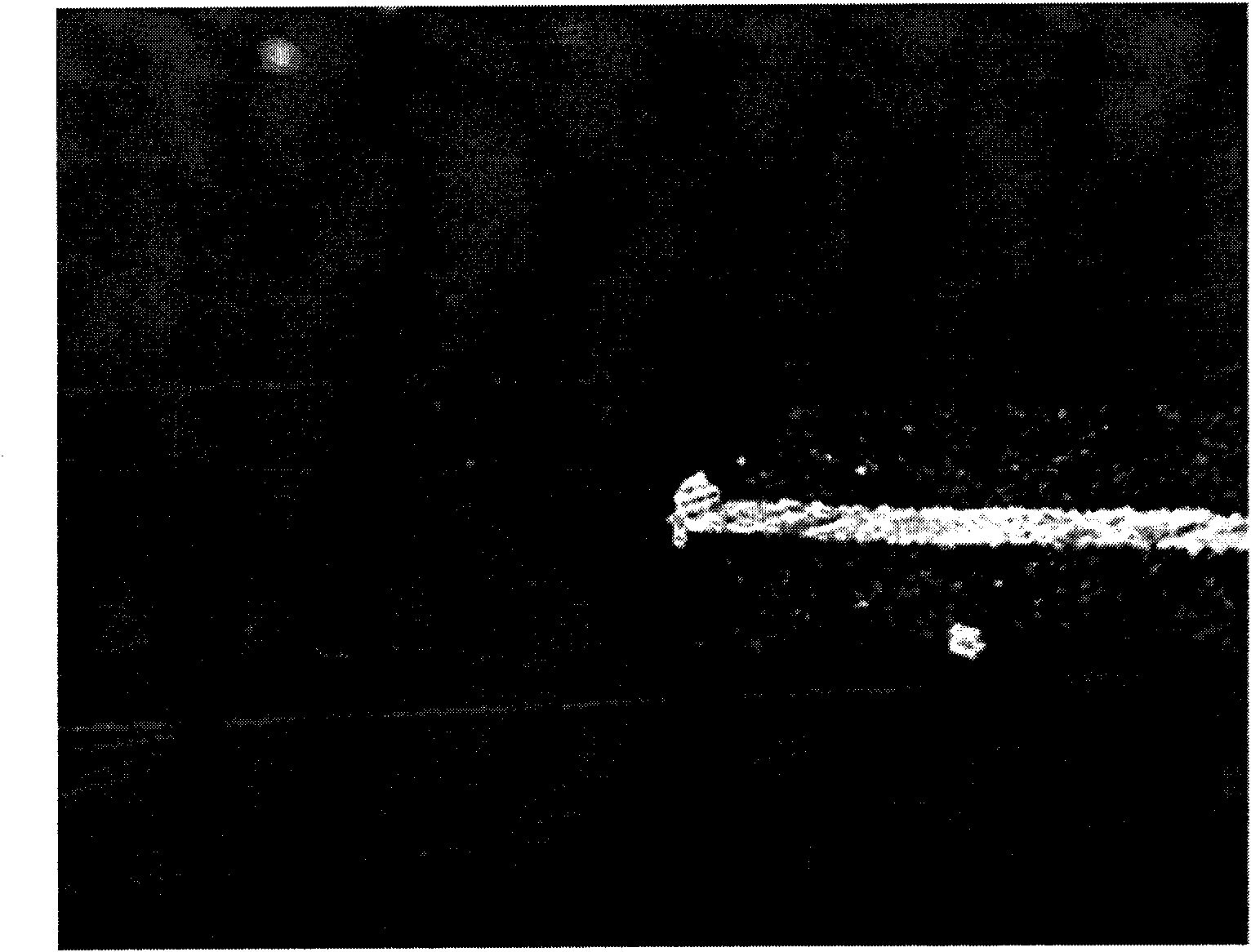

Carbon fiber surface silica dioxide coating preparation method

The invention relates to a method for preparing silicon dioxide coating on the surface of carbon fiber, belonging to the material technological area. In the invention alcohols is adopted as the solvent. Ethyl orthosilicate generates hydrolysis reaction under the acidic condition to form silicon dioxide precursor solution. The silicon precursor solution dips the pre-treating carbon fiber. It is volatilized by increasing the temperature slowly and then is sintered to generate polycondensation. Silicon dioxide coating is formed on the single-silk surface of carbon fiber and the thickness of coating is less than 1 mum. The coating is smooth and not easy to break off. The carbon fiber maintains the softness and stitchability of original carbon fiber on the one hand. At the same time the oxidative resistance is improved and the infiltrating of compound material with the base in preparing is improved.

Owner:SHANGHAI JIAO TONG UNIV

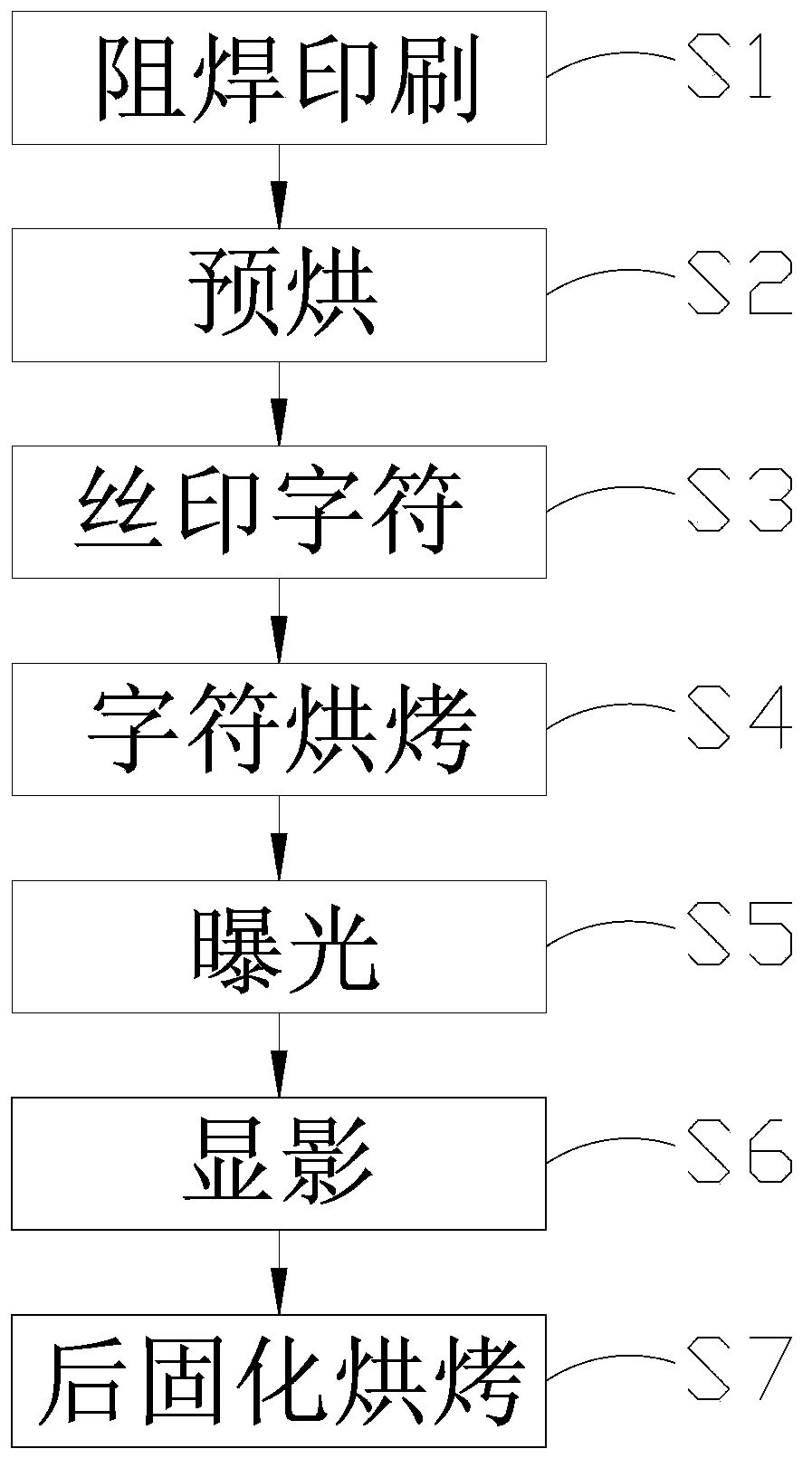

Silk screen printing technology for printed circuit board

ActiveCN103660652AShorten the timeReduce character dropoutPrinted circuit manufactureOther printing apparatusSolventSolder mask

The invention provides a silk screen printing technology for a printed circuit board. The silk screen printing technology for the printed circuit board comprises the steps that a solder mask material is printed on the circuit board after penetrating through a first silk screen template, so that solder mask printing is achieved; pre-drying is conducted so that a solvent in the solder mask material can be removed, and a part of the solder mask material is hardened; a character printing material is printed on the hardened part of the solder mask material after penetrating through a second silk screen template; the character printing material is dried so that a solvent in the character printing material can be removed; exposure is conducted so that sensitization polymerization can occur on a part of the solder mask material; development is conducted so that the part on which sensitization polymerization does not occur of the solder mask material is removed through chemical reaction; post-solidification and post-baking are conducted so that the solder mask material can be hardened thoroughly. According to the silk screen printing technology for the printed circuit board, silk printing of a character is conducted before solder mask exposure, time from solder mask printing to silk printing of the character is greatly shortened, pollution to the surface of printing ink in the exposure process, in the development process and in the post-solidification and post-baking process is avoided, the occurrence rate of the phenomenon of character disengagement caused by poor combination, caused by aging and pollution, between the character and a solder mask layer is reduced.

Owner:SHENNAN CIRCUITS

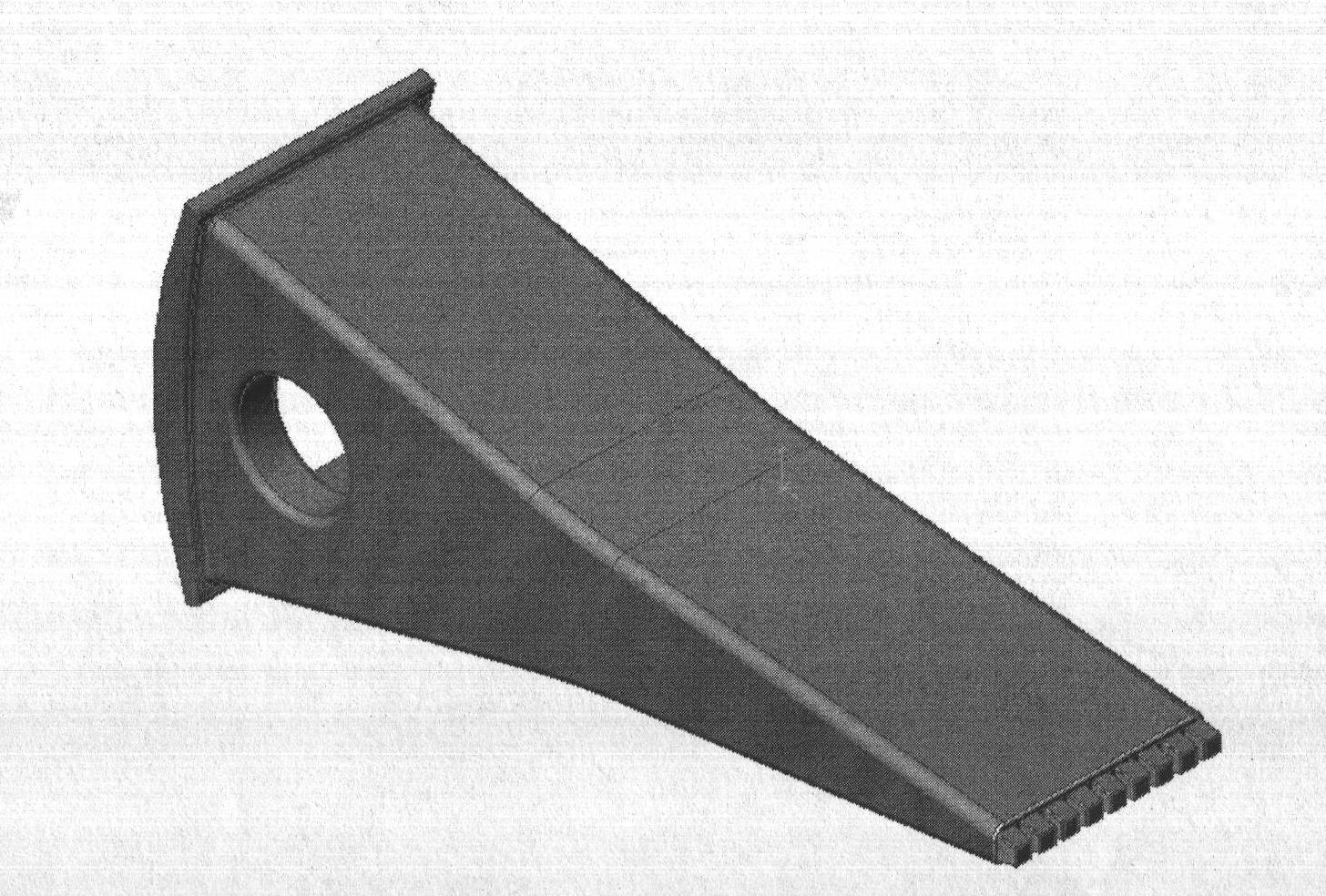

Composite dipper tooth of excavator and manufacturing method thereof

InactiveCN102182223AHigh hardnessHigh strengthSoil-shifting machines/dredgersExcavatorUltimate tensile strength

The invention relates to a composite dipper tooth of an excavator and a manufacturing method thereof, belonging to the field of high-tech engineering materials and application thereof. The novel composite dipper tooth comprises two parts of a bar type tooth tip (tooth bar) and a dipper tooth substrate (tooth substrate) and is formed by high temperature casting. The tooth bar material is novel high-rigidity and high-strength composite metal ceramics and comprises one or more of WC, TiCN, TiN or TiC-based composite metal ceramics; the tooth substrate is high / low chrome alloy steels or high manganese steels with higher rigidity and strength; a composite dipper tooth structure comprises a plurality of tooth bars of wedge shapes, the tooth bars are embedded at the front end of the tooth substrate, and a small section of each tooth bar is exposed out of a steel body, and a certain distance is arranged between tooth bars. The manufacturing method of the composite dipper tooth of the excavator sequentially comprises the following steps of: prefabricating the tooth bars; smelting alloy steels; casting the composite dipper tooth; and demolding. The tooth bar material is characterized by high rigidity, high strength and wearing resistance; the wearing resistance of the dipper tooth is improved and the consumption of wearing materials is reduced due to an intermittent structure, raw materials are saved, the cost is lowered, a contact area between the tooth bars and the tooth substrate is increased, the binding force is improved and the service life of the dipper tooth is prolonged.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Preparation method of surface coating capable of lowering degradation rate of fully-degradable magnesium alloy vascular stent

ActiveCN104189963AReduce the degradation rateReduce sheddingSurgeryCoatingsMg alloysBiocompatibility

The invention relates to a preparation method of a surface coating capable of lowering the degradation rate of a fully-degradable magnesium alloy vascular stent. The method comprises the following steps: preparing a silane coupling agent on a magnesium alloy surface in a way that a silane coupling agent and an organic solvent are mixed, the silane coupling agent is grafted to the magnesium alloy surface of a biodegradable vascular stent by adopting a dip coating method and heating and curing are performed to form a coating; and preparing a polymer coating on the surface pre-treated by the silane coupling agent in a way that a spin-coating method is adopted to coat a polymer on a sample surface treated by the silane coupling agent, vacuum drying is realized and the polymer coating is formed after solvent volatilization. Through the technical scheme, a strong binding force exists between the polymer coating on the magnesium alloy surface pre-treated by the silane coupling agent and the surface of the fully-degradable magnesium alloy vascular stent, so that the magnesium alloy base body is prevented from excessively quick degradation, and the biocompatibility is improved; and as the coating is completely degraded with the base body at last, no toxic or side effects are brought to a human body.

Owner:JIANGSU FENGYUAN MEDICAL DEVICES CO LTD

Anode plate for lithium ionic cell and preparation thereof

InactiveCN101425572AImprove cycle performanceReduce sheddingElectrode manufacturing processesElectrode carriers/collectorsTitaniumCopper

The invention provides a negative sheet for a lithium ion battery, which comprises a collector body and a negative active material layer coated on the collector body. The negative active material comprises a component A and a component B. The component A is simple-substance silicon; the component B is one or some of copper, titanium, aluminum, iron, nickel, zinc and cobalt, wherein the negative active material layer is of a porous structure. The invention also provides a preparation method of the negative sheet for the lithium ion battery. The negative active material layer of the negative sheet for the lithium ion battery is of a porous structure, thereby ensuring that the negative active material can carry out volume expansion through a hole, effectively abating the fall-off of the negative active material on the negative sheet, and improving the cycle performance of the lithium ion battery with the negative sheet.

Owner:海宁市盐官工业投资有限公司

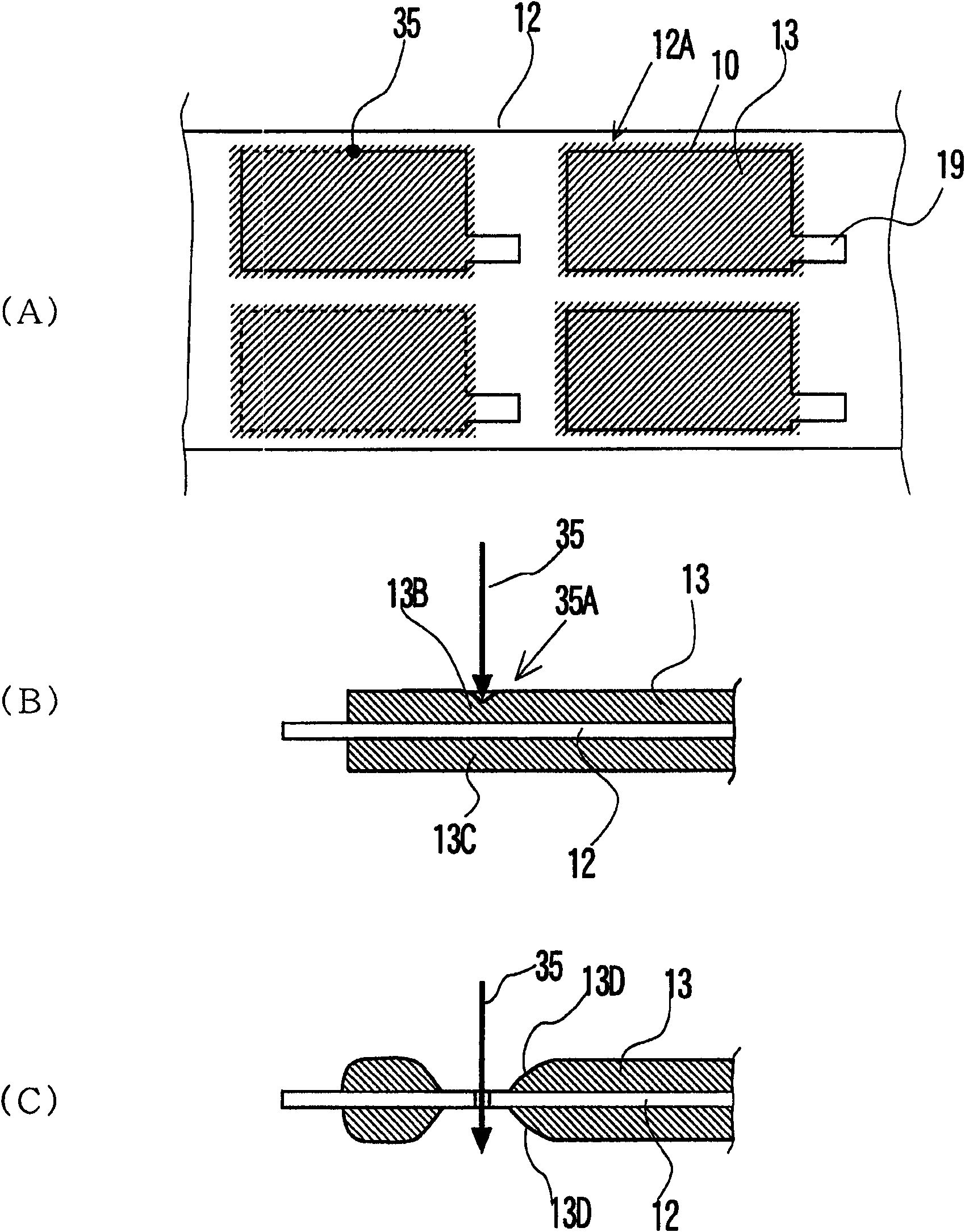

Stacked secondary battery and method of manufacturing the same

InactiveCN101640280AImprove adhesion strengthExcellent charge and discharge characteristicsElectrode manufacturing processesLarge-sized flat cells/batteriesSlurryBiomedical engineering

A stacked secondary battery is formed by laying plate-shaped positive electrodes and plate-shaped negative electrodes one on the other by way of separators, wherein a collector is disposed at the front end of the end facet of each of the positive electrodes or the negative electrodes as viewed in a direction orthogonal relative to the stacking direction and has an active substance layer formed onthe collector by applying slurry of particles of an active substance with a gap separating it from the front end or the electrode active substance layer is made to show a thickness varying from the front end toward the inside.

Owner:NEC ENERGY DEVICES LTD

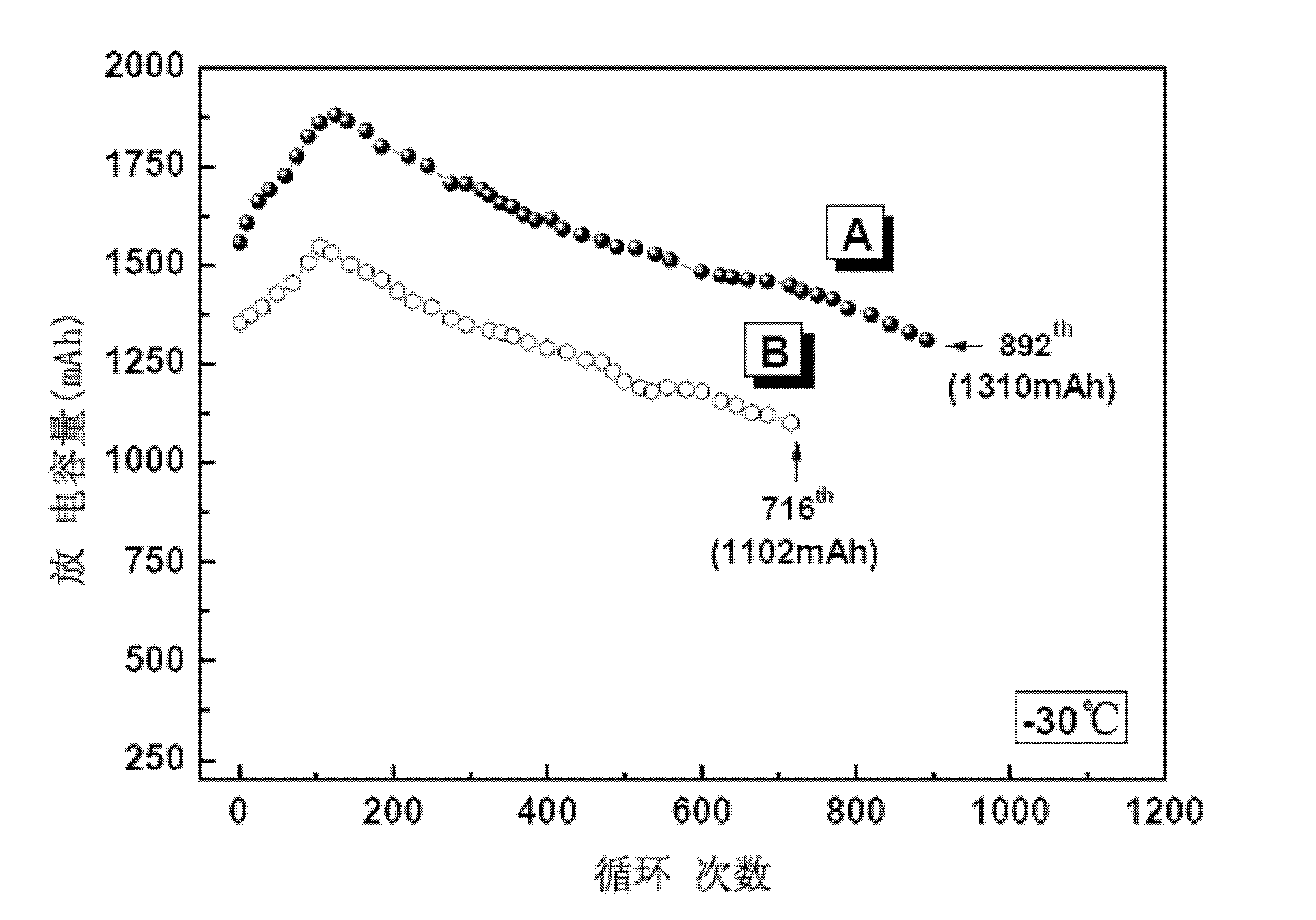

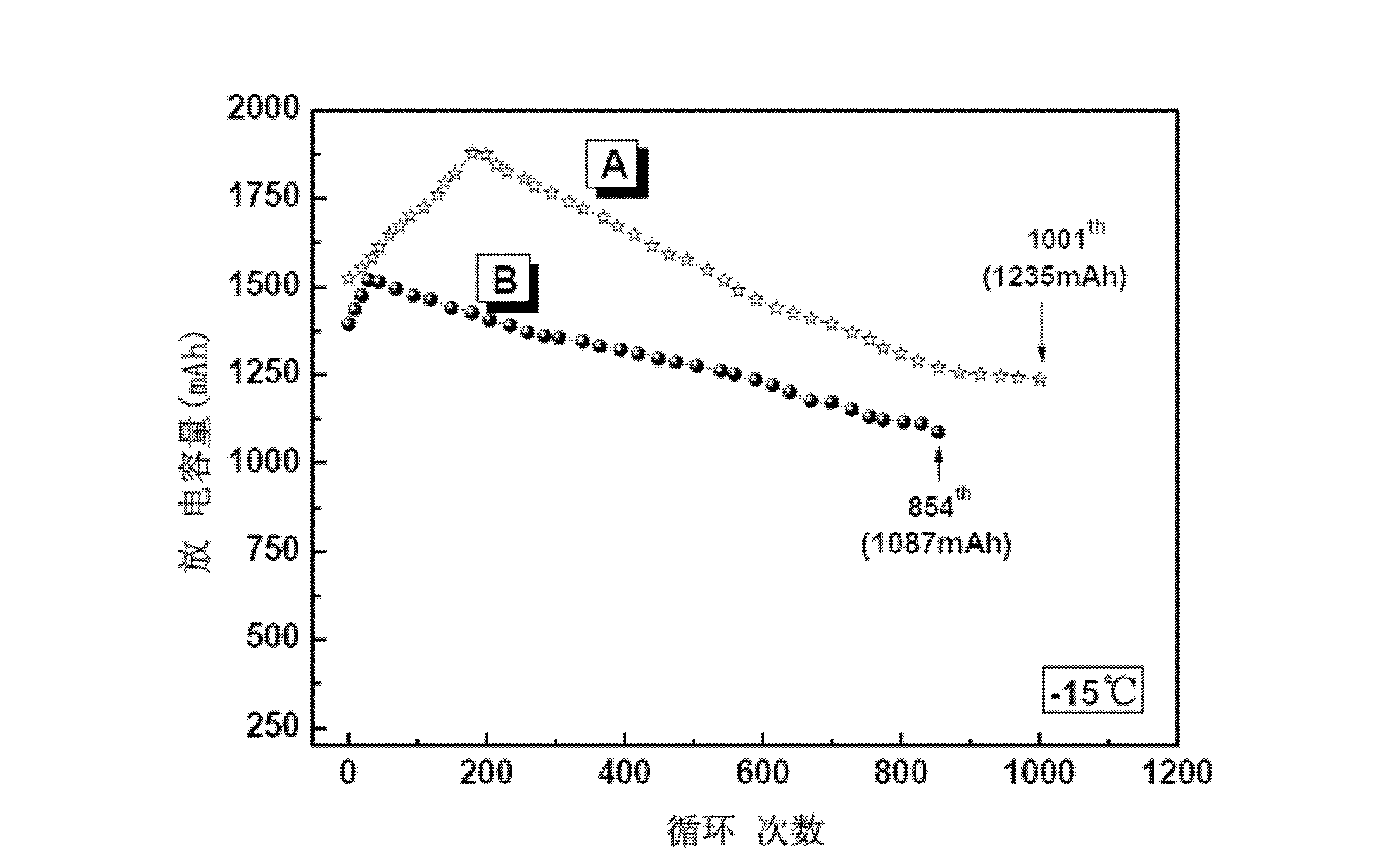

Electrolyte for lithium ion battery and preparation method thereof

ActiveCN102637901AGood effectImprove charge and discharge efficiencySecondary cellsLithium oxideLithium hydroxide

The invention discloses an electrolyte for a lithium ion battery and a preparation method thereof. The electrolyte consists of a main electrolyte, an electrolyte additive, a main solvent and a solvent additive. The preparation method comprises the following steps of: A. under the condition of vacuum or inert gas protection, respectively mixing the main solvent and the solvent additive with a drying agent (lithium oxide) which is dried to be at constant weight in advance, and mixing and filtering to remove the lithium oxide and lithium hydroxide sediment; B. uniformly mixing the dried main solvent and the dried solvent additive from the step A; and C. adding a main electrolyte mixture and an electrolyte additive into the solvent mixed in the step B, and agitating and dissolving under the vacuum and inert gas protection to prepare a solution with the mass mol concentration of the main electrolyte of 0.5-1.5 M. The electrolyte has the advantages of abundant resources, low price and no toxin, effectively improves the work temperature range of the battery and effectively prolongs the circulating service life of the battery, so that various types of the lithium ion batteries are manufactured; and the electrolyte is particularly suitable for manufacturing a lithium ion power battery with high power capacity and high multiplying power charging and discharging capacity.

Owner:广州云通锂电池股份有限公司

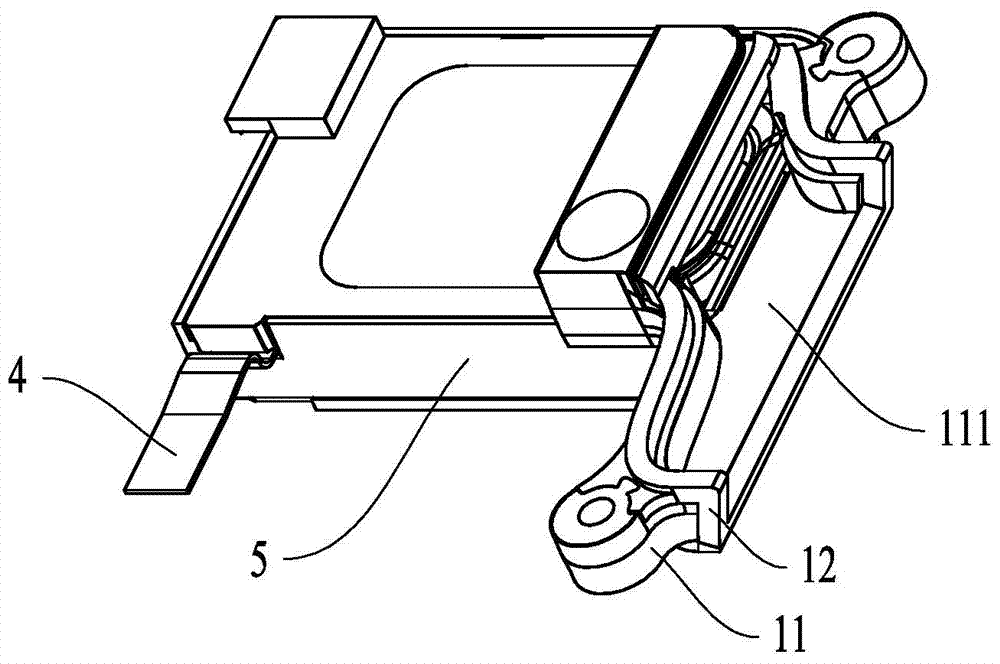

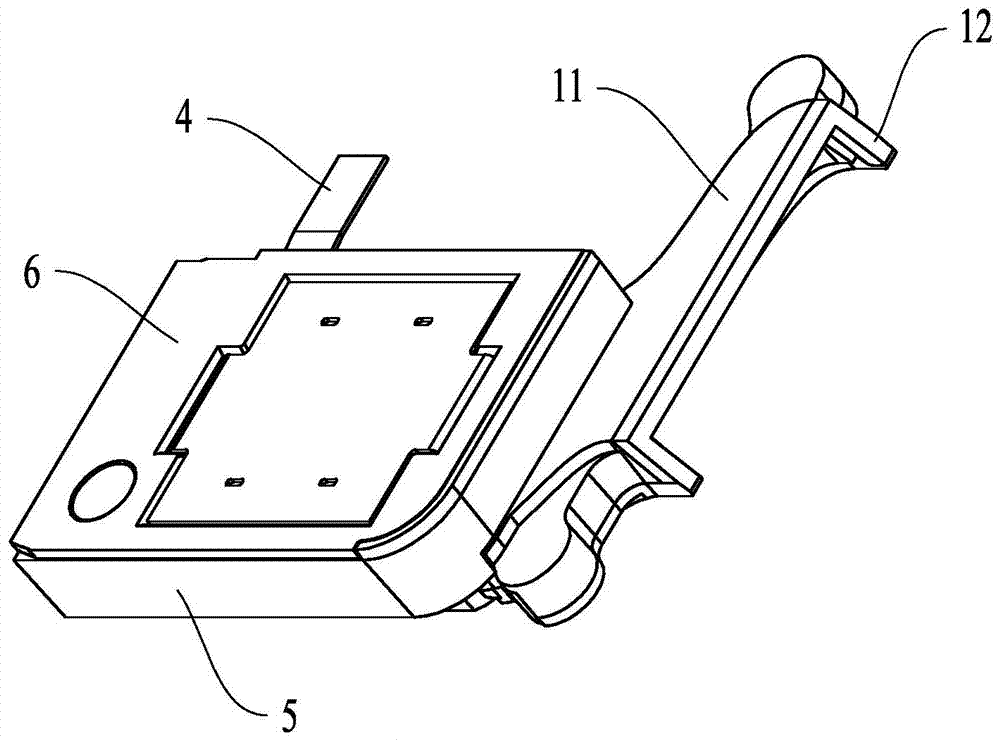

Terminal, optical filter module and manufacturing method thereof, and camera module and manufacturing method thereof

ActiveCN107422444AImprove bindingReduce sheddingTelevision system detailsColor television detailsEngineeringCamera module

The present invention discloses an optical filter module. The optical filter module comprises a pedestal; and an optical filter, wherein the at least portions of two opposite sides of the optical filter are embedded into the pedestal and are integrally molded with the pedestal. The at least portions of the two opposite sides of the optical filter are embedded into the pedestal and are integrally molded with the pedestal so as to greatly enhance the binding force between the optical filter module and the pedestal and greatly reduce the possibility of optical filter module falling-off or fragmentation. The present invention further provides a camera module, a terminal, an optical filter module manufacturing method and a camera module manufacturing method.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com