Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

515 results about "Aviation fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aviation fuel is a specialized type of petroleum-based fuel used to power aircraft. It is generally of a higher quality than fuels used in less critical applications, such as heating or road transport, and often contains additives to reduce the risk of icing or explosion due to high temperature, among other properties.

Production of Aviation Fuel from Biorenewable Feedstocks

ActiveUS20090158637A1Refining to change hydrocarbon structural skeletonHydrocarbon purification/separationAlkaneVegetable oil

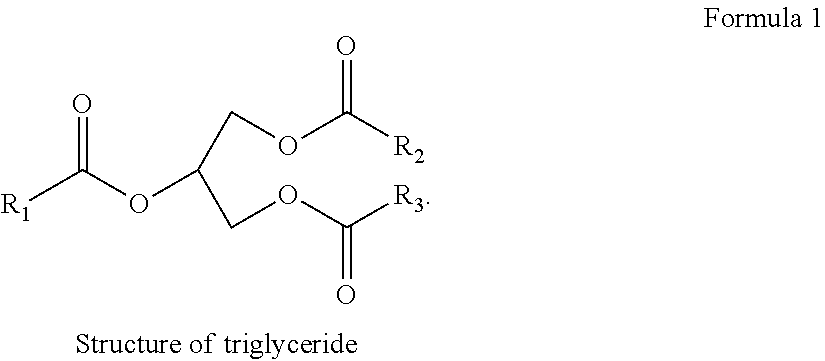

A process has been developed for producing aviation fuel from renewable feedstocks such as plant oils and animal fats and oils. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide n-paraffins having from about 8 to about 24 carbon atoms. At least some of the n-paraffins are isomerized to improve cold flow properties. At least a portion of the paraffins are selectively cracked to provide paraffins meeting specifications for different aviation fuels such as JP-8.

Owner:UOP LLC

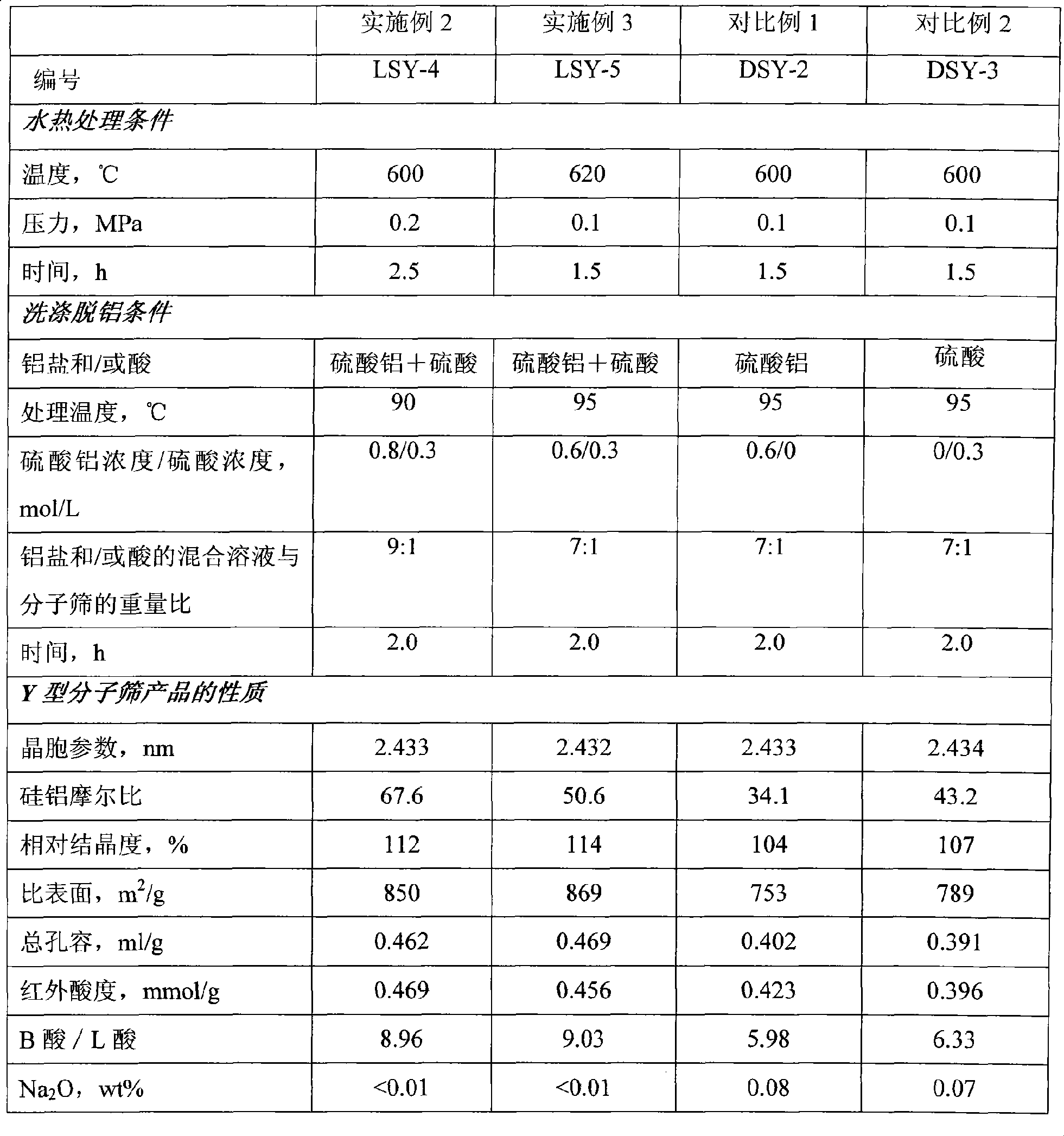

Hydrocracking catalyst and preparation method thereof

ActiveCN101380589AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingCrystallinityCell parameter

The invention discloses a hydrocracking catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metals and a carrier containing modified Y molecular sieve, alumina and amorphous aluminium silicon, wherein, the Y molecular sieve is prepared by the following method: the Y molecular sieve undergone hydro-thermal treatment by mixed water solution of aluminium salt and acid is adopted; the performance of the Y molecular sieve is as follows: specific surface is 800m<2> / g-900m<2> / g, total aperture volume is 0.40ml / g-0.50ml / g, relative crystallinity is 90%-130%, cell parameter is 2.434-2.440nm, aluminium silicon mol ratio is 20-100, infrared acid volume is 0.3-0.8mmol / g, the mol ratio of acid B and acid L is above 7.0, sodium oxide content is less than or equal to 0.05wt%. The catalyst prepared by the invention has the advantages of high catalytic activity, good target product selectivity and can produce heavy naphtha, aviation fuel and diesel fuel, and the like, with high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production of Aviation Fuel from Renewable Feedstocks

ActiveUS20090283442A1Improve solubilityMinimize severityTreatment with plural serial cracking stages onlyRefining to change hydrocarbon structural skeletonIsomerizationBoiling point

A hydrocarbon product stream having hydrocarbons with boiling points in the aviation fuel range is produced from renewable feedstocks such as plant and animal oils. The process involves treating a renewable feedstock by hydrogenating, deoxygenating, isomerization, and selectively hydrocracking the feedstock to produce paraffinic hydrocarbons having from about 9 to about 16 carbon atoms and a high iso / normal ratio in a single reaction zone containing a multifunctional catalyst, or set of catalysts, having hydrogenation, deoxygenation, isomerization and selective hydrocracking functions.

Owner:UOP LLC

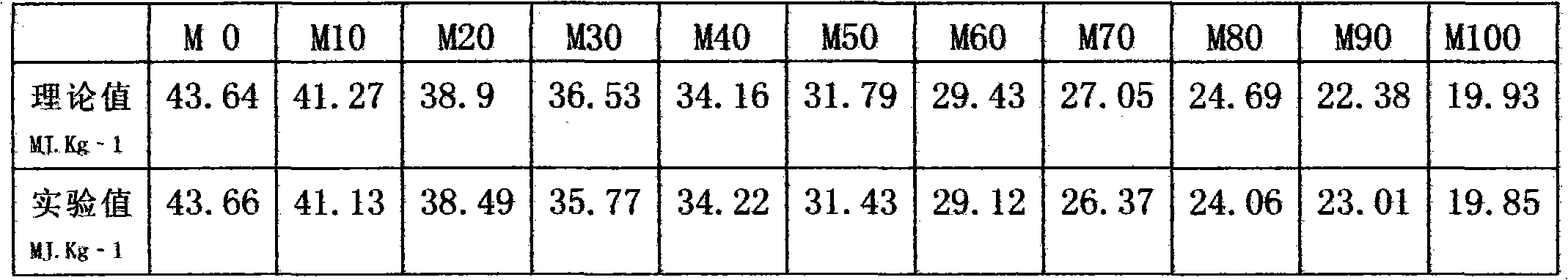

Methanol diesel oil manufacturing mode

The invention relates to a manufacturing mode of environment-friendly and energy-saving M15_M85 methanol diesel oil. The methanol diesel oil is composed of diesel oil, methanol, and additives. The methanol diesel oil is prepared with operations under normal temperatures and normal pressures. The invention discloses a plurality of common additives used for preparing methanol diesel oil in modern times. If explosives and aviation fuels are appropriately utilized, methanol defalcated heat value can be well compensated. The theory is tentatively considered as a gaseous detonation theory. The additives can be selected from nitric acid esters, nitrates, nitro compounds, non-aromatic compounds, peroxides, and the like.

Owner:陈若歆

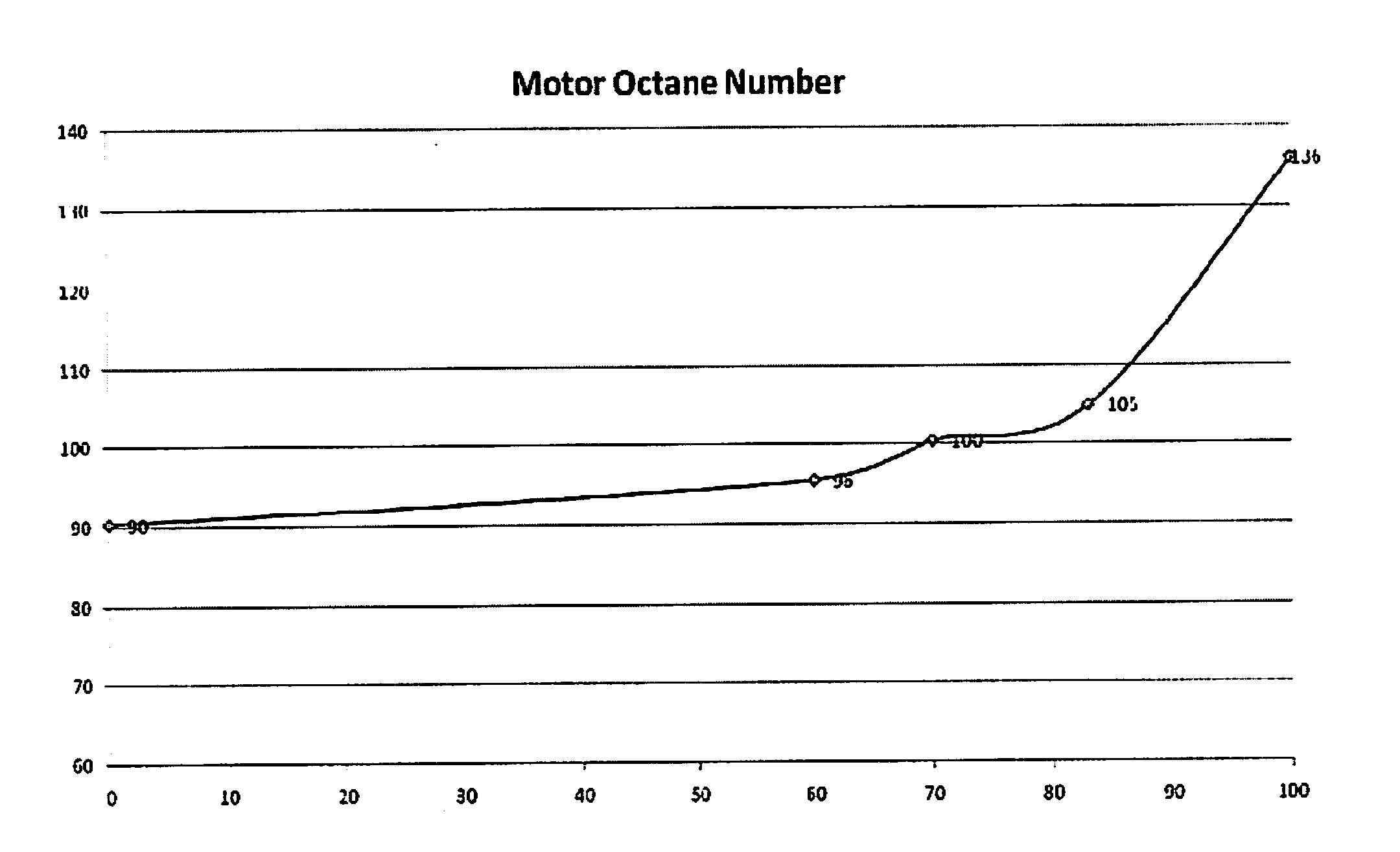

Lead-Free Aviation Fuel

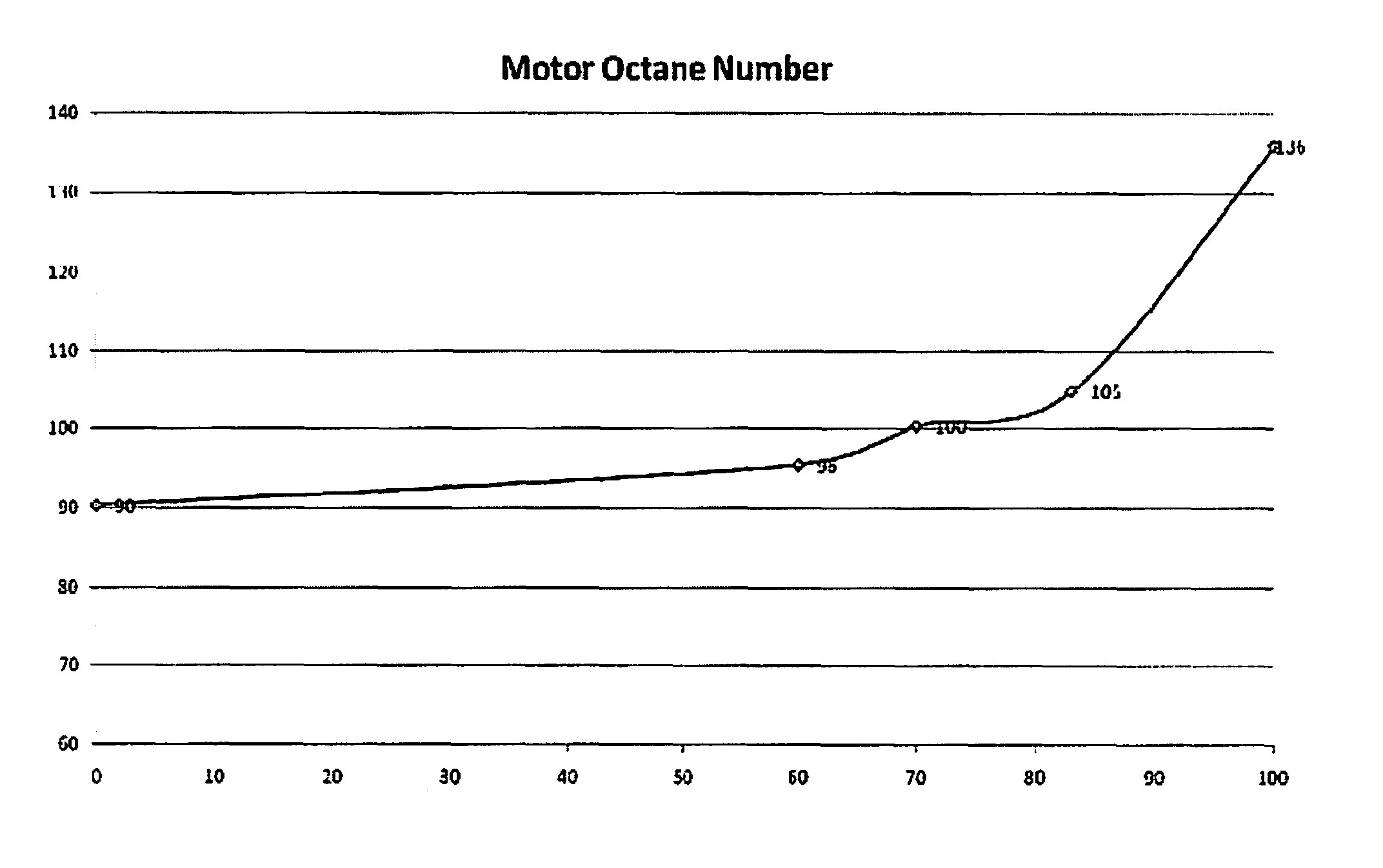

Lead-free aviation fuel composition with a MON greater than 100, made up of a major component of a fuel made from Avgas and a minor component of at least two compounds from the group of esters of at least one mono-or poly-carboxylic acid and at least one mono- or polyol, anhydrides of a least one mono- or poly-carboxylic acid, preferably aromatic ethers at a level of at least 5% w / w and ketones at a level of more than 10% w / w.

Owner:TOTAL PUTEAUX FR

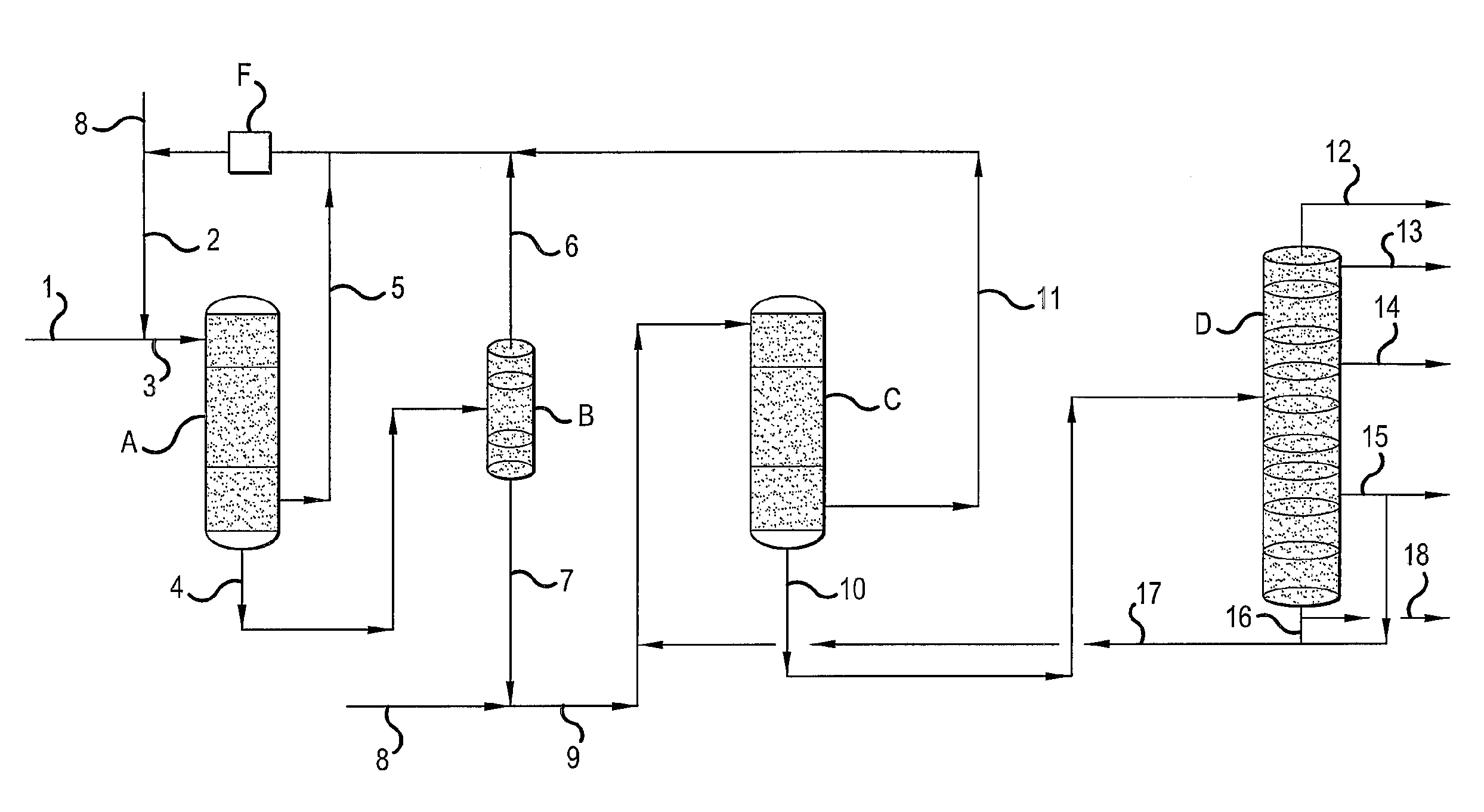

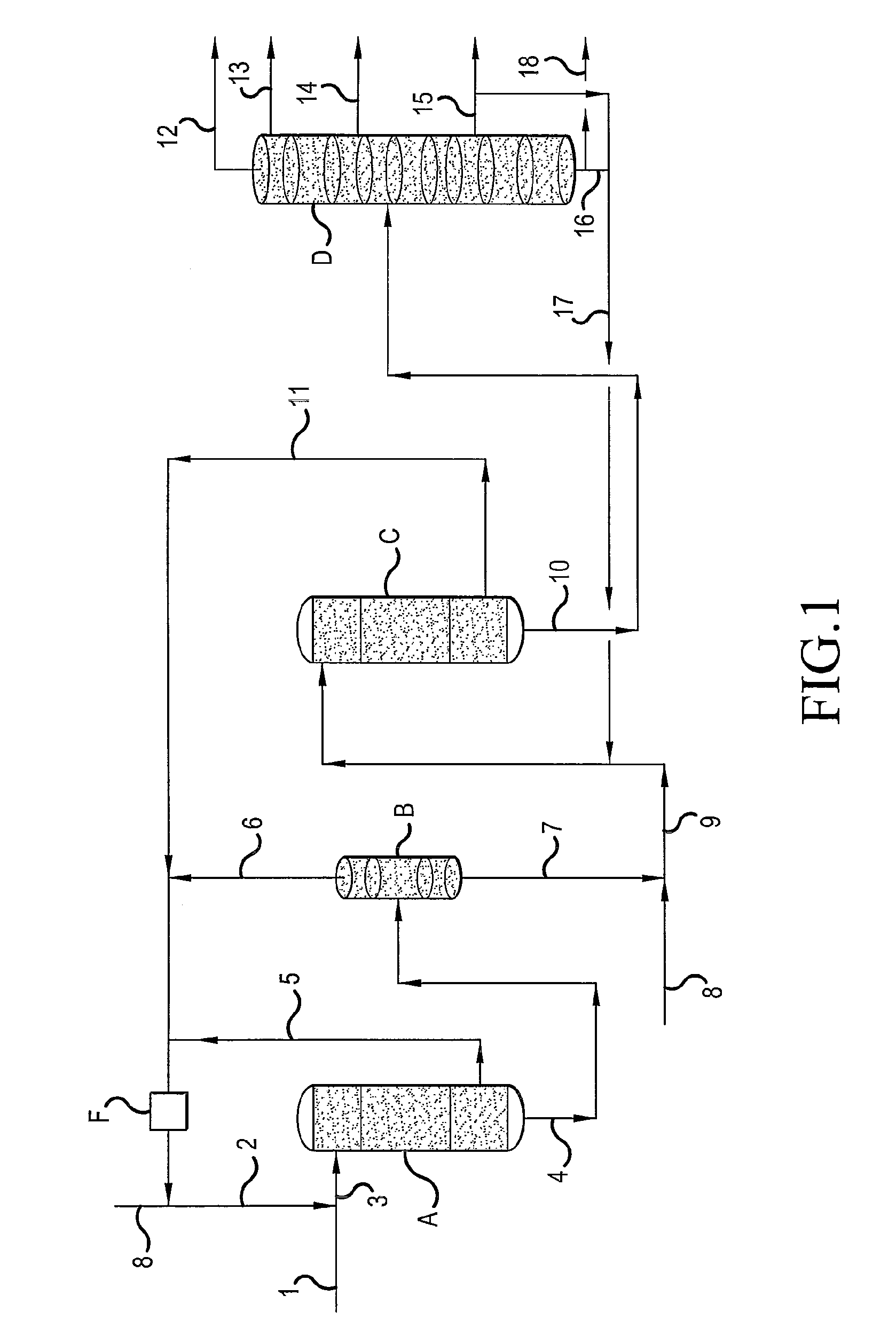

Process for the manufacture of hydrocarbon components

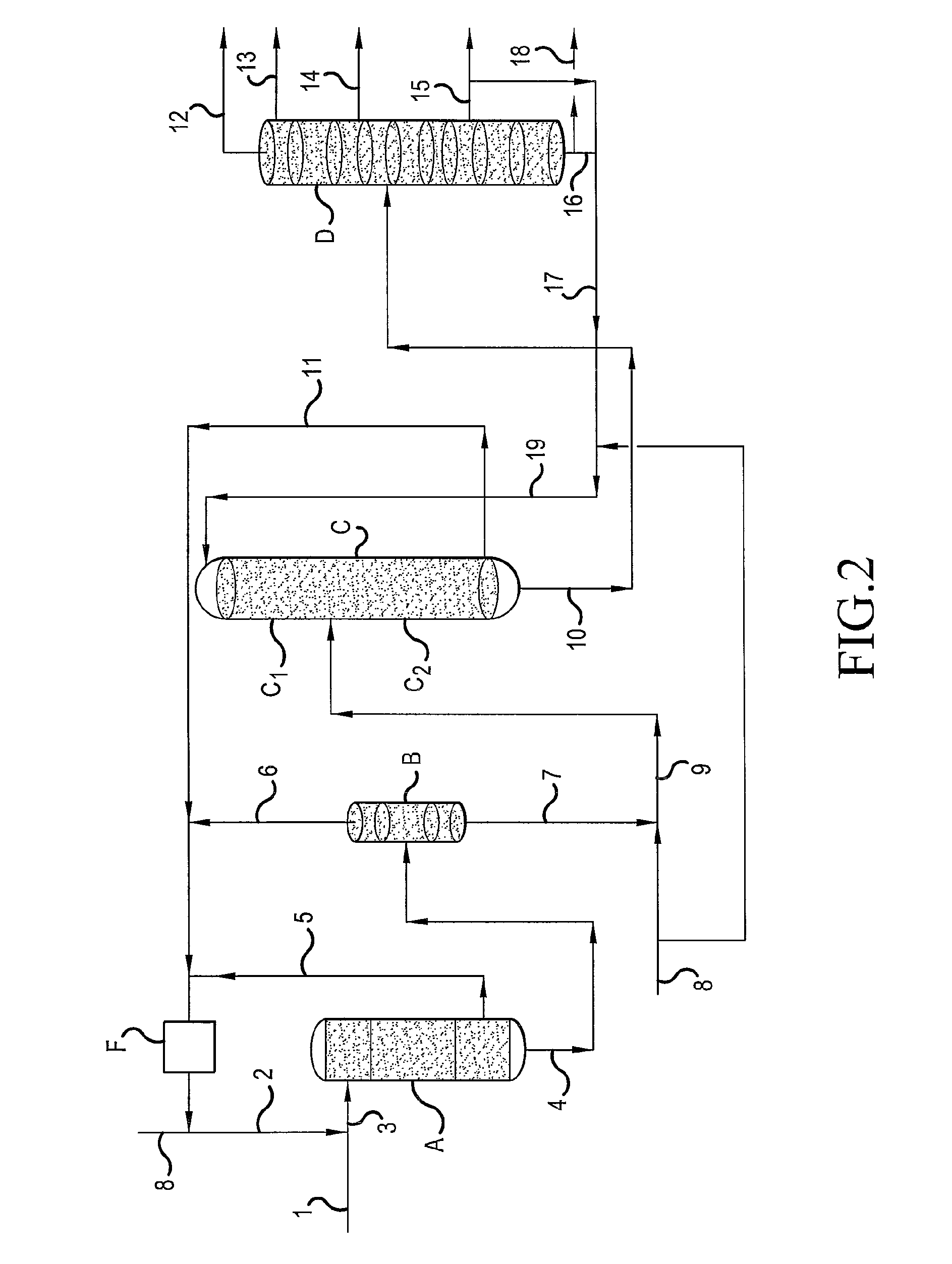

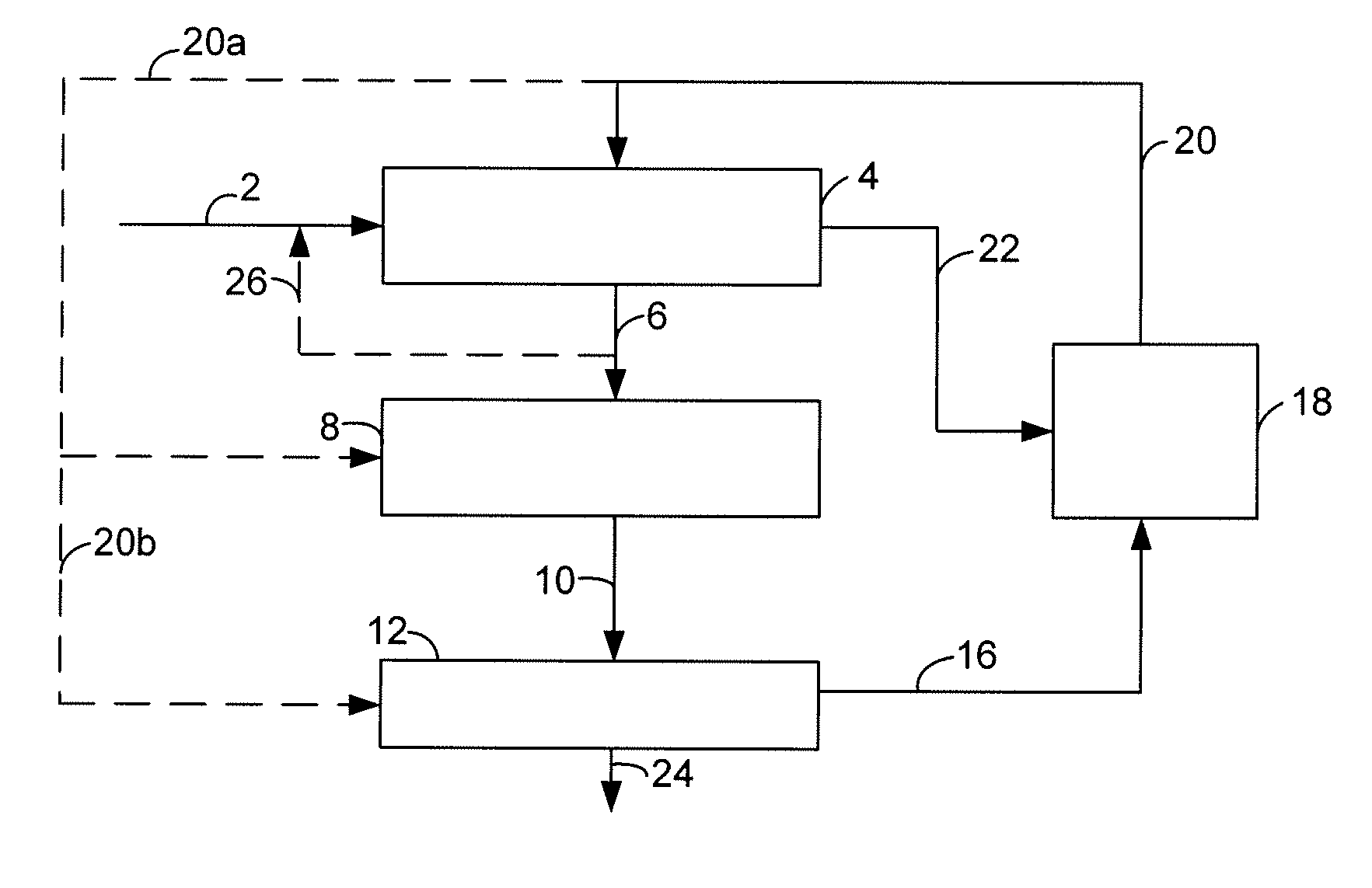

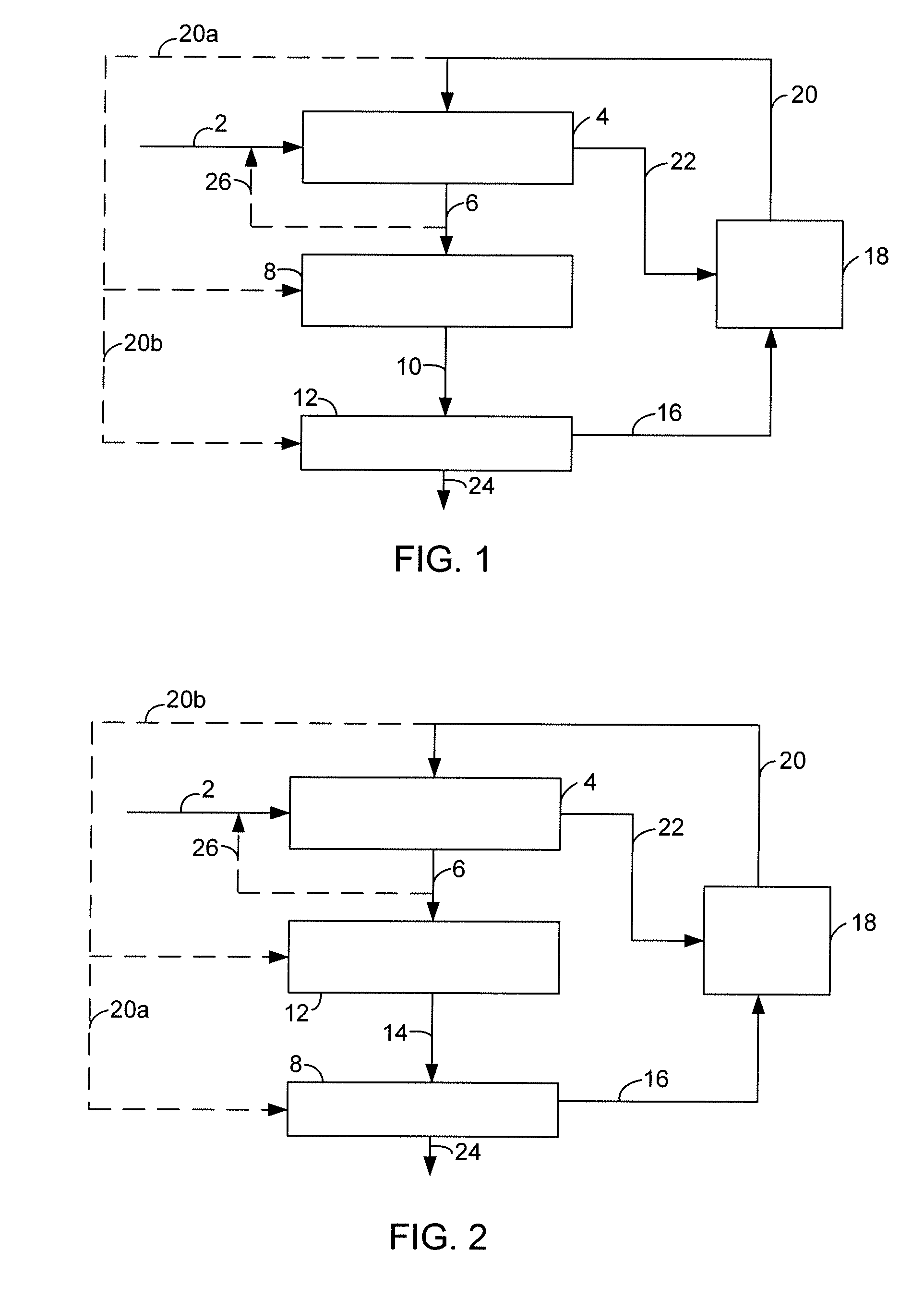

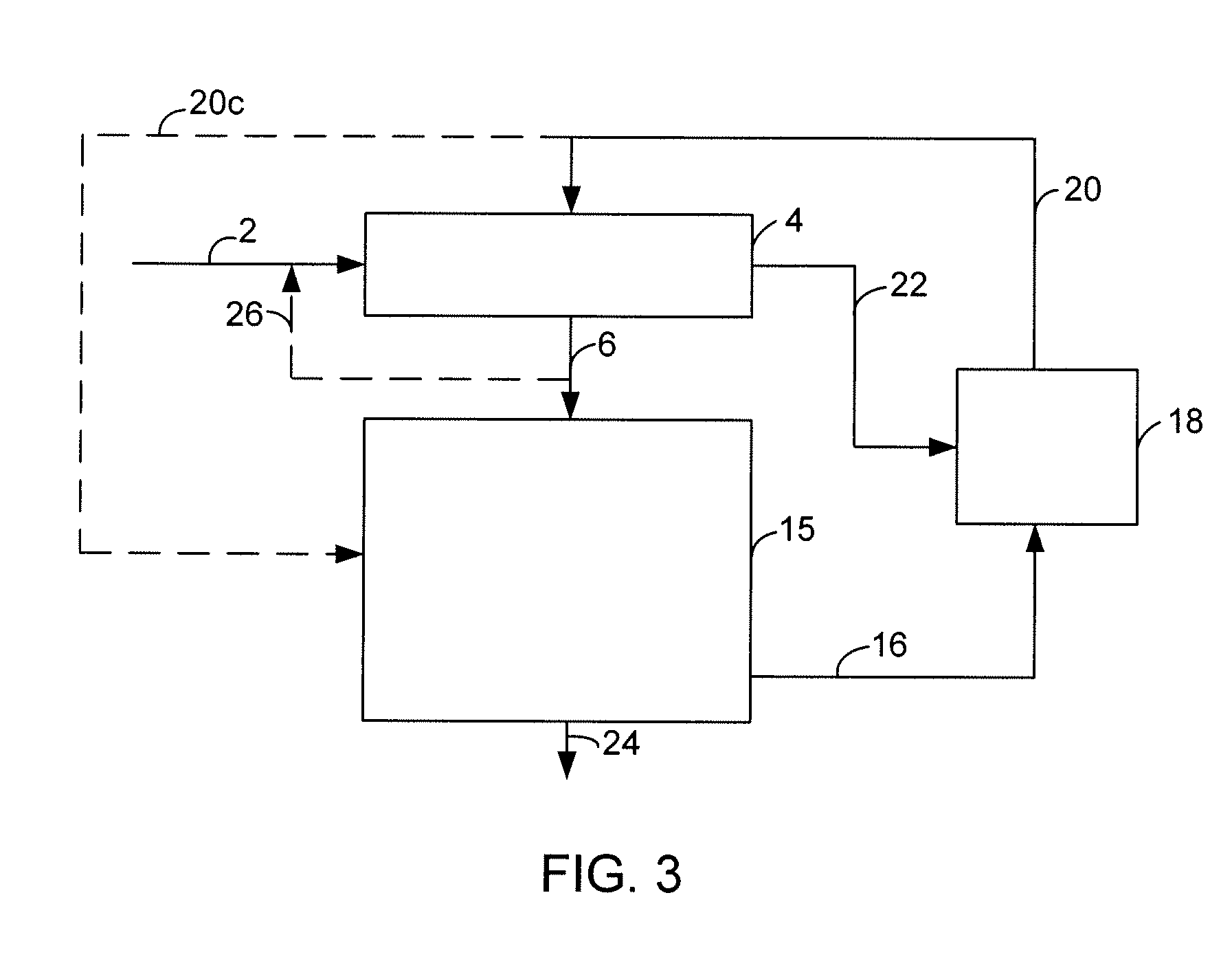

The present invention relates to hydrocarbons and particularly to the manufacture of hydrocarbon components suitable as aviation fuels or jet fuels and as blending stocks for aviation fuels. The process comprises the stages, wherein in the first stage an oil feed of biological origin and hydrogen gas are subjected to conditions sufficient to effect hydrodeoxygenation in the presence of a hydrodeoxygenation catalyst to yield n-paraffins;in the second stage the n-paraffins and hydrogen gas are subjected to conditions sufficient to effect isomerisation in the presence of an isomerisation catalyst to yield isoparaffins and separating fractions; andrecycling the fraction boiling at a temperature above 200° C. under atmospheric pressure obtained from the second stage to reisomerisation, where isomerisation is effected in the presence of an isomerisation catalyst.

Owner:NESTE OIL OY

Method for synthesizing high-density aviation fuel by using cyclopentanone as raw material

ActiveCN104232140AImprove combustion effectIncreased carrying energyLiquid hydrocarbon mixture productionBio-feedstockCarbon numberSolvent free

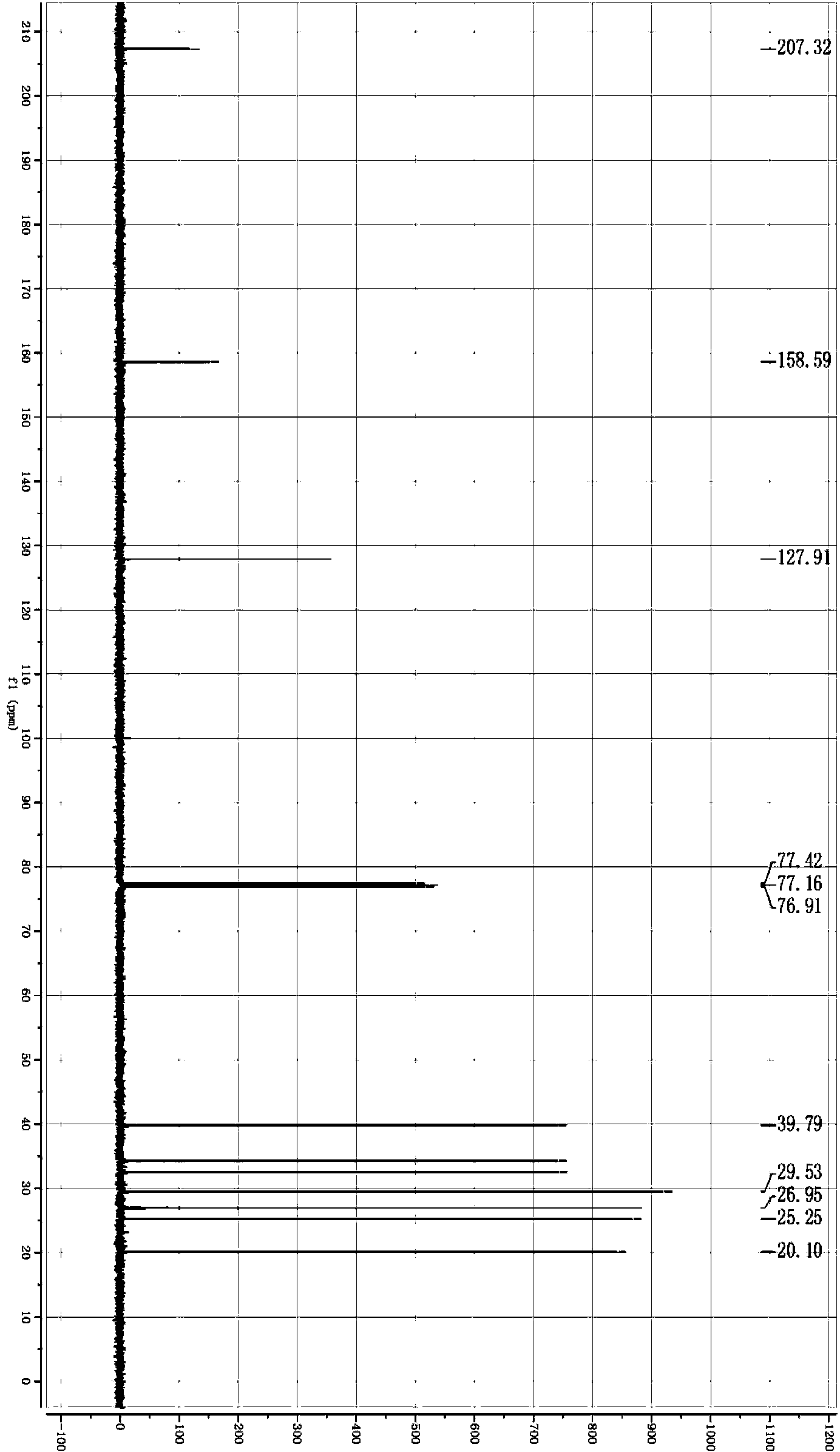

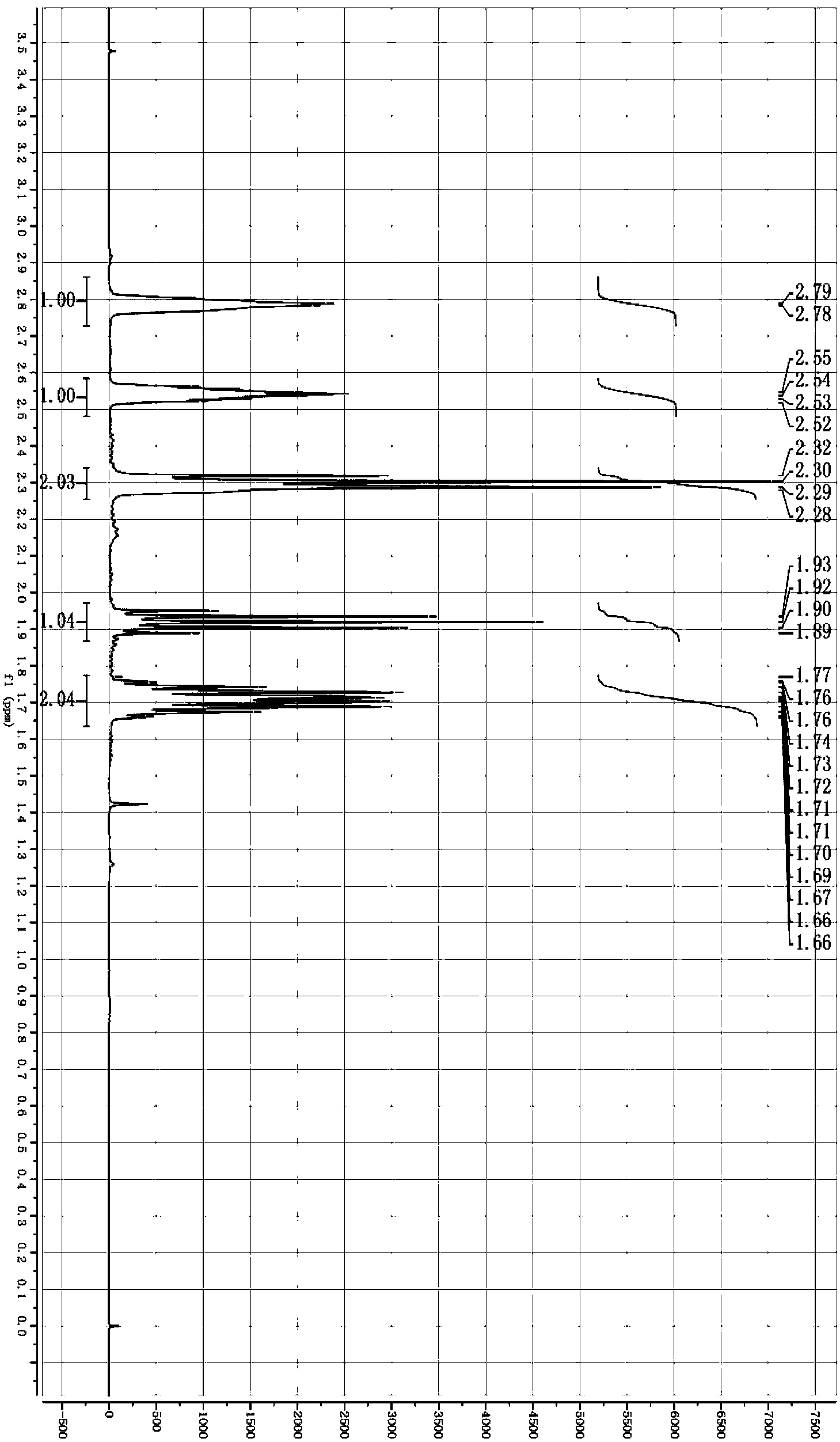

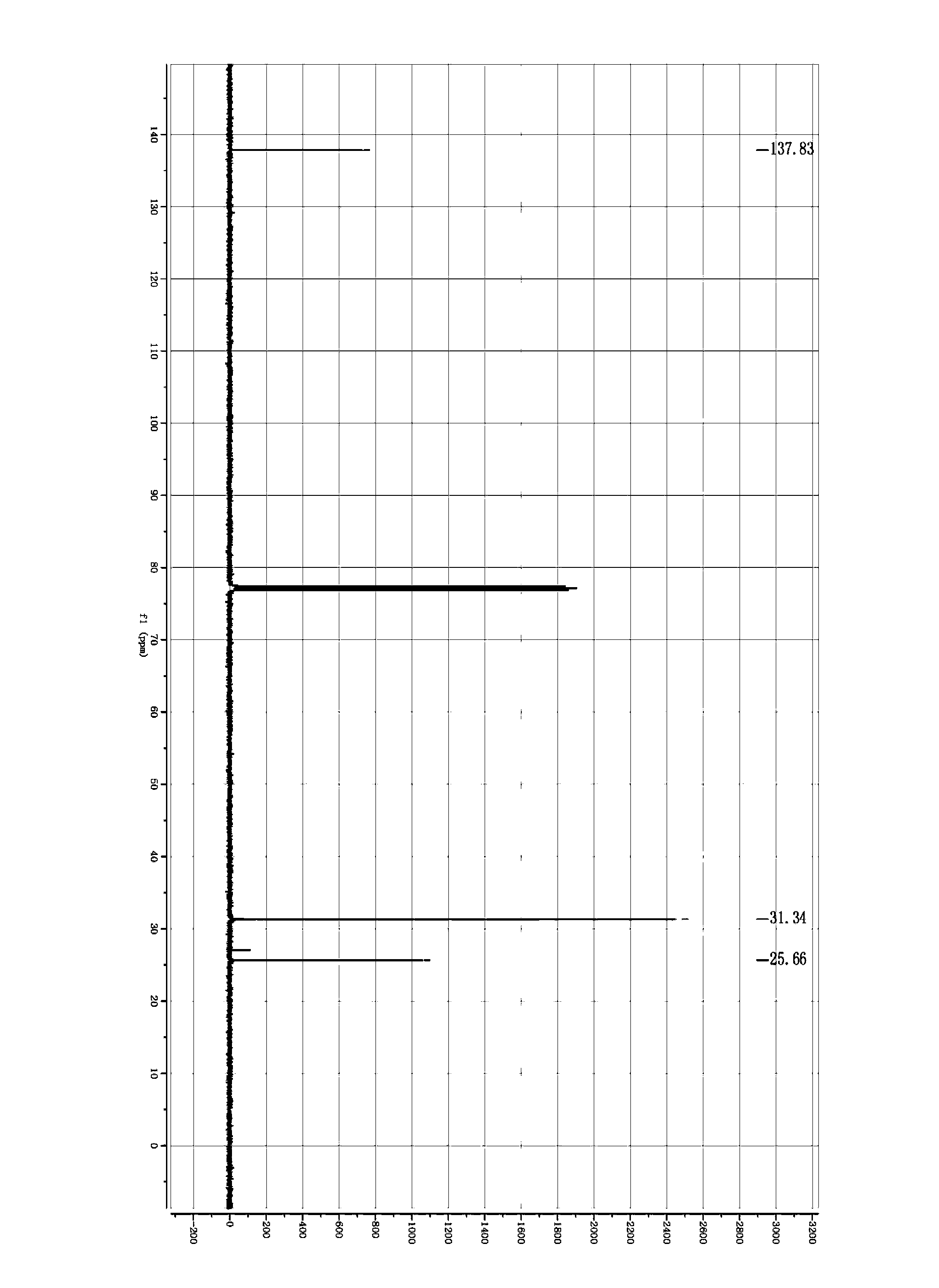

The invention relates to a synthetic route of a hydrocarbon fuel with high density and high volumetric calorific value by using a lignocelluloses-based platform chemical compound as a raw material and completely independent of fossil energy. A liquid fuel obtained by the method can be used in various aircrafts or used as an additive to raise combustion performance of aviation fuel. The method is divided into two parts: 1) under the promotion action of an acid / base catalyst, cyclopentanone (furfural selective hydrogenation product) is subjected to an aldol self-condensation reaction to synthesize unsaturated organic compounds with C10 and C15 polycyclic structures; and 2) a metal loaded A / X catalyst is used to carry out a one-step hydrodeoxygenation and hydrogenation reaction on products generated from the step 1 under low-temperature solvent-free conditions, so as to obtain polycyclic hydrocarbon fuel with carbon number being 10 and 15. The liquid fuel has high density (C10: 0.92g / cm<3>; C15: 1.12g / cm<3>), can be used to effectively raise carrying energy of an aircraft and reduce fuel consumption rate, and meets requirements of high navigational speed, large load and long range.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Renewable engine fuel

InactiveUS20080168706A1Efficient propulsion technologiesLiquid carbonaceous fuelsCarbon numberAlkane

The present invention provides fully renewable engine fuels derived completely from biomass sources. The fully renewable engine fuel is comprised of one or more low carbon number esters, one or more pentosan-derivable furans, one or more aromatic hydrocarbon, one or more C4-C10 straight chain alkanes derivable from polysaccharides, and one or more bio-oils. In addition, the fuel may contain triethanolamine. Such a lower octane renewable fuel may be utilized, for example, in automobile fuel, 100 LL aviation fuel applications, and turbine engine applications. These ethanol-based, fully renewable fuels may be formulated to have a wide range of octane values and energy, and may effectively be used to replace 100LL aviation fuel (known as AvGas), as well as high octane, rocket, diesel, and turbine engine fuels.

Owner:SWIFT ENTERPRISES

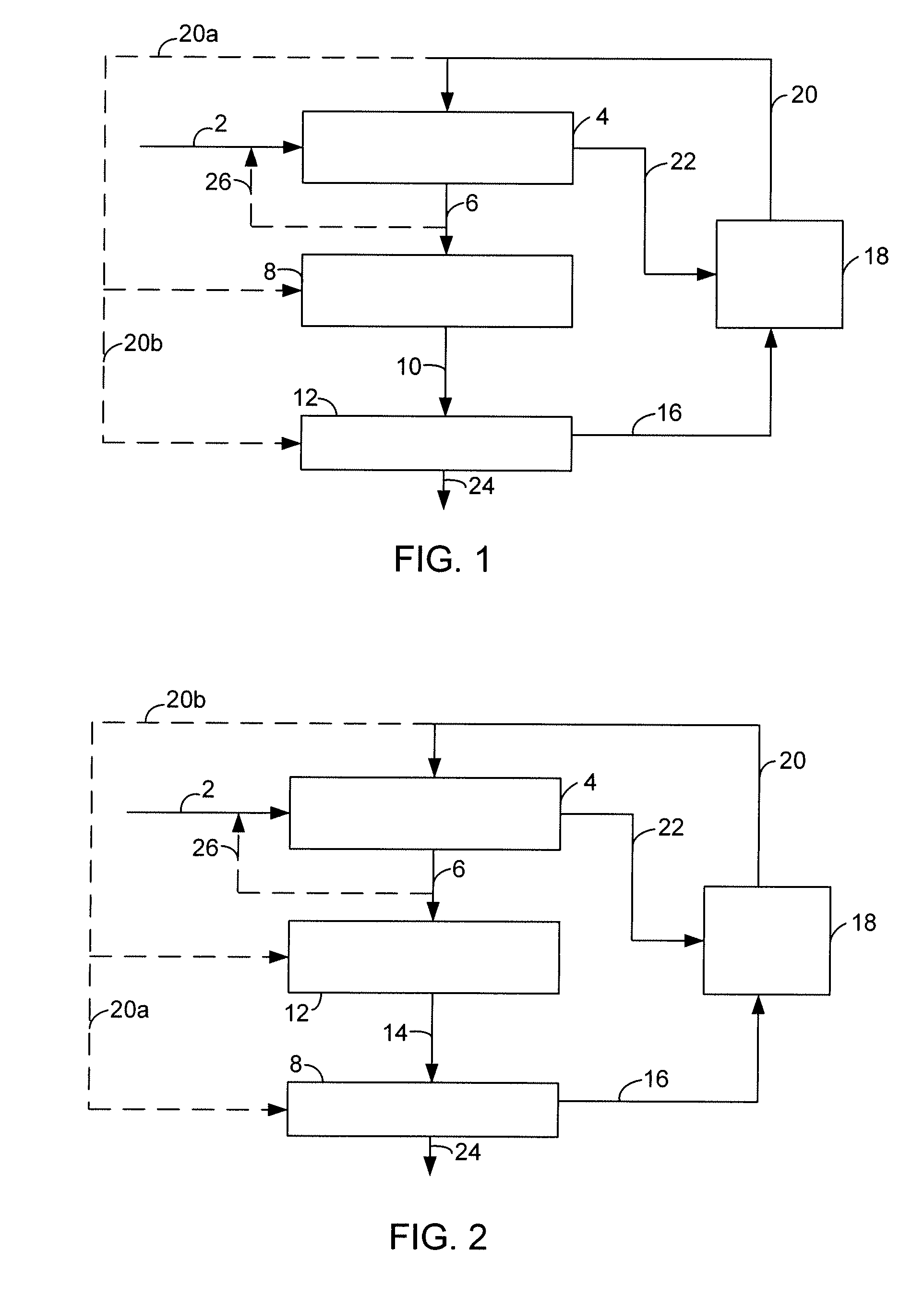

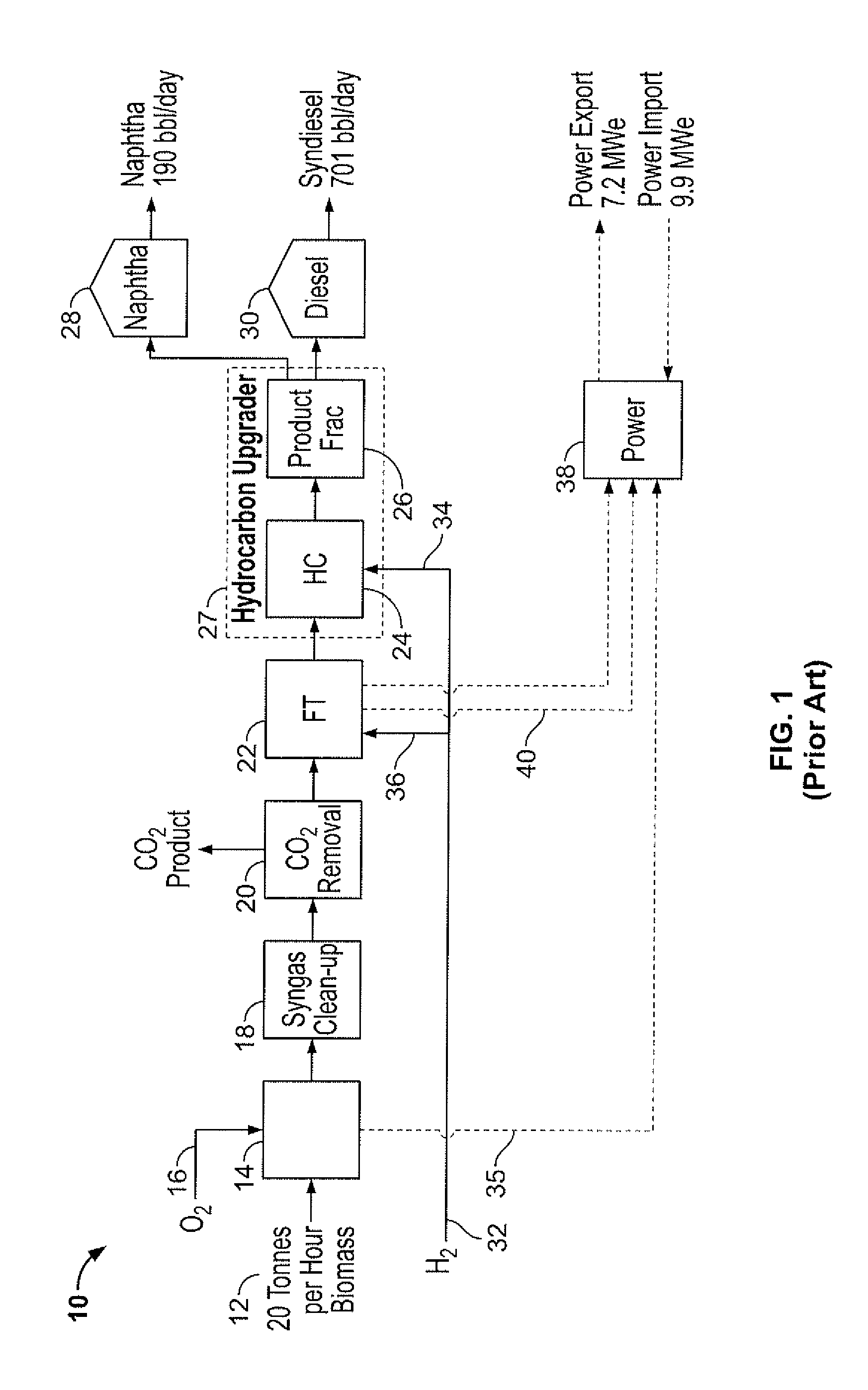

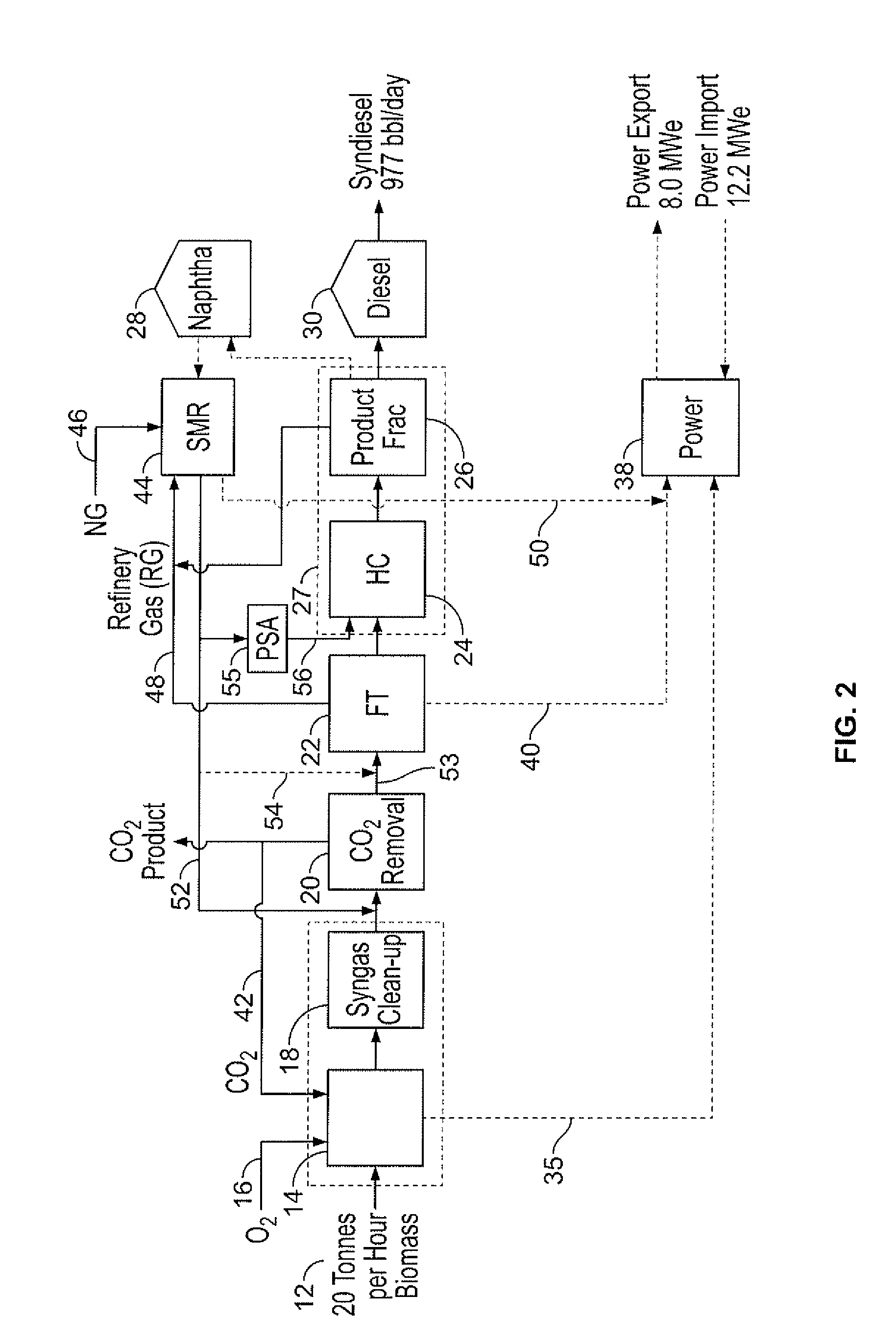

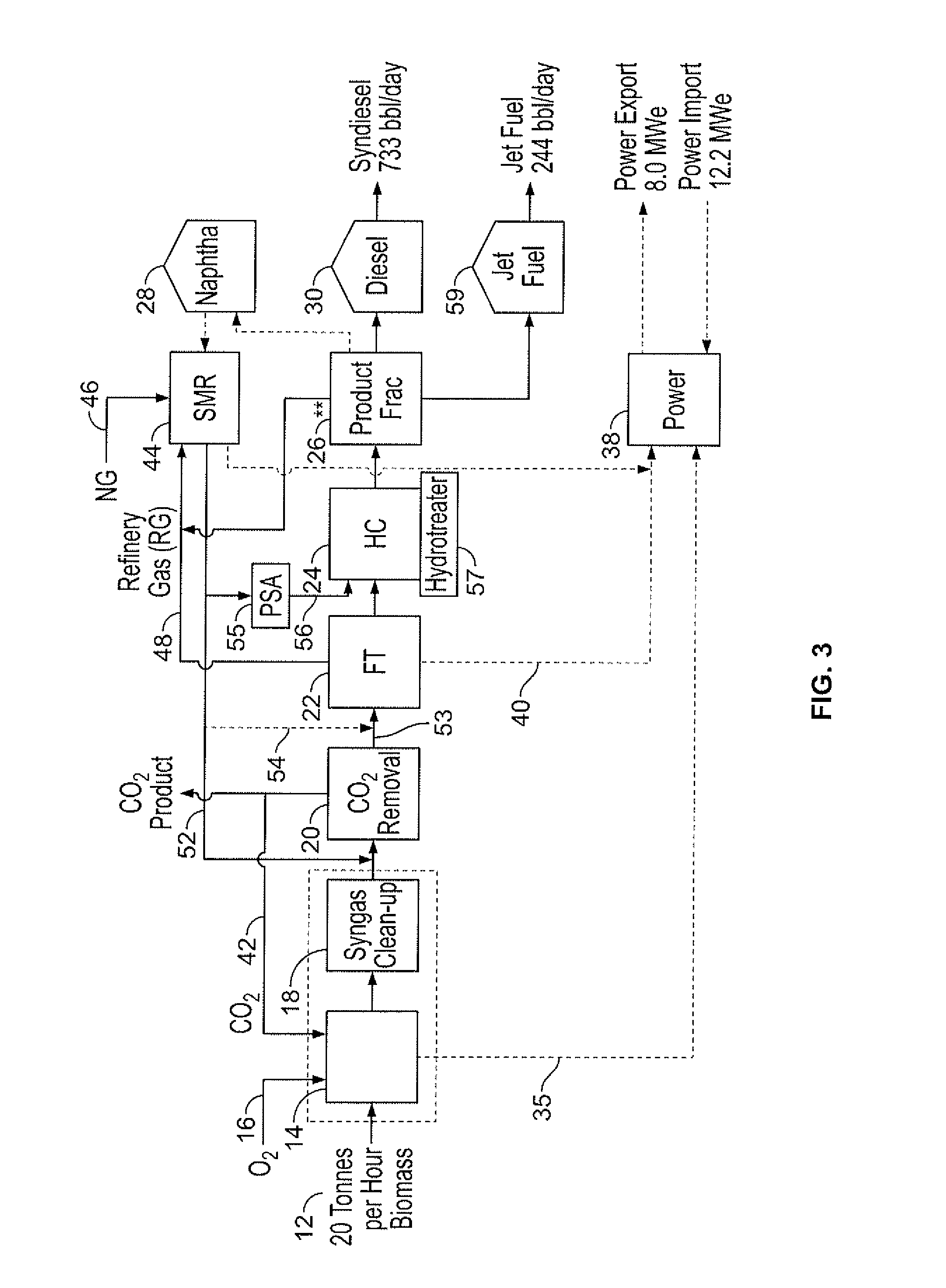

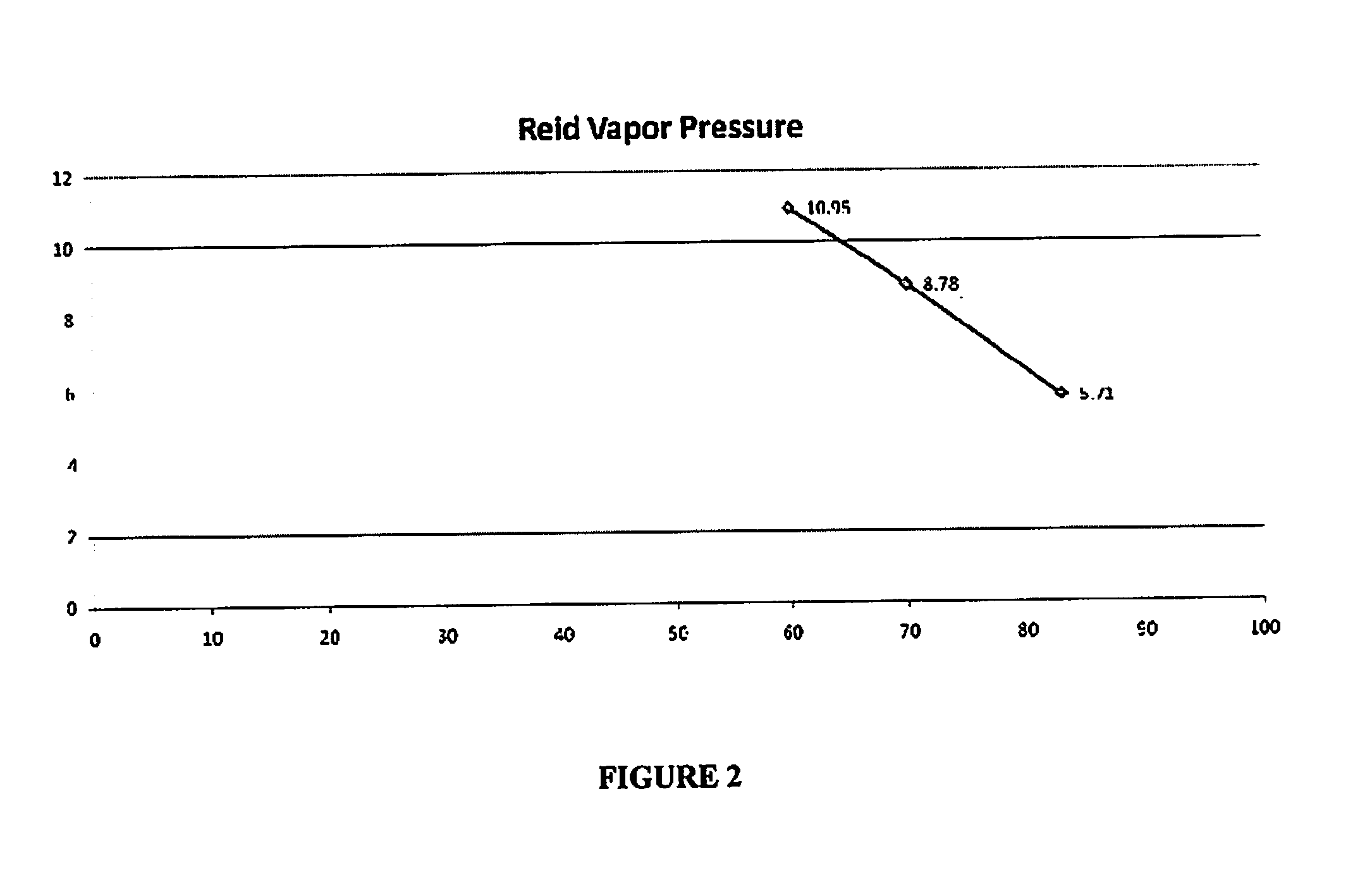

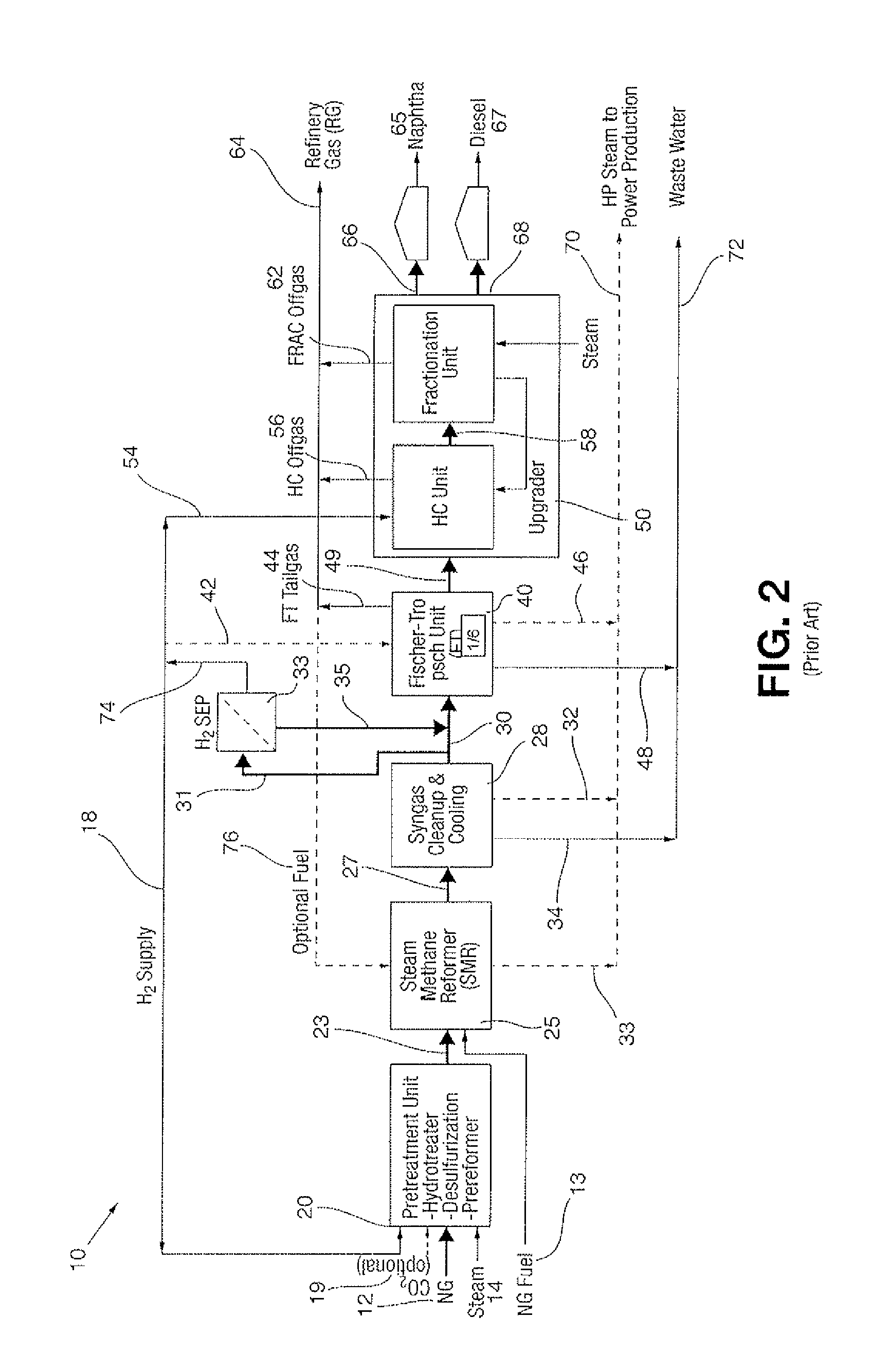

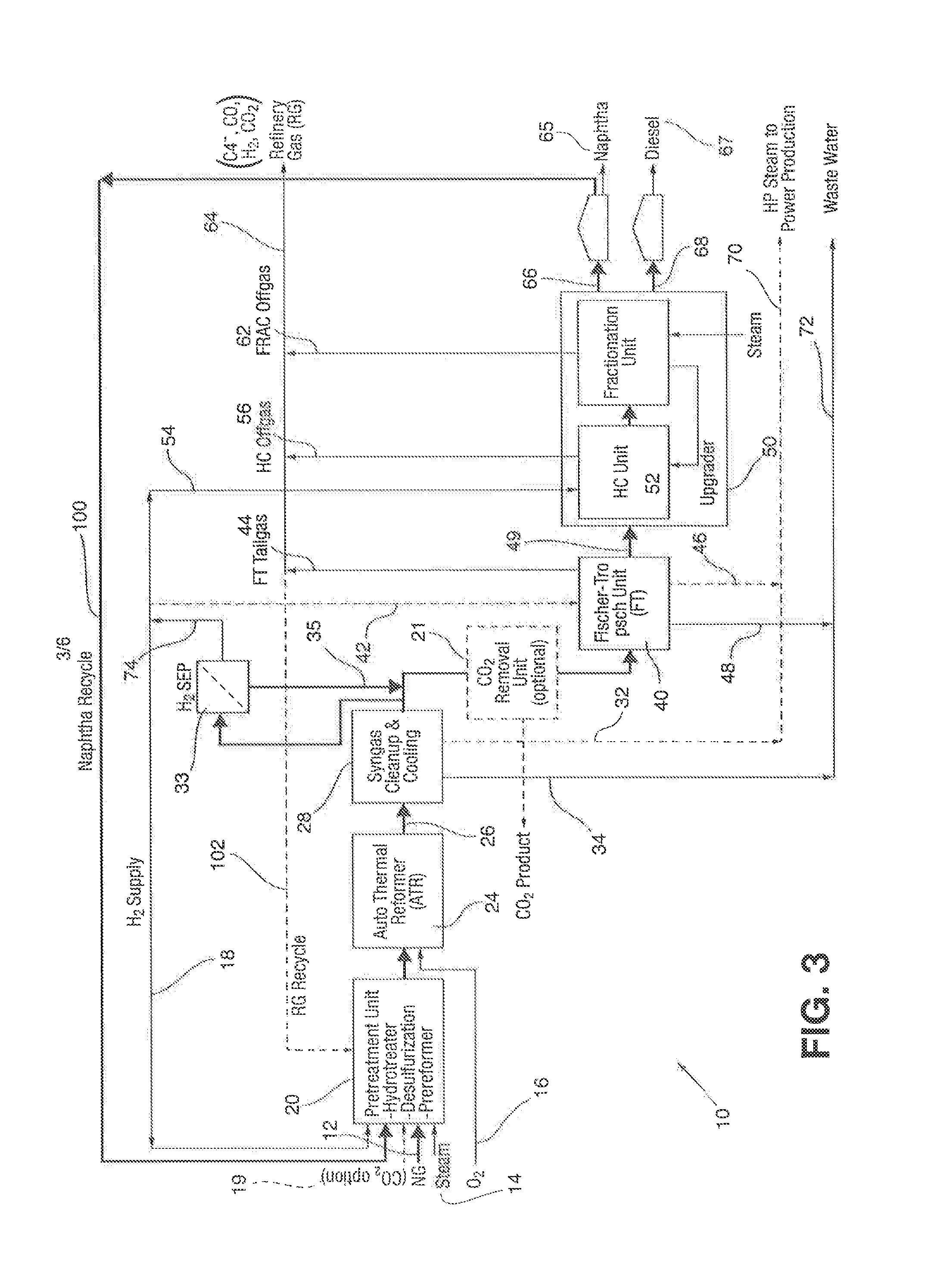

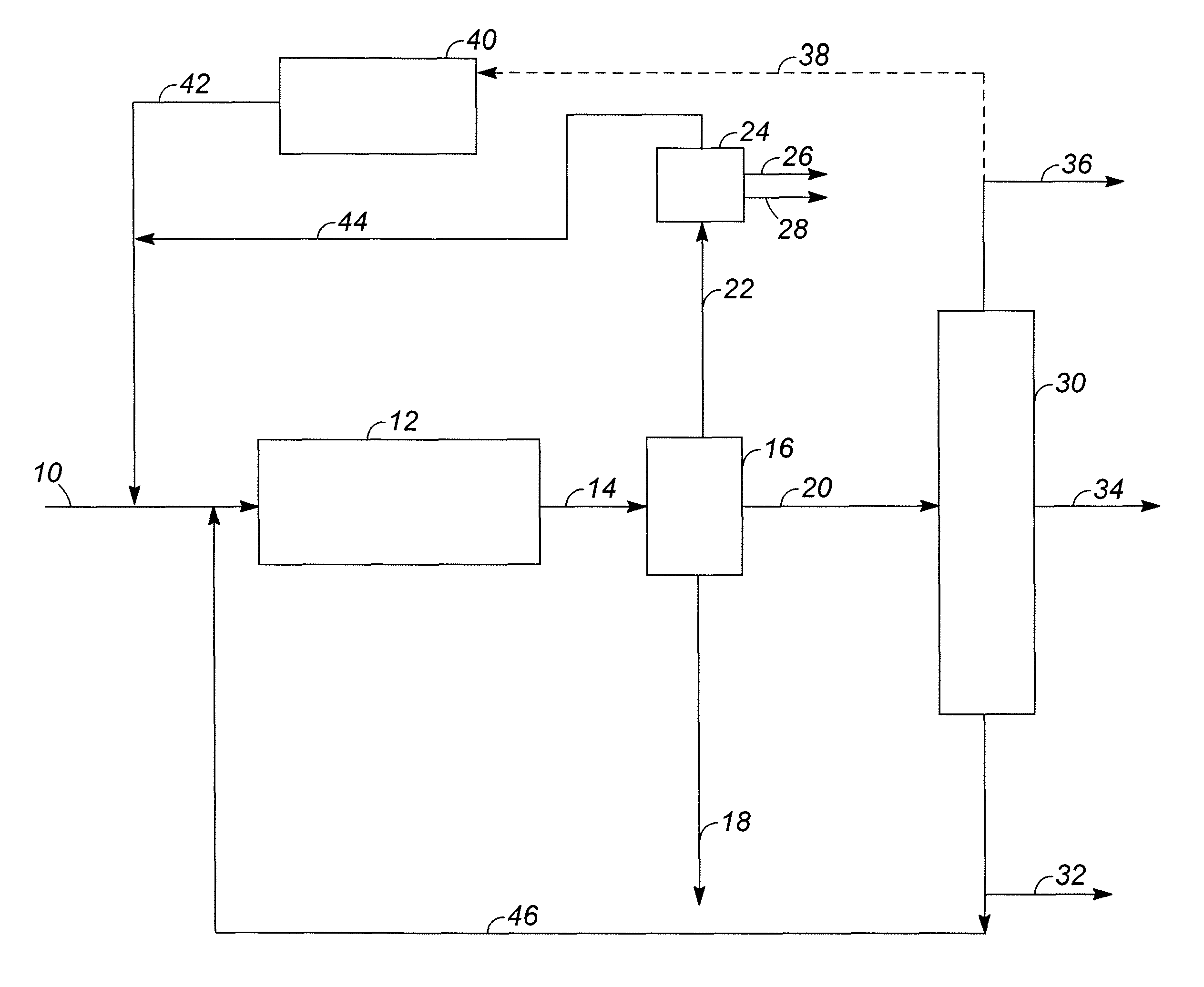

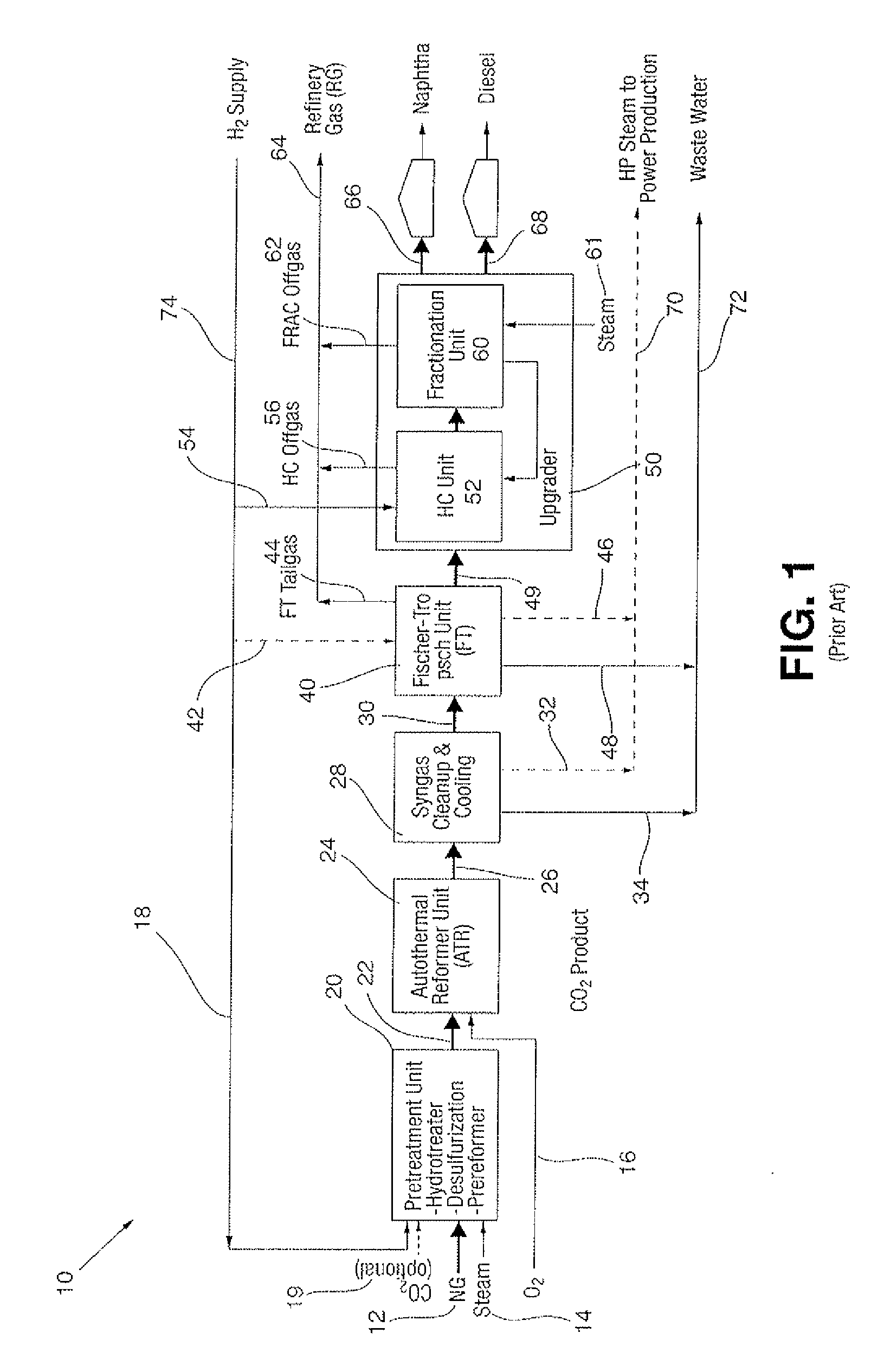

Enhancement of fischer-tropsch process for hydrocarbon fuel formulation

ActiveUS20120208902A1Increase productionIncrease conversionsBiofuelsGas modification by gas mixingSyngasNaphtha

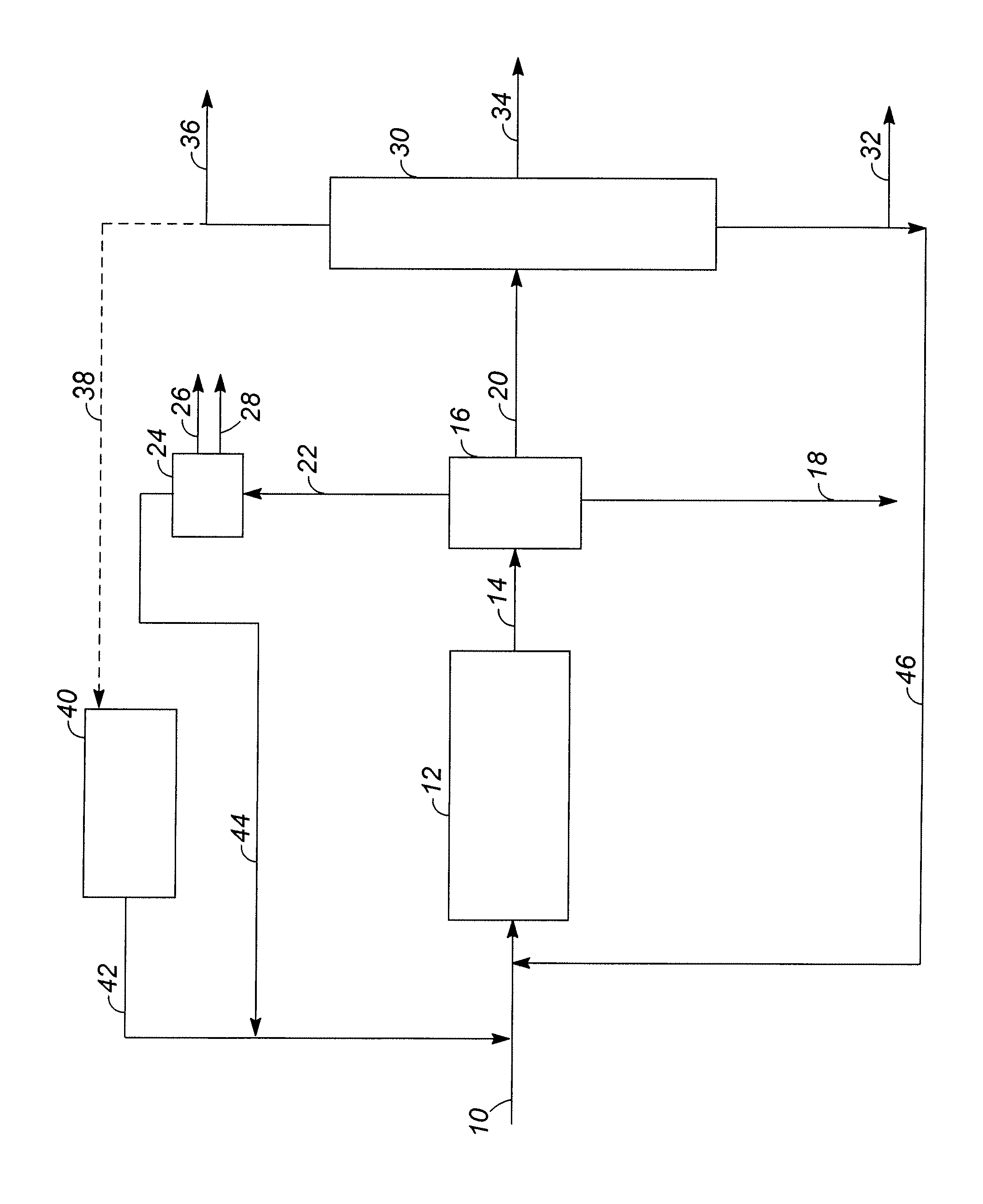

An enhanced Fischer-Tropsch process for the synthesis of sulfur free, clean burning, green hydrocarbon fuels, examples of which include syndiesel and aviation fuel. Naphtha is destroyed in a hydrogen generator and recycled as feedstock to a syngas (FT) reactor in order to enhance the production of syndiesel from the reactor. A further variation integrates a second hydrogen generator capturing light hydrocarbon gas for conversion to hydrogen and carbon monoxide which supplements the Fischer-Tropsch reactor. The result is a considerable increase in the volume of syndiesel formulated. A system for effecting the process is also characterized in the specification.

Owner:EXPANDER ENERGY

Renewable Engine Fuel

ActiveUS20080244961A1Boost octaneIncrease energy contentHydrocarbon purification/separationBiofuelsFuranCarbon number

The present invention provides fully renewable engine fuels derived completely from biomass sources. In one embodiment the fully renewable engine fuel is comprised of one or more low carbon number esters, one or more pentosan-derivable furans, one or more aromatic hydrocarbon, one or more C4-C10 straight chain alkanes derivable from polysaccharides, and one or more bio-oils. In addition, the fuel may contain triethanolamine. Such a lower octane renewable fuel may be utilized, for example, in automobile fuel, 100 LL aviation fuel applications, and turbine engine applications. These ethanol-based, fully renewable fuels may be formulated to have a wide range of octane values and energy, and may effectively be used to replace 100 LL aviation fuel (known as AvGas), as well as high octane, rocket, diesel, and turbine engine fuels. In another embodiment, there is provided a synthetic high octane aviation fuel comprising isopentane and mesitylene, and process of producing same from a biomass.

Owner:SWIFT ENTERPRISES

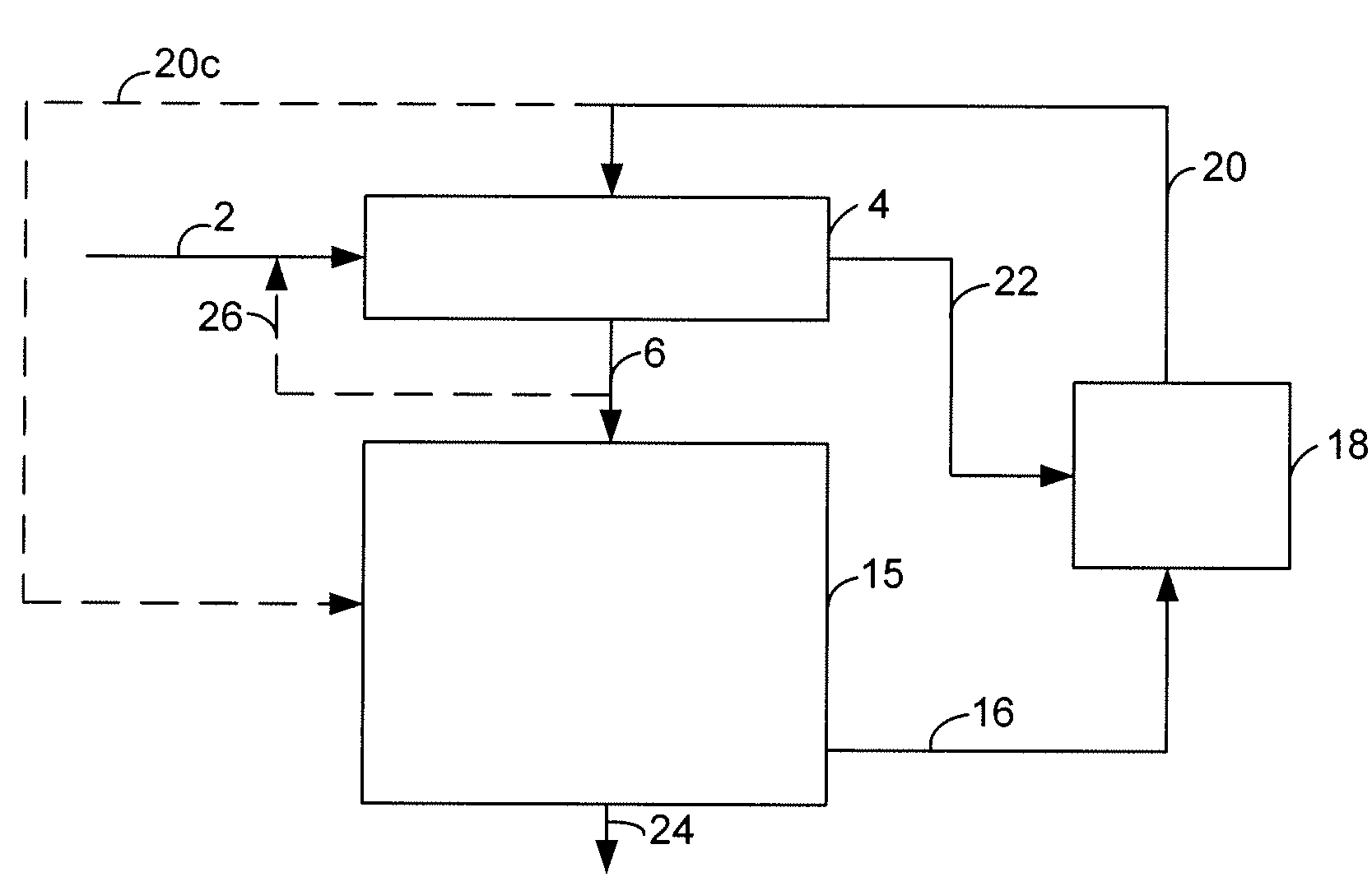

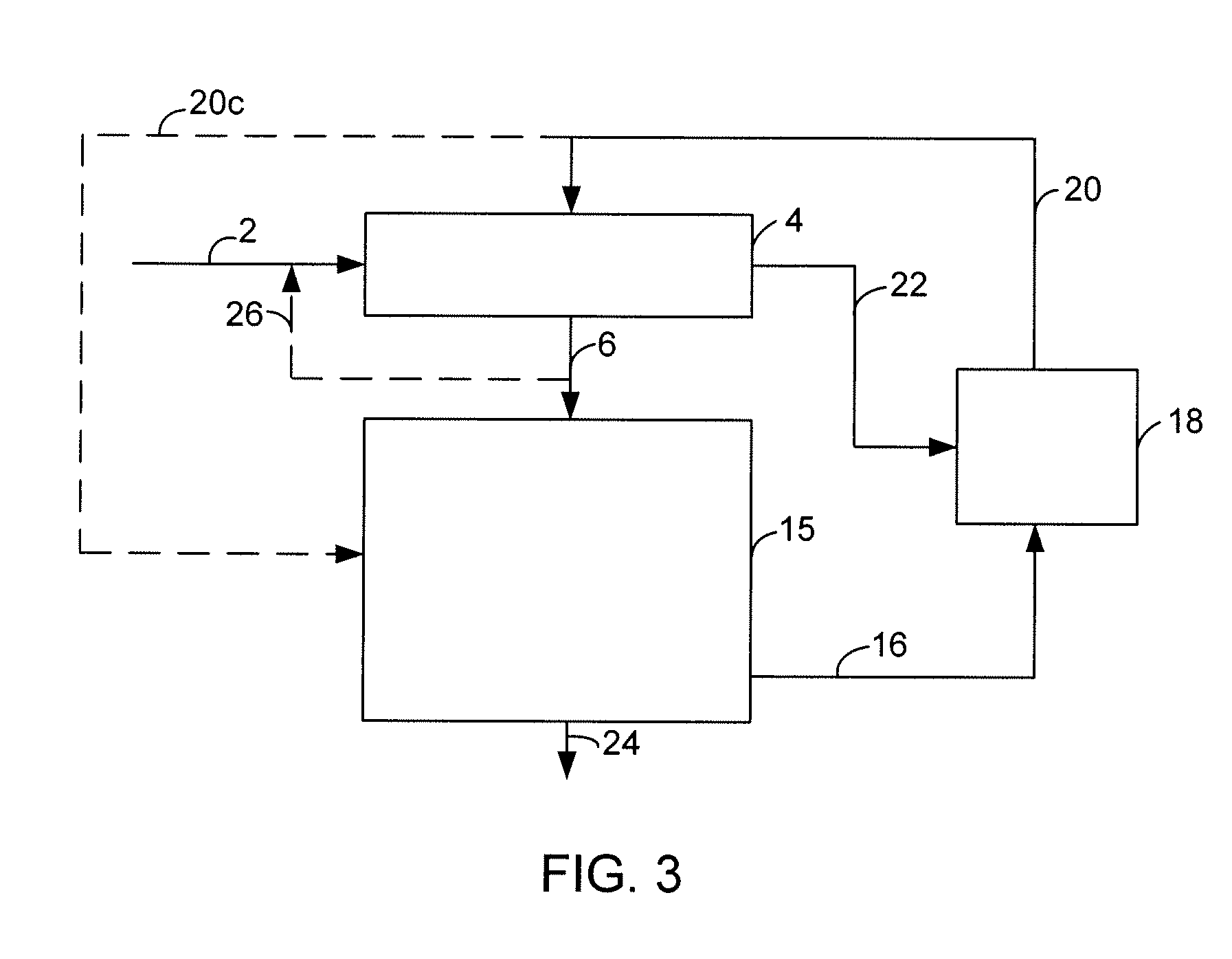

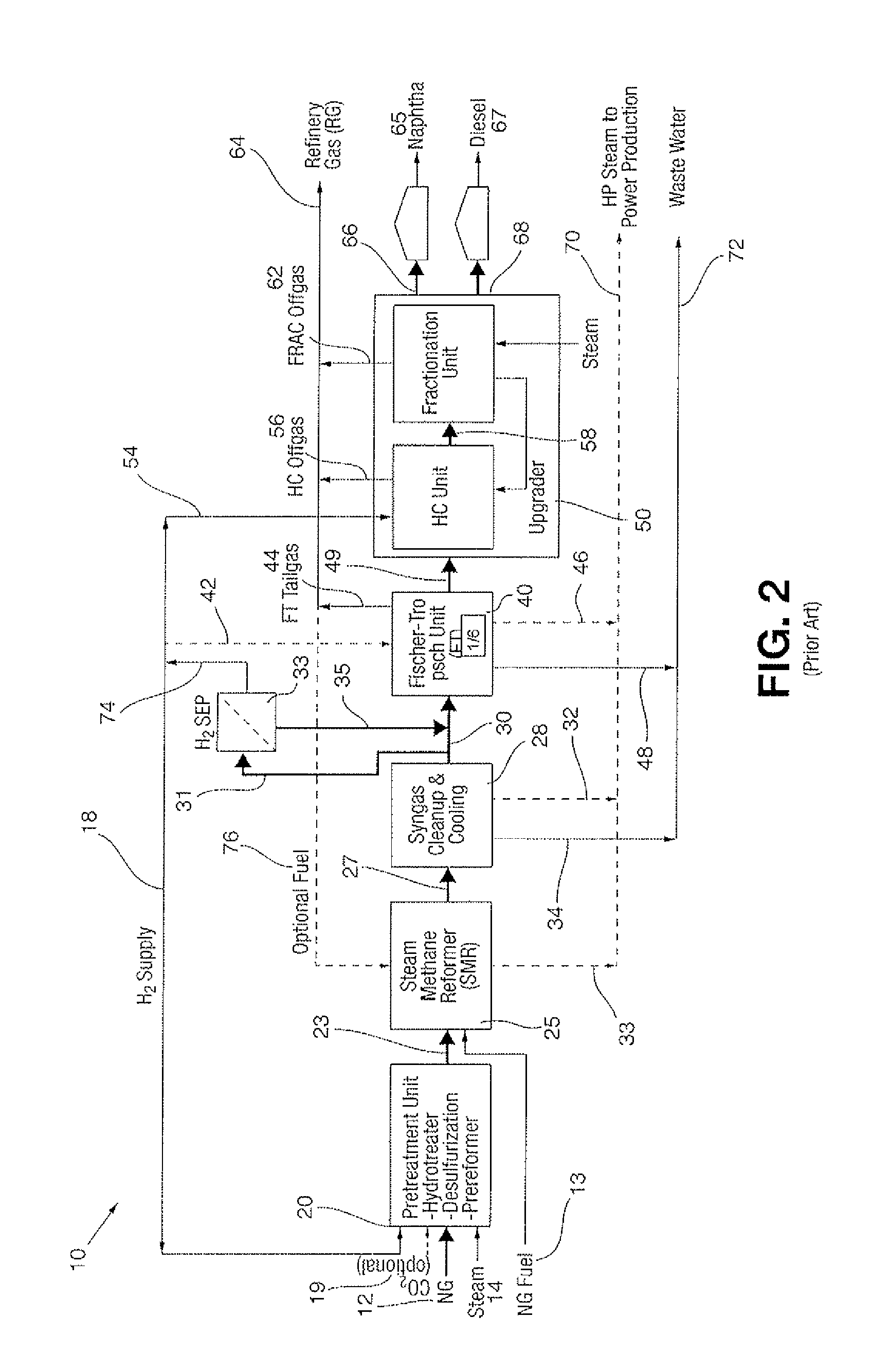

Enhancement of Fischer-Tropsch process for hydrocarbon fuel formulation in a GTL environment

ActiveUS8889746B2Increase productionRaise the ratioHydrogenOrganic compound preparationSyngasNaphtha

An enhanced Fischer-Tropsch process for the synthesis of sulfur free, clean burning, hydrocarbon fuels, examples of which include syndiesel and aviation fuel. Naphtha is destroyed in a syngas generator and recycled as feedstock to an Fischer-Tropsch (FT) reactor in order to enhance the production of syndiesel from the reactor. The process enhancement results is the maximum production of formulated syndiesel without the formation of low value by-products.

Owner:EXPANDER ENERGY

Production of aviation fuel from renewable feedstocks

ActiveUS8039682B2Improve solubilityMinimize severityRefining to change hydrocarbon structural skeletonHydrocarbon purification/separationIsomerizationBoiling point

A hydrocarbon product stream having hydrocarbons with boiling points in the aviation fuel range is produced from renewable feedstocks such as plant and animal oils. The process involves treating a renewable feedstock by hydrogenating, deoxygenating, isomerization, and selectively hydrocracking the feedstock to produce paraffinic hydrocarbons having from about 9 to about 16 carbon atoms and a high iso / normal ratio in a single reaction zone containing a multifunctional catalyst, or set of catalysts, having hydrogenation, deoxygenation, isomerization and selective hydrocracking functions.

Owner:UOP LLC

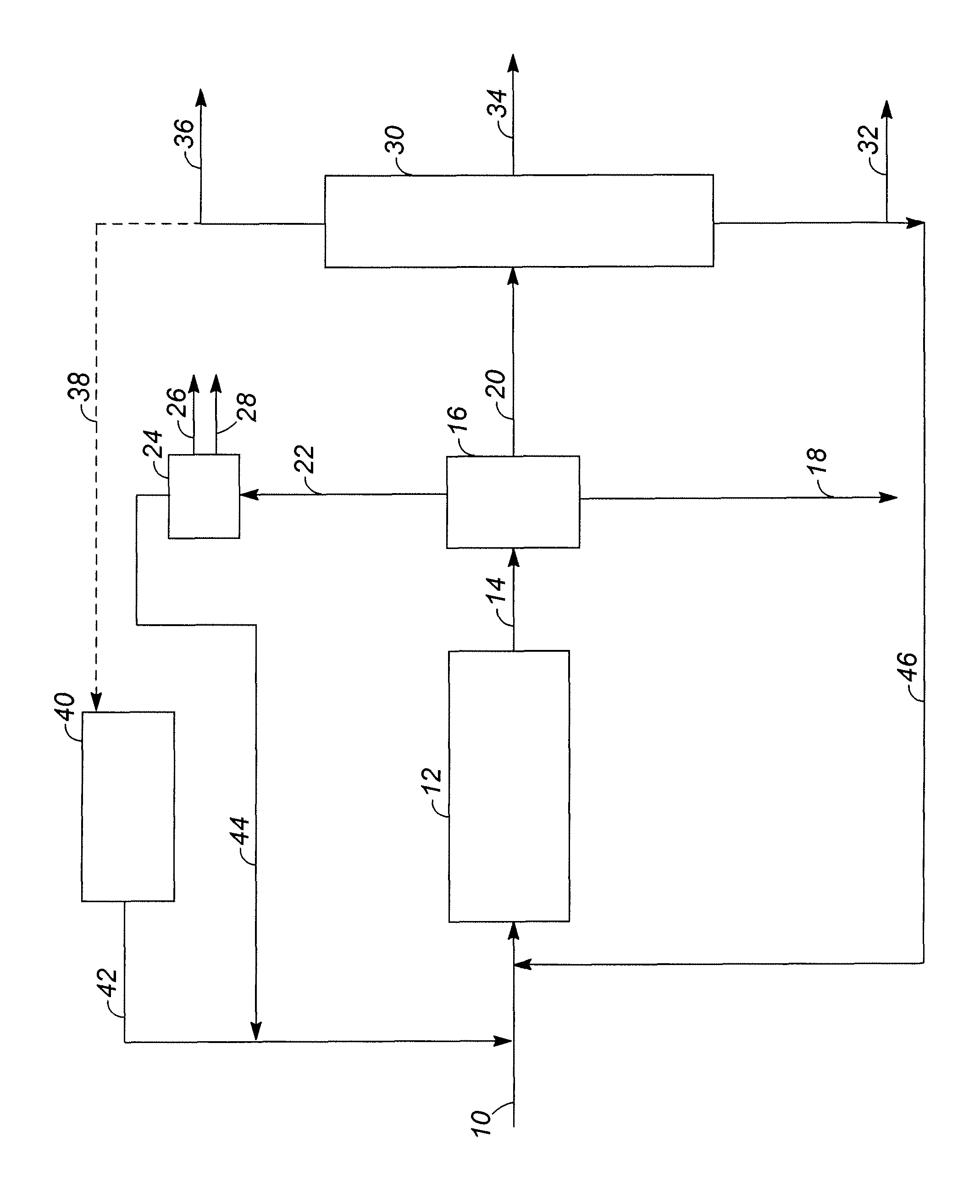

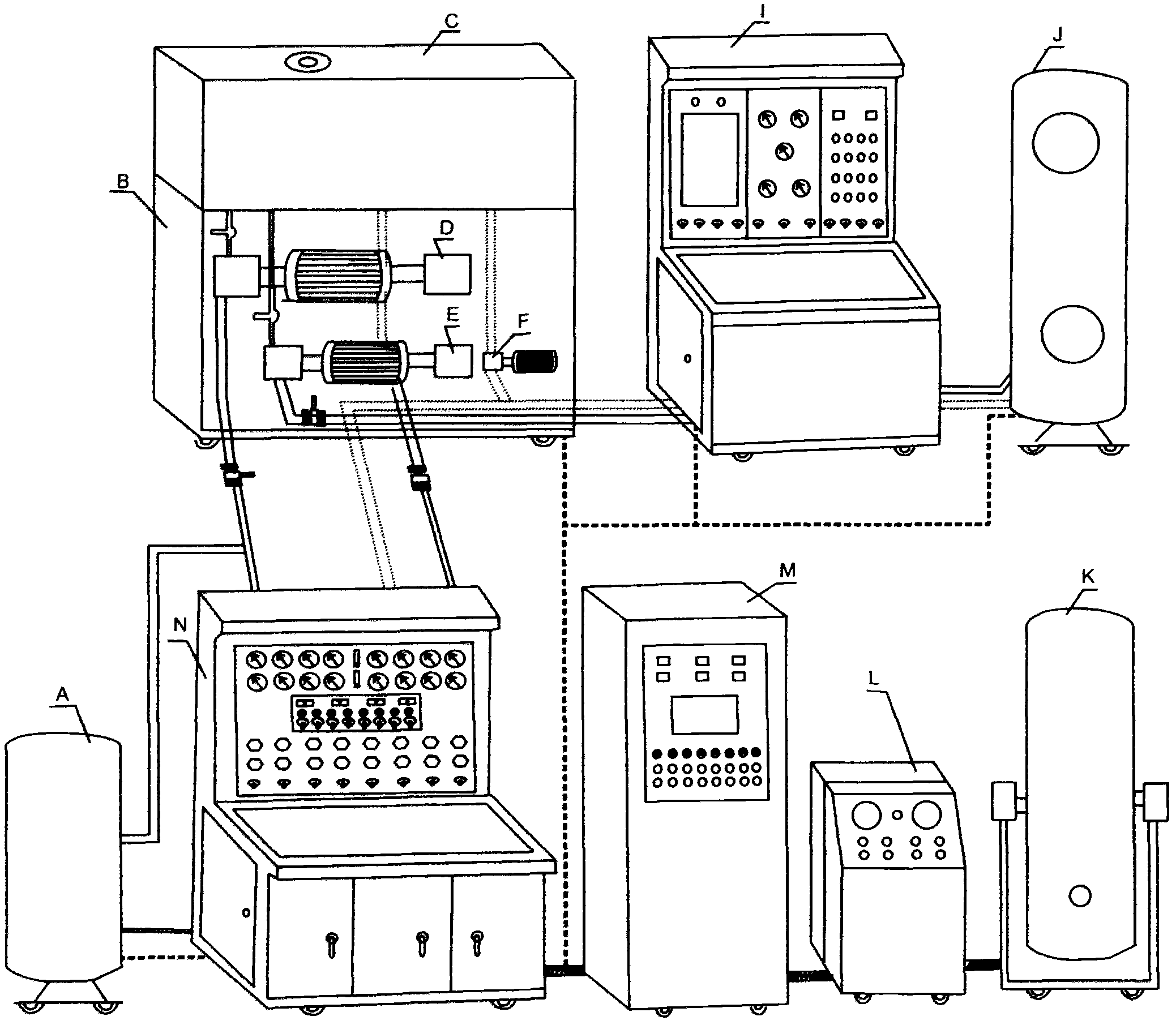

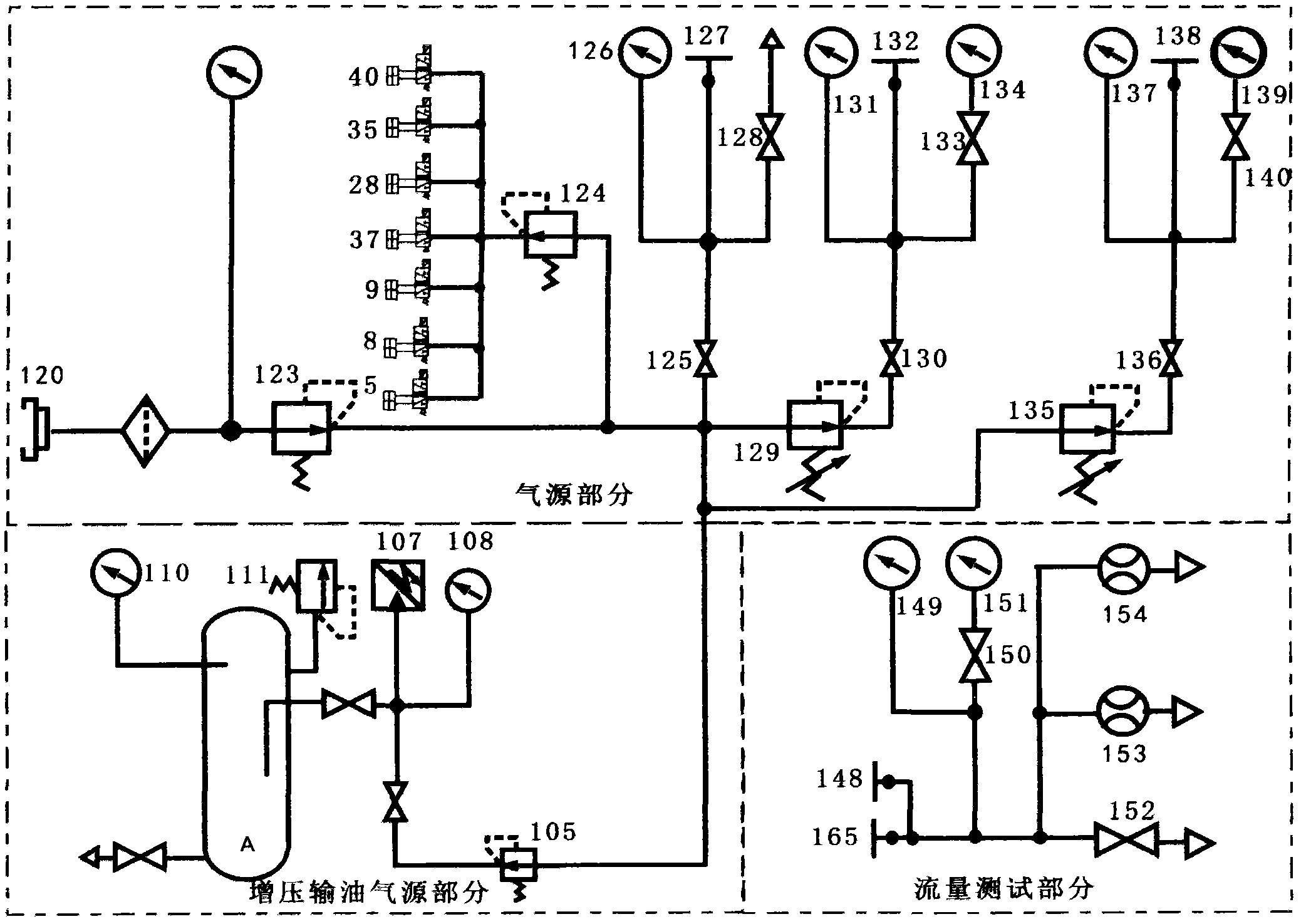

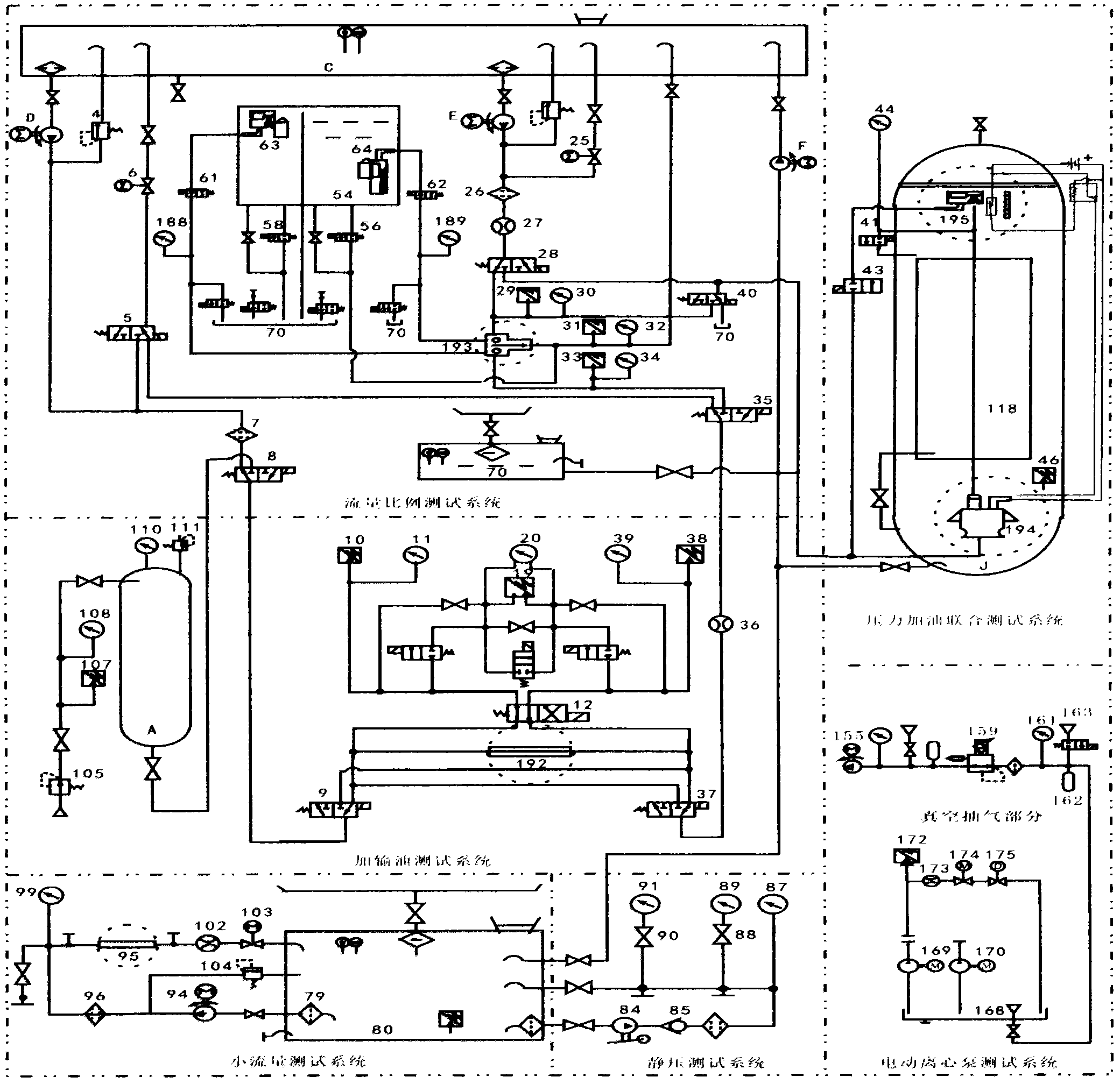

Integrated testing system for aviation fuel accessories

InactiveCN102589860AReduce purchasing costsLower requirementMachine part testingPump testingAviationAircraft fuel system

The invention relates to an integrated testing system for aviation fuel accessories. The integrated testing system comprises an electric control cabinet, a mechanical operating platform, an integrated pump station, a flow proportion testing platform, a pneumatic testing system and a fuel testing system, wherein the mechanical operating platform is connected with a pressurizing oil delivery gas storage tank through the pneumatic testing system; the integrated pump station is connected with the fuel testing system through an oil delivery pipeline; the pneumatic testing system is connected with the fuel testing system through a pneumatic pipeline; the flow proportion testing platform is connected with a pressure refueling joint testing oil tank; and the electric control cabinet is electrically connected with the mechanical operating platform, the integrated pump station, the flow proportion testing platform, the pneumatic testing system, the fuel testing system, the pressurizing oil delivery gas storage tank and the pressure refueling joint testing oil tank. The integrated testing system can perform performance test on all accessories of an aircraft fuel system, is high in integrity,convenient to maintain, compact in structure, small in occupation area and low in cost and expenditure, and is in accordance with specific using environment and support conditions under the field condition of an aviation equipment support army.

Owner:QINGDAO CAMPUS AVIATION ENG COLLEGE OF THE PEOPLES LIBERATION ARMY NAVY

Renewable engine fuel

Owner:SWIFT ENTERPRISES

Fuel oil base and aviation fuel composition containing same

ActiveUS20140323777A1Excellent life cycle COImprove low temperature fluidityRefining to change hydrocarbon structural skeletonLiquid carbonaceous fuelsAlkaneVegetable oil

The aviation fuel oil base of the present invention is obtained by hydrotreating an oil to be treated containing an oxygen-containing hydrocarbon compound derived from an animal or vegetable oils and fat and a sulfur-containing hydrocarbon compound and then hydroisomerizing the resultant hydrotreated oil, wherein a yield of a fraction having a boiling range of 140 to 300° C. is 70 mass % or more; an isoparaffin content is 80 mass % or more; a content of isoparaffin having 2 or more branches is 17 mass % or more; an aromatic content is less than 0.1 vol %; an olefin content is less than 0.1 vol %; a sulfur content is less than 1 mass ppm; and an oxygen content is less than 0.1 mass %.

Owner:JX NIPPON OIL & ENERGY CORP

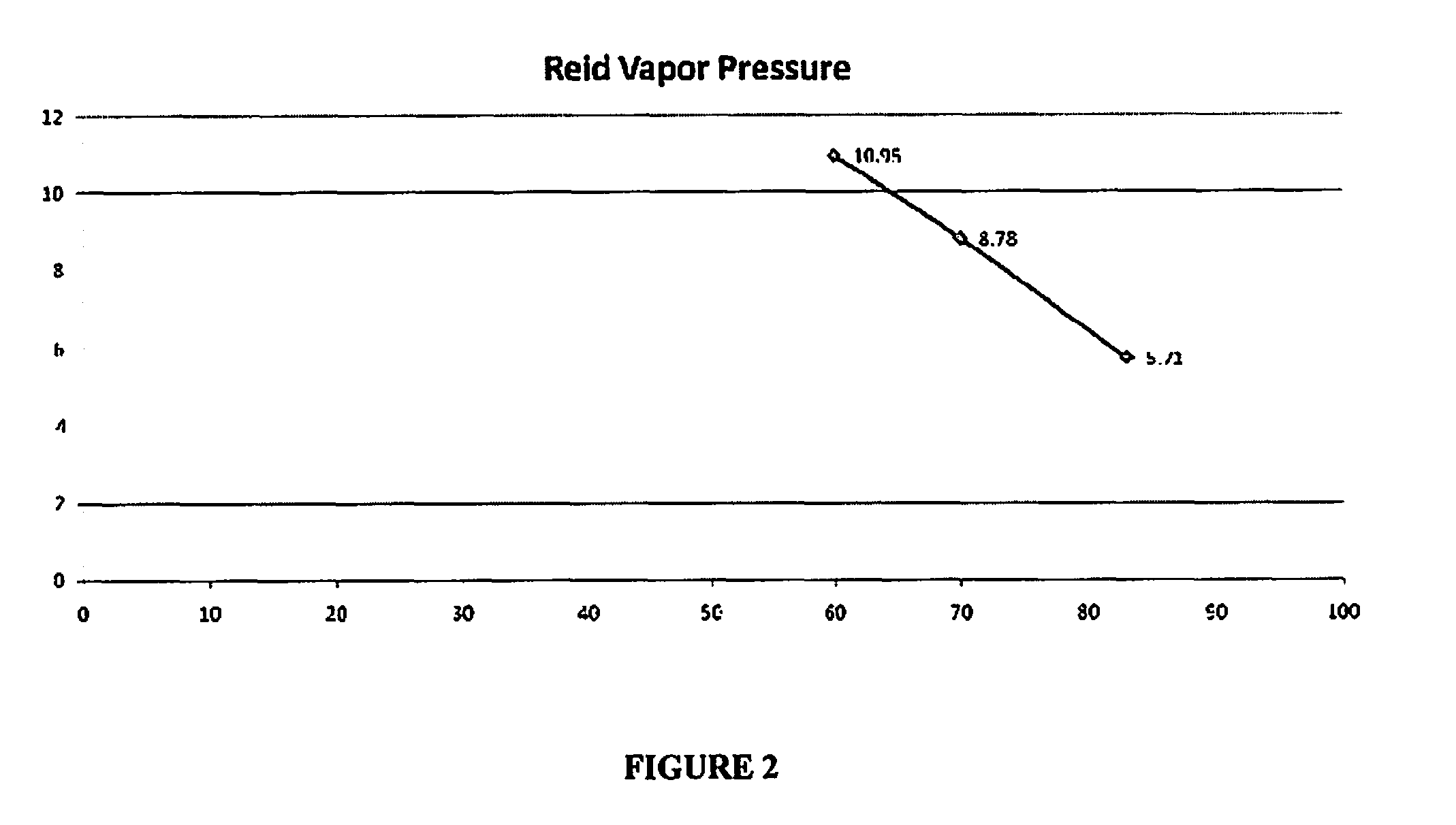

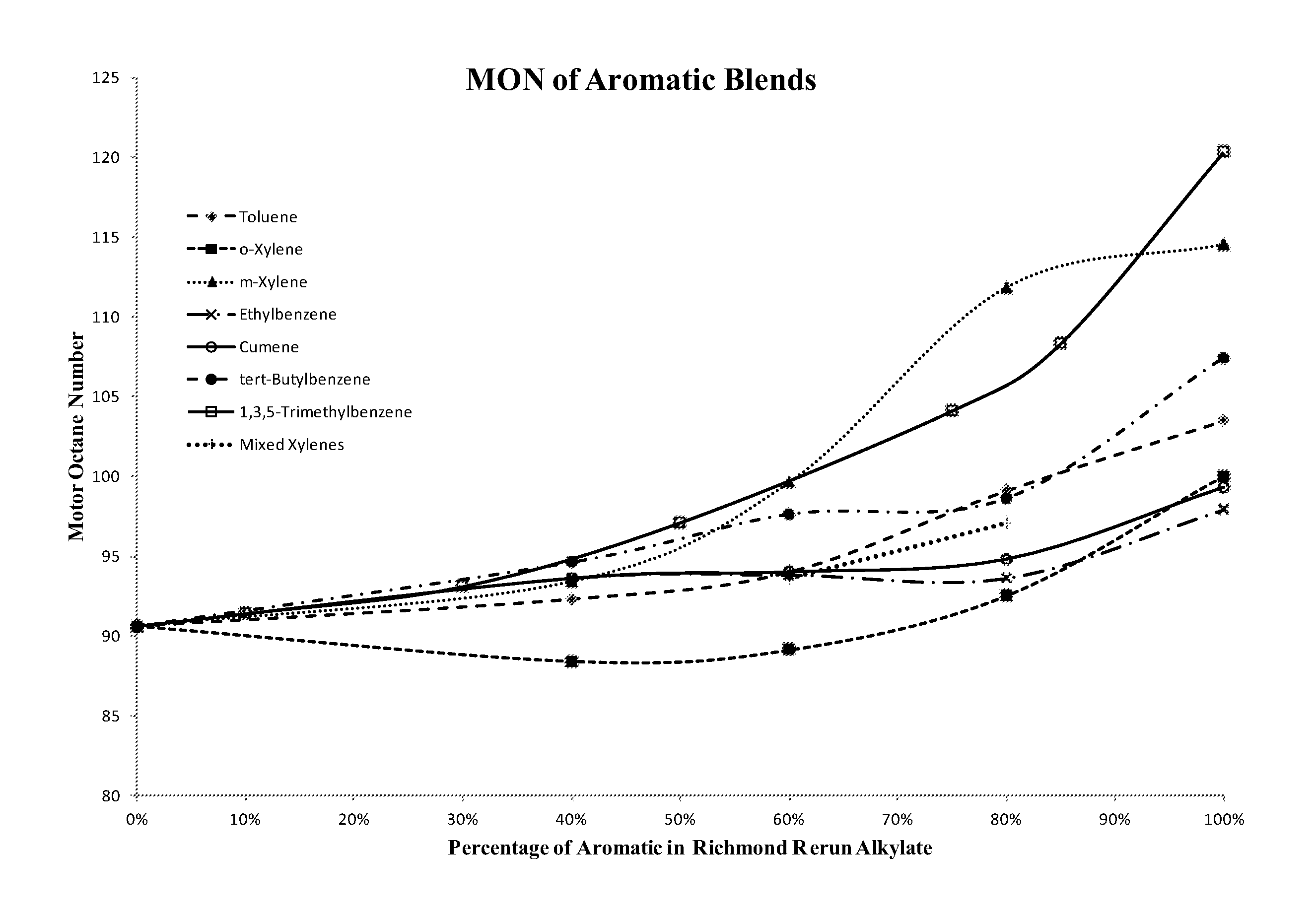

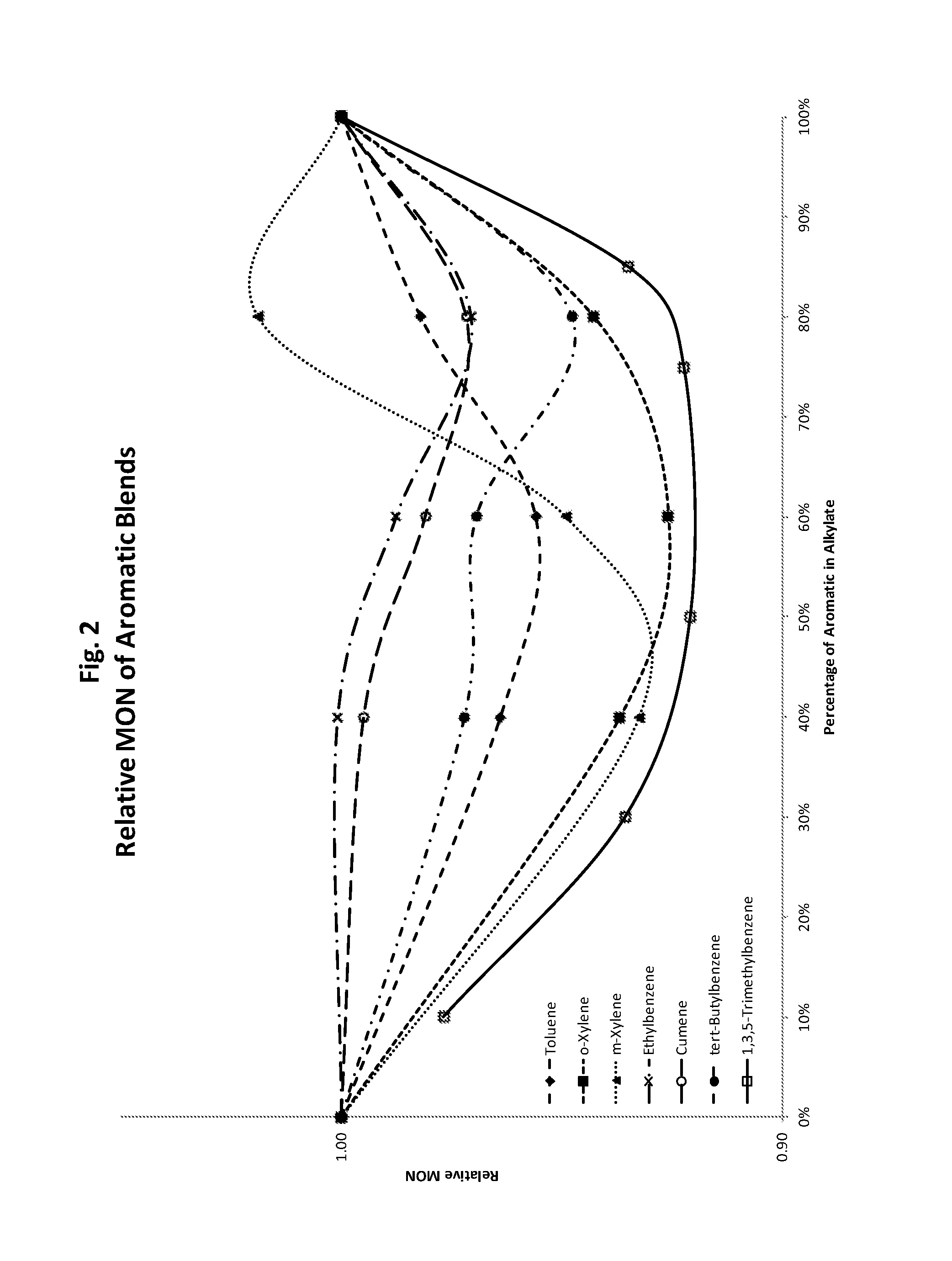

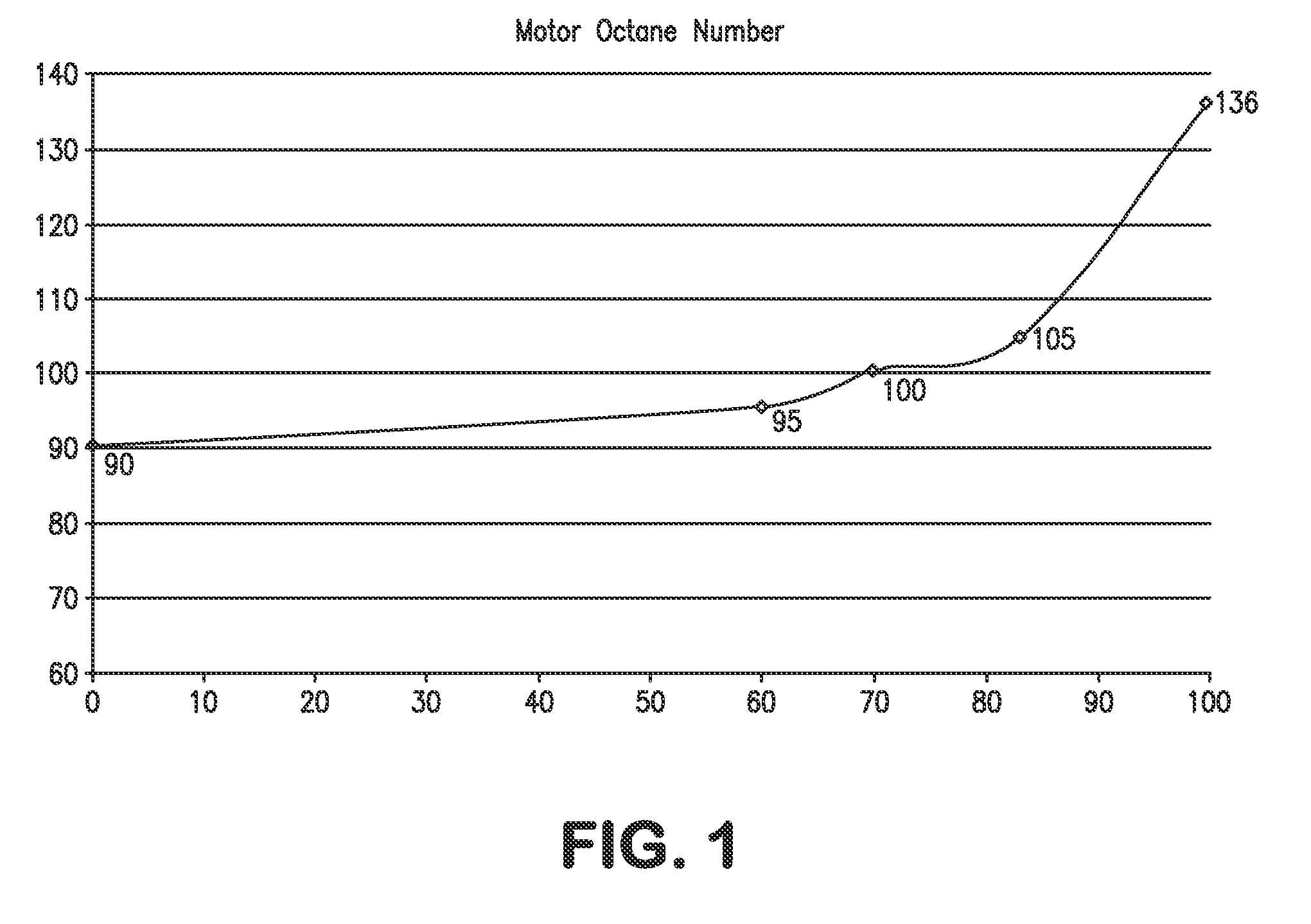

High octane aviation fuel composition

An unleaded aviation fuel composition, containing at least one saturated branched aliphatic hydrocarbon having a carbon number in the C4 to C10 range, further contains sufficient m-xylene to yield a fuel having a MON of at least 98. A process is further provided for producing the unleaded aviation fuel composition by admixing a m-xylene enriched liquid with alkylate.

Owner:CHEVROU USA INC

Renewable engine fuel and method of producing same

ActiveUS8313540B2Avoid poisoningHydrocarbon from oxygen organic compoundsLiquid carbonaceous fuelsRocketPetroleum

Owner:SWIFT ENTERPRISES

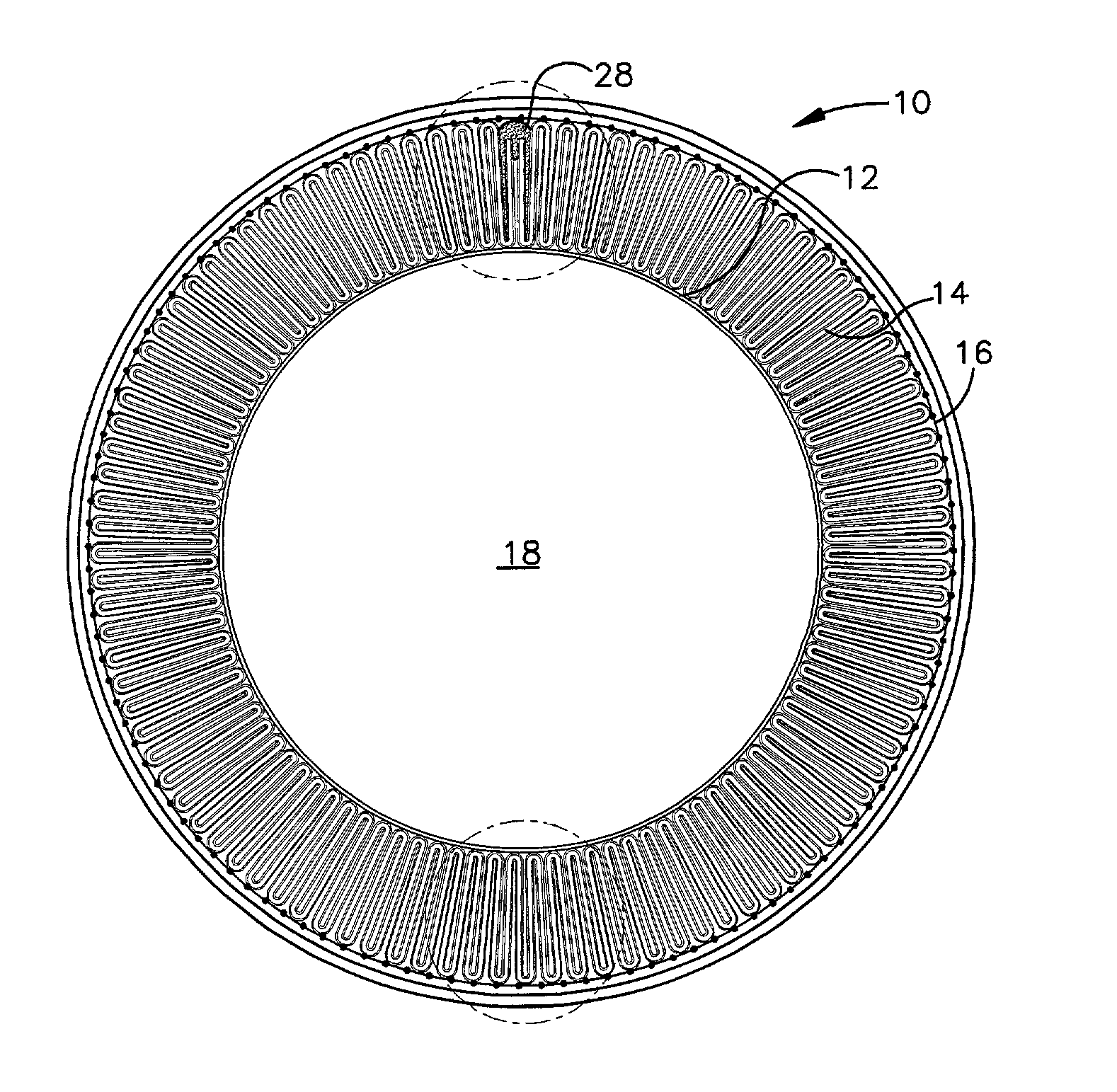

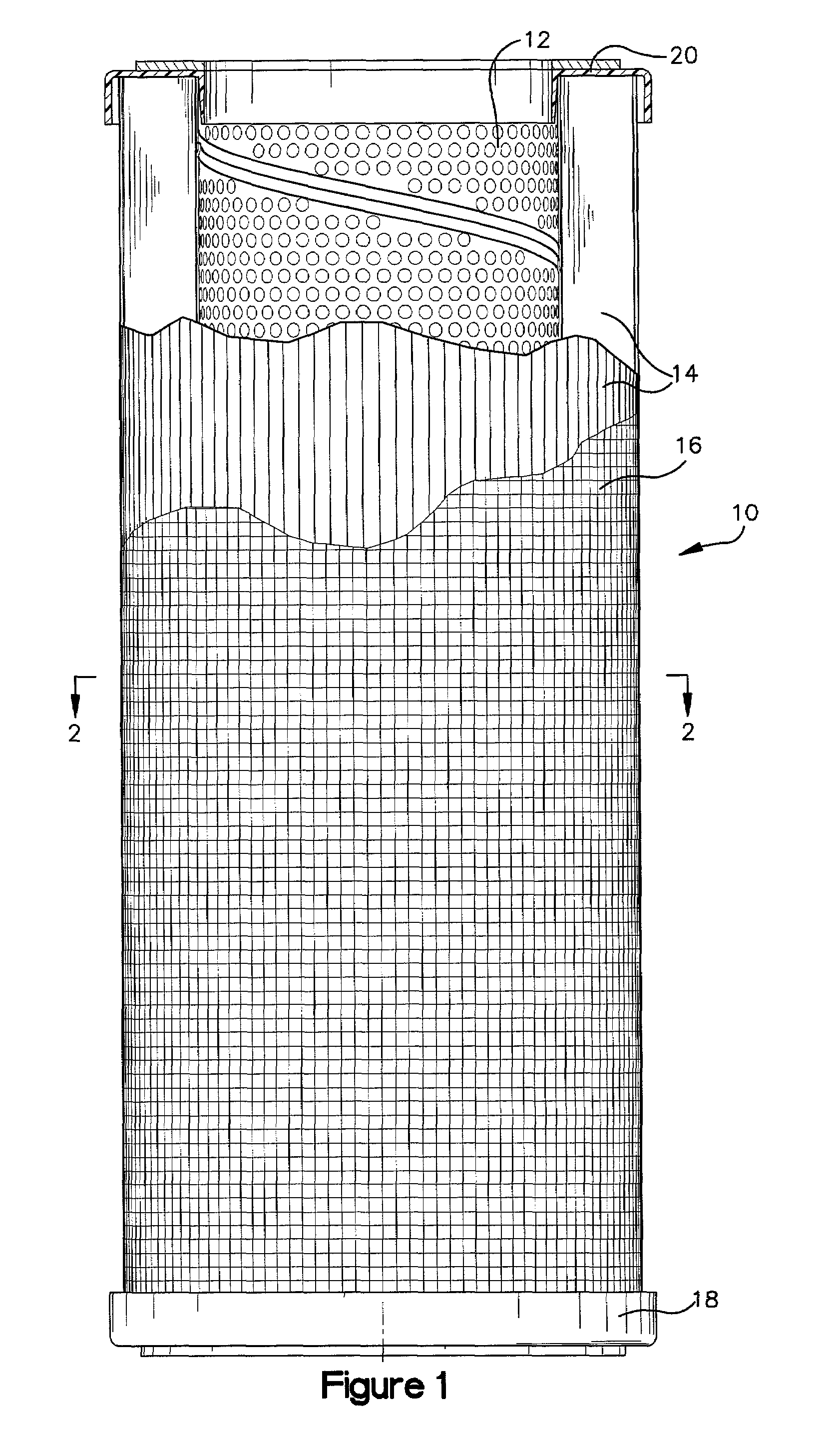

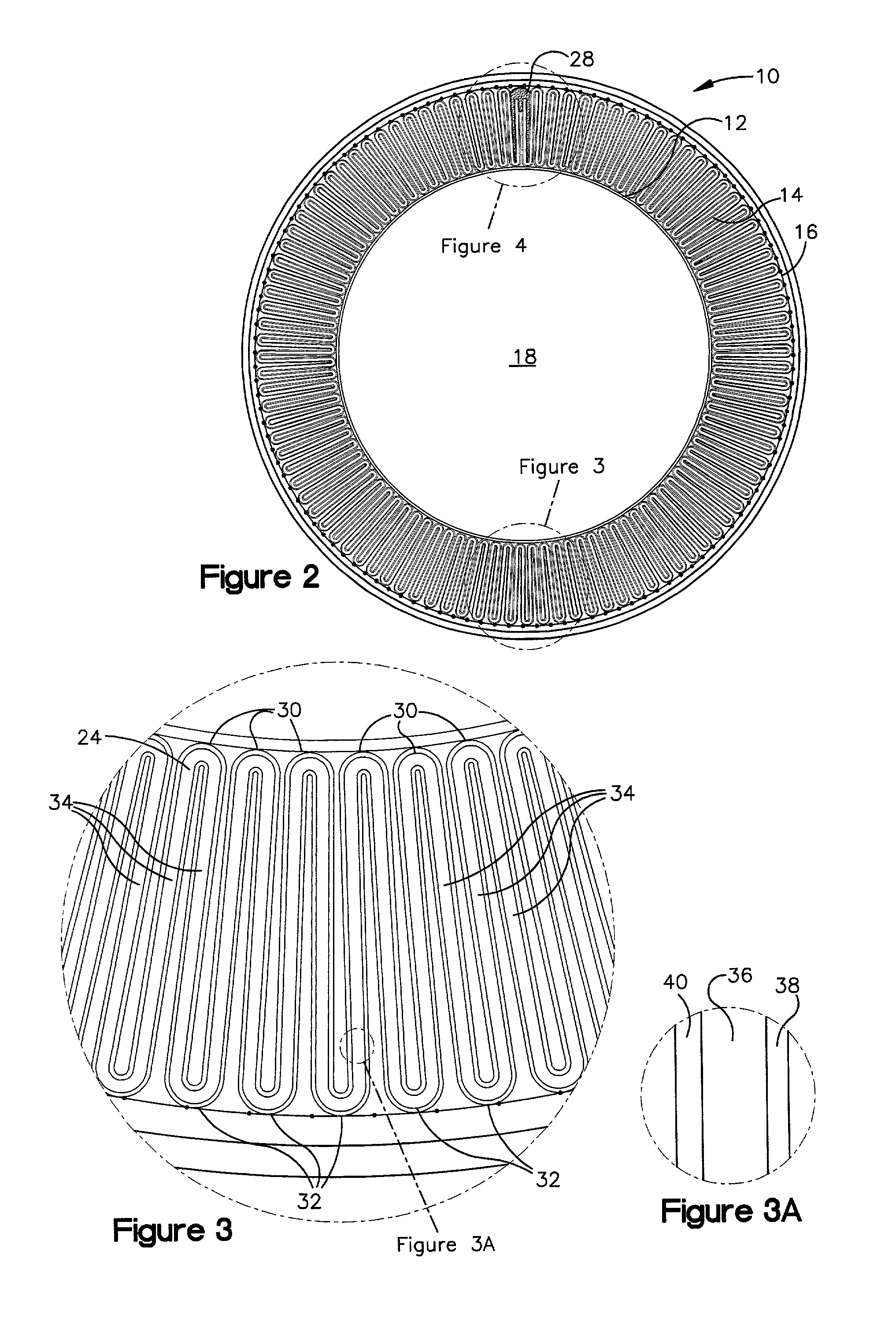

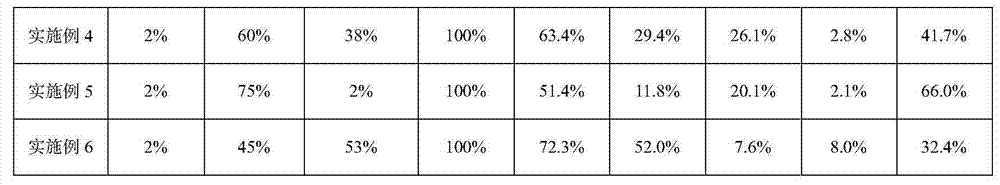

Filter element and method of making

InactiveUS7438812B2Solution to short lifeImprove efficiencyDispersed particle filtrationLiquid suspension thickening by filtrationFilter mediaCellulose fiber

A filter element (10) is provided which can be used to remove microsize contaminant particles (i.e., about 0.5 μm to about 25.0 μm) from aviation fuel. The filter element (10) includes a cylindrical pleated filter media (14) and an exoskeleton support structure (16) supporting the filter media (14). The filter media (14) has a pleat density of about eight to about thirteen pleats per inner diameter inch and is formed only from cellulose-fiber-free and woven-mesh-free layers. The exoskeleton support structure (16) is a screen which is thermally bonded to the pleats' peaks in such a manner that the filter media (14) is sufficiently supported without conventional endoskeleton support layers.

Owner:PARKER INTANGIBLES LLC

Method for preparing biological aviation fuel by using litsea cubeba kernel oil

InactiveCN102719317AImprove qualityImprove cleanlinessFatty acids production/refiningLiquid carbonaceous fuelsIsomerizationHydrogenation reaction

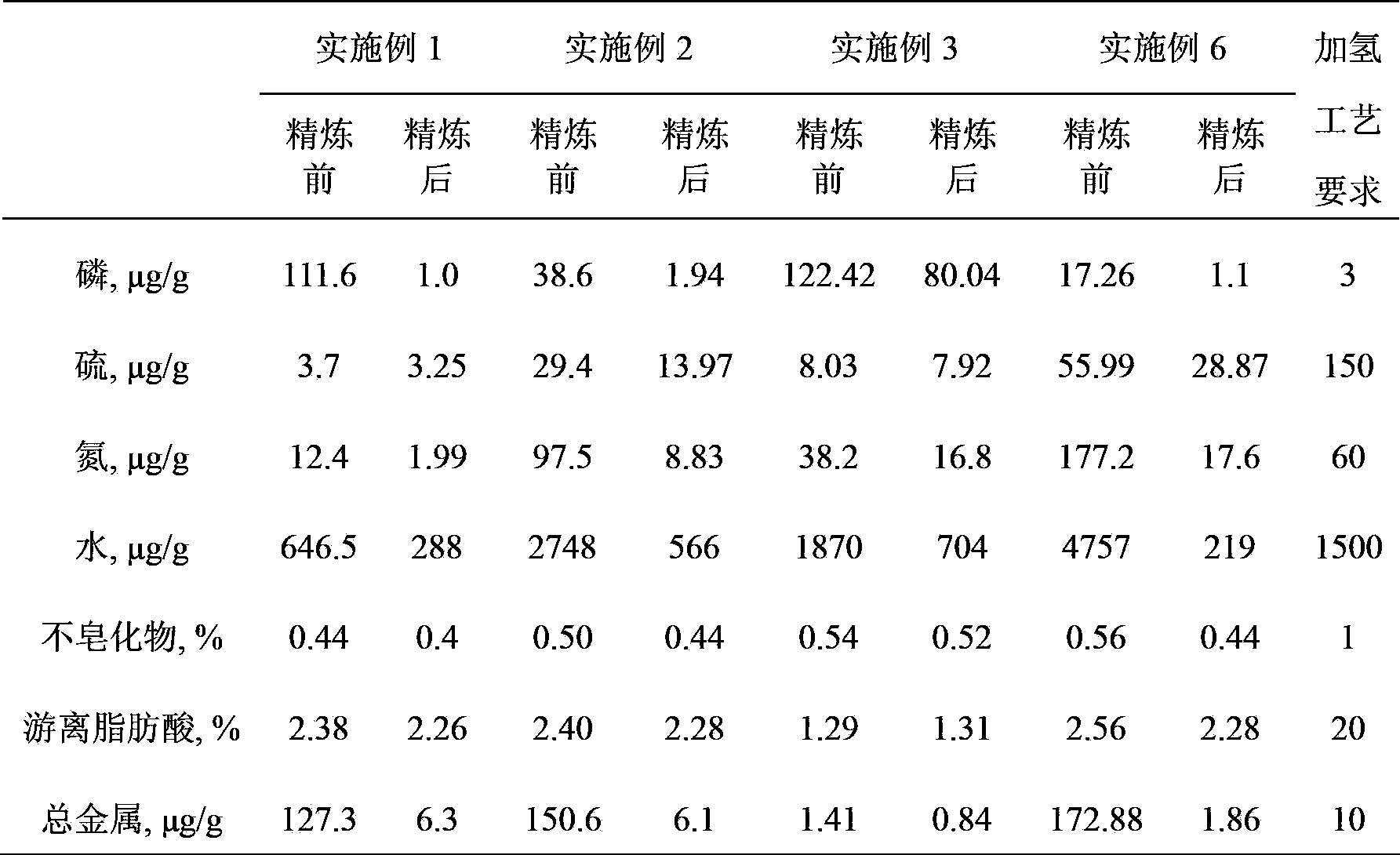

The invention discloses a method for preparing biological aviation fuel by using litsea cubeba kernel oil, comprising the following steps of: (1) refining the litsea cubeba kernel oil; (2) introducing the refined litsea cubeba kernel oil into a fixed-bed hydrogenation reaction device and sequentially carrying out hydrogenation and deoxygenation reaction and isomerization reaction; (3) collecting liquid-phase components through a condenser; (4) distilling and collecting distillate with the temperature of 150-280 DEG C; and (5) refining the collected distillate through a fiber liquid membrane-composite adsorption unifying device and a dielectric field refining device to obtain the biological aviation fuel meeting the aviation fuel specification. By using the method, the obtained biological aviation fuel contains no sulfur and arene and is good in quality, high in cleanliness and environment-friendly.

Owner:WEIMING BIO ENERGY CO LTD +1

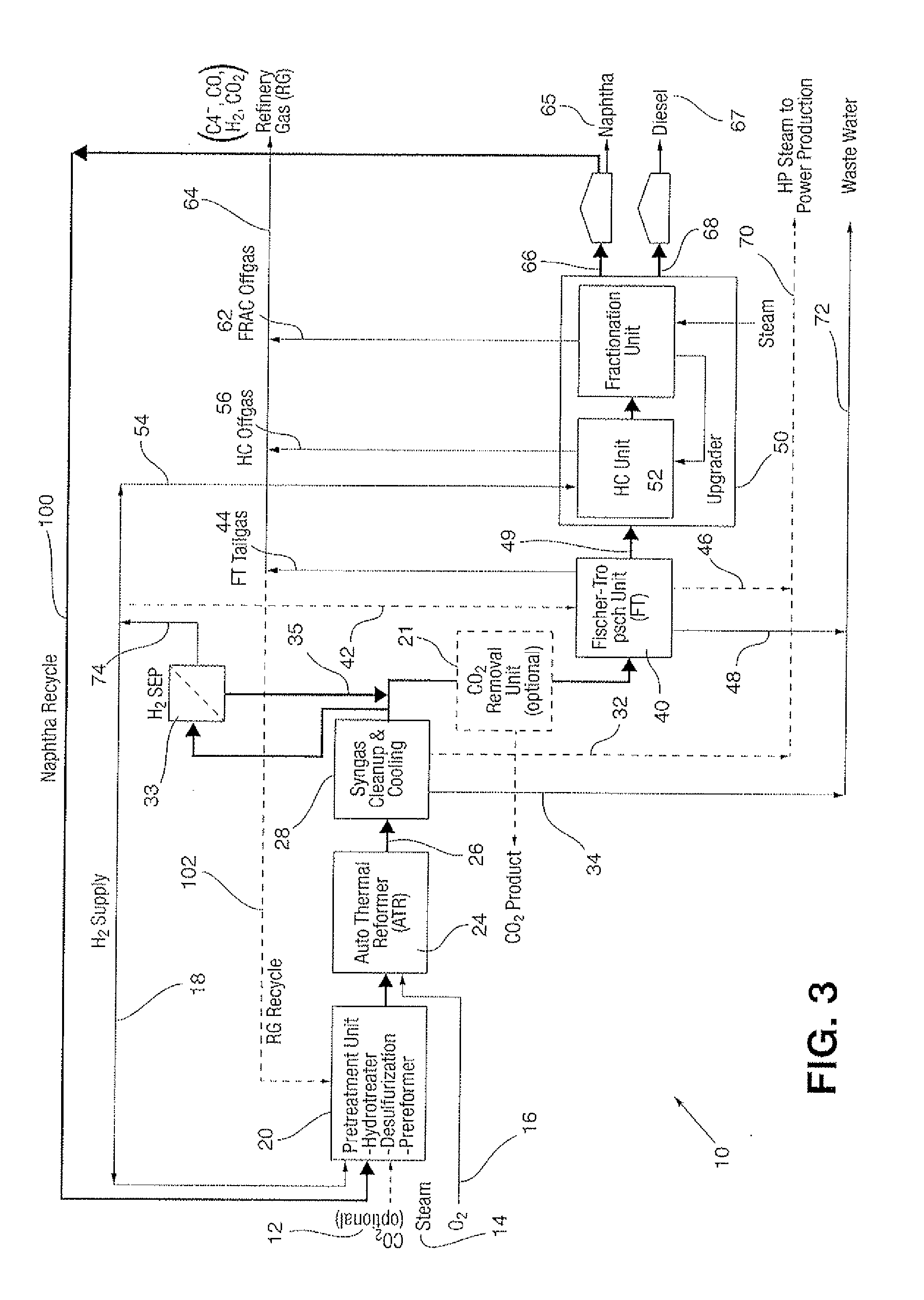

Enhancement of fischer-tropsch process for hydrocarbon fuel formulation in a GTL environment

ActiveUS20130065974A1High hydrogen to carbon monoxide ratioIncrease volumeHydrogenOrganic compound preparationSyngasNaphtha

An enhanced Fischer-Tropsch process for the synthesis of sulfur free, clean burning, hydrocarbon fuels, examples of which include syndiesel and aviation fuel. Naphtha is destroyed in a syngas generator and recycled as feedstock to an Fischer-Tropsch (FT) reactor in order to enhance the production of syndiesel from the reactor. The process enhancement results is the maximum production of formulated syndiesel without the formation of low value by-products.

Owner:EXPANDER ENERGY

Renewable Engine Fuel And Method Of Producing Same

The present invention provides non-petroleum high-octane fuel derived from biomass sources, and a method of producing same. The method of production involves reducing the biomass feedstocks to sugars, fermenting the sugars using microorganisms or mutagens thereof to produce ethanol or acetic acid, converting the acetic acid or ethanol to acetone, and converting the acetone to mesitylene and isopentane, the major components of the renewable engine fuel. Trimerization of acetone can be carried out in the presence of a catalyst containing at least one metal selected from the group consisting of niobium, iron and manganese. The ethanol can be converted to mesitylene in a dehydration reaction in the presence of a catalyst of zinc oxide / calcium oxide, and unreacted ethanol and water separated from mesitylene by distillation. These ethanol-based, biomass-derived fuels are fully renewable, may be formulated to have a wide range of octane values and energy, and may effectively be used to replace 100 LL aviation fuel (known as AvGas), as well as high-octane, rocket, diesel, turbine engine fuels, as well as two-cycle, spark-ignited engine fuels.

Owner:SWIFT ENTERPRISES

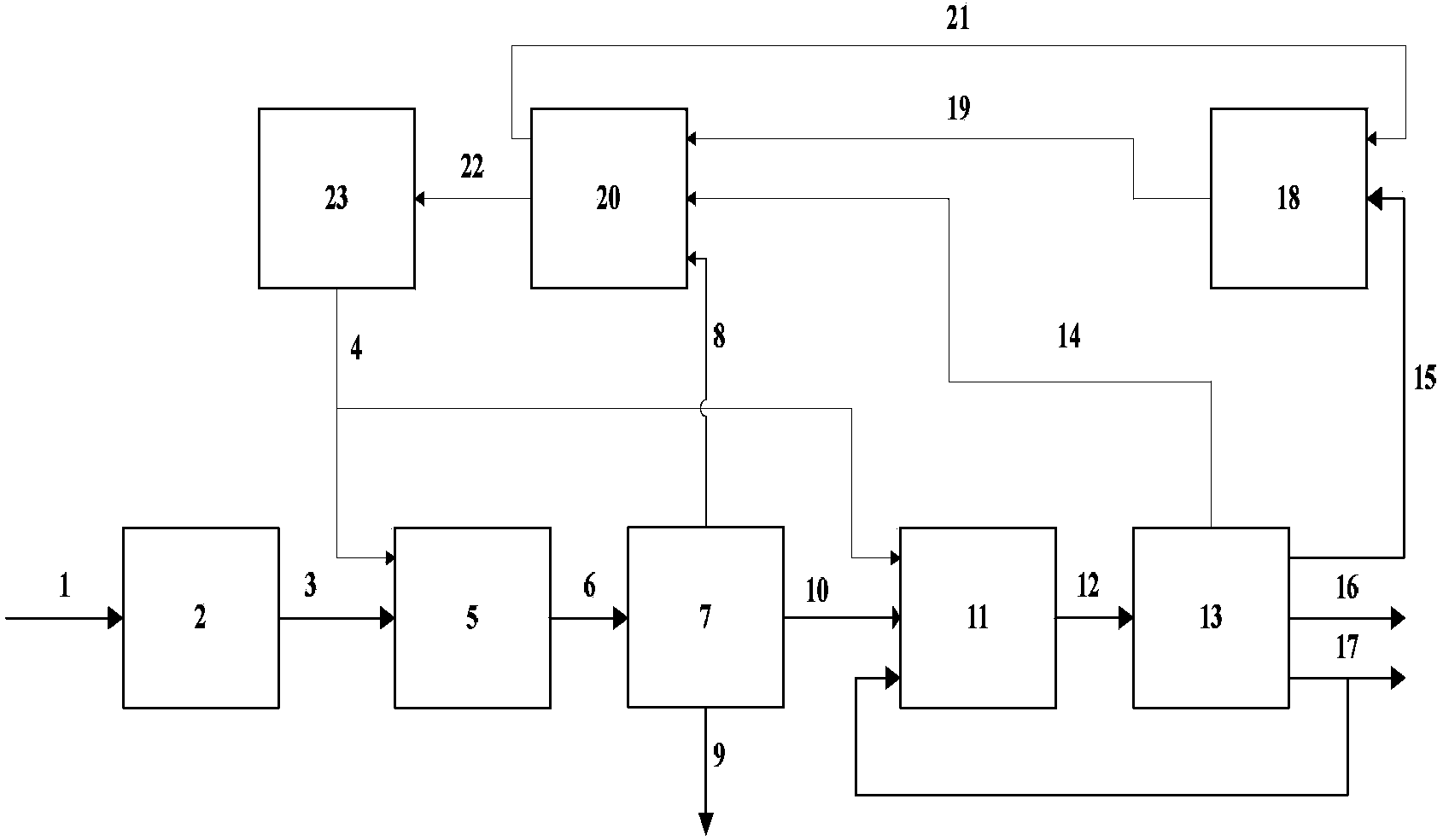

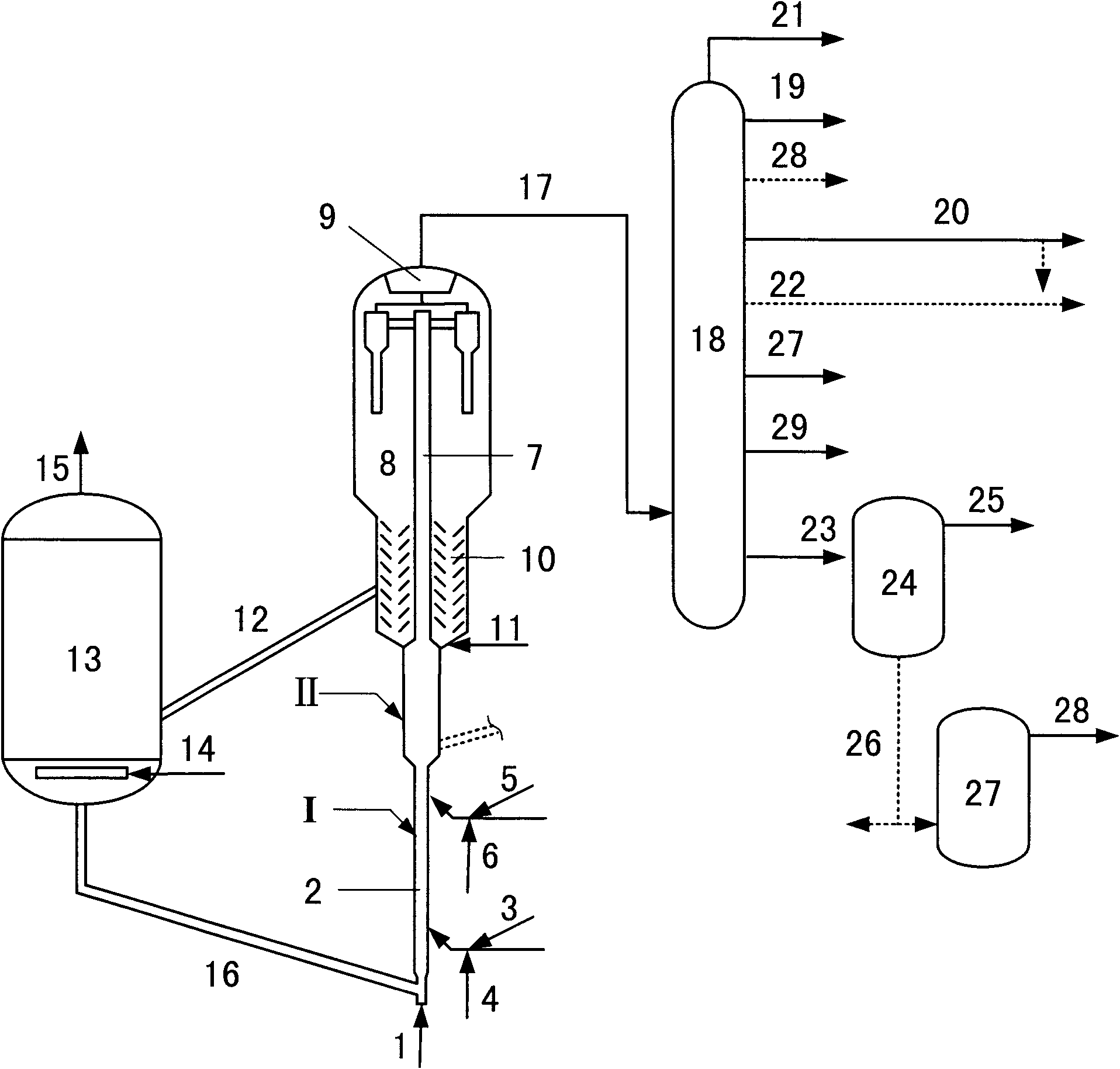

Method for production of diesel oil fraction and aviation fuel fraction by use of animal and plant oils and fats

The invention relates to a method for production of a diesel oil fraction and an aviation fuel fraction by use of animal and plant oils and fats, and the method comprises the following steps: a) performing refining processing on the animal and plant oils and fats; b) performing catalytic hydrogenation and deoxidation to obtain saturated linear alkanes and propane; c) performing hydroisomerization and hydrocracking processing to obtain an alkane material flow with higher branched chain degree; d) separating to obtain liquid hydrocarbons and gaseous hydrocarbons with the boiling point within the boiling point range of diesel oil, aviation fuels and naphtha; e) directly collecting the diesel oil fraction as a product, or cycling in whole or in part to continue isomerization and cracking reaction to increase production of the aviation fuel fraction; and f) mixing propane gaseous hydrocarbon and naphtha for steam reforming hydrogen production reaction, separating and purifying the obtained hydrogen to enter into a circulating hydrogen system; the method is used in the production of the renewable diesel oil and aviation fuels with excellent combustion performance and cold flow performance, and meanwhile efficient utilization of by-products and in-system supplement of hydrogen consumption can be realized.

Owner:PETROCHINA CO LTD

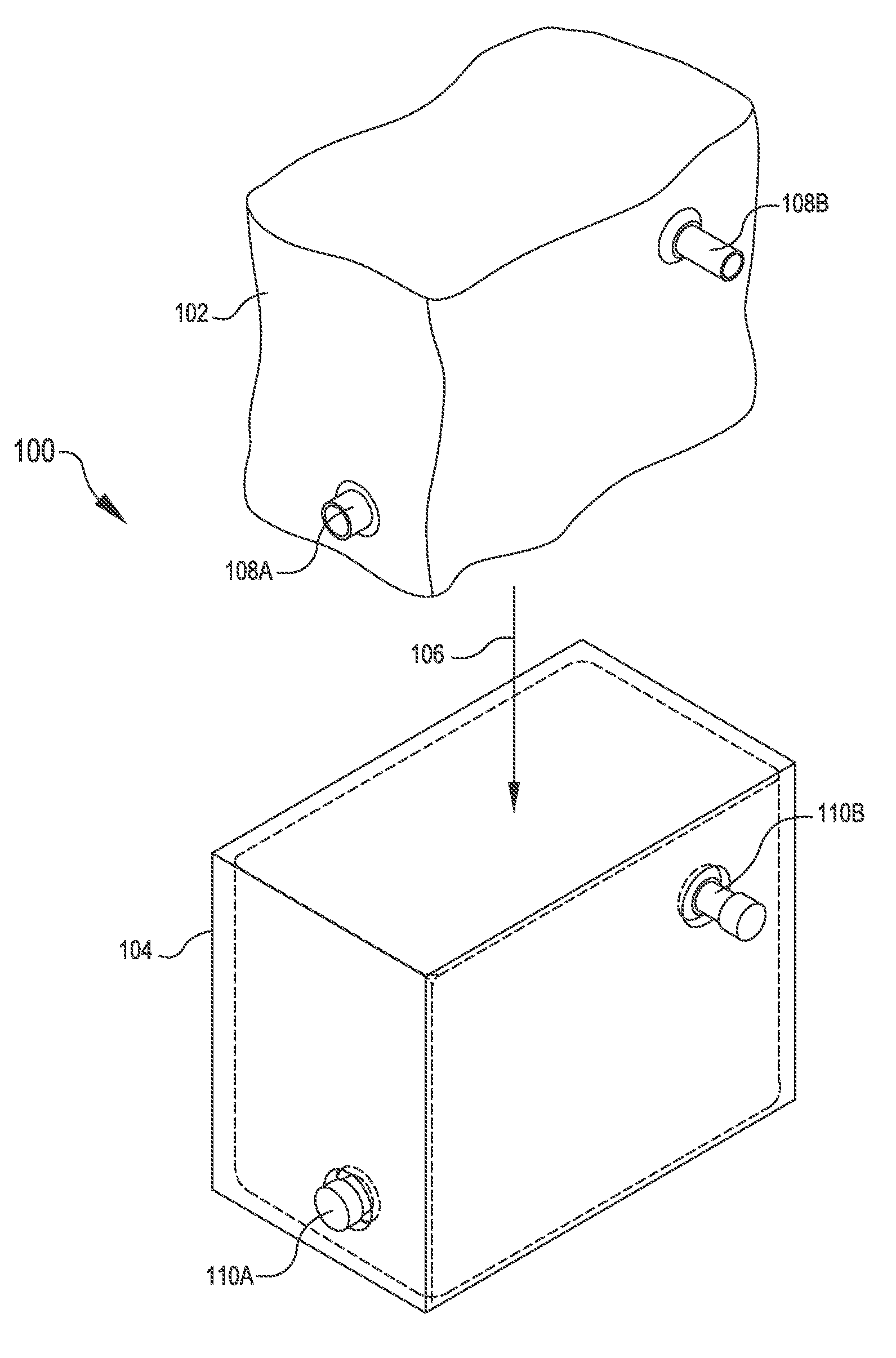

Aviation fuel tank with rigid wall for crash energy absorption

ActiveUS20150274311A1Improve energy absorptionReduce thicknessPower plant fuel tanksContainer filling methodsAviationFiber

Embodiments of the present invention relate generally to fuel tanks for aviation, and particularly to construction of rigid tank walls that have been found useful in absorbing energy of a magnitude expected during a crash. In some aspects, the rigid tank wall construction includes particular materials, such as a thermoplastic resin matrix. In some aspects, the rigid tank wall construction includes a particular arrangement of reinforcing fibers, such as a twill weave pattern.

Owner:SAFRAN AEROSYST

Deoxygenation of materials of biological origin

ActiveUS20110087058A1Quality improvementReduce hydrogen consumptionHydrocarbon from carbon oxidesOrganic-compounds/hydrides/coordination-complexes catalystsIridiumRhenium

The present invention relates to a method for the deoxygenation of materials of biological origin and particularly to the removal of oxygen from biomass derived organic compounds with carbon monoxide, to yield linear and branched hydrocarbons suitable as biofuels or as blending stocks or components for biofuels, such as gas, gasoline, diesel fuel and aviation fuel, as well as solvents. The method comprises contacting a feedstock with carbon monoxide in the presence of a catalyst comprising a metal selected from a group consisting of ruthenium, manganese, rhodium, rhenium, osmium, iridium, molybdenum, copper, zinc, palladium, platinum and cobalt, in the presence of water, under alkaline conditions at a temperature from 150 to 350° C. and under a pressure from 0.1 to 150 bar, to produce hydrocarbons.

Owner:NESTE OIL OY

Production of aviation fuel from biorenewable feedstocks

ActiveUS8742183B2Refining to change hydrocarbon structural skeletonHydrocarbon purification/separationAlkaneVegetable oil

A process has been developed for producing aviation fuel from renewable feedstocks such as plant oils and animal fats and oils. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide n-paraffins having from about 8 to about 24 carbon atoms. At least some of the n-paraffins are isomerized to improve cold flow properties. At least a portion of the paraffins are selectively cracked to provide paraffins meeting specifications for different aviation fuels such as JP-8.

Owner:UOP LLC

Method for preparing high-quality fuel oil from inferior crude oil

ActiveCN101993726AImproved raw material propertiesExtended operating cycleTreatment with hydrotreatment processesChemical recyclingWaxLighter fuel

The invention discloses a method for preparing high-quality fuel oil from inferior crude oil. The inferior crude oil enters first and second reaction zones of a catalytic conversion reactor in turn to contact a catalytic conversion catalyst and respectively perform primary reaction and secondary reaction, and after a reaction product and a spent catalyst are subjected to gas-solid separation, the spent catalyst is stripped and scorched in turn and is returned to the reactor for recycling; the reaction product is separated to obtain propylene, light fuel oil, catalyzed wax oil and other products, wherein the catalyzed wax oil enters a hydrocracking device and is separated to obtain products such as gasoline, an aviation fuel, diesel oil, hydrocracked tail oil and the like; and the hydrocracked tail oil is circulated to the first reaction zone of the catalytic conversion reactor and / or other catalytic conversion devices for further reaction to obtain a desired product, namely the light fuel oil, and a byproduct, namely the propylene. By the method, a diesel cetane number is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

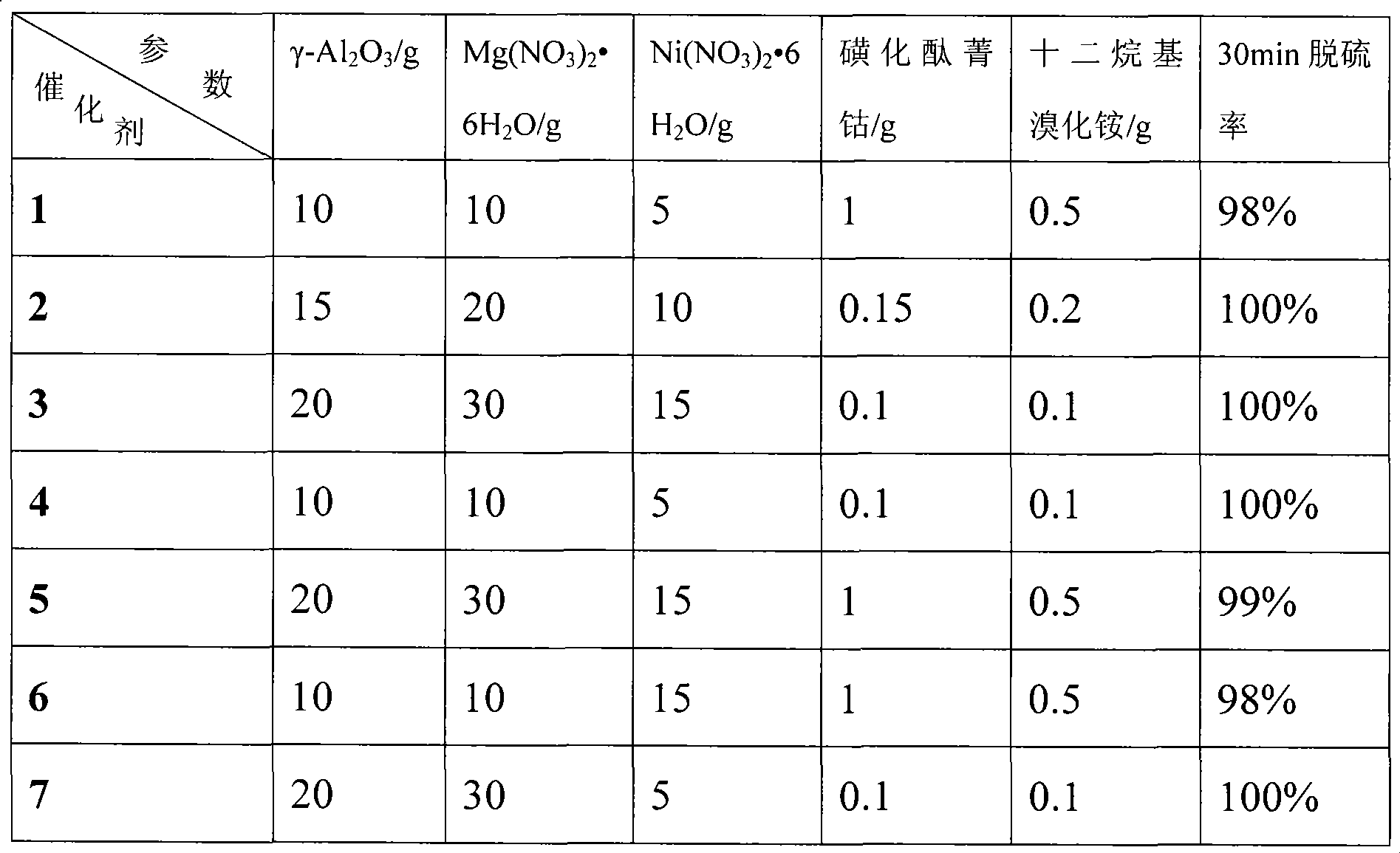

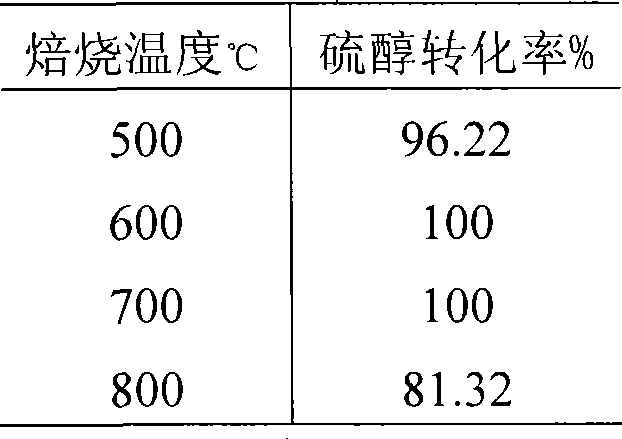

Solid catalyst for petroleum liquid component sweetening and preparation method

InactiveCN101474574AIncrease alkalinityHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oils refiningKeroseneAlkali metal oxide

Disclosed is a solid catalyst used for removal of mercaptans of petroleum liquid ingredients. The catalyst uses gamma-Al2O3 as a carrier, first loads a metal nitrate on the carrier by immersion method and then bakes the metal nitrate to realize loading of alkali metal oxide on the carrier gamma-Al2O3 so as to produce the alkali catalyst carrier, and then uses the mixed solution of sulfonated cobalt phthalocyanine and ethanol water added with quaternary ammonium salt or organic base as impregnating solution to impregnate the carrier to obtain the target catalyst after drying. The catalyst is mainly suitable for removal of mercaptans of liquefied petroleum gas, gasoline, kerosene, naphtha, aviation fuel, liquid propylene and other liquefied petroleum ingredients. Experiments prove that the thiol conversion rate can stand at 100% in 20min and the life of the catalyst exceeds 300h.

Owner:CHANGCHUN UNIV OF TECH

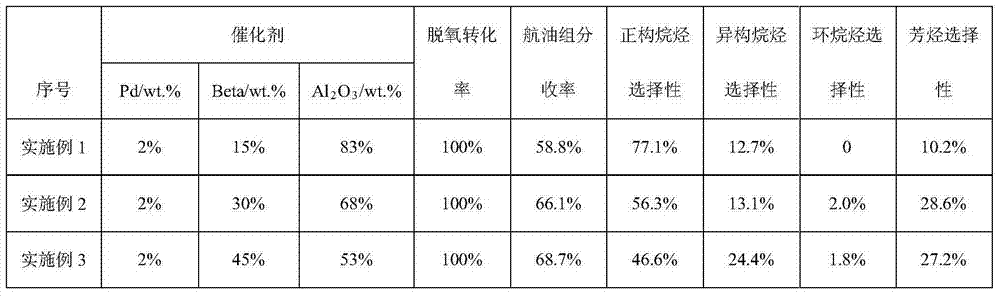

Catalyst for preparing aviation kerosene components through one-step hydrodeoxygenation cracking isomerization of grease and preparation method of catalyst

InactiveCN103920528AHigh calorific valueModerate densityMolecular sieve catalystsLiquid hydrocarbon mixture productionIsomerizationKerosene

The invention relates to a catalyst for preparing aviation kerosene components through one-step hydrodeoxygenation cracking isomerization of grease and a preparation method of the catalyst. The catalyst is mainly used for the process of preparing new-generation ultra-clean aviation fuel oil substitution components through one-step catalytic hydrogenation of grease model compounds, grease and derivatives of the grease. The catalyst provided by the invention is loading noble metal / composite solid acid carrier catalyst which is composed of 0.2-5.0% of Pd, 5-85% of a bata molecular sieve, 10-94.8% of Al2O3. With the adoption of the catalyst, the grease and the grease model compounds can be converted into the biological aviation kerosene components (C8-C16) through hydrogenation, deoxygenation, cracking and isomerization. The catalyst obtained by the preparation method has the advantages of high activity, high selectivity, low hydrogen consumption and the like, and has great significance in promoting development of biological aviation kerosene and reduction of carbon emission; in evaluation for the catalytic activity of the catalyst, the hydrodeoxygenation conversion rate of grease is 100%, and the yield of the aviation kerosene components is 72.3%.

Owner:KUNMING INST OF PRECIOUS METALS

Method for extraction of unsaturated fatty acid from oil-containing microalgae and preparation of aviation fuels

ActiveCN103224835AWith extractionHas the dual performance of rectificationFatty oils/acids recovery from wasteFatty-oils/fats separationOil and greaseAviation

The invention provides a method for extraction of unsaturated fatty acid from oil-containing microalgae and preparation of aviation fuels. The method includes: 1) subjecting microalgae to crushing and wall breaking to obtain microalgal powder particles and adding an entrainer, extracting the unsaturated fatty acid in the microalgal powder particles by a supercritical CO2 extraction technique to obtain mixed oil and algal residue; 2) conducting separation and enrichment on the mixed oil extracted in step 1) to obtain unsaturated fatty acid and residual oil; and 3) performing thermal cracking on the algal residue obtained in step 1) to obtain pyrolytic bio-oil, then mixing the pyrolytic bio-oil with the residual oil, and performing a hydrogenation treatment to obtain a kerosene-containing main product and a byproduct containing gasoline and diesel. According to the method, the unsaturated fatty acid extraction rate can reach 80-95%, and the total extraction rate of oil is 70-90%. The obtained kerosene ingredient can reach the standard of aviation kerosene.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com