Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

769results about How to "Reduce coking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

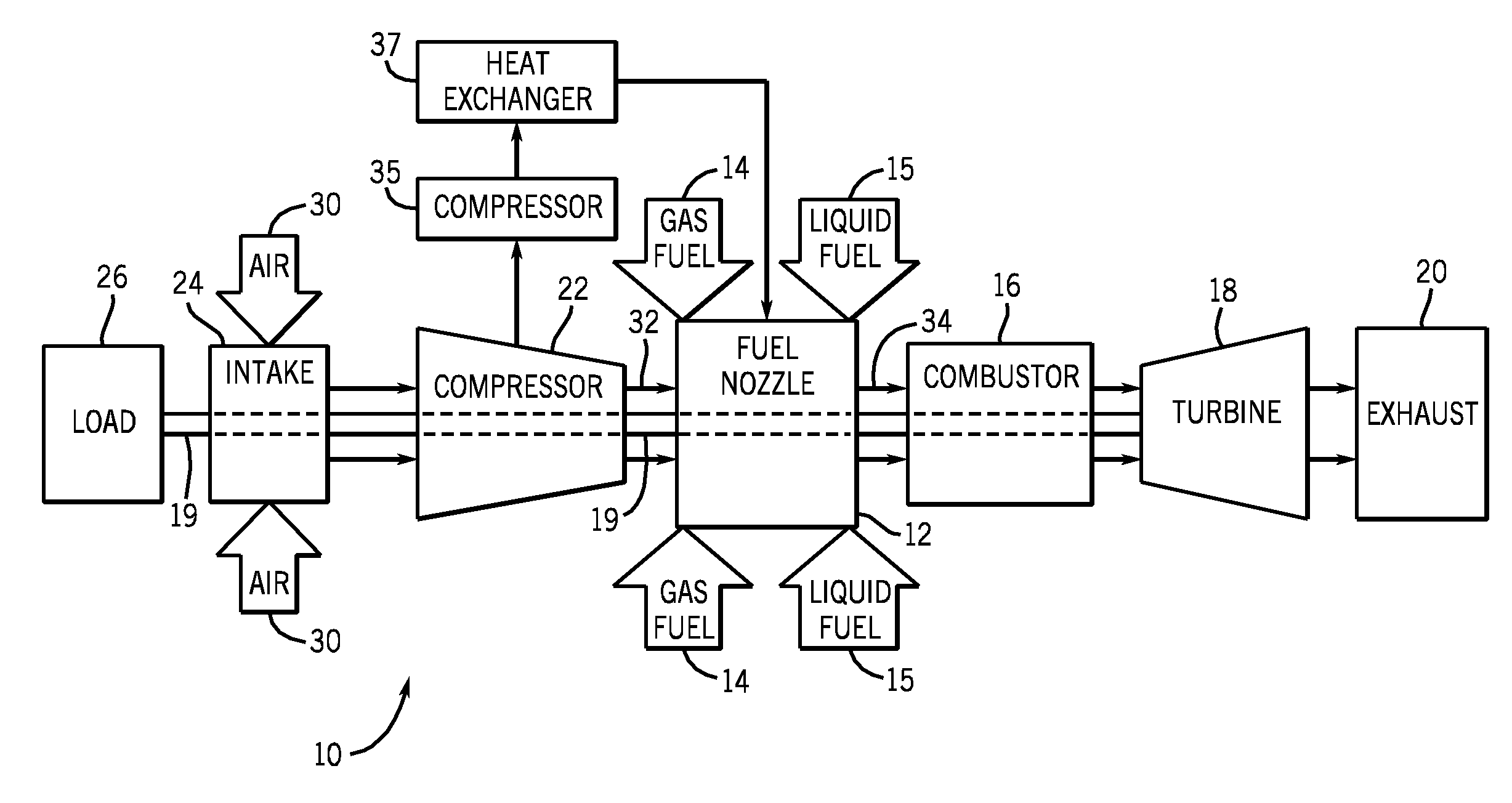

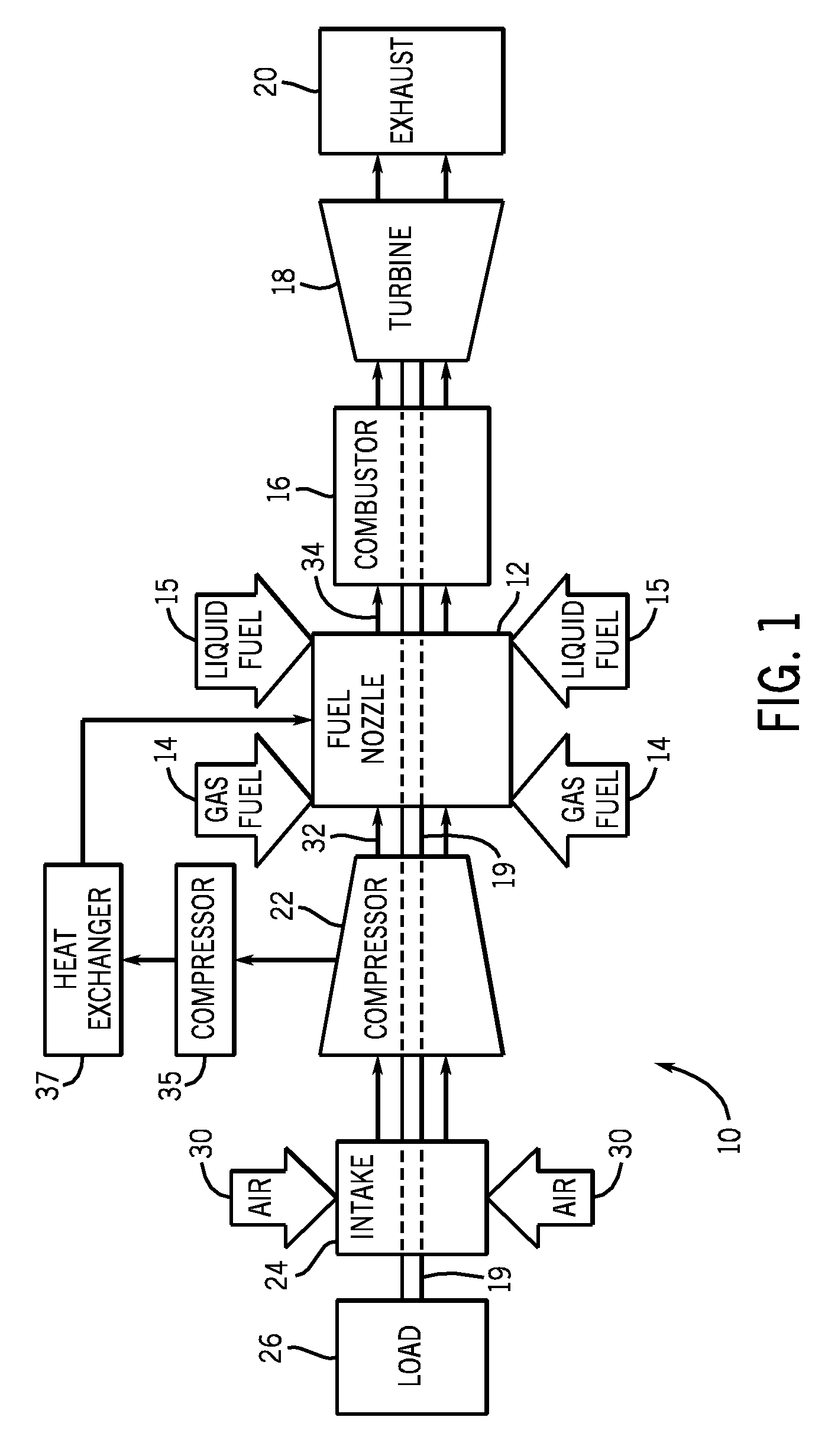

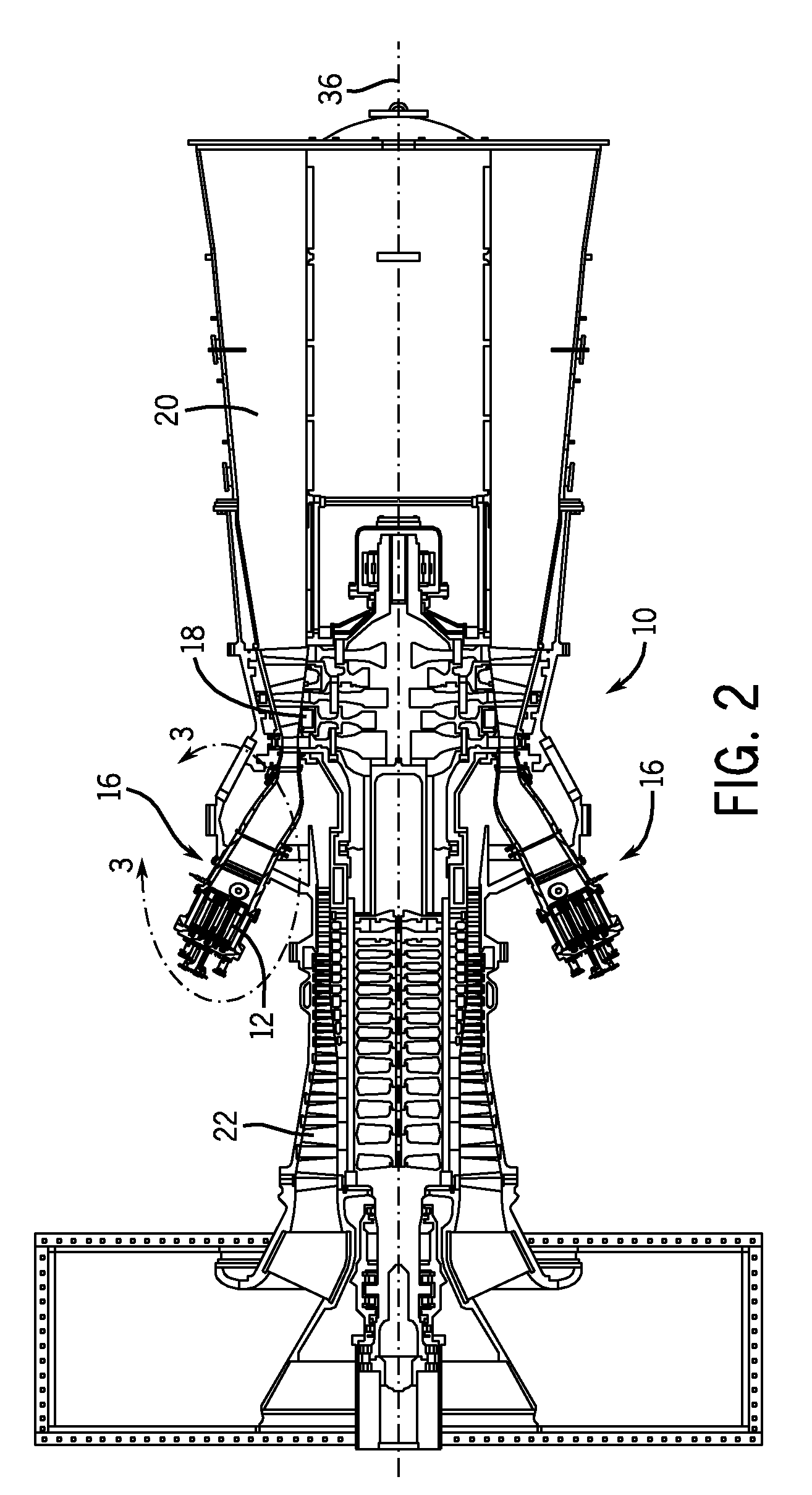

Apparatus for fuel injection in a turbine engine

InactiveUS20110016866A1Reduce cokingTurbine/propulsion fuel supply systemsContinuous combustion chamberLiquid fuelEngineering

In one embodiment, a system includes a fuel injector including a liquid fuel passage extending to a first port in a tip portion. The fuel injector also includes a selectable flow passage extending to a second port in the tip portion. The selectable flow passage surrounds the liquid fuel passage to the tip portion, the selectable flow passage is configured to selectively receive a gas fuel flow and an air flow, and the selectable flow passage has a flow temperature configured to cool a liquid fuel flowing through the liquid fuel passage to reduce coking.

Owner:GENERAL ELECTRIC CO

Straw densification briquetting fuel preparation method for biomass power generation and boiler combustion

InactiveCN101768494ARaise the ash melting pointImprove combustion effectBiofuelsSolid fuelsSolid fuelPotassium ions

The invention provides a straw densification briquetting fuel (SDBF) preparation method for biomass power generation and boiler combustion, solving problems of low ash fusion point, easily coking, serious corrosion to boilers and the like of direct straw combustion. In the invention, straw is pre-processed through steam explosion or with diluted acid then is subjected to enzyme hydrolysis with cellulose, and the enzyme hydrolysis residue is briquetted to be used as fuel for biomass power generation or boiler combustion. The pre-processed and enzyme-hydrolysis straw can be briquetted easily; cellulose and hemicellulose in the pre-processed and enzyme-hydrolysis straw are removed basically, lignin content and calorific value increase, potassium ion, sodion and chloridion are removed, thereby improving ash fusion point of straw, reducing coking and boiler corrosion in combustion process, and improving combustion performance of straw. The straw solid fuel prepared by the invention can be used as fuel for common domestic boilers. Sugar produced by enzymolysis can be used as a fermentation carbon source for large-amount fermented products, so as to improve comprehensive utilization value of straw.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

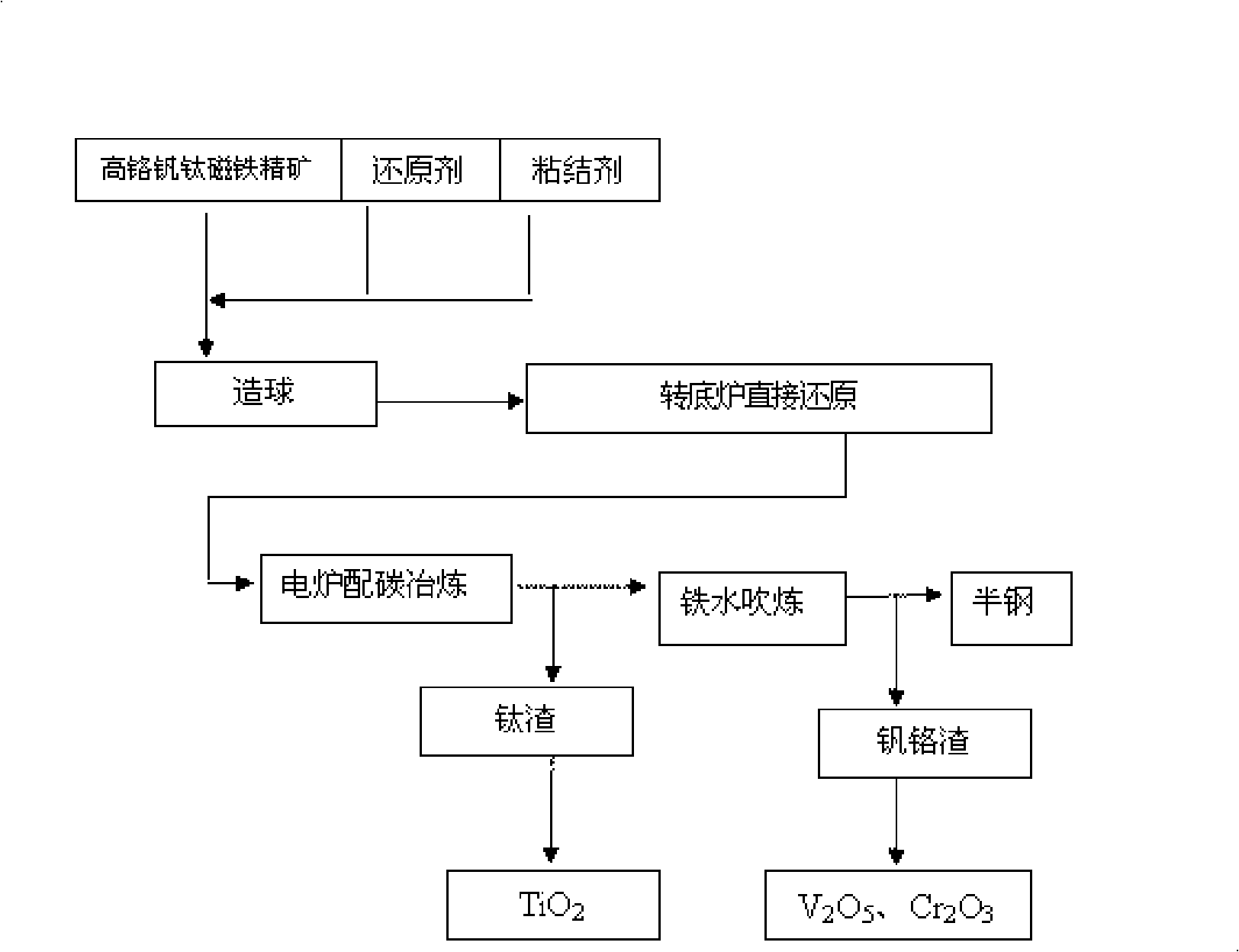

Method for extracting multi-metallic element from high chromium vanadium titanium octahedral iron ore

The invention discloses a method for extracting various metal elements from high chromium-vanadium titanomagnetite. The method is characterized in that high chromium-vanadium titanomagnetite concentrate is put in a rotary hearth furnace for direct reduction after feeding, briquetting and drying; during the reduction process, metallized pellets are obtained through the adjustment and the control of technological parameters such as reduction temperature, reducing atmosphere, etc., wherein, the metallization rate of the metallized pellets is more than 90 percent, and the carbon residue content thereof is 0.5 to 4.5 percent. The obtained metallized pellets are put in an electric stove, and then carbon-containing reducing agent that is pellets for smelting, wherein, the weight of the carbon-containing reducing agent is 8 to 35 percent of the metallized pellets; therefore, titanium slag and vanadium-chromium hot metal are obtained; the vanadium-chromium hot metal is performed through converting by the control of time and temperature under certain oxygen tension to obtain vanadium-chromium slag and semisteel. The titanium slag is processed through the existing technology of a sulfuric acid method or a chlorination method, the vanadium-chromium slag is processed according to certain working procedures, and then TiO2, V2O5 and Cr2O3 are finally extracted and obtained.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +1

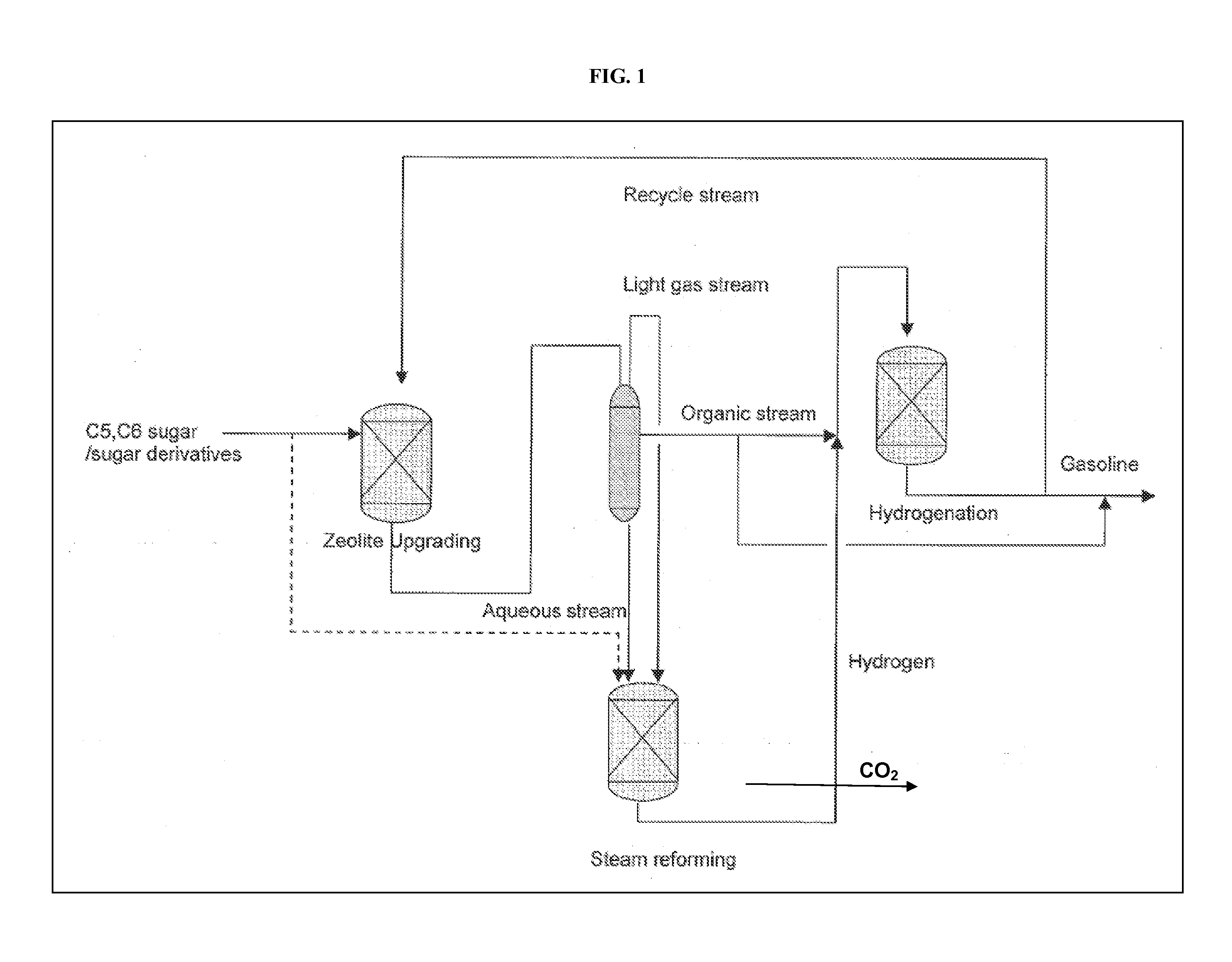

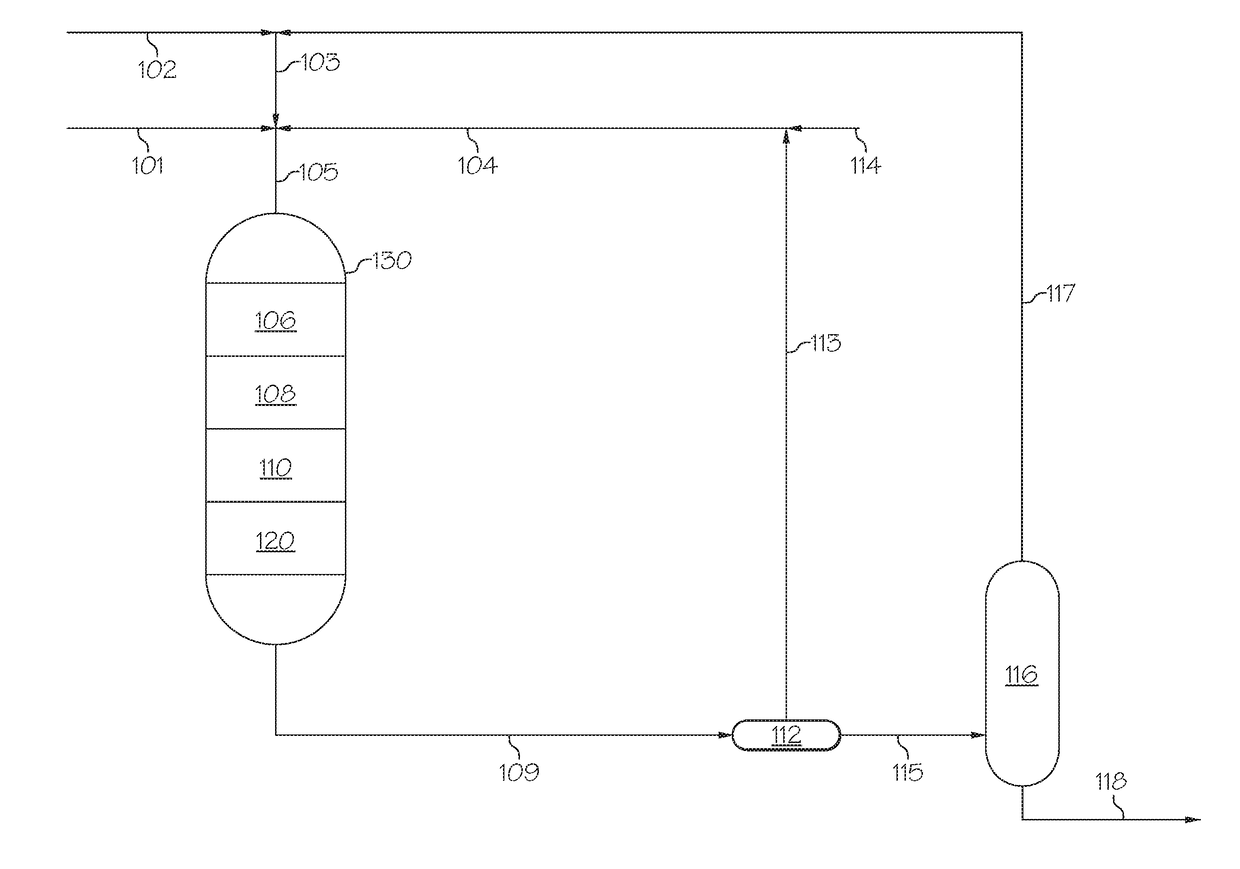

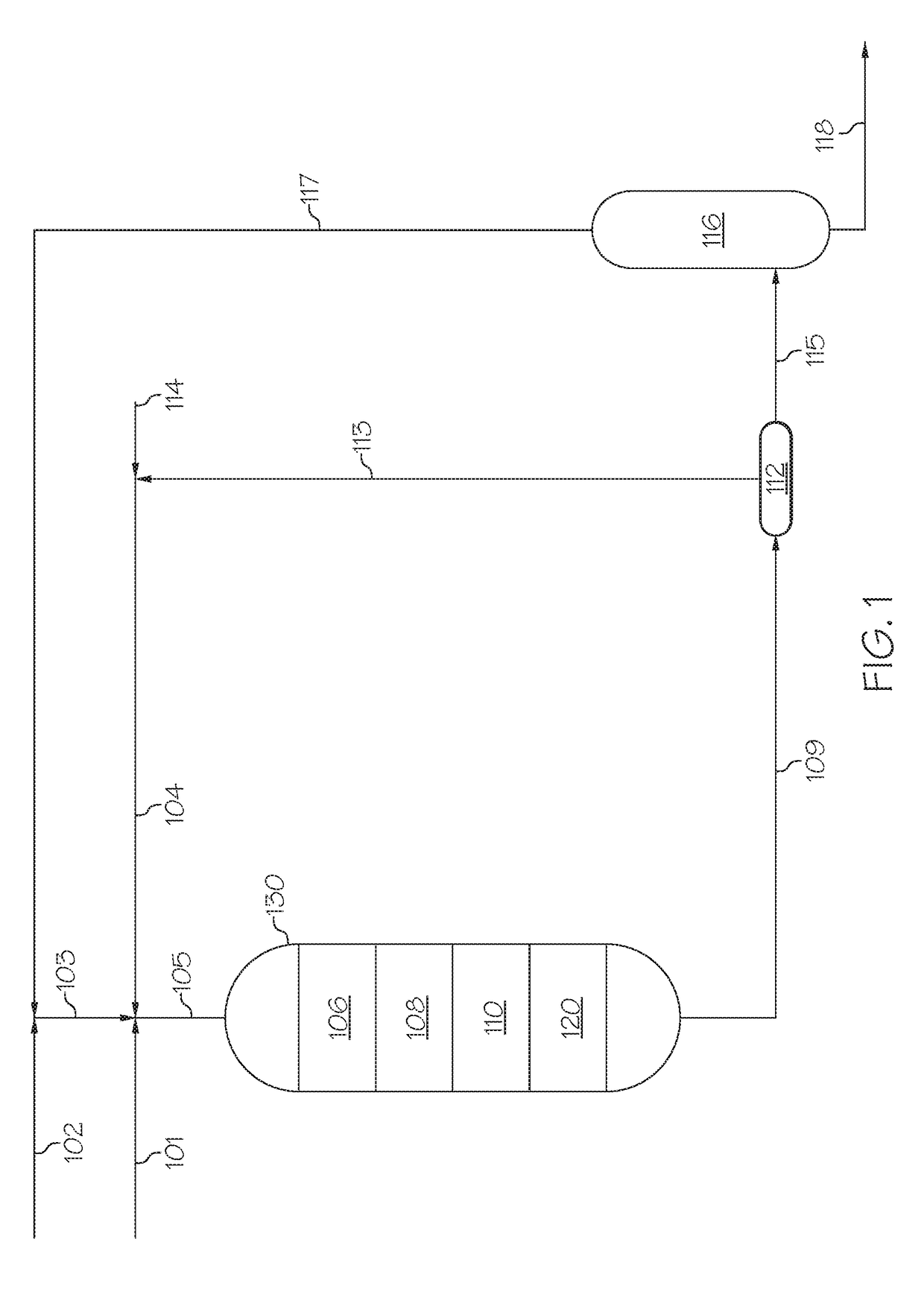

Carbohydrates upgrading and hydrotreating to hydrocarbons

ActiveUS20110263916A1Easy to convertReduced liquid yieldHydrogenBiofuelsCarbon footprintLiquid hydrocarbons

Technologies to convert biomass to liquid hydrocarbon fuels are currently being developed to decrease our carbon footprint and increase use of renewable fuels. Since sugars / sugar derivatives from biomass have high oxygen content and low hydrogen content, coke becomes an issue during zeolite upgrading to liquid hydrocarbon fuels. A process was designed to reduce the coke by co-feeding sugars / sugar derivatives with a saturated recycle stream containing hydrogenated products.

Owner:PHILLIPS 66 CO

Polyester POY spinning finish and production method thereof

The invention discloses a polyester POY spinning finish, comprising 81-88% of lubricating agent, 3-5% of emulsifying agent, 4-7% of tow collecting agent, 3-5% of antistatic agent and 2-4% of additive by weight. The invention also discloses a production method of the polyester POY spinning finish. The product not only can endow the fibers with good processability but also is environment-friendly, overcomes the phenomenon that the finish corrodes equipment and can ideally solve the problem of easy cohesion on guide rolls during apparent cohesion and reduce fluff and broken yarns.

Owner:绍兴市上虞皇马化学有限公司

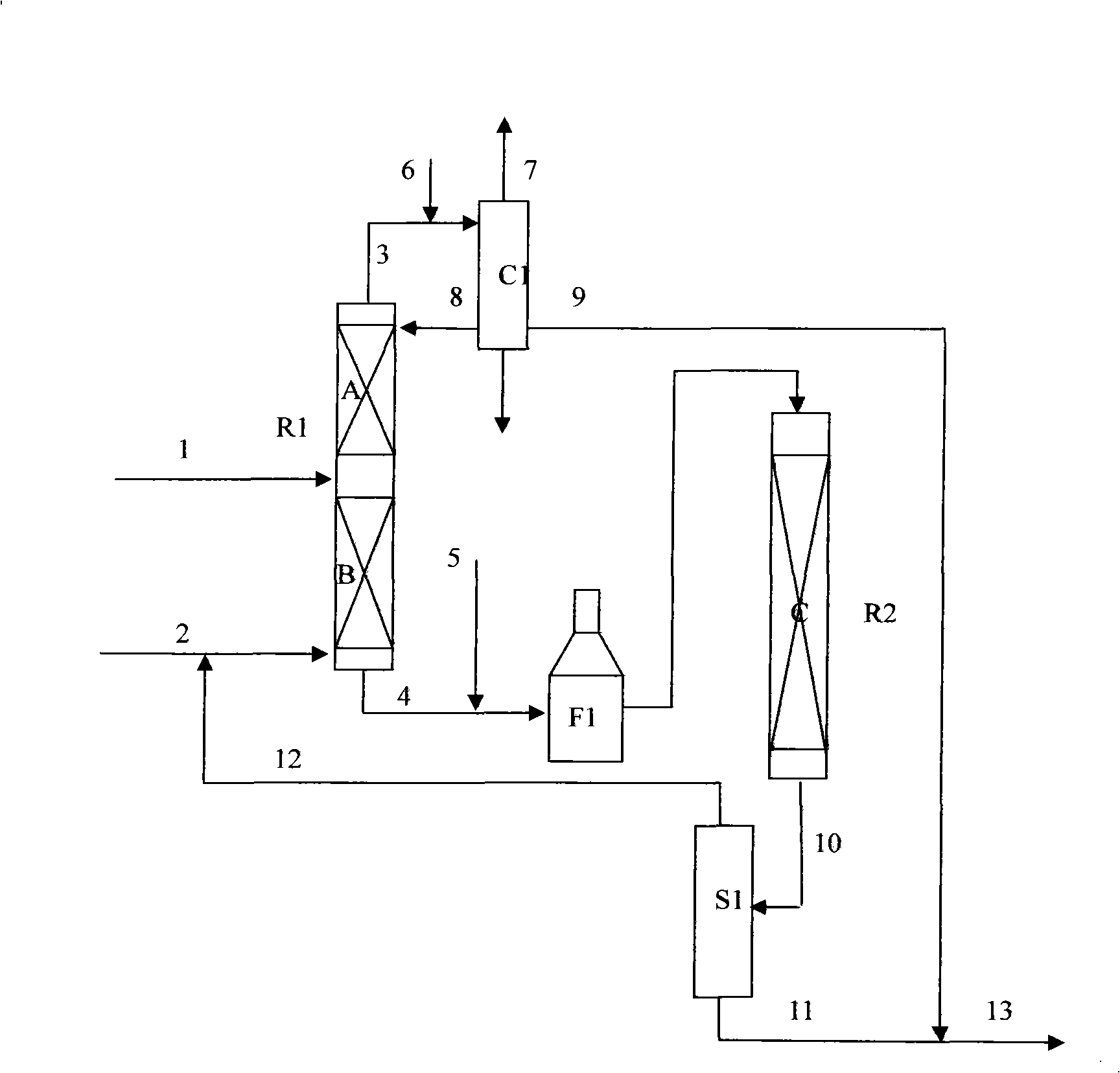

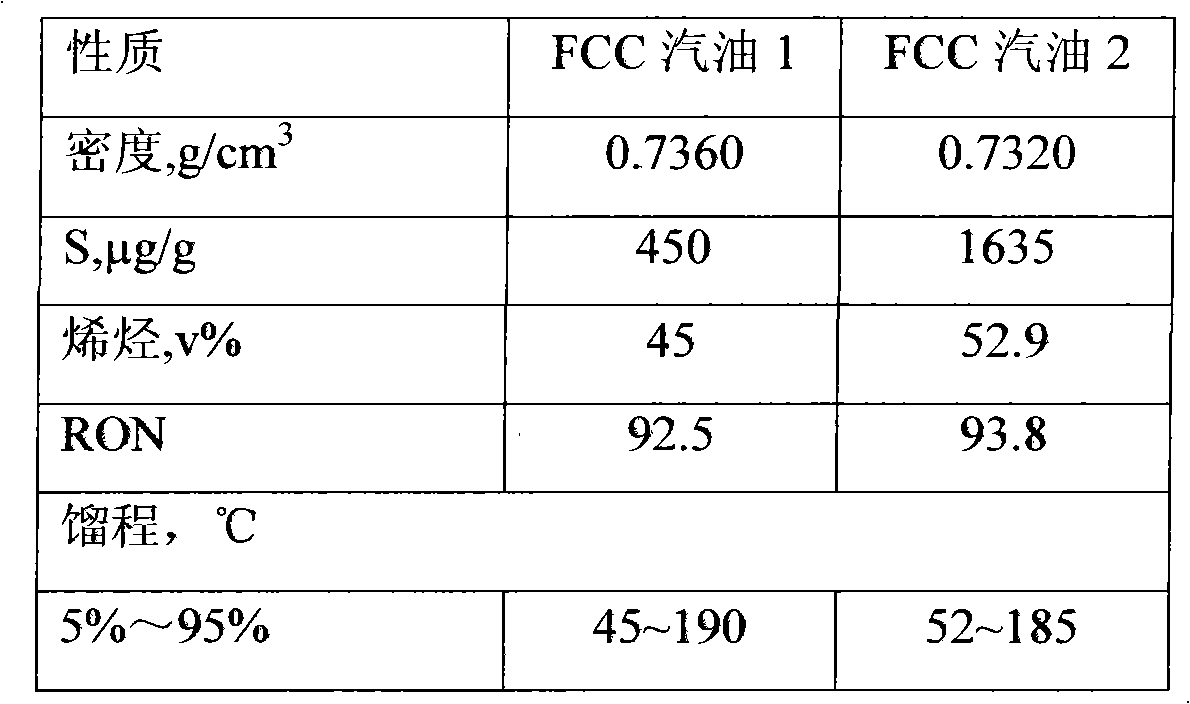

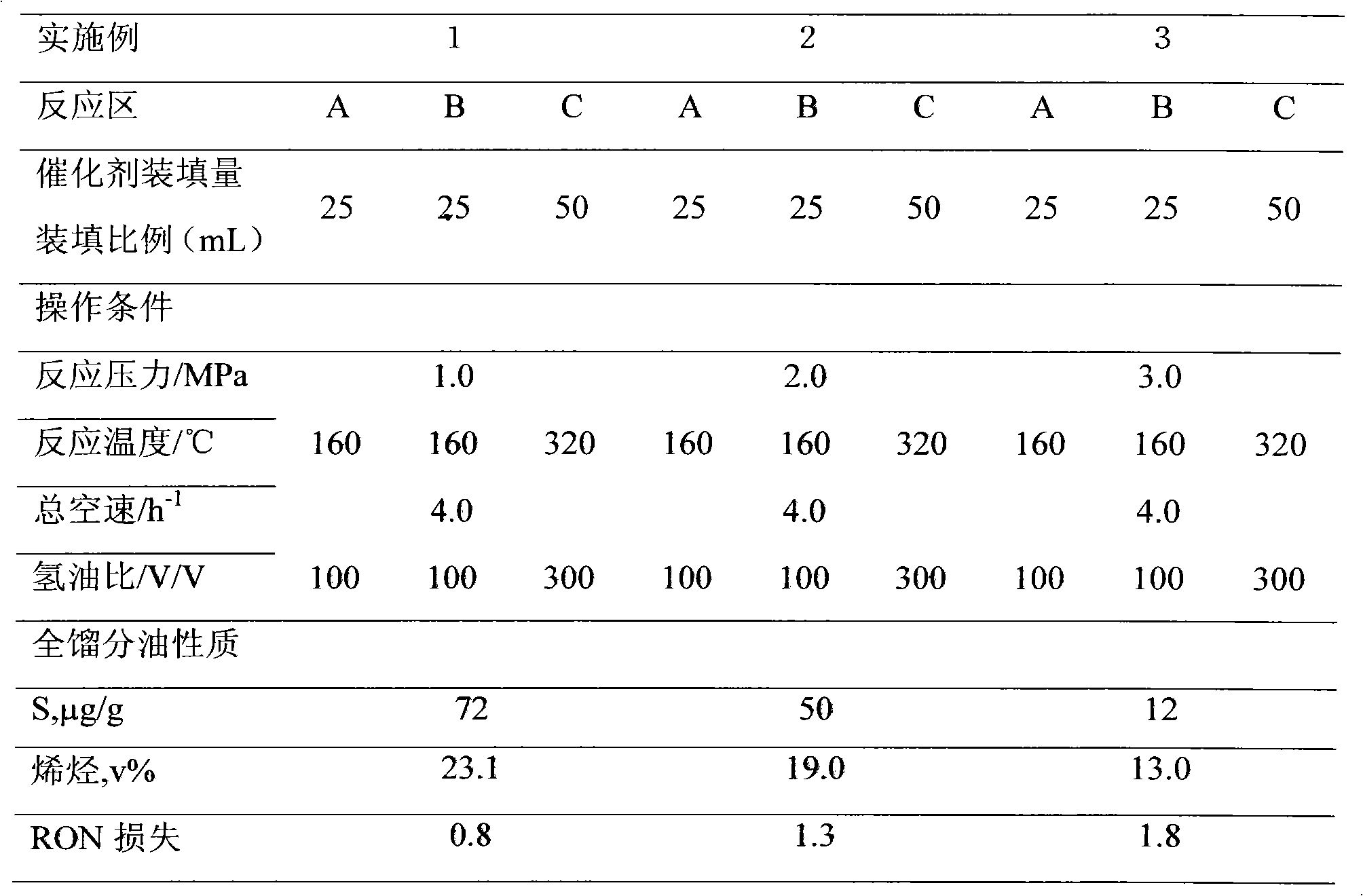

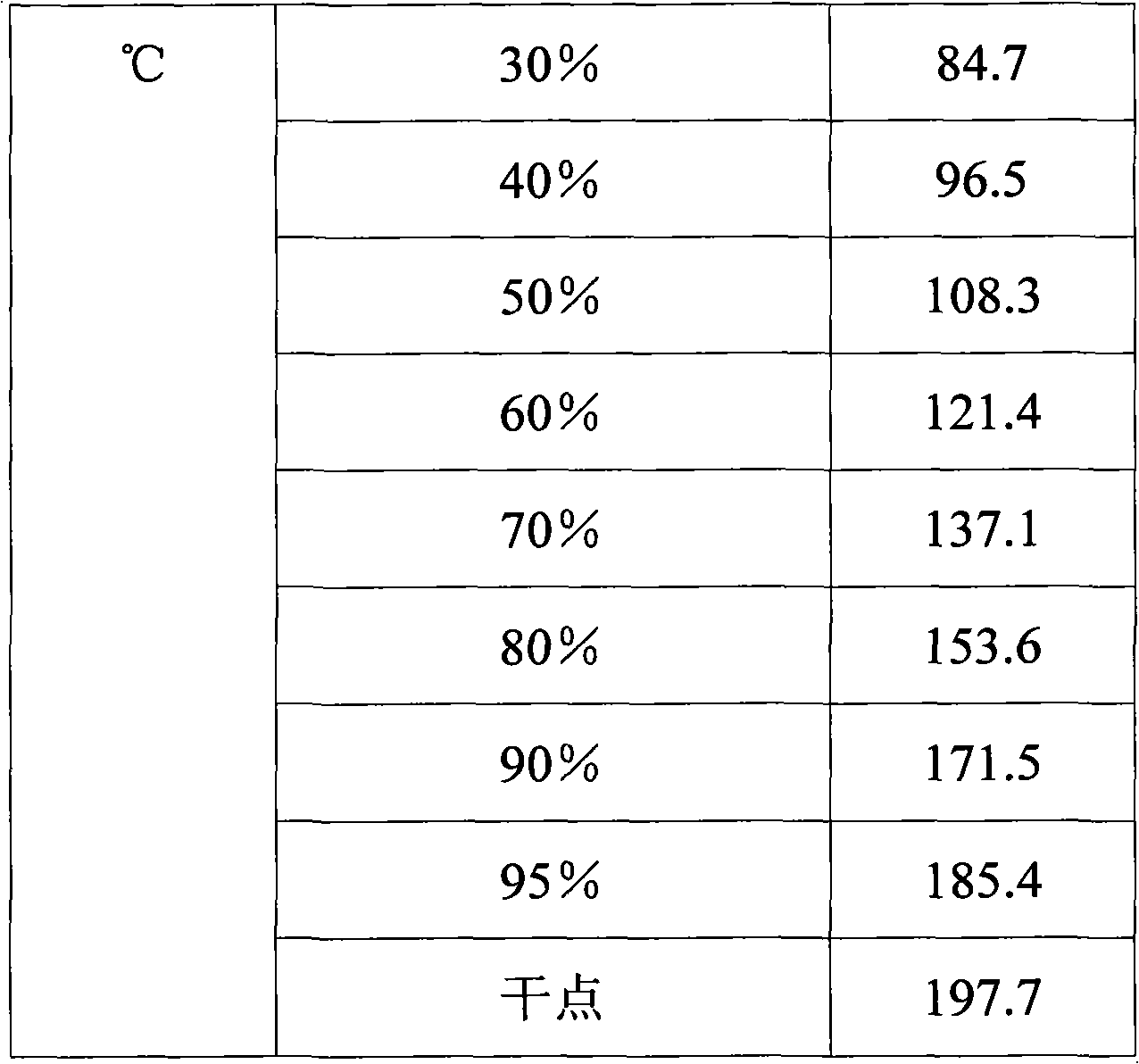

Hydrotreating process for light hydrocarbons

ActiveCN101343563AReduce saturationReduce cokingTreatment with hydrotreatment processesIsomerizationGas phase

The invention discloses a lightweight hydrocarbon hydrogenising method, which adopts a first stage countercurrent hydrogenising reactor and a conventional co-current hydrogenising reactor connected in series. The raw material enters into a flash evaporation area of the countercurrent hydrogenising reactor at a lower temperature, gas-phase hydrocarbon flows upwards and performs a reaction of diene and mercaptan producing sulfide and a diene hydrogenising reaction at the upper part of the countercurrent hydrogenising reactor, high boiling sulfide generated by the upper part reaction and liquid-phase hydrocarbon after the raw material flash evaporation flow downwards together, and an alkylation reaction of thiophene sulfur and olefin is generated; Hydrogen enters at the bottom of the countercurrent hydrogenising reactor and flows upwards. Liquid phase discharged at the bottom of the countercurrent hydrogenising reactor and new hydrogen are mixed and enter into the co-current hydrogenising reactor to perform the reactions, such as deep hydrodesulfurization, selective cracking or isomerization and the like after being heated. The method has the advantages that the technological process is simple, the desulphurization effect is good, the octane value loss is low, the product yield is high, and the required equipment is few. The method is mainly used for the secondary processing the poor-quality gasoline, namely, the upgrading process of catalytic cracking gasoline, coking gasoline or thermal cracking gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving running period of hydrogenation plant for poor petroleum naphtha

ActiveCN101343566AReduce cokingLess investmentTreatment with hydrotreatment processesNaphthaNitrogen

The invention relates to a method for enhancing the running period of a poor-quality naphtha hydrogenising device. The invention adopts the method that a reactor is additionally arranged before a heating furnace, and the poor-quality naphtha first performs a selective diene hydrogenising and removing organosilicon compounds reaction at a lower reaction temperature, and then passes through a main reactor and performs a hydrogenising reaction to remove sulphur and nitrogen impurity and olefin saturation. Compared with the prior art, the method has the advantages that the process is simple, the heating furnace tube and the heat exchanger shell side coking are effectively alleviated and the organosilicon compounds are removed, and the running period of the device is prolonged. The method can be applied to various secondary processing naphtha hydrofining processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

System for preparing bio-oil and activated carbon by microwave pyrolysis

ActiveCN104560074AReduce cokingOvercome the gas-solid two-phase contact differenceCarbon compoundsDirect heating destructive distillationActivated carbonGas pipeline

The invention discloses a system for preparing bio-oil and activated carbon by microwave pyrolysis. The system comprises a microwave pyrolysis reactor, a cyclone separator, a condenser, a coke storage bin, a microwave activation reactor, a gas burner, an activated carbon cooling tower and a nitrogen generator, wherein the microwave pyrolysis reactor is connected with the cyclone separator through a pipeline; a gas outlet in the top of the cyclone separator is connected with the condenser; the bottom of the cyclone separator is connected with the coke storage bin; the bottom of the coke storage bin is connected with a material inlet of the microwave activation reactor; a material outlet of the microwave activation reactor is connected with a feed opening of the activated carbon cooling tower through a pipeline; a gas outlet of the microwave activation reactor is connected with a feed pipeline of the gas burner through a pipeline; a gas outlet of the condenser is connected with the gas burner through a pipeline; a gas outlet pipeline of the gas burner is divided into two paths, wherein one path is connected with the microwave activation reactor, and the other path is connected with a fluidizing gas and spouting gas pipeline of the microwave pyrolysis reactor; a gas inlet of the activated carbon cooling tower is connected with a nitrogen pipeline; a gas outlet of the activated carbon cooling tower is merged into the fluidizing gas and spouting gas pipeline through a pipeline; a material outlet is formed in the bottom of the activated carbon cooling tower. The system is high in biomass pyrolysis rate, can obtain high-yield bio-oil and high-quality activated carbon products, and has a favorable application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

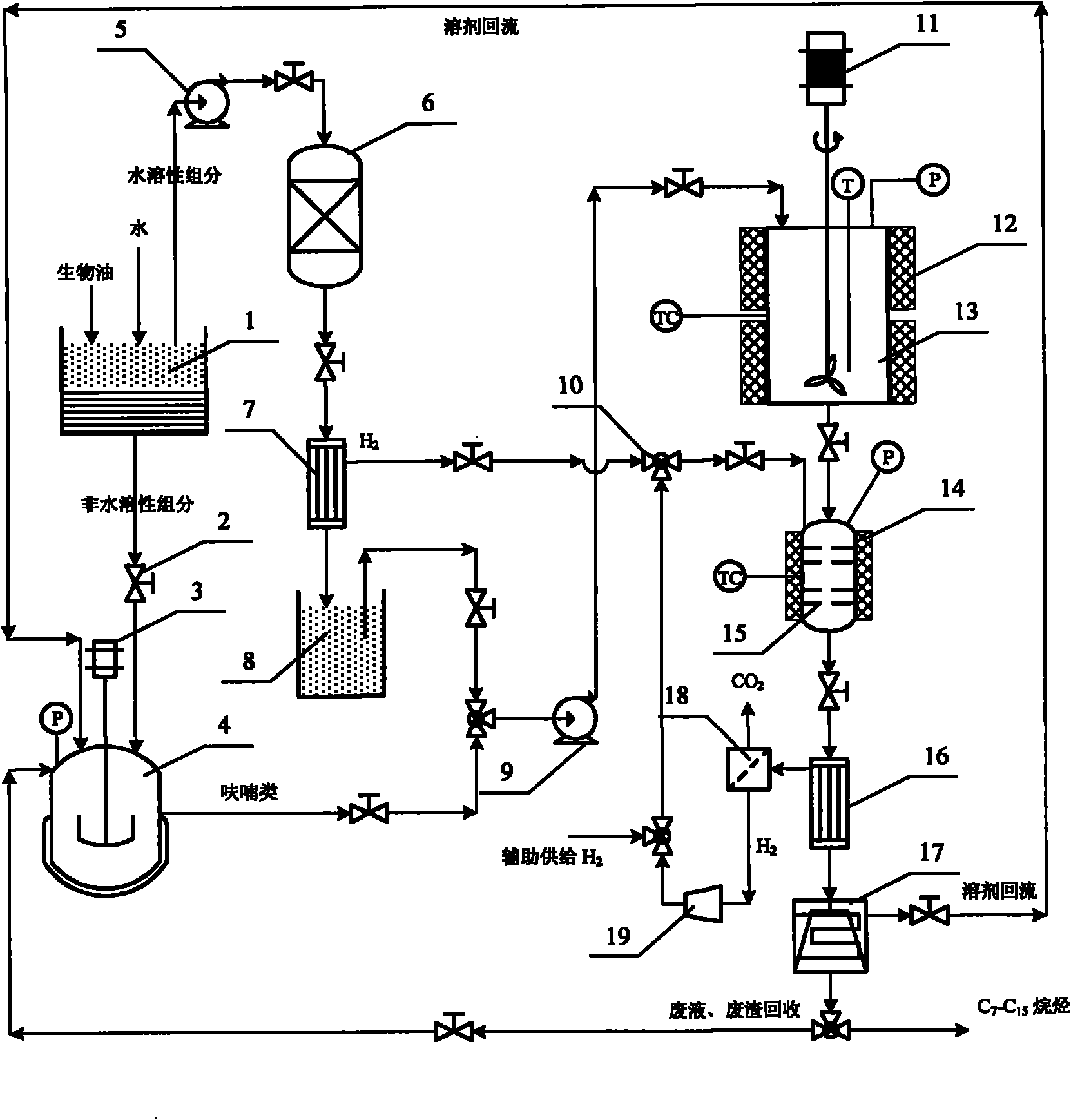

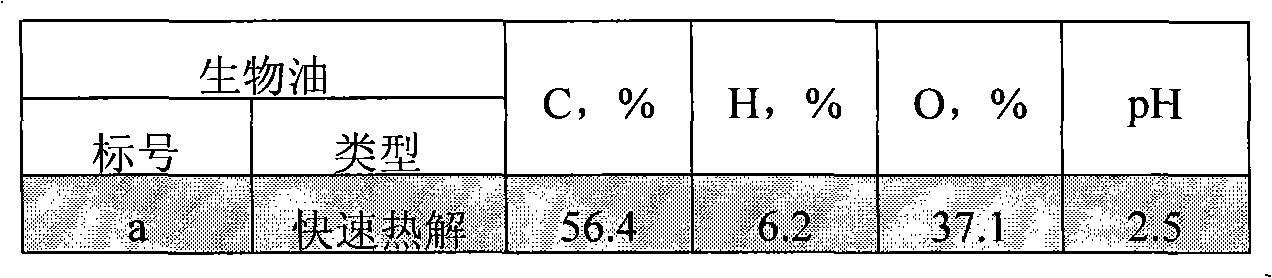

Method for preparing liquid alkane fuel by upgrading bio-oil in aqueous phase catalytic mode

ActiveCN101870881AHigh recovery rateReduce latent heat loss of vaporizationLiquid hydrocarbon mixture productionBio-feedstockAlkaneDesorption

The invention provides a method for preparing liquid alkane fuel by upgrading bio-oil in an aqueous phase catalytic mode. The method comprises the following steps of: 1) pretreating the bio-oil to obtain a water-soluble component and a water-insoluble component; 2) performing a pressurized acid hydrolysis process on a furan compound of the water-insoluble component to prepare the furan compound; 3) performing a reforming and hydrogen production reaction on the water-soluble component; 4) mixing the furan compound with a liquid-phase product separated from the step 3) to perform an aldol condensation reaction to increase carbon chains; and 5) performing a hydrogenation and dehydration reaction on an aldol condensation product to obtain liquid linear alkane. The method has the advantages that: an upgrading process, which is performed in a double-phase system, can effectively contribute to the desorption of an intermediate product from the surface of a catalyst and the mass transfer of an upgraded product, and can reduce the risk of carbon deposition on the surface of the catalyst; the quality of oil obtained by the method is high; the energy density and the energy grade of the bio-oil are improved greatly; and the liquid alkane fuel can be obtained from all kinds of bio-oil so as to partially substitute for the conventional widely-used fossil gasoline and diesel oil fuel.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

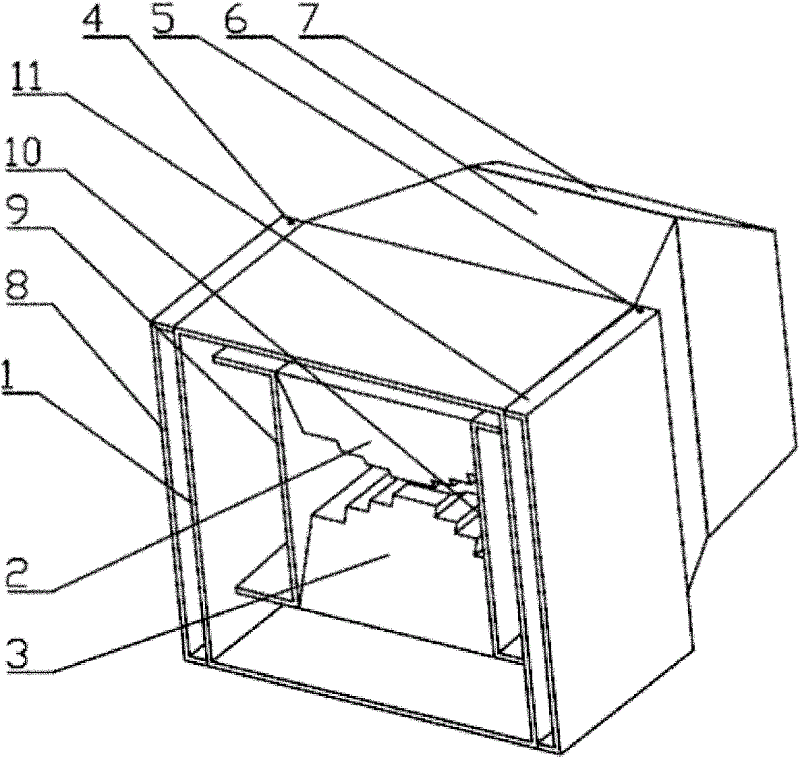

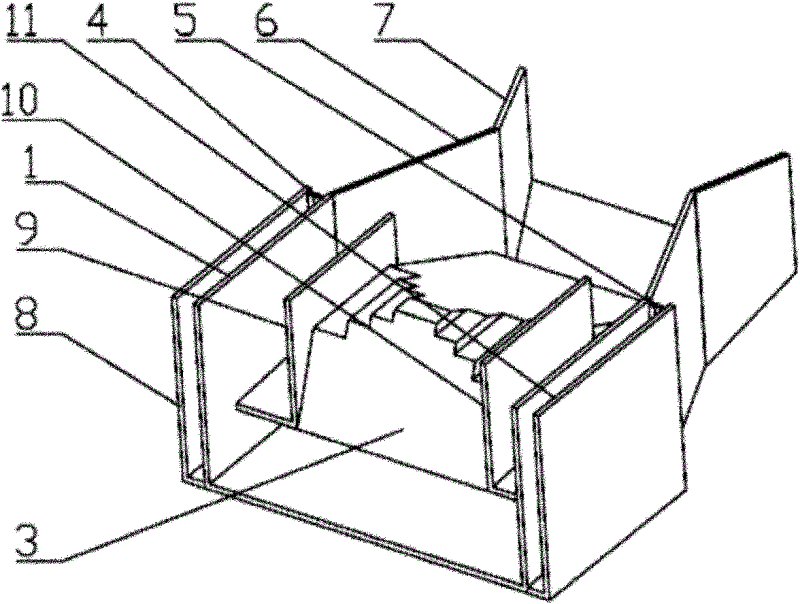

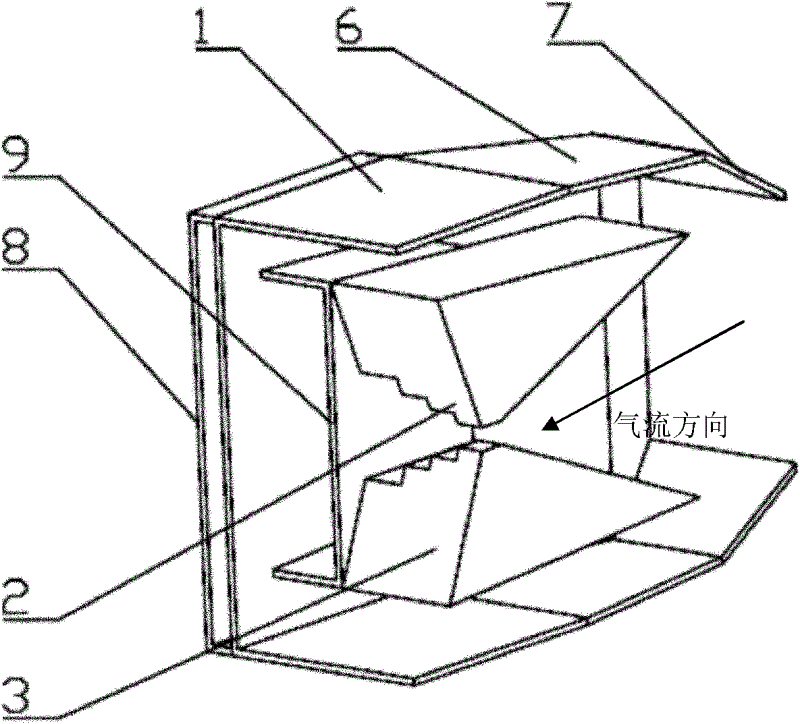

Pulverized coal decoupling combustor with low nitrogen oxide discharge and pulverized coal decoupling combustion method with low nitrogen oxide discharge

InactiveCN102620291ASeparation perimeter lengthSmall steering anglePulverulent fuel combustion burnersIndirect carbon-dioxide mitigationProcess engineeringCoal

The invention relates to a pulverized coal decoupling combustor with low nitrogen oxide discharge and a pulverized coal decoupling combustion method with low nitrogen oxide discharge. The method is implemented through the following two stages: a) stage 1, firstly separating mixed airflow of pulverized coal and air into a concentrated part and a dilute part by virtue of the pulverized coal decoupling combustor provided by the invention, igniting the concentrated pulverized coal airflow, then feeding the concentrated pulverized coal airflow into a hearth, and performing combined combustion on the concentrated pulverized coal airflow and the dilute pulverized coal airflow; and b) stage 2, mixing the mixed airflow with secondary air in the hearth, and fully combusting the pulverized coal semicoke generated in the stage 1 under conditions of rich oxygen and high temperature which is insufficient to generate thermal NOx, wherein in the stage 1, the pulverized coal is pyrolyzed, gasified and gas-fired under reducing atmosphere, volatile components are fully separated out, products of pyrolysis and gasification are utilized to convert fuel-type NOx into more stable N2. According to the invention, an integration design of pulverized coal condensation, stable combustion and low nitrogen oxide discharge can be realized, the equipment structure is compact, the pulverized coal condensation effect is good, the stable combustion capability is strong, and the potential of inhibiting NOx from generating is high.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

Process for preparing coal-based agglomerated activated carbon

The invention discloses a process for preparing coal-based agglomerated activated carbon. The process has the following beneficial effects: the non-caking coal produced in the wide ditches is taken as a main raw material; the special caking coal type, namely gas-fat coal, is blended in the coal blending procedure; furthermore, the oxidation procedure is added in the process; the process parameters such as pulverized coal particle distribution, forming pressure, coal activation temperature and time and the like in the general production process are adjusted; at the same time, the slow carbonization technology is used instead of the traditional rapid carbonization procedure; and oxygen-enriched air is fed into activation equipment. The coal-based activated carbon prepared by the process can ensure the product strength and bulk density on the basis of satisfying the iodine adsorption of the activated carbon and is better in industrial application value.

Owner:SHENHUA XINJIANG ENERGY

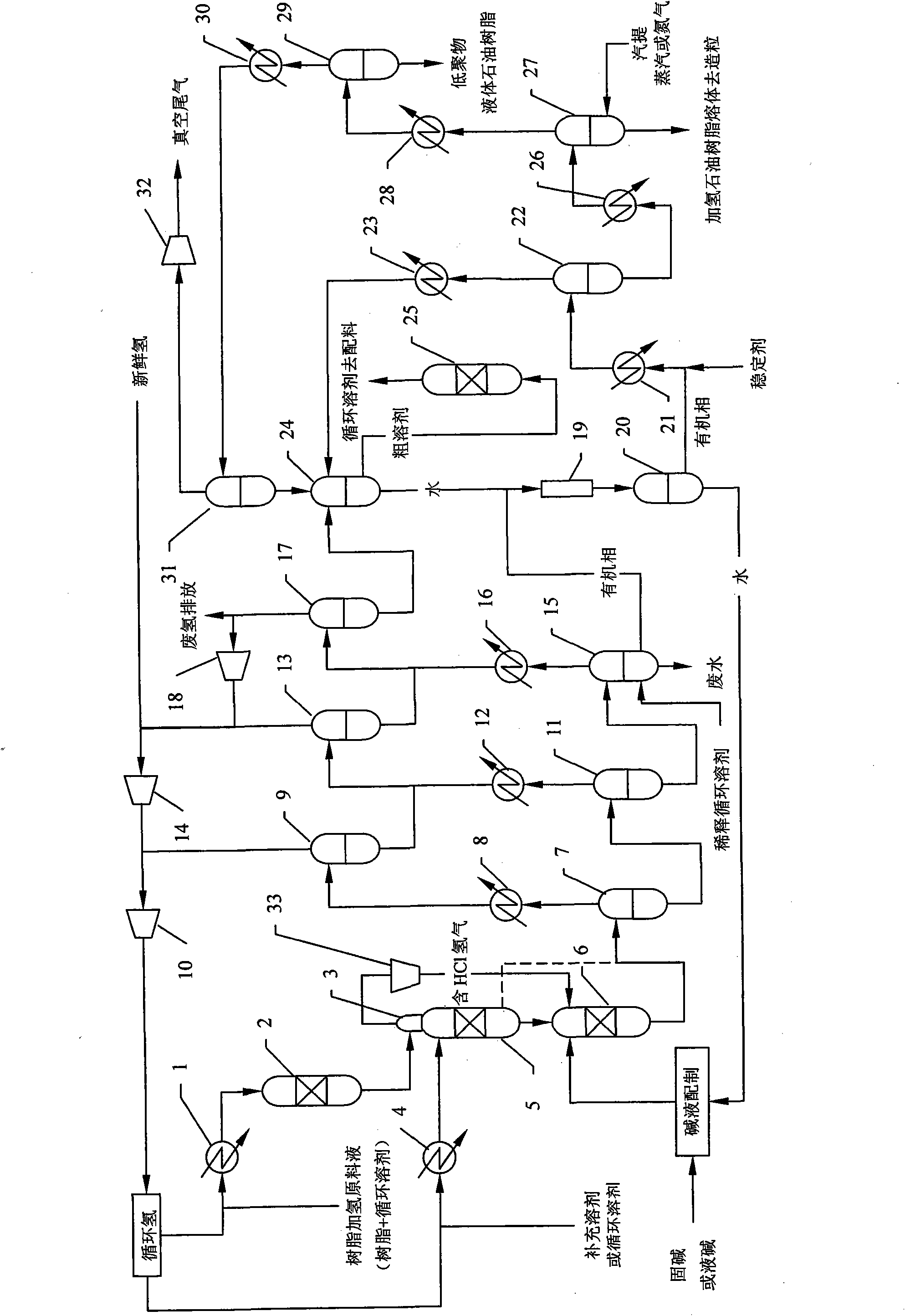

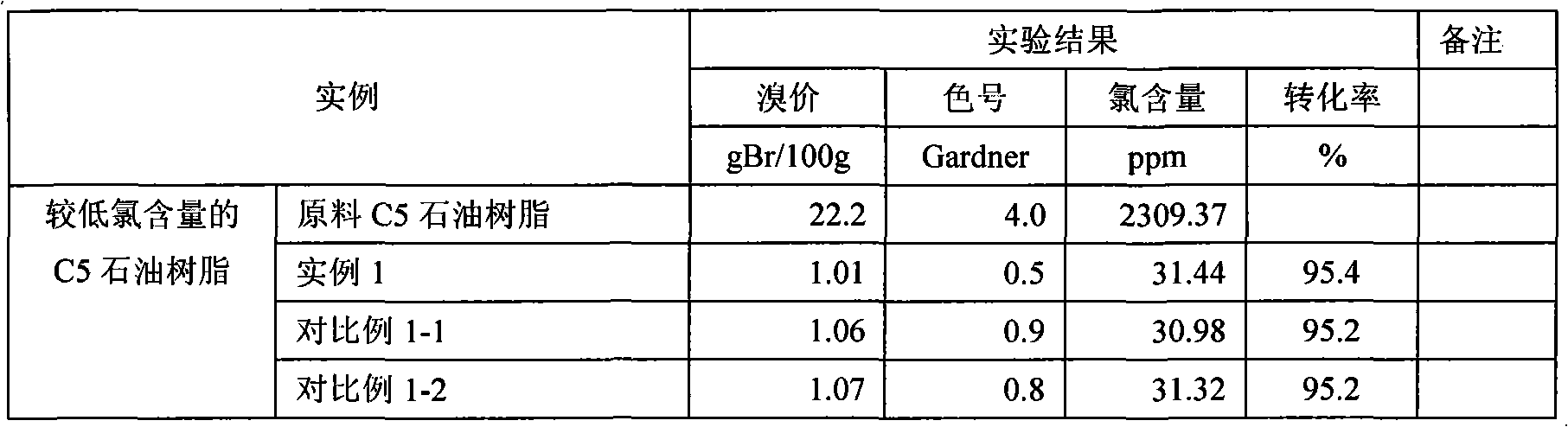

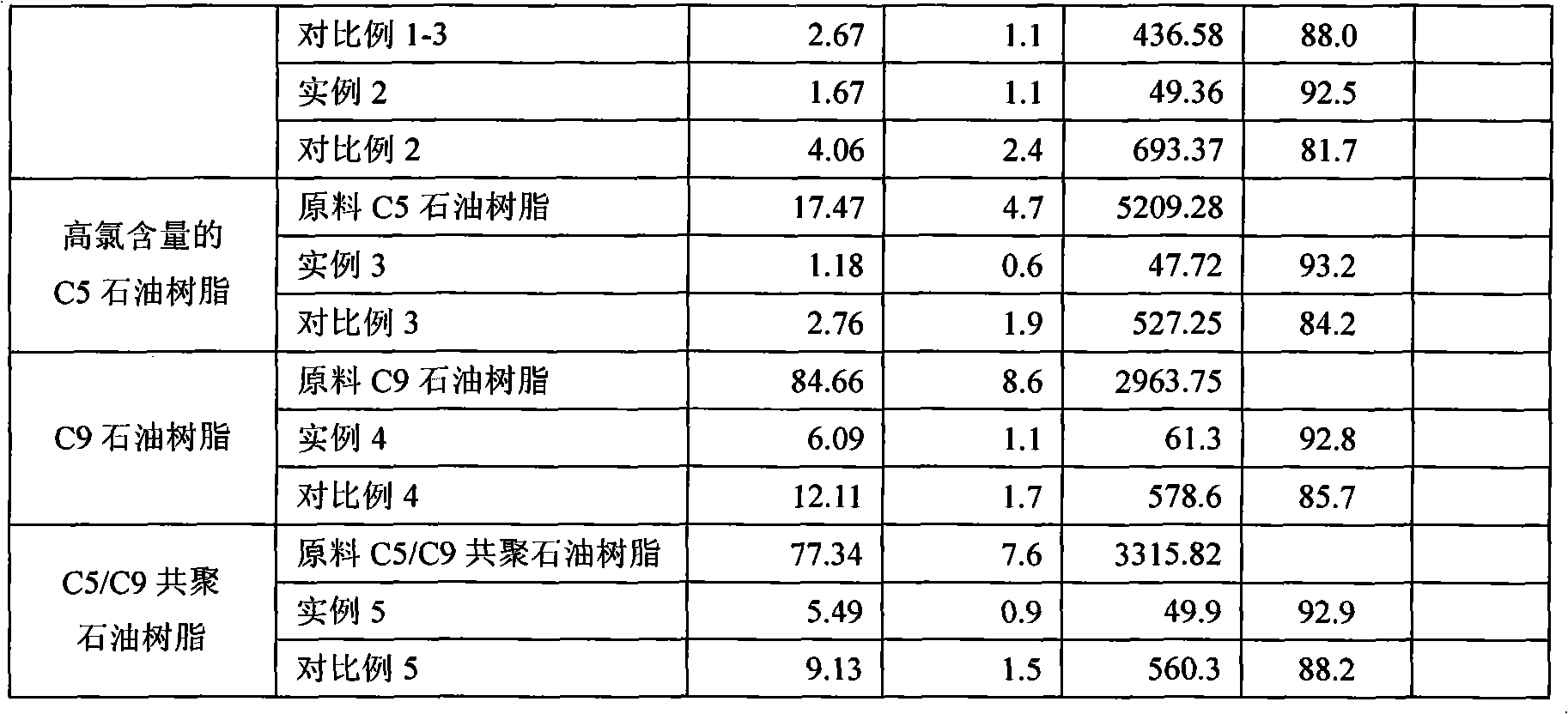

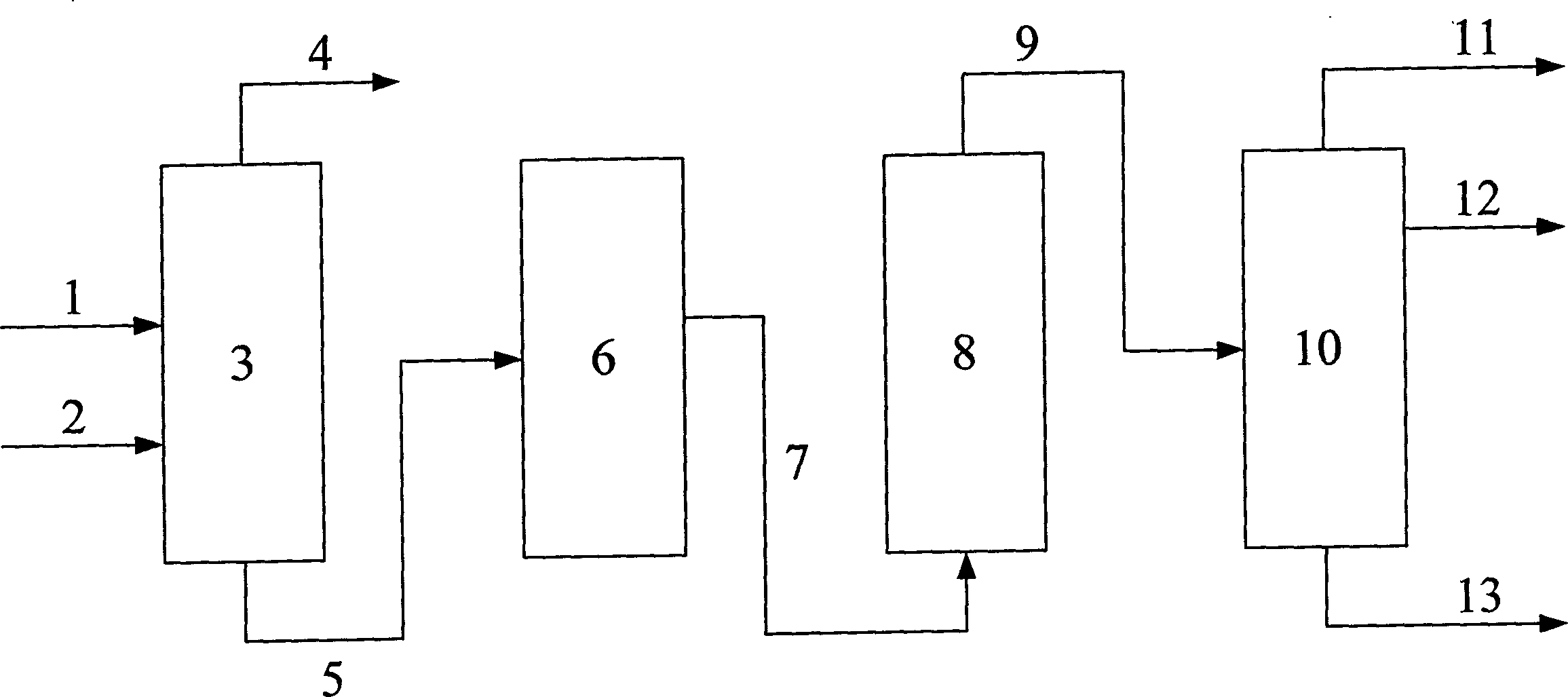

Industrial manufacture method for hydrogenated petroleum resin

ActiveCN102382259ASimplify the caustic cleaning processReduce corrosionPetroleum resinHydrogenation reaction

The invention relates to an industrial manufacture method for hydrogenated petroleum resin, which comprises the following steps of: generating hydrogenation reaction on petroleum resin which is obtained by polymerizing cracking C5 and C9 fractions under the proper condition of the existence of hydrogenation catalyst and solvents by adopting the processes of two-section hydrogenation and combination alkaline cleaning neutralization; hydrogenating the unsaturated component in the petroleum resin to reduce double-bond content; hydrogenating a non-ferrous perssad to fade; hydrogenating to remove chlorine retained in the polymerization process; and carrying out alkaline cleaning, water cleaning, stabilizer injection and solvent removal to obtain light or colourless hydrogenated petroleum resin. The method further simplifies the process through the organic combination of unit operation, and the industrial manufacture method for the hydrogenated petroleum resin, which has the advantages of wide adaptability on hydrogenated raw materials, less corrosion on system equipment, high product quality and high production capability is formed.

Owner:CHINA PETROLEUM & CHEM CORP

Combined technologic process for manufacturing petroleum residue

InactiveCN1485412AReduce cokingIncrease line speedTreatment with plural serial stages onlyGasolineResidual oil

A method of processing residual oil. It comprises: after preheating, introducing the raw material into the upper portion of a solvent deasphalting extraction tower, the solvent is introduced into thelower portion of the extraction tower at the predetermined proportion, residual oil and the solvent contacting refluently and extracting, recycling solvent from deasphalted oil containing a great amount of the solvent, deasphalted oil containing a small quality of the solvent is discharged from the bottom of the tower without recycling solvent and enters the heating oven for heating, then entering a fractionating tower, fractionating gases, gasoline and residual oil with reduced viscosity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation combined method for diesel oil

ActiveCN101724457ADeep modificationReduce cokingTreatment with hydrotreatment processesHydrogenCombined method

The invention discloses a hydrogenation combined method for diesel oil, which comprises the following steps: dividing a straight-run diesel oil raw material and / or a coking diesel oil raw material into two parts of materials, performing hydro-upgrading reaction on one part of the material after being mixed with a catalytically cracked diesel oil raw material, and performing hydro-refining reaction on the other part of the material. The hydro-refining reaction and the hydro-upgrading reaction share a set of hydrogen recycling system. The combined method of the invention meets the requirement of products with different amounts and quality by flexibly adjusting raw oil ratio of two reaction zones, reduces operating severity of a hydro-upgrading reaction zone and prolongs the operation cycle at the same time. In addition, the method of the invention simplifies the process flow, can decrease equipment and reduces investment and operation cost. The method is suitable for hydro-processes of various inferior-quality distillate raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

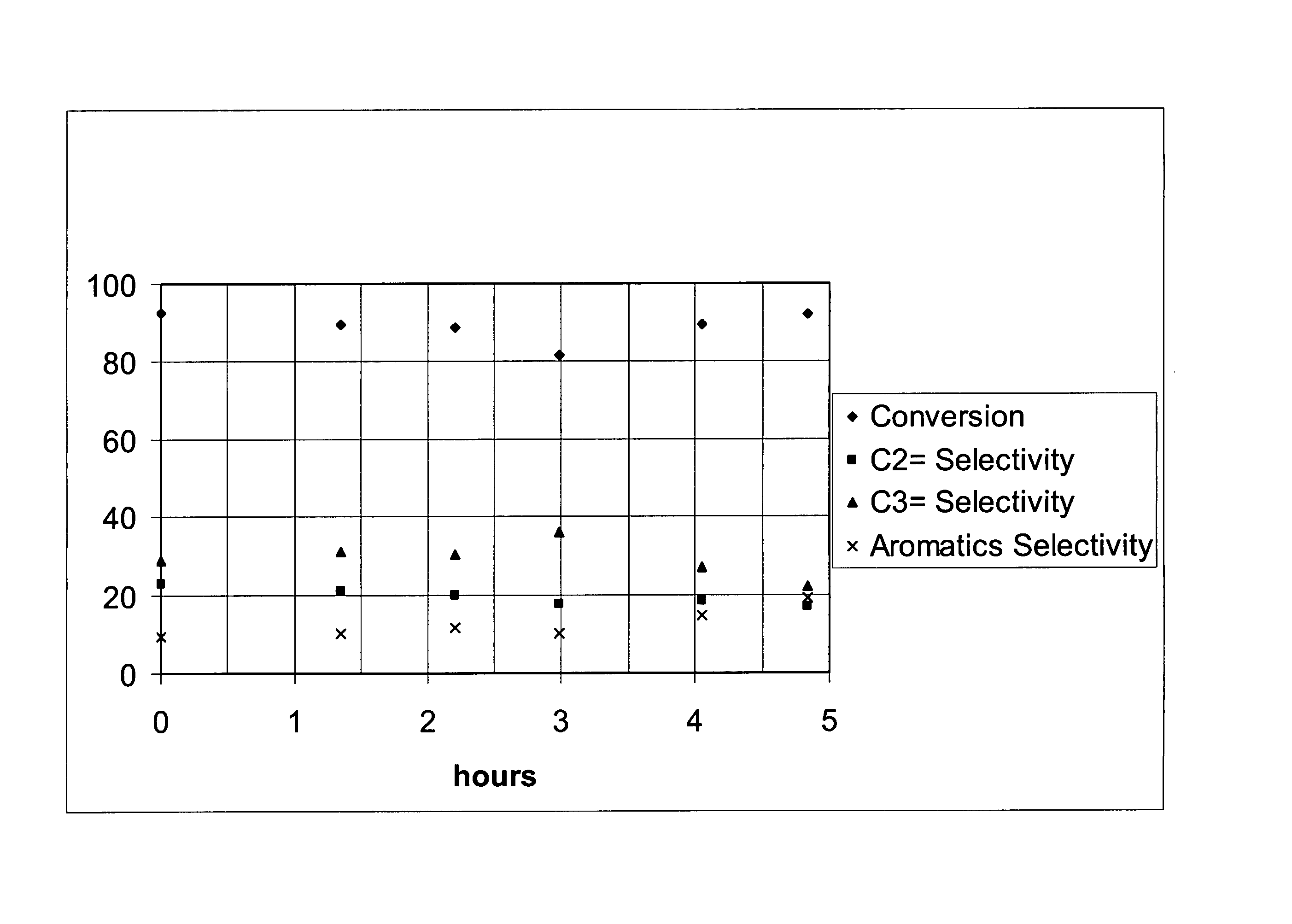

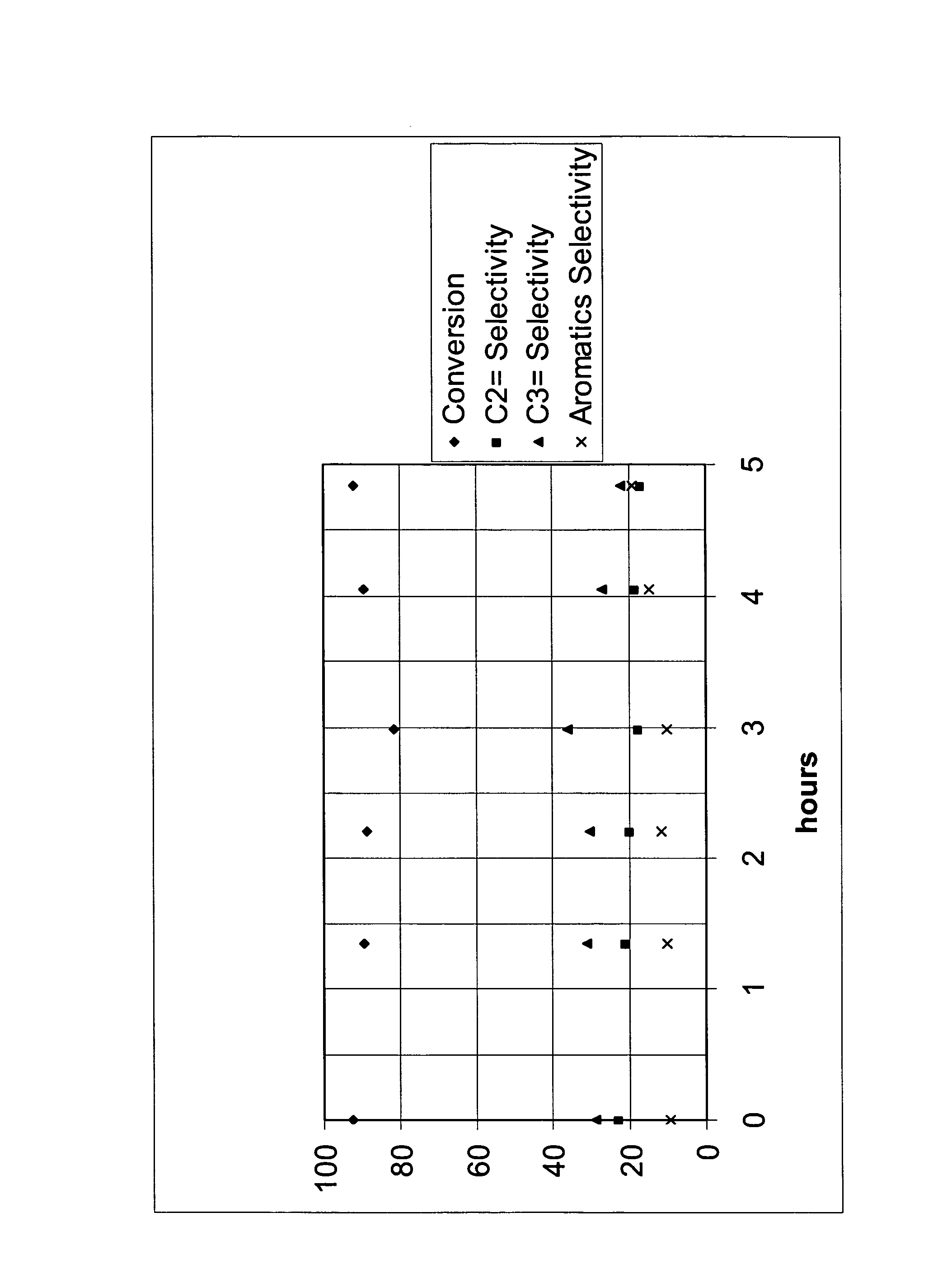

Nanocrystalline silicalite for catalytic naphtha cracking

InactiveUS7459596B1High silica to alumina ratioSmall crystal sizeCatalytic crackingHydrocarbonsNaphthaSilicon dioxide

A method is provided for converting a hydrocarbon feedstock in the naphtha boiling range to light olefins. The method includes contacting the hydrocarbon feedstock with a zeolitic material having a crystal size from 50 to 300 nanometers, having a silica to alumina ratio greater than 200 and where the zeolitic material has a silicalite structure.

Owner:UOP LLC

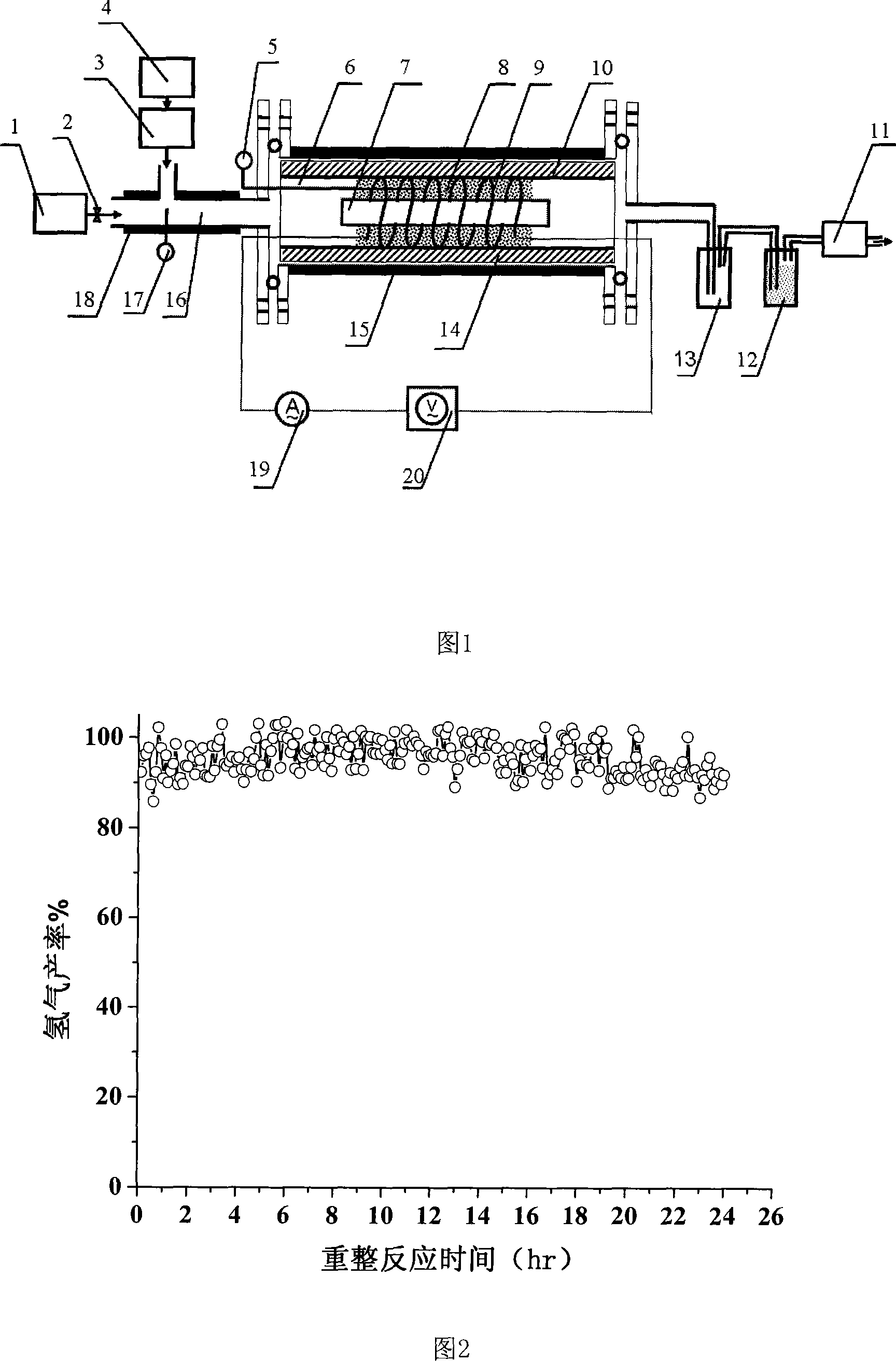

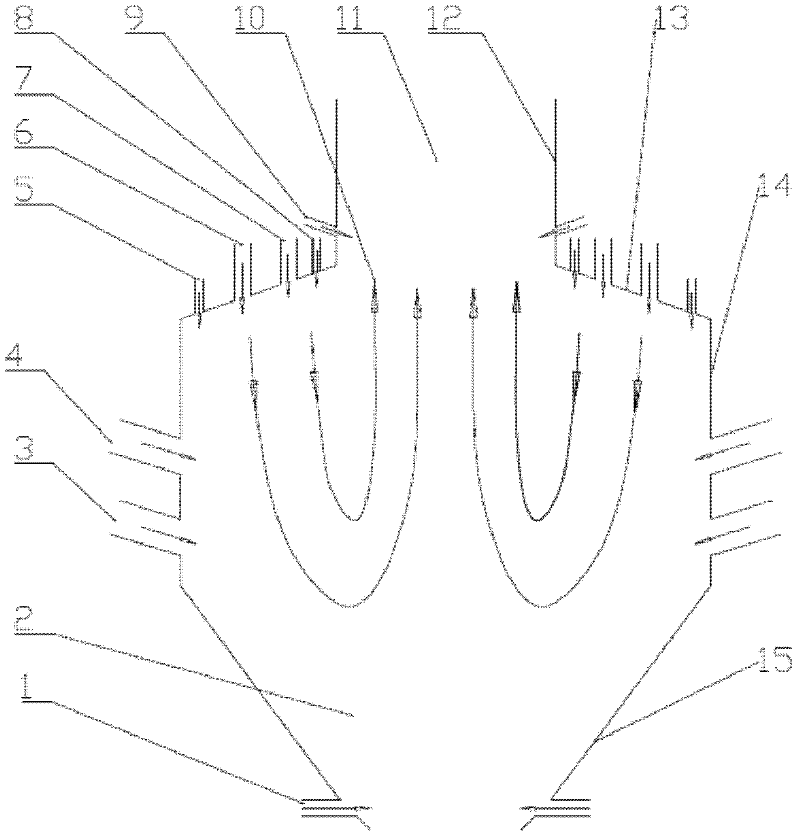

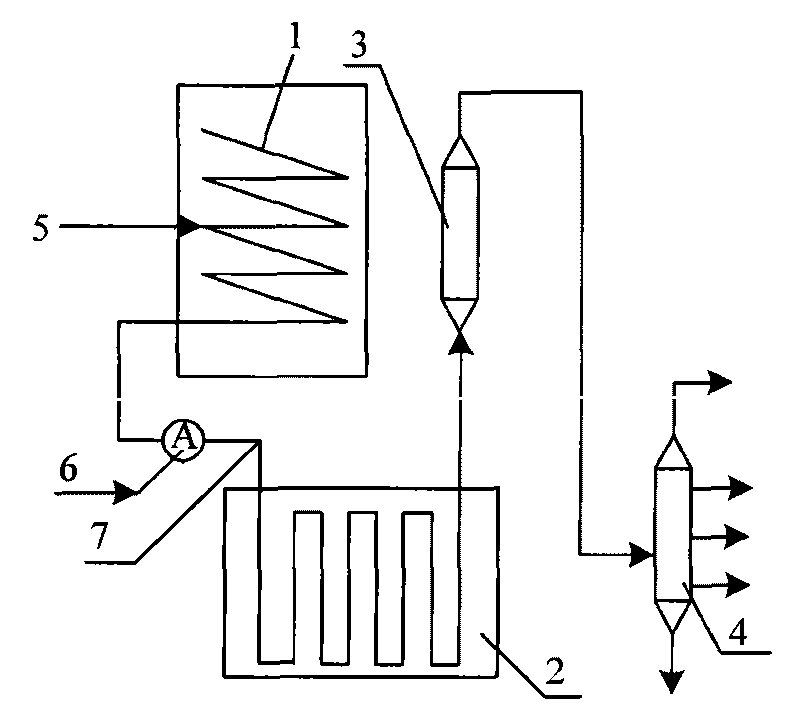

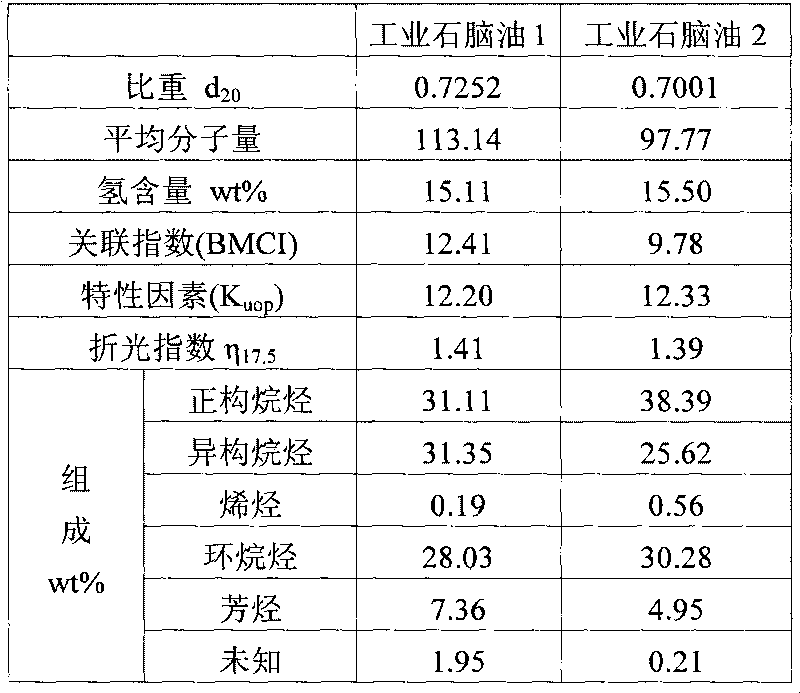

Device and method for preparing hydrogen by the electrocatalysis water vapour recapitalization biological oil

The invention relates to the technology of electrocatalytic reforming of organic compounds, in particular to a method and device for producing hydrogen from bio-oil by electrocatalytic steam reforming. The device includes a cylindrical reactor with a reforming catalyst and an external heating furnace, a bio-oil storage tank, a steam generator connected to an inlet pipeline with a preheating device, and a tail gas collection and purification system on the output pipeline. An electric furnace wire is arranged in the inner cavity of the device. When producing hydrogen, the external power supply of the electric furnace wire is first connected to heat the catalyst; then the mixed fluid of raw bio-oil and water vapor is passed into the inner cavity of the reactor, so that the bio-oil can be electrocatalyzed by water in a water vapor atmosphere and a medium temperature environment. Steam reforming reaction and water gas shift reaction convert carbon-hydrogen-oxygen-containing organic matter into hydrogen and carbon dioxide mixed gas. The invention utilizes heating electric furnace wire to provide hot electrons for the catalyst surface to dissociate and degrade various complex carbon-hydrogen-oxygen macromolecules in bio-oil, and obtain high hydrogen yield and bio-oil conversion under the condition of 450-550°C Rate.

Owner:UNIV OF SCI & TECH OF CHINA

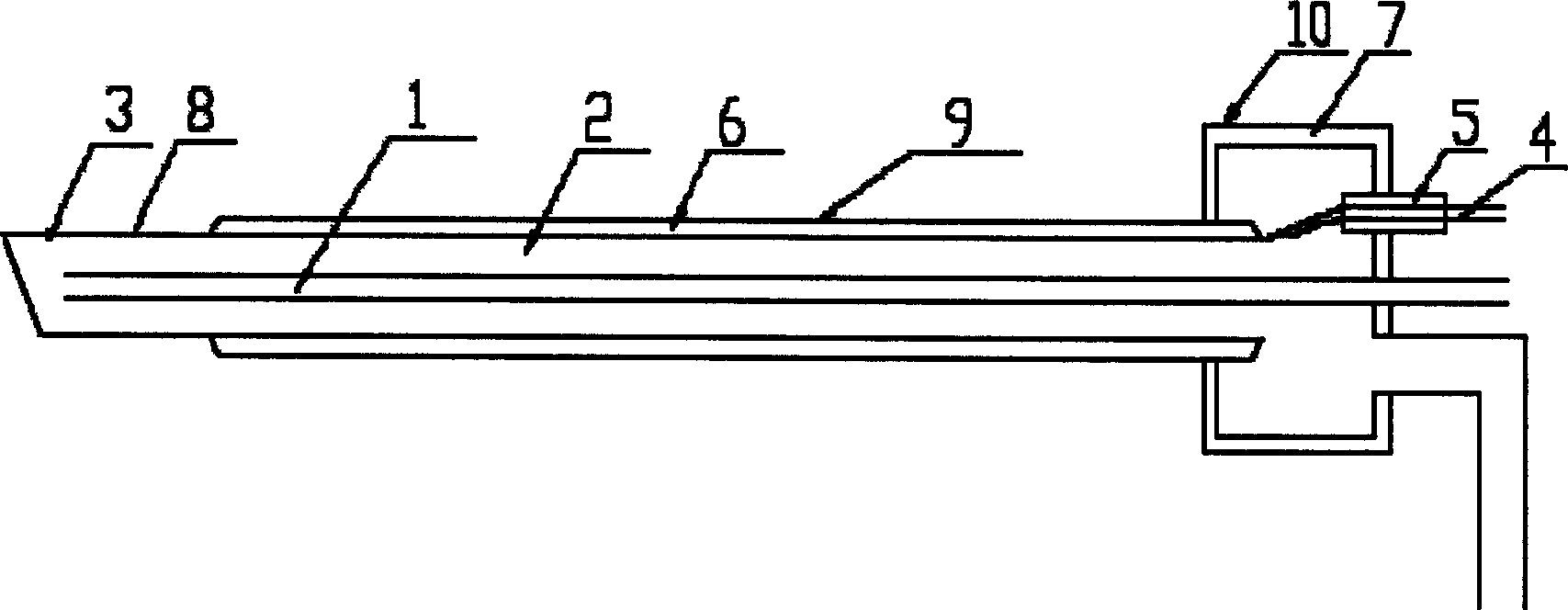

A W-type flame decoupling combustion furnace and decoupling combustion method

InactiveCN102297421AReduce reducing atmosphereReduce corrosionAir/fuel supply for combustionNon-combustible gases/liquids supplyStructural engineeringHearth

The invention relates to a W-type flame decoupling combustion furnace and a decoupling combustion method. A hearth of the decoupling combustion furnace is enclosed by a front and a back side walls, an upper hearth side wall (12), a lower hearth arch (13), a lower hearth side wall (14), and a lower hearth cold ash hopper wall (15); the lower hearth arch (13) is provided with several groups of symmetric super-dense primary air nozzle (8), dense primary air nozzle (7) and light primary air nozzle (6) which are orderly arranged from the hearth center to the outside; the several groups of primary air nozzles (8, 7, 6) are uniformly arranged between the front and the back walls on the lower hearth arch (13) with a downward nozzle direction; several above-side wall secondary air nozzles (4) are symmetrically arranged on the lower hearth side wall (14); the above-side wall secondary air nozzles (4) and the primary air nozzles (8, 7, 6) are staggeredly arranged along the anterior / posterior direction; several below-side wall secondary air nozzles (3) are arranged between the front and the back walls on the lower hearth side wall (14). The device of the invention reduces the generation of NOx and fly ash combustible matter.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for restraining cracking furnace pipe from coking

ActiveCN103421531AThe method is simpleSimple technologyThermal non-catalytic crackingCoke ratePre treatment

The invention provides a method for restraining a cracking furnace pipe from coking. The method comprises the following steps: pre-treating the inner surface of the cracking furnace pipe before a coking restraining coating of the inner surface of the cracking furnace pipe is coated; coating a coking resistant coating on the inner surface of the cracking furnace pipe; adding a coking inhibitor into cracking raw materials. According to the invention, the coke formation is reduced through the recombination of the coking resistant technology, so that the hydrocarbon high-temperature cracking coking rate is greatly reduced, and the use cycle of hydrocarbon cracking equipment is prolonged.

Owner:内蒙古冠泰环保科技有限公司

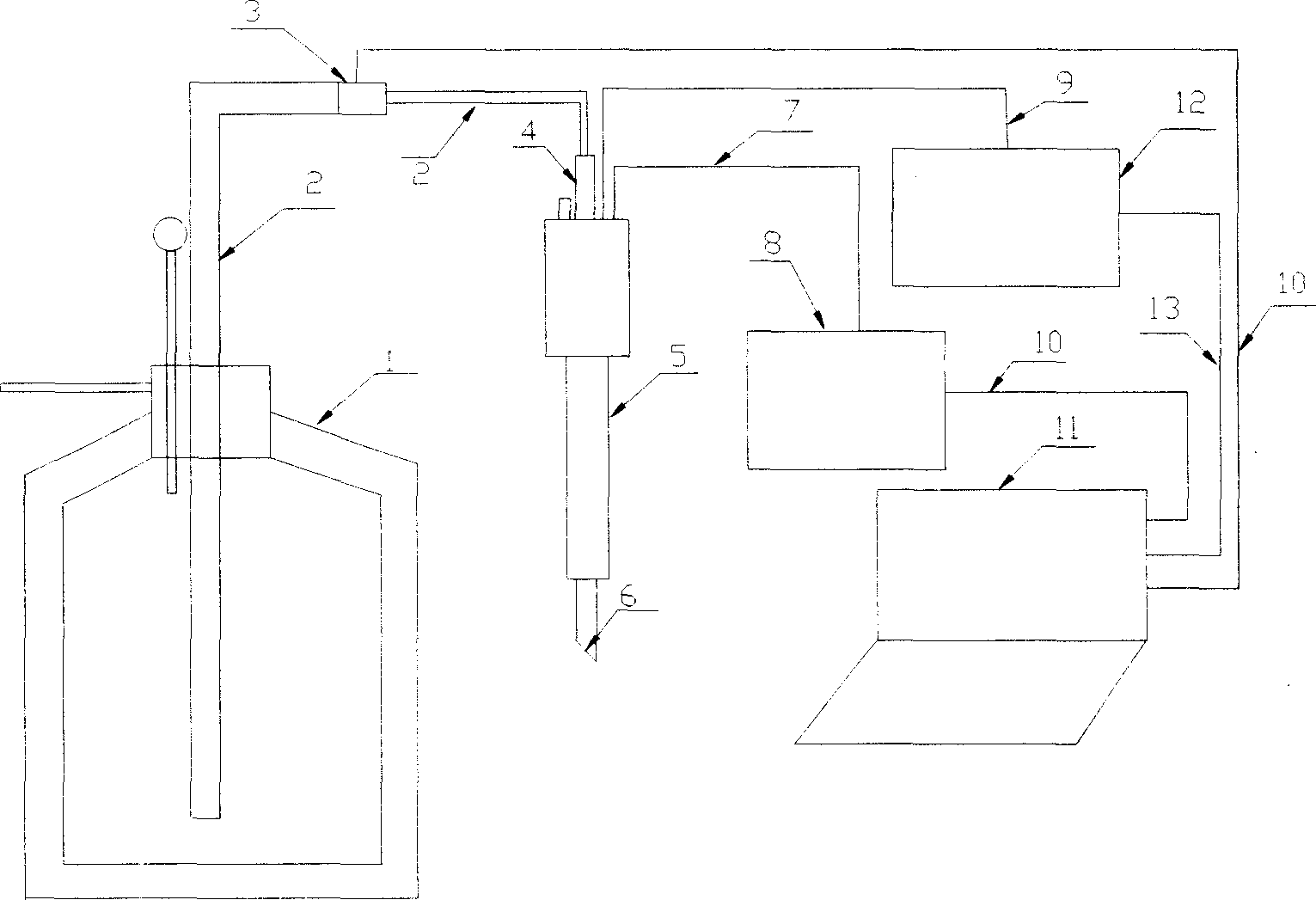

Online monitoring method for flue gas temperature of hearth outlet of power station boiler

InactiveCN101806626AGood for the economyIncrease the effective caliberRadiation pyrometryPower stationFlue gas

The invention discloses an online monitoring method for the flue gas temperature of a hearth outlet of a power boiler, comprising the steps of: placing a plurality of targets at a vertical section near a smokestack of a boiler for sensing the temperature; installing a near infrared imaging device on the side wall of a horizontal flue of the boiler for collecting the radiation energy of the targets; carrying out communication by the near infrared imaging device with a computer through a serial port and RS232, sending the collected radiation energy of the targets to the computer, calculating by the computer to obtain temperature data of the targets; and then sending the temperature data of the targets to a host computer for processing, and converting the temperature to the flue gas temperature of the position of the targets. The invention has the advantages that the average temperature at the section of the hearth outlet, the average temperature of the upper / lower and left / right side, and the highest / the lowest temperature can be continuously monitored, the distribution curve of the temperature of the section can be drawn, and a plurality of alarm functions are set; and the invention is beneficial to the safe and economic operation of a boil with a large capacity and high parameters.

Owner:四川东脑电气工程有限公司

Method for reducing ethylene cracking furnace tube coking and improving ethylene selectivity

ActiveCN101724827AReduce generationReduce depositionChemical vapor deposition coatingBulk chemical productionWater vaporGas phase

The invention discloses a method for reducing ethylene cracking furnace tube coking and improving ethylene selectivity, belonging to the cracking technology. The method comprises the following steps: injecting on line the pretreating solution containing ceramics elements, such as Si, Al, Ca, B and the like as well as catalytic activity elements, such as Ag, Cr, Cu, Ti, Mn and the like into a cracking furnace tube during steam hot preparation at the temperature of 500-1000 DEG C; carrying out vapour phase deposition on the elements onto the inner wall of the furnace tube; at the temperature of 700-1100 DEG C, in the carrier gas atmosphere taking inert gas as the main component, carrying out constant-temperature heat treatment on the furnace tube; and finally, forming a ceramics coating on the inner surface of the furnace tube. The coating reduces more than 80% of deposition on the inner wall of the furnace tube by coke and improves ethylene selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Needle type cold and hot alternative tumor therapeutic head

ActiveCN1561925AReduce tissue cokingProtect health organizationSurgical instruments for heatingSurgical instruments for coolingNeedle typeAbnormal tissue growth

A medical needle for treating tumor by alternative freezing and heating is composed of internal and external tubes, ttemp sampling unit, shielded single-core line, temp signal output line, insulating vacuum layer, and hand-held external sleeve layer.

Owner:MAGI CO LTD

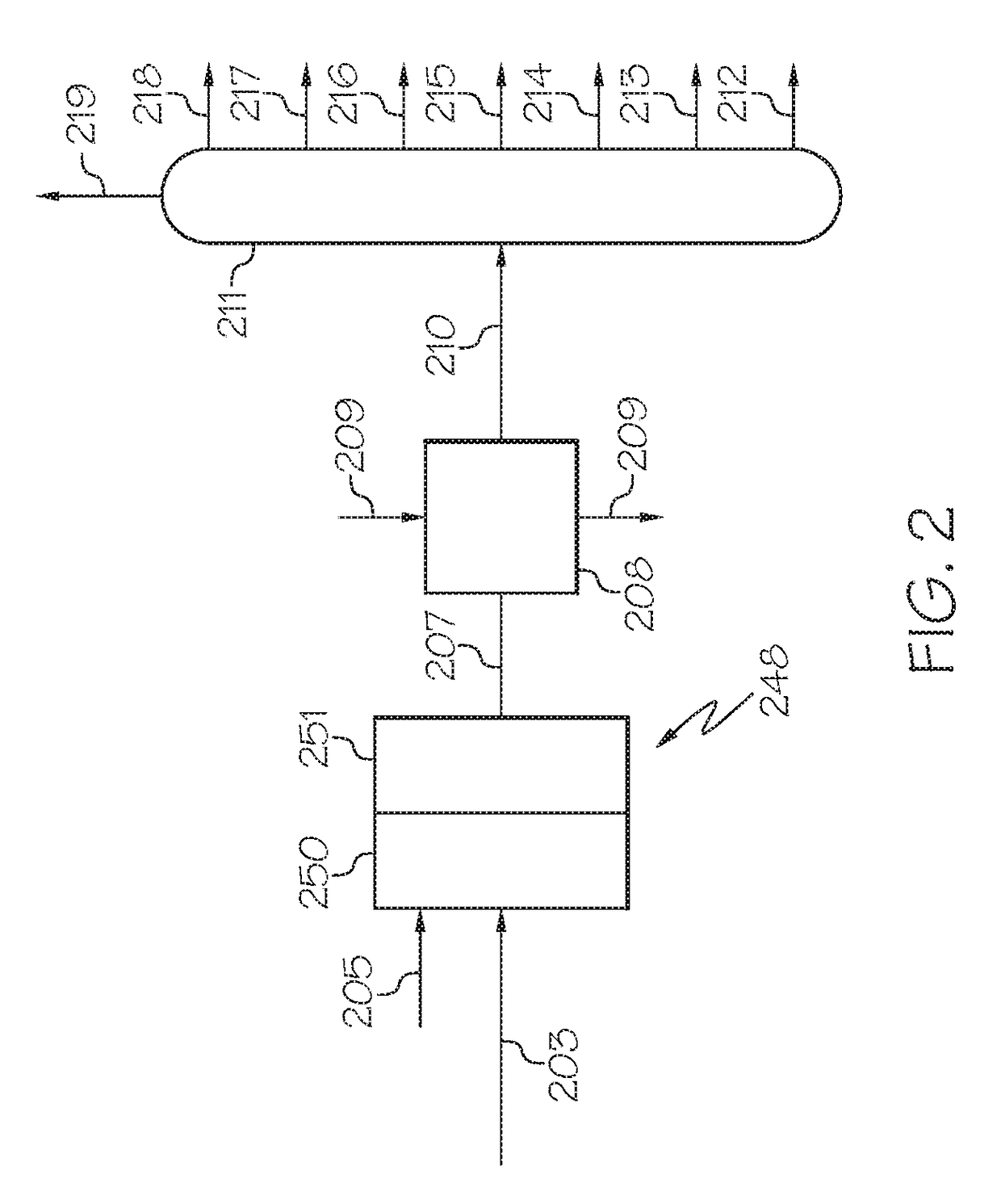

Zeolites, the production thereof, and their uses for upgrading heavy oils

ActiveUS20180333708A1Low costLess expensiveCatalytic crackingMolecular sieve catalystsFuel oilChemistry

According to one or more embodiments, a nano-sized, mesoporous zeolite particle may include a microporous framework comprising a plurality of micropores having diameters of less than or equal to 2 nm and a BEA framework type. The nano-sized, mesoporous zeolite particle may also include a plurality of mesopores having diameters of greater than 2 nm and less than or equal to 50 nm. The zeolite particles may be integrated into hydrocracking catalysts and utilized for the cracking of heavy oils in a pretreatment process.

Owner:SAUDI ARABIAN OIL CO

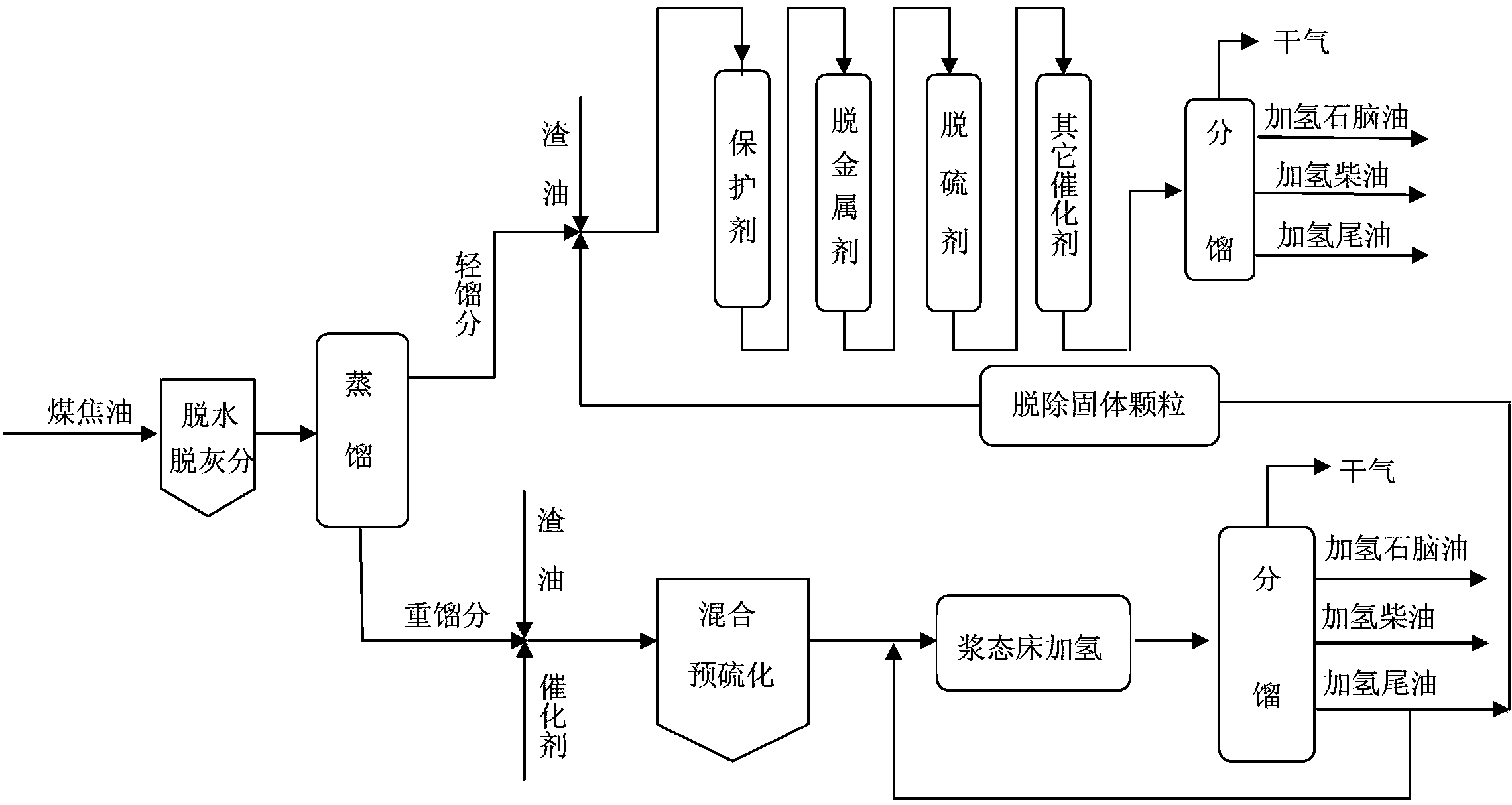

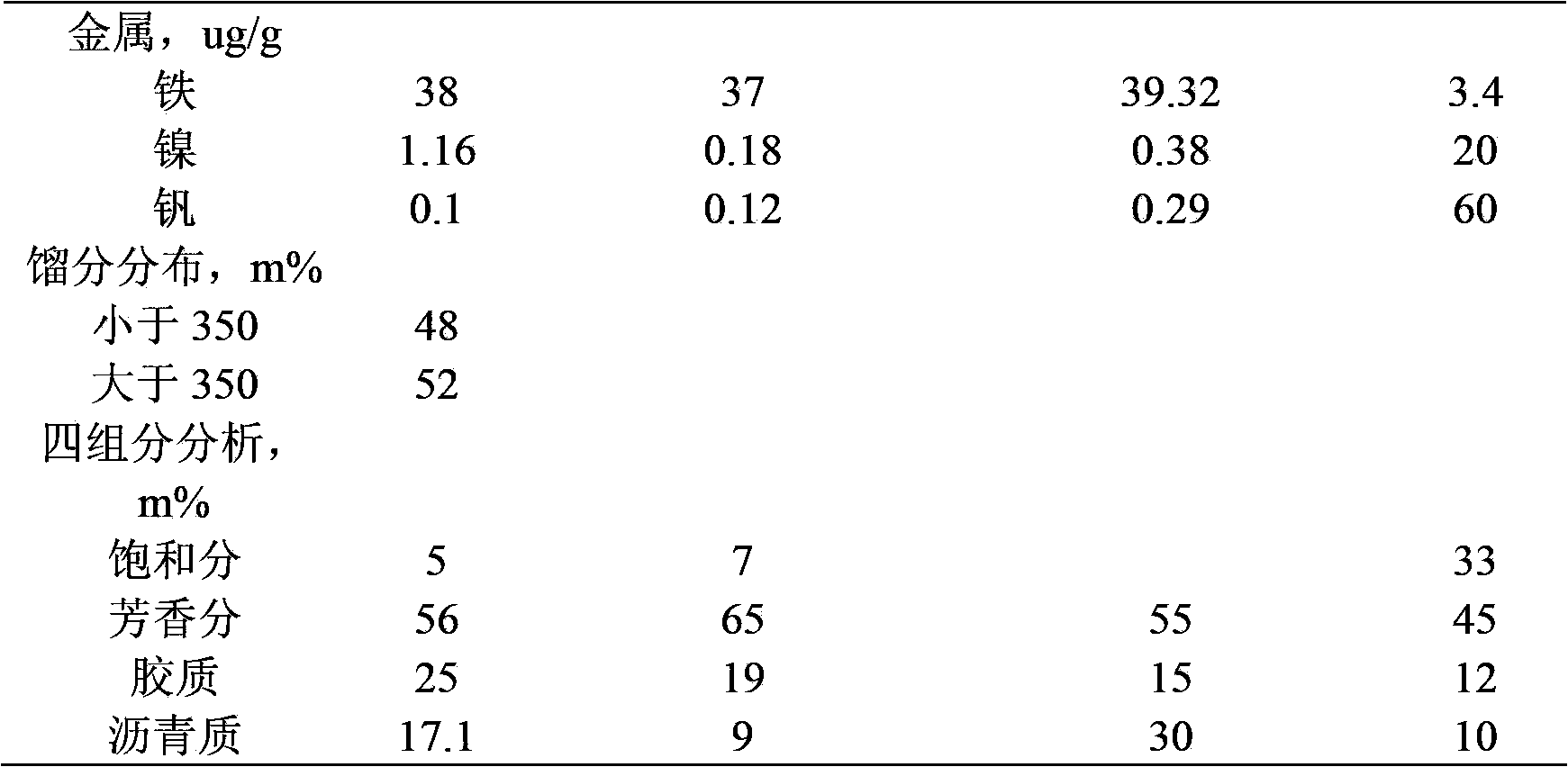

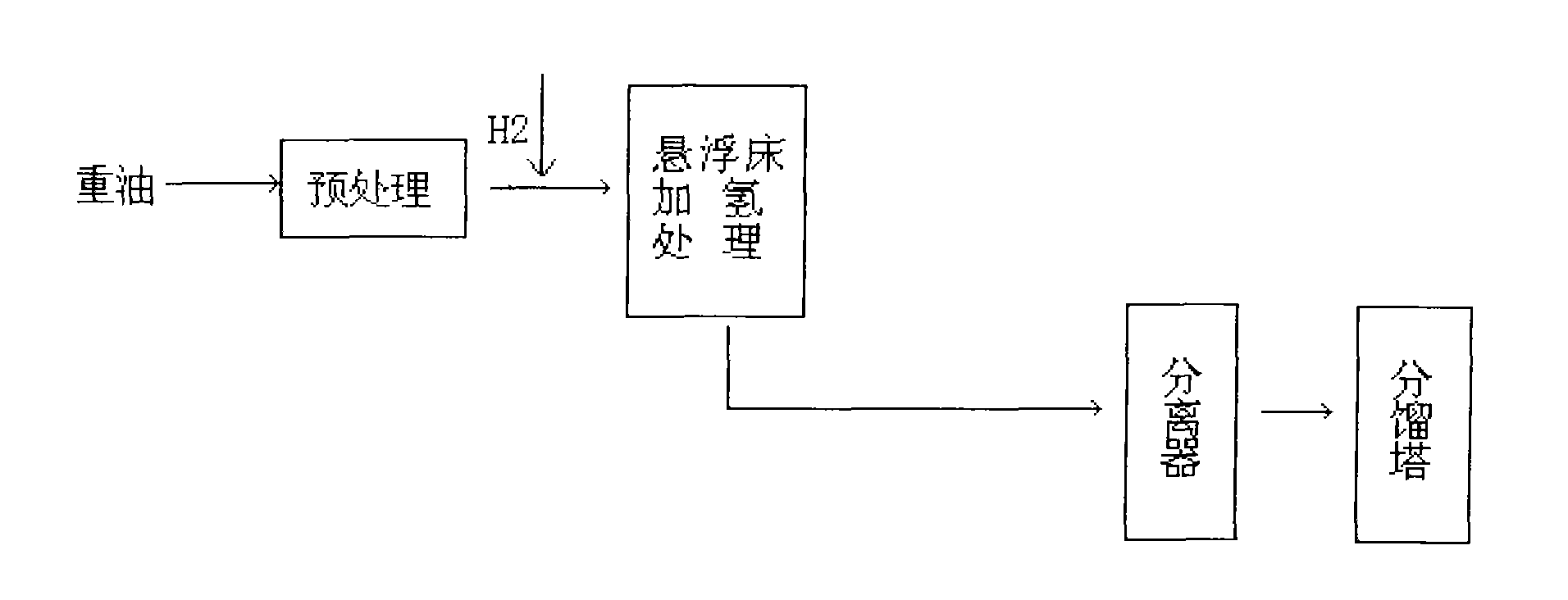

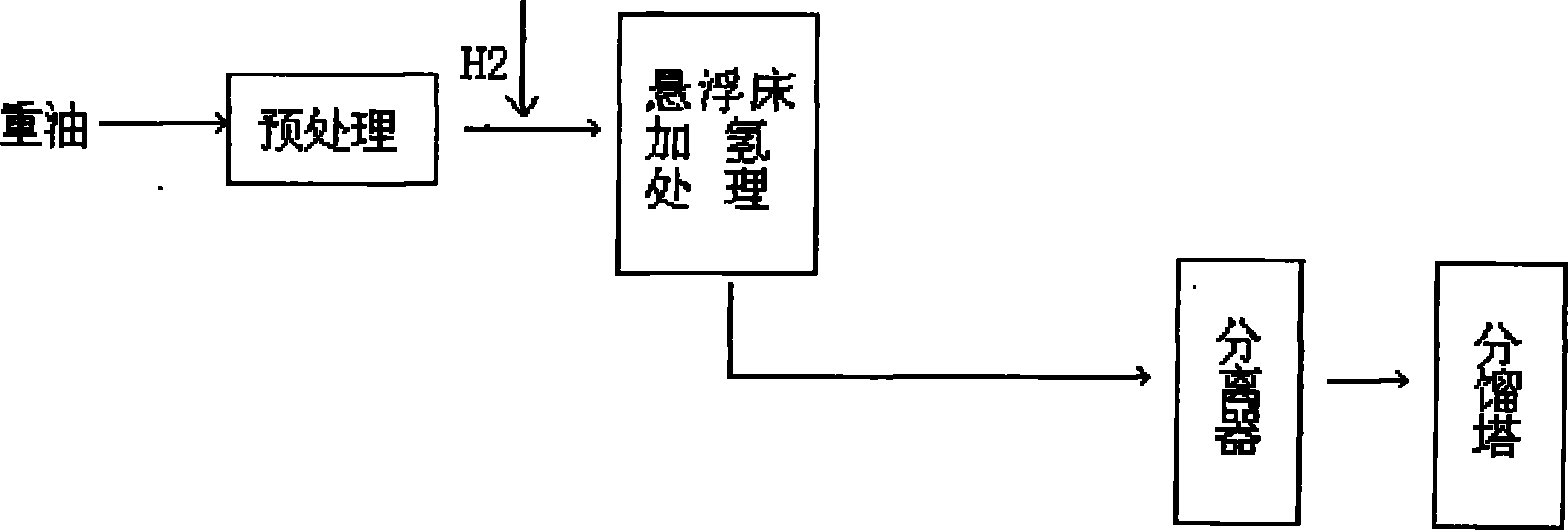

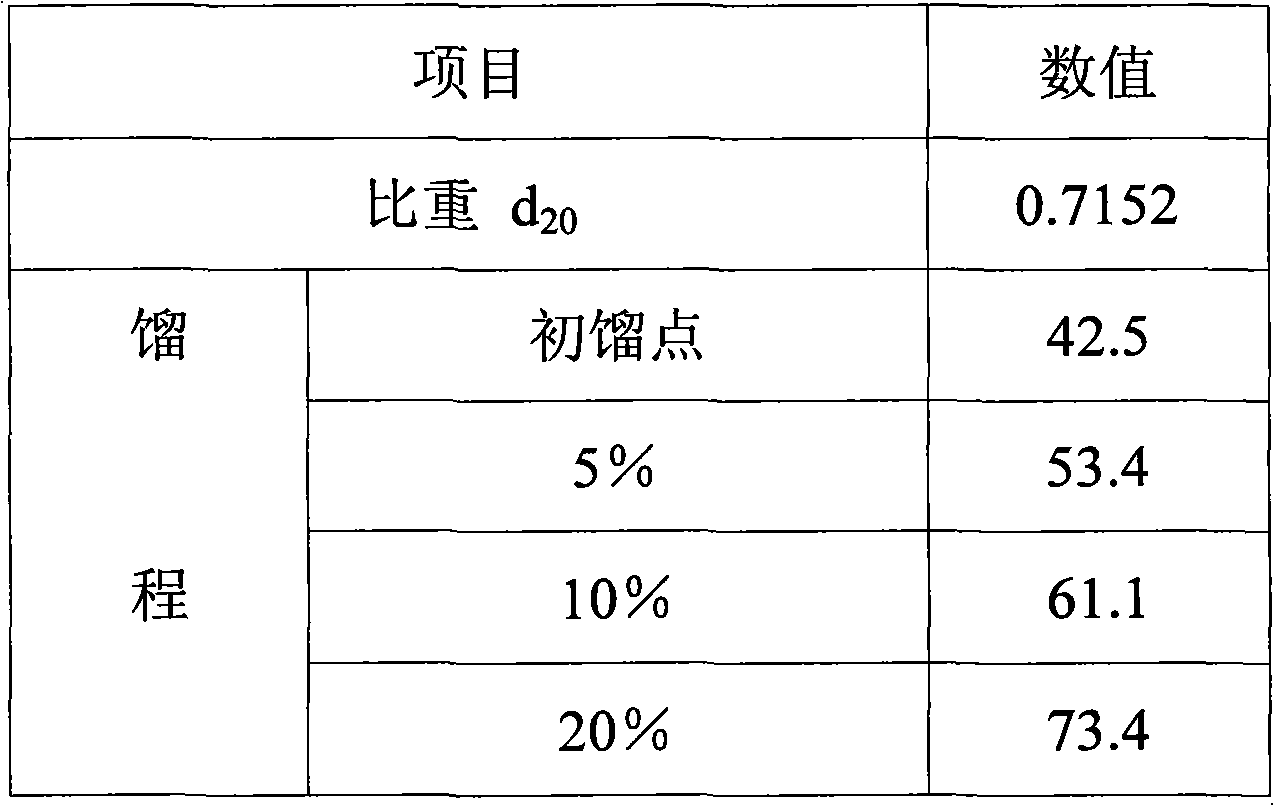

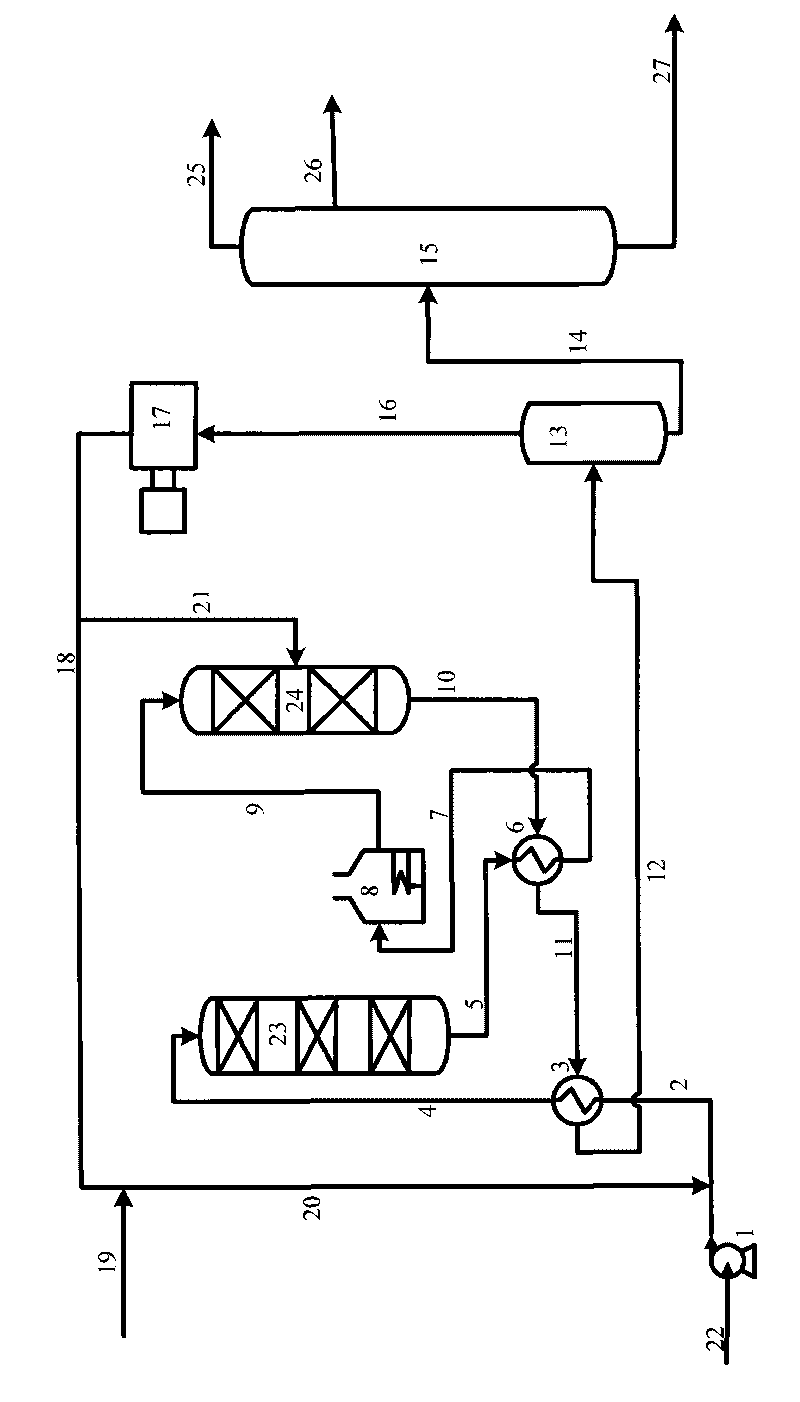

Combined hydrogenation process method for treating coal tar and residual oil

InactiveCN103540353ALow viscosityImprove diffusion abilityTreatment with hydrotreatment processesFixed bedSlurry

The invention relates to a combined hydrogenation process method for treating coal tar and residual oil. The method comprises the following steps: distilling coal tar with water and solid particles removed to obtain light coal tar fraction not larger than 350 DEG C and heavy coal tar fraction larger than 350 DEG C; mixing the heavy coal tar fraction larger than 350 DEG C with residual oil, hydrogen and a catalyst, reacting the mixture in a slurry bed hydrogenation reactor, and conveying hydrogenation tail oil of 350-470 DEG C to a fixed bed residual oil hydrogenation unit; reacting the light coal tar fraction not larger than 350 DEG C with the residual oil and the hydrogen or the hydrogenation tail oil in the fixed bed residual oil hydrogenation unit, and separating the reaction products to obtain a dry gas, hydrogenated naphtha, hydrogenated diesel oil and hydrogenated residual oil. According to the method, slurry bed hydrogenation treatment is organically combined with the fixed bed residual oil hydrogenation process to process all coal tar fractions so as to improve the utilization rate of the coal tar, expand the source of residual oil hydrogenation raw materials, prolong the operation period of the fixed bed residual oil hydrogenation unit and improve the impurity removal rate of the residual oil hydrogenation product.

Owner:PETROCHINA CO LTD

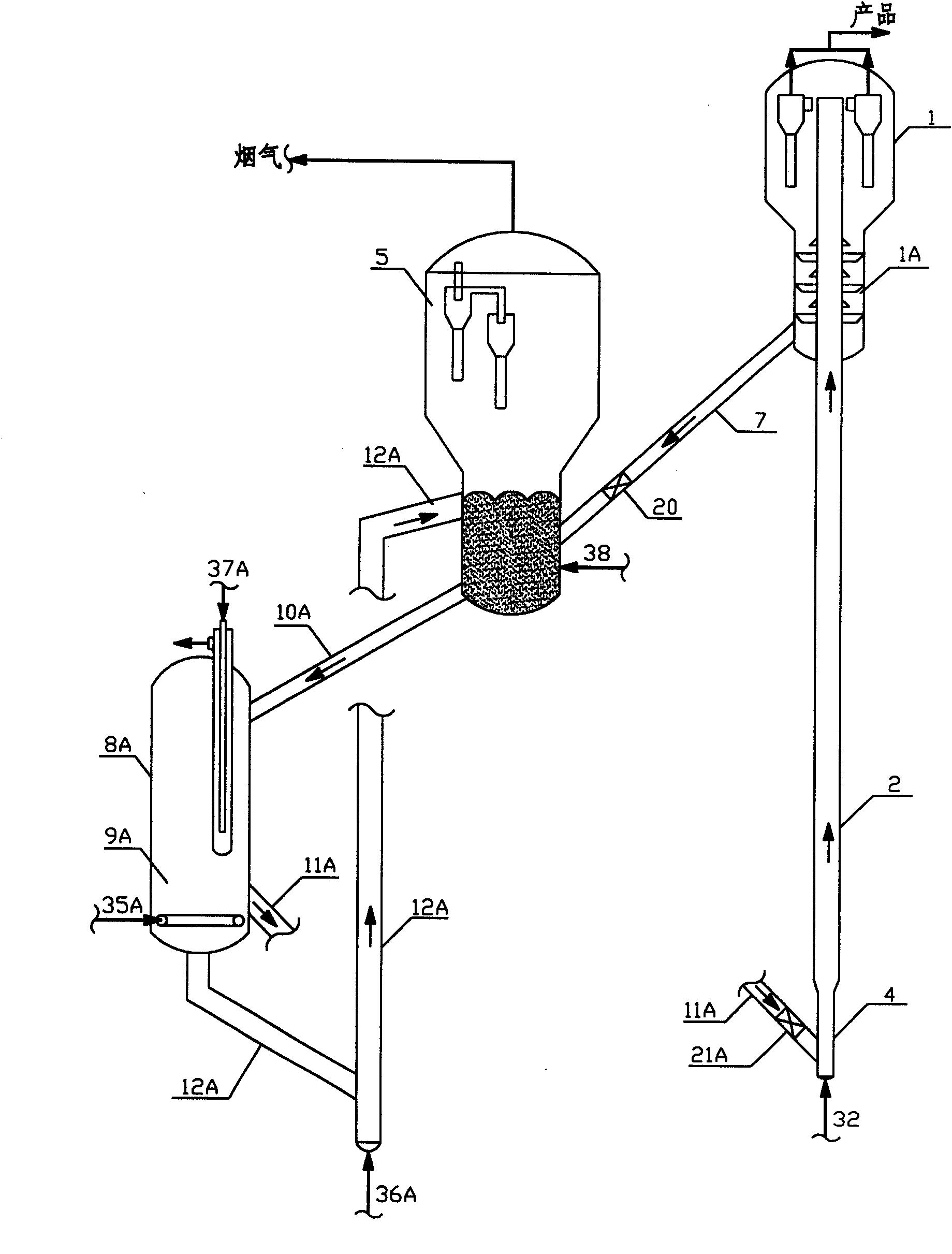

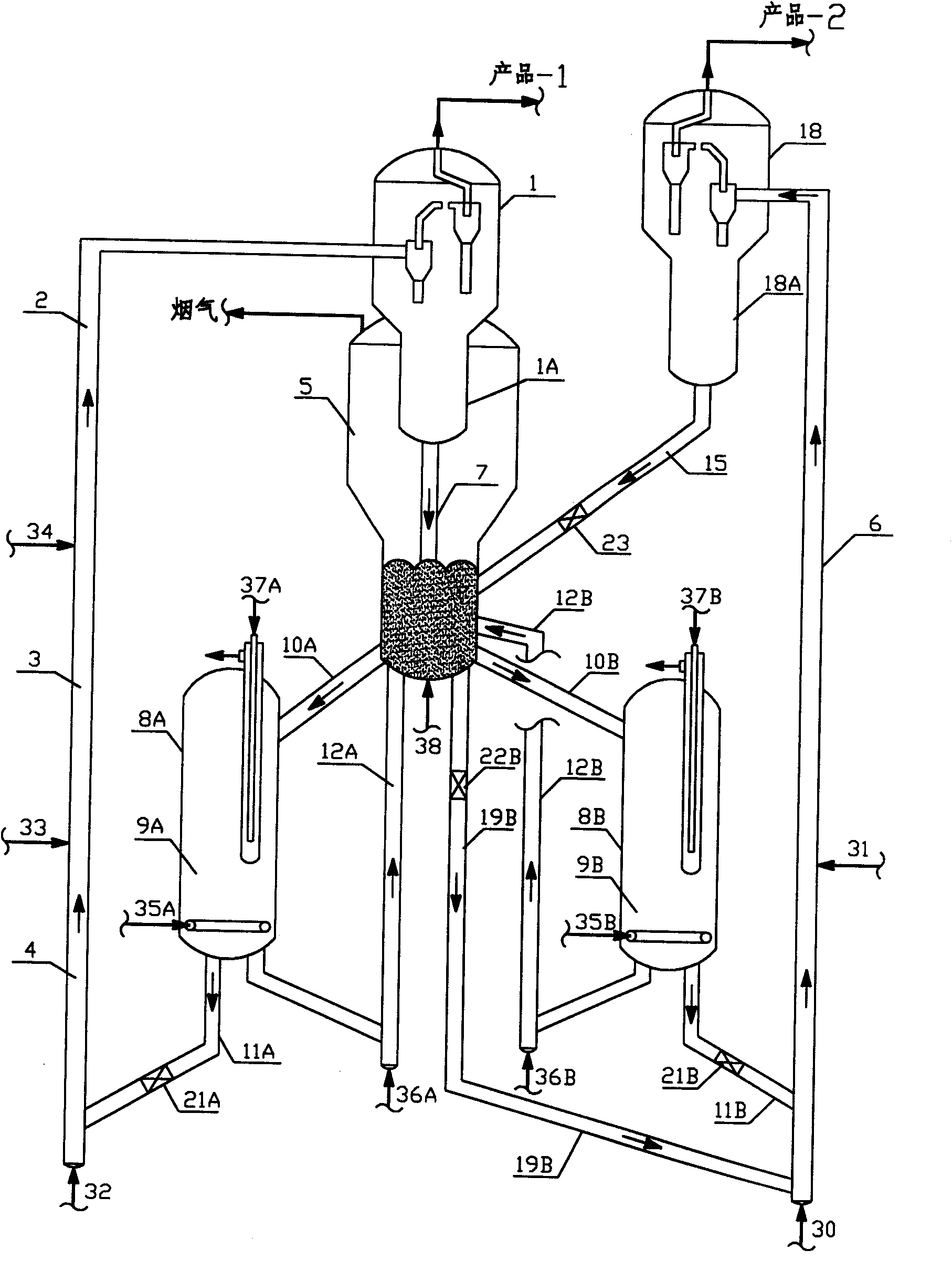

Method and device for circulating cold regenerated catalyst

The invention provides a method for circulating a cold regenerated catalyst and application thereof. A regenerated catalyst from a regenerator is cooled by a catalyst cooler to between 200 and 720DEGC, and is not mixed with a hot regenerated catalyst to directly enter a riser reactor, or is mixed with another part of uncooled hot regenerated catalyst into a mixed regenerated catalyst of which thetemperature is not lower than that of the regenerator to enter the riser reactor; and a hydrocarbon raw material undergoes contact reaction with the catalyst in the riser reactor, the reaction material flow enters a settler for the separation of the catalyst and oil gas, the separated catalyst to be regenerated is subjected to steam stripping in a steam stripping section, and then enters the regenerator for coke burning regeneration, and the regenerated catalyst is cooled and returns to the riser reactor for recycling. The method for circulating the cold regenerated catalyst has wide application, can be used for various fluid catalytic cracking processes comprising resid fluid catalytic cracking, wax oil catalytic cracking, gasoline catalytic conversion upgrading and the like, and also can be sued for other gas-solid reaction processes comprising residual oil pretreatment, fluid coking and the like.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

Catalytic cracking catalyst for reducing coke yield and producing gasoline

ActiveCN103506153AImprove stabilityIncrease profitCatalytic crackingMolecular sieve catalystsMolecular sieveGasoline

The invention relates to a catalytic cracking catalyst for reducing coke yield and producing gasoline. Based on the weight of the dry base, the catalytic cracking catalyst contains 10wt%-50wt% of modified Y type molecular sieve, no more than 30wt% of specific rare earth-containing Y type molecular sieve, 10wt%-70wt% of clay and 10wt%-40w% of inorganic oxide binder based on oxide base, wherein the lattice constant of the modified Y type molecular sieve is 2.420-2.440nm; by calculating in percentage by weight, P accounts for 0.05-6%, RE2O3 accounts for 0.03-10%, aluminum oxide is less than 22%, and the specific hydroxyl nest concentration is less than 0.35mmol / g. The catalytic cracking catalyst provided by the invention can reduce green coke, improve the utilization rate of heavy oil and improve gasoline selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy oil hydrogenation modifying method

The invention discloses a heavy oil modifying method which comprises the following steps: mixing a heavy oil raw material with a homogeneous catalyst, and mixing with a supercritical hydrogen supply solvent, wherein the content of the hydrogen supply solvent in the heavy oil raw material is 50 mug / g-5wt%; and in the presence of hydrogen, carrying out heavy oil hydrocracking reaction on the mixture of the heavy oil raw material, the catalyst and the hydrogen supply solvent under certain reaction conditions. In the heavy oil modifying method, suspension bed hydrocracking and supercritical treatment are organically combined, and the respective advantages are given full play to achieve the effect of synergic cooperation, thereby reducing the coking tendency, enhancing the impurity removal capacity and also enhancing the operational stability of the suspension bed hydrocracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

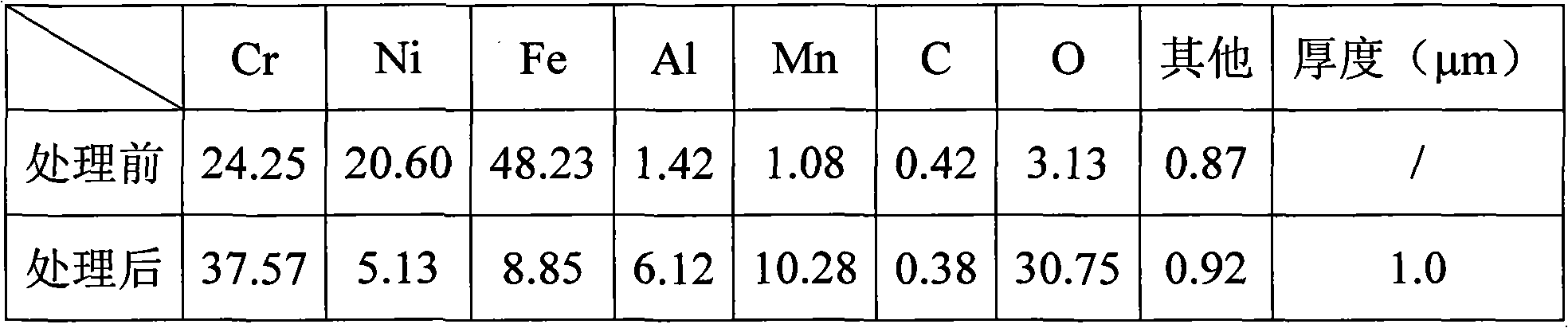

Cracking furnace tube for retarding coking and carburizing of ethylene cracking furnace tube, and manufacturing method thereof

ActiveCN102399571AInhibit cokingInhibition of carburizationThermal non-catalytic crackingCarbon numberPetroleum

The present invention relates to a cracking furnace tube for retarding coking and carburizing of an ethylene cracking furnace tube, and a manufacturing method thereof. According to the present invention, the inner surface of the cracking furnace tube is provided with a layer of an oxide film, wherein the oxide film comprises at least one element selected from Cr, Ni, Fe, Mn, Al, Si and B; the manufacturing method comprises: directly adding at least one element selected from Al, Si or B to a nickel-chromium alloy containing elements of Cr, Ni, Fe, Mn and C during the conventional cracking furnace tube manufacturing process to prepare the tube, then carrying out a heat treatment for the resulting tube under low oxygen partial pressure atmosphere to generate a layer of the metal and / or nonmetal oxide thin film on the inner surface of the tube; when the cracking furnace tube of the present invention is adopted for producing olefin with low carbon number by the petroleum hydrocarbon cracking furnace, the deposition of the coke on the inner wall of the furnace tube can be reduced by more than 70%.

Owner:CHINA PETROLEUM & CHEM CORP +2

Temperature-rising-reducing rate controllable cold-hot alternating tumour therapeutical system

ActiveCN1709212AProtect health organizationOvercoming efficiency lossTherapeutic coolingTherapeutic heatingKilling rateRadio frequency

The present invention relates to a cold-heat alternative oncology therapy system whose temperature-rising and temperature-lowering rate can be controlled. Said system includes the following components: liquid nitrogen transferring pipe, high pressure liquid nitrogen Dewar's container, low-temperature electromagnetic valve, needle cold-heat alternative therapeutic head, gas-liquid separation device, radio frequency generation device, temperature collection device and control system. Said invention makes the low-temperature operating knife and radio frequency thermotherapy be combined together so as to raise killing rate of malignant tumor.

Owner:MAGI CO LTD

Method for improving quality of bio-oil

ActiveCN104560102ARaise the pHImprove qualityBiofuelsEfficient propulsion technologiesAlkaneNitrogen atmosphere

The invention relates to a method for improving the quality of bio-oil. The method comprises the following steps: adding bio-oil produced by the pyrolysis into an autoclave, adding calcium oxide and reacting for 1-4 hours at 30-80 DEG C under nitrogen atmosphere, heating to 160-180 DEG C, reacting for 0.5-2 hours, and finally cooling to 80-120 DEG C, and further carrying out heat preservation and reacting for 0.5-2 hours to obtain precursors of C7-C15 alkane fuels. By the method, the content of acid in the bio-oil can be well decreased, the pH and stability of the bio-oil are increased and meanwhile, produced ketone substances and aldehyde substances in the bio-oil can be reacted to obtain the precursors of the C7-C15 alkane fuels and thus the quality of the bio-oil is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for producing aromatics extraction raw material

ActiveCN101724456AMeet the requirements of the feedReduce cokingTreatment with hydrotreatment processesSulfurGasoline

The invention relates to a hydrogenation method for producing an aromatics extraction raw material. The method adopts two hydrogenation units and performs different reactions at different temperatures, wherein the first hydrogenation unit is filled with protective agents with different specifications in a graded loading mode; the protective agents are mainly used for removing diene, delaying the coking of the top part of a catalyst bed layer and prolonging the running period of a device at a low temperature; the second hydrogenation unit is filled with a hydrorefining catalyst for desulfurization, denitrification and alkene saturation at a high temperature and alkene saturation as little as possible. The hydrogenation method broadens the source of the aromatics extraction raw material; through the method provided by the invention, gasoline fractions with high diene value content and high impurity content can be converted; and the obtained product has the nitrogen content and the sulphur content of less than 1 mu g / g, and the bromine value of less than 0.5 gBr / 100g so as to meet the requirement of an aromatics extraction device on feeding.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com