Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

531results about How to "Less investment in equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

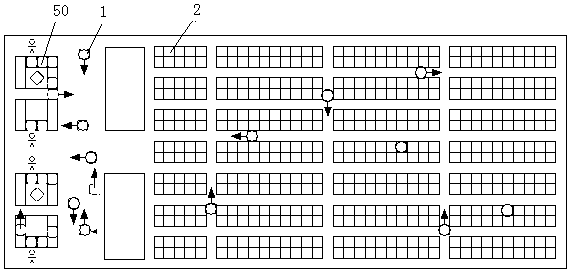

Goods sorting method based on intelligent AGV

InactiveCN104142682ALess investment in equipmentLow implementation costPosition/course control in two dimensionsAutomatic guidanceTransport engineering

The invention relates to a goods sorting method based on an intelligent AGV, and relates to the technical field of storage. The technical problems that the implementation period of an existing system is long, and the implementation cost is high are solved. According to the method, a lifting mechanism which can be used for lifting a goods shelf to be lifted is arranged on the AGV, and the goods shelf is a square shelf body with a space allowing the AGV to pass through arranged at the bottom; when goods sorting is implemented, the AGV automatically travels to the position under a target goods shelf, the lifting mechanism is used for lifting the target goods shelf away from the ground, then the goods shelf is carried to a sorting work station automatically; sorting personnel at the sorting work station take down target goods from the goods shelf according to the scanning result of a laser indicator, after sorting is completed, the AGV then carries the goods shelf to return to the original stacking point of the goods shelf, and then the lifting mechanism is used for placing the target goods shelf back to the ground. The goods sorting method based on the intelligent AGV is short in implementation period, and convenient to dismount, transfer and expand.

Owner:SHANGHAI QUICKTRON INTELLIGENT TECH CO LTD

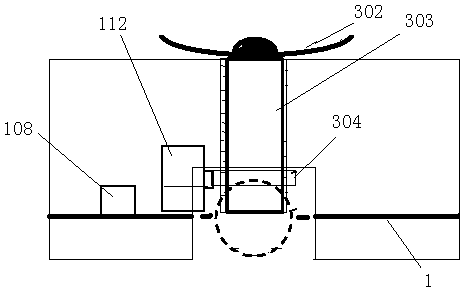

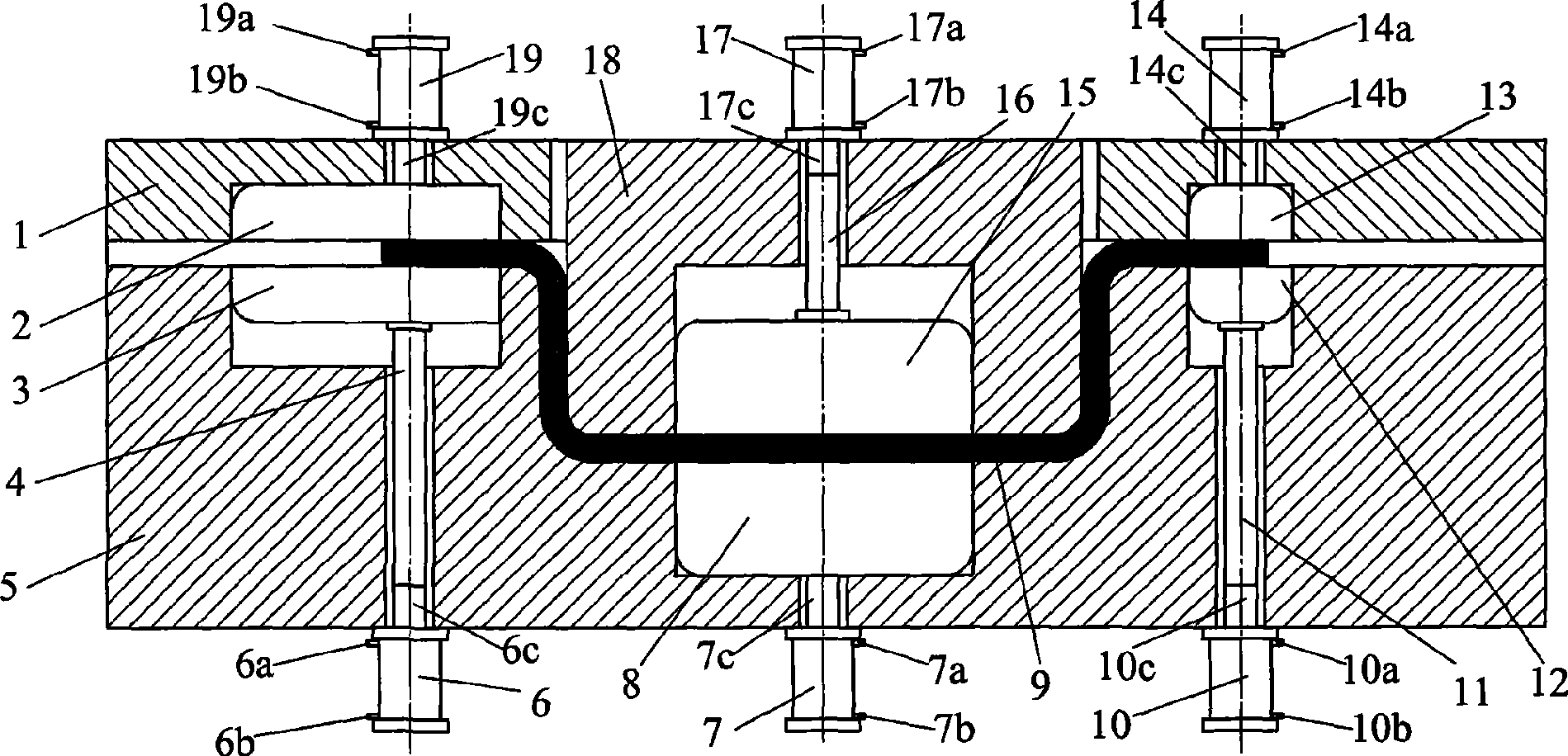

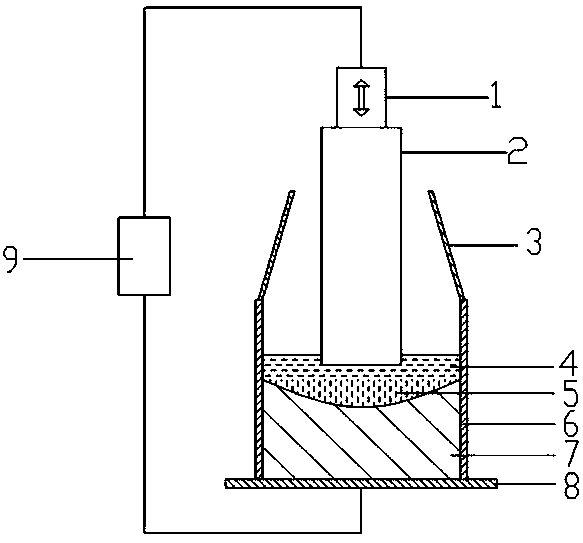

Thermoforming, hole-punching and edge-cutting integrated technique and mold of high-duty steel part

InactiveCN101486061ALess investment in equipmentSmall footprintShaping toolsPerforating toolsSteel platesHot stamping

The invention provides hot-forming, punching and edge-cutting integral technology and a hot-forming, punching and edge-cutting integral die for high strength steel parts. The integral technology comprises the following steps: arranging an edge-cutting and punching tool on a hot-forming die of the high strength steel parts; placing high strength steel plate materials which is heated to be completely austenized into the hot-forming die for punching before hot stamping forming of the high strength steel plate materials; utilizing the edge-cutting and punching tool on the hot-forming die to perform edge-cutting and punching operations on workpieces subjected to stamping after the hot-forming die is closed; cooling the hot-forming die after the operations are over; and utilizing die components which contact formed parts to quench the formed parts. The integral die comprises a forming convex die, a forming concave die, an upper punching tool, a lower punching tool, an upper edge-cutting tool and a lower edge-cutting tool. The integral technology and the integral die reduce the production cost of the hot-formed parts, and shorten the production period of the hot-formed parts; and the hot-formed parts have high edge-cutting and punching quality and high dimension precision and shape precision.

Owner:SHANDONG UNIV

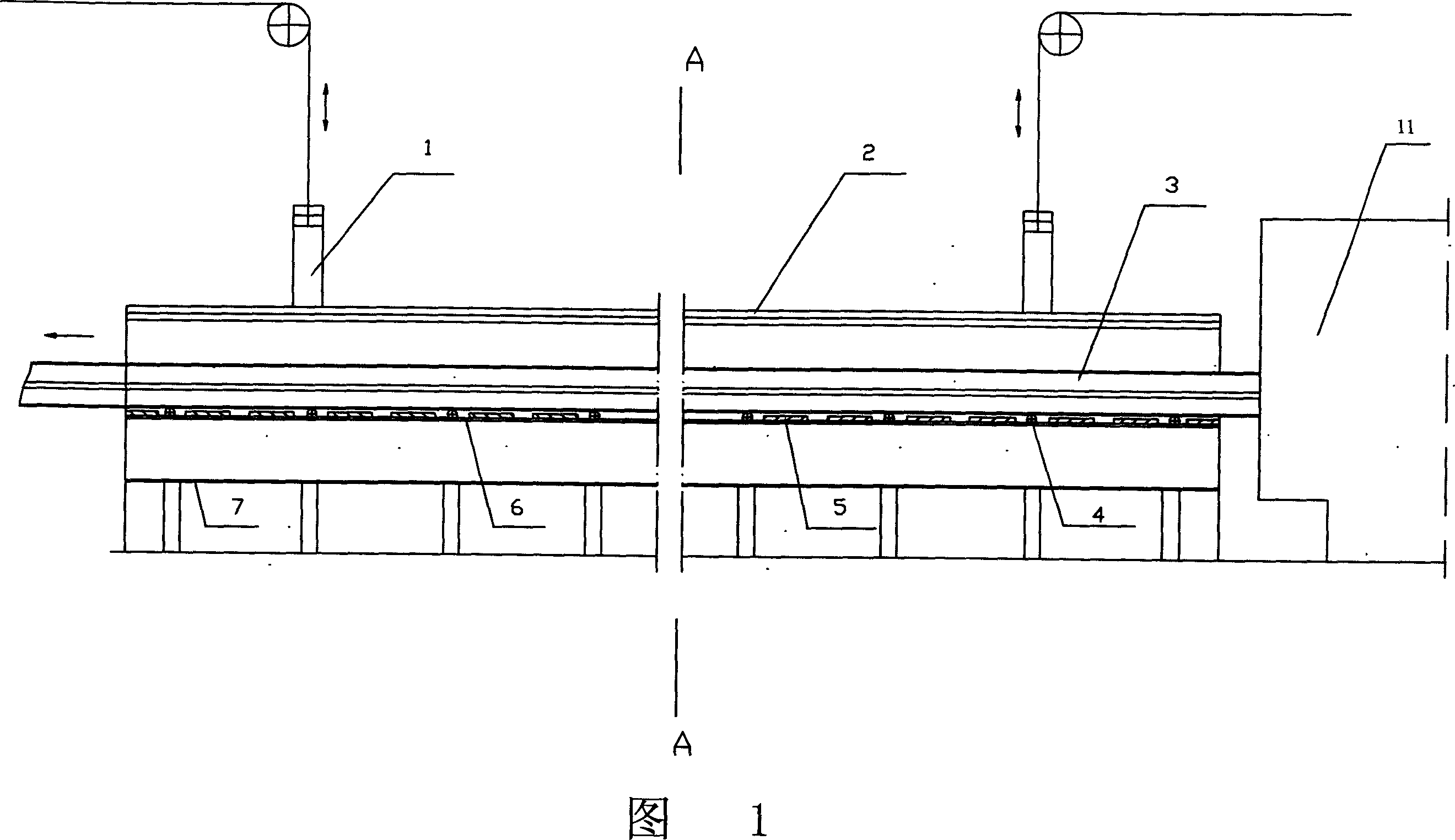

A method for making semi-processed cold rolled silicon steel in thin slab continuous casting and continuous rolling process

ActiveCN1864879ALess investment in equipmentReduce process linksMelt-holding vesselsRoll mill control devicesThin slabAluminium

The invention relates to a method for using sheet blank continuous casting continuous rolling to produce silicon steel. In the BOF smelt process, it uses bottom argon blow technique in the whole processes; adds composite deoxidant and aluminum into steel pack when outputting steel to remove oxygen; adds manganese, silicon steel and ferro-phosphorus to alloy; blows argon to the melt steel in all process; uses LF furnace to refine the melt steel; using CSP continuous casting machine to cast the melt steel into casting blank; heats the casting blank via TF furnace to be rolled by continuous rolling machine to be hot rolling sheet coil; acid washes hot rolling plate to be cold rolled via rough roller cold rolling machine to be cold rolled sheet coil; anneals via the anneal furnace; flattens the annealed sheet coil via flatten machine group while the extending rate is 2-18%; corrects the sheet shape via correct machine; packs and stores the coil into the storehouse. The inventive method can reduce the cost of producing device and improve the additive value of sheet blank continuous casting continuous rolling product.

Owner:湖南华菱涟钢特种新材料有限公司 +1

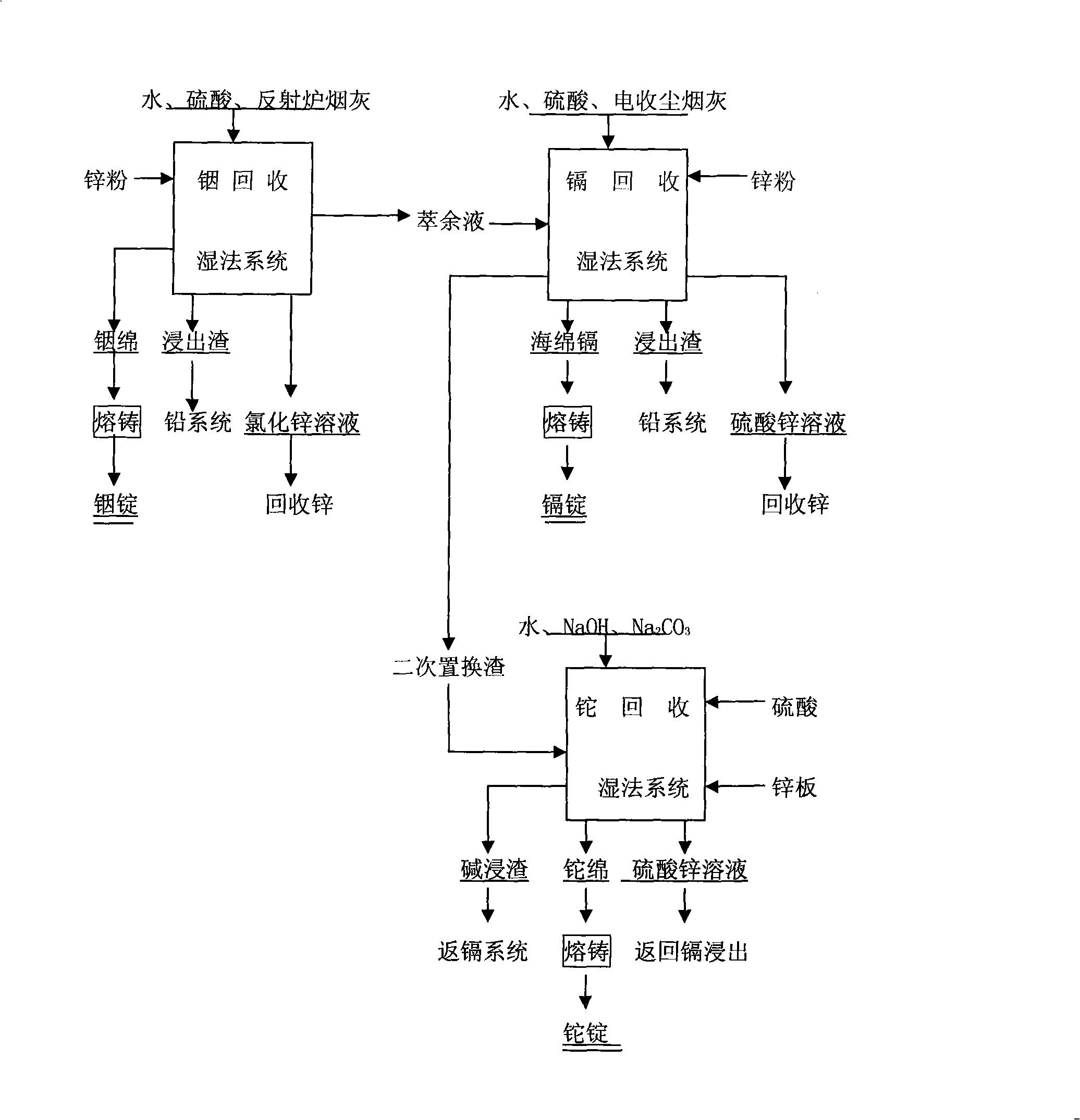

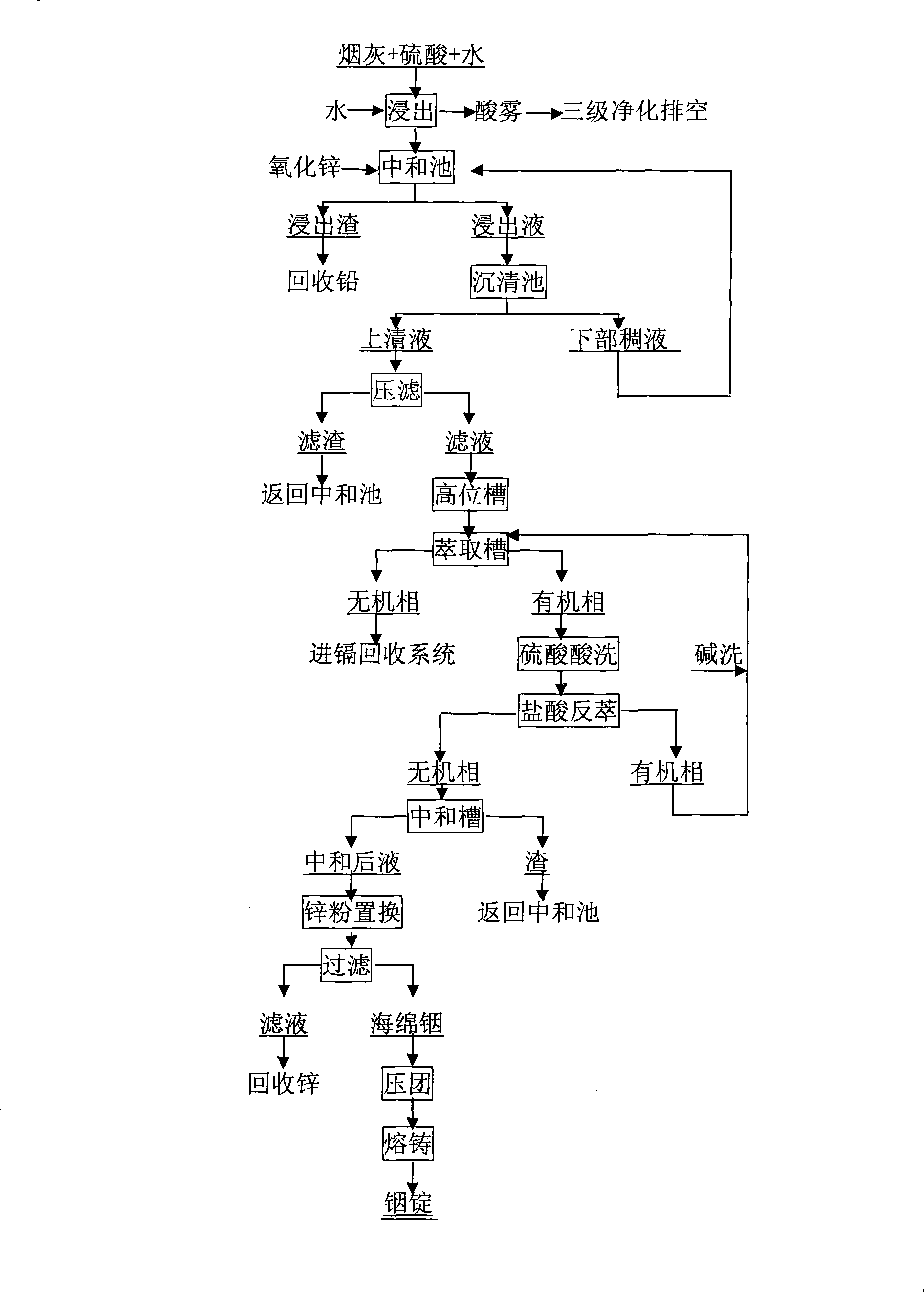

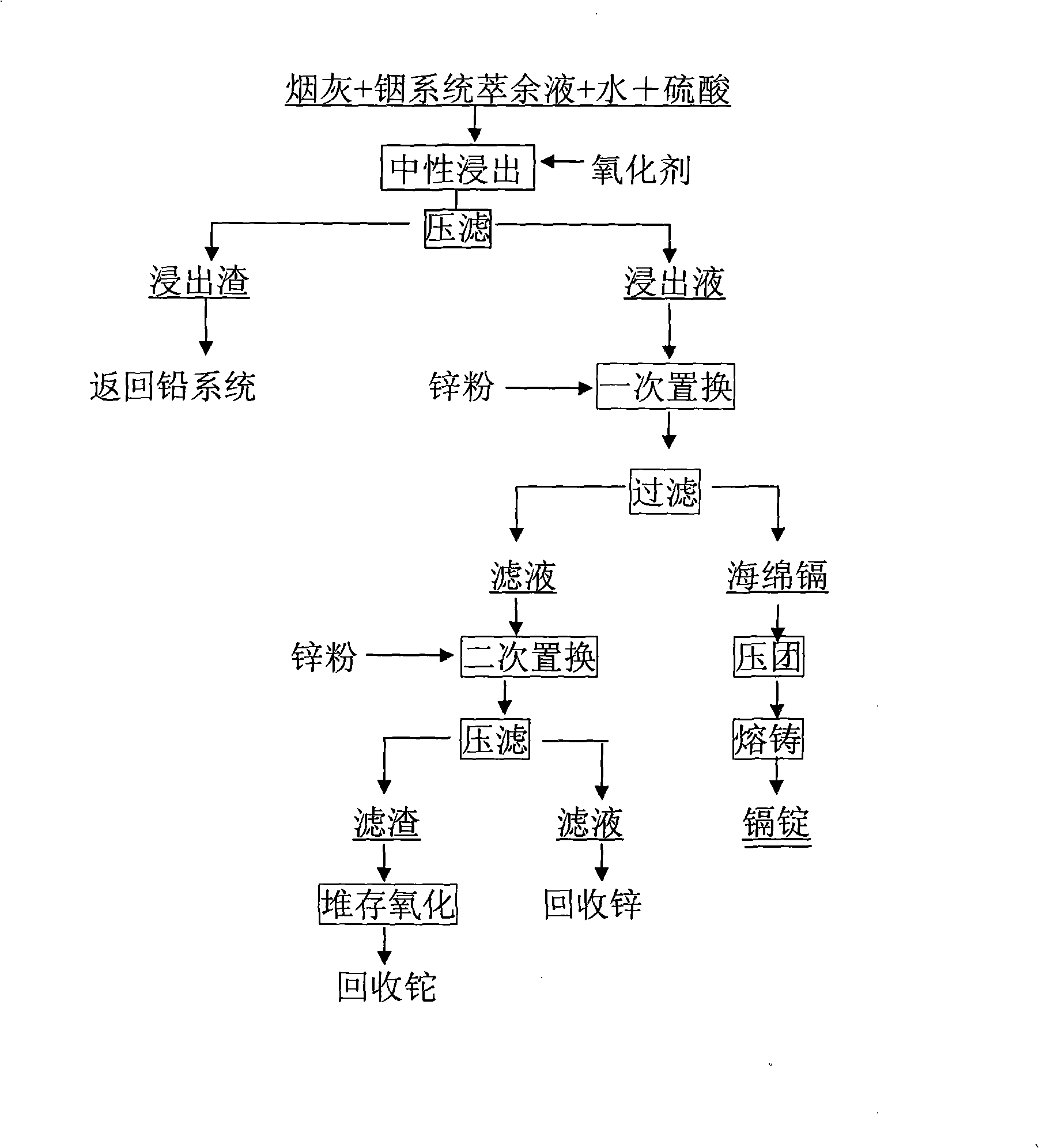

Process for comprehensive recovery of indium, cadmium, thallium and zinc from lead system smoke

InactiveCN101255502ALess investment in equipmentImprove efficiencyProcess efficiency improvementZinc sulfate monohydrateIndium

The invention relates to a method for comprehensively recycling indium, cadmium , thallium and zinc from electric precipitation dust and reverberator dust in a lead smelting system. Indium in the reverberator dust is recycled by leaching, extracting, back extracting and cementing, the post-replacing liquid can be used for recycling zinc butter or preparing nanometer zinc oxide, middle faffinate is used for leaching electric precipitation dust, cementing out cadmium and further producing pure cadmium, the residual liquid mainly includes zinc sulfate solution as the raw material for preparing zinc oxide, zinc sulfate monohydrate, zinc vitriol to recycle zinc, the slag produced in the leaching process is returned to a lead system for recycling lead, secondary cementing slag produced by a cadmium system is pile-up oxidized and leached by alkali, the slag is returned to the cadminum system for recycling cadmium and zinc, the liquid is added with sulphuric acid to adjust the pH value, then thallium is recycled by a zinc plate. The process takes indium recycle and cadmium recycle into consideration and optimizes the process, indium, cadmium , thallium and zinc in the raw material are recycled at the same time, so that better economical benefit can be produced.

Owner:HENAN YUGUANG GOLD & LEAD

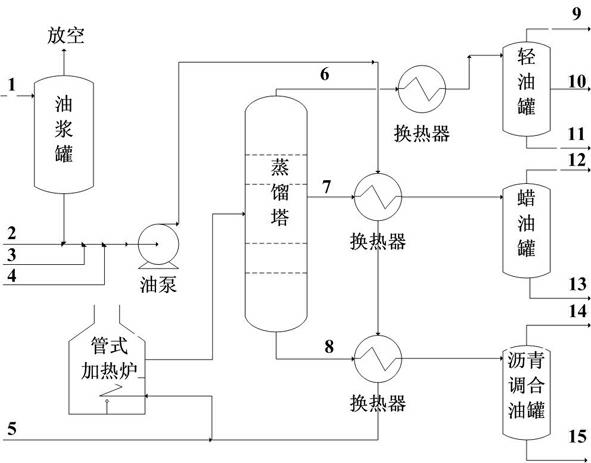

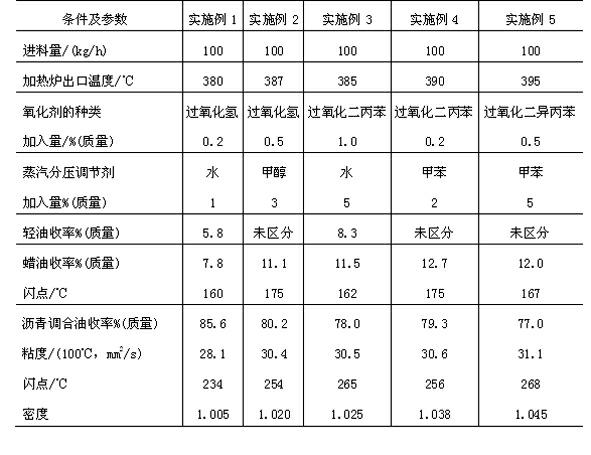

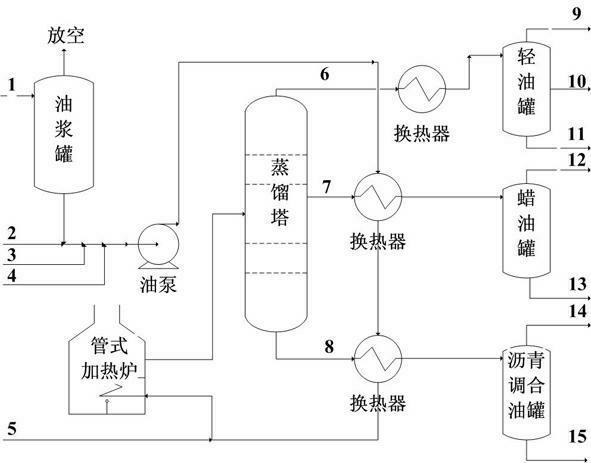

Method for producing asphalt blending oil by normal pressure distillation of catalytic slurry oil

InactiveCN102559250ALess investment in equipmentSimplify operating proceduresTreatment with plural serial refining stagesWaxBoiling point

Owner:甘黎明 +2

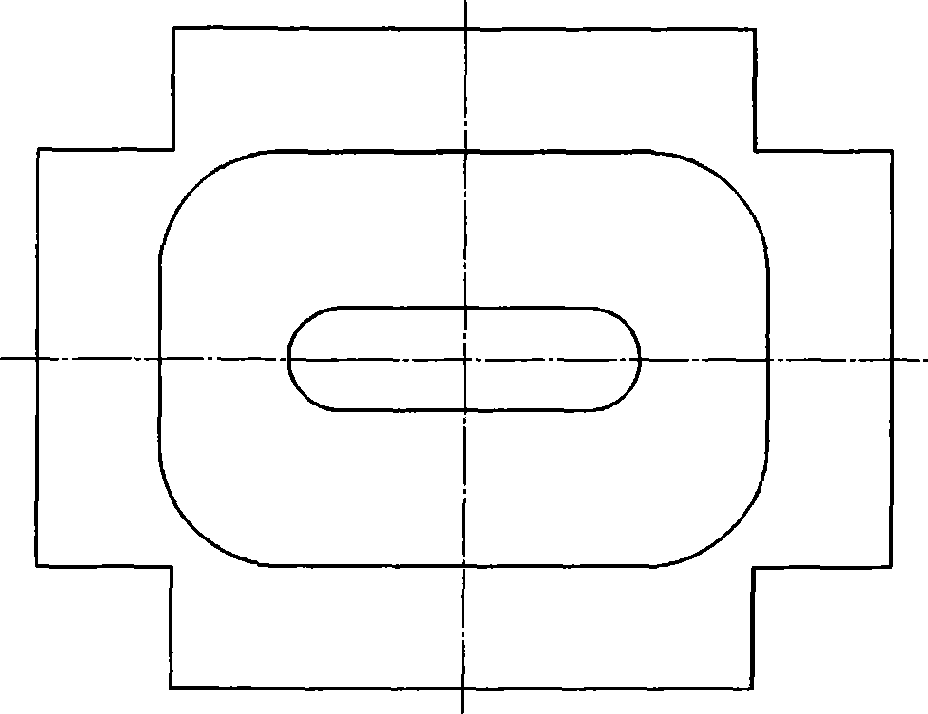

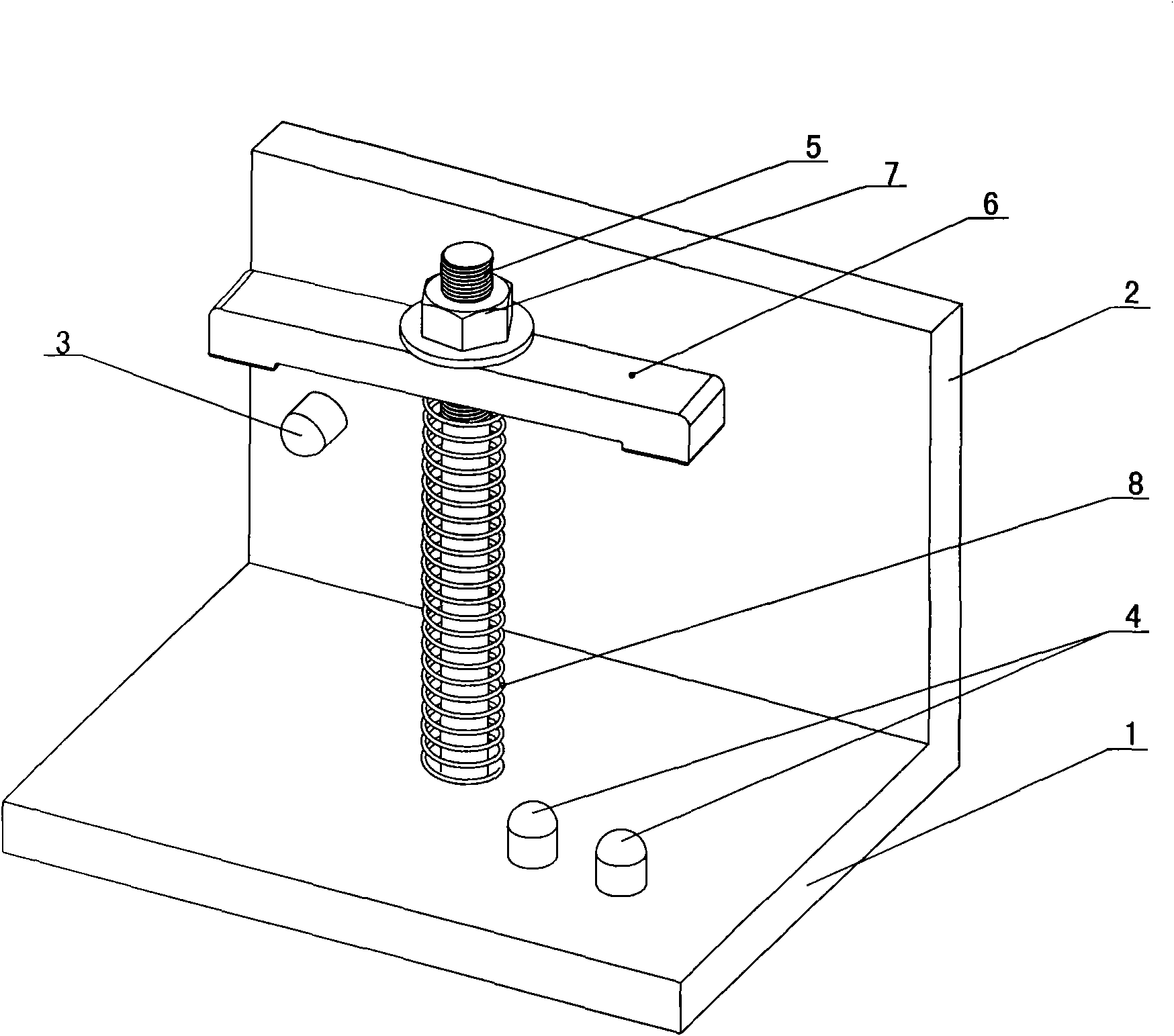

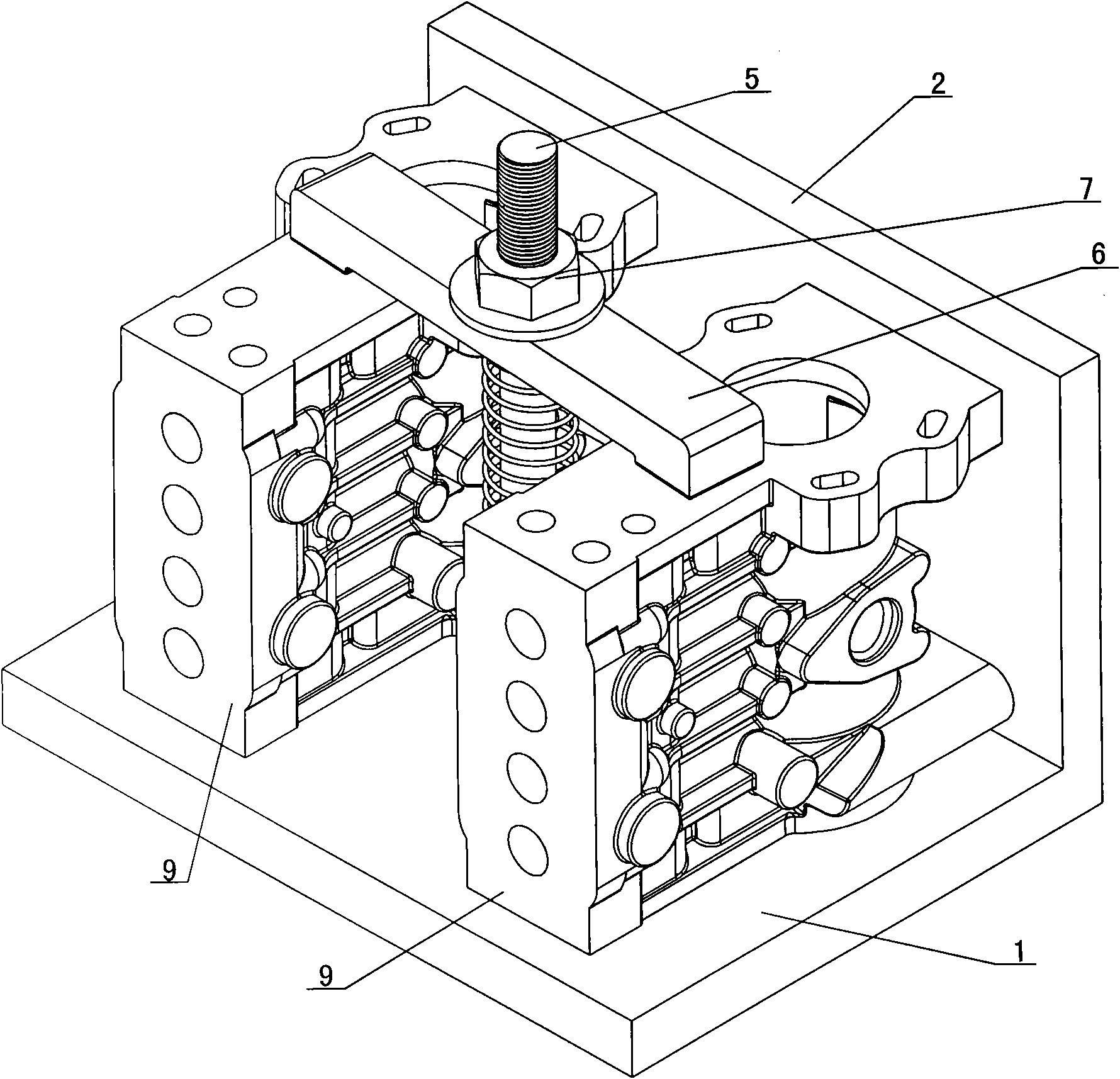

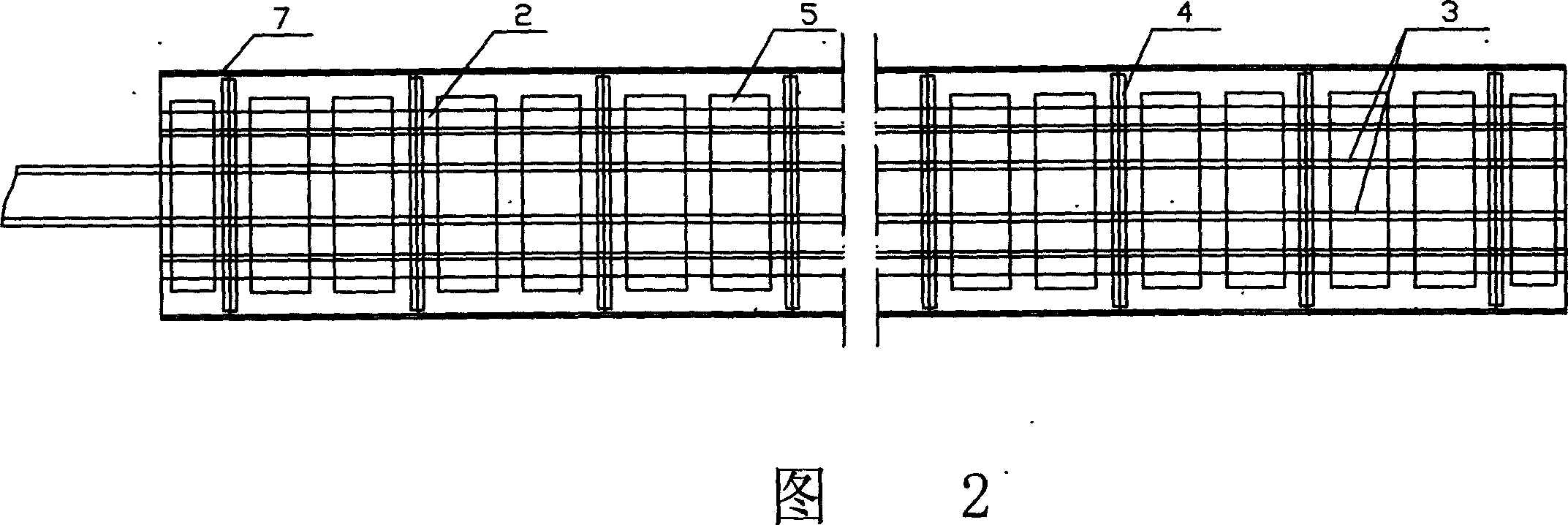

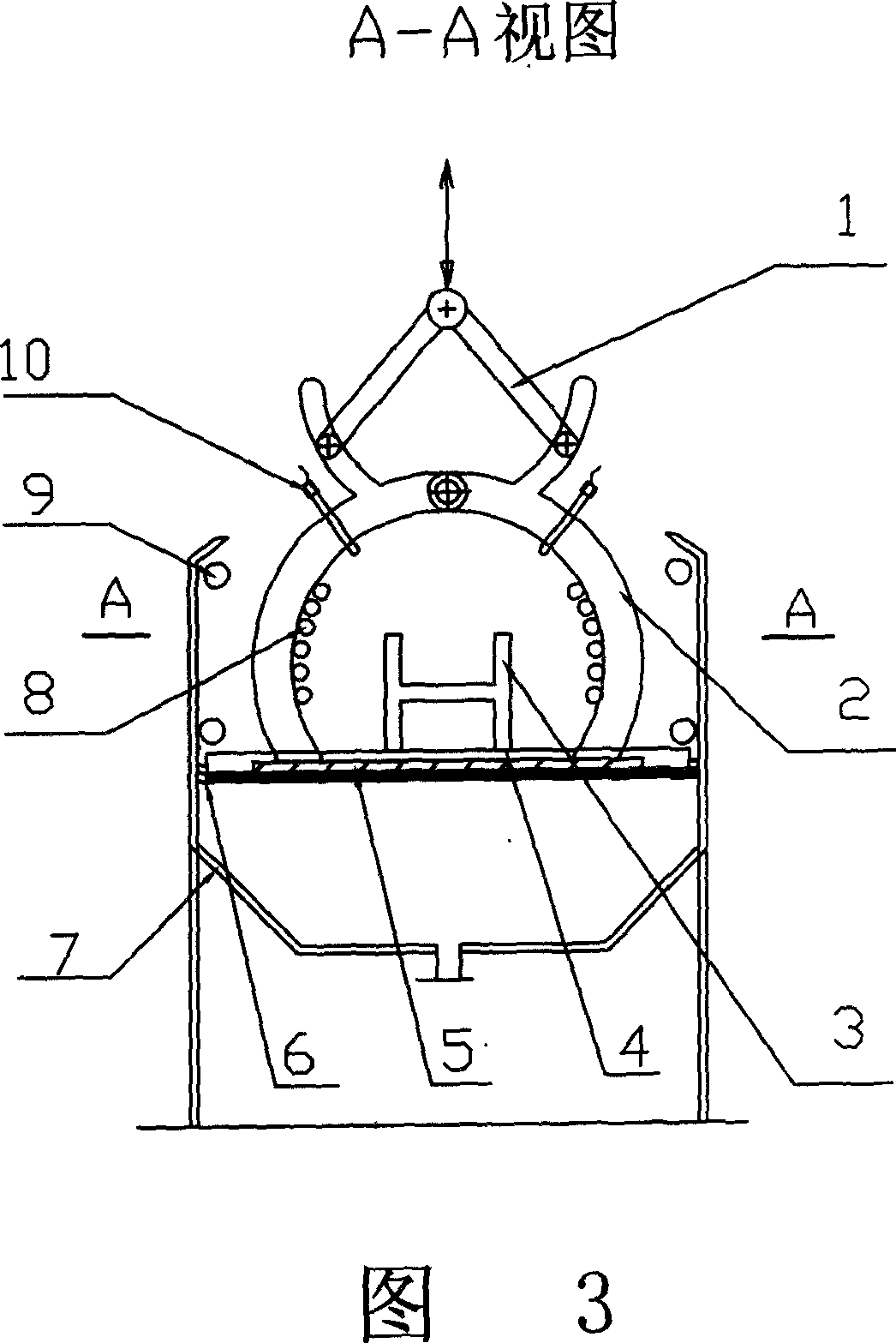

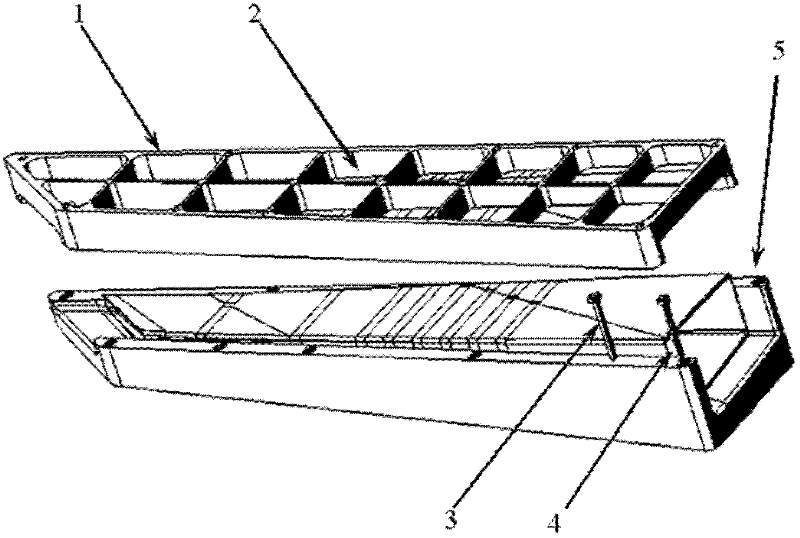

Clamp for processing a plurality of slender holes on workpiece and processing method thereof

InactiveCN101596684ALess investment in equipmentSimple fixture structureMilling equipment detailsPositioning apparatusProduct processingEngineering

The invention relates to a clamp for processing a plurality of slender holes on a workpiece, belonging to machining technical field. A bottom plate (1) and a side plate (2) are in L-shaped; a stud bolt (5) is fixedly arranged in the middle of the bottom plate (1), and a spring (8) is sheathed on the stud bolt (5); the upper part of the stud bolt (5) is respectively provided with a pressure plate (6) and a nut (7); a guide pin (4) is arranged on one side of the stud bolt (5) on the bottom plate (1), and a positioning pin (3) is arranged on one side of the side plate (2). The invention fixes a workpiece by the simple clamp. Processing carried out on the existing high-cost horizontal processing center is changed for processing carried out on low-cost digital-control milling machines or vertical processing center, which reduces equipment investment. The clamp of the invention has simple structure and short production cycle, and therefore, the clamp of the invention is suitable for product processing with small lot, wide varieties and short development cycle. The invention has the advantages of reasonable design, simple method and the like.

Owner:洛阳古城机械有限公司

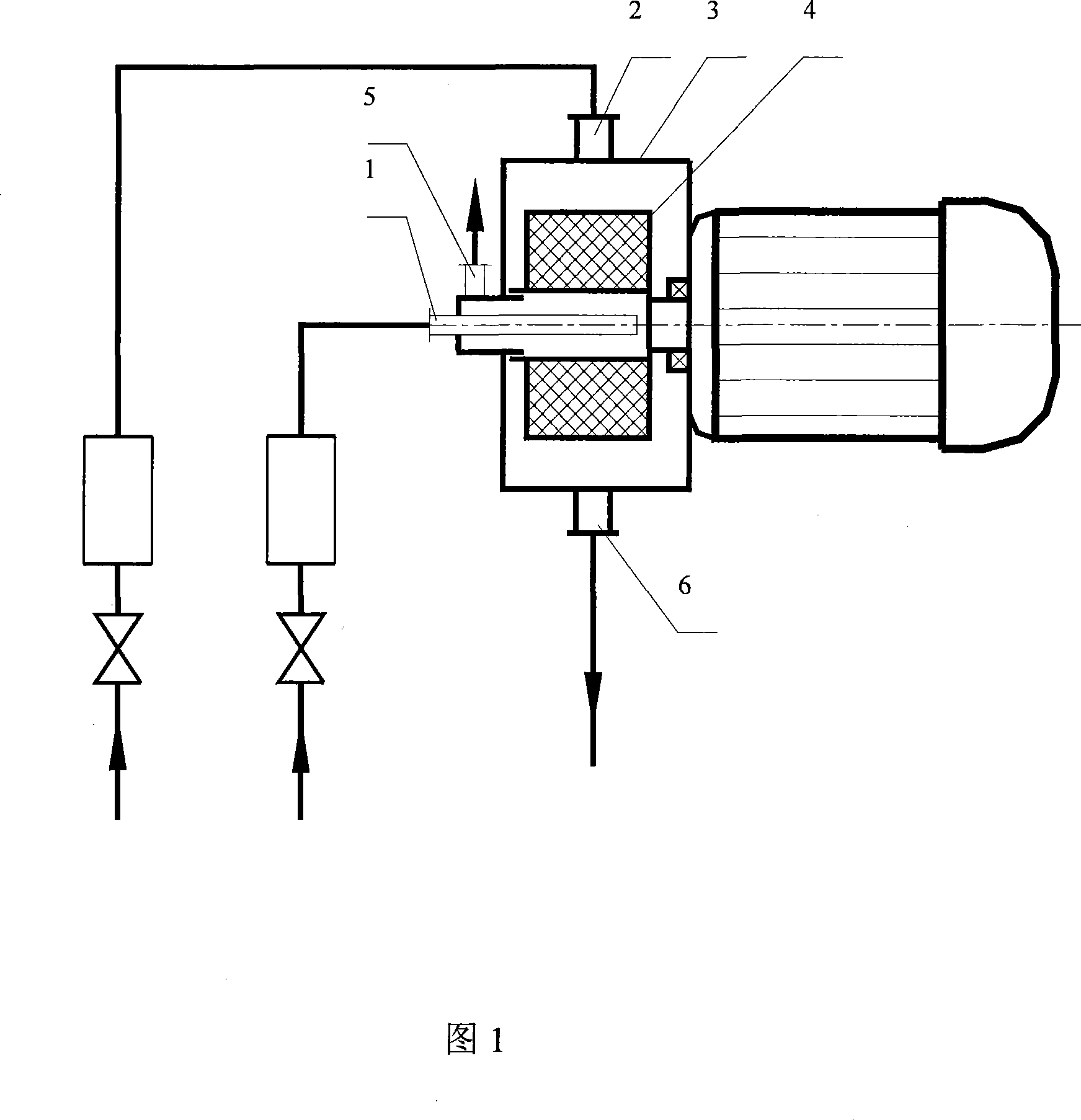

Method for removing CO2 from conversion gas

InactiveCN101168115ALess investment in equipmentReduce energy consumptionProductsReagentsEngineeringHypergravity

The invention provides a method for removing CO2 in exchanging gas. The method employs a hypergravity revolving bed which enables an absorber and the exchanging gas to be contacted in the manner of adverse current or cross current in the hypergravity revolving bed. The removing of CO2 is processed under the condition of hypergravity. The current rate of gas and liquid is 5 to 1-35 to 1, and the rotation speed of the rotor of the hypergravity revolving bed is 100-3000 circles per minute. The absorber is hot potash solution and caustic lye of soda solution or caustic potash solution which are added with an activating agent. The percentage concentration of the quality of the hot potash solution is 20-60%, the percentage concentration of the quality of the activating agent is 1-5%, and the percentage concentration of the quality of the caustic lye of soda solution or caustic potash solution is 1-40%. In the time of absorption and reaction, the pressure is 0.5-4.0 MPa, and the temperature is 60-120 degrees. The invention is capable of removing the amount of CO2 in raw gas to be below 0.1% (volume). The invention has the advantages of little equipment investment, low energy consumption, small occupied volume and the like.

Owner:PETROCHINA CO LTD +1

High-oryzanol rice bran oil two-phase extraction de-acidification refining technology

InactiveCN101984028AReduce refining consumptionGreat tasteFatty-oils/fats refiningEdible oils/fatsDistillationPhosphoric acid

A high-oryzanol rice bran oil two-phase extraction de-acidification refining technology includes processes of degumming with phosphoric acid, centrifugal separation, two-phase extraction de-acidification, separatory distillation for solvent removal, vacuum drying, adsorptive de-coloration, deodorization, de-waxing and the like. The refined rice bran oil produced by the technology is clear, transparent and odour free, and has good tastes, Physical and Chemical characters of acid value and the like of the refined rice bran oil are in accordance with the second grade of national edible oil standard, and simultaneously, content of the produced rice bran oil is more than 1.5%. The whole technology is simply, few devices are invested for the technology, the rice bran oil products have high yield and purity, product quality can be easily controlled, and a new way for producing high-quality nutritious rice bran oil is provided.

Owner:HUNAN AGRICULTURAL UNIV +1

Blended centrifuging glass cotton fiber felt and its making method

InactiveCN1619038ALess investment in equipmentIncrease production capacityNon-woven fabricsWoolPlant fibre

The present invention relates to a mixed centrifugal glass wool fibre felt. It is formed from mixture of centrifugal glass wool and inorganic fibre or organic fibre, in which the mass ratio of centrifugal glass wool and inorganic fibre or organic fibre is 2:8-6:4. The described organic fibre can be plant fibre or animal fibre, and the described inorganic fibre can be mineral wool, rock wool or glass fibre. Said invention also provides its production method.

Owner:严煜

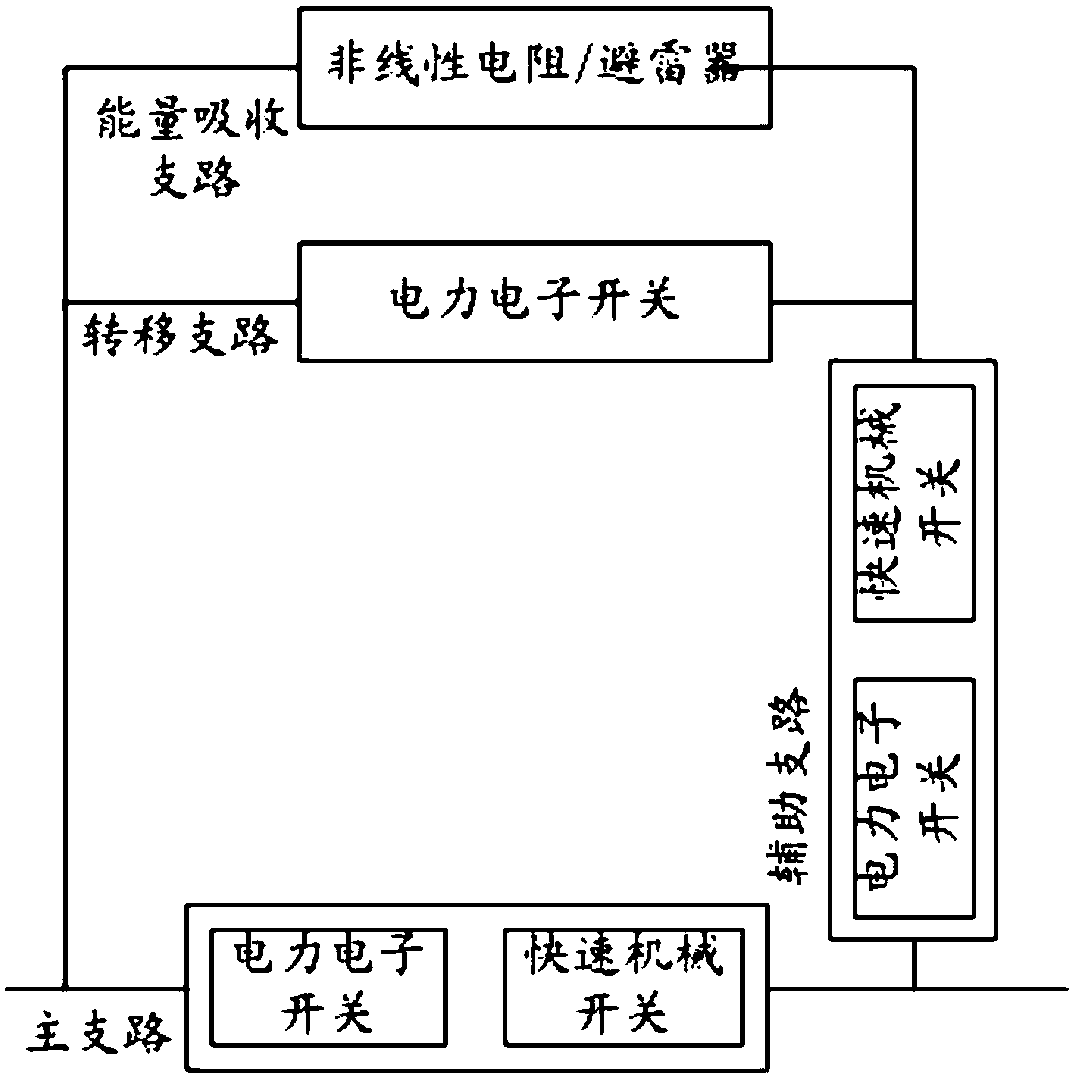

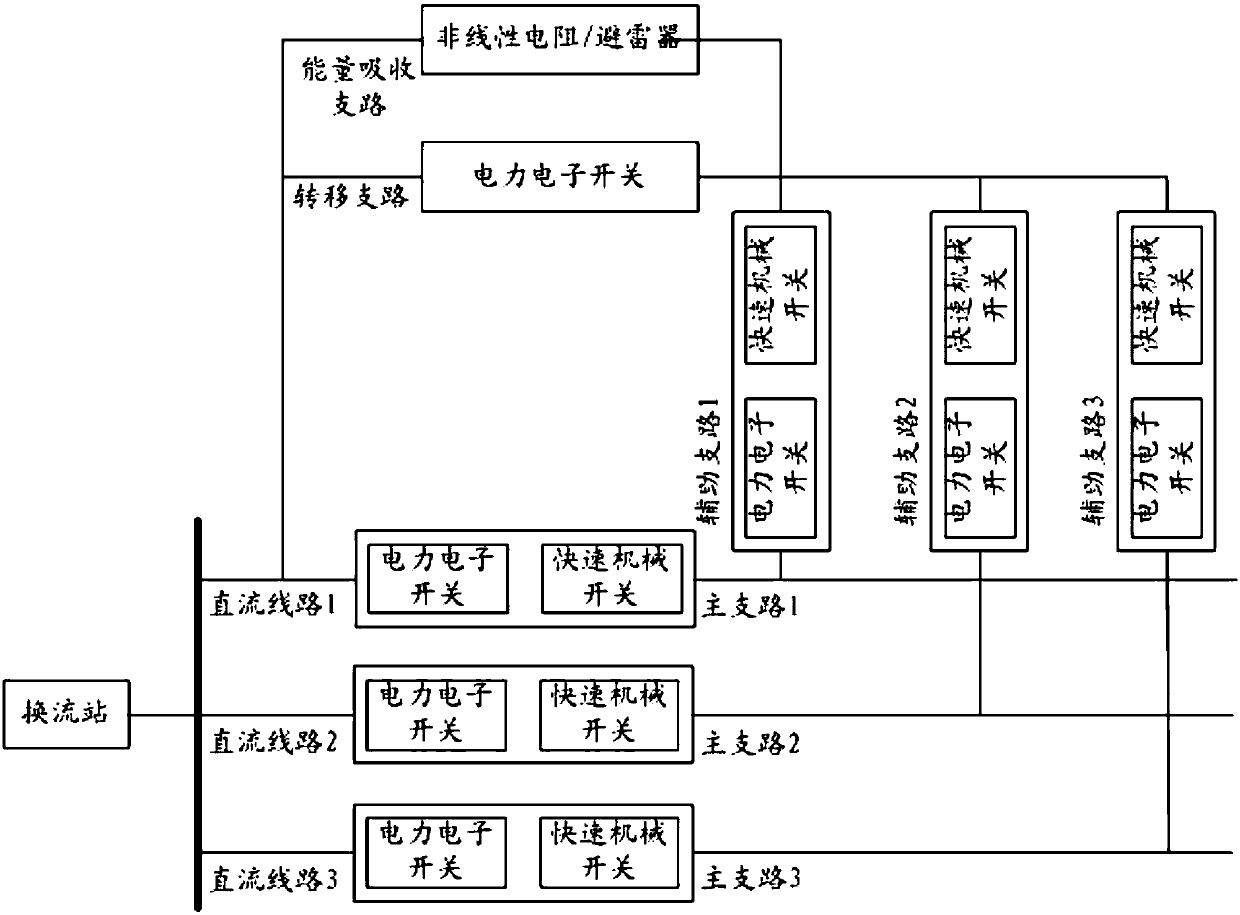

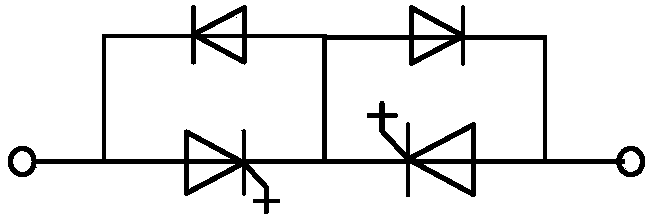

Novel combined type DC breaker and application method thereof

ActiveCN107645154AEnsure safetyIsolate faultBoards/switchyards circuit arrangementsElectric power transfer ac networkMain branchEnergy absorption

The invention provides a novel combined type DC breaker, comprising a transferring branch, an energy absorption branch, and at least two main branches and at least two auxiliary branches. The transferring branch is in parallel with the energy absorption branch. The main branch is corresponding to the auxiliary branch in a one-to-one manner. The main branch is connected to the DC outlet of a DC busin a high-voltage direct current (HVDC) transmission system. The auxiliary branch is in series with the transferring branch, and then is in parallel with the two ends of the main branch correspondingto the auxiliary branch. Compared with the prior art, the invention is advantageous in that the application economy performance of a high-voltage DC breaker in a flexible DC grid can be improved; theestablishment of the DC grid and the popularization and application of the mixed type DC breaker can be facilitated.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD

Method for extracting rice protein powder by utilizing enzyme-alkali method

The invention provides a method for extracting rice protein powder by utilizing enzyme-alkali method. The method in the invention takes rice residue as raw materials and comprises the following steps: washing with water, eliminating sugar, carrying out milling refining on the colloid, eliminating residue starch by utilizing starch enzyme, pre-extracting alkali protease, adding alkali for extraction, centrifuging and taking the supernate to mix to neutrality, inactivating enzymes and sterilizing, and spraying and drying to obtain the rice protein powder. The rice protein powder produced by utilizing the process has faint yellow color, delicate taste and good solubility, and can be maintained well from physicochemical function. The invention has simple process, few investment device, high yield and purity of products, good solubility, and easily-controlled product quality, is suitable for practice popularization and provides a new route for the extraction of rice protein.

Owner:长沙湘博医药科技有限公司

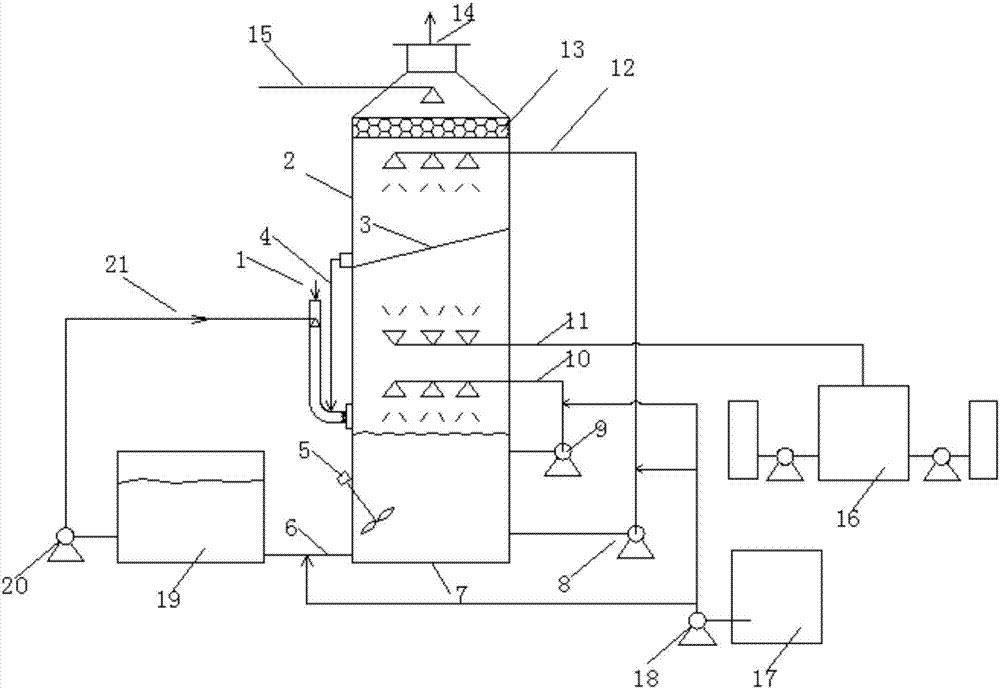

Chlorine dioxide gas-phase oxidation desulfurization and denitrification integrated device and process thereof

PendingCN106975337ASimple processLess investment in equipmentGas treatmentDispersed particle separationFlue gasSlurry flow

The invention discloses a chlorine dioxide gas-phase oxidation desulfurization and denitrification integrated device and process thereof. The device comprises a two-stage type tower body, wherein a liquid tank is arranged at the bottom of the inner part of the tower body; a flue gas inlet is formed in the side wall of the tower body positioned above the liquid tank; a desulfurization spraying pipe, a chlorine dioxide gasification spraying pipe and a partition plate for dividing the inner cavity of the tower body into an upper part and a lower part and is arranged at an inclined angle; the chlorine dioxide gasification spraying pipe is connected with a chlorine dioxide preparation device; a denitrification spraying pipe is connected with a crystallization tank; and the crystallization tank is connected with a flue gas inlet by a crystallization slurry flow return pipe. According to the device and the process provided by the invention, NO is effectively oxidized by adopting a chlorine dioxide gas phase; meanwhile, SO2 and NOX as well as harmful substances such as powder, mercury and the like in the flue gas are adsorbed and removed; and the device and the process provided by the invention has the advantages of simple process, less equipment investment, low operation cost, convenient operation and the like.

Owner:包训祥

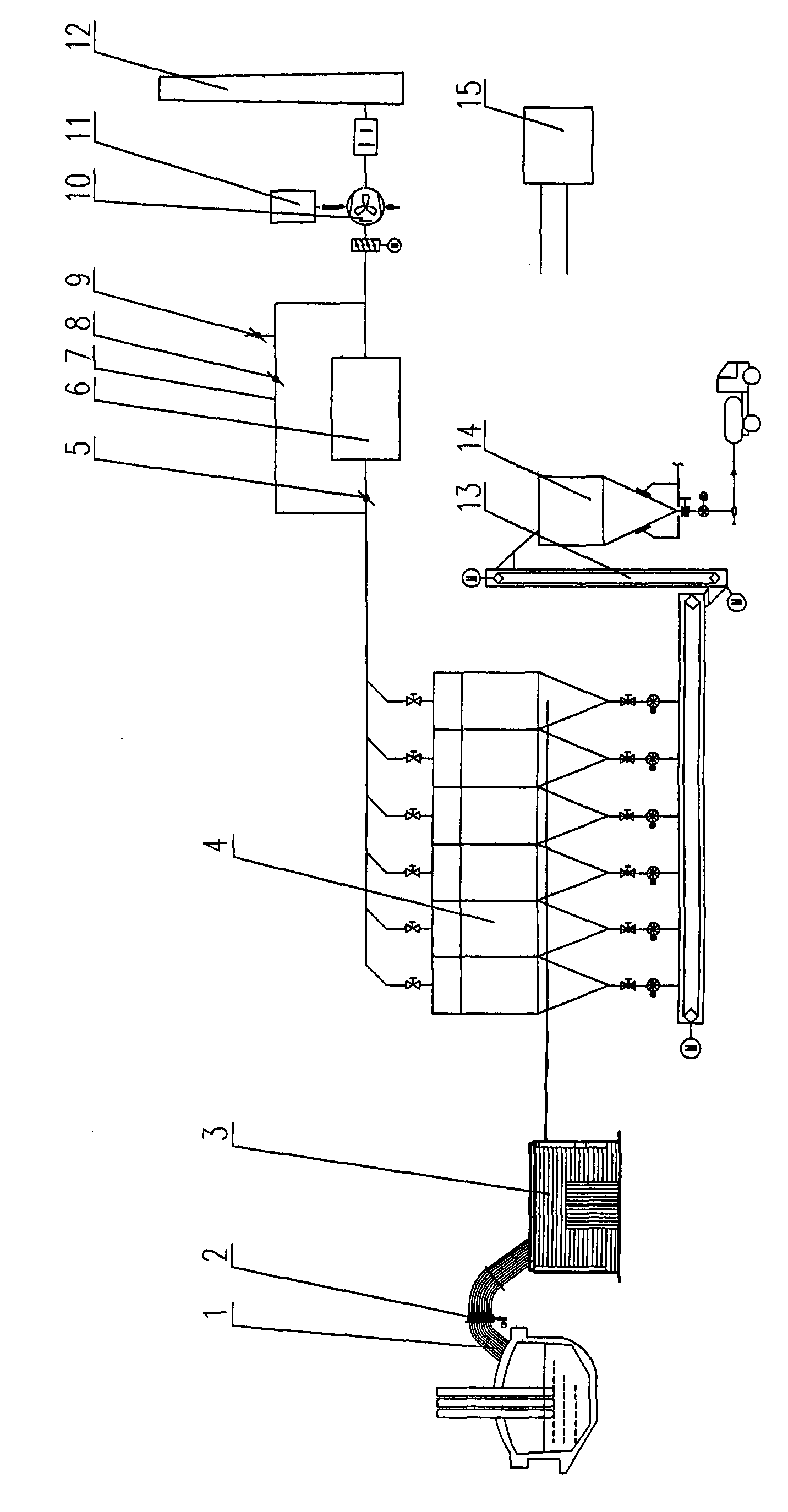

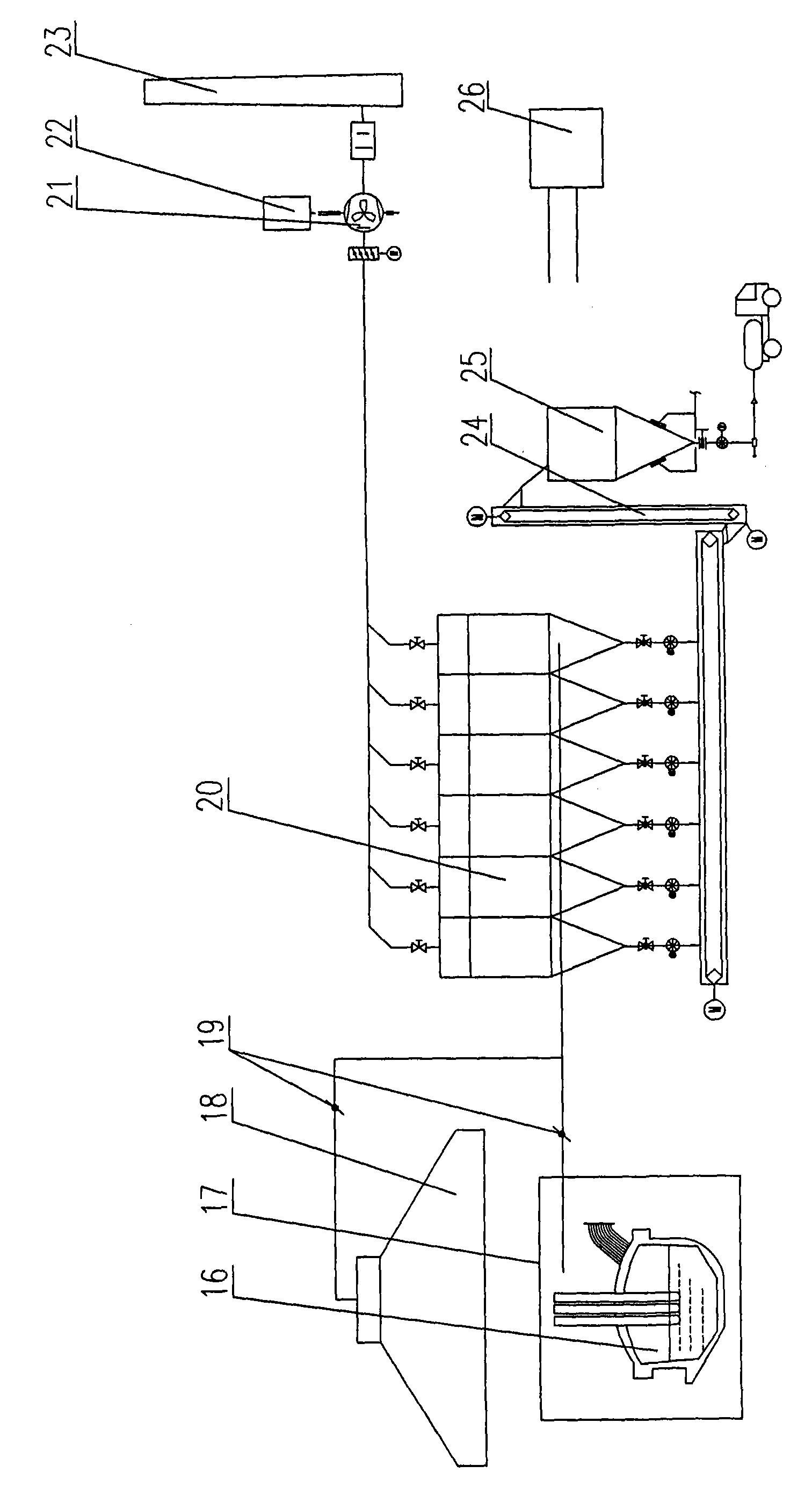

Flue gas waste heat recovery and negative energy consumption dust-removal system for electric stove

InactiveCN101539369AEasy to recycleSave on wear and maintenance costsDispersed particle filtrationIncreasing energy efficiencyCombustion chamberEvaporation

The invention relates to a flue gas waste heat recovery and negative energy consumption dust-removal system for an electric stove, comprising a first flue gas dust-removal and waste heat recovery system for the electric stove which is connected with the smoke hole of the electric stove to absorb high temperature flue gas generated by the electric stove during smelting phase and a secondary flue gas dust-removal system for the electric stove which is in charge of absorbing the flue gas generated by the electric stove during charging and tapping phase. The first flue gas dust-removal and waste heat recovery system for the electric stove comprises a water cooling travelling tube, an evaporation cooling device, a high temperature resistant dust remover, a waste heat boiler, a dust removal fan and a chimney; wherein the evaporation cooling device replaces the original water cooling flue gas path and combustor. The secondary flue gas dust-removal system for the electric stove comprises a collecting cover, a dust remover worked at normal temperature, a dust removal fan and a chimney. The invention is high in dust removal efficiency and high in vapor recovery rate, saves a first cooling device and a secondary cooling device, reduces device investment and maintenance charge and prolongs the service life of the filter pocket of the dust remover.

Owner:BAOSTEEL ENG & TECH GRP

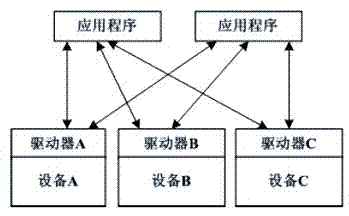

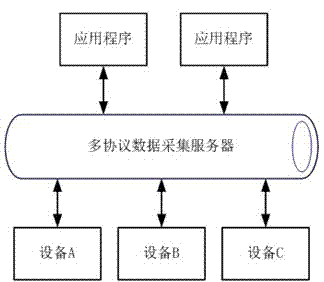

Multi-protocol data collection system and method of various equipment sensors

InactiveCN103501291ALess investment in equipmentGood value for moneyTransmissionPerformance ratioCross-platform

The invention discloses a multi-protocol data collection system and method of various equipment sensors. According to the method, multi-protocol data collection of the various equipment sensors is achieved through a multi-protocol controller, a collection data storage, a simple multi-protocol configurator and a communication result displayer; universality of multi-protocol data collection of the various equipment sensors is achieved through an open connector; multi-protocol real-time data collection supported by the cross-platform, multiple-system and long-distance Internet is achieved by the application of a B / S structure. Due to the flexibility and expandability of a programming interface, data collection of a sensor of new equipment and new collection protocol expansion can be increased swiftly on the basis of an existing system modeling. Investment of on-spot equipment can be lowered due to the integrated system, and a data collection solution with the optimal cost-performance ratio is achieved due to seamless connection between the system and a data system of the equipment.

Owner:上海汉乾信息科技发展有限公司

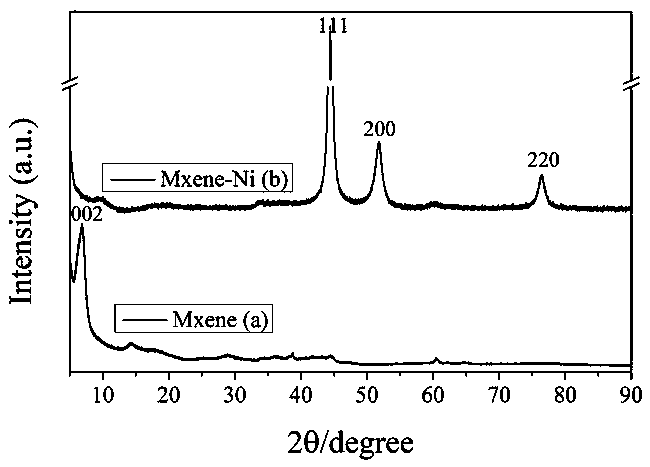

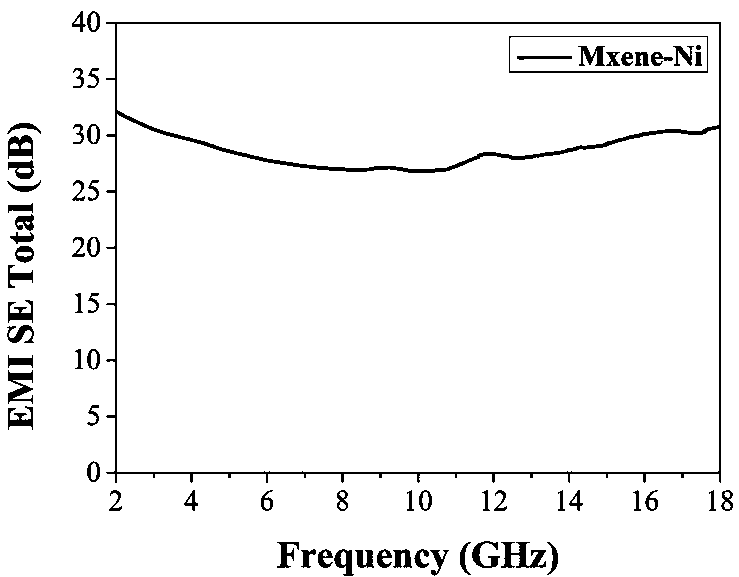

MXene-magnetic metal composite material and preparation method thereof

ActiveCN109712769AImprove conductivityImprove magnetic propertiesInorganic material magnetismNanotechnologyMaterials preparationHydrazine compound

The invention belongs to the field of nano magnetic composite material preparation, and discloses a MXene-magnetic metal composite material and a preparation method thereof. The MXene-magnetic metal composite material is composed of flake MXene and magnetic metal nanoparticles uniformly loaded on the MXene. The preparation method comprises the steps of: dispersing the Mxene in a mixed liquid consisting of ethylene glycol and water, adding a magnetic metal salt into the mixed liquid and stirring the mixture, then adding NaOH into the mixture to adjust a system pH value to 8-14, then adding hydrazine hydrate into the mixture, and stirring the mixture evenly; heating the mixture to 60-120 DEG C and keeping the temperature for 0.2 to 8 h; cooling, separating, washing and drying the mixture toobtain the MXene-magnetic metal composite material. The preparation method adopts the ethylene glycol and water as a solvent and the MXene as a carrier, the magnetic cations are adsorbed on the surface of the MXene selectively and heated at the temperature of 60-120 DEG C, the magnetic cations are gradually reduced to magnetic nanoparticles under the common reducing action of hydrazine hydrate andethylene glycol, and the final prepared MXene-magnetic metal composite material integrates the properties of the MXene and magnetic metal.

Owner:ZHENGZHOU UNIV

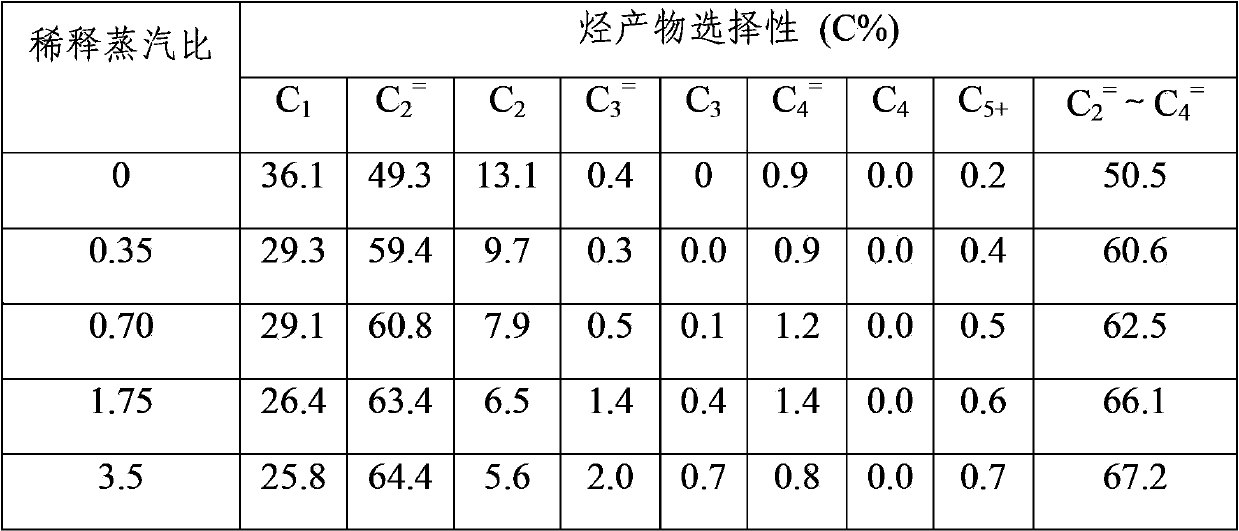

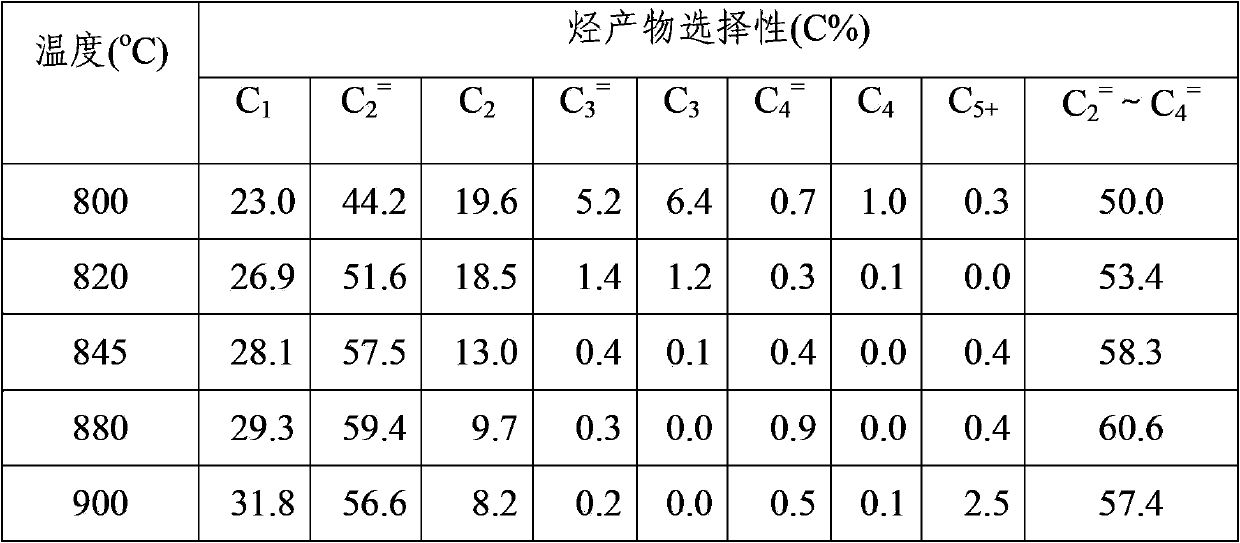

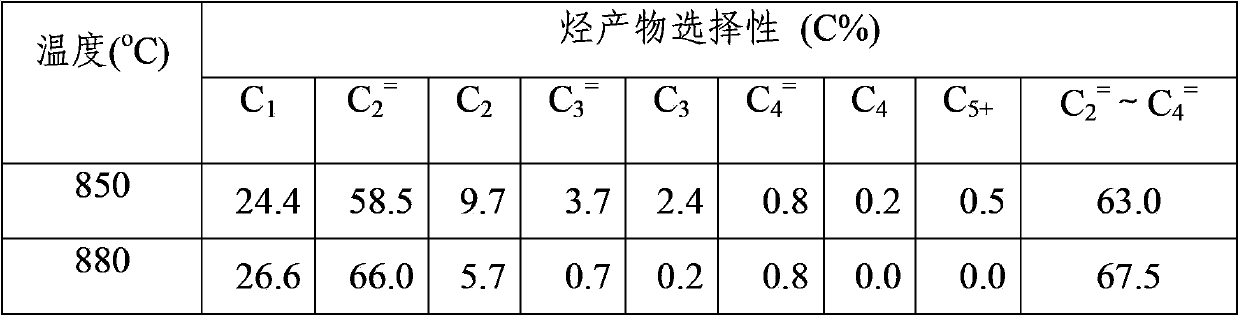

Method for production of low carbon olefins from synthetic gas via low carbon alkanes

InactiveCN103864556ALess investment in equipmentReduce energy consumptionHydrocarbon from carbon oxidesHydrocarbonsSyngasChemistry

The invention relates to a method for production of low carbon olefins from a synthetic gas via low carbon alkanes. The low carbon olefins are produced by adopting a two stage reactor in series way. A first stage reactor is filled with a multifunctional composite catalyst, in the reaction conditions of the temperature of 260-450 DEG C, the space velocity of 500-5000h <-1>, the pressure of 1.0-5.0MPa, the H2 / CO molar ratio of 0.5-5.0, the synthesis gas reacts on the multifunctional composite catalyst to produce a hydrocarbon product mainly comprising low carbon alkanes. The product directly enters without separation into a second stage reactor to produce low carbon olefins mainly comprising ethylene by a thermal cracking way; also the product can be divided into two parts, one part of the product mainly comprising methane and ethane produces the ethylene by the thermal cracking way, and the other part of the product mainly comprising propane and butane produces the low carbon olefins mainly comprising propylene and butylenes by catalytic dehydrogenation and other ways.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

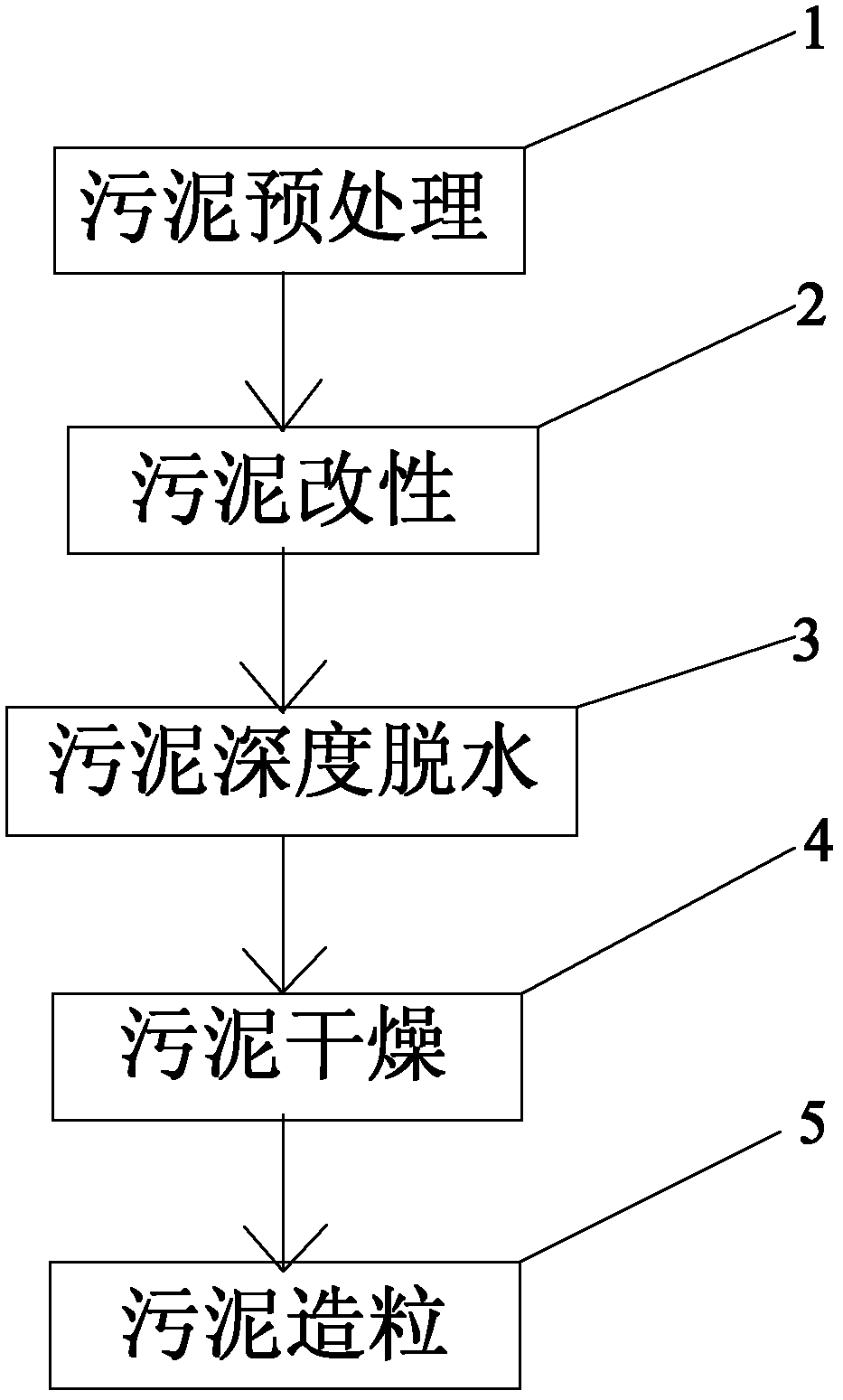

Production method of sludge biomass environment-friendly fuel

ActiveCN102491608ASimple processLess investment in equipmentSludge treatment by de-watering/drying/thickeningBiofuelsBiomassHeavy metals

The invention discloses a production method of a sludge biomass environment-friendly fuel. The method comprises the following steps: 1) sludge pretreatment: conveying sludge to a pretreatment pool, adding deodorant and bactericide and stirring uniformly; 2) sludge modification: conveying pretreated sludge to a reaction tank, adding modifier, sulfur fixing agent and heavy metal stabilizing agent, reacting uniformly and adding crushed biomass; 3) sludge depth dehydration: carrying out depth dehydration on the modified sludge; and 4) sludge drying: fragmenting the sludge cake treated with depth dehydration and drying. Compared with a prior art, the production method of sludge biomass environment-friendly fuel provided by the invention can realize quantitative reduction, harmlessness, stabilization and resource of sludge treatment, effectively solve a problem of secondary pollution of sludge and obtain the biomass environment-friendly fuel; besides, the fuel can substitute coal for combustion in boiler, make up sludge treatment cost as well as effectively solve a social problem of energy shortage.

Owner:深圳市泽源能源股份有限公司

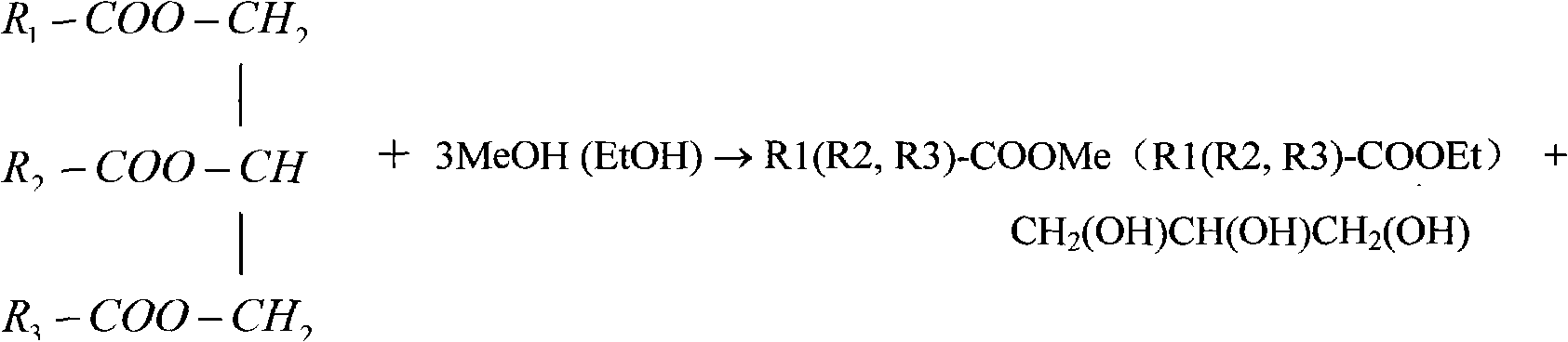

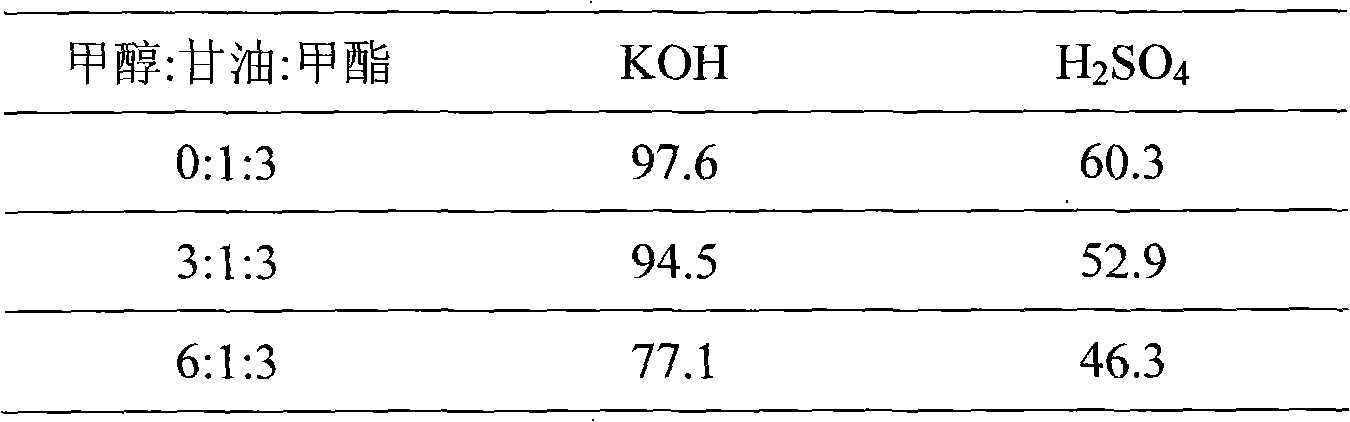

Quick and clean process for preparing biological diesel oil with esterification/ester exchange reaction

InactiveCN101319169ALess investment in equipmentReduce energy consumptionFatty acid esterificationBiofuelsVegetable oilBiodiesel

The invention relates to a novel process for preparing biodiesel through natural oil which has different acid numbers and a rapid esterification / ester interchange reaction with catalysts of minute quantity at an alcohol-oil consolute temperature. The process comprises the following steps of: taking animal and vegetable oil as raw materials, adding the oil and methanol into a reaction kettle according to an alkyd mol ratio of 2 to 1-10 to 1 for rapid esterification, and adding the acid catalyst of minute quality which is 0.01-1 per mille of the weight of the oil with reaction conditions of 120-200 DEG C, 2.0-8.0Mpa, and 10-30min; after neutralization deacidification, adding refined oil and methane into a high-pressure reaction kettle according to a mol ratio of 1 to 6-1 to 20 for rapid ester interchange, and adding a base catalyst of minute quality which is 0.01-1 per mille of the weight of the refined oil with reaction conditions of 140-200 DEG C, 2.0-8.0Mpa, and 5-20min; carrying out the sedimentation or centrifuge of a reaction product, and generating a qualified biodiesel product after removing methane through upper layer liquid phase distillation. The process uses minute quantity of catalysts and does not need separation with quick reaction and simple procedure without pollution and corrosion. The process has the advantages of mild conditions, environmental protection and remarkable efficiency.

Owner:SICHUAN UNIV

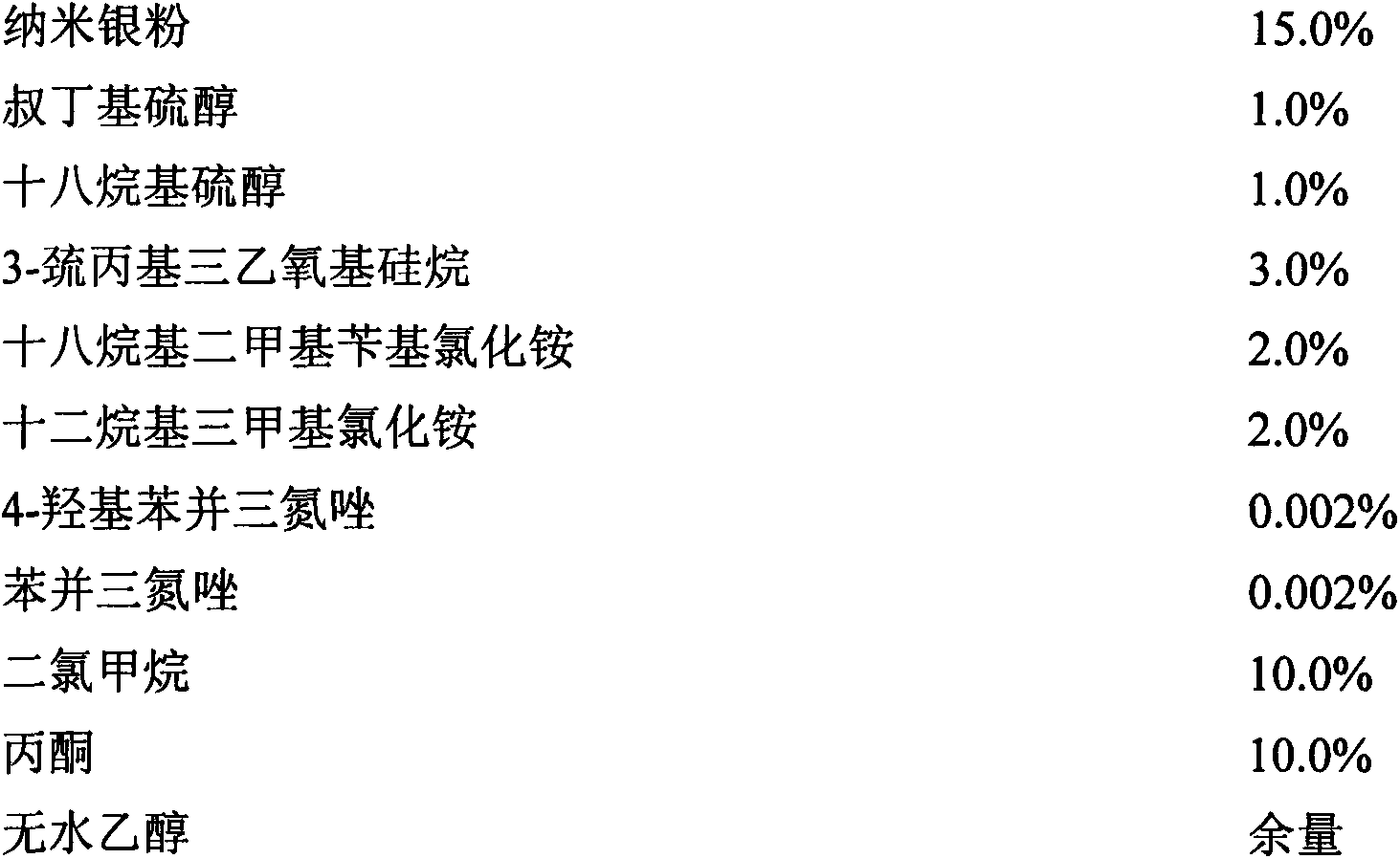

Modified nano silver powder preparing method

ActiveCN103817321ASimple production processLess investment in equipmentMaterial nanotechnologySilane couplingSurface modification

The invention discloses a modified nano silver powder preparing method. The method includes adopting thioalcohol, thiol-contained silane coupling agent, cationic surface active agent, corrosion inhibitor and organic solvent as raw materials, performing surface modification on the nano silver powder, and preparing and obtaining the modified nano silver powder; and the problems that the nano silver powder agglomerates easily and is poor in solubility after being combined with other materials are solved; the method is simple and practical in process, low in equipment investment, low in energy consumption and free of environment pollution, the applying range of the modified nano silver powder is broad, promotion and application are facilitated, and the method has promised application prospect.

Owner:NANJING FORESTRY UNIV

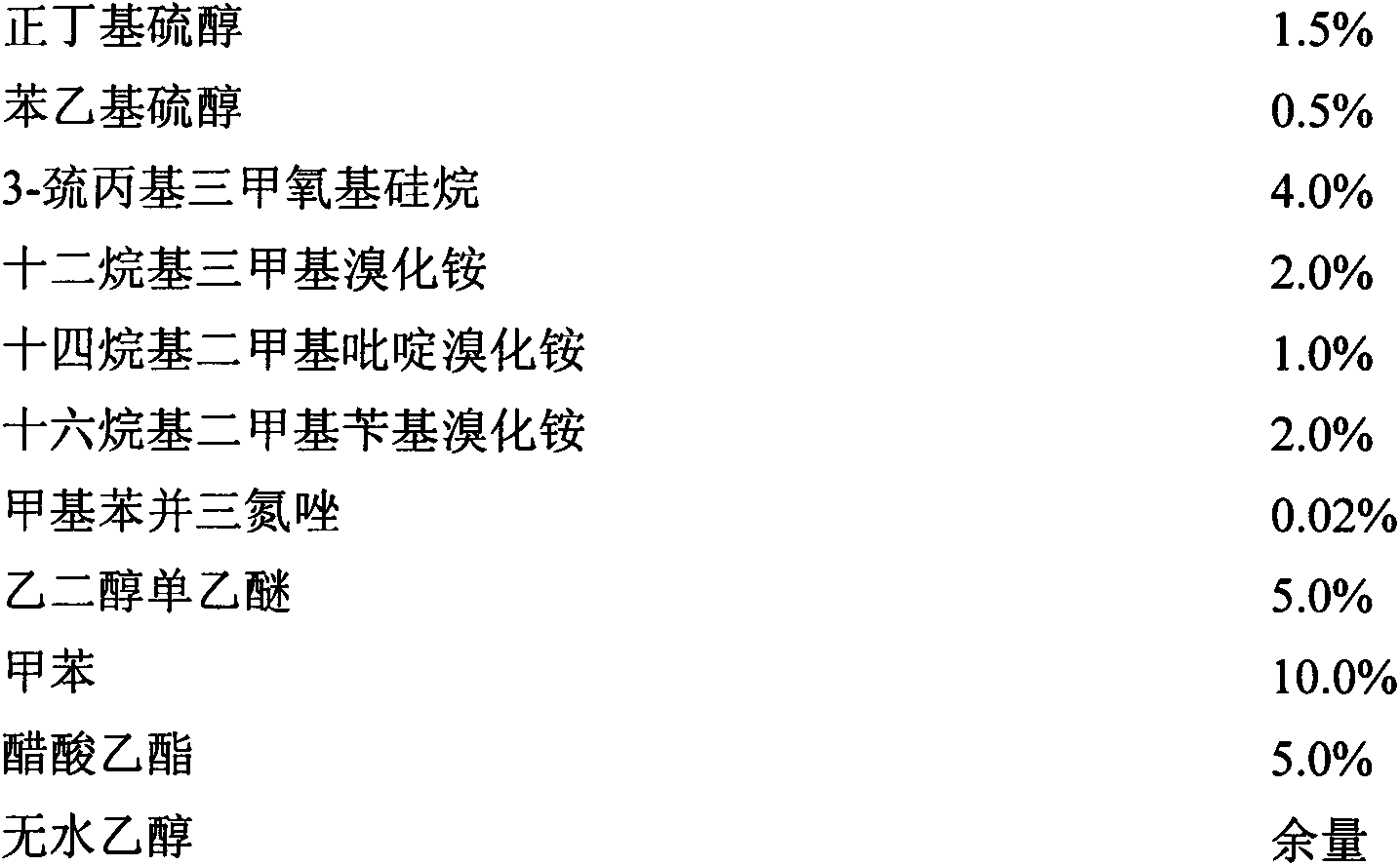

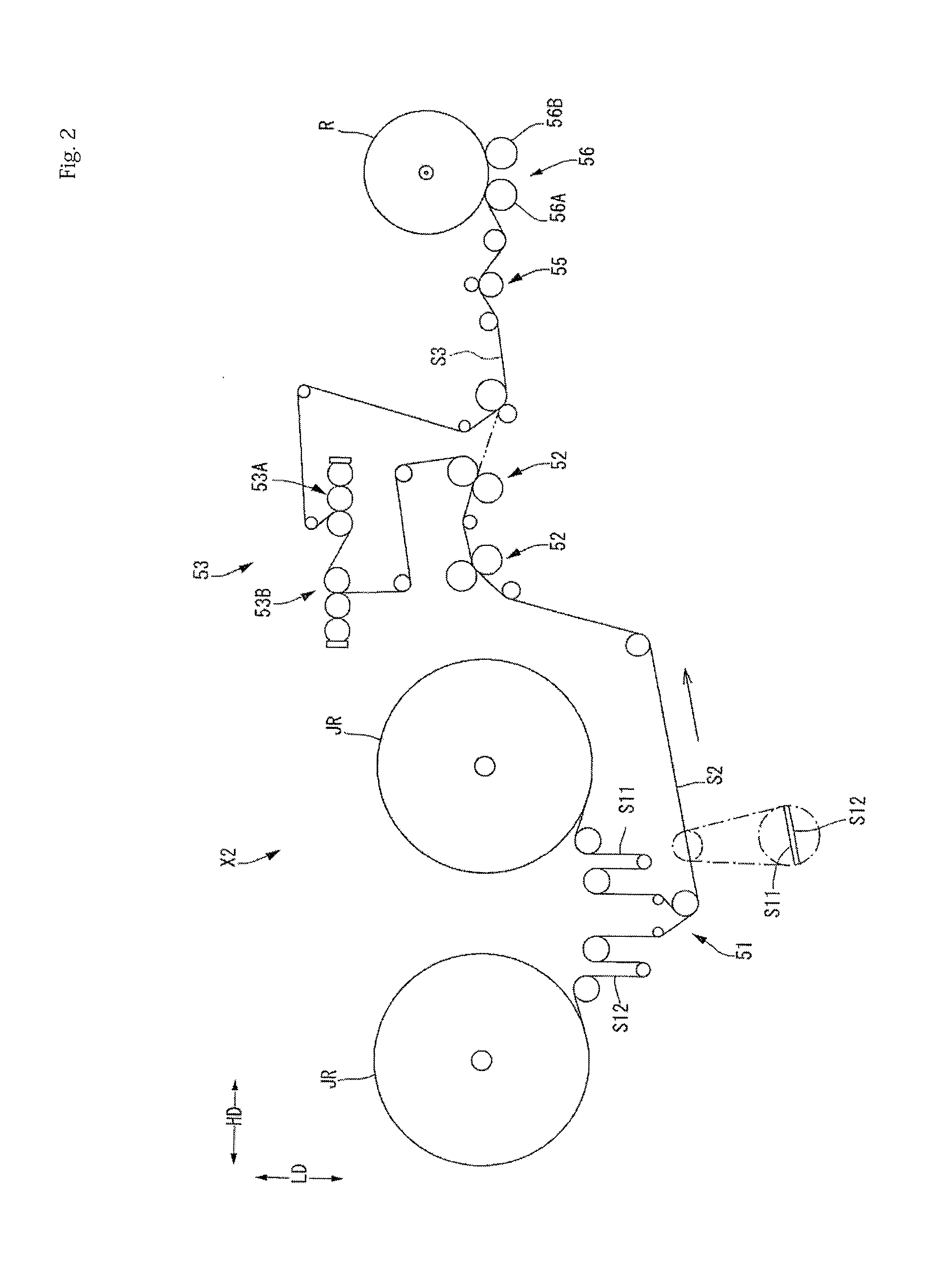

Method for manufacturing toilet roll products and toilet roll products

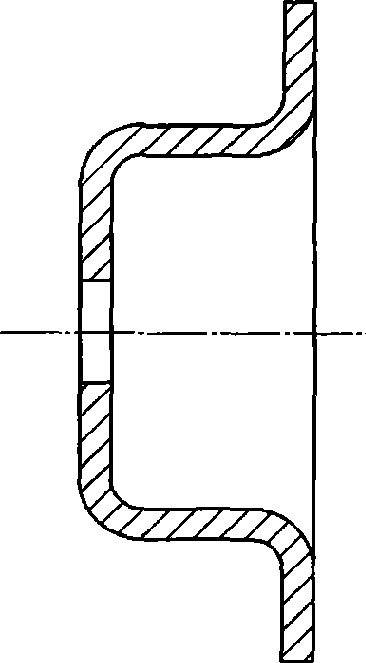

ActiveUS20130323453A1Low facility investmentLess investment in equipmentStampsFlexible coversReverse currentIon-exchange membranes

Provided are an electrolytic cathode structure that can suppress the degradation of an activated cathode even if a reverse current flows upon the stoppage of operation of an electrolyzer in an electrode structure allowing the distance between the electrode and an electrode current collector to be maintained at an approximately constant value, and an electrolyzer using the same.The electrolytic cathode structure includes a metal elastic cushion member 1 compressed and accommodated between an activated cathode 2 and a cathode current collector 3. At least a surface layer of the cathode current collector 3 consumes a larger oxidation current per unit area than the activated cathode. The electrolyzer is partitioned by an ion exchange membrane into an anode chamber for accommodating an anode and a cathode chamber for accommodating a cathode. The electrolytic cathode structure is used for the cathode.

Owner:DAIO PAPER CORP

Method for preparing edible walnut oil and degreasing walnut protein milk

InactiveCN101278748ASimple production processLess investment in equipmentProtein composition from vegetable seedsEdible oils/fatsSide productSunflower seed

A production method of edible walnut oil and degreased walnut protein milk comprises selecting materials, soaking, sanitizing, peeling, removing astringency, jordaning, centrifugalizing, sterilizing, refining, decoloring, preparing for degreased walnut milk etc. The production method of the edible walnut oil and the degreased walnut protein milk provided by the invention can not only use walnut kernel as raw material to produce two products of the walnut oil and the degreased walnut protein milk simultaneously, but also uses olive, peanut kernels, sunflower seeds kernels, sesame kernel, soybeans and vegetable seeds or the mixture of the substances to substitute the walnut kernel to produce corresponding edible oil and degreased protein milk, or different edible oil is confected into a blend oil, which can use the original nutrient components of the raw materials and does not contain chemically extracted bad side product, and the invention has simple production technique, few investment in equipment and high oil yield, so the invention is fit for modern automatic production.

Owner:TIANJIN TIDAI MEDICINE SCI & TECH

Method for preparing pesticide avermectin microcapsule

InactiveCN1663379ALess investment in equipmentProcess is easy to controlBiocideAnimal repellantsPrepolymerChemistry

The invention relates to a pesticide formulation of nimbin and emamectin benzoate and preparing method belonging to the technology field of pesticide preparation, wherein the conventional in-situ polymerization method is improved for the preparing process, which comprises the preparation of ureaformaldehyde resin prepolymer aqueous solution, preparation of avermectin mixture solution and the preparation of avermectin microcapsule. The invention solves the problem of influenced drug effect by the combination of avermectin and soil, the drug effective period is also extended.

Owner:YUNNAN UNIV

On-line thermal-insulating quenching apparatus and process

ActiveCN101029378ALess investment in equipmentReduce energy consumptionQuenching devicesQuenchingElectric heating

Owner:FUJIAN MINFA ALUMINUM

Dry flue gas desulphurization method using steel slag or blast furnace slag as absorbing agent

InactiveCN101797467ASmall system footprintLess investment in equipmentDispersed particle separationSlagFlue gas

The invention relates to a dry flue gas desulphurization method using steel slag or blast furnace slag as absorbing agents, which comprises the following steps: adopting a nitrification circulation fluidized bed flue gas desulphurization device; selecting the steel slag or the blast furnace slag with the granularity smaller than or equal to 0.048 mm to be sprayed into a desulphurization tower by a pneumatic conveying method; spraying process water into the desulphurization tower through an atomization water spraying nozzle; introducing the flue gas into the desulphurization tower from a flue gas inlet of a pre-dust-removal section; making the desulphurized flue gas enter a secondary dust remover; spraying circulation dust into the desulphurization tower by the pneumatic conveying method; discharging the dust into an external transportation dust field from an external dust discharge outlet; and discharging the clean flue gas into a chimney through a draught fan to be discharged into the atmosphere. The invention adopts the steel slag or the blast furnace slag as the absorbing agents, the desulphurization cost is low, the nitrification circulation fluidized bed flue gas desulphurization device is adopted, ground occupied by the system can be saved, the equipment investment can be reduced, and in addition, the desulphurization effect is good.

Owner:周建安

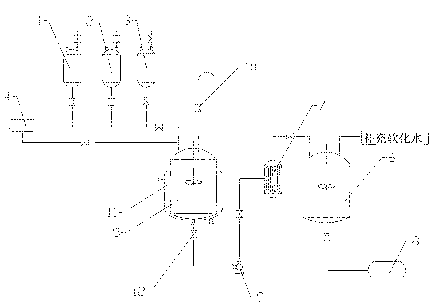

Production device and production method of liquid sodium dimethyl dithiocarbamate

The invention discloses a production device and a production method of liquid sodium dimethyl dithiocarbamate. The production device comprises a reaction kettle, wherein the upper part of the reaction kettle is respectively communicated with a dimethylamine head tank, a sulfur dioxide head tank and a sodium hydroxide head tank by pipelines; the lower part of the reaction kettle is connected with a reaction kettle dump valve; and the reaction kettle dump valve is sequentially communicated with a filter, a finished product allocation tank and a finished product storage tank sequentially by pipelines. The production method comprises the following steps of: measuring carbon bisulfide, a 30% sodium hydroxide solution and 40% dimethylamine at a mass ratio, placing a dimethylamine solution into the reaction kettle, mixing, supplying a cooling medium to a reaction kettle jacket and an internal cooling coil tube, pressing carbon bisulfide into a synthetic kettle when the temperature of the kettle drops to 10-20 DEG C, then pressing the 30% sodium hydroxide solution into the synthetic kettle, slowly opening a synthetic kettle dump valve, and pressing a material in the reaction kettle into the filter and then into the finished product allocation tank.

Owner:青岛中科荣达新材料有限公司

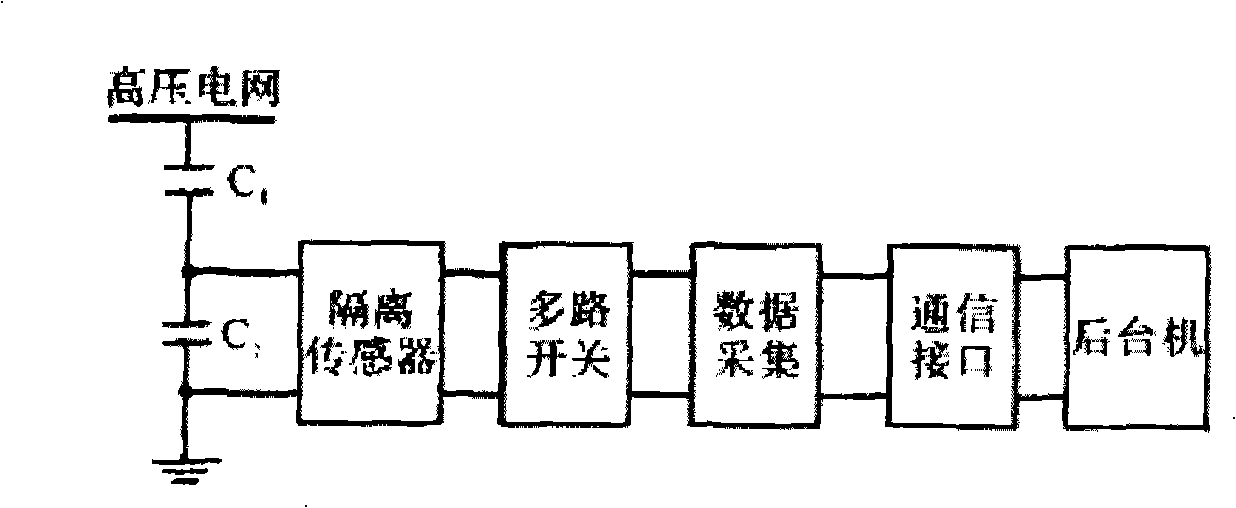

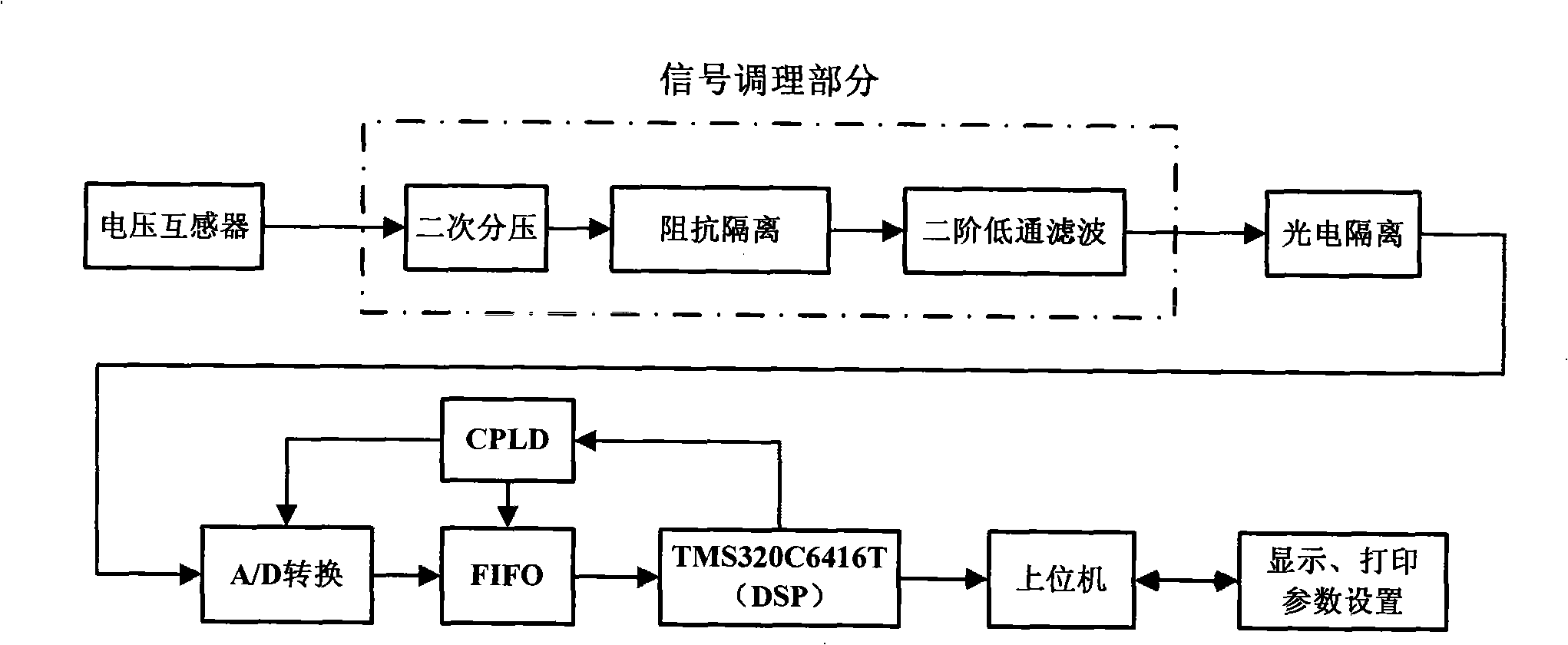

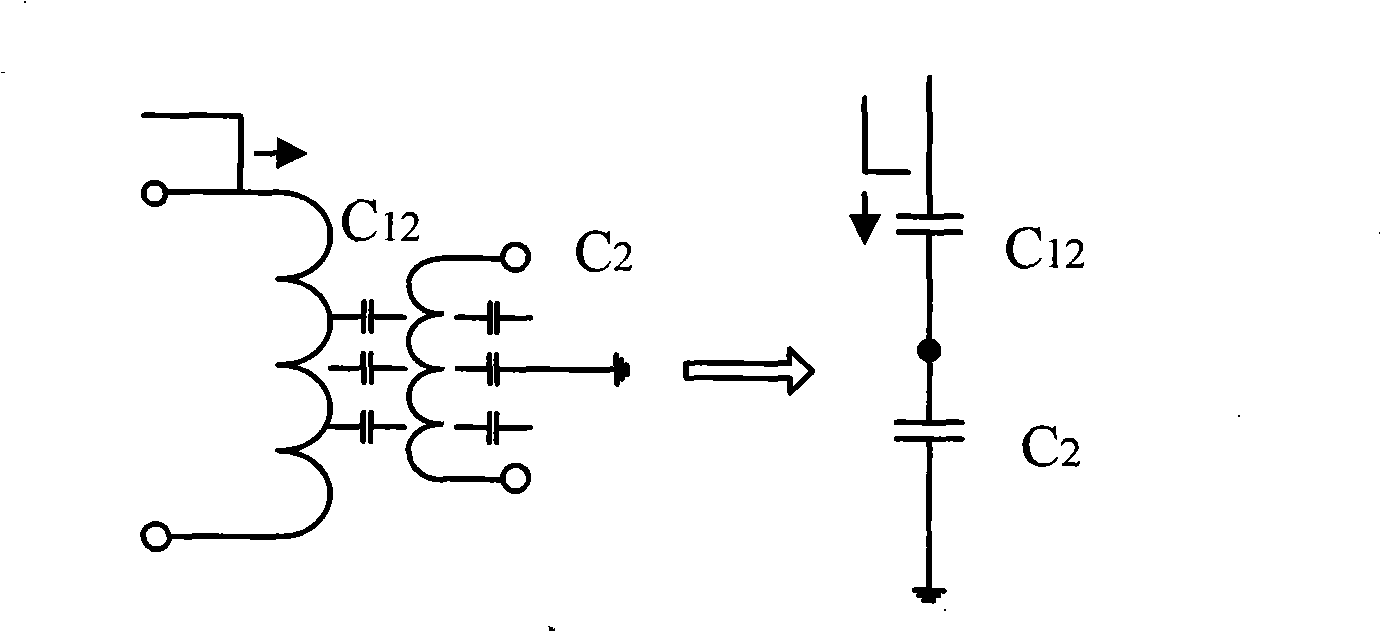

35KV power distribution station internal and external over voltage monitoring method based on voltage mutual inductor sample

InactiveCN101408565ALess investment in equipmentNo additional electrical nodes requiredCurrent/voltage measurementData bufferPower grid

The invention relates to a method for monitoring the internal and external overvoltage in a power distribution station based on the sample of a voltage transformer, which comprises the following steps: (1) each phrase voltage signal is collected by the voltage transformer; (2) each phrase voltage signal is sent into a digital signal processor as a sample voltage signal after signal conditioning, photoelectric isolation, and the processing by a analog-to-digital converter and a data buffer, and the digital signal processor can continuously process each phrase sample voltage signal at the sample point to obtain each phrase voltage sample value of each sample point; (3) the digital signal processor can make the comparison between each phrase voltage sample value and the preset voltage reference value and judge that whether the internal and external overvoltage exist or not; each phrase voltage sample value is sent into the storage area of the digital signal processor, the voltage signal is uploaded by a communication interface, and an upper computer records the waveform and the parameter of the transient overvoltage, monitors all the internal and external overvoltage generated in a power system, and records the generation process of the overvoltage on line completely and precisely. The method of the invention has the advantages of safety and practicality, as well as rather less equipment investment.

Owner:CHANGZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER +1

Method for manufacturing hollow box type element with non-circular section from carbon fiber composite

InactiveCN102555231AReduce pressure and strength requirementsLess investment in equipmentCarbon fiber compositeCircular section

The invention relates to a method for manufacturing hollow box type element with non-circular section from carbon fiber composite, mainly comprising the following steps: preparing a female die outer shape mold for solidification of parts, a female die inner shape mold, a male die for the lay-up, and a soft mold for solidification; laying up the composite on the male die; placing vacuum bags into the inner space of the part and packaging the mold with vacuum bags; applying vacuum to the inner and outer vacuum bags so that the part billet can fit to the cavity of the mold; pre-pressing the mold at a mediate temperature, during which the solidifying pressure and the temperature point for application of the pressure are determined by calculation and experiment. By applying pressure from both inside and outside, applying pressure for molding solidification from the cavity of the mold, and applying completely same pressure to the surface of the mold at the same time to balance the internal pressure of the mold, the method of invention solves the defect that the method in the prior art cannot apply pressure to complex sections, variable sections and angles, and also solves the problems of angle layering and difficult mold releasing of light hollow elements with irregular sections like rectangular tubes.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

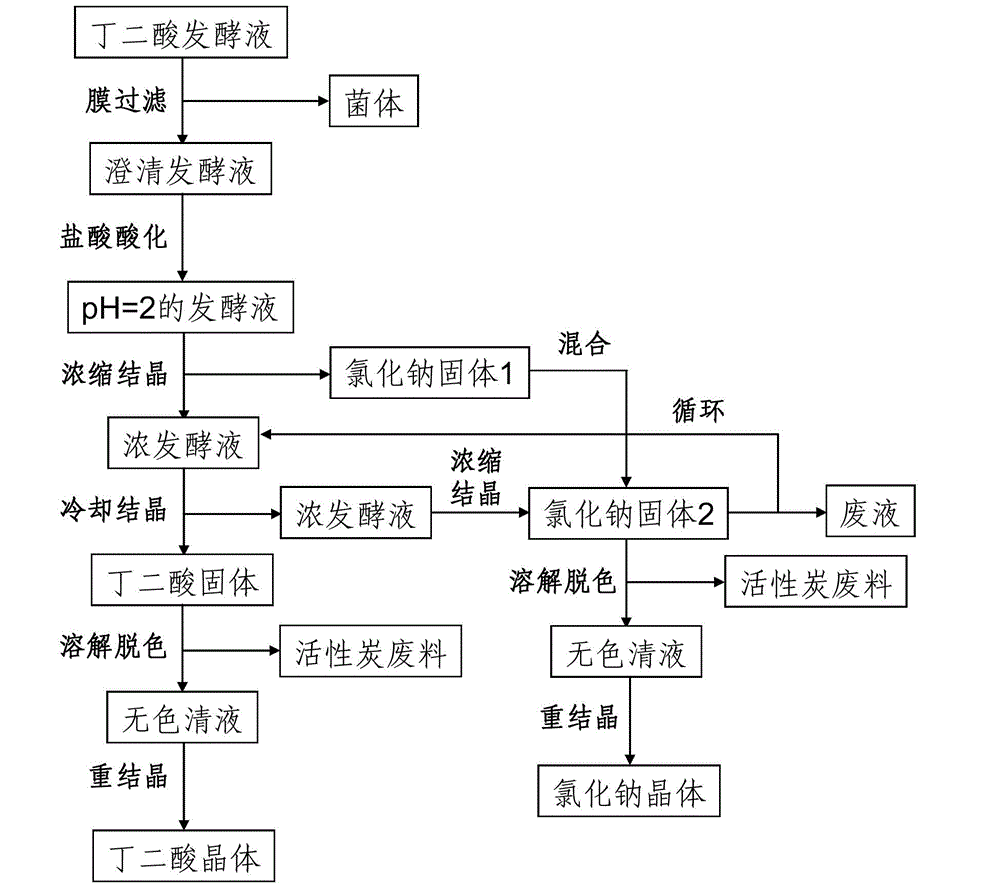

Method of extracting succinic acid from microorganism fermentation liquor

ActiveCN102942472ALess investment in equipmentLow running costAlkali metal halide purificationCarboxylic compound separation/purificationUltrafiltrationChemistry

The invention discloses a method of extracting succinic acid from microorganism fermentation liquor. The method includes the following steps: (1) sodium succinate fermentation liquor obtained through microorganism fermentation is clarified through an ultrafiltration membrane or micro-filtration membrane for removing thalli or other large-particle impurities; (2) the clarified fermentation liquor is acidized through concentrated hydrochloric acid to reach pH ranging from 1 to 3, and the pH is preferentially 2.0; (3) the acidized liquor is subjected to reduced pressure distillation concentration to be with succinic acid concentration at 300-400g / L, and sodium chloride precipitations are removed through solid-liquid separation; (4) the filter liquor obtained in the step (3) is subjected to cooling crystallization under stirring at temperature to be 5 DEG C to obtain succinic acid solids; (5) the filter liquor obtained in the step (4) continues to be concentrated to obtain second sodium chloride precipitations; (6) the residual mother liquor is subjected to cyclic operation according to the step (4) and the step (5) to obtain succinic acid solids and sodium chloride solids; and (7) succinic acid solids and sodium chloride solids are dissolved, discolored and recrystallized to obtain high-purity succinic acid crystals and sodium chloride crystals.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

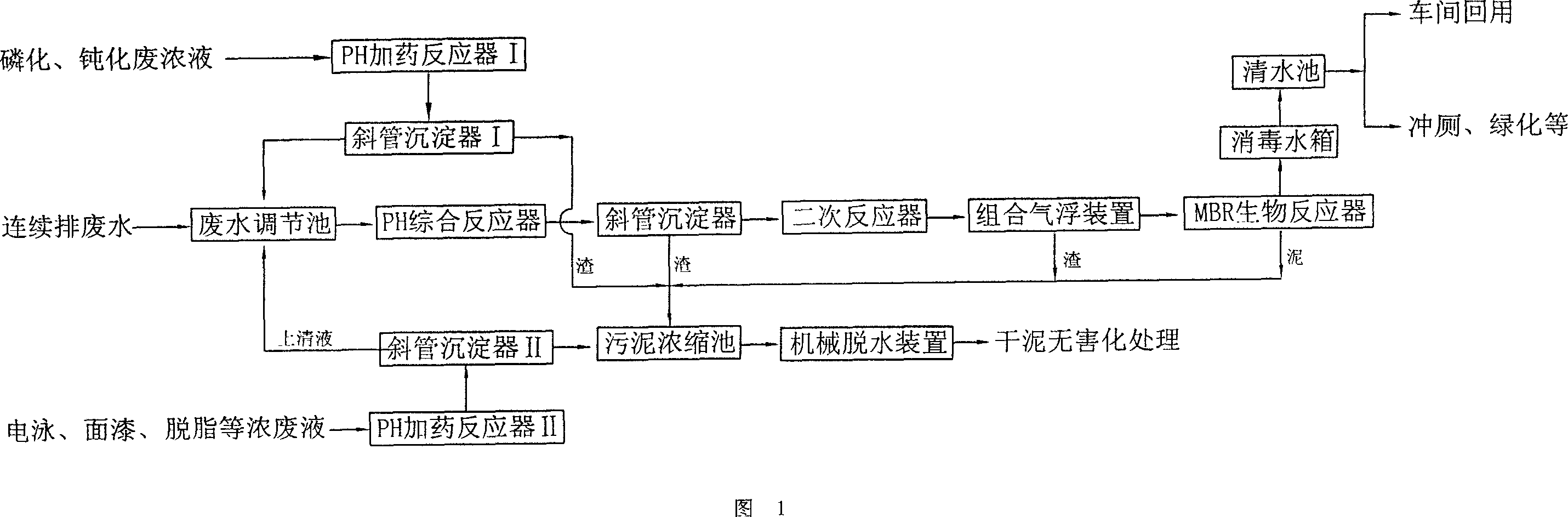

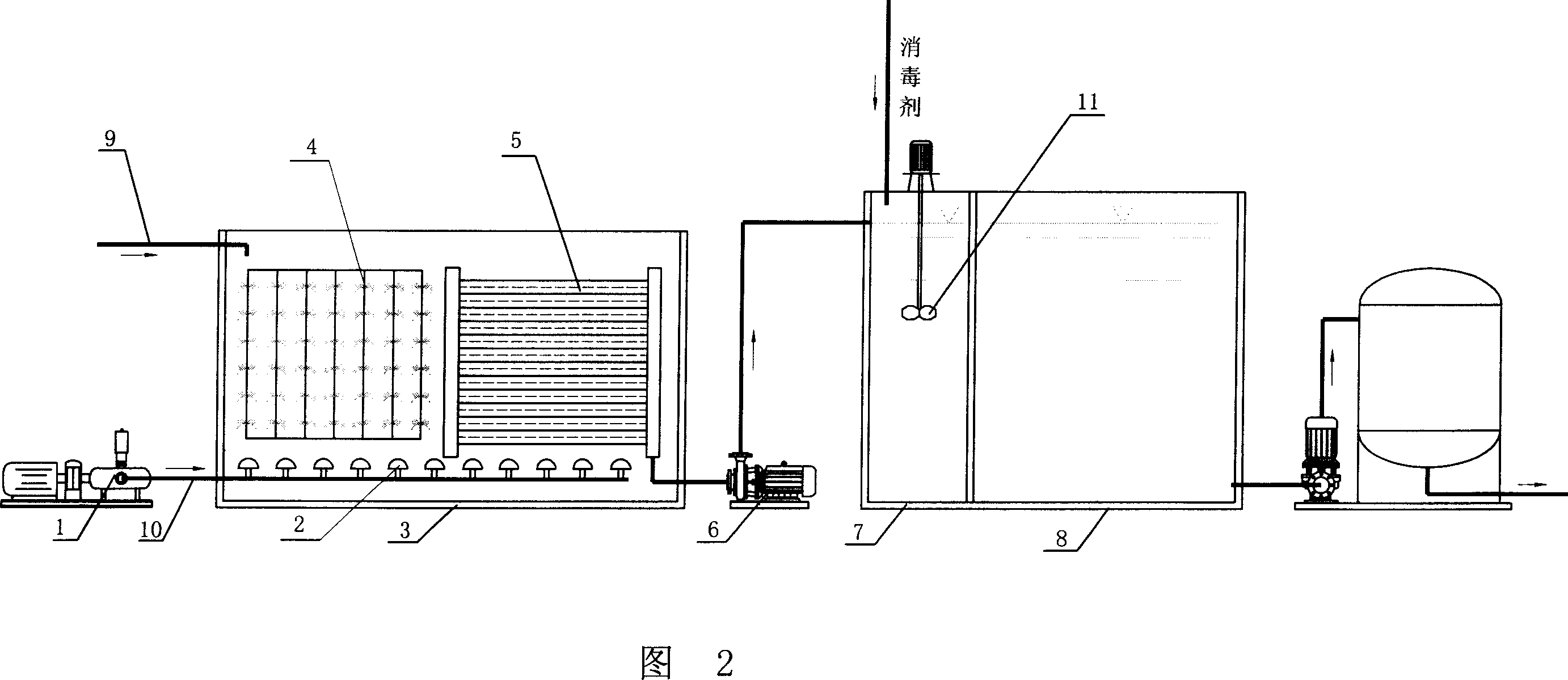

Complete process for treating coated industrial waste water

InactiveCN101028962AShort processLess investment in equipmentMultistage water/sewage treatmentSewageWater quality

A complete treating technology for the coating sewage includes such steps as regulating pH value of said sewage, adding flocculant, coagulating reaction, separating out supernatant by slant-tube depositor, removing floating dregs by combined air-floating unit, biochemical treating by elastic filler YDT and biomembrane reactor, disinfecting, and reusing the resultant water.

Owner:YANGZHOU HENGTONG ENVIRONMENT PROTECTION TECH

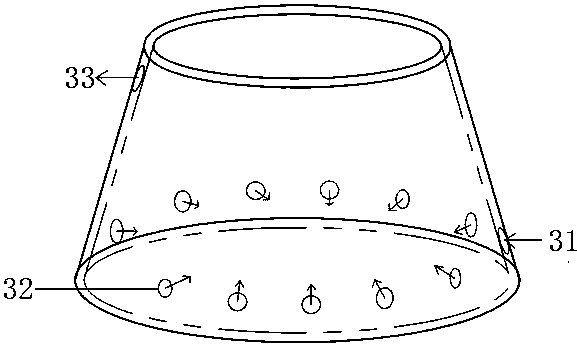

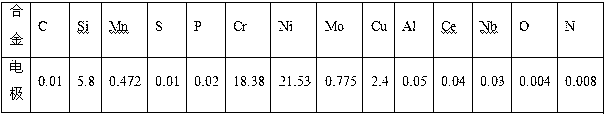

Manufacturing method of high silicon stainless steel for resisting high temperature concentrated sulphuric acid and equipment thereof

ActiveCN107312937AReduce entryUniform compositionIncreasing energy efficiencyIntermediate frequencyChemical element

The invention relates to a manufacturing method of high silicon stainless steel for resisting the high temperature concentrated sulphuric acid and equipment thereof. Firstly, ingredients of chemical elements of a steel ingot are designed, and a round-shaped electrode is smelted through the technology of intermediate frequency induction furnace primary smelting and argon oxygen decarburizing furnace refining; and the steel ingot is smelted through the technology of electro slag remelting (ESR). The equipment of the manufacturing method of the high silicon stainless steel for resisting the high temperature concentrated sulphuric acid includes the electrode and a liquid slag pool; a protection cover is arranged above the liquid slag pool, an inner cavity is formed in the protection cover, and the electrode is arranged in the inner cavity; an inner wall air outlet hole for inert gas is formed in the bottom of the protection cover, a main air inlet hole for the inert gas is formed below the side face, and a main air inlet hole for the inert gas is formed above the side face. The high silicon stainless steel prepared by the method and the equipment is high in concentrated sulphuric acid corrosion resistance under a high temperature environment, and the corrosion rate of the high silicon stainless steel is lower than 0.08mm / year in a H2SO4 solution with the concentration of 98% at the temperature of 150 DEG C.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com