MXene-magnetic metal composite material and preparation method thereof

A magnetic metal and composite material technology, applied in the direction of inorganic material magnetism, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of high Snoek limit, poor comprehensive performance of materials, etc., and achieve low cost, good conductivity and Magnetic performance, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of MXene-magnetic metal composite material, the steps are as follows:

[0035] (1) Put 2 g of MAX phase material in 40 mL of hydrochloric acid (40% mass concentration) and 2 g of lithium fluoride mixture, etch at 35 °C for 24 h, wash and dry to obtain MXene;

[0036] (2) Disperse 80 mg of MXene prepared in step (1) in a mixture of 100 mL of ethylene glycol and 9 mL of deionized water and stir evenly, then add 1.18 g of nickel chloride hexahydrate (NiCl 2 ·6H 2 (0) and stir, then add NaOH to adjust the pH value of the system to be 10, then add 5 mL of hydrazine hydrate, stir;

[0037] (3) Heat the mixed solution obtained in step (2) to 80 °C and keep it warm for 1 h;

[0038] (4) The solution obtained in step (3) was cooled, separated, washed with deionized water and ethanol for several times, and dried to obtain the MXene-magnetic metal composite material (referred to as MXene-Ni).

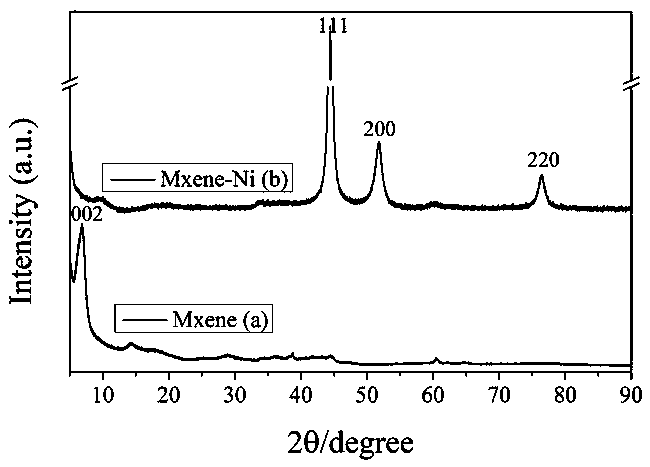

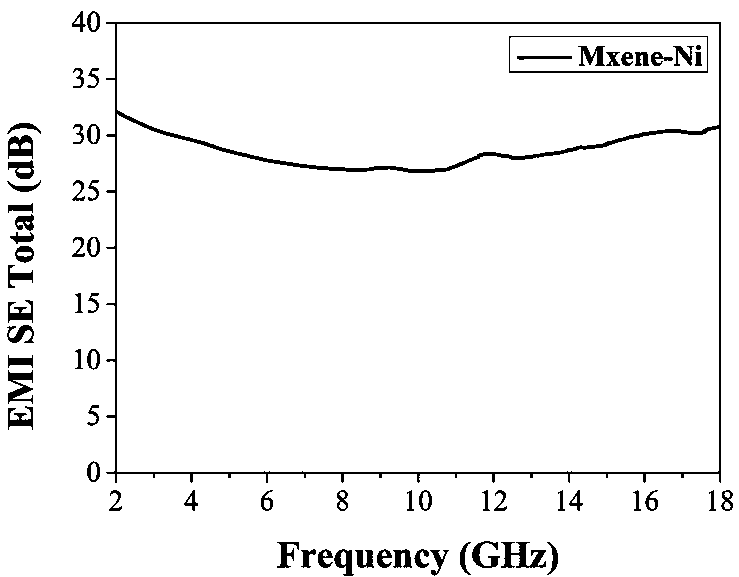

[0039] The scanning electron microscope picture of the MXene-ma...

Embodiment 2

[0043] A preparation method of MXene-magnetic metal composite material, the steps are as follows:

[0044](1) Place 1 g of MAX phase material in 20 mL of hydrochloric acid (40% mass concentration) and 1 g of lithium fluoride mixture, etch at 35 °C for 25 h, wash and dry to obtain MXene;

[0045] (2) Disperse 50 mg of MXene prepared in step (1) in a mixture of 48 mL of ethylene glycol and 6 mL of deionized water and stir evenly, then add 0.59 g of nickel chloride hexahydrate (NiCl 2 ·6H 2 (2) and stir, then add NaOH to adjust the pH of the system to be 11, then add 2.5 mL of hydrazine hydrate, stir;

[0046] (3) Heat the mixed solution obtained in step (2) to 78 °C and keep it warm for 1 h;

[0047] (4) The solution obtained in step (3) was cooled, separated, washed with deionized water and ethanol for several times, and dried to obtain the MXene-magnetic metal composite material (referred to as MXene-Ni).

[0048] The scanning electron microscope picture of the MXene-magnet...

Embodiment 3

[0050] A preparation method of MXene-magnetic metal composite material, the steps are as follows:

[0051] (1) Place 1 g of MAX phase material in 20 mL of hydrochloric acid (40% mass concentration) and 1 g of lithium fluoride mixture, etch at 35 °C for 25 h, wash and dry to obtain MXene;

[0052] (2) Disperse 100 mg of MXene prepared in step (1) in a mixture of 51 mL of ethylene glycol and 5 mL of water and stir evenly, then add 0.5 g of nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 (0) and stir, then add NaOH to adjust the pH value of the system to be 10, then add 2 mL of hydrazine hydrate, stir;

[0053] (3) Heat the mixed solution obtained in step (2) to 78 °C and keep it warm for 1 h;

[0054] (4) The solution obtained in step (3) was cooled, separated, washed with deionized water and ethanol for several times, and dried to obtain the MXene-magnetic metal composite material (referred to as MXene-Ni).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com