Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

158 results about "Black iron oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

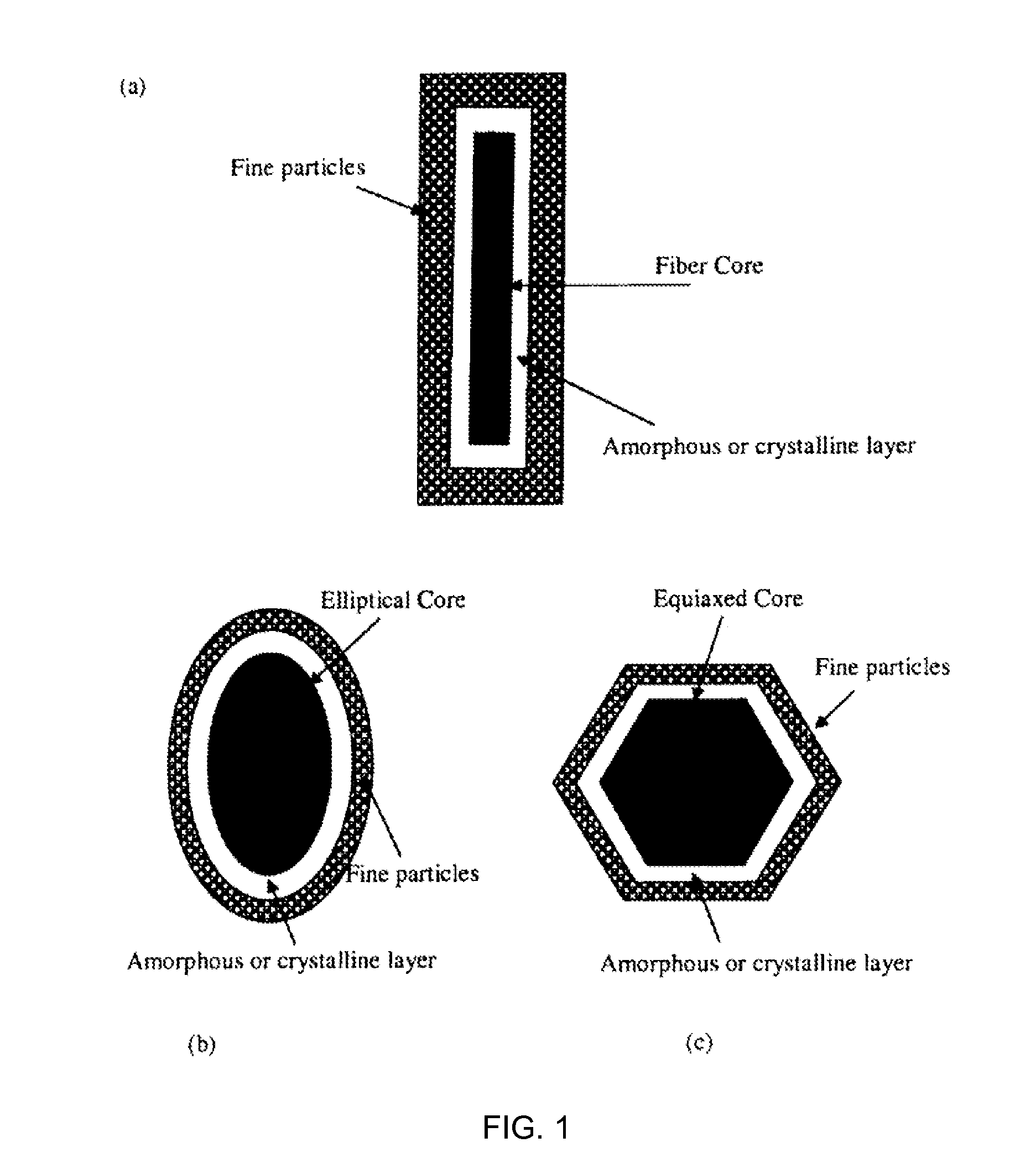

Marble-like composite materials and methods of preparation thereof

InactiveUS20140127450A1Low costIncrease consumptionLayered productsCoatingsCalcium silicateFlexural strength

The invention provides novel marble-like composite materials and methods for preparation thereof. The marble-like composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production. The precursor materials include calcium silicate and calcium carbonate rich materials, for example, wollastonite and limestone. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as pigments (e.g., black iron oxide, cobalt oxide and chromium oxide) and minerals (e.g., quartz, mica and feldspar). These marble-like composite materials exhibit veins, swirls and / or waves unique to marble as well as display compressive strength, flexural strength and water absorption similar to that of marble.

Owner:RIMAN RICHARD E +1

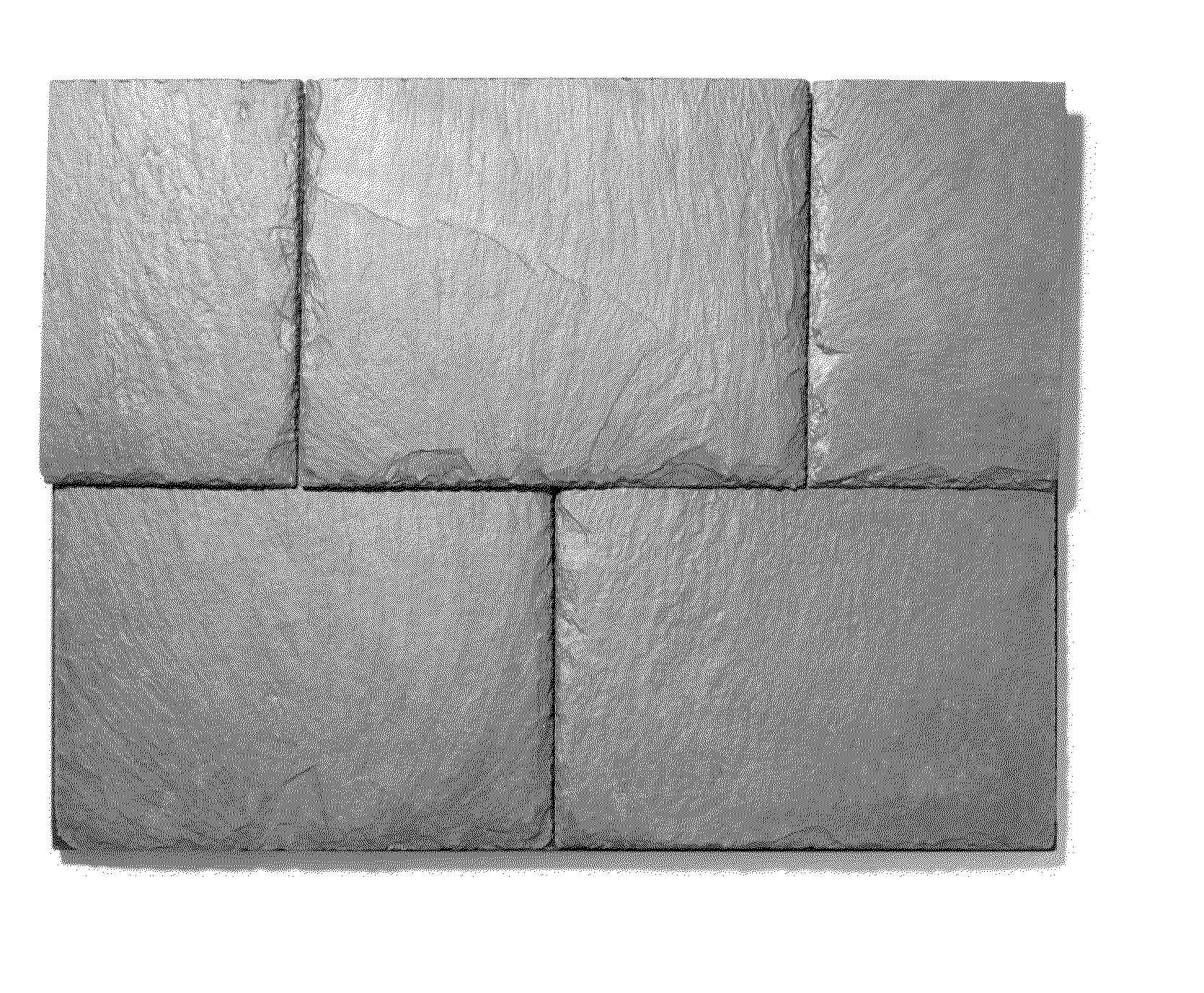

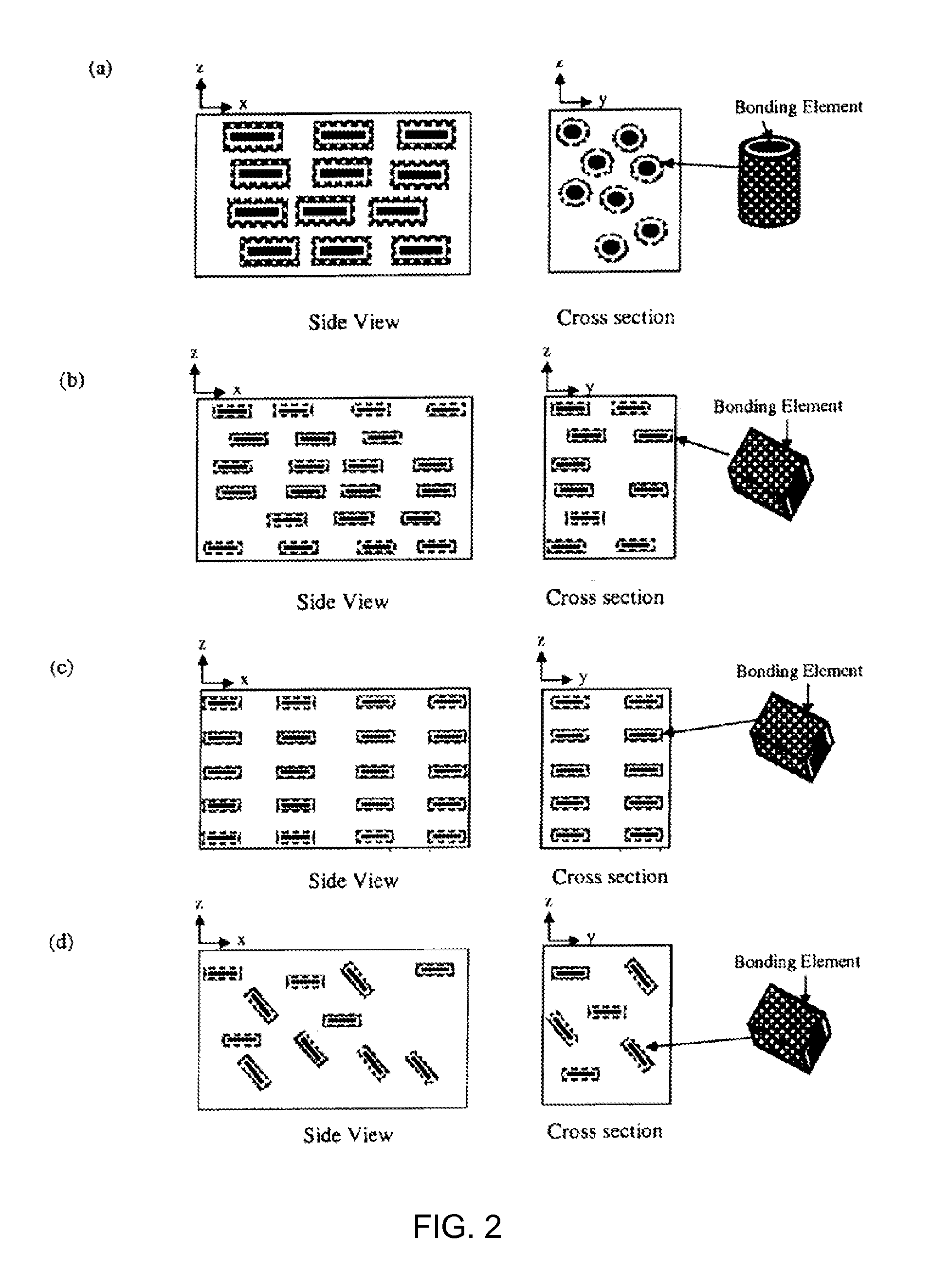

Slate-like composite materials and methods of preparation thereof

InactiveUS20140127458A1Low costIncrease consumptionRoof covering using tiles/slatesRecord information storageCalcium silicateFlexural strength

The invention provides novel slate-like composite materials and methods for preparation thereof. The slate-like composite materials can be readily produced from widely available, low cost precursor materials by a process suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as colored glass, colored sand, and colored quartz particles, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These slate-like composite materials exhibit visual patterns unique to slate as well as display compressive strength, flexural strength and water absorption similar to that of slate.

Owner:ZAMBRZYCKI DAWID +6

Pavers and block composite materials and methods of preparation thereof

ActiveUS20140314990A1Acceptable compressive strengthLow costRecord information storageCeramic shaping apparatusCalcium silicateCOLORED MATERIAL

The invention provides novel paving stones and construction block composite materials and methods for preparation thereof. The paving stones and construction block composite materials can be readily produced from widely available, low cost precursor materials by a production process that involves compacting in a mold that is suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which can comprise silicon dioxide-rich materials. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These paving stones and construction block composite materials exhibit visual patterns similar to stone as well as display compressive strength and water absorption equal to or better than that of stone.

Owner:SOLIDIA TECH

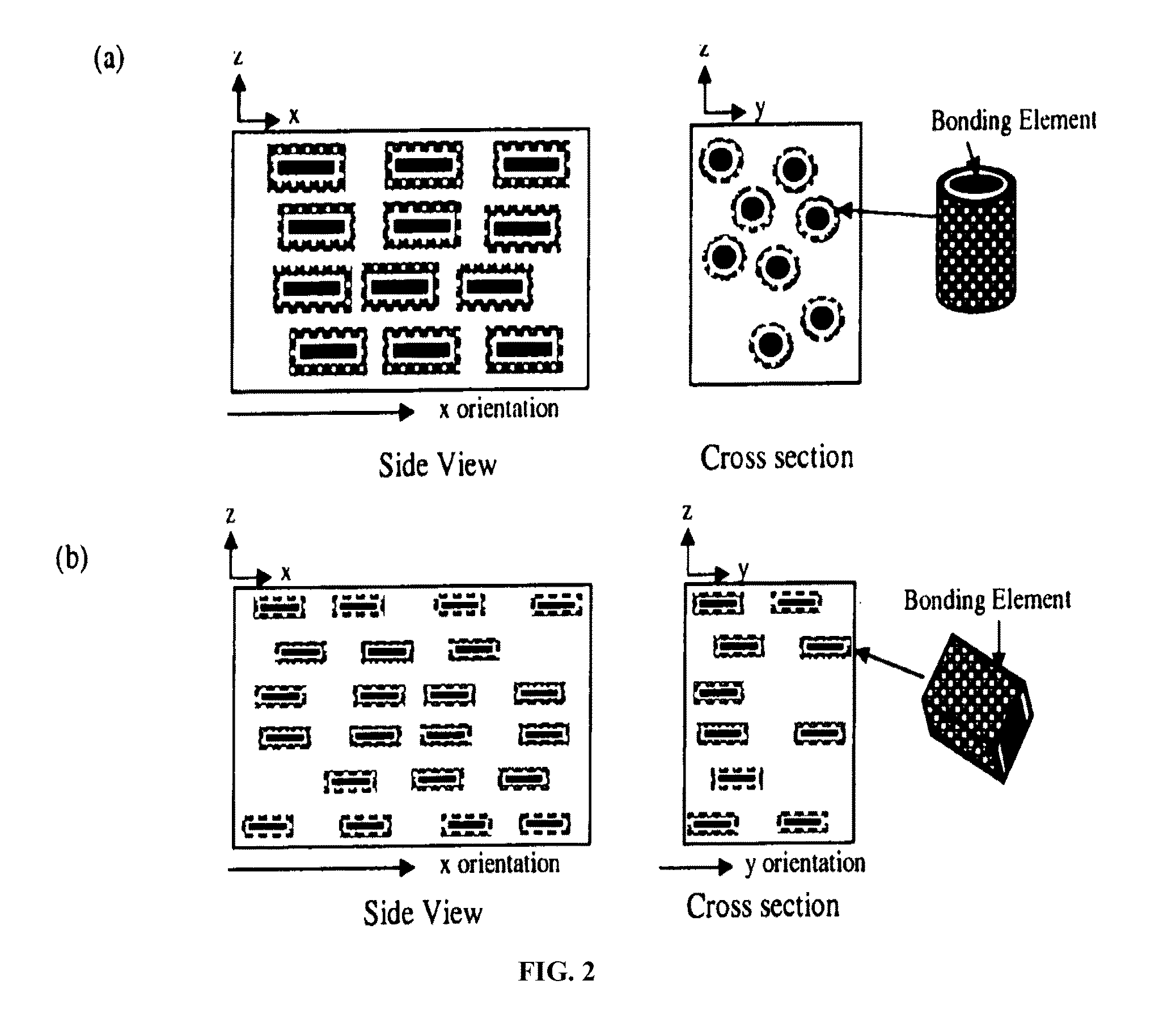

Wood-like composite materials and methods of preparation thereof

InactiveUS20140342124A1High compressive strengthLow water absorptionConstruction materialNatural patternsCalcium silicateFlexural strength

The invention provides novel wood-like composite materials and methods for preparation thereof. The wood-like composite materials can be readily produced from widely available, low cost precursor materials by a production process that involves casting in a mold that is suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These wood-like composite materials exhibit visual patterns unique to wood as well as display compressive strength, flexural strength and water absorption superior to that of wood.

Owner:ZAMBRZYCKI DAWID +4

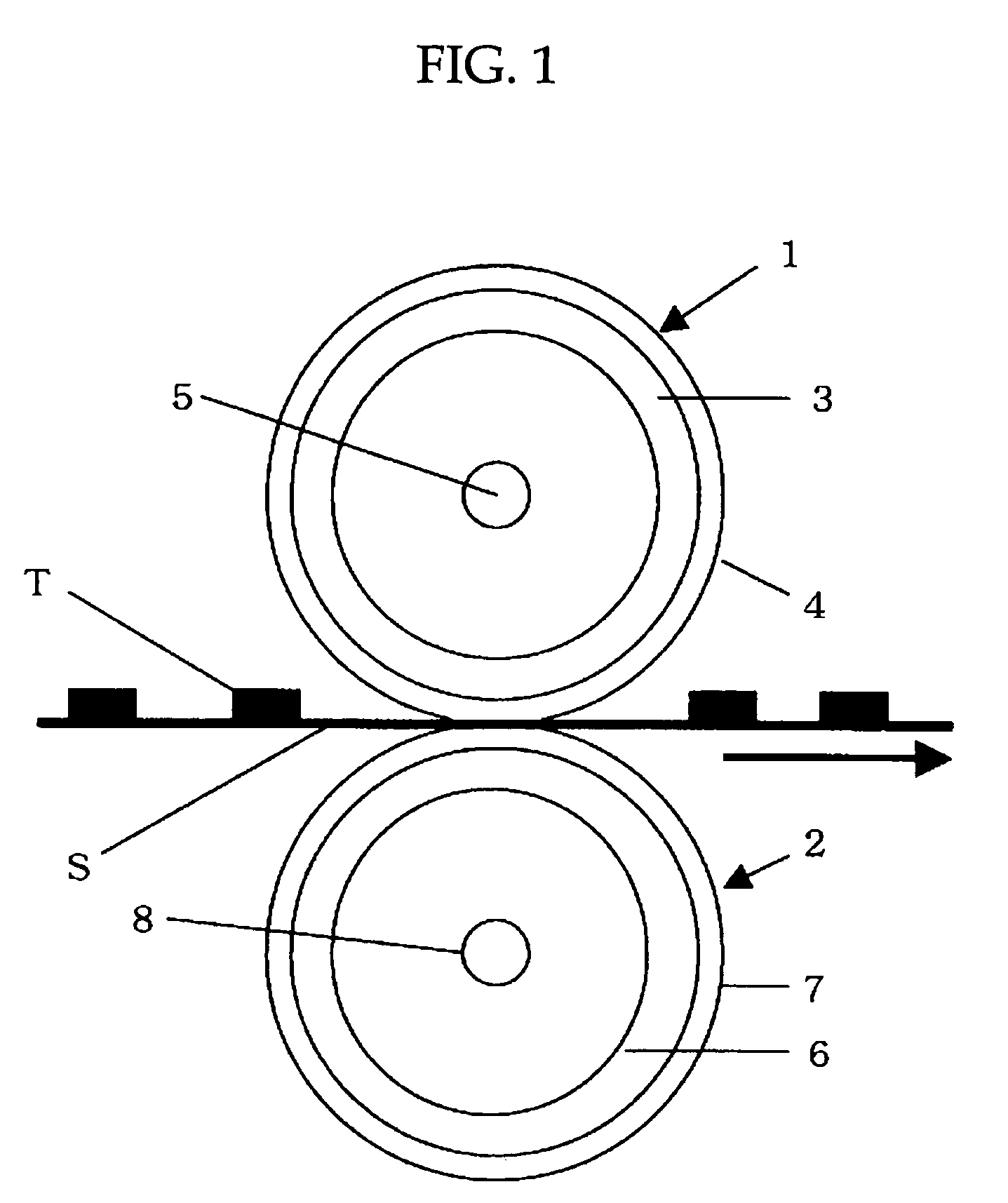

Toner for electrophotography, and image fixing process, image forming process, image forming apparatus and process cartridge using the same

InactiveUS7217485B2Sufficient electroconductivityImprove charging effectElectrographic process apparatusDevelopersX-rayImage formation

A toner for electrophotography contains a binder resin, a charge control agent, and a colorant. The colorant is a black iron oxide compound containing 10 to 45% by weight of titanium component calculated in terms of Ti atom in relation to Fe atom when measured by wavelength dispersive X-ray fluorescence spectrometry. Peaks at Bragg angle 2θ of the toner to CuKα X-ray are peak A at 32.9 degrees ±0.3 degrees and peak B at 35.5 degrees ±0.3 degrees, and X ray intensity ratio between peaks A and B (A / B) is in the range of 0.3 to 2.0 at a scan speed of 0.5 to 4 degrees / min.

Owner:RICOH KK

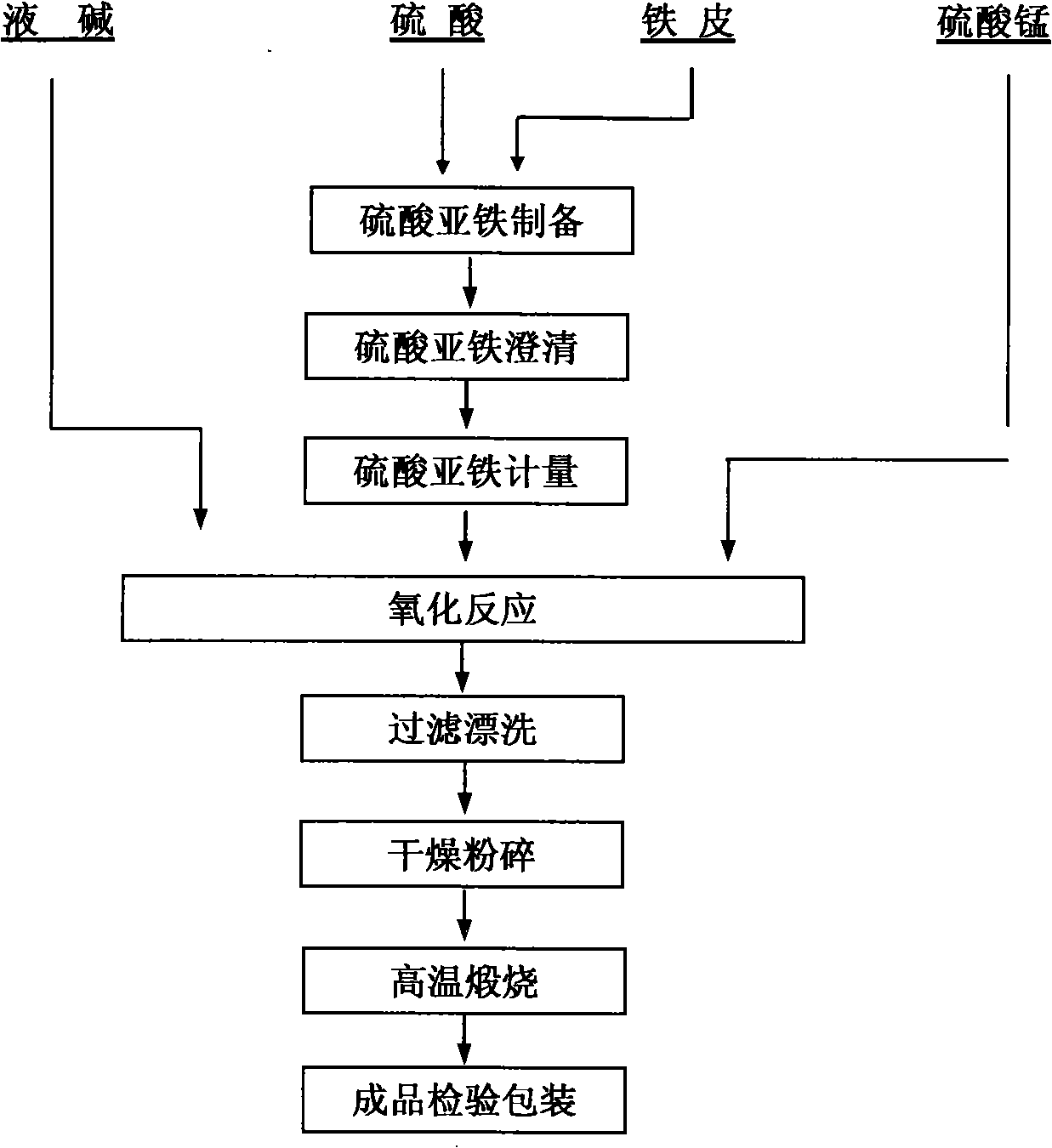

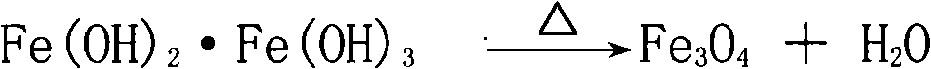

Fire resistant black iron oxide pigment and preparation method thereof

ActiveCN101314678AImprove acid resistanceGood alkali resistanceInorganic pigment treatmentFerric oxidesEngineering plasticManganese oxide

The invention relates to an inorganic iron oxide black pigment, in particular to a heat-resistant iron oxide black pigment (manganese ferrite black) and the preparation method thereof. The heat-resistant iron oxide black pigment comprises manganese ferrite black prepared from ferroferric oxide and manganese oxide by high-temperature lattice reaction, wherein the molar ratio of iron element to manganese pigment in the pigment is 1.5:1 to 5:1. The heat-resistant iron oxide black pigment has high heat resistance up to 700 DEG C or above, and can be widely used for ceramic, engineering plastic, color sand, etc., for products manufactured at high temperature, and for coloring agent for products. Meanwhile, the inorganic iron oxide black pigment has the advantages of high acid resistance, high alkali resistance and high light absorbability.

Owner:ZHEJIANG HUAYUAN PIGMENT CO LTD

Wear-resisting ceramic coating for non-stick cookware and preparation method thereof

The invention discloses a wear-resisting ceramic coating for non-stick cookware and a preparation method thereof. The coating is composed of a component A and a component B, wherein the weight ratio of the component A to the component B is (2.8-3.2): (1.8-2.0); the component A is composed of silicon dioxide sol, aluminum oxide sol, zirconium oxide sol, water soluble polyester modified epoxy resin, ultrafine aluminum oxide powder processed by azeotropic distillation method, black iron oxides, ultrafine spherical ceramic powder, isopropyl alcohol, deionized water, hydroxyethyl cellulose acetate butyrate and fluorosilicon oil; and the component B is composed of methyl triethoxysilane, amino dimethyldiethoxylsilane, dimethyl dimethoxy silicane, isopropyl alcohol and alcohol. The preparation method comprises the following steps of: mixing the component A and the component B of the coating in a weight ratio of (2.8-3.2): (1.8-2.0); and hermetically stirring and curing the obtained mixture for at least 3 hours under the conditions of 35 DEG C and 800-1000 rpm, thereby obtaining the coating. According to the invention, through carrying out polycondensation reaction on metal oxide colloids and polysiloxane, the bonding strength of a film forming matter is improved.

Owner:JIANGMEN ANNUOTE COOKING UTENSILS MFG

Microcapsules comprising black pigments

Monolayered microcapsules comprising a black pigment and cosmetic formulations comprising them are provided for use particularly in mascara and eye liner formulations. The black pigment may be carbon black, black iron oxide, or both.

Owner:TAGRA BIOTECH

Pigment dispersion and related method of manufacture

InactiveUS7094395B1Inhibition of agglomerationLower potentialCosmetic preparationsMake-upPigment dispersionHydrophile

A method for producing a colored cosmetic composition having inorganic pigments resistant to agglomeration in an oil-in-water emulsion. The method includes the following: preparing an oil dispersion by adding inorganic pigments directly to an oil; preparing an aqueous base that includes water; combining the oil dispersion and aqueous base; and partitioning the inorganic pigments between the oil and the aqueous phase under controlled conditions, for example, hydrophile-lipophile balance, agitation time and speed, and cooling rate. The present invention provides a process to easily disperse iron-oxide pigments, even black iron-oxide pigments, in oil-in-water emulsions. The present invention provides colored cosmetic compositions that have excellent properties, such as smoothness, adhesion to skin, uniform color, ease of removal, smudge resistance and non-oiliness.

Owner:ACCESS BUSINESS GRP INT LLC

Antibacterial corrosion-resistant ceramic coating of non-stick pan and preparation method of coating

ActiveCN103483885AImprove mechanical propertiesImprove performanceAntifouling/underwater paintsPaints with biocidesEpoxyPolyester

The invention relates to an antibacterial corrosion-resistant ceramic coating of a non-stick pan and a preparation method of the coating, and belongs to the technical field of ceramic machining. The antibacterial corrosion-resistant ceramic coating comprises the components in parts by weight as follows: 35-40 parts of silicon oxide sol, 5-9 parts of aluminum oxide sol, 1-3 parts of zirconium oxide sol, 5-8 parts of a water soluble polyester modified epoxy resin, 1-3 parts of black iron oxide, 5-8 parts of spherical ceramic micro powder, 8-12 parts of absolute ethyl alcohol, 1-3 parts of silver nitrate, 1-3 parts of aluminum nitrate, 1-3 parts of and fluoride silicone oil and 10-15 parts of deionized water. The preparation method comprises the steps as follows: the materials are mixed according toin the ratio, stirred for 4-6 h in a sealing manner at a temperature of 35-42 DEG C and a rotating speed of 300-350 rpm (revolutions per minute), and then calcinated at a high temperature of 300-350 DEG C; and composite ceramic material powder is composited. The coating of the non-stick pan has good mechanical property, is high in strength, high-temperature-resistant, abrasion-resistant and scratch-resistant, and has an antibacterial function; and the preparation technology is simple, and the coating is non-toxic and harmless to the environment.

Owner:浙江飞哲科技股份有限公司

Preparation method of black iron oxide particles with corrosion inhibition performance

InactiveCN103289442AGood corrosion inhibition effectLiquidPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsViscous liquidEthyl(hydroxyethyl)cellulose

The invention discloses a preparation method of black iron oxide particles with corrosion inhibition performance. The method comprises the following steps of: dissolving urotropin, ethyl hydroxy ethylcellulose and lauryl sodium sulfate in deionized water according to the definite weight ratio, thereby obtaining a viscous liquid; putting black iron oxide into a granulating machine for granulating while evenly spraying the viscous liquid onto the black iron oxide powder at the same time, thereby forming small black iron oxide particles; and drying and screening the small black iron oxide particles, thereby obtaining a finished product. According to the method, the black iron oxide is modified by the urotropin and other components, so that the corrosion inhibition performance of the black iron oxide is enhanced; and the liquidity and the dispersibility of a black iron oxide pigment are realized. The produced black iron oxide has the characteristics of being excellent in temperature resistance, good in acid and alkali resistance, strong in light absorption, high in tinting strength, good in compatibility and dispersibility and the like, thereby being wide in market prospect.

Owner:TONGLING RELY TECH

Marble-like composite materials and methods of preparation thereof

InactiveUS20160236984A1Low costIncrease consumptionThin material handlingCarbon captureCalcium silicateFlexural strength

The invention provides novel marble-like composite materials and methods for preparation thereof. The marble-like composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production. The precursor materials include calcium silicate and calcium carbonate rich materials, for example, wollastonite and limestone. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as pigments (e.g., black iron oxide, cobalt oxide and chromium oxide) and minerals (e.g., quartz, mica and feldspar). These marble-like composite materials exhibit veins, swirls and / or waves unique to marble as well as display compressive strength, flexural strength and water absorption similar to that of marble.

Owner:SOLIDIA TECH

Preparation method of special inorganic anti-veining additive for casting

ActiveCN104493075AReduce the amount addedReduce manufacturing costFoundry mouldsFoundry coresMicrosphereLithium carbonate

The invention relates to a preparation method of an additive, and in particular relates to a preparation method of a special inorganic anti-veining additive for casting. The method comprises the following steps: respectively sieving iron oxide red and black iron oxide through a sieve of 70mesh; removing oversize materials and remaining the residues on the sieve for later use; respectively sieving spodumene, kyanite and hollow microspheres through a sieve of 30mesh; removing oversize materials and remaining the residues on the sieve for later use; sequentially feeding the sieved raw materials, potassium carbonate and lithium carbonate into a special agitating device according to a technical formula; then starting to agitate for mixing; discharging after mixing. The special inorganic anti-veining additive has the advantages that the addition quantity is small, the influence on the strength of moulding sand is low, the anti-veining effect is good, and the production cost can be effectively decreased.

Owner:共享新材料(山东)有限公司

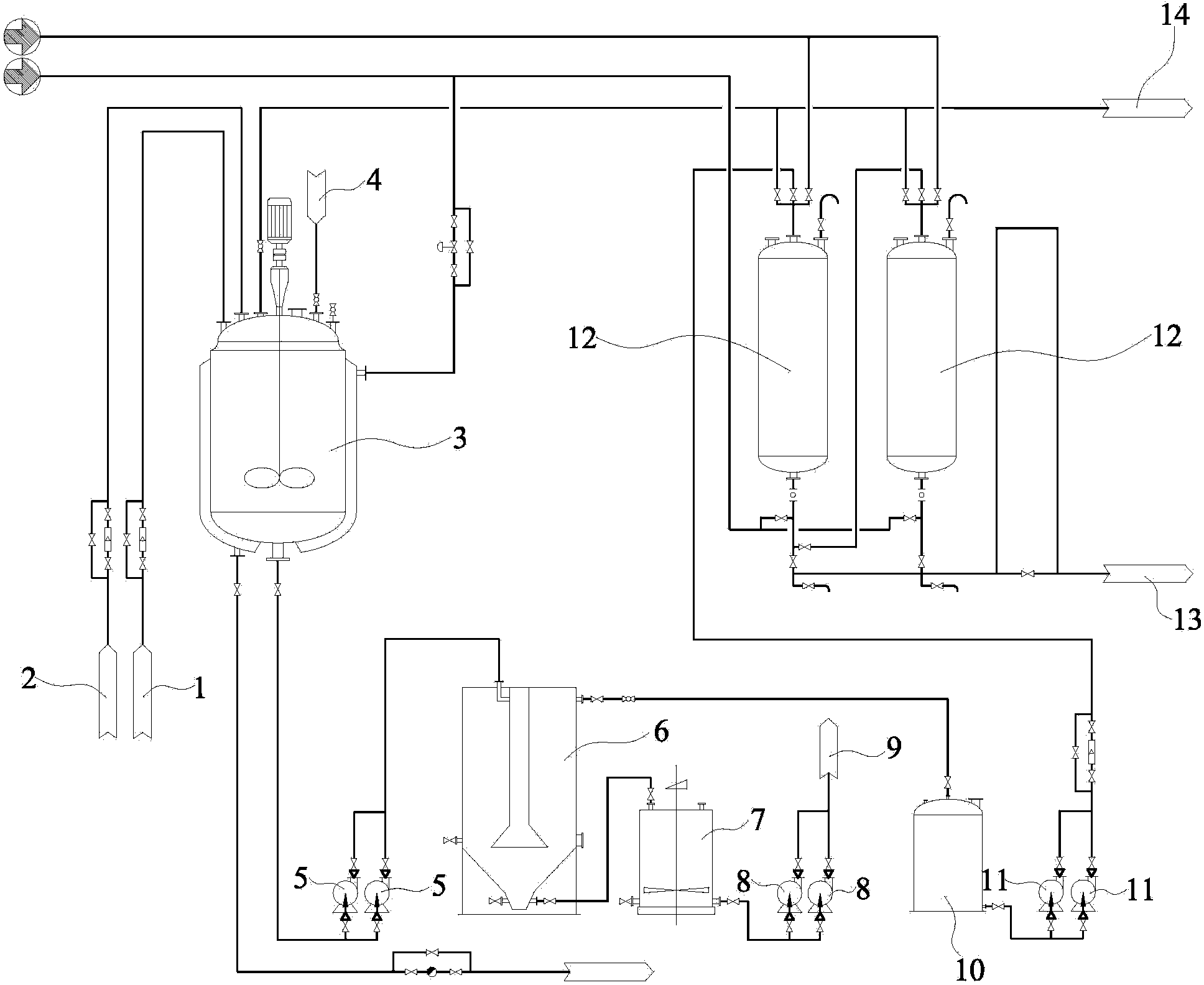

Method for rapidly preparing black iron oxide from ferrous sulfate as titanium dioxide waste residue

InactiveCN104016418AReduce manufacturing costImprove oxidation efficiencyFerroso-ferric oxidesSocial benefitsSulfate

The invention discloses a method for rapidly preparing black iron oxide from ferrous sulfate as a titanium dioxide waste residue and belongs to the technical field of chemical engineering. The method comprises the following steps: a, removing impurities from ferrous sulfate to obtain a ferrous sulfate solution; b, taking a part of ferrous sulfate solution, diluting until the concentration is 10-15%, then introducing air or oxygen, controlling the pH value of the solution at 3-6, controlling the reaction temperature at 20-30 DEG C, and reacting until the color of the solution becomes earthy yellow, so as to obtain a crystal seed liquid; simultaneously and continuously adding the residue ferrous sulfate solution and ammonia to the crystal seed liquid, stirring and heating, controlling the pH value of the solution at 3.0-9.5, controlling the temperature at 70-90 DEG C, while continuously introducing air or oxygen, reacting for 5 to 6 hours, and filtering to a black iron precipitate; c, washing the iron black precipitate, filtering and drying to obtain the black iron oxide product. Since the process for preparing the black iron oxide disclosed by the invention requires only 5-6 hours and has the advantages of short time and low cost, and the method has relatively high economical and social benefits.

Owner:攀枝花市大牛科技有限公司

Graphene non-stick coating and application thereof

InactiveCN105348950AImprove mechanical propertiesImprove thermal conductivityCoatingsWater basedEpoxy

The invention discloses a graphene non-stick coating which is prepared from, by weight, 0.5-2 parts of graphene powder, 35-40 parts of silica gel, 30-50 parts of polytetrafluoroethylene water-based resin, 5-8 parts of water-soluble polyester modified epoxy resin, 2-4 parts of silicone oil, 1-3 parts of black iron oxide, 5-8 parts of spherical ceramic micro powder, 4-8 parts of aluminum oxide wear-proof powder, 1-3 parts of aluminum nitrate and 10-15 parts of deionized water. The non-stick coating is used for kitchenware with a ceramic or metal base. The coating is high in heat conductive coefficient, good in ductility, capable of being tightly combined with base materials, long in service life and strong in market competitiveness.

Owner:无锡大塘复合材料有限公司

Method for preparing black iron oxide by utilizing yellow ammonium iron alum slag

InactiveCN102718267ASimple processReduce manufacturing costPigmenting treatmentFerroso-ferric oxidesSlagAqueous sodium hydroxide

The invention provides a method for preparing black iron oxide by utilizing yellow ammonium iron alum slag. The method comprises the following basic steps: placing yellow ammonium iron alum slag in an oven for drying at the temperature of 100-150 DEG C for 1-3h; placing the dried yellow ammonium iron alum slag into a porcelain boat which is put into a tubular furnace, and conducting calcining treatment in N2 atmosphere at the calcining temperature of 900-1200 DEG C for 5-60 min; absorbing SO2 and SO3 contained in discharged waste gas using 5-30% ammonium hydrogen carbonate aqueous solution to obtain a by-product ammonium sulfate; and after cooling calcining slag in N2 atmosphere, placing the calcining slag in 3-20mol / L sodium hydroxide aqueous solution, mixing and reacting for 1-6h at the temperature of 100-200 DEG C, and obtaining a product with Fe3O4 content more than 90% by filtering, washing and drying, wherein the product reaches the standards of HG / T 2250-91 black iron oxide pigment. The method has the advantages of being short in production process and simple and convenient in operation, turning wastes into valuables, and having double benefits of environmental protection and economy.

Owner:GUANGXI UNIV

Thermoformed food containers with colorfast high color density black pigment

ActiveUS20030190443A1Sufficient color densitySolve the lack of densityEnvelopes/bags making machinerySynthetic resin layered productsPolymer scienceVolumetric Mass Density

A black pigmented disposable food container is preferably made from a polypropylene matrix polymer, optionally including polyethylene and further includes a mineral filler and a black colorant composition consisting essentially of a black iron oxide pigment and a green pigment.

Owner:GPCP IP HLDG LLC

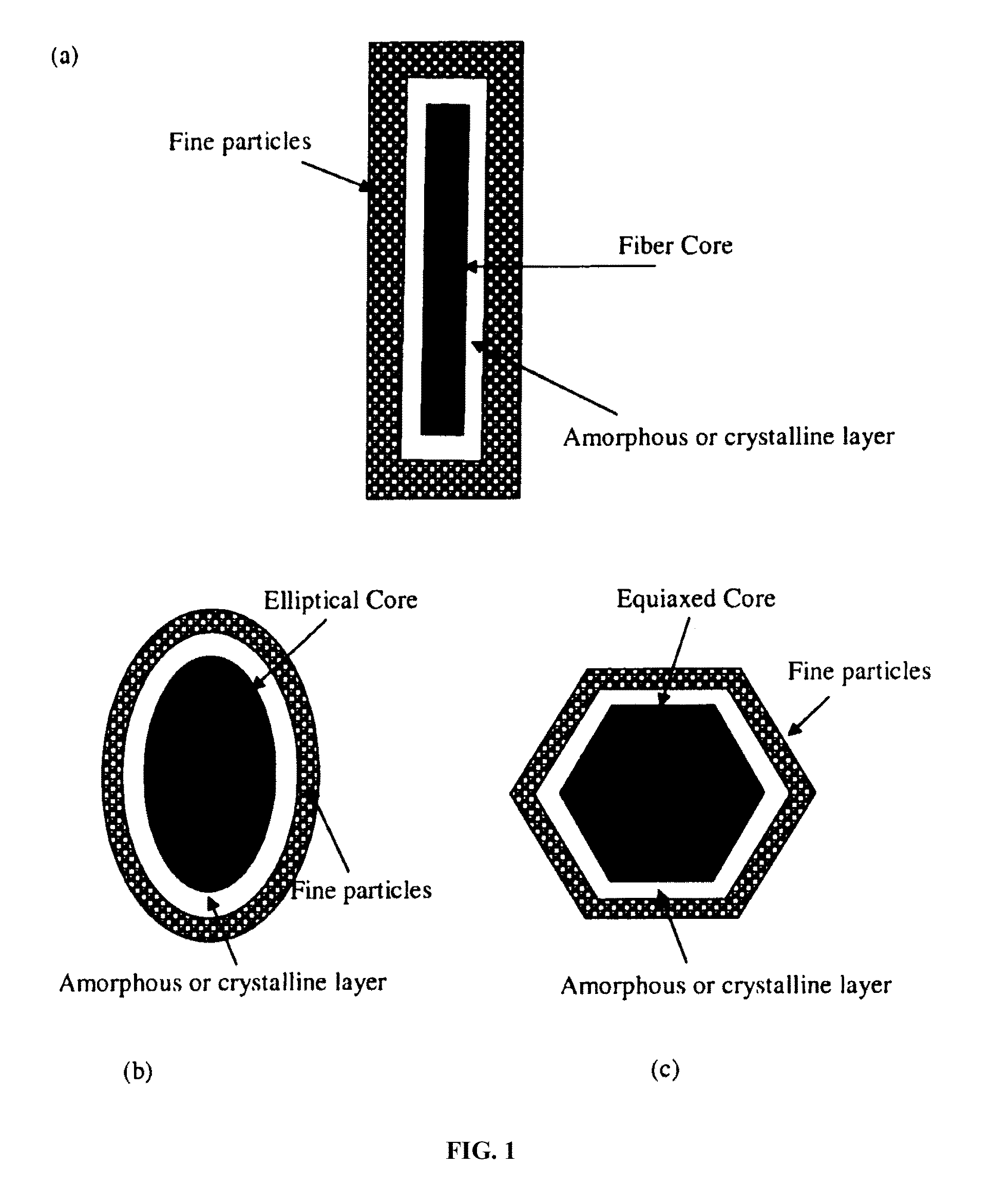

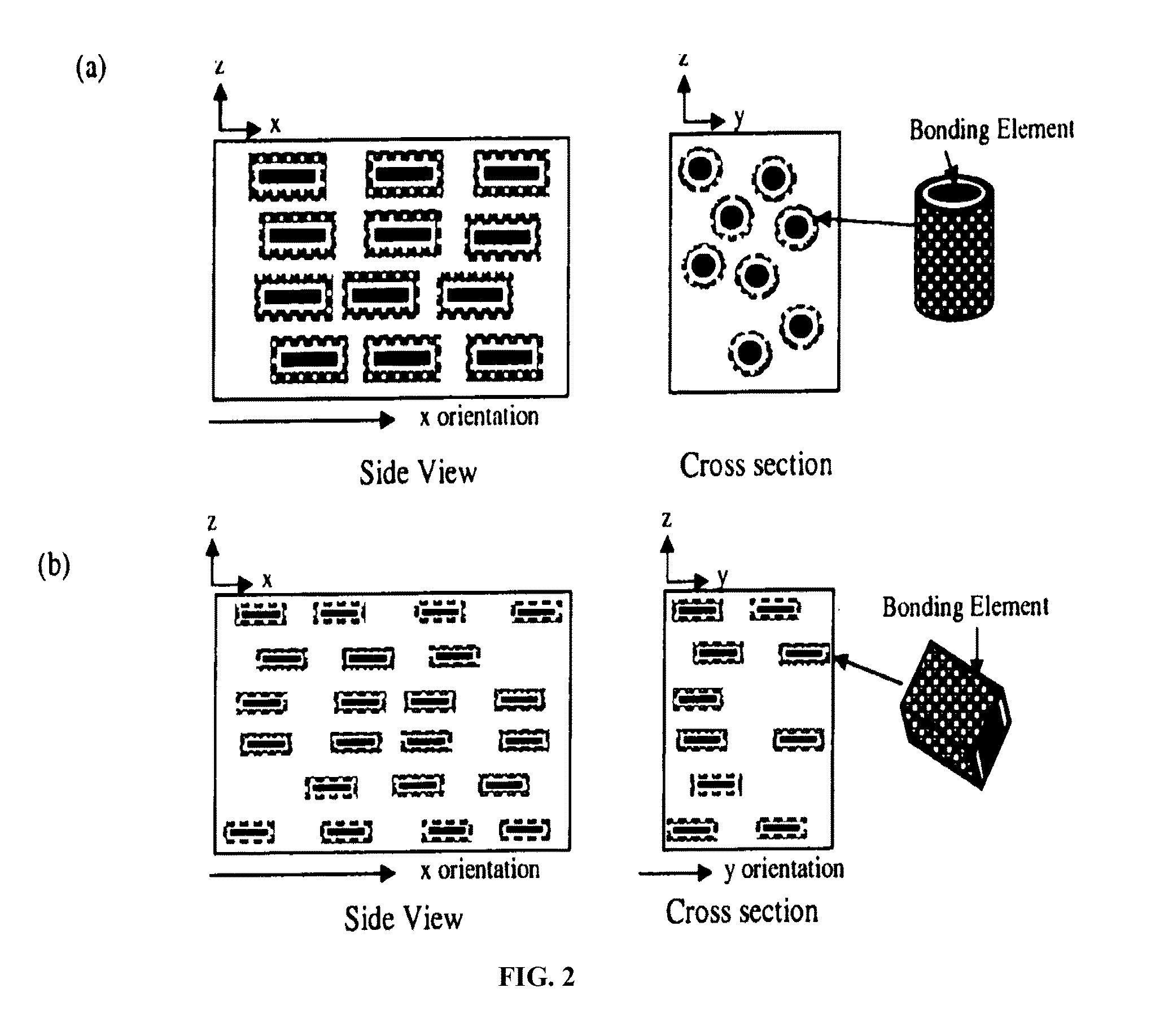

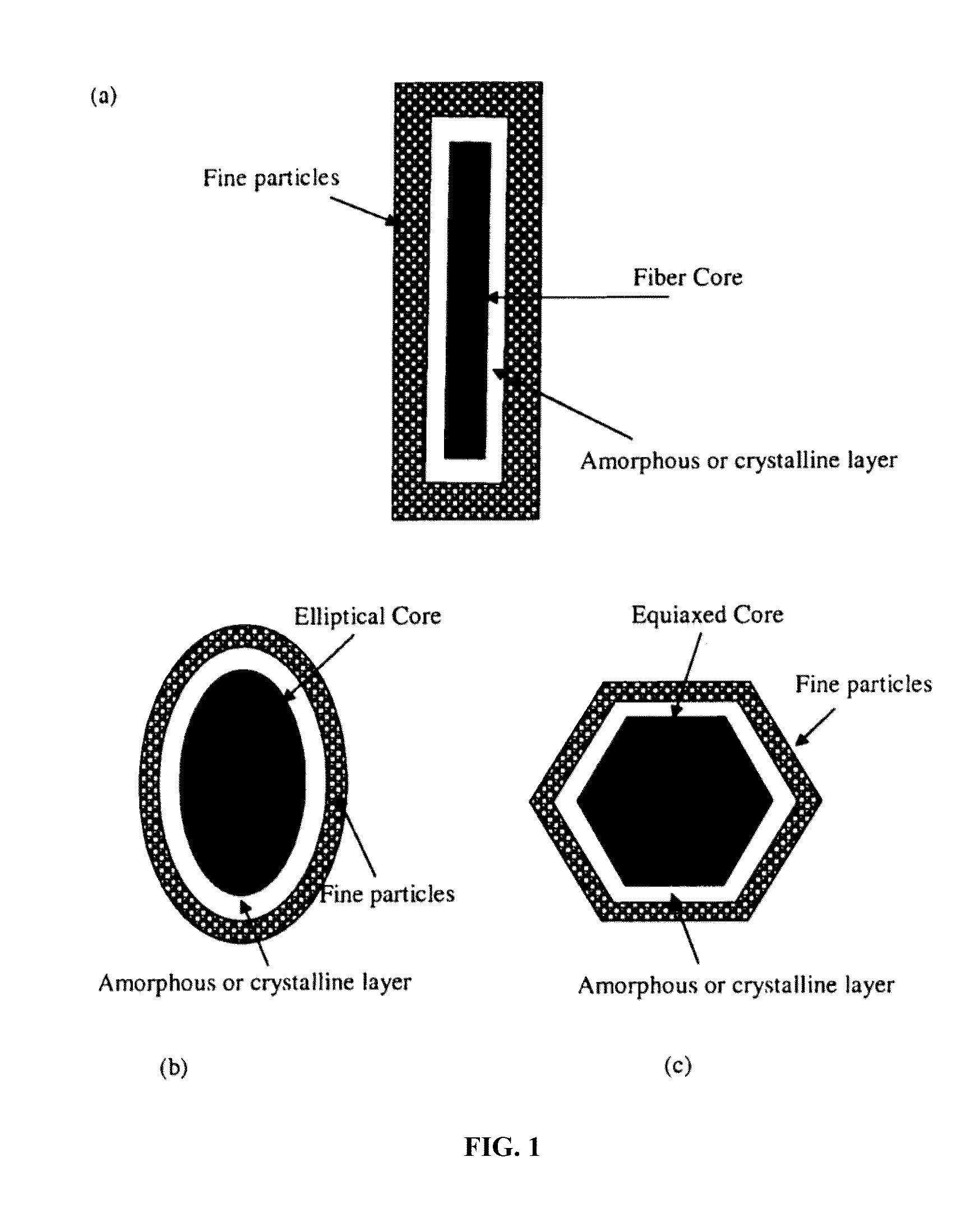

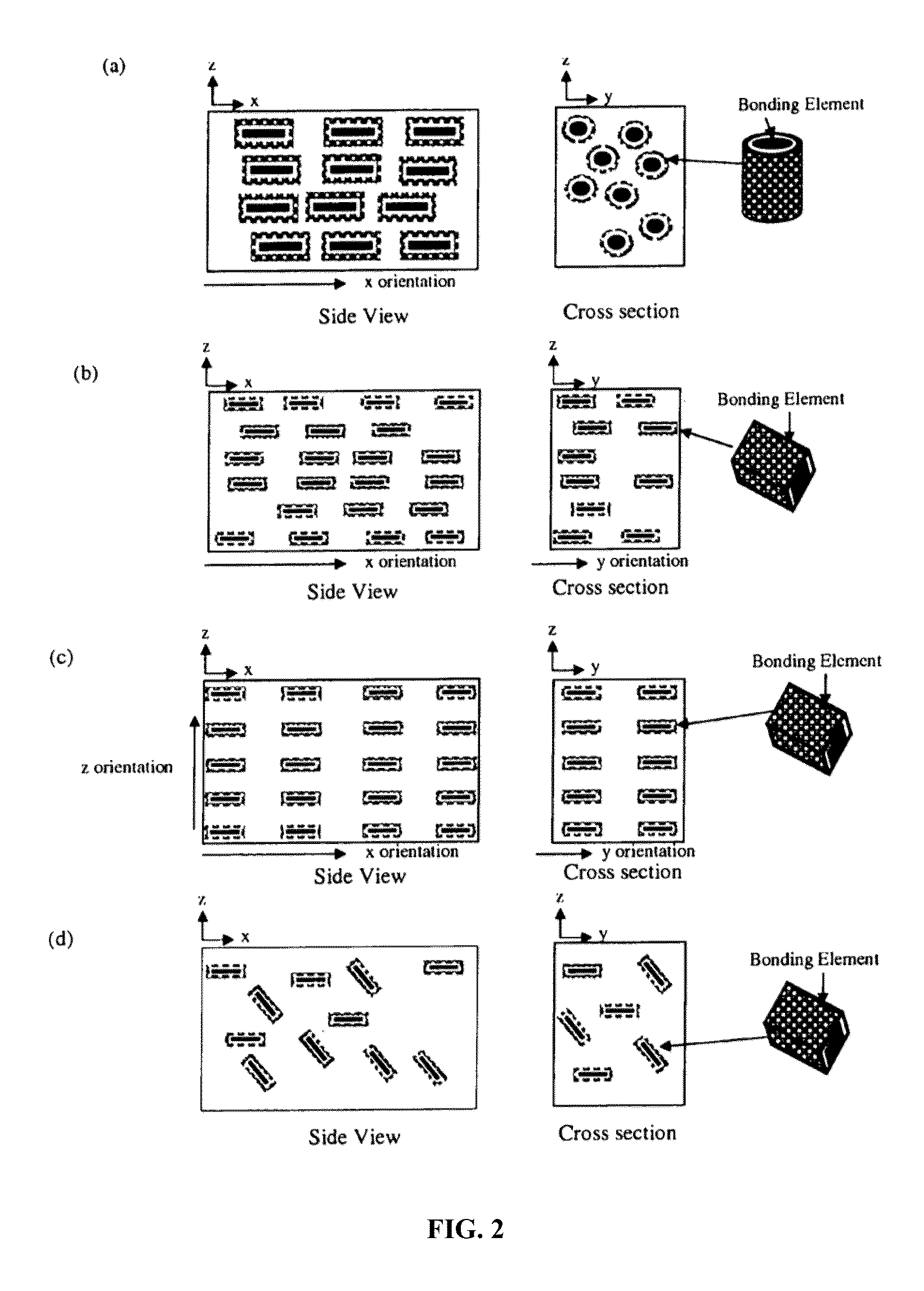

Black iron-based composite particles, process for producing the same, paint and rubber or resin composition containing the same

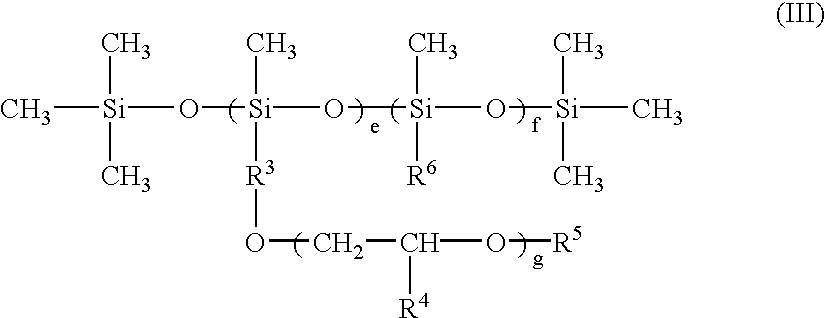

InactiveUS6420030B1Improve acid resistanceImprove the immunityMaterial nanotechnologyLiquid surface applicatorsSilane compoundsAlkoxy group

Black iron-based composite particles of the present invention comprise: as a core particle black iron oxide particle or black iron oxide hydroxide particle having an average particle size of 0.08 to 1.0 .mu.m; a coating layer formed on the surface of the black iron oxide particle or black iron oxide hydroxide particle, comprising at least one organosilicon compound selected from the group consisting of: (1) organosilane compounds obtained from alkoxysilane compounds, (2) polysiloxanes, or modified polysiloxanes and (3) fluoroalkyl organosilane compounds obtained from fluoroalkylsilane compounds; and carbon black coat formed on said coating comprising said organosilicon compound, in an amount of 1 to 30 parts by weight based on 100 parts by weight of said black iron oxide particles or black iron oxide hydroxide particles. Such black iron-based composite particles have an excellent dispersibility in a vehicle, or a rubber or resin composition on the basis of a small amount of the carbon black which are desorbed from the surface of the black iron-based composite particles, and a high blackness substantially identical to a blackness of carbon black fine particles used solely, even when carbon black is contained therein only in a small amount.

Owner:TODA IND

Ultra-violet cure coating

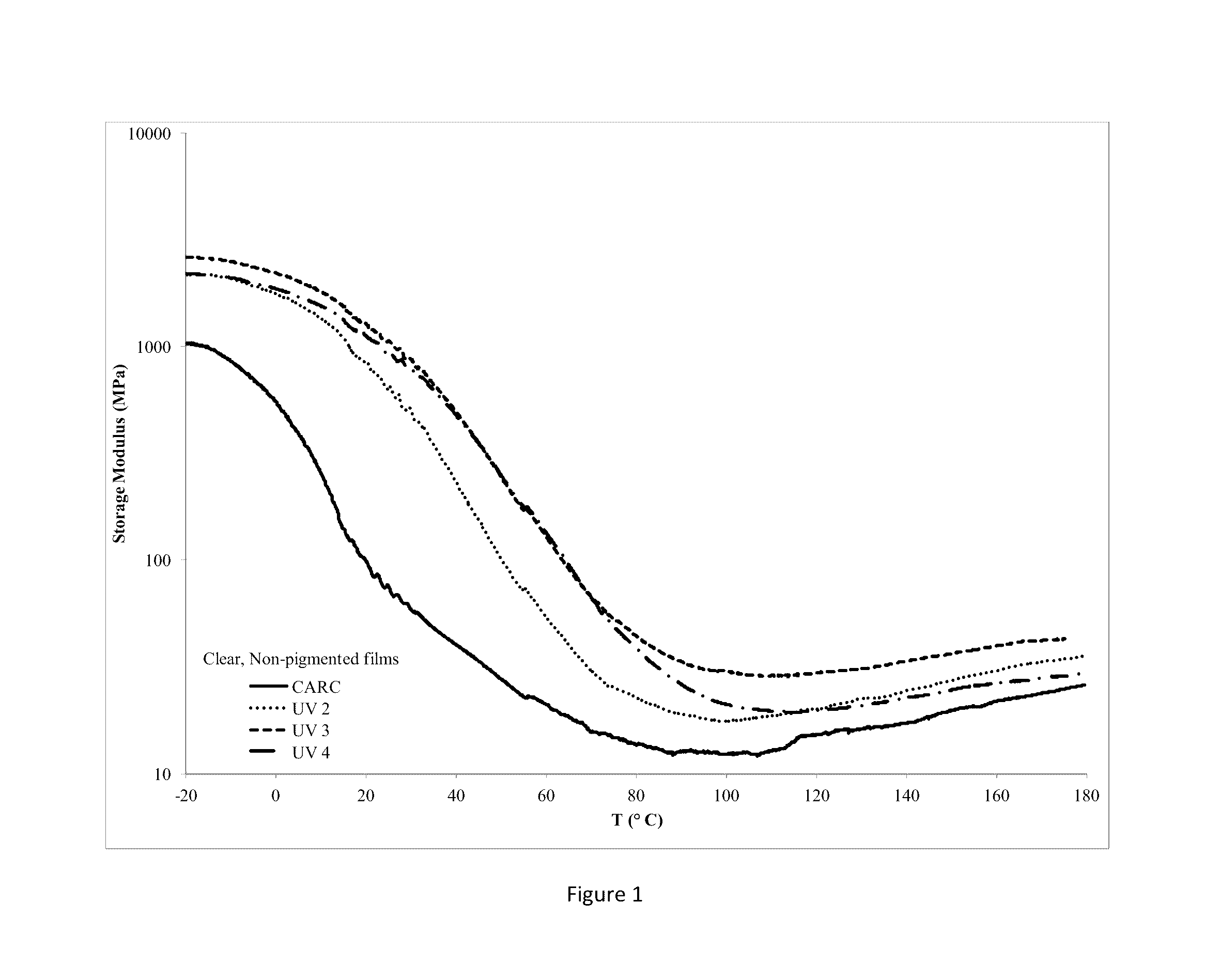

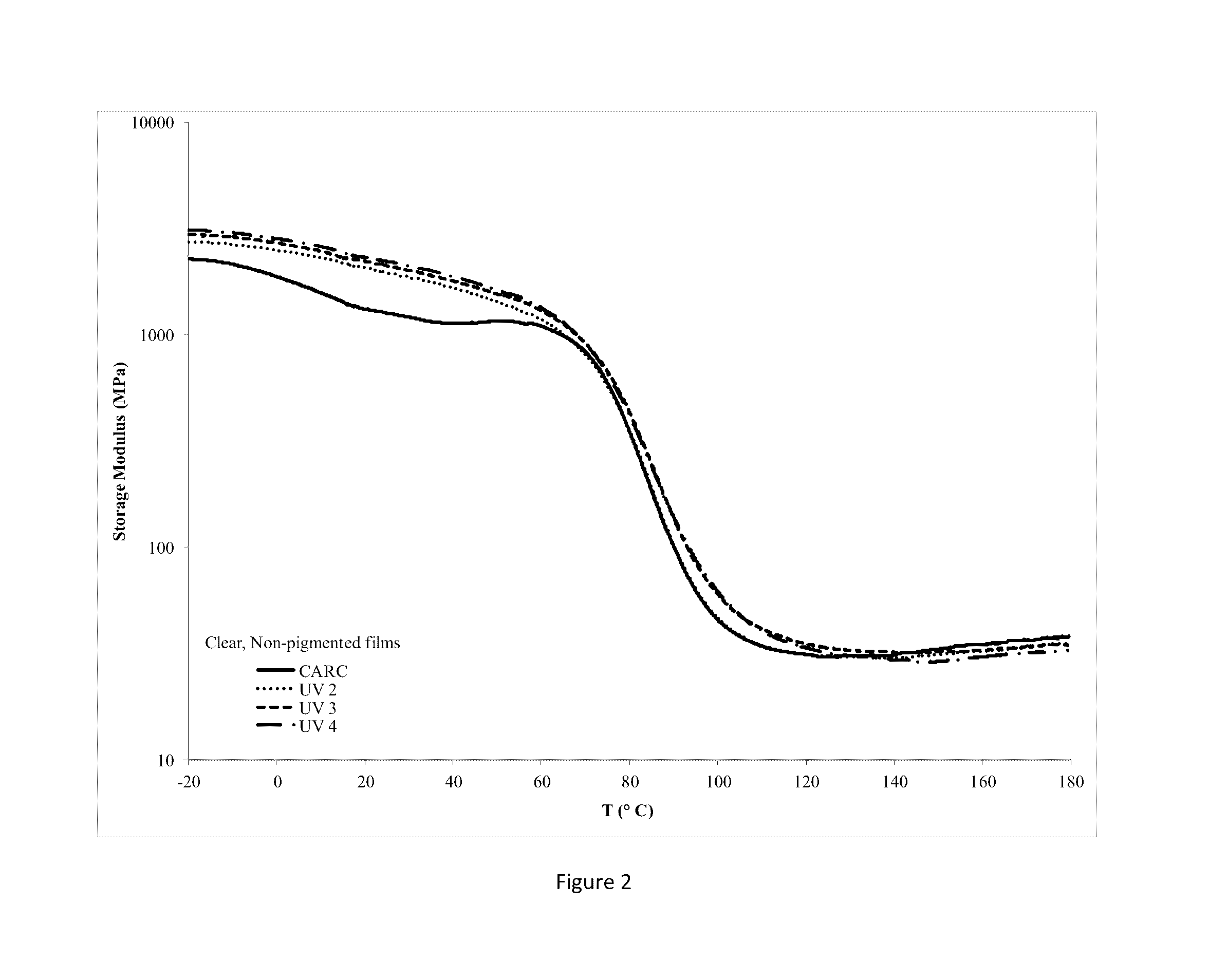

ActiveUS9505936B1Fast curingImprove performancePolyurea/polyurethane coatingsCamouflage paintsWater dispersibleUV curing

Several low observable aqueously dispersed polymeric materials with dual cure properties utilizing both ambient and UV curing modalities are provided. Compositions are suitable for coating a substrate such as those used in military, hunting, or other applications for which low visibility is desired. A water dispersible low observable curable composition includes an aqueously dispersed hydroxyl functional polyurethane resin, an aqueously dispersed urethane acrylate resin; and one or more low solar absorbing pigments. In some embodiments, the acrylate resin present at less than 50% total resin weight. Preferred pigments include those that are cobalt free, do not absorb significant UV radiation during cure, and provide reduced surface temperature resulting in low IR signature. Illustrative pigments include chromium oxide green, magnesium ferrite, red iron oxide (Fe2O3), black iron oxide (Fe3O4), zinc ferrite (ZnFe2O4), or combinations thereof.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Method for preparing black iron oxide wrapped with silicon dioxide

InactiveCN103333523AImprove water resistanceImprove dispersion stabilityPigment treatment with macromolecular organic compoundsFlocculationWeather resistance

The invention discloses a method for preparing black iron oxide wrapped with silicone dioxide. The method comprises the following steps of firstly adding water and dissolving ferrous sulfate, then adding sodium hydroxide solution to neutralize all ferrous ions, obtaining ferrous hydroxide gel, after oxidizing reaction by aerating air, washing, drying, and smashing so as to obtain the black iron oxide; then taking ethyl orthosilicate as the raw material, forming a layer of continuous compact silicone dioxide film on the surface of the black iron oxide through a sol-gel method, and obtaining the black iron oxide wrapped with the silicone dioxide. The black iron oxide prepared by the method has the characteristics of good acid-base resistance property, weather resistance, compatibility, dispersibility, flocculation resistance, strong tinting strength, and the like, thus being widely used in various paintings and having prosperous market prospect.

Owner:ANHUI TOPTECHSCR ENVIRONMENTAL SCI & TECH

Clear isolation cream

InactiveCN103340812AMild in natureKeep it detailed and fullCosmetic preparationsToilet preparationsButanediolBenzioc acid

The invention discloses a clear isolation cream. The clear isolation cream contains propylene glycol, butanediol, glycine betaine, sodium chloride, magnesium sulfate, methyl parahydroxybenzoats, para hydroxybenzene propyl ester, EDTA (Ethylene Diamine Tetraacetic Acid) disodium, cetyl PEG / PPG-10 / 1 polydimethylsiloxane, Dimeticone, caprylic acid, triglyceride fatty acid, shea butter, microcrystalline wax, beeswax, polydimethylsiloxane, grape seed oil, sodium hyaluronate, essence, arbutin, adenosine, allantoin, iron oxide yellow, iron oxide red, black iron oxide and water. The evaluation of users and the result of test on the skin of the users show that the isolation cream has better isolation effect, the cream preparation is light and breathable, and the clear isolation cream can effectively isolate harmful matters in make-up products and the air, block ultraviolet rays, protect the skin from being hurt without blocking pores, and can keep the skin supple and full.

Owner:开平市美康泉生物科技有限公司

Tough heat-conductive antibacterial non-stick coating

InactiveCN105348882AImprove antibacterial propertiesImprove mechanical propertiesAntifouling/underwater paintsPaints with biocidesWater basedPolyester

The invention discloses a tough heat-conductive antibacterial non-stick coating which is prepared from, by weight, 1-2 parts of graphene powder, 10-20 parts of nano SiO2 dispersion liquid, 10-15 parts of aluminum oxide sol, 10-15 parts of zirconium oxide sol, 2-4 parts of bentonite, 1-3 parts of black iron oxide, 8-10 parts of polyimide, 30-50 parts of polytetrafluoroethylene water-based resin, 5-20 parts of acrylic acid, 5-8 parts of water-soluble polyester modified epoxy resin, 1-3 parts of fluorosilicone oil, 1-2 parts of silver nitrate, 1-2 parts of aluminum nitrate and 3-5 parts of butyl cellosolve. The coating is good in ductility, high in toughness, resistant to wear, not prone to cracking and high in heat conductivity, has the antibacterial function and can be widely applied to kitchen cookware and tableware.

Owner:无锡大塘复合材料有限公司

Process for preparing black iron oxide by utilizing wastewater generated in production of chlorinated benzene

The invention discloses a process for preparing black iron oxide by utilizing wastewater generated in production of chlorinated benzene. The process comprises the following concrete steps: reducing the Fe<3+> in water-washing waste acid water generated in the production of the chlorinated benzene to be Fe<2+> in a reaction kettle by using a reducing agent, then adding alkaline water to react the Fe<2+> and alkaline to form iron mud (Fe(OH)2), depositing the iron mud in a settling vat to obtain an iron mud solid, filtering the iron mud solid by a filter press, oxidizing the iron mud solid into the black iron oxide (Fe3O4) at an alkaline condition, sending the clear water in the upper part of the reaction kettle and the clear water settled in the upper part of the settling vat into a resin column for adsorbing organics, and then discharging the water into a clear water treating pond for treatment. According to the product black iron oxide prepared by the process, utilization of solid wastes is realized, wastes are changed into valuable things and the cost is saved; by using a separating and setting apparatus, separation of the iron mud and the water is realized, the energy consumption is reduced, and the content of insoluble solid substances in the water is greatly reduced; by using the resin column to adsorb the organics in the water, up-to-standard discharge of the wastewater is realized.

Owner:ANHUI BAYI CHEM IND

Black brick in archaizing building and preparation method thereof

InactiveCN107151133AReasonable useHigh compressive strengthCeramic materials productionClaywaresFreeze thawingFiber

The invention relates to a black brick in archaizing building and a preparation method thereof, and relates to the technical field of the black brick. The black brick is prepared from the following raw materials in parts: 80-90 parts of cement, 60-70 parts of ash powder, 50-60 parts of riverway sludge, 45-55 parts of solid waste fiber stuff, 10-25 parts of sand, 10-15 parts of black iron oxide, 10-15 parts of green iron oxide, 2-10 parts of granolithic, 2-10 parts of electric lime, 1-8 parts of enhancer, 1-6 parts of water-repellent preservative, 2-7 parts of sintering additive and 200-300 parts of water. The resource is reasonably utilized, the preparation method is simple, the cost is lowered, and the prepared black brick is good in compressive strength and excellent in freeze-thawing resistance.

Owner:温州月煌科技有限公司

Method for removing iron ions in trivalent chromium acid solution

ActiveCN106399688AAchieve recyclingRealize high-value utilizationProcess efficiency improvementOxalateIron oxide black

The invention discloses a method for removing iron ions in a trivalent chromium acid solution. The method includes the following steps that an additive is added into the trivalent chromium acid solution to reduce the trivalent ferric ions to bivalent ferric ions, then an oxalate solution is added, leached materials are subjected to liquid-solid separation, and the trivalent chromium acid solution obtained after iron removing is used for producing a chromium slat product; and ferrous oxalate obtained after iron removing is subjected to oxidation leaching in an alkali solution, iron in the ferrous oxalate is converted into ferroferric oxide, oxalate is leached into the solution liquid-solid separation is carried out, an oxalate leaching agent is obtained and used for cyclically removing iron, and the obtained ferroferric oxide becomes a black iron oxide pigment after being dried. According to the method, consumption of an iron removing agent is greatly reduced, iron is removed thoroughly through the trivalent chromium acid solution, the byproduct of black iron oxide can reach the pigment performance of domestic 722 black iron oxide and does not contain high-toxicity hexavalent chromium, and the method can be used in the industries of buildings, coatings and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

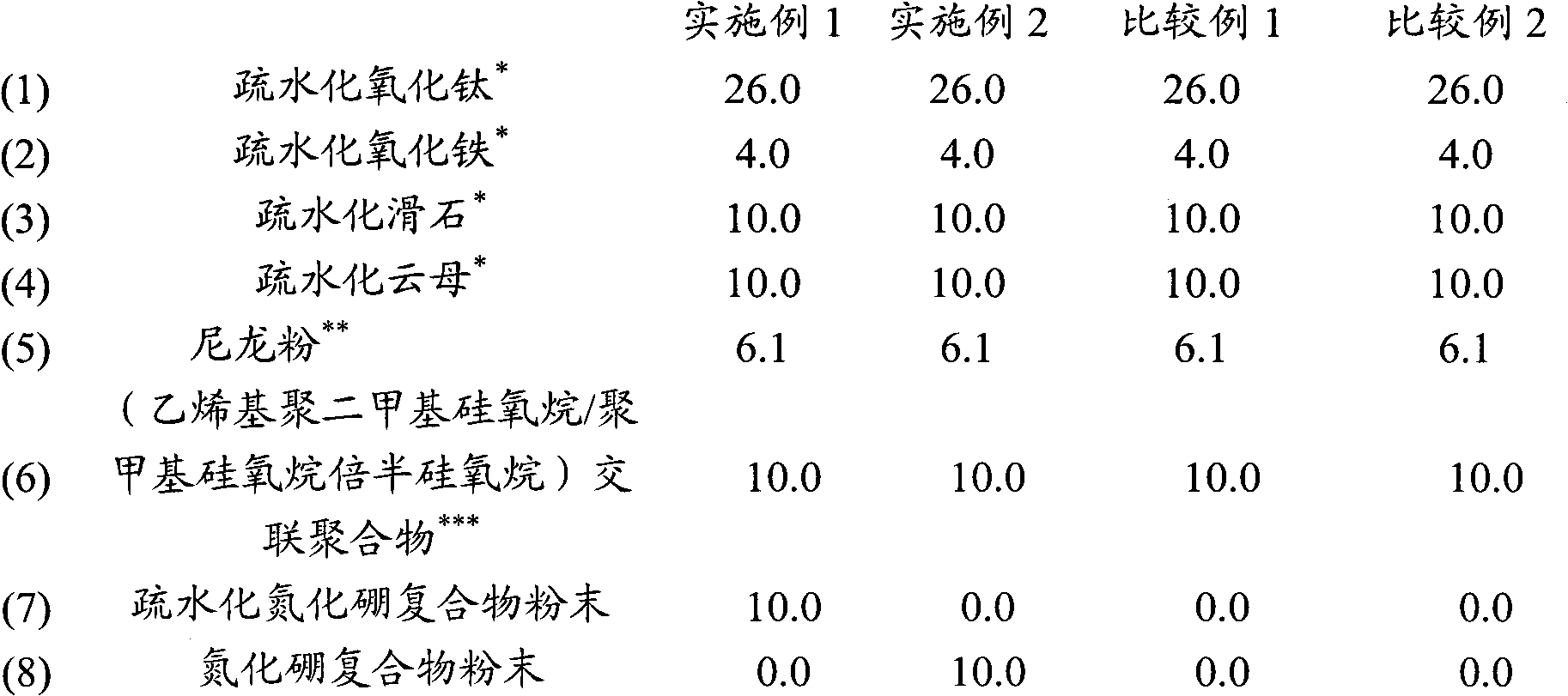

Cosmetic composition comprising boron nitride complex powder

A cosmetic composition comprising a boron nitride complex powder in which particles of metal oxide are attached to at least a part of the surface of a base material consisting of boron nitride. The metal oxide is preferably a combination of titanium dioxide, yellow iron oxide, red iron oxide and black iron oxide. Preferred compositions include liquid or powder foundation, lipstick, eye shadow, eye liner and mascara. The cosmetic composition comprising a cosmetic powder is capable of imparting smoothness to the touch, lively finish with fine texture and natural glow, and adhesion to the skin when applied to the skin.

Owner:CHANEL PARFUMS BEAUTE SAS

Preparation method for organosilicone high temperature resisting black iron oxide

ActiveCN103421355AImprove high temperature stabilityImprove high temperature resistancePigment treatment with organosilicon compoundsPigment physical treatmentWater bathsSilanes

The invention discloses a preparation method for organosilicone high temperature resisting black iron oxide, wherein the black iron oxide is prepared by adopting the sodium hydroxide oxidation method, and the preparation method comprises the following steps: a black iron oxide filter cake, which is not kiln dried, is directly used; ethanol solution, the weight of which is 2-3% of that of the black iron oxide filter cake, and silica sand, the weight of which is 1-2% of that of the black iron oxide filter cake, are added; the mixture is ground for 15-20 minutes at the speed of 1500-2500 rpm; the powder is taken out and dried, appropriate water is added, pulping is performed for 20-25 minutes, and seriflux with the concentration of 55-60% is prepared; methyl triethoxy silane, the weight of which is 4-6% of that of the seriflux, dimethyl dioxethyl silane, the weight of which is 2-3% of that of the seriflux, phenyl triethoxy silane, the weight of which is 5-8% of that of the seriflux, and hollow floating beads, the weight of which is 0.3-0.4% of that of the seriflux, are added, and the mixture is heated in water bath to 60-70 DEG C and stirred for 2-3 hours; a colloid mill is utilized to grind the seriflux until the grain size is less than 40 Mum; filtering, drying and powdering are performed, and the finished product is generated. The black iron oxide, disclosed by the invention, has superior high temperature resisting property and can bear the high temperature of 500-600 DEG C.

Owner:ANHUI QILIN CHEM TECH +1

Nanometer inorganic non-sticking water-based paint and preparation method thereof

The invention discloses nanometer inorganic non-sticking water-based paint and a preparation method thereof. The paint is composed of components A and components B according to weight ration as 3:1. The components A are composed of silicon oxide sol, alumina seed crystal, yttrium oxide seed crystal, rutile titanium dioxide, nanometer silicon dioxide, black iron oxide, isopropanol, deionized water, carboxymethyl acetic acid butyrate cellulose and polyvinyl alcohol. The components B are composed of methyl triethoxy silane, tetraethoxysilane, metasilicic acid methyl ester, isopropanol and ethanol. The preparation method includes: mixing the components A and the components B of the paint according to the weight ration as 3:1, and stirring and curing for more than 12 hours in sealing mode at the temperature of 35 DEG C and under the condition of 200-300 rpm to obtain the nanometer inorganic non-stick water-based paint. The nanometer inorganic non-sticking water-based paint uses natural ore and metal oxide as raw materials, water is used as a dispersion medium in a preparation process, pollution of solvent in conventional paint on environment is solved fundamentally, and products do not contain volatile organic compounds (VOC).

Owner:JIANGMEN ANNUOTE COOKING UTENSILS MFG

Baking-free antique black brick and preparation method thereof

The invention relates to a baking-free antique black brick and a preparation method thereof. The baking-free antique black brick comprises a basic layer and a surface layer, wherein the basic layer iscomprises clay residues, recycled aggregates and cement; the surface layer comprises white portland cement, slag powder, recycled fine aggregates, black iron oxide and green iron oxide. The clay residues are adopted to serve as one of the production raw materials of the baking-free antique black brick, the utilization rate and the additional value of the clay residues are improved, and the utilization of building waste resources is improved; moreover, the baking-free antique black brick prepared from the method can meet various performance indexes, and is suitable for masonry engineering anddecoration engineering; the production process is simple, the disposal efficiency is high, the treatment capacity is high, the field application effect is good, and the baking-free antique black brickhas good economic benefits and social benefits.

Owner:深圳市绿志新型建材研究院有限公司

Quick dry type polyurethane sealant and preparation method thereof

InactiveCN105505282AReasonable balance of flexibilityReasonable balance of strengthNon-macromolecular adhesive additivesOther chemical processesExtensibilityAntioxidant

The invention discloses quick dry type polyurethane sealant which comprises a main material A and a curing agent B. The main material A is prepared from, by weight, 25-35 parts of two-functionality-degree polyether polyol, 0-5 parts of three-functionality-degree polyether polyol, 25-35 parts of dioctyl phthalate, 0.5-1 part of dibutyltin dilaurate, 30-40 parts of calcium carbonate, 5-10 parts of hydrophobic modified gas-phase silicon dioxide, 0-0.5 part of antioxidant, 0-0.5 part of ultraviolet light absorber and 1-2 parts of black iron oxide. The curing agent B is prepared from, by weight, 25-35 parts of diphenyl-methane-diisocyanate, 55-75 parts of polypropylene oxide glycol, 15-25 parts of three-functionality-degree polyether polyol and 0-0.5 part of dibutyltin dilaurate. In the use process, the main material A and the curing agent B are evenly mixed for use according to the weight ratio of 3 to 1. The polyurethane sealant can be rapidly dried, has high tensile strength and breaking extensibility and is excellent in comprehensive mechanical performance and suitable for occasions where rapid curing is needed.

Owner:安徽万诚达新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com