Apparatus and method for preventing coking drum oil gas vent from coking

A coke tower, oil and gas technology, applied in the petroleum industry, cracking, non-catalytic thermal cracking, etc., can solve problems such as unreasonable injection methods, achieve the effects of increasing the yield of liquid products, preventing coking, and reducing the possibility of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

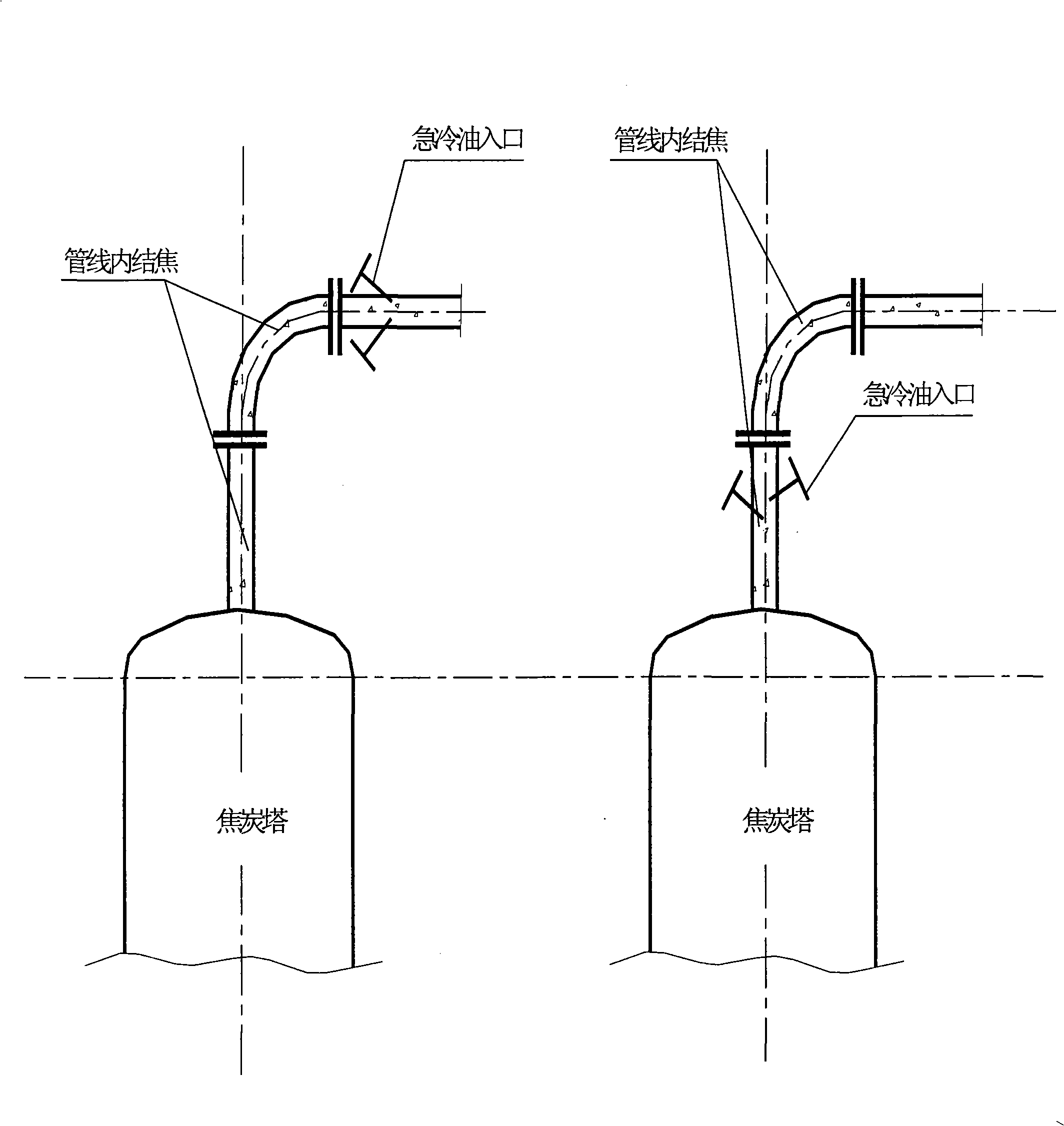

Problems solved by technology

Method used

Image

Examples

Embodiment

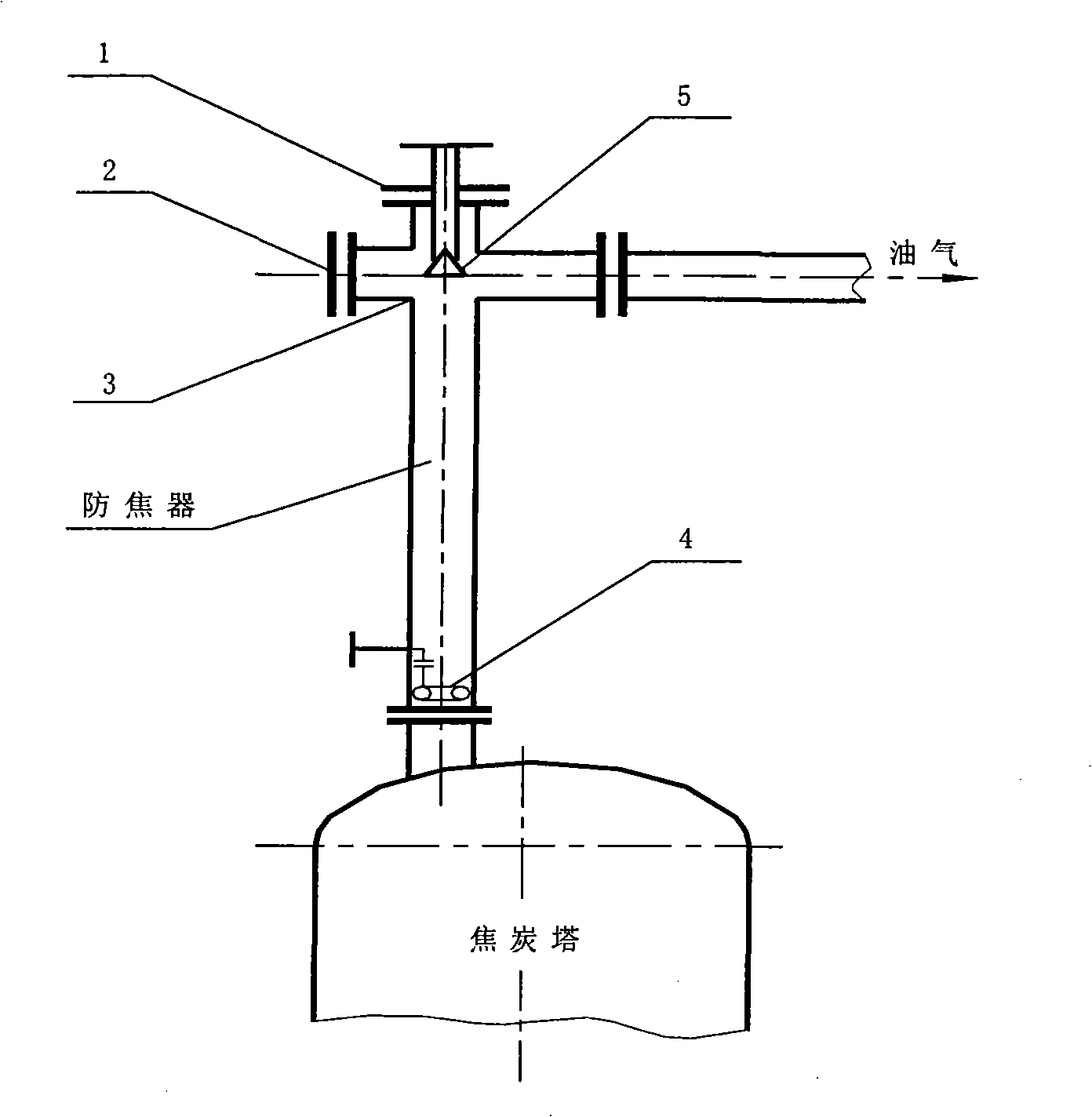

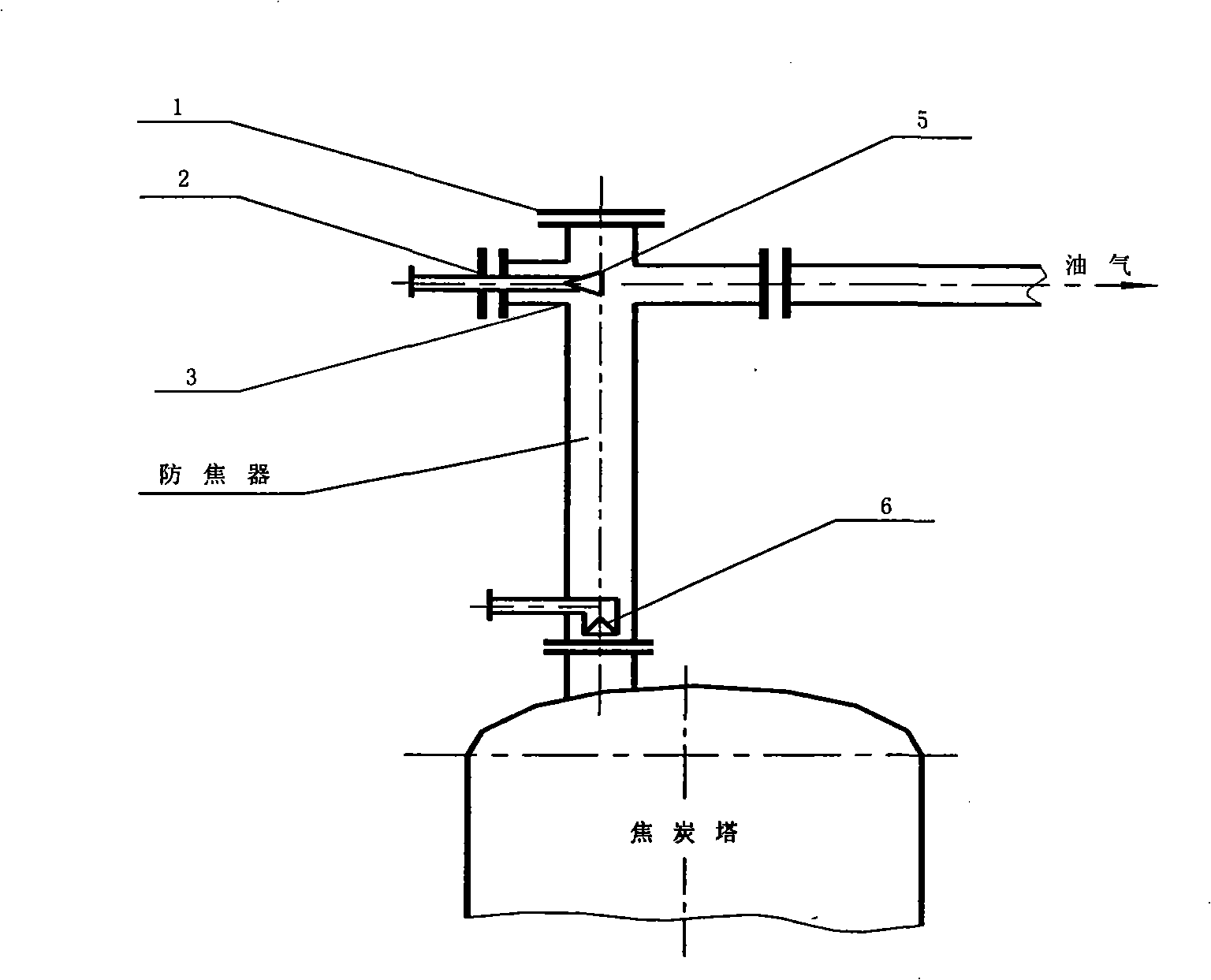

[0028] in such as figure 2 , 3 In the injection process of the two-stage quenching oil at the top of the coke tower shown:

[0029] (1) The type of thermal coking raw material is mixed vacuum residue with light sand and heavy sand, the processing capacity is 2.6 million tons per year, the operating temperature is 410-420°C, the operating pressure is 0.1-0.3Mpa, and it is carried out in the coke tower After coking, the temperature of the hot oil and gas is 430-440, and it is discharged from the outlet at the top of the tower at a flow rate of 180 tons per hour.

[0030] (2) Heavy diesel oil is used for the first-stage quenching oil injection, the injection flow rate is 9-18 tons / hour, and the number of openings on the ring pipe is generally 10-30.

[0031] (3) Heavy diesel oil is also used for the second-stage quenching oil injection, and the injection volume is 5-10 tons / hour.

[0032] By rapidly cooling the high-temperature oil and gas at the top of the tower to 410-420°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com