Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

964 results about "Hydrogenolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenolysis is a chemical reaction whereby a carbon–carbon or carbon–heteroatom single bond is cleaved or undergoes lysis (breakdown) by hydrogen. The heteroatom may vary, but it usually is oxygen, nitrogen, or sulfur. A related reaction is hydrogenation, where hydrogen is added to the molecule, without cleaving bonds. Usually hydrogenolysis is conducted catalytically using hydrogen gas.

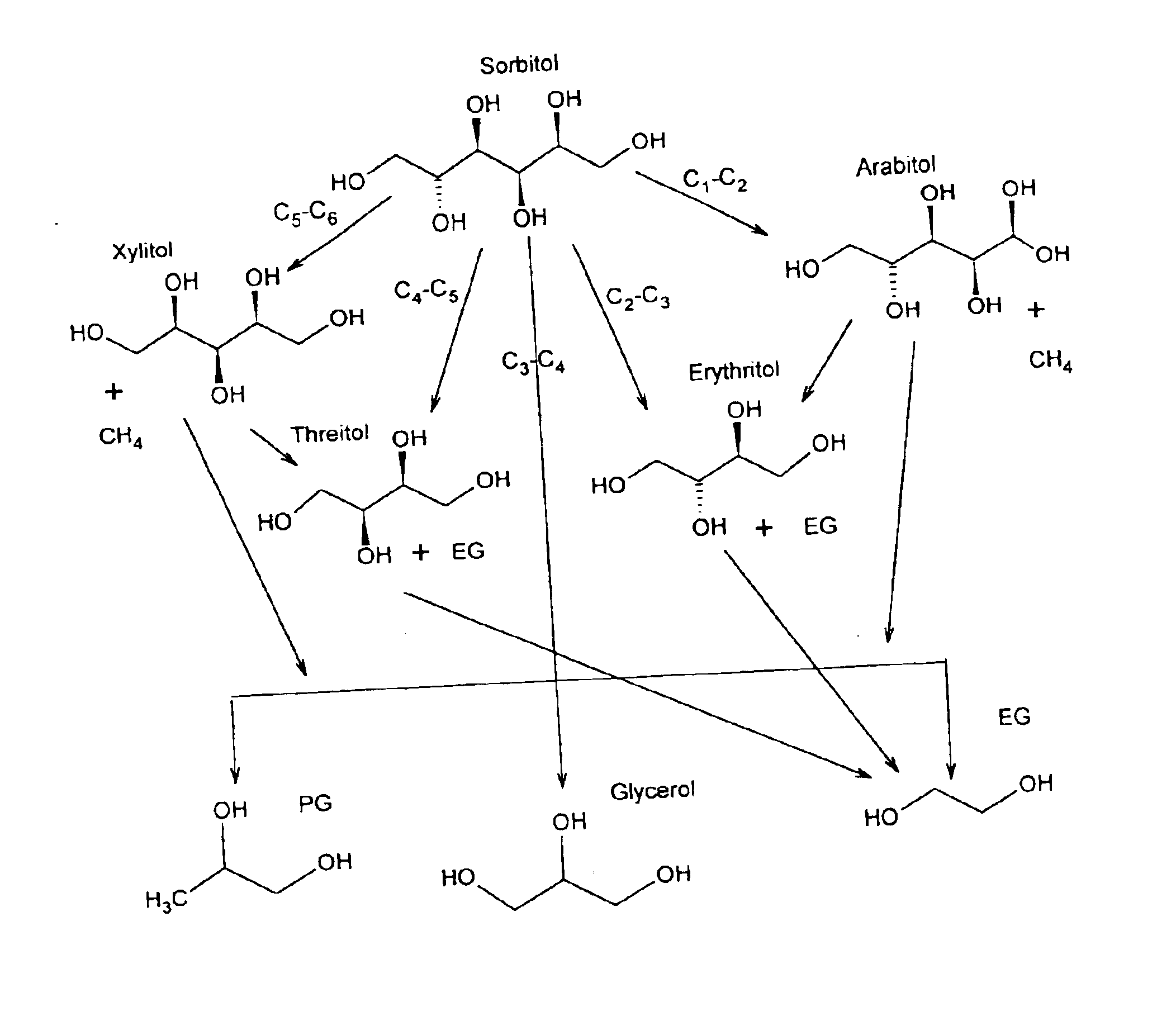

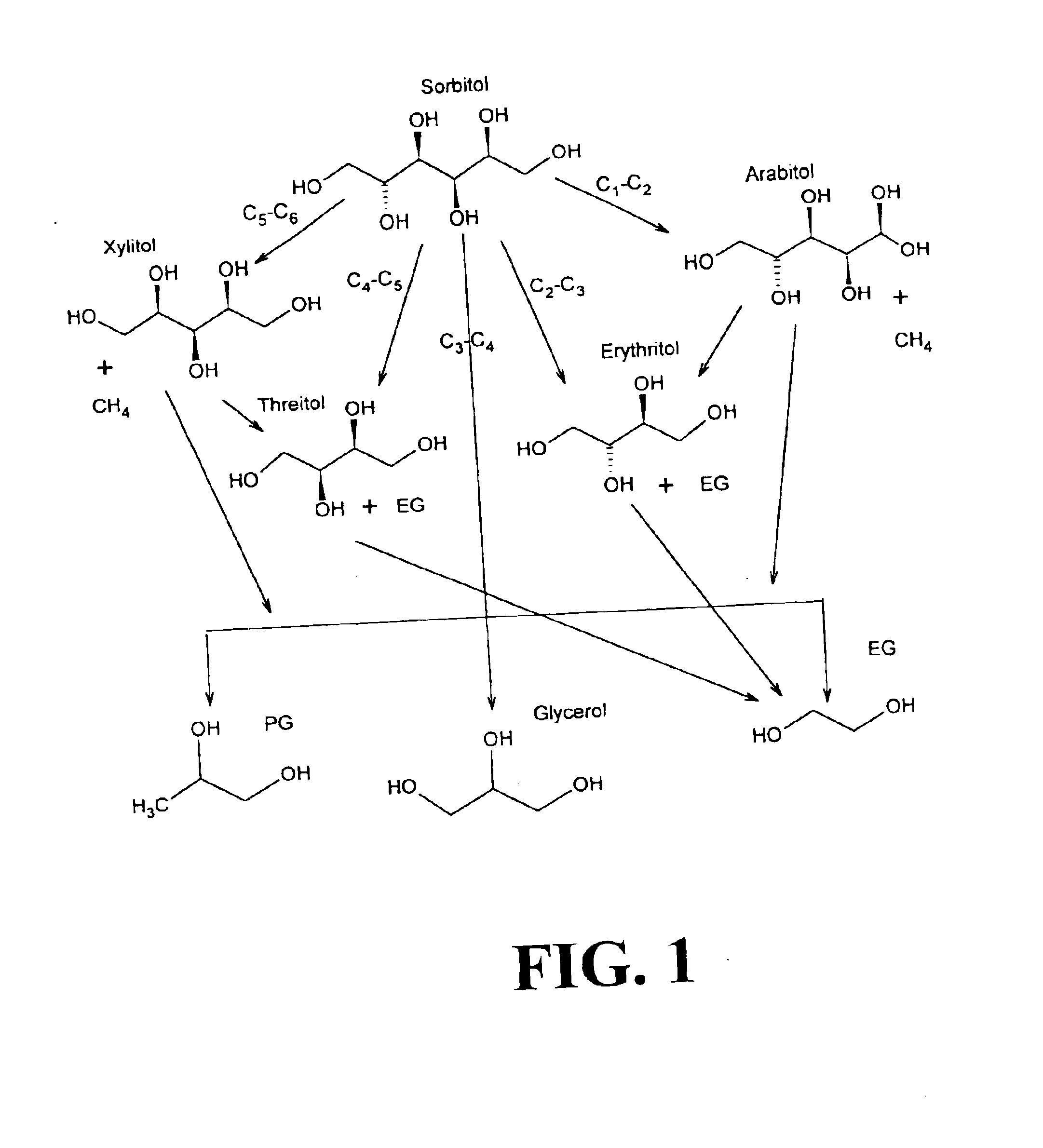

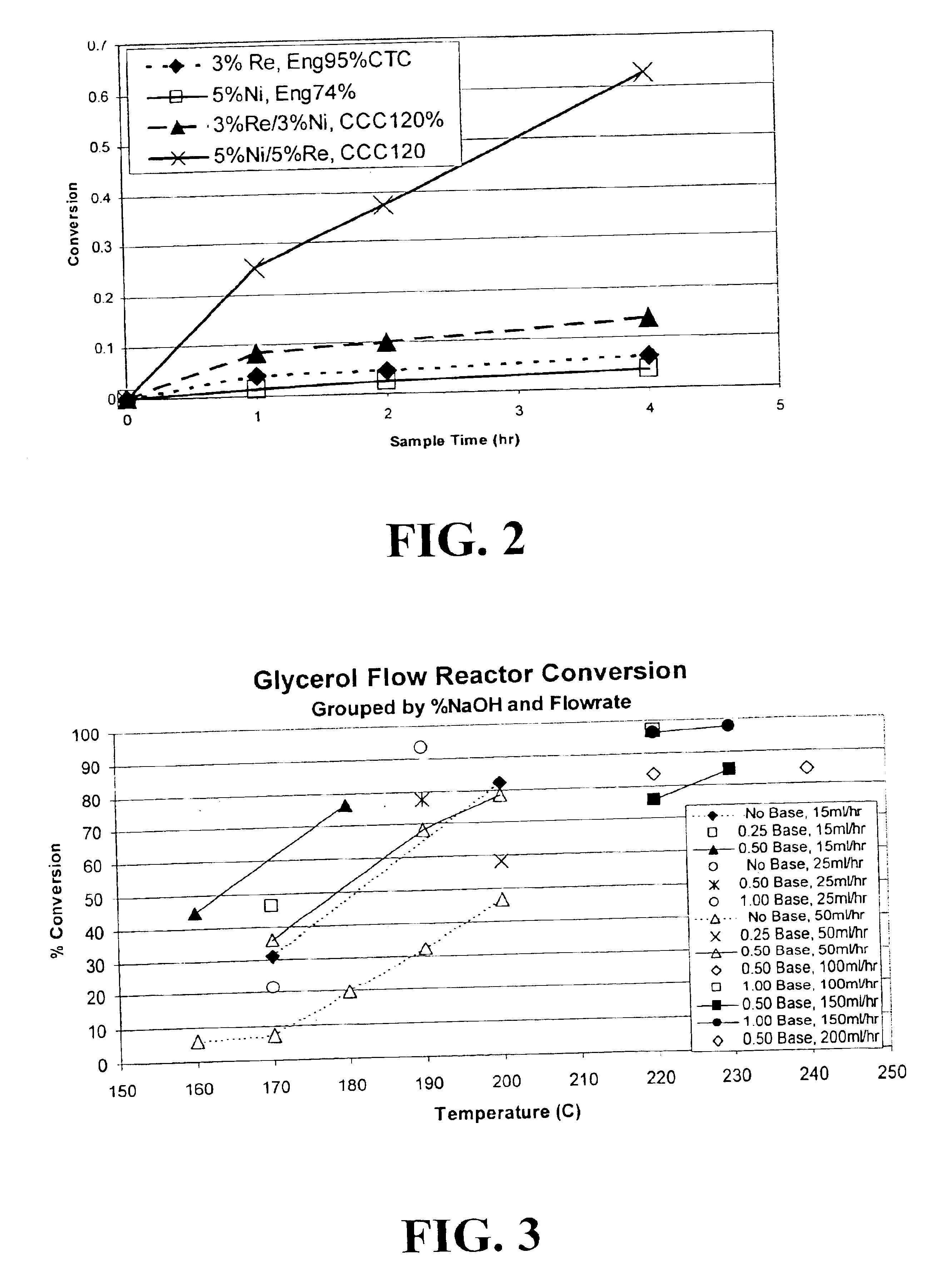

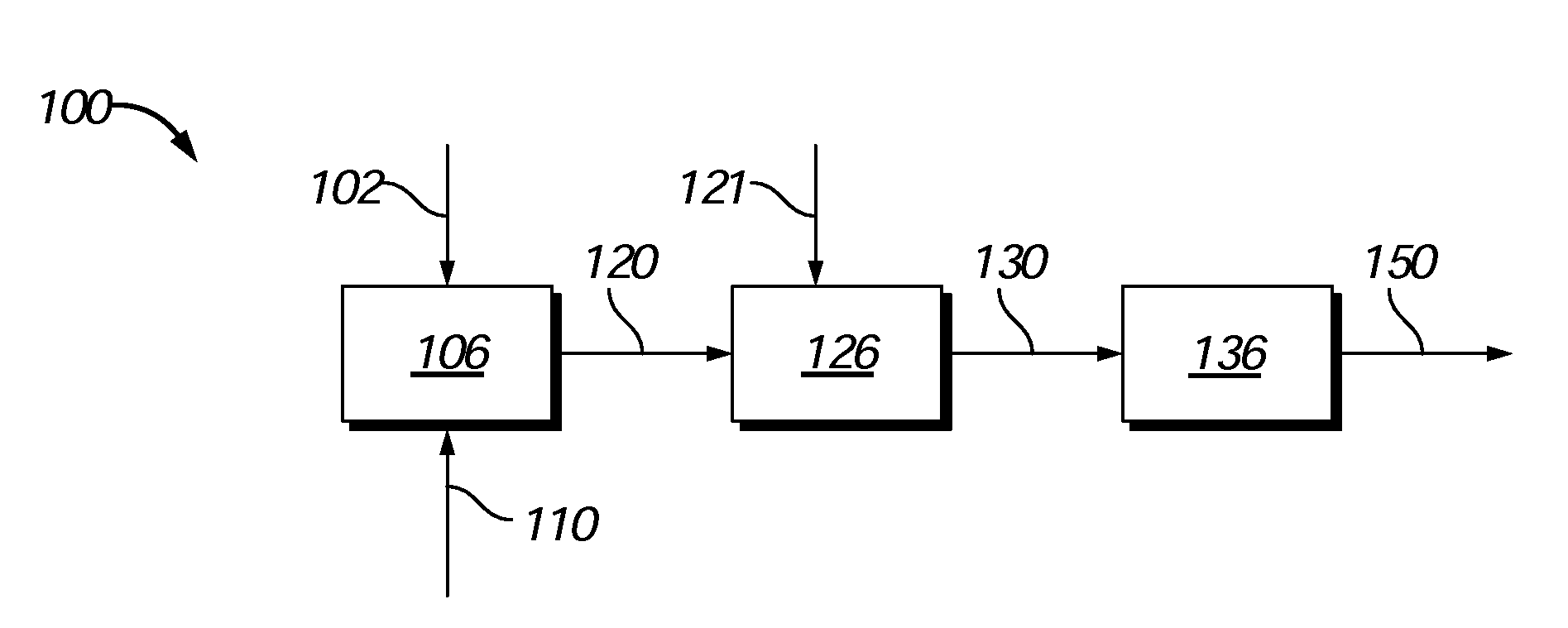

Hydrogenolysis of 6-carbon sugars and other organic compounds

InactiveUS6841085B2High selectivityHigh activityBiocideHydroxy compound active ingredientsHydrogenAlcohol sugars

Methods for hydrogenolysis are described which use a Re-containing multimetallic catalyst for hydrogenolysis of both C—O and C—C bonds. Methods and compositions for reactions of hydrogen over a Re-containing catalyst with compositions containing a 6-carbon sugar, sugar alcohol, or glycerol are described. It has been surprisingly discovered that reaction with hydrogen over a Re-containing multimetallic catalyst resulted in superior conversion and selectivity to desired products such as propylene glycol.

Owner:MICHIGAN STATE UNIV +1

Process to produce biofuels from biomass

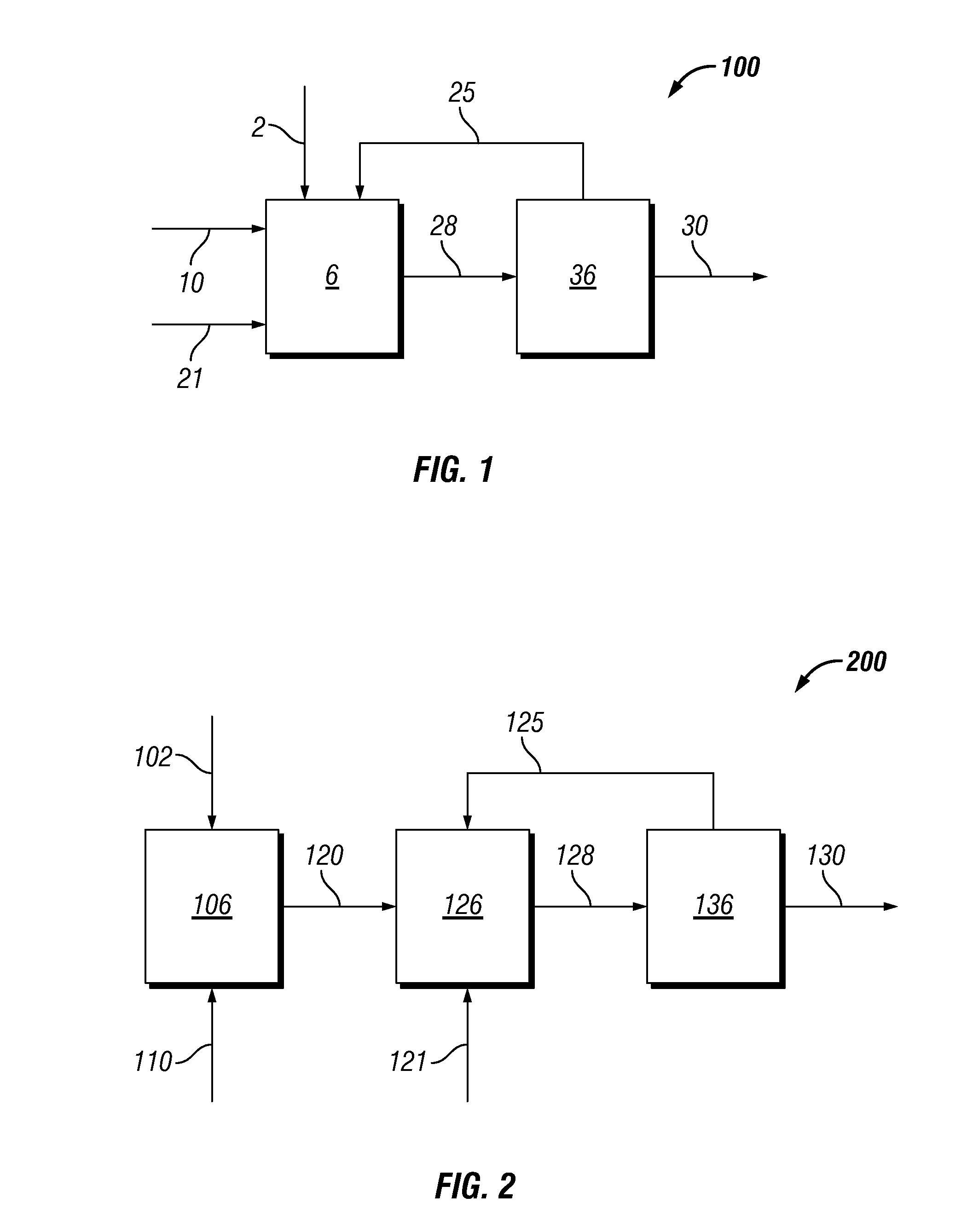

Biofuels can be produced by: (i) providing a biomass containing celluloses, hemicelluloses, lignin, nitrogen compounds and sulfur compounds; (ii) contacting the biomass with a digestive solvent to form a pretreated biomass containing carbohydrates; (iii) contacting the pretreated biomass with hydrogen in the presence of a supported hydrogenolysis catalyst containing (a) sulfur, (b) Mo or W, and (c) Co and / or Ni incorporated into a suitable support to form a plurality of oxygenated intermediates, and (vi) processing at least a portion of the oxygenated intermediates to form a liquid fuel.

Owner:SHELL OIL CO

Process to produce biofuels from biomass

Biofuels can be produced by: (i) providing a biomass containing celluloses, hemicelluloses, lignin, nitrogen compounds and sulfur compounds; (ii) removing sulfur compounds and nitrogen compounds from the biomass by contacting the biomass with a digestive solvent to form a pretreated biomass containing carbohydrates and having less than 35% of the sulfur content and less than 35% of the nitrogen content of untreated biomass on a dry mass basis; (iii) contacting the pretreated biomass directly with hydrogen in the presence of a hydrogenolysis catalyst to form a plurality of oxygenated intermediates, and (vi) processing at least a portion of the oxygenated intermediates to form a liquid fuel.

Owner:SHELL OIL CO

Hydrothermal hydrocatalytic treatment of biomass

A method of hydrothermal hydrocatalytic treating biomass is provided. Lignocellulosic biomass is treated with a digestive solvent to form a pretreated biomass containing soluble carbohydrates. The pretreated biomass is contacted, with hydrogen at a temperature in the range of 150° C. to less than 300° C. in the presence of a pH buffering agent and a supported hydrogenolysis catalyst containing (a) sulfur, (b) Mo or W, and (c) Co, Ni or mixture thereof, incorporated into a suitable support, to form a plurality of oxygenated hydrocarbons.

Owner:SHELL OIL CO

Biofuels via hydrogenolysis-condensation

ActiveUS20110154721A1Easy to oxidizePromote hydrolysis reactionBiofuelsEfficient propulsion technologiesHydrogenPolyol

A method comprises a providing a carbohydrate; reacting the carbohydrate directly with hydrogen in the presence of a hydrogenolysis catalyst to produce a reaction product comprising a polyol; and then processing at least a portion of the reaction product to form a fuel blend.

Owner:SHELL USA INC

Biofuels via hydrogenolysis and dehydrogenation-condensation

ActiveUS20110282115A1Easy to oxidizePromote hydrolysis reactionBiofuelsEfficient propulsion technologiesHydrogenDehydrogenation

A method comprising providing a carbohydrate feed; contacting at least a portion of the carbohydrate feed directly with hydrogen in the presence of a hydrogenolysis catalyst to produce a first reaction product comprising a stable hydroxyl intermediate; contacting at least a portion of the first reaction product comprising the stably hydroxyl intermediates with a dehydrogenation catalyst to form a second reaction product; and contacting at least a portion of the second reaction product with a condensation catalyst comprising a base functionality to form a fuel blend.

Owner:SHELL USA INC

Recyclable buffer for the hydrothermal hydrocatalytic treatment of biomass

InactiveUS20140166221A1Minimal lossMaintain activityPulp bleachingLiquid hydrocarbon mixture productionCelluloseHydrogen

A method of hydrothermal hydrocatalytic treating biomass is provided. Lignocellulosic biomass solids is provided to a hydrothermal digestion unit in the presence of a digestive solvent, at least one of ammonia or a source of ammonia, and a supported hydrogenolysis catalyst containing (a) sulfur, (b) Mo or W, and (c) Co, Ni or mixture thereof, incorporated into a suitable support. The lignocellulosic biomass solids and digestive solvent are heated in the presence of hydrogen, supported hydrogenolysis catalyst and the at least one of ammonia or a source of ammonia forming a product solution containing plurality of oxygenated hydrocarbons and ammonia. At least a portion of ammonia is separated and recycled to the hydrothermal digestion unit.

Owner:SHELL OIL CO

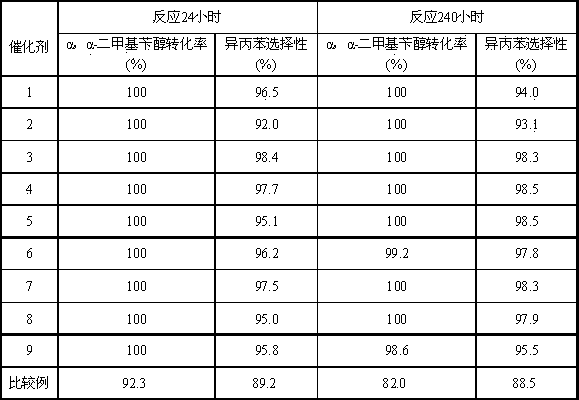

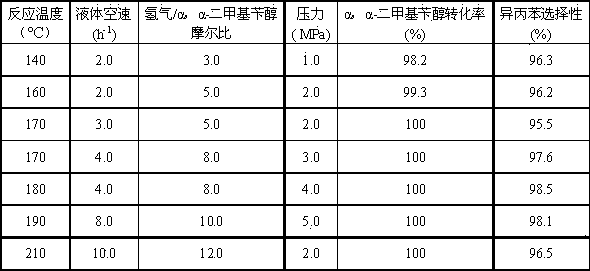

Alpha, alpha-dimethylbenzyl alcohol hydrogenolysis method for preparing isopropyl benzene

InactiveCN104230640AImprove technical effectHydrocarbon from oxygen organic compoundsMetal/metal-oxides/metal-hydroxide catalystsHydrogenAlcohol

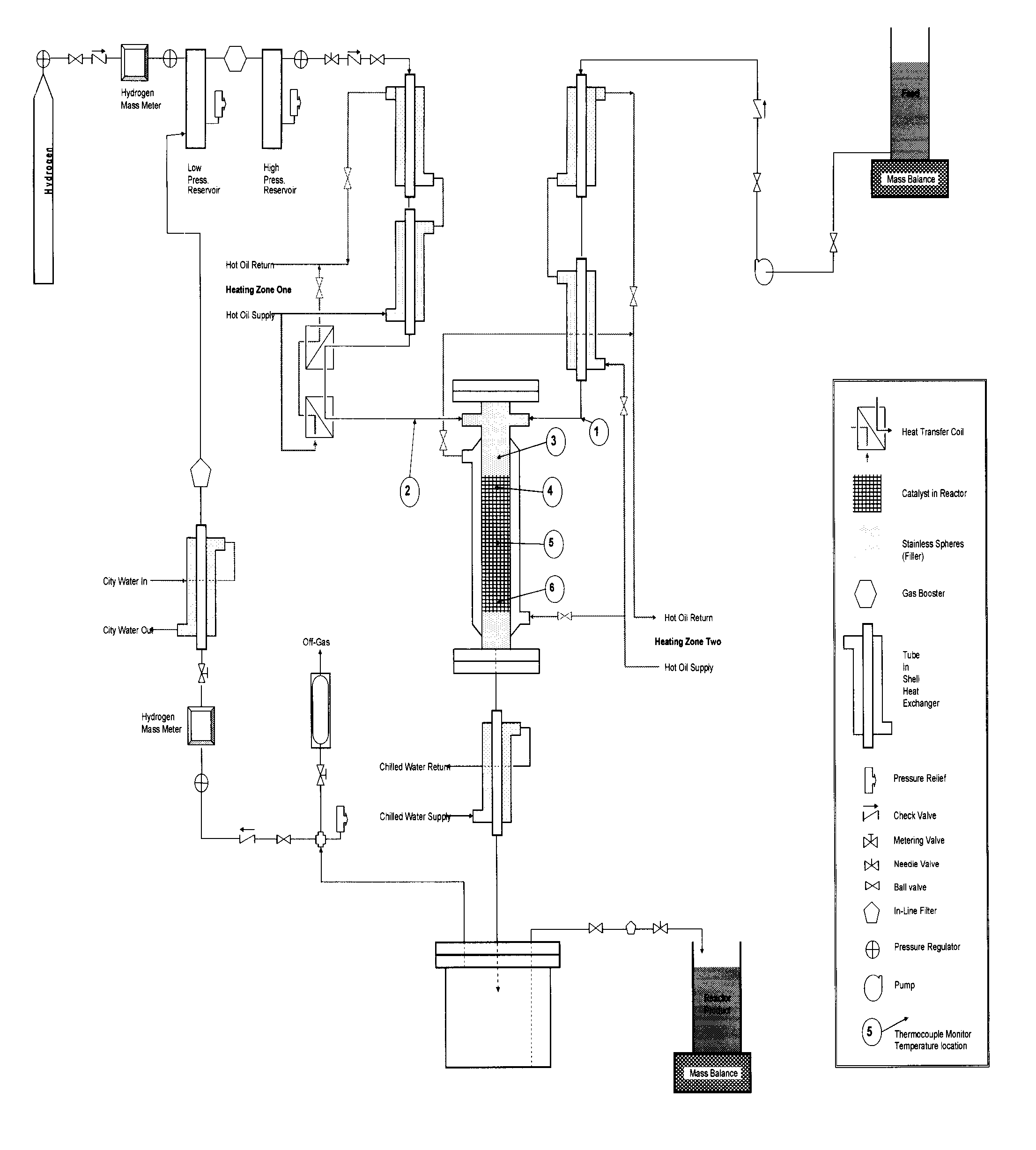

The invention relates to an alpha, alpha-dimethyl-benzyl carbinol hydrogenolysis method for preparing isopropyl benzene, and mainly solves the problems of poor stability of catalyst and serious environmental pollution in the isopropyl benzene production process. A technical scheme for solving the problem is as below: introducing raw materials of hydrocarbons containing alpha, alpha-dimethylbenzyl alcohol and hydrogen into a hydrogenolysis reaction zone, and reacting the raw materials with a catalyst by contact to produce isopropyl benzene. The catalyst comprises the following components by weight: a) 0.1-2.0 parts of Pd metal or oxide; b) 85.0 to 97.0 parts of SiO2; c) 1.0-10.0 parts of at least one selected from Ni or oxide thereof, Co or oxide thereof, and Cu or oxide thereof; and d) 1.0 to 5.0 parts of at least one selected from Mg or oxide thereof, Ca or oxide thereof and Ba or oxide thereof. The method can be used in industrial production of isopropyl benzene by alpha, alpha-dimethyl-benzyl carbinol hydrogenolysis.

Owner:CHINA PETROLEUM & CHEM CORP +1

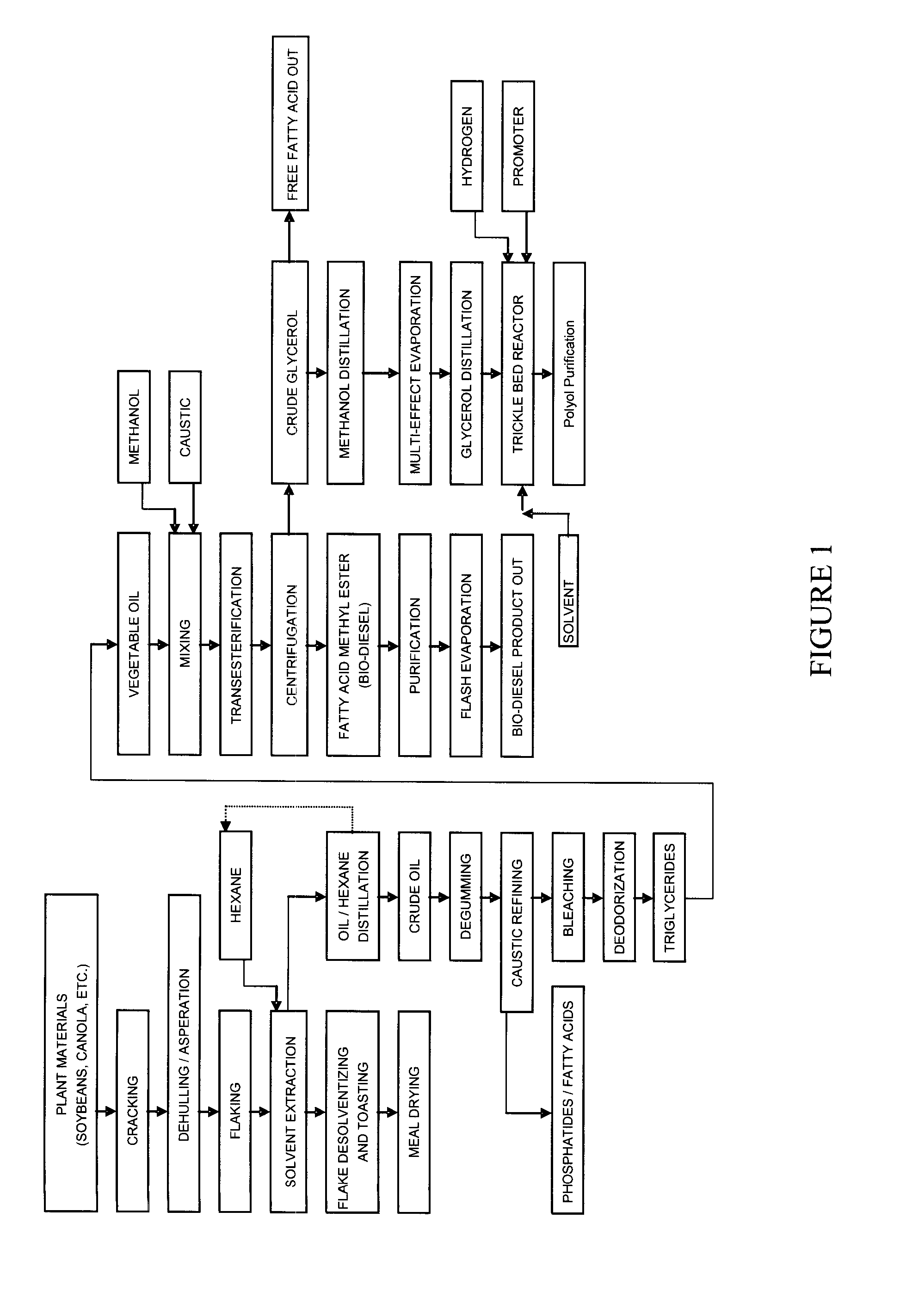

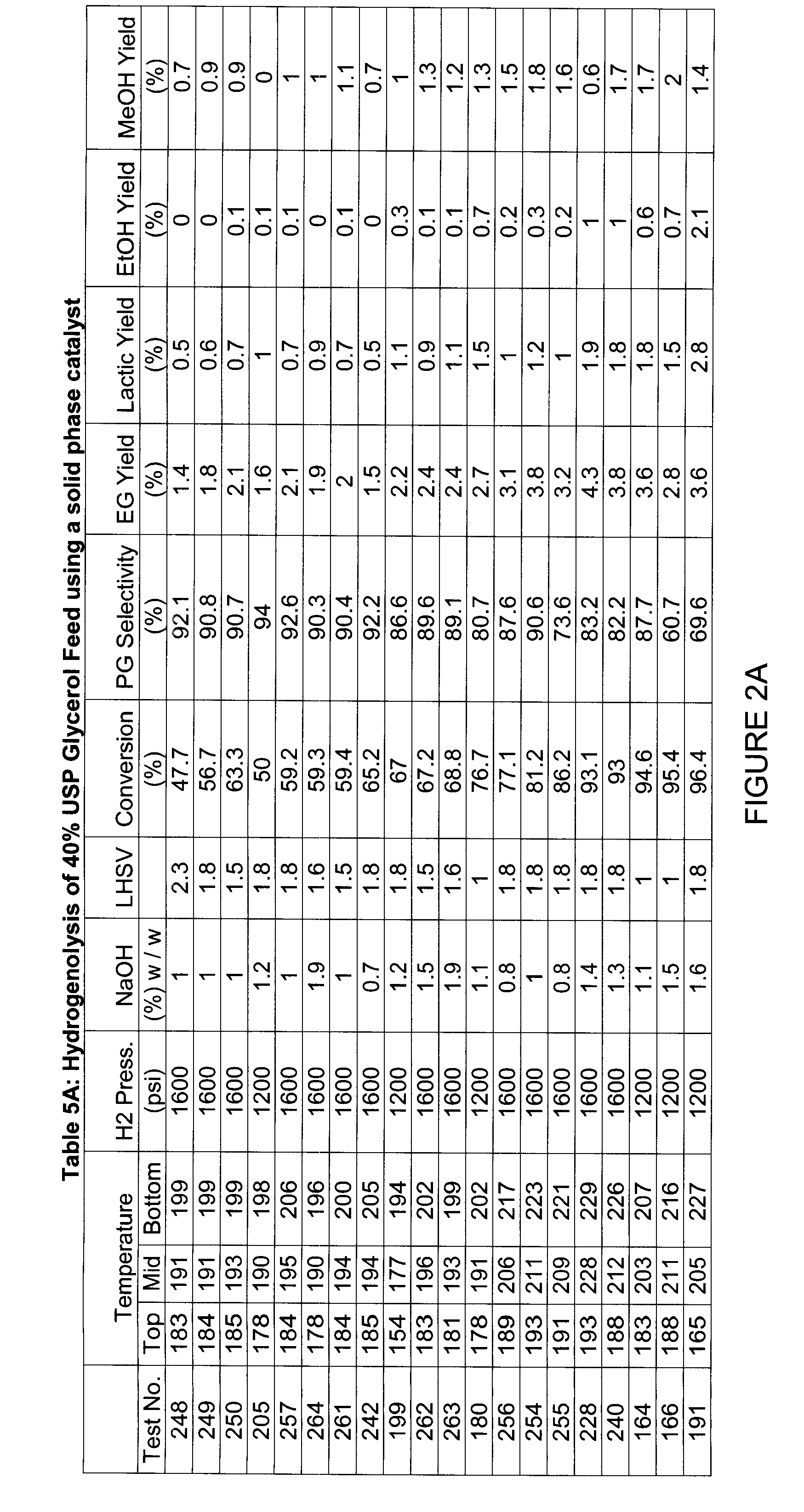

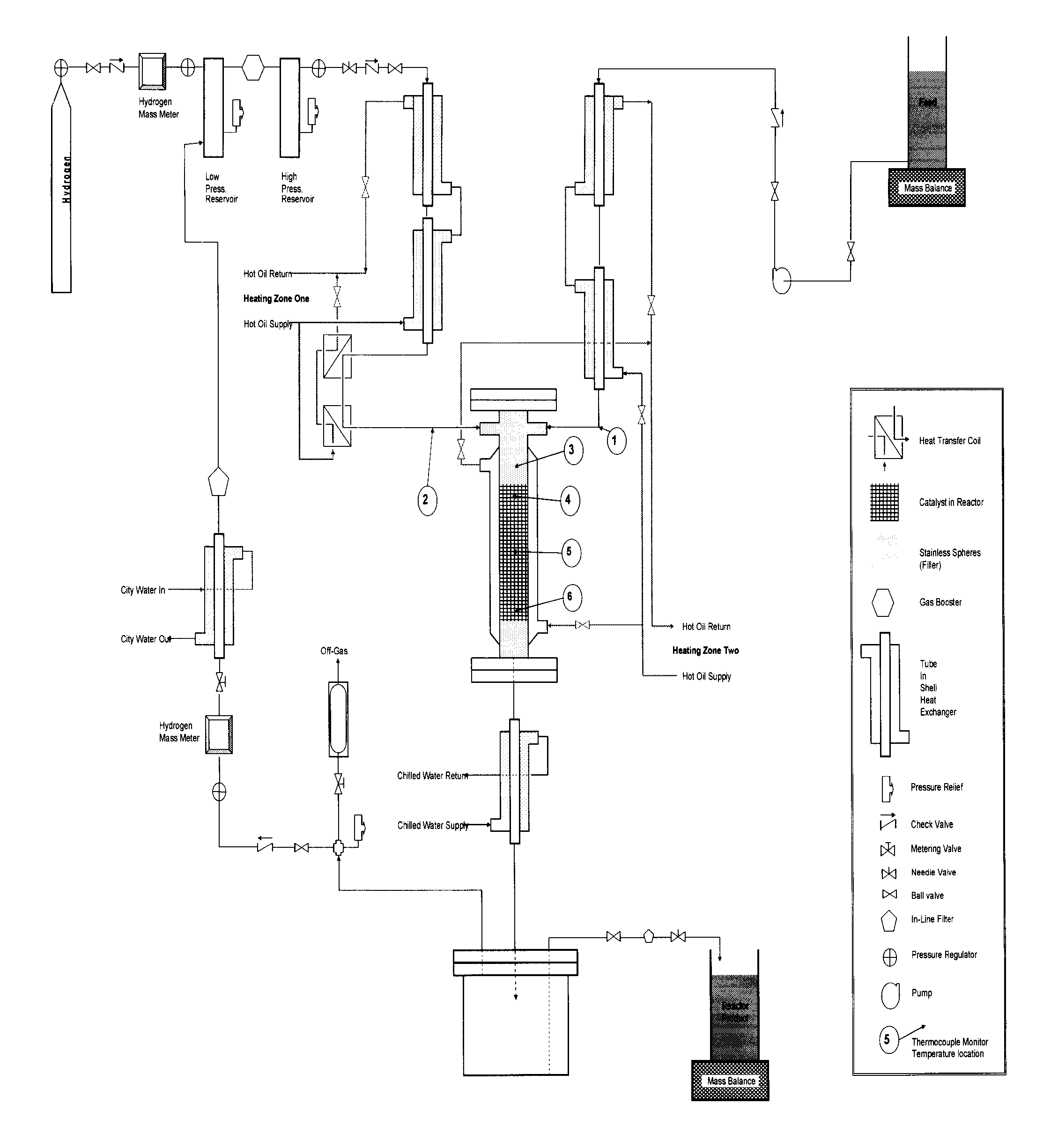

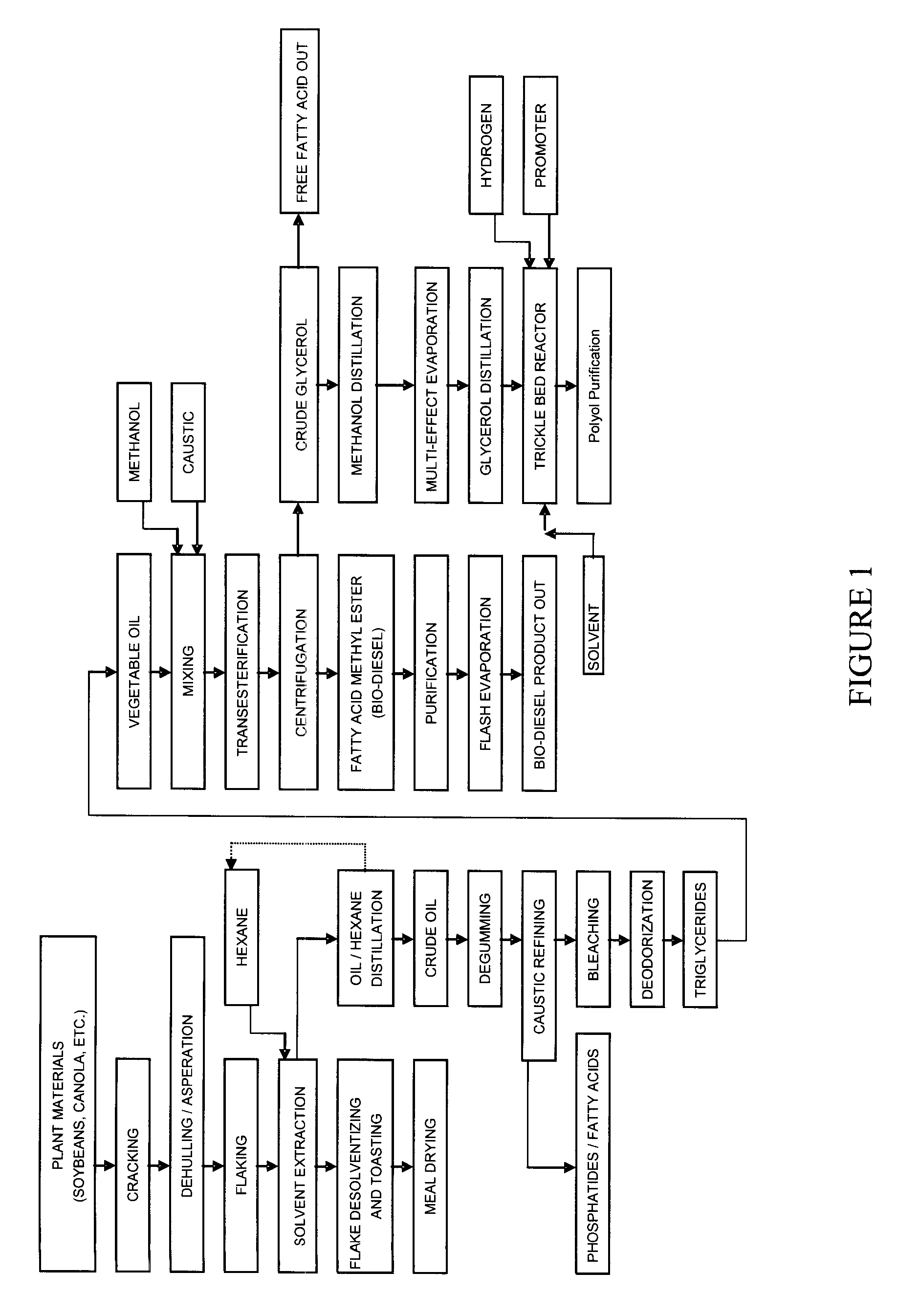

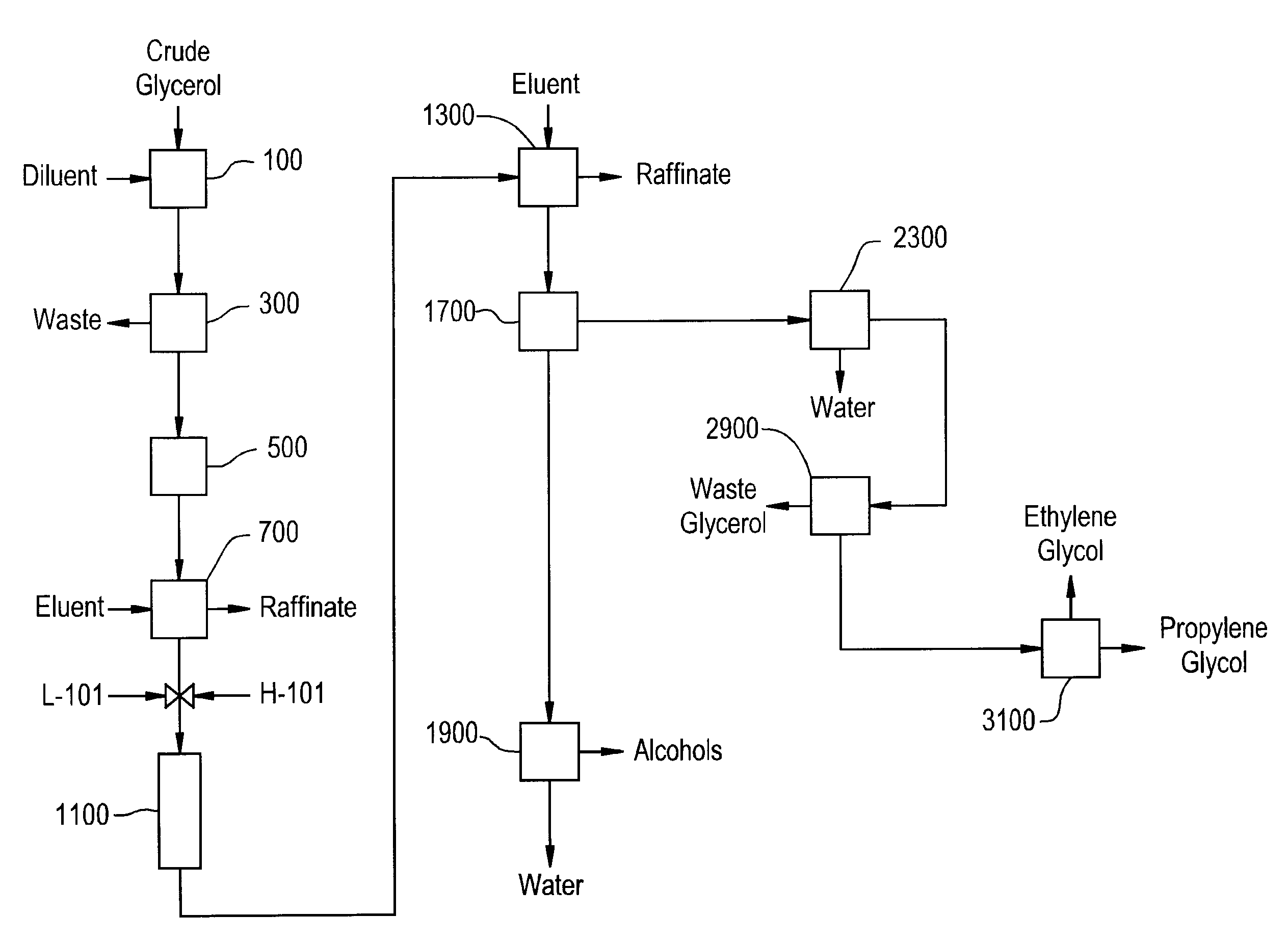

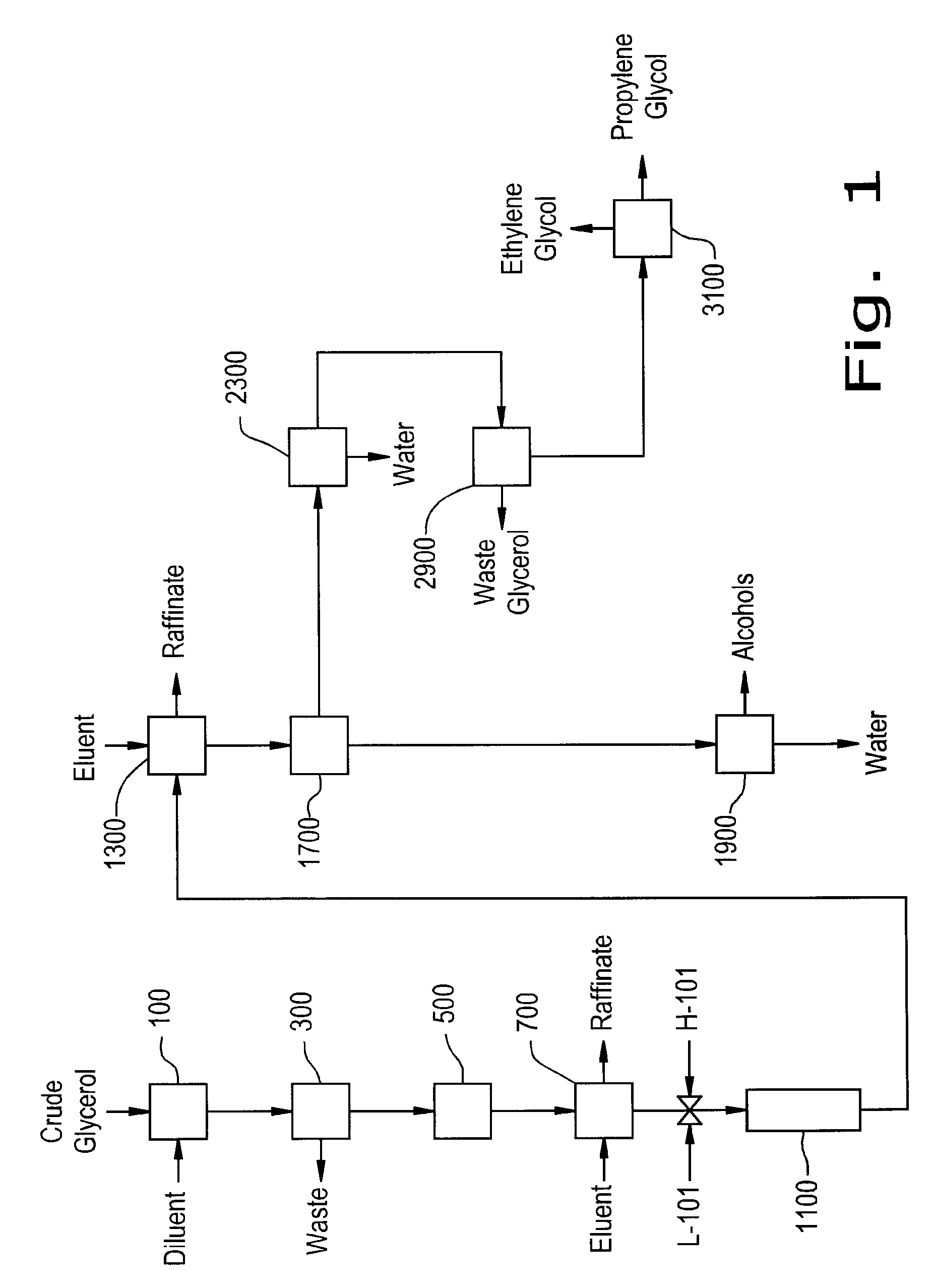

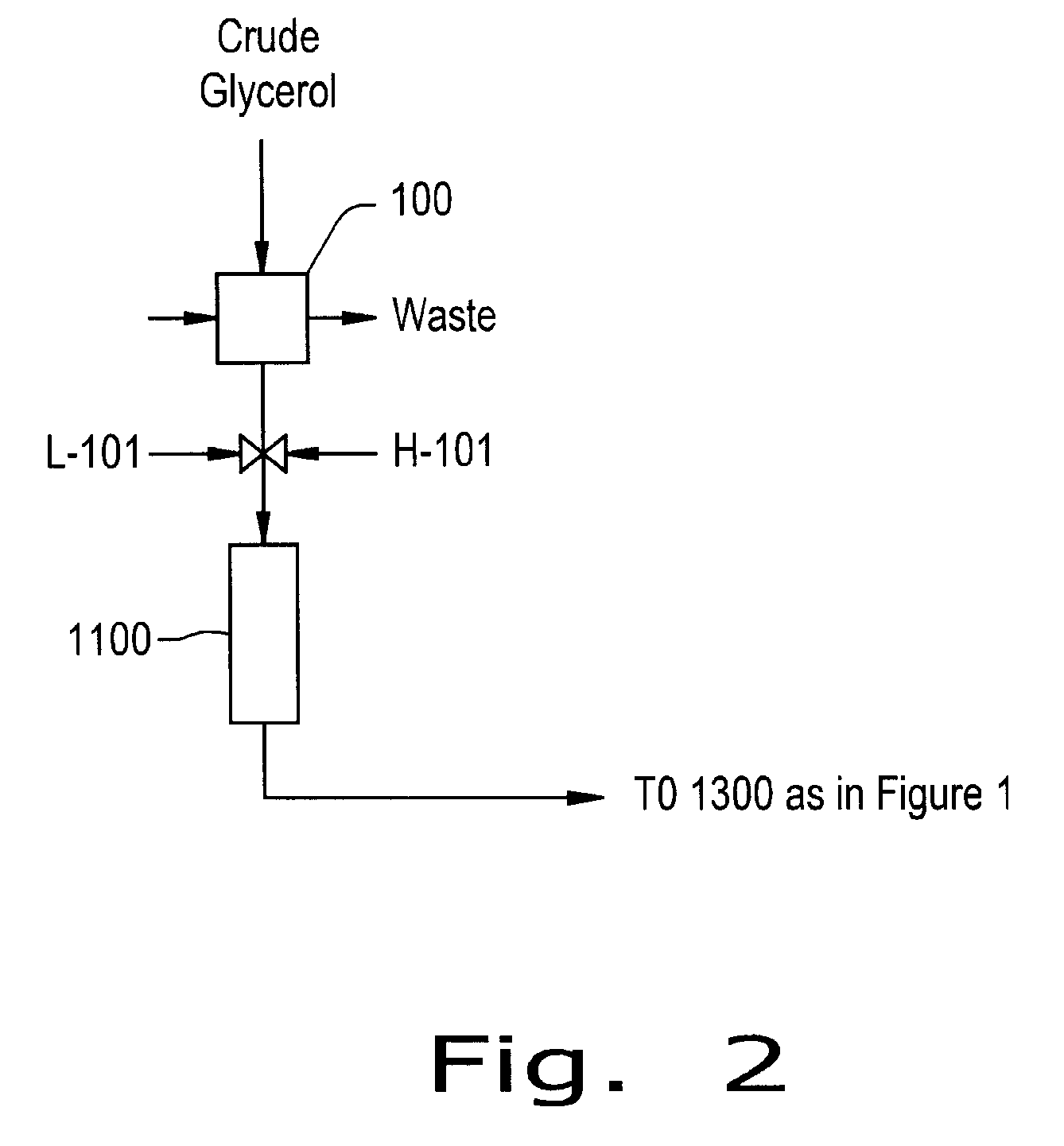

Hydrogenolysis of Glycerol and Products Produced Therefrom

ActiveUS20080228014A1Organic compound preparationPreparation by OH group eliminationGlycerolRadiochemistry

Owner:ARCHER DANIELS MIDLAND CO

Hydrogenolysis of Glycerol and Products Produced Therefrom

Owner:ARCHER DANIELS MIDLAND CO

Preparation of Derivative of Polyhydric Alcohols

A method for converting a polyhydric alcohol into propylene glycol and butanediols is disclosed. Also disclosed are methods for converting polyhydric alcohols into three-carbon products and four-carbon products. Also disclosed are methods for maximizing conversion of polyhydric alcohols and minimizing formation of reaction products that are difficult to remove from the desired product. In other embodiments, methods are described to optimize use of reactants, including hydrogen, in hydrogenolysis of polyhydric alcohols.

Owner:ARCHER DANIELS MIDLAND CO

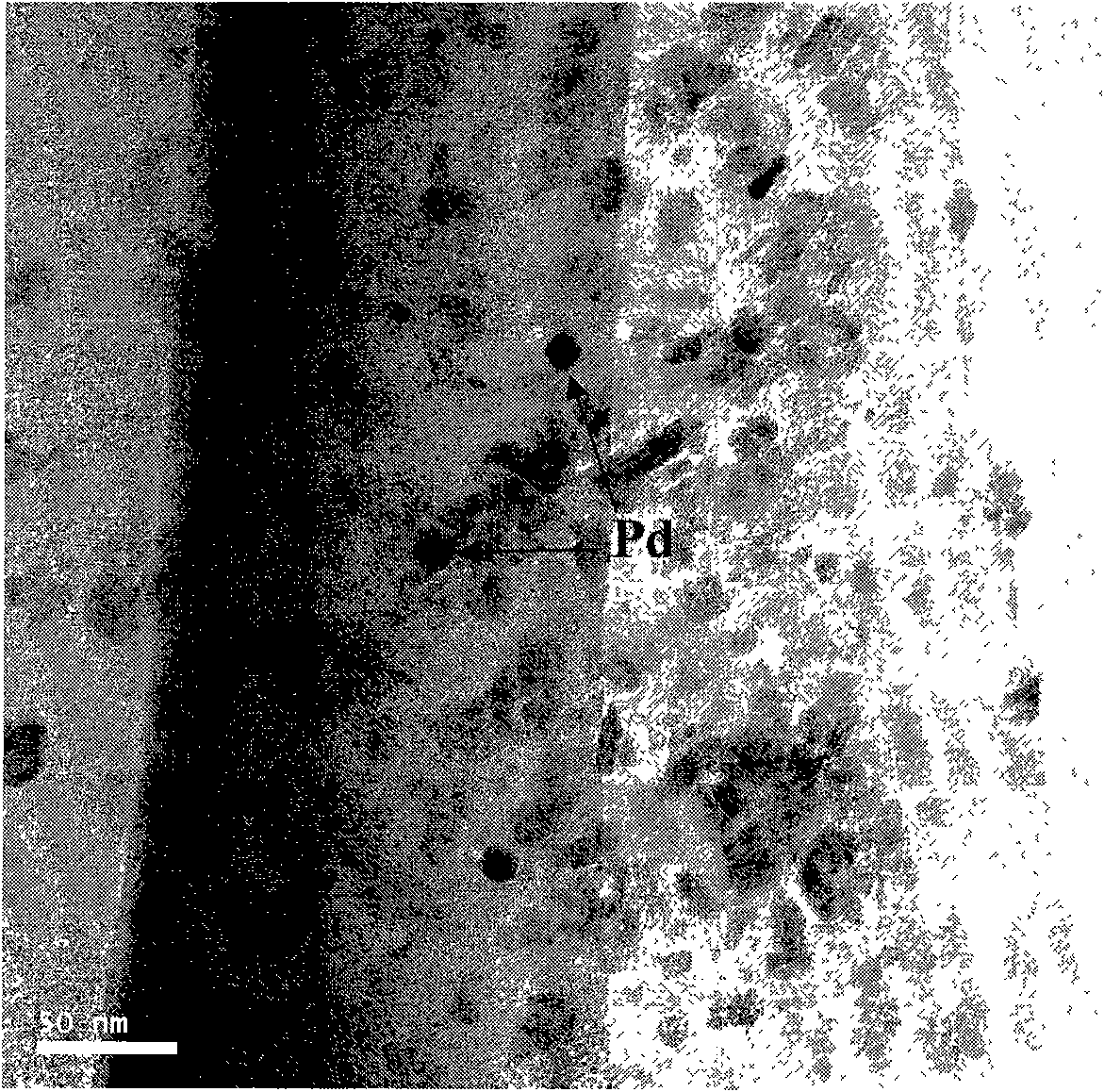

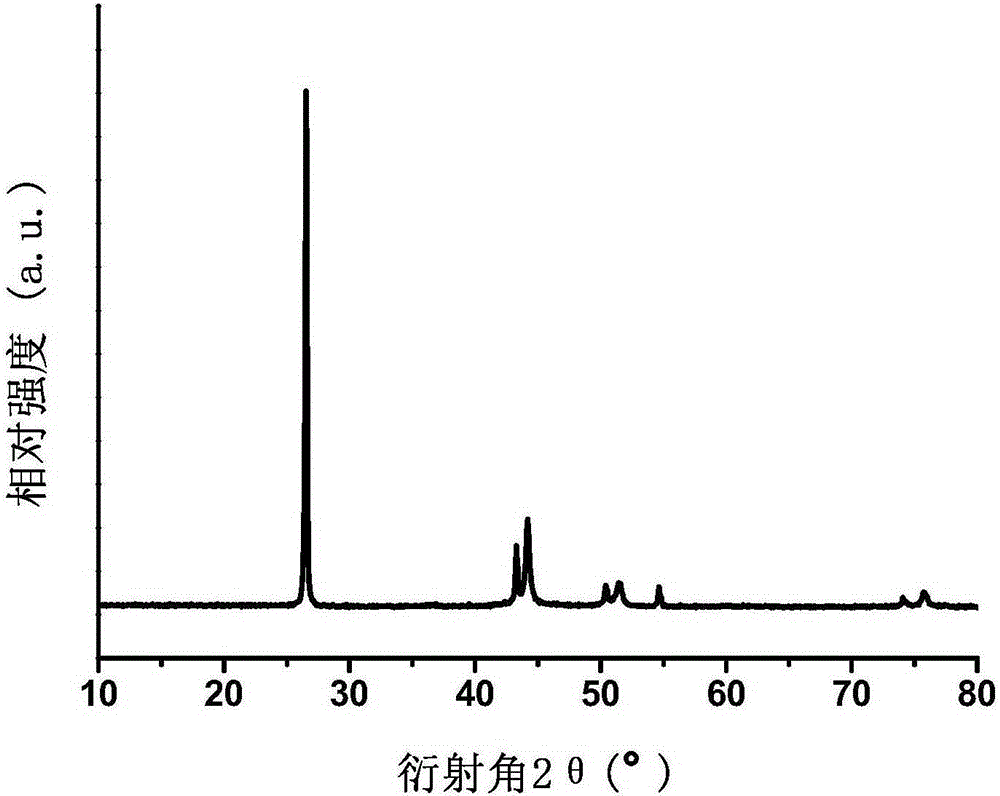

Alpha, alpha-dimethyl-benzyl carbinol direct hydrogenolysis method for preparing isopropyl benzene

The invention relates to an alpha, alpha-dimethyl-benzyl carbinol direct hydrogenolysis method for preparing isopropyl benzene, and mainly solves the problem of poor stability of catalyst in the prior art for isopropyl benzene production by alpha, alpha-dimethyl-benzyl carbinol hydrogenolysis. A technical scheme for solving the problem is as below: introducing raw materials of hydrocarbons containing alpha, alpha-dimethyl-benzyl alcohol and hydrogen into a hydrogenolysis reaction zone, and reacting the raw materials with a catalyst by contact to produce isopropyl benzene. The catalyst comprises the following components by weight: a) 0.2-2.0 parts of Pd; b) 91.0-98.0 parts of active carbon; and c) 1.0-10.0 parts of at least one selected from Ni or oxide thereof, Co or oxide thereof, Cu or oxide thereof and Sn or oxide thereof. The method can be used for industrial production of isopropyl benzene by alpha, alpha-dimethyl-benzyl carbinol hydrogenolysis.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing 1, 2-trimethylene glycol by glycerol hydrogenoiysis and preparation thereof

InactiveCN101214440AIncrease conversion rate per passHigh activityPreparation by OH group eliminationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementGlycerol

The invention relates to a catalyst of a 1, 2-propanediol prepared by hydrogenolysis of glycerine. The catalyst is a compound oxide, and contains cuprocide (weight fraction) 25 percent to 60 percent, zinc oxide 35 percent to 70 percent, aluminum oxide (weight fraction) 0 percent to 10 percent and at least one or a plurality of rare-earth oxides 0.5 percent to 10 percent of rare earth elements, such as Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, etc. The catalyst is used in continuous hydrogenolysis reaction of glycerine, in which the conversion rate of the glycerine is high, the selectivity of the 1, 2-propanediol is high and the activity of the catalyst is very stable. The invention also provides the preparation method of the catalyst and application of the catalyst in preparation of 1, 2-propanediol by hydrogenolysis reaction of glycerine.

Owner:NANJING UNIV OF TECH

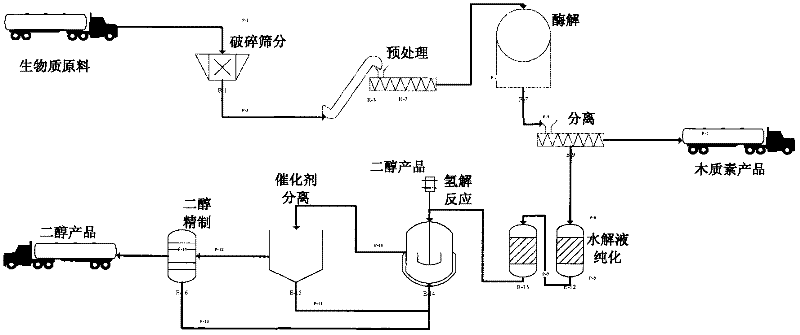

Method for preparing dihydric alcohol from lignocellulosic biomass

ActiveCN102286548AWidely distributedFully distributedOrganic compound preparationHydroxy compound preparationLiquid glucoseFiber

The invention relates to a method for preparing dihydric alcohol from lignocellulosic biomass, which has main steps of: 1, adding alkali liquor, acid liquor or water for pretreatment after lignocellulosic biomass crushing; 2, carrying out enzymolysis and concentrating liquid glucose filtered through enzymolysis after decoloration and ion exchange impurity removal; 3, adding catalysts with hydrogenation hydrogenolysis activity for carrying out hydrogenation hydrogenolysis reaction on the concentrated liquid glucose under the conditions of the pH being 8 to 14, the temperature being 130 to 250 DEG C and hydrogen atmosphere, separating the catalysts, and producing various dibasic alcohol with the carbon number being 2 to 6 after product rectification. The method utilizes the lignocellulosic biomass pretreatment-zymolyting glucose liquid as raw materials, and monosaccharide, soluble polysaccharides and sugar degradation products can respectively react, so both the efficiency and the process controllability can be greatly improved, and products can be independently used through separation and can be directly used for producing unsaturated polyester resin, polyurethane, fuel additives, surface active agents, emulsifying agents, motor vehicle antifreeze fluid and the like without depth separation.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

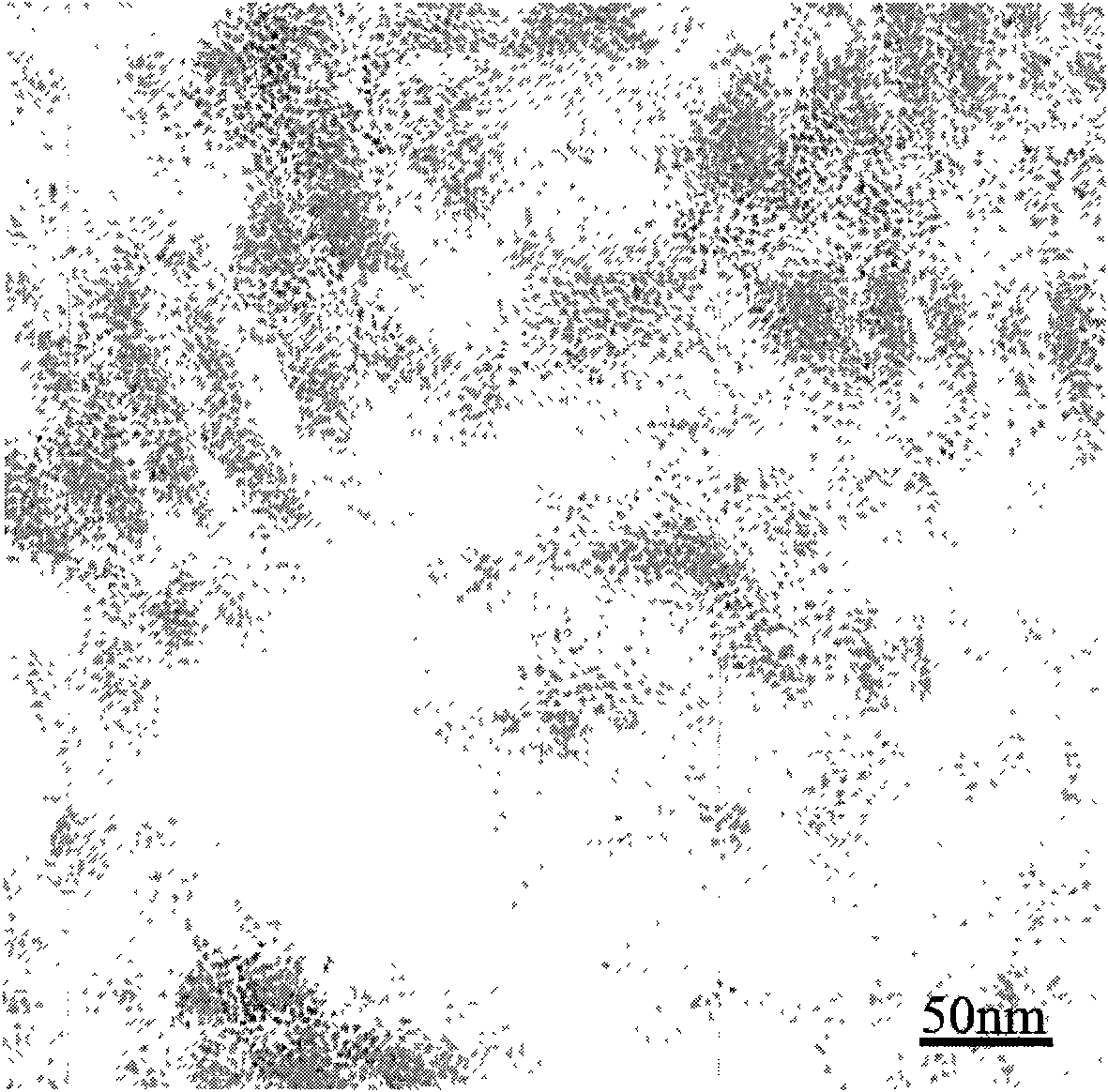

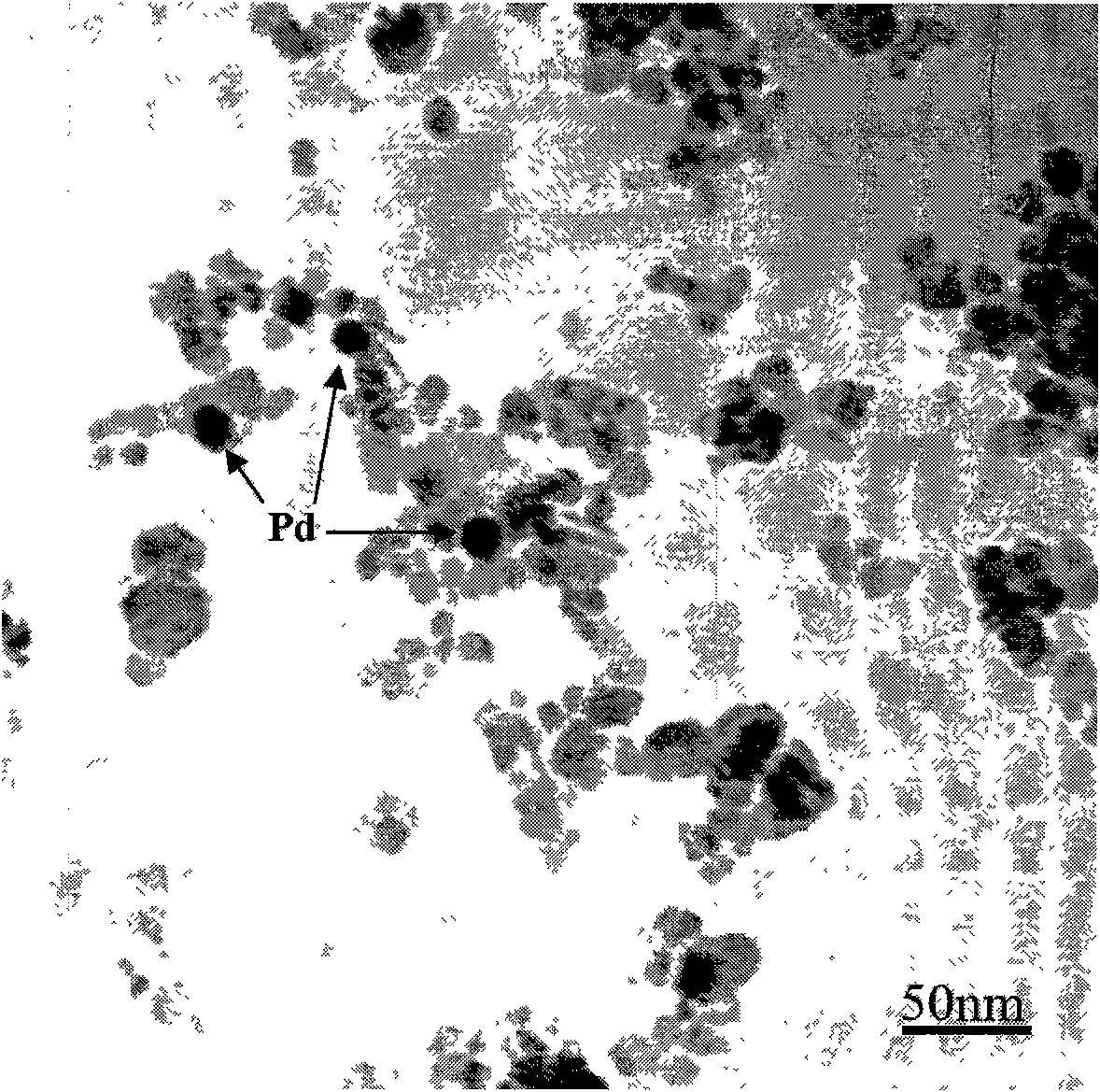

Loading type Pd base metal nanometer cluster catalyst, preparing method and applications thereof

ActiveCN101767018AImprove catalytic performanceNo catalytic hydrogenolysis dechlorinationOrganic compound preparationChemical recyclingNitro compoundIron oxide

The invention discloses a loading type Pd base metal nanometer cluster catalyst, a preparing method and applications thereof. The catalyst comprises Pd metal nanometer particles of 1-25nm, or bimetal or polymetal nanometer particles containing Pd, and ferric oxide nanometer particles, wherein the ferric oxide nanometer particle is used as the carrier, has the primary particle size of 5-200nm, and has the general formula of FeyOx; the bimetal or polymetal nanometer particles are selected from one or a plurality of Pt, Rh, Ru, Os, Ir and Re; when the metal nanometer particles are Pd nanometer particles, x / y is greater than 1, but is smaller than 4 / 3, or is greater than 4 / 3, but is smaller than 3 / 2; and when the metal nanometer particles are bimetal or polymetal nanometer particles containing Pd, x / y is greater than 1, but is smaller than or equal to 3 / 2. The catalyst has excellent activity, selectivity and stability on the selective hydrogenating synthesis chlorinated arylamine of the chlorinated aromatic compounds, solves the problems of hydrogenolysis and dechlorination of products in the process of the Pd catalyst catalyzing the chlorinated aromatic compounds to hydrogenate to prepare the chlorinated arylamine, and has important industrial application values.

Owner:PEKING UNIV

Desulphurisation material

A particulate desulphurisation material is described comprising one or more nickel compounds, a zinc oxide support material, and one or more alkali metal compounds wherein the nickel content of the material is in the range 0.3 to 10% by weight and the alkali metal content of the material is in the range 0.2 to 10% by weight. A method of making the desulphurisation material is also described comprising the steps: (i)contacting a nickel compound with a particulate zinc support material and an alkali metal compound to form an alkali-doped composition, (ii)shaping the alkali-doped composition, and (iii)drying, calcining, and optionally reducing the resulting material. The desulphurisation material may be used to desulphurise hydrocarbon gas streams with reduced levels ofhydrocarbon hydrogenolysis.

Owner:JOHNSON MATTHEY PLC

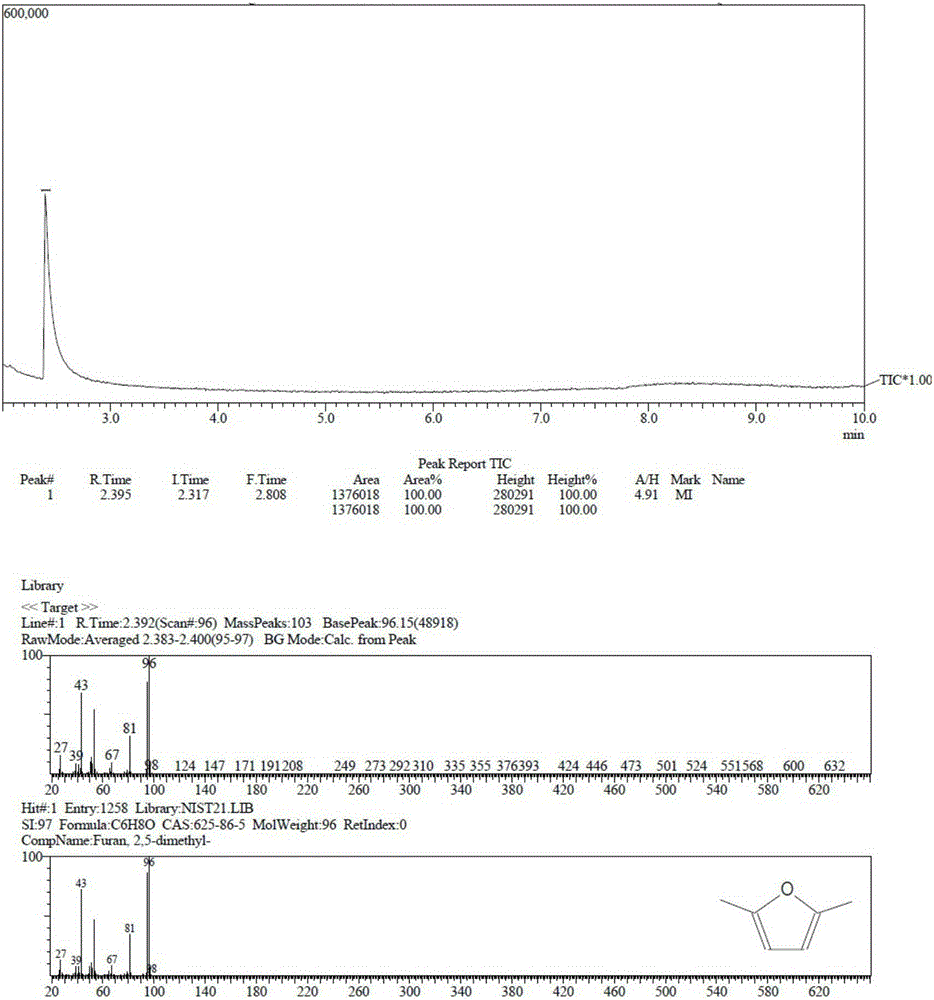

Catalyst for preparing 2,5-dimethylfuran through selective hydrogenolysis of 5-hydroxymethylfurfural and preparation method of catalyst

ActiveCN105251491ALow costPlay a protective roleOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsCarbon layerHydroxymethylfurfural

The invention discloses a catalyst for preparing 2,5-dimethylfuran through selective hydrogenolysis of 5-hydroxymethylfurfural and a preparation method of the catalyst. The catalyst consists of a catalyst carrier and carbon layer coated reactive metals, wherein the catalyst carrier comprises a carbon-based carrier, SiO2, TiO2 or Al2O3 and the like; and the reactive metals are selected from Co, Fe, Ni, Cu or Zn and other base metals. Compared with the conventional catalyst system, the catalyst disclosed by the invention has the advantages that (1) the reactive metal of the catalyst refers to a first transition metal, and the raw materials are cheap and readily available; (2) compared with a noble metal catalyst, the catalyst disclosed by the invention has extremely high activity and selectivity; and (3) the catalyst has magnetism and is easy to recycle.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Shaped metal fixed-bed catalyst, a process for its preparation and its use

A shaped metal fixed-bed catalyst is disclosed which contains at least one catalyst alloy formed of a catalyst metal and an extractable alloying component. The catalyst is activated in an outer layer with a thickness of 0.1 to 2.0 mm starting from the surface by complete or partial extraction of the extractable alloying component. The catalyst may also contain promoters. The catalyst is distinguished from known catalyst in that it is formed exclusively of the catalyst alloy and has a total pore volume of 0.1 to 0.6 ml / g. The catalyst is used for hydrogenation, dehydrogenation and hydrogenolysis reactions.

Owner:DEGUSSA AG

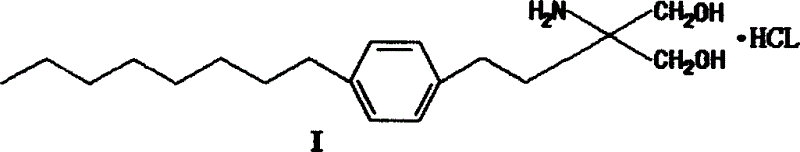

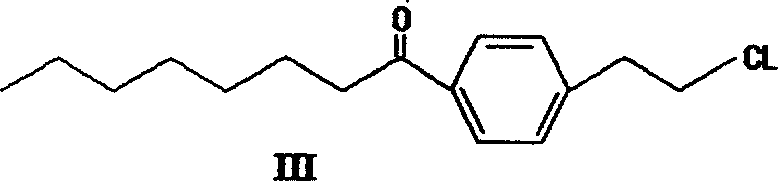

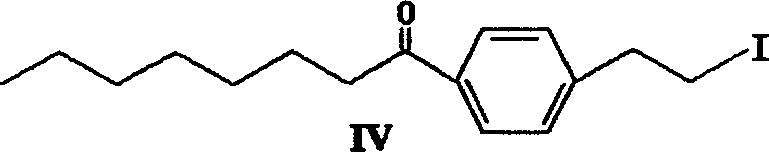

Method for preparing 2-para octylphenyl ehtyl-2-amino propanediol

InactiveCN1528738AEasy to manufactureEfficient manufacturingOrganic compound preparationAmino-hyroxy compound preparationSodium iodidePropanediol

The invention provides a method to prepare a compound method, including the steps: ethylbenzene and capryl chloride make Friedel-Crafts reaction to generate p-capryl chloroethylbenzene; convert capryl chloroethylbenzene under the action of sodium iodide into p-capryl iodoethylbenzene; p-capryl iodoethylbenzene and acetylamino diethyl malonate condense under the action of alkali to generate 2-(p-capryl phenethyl)-2-acetylamino diethyl malonate; or p-capryl iodoethylbenzene makes elimination reaction under the action of alkali to generate p-capryl styrene, which together with acetylamino diethyl malonate condenses under the action of alkali into 2-(p-capryl phenethyl)-2- acetylamino diethyl malonate; a compound is reduced into 2-[4-(1-hydroxyoctyl) phenethyl-]2- acetylamino propylene alcohol; the other coumpound makes hydrogenolysis to obtain 2-(p-octyl phenethyl)-acetylamino propylene alcohol; make alkali hydrolyzation and then acidifies them into salt, so as to obtain it. It also provides a method to prepare intermediate in the above preparing course.

Owner:马启明

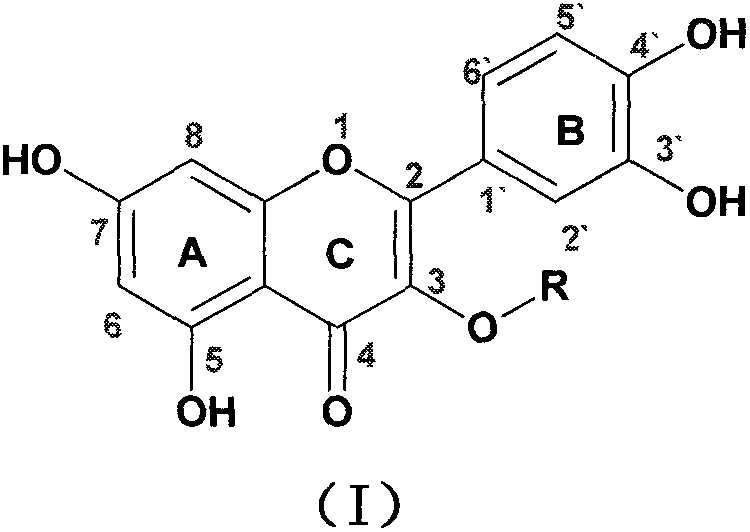

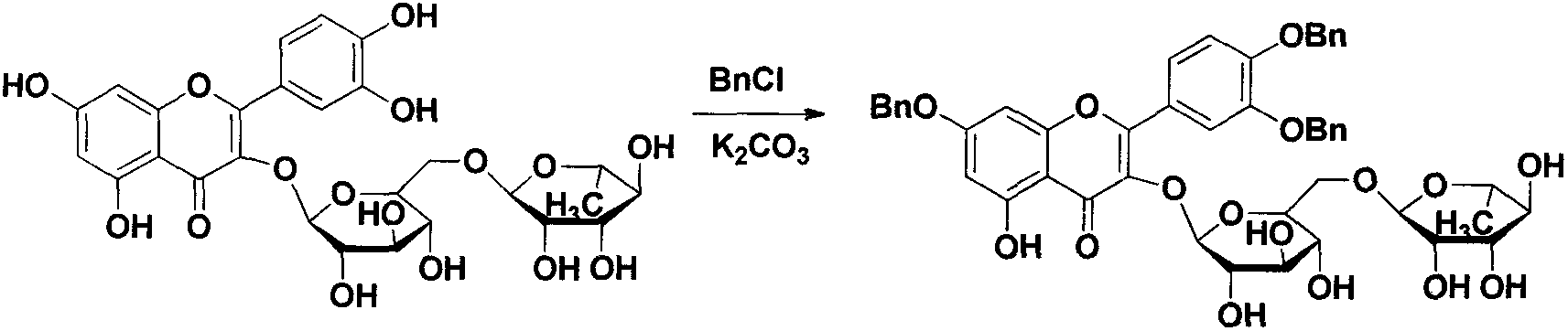

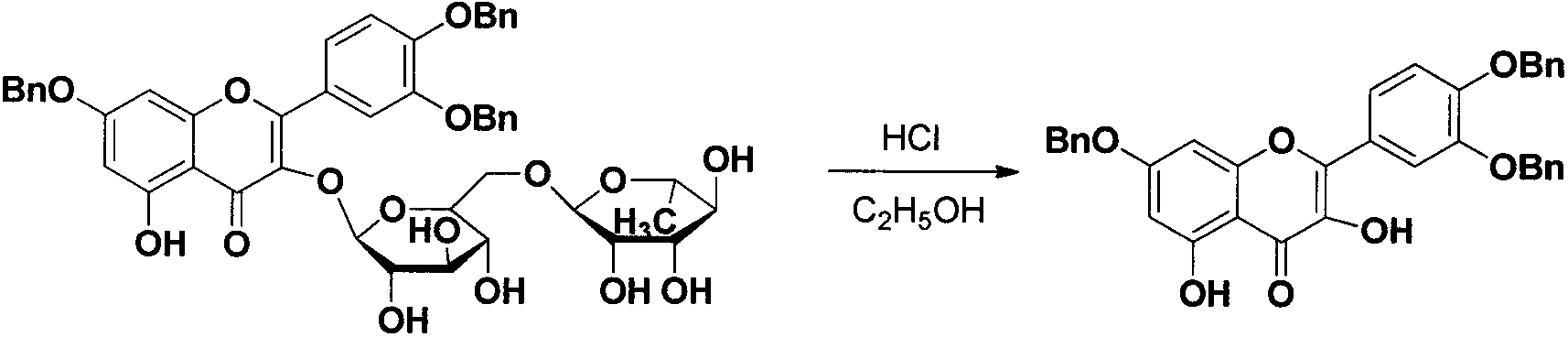

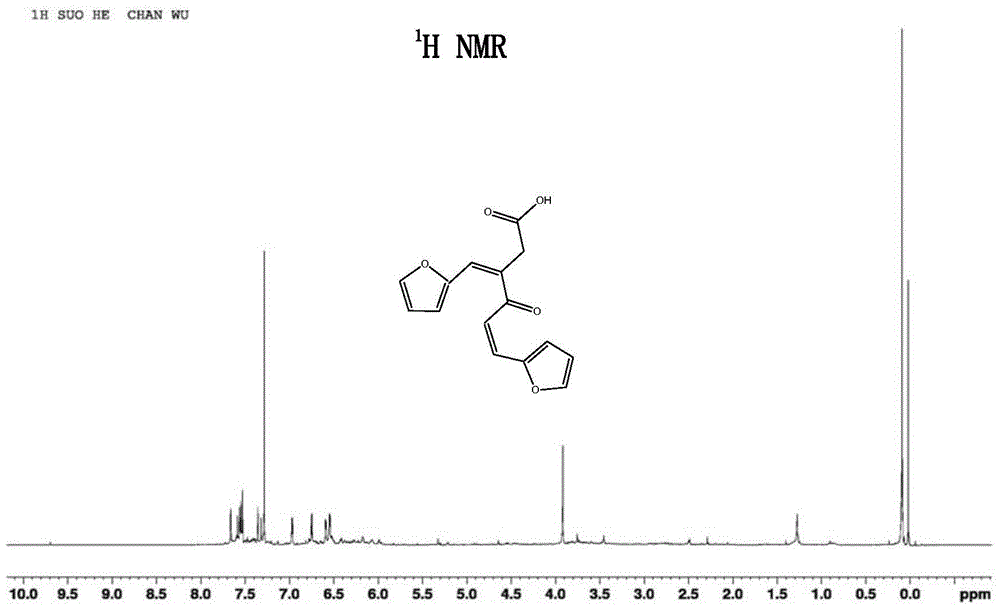

Quercetin-3-O-acyl ester and preparation method thereof

InactiveCN102659735AEnhanced inhibitory effectOrganic active ingredientsOrganic chemistryRutinHydrolysis

The invention relates to quercetin-3-O-acyl ester and a preparation method thereof and belongs to the technical field of pharmaceutical chemistry. The preparation method comprises the following steps: taking cheap rutin as a starting raw material and preparing a quercetin-3-O-acyl ester compound through benzylation, hydrolysis under the acidic conditions, esterification, catalytic hydrogenolysis and other reactions. The method has the characteristics of good selectivity, mild reaction condition, high yield, low cost, simplicity and convenience in operation, easiness in industrial production and the like. In addition, the inhibitory effect of the obtained quercetin-3-O-acyl ester on human esophageal squamous carcinoma cells EC9706, human prostatic cancer cells PC-3 and human gastric cancer cells MGC-803 is remarkably superior to that of quercetin; and the quercetin-3-O-acyl ester can be used in the field of foods and medicines and is possible to develop into a new candidate drug for treating tumor.

Owner:ZHENGZHOU UNIV

Method of preparing long chain alkane for jet fuel by virtue of sugar platform compound

ActiveCN104650947AReduce usageAchieve phase separationLiquid hydrocarbon mixture productionBio-feedstockAlkaneIsomerization

The invention discloses a method of preparing long chain alkane for a jet fuel by virtue of a sugar platform compound. The method comprises the following steps: carrying out aldol condensation on the sugar platform compound in an aqueous solution under catalysis of alkali to generate a long chain oxygenated compound with ten to seventeen carbons; and then carrying out hydrogenation under the action of a metal catalyst, and finally carrying out hydrogenation, deoxidation, isomerization, cracking and cyclization under the action of the metal catalyst to generate a long chain n-alkane / isoparaffin with eight to fifteen carbons. According to the method disclosed by the invention, other organic solvents are prevented from being used, and in the condensation process, condensation products are separated from one another, a solid condensation product is directly separated from the aqueous solution, and the energy consumption is lowered; a solid product is dissolved by an alcohol solvent, the subsequent hydrogenation and deoxidation processes are carried out on the solid product, and the alcohol solvent can be provided by sugar / sugar alcohol hydrogenolysis; meanwhile, hydrogen needed by the technological process can be directly provided by the reforming process of a sugar alcohol solution, and the C component and the H component in a biological jet fuel and the solvent used in the process can be from biomass materials.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

Catalyst for the production of polyols by hydrogenolysis of carbohydrates

InactiveUS20070135301A1Catalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSilicon dioxidePt element

A catalyst for the hydrogenolysis of carbohydrates is disclosed. The catalyst comprises nickel metal on an alumina-silica support. Optionally, the catalyst may be promoted with noble metals selected from the group consisting of copper, ruthenium, rhodium, palladium, platinum, gold, silver, and combinations thereof.

Owner:SUD CHEM INC

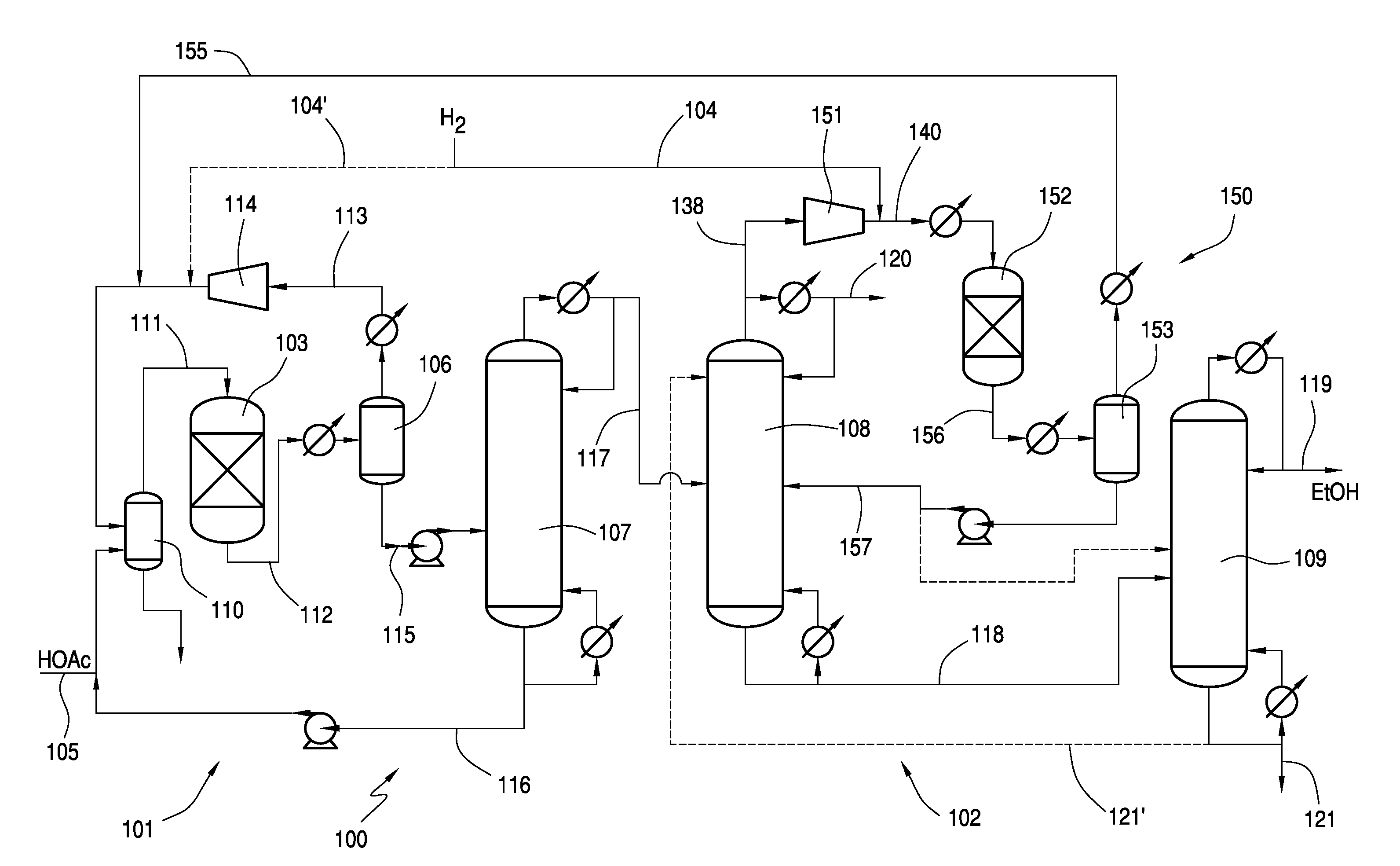

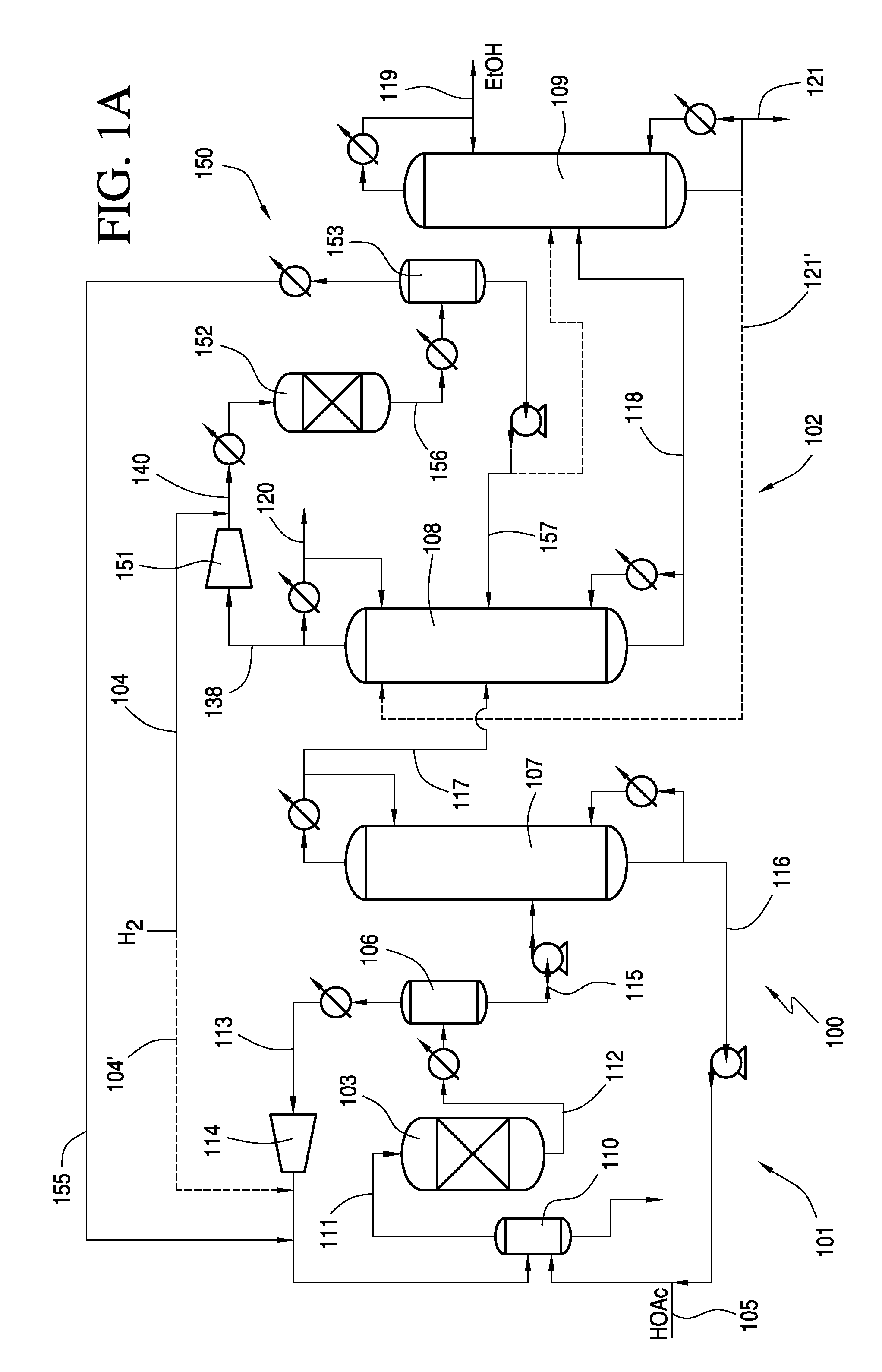

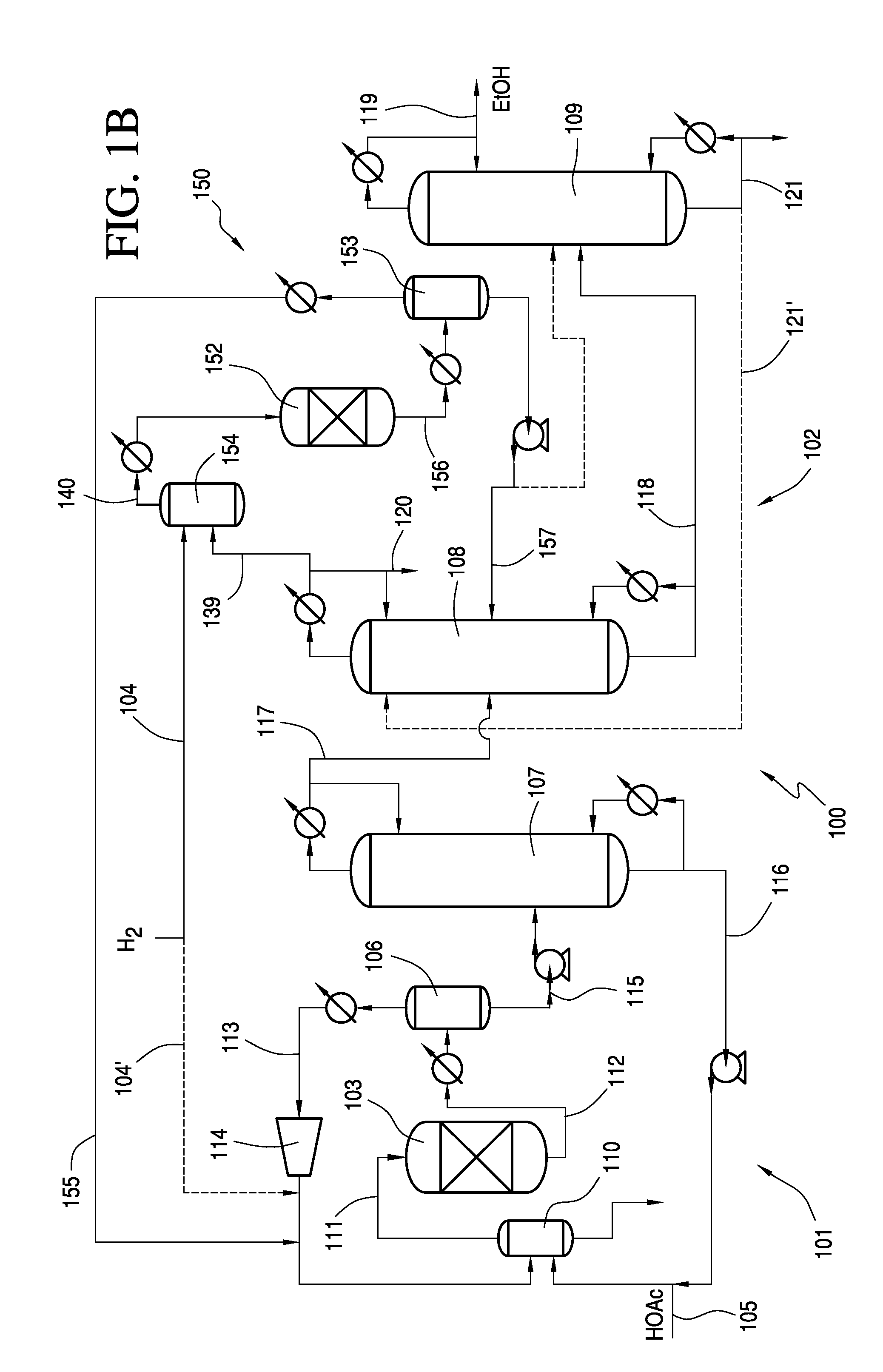

Hydrogenolysis of Ethyl Acetate in Alcohol Separation Processes

InactiveUS20120010446A1Organic compound preparationCarboxylic acid esters preparationAcetic acidAlcohol

Recovery of ethanol from a crude ethanol product obtained from the hydrogenation of acetic acid and by reacting a portion of the crude ethanol product or one or more derivative streams containing ethyl acetate obtained therefrom in the presence of hydrogen, via hydrogenolysis. The one or more derivative streams comprise ethyl acetate that are reacted in via hydrogenolysis form additional ethanol that may be directly or indirectly fed to the separation zone or the hydrogenation reactor.

Owner:CELANESE INT CORP

Process for producing hydrogenolysis products of polyhydric alcohols

ActiveUS8188321B2Good choiceHigh yieldOxygen-containing compound preparationMolecular sieve catalystsAlcoholPolyol

The present invention relates to a process for producing hydrogenolysis products of polyhydric alcohols with a good selectivity and a high yield, as well as hydrogenolysis catalysts used in the production process. The present invention provides (1) a process for producing a hydrogenolysis product of a polyhydric alcohol which includes the step of reacting the polyhydric alcohol with hydrogen in the presence of a catalyst containing a copper component, wherein the catalyst is a catalyst (A) containing the copper component, an iron component and an aluminum component, or a catalyst (B) containing the copper component and a silicon component; and (2) a hydrogenolysis catalyst for polyhydric alcohols which includes a copper component, an iron component and an aluminum component, and (3) a hydrogenolysis catalyst for polyhydric alcohols which includes a copper component and a silicon component.

Owner:KAO CORP

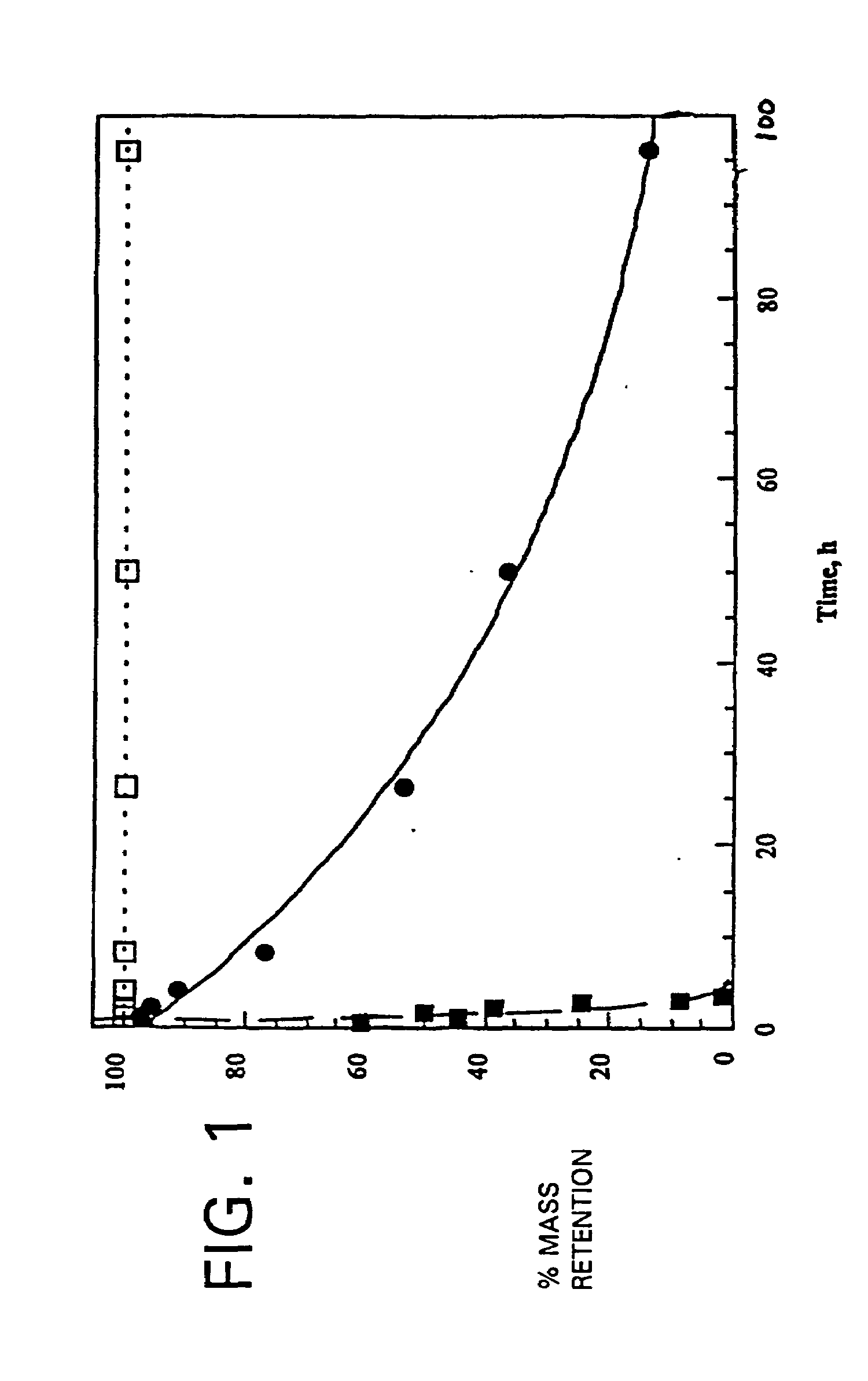

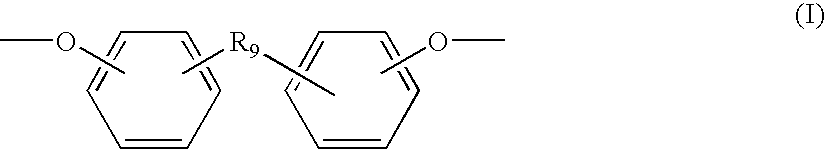

Biodegradable, anionic polymers derived from the amino acid l-tyrosine

InactiveUS20080152690A1Inhibition formationPromote absorptionSuture equipmentsPowder deliveryTyrosineAmino acid

Polymers with a hydrolytically labile polymer backbones with non-toxic biocompatible diphenolic repeating units having the structure:wherein R9 is an alkyl, aryl or alkylaryl group with up to 18 carbon atoms having a pendent carboxylic acid group or the benzyl ester thereof; andnon-toxic biocompatible diphenolic repeating units having the structure:wherein R12 is an alkyl, aryl or alkylaryl group with up to 18 carbon atoms having a pendent carboxylic acid ester group selected from straight and branched alkyl and alkylaryl esters containing up to 18 carbon atoms and ester derivatives of biologically and pharmaceutically active compounds covalently bonded to the polymer, provided that said ester group is not a benzyl group or a group that is removed by hydrogenolysis. Implantable medical devices and treatment methods using the polymers are also disclosed.

Owner:RUTGERS THE STATE UNIV

Method for producing isopropylbenzene by hydrogenolysis of alpha, alpha-dimethyl benzyl alcohol

InactiveCN101735004AHydrocarbon from oxygen organic compoundsMetal/metal-oxides/metal-hydroxide catalystsHydrogen pressureReaction temperature

The invention relates to a method for producing isopropylbenzene by the hydrogenolysis of alpha, alpha-dimethyl benzyl alcohol, which mainly solves the problems of environmental pollution of a chromium-containing catalyst system in the traditional hydrogenolysis production of the alpha, alpha-dimethyl benzyl alcohol, higher reaction temperature and pressure, large energy consumption and power consumption and corrosion of an additive to equipment. The invention better solves the problems by adopting the technical scheme that the catalytic hydrogenolysis of the alpha, alpha-dimethyl benzyl alcohol is carried out to convert the raw material of the alpha, alpha-dimethyl benzyl alcohol after alkali wash into the isopropylbenzene by hydrogen gas and a bifunctional catalyst containing Pd or Pd-Pt metal under the conditions that the temperature is 80-200 DEG C and the hydrogen pressure calculated by the gage pressure is 0.1-2.0MPa. The invention can be used for the industrial production of the isopropylbenzene prepared by the hydrogenolysis of the alpha, alpha-dimethyl benzyl alcohol.

Owner:CHINA PETROLEUM & CHEM CORP +1

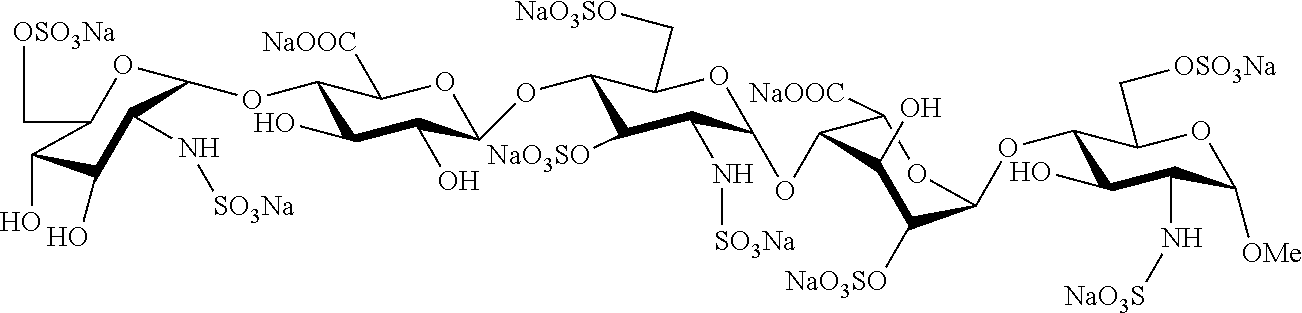

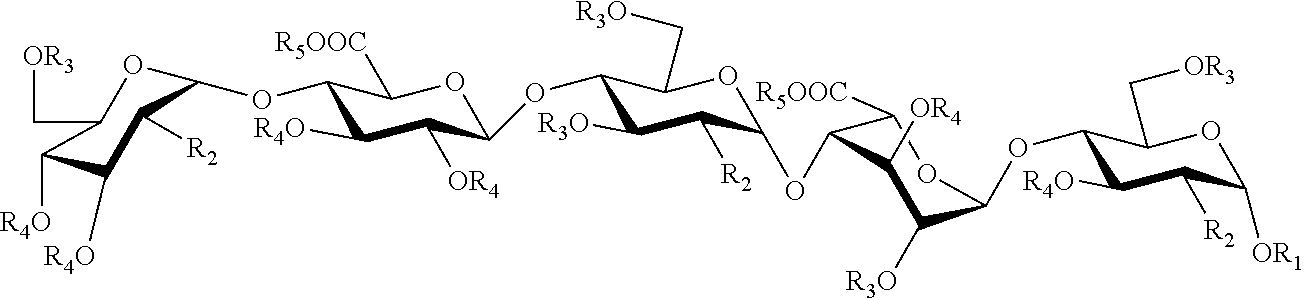

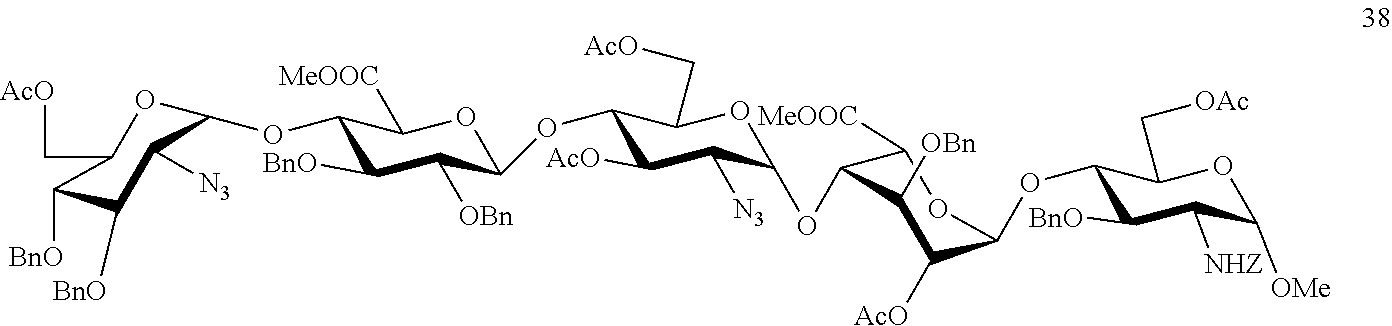

Process for the synthesis of unprotected pentasaccharides from a protected pentasaccharide precursor

InactiveUS20110306757A1Short processing timeGood reproducibilitySugar derivativesEsterified saccharide compoundsSulfationCombinatorial chemistry

Procedure for the synthesis of deprotected pentasaccharides from a protected precursor pentasaccharide through a reaction procedure having five stages whereamong is included an N-sulphation of amino groups and a hydrogenolysis of benzyl groups. Through this procedure a drastic reduction is achieved in the total synthesis time in comparison with the process traditionally employed, together with increased reproducibility thereof, permitting the standardisation thereof.

Owner:LAB FARM ROVI SA

Process to produce biofuels from biomass

InactiveUS20120156743A1Liquid carbonaceous fuelsLiquid hydrocarbon mixture productionHydrogenBiofuel

A method to produce biofuels from biomass is provide by contacting the biomass with an aqueous media to form an extracted biomass, separating at least a portion of an aqueous liquor from the extracted biomass thereby providing the aqueous liquor stream comprising soluble carbohydrates; contacting the aqueous liquor stream with a purification substrate effective to remove sulfur compounds and nitrogen compounds thereby producing a treated carbohydrate stream having less than 35% of the sulfur content and less than 35% of the nitrogen content of the untreated aqueous liquor feed, based on the untreated aqueous liquor stream, then contacting the treated carbohydrate stream directly with hydrogen in the presence of a hydrogenolysis catalyst to form a plurality of oxygenated intermediates; and processing at least a portion of the oxygenated intermediates to form a liquid fuel.

Owner:SHELL OIL CO

Dual-functional hydrogenation catalyst

InactiveCN101722006AHigh mechanical strengthLow starting temperatureGaseous mixture working upMetal/metal-oxides/metal-hydroxide catalystsRare earthCobalt

The invention relates to a dual-functional hydrogenation catalyst, which comprises a carrier and an active component. The dual-functional hydrogenation catalyst is characterized in that alumina is used as the carrier, the carrier also comprises a titanium component which accounts for 2 to 55 percent of the total weight of the catalyst based on the mass of TiO2, and the alumina accounts for 20 to 85 percent of the mass of the catalyst; the active component is molybdenum or a mixed component of molybdenum and cobalt, the cobalt accounts for 0 to 7.5 percent of the total weight of the catalyst, and the molybdenum accounts for 5.0 to 18 percent of the total weight of the catalyst; and one or more of nickel, copper and rare-earth compound serving as co-catalyst components is / are added into the catalyst, wherein the nickel accounts for 0.5 to 7.5 percent of the total weight of the catalyst, the copper accounts for 0.05 to 1.0 percent of the total weight of the catalyst, and the rare-earth compound accounts for 0.5 to 5.0 percent of the total weight of the catalyst. The prepared catalyst applied in a hydrogenation refining process for high-olefin raw materials such as coking dry gas or catalytic dry gas and the like has good organic sulfur hydrogenolysis and olefin saturation performance.

Owner:SHANDONG QILU KELI CHEMICAL RESEARCH INSTITUTE CO LTD

Method for preparing 1,3-propylene glycol by utilizing glycerol one-step hydrogenolysis method

InactiveCN102344341AStrong acidStrong specific surface areaMolecular sieve catalystsPreparation by OH group eliminationPtru catalystSolid acid

The invention relates to a method for preparing 1,3-propylene glycol by utilizing a glycerol one-step hydrogenolysis method, in particular to preparation of a loaded solid acid bifunctional catalyst and a method for preparing 1,3-propylene glycol by virtue of glycerol selective hydrogenolysis by utilizing the catalyst. The method provided by the invention comprises the step of introducing hydrogen and reacting for 6-48 hours under the conditions that glycerol is taken as raw material, solvent and catalyst exist, reaction temperature is 100-230 DEG C and reaction pressure is absolute pressure of 0.2-10.0MPa. In the bimetal modified loaded strong acid catalyst prepared by adopting the method provided by the invention, a second non-precious metal is doped into the catalyst, dispersion degree of previous metal is further improved, thus the catalyst has stronger acidity, larger specific area and good stability; in the catalyst containing trace previous metal, cheap non-previous metal is introduced; glycol conversion rate is improved under lower reaction pressure while selectivity of 1,3-propylene glycol is obviously improved; meanwhile, effective utilization rate of the previous metal is improved, and cost of the catalyst is reduced.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com