Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

544 results about "Nickel compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compounds of nickel are chemical compounds containing the element nickel which is a member of the group 10 of the periodic table. Most compounds in the group have an oxidation state of +2. Nickel is classified as a transition metal with nickel(II) having much chemical behaviour in common with iron(II) and cobalt(II). Many salts of nickel(II) are isomorphous with salts of magnesium due to the ionic radii of the cations being almost the same. Nickel forms many coordination complexes. Nickel tetracarbonyl was the first pure metal carbonyl produced, and is unusual in its volatility. Metalloproteins containing nickel are found in biological systems.

Electrical connection

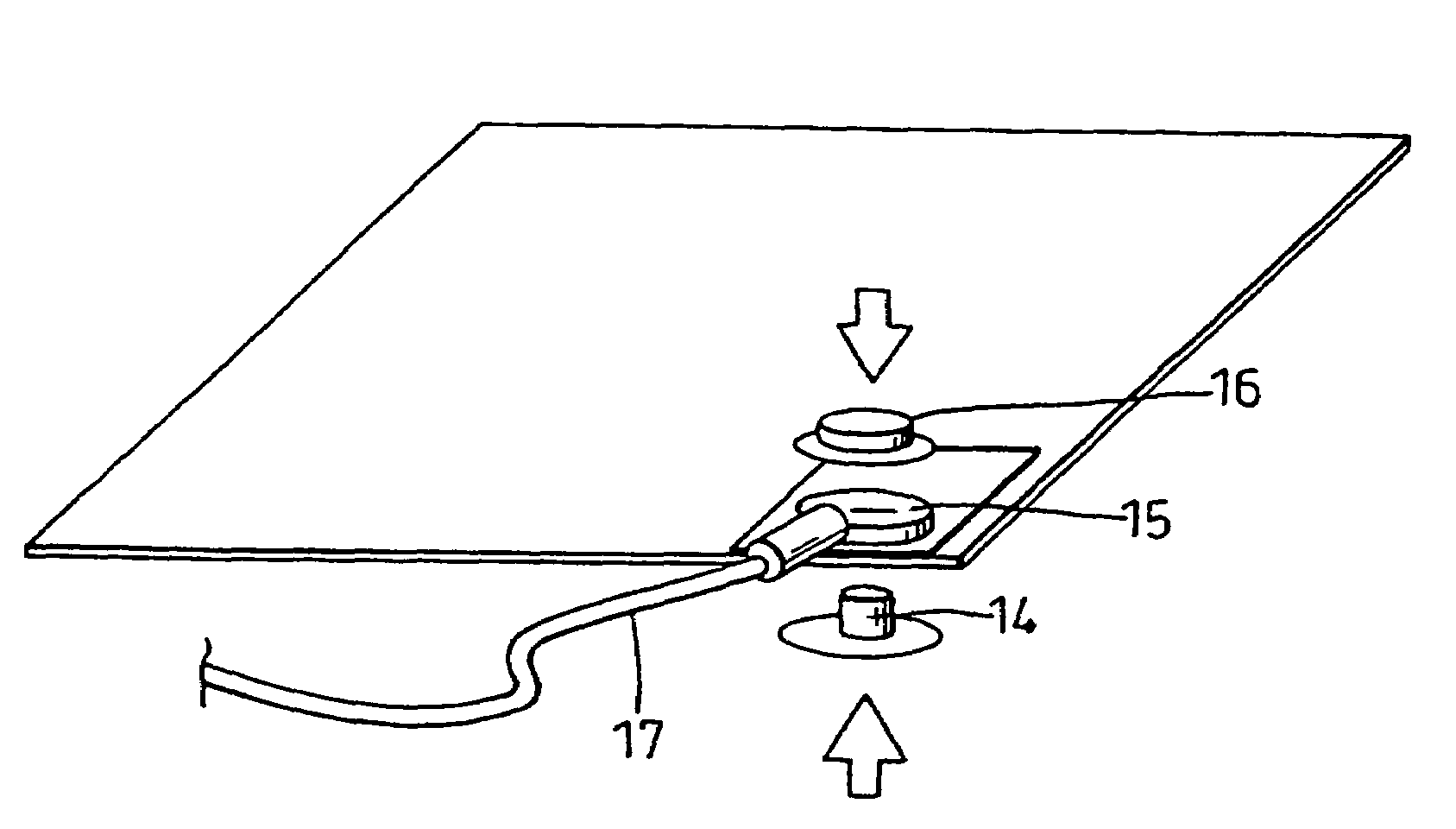

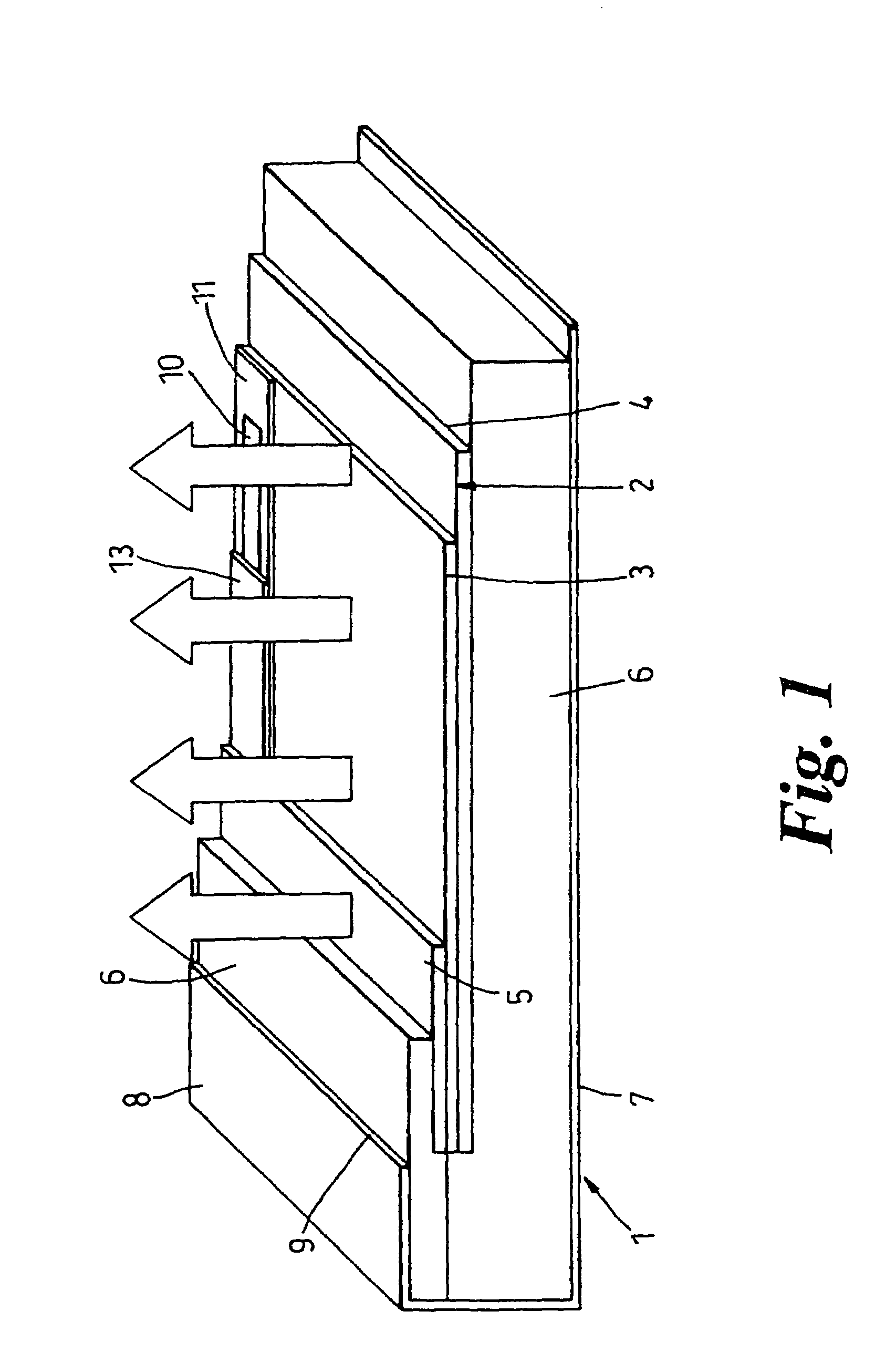

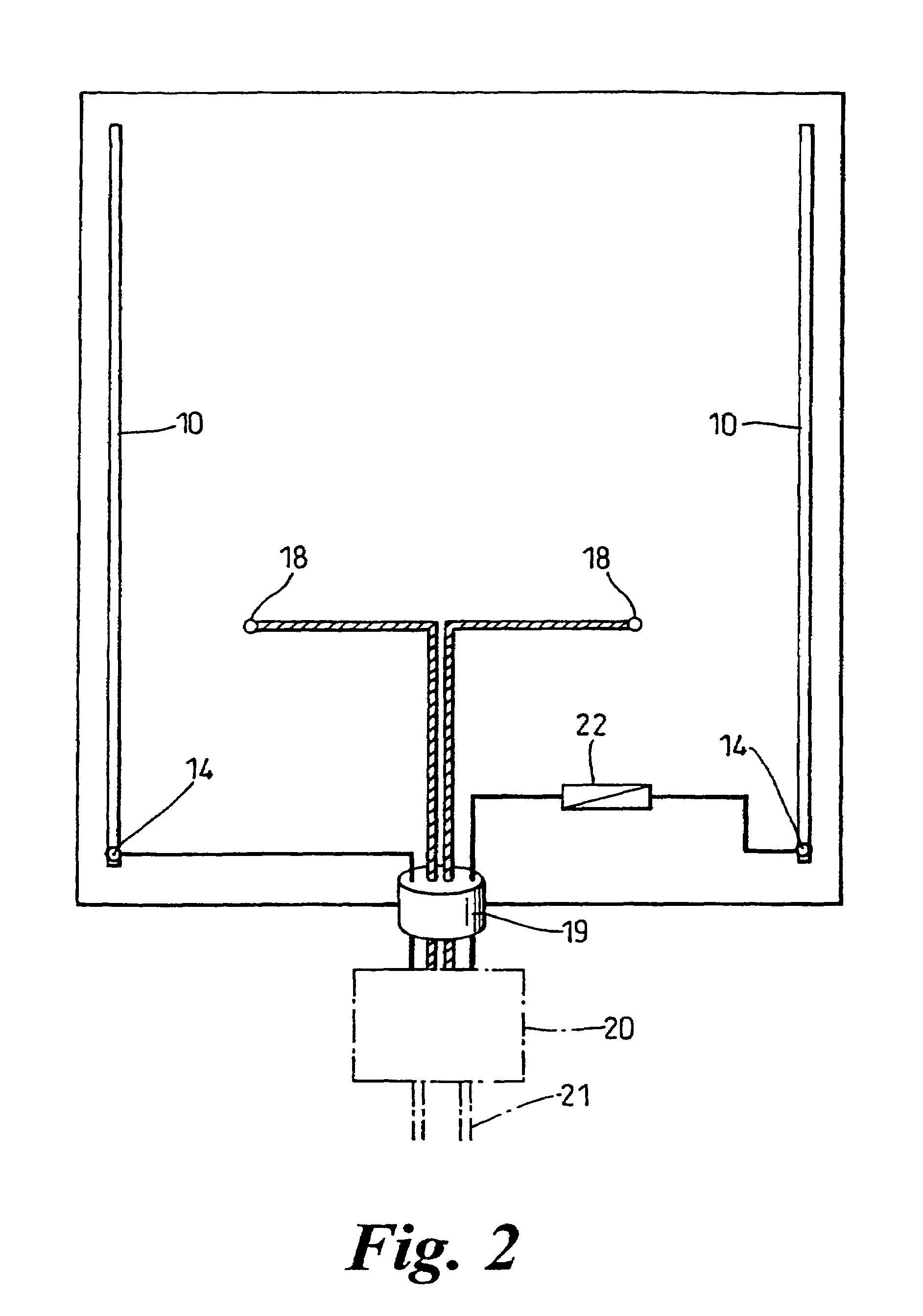

InactiveUS6974935B2Low viscosityNon-metal conductorsElectrically conductive connectionsCold spotAdhesive

A device for connecting a source of electrical power to a coating or film incorporating carbon particles, an objective met by providing a coating of a nickel compound to the coating or film of carbon particles, and applying to the nickel coating a tin-copper tape coated with a silver-loaded conductive adhesive. What results is a uniform heating effect over a relatively wide area, substantially free from hot and cold spots or areas.

Owner:INSPIRATION HEALTHCARE GRP PLC

Hydrogenation catalyst, its process and use

ActiveCN1644656AIncrease surface areaLarge hole volumeRefining by selective hydrogenationAluminium hydroxideNickel compounds

A hydrogenation catalyst and its preparation and use are disclosed. The said catalyst consists of NiO 10-30wt.% and Al2O3 70-90wt.%, obtained by: drying quasi-hydrated aluminum oxide powder, passing steam to ream, roasting to have macroporous aluminum oxide carrier, dipping it in a solvent containing nickel compound, filtering, drying, roasting to form the final product. It is suitable for fractional oil containing dialkene and styrene and their derivatives to directly prepare solvent with high aromatic hydrocarbon and gasoline with high octane level by hydrogenation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

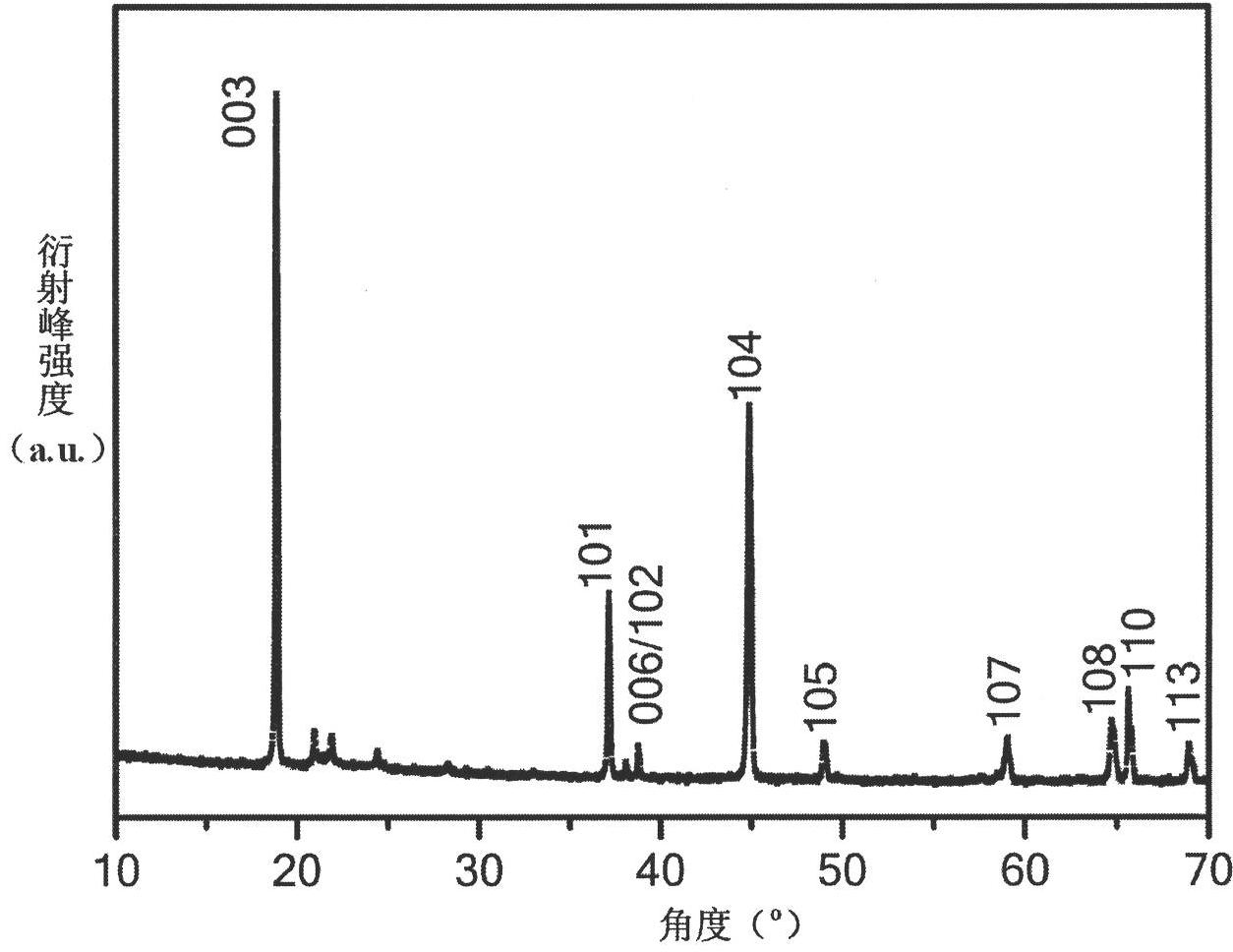

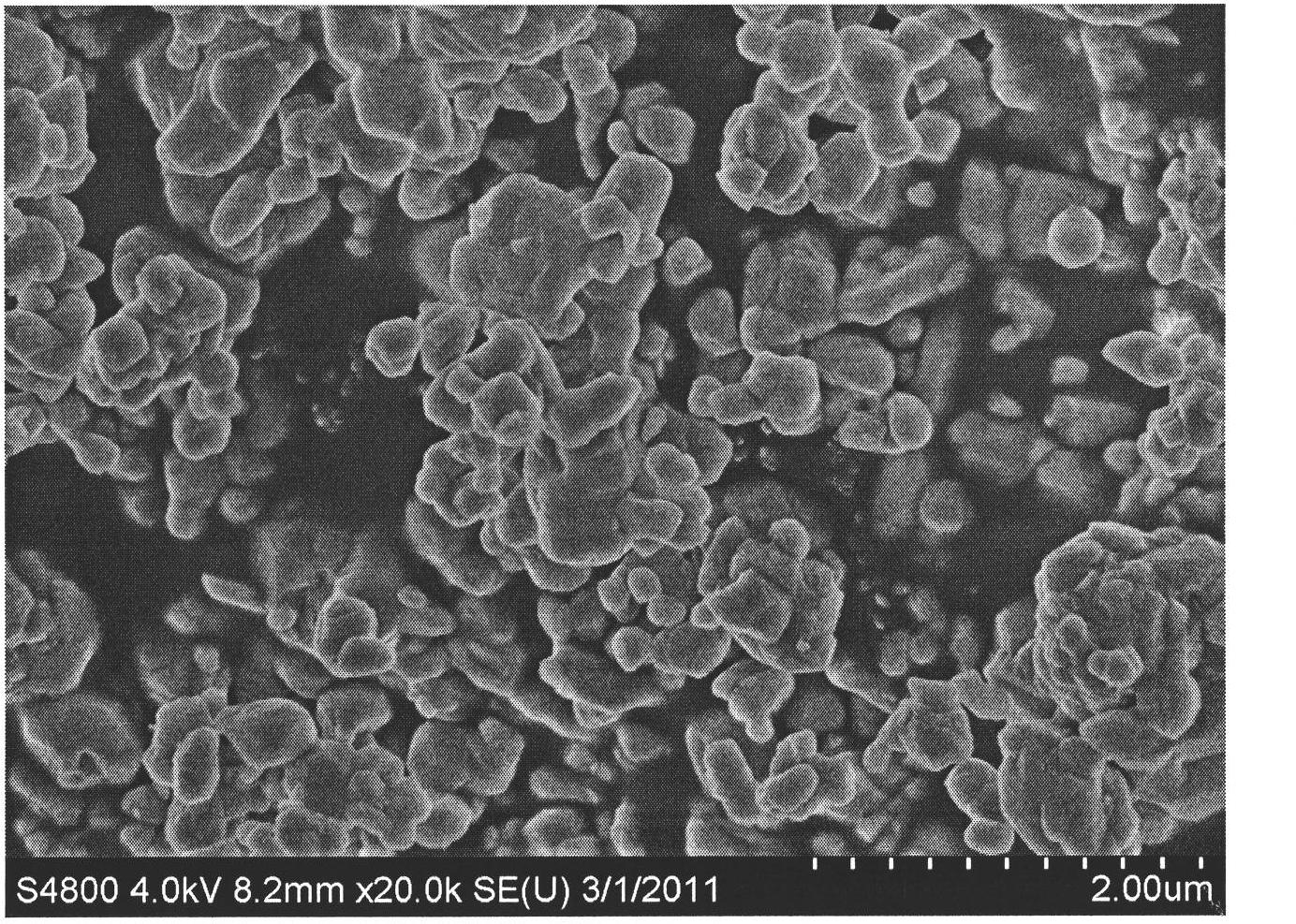

Layered lithium-nickel-based compound oxide powder and its production process

ActiveUS20050158546A1High bulk densityGood rate characteristicsElectrode thermal treatmentSolid electrolyte cellsLiquid mediumNickel compounds

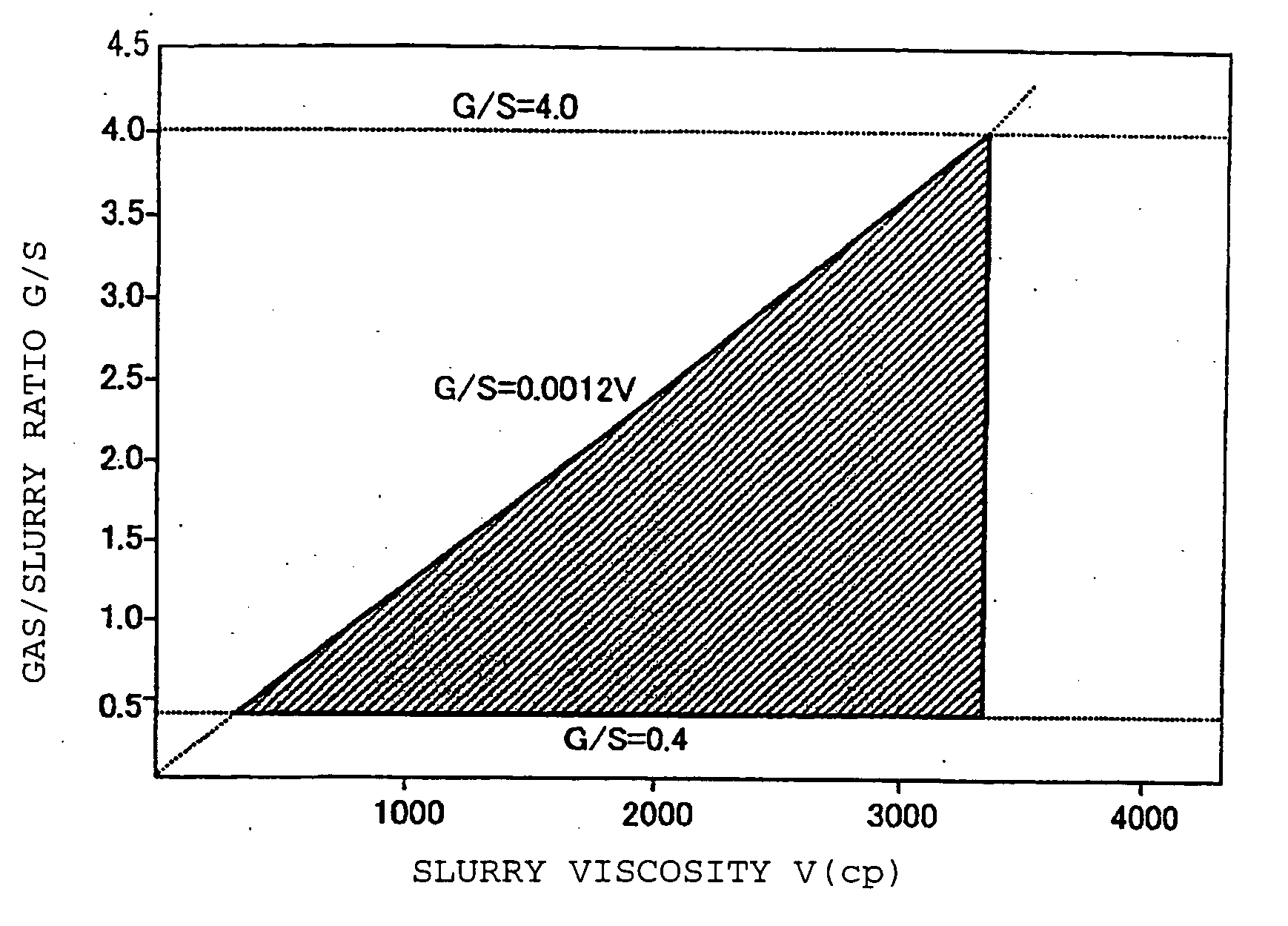

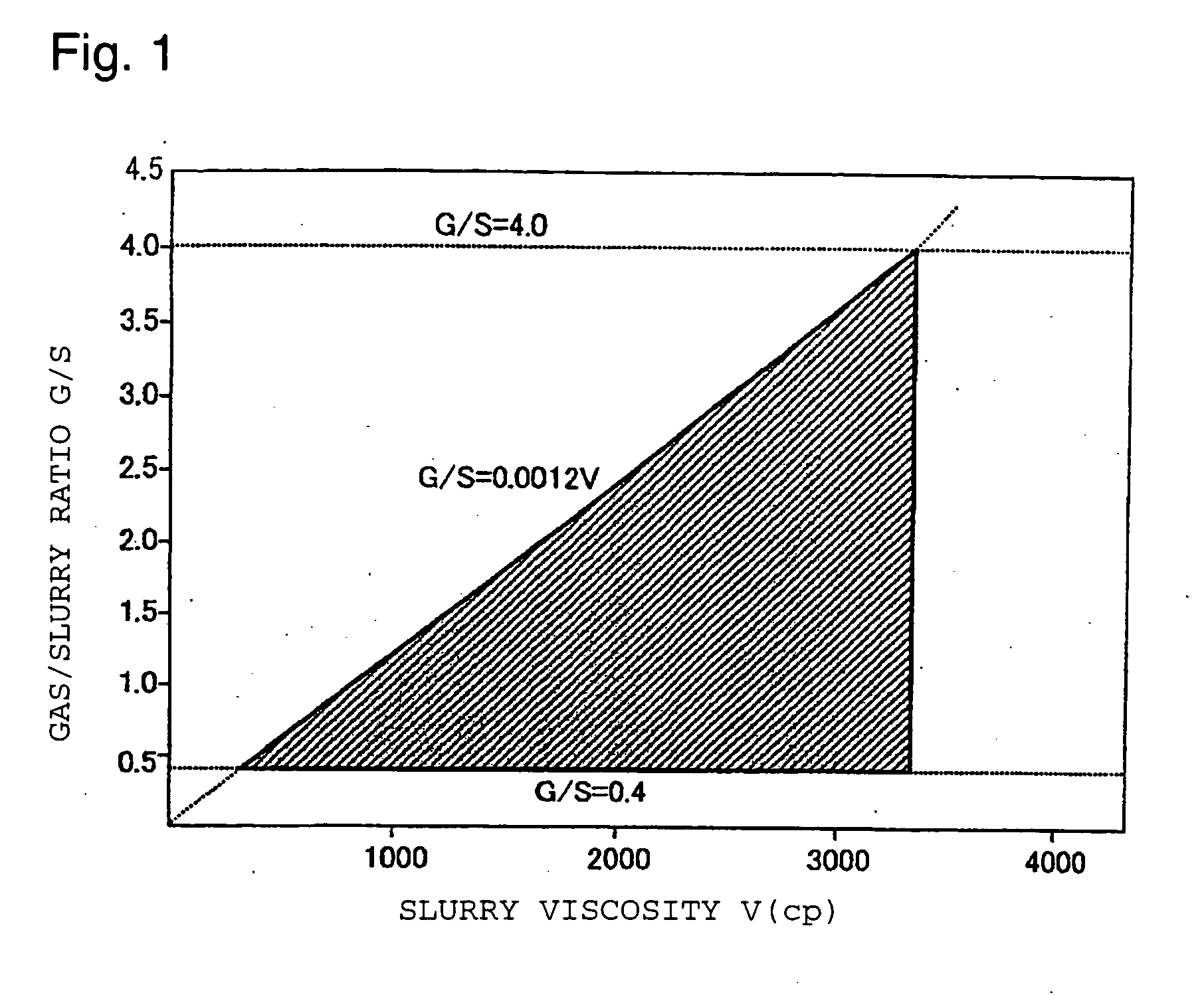

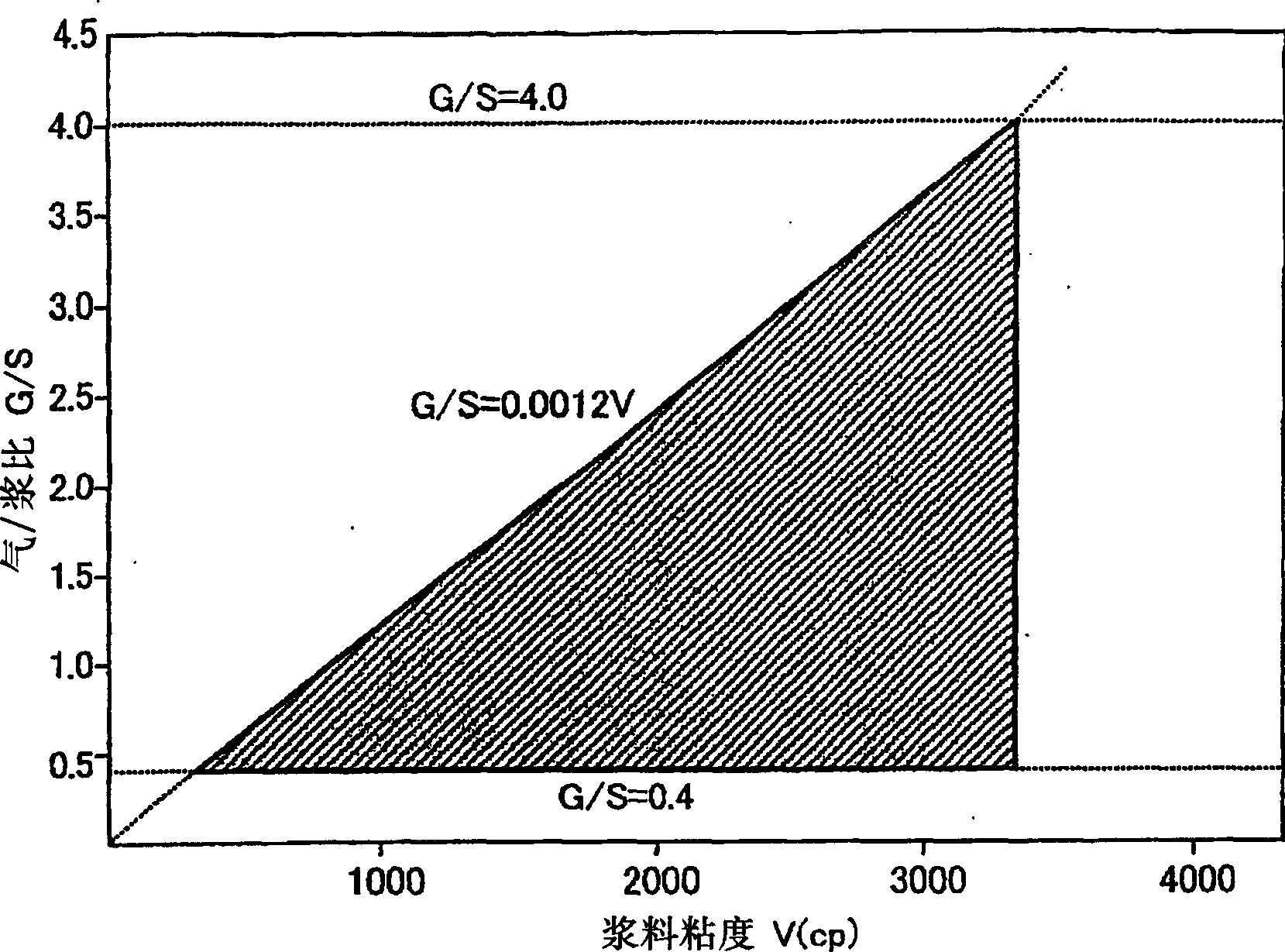

A layered lithium-nickel-based compound oxide powder for a positive electrode material for a high density lithium secondary cell, capable of providing a lithium secondary cell having a high capacity and excellent in the rate characteristics also, is provided. A layered lithium-nickel-based compound oxide powder for a positive electrode material for a lithium secondary cell, characterized in that the bulk density is at least 2.0 g / cc, the average primary particle size B is from 0.1 to 1 μm, the median diameter A of the secondary particles is from 9 to 20 μm, and the ratio A / B of the median diameter A of the secondary particles to the average primary particle size B, is within a range of from 10 to 200. In production of a layered lithium-nickel-based compound oxide powder, which comprises spray drying a slurry having a nickel compound and a transition metal element compound capable of substituting lithium other than nickel, dispersed in a liquid medium, followed by mixing with a lithium compound, and firing the mixture, the spray drying is carried out under conditions of 0.4≦G / S≦4 and G / S≦0.0012 V, when the slurry viscosity at the time of the spray drying is represented by V (cp), the slurry supply amount is represented by S (g / min) and the gas supply amount is represented by G (L / min).

Owner:MITSUBISHI CHEM CORP

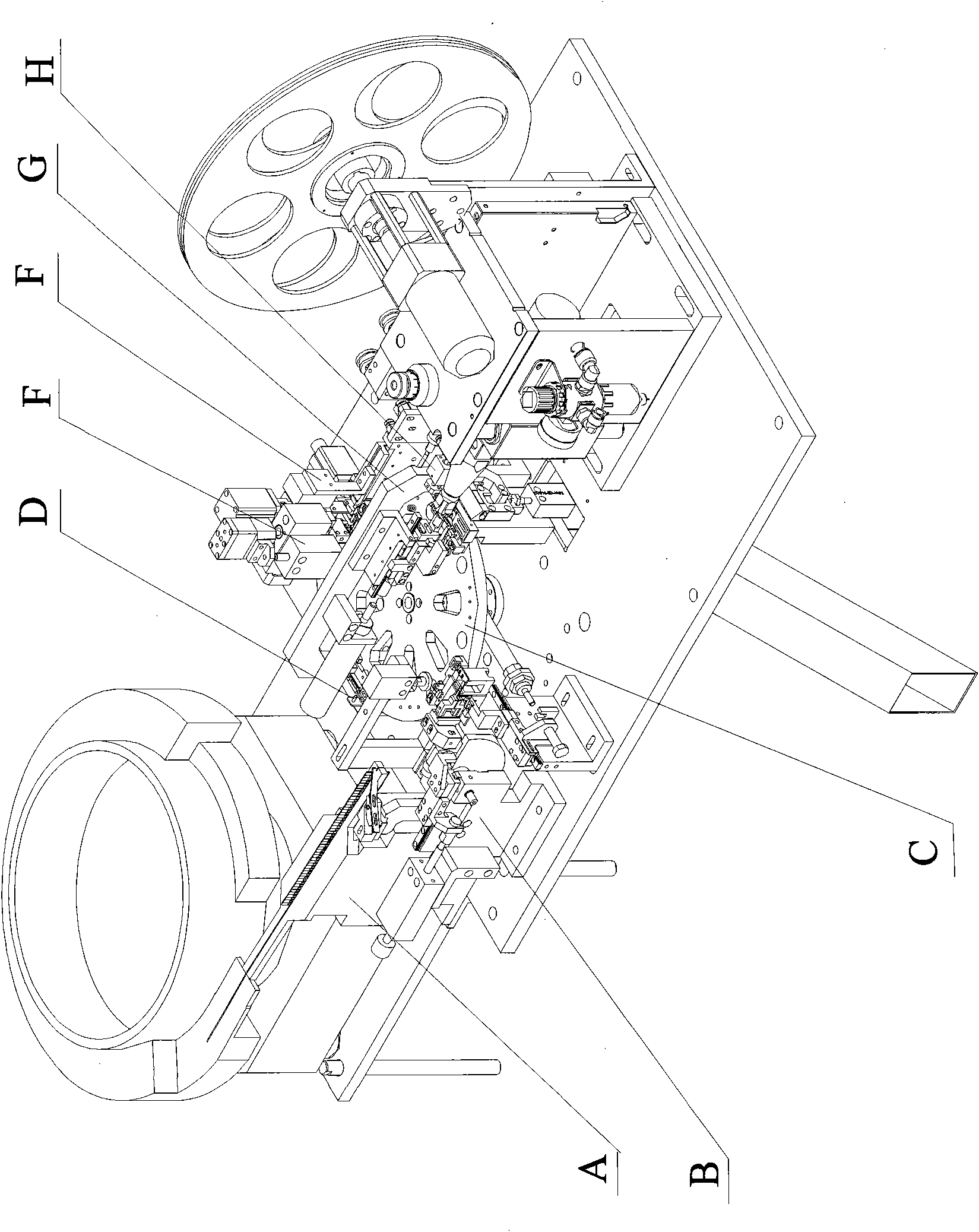

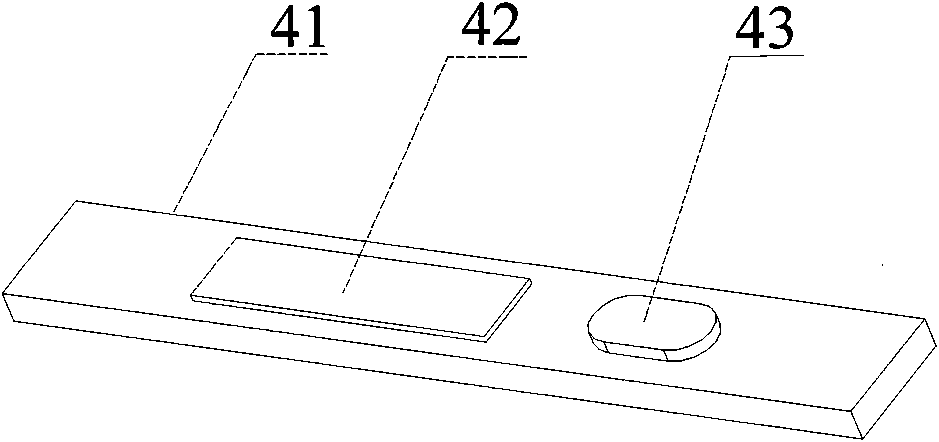

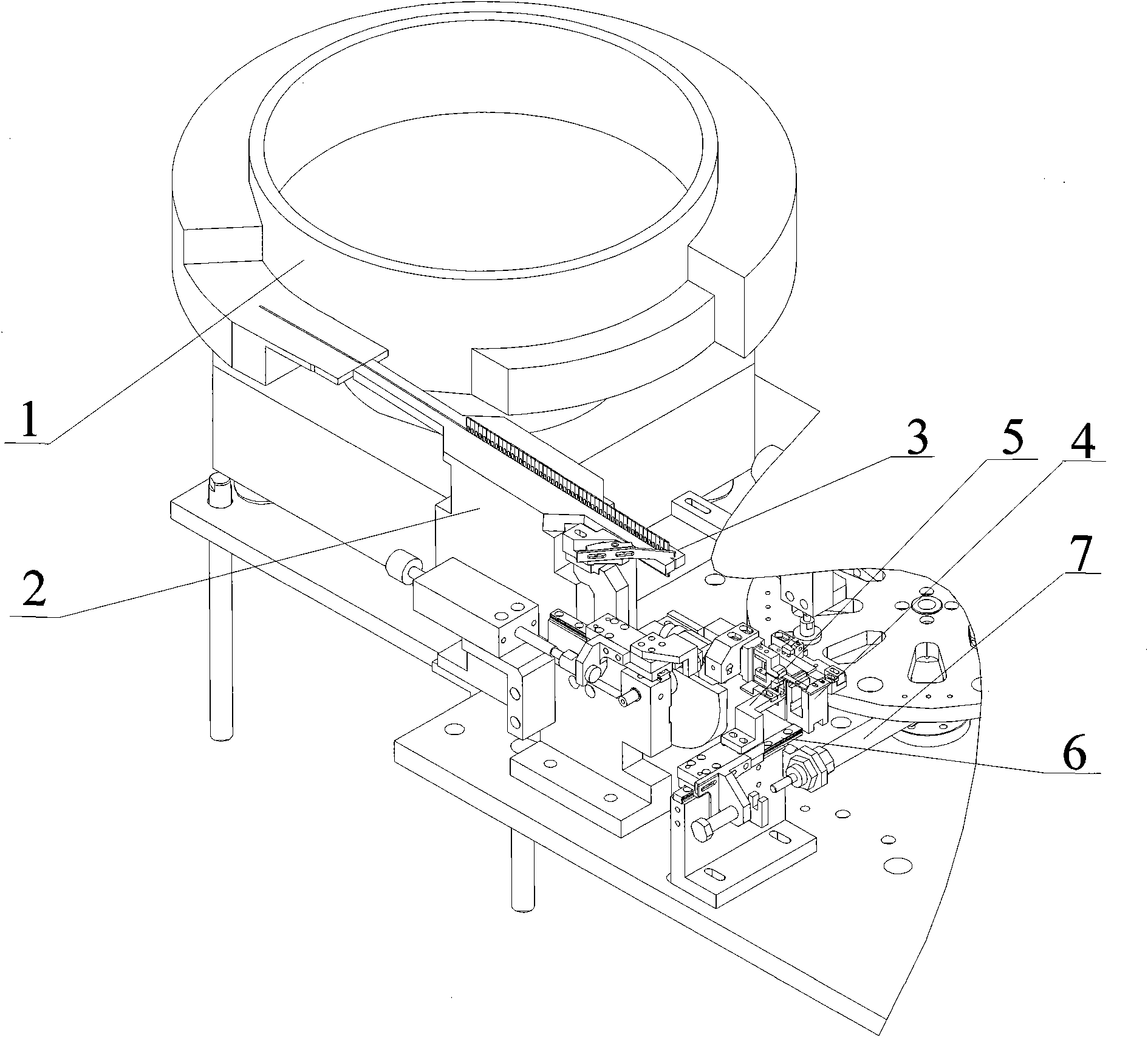

Automatic welding machine of aluminum-nickel compound piece of lithium ion battery cover plate

ActiveCN101913029AChange choresSave human effortWelding apparatusAutomatic controlUltrasonic welding

The invention provides an automatic welding machine of an aluminum-nickel compound piece of a lithium ion battery cover plate, consisting of a feeding mechanism A, a feeding turnover mechanism B, a turnplate mechanism C, a detection mechanism D, a nickel piece feeding mechanism E, a spot-welding machine F, an ultrasonic welding mechanism G, a banking mechanism H and an automatic control mechanism, wherein the feeding mechanism A, the feeding turnover mechanism B, the turnplate mechanism C and the detection mechanism D are arranged on the tabletop of the automatic welding machine; the nickel piece feeding mechanism E, the spot-welding machine F, the ultesonic welding mechanism G and the banking mechanism H are arranged on the turnplate mechanism C; the aluminum-nickel compound piece is placed on the lithium ion battery cover plate through the feeding mechanism A, the feeding turnover mechanism B, the turnplate mechanism C, the detection mechanism D and the nickel piece feeding mechanism E; and the lithium ion battery cover plate is automatically welded with the aluminum-nickel compound piece through the spot-welding machine F, the ultrasonic welding mechanism G and the banking mechanism H. The invention ensures that the whole process flow realizes the automation, changes the traditional mode for manually finishing miscellaneous work, librates the large amount of labor force, greatly improves the work conditions, greatly increases the yield, greatly reduces the manufacturing cost and simultaneously and effectively ensures the quality of products.

Owner:HUNAN HUAHUI NEW ENERGY

Active carbon desulfurization catalyst and preparation method thereof

InactiveCN101954284ANo pollution in the processHigh yieldDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNickel compoundsCopper oxide

The invention provides an active carbon desulfurization catalyst and a preparation method thereof. The catalyst consists of carrier activated carbon and an active ingredient metal oxide mixture, wherein the metal oxide mixture is the mixture of copper oxide, iron oxide, aluminum oxide, nickel oxide, manganese oxide, cobalt oxide and zinc oxide. The preparation method comprises the following steps of: mixing a copper-containing compound, an iron-containing compound, an aluminum-containing compound, a nickel-containing compound, a manganese-containing compound, a cobalt-containing compound and a zinc-containing compound; dissolving the mixture; dispersing the active carbon into the mixed solution; and filtering, washing, drying and calcining the mixture. The preparation method is simple and the obtained catalyst has high desulfurization efficiency.

Owner:DONGHUA UNIV

Preparation method of high-capacity layered lithium-rich manganese-based oxide

ActiveCN102354741AImprove charge and discharge efficiencyImprove cycle performanceCell electrodesManganeseNickel compounds

The invention relates to a preparation method of a high-capacity layered lithium-rich manganese-based oxide, and the method is characterized by comprising the following steps: a) fully mixing a nickel-containing compound, a manganese-containing compound I and a cobalt-containing compound with a solvent so as to get a solution or suspension; b) adding a precipitator into the solution or suspension obtained in the step a), and filtering to obtain a precipitate; c) drying the precipitate obtained in the step b) so as to get a precursor; d) uniformly mixing the precursor obtained in the step c), a manganese-containing compound II, a doping element M-containing compound and a lithium-containing compound in proportion so as to get mixed powder; and e) performing heat treatment on the mixed powder obtained in the step d) so as to get an ultrahigh-capacity manganese series lithium transition metal compound oxide with an expression of Li(Li0.2Mn0.8-delta-alpha-beta-Ni alpha Co beta M delta)O2. Compared with the prior art, the preparation method provided by the invention has the advantages of high utilization rate of raw materials and low production cost, and the prepared lithium-rich manganese-based oxide has the advantages of excellent charge-discharge performance and excellent cycle performance.

Owner:宁波富理电池材料科技有限公司

High-voltage charge type nonaqueous electrolyte secondary cell

ActiveUS20090181311A1Improve cycle performanceInhibit reduction in cycle propertyOrganic electrolyte cellsLi-accumulatorsNickel compoundsSolvent

The preservation performance of a nonaqueous electrolyte secondary cell charged to high potential is improved while the initial capacity and the cycle property of the cell are also improved. The nonaqueous electrolyte secondary cell includes: a positive electrode having lithium phosphate and a positive electrode active material containing lithium cobalt compound oxide and lithium manganese nickel compound oxide having a layer structure, the lithium cobalt compound oxide having at least zirconium and magnesium added in LiCoO2; a negative electrode having a negative electrode active material; and a nonaqueous electrolyte having a nonaqueous solvent and an electrolytic salt. The potential of the positive electrode is more than 4.3 V and 5.1 V or less based on lithium. The nonaqueous electrolyte contains vinylene carbonate as the nonaqueous solvent and, as the electrolytic salt, at least one of lithium bis(pentafluoroethane sulfonyl)imide and lithium bis(trifluoromethane sulfonyl)imide at 0.1 M or more and 0.5 M or less. The nonaqueous electrolyte contains 1,3-dioxane.

Owner:PANASONIC ENERGY CO LTD

Magnesium alloy with zinc and nickel compound plating layers and preparation method thereof

The invention discloses a magnesium alloy with zinc and nickel compound plating layers and a preparation method thereof. A zinc plating layer of the magnesium alloy is taken as a bottom layer with the width between 20 microns and 25 microns, a nickel plating layer is taken as a surface layer, and the total width of the zinc plating layer and the nickel plating layer is less than or equal to 40 microns. The method comprises the following steps: firstly, plating preliminary treatment, i.e. zinc is activated in an acid solution and then soaked in sulphate; secondly, zinc electrodeposition, i.e. after the zinc is soaked in the sulphate in the first step, the zinc layer of the magnesium alloy is electrodeposited; thirdly, nickel bright plating, i.e. the magnesium alloy which is nicely processed in the second step is brightly plated with nickel in a nickel plating solution; fourthly, sodium silicate water solution sealing. With the method, the obtained zinc plating layer is nicely combined with a base body, has uniform width and high corrosion resistance, can be taken as a protective plating layer to be singly used and can be also taken as a transition layer to carry out plating or chemical plating or other protective or decorative platings, and the nickel plating layer obtained from the zinc plating layer by plating is nicely combined with the zinc plating layer and is uniform, exquisite, bright and beautiful.

Owner:SOUTHEAST UNIV

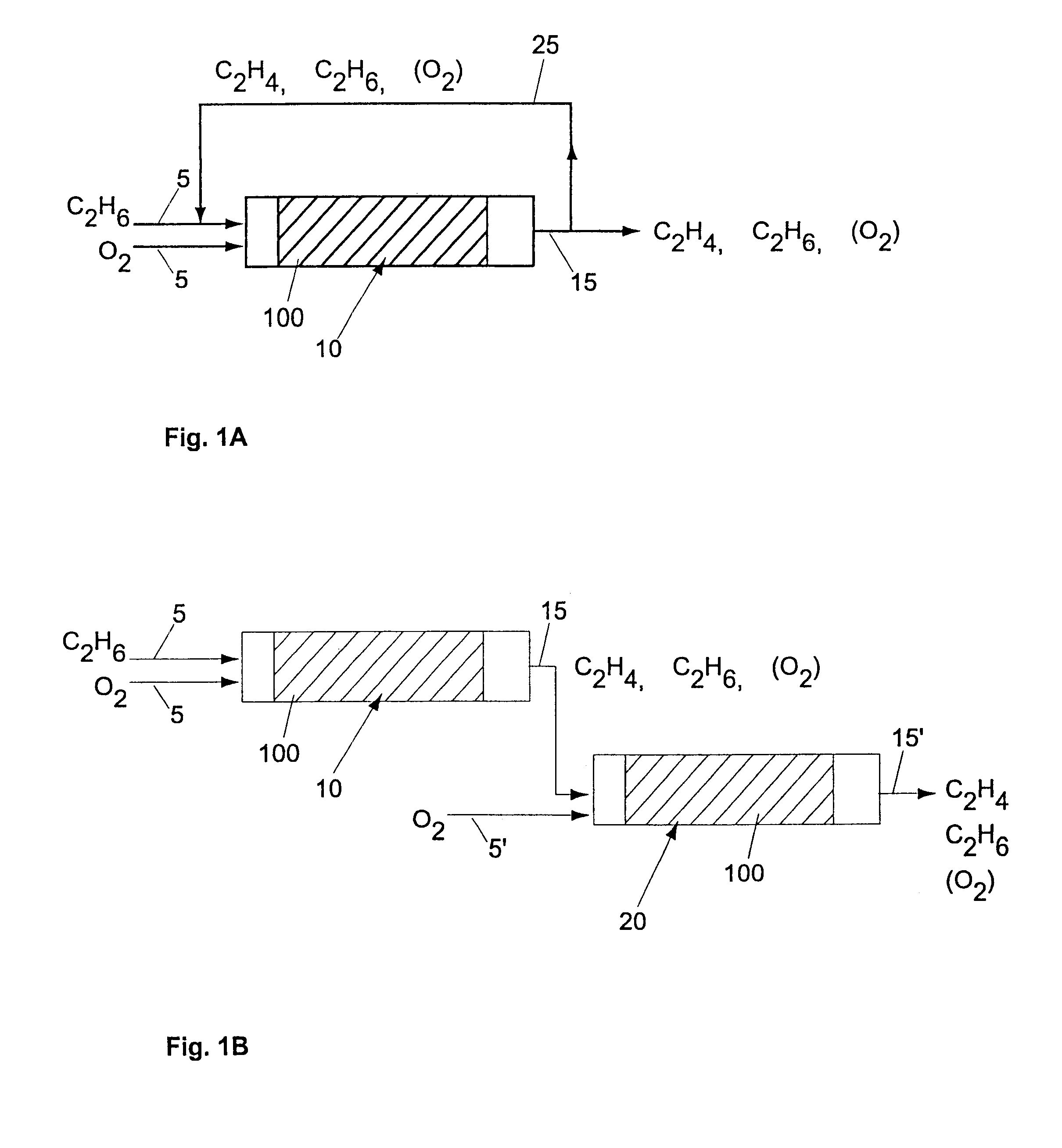

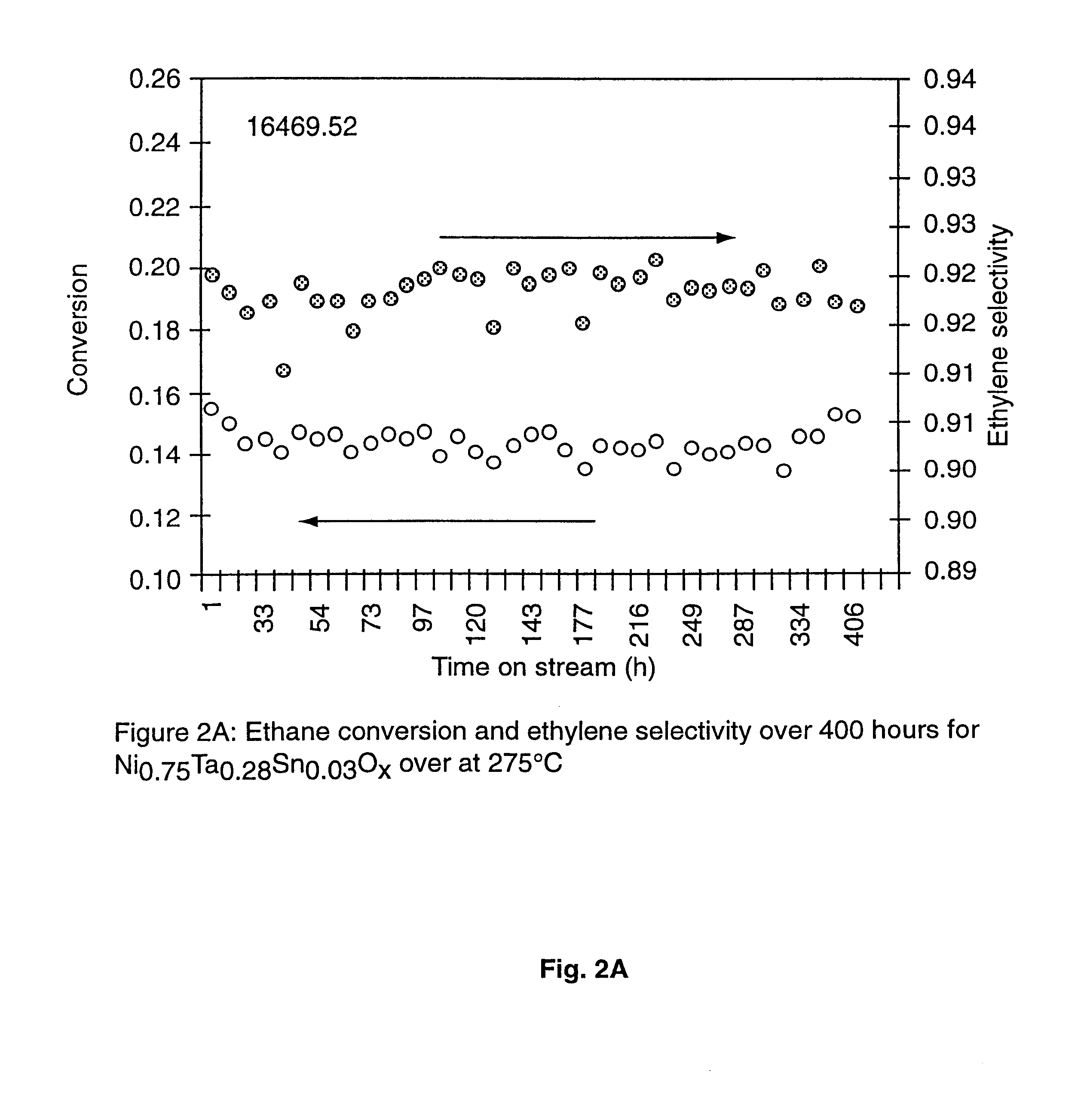

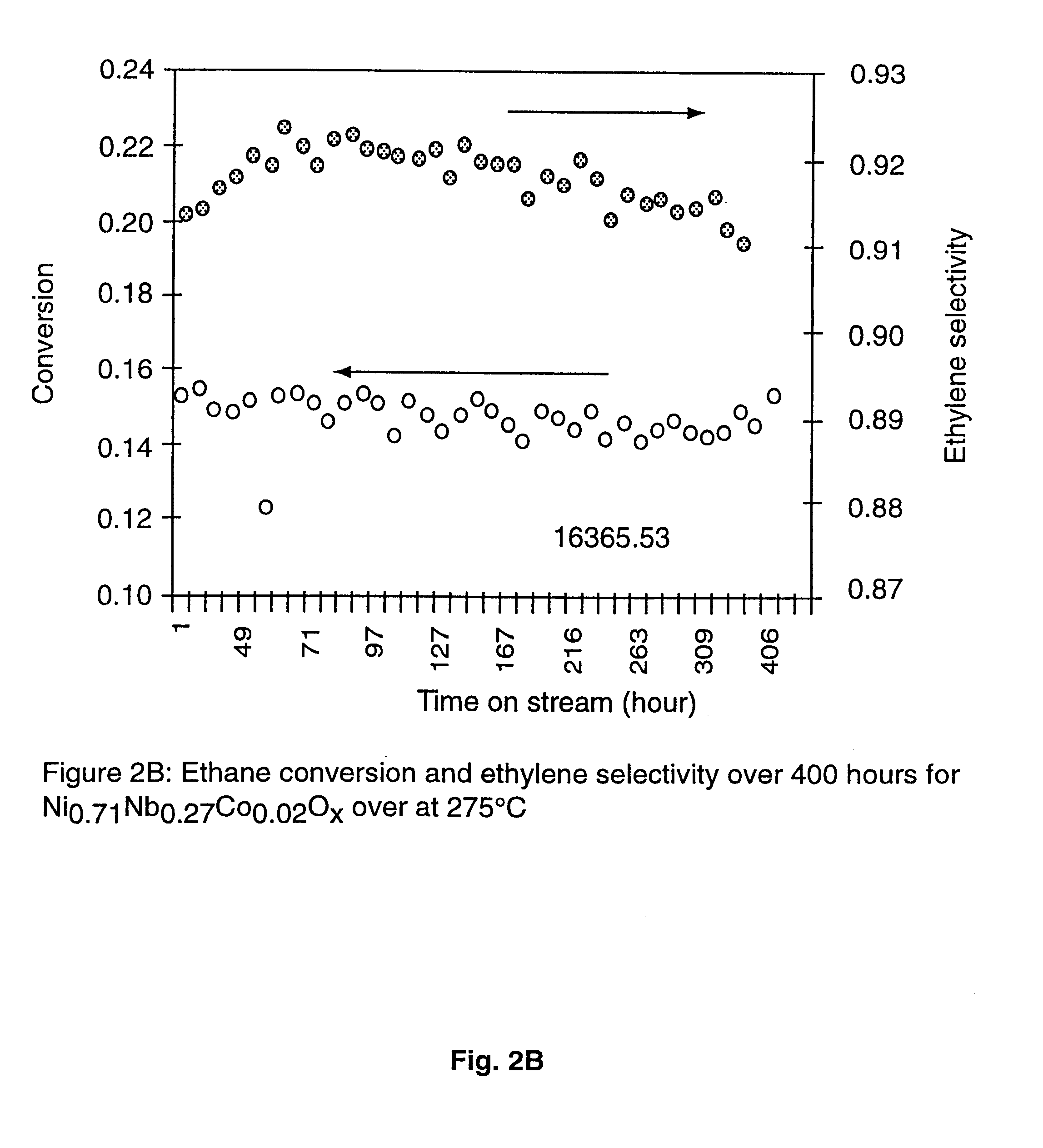

Ni catalysts and methods for alkane dehydrogenation

Owner:CELANESE INT CORP

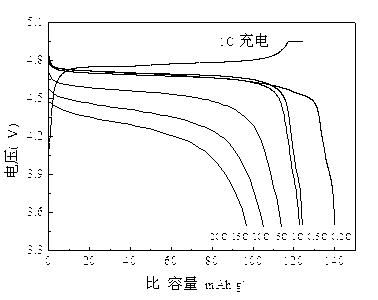

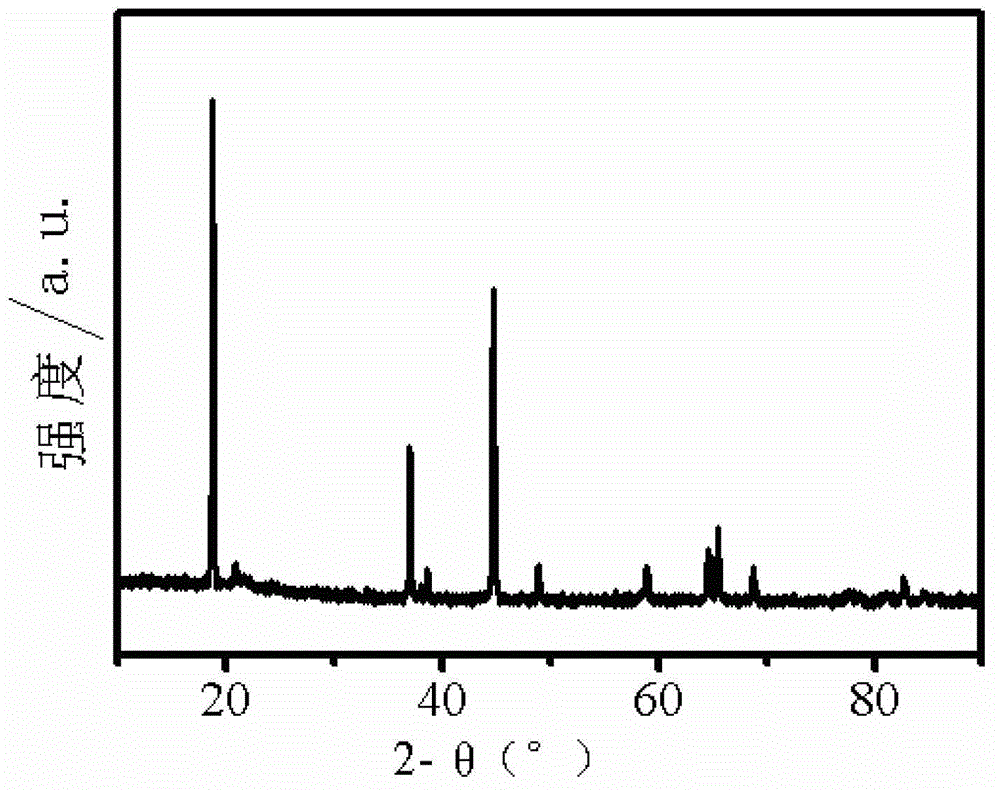

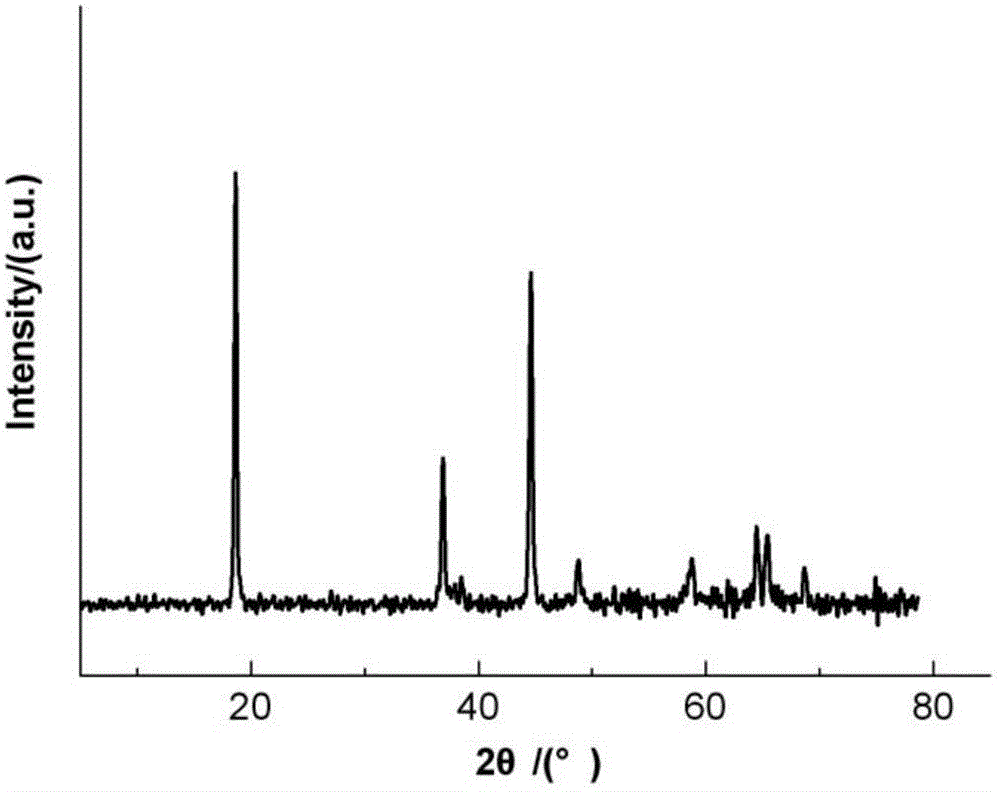

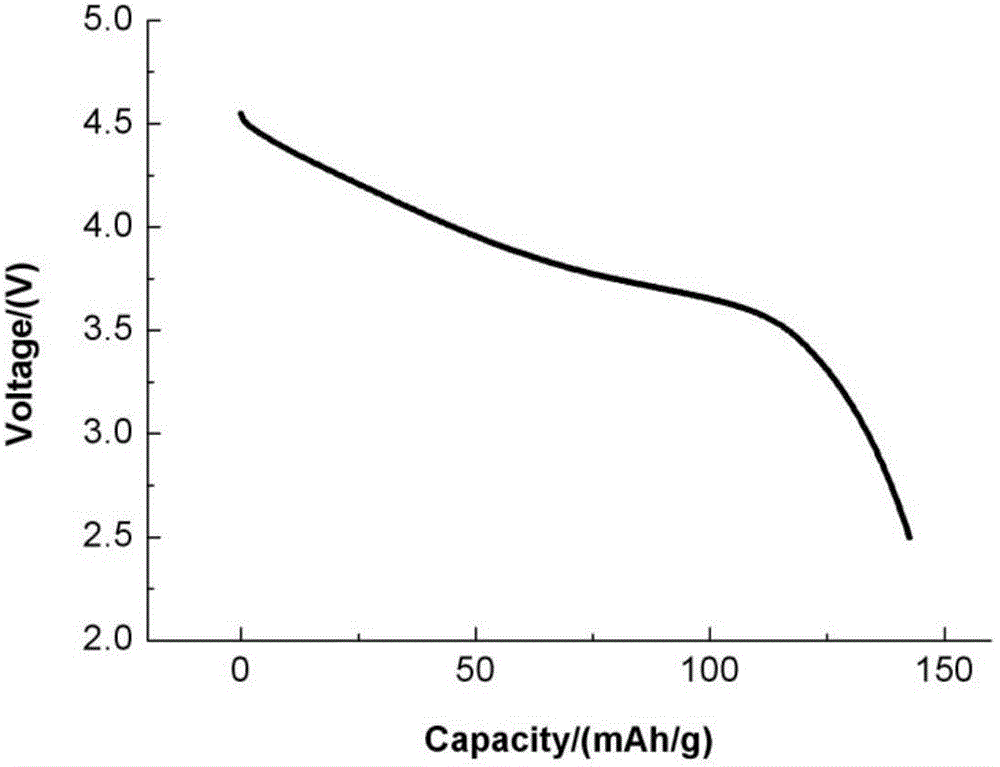

Preparation method of positive pole material (spinel type lithium nickel manganese oxide) of high-voltage lithium ion battery

ActiveCN103227323AAccurately control the ratioReduce concentrationCell electrodesElectrical batteryNickel compounds

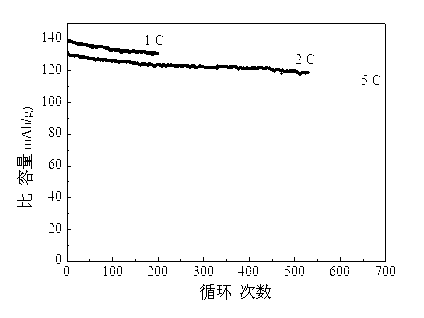

The invention relates to a preparation method of a positive pole material (spinel type lithium nickel manganese oxide) of a high-voltage lithium ion battery, which comprises the following steps: simultaneously dissolving a lithium-containing compound, a manganese-containing compound and a nickel-containing compound instead of adding a lithium source afterwards, and ensuring that the lithium compound, the nickel compound and the manganese compound are evenly mixed; and adding precipitant to generate manganese-containing precipitate, wherein the generated manganese-containing precipitate provides crystal nuclei for further precipitation in the hydrothermal process, particles having different sizes can be obtained by controlling hydrothermal conditions, the particle sizes of the products can be increased by decreasing the concentrations of the metal salts, increasing the hydrothermal temperature and prolonging the hydrothermal time, and materials having different shapes can be obtained or porous materials can be prepared by adding different additives. The method omits the steps of filtration and water washing; and the synthesis process is economic and environment-friendly. The lithium nickel manganese oxide material prepared by the invention is in a spinel structure, and is high in crystallinity and excellent in electrochemical performance; and the specific capacity can be up to 130-142mAh / g, 120-135mAh / g and 105-120mAh / g in case of 1C, 2C and 5C rate discharge.

Owner:南京时拓能源科技有限公司

Desulphurisation material

A particulate desulphurisation material is described comprising one or more nickel compounds, a zinc oxide support material, and one or more alkali metal compounds wherein the nickel content of the material is in the range 0.3 to 10% by weight and the alkali metal content of the material is in the range 0.2 to 10% by weight. A method of making the desulphurisation material is also described comprising the steps: (i)contacting a nickel compound with a particulate zinc support material and an alkali metal compound to form an alkali-doped composition, (ii)shaping the alkali-doped composition, and (iii)drying, calcining, and optionally reducing the resulting material. The desulphurisation material may be used to desulphurise hydrocarbon gas streams with reduced levels ofhydrocarbon hydrogenolysis.

Owner:JOHNSON MATTHEY PLC

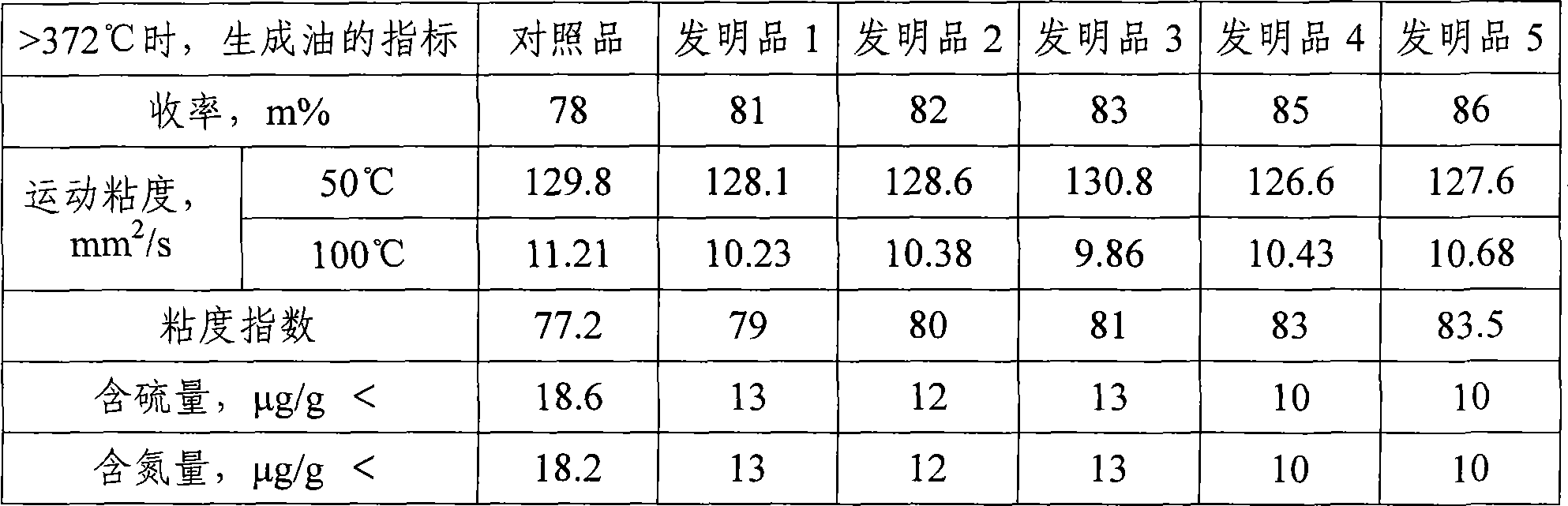

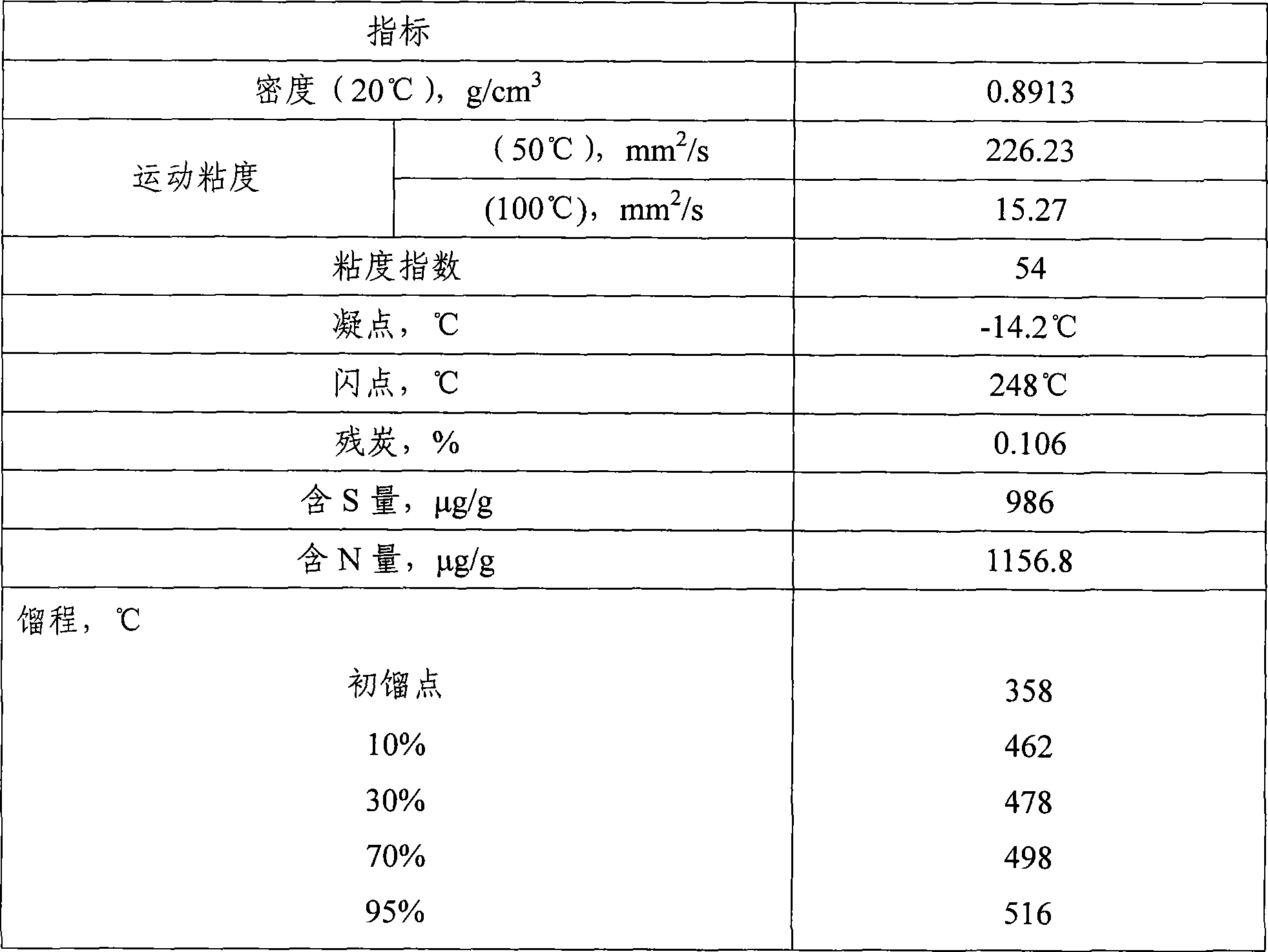

Teeth spherical heavy oil hydrotreating catalyst and preparation method thereof

ActiveCN101497044AAchieve technical effectLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentHydrodesulfurizationReaction temperature

The invention discloses a dentiform sphere shaped heavy oil hydrotreated catalyst and a preparation method thereof. The catalyst comprises an active composition, an addition agent and a dentiform sphere shaped aluminum oxide carrier, wherein the active composition comprises compounds of cobalt and nickel, and a compound of molybdenum or / and tungsten; the addition agent comprises a compound of phosphor, silicon, boron or halogen or compounds of any two compositions of the phosphor, the silicon, the boron and the halogen; and compositions according to gross weight of the dentiform sphere shaped heavy oil hydrotreated catalyst comprise: 2 to 6 percent of the cobalt compound, 3 to 10 percent of the nickel compound, 0 to 26 percent of the molybdenum compound, 0 to 8 percent of the tungsten compound, and 0.5 to 2 percent of the addition agent. The catalyst has the characteristics of high specific surface area, large pore volume, high strength, proper surface acid content, small bed pressure drop, low reaction temperature and high activity of hydrodesulfurization and denitrification. The preparation method comprises preparation of a precursor substance of the aluminum oxide carrier, preparation of the dentiform sphere shaped aluminum oxide carrier, preparation of a catalyst steeping fluid and preparation of the catalyst. The preparation process can be mastered and realized simply and easily.

Owner:BEIJING GAOXIN LIHUA TECH CO LTD

Hydroprocessing catalyst and its prepn process

ActiveCN1609171AIncreased number of small and medium poresHigh reactivityHydrocarbon oils refiningHydrodesulfurizationActive component

The present invention is one kind of hydroprocessing catalyst and its preparation process. The catalyst contains alkali assistant and active components including Ni and Mo and / or W, with the atom number of Ni accounting for 0.3-0.9 of the total atom number of Ni and Mo and / or W; and the pore volume of 2-6 nm pores accounts for 70-90 % of total pore volume. The catalyst is prepared through mixing different pore structures of alumina to form carrier, soaking the alumina carrier first with alkali assistant aqua and then Mo and / or W compounds aqua and Ni compound aqua. Compared with available technology, the catalyst of the present invention has high Ni content in active components, more middle and small sized holes, high hydrogenation mercaptol-eliminating and olefin-saturating activity, and is especially suitable for mercaptol-eliminating process after hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lithium-rich manganese-based anode material and method for manufacturing same

ActiveCN102916169AImprove featuresUniform structureCell electrodesSecondary cellsPtru catalystActive agent

The invention discloses a lithium-rich manganese-based anode material and a method for manufacturing the same. The method includes steps of (a), providing mixed solution containing lithium compounds, nickel compounds and manganese compounds, optional titanium compounds, optional iron compounds, optional cobalt compounds or an optional combination of the titanium compounds, the ion compounds and the cobalt compounds; (b), adding complexing agents, catalysts and surfactants into the mixed solution to form pre-coagulated substances; and (c), calcining the pre-coagulated substances to obtain the lithium-rich manganese-based anode material Li[LixNiaMnbM1-a-b-x]O2 or a combination of lithium-rich manganese-based anode materials. The complexing agents, the catalysts and the surfactants are used for forming the pre-coagulated substances, the complexing agents contain resorcinol and formaldehyde, in the molecular formula of the lithium-rich manganese-based anode material, the M represents Ti, Fe, Co or a combination of the Ti, the Fe and the Co, the x is larger than 0 and is smaller than or equal to 0.4, the a is larger than 0 and is smaller than or equal to 0.5, the b is larger than or equal to 0.33 and smaller than or equal to 0.6, and a result of 1-a-b-x is larger than or equal to 0. The lithium-rich manganese-based anode material is of a multi-channel porous structure, is small in grain size, uniform in grain distribution, advanced in porosity and stable in electrochemical performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

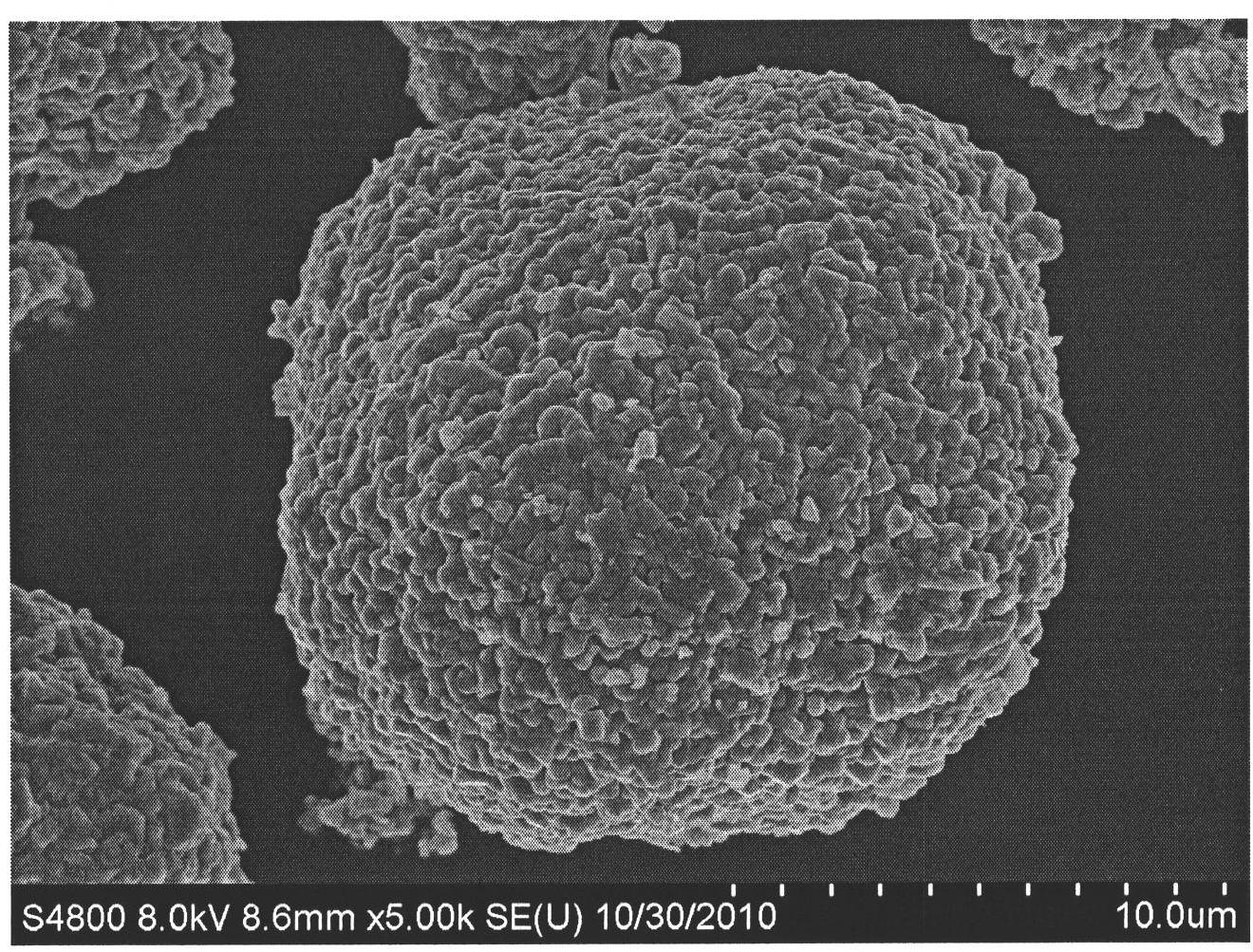

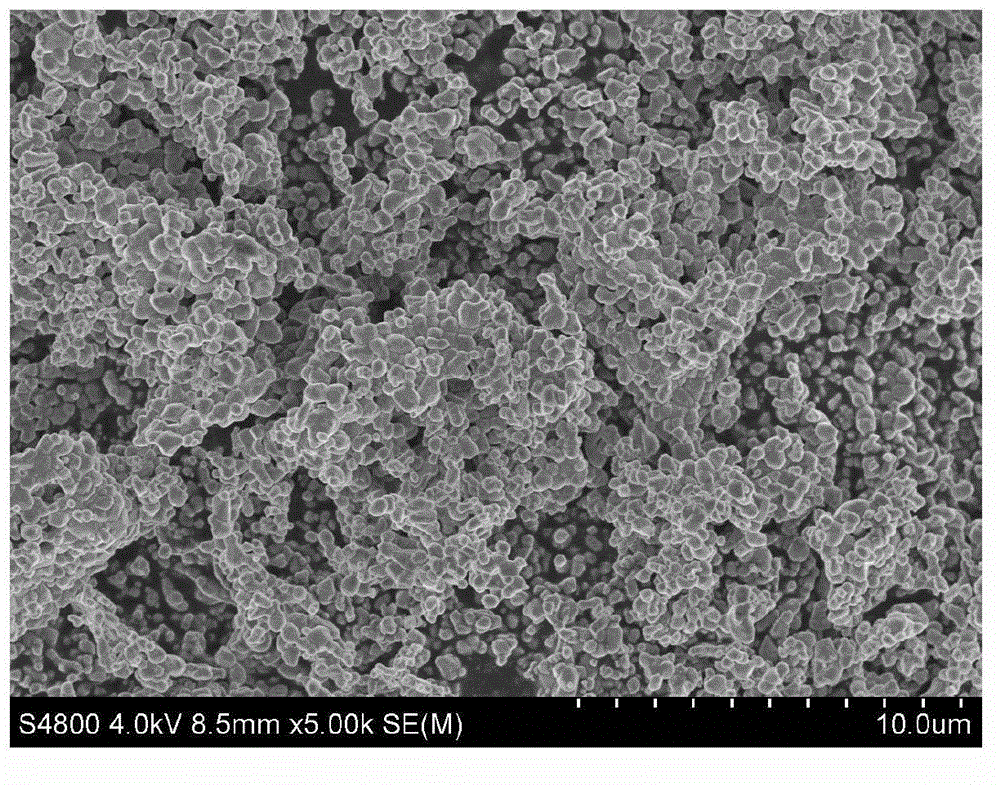

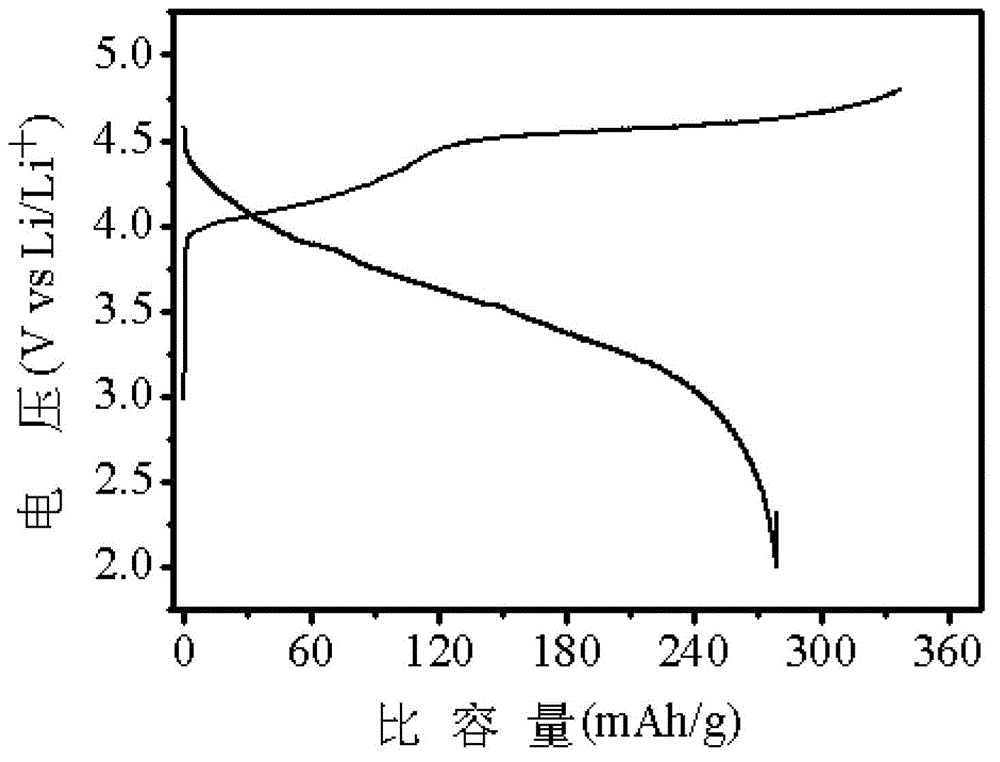

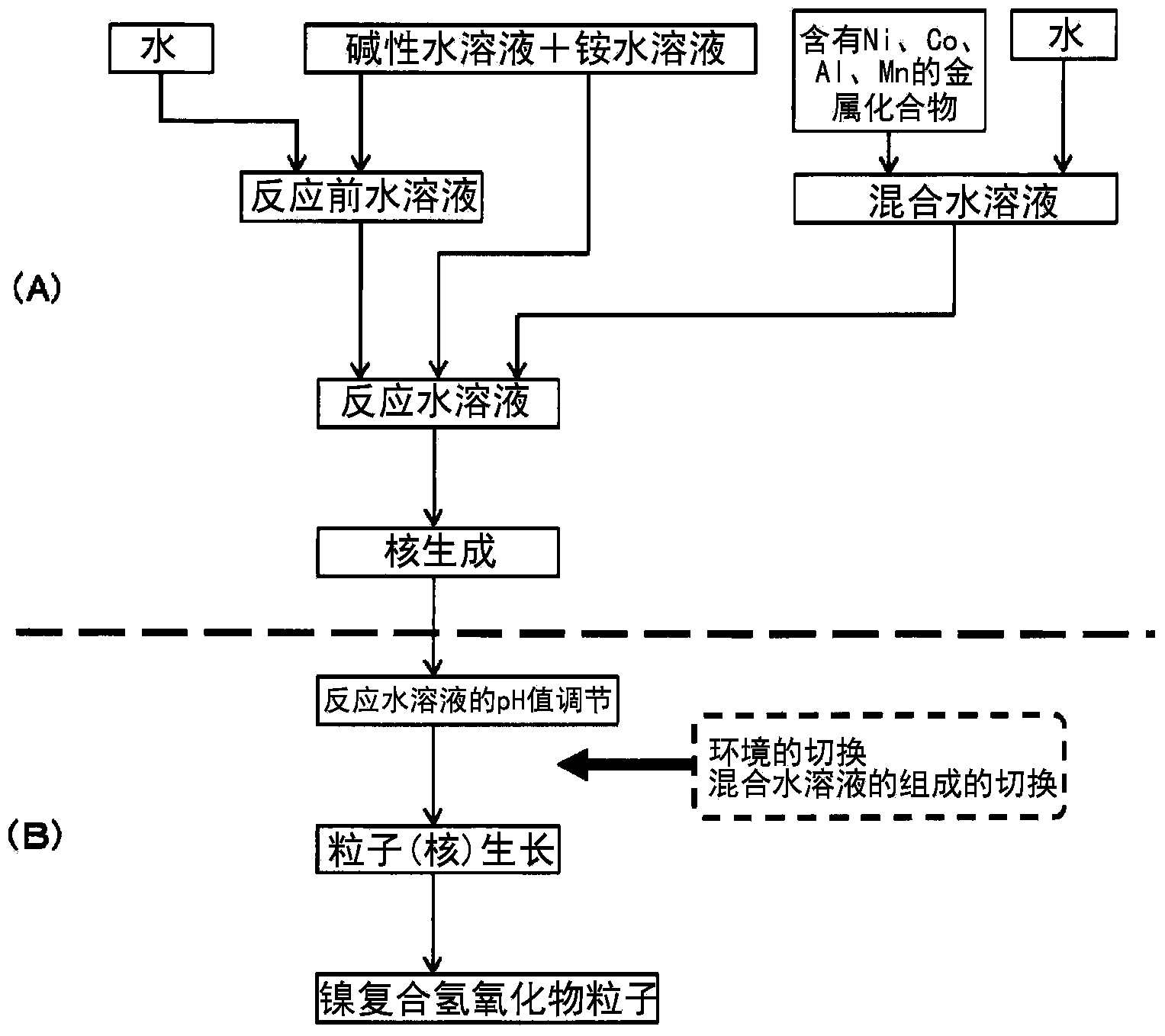

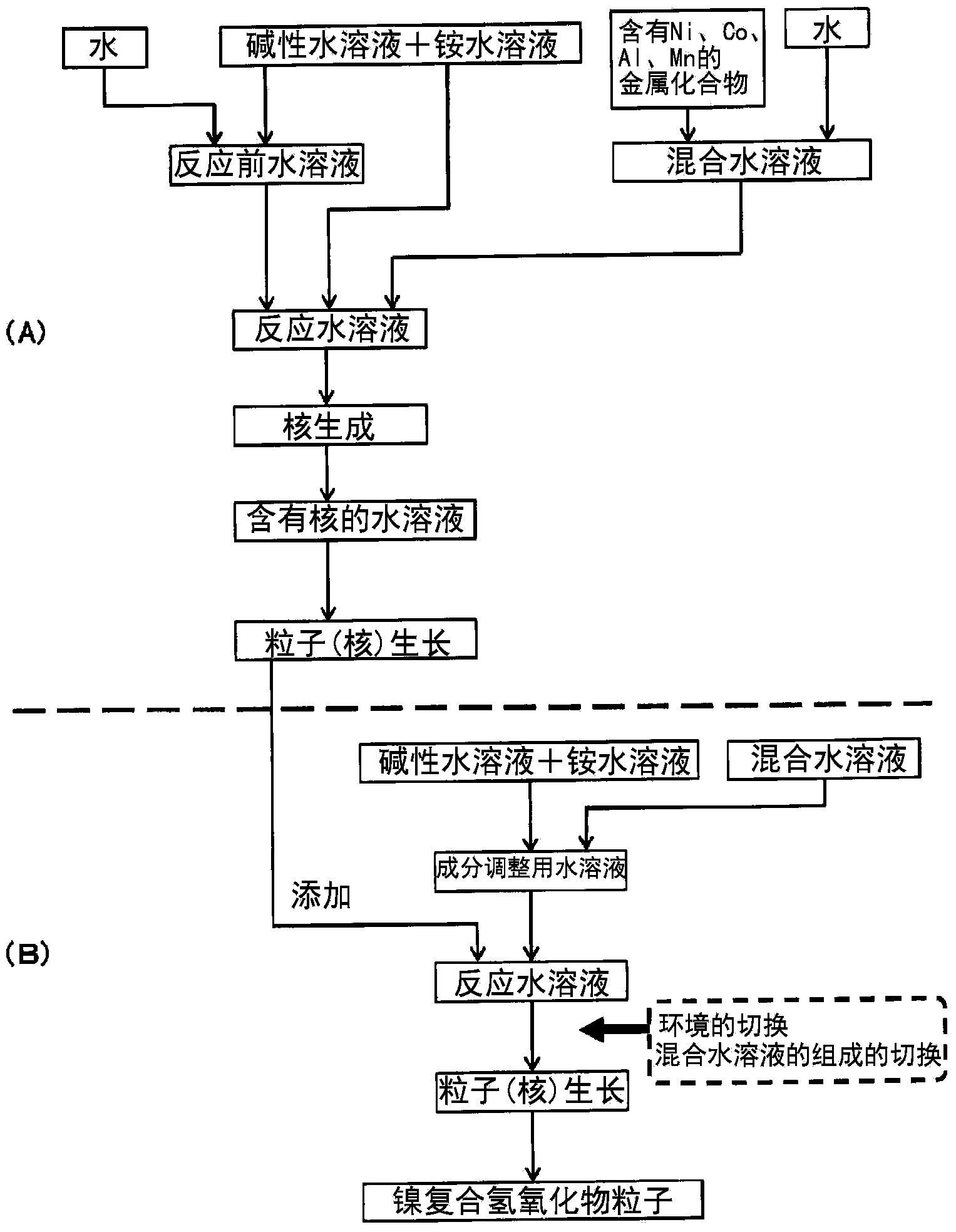

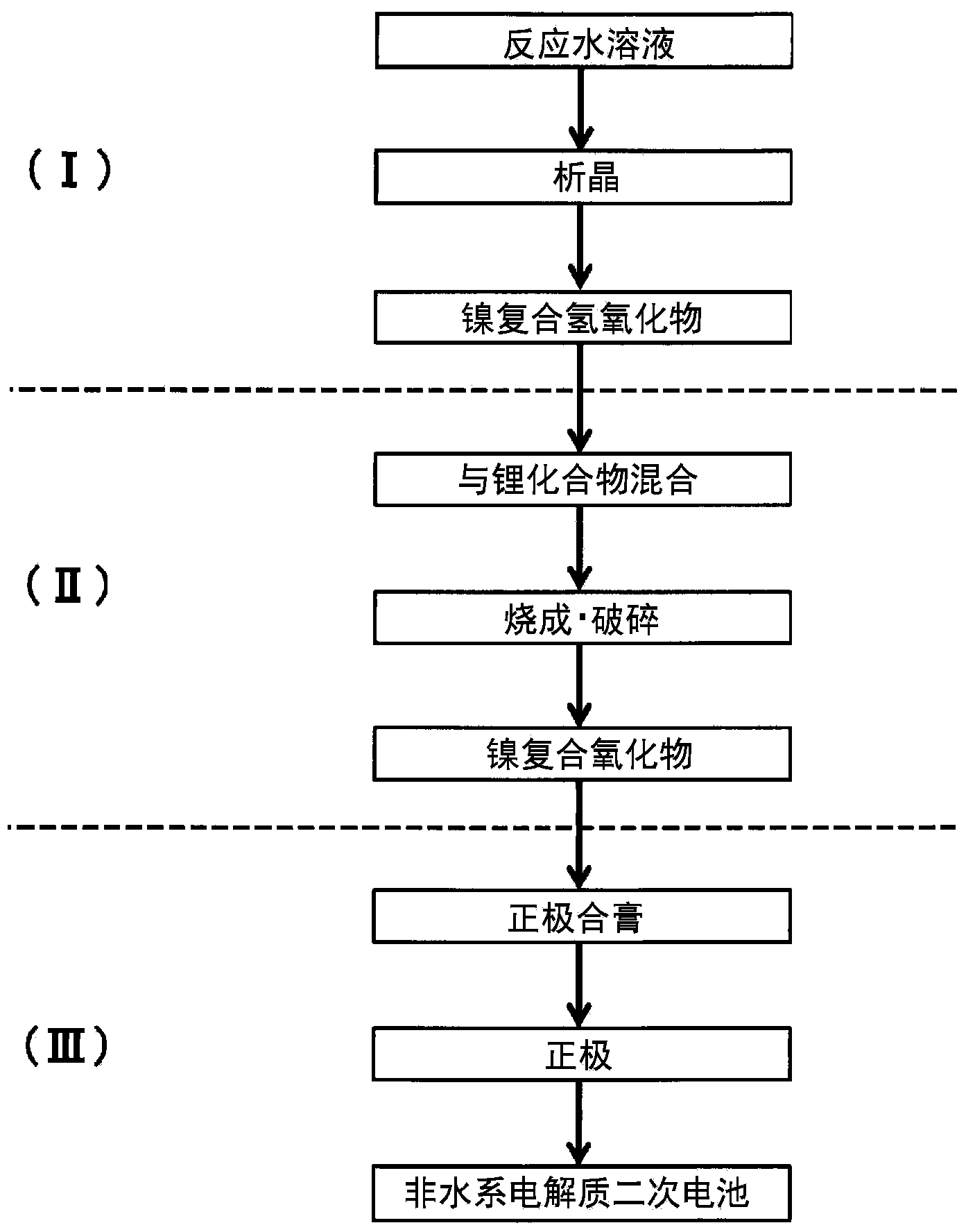

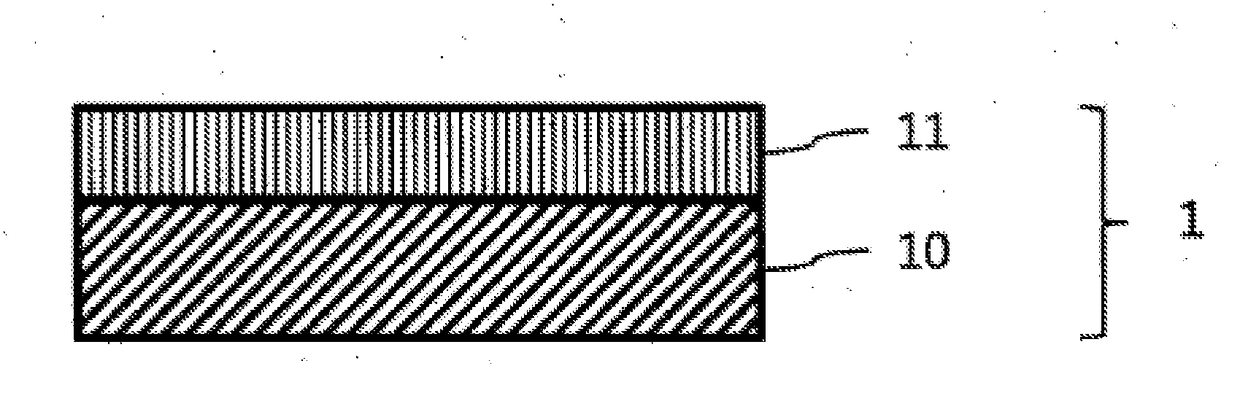

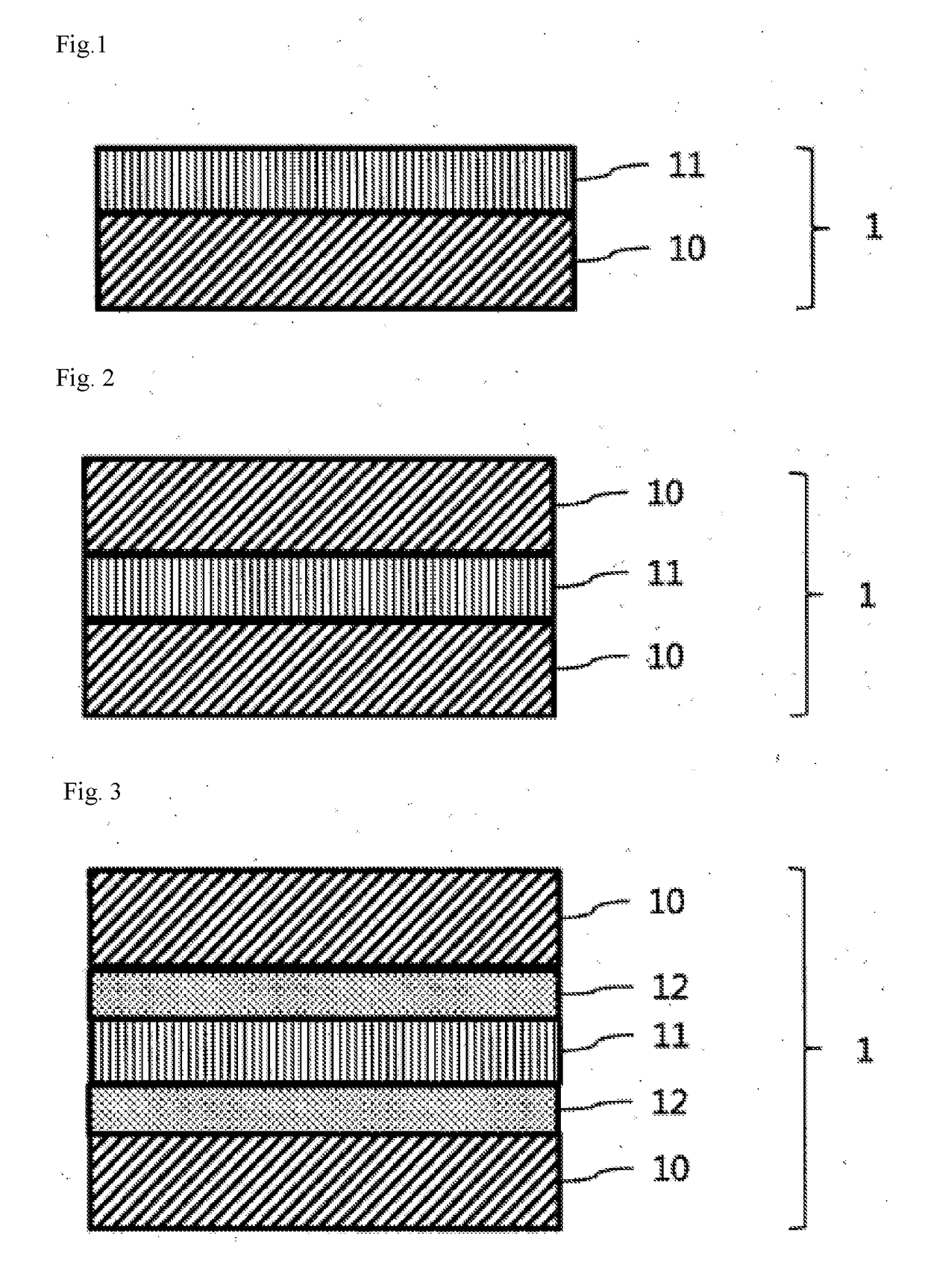

Nickel compound hydroxide and method for producing same, positive pole active substance for nonaqueous electrolyte secondary cell and method for producing same, and nonaqueous electrolyte secondary cell

ActiveCN104136376AIncrease capacityExcellent cycle characteristicsElectrode thermal treatmentFinal product manufactureElectrical batteryManganese

Provided is a lithium composite oxide having a uniform and suitable particle size and high specific surface area due to a hollow structure that can be produced on an industrial scale. A nickel composite hydroxide as a raw material thereof is obtained controlling the particle size distribution of the nickel composite hydroxide, the nickel composite hydroxide having a structure comprising a center section that comprises minute primary particles, and an outer-shell section that exists on the outside of the center section and comprises plate shaped primary particles that are larger than the primary particles of the center section, by a nucleation process and a particle growth process that are separated by controlling the pH during crystallization, and by controlling the reaction atmosphere in each process and the manganese content in a metal compound that is supplied in each process.

Owner:SUMITOMO METAL MINING CO LTD

Surface-treated galvanized steel sheet with superior flat-portion corrosion resistance, blackening resistance, and appearance and corrosion resistance after press forming and aqueous surface-treatment liquid for galvanized steel sheet

ActiveUS20100035055A1Nice appearanceImprove corrosion resistanceOther chemical processesPretreated surfacesParticulatesWater dispersible

An aqueous surface-treatment liquid is a treatment liquid containing a water-soluble zirconium compound, water-dispersive particulate silica, a silane coupling agent, a vanadic acid compound, a phosphoric acid compound, a nickel compound, and an acrylic resin emulsion in particular proportions. A surface-treated galvanized steel sheet produced using the treatment liquid is a galvanized steel sheet having a surface-treatment coating on a surface thereof, and the coating contains a zirconium compound, particulate silica, a silane-coupling-agent-derived component, a vanadic acid compound, a phosphoric acid compound, a nickel compound, and an acrylic resin in particular proportions. The amount of coating on a zirconium basis is 10 to 200 mg / m2. This surface-treated galvanized steel sheet is chromate-free and has superior flat-portion corrosion resistance, blackening resistance, and appearance and corrosion resistance after press forming.

Owner:JFE STEEL CORP

Ceramic silicon rubber and preparation method thereof

InactiveCN106046797ADoes not affect the mechanicalWill not affect mechanicsZinc borateNickel compounds

The invention discloses ceramic silicon rubber and a preparation method thereof and relates to rubber and a preparation method thereof. The ceramic silicon rubber is prepared from, in parts by weight, 100 parts of silicon rubber, 10-60 parts of fumed silica, 0-10 parts of hydroxyl silicone oil, 0.00001-10 parts of metal nickel or a nickel compound calculated based on nickel, 0-10 parts of a coupling agent, 10-180 parts of zinc borate type porcelainized powder, 10-60 parts of a hydroxide flame-retardant and 0.01-5 parts of a vulcanizing agent. The materials are mixed in a kneading machine, vacuumized, then added to the kneading machine and uniformly mixed, bulk ceramic rubber is formed, cooled and mixed with the vulcanizing agent for open milling, and the flame-retardant ceramic silicon rubber is obtained. According to the ceramic silicon rubber, due to the fact that the nickel compound is added to the flame-retardant ceramic silicon rubber, the sintering temperature of the flame-retardant ceramic silicon rubber is reduced, the preparation reaction speed is increased, the production efficiency is improved, and the production cost is reduced.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

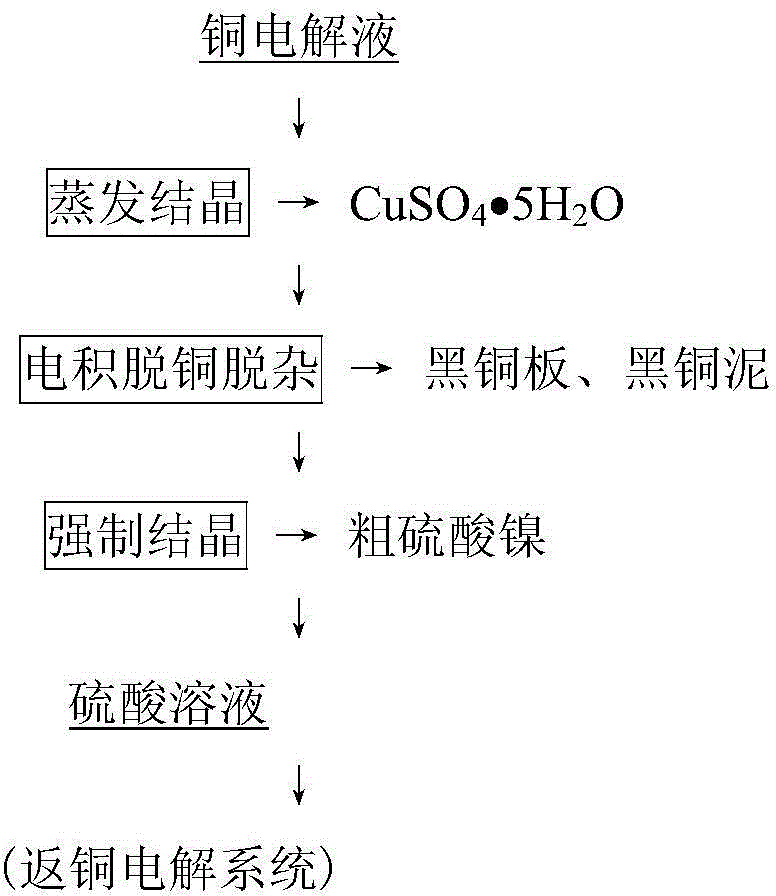

Copper electrolyte purifying technology

ActiveCN104962738AHigh removal rateEliminate generationPhotography auxillary processesProcess efficiency improvementSorbentSludge

The invention discloses a copper electrolyte purifying technology which comprises the following steps: adding a crystallizing agent into copper electrolyte or pre-decoppering post-liquid or adding a crystallizing agent into copper electrolyte after adsorption impurity removal treatment or pre-decoppering post-liquid; crystallizing to obtain copper-nickel compound salt; and separating and recycling copper and nickel from the obtained copper-nickel compound salt to realize purification of the copper electrolyte, wherein in the adsorption impurity removal treatment, an oxide of antimony and / or bismuth and the hydrate thereof are adopted as adsorbents to selectively adsorb the impurities As, Sb and Bi in the copper electrolyte, and the generation of black copper sludge, black copper plates and AsH3 gas can be thoroughly eliminated in a copper electrolyte purifying process. The technology disclosed by the invention has the advantages of simple process, simplicity and convenience in operation, low cost, high efficiency, good operation environment and the like, and is suitable for the industrial production of copper electrolyte purification.

Owner:CENT SOUTH UNIV

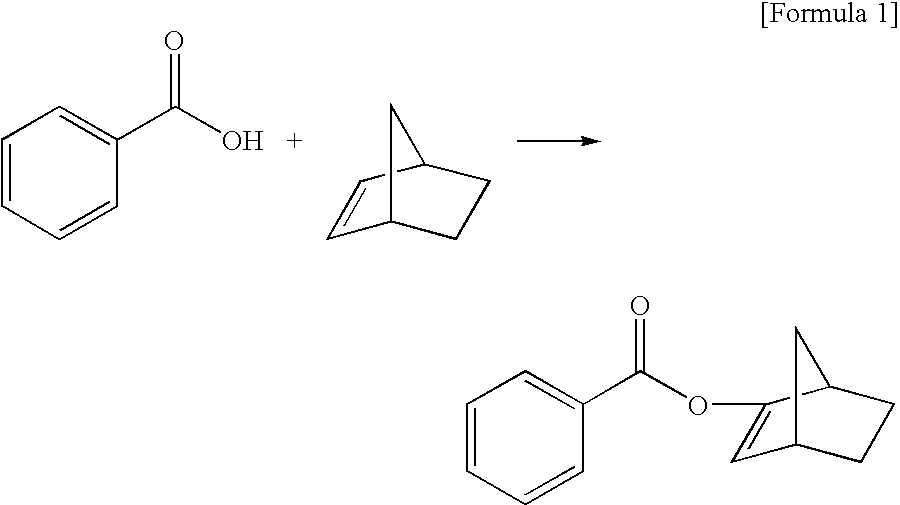

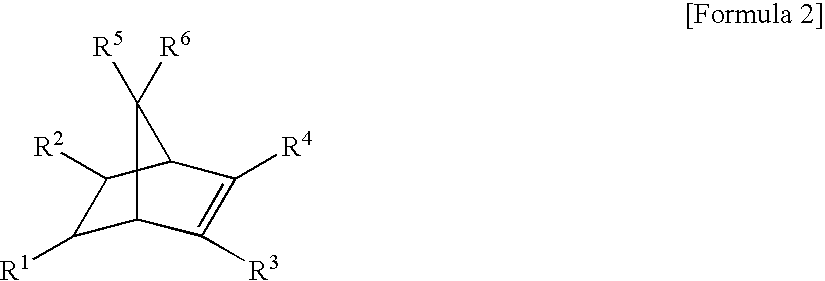

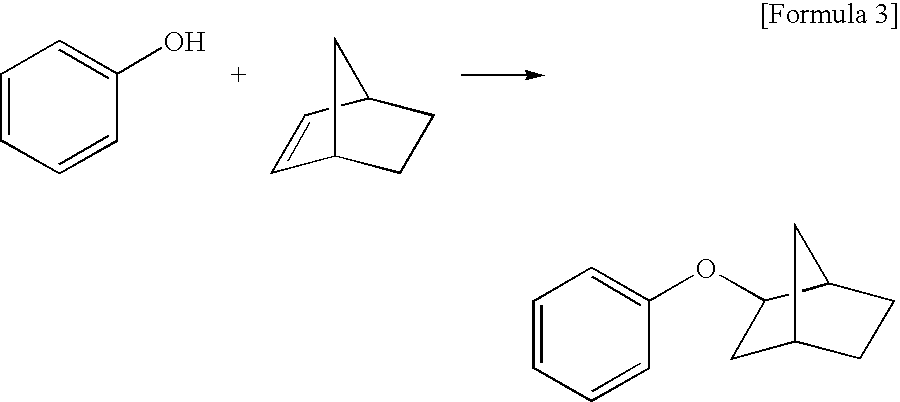

Process for Production of Carboxylic Acid Ester or Ether Compound

InactiveUS20090012324A1Easy to operateEconomical to useOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholNickel compounds

Disclosed is a process for production of a carboxylic acid ester from a carboxylic acid and an olefin or production of an ether compound from an alcohol and an olefin at low cost and with high yield in an industrially advantageous manner. The process comprises the step of reacting a carboxylic acid with an olefin to yield a corresponding carboxylic acid ester or reacting an alcohol with an olefin to yield a corresponding ether compound. In the process, a catalyst comprising a combination of (i) at least one metal compound selected from an iron compound, a cobalt compound and a nickel compound and (ii) an acidic compound is used.

Owner:NAT INST OF ADVANCED IND SCI & TECH

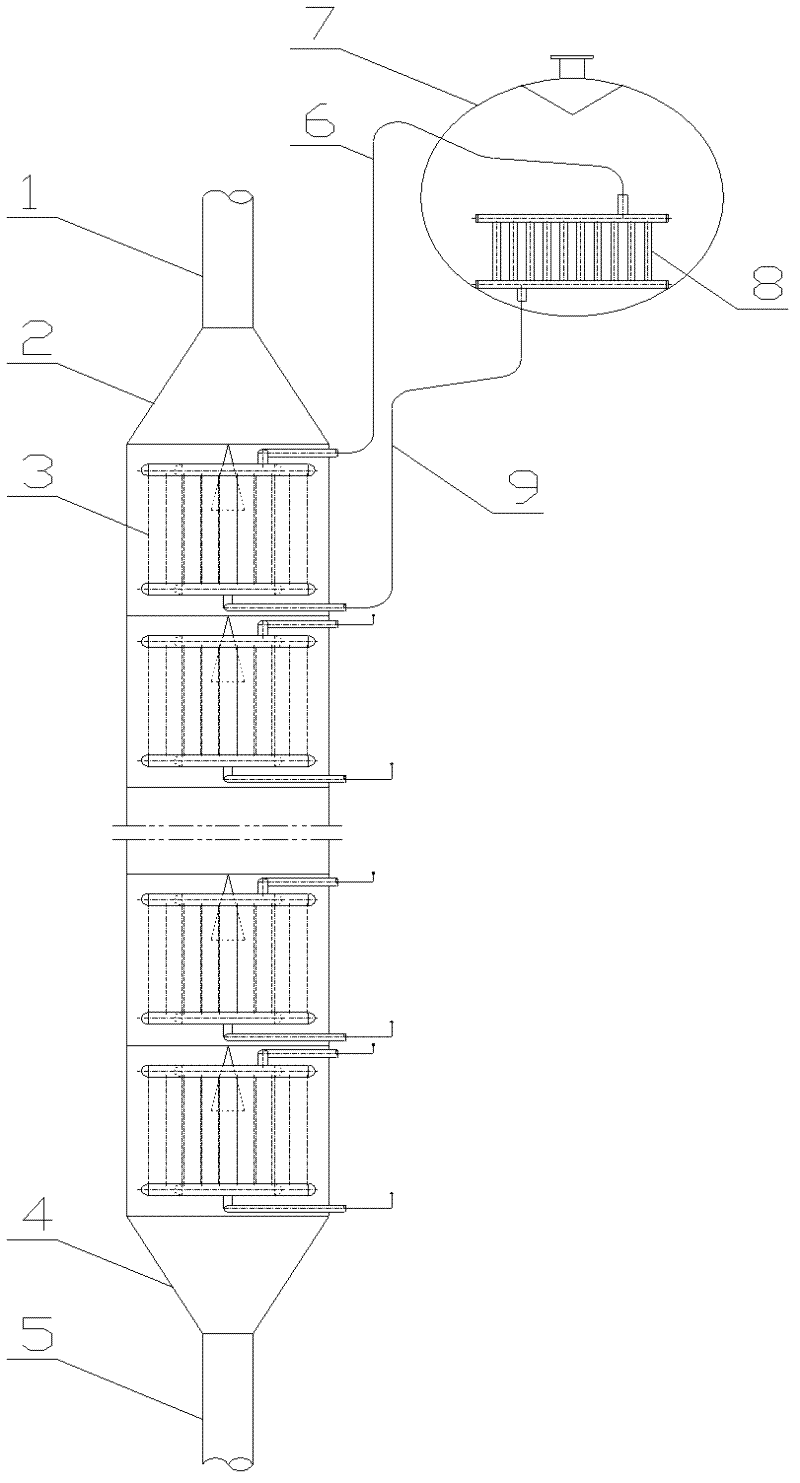

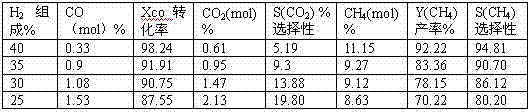

Methanation catalyst, preparation process thereof and methanation reaction device

InactiveCN102247850AHigh activityGuaranteed qualityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMethanation

The invention belongs to the fields of new chemical process techniques and new energy development, in particular to a methanation catalyst, a preparation process thereof and a methanation reaction device for the catalyst. The methanation catalyst comprises the following components in percentage by mass: 10-60 percent of nickel compound serving as an active component, 0-5 percent of auxiliary agent and the balance of carrier. The preparation process for the methanation catalyst comprises the steps of dissolving, mixing, dipping, precipitating, filtering, drying, forming and the like. The methanation reaction device comprises at least two units of reducing separate heat pipe phase change heat removing combined devices, wherein each reducing separate heat pipe phase change heat removing combined device comprises a reactor, reducing pipes at the two ends of the reactor, more than one heat absorbing section in the reactor and a condensate steam package which is connected with the heat absorbing section.

Owner:GUANGZHOU BOXENERGY TECH

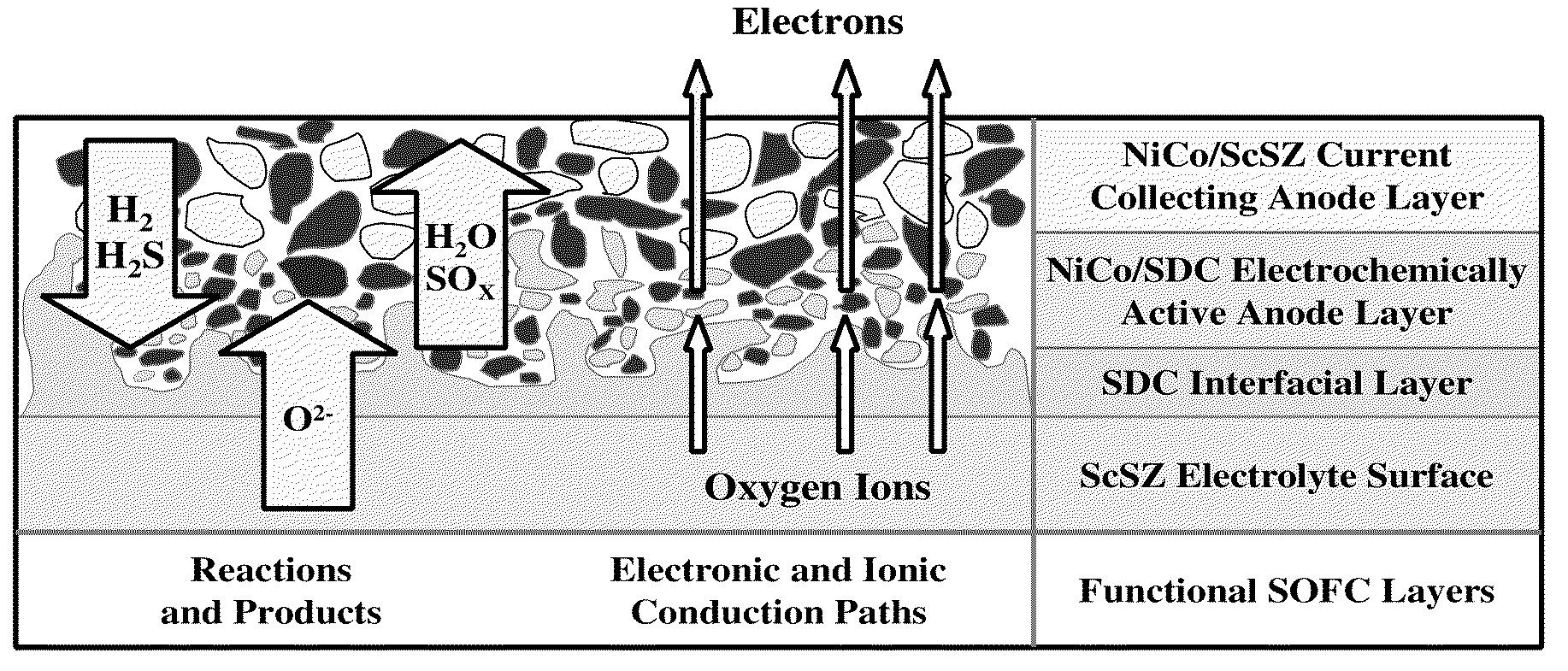

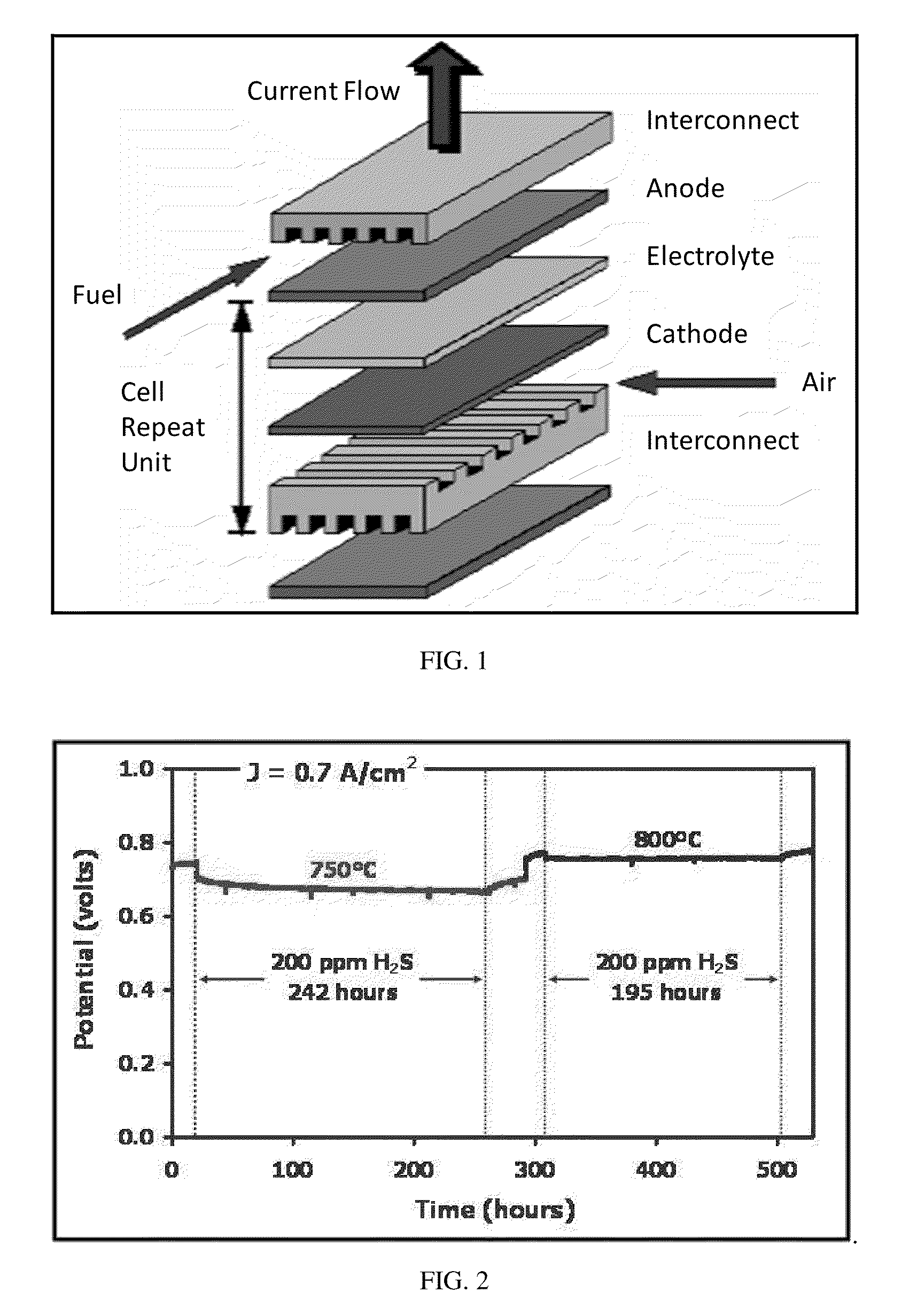

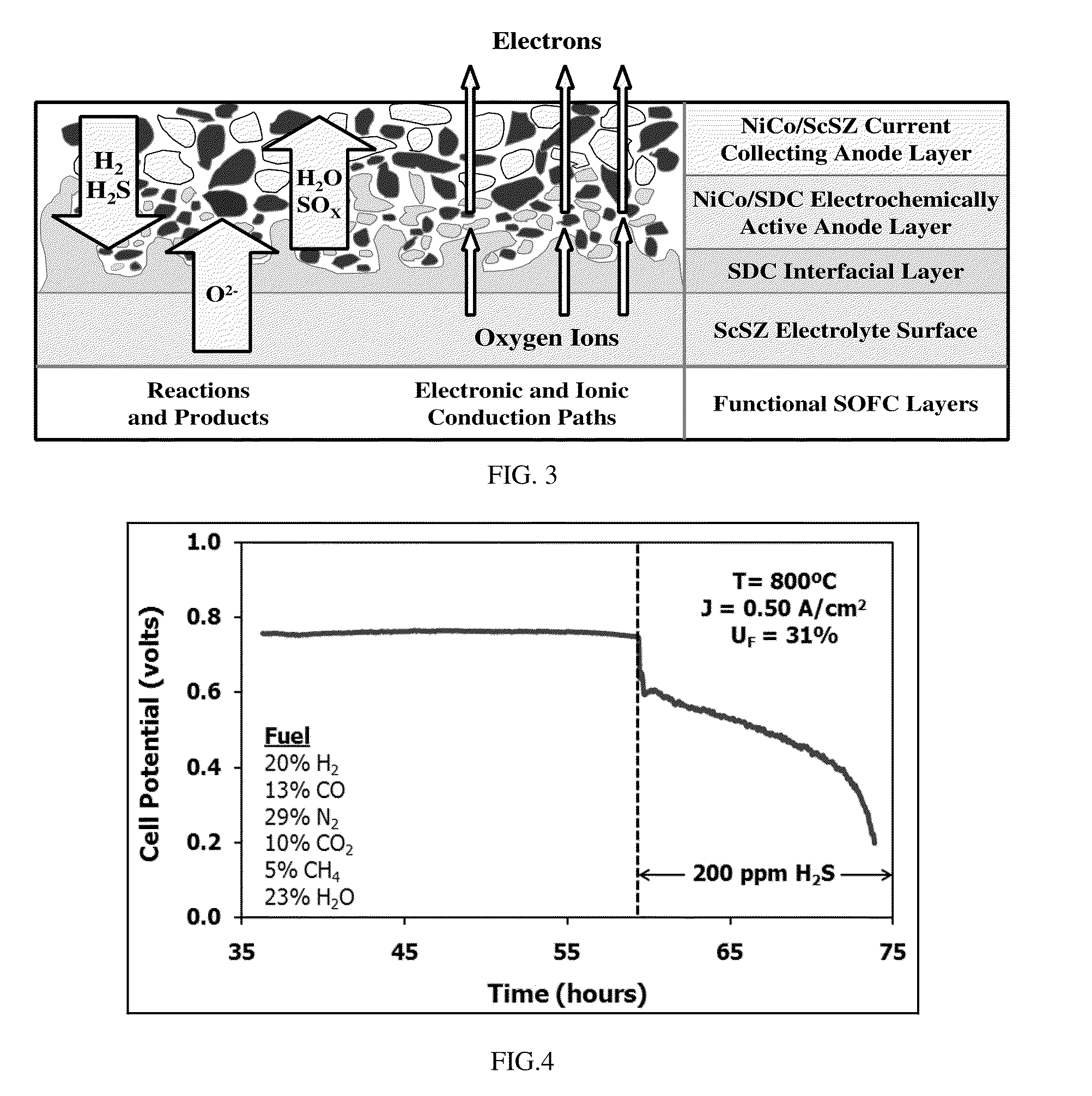

Current Collectors for Solid Oxide Fuel Cell Stacks

A sulfur tolerant anode current collector material includes a mesh or foam that includes a cermet. The cermet includes a metallic component and a ceramic component. The metallic component includes nickel, an alloy including nickel and cobalt, or a mixture including a nickel compound and a cobalt compound. The ceramic component includes a mixed conducting electrolyte material.

Owner:NEXCERIS INNOVATION HLDG LLC

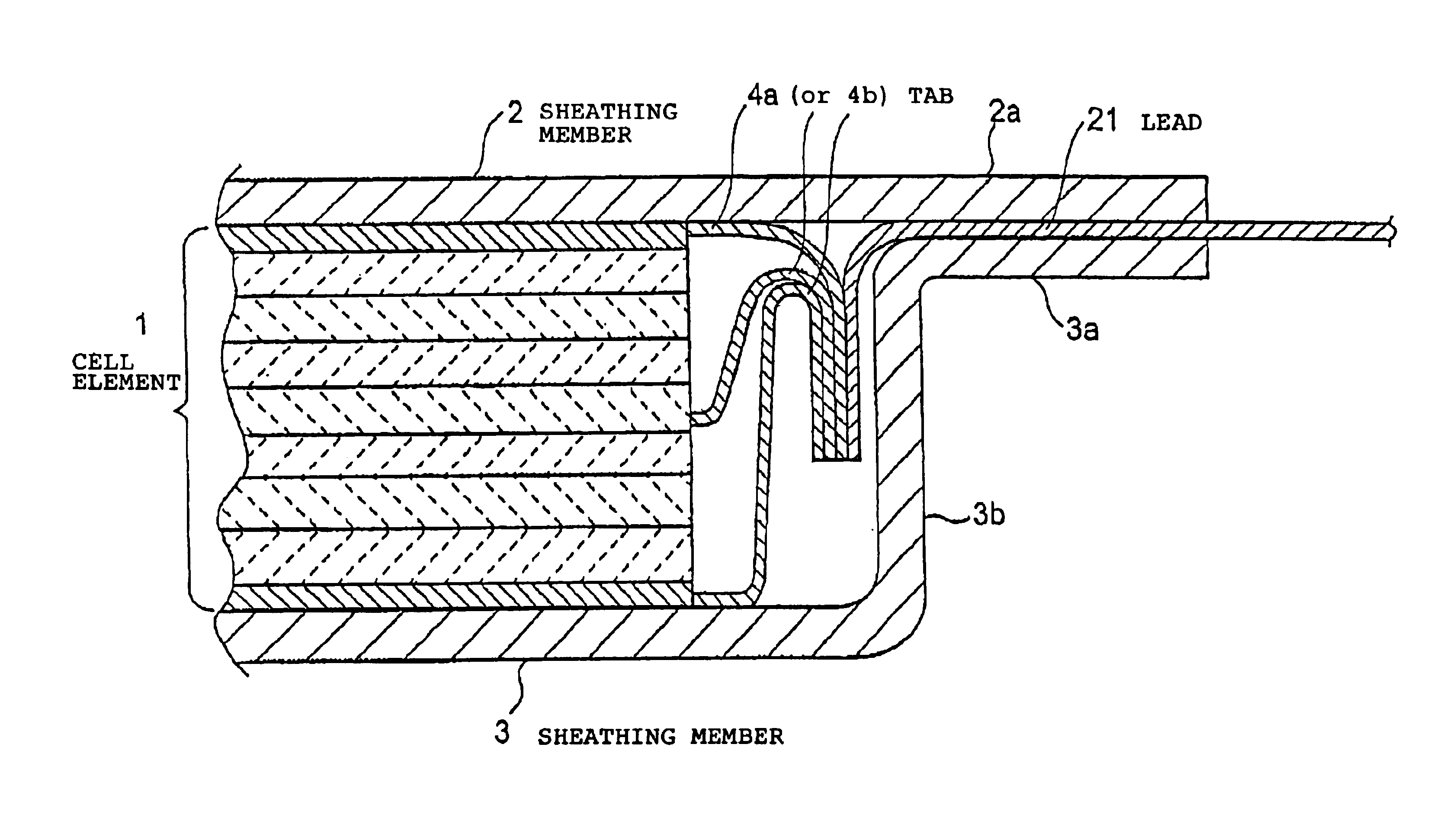

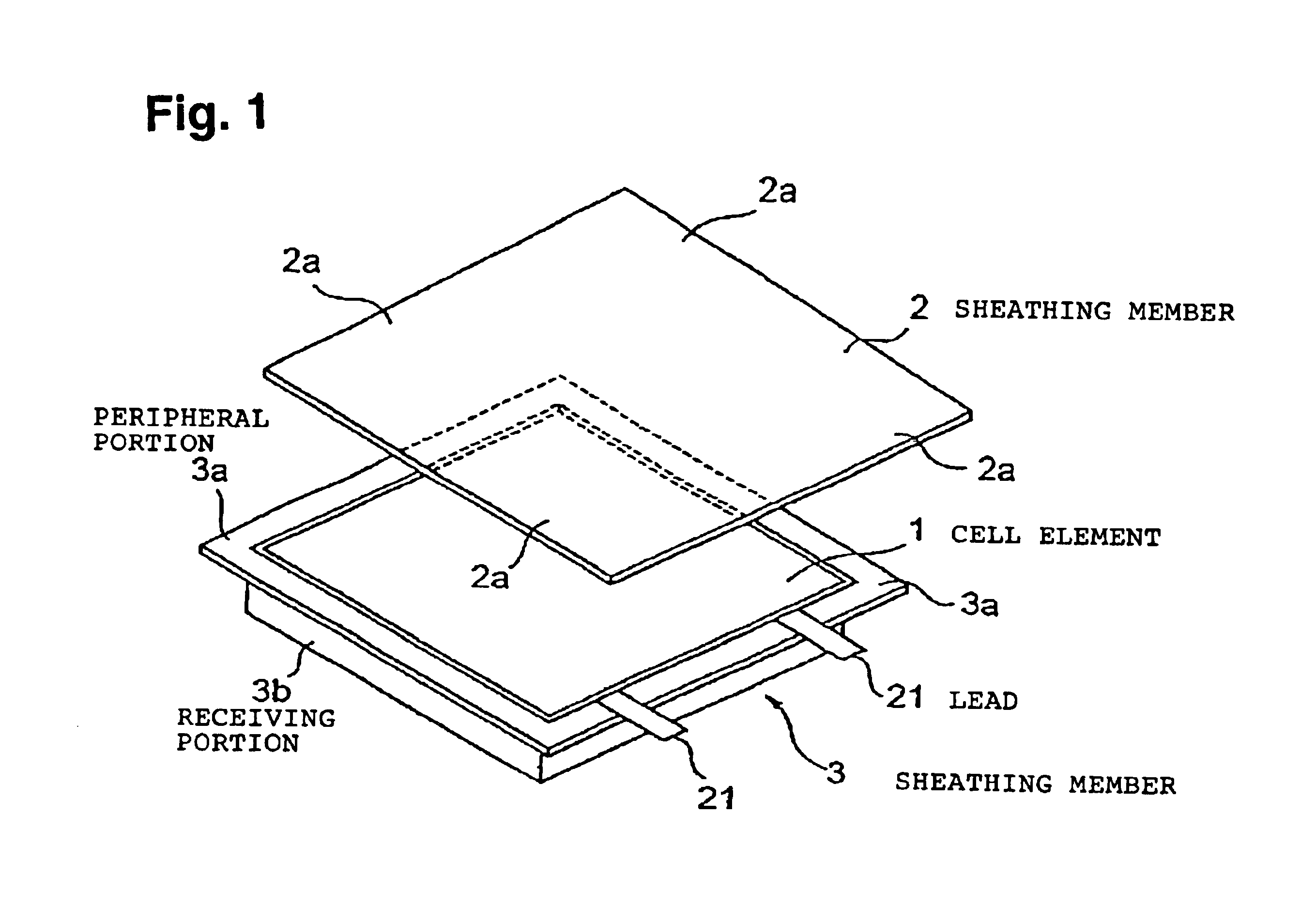

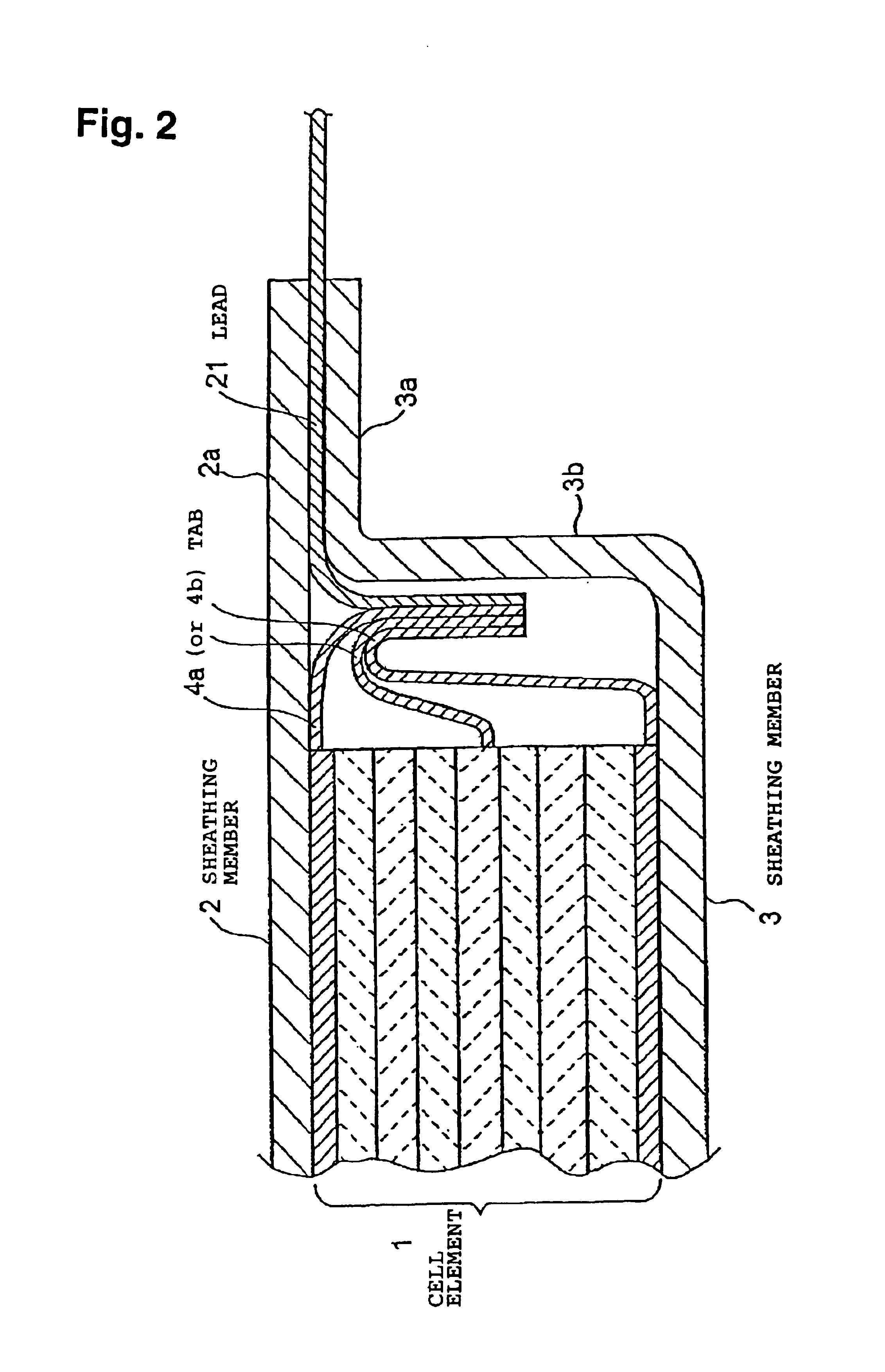

Lithium secondary cell

InactiveUS6939644B2Extension of timeImprove responseSmall-sized cells cases/jacketsActive material electrodesLithiumNickel compounds

To increase safety against overcharging of a lithium secondary cell which uses a lithium-nickel compound oxide as a positive electrode active material. A lithium secondary cell comprises a casing (2,3) and a lithium secondary cell element (1) using a lithium-nickel compound oxide as a positive electrode active material, accommodated in the casing. The specific surface area of the lithium-nickel compound oxide is from 0.1 to 10 m2 / g, and a surface area capacity ratio S / C, i.e. a ratio of a cell surface area S (cm2) to a cell capacity (mAh), is from 0.05 to 5.

Owner:MITSUBISHI CHEM CORP

Method for preparing lithium ion battery anode material nickle cobalt lithium manganate

ActiveCN101355161AImprove performanceImprove electrochemical performanceCell electrodesManganates/permanganatesLithium hydroxideManganese

The invention relates to a method for preparing a LiCoxNiyMnzO2 anode material for a lithium ion battery, belonging to the preparation technical filed of the anode material of the lithium ion battery. The method comprises the following steps that manganese compound, nickel compound, LiCoO2 and lithium hydroxide are taken as raw materials; a well precursor combined by lithium, manganese, cobalt and nickel is obtained through hydrothermal reaction; then, a lithium source is added in the precursor to obtain a precursor through grinding; and finally, LiCoxNiyMnzO2 with excellent properties is obtained after the precursor is baked once. The method has the advantages of simple and easily controlled technological process, low production cost of prepared product and stable and controllable product performance, and can be used in industrial production.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for preparing lithium-rich solid solution cathode material through reduction

ActiveCN102881874ALow costWide variety of sourcesCell electrodesHybrid/EDL manufactureNickel compoundsManganese

The invention relates to a method for preparing a lithium-rich solid solution cathode material through reduction. The method is characterized by comprising the following steps of: weighing a lithium compound, a nickel compound, a manganese compound, a cobalt compound and a reducing agent in a molar ratio of lithium ions to nickel ions to manganese ions to cobalt ions to the reducing agent of (1+x):(1-x).y:(x+z-x.z):(1-x).k:q; and mixing the reducing agent and a wet grinding medium, mixing the weighed nickel compound, manganese compound and cobalt compound in a mixture, performing wet grinding and mixing, adding ammonia water, performing wet grinding again, aging, drying, putting a precursor in air, oxygen-rich gas or pure oxygen atmosphere, and performing two-section or two-time sectional sintering to prepare the lithium-rich solid solution cathode material xLi2MnO3.(1-x)Li[NiyMnzCok]O2. The electrode material prepared by the method has uniform composition, high discharge performance, and high discharge cycle performance particularly under the high-current condition.

Owner:FUJIAN NORMAL UNIV

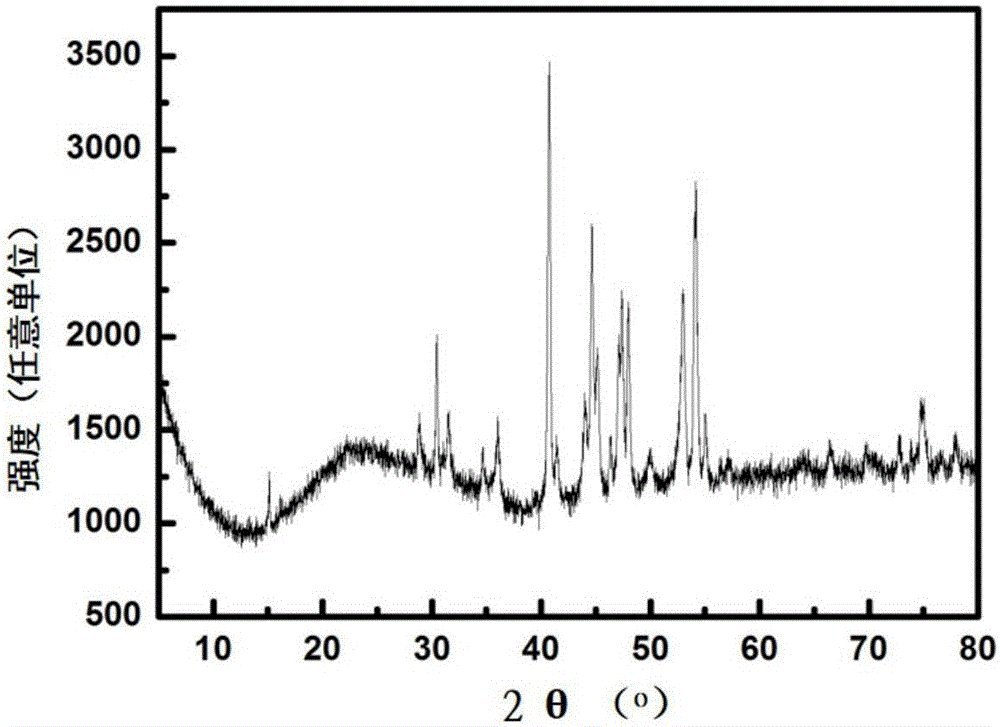

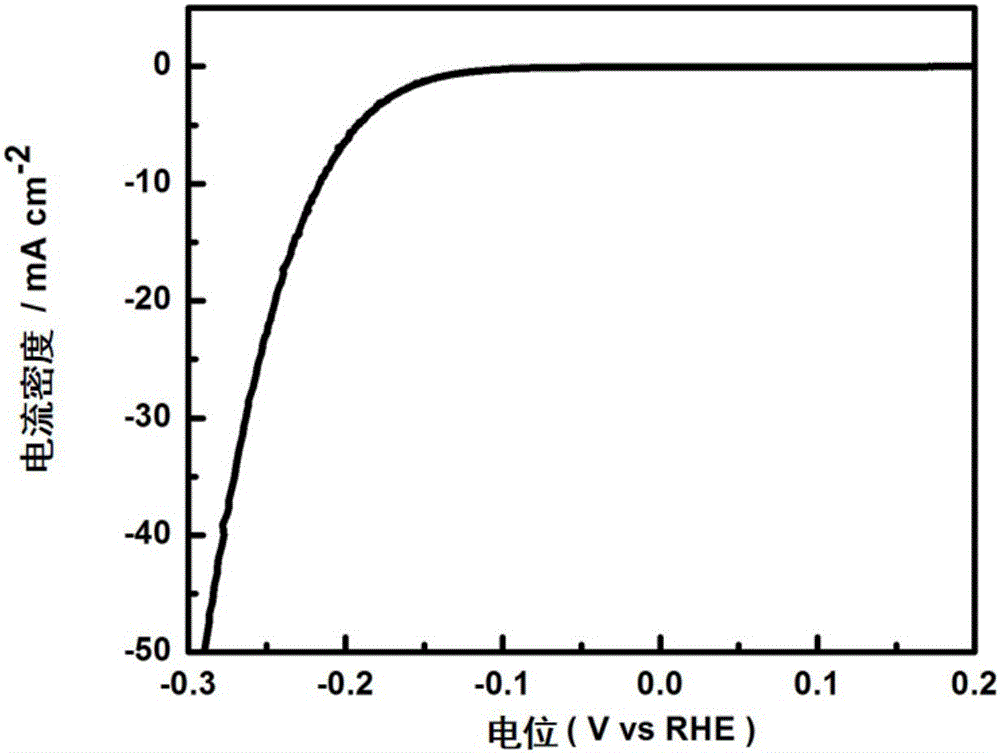

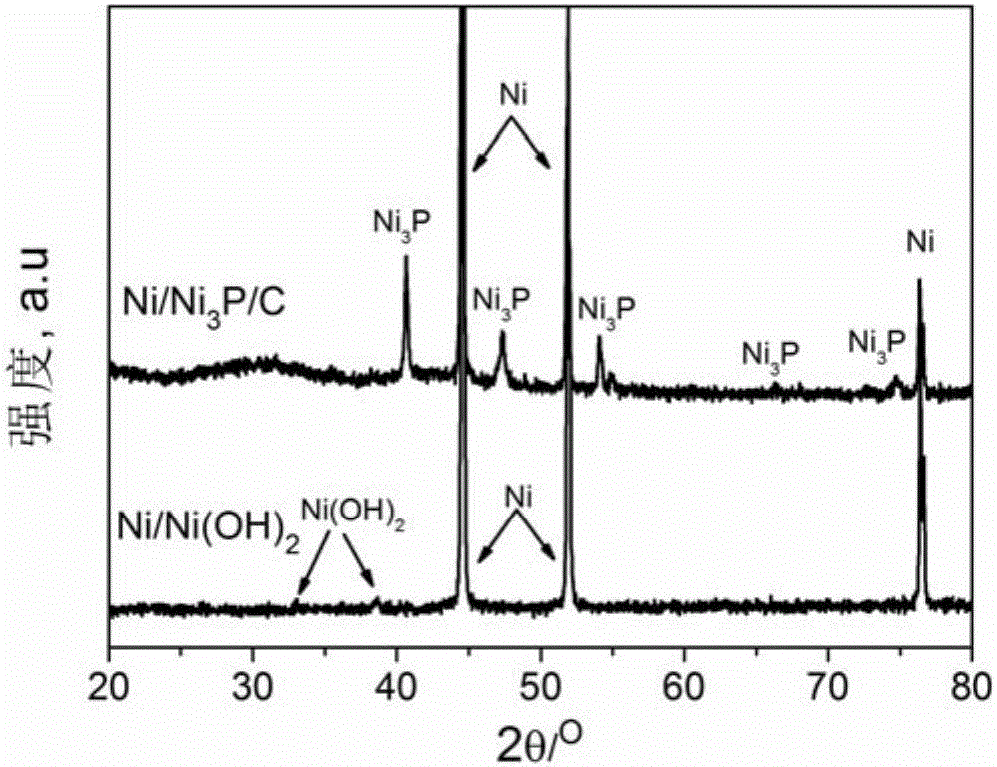

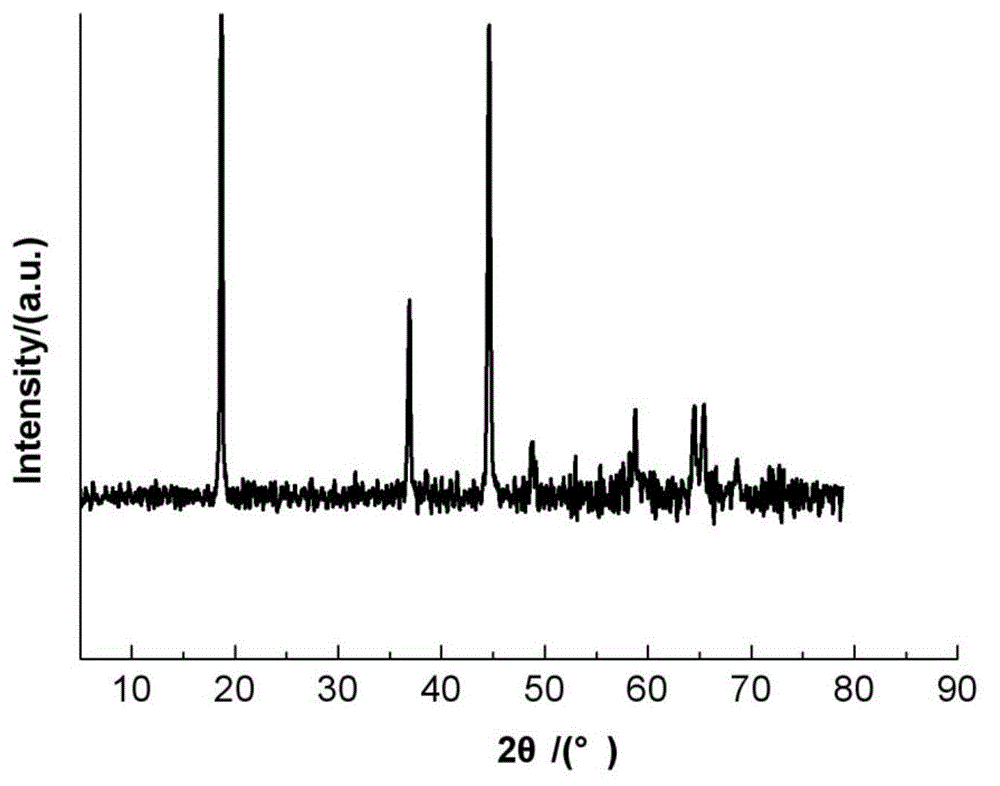

Micron nickel phosphide electro-catalytic material used for hydrogen evolution/oxygen evolution double functions

InactiveCN105854911AControl release speedAchieving controllable synthesisPhysical/chemical process catalystsCell electrodesMicron scaleNickel compounds

The invention provides a micron nickel phosphide electro-catalytic material used for hydrogen evolution / oxygen evolution double functions and belongs to the technical field of novel materials. A nickel compound is used as a precursor and a high-boiling-point organic matter is used as a solvent; the material has the characteristics of controlling the synthesis of micron nickel phosphide materials on a microcosmic level and the like; preparation conditions are rapid and moderate; a generated compound of Ni2P and Ni5P4 is of micron-grade nickel phosphide particles and the grain diameter is 5-10 microns; the prepared material can be used for electro-catalytic hydrogen evolution and oxygen evolution double functions and has a good electro-catalytic property; and the material has important meanings on industrial production of the micron-scale nickel phosphide material and application and development of the material, and has a relatively wide application range.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

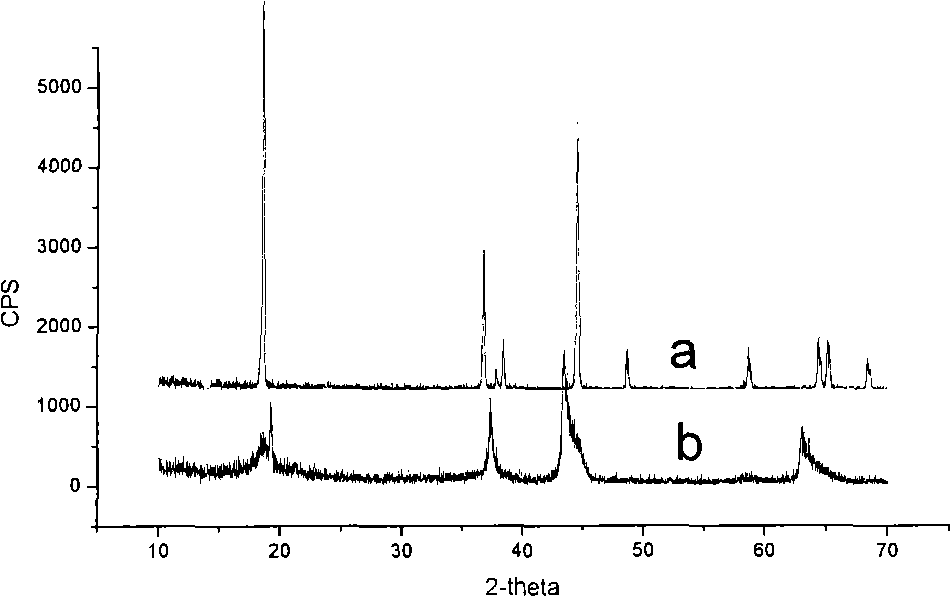

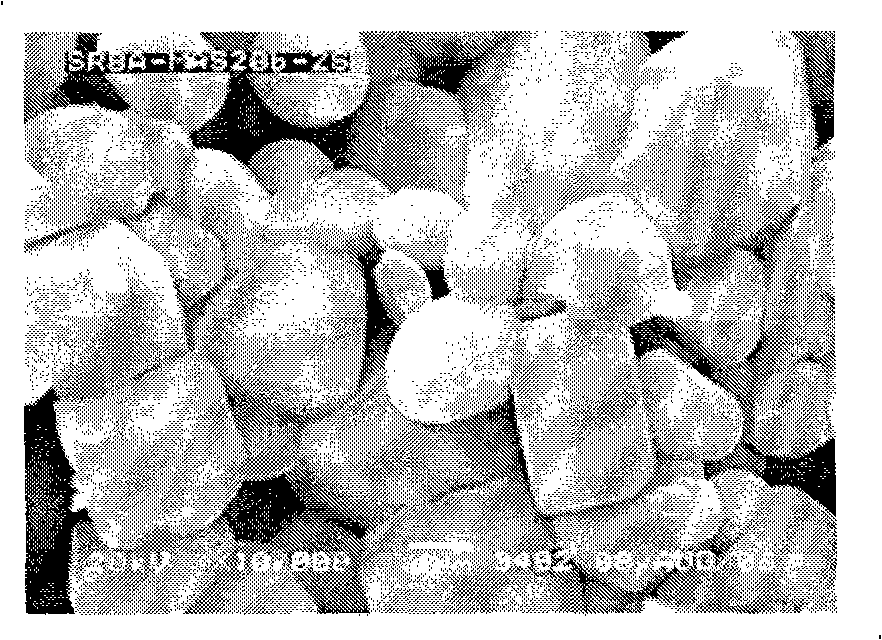

Layered lithium nickel composite oxide powder and process for producing the same

ActiveCN1698223AHigh bulk densityImprove featuresSecondary cellsActive material electrodesLiquid mediumNickel compounds

A layered lithium-nickel-based compound oxide powder for a positive electrode material for a high density lithium secondary cell, capable of providing a lithium secondary cell having a high capacity and excellent in the rate characteristics also, is provided. A layered lithium-nickel-based compound oxide powder for a positive electrode material for a lithium secondary cell, characterized in that the bulk density is at least 2.0 g / cc, the average primary particle size B is from 0.1 to 1 mum, the median diameter A of the secondary particles is from 9 to 20 mum, and the ratio A / B of the median diameter A of the secondary particles to the average primary particle size B, is within a range of from 10 to 200. In production of a layered lithium-nickel-based compound oxide powder, which comprises spray drying a slurry having a nickel compound and a transition metal element compound capable of substituting lithium other than nickel, dispersed in a liquid medium, followed by mixing with a lithium compound, and firing the mixture, the spray drying is carried out under conditions of 0.4<=G / S<=4 and G / S<=0.0012 V, when the slurry viscosity at the time of the spray drying is represented by V (cp), the slurry supply amount is represented by S (g / min) and the gas supply amount is represented by G (L / min).

Owner:MITSUBISHI RAYON CO LTD

Color conversion composition, color conversion film and backlight unit, display and lighting device each comprising same

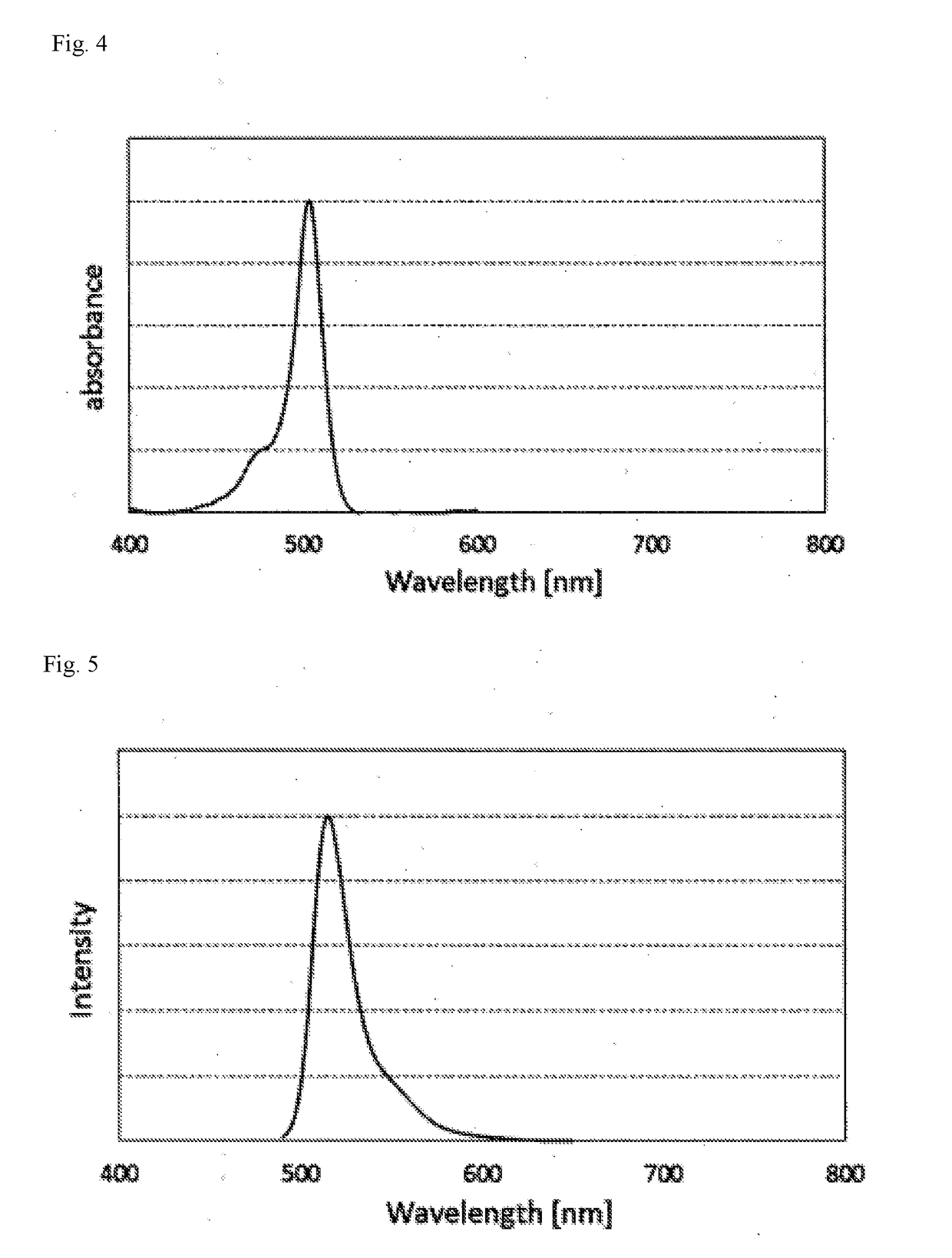

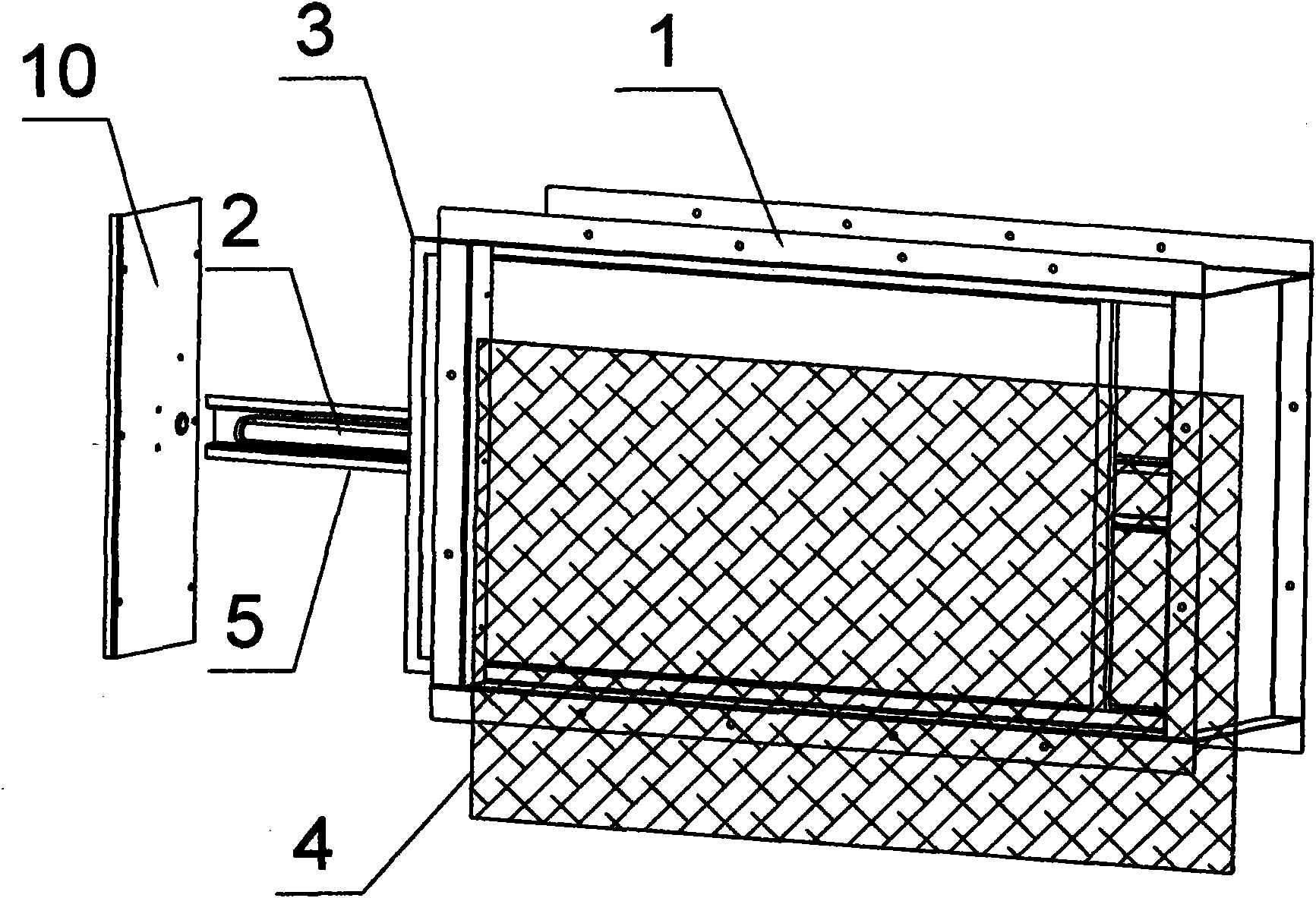

ActiveUS20180208838A1High color purityIncreased durabilityLuminescent paintsLuminescent compositionsLiquid-crystal displayNickel compounds

A color conversion composition converting incident light to light having a longer wavelength than the incident light, and containing the following components (A)-(C): (A) at least one luminescent material; (B) a binder resin; and (C) at least one of tertiary amines, catechol derivatives and nickel compounds, in which the tertiary amines, the catechol derivatives and the nickel compounds have a molar extinction coefficient ε of 100 or less over the whole wavelength range from 400 nm to 800 nm is provided. This color conversion composition achieves a good balance between improvement of color reproducibility and durability if used for a liquid crystal display or an LED lighting device.

Owner:TORAY IND INC

Photocatalysis air purifying device

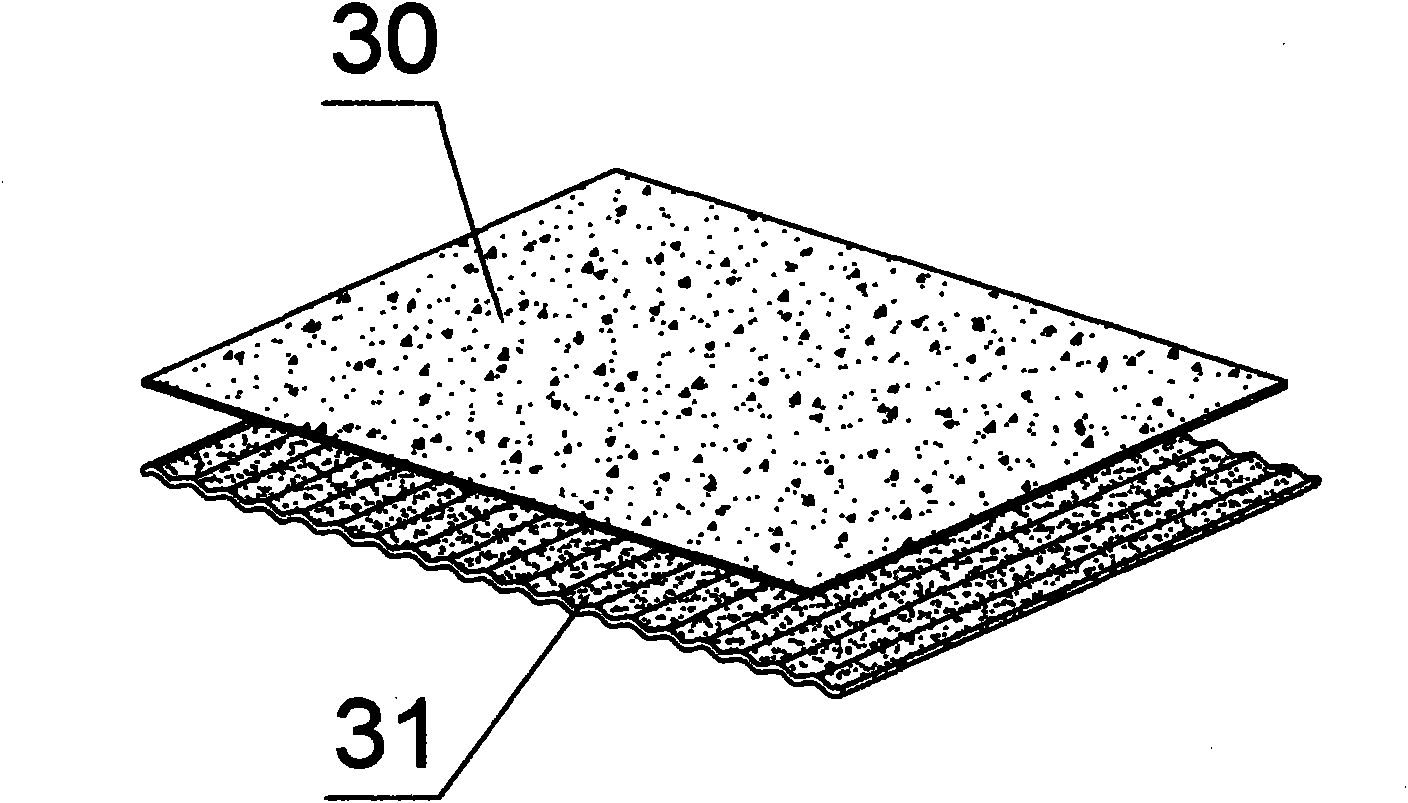

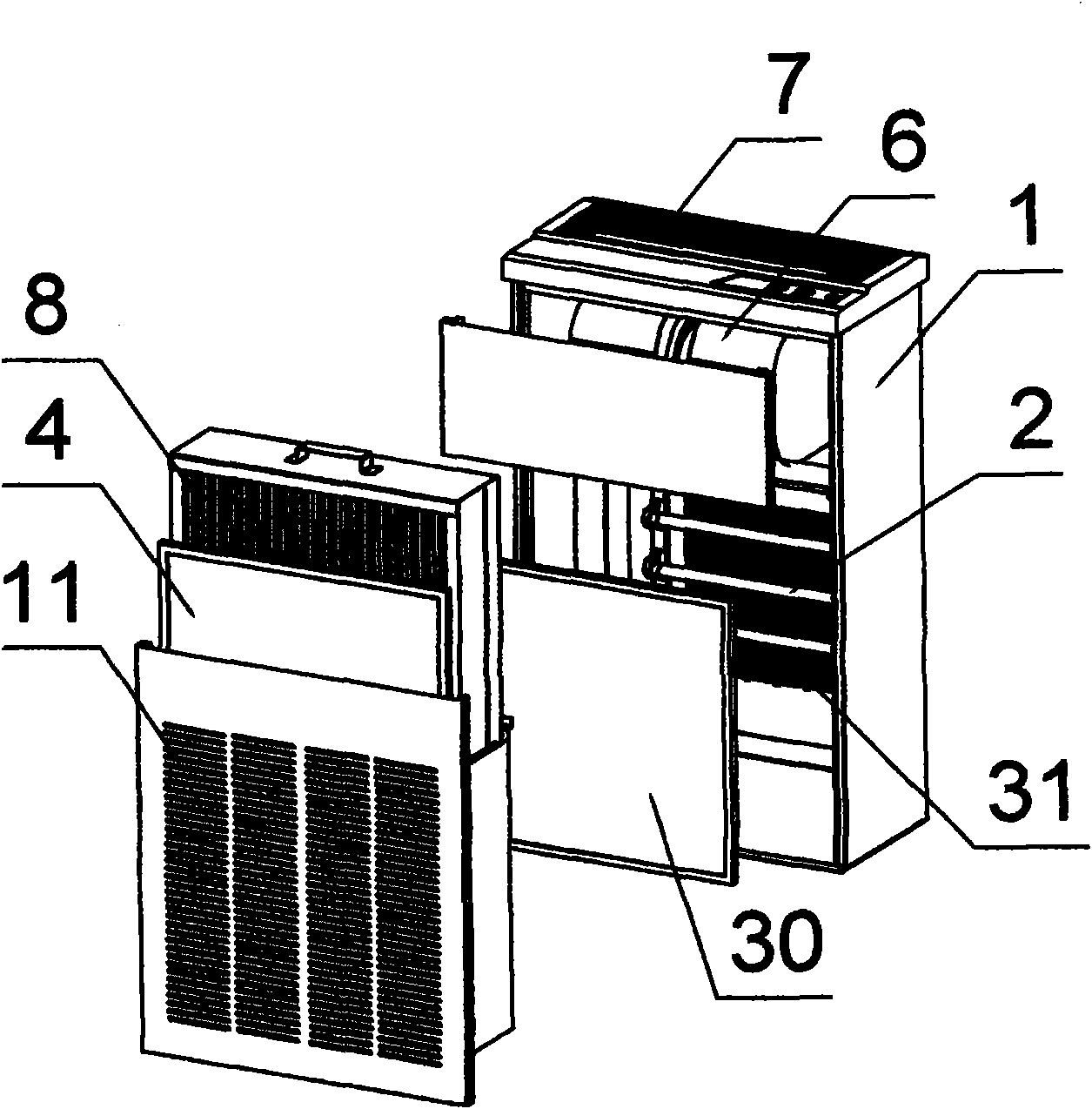

InactiveCN102078634AHigh load rateEfficient removalLighting and heating apparatusAir conditioning systemsAntibiosisNickel substrate

The invention relates to a photocatalysis air purifying device. The device comprises a frame (1) and an ultraviolet lamp tube (2) installed in the frame (1), wherein the frame (1) is provided with an airflow passageway with a cross-ventilation function. The device is characterized in that the frame (1) is internally provided with a titanium-nickel compounded photocatalysis net (3); the titanium-nickel compounded photocatalysis net (3) comprises a photocatalysis titanium net (30) and a photocatalysis nickel net (31); the titanium-nickel compounded photocatalysis net (3) is a compounded photocatalysis antibiosis foam metal net of a three-dimensional space structure and comprises a foam nickel substrate and TiO2 loaded on the surface of the foam nickel substrate; the air inlet of the airflow passageway of the frame (1) is provided with a dust filtering net (4); the outlet of the airflow passageway of the frame (1) is provided with strip bars (7) or a porous baffle; and a fan (6) is arranged in the frame (1) or at the rear part of the frame (1). By using the photocatalysis air purifying device of such structure, the effects of volatile organic compound (VOC) degradation, disinfection and sterilization are obvious.

Owner:潘华耿

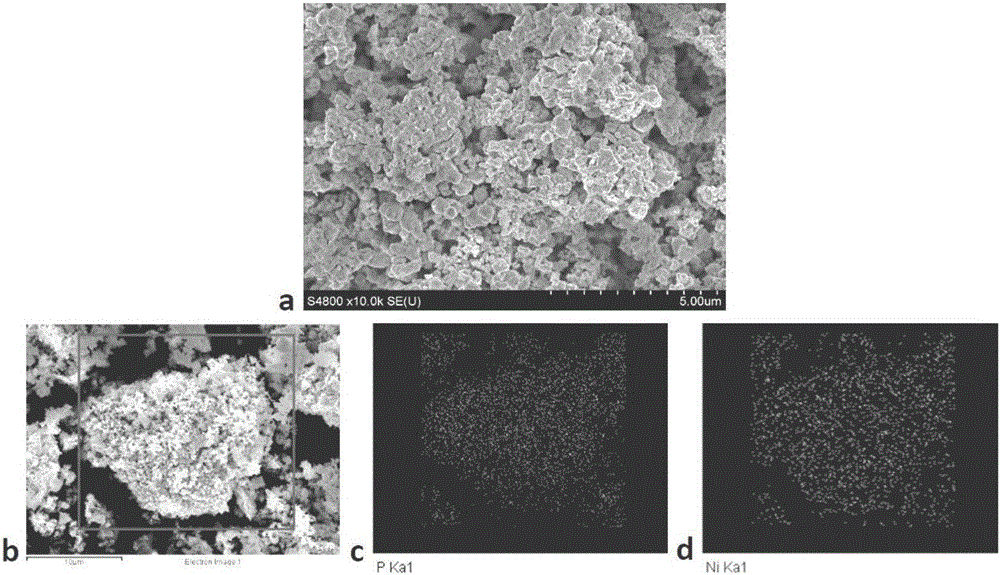

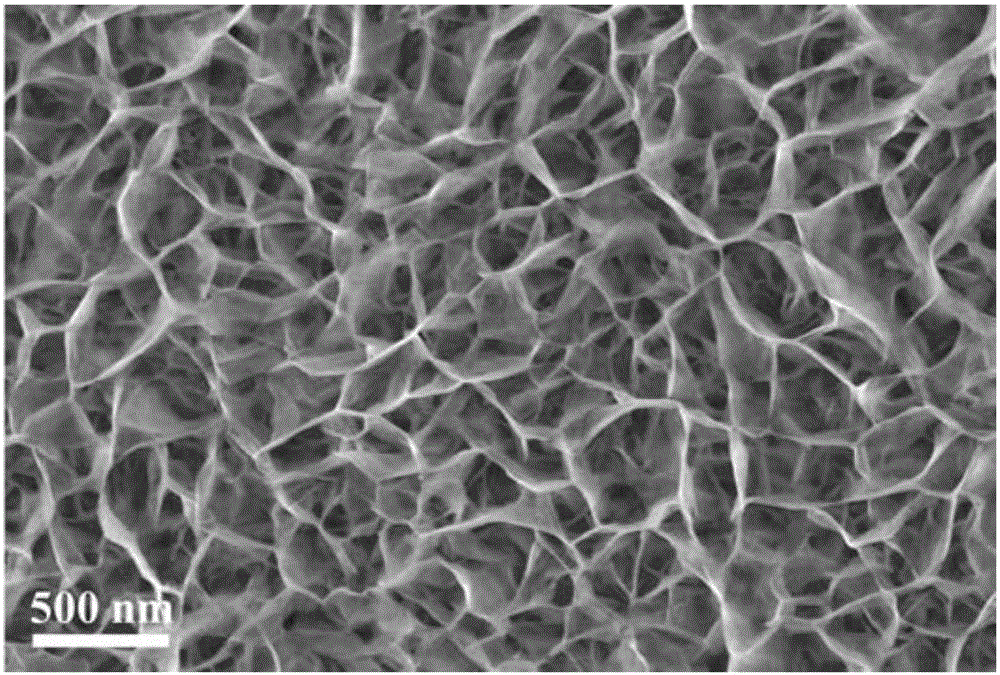

Foamed nickel self-supported flake-shaped Ni3P/C composite material for sodium ion battery negative electrode and preparation method for composite material

ActiveCN105720236AImprove performanceExcellent rate performanceNegative electrodesCarbon coatingThermal insulation

The invention discloses a foamed nickel self-supported flake-shaped Ni3P / C composite material for a sodium ion battery negative electrode and a preparation method for the composite material. According to the composite material, the flake-shaped Ni3P is uniformly growing on the foamed nickel; and the Ni3P is uniformly coated with a C film. The preparation method for the composite material comprises the steps of taking a nickel compound as the raw material, and uniformly growing a flake-shaped nickel hydroxide layer on the surface of the nickel compound through a hydrothermal method; then taking sodium hypophosphite as a phosphorus source, and performing thermal insulation at a temperature of 300 DEG C for 2h to prepare the foamed nickel self-supported flake-shaped Ni3P material; and finally, performing carbon coating on the foamed nickel self-supported flake-shaped Ni3P material to obtain the foamed nickel self-supported flake-shaped Ni3P / C composite material. The sodium ion battery prepared from the Ni3P / C composite material prepared by the invention has excellent specific capacity, rate capability and stable cycling performance; and in addition, the preparation method is simple and feasible, wide in raw material resources and suitable for industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing lithium-enriched solid solution cathode material by doping iron, copper and tin ions

The invention provides a method for preparing a lithium-enriched solid solution cathode material by doping iron, copper and tin ions, which is characterized in that a preparation process is formed by the following steps of: mixing a nickel compound, a manganese compound, a cobalt compound and an M compound, which are weighed to form a mixture 1; adding a wet milling medium and organic weak acid; carrying out wet milling and mixing and adding a lithium compound; after carrying out the wet milling and the mixing, utilizing a vacuum drying or spraying drying method to treat a precursor 1 to prepare a dry precursor 2; putting the precursor 2 into air, oxygen-enriched gas or pure oxygen atmosphere; and utilizing a two-section sintering method or a two-time subsection sintering method to prepare the lithium-enriched solid solution cathode material of xLi2MnO3*(1-x)Li[NiyMnzCokMq]O2. An electrode material prepared by the method disclosed by the invention is uniformly formed and has a very good discharging performance; and particularly, the electrode material has the excellent circulating discharging performance under a large-current condition.

Owner:DYNABAT NEW ENERGY SCI & TECH CO CLD FUJIAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com