Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

144 results about "Iron Black" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing iron oxide black

This is the producing method of a kind of oxidized iron oxide black including following contents: prepare ferrite watery solution; use sodium hydroxide as neutralizaing agent and react with ferrite watery solution to produce hydroxide ferrous; use oxygenous gas as oxidant, and react with said hydroxide ferrous to produce iron oxide black; make the prepared iron oxide black water washed, sieved, dried and comminuted orderly to get blue oxidized iron oxide black pigment product. The oxidized iron oxide black produced by this method has high purity and thin crystal grain, the grain size of produced pigment is thin and even, and has saturated blue ink light black and stable effect to light and atmosphere. It also has strong pigmentation strength and hiding power, and can be used in such fine chemical industry products as printing ink and carbon powder. The farther project is using waste residue containing ferrous sulfate and vented in titanium oxide powder production, to produce ferrous sulfate watery solution and produce oxidized iron oxide black, which can adequately use industry waste material to produce oxidized iron oxide black products of high quality, and reduce environmental pollution.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Preparation process of medium temperature resistant iron oxide black

InactiveCN101824236ADoes not change color smallLittle changeInorganic pigment treatmentIron oxide blackThermal insulation

The invention discloses a preparation process of medium temperature resistant iron oxide black; iron oxide black is obtained through an oxidation method, a filter cake which is not dried is directly used, the iron oxide black, the filter cake and the water are added in, a beating machine is controlled to prepare serum with a certain concentration, water-soluble additive is added in during a beating process, neutralizer is added, and the pH value is regulated; and the stirring is continued, iron black is produced through normal steps after heat insulation, dried and beaten into powder, and the medium temperature resistant iron oxide black is obtained. The iron oxide black prepared by the process can stand 260 to 270DEG C, does not discolor or has small color changes; and the iron black has the advantages of good heat resistant performance, and no flammability and no easy discoloring when in transportation and storage, ensures small heating color changes as well as the safety of transportation and storage, and simultaneously can be used at 270DEG C.

Owner:南通宝聚颜料有限公司

Method for producing iron oxide black

ActiveCN1709984AHigh tinting strengthUniform particle sizePigmenting treatmentReaction rateIron Black

The invention relates to the producing method of a kind of oxidized iron black. It includes following steps: add ferrite watery solution into neutralization action pot, add ammonia and mix round watery solution to neutralize it to prepare hydroxidized ferrous gelatin, transmit the produced gelatin into oxidizing reaction pot; send oxygenous gas and meanwhile heat gelatin to make it oxidated, after reaction we can get oxidized iron oxide black pulp; separate iron oxide black and mother liquor in pulp; make the separated iron oxide black water washed, sieved, dried and comminuted orderly to get finished products. This method adopts liquid phase method to make its reaction rate greatly improved, the particle granularity of oxidized iron oxide black finished products even; it has higher pigmentation strength, and the obtained product contains 96.5% Fe3O4. Compared with the industry appointed standard sample, its pigmentation strength is 200% - 250%; ulteriorly make offal in producing titanium oxide powder as material of this method, which is beneficial to circulation usage of industry waste material and environmental protection, and can greatly reduce producing cost.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

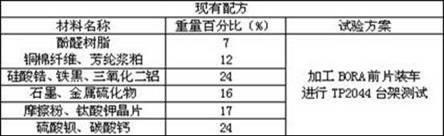

Method for producing brake block by scaly tartar salt

InactiveCN101178104AReduce heat transferExcellent high temperature braking performanceOther chemical processesFriction liningThermal energyMetallic sulfide

The invention relates to a method for preparing brake pads by using scaly potassium carbonate in the field of auto parts processing. The raw material composition and weight percentage are respectively: 5-10 binder, 15-25 reinforcement fiber, 20-30 abrasive, 15-25 lubricant and 30-40 regulator. The binder is modified phenolic resin, including nitrile modified phenolic resin or silicon modified phenolic resin, the reinforcing fiber includes copper cotton fiber and aramid pulp or a combination of ceramic fiber and aramid pulp, and the abrasive includes One or more combinations of zirconium silicate, iron black, aluminum oxide, and friction powder. The lubricant includes a combination of inorganic lubricant or organic lubricant and metal sulfide. The regulator is flaky potassium titanate, or flake Any combination of potassium titanate, barium sulfate and calcium carbonate. The brake pad prepared by the invention can well absorb the heat energy released by high-speed braking and reduce the heat conduction of the brake pad. So it has excellent high temperature braking performance and braking comfort.

Owner:信义集团公司

Preparation process of novel flame-retardant silicone rubber

The invention discloses a preparation process of novel flame-retardant silicone rubber. The preparation process includes: mixing hydrotalcite, ammonium polyphosphate and magnesium hydroxide to obtain filler, mixing alpha, omega-dihydroxy polydimethyl siloxane, silicone oil and nano calcium carbonate to obtain substrate, mixing the substrate and the filler to obtain base stock, mixing iron black, silicone oil, cross-linking agent, thickening agent and catalyst for reaction to obtain color paste, and mixing the base stock with the color paste to obtain the novel flame-retardant silicone rubber. The hydrotalcite, the ammonium polyphosphate and the magnesium hydroxide are heated to certain temperature for endothermic decomposition reaction so as to achieve flame retarding. The preparation process has the advantages that the prepared novel flame-retardant silicone rubber has fine flame retardancy up to level FV-0.

Owner:SICHUAN KELIXIN NEW MATERIALS CO LTD

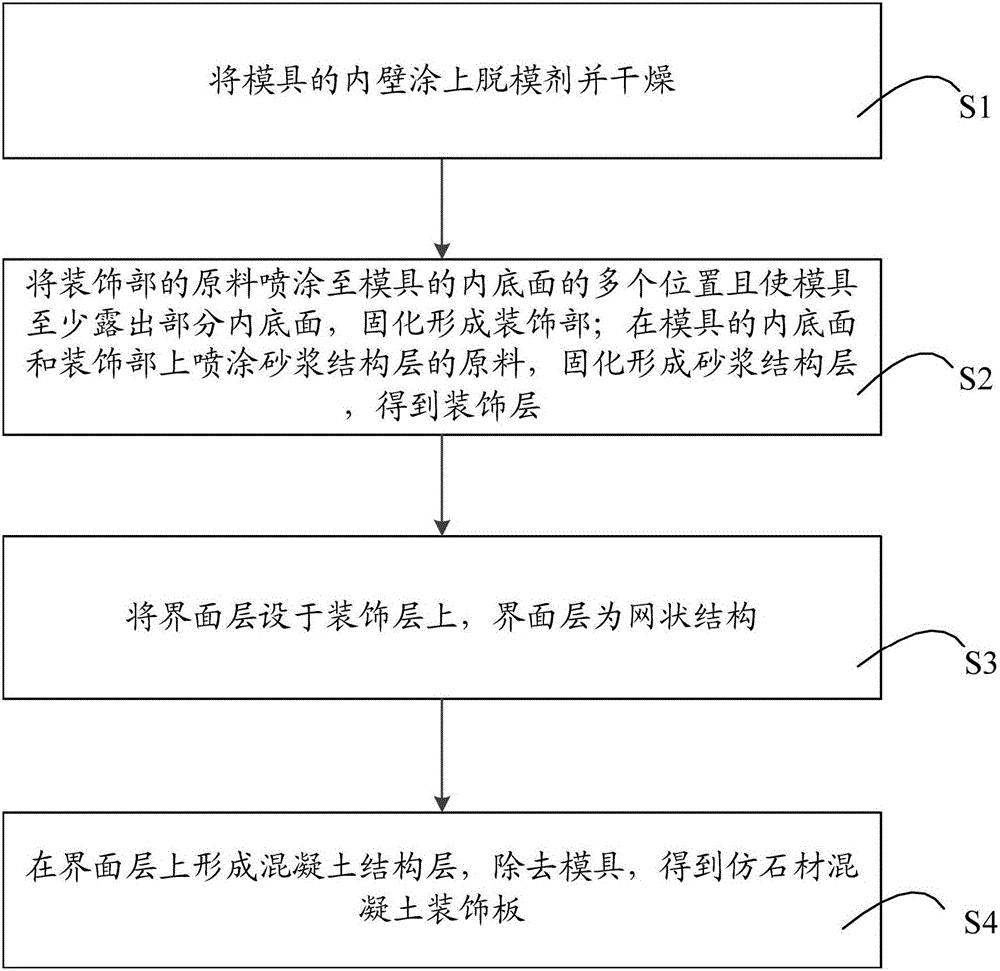

Imitation stone concrete decorative boards and preparation method thereof

The present invention discloses imitation stone concrete decorative boards and a preparation method thereof. The imitation stone concrete decorative boards and preparation method thereof comprises concrete structure layers, interface layers and decorative layers. The interface layers are in mesh structures and arranged on the concrete structure layers. The decorative layers are arranged on the interface layers, the decorative layers comprise mortar structure layers and a plurality of decorative parts distributed on the outer surface of the mortar structure layers, and the mortar structure layers at least expose parts of the outer surfaces. The raw materials of the mortar structure layers and the raw materials of the decorative parts comprise the following raw materials in parts by weight: 800-950 parts of cement, 600-900 parts of quartz sand at 20-40 meshes, 200-350 parts of quartz sand at 40-70 meshes, 80-130 parts of a water reducing agent, 0.1-0.6 part of cellulose ether, 90-135 parts of water and 5-15 parts of pigments. The pigments in the raw materials of the mortar structure layers and raw materials of the decorative parts are all one of iron black, iron yellow and titanium white. The pigments in the raw materials of the mortar structure layers and the raw materials of the decorative parts are not the same kind. In the imitation stone concrete decorative boards, the decorative layers obtained by using the raw materials of the decorative layers are strong in strength and thus good in durability. Besides, the decorative layers use different colors to embellish with each other to form the decorative board effects of imitation granite.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

Formula for preparing brake pads by utilizing acicular ceramic fiber

InactiveCN102619907APromote absorptionReduce heat transferOther chemical processesBraking membersAdhesiveMetallic sulfide

The invention provides a preparing formula of brake pad by utilizing acicular ceramic fiber. Ingredients of the formula comprise (by weight) 5%-10% of adhesive, 15%-20% of reinforced fiber, 20%-30% of abrasive, 15%-25% of lubricant, 10%-15% of modifier and 20%-30% of filler, wherein the adhesive is phenolic resin, or silicon modified phenolic resin, or butyronitrile modified phenolic resin or mixture of the three, the reinforced fiber is acicular ceramic fiber, or aramid pulp, or copper fiber or mixture of the three, the abrasive is zirconium silicate, or iron black, or aluminium oxide or mixture of the three, the lubricant is graphite, or metal sulfide or mixture of the both, the modifier is friction powder, or potassium titanate wafer or mixture of the both, and the filler is barium sulfate, or calcium carbonate or mixture of the both. By the aid of the preparing formula of brake pad by utilizing acicular ceramic fiber, the heat energy generated from rapid brake can be effectively absorbed by the finished brake pad in usage, and the thermal conductivity of the brake pads can be reduced, so that the brake pads have excellent braking performances in terms of high-temperature resistance, rapidness and comfortability.

Owner:DONGYING BORUI BRAKE SYST

Method for rapidly preparing black iron oxide from ferrous sulfate as titanium dioxide waste residue

InactiveCN104016418AReduce manufacturing costImprove oxidation efficiencyFerroso-ferric oxidesSocial benefitsSulfate

The invention discloses a method for rapidly preparing black iron oxide from ferrous sulfate as a titanium dioxide waste residue and belongs to the technical field of chemical engineering. The method comprises the following steps: a, removing impurities from ferrous sulfate to obtain a ferrous sulfate solution; b, taking a part of ferrous sulfate solution, diluting until the concentration is 10-15%, then introducing air or oxygen, controlling the pH value of the solution at 3-6, controlling the reaction temperature at 20-30 DEG C, and reacting until the color of the solution becomes earthy yellow, so as to obtain a crystal seed liquid; simultaneously and continuously adding the residue ferrous sulfate solution and ammonia to the crystal seed liquid, stirring and heating, controlling the pH value of the solution at 3.0-9.5, controlling the temperature at 70-90 DEG C, while continuously introducing air or oxygen, reacting for 5 to 6 hours, and filtering to a black iron precipitate; c, washing the iron black precipitate, filtering and drying to obtain the black iron oxide product. Since the process for preparing the black iron oxide disclosed by the invention requires only 5-6 hours and has the advantages of short time and low cost, and the method has relatively high economical and social benefits.

Owner:攀枝花市大牛科技有限公司

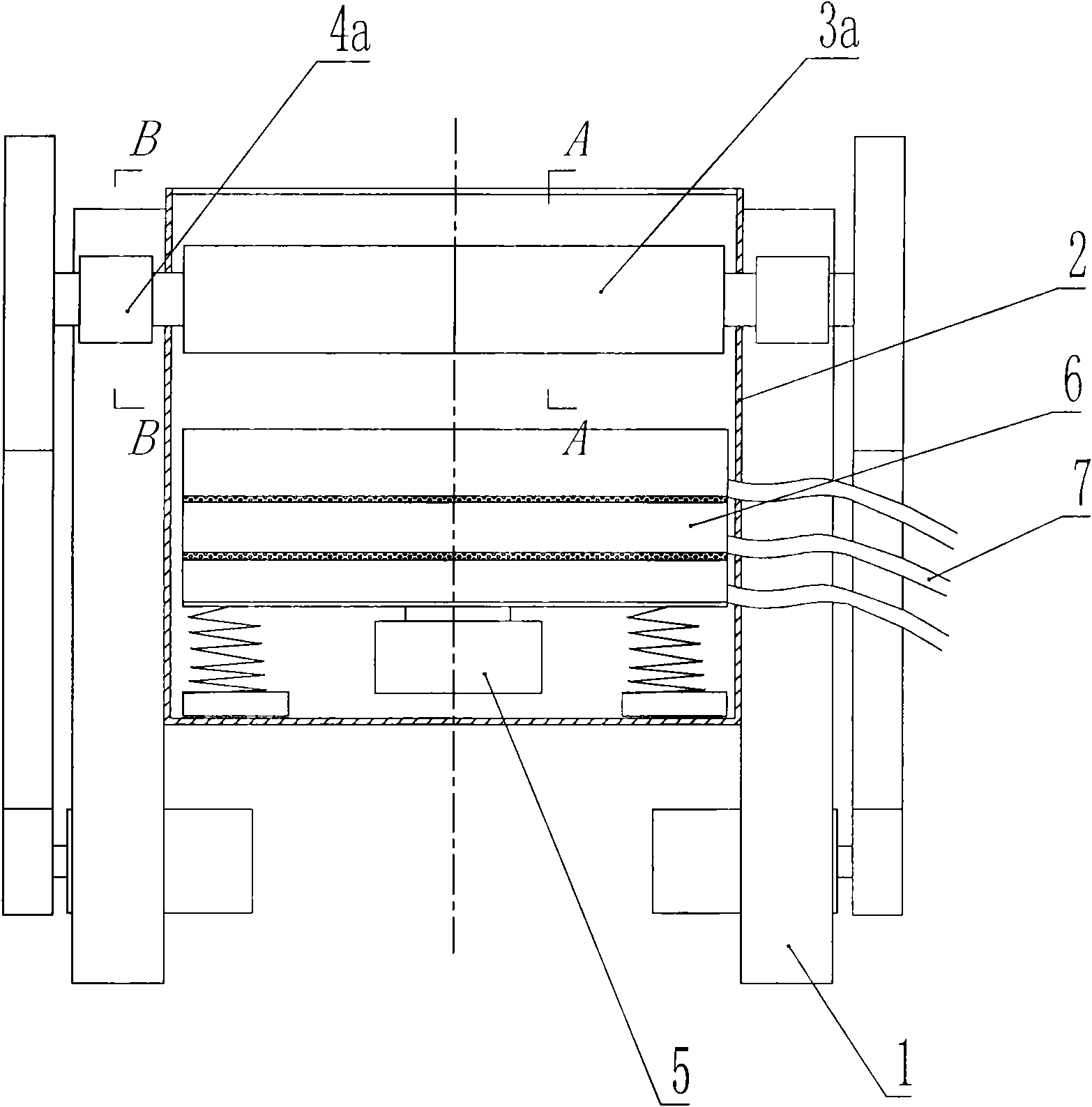

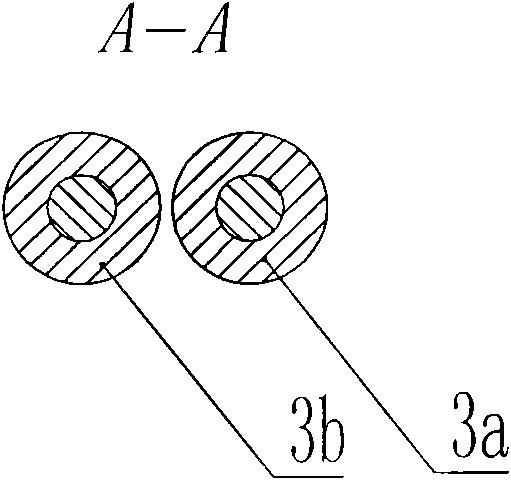

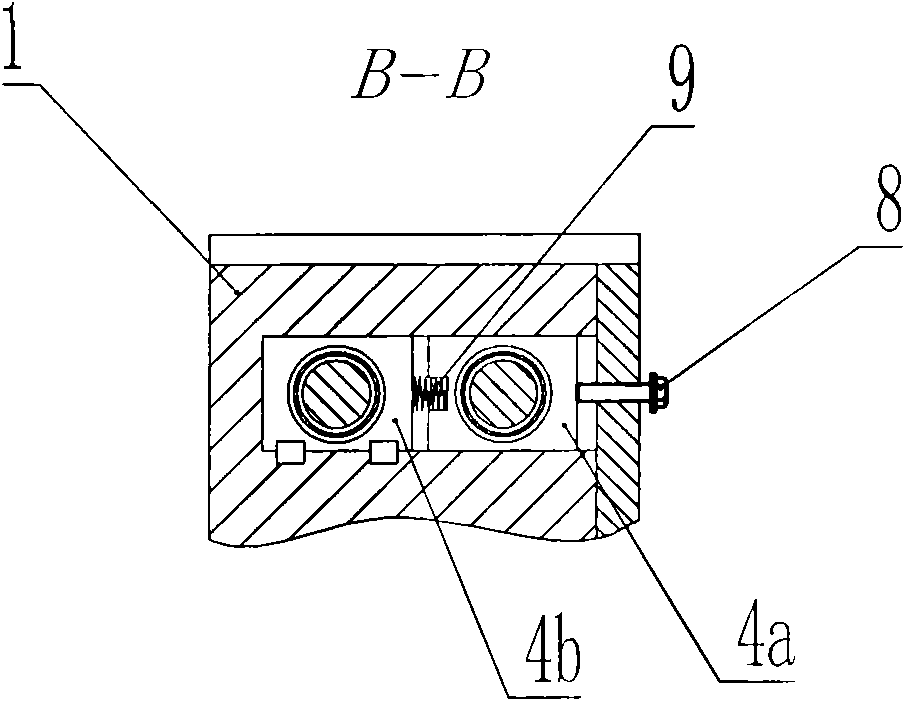

Manufacturing method of granular iron oxide black pigment and double-roller grinder for realizing same

InactiveCN101845240AGuaranteed to be pureTinting strength unchangedGrain treatmentsPigment physical treatmentIron oxide blackElectric machine

The invention mainly discloses a manufacturing method of granular iron oxide black pigment, which comprises the steps of: sending iron black block material with the water content of 1-2% into a double-roller grinder, and grinding the dry iron black block material into granules with the needed size in the double-roller grinder; then, classifying by a rotary vibration sieve; and collecting granular iron oxide black of 20-80 meshes. The technique has the advantages of solving the problem of the occupational disease caused by dust pollution of iron oxide pigment industry, improving the working environment of workers and protecting the health of the workers. The invention also discloses the double-roller grinder for realizing the method, the upper part of the grinder is provided with a pair of rollers which are provided with a fit clearance adjusting mechanism; three layers of vibrating screens which are driven by an eccentric motor and have the number of sieve meshes that are increased gradually from top to bottom are positioned just under the rollers; and the edges of the vibrating screens are provided with discharge holes. The double-roller grinder leads the material to be bitten into a grinding area by utilizing the frictional force of roller surfaces, thus crushing the material by extruding or splitting.

Owner:南通宝聚颜料有限公司

Method for preparing split-phase coloring iron black glaze

The invention relates to a method for preparing split-phase coloring iron black glaze, which comprises the steps of: preparing a boron frit: uniformly grinding feldspar, quartz, calcite, boric acid, NaNO3 and Li2CO3 in a mortar, putting a material mixture in a high-temperature furnace into a crucible calcined to a temperature of 1260 DEG C, melting for 10min and hardening; mixing the feldspar, the quartz, Suzhou soil, the calcite, talcum, ZnO, calcium phosphate, the boron frit, Fe2O3, cellulose, sodium tripolyphosphate and CMC (Carboxy Methylated Cellulose), finely grinding to 250-mesh, regulating the specific weight of glaze slip to be 1.7g / cm<3>; and uniformly applying the glaze slip to a blank, raising the temperature to 1160-1240 DEG C, insulating for 20-50min, then naturally cooling. The coloring is carried out by using split-phase textures generated by the frit in a glaze firing process. Less coloring oxides are used to generate higher coloring capacity, thus, iron black glaze which has the content of ferric oxide only accounting for 30-50 percent relative to that of a color material in the common glaze and has the advantages of low cost, high stability and high blackness is prepared.

Owner:江苏梵想建材科技有限公司

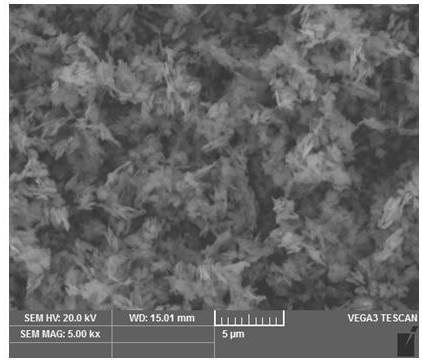

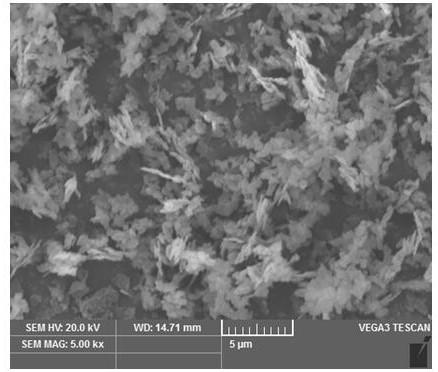

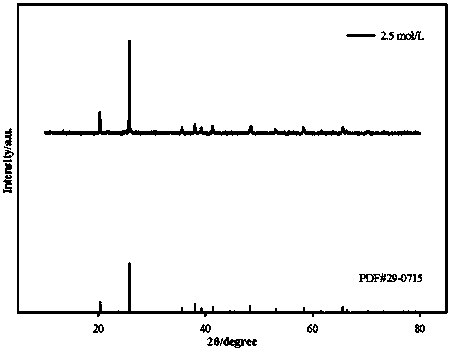

Preparation method for iron phosphate nanosheets

ActiveCN110294466AHigh purityAvoid interferenceMaterial nanotechnologyPhosphorus compoundsFiltrationPhosphate

The invention discloses a preparation method for iron phosphate nanosheets. The preparation method comprises the steps that iron black is slowly added to phosphoric acid with the concentration of 1.5-3.0 mol / L, stirring and heating are conducted for reacting, and after the reaction, the iron phosphate nanosheets are obtained through suction filtration, washing, drying, dewatering and other steps.The iron phosphate prepared by using the method has a nanosheet-shaped morphology, the thickness of the nanosheets is 70-80 nanometers, and the specific surface area is high. By optimizing the reaction conditions, in the reaction procsess, the pH value does not need to be adjusted, and no oxidizing agents are added; the interference with anionic and cationic impurities is effectively avoided, theiron phosphate obtained by using the method is free of impurity phases and high in purity. Besides, less water is used for washing iron phosphate precipitation, the iron phosphate synthesizing cost isreduced, and the pollution to the environment is reduced. The technology is simple, operation is convenient, industrial production is facilitated, and the preparation method is wide in application prospect.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Environment-friendly brake pad adopting copper-free microcrystalline friction materials

ActiveCN103821852ARich in microporesImprove frictional stabilityOther chemical processesBraking membersBrucitePetroleum coke

An environment-friendly brake pad adopting copper-free microcrystalline friction materials is made from components including acrylic pulp, mullite ceramic fibers, brucite fibers, nano tin powder, zinc sulfide, brown aluminum oxide, antimony sulfide, cellulosic fibers, iron black, calcium carbonate whiskers, calcium sulfate whiskers, potassium titanate, crystalline flake graphite, calcined petroleum coke, flake aluminum powder, nitrile rubber powder, phenolic resin, nanometer manganese hydroxide and molybdenum disulfide. Through reasonable collocation of the multiple components, advantages of the various components given full play to the friction materials can be guaranteed. By the reasonable collocation of the new fiber materials, the defect of respect performance can be made up, and high performance can be produced due to mutual influenced action. The environment-friendly brake pad is good in resistance to high-temperature recession, long in service life, good in wear-resisting performance, stable in friction coefficient and environment friendly.

Owner:摩擦一号制动科技(仙桃)有限公司

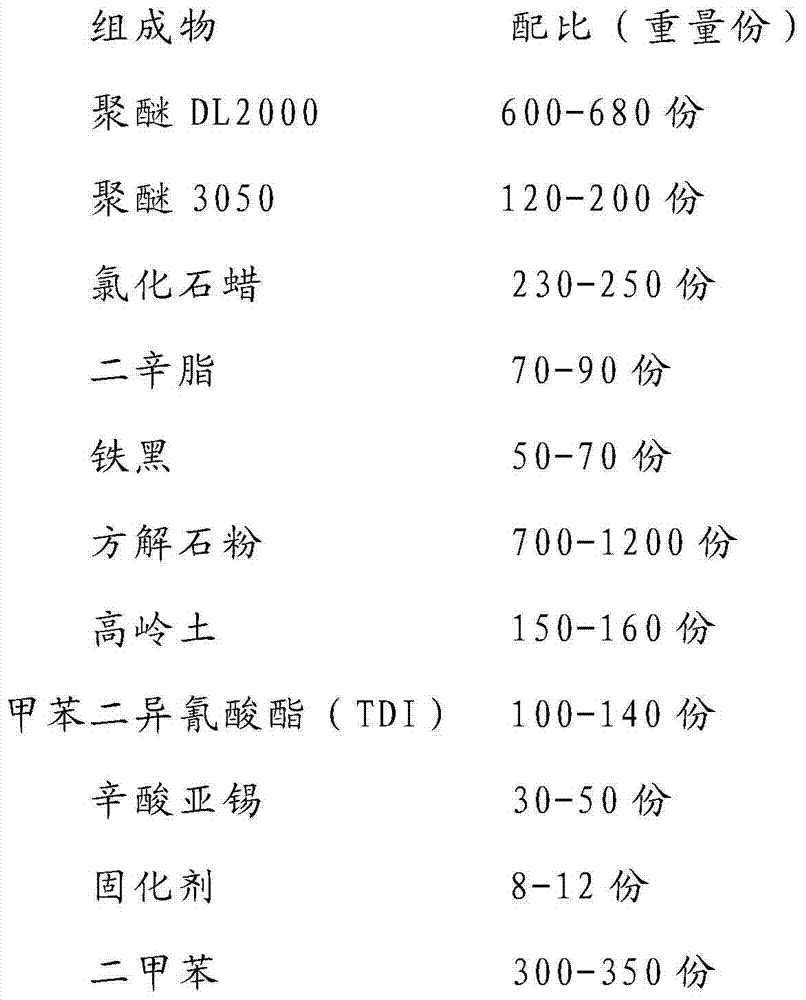

Single-composition polyurethane waterproof paint and preparation method thereof

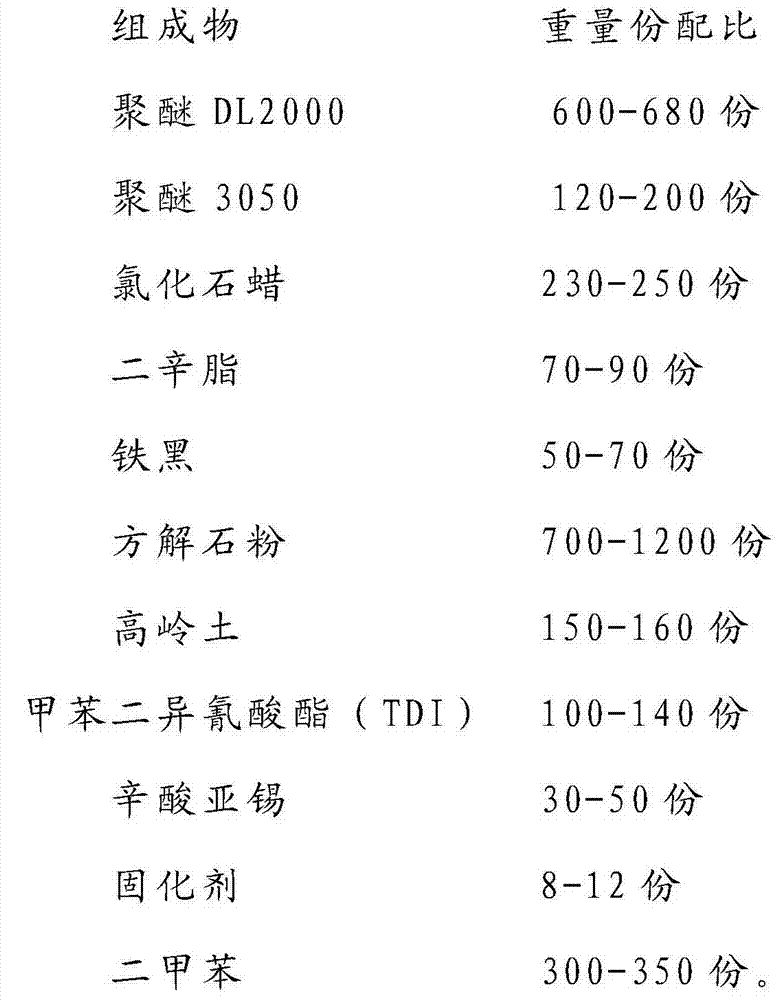

Related single-composition polyurethane waterproof paint is prepared by mixing materials of the following formula, in parts by weight, 600-680 parts of polyether DL2000, 3050 120-200 parts of polyether, 230-250 parts of chlorinated paraffin, 70-90 parts of dioctyl phthalate, 50-70 parts of iron black, 700-1200 parts of calcite powder, 150-160 parts of kaolin, 100-140 parts of toluene diisocyanate (TDI), 30-50 parts of stannous octoate, 8-12 parts of a curing agent, and 300-350 parts of xylene. Compared with conventional polyurethane waterproof paint, the single-composition polyurethane waterproof paint is simple for film coating, good in coating effect, free of surface bubbles, and good in tensile strength and elongation at break, and dried polyurethane is smooth and flat in surface and excellent in bonding effect.

Owner:武汉市恒星防水材料有限公司

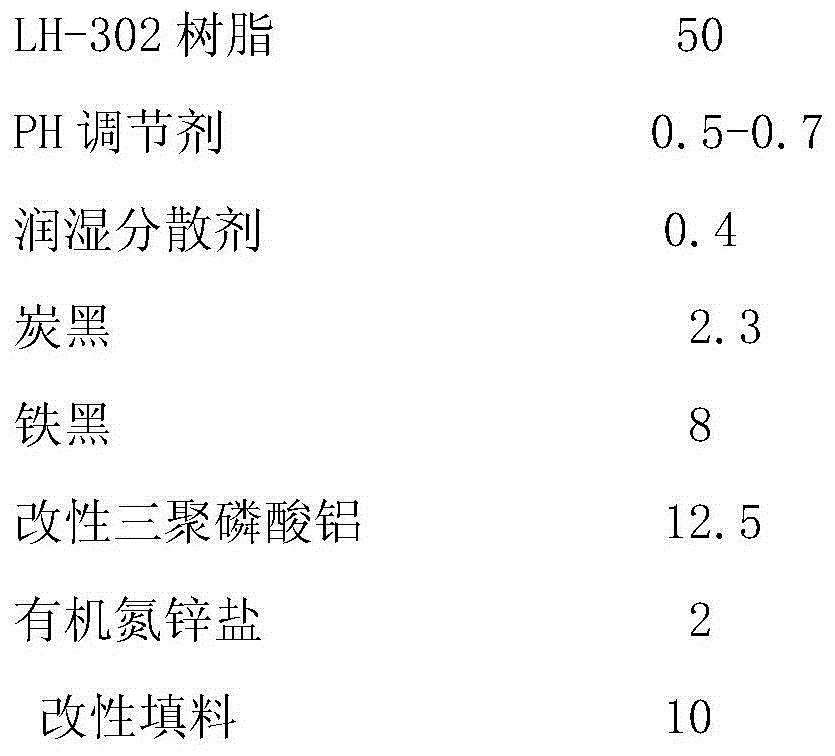

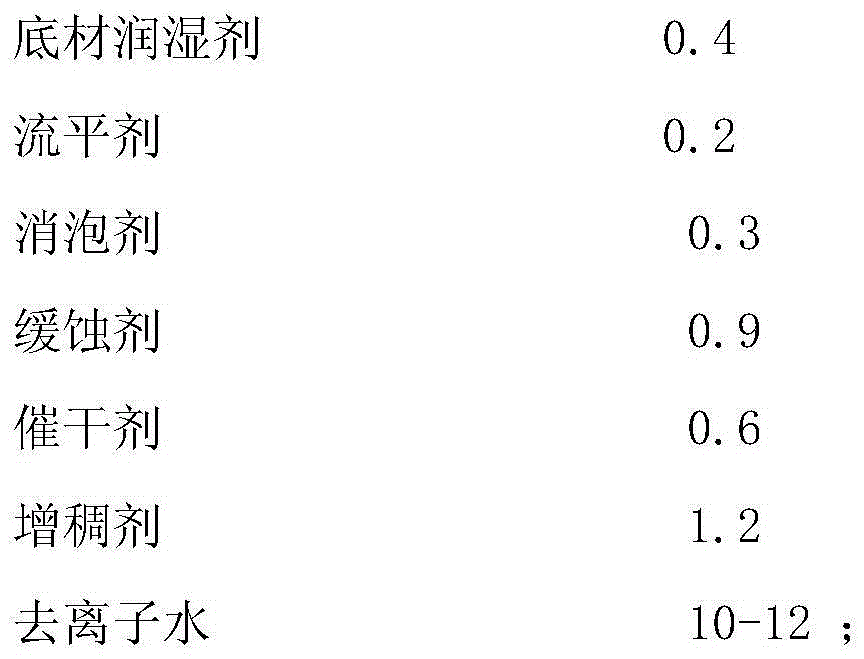

Water-based antiseptic paint for automotive chassis and preparation method thereof

ActiveCN103555121AImprove paint film performanceStrong adhesionAnti-corrosive paintsWater basedAutomotive paint

The invention provides a water-based antiseptic paint for an automotive chassis. The automotive paint is prepared by mixing the following components in parts by weight: 48-52 parts of LH-302 resin, 2.0-2.5 parts of carbon black, 7-9 parts of iron black, 12-13 parts of modified aluminum tripolyphosphate, 1-3 parts of organic nitrogen zinc salt, 9-11 parts of modified filler, 0.3-0.5 parts of wetting dispersant, 0.8-1.0 part of corrosion inhibitor, 0.3-0.5 parts of substrate wetting agent, 0.1-2.0 parts of assistant and 10-12 parts of deionized water. The water-based antiseptic paint for the automotive chassis provided by the invention can be naturally dried at normal temperature and can be dried at a low temperature (dried for 0.5 hour at 80-90 DEG C), the paint film property is remarkably enhanced, and the adhesive force, the hardness and the salt fog resistance are ideal. The paint is mainly used for automobile axles, automotive chassis, auto parts and the like.

Owner:ANQING LINGHU PAINT

Method for producing sedan car brake block floating material by using grinding waste material

The invention relates to a preparation technique field of brake block of a car, in particular to a method for using grinding waste to prepare buoyant material of the brake block of the car. The technical proposal is as follows: the preparation of resin, fiber, a grind-enhancing agent, a grind-reducing agent, a friction modifier and a filling agent is carried out by the following technique steps of: blenching, mixing, cold forming type, vulcanization, grinding and inspection, wherein, the grind-reducing is graphite and the friction modifier is frictional powder. The resin adopts phenolic resin, the fiber adopts that aramid short fiber, ceramic fiber and copper fiber are mixed, the grind-enhancing agent adopts that zircon and iron black are mixed, the filling agent adopts that barium sulfate, potassium titanate, grinding material and tire powder are mixed. The invention uses the existing technique to prepare the buoyant material of the brake block of the car by adding the grinding waste material so as to reduce the cost. By using the product processed by the materials, the shearing strength meets the requirements, the friction performance also meets requirements and the cost is reduced.

Owner:信义集团公司

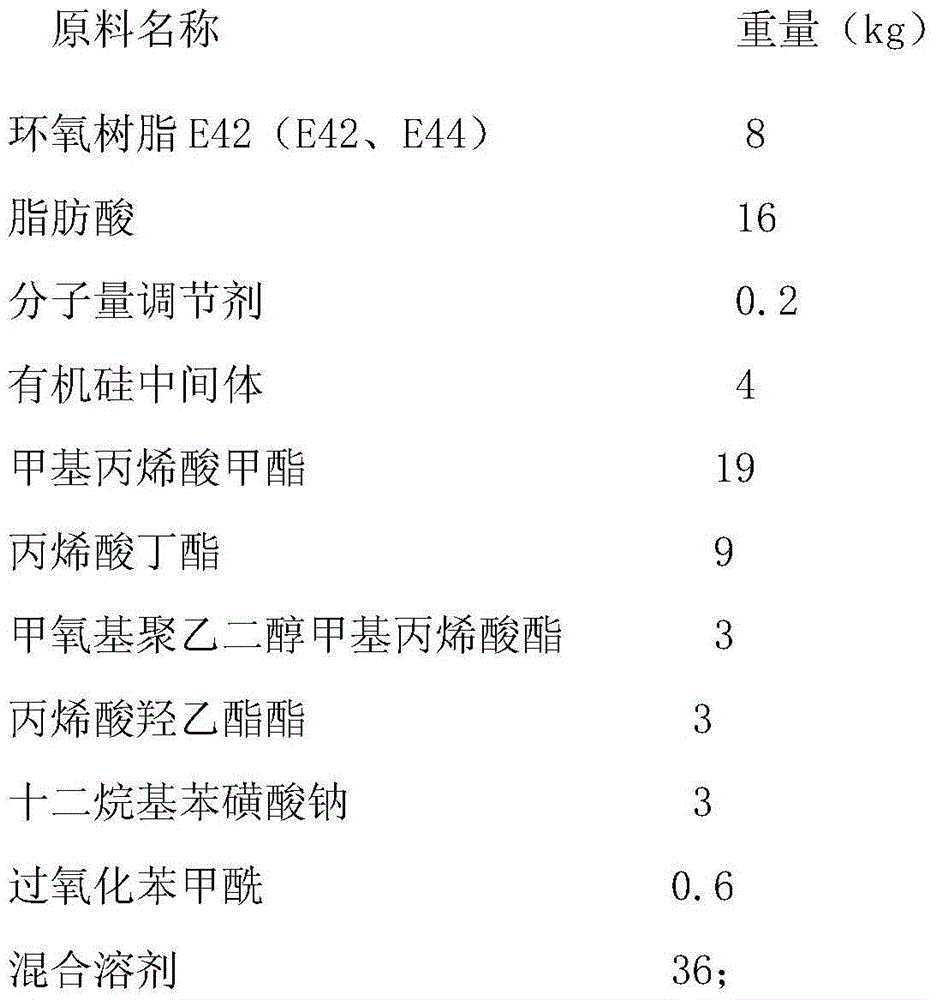

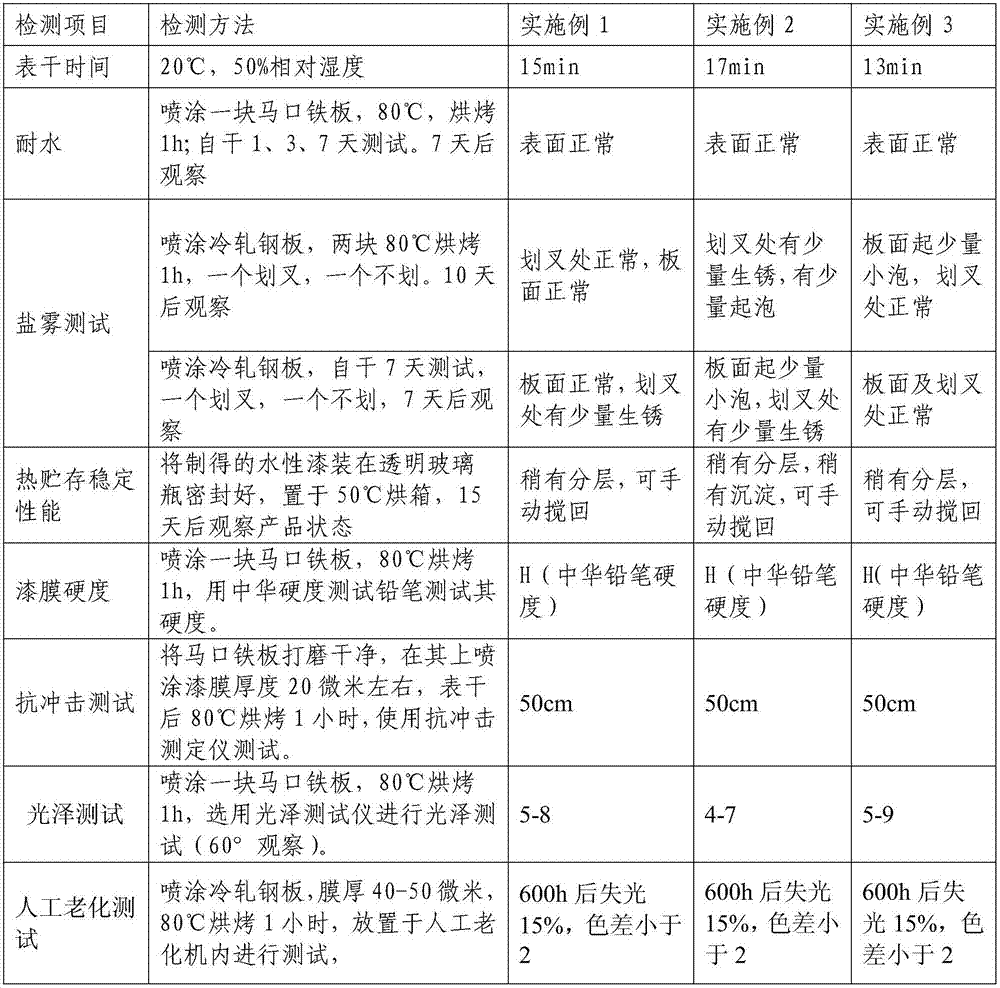

Environment-friendly waterborne coating used for dip coating of track shoe and preparation method thereof

InactiveCN107474700AImprove protectionSmall smellAnti-corrosive paintsMetallic material coating processesEpoxyDip-coating

The invention discloses an environment-friendly waterborne coating used for dip coating of track shoe. The environment-friendly waterborne coating is prepared from the following raw materials in percentages by weight: 35 to 50% of a waterborne acrylic modified epoxy emulsion, 0.25 to 0.75% of an antifoaming agent, 1.5 to 3.25% of a dispersing agent, 18 to 28% of deionized water, 0.38 to 0.93% of a neutralizing agent, 0.21 to 0.79% of a leveling and wetting agent, 1.51 to 2.39% of a flash-rust inhibitor, 0.35 to 1.23% of carbon black, 5.23 to 8.36% of iron black, 6.43 to 8.07% of barium sulfate, 6.22 to 8.69% of composite zinc phosphate, 4.31 to 5.57% of a thixotropic anti-settling agent, 3.43 to 5.07% of aluminum tripolyphosphate, 2.43 to 3.27% of talcum powder, 0.33 to 0.67% of matting powder and 0.32 to 0.58% of a thickening agent. The waterborne coating prepared by using the method provided by the invention has the following advantages: the VOC is no more than 85 g / L; the odor is low; the environment is avoided from pollution; meanwhile, the waterborne coating has matte, water resistance, salt fog resistance, excellent surface drying time, stable heat storage performance, and excellent coating film mechanical strength and impact resistance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

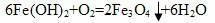

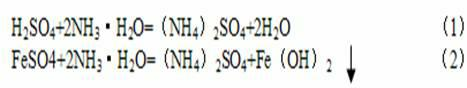

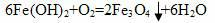

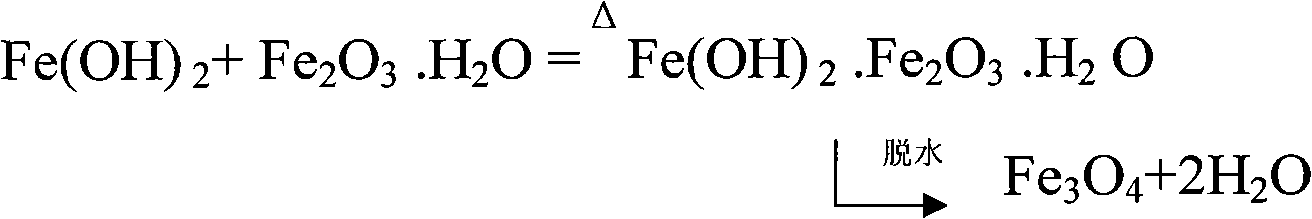

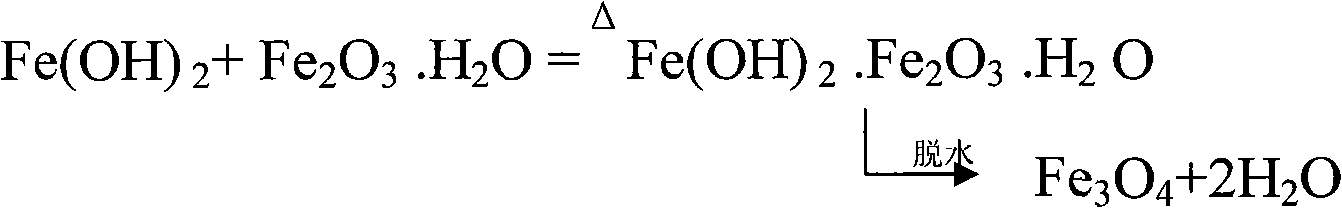

Method for preparing ammonium sulfate and Fe3O4 from titanium dioxide production waste acid solution

InactiveCN102086039AMature technologySimple processFerroso-ferric oxidesAmmonium sulfatesIron BlackFilter press

The invention relates to a method for preparing ammonium sulfate and Fe3O4 from titanium dioxide production waste acid solution. The method is characterized by comprising the following steps: (1) concentrating the titanium dioxide production waste acid solution to 25-35wt%, sending the concentrated solution to a storage tank for standby; (2) sending the solution concentrated in the step (1) to an oxidation pond, introducing ammonia water, stirring with a stirrer to perform neutralization reaction; (3) introducing steam in the oxidation pond after the reaction to ensure that the temperature of the solution is increased to 90-95 DEG C, introducing compressed air at 60 DEG C while heating continuously to ensure that the oxidation reaction of Fe(OH)2 is performed continuously and Fe3O4 precipitate is obtained; and (4) sending the precipitated Fe3O4 to a filter press to perform solid-liquid separation, wherein the solid is iron black and the liquid is ammonium sulfate solution. In the method of the invention, the titanium dioxide production waste acid is used to react with ammonia water to prepare ammonium sulfate; and the technology is mature and the process is simple and is convenient to operate.

Owner:LUOHE XINGMAO TITANIUM IND

Color additive of cement concrete and color steel fibre concrete with said additive

The color additive consists of coloring agent, dispersant, composite early strength effective water reducing agent and swelling agent. Specifically, it consists of iron black or carbon black as coloring agent, calgon or STPP as dispersant, water reducing agent and potassium aluminum sulfate as swelling agent. The color additive can change the color of cement concrete and improve the performanceof cement concrete. Specially, when the cement concrete with the color additive is used in the extension joint of asphalt bridge surface of expressway, the less color difference can raise the safetyof running vehicles.

Owner:王文炳 +3

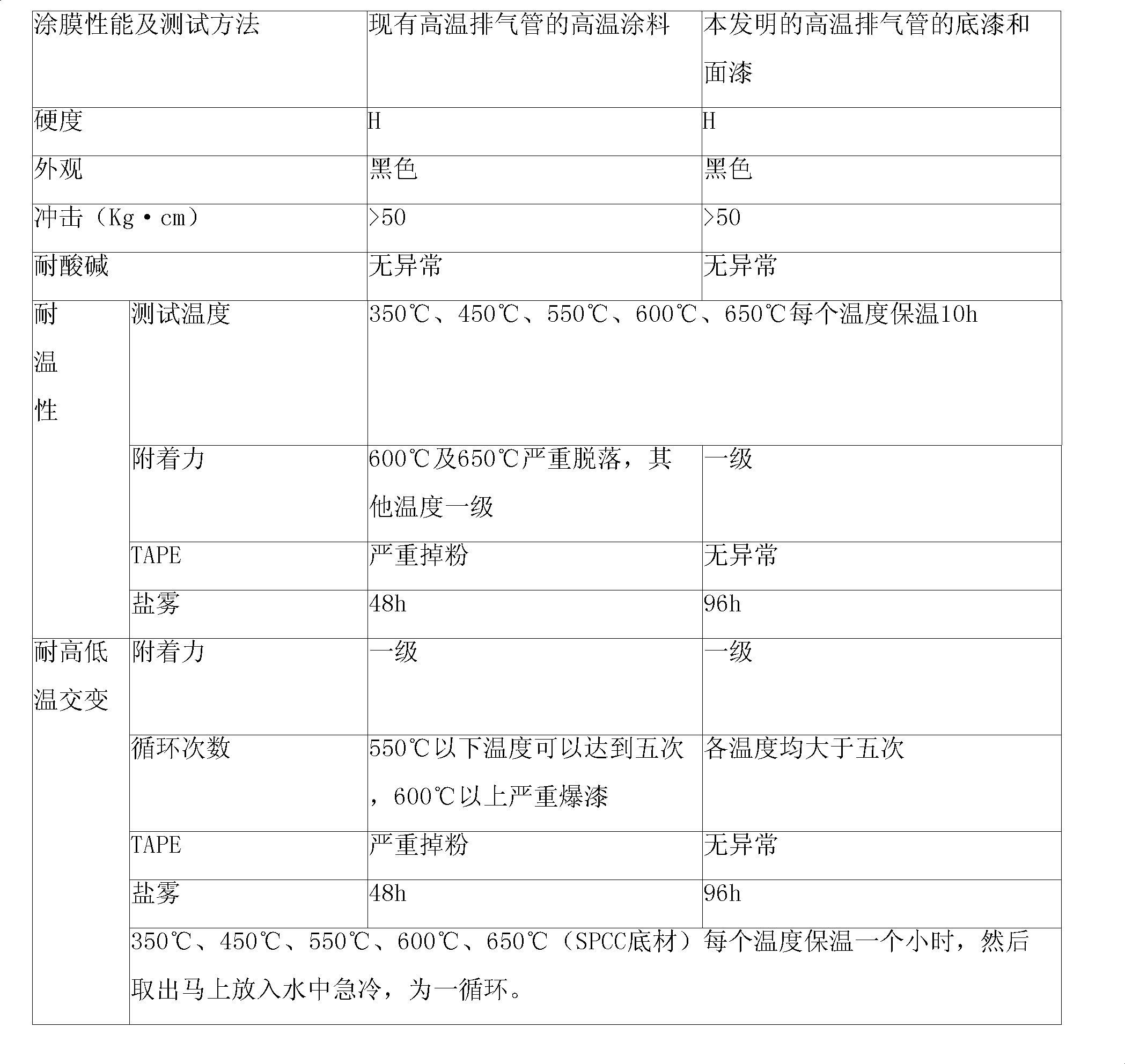

A high-temperature exhaust pipe primer and finish

The invention discloses a high-temperature exhaust pipe primer, including the following components: epoxy-modified silicone resin, epoxy resin, filler, chromium and iron black powder, anti-settling agents and solvents. The invention also discloses a high-temperature exhaust pipe finish, including the following components: methyl phenyl siloxane resin, epoxy resin, filler, chromium and iron black powder, anti-settling agents and solvents. The inventive primer and finish can achieve full temperature range of protection by regulation of primer and finish matching, has a good temperature resistance, coating sintering character and salt spray resistance, and can satisfy the requirement of long-term use in the temperature range of 550-650 DEG C. The coating is not easy to crack, and the phenomenon of powder dropping and rust stripping will not appear after high temperature.

Owner:江苏四方威凯科技有限公司

Method for manufacturing free flowing granular ferric oxide black pigment

InactiveCN102618090AGood sphericityGood free-flowing propertiesPigment treatment with macromolecular organic compoundsPigment physical treatmentSpray GranulationSlurry

The invention discloses a method for manufacturing a free flowing granular ferric oxide black pigment. The method mainly comprises the steps of preparing ferric oxide black liquid slurry and then obtaining the free flowing granular ferric oxide black pigment by granulation, namely preparing the slurry containing 48 to 60 percent of iron black solid from pre-dispersed ferric oxide black cakes, adding a certain amount of granulating additive, stirring, and performing colloid milling to obtain the iron black slurry; and spraying the prepared ferric oxide black liquid slurry to a granulation tower according to the flow rate of 80 to 120 kilograms per hour, atomizing, drying droplets in the tower during natural falling into granular powder through hot airflow in the tower, and discharging from the bottom of a drying tower. The granular ferric oxide black pigment obtained by spray granulation in the method has the characteristics of good spherical degree and uniform granules of which diameters are 60 to 160 microns, and the granular pigment has good free flowing property; and when the pigment is used, the pigment is convenient for conveying with material pipelines, automatic metering and the like, and does not produce a powder wall stagnation phenomenon in the pipelines and containers.

Owner:南通宝聚颜料有限公司

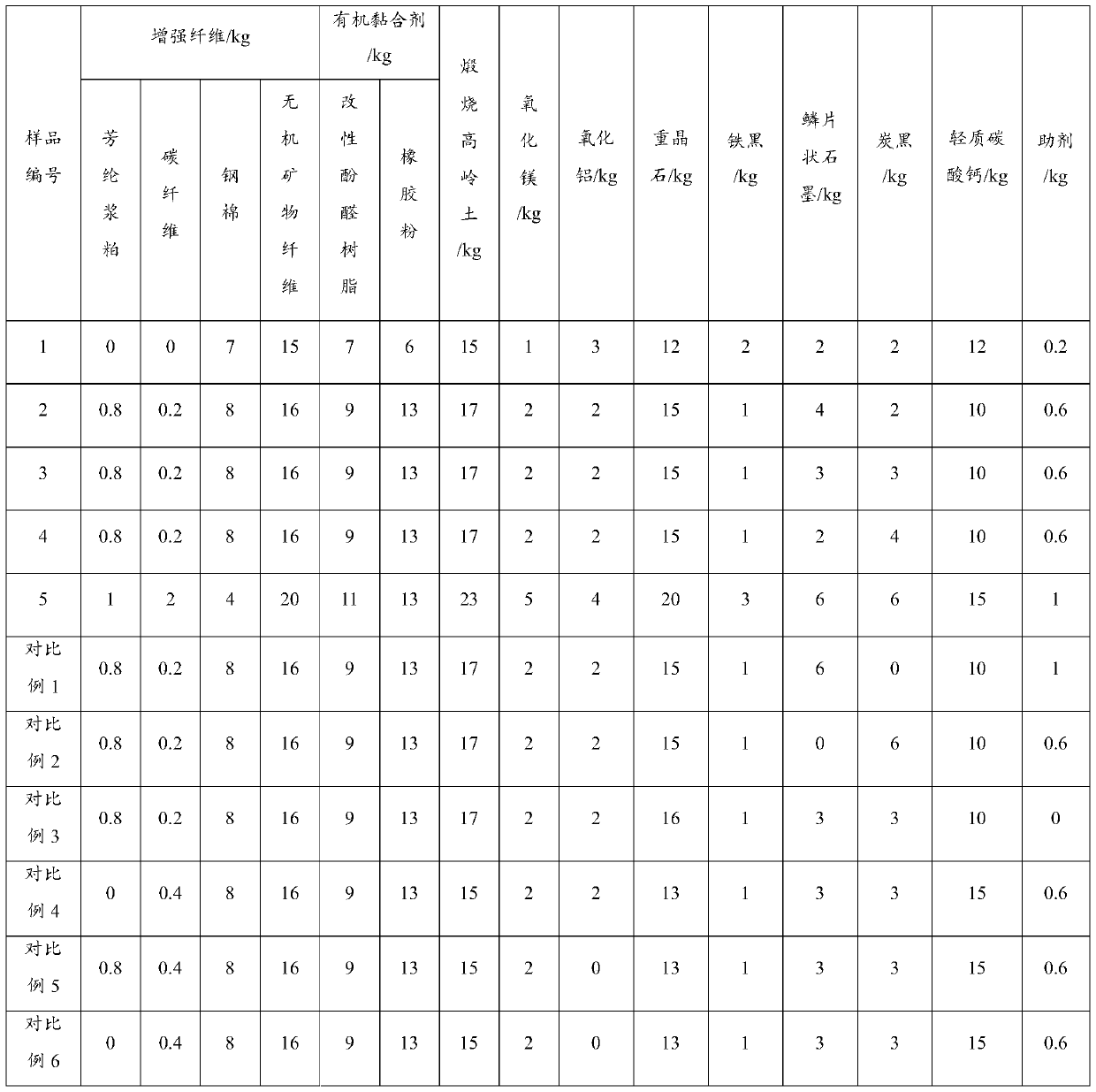

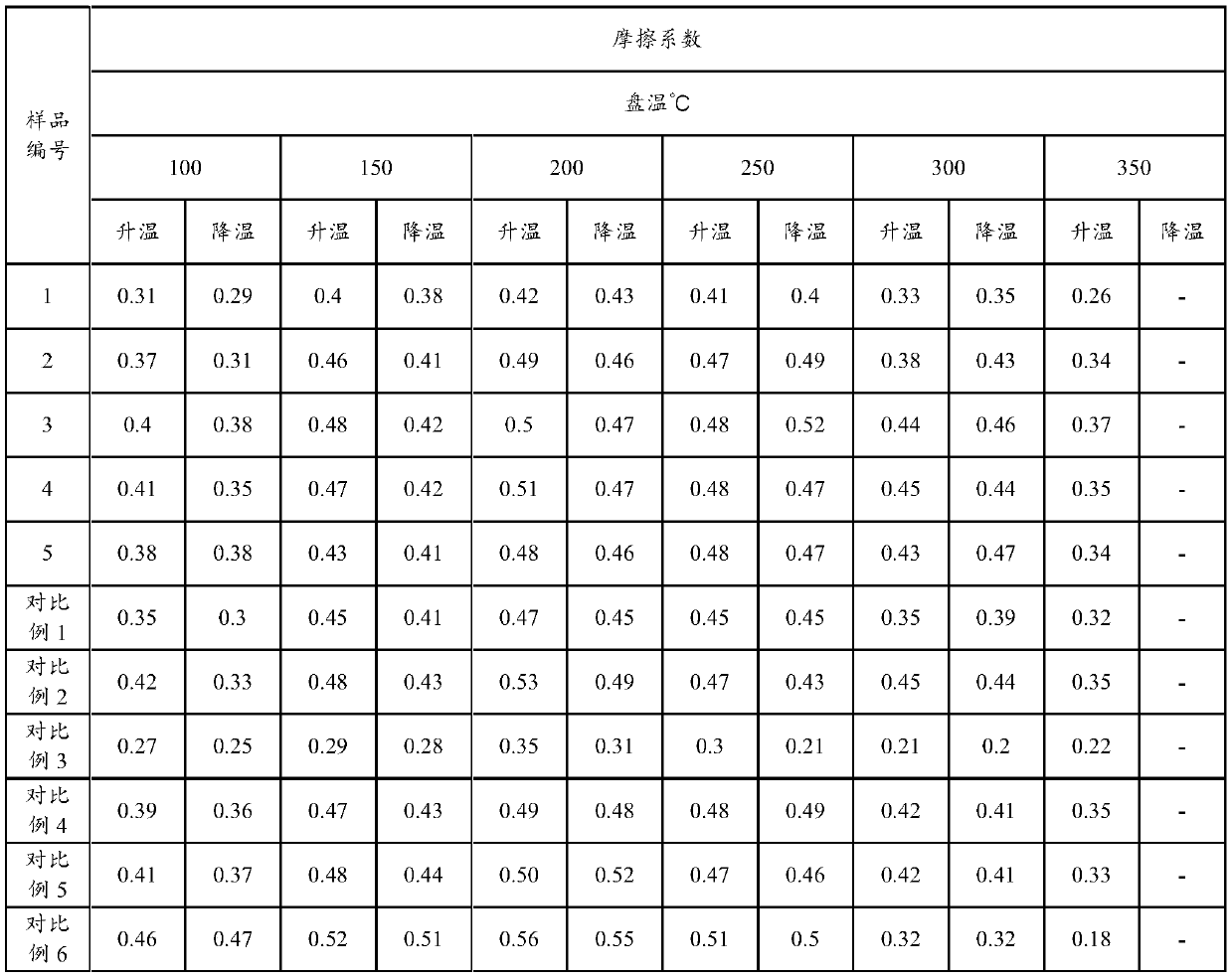

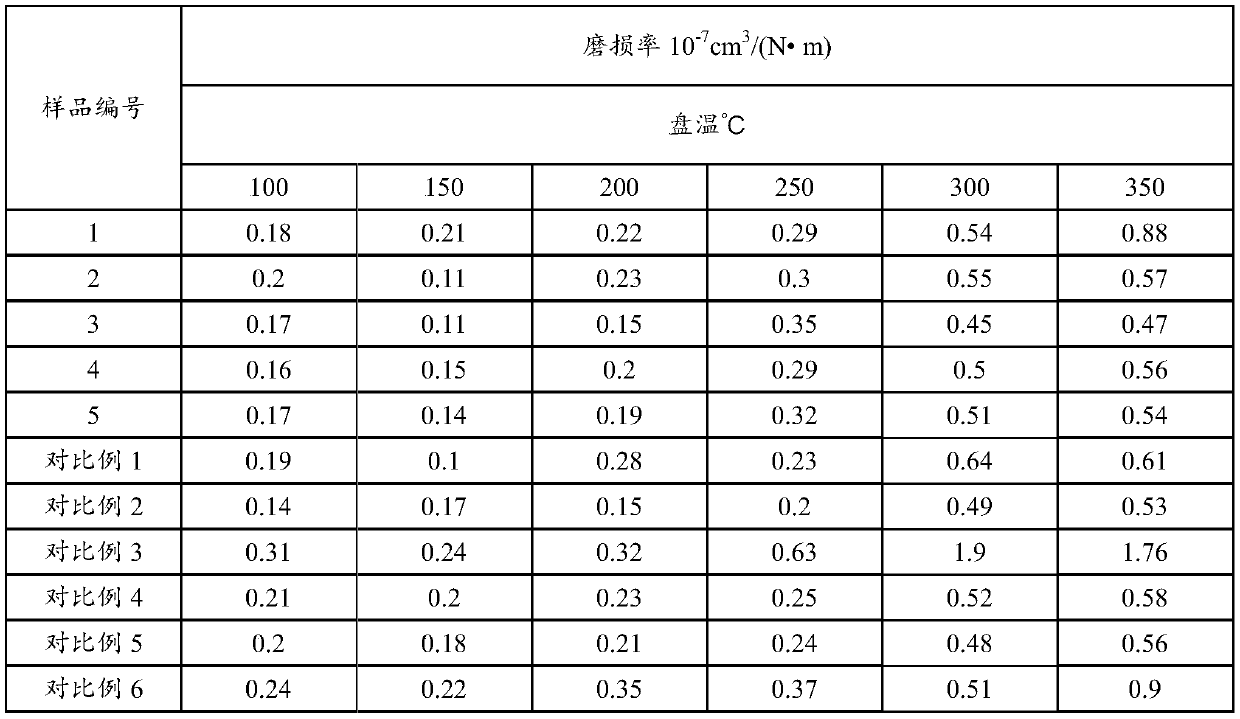

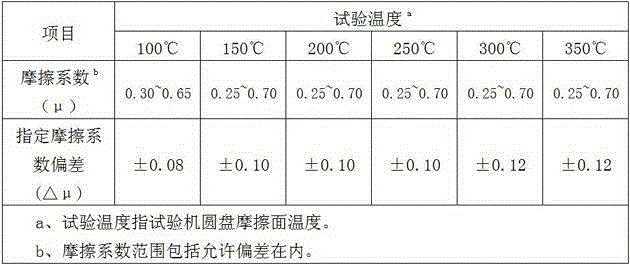

Environment-friendly high-performance friction material for automobile brake pad and preparation method thereof

PendingCN109780106AStable and moderate coefficient of frictionImprove heat resistanceFriction liningFiberAdhesive

The invention discloses an environment-friendly high-performance friction material for an automobile brake pad and a preparation method thereof. The environment-friendly high-performance friction material comprises the following raw materials of, by weight, 22-27 parts of reinforced fibers, 13-24 parts of an organic adhesive, 15-23 parts of calcined kaolin, 1-5 parts of magnesium oxide, 2-4 partsof aluminum oxide, 12-20 parts of barite, 1-3 pars of iron black, 2-6 parts of flaky graphite, 2-6 parts of carbon black, 10-15 parts of light calcium carbonate and 0.2-1 part of an assistant. The preparation method of the environment-friendly high-performance friction material comprises the following steps of material mixing, drying, hot pressing and heat treatment. The environment-friendly high-performance friction material and the preparation method thereof have the advantages that asbestos, metal sulfide and harmful heavy metal elements are not added, and the environment friendly effect isachieved; the friction coefficient is stable and moderate, the heat resistance is high, the abrasion rate is low, and braking noise is low; and the preparation technology is simple, easy to operate and suitable for industrial production, and the social and economic benefits are obvious.

Owner:QILU UNIV OF TECH

Method for preparing chromium iron black from electroplated chromium-containing waste water in recycling mode

InactiveCN106277456ATake advantage ofIncrease economic value addedIron oxides/hydroxidesWater contaminantsIron BlackFerrochrome

The invention discloses a method for preparing chromium iron black from electroplated chromium-containing waste water in a recycling mode. The method comprises the following steps that 1, the total chromium, chromium (III) and chromium (VI) content in the electroplated chromium-containing waste water is measured, the pH of the waste water is adjusted to range from 8 to 11 with liquid caustic soda, and an oxidizing agent is added to oxidize chromium (III) into chromium (VI); 2, the pH of the oxidized waste water is adjusted to range from 3 to 4 with sulfuric acid, an iron-containing agent is added, stirring is carried out at normal temperature for reacting, and a reaction solution is obtained; 3, liquid caustic soda is added into the reaction solution obtained in the step 2, the pH is adjusted to range from 8 to 9, then an aeration reaction is carried out, filtering and separation are carried out, and a filter cake and filtrate are obtained, wherein the filtrate is waste water obtained after chromium removal and can be directly drained or used for the rinsing section in the step 4; the filter cake obtained in the step 3 is subjected to rinsing, drying, calcining and smashing, and the chromium iron black product is obtained. Chromium in the electroplated chromium-containing waste water is converted into chromium iron black pigments with high economic additional value through a simple process path, the problem about treatment of the electroplated chromium-containing waste water is solved, chromium resources are reutilized, and sustainable development of the resources is achieved.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

High temperature resistant anticorrosive paint and preparation method thereof

InactiveCN102051117AStrong adhesionImprove impact resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyIsobutanol

The invention belongs to the technical field of light industry, in particular to a high temperature resistant anticorrosive paint and a preparation method thereof. The invention provides a high temperature resistant anticorrosive paint which is efficient and stable and a preparation method thereof. The paint contains a component A, a component B and a component C. The component A comprises the following components by weight percent: 1.0-2.0% of bentonite and 3.0-6.0% of butyl acetate. The component B comprises the following components by weight percent: 6.0-10.0% of epoxy resin and 4.0-6.0% of amino resin. The component C comprises the following components by weight percent: 28.0-32.0% of organosilicon resin A, 3.0-7.0% of organosilicon resin B, 1.0-3.0% of organic inhibitor, 1.0-2.0% of color black, 1.0-2.0% of titanium dioxide powder, 10.0-15.0% of graphite black, 2.0-6.0% of high temperature iron black, 10.0-17.0% of talcum powder, 3.0-7.0% of aluminum tripolyphosphate and 3.0-6.0% of isobutanol.

Owner:孙向勇

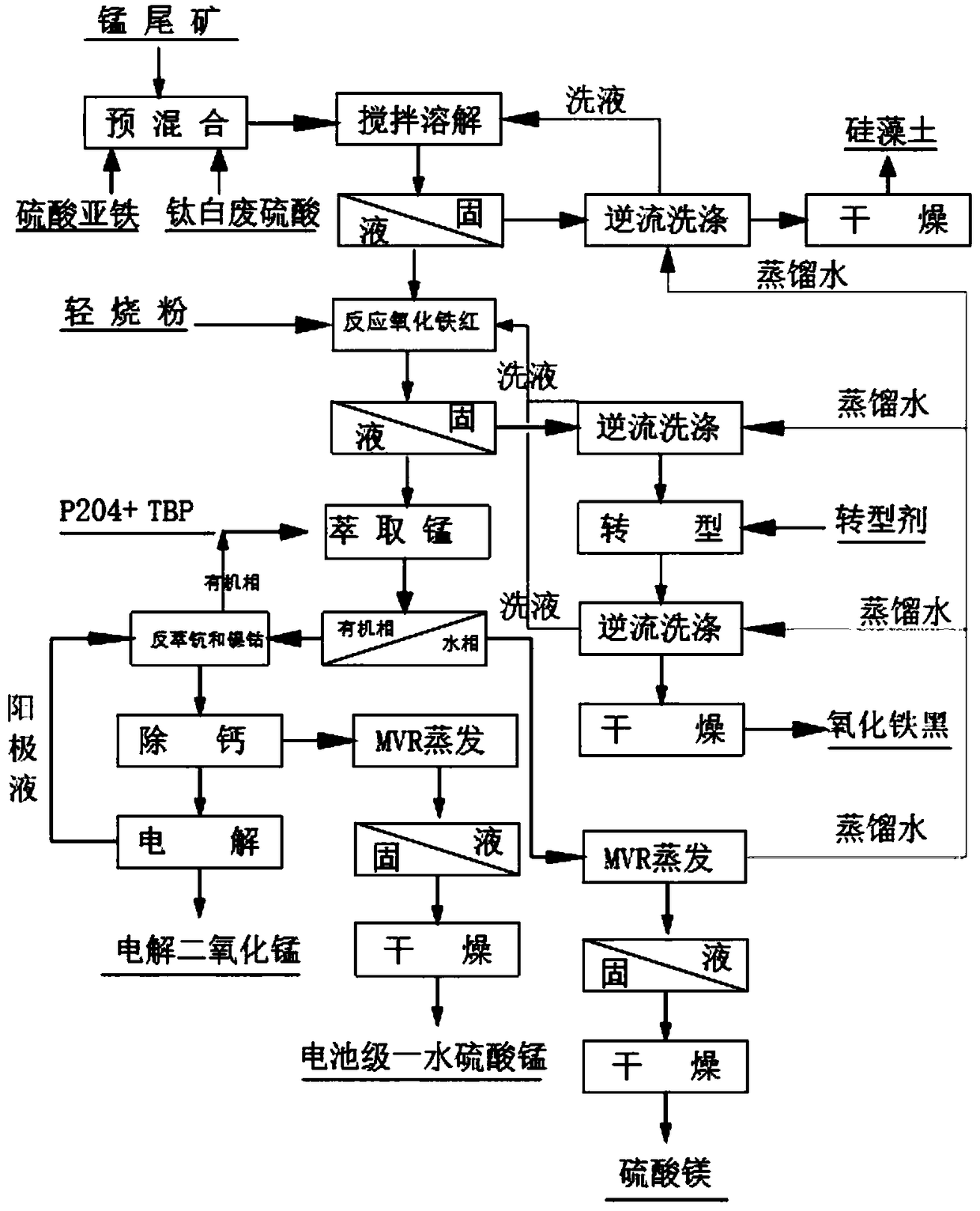

Method for producing battery-grade manganese sulfate through manganese tailings and titanium dioxide waste sulphuric acid

ActiveCN109354071AAchieve recyclingImprove protectionSilicaFerroso-ferric oxidesEcological safetyManganese

The invention provides a method for producing battery-grade manganese sulfate through manganese tailings and titanium dioxide waste sulphuric acid. The method comprises the specific steps that titanium dioxide waste sulphuric acid is subjected to reduction and leaching, the manganese tailings are ground to be fine, after solid-liquid separation, white filter residues are used as diatomite, a leaching solution is extracted by a P204 extraction agent, then light roasting powder or magnesium oxide is used for saponification, after impurity removal, battery-grade manganese sulfate is obtained through evaporation and crystallization, and byproducts comprise iron black and magnesium sulfate. According to the method, the manganese tailings and titanium dioxide waste acid are treated in cooperation, the ecological safety problem caused by accumulation of the manganese tailings is solved, a brand new utilization route for titanium dioxide waste acid is also provided, and the comprehensive utilization additional value of the manganese tailings and titanium dioxide waste acid is increased. Prepared battery-grade manganese sulfate is high in quality, simple in process and low in production cost, all the manganese tailings and titanium dioxide waste sulphuric acid are recycled, secondary pollution is not caused, zero discharge of wastewater is achieved, and the method is beneficial to environmental protection and comprehensive utilization of resources.

Owner:宣城市安工大工业技术研究院有限公司

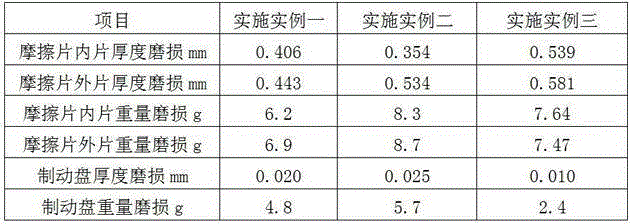

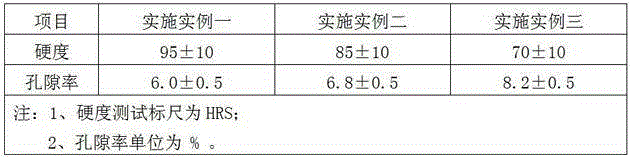

Safety type friction material having high cleaning performance and friction plate preparation method

InactiveCN105400493AGuaranteed flatnessReduce porosityOther chemical processesFriction liningFiberActivated carbon

The invention aims to provide a friction material having high cleaning performance while having high friction coefficient and safety performance and a friction plate preparation method. The friction material comprises, by weight percentage, 4-10% of resin, 6-10% of coke dust, 0.5-5% of nitrile powder, 1-8% of tire powder, 1-4% of corundum, 9-20% of graphite, 1-3% of iron black, 1-3% of activated carbon, 2-5% of friction powder, 20-30% of fiber and 30-55% of packing. The method for preparing a friction plate by utilizing the materials comprises a step (1) of mixing the materials: manufacturing a friction material mixed material; a step (2) of performing prepressing: preforming the mixed material; a step (3) of performing hot pressing: placing pressed blank in a die to undergo hot pressing, and performing interval exhaust-gas disposal; a step (4) of performing heat treatment: performing constant-speed warming and thermal insulation in a graded manner from room temperature to 185 DEG C; and a step (5) of performing size processing. The friction material is applied to the field of friction materials.

Owner:ZHUHAI HUALI FRICTION MATERIAL

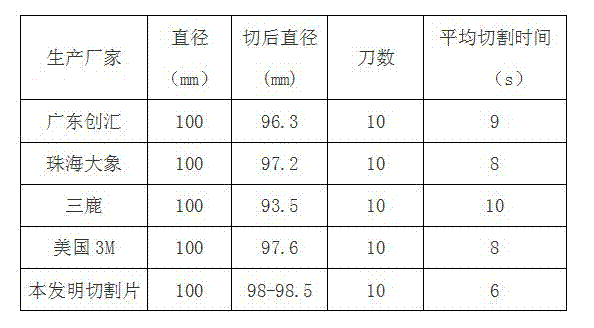

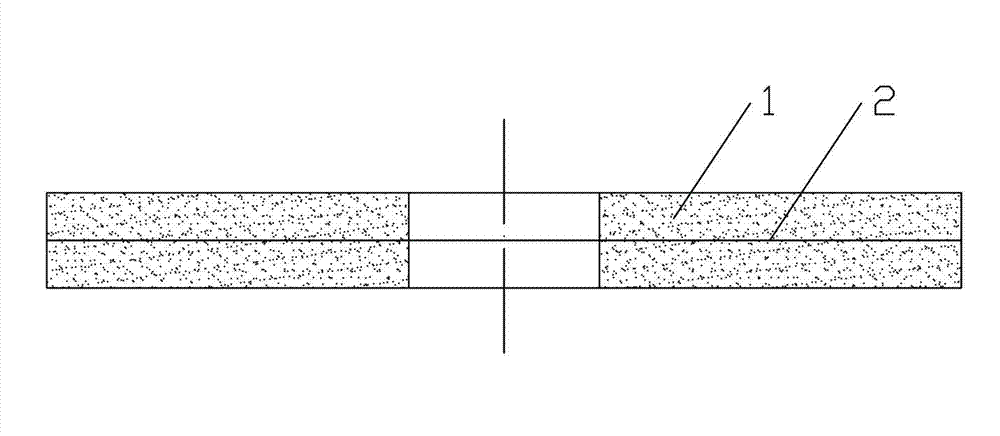

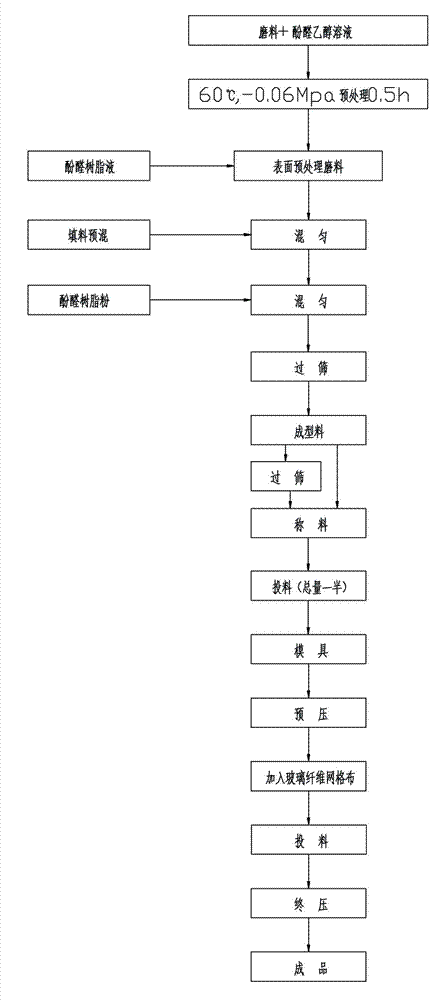

Rare earth composite corundum reinforced fiber ultrathin resin cutting blade and production method thereof

InactiveCN103111947AHigh strengthIncrease strength, hardnessAbrasion apparatusGrinding devicesFiberRare earth

The invention relates to a grinding tool used in industrial production and processing and belongs to a rare earth composite corundum reinforced fiber ultrathin resin cutting blade and a production method thereof. The rare earth composite corundum reinforced fiber ultrathin resin cutting blade is characterized by being provided with a grinding material blade; the center of the grinding material blade is provided with a layer of fiberglass grid mesh. The grinding material blade is composed of the following raw materials based on weight proportion: the rare earth composite corundum 100, phenolic aldehyde ethanol solution 100, phenolic aldehyde resin-oatmeal 10-15, phenolic aldehyde resin liquid 16-28, kryocide 6-10, iron black 1-5, gypsum 3-8 and ferrous sulfide 3-8. The production method of the rare earth composite corundum reinforced fiber ultrathin resin cutting blade comprises the following steps: preprocessing the rare earth composite corundum and the phenolic aldehyde ethanol solution; then adding the phenolic aldehyde resin liquid, the phenolic aldehyde resin-oatmeal and filler successively to prepare molding materials; and lastly mixing the fiberglass gird mesh to press a finished product in a molding mould. The rare earth composite corundum reinforced fiber ultrathin resin cutting blade obviously enhances intensity, rigidity, shock resistance capacity of the cutting blade, reduces material consumption, reduces environmental pollution and can be widely applied to various metal part processing.

Owner:湖北天马研磨材料有限公司

Production method for spherical iron oxide black magnetic powder used for laser printing, and spherical iron oxide black magnetic powder

InactiveCN101403869AImprove performanceNarrow particle size distributionFerric oxidesDevelopersIron saltsIron oxide black

The invention discloses a preparation method of spherical iron black magnetic powder for laser printing and the spherical iron black magnetic powder. Iron salt, basic solution, industrial scrap iron shavings, and scrap iron wires or waste iron sheets are taken as raw materials, two-step oxidation is carried out to generate iron oxide yellow by using the raw materials, and then the iron oxide yellow is added to prepare the spherical iron black magnetic powder. In the method, the magnetic powder is obtained by oxidizing the raw materials twice and then adding the obtained oxide, has comparatively stable performance, narrow particle size distribution and comparatively low coercive force, and is better than the common magnetic powder used in laser printers. The magnetic powder has the advantages of high definition, high blackness and the like.

Owner:南通宝聚颜料有限公司

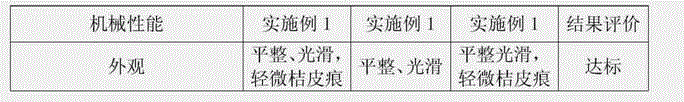

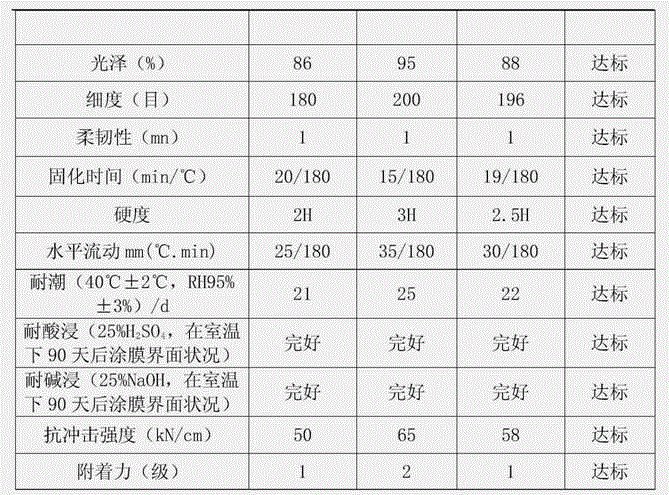

Formula and preparation method of polyester/epoxy resin powder coating

InactiveCN104893514AReduce manufacturing costGood compatibilityPowdery paintsPolyester coatingsPolyesterEpoxy

The invention discloses a formula and a preparation method of a polyester / epoxy resin powder coating. The formula of the powder coating comprises 723.6-750.0g of waste PET particles, 0.3-0.5mol of glycidyl methacrylate polymer, 0.98-1.02mol of dibasic acid anhydride, 1.71-1.80mol of dibasic alcohol, 0.1% of a catalyst, 10-25% of a high temperature resistant filler, 3-10% of a high temperature resistant pigment, 0.5-2% of a leveling agent and 25-40% of a curing agent. The relative molecular weight of the waste PET particles is 18000-23000, and the melting point of the waste PET particles is not lower than 260DEG C; the curing agent is one of aliphatic polyamine, alicyclic polyamines, low molecular polyamide and modified aromatic amine; the dibasic acid anhydride is dibasic acid anhydride starch ester; the high temperature resistant filler is one of mica powder, silicate powder and talcum powder; and the high temperature resistant pigment is one of titanium dioxide, iron oxide red and complex iron black. The coating has the advantages of good leveling property, good glossiness, low cost, and high economic and social benefits.

Owner:马倩

Aqueous metal member special-purpose paint and preparation thereof

InactiveCN101255303AGood gloss retentionImprove corrosion resistanceLiquid surface applicatorsEmulsion paintsEpoxyLow speed

The invention discloses a kind of paint special for aquose hardware and preparation method thereof, comprising deionized water, propylene glycol, dispersant, antifoaming agent, wetting agent, imported carbon black, iron black, aquose modified acrylic resin, aquos epoxy resin, propandiol butyl ether and propylene glycol ether. The preparation method comprises: adding deionized water and propylene glycol in a stock boiler, and stirring at low speed; adding dispersant, antifoaming agent and wetting agent in turn and uniformly mixing; adding imported carbon black and iron black and dispersing at high speed to form uniform paint slurry; grinding the paint slurry and conveying them into a blending pot; after stirring at low speed, adding the aquos modified acrylic resin, aquos epoxy resin, propandiol butyl ether and propylene glycol ether in turn after stirring, adding deionized water to dilute. The paint has good stability, high painting effeciency, stable quality, uniform paint film, smooth surface, good hardness, strong adhesion, good anti-corrosive property, good hanging paint performance at corner, no uncoated position, saltfog resistant for 48 hours, suitable for spraying; environmental protection, low cost and wide application range.

Owner:刘善江

Rust-proof and corrosion-resistant coating for turning lathe

InactiveCN104861754AAnti-rust for a long timeImprove corrosion resistanceAnti-corrosive paintsEpoxyDiboride

The invention discloses a rust-proof and corrosion-resistant coating for a turning lathe. The coating comprises the following components in parts by weight: 30-50 parts of a silicon epoxy resin polymer, 4-10 parts of barium petroleum sulfonate, 7-14 parts of aluminum tripolyphosphate, 1-5 parts of nano zinc oxide, 2-6 parts of copper chromium iron black, 3-9 parts of acrylonitrile, 5-12 parts of amino resin, 2-8 parts of sodium fluosilicate, 6-10 parts of vanadium diboride and 8-14 parts of xylene. The mechanical rust-proof coating provided by the invention is long in rust-proof time and good in corrosion resistance, rust-proof oil does not need to be cleaned before coating, additional coating additives do not need to be added, and the coating can be used for long-term seal storage and rust prevention of metal mechanical workpieces.

Owner:王俐帧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com