Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7991 results about "Paraffin oils" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paraffin wax, a white or colourless soft solid that is used as a lubricant and for other applications. Liquid paraffin (drug), a very highly refined mineral oil used in cosmetics and for medical purposes. Alkane, a saturated hydrocarbon. Kerosene, a fuel that is also known as paraffin.

Production of diesel fuel from vegetable and animal oils

A process for producing a fuel composition from vegetable and / or animal oil comprises hydrodeoxygenating and hydroisomerizing the oil in a single step. The fuel composition has acceptable lubricity and comprises a mixture of C14 to C18 paraffins having a ratio of iso to normal paraffins of 2 to 8 and less than 5 ppm sulfur.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

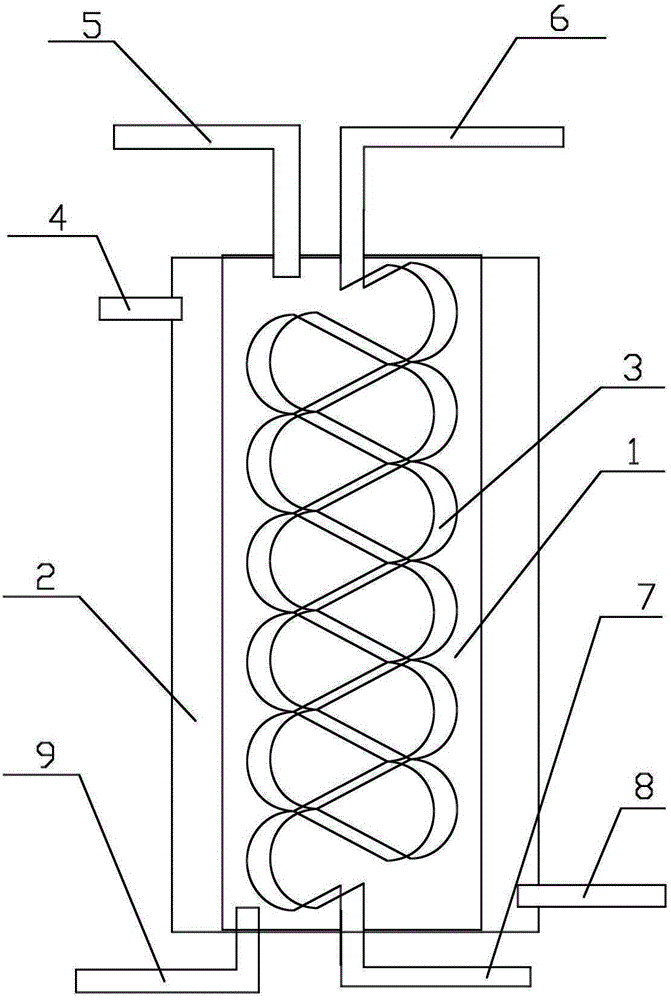

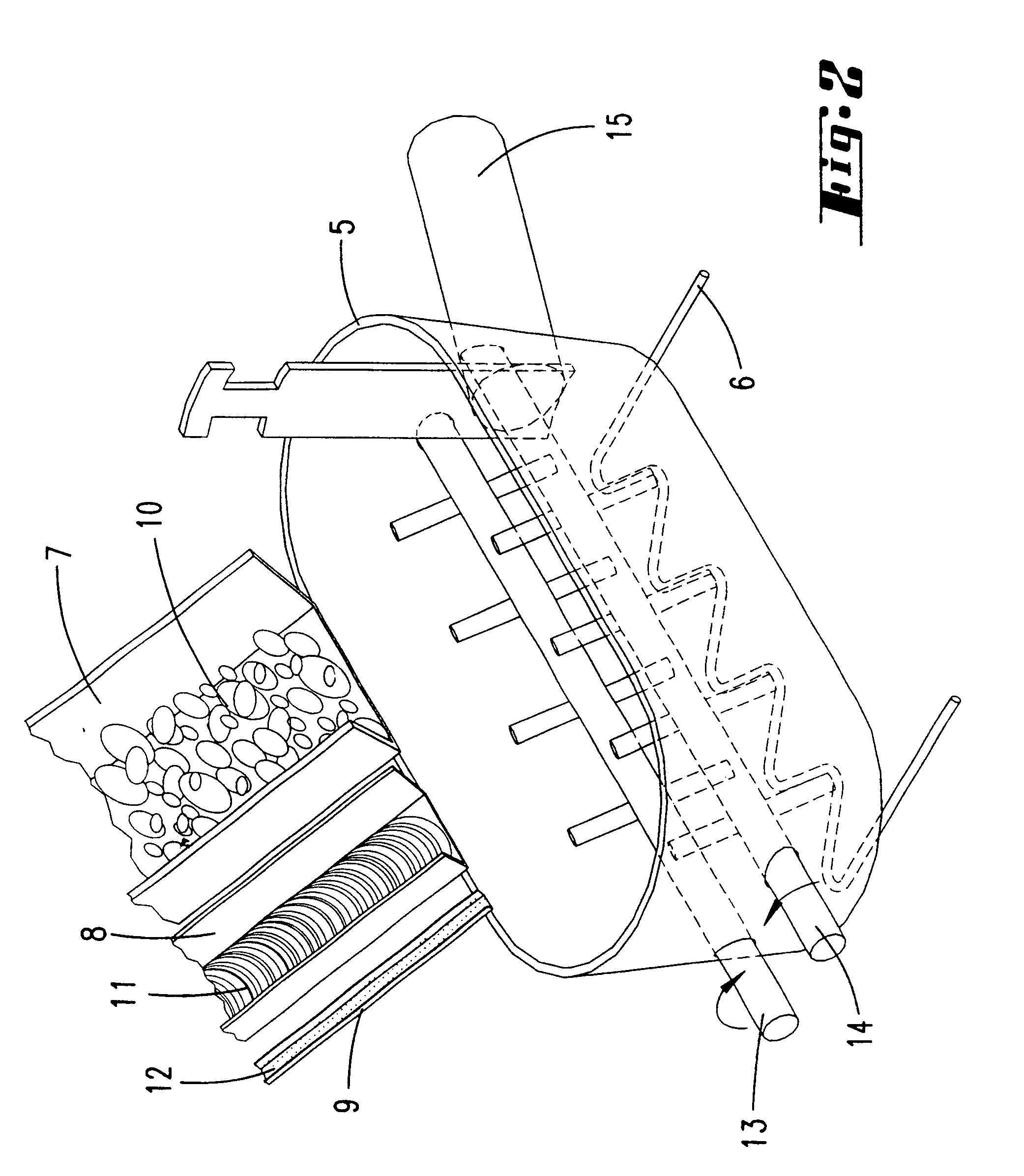

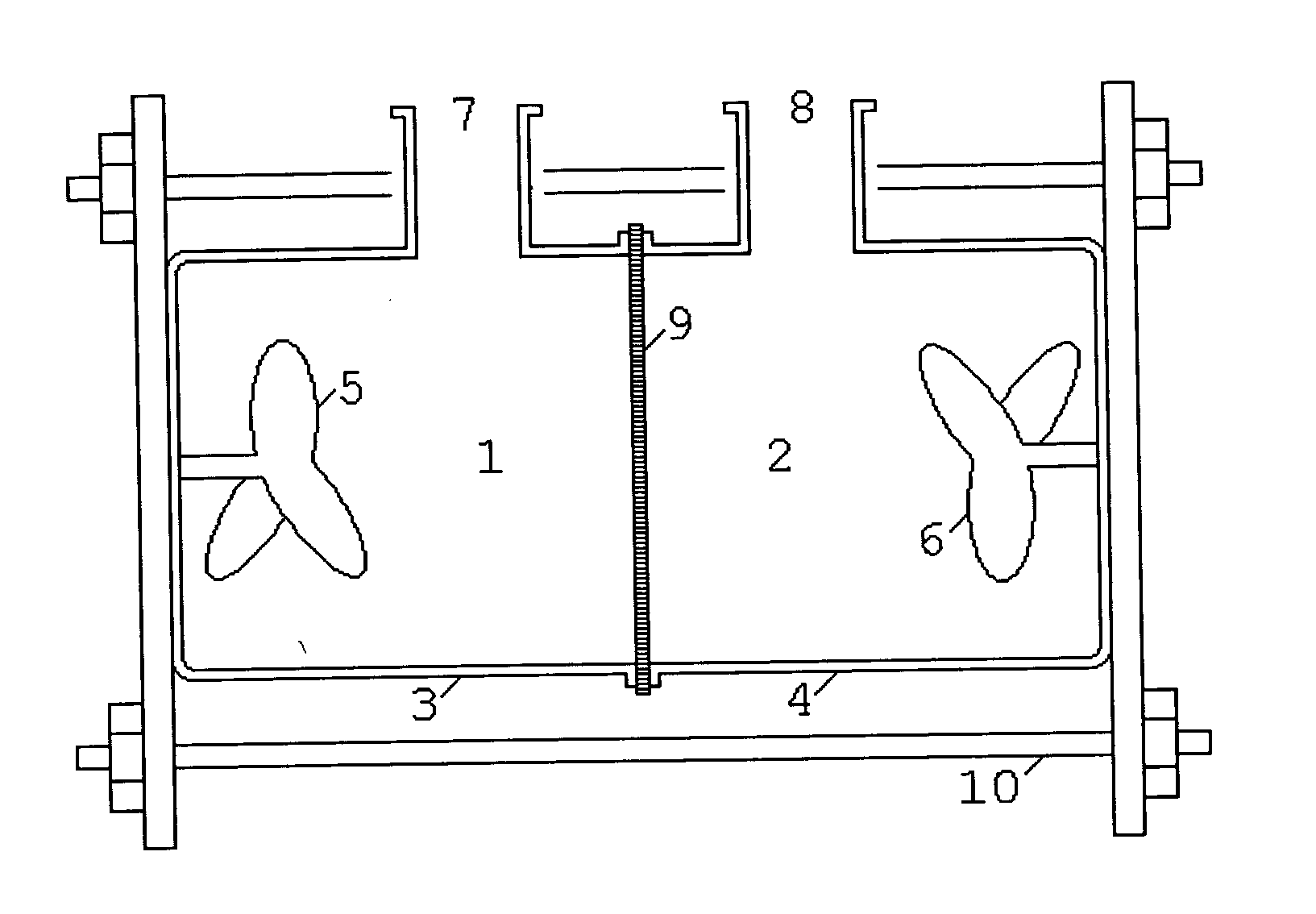

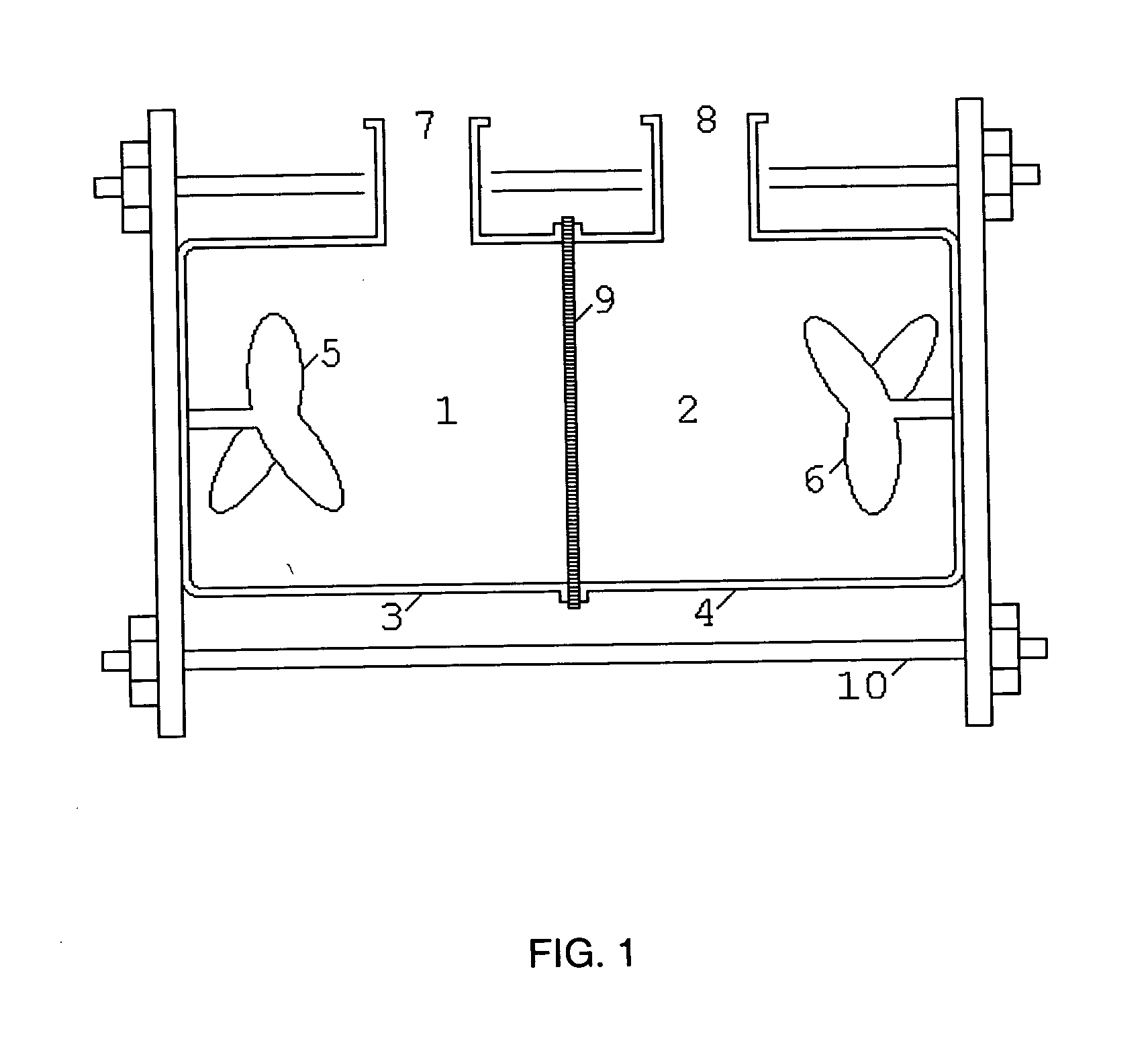

Efficient paraffin sweatbox

InactiveCN102977917AHeating evenlyMeet production requirementsPetroleum wax recoveryParaffin waxParaffin oils

The invention discloses an efficient paraffin sweatbox. The sweatbox comprises an inner cavity, a heating layer, a heating tube, an outer water inlet tube, a feeding tube, an inner water inlet tube, an inner water outlet tube, an outer water outlet tube and a discharging tube, wherein a heating tube which is arranged in a rotating mode is arranged inside the inner cavity; the feeding tube is arranged on the upper part of the inner cavity; the discharging tube is arranged on the lower part of the inner cavity; the heating layer is arranged outside the inner cavity; the external water inlet tube is arranged on the upper part of the heating layer; the outer water outlet tube is arranged on the lower part of the heating layer; the inner water inlet tube connected to the outer side of the inner cavity is arranged on the upper part of the heating tube; and the inner water outlet tube connected to the outer side of the inner cavity is arranged at the lower side of the heating tube. The heating tube which is extended like a spring in a rotating mode is arranged inside the effective paraffin sweatbox, so that the paraffin is heated uniformly; and the efficient paraffin sweatbox is used in the industry.

Owner:DALIAN LONSIN NEW MATERIALS

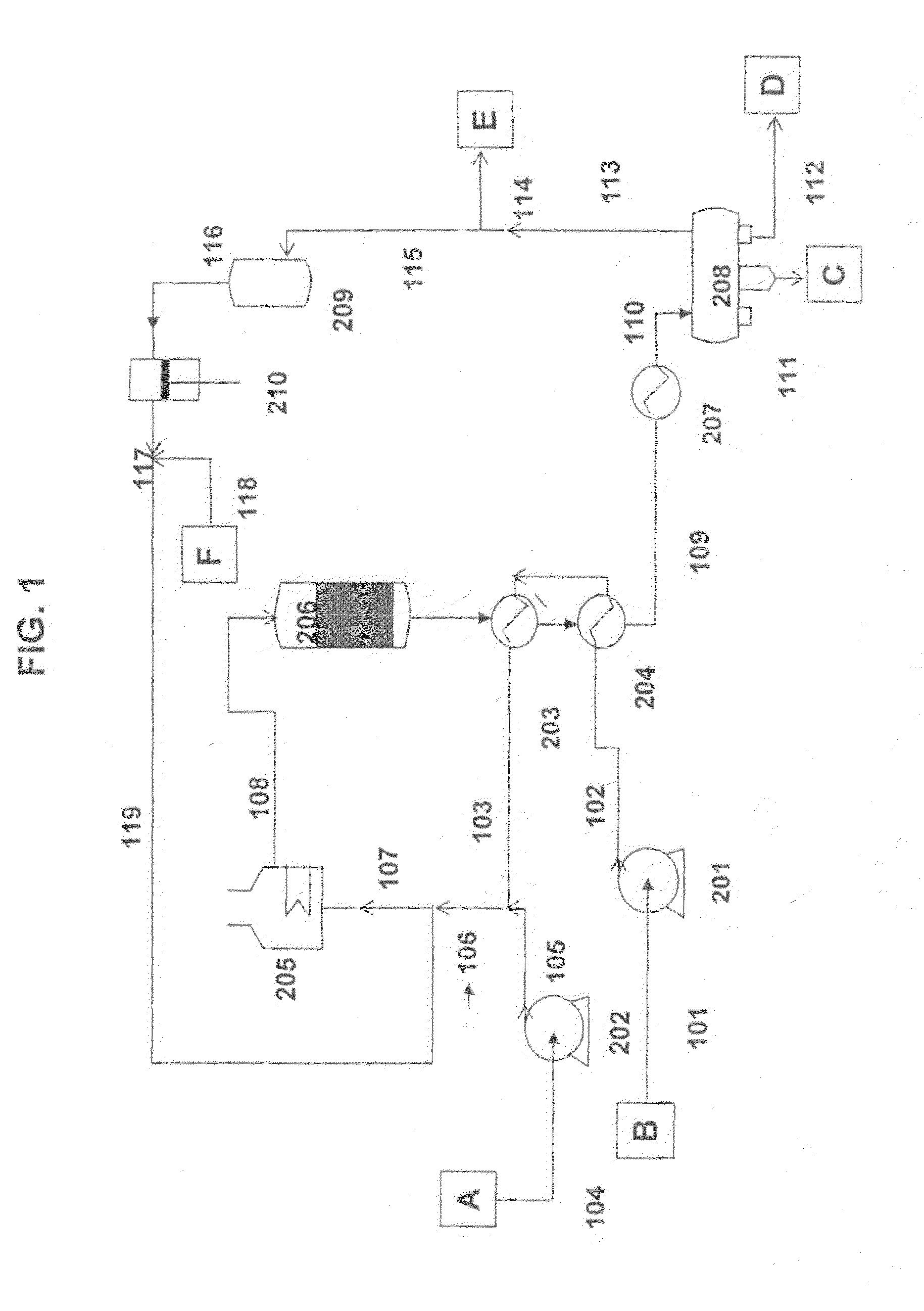

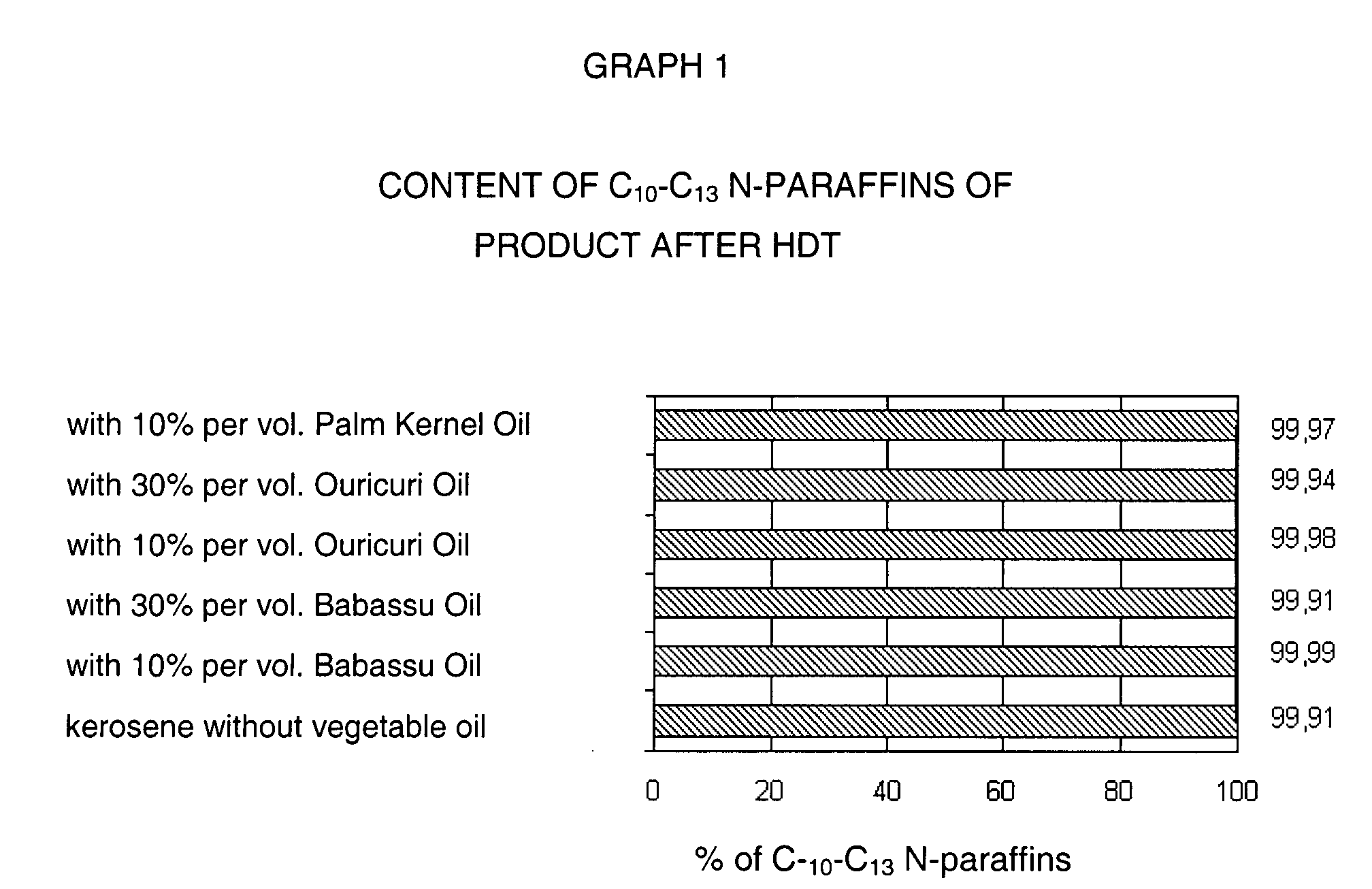

Process to obtain N-paraffins from vegetable oil

The process described by this invention involves the hydroconversion of vegetable oils appropriately selected for the production of N-paraffins, through hydrotreatment of a stream of vegetable hydrocarbon oils in and / or natural fats that may be used in a pure state or in a mixture with mineral hydrocarbon oil. This mixture flow is submitted to the process of hydrotreatment, obtaining as a result, a product flow with an elevated content of N-paraffins in the range of C10-C-13. This process provides an alternative to the usual process that uses a mineral hydrocarbon oil load (petroleum kerosene of paraffin base) to produce C10-C13 N-paraffins that are raw materials for the production of detergents (LAB), being, therefore, especially advantageous for use in situations where kerosene is a limiting factor for producing N-paraffins, resulting in a product of good quality with a reasonable gain in the production of N-paraffins.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Lubricating oil formulations

Lubricating oil compositions having excellent thermal and oxidative stability, wear control, copper corrosion control and compatibility with seal materials comprising a mineral oil having a) a Viscosity Index of greater than 110 and an aniline point of greater than 110 DEG C. and / or b) a linear+single ring paraffin content of greater than 68 wt %, and at least one polymer selected from olefin (co) polymer(s), polyalkyl (meth) acrylate(s) and mixtures thereof. The lubricating oil compositions are particularly useful as manual transmission and axle lubricants.

Owner:AFTON CHEM INTANGIBLES

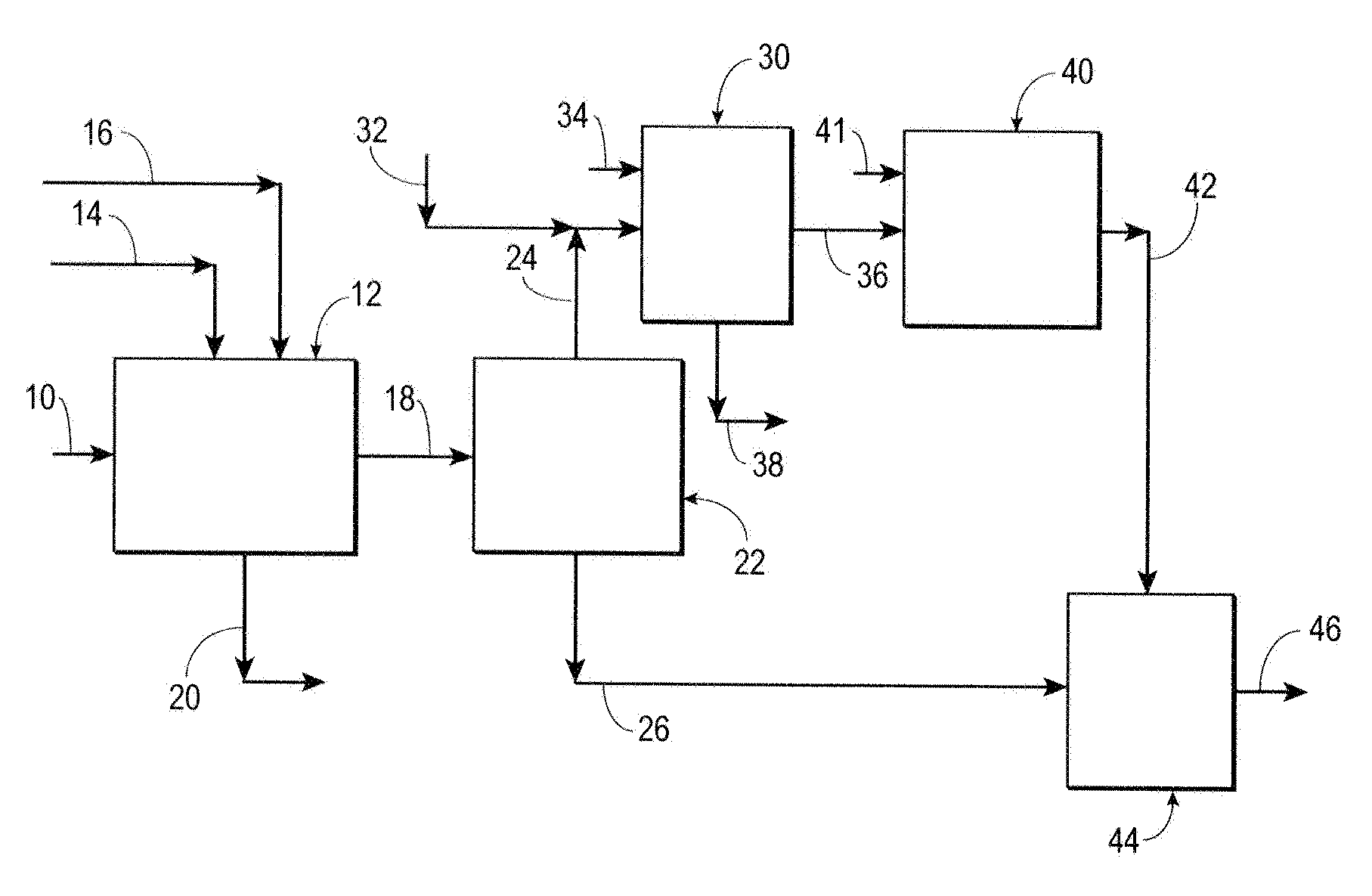

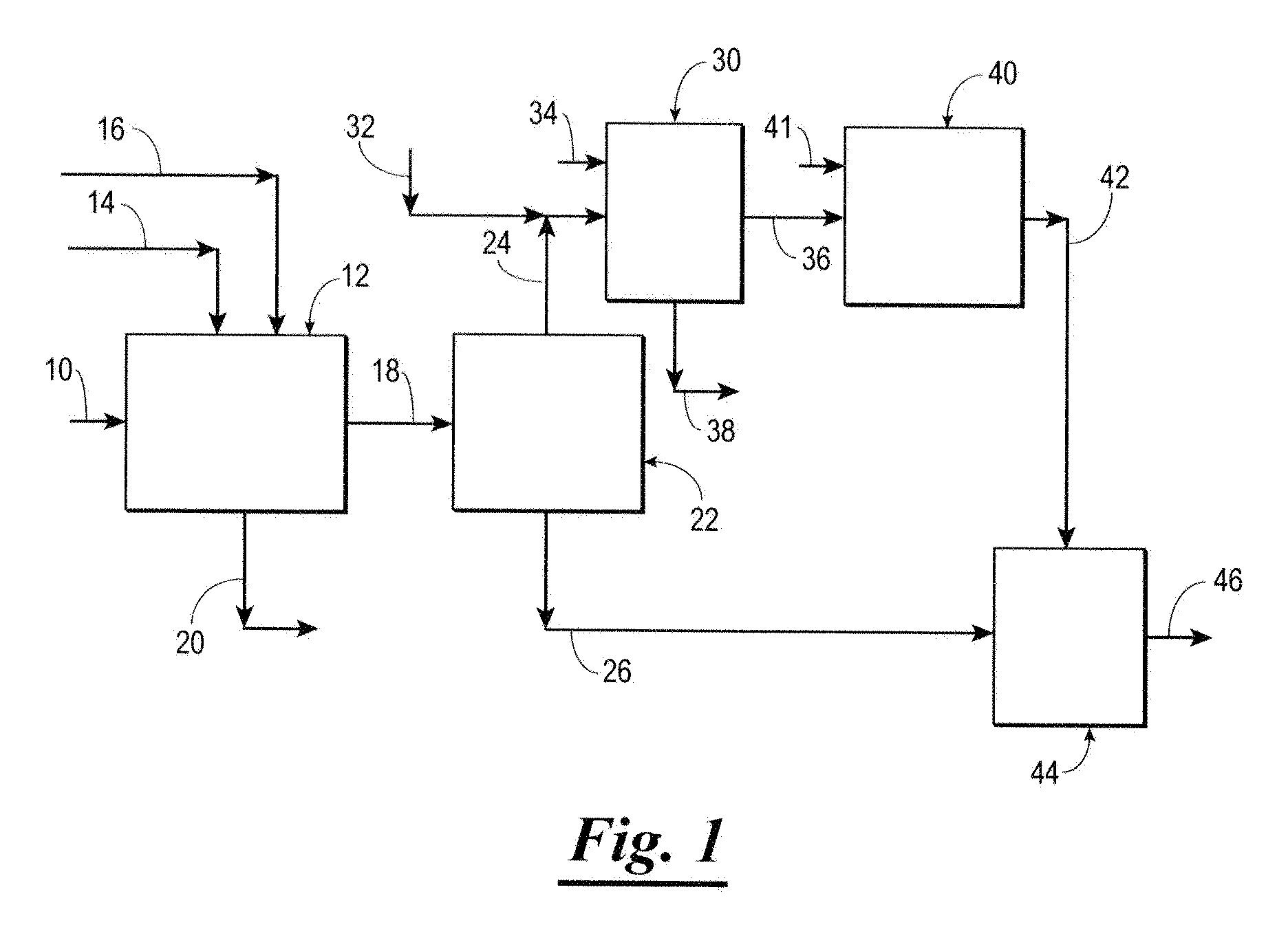

Process for producing bio-derived fuel with alkyl ester and iso-paraffin components

InactiveUS20080163543A1Improve low temperature performanceImprove the lubrication effectBiofuelsLiquid carbonaceous fuelsAlkaneParaffin oils

A process for producing a diesel fuel of biological origin. The process includes a biological component to be trans-esterified into a fatty acid alkyl ester. A fraction of the fatty acid alkyl ester is hydrodeoxygenated and hydroisomerized to produce an iso-paraffinic hydrocarbon. The fatty acid alkyl ester and the iso-paraffin components are combined into a middle distillate product suitable for direct use as diesel or jet fuel.

Owner:REG SYNTHETIC FUELS LLC

Alcohol-free transdermal analgesic composition and processes for manufacture and use thereof

InactiveUS7052715B2Reduced shelf lifeImprove permeabilityOrganic active ingredientsBiocideAlkaneAlcohol free

The instant invention is directed toward a dermal delivery system composition comprising an aqueous base vehicle including American Emu oil, Isopropyl Palmitate (PROTACHEM IPP), PEG-8 (a polyethylene glycol available under the tradename PROTACHEM 400), methylsulfonylmethane (MSM) and SEPIGEL 305 (a combination including polyacrylamide / C13–C14 Iso-paraffin and Laureth-7), in combination with an analgesic composition, such as ibuprofen, and to processes for the manufacture and use thereof.

Owner:ALL NATURAL FMG

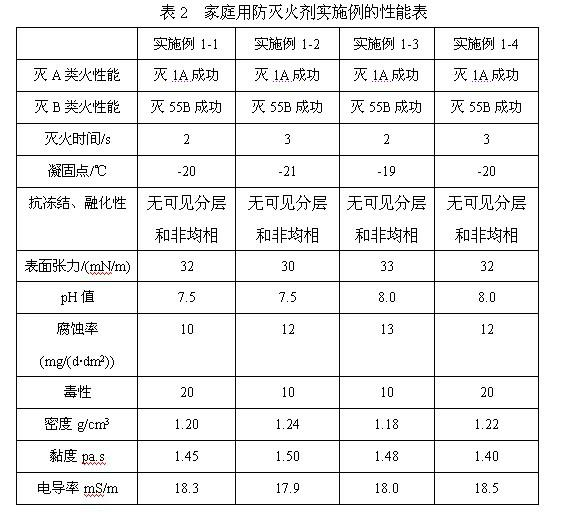

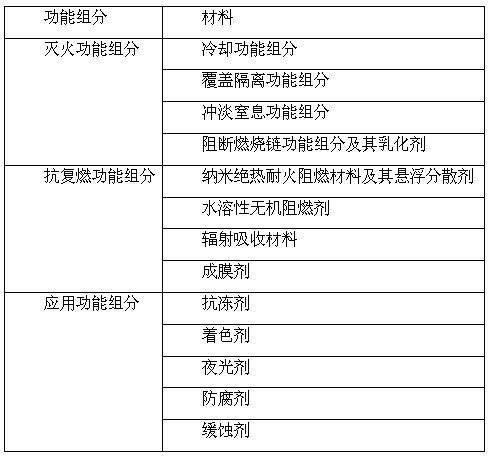

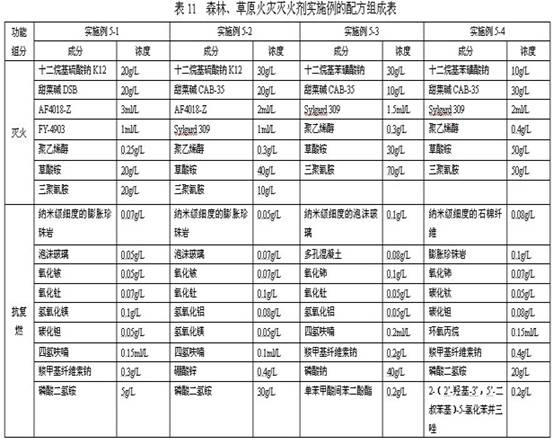

Built-up synergetic class-A/B water extinguishing agent series

The invention discloses a built-up synergetic class-A / B water extinguishing agent series. Class-A fires caused by solid substances (such as woods, cottons, wools, linens, paper) and products thereof and class-B fires caused by liquid or melted solids such as gasoline, kerosene, diesel oil, crude oil, methanol, ethanol, asphalt, paraffin waxes and the like can be put out rapidly through the functions such as heat absorption and cooling, diluting and smothering, insulating and covering, suppressing and blocking combustion chains, and the like which are synergetically performed by various extinguishing functional components, and a high-temperature-resistant thermal-insulation and fire-retarding covering layer is formed on the surface of an inflammable matter by various after-combustion functional components so as to achieve the effect of after-combustion resistance. Because the class A / B fires relate to multiple occasions of daily life and production activities, the extinguishing agent disclosed by the invention can be used in the fields of home fire prevention and extinguishing, urban architecture fire prevention and extinguishing, oil depot and gasoline station fire prevention and extinguishing, vehicle and ship fire prevention and extinguishing, forest and grassland fire prevention and extinguishing, mine fire prevention and extinguishing, confined spaces (such as civil air-defense architectures) fire prevention and extinguishing.

Owner:NANJING UNIV OF SCI & TECH

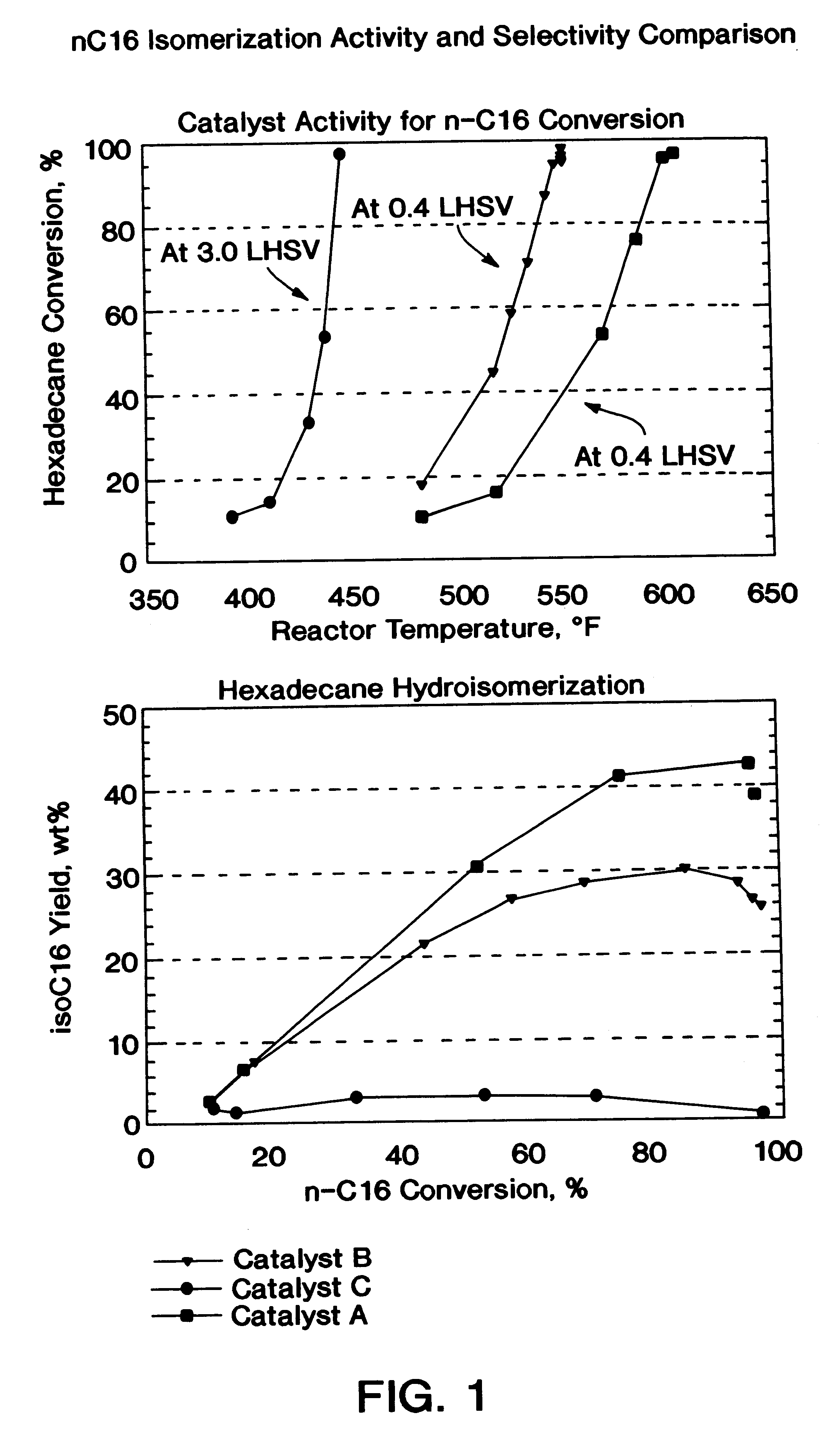

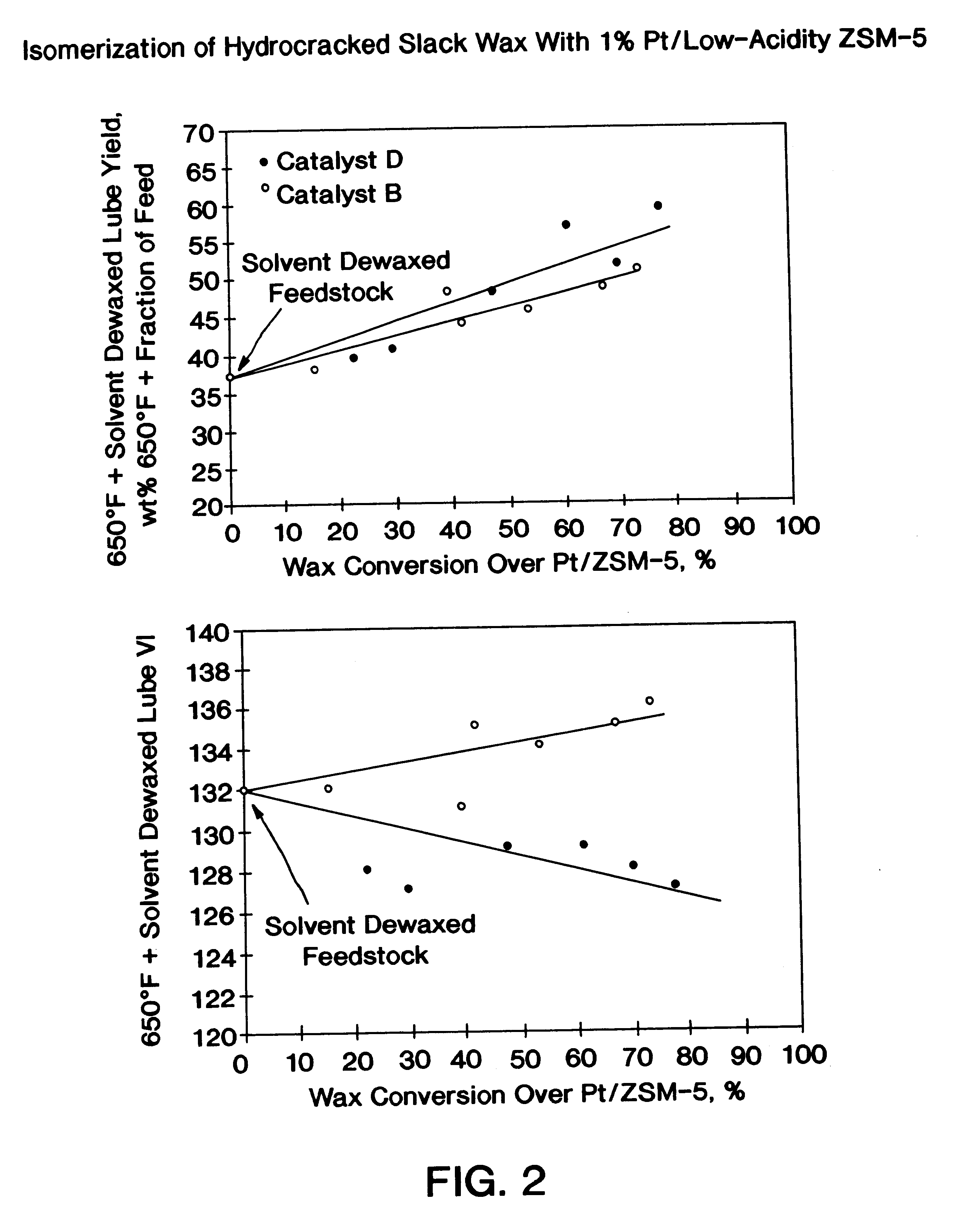

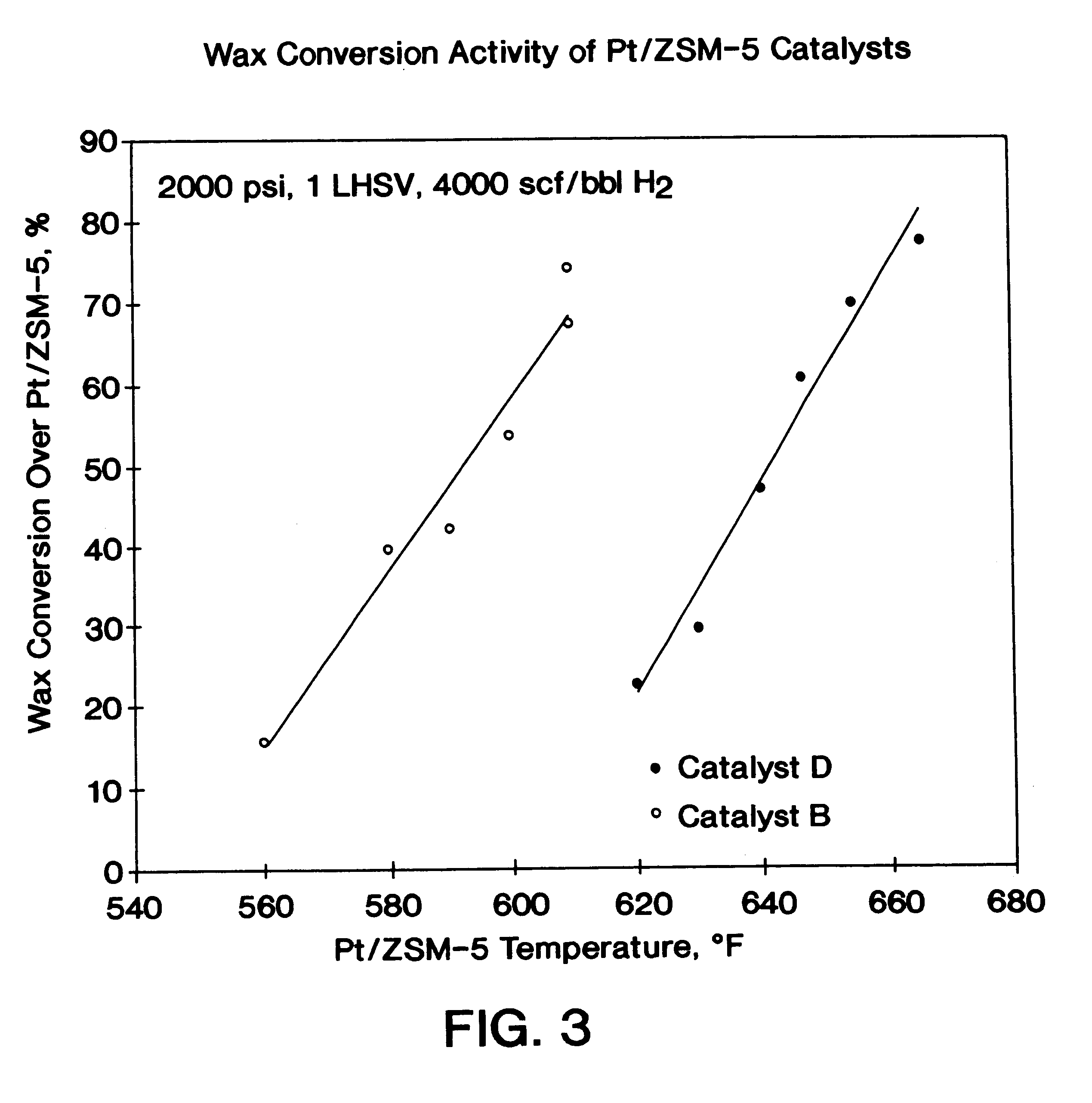

Production of high viscosity lubricating oil stock with improved ZSM-5 catalyst

InactiveUS6294077B1Low pour pointHigh viscosity indexMolecular sieve catalystsRefining to change hydrocarbon structural skeletonHydrogenParaffin oils

The present invention is a process for producing a high viscosity index and low pour point lubricating oil base stock which comprises catalytically converting a hydrotreated hydrocarbon lube oil feedstock containing waxy paraffins in the presence of hydrogen and in the presence of a low acidity ZSM-5 catalyst having a highly dispersed noble metal component. The ZSM-5 catalyst is subjected to controlled acidity reduction to an alpha value below 15 prior to incorporation of the noble metal component.

Owner:MOBIL OIL CORP

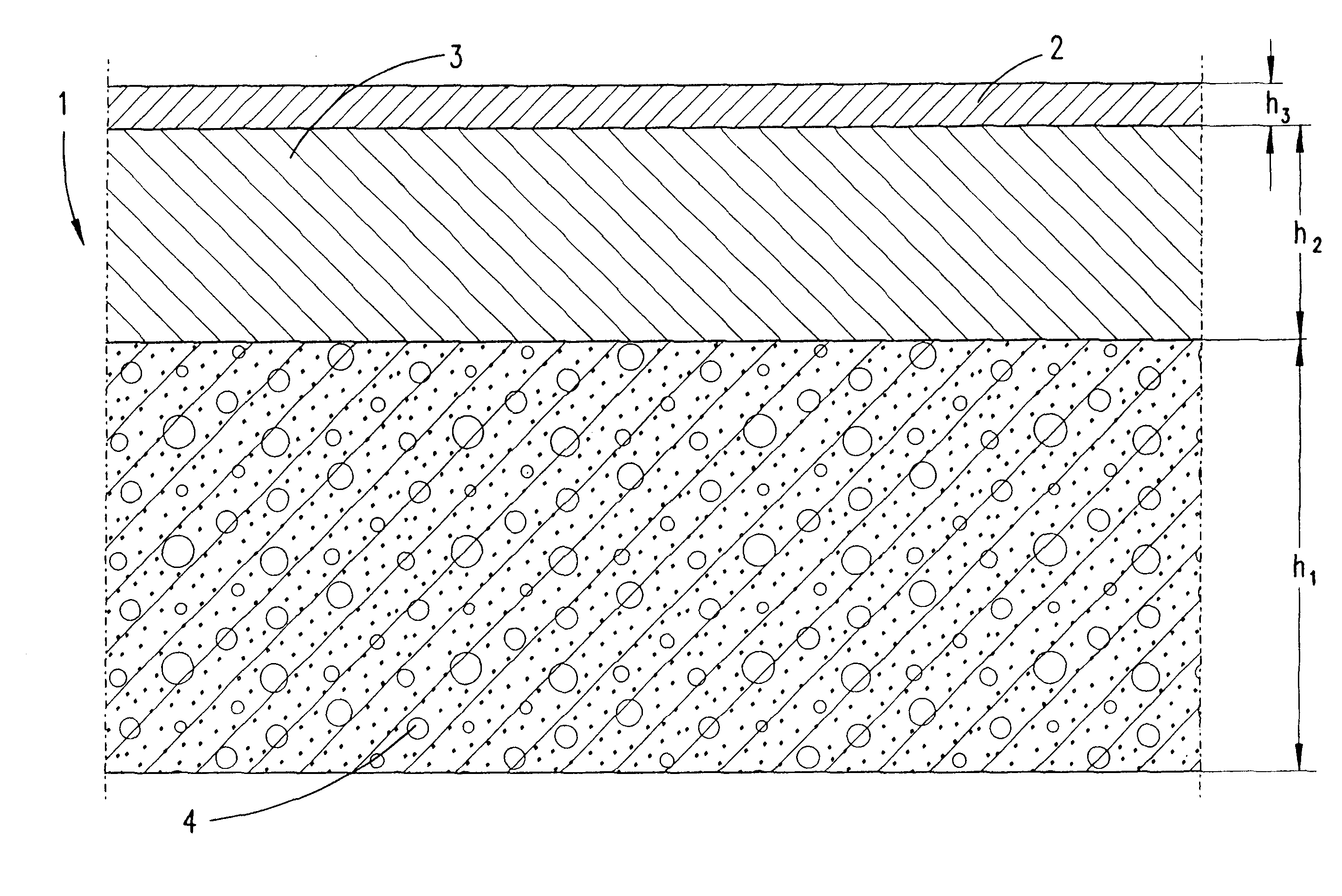

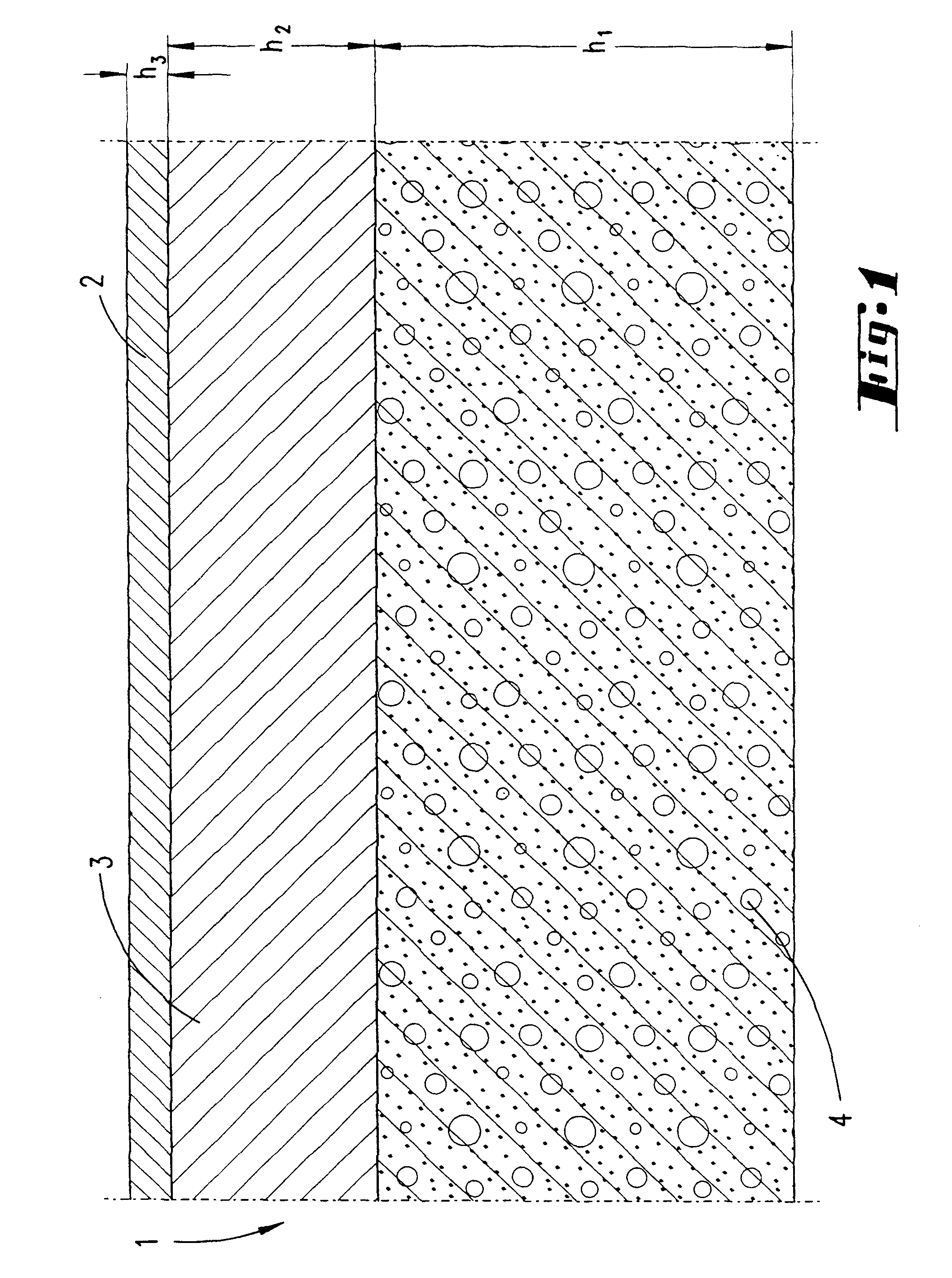

Bitumen or asphalt for producing a road topping, road topping and method for the production of bitumen or asphalt

InactiveUS6588974B2Good effectReduction in strengthIn situ pavingsPaving detailsParaffin waxParaffin oils

The invention relates to bitumen or asphalt for producing a road topping, whereby said bitumen or asphalt contains a proportion of paraffin obtained by Fischer-Tropsch synthesis (FT paraffin). The invention also relates to a road topping with said bitumen and to a method for producing a corresponding road topping or roadway / covering using said bitumen.

Owner:SCHUMANN SASOL SOUTH AFRICA

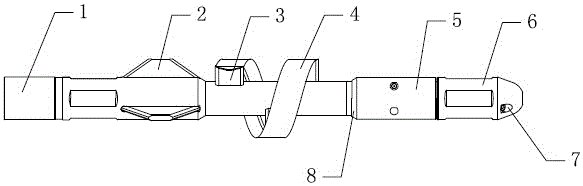

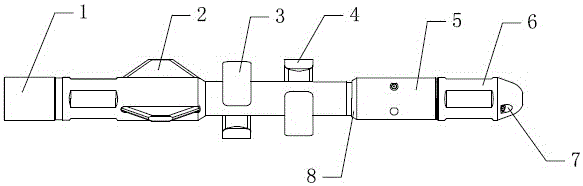

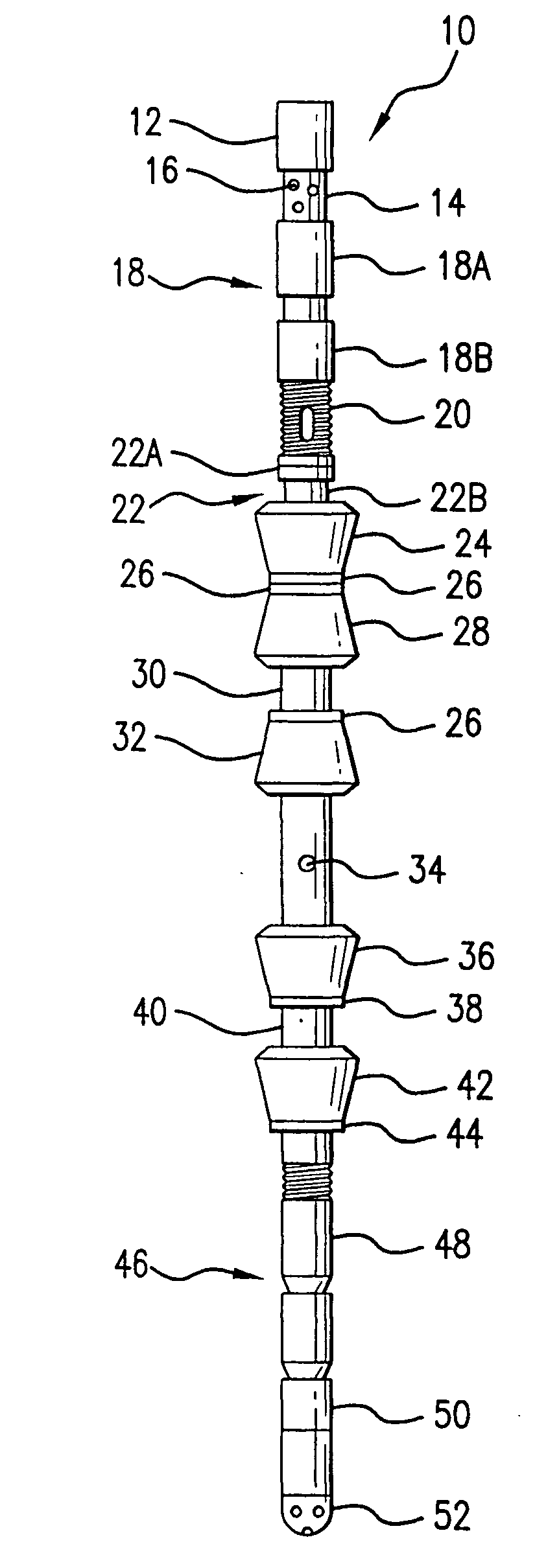

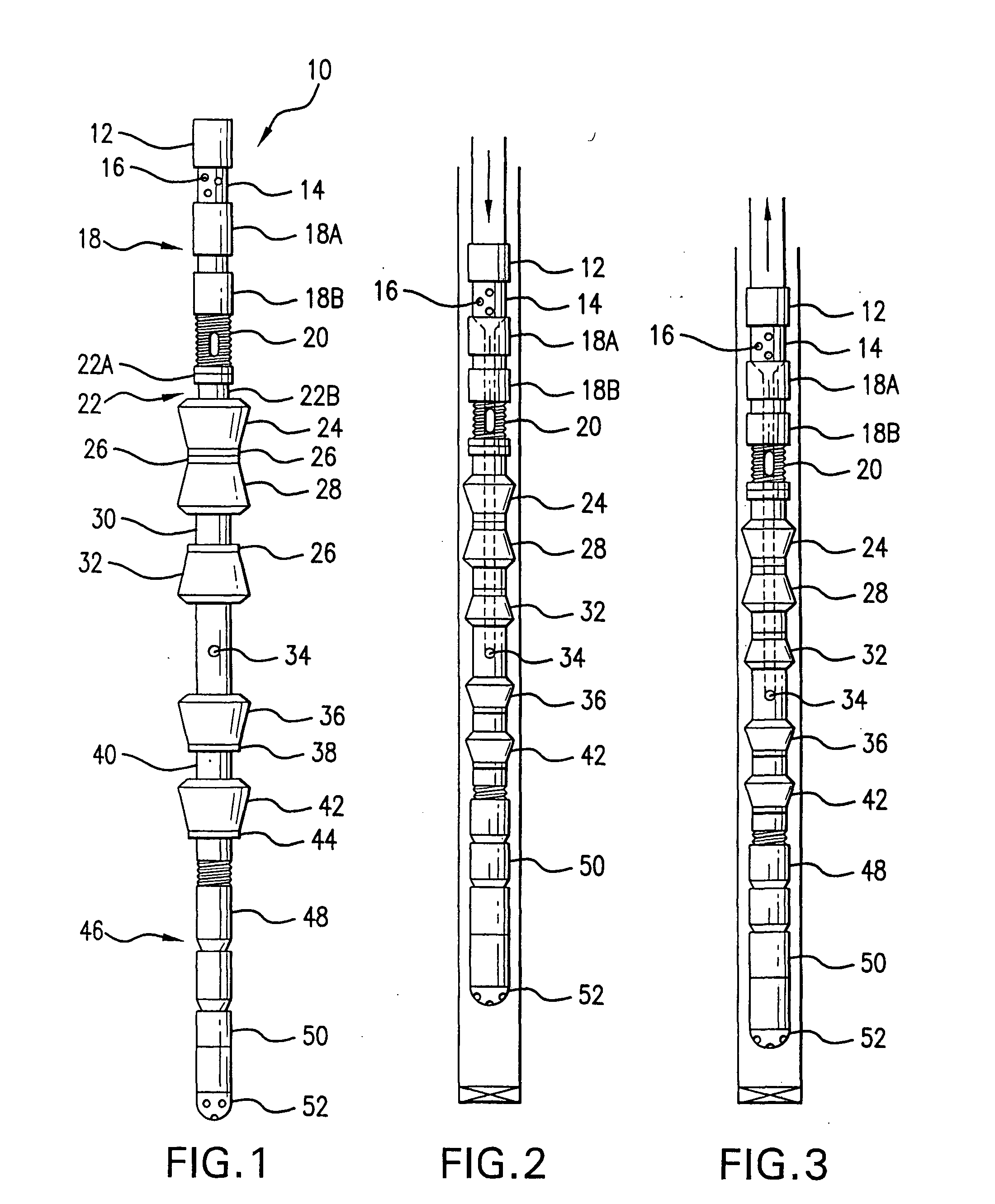

Oil and gas field coiled tubing paraffin removal and contaminant release process and tool thereof

PendingCN106761561AWill not artificially cause blockageImprove cleanlinessCleaning apparatusWaxCoiled tubing

The invention relates to an oil and gas field coiled tubing paraffin removal and contaminant release process and a tool thereof. Paraffin removal is performed by using coiled tubing, and removed paraffin can be recycled to the ground, and therefore a wellbore cannot be blocked due to human factors. A flushing port is designed at the upper end of a flushing tool, and then paraffin remaining on mechanical scraping portions can be cleared. The coiled tubing is connected with the paraffin removal and contaminant release tool for paraffin removal and contaminant release. The flushing tool at the front end of a pipe string can first perform 360 degree hydraulic cleaning on the wellbore, and then along with descending of the pipe string, a paraffin remover in the pipe string performs mechanical cleaning on the wellbore, and therefore dual cleaning mode combining the hydraulic cleaning with mechanical scraping is achieved, removal effects are greatly improved, cost is saved, and work efficiency is improved.

Owner:JEREH ENERGY SERVICES

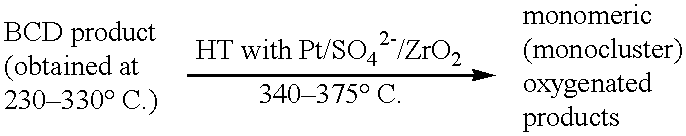

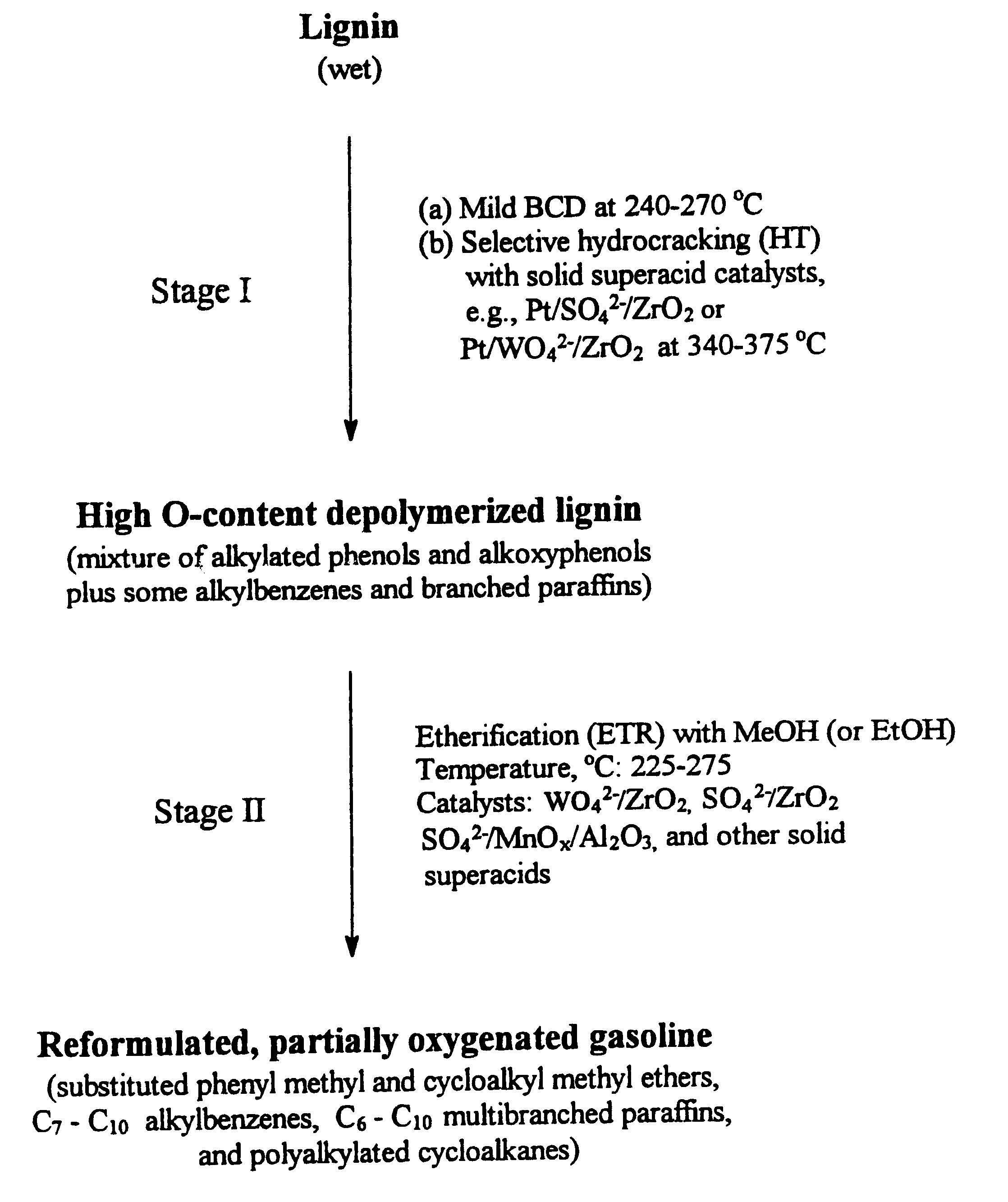

Process for conversion of lignin to reformulated, partially oxygenated gasoline

InactiveUS6172272B1Short reaction timeMaintain good propertiesOrganic compound preparationHydrocarbon from oxygen organic compoundsDepolymerizationMethyl group

A high-yield process for converting lignin into reformulated, partially oxygenated gasoline compositions of high quality is provided. The process is a two-stage catalytic reaction process that produces a reformulated, partially oxygenated gasoline product with a controlled amount of aromatics. In the first stage of the process, a lignin feed material is subjected to a base-catalyzed depolymerization reaction, followed by a selective hydrocracking reaction which utilizes a superacid catalyst to produce a high oxygen-content depolymerized lignin product mainly composed of alkylated phenols, alkylated alkoxyphenols, and alkylbenzenes. In the second stage of the process, the depolymerized lignin product is subjected to an exhaustive etherification reaction, optionally followed by a partial ring hydrogenation reaction, to produce a reformulated, partially oxygenated / etherified gasoline product, which includes a mixture of substituted phenyl / methyl ethers, cycloalkyl methyl ethers, C7-C10 alkylbenzenes, C6-C10 branched and multibranched paraffins, and alkylated and polyalkylated cycloalkanes.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

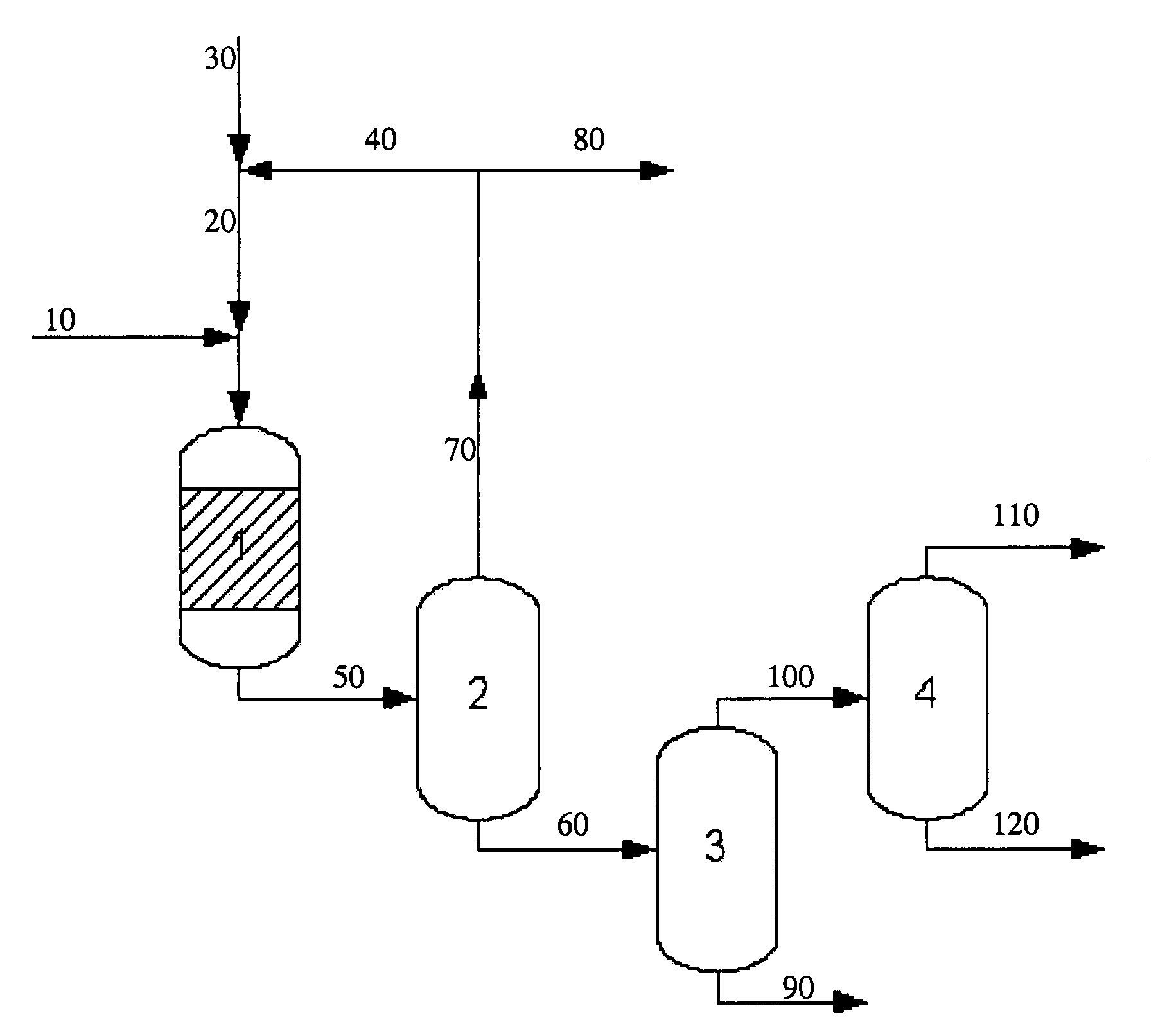

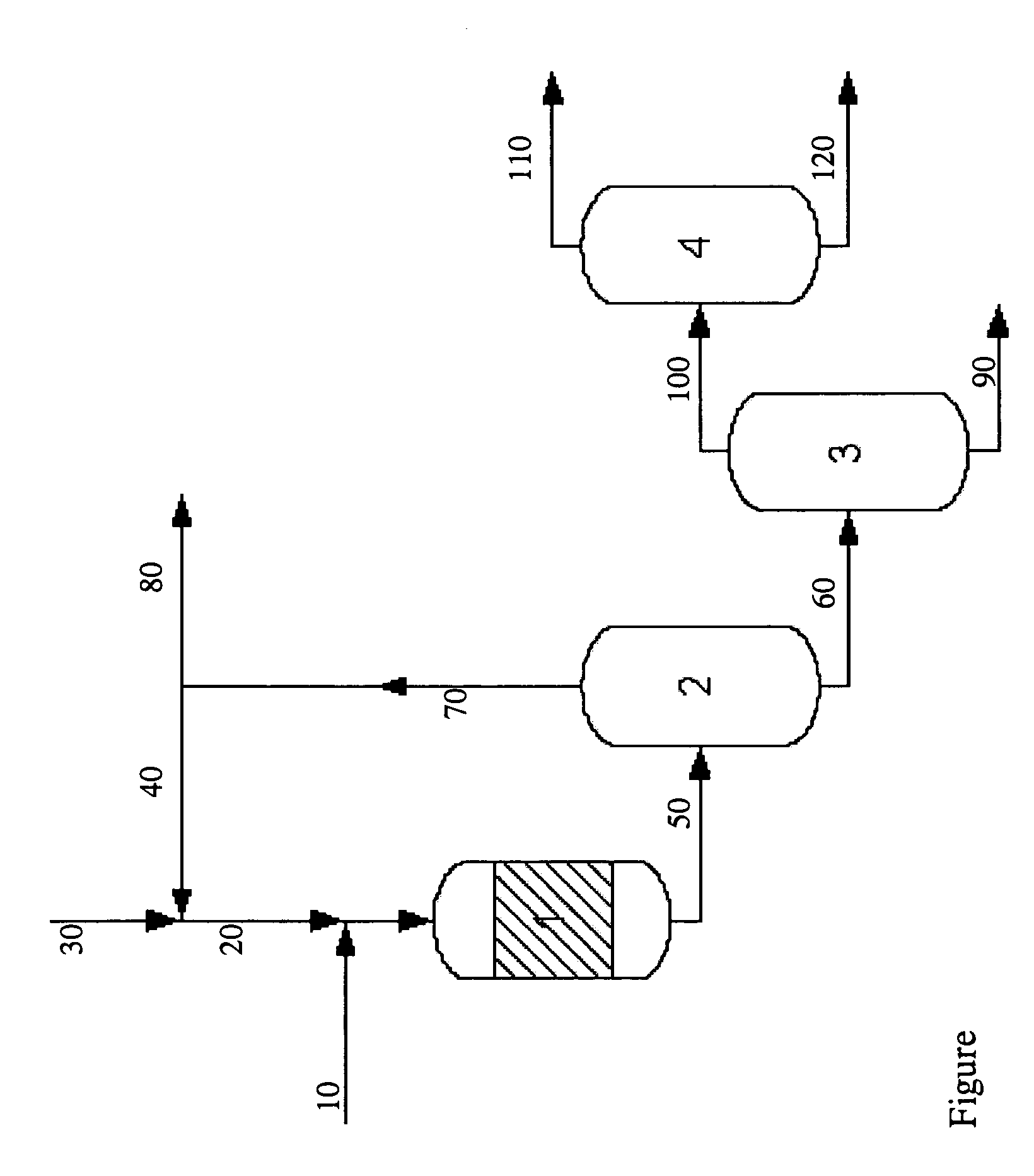

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises a non-precious metal and an oxide to produce a hydrocarbon product having a ratio of odd-numbered hydrocarbons to even-numbered hydrocarbons of at least 2:1.

Owner:REFINING TECH SOLUTIONS LLC

Oily cosmetic composition in aerosol form

InactiveUS20080031908A1Process stabilityHappy to useCosmetic preparationsHair cosmeticsParaffin waxSolid particle

Aerosol product containing an oily composition containing at least one oil, and at least one hydrocarbon compound having a melting point greater than or equal to 30° C., the compound being in the form of solid particles and one or more propellants. The hydrocarbon compound can notably be a paraffin or a fatty acid amide. Used for cleaning and / or make-up removal of the skin and / or of the hair, care of the skin and / or of the hair, for protecting the skin against the sun, and for make-up of the skin.

Owner:LOREAL SA

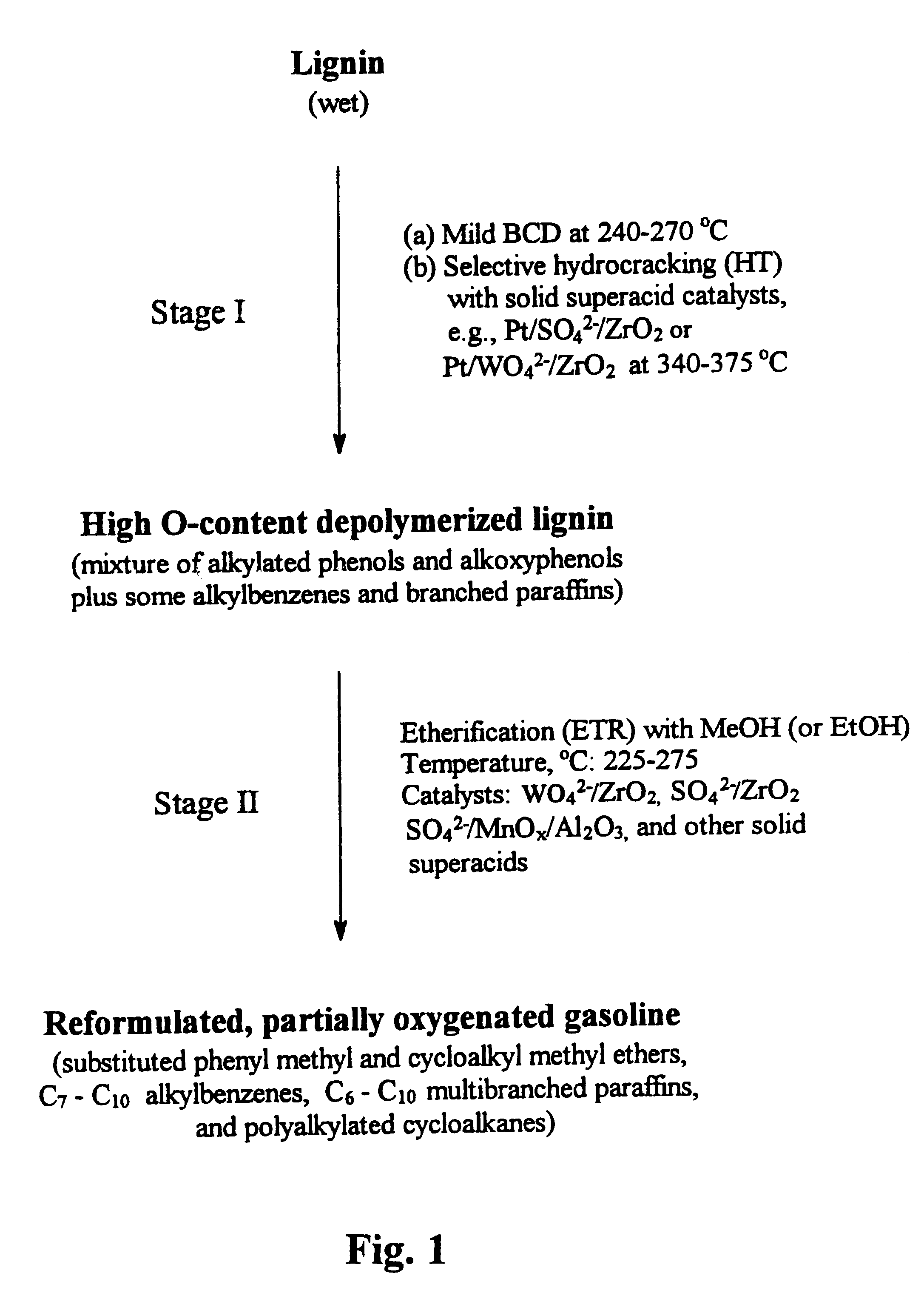

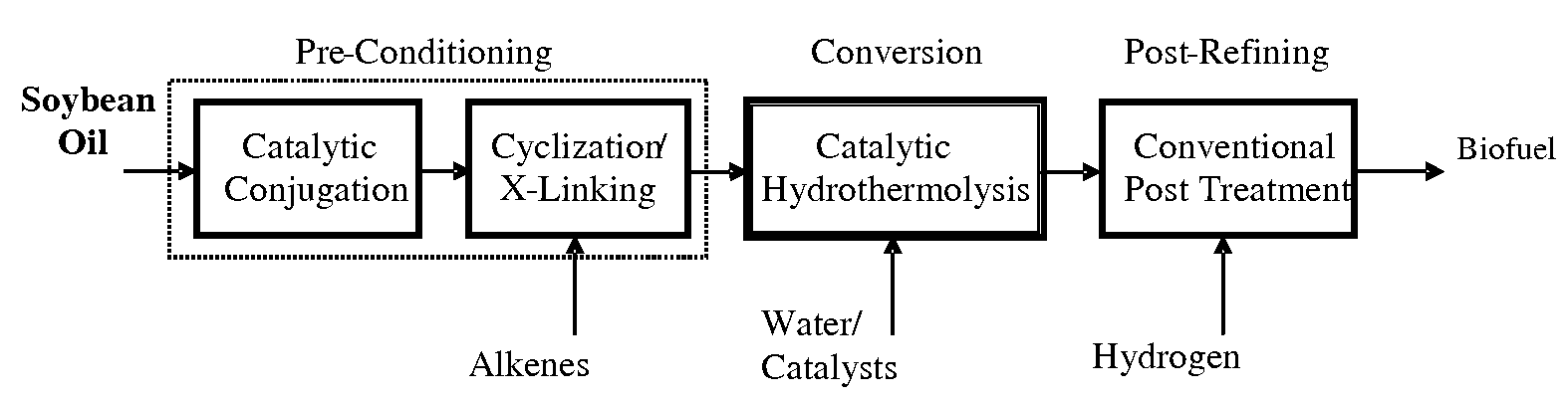

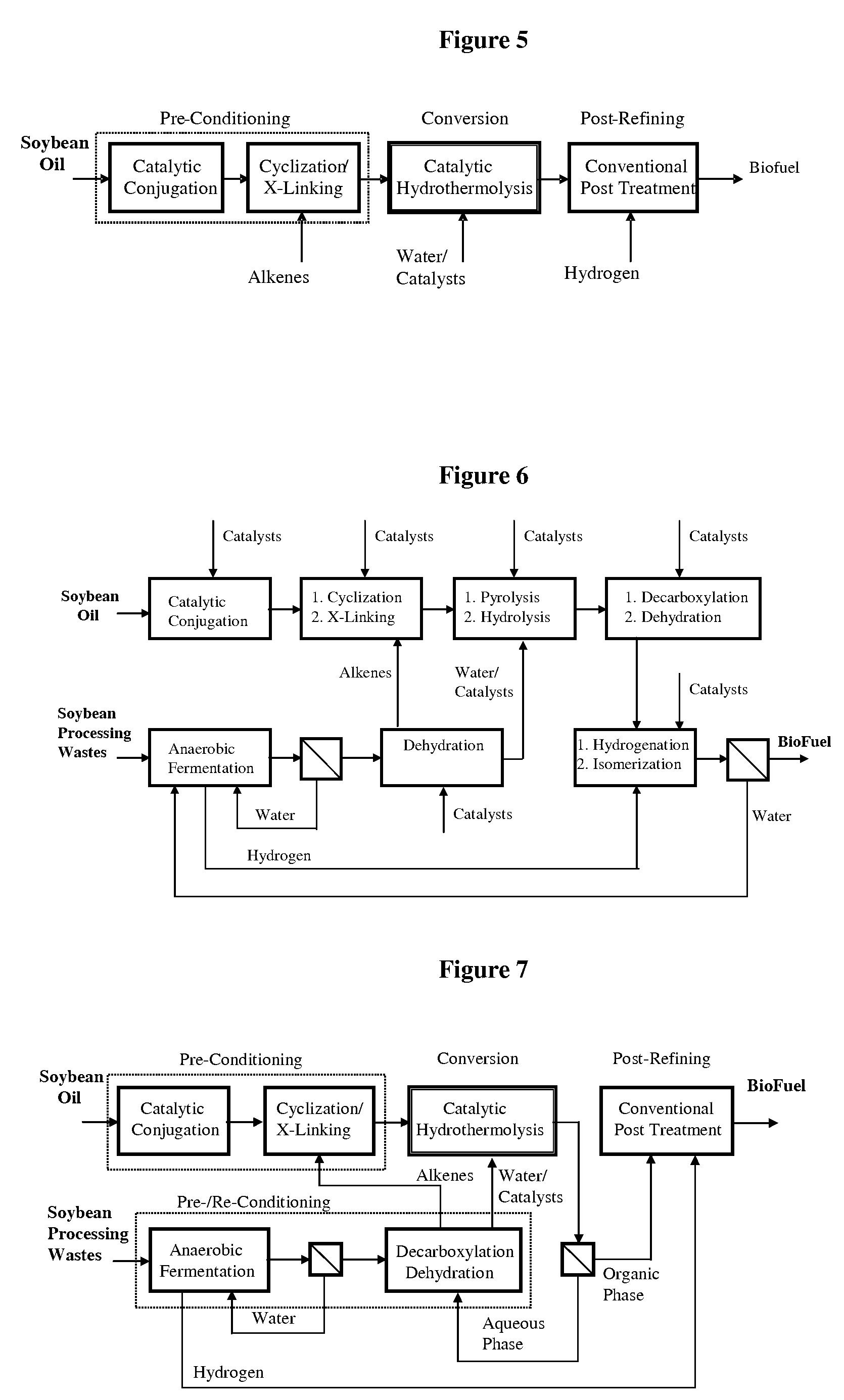

Method of converting triglycerides to biofuels

ActiveUS7691159B2Improve chemical and physical and combustion qualityImprove thermal stabilityFatty acid chemical modificationOrganic compound preparationCross-linkIsomerization

A triglyceride-to-fuel conversion process including the steps of (a) preconditioning unsaturated triglycerides by catalytic conjugation, cyclization, and cross-link steps; (b) contacting the modified triglycerides with hot-compressed water containing a catalyst, wherein cracking, hydrolysis, decarboxylation, dehydration, aromatization, or isomerization, or any combination thereof, of the modified triglycerides produce a crude hydrocarbon oil and an aqueous phase containing glycerol and lower molecular weight molecules, and (c) refining the crude hydrocarbon oil to produce various grades of biofuels. A triglyceride-to-fuel conversion process further including the steps of (a) carrying out anaerobic fermentation and decarboxylation / dehydration, wherein the anaerobic fermentation produces hydrogen, volatile acids, and alcohols from fermentable feedstocks, and the decarboxylation / dehydration produces alkenes from the volatile acids and alcohols, respectively; (b) feeding the alkenes to the cyclization process; (c) feeding the hydrogen to the post refining process; and (d) recycling the aqueous phase containing glycerol to the decarboxylation / dehydration process. A biofuel composition including straight-chain, branched and cyclo paraffins, and aromatics. The paraffins are derived from conversion of triglycerides. The aromatics are derived from conversion of either triglycerides, petroleum, or coal.

Owner:APPLIED RES ASSOCS INC

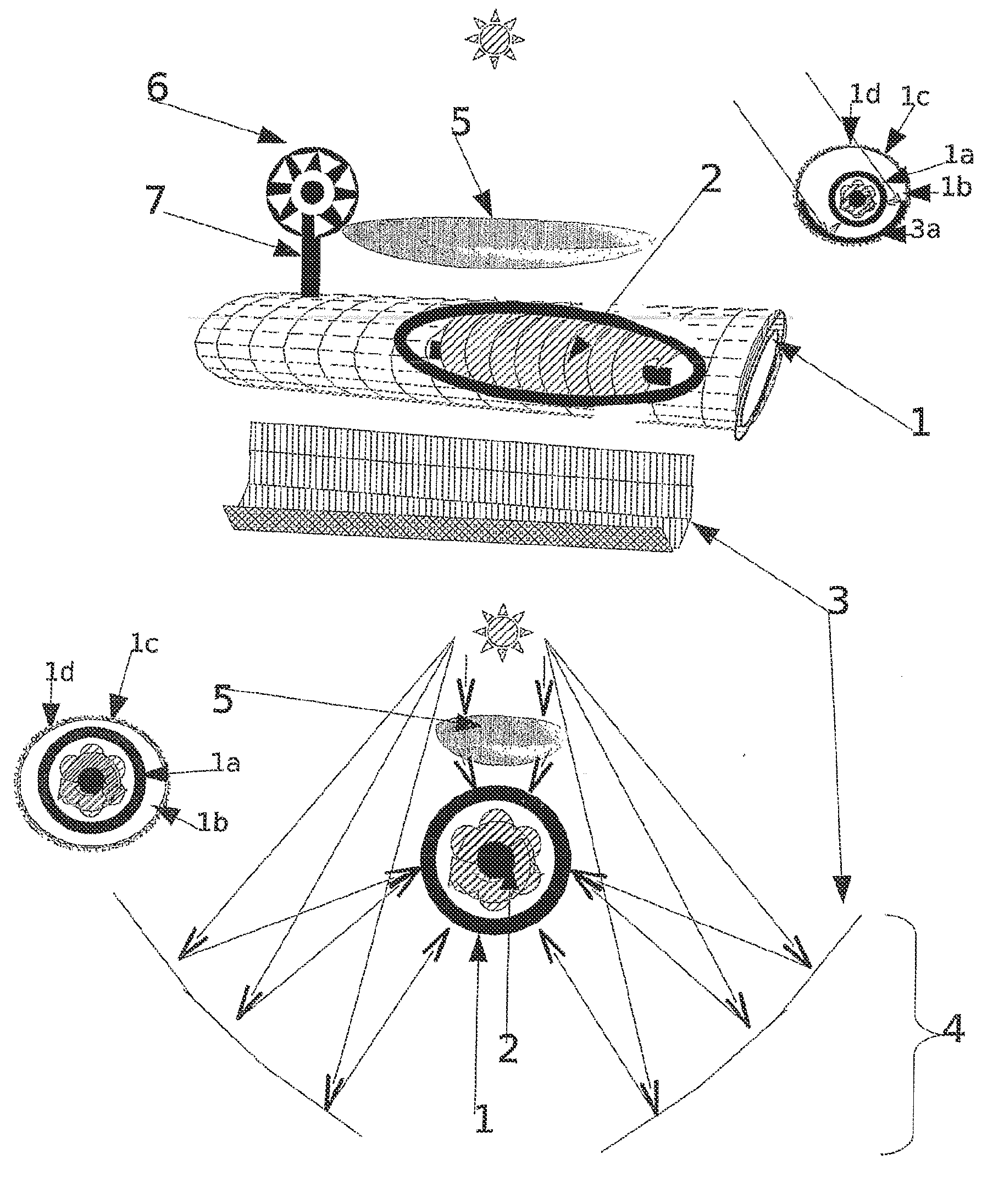

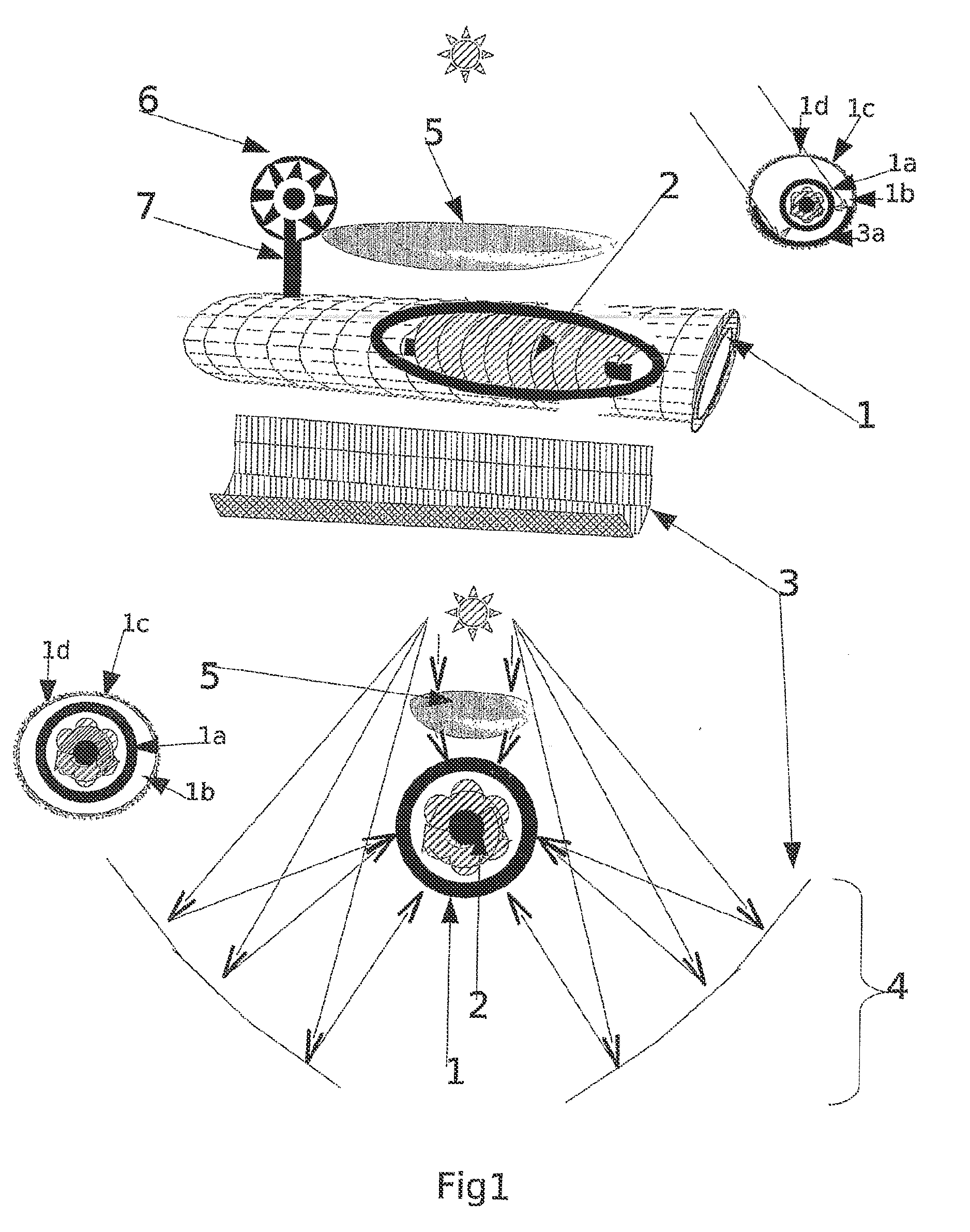

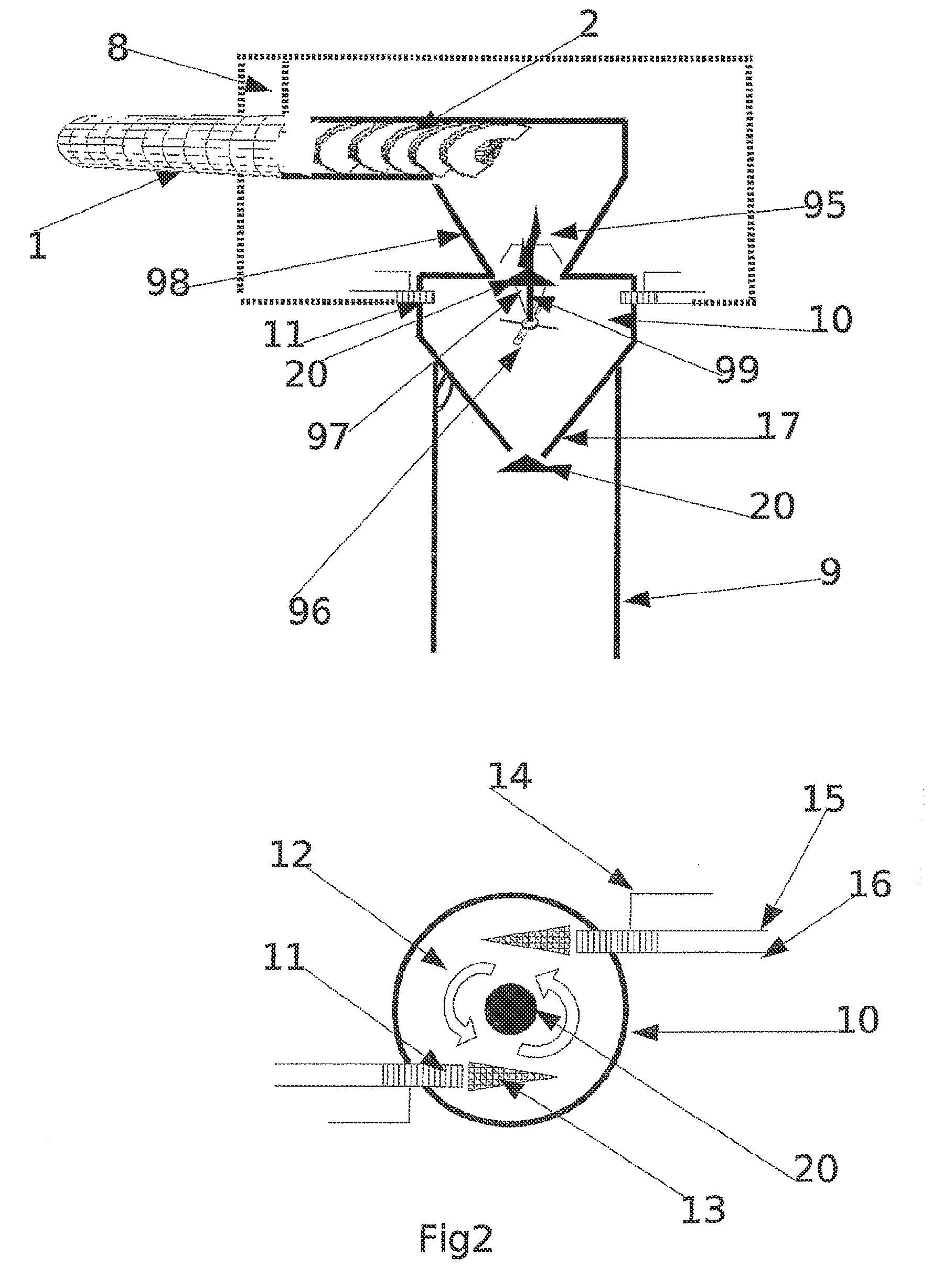

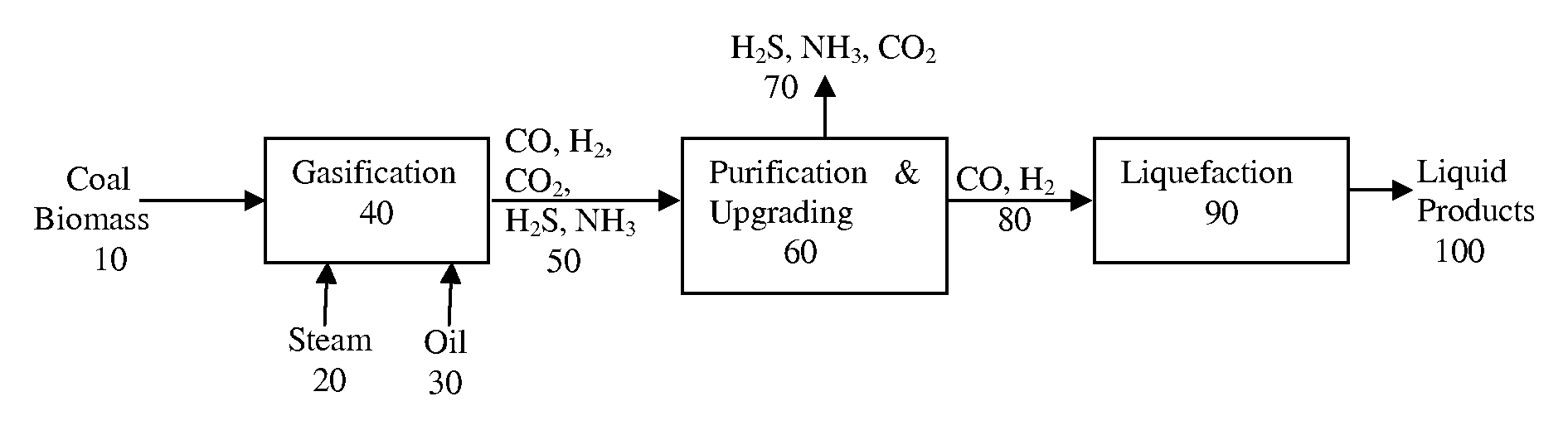

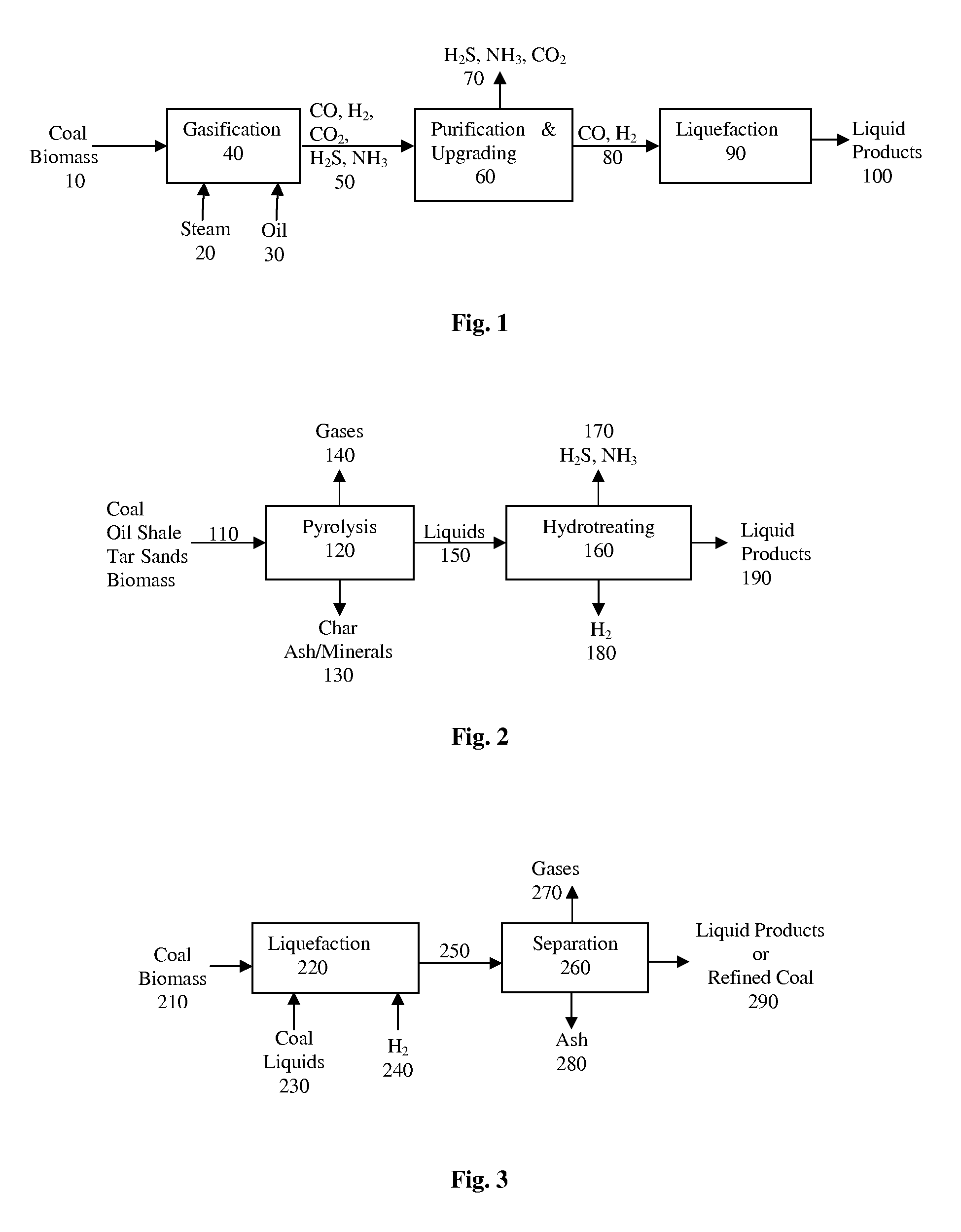

Method using solar energy, microwaves and plasmas to produce a liquid fuel and hydrogen from biomass or fossil coal

ActiveUS20100258429A1Promote gasificationImproving thermal inertiaElectrical coke oven heatingSolar heating energySludgeFractionating column

A system uses thermal solar energy coupled with microwaves and plasma for producing carbon monoxide (CO) and dihydrogen (H2) from carbonated compounds (biomass, domestic waste, sludge from waste water, fossil coal), wherein the obtained gaseous mixture yields, amongst others, hydrocarbon fuels (olefins, paraffin), esters, and alcohols via a Fischer-Tropsch synthesis. In a first step the carbonated compounds are roasted and pyrolized to produce char and dry coal, and a mixture of superheated gases containing CO2, steam, tars and non-condensable volatile materials. The method includes in a second step, and from the pyrolyis products (char or coal, gas mixture), generating a syngas substantially containing a mixture of carbon monoxide and dihydrogen, the mixture being used in Fischer-Tropsch synthesis units. After the Fischer-Tropsch step, the synthesis products are separated in a distillation column after heating in solar furnaces of mixed furnaces (solar / microwave).

Owner:UGOLIN NICOLAS

Vegetable oil candle

InactiveUS6730137B2Novel burning and fragrance characteristicBiofuelsSolid fuelsParaffin waxVegetable oil

A candle composition has a paraffin wax mixture of a high melting point paraffin wax and a low melting point paraffin wax, and a hydrogenated vegetable oil that is present in a greater amount than the mixture of the varying grades of paraffin wax, and the vegetable oil contains no more than 0.15% free fatty acid, with the remainder being triglycerides. Candles of the composition have good burn characteristics, particularly good fragrance intensity and produce a unique crystallization effect after the first burn.

Owner:BEAUTYAVENUES

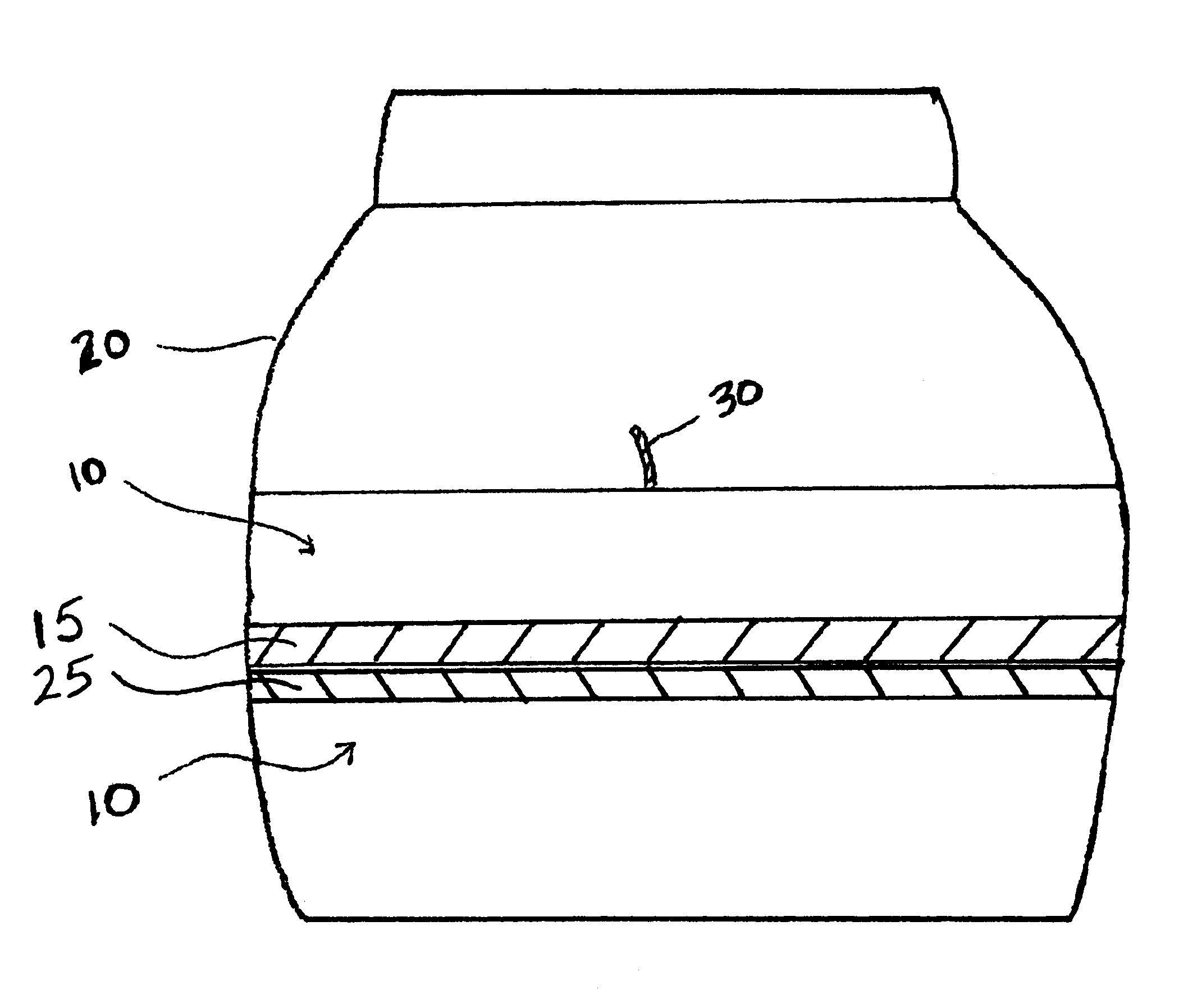

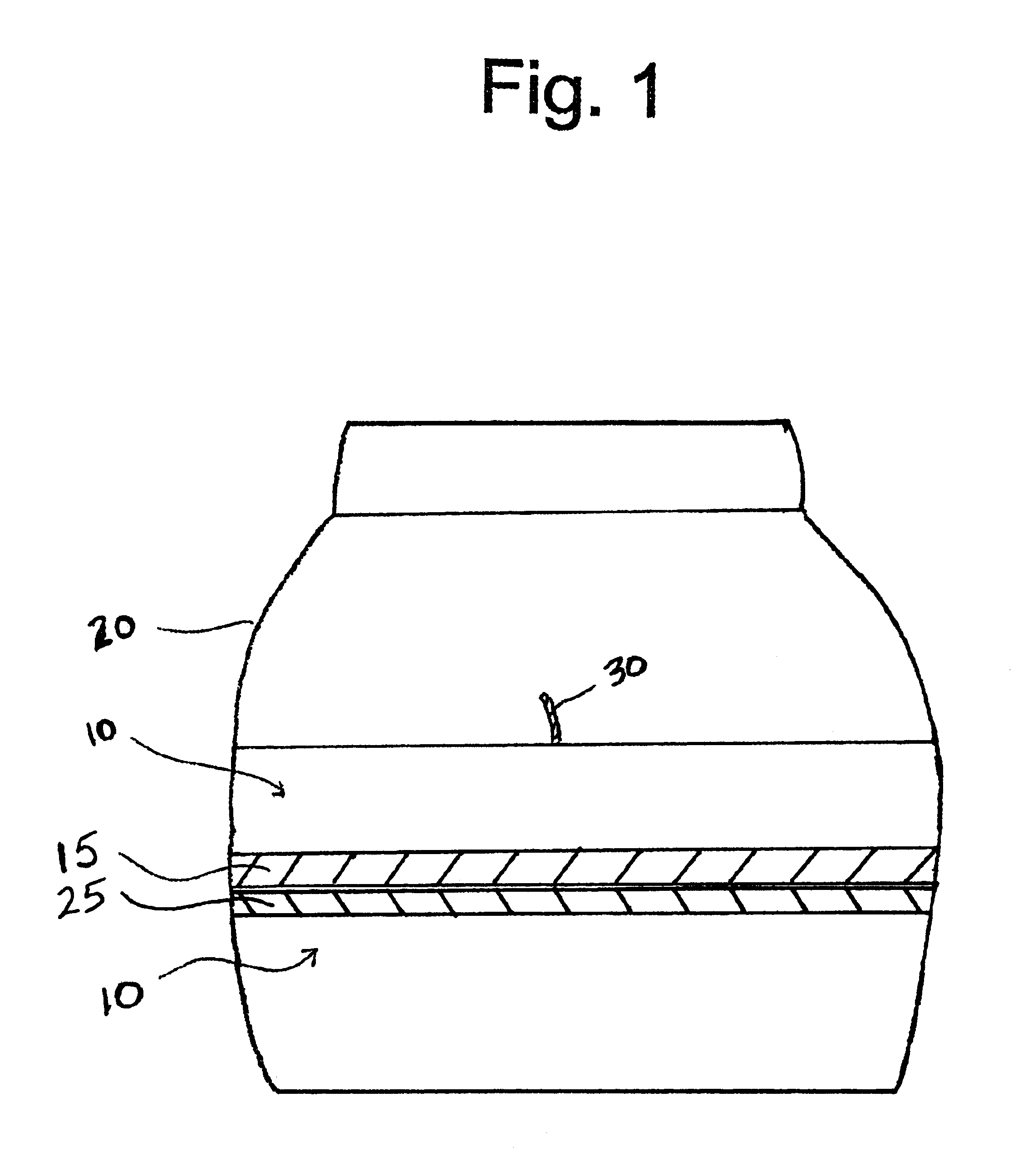

Phase-transition composite material, preparation method and application thereof

ActiveCN102408877APhase transition temperature is suitableLarge latent heat of phase changeClimate change adaptationHeat proofingParaffin waxThermal insulation

The invention relates to a phase-transition composite material which comprises: A) 30-65% of phase-transition materials which are low melting point paraffin with a melting point of 25-45 DEG C and / or dodecanol; B) 25-45% of carrier materials which are high density polyethylane and / or ethane-vinylacetate copolymer; C) 5-15% of inorganic fillers which are porous substances and are selected from one or two of expanded perlite and expandable graphite; D) 1-10% of heat-conduction reinforcing agents; and E) 1-10% of fire retardants. The composite material has an appropriate phase transition temperature which matches the building ambient temperature, has great phase transition latent heat, excellent heat-preservation and heat-insulation performance, is fireproof and flame-retardant, is easy to process, and has greatly reduced phase-transition material leakage. The invention also relates to a method for preparing the phase-transition composite material, which comprises the thermal insulation mortar of the phase-transition composite material and a method of heat preservation of a wall by using the mortar.

Owner:BEIJING UNIV OF CHEM TECH +1

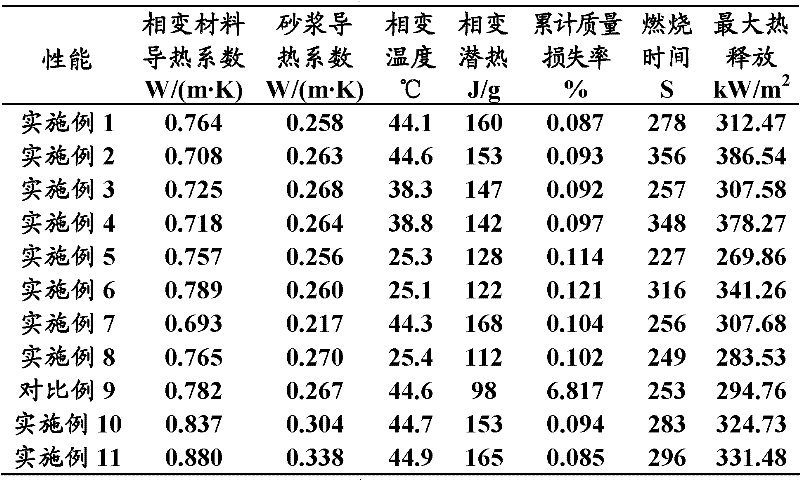

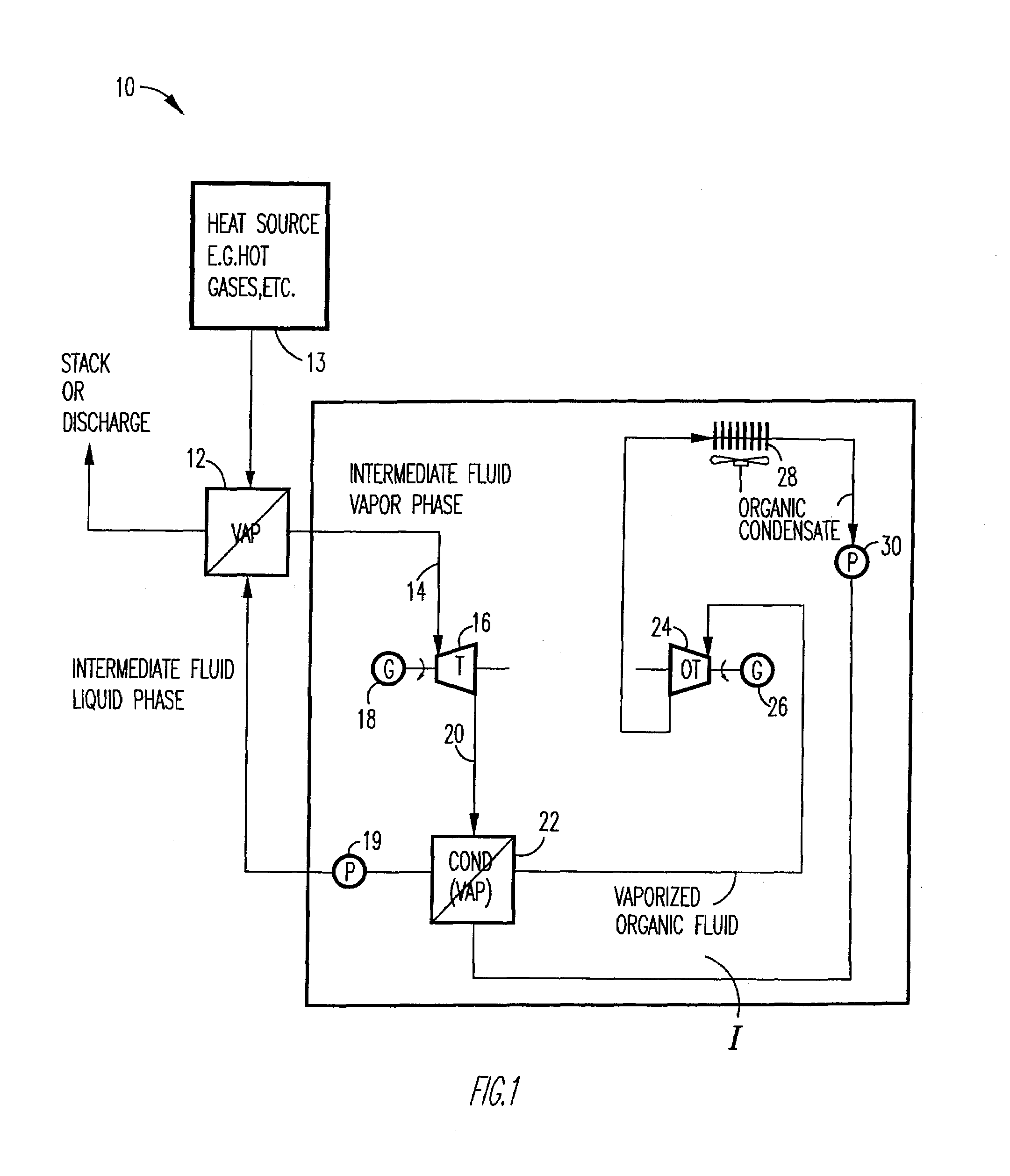

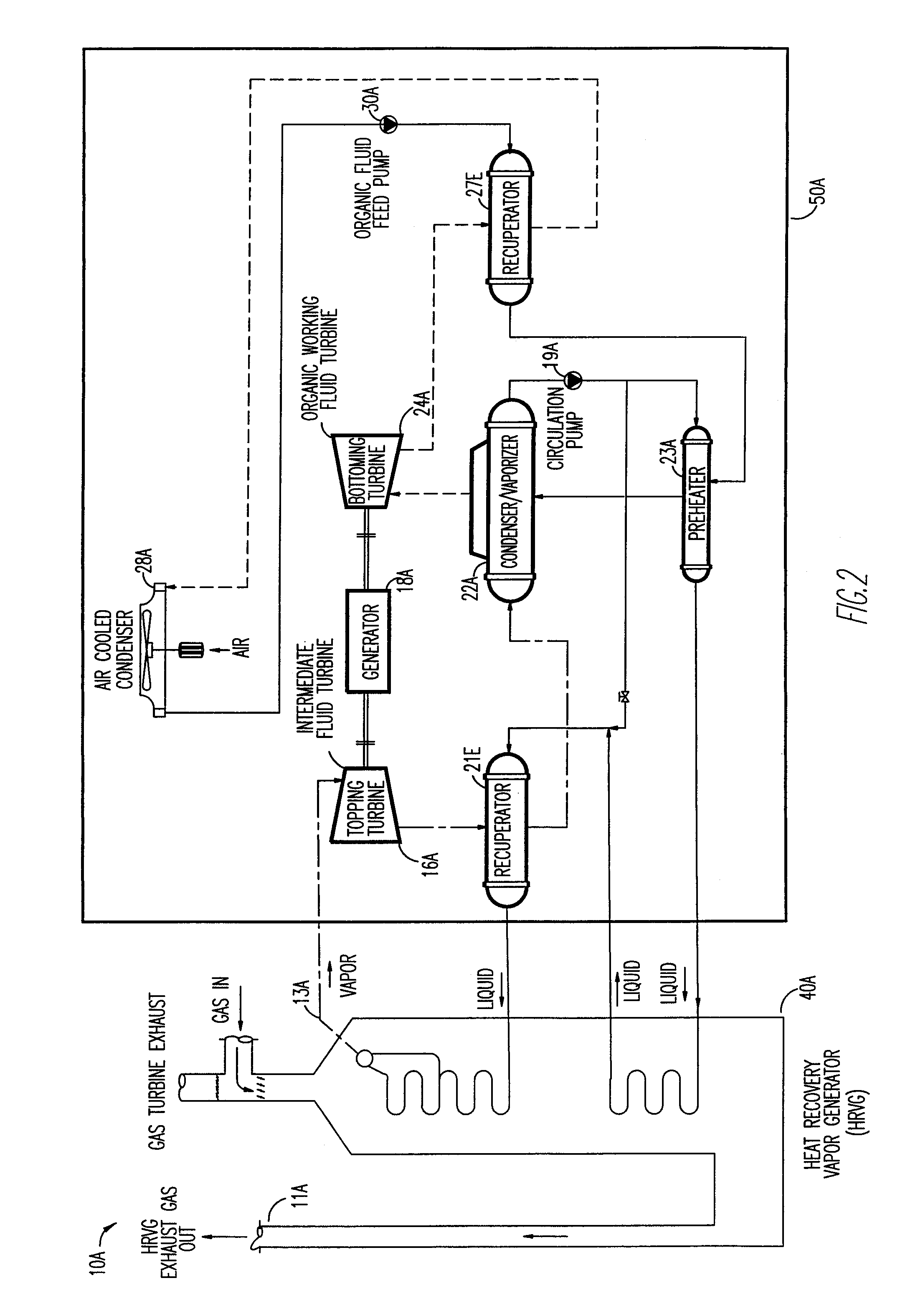

Organic working fluids

ActiveUS7225621B2Improve thermal stabilityStable compoundAuxillary drivesFrom solar energyHuman useAlkane

The present invention provides an improved, commercially available organic working fluid, which is operable under a broad range of temperatures, is thermally stable, has a high auto-ignition temperature, low freezing point and high critical temperature and is benign to the environment, and safe for human use. Such an organic working fluid is useful in organic Rankine cycle (ORC) power plants or units and other systems of the like; as an intermediate fluid for heat-recovery wherein heat from various heat sources is transferred using the intermediate fluid to a further working fluid and converted into work, and the intermediate fluid is also exploited to produce electricity. Such organic working fluids are also operable as heat transfer fluids either in ORC power plants or units or in other heat transfer systems. For this purpose the present invention presents a working fluid comprising at least one highly branched, heavy iso-paraffin hydrocarbons, or a mixture of two or more of such hydrocarbons. Preferably, at least one highly branched iso-paraffin hydrocarbon is present as the major component (i.e. at least 50% by volume) in the working fluid. A preferred sub-class of the class of the branched iso-paraffins which are suitable to be incorporated in organic working fluids of the present invention includes 8 to 20 carbon atom-containing hydrocarbons having at least one methyl radical (CH3) arranged to achieve a highly stable compound.

Owner:ORMAT TECH INC

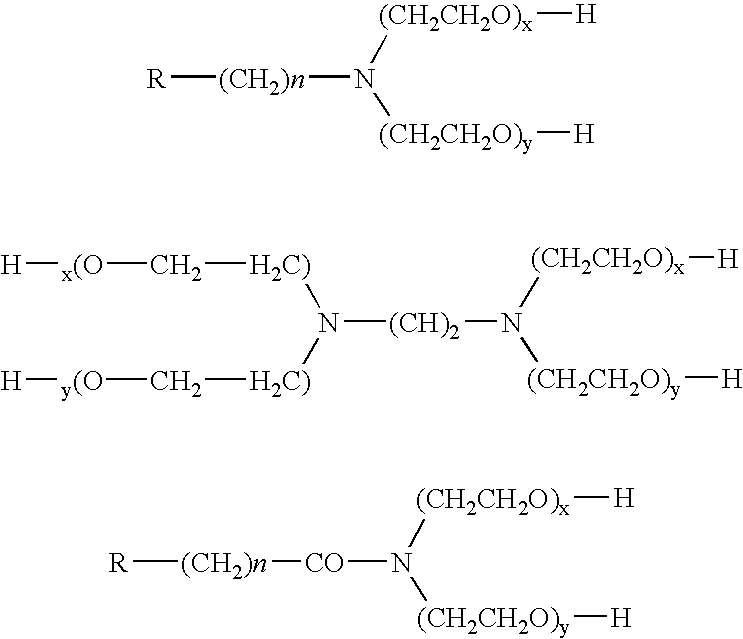

Method of using water-in-oil emulsion to remove oil base or synthetic oil base filter cake

ActiveUS7481273B2Improve breathabilityHighly efficient in breakingCleaning apparatusScale removal and water softeningParticulatesParaffin wax

Fluid producing or injecting wells may be treated with a water-in-oil emulsion for the removal or inhibition of unwanted particulates, including pipe dope, asphaltenes and paraffins. In addition, such emulsions are effective in the displacement of oil base drilling muds and / or residues from such muds from wells. The emulsion may also be used to break the interfacial and / or rheological properties of oil base mud and synthetic oil base mud filter cakes, and act as a demulsifier to break the water-in-oil emulsion present in such oil base and synthetic oil base muds. The water-in-oil emulsions may optionally contain a dispersing agent as well as a surfactant.

Owner:BAKER HUGHES INC

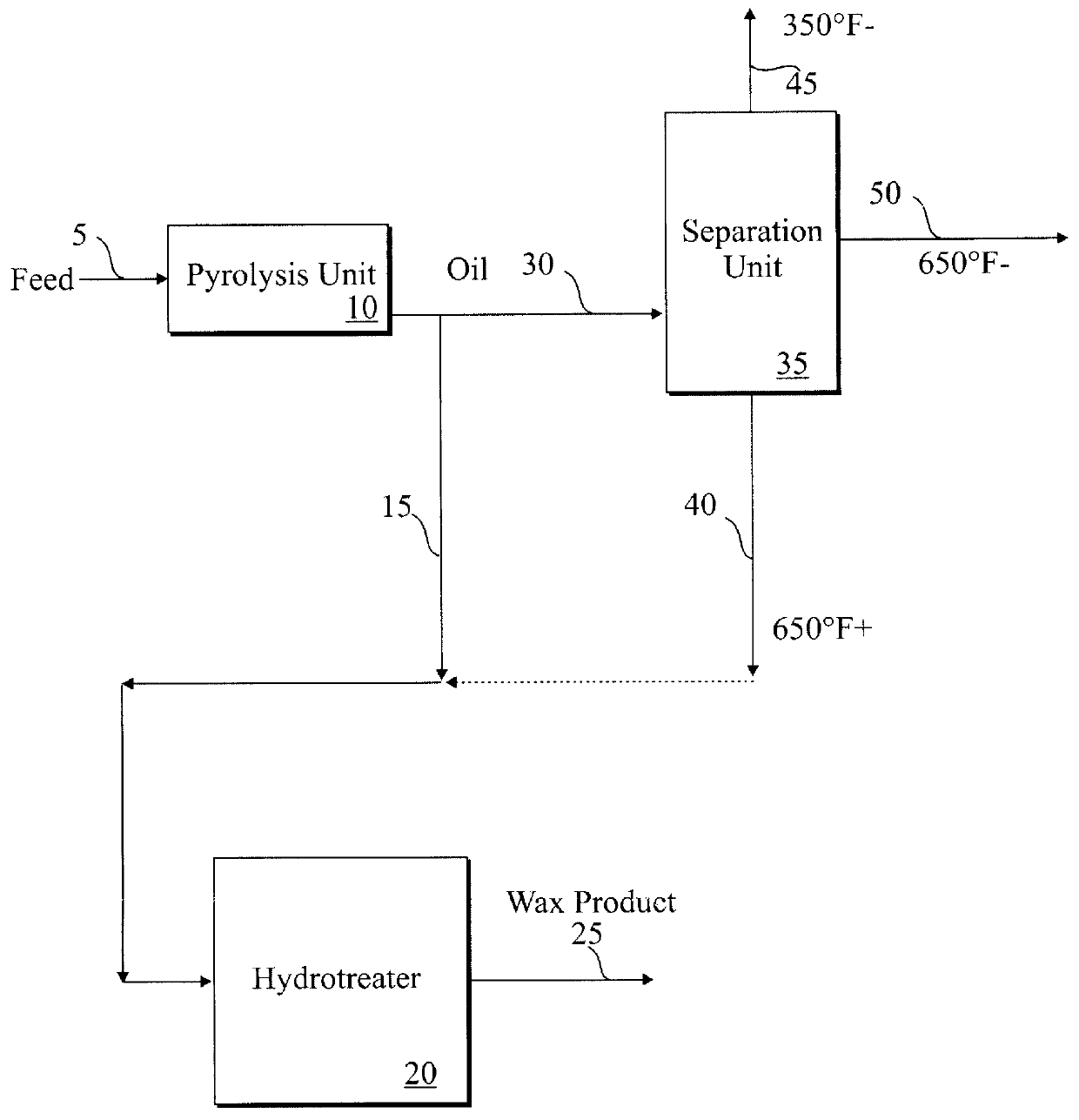

Method for making a heavy wax composition

InactiveUS6143940ATreatment with plural serial cracking stages onlyTreatment with plural serial stages onlyWaxAlkane

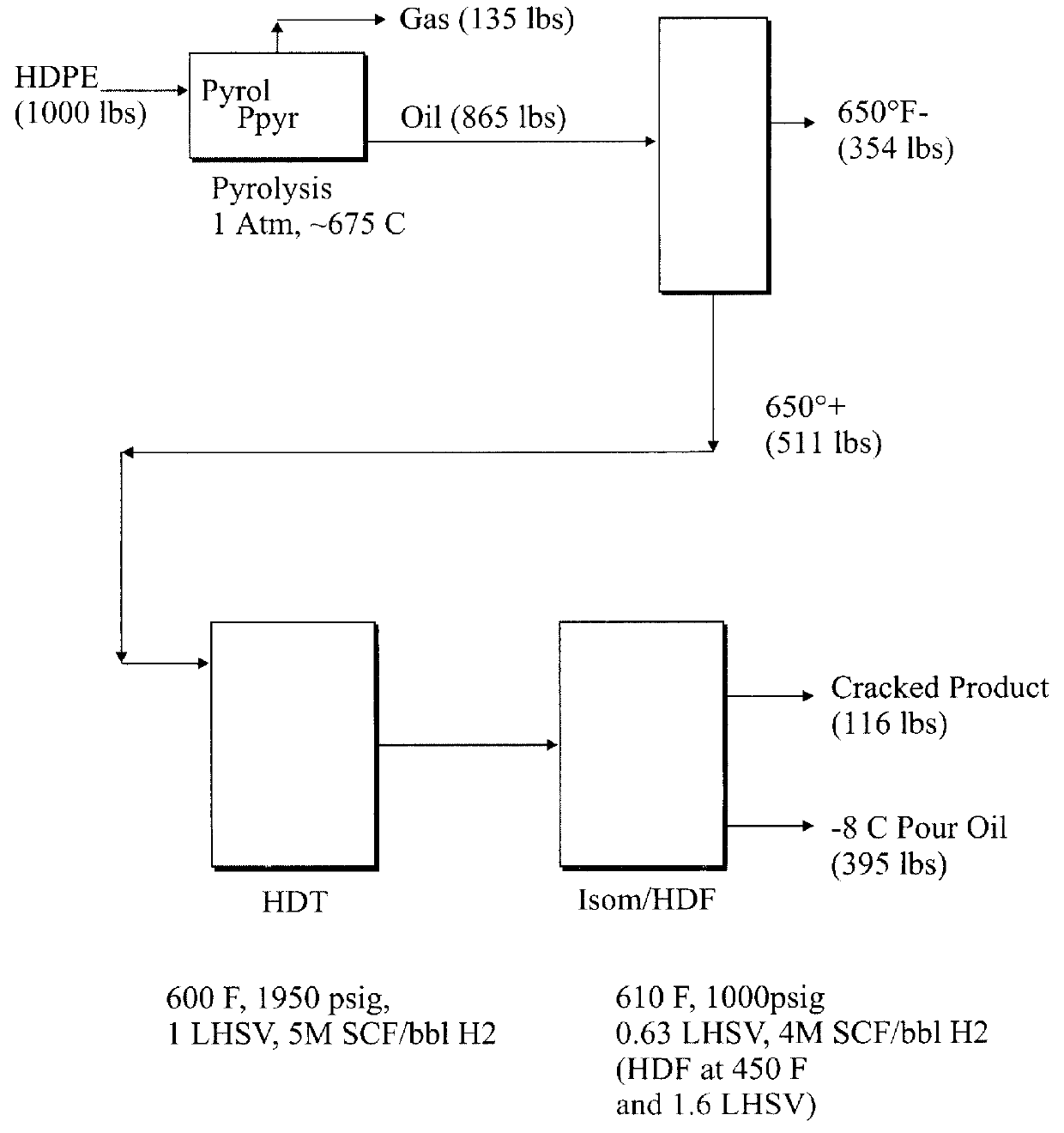

The invention includes a process of making a wax composition including: a process for making a heavy wax composition including the steps of (1) contacting a waste plastics feed containing primarily polyethylene in a pyrolysis zone at sub-atmospheric pressure, whereby at least a portion of the waste plastics feed is cracked, thereby forming a pyrolysis zone effluent including 1-olefins and n-paraffins; and (2) passing the pyrolysis zone effluent to a hydrotreating zone, for contacting with a hydrotreating catalyst at catalytic conditions.

Owner:UNIV OF KENTUCKY RES FOUND

Biodegradable high performance hydrocarbon base oils

InactiveUS6506297B1Refining to change hydrocarbon structural skeletonLiquid hydrocarbon mixture productionAlkaneWax

Discloses novel biodegradable high performance hydrocarbon base oils useful as lubricants in engine oil and industrial compositions, and process for their manufacture. A waxy, or paraffinic feed, particularly a Fischer-Tropsch wax, is reacted over a dual function catalyst to produce hydroisomerization and hydrocracking reactions, at 700° F.+ conversion levels ranging from about 20 to 50 wt. %, preferably about 25-40 wt. %, sufficient to produce a crude fraction, e.g., a C5-1050° F.+ crude fraction, containing 700° F.+ isoparaffins having from about 6.0 to about 7.5 methyl branches per 100 carbon atoms in the molecule. The methyl paraffins containing crude fraction is topped via atmospheric distillation to produce a bottoms fraction having an initial boiling point between about 650° F. and 750° F. which is then solvent dewaxed, and the dewaxed oil is then fractionated under high vacuum to produce biodegradable high performance hydrocarbon base oils.

Owner:EXXON RES & ENG CO

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

ActiveUS20080308458A1Fatty acid chemical modificationMolecular sieve catalystsParaffin waxVegetable oil

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises a non-precious metal a first oxide and optionally a second oxide wherein at least one of the first oxide or second oxide comprises a zeolite, through hydrodeoxygenation and one or both of hydroisomerization and hydrocracking.

Owner:REFINING TECH SOLUTIONS LLC

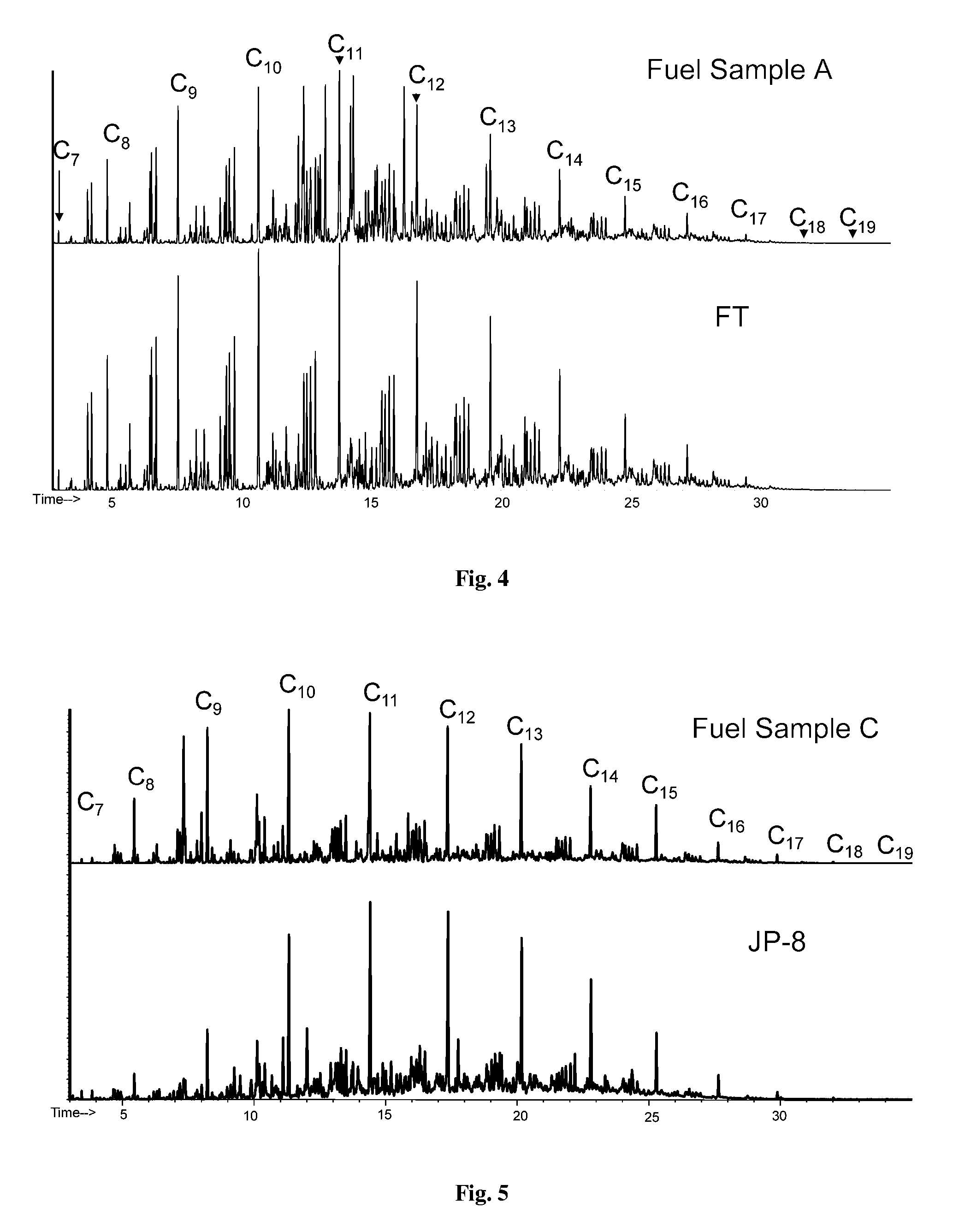

Aviation-grade kerosene from independently produced blendstocks

InactiveUS20090000185A1Liquid carbonaceous fuelsLiquid hydrocarbon mixture productionKeroseneParaffin oils

Aviation-grade kerosene comprising a first blendstock derived from non-petroleum feedstock and comprising primarily hydrocarbons selected from the group consisting of isoparaffins and normal paraffins, and a second blendstock comprising primarily hydrocarbons selected from the group consisting of cycloalkanes and aromatics.A method for the production of aviation-grade kerosene comprising producing a first blendstock from at least one non-petroleum feedstock, the first blendstock comprising primarily hydrocarbons selected from the group consisting of isoparaffins and normal paraffins; producing a second blendstock comprising primarily hydrocarbons selected from the group consisting of cycloalkanes and aromatics; and blending at least a portion of the first blendstock with at least a portion of the second blendstock to produce aviation-grade kerosene.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

Process for making a lubricating composition

InactiveUS6288296B1Improvement ingredientsTreatment with plural serial stages onlyHydrocarbons from unsaturated hydrocarbon additionAlkaneIsomerization

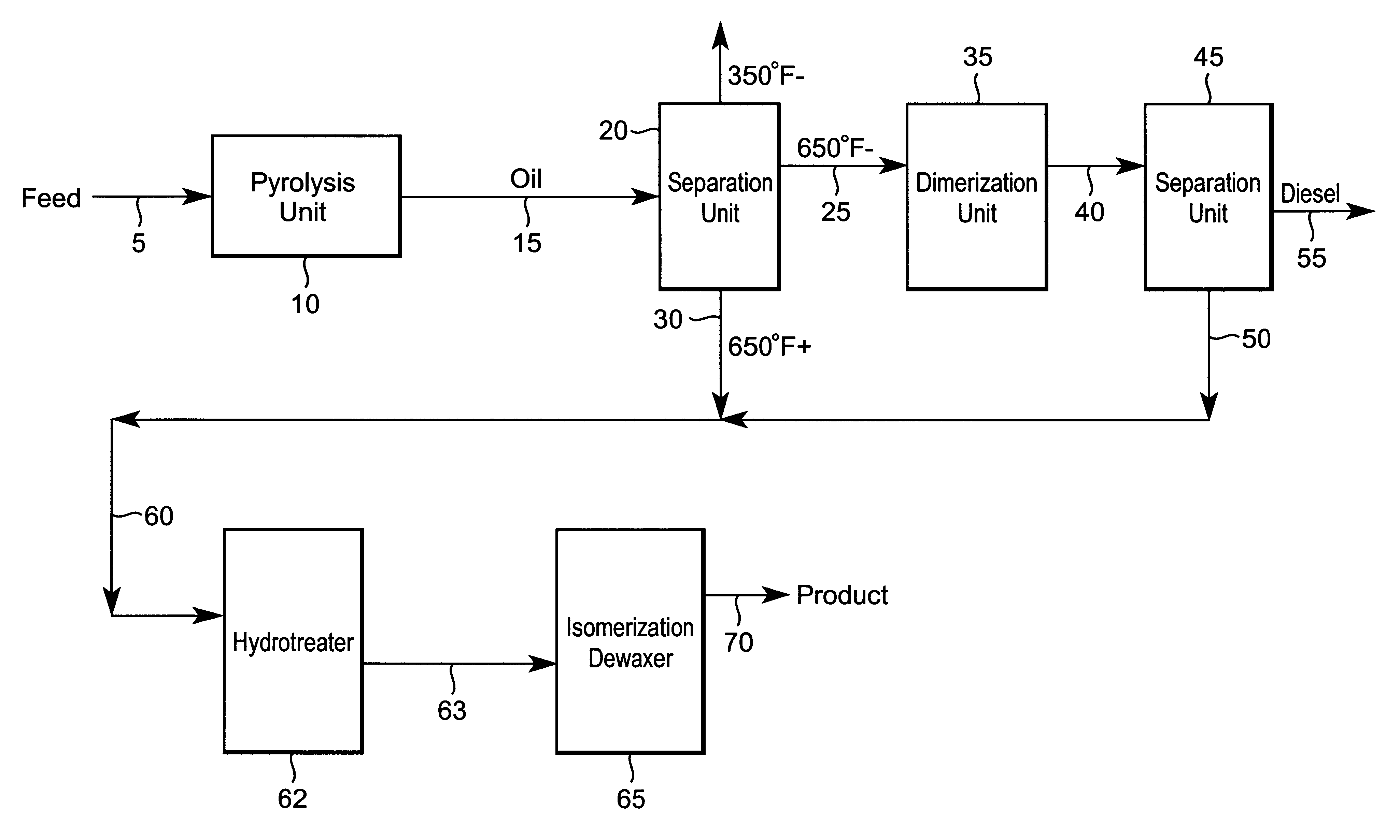

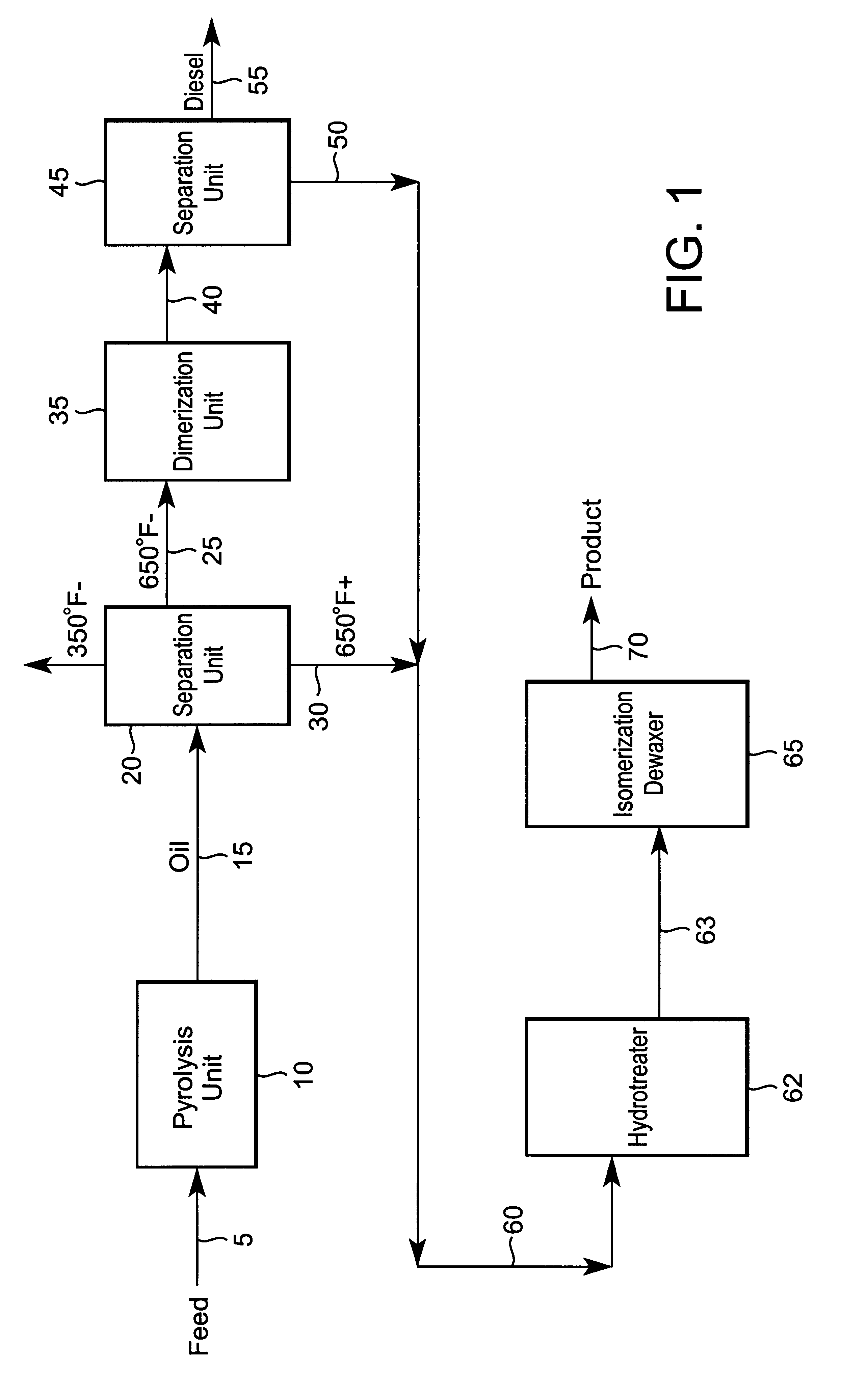

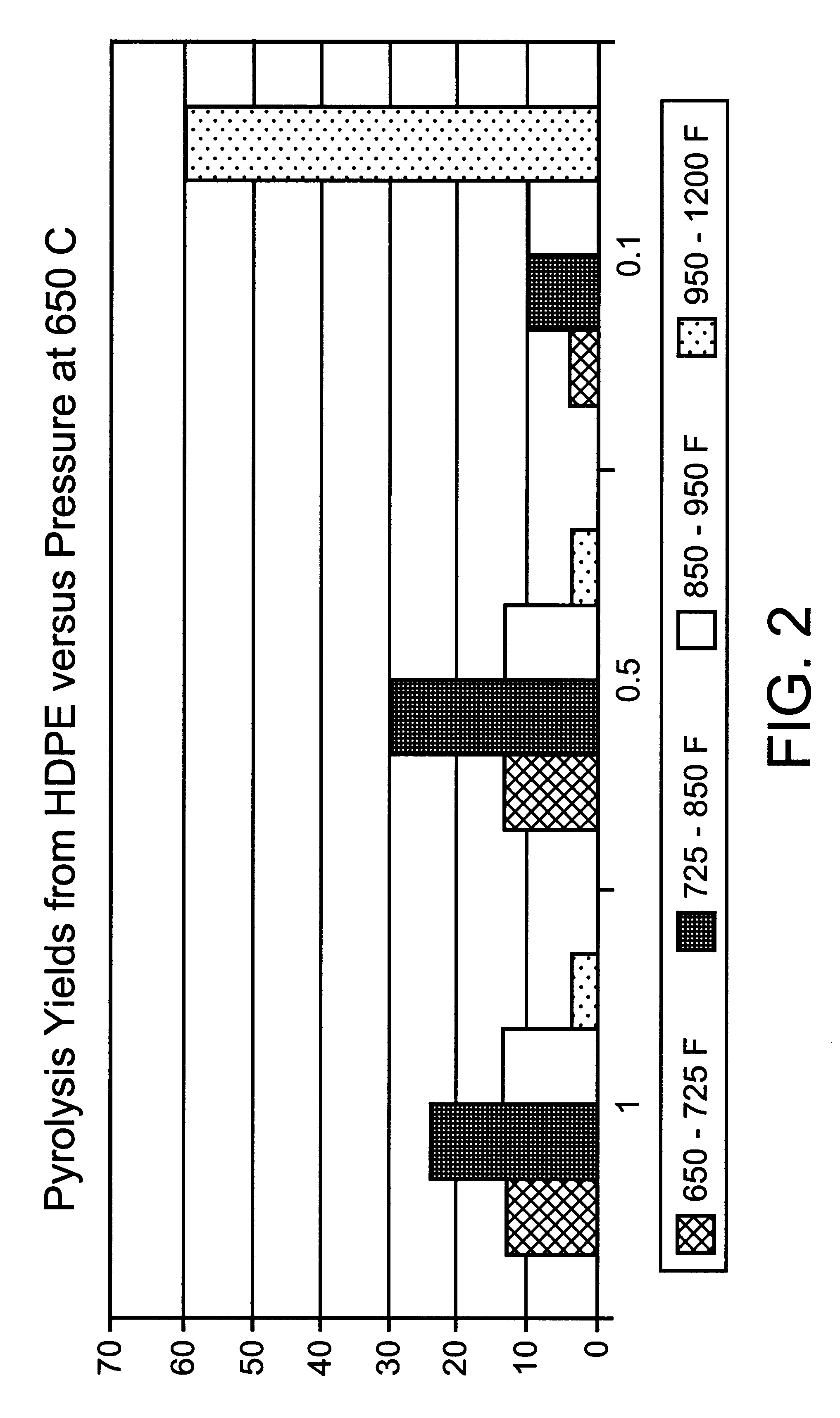

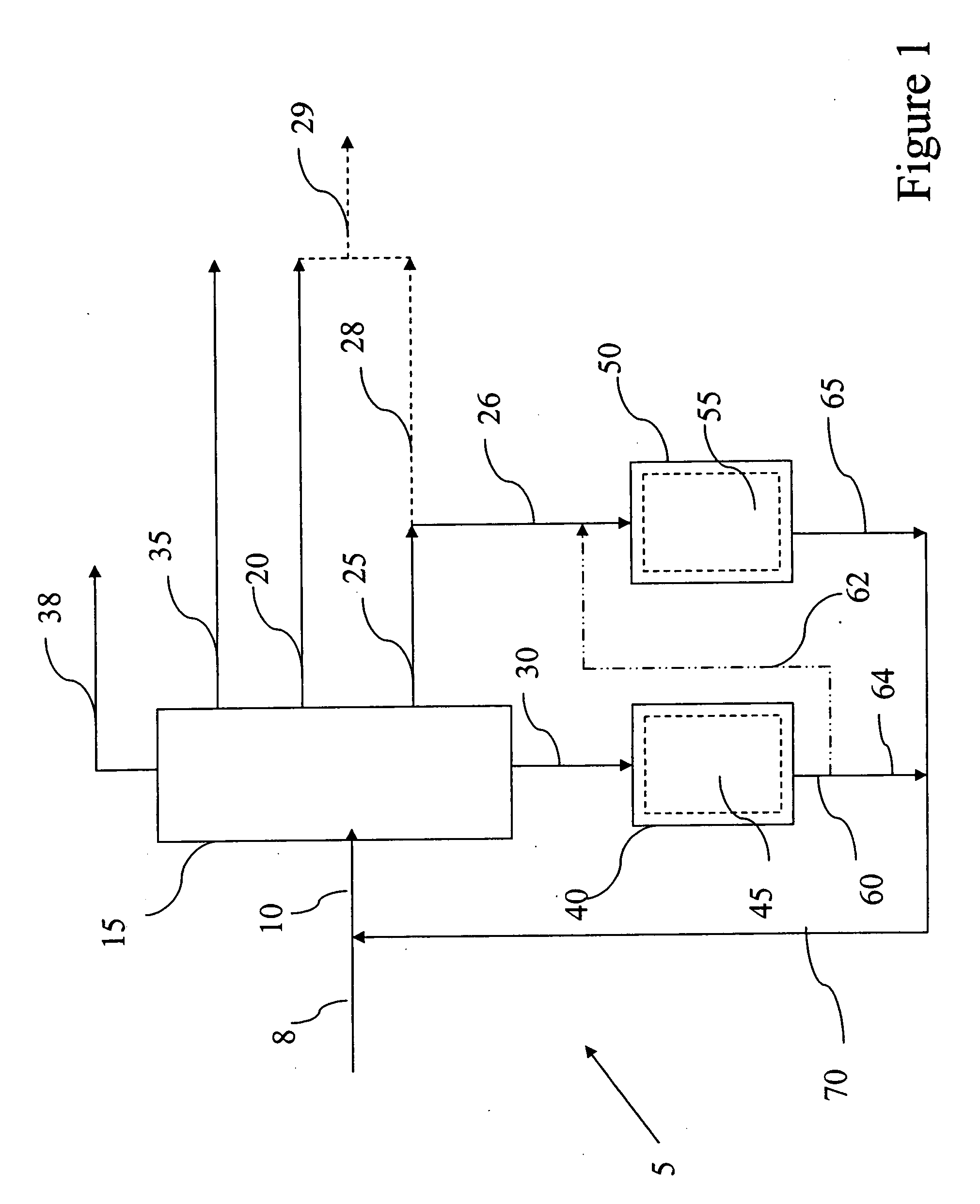

The invention includes a process of making a lubricating oil composition including: a process for making a high VI lubricating oil composition including the steps of (1) contacting a waste plastics feed including mainly polyethylene in a pyrolysis zone at pyrolysis conditions, whereby at least a portion of the waste plastics feed is cracked, thereby forming a pyrolysis zone effluent including 1-olefins and n-paraffins; (2) passing the pyrolysis zone effluent, including a heavy fraction and a middle fraction, the pyrolysis effluent middle fraction including 1-olefins, to a separations zone; where the pyrolysis effluent heavy fraction portion is separated from the pyrolysis effluent middle fraction; (3) passing the pyrolysis effluent middle fraction to a dimerization zone, where at least a portion of the pyrolysis effluent middle fraction is converted to a lube oil range material; and (4) passing at least a portion of the lube oil range material to a catalytic isomerization dewaxing zone, where at least a portion of the lube oil range material is contacted with a isomerization dewaxing catalyst at isomerization dewaxing conditions thereby forming a high VI lubricating oil composition.

Owner:CHEVROU USA INC

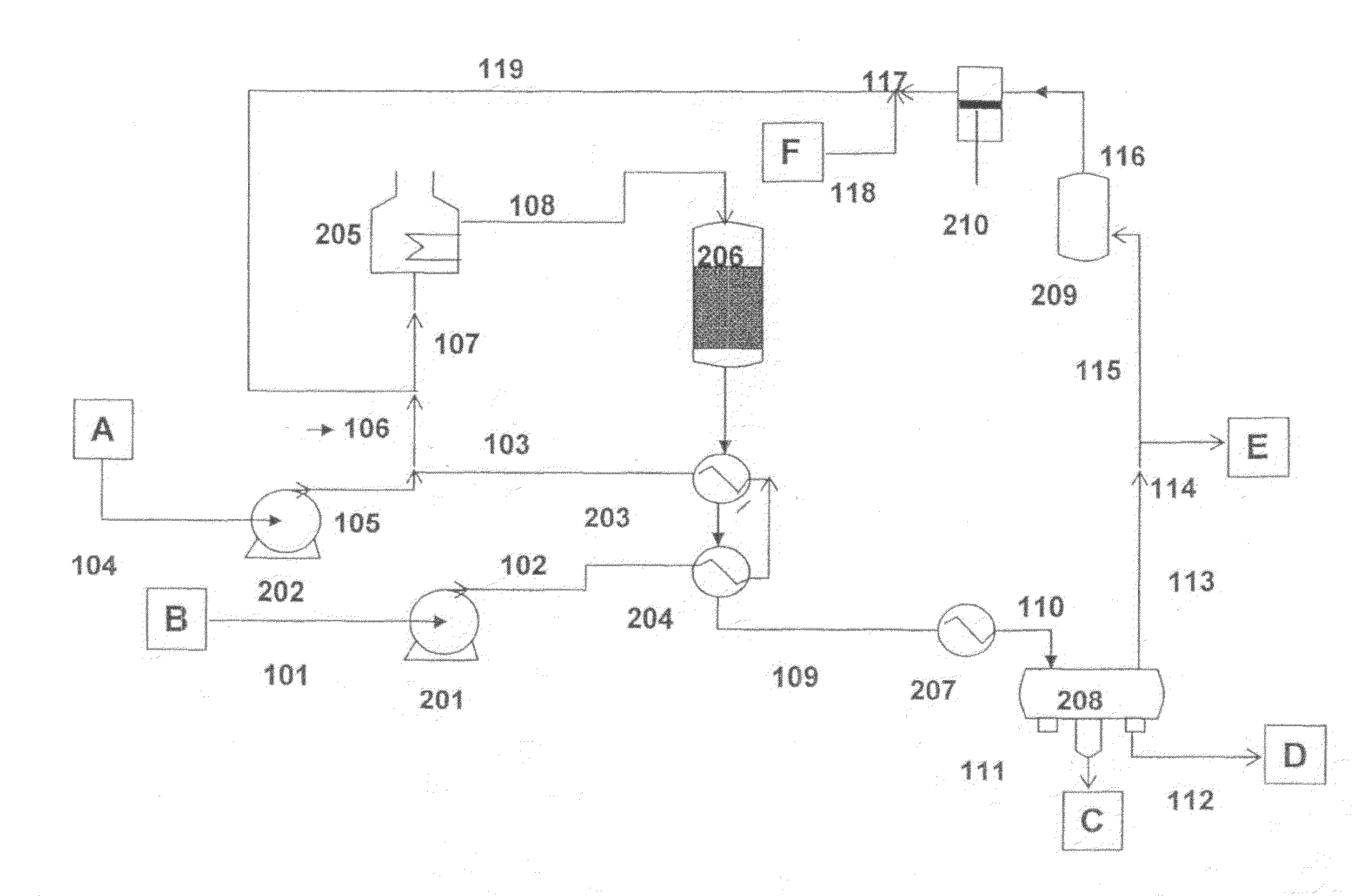

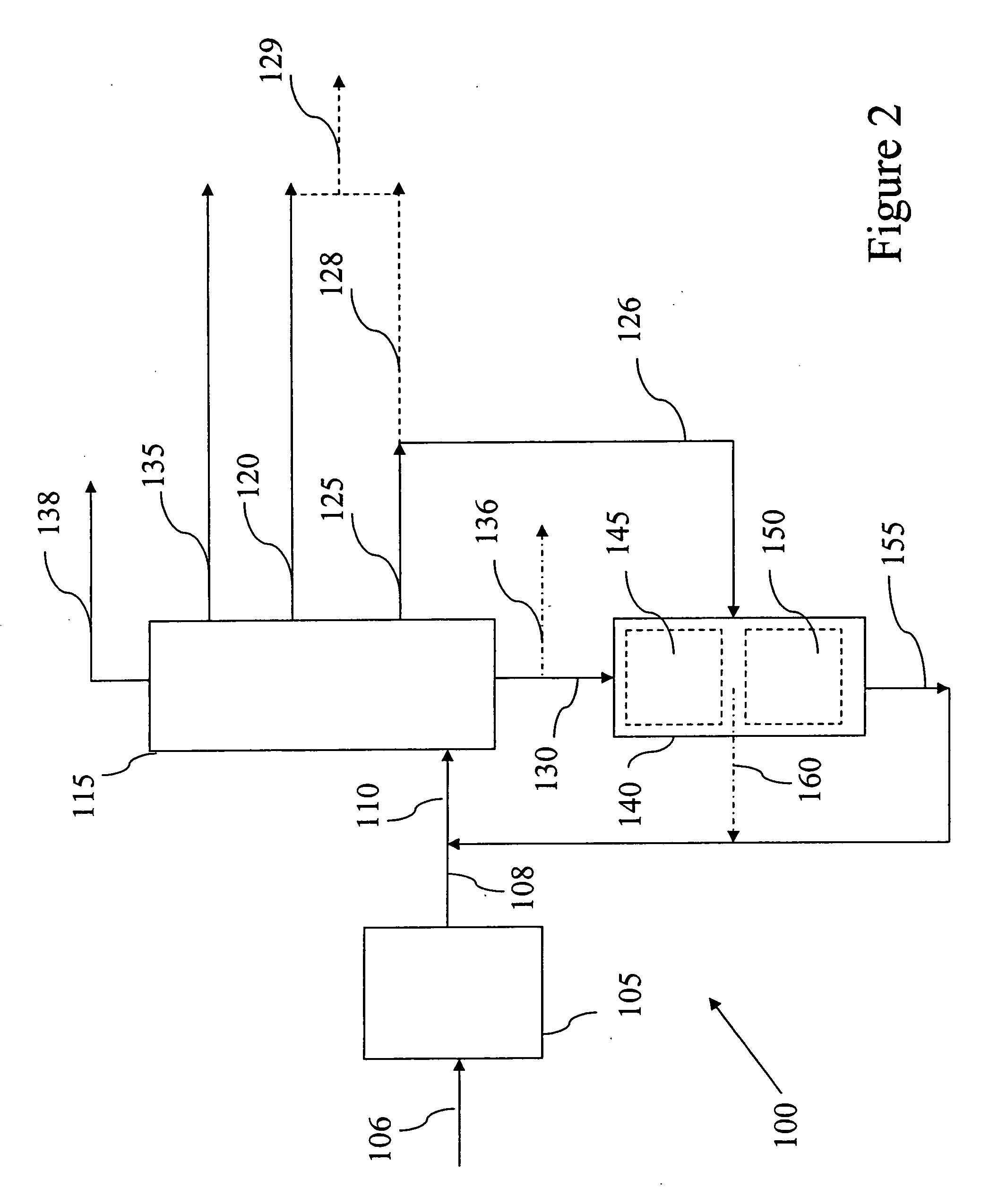

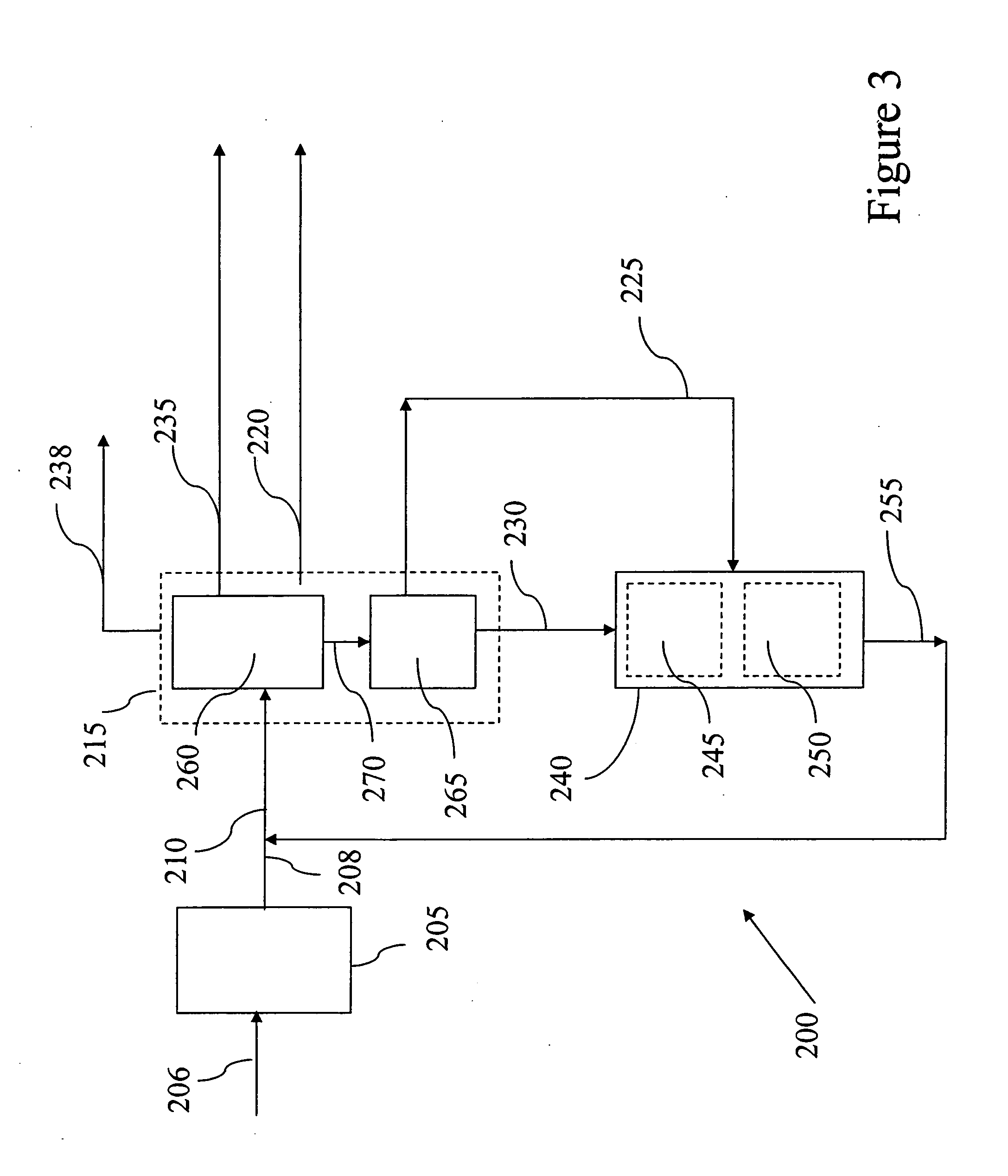

Hydroprocessing methods and apparatus for use in the preparation of liquid hydrocarbons

ActiveUS20050205462A1Easy to prepareEnhancing yield and cold-flow propertyTreatment with plural parallel cracking stages onlyTreatment with plural parallel stages onlyWaxProduction rate

The present invention is generally related towards enhancing the yield and / or cold-flow properties of certain hydrocarbon products, increasing the degree of isomerization in a diesel product and / or increasing the production rate of a diesel product. The embodiments generally include reducing the residence time of lighter hydrocarbon fractions during hydrocracking, thereby decreasing secondary cracking, by various configurations of introducing at least two hydrocarbon feedstreams of different boiling ranges at different entry points in a hydrocracking unit. A method further includes forming a hydrocarbons stream comprising primarily C5+ Fischer-Tropsch hydrocarbon products; fractionating hydrocarbons stream to form at least a wax fraction and an intermediate fraction which serve as separate feedstreams to a hydrocracking unit comprising at least two hydroconversion zones. One embodiment comprises the use of a bifunctional catalyst in one of the hydrocracking zones so as to favor hydroisomerization of hydrocarbons to favor the formation of branched paraffins boiling in the diesel range.

Owner:PHILLIPS 66 CO

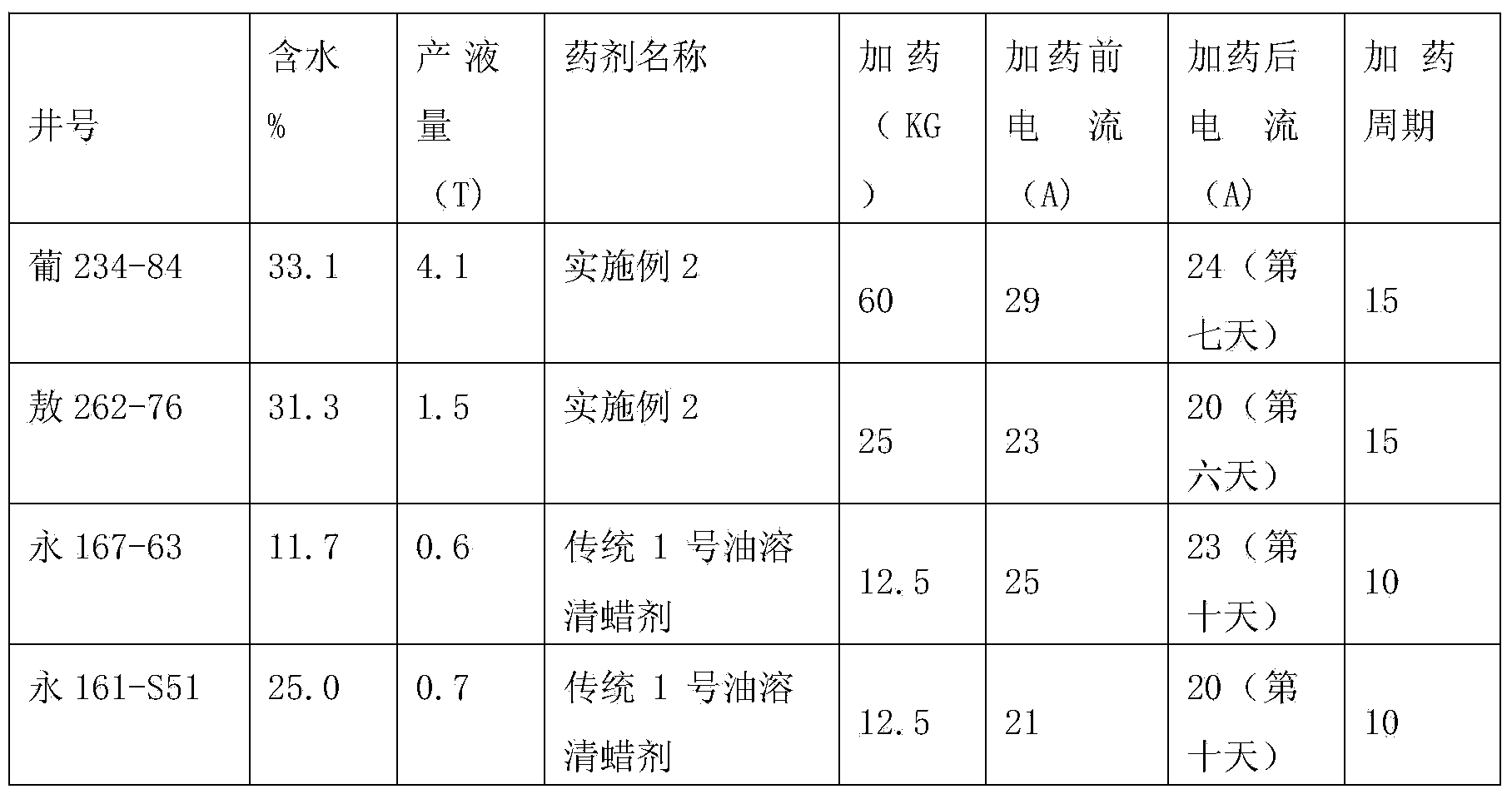

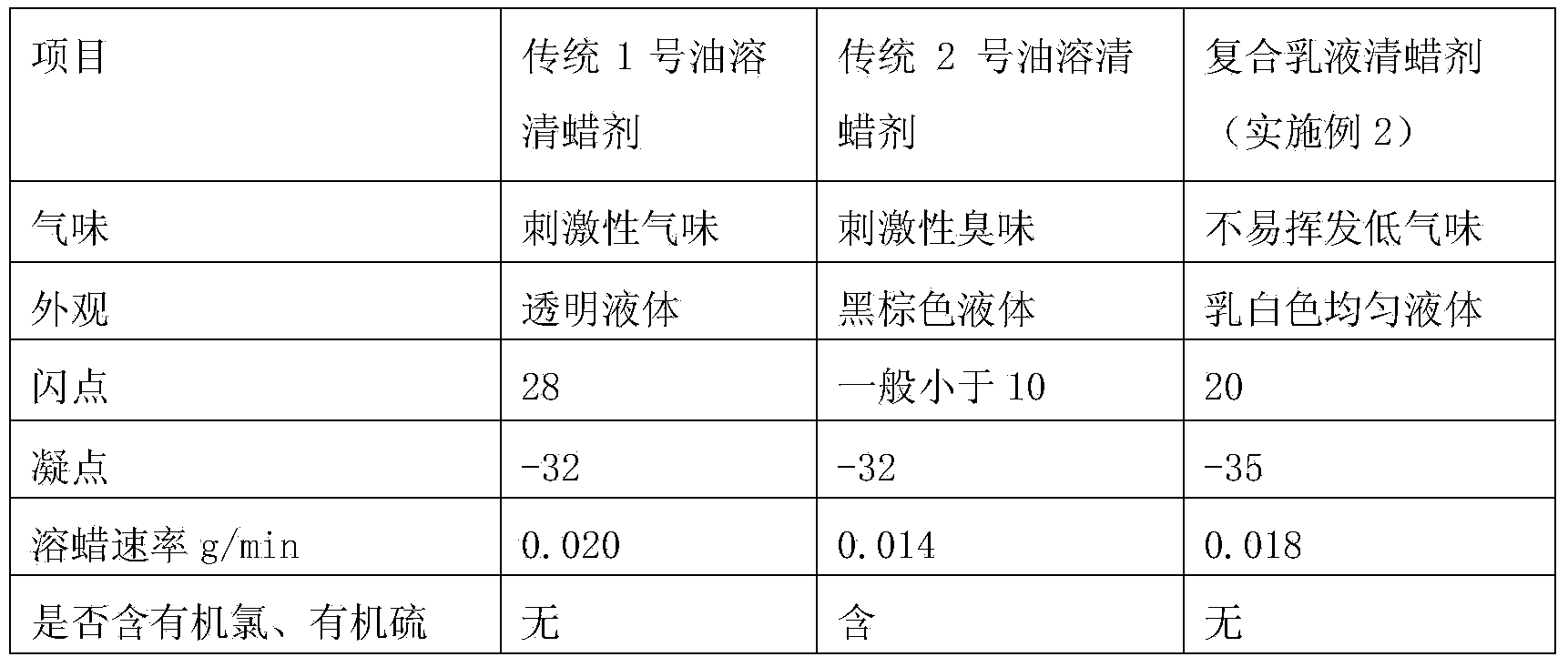

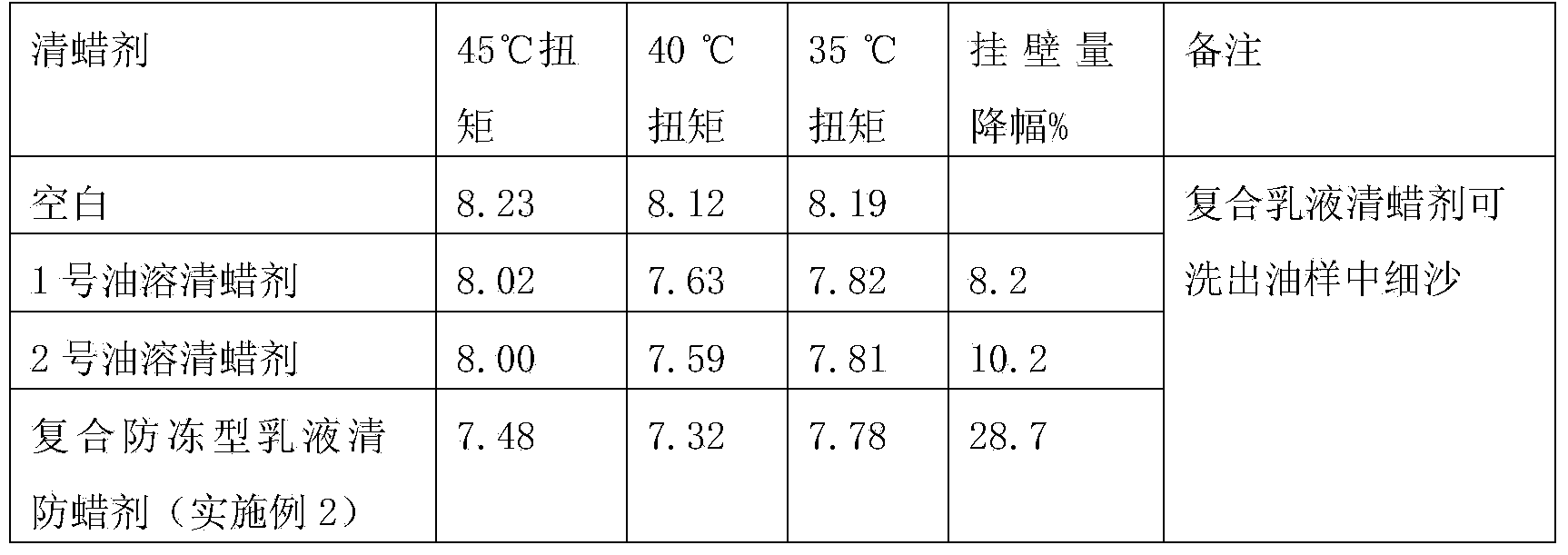

High-efficient environment-friendly composite antifreezing emulsion paraffin remover and inhibitor

InactiveCN103642477AEasy to separateIt has the function of washing oil, reducing viscosity and preventing waxDrilling compositionWaxOrganic solvent

The invention relates to a high-efficient environment-friendly composite antifreezing emulsion paraffin remover and inhibitor, which mainly solves problems of oil well large operation load caused by severe paraffin precipitation of high paraffin-containing oil wells at alpine regions, and compromising oil well yield caused by short hot washing period. The paraffin remover and inhibitor comprises a main agent of A agent system, and an auxiliary agent of B agent system, wherein the main agent of A agent system comprises the following component by weight: 1-3% of oil-soluble high-molecular polymer, 40-60% of aromatic hydrocarbon organic solvents, 10-20% of low carbon alcohol, 3-10% of composite emulsifiers, and 10-30% of water; the auxiliary agent of B agent system comprises the following component by weight: 7-15% of acid electrolytes, and 85-93% of water; the ratio of the main agent of A agent system to the auxiliary agent of B agent system is 100:0.8-1.2. The high-efficient environment-friendly composite antifreezing emulsion paraffin remover and inhibitor can effectively remove paraffin and inhibit paraffin, reaches the purposes of reducing oil well operation load and prolonging well washing period, has a low condensation point, and thus is especially suitable for winter paraffin removal at alpine regions.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

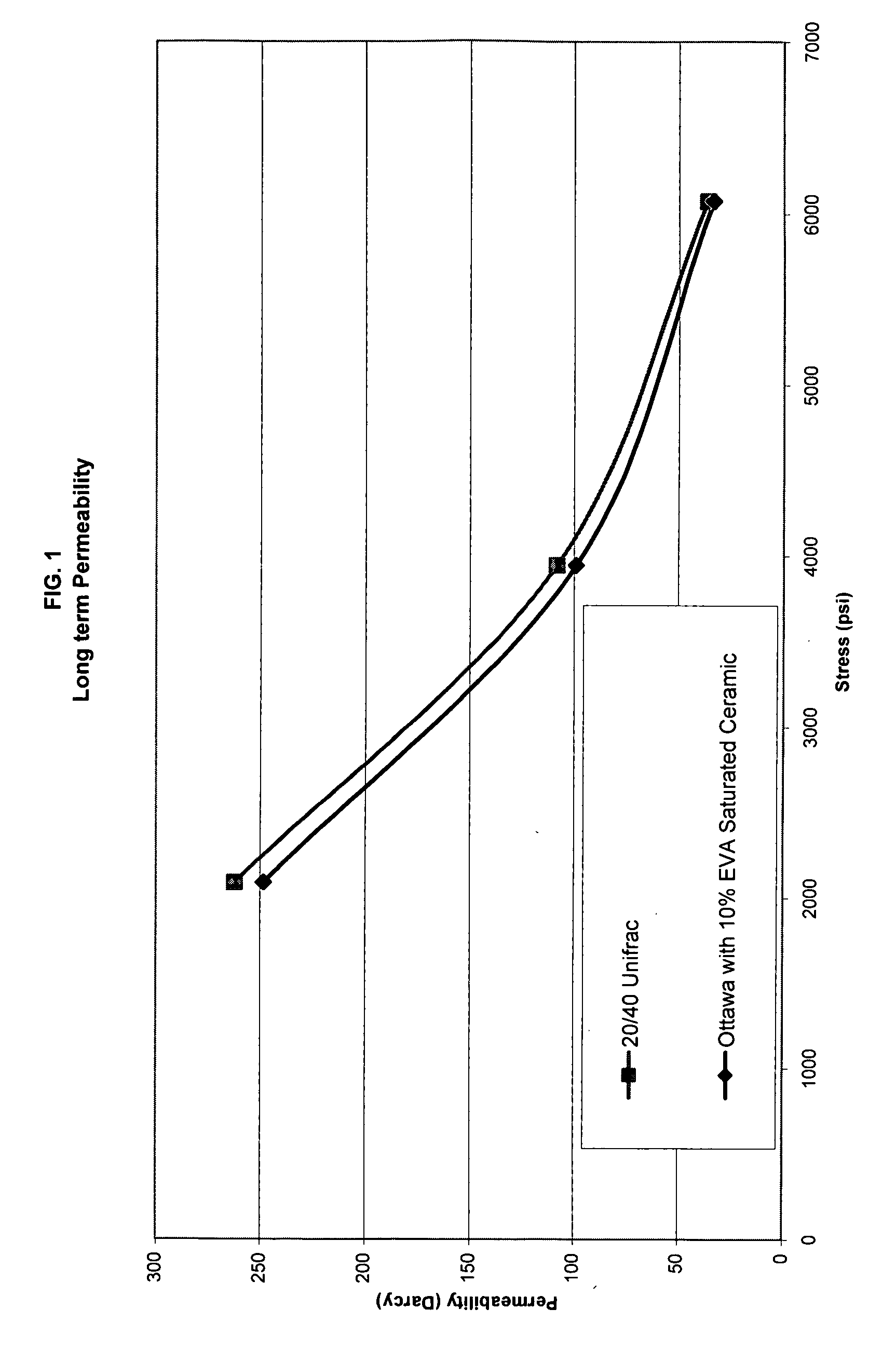

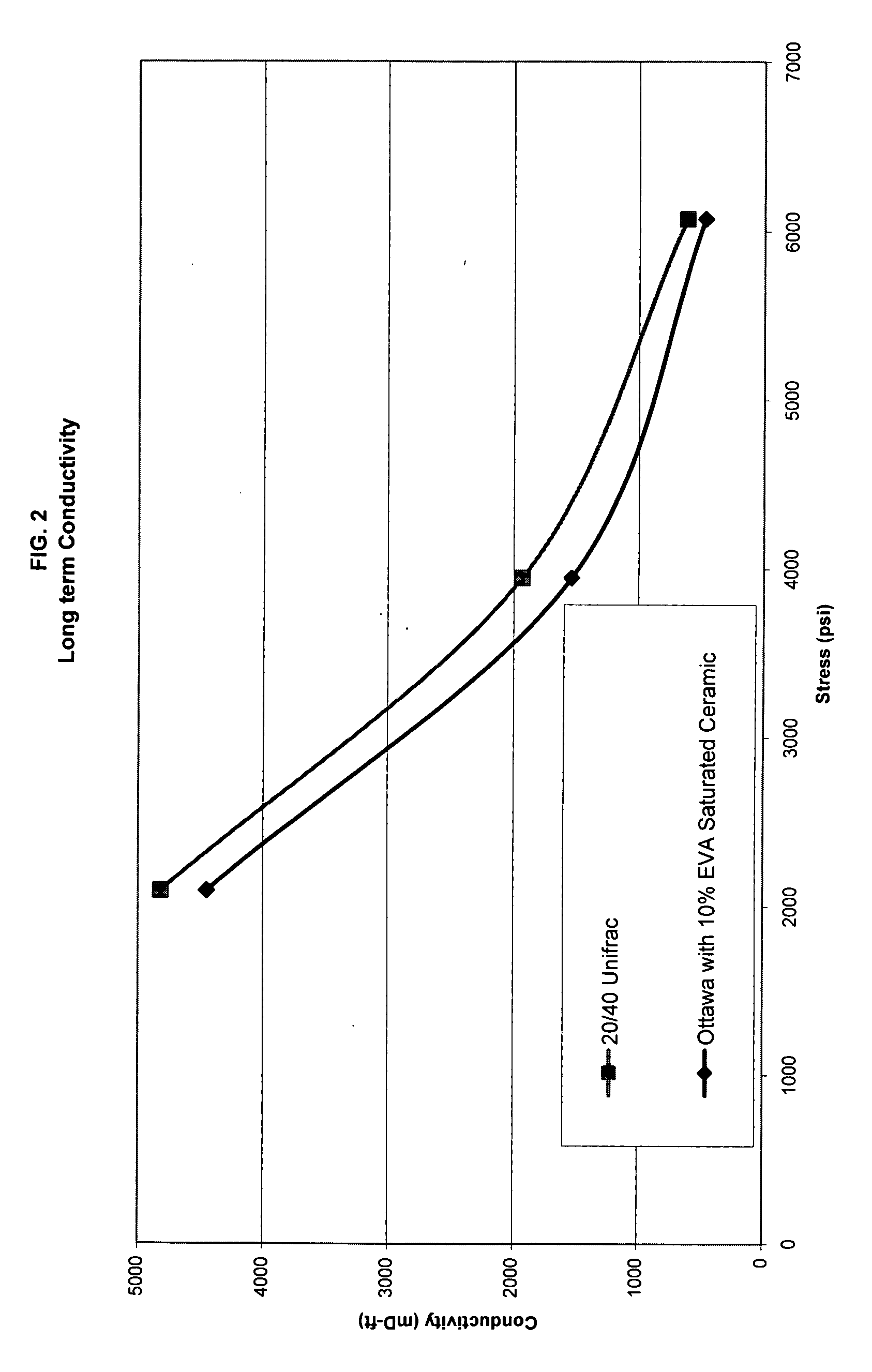

Porous composites containing hydrocarbon-soluble well treatment agents and methods for using the same

Composites containing a hydrocarbon-soluble well treatment agent may be supplied to a well using a porous particulate. Such well treatment agents may for example inhibit the formation of paraffins, salts, gas hydrates, asphaltenes and / or other deleterious processes such as emulsification (both water-in-oil and oil-in-water). Further, other well treatment agents include foaming agents, oxygen scavengers, biocides and surfactants as well as other agents wherein slow release into the production well is desired.

Owner:BAKER HUGHES INC

Oil well cleaning compositions

InactiveUS20120234548A1Increase output flowEasy to useCleaning apparatusFluid removalDemulsifierHydrocarbon solvents

A method for cleaning oil wells to increase the flow of oil thereof by use of a unique cleaning emulsion comprising of water, hydrocarbon solvent, terpene hydrocarbon material, demulsifier, detergent, and optionally an acid. This one step method provides for the simultaneously cleaning / removal of asphaltene and / or paraffin and scale at a wide range of temperatures. This method can be used alone or with the assistance of a wash tool which is a combination pressure and surge wash tool having a nipple assembly, or a hydro self-rotating nozzle wash tool.

Owner:DYER RICHARD J

Modified hydrocarbon cleaning agent

The invention relates to the technical field of the cleaning agent, in particular to a modified hydrocarbon cleaning agent. The main technical scheme in the invention is as follows: additives are added in the hydrocarbon cleaning agent which contains solvent without aromatic hydrocarbons, solvent with low aromatic hydrocarbons and C10-13 normal paraffin or isoparaffin, namely alcohol additive, ester additive and ether additive are added in the hydrocarbon cleaning agent D40, D60, D65 and D80 and the hydrocarbon cleaning agent C10, C11, C12 and C13 to ensure that the modified hydrocarbon cleaning agent has high cleaning capability, high KB value, low aniline point, low cost, little odor and high recovery rate, can be used to clean macromolecular pollutants such as wax, resin, printing ink and rosin and can be heated for cleaning in a special device.

Owner:广东新球清洗科技股份有限公司

Process for the separation of olefins and paraffins

InactiveUS20050154247A1Carry-outImprove energy efficiencyMembranesSemi-permeable membranesAlkaneParaffin oils

A process for the separation of olefinic hydrocarbons from a liquid feedstock composition comprising at least one olefinic hydrocarbon and at least one paraffinic hydrocarbon, said process comprising contacting the liquid feedstock with a supported ionic liquid membrane wherein the supported ionic liquid membrane comprises a membrane impregnated with an ionic liquid composition.

Owner:SHELL OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com