Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

221results about "Carbon capture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods of sequestering co2

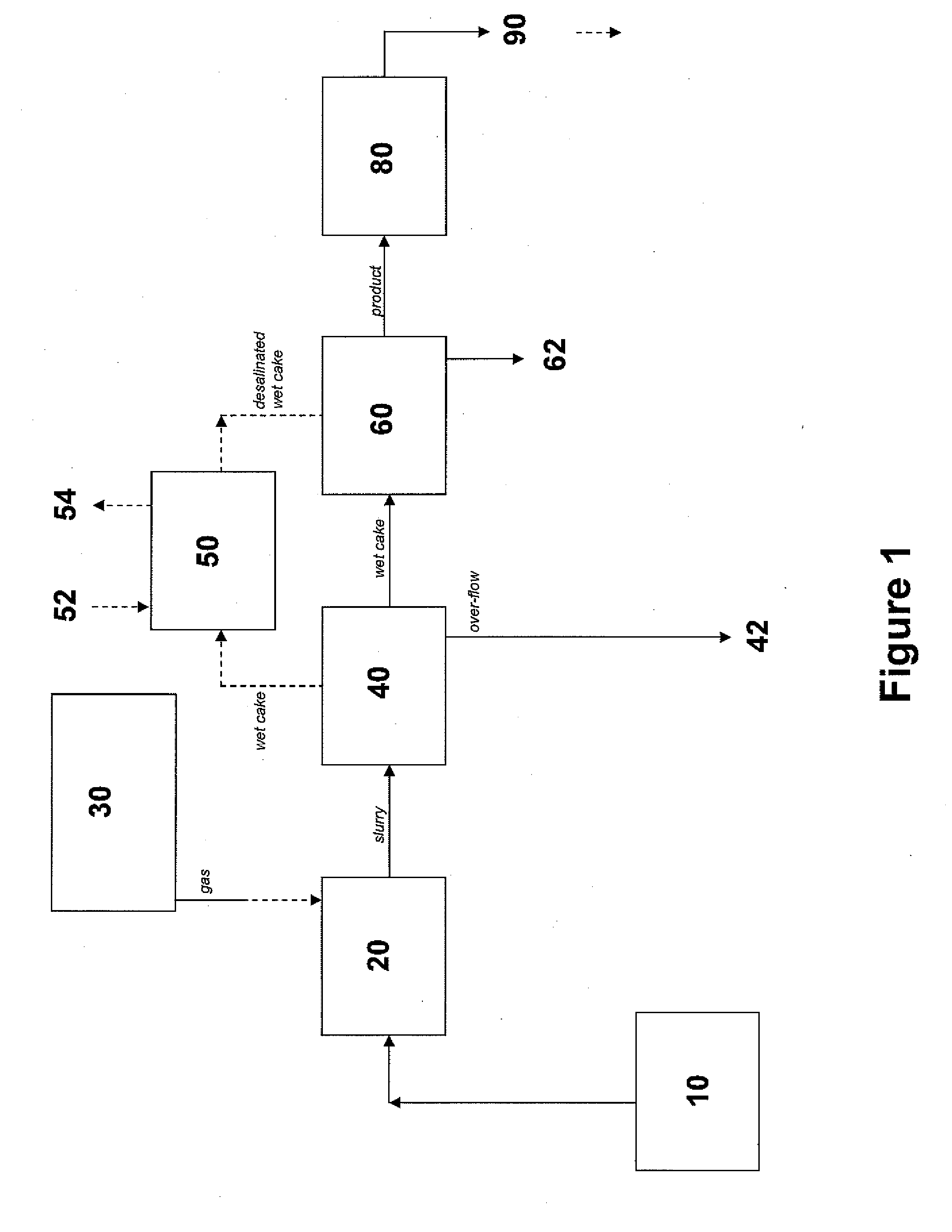

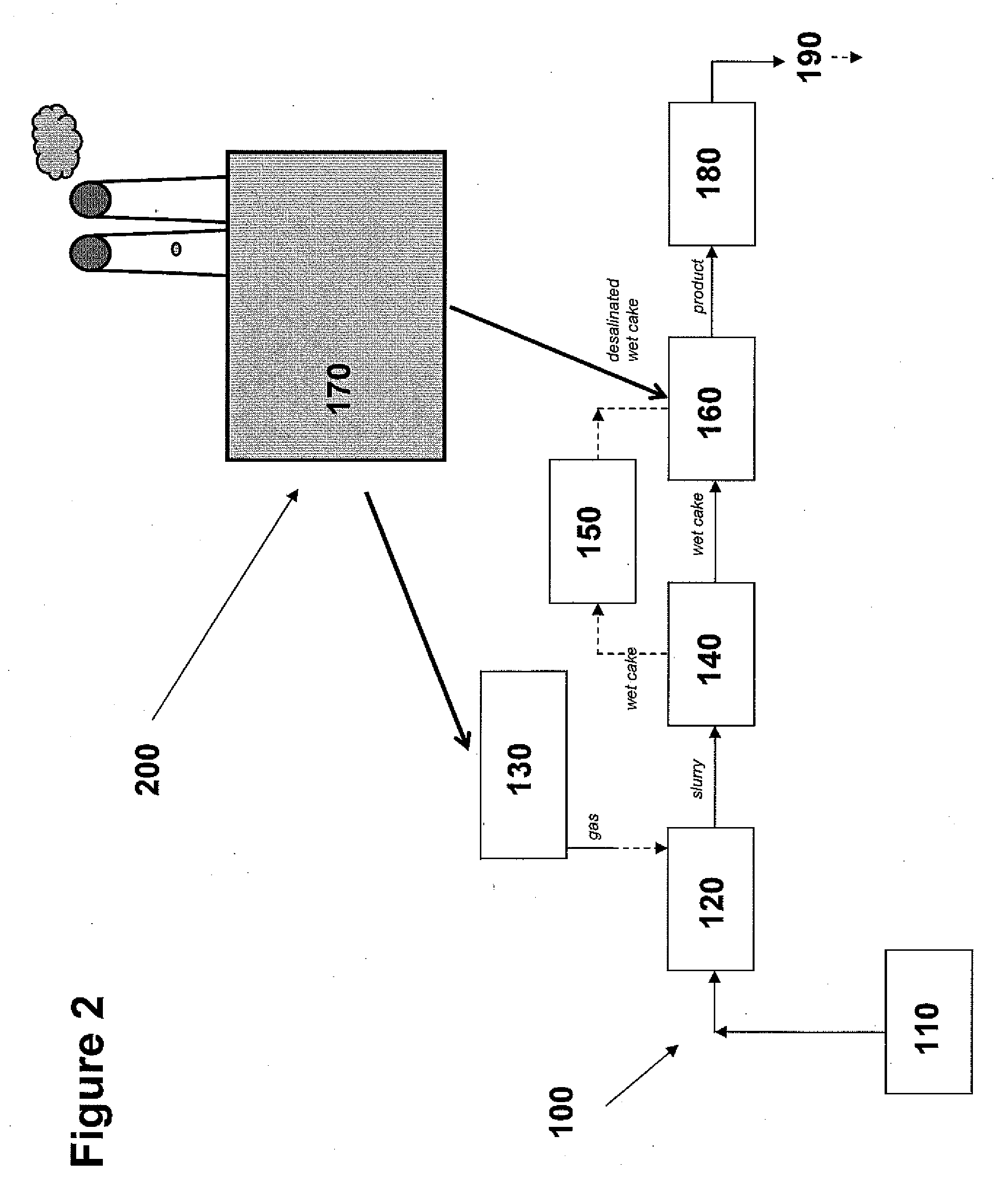

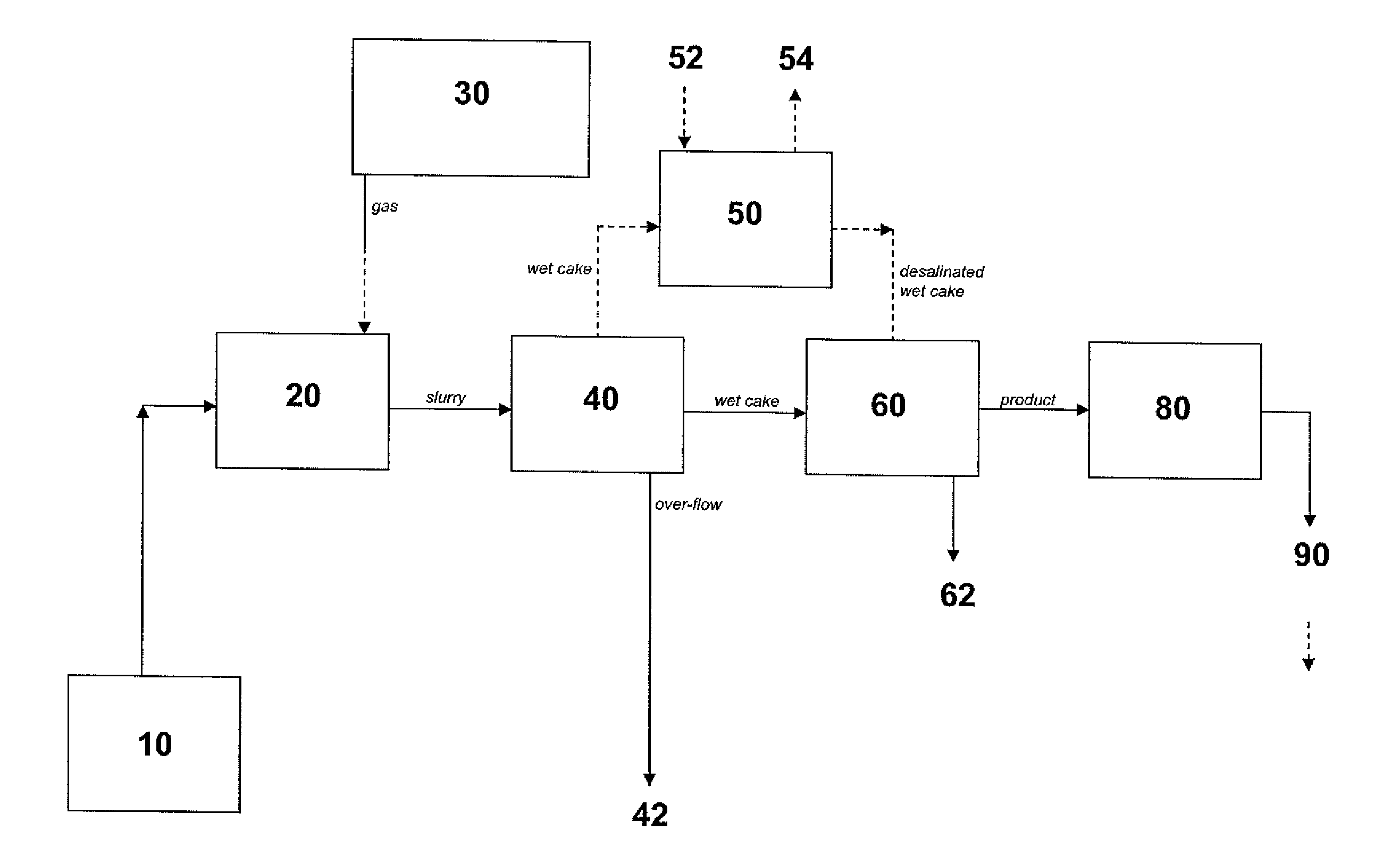

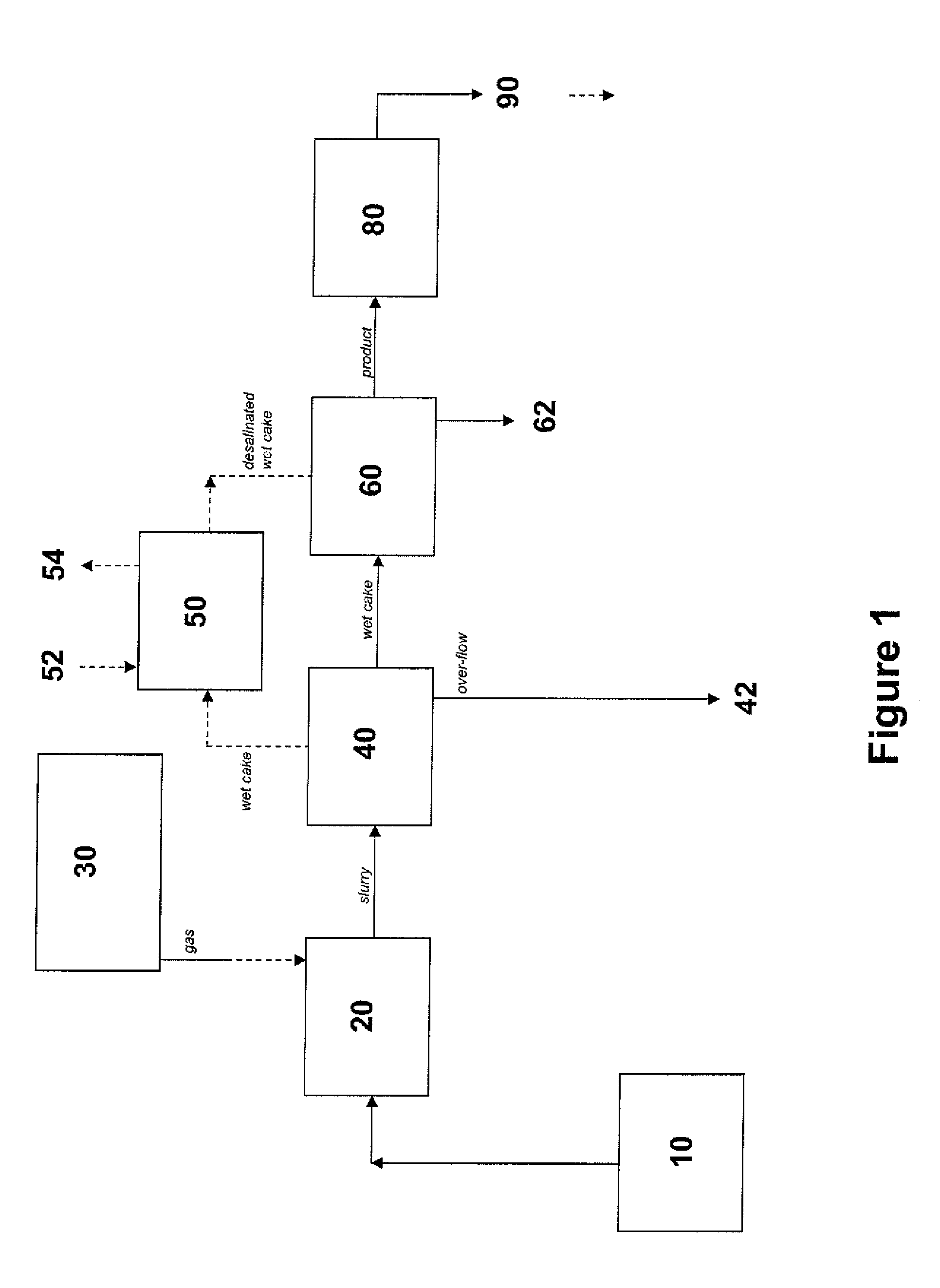

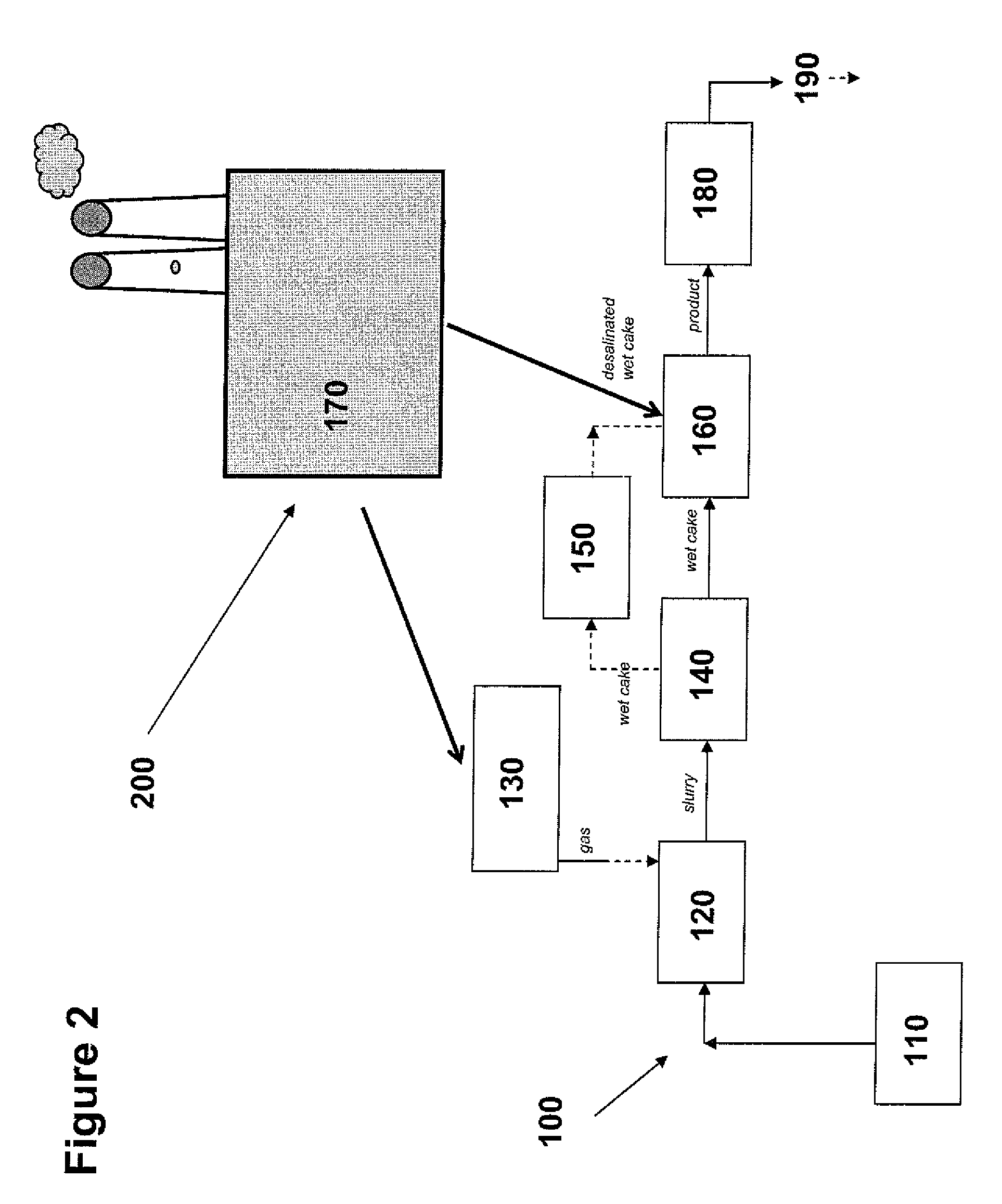

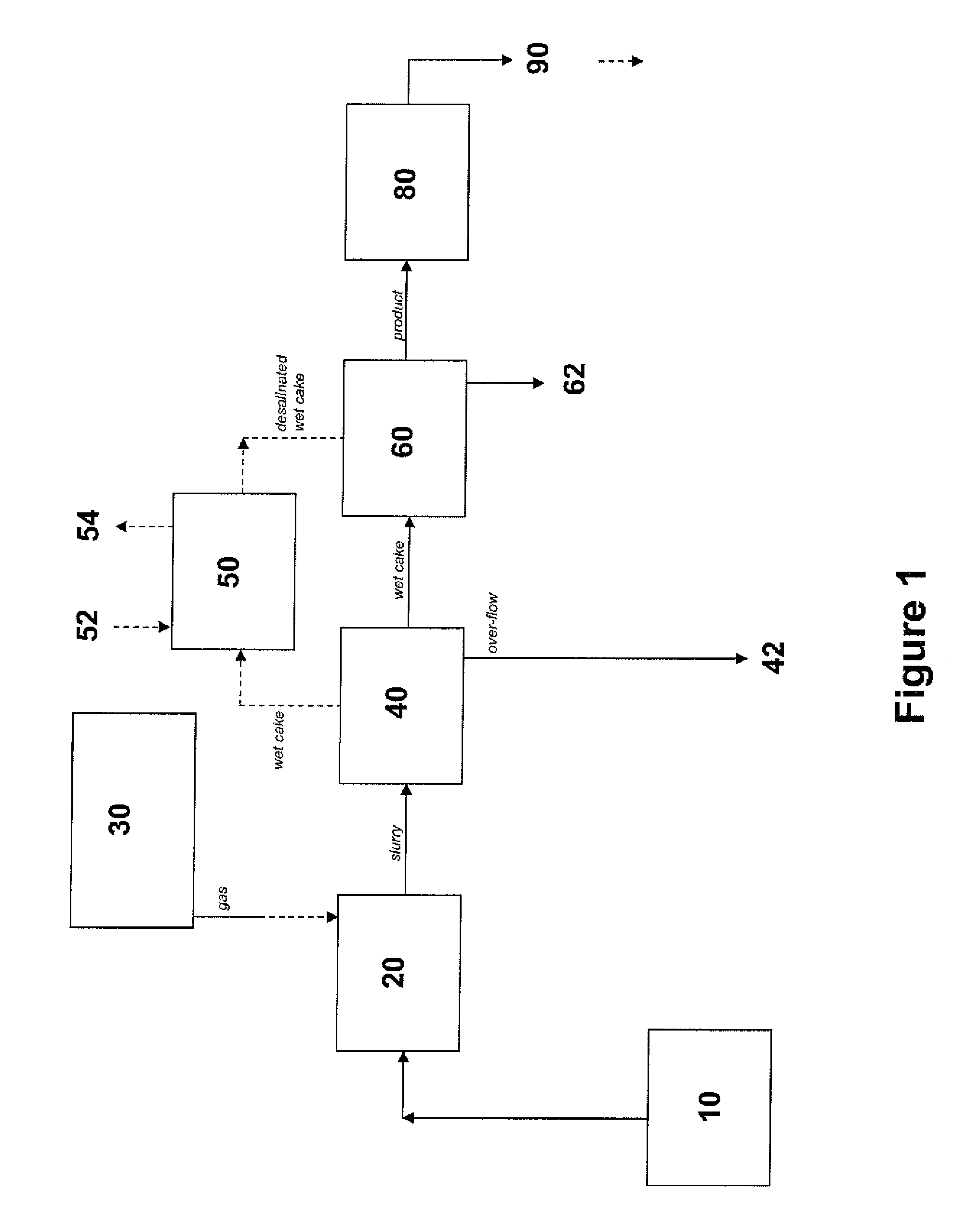

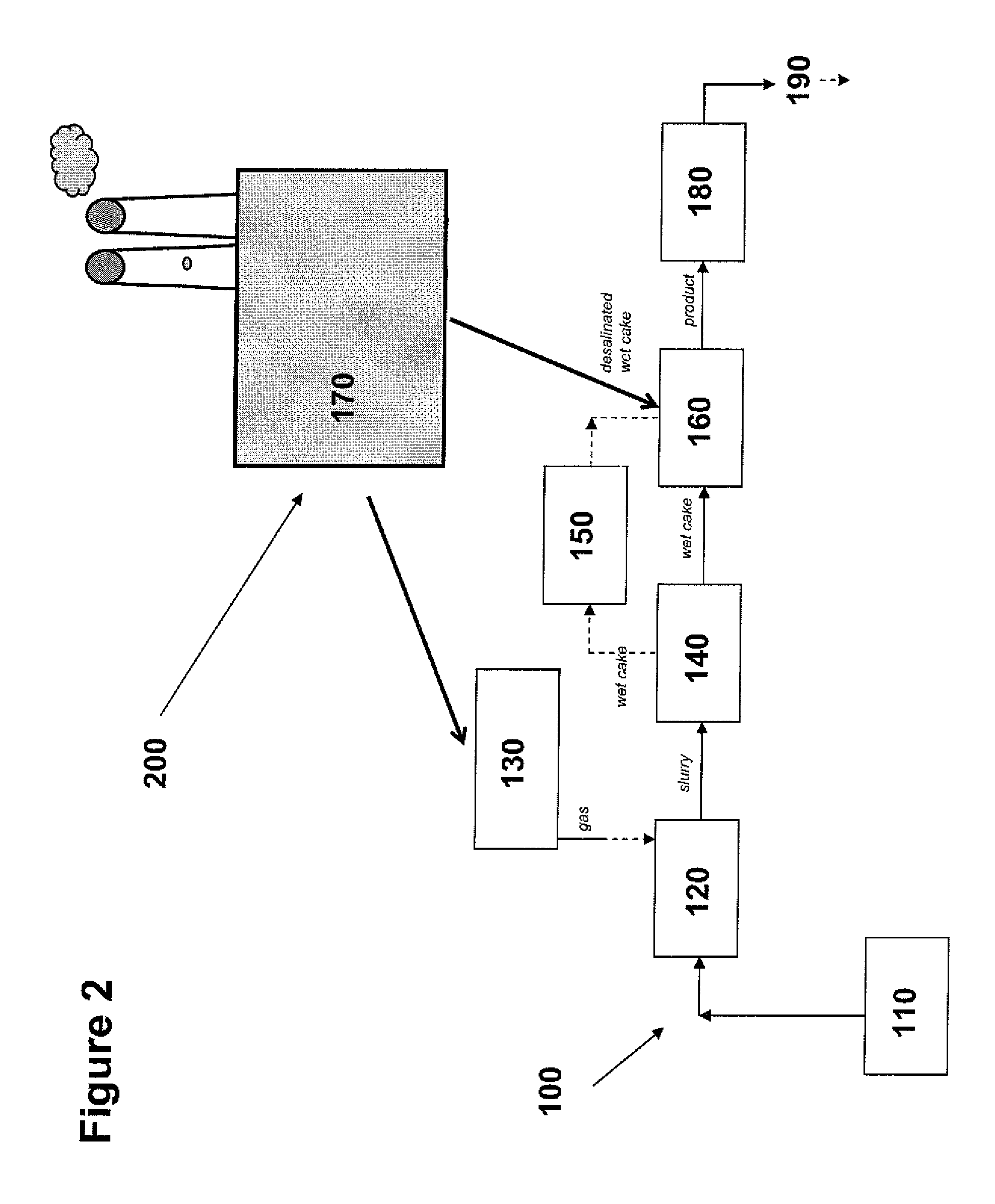

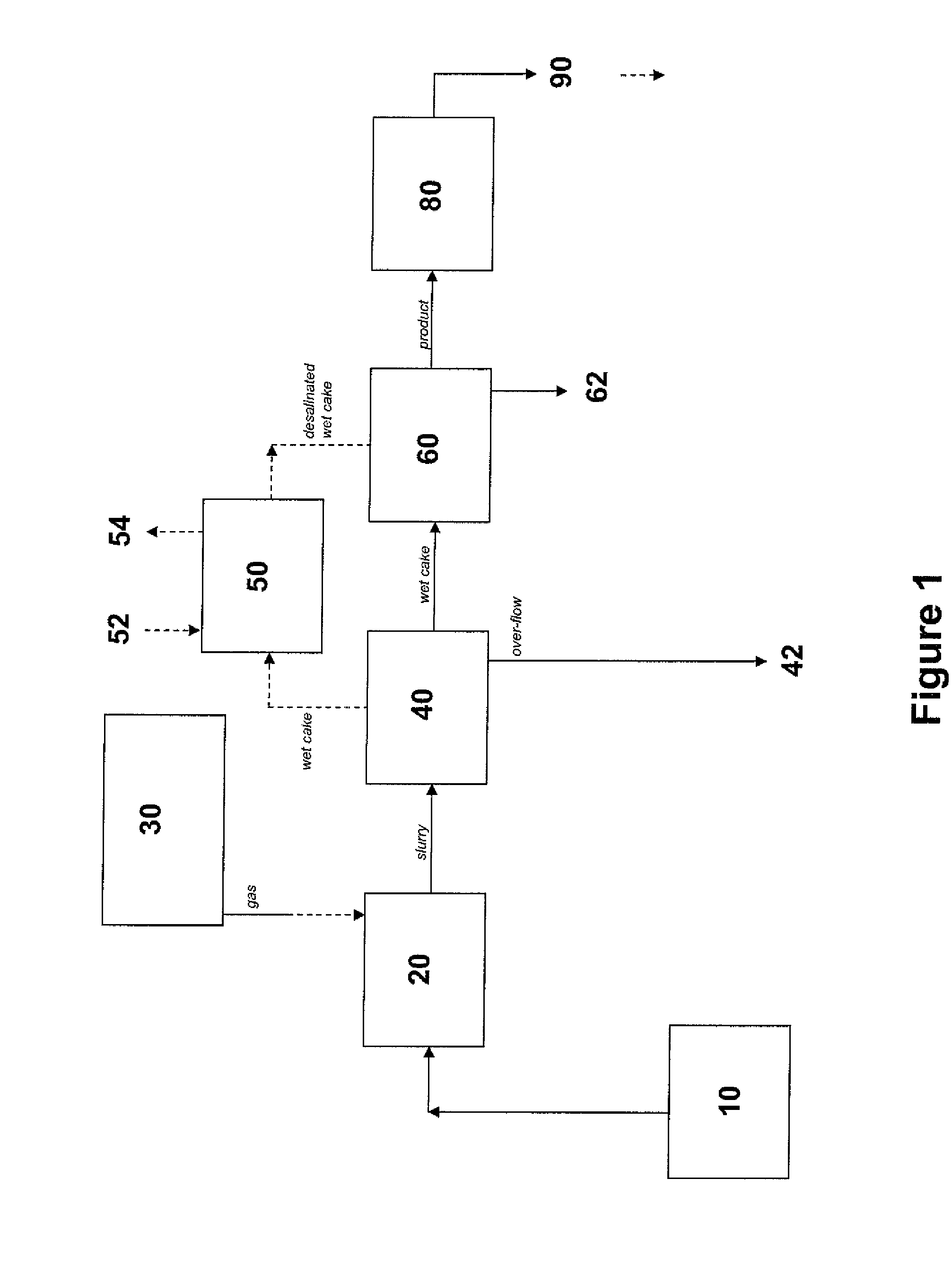

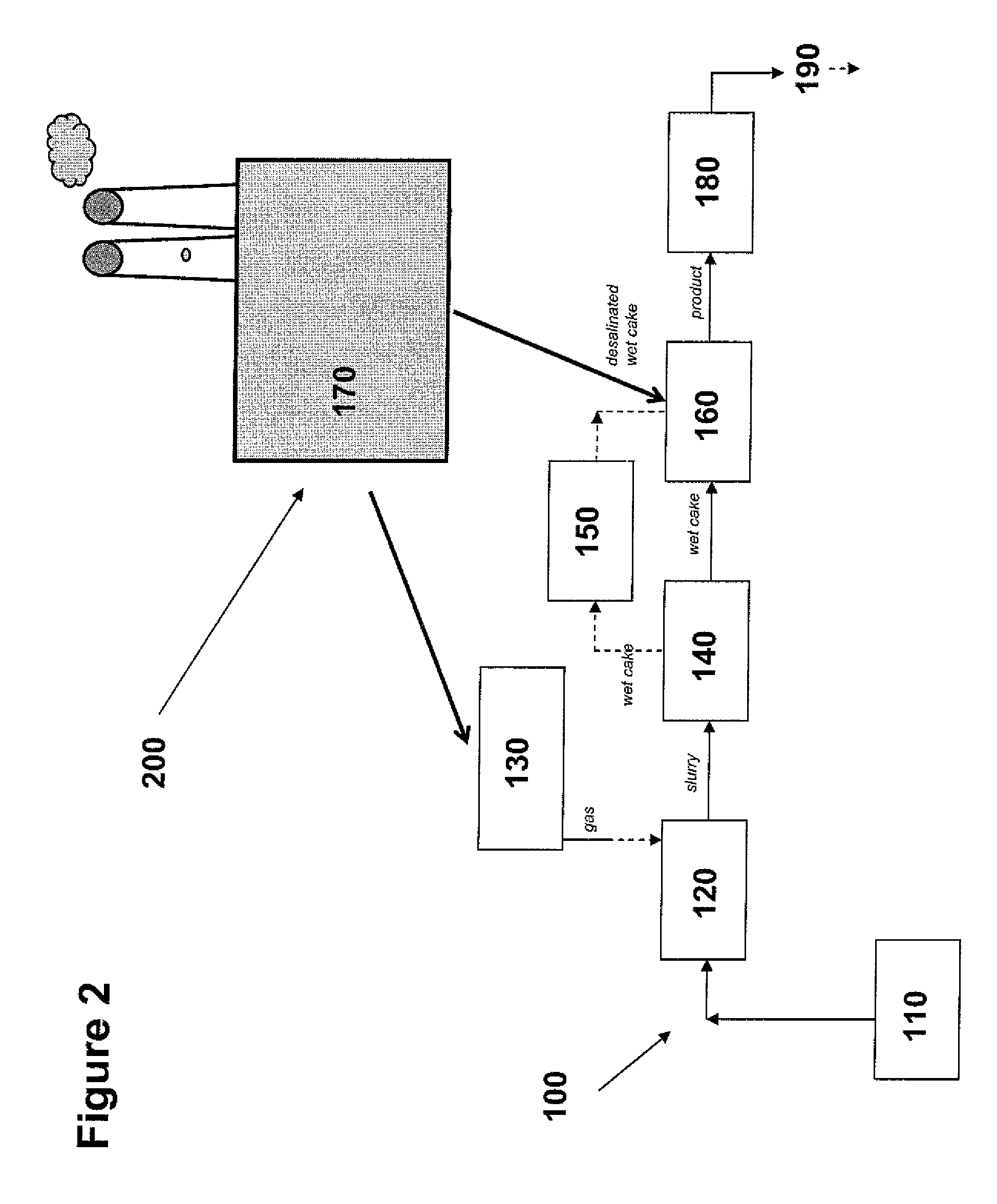

Methods of sequestering carbon dioxide (CO2) are provided. Aspects of the methods include precipitating a storage stable carbon dioxide sequestering product from an alkaline-earth-metal-containing water and then disposing of the product, e.g., by placing the product in a disposal location or using the product as a component of a manufactured composition. Also provided are systems for practicing methods of the invention.

Owner:ARELAC INC

Carbonaceous Fuels and Processes for Making and Using Them

The present invention provides carbonaceous fuels and processes for making them. Moreover, the invention also relates to processes using the carbonaceous fuels in the production of cement products. One embodiment of the invention is a carbonaceous fuel comprising (a) unconverted fines of a carbonaceous feedstock, the carbonaceous feedstock having an ash content of greater than 1%, the fines having an average particle size less than about 45 μm; and (b) a char residue formed by catalytic gasification of the carbonaceous feedstock, the char residue having an ash content of greater than about 30%, wherein the ash includes at least one aluminum-containing compound or silicon-containing compound; and having a weight ratio of fines to char residue in the range of about 4:1 to about 1:4, and a total dry basis wt % of carbon of least about 40%. Another embodiment of the invention is a process of making a cement product comprising: (a) providing a carbonaceous fuel as described above; (b) passing the carbonaceous fuel into a cement-making zone; and (c) at least partially combusting the carbonaceous fuel to provide heat for a cement producing reaction within the cement-making zone.

Owner:SURE CHAMPION INVESTMENT LTD

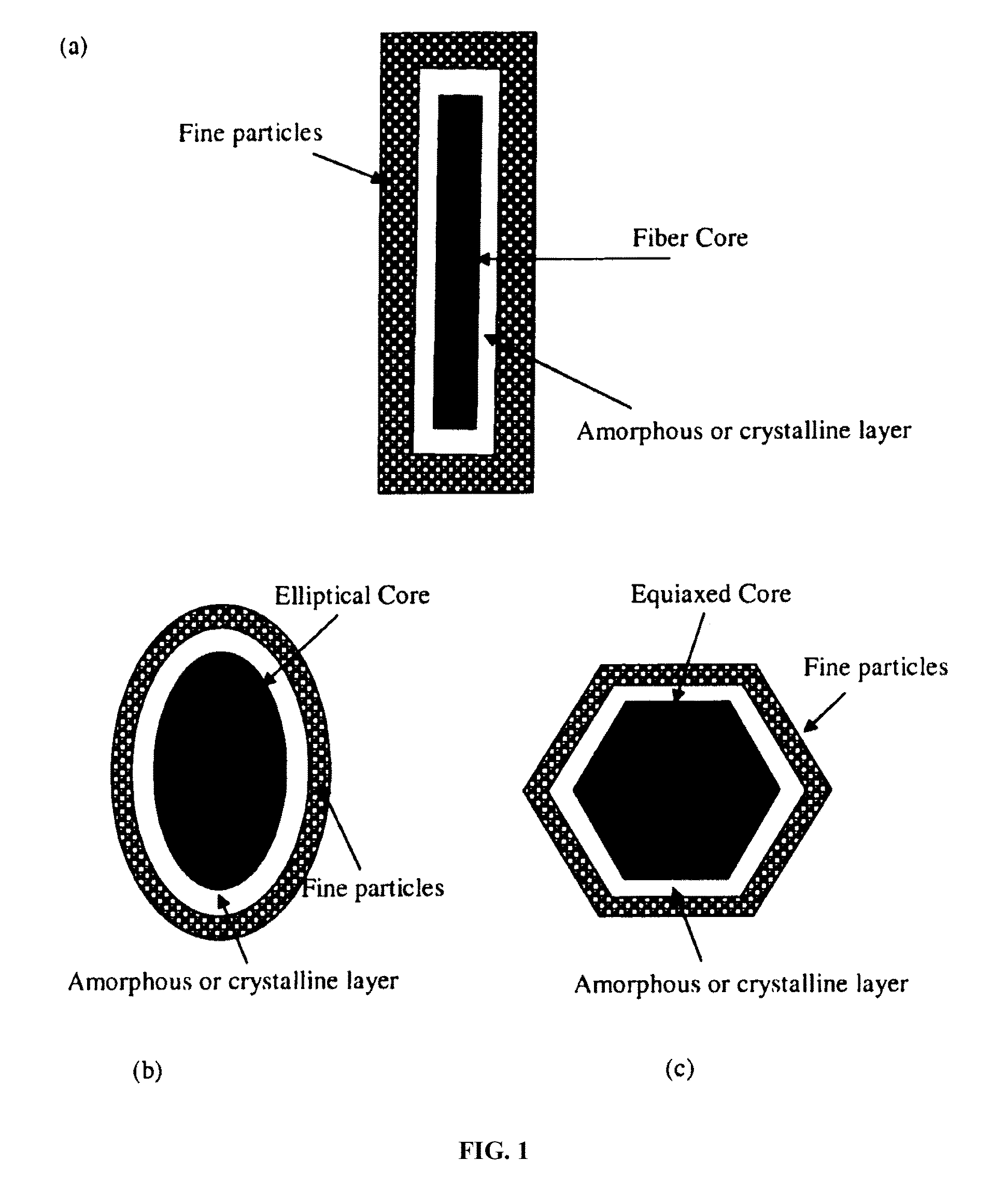

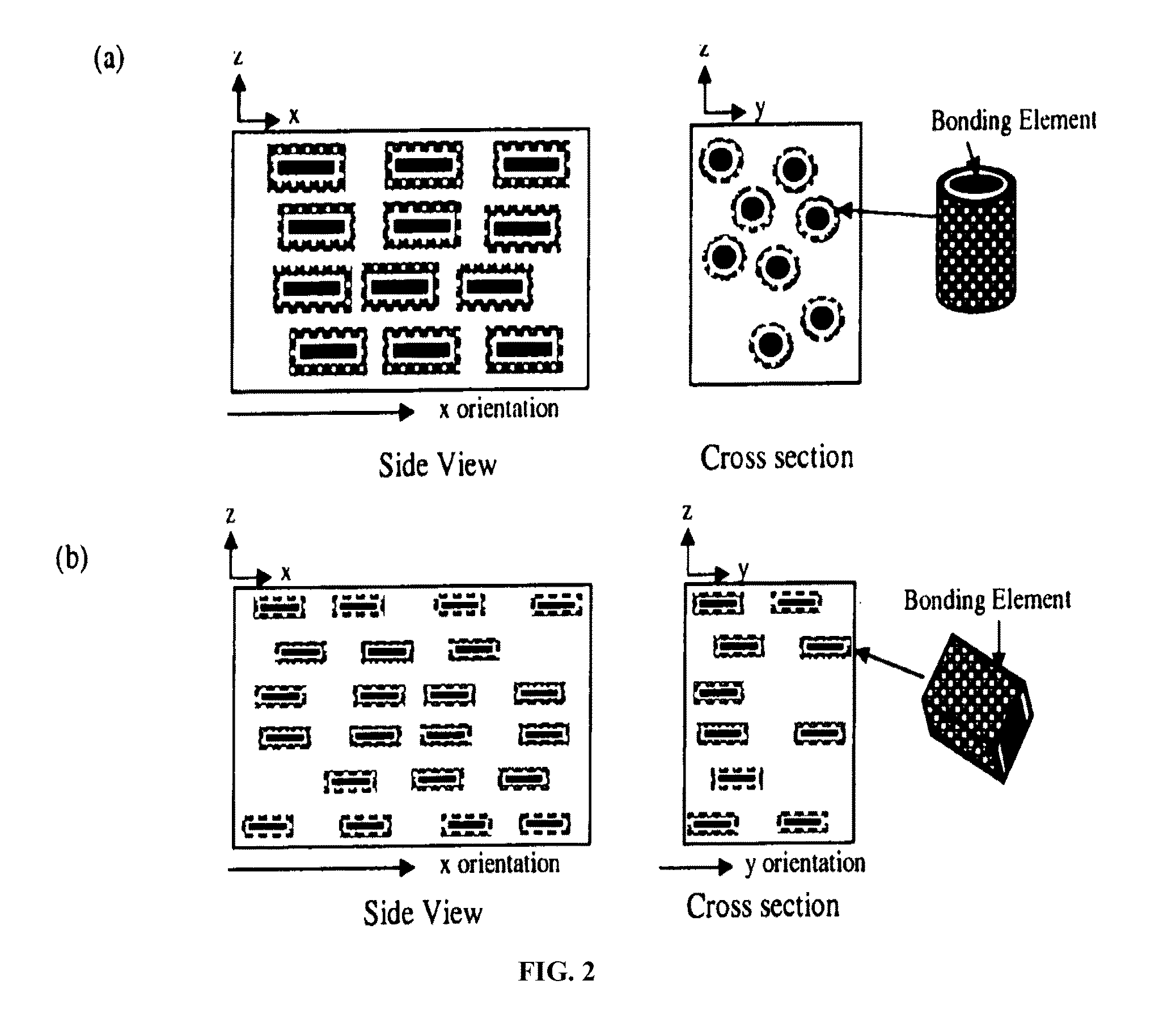

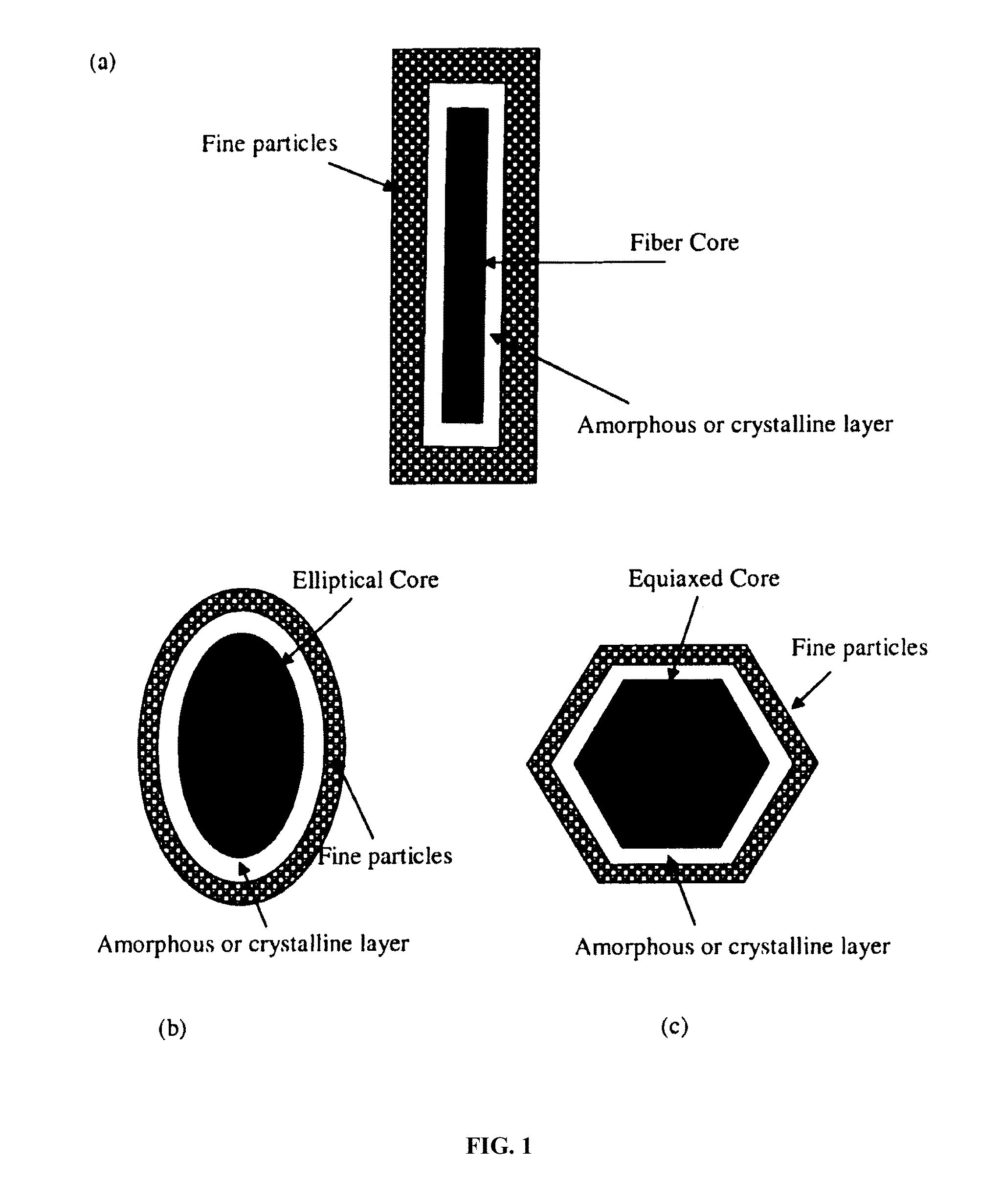

Rocks and aggregate, and methods of making and using the same

ActiveUS20100024686A1Calcium/strontium/barium carbonatesPigmenting treatmentCarbonateToxic industrial waste

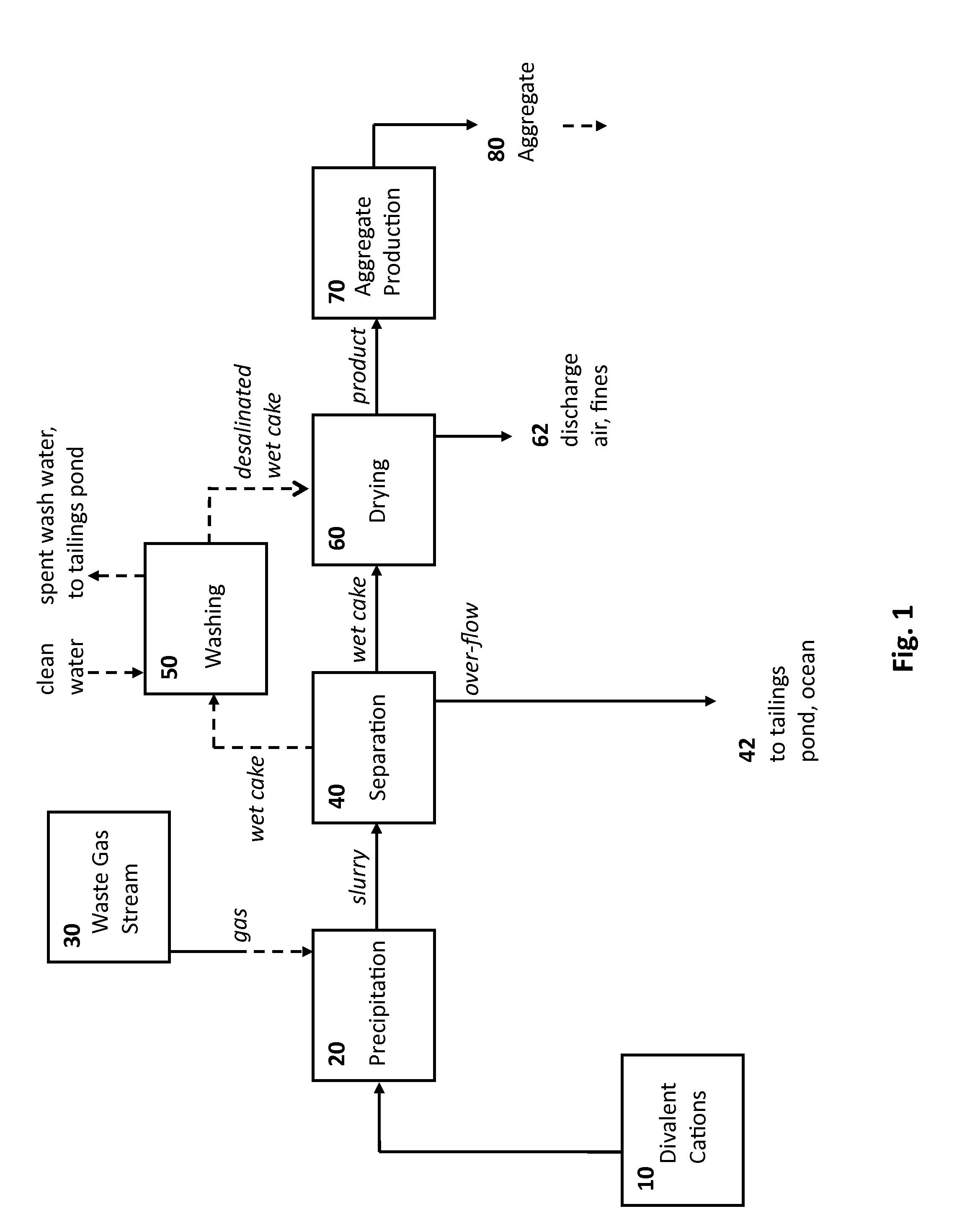

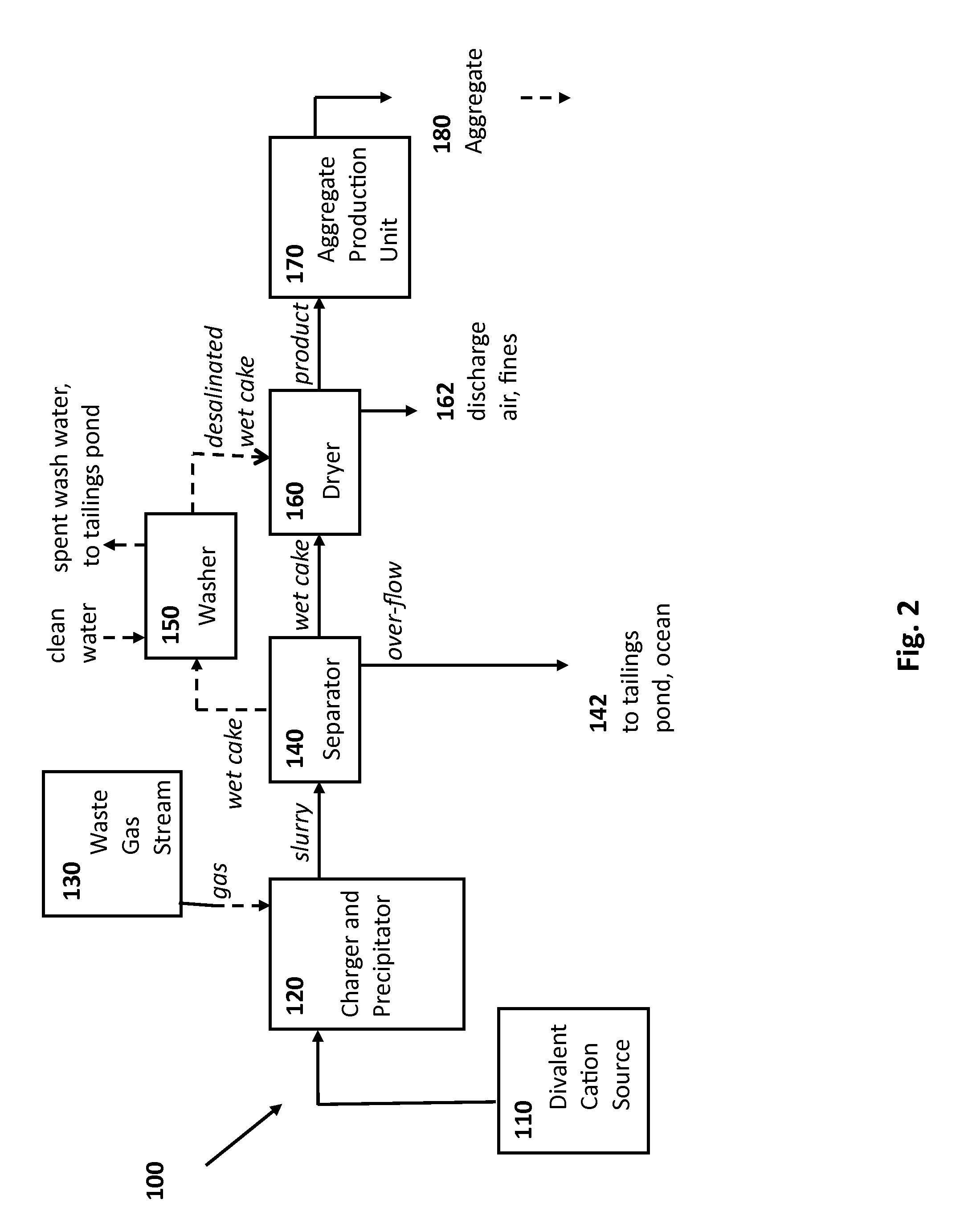

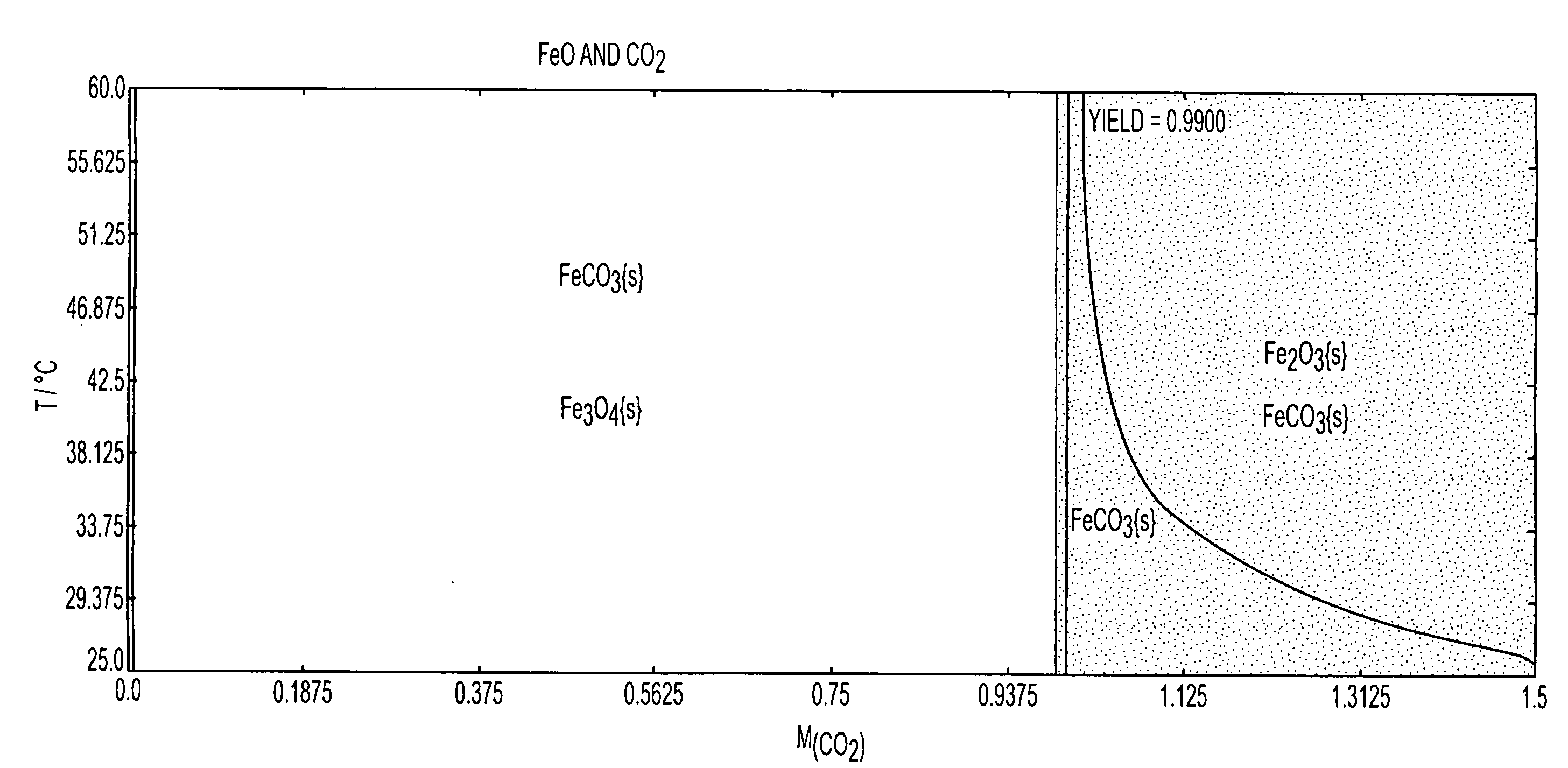

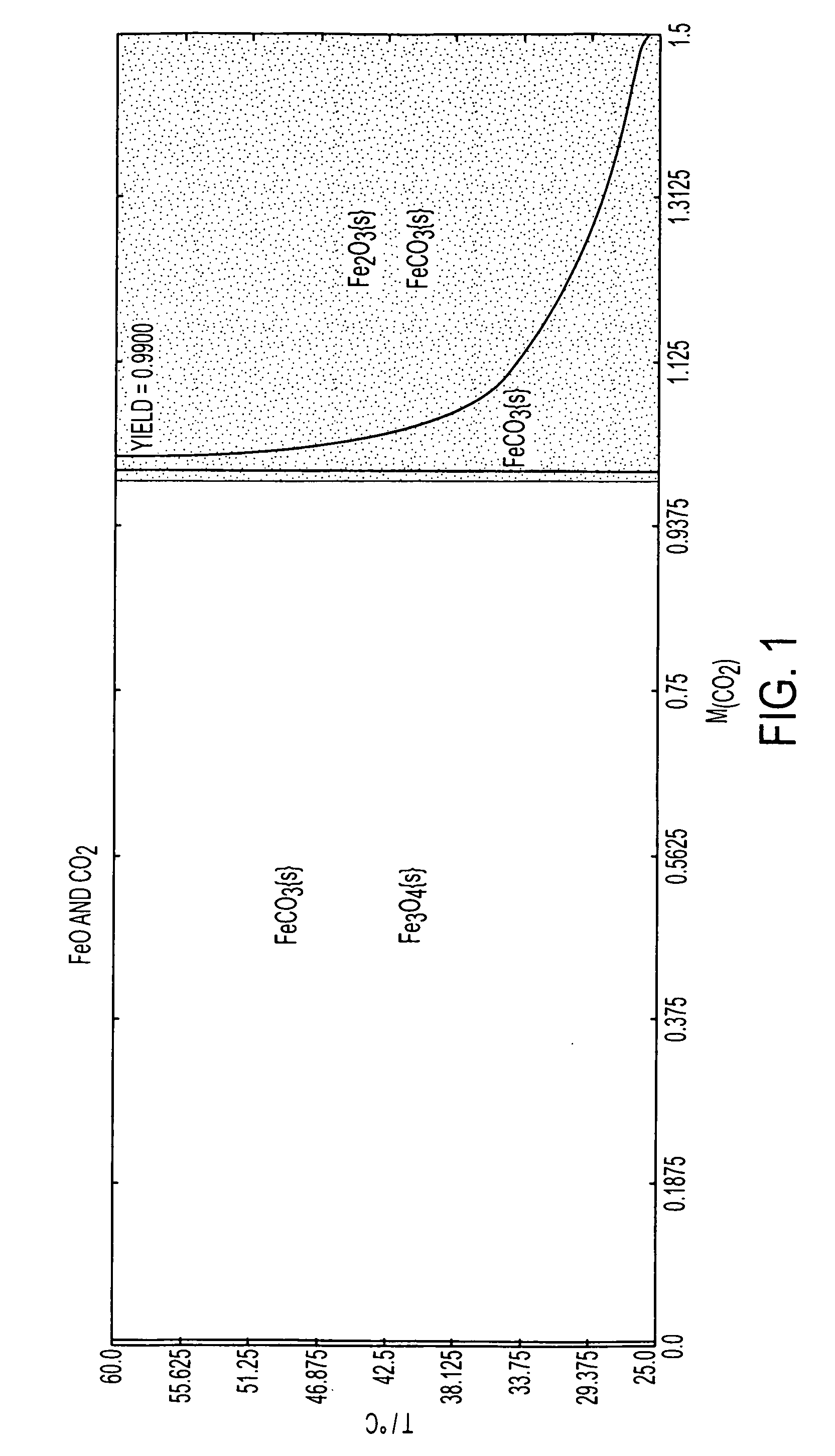

Compositions comprising synthetic rock, e.g., aggregate, and methods of producing and using them are provided. The rock, e.g., aggregate, contains CO2 and / or other components of an industrial waste stream. The CO2 may be in the form of divalent cation carbonates, e.g., magnesium and calcium carbonates. Aspects of the invention include contacting a CO2 containing gaseous stream with a water to dissolve CO2, and placing the water under precipitation conditions sufficient to produce a carbonate containing precipitate product, e.g., a divalent cation carbonate.

Owner:ARELAC INC

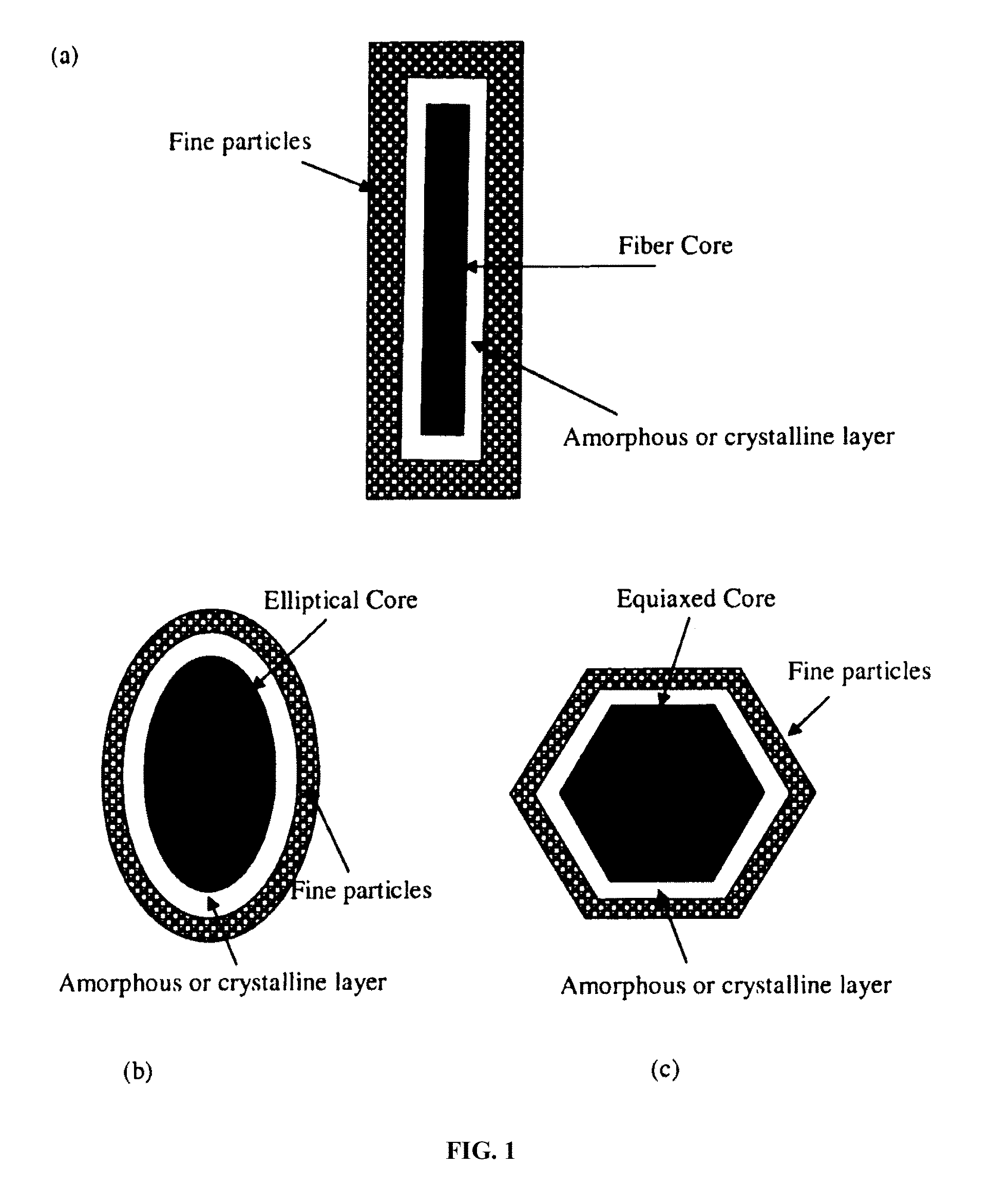

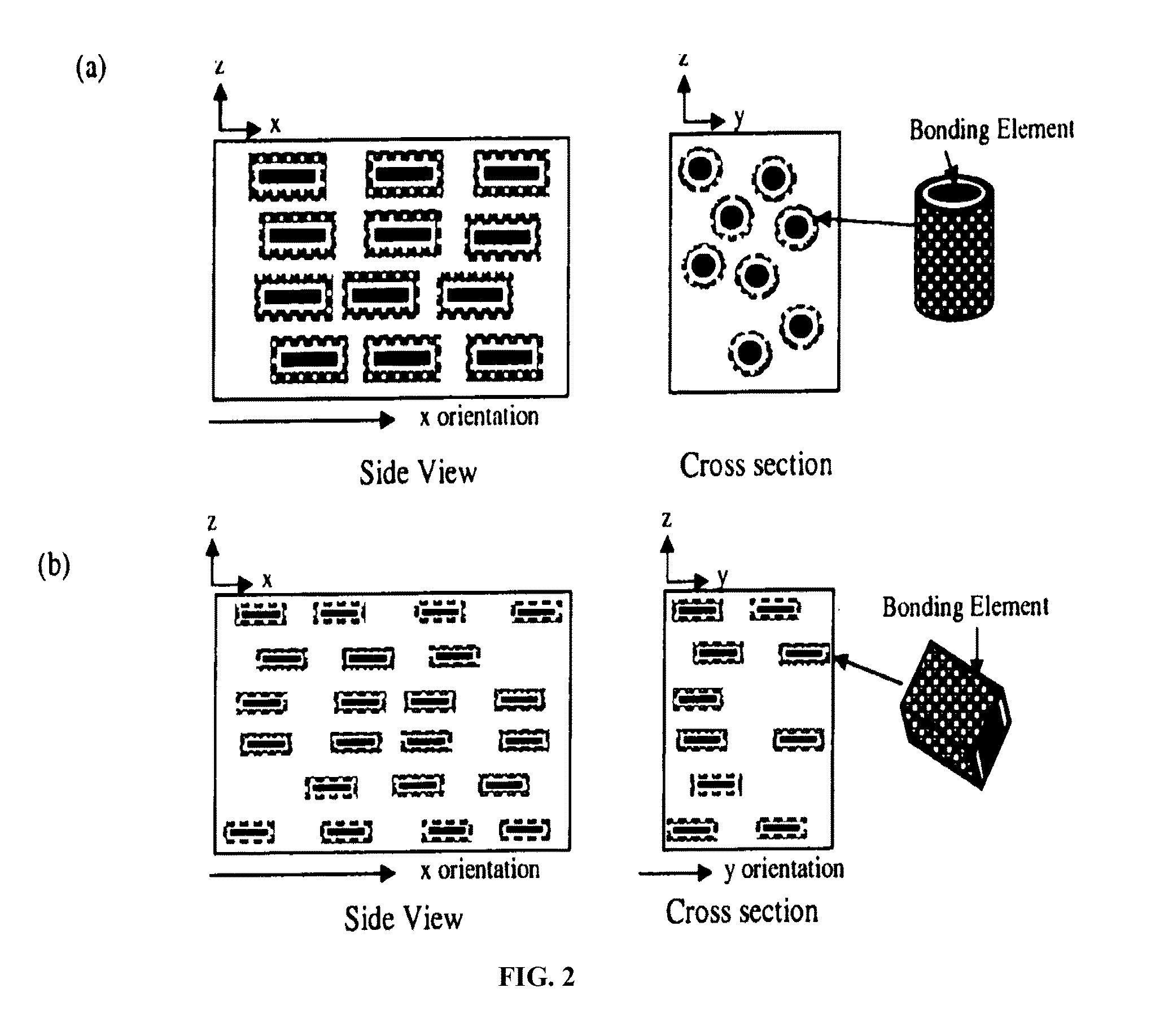

Systems and methods for carbon capture and sequestration and compositions derived therefrom

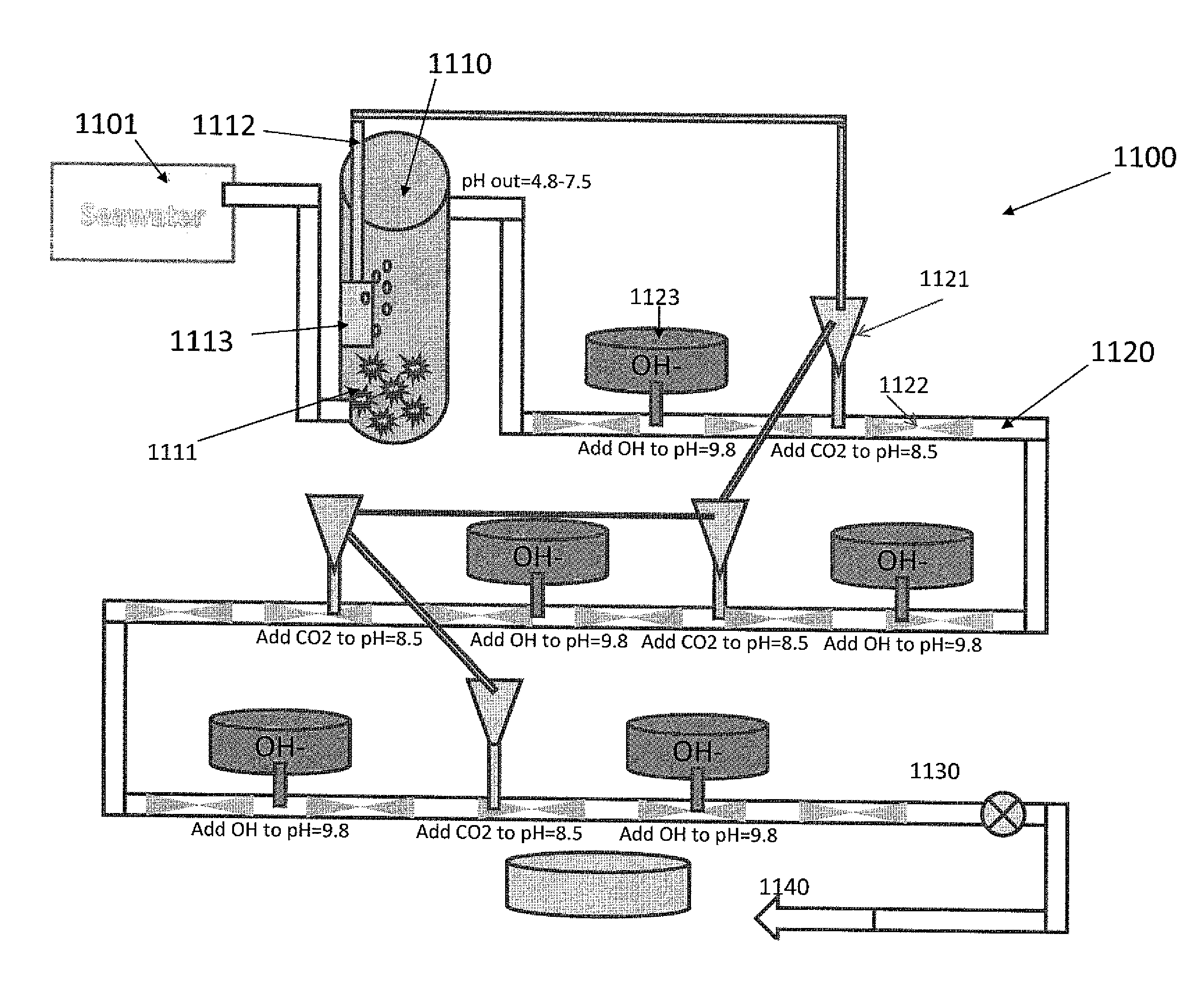

ActiveUS20090143211A1Promote formationCalcium/strontium/barium carbonatesNitrogen compoundsInterior spaceProduct formation

A method of sequestering a greenhouse gas is described, which comprises: (i) providing a solution carrying a first reagent that is capable of reacting with a greenhouse gas; (ii) contacting the solution with a greenhouse gas under conditions that promote a reaction between the at least first reagent and the greenhouse gas to produce at least a first reactant; (iii) providing a porous matrix having interstitial spaces and comprising at least a second reactant; (iv) allowing a solution carrying the at least first reactant to infiltrate at least a substantial portion of the interstitial spaces of the porous matrix under conditions that promote a reaction between the at least first reactant and the at least second reactant to provide at least a first product; and (v) allowing the at least first product to form and fill at least a portion of the interior spaces of the porous matrix, thereby sequestering a greenhouse gas.

Owner:RUTGERS THE STATE UNIV

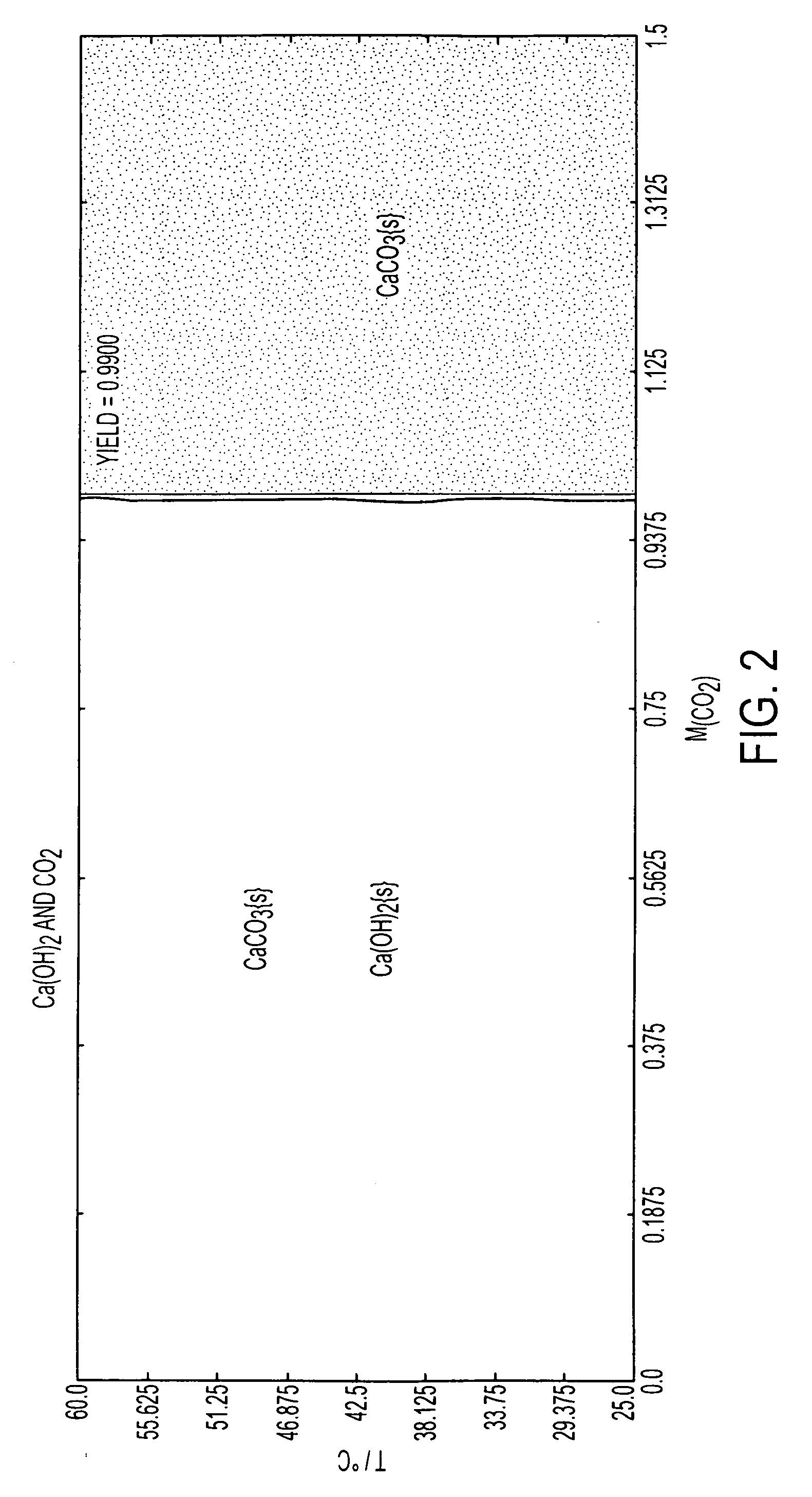

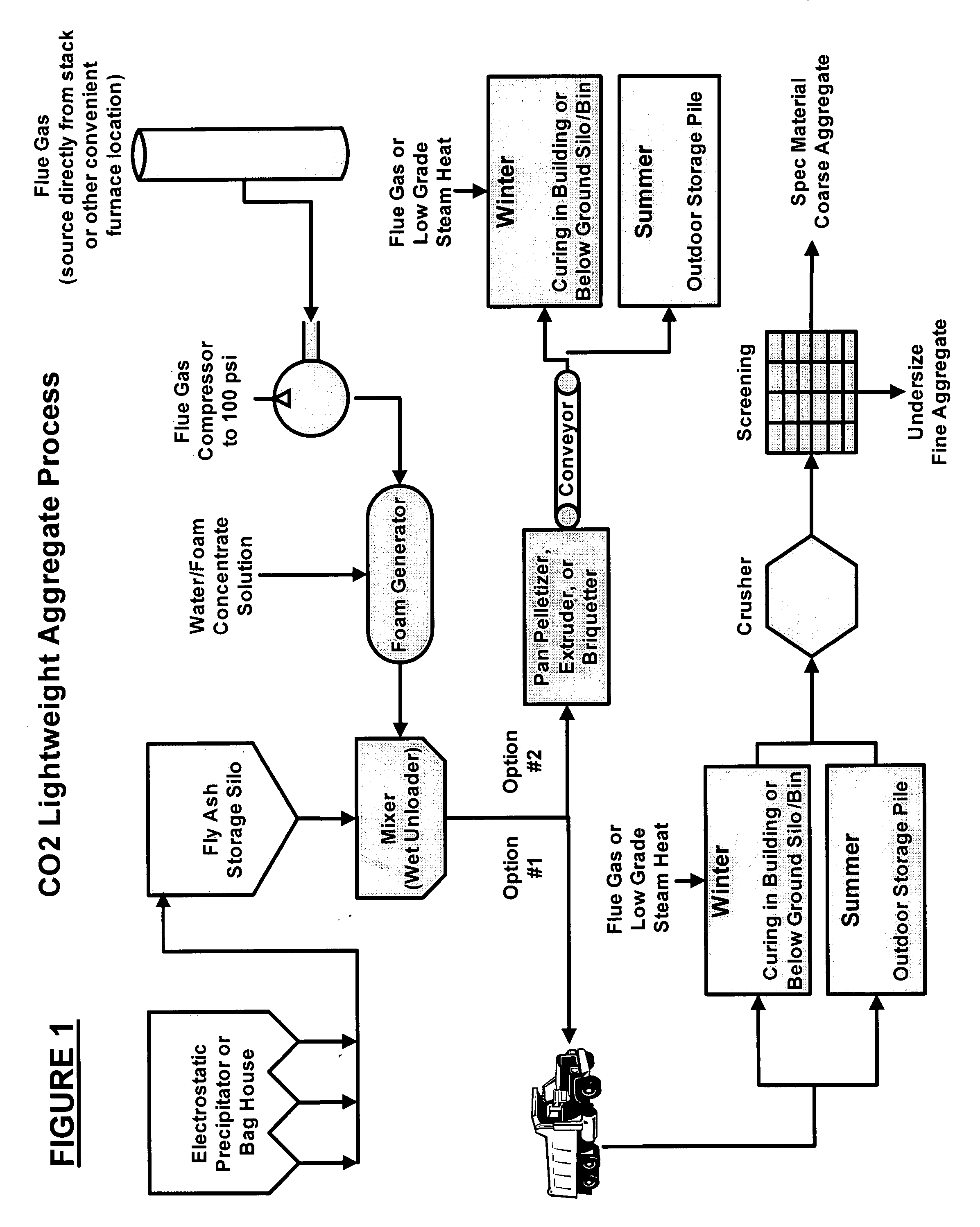

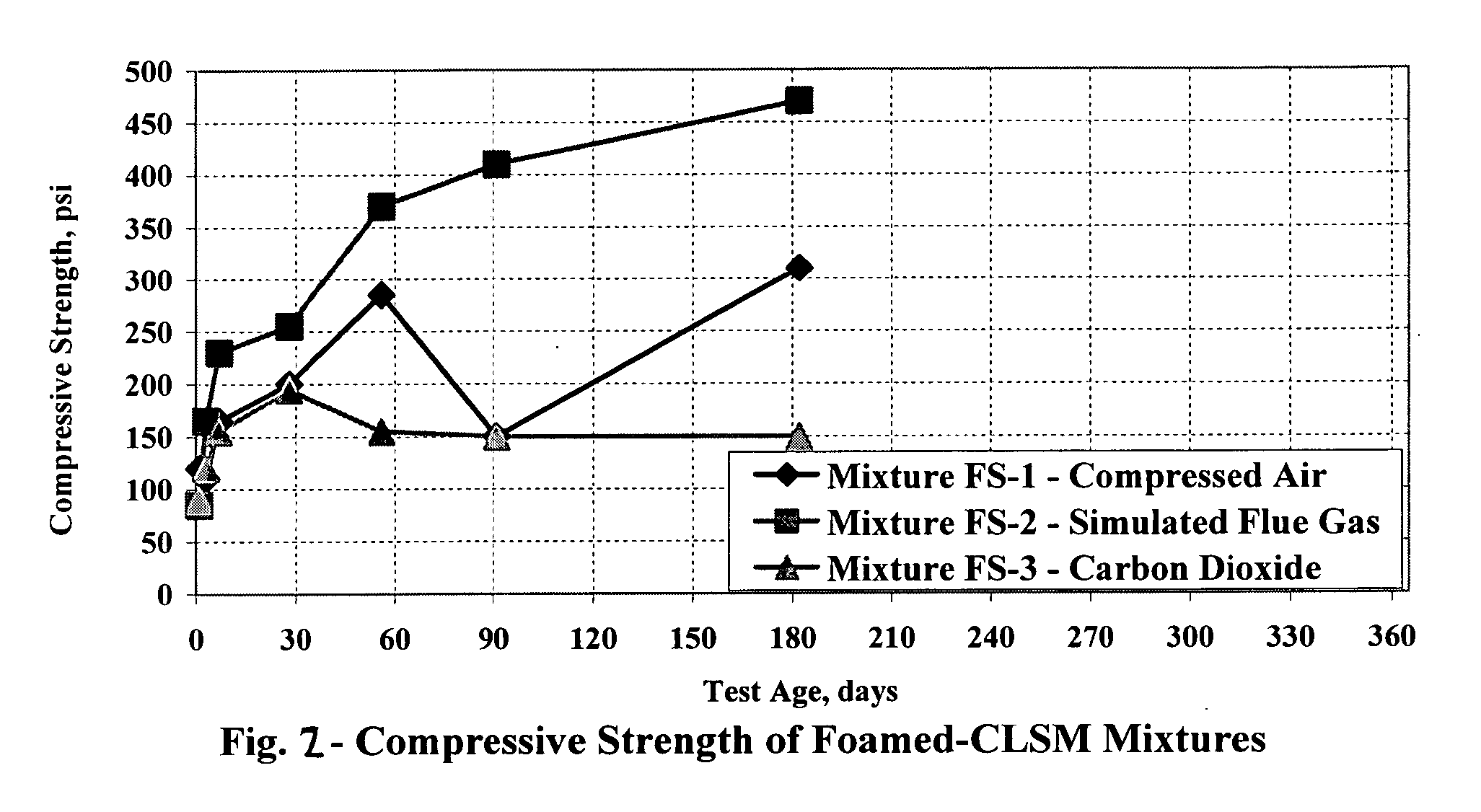

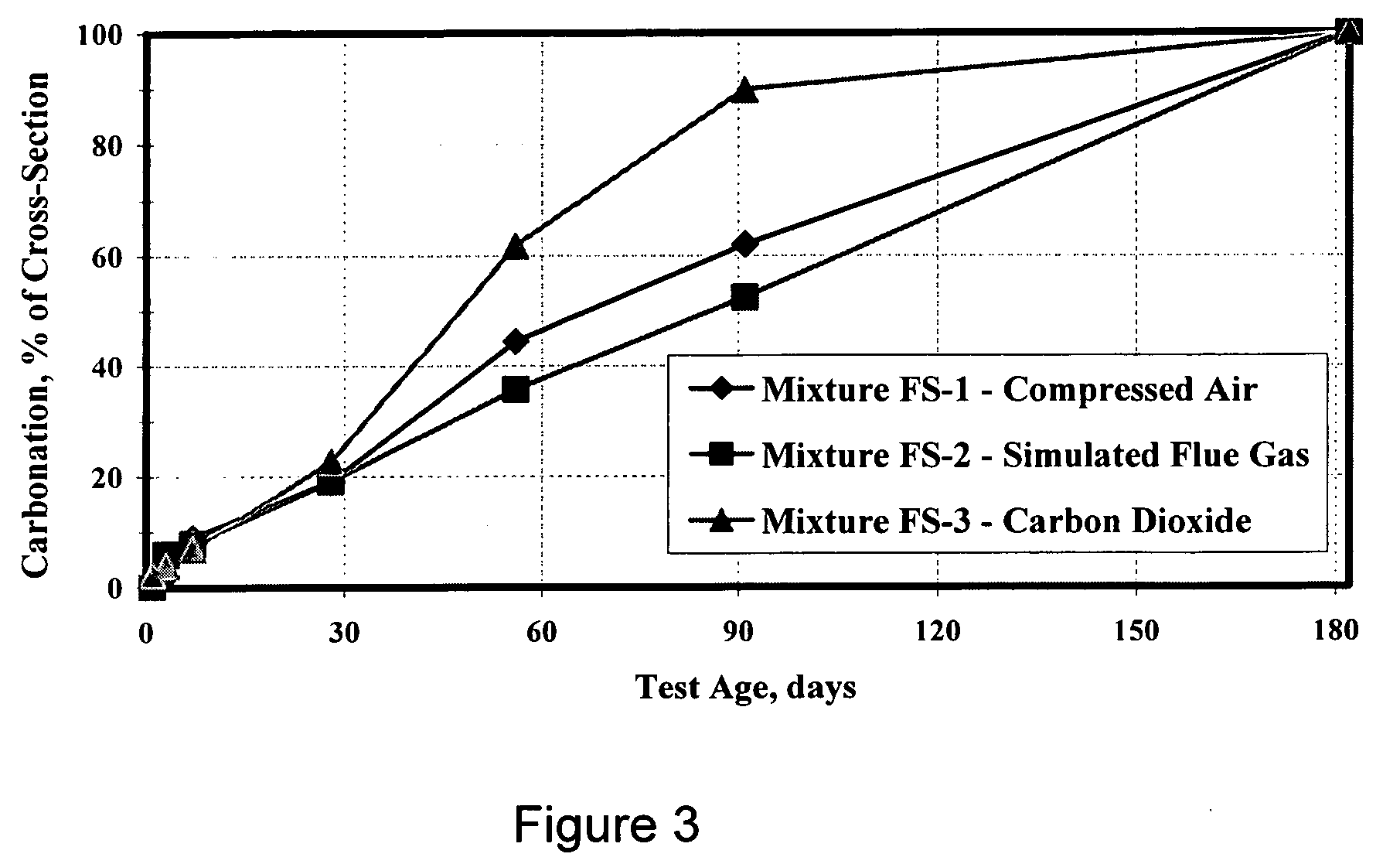

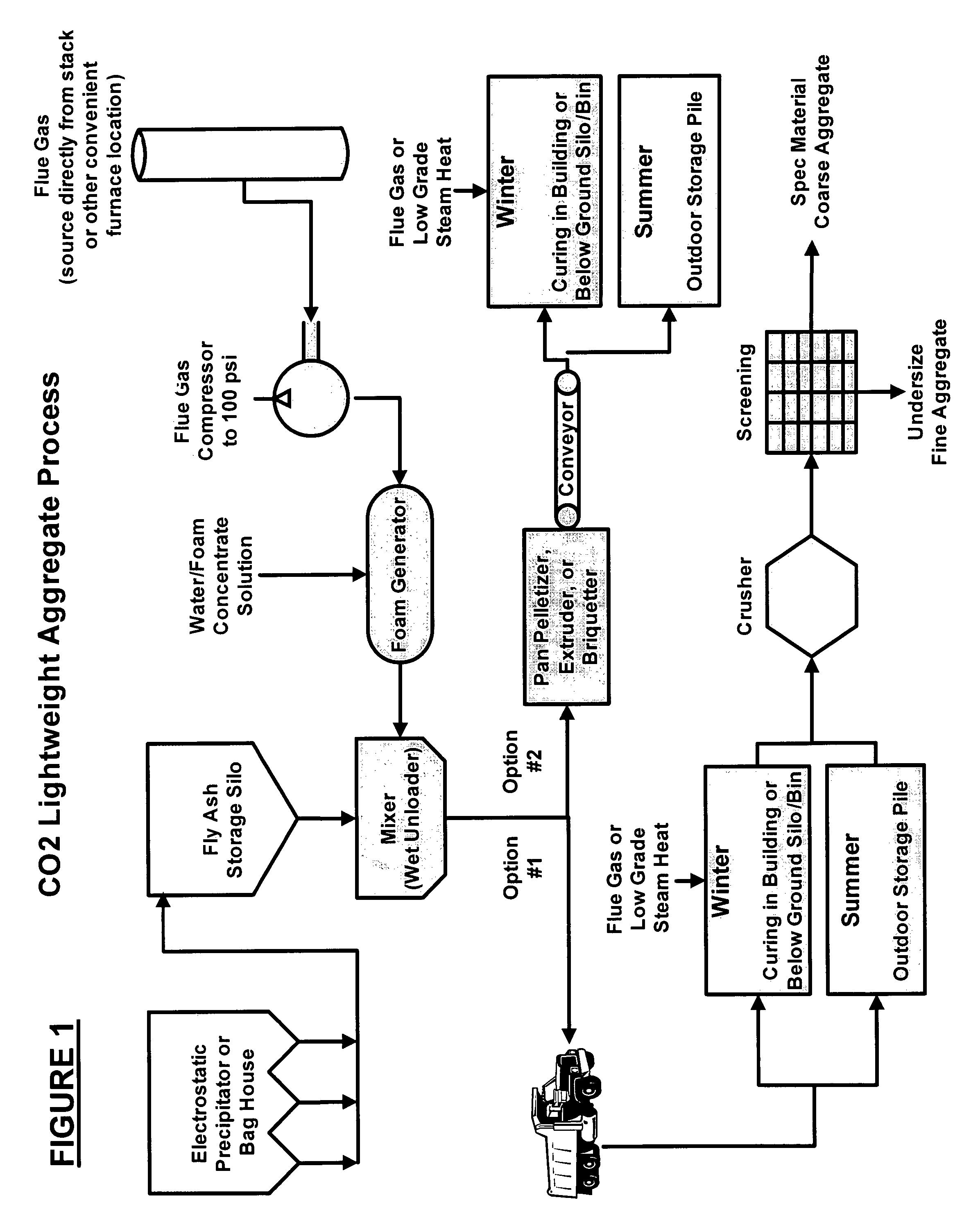

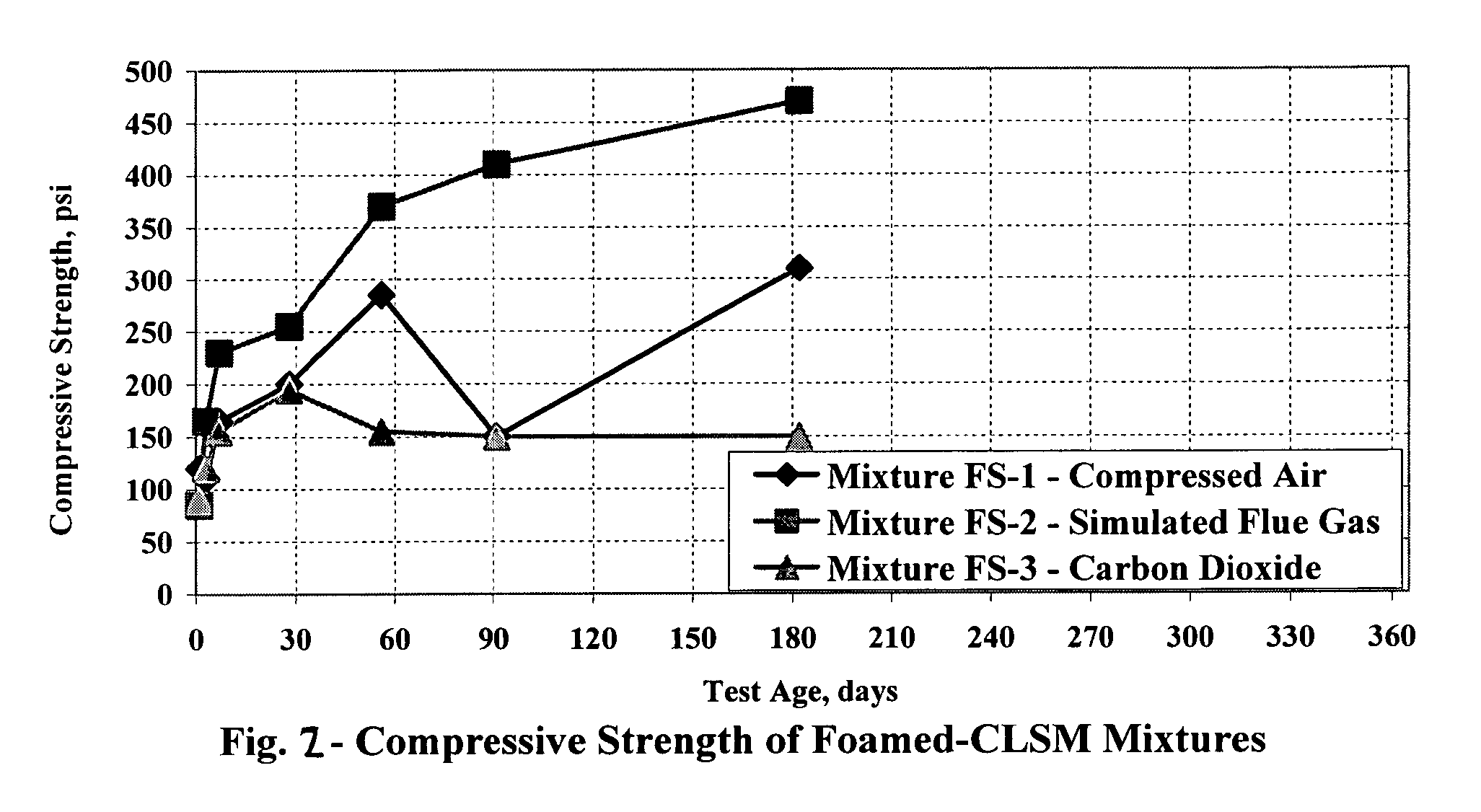

Carbon dioxide sequestration in foamed controlled low strength materials

InactiveUS20060185560A1Improve the environmentEasy to useProductsReagentsCombustion chamberMaterials science

A process for sequestering carbon dioxide from the flue gas emitted from a combustion chamber is disclosed. In the process, a foam including a foaming agent and the flue gas is formed, and the foam is added to a mixture including a cementitious material (e.g., fly ash) and water to form a foamed mixture. Thereafter, the foamed mixture is allowed to set, preferably to a controlled low-strength material having a compressive strength of 1200 psi or less. The carbon dioxide in the flue gas and waste heat reacts with hydration products in the controlled low-strength material to increase strength. In this process, the carbon dioxide is sequestered. The CLSM can be crushed or pelletized to form a lightweight aggregate with properties similar to the naturally occurring mineral, pumice.

Owner:WISCONSIN ELECTRIC POWER

Methods of sequestering co2

Methods of sequestering carbon dioxide (CO2) are provided. Aspects of the methods include precipitating a storage stable carbon dioxide sequestering product from an alkaline-earth-metal-containing water and then disposing of the product, e.g., by placing the product in a disposal location or using the product as a component of a manufactured composition. Also provided are systems for practicing methods of the invention.

Owner:CALERA CORP

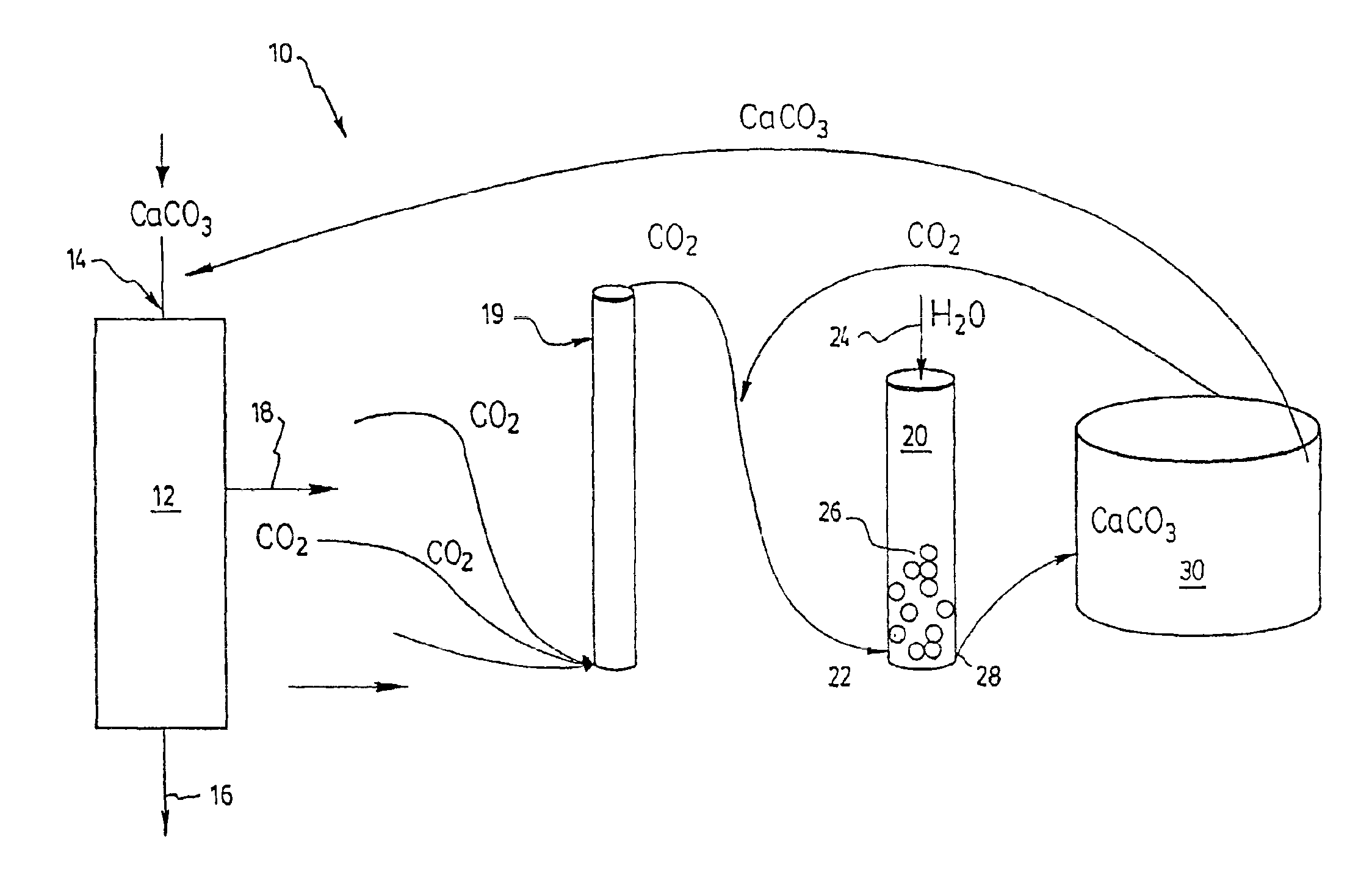

Process and a plant for the production of Portland cement clinker

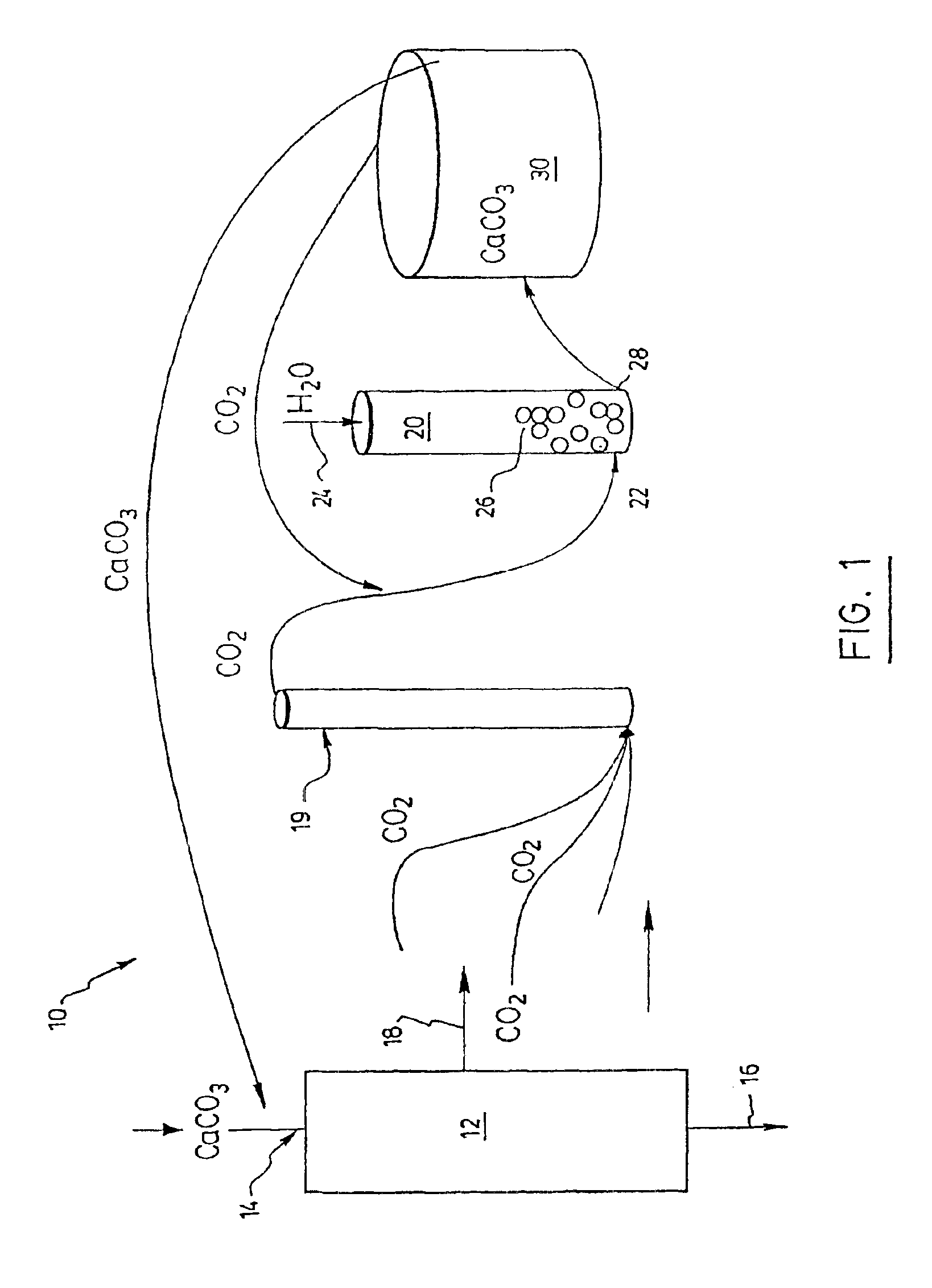

InactiveUS6908507B2Emission reductionReduce carbon dioxide emissionsGas treatmentDispersed particle separationCalcium in biologyHydrogen

A process is disclosed for producing cement clinker, comprising the steps of: a) providing a mixture of ground calcareous materials and ground argillaceous materials; b) heating the mixture of step a) to a temperature sufficient to calcine and fuse the ground materials to form the cement clinker, and thereby producing an exhaust gas containing CO2; c) catalysing the hydration of at least a portion of the CO2 contained in the exhaust gas and producing a solution containing bicarbonate ions and hydrogen ions; and d) adding to the solution obtained in step c) metal ions, and adjusting the pH of the solution to precipitate a carbonate or said metal. Preferably, the metal ions are Ca++ obtained from the dissolution of a material selected from the group consisting of CaCl2, cement kiln dust and sea salts and the carbonate is CaCO3 which is advantageously recycled into the process by adding the CaCO3 to the mixture of step a). A cement plant for performing this process is also disclosed.

Owner:CO2 SOLUTION

Methods of sequestering co2

Methods of sequestering carbon dioxide (CO2) are provided. Aspects of the methods include precipitating a storage stable carbon dioxide sequestering product from an alkaline-earth-metal-containing water and then disposing of the product, e.g., by placing the product in a disposal location or using the product as a component of a manufactured composition. Also provided are systems for practicing methods of the invention.

Owner:CALERA CORP

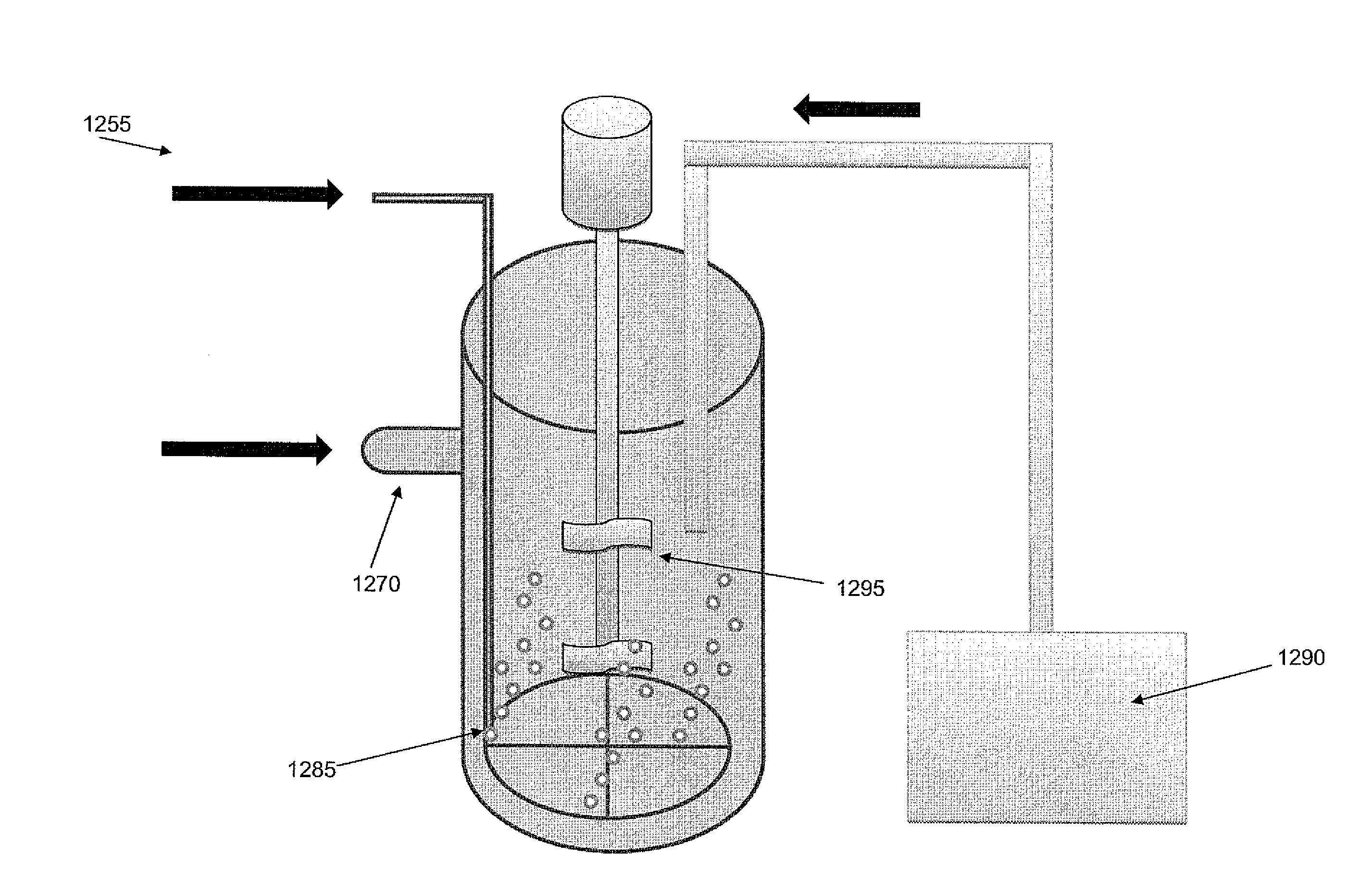

Electrochemical methods of sequestering co2

InactiveUS20100135865A1Calcium/strontium/barium carbonatesCombination devicesAlkaline earth metalElectrochemical cell

Methods of sequestering carbon dioxide (CO2) are provided. Aspects of the methods include precipitating a storage stable carbon dioxide sequestering product from an alkaline-earth-metal-containing water and then disposing of the product, e.g., by placing the product in a disposal location or using the product as a component of a manufactured composition. Also provided are systems for practicing methods of the invention.

Owner:CALERA CORP

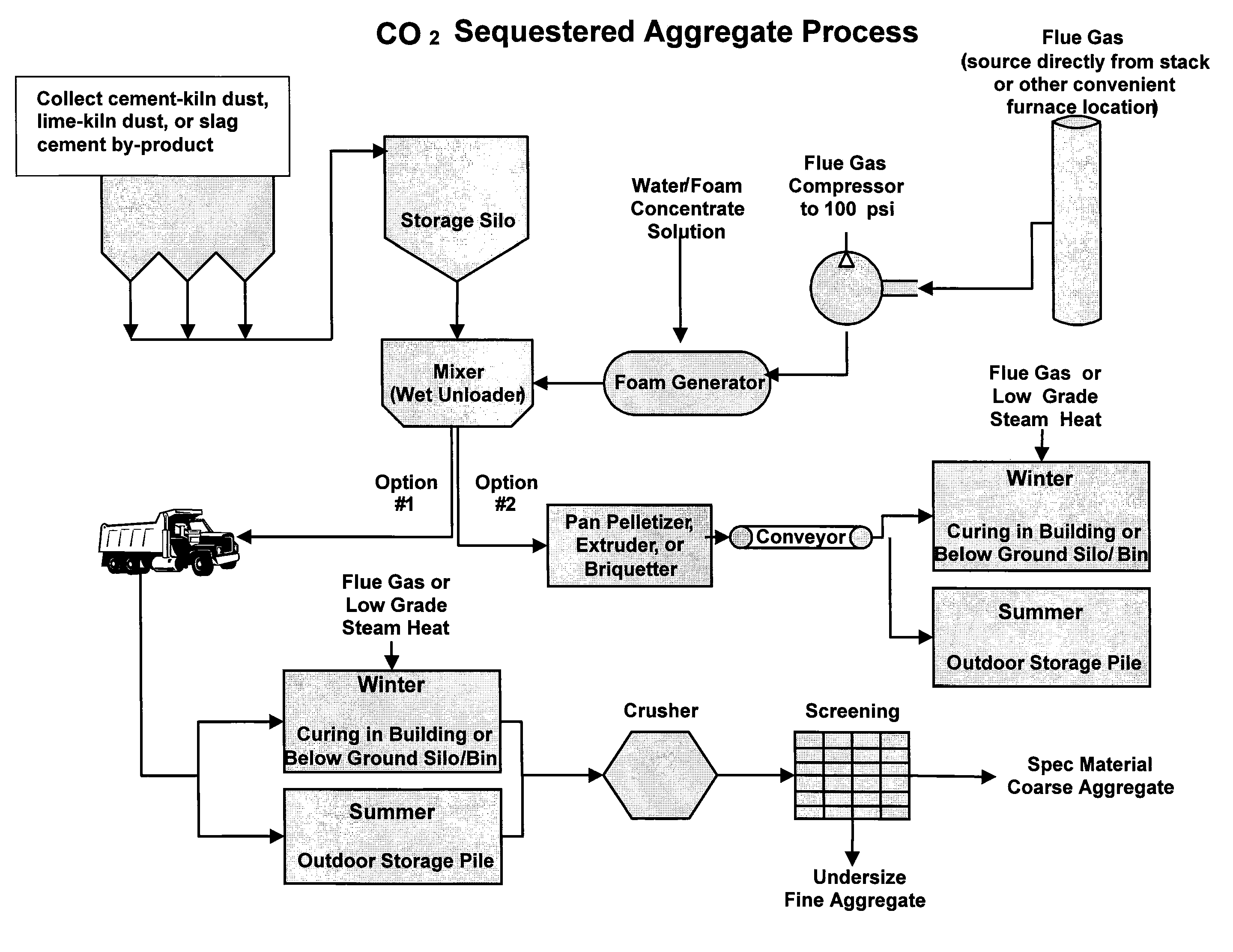

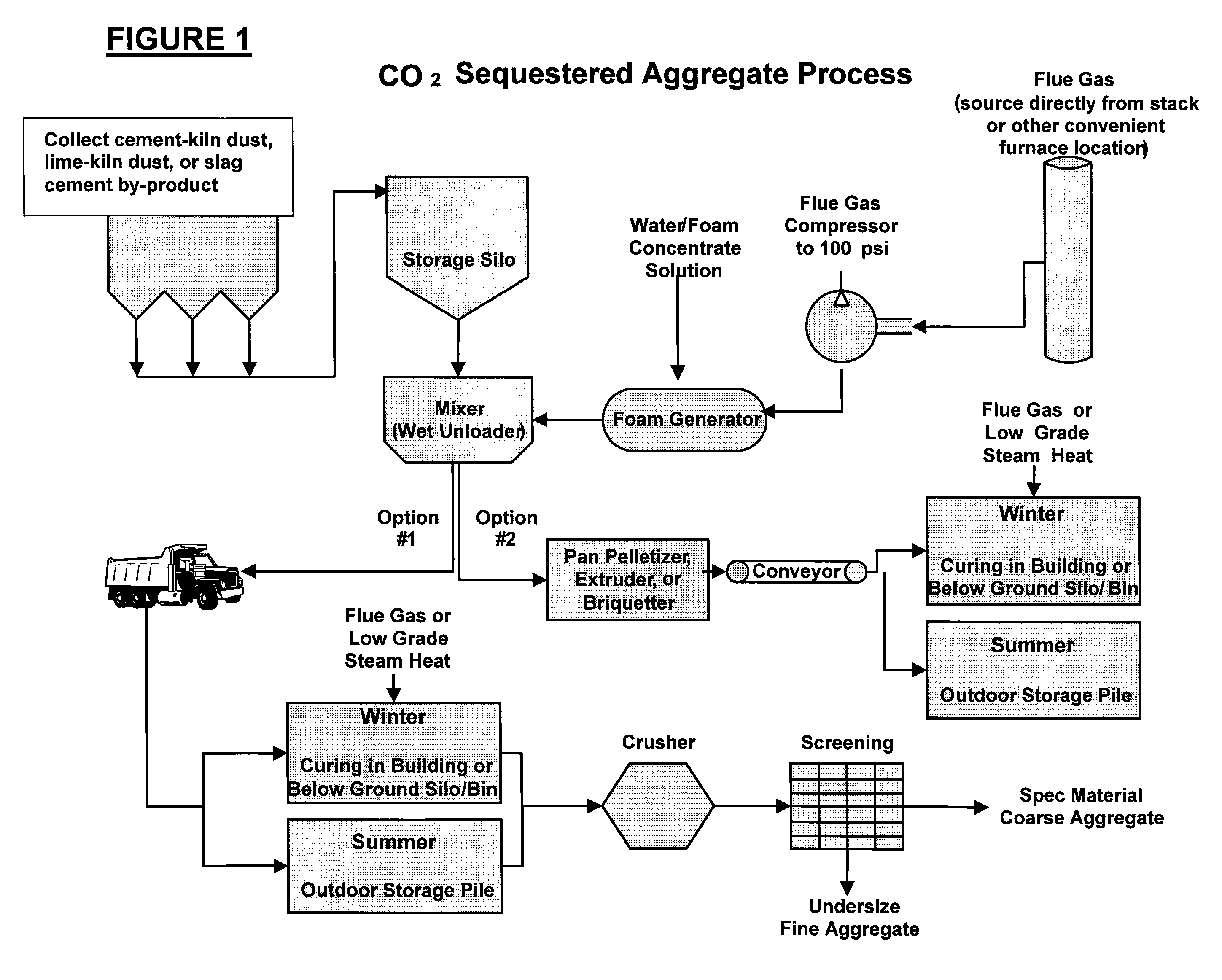

Carbon Dioxide Sequestration in Foamed Controlled Low Strength Materials

A process for sequestering carbon dioxide from the exhaust gas emitted from a combustion chamber is disclosed. In the process, a foam including a foaming agent and the exhaust gas is formed, and the foam is added to a mixture including a cementitious material (e.g., cement-kiln dust, lime kiln dust, or slag cement) and water to form a foamed mixture. Thereafter, the foamed mixture is allowed to set, preferably to a controlled low-strength material having a compressive strength of 1200 psi or less. The carbon dioxide in the exhaust gas reacts with hydration products in the controlled low-strength material and in turn sequesters the carbon dioxide.

Owner:WISCONSIN ELECTRIC POWER

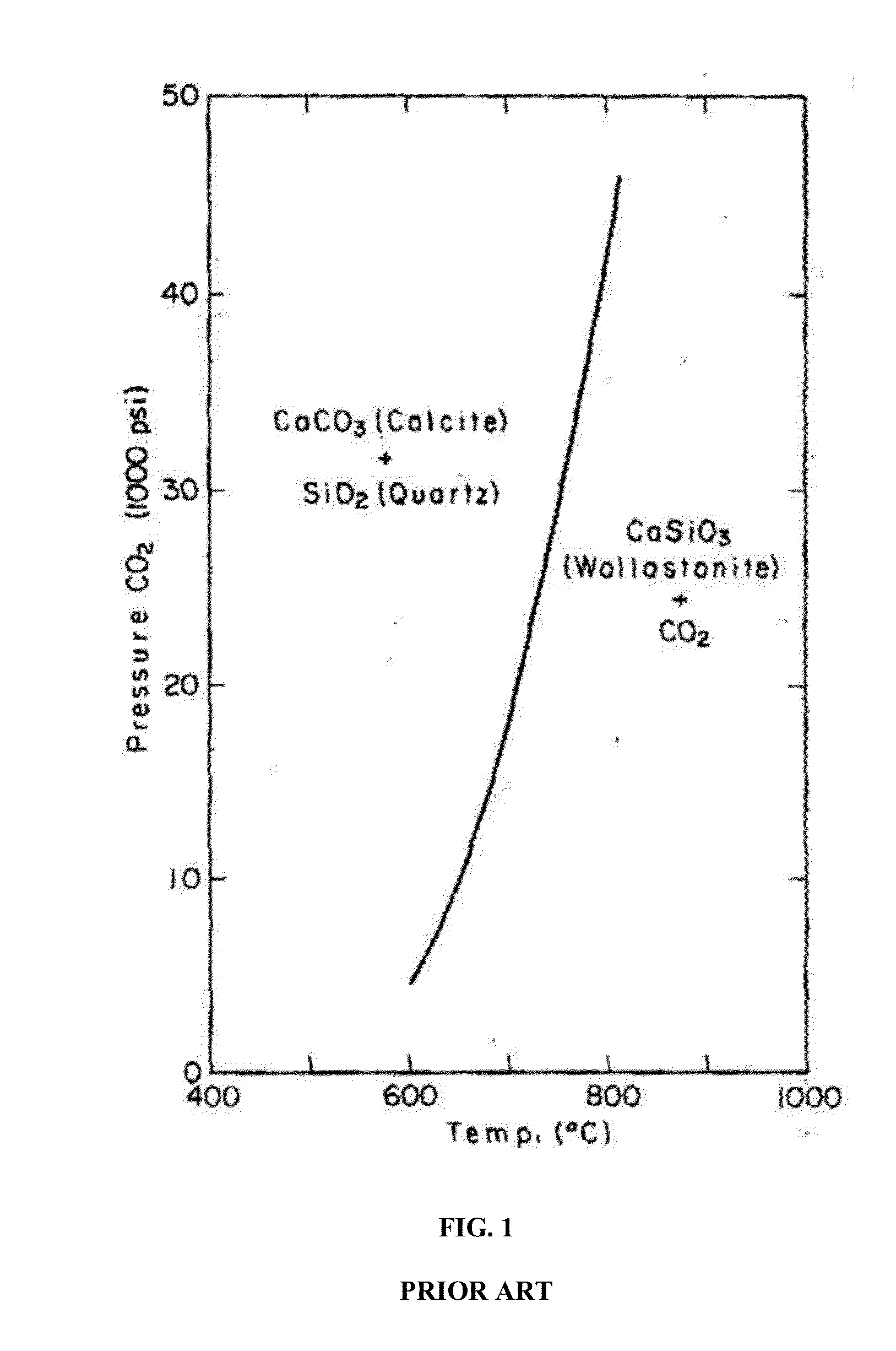

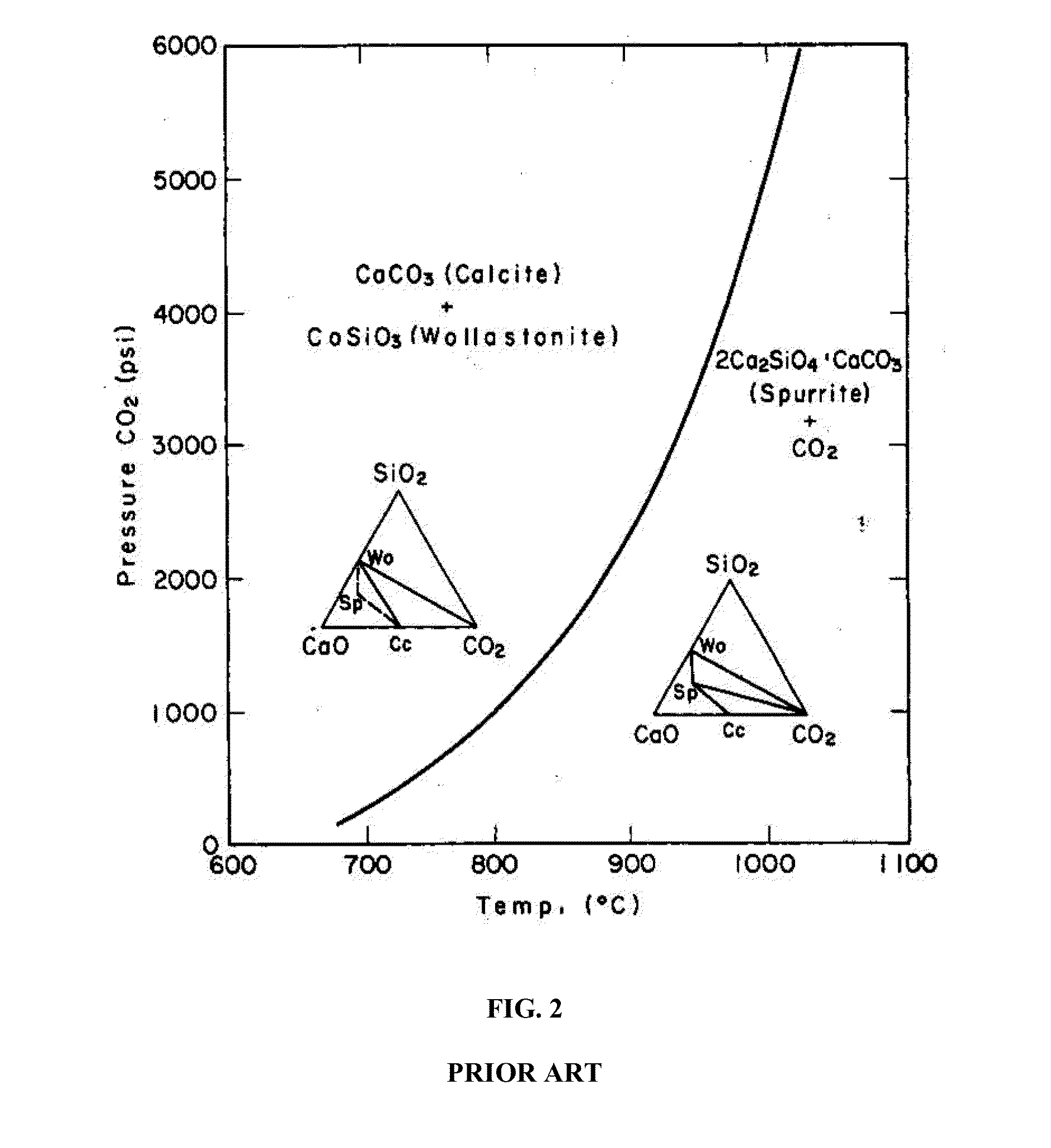

Marble-like composite materials and methods of preparation thereof

InactiveUS20140127450A1Low costIncrease consumptionLayered productsCoatingsCalcium silicateFlexural strength

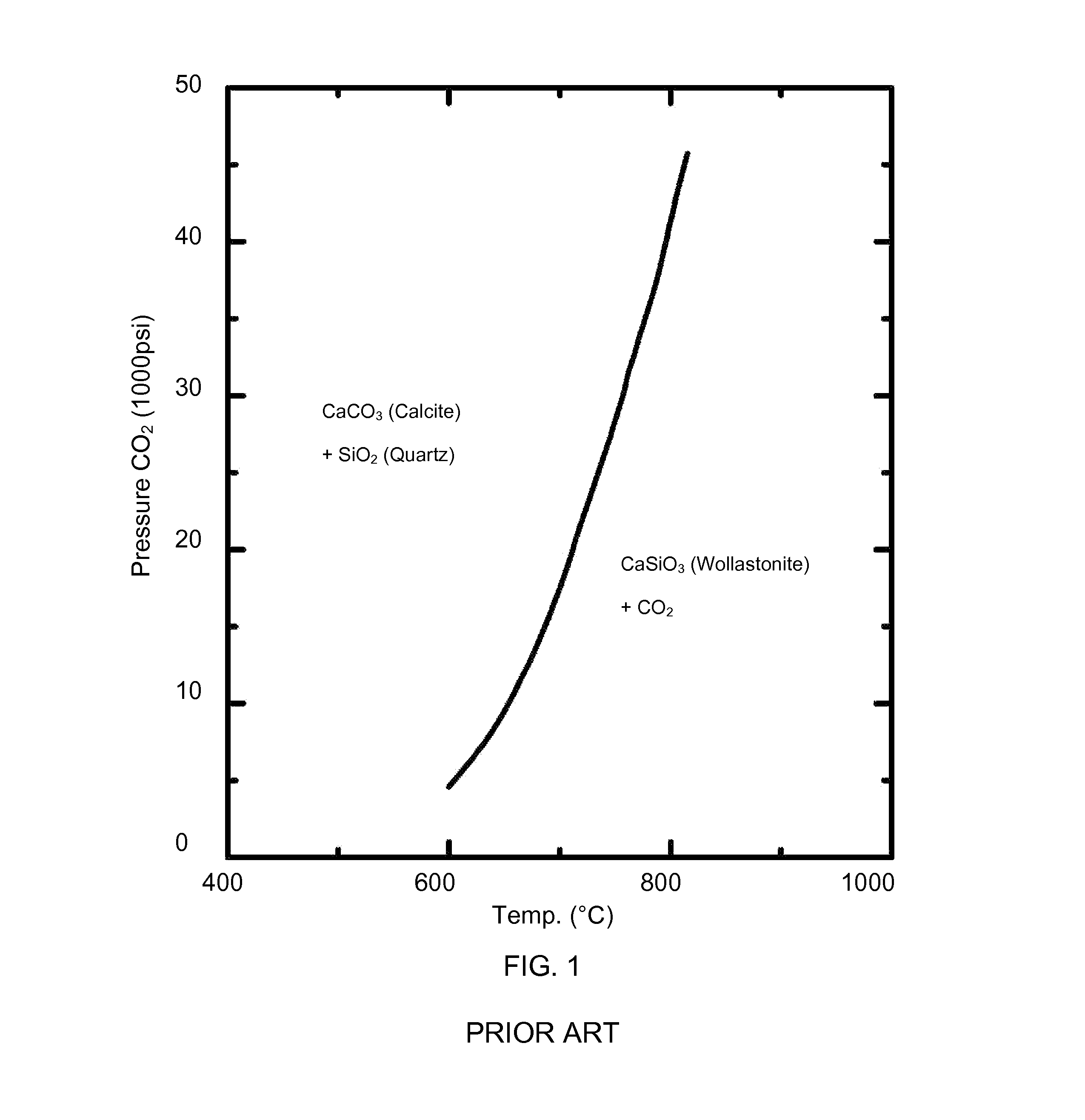

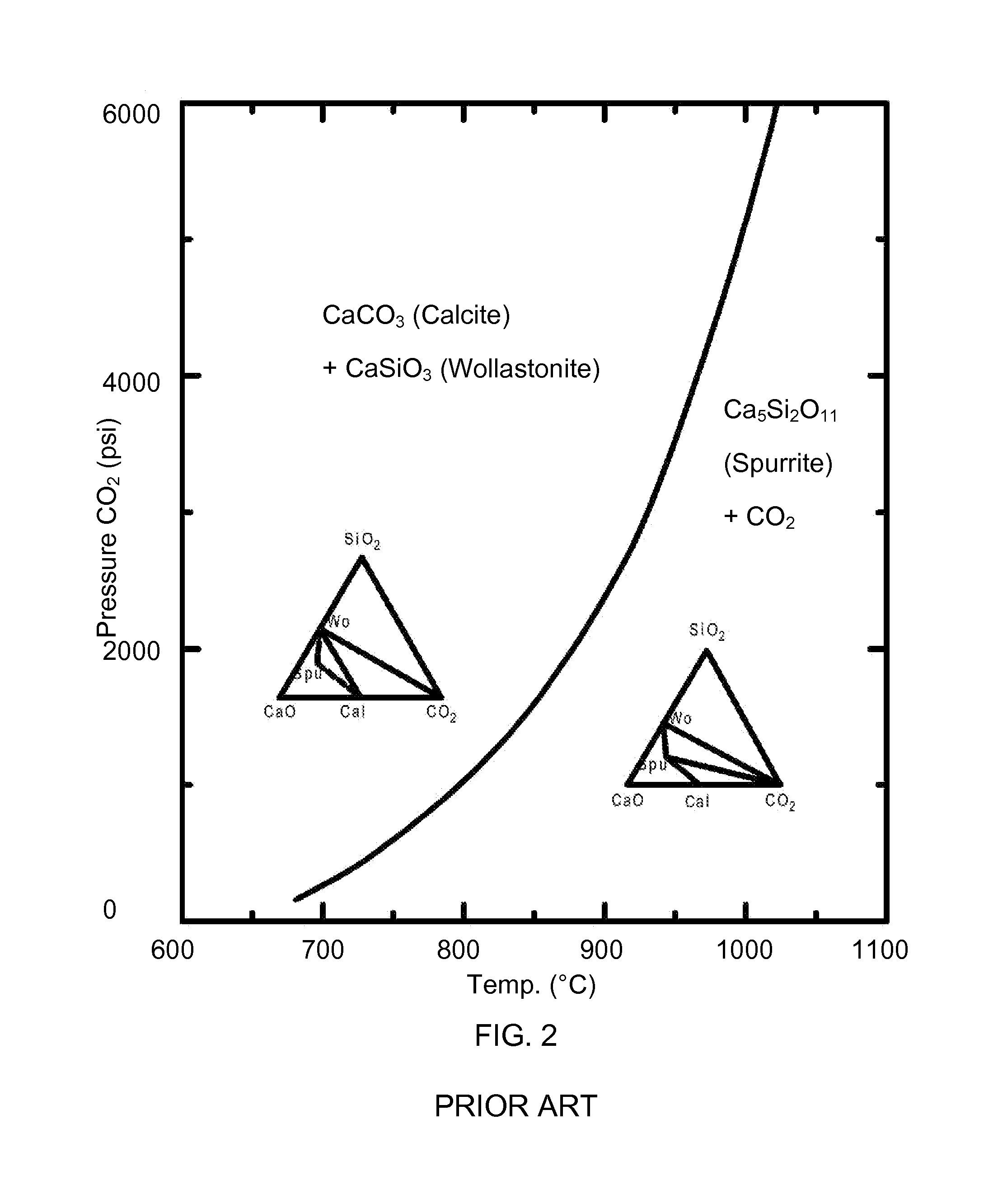

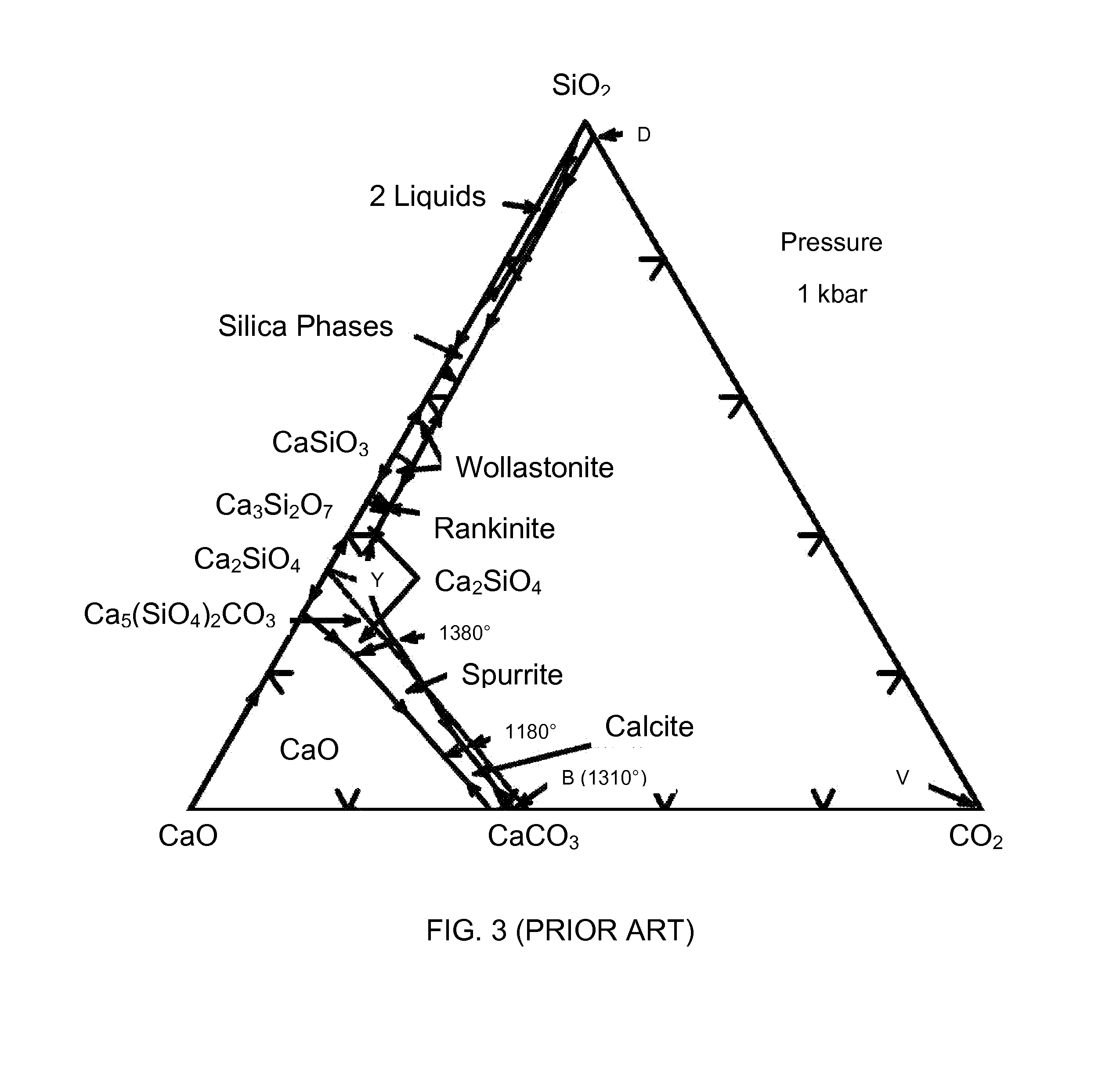

The invention provides novel marble-like composite materials and methods for preparation thereof. The marble-like composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production. The precursor materials include calcium silicate and calcium carbonate rich materials, for example, wollastonite and limestone. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as pigments (e.g., black iron oxide, cobalt oxide and chromium oxide) and minerals (e.g., quartz, mica and feldspar). These marble-like composite materials exhibit veins, swirls and / or waves unique to marble as well as display compressive strength, flexural strength and water absorption similar to that of marble.

Owner:RIMAN RICHARD E +1

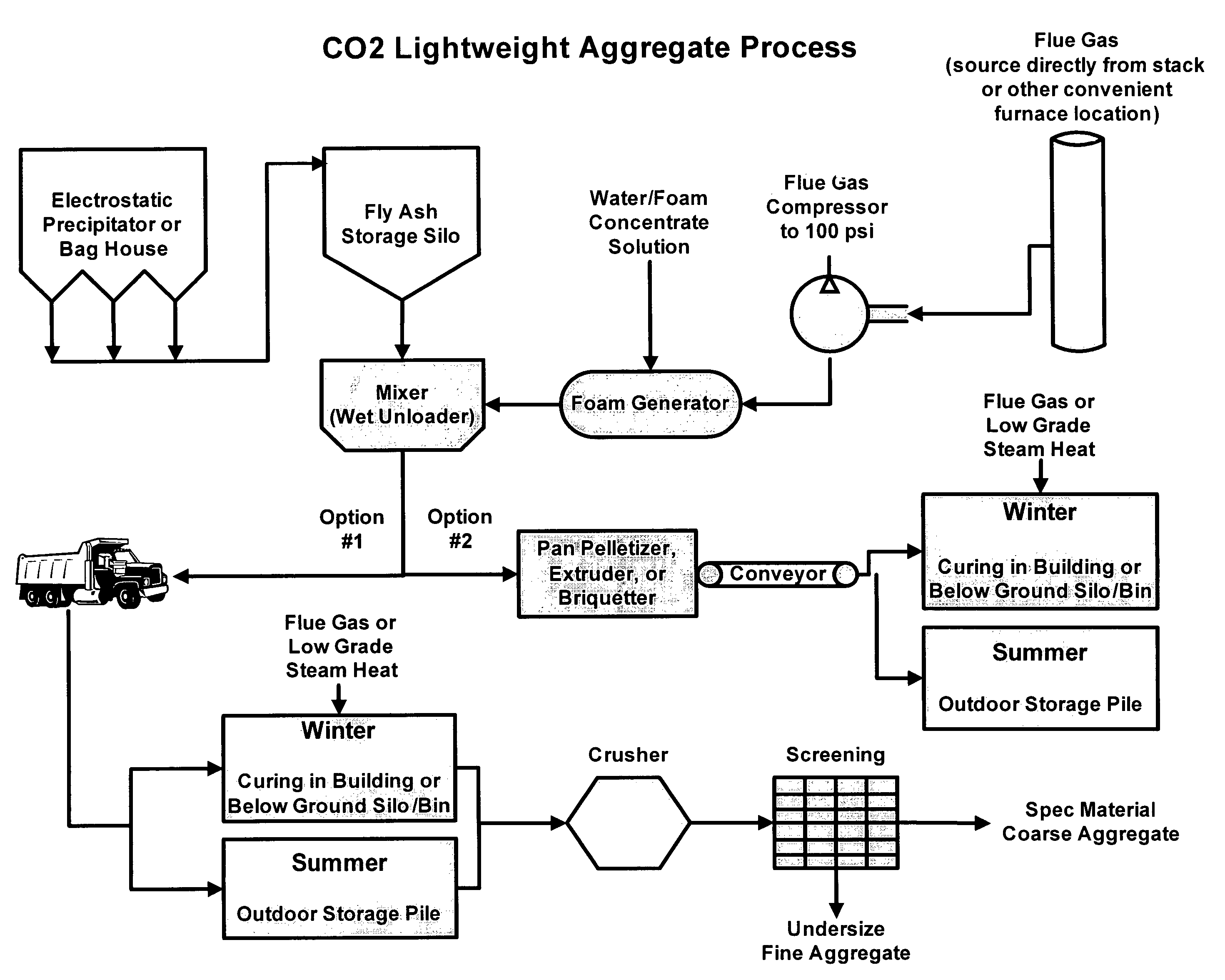

Carbon dioxide sequestration in foamed controlled low strength materials

A process for sequestering carbon dioxide from the flue gas emitted from a combustion chamber is disclosed. In the process, a foam including a foaming agent and the flue gas is formed, and the foam is added to a mixture including a cementitious material (e.g., fly ash) and water to form a foamed mixture. Thereafter, the foamed mixture is allowed to set, preferably to a controlled low-strength material having a compressive strength of 1200 psi or less. The carbon dioxide in the flue gas and waste heat reacts with hydration products in the controlled low-strength material to increase strength. In this process, the carbon dioxide is sequestered. The CLSM can be crushed or pelletized to form a lightweight aggregate with properties similar to the naturally occurring mineral, pumice.

Owner:WISCONSIN ELECTRIC POWER

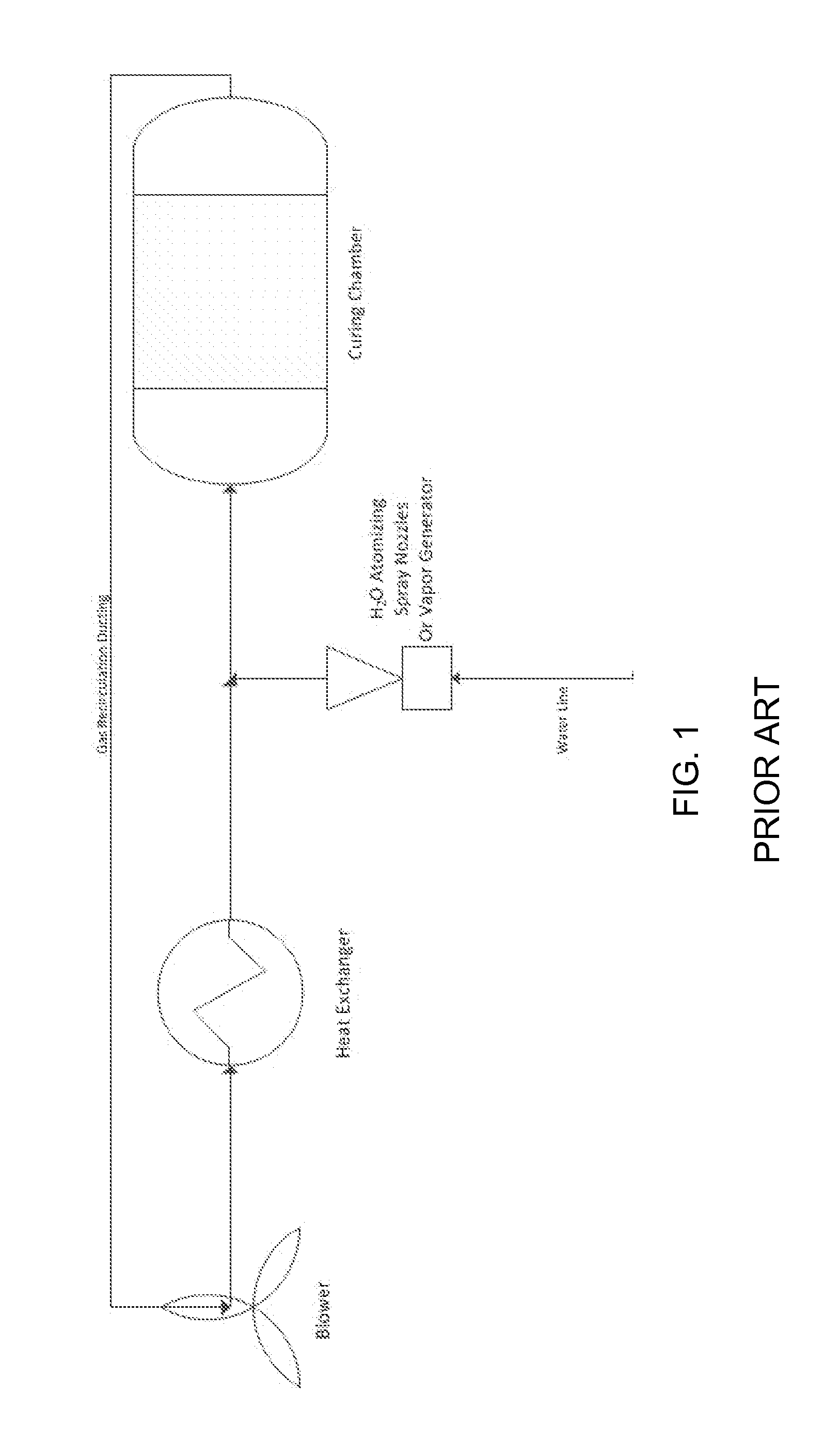

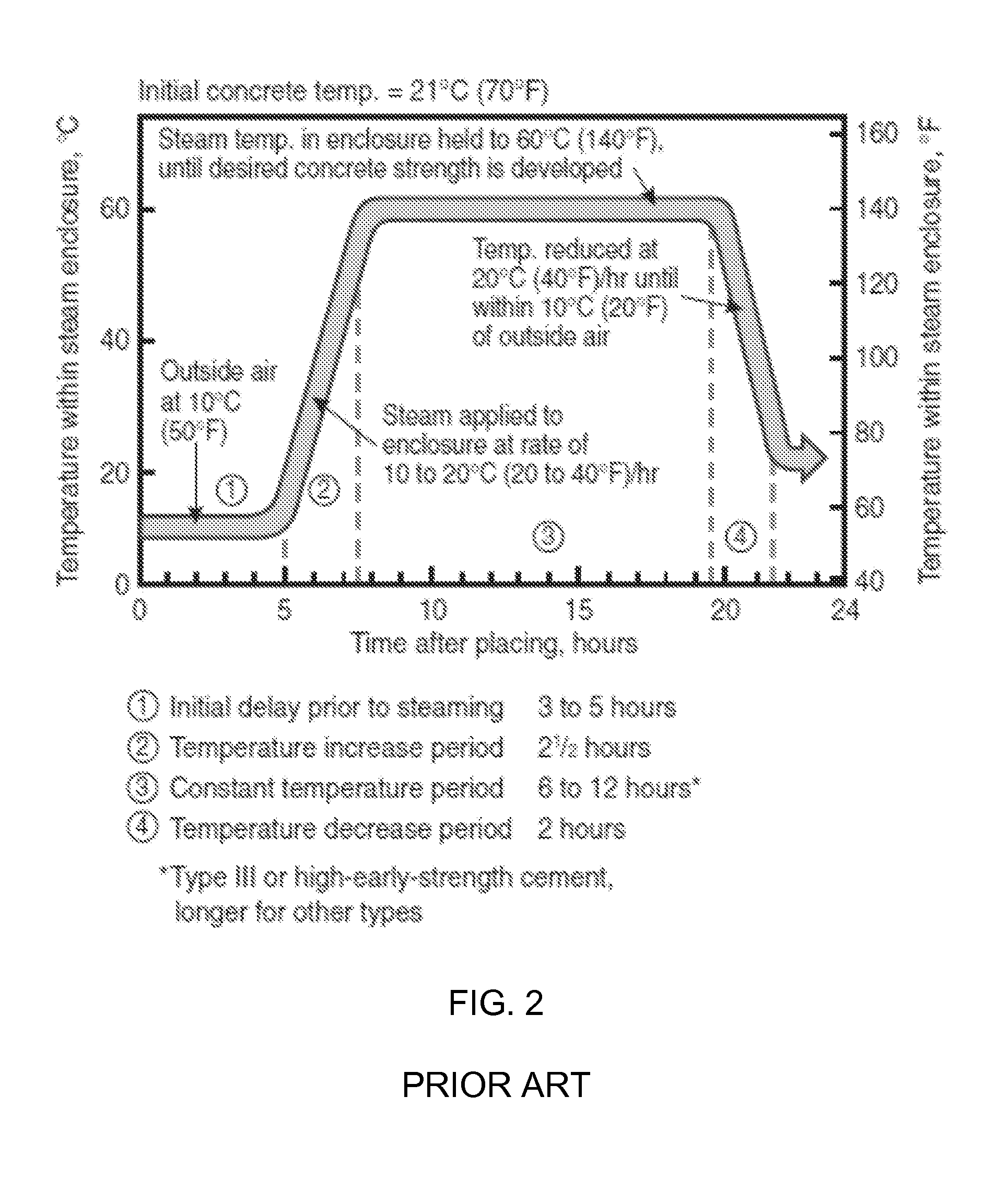

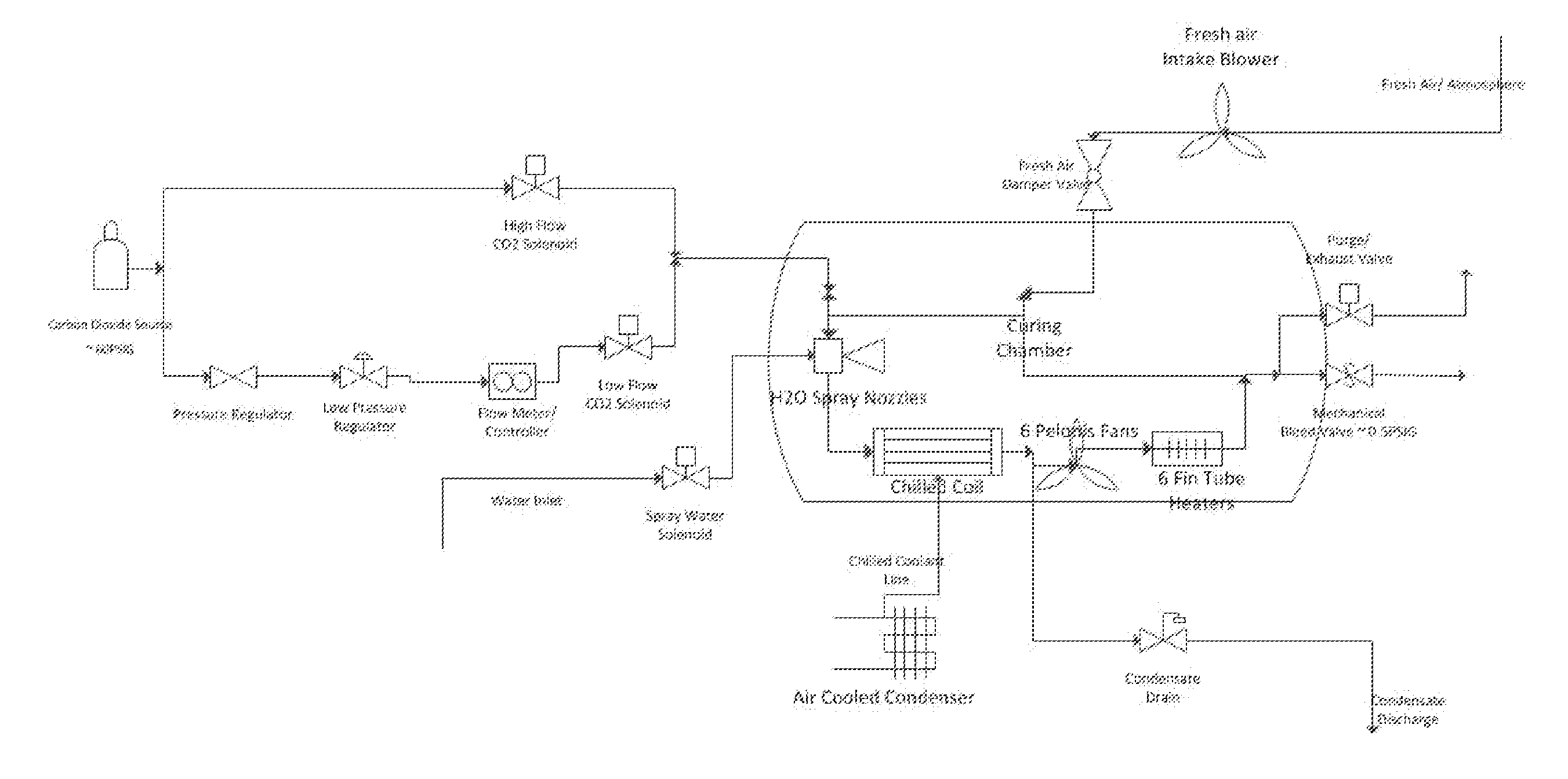

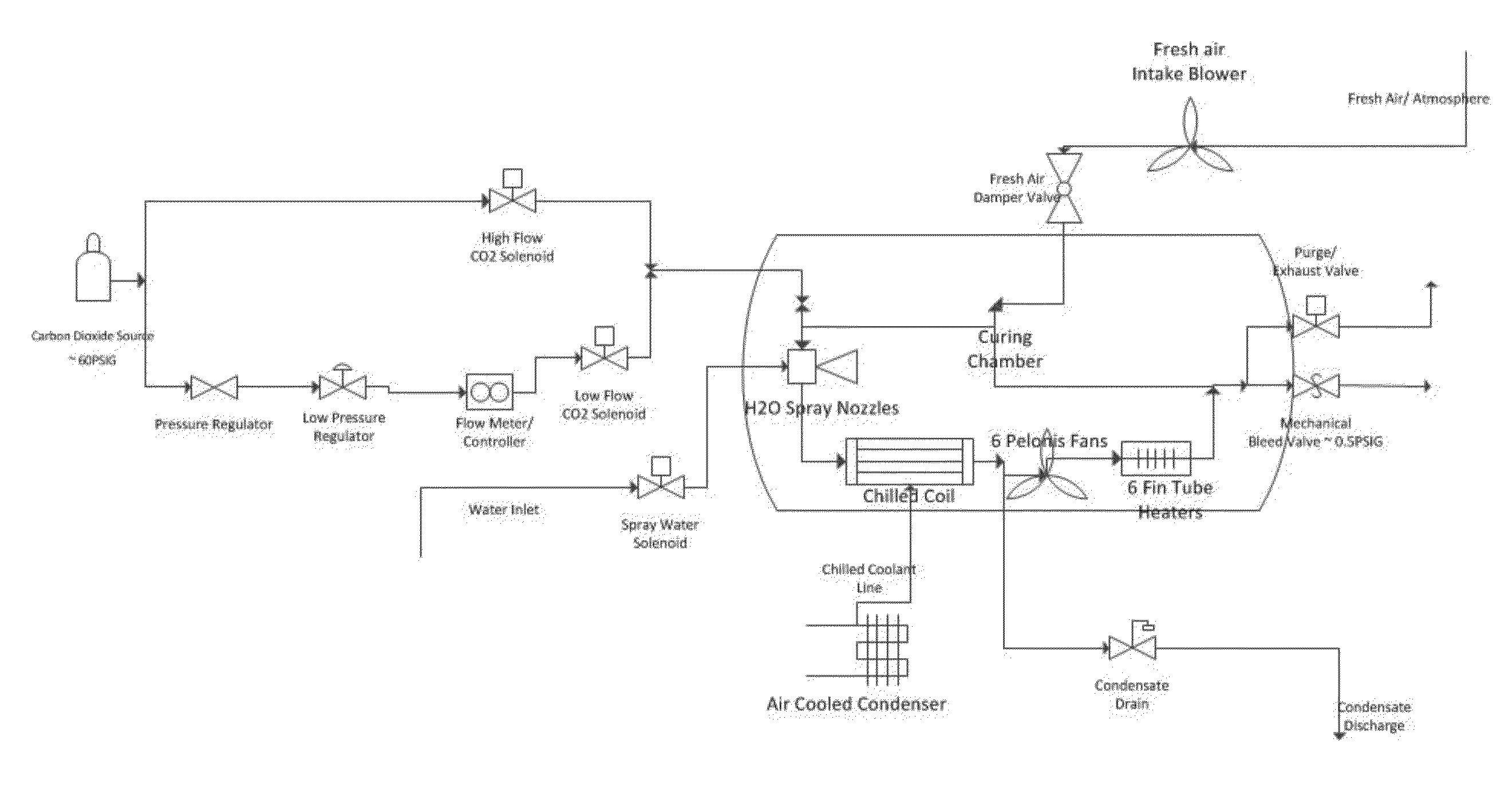

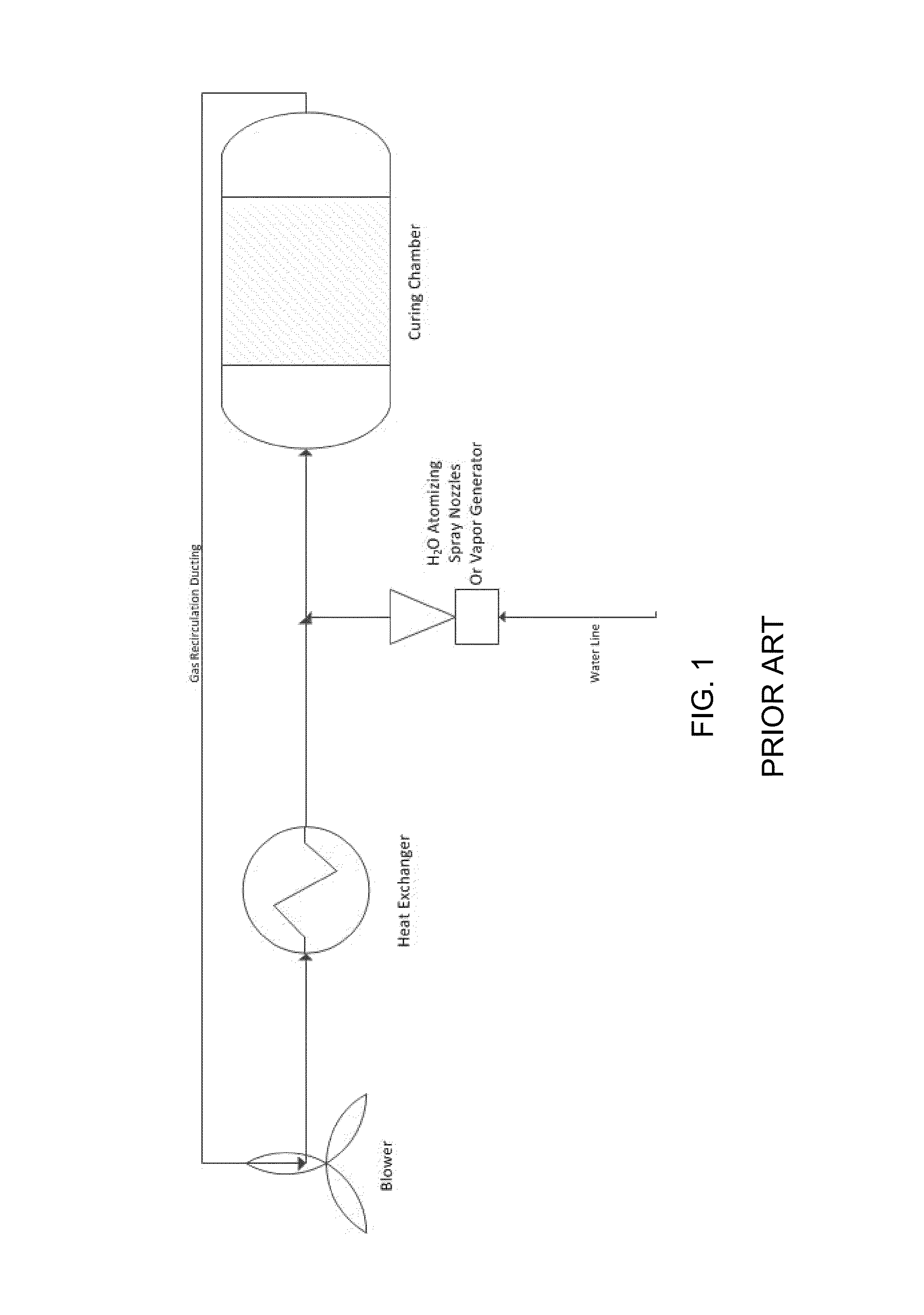

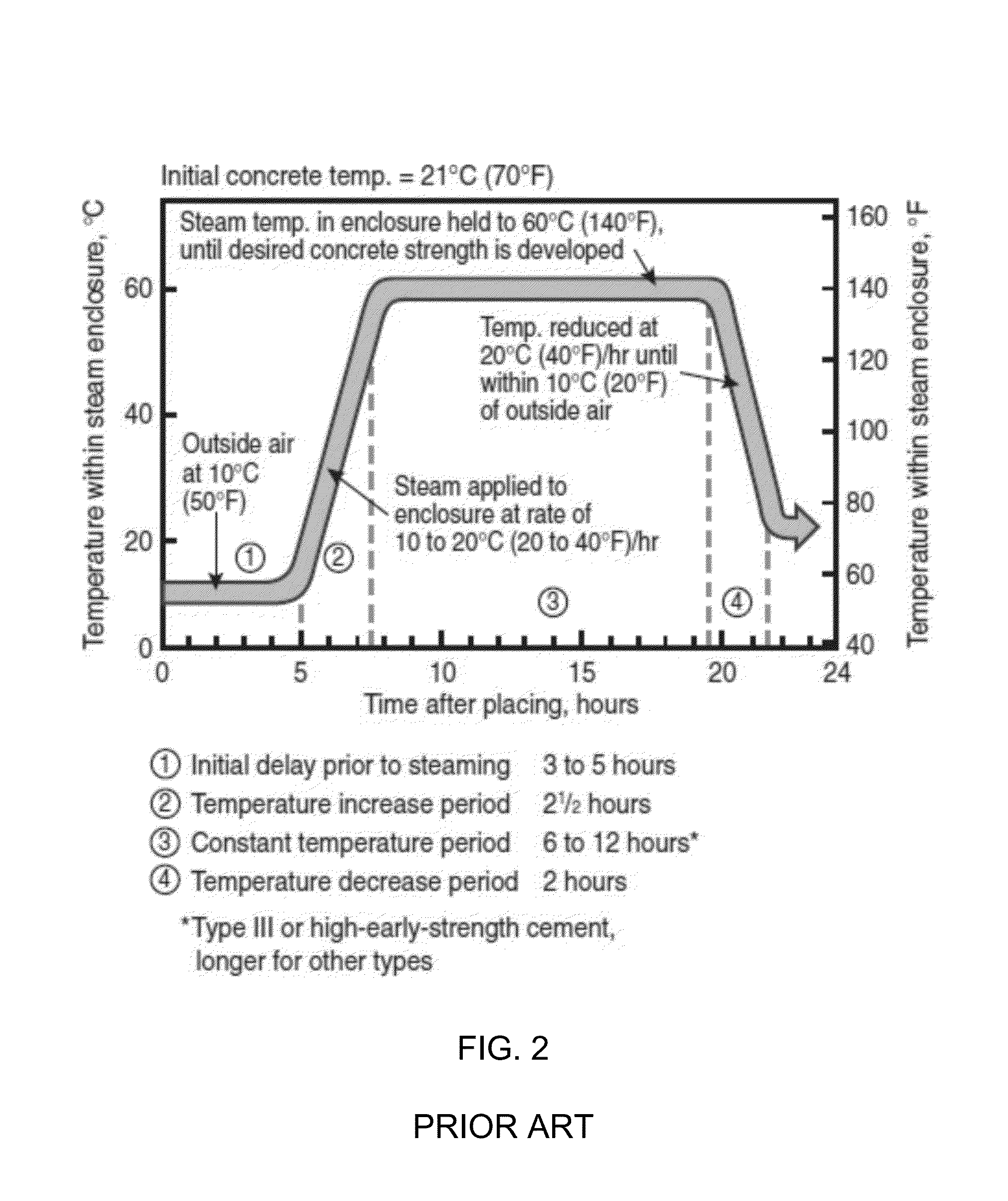

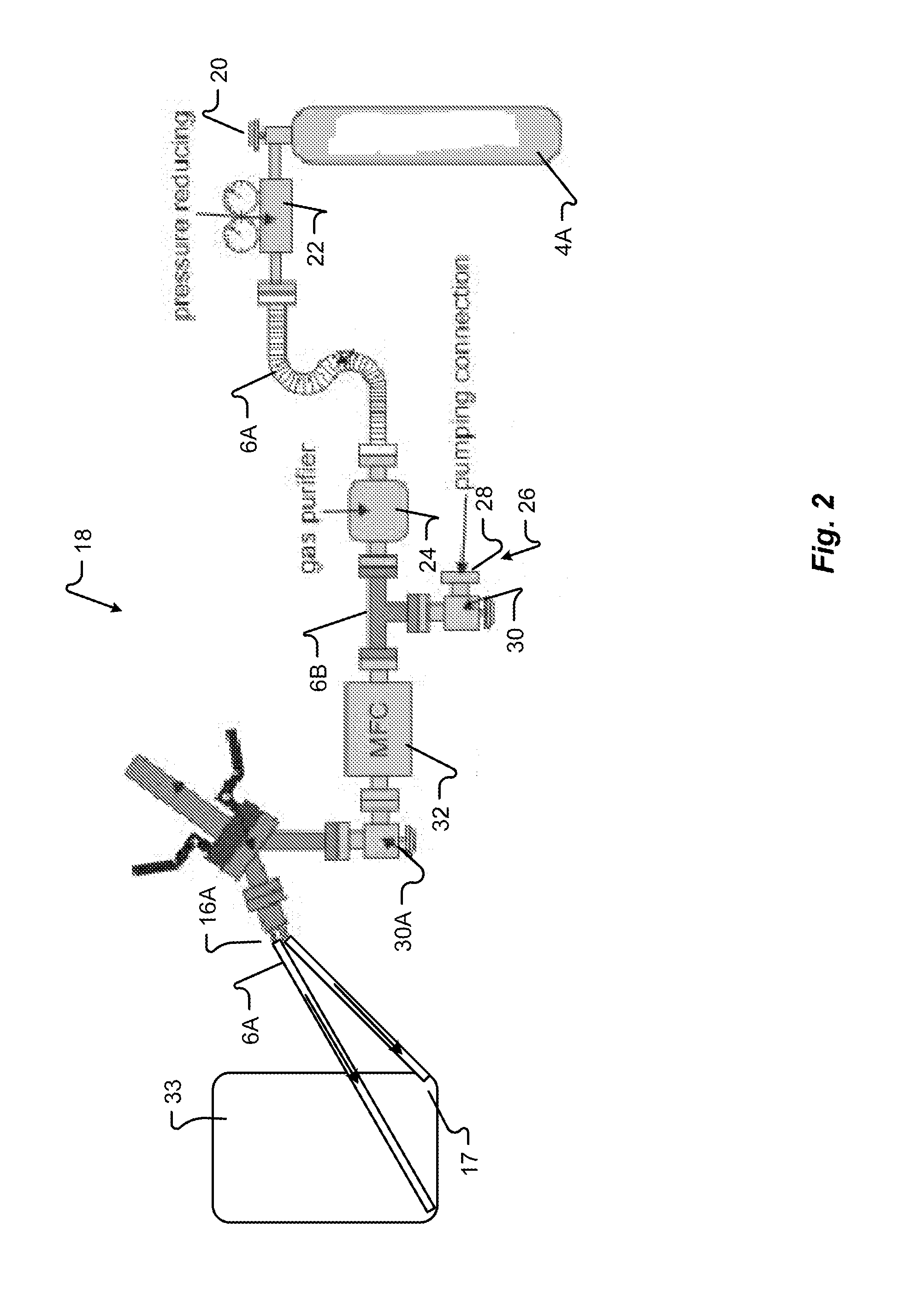

Curing systems for materials that consume carbon dioxide and method of use thereof

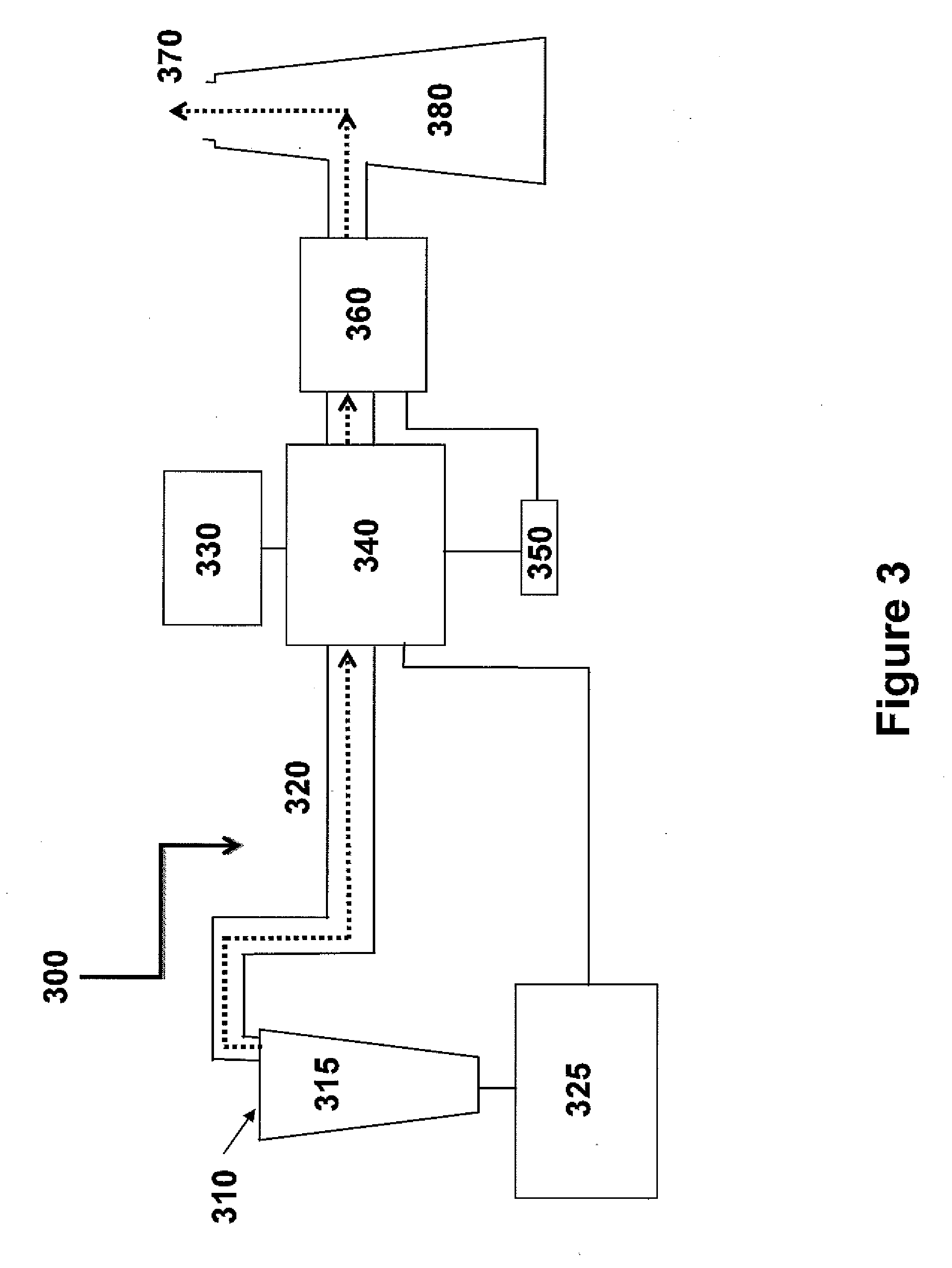

ActiveUS20140322083A1Low costIncrease consumptionMuffle furnacesTemperatue controlProcess engineeringProduct gas

The invention provides a curing system that is useful for curing materials that consume carbon dioxide as a reagent. The system has a curing chamber that contains the material to be cured and a gas that contains carbon dioxide. The system includes apparatus that can deliver carbon dioxide to displace ambient air upon loading the system, that can provide carbon dioxide as it is needed and as it is consumed, that can control carbon dioxide concentration, temperature and humidity in the curing chamber during the curing cycle and that can record and display to a user the variables that occur during the curing process.

Owner:SOLIDIA TECH

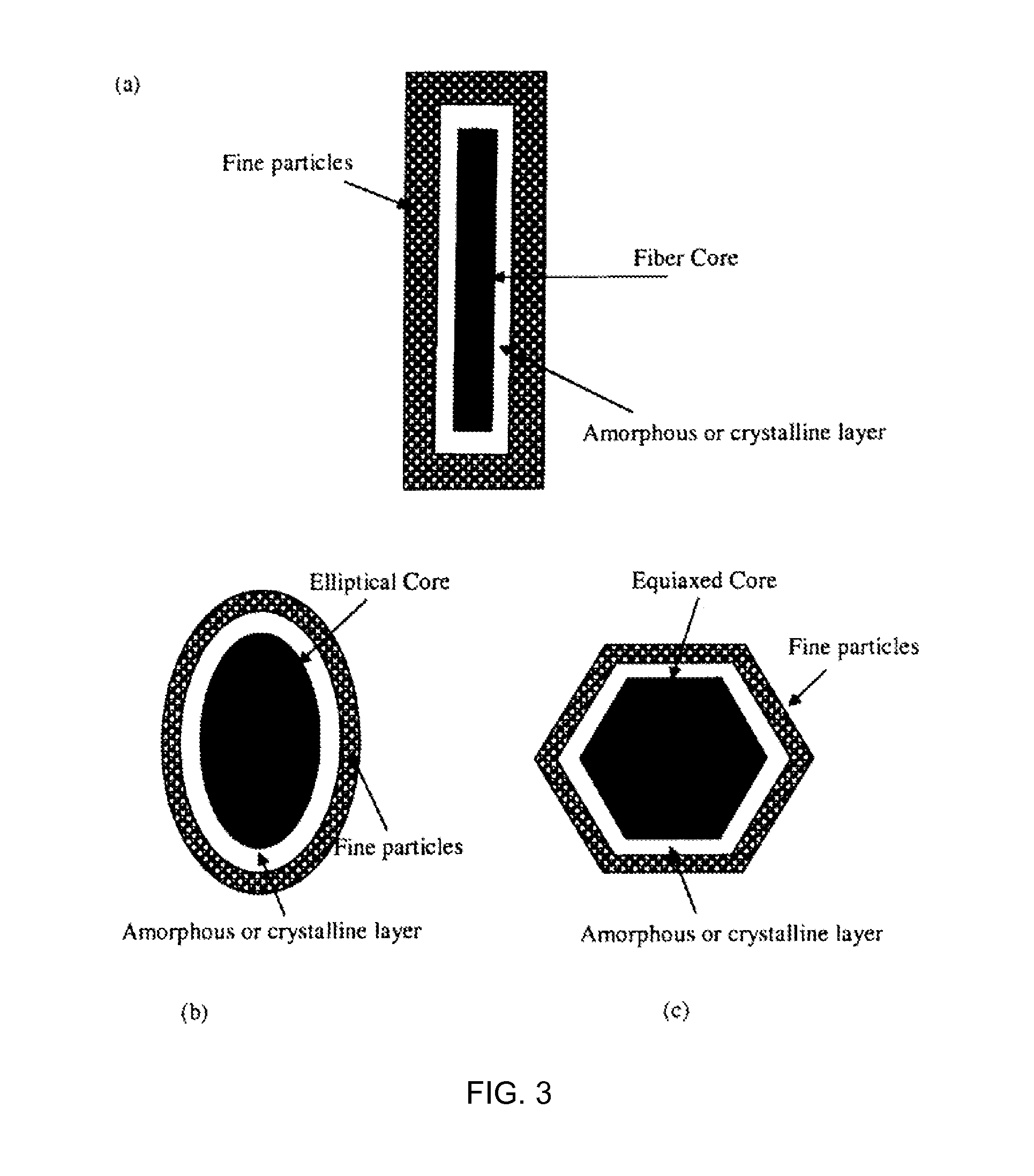

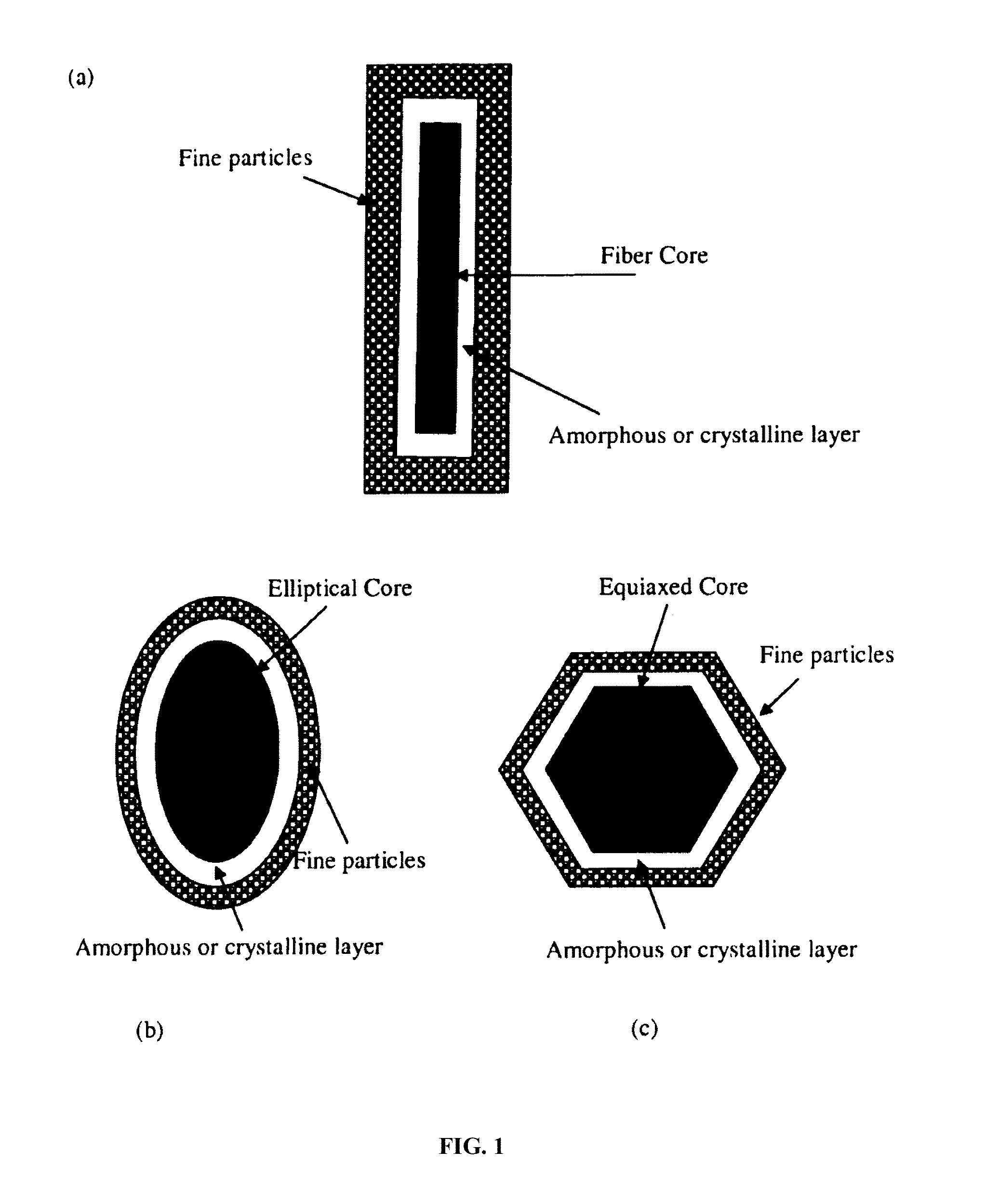

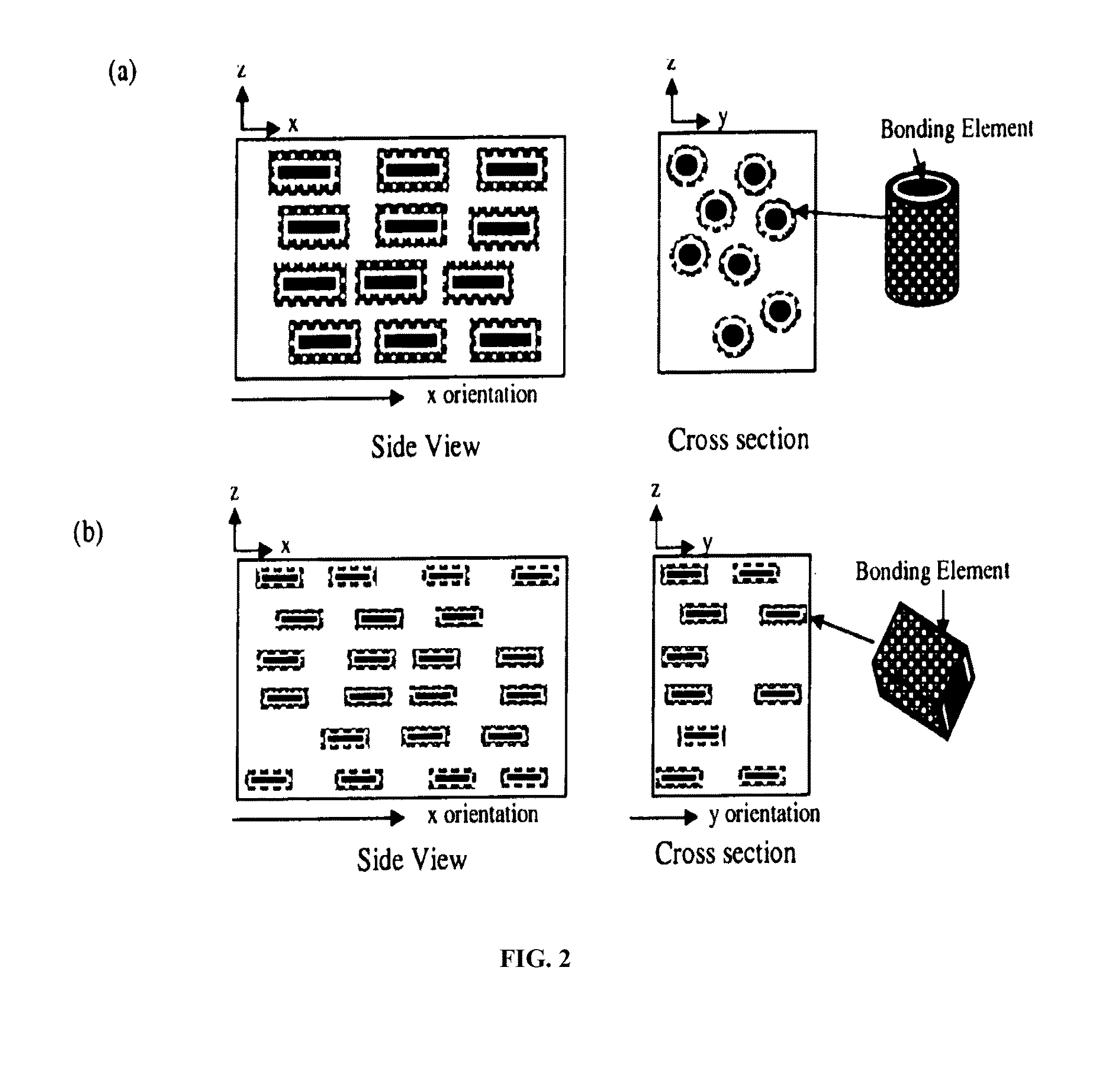

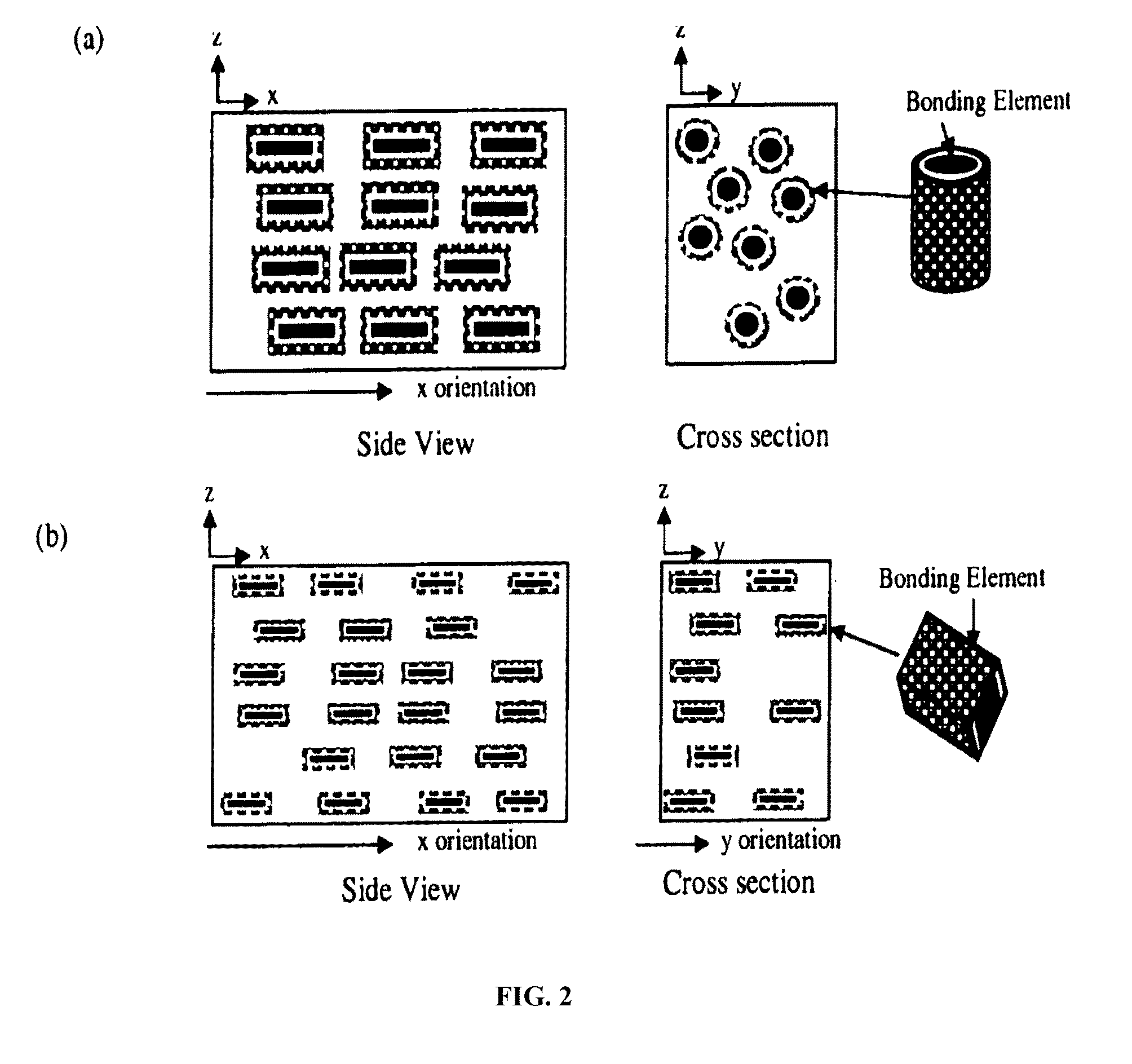

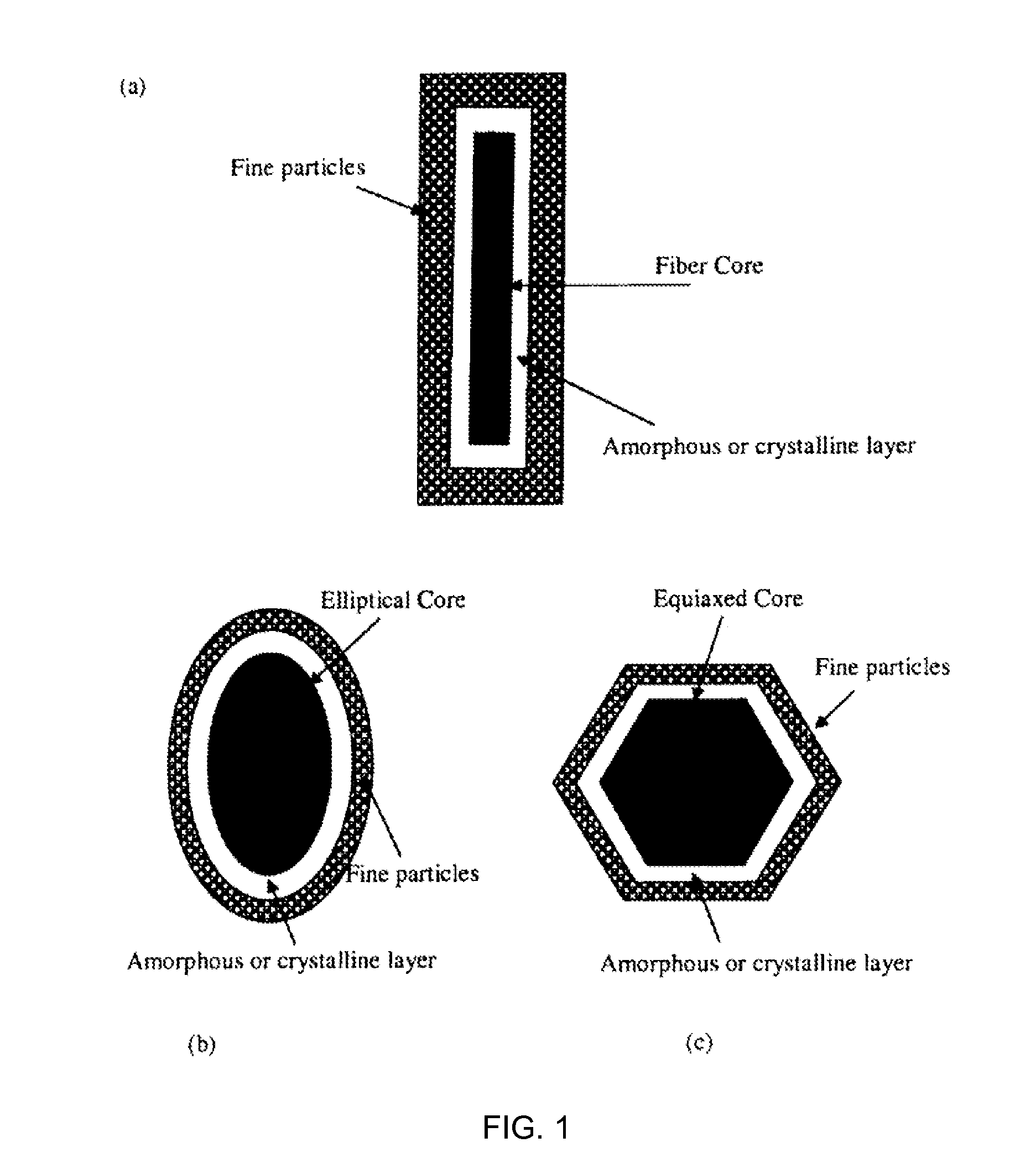

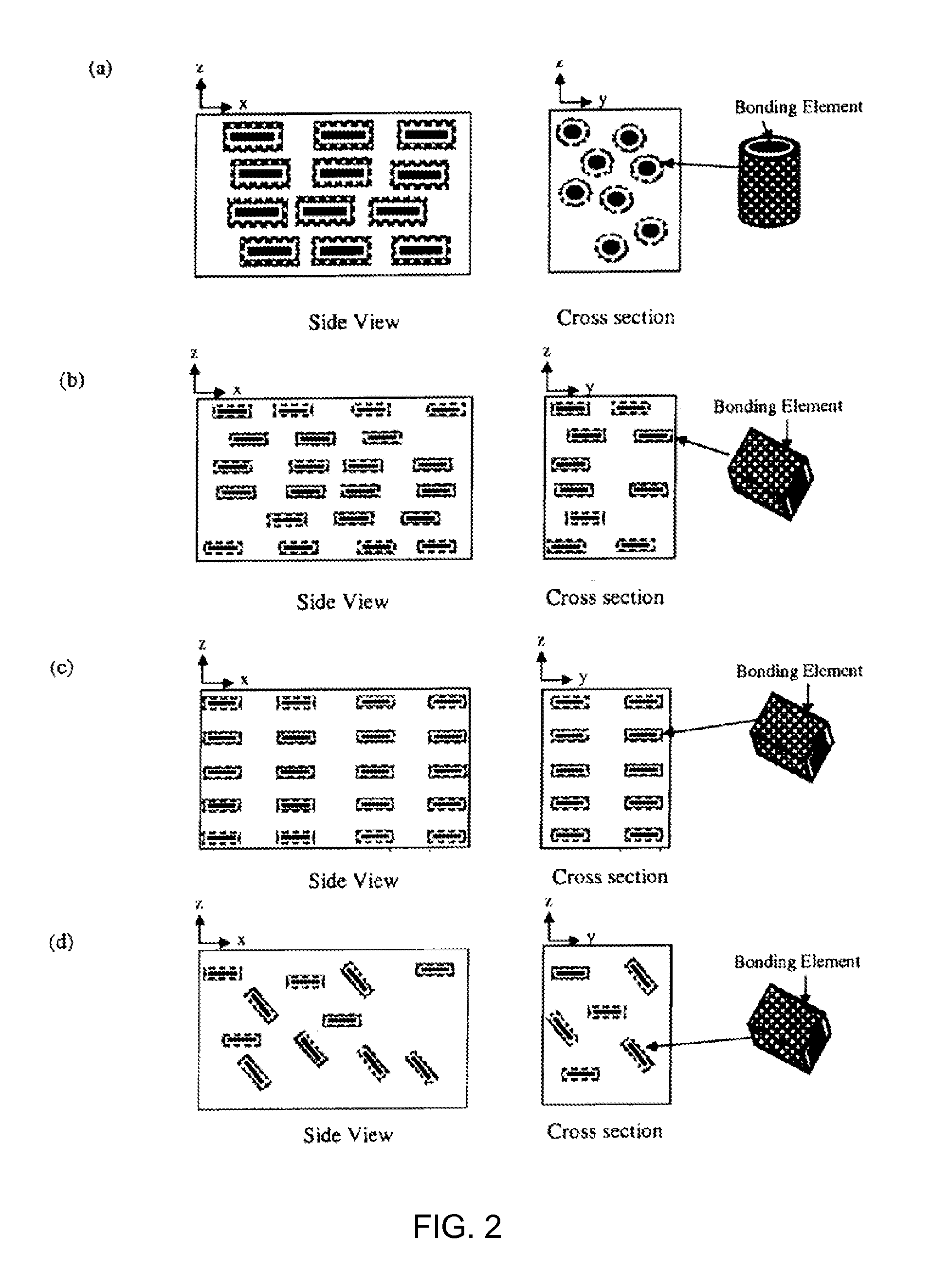

Composite railroad ties and methods of production and uses thereof

ActiveUS20140263683A1Excellent physical and performance characteristicExcellent weatherability and performance characteristicBallastwayCeramic shaping apparatusCarbon footprintMethods of production

The invention provides novel railroad ties manufactured from novel composite materials that possess excellent physical and performance characteristics matching or exceeding existing concrete RRTs. The RRTs of the invention can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production with improved energy consumption and more desirable carbon footprint and minimal environmental impact.

Owner:SOLIDIA TECH

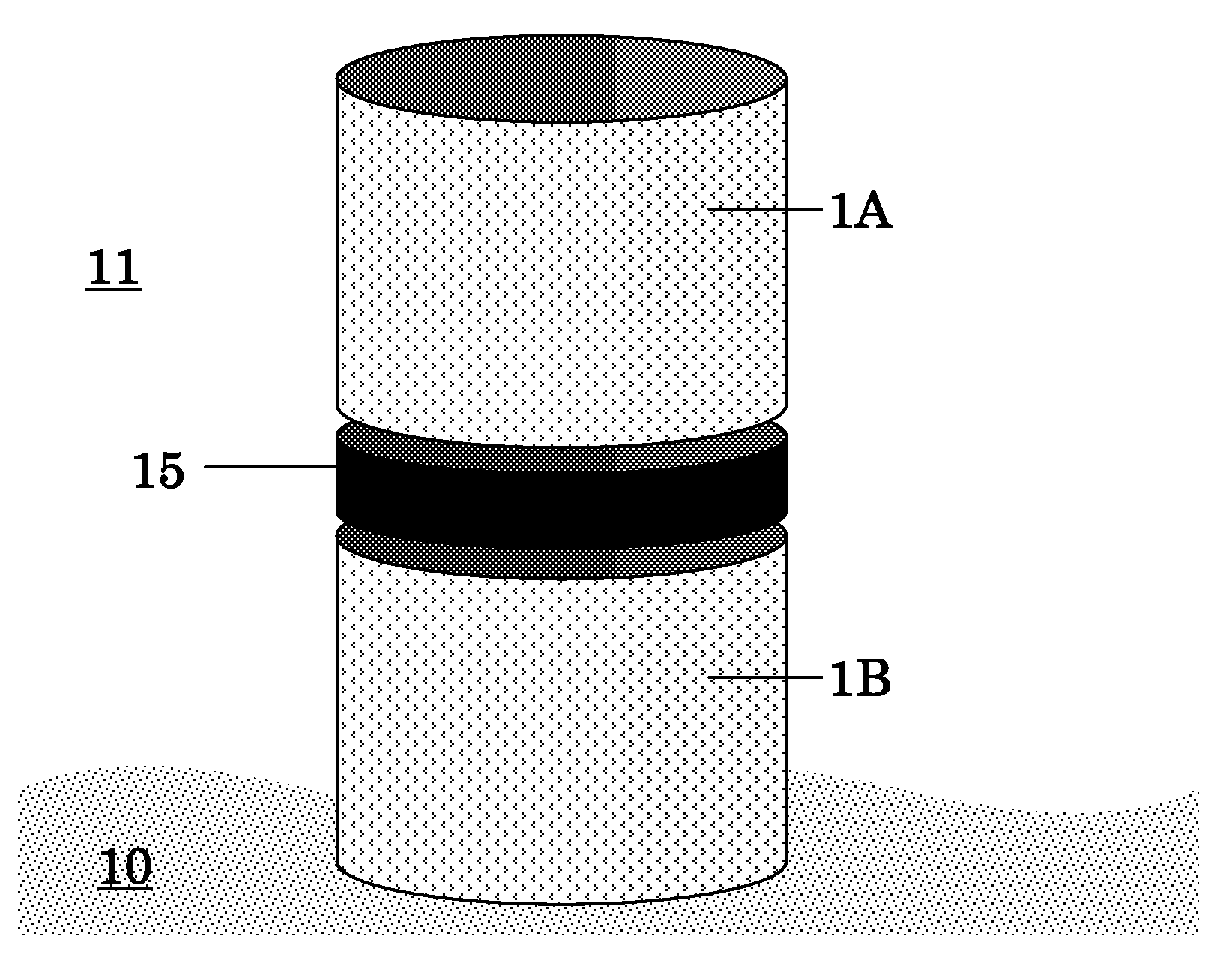

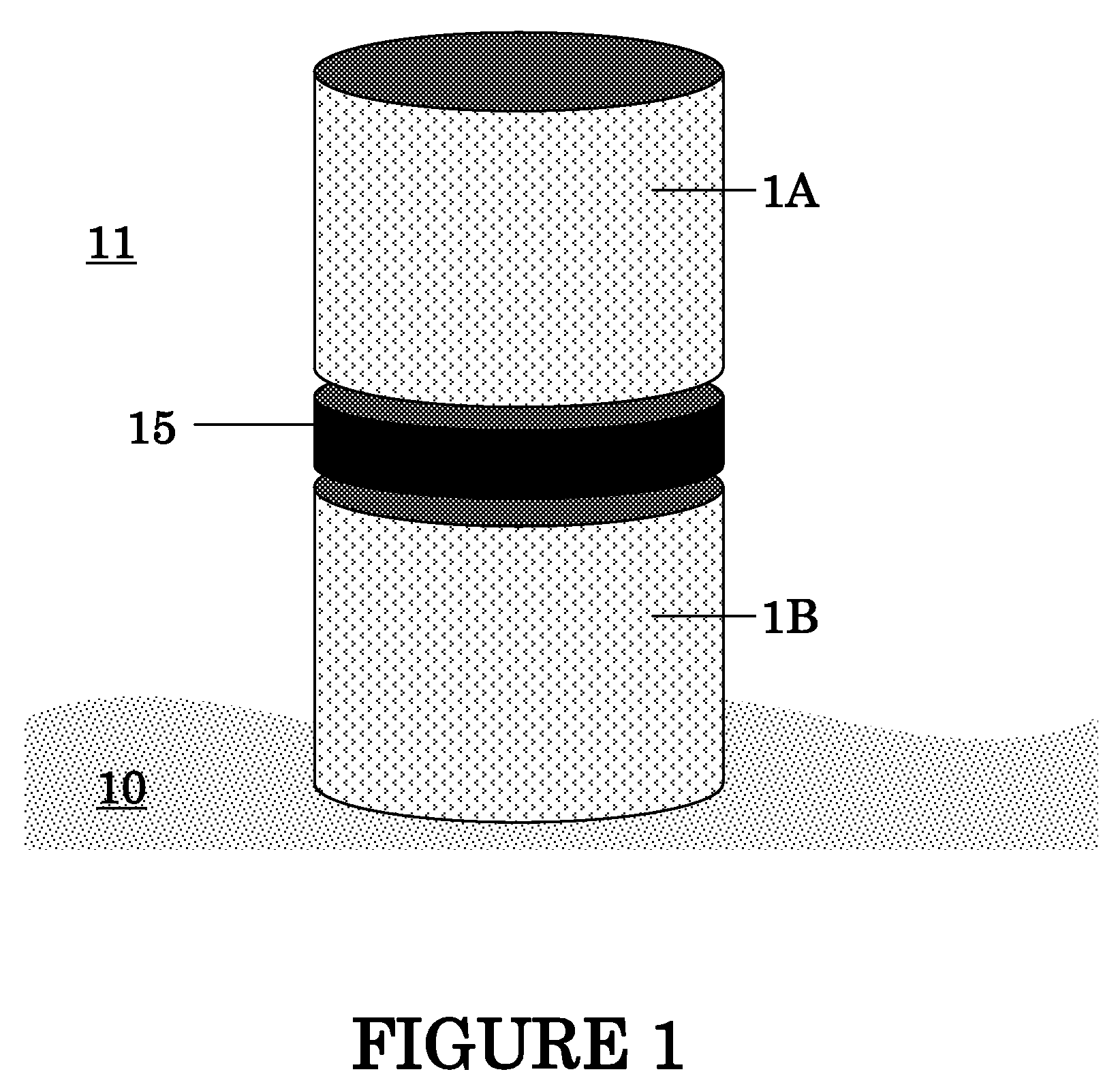

Geopolymer composition and application for carbon dioxide storage

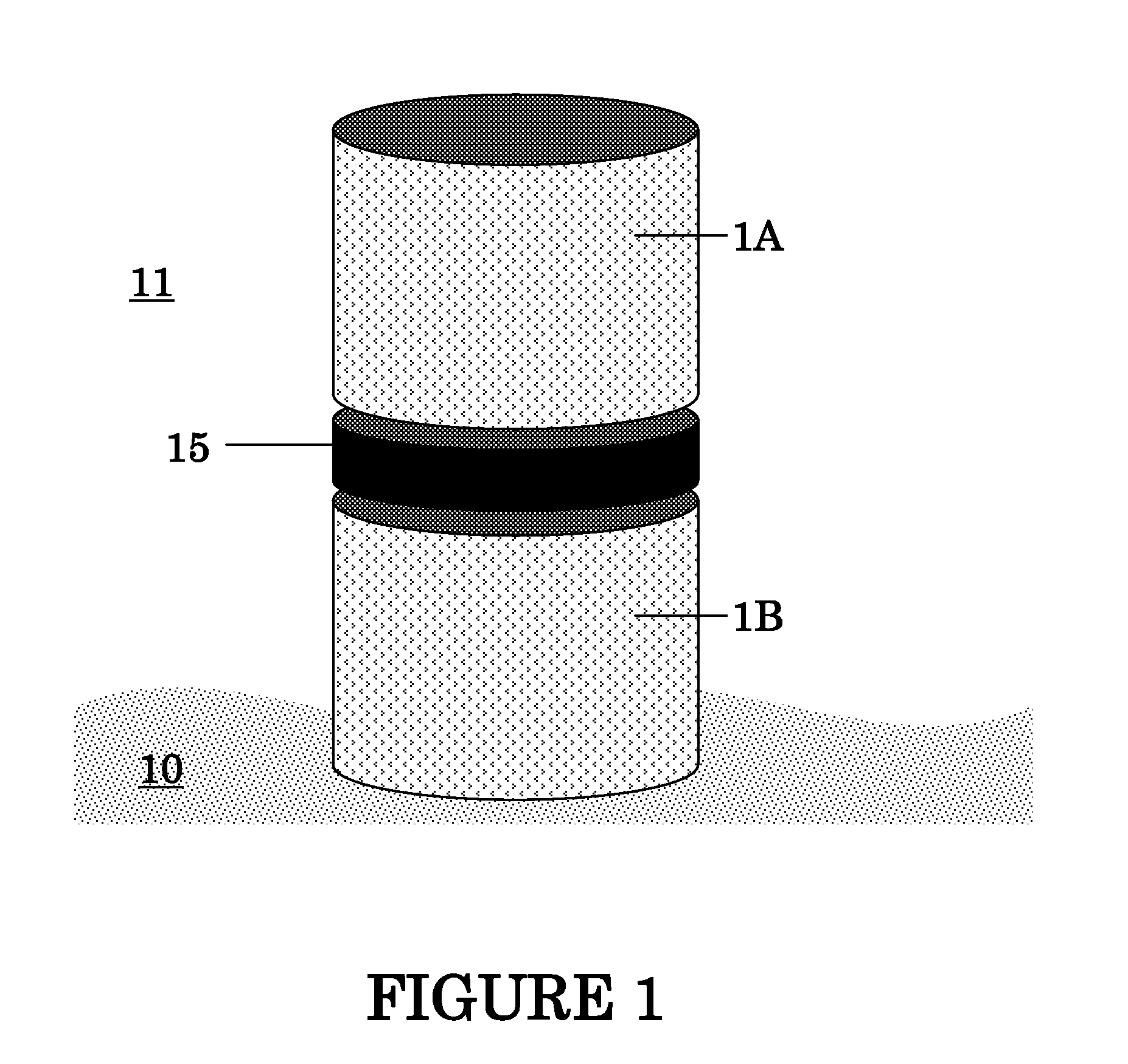

InactiveUS20080028995A1Enhanced pumpabilityImprove stabilityLiquid surface applicatorsSolid waste managementCo2 storageGeopolymer

The invention provides geopolymeric compositions intended for use in carbon dioxide injection or production wells or storage reservoirs and preferably in a supercritical carbon dioxide conditions. The geopolymeric composition is formed from a suspension comprising an aluminosilicate source, a metal silicate, an alkali activator, a retarder and / or an accelerator and a carrier fluid wherein the oxide molar ratio M2O / SiO2 is greater than 0.20 with M an alkali metal.

Owner:SCHLUMBERGER TECH CORP

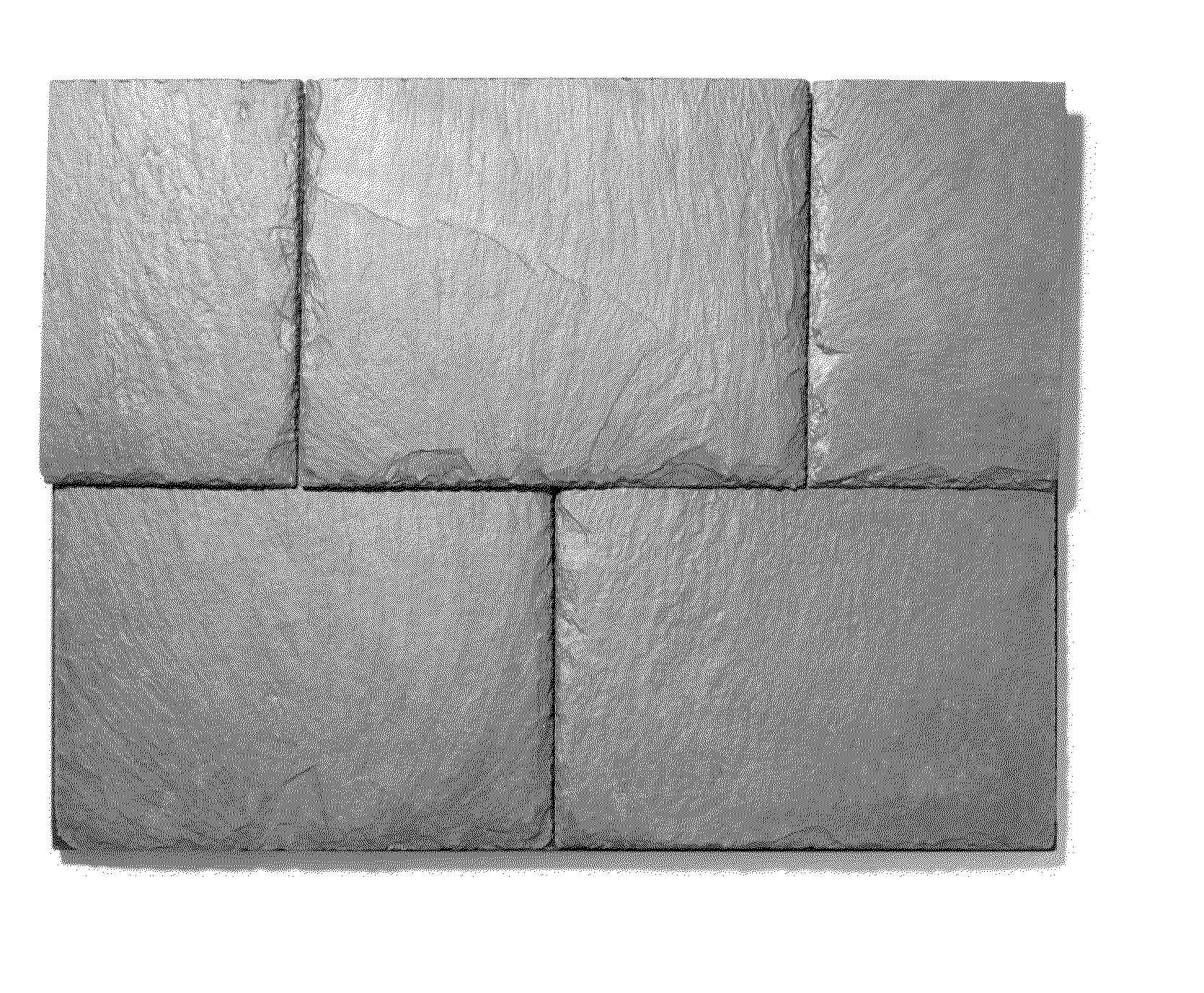

Slate-like composite materials and methods of preparation thereof

InactiveUS20140127458A1Low costIncrease consumptionRoof covering using tiles/slatesRecord information storageCalcium silicateFlexural strength

The invention provides novel slate-like composite materials and methods for preparation thereof. The slate-like composite materials can be readily produced from widely available, low cost precursor materials by a process suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as colored glass, colored sand, and colored quartz particles, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These slate-like composite materials exhibit visual patterns unique to slate as well as display compressive strength, flexural strength and water absorption similar to that of slate.

Owner:ZAMBRZYCKI DAWID +6

Aerated composite materials, methods of production and uses thereof

InactiveUS20140272216A1Excellent physicalExcellent performance characteristicSolid waste managementLayered productsCarbon footprintMethods of production

The invention provides novel aerated composite materials that possess excellent physical and performance characteristics of aerated concretes, and methods of production and uses thereof. These composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production with improved energy consumption, desirable carbon footprint and minimal environmental impact.

Owner:DEO OMKAR +6

Pavers and block composite materials and methods of preparation thereof

ActiveUS20140314990A1Acceptable compressive strengthLow costRecord information storageCeramic shaping apparatusCalcium silicateCOLORED MATERIAL

The invention provides novel paving stones and construction block composite materials and methods for preparation thereof. The paving stones and construction block composite materials can be readily produced from widely available, low cost precursor materials by a production process that involves compacting in a mold that is suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which can comprise silicon dioxide-rich materials. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These paving stones and construction block composite materials exhibit visual patterns similar to stone as well as display compressive strength and water absorption equal to or better than that of stone.

Owner:SOLIDIA TECH

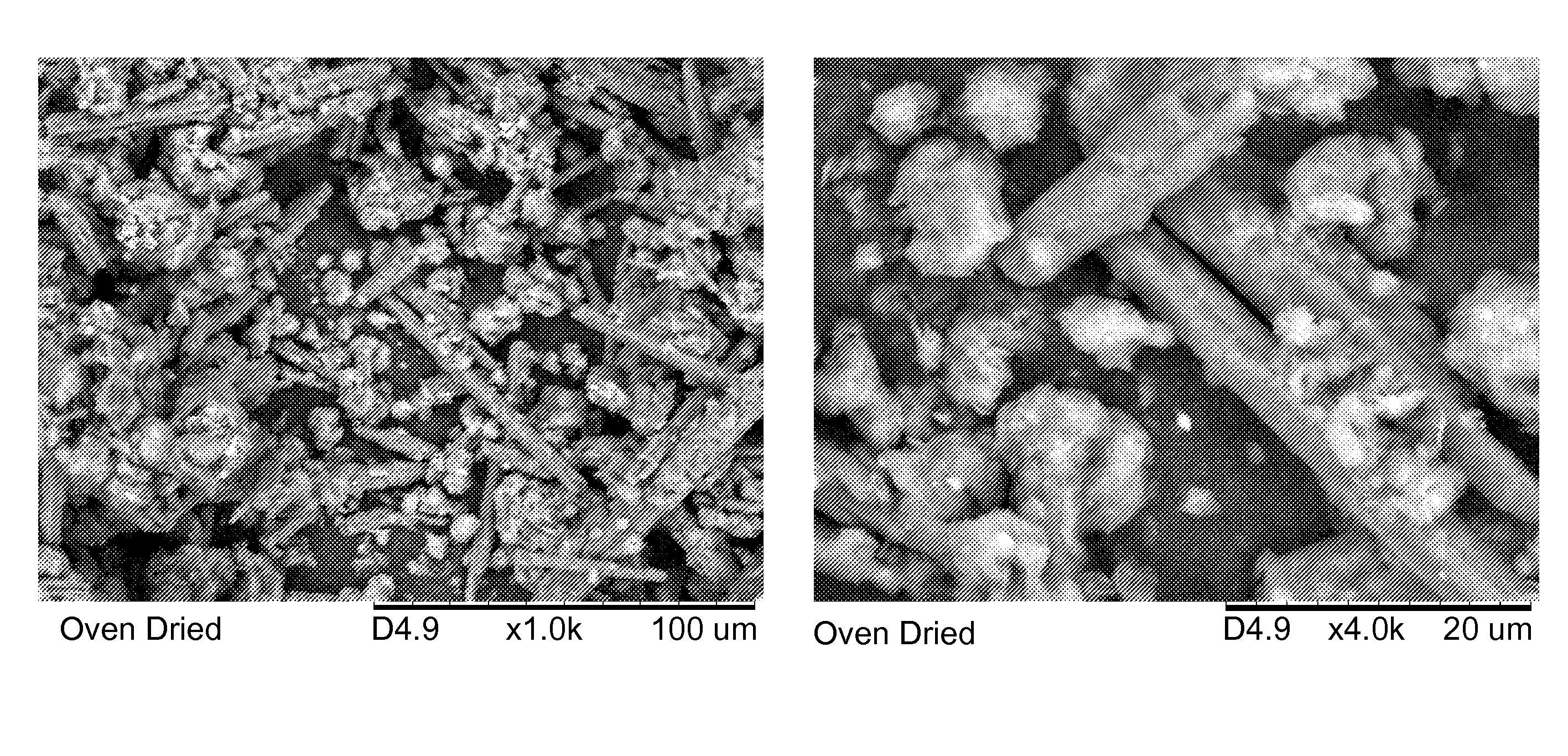

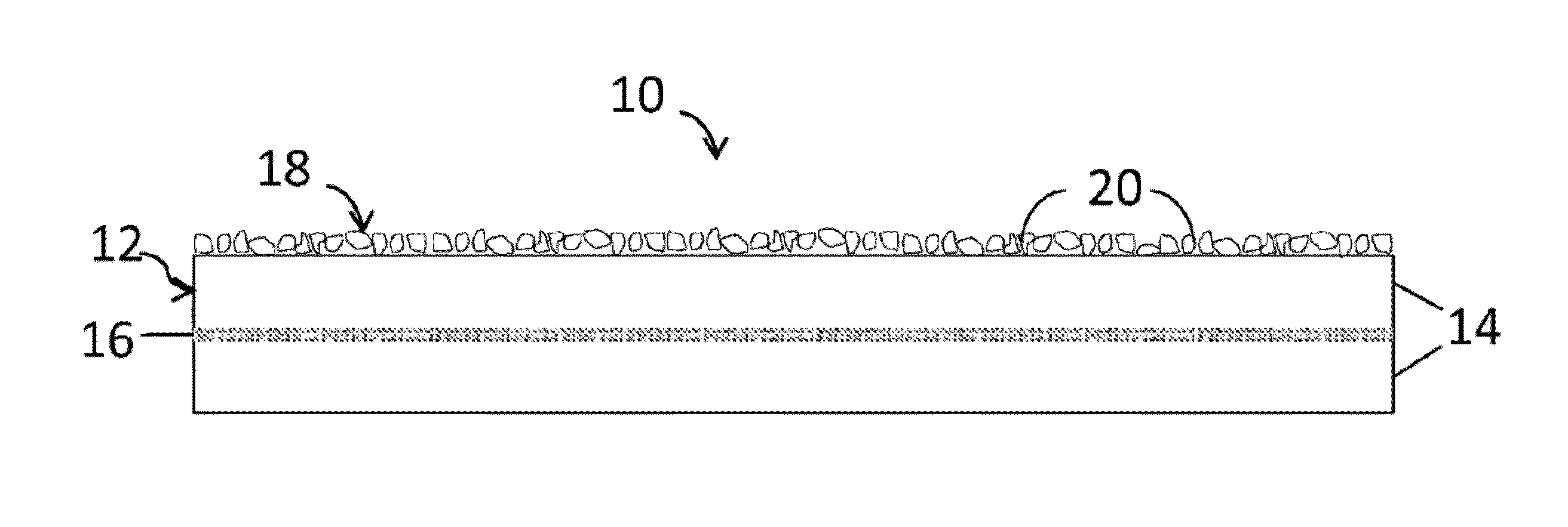

Rapid curing of thin composite material sections

A method of preparing and rapidly curing a composite material having a thin cross section. The composite material includes a mixture of solid particles, at least some of which are a material that reacts with CO2, such as a silicate, for example Wollastonite. The green material is prepared by mixing the solid components with a liquid such as water to form a slurry, and forming green bodies by placing the slurry in forms. The green bodies are reacted with CO2 to form cured composite materials having thin sections, in the range of 10 to 15 mm. Curing in periods of 6 hours has been demonstrated.

Owner:SOLIDIA TECH

Wood-like composite materials and methods of preparation thereof

InactiveUS20140342124A1High compressive strengthLow water absorptionConstruction materialNatural patternsCalcium silicateFlexural strength

The invention provides novel wood-like composite materials and methods for preparation thereof. The wood-like composite materials can be readily produced from widely available, low cost precursor materials by a production process that involves casting in a mold that is suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These wood-like composite materials exhibit visual patterns unique to wood as well as display compressive strength, flexural strength and water absorption superior to that of wood.

Owner:ZAMBRZYCKI DAWID +4

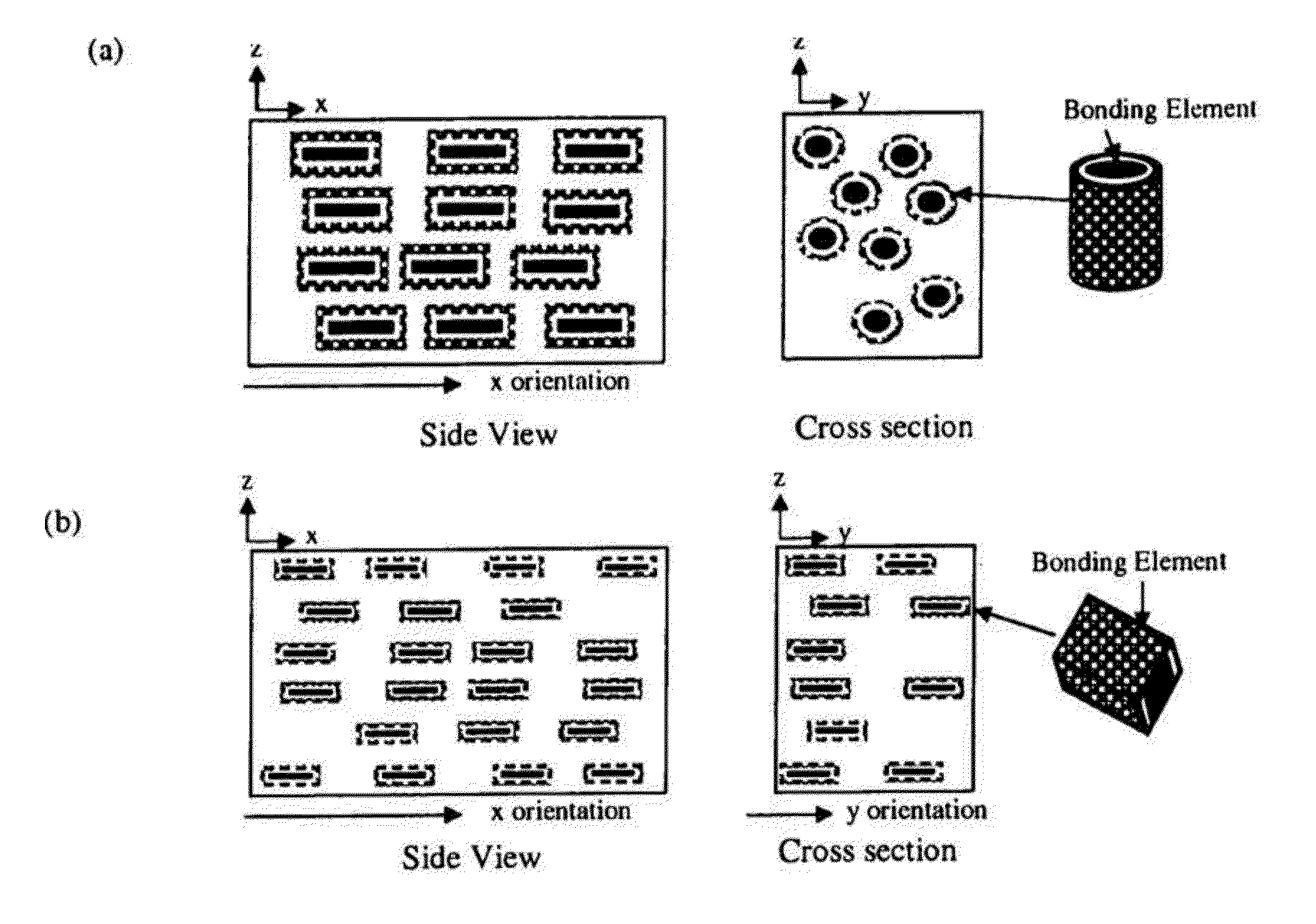

Production of a mainly carbonate bonded article by carbonation of alkaline materials

ActiveUS20110165400A1Avoid crackingLow water absorptionSolid waste managementOther chemical processesPorosityAlkaline earth metal

A method of producing a mainly carbonate bonded article includes a step of providing an alkaline granular material having one or more alkaline earth metal silicate phases. The method includes a step of compacting the granular material to obtain a compact of the granular material. The porosity of the compact is smaller than or equal to 37% by volume. The intrinsic permeability of the compact is at least 1·10−12 cm2. The method also includes a reacting step arranged to form at least 5% by weight of carbonates (CO32−), by reacting the granular material with carbon dioxide in the presence of water, thus transforming the compact into the article. In the reacting step, the compact, being unsaturated with moisture at the beginning of the reacting step, is brought in an atmosphere having carbon dioxide. The atmosphere is at a temperature of at least 70° C. and at a pressure of at least 0.5 MPa. The pressure is also higher than the saturated vapor pressure of water at the temperature. As a result, at least a portion of the carbonates are formed by reaction of the one or more alkaline earth metal silicate phases. Articles are also obtained by the method.

Owner:CARBSTONE INNOVATION

Method and apparatus for curing co2 composite material objects at near ambient temperature and pressure

Apparatus and methods for curing composite compositions that react with CO2. The apparatus in general includes an easily transportable and easily assembled curing structure, such as a plastic sheet housing supported by gas pressure and / or by mechanical supports. Apparatus for providing reagent CO2, for measuring water content and for removing water, and for controlling temperature, flow rates and flow directions through the curing structure. Examples of curing procedures and examples of cured materials in desired shapes are described.

Owner:SOLIDIA TECH

Curing systems for materials that consume carbon dioxide and method of use thereof

ActiveUS9221027B2Low costIncrease consumptionMuffle furnacesDrying gas arrangementsProcess engineeringAmbient air

The invention provides a curing system that is useful for curing materials that consume carbon dioxide as a reagent. The system has a curing chamber that contains the material to be cured and a gas that contains carbon dioxide. The system includes apparatus that can deliver carbon dioxide to displace ambient air upon loading the system, that can provide carbon dioxide as it is needed and as it is consumed, that can control carbon dioxide concentration, temperature and humidity in the curing chamber during the curing cycle and that can record and display to a user the variables that occur during the curing process.

Owner:SOLIDIA TECH

Pervious composite materials, methods of production and uses thereof

ActiveUS20140363665A1Excellent physical and performance characteristicEasy to produceRecord information storageCeramic shaping apparatusEnvironmental effectCarbon footprint

The invention provides novel pervious composite materials that possess excellent physical and performance characteristics of conventional pervious concretes, and methods of production and uses thereof. These composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production with improved energy consumption, desirable carbon footprint and minimal environmental impact.

Owner:SOLIDIA TECH

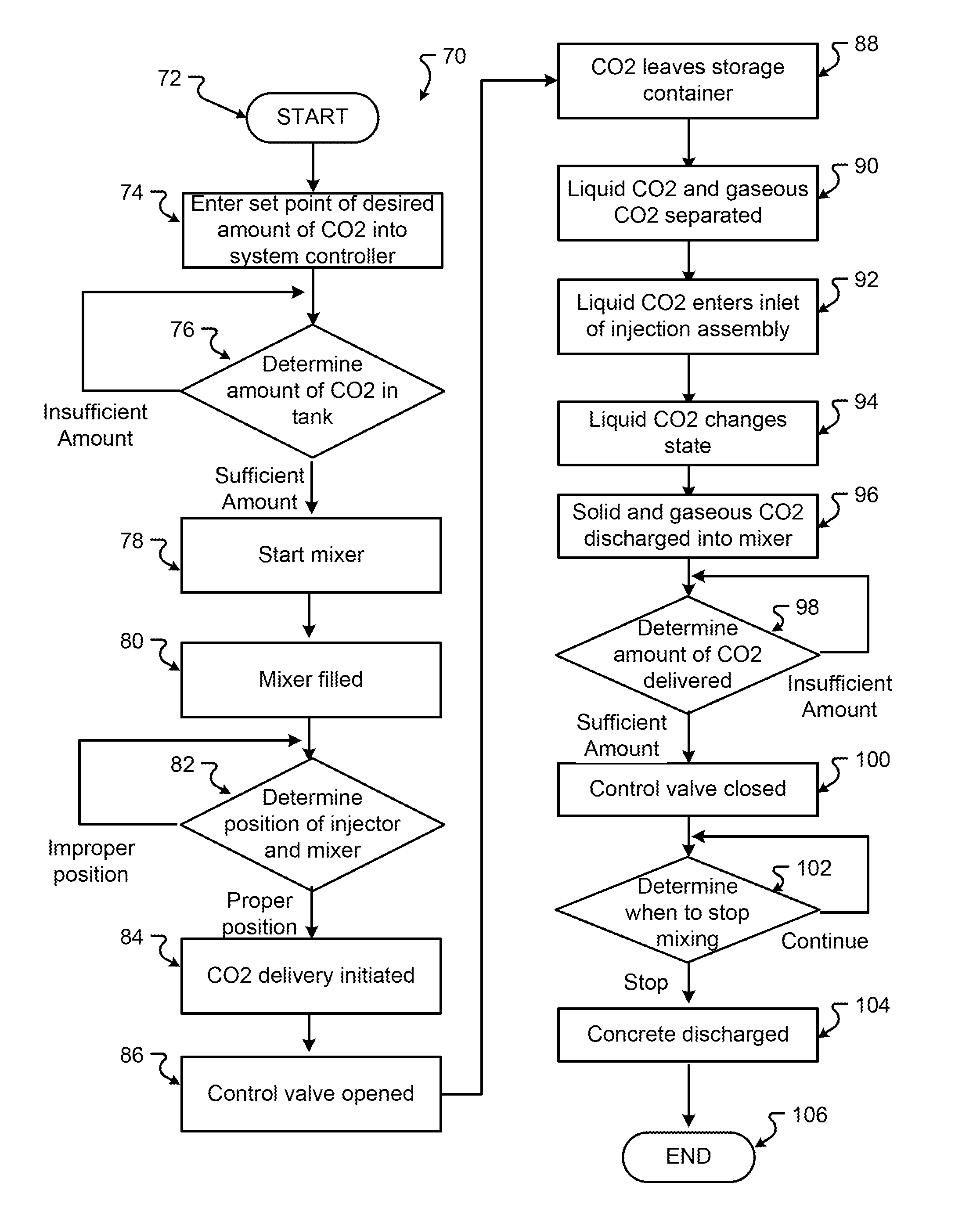

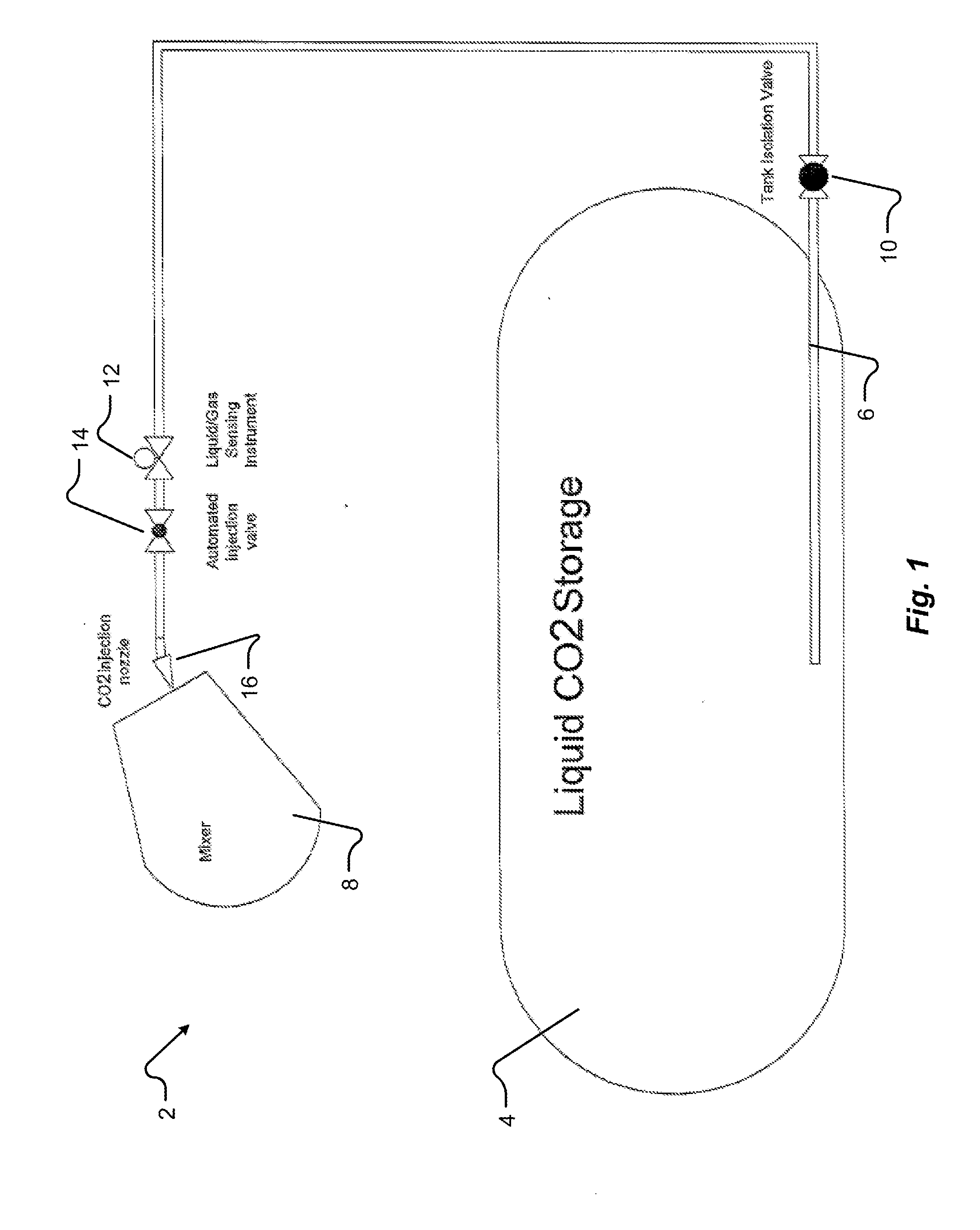

System and method of applying carbon dioxide during the production of concrete

InactiveUS20140216303A1Low costReduce energy consumptionFlow mixersTransportation and packagingMulti materialProcess engineering

The present disclosure involves systems and methods for applying CO2 to concrete, which may be performed in-situ or through a separate, stand-alone process. According to another embodiment disclosed herein, a system and method for applying CO2 to one or more materials used in the production of concrete is also provided.

Owner:CARBONCURE TECH

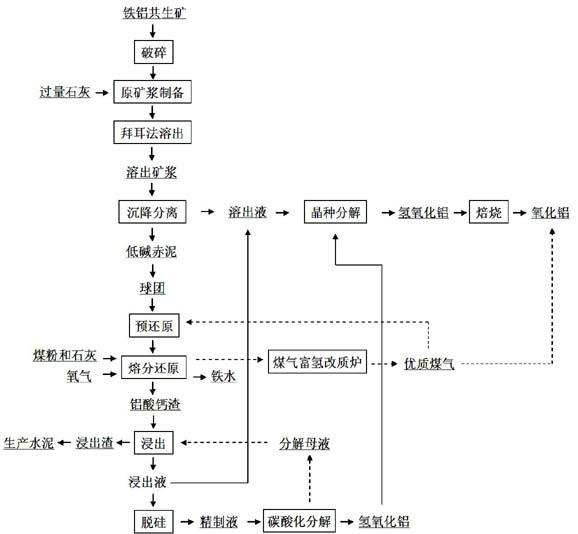

Comprehensive utilization method of high-ferrum and low-grade bauxite

ActiveCN102583477AReduce alkalinityHigh dissolution rateAluminium oxide/hydroxide preparationCarbon captureRotary furnaceCalcium aluminate cements

A comprehensive utilization method of high-ferrum and low-grade bauxite belongs to the technical of metallurgy and is carried out according to the steps as follows: a large proportion of aluminium oxide is extracted through a Bayer process technology that excess lime is added, produced low-alkali red mud is pre-reduced through a coal-based rotary furnace process technology, then high-temperature melting separation of aluminium slag / ferrum is realized by adopting a ferrum bath oxygen coal jetting technology, formed aluminium slag generates calcium aluminate cement after being quenched and tempered, calcium aluminate cement slag is leached with low sodium carbonate solution, a part of leached crude solution and digestion slurry by the Bayer process are mixed and enter a Bayer process system to extract aluminium oxide, and the other part is desilicated and then is resolved in a carbonation manner, aluminum hydrate, which is the decomposition product, is conveyed to the Bayer process system as seed crystal, and resolved mother liquid is used for leaching calcium aluminate cement slag after being mixed. The method provided by the invention can not only ensure efficient dissociation extraction of ferrum and aluminium, but also be practicable in technology and economic benefit, thereby comprehensively utilizing high-ferrum bauxite resource of China effectively.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

Geopolymer composition and application for carbon dioxide storage

InactiveUS7846250B2Good pumpability and stabilitySolid waste managementAlkali metal silicate coatingsCo2 storageGeopolymer

The invention provides geopolymeric compositions intended for use in carbon dioxide injection or production wells or storage reservoirs and preferably in a supercritical carbon dioxide conditions. The geopolymeric composition is formed from a suspension comprising an aluminosilicate source, a metal silicate, an alkali activator, a retarder and / or an accelerator and a carrier fluid wherein the oxide molar ratio M2O / SiO2 is greater than 0.20 with M an alkali metal.

Owner:SCHLUMBERGER TECH CORP

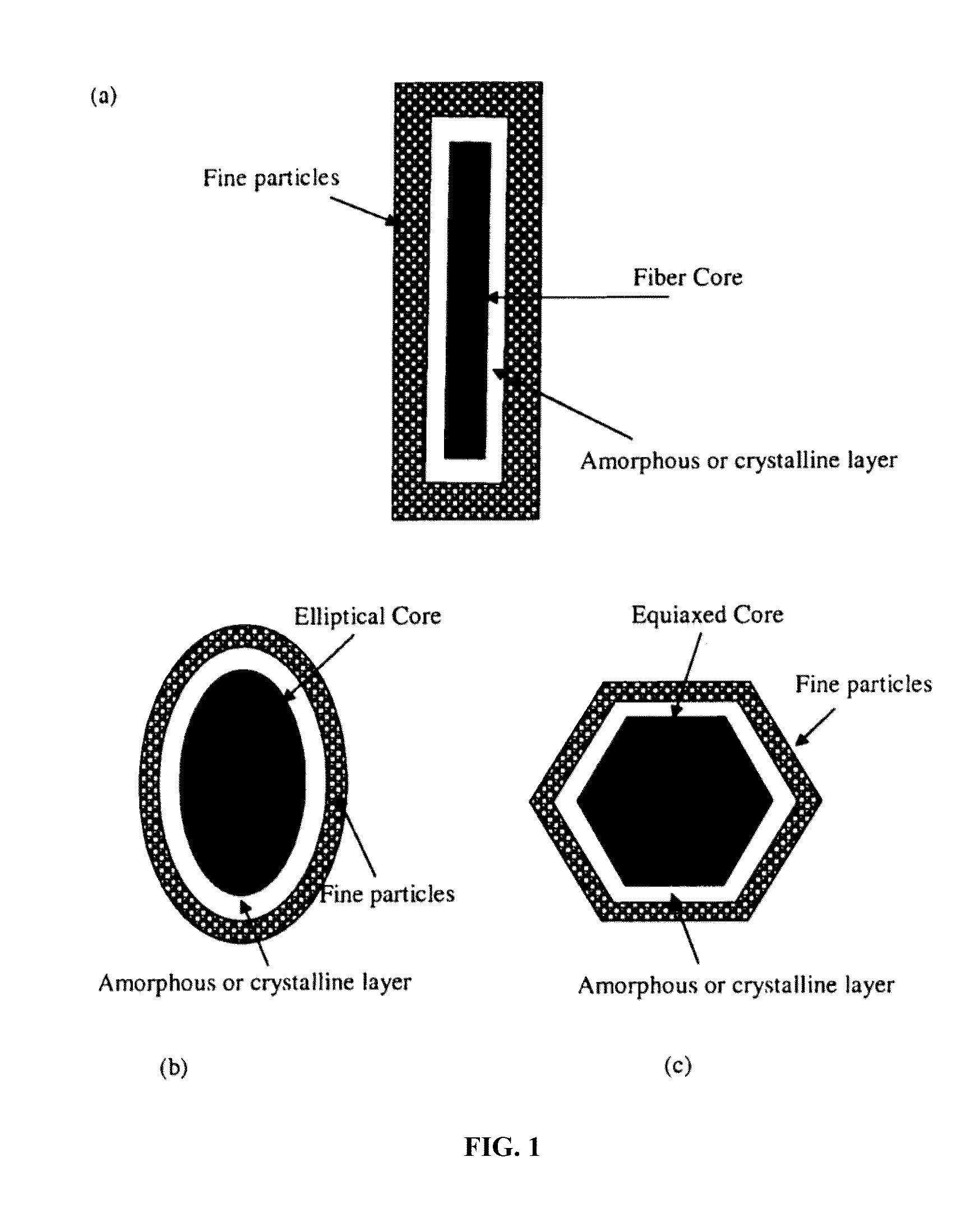

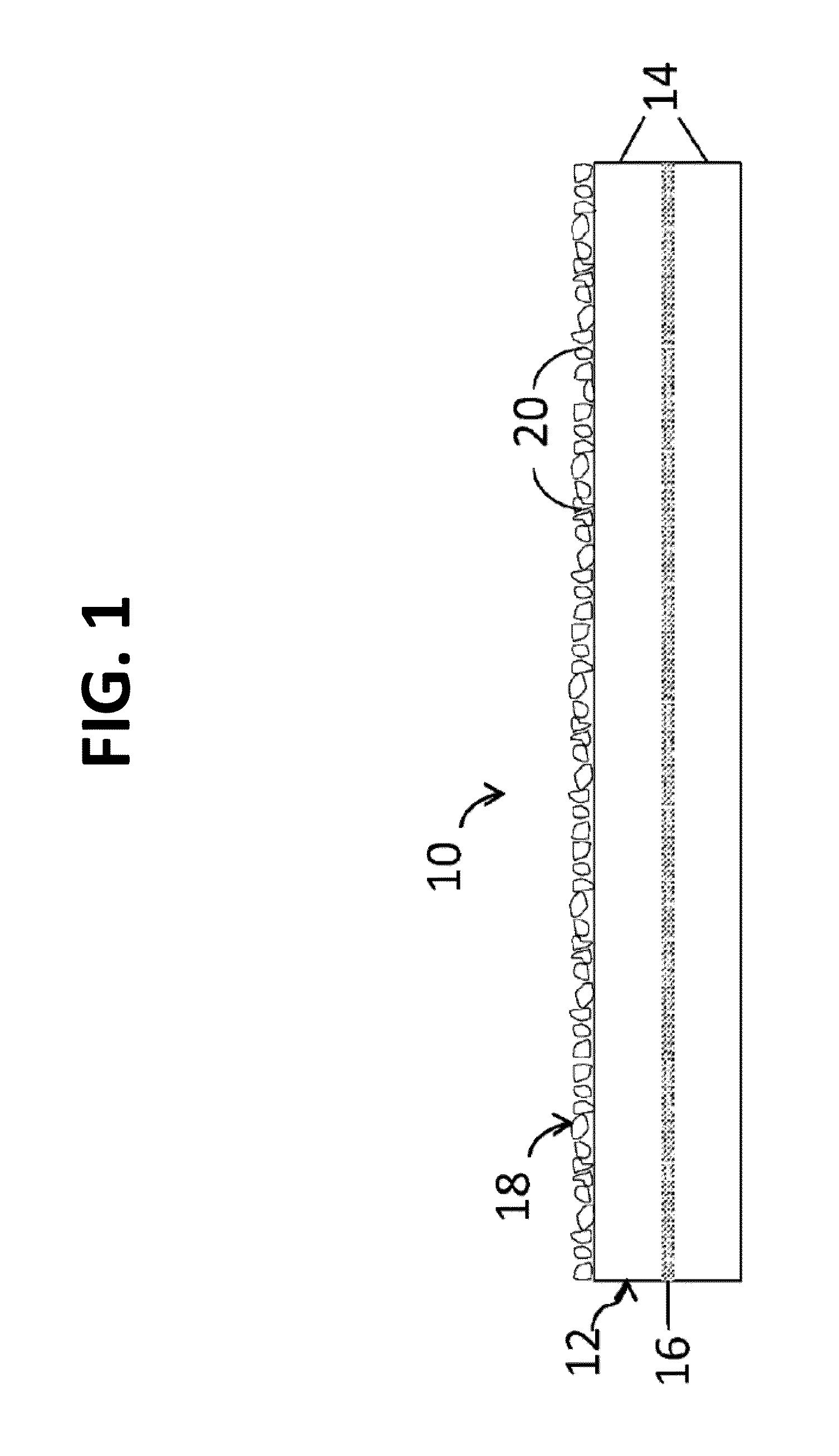

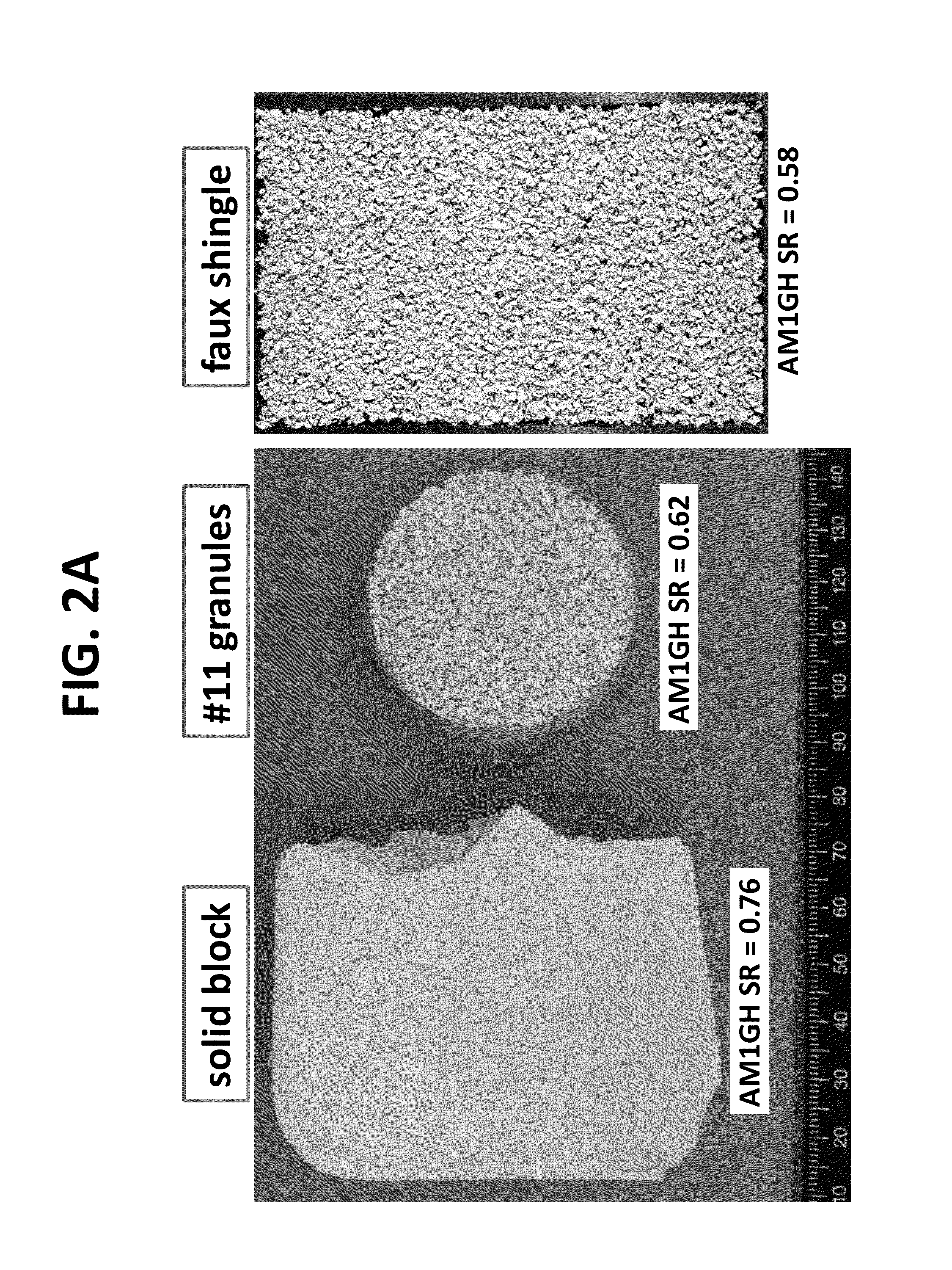

Highly reflective microcrystalline/amorphous materials, and methods for making and using the same

ActiveUS20140271440A1Increase in albedoMitigate the urban heat island effectCalcium/strontium/barium carbonatesPigmenting treatmentAlbedoCarbonate

Compositions comprising highly reflective microcrystalline / amorphous materials are provided. In some instances, the highly reflective materials are microcrystalline or amorphous carbonate materials, which may include calcium and / or magnesium carbonate. In some instances, the materials are CO2 sequestering materials. Also provided are methods of making and using the compositions, e.g., to increase the albedo of a surface, to mitigate urban heat island effects, etc.

Owner:BLUE PLANET SYST CORP

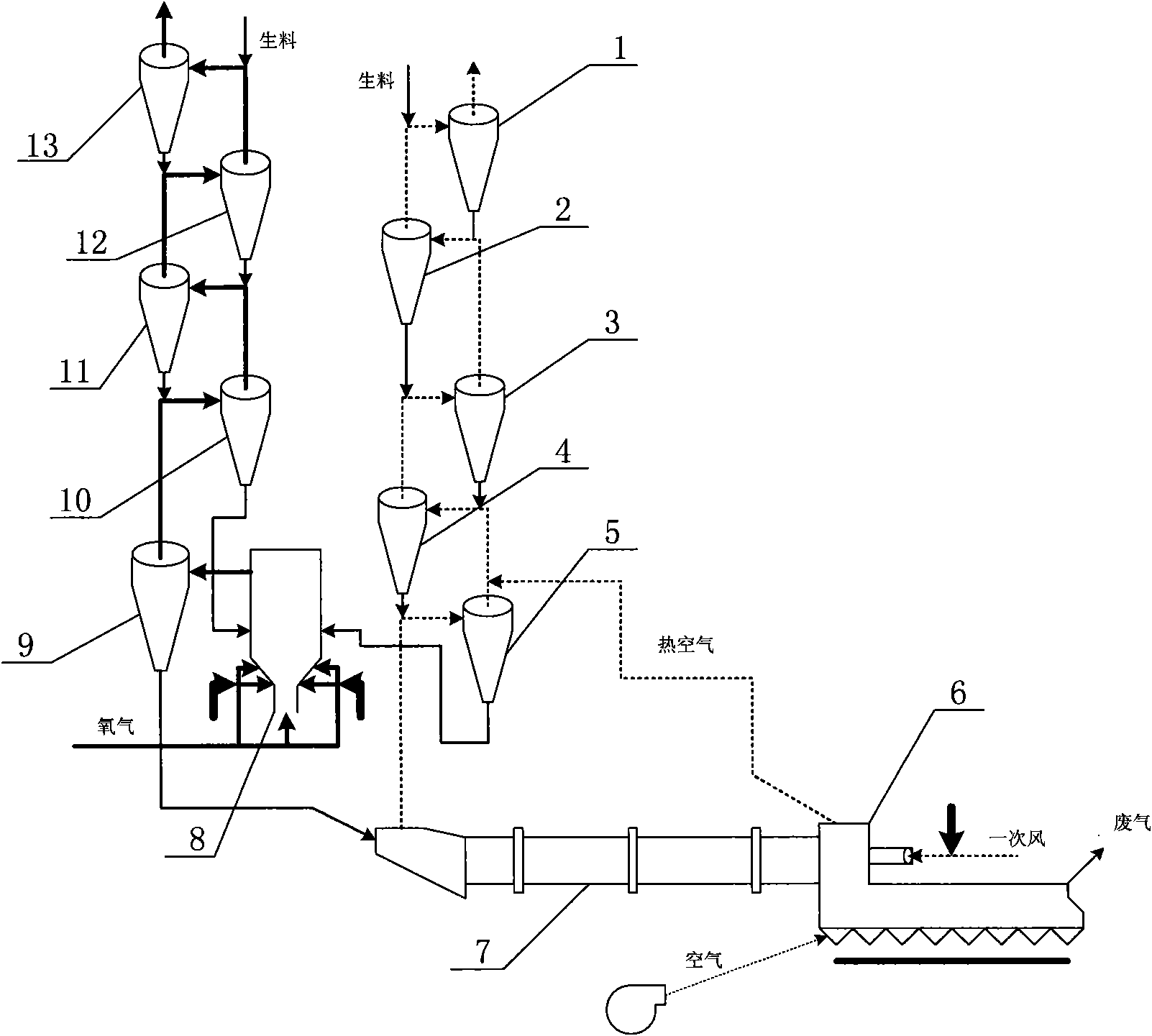

Method for producing partial full-oxygen type cement suitable for separation and collection of CO2

The invention discloses a method for producing partial full-oxygen type cement suitable for separation and collection of CO2, which is a cement production process combining a process of pre-decomposing cement raw materials by using full-oxygen combustion and a process of baking clinkers by using conventional heated air combustion and can effectively solve the problems of the separation and collection of the CO2 in the cement production process. The raw materials subjected to the decomposition of carbonate in a decomposing furnace are separated through a fifth-stage cyclone and enter a rotary kiln, and the combustion way of the rotary kiln is different from the conventional way; the other part of heated air is discharged by a grate cooler to serve as secondary air for combustion, wherein the temperature of the firing zone in the kiln reaches 1,800 DEG C; the heat from fuel combustion is transmitted to materials; the materials are calcined into clinkers; the clinkers from the rotary kiln enter the grate cooler and then enter a rear material receiving device after being cooled; smoke from the rotary kiln enters a right five-stage preheater and is mixed with the heated air from the grate cooler at the output of the five-stage preheater; and the mixed air enters a fourth-stage preheater, gradually rises and is discharged from the top of a first-stage preheater to an exhaust gas processing system.

Owner:SOUTHEAST UNIV

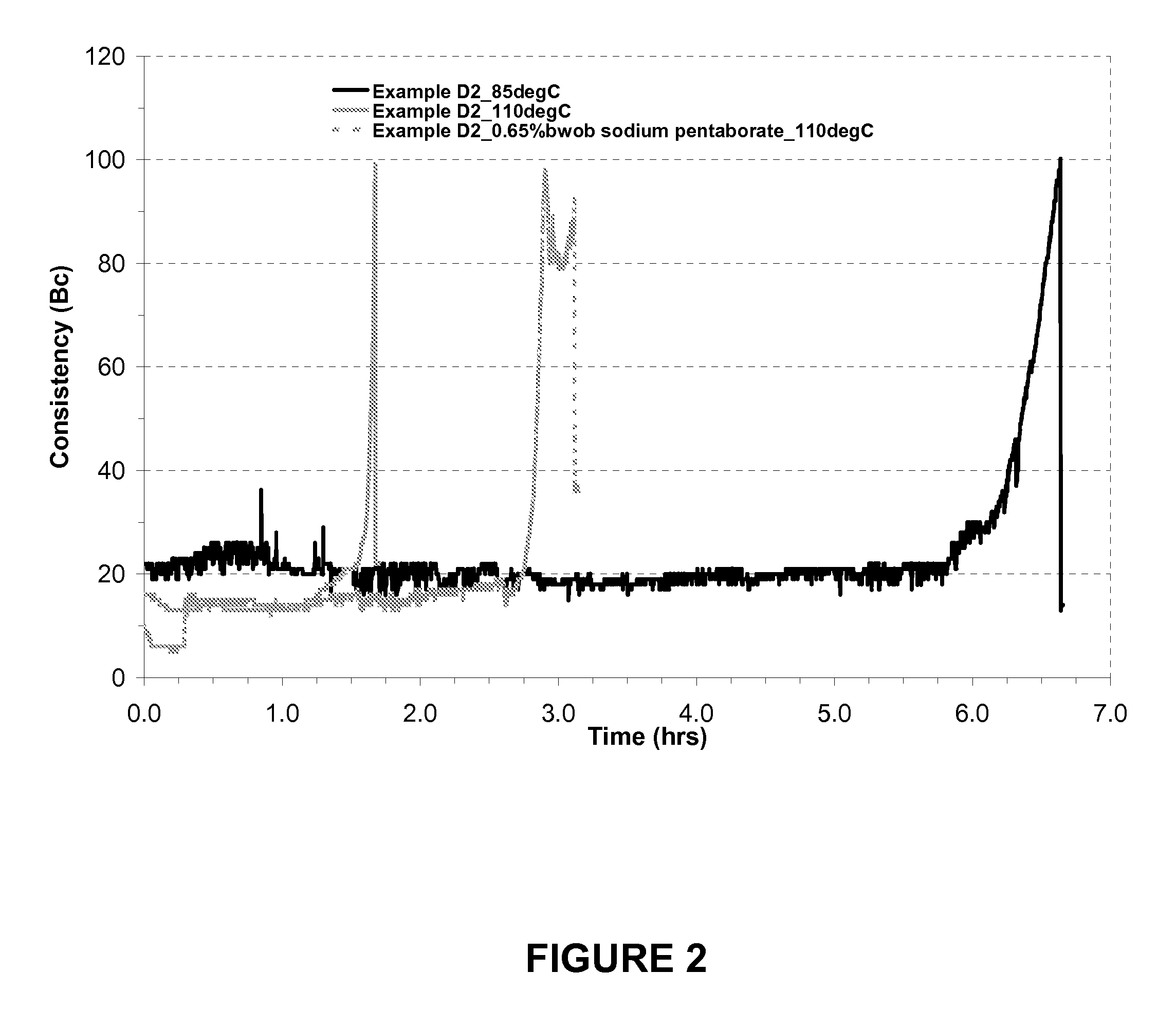

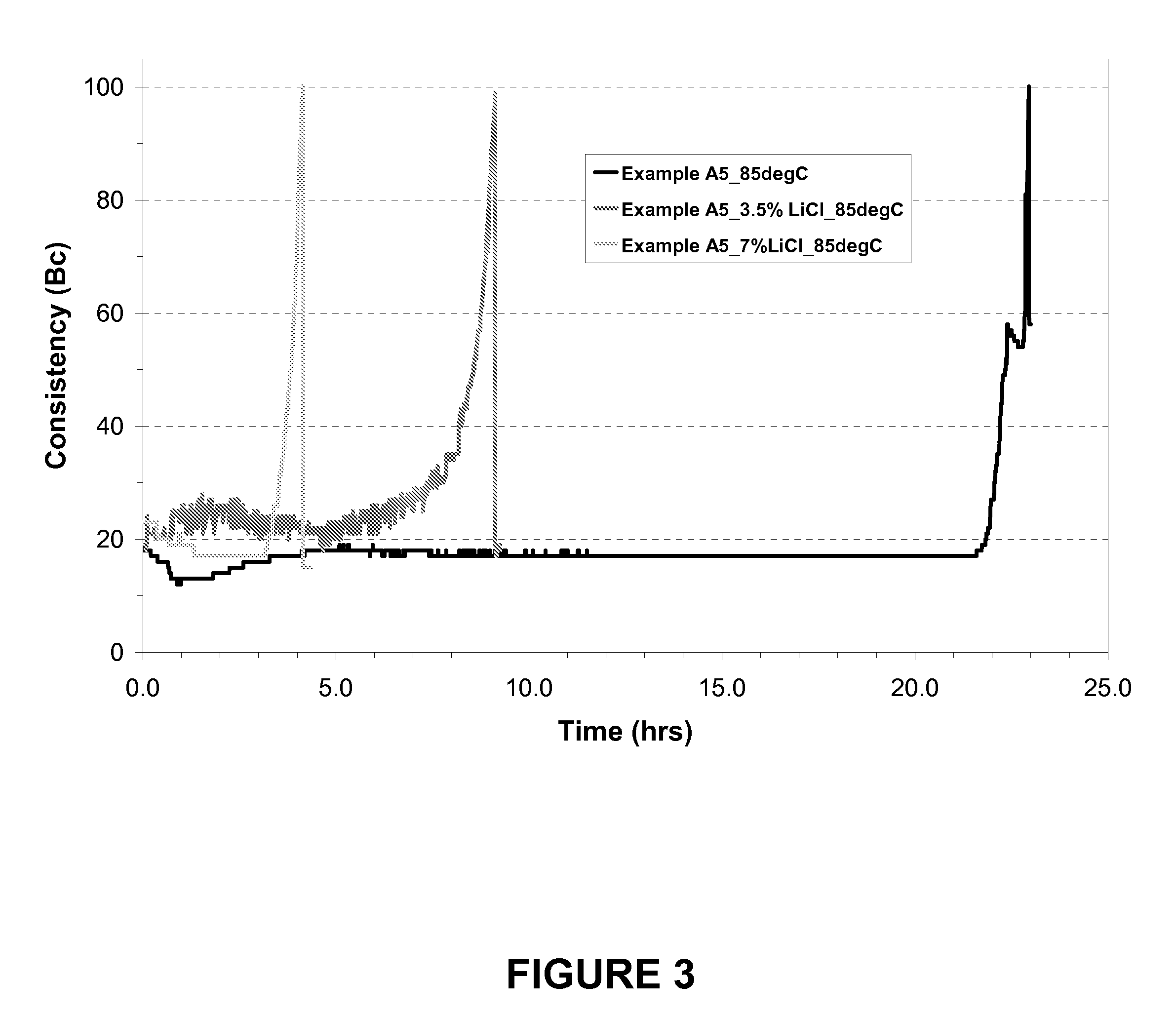

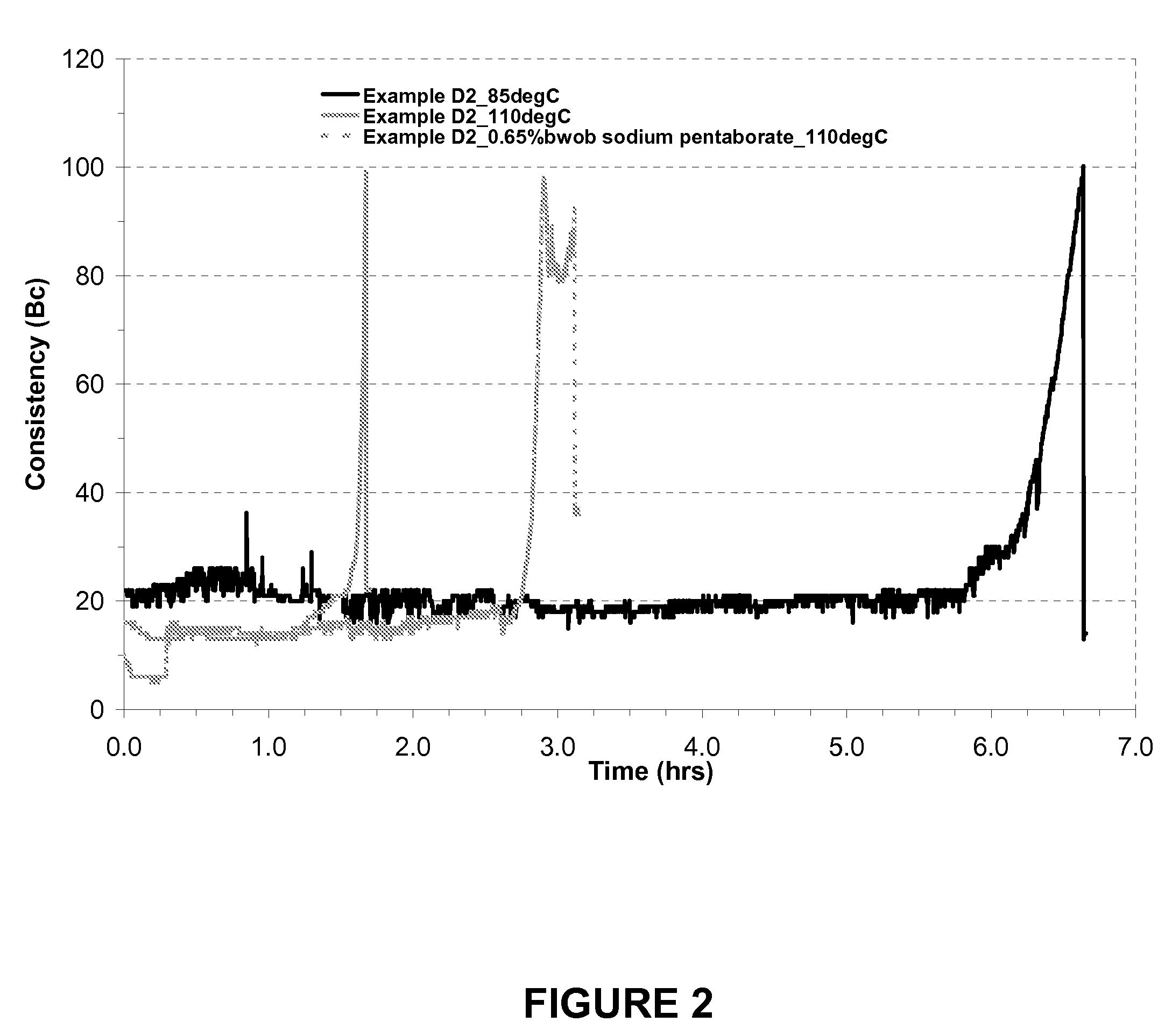

Compositions and methods for controling setting of carbonatable calcium silicate cements containing hydrating materials

The invention provides compositions and methods for controlling setting of carbonatable calcium silicate compositions that are contaminated with hydrating materials. These carbonatable calcium silicate cements are suitable for use as non-hydraulic cement that hardens by a carbonation process and may be applied in a variety of concrete components in the infrastructure, construction, pavement and landscaping industries.

Owner:SOLIDIA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com