Method of preparing long chain alkane for jet fuel by virtue of sugar platform compound

A technology for aviation fuel and long-chain alkanes, which is used in the preparation of liquid hydrocarbon mixtures, biological raw materials, and processing of hydrocarbon oils, etc., to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: condensation reaction

[0048]

[0049] Add 9.6 grams of furfural and 11.5 grams of levulinic acid into a three-necked flask (the molar ratio of furfural to levulinic acid is 1:1), then add 20 mL of 7.5 mol / L sodium hydroxide solution, and magnetically Sub-stirring, the reaction stopped after 4h. The reacted solution was neutralized by sulfuric acid, filtered, and washed three times with deionized water. After the filtrate is analyzed by liquid chromatography, the conversion rate of furfural reaches 95%, and the conversion rate of levulinic acid reaches 98%. The filtered solid was analyzed by nuclear magnetic resonance as the target condensation product (C 10 long-chain oxygen-containing compounds), and the mass yield of the condensation product is calculated to reach 92% after drying treatment.

Embodiment 2

[0050] Embodiment 2: condensation reaction

[0051]

[0052] Add 9.6 grams of furfural and 11.5 grams of levulinic acid into a three-necked flask (the molar ratio of furfural to levulinic acid is 1:1), then add 20 mL of 7.5 mol / L potassium hydroxide solution, and magnetically Sub-stirring, the reaction stopped after 4h. The reacted solution was neutralized by sulfuric acid, filtered, and washed three times with deionized water. After the filtrate is analyzed by liquid chromatography, the conversion rate of furfural reaches 93%, and the conversion rate of levulinic acid reaches 97%. The filtered solid was analyzed by nuclear magnetic resonance as the target condensation product (C 10 long-chain oxygen-containing compounds), and the mass yield of the condensation product is calculated to reach 90% after drying treatment.

Embodiment 3

[0053] Embodiment 3: condensation reaction

[0054]

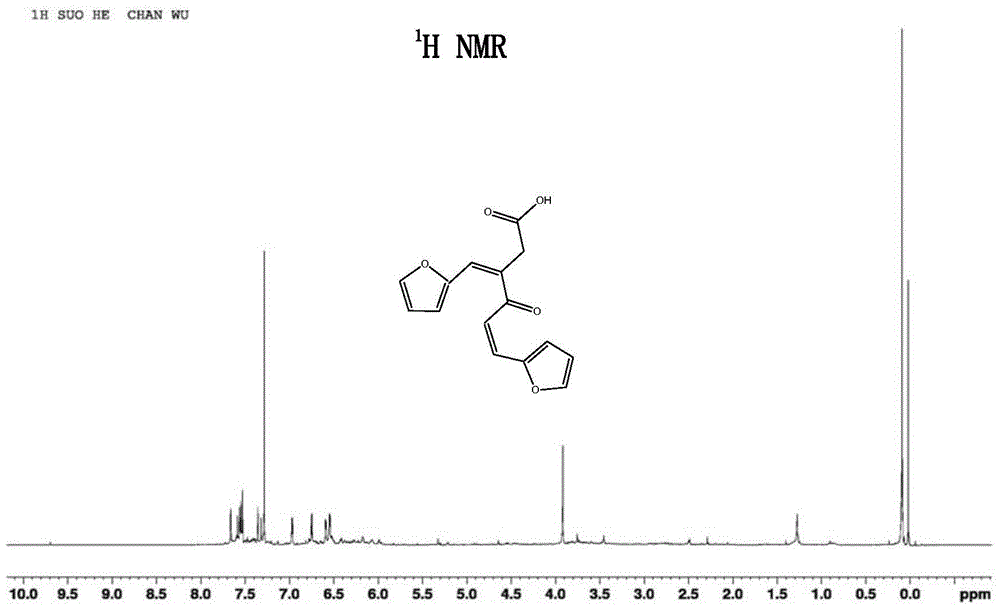

[0055] Add 19.2 grams of furfural and 11.5 grams of levulinic acid into a three-necked flask (the molar ratio of furfural to levulinic acid is 2:1), then add 20 mL of 7.5 mol / L sodium hydroxide solution, and magnetically Sub-stirring, the reaction stopped after 4h. The reacted solution was neutralized by sulfuric acid, filtered, and washed three times with deionized water. After the filtrate is analyzed by liquid chromatography, the conversion rate of furfural reaches 90%, and the conversion rate of levulinic acid reaches 99%. The filtered solid was analyzed by nuclear magnetic resonance as the target condensation product (C 15 long-chain oxygenates), 1 HNMR diagram and 13 The CNMR diagrams are as figure 1 and 2 shown. got C 10 The mass yield of the condensation product after the drying treatment of the long-chain oxygenate reaches 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com