Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9589results about "Educts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods of sequestering co2

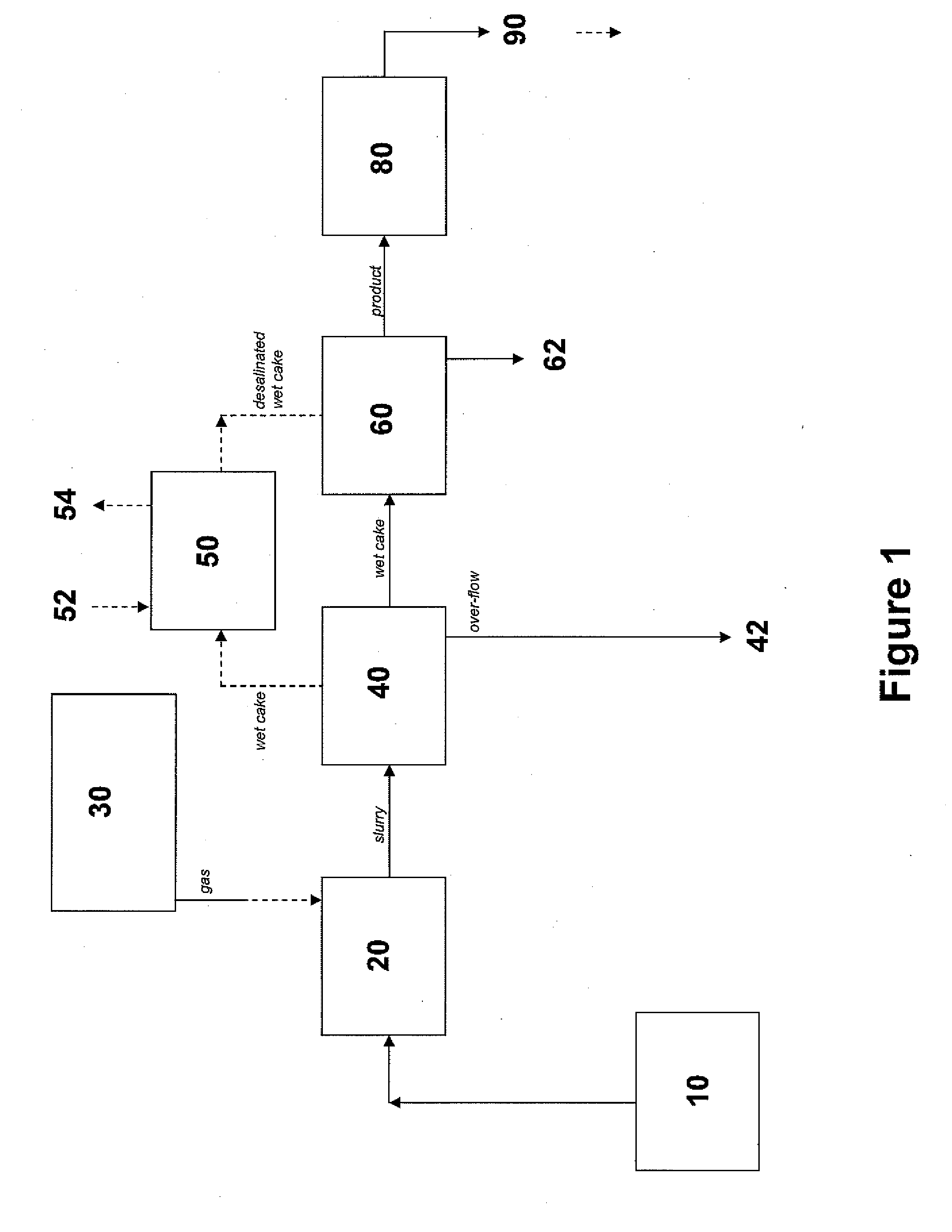

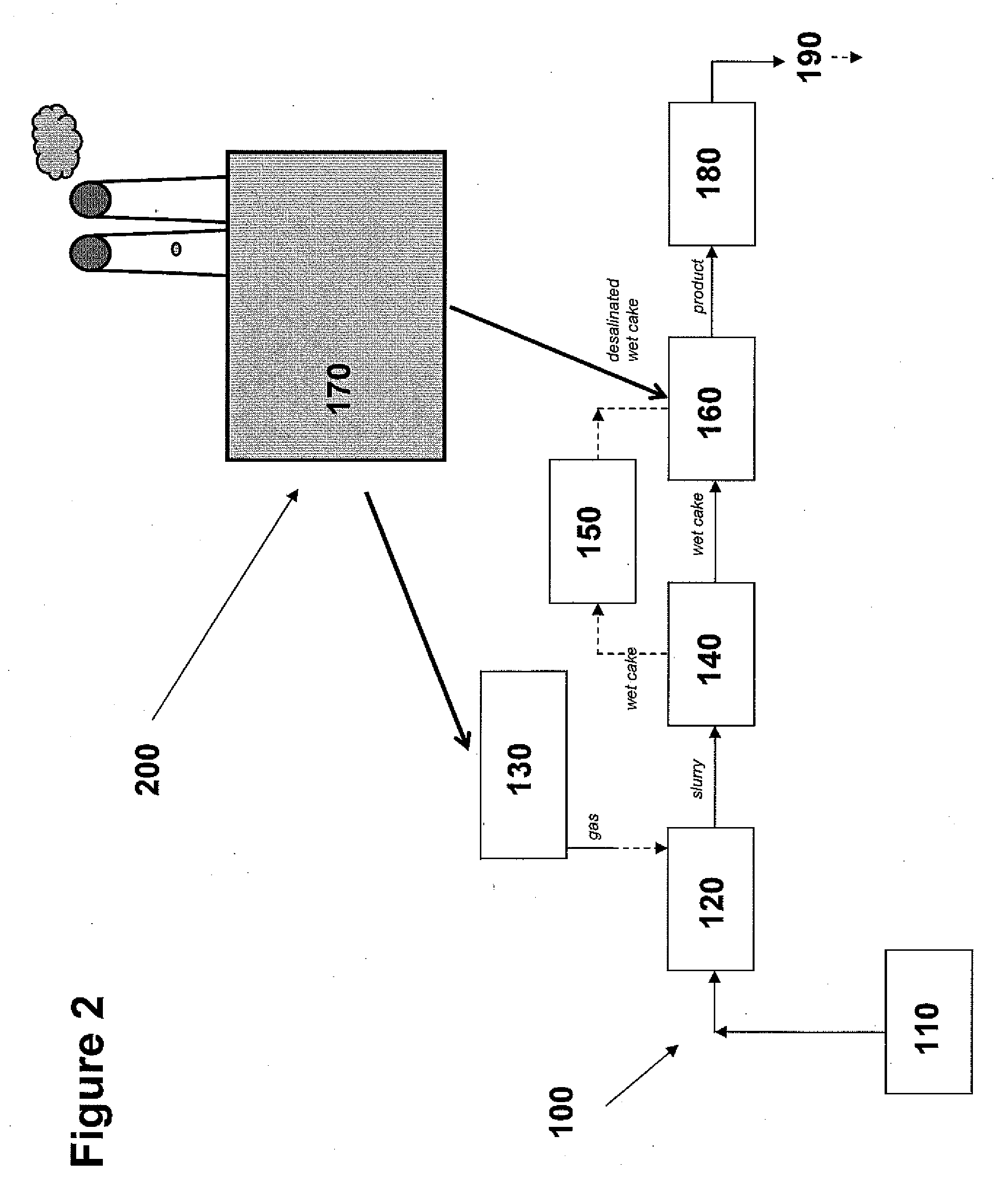

Methods of sequestering carbon dioxide (CO2) are provided. Aspects of the methods include precipitating a storage stable carbon dioxide sequestering product from an alkaline-earth-metal-containing water and then disposing of the product, e.g., by placing the product in a disposal location or using the product as a component of a manufactured composition. Also provided are systems for practicing methods of the invention.

Owner:ARELAC INC

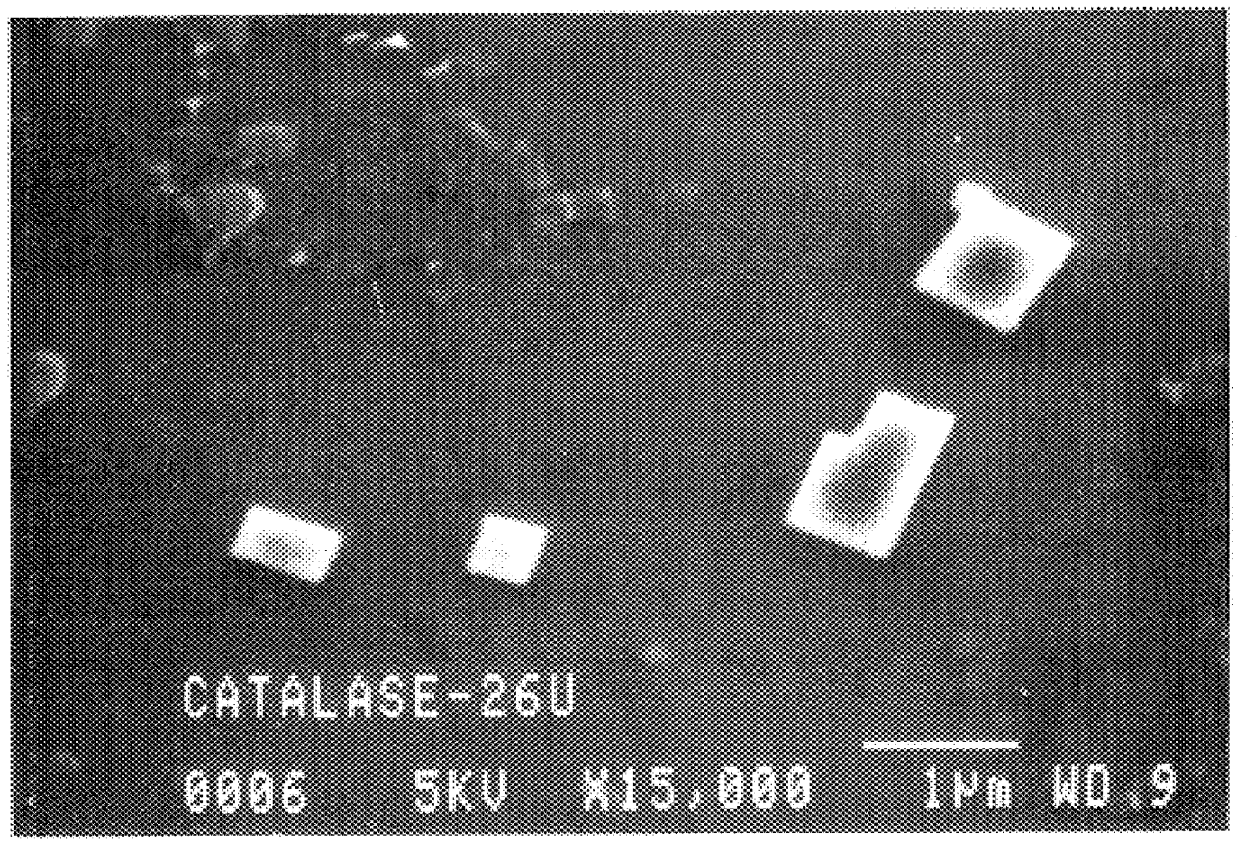

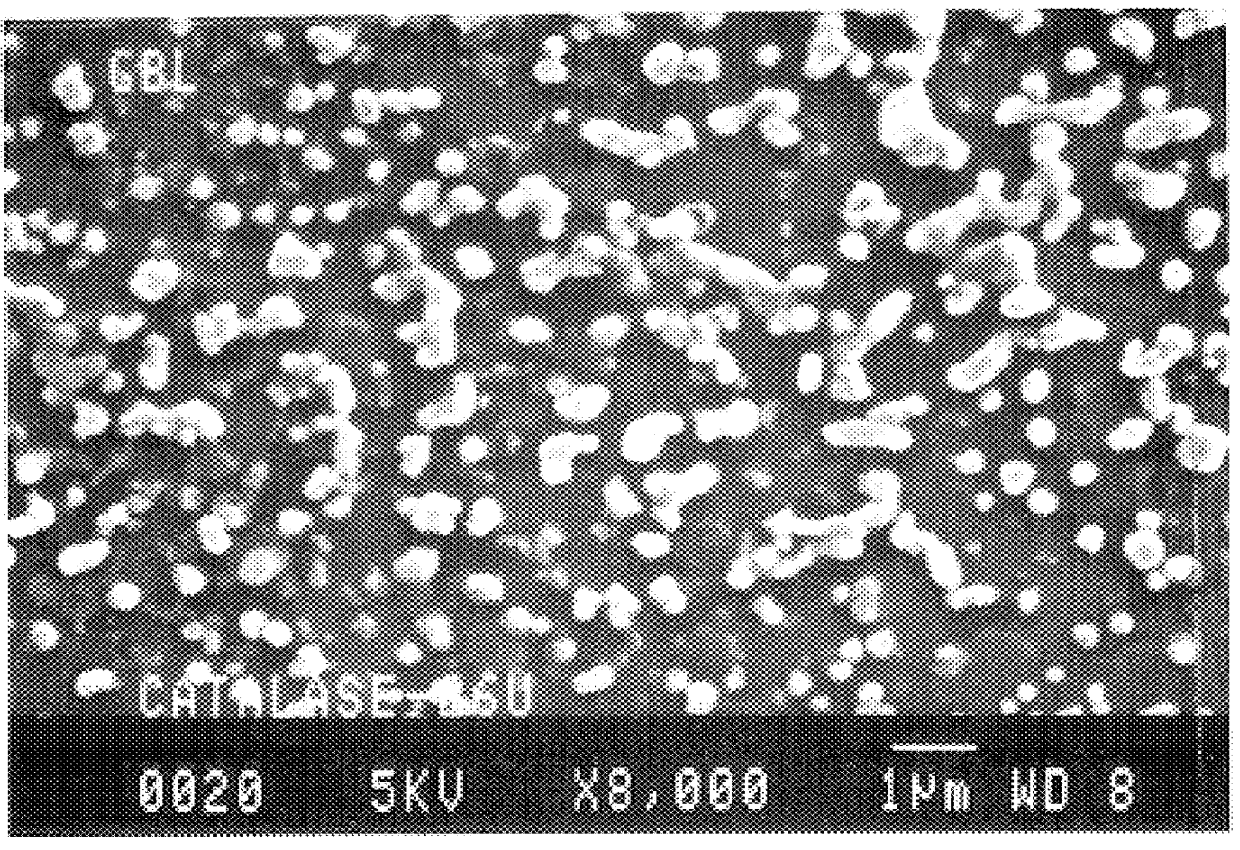

Preparation of protein microparticles by supercritical fluid precipitation

InactiveUS6063910AUniform and fine particle sizePowder deliveryPeptide/protein ingredientsMicroparticleSolvent

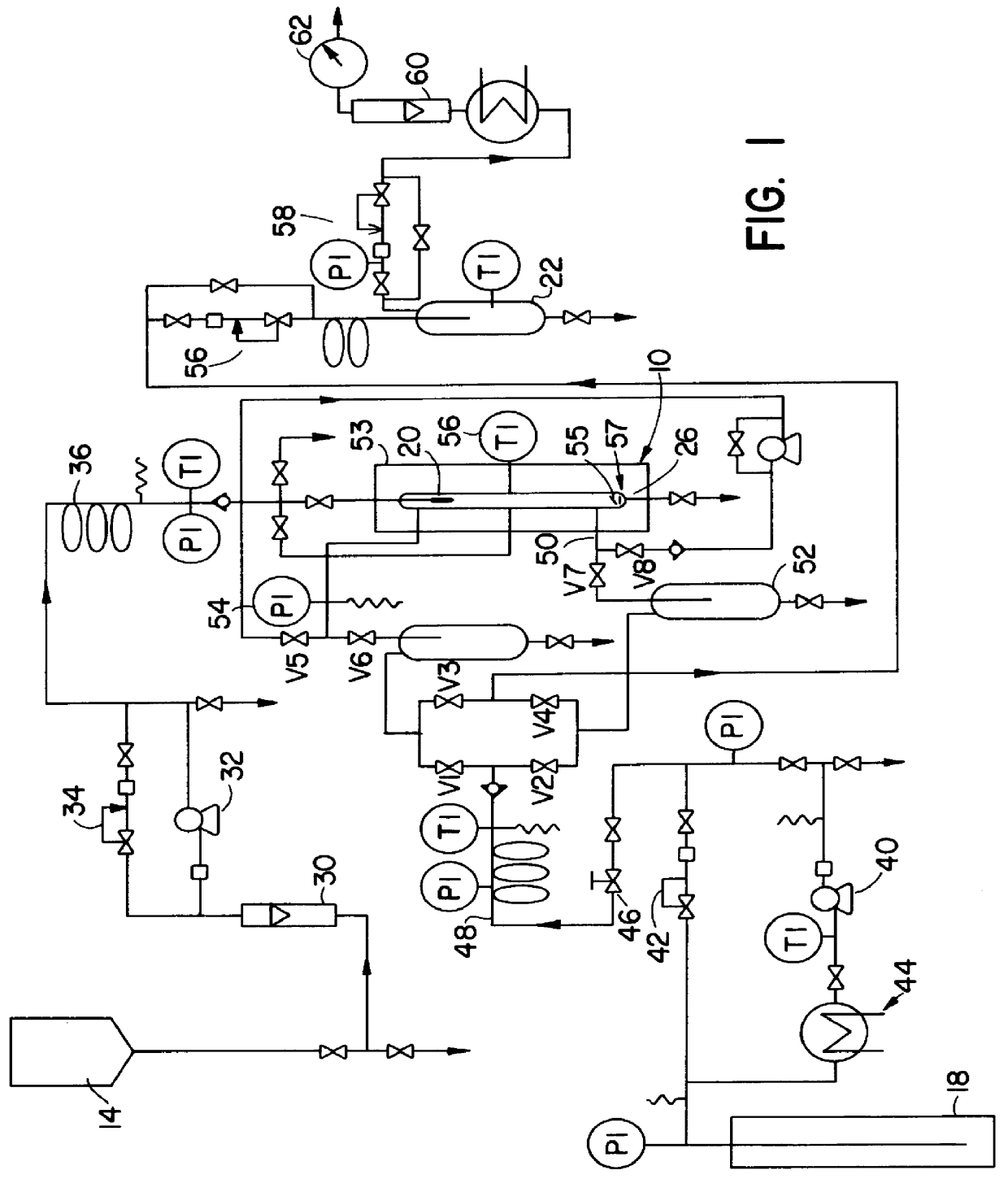

The present invention comprises passing a solution of a soluble material, preferably a protein, in a solvent through a continuum of supercritical antisolvent fluid and precipitating the soluble material. This can be conducted by passing the solution through the continuum of supercrital fluid in the form of droplets, which can be sprayed through the supercritical fluid. The plurality of droplets can be passed cocurrently or countercurrently with respect to a stream of antisolvent fluid. Alternatively, the solution can be passed through the continuum of supercritical antisolvent fluid in the form of a thin film or a plurality of fine streams.

Owner:THE TRUSTEES FOR PRINCETON UNIV

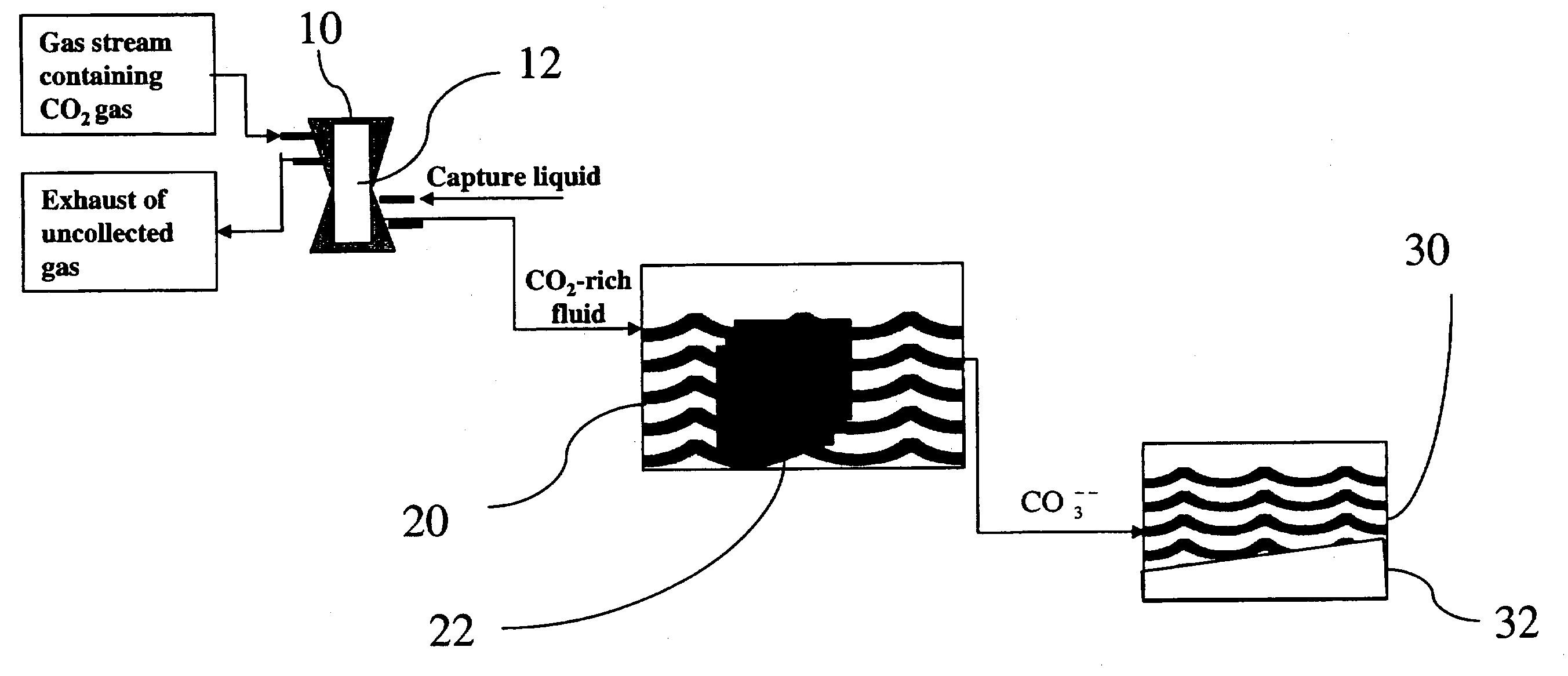

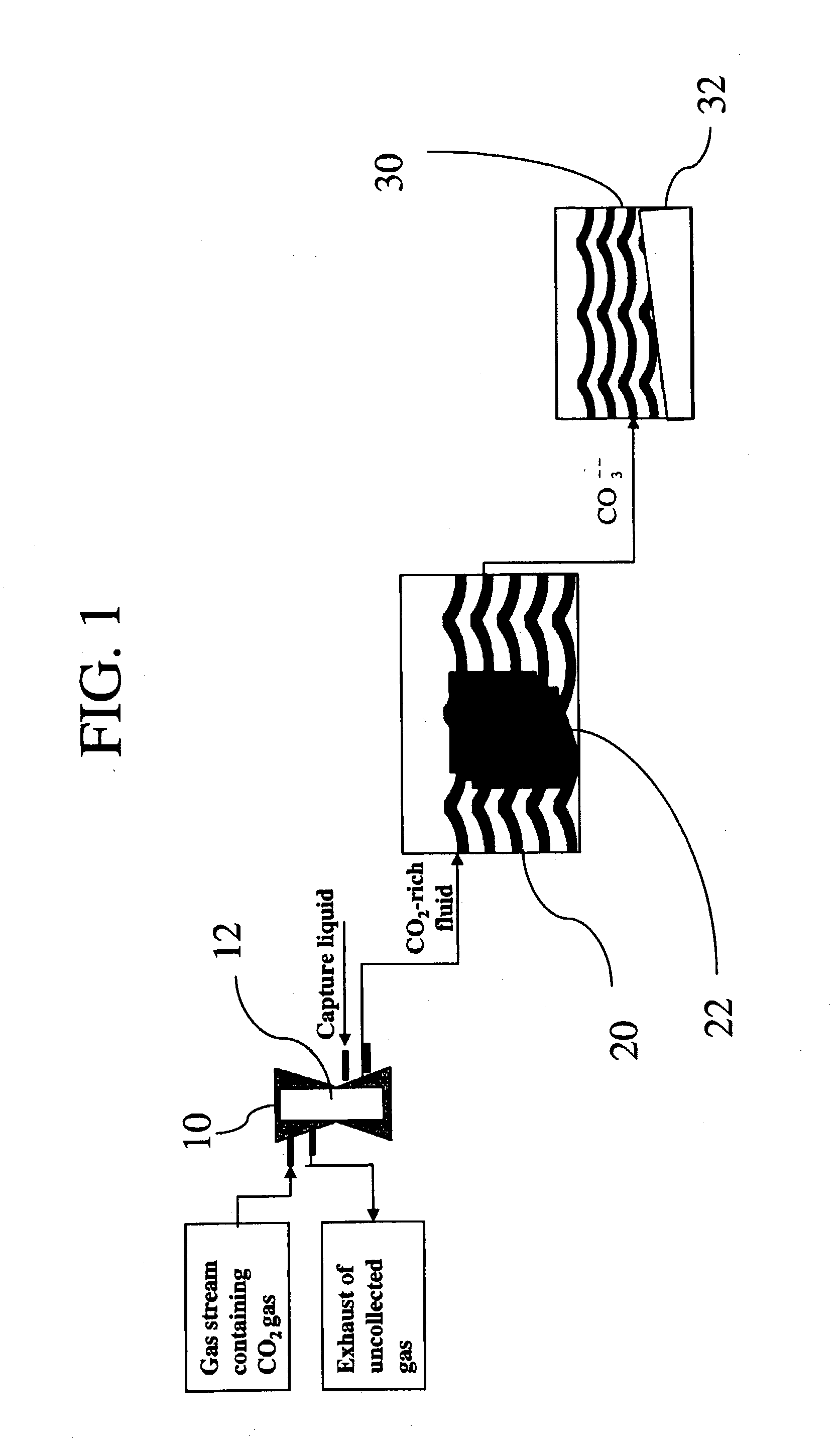

Sequestration of carbon dioxide

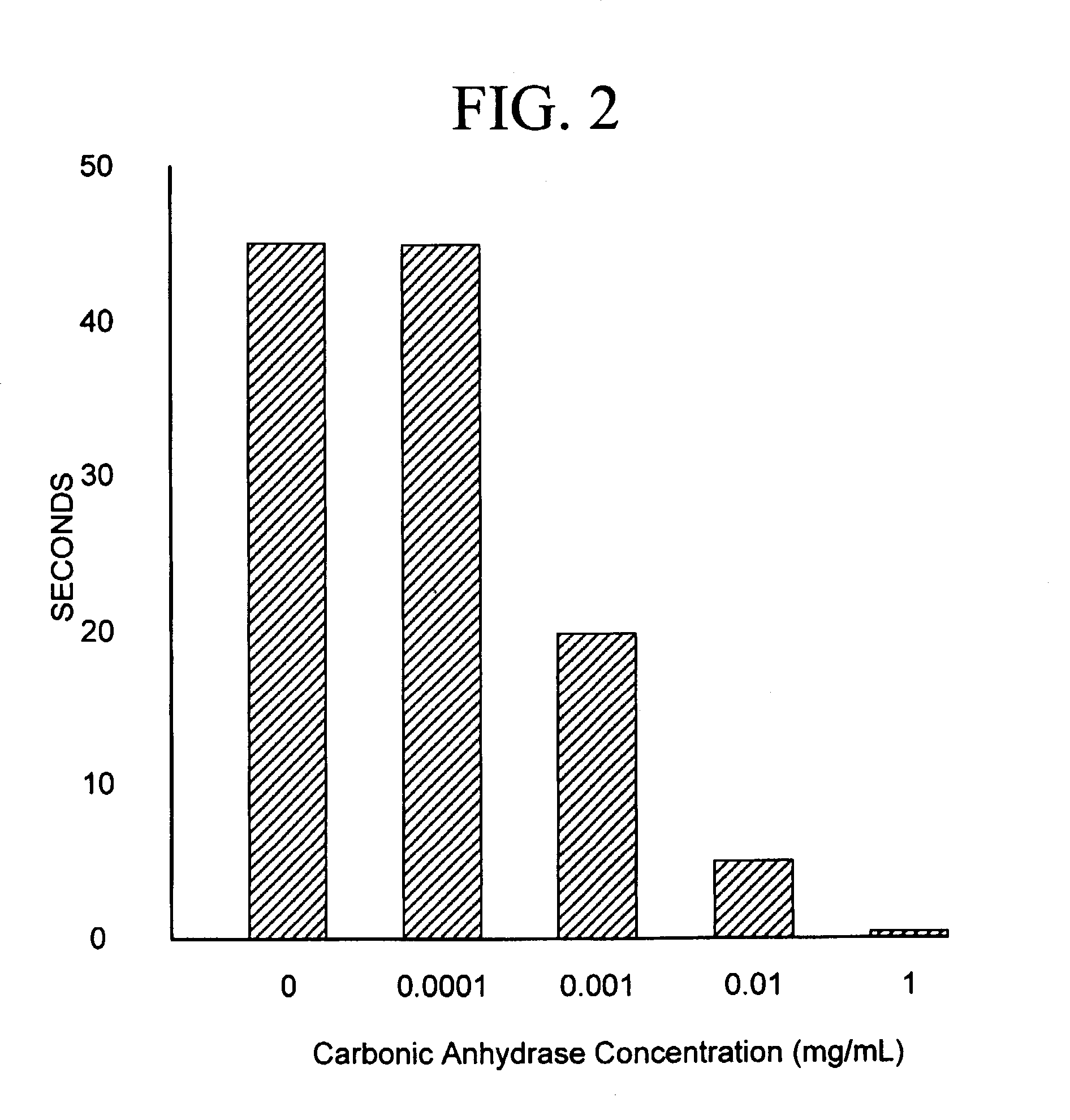

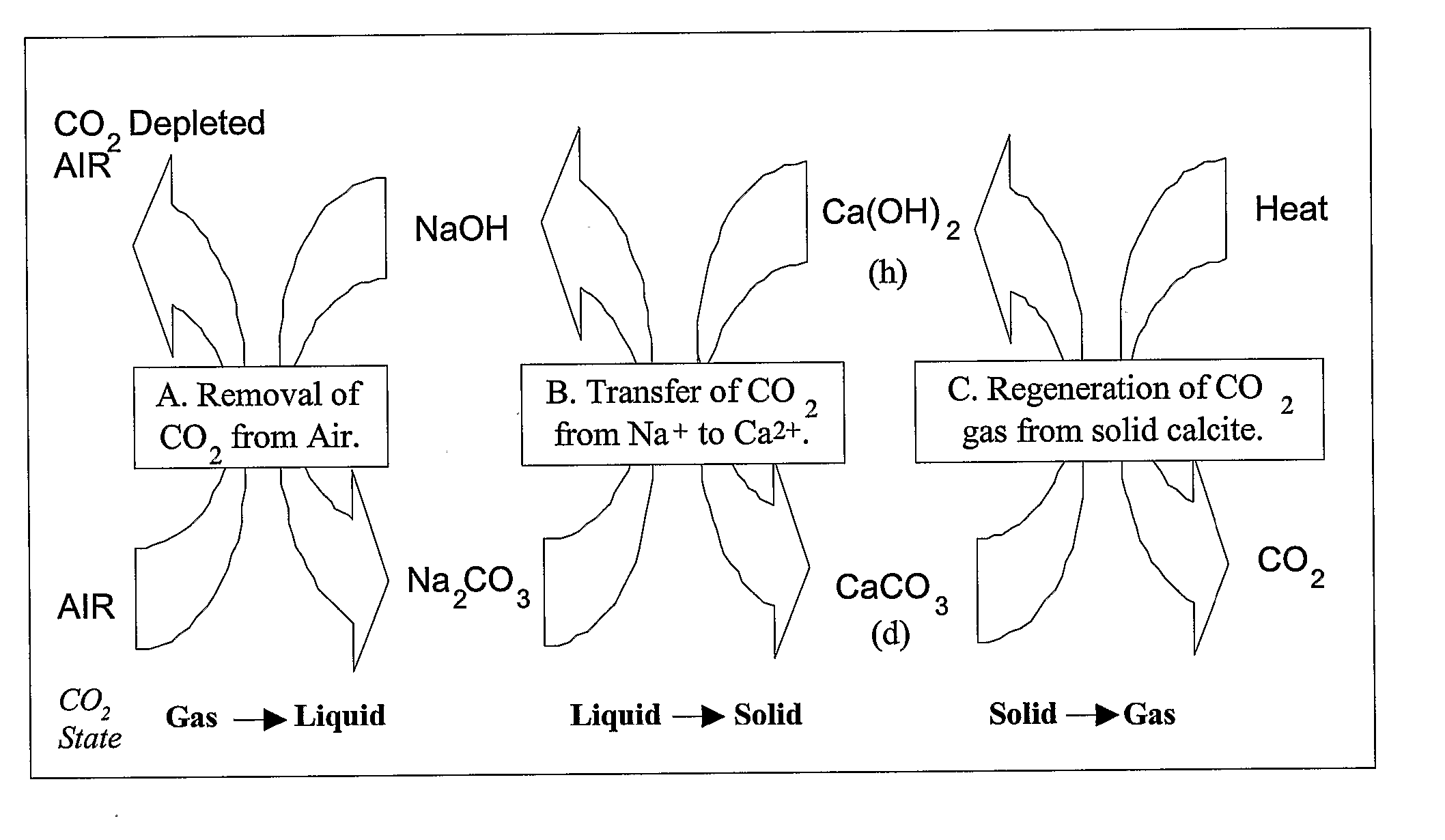

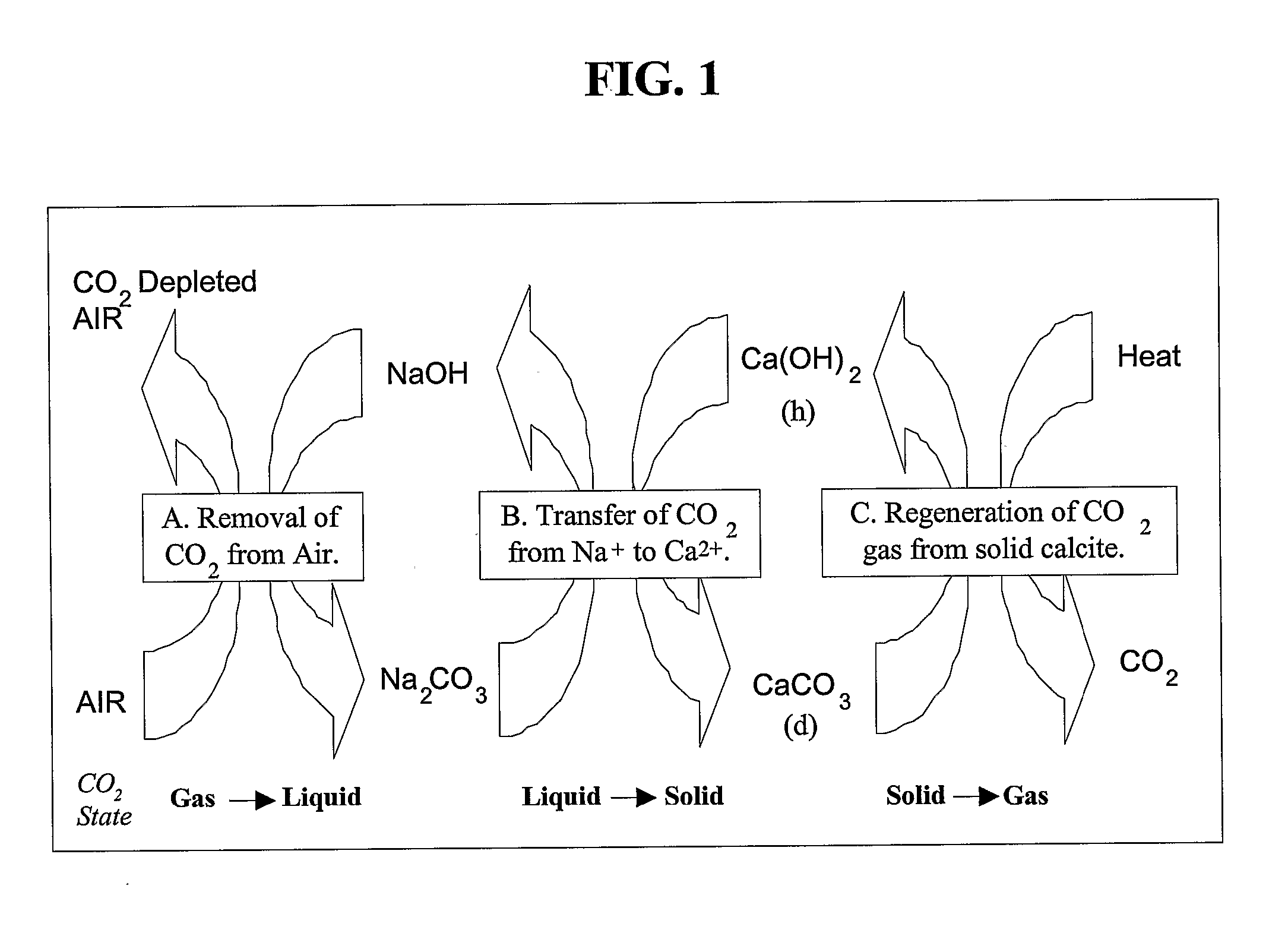

ActiveUS7132090B2Safe storageLarge specific surface areaCalcium/strontium/barium carbonatesProductsProduct gasMineral ions

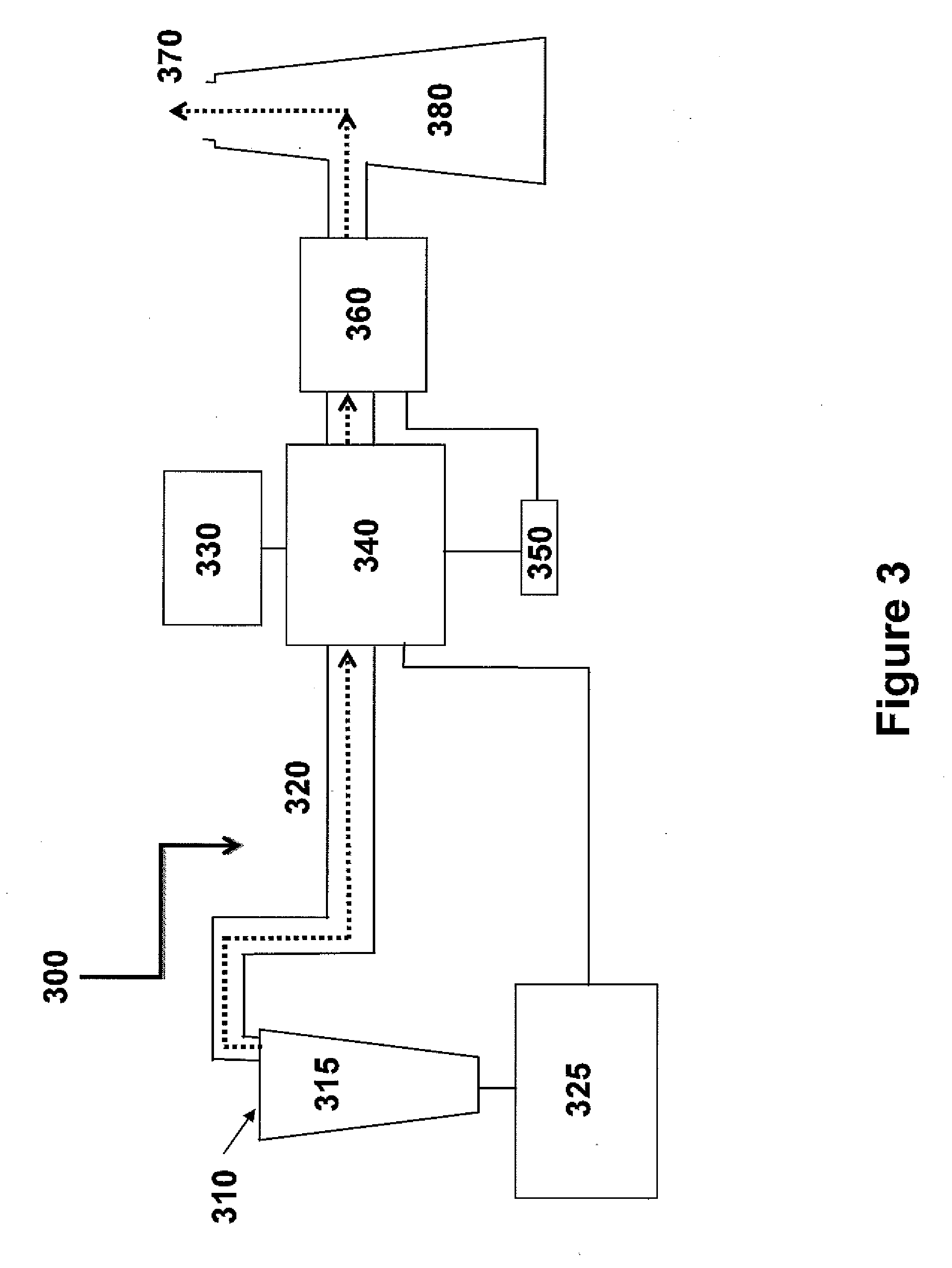

A process for selectively removing carbon dioxide from a gaseous stream by converting the carbon dioxide to a solid, stable form is provided. In a sequestration process, carbon dioxide enriched air is passed through a gas diffusion membrane to transfer the carbon dioxide to a fluid medium. The carbon dioxide rich fluid is then passed through a matrix containing a catalyst specific for carbon dioxide, which accelerates the conversion of the carbon dioxide to carbonic acid. In the final step, a mineral ion is added to the reaction so that a precipitate of carbonate salt is formed. This solid mineral precipitate can be safely stored for extended periods of time, such as by burying the precipitate in the ground or depositing the precipitate into storage sites either on land or into a body of water. An apparatus for removing carbon dioxide from a gaseous stream is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

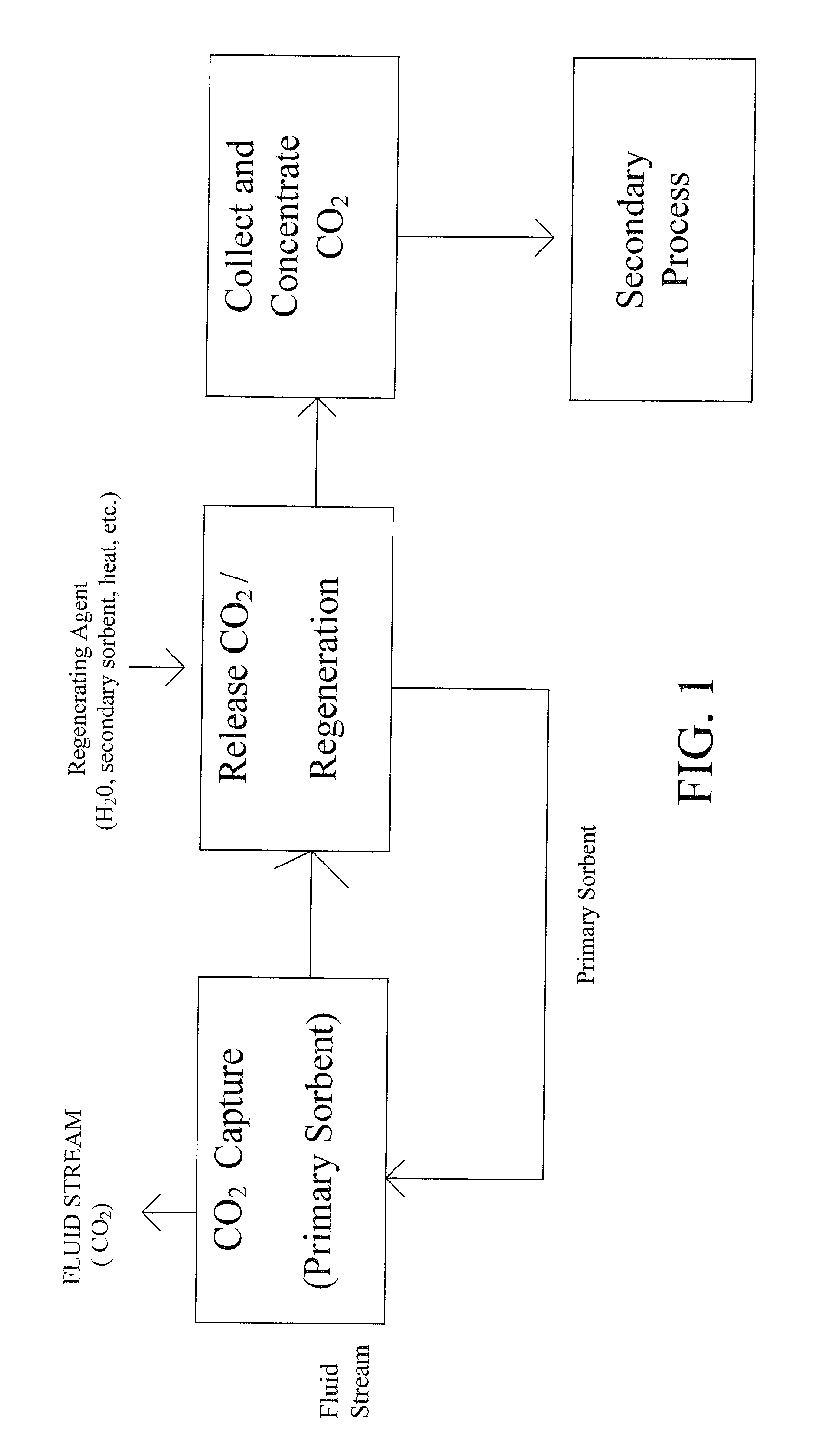

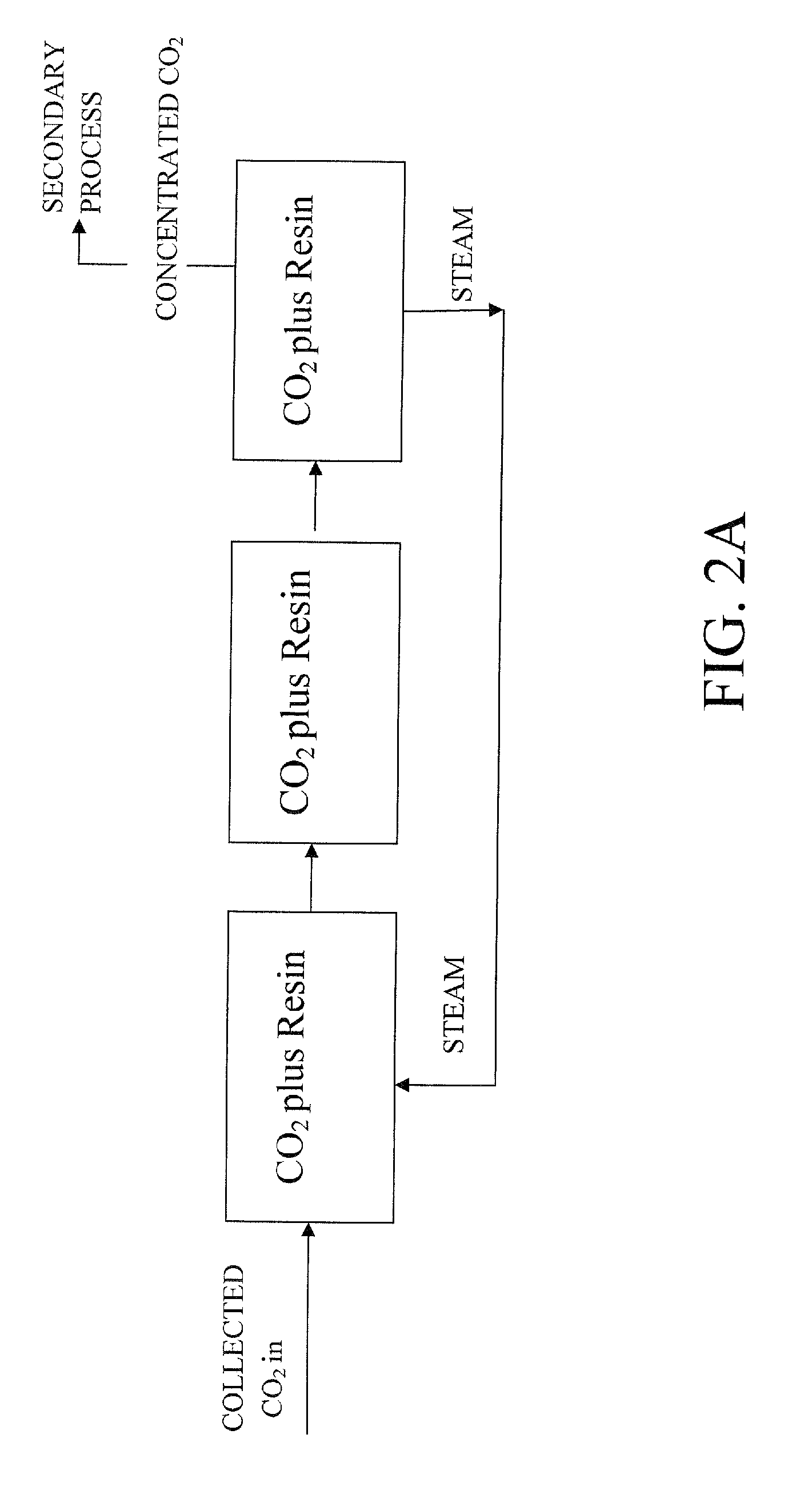

Carbon Dioxide Capture and Mitigation of Carbon Dioxide Emissions

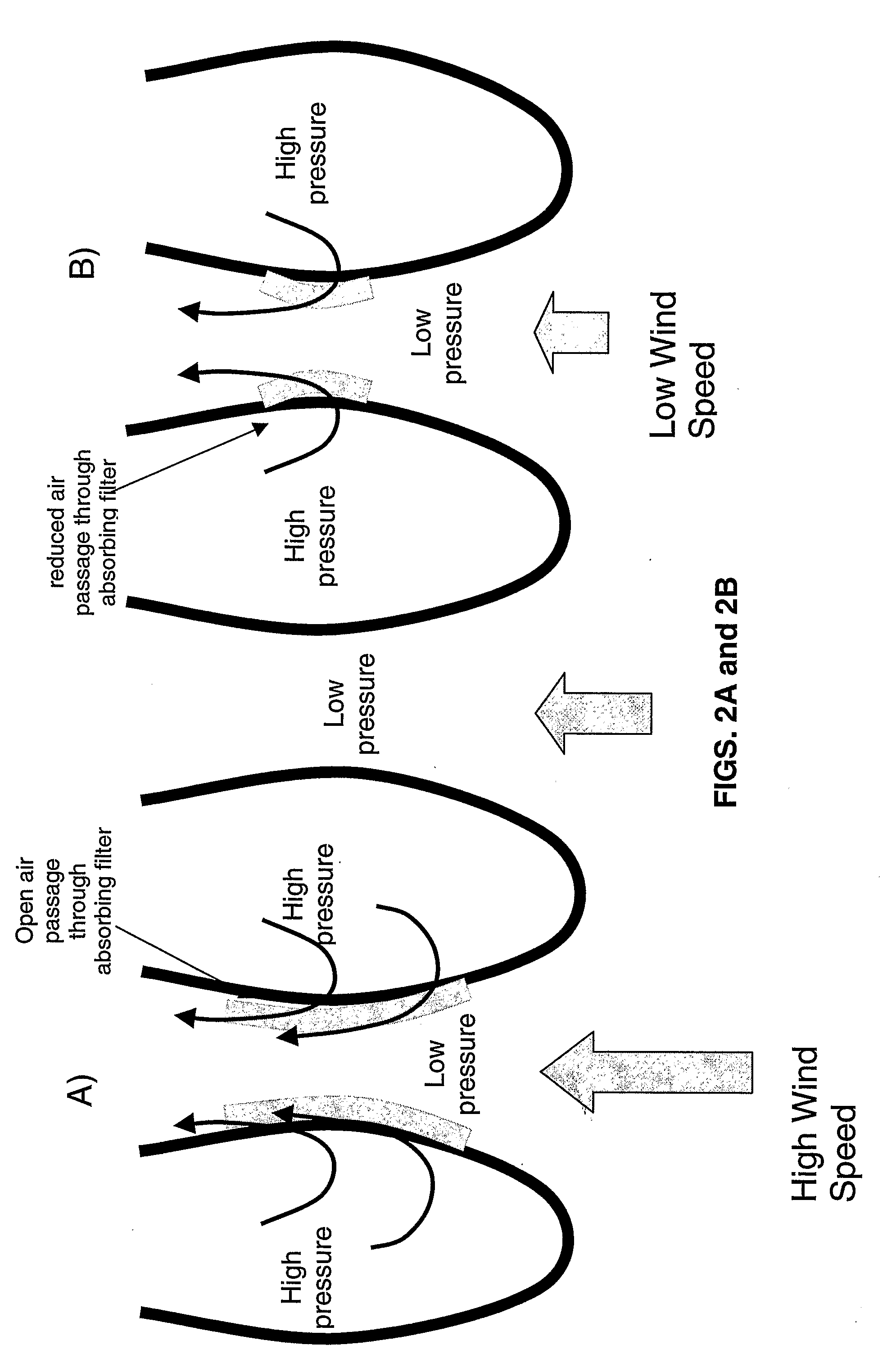

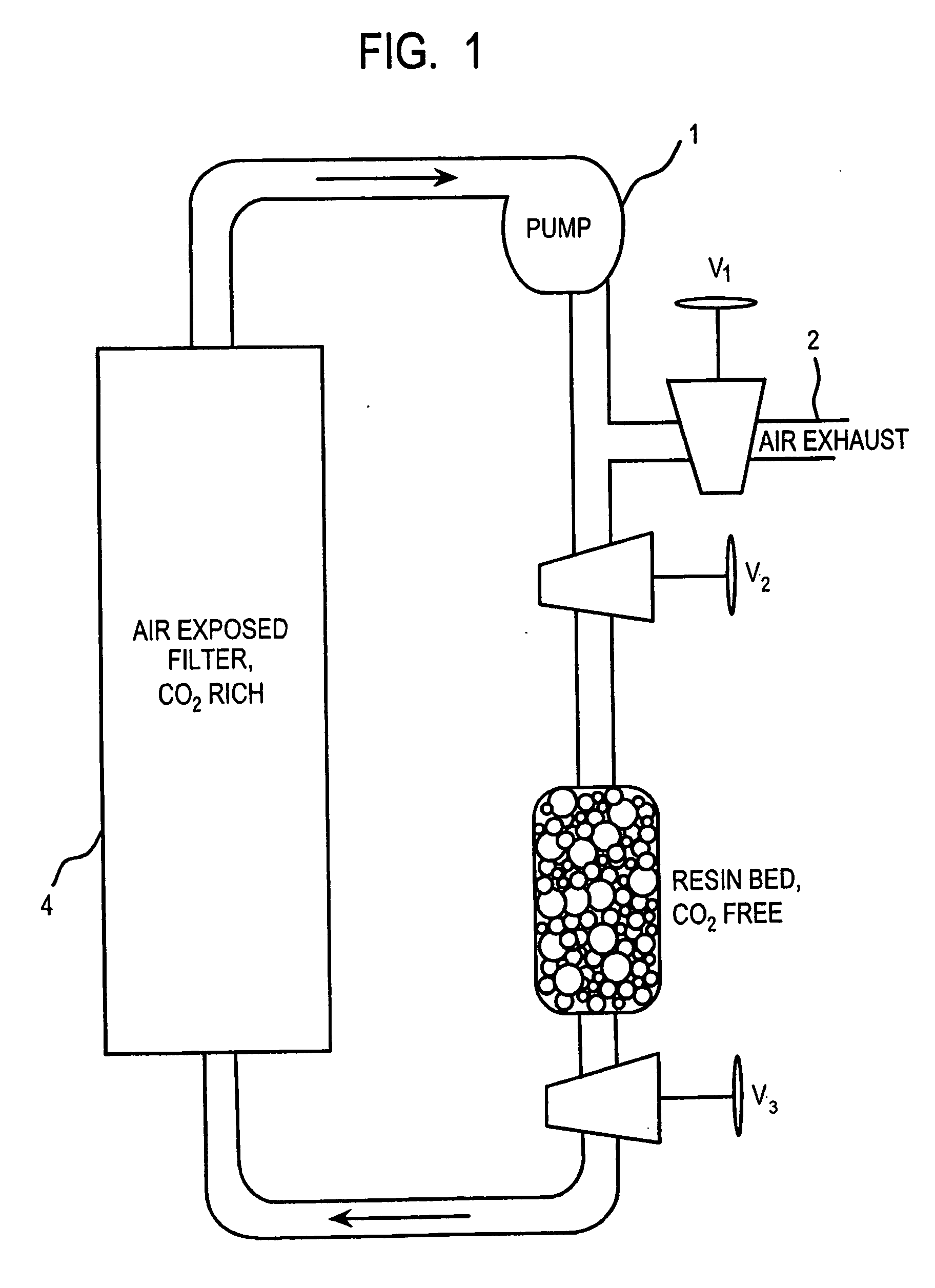

InactiveUS20080031801A1Pressure dropCalcium/strontium/barium carbonatesLiquefactionSorbentSolid surface

The present invention describes methods and systems for extracting, capturing, reducing, storing, sequestering, or disposing of carbon dioxide (CO2), particularly from the air. The CO2 extraction methods and systems involve the use of chemical processes, mineral sequestration, and solid and liquid sorbents. Methods are also described for extracting and / or capturing CO2 via condensation on solid surfaces at low temperature.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK +1

Biomass Char Compositions for Catalytic Gasification

InactiveUS20090217575A1Efficient utilization of carbonEfficient comprehensive utilizationProductsReagentsParticulatesHydrogen

Particulate compositions are described comprising an intimate mixture of a biomass char producedfrom the combustion of a biomass, such as switchgrass or hybrid poplar, with at least a second carbonaceous material, such as petroleum coke or coal, and, optionally a gasification catalyst, for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

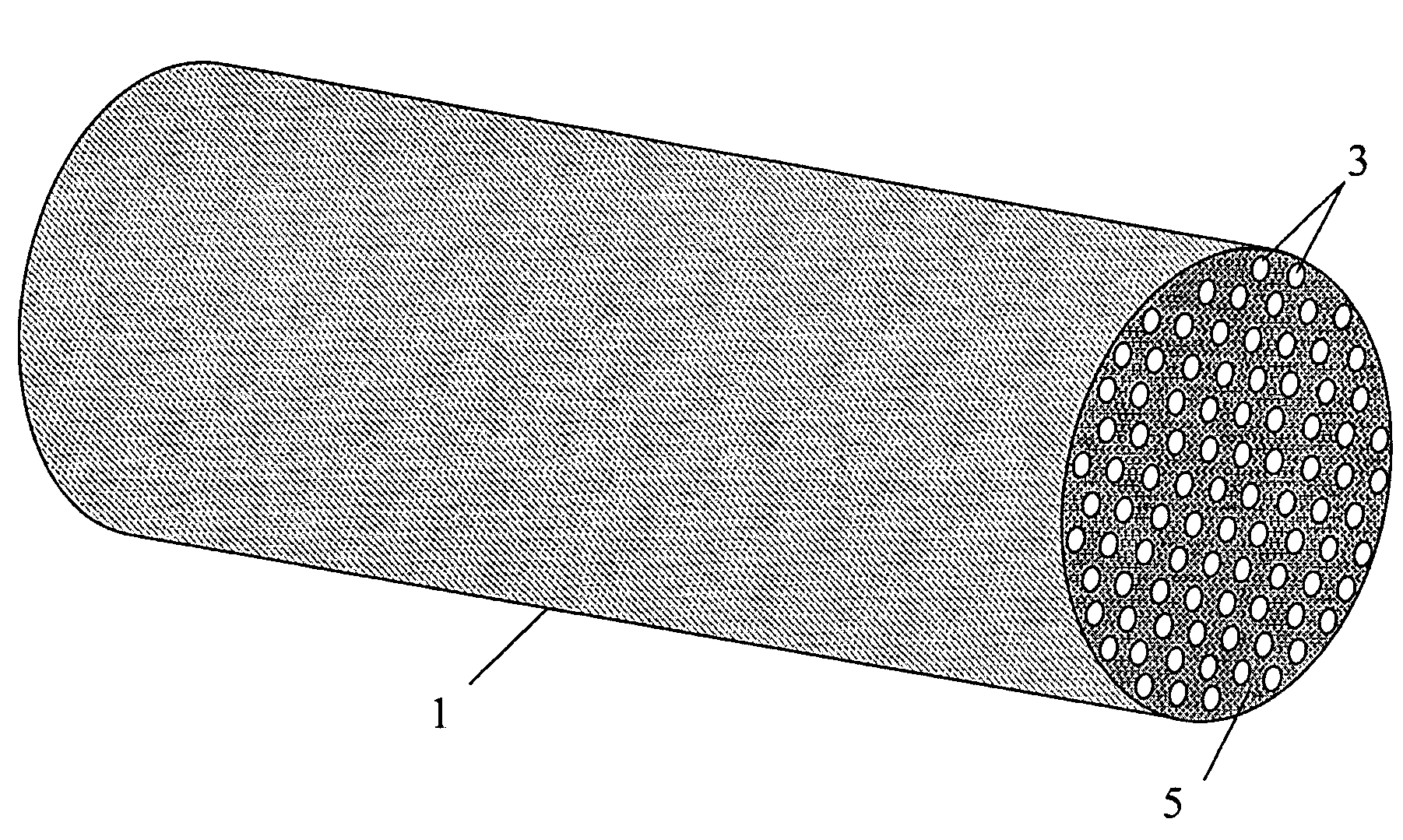

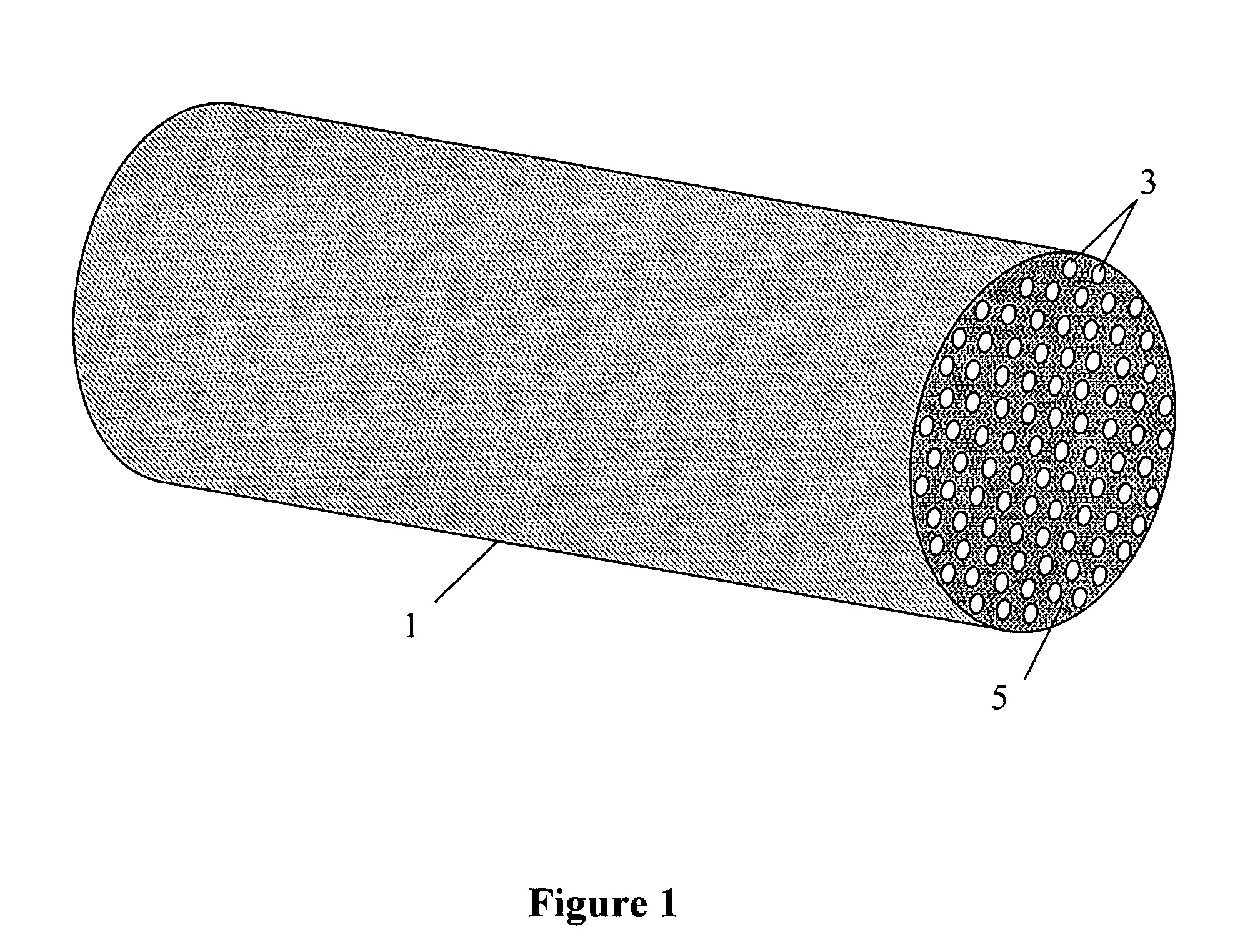

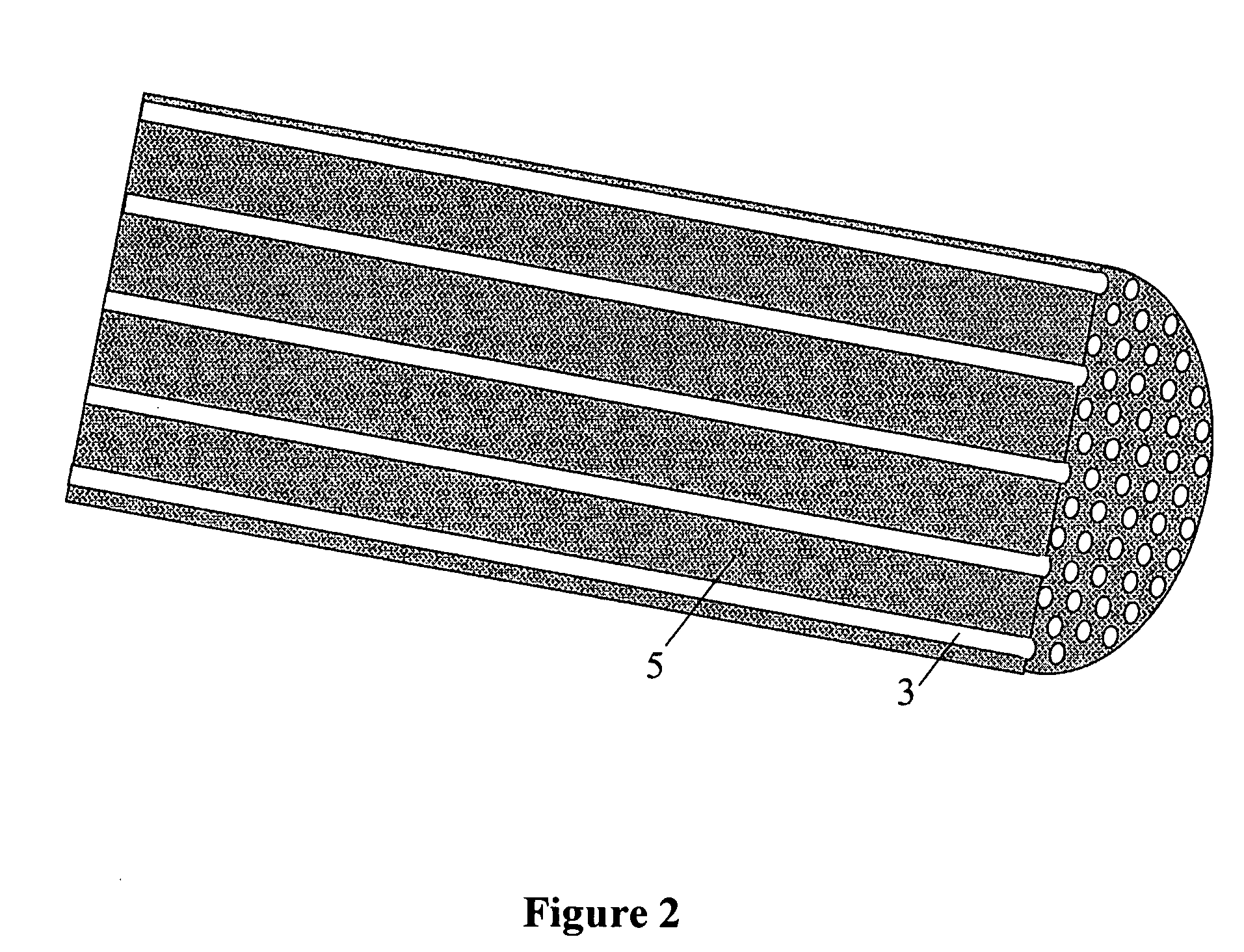

Low mesopore adsorbent contactors for use in swing adsorption processes

The present invention relates to engineered structured adsorbent contactors for use in pressure swing adsorption and thermal swing adsorption processes. Preferably, the contactors contain engineered and substantially parallel flow channels wherein 20 volume percent or less of the open pore volume of the contactor, excluding the flow channels, is in the mesopore and macropore range.

Owner:EXXON RES & ENG CO

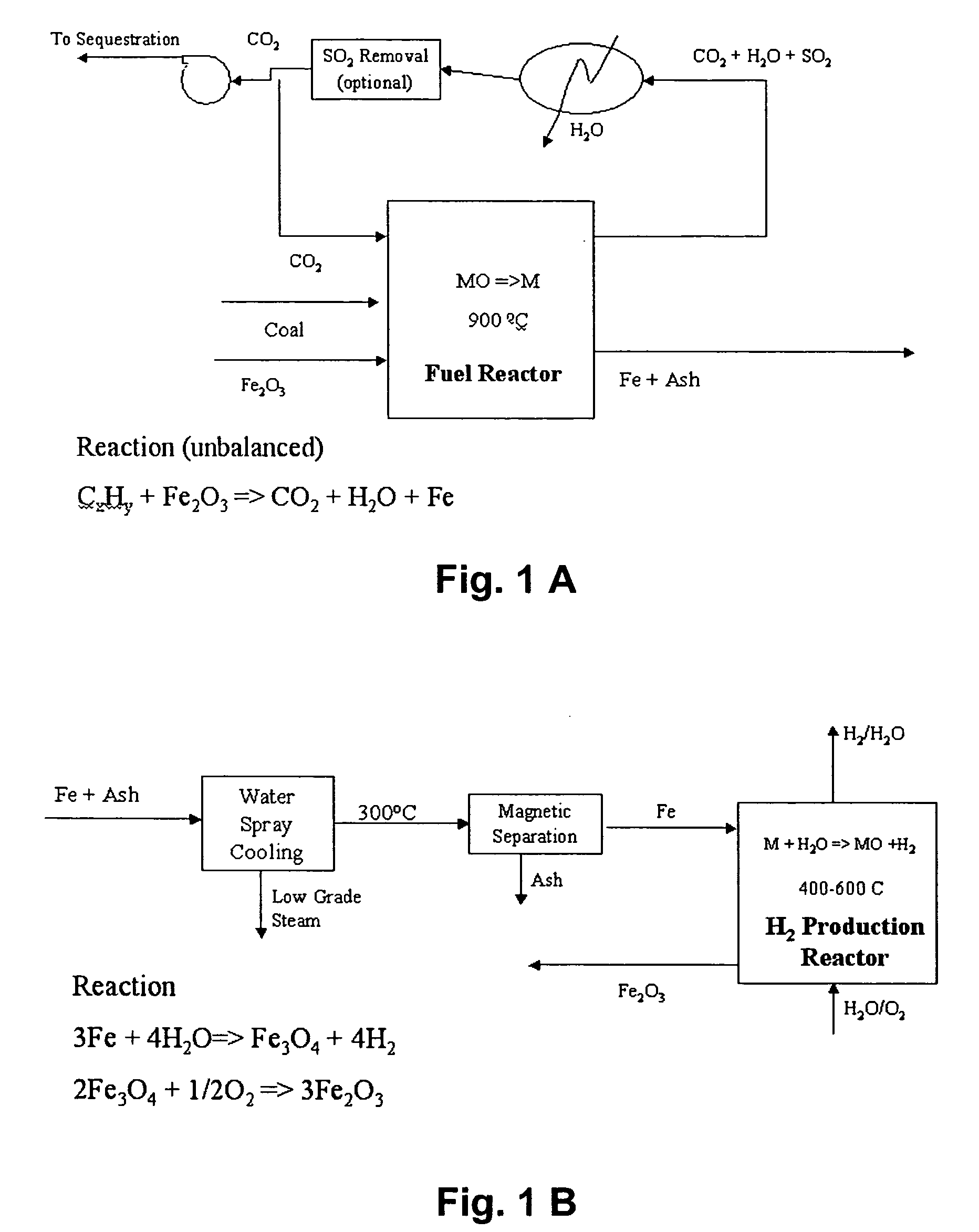

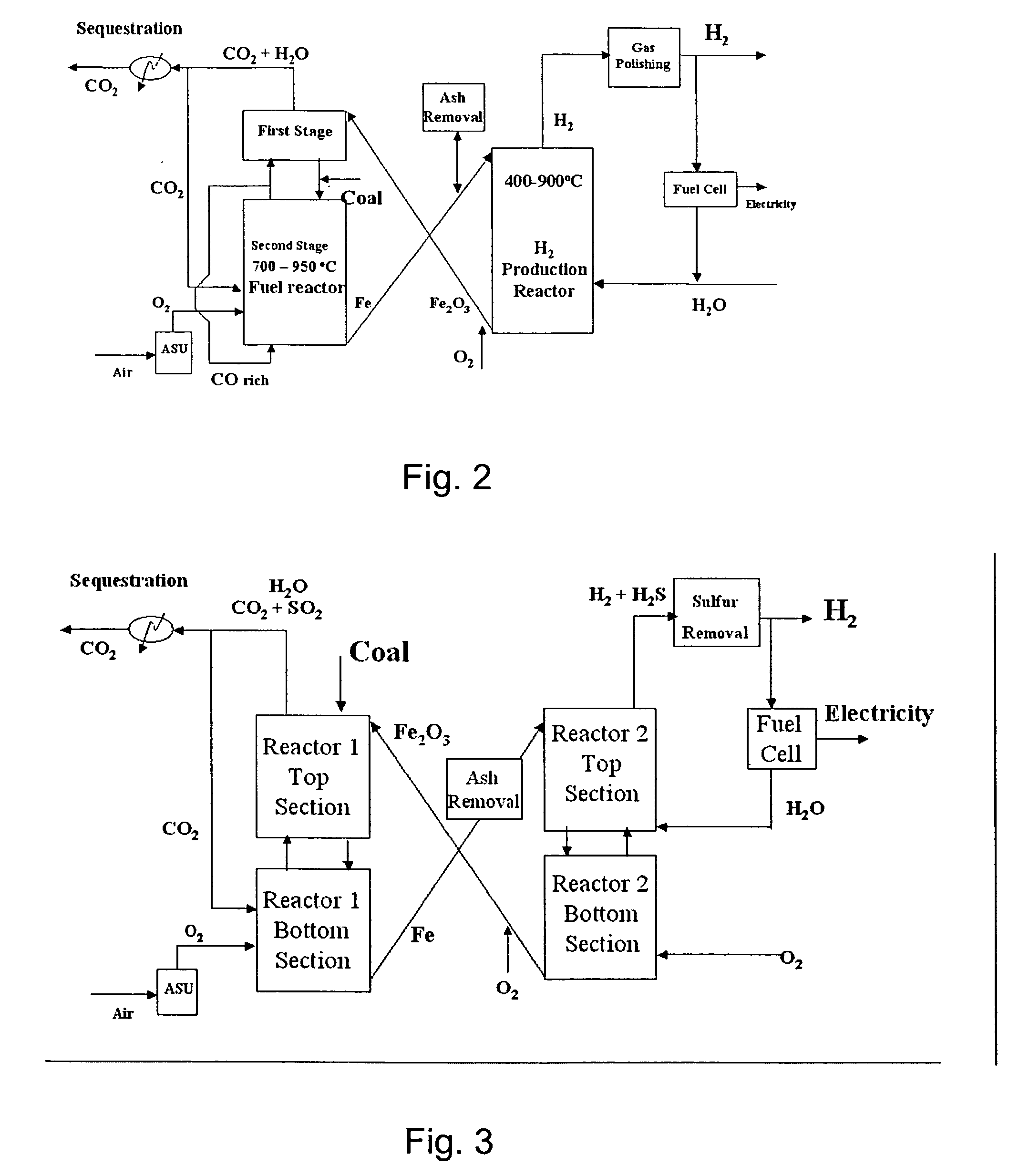

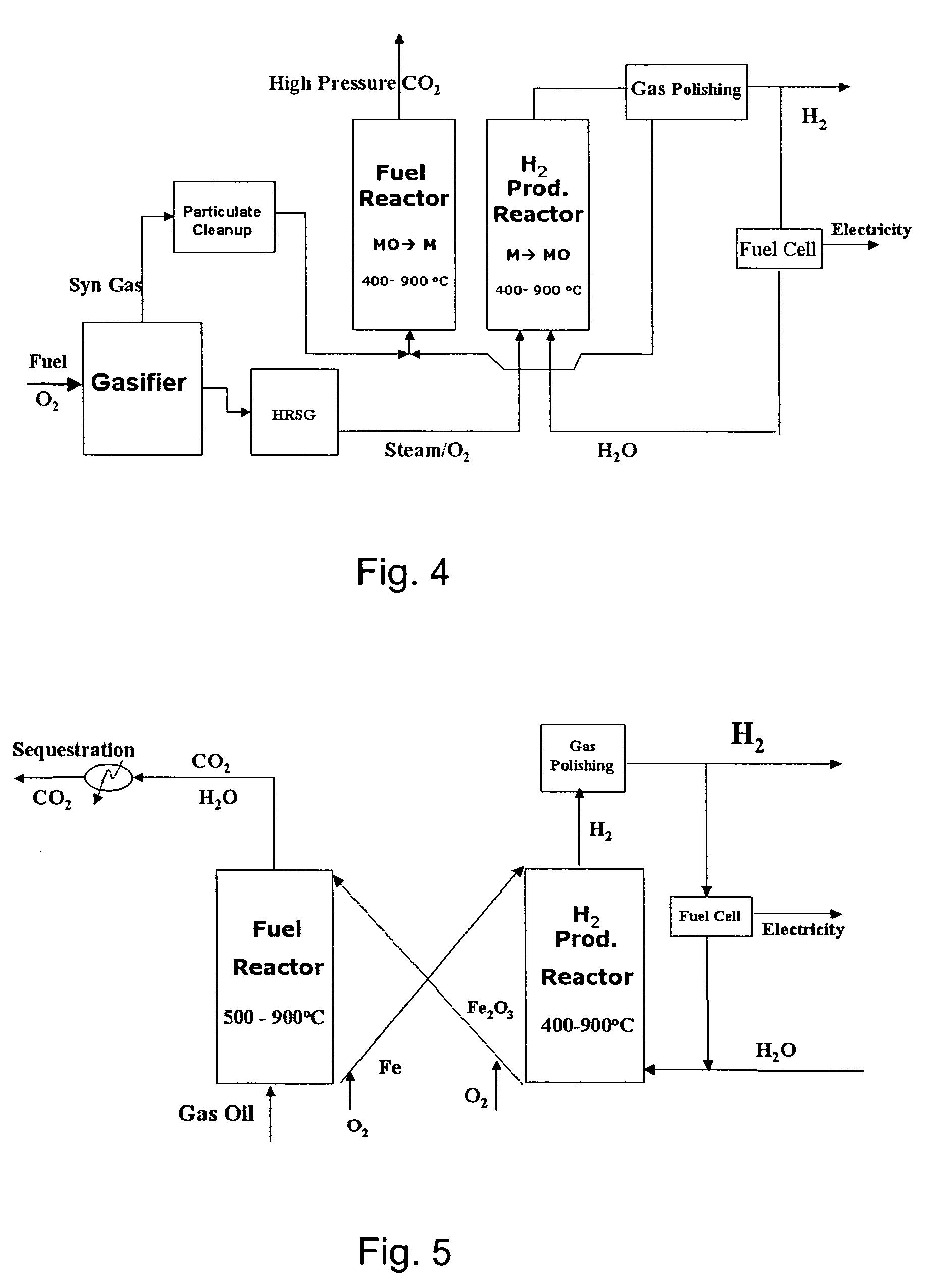

Combustion looping using composite oxygen carriers

ActiveUS20050175533A1Increase surface areaImprove energy conversion efficiencyHydrogen productionIndirect carbon-dioxide mitigationHydrogenCombustion

A method for producing hydrogen gas is provided and comprises reducing a metal oxide in a reduction reaction between a carbon-based fuel and a metal oxide to provide a reduced metal or metal oxide having a lower oxidation state, and oxidizing the reduced metal or metal oxide to produce hydrogen and a metal oxide having a higher oxidation state. The metal or metal oxide is provided in the form of a porous composite of a ceramic material containing the metal or metal oxide. The porous composite may comprise either a monolith, pellets, or particles.

Owner:OHIO STATE INNOVATION FOUND

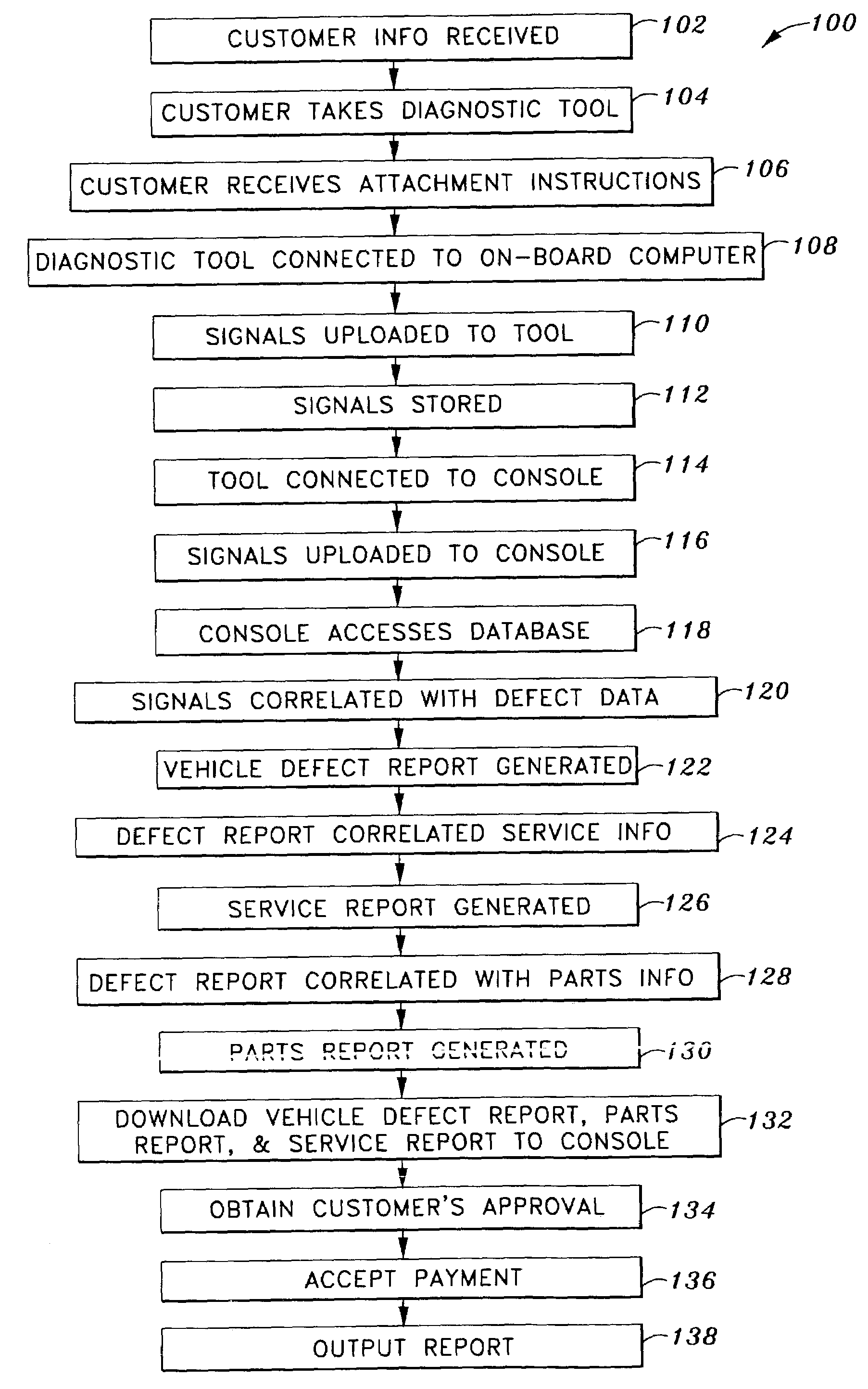

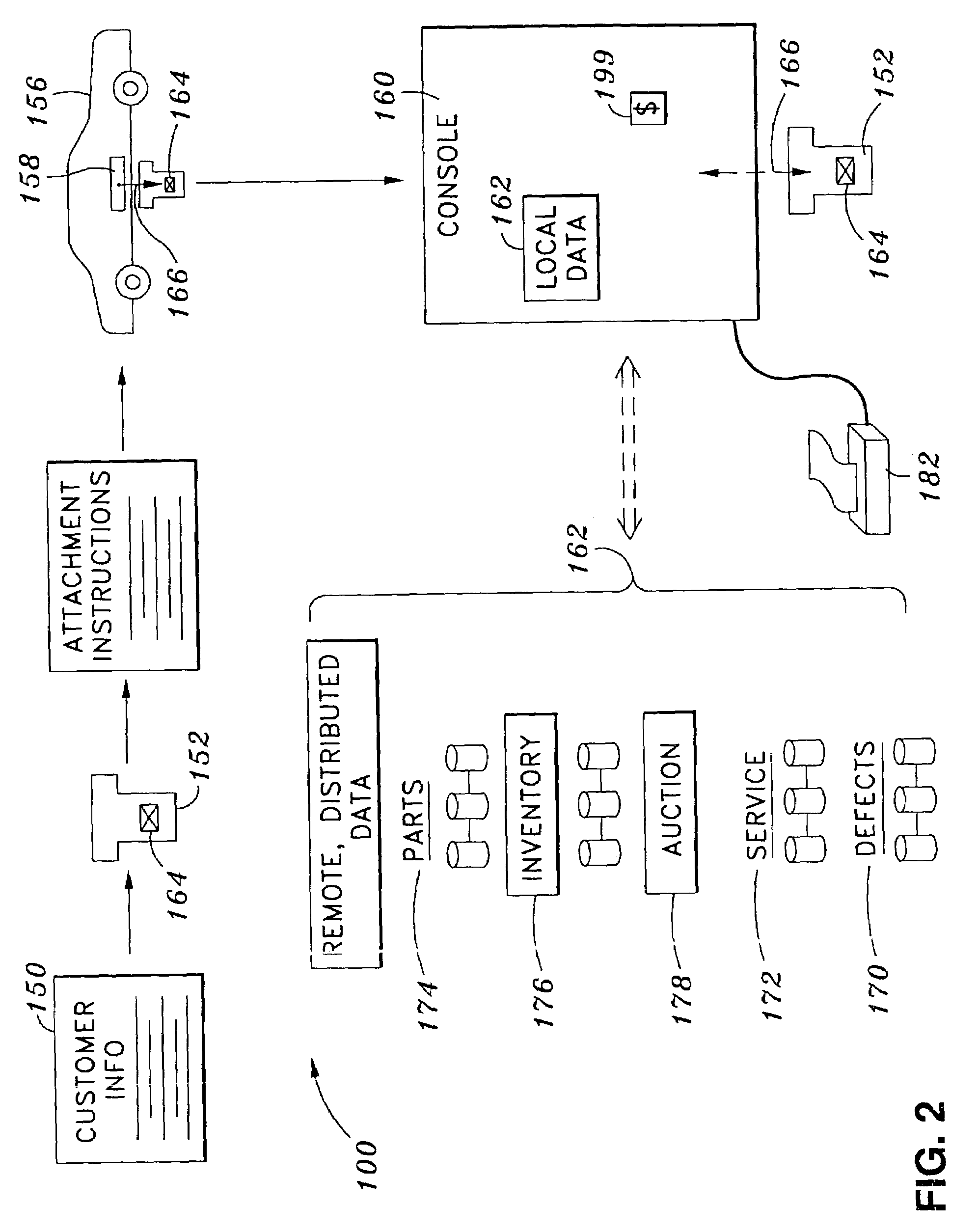

Use of automotive diagnostics console to diagnose vehicle

InactiveUS7376497B2Less costlyPromote repairVehicle testingBio-organic fraction processingPaymentEngineering

A customer driven process of diagnosing and repairing a vehicle. The process involves temporarily providing a customer with a diagnostic tool that can receive vehicle diagnostic signals from a vehicle on-board computer. The customer then uses the tool to upload diagnostic signals from the car, and returns the tool to the automotive parts / service facility. The vehicle diagnostic signals are communicated to a console, which then accesses a database(s). The database(s) includes information relating to the vehicle malfunction, the repairs needed, and the parts required to complete those repairs. The process also allows automatic scheduling of repairs and purchasing of parts from the automotive parts / service facility. Upon payment of any prescribed fees, the process outputs report information to the customer.

Owner:INNOVA ELECTRONICS

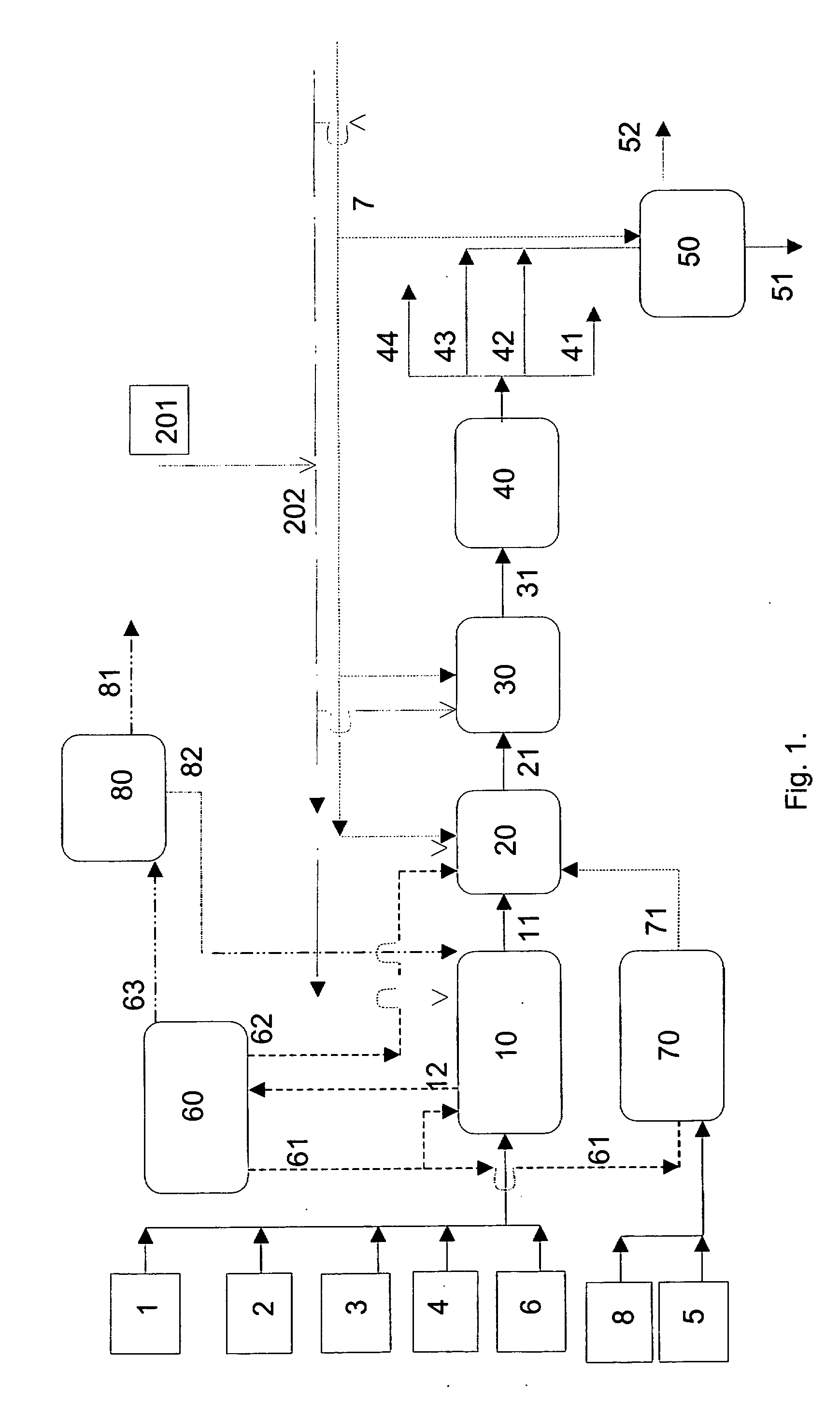

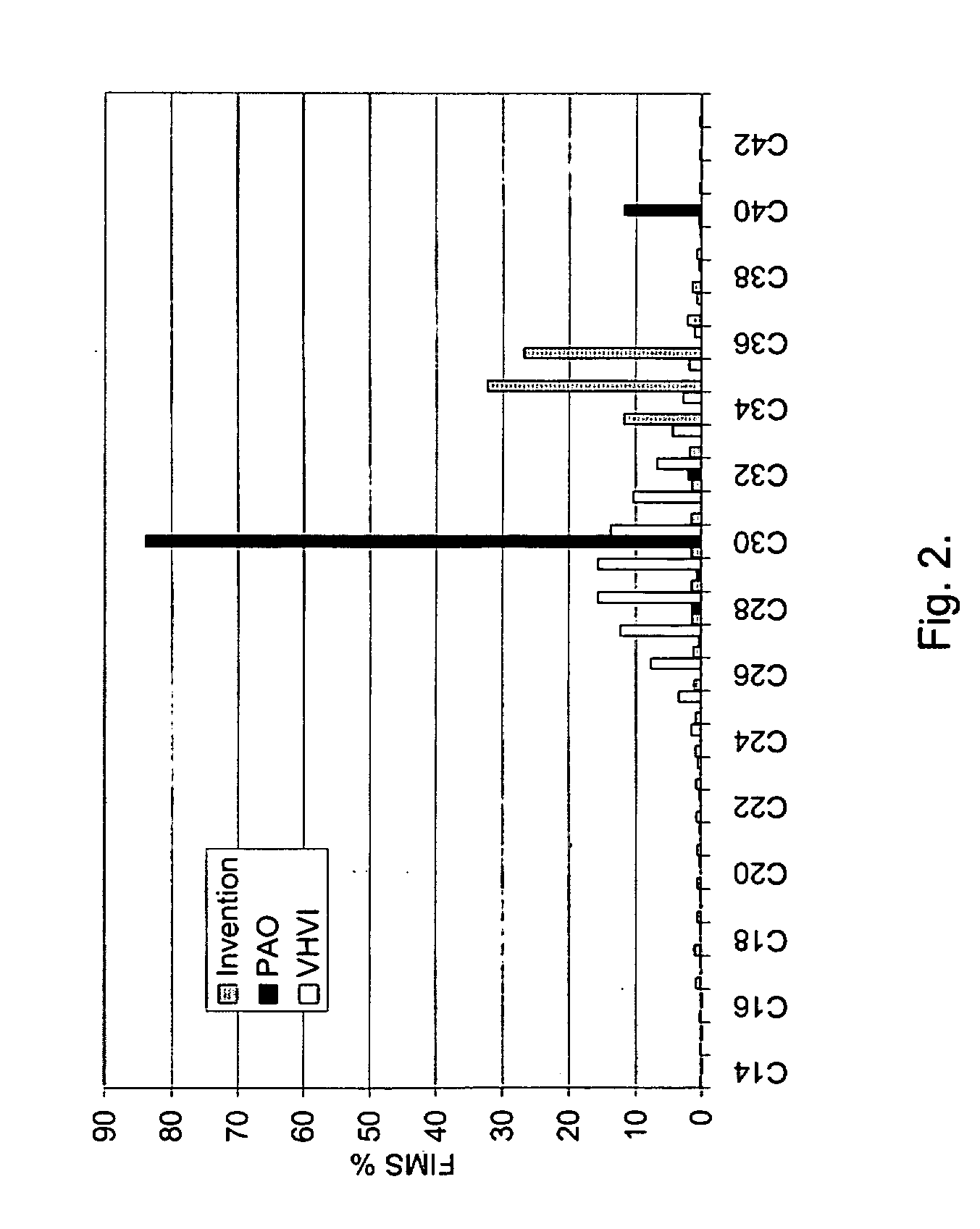

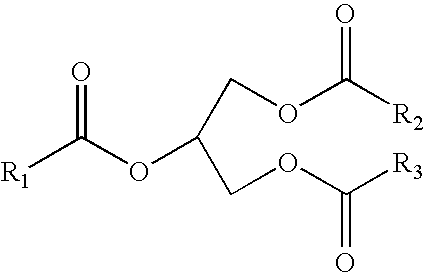

Process for producing a saturated hydrocarbon component

ActiveUS20070131579A1Reduce carbon dioxide emissionsIncrease carbon dioxide loadProductsReagentsCarboxylic acidBase oil

The invention relates to a process for producing high-quality saturated base oil or a base oil component based on hydrocarbons. The process of the invention comprises two main steps, the oligomerization and deoxygenation. A biological starting material containing unsaturated carboxylic acids and / or esters of carboxylic acids is preferably used as the feedstock.

Owner:NESTE OIL OY

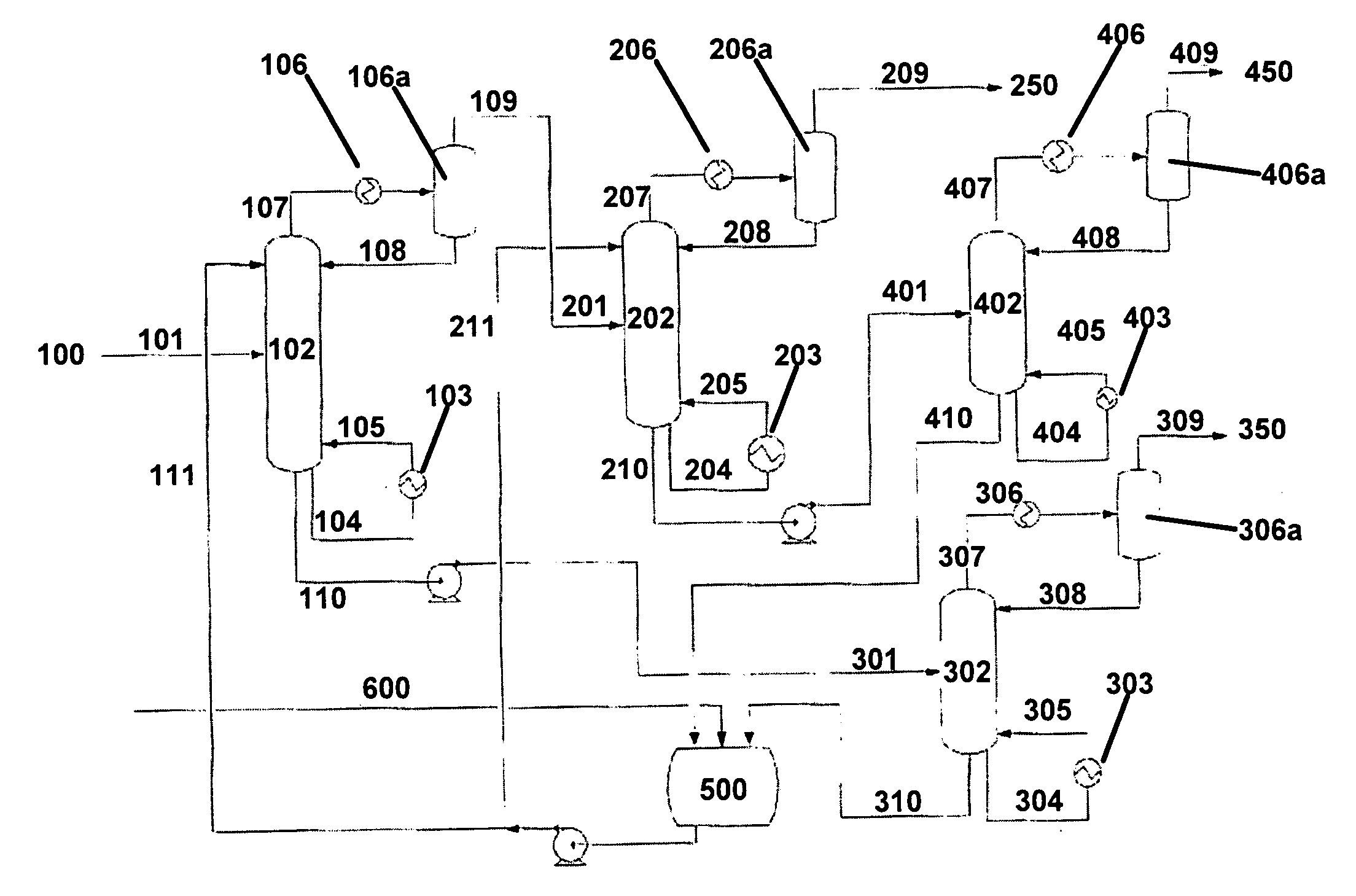

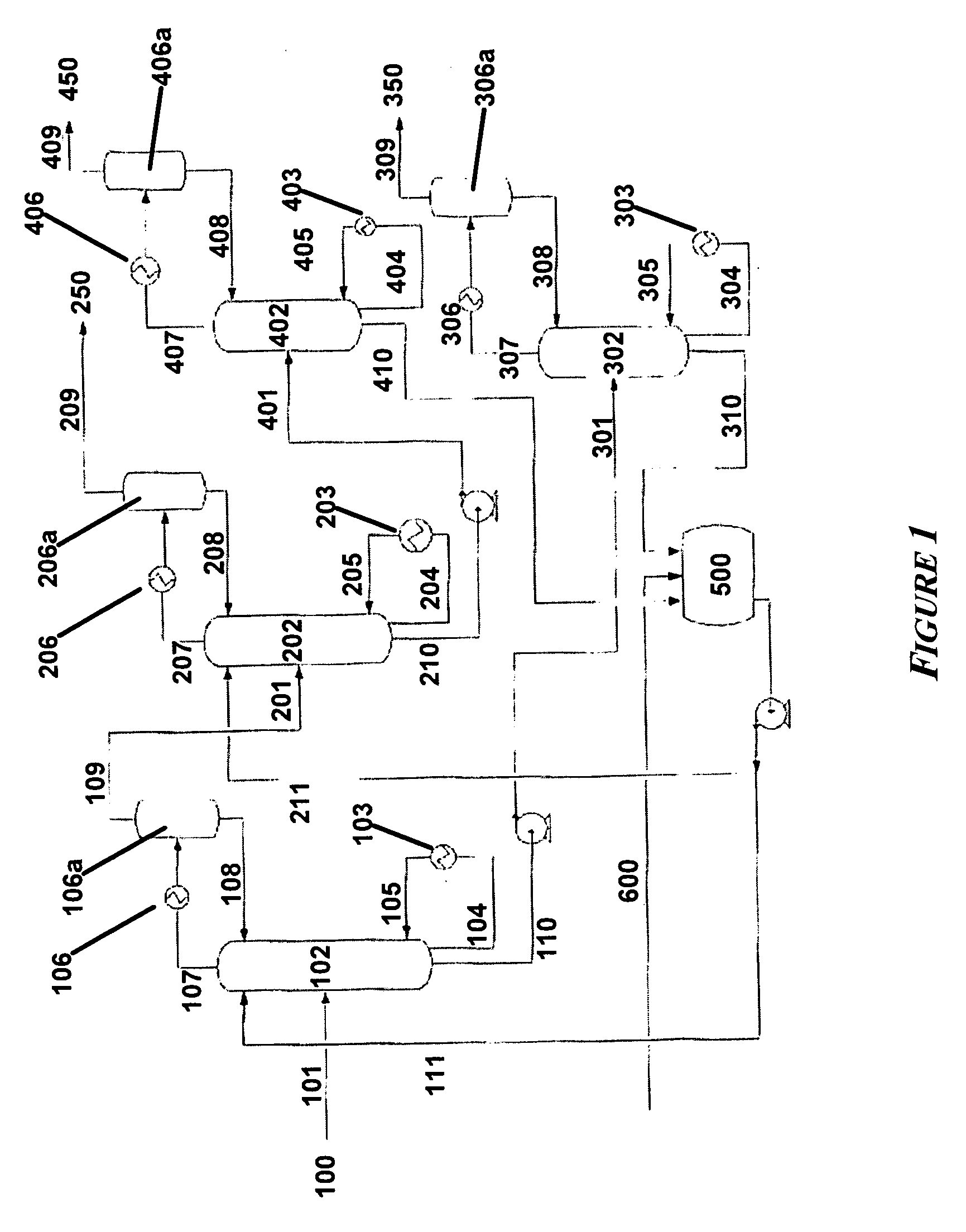

Selective Removal and Recovery of Acid Gases from Gasification Products

Processes and apparatuses are described for the selective removal and recovery of acid gases from a gas source comprising at least hydrogen sulfide and carbon dioxide. A step-wise approach is illustrated wherein hydrogen sulfide may be selectively removed from a gas source by treatment with methanol under conditions where substantially all the hydrogen sulfide may be removed. The partially purified gas source may then be provided with a second treatment with methanol under conditions which selectively remove carbon dioxide from the gas stream. Such methods are generally applicable to any gas source comprising at least hydrogen sulfide and carbon dioxide, for example, a gas source produced from the catalytic gasification of a carbonaceous material, the combustion of a carbonaceous material, or the oxy-blown gasification of a carbonaceous material.

Owner:SURE CHAMPION INVESTMENT LTD

Method and apparatus for producing synthesis gas from carbonaceous materials

A method of producing syn gas from biomass or other carbonaceous material utilizes a controlled devolatilization reaction in which the temperature of the feed material is maintained at less than 450° F. until most available oxygen is consumed. This minimizes pyrolysis of the feed material. The method and apparatus utilizes the formed synthesis gas to provide the energy for the necessary gasification. This provides for a high purity syn gas and avoids production of slag.

Owner:JBK EXTRACTIONS

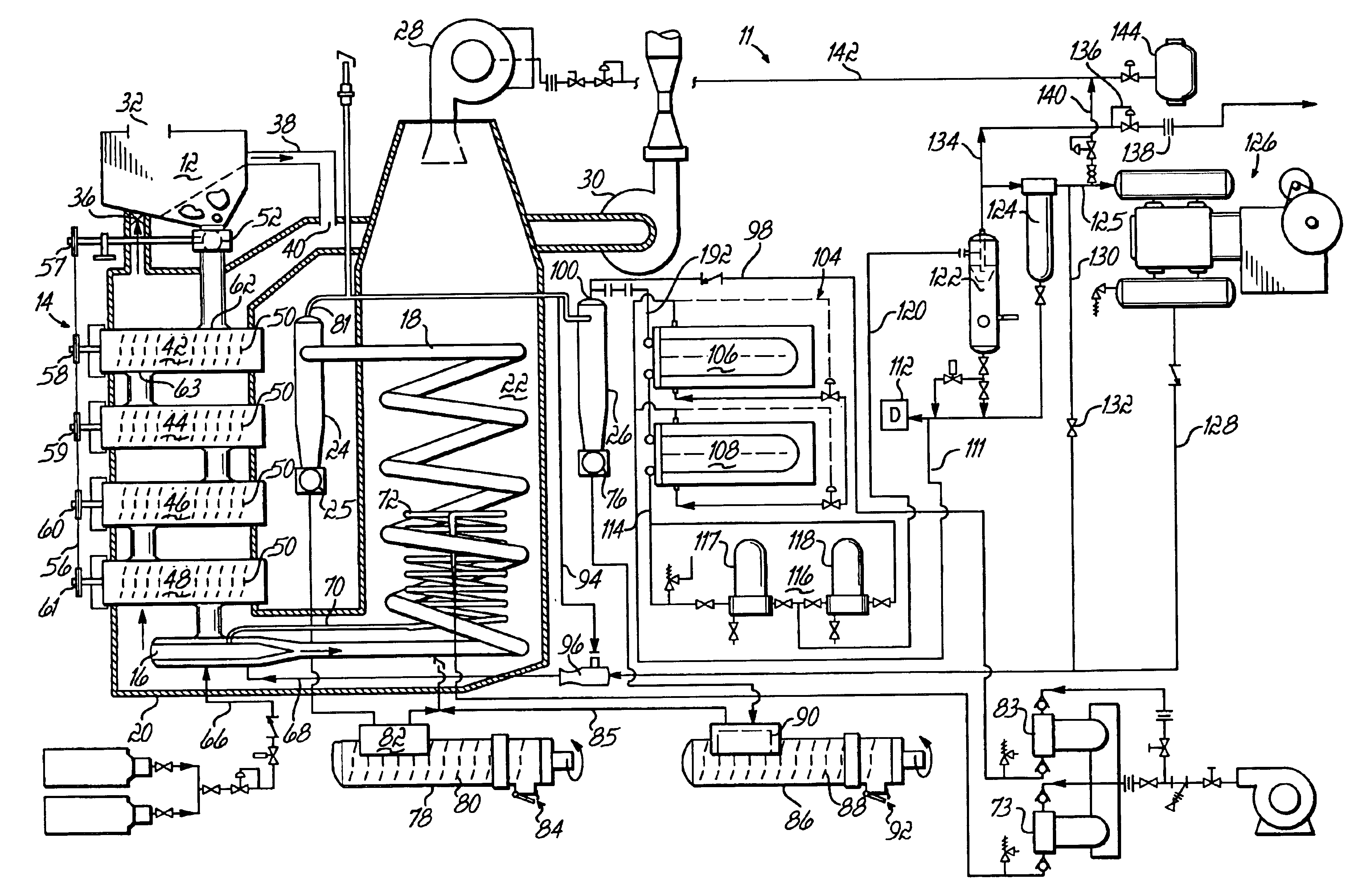

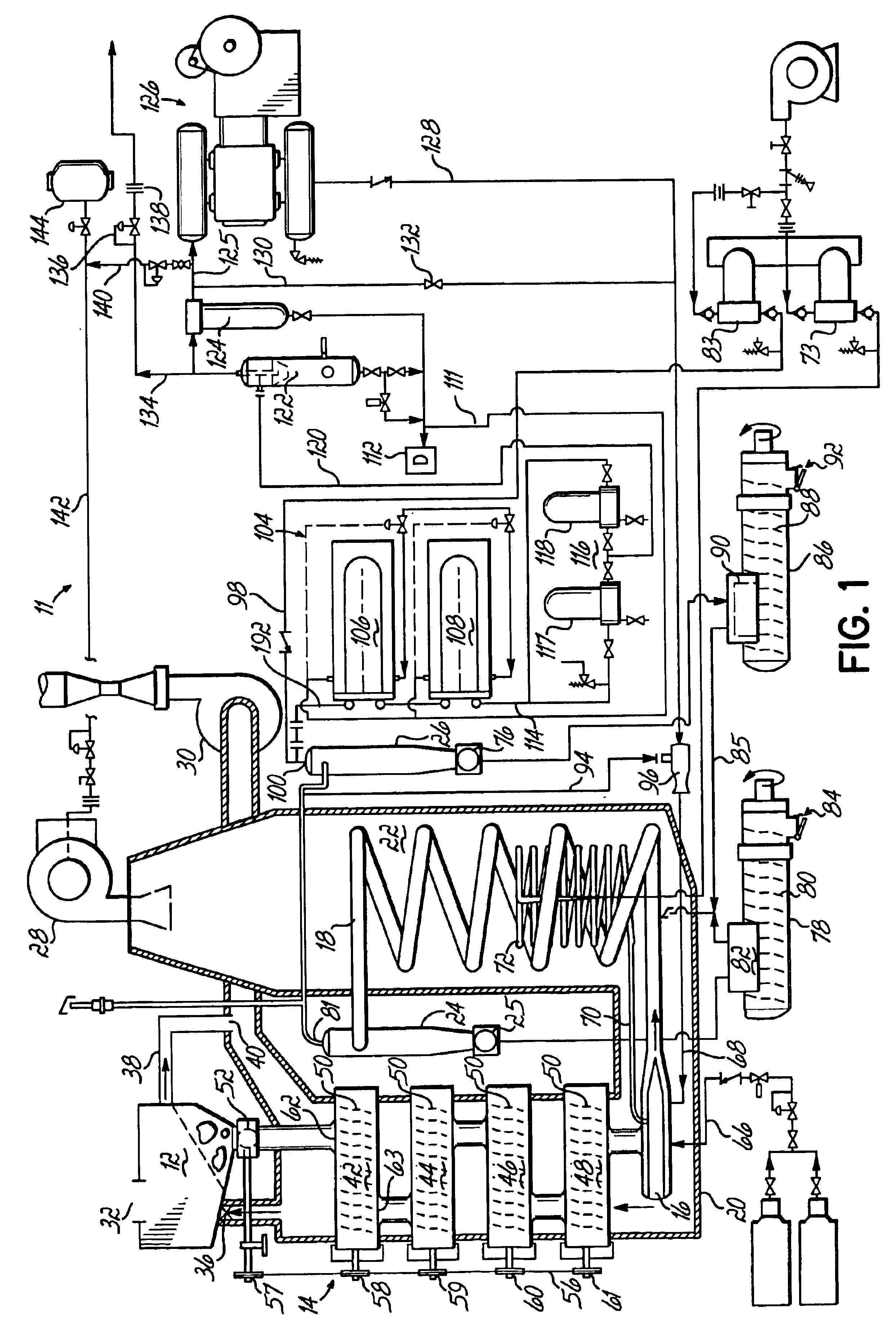

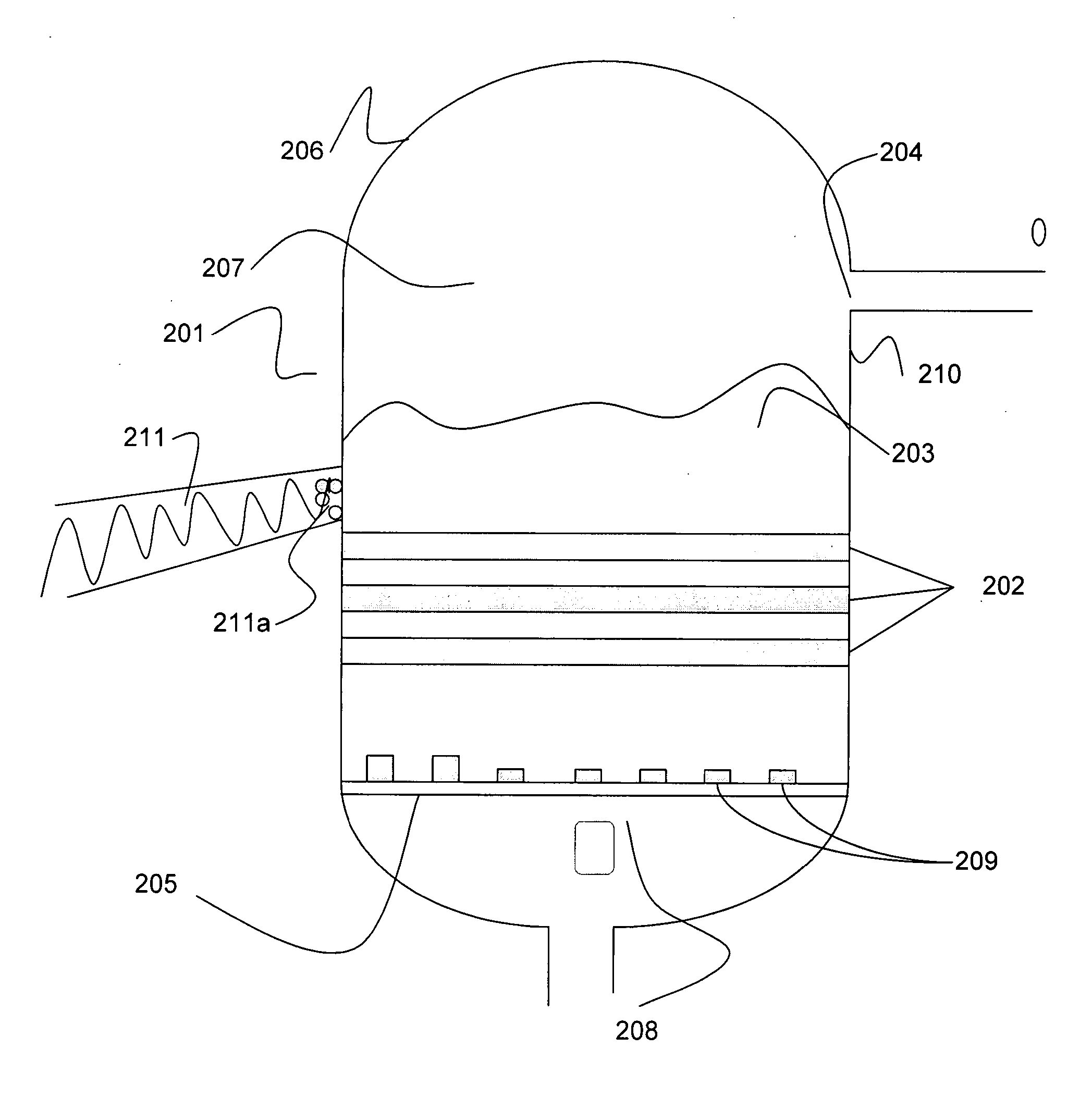

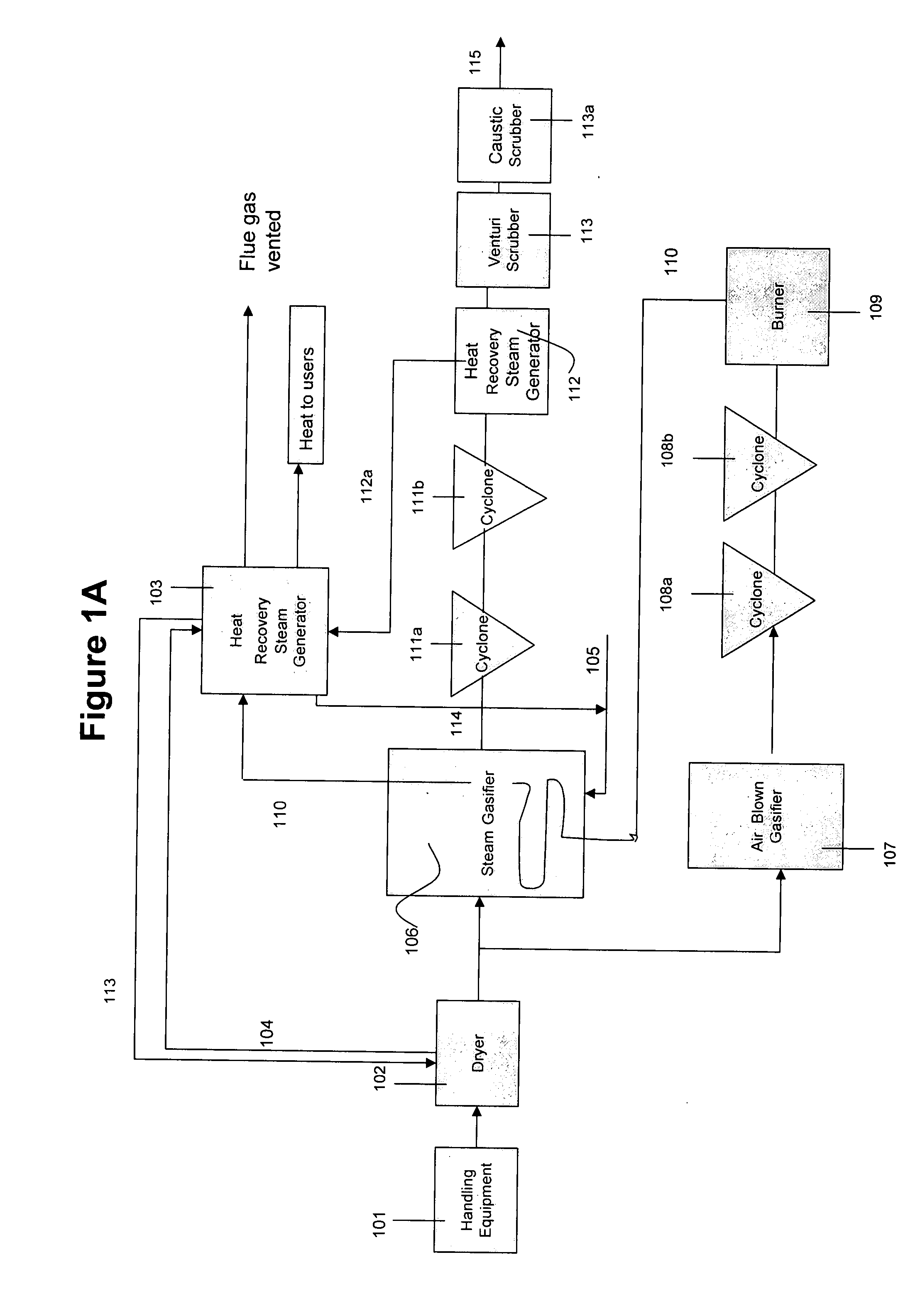

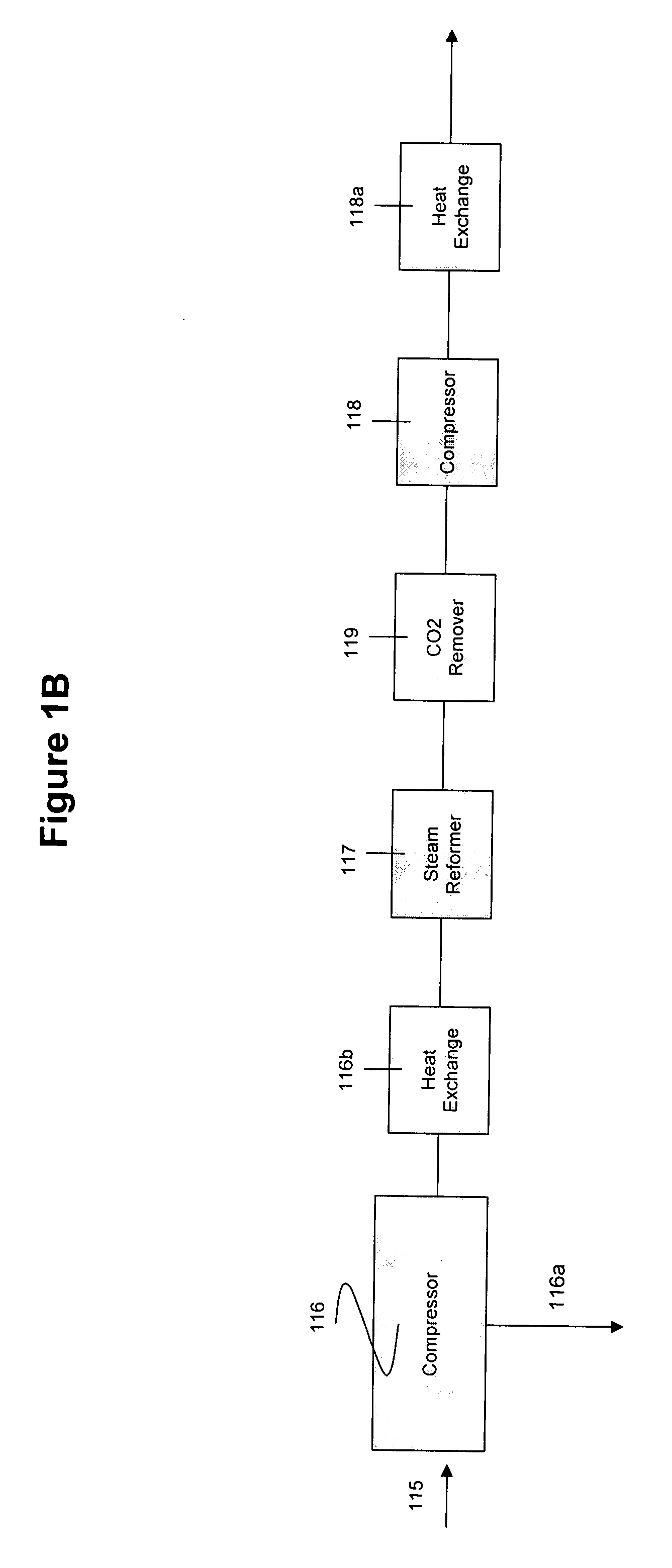

System and method for converting biomass to ethanol via syngas

A method and apparatus for synthesizing ethanol using synthetic routes via synthesis gas are disclosed. A method and apparatus for gasifying biomass, such as biomass, in a steam gasifier that employs a fluidized bed and heating using hot flue gases from the combustion of synthesis gas is described. Methods and apparatus for converting synthesis gas into ethanol are also disclosed, using stepwise catalytic reactions to convert the carbon monoxide and hydrogen into ethanol using catalysts including iridium acetate.

Owner:WOODLAND BIOFUELS

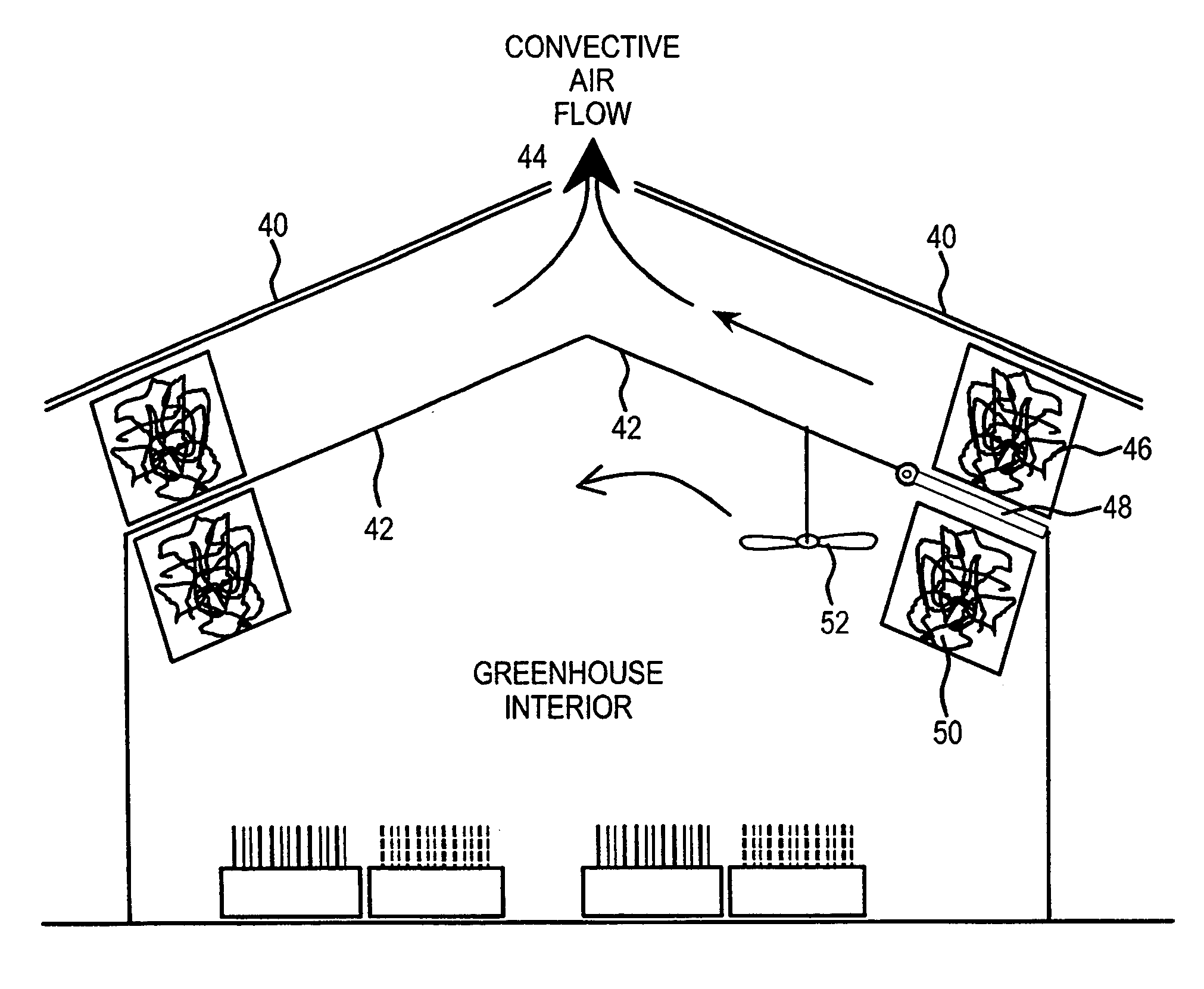

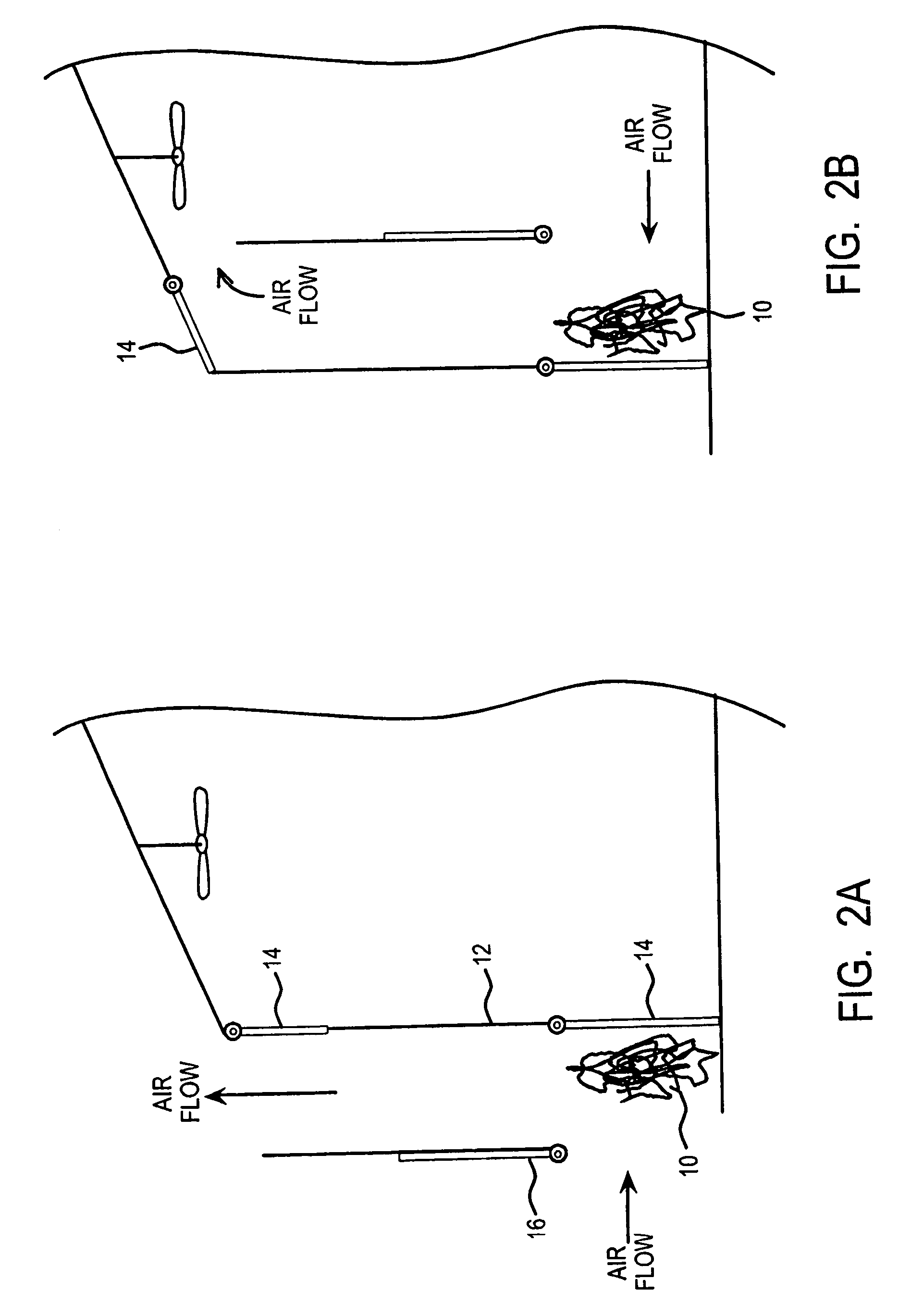

Method and apparatus for extracting carbon dioxide from air

A method and apparatus for extracting CO2 from air comprising an anion exchange material formed in a matrix exposed to a flow of the air, and for delivering that extracted CO2 to controlled environments. The present invention contemplates the extraction of CO2 from air using conventional extraction methods or by using one of the extraction methods disclosed; e.g., humidity swing or electro dialysis. The present invention also provides delivery of the CO2 to greenhouses where increased levels of CO2 will improve conditions for growth. Alternatively, the CO2 is fed to an algae culture.

Owner:CARBON SINK

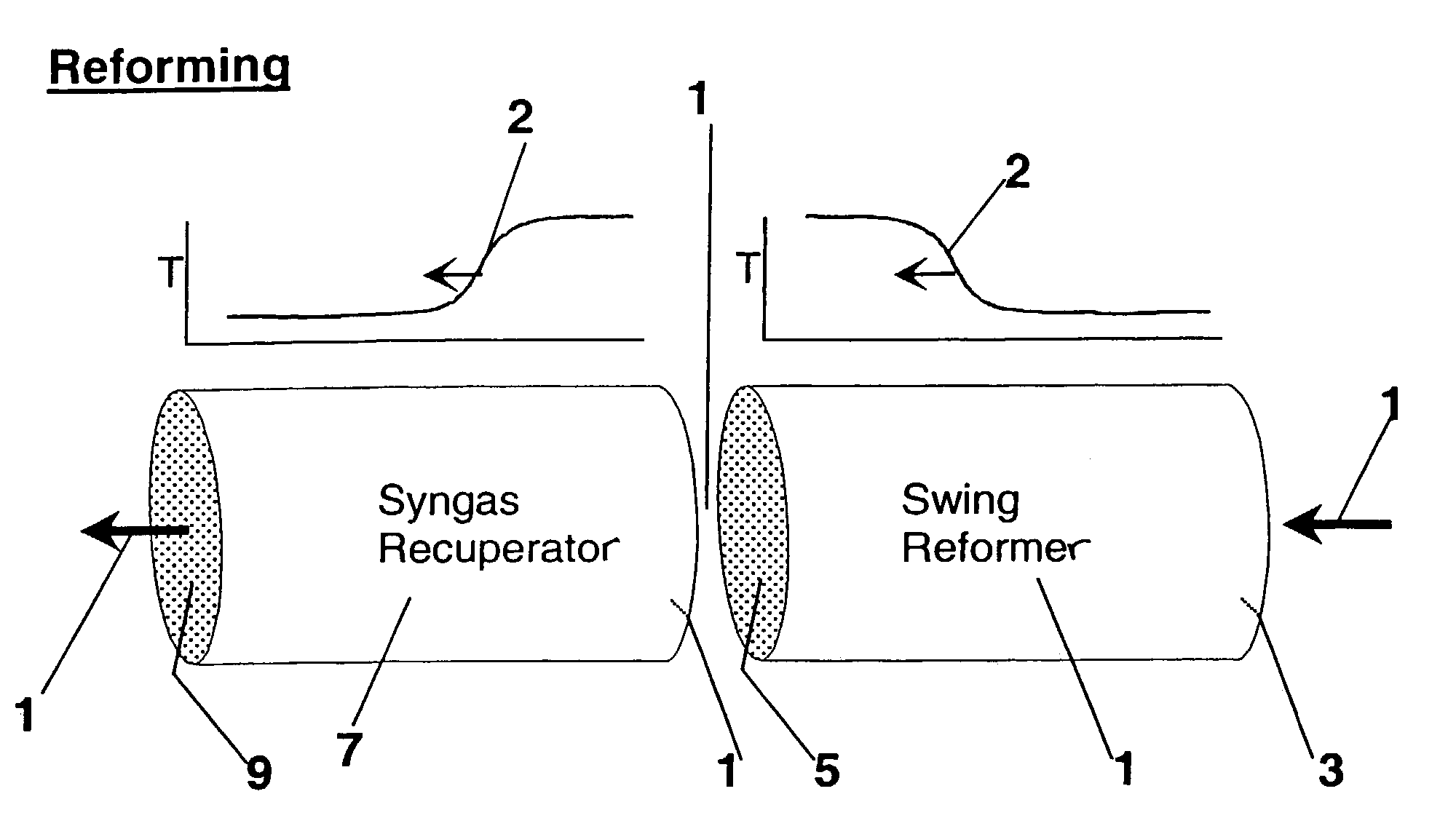

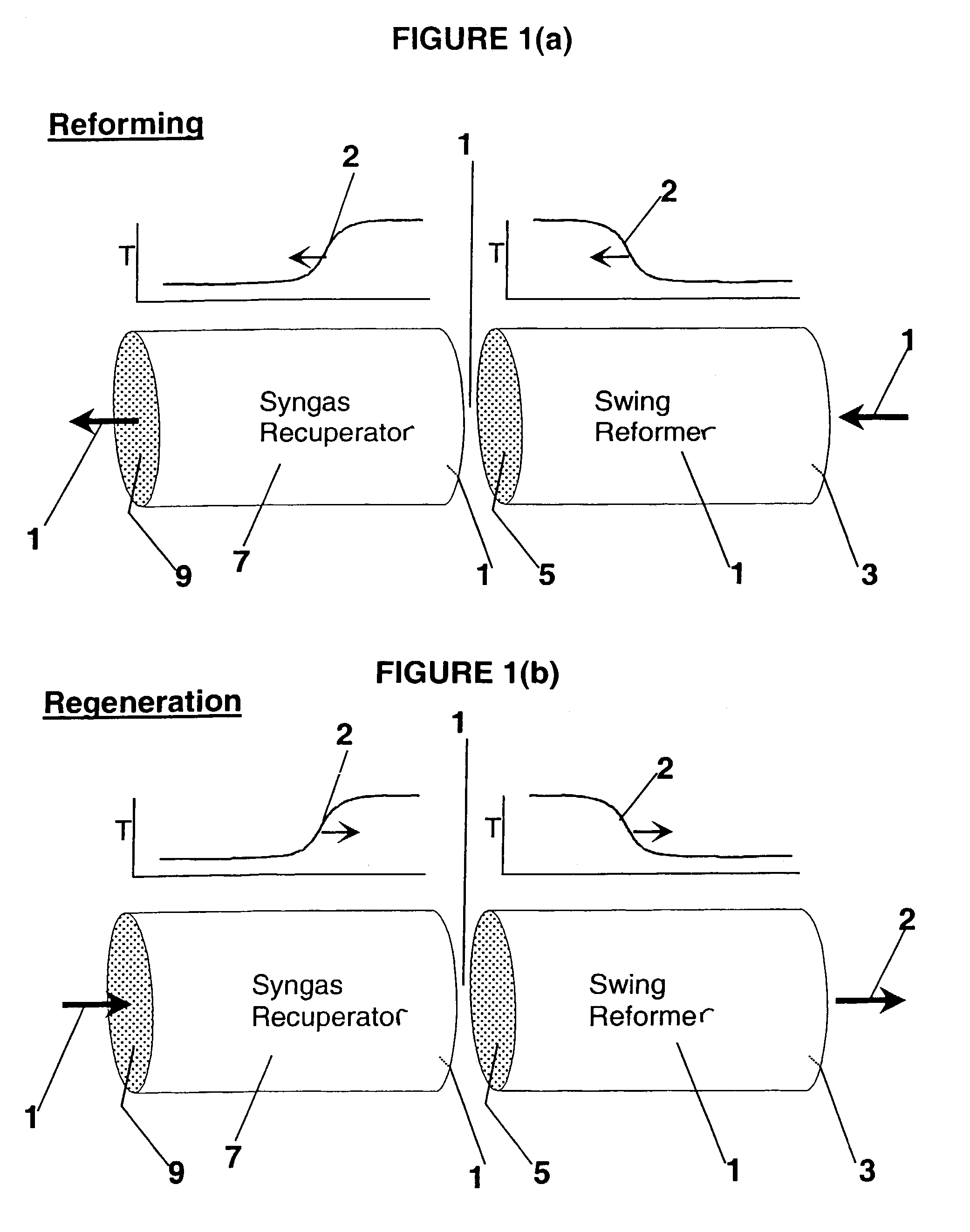

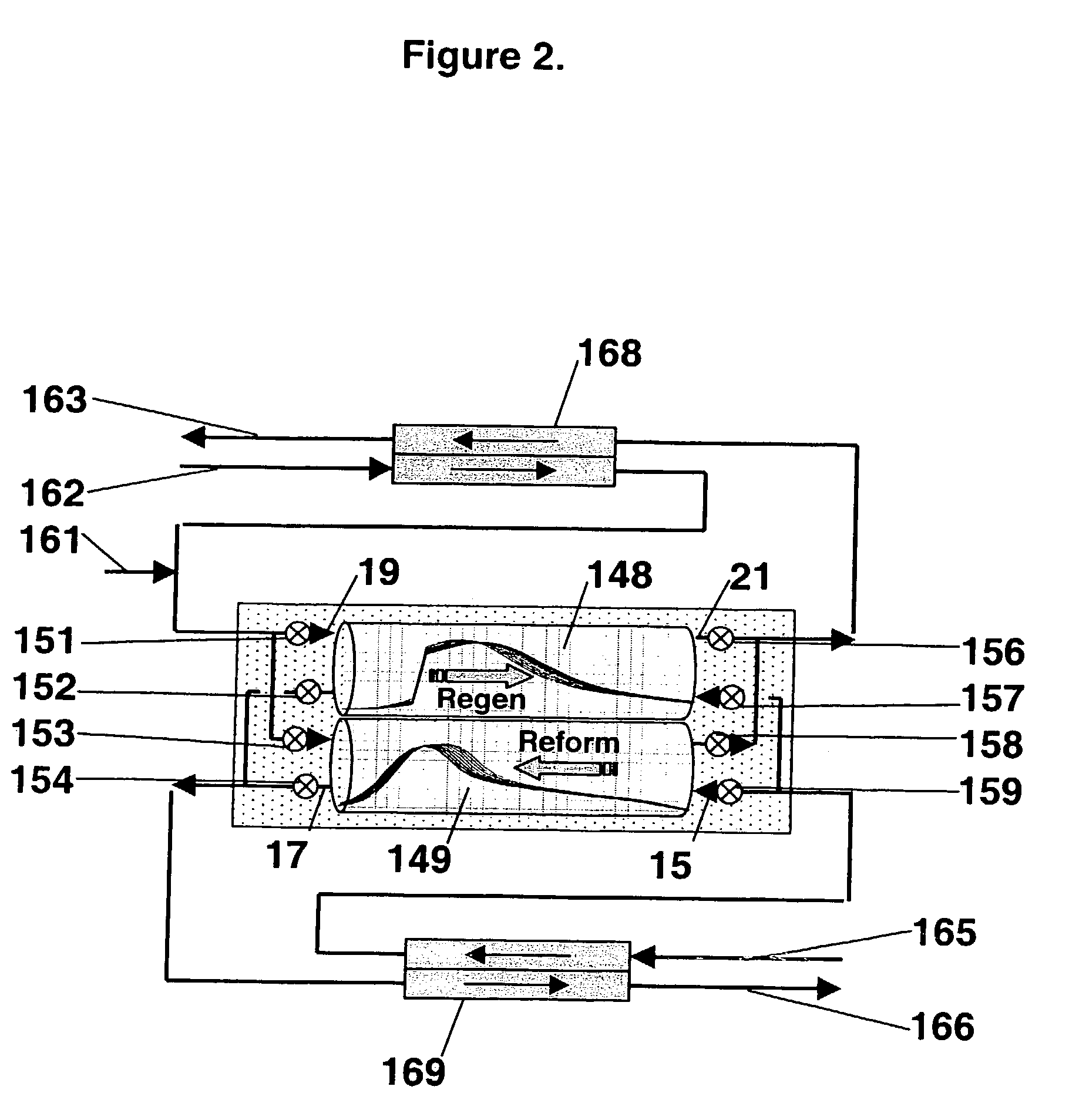

Pressure swing reforming

Synthesis gas is produced though a cyclic method where the first step of the cycle includes reforming a hydrocarbon feed over a catalyst to synthesis gas in a first zone of a bed and the second step reheats this first zone. A hydrocarbon feed is introduced to a bed along with CO2 and optionally steam where it is reformed into synthesis gas. The synthesis gas is collected at a second zone of the bed and an oxygen-containing gas is then introduced to this second zone of the bed and combusted with a fuel, thereby reheating the first zone to sufficient reforming temperatures. Additionally, a non-combusting gas can also be introduced to the second zone to move heat from the second zone to the first zone.

Owner:EXXON RES & ENG CO

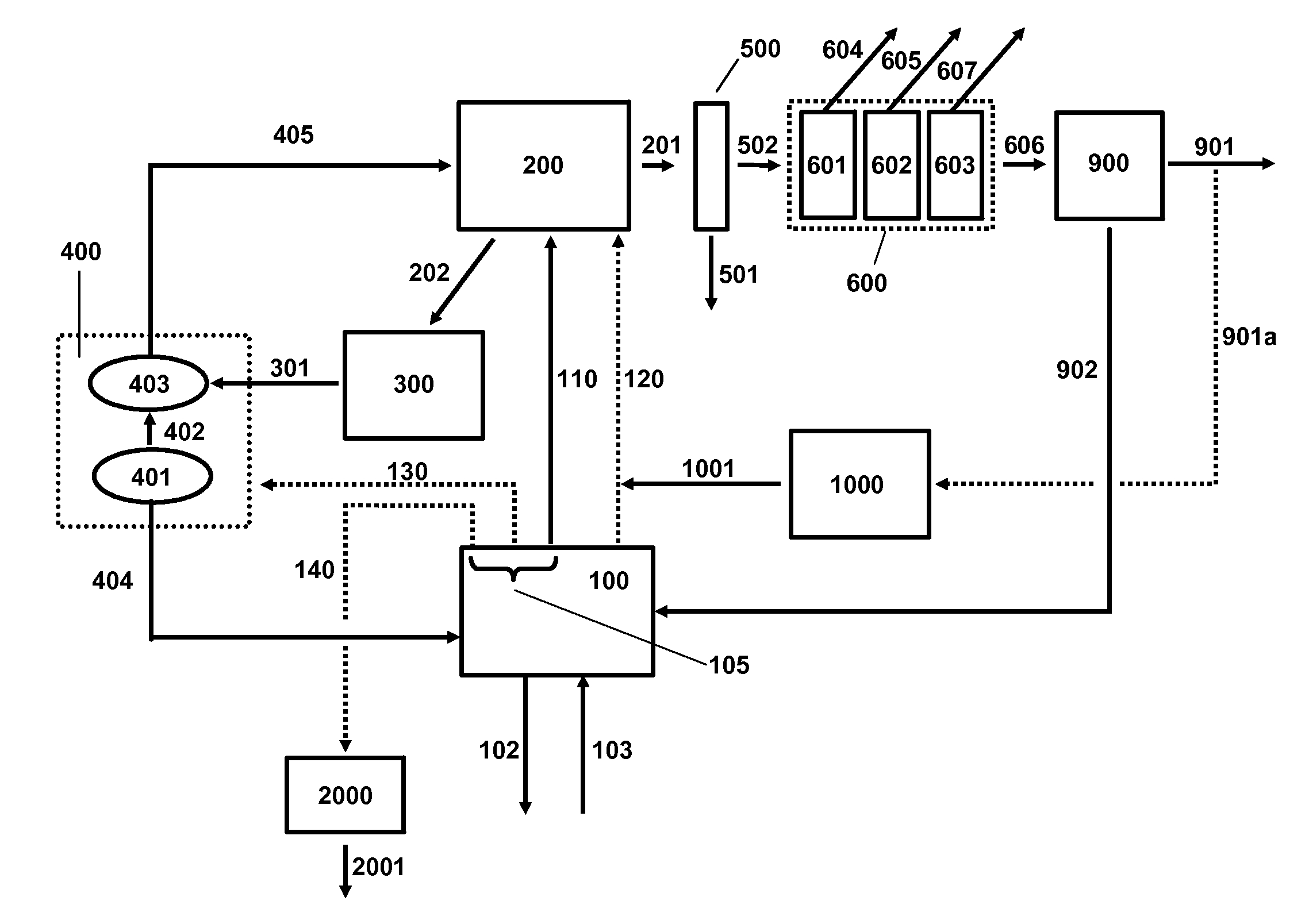

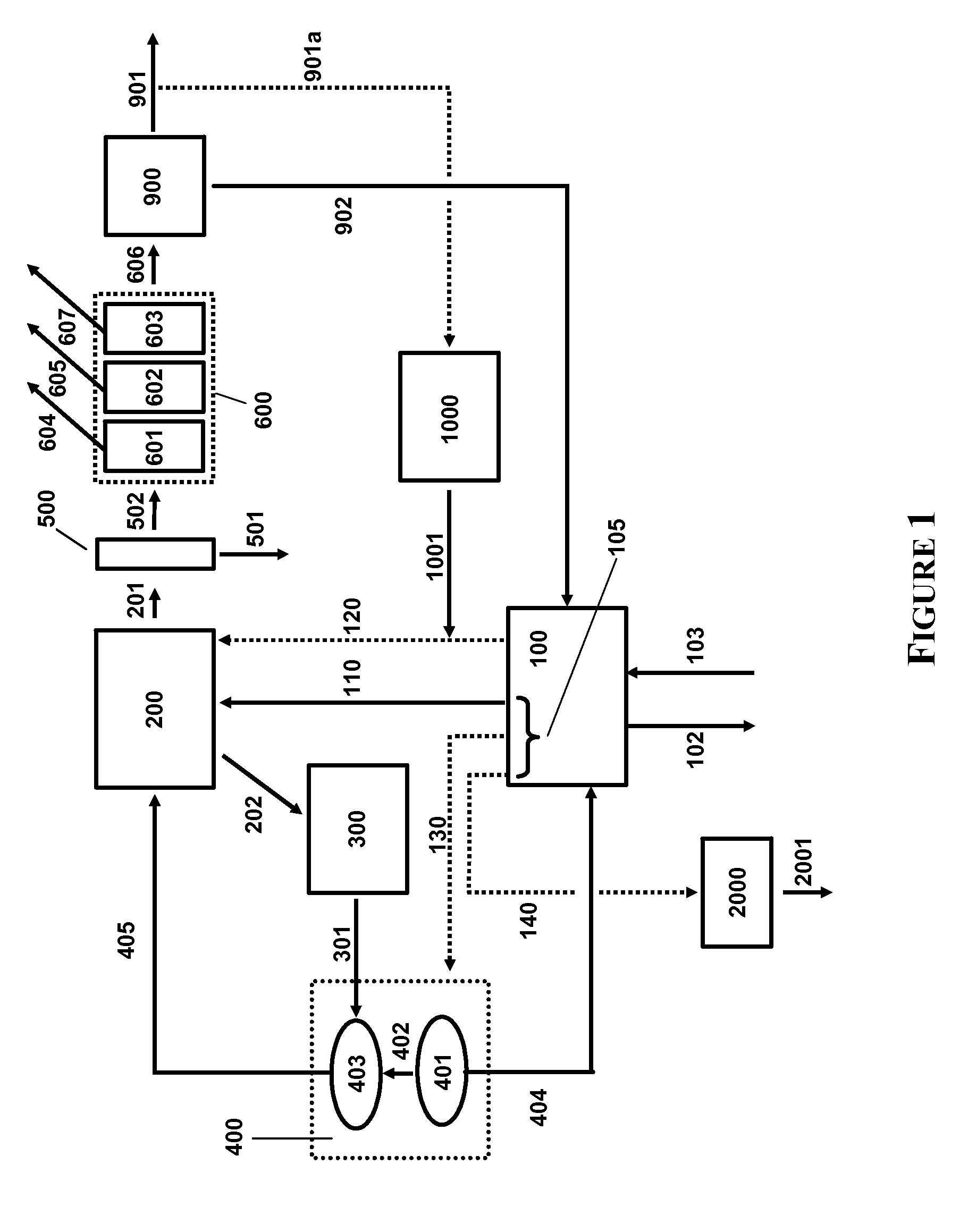

Steam Generation Processes Utilizing Biomass Feedstocks

Integrated catalytic gasification processes are provided involving generating steam for converting carbonaceous materials to combustible gases, such as methane. Generally, steam generated from the combustion of a biomass is provided to a catalytic gasifier, wherein under appropriate temperature and pressure conditions, a carbonaceous feedstock is converted into a plurality of product gases, including, but not limited to, methane, carbon monoxide, hydrogen, and carbon dioxide.

Owner:SURE CHAMPION INVESTMENT LTD

Process for sequestering carbon dioxide and sulfur dioxide

A process for sequestering carbon dioxide, which includes reacting a silicate based material with an acid to form a suspension, and combining the suspension with carbon dioxide to create active carbonation of the silicate-based material, and thereafter producing a metal salt, silica and regenerating the acid in the liquid phase of the suspension.

Owner:PENN STATE RES FOUND

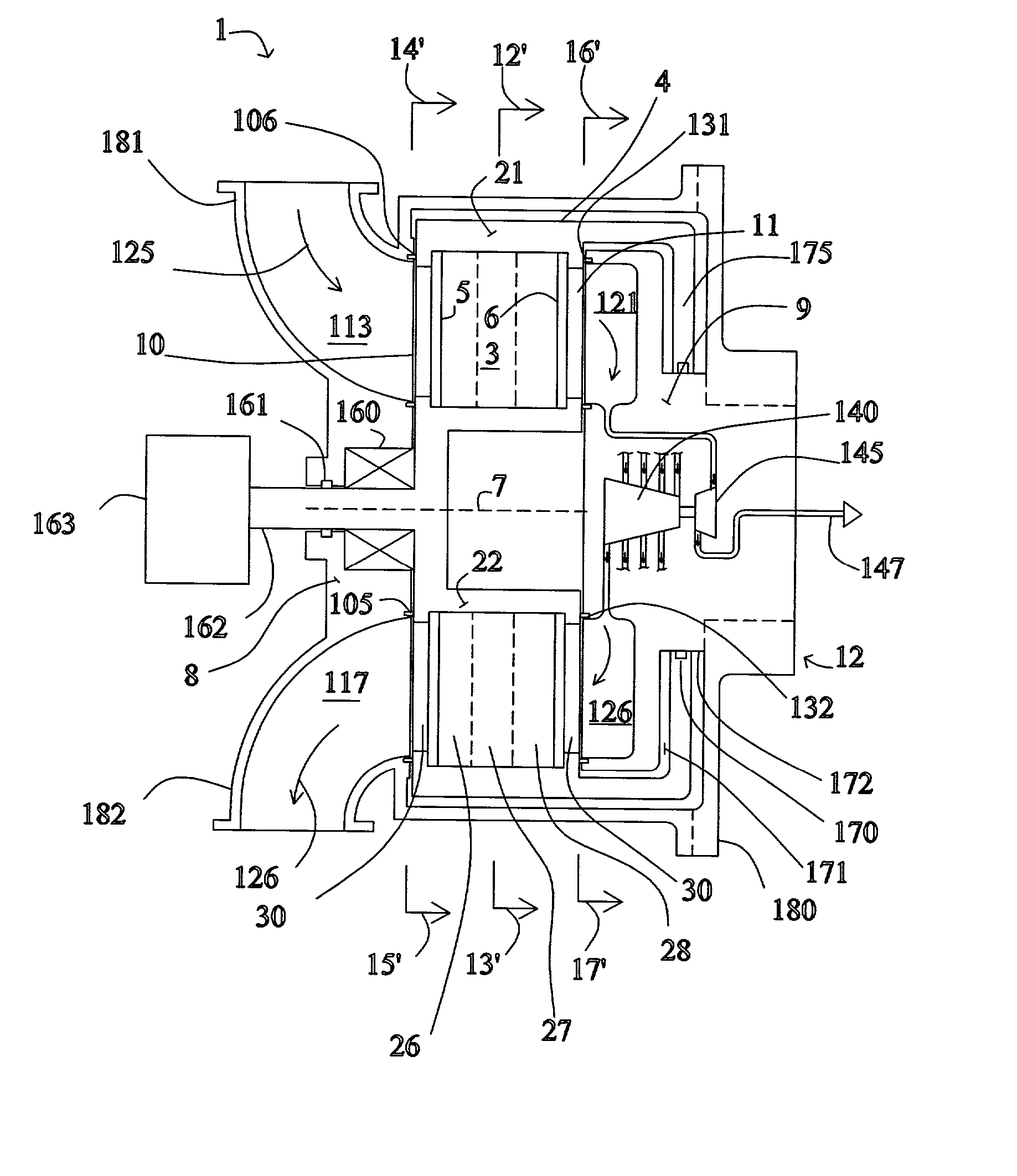

Energy efficient gas separation for fuel cells

InactiveUS20020142208A1Improve efficiencyReduce the ratioFuel cell heat exchangeFused electrolyte fuel cellsEngineeringDelivery system

An electrical current generating system is disclosed that includes a fuel cell operating at a temperature of at least about 250° C. (for example, a molten carbonate fuel cell or a solid oxide fuel cell), a hydrogen gas separation system or oxygen gas delivery system that includes a compressor or pump, and a drive system for the compressor or pump that includes means for recovering energy from at least one of the hydrogen gas separation system, oxygen gas delivery system, or heat of the fuel cell. The drive system could be a gas turbine system. The hydrogen gas separation system or the oxygen gas delivery system may include a pressure swing adsorption module.

Owner:AIR PROD & CHEM INC

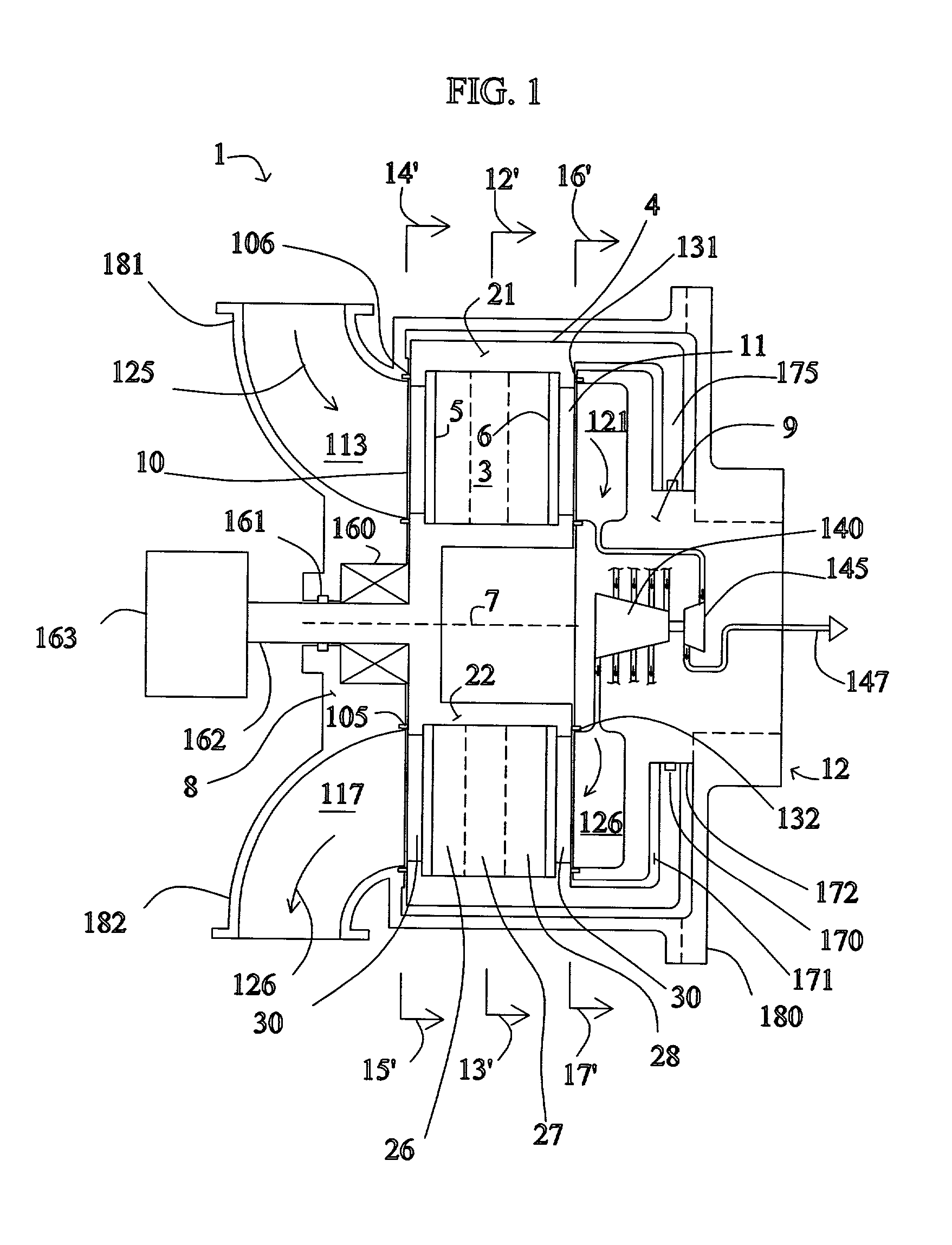

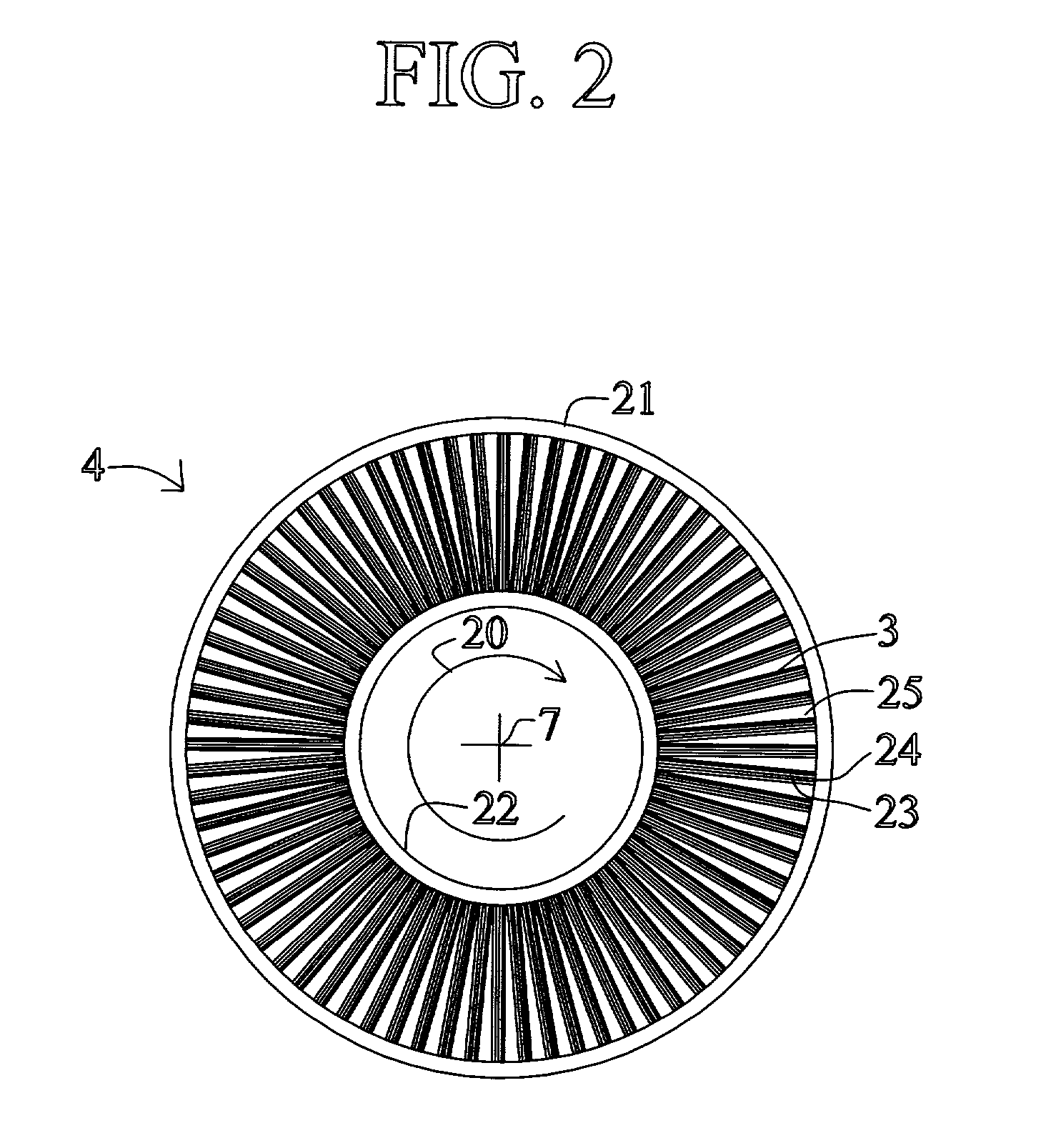

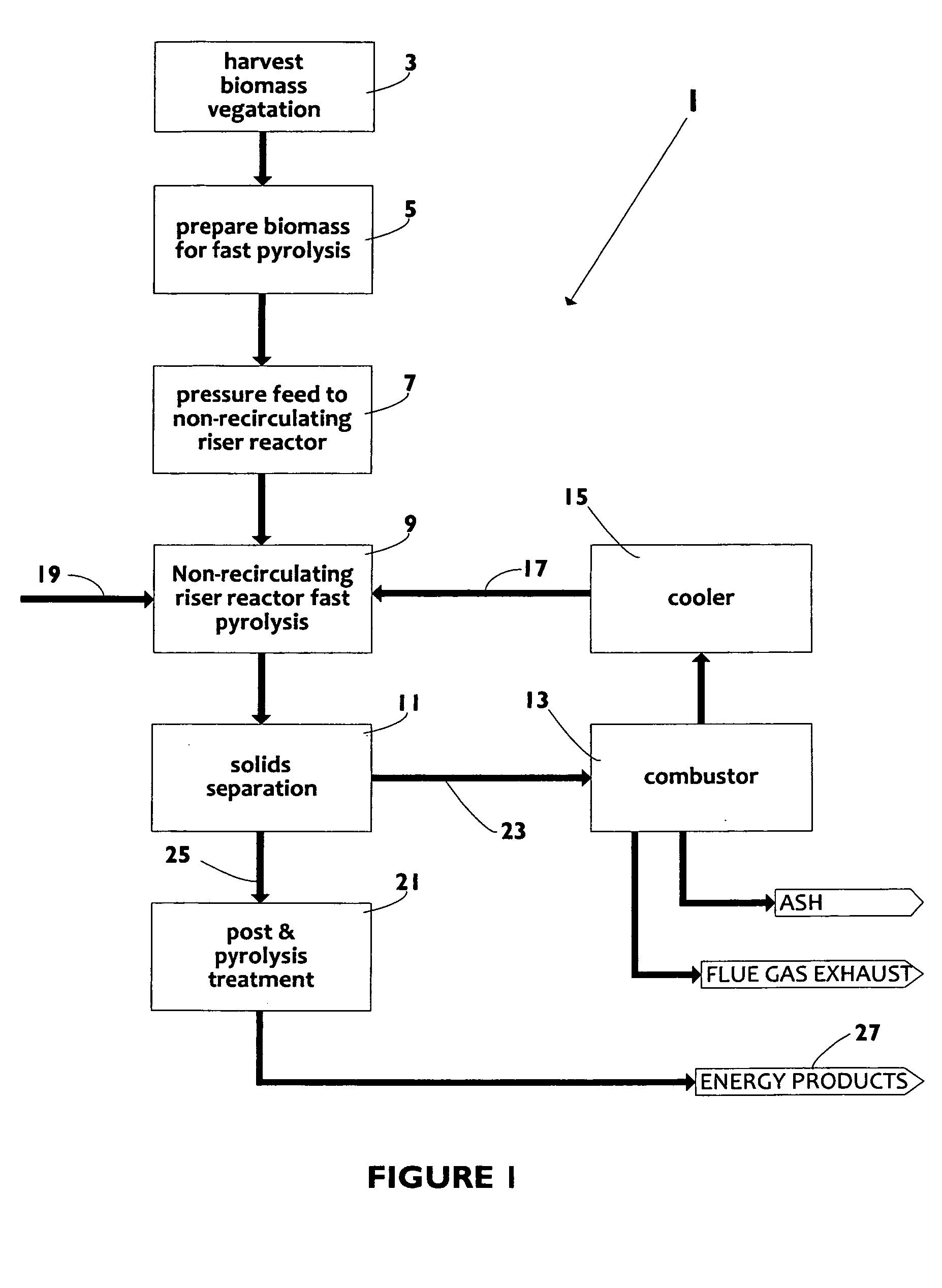

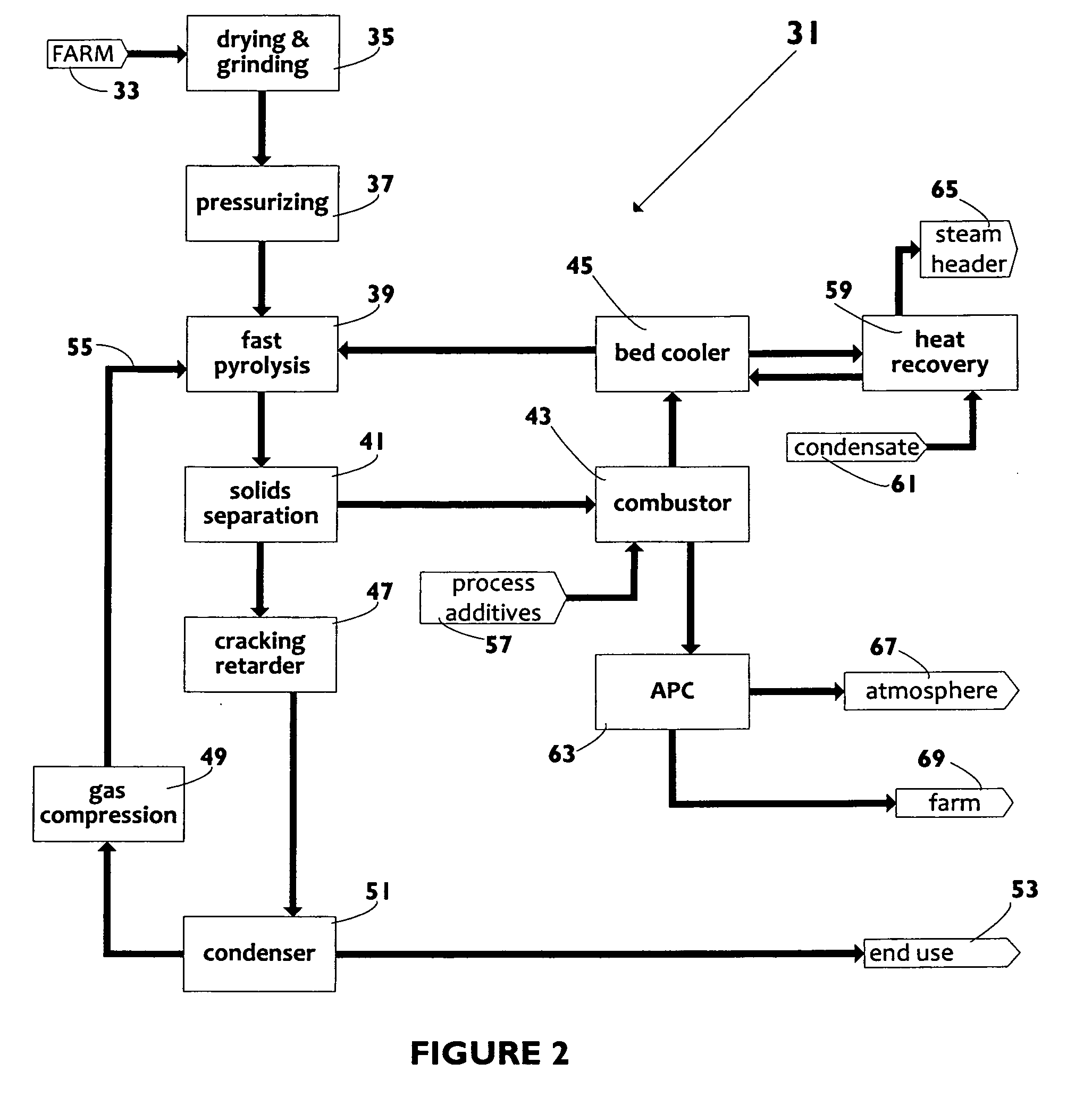

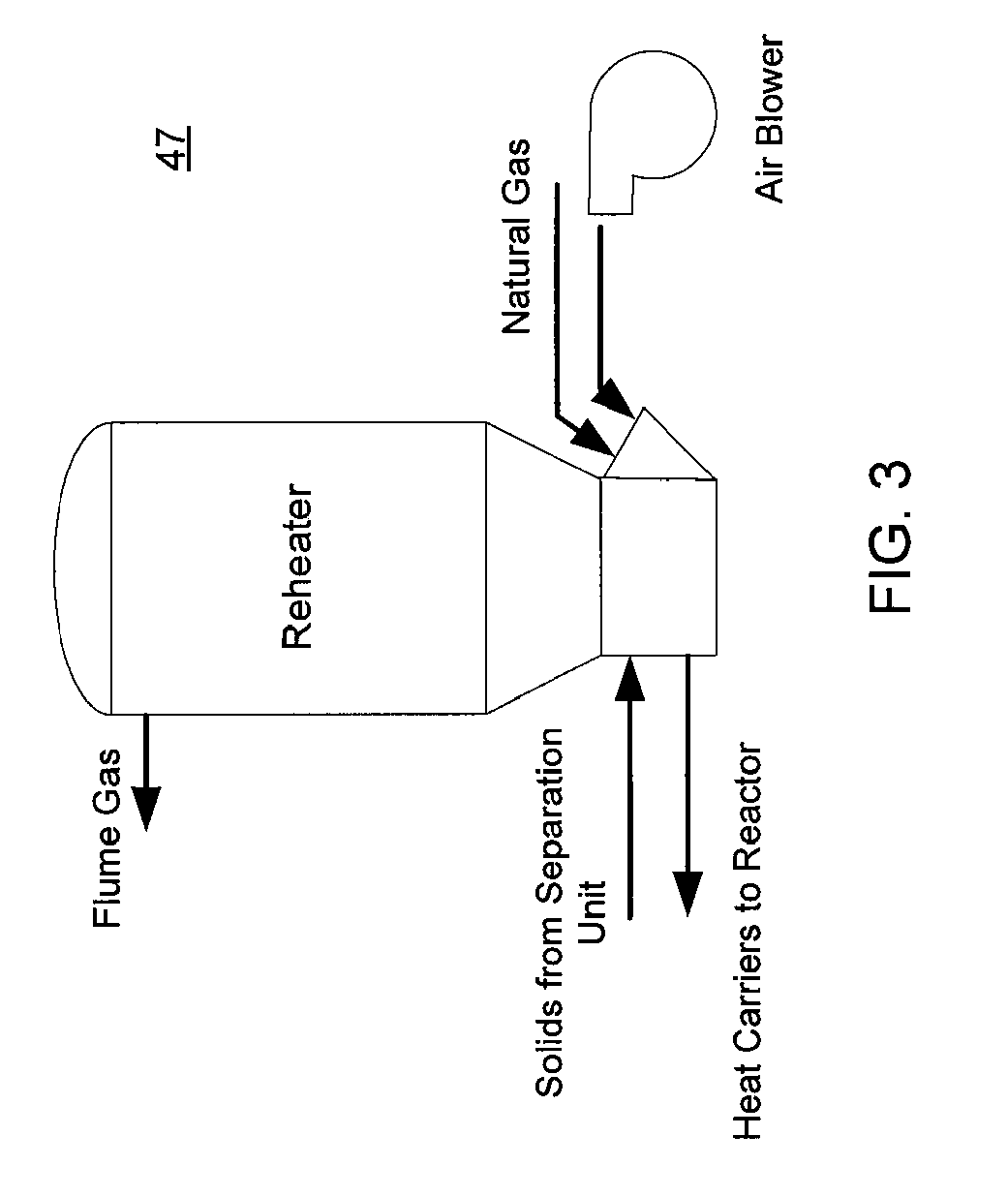

Biomass fast pyrolysis system utilizing non-circulating riser reactor

A biomass fast pyrolysis system for conversion of biomass vegetation to synthetic gas and liquid fuels includes: a) a non-circulating riser reactor for pyrolysis of biomass vegetation feedstock utilizing a heat carrier, the non-circulating riser reactor being physically structured and adapted to have a rate of reaction of at least 8,000 biomass vegetation feedstock lbs / hr / ft2, utilizing a ratio of heat carrier to biomass vegetation feedstock of about 7:1 to about 11.5:1, the riser reactor having a base input region at its bottom, a central reaction region and an output region at its top, the riser reactor including a cyclone disengager at its output region for separation of pyrolysis resulting char and heat carrier from the pyrolysis product gases, the cyclone disengager having an output downcomer and an output upcomer, the cyclone disengager output downcomer being connected to and feeding into a side combustor unit, the riser reactor being a non-circulating riser reactor in that the heat carrier is not returned directly to the riser reactor from the cyclone disengager and travels first down the cyclone disengager output downcomer to the side combustor unit; and, b) the side combustor unit for combusting pyrolysis resultant char and reheating the heat carrier the side combustor having a heat carrier downcomer connected to the base input region of the riser reactor.

Owner:INNOVATIVE ENERGY GLOBAL

Coal Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst. The particulate compositions are gasified in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

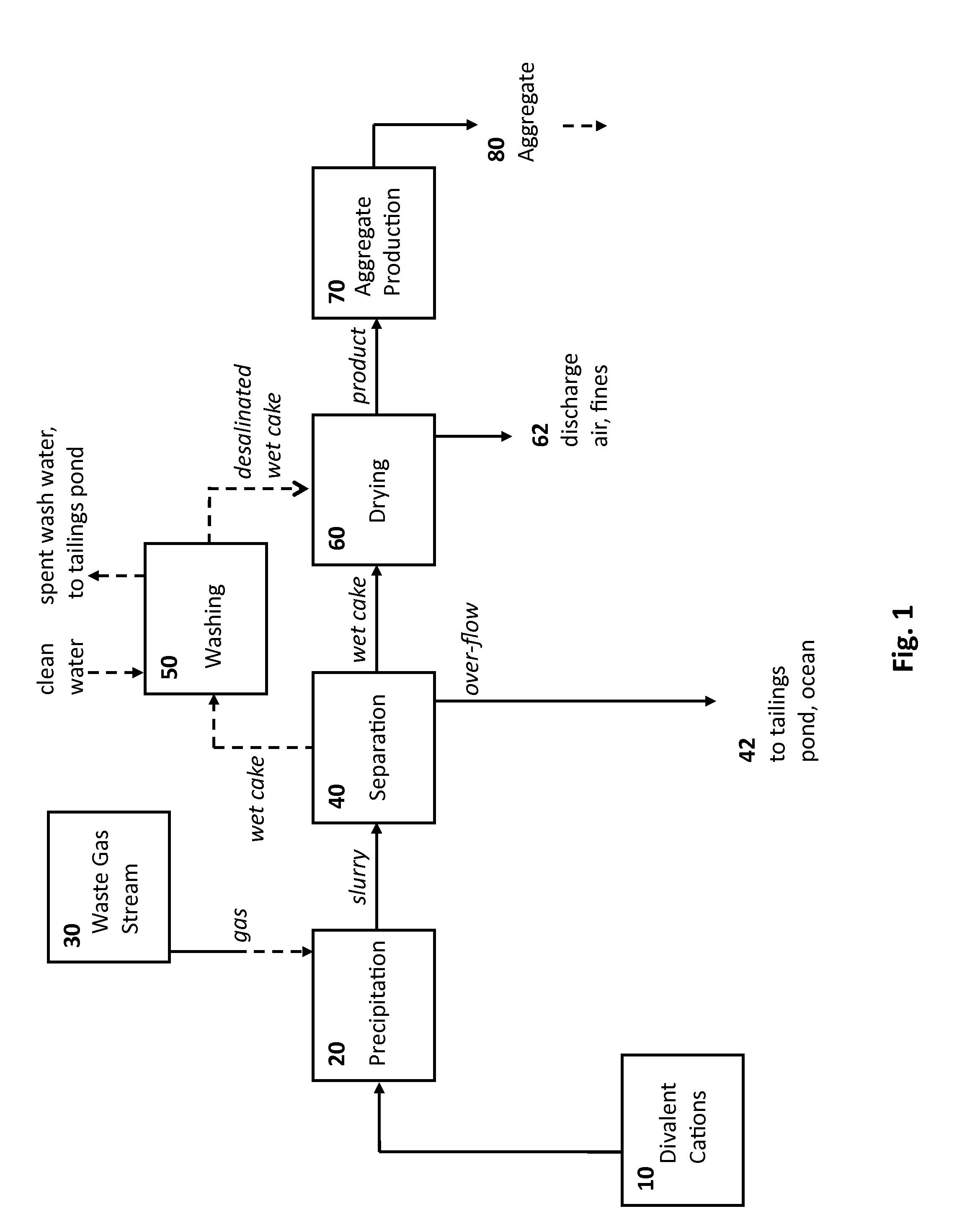

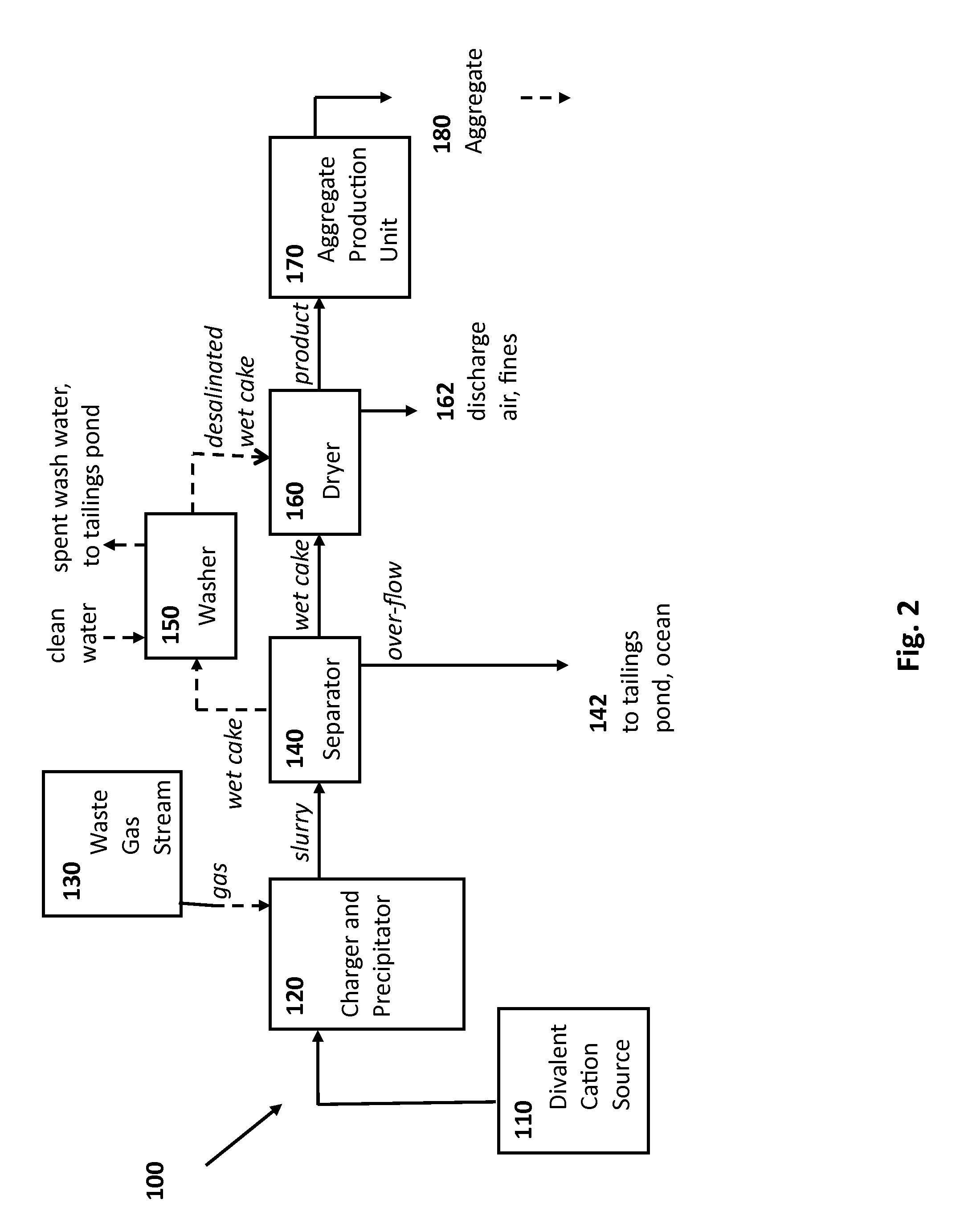

Rocks and aggregate, and methods of making and using the same

ActiveUS20100024686A1Calcium/strontium/barium carbonatesPigmenting treatmentCarbonateToxic industrial waste

Compositions comprising synthetic rock, e.g., aggregate, and methods of producing and using them are provided. The rock, e.g., aggregate, contains CO2 and / or other components of an industrial waste stream. The CO2 may be in the form of divalent cation carbonates, e.g., magnesium and calcium carbonates. Aspects of the invention include contacting a CO2 containing gaseous stream with a water to dissolve CO2, and placing the water under precipitation conditions sufficient to produce a carbonate containing precipitate product, e.g., a divalent cation carbonate.

Owner:ARELAC INC

Biomass Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a biomass, such as switchgrass or hybrid poplar, a non-biomass carbonaceous material, such as petroleum coke or coal, and a gasification catalyst, where the gasification catalyst is loaded onto at least one of the biomass or non-biomass for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

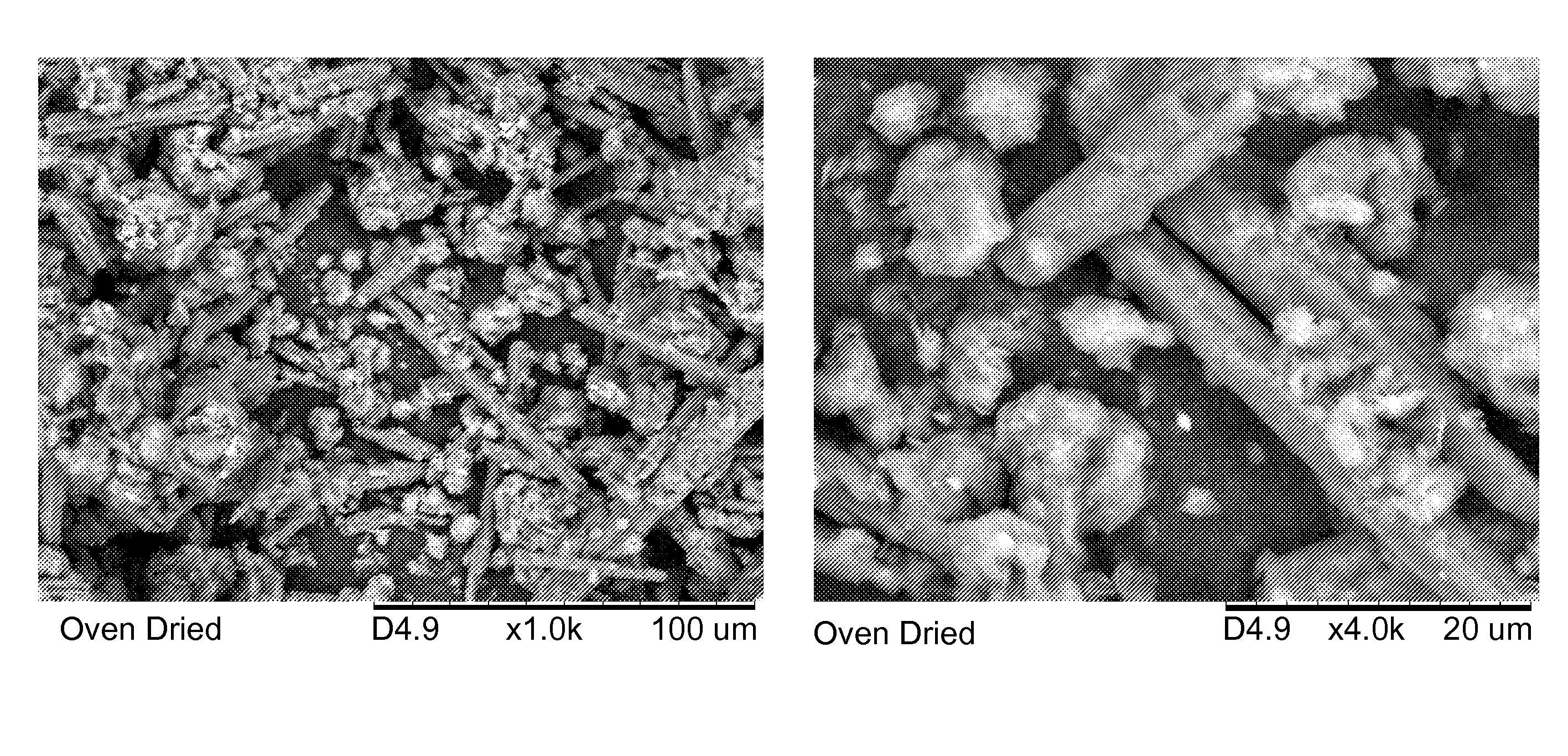

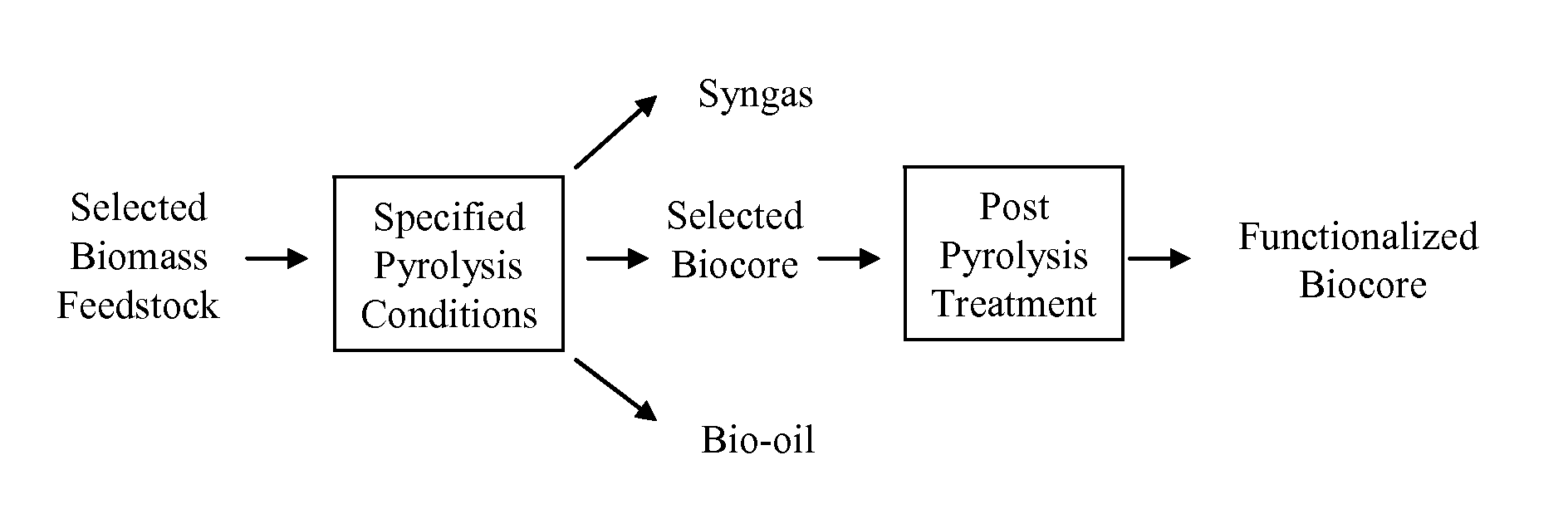

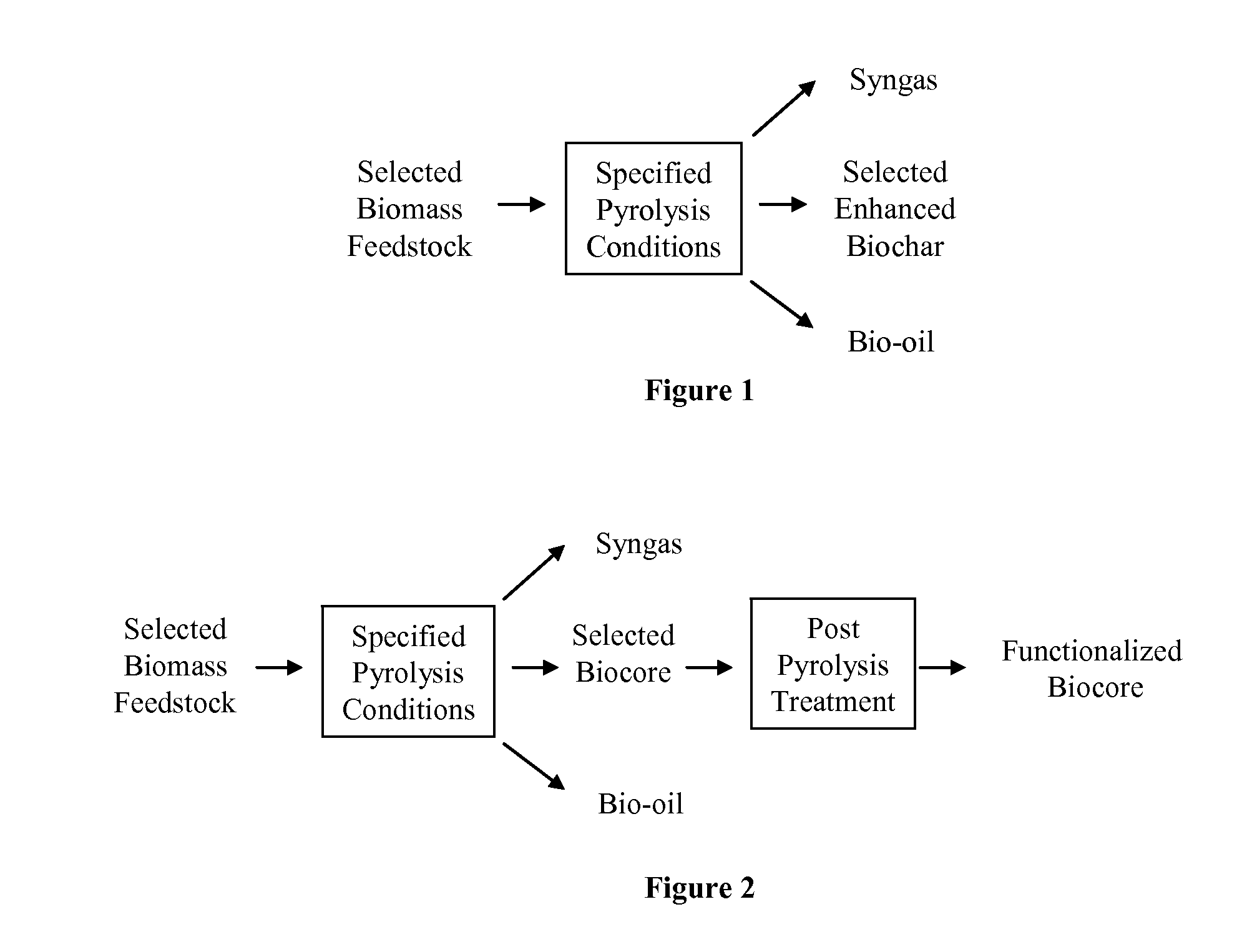

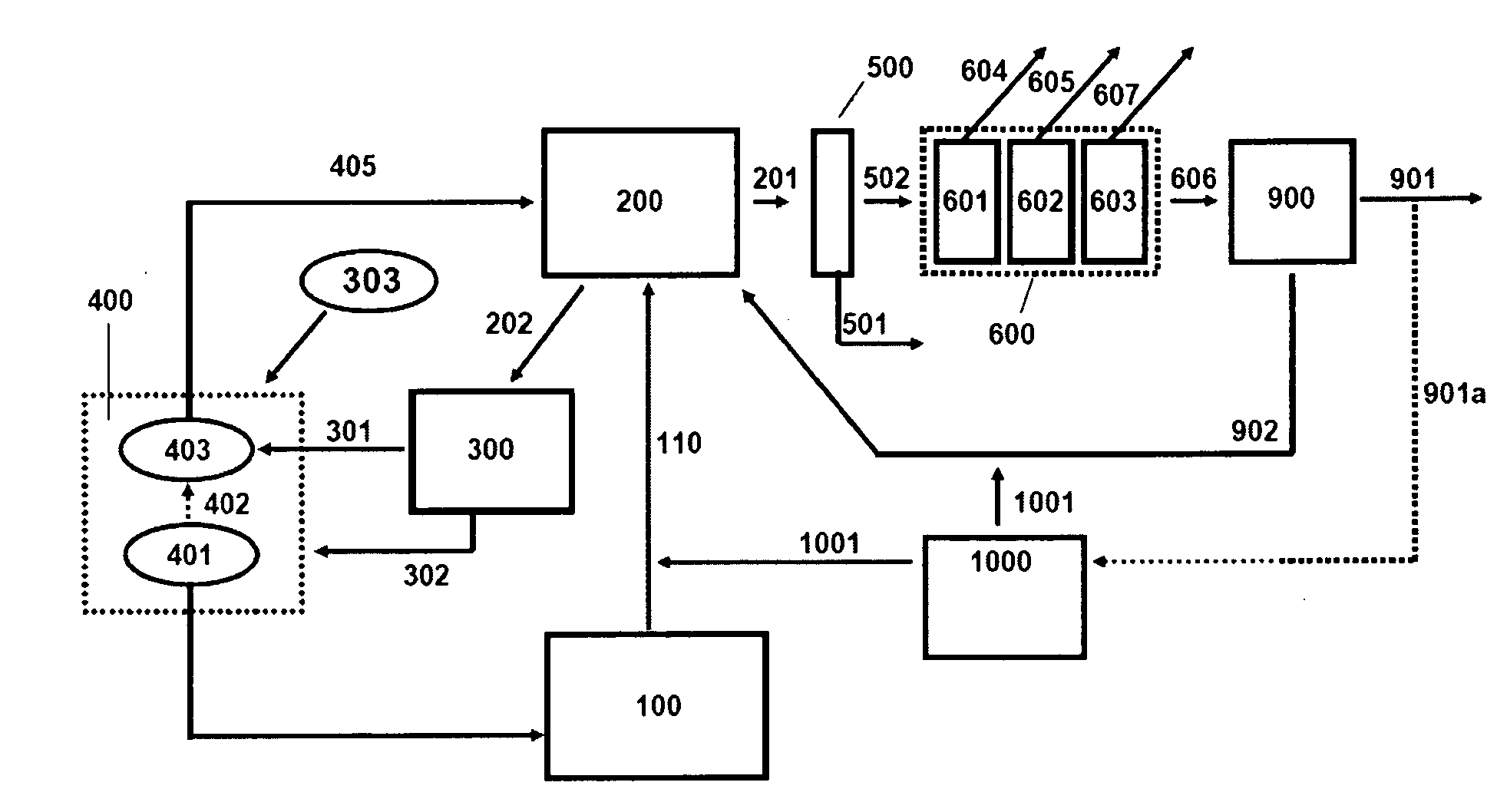

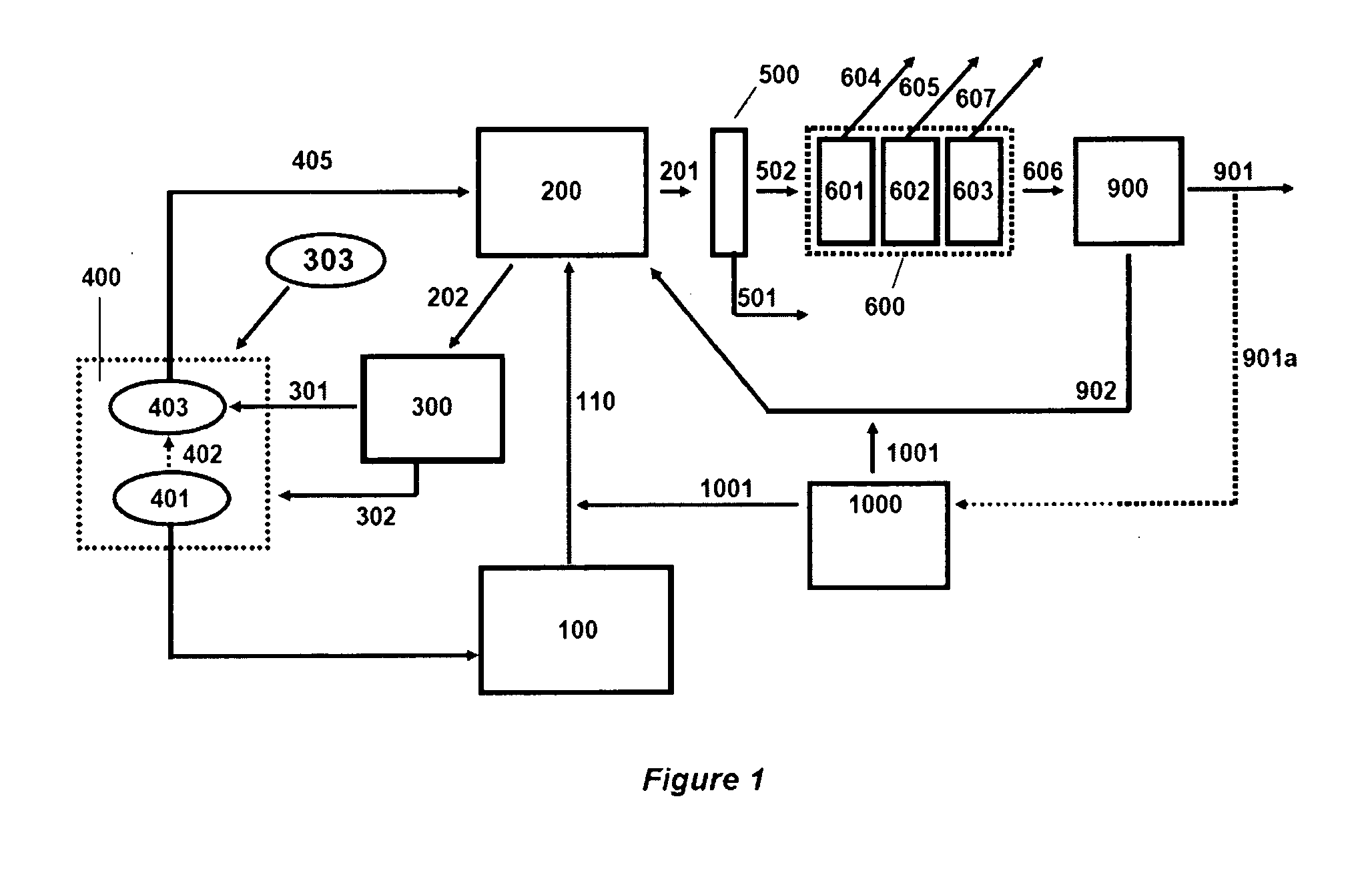

Biochar

ActiveUS8361186B1Enhanced and functionalizedCalcareous fertilisersMagnesium fertilisersForming gasBiological activation

The invention provides for methods, devices, and systems for pyrolyzing biomass. A pyrolysis unit can be used for the pyrolysis of biomass to form gas, liquid, and solid products. The biomass materials can be selected such that an enhanced biochar is formed after pyrolysis. The biomass can be pyrolyzed under specified conditions such that a selected biochar core is formed. The pyrolysis process can form a stable biochar core that is inert and / or resistant to degradation. The biochar or biochar core can be functionalized to form a functionalized biochar or functionalized biochar core. Functionalization can include post-pyrolysis treatments such as supplementation with microbes or physical transformations including annealing and / or activation.

Owner:FULL CIRCLE BIOCHAR

Co-Feed of Biomass as Source of Makeup Catalysts for Catalytic Coal Gasification

Continuous processes are provided for converting a carbonaceous feedstock comprising biomass containing alkali metal, non-biomass components, and at least one gasification catalyst including an alkali metal recovered from solid char, into a plurality of gaseous products including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons.

Owner:SURE CHAMPION INVESTMENT LTD

Catalytic Gasification Particulate Compositions

ActiveUS20090229182A1Efficient use ofBiofuelsGas modification by gas mixingPtru catalystPetroleum coke

Particulate compositions are described comprising a carbonaceous material, such as petroleum coke and / or coal, treated or otherwise associated with a gasification catalyst, where the catalyst is at least in part derived from a leachate from a biomass char, for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

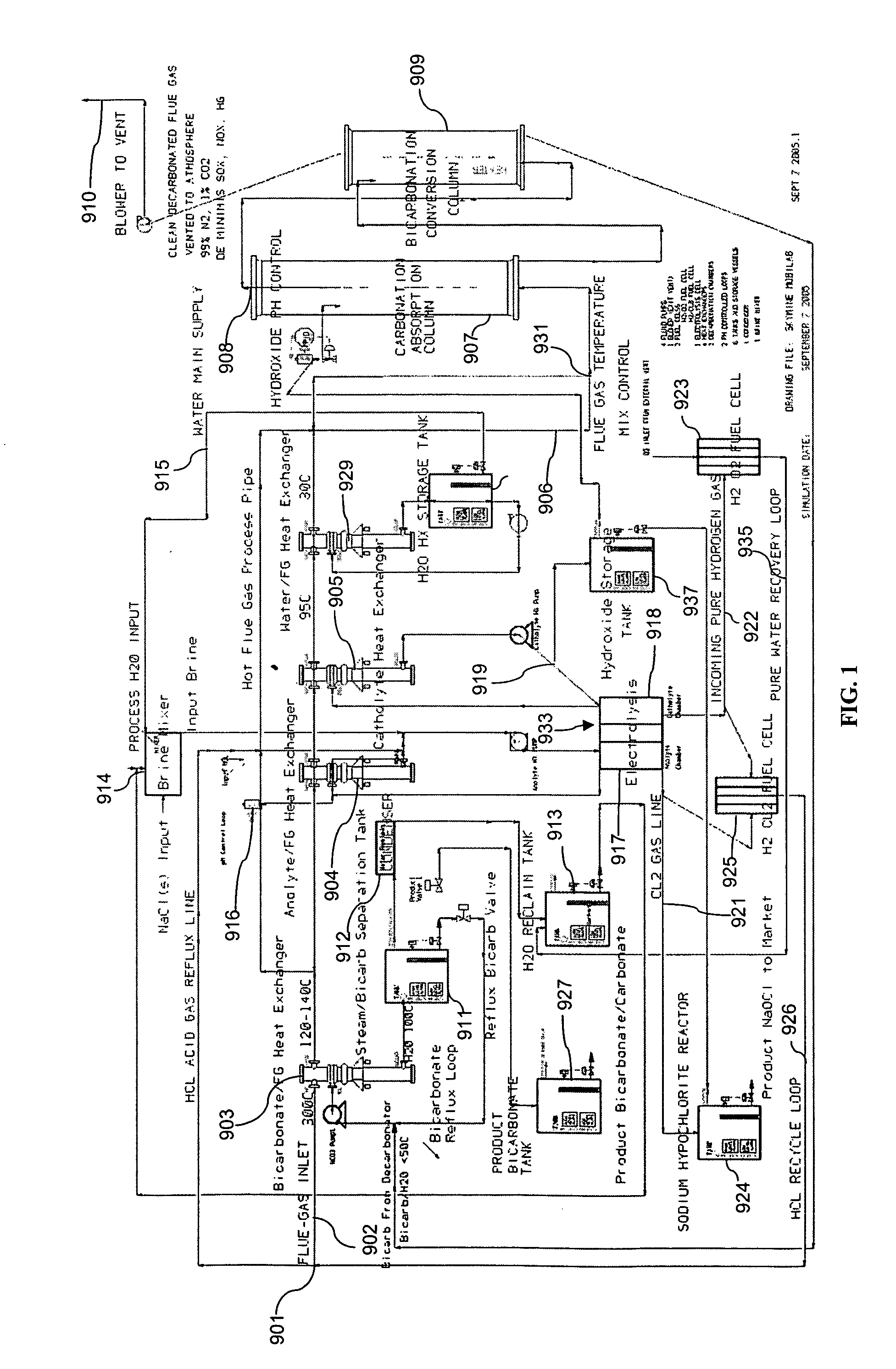

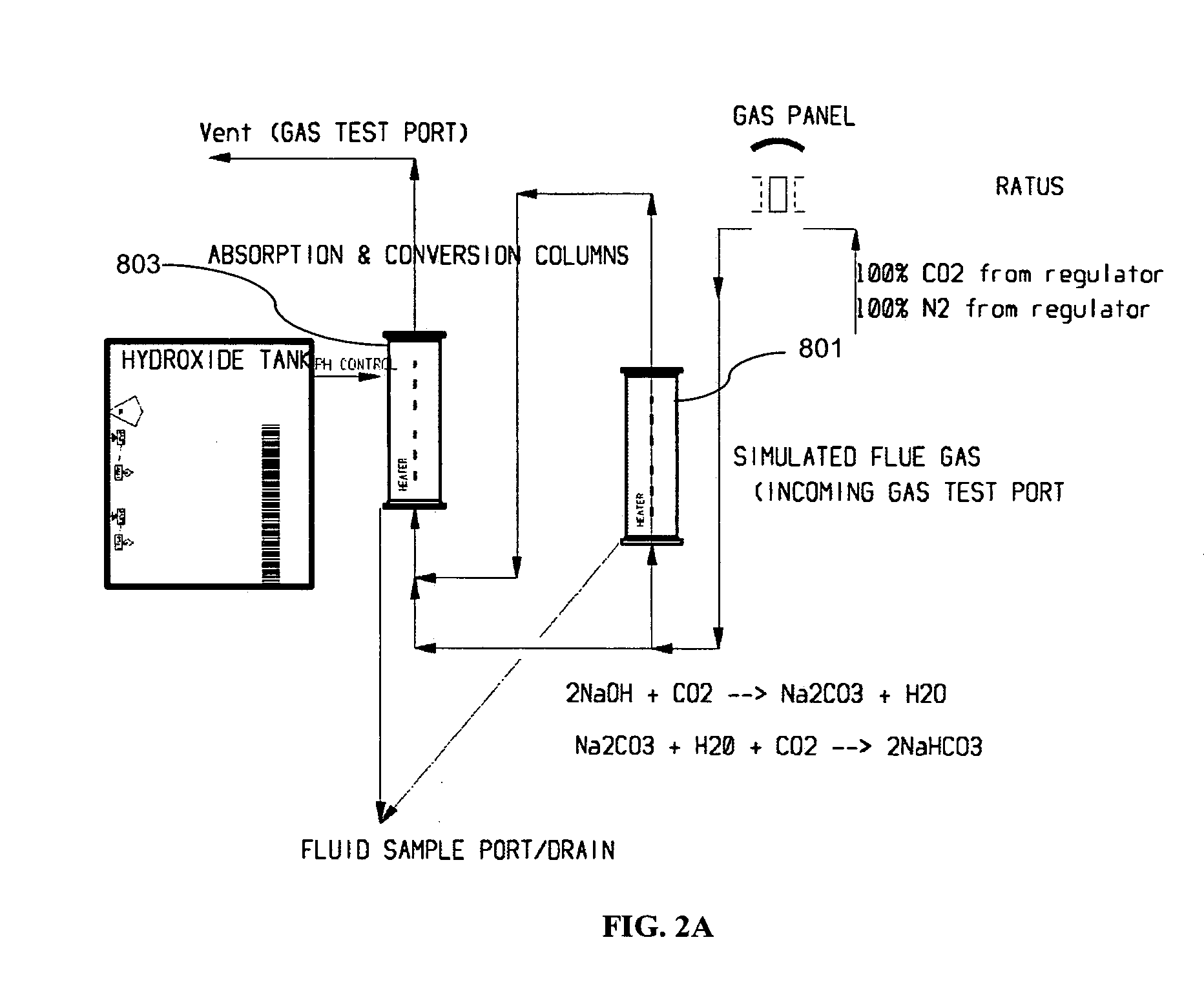

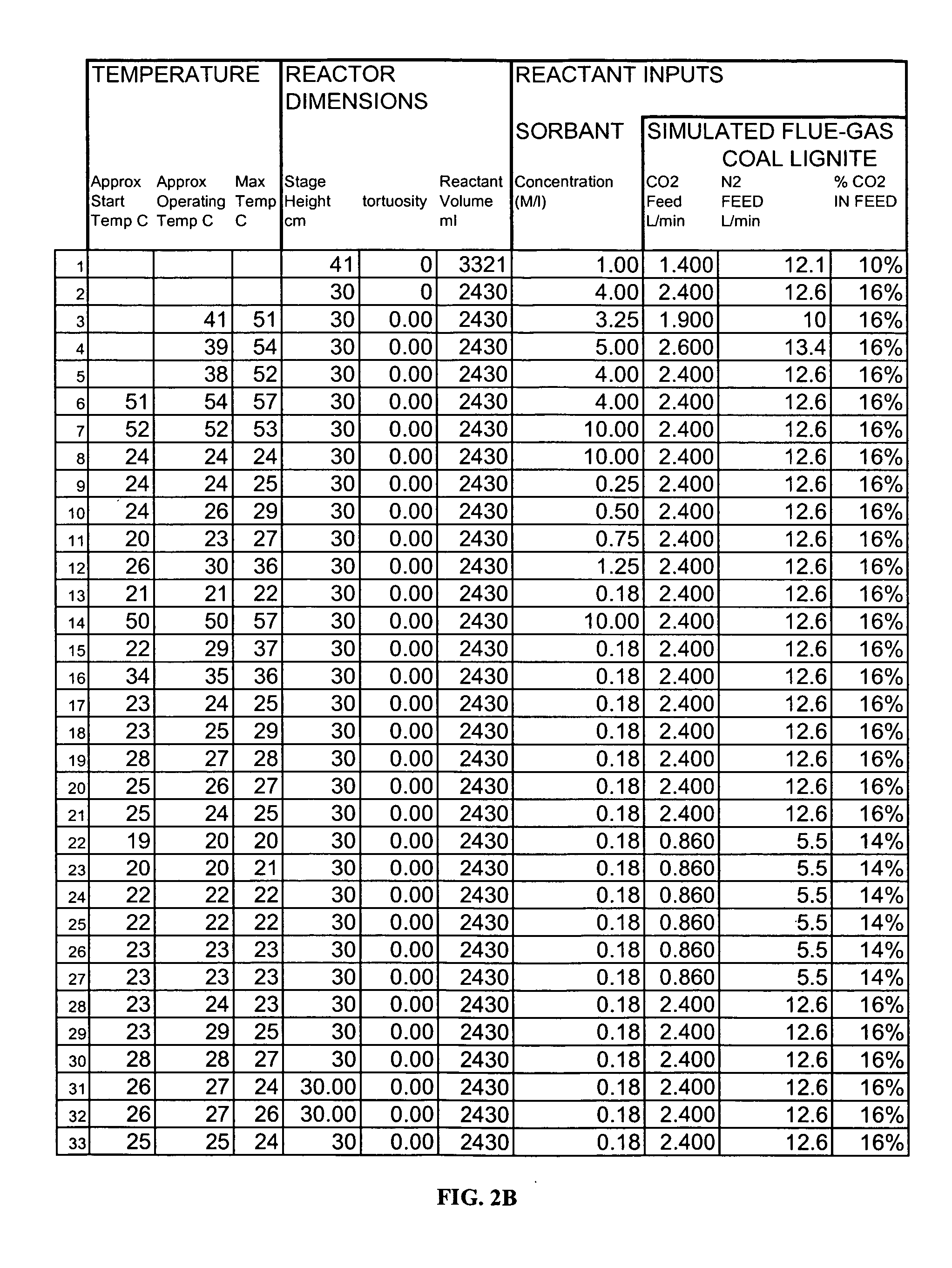

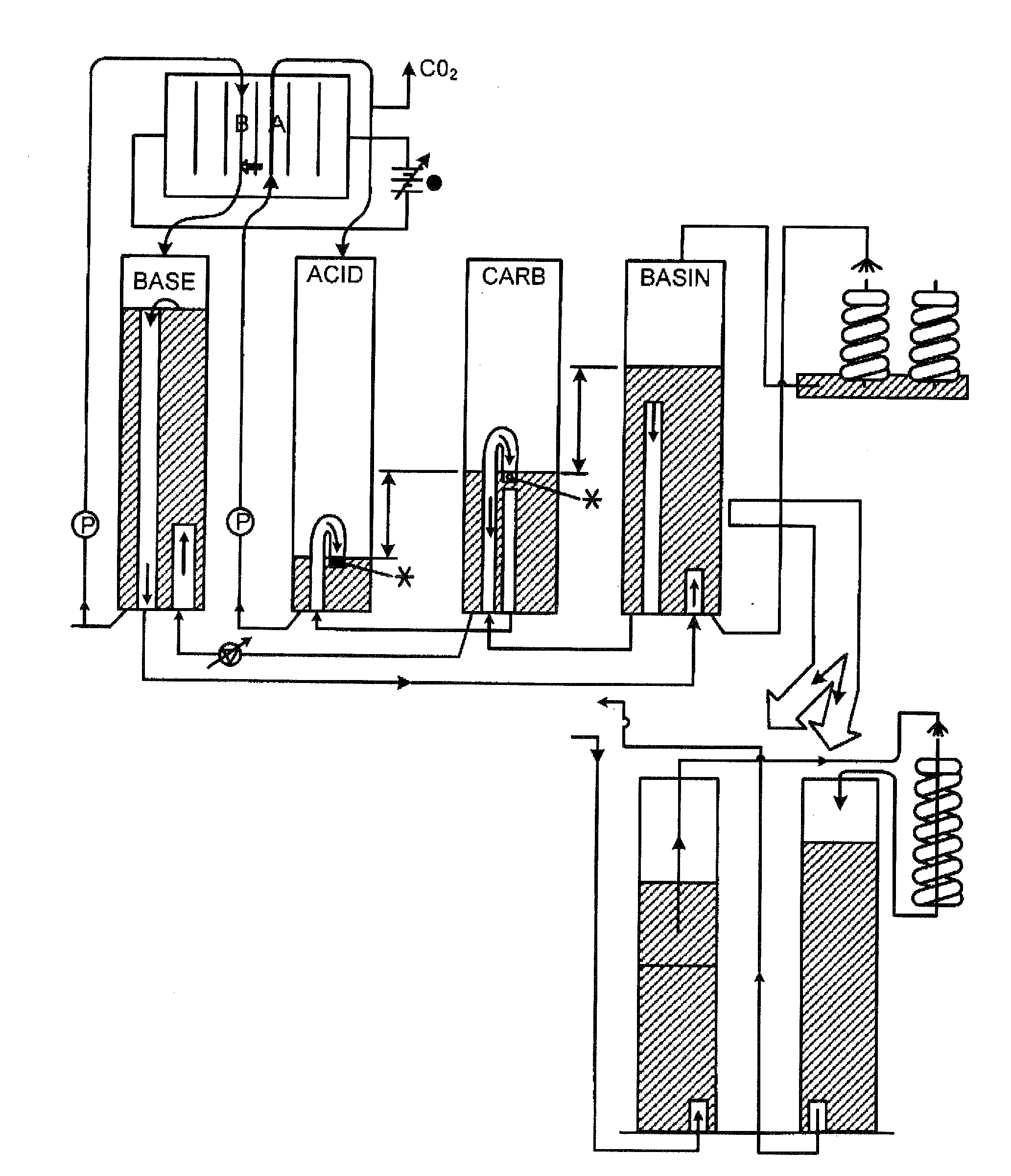

Removing carbon dioxide from waste streams through co-generation of carbonate and/or bicarbonate minerals

ActiveUS20060185985A1Improve ecologic efficiency of processEcologic efficiencyCalcium/strontium/barium carbonatesElectrolysis componentsElectrolysisWaste stream

Apparatuses and methods for removing carbon dioxide and other pollutants from a gas stream are provided. The methods include obtaining hydroxide in an aqueous mixture, and mixing the hydroxide with the gas stream to produce carbonate and / or bicarbonate. Some of the apparatuses of the present invention comprise an electrolysis chamber for providing hydroxide and mixing equipment for mixing the hydroxide with a gas stream including carbon dioxide to form an admixture including carbonate and / or bicarbonate.

Owner:CARBONFREE CHEM HLDG LLC

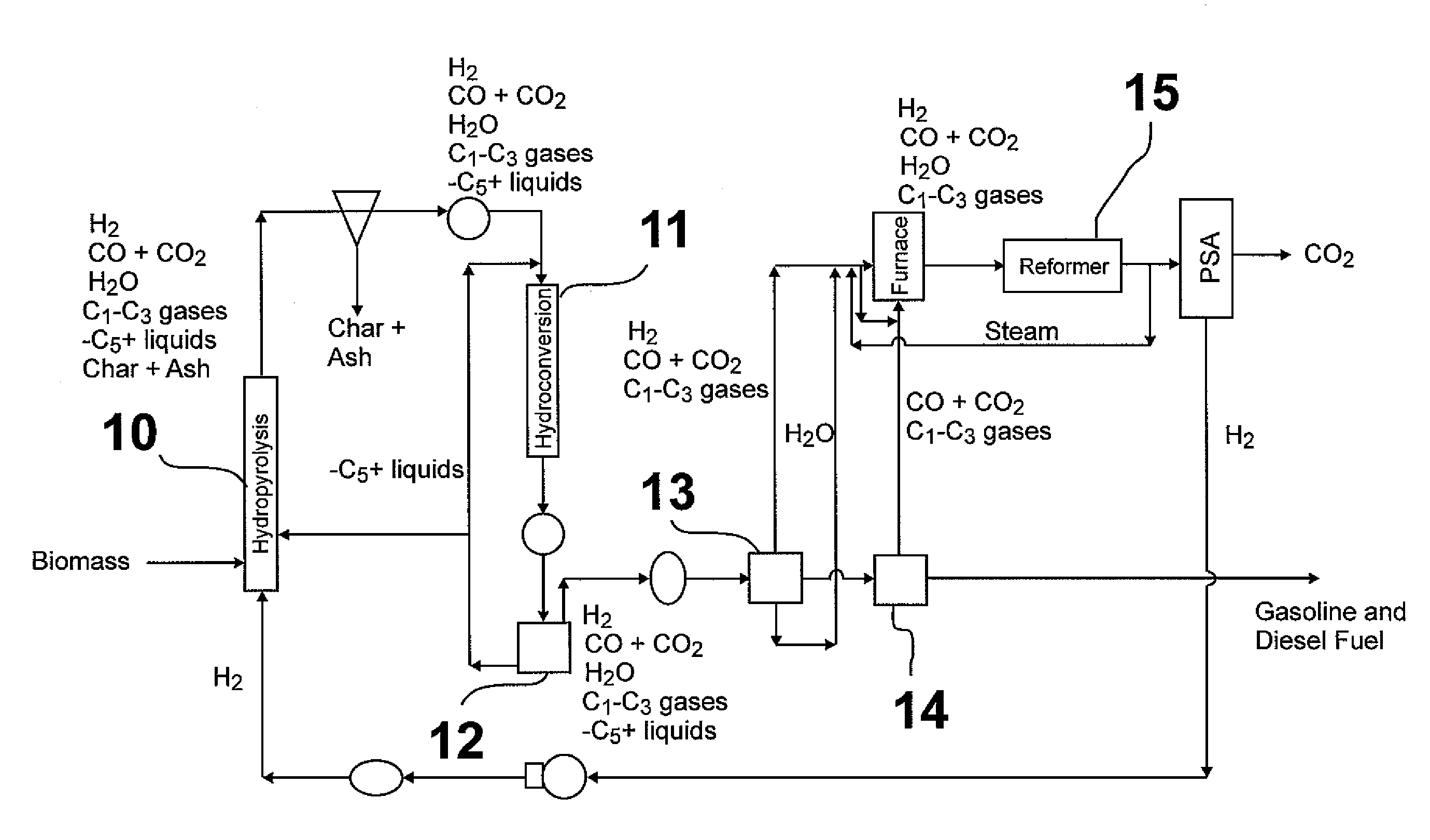

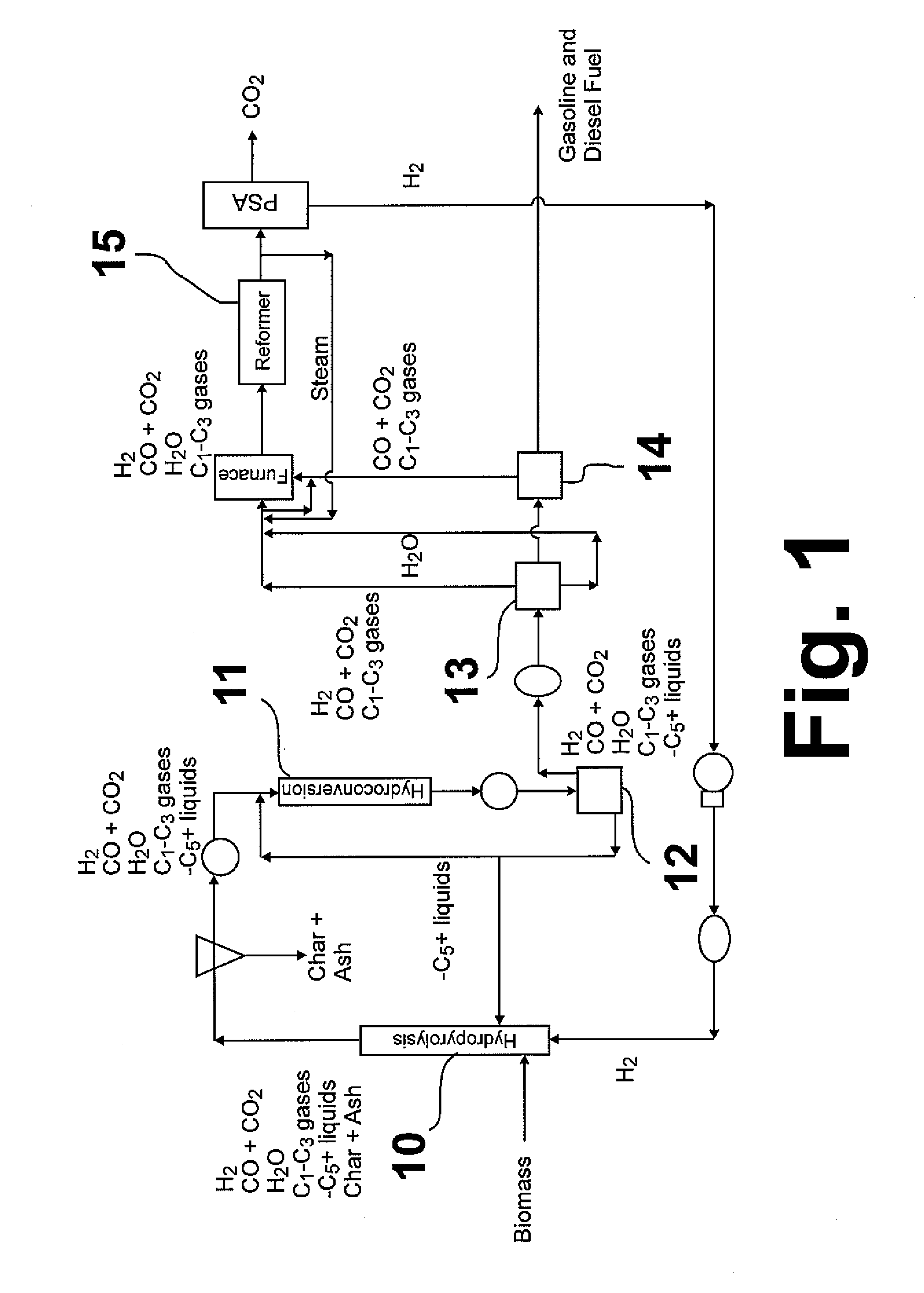

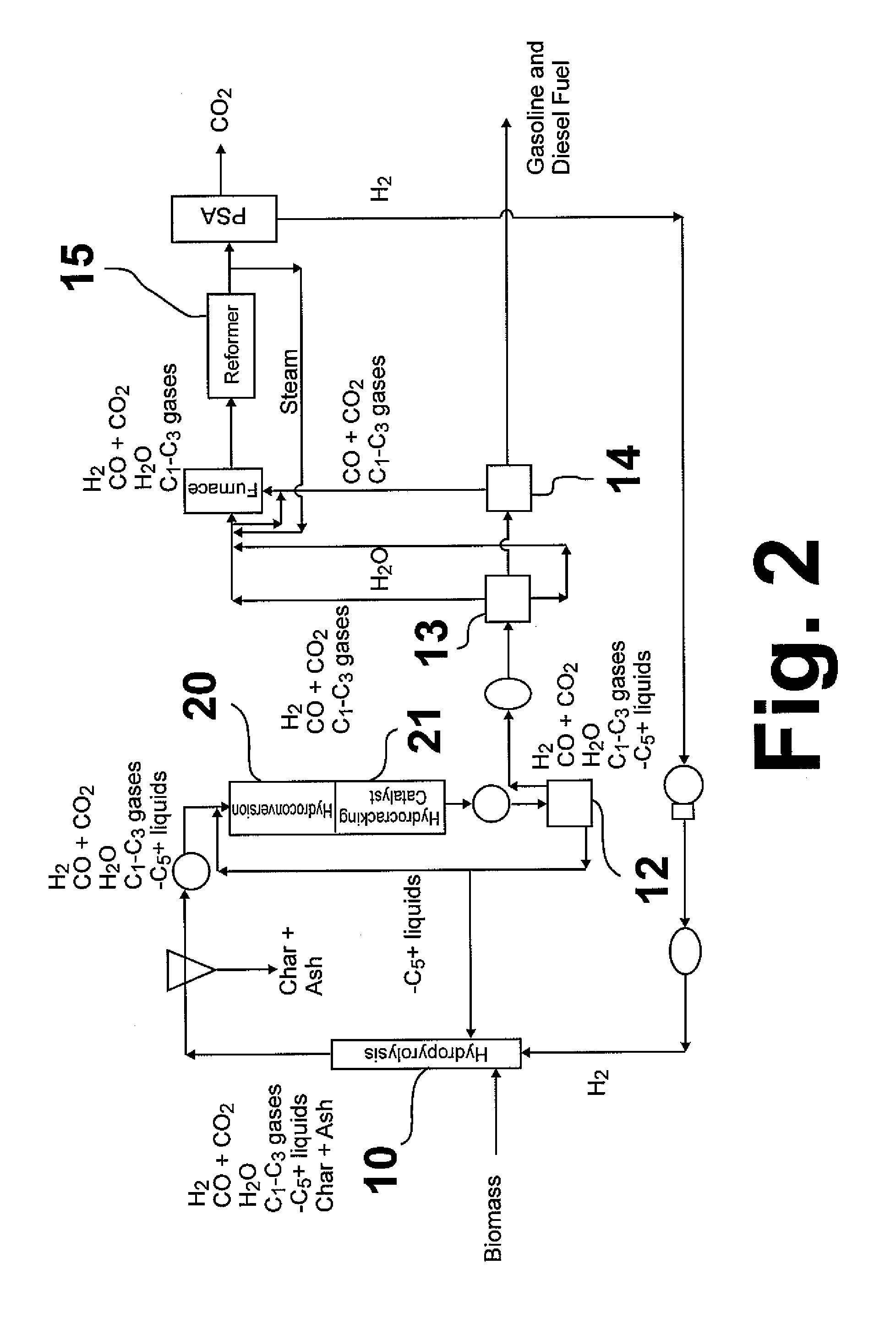

Hydropyrolysis of biomass for producing high quality liquid fuels

A self-sustaining process for producing high quality liquid fuels from biomass in which the biomass is hydropyrolyzed in a reactor vessel containing molecular hydrogen and a deoxygenating catalyst, producing a partially deoxygenated hydropyrolysis liquid, which is hydrogenated using a hydroconversion catalyst, producing a substantially fully deoxygenated hydrocarbon liquid and a gaseous mixture comprising CO and light hydrocarbon gases (C1-C3). The gaseous mixture is reformed in a steam reformer, producing reformed molecular hydrogen, which is then introduced into the reactor vessel for hydropyrolizing the biomass. The deoxygenated hydrocarbon liquid product is further separated to produce diesel fuel, gasoline, or blending components for gasoline and diesel fuel.

Owner:GAS TECH INST

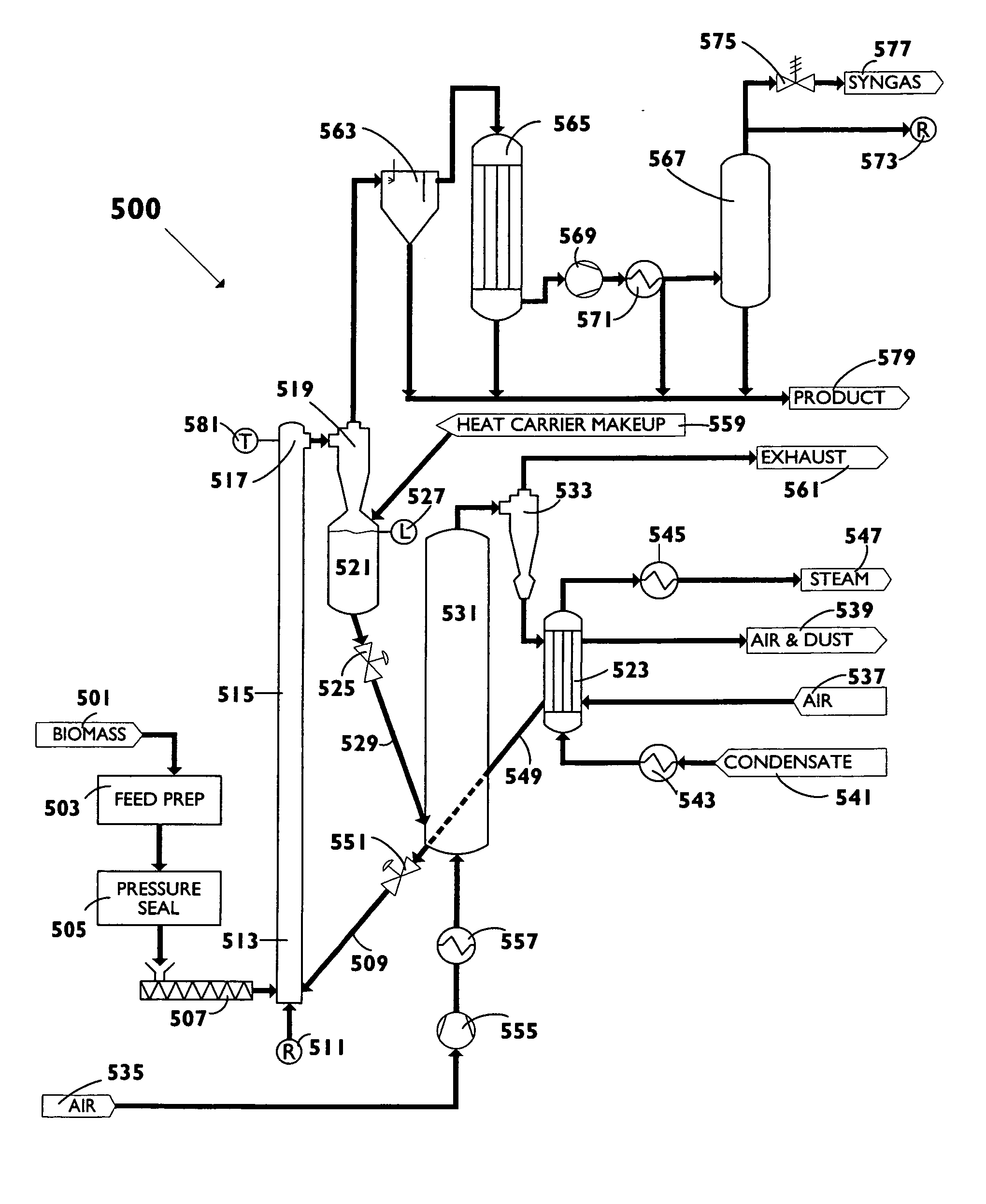

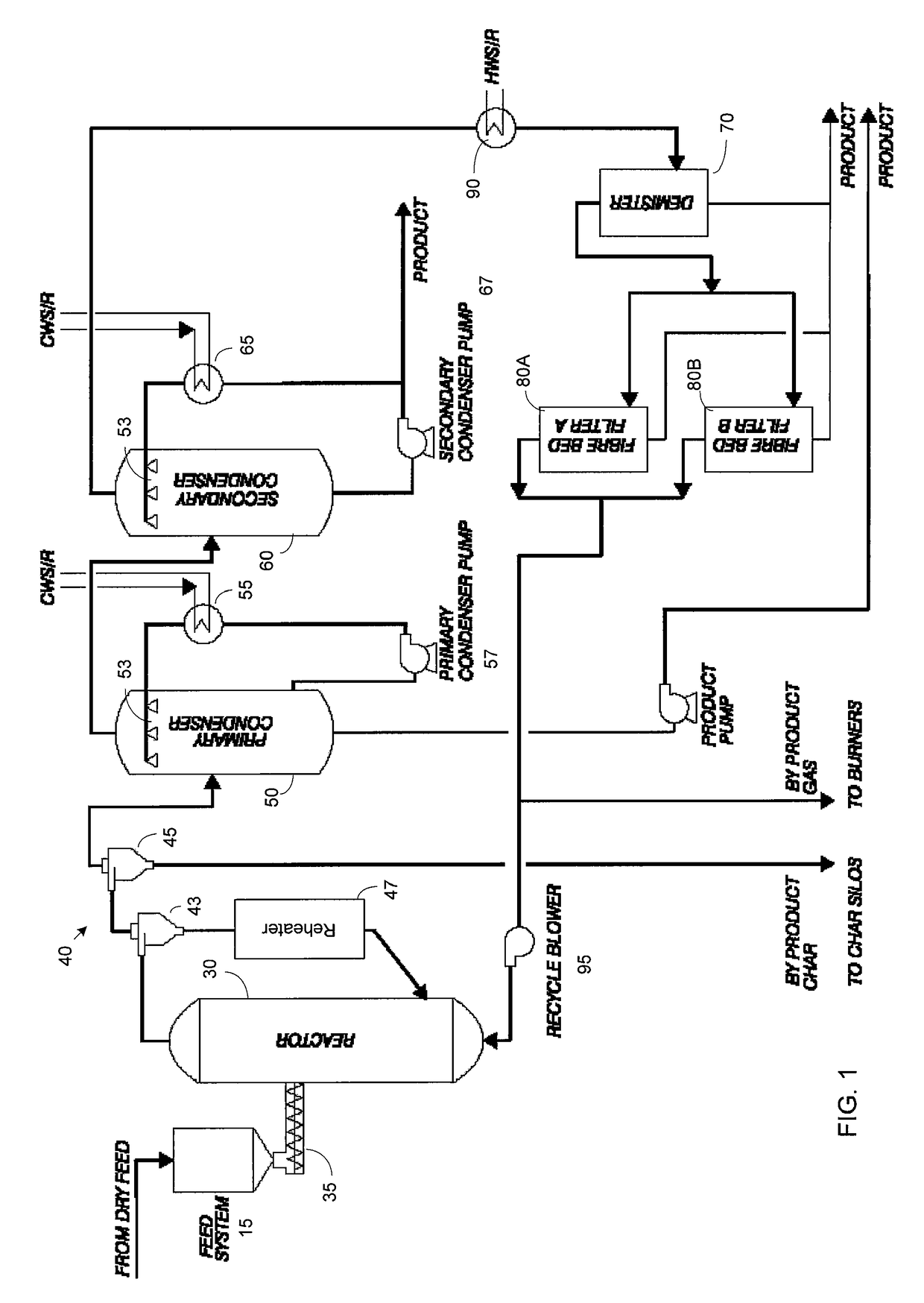

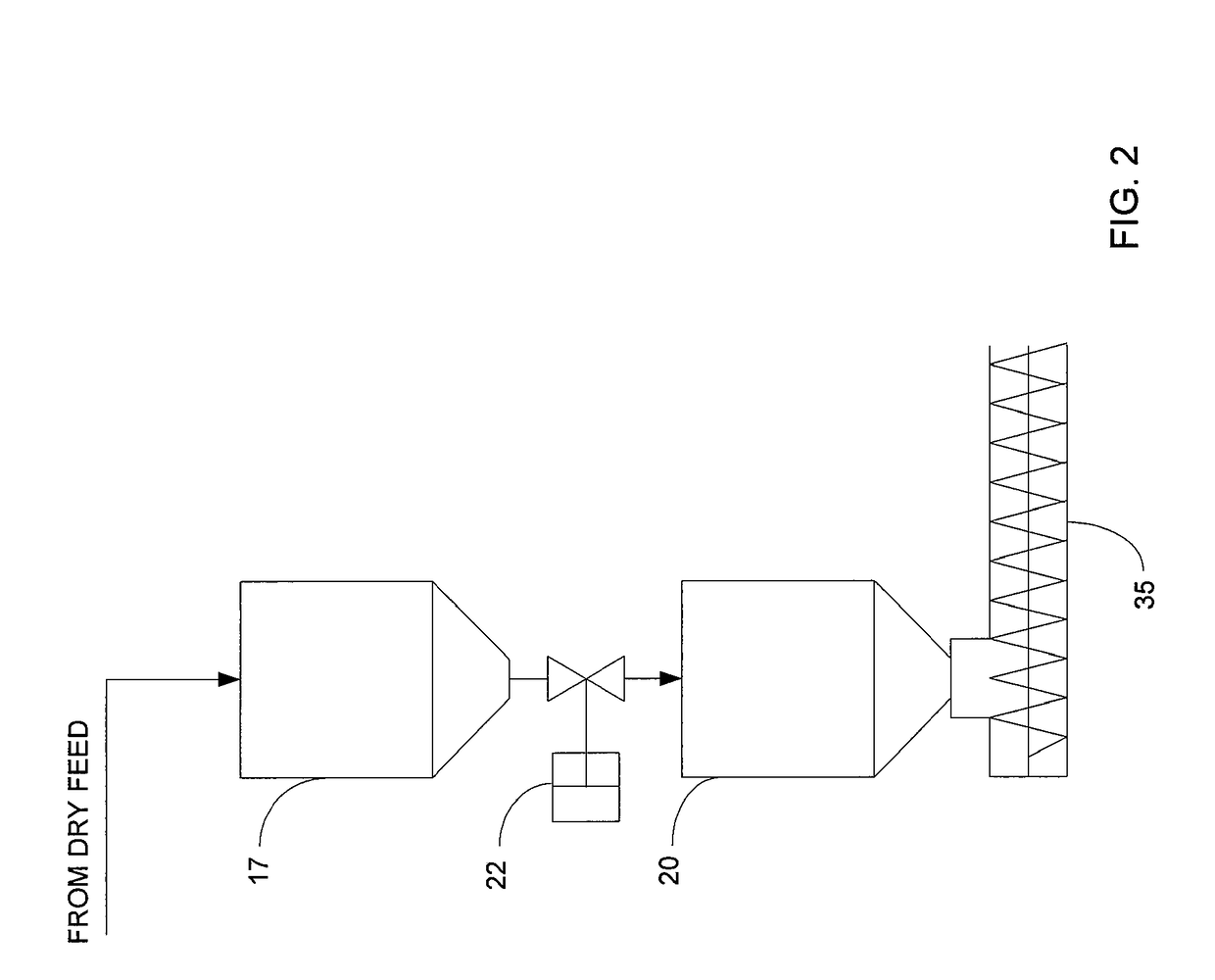

Rapid thermal conversion of biomass

ActiveUS7905990B2Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingSolid waste disposalLiquid productHeat carrier

A rapid thermal conversion process for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. Biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. The liquid product may itself be used as the quench media.

Owner:ENSYN RENEWABLES

Systems and methods for carbon capture and sequestration and compositions derived therefrom

ActiveUS20090143211A1Promote formationCalcium/strontium/barium carbonatesNitrogen compoundsInterior spaceProduct formation

A method of sequestering a greenhouse gas is described, which comprises: (i) providing a solution carrying a first reagent that is capable of reacting with a greenhouse gas; (ii) contacting the solution with a greenhouse gas under conditions that promote a reaction between the at least first reagent and the greenhouse gas to produce at least a first reactant; (iii) providing a porous matrix having interstitial spaces and comprising at least a second reactant; (iv) allowing a solution carrying the at least first reactant to infiltrate at least a substantial portion of the interstitial spaces of the porous matrix under conditions that promote a reaction between the at least first reactant and the at least second reactant to provide at least a first product; and (v) allowing the at least first product to form and fill at least a portion of the interior spaces of the porous matrix, thereby sequestering a greenhouse gas.

Owner:RUTGERS THE STATE UNIV

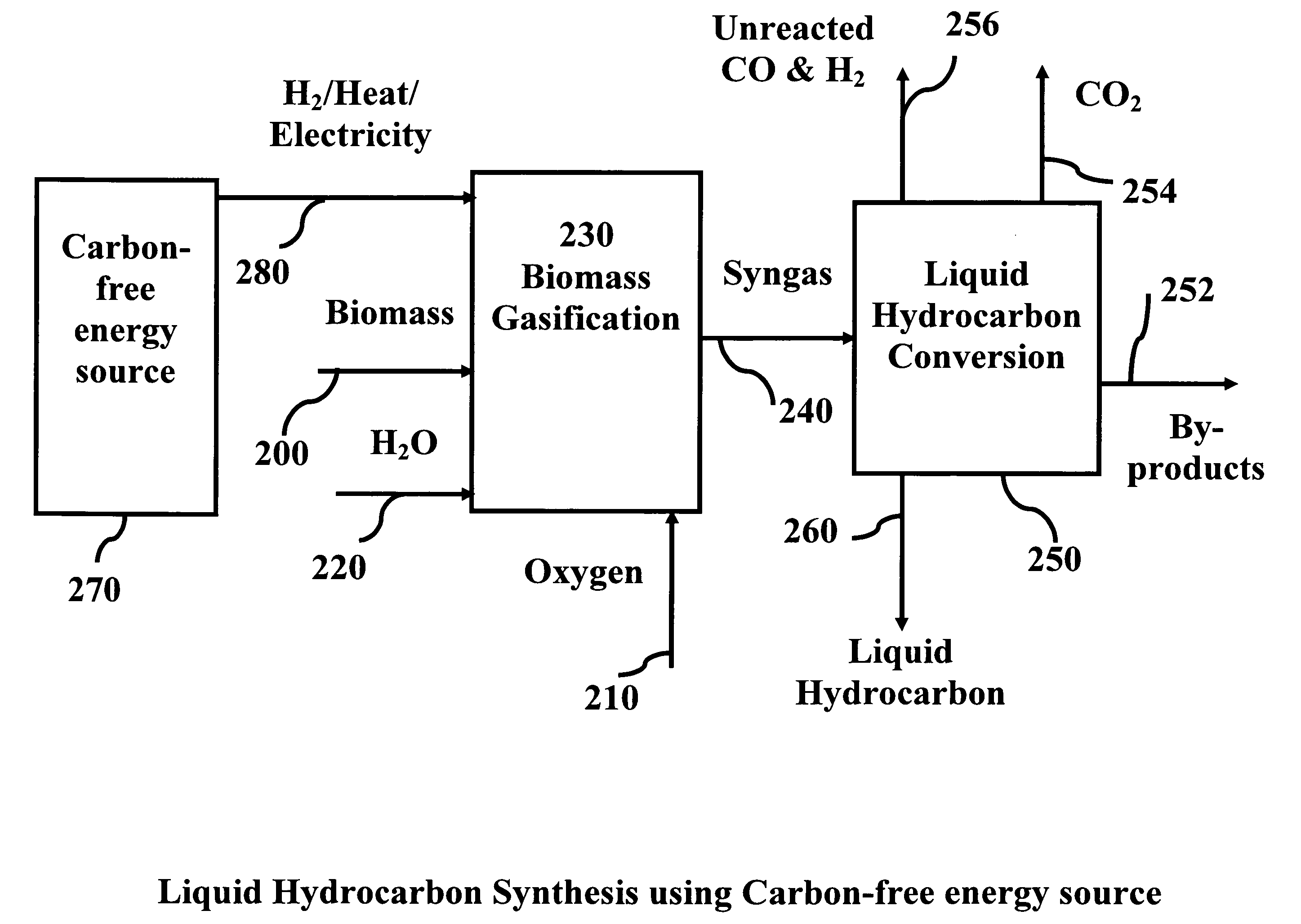

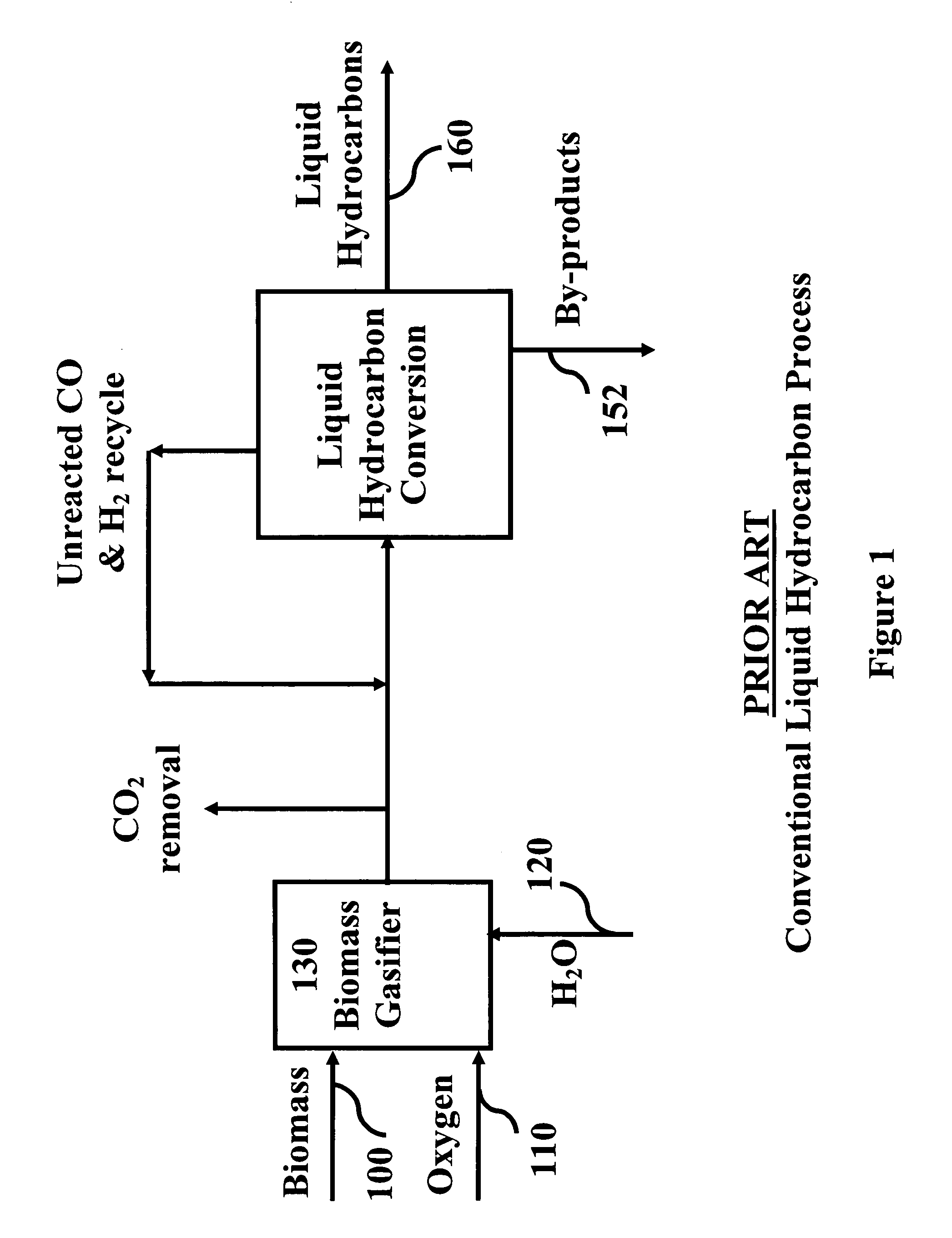

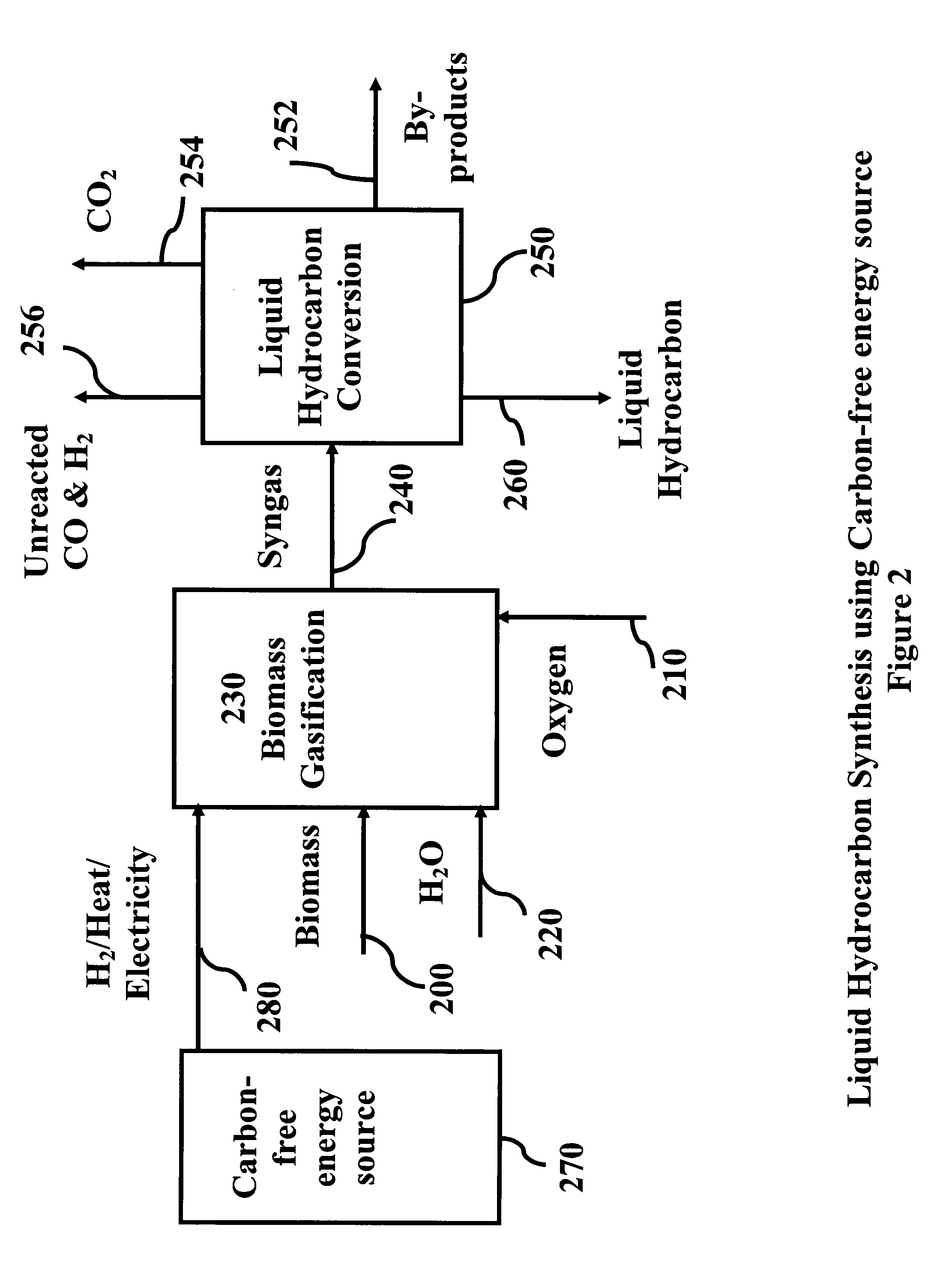

System and process for producing synthetic liquid hydrocarbon

ActiveUS20080115415A1Improve carbon efficiencyReduce area requirementsMuffle furnacesCarbon compoundsOxygenElectrolysis of water

Production of synthetic liquid hydrocarbon fuel from carbon containing moieties such as biomass, coal, methane, naphtha as a carbon source and hydrogen from a carbon-free energy source is disclosed. The biomass can be fed to a gasifier along with hydrogen, oxygen, steam and recycled carbon dioxide. The synthesis gas from the gasifier exhaust is sent to a liquid hydrocarbon conversion reactor to form liquid hydrocarbon molecules. Unreacted CO & H2 can be recycled to the gasifier along with CO2 from the liquid hydrocarbon conversion reactor system. Hydrogen can be obtained from electrolysis of water, thermo-chemical cycles or directly by using energy from carbon-free energy sources.

Owner:PURDUE RES FOUND INC

Extraction and sequestration of carbon dioxide

The present disclosure provides a method and apparatus for extracting carbon dioxide (CO2) from a fluid stream and for delivering that extracted CO2 to controlled environments for utilization by a secondary process. Various extraction and delivery methods are disclosed specific to certain secondary uses, included the attraction of CO2-sensitive insects, the ripening and preservation of produce, and the neutralization of brine.

Owner:KILIMANJARO ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com