Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

990results about How to "Avoid coking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible tube type solid-liquid processing machine with filtering, heat-exchange and hot compression function

InactiveCN1966129ALow costSimplify equipment componentsSemi-permeable membranesStationary filtering element filtersSlagEngineering

The invention relates to a flexible tubular solid liquid processor, with filter, heat exchange and thermal extraction functions, wherein the filter element at least comprises one flexible tubular membrane unit, upper flange room and lower flange room; the hydraulic extracting system comprises pressure container, extract pump and tubes; the material liquid of container can be filtered by the tubular filter membrane of membrane unit, and said material liquid can be used as work medium to extract the concentrated material liquid in the filter room of membrane unit and discharge filter slag; the pressure container or the filter room of membrane unit can be filled with medium to exchange heat, to realize thermal filter or extraction; the filter element is arranged on the bearing base inside the pressure container; the filter rotator can rotate the filter element to realize cross-flow filter; and the invention can be arranged with gas or water reverse tube and vacuum filter tube; the slag discharge system comprises slag discharger or tubular inner / outer membrane scraper, or vibration slag discharger, or compression slag discharger.

Owner:张民良

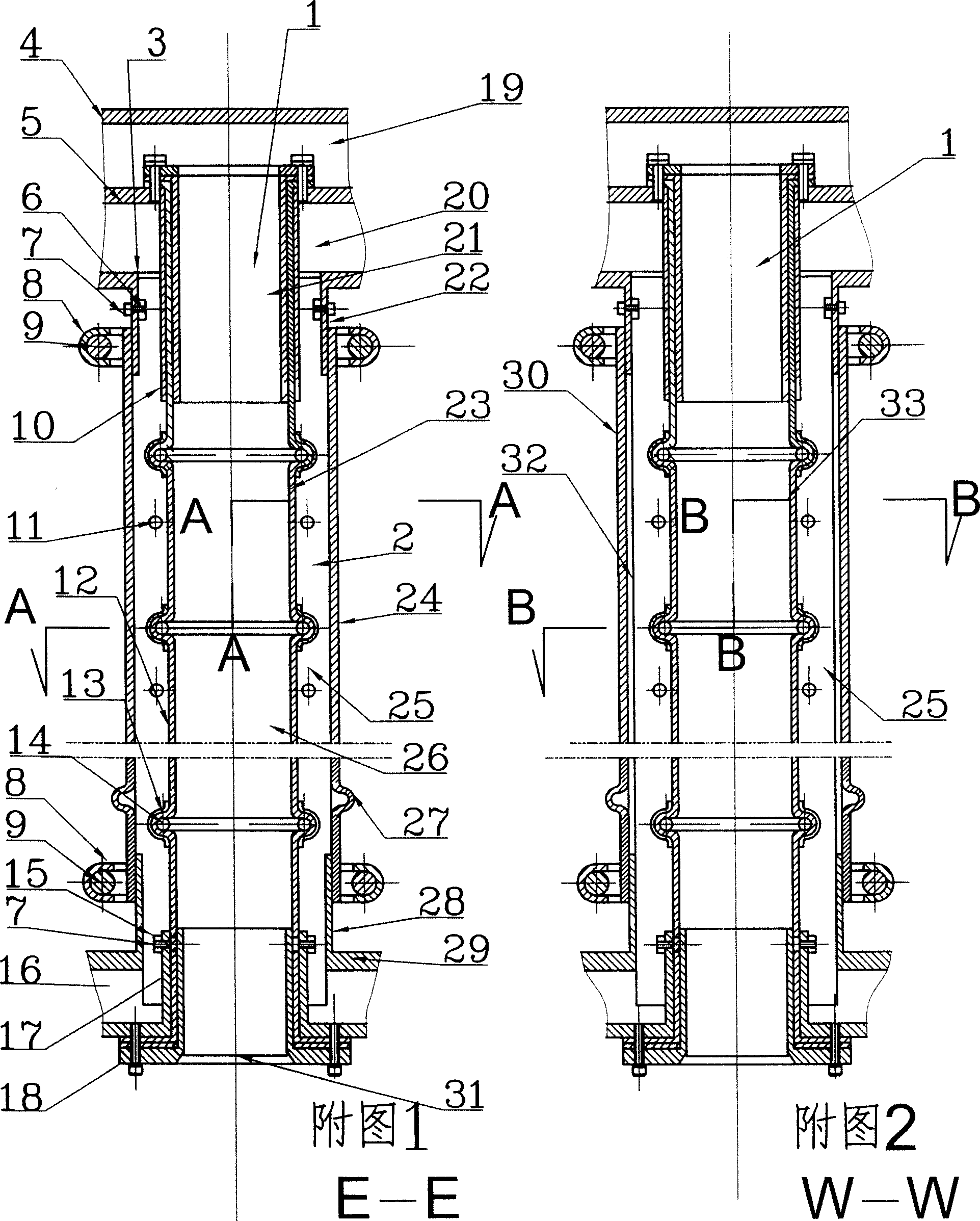

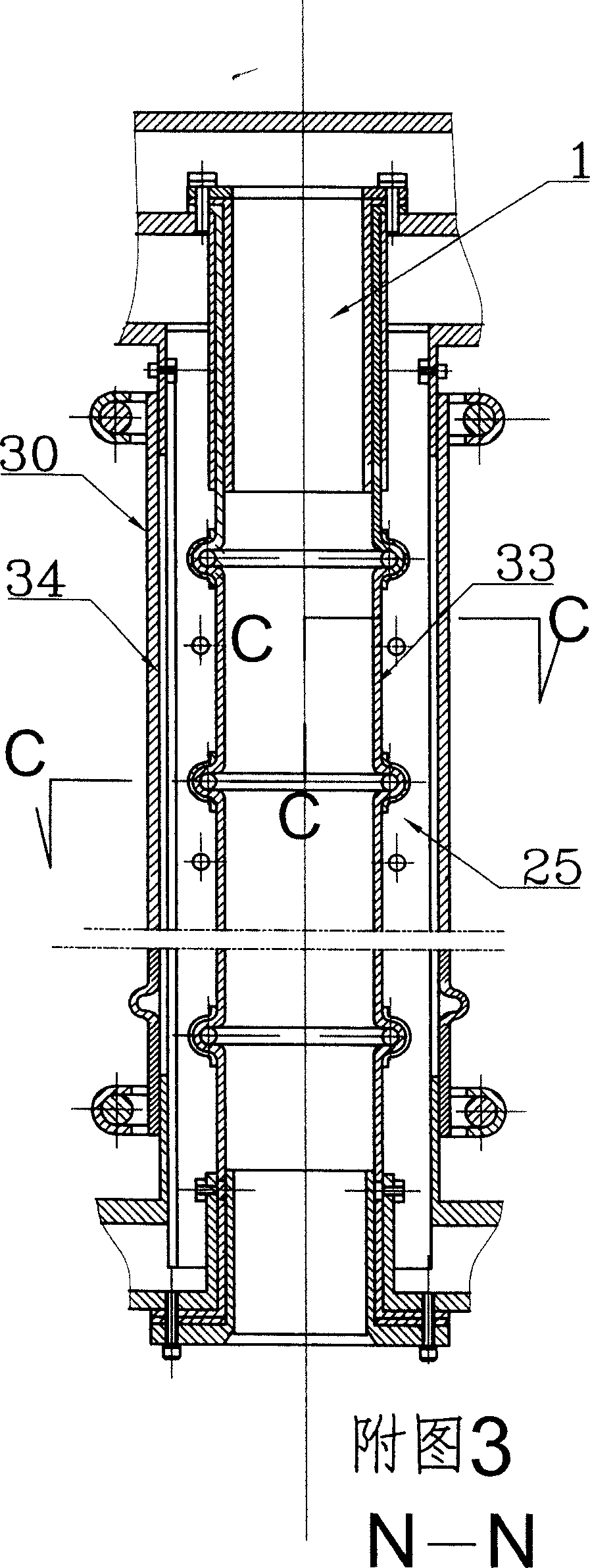

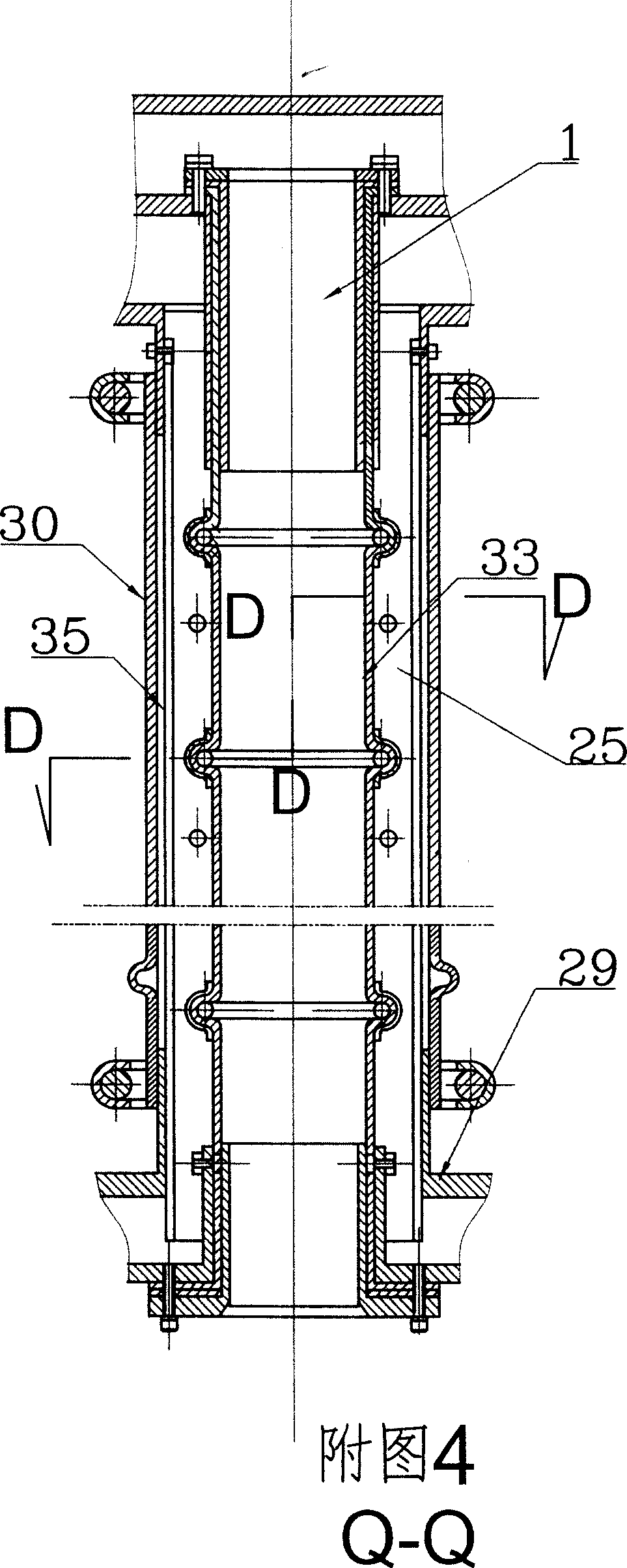

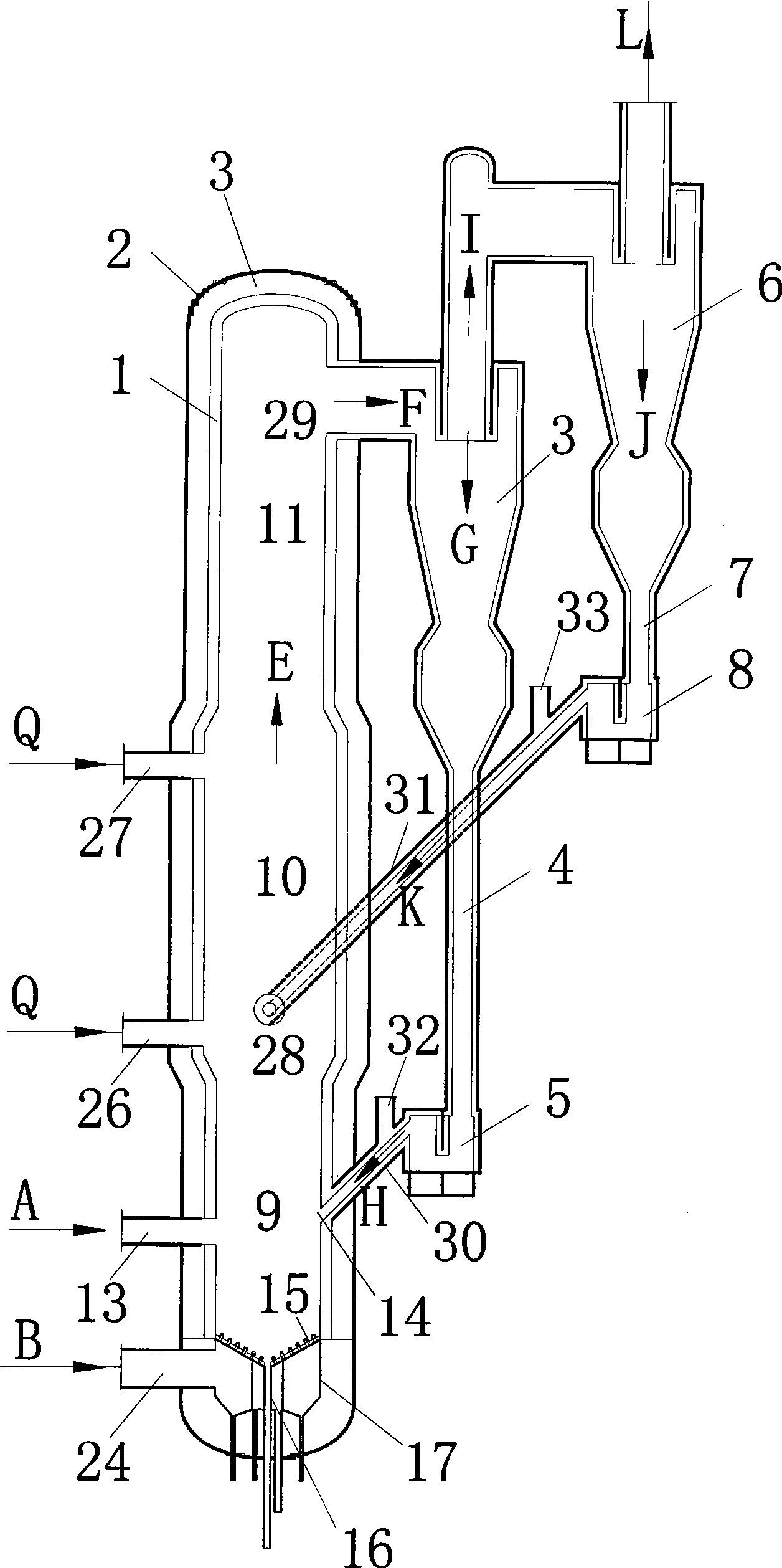

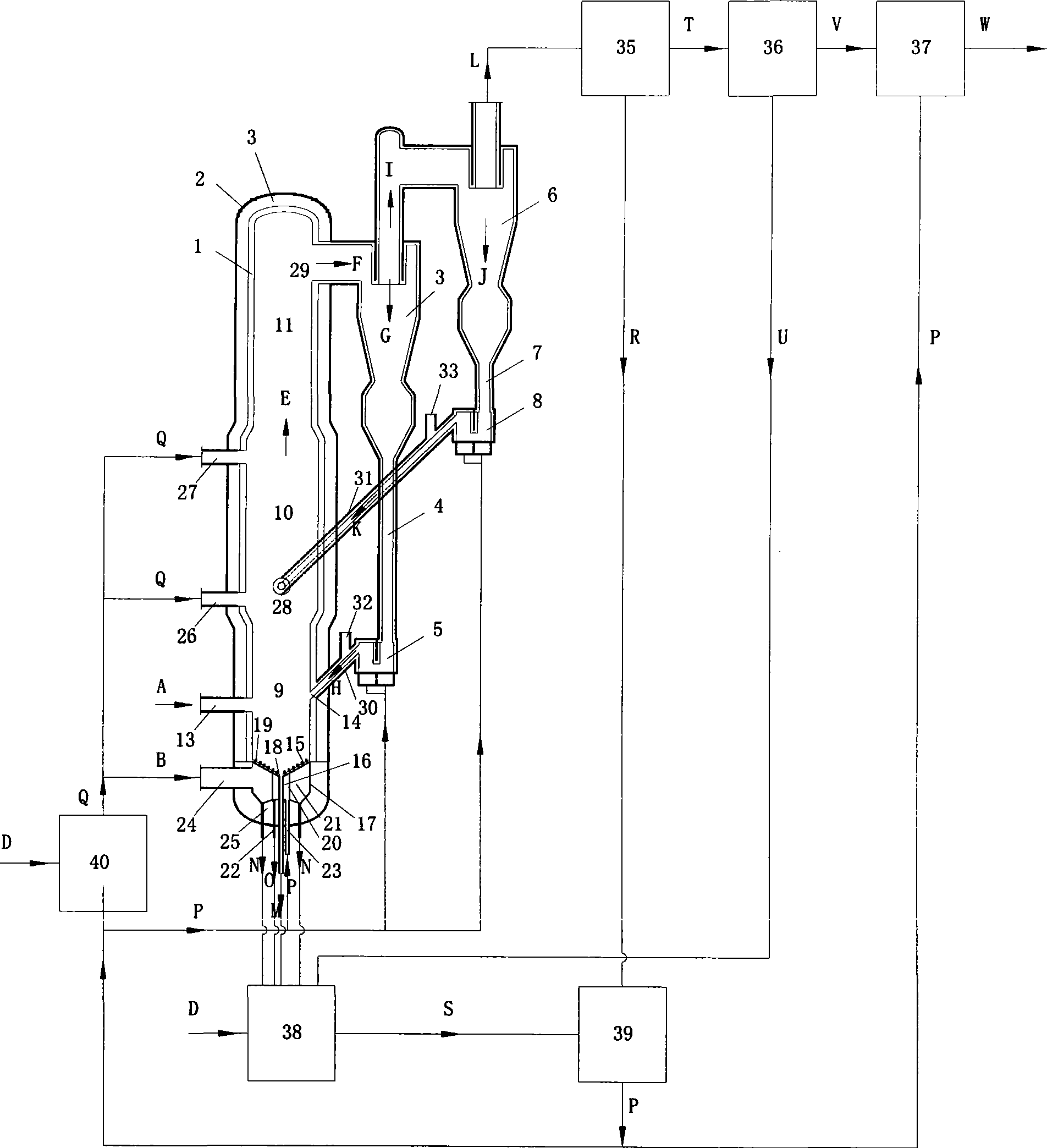

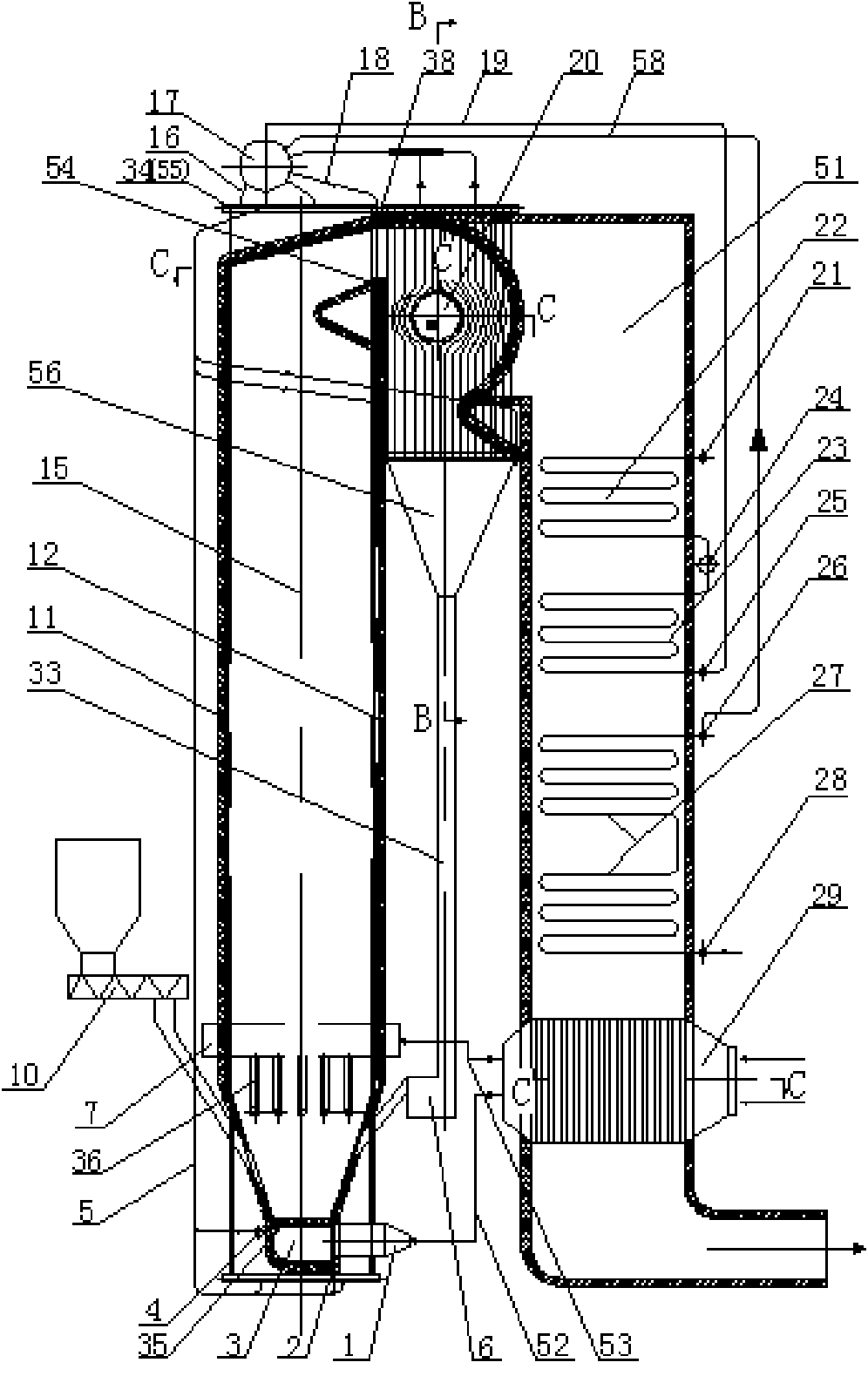

High-density pressurized fluidized bed coal gasification apparatus and method

ActiveCN101372635AGood amplification performance of flow dynamic characteristicsImprove carbon conversionCombined combustion mitigationGranular/pulverulent flues gasificationProcess engineeringTransformation ratio

A high-density pressurized fluid bed coal gasification device and a method relate to a gasification device and a method which are especially suitable for the efficient treatment of the high-sulfur, high-ash and high ash fusion point coal with high reserve volume in China and have the advantages of broad coal type adaptability, high carbon transformation ratio in the gasification process, high heat value of coal gas, low investment and excellent environment-friendly performance. A gasification reactor (1) is arranged in a pressure shell (2) and is divided into a dense-phase turbulent flow fluidizing section (9), a high-density core-annulus flow section (10) and a density rapid flow section (11) from bottom to top, and according to the gasification character of the goal with high sulfur, high ash and high ash fusion point, flow states with different features are adopted for pressurizing and sectionalized gasification from bottom to top and the pressure for gasification is 1.0-2.5MPa.

Owner:SOUTHEAST UNIV

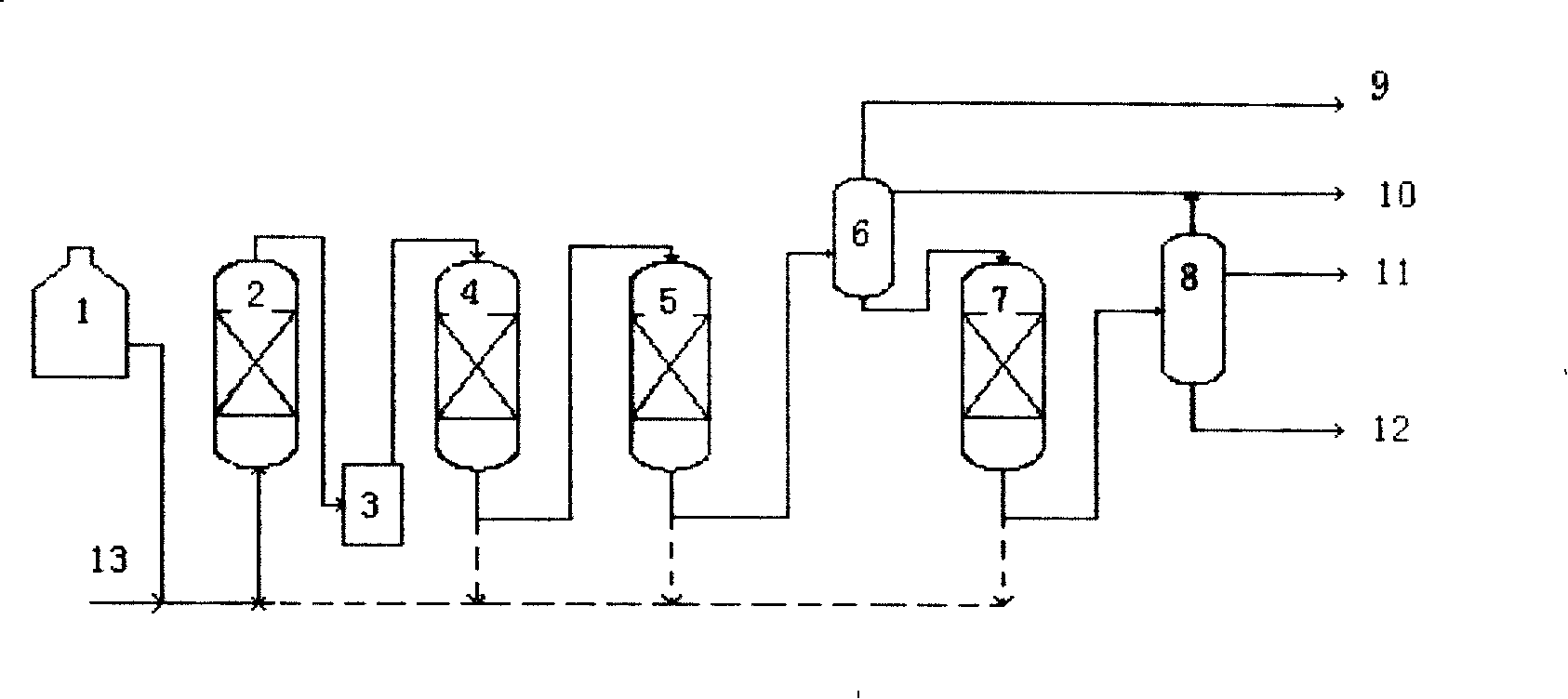

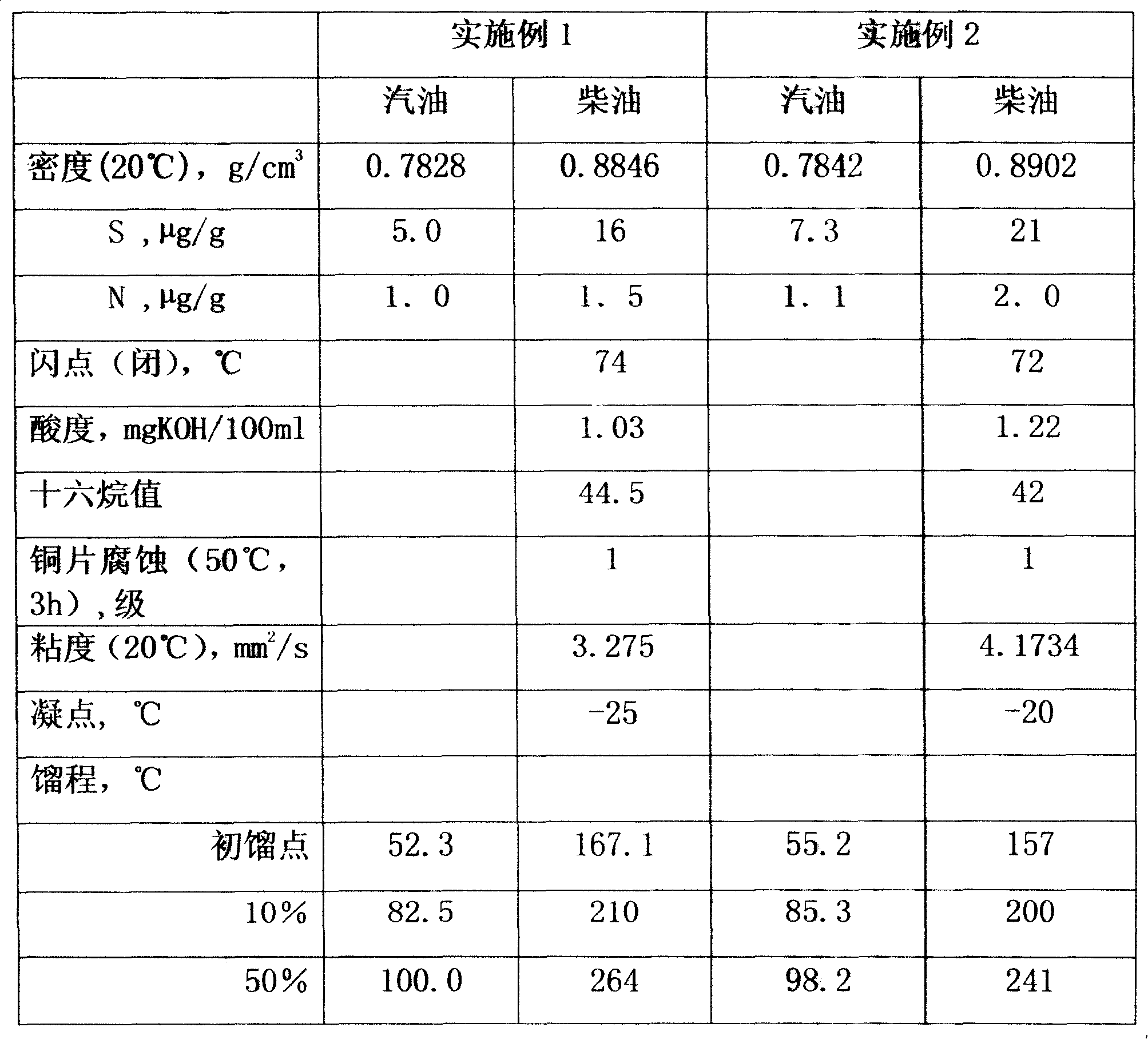

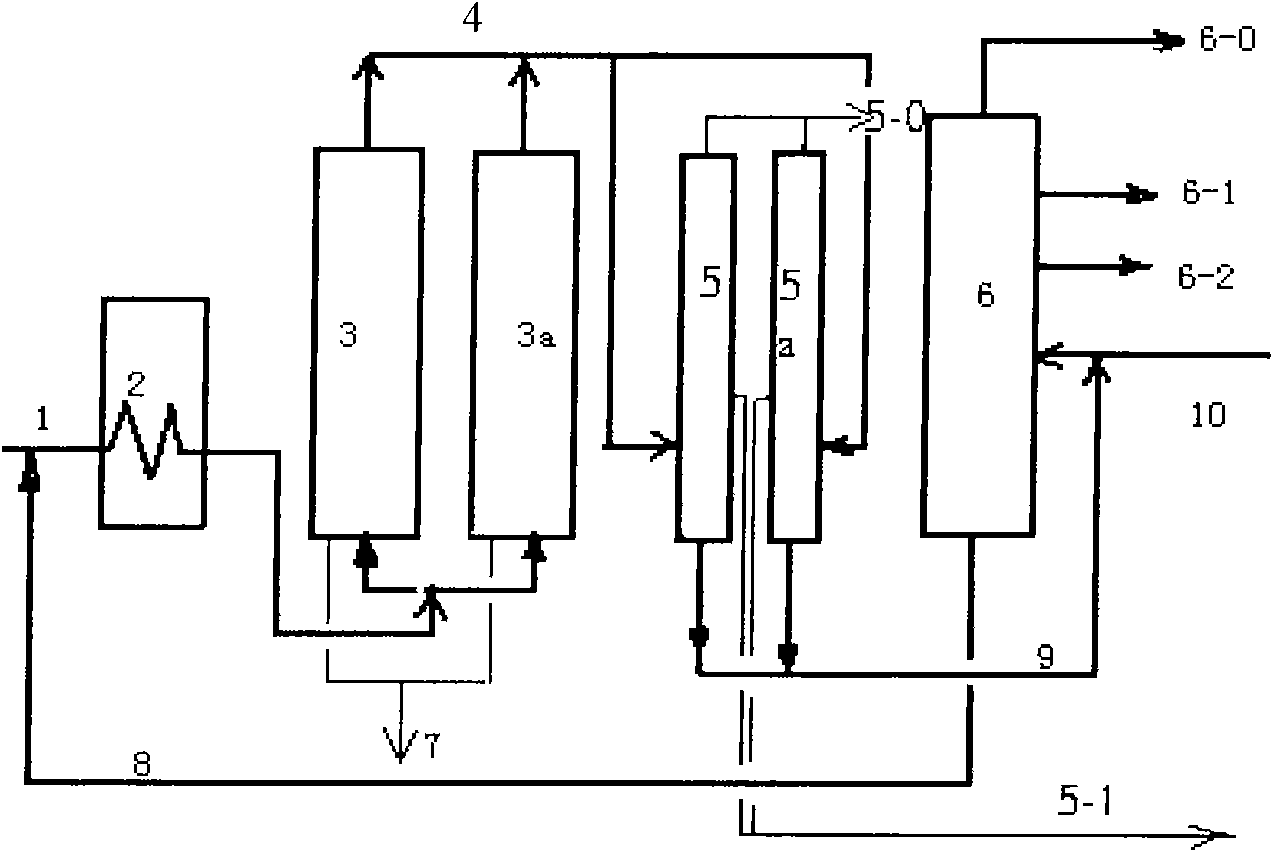

Coal tar multistage hydrogenation treatment technique

ActiveCN101240193AFully activeSolve cokingTreatment with hydrotreatment processesHydrogenation reactionGasoline

The invention discloses a coal-tar oil multistage hydrogenation craft, which belongs to coal chemical industry technology area. The method of the invention is that coal-tar oil fraction oils like impurities, sols, high content, asphaltenes, oxygen element, and so on, with high content or entire fraction are delivered into pre-hydrogenation reaction chamber by pump and are carried on pre-hydrogenation processing, then are successively followed by hydrogenation and demetallization, and depth hydrogenation reaction. After carried on separation of water and lightweight components, the generative fluid enters into a hydrocracking reactor, passes by a distiller to get gasoline fractions, diesel oil and hydrocracking tail oil out. Compared with the prior art, the invention can guarantee the long-period stability operation of the installation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation process for producing catalytically cracked material

ActiveCN101020843AImprove processing depthExpand sourceRefining to eliminate hetero atomsHydrogenation processResidual oil

The hydrogenation process for producing catalytically cracked material includes the successive contacting and reaction of the mixture of material oil and hydrogen with hydrogenation protecting agent, residual oil hydrogenating and demetallizing agent and residual oil hydrogenating and desulfurizing agent, cooling the reaction resultants, and separating obtain hydrogen-rich liquid and gas products. The catalyst includes hydrogenation protecting agent in 2-10 vol%, residual oil hydrogenating and demetallizing agent in 5-70 vol%, and residual oil hydrogenating and desulfurizing agent 20-93 vol%. The present invention makes it possible to produce high quality catalytically cracked material via adding residual oil in 5-50 wt% into gas oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

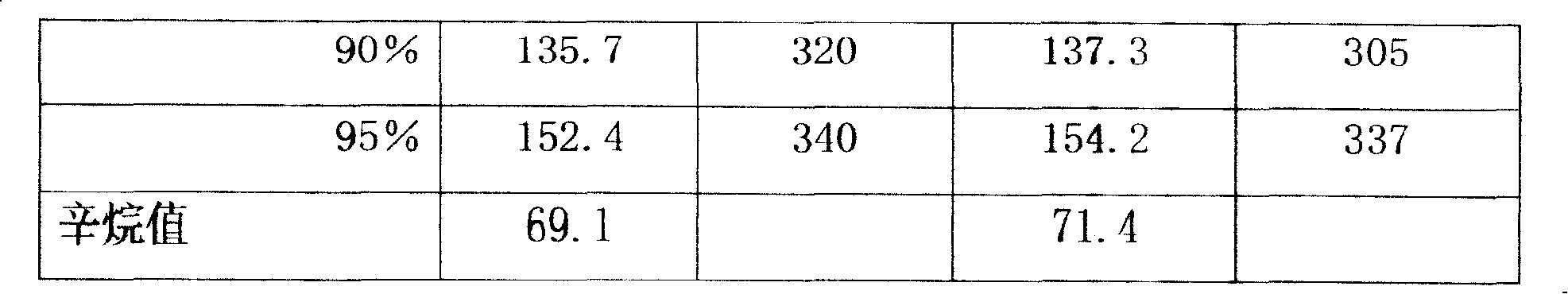

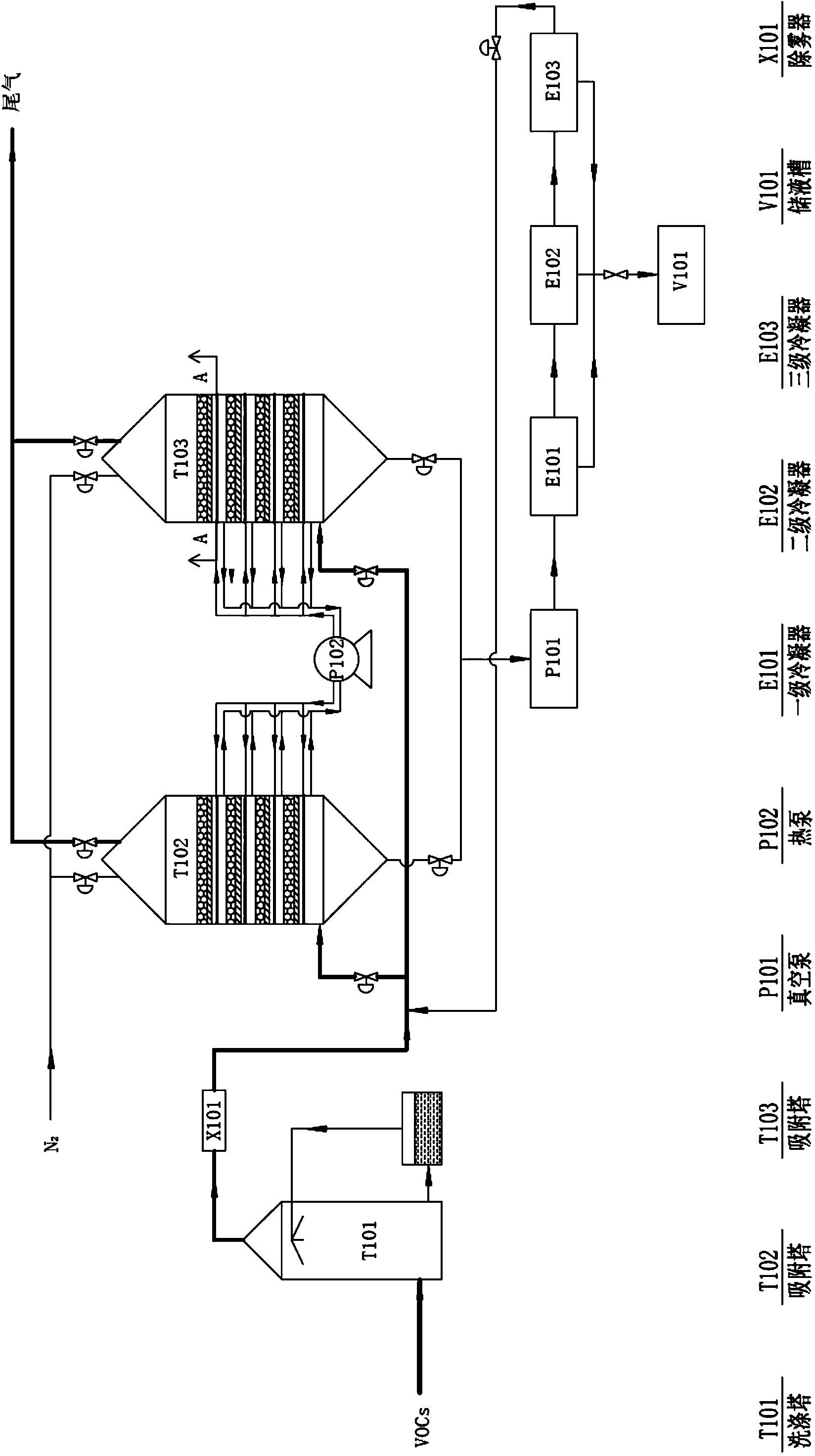

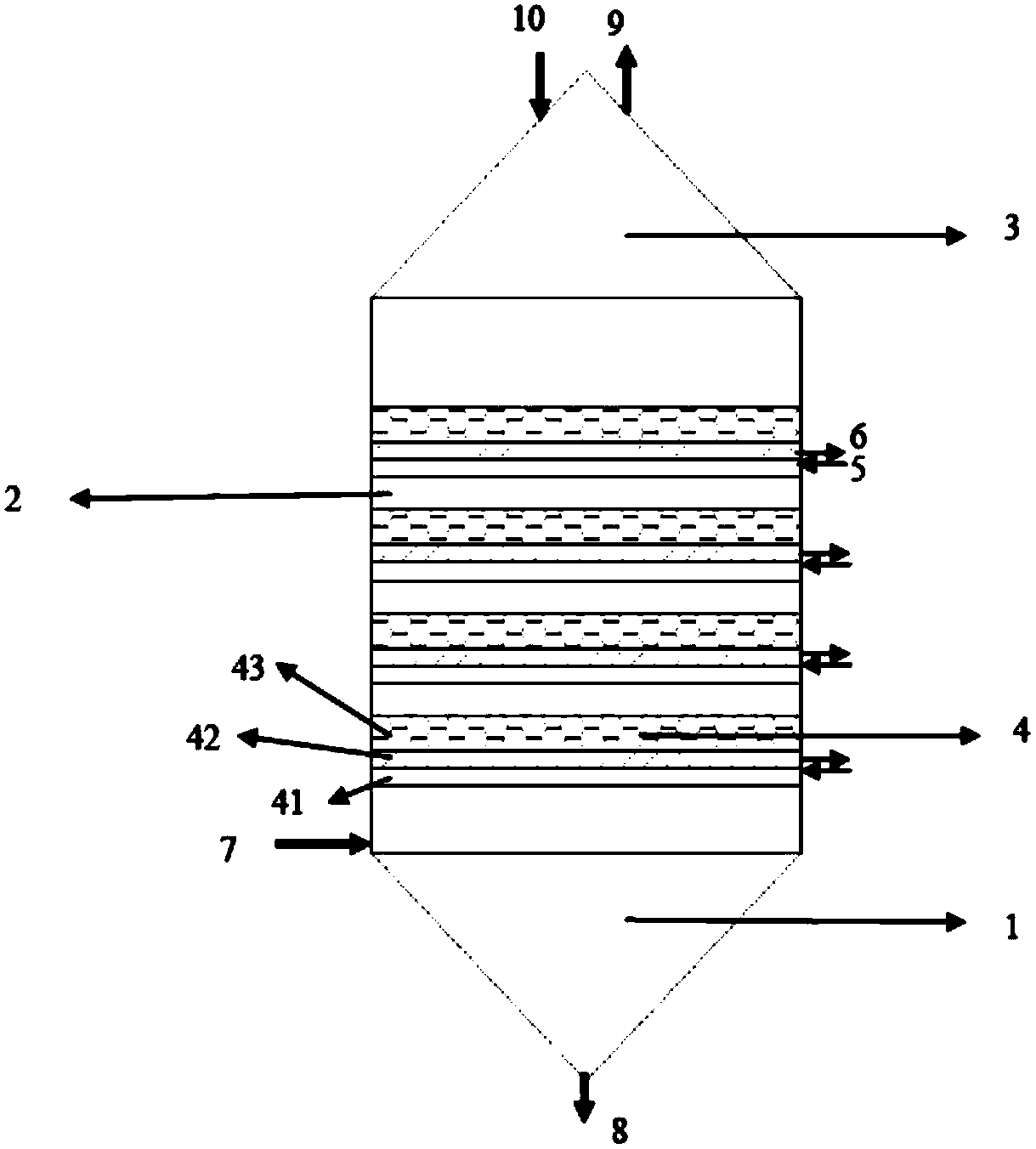

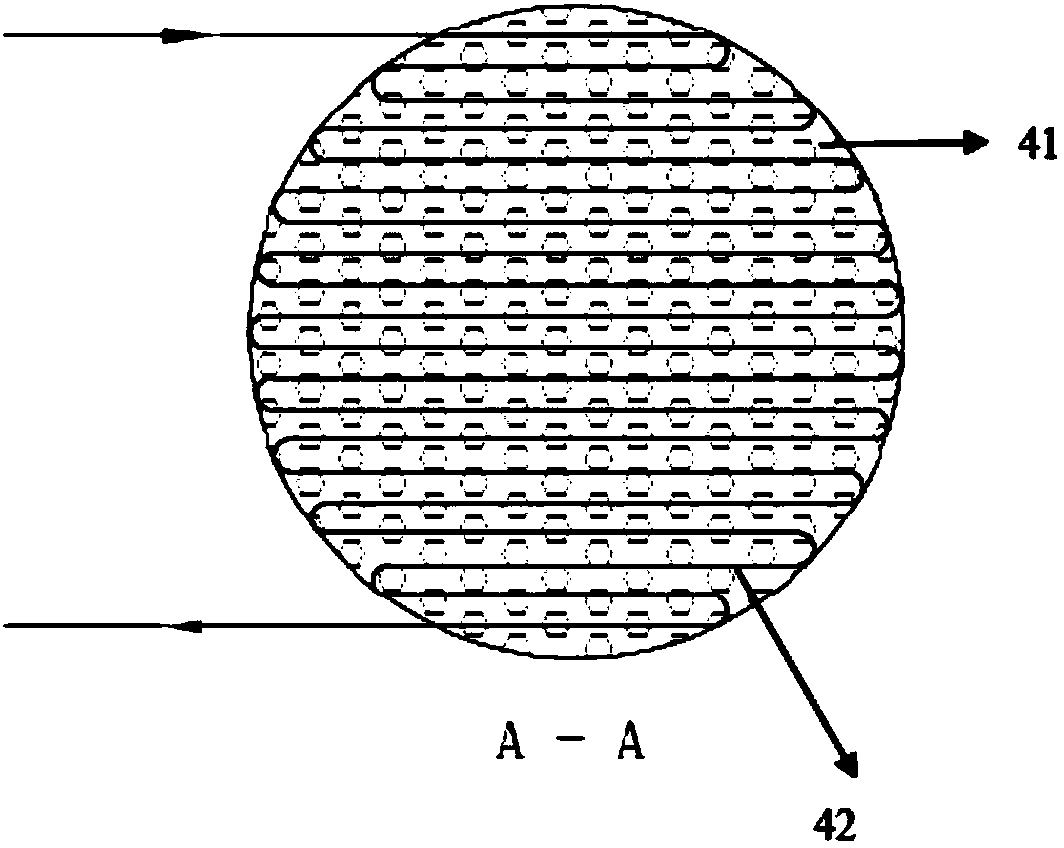

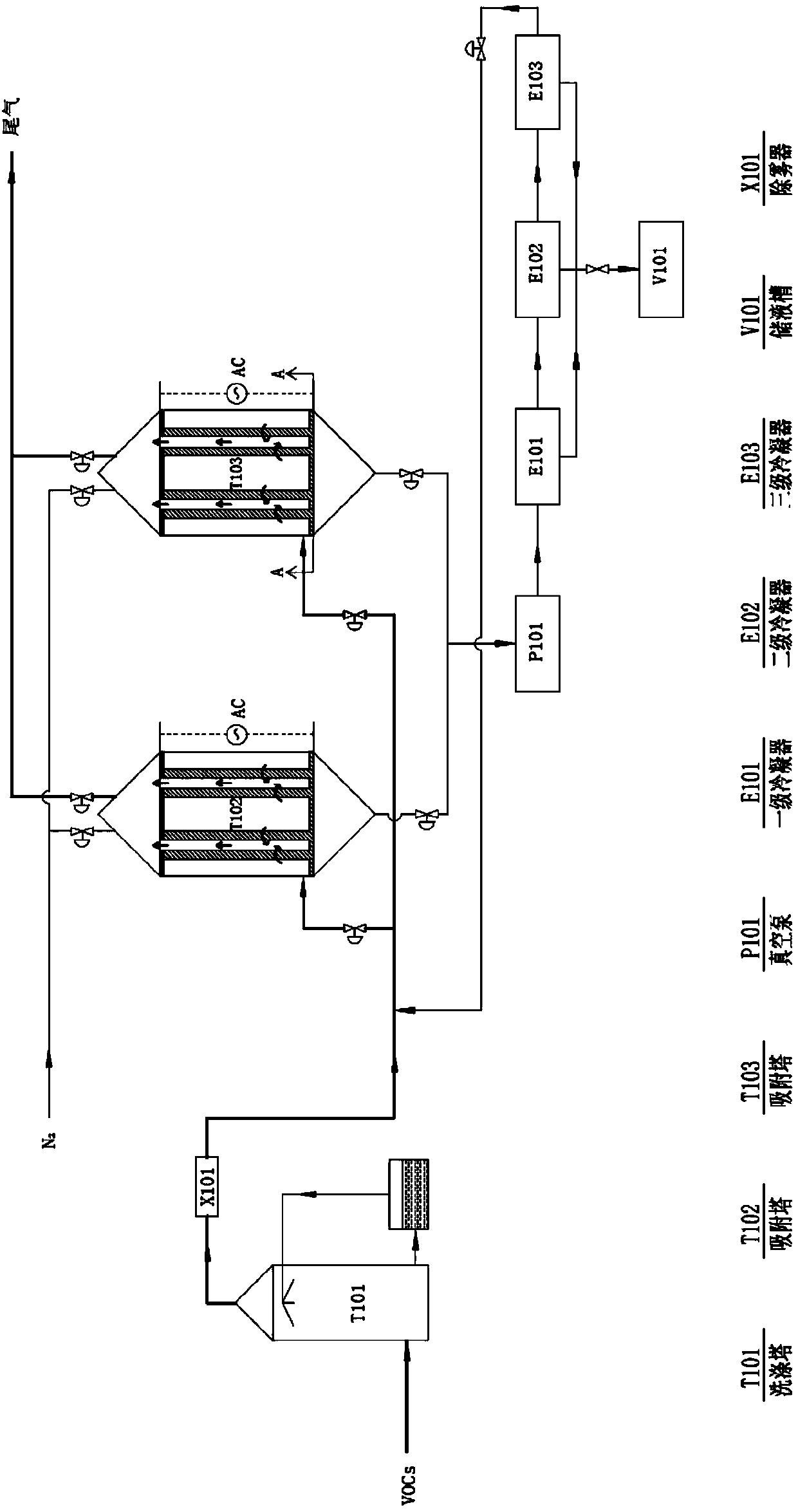

Organic waste gas adsorbing recovery device and process

ActiveCN103877827AHigh recovery rateAvoid cokingDispersed particle separationProduct gasHigh concentration

The invention discloses an organic waste gas adsorbing recovery device and a process. The device comprises at least two macromolecule resin adsorbing towers, a heat pump, a vacuum pump, a condenser, a liquid storing tank and the like, wherein the macromolecule resin adsorbing towers are internally provided with waste gas inlet regions, purifying regions for adsorbing and purifying gas and a purifying gas discharging region; the purifying regions are provided with adsorbing layers which are horizontally paved, the adsorbing layers are composed of multi-hole supporting plates fixed on the adsorbing towers, heat exchanging coils paved above the multi-hole supporting plates and macromolecule resin layers which are fully paved on the cross sections of the adsorbing towers above the heat exchanging coils successively in a overlaying manner, and the heat exchanging coils are provided with inlets and outlets communicated with the heat pump arranged outside the adsorbing towers. The organic waste gas adsorbing recovery device and the process provided by the invention have the advantages that a non-flammable macromolecule resin is adopted as an adsorbing material, the removing rate of middle-high concentration organic waste gas is more than 98%, the organic waste gas recovery rate is more than 95%, the resin is fully regenerated, and the organic waste gas can reach the discharge standard.

Owner:杭州润信科技有限公司

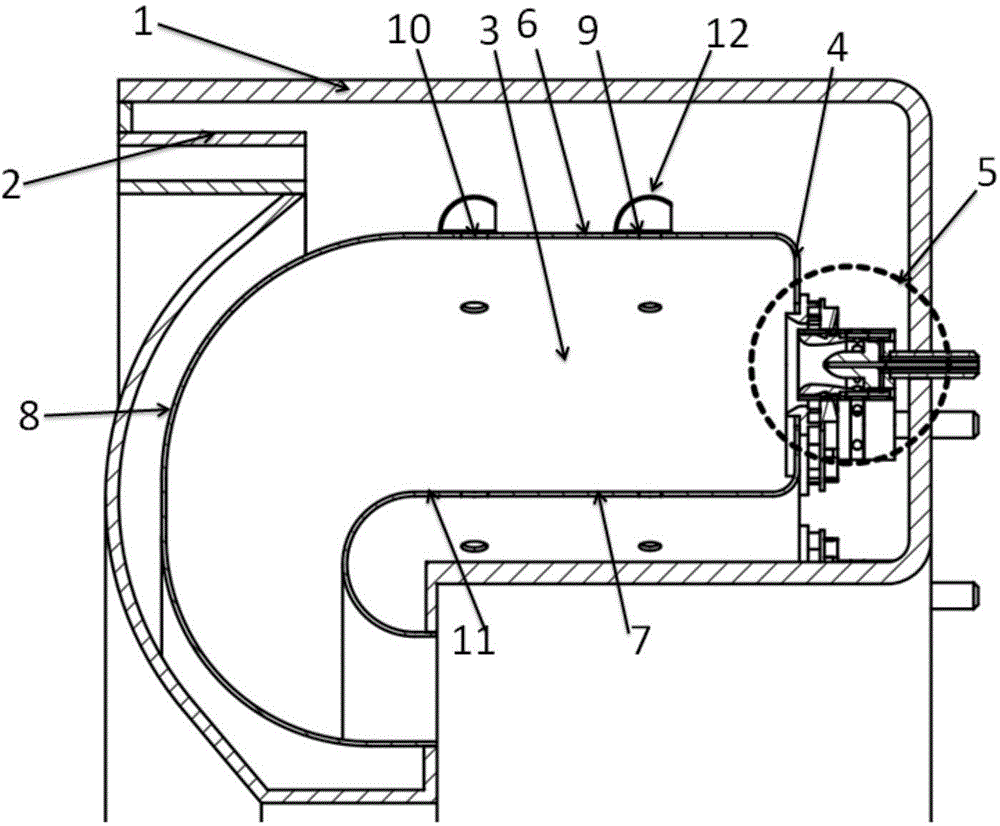

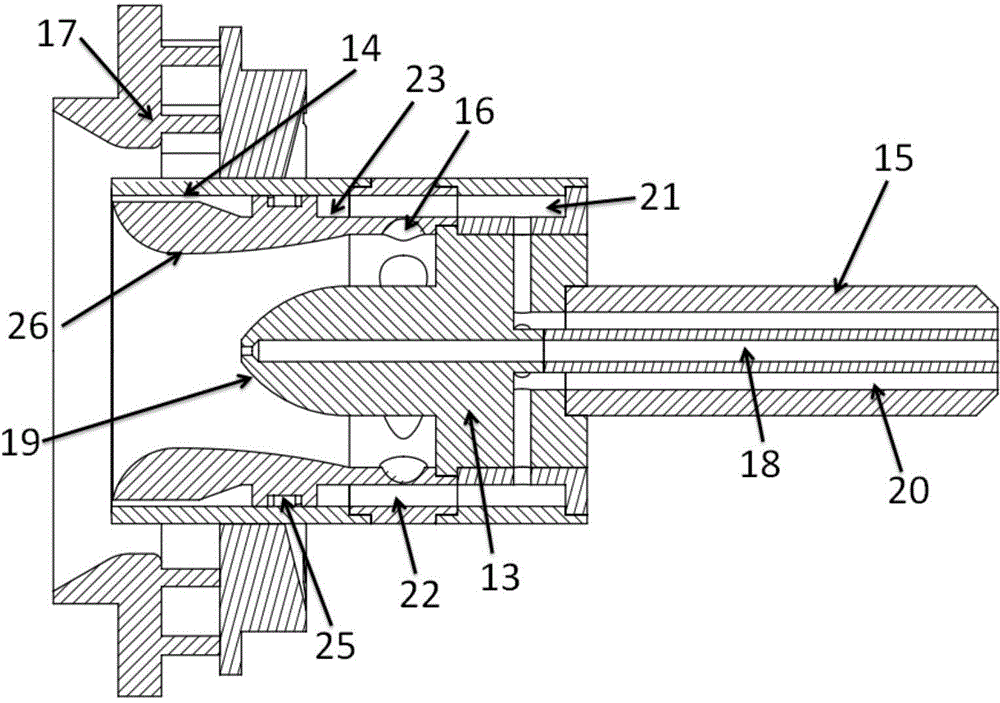

Reverse flow combustor allowing wider range of stable running

ActiveCN104676650AAvoid cokingGuarantee atomization qualityContinuous combustion chamberCombustorCombustion chamber

The invention provides a reverse flow combustor allowing a wider range of stable running. The reverse flow combustor comprises a diffuser, a combustor casing, a flame cylinder head end wall, a flame cylinder outer wall, a flame cylinder inner wall, a large elbow and a head atomizer. Air enters the combustor through the diffuser; part of the air enters a flame cylinder through the head atomizer; another part of the air enters through a main combustion hole of the flame cylinder and a mixing hole thereof, the remaining enters from a cooling structure. The air and fuel fully mix and combust in the flame cylinder. After passing by two 180-degree turns, the air leaves the combustor. The head atomizer performs atomizing in a mixed mode of pressure centrifugal atomizing and pre-swirling prior to pre-film air atomizing; the fuel is fed through a main oil circuit and an auxiliary oil circuit; the main combustion hole arranged in the outer wall of the flame cylinder and the mixing hole thereof are provided with a hood, jets are avoided flowing to the head, and inner and outer jets are ensured being symmetrical. The range of stable running of the reverse flow combustor can be expanded, and uniformity of fuel gas temperature of an outlet is guaranteed.

Owner:BEIHANG UNIV

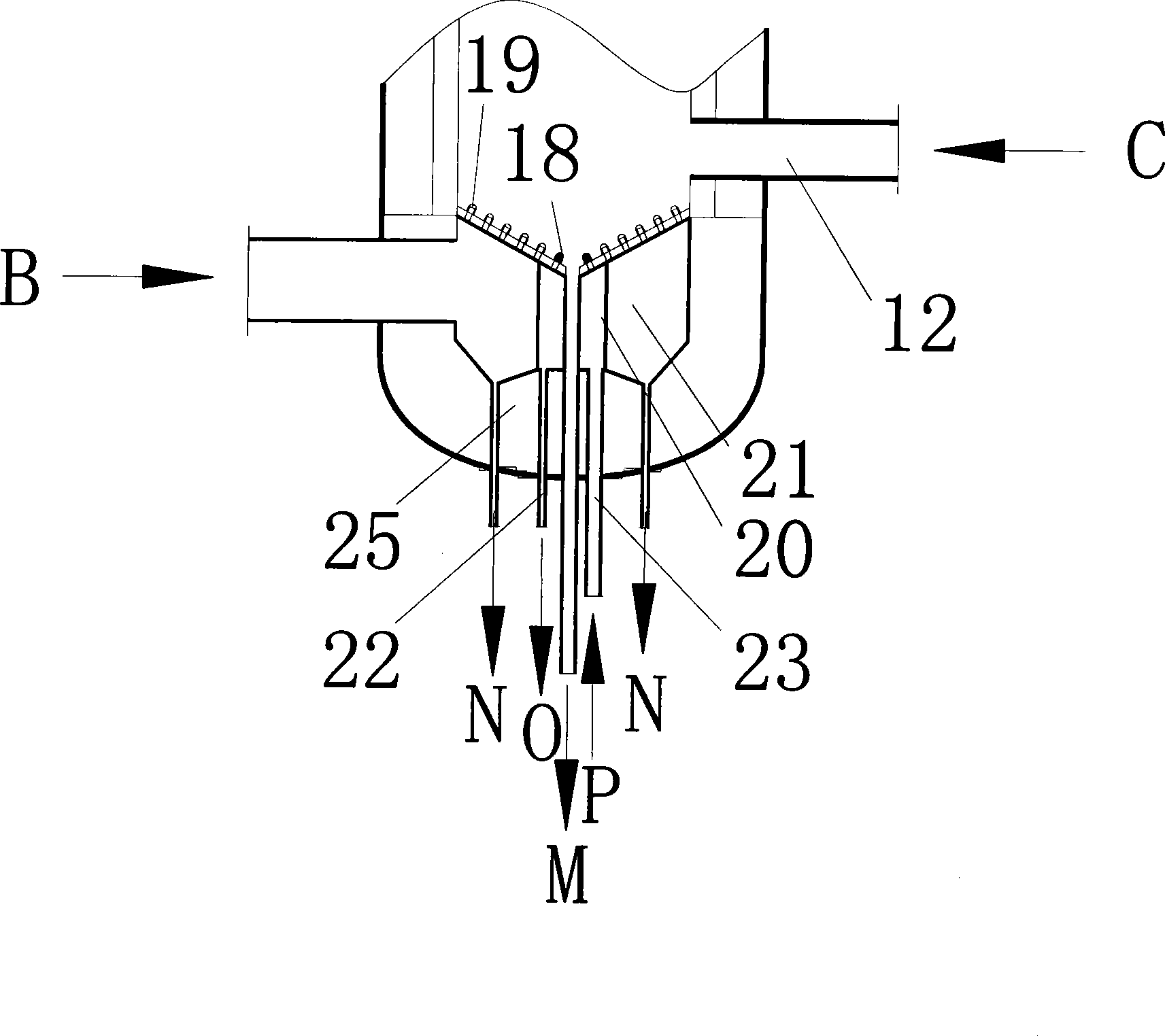

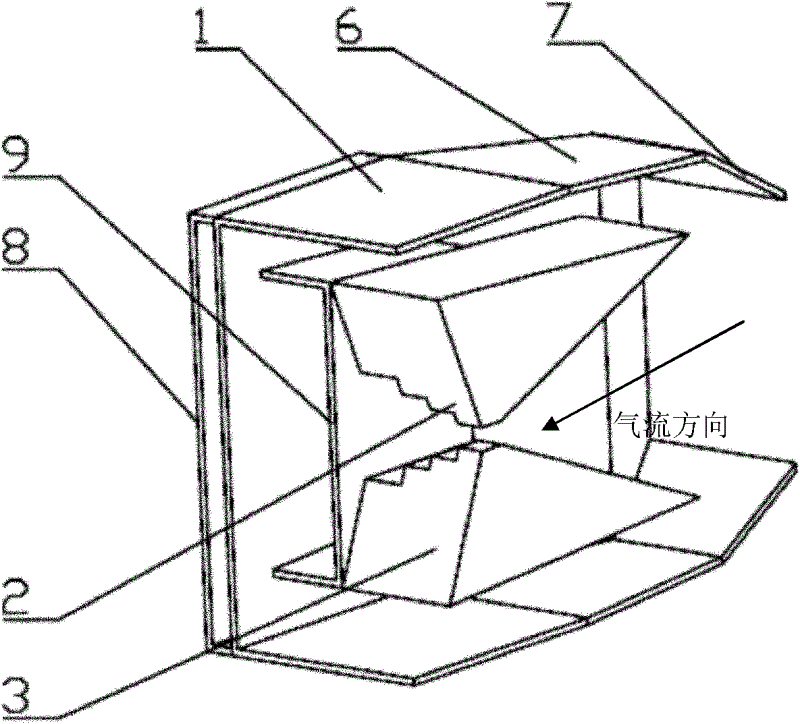

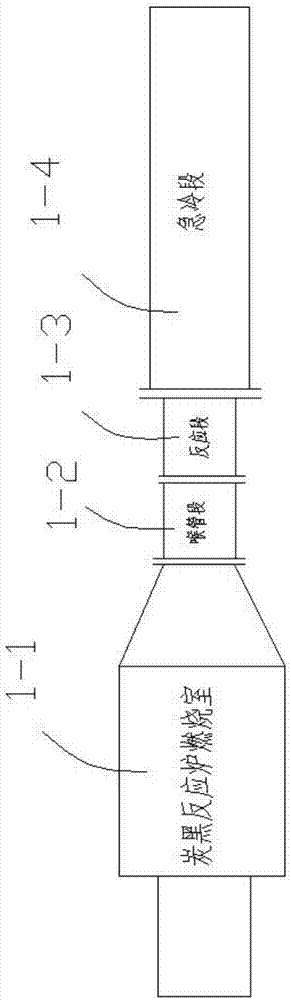

Pulverized coal decoupling combustor with low nitrogen oxide discharge and pulverized coal decoupling combustion method with low nitrogen oxide discharge

InactiveCN102620291ASeparation perimeter lengthSmall steering anglePulverulent fuel combustion burnersIndirect carbon-dioxide mitigationProcess engineeringCoal

The invention relates to a pulverized coal decoupling combustor with low nitrogen oxide discharge and a pulverized coal decoupling combustion method with low nitrogen oxide discharge. The method is implemented through the following two stages: a) stage 1, firstly separating mixed airflow of pulverized coal and air into a concentrated part and a dilute part by virtue of the pulverized coal decoupling combustor provided by the invention, igniting the concentrated pulverized coal airflow, then feeding the concentrated pulverized coal airflow into a hearth, and performing combined combustion on the concentrated pulverized coal airflow and the dilute pulverized coal airflow; and b) stage 2, mixing the mixed airflow with secondary air in the hearth, and fully combusting the pulverized coal semicoke generated in the stage 1 under conditions of rich oxygen and high temperature which is insufficient to generate thermal NOx, wherein in the stage 1, the pulverized coal is pyrolyzed, gasified and gas-fired under reducing atmosphere, volatile components are fully separated out, products of pyrolysis and gasification are utilized to convert fuel-type NOx into more stable N2. According to the invention, an integration design of pulverized coal condensation, stable combustion and low nitrogen oxide discharge can be realized, the equipment structure is compact, the pulverized coal condensation effect is good, the stable combustion capability is strong, and the potential of inhibiting NOx from generating is high.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

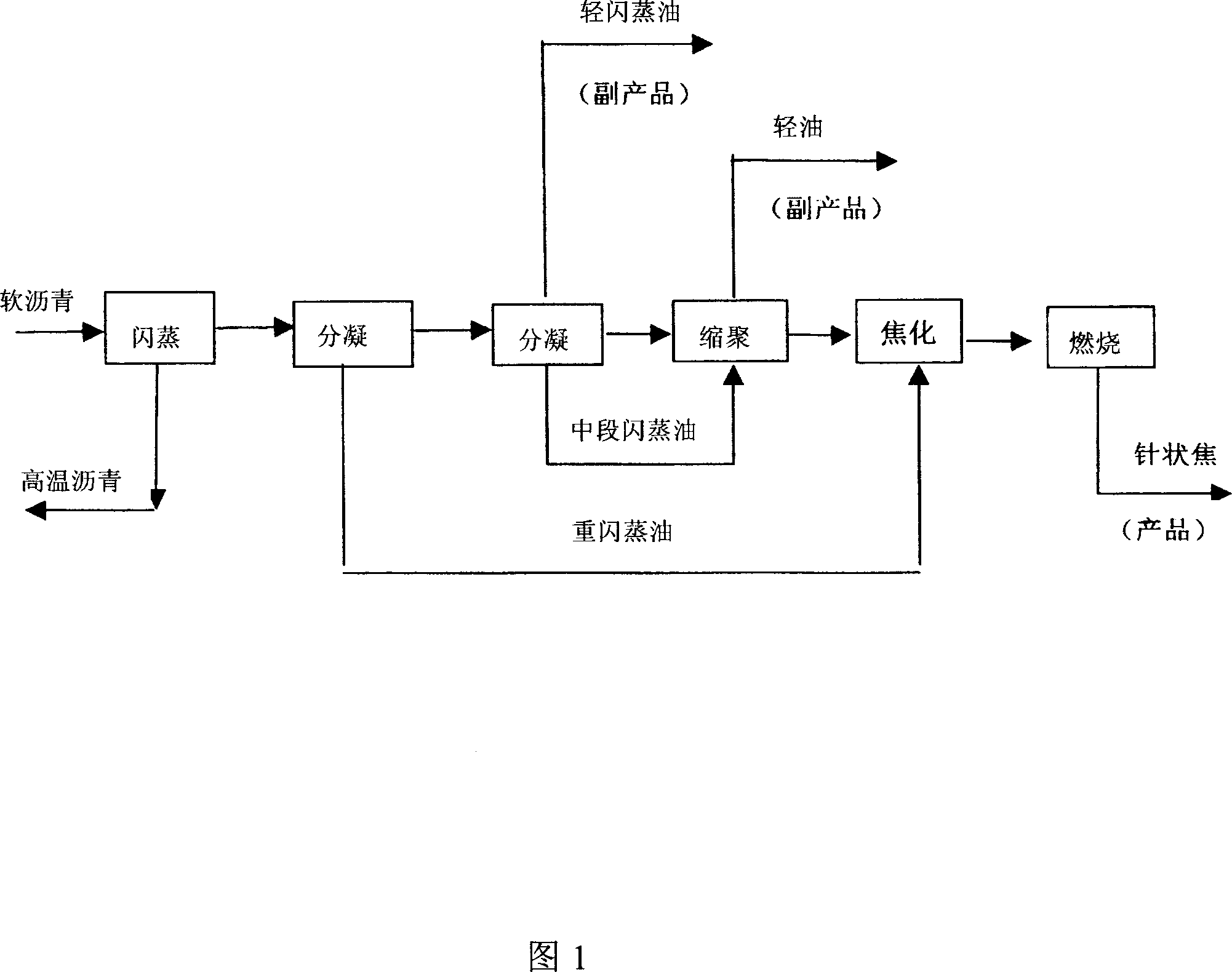

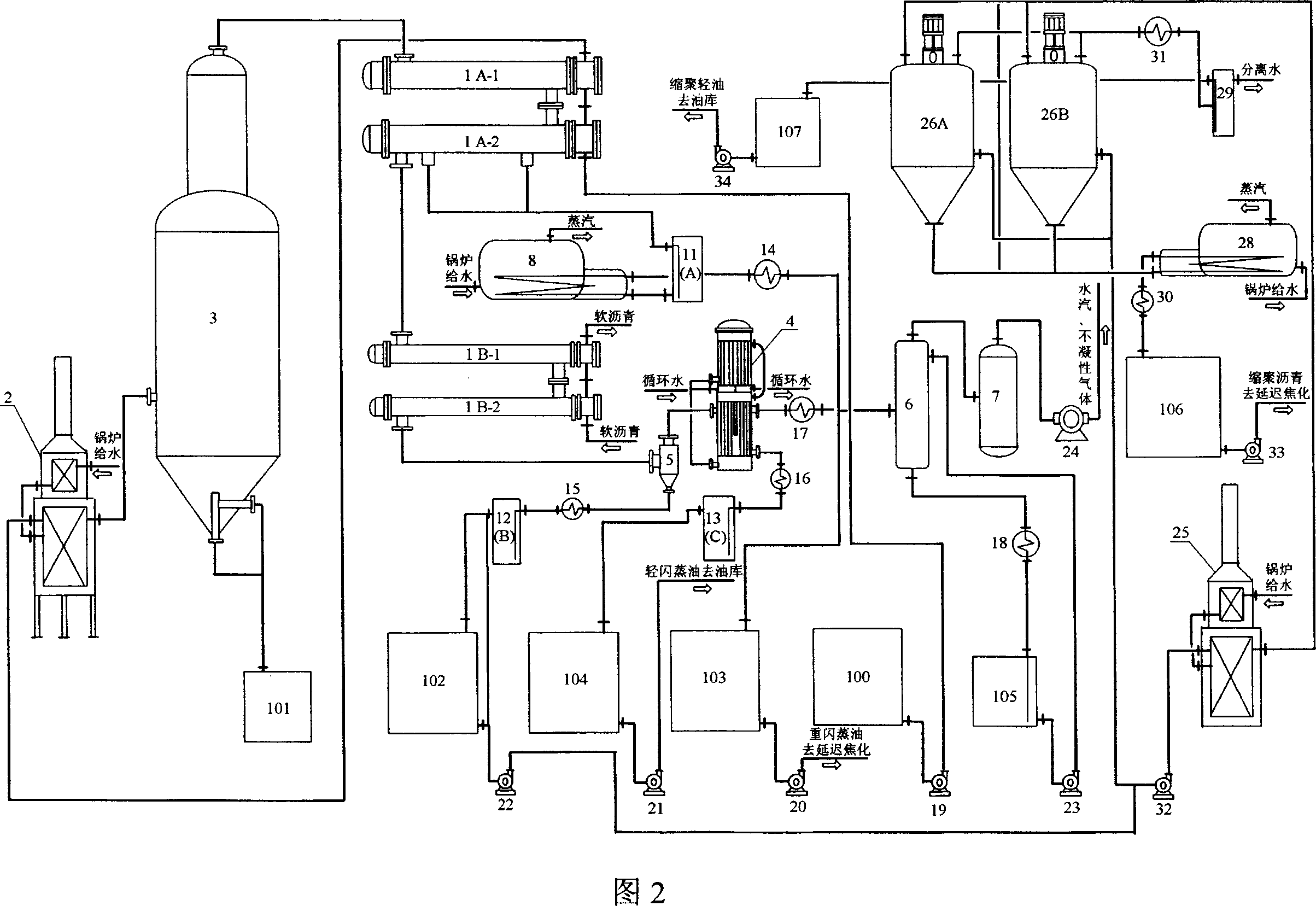

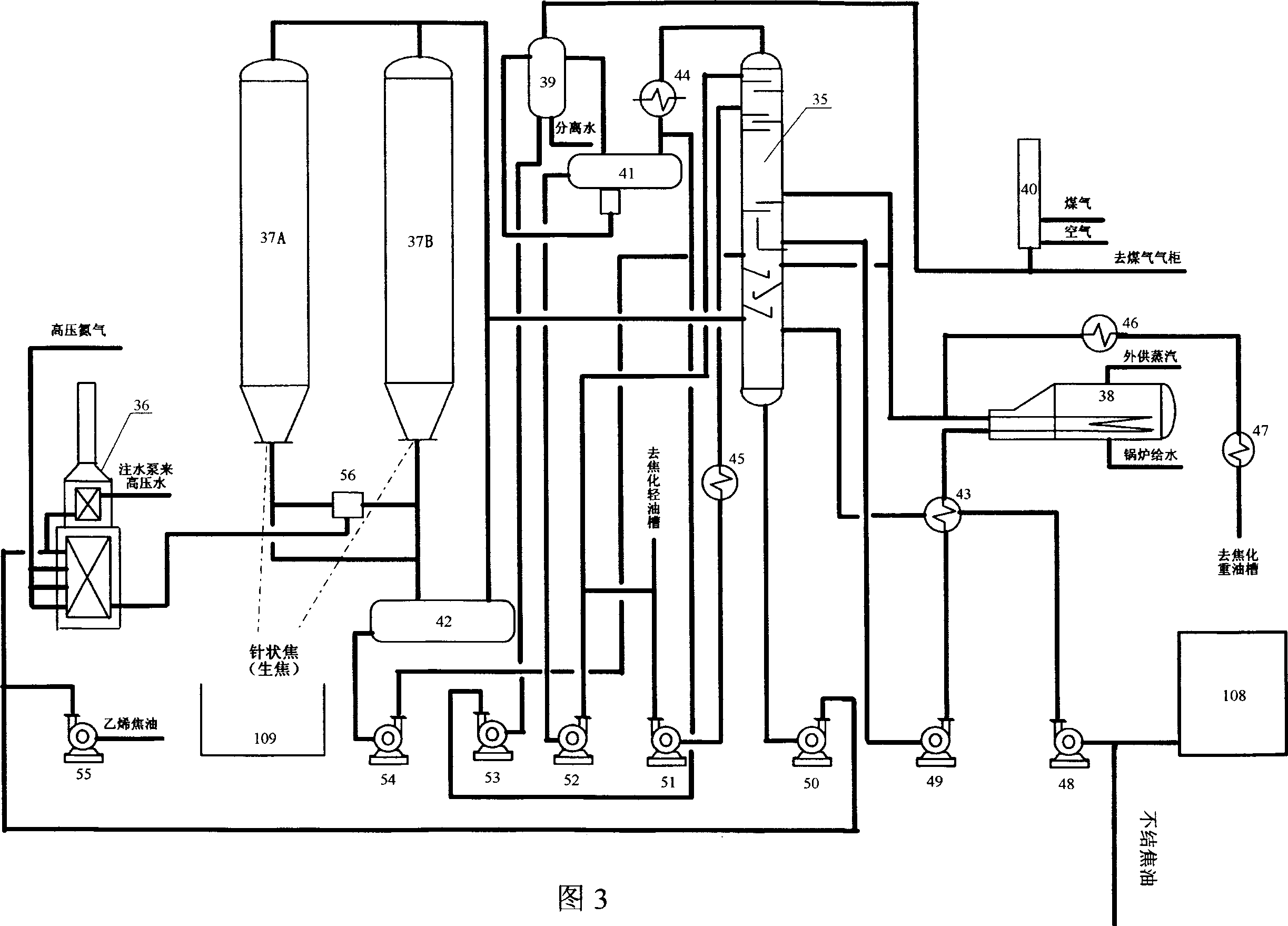

Industrial producing process for coal series needle coke

ActiveCN1944578AHigh molecular weightSmall molecular weightCoking carbonaceous materialsGraphite electrodeGraphite

The industrial producing process of coal series needle coke includes the following steps: stepped condensing the flash oil produced in vacuum flashing of coal tar pitch to obtain three, heavy, medium and light, fractions; polycondensating the medium fraction in an improved pitch circulating process to obtain condensed pitch; delay coking the condensed pitch and the heavy fraction and injecting N2 into the un-coked oil in the later coking stage to perform the final heating and coke drawing of the needle coke forming course; and final high temperature calcining to obtain coal series needle coke. Thus produced coal series needle coke has low thermal expansion coefficient and may be used in producing high power and super high power graphite electrode.

Owner:山西宏特煤化工有限公司

Combined processing method capable of improving coking liquid-phase product yield

ActiveCN101619237ALow costReduce operating costsThermal non-catalytic crackingVacuum distillationWaxEconomic benefits

The invention discloses a combined processing method capable of improving coking liquid-phase product yield. In the method, coke powder is removed from high-temperature oil gases produced by a delayed coking device in a coke powder-removing tank, light components are extracted at the same time, heavy components enter a reduced pressure distillation device to separate a wax oil fraction, and obtained vacuum residues are used as delayed coking feed. The method avoids product fractionation in the prior coking fractional distillation column, thereby greatly reducing investment and operation cost.The method improves the yield of coking waxy oil and ensures the quality of the coking waxy oil. With the increase of the extraction amount of the coking waxy oil, the amount of coking circulation oil is greatly reduced and the processing capacity of the coking device is improved, so the economic benefits are increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production system and process of pigment carbon black with low impurity content

The invention discloses a production system and process of pigment carbon black with low impurity content and relates to the field of production of carbon black. The production system comprises a raw material supply device, a reaction device, pre-heating devices, a collection device, a granulation device and a storage and packaging device, wherein air, raw oil and fuel oil enter the reaction device from the respective pre-heating devices; carbon black flue gas passing through the reaction device is used for pre-heating the air and the raw oil and sequentially enters the collection device, the granulation device and the storage and packaging device to finish carbon black collection; in the production process, the raw oil passes through four paths of filtering devices in advance; before an additive is blended, the raw oil is pre-dissolved with water; quenched water needs to be purified; an ultrafine grinding device is arranged in the collection device; the content of non-carbon impurities in a production process is effectively reduced and the purity of the pigment carbon black is improved; advanced equipment and process technology are adopted so that the aim of reducing the content of the impurities in a carbon black finished product is realized.

Owner:四川博蓝科新材料有限公司

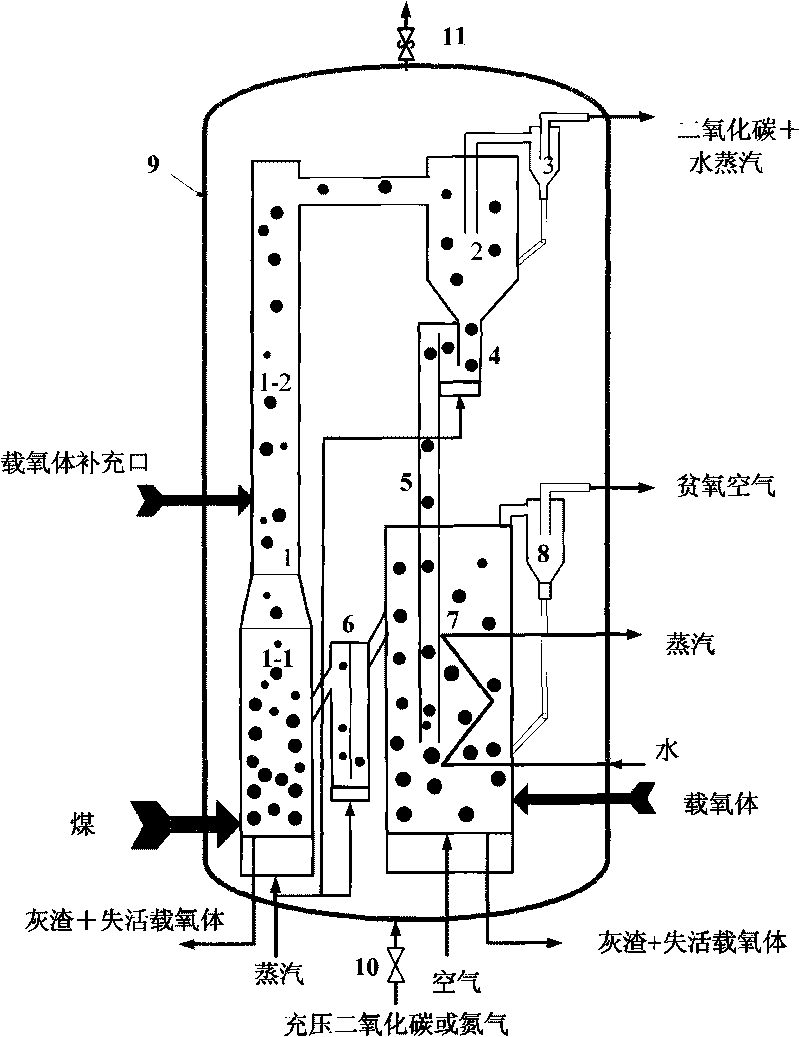

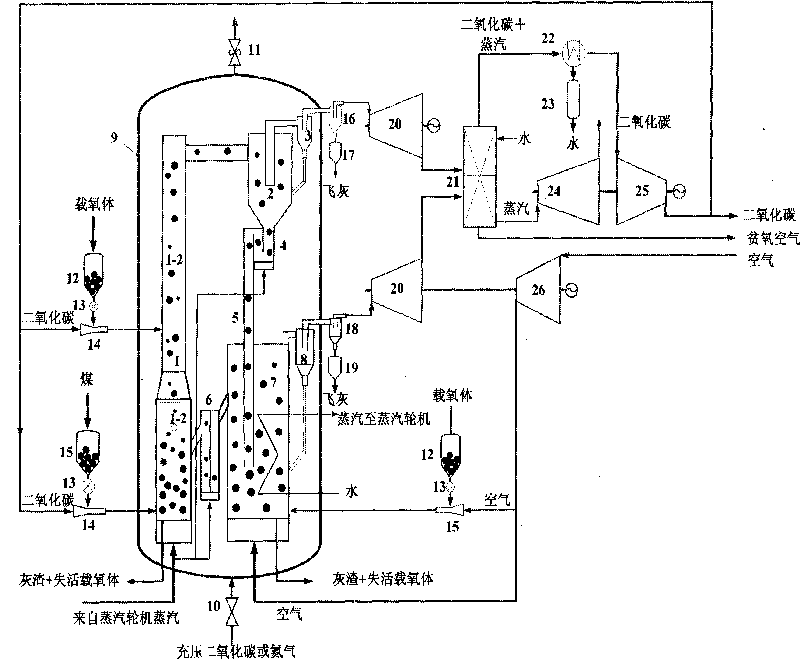

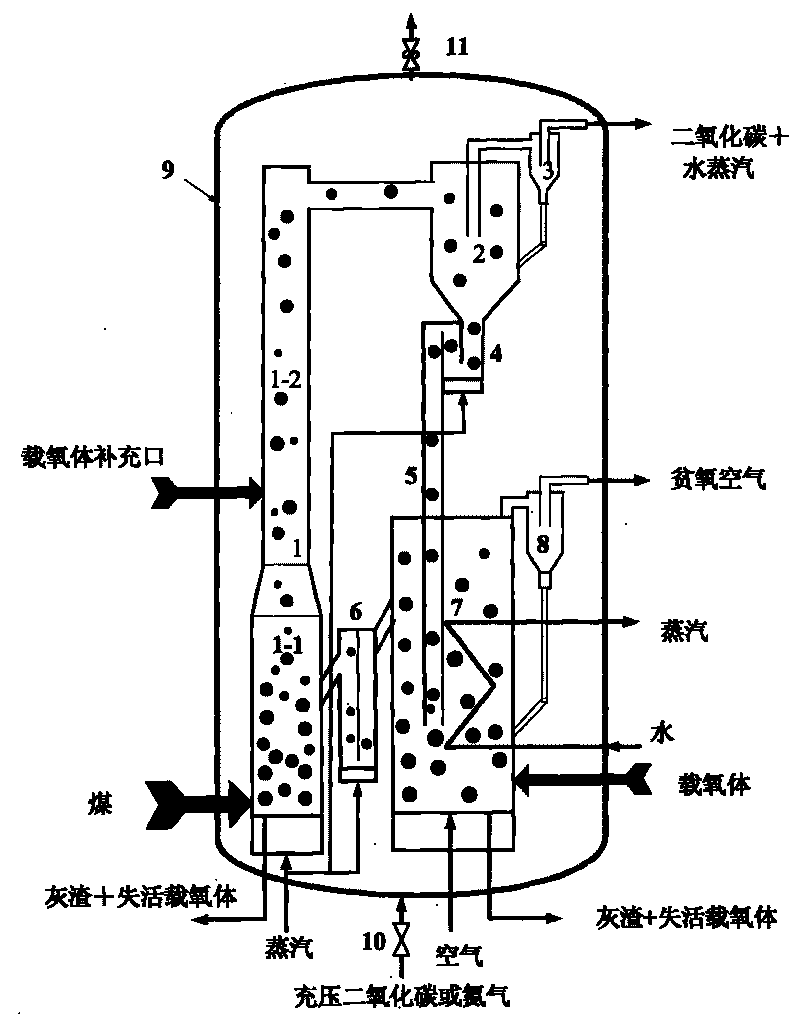

Coal combustion apparatus capable of separating carbon dioxide and separation method thereof

InactiveCN101699187AEasy to handleReduced compression energy consumptionExothermal chemical reaction heat productionCarbon compoundsCycloneEngineering

The invention provides a coal combustion apparatus capable of separating carbon dioxide, which is mainly formed by connecting a fuel reactor, a primary cyclone separator, a dipleg and an air reactor in series; wherein the lower part of the fuel reactor is provided with a mixing chamber with large cross section, and the upper part thereof is provided with a lifting tube with small cross section; and the height of the lifting tube is over three times higher than that of the mixing chamber. The invention also provides a method using the coal combustion apparatus capable of separating the carbon dioxide to separate the carbon dioxide. The fuel reactor adopts the structure of a reactor with long residence time, internal circulation can be formed by granules, and the gas-solid turbulence is improved; the air reactor adopts a moving fluidized bed to ensure the operation to be stable, so that the heat can be evenly released; meanwhile, a heat exchanger is arranged inside the bed, so that coking caused by local overheating since a great deal of heat is released in a centralized way in oxidation reaction can be avoided. Furthermore, the fuel reactor and the air reactor run under the pressure, so that the equipment can be compact, the utilization efficiency of system energy is high, and the subsequent carbon dioxide compression energy consumption is reduced.

Owner:SOUTHEAST UNIV

Hydrofining process of waste lubricating oil

ActiveCN104611058AHigh compressive strengthExtended service lifeTreatment with hydrotreatment processesHydrogenation reactionReaction temperature

The invention provides a hydrofining process of waste lubricating oil. The process comprises: after pre-treating, dewatering and removing impurities from a raw material, removing pitch and colloid in a propane extraction or wiped film vaporization device, and perfecting the product quality via a two-stage hydrofining reactor, and filling a hydrogenation protective agent and a demetallization agent in a pre-hydrogenation reaction, wherein the reaction temperature is 310-360 DEG C, the pressure is 6-12 MPa, the volume ratio of hydrogen to oil is 100-300, and the liquid volume space velocity is 0.5-1.2h<-1>, the reaction temperature of a main hydrogenation reactor is 320-400 DEG C, the pressure is 6-12 MPa, the volume ratio of hydrogen to oil is 500-1000, the liquid volume space velocity is 0.2-0.6h<-1>, and the used catalyst is Ni-Mo-W-Ce / Al2O3 or Ni-Mo-P-La / Al2O3; no acid or alkali waste is discharged in the production process, thereby being environmentally friendly and pollution-free, the recovery rate of the waste oil is higher than 95%, and the oil quality can be greatly improved to increase the economic benefits.

Owner:WUHAN KELIN FINE CHEM

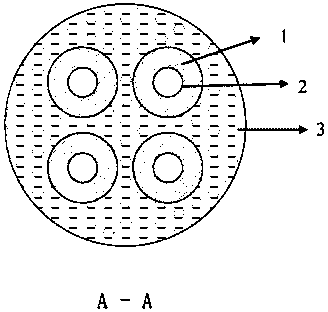

Device and process for recycling volatile organic gas in adsorption-desorption manner

ActiveCN103736359AHigh recovery rateComplete regenerationDispersed particle separationVapor condensationOrganic moleculesChemistry

The invention discloses a device for recycling a volatile organic gas in an adsorption-desorption manner and a utilization method of the device. The device comprises activated carbon fiber adsorption towers, a vacuum pump, a condenser and a liquid storage pot, wherein an activated carbon fiber adsorption column as well as an upper fixing rack and a lower fixing rack which are used for fixing the activated carbon fiber adsorption column are arranged in each adsorption tower; the activated carbon fiber adsorption column is formed by a hollow insulating pipe which has an airtight bottom and an upper opened end and activated carbon fiber fabric which wraps the wall of the side surface of the hollow insulating pipe; air through holes are formed in the wall of the side surface of the hollow insulating pipe; the wall of the side surface of the hollow insulating pipe is completely wrapped by the activated carbon fiber fabric; two ends of the activated carbon fiber adsorption column are connected with an electrode in which a current can be conducted. According to the device, organic molecules adsorbed by a plurality of activated carbon fiber adsorption towers are recycled in a desorption condensation manner through the combination of electric-heating and vacuum technologies. According to the process of the device, the continuous adsorption-desorption recycling of the organic waste gas can be realized, so that the recycling rate of the organic waste gas is high and the activated carbon fiber can be completely regenerated.

Owner:ZHEJIANG UNIV OF TECH

Ball grinder available for solid state reaction of powder

InactiveCN101823013AImprove mechanical energyMeeting the Energy Requirements of Solid-State Chemical ReactionsGrain treatmentsChemical reactionHigh energy

The invention relates to a ball grinder available for the solid state reaction of powder, which mainly comprises a ball grinding cylinder, an electromotor, a driving device, a grinding ball and a material inlet and outlet, wherein the horizontal type ball grinding cylinder is fixedly supported on a bracket; a jar is internally provided with the girding ball; the center of the ball grinding cylinder is provided with a rotatable main shaft; the main shaft is driven by the electromotor through the driving device to rotate; the main shaft is provided with a blade, wherein the rotating speed of the blade is 300-2000 r / min; the mechanical energy is transmitted to the grinding ball through the beating of the blade, so that the grinding ball can irregularly move with high speed; the bottom of theball grinding cylinder is in the shape of gradient with 0-30 degrees from the two ends to the center; the jar body of the ball grinding cylinder is provided with a cooling sleeve and an inlet and an outlet of cooling medium; and the jar body of the ball grinding cylinder is provided with an air exhausting opening and an air inlet. The ball grinder can lead the grinding ball to generate higher mechanical energy to provide high energy for inducing the solid state reaction among materials, thereby smashing, grinding and dispersing the materials and directly reacting to generate nanometer composite oxide.

Owner:BEIJING UNIV OF CHEM TECH

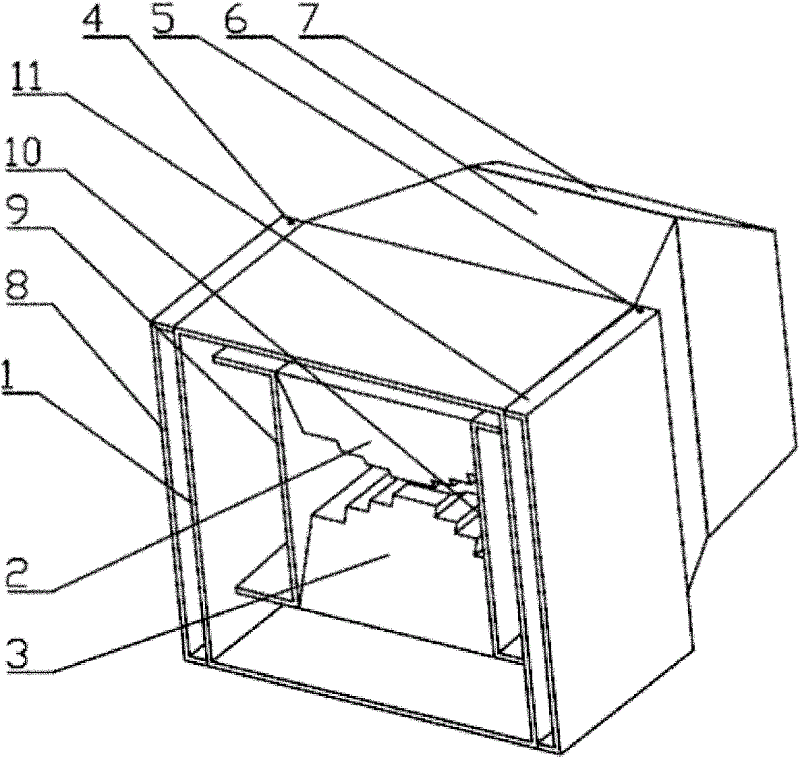

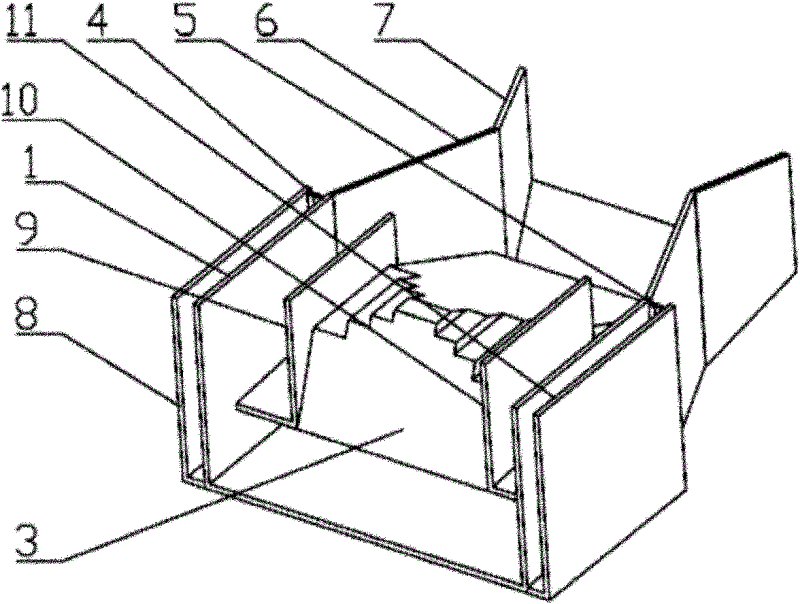

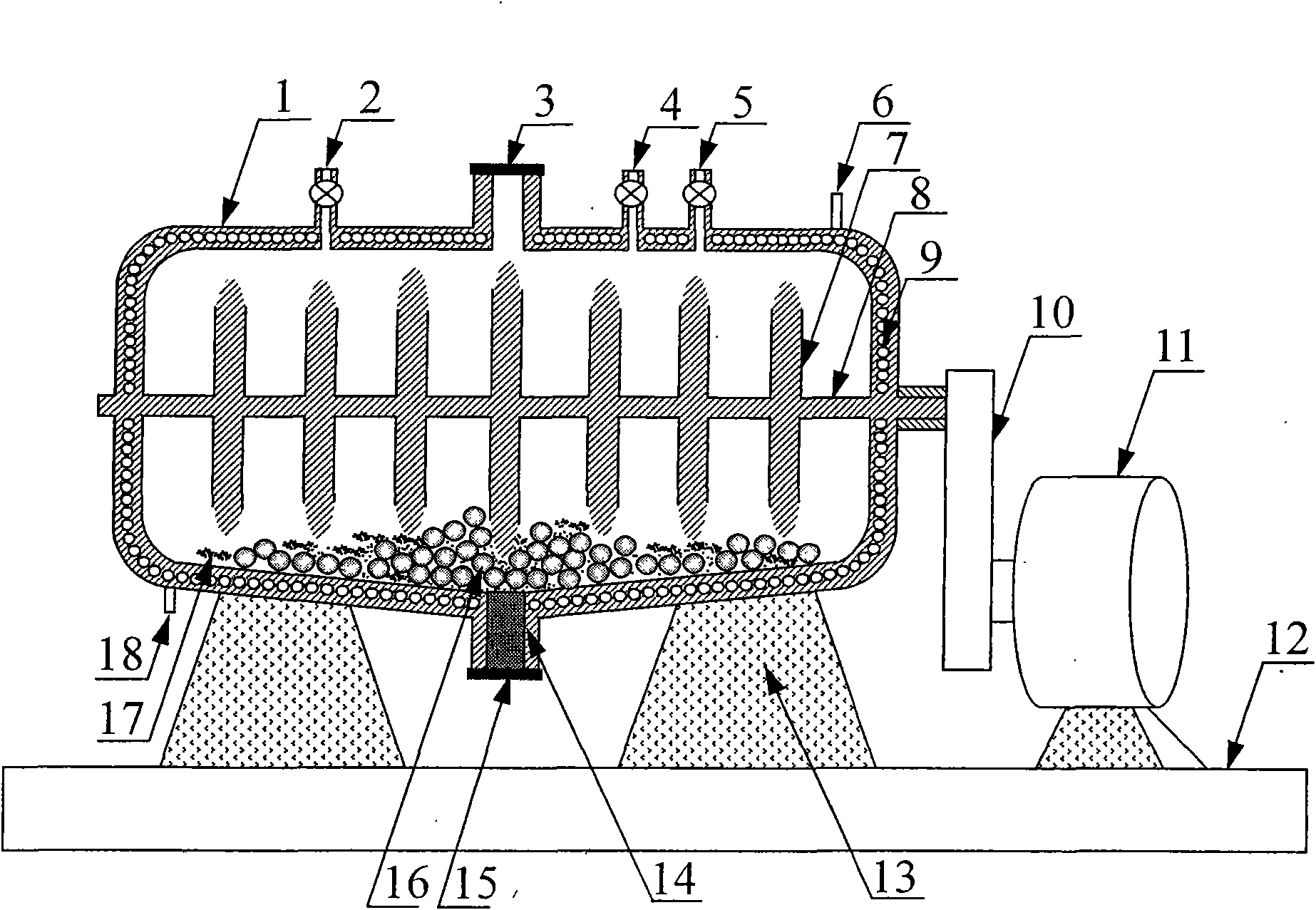

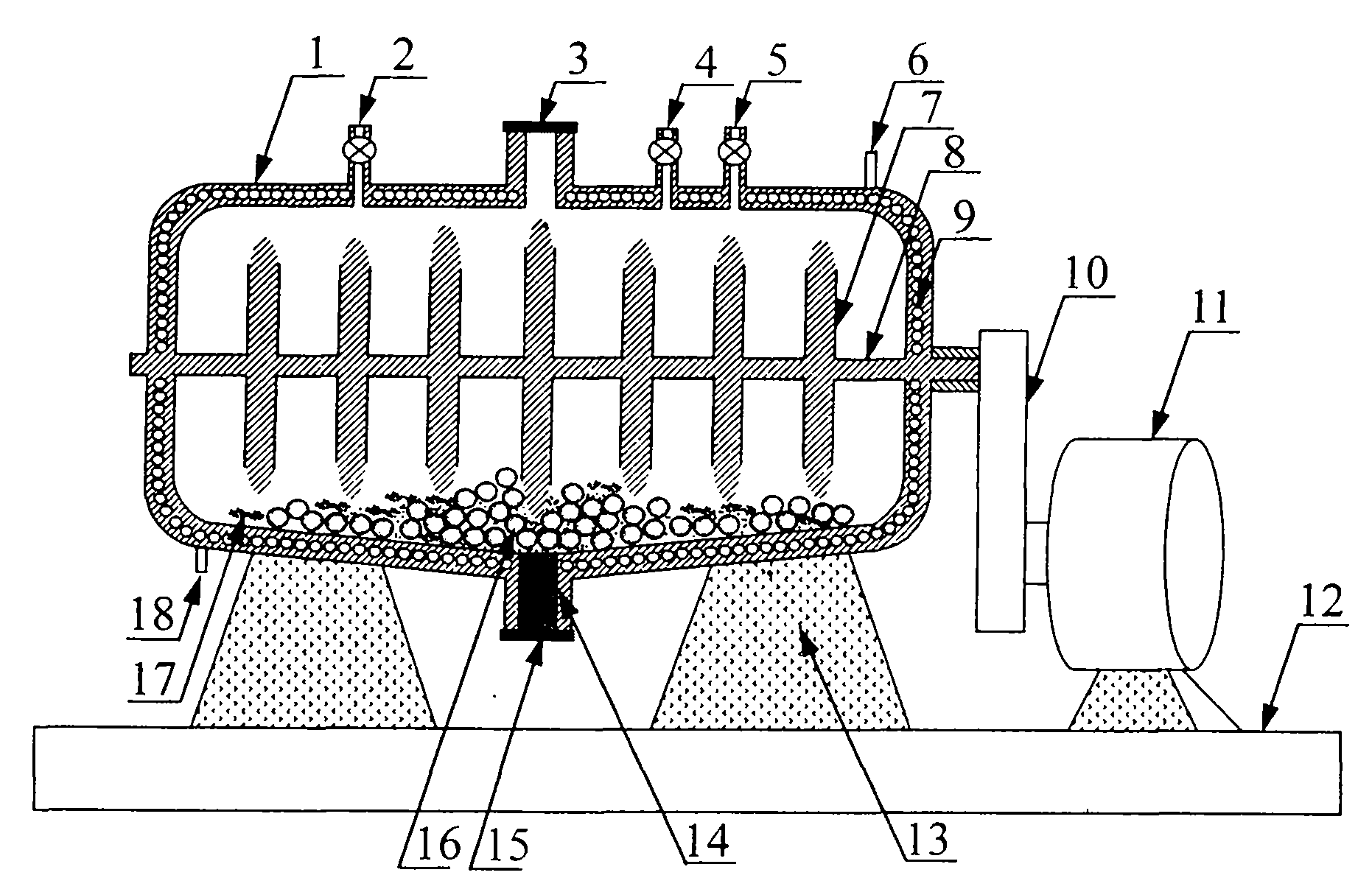

Water-cooled or air-cooled high-temperature horizontal cyclone separator of circulating fluidized bed with accelerating section

A water-cooled or air-cooled high-temperature horizontal cyclone separator of a circulating fluidized bed with an accelerating section relates to a water-cooled or air-cooled high-temperature horizontal cyclone separator. The invention aims to solve the problem that the separator of the existing circulating fluidized bed boiler has large volume, complicated structure and high production cost. In the water-cooled high-temperature horizontal cyclone separator, a first left membrane wall and a right membrane wall are connected with a circular arc membrane wall and the outlet end of a first accelerating section, the inlet end of the first accelerating section is connected with a hearth, the first left and right membrane walls are provided with a first exhaust pipe, the upper and lower ends of the first left membrane wall and the upper and lower ends of the first right membrane wall are communicated with a membrane wall upper header and a first annular header, the upper end of the circular arc membrane wall is communicated with a front / rear wall membrane wall collection upper header, the lower end is communicated with the first annular header; and the structure difference between the water-cooled high-temperature horizontal cyclone separator and the air-cooled high-temperature horizontal cyclone separator is that the membrane wall is changed to the air-cooled water wall. The invention has simple and compact structure and high separation efficiency, and can be used in large-size or medium-size circulating fluidized bed boilers.

Owner:HARBIN INST OF TECH

Mesoporous carbon-supported composite metal oxide catalyst and preparation method thereof

InactiveCN102485331AIncrease surface areaLarge apertureHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsMesoporous carbonCarbon deposition

The invention discloses a mesoporous carbon-supported composite metal oxide catalyst and a preparation method thereof. Compared with the prior art, the mesoporous carbon-supported composite metal oxide catalyst has a high specific surface area and a large aperture size, is conducive to rapid diffusion of reactants and products in an aperture channel, avoids deep oxidation, coking and carbon deposition, and has good catalyst activity and a long catalyst life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Second-active-center-containing catalyst hydrogenation apparatus startup method

ActiveCN106947527AImprove usage activityConvenience and Economic PathwayTreatment with hydrotreatment processesProduct gasChemistry

The present invention discloses a startup sulfurization method of a hydrocracking apparatus. According to the present invention, with the grading use of the ex-situ presulfided catalyst, the hydrogenation catalyst containing the second active center is pre-protected with the hydrogen sulfide gas produced in the heating process while a certain auxiliary gas can be selectively injected according to different preparation methods of the second active center catalysts, such that the wet startup is converted into the dry startup; and the activity of the catalyst can be improved with the method of the present invention, and the method is suitable for the sulfurization startup process of the hydrogenation catalyst containing the second active center.

Owner:CHINA PETROLEUM & CHEM CORP +1

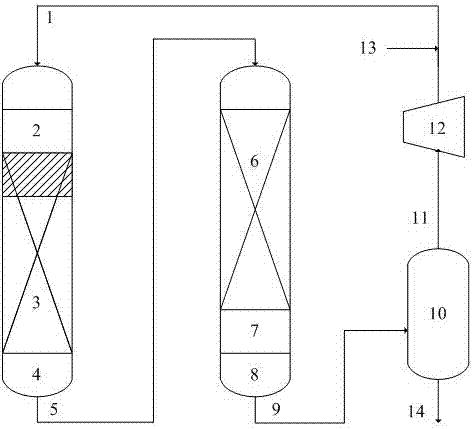

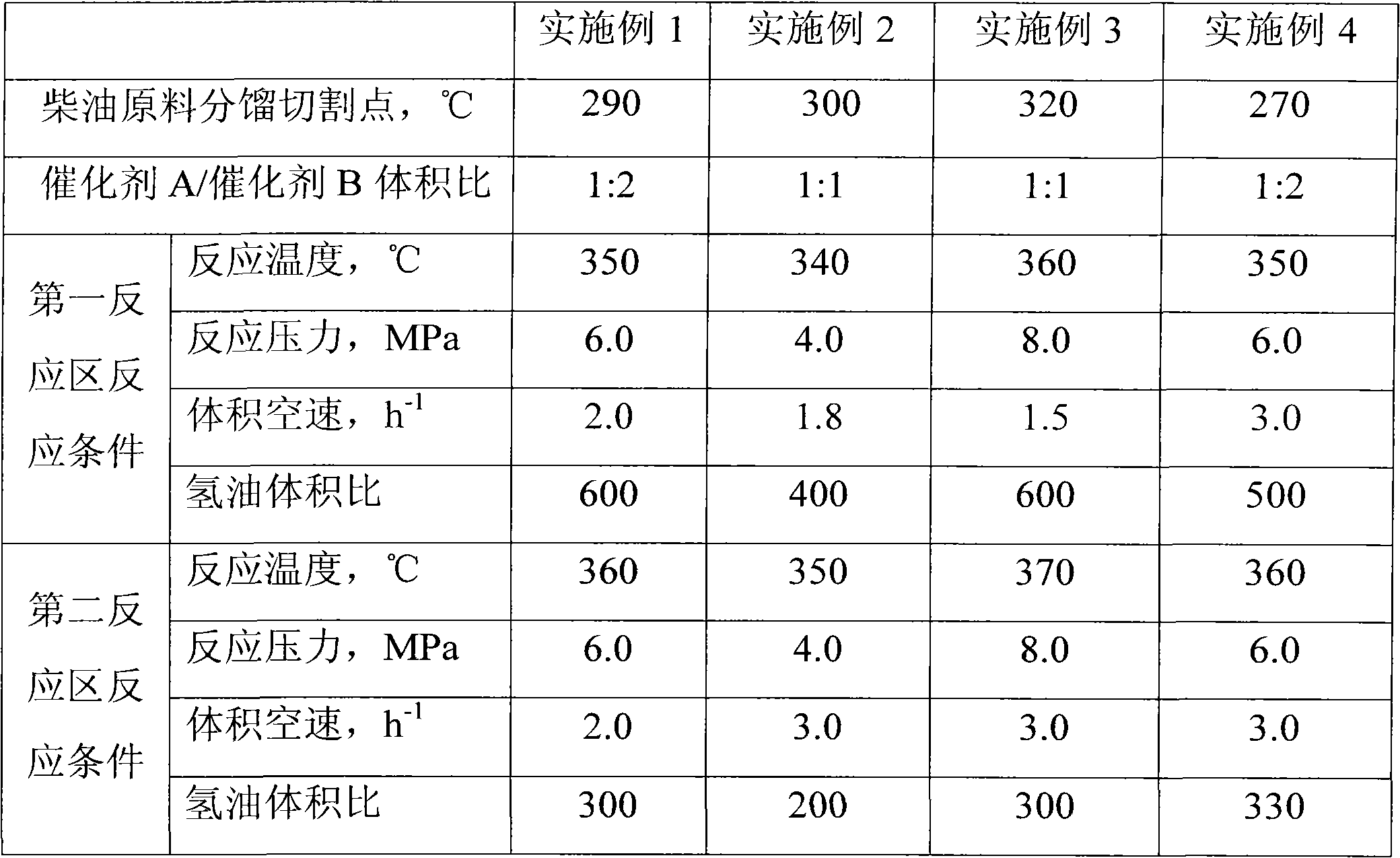

Hydrogenation technology for diesel

ActiveCN102041071AUniform temperature distributionExtended service lifeTreatment with hydrotreatment processesHydrogenNitrogen

The invention discloses a hydrogenation technology for diesel, comprising the following steps: distilling a diesel raw material into light components and heavy components; under the hydrogenation refined condition, carrying out hydrorefining reaction on the heavy components in a first reaction region; mixing effluents at the first reaction region with the light components to enter a second reaction region for the hydrorefining reaction; and carrying out separation treatment on the effluents in the second reaction region. Compared with the prior art, by the technology in the invention, released reaction heat is effectively utilized in the hydrorefining process of the diesel raw material, a great amount of cold hydrogen is not used, and the negative influence of nitrogenous compounds and nuclei aromatics in the heavy components on deep desulfuration reaction of the diesel is overcome; and simultaneously, the technology is simple, energy consumption is reduced, and ultra low sulfur diesel products can be manufactured by using the technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy oil hydrogenation modifying method

The invention discloses a heavy oil modifying method which comprises the following steps: mixing a heavy oil raw material with a homogeneous catalyst, and mixing with a supercritical hydrogen supply solvent, wherein the content of the hydrogen supply solvent in the heavy oil raw material is 50 mug / g-5wt%; and in the presence of hydrogen, carrying out heavy oil hydrocracking reaction on the mixture of the heavy oil raw material, the catalyst and the hydrogen supply solvent under certain reaction conditions. In the heavy oil modifying method, suspension bed hydrocracking and supercritical treatment are organically combined, and the respective advantages are given full play to achieve the effect of synergic cooperation, thereby reducing the coking tendency, enhancing the impurity removal capacity and also enhancing the operational stability of the suspension bed hydrocracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

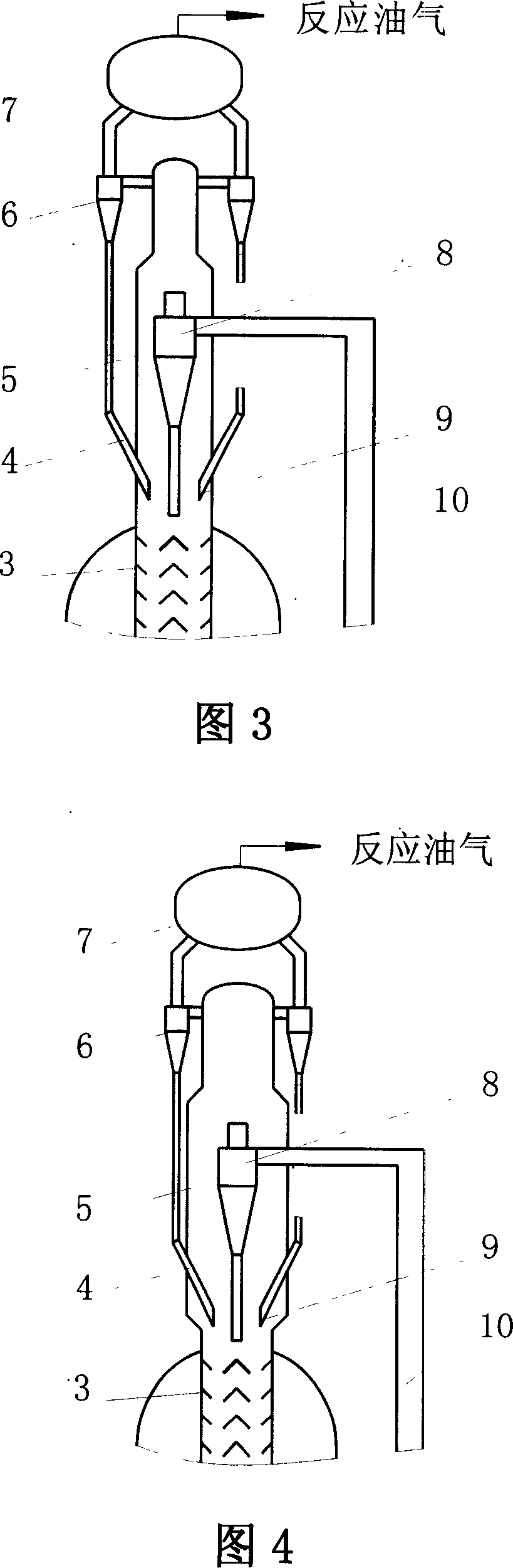

Circulating fluidized bed reaction device for preparing olefins by using paraffin dehydrogenation

ActiveCN104549073AReduce polycondensation reactionResponse blockingHydrocarbonsChemical/physical processesThermal energyAlkane

The invention discloses a fluidized bed reaction device for preparing olefins by using paraffin dehydrogenation and a paraffin dehydrogenation method. The reaction device is a reducing tank body, and the tank body is divided into a gas stripping section, a reaction section and a catalyst settling section from bottom to top, wherein the diameter of the reaction section is larger than the diameter of the gas stripping section; and a heat exchanger is arranged in the settling section. According to the reaction device, raw materials and high-temperature oil gas are subjected to heat exchange in the reaction device, the raw materials are gasified and heated by utilizing the heat energy of the high-temperature oil gas, the high-temperature oil gas is cooled by virtue of heat exchange, the mutual energy is well utilized, coking of the reaction device due to high temperature is avoided, multiple effects are organically combined together, particularly a heat exchanger structure of connecting multiple heat exchange boxes in series together is adopted, the vibration caused by rapid gasification of the raw materials can be effectively avoided, and large temperature difference heat exchange can be realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

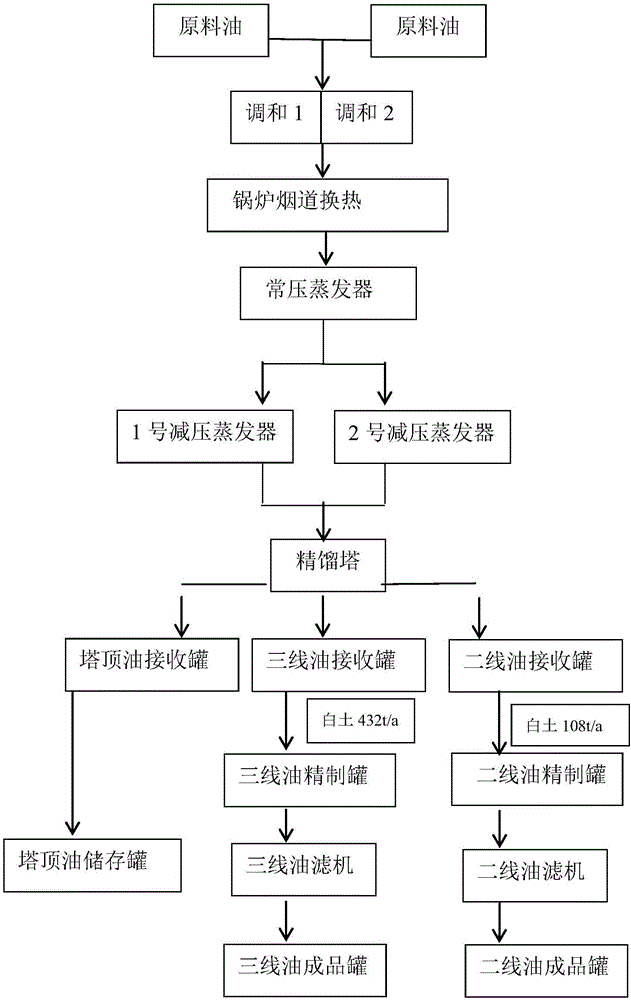

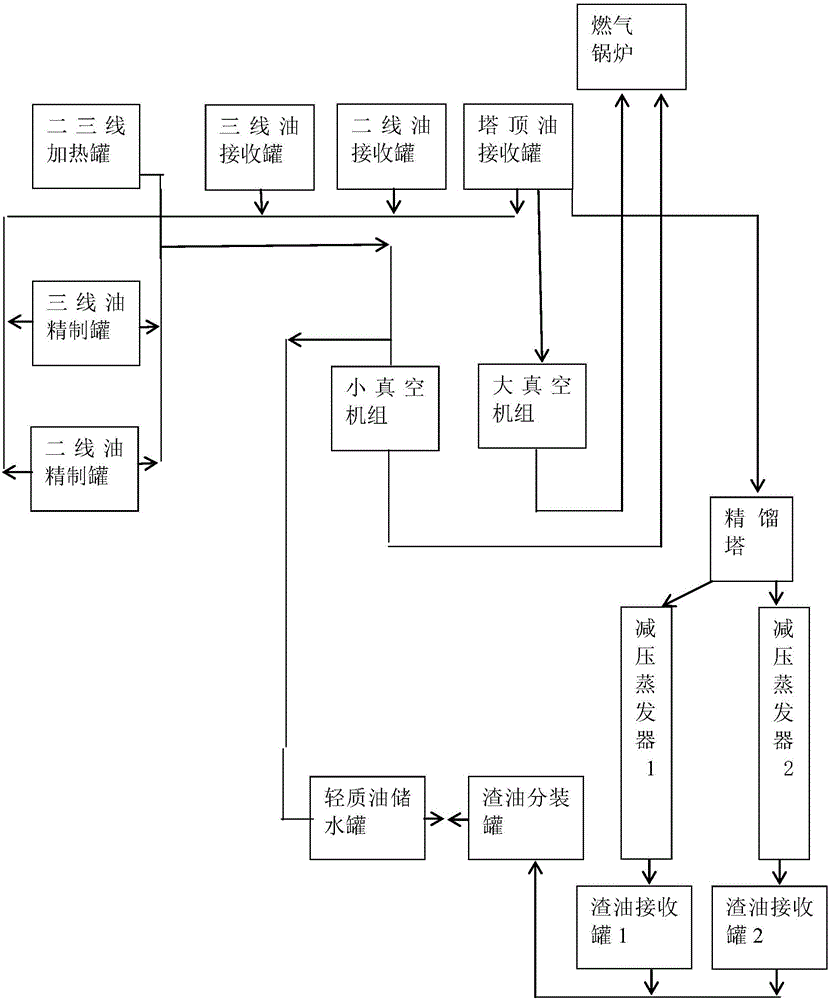

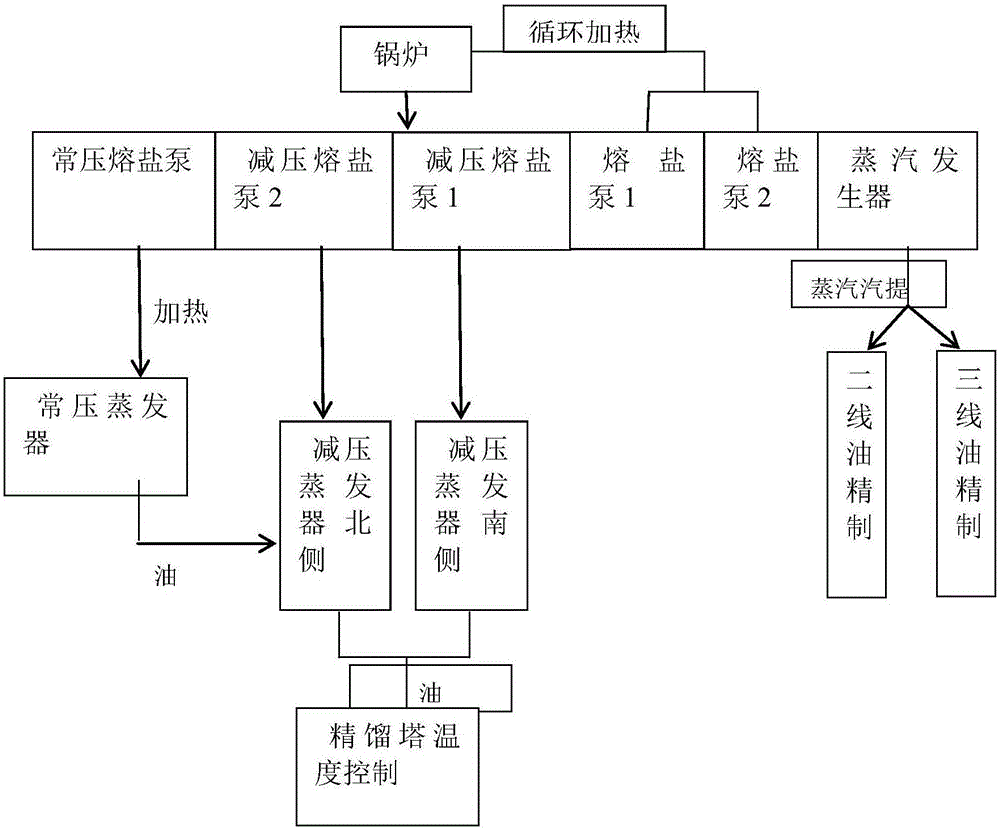

Refining technique of base oil regenerated from used lubrication oil

Disclosed is a refining technique of base oil regenerated from used lubrication oil, and the refining technique comprises the following steps of 1, removing solid waste, which includes removing solid waste from used lubrication oil by centrifugation; 2, solvent pretreatment, which includes extracting mixed impurities and moisture through a solvent and obtaining raw oil after removing upper oil; 3, flocculation treatment, which includes turning mixtures obtained from step 2 into a mixture of flocculation; 4, atomospheric distillation; 5, carrying out reduced pressure distillation; 6, carrying out rectification; 7, solvent refining: putting oil produced from a rectifying column into a treatment tank and when the height of the oil level in the treatment tank reaches 65%-75% of the height of the treatment tank, adding by mass 10%-40% of 1-Methyl-2-pyrrolidinone, and carrying out solvent refining. The refining technique of base oil regenerated from used lubrication oil has the advantages of low investment and high yield efficiency, meanwhile, the refining technique accords with the requirement of environmental protection, reduces vacuum residuum by 15%, improves product yield, facilitates the overhauling of equipment, prolongs the production period, largely improves production efficiency and appearance quality of minus line oil, and helps to obtain high quality regenerated base oil.

Owner:济南亿诺再生资源有限公司

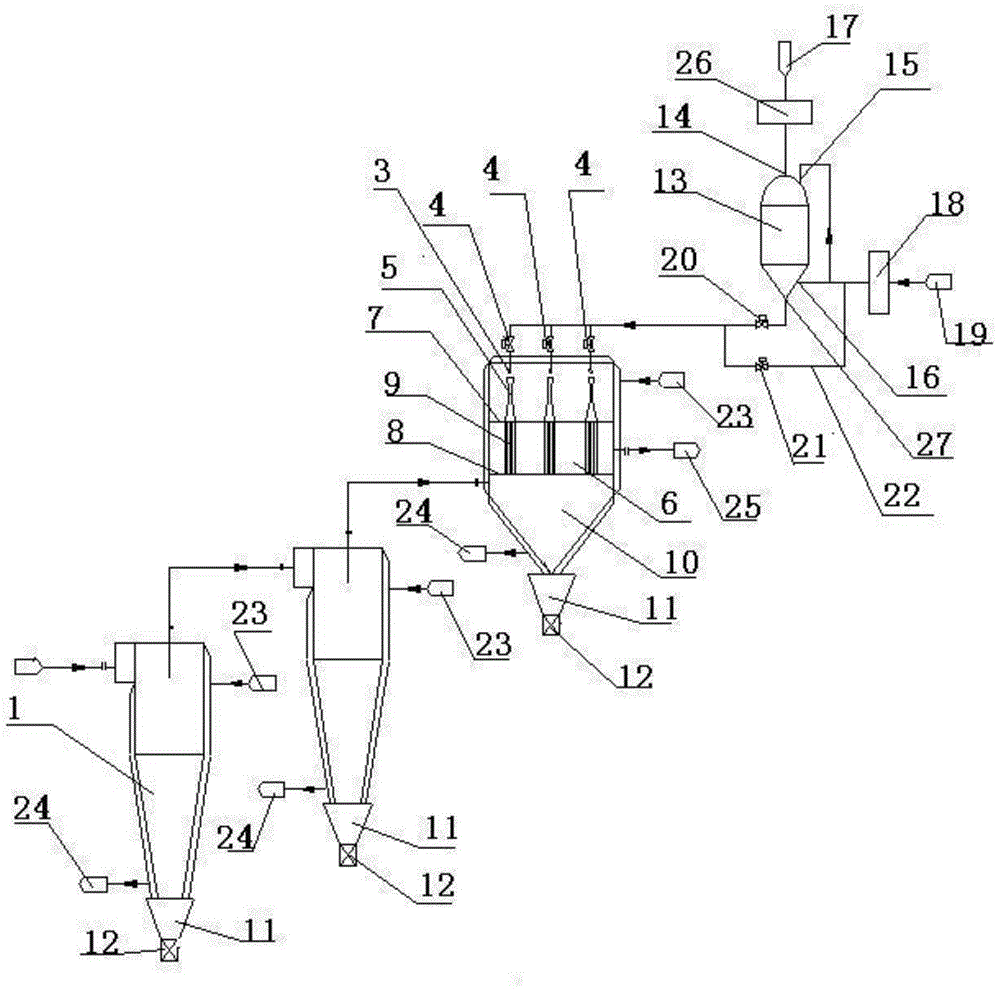

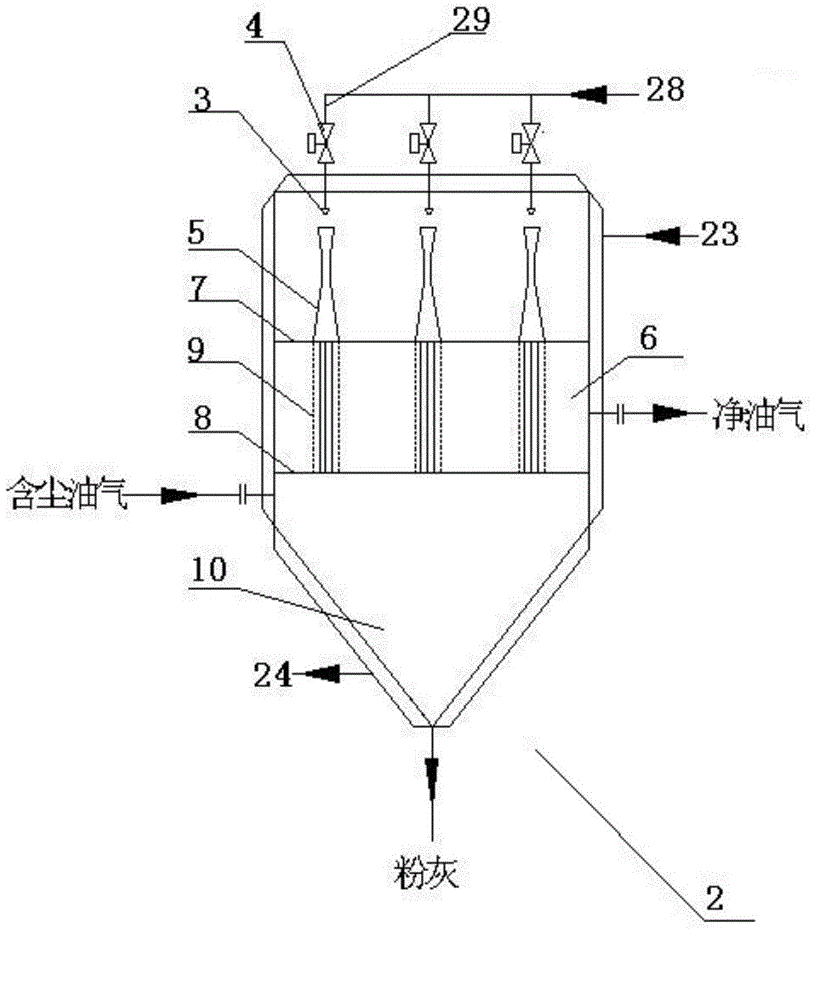

Dust removal device and method for oil gas during pulverized coal pyrolysis/retorting

The invention provides a dust removal device and method for oil gas during pulverized coal pyrolysis / retorting. The device comprises a dust removal pretreatment unit, an oil gas filter and a sand-blasting tank which are sequentially connected, wherein the dust removal pretreatment unit comprises at least two stages of cyclone separators connected in series; the oil gas filter adopts a closed tank, and nozzles, venture tubes, an oil gas purification chamber, a gas collecting chamber and dust hoppers are arranged in the oil gas filer from top to bottom sequentially; the nozzles are arranged at the top of the tank and communicated with the outside; the venture tubes are correspondingly and perpendicularly arranged below the nozzles; the oil gas purification chamber is perpendicular to the venture tubes and provided with hollow filter element groups inside, and the hollow filter element groups are in sealing connection with an upper tube plate and a lower tube plate of the oil gas purification chamber; the gas collecting chamber is coaxially communicated with filter elements; dust valves are arranged at the lower ends of the dust hoppers; the sand-blasting tank is a closed tank, a sand inlet is formed in the top and communicated with a sand pipeline inlet through a sand preheater, gas inlets are formed in the top and in the lower side part respectively and are communicated with a reverse blowing gas pipeline inlet through a reverse blowing gas preheater, and a sand outlet is formed in the bottom and communicated with the oil gas filter. The problems of poor oil gas dust removal effect, low efficiency, instable operation and the like of an existing device are solved.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

Front coal gasification grate-firing device and combustion method thereof

InactiveCN103234196ASpeed up the drying and heating processReduce incomplete combustion lossesSolid fuel combustionCombustion apparatusHearthGrate firing

The invention discloses a front coal gasification grate-firing device and a combustion method thereof. By the aid of the front coal gasification grate-firing device and the combustion method thereof, the problems of emission of the high NOx content and the high SOx content of traditional chain layer burners are solved, and the boiler efficiency is improved. The front coal gasification grate-firing device comprises a coal bucket, a coal gasification chamber and a coke discharge pipe which are communicated sequentially, a gas pipe is arranged at the top of the coal gasification chamber, an injection nozzle is arranged inside the gas pipe, communicated with a secondary air pipeline through an injection air pipeline and parallel with the secondary air pipeline, an opening of the injection nozzle faces towards a hearth, the secondary air pipeline and the gas pipe are arranged in parallel in an up-and-down mode and communicated with the hearth, a bottom bellows is installed at the bottom of the coal gasification chamber, communicated with a gasification air pipeline and communicated with the coal gasification chamber through a fire grate I, the fire grate I is inclined towards the inlet direction of the coke discharge pipe, a coke breaking machine is installed at the position of an inlet of the coke discharge pipe, and an outlet of the coke discharge pipe is located above a fire grate II at the bottom of the hearth.

Owner:SHANDONG UNIV

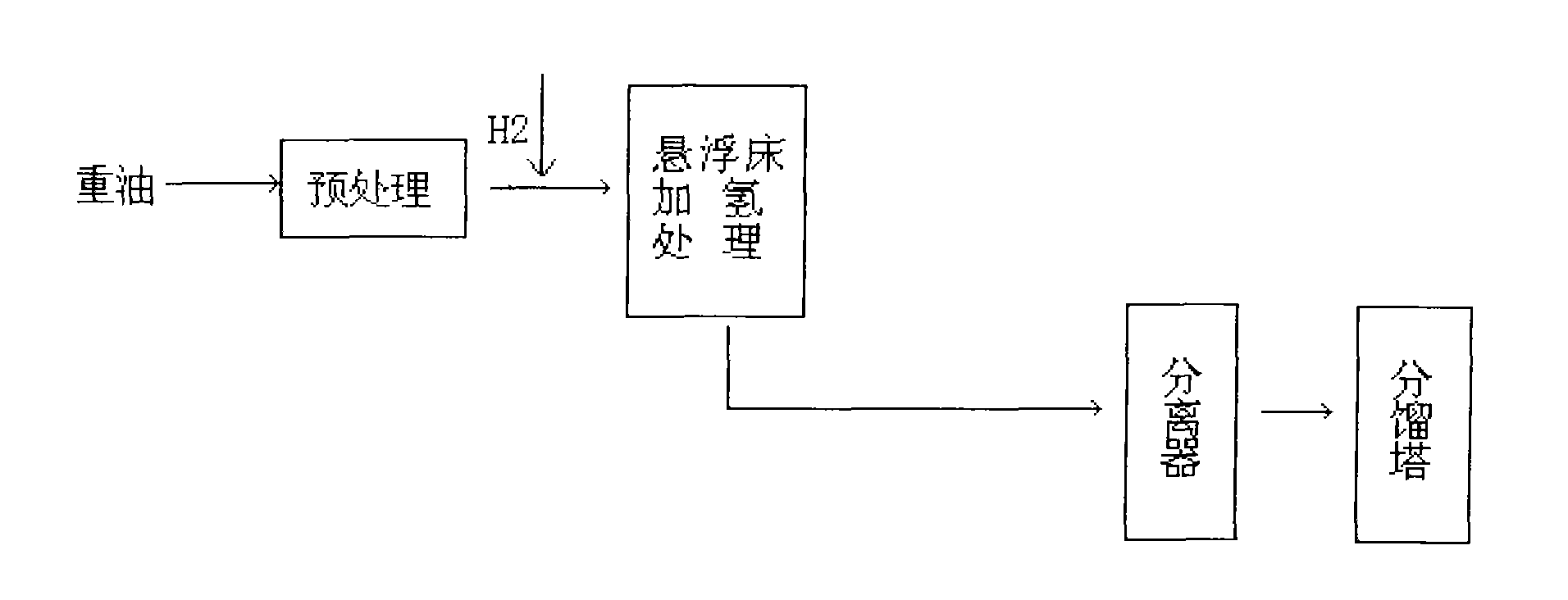

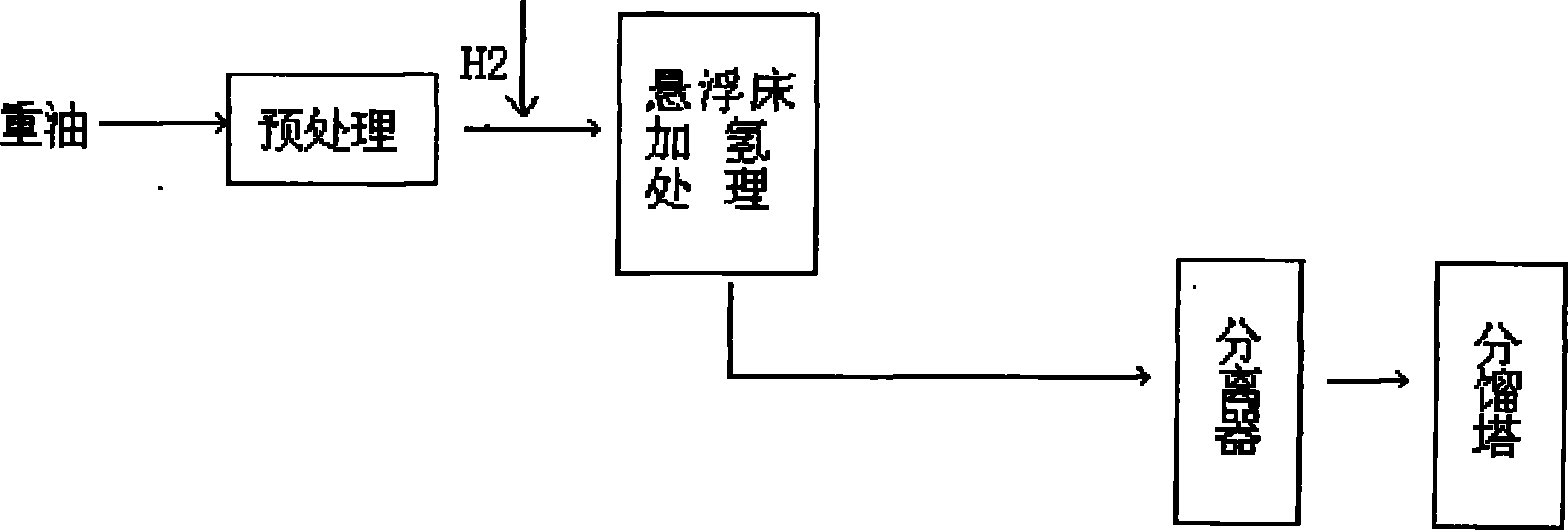

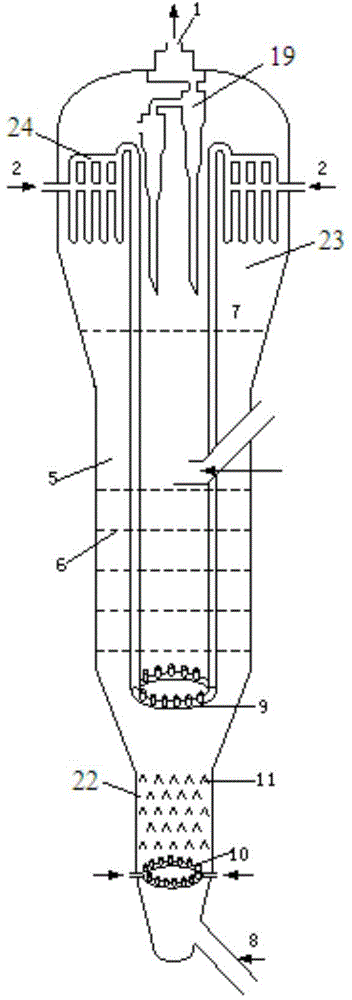

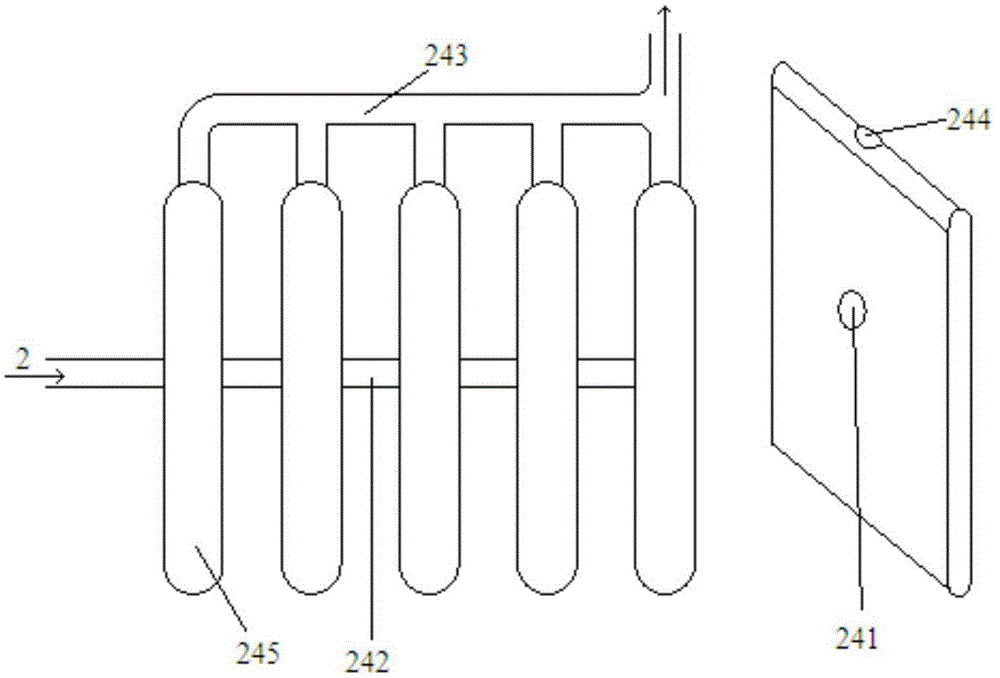

Heavy oil hydrogenation method and hydrogenation system

ActiveCN108659882AEnough time to stayGuaranteed conversion rateTreatment with hydrotreatment processesHydrogenRetention time

The invention relates to a heavy oil hydrogenation method and a hydrogenation system. The heavy oil hydrogenation method comprises the steps of mixing heavy oil, circulation oil, a valcanizer and a catalyst, performing hydrocracking on the heavy oil, the circulation oil, the valcanizer, the catalyst and hydrogen in a first reactor to form a first reaction product, allowing part of first reaction product to return to the first reactor, performing hydrocracking on the rest of the first reaction product in a second reactor to form a second reaction product, dividing the second reaction product into a light component and a heavy component, returning part of the heavy component to the second reactor, separating the rest of the heavy component to form distillate oil as the circulation oil, and hydrofining the light component in a third reactor to form a light oil product. The method improves heat transfer and mass transfer efficiency, ensures retention time of the material in the reactors, and increases a heavy oil conversion rate and a light oil yield. According to the hydrogenation system for the method, internal members of the reactors are simplified, and equipment investment and operation energy consumption are reduced.

Owner:CCTEG CHINA COAL RES INST

Fluidized bed reactor of biomass tar

ActiveCN103920430AAvoid cokingEfficient removalTreatment with hydrotreatment processesTar working-up by chemical refiningHydrogenFluidized bed

The invention provides a fluidized bed reactor of biomass tar. The fluidized bed reactor at least comprises a reactor shell for containing a reaction material; a distributor is fixedly arranged at the lower part inside the reactor shell; a device for preventing a catalyst from escaping is arranged at the upper part of the reactor; a raw material inlet and a product outlet are formed in the reactor shell; the raw material inlet at least comprises a biomass tar inlet; the biomass tar inlet is arranged at the lower part of the lateral wall of the reactor shell and above the distributor. According to the fluidized bed reactor disclosed by the invention, the biomass tar inlet is arranged above the distributer, boiling is effectively performed by virtue of the impact effect of hydrogen and circulating liquid entering from the lower part of the distributor, and the condition that the catalyst fully contacts the biomass tar and is fully mixed with the biomass tar for quickly reacting can be ensured, so that the coking phenomenon generated by polymerization reaction of biomass tar is prevented.

Owner:HENAN BUF BIOENERGY CO LTD

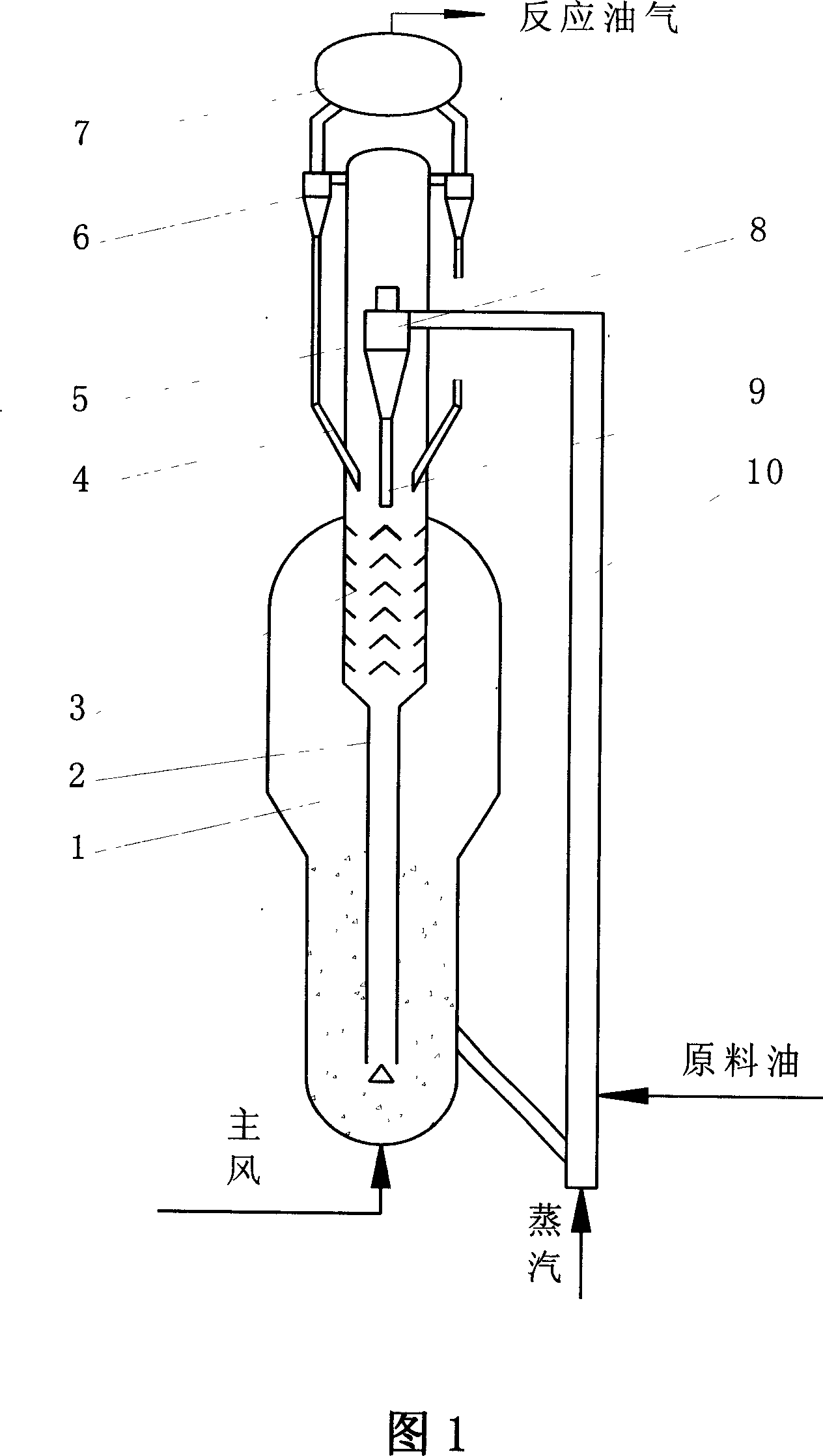

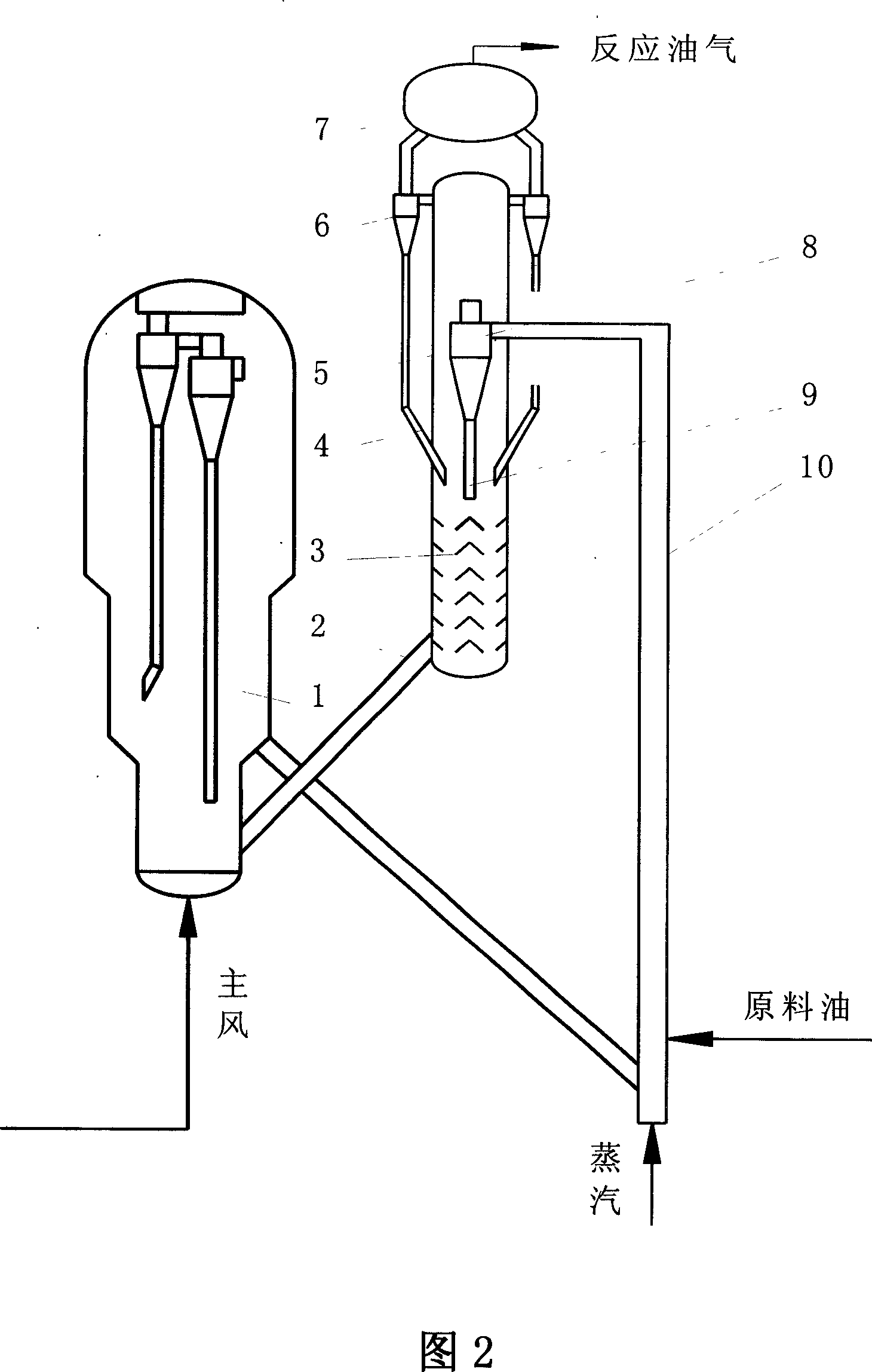

Catalytic cracker with internal tubular settler

The present invention is fluid catalytic cracker with fast separation of oil gas from catalyst. The fluid catalytic cracker has a riser with outlet connected to thick coiled pipe inside the tube settler, a stripping device below the tube settler, a catalyst regenerator connected through pipe tot lower end of the stripping device, and a top coiled pipe outside the tube settler. The fluid catalytic cracker can realize the efficient and fast gas-solid separation in the separation efficiency as high as 99.99 %, reduce average oil gas residence time to less than 2-3 sec and decrease scaling, and has compact structure and low cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

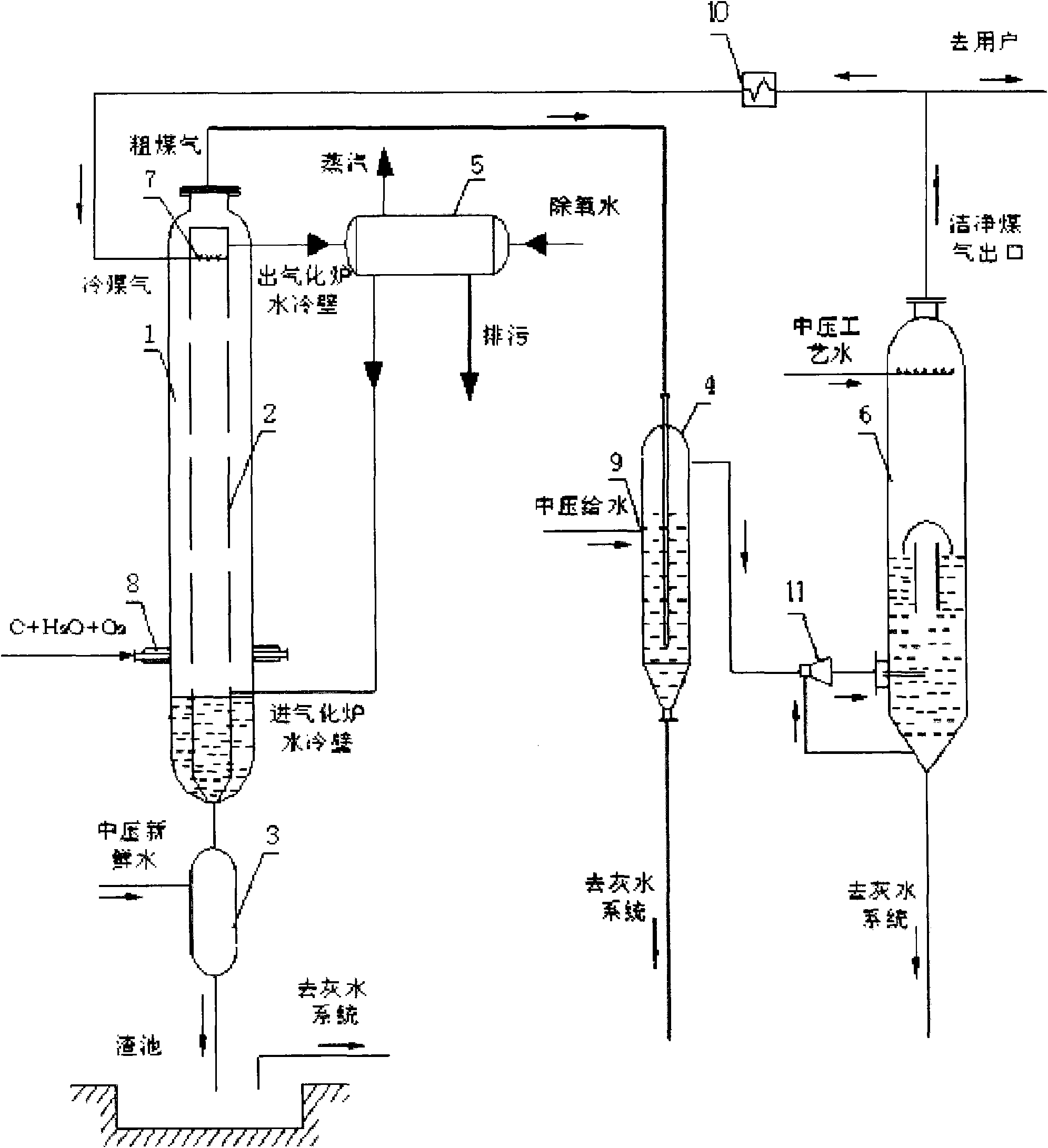

Under nozzle-type entrained flow gasification shock chilling device and shock chilling technology

InactiveCN101550361AIrritable cold curingLow costCombined combustion mitigationGranular/pulverulent flues gasificationWater vaporSlurry

The invention relates to an under nozzle-type entrained flow gasification shock chilling device and a shock chilling technology; the shock chilling device comprises a gasification furnace 1; a nozzle 8 is arranged at the lower part of the gasification furnace 1; wherein a gas outlet of the gasification furnace 1 is communicated with the raw gas inlet of a shock chilling tank 4; a gas outlet of the shock chilling tank 4 is connected with the raw gas inlet of a Venturi washer 11; and a gas outlet of the Venturi washer 11 is communicated with the gas inlet of a washing tower 6. Powdered or slurry coal powder and a gasification agent are sprayed to the gasification furnace 1 through the nozzle 8 to react and generate raw gas; the raw gas flows up and down in the gasification furnace 1; the raw gas is mixed with cool gas through a gas shock chiller 7 and then enters the shock chilling tank 4 to carry out water shock chilling; the gas enters the Venturi washer 11 and the washing tower 6 to be washed and purified; a part of the purified gas is conveyed to the user for use, and the other part thereof flows to the gas chiller 7 at the upper part of the gasification through thermal circulation to carry out shock chilling to the raw gas; therefore, the raw gas contains more water vapor. The device and the technology are characterized by low construction cost and high system overall efficiency.

Owner:XIAN THERMAL POWER RES INST CO LTD

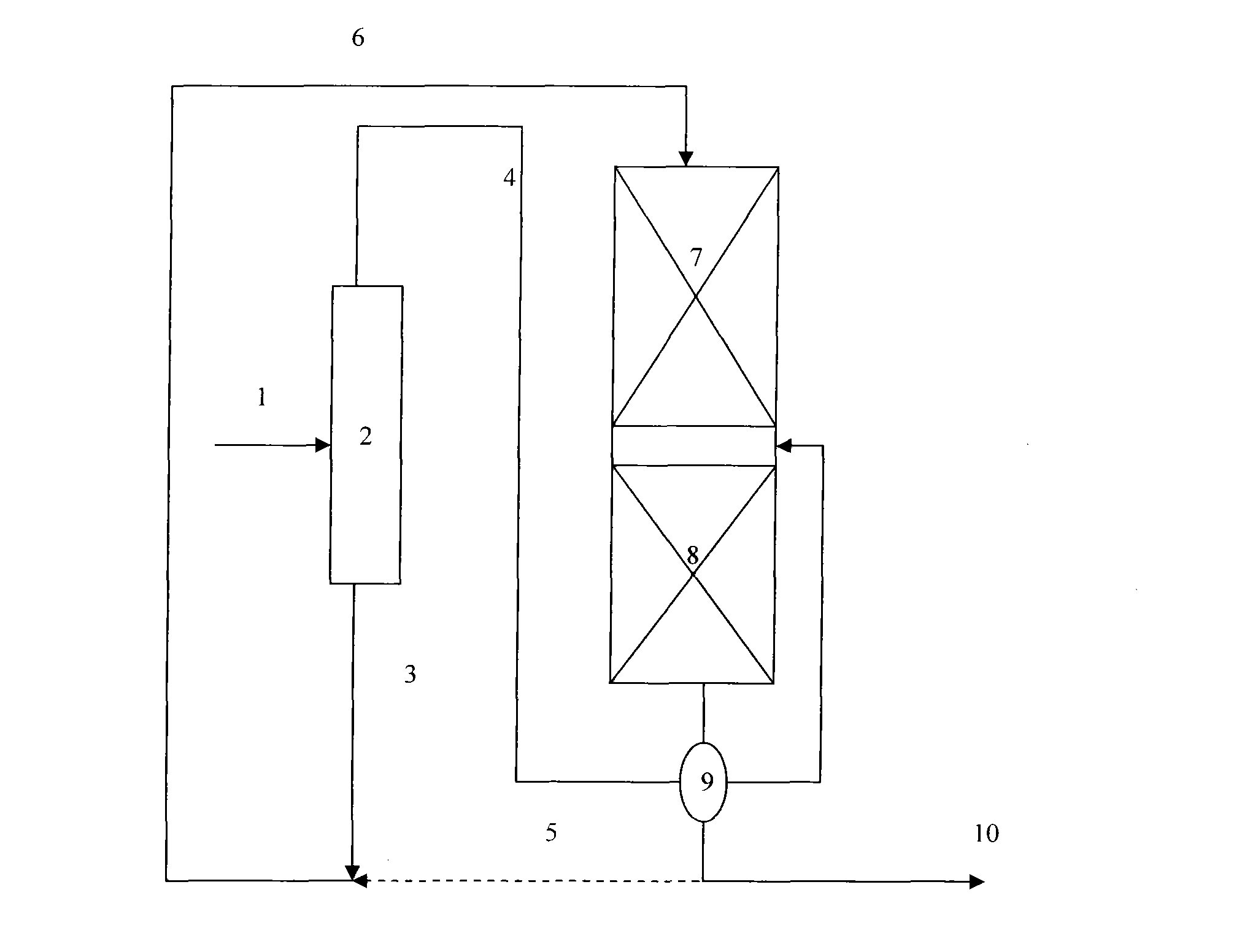

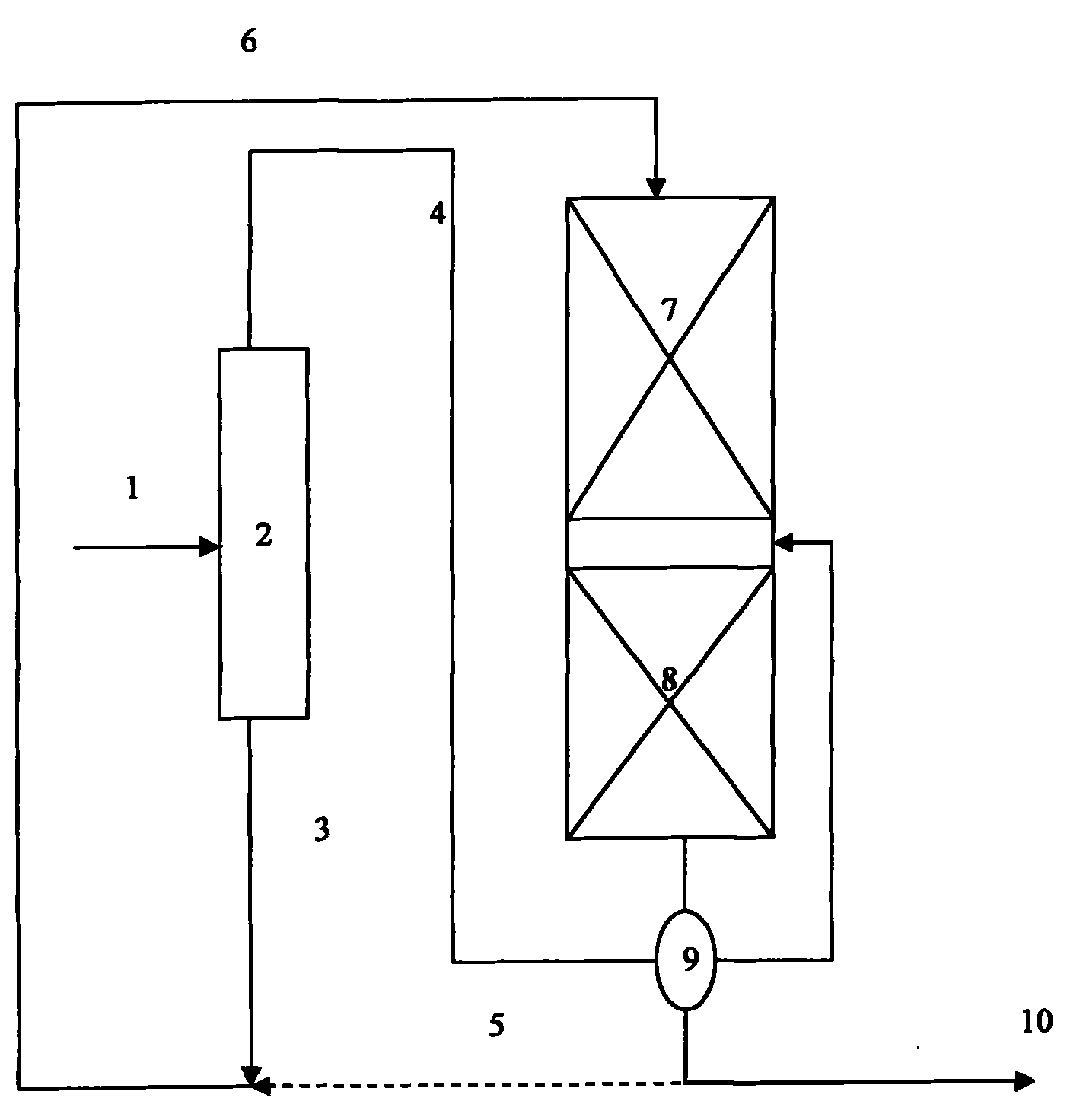

Two-stage hydrogenation process of coal tar

ActiveCN102851071AHigh yieldOvercome expensiveTreatment with hydrotreatment processesPtru catalystThermodynamics

The invention discloses a two-stage hydrogenation process of coal tar. The process comprises the steps of: (a) sending a coal tar raw material into a hydrotreating reaction section, and carrying out a hydrotreating reaction on the coal tar by contacting with a hydrotreating catalyst in the presence of hydrogen and under hydrogenation conditions; (b) carrying out gas-liquid separation on an effluent from the hydrogenating reaction section, and sending a separated liquid phase into the a fractionation device, in order to distillate out a light fraction and a heavy fraction; (c) sending at least part of the heavy fraction from the step (b) into a hydrocracking reaction section, and carrying out a hydrocracking reaction on the heavy fraction by contacting with a hydrocracking catalyst in the presence of hydrogen and under hydrogenation cracking conditions; and (d) sending an effluent from the hydrocracking reaction section into a hot high pressure separator, in order to separate out a gas phase and a liquid phase, and sending at least part of the liquid phase to the hydrotreating reaction section in the step (a). Compared with the prior art, the method provided by the invention improves the yield of light fuel production from coal tar, prolongs the service life of a catalyst, and increases operation cycle of the device.

Owner:上海竣铭化工工程设计有限公司

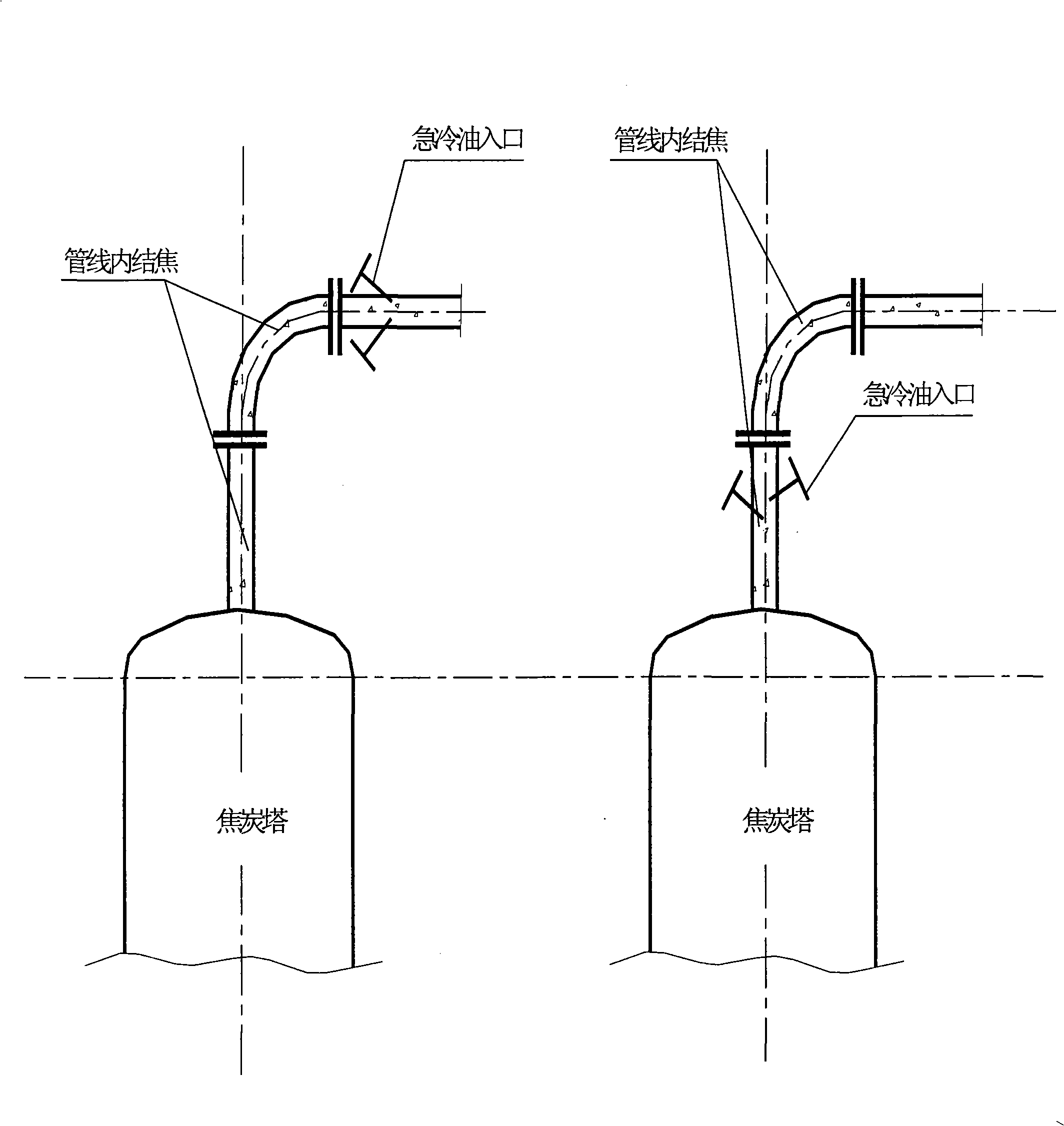

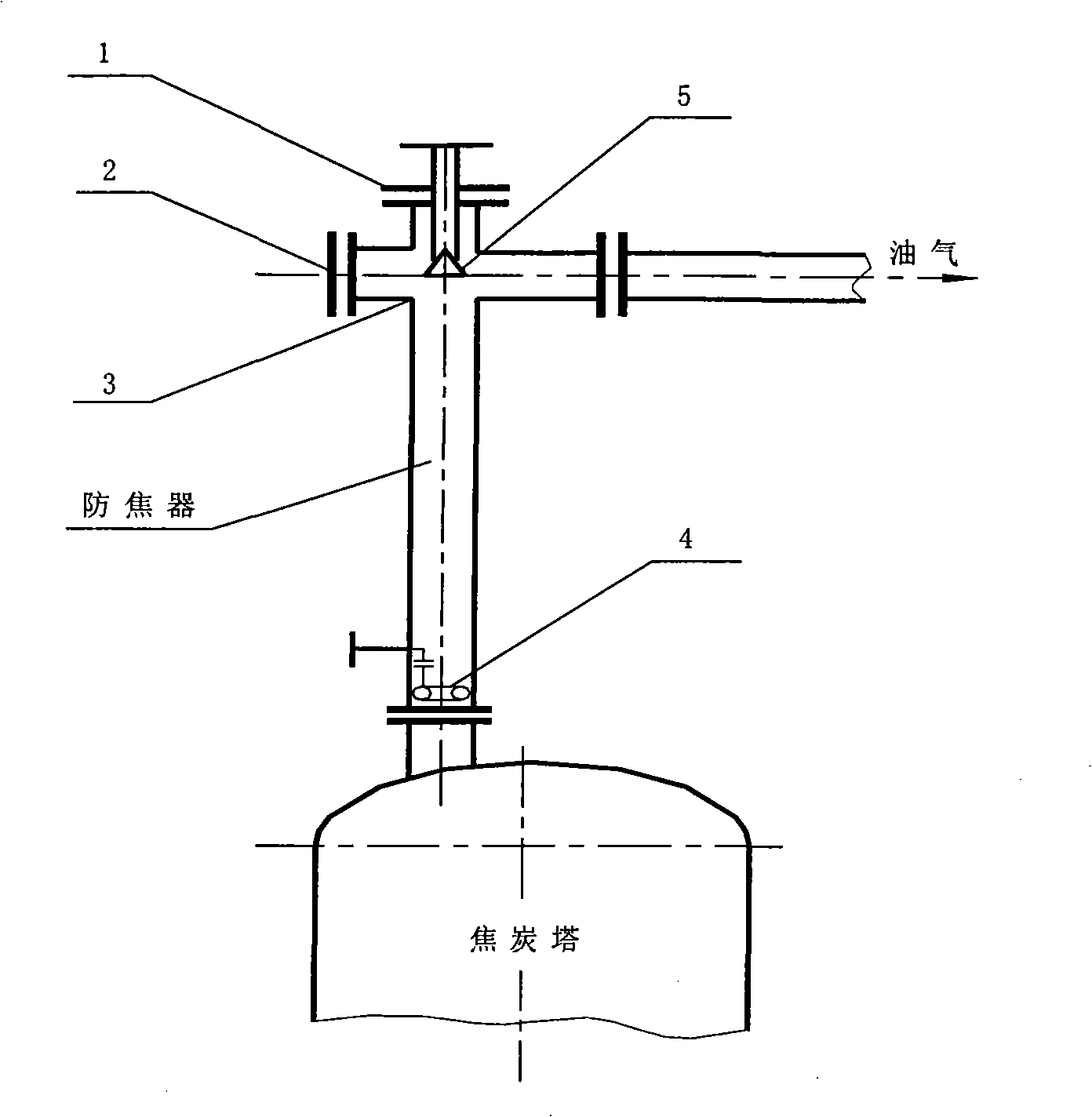

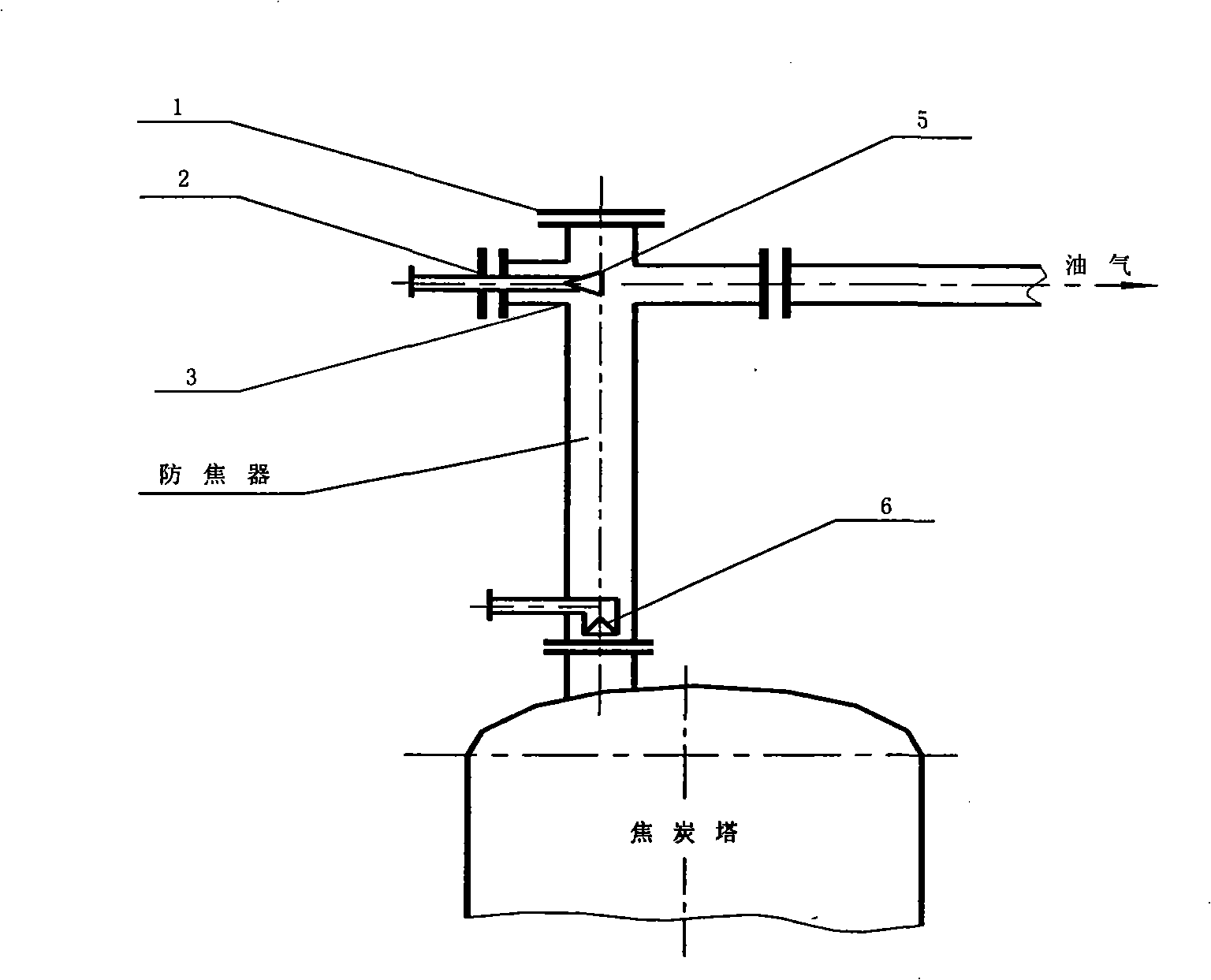

Apparatus and method for preventing coking drum oil gas vent from coking

InactiveCN101343553AEven contactReduces the possibility of cokingThermal non-catalytic crackingLiquid hydrocarbon mixture recoveryLiquid productInjection equipment

The invention relates to a device for preventing the oil and gas outlet of a coking tower from being coked and the application method, which comprises that at least two levels of quenching oil injection equipments are adopted on the oil and gas pipeline at the oil and gas outlet position at the top of the coking tower. Wherein a first level injection is arranged at the oil and gas outlet position at the top of the tower, which is close to the cover head of the coking tower as much as possible and can stop pyrogenic reaction as early as possible; quenching oil is mainly centralized at the oil and gas outlet position at the top of the tower through a multi points injection mode, thus the first level injection is ensured to be fully contaced with the oil and gas to reduce the temperature; a second level injection is arranged at the oil and gas pipeline after the first level injection is injected. The method further improves the processing capacity of the coking tower, and ensures the operating pressure of the coking tower is reduced, the method is favorable for improving the yield of the liquid products of the device, thus to ensure the applicability of the device on processing the residual oil with high asphaltine content to be improved.

Owner:CHINA PETROCHEMICAL CORP +1

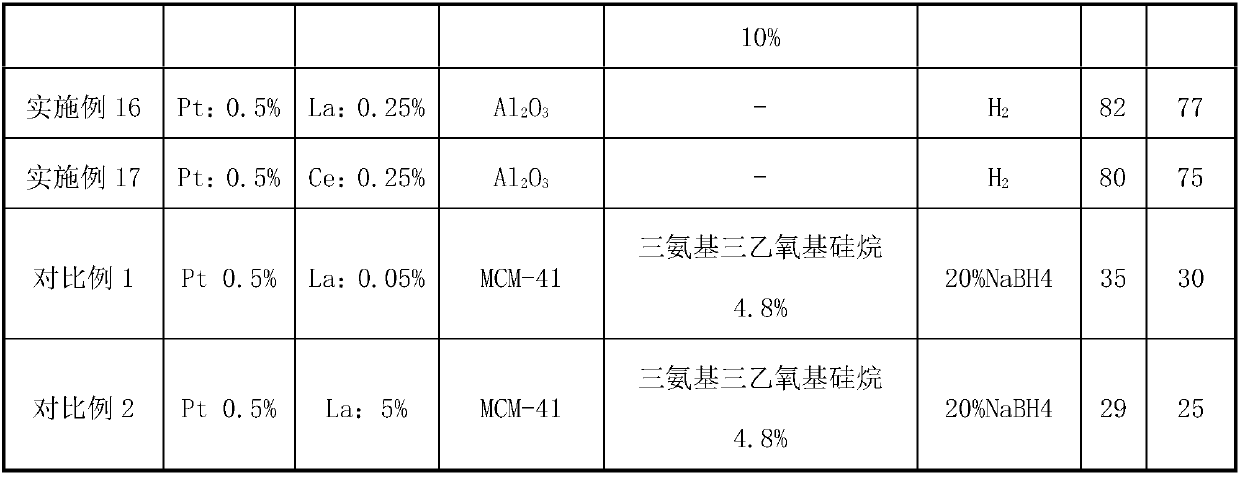

Dehydrogenation catalyst and preparation method thereof

PendingCN109701588AHigh activityImprove stabilityHydrogenMolecular sieve catalystsRare-earth elementAlkane

The invention discloses a dehydrogenation catalyst and a preparation method thereof. The dehydrogenation catalyst includes: (a) 0.1 to 5 parts of at least one metal, selected from the group VIII elements of the periodic table, or alloys thereof; (b) 0.1 to 3 parts of at least one element, selected from rare earth elements, oxides thereof; and (c) 72 to 99 parts of a carrier. The preparation methodincludes: (1) performing nitride treatment on the carrier to obtain a nitrogen-containing carrier; (2) introducing the active components in an impregnation or precipitation manner; (3) reducing the active components in a low temperature manner to prepare the catalyst. The invention is to solve the technical problems that active components are non-uniform in dispersion and the catalyst is liable to coke and is poor in activity and stability. The dehydrogenation catalyst, when being used for low-carbon alkane dehydrogenation or dehydrogenation reactions of organic liquid hydrogen storage materials, is high in active component dispersibility, is free of acidity of the carrier, is basically free of coking during reactions, and is high in activity and stability. The catalyst can be used in industrial application of the dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com