Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5679results about How to "Quick effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

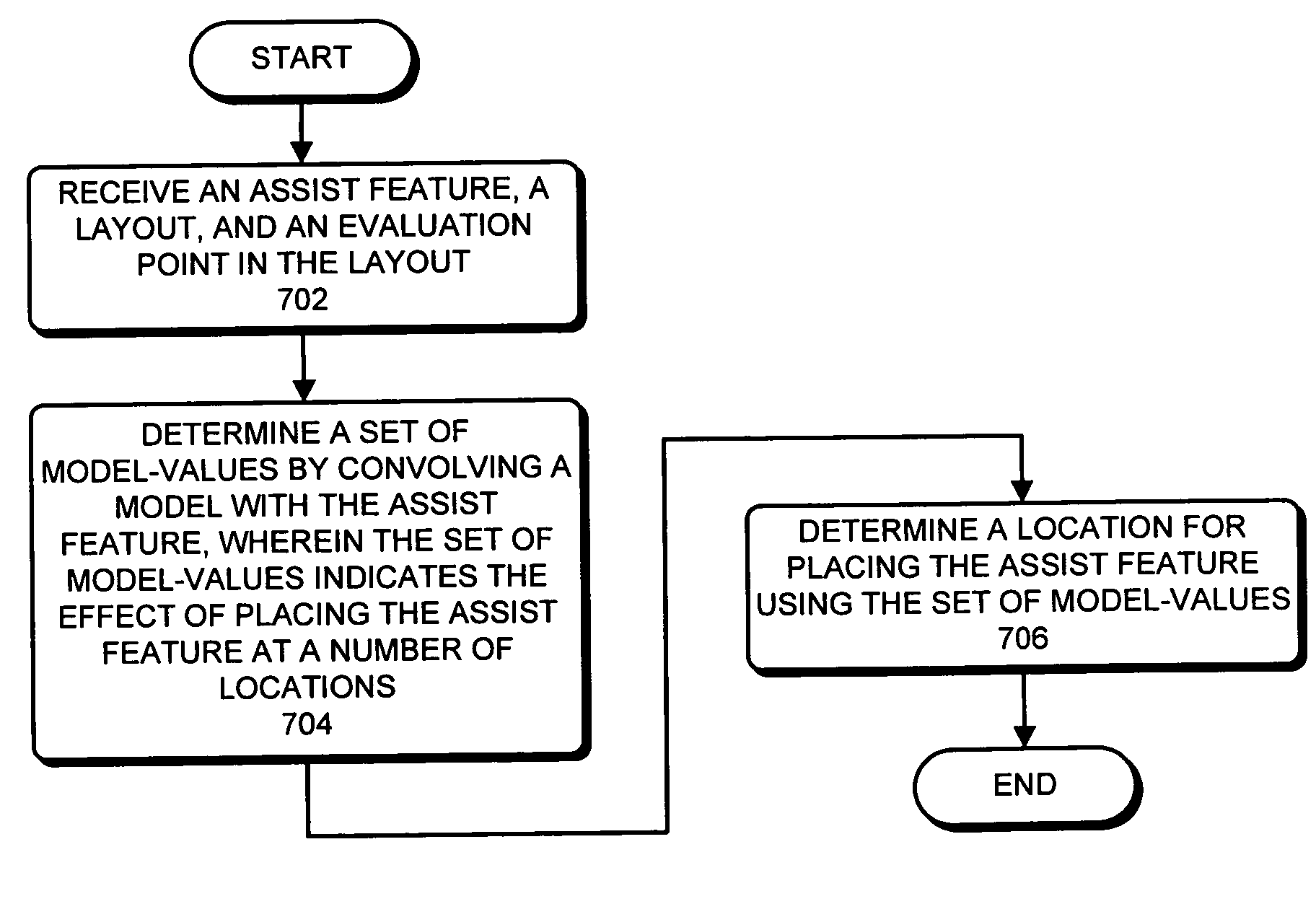

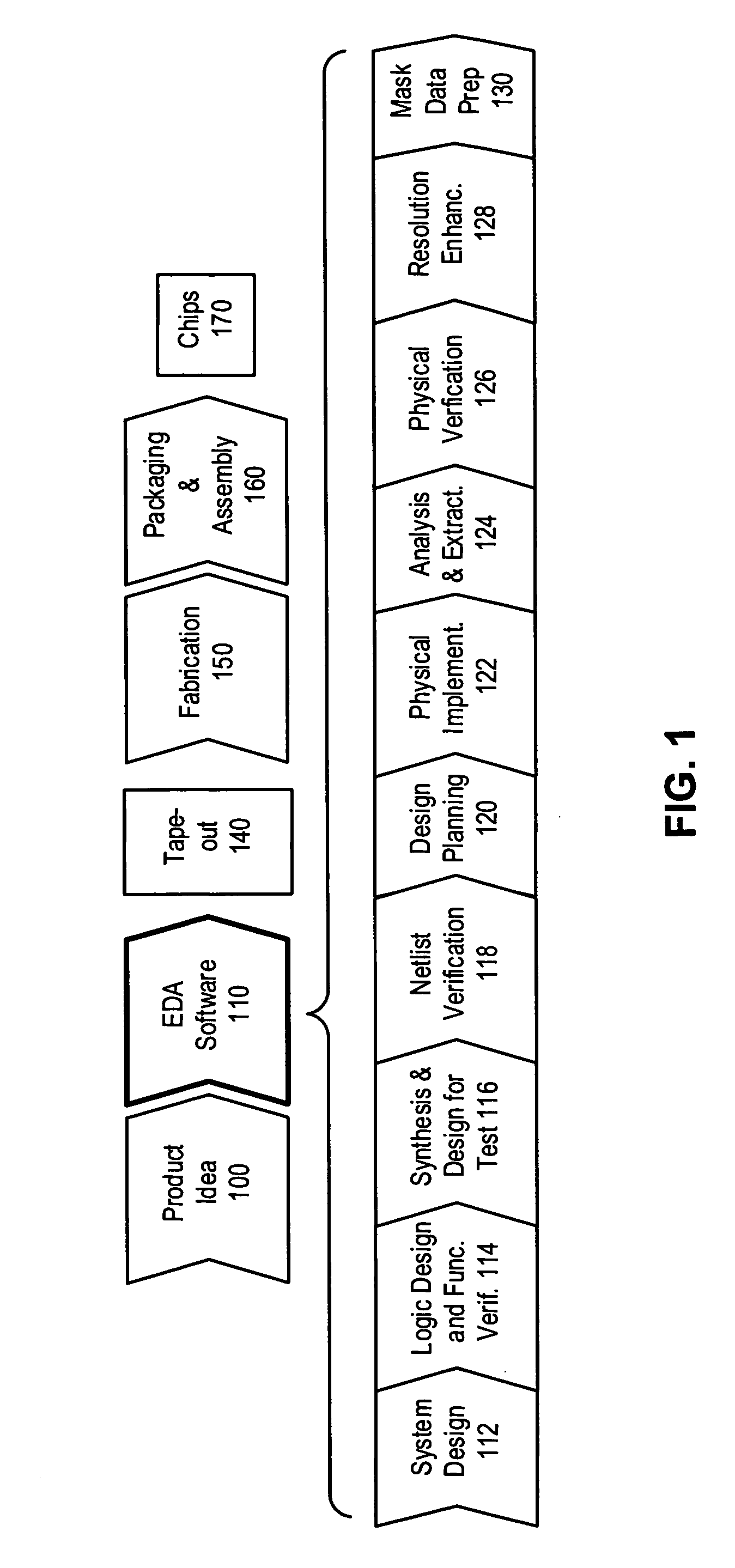

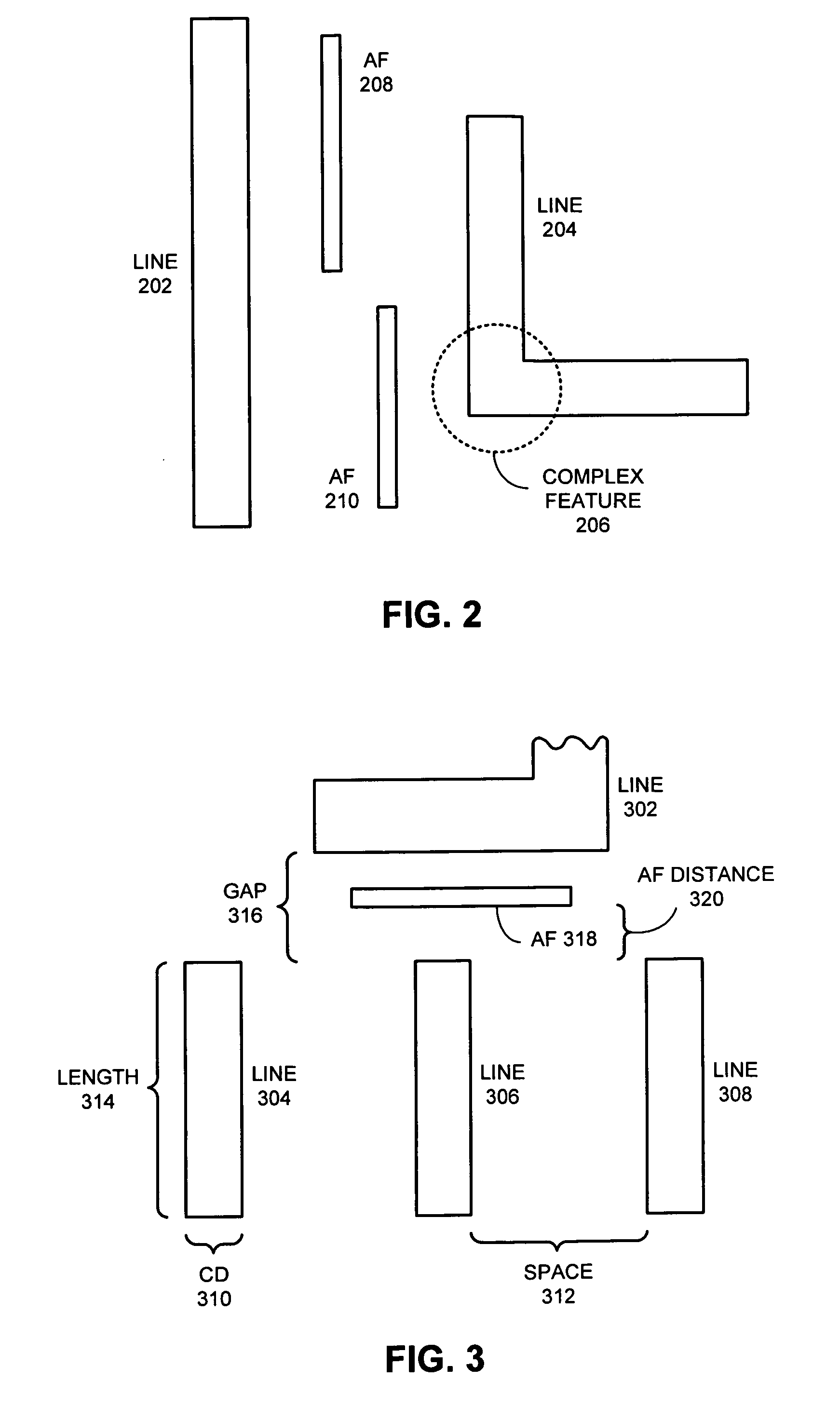

Method and apparatus for quickly determining the effect of placing an assist feature at a location in a layout

ActiveUS20070038973A1Quick effectOptimize locationPhotomechanical apparatusCAD circuit designEngineeringSystem usage

One embodiment of the present invention determines the effect of placing an assist feature at a location in a layout. During operation, the system receives a first value which was pre-computed by convolving a model with a layout at an evaluation point, wherein the model models semiconductor manufacturing processes. Next, the system determines a second value by convolving the model with an assist feature, which is assumed to be located at a first location which is in proximity to the evaluation point. The system then determines the effect of placing an assist feature using the first value and the second value. An embodiment of the present invention can be used to determine a substantially optimal location for placing an assist feature in a layout.

Owner:SYNOPSYS INC

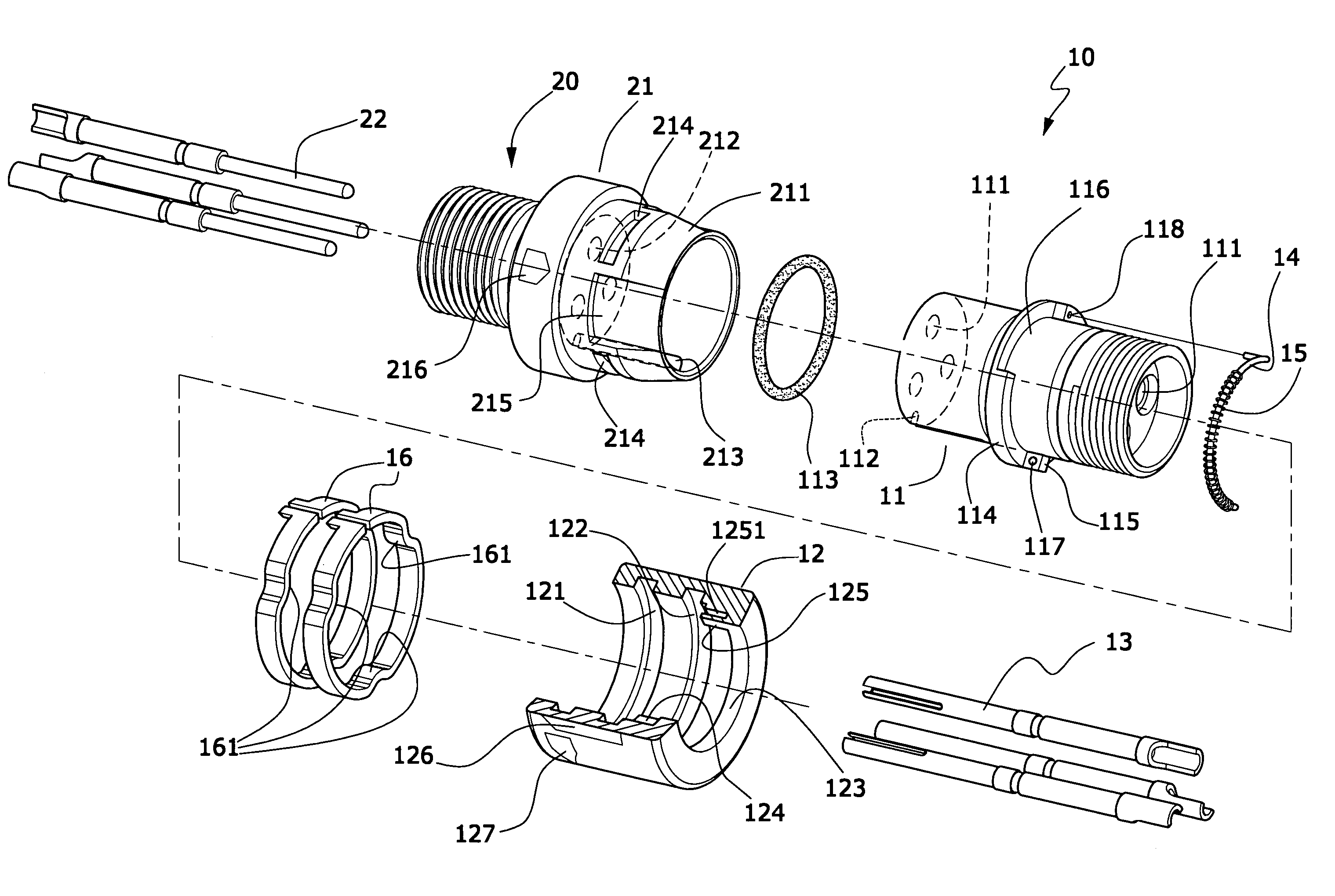

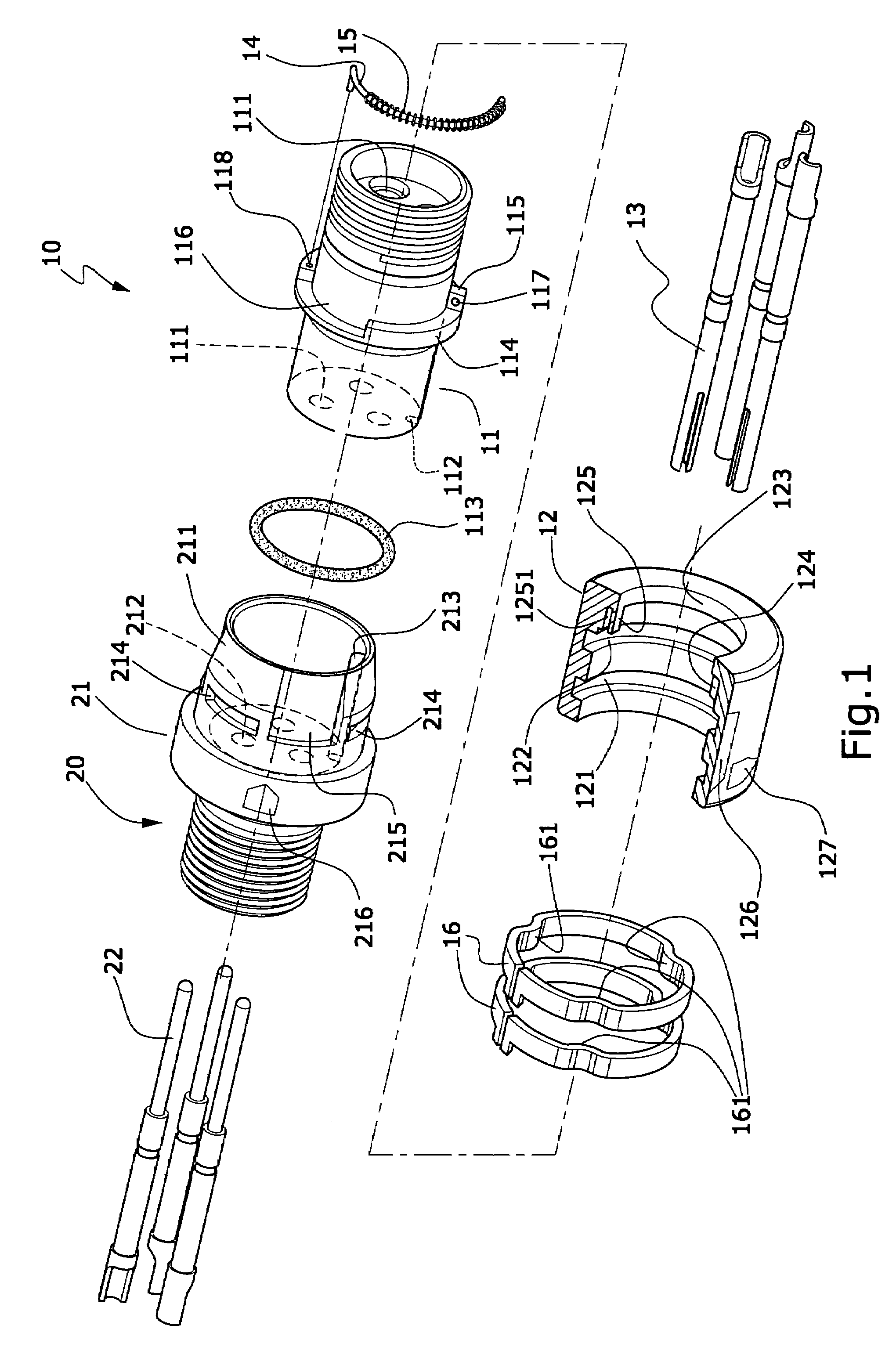

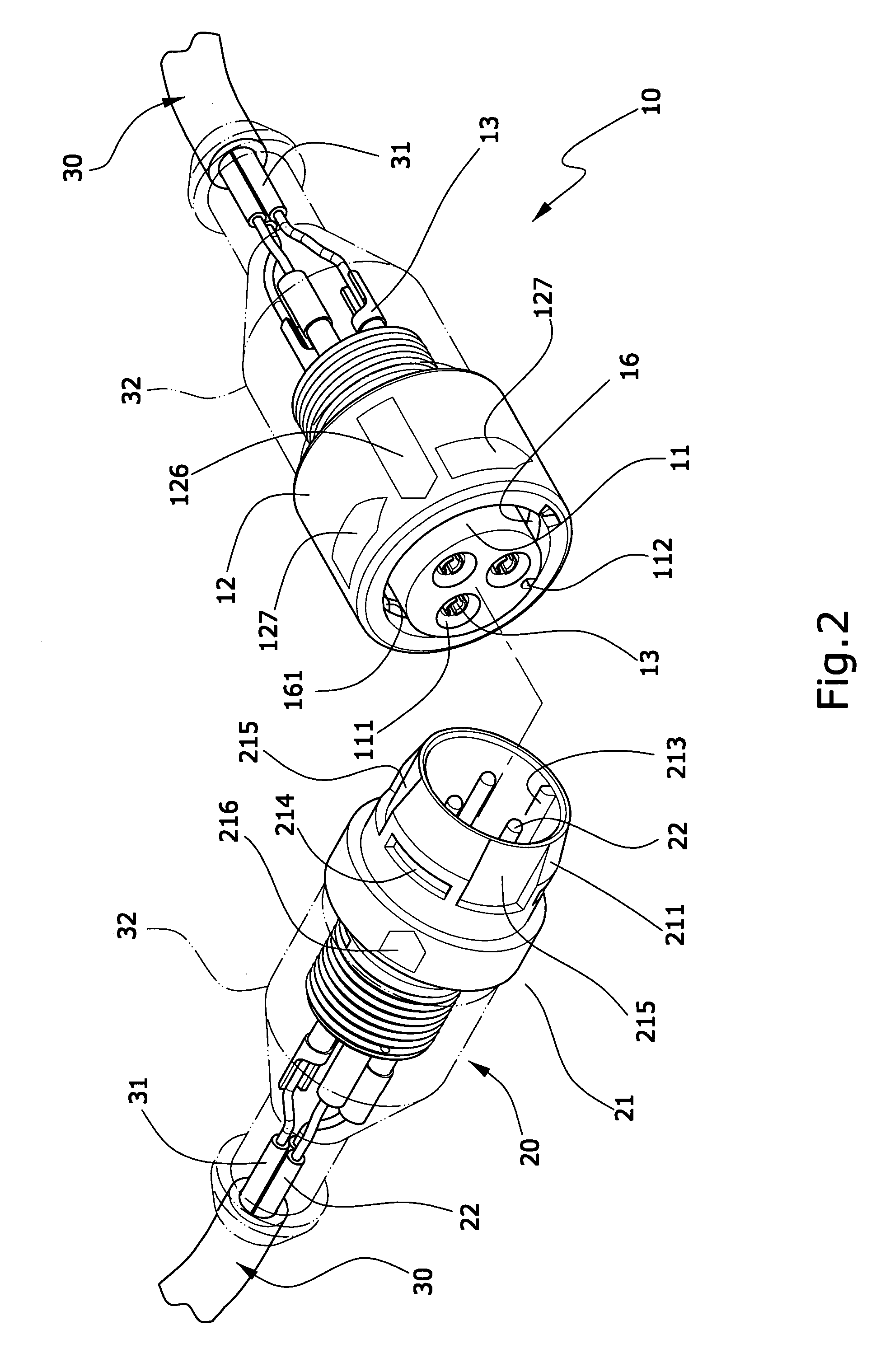

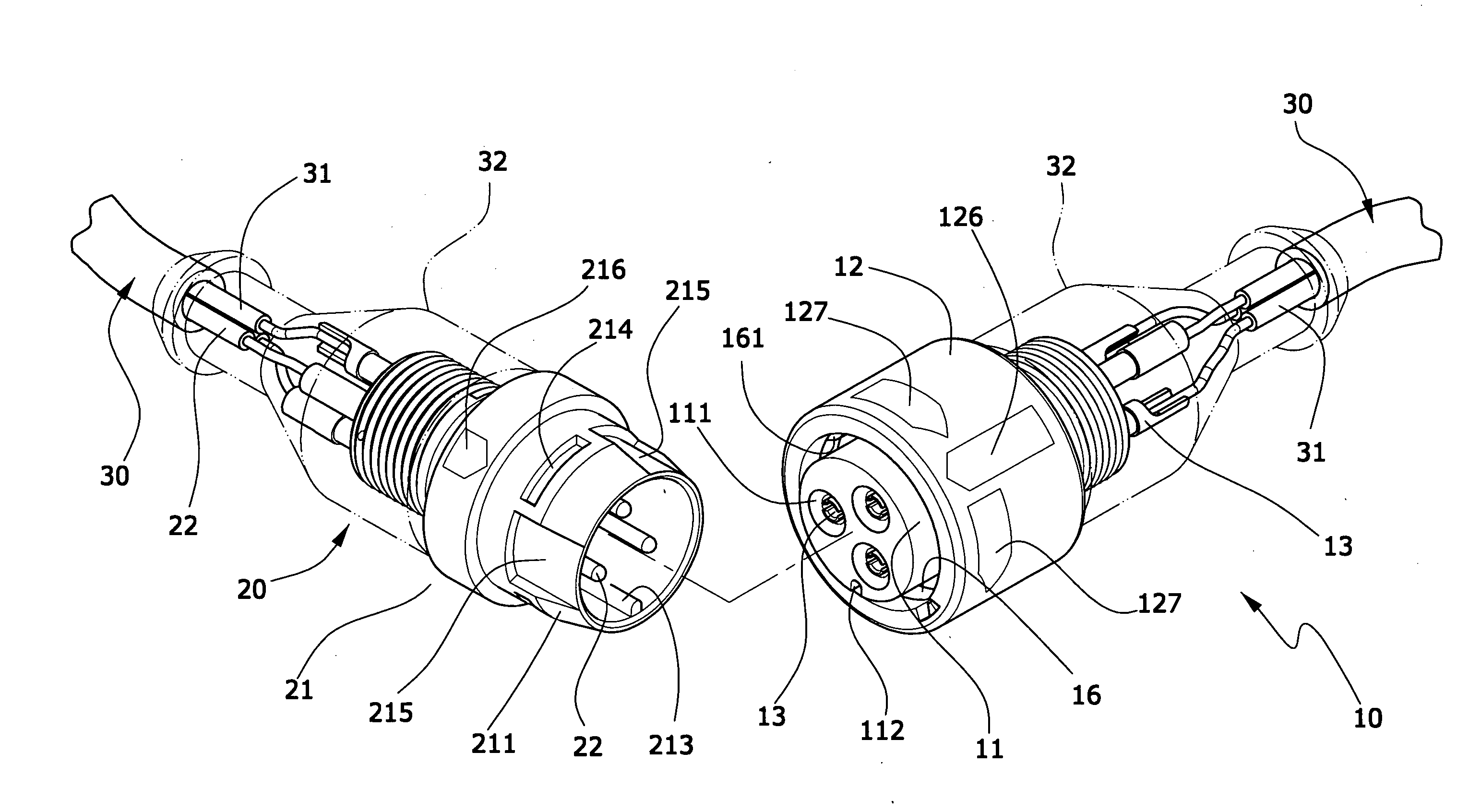

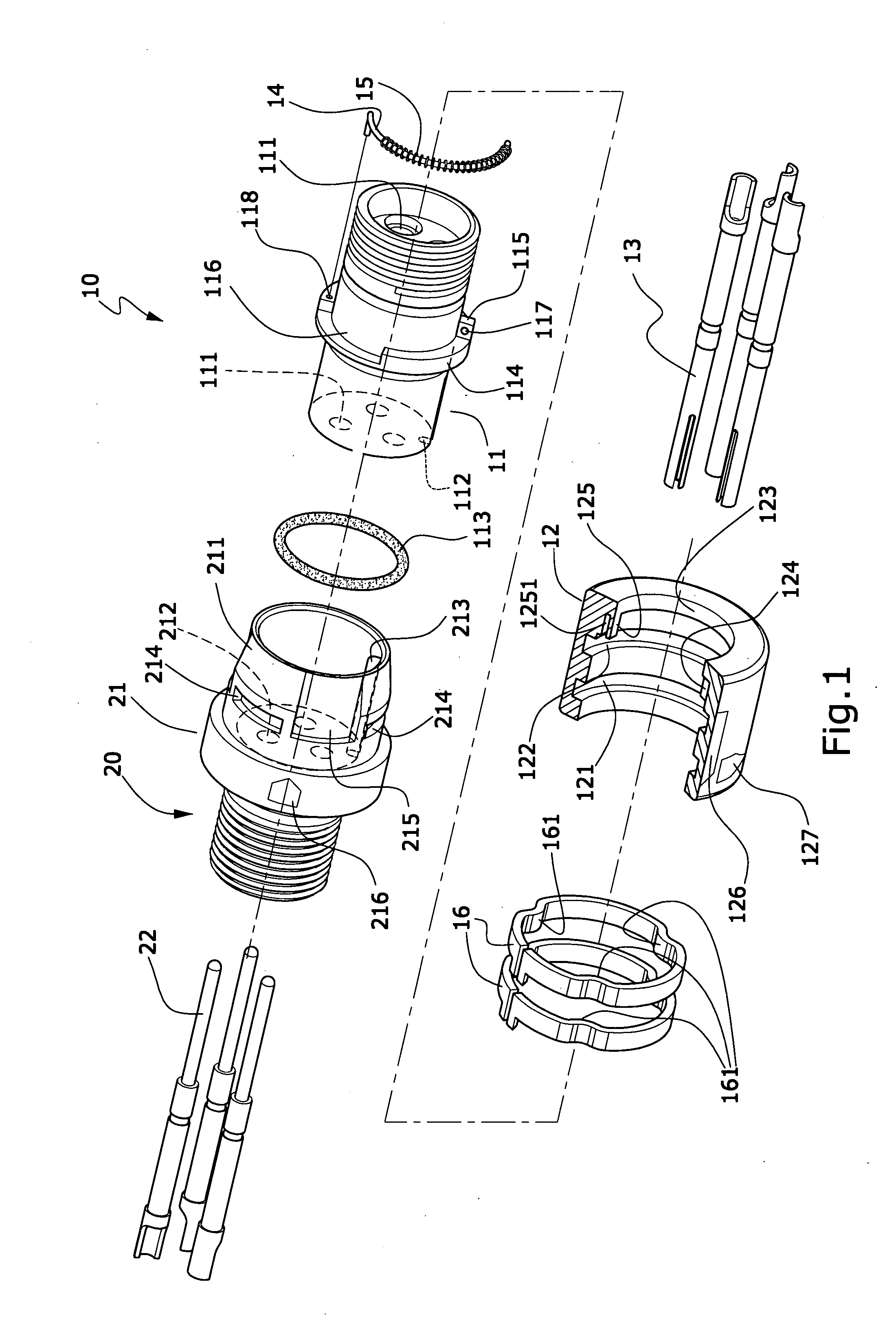

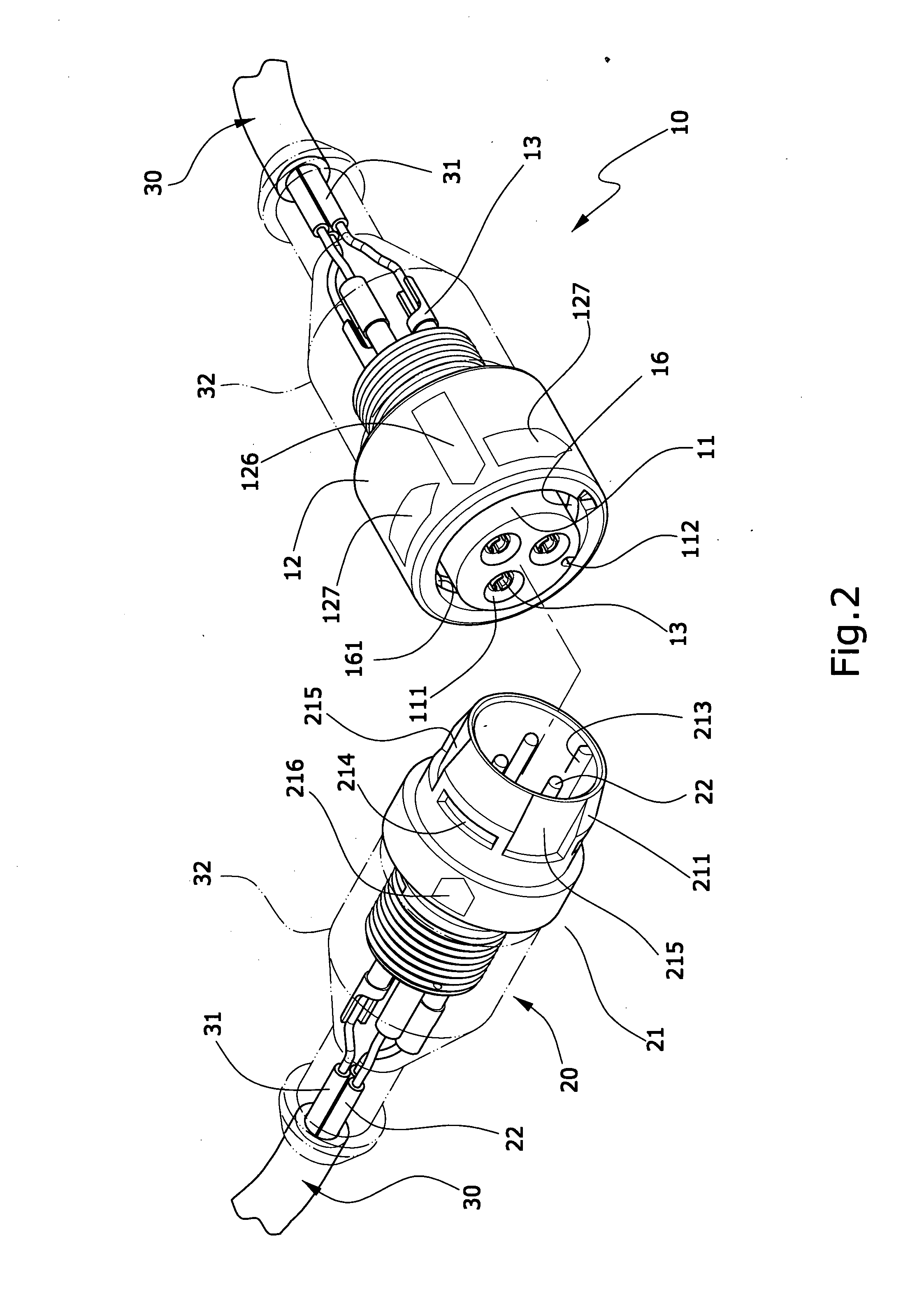

Fast coupling structure of waterproof cable connector

InactiveUS7422463B2Firmly connectedEasy to disassembleElectrically conductive connectionsSecuring/insulating coupling contact membersCouplingElectric power system

The invention relates to a fast coupling structure of waterproof cable connector, mainly comprising a male connecting joint and a female connecting joint, both are positioned on the cable end for connection of electric power source or signals on an electric apparatus; the invention enables both of the male and the female connecting joints to have the fast coupling function and the waterproof effects; therefore, a user is able to easily and quickly connect or disassemble the coupling structure.

Owner:KUO KO AN

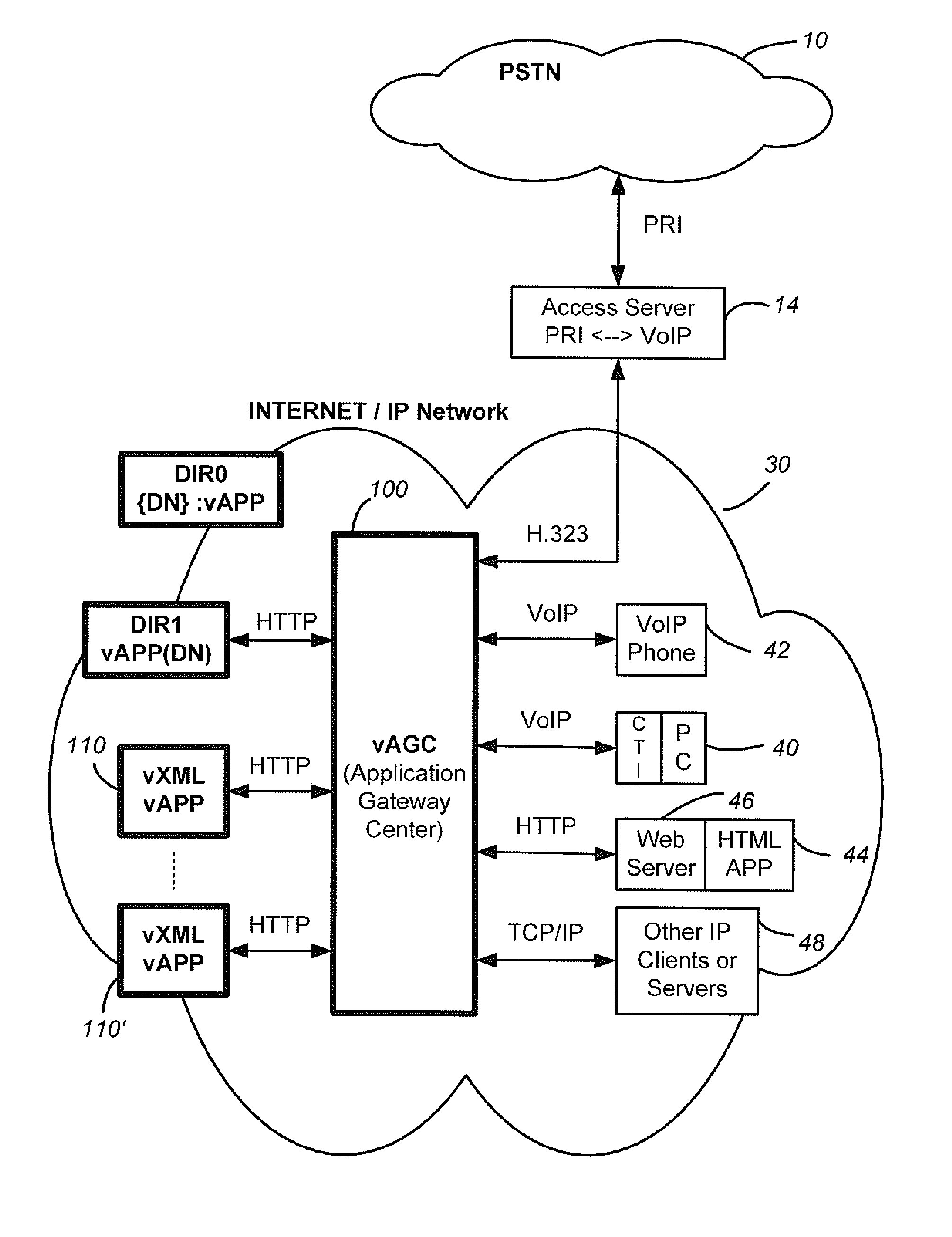

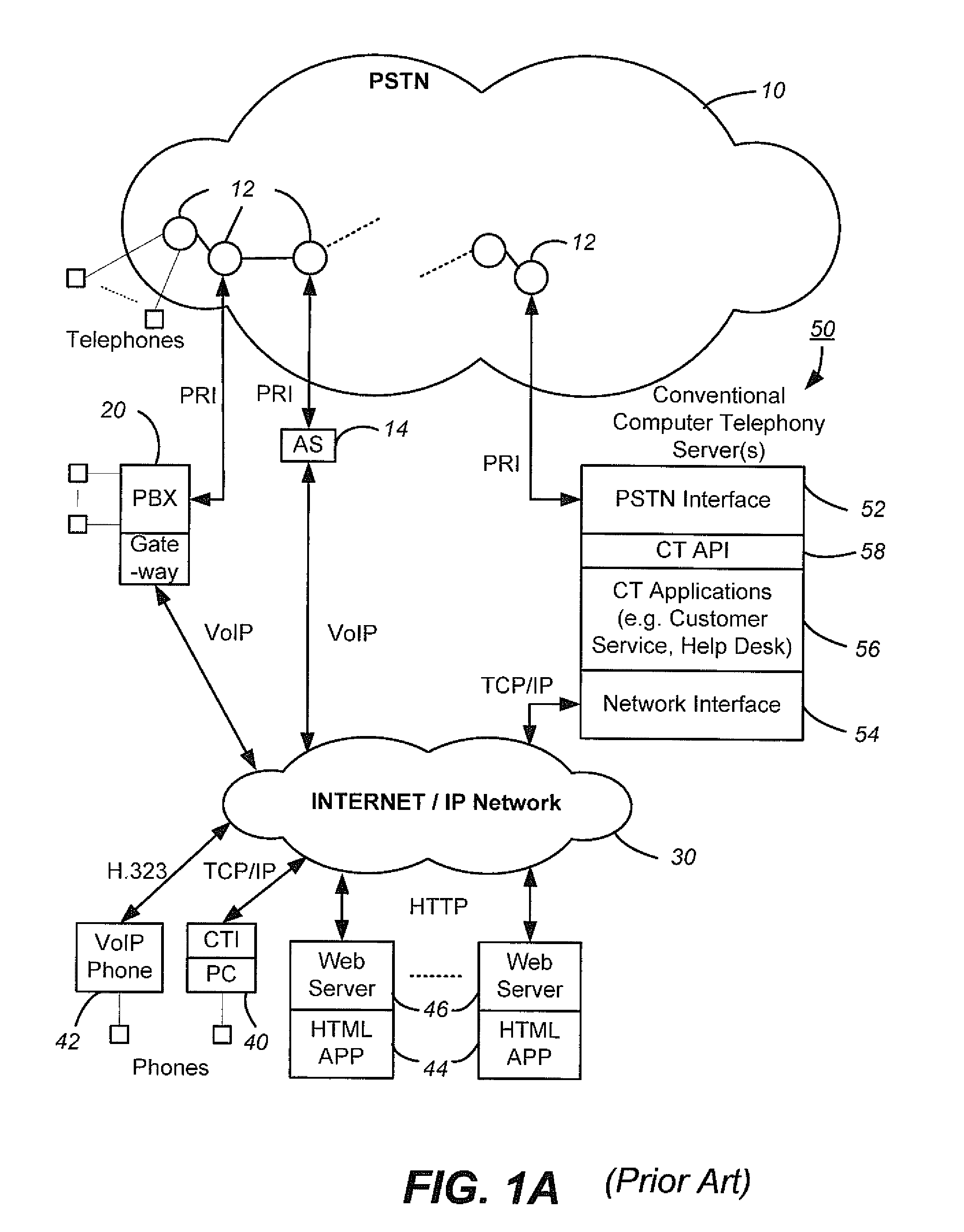

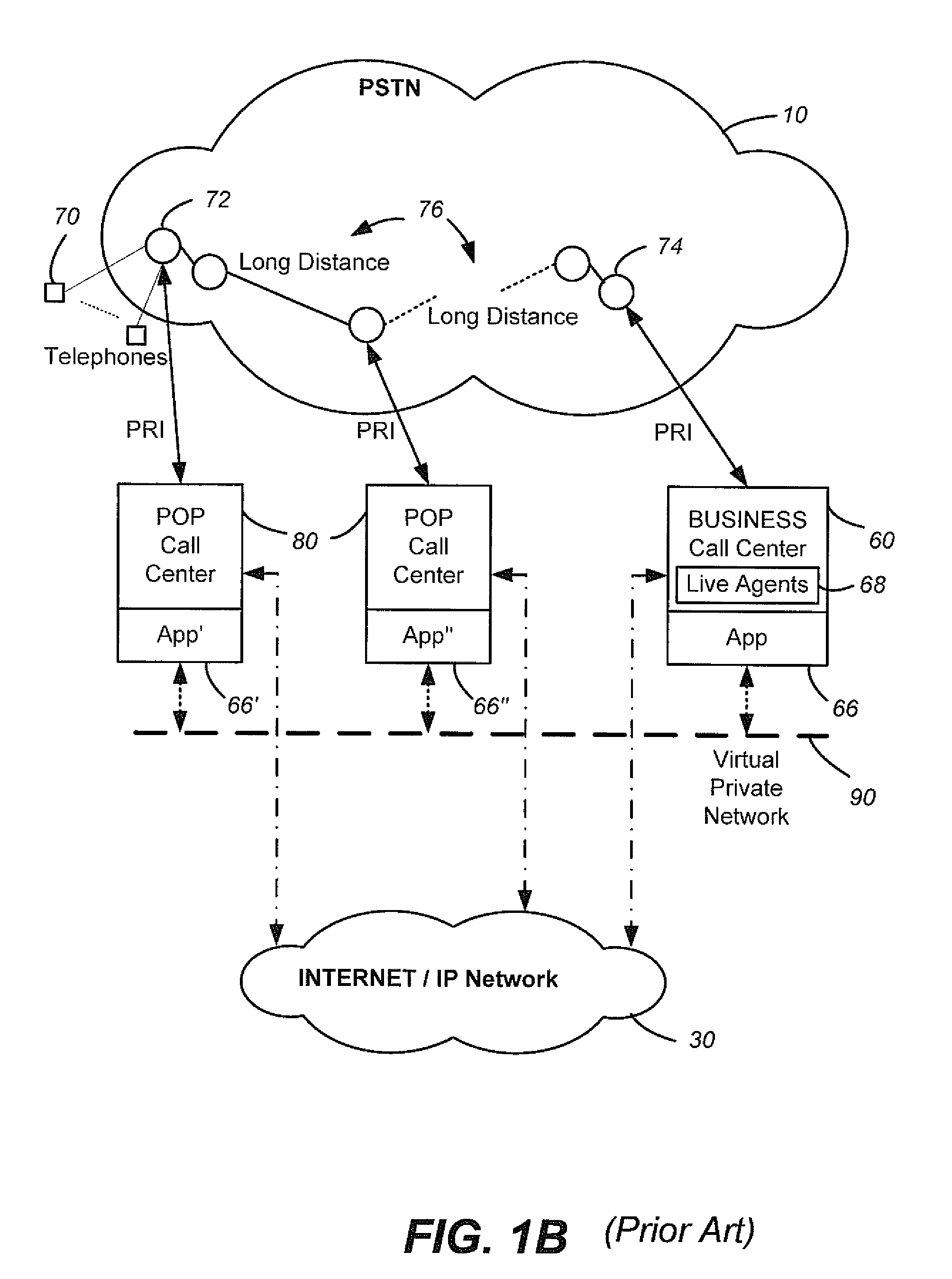

System and method for dynamic telephony resource allocation between premise and hosted facilities

ActiveUS8355394B2Easily allocateEasy allocation of resourceData switching by path configurationAutomatic exchangesPopulationSpeech sound

A population of networked Application Gateway Centers or voice centers provides telephony resources. The telephony application for a call number is typically created by a user in XML (Extended Markup Language) with predefined telephony XML tags and deployed on a website. A voice center provides facility for retrieving the associated XML application from its website and processing the call accordingly. The individual voice centers are either operated at a hosted facility or at a customer's premise. Provisioning Management Servers help to allocate telephony resources among the voice centers. This is accomplished by suitably updating a voice center directory. In this way, the original capacity at a premise, predetermined by the hardware installed, can be adjusted up or down. If the premise is under capacity, it can be supplemented by that from a hosted facility. If the premise has surplus capacity, it can be reallocated for use by others outside the premise.

Owner:ALVARIA INC

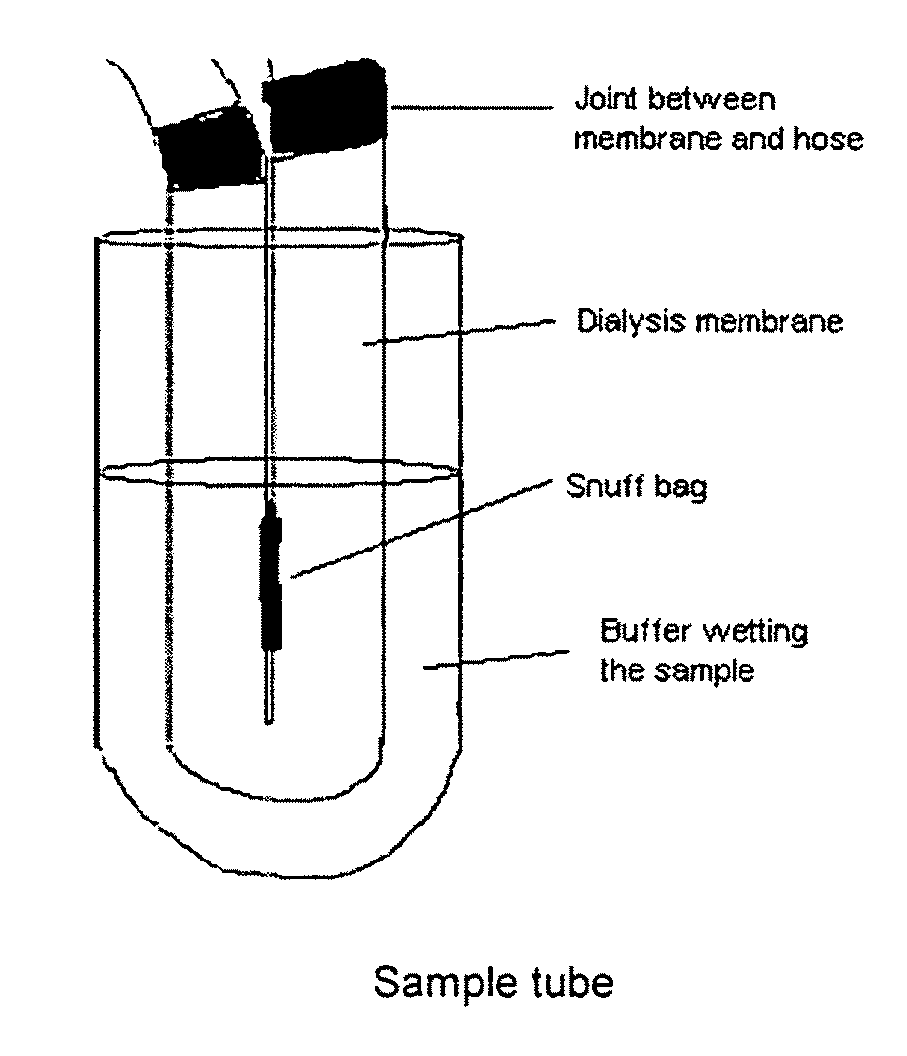

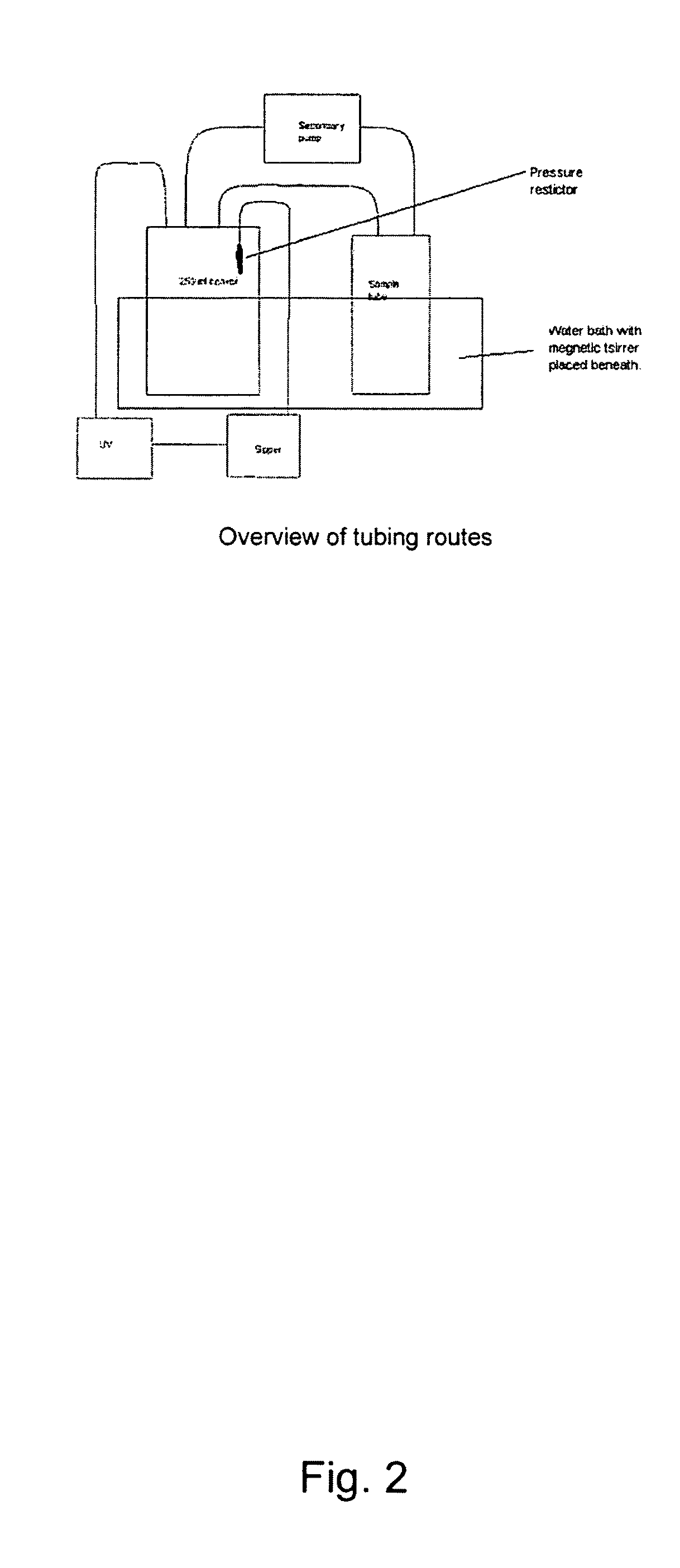

Snuff Composition

ActiveUS20090293895A1Quick effectRapid onsetPowder deliveryOrganic active ingredientsCellulosePharmacology

Use of a nicotine-cellulose combination for the preparation of a snuff composition for achievement of a fast onset of action of nicotine after application of the snuff composition to the oral cavity of a subject, wherein the composition has a high release rate so that when subjected to an in vitro dissolution test about 45% or more of the total content of nicotine is released within 30 minutes. Moreover, the invention relates to an improved snuff composition for application to the oral cavity.

Owner:MODORAL BRANDS INC

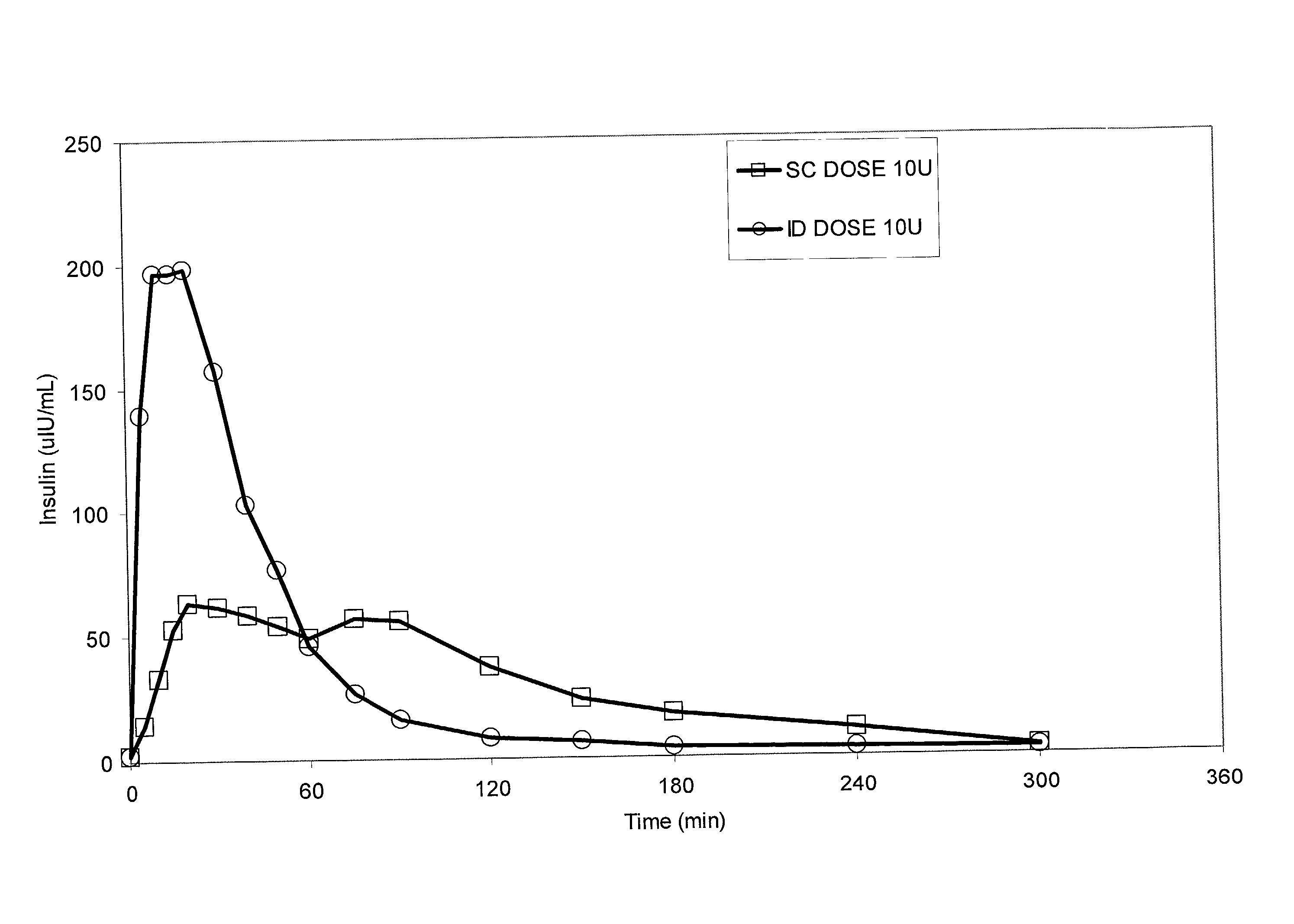

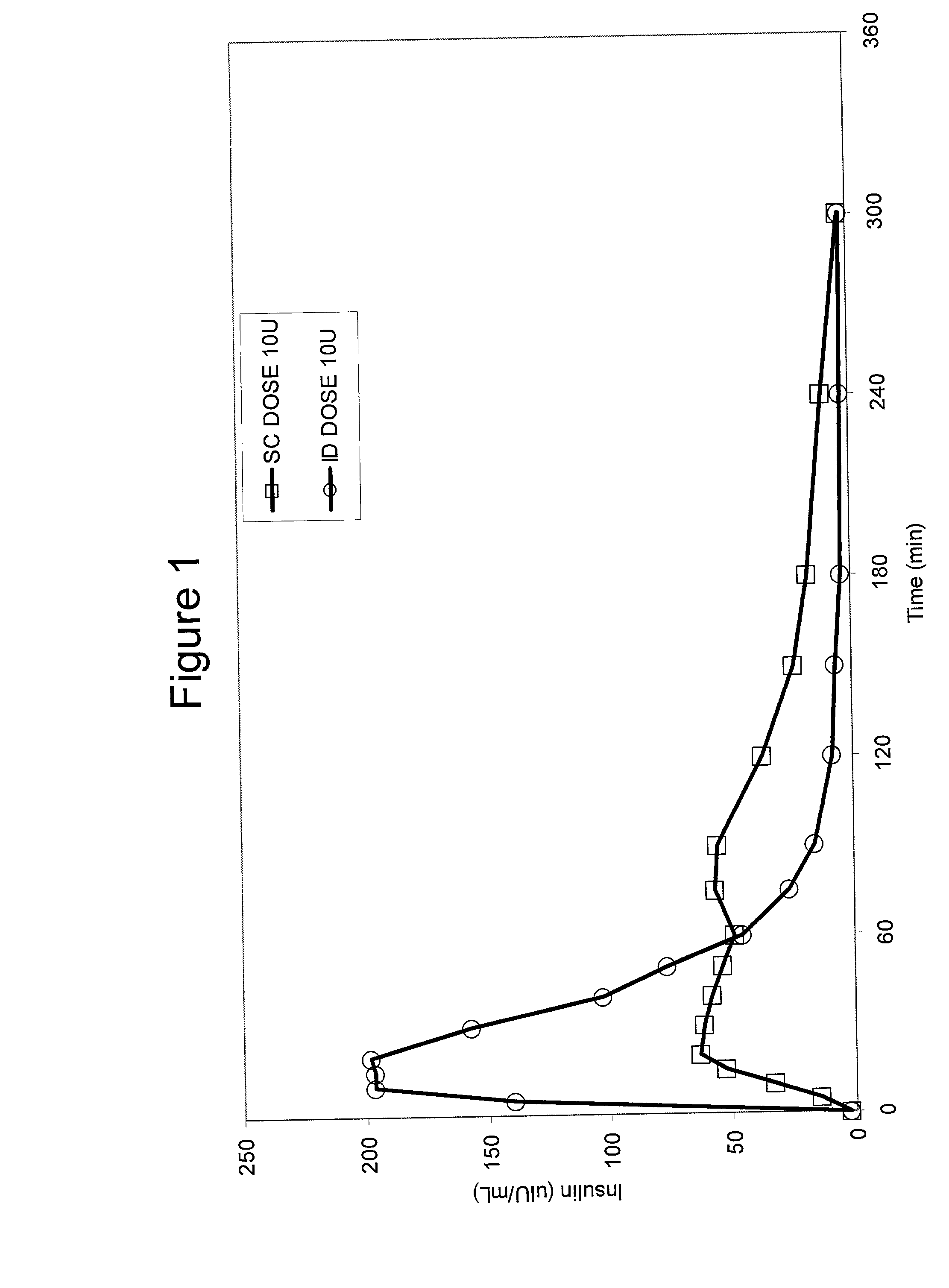

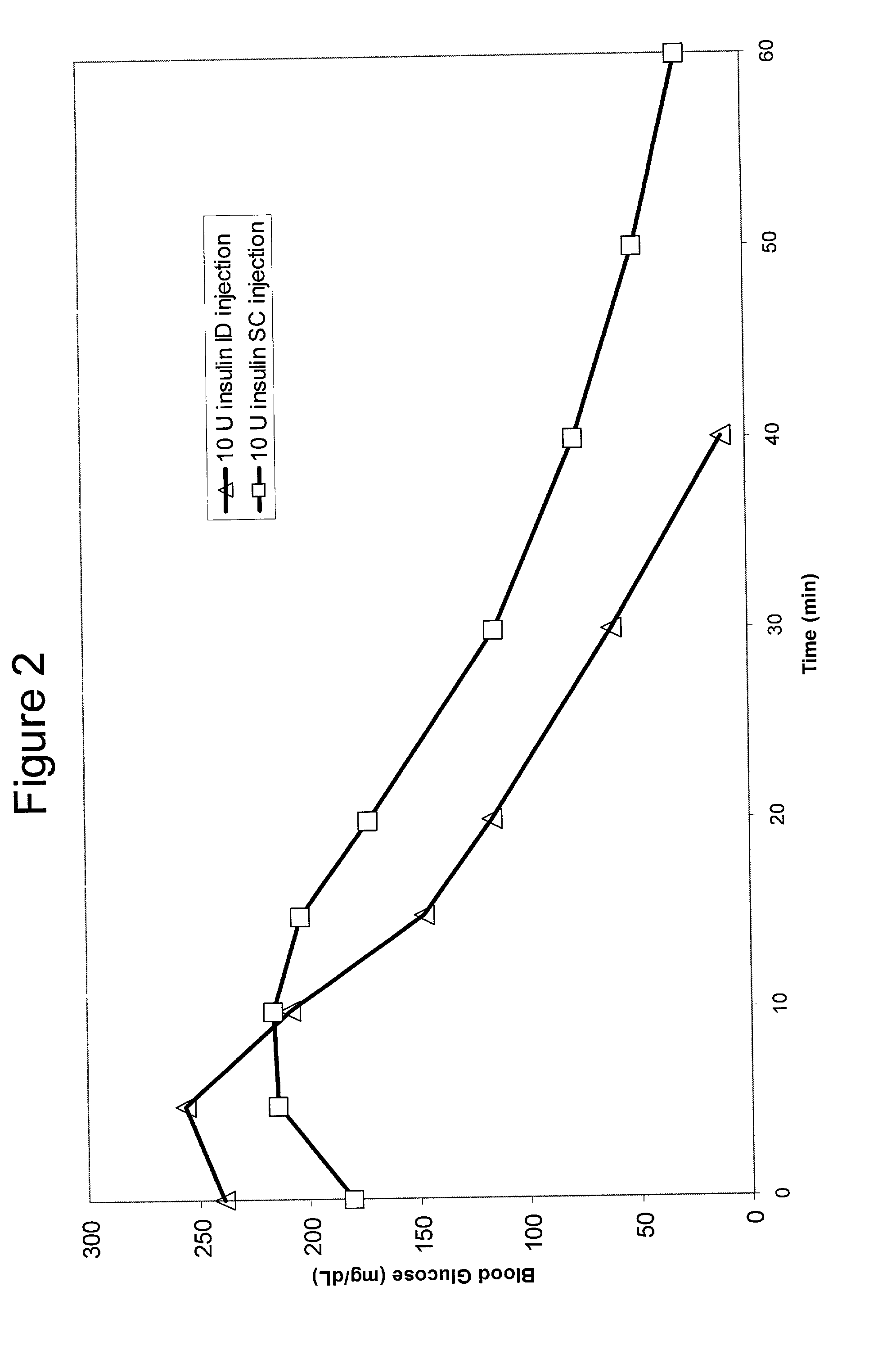

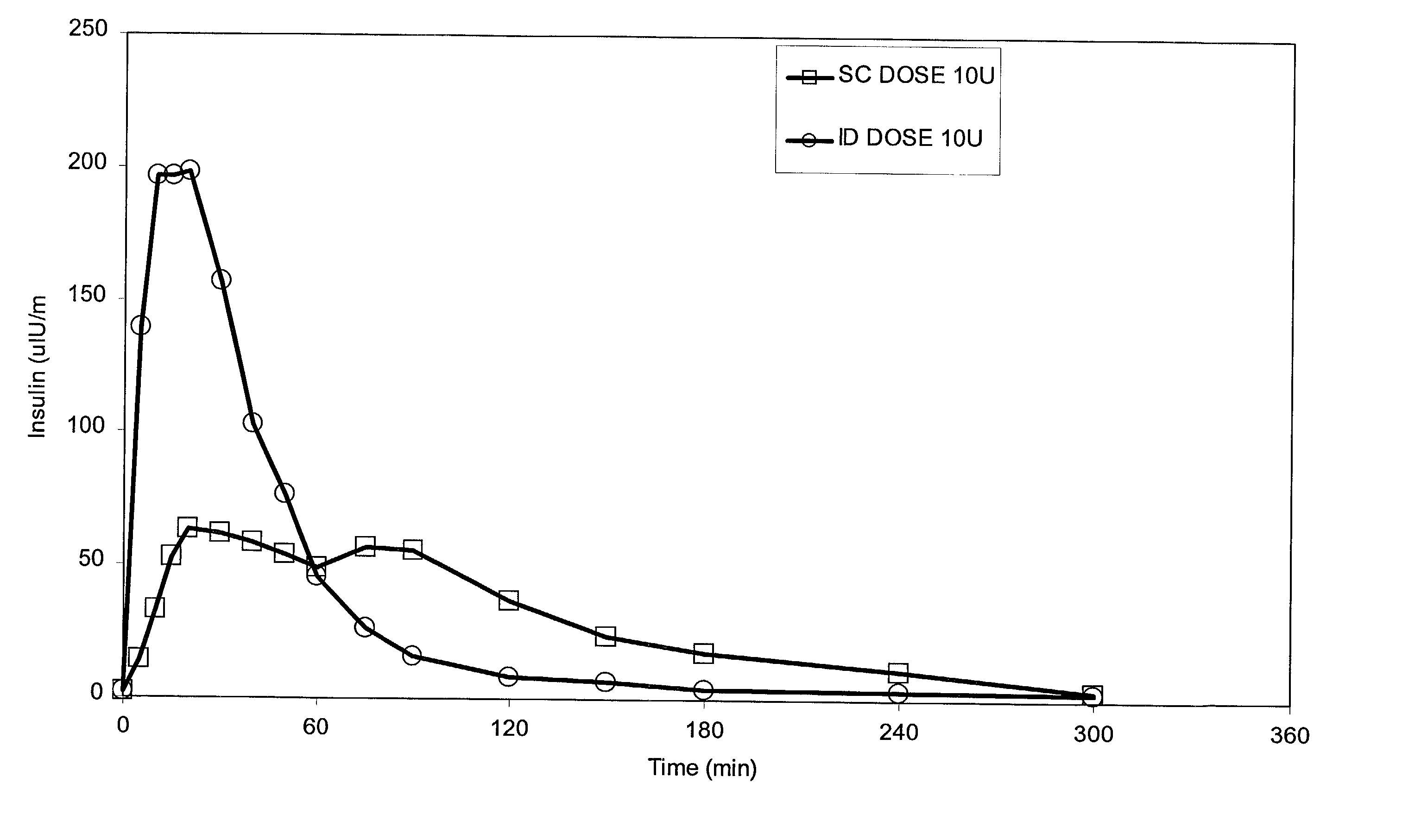

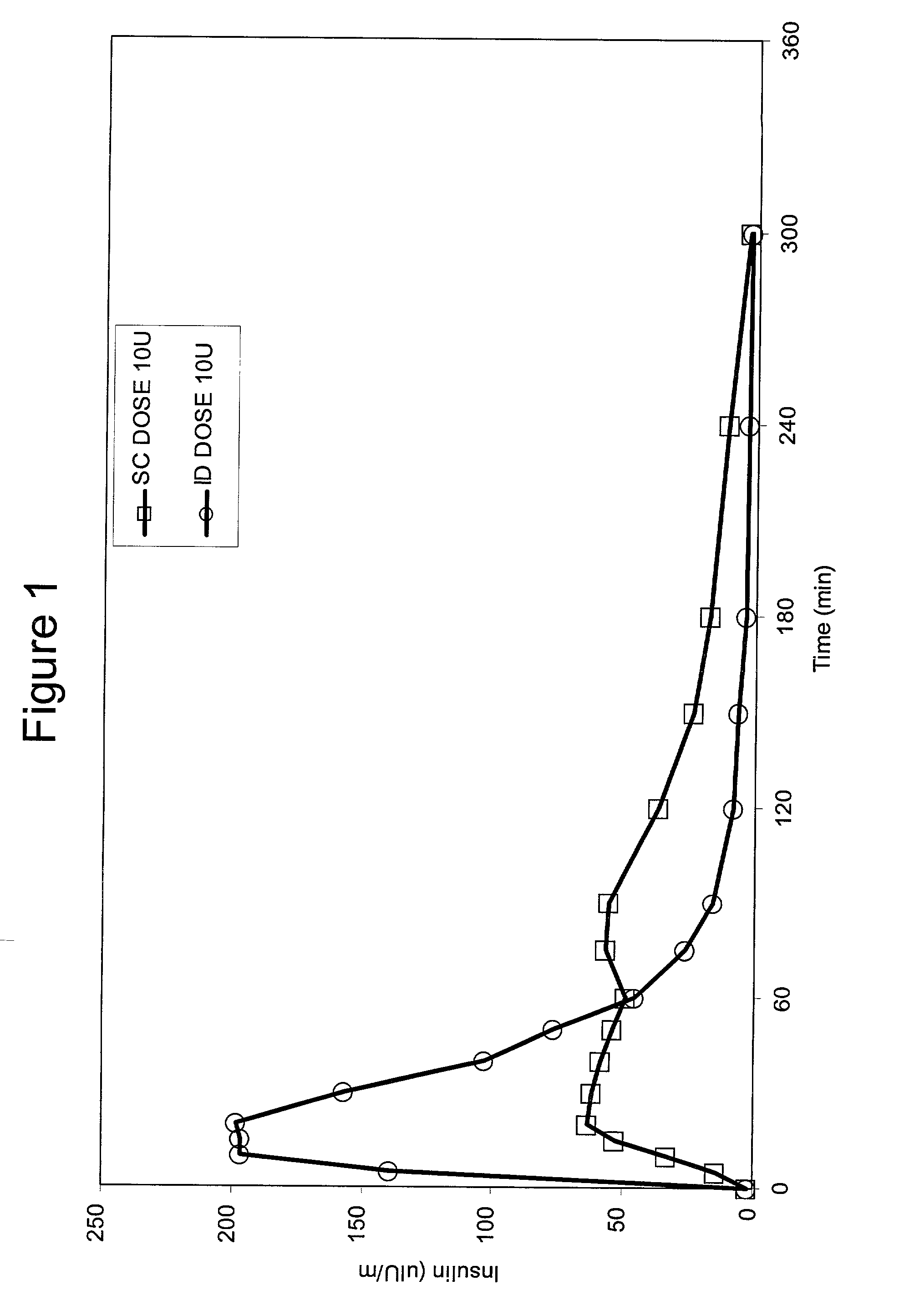

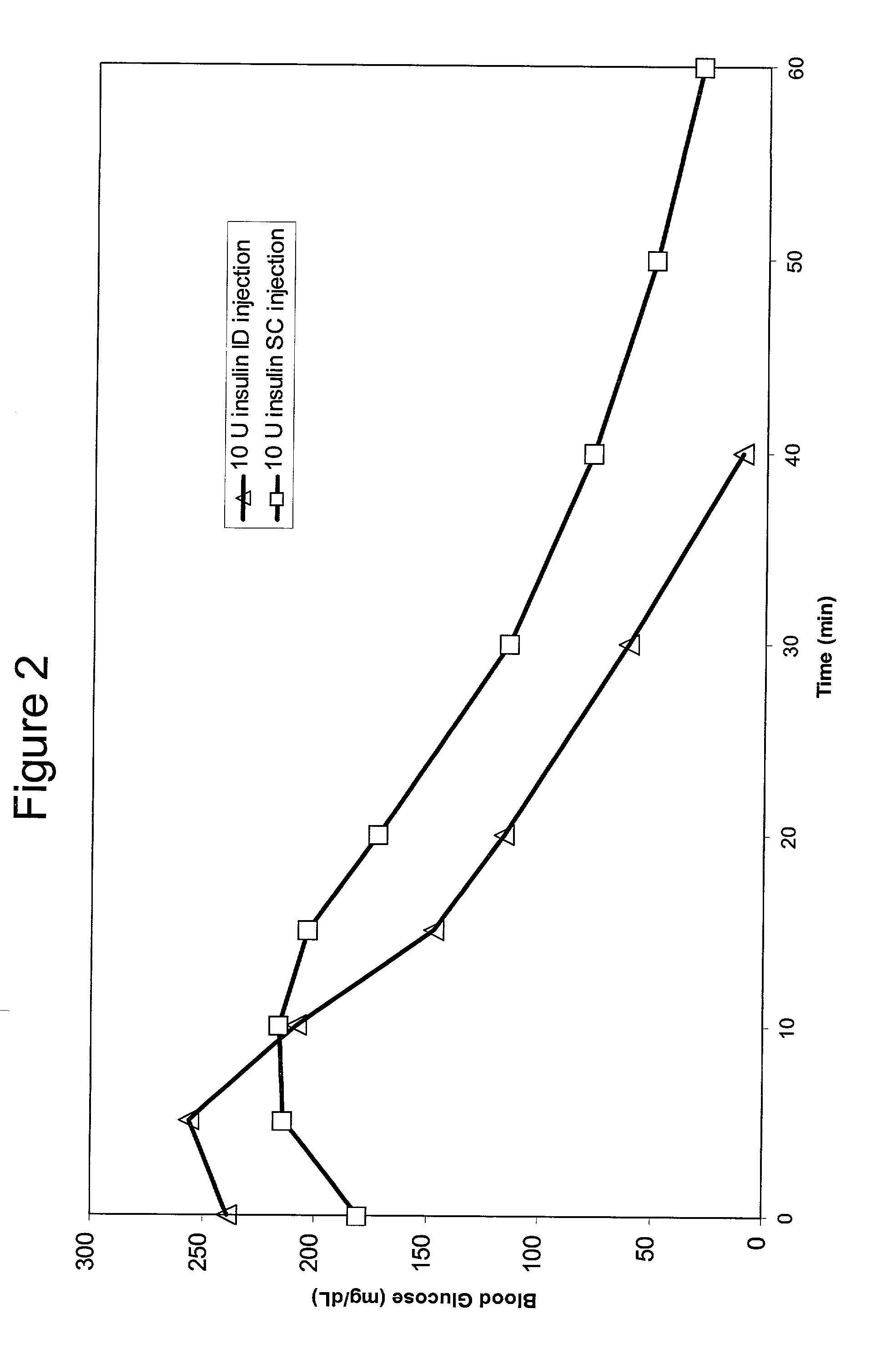

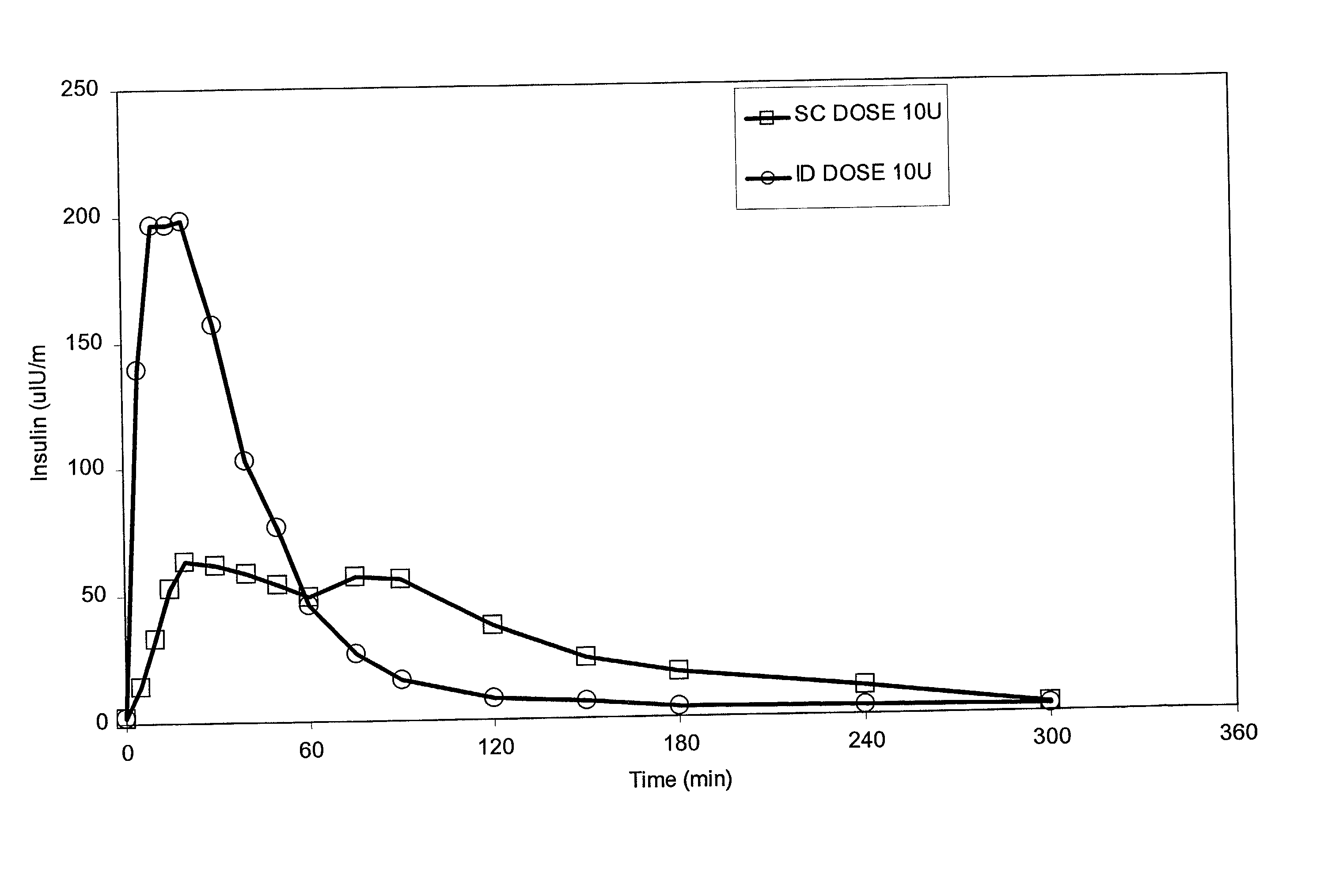

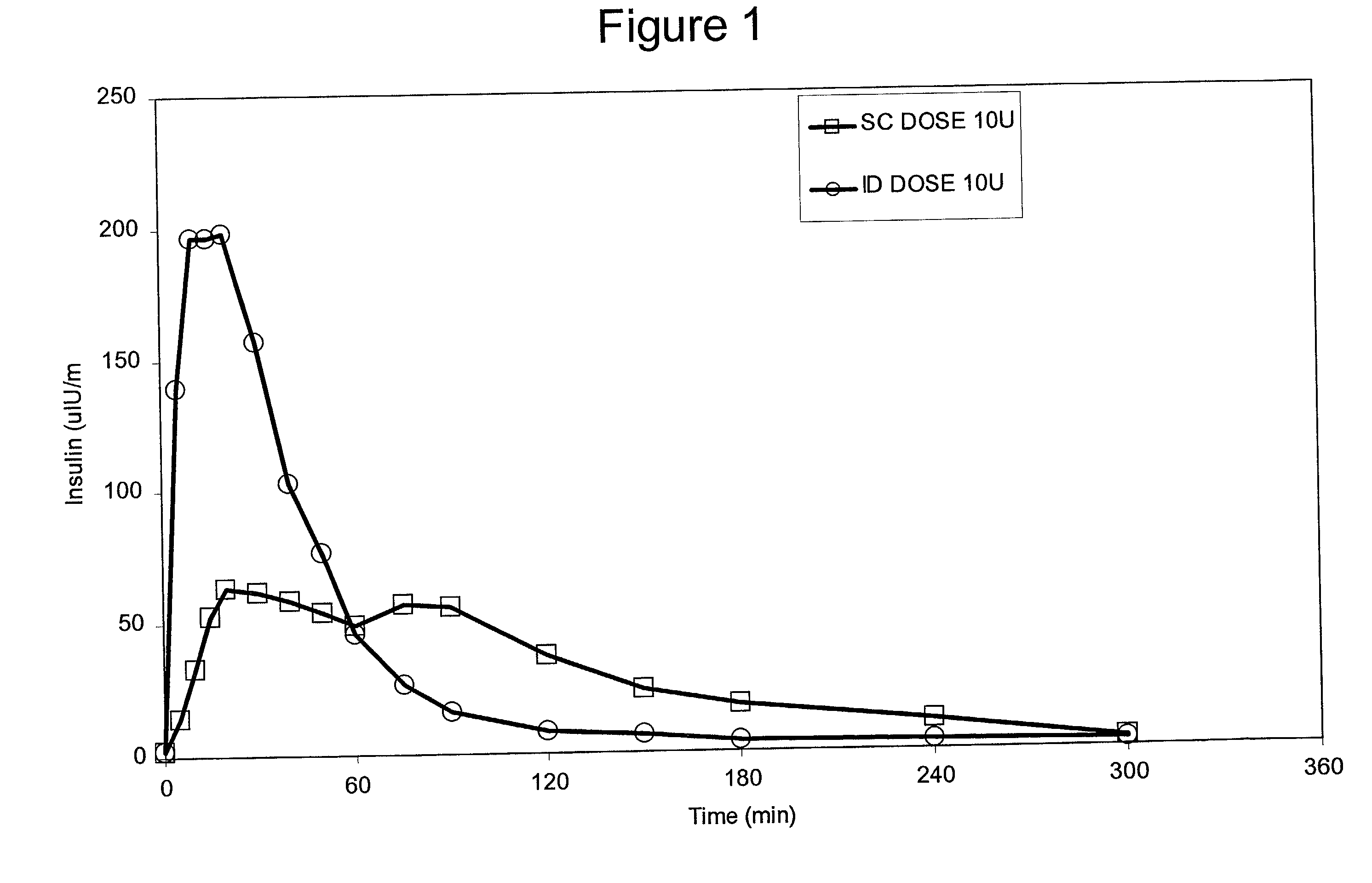

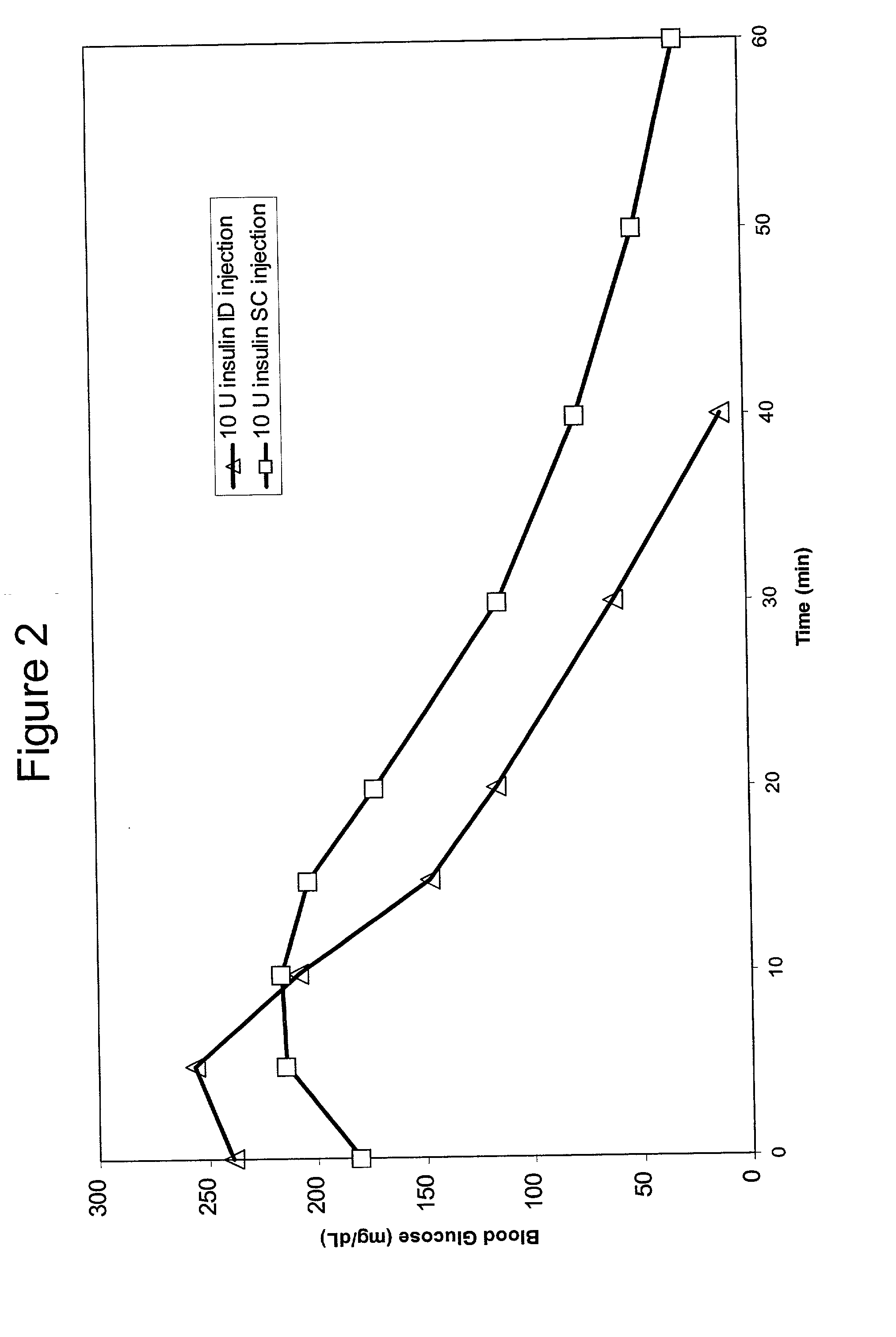

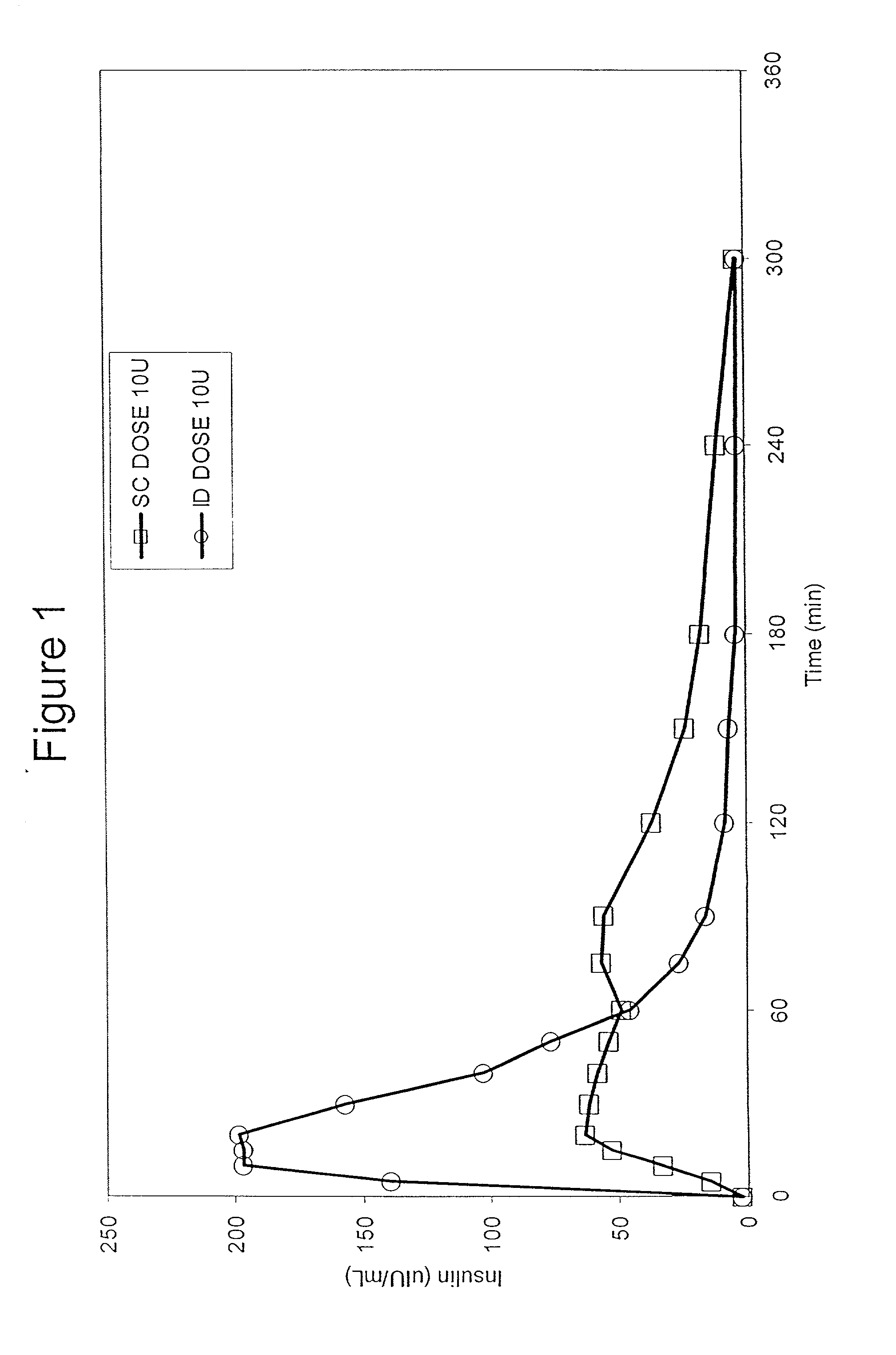

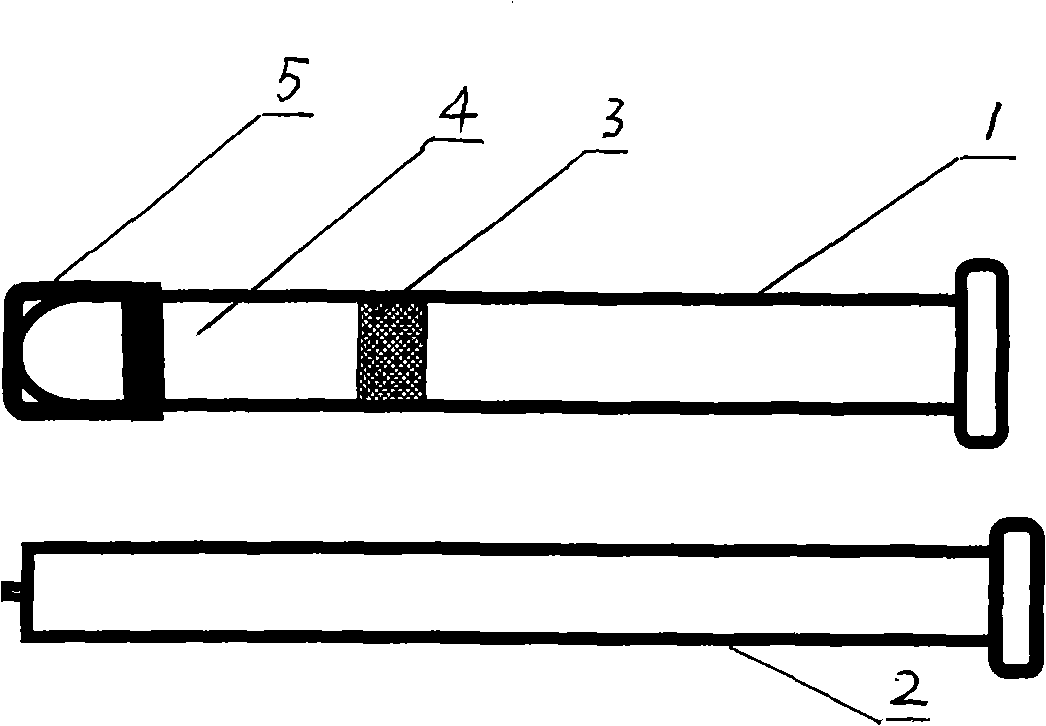

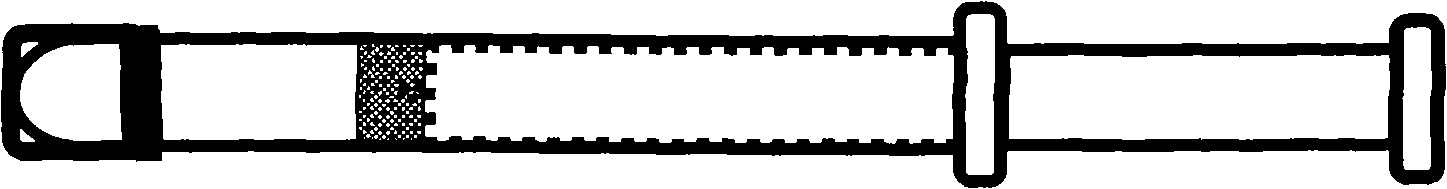

Method for altering drug pharmacokinetics based on medical delivery platform

InactiveUS20020095134A1Increase uptakeRapid uptake rateOrganic active ingredientsAmpoule syringesMedicineSurgery

A method for directly delivering whereby a substance is introduced into an intradermal space within mammalian skin which involves administering the substance through at least one small gauge hollow needle having an outlet with an exposed height between 0 and 1 mm. The outlet is inserted into the skin to a depth of between 0.3 mm and 2 mm such that the delivery of the substance occurs at a depth between 0.3 mm and 2 mm.

Owner:BECTON DICKINSON & CO

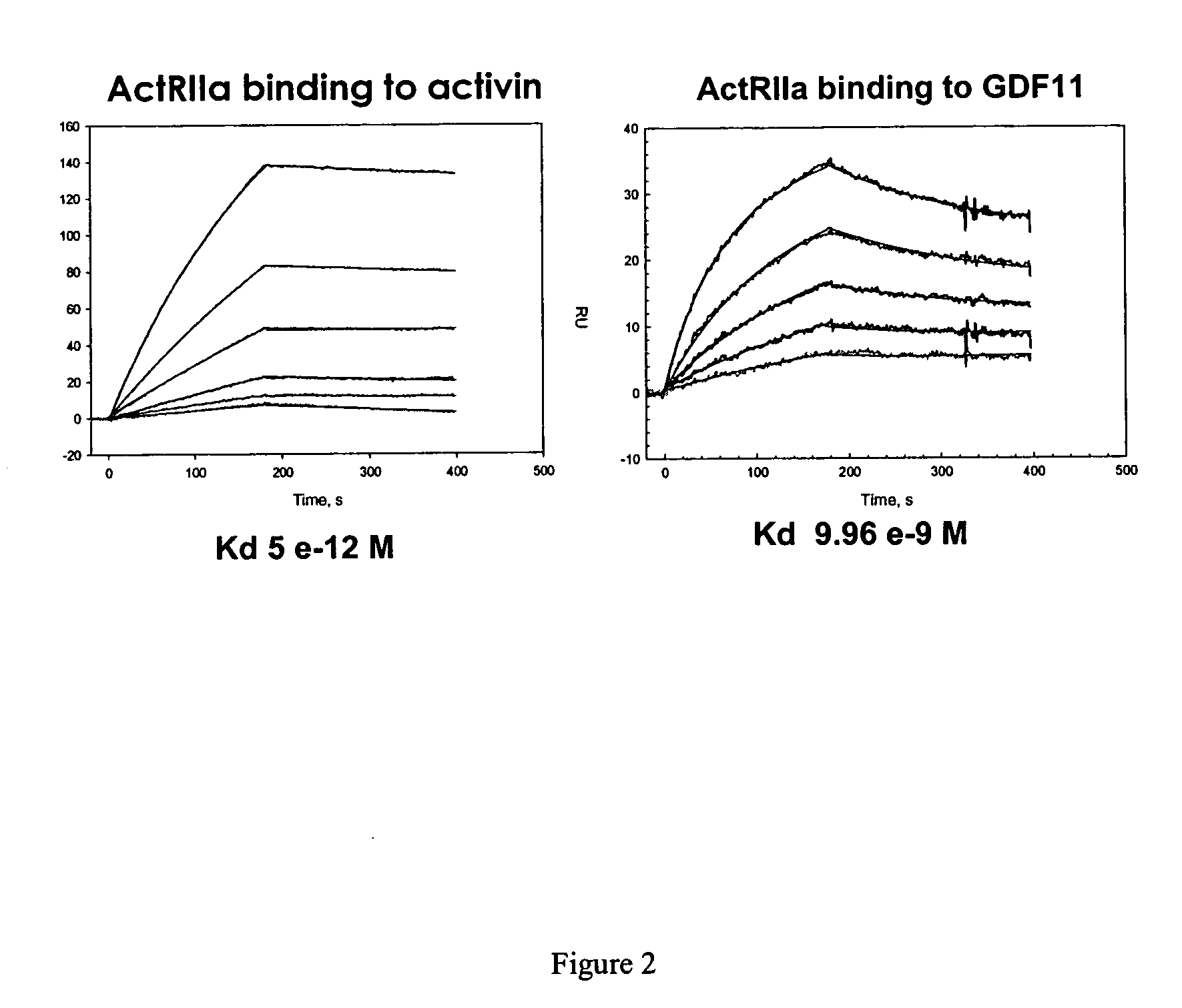

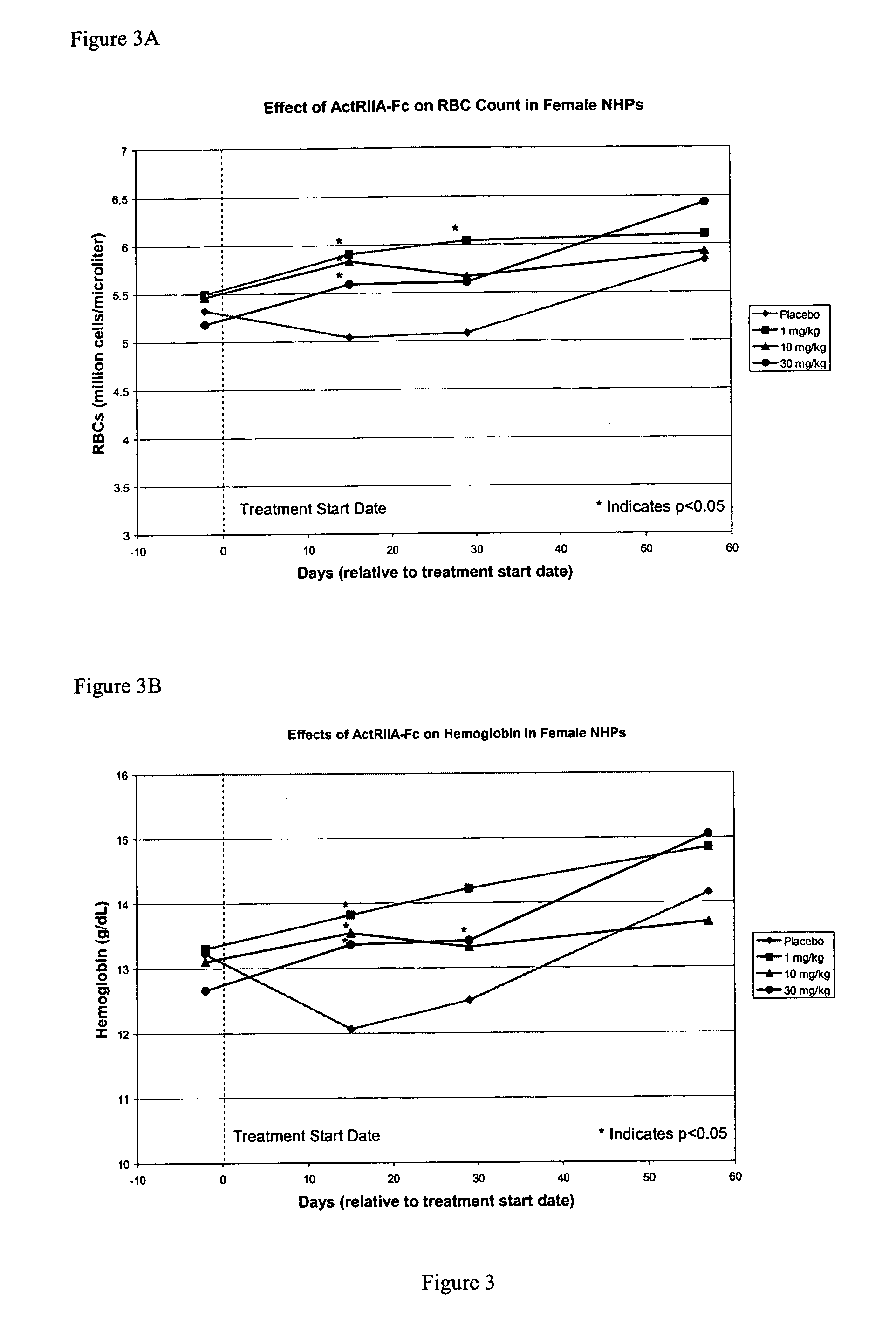

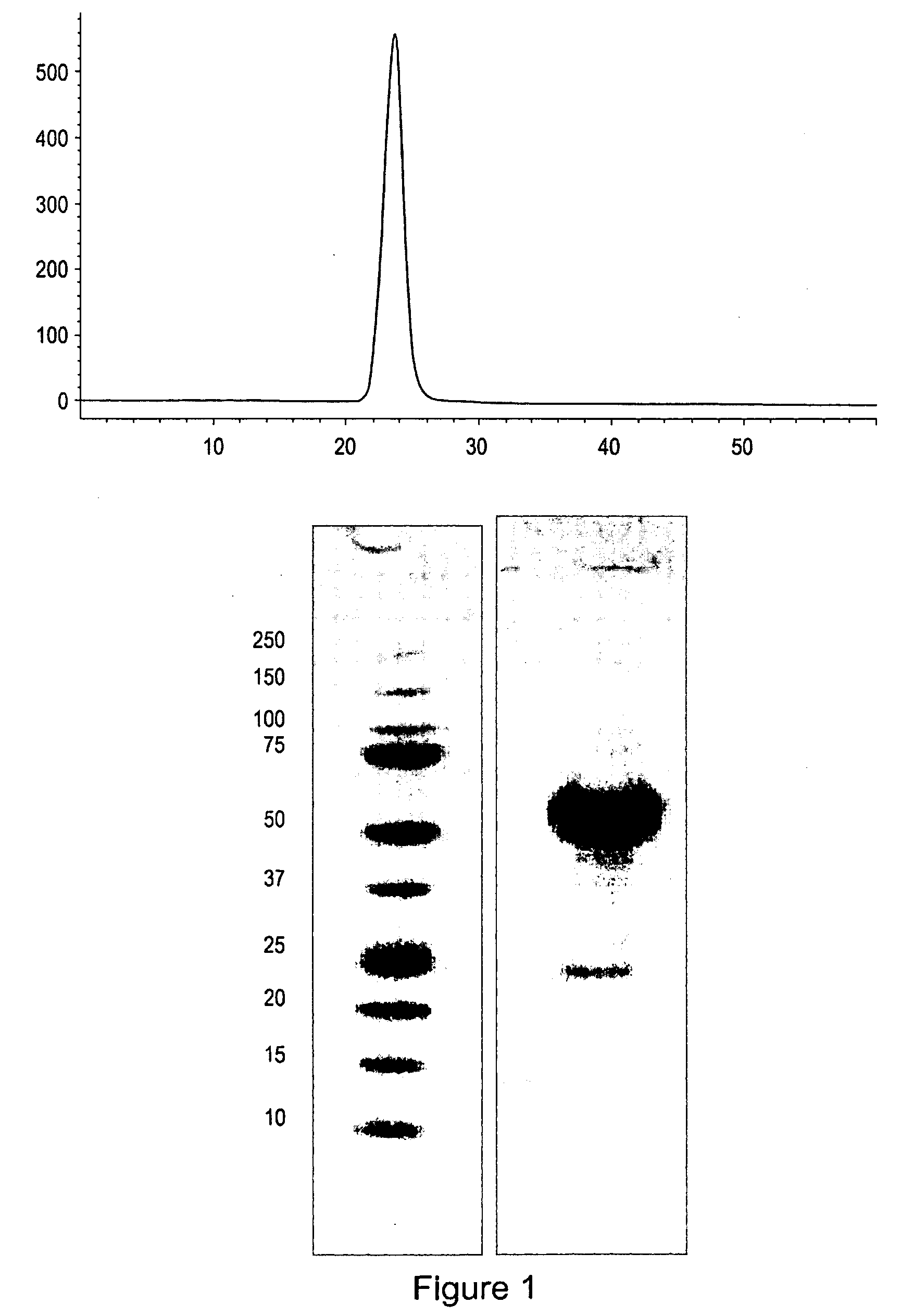

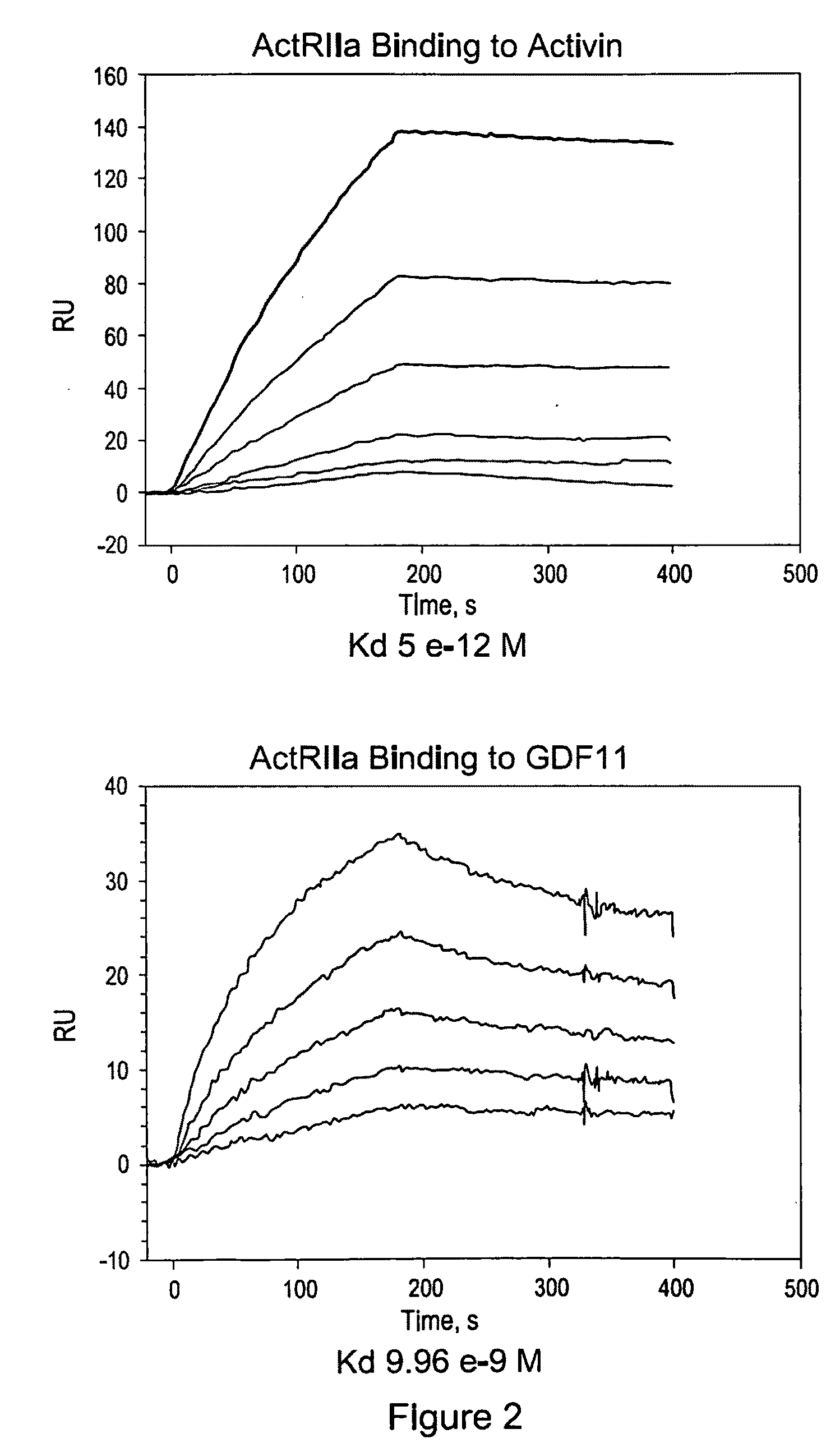

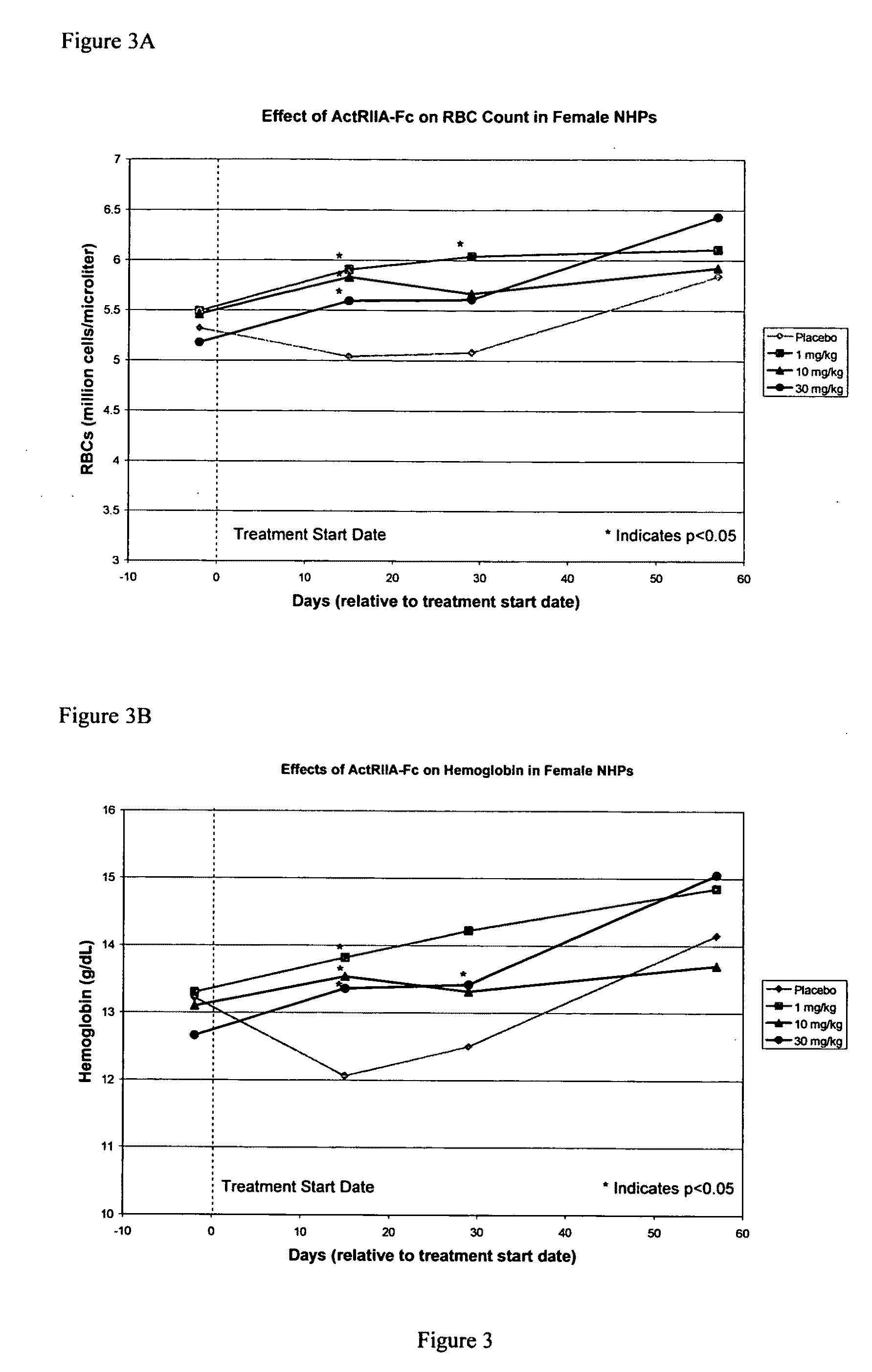

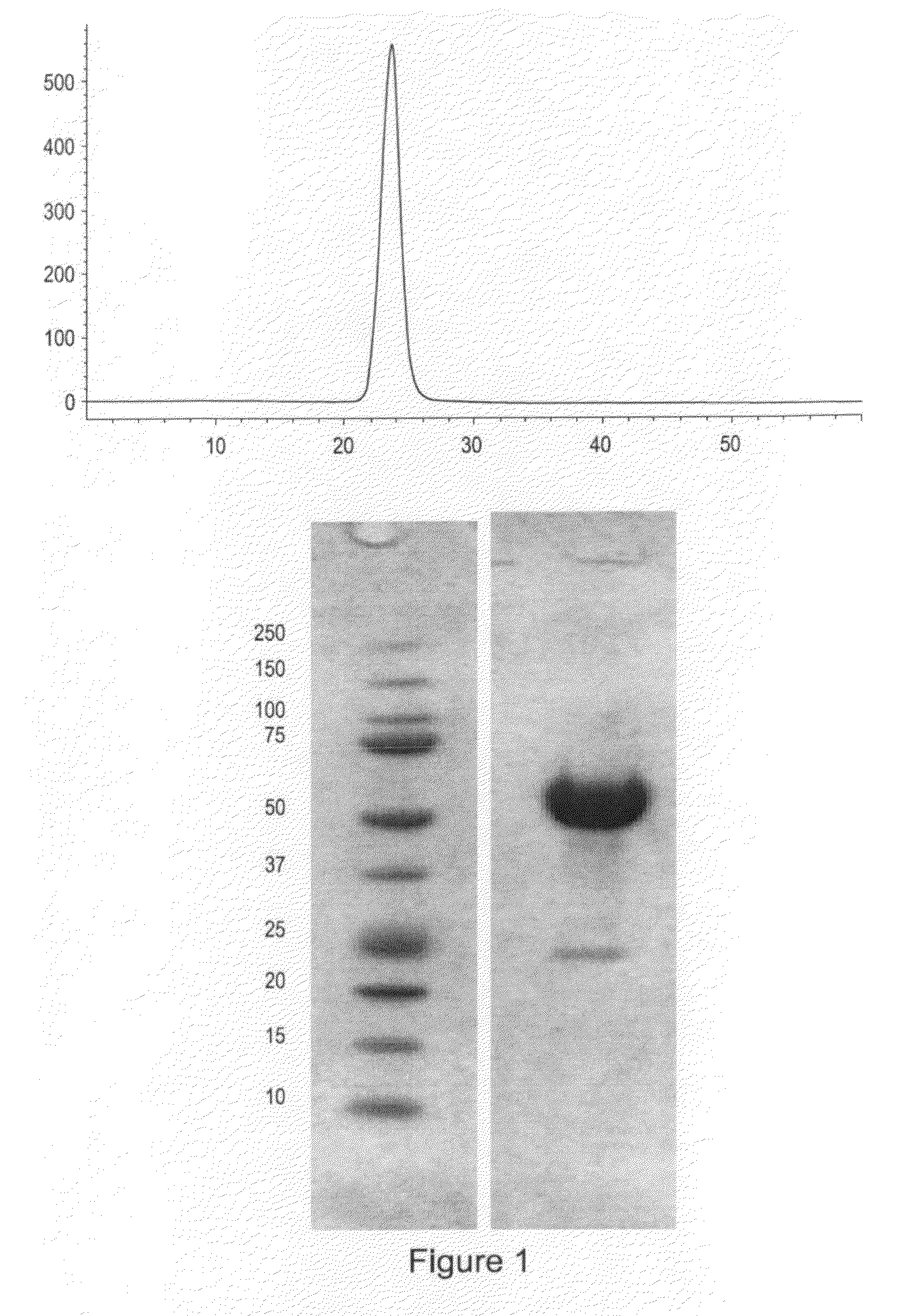

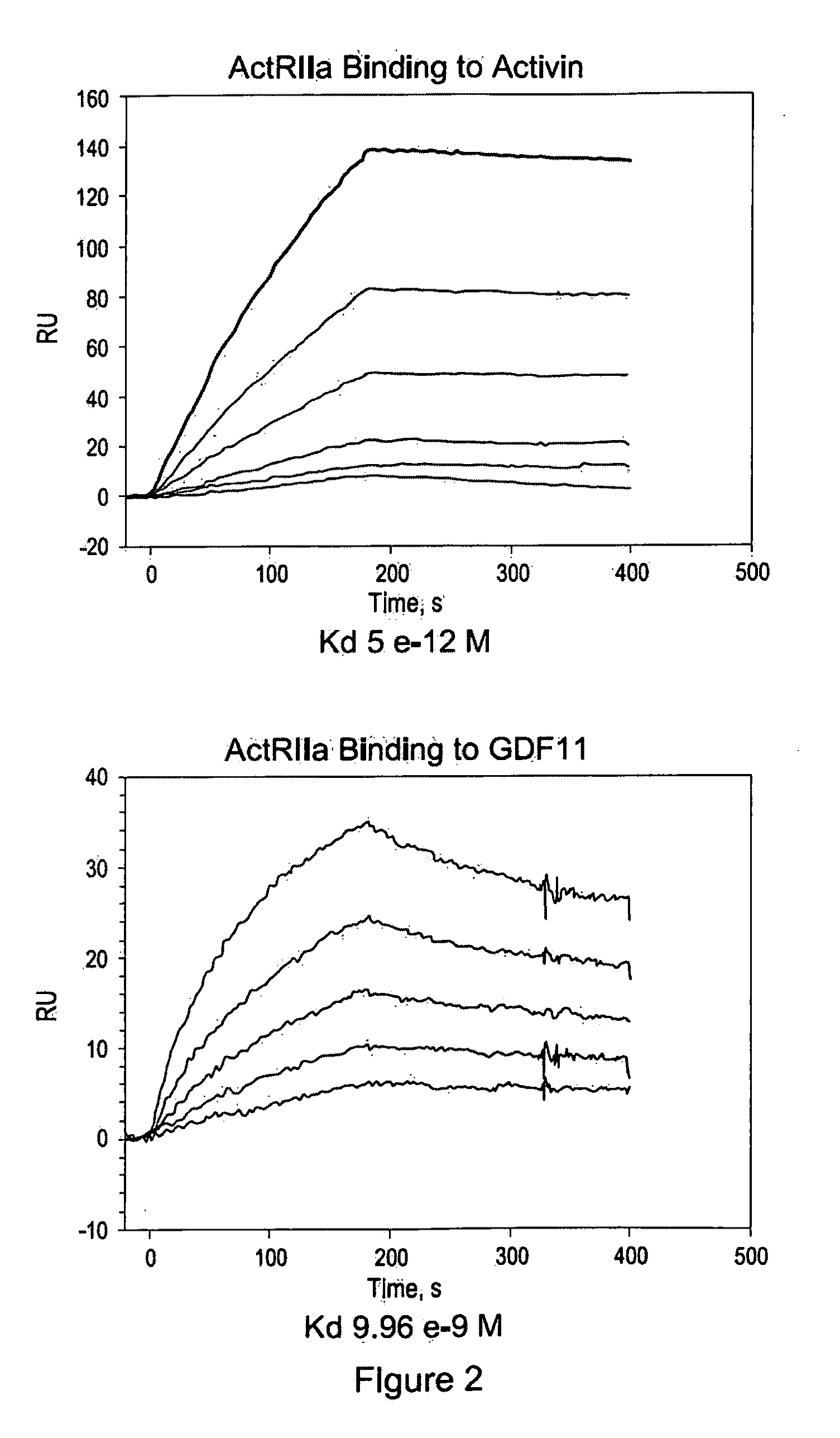

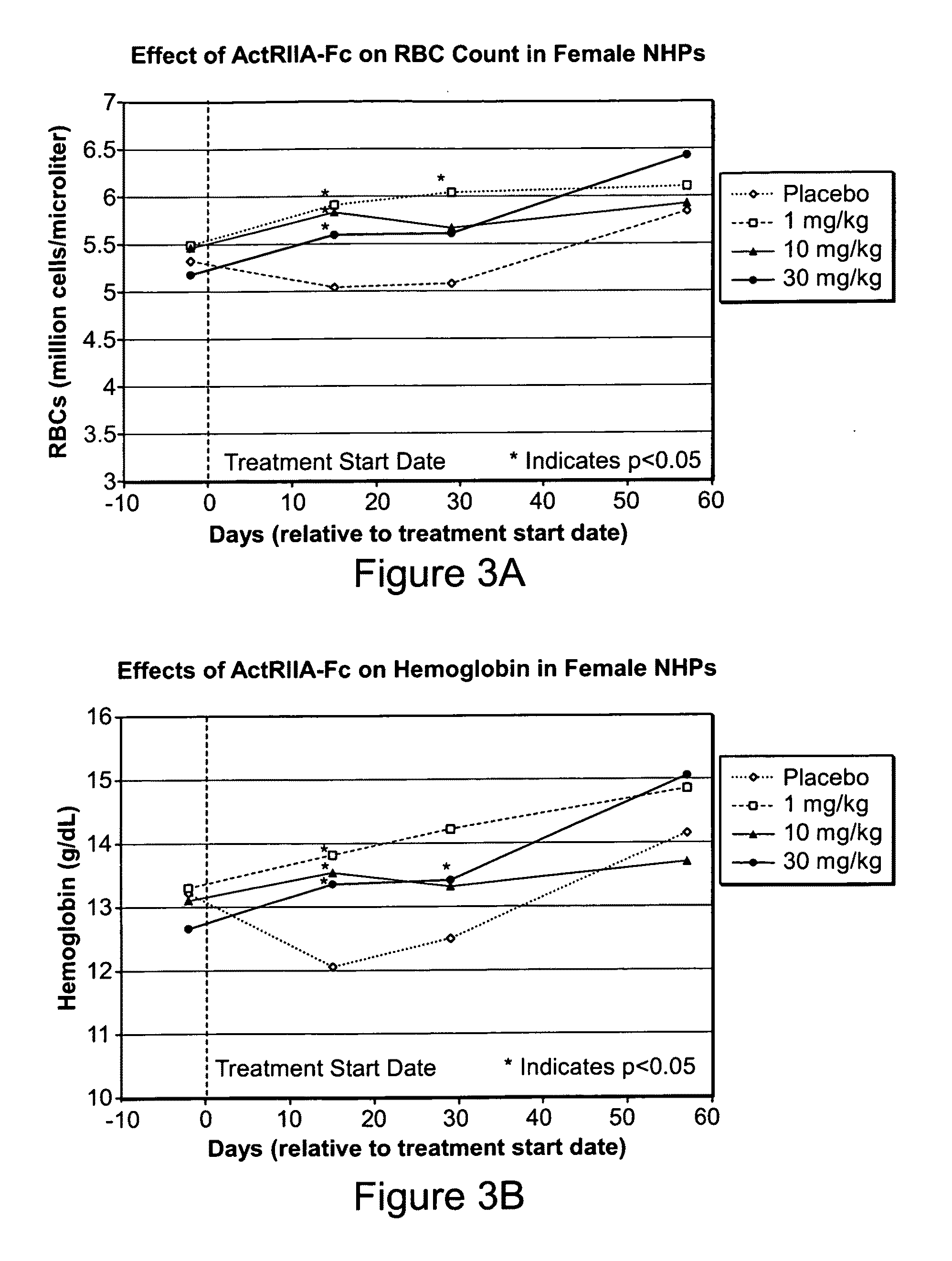

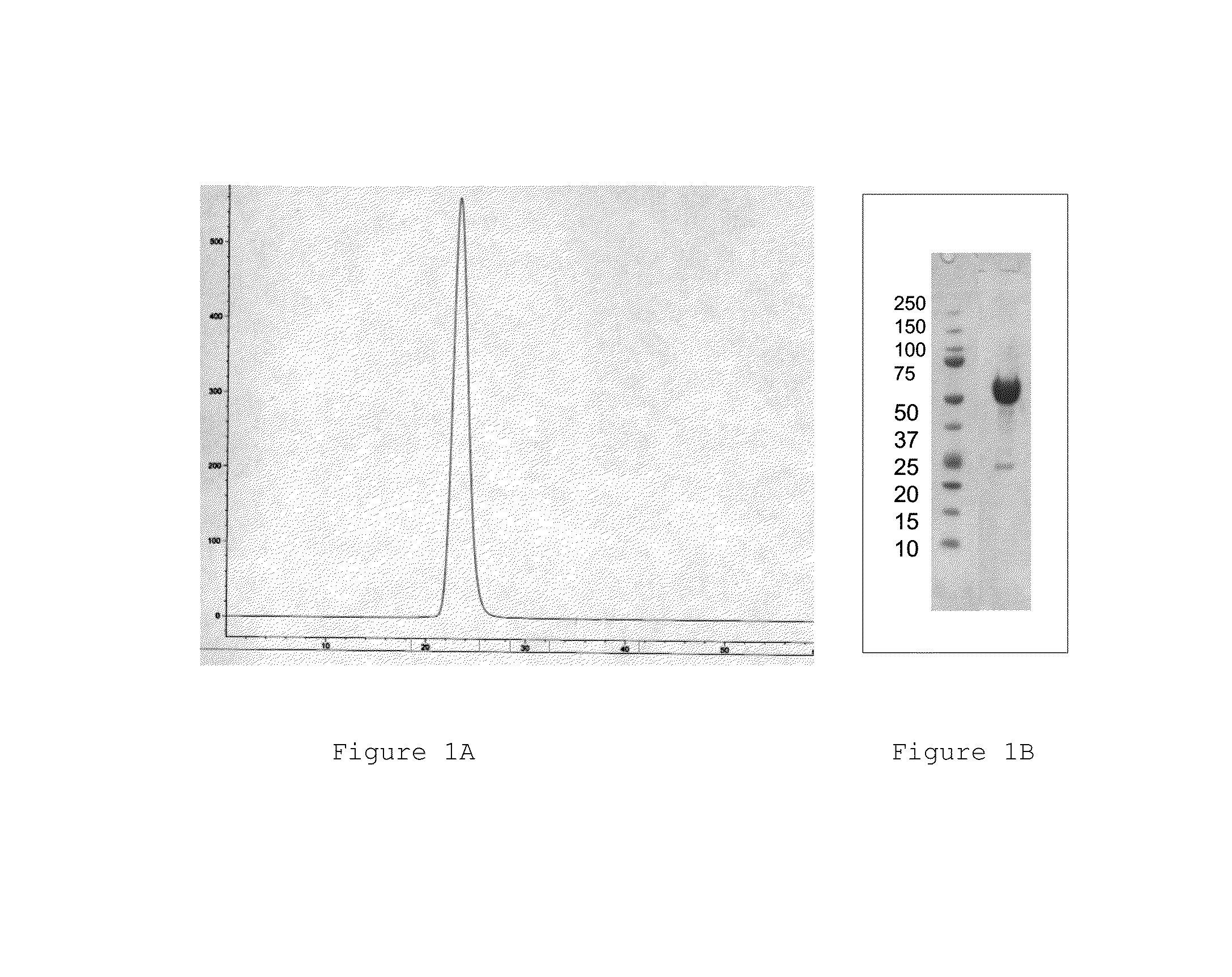

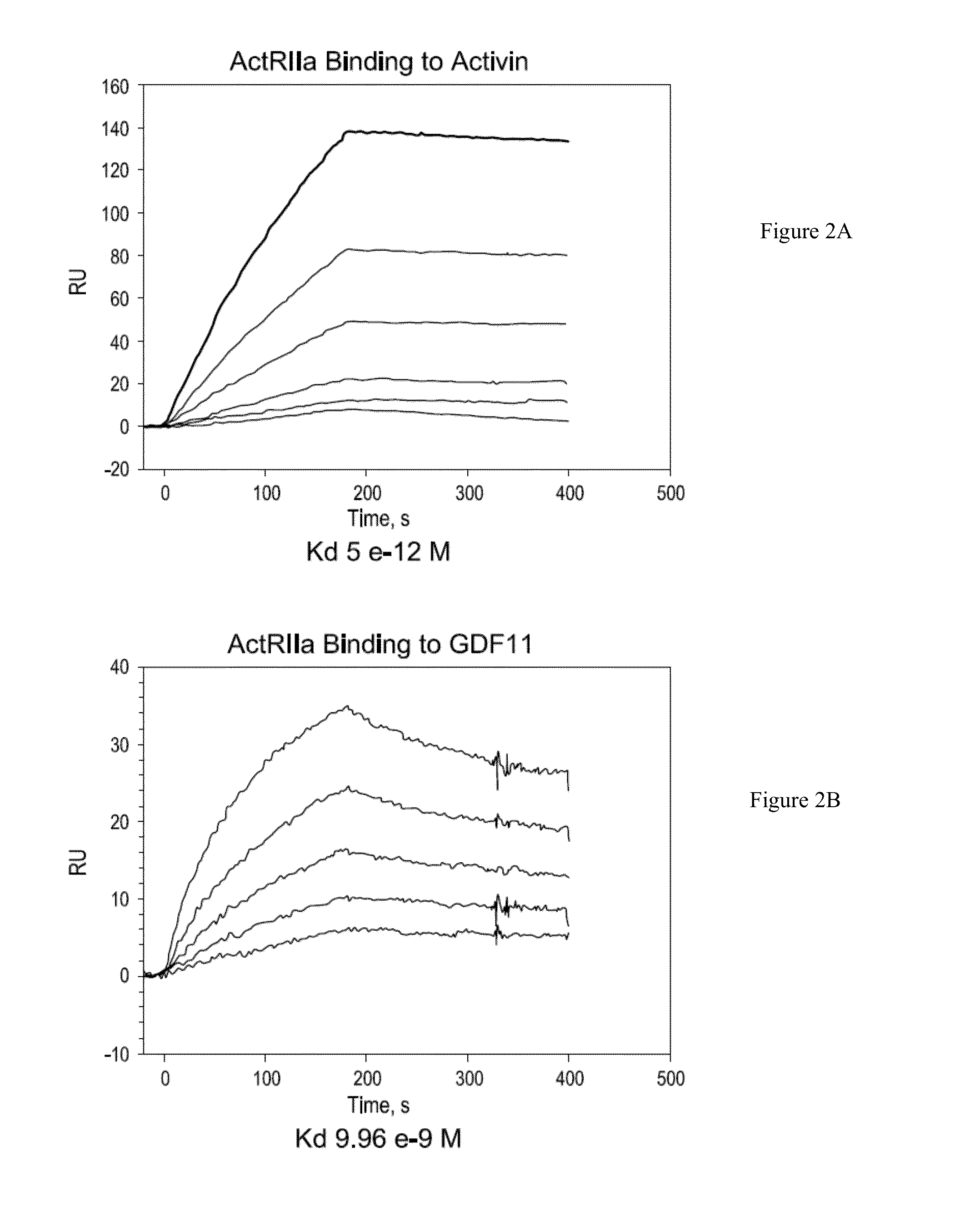

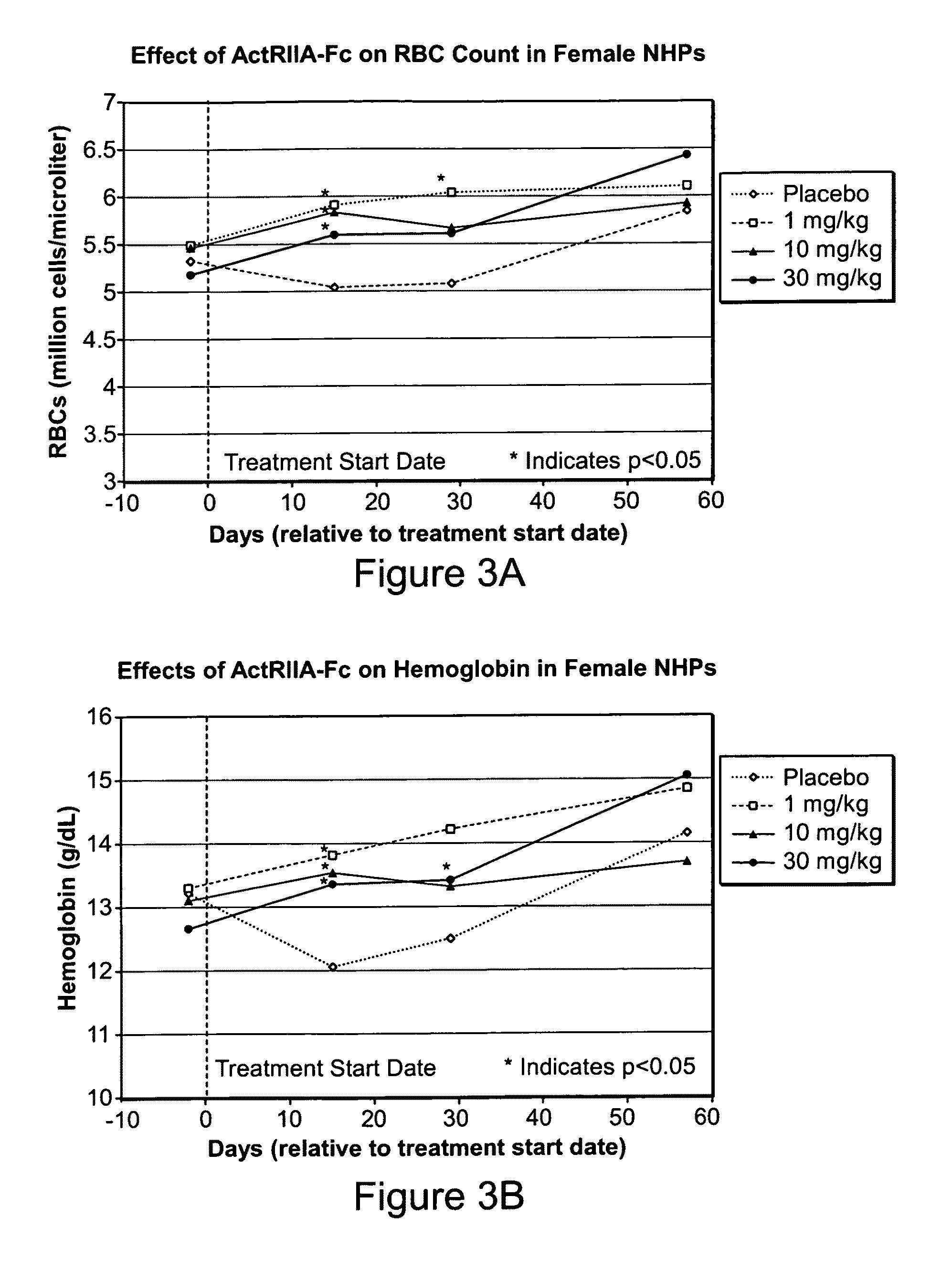

Activin-ActRII antagonists and uses for increasing red blood cell levels

ActiveUS20090047281A1Easy to produceReduce expressionCompound screeningApoptosis detectionPrimateRed Cell

In certain aspects, the present invention provides compositions and methods for increasing red blood cell and / or hemoglobin levels in vertebrates, including rodents and primates, and particularly in humans.

Owner:ACCELERON PHARMA INC

Film-Shaped Mucoadhesive Administration Forms For Administering Cannabis Agents

InactiveUS20060039959A1Improving acceptance and complianceQuick effectOrganic active ingredientsBiocideCannabisActive agent

A film-shaped, mucoadhesive administration form having a content of at least one active agent. The active agent is a cannabis agent.

Owner:LTS LOHMANN THERAPIE-SYST AG

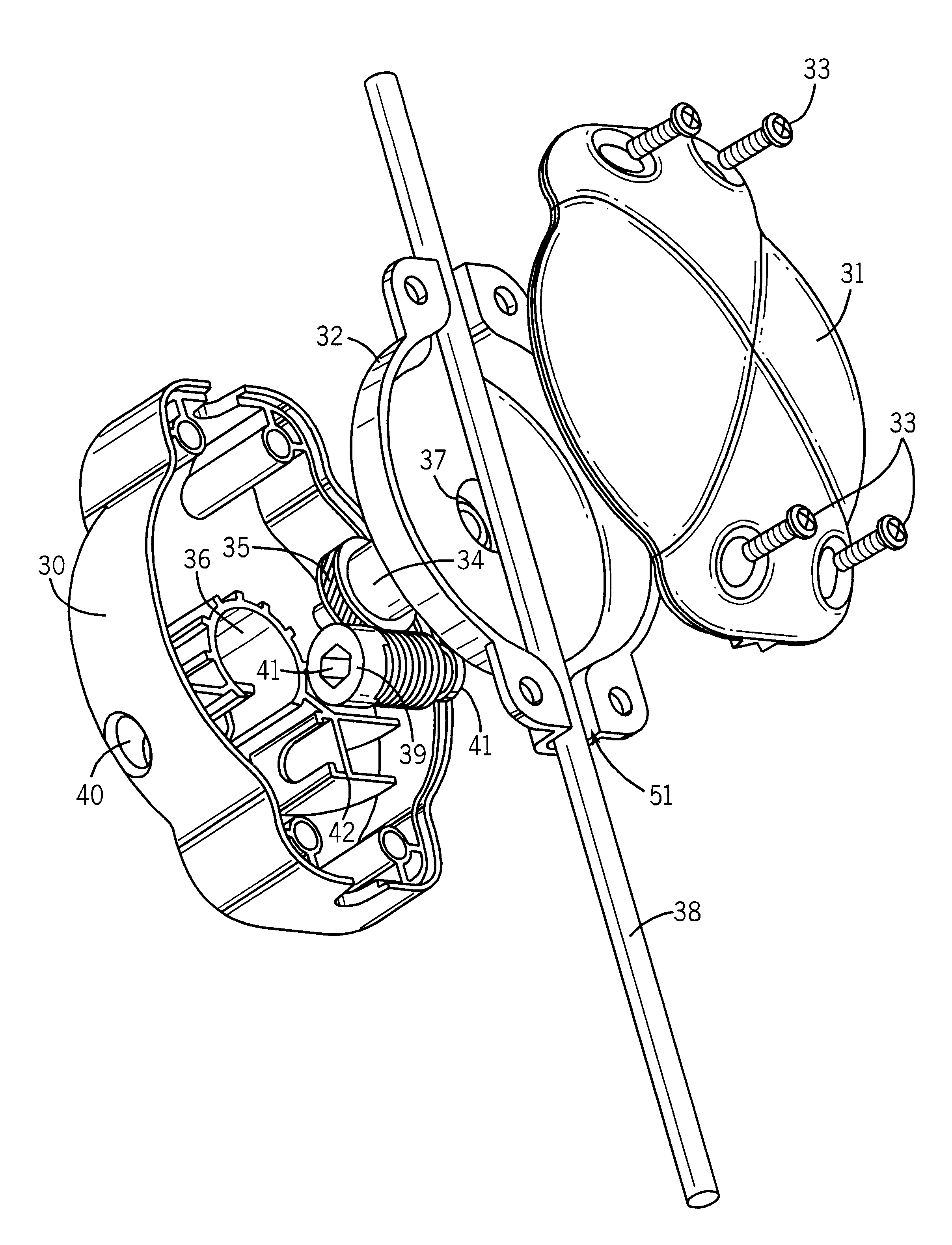

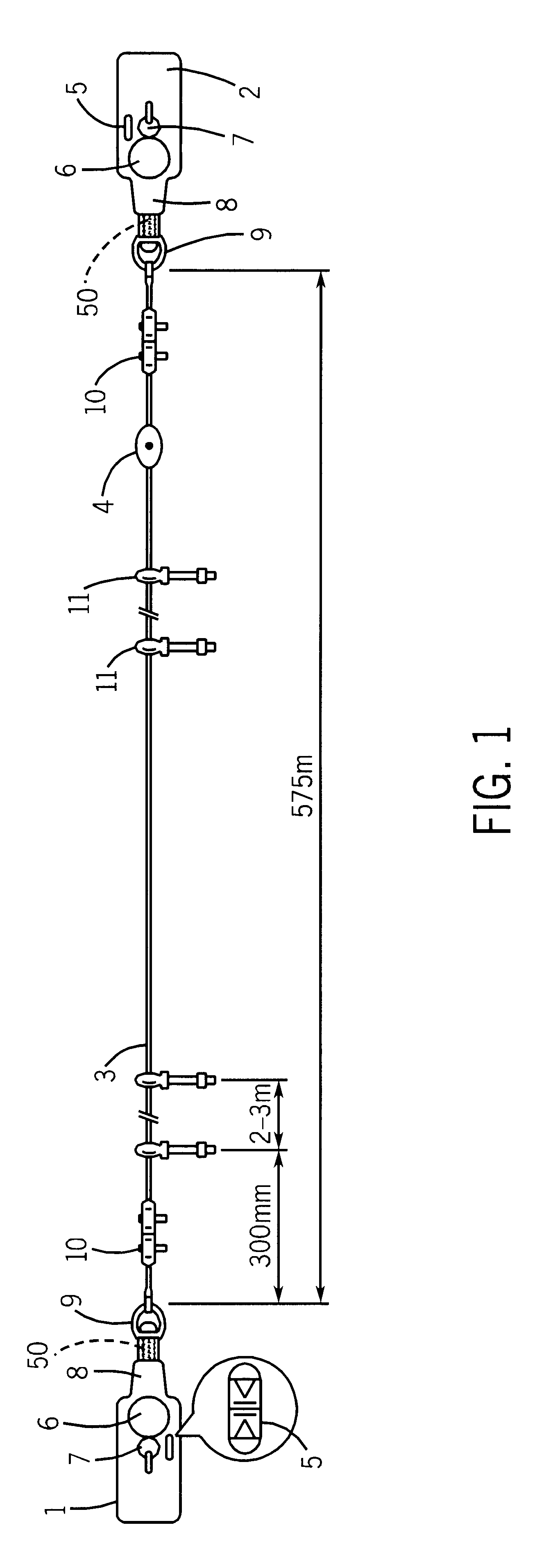

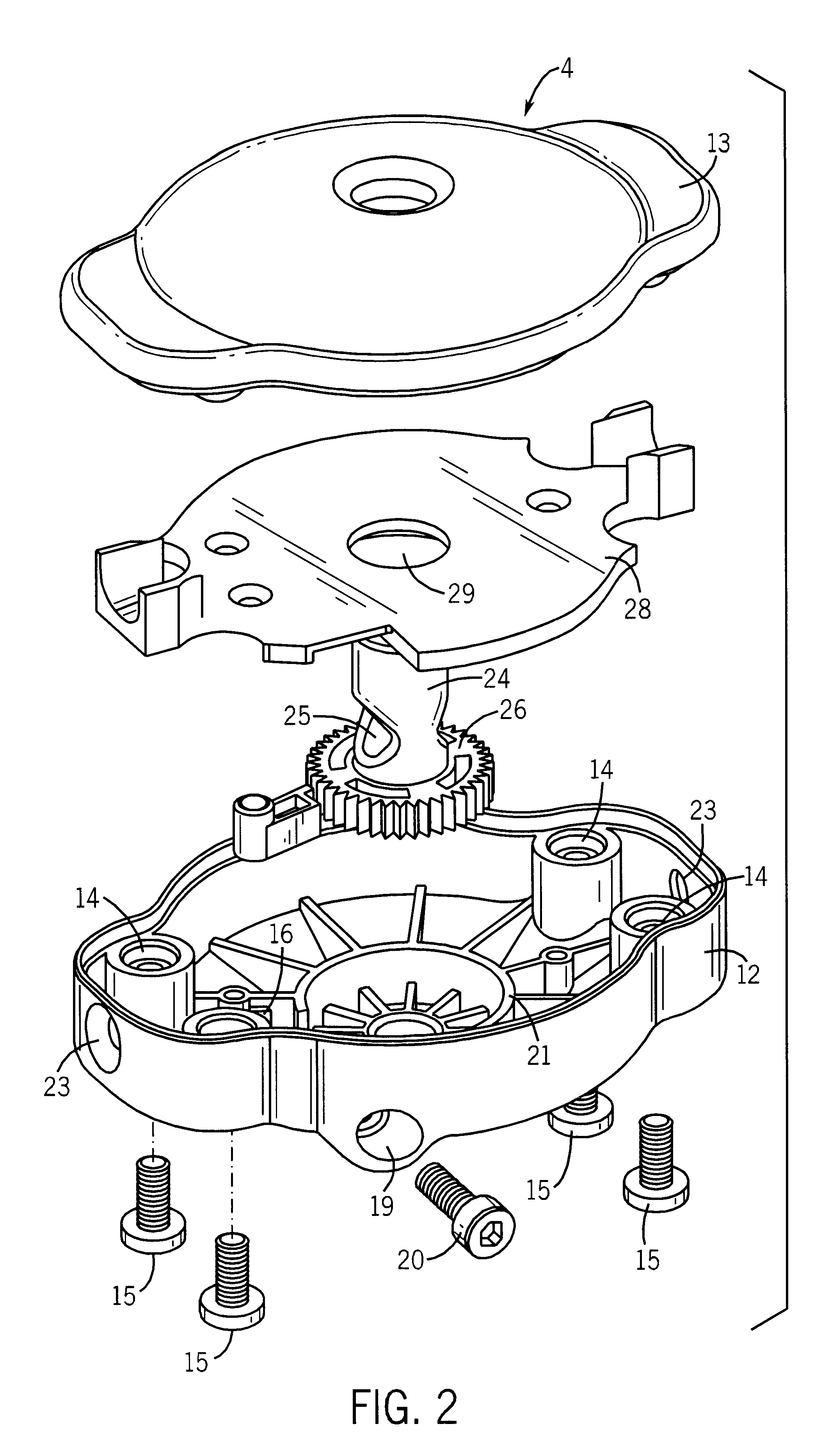

Modified rope tensioner

InactiveUS6705179B1Avoid unwindingQuick effectControlling membersContact mechanismsScrew threadEngineering

A rope tensioner sets the tension of a rope operated switch assembly actuable to switch between first and second conditions on a change in tension of the rope. The tensioner comprises a body, a rotatable member which engages the rope, a shaft for rotating the member relative to the body to adjust tension in the rope by winding the rope around the member, and a lock to lock the member in position relative to the body. The rope opperated switch assembly is much simpler to install than previous assemblies, as the tensioner may be simply threaded or otherwise installed onto the rope without the rope having to be cut.

Owner:ROCKWELL AUTOMATION

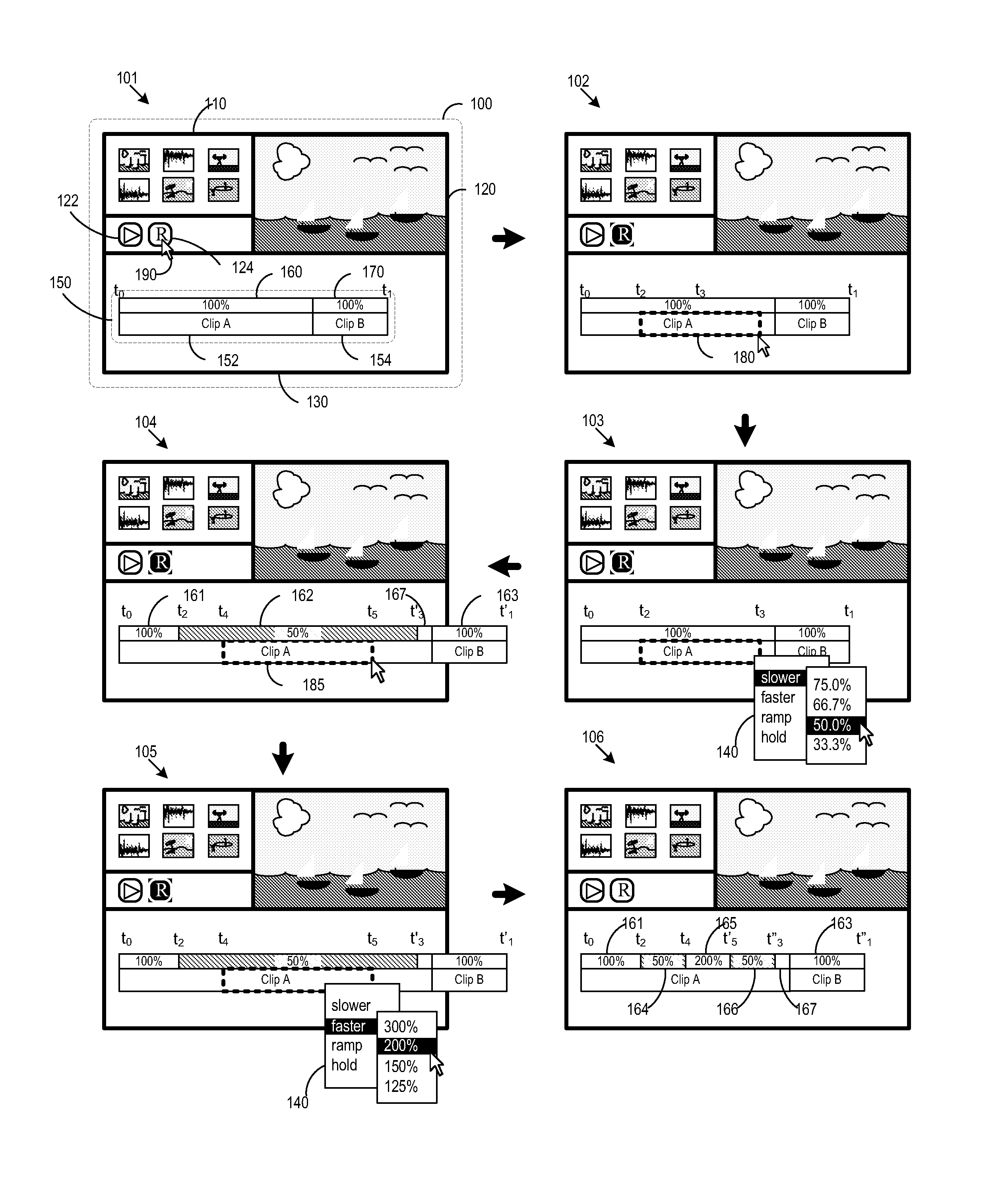

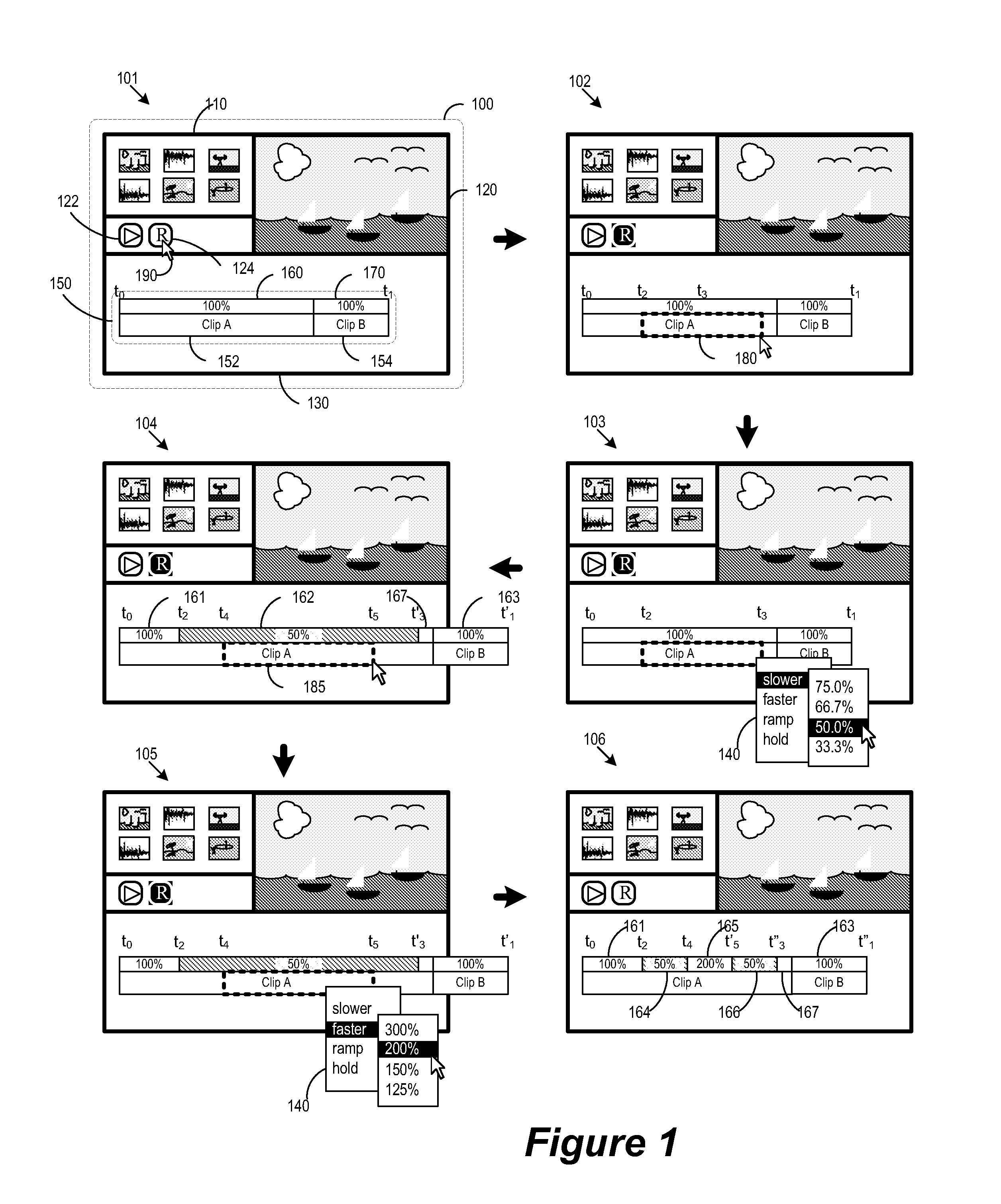

Retiming media presentations

ActiveUS20120210228A1Quick effectFaster rateVideo data browsing/visualisationElectronic editing digitised analogue information signalsComputer graphics (images)Slow speed

A novel method for retiming a portion of a media content (e.g., audio data, video data, audio and video data, etc.) in a media-editing application is provided. The media editing application includes a user interface for defining a range in order to select a portion of the media content. The media editing application performs retiming by applying a speed effect to the portion of the media content selected by the defined range. For a faster speed effect, the media editing application retimes the selected portion of the media content by sampling the media content at a faster rate. For a slower speed effect, the media editing application retimes the selected portion of the media content by sampling the content at a slower rate.

Owner:APPLE INC

Activin-actrii antagonists and uses for increasing red blood cell levels

ActiveUS20090163417A1Reduce expressionIncrease redCompound screeningApoptosis detectionPrimateRed Cell

In certain aspects, the present invention provides compositions and methods for increasing red blood cell and / or hemoglobin levels in vertebrates, including rodents and primates, and particularly in humans.

Owner:ACCELERON PHARMA INC

Intradermal delivery of substances

InactiveUS20040073160A1Increase uptakeRapid uptake rateJet injection syringesPeptide/protein ingredientsWhole bodyGrowth hormone

A method for administration of a substance into the dermis of a mammal is disclosed. The method involves administration into the dermis by injection which results in improved systemic absorption relative to that obtained upon subcutaneous administration of the substance. The substance administered may be a growth hormone, a low molecular weight heparin or a dopamine receptor agonist.

Owner:PHARMACIA CORP

Antagonists of activin-actriia and uses for increasing red blood cell levels

ActiveUS20100028331A1Easy to produceReduce expressionPeptide/protein ingredientsAntibody mimetics/scaffoldsPrimateRed Cell

In certain aspects, the present invention provides compositions and methods for increasing red blood cell and / or hemoglobin levels in vertebrates, including rodents and primates, and particularly in humans.

Owner:ACCELERON PHARMA INC

Chinese medicinal preparation for treating cancer and preparation method thereof

ActiveCN102772745AReduce manufacturing costLow recurrence rateAntineoplastic agentsPlant ingredientsBarbed Skullcap HerbMedicinal herbs

The invention relates to a Chinese medicinal preparation for treating cancer, and the Chinese medicinal preparation is prepared from 110 raw material drugs, such as yew, barbed skullcap herb, hairyvein agrimony and laggera pterodonta. The preparation can be oral solution, granules, powder, capsules, electuary and tablets. 110 Chinese medicaments are adopted, and monarch, minister, assistant and guide drugs are reasonably compatible and are comprehensively taken to play the effect of treating both principal and secondary aspect of cancers. The raw material drugs adopted in the Chinese medicinal preparation are common Chinese medicaments, and are low in manufacture cost and small in side effect. The medicament has the advantages of capabilities of effectively strengthening the body immunity and attacking pathogen without hurting a body along with quick response, high curative rate, high heal rate, low relapse rate, treatment of both principal and secondary aspect of cancers, safety and reliability, and can be used for treating various types of cancers, especially lung cancer, gastric cancer, liver cancer, esophagus cancer, pancreatic cancer, cervical cancer and breast cancer.

Owner:卢速江

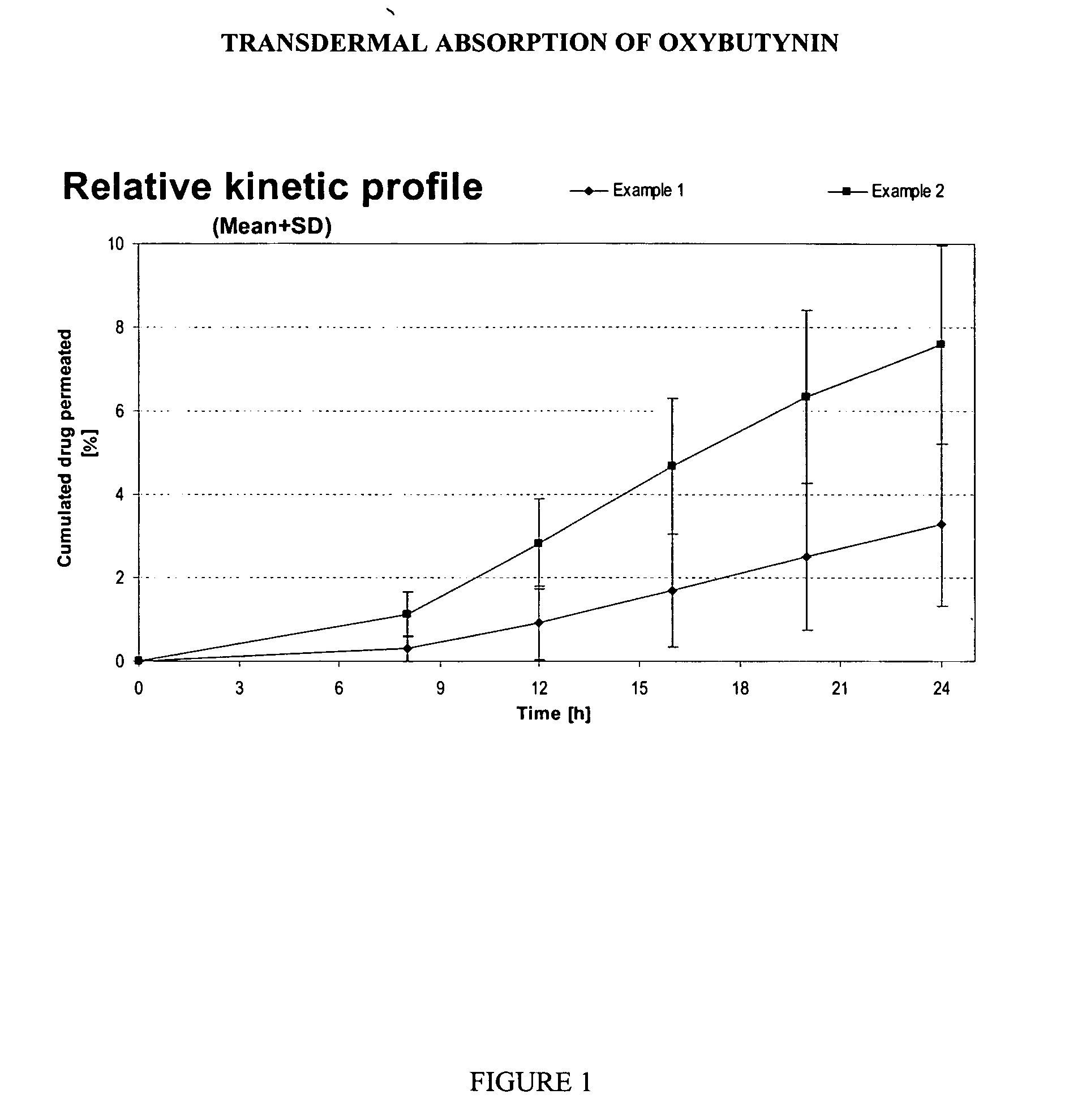

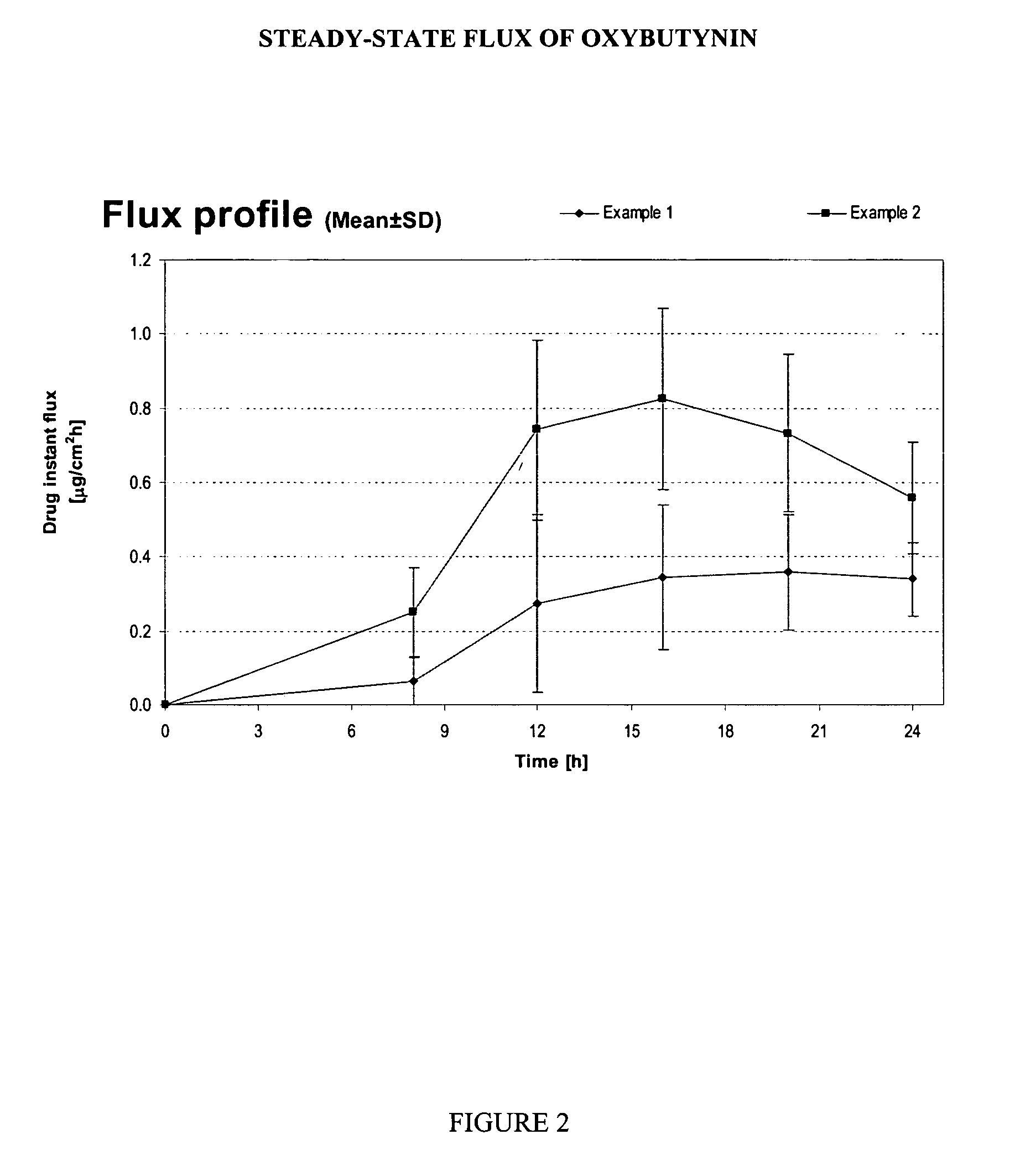

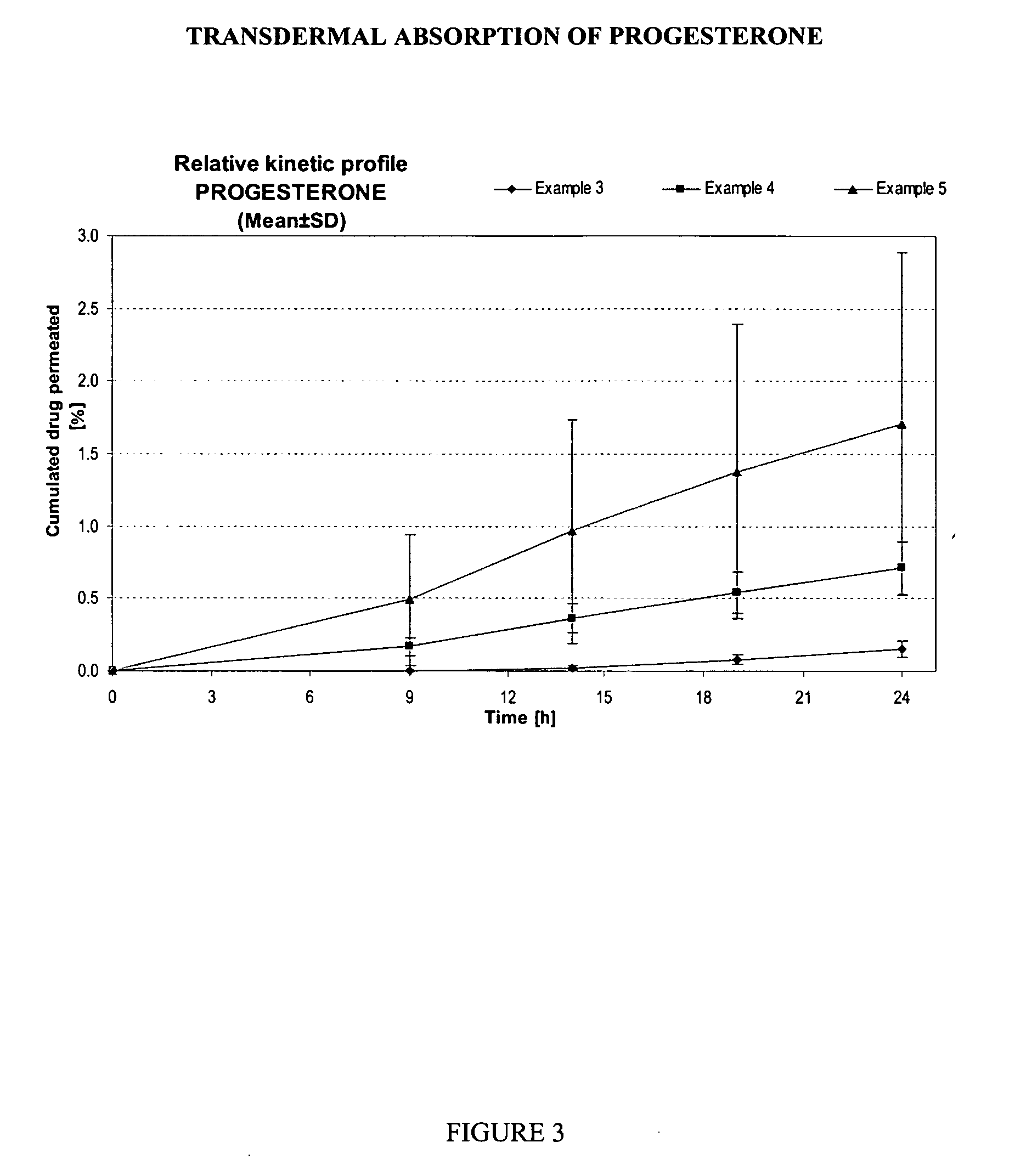

Permeation enhancer comprising genus Curcuma or germacrone for transdermal and topical administration of active agents

InactiveUS20050244522A1Increase permeationImprove permeabilityBiocideOrganic active ingredientsTetraglycolGermacrone

A formulation, method and system for the topical, transdermal or transmucosal administration of a therapeutically effective active agent. Particularly, the invention provides a formulation, system and method for enhancing the permeation or penetration of active agents across the dermal or mucosal surfaces of a mammalian subject. The formulation includes a plant extract of the genus Curcuma of the family Zingiberaceae, a germacrone, or a natural or synthetic constituent thereof, which has been found to increase penetration of the active agent across the dermal or mucosal surface. If desired, a secondary permeation enhancer of a polyalcohol, a monoalkyl ether of diethylene glycol, a tetraglycol, or a mixture thereof can be used for certain active agents for optimal permeation enhancement.

Owner:ANTARES PHARMA IPL

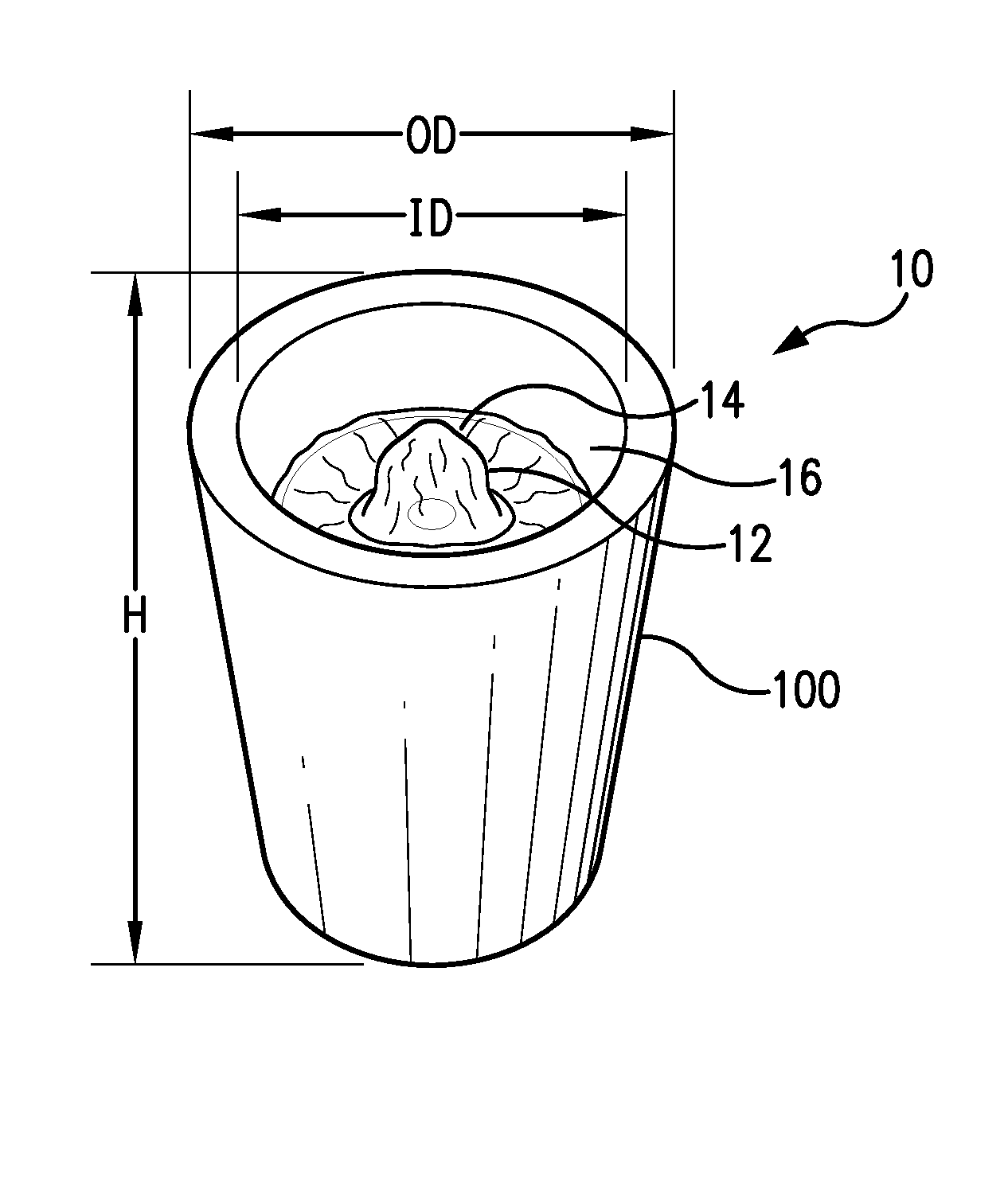

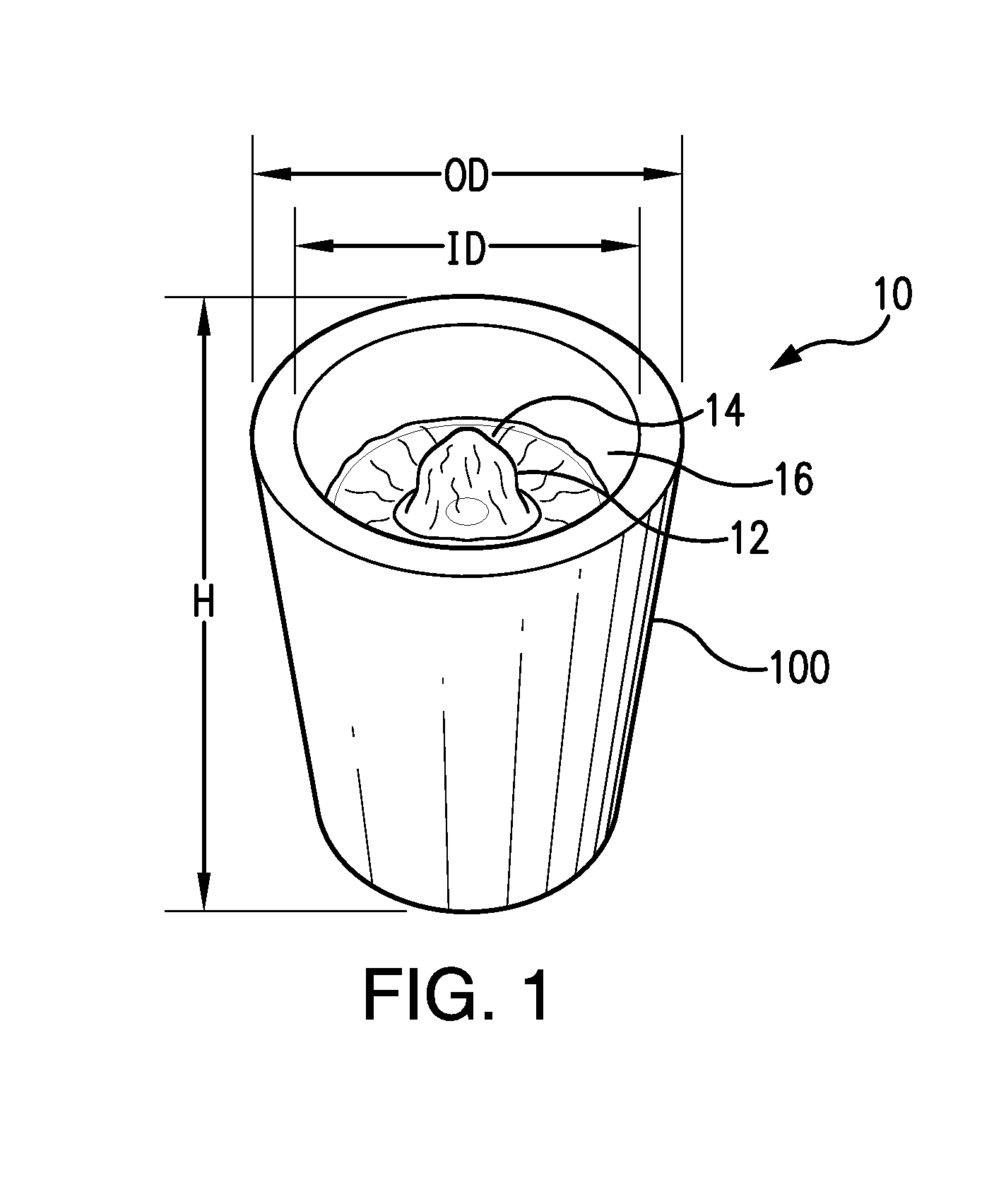

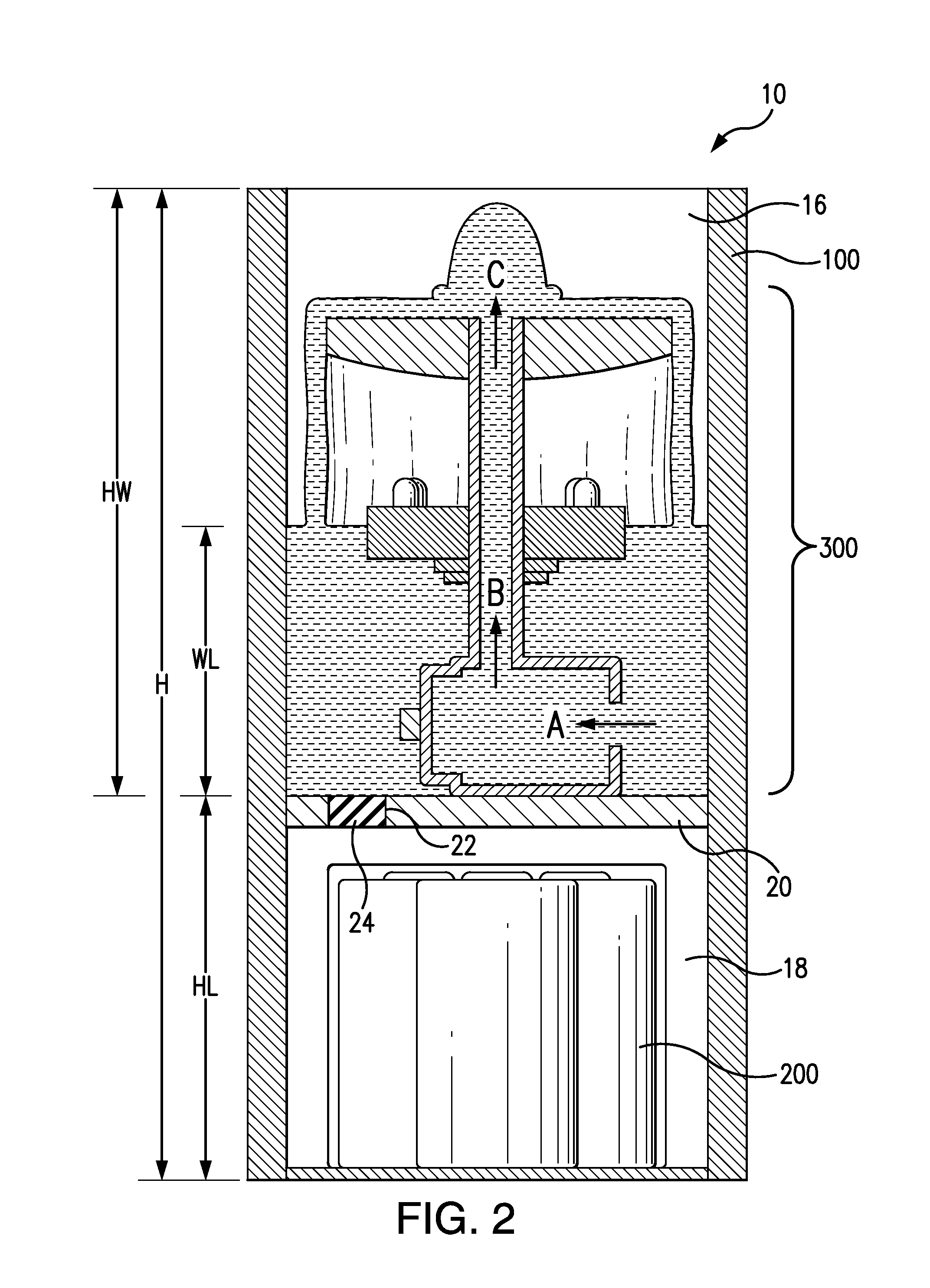

Flameless Candle with Integrated Fountain

ActiveUS20130223043A1Easy to moveReduce sizePoint-like light sourceLighting elementsEngineeringFlameless candles

A decorative display apparatus comprising a flameless candle with an integrated fountain is disclosed. The flameless candle with integrated fountain is designed to be a stand-alone device. The flameless candle with integrated fountain includes a translucent candle body containing a water reservoir to which an optional scent may be added, a power source which may be a battery, USB or DC supply from an AC converter, a pump and an integrated water and light diffuser. The flameless candle with integrated fountain may be operated in either candle-only mode or candle and fountain mode. The device may also be operated on a timer.

Owner:INNOVATIVE FOUNTAINS INC

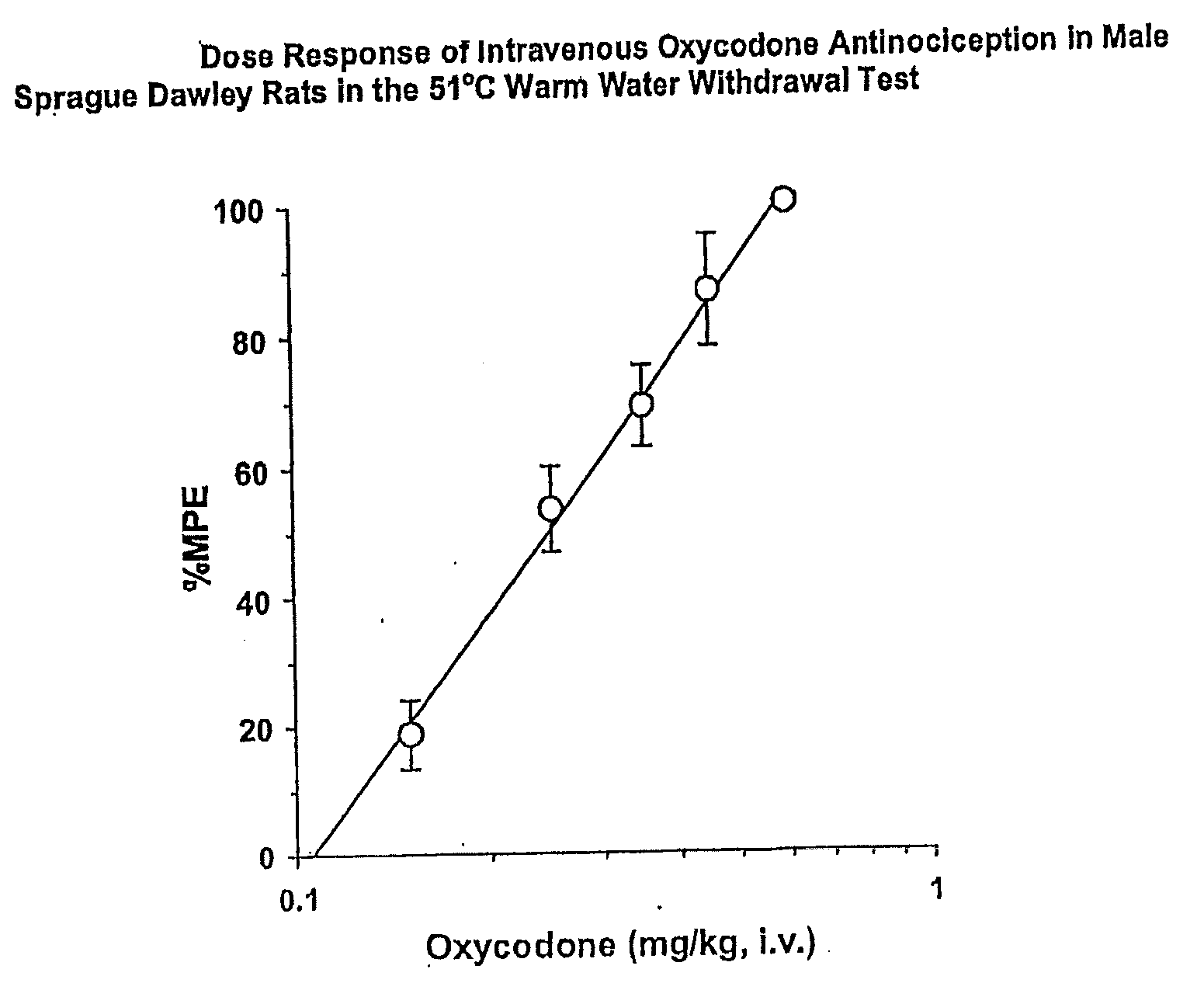

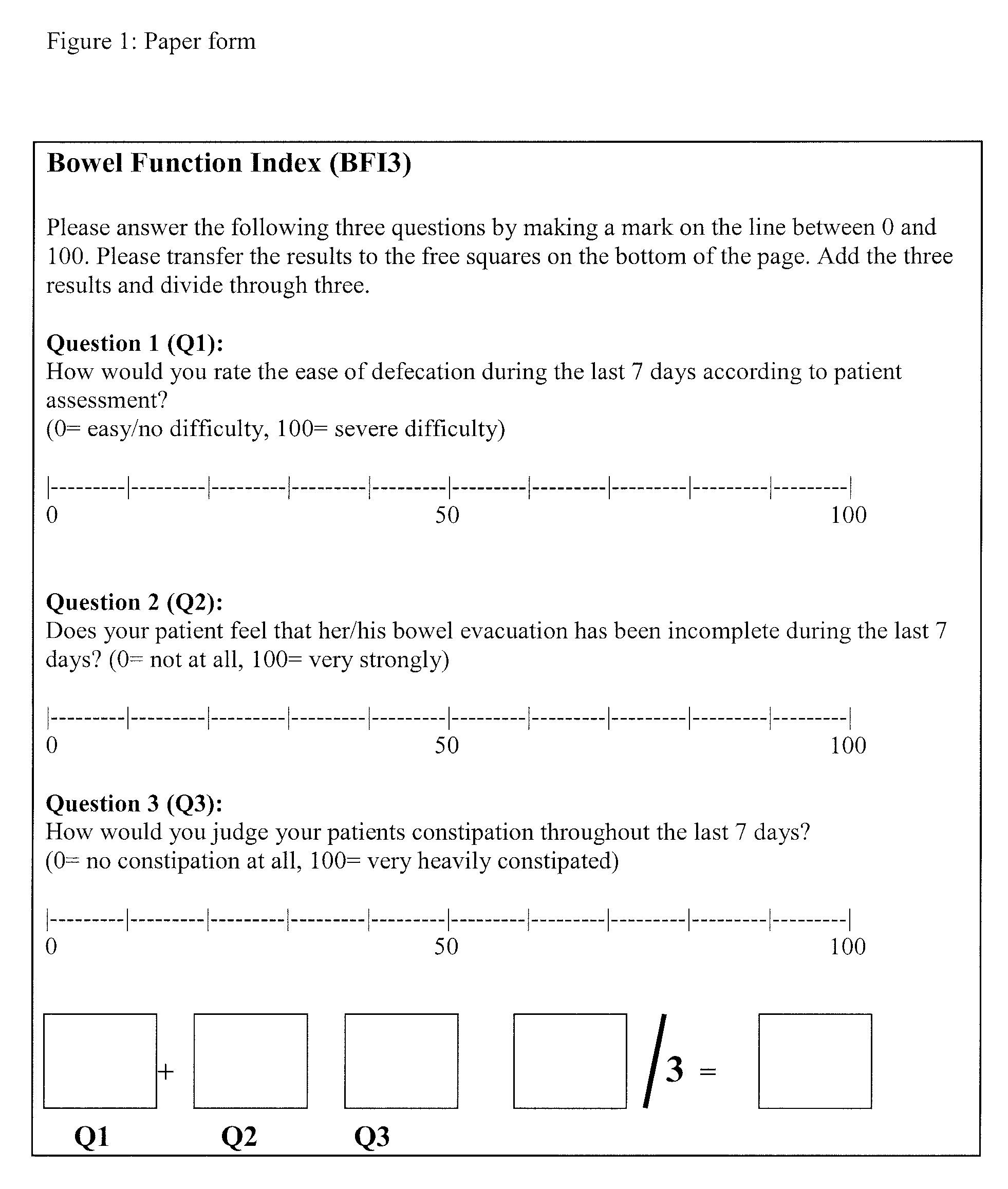

Dosage Form Containing Oxycodone and Naloxone

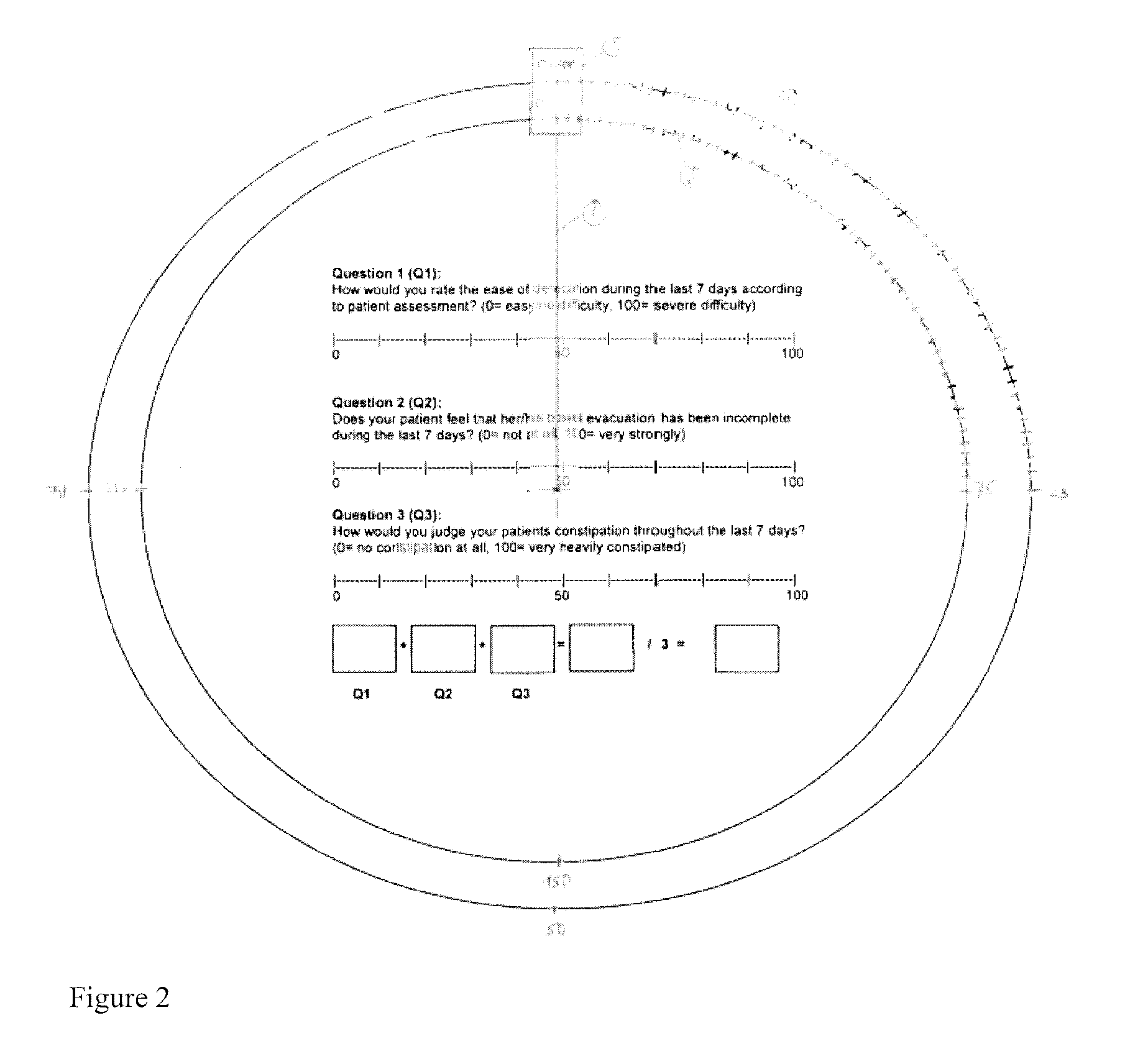

The present invention concerns a dosage form comprising oxycodone and naloxone which is characterized by specific in vivo parameters such as tmax, Cmax, AUCt value, mean bowel function score and / or duration of analgesic efficacy.

Owner:PURDUE PHARMA LP

System and Method for Analyzing Progress of Labor and Preterm Labor

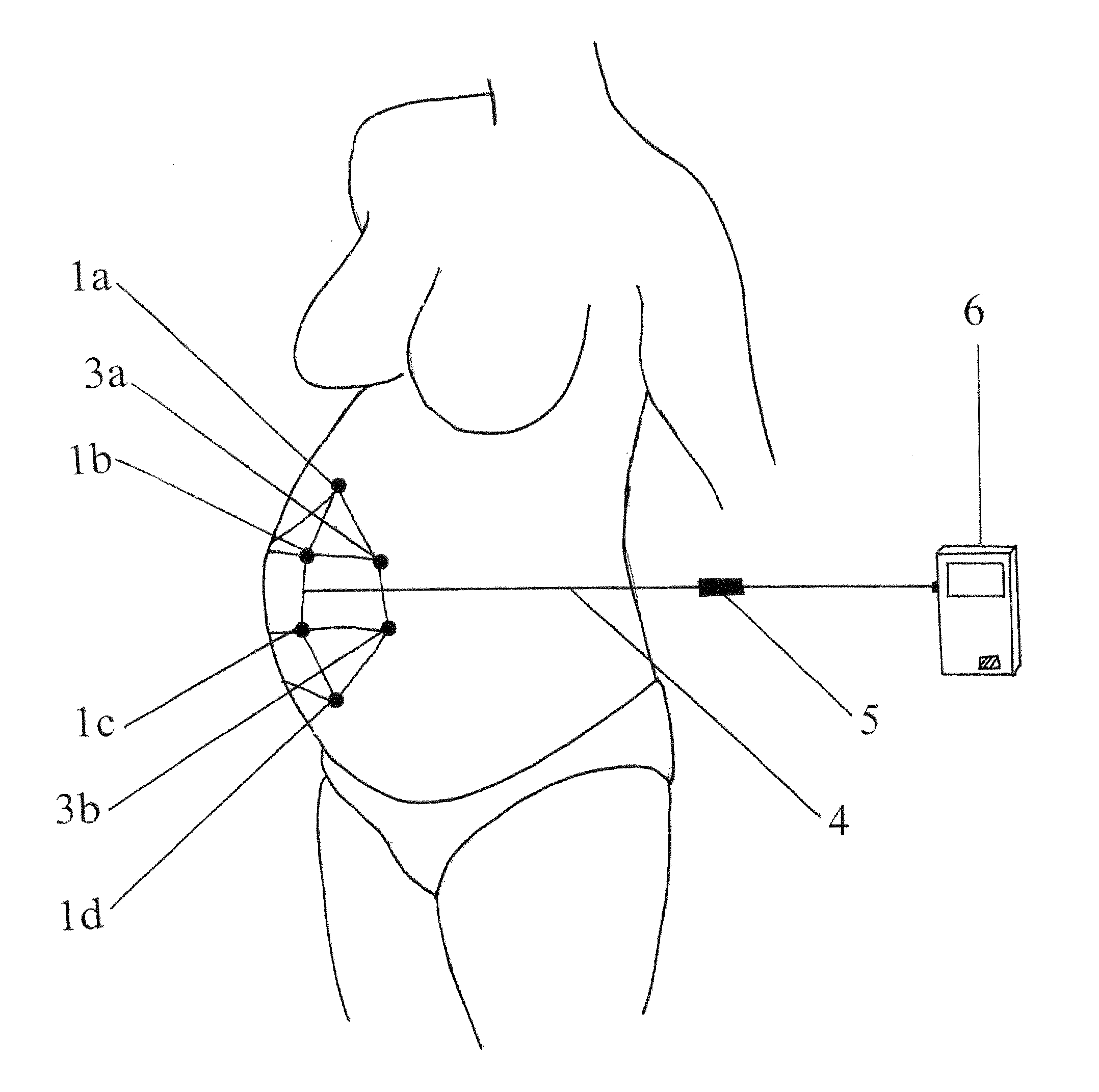

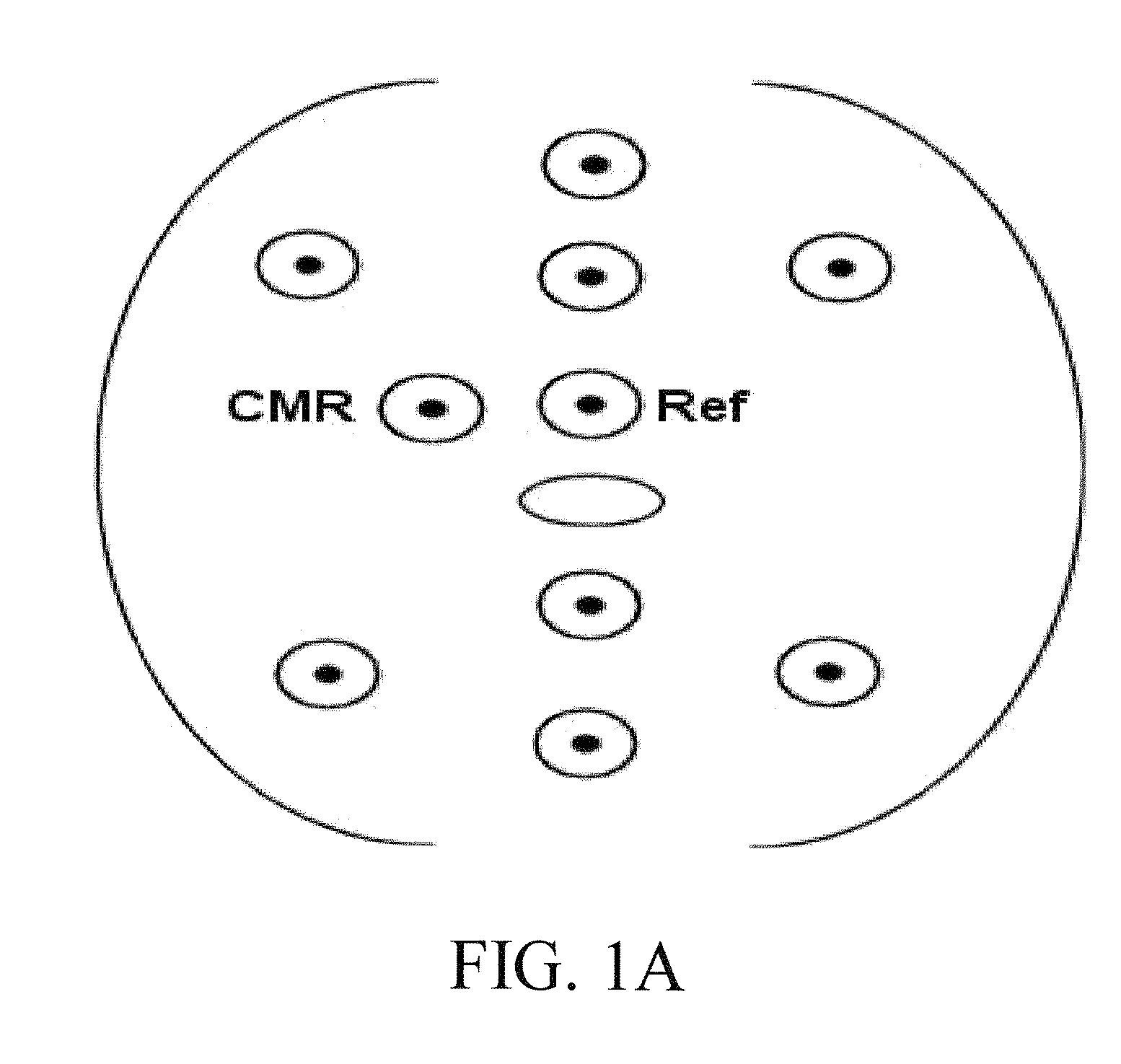

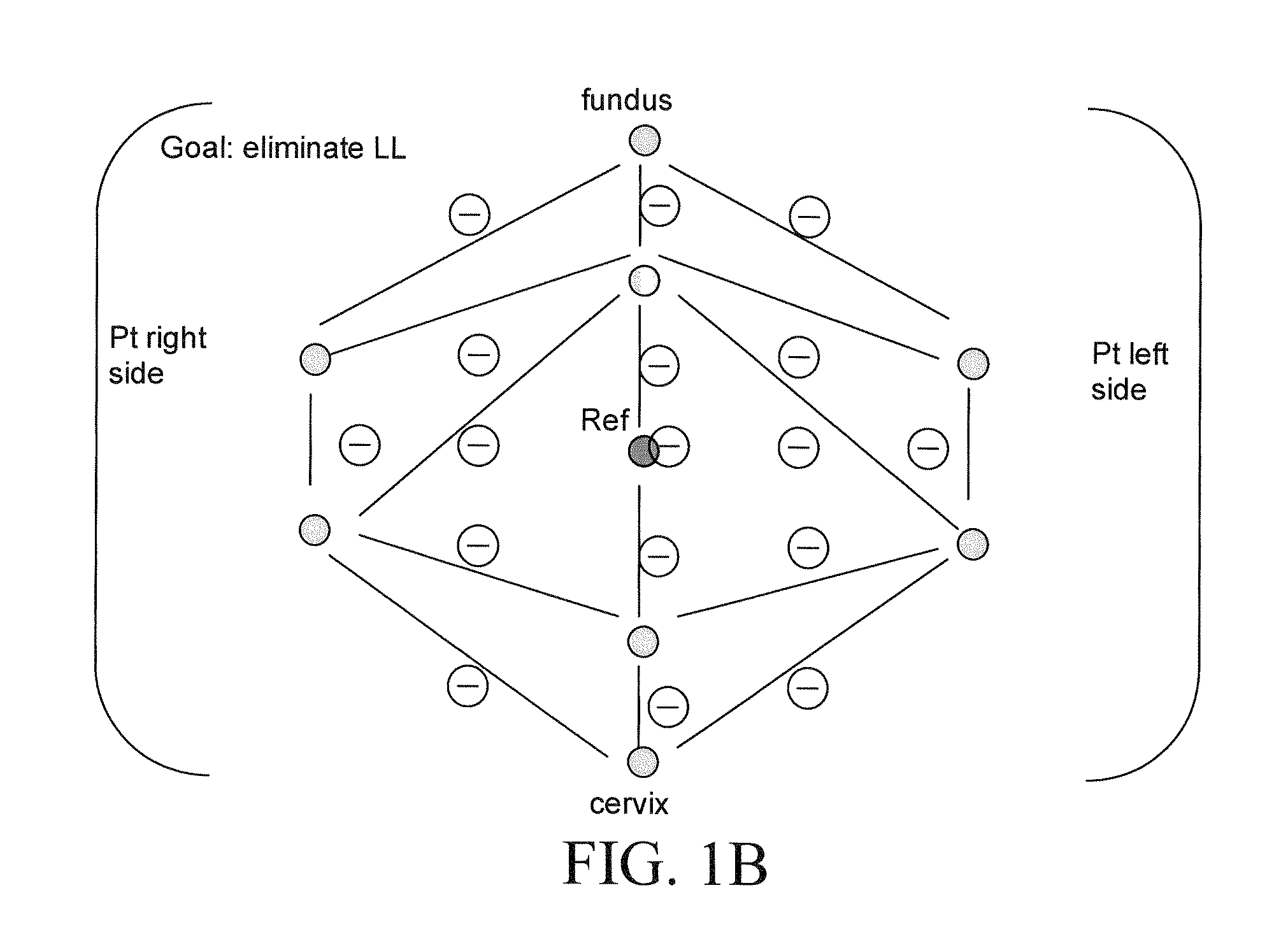

ActiveUS20090299212A1Improve satisfactionAccurate identificationElectromyographyPerson identificationGraphicsNeural network system

Systems and methods for monitoring uterus contraction activity and progress of labor. The system of the subject invention can comprises (1) a plurality of sensors; (2) an amplifying / filtering means; (3) a computing means; and (4) a graphical user interface. Accurate clinical data, which can be extracted and provided to the user in real-time using the system of the invention, include without limitation, progress of labor, prediction and monitoring of preterm labor, and intrauterine pressure prediction. In a preferred embodiment, the system of the invention includes an intelligence means, such as a neural network system, to analyze and interpret clinical data for use in clinical diagnosis as well as delivery strategy.

Owner:UNIV OF FLORIDA RES FOUNDATION INC +1

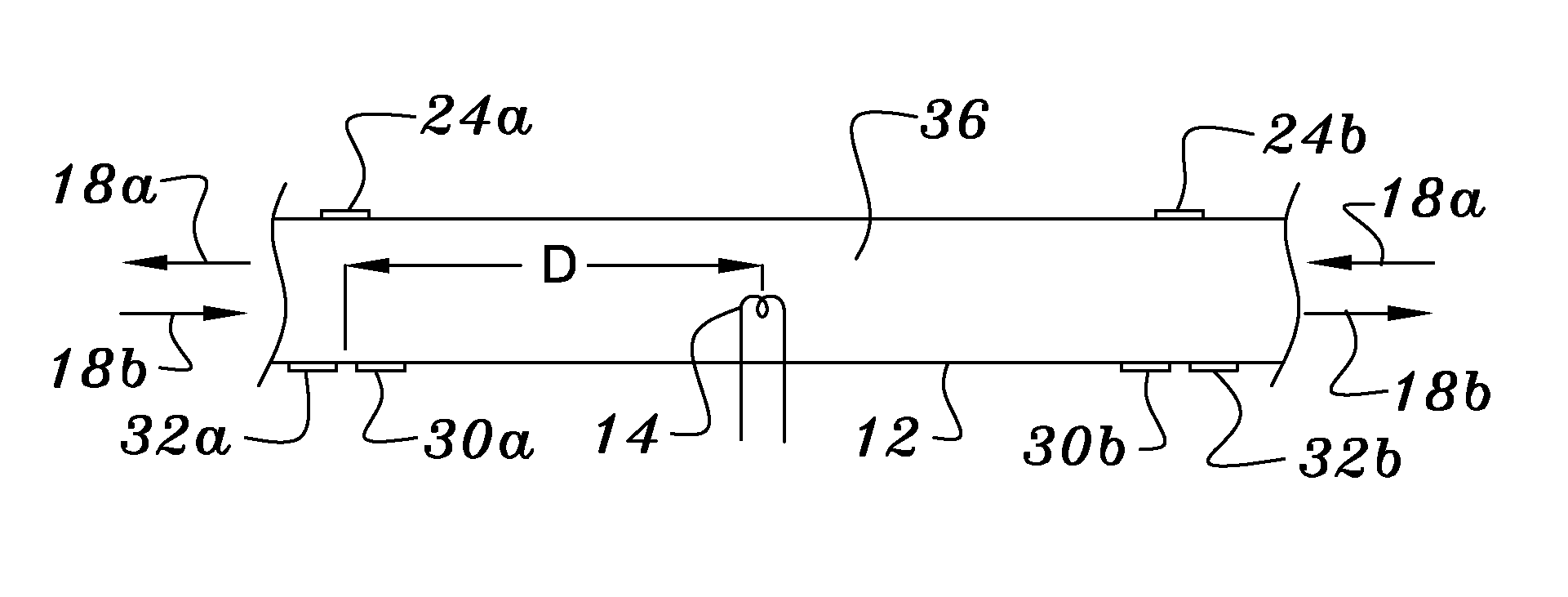

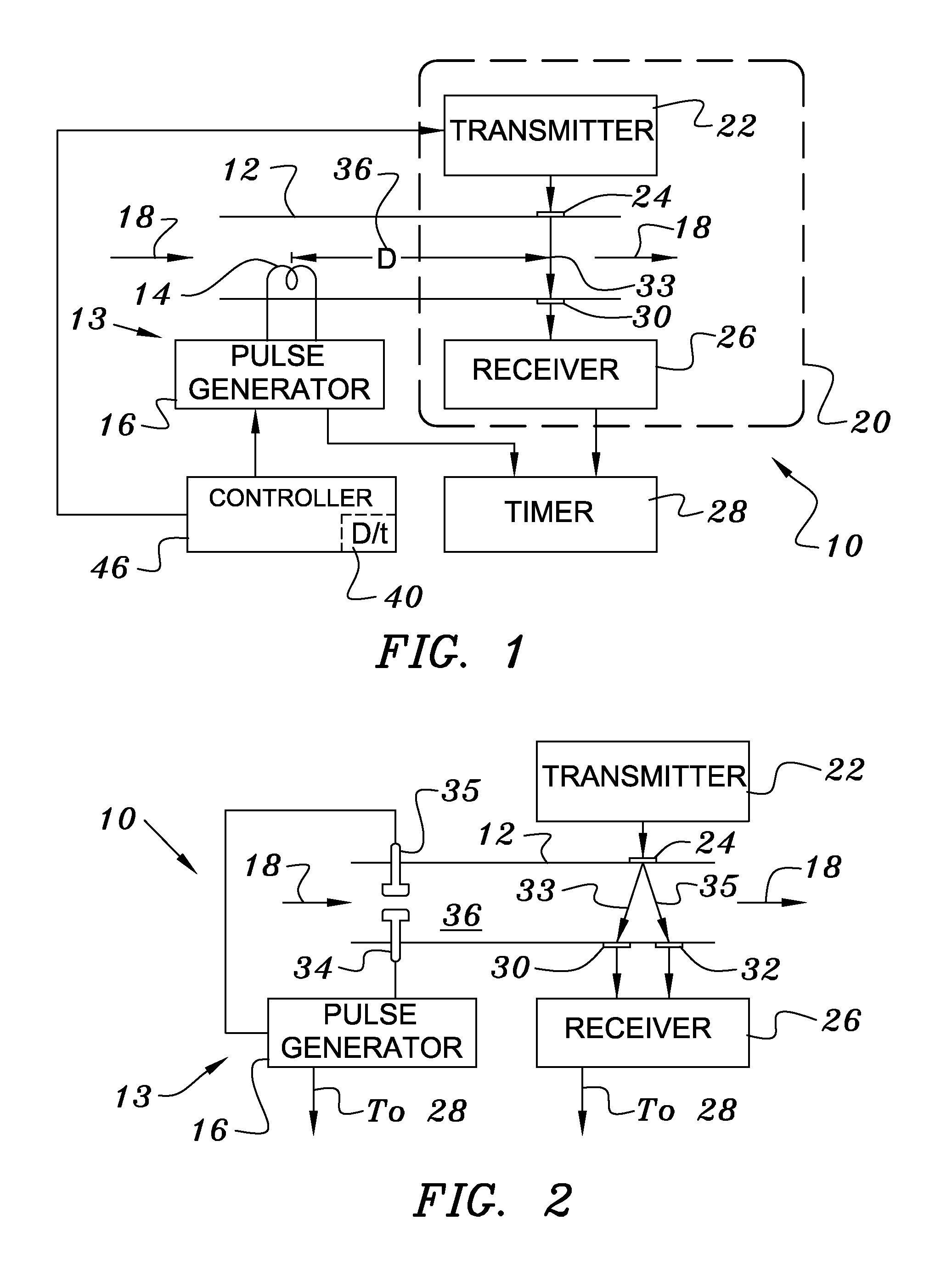

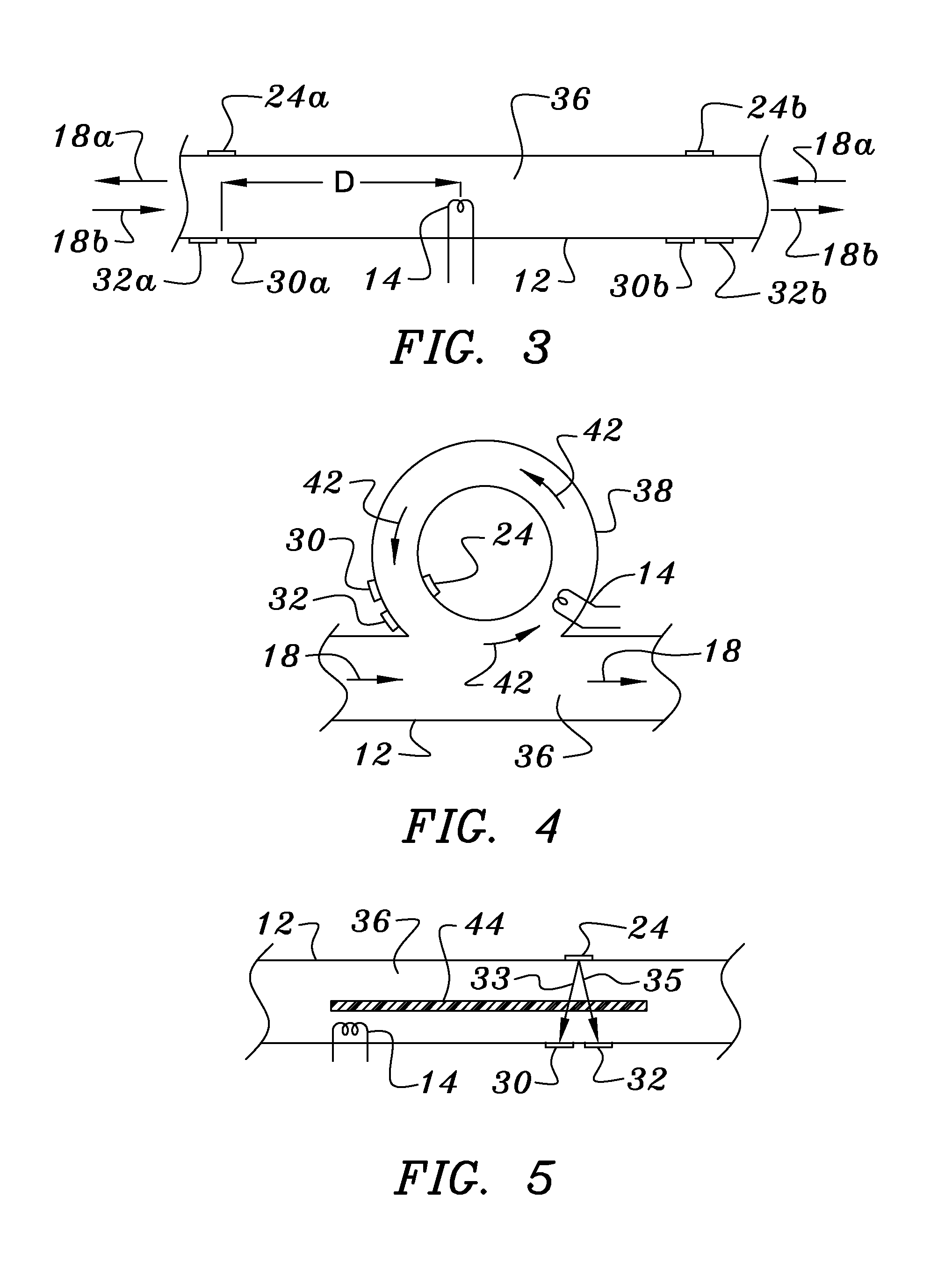

Thermal pulsed ultrasonic flow sensor

InactiveUS7270015B1Practical size limitationSmall sizeVolume/mass flow measurementDiagnostic recording/measuringAcoustic transmissionTransducer

In thermal pulse flow measurements a relatively small bolus of flowing fluid is heated or cooled and the time required for the bolus to move downstream a known distance is measured. In many fluids, changing the temperature changes the acoustic transmission properties of the bolus from those of the rest of the fluid, so the bolus can be detected when it intersects an acoustic beam. The use of an acoustic beam or beams, which are usually defined between acoustic transmitting receiving transducers, typically provides a high frequency carrier which is modulated by the change in acoustic properties of the bolus when it passes between the two transducers. When compared to conventional thermal measurements, this acoustic approach provides faster response times and can thus be used for measuring higher flow rates.

Owner:ONICON INC

Traditional Chinese medicine preparation for treating cancer and preparation method thereof

InactiveCN101670071AReduce manufacturing costLow cure rateAmphibian material medical ingredientsAnthropod material medical ingredientsCauses of cancerSide effect

The invention discloses a traditional Chinese medicine preparation for treating cancer, which is prepared by 103 types of bulk drugs such as solidago decurrens, Chinese sage herb, hypericum japonicumand the like. A preparation method of the traditional Chinese medicine preparation comprises the following steps: preparing the bulk drugs into water extract by a conventional method; using the prepared water extract for preparing oral solution by a traditional method; drying the obtained water extraction, then conducting grinding and sieving; taking the throughs for extracting powder, and using the extracted powder for preparing tablets, granules, electuaries or capsules by a traditional method. The preparation method also can be as follows: sieving out the dust of the bulk drugs, conductinggrinding and sieving, taking the throughs, conducting disinfection and sterilization to obtain raw powder, and using the raw powder for preparing tablets, granules, electuaries or capsules by a traditional method. With drugs mixed rationally, the traditional Chinese medicine preparation addresses both the symptoms and root causes of cancer. The bulk drugs are frequently-used common Chinese drugs,have low preparation cost and small side effect, and can effectively enhance own immunity, attack pathogen while do not damage body. The traditional Chinese medicine preparation can cure various typesof cancer, particularly lung cancer, stomach cancer, liver cancer, esophageal cancer, pancreatic cancer, cervical cancer and breast cancer.

Owner:卢速江

Antagonists of activin-actriia and uses for increasing red blood cell levels

ActiveUS8895016B2Reduce expressionIncrease red blood cell and hemoglobin levelPeptide/protein ingredientsAntibody mimetics/scaffoldsPrimateRed blood cell

In certain aspects, the present invention provides compositions and methods for increasing red blood cell and / or hemoglobin levels in vertebrates, including rodents and primates, and particularly in humans.

Owner:ACCELERON PHARMA INC

Enhanced pharmacokinetic profile of intradermally delivered substances

InactiveUS20030073609A1Increase uptakeEnhanced iontophoresisPowder deliveryOrganic active ingredientsWhole bodyGrowth hormone

A method for administration of a substance into the dermis of a mammal is disclosed. The method involves administration into the dermis by injection which results in improved systemic absorption relative to that obtained upon subcutaneous administration of the substance. The substance administered may be a growth hormone, a low molecular weight heparin or a dopamine receptor agonist.

Owner:PHARMACIA CORP

Compositions for improving gastrointestinal nutrient and drug absorption

InactiveUS20080193531A1Promote absorptionQuick effectOrganic active ingredientsHeavy metal active ingredientsNutrientDrug

The present invention provides pharmaceutical compositions and methods for improving the absorption of nutrients and / or drugs in the gastrointestinal tract of a subject. Typically, the pharmaceutical compositions comprise a first agent that increases the pH of the stomach, and one or more agents selected from a pH lowering agent, a vitamin, a mineral, and a drug.

Owner:DRAGTEK CORP

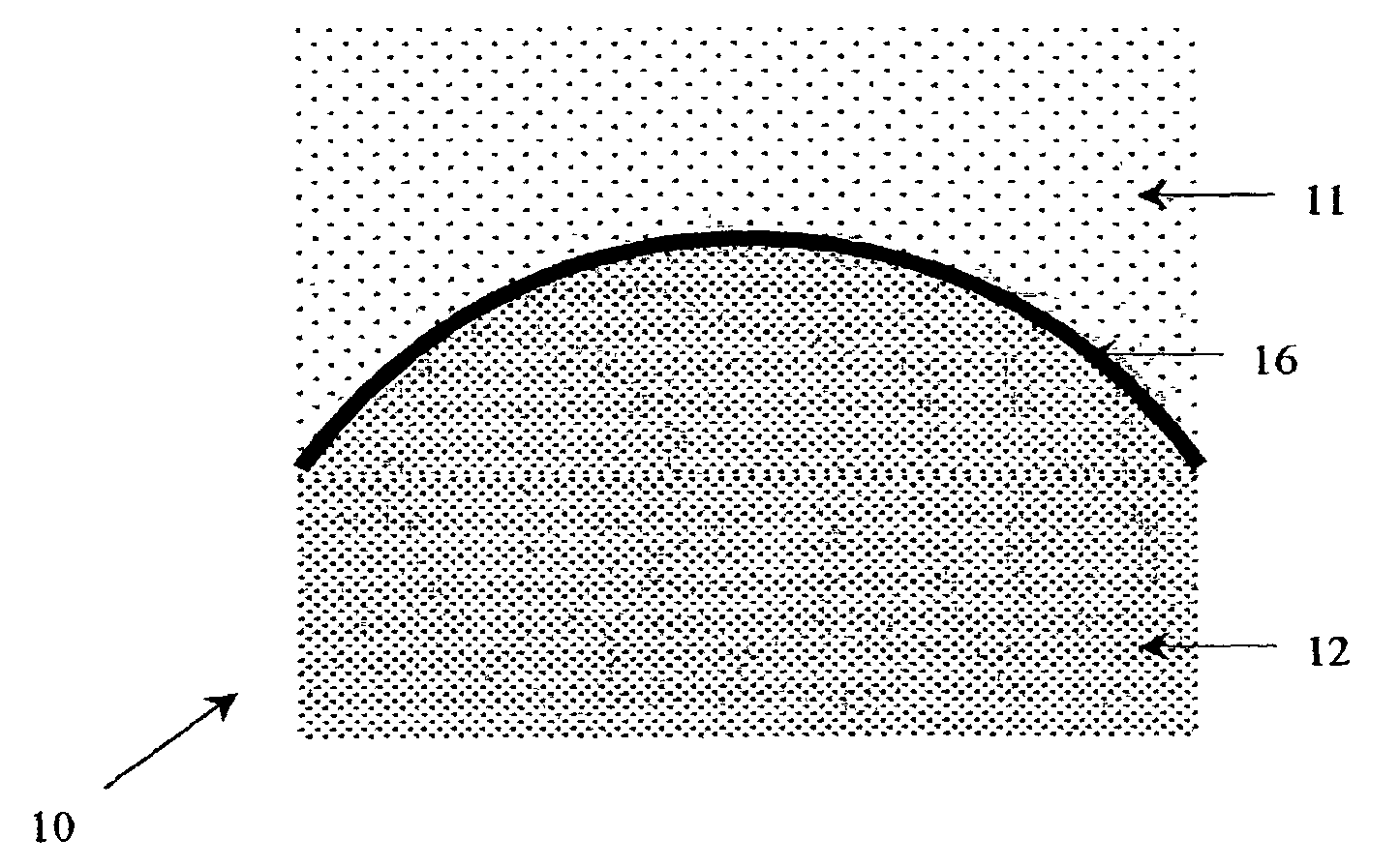

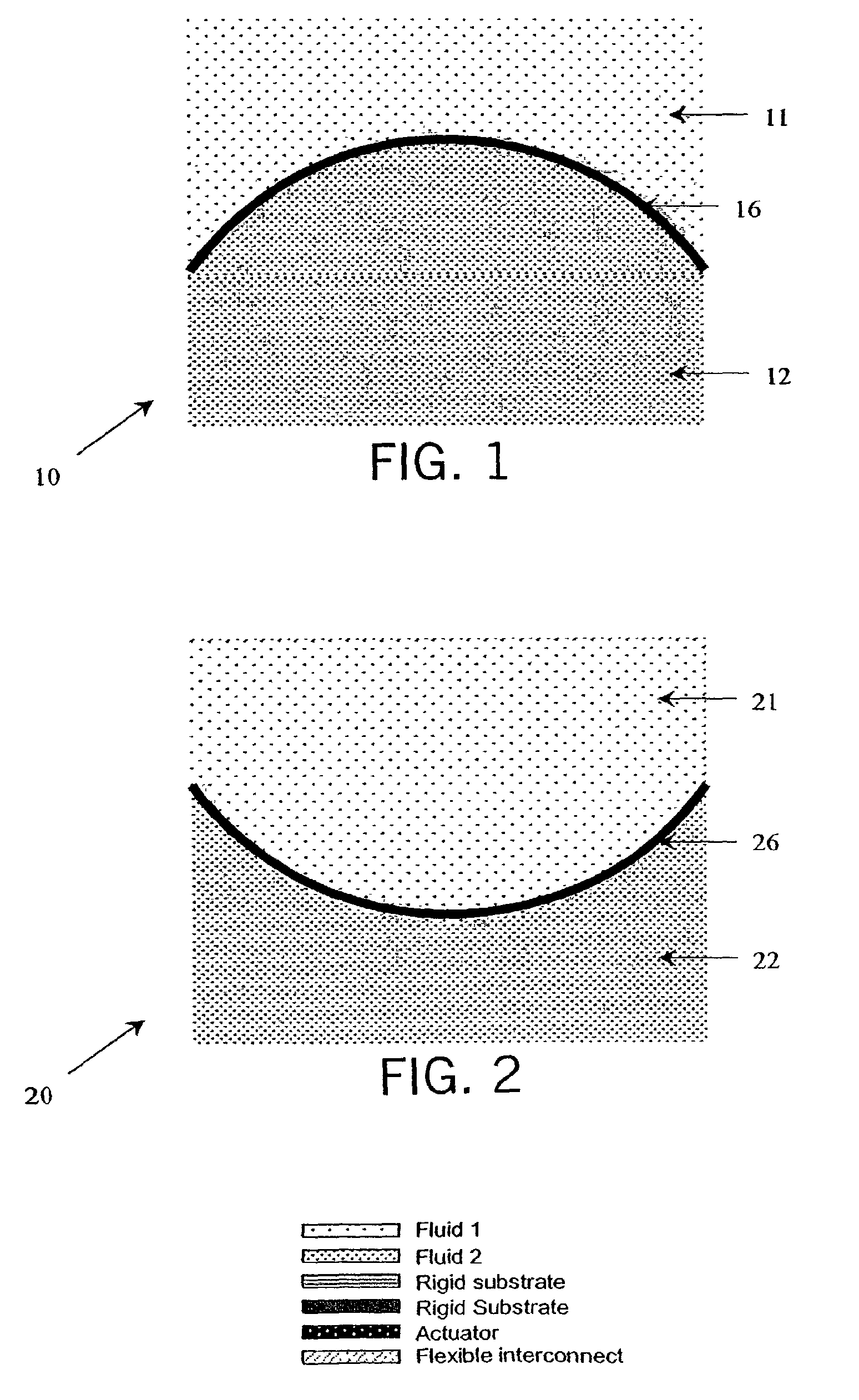

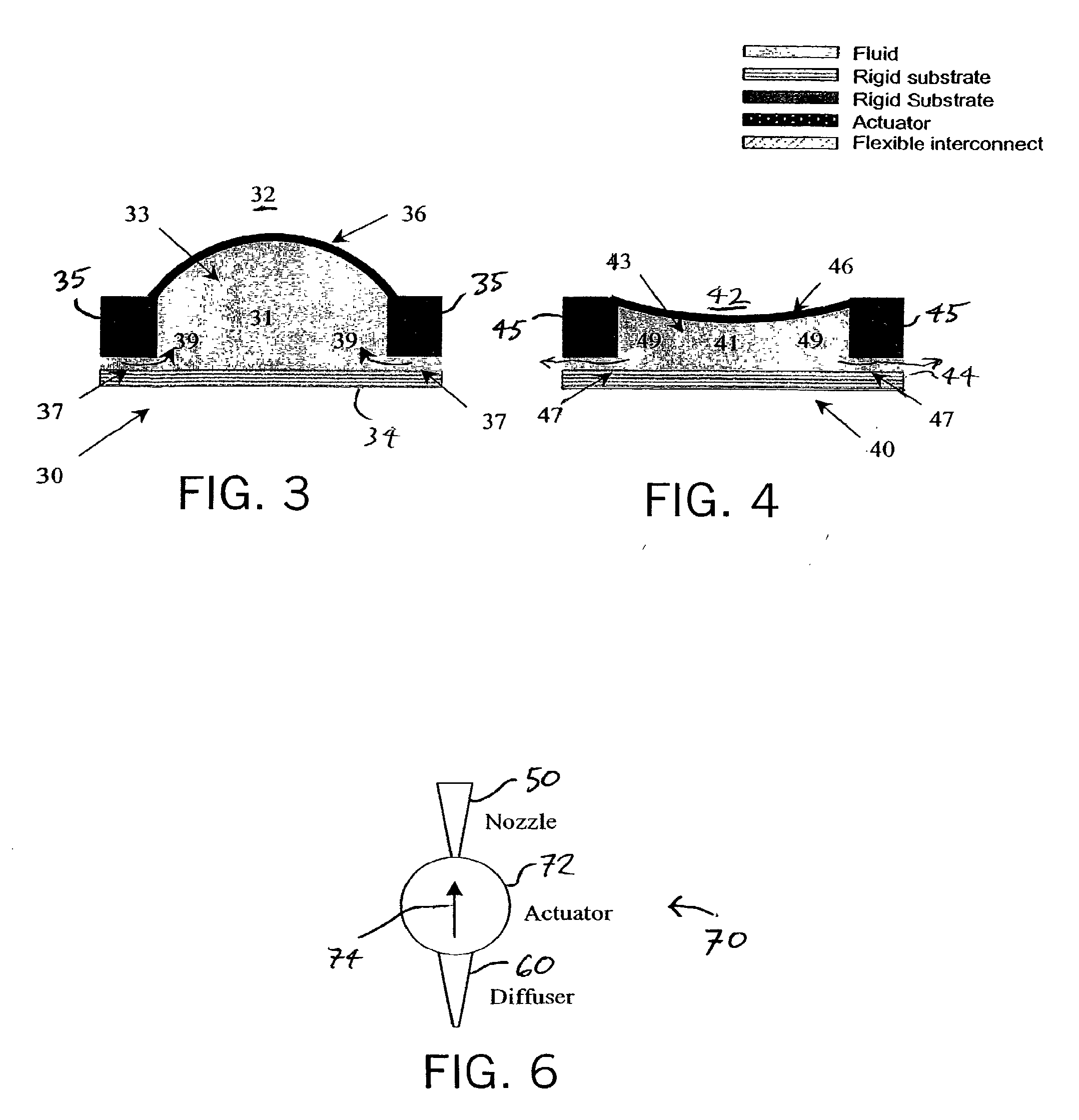

Fluidic Adaptive Lens Systems with Pumping Systems

The present invention in various embodiments relates to a variety of different types of fluidic adaptive lens systems, pumping systems for implementation in such lens systems, other systems employing such lens systems, and related methods of fabrication. In at least some embodiments, the present invention relates to a lens system that includes a reservoir having at least one flexible wall, a first actuator coupled in relation to the reservoir, and a terminal at which is located at least one of an integrated fluidic lens and a port configured to be coupled to an external fluidic lens. The terminal is coupled to at least one of the reservoir and the actuator, and at least one of the actuator and a first pumping system including the actuator is capable of causing fluid to be moved at least one of from the reservoir toward the terminal, and from the terminal toward the reservoir.

Owner:RGT UNIV OF CALIFORNIA +1

Fast coupling structure of waterproof cable connector

InactiveUS20080194137A1Firmly connectedEasy to disassembleElectrically conductive connectionsSecuring/insulating coupling contact membersCouplingSignal on

The invention relates to a fast coupling structure of waterproof cable connector, mainly comprising a male connecting joint and a female connecting joint, both are positioned on the cable end for connection of electric power source or signals on an electric apparatus; the invention enables both of the male and the female connecting joints to have the fast coupling function and the waterproof effects; therefore, a user is able to easily and quickly connect or disassemble the coupling structure.

Owner:KUO KO AN

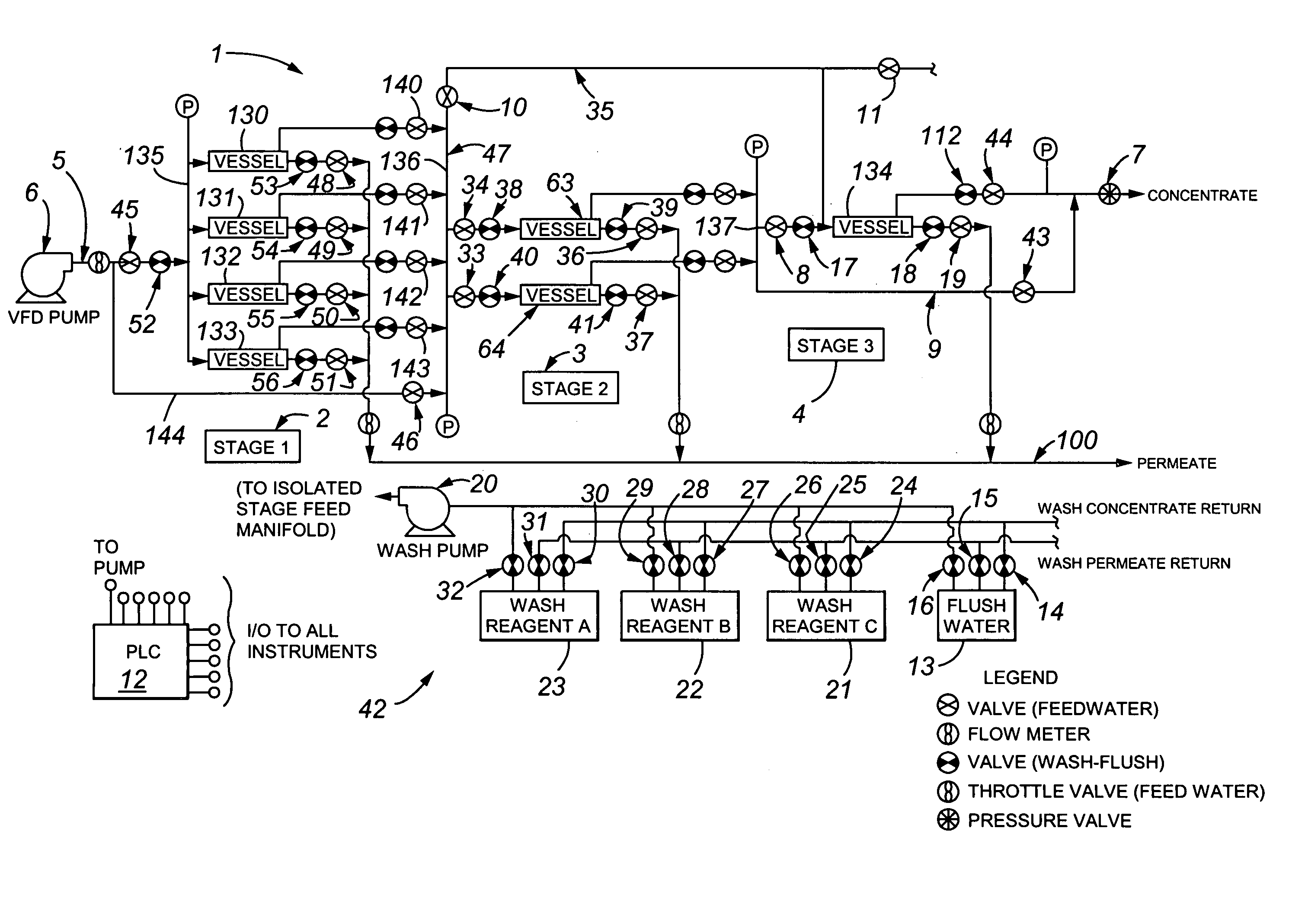

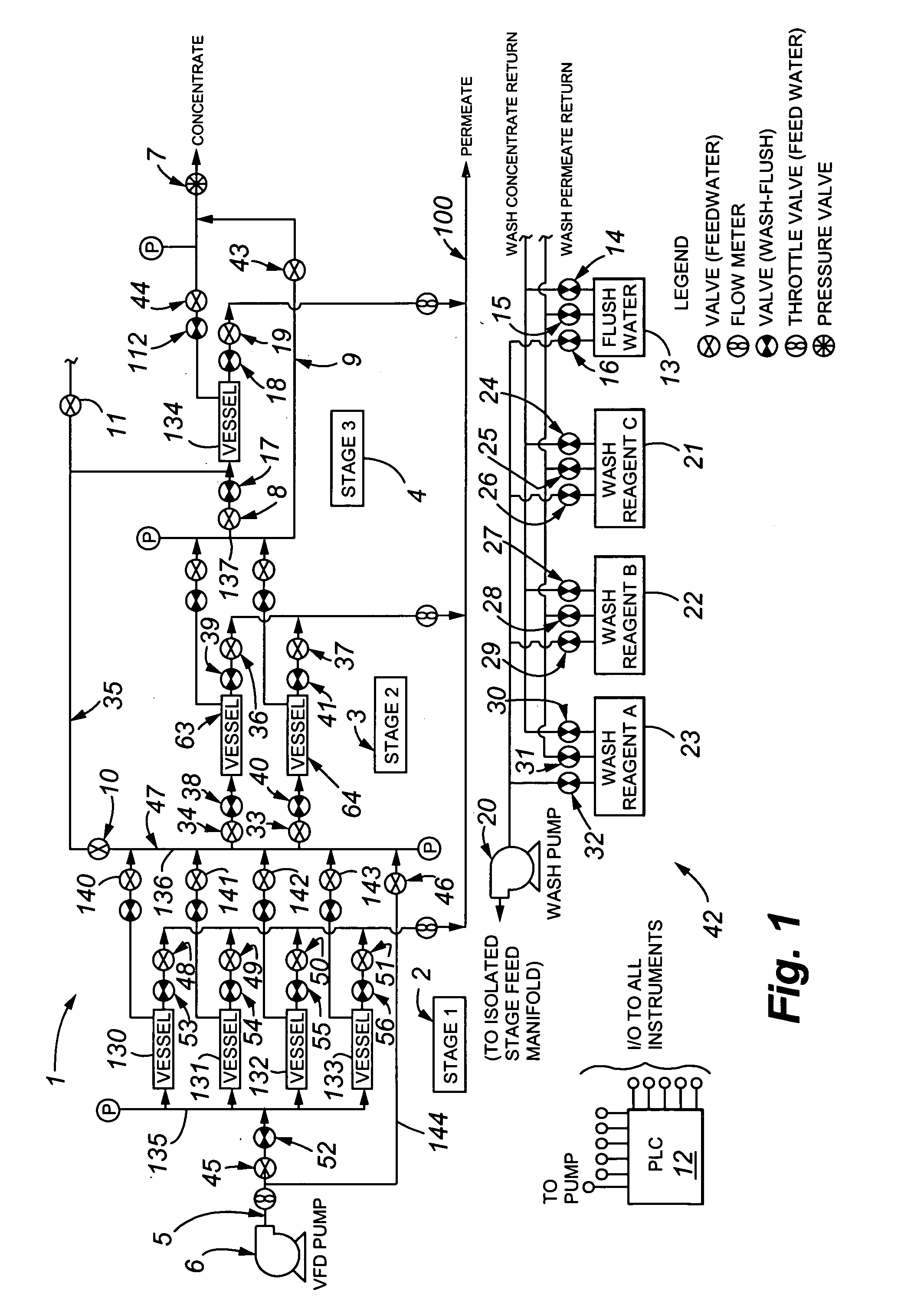

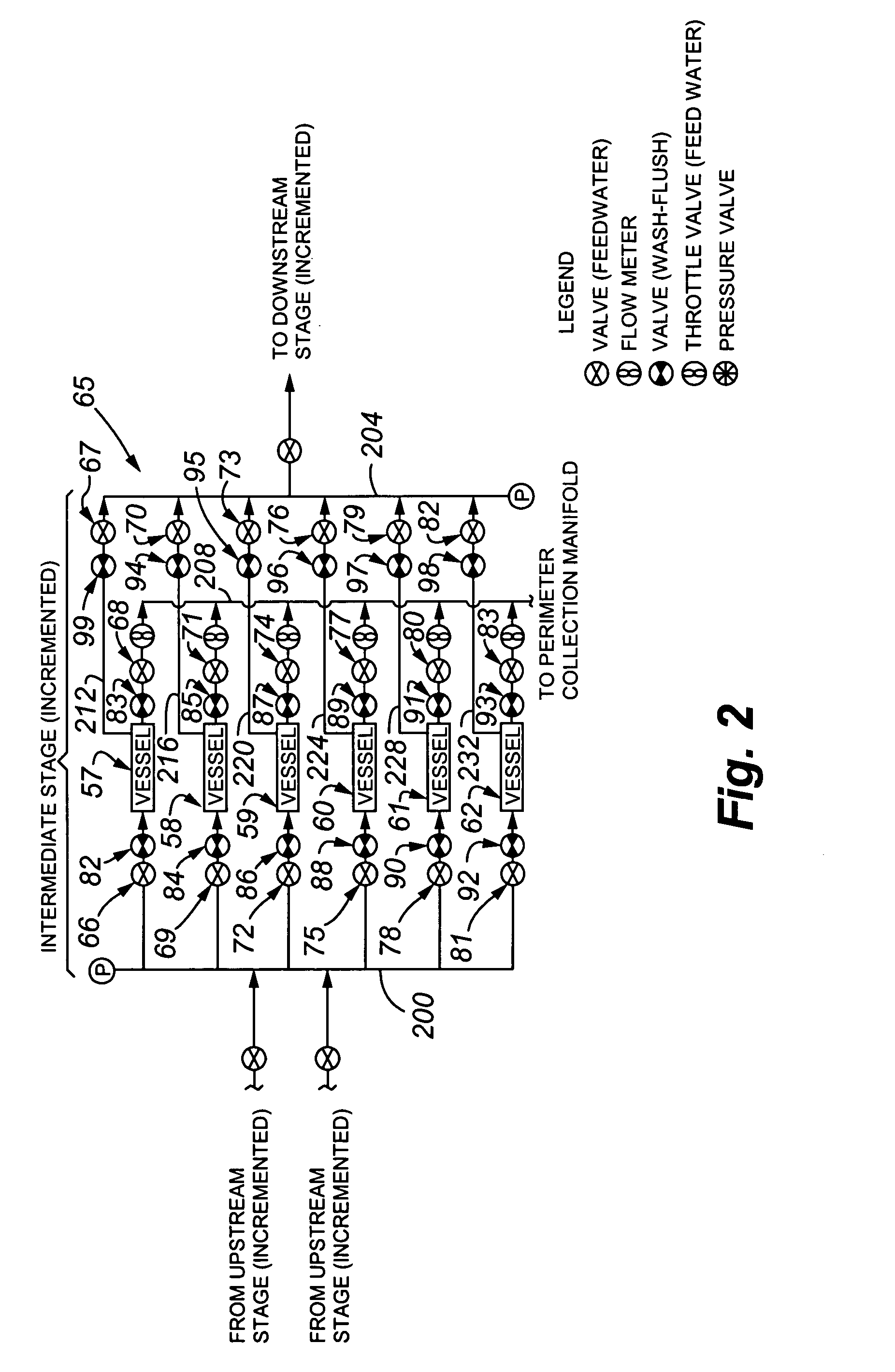

Continuous production membrane water treatment plant and method for operating same

InactiveUS20050067341A1Reduce the impactQuick effectWater treatment parameter controlMembranesWater useProcess logic

A method is provided for the continuous production of treated waters using a staged, tapered array membrane plant by a process of process-logic-controlled (PLC) stage or stage increment isolation and removal from service, washing and return-to-service concurrent with the continued operation of all other stages and / or stage increments of the plant. Specifically, there are plant mounted input / output sensors that supply the PLC with the data required to identify the location and degree of “fouling” of the individual stages or stage increments of a tapered array membrane water treatment plant, where fouling is defined as a loss of water flow through a membrane surface at a given pressure when compared to a water flow standard for the surface. When a stage or stage increment of a plant is defined by this process to be “fouled,” the PLC commands the initiation of a sequence of automated valve openings and closings to a) remove the fouled stage or stage increment from feed water treatment service, b) to flush and wash the stage or stage increment, and c) to return the stage or stage increment to feed water treatment service. Optionally the PLC function can be extended to include the monitoring and control of ancillary valves and a variable-frequency-drive feed water pump to command the parts of a plant that remain on-line during the process of a stage or stage increment wash to continue to produce more, or less, or volumetrically identical amounts of membrane water treatment process permeate by combinations of valve re-settings, pump speed adjustments, and stage-to-stage intermediate water diversion.

Owner:HW PROCESS TECH

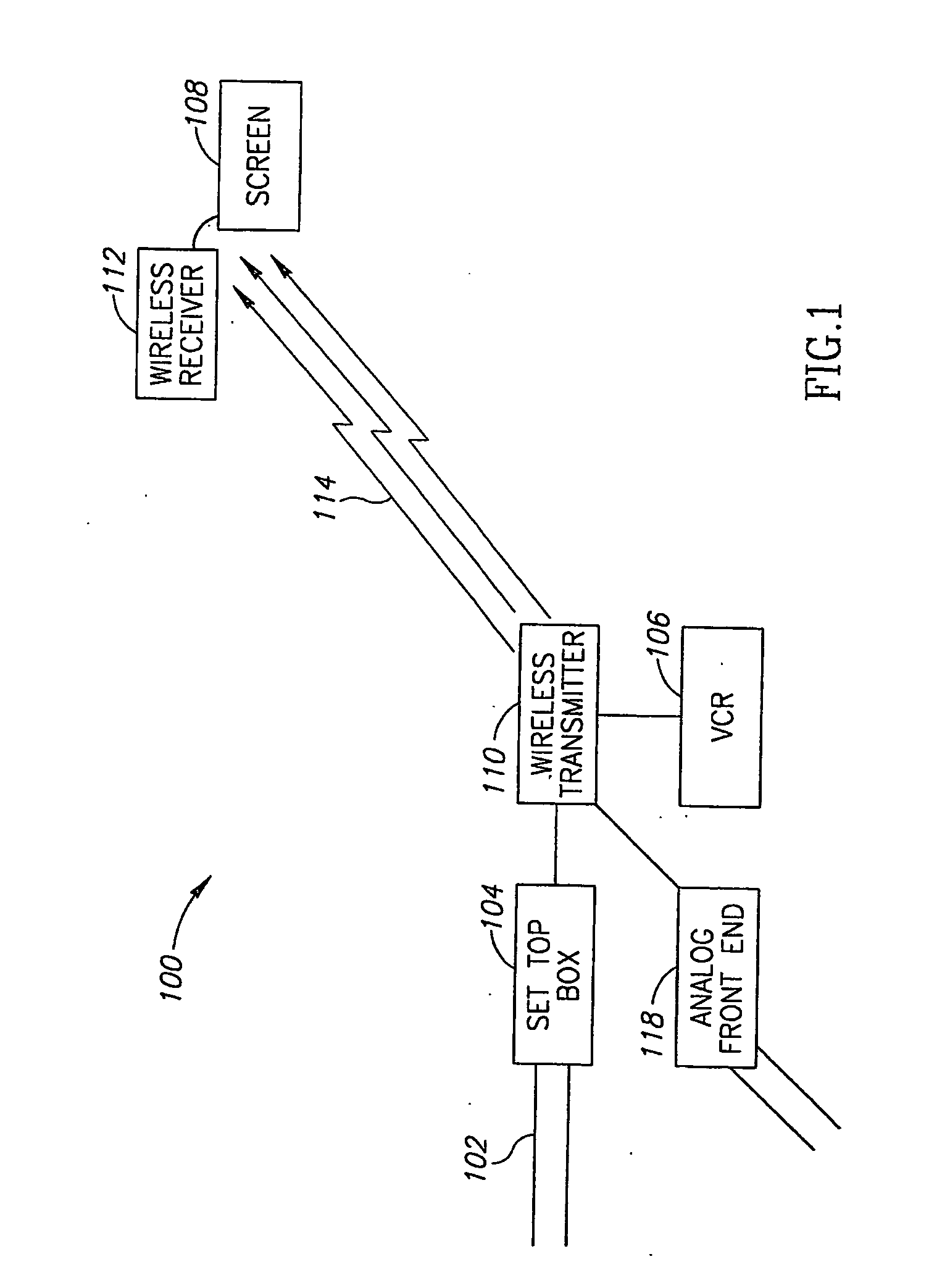

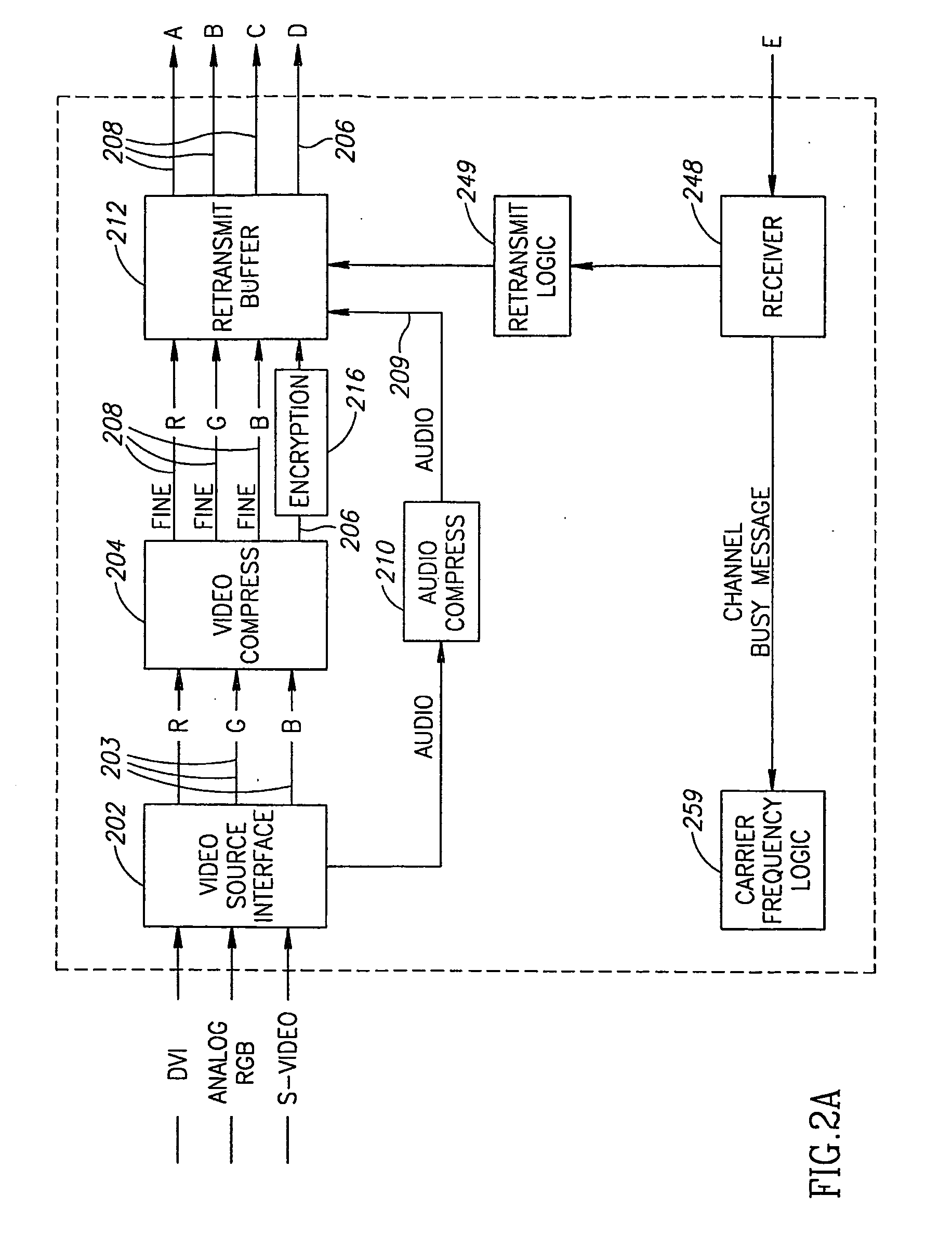

Wireless Transmission of High Quality Video

InactiveUS20080123739A1Simpler compression procedureEasy to compressSpatial transmit diversityPulse modulation television signal transmissionWireless transmissionComputer graphics (images)

A method of transmitting video images. The method includes providing a high definition video stream, compressing the video stream using an image domain compression method, in which each pixel is coded based on a vicinity of the pixel and transmitting the compressed video stream over a fading transmission channel.

Owner:AMIMON

Method and device for reducing therapeutic dosage

InactiveUS20020156453A1Increase uptakeRapid uptake rateAmpoule syringesJet injection syringesBiomedical engineeringBioavailability

Methods and devices for administration of substances into the intradermal layer of skin with improved bioavailability.

Owner:BECTON DICKINSON & CO

Erigeron breviscapus oral caving fast disintegration tablet and its preparation method

InactiveCN1429618AShorten the dissolution timeQuick effectOrganic active ingredientsUnknown materialsErigeron breviscapusActive component

A fast disintegrant tablet using the extract of Erigeron breviscapus as its active components for oral cavity contains the said active component (5-20 wt.%), disintegrant (2-10), lubricant (0.2-2), flowing aid (0.1-1.5), additive (0-0.5) and filter (the rest). The features fast disintegrating speed (60 seconds after it encounters saliva).

Owner:TSINGHUA UNIV

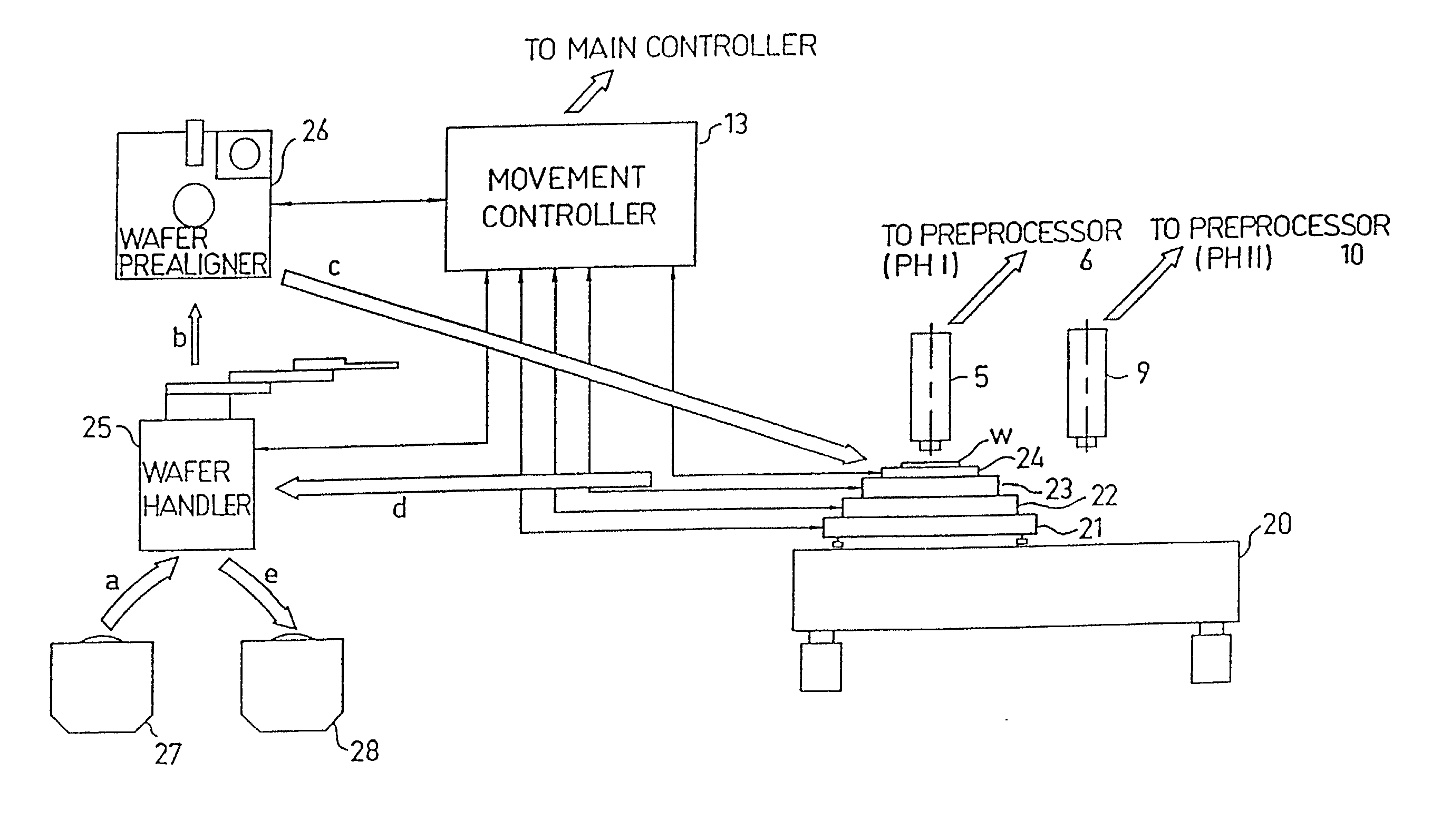

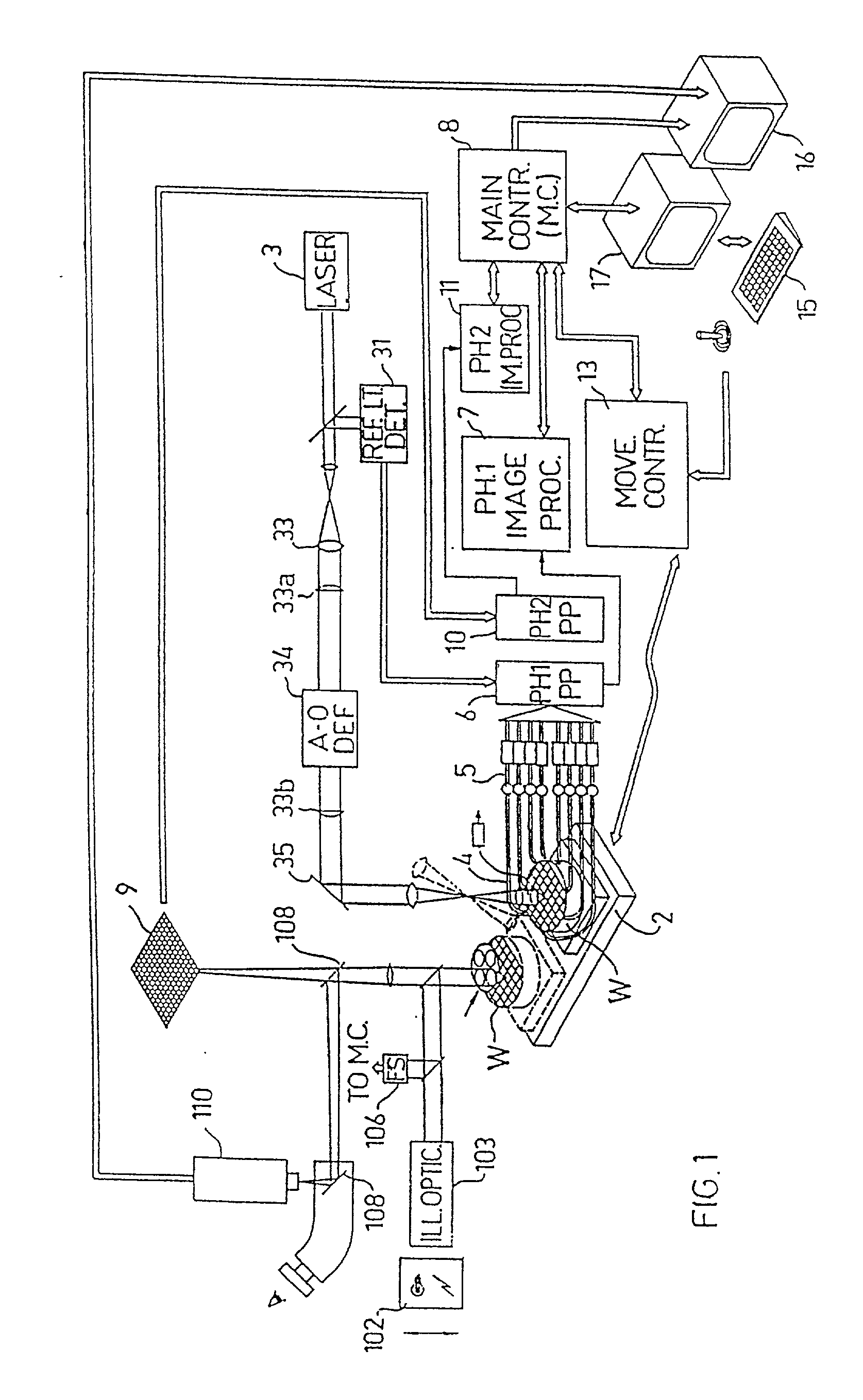

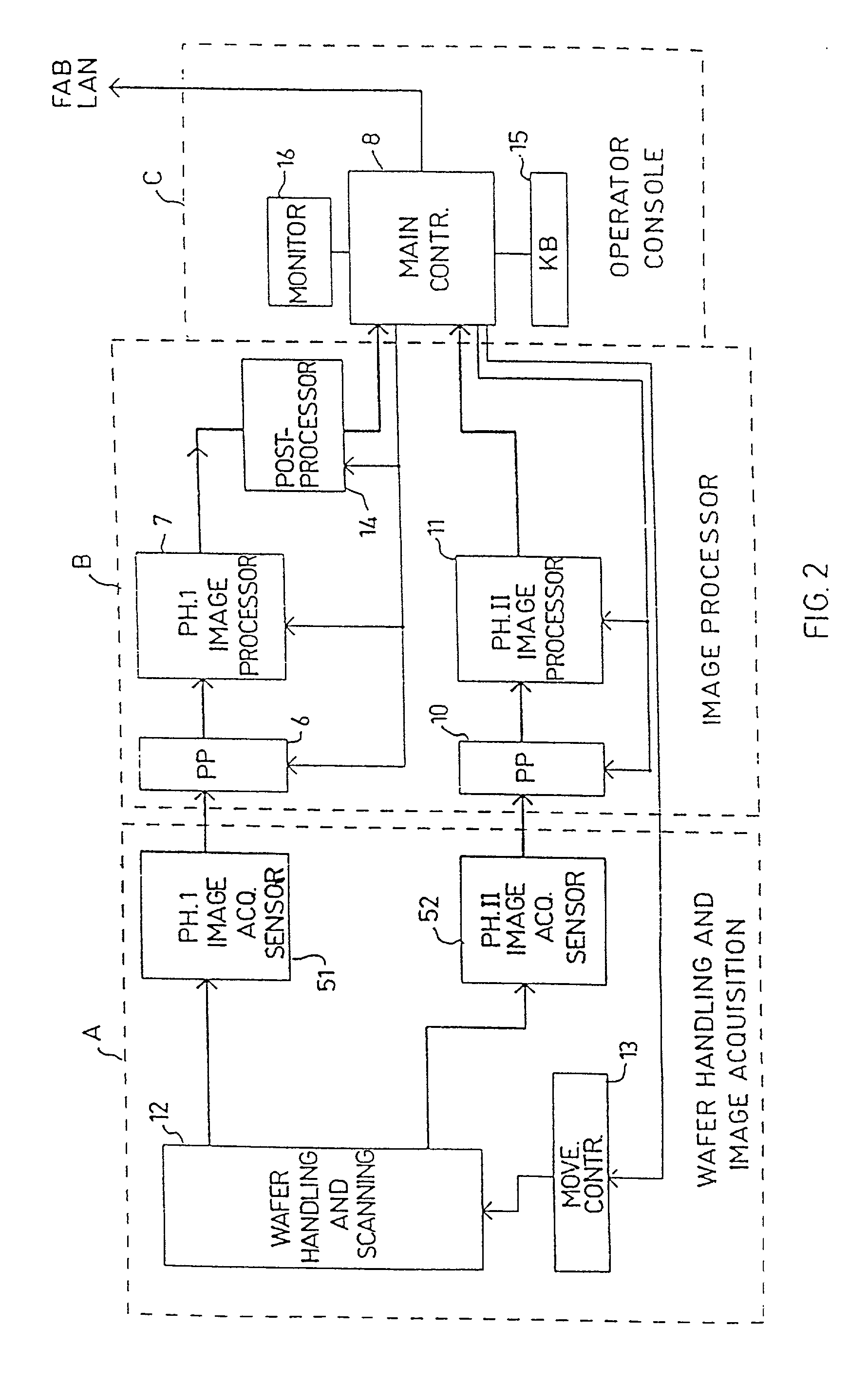

Optical inspection apparatus for defect detection

InactiveUS20020039436A1Increase speedLow rateCharacter and pattern recognitionColor television detailsImage resolutionHigh spatial resolution

A method and apparatus for inspecting the surface of articles, such as chips and wafers, for defects, includes a first phase of optically examining the complete surface of the article inspected at a relatively high speed and with a relatively low spatial resolution, and a second phase of optically examining with a relatively high spatial resolution only the suspected locations for the presence or absence of a defect therein.

Owner:APPLIED MATERIALS INC

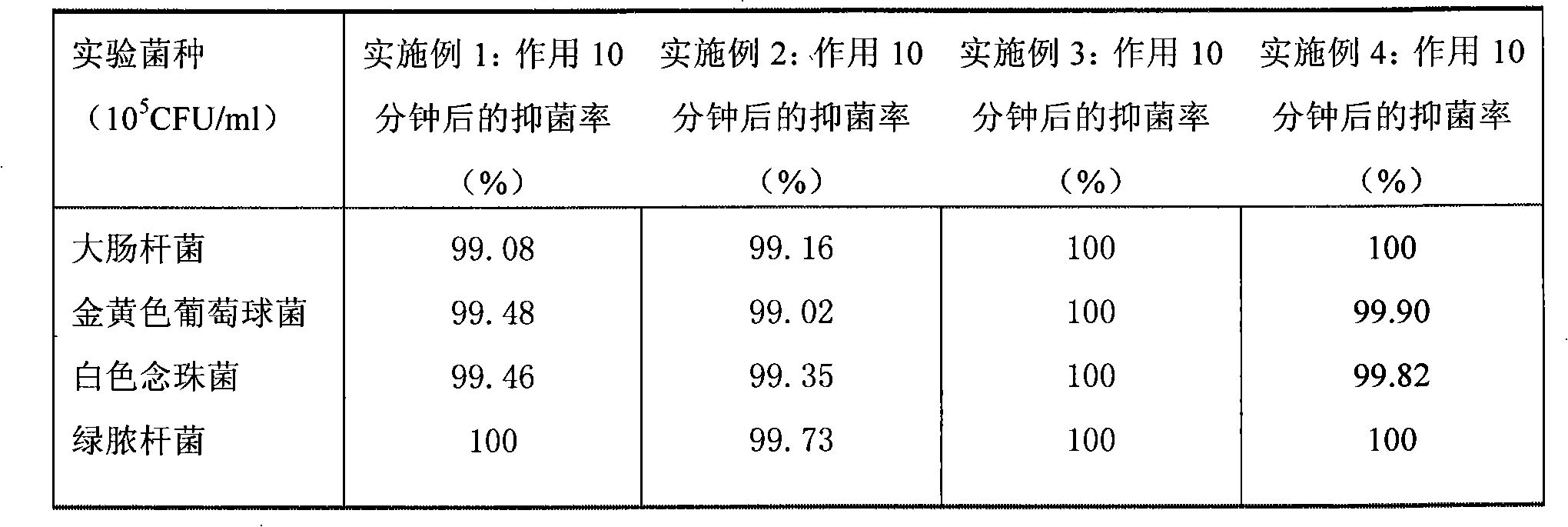

Chitosan nano silver gel agent and uses thereof

ActiveCN101278896APromote healingGood tissue repair functionOrganic active ingredientsInorganic active ingredientsTissue repairCervicitis

The invention relates to a chitosan nano silver gelata used for treating an inflammation in a lower genital tract, cervicitis and cervical erosion of female and empyrosis, scalding, bedsore infection and other skin inflammations such as tinea manus and pedes, and various wound infections, etc. The medicinal raw materials of the chitosan nano silver gelata of the invention are the nano silver and chitosan polymer in respective therapy dose; the nano silver is the nano silver powder or the nano silver colloid; the chitosan polymer is the chitosan and the chitin and one or more than one derivative of the chitosan and the chitin. The product of the invention has the advantages of high efficiency and being nonpoisonous, and has an extremely strong antibacterial action and an excellent therapeutic effect; compared with other nano silver gelata, the chitosan nano silver gelata of the invention has the advantages of perfect sterilizing effect, long-lasting effect and tissue repair function.

Owner:SAIKE SAISI BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com