Composite coating magnesium/magnesium alloy biology device and preparation method thereof

A biomedical and composite coating technology, applied in coatings, medical science, blood vessels, etc., can solve the problems of degradation time and strength, disproportionate rigidity, poor controllability of degradation, poor processing stability, etc., to avoid premature failure, The effect of preventing surface degradation and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

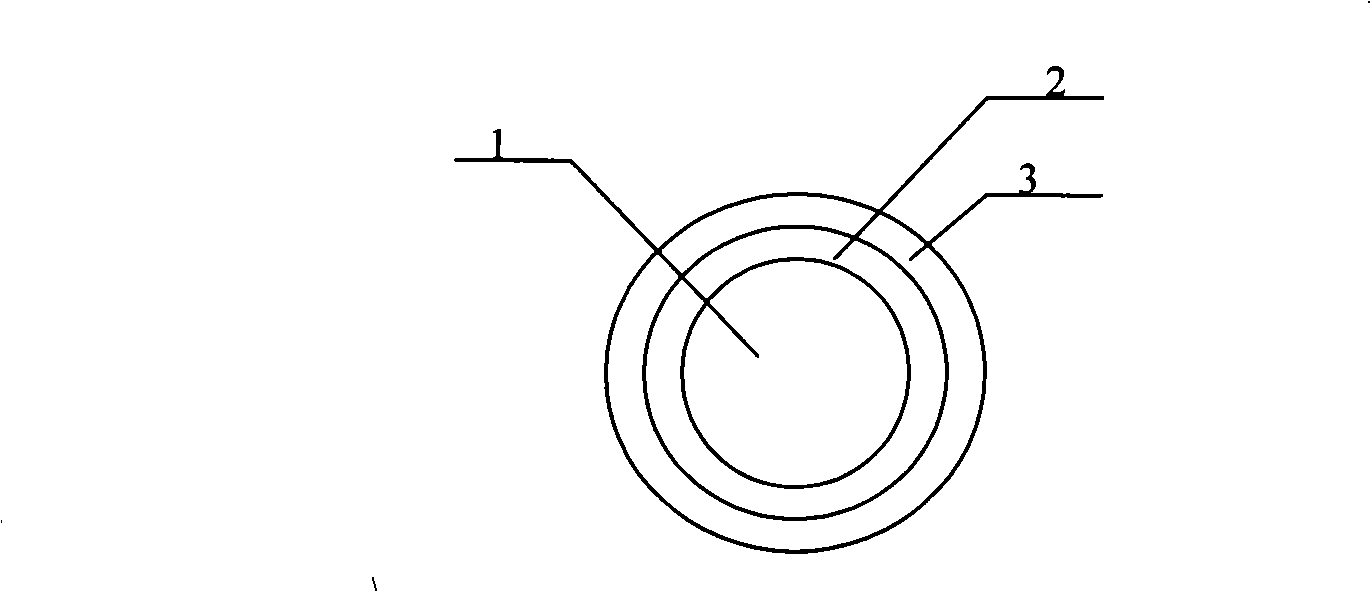

Image

Examples

Embodiment 1

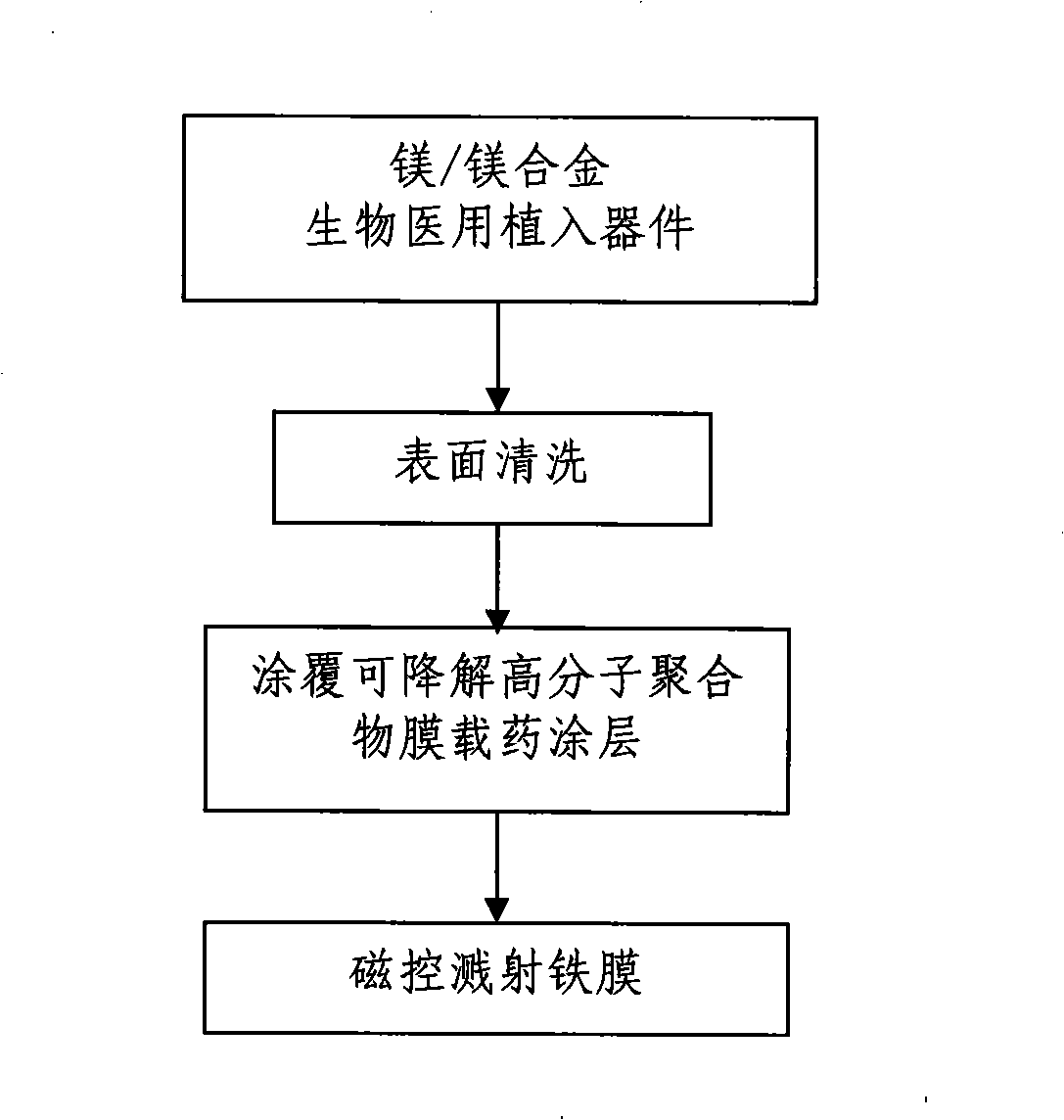

[0037] The preparation method of the composite coating magnesium alloy medical stent mainly includes 1) the processing and preparation of the magnesium alloy stent; 2) the coating of the degradable polymer film on the surface of the magnesium alloy; 3) the preparation of the iron film by magnetron sputtering.

[0038] After the AZ31B magnesium alloy is polished, it is laser-engraved into a vascular stent. Then cleaning includes (1) cleaning with a medical ethanol solvent with a concentration of 75%; (2) cleaning with an analytically pure acetone solution with a concentration of 99.5%; (3) cleaning with deionized water in an ultrasonic wave with an ultrasonic frequency of 50khz. The cleaning time of each step is 10 minutes, and the cleaned bracket is placed in a dryer to dry.

[0039] Use tetrahydrofuran as a solvent to dissolve the degradable polymer PLGA with a concentration of 1.5% (mass percentage), shake it evenly with a shaker, spray it on the surface of the dried magnesi...

Embodiment 2

[0043] After the AZ91D magnesium alloy is polished, it is laser engraved into a vascular stent. Then cleaning, including (1) cleaning with a medical ethanol solvent with a concentration of 75%; (2) cleaning with acetone analytically pure solution with a concentration of 99.5%; (3) cleaning with deionized water in an ultrasonic wave with an ultrasonic frequency of 28 ~100khz. The cleaning time of each step is 10 minutes, and the cleaned bracket is placed in a dryer to dry.

[0044] Use chloroform as a solvent to dissolve the degradable polymer poly-L-lactic acid (PLLA), with a concentration of 1.5% (mass percentage), shake it evenly with a shaker, spray it on the surface of the magnesium alloy stent after cleaning, and let it dry naturally in the air. Put it into the LGJ-12 vacuum freeze dryer, negative pressure the polymer film layer for 30 minutes, and the negative pressure value is 6 Pascals. The number of times of spraying is determined by the thickness of the coating, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com