Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

306 results about "Thermal impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The thermal impact of stormwater flow to a stream is a function of both the volume of flow, and the temperature differential between the runoff and the stream. A simple mixing model can be used to estimate the thermal impact of a predicted effluent flow to a stream with a given thermal regime.

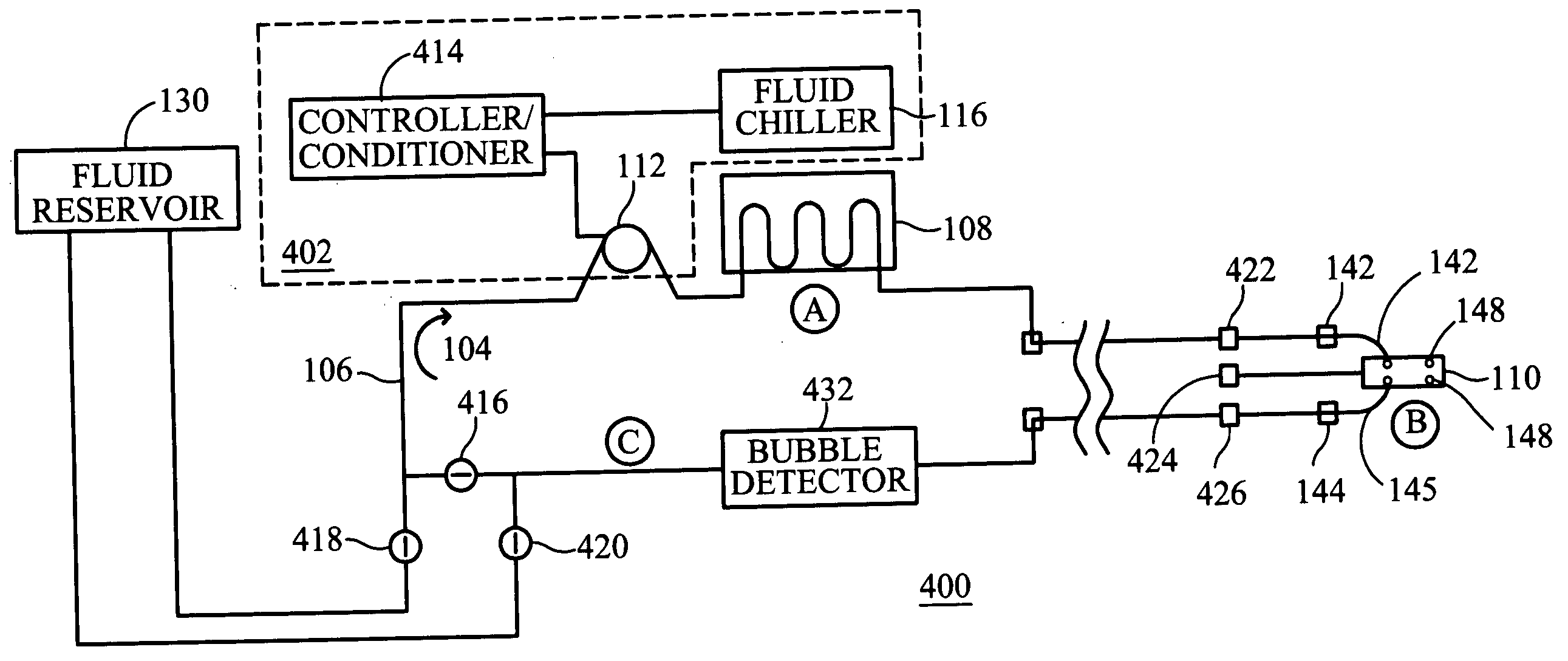

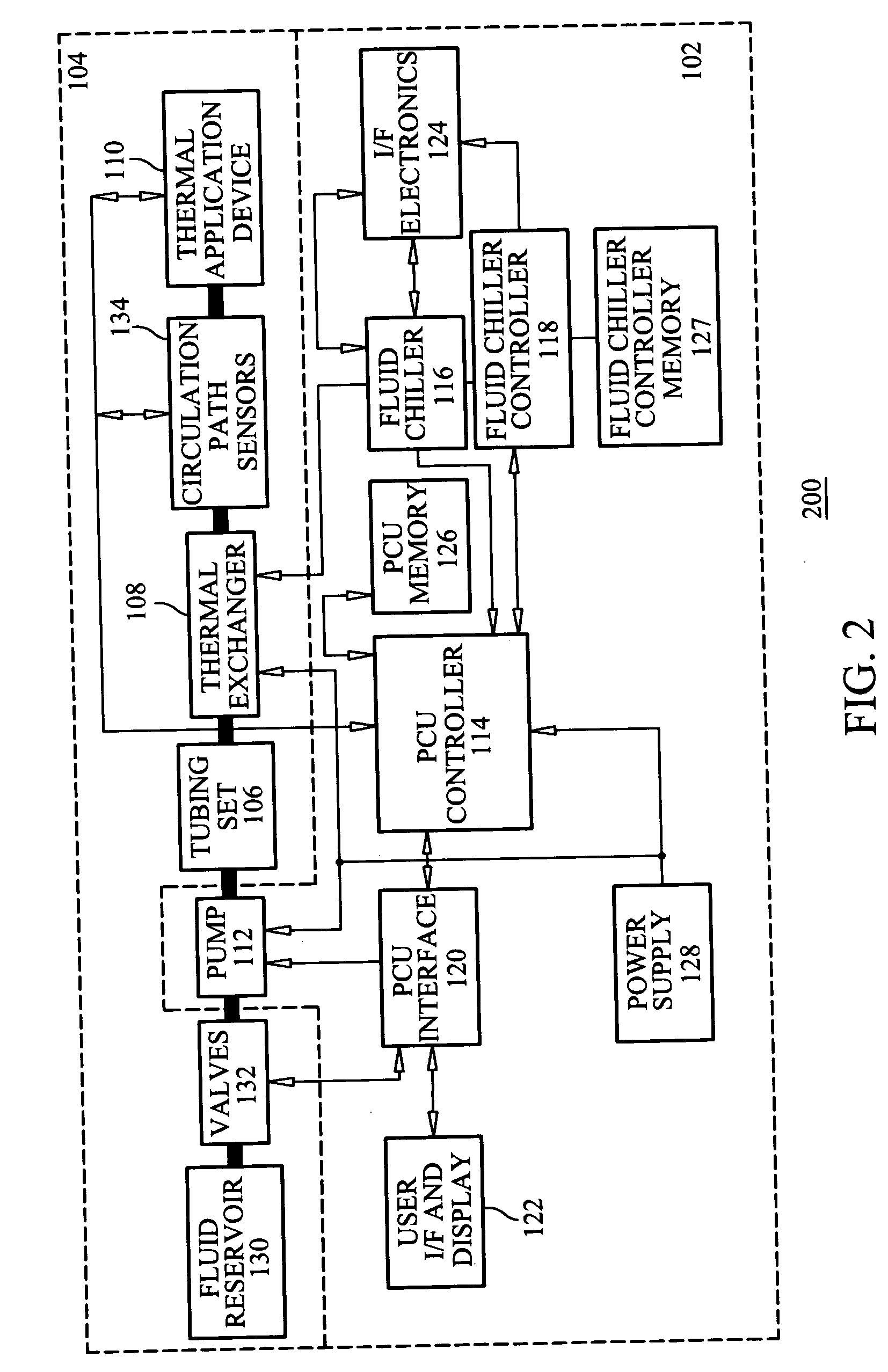

System and method for cooling internal tissue

A system, device and method for thermally affecting tissue are provided. The system includes a pump / controller unit having a pump for pumping a thermally conductive fluid through the system, a fluid chiller for thermally treating the conductive fluid, a controller circuitry for measuring and controlling the temperature of the conductive fluid, and a fluid circulation path having an extension tubing set for circulating the thermally conductive fluid, a thermal application device having at least one flow passage that is in fluid communication with the tubing set, a thermal exchanger element in fluid communication with the tubing set that interfaces with the fluid chiller, where the tubing set operably interfaces with a pump to enable the pump to circulate a thermally conductive fluid through a fluid circulation path. The fluid circulation path may have various sensors providing temperature and pressure readings to the pump / controller unit.

Owner:SEACOAST TECH

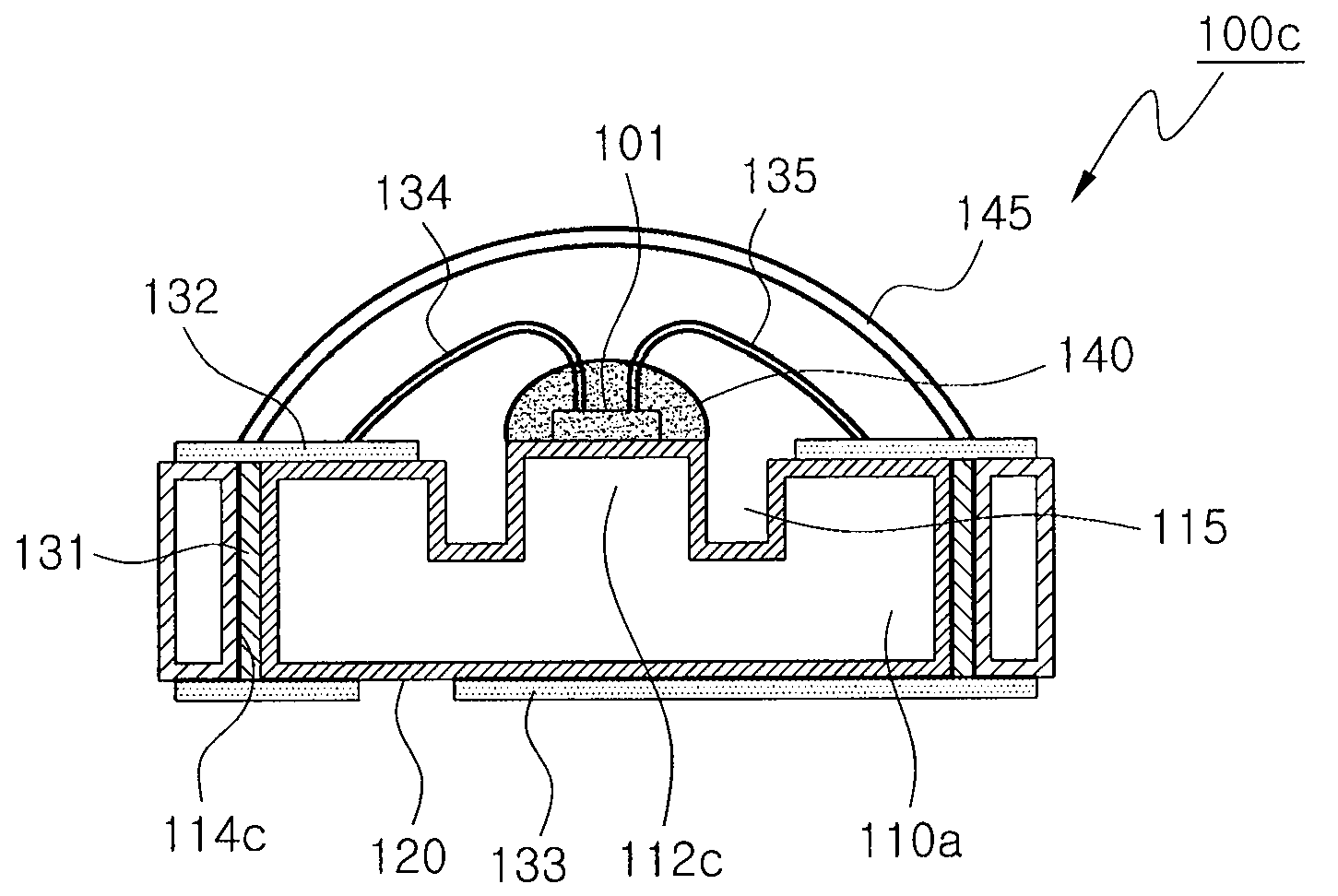

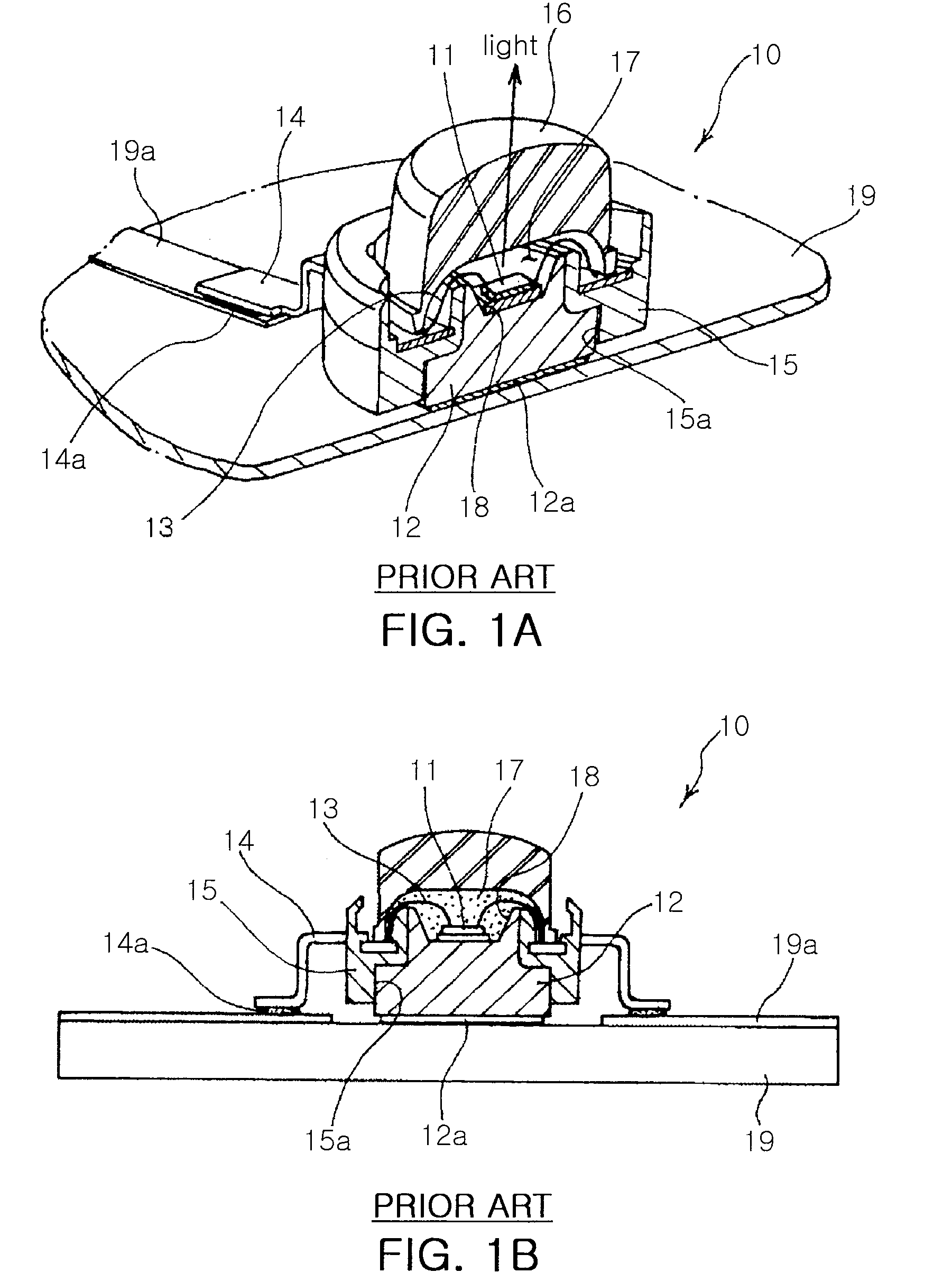

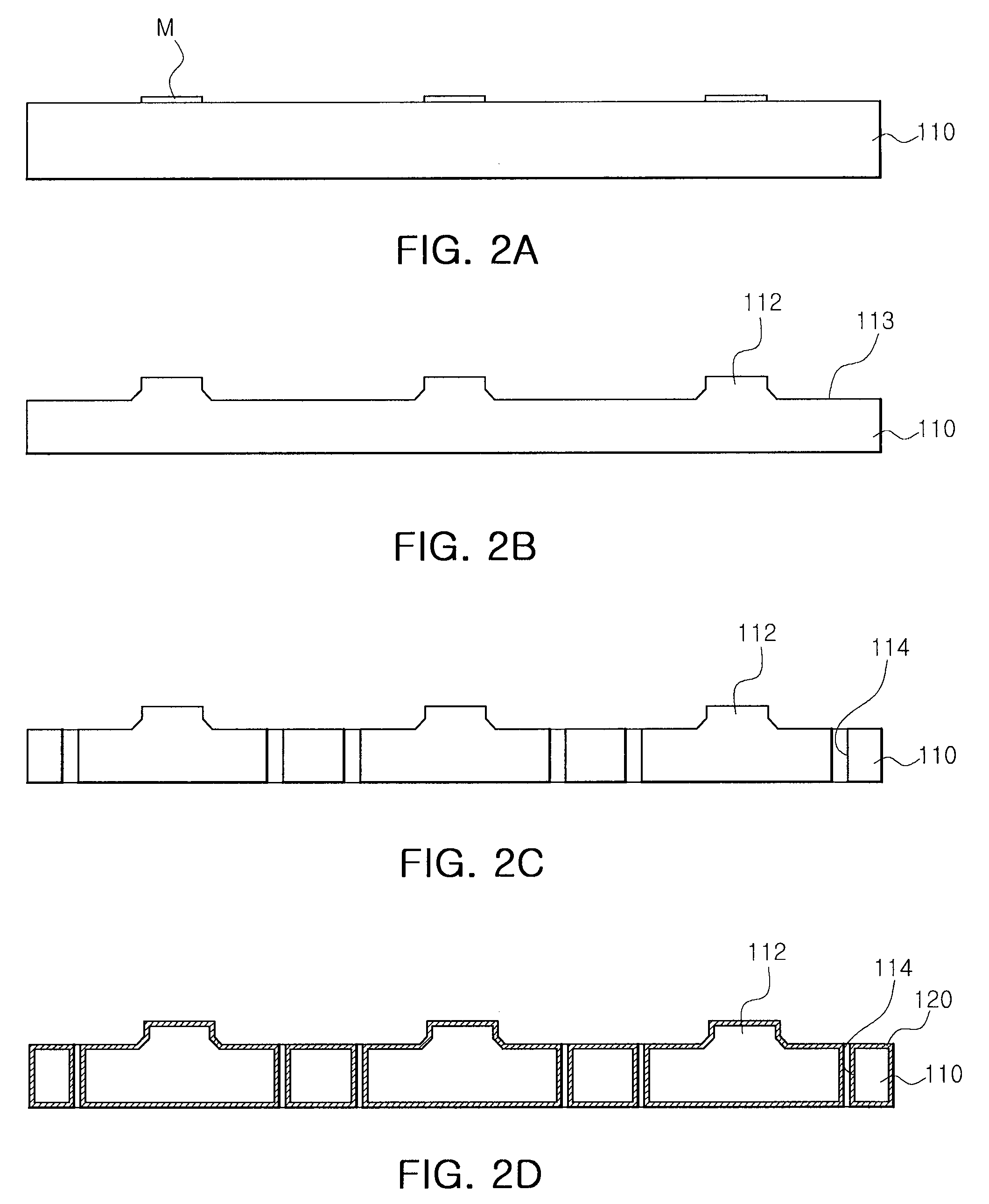

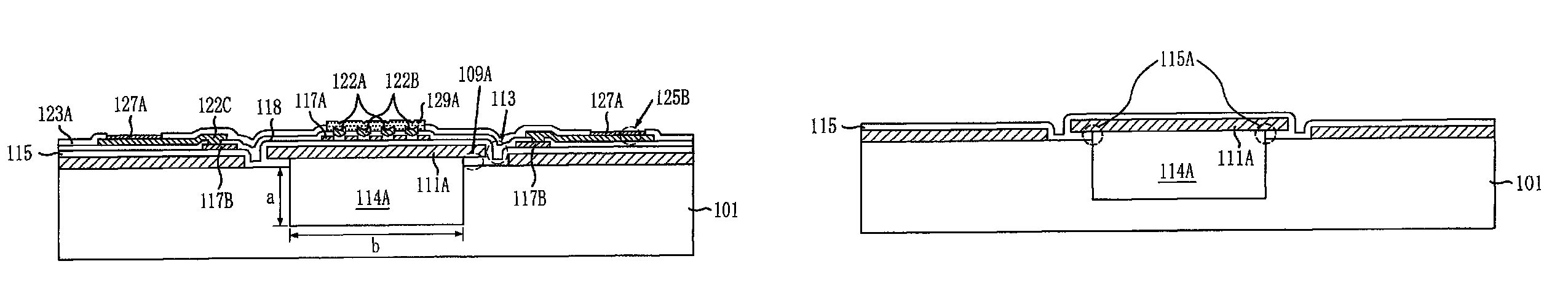

High power light emitting diode package and manufacturing method thereof

InactiveUS20090166664A1Improve cooling effectMinimized in optical lossSolid-state devicesSemiconductor/solid-state device manufacturingThermal impactThermal coefficient

There is provided a high power LED package and a method of manufacturing the same. The method includes: forming at least one chip mounting part and at least one through hole in a metal plate; forming an insulating layer of a predetermined thickness on an entire outer surface of the metal plate; forming an electrode part to be electrically connected to a light emitting chip mounted on the chip mounting part; and cutting the metal plate along a trimming line to separate the package. The LED package is free from thermal impact resulting from different thermal coefficients among components, thus ensuring stable heat radiation characteristics in a high temperature atmosphere. Also, the LED package is minimized in optical loss to improve optical characteristics. In addition, the LED package is simplified in a manufacturing and assembly process and thus can be manufactured in mass production at a lower cost.

Owner:SAMSUNG ELECTRONICS CO LTD

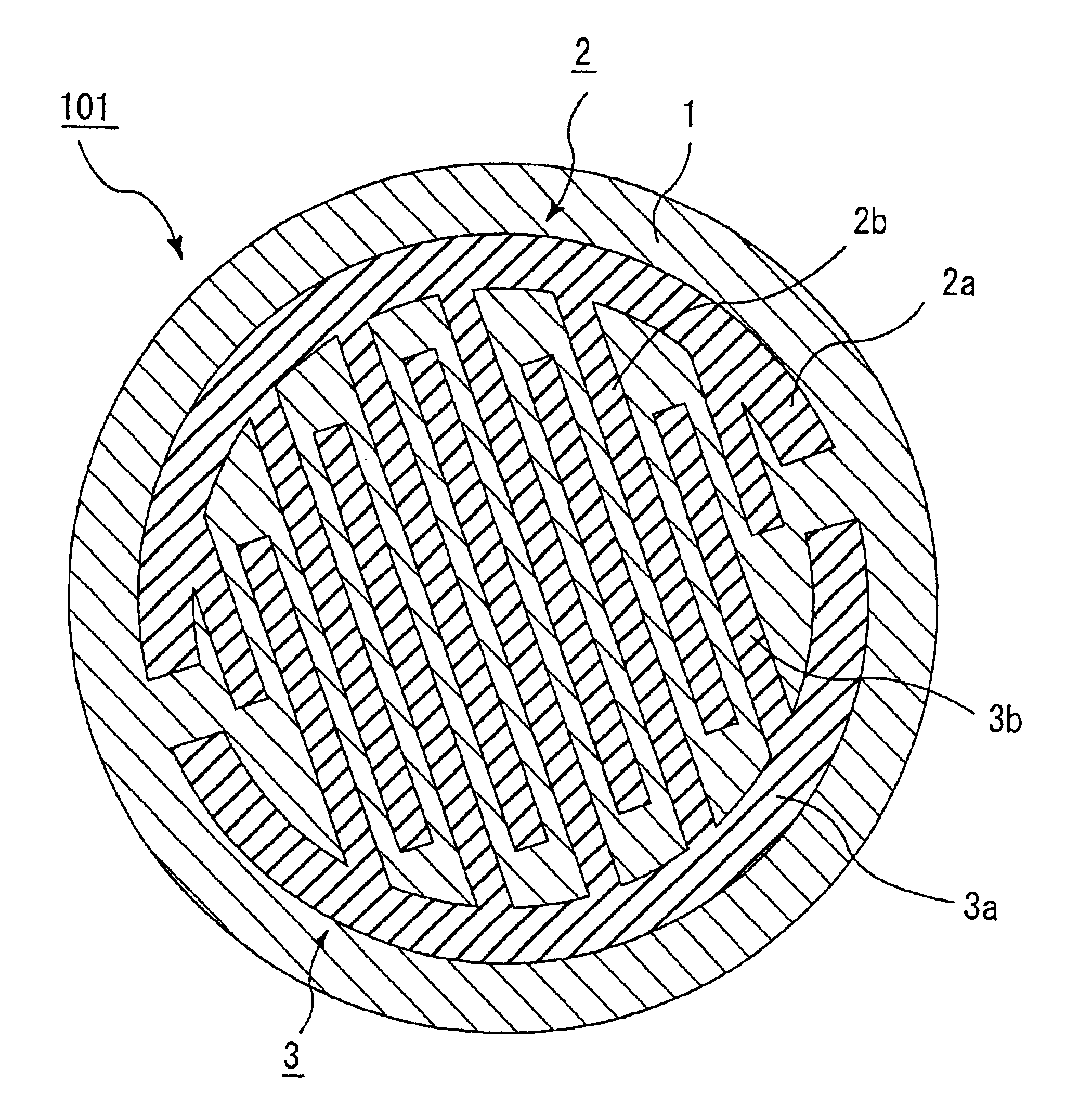

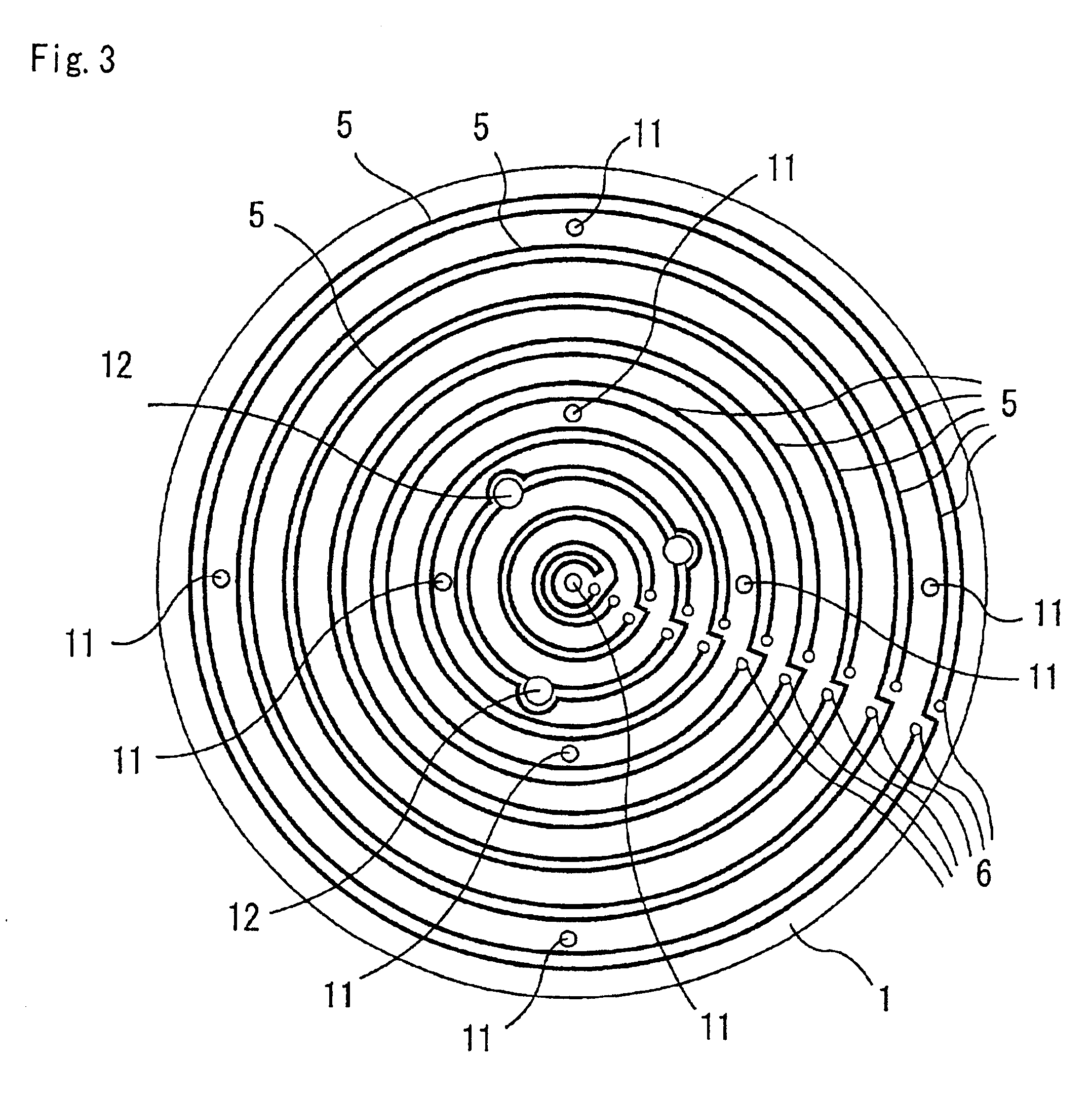

Ceramic substrate for a semiconductor production/inspection device

InactiveUS6891263B2Increase the number ofLower volume resistivitySemiconductor/solid-state device detailsSolid-state devicesNon oxide ceramicsElectrical conductor

The present invention provides a ceramic substrate which can keep a sufficiently large breakdown voltage even if the pore diameter of its maximum pore is 50 μm or less to be larger than that of conventional ceramic substrates, can give a large fracture toughness value because of the presence of pores, can resist thermal impact, and can give a small warp amount at high temperature. The ceramic substrate of the present invention is a ceramic substrate for a semiconductor-producing / examining device having a conductor formed on a surface of the ceramic substrate or inside the ceramic substrate, wherein: the substrate is made of a non-oxide ceramic containing oxygen; and the pore diameter of the maximum pore thereof is 50 μm or less.

Owner:IBIDEN CO LTD

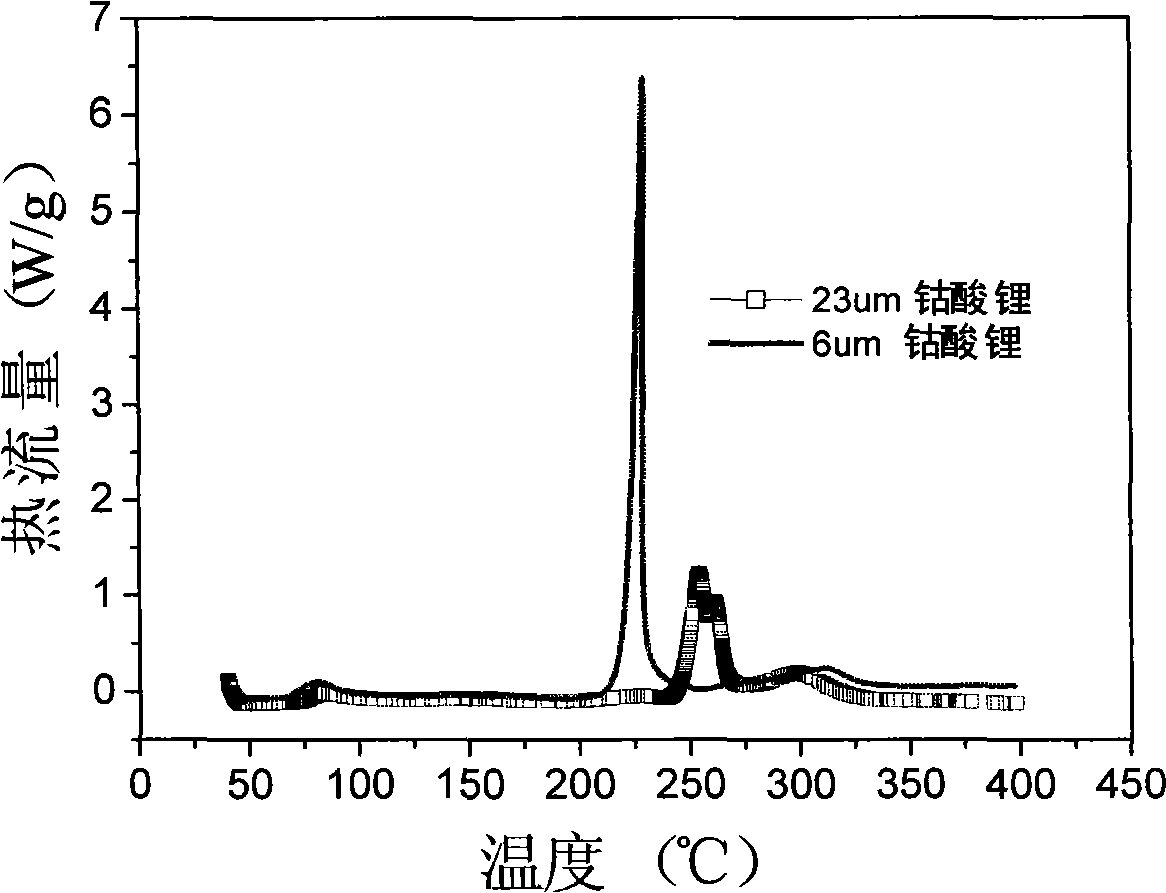

Super-size and high-density lithium cobalt oxide and method for preparing the same

ActiveCN101284681ALarge particle sizeHigh tap densityCell electrodesLithium compoundsHigh densityThermal impact

The invention relates to a high-density lithium cobalt oxide power material with a super-large grain diameter. The method comprises the steps of mixing a cobalt compound, a lithium compound or meanwhile a small amount of doping element compounds; sintering for 3 to 30 hours at the high temperature of 950 to 1,100 DEG C to form a block sintered product; crushing and grading the product to obtain the lithium cobalt oxide power material (molecular formula is LiaCo1-bMbO2), wherein, when b is not equal to 0, the middle diameter of the lithium cobalt oxide containing the doping elements is larger than or equal to 15 Mum, and the tap density is higher than or equal to 2.5g / cm<3>; when b is equal to 0, the middle diameter of the lithium cobalt oxide without the doping elements is larger than 20 Mum, and the tap density is higher than or equal to 2.6g / cm<3>. the 3.6V platform capacity rate of the material as the anode active substance for a lithium battery is higher than or equal to 75%; in the thermal impact test in a 150 DEG C thermotank, the lithium battery with the material is free from leakage and does not catch fire or explode for 60 minutes; the 1C5A specific capacity of the material in the battery is larger than or equal to 135mAh / g.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

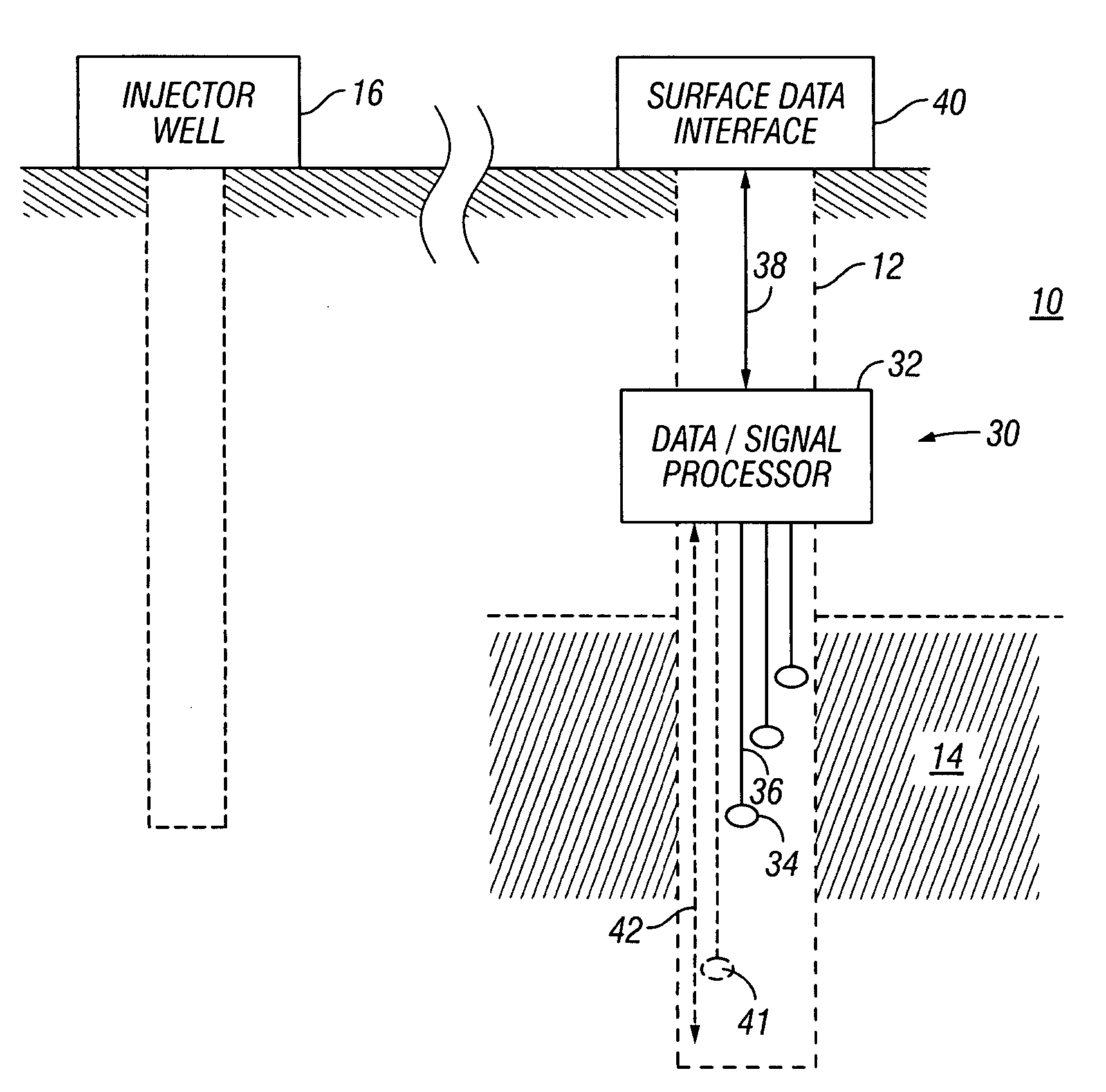

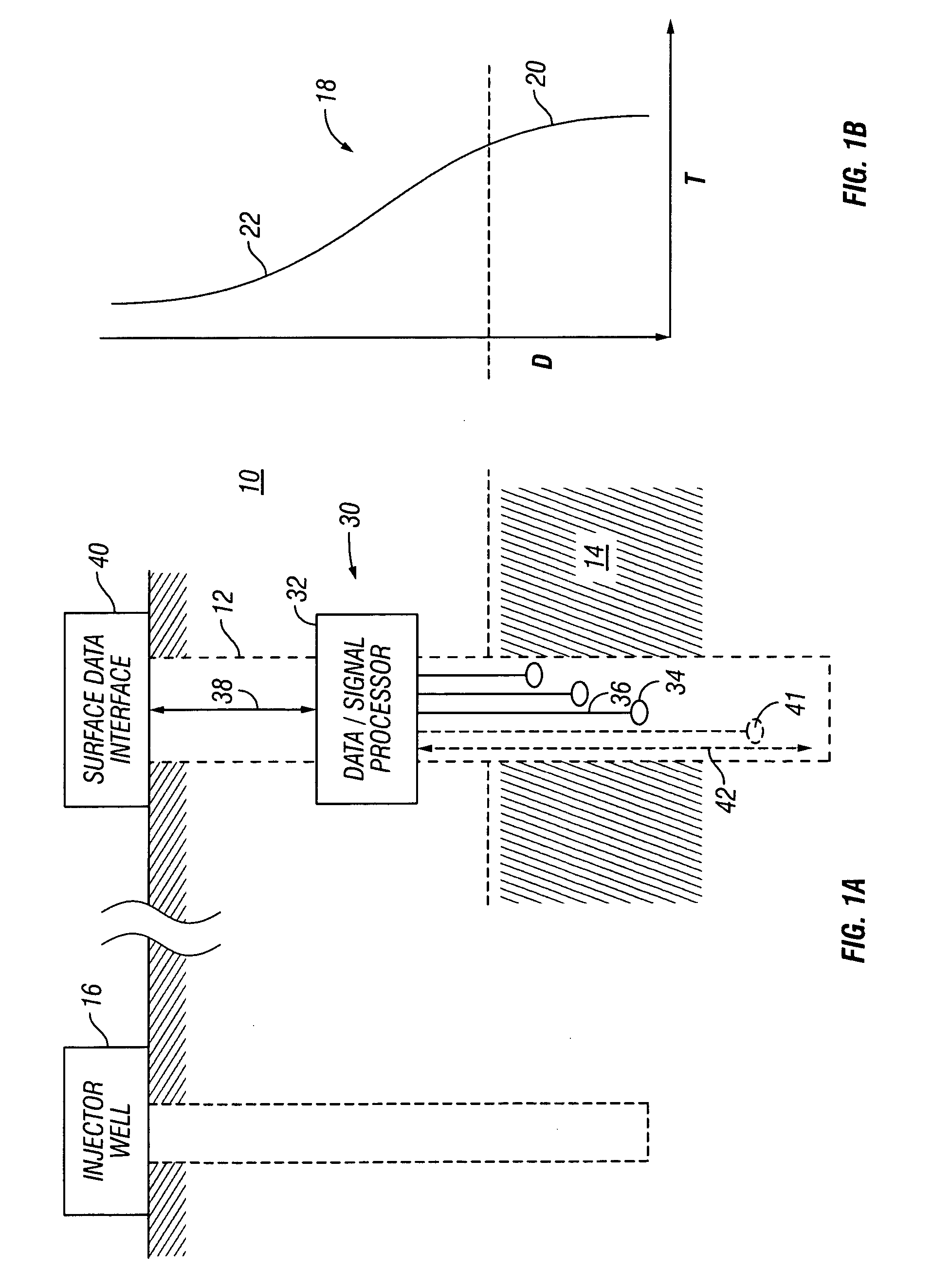

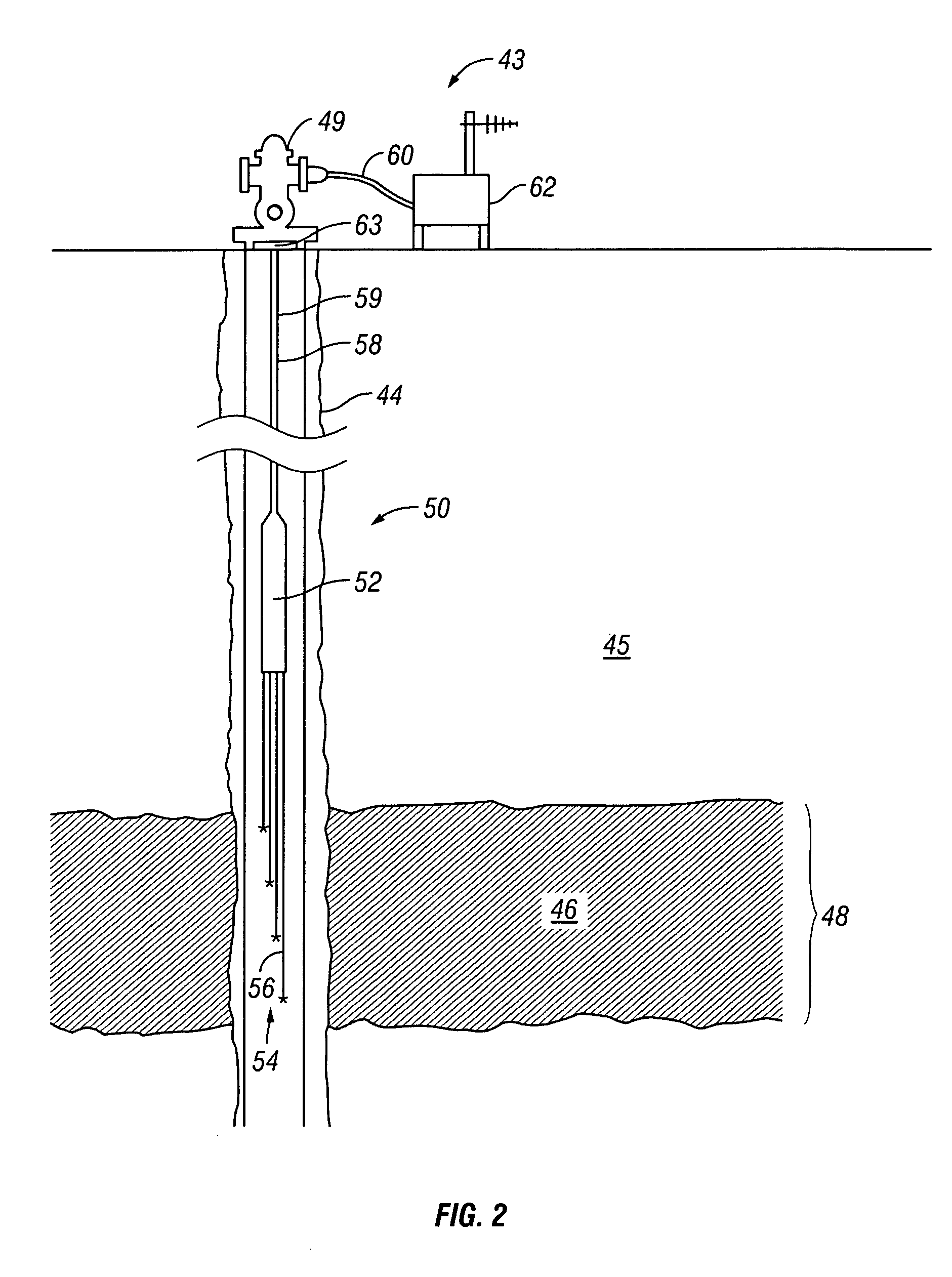

Systems and methods for acquiring data in thermal recovery oil wells

ActiveUS20060250274A1Electric/magnetic detection for well-loggingSurveyHeat-affected zoneThermal impact

In connection with thermal recovery projects, a system determines temperature gradients for a heat affected zone associated with a subterranean hydrocarbon reservoir. An exemplary system includes a plurality of temperature sensors distributed in the wellbore at least partially along the heat affected zone. A downhole processor positioned proximate and substantially outside of the heat affected zone receives and digitizes the temperature measurements. A data link such as a data cable coupled to the downhole processor conveys the temperature measurements to a surface interface.

Owner:CORE LAB CANADA

Resistance welding superposition technology for PCB thick copper lines

ActiveCN101534612AIncreasing the thicknessInhibit sheddingNon-metallic protective coating applicationProduction scheduleCooking & baking

The invention discloses a resistance welding superposition technology for PCB thick copper lines, comprising the steps of: at first, printing resistance welding ink on the surface of a PCB and forming a first resistance welding layer via screen printing resistance welding; and pre-drying while remaining 75 DEG C and semi-hardening the first resistance welding layer after cooling; then printing the resistance welding on the first resistance welding layer once again in order to form a second resistance welding layer; pre-drying once again while remaining 75 DEG C and semi-hardening the first resistance welding layer and the second resistance welding layer after cooling; eventually, hardening the resistance welding layer and the second resistance welding layer completely subsequent to the segmented baking of the semi-hardened PCB. The invention requires only one-time resistance welding pattern transfer and high-temperature baking by the superposition printing on the thickness of the resistance welding, which increases the thickness of the resistance welding layer, thickens, in particular, the thickness of the resistance welding layer at corners of the lines, and avoids the problems of resistance welding blistering and falling in thermal impact procedures of post-processing procedure, and meanwhile, using the inventive technology shortens production procedure dramatically, speeds up production schedule and lowers production cost.

Owner:SHENZHEN BOMIN ELECTRONICS

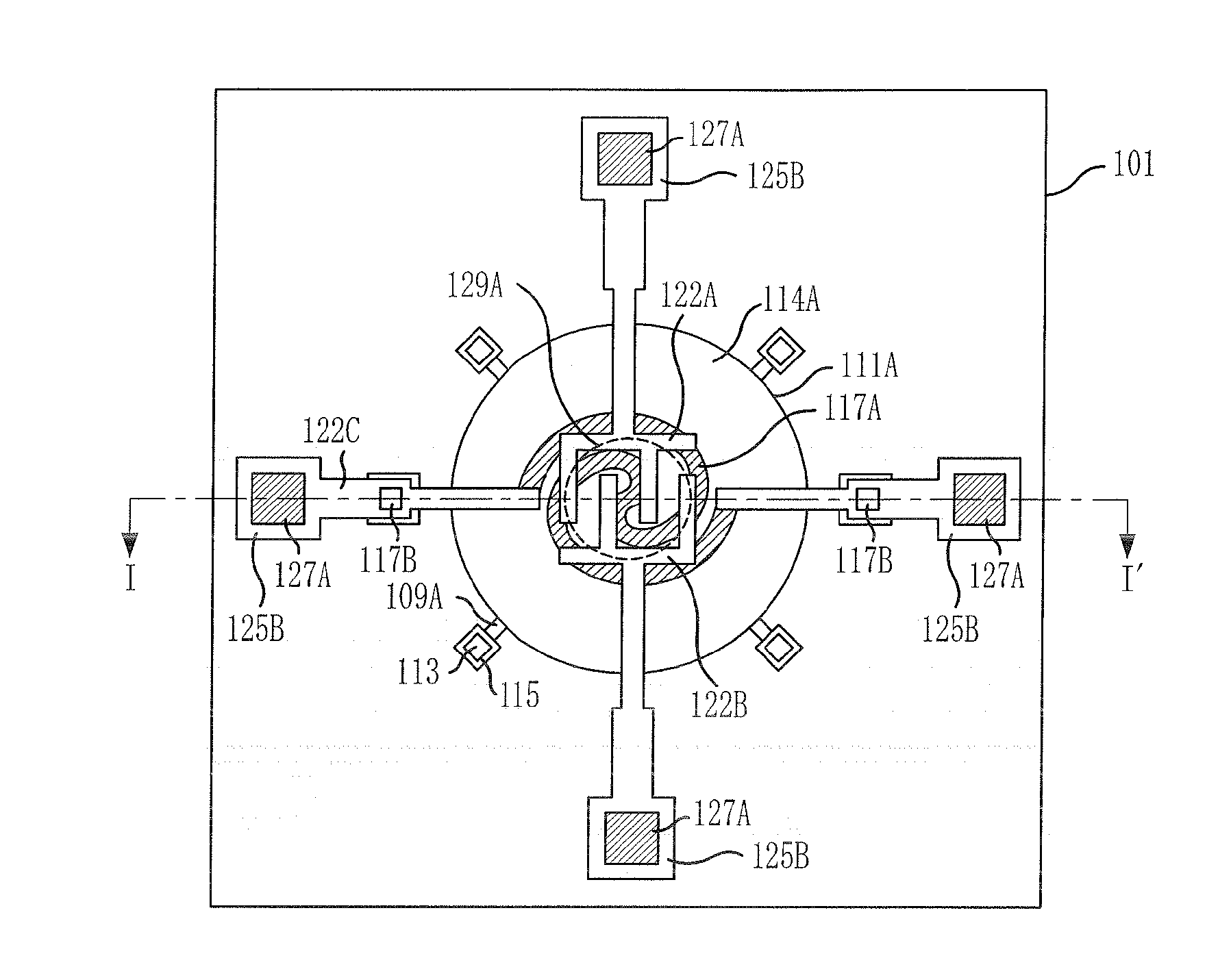

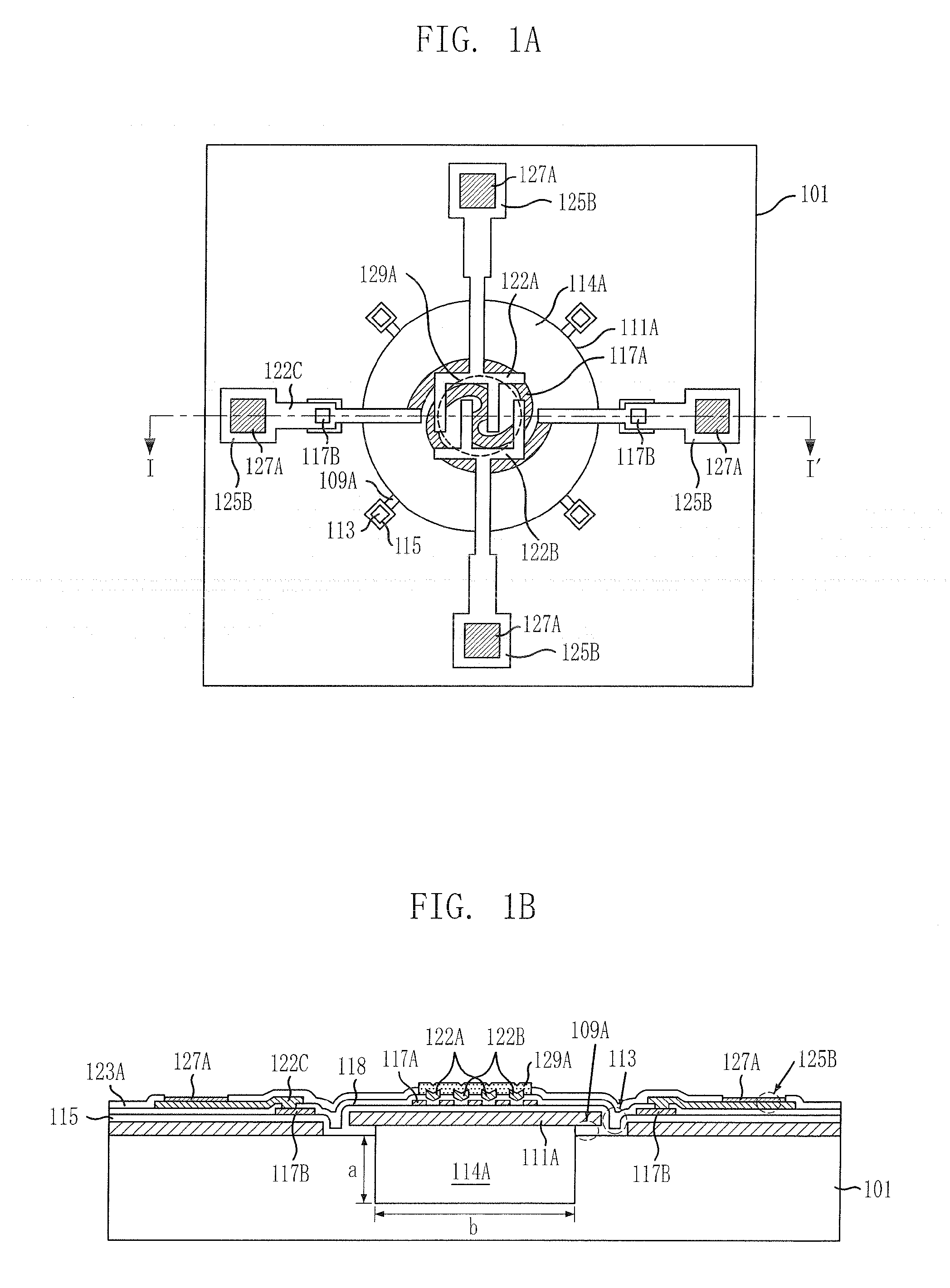

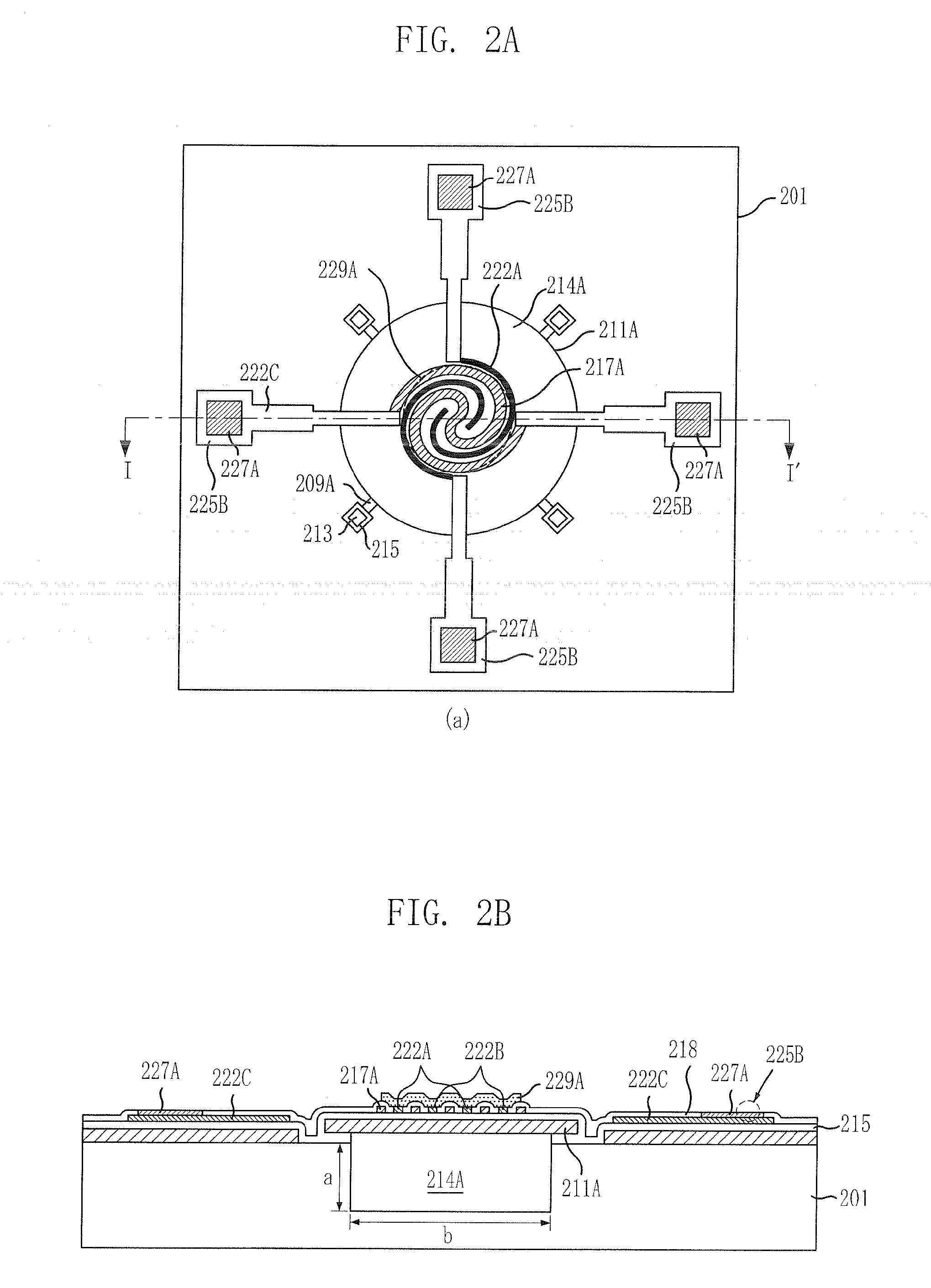

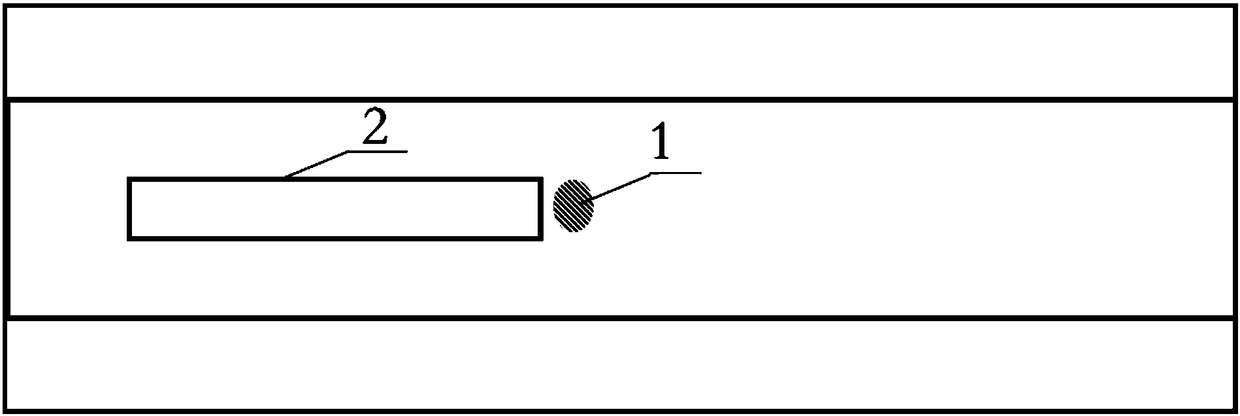

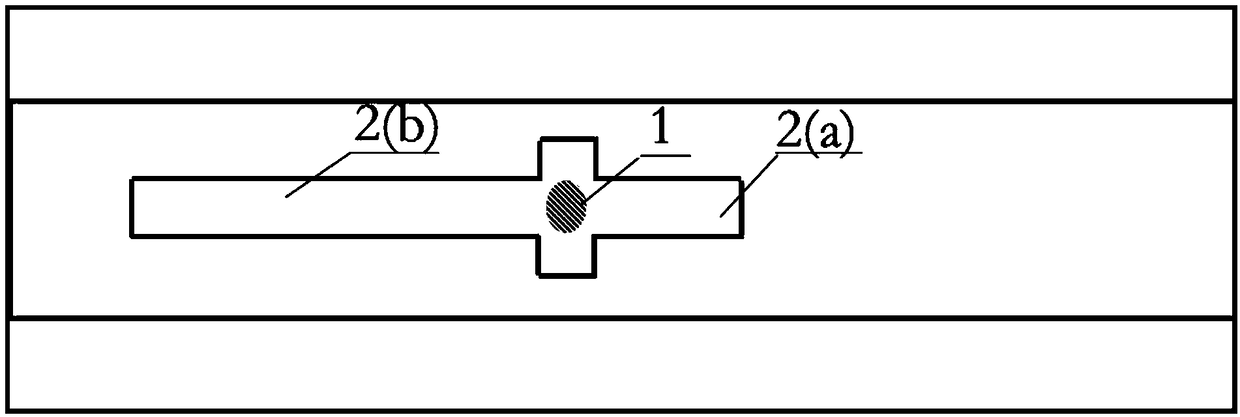

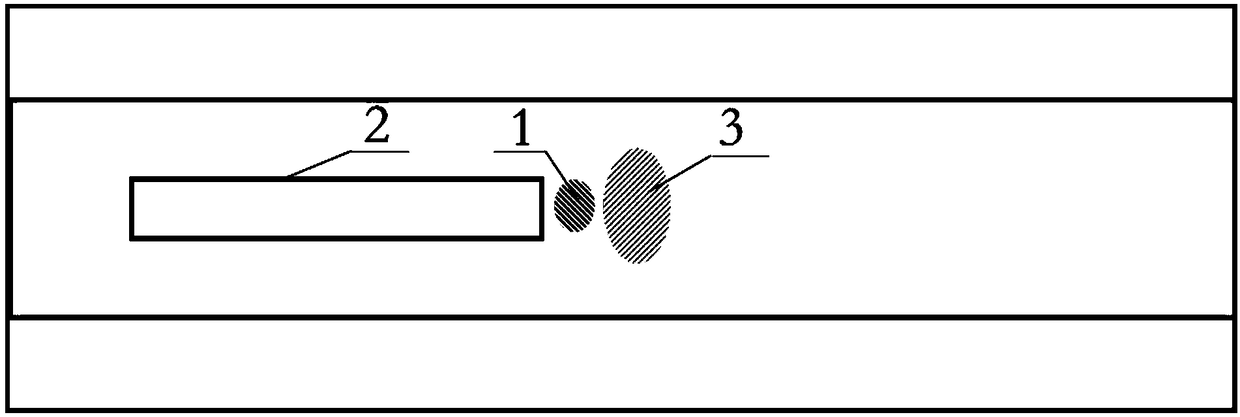

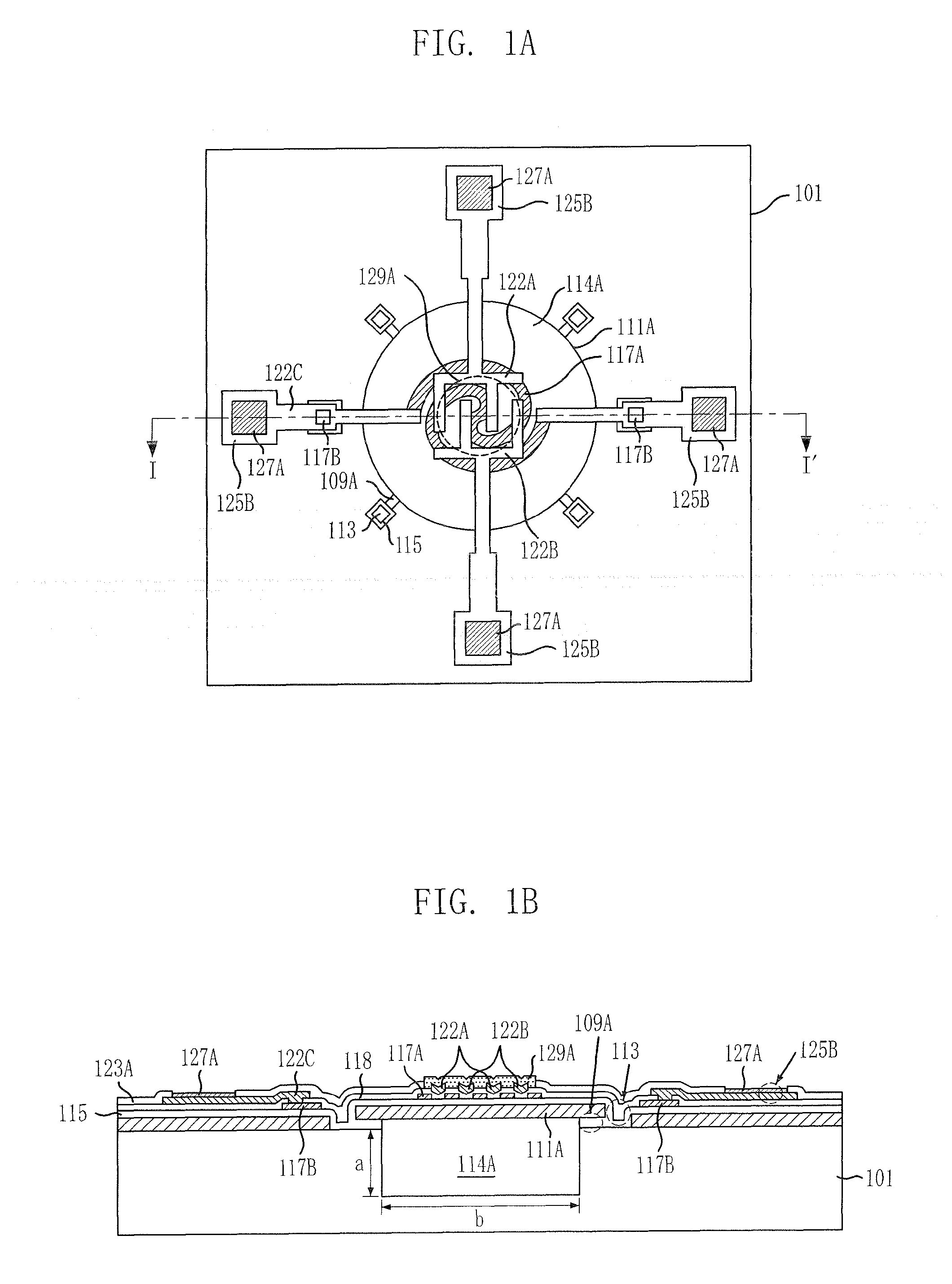

Micro gas sensor and method for manufacturing the same

ActiveUS20080134753A1High measurement accuracyMinimize height differenceAnalysing fluids using sonic/ultrasonic/infrasonic wavesUsing mechanical meansThermal impactMechanical impact

Provided are a micro gas sensor for measuring a gas concentration configured to achieve a high heating and cooling rate of a gas sensitive layer, achieve temperature uniformity, and achieve durability against thermal impact and mechanical impact; and a method for manufacturing the micro gas sensor. The micro gas sensor includes: a vacuum cavity disposed in a substrate; a support layer covering the vacuum cavity; a sealing layer sealing the support layer and the vacuum cavity; a micro heater disposed on the sealing layer; a plurality of electrodes disposed on the micro heater, insulated from the micro heater; and a gas sensitive layer covering the electrodes.

Owner:ELECTRONICS & TELECOMM RES INST

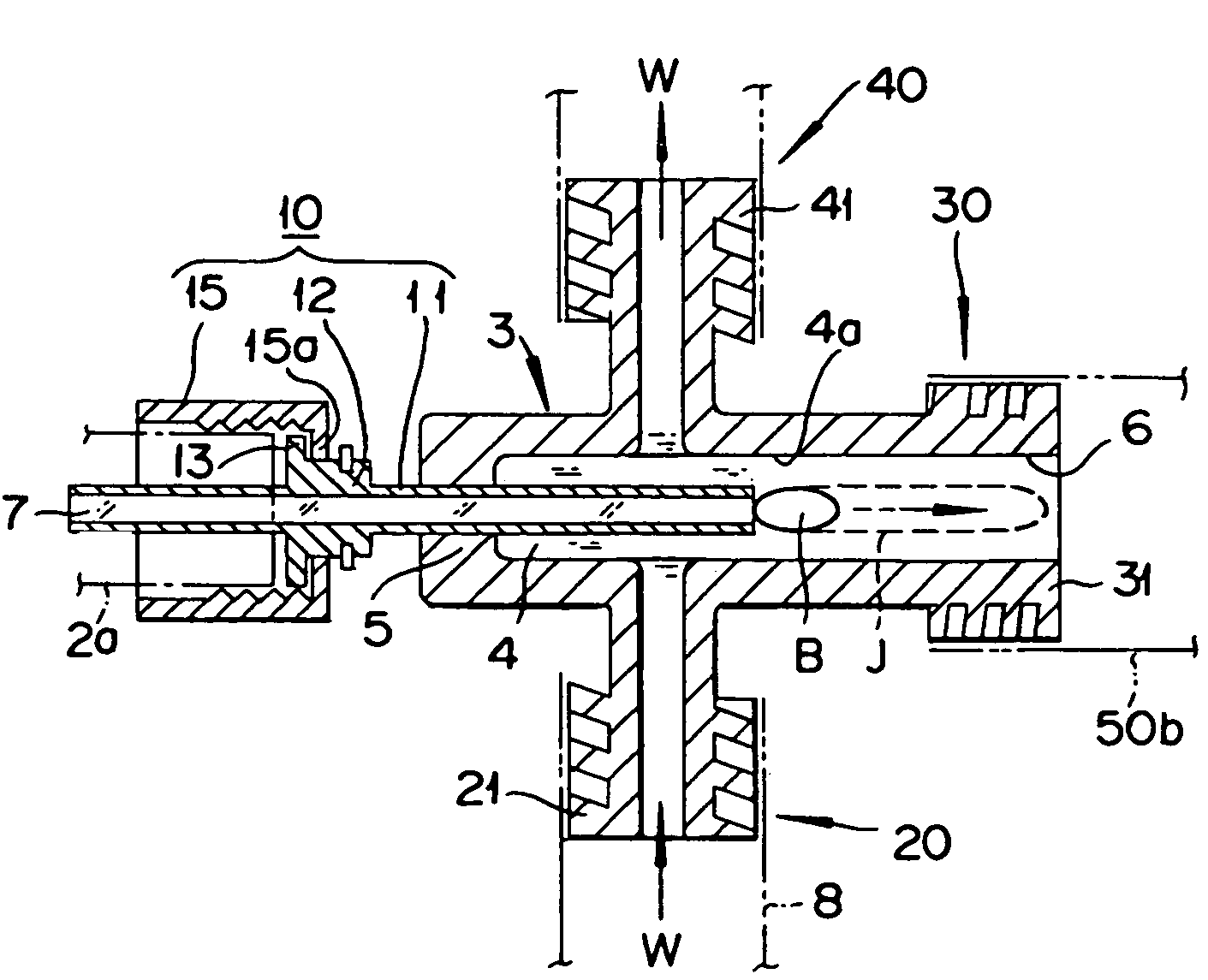

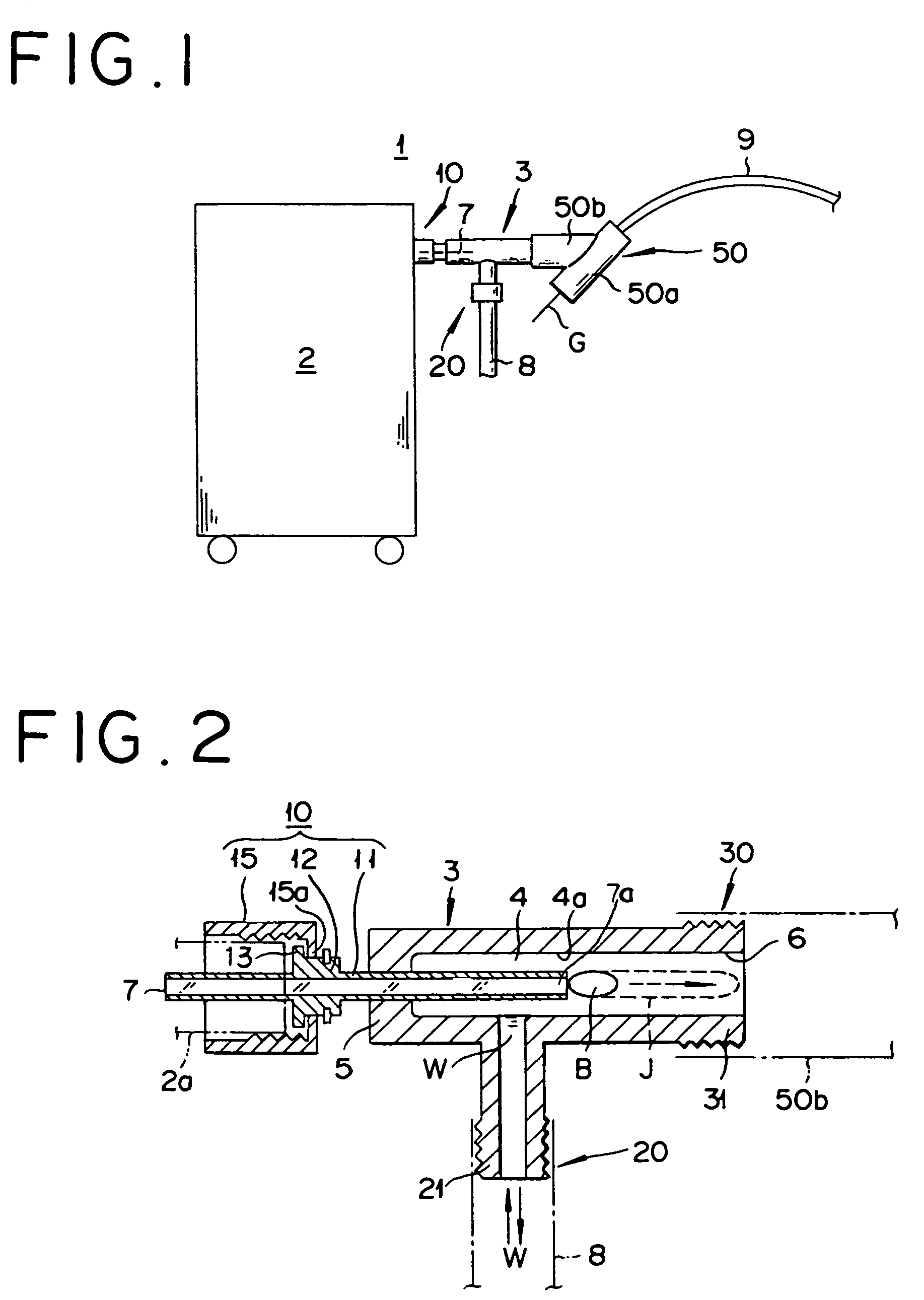

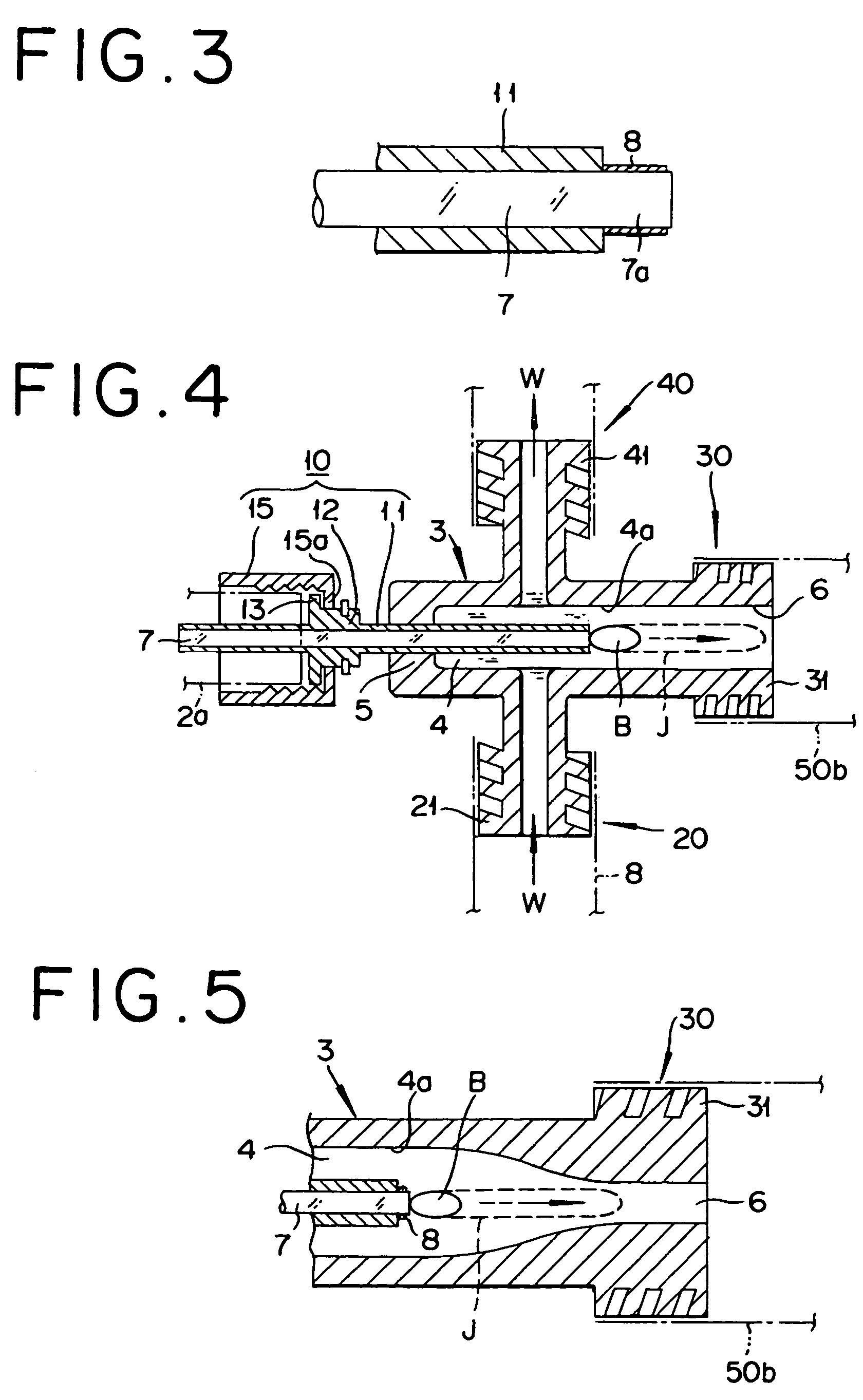

Laser induced liquid jet generating apparatus

InactiveUS7740626B2Guaranteed uptimeAllow useSurgical instrument detailsFluid jet surgical cuttersLiquid jetThermal impact

Owner:TERUMO KK

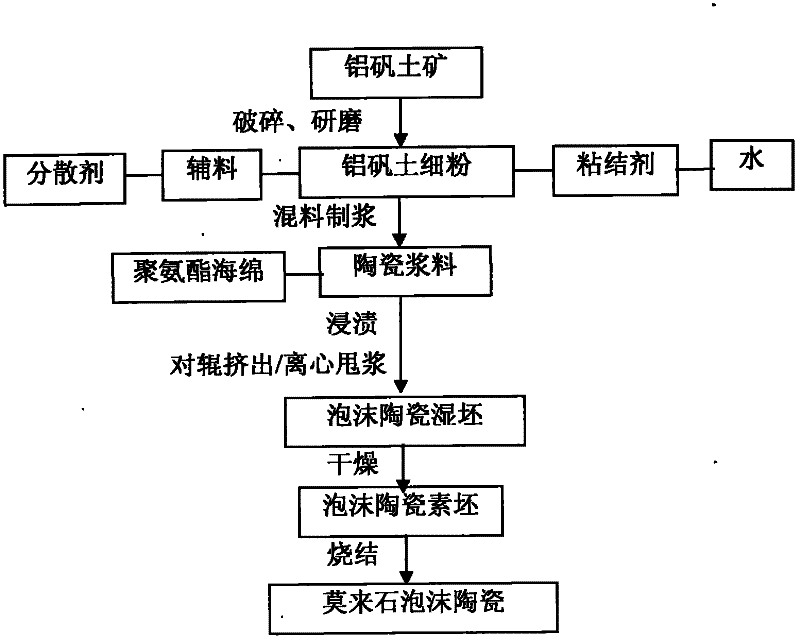

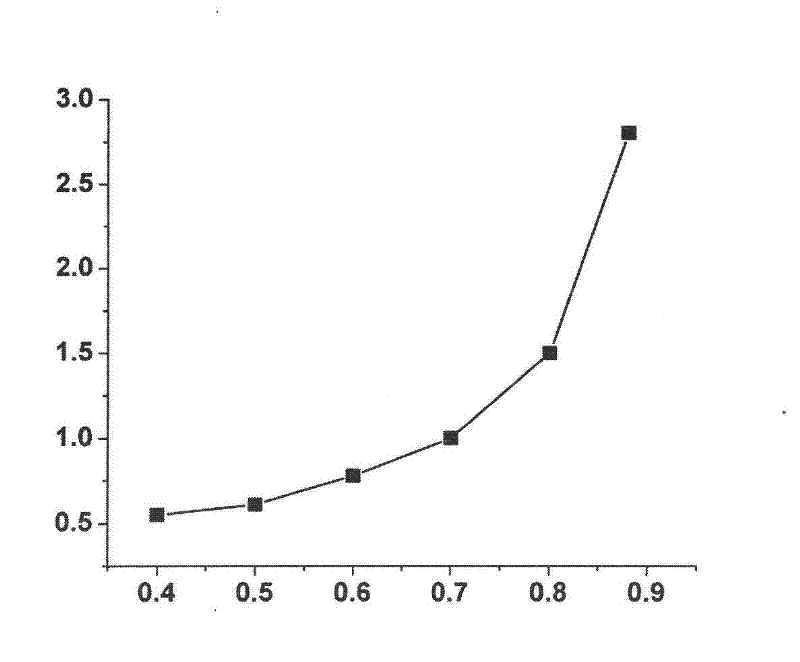

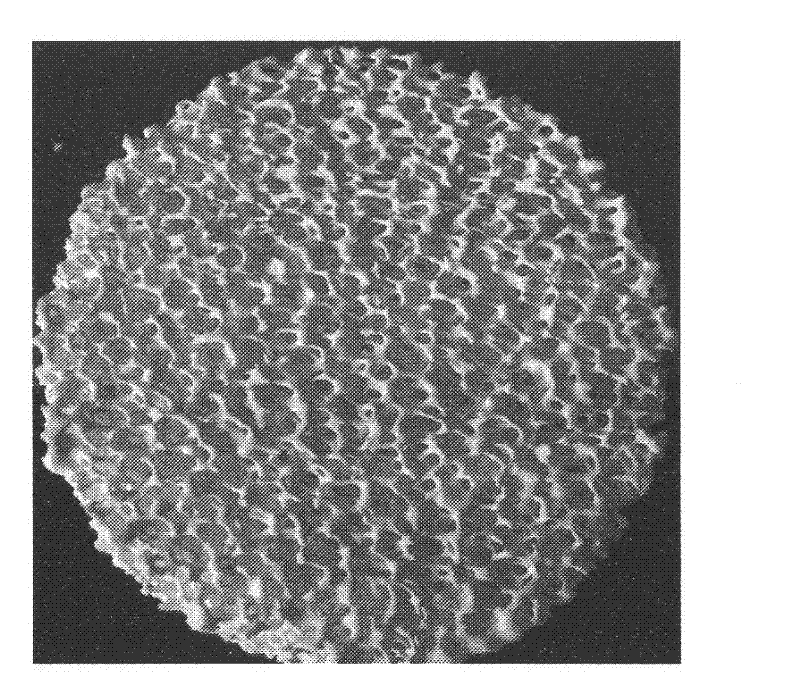

Mullite ceramic foam filter for casting and preparation method thereof

InactiveCN102173856AGood purification effectImprove filtering effectFiltration separationCeramicwareMulliteSlurry

The invention belongs to the field of porous ceramic, and provides a mullite ceramic foam filter for casting. The mullite ceramic foam filter for casting comprises the following chemical components: 40-80 wt% of Al2O3, 10-50 wt% of SiO2 and 1-10 wt% of alkali-earth oxide. The mullite ceramic foam filter for casting is in a mutually-communicated mesh porous structure. The preparation method comprises the following steps: using natural alumina containing 40-80 wt% of Al2O3 as the main raw material, adding one or more of silicon dioxide, aluminum oxide, kaolin, bentonite and talcum powder as the auxiliary material, and adding adhesive, dispersant and water to obtain a ceramic slurry; and immersing polyurethane sponge foam into the slurry, removing the excessive slurry, drying, and sintering at high temperature to obtain the mullite ceramic foam filter. The invention has excellent thermal impact resistance and molten metal attack resistance, and can be widely used for filtering, purifying and rectifying aluminum, aluminum alloy, copper, iron or any other molten metal liquid, thereby greatly enhancing the quality and yield of castings.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

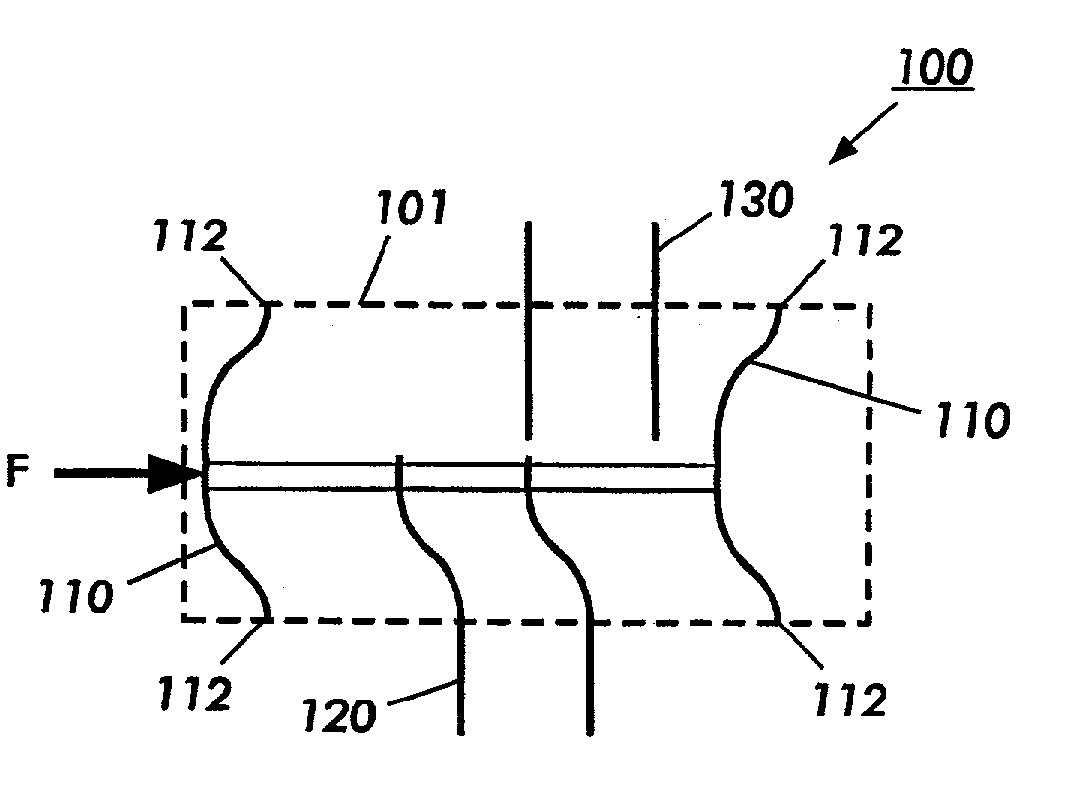

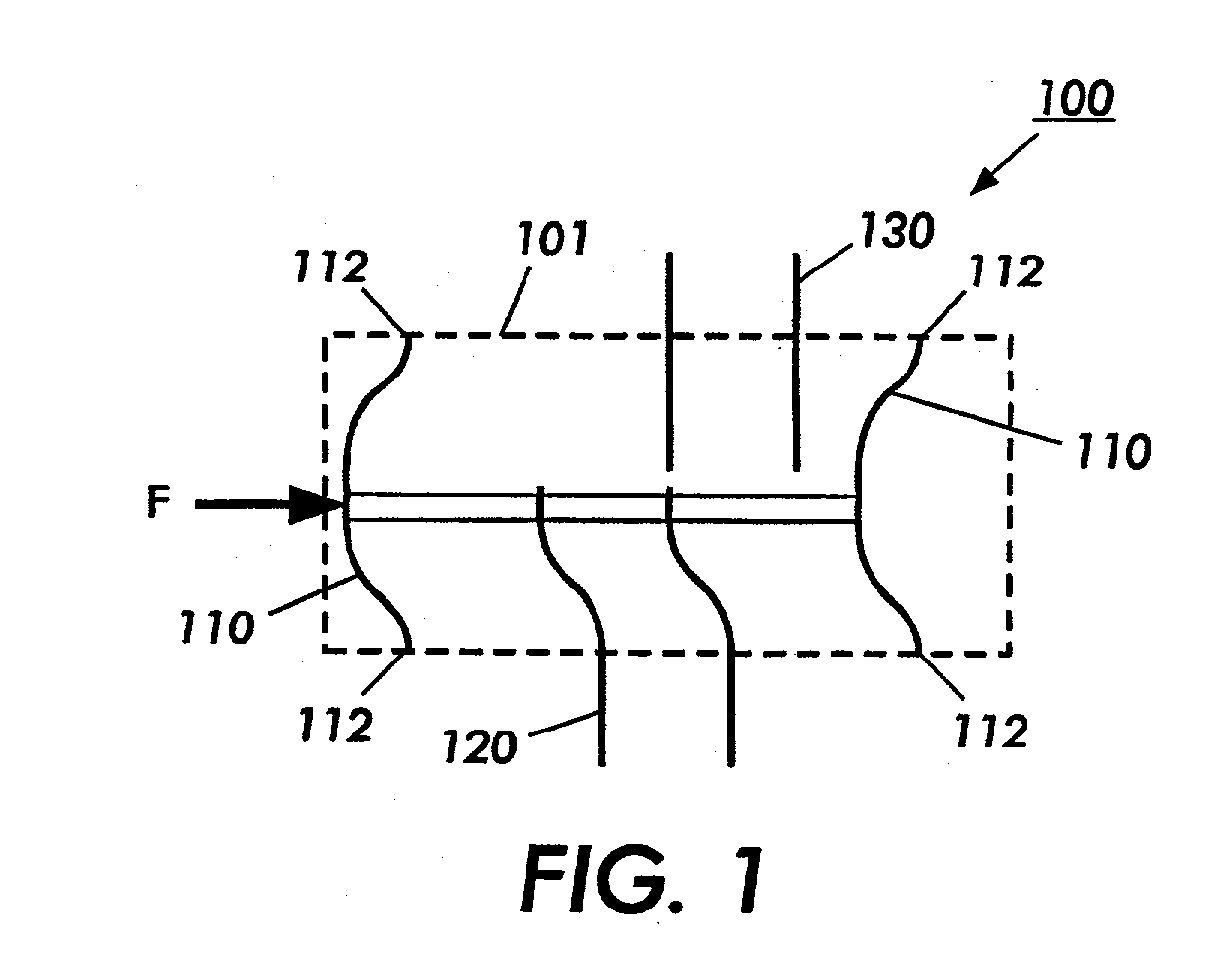

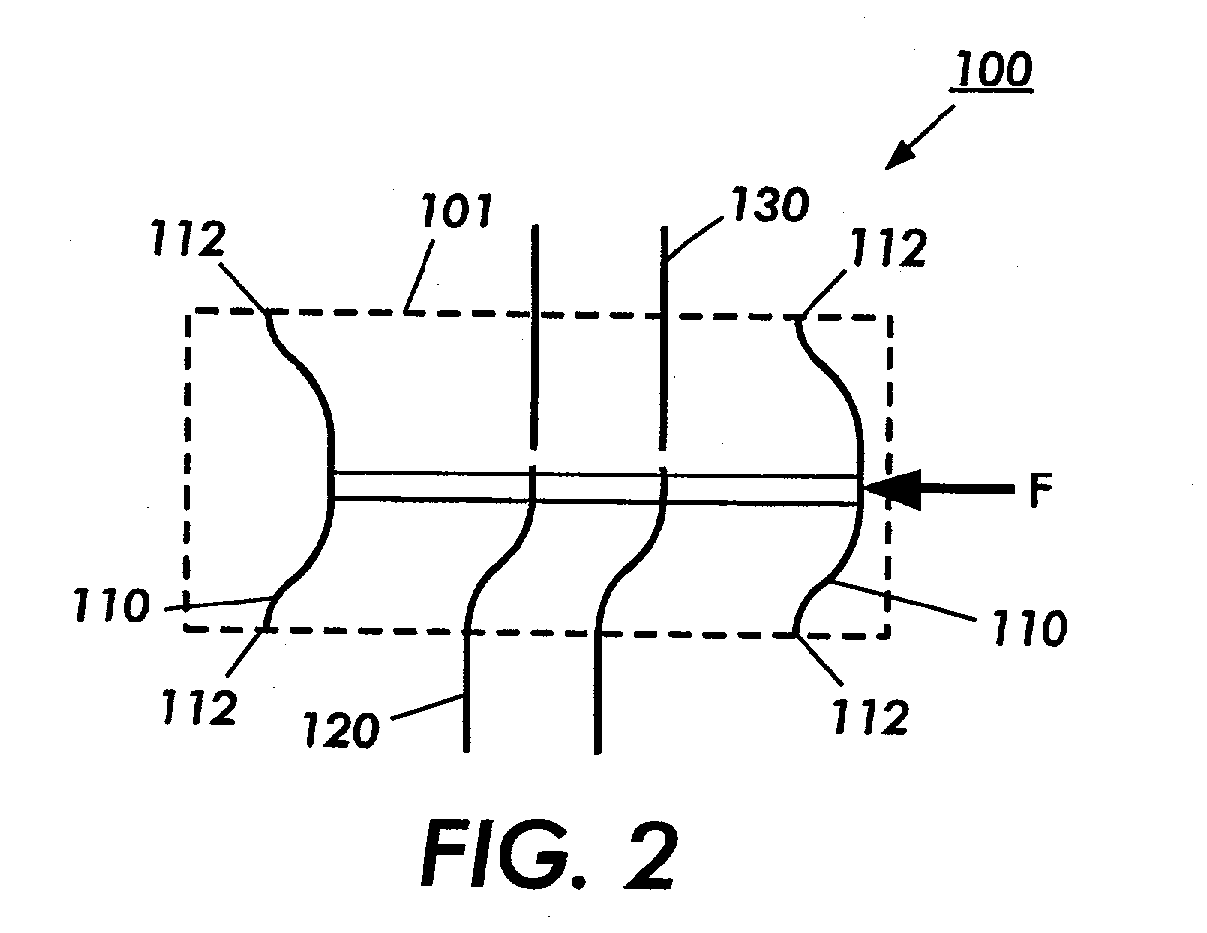

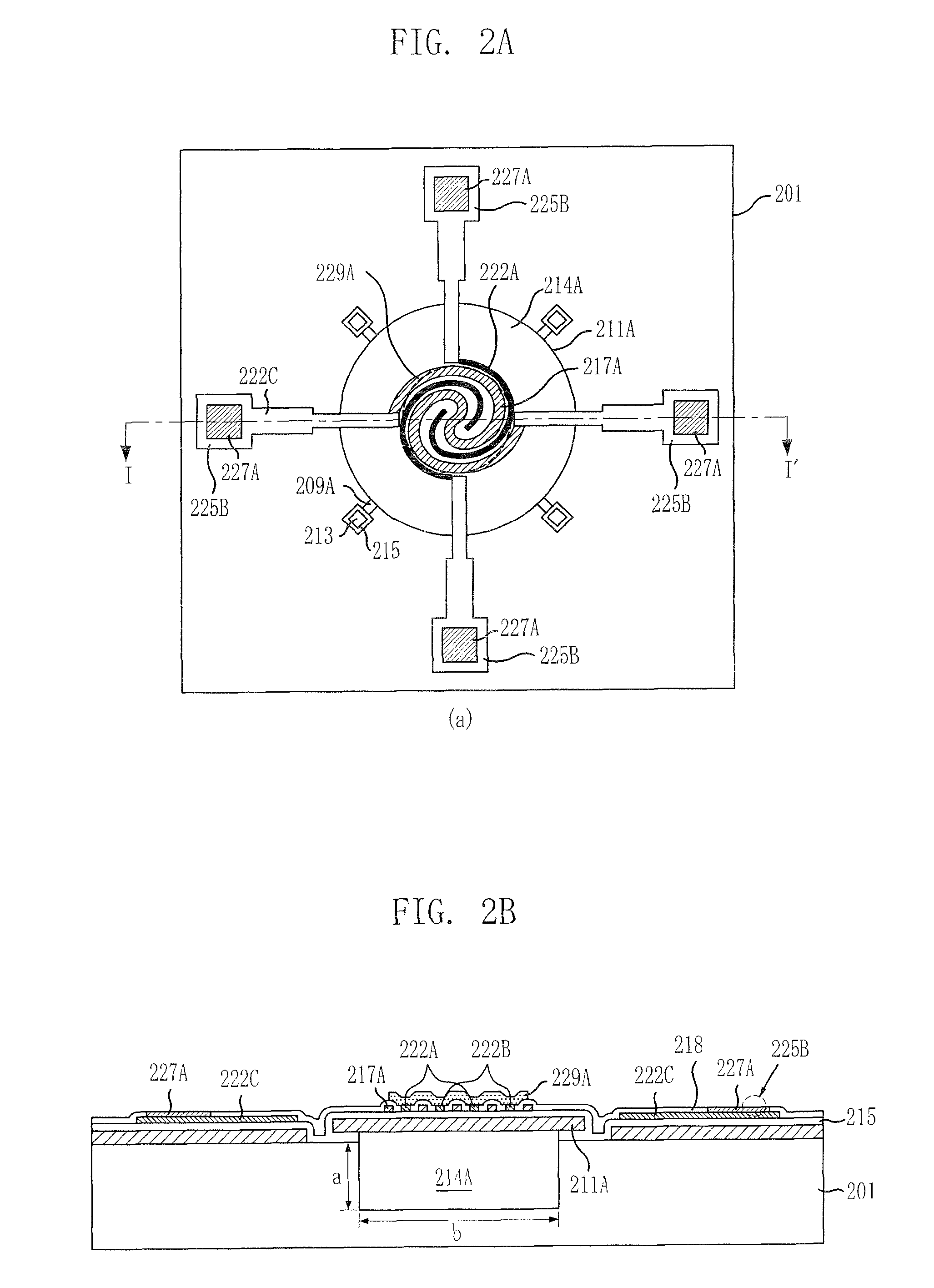

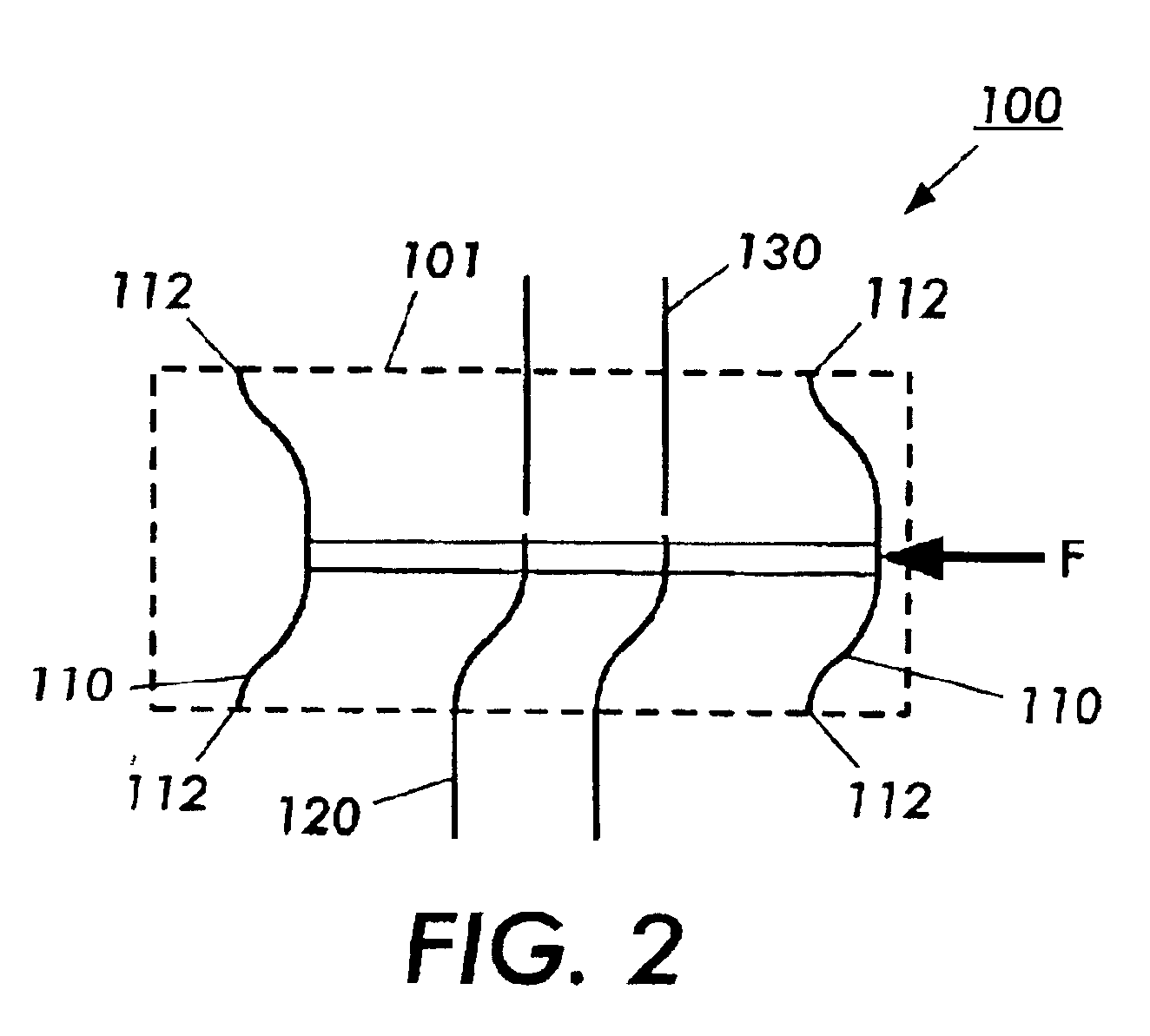

Bistable microelectromechanical system based structures, systems and methods

InactiveUS20030210115A1Increase flexibilityReduce complexityElectrostatic/electro-adhesion relaysCoupling light guidesStable stateThermal impact

A bistable microelectromechanical system (MEMS) based system comprises a micromachined beam having a first stable state, in which the beam is substantially stress-free and has a specified non-linear shape, and a second stable state. The curved shape may comprises a simple curve or a compound curve. In embodiments, the boundary conditions for the beam are fixed boundary conditions, bearing boundary conditions, spring boundary conditions, or a combination thereof. The system may further comprise an actuator arranged to move the beam between the first and second stable states and a movable element that is moved between a first position and a second position in accordance with the movement of the beam between the first and second stable states. The actuator may comprise one of a thermal actuator, an electrostatic actuator, a piezoelectric actuator and a magnetic actuator. The actuator may further comprise a thermal impact actuator or a zippering electrostatic actuator.

Owner:XEROX CORP

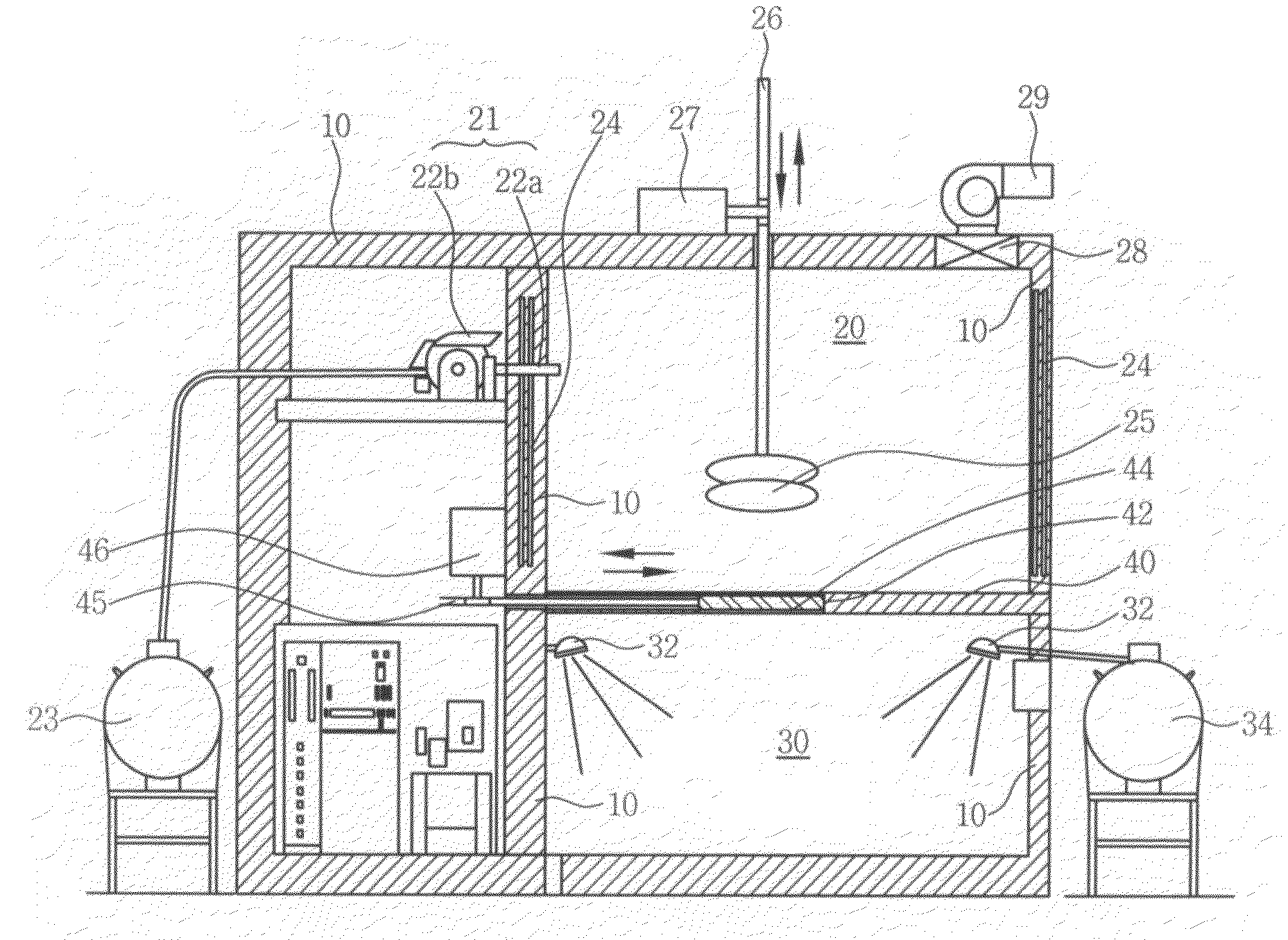

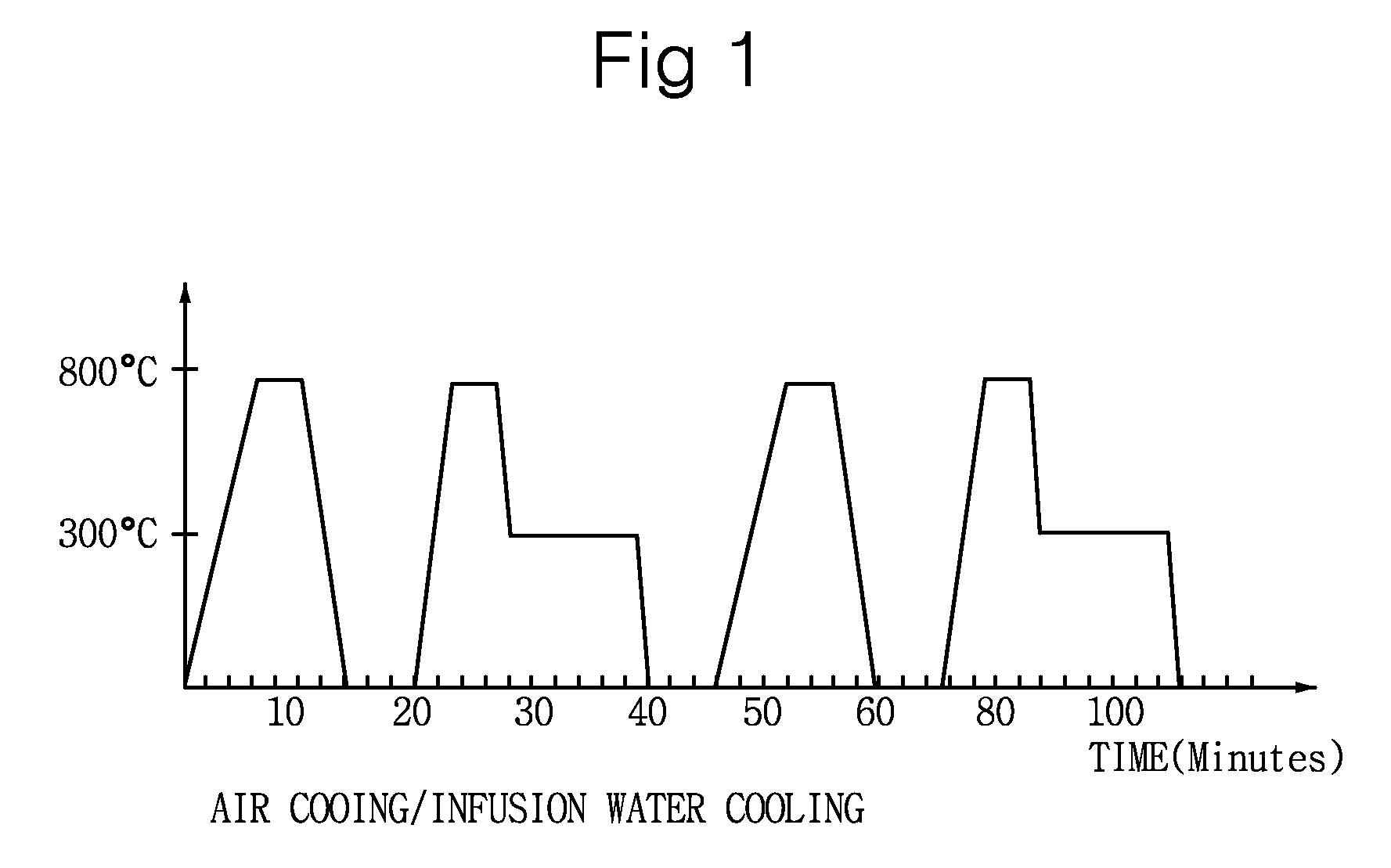

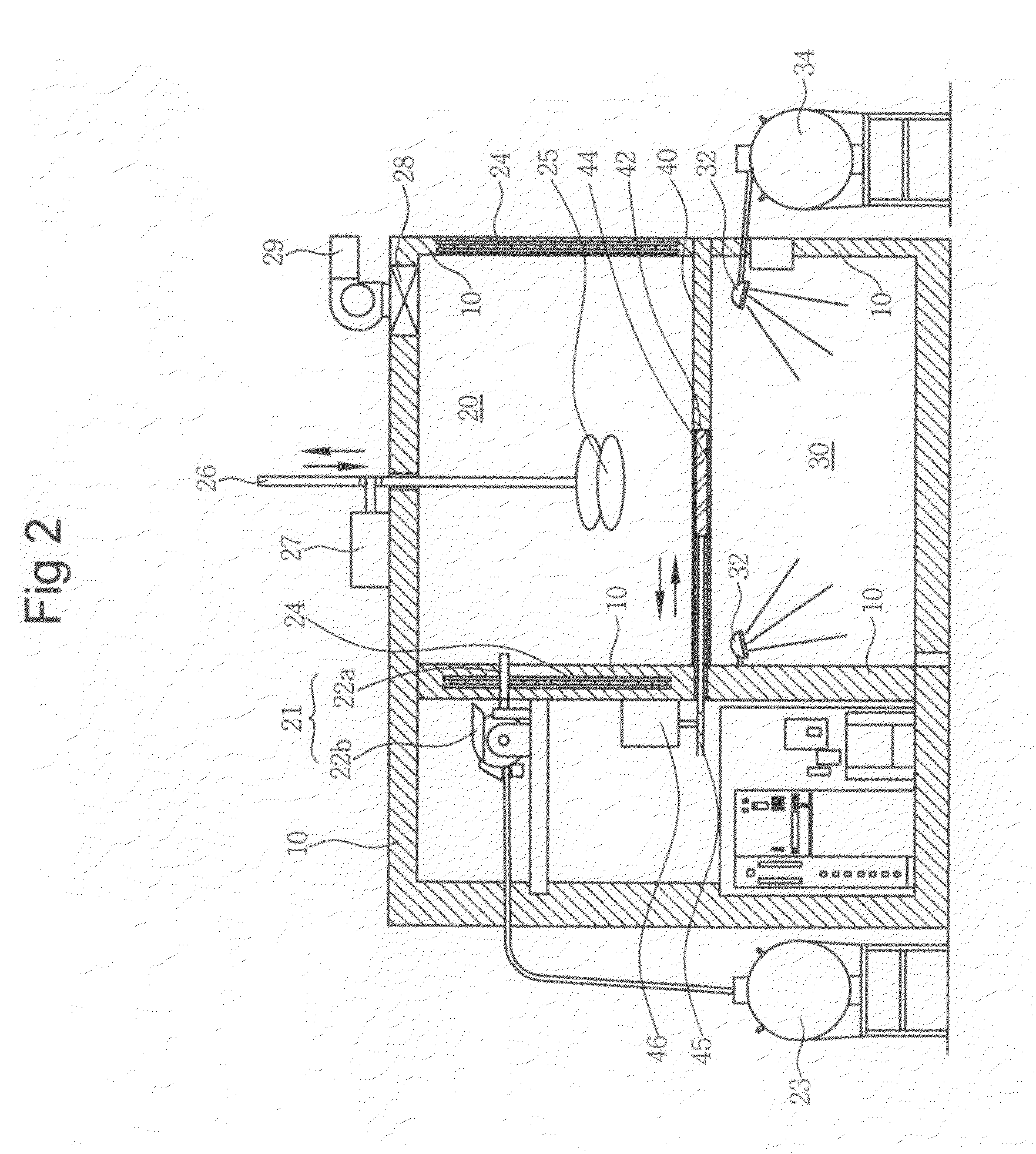

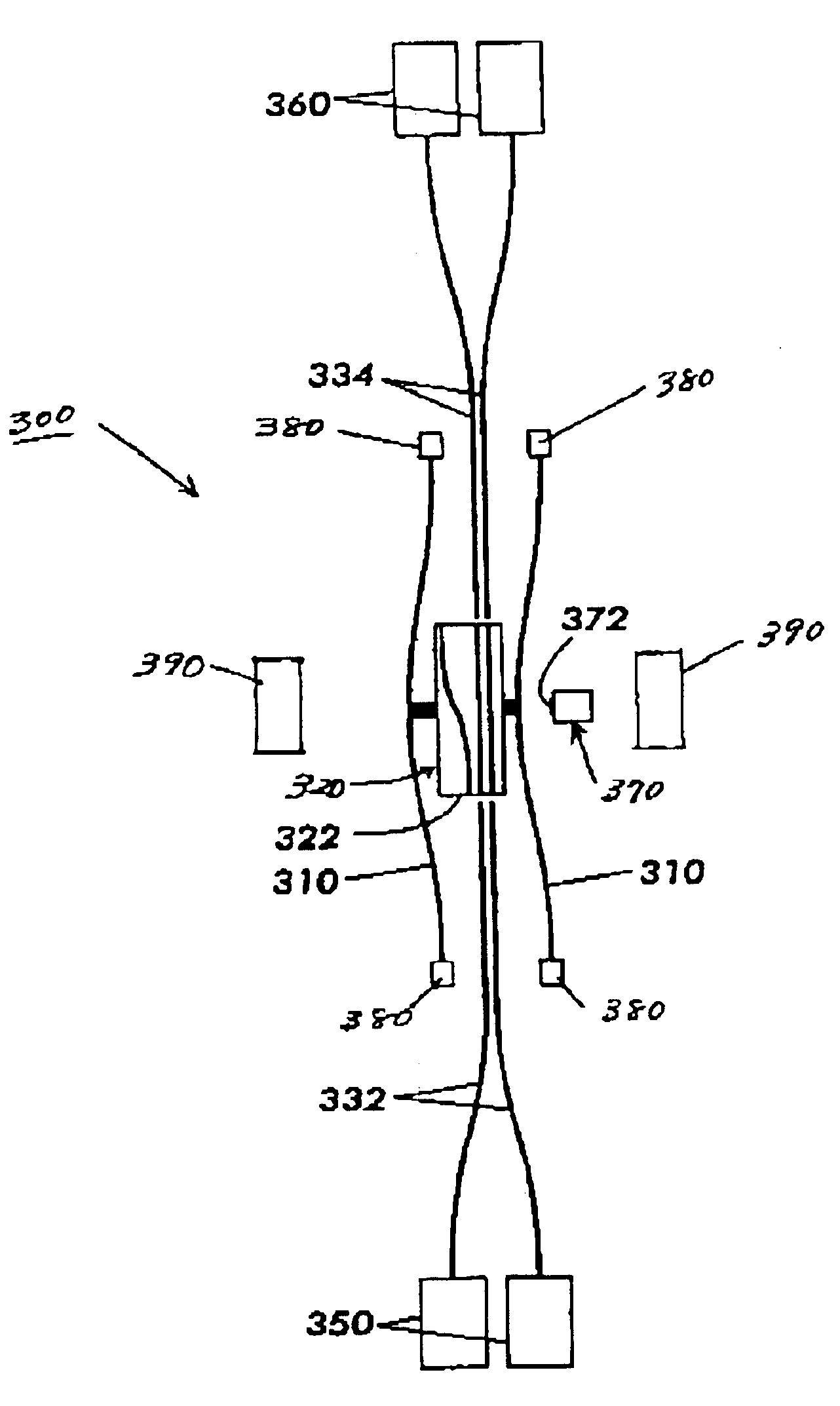

Simulation test system for thermal impact ageing of power transmission insulator

InactiveUS20100080261A1Improve reliabilityAccurate realizationWeather/light/corrosion resistanceElectrical testingThermal impactTest sample

The present invention relates to a simulation test system for thermal impact ageing of a power transmission insulator which simulation tests an influence of a forest fire on the power transmission insulator. The present invention provides a simulation test system of thermal impact ageing for a power transmission insulator, which includes a heating chamber provided with a flame supplying part and electric heating parts in fireproof walls and a partition wall having an opening / closing door in a lower part thereof; a cooling chamber placed under the heating chamber and provided with a cooling nozzle in a fireproof wall; a sample lifting device for selectively lifting a test sample up and down through the heating chamber and the cooling chamber; a door transporting device for slidingly moving the opening / closing door; and a central control part for controlling the flame supplying part, the electric heating part, the opening / closing door, the cooling nozzle, the sample lifting device and the door transporting device independently and respectively. Therefore, since the heating chamber and the cooling chamber are configured independently from each other, heating and cooling tests for the test sample can be performed individually or together.

Owner:KOREA ELECTRIC POWER CORP

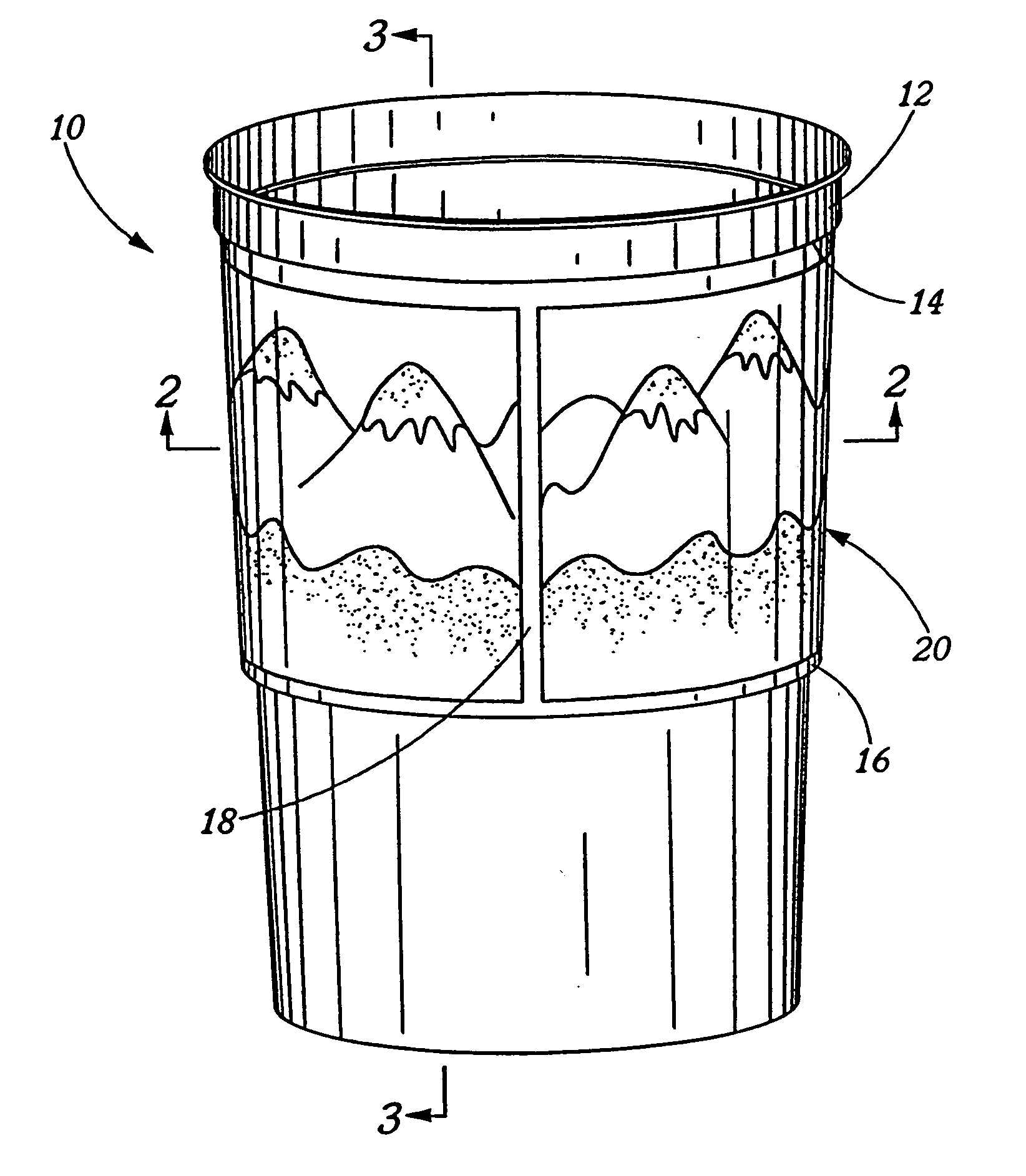

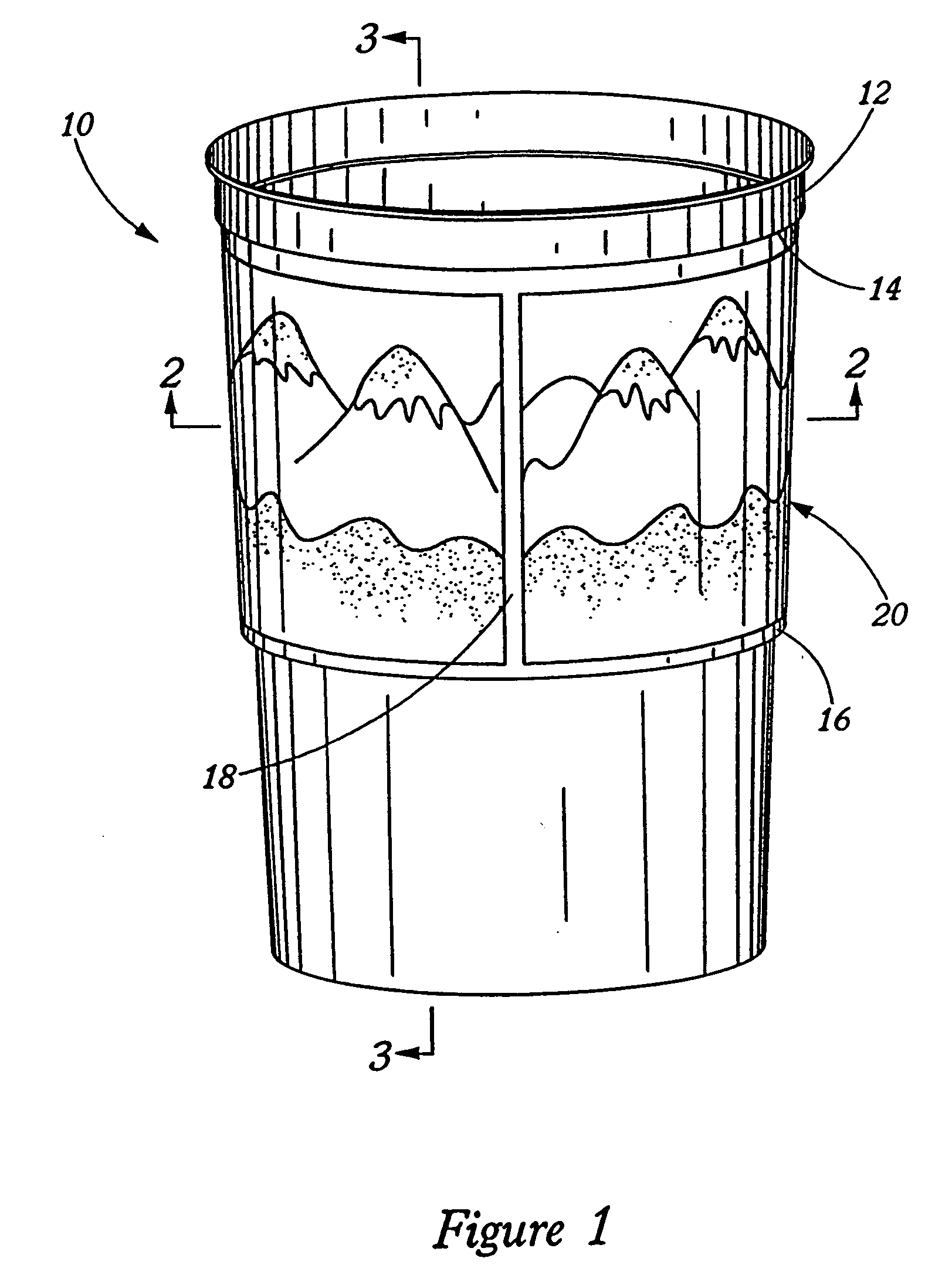

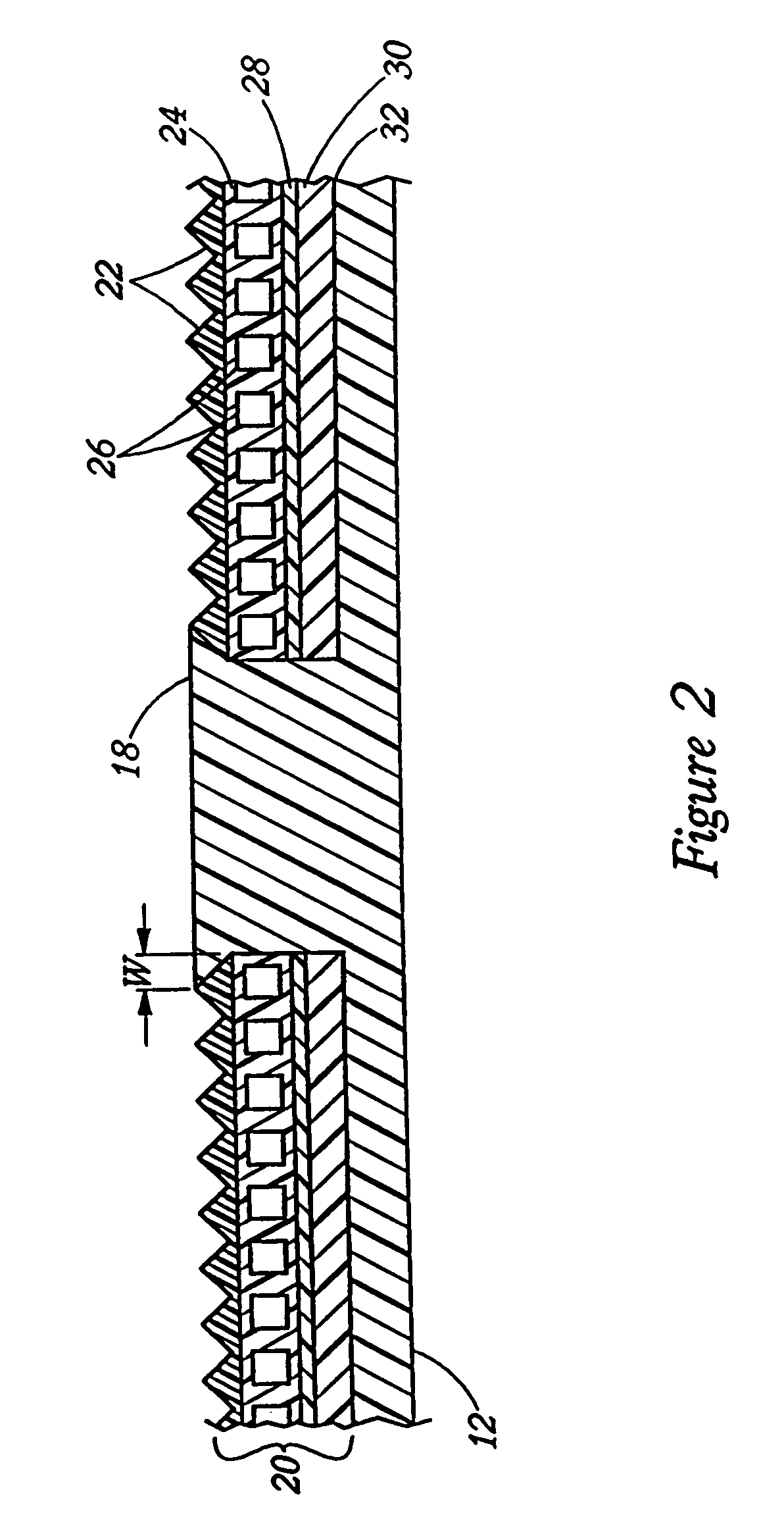

Method of bonding a lenticular lens sheet to plastic objects and objects made from same

InactiveUS20050053737A1Efficient and economicalQuality improvementEnvelopes/bags making machineryContainer decorationsPolyesterBond interface

A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:TRAVEL TAGS

Epoxy resin composition and electronic part

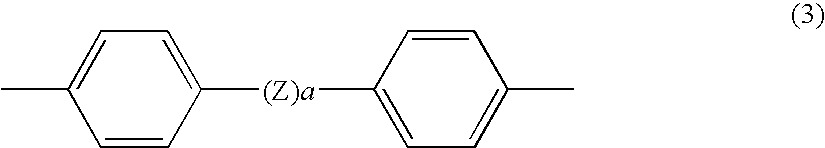

InactiveUS6905768B2Improve flame retardant performanceExcellent heat resistance and thermal impact resistance and solder crackingOther chemical processesGroup 5/15 element organic compoundsEpoxyThermal impact

The epoxy resin of the invention comprises (A) an epoxy resin, (B) at least one member selected from the group consisting of a phenolic hydroxyl group-containing compound, a urea resin and a melamine resin, (C) a crosslinked phenoxyphosphazene compound, and (D) an inorganic filler powder, the amount of component (C) being in the range of 0.01 to 30 wt. % based on the total amount of components (A), (B) and (C), and the amount of component (D) being in the range of 60 to 98 wt. % based on the total amount of components (A), (B), (C) and (D). The epoxy resin composition of the invention and a molded product are halogen-free and antimony-free and are excellent in flame retardancy. When an element for an electronic part such as LSI and VLSI is encapsulated by the epoxy resin composition of the invention, the obtained electronic part is outstanding in heat resistance, moisture resistance, thermal impact resistance and like properties.

Owner:OTSUKA CHEM CO LTD

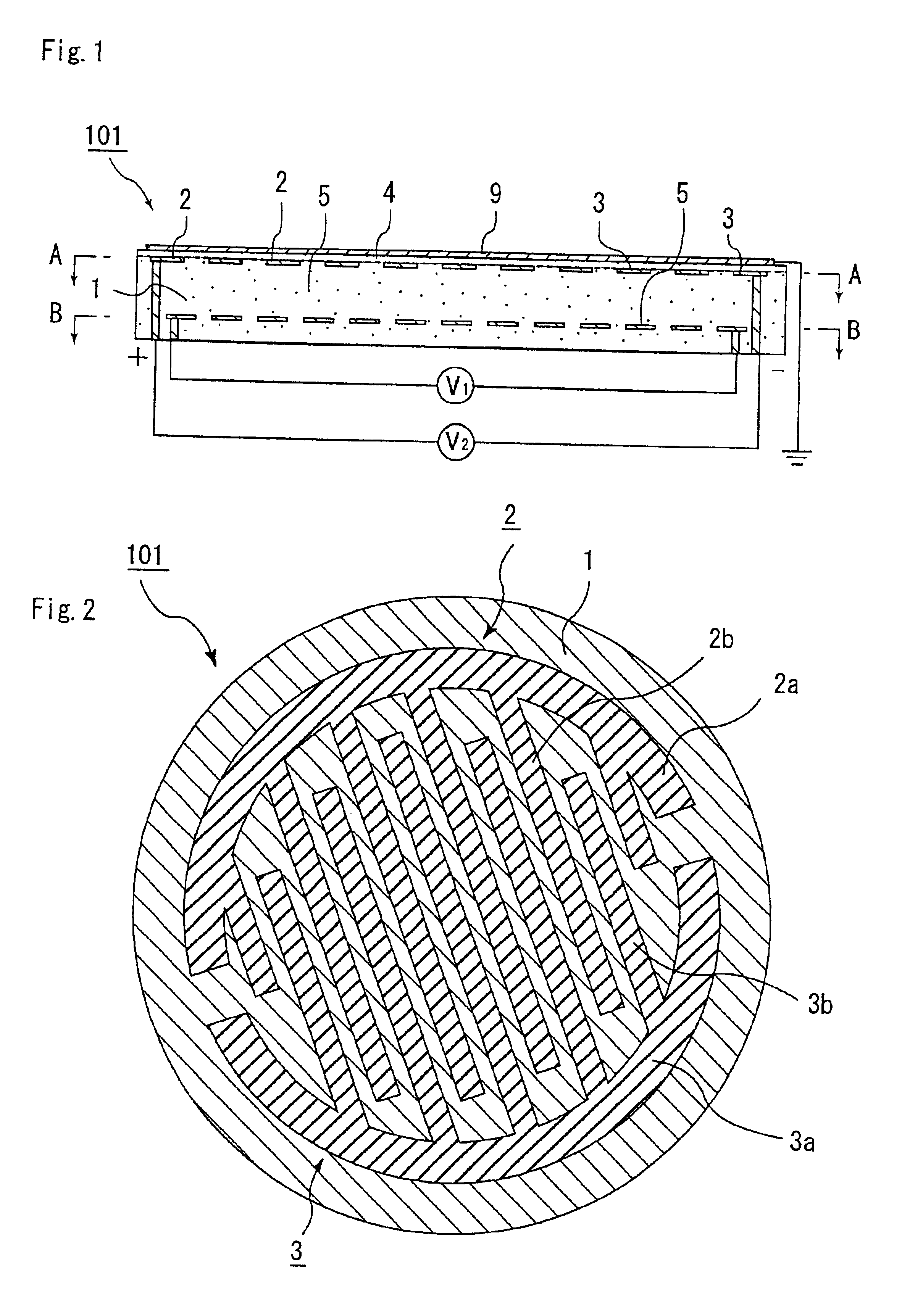

Ceramic substrate for semiconductor manufacturing, and method of manufacturing the ceramic substrate

InactiveUS6960743B2Improve the heating effectSmall surface roughnessSemiconductor/solid-state device manufacturingHot plates heating arrangementsThermal impactMetallurgy

A ceramic substrate for a semiconductor-producing / examining device, in which it is possible to promptly raise its temperature, a heating face thereof has a small temperature variation, and no semiconductor wafer and the like is damaged or distorted by thermal impact. The ceramic substrate for a semiconductor-producing / examining device has a resistance heating element formed on a surface thereof or inside thereof, wherein a projected portion for fitting a semiconductor wafer is formed along the periphery thereof and a large number of convex bodies, which make contact with the semiconductor wafer, are formed inside the projected portion.

Owner:IBIDEN CO LTD

Flexible display substrate thin film and manufacturing method therefor, and display apparatus

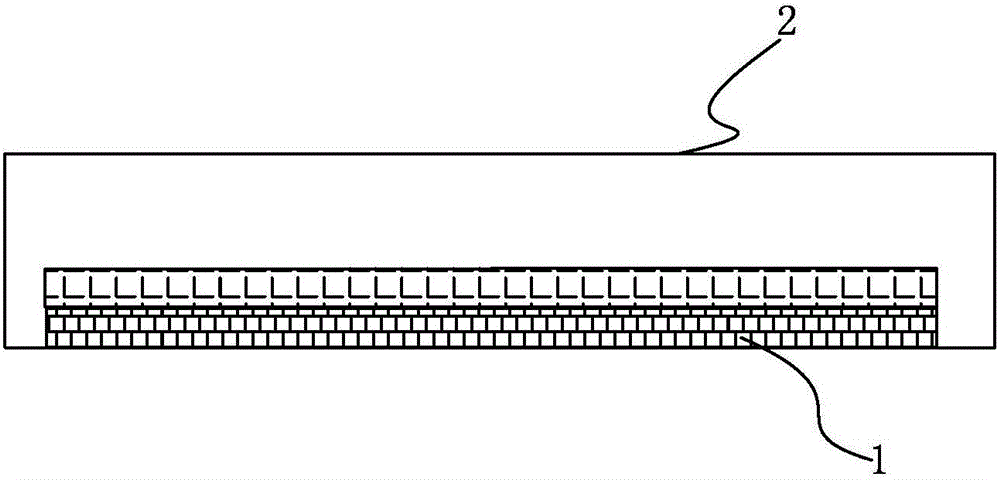

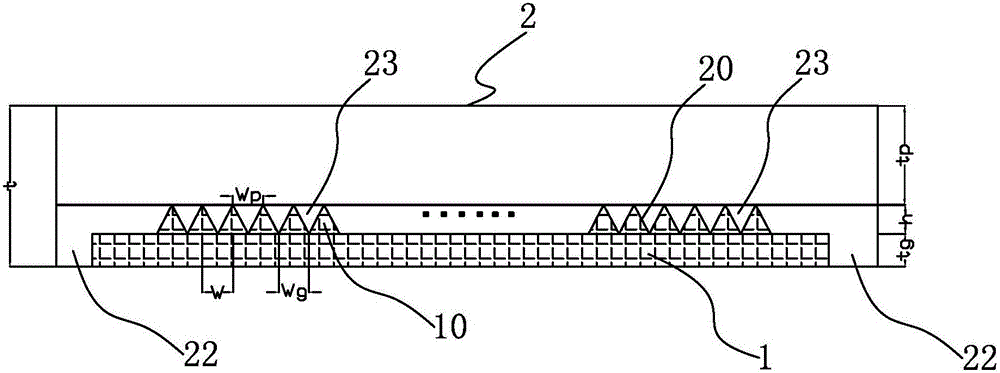

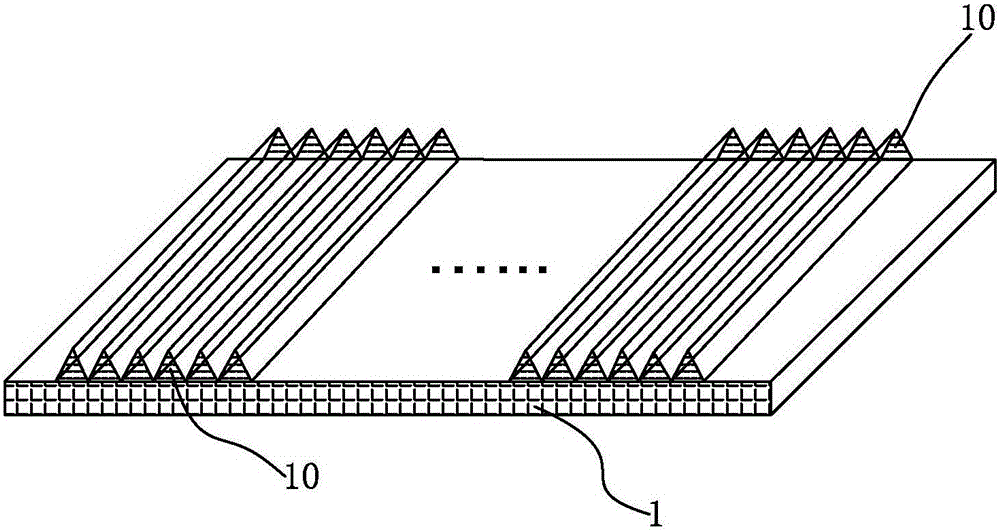

ActiveCN105679774AExcellent gas barrier performanceImprove impact resistanceSynthetic resin layered productsSolid-state devicesThermal impactMechanical impact

The invention discloses a flexible display substrate thin film and a manufacturing method therefor, and a display apparatus. The flexible display substrate thin film comprises a glass thin film and a plastic thin film for coating the glass thin film, wherein multiple convex parts are arranged on the upper surface of the glass thin film; multiple concave parts for accommodating the convex parts are arranged on the lower surface of the plastic thin film; and the multiple convex parts are arranged transversely, vertically or in an array manner on the glass thin film. The flexible display substrate thin film has simple manufacturing process and excellent gas barrier property; for avoiding glass thin film fracture or cracks caused by mechanical impact or thermal impact, the weight of the flexible display substrate thin film can be lowered, and the buffering shock absorption function of the plastic thin film can be utilized, so that the anti-fall-off performance and impact-resistance of the flexible display substrate thin film are greatly improved.

Owner:DALIAN DKE LCD CO LTD

Manufacture technique for thermonuclear reactor flow-passage containing parts

InactiveCN101332557AImprove cleanlinessAvoid damageNon-electric welding apparatusAs elementHeat-affected zone

The invention discloses a production process applicable to runner-containing parts in a fusion reactor blanket. The production process includes the steps: first, a plate and a runner-containing rectangular tube are manufactured according to the design and undergo precision surface working, the roughness Ra is less than 6.3Mum; second, the runner-containing parts are cleaned and decontaminated and then heated in vacuum for degassing; third, the runner-containing parts are vacuumized in an electron beam welding machine and the periphery of the surface to be welded is hermetically welded; and then the runner-containing parts are put into a hot isostatic pressing furnace for forming by hot isostatic pressing diffusion welding; finally, bending forming, heat treatment and machining, and the like, are performed. By adopting the production process; the runner-containing parts manufactured by the production process have reliable and uniform comprehensive performance without the weak performance zones of the heat affected zone, and the like, resulting from the fusion welding process or the defects such as element segregation and air vent, and the like, existing in the similar casting parts, thereby, the production process is particularly applicable to the production of the runner-containing part with the fusion reactor blanket under the condition of intense neutron radiation.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Method for efficiently compounding fusion-covering reinforced steel rail through laser and auxiliary heat source

ActiveCN108456879AReduce temperature gradientAvoid crackingFurnace typesMetallic material coating processesMelting tankHeat-affected zone

The invention discloses a method for efficiently compounding a fusion-covering reinforced steel rail through laser and an auxiliary heat source. The laser and the auxiliary heat source act on a to-be-fusion-covered area on the surface of the steel rail simultaneously, as a main heat source, the laser makes the material of a fusion-covering layer and the material on part of the base of the surfaceof the steel rail quickly fused simultaneously to form a fusion pool, the auxiliary heat source and the laser heat source move in the same direction at the same speed and preheat and / or postheat the laser fusion pool, a heat influence area and the surface layer of the base of the steel rail, the temperature gradient of the steel rail is lowered, thus the cooling speed of the steel rail is lowered,and the phenomena of transforming of a martensite in a heat influence area and cracking are avoided. Through the compounding effect, the critical cooling time for transforming an austenite to a pearlite is shortened in the heat influence area wherein the cooling time is larger than a CCT curve or a TTT curve, so that the mechanical performance among the fusion-covering layer, the heat influence area and the base is reasonably matched, the rigidity curve is smooth in distribution, and the overall fatigue performance is good. The method can fuse-cover a metal layer on the surface of a field ofa railway steel rail on line and can also achieve fuse-covering machining on the surface of the steel rail in a production workshop.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Micro gas sensor and method for manufacturing the same

ActiveUS7963147B2High measurement accuracyAnalysing fluids using sonic/ultrasonic/infrasonic wavesUsing mechanical meansThermal impactMechanical impact

Provided are a micro gas sensor for measuring a gas concentration configured to achieve a high heating and cooling rate of a gas sensitive layer, achieve temperature uniformity, and achieve durability against thermal impact and mechanical impact; and a method for manufacturing the micro gas sensor. The micro gas sensor includes: a vacuum cavity disposed in a substrate; a support layer covering the vacuum cavity; a sealing layer sealing the support layer and the vacuum cavity; a micro heater disposed on the sealing layer; a plurality of electrodes disposed on the micro heater, insulated from the micro heater; and a gas sensitive layer covering the electrodes.

Owner:ELECTRONICS & TELECOMM RES INST

Method of coating catalyst carrier layer of metal-metal oxide, method of depositing active catalyst particles onto metal substrates for preparing metal monolith catalyst modules, and module thereby

Disclosed is a method of coating a porous carrier layer of metal-metal oxide and depositing an active catalyst component on metal substrates, and a monolith module useful as a catalytic reactor with low pressure drop prepared using the metal substrate having the deposited catalyst. By forming the porous carrier particle layer on the metal substrate and depositing the catalyst particles thereon, the catalyst particles are drastically increased in deposition strength and impact durability. Also, the disclosed monolith catalyst module is used for a long time while the catalyst is not detached under high mechanical or thermal impact and high conversion efficiency thereof is maintained at a desired level, due to securely deposited catalyst particles.

Owner:POHANG UNIV OF SCI & TECH +1

Bistable microelectromechanical system based structures, systems and methods

InactiveUS6828887B2Increase flexibilityReduce potential out-of-plane bucklingElectrostatic/electro-adhesion relaysCoupling light guidesStable stateThermal impact

A bistable microelectromechanical system (MEMS) based system comprises a micromachined beam having a first stable state, in which the beam is substantially stress-free and has a specified non-linear shape, and a second stable state. The curved shape may comprises a simple curve or a compound curve. In embodiments, the boundary conditions for the beam are fixed boundary conditions, bearing boundary conditions, spring boundary conditions, or a combination thereof. The system may further comprise an actuator arranged to move the beam between the first and second stable states and a movable element that is moved between a first position and a second position in accordance with the movement of the beam between the first and second stable states. The actuator may comprise one of a thermal actuator, an electrostatic actuator, a piezoelectric actuator and a magnetic actuator. The actuator may further comprise a thermal impact actuator or a zippering electrostatic actuator.

Owner:XEROX CORP

Double-component solvent-free polyurethane structural adhesive coated at normal temperature, as well as preparation method and application method thereof

ActiveCN104449538ANon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterThermal impact

The invention provides a double-component solvent-free polyurethane structural adhesive coated at normal temperature, as well as a preparation method and an application method thereof. The double-component solvent-free polyurethane structural adhesive comprises a component A and a component B, wherein the component A contains aromatic and / or aliphatic and / or alicyclic diisocyanate, polyester polyol and / or polyether polyol and / or plant oil modified polyol with two or more functionality degrees, and / or polyol of which the carbon chain length is smaller than C12; the component B contains at least one polyol a of which the carbon chain length is smaller than C12, polyol b with at least two or more functionality degrees, plant oil modified polyol c, aromatic and / or aliphatic and / or alicyclic diisocyanate d, a solid powder filler e, a siloxane coupling agent f and a curing speed regulating agent g. The double-component solvent-free polyurethane structural adhesive is applicable to adhesion of metals, woods, plastics and hard foam materials. The double-component solvent-free polyurethane structural adhesive has the advantages of being simple to operate, convenient to use, good in safety, free of solvent, friendly to environment, excellent in adhesive property and stripping resistance and relatively good in thermal impact resistance.

Owner:康达新材料(集团)股份有限公司

Ultralow-expansion coefficient high transparent glass-ceramics and method for producing its product

The present invention relates to a Li2O-Al2O3-SiO2 system ultra-low expansion coefficient high-transparency glass-ceramic and production method of the products. Calculated by weight percentage, the ultra-low expansion coefficient high-transparency glass-ceramic is composed of 3.2 to 4.6 percent of Li2O, 18.0 to 23.6 percent of Al2O3, 64.1 to 69.4 percent of SiO2, 0.3 to 0.8 percent of MgO, 0.8 to 2.5 percent of BaO, 0.3 to 0.8 percent of R2O, 0.01 to 0.4 percent of Y2O3, 1.8 to 2.5 percent of TiO2, 1.6 to 2.4 percent of ZrO2, 1.1 to 1.8 percent of P2O5, 0.6 to 1.5 percent of Sb2O3, 0.3 to 1.0 percent of NaCl and 1.0 to 2.0 percent of NH4NO3. The heat-resistant glass plates and heat-resistant glass products can be manufactured by using the formula and the corresponding forming die. The present invention has the advantages that the production technique is simple, the produced products have low expansion coefficient, good transparency, high thermal impact temperature, high strength, have constant transparency when being used under the temperature of 700 Celsius system for a long time, the products have long service life, etc.

Owner:广东科迪微晶玻璃实业有限公司 +1

Thick film circuit heating part based on minicrystal glass base plate and its making technology

ActiveCN101106842AEliminate magnetic pollutionImprove insulation performanceNon-conductive material with dispersed conductive materialResistor manufactureRare earthSlurry

The invention discloses a rare earth thick film circuit controllable electroheat (resistor) element based on microcrystalline glass substrate and the preparation method thereof. The element includes a substrate and a series of electric slurry. The electric slurry is formed on the substrate and includes packaging slurry and electrode slurry. Each kind of the electric slurry is composed of three parts: a functional phase, an inorganic binding phase and an organic carrier phase. The electric slurry also includes rare earth resistor slurry. Also disclosed includes a microcrystalline glass substrate, and formulas for packaging slurry, rare earth resistor slurry, and rare earth electrode slurry. The invention has the advantages of vertical heat transmission, uniform and controllable heating temperature field, rapid respond speed, high power density, strong thermal impact resistance, no magnetic leakage, green, environment protection, energy saving, and high safety and reliability.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

Acoustic Wave Sensor

InactiveUS20080291784A1High resolutionSubsonic/sonic/ultrasonic wave measurementFluid pressure measurement by electric/magnetic elementsElectricityThermal impact

In an acoustic wave sensor for detecting a distance to an object and an orientation where the object is located with using acoustic waves, an acoustic wave generating device generating an acoustic wave by applying thermal impact to the air with no mechanical vibration is used as a wave transmitting device, and an electric capacitance microphone converting variation of pressure due to acoustic wave to variation of an electric signal is used as each wave receiving device. Therefore, dead zone caused by reverberation component included in the acoustic wave transmitted from the wave transmitting device and dead zone caused by reverberation component included in wave receiving signals outputted from the wave receiving devices can be shortened and angular sensitivity of the acoustic wave sensor can be increased, in comparison with a conventional acoustic wave sensor using piezoelectric devices as the wave transmitting device and the wave receiving devices.

Owner:PANASONIC CORP

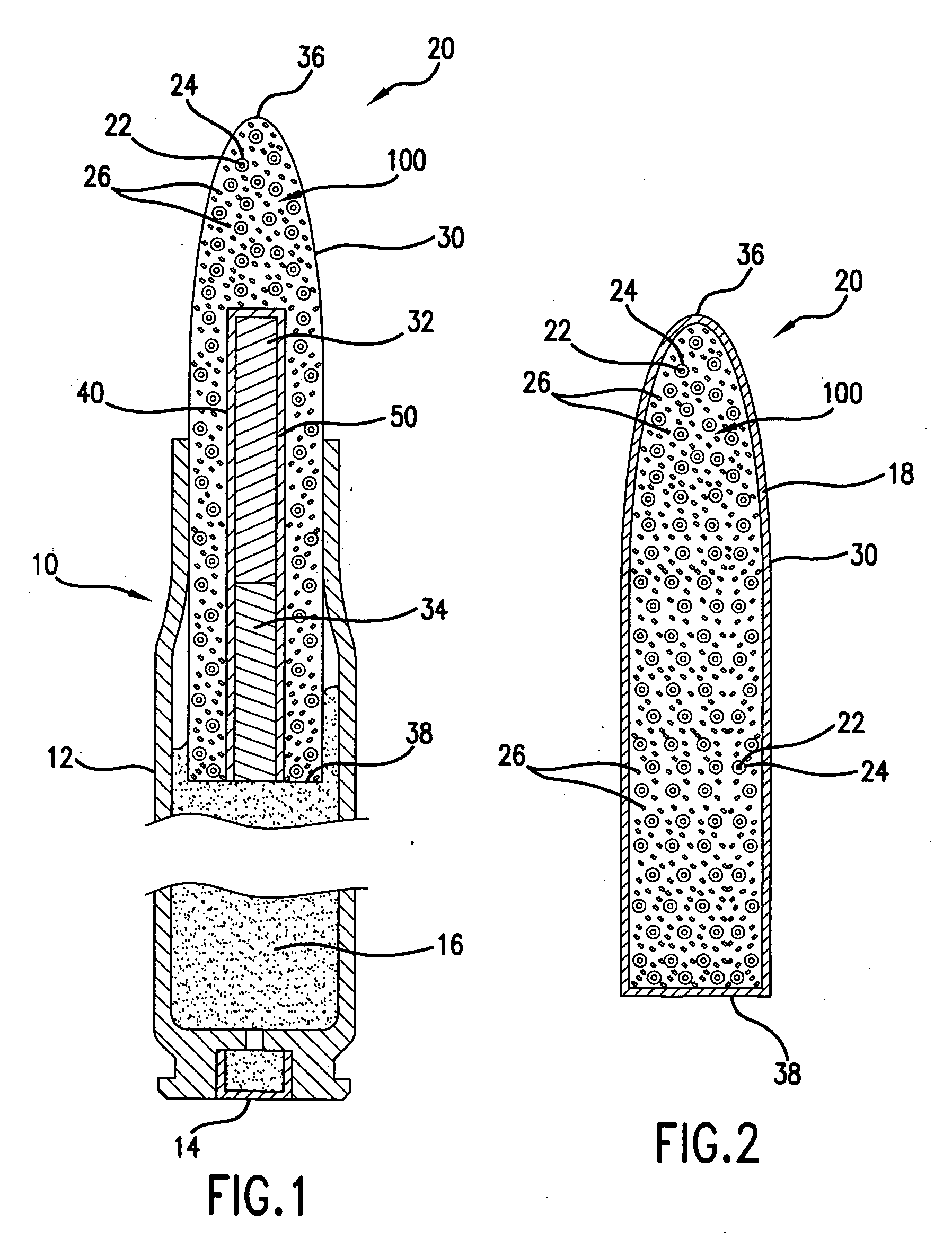

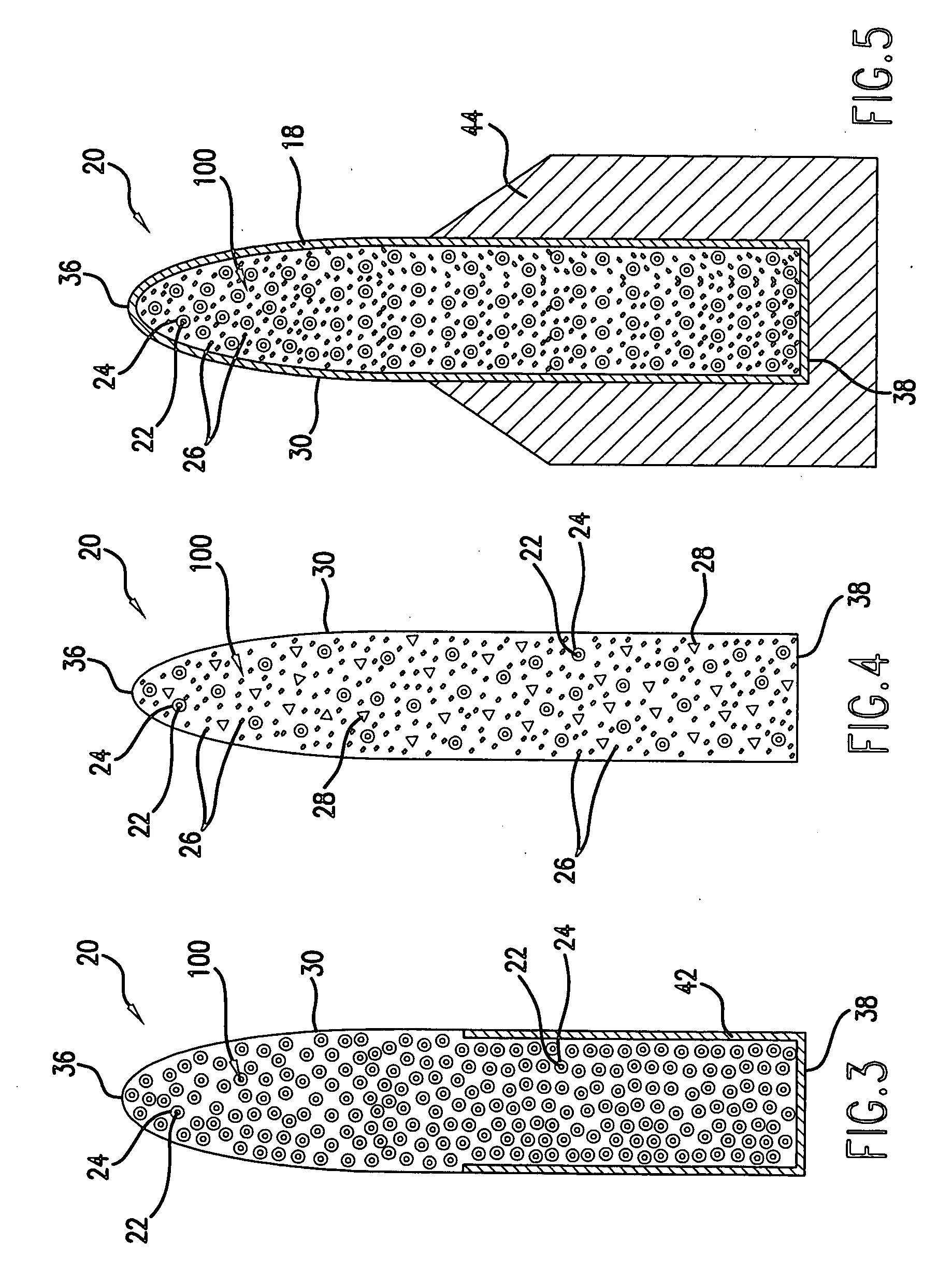

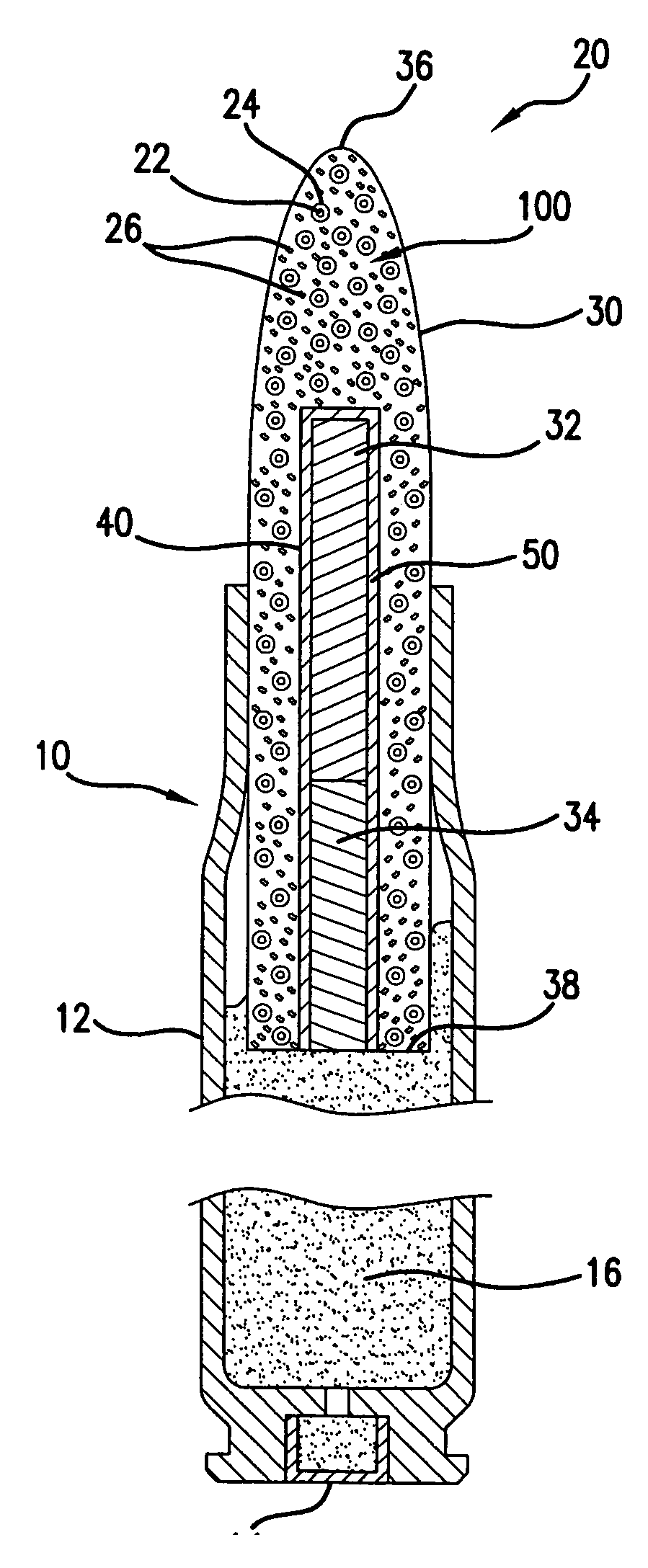

Method and apparatus for a projectile incorporating a metasable interstitial composite material

InactiveUS20060288897A1Rapid thermal oxidation effectHigh-temperature reactionAmmunition projectilesProjectilesSelf-propagating high-temperature synthesisThermal impact

A method and apparatus for incorporating nanophase elemental materials and metastable interstitial composite materials into projectiles, projectile fragments, ordnance casings, warheads and structural components. The projectile, fragments and casings include an elemental material capable of oxidizing. A coating material that is capable of preventing oxidation of the elemental material and an oxidizing agent may be present and be capable of reacting with the elemental material so that a self-propagating high temperature synthesis reaction from a stabilized solid material is yielded for the purpose of rendering terminal effects or thermal impact to a target at impact.

Owner:NEWTEC SERVICES GROUP

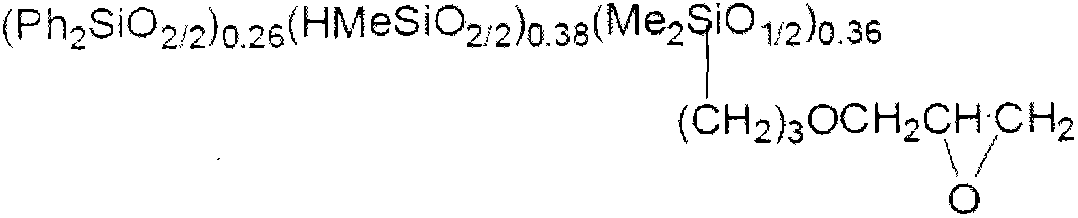

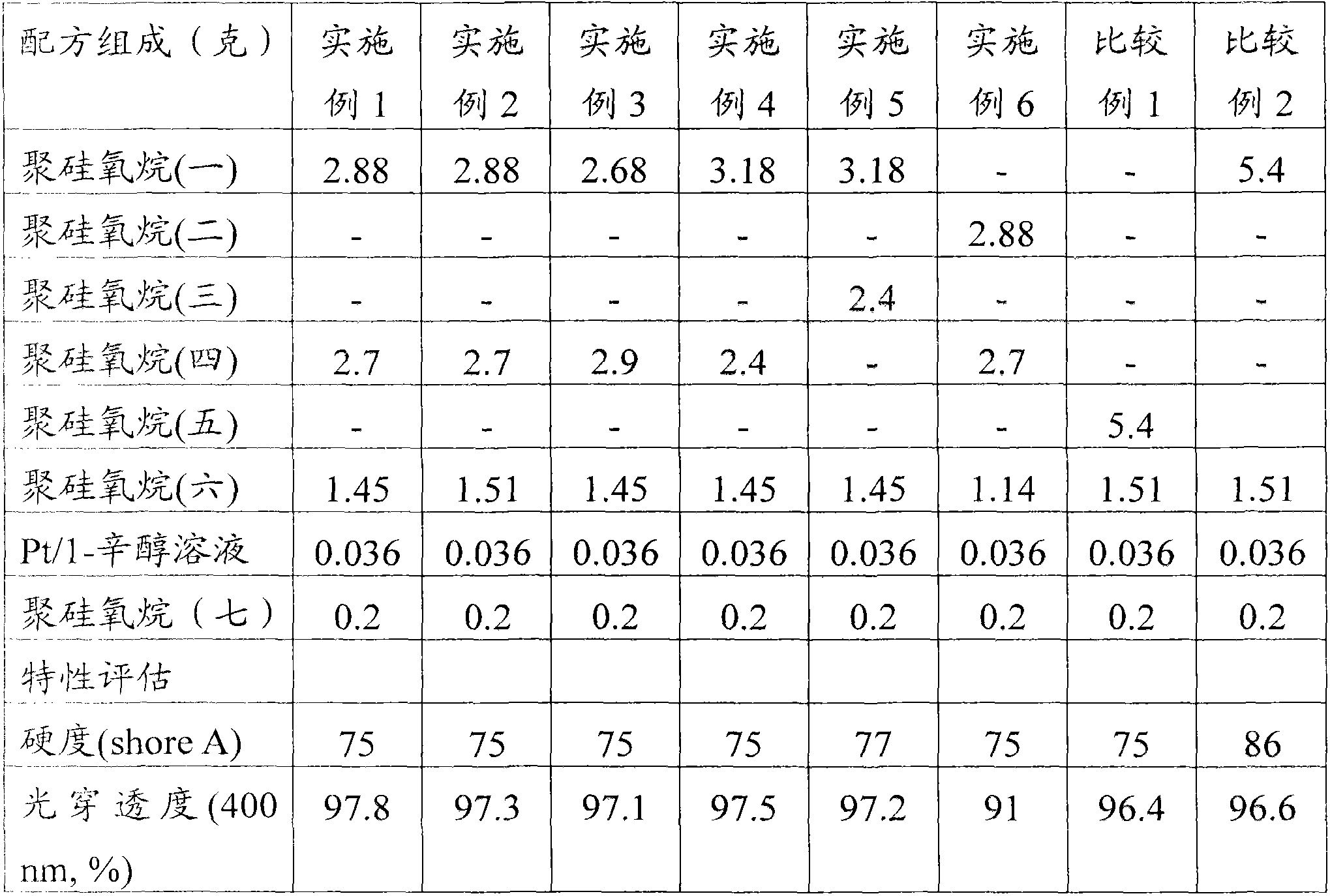

Hardenable siloxane resin composition for light emitting diode element

ActiveCN102464887AExcellent temperature difference thermal shock resistanceExcellent crack resistanceSemiconductor devicesThermal impactCrack resistance

The invention discloses a hardenable siloxane resin composition which contains alkenyl-containing netty polysiloxane (A) with high crosslinking degree, alkenyl-containing netty polysiloxane (B) with low crosslinking degree, silicon-hydrogen-bond-containing polysiloxane (C) and a catalyst (D) for hydrosilylation reaction and optionally contains silicon-hydrogen-bond-containing polysiloxane (E) with an epoxy group. The hardenable siloxane resin composition provided by the invention is suitable for a packaging gum formula of an LED (Light Emitting Diode) device and has excellent temperature-difference thermal impact performance, gum crack resistance and stability.

Owner:DAXIN MATERIALS

Method and apparatus for a projectile incorporating a metastable interstitial composite material

InactiveUS7770521B2Quick effectHigh-temperature reactionAmmunition projectilesProjectilesSelf-propagating high-temperature synthesisThermal impact

A method and apparatus for incorporating nanophase elemental materials and metastable interstitial composite materials into projectiles, projectile fragments, ordnance casings, warheads and structural components. The projectile, fragments and casings include an elemental material capable of oxidizing. A coating material that is capable of preventing oxidation of the elemental material and an oxidizing agent may be present and be capable of reacting with the elemental material so that a self-propagating high temperature synthesis reaction from a stabilized solid material is yielded for the purpose of rendering terminal effects or thermal impact to a target at impact.

Owner:NEWTEC SERVICES GROUP

Preparation method for water erosion resistant coating of last-stage long blade

ActiveCN103276391AUniform compositionUniform tissueBlade accessoriesMachines/enginesManufacturing technologyThermal impact

The invention belongs to the laser cladding field, relates to a preparation method for a water erosion resistant coating of a last-stage long blade, and particularly relates to a method for preparing a water erosion resistant coating of a last-stage long blade of a large nuclear turbine. The preparation method for the water erosion resistant coating of the last-stage long blade comprises the following steps of drying alloy powder, clamping a blade on a platform with the blade in a horizontal position; selecting a semiconductor laser; adjusting by a coaxially focused powder feeding system; setting the size of a molten pool; and cladding the water erosion resistant coating by the laser. The preparation method can be used in preparing the water erosion resistant coating of the last-stage long blade of the large nuclear turbine. The hardness distribution of a cladding layer is uniform with an up-down deviation within 10% and the hardness of 500 HV; the thermal impact performance and water erosion resistance of the cladding layer are excellent; the deformation of the last-stage long blade after the laser cladding is small; and profile tolerance meets the processing and manufacturing technological requirements of the long blades by nuclear power.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD +1

Shell for packaging microwave assembly and laser sealing method of shell

InactiveCN102496552AControlled Thermal ShockReduce thermal shockTransit-tube vessels/containersVessels or leading-in conductors manufactureMicrowaveThermal impact

The invention relates to a shell for packaging a microwave assembly and a laser sealing method of the shell. The shell for packaging the microwave assembly comprises an aluminum silicon alloy shell and a 4047 aluminum alloy cover plate, wherein the aluminum silicon alloy shell is abutted with the 4047 aluminum alloy cover plate. The laser sealing method comprises the following steps of: cleaning the aluminum silicon alloy shell and the 4047 aluminum alloy cover plate by using acetone, then abutting the aluminum silicon alloy shell with the 4047 aluminum alloy cover plate by using a tool, then fixing the aluminum silicon alloy shell and the 4047 aluminum alloy cover plate by using an Nd:YAG laser, and continuously integrally welding the shell by using the Nd-YAG laser, welding from the bottom of the aluminum silicon alloy shell until reaching the surface of the 4047 aluminum alloy cover plate, wherein the two welding processes are carried out in a nitrogen protective gas. The invention is used for carrying out sealing by using the laser, is easy to realize, has good sealing property and controllable welding depth, can be used for repaired for two times, has little thermal impact to a substrate and a chip because local heating is adopted in the welding process, can realize automatic operation, and has no soldering flux pollution and high reliability.

Owner:WUXI HUACE ELECTRONICS SYST

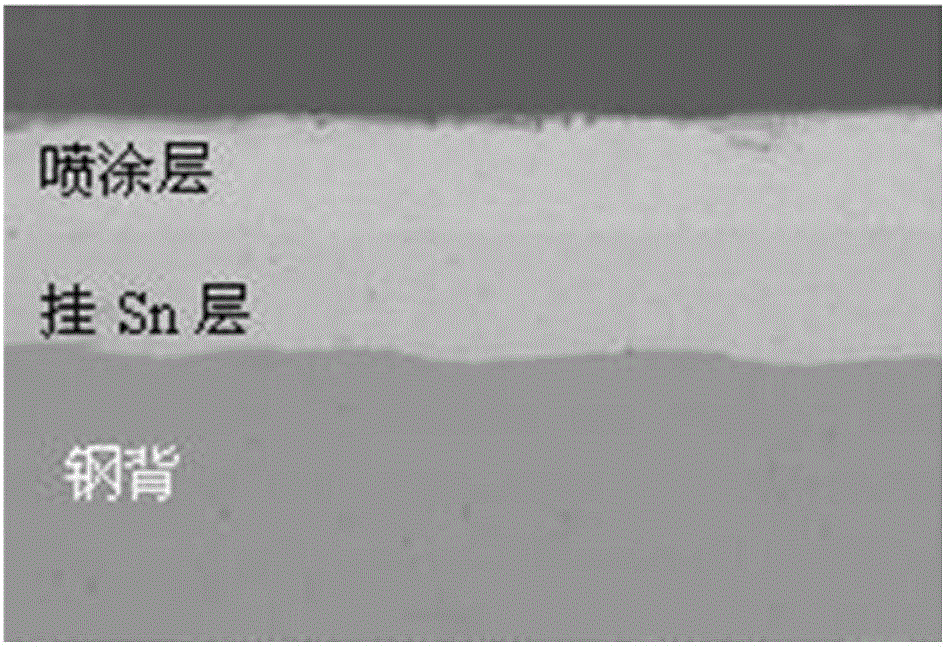

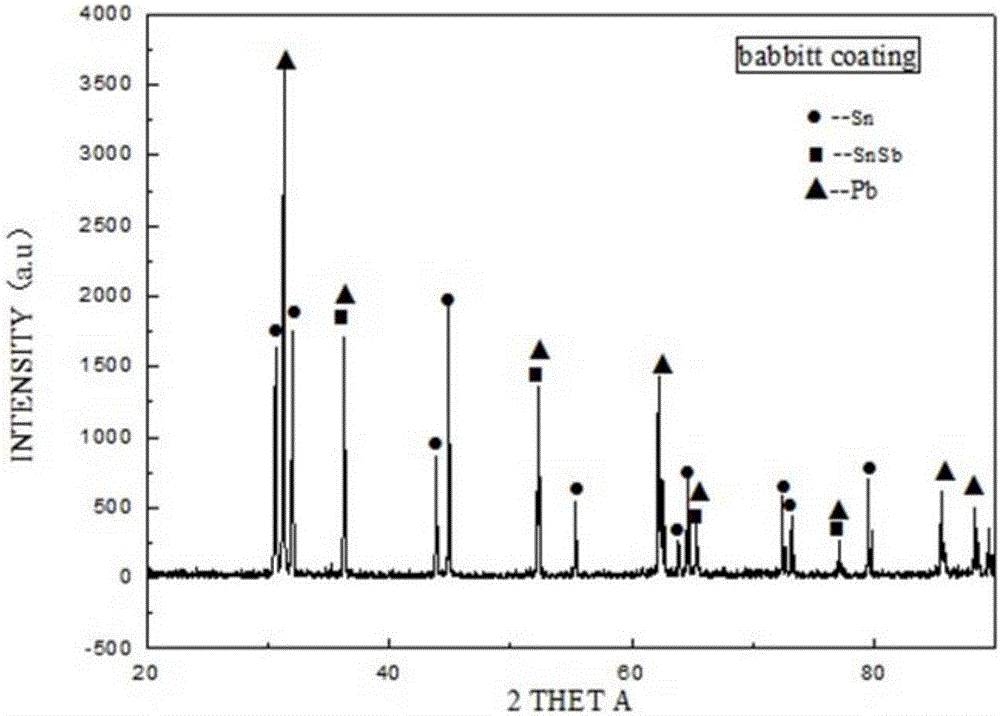

Method for coating bearing bush steel backing with Babbitt metal coating

ActiveCN106435563AImprove product qualityImprove the level ofHeat inorganic powder coatingSocial benefitsThermal spraying

The invention relates to the technical field of preparation and repair of sliding bearing Babbitt metal anti-friction layers. The novel cold spraying technology is introduced into manufacturing and repair remanufacturing of a Babbitt metal sliding bearing bush lining anti-friction layer, atomization powder feeding is adopted to obtain coating microstructures with uniform components and fine dispersely-distributed and uniformly-dense crystal grains and second phases through cold spraying, and the good interface bonding characteristic is obtained through tinning layer setting and sprayed thermal treatment; the defects of poor structure uniformity, thermal impact, stress, cracking and oxidizing burning losses existing in the technologies such as a traditional casting method, an overlaying method and a thermal spraying method are overcome, the bearing bush component preparation quality and level are improved, the bush burning frequency is decreased, stopping supercritical vibration is lowered, the stability, accuracy and reliability of a bearing transmission unit are improved, and the service life of the bearing transmission unit is prolonged; the method is rapid, efficient and environmentally friendly, is used for bearing bush manufacturing and repair remanufacturing, and has good economic benefits and social benefits.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com