Method for removing CO2 from conversion gas

A gas conversion and removal technology, applied in separation methods, chemical instruments and methods, using liquid contact hydrogen separation, etc., to achieve the effects of small space occupied by equipment, low energy consumption, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Raw material gas composition: hydrogen: 60.9% nitrogen: 19.69% carbon dioxide: 18.36% carbon monoxide: 0.3% and the balance is inert gas.

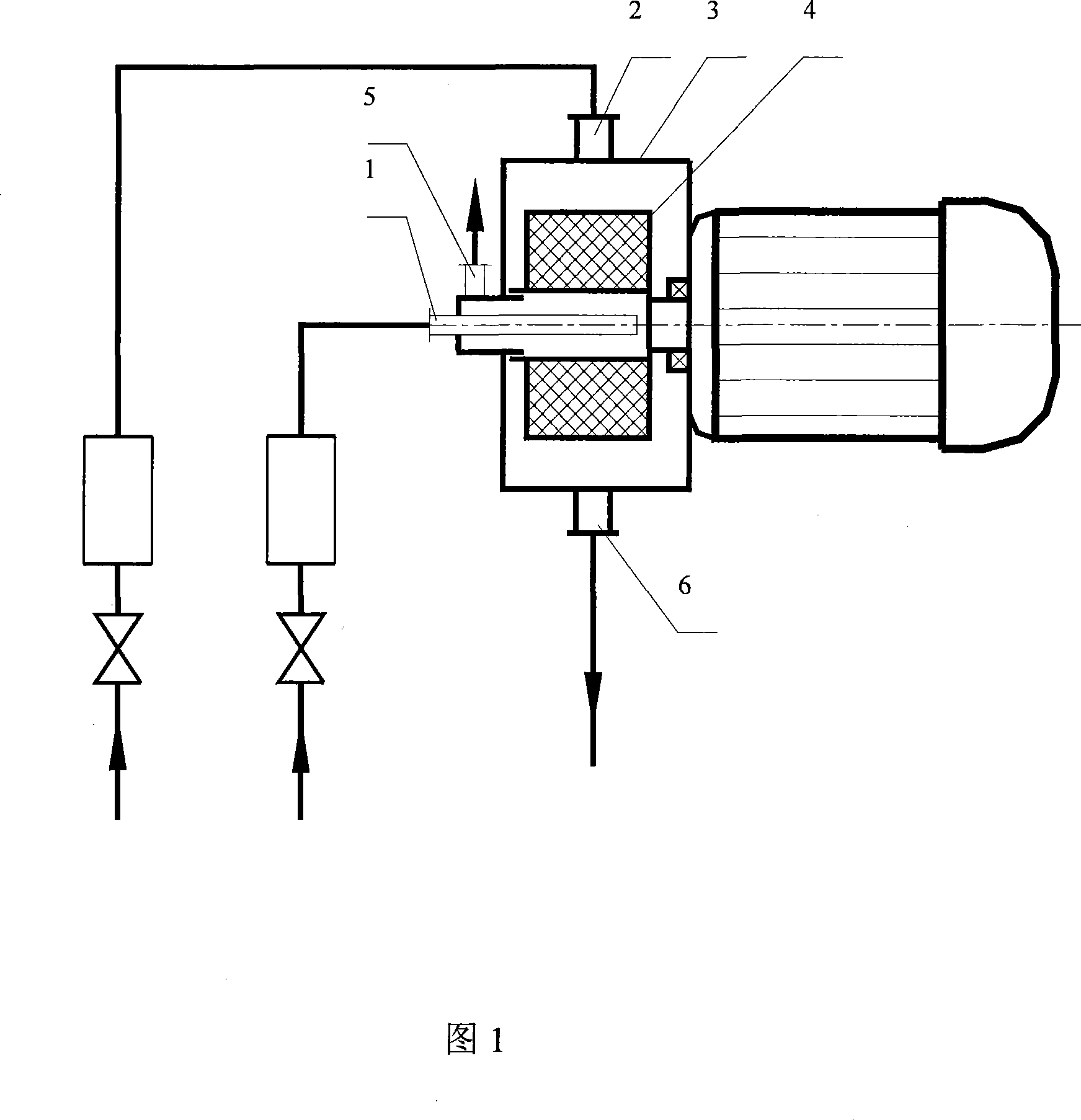

[0024] Absorbent composition: Potassium carbonate: 27%, diethanolamine: 2.5%, and the balance is desalted water. Adjust the temperature of the system to 75°C, adjust the pressure to 1.8Mpa, start the supergravity rotating bed reactor, adjust the rotor speed to 900r / m, and then open the control valve of the liquid inlet of the reactor, and the absorbent is distributed by the liquid through the liquid phase inlet pipe 1 The device is sprayed to the inner edge of the supergravity rotating bed rotor 4, and the flow rate of the regulating liquid is 70 liters / hour, and the CO containing CO from the previous section 2 The shifted gas enters the high-gravity rotating bed reactor through the gas phase inlet pipe 2, and contacts with the absorption liquid countercurrently in the rotor of the high-gravity rotating bed, and conducts CO under hi...

Embodiment 2-12

[0026] Process flow and step are with embodiment 1, and the flow rate of temperature, pressure, gas-liquid, rotor speed and test result of each embodiment are shown in Table 1.

[0027] The absorbent is a hot potassium alkali solution with an activator added, and the mass percentage concentrations are 20-60%, 25-40%, 30-35%, respectively, and the activator is diethanolamine or ACT-1, and the mass percentage concentrations are 1-35%. 5%, 1.5-4%, 2-3.5%. The absorbent is sodium hydroxide or potassium hydroxide solution, and the mass percent concentration is 1-40%, 5-35%, and 10-30% respectively.

[0028] Process conditions and test results of each embodiment of table 1

[0029] implement

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com