Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

903 results about "Mg alloys" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium alloys (Mg alloys) are a series of mixtures of magnesium with other elements such as aluminum, copper, zinc, rare earth elements, silicon, zirconium and other.

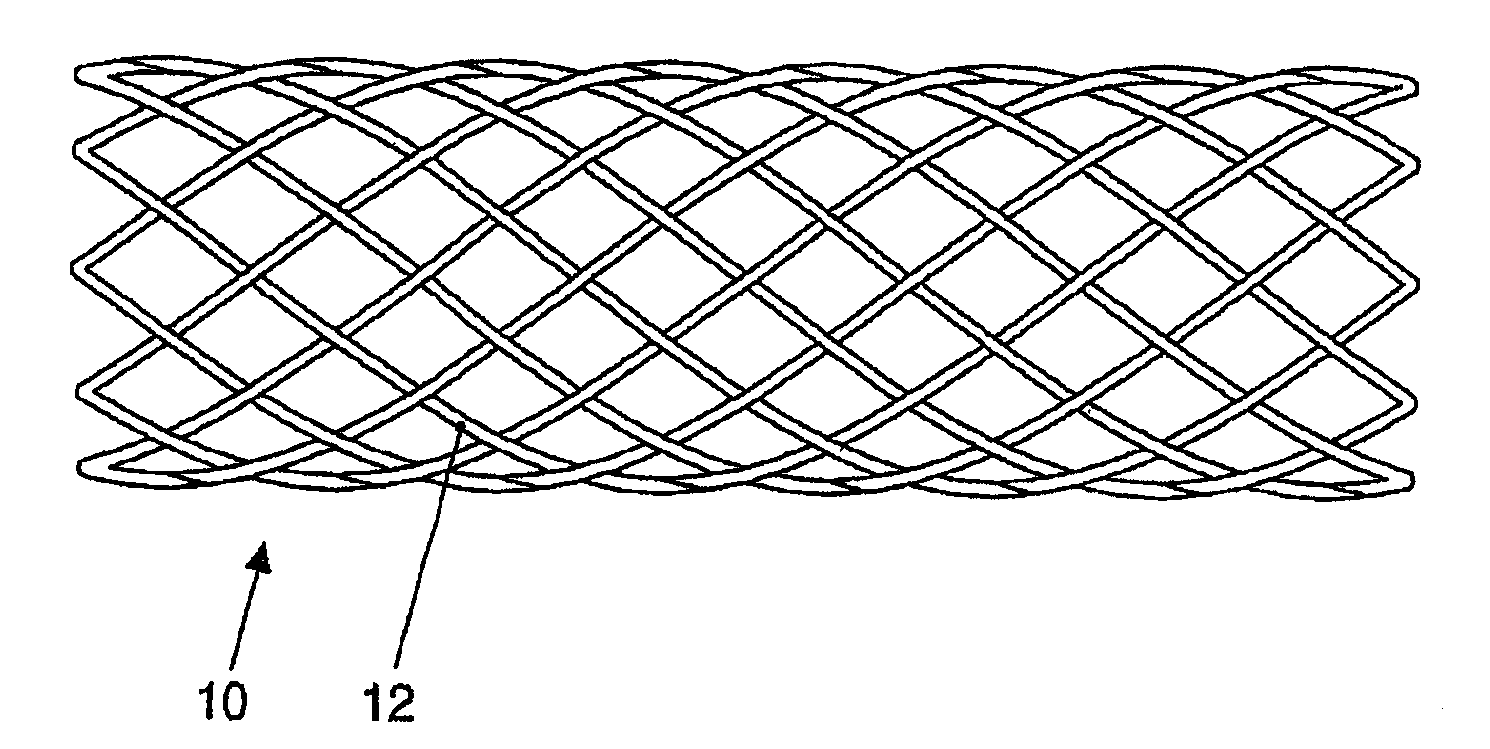

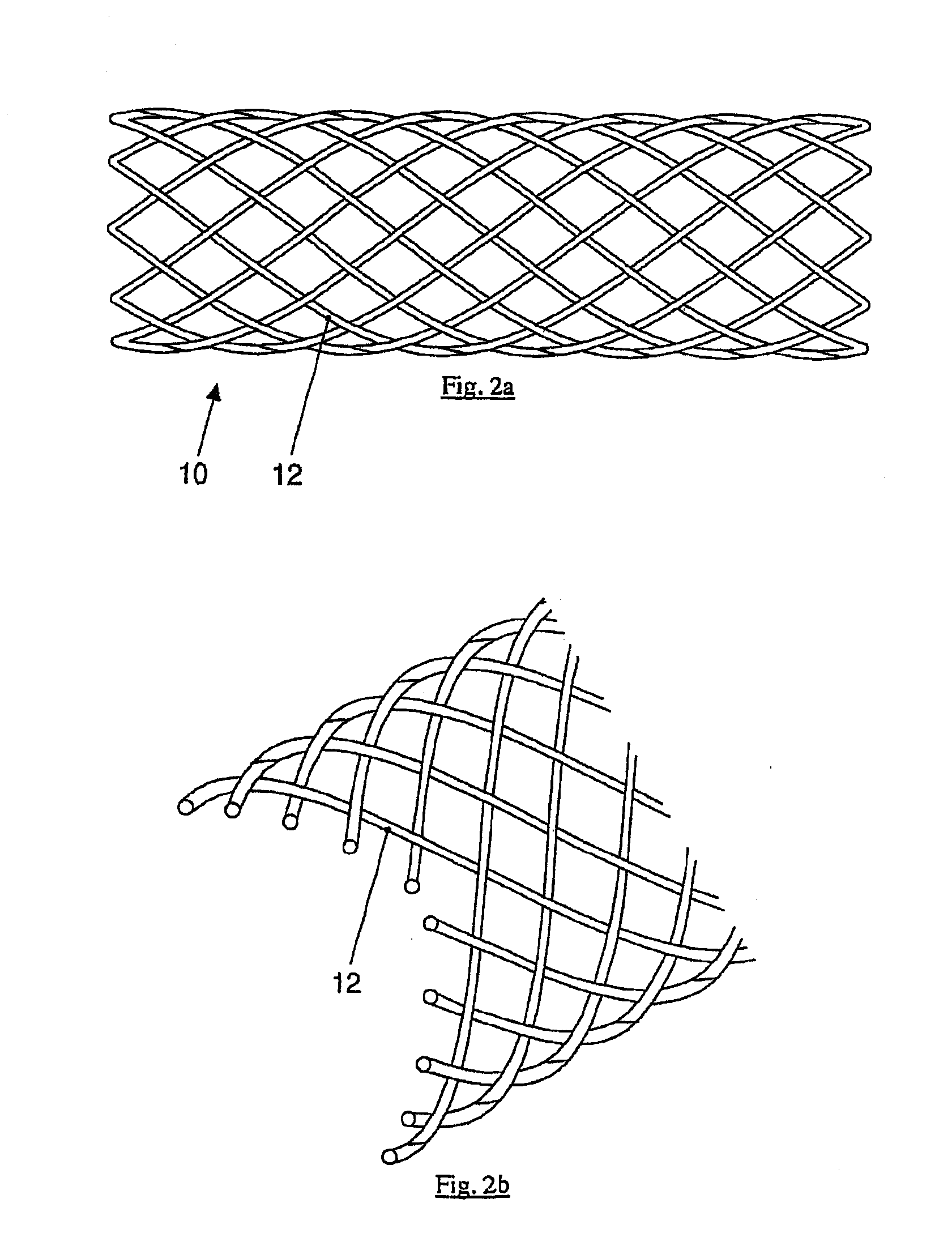

Absorbable Medical Implant Made of Fiber-Reinforced Magnesium or Fiber-Reinforced Magnesium Alloys

ActiveUS20080103594A1High biocompatibilityImproved propertyProsthesisStentsFibre reinforcementMagnesium alloy

A medical implant comprising a composite material which is composed of reinforcement fibers made of a magnesium-containing, bio-corrosive alloy, another bio-corrosive alloy containing a main component that is selected from the group consisting of Mg, Ca, Fe, and Y, or a non-biodegradable fiber material, embedded in a matrix made of crystalline magnesium or magnesium alloys.

Owner:BIOTRONIK

High boron wear-resisting casting steel and preparation process thereof

InactiveCN100999803ASufficient sourceReduce manufacturing costFurnace typesHeat treatment process controlFerromanganeseAluminium

The present invention discloses one kind of antiwear high-boron cast steel and its preparation process. The antiwear high-boron cast steel has the chemical components including C 0.10-0.50 wt%, B 0.8-5.0 wt%, Cu 0.3-0.6 wt%, Mn 0.8-2.0 wt%, Cr 1.0-2.5 wt%, Si less than 1.5 wt%, Ti 0.08-0.20 wt%, Ce 0.04-0.12 wt%, Mg 0.02-0.18 wt%, N 0.06-0.18 wt%, S less than 0.05 wt%, P less than 0.05 wt%, and Fe and inevitable impurity for the rest. Its preparation process includes smelting in an electric furnace while adding ferromanganese, frrroboron and Al to deoxidize, composite modification of molten steel, fast cooling, and low temperature tempering to eliminate stress. The present invention has simple production process, low production cost and other advantages.

Owner:XI AN JIAOTONG UNIV

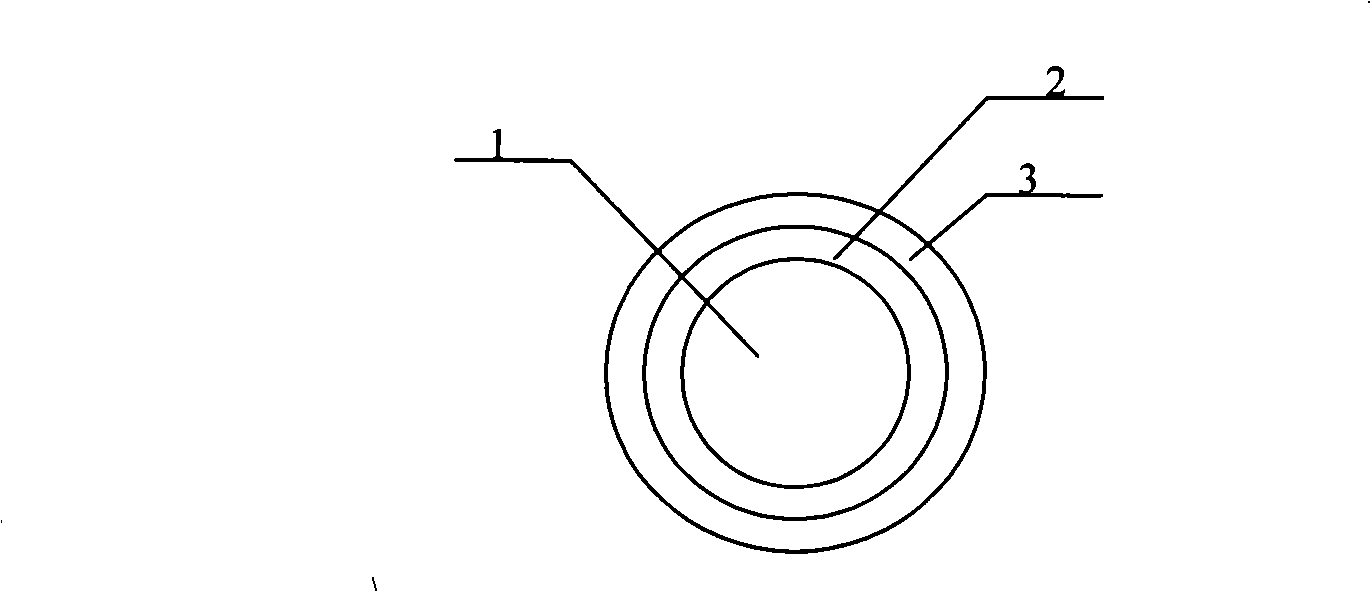

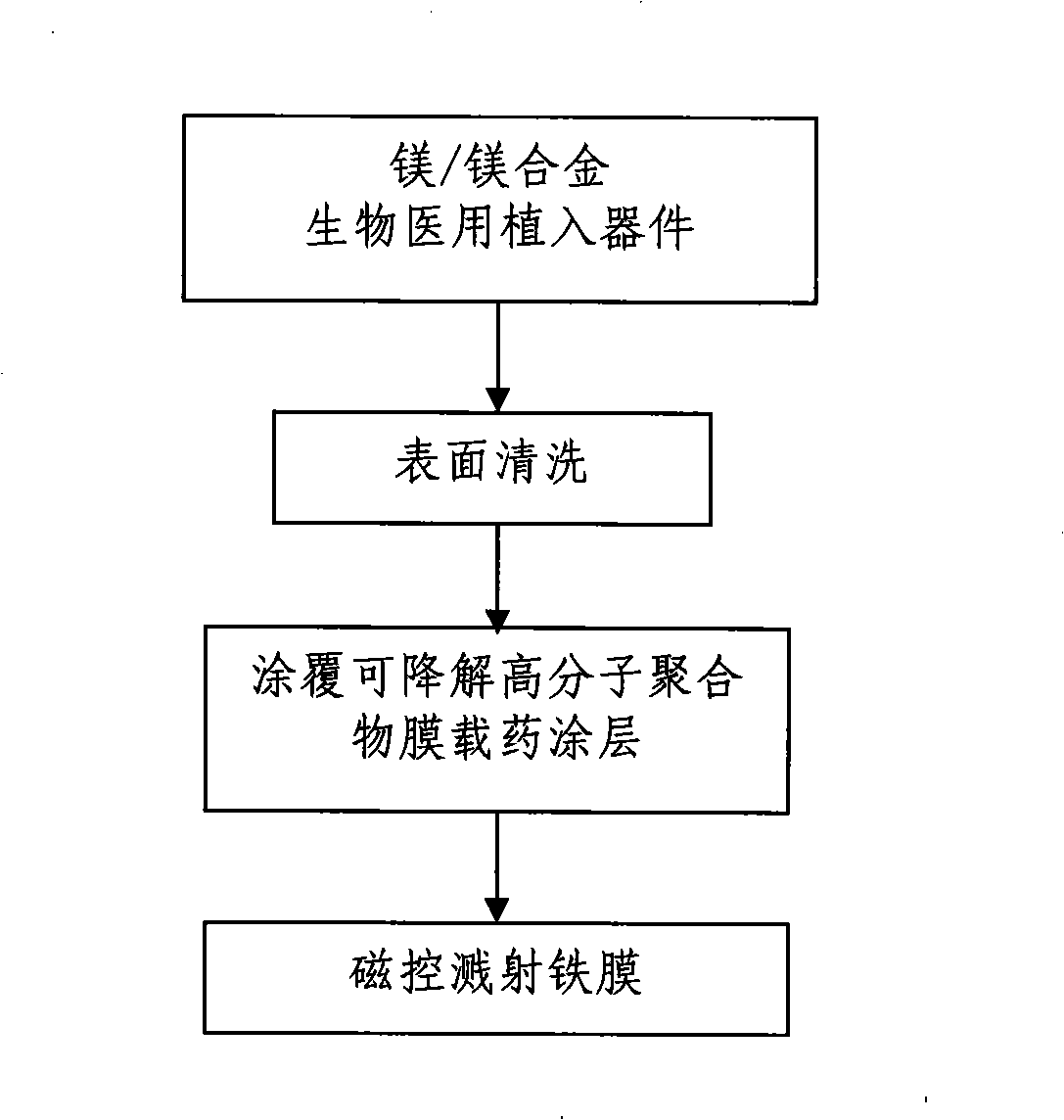

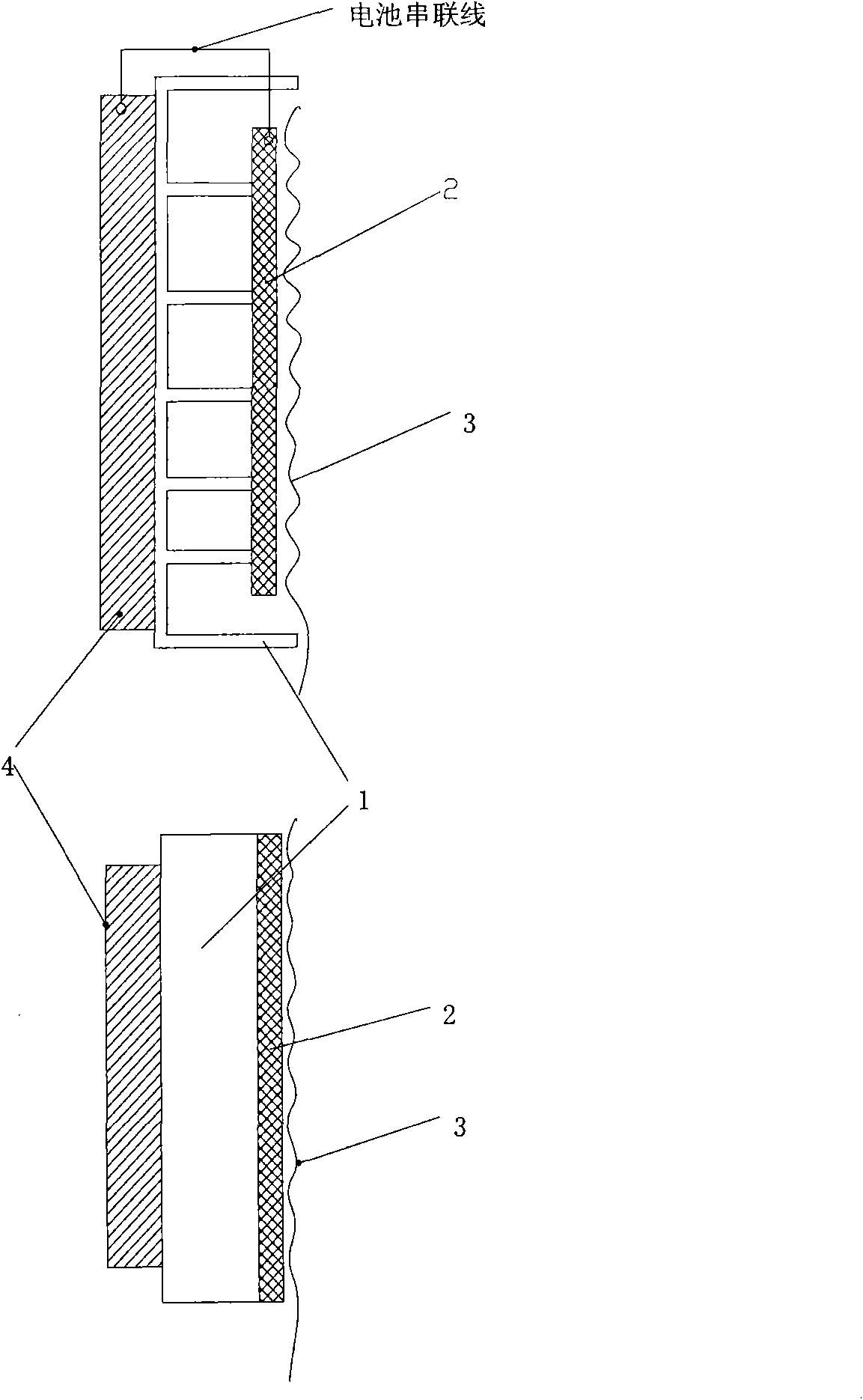

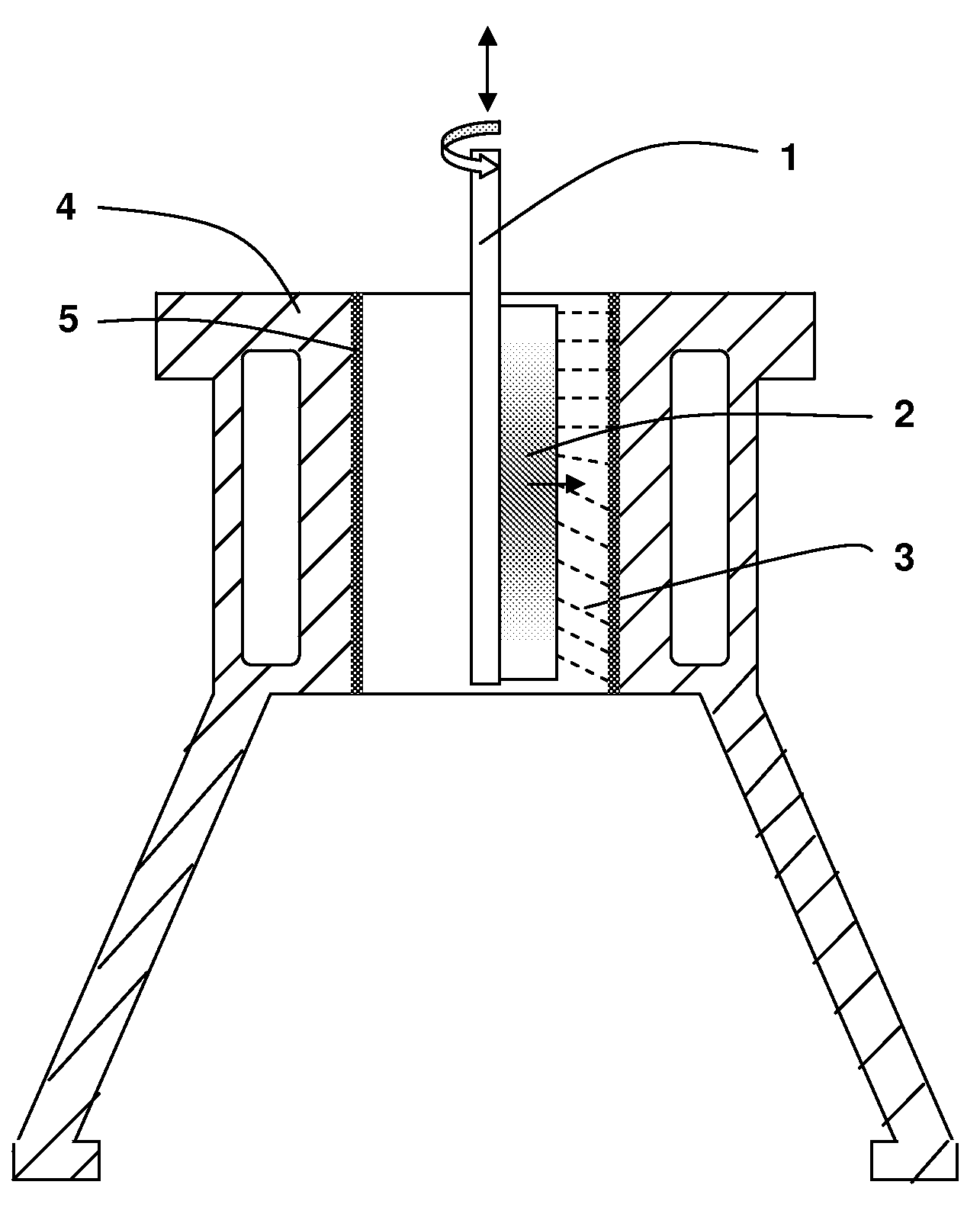

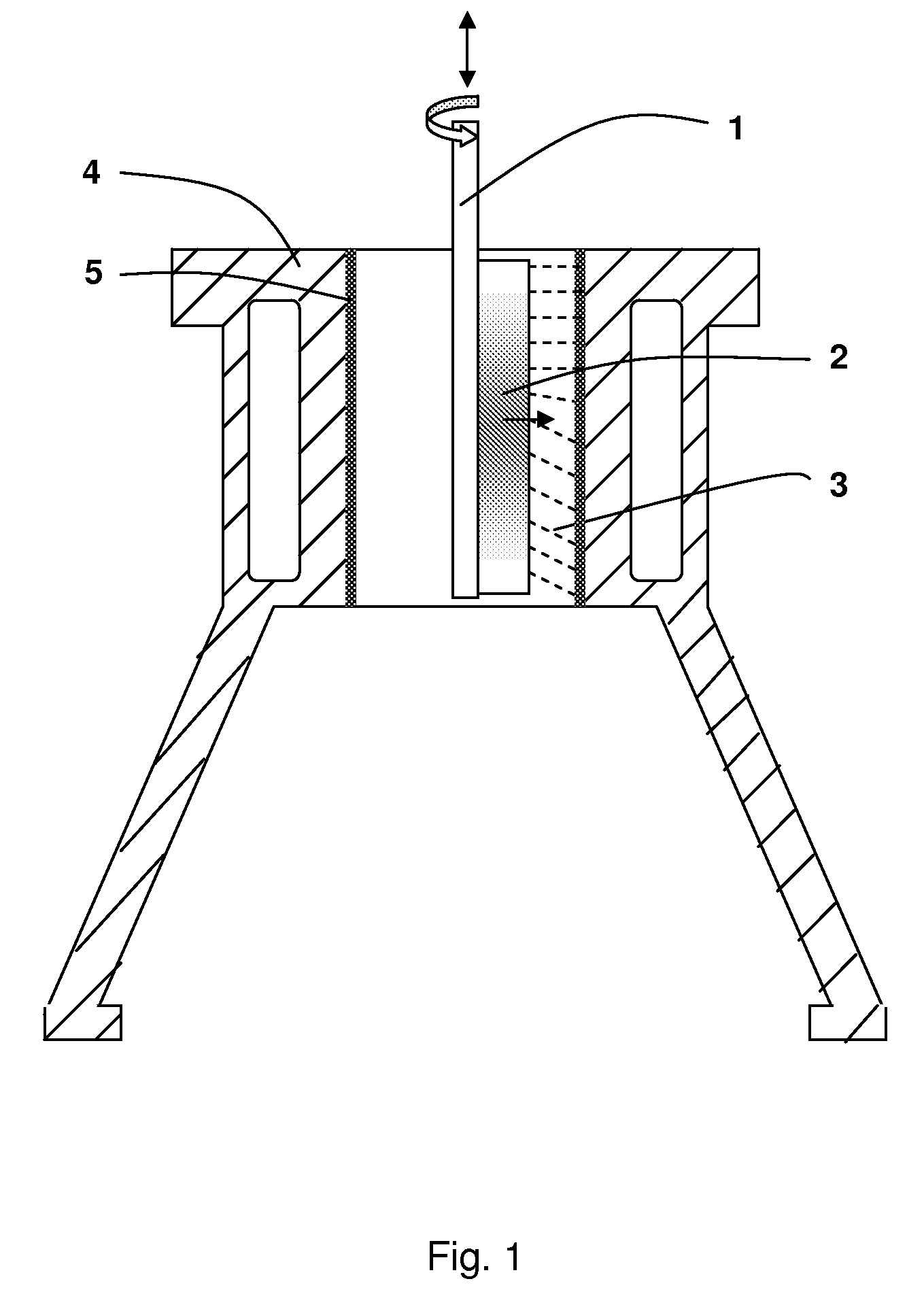

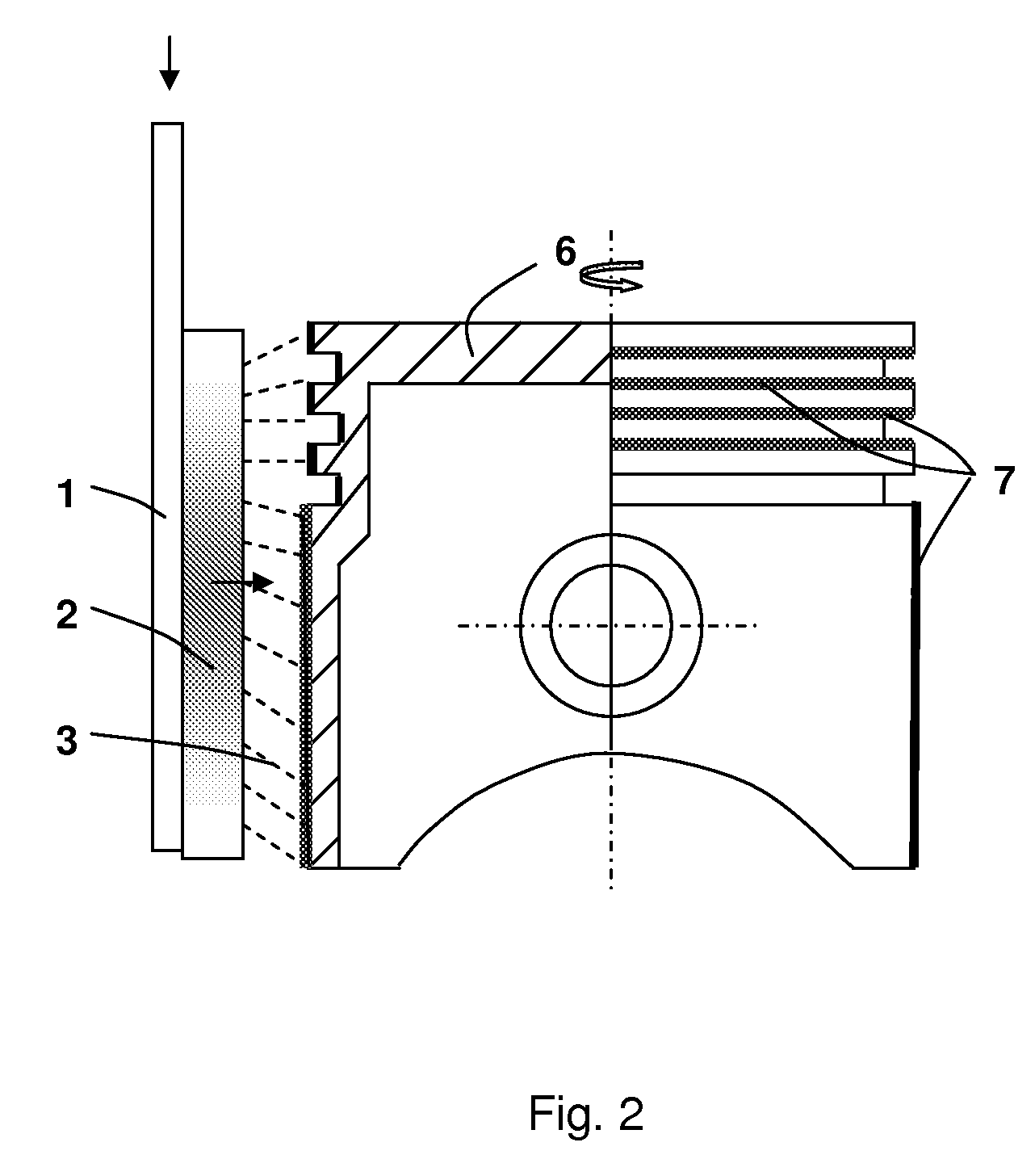

Composite coating magnesium/magnesium alloy biology device and preparation method thereof

The invention relates to a magnesium / magnesium alloy biomedical appliance with compound coating and the preparation method thereof. The biomedical appliance comprises a magnesium / magnesium alloy matrix (1), a film (2) made of degradable high-polymer material on the surface of the magnesium / magnesium alloy matrix and an iron film (3) on the surface of the degradable high-polymer material; the preparation method comprises the following steps: firstly, the magnesium / magnesium alloy material is processed into a biomedical appliance in specific shape; secondly, the degradable polymer film is coated; and thirdly, the iron film is plated through magnetron sputtering. The magnesium / magnesium alloy biomedical appliance with compound coating has the advantages that not only the superior performances of metallic material and degradable high polymer material are maintained, but also the service life of the appliance is effectively prolonged, the operation is safe, and the medical clinical needs are met.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

Magnesium aluminate spinel foamed ceramic filter as well as preparation method thereof

ActiveCN103553686APrevent plastic crackingImprove high temperature stabilityCeramicwareMg alloysSlurry

The invention relates to a magnesium aluminate spinel foamed ceramic filter which is excellent in high-temperature chemical stability and thermal shock resistance. A preparation method of the magnesium aluminate spinel foamed ceramic filter comprises the following steps: firstly, using water-base resin, a dispersing agent and water as a solvent, forming ceramic powder by using magnesium aluminate spinel powder, aluminum oxide powder and magnesium hydroxide powder, and mechanically stirring to prepare slurry; soaking polyurethane porous sponge serving as a carrier in slurry, pressing to remove excessive slurry to prepare a preform body, drying and sintering to obtain the magnesium aluminate spinel foamed ceramic filter. The foamed ceramic filter disclosed by the invention can satisfy rigorous requirements of filtering of molten magnesium alloy, has good high-temperature stability, does not pollute the alloy, has good filtering and adsorbing effect on inorganic impurities in the molten magnesium alloy, and is good in filtering and purifying effect, small in fluid resistance, and large in filtration yield; and good using effect is obtained through trial in casting production of metal magnesium and magnesium alloy.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

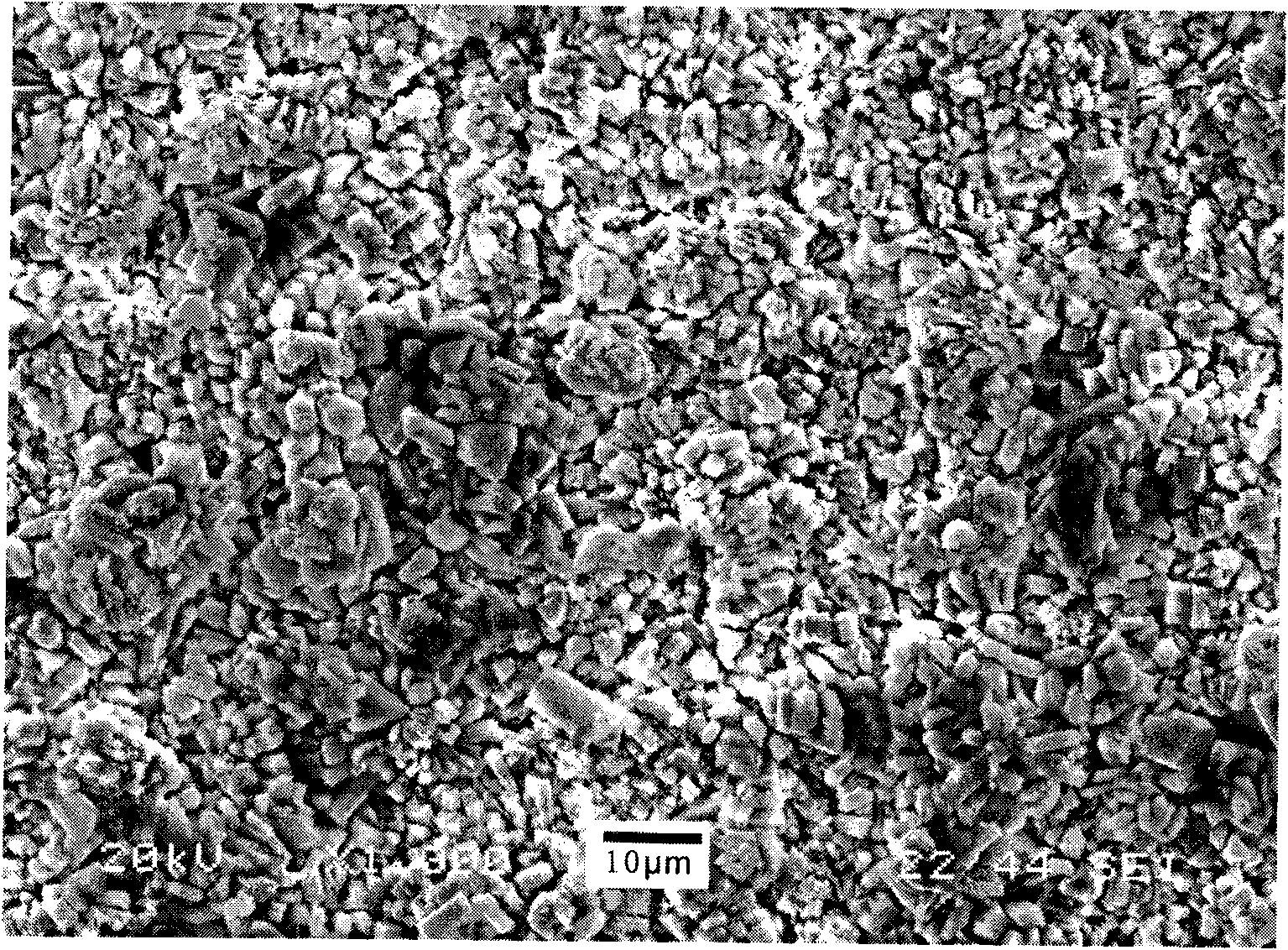

Hydroxylapatite coating magnesium alloy medical inner implantation material and method of preparing the same

The invention relates to a hydroxyapatite coating magnesium alloy medical implantation material and a preparation method thereof. The hydroxyapatite coating magnesium alloy medical implantation material is characterized in that: the surface of a magnesium alloy substrate is attached with a hydroxyapatite coating layer. The preparation method of the hydroxyapatite coating magnesium alloy medical implant material can adopt the bionic solution growing method, the ion beam deposition method, the coating and sintering process, the plasma spray method, the discharge plasma sintering method or the electrophoresis deposition method. The magnesium alloy material with the hydroxyapatite coating structure which is provided by the invention can effectively slow down the degradation rate of the magnesium alloy; at the same time, the coating layer can not only have great tissue compatibility, but can also be conductive to connective tissue attachment and the growth of the bone tissues, improve the bone healing rate and shorten the healing time.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH +1

Method for processing surface of magnesium alloy

InactiveCN101092694AReduced insulationPrevent breakdownAnodisationLiquid/solution decomposition chemical coatingMicro arc oxidationChemical plating

This invention discloses a surface treatment method for Mg-based material. The method comprises: (1) performing micro-arc oxidation treatment on Mg or Mg alloy work piece as the anode in a Cl--free alkaline micro-arc oxidation electrolyte; (2) activating; (3) performing preliminary chemical plating of Ni; (4) performing chemical plating of Ni; (5) performing thermal treatment. The micro-arc oxidation treatment comprises: (1) applying a positive pulse with an average current density of 5-20 A / dm2 until the voltage is automatically elevated to a critical value, and applying a constant working voltage of 50-80 V (total time = 5-30 min); (2) applying a positive pulse of 30-300 V and a negative pulse of 0-200 V with an average current density of 0.5-15 A / dm2 (total time = 10-60 min). The activation comprises: (1) performing anode alkaline coarsening treatment for 3-10 min; (2) performing surface activation treatment; (3) performing cathode alkaline electrification reduction activation treatment; (4) performing cathode acidic electrification dispergation activation treatment. The treated Mg alloy work piece has high corrosion resistance of ceramic materials and the properties and touch sense of metal materials.

Owner:李克清 +1

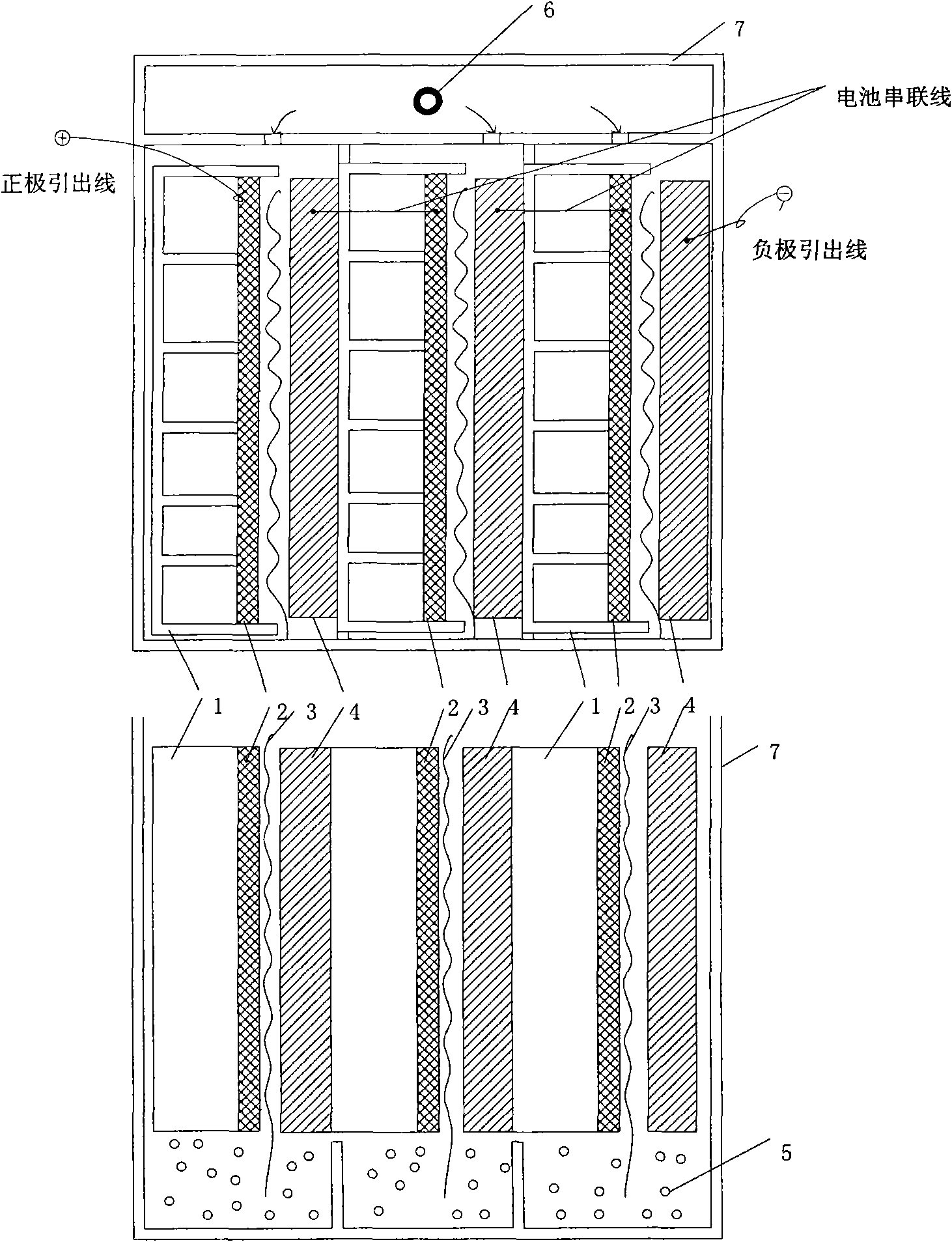

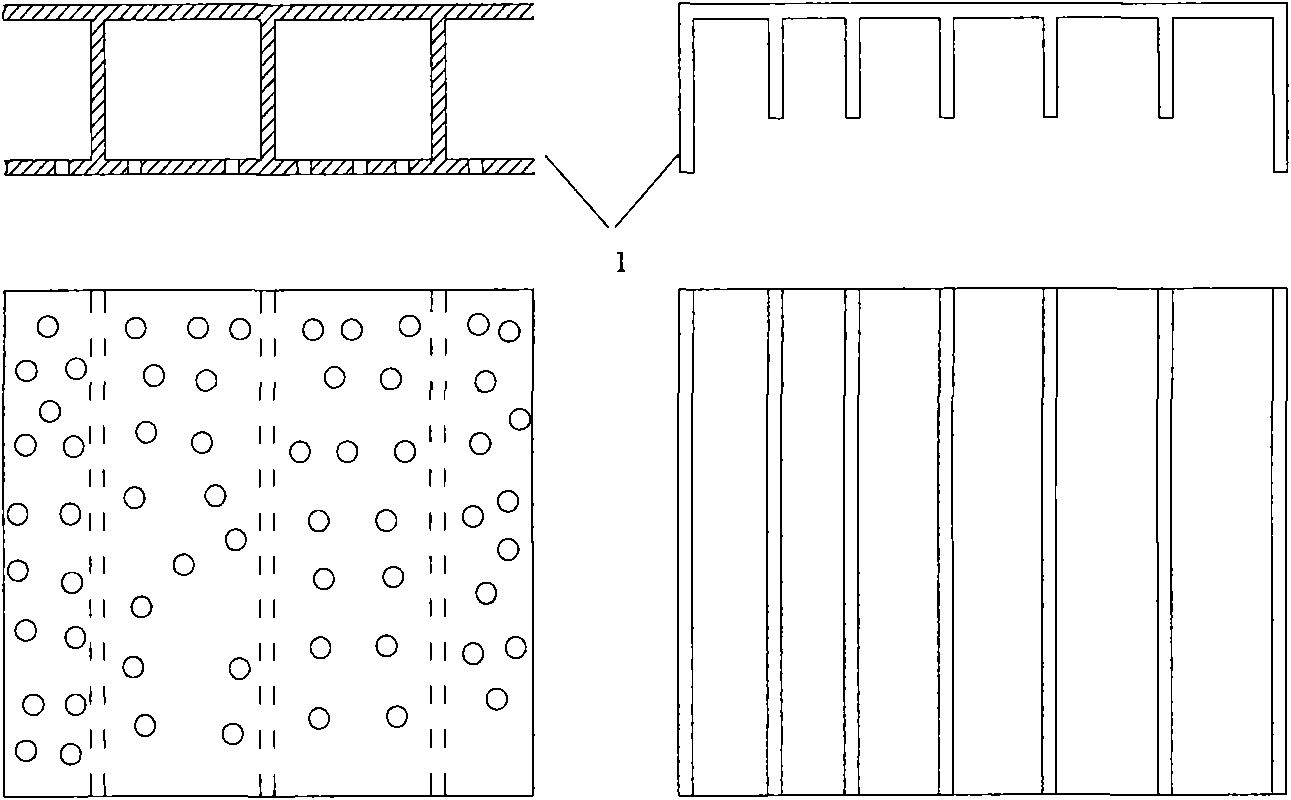

Stack-layered magnesium-air batteries

The application relates to a stack-layered magnesium-air batteries, which is characterized in that a plurality of assembly units is connected in series or in parallel to form the stack layer structure, electrolyte is injected before using, the assembly unit comprises an isolation air feed plate, an air electrode, an isolation membrane, an anode; a plurality of units are repeatedly stacking ordered, winded integrally by a fastener, and assembled into a outer shell; liquid injection pores are disposed on the outer shell, an electrolyte storage slot is disposed on the bottom of the shell, wherein the liquid injection pore is also used as an air inlet pore; the anode is made form magnesium alloy; the electrolyte storage slot is pre-filled with water absorption material; the isolation membrane is made from water absorbing paper dried after water absorbing resin dipping; structure of the isolation air feed plate a hollow plate or a comb-shaped plate with sieve pores, which not only is used as the insulation between batteries, but also functions as a channel for delivering air from external space to the air electrode. The electrolyte needed for the batteries are inputted from the liquid injection pore, stored in the electrolyte storage slot, and distributed to each assembly unit by capillary action of the isolation membrane.

Owner:山西银光华盛镁业股份有限公司

Magnesium alloy with zinc and nickel compound plating layers and preparation method thereof

The invention discloses a magnesium alloy with zinc and nickel compound plating layers and a preparation method thereof. A zinc plating layer of the magnesium alloy is taken as a bottom layer with the width between 20 microns and 25 microns, a nickel plating layer is taken as a surface layer, and the total width of the zinc plating layer and the nickel plating layer is less than or equal to 40 microns. The method comprises the following steps: firstly, plating preliminary treatment, i.e. zinc is activated in an acid solution and then soaked in sulphate; secondly, zinc electrodeposition, i.e. after the zinc is soaked in the sulphate in the first step, the zinc layer of the magnesium alloy is electrodeposited; thirdly, nickel bright plating, i.e. the magnesium alloy which is nicely processed in the second step is brightly plated with nickel in a nickel plating solution; fourthly, sodium silicate water solution sealing. With the method, the obtained zinc plating layer is nicely combined with a base body, has uniform width and high corrosion resistance, can be taken as a protective plating layer to be singly used and can be also taken as a transition layer to carry out plating or chemical plating or other protective or decorative platings, and the nickel plating layer obtained from the zinc plating layer by plating is nicely combined with the zinc plating layer and is uniform, exquisite, bright and beautiful.

Owner:SOUTHEAST UNIV

Magnesium alloy micro-arc oxidation electrolyte and micro-arc oxidation method

InactiveCN103173838ANo pollution in the processLess strong alkaliAnodisationElectrolytic agentAluminate

The invention relates to a magnesium alloy micro-arc oxidation electrolyte and a micro-arc oxidation method. The electrolyte comprises phytate (or phytic acid), a calcic electrolyte, and further one or more added electrolytes as follows: carbonate, silicate, boric acid or borate, and aluminate or aluminum hydroxide. The micro-arc oxidation method comprises the following steps of: pre-treatment; micro-arc oxidation; and post-treatment. The micro-arc oxidation electrolyte provided by the invention does not contain Cr<6+>, F<-> and PO4<3->, and even if strong base used is less, so that the environment is not polluted. The film obtained by the micro-arc oxidation method is smooth in surface, good in corrosion resistance and better in antibacterial performance and biological activity. According to the method, raw materials are easily available, and the method is suitable for industrialized production.

Owner:JIANGXI SCI & TECH NORMAL UNIV

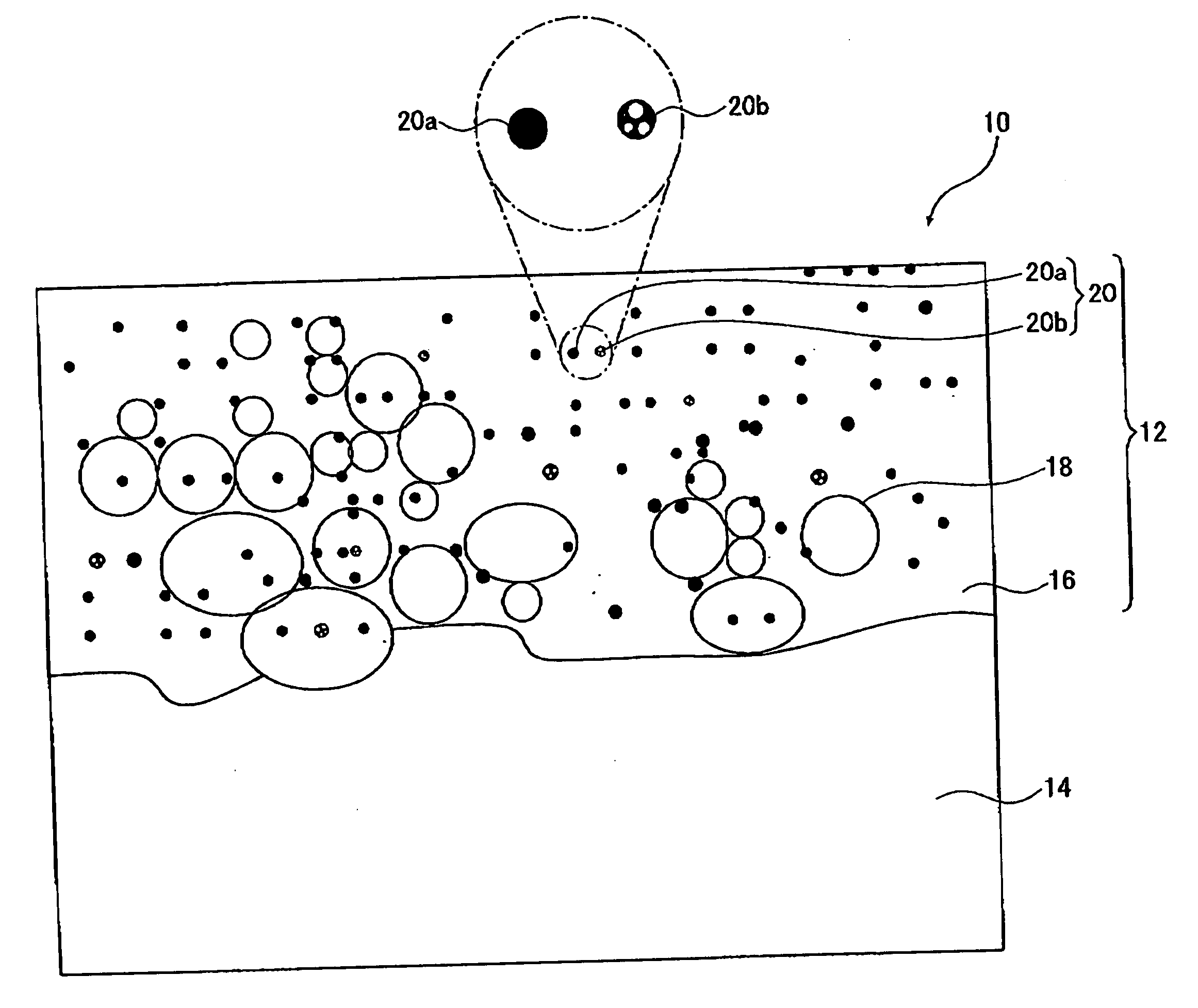

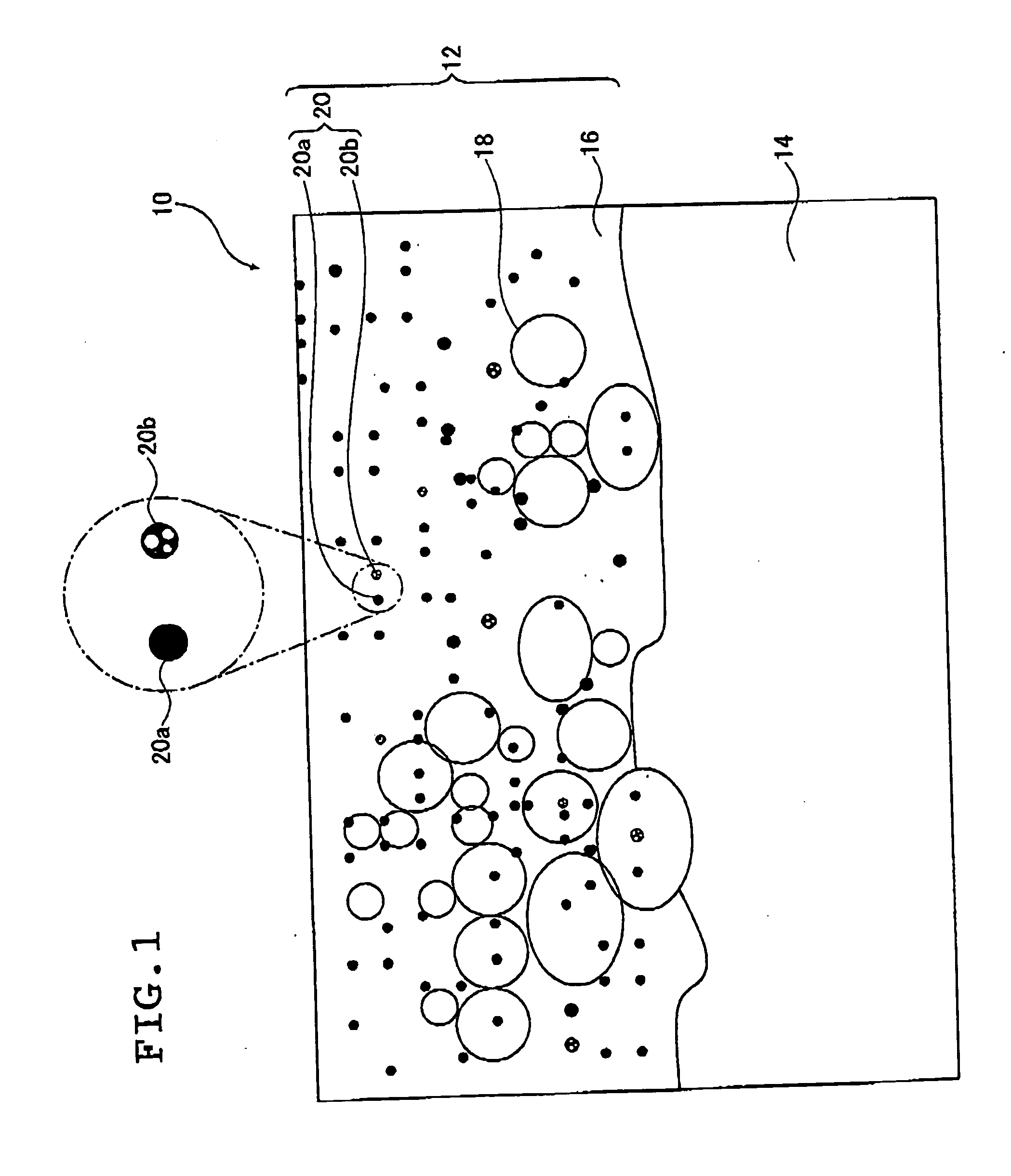

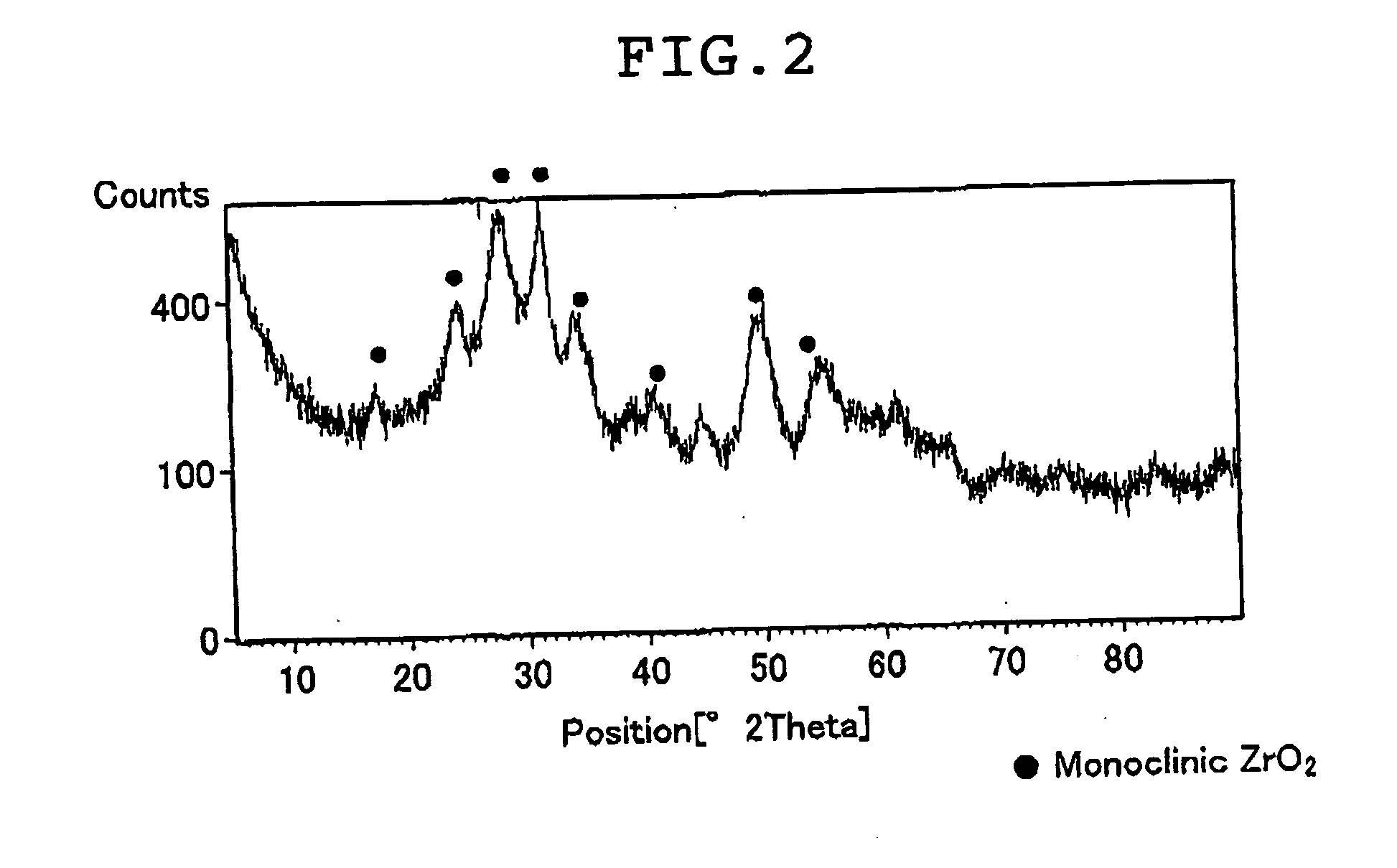

Method for coating a metal with a ceramic coating, electrolyte used therefor, ceramic coating, and metal material

InactiveUS20100025253A1Excellent abrasion resistanceReduce attackAnodisationElectrolytic inorganic material coatingElectrolysisCeramic coating

This invention provides a method for coating a ceramic film on a metal, which can form dense films on various bases of metals such as magnesium alloys. The formed ceramic film has excellent abrasion resistance, causes no significant attack against a counter material, and has excellent corrosion resistance. The method comprises electrolyzing a metallic base in an electrolysis solution using the metallic base as a working electrode while causing glow discharge and / or arc discharge on the surface of the metallic base to form a ceramic film on the surface of the metallic base. The electrolysis solution contains zirconium oxide particles having an average diameter of not more than 1 μm, satisfies the following formulae (1) to (3): 0.05 g / L≦X≦500 g / L (1), 0 g / L≦Y≦500 g / L (2), and 0≦Y / X≦10 (3); and has a pH value of not less than pH 7.0. In the formulae (1) to (3), X represents the content of zirconium oxide particles in the electrolysis solution; and Y represents the content of a compound of at least one element selected from the group consisting of Mg and the like, other than zirconium oxide.

Owner:NIHON PARKERIZING

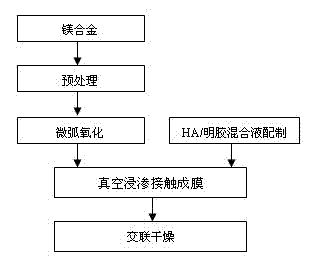

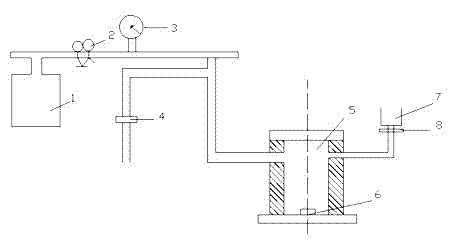

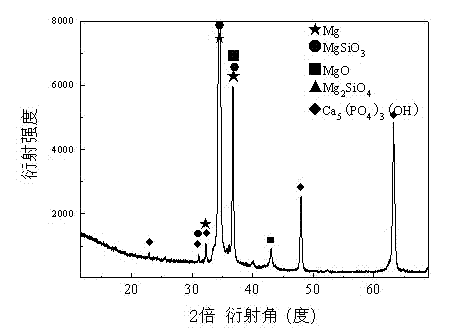

Medical magnesium alloy surface degradable composite protective film layer and preparation method thereof

InactiveCN102397584AImprove biological activityImprove bindingAnodisationSurgeryPlasma electrolytic oxidationComposite film

The invention relates to a medical magnesium alloy surface degradable composite protective film layer and a preparation method thereof. The degradable composite protective film is prepared on a medical magnesium alloy surface and has an internal and external bilayer film structure: the internal layer film is prepared by a microarc oxidation technology, a magnesium oxide and magnesium silicate ceramic phase is used as a substrate, and nanometer zirconia particles used for toughening and strengthening and hydroxyapatite particles used for improving bioactivity are dispersed and distributed in the substrate phase; and the external layer film is prepared in a vacuum infiltration method, gelatin is used as a substrate, and hydroxyapatite particles are dispersed and distributed in the gelatin substrate. The composite film layer can obviously improve the corrosion resisting property and toughness of material so as to achieve the purpose of controllable degradation, and simultaneously the composite film layer can improve the biocompatibility of the material.

Owner:SOUTHEAST UNIV

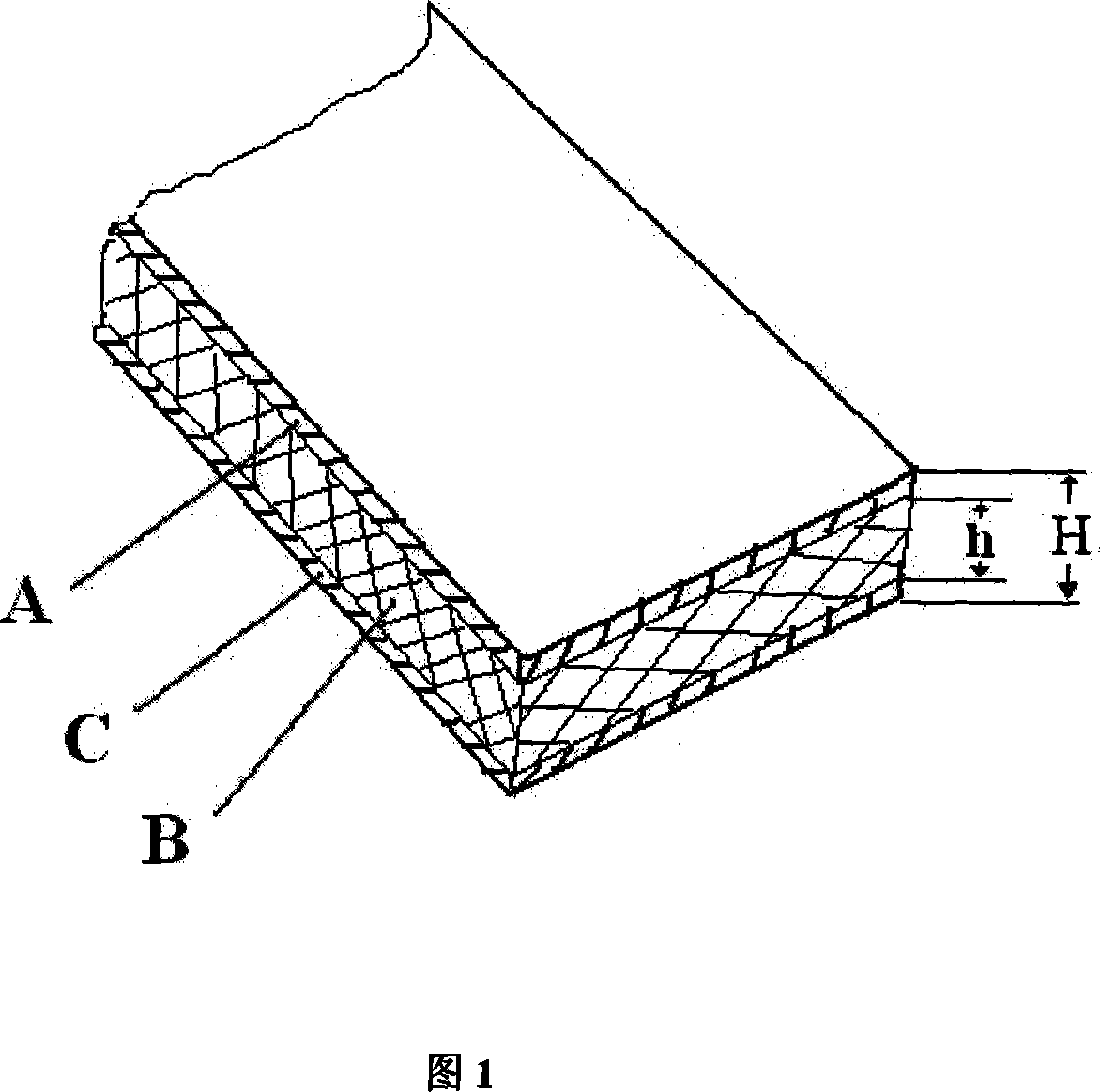

Composite magnesium plate ribbon of magnesium clad aluminum product and composition method

InactiveCN101049745AReduce crackingReduce scratchesAuxillary arrangementsMetal rolling arrangementsIngotHeating furnace

An Al material clad Mg-base band is prepared from the Mg plate or Mg plate ingot as basic material and the cladding Al sheets through hot rolling or cold rolling to attach said Al sheets to both surfaces of basic material. It has high cold deformation power and anticorrosion ability.

Owner:SOUTHWEST UNIVERSITY

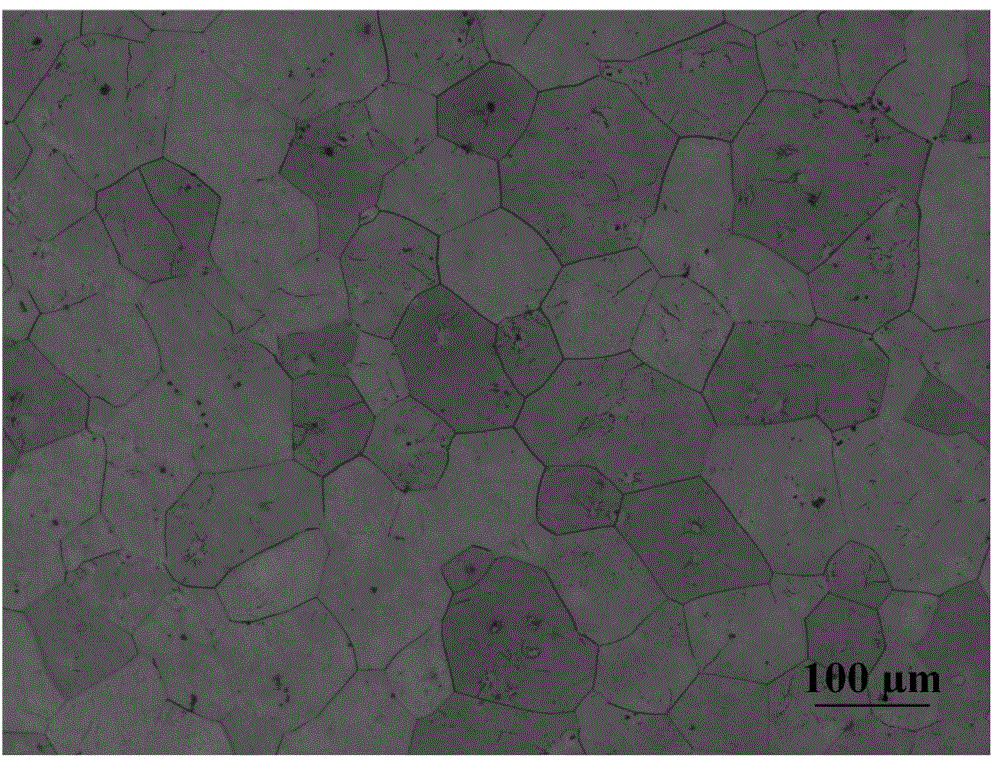

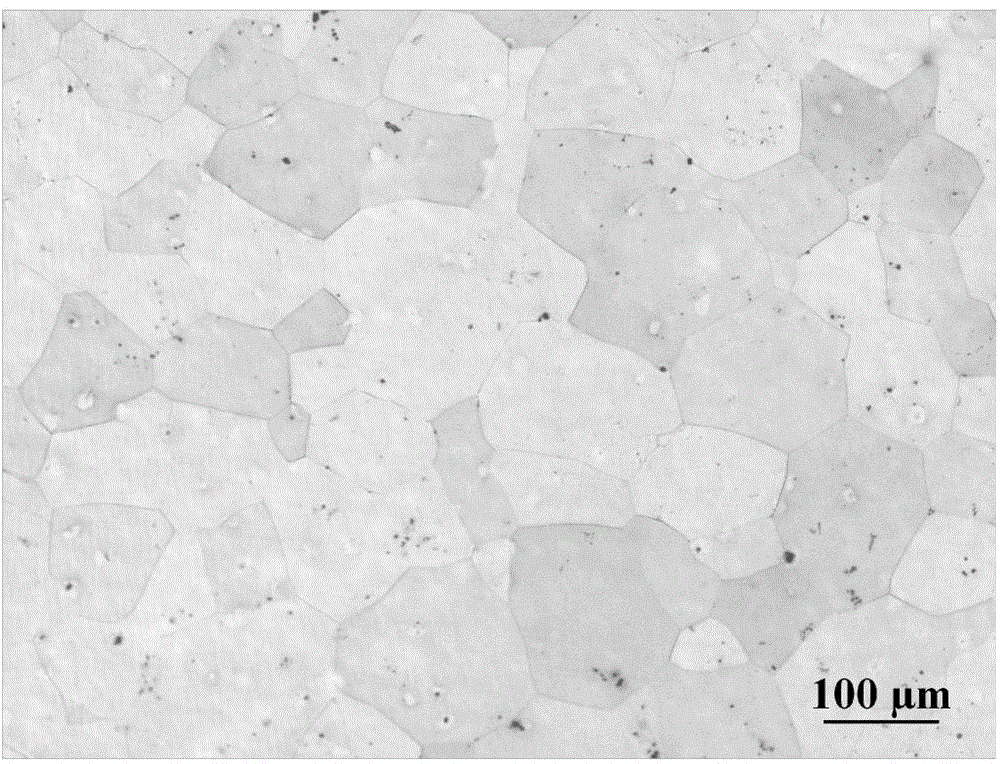

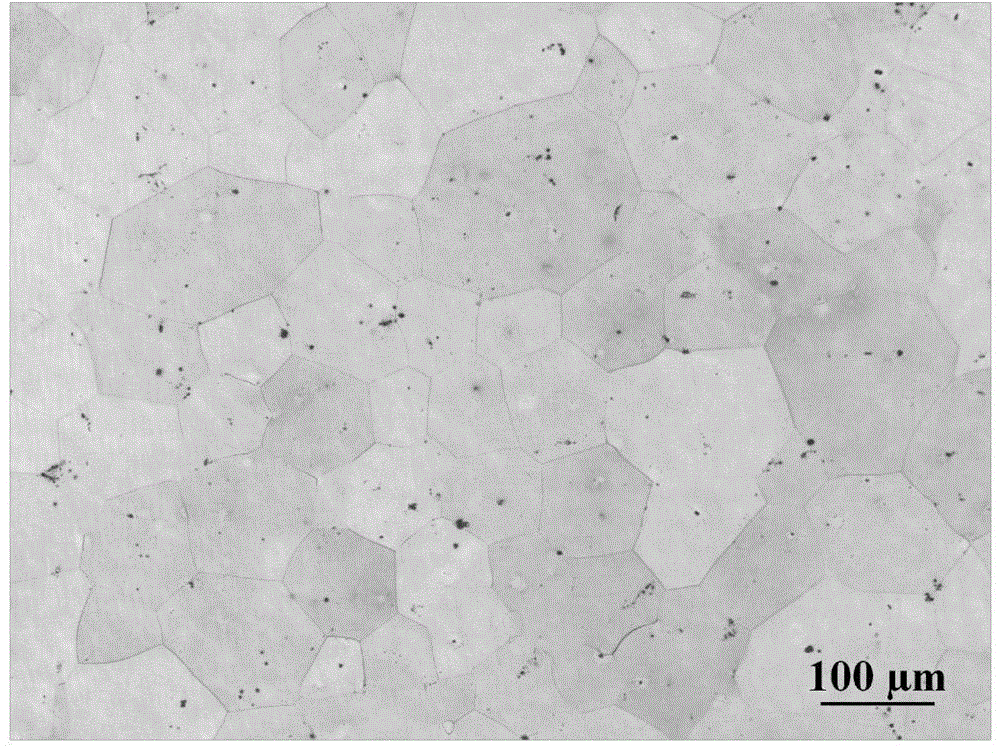

Magnesium Alloy With Adjustable Degradation Rate

ActiveUS20140261911A1Reduce the degradation rateSurgeryPharmaceutical delivery mechanismMg alloysGrain structure

An alloy and an implant having a three-dimensional structure based on such alloy. The alloy comprises a MgZnCa alloy containing nanosized precipitates being less noble than the Mg matrix alloy and having a Zn content ranging 0.1 wt. % Zn to 2 wt. % Zn and a calcium content ranging from 0.2 wt. % to 0.5 wt. %, and having less than 0.04 wt. % of one or more other elements with the remainder being Mg. For these micro-alloys, any second phase generated during the solidification process can be completely dissolved by a solution heat treatment. Finely dispersed nanosized precipitates can then be generated by a subsequent aging heat treatment step. These precipitates are used to “pin” the grain boundaries and to prevent the coarsening of the grain structure during further processing to achieve grain sizes below 5 μm.

Owner:DEPUY SYNTHES PROD INC

Friction stir welding process for enhancing mechanical property of joint

ActiveCN102528268AReduce the temperatureImprove performanceNon-electric welding apparatusHeat-affected zoneMetallic materials

The invention relates to the field of metal material welding, and particularly provides a friction stir welding process for enhancing the mechanical property of a joint. The friction stir welding process is applicable to welding for metal materials such as aluminum alloys, magnesium alloys, copper alloys, steel and the like, and solves the problems that heat generated in a weld nugget is difficult in rapid transmission, annealing and softening functions of an HAZ (heat affected zone) are obvious, and the like. A stirring head with a small-size shaft shoulder is used for welding with low heat input friction stir welding parameters, welding lines are rapidly cooled by high-pressure flow cooling media during welding, and the friction stir welding joint with an excellent performance is obtained. The friction stir welding process can be used for obviously enhancing the mechanical property of the welding joint, and is particularly applicable to welding for precipitation strengthened, machined and hardened on-ferrous metal materials and steel materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

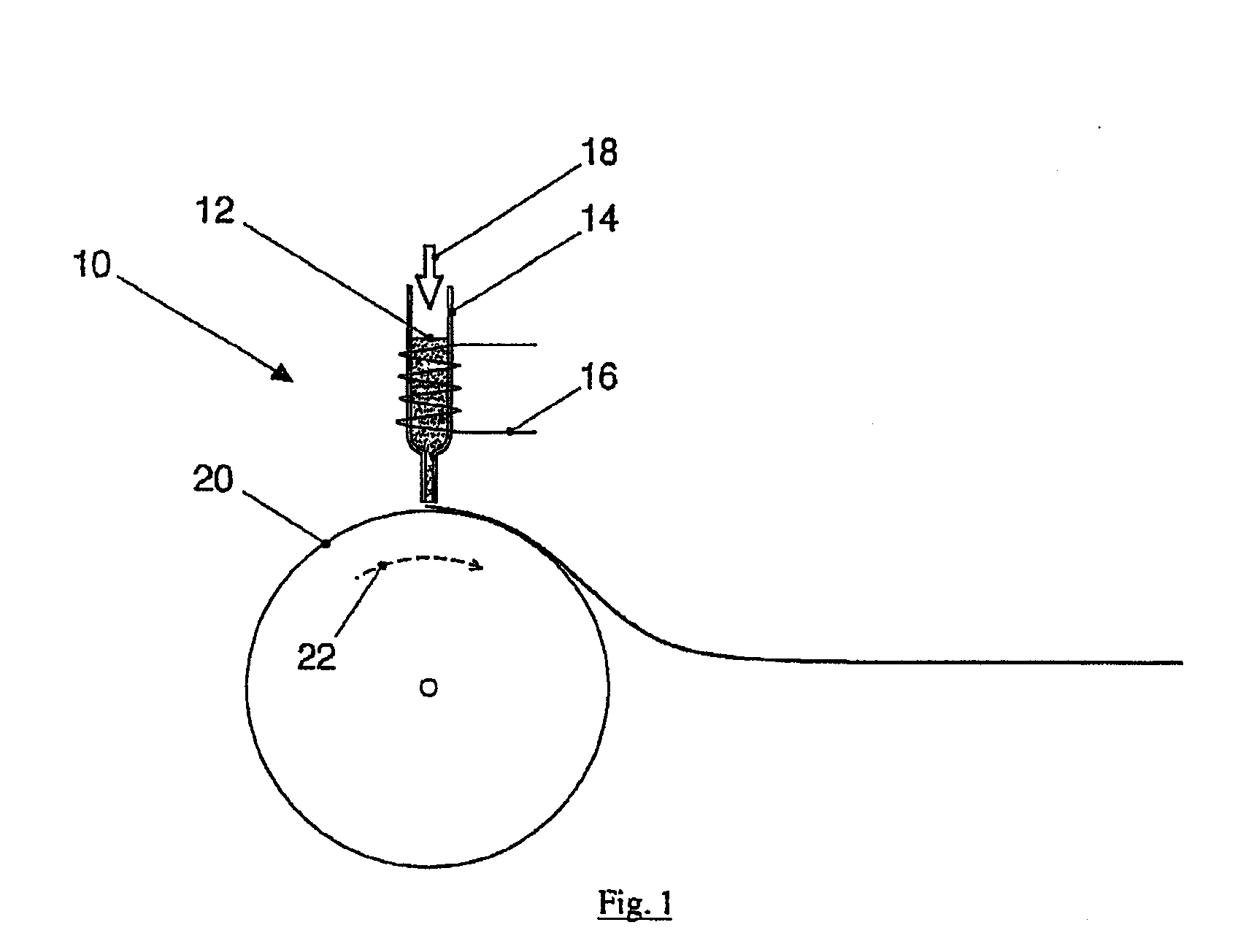

Preparation method of surface coating capable of lowering degradation rate of fully-degradable magnesium alloy vascular stent

ActiveCN104189963AReduce the degradation rateReduce sheddingSurgeryCoatingsMg alloysBiocompatibility

The invention relates to a preparation method of a surface coating capable of lowering the degradation rate of a fully-degradable magnesium alloy vascular stent. The method comprises the following steps: preparing a silane coupling agent on a magnesium alloy surface in a way that a silane coupling agent and an organic solvent are mixed, the silane coupling agent is grafted to the magnesium alloy surface of a biodegradable vascular stent by adopting a dip coating method and heating and curing are performed to form a coating; and preparing a polymer coating on the surface pre-treated by the silane coupling agent in a way that a spin-coating method is adopted to coat a polymer on a sample surface treated by the silane coupling agent, vacuum drying is realized and the polymer coating is formed after solvent volatilization. Through the technical scheme, a strong binding force exists between the polymer coating on the magnesium alloy surface pre-treated by the silane coupling agent and the surface of the fully-degradable magnesium alloy vascular stent, so that the magnesium alloy base body is prevented from excessively quick degradation, and the biocompatibility is improved; and as the coating is completely degraded with the base body at last, no toxic or side effects are brought to a human body.

Owner:JIANGSU FENGYUAN MEDICAL DEVICES CO LTD

Mg-gd-y-zn-zr alloy and process for preparing the same

A Mg—Gd—Y—Zn—Zr alloy with high strength and toughness, corrosion resistance and anti-flammability and a process for preparation thereof are disclosed. The components and the mass percentages thereof in the Mg—Gd—Y—Zn—Zr alloy are: 3.0%≤Gd≤9.0%, 1.0%≤Y≤6.0%, 0.5%≤Zn≤3.0%, 0.2%≤Zr≤1.5%, the balance being Mg and inevitable impurities. The process for preparation thereof comprises: adding pure Mg into a smelting furnace for heating, then introducing mixed gases of CO2 and SF6 into the furnace for protection; adding other raw materials in sequence when the pure Mg is completely melted; preparing an ingot; conducting a homogenization treatment on the ingot prior to extrusion; conducting an aging treatment on the extruded alloy. A wrought magnesium alloy having superior overall performances and good fracture toughness, corrosion resistance and anti-flammability, with a small amount of rare earth element is obtained by adjusting the proportion of the alloy elements and by conventional casting, extrusion and heat treatment processes. The cost of the alloy is reduced while the strength of the alloy is maintained.

Owner:THE BOEING CO

High-strength and high-elasticity-modulus casting Mg alloy and preparation method thereof

The invention provides a high-strength and high-elasticity-modulus casting Mg alloy and a preparation method thereof. The Mg alloy comprises 6-12wt% of Gd, 1-5wt% of Li, 1-5wt% of Y, 2-6wt% of Al, the balance of Mg and inevitable impurities, wherein the total content of Si, Fe, Cu and Ni in the impurities is smaller than 0.03wt%. The preparation method of the Mg alloy includes the sequential steps of vacuum melting and heat treatment. Compared with the prior art, the preparation method has the advantages that by adopting a vacuum induction melting furnace for melting, inclusions generated in the melting process are reduced, and the retention time of a melt at a high temperature is substantially shortened; the effects of solution strengthening and age hardening of the Mg alloy can be fully exerted under the optimized heat treatment process.

Owner:SHANGHAI JIAO TONG UNIV +1

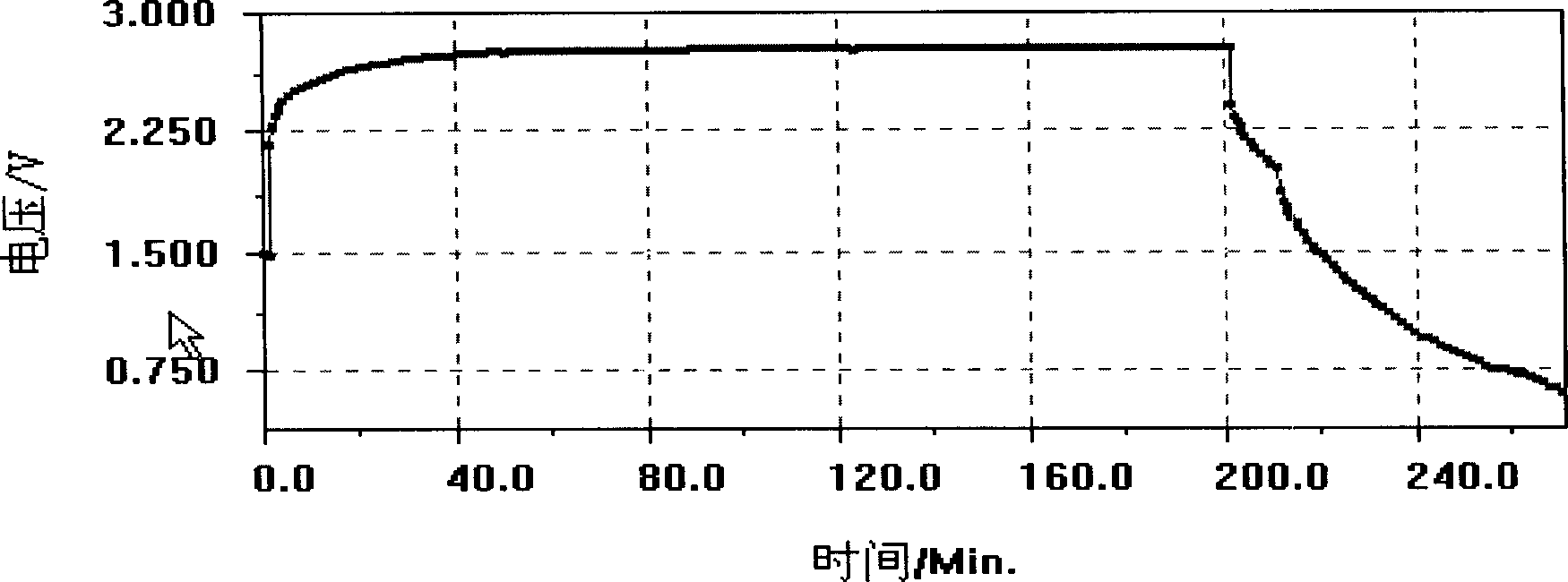

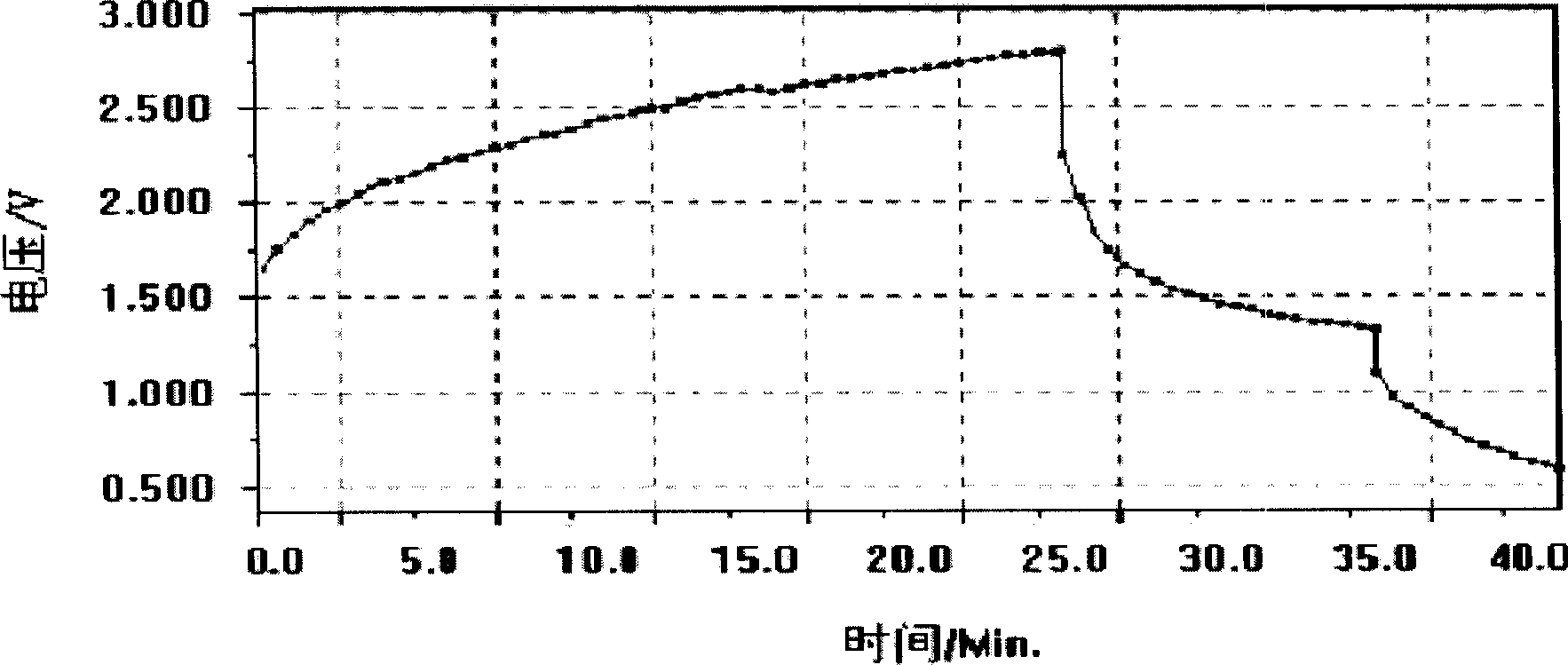

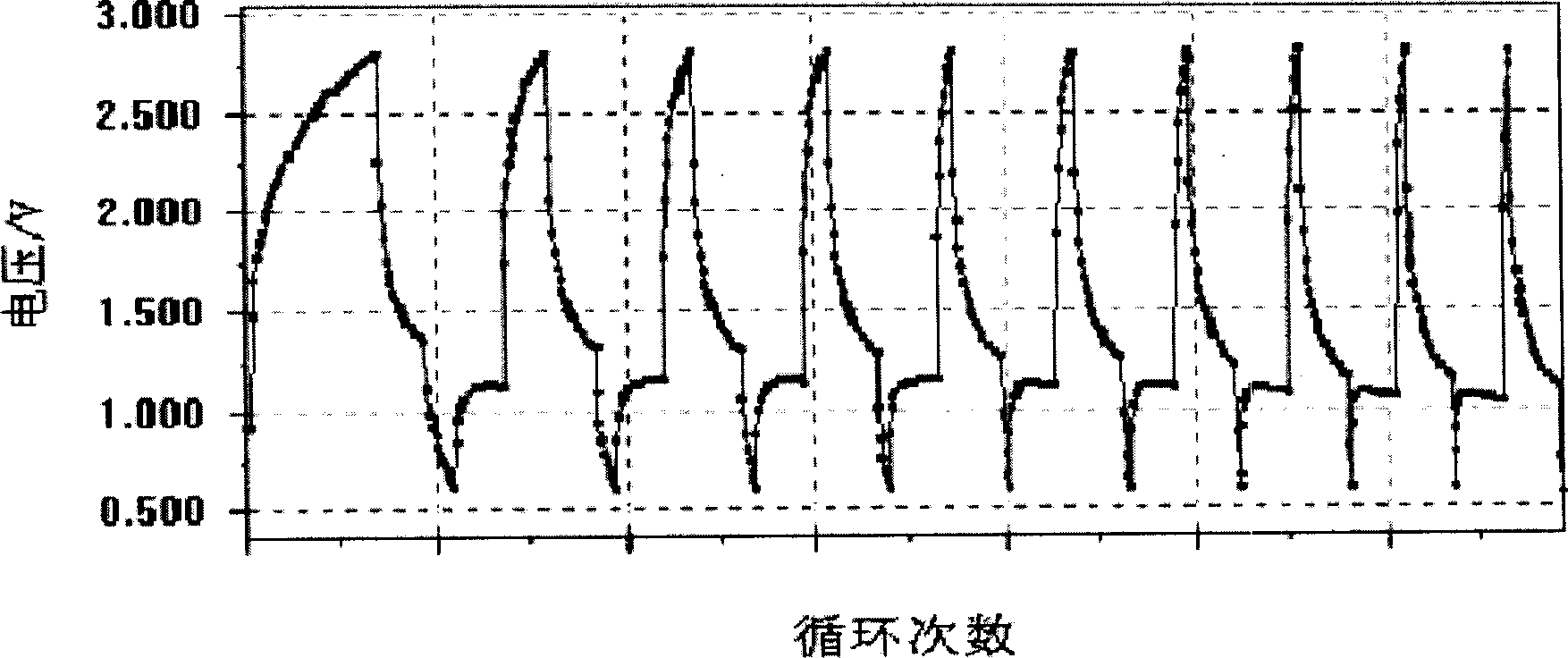

Chargeable magnesium battery

InactiveCN1411083ACharge and discharge balanceLow priceFinal product manufactureCell electrodesBattery chargeAlloy

This invention relates to the manufacture of secondary batteries charged by Mg including electrode materials, electrolytic material and their preparation method in which the negative is made of Mg alloy with component of MgMxMy(o<x, y<0.5) alloy above binary (M is Ni, Cu, Ti, Co, Si, B etc.), the positive is made of nanometer degree M2Co2O4(O<z<2, O<t<3) or MoS2 and the liquid electrolyte is metal organic compound Mg(ZnBuCl2)2. The said battery system has balance of charge / discharge with open voltage of about 2.0 V.

Owner:NANKAI UNIV

Magnesium alloy boride iron illiminating flux and its production method

A deironing boride flux for Mg-alloy contains magnesium chloride, potassium chloride, sodium chloride, calcium chloride, calcium fluoride, barium chloride, and boron oxide and / or sodium borate as deironing agent. Its advantages are high power removing impurities and Fe from molten Mg-alloy, easy separation, and low cost.

Owner:SHANGHAI HAOHUA MOLD

Flame-retarding paint for casting Mg-alloy and its preparing process

InactiveCN1381321AStrong coatingStrong thixotropyFoundry mouldsFoundry coresPorosityCarboxymethylcellulose Sodium

A fire-retarding paint for casting Mg-alloy with lost mould is prepared from magnesia sand powder, perlite powder, mica powder silica sol, white emulsoid, polyacrylamide, carboxymethylcellulose sodium, adsorbent and flame-retarding agent through preparing solution from adsorbent, carboxymethylcellulose sodium, polyacrylamide and water, and mixing with others. It can make the Mg-alloy casting havesmooth surface.

Owner:SHANGHAI AIERSI LIGHT ALLOY

Medical degradable and absorbable Mg-Sr-Ca series magnesium alloy implant and preparation method thereof

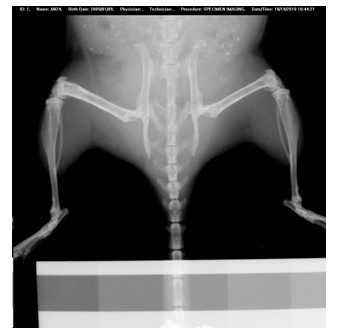

The invention relates to a medical degradable and absorbable Mg-Sr-Ca series magnesium alloy implant and a preparation method thereof. The medical implant is made of a Mg-Sr-Ca series alloy, wherein strontium is 0 to 5 percent (but not 0) of the weight of the Mg-Sr-Ca series alloy; calcium is 0 to 2 percent (but not 0) of the weight of the Mg-Sr-Ca series alloy; a small amount of one or more of trace elements, namely manganese, zirconium, tin, rare earth and yttrium may be contained, and are not more than 2 percent of weight of the Mg-Sr-Ca series alloy; and the balance is magnesium. In-vivo and in-vitro tests prove that the Mg-Sr-Ca series alloy implant is nontoxic, has high histocompatibility, and is a reliable biomedical implant material.

Owner:浙江海圣医疗器械股份有限公司

Magnesium alloy bone surgery internal fixation and implantation material

InactiveCN101264339ADegradation rate regulationPromote healingSurgeryProsthesisBiocompatibility TestingInternal fixation

The invention relates to a magnesium alloy internal fixation and implant material used in orthopedic surgeries, which is characterized in that the pure magnesium is used as the substrate, and calcium and zinc elements are added into the pure magnesium; wherein, the zinc accounts for 2-5%, and the calcium accounts for 1-3%. The magnesium alloy internal fixation and implant material used in orthopedic surgeries has the advantages of enjoying favorable biocompatibility, excellent mechanical property and controllable degradation rate, and meeting the demands for internal fixation and implant materials in orthopedic surgeries, thus being particularly suitable for screw plate systems and intramedullary pin systems.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH +1

Magnesium alloy surface zinc-calcium series phosphating solution and conversion treatment process thereof

InactiveCN101671824AGood protectionImprove corrosion resistanceMetallic material coating processesConversion coatingPhosphate

The invention discloses magnesium alloy surface zinc-calcium series phosphating solution and a conversion treatment process thereof; the magnesium alloy surface phosphating solution is aqueous solution formed by the following constituents, namely, every liter solution contains: 10-30g of disodium hydrogen phosphate, 4-6g of zinc nitrate, 2-4g of sodium nitrite, s0.5-2g of sodium fluoride, and 0.-2g of calcium nitrate; the process for carrying out surface conversion treatment to the phosphating solution comprises the following process flows: alkaline washing and degreasing->rinsing->acidity activation->rinsing->surface activation->rinsing->phosphating->rinsing->drying; the working temperature is 40-70 DEG C, and the time is 5-60 minutes. The conversion treatment process can obtain phosphateconversion coating on the surface of the magnesium alloy, wherein the conversion coating has good protectiveness, is fine and uniform and stable, and has strong adhesive force, and can improve the corrosion-resisting property of magnesium alloy parts; the conversion treatment process is stable and easy to control, and has low cost.

Owner:CHONGQING UNIV OF TECH

Method of forming an oxide coating with dimples on its surface

InactiveUS20080248214A1Reduce manufacturing costFlat surfaceVacuum evaporation coatingSputtering coatingMg alloysHigh pressure

This invention involves a process of forming an oxide coating with dimples on Al, Mg and Ti alloys. The oxide coating with dimples on its surface is produced by the process consisting of an electrochemical etching on the surface of those alloys followed by plasma oxidation in an alkaline electrolytic solution using a high voltage power supply. The as-prepared coating has smooth surface finish and improved properties being suitable for wear and corrosion protection of materials which have contacts with each other. The present invention can also be applied onto Al—Si and Mg alloys for wear and corrosion-wear prevention of sleeveless aluminium and magnesium engines.

Owner:NIE XUEYUAN +1

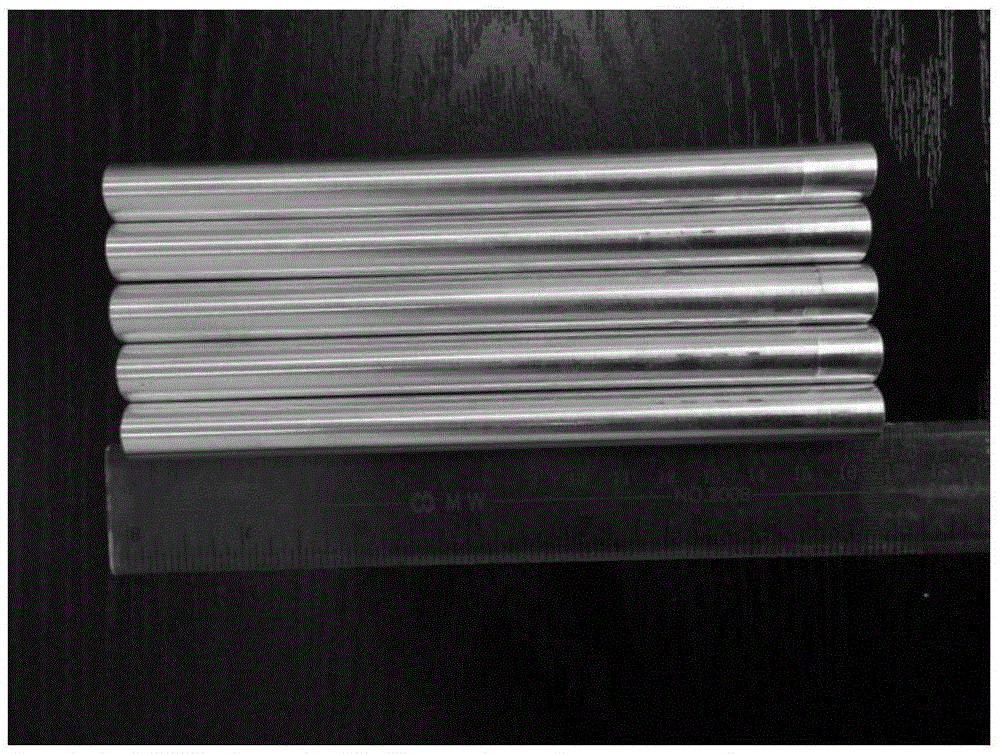

Degradable magnesium alloy implanting material for bone fixation and preparing method of degradable magnesium alloy implanting material

ActiveCN105349858AImprove and enhance mechanical propertiesImproved and enhanced biocompatibilityMg alloysBiomechanics

The invention relates to a degradable magnesium alloy implanting material for bone fixation and a preparing method of the degradable magnesium alloy implanting material. The implanting material is prepared from, by mass percent, 0.5-4% of Mg, 0.5-4% of Ag and the balance Y. The preparing method of the implanting material comprises the steps of ingot casting metallurgy, extruding, rolling and heat treatment. The prepared implanting material meets the requirement of plates, rods and profiles, wherein the plates, the rods and the profiles serve in biological fluid environments. By means of alloy materials, the good comprehensive mechanical performance needed by bone fixing materials is ensured, the beneficial effects of being capable of inhibiting bacteria, resistant to corrosion, free of cytotoxicity, good in biological mechanical property and the like are achieved, and the alloy materials can be degraded under the biological fluid environments. The implanting material can serve as bone nails or marrow nails or bone fraction plates or other various devices to be used under the medical conditions, and the comprehensive performance is good; and especially, the implanting material has both the biomechanical property and the biodegradable performance at the same time, and the typical defect of existing metal materials of a titanium alloy or stainless steel or high polymer materials in application of the department of orthopaedics is overcome.

Owner:CENT SOUTH UNIV

Mg Li Sr alloy and its electrlysis preparing method

InactiveCN101070576AWide variety of sourcesChange the problem of low mechanical propertiesMg alloysElectrolysis

One kind of Mg-Li-Sr alloy and its the electrolysis preparation method, which belongs to magnesium alloy material and it's the preparation technology area. The component and quality percentage of the alloy include: Lithium: 5-15%wt, strontium: 0.1-5%wt, aluminum:0.5-3%, zinc:0.5-3%, the remainder is magnesium, comparing with LA141Mg-Li alloy, the anticreep and corrosion resistance performance of the Mg-Li-Sr alloy are enhancement. This invention uses molten salt electrolysis method to prepare the Mg-Li-Sr alloy, its step is: melting magnesium alloy; configurating electrolyte; adding the electrolyte to magnesium melt body; The anode inducts in electrolyte, the negative pole inducts the Mg melt body; then made contact to electrolysis, lithium and strontium separate out and enter magnesium melt body, then obtain the liquid state Mg-Li-Sralloy, and get the Mg-Li-Sr alloy after condensation. Prepared the Mg-Li-Sr alloy with molten salt electrolysis has improved utilization rate of the material, and it is a new method to preparing Mg-Li-Sralloy.

Owner:CHONGQING UNIV

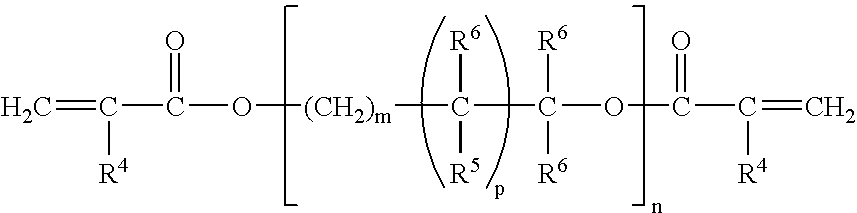

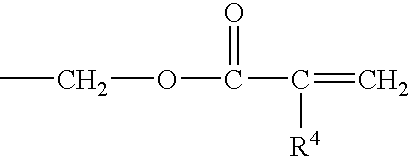

Adhesive compositions for bonding passive substrates

InactiveUS20030217808A1Polyureas/polyurethane adhesivesSynthetic resin layered productsHydrazine compoundOnium

Adhesive compositions are disclosed which cure rapidly and completely on confinement between passive substrates, such as magnesium alloys, that are deficient in transition metals and transition metal ions. The compositions include one or more acrylate resins, one or more peroxy free radical initiators, one or more onium salts, and an accelerator such as acetylphenyl hydrazine desirably in an amount of about 1.0% or less by weight of the composition. These compositions provide exceptional bonding to such substrates without the need for a transition metal primer. Methods of making and using such compositions are also disclosed.

Owner:HENKEL IP & HOLDING GMBH

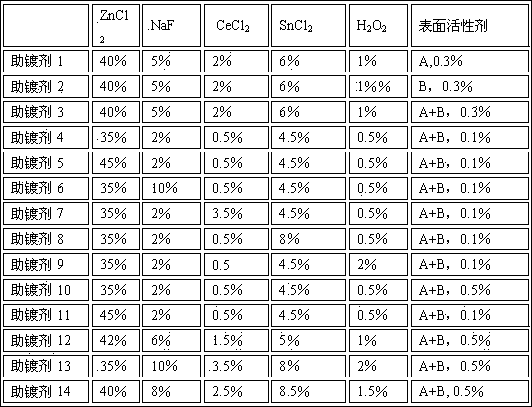

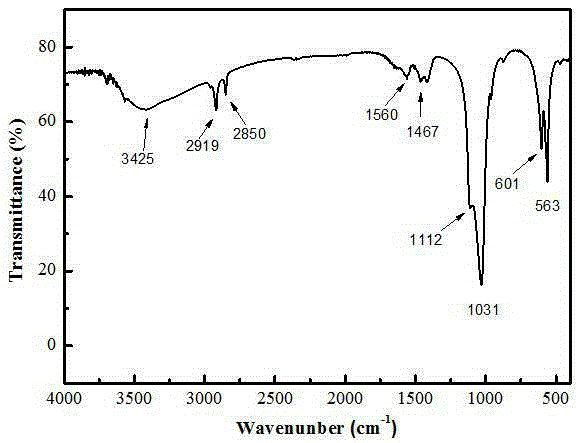

Plating assistant agent for zinc aluminum magnesium alloy hot dipping for steel wire

ActiveCN103510031AImprove bindingInhibit sheddingHot-dipping/immersion processesMg alloysActive agent

The invention relates to a plating assistant agent for zinc-aluminum-magnesium alloy hot dipping for a steel wire and belongs to the technical field of steel and iron material surface plating processes. The plating assistant agent is composed of 35-45 percent of ZnCl2, 2-10 percent of NaF2, 0.5-3.5 percent of CeCl2, 4.5-8.5 percent of SnCl2, 0.5-2 percent of H2O2, 0.1-05 percent of a surfactant and water in balancing amount. The surfactant is fatty alcohol ether sodium sulfate and / or sodium dodecyl sulfate. According to the invention, through a reasonable plating assistant agent formula, zinc-aluminum-magnesium alloy plating is obtained on the surface of the steel wire through hot dipping. The plating and the steel wire keep original performance respectively, more than 99.9 percent of a metallurgical bonding interface is obtained, the plating is compact in structure, plating leakage is avoided, and a zinc-aluminum-magnesium ternary eutectic with excellent corrosion resistance is formed. The corrosion resistance performance of the alloy plating is 2-4 times than that of normal hot-dipped pure zinc plating. The plating assistant agent is low in cost, can be used repeatedly and facilitates industrial production.

Owner:STATE GRID CORP OF CHINA +1

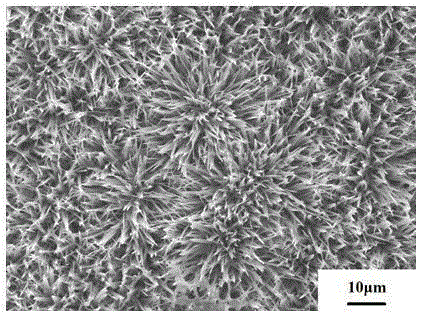

Hydrophobic composite biological activity coating on surface of pure-magnesium or magnesium alloy and preparation method of hydrophobic composite biological activity coating

InactiveCN105420789AImprove compactnessGood biocompatibilityAnodisationProsthesisMicro arc oxidationMagnesium phosphate

The invention relates to the technical field of surface treatment of bio-medical metal materials, in particular to a hydrophobic composite biological activity coating on the surface of pure-magnesium or magnesium alloy and a preparation method of the hydrophobic composite biological activity coating. The method includes the technical processes of preparing a micro-arc oxidation coating on the surface of a magnesium matrix material firstly, preparing a hydroxyapatite coating on the basis of the micro-arc oxidation coating to form a composite active coating, and carrying out hydrophobic treatment on the composite active coating finally to form the hydrophobic composite biological activity coating. The hydrophobic composite biological activity coating on the surface of the magnesium alloy is composed of magnesium oxide, magnesium phosphate and hydroxyapatite and has a compact layer ranging from 5 micrometers to 10 micrometers and a band-shaped hydroxyapatite array, the contact angle of the coating and simulated body fluid is larger than 90 degrees, and the coating shows hydrophobicity. The hydrophobic composite biological activity coating has the beneficial effects of high corrosion resistance, good biocompatibility, good bone induction capacity and the like, and has the wide application prospect.

Owner:FUZHOU UNIV

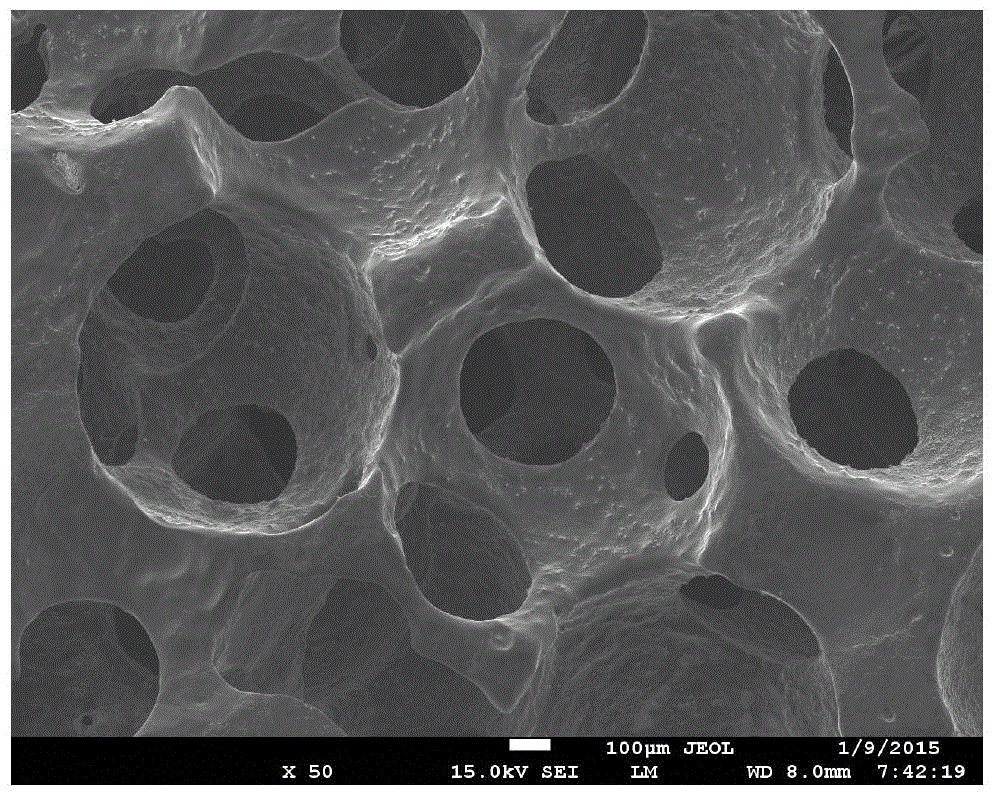

Degradable three-dimensional porous magnesium-based biomaterial and preparation method thereof

The invention discloses a degradable three-dimensional porous magnesium-based biomaterial and a preparation method thereof. The porous magnesium and magnesium alloy materials are in a three-dimensional through complete opening structure; the hole pattern is a sphere with a controllable dimension; intercommunicating holes are uniform in distribution and controllable in dimension; and a magnesium fluoride film is uniformly generated on the surface of each hole wall. The holes of the material obtained by the method are uniform in overall distribution; the porosity and the mechanical property are controllable; titanium sphere or iron sphere particles are sintered in preparation, so as to obtain a porous preform with spherical openings; magnesium and magnesium alloy infiltrate into the preform and then are cooled to room temperature; and the preform is removed through hydrofluoric acid solution corrosion. The preparation method is simple in preparation technology and convenient to operate; an anti-corrosion anti-fouling membrane is formed on a magnesium and magnesium alloy matrix surface in the removal process of the preform; the magnesium-based biomaterial is good in connectivity, and relatively high in porosity and strength; the hole wall is free of corrosion or pore-forming agent residue phenomenon; a closed hole does not exist; and the magnesium-based biomaterial can be used as a new generation of degradable tissue engineering scaffold.

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com