Single-composition polyurethane waterproof paint and preparation method thereof

A polyurethane waterproof, one-component technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as easy foaming, unsightly surface effect, and sticky surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

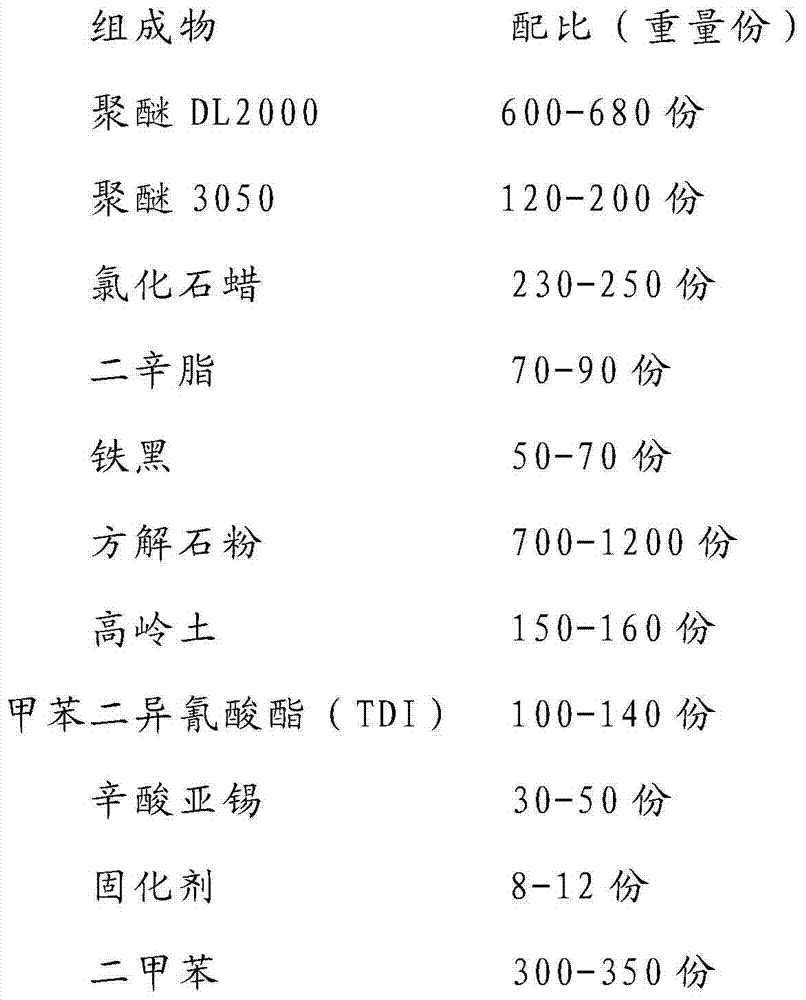

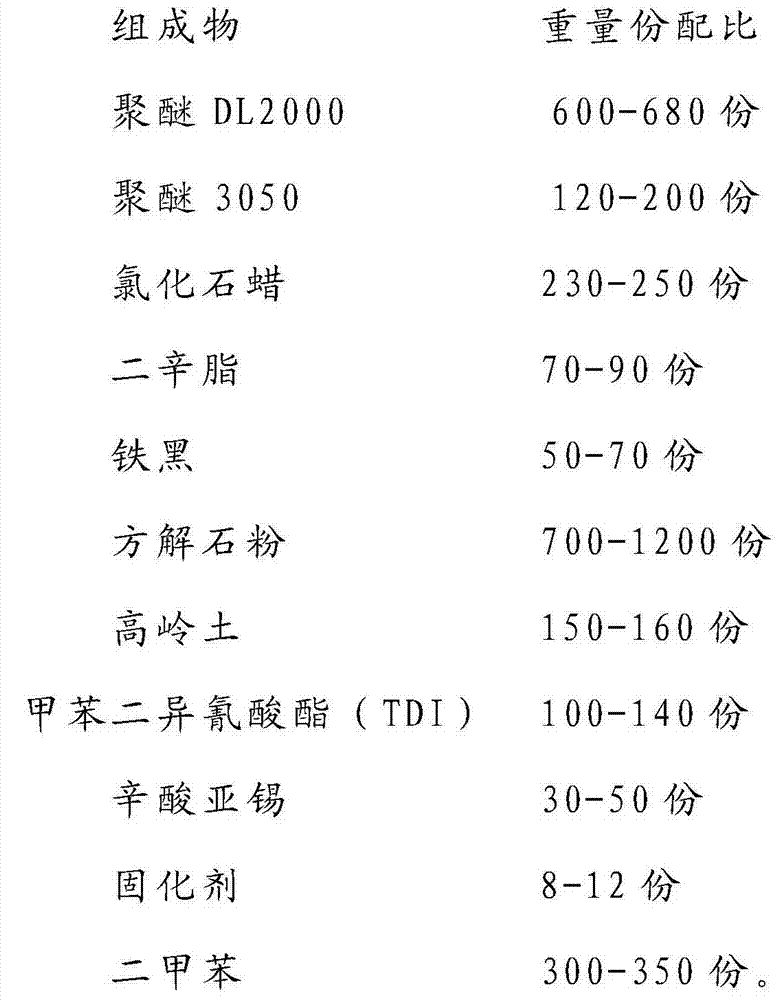

Image

Examples

Embodiment 1

[0018] In a 3.5 ton reactor, add polyether DL2000 640kg, polyether 3050160kg, chlorinated paraffin 240kg, dioctyl 80kg. Heat and stir, add iron black 60kg, calcite powder 700kg, kaolin 152kg, light calcium 500kg, heat to 115°C, keep the temperature at 115-120°C, keep warm for 2 hours, vacuumize during the heat preservation process, the vacuum degree is -0.09MPa. Then add TDI to react, the reaction time is 2 hours, the temperature is 85°C, after the reaction is completed, stannous octoate is added to catalyze the reaction, the reaction time is 1 hour, the temperature is 85°C. After the reaction is completed, add a curing agent, a special catalyst, and xylene, mix well, and lower the temperature to 60°C to discharge.

Embodiment 2

[0020] In a 3.5 ton reactor, add polyether DL2000600kg, polyether 3050200kg, chlorinated paraffin 240kg, dioctyl 80kg. Heat and stir, add iron black 60kg, calcite powder 1200kg, kaolin 152kg, heat to 115°C, keep the temperature at 115-120°C, keep warm for 2 hours, vacuumize during the heat preservation process, the vacuum degree is -0.09MPa. Then add TDI to react, the reaction time is 2 hours, the temperature is 85°C, after the reaction is completed, stannous octoate is added to catalyze the reaction, the reaction time is 1 hour, the temperature is 85°C. After the reaction is completed, add a curing agent, a special catalyst, and xylene, mix well, and lower the temperature to 60°C to discharge.

Embodiment 3

[0022] In a 3.5-ton reactor, add 680kg of polyether DL2000, 120kg of polyether 3050, 240kg of chlorinated paraffin, and 80kg of dioctyl ester. Heat and stir, add iron black 60kg, calcite powder 1000kg, kaolin 152kg, light calcium 200kg, heat to 115°C, keep the temperature at 115-120°C, keep warm for 2 hours, vacuumize during the heat preservation process, the vacuum degree is -0.09MPa. Then add TDI to react, the reaction time is 2 hours, the temperature is 85°C, after the reaction is completed, stannous octoate is added to catalyze the reaction, the reaction time is 1 hour, the temperature is 85°C. After the reaction is completed, add a curing agent, a special catalyst, and xylene, mix well, and lower the temperature to 60°C to discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com