Preparation method of lithium-copper composite negative electrode foil piece

A foil and negative electrode technology, applied in the field of preparation of lithium-copper composite negative electrode foil, can solve the problems of inability to realize large-scale production and application, lithium metal power failure, poor mechanical strength, etc., to avoid weak bonding, Improve contact and facilitate the effect of production scale-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

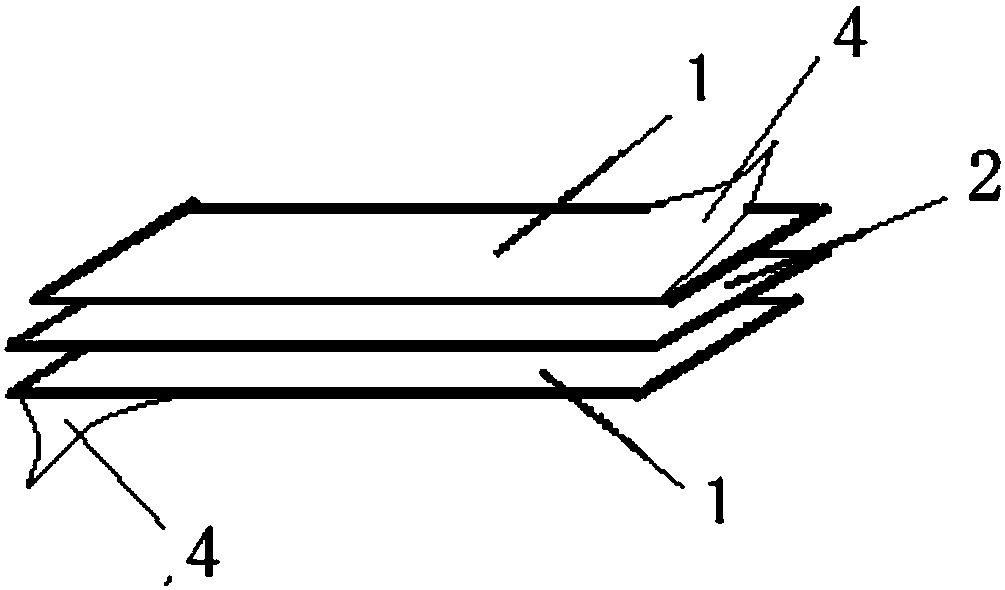

[0017] see attached figure 1 , 2 , the present embodiment provides a preparation method of a lithium-copper composite negative electrode foil. The lithium metal foil is evenly adhered on the surface of the copper foil by using a spaced local pressure enhancement method to form a lithium-copper composite negative electrode foil. The specific method steps as follows:

[0018] 1) Sandwich the copper foil 2 between the lithium metal foils 1 to form a lithium foil / copper foil / lithium foil sandwich layer;

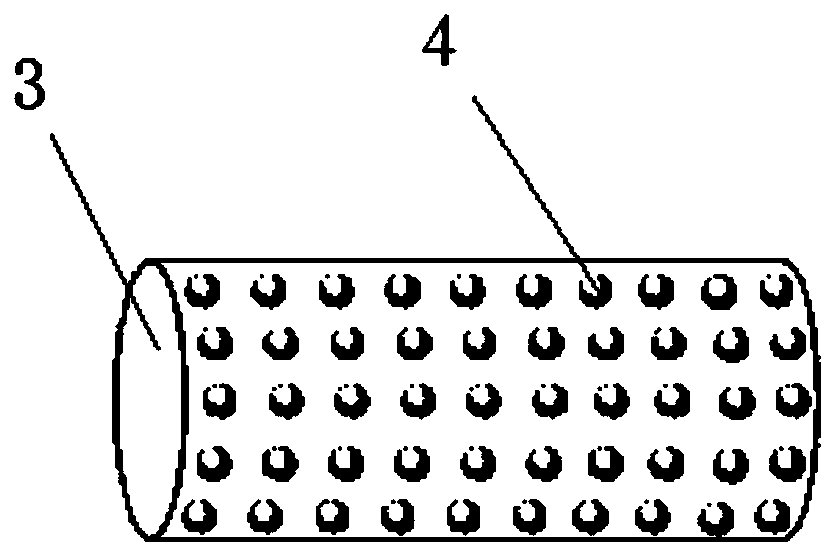

[0019] 2) Use ordinary calendering equipment, start the traction system, make the lithium foil / copper foil / lithium foil sandwich layer pass through the rolling roller 4 to form interval partial pressure on it, the pressure range is 0.05MPa~5MPa, and make a pre-composite lithium foil / copper foil / lithium foil sandwich;

[0020] 3) Pass the pre-composite lithium foil / copper foil / lithium foil sandwich sheet through the rolling roller again, and apply pressure for shaping. The pre...

Embodiment 1

[0026] A preparation method of a lithium-copper composite negative electrode foil, the steps are as follows:

[0027] 1) A 6-micron-thick copper foil is sandwiched between two layers of 50-micron-thick lithium foil to form a sandwich structure.

[0028] 2) Start the traction system so that the lithium foil / copper foil / lithium foil sandwich layer passes through the upper and lower rollers. The upper roller is a concave-convex plate, and the convex shape is circular, with a diameter of 500 microns and a circular interval of 1 mm. Use rolling rollers to form interval partial pressure, and pre-composite lithium foil and copper foil;

[0029] 3) Make the pre-composite lithium foil / copper foil / lithium foil sandwich sheet pass through the rolling roller again, and apply pressure for shaping to obtain the composite lithium metal negative electrode foil).

Embodiment 2

[0031] A preparation method of a lithium-copper composite negative electrode foil, the steps are as follows:

[0032] 1) A 6-micron-thick copper foil is sandwiched between two layers of 50-micron-thick lithium foil to form a sandwich structure.

[0033] 2) Start the traction system so that the lithium foil / copper foil / lithium foil sandwich layer passes through the upper and lower flat pressing plates. The upper flat pressing plate is a concave-convex plate. The pressure plate forms a spaced local pressure enhancement, and pre-composites the lithium foil and the copper foil.

[0034] 3) Make the pre-composite lithium foil / copper foil / lithium foil sandwich sheet pass through the rolling roller again, and apply pressure for shaping to obtain a composite lithium metal negative electrode foil.

[0035] The spaced local pressure enhancement method adopted in the present invention adopts rolling or flat pressing, the surface of the rolling roller or flat pressing plate is a concave-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com