Mullite ceramic foam filter for casting and preparation method thereof

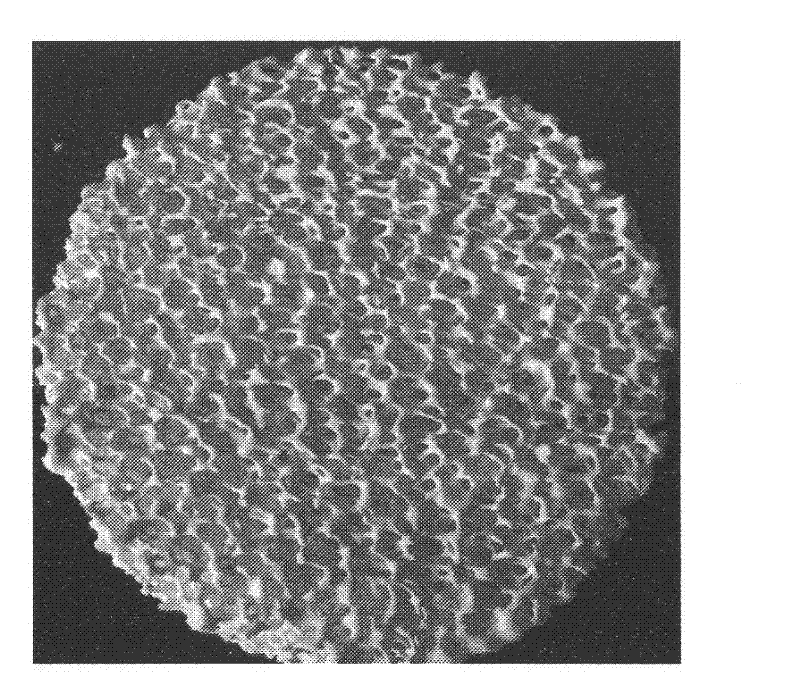

A foamed ceramic and mullite technology, applied in the field of porous ceramics, achieves the effects of good filtration and adsorption, obvious purification effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

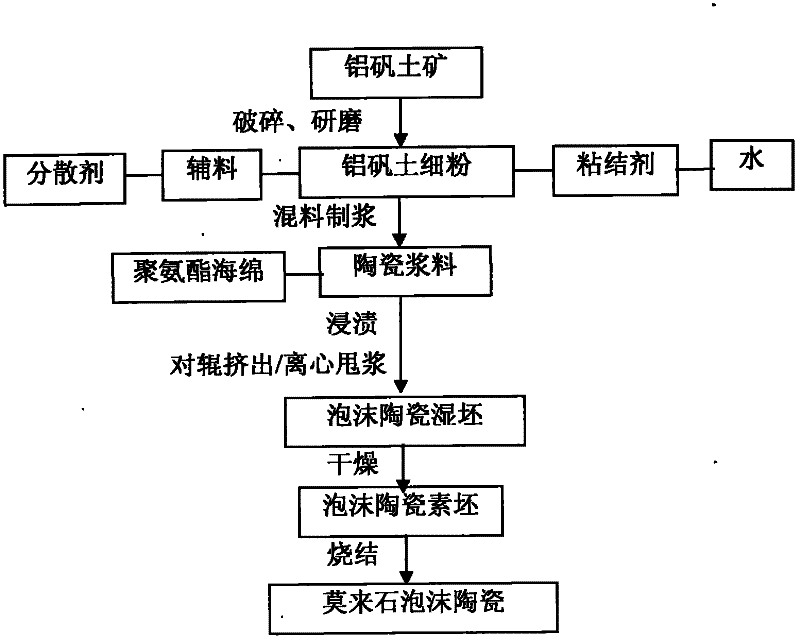

Method used

Image

Examples

Embodiment 1

[0033] Take 40wt% Al 2 o 3 , 50wt% SiO 2 10Kg of bauxite, after being crushed by jaw crusher and roller crusher, put into ball mill and grind into bauxite fine powder with particle size less than 200 mesh, then add 4.9Kg of alumina powder, 0.9Kg of dextrin, 0.1Kg of bauxite polyethylene glycol, put the powder into a stirrer, add 20.5Kg of water, and stir evenly to obtain a ceramic slurry.

[0034] Soak 20PPI sponge in 5% dilute hydrochloric acid solution for 30 minutes, wash with water, dry, and cut into square pieces of 75x75x22mm. Soak the sponge sheet in the above ceramic slurry to make the sponge fully absorb the slurry. Then make the sponge that has fully absorbed the ceramic slurry pass through a double-roll extruder, and adjust the roller gap of the double-roll extruder to squeeze out excess slurry in the sponge to obtain a foamed ceramic wet body.

[0035] Put the wet ceramic foam body into an oven, keep it at 100°C for 4 hours to dry, and obtain the ceramic foam g...

Embodiment 2

[0037] Take 80wt% Al 2 o 3 , 10wt% SiO 2 10Kg of bauxite is crushed by jaw crusher and roller crusher, calcined at 400°C for 2 hours, then put into a ball mill and ground into bauxite fine powder with a particle size of less than 200 mesh, and then add 1Kg of silica powder, Put 0.5Kg of kaolin, 0.3Kg of talcum powder, 0.5Kg of silica sol with a solid content of 25wt%, and 0.19Kg of sodium polyacrylate into a ball mill, add 9.75Kg of water, and fully ball mill to obtain a uniformly dispersed ceramic slurry.

[0038] Soak a 5PPI sponge in 10% sodium hydroxide solution for 60 minutes, wash it with water, dry it, and cut it into discs with a diameter of 50 mm and a thickness of 20 mm. Soak the sponge disc in the above ceramic slurry to make the sponge fully absorb the slurry. Then, the sponge that has fully absorbed the ceramic slurry is passed through a centrifugal pulper, and the excess slurry in the sponge is squeezed out by adjusting the rotating speed and centrifugation ti...

Embodiment 3

[0041] Take 54wt% Al 2 o 3 , 38wt% SiO 2 10Kg of bauxite is crushed by jaw crusher and roller crusher, calcined at 600°C for 4 hours, then put into ball mill to grind into bauxite fine powder with a particle size of less than 200 mesh, and then add 2.0Kg kaolin, 0.2Kg Bentonite, 1.0Kg talcum powder, 0.6Kg polyvinyl alcohol, 0.1Kg ammonium polyacrylate, put the above raw materials into a mixer, add 5.3Kg water, and stir well to obtain a uniformly dispersed ceramic slurry.

[0042] Soak a 60PPI sponge in 15% potassium hydroxide solution for 20 minutes, wash it with water, dry it, and cut it into discs with a diameter of 75 mm and a thickness of 22 mm. Soak the sponge disc in the above ceramic slurry to make the sponge fully absorb the slurry. Then let the sponge that has fully absorbed the ceramic slurry go through a centrifugal pulper to shake the pulp, adjust the speed and centrifugation time of the centrifugal pulper to squeeze out the excess slurry in the sponge, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com