Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2439results about How to "Extended operating cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing ethylene tar

The invention discloses a method for processing ethylene tar, which selects an appropriate cutting point to fractionate the ethylene tar into a light fraction and a heavy fraction aiming at the characteristics of high content of arene, colloid and carbon residue in the ethylene tar. The light fraction passes through a hydrogenation protection reaction zone, a hydrofining reaction zone and a hydrocracking reaction zone sequentially to obtain a gasoline fraction and a diesel oil fraction; and the heavy fraction is used as a universal type carbon fiber asphalt stock. The method for processing the ethylene tar makes full use of the total fraction of the ethylene tar and increases the additional value of the ethylene tar. In addition, the method enables the arene after hydrostturation in the ethylene tar to open ring, crack moderately and / or isomerize by selecting two types of hydrocracking catalysts to perform grading loading so as to obtain the diesel oil fraction with condensation point less than -40 DEG C in high yield and obtain a side product high-octane gasoline fraction at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

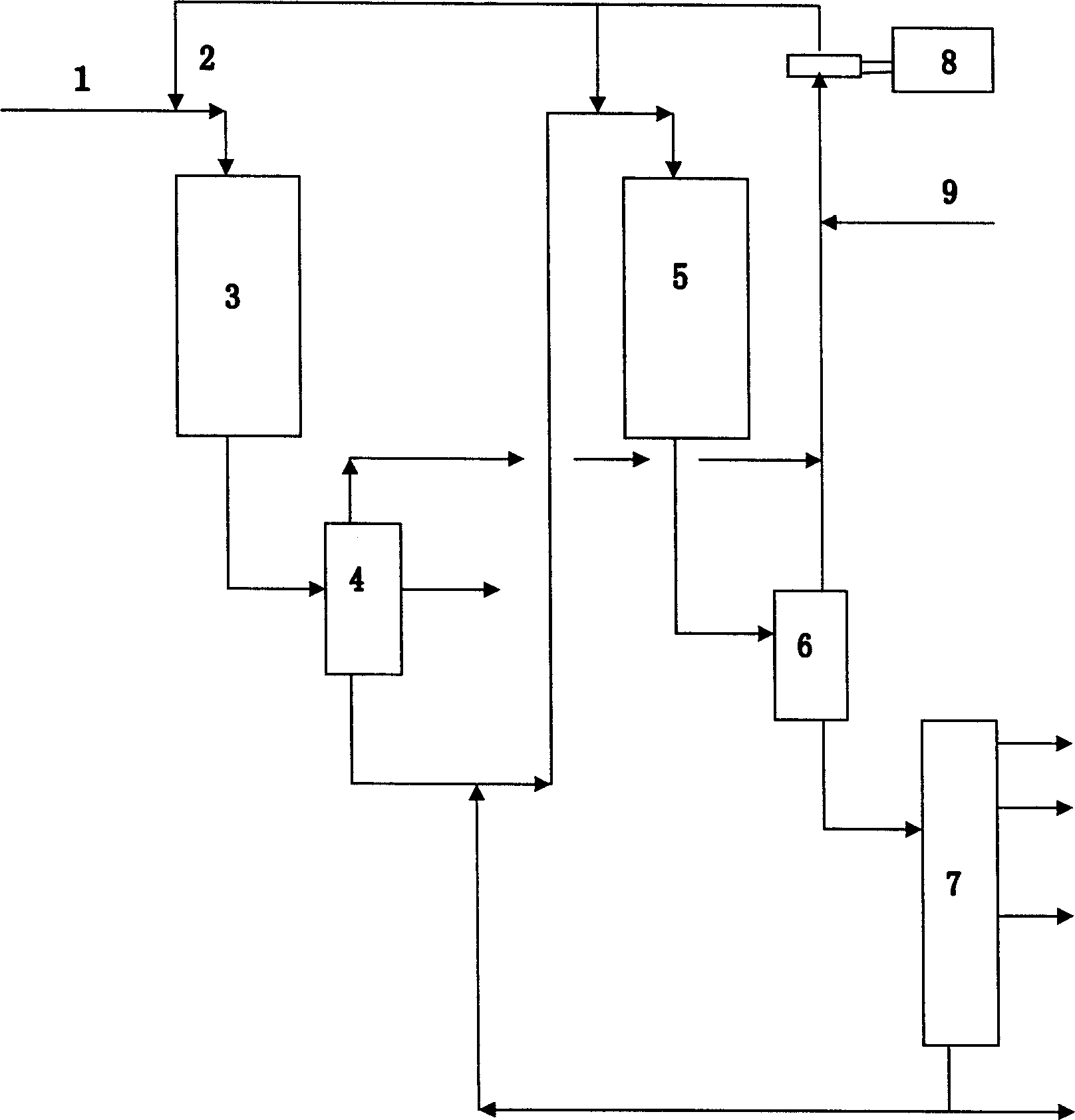

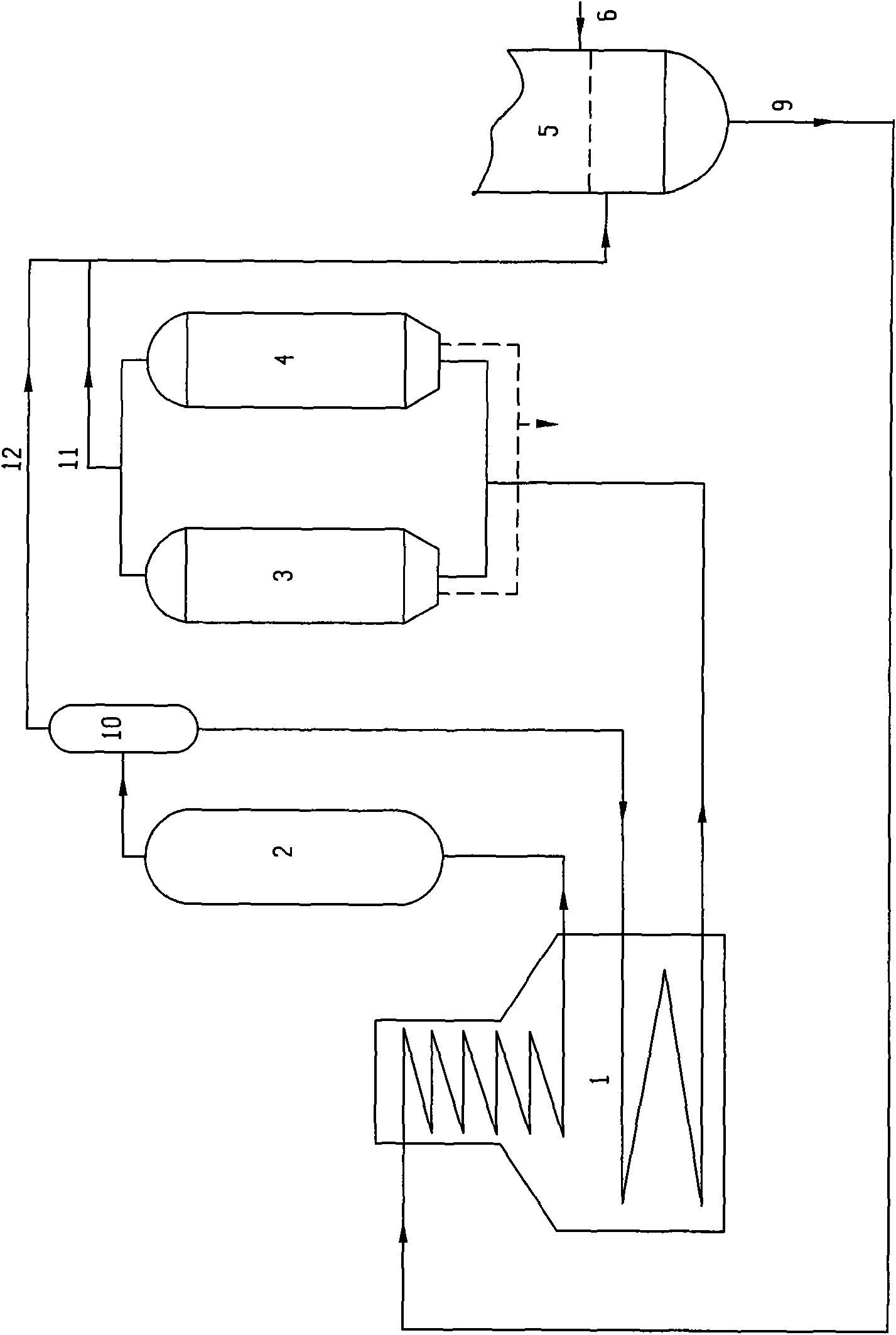

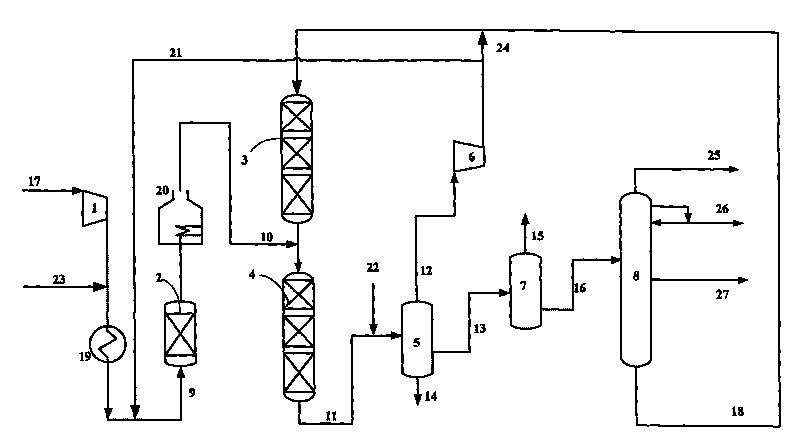

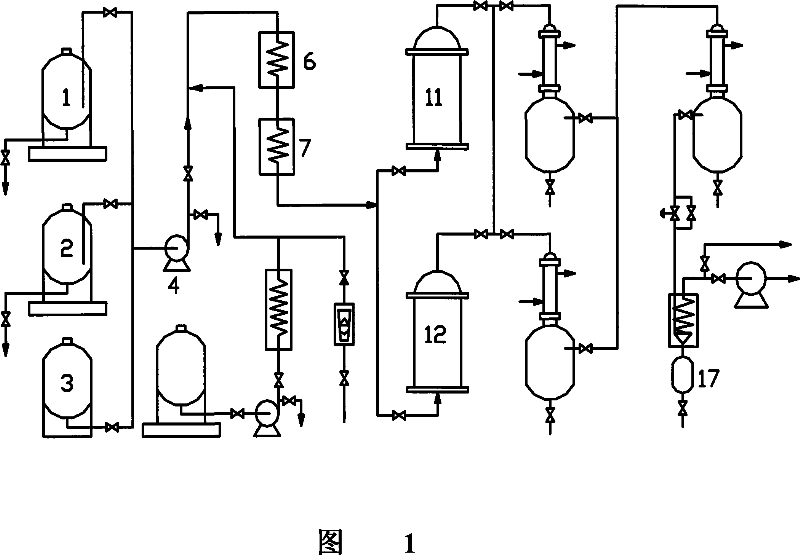

Coal tar whole fraction hydrotreatment process

ActiveCN1766058AImprove operating conditionsSimple processTreatment with hydrotreatment processesFixed bedGasoline

The invention discloses a hydrocracking treatment technique for coal tar total distillate, which comprises: first mixing with homogeneous catalyst, or adding impurity, gum, asphaltene and coal oil total distillate contained much oxygen element directly into suspended-bed hydrogenation device; cutting the stream with distilling plant to discharge water, distillate less than 370Deg that enters fixed bed reactor for hydrorefining reaction to cut gasolene less than 150Deg and diesel oil 150-370Deg, and tail oil less than 370Deg that recycles to said reactor and converts into light oil product. Compared with prior art, this invention is simple, but high conversion rate and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

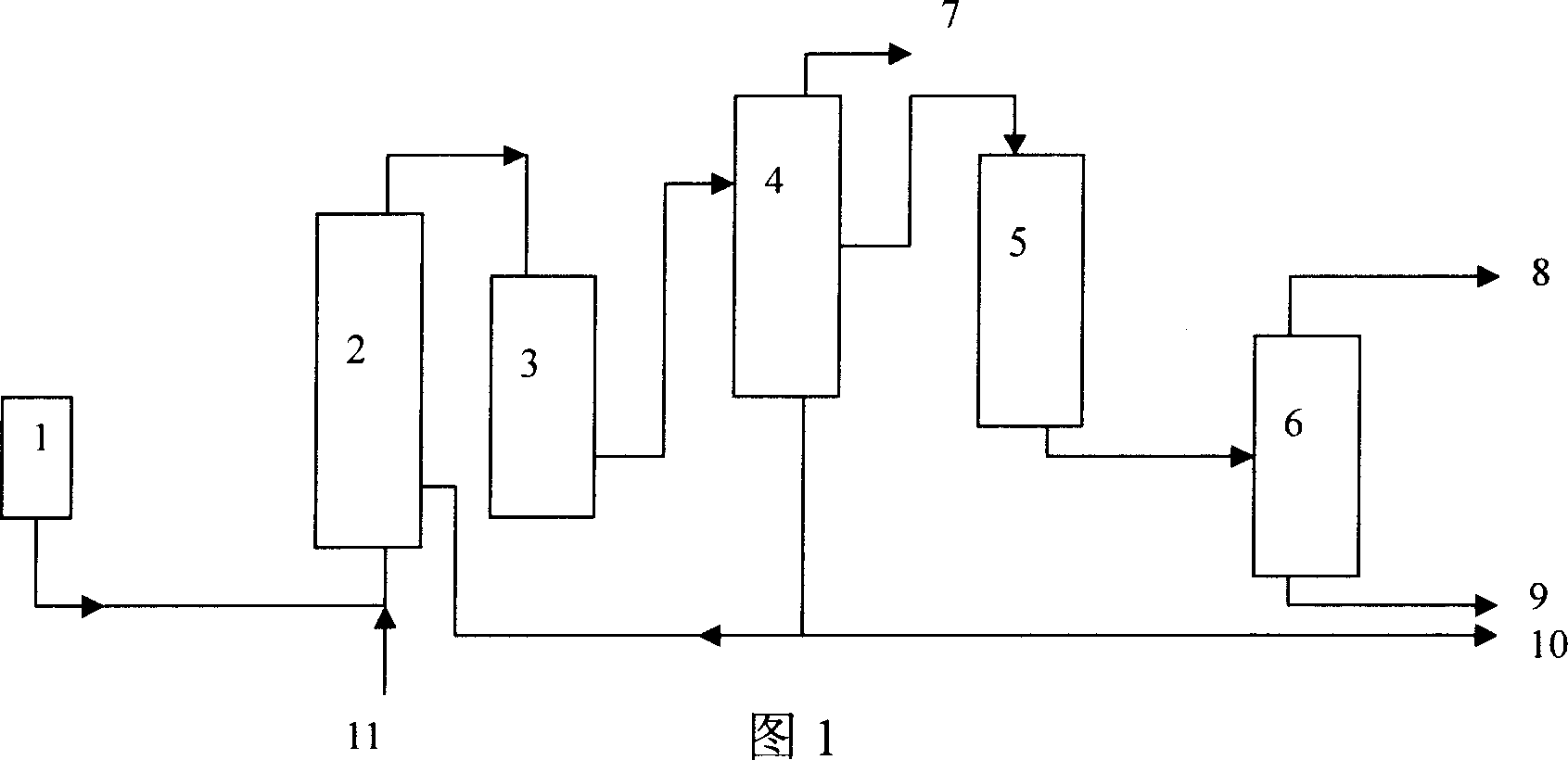

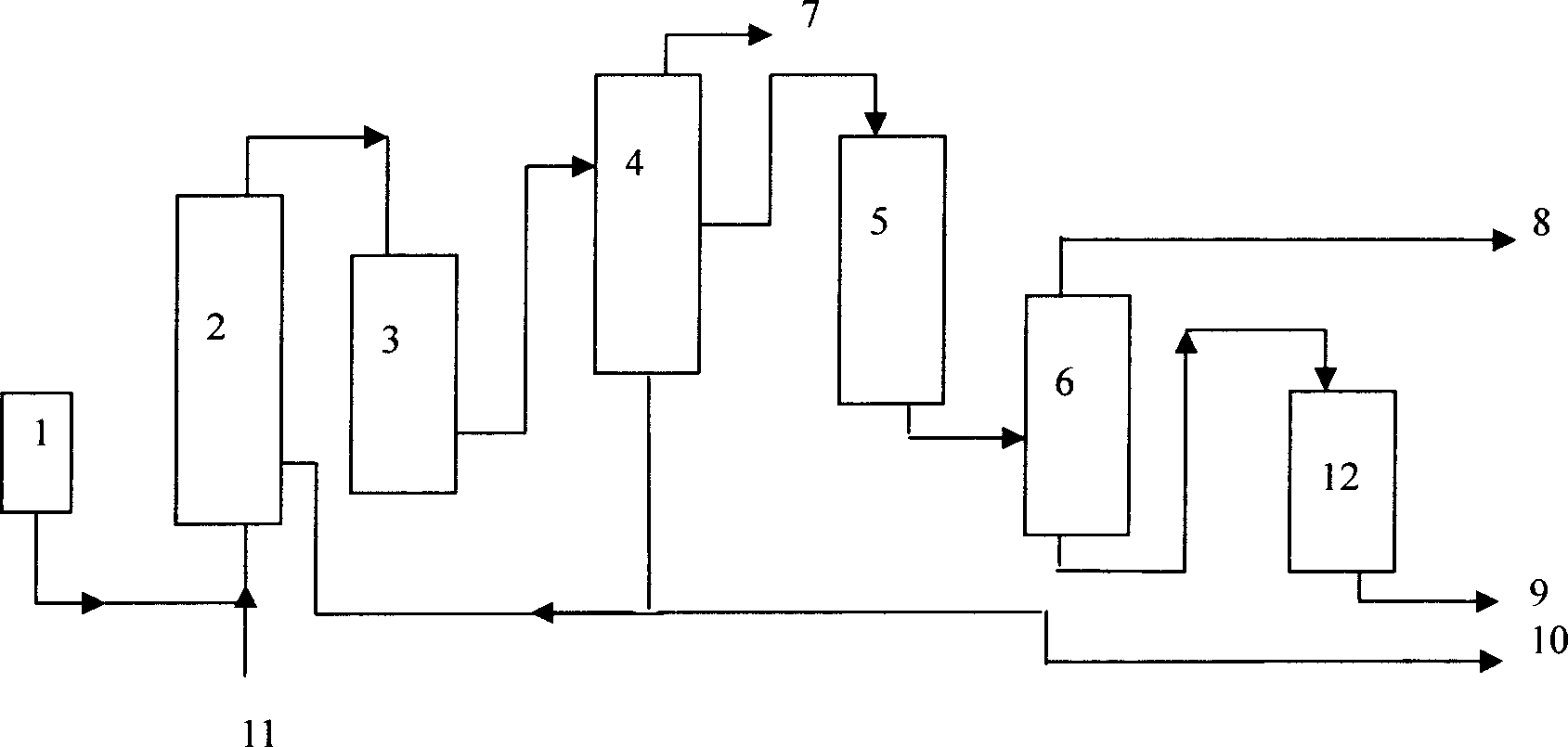

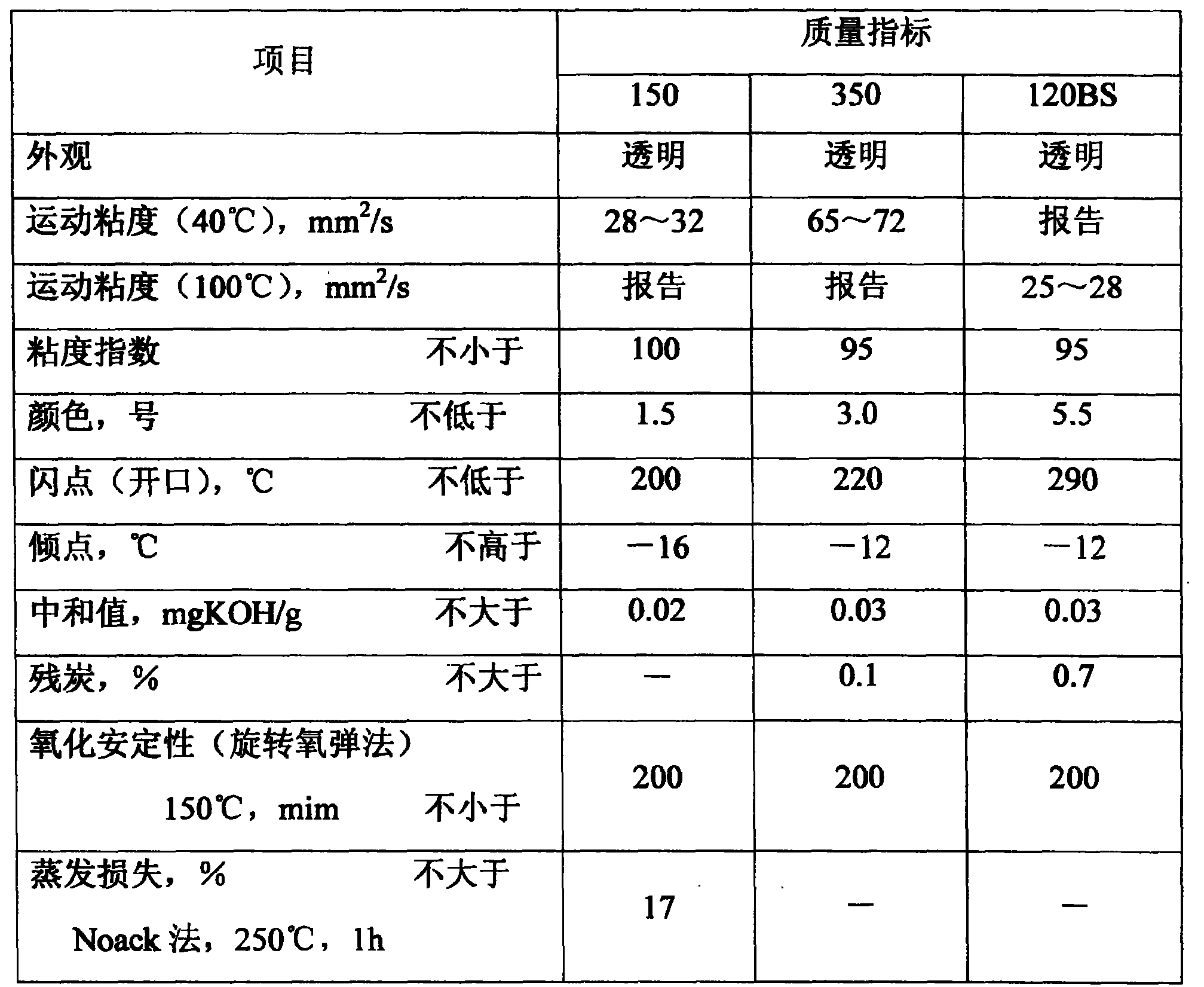

Method for producing lubricating oil basic oil

ActiveCN101173191AMeet the indicator requirementsLow pour pointTreatment with hydrotreatment processesBase-materialsBase oilPour point

The invention discloses a method for producing lube base oil, which is characterized in that low-pressure hydroisomerization and adsorption treatment are adopted and organically combined, and the lube base oil meeting the standard of HVIW is obtained; the raw material firstly enters a low-pressure hydroisomerizing reactor, and the pour point is lowered; after gas-liquid separation of the heterogeneous product, adsorption treatment is done to the separated lube fraction for color enhancement and stability improvement. The invention has the advantages that adaptability of the raw oil is strong; operating condition is mild; investment and operating cost is low; and the prepared lube base oil meeting the standard of HVIW can be applied to blinding with various brands of high-grade lube.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation catalyst, its process and use

ActiveCN1644656AIncrease surface areaLarge hole volumeRefining by selective hydrogenationAluminium hydroxideNickel compounds

A hydrogenation catalyst and its preparation and use are disclosed. The said catalyst consists of NiO 10-30wt.% and Al2O3 70-90wt.%, obtained by: drying quasi-hydrated aluminum oxide powder, passing steam to ream, roasting to have macroporous aluminum oxide carrier, dipping it in a solvent containing nickel compound, filtering, drying, roasting to form the final product. It is suitable for fractional oil containing dialkene and styrene and their derivatives to directly prepare solvent with high aromatic hydrocarbon and gasoline with high octane level by hydrogenation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

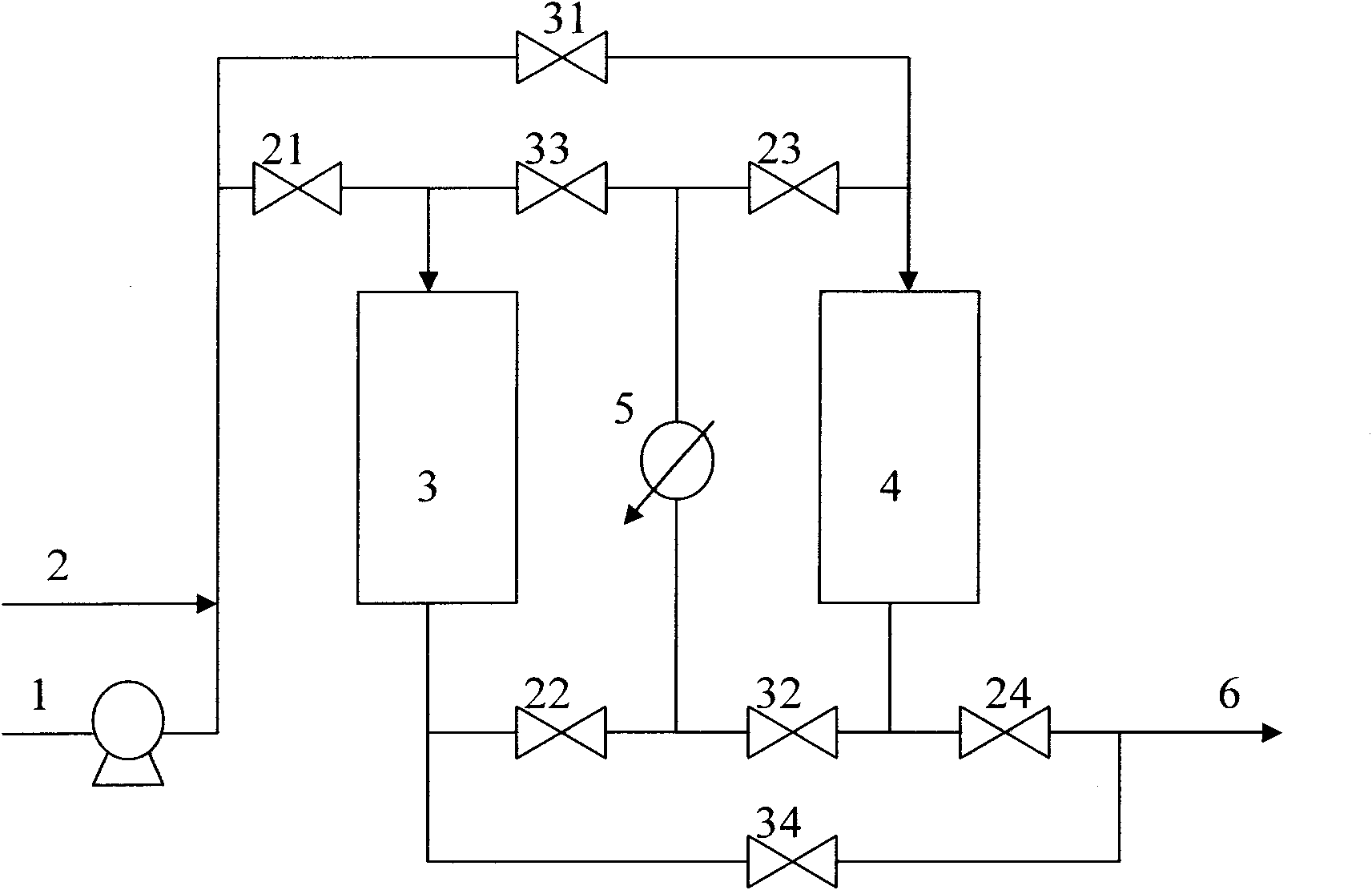

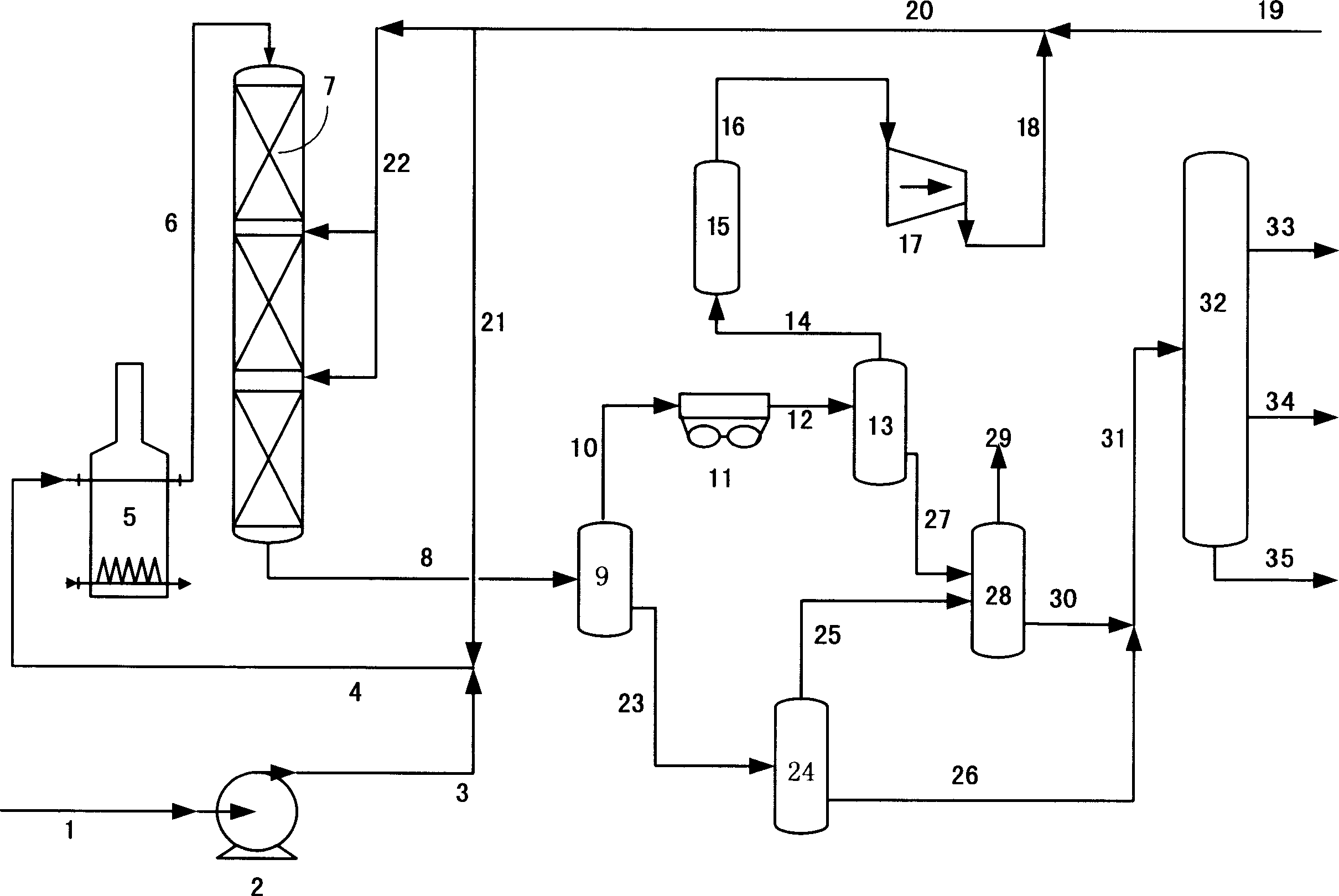

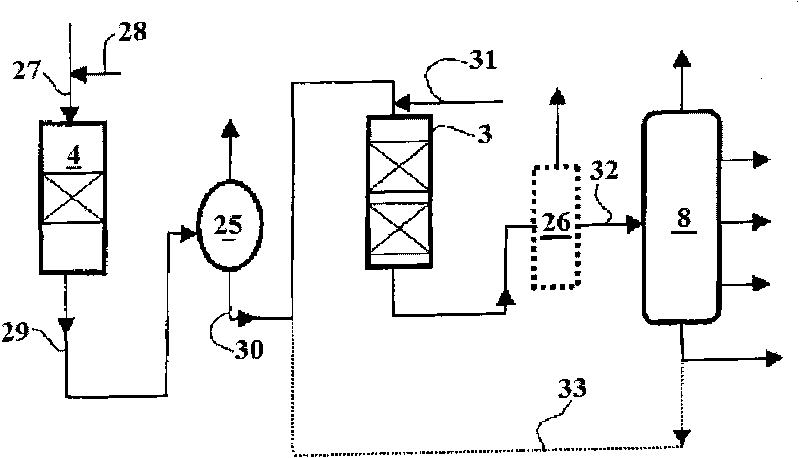

Method of hydrogenating liquefied petroleum gas to prepare ethylene cracking feed

ActiveCN102311787AEffective temperature controlTemperature controlLiquid hydrocarbon mixtures productionTreatment with hydrotreatment processesHydrogenAlkene

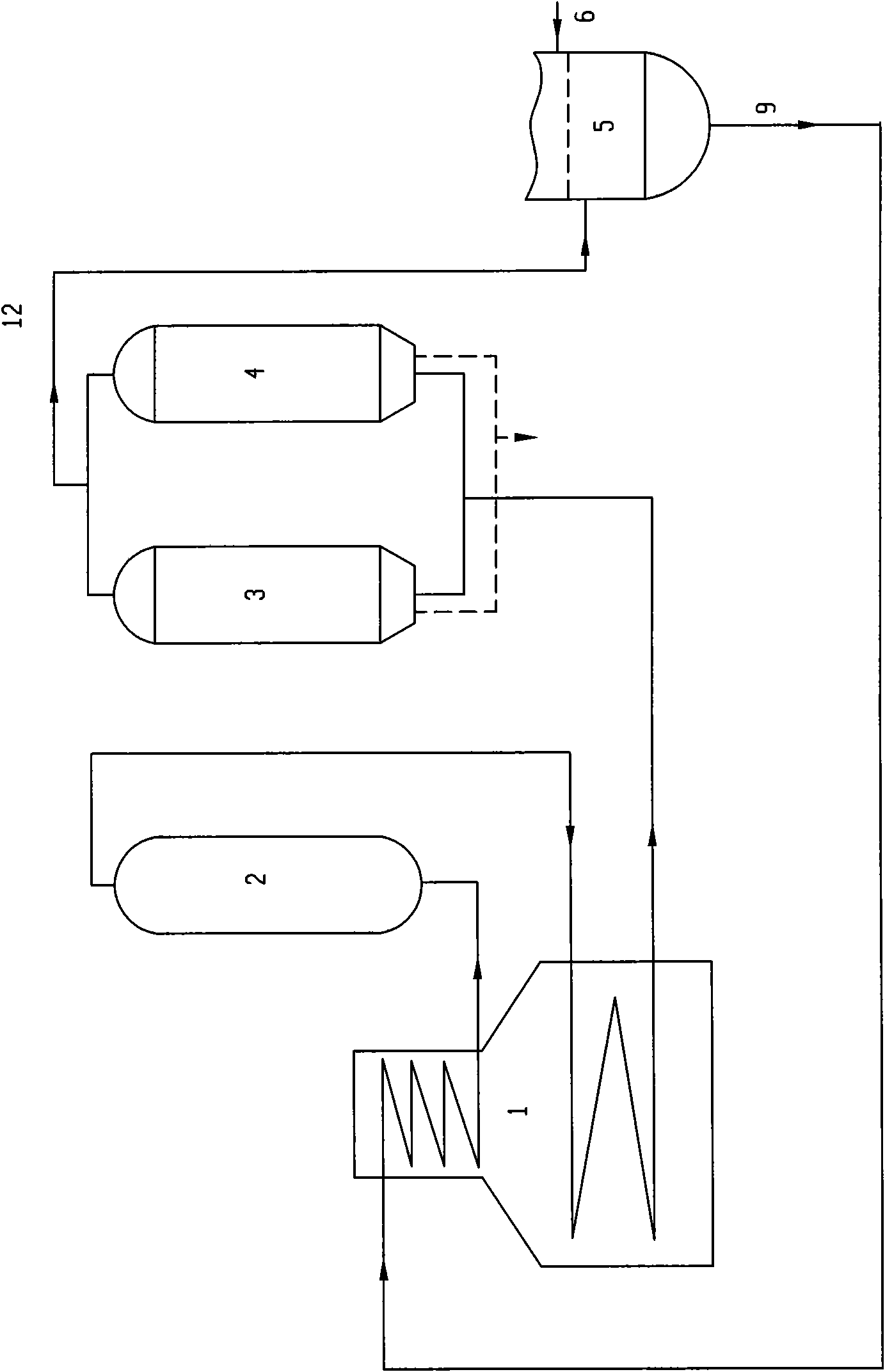

The invention discloses a method of hydrogenating liquefied petroleum gas to prepare ethylene cracking feed, which is provided with two reaction sections. Reaction material cooling operation is carried out between the two reaction sections, the mixture of C4 fraction raw material and hydrogen is cooled after passing through the first reaction section, then enters the second reaction section, non-precious metal hydrofining catalysts are arranged in the two reaction sections, and a reaction material flow switching device is arranged between an inlet and an outlet of the two reaction sections to change the sequence of the reaction material flow entering the two reaction sections. The method disclosed by the invention solves the problem that the olefin content does not reach the standard due to thermodynamic control factors, simultaneously the catalysts are entirely fully utilized, and the operating cycle can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

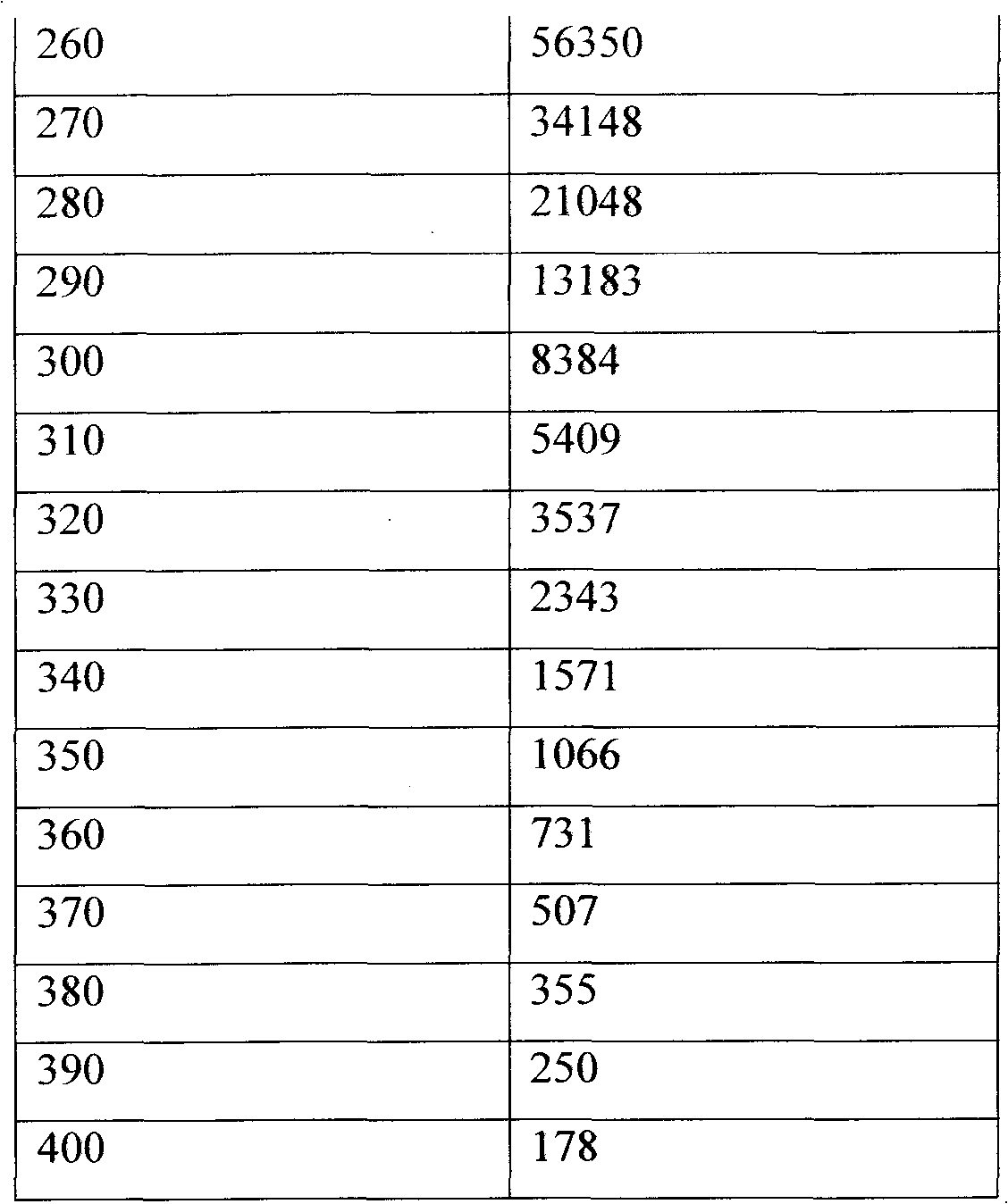

Recycling method of high-salinity wastewater

ActiveCN104591464AProcess conditions are stableEasy to industrializeMultistage water/sewage treatmentEnergy based wastewater treatmentChemistryCoal chemical industry

The invention discloses a recycling method of high-salinity wastewater. Sodium sulfate and sodium chloride are recycled through three steps of primary evaporative crystallization, cooling crystallization and secondary evaporation crystallization. According to the method disclosed by the invention, sodium sulfate and sodium chloride in the high-salinity wastewater of coal chemical industry can be effectively recycled; the method is simple and stable in technological conditions; industrial popularization is facilitated; the recycled sodium sulfate and sodium chloride meet the quality requirements of industrial products, and can be directly recovered and applied mechanically or sold as byproducts, so that the target of treating the high-salinity wastewater is reached; the requirements of the current environment-friendly situation are met; waste is changed into treasures; resource utilization of salts is achieved; and benefits of factories are improved.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP +1

A hydrogenation method for producing diesel oil in low sulphur

ActiveCN101092573AHigh activityLow operating pressureRefining to eliminate hetero atomsLiquid productHydrogen

This invention discloses a hydrogenation method for producing low-sulfur diesel oil. The method comprises: mixing base oil with hydrogen, introducing into a hydrogenation reactor to orderly contact hydrogenation protecting agent, hydrorefining catalyst I, hydrorefining catalyst II and freely selected hydrorefining catalyst III for reactions, cooling the effluent, and separating to obtain hydrogen-rich gas and liquid product. With the synergism of the catalysts, the whole catalyst activity is improved. By the method, high-sulfur, high-nitrogen and high-metal content diesel oil fraction can be treated under mild conditions, and low-sulfur diesel oil that can meet Europe III standard and Europe IV standard can be obtained. The method has such advantages as simple process, low operation pressure, low apparatus investment and low operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for producing good quality catalytic cracking material

ActiveCN101007964AReduced activityDelay pressure drop riseRefining to eliminate hetero atomsHydrogenNaphtha

The invention relates to a hydrogenation method for high- quality catalytic cracking material. It comprises: carrying out hydrogenation and modifying reaction for mixture of raw oil and hydrogen gas in hydrogenation preservative, any hydrogenation demetalation catalyst and hydrogenation treating catalyst in turn; and the filling volumetic percentage of mentioned preservative and catalyst are 2- 15%, 0- 30% and 55-95%, cooling reactant and separating and getting a large amount of refined gas oil fraction, part of low-sulphur diesel fraction and little amount of benzine naphtha fraction, and the refined gas oil fraction is the catalytic cracking material. The invention can prolong the operation cycle for device under high percentage of desulfurization, the activity of employed catalyst is high, and the rational packing method ensures better catalyst activity, and reduces production cost. The invention is characterized by simple process, low operation pressure, low device investment and operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

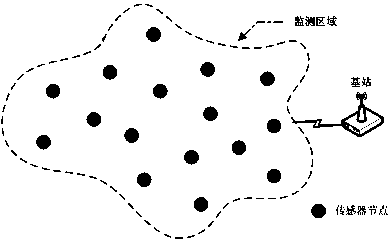

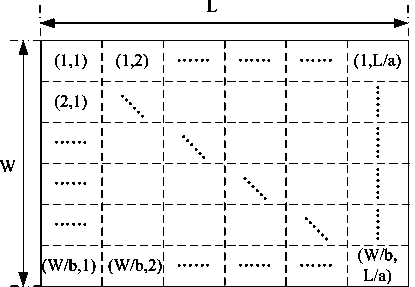

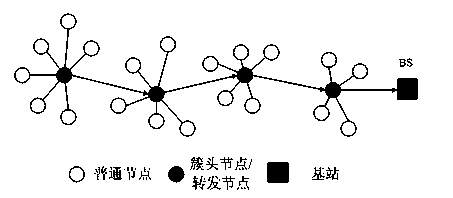

LEACH protocol improvement method capable of lowering energy consumption

ActiveCN103916942ABalanced burdenAvoid failurePower managementNetwork topologiesData transmissionNetwork topology

The invention provides an LEACH protocol improvement method capable of lowering energy consumption. A basic system comprises normal nodes, cluster header nodes, forwarding nodes and a base station. The specific cycle operation steps comprise network topology determination, initialization, selection of the cluster header nodes, cluster forming, data transmission, selection of the cluster header nodes and cluster forming. According to the defects of an LEACH protocol, improvement is conducted from the aspects of selection of cluster heads, cluster forming and a data transmission mode. In selection of the cluster heads, the comprehensive influences of the energy of the nodes, the distance to the base station and density are considered, the burdens of the cluster heads are balanced, and distribution and energy consumption of the selected cluster header nodes are made balanced in a network. In cluster forming, the mode of grid clustering is used, the nodes calculate the two-dimensional values of grids where the nodes are placed by themselves, and the effectiveness of node energy is guaranteed. In data transmission mode, a routing mode with single-hop and multi-hop combined is used according to the distance of the cluster header nodes and the base station, the energy consumption of network nodes is lowered by the purpose that the energy utilization rate is highest.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Catalysts grading method for coker dry gas hydrogenation for preparation of ethylene cracking feed

ActiveCN105273756AHigh activityLow costGaseous mixture working upHydrogenation reactionReaction temperature

The invention discloses a catalysts grading method for coker dry gas hydrogenation for preparation of ethylene cracking feed. According to the method, coker dry gas is contacted with a hydrogenation catalyst to carry out a hydrogenation reaction, and olefin in coker dry gas is saturated to further obtain an ethylene cracking feedstock, wherein three hydrogenation reaction zones are successively arranged in a hydrogenation reactor. By reasonable grading of catalysts in different systems, advantages of the respective catalysts during different hydrogenation processes are fully performed. By synergism among the catalysts and by cooperation of reaction temperature gradients of the three hydrogenation reaction zones, activity of the monolithic catalyst is raised.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for hydrogenating modifying faulty gasoline

ActiveCN1597865ASimple processEasy to operateTreatment with hydrotreatment processesOrganic sulfide compoundIsomerization

The invention provides a process method for making hydrodesulfation and alkene reduction on the bad gasoline, like all-fractional FCC gasoline, etc. Under the conditions of hydrogen gas existence and temperature gradually rising, to contact with three catalysts forms three reaction regions. The first reaction region has lower temperature and uses hydrofining catalyst and mainly eliminates di-alkene in the gasoline; the second reaction region has higher temperature and uses selective hydrodesulfation catalyst and mainly eliminates organic sulfide and some alkenes; the third reaction region has the highest temperature, uses gasoline modifying catalyst and makes the modifying reactions including aromatization, isomerization and benzene alkylation, increasing octane number of gasoline and improving product quality. It has the advantages of simple flow, being easy to operate, fully using reaction heat, prolonging the operating cycle of catalyst, high liquid yield, low hydrogen consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

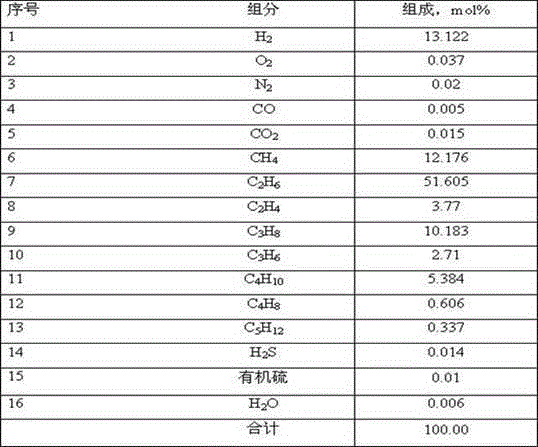

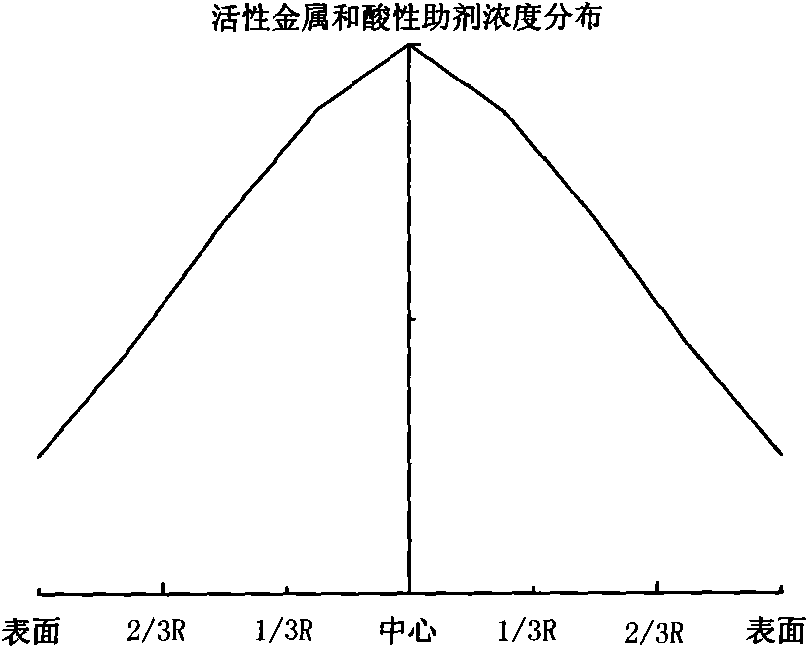

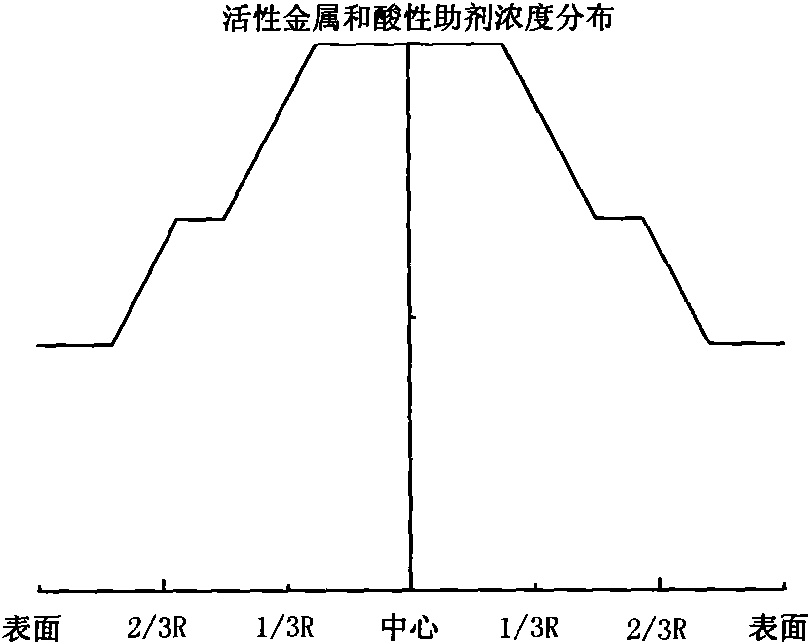

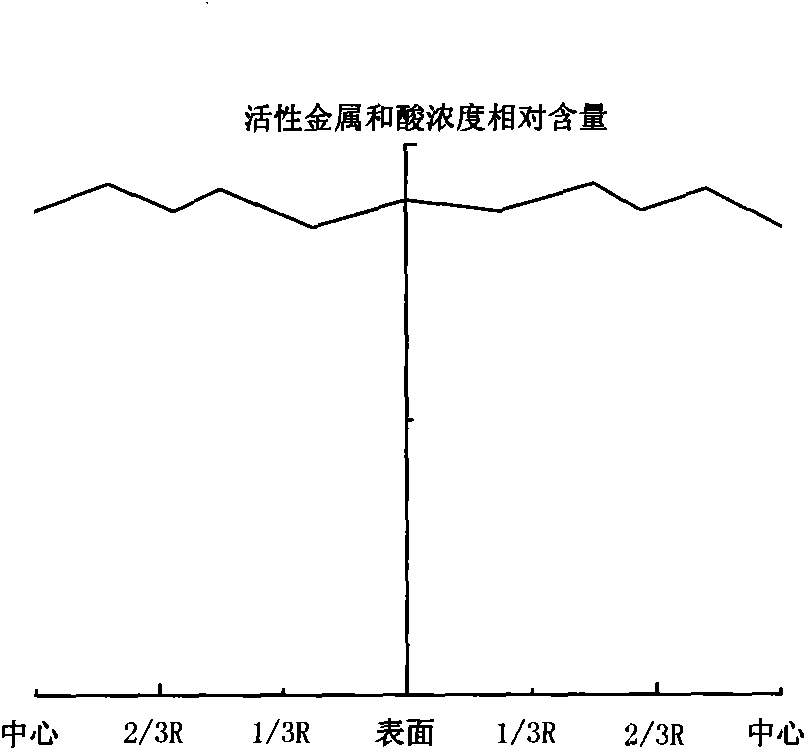

Graded composition of heavy oil hydrogenation catalysts

ActiveCN101928593ASlow down inactivationExtended operating cycleRefining to eliminate hetero atomsPorosityGranularity

The invention relates to a graded composition of heavy oil hydrogenation catalysts. 5 to 55 percent of hydrodemetallization catalyst, 5 to 55 percent of hydrodesulfurization catalyst and 5 to 55 percent of hydrodenitrogenation catalyst are filled into a reactor from the top to the bottom respectively; along the flow direction, the activity of the catalysts is gradually increased, the aperture is gradually reduced, the granularity is gradually reduced and the porosity is gradually reduced; the active metal ingredients and the acid aid concentrations of the demetallization catalyst and the desulfurization catalyst are in non-uniform distribution, the active metal ingredient and the acid aid concentration of the demetallization catalyst are in gradient reduction, and the active metal ingredient and the acid aid concentration of the denitrogenation catalyst are in gradient increment; the active metal ingredient and the acid aid concentration of the desulfurization catalyst are in uniform distribution; the demetallization catalyst, the desulfurization catalyst and the denitrogenation catalyst consist of one or more catalysts respectively; and the demetallization, carbon residue removal, desulfurization and denitrogenation activities and stability of the catalyst graded composition system are high, and the service life is long.

Owner:PETROCHINA CO LTD

Method for hydrotreating high-sulfur and high-metal residual oil

ActiveCN101519603AHigh porosityReduced inactivation rateRefining to eliminate hetero atomsNaphthaHydrogen

The invention provides a method for hydrotreating high-sulfur and high-metal residual oil, which comprises the following steps: the residual oil and catalytic cracking recycle oil are in contact with a residual oil hydrogenation catalyst in the presence of hydrogen gas and under the hydrotreating reaction condition so as to carry out a hydrotreating reaction; the reaction product is separated to obtain gas, hydrogenated naphtha, hydrogenated diesel oil and hydrogenated residual oil. The residual oil hydrogenation catalyst is a combination of at least two catalysts, namely, an up-flow reactor catalyst and a fixed-bed hydrogenation catalyst and the two catalysts are respectively put in an up-flow reactor and a fixed-bed reactor; the ratio of the up-flow reactor catalyst and the fixed-bed hydrogenation catalyst is 30:70 to 70:30. The method can treat the high-sulfur and high-metal residual oil and effectively slow down the ascending speed of the pressure drop of the fixed-bed catalyst bed, thus realizing the long-term running of the device. Besides, the method can combine the residual oil hydrotreating and catalytic cracking more effectively and has better implementation effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of hydro up grading isomerizing pour point depression to produce diesel oil

ActiveCN1718683ALittle impact on yieldExtended operating cycleHydrocarbon oils refiningNaphthaSulfur

A process for preparing the clean diesel oil by hydromodifying, isomerizing and lowering pour point features that the fractional oil raw material and H2 pass through a catalyst bed to obtain clean high-quality diesel and the naphtha product with low contents of sulfur and nitrogen and high content of arylhydrocarbon. Said catalyst bed contains hydrocatalyst bed containing beta zeolite (0.5-20 wt.%).

Owner:CHINA PETROLEUM & CHEM CORP +1

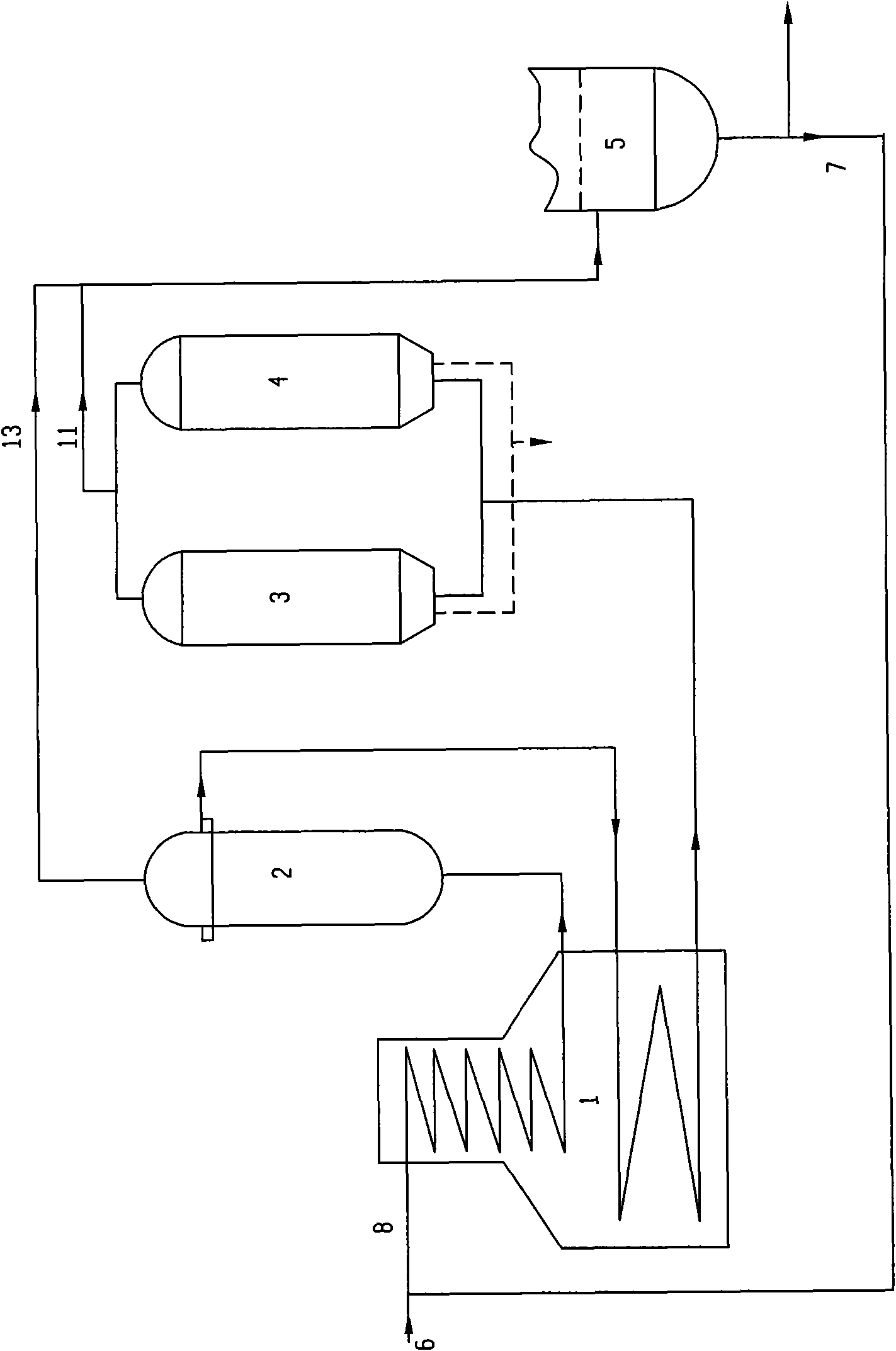

Coal tar hydrocracking method

InactiveCN1876767AExtended service lifeImprove natureTreatment with hydrotreatment processesHigh pressureChemistry

The invention discloses the coal oil hydrocracking method. The method comprises the following steps: mixing the coal oil and hydrogen gas, adding them into hydrogenation reaction chamber, getting the generating oil, putting the generating oil into heat-high pressure separator, getting light-end products and water from upper logistics, putting lower logistics and hydrogen gas into hydrocracker reaction chamber, getting hydrocracking product, putting the product into high pressure separator, getting hydrogen gas to be used again, and putting the liquid into fractionating tower to get gas, petrol, diesel, light-end products and tail oil. The invention uses low grade coal oil to produce premium grade gasoline and diesel.

Owner:胜帮科技股份有限公司

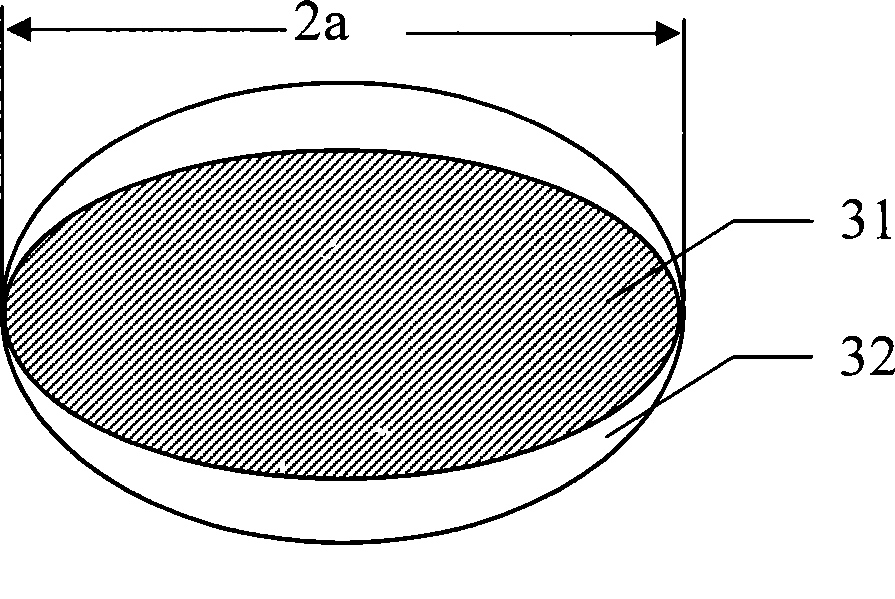

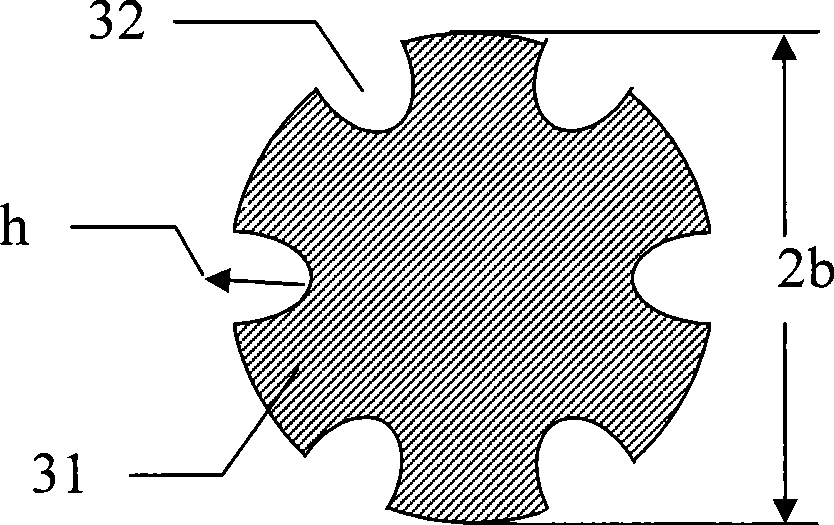

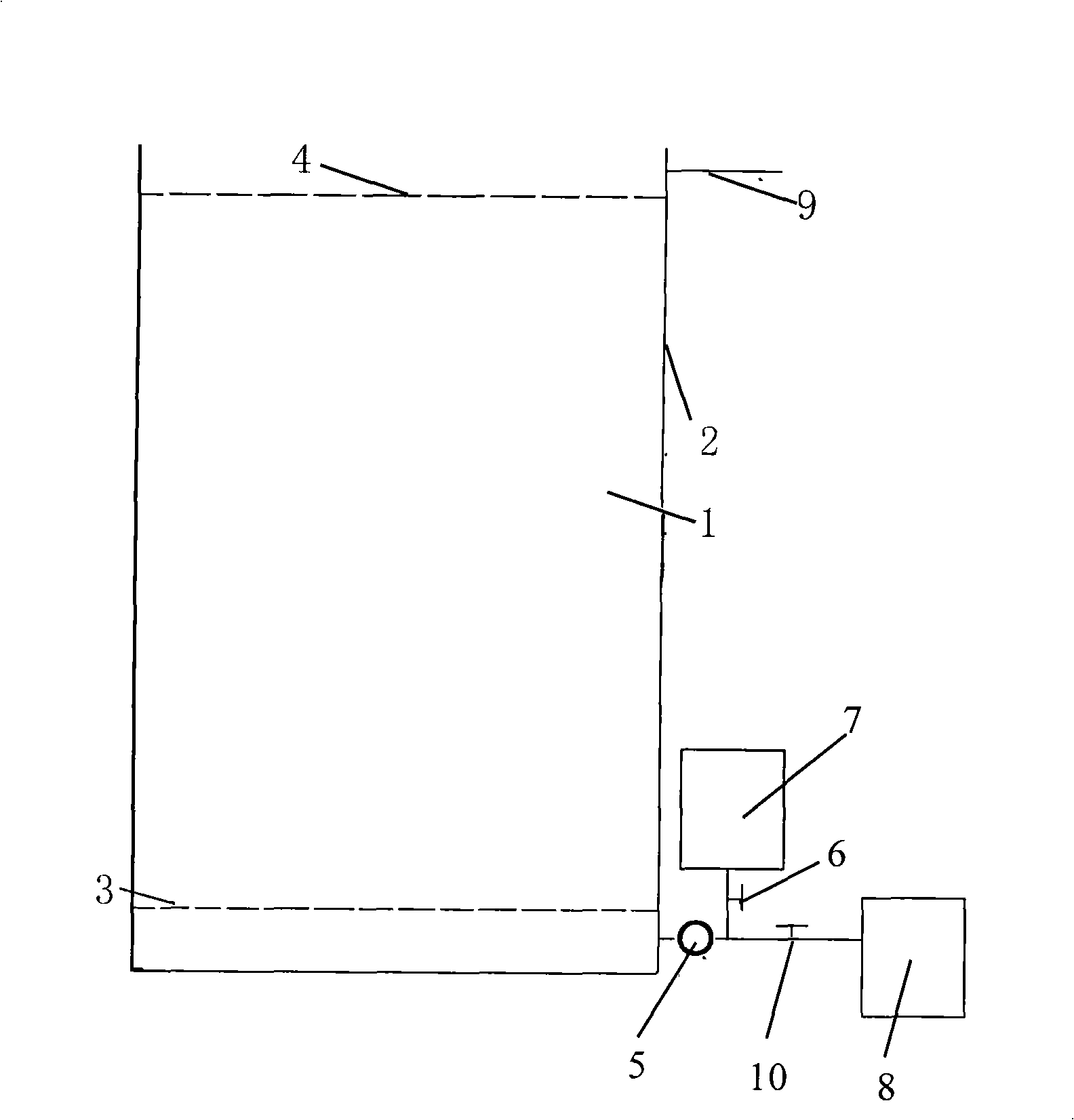

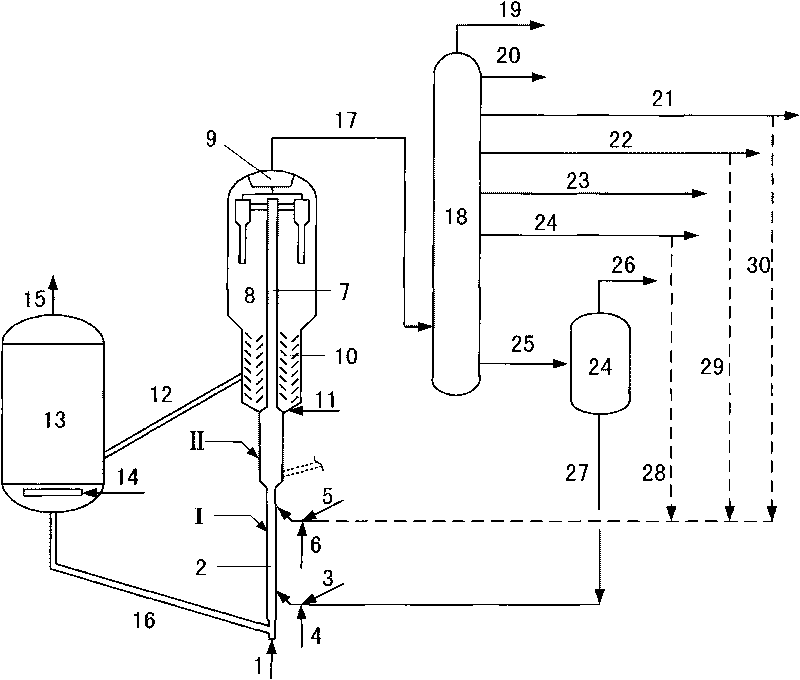

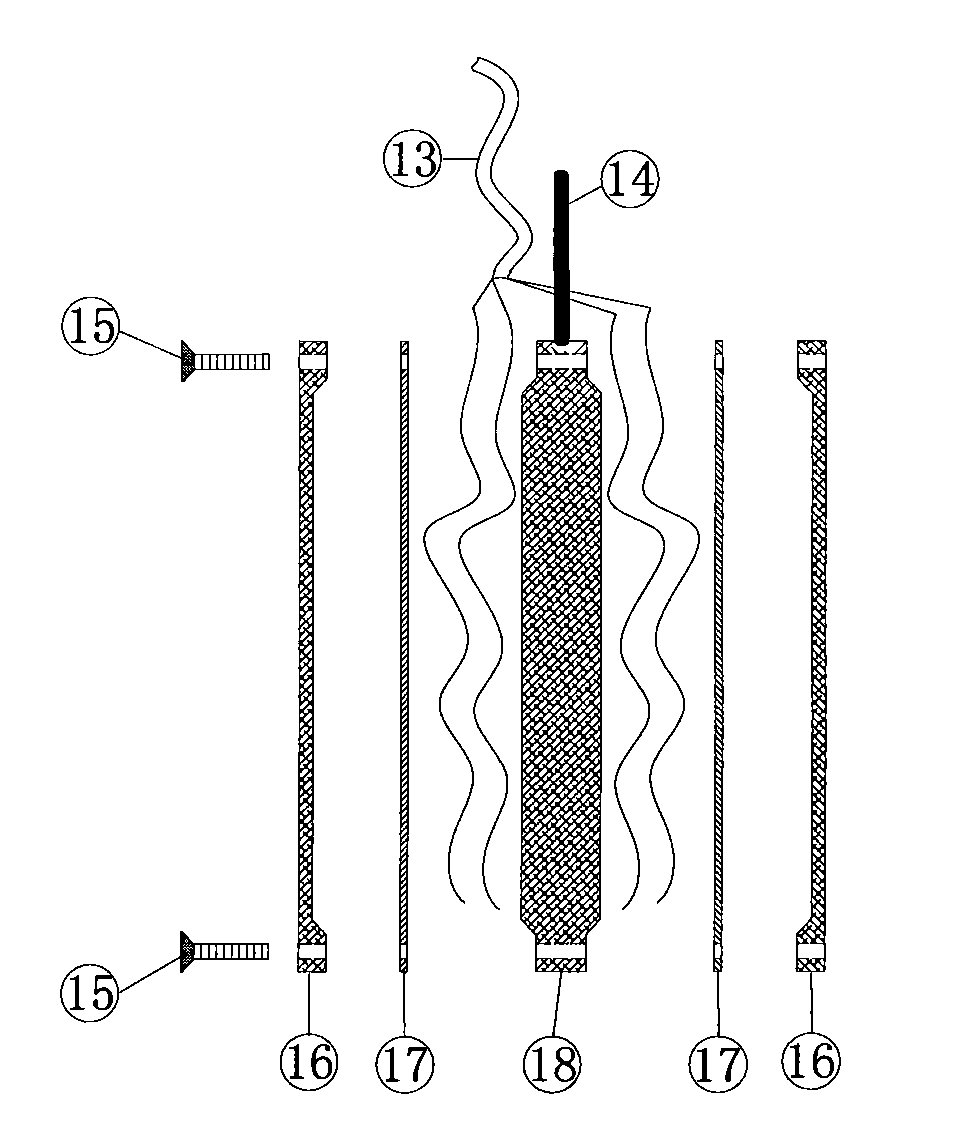

Non-catalytic partial oxidation gasification furnace of inferior raw material

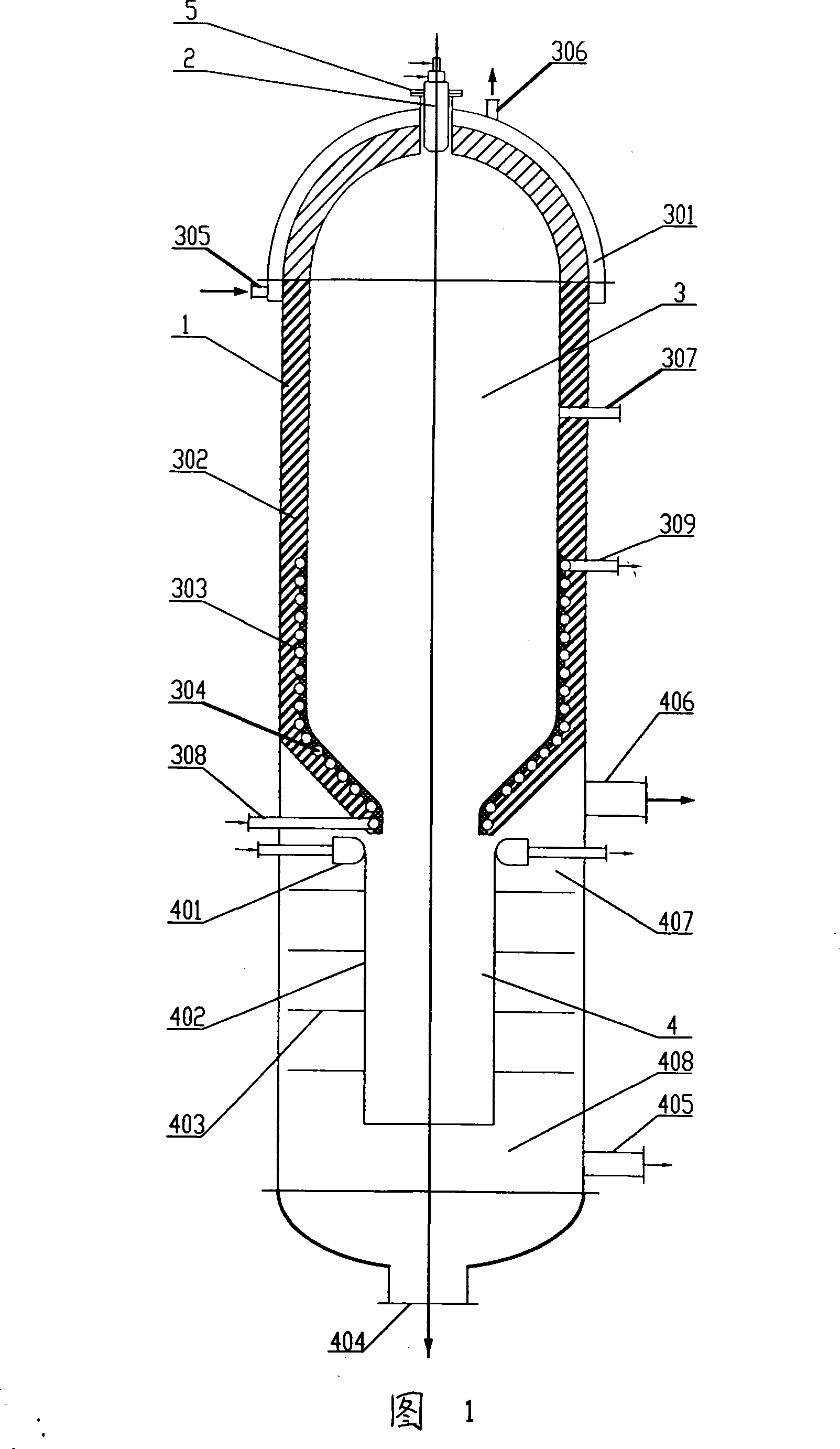

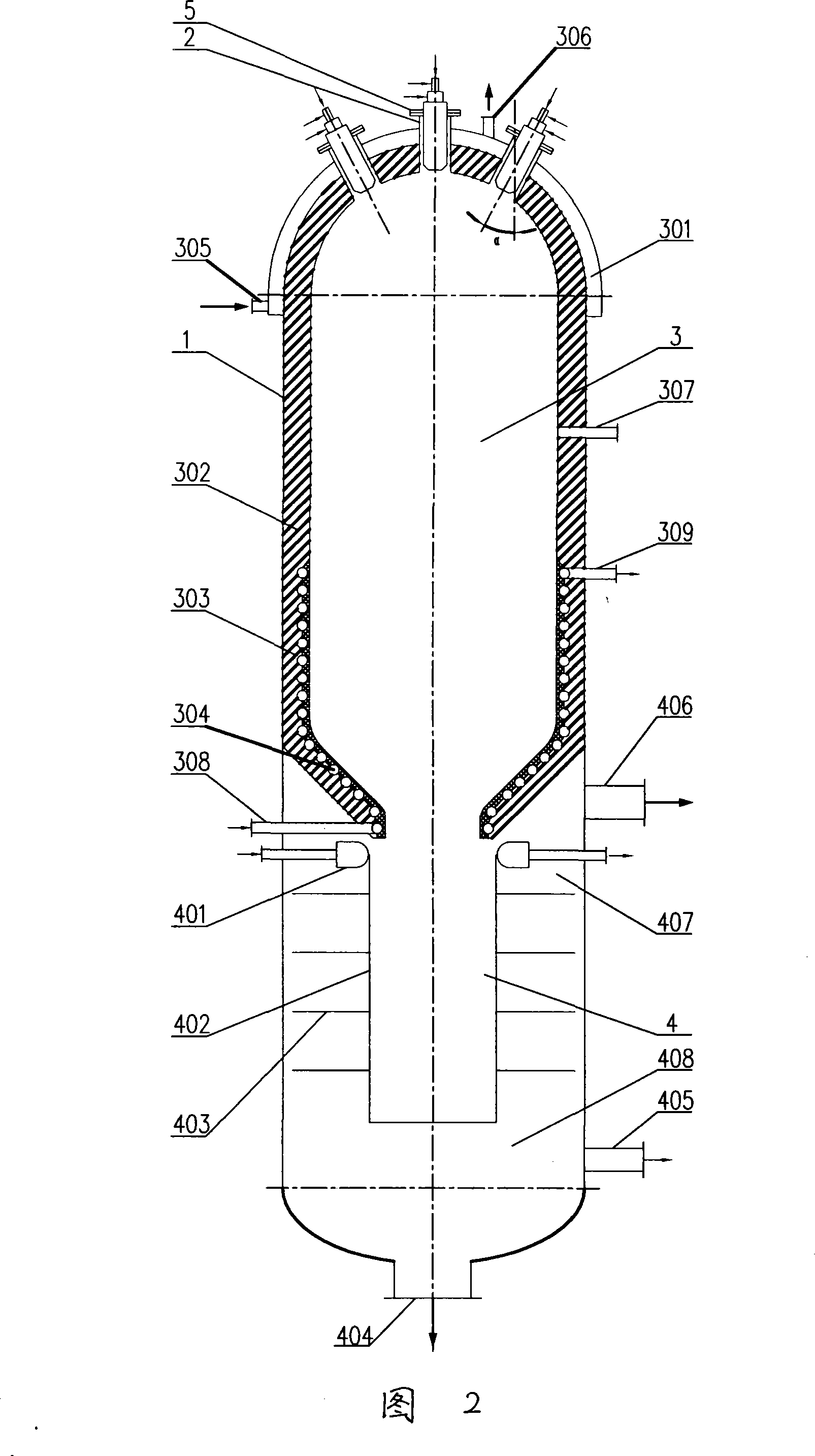

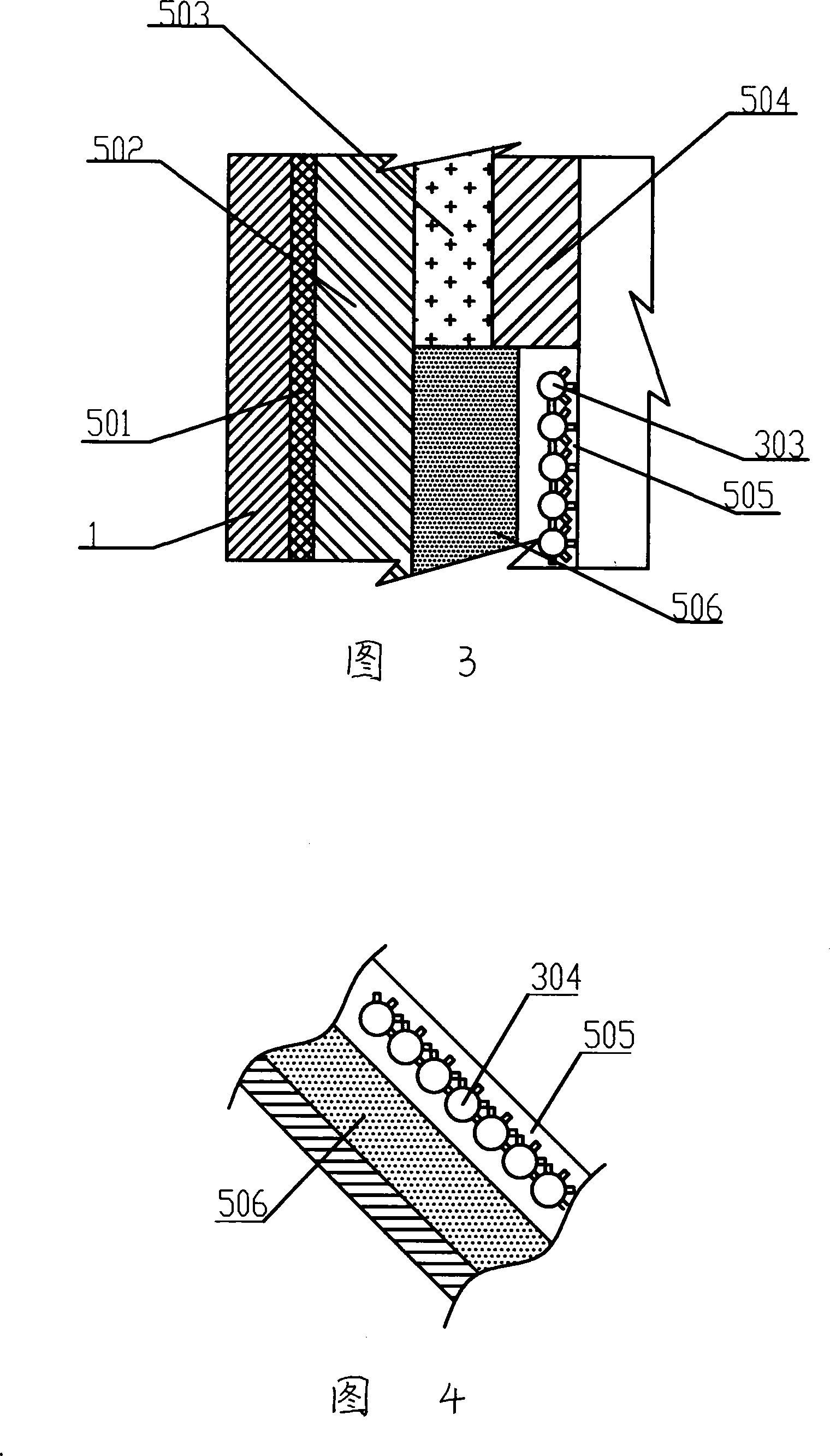

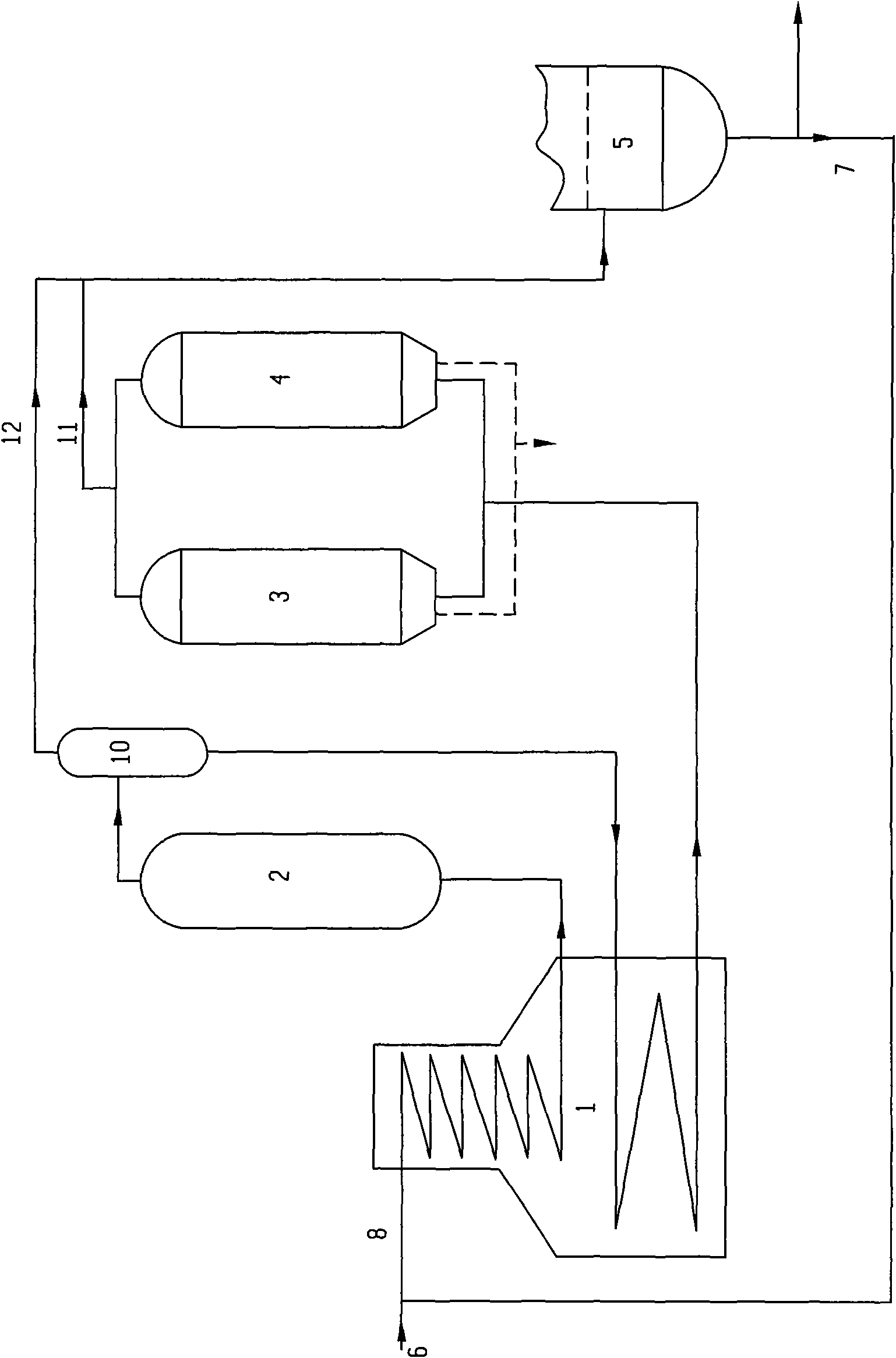

ActiveCN101245263AAvoid overheatingExtended operating cycleHydrogenGranular/pulverulent flues gasificationSyngasSlag

The invention relates to a gasification furnace used for preparing synthesis gas, in particular to a multi-jet vertical airflow bed. An oxidative gasification furnace for non-catalytic parts of inferior raw materials comprises that at least a jet (2) on the top part of a gasification reaction chamber (3) which is communicated with a chilling washing chamber (4) and is characterized in that the gasification reaction chamber (3) is arranged on the upper part of the gasification furnace while the chilling washing chamber (4) is arranged at the lower part of the gasification furnace; the gasification reaction chamber (3) and the chilling washing chamber (4) share a pressure bearing cylinder (1). The gasification furnace has the advantages of avoiding the excessive temperature of the upper part of the gasification reaction chamber and also prolonging the service life of a part at a slag export region of the lower part of the gasification reaction chamber.

Owner:CHINA PETROCHEMICAL CORP +3

Hydro-cracking method for blending ethylene bottom oil

The invention discloses a hydro-cracking method for blending ethylene bottom oil, which is different from the method for processing the conventional ethylene bottom oil and comprises the following steps: blending an ethylene bottom oil light end into a conventional hydro-cracking raw material for hydro-cracking, in the presence of hydrogen, sequentially contacting the ethylene bottom oil light end with a hydro-guard catalyst, a hydro-refining catalyst, a hydro-residue carbon removing catalyst and a hydro-cracking catalyst; separating an effluent of hydro-cracking reaction to obtain light fuel oil. The method of the invention adopts a method of grading the hydrogenation catalyst, can process the ethylene bottom oil light end and produce diesel oil having a high cetane number and a low condensation point and a naphtha having high arene, and is not obviously changed in a BMCI value of tail oil and a smoke point of a jet fuel when compared with the conditions before blending the ethylene bottom oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

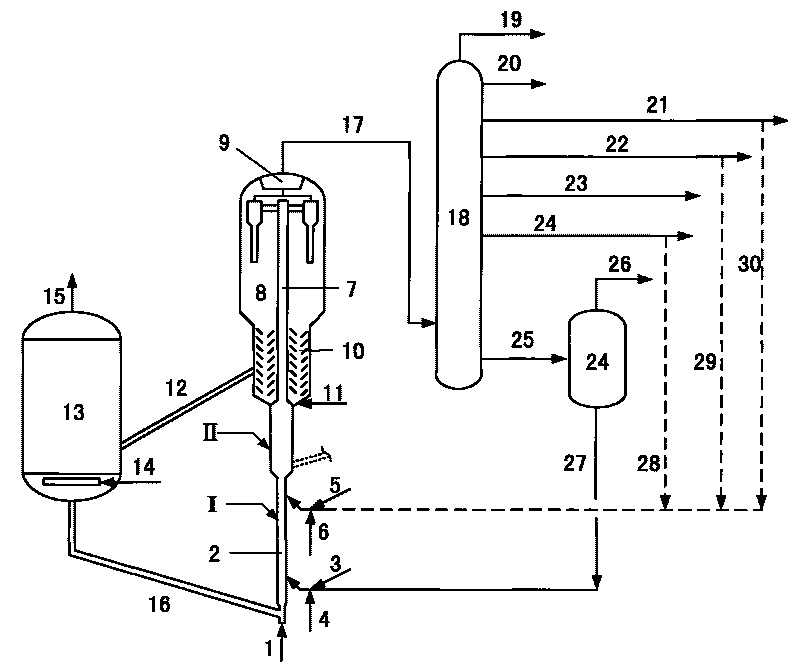

Improved delayed coking process

ActiveCN101597518AHigh yieldReduce yieldCoking carbonaceous materialsHydrocarbon oils treatmentLiquid productFractionation

The invention discloses an improved delayed coking process, aiming at solving the defects of serious heating furnace coking, low liquid product yield and the like in the current delayed coking processes. The process is characterized in that feeds are heated to 360-460 DEG C in a convection chamber or a convection chamber and a radiation chamber of the heating furnace, and then enter a visbreakingreactor for cracking reaction; heavy oil separated from the reaction product enters the radiation chamber of the heating furnace to be heated to 480-515 DEG C and then enters a coke tower; oil gas out of the coke tower singly enters or enters a fractionating tower after being mixed with the gas in the visbreaking reactor for fractionation. By adopting the process of the invention, the delayed coking liquid product yield can be improved, the coke yield reduced, the operation cycle of the delayed coking unit lengthened and the equipment investment lowered at the same time.

Owner:CHINA PETROCHEMICAL CORP +1

Method for hydrocracking of coked wax oil

The invention provides a method for hydrocracking of coked wax oil, which comprises: contact reaction of raw materials, hydrogen and a hydrogenation protection catalyst under the condition for hydrogenation protection reaction, wherein oil in the raw materials is coked wax oil or mixed oil containing coked wax oil; contact reaction of products in the hydrogenation protection reaction, products ofhydrocracking reaction and a hydrogenation refining catalyst under the condition for hydrogenation refining reaction; separation of light distillates, intermediate distillates and heavy distillates with initial boiling points being 350-360 DEG C from products of the hydrogenation refining reaction; and contact reaction of the heavy distillates with the initial boiling points being 350-360 DEG C and a hydrocracking catalyst under the condition for hydrocracking reaction, thereby obtaining products of the hydrocracking reaction. The method of the invention prolongs the operating cycle of the device, the consumption of the hydrocracking catalyst is low, and the yield of the intermediate distillates in the products is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating heavy metal-containing acidic waste water and recycling heavy metal with biomass fixed bed

InactiveCN101402491AWide variety of sourcesIncrease loadBiological water/sewage treatmentSulfate-reducing bacteriaSludge

The invention discloses a method for treating acidic waste water containing heavy metal and reclaiming the heavy metal through a biomass fixed bed, which is characterized in that dry solid biomass capable of being decomposed by microbes is granulated and filled into a container with a supporting layer and a water distributing device so as to form a fixed bed microbe reactor; sewage disposal plant sludge containing sulfate reducing bacteria is taken as the source of microbe bacteria on the fixed bed, and the microbes are cultured, proliferated and acclimated to adapt to the environment of the biomass filler fixed bed through the backflow circulation of the outputted water or taking ferrous sulfate aqueous solution as the inputted water; acid effluent containing heavy metallic ions is led into the fixed bed for direct filtration; and when the water filtering speed can not meet the preset requirements, the operation is stopped, substances in the fixed bed are taken out, the heavy metal is reclaimed through smelting, and the fixed bed microbe reactor is refilled. The method is suitable for waste water containing Cr2O7 <2->, AsO3 <2->, Cu <2+>, Hg <2+> Ag <+>, Cd <2+> and the like. The method can be used for reclaiming the valuable metal resources with low waste water treatment cost.

Owner:HEFEI UNIV OF TECH

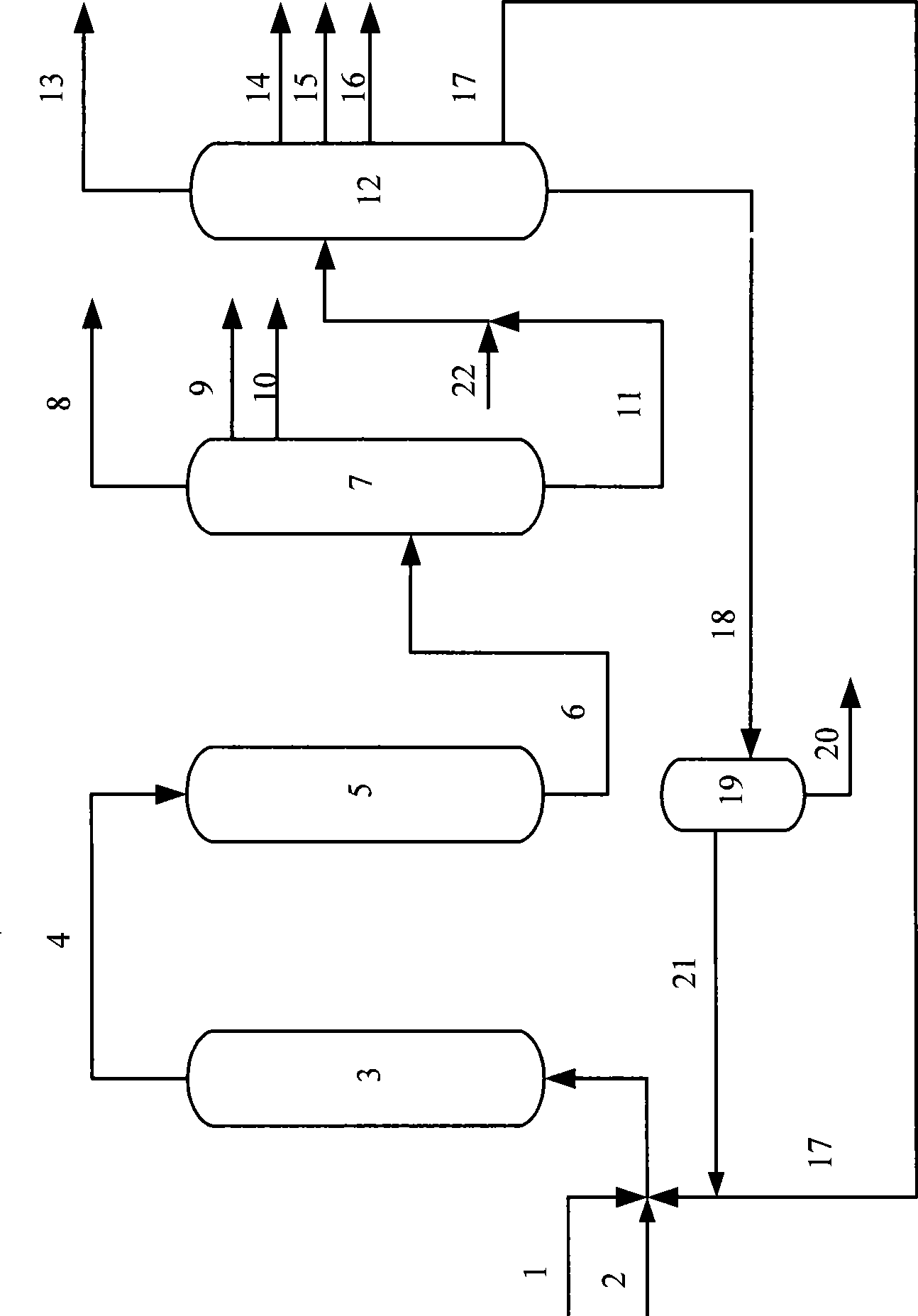

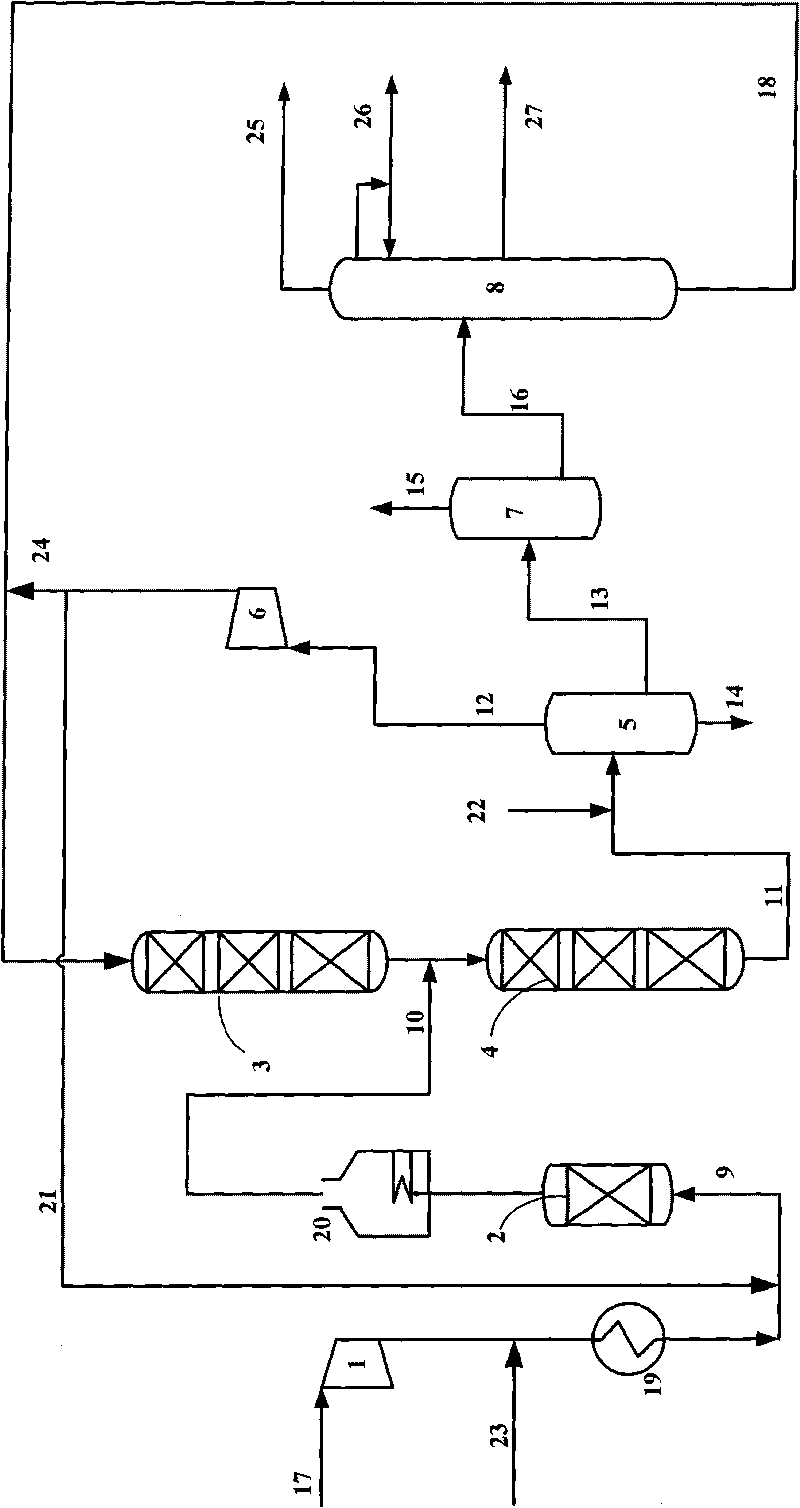

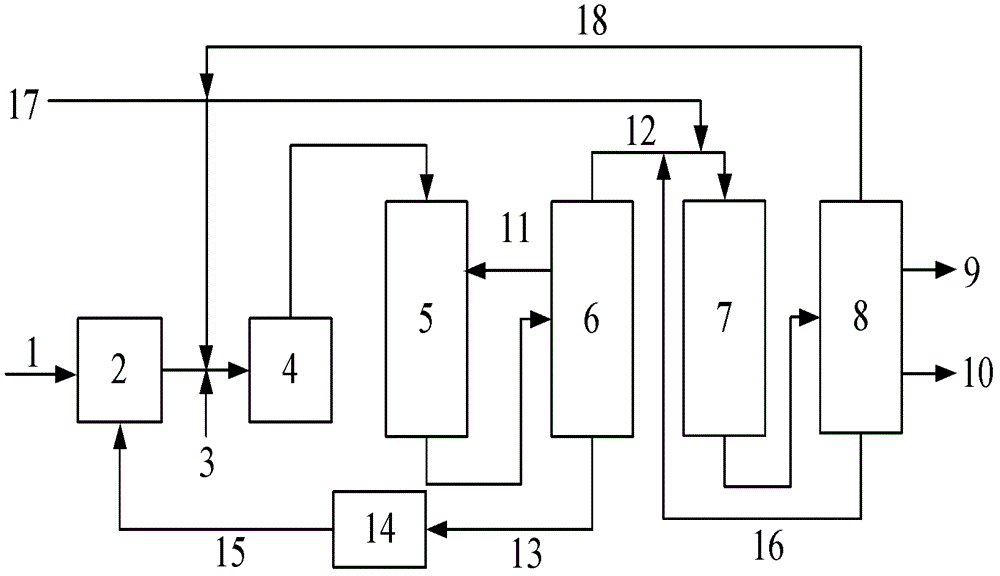

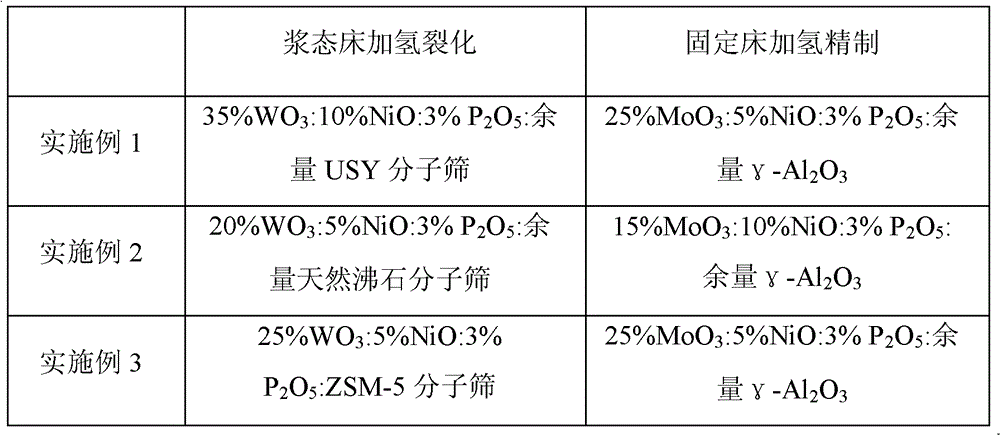

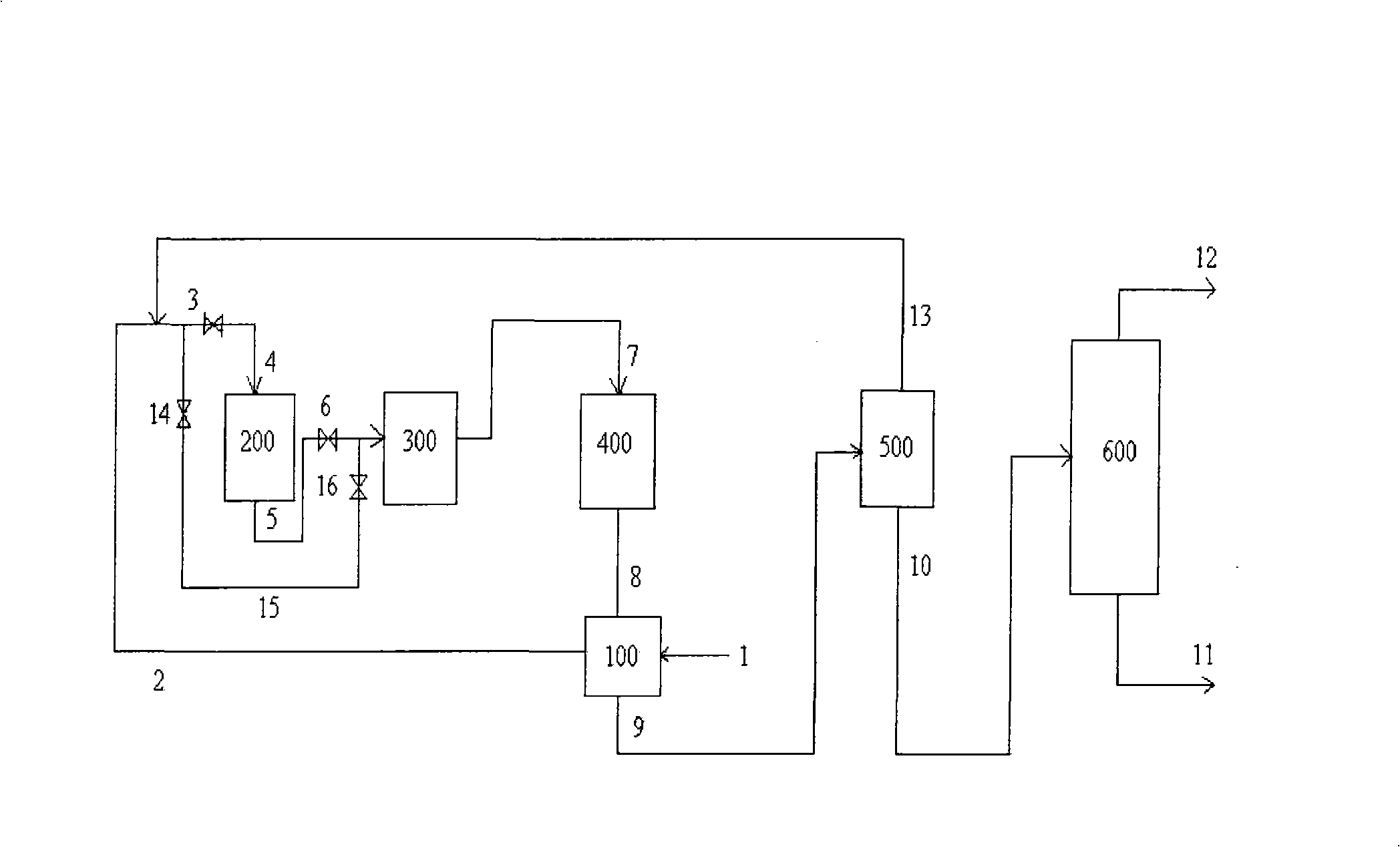

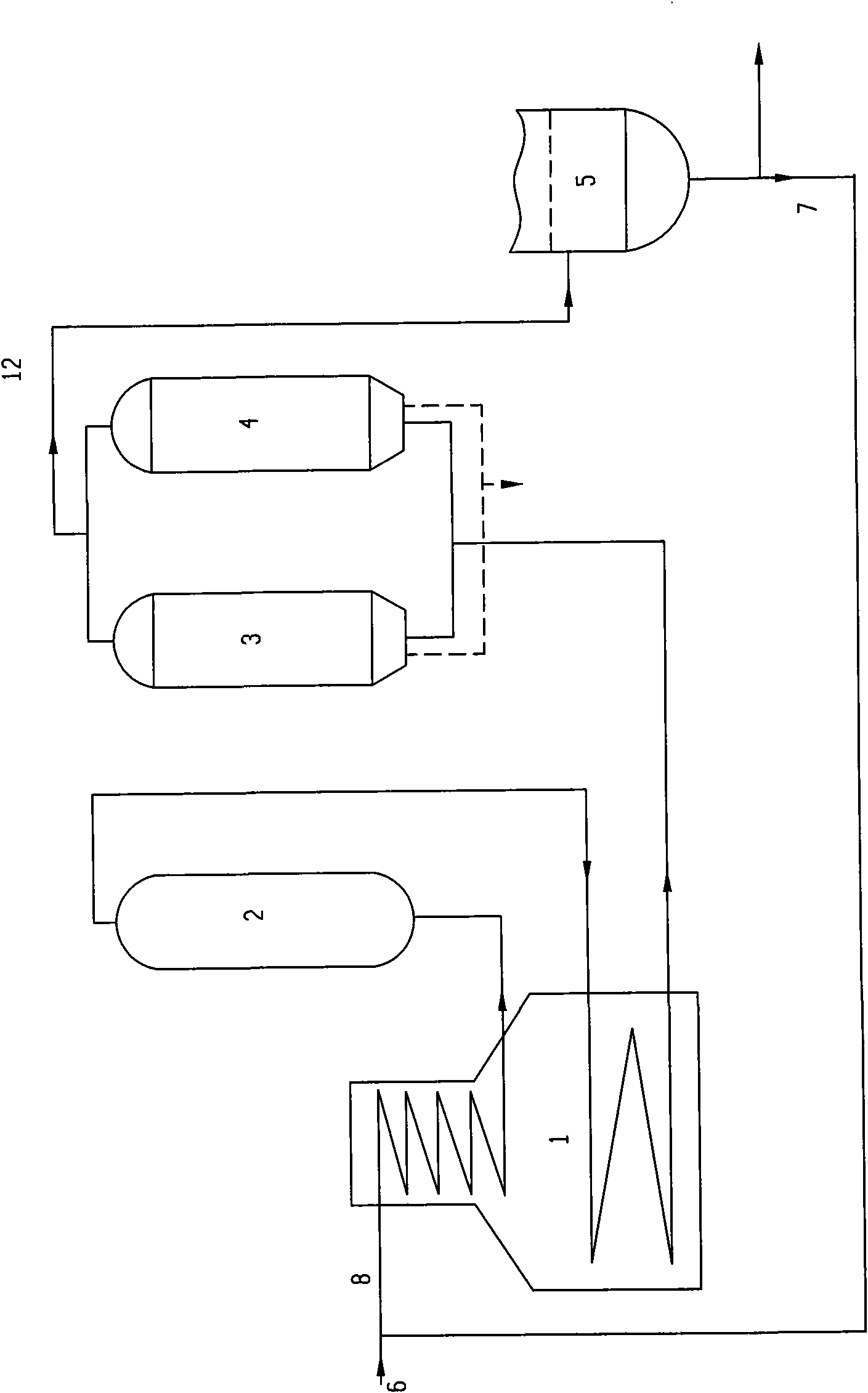

Coal tar full-fraction hydrogenation method for coupling slurry bed and static bed

The invention relates to a coal tar full-fraction hydrogenation method for coupling a slurry bed and a static bed. The coal tar full-fraction hydrogenation method mainly comprises a coal tar material pretreatment unit, a slurry bed hydrocracking unit, a primary hydrogenation product fractionation unit, a static bed hydrorefining unit, and a product distilling unit, wherein the coal tar full-fraction oil is subjected to pretreatment such as dewatering and dedusting, and enters a slurry bed reactor to carry out hydrocracking reaction after being mixed and pre-heated together with a hydrocracking catalyst; the reacted primary hydrogenation product enters the static bed hydrorefining unit through a light component obtained by fractionation; the middle fraction and the catalyst return to a slurry bed hydrogenation reactor in a circulating manner; a light component returns to a tar pretreatment unit to hydrogenate in circulation after removing a part of catalyst and coke generated in a cracking manner, and the light component is rectified to obtain naphtha and diesel oil product after common hydrorefining. The method is coal tar full-fraction hydrogenation; the utilization rate of the coal tar is improved to the maximal extent; and the coking of the heavy component of the coal tar and inactivation of the catalyst are effectively delayed by the process for coupling the slurry bed and the static bed, and the production cycle is also prolonged.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

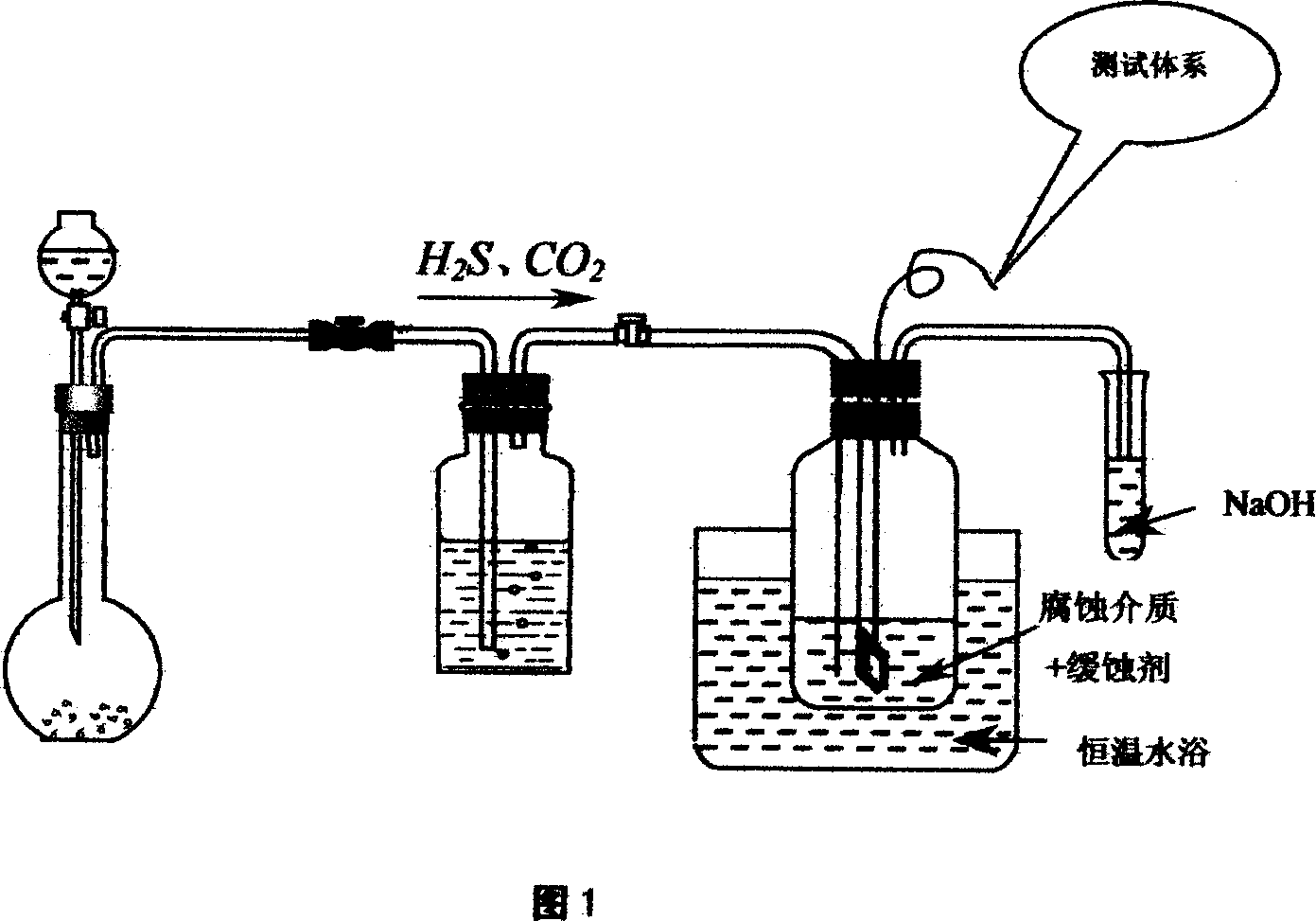

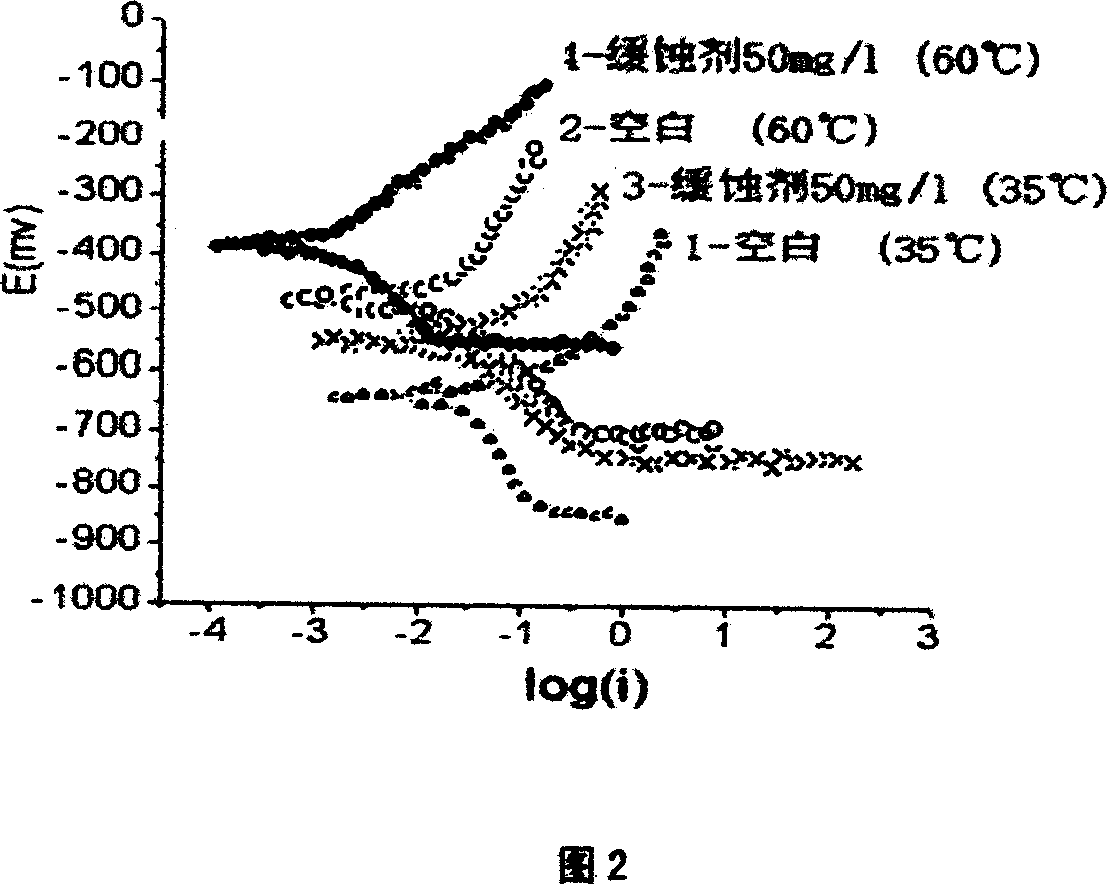

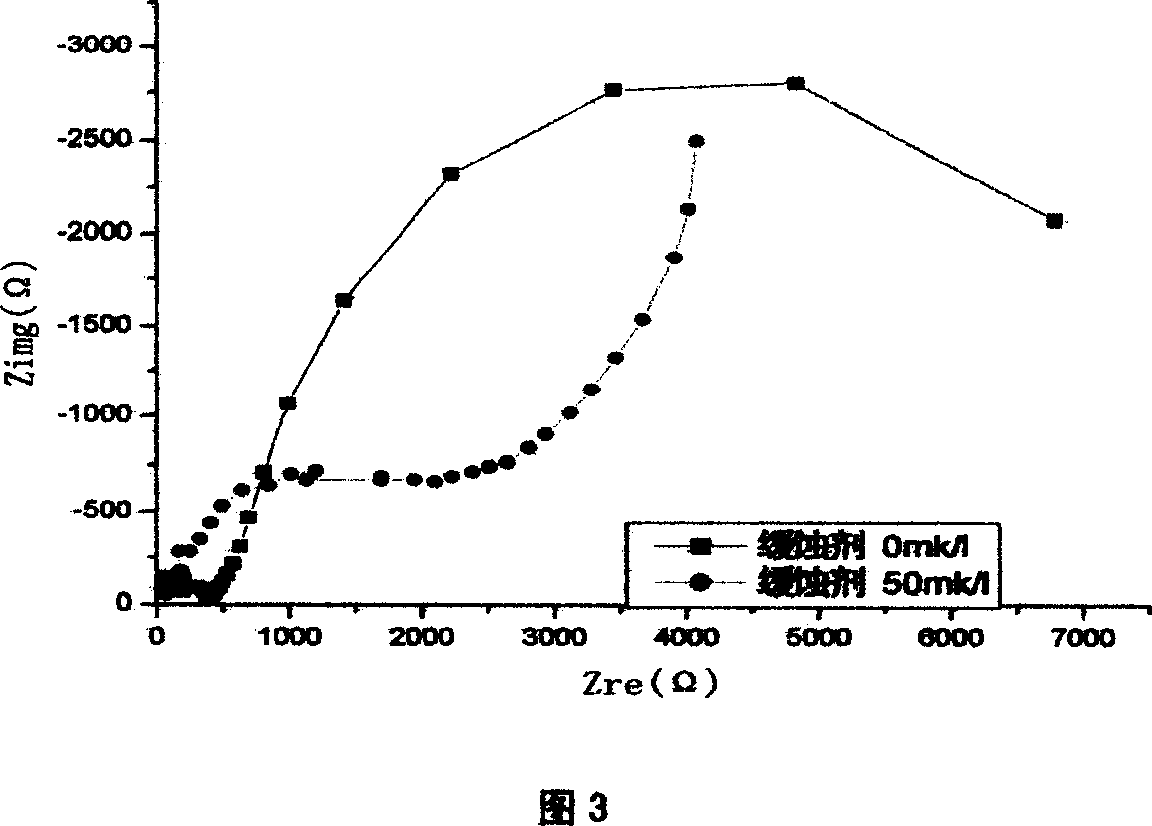

Corrosion inhibitor resistant to H2S and CO2

InactiveCN1966774ADoes not affect separation efficiencyGood corrosion inhibition effectBorehole/well accessoriesIsopropyl alcoholFatty alcohol

The invention relates the chemical engineering field, especially a H2 and CO2 inhibiter. H2 and CO2 are produced accompany to oil-gas field exploitation and transfusion process, and can corrode exploitation equipment. The inhibiter contains at least (by wt. %): isopropyl alcohol 10-30, fatty alcohol polyoxyethylene ether .1-0.5, and litol polyoxyethylene ether 0.1- 1.0. The inhibiter can be used in oil / water well with high temperature and pressure, and has the advantages of good corrosion resistance, low consumption, low cost and high efficiency.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

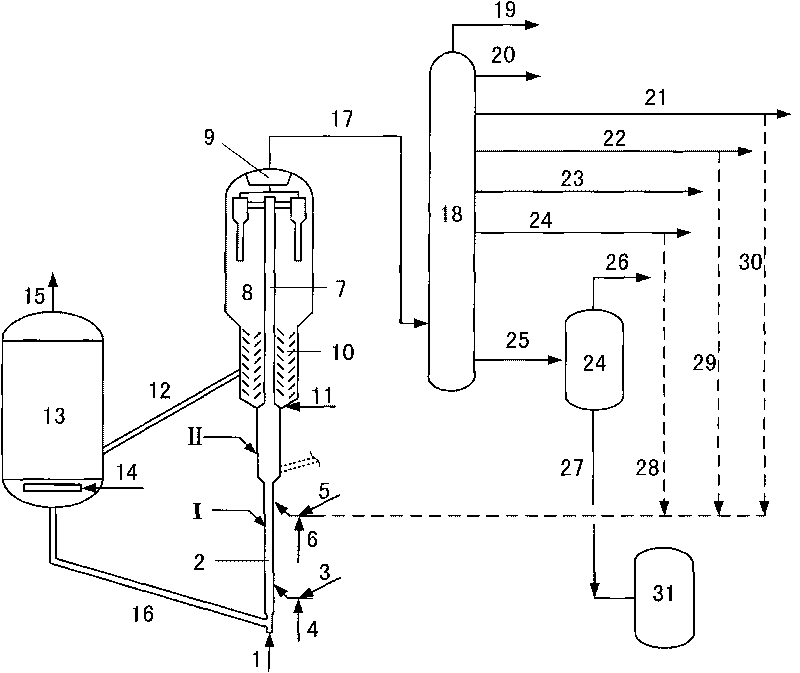

Method for preparing light-weight fuel oil and propylene from inferior raw oil

ActiveCN101724430AExtended operating cycleImprove propertiesCatalytic crackingOrganic chemistryAlkaneWax

The invention provides a method for preparing light-weight fuel oil and propylene from inferior raw oil. The method comprises the following steps that: the inferior raw oil enters a first and second reaction areas of a catalytic conversion reactor in sequence to contact the catalytic conversion catalyst to undergo the primary reaction and the secondary reaction, the reaction products and the spent catalyst undergo solid-liquid separation, and the spent catalyst undergoes steam stripping and singeing in sequence and then is returned to the reactor for recycling; the reaction products are separated to obtain propylene, gasoline, catalytic wax oil and other products, wherein the catalytic wax oil enters an aromatic extraction device for separation so as to obtain extract oil and raffinate oil; and the raffinate oil is cycled to the first reaction area of the catalytic conversion reactor or / and other catalytic conversion devices for further reaction to obtain the target products of propylene and gasoline. In the method, the inferior raw oil undergoes the mild catalytic conversion, the obtained catalytic wax oil undergoes aromatic extraction, and the extract oil richly contains double ring arenas and is a quite good chemically raw material; and the raffinate oil richly contains alkanes and naphthenic hydrocarbons, and is quite suitable for catalytic conversion, so that the highly efficient utilization of gasoline resources is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

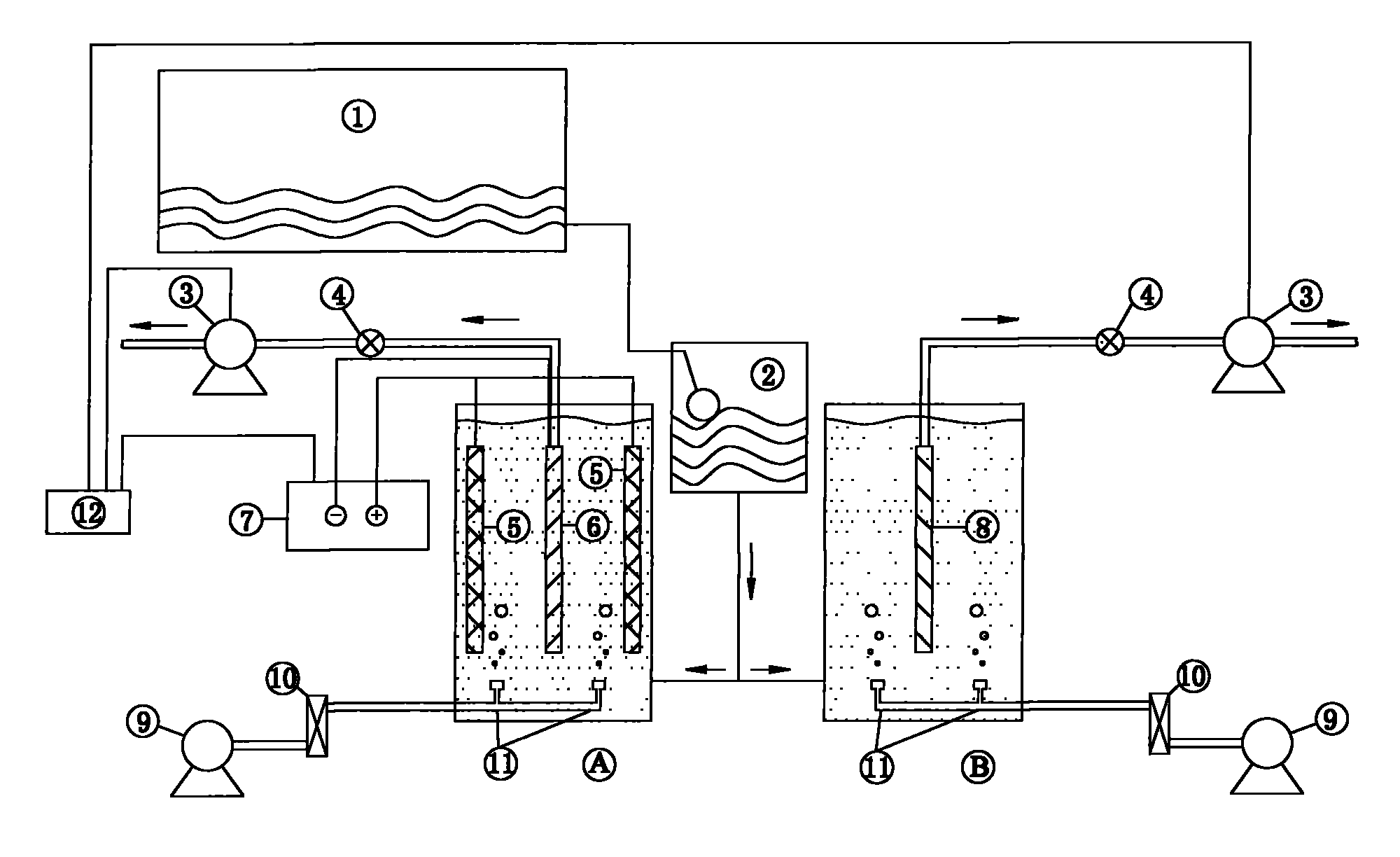

Method for improving pollution resistance and flux of membrane by using weak electric field

InactiveCN101941759AEasy to controlHigh throughput levelSustainable biological treatmentBiological water/sewage treatmentCopper wireBiology

The invention discloses a method for improving pollution resistance and flux of a membrane by using a weak electric field, which belongs to the technical field of membrane bioreactors (MBR) and is characterized in that: based on a principle that homo-polarity repels, a weak negative electric field is applied near a membrane face to increase resistance to pollutant and push the membrane pollutant away from the membrane surface and therefore has the effects of delaying the formation of a filter cake layer, increasing the pollution resistance of the membrane, improving the flux and prolonging a filtration operation period. The method is to use a conductive copper wire arranged in a plate type membrane component as a cathode or directly apply the weak negative electric field to a membrane material with the conductive property. The method has the advantages that: energy consumption is low, high-intensity electric field is avoided, and the operation is carried out in an intermittent way; the composition and metabolic characteristics of microbes are considerably influenced and the water treatment capability of the microbes is influenced; the method is convenient to implement, and power can be supplied by waste water, sludge and microbe fuels, so that additional energy consumption is avoided and water treatment capability is improved. Thus, the method has a very promising application prospect.

Owner:DALIAN UNIV OF TECH

Method for improving running period of hydrogenation plant for poor petroleum naphtha

ActiveCN101343566AReduce cokingLess investmentTreatment with hydrotreatment processesNaphthaNitrogen

The invention relates to a method for enhancing the running period of a poor-quality naphtha hydrogenising device. The invention adopts the method that a reactor is additionally arranged before a heating furnace, and the poor-quality naphtha first performs a selective diene hydrogenising and removing organosilicon compounds reaction at a lower reaction temperature, and then passes through a main reactor and performs a hydrogenising reaction to remove sulphur and nitrogen impurity and olefin saturation. Compared with the prior art, the method has the advantages that the process is simple, the heating furnace tube and the heat exchanger shell side coking are effectively alleviated and the organosilicon compounds are removed, and the running period of the device is prolonged. The method can be applied to various secondary processing naphtha hydrofining processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

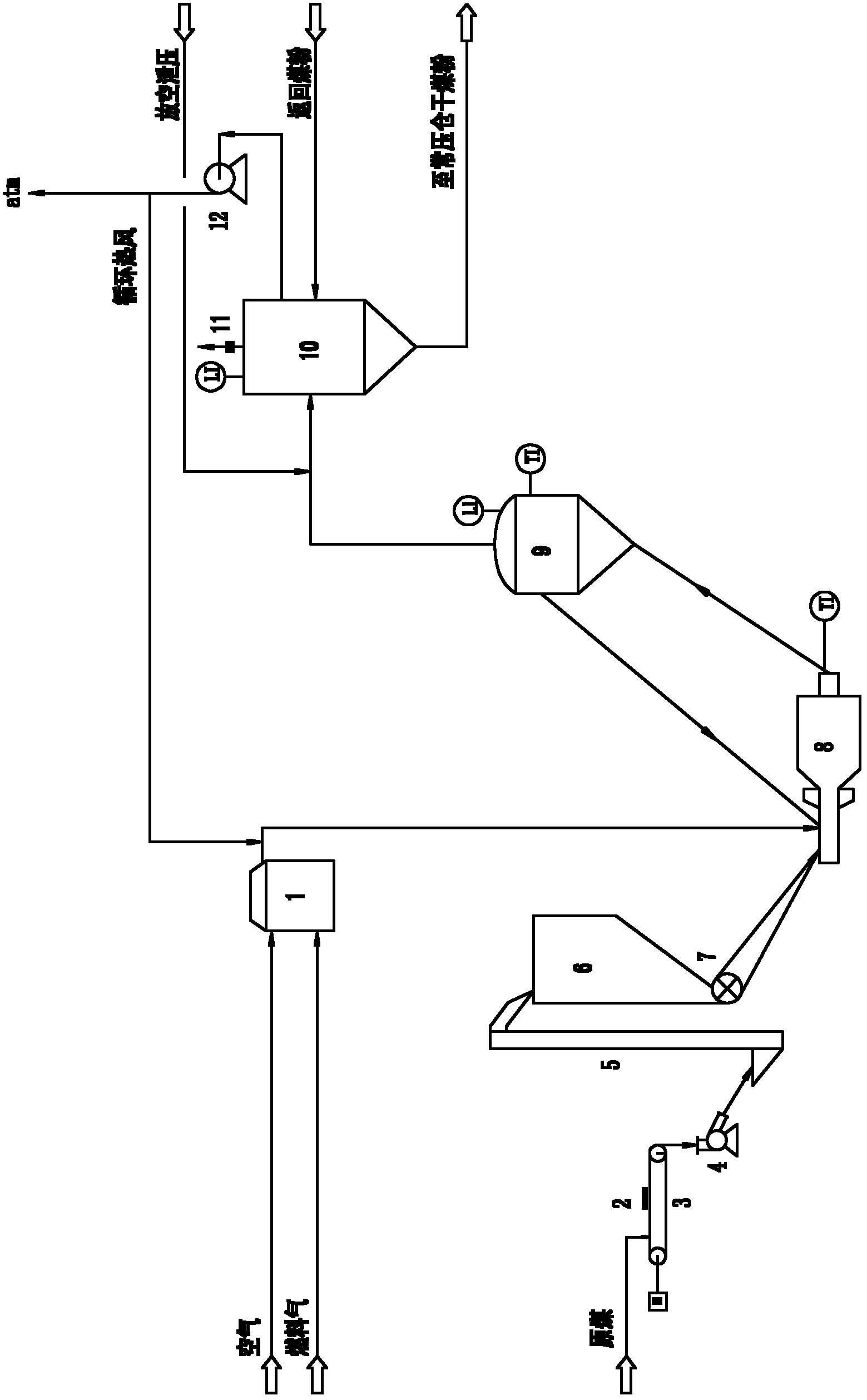

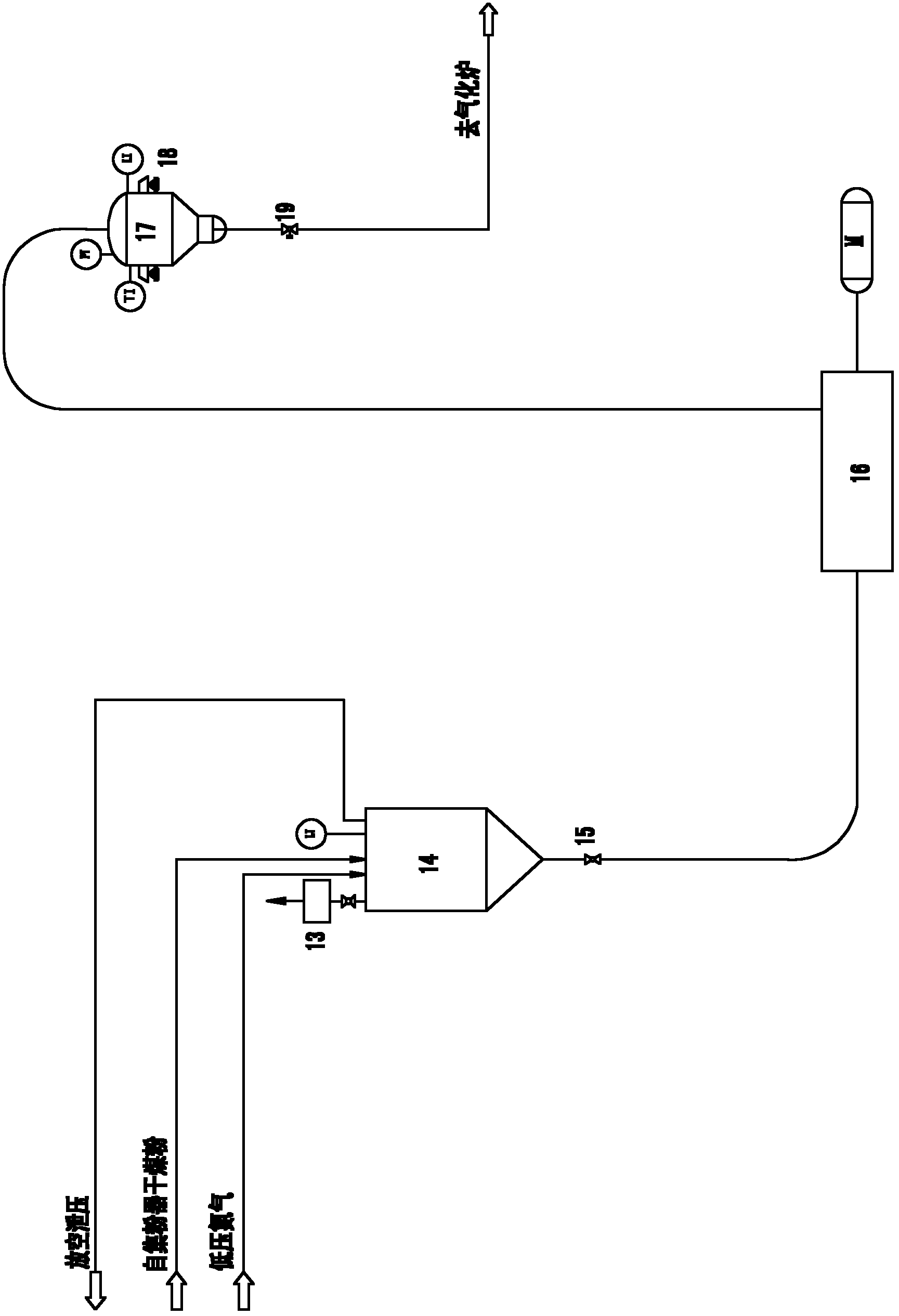

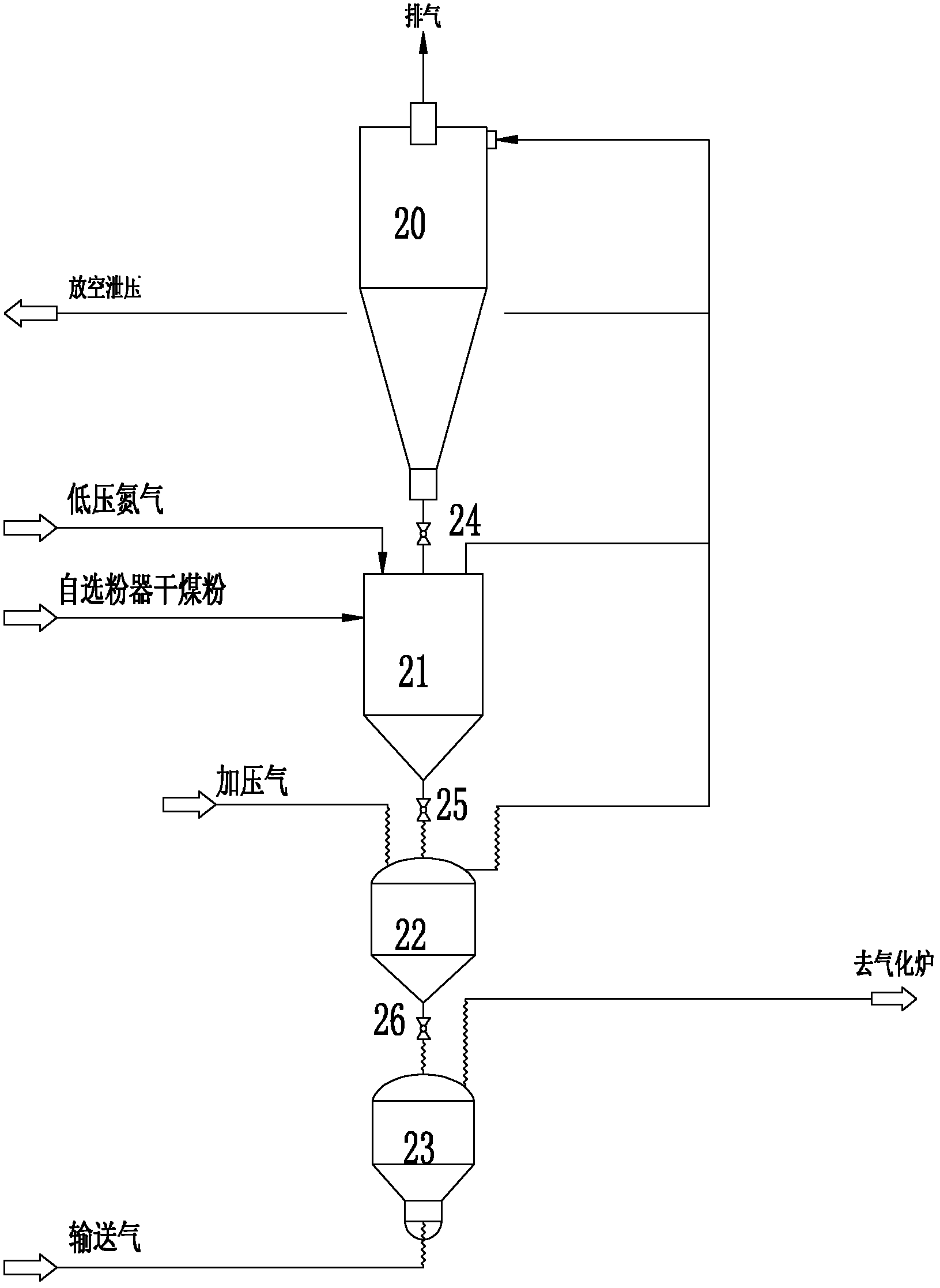

Method for producing synthesis gas by using coal powder as raw material

ActiveCN102352268AImprove utilization efficiencyWon't happenMultistage water/sewage treatmentCombined combustion mitigationProcess configurationAnthracite

The invention discloses a pressurization high temperature gasification method of dry coal powder. The method comprises the following five steps: the preparation of dry coal powder, the pressurization delivery of the dry coal powder, the pressurization and high temperature gasification of the dry coal powder, the cooling of high temperature crude synthesis gas and molten ash and the washing and purifying of the crude synthesis gas, and the treatment of water containing fine ash. The method is suitable for not only the bituminous coal with low ash content and low ash fusion point, but also other types of coal, which widely exist at home and abroad, have different metamorphic degrees and qualities and contain the coal with low ash content and high ash fusion point, the coal with high ash content and low ash fusion point and the anthracite, bituminous coal and lignite with high ash content and high ash fusion point. The method has good gasification index, simple equipment, flexible process configuration, low investment and operation convenience, the large-scale product is easy to realize, and the method has the beneficial effects of wide raw material application range, environmental friendliness and the like.

Owner:THE NORTHWEST RES INST OF CHEM IND

Coking inhibitor and preparation method and application thereof

InactiveCN101037618AImprove performanceImprove hydrogen supply capacityTreatment apparatus corrosion/fouling inhibitionHydrocarbon mixturesBoiling point

The invention discloses a agglomerating inhibiting agent, preparing method and application thereof. The agglomerating inhibiting agent is selected from one or more hydrogenizating upgrading products of hydrocarbon mixture of coal oil, ethylene tar oil, catalytic crackingre cycle stock, catalytic crackingre slurry oil, catalytic crackingre heavy oil, catalytic crackingre extract oil and coking hydrowax, which contain 65-100 wt% of cyclane and arene, boilingpoint is 150 DEG C to 500 DEG C. The agglomerating inhibiting agent is used for preventing, slowing and removing agglomerating of apparatus and pipilines in process of petroleum refining and petrochemical processing.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Delayed coking process

ActiveCN101591561AHigh yieldReduce yieldThermal non-catalytic crackingTreatment with plural serial stages onlyLiquid productWork period

The invention discloses a delayed coking process, which aims to overcome the defects of serious furnace coking and low liquid product yield and the like for a heating furnace in the prior delayed coking process. The delayed coking process is characterized by comprising the following steps: heating input materials to a temperature of between 360 and 460 DEG C in a convection chamber or the convection chamber and an irradiation chamber of the heating furnace, then putting the input materials into a visbreaking reactor to perform cracking reaction; putting reaction products into the irradiation chamber of the heating furnace, heating the reaction products to a temperature of between 480 and 515 DEG C, and then putting the reaction products into a coking tower; and putting oil gas from the coking tower into a coking fractionating tower to perform fractionating. The delayed coking process can improve the delayed coking liquid product yield, reduce the coke yield, prolong the start working period of delayed coking devices, and simultaneously reduce the equipment investment.

Owner:CHINA PETROCHEMICAL CORP +1

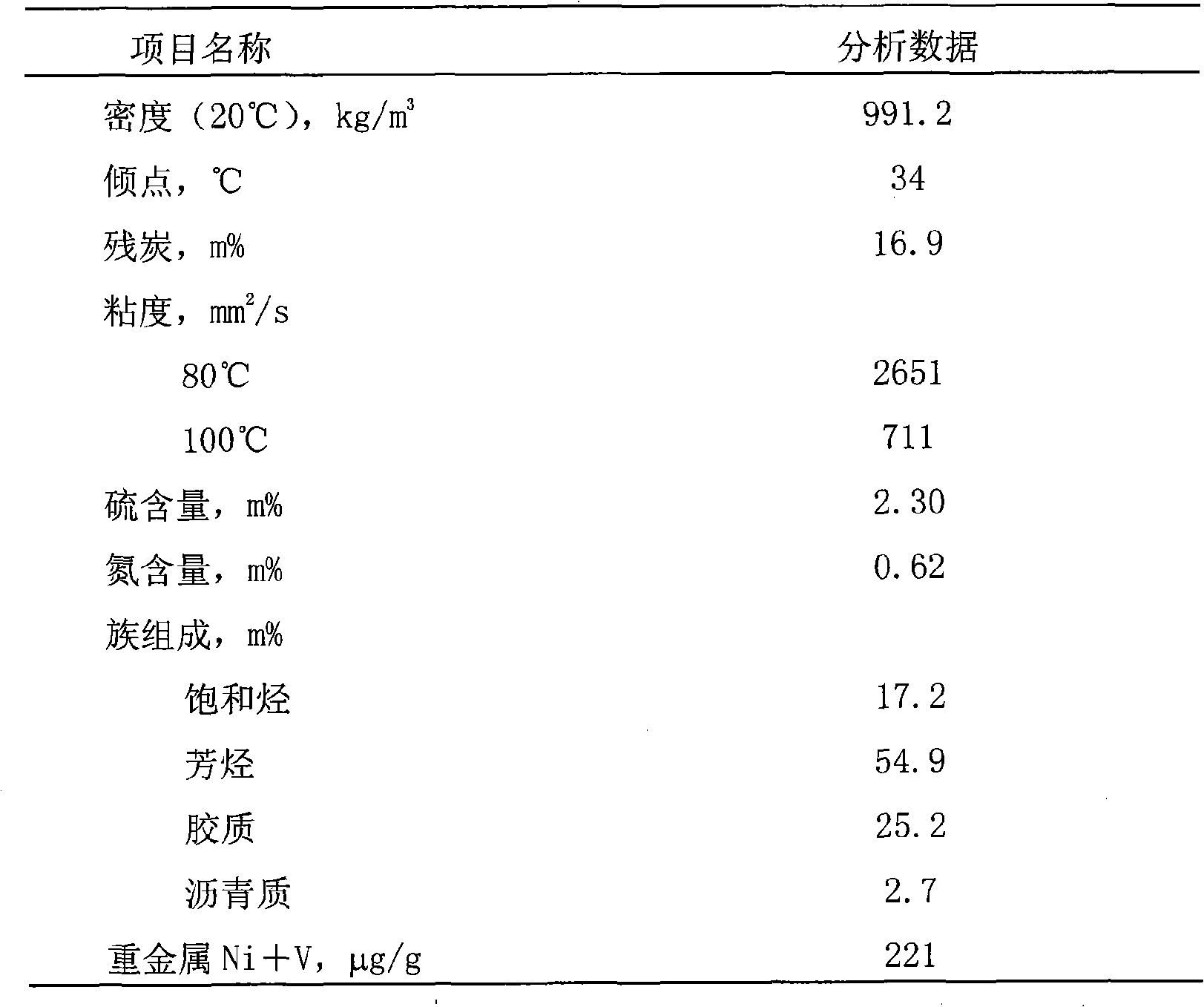

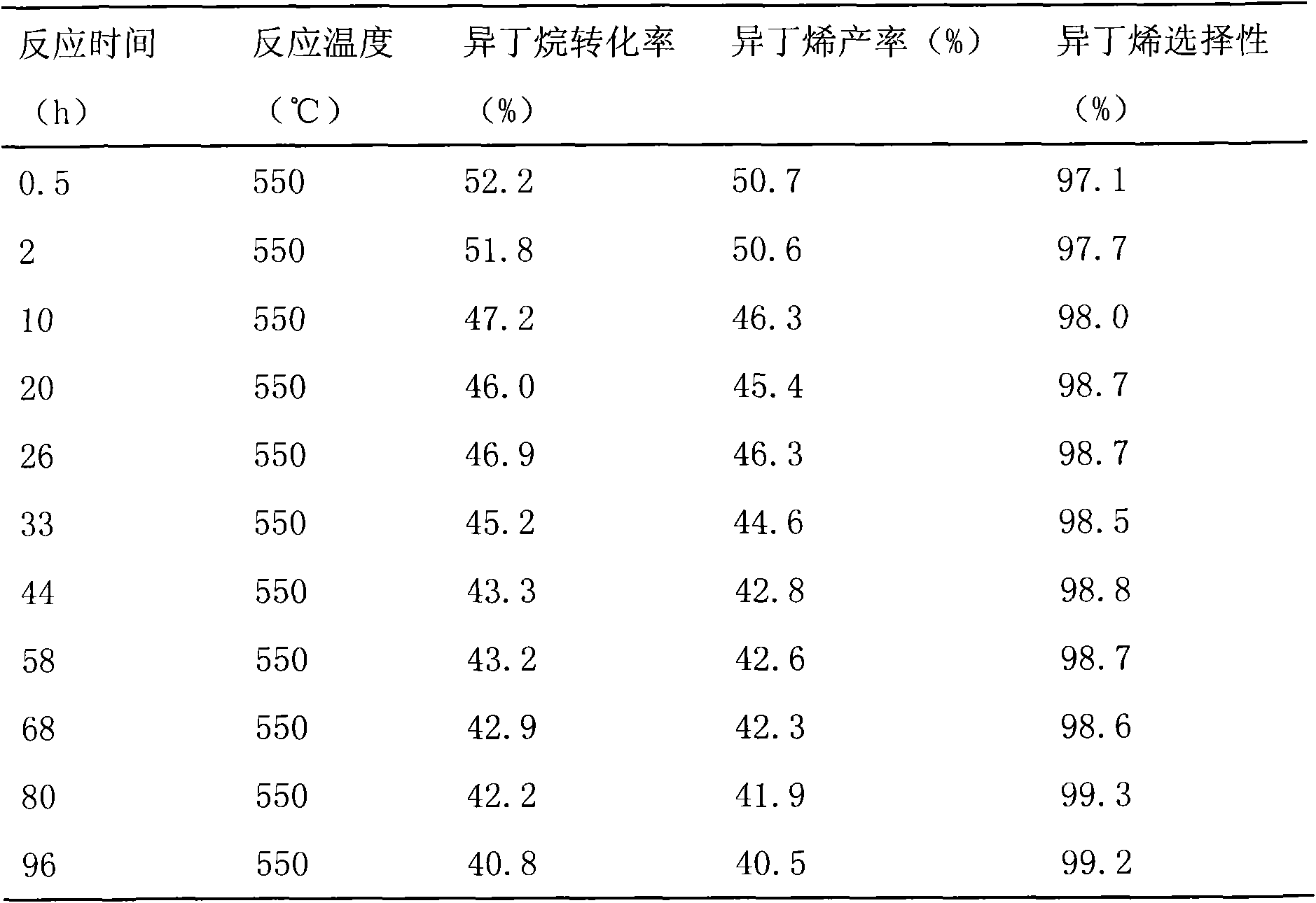

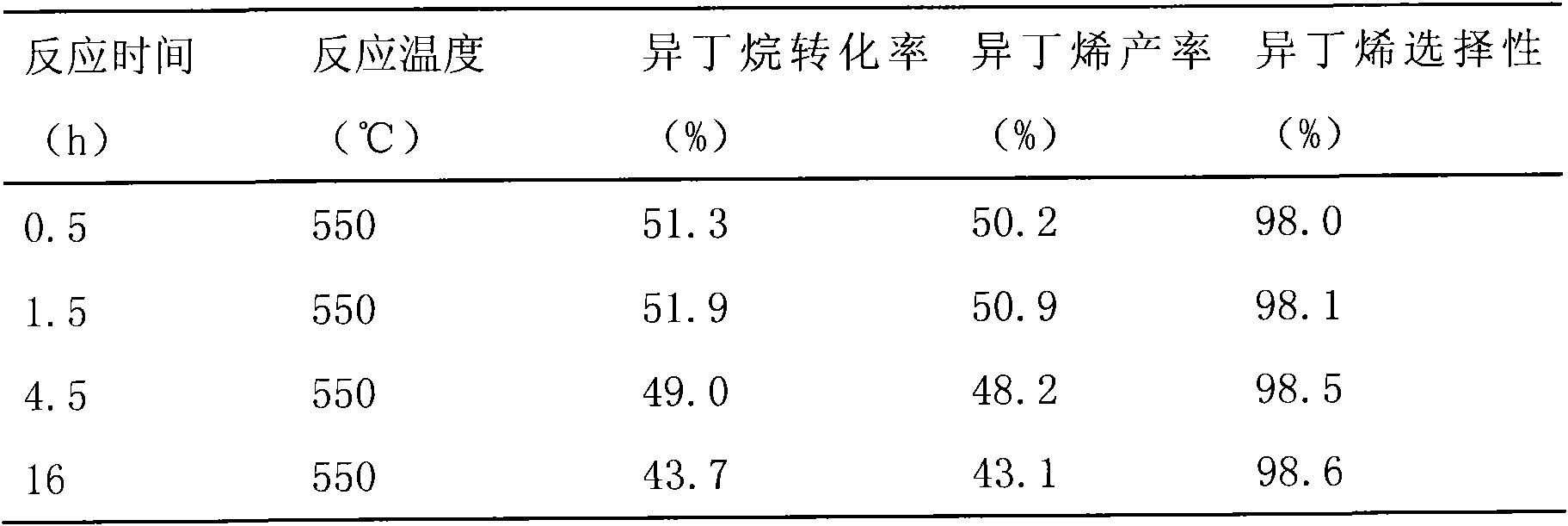

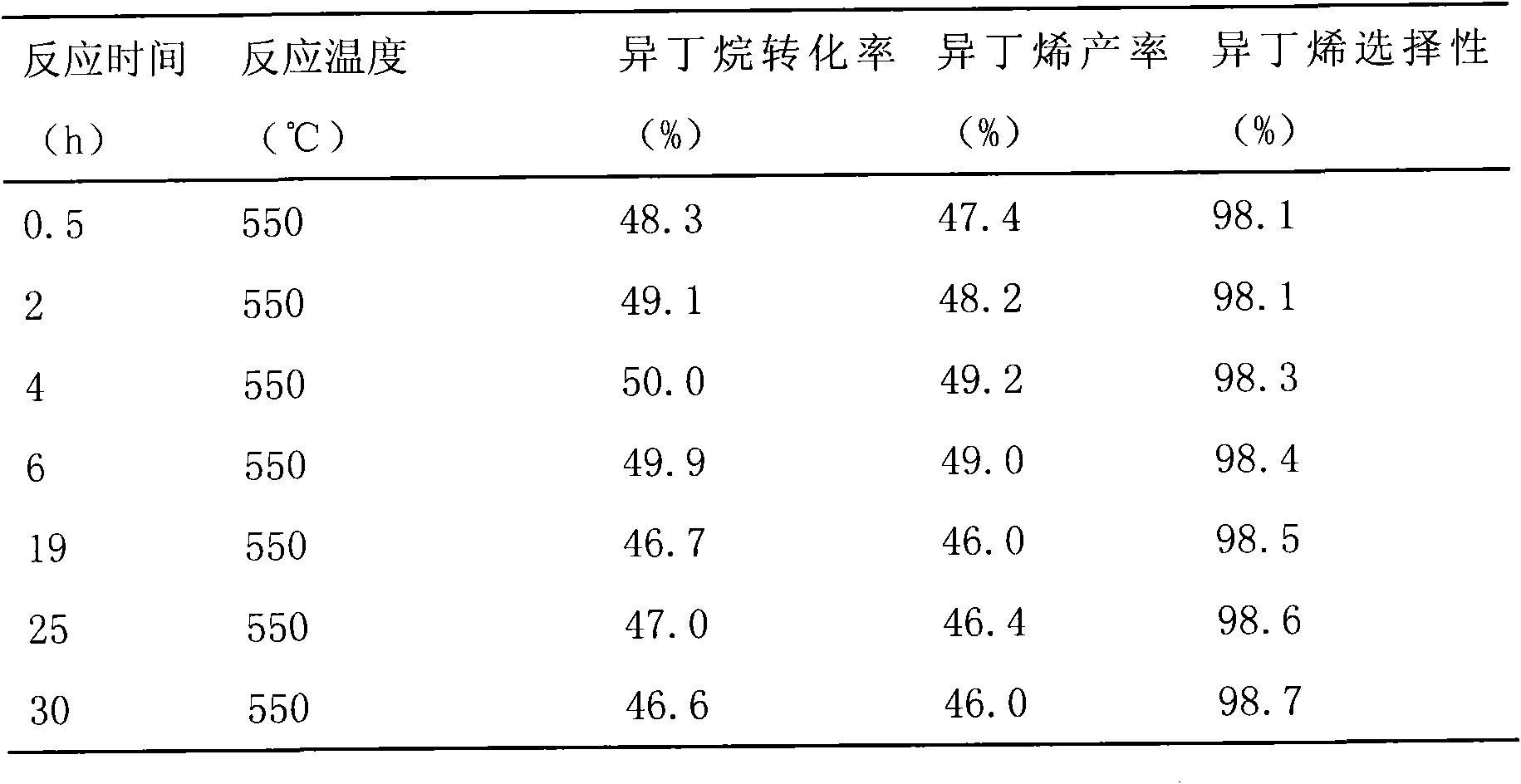

Catalyst for preparation of isobutene by isobutene dehydrogenation as well as preparation process and dehydrogenation process thereof

InactiveCN102000593AExtended operating cycleExtend your lifePhysical/chemical process catalystsHydrocarbonsOxideIsobutane

The invention relates to a catalyst for the preparation of isobutene by isobutene dehydrogenation as well as a preparation process and a dehydrogenation process thereof. In the catalyst, a heat-resistant oxide is used as a carrier, a platinum group metal element is used as a main catalyst, an IVA group metal element is used as a first assistant, an alkali metal element is used as a second assistant, and a halogen element is used as a modifier. The catalyst is prepared by loading a solution containing the active components onto the heat-resistant oxide carrier in one step by adopting an isopyknic immersion method, has higher isobutene conversion rate, better isobutene selectivity and favorable stability by using a mixture of hydrogen and water vapor as a diluent, and is suitable for the application in industrialized production.

Owner:BEIJING UNIV OF CHEM TECH +1

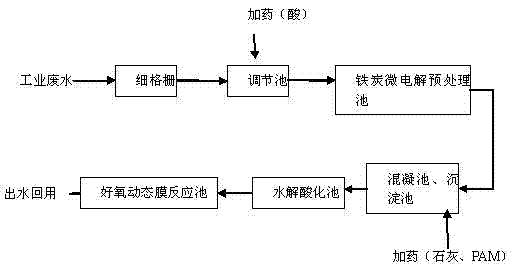

Iron-carbon micro-electrolysis-dynamic membrane wastewater deep treatment process

ActiveCN102372401AStable water outputEasy to handleMultistage water/sewage treatmentSuspended particlesWater use

The invention relates to an iron-carbon micro-electrolysis-dynamic membrane wastewater deep treatment process. The process comprises the following steps: pretreating pollutants in industrial wastewater by iron-carbon micro-electrolysis so as to remove partial pollutants and improve the biochemical performance of the wastewater; then, carrying out microorganism degradation by mainly using mixed liquids in a hydrolysis acidification pool and an aerobic dynamic membrane reaction pool so as to remove the pollutants; and finally, completing the solid-liquid separation and water discharge process of the mixed liquid with a dynamic membrane assembly. The invention aims at providing the iron-carbon micro-electrolysis-dynamic membrane wastewater deep treatment process which is simple in process flow and efficient; the process can be effectively used for removing the difficultly-degradable organic substances in the industrial wastewater and improving the biochemical performance of the wastewater, and has obvious decoloring effect and good solid-liquid separation effect; the effluent is clear and does not contain suspended particles; and the process is suitable for standard-reaching discharge and deep treatment of various industrial wastewaters (such as dyeing and printing wastewater, pharmaceutical wastewater, heavy metal wastewater, coking wastewater, paper-making wastewater and the like), and the index of the quality of the treated effluent can meet the water quality standard of reused water.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com