Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

324results about How to "Promote gasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions for Catalytic Gasification of a Petroleum Coke

InactiveUS20090090056A1Cost-effective and high-yielding productionPromote gasificationHydrogenGaseous fuelsParticle compositionMethane gas

The present invention relates to particulate compositions of a lower ash type petroleum coke containing at least two preselected components (alkali metal and calcium) that exhibit an efficient, enhanced-yielding gasification to value added gaseous products, particularly when used in a steady-state integrated gasification process. The compositions of the present invention are particularly useful for catalytic gasification of petroleum coke at moderate temperatures ranging from about 450° C. to about 900° C. Advantageously, the compositions can be readily incorporated into fluidized bed gasification units, and can result in a cost-effective, high-yielding production of methane gas from petroleum coke.

Owner:SURE CHAMPION INVESTMENT LTD

Compositions for Catalytic Gasification of a Petroleum Coke

InactiveUS20090090055A1Improved gasification activityCost-effective and high-yielding productionHydrogenGaseous fuelsParticle compositionChemistry

The present invention relates to particulate compositions of a lower ash type petroleum coke containing at least two preselected components (alkali metal and iron) that exhibit an efficient, enhanced-yielding gasification to value added gaseous products, particularly when used in a steady-state integrated gasification process. The compositions of the present invention are particularly useful for catalytic gasification of petroleum coke at moderate temperatures ranging from about 450° C. to about 900° C. Advantageously, the compositions can be readily incorporated into fluidized bed gasification units, and can result in a cost-effective, high-yielding production of methane gas from petroleum coke.

Owner:SURE CHAMPION INVESTMENT LTD

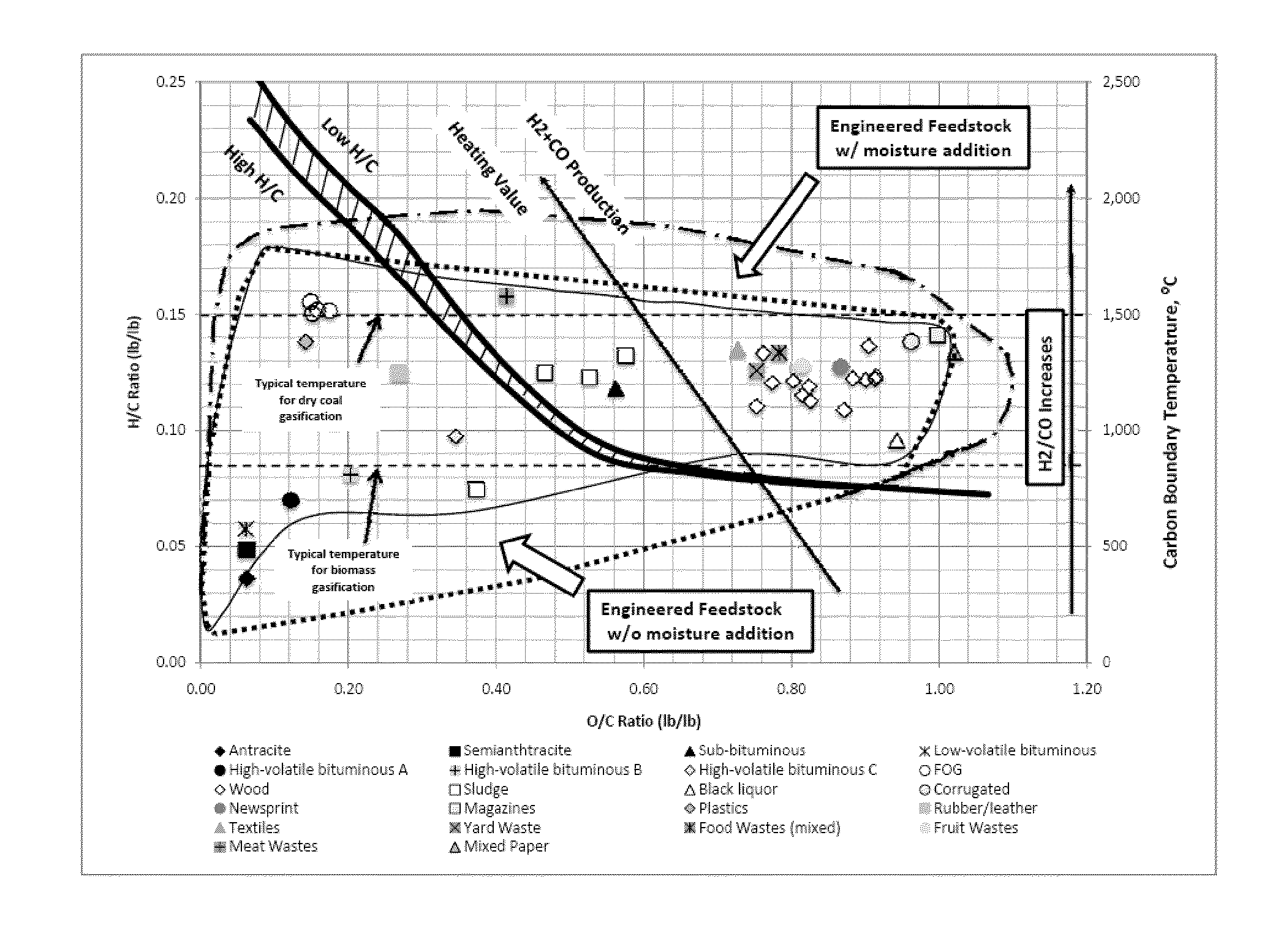

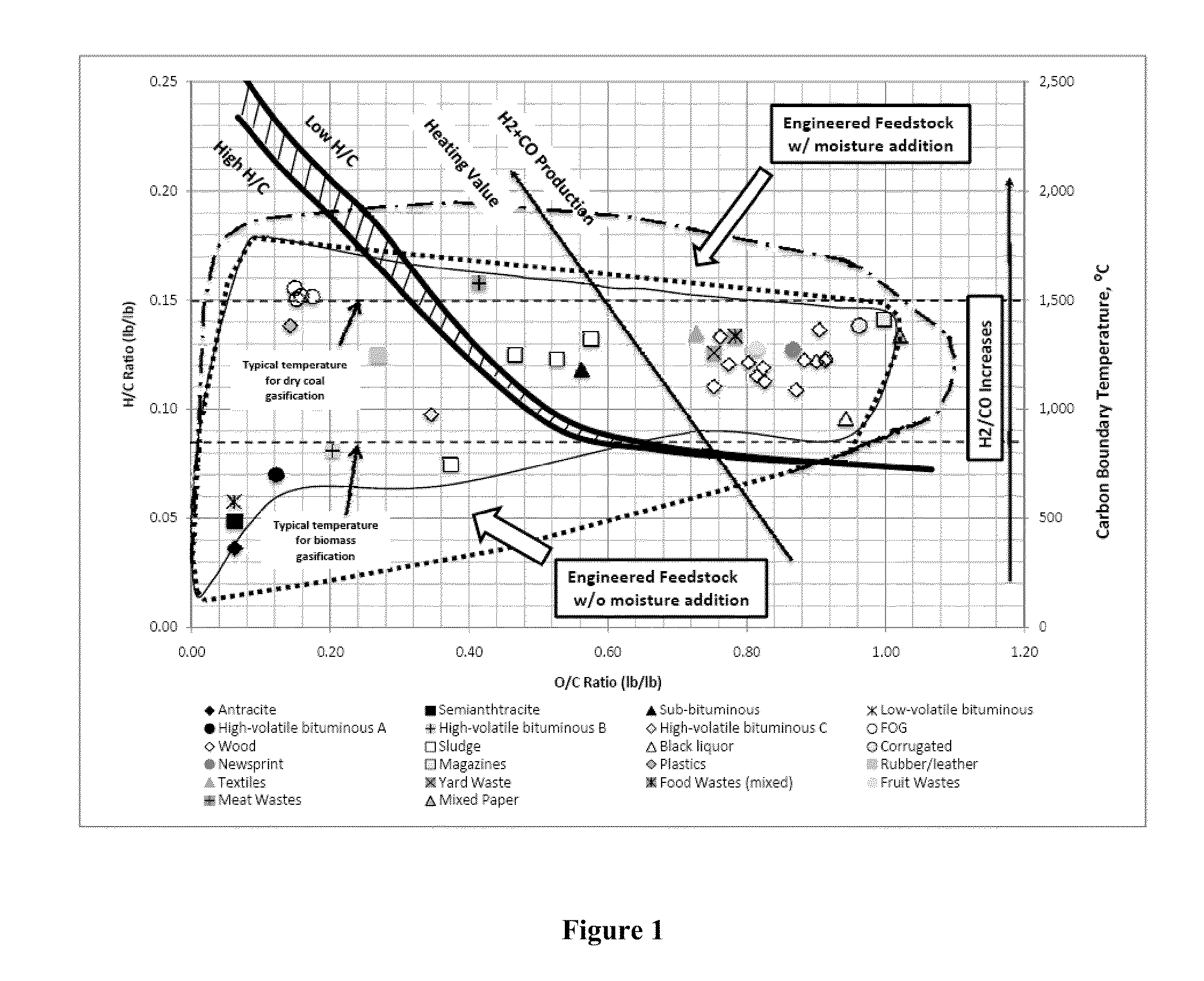

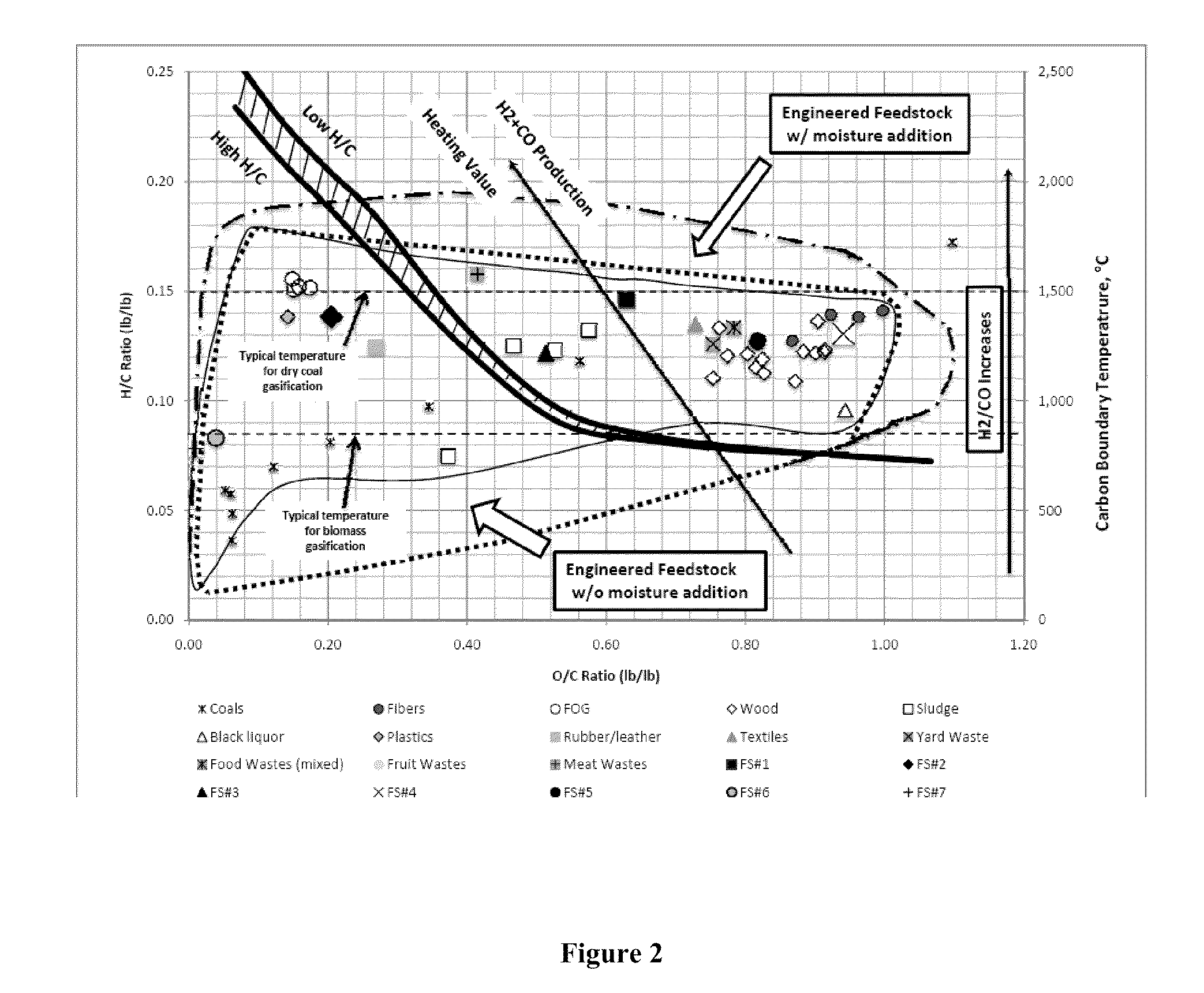

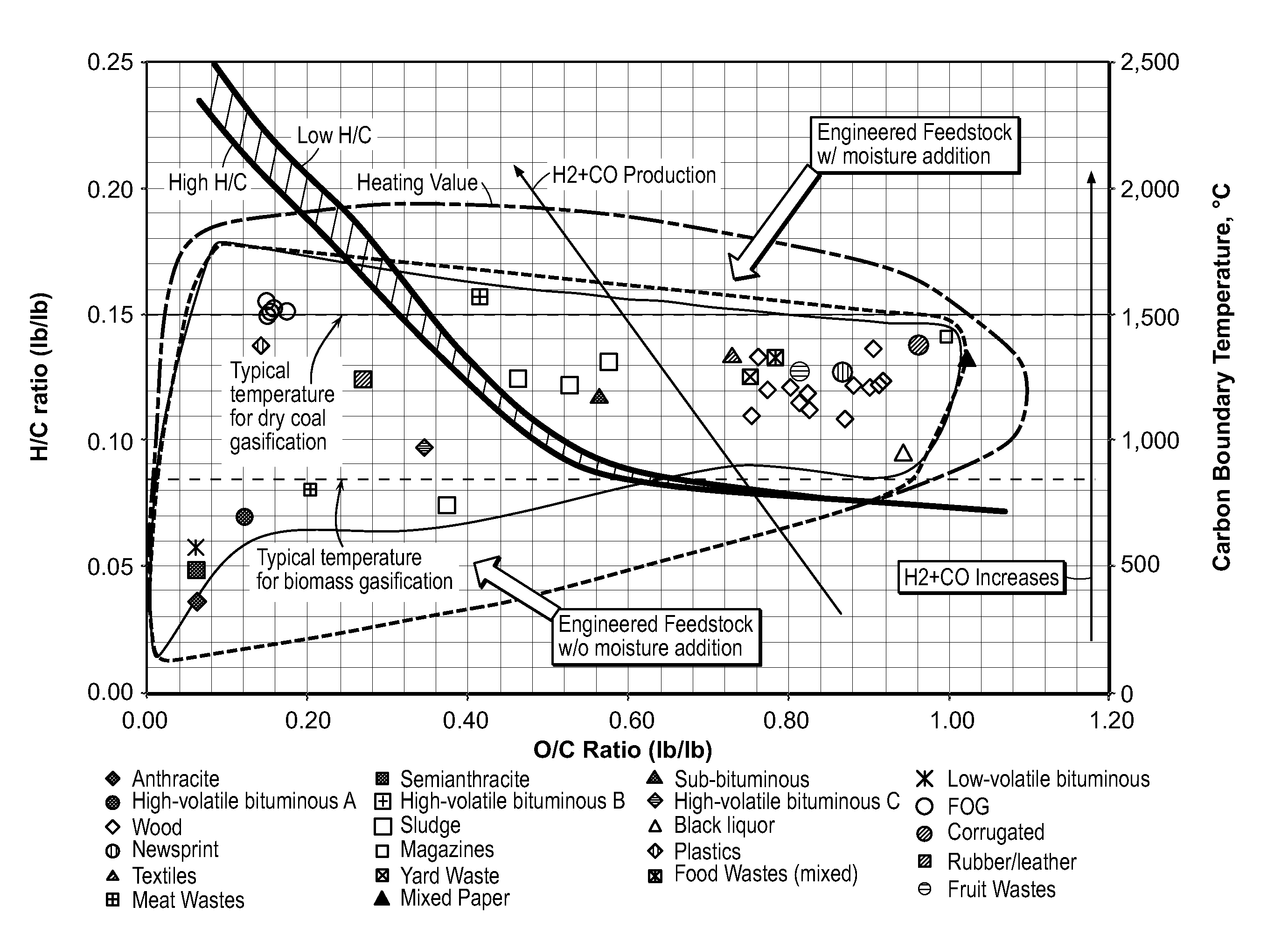

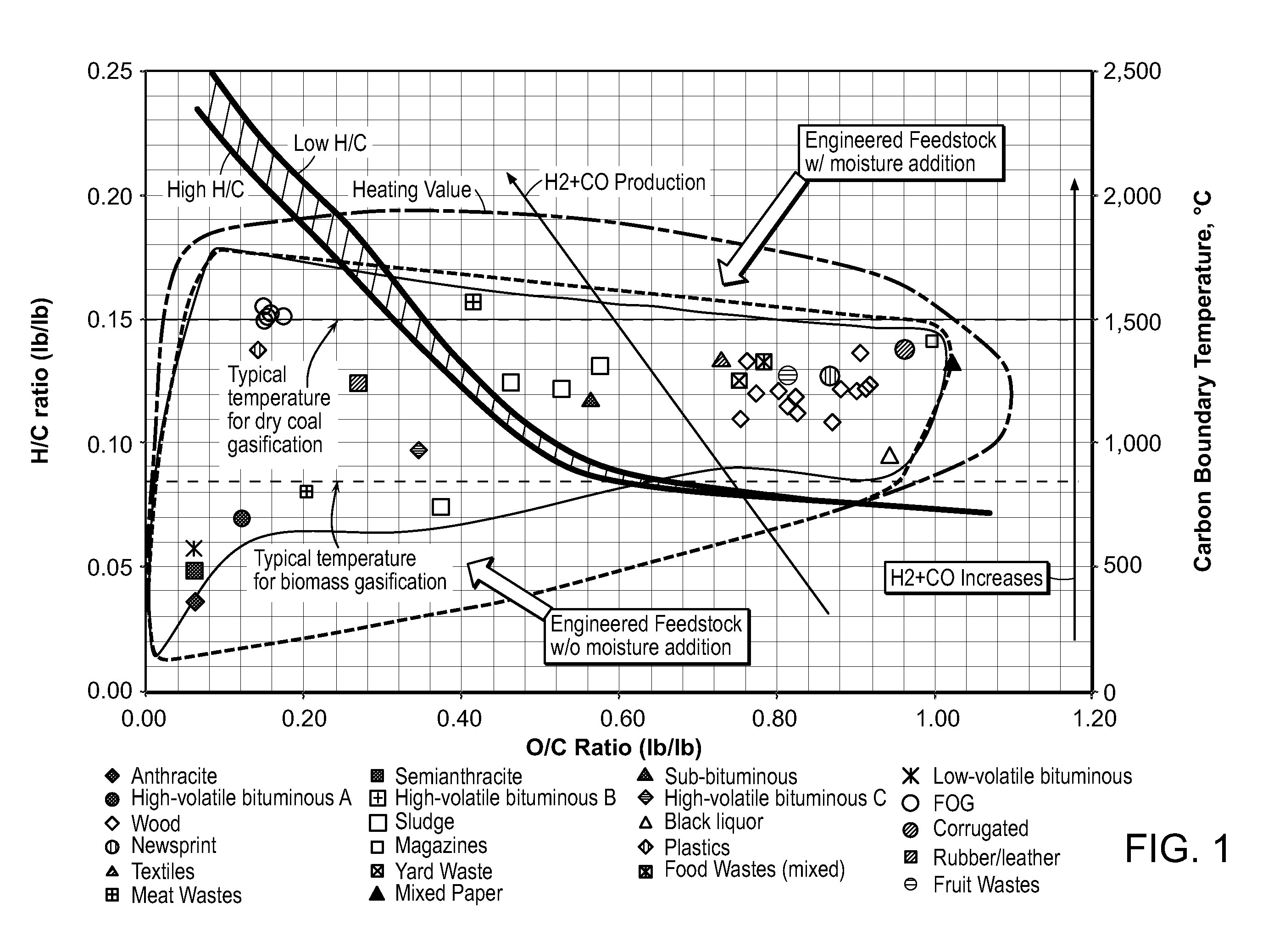

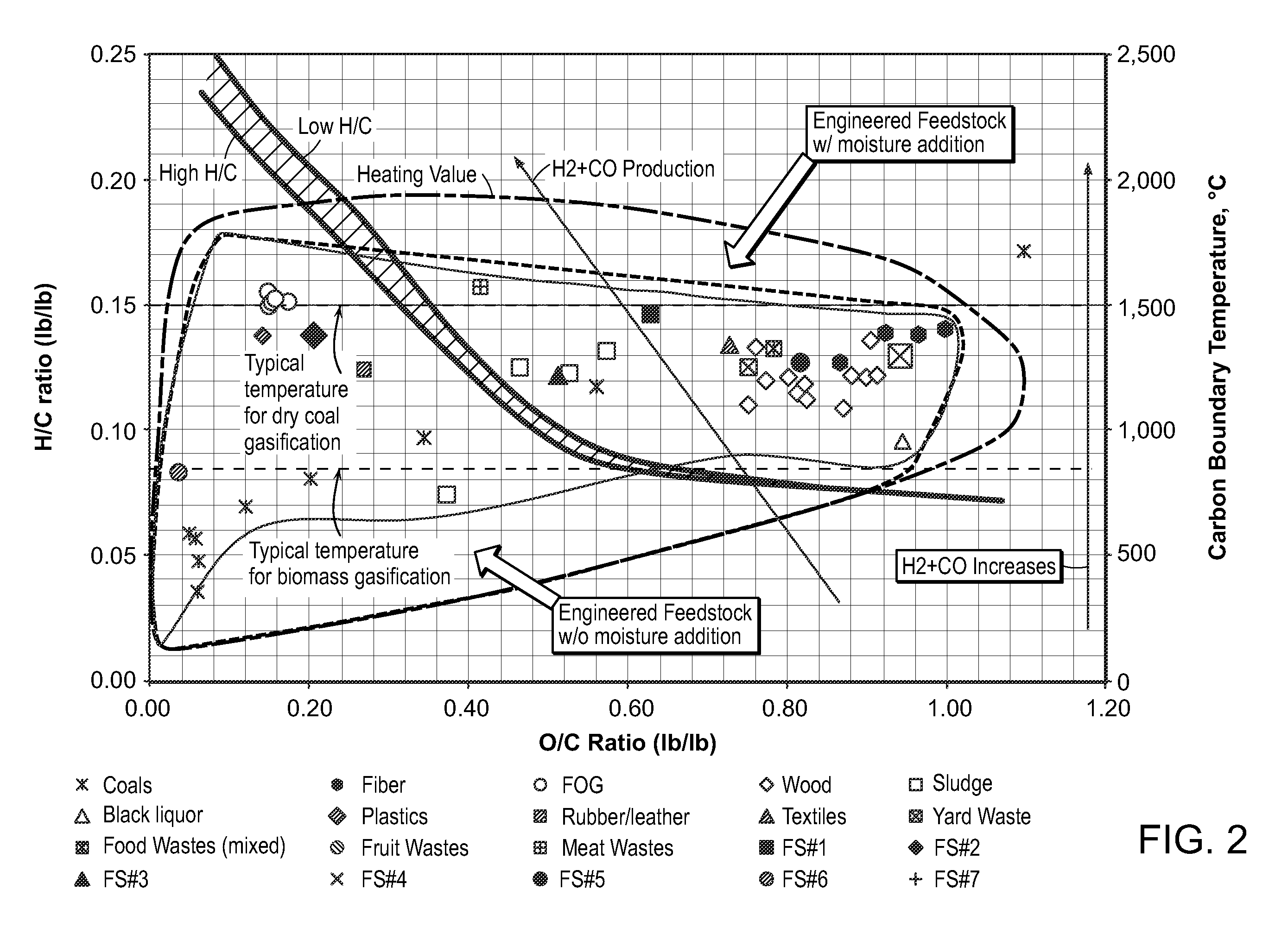

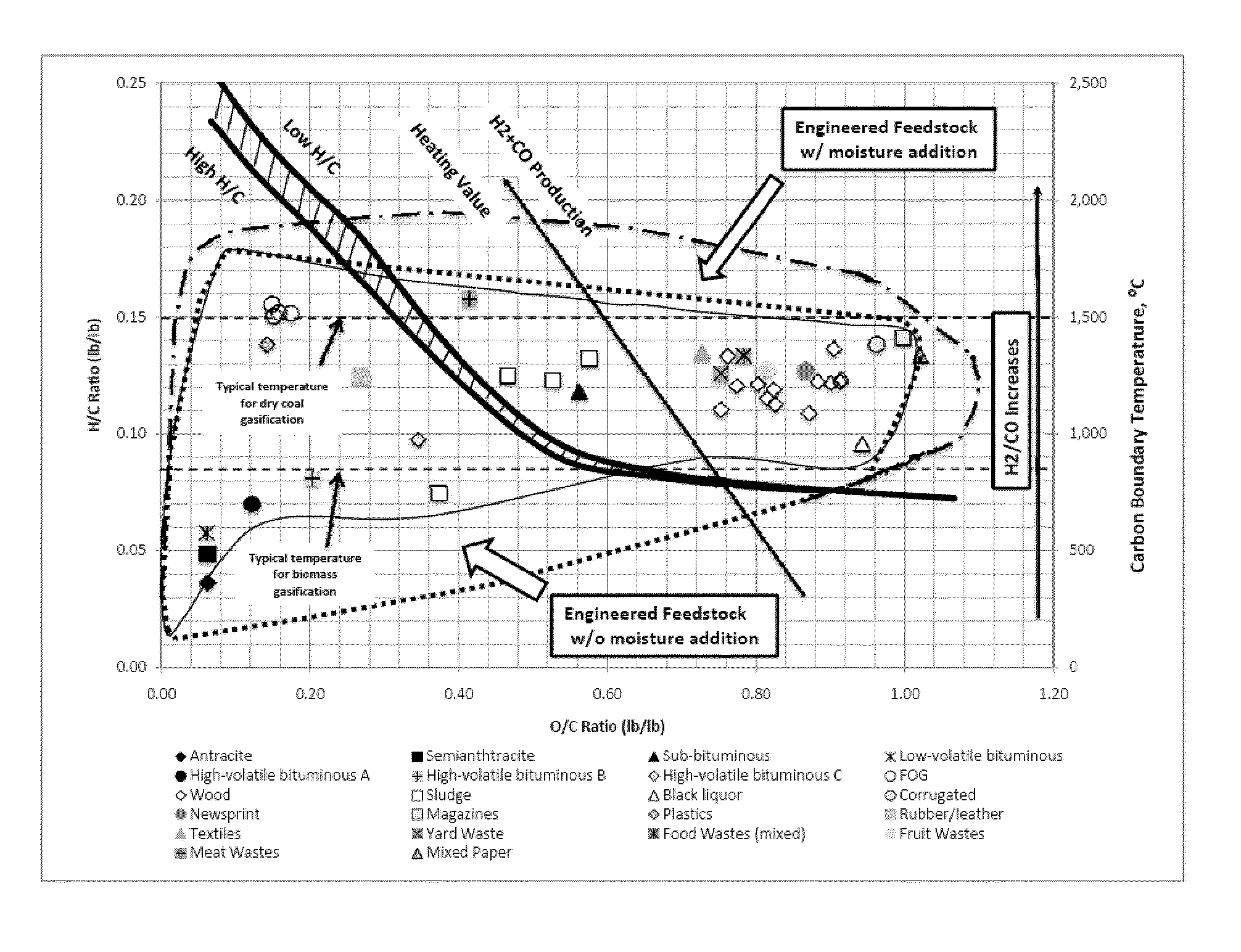

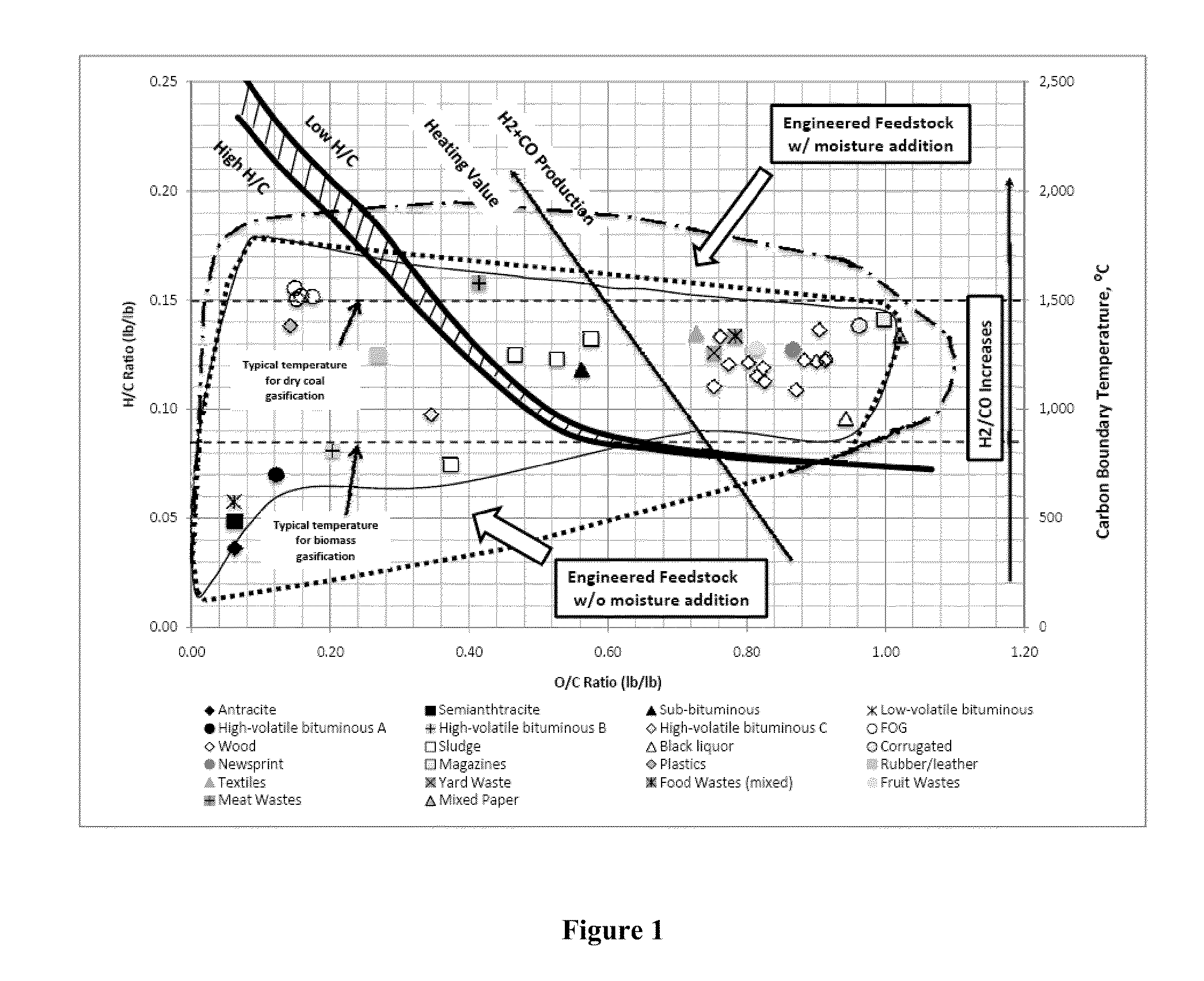

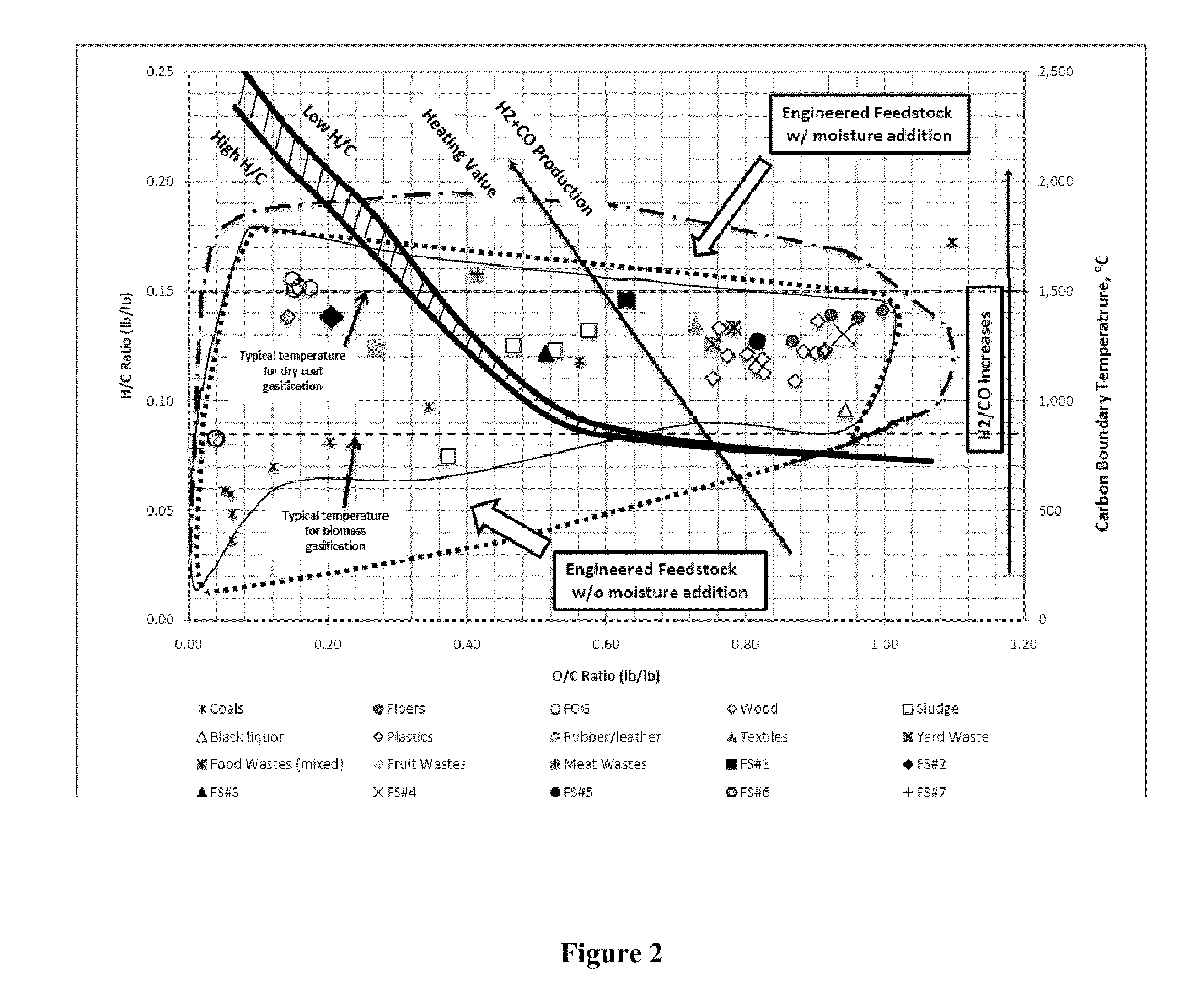

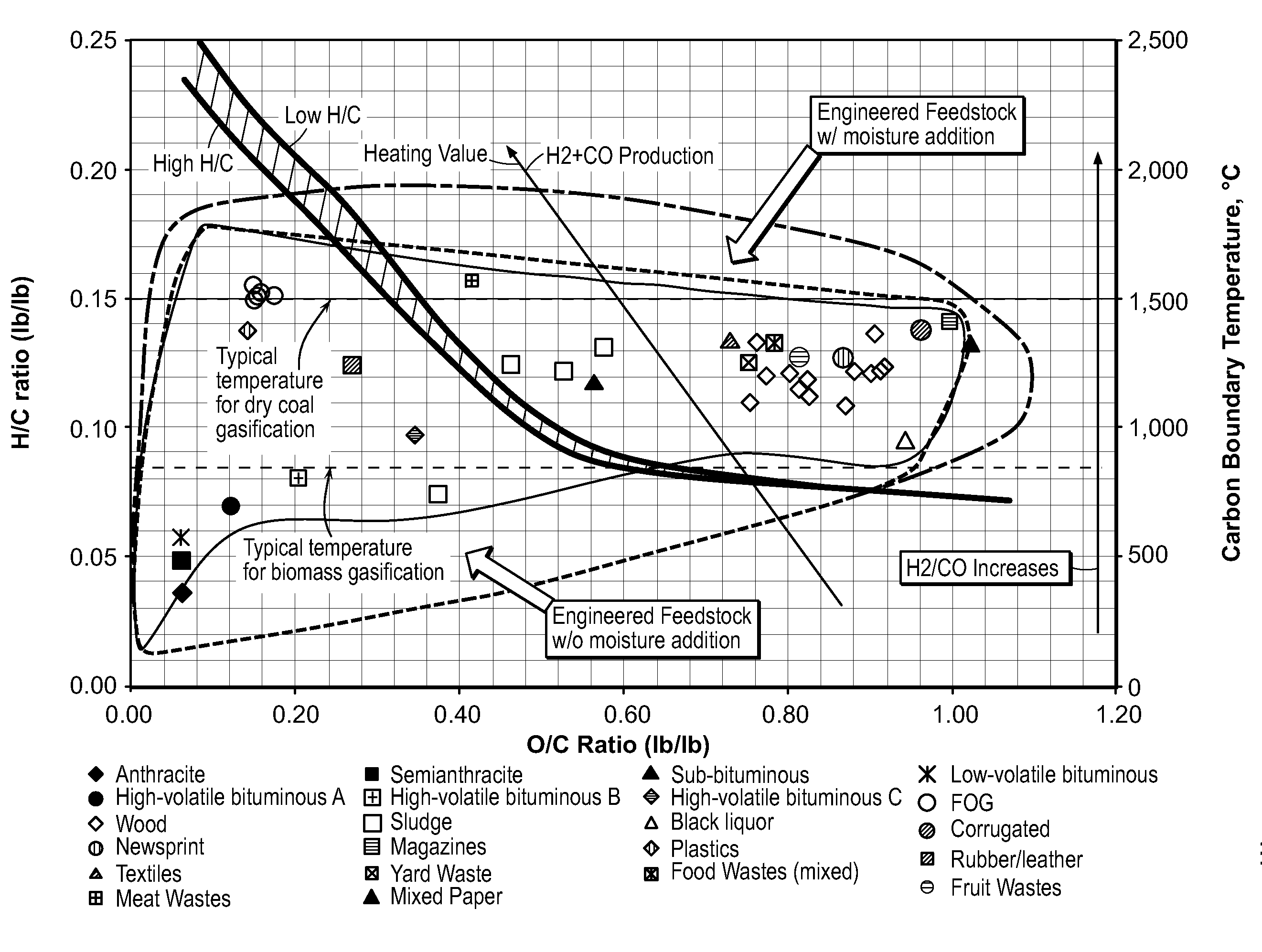

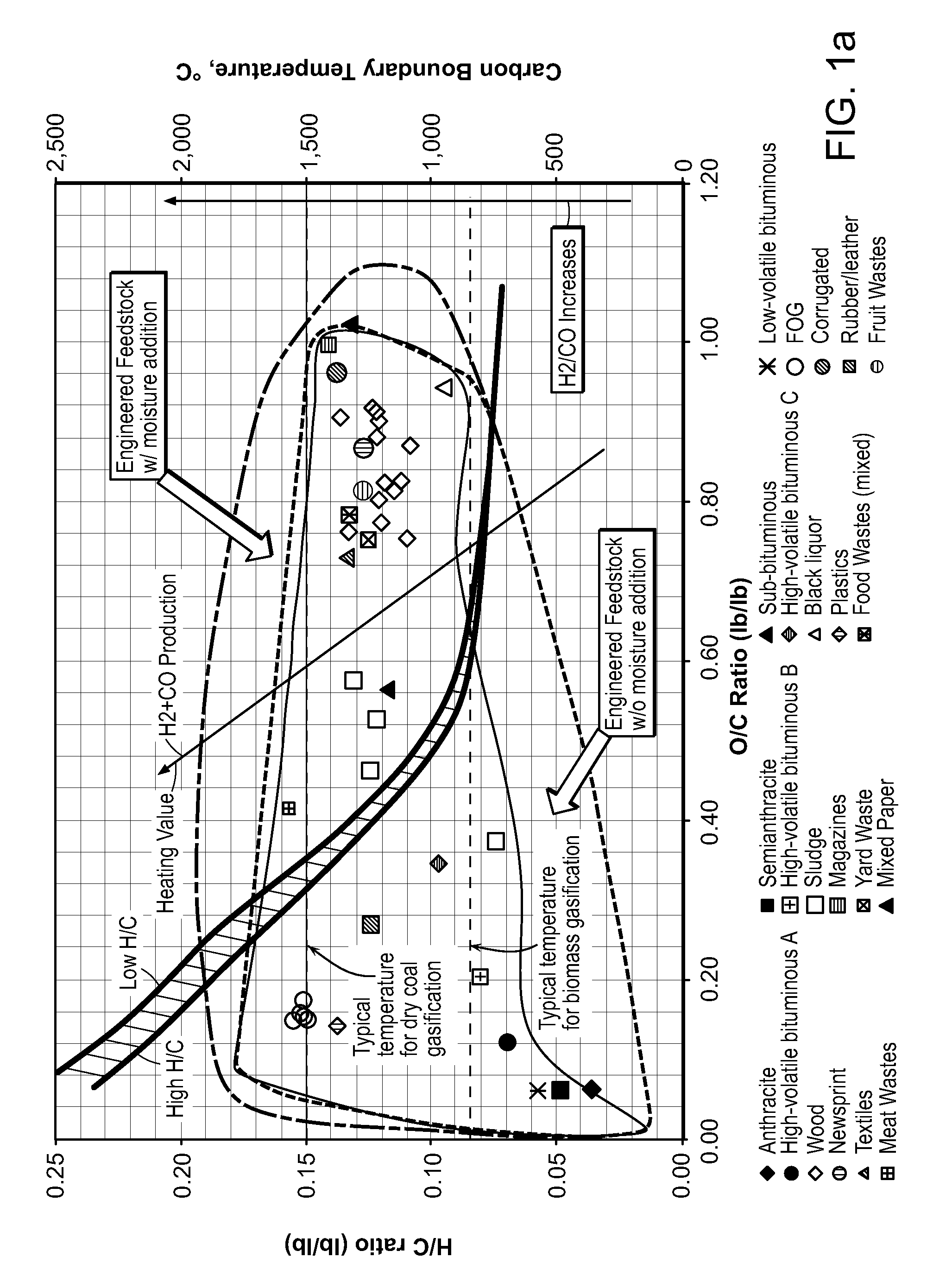

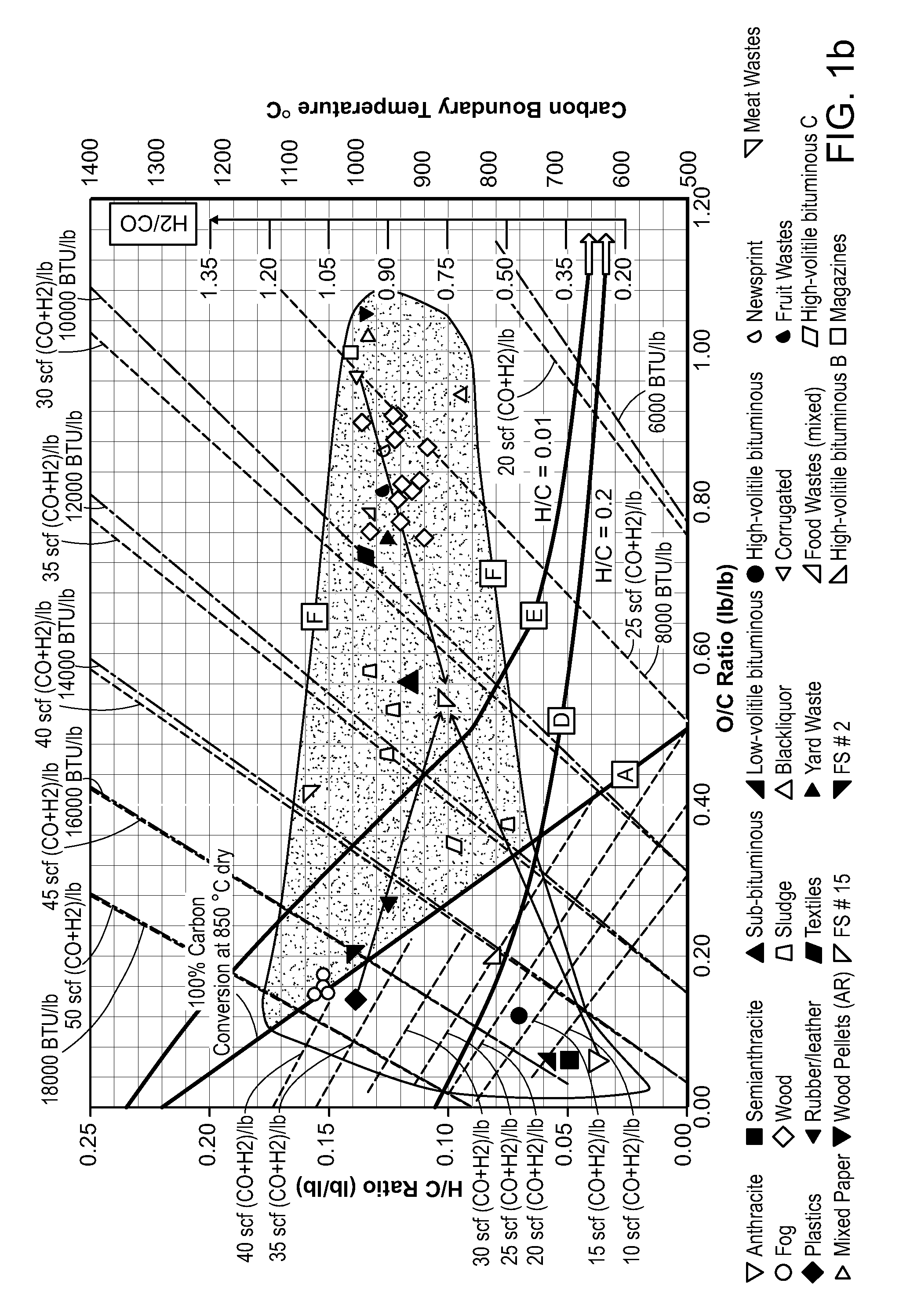

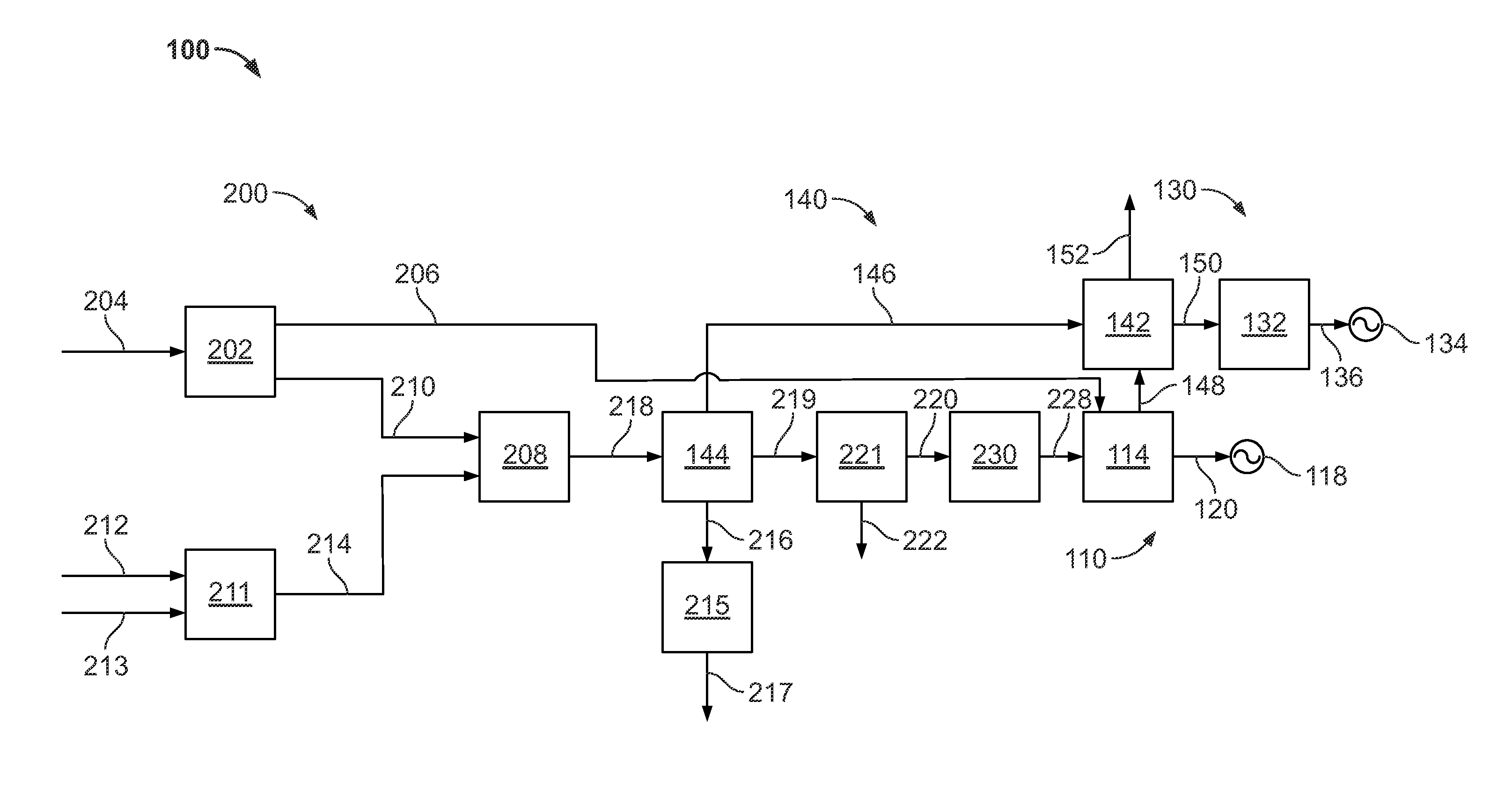

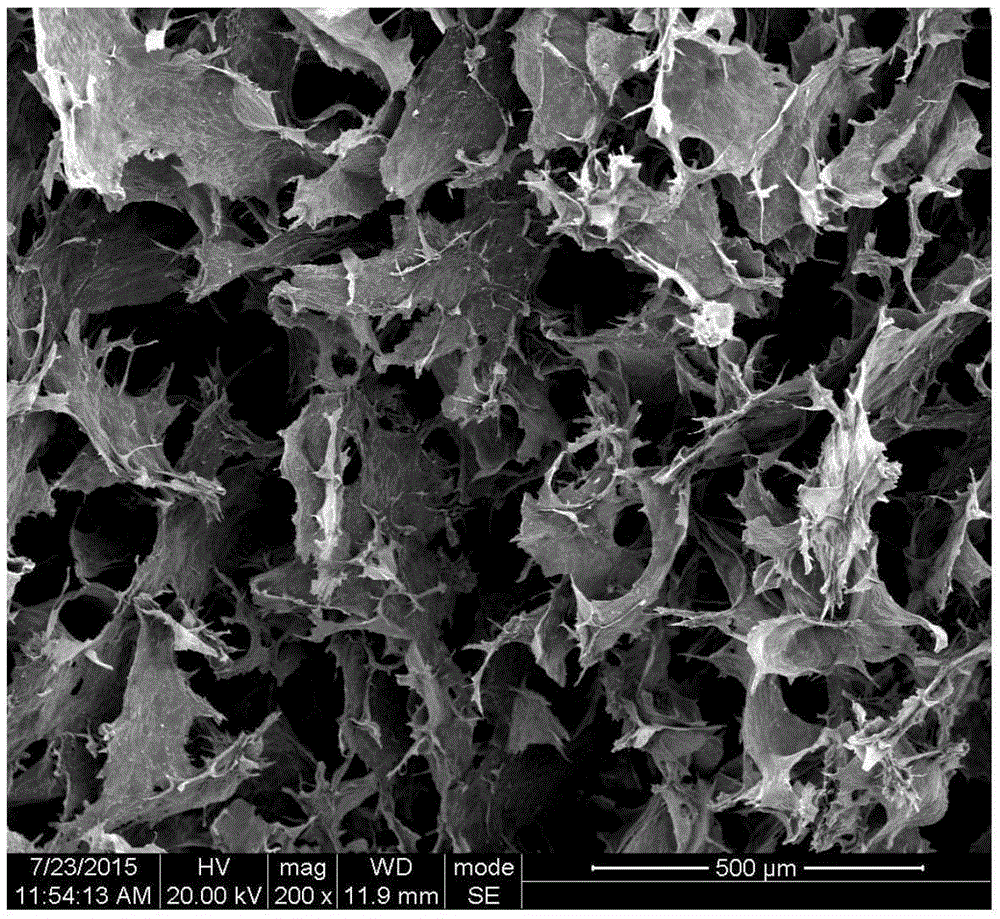

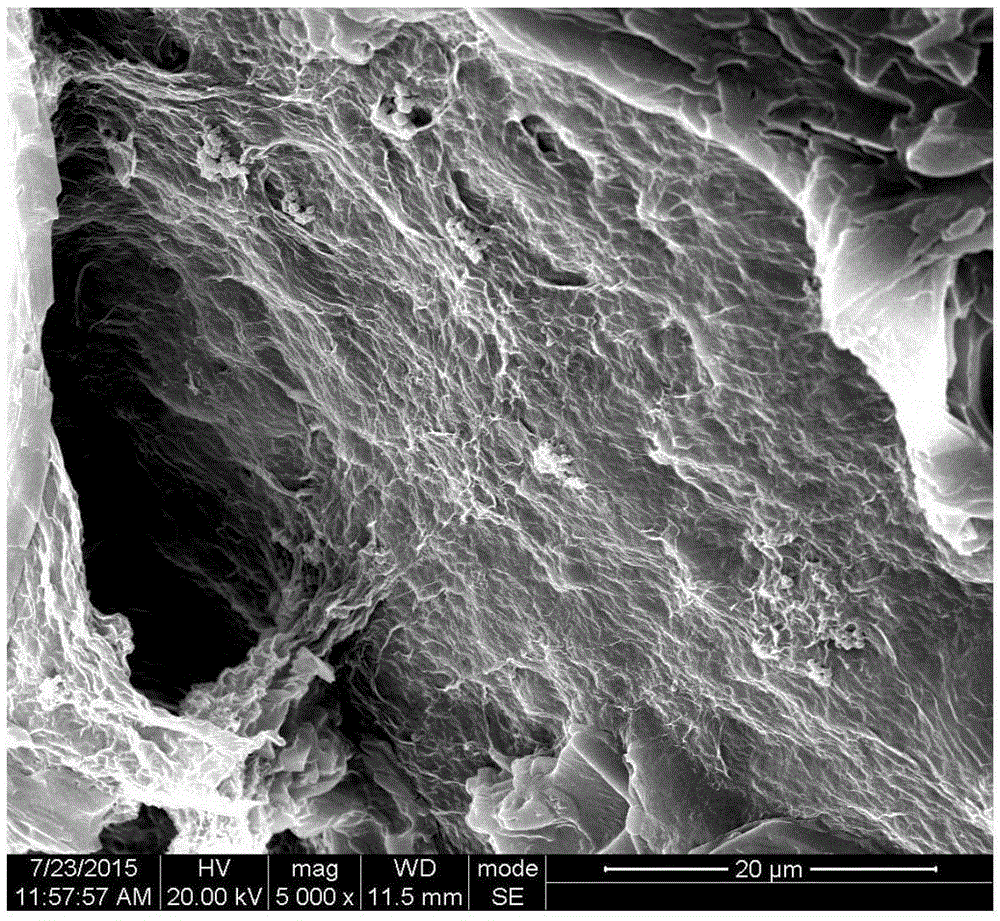

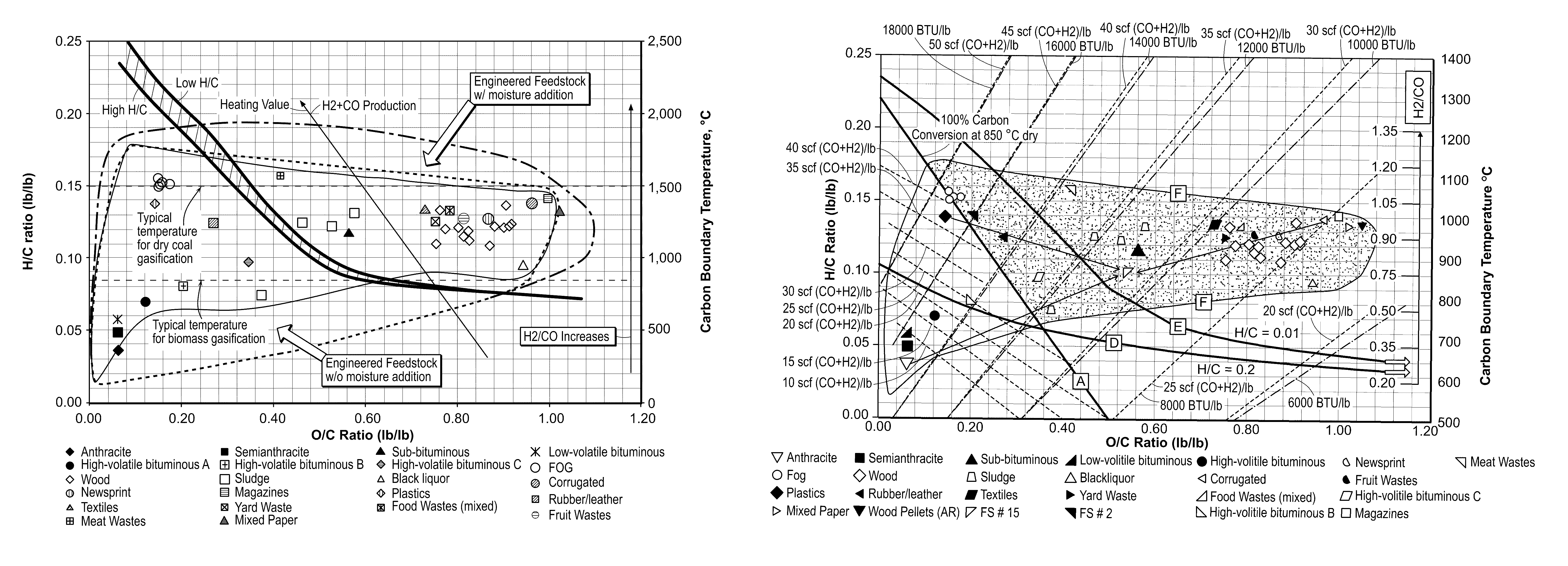

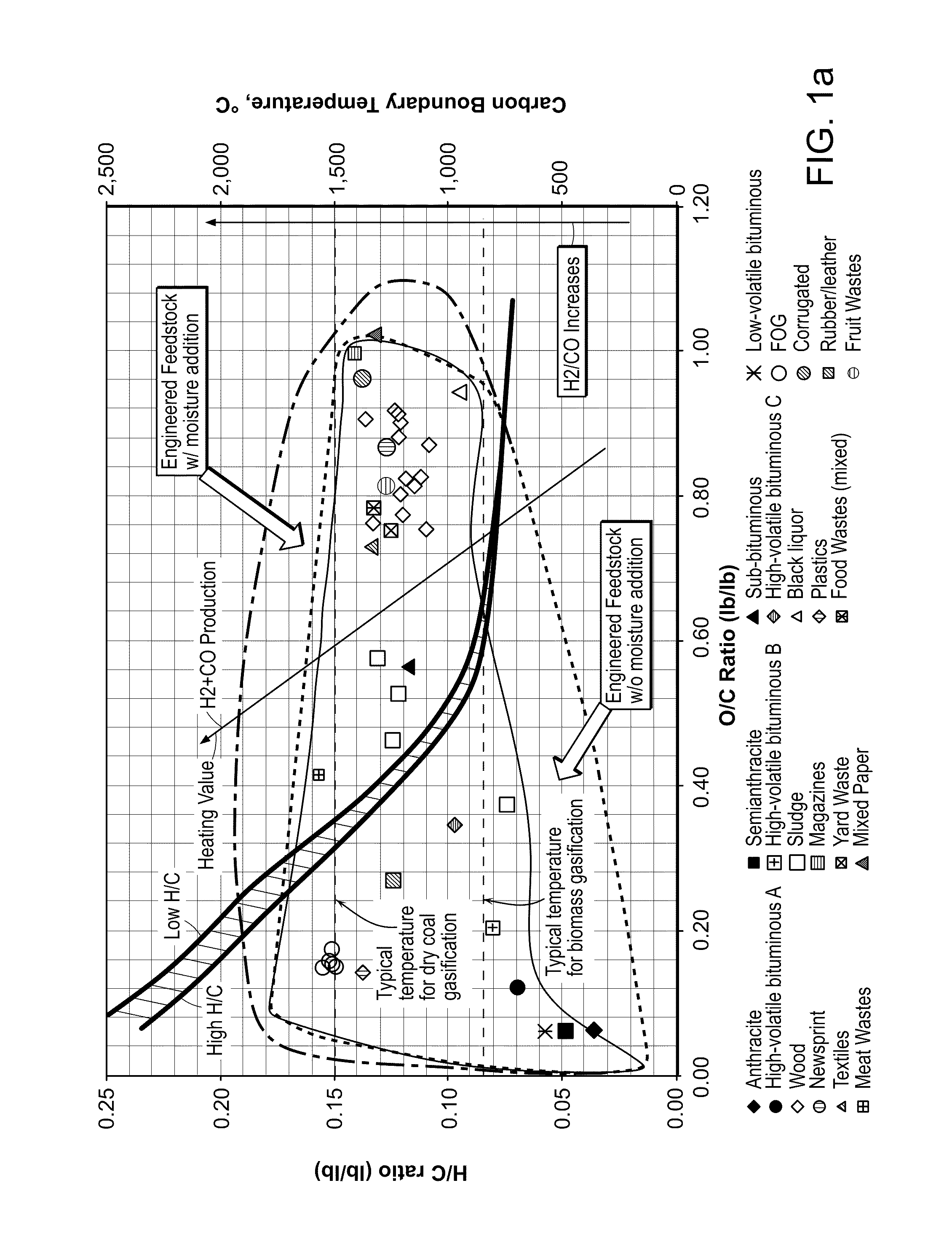

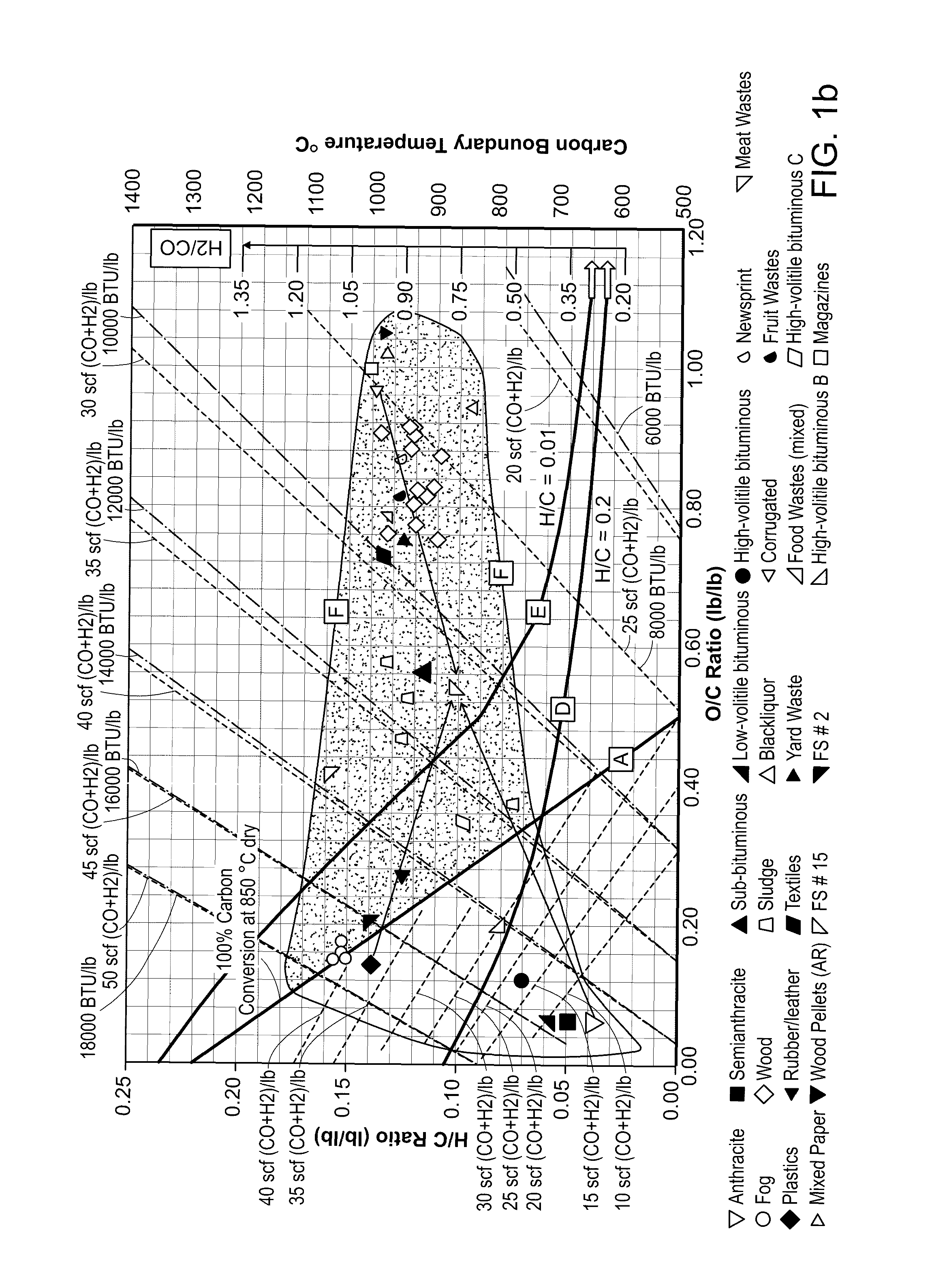

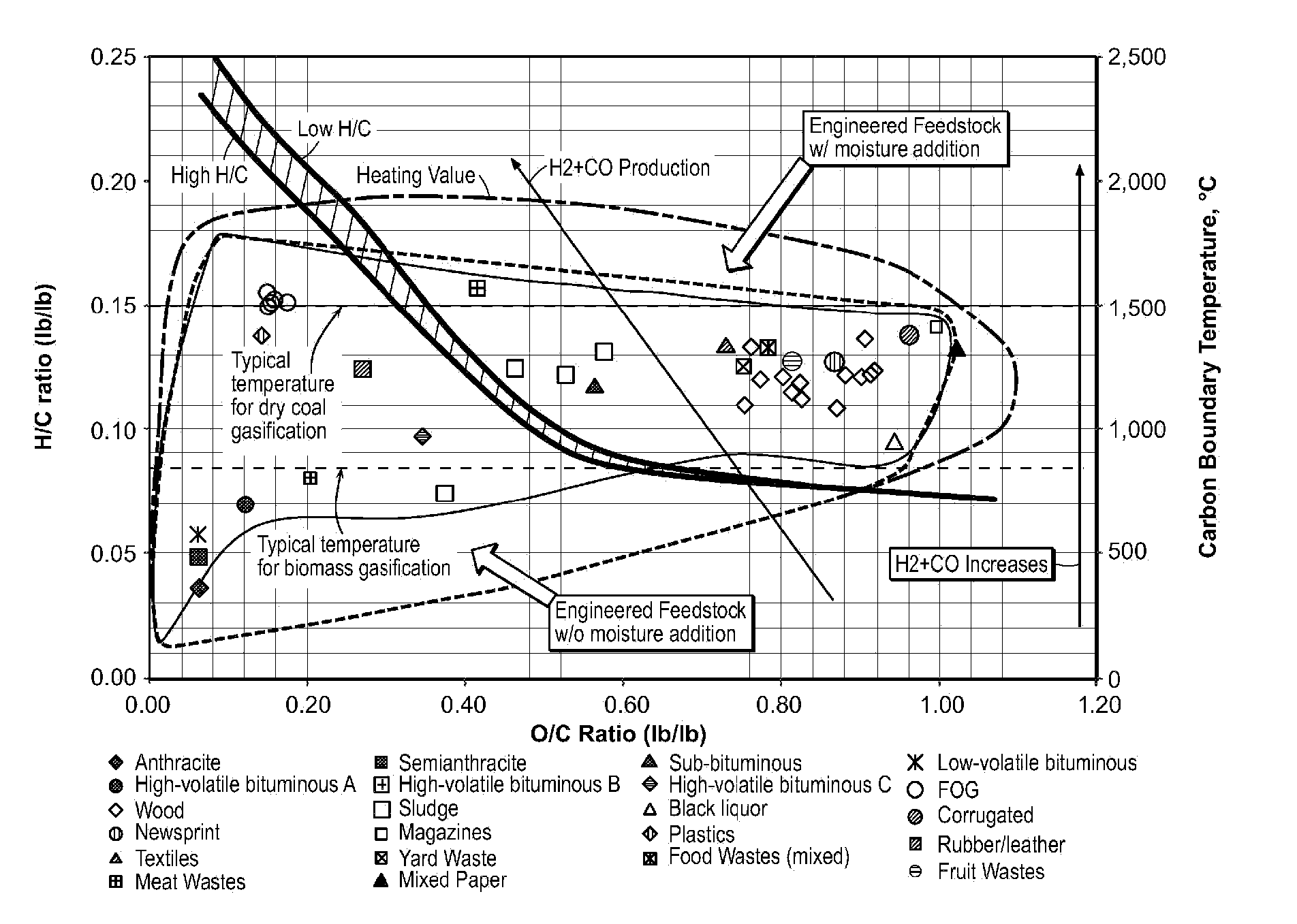

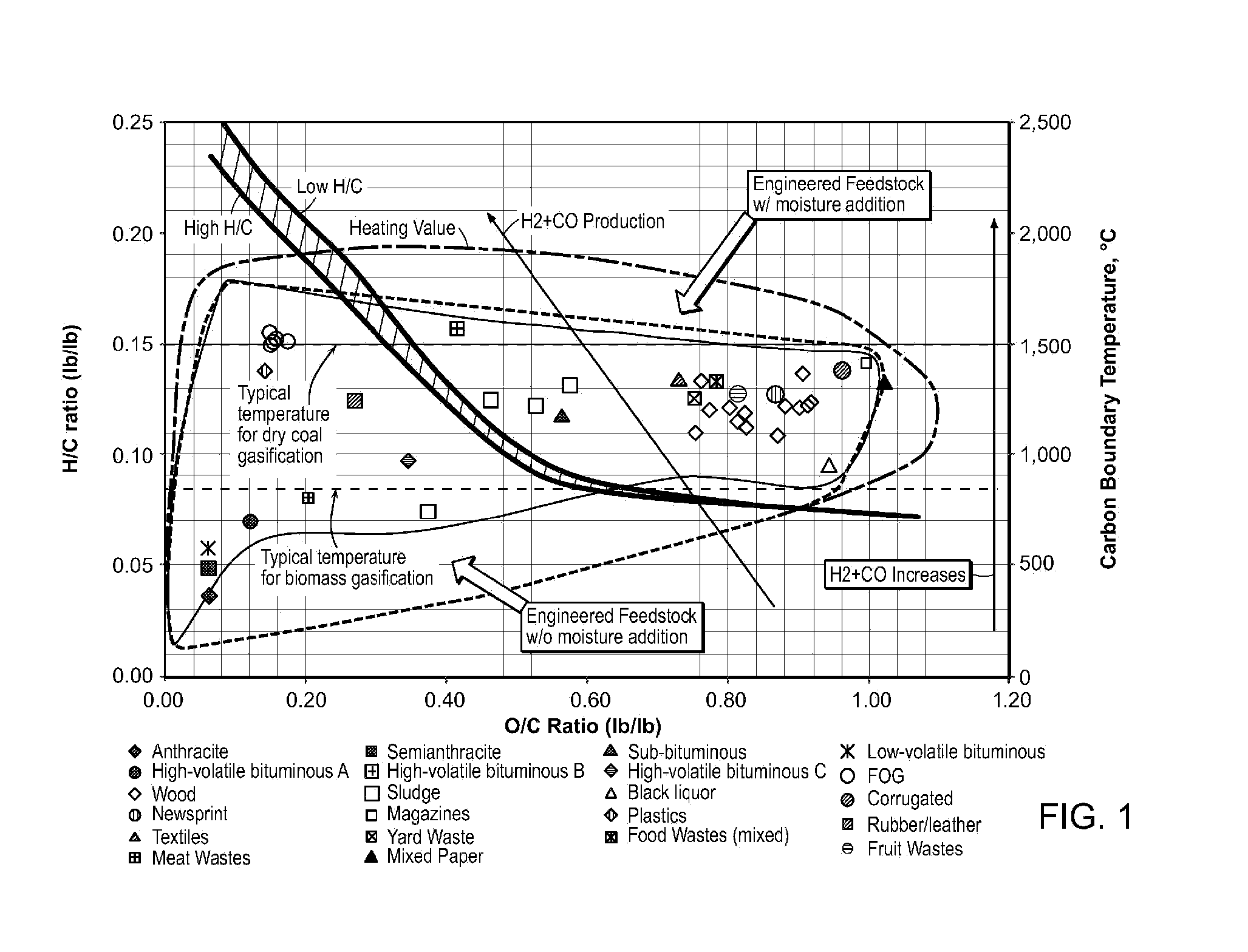

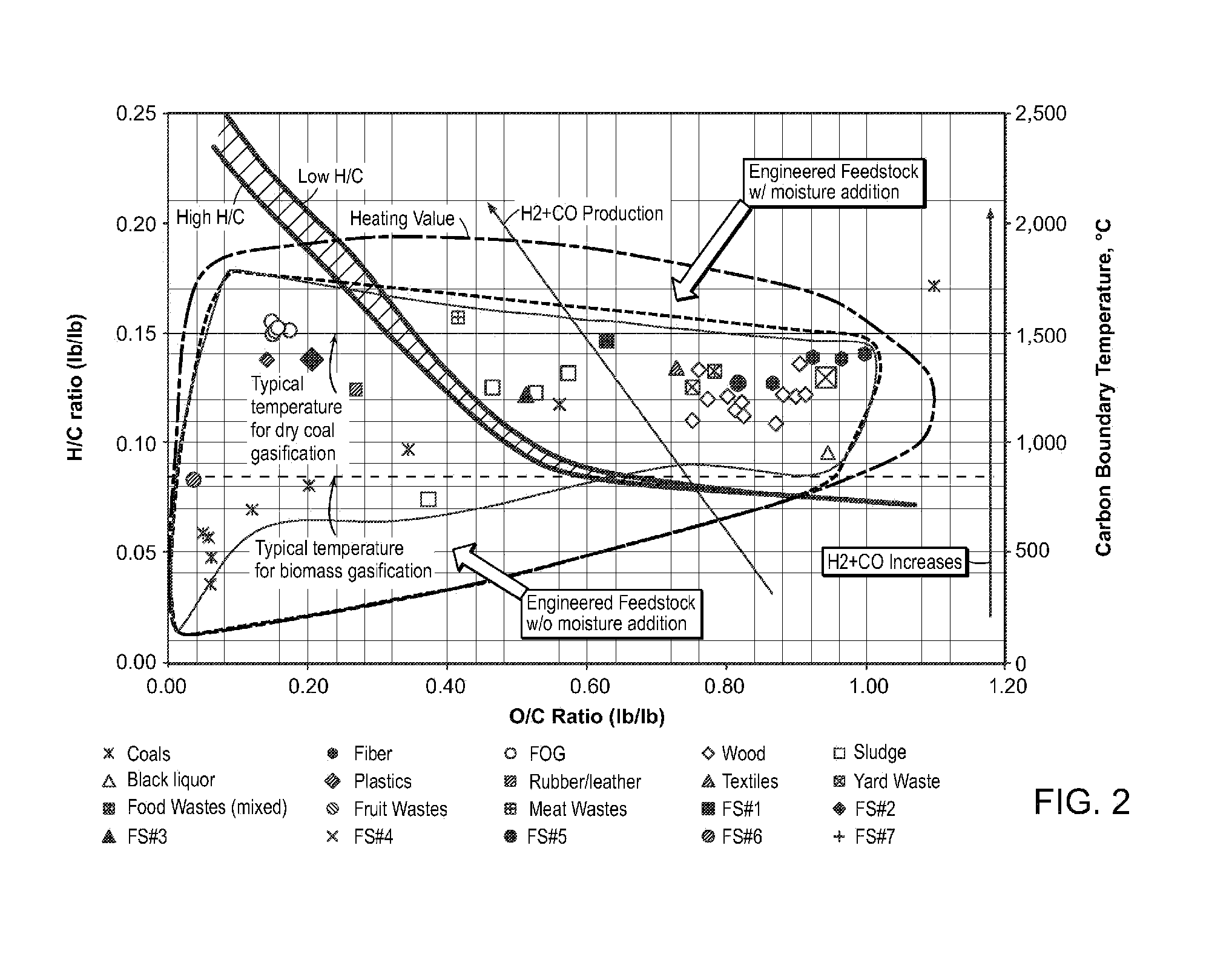

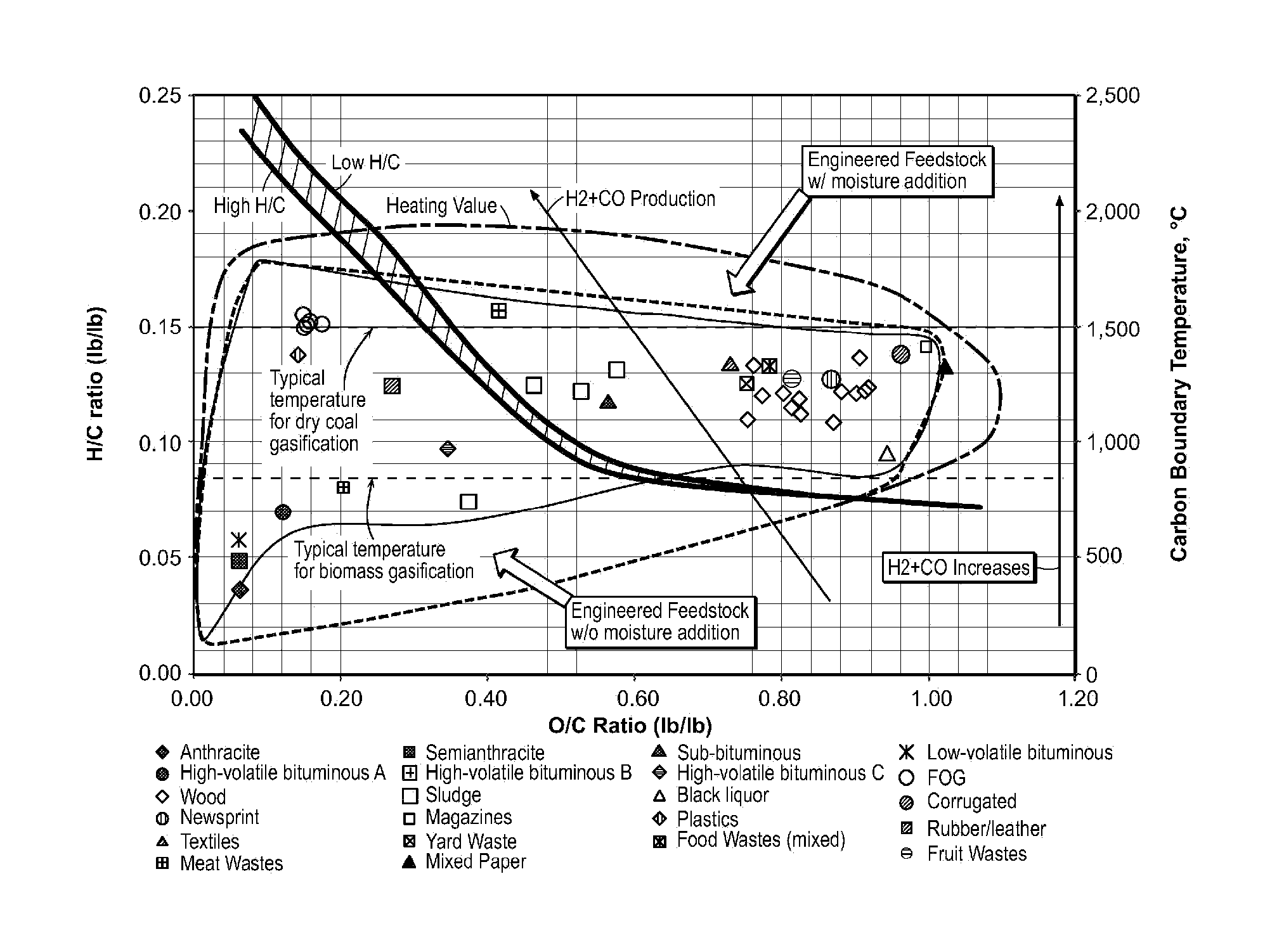

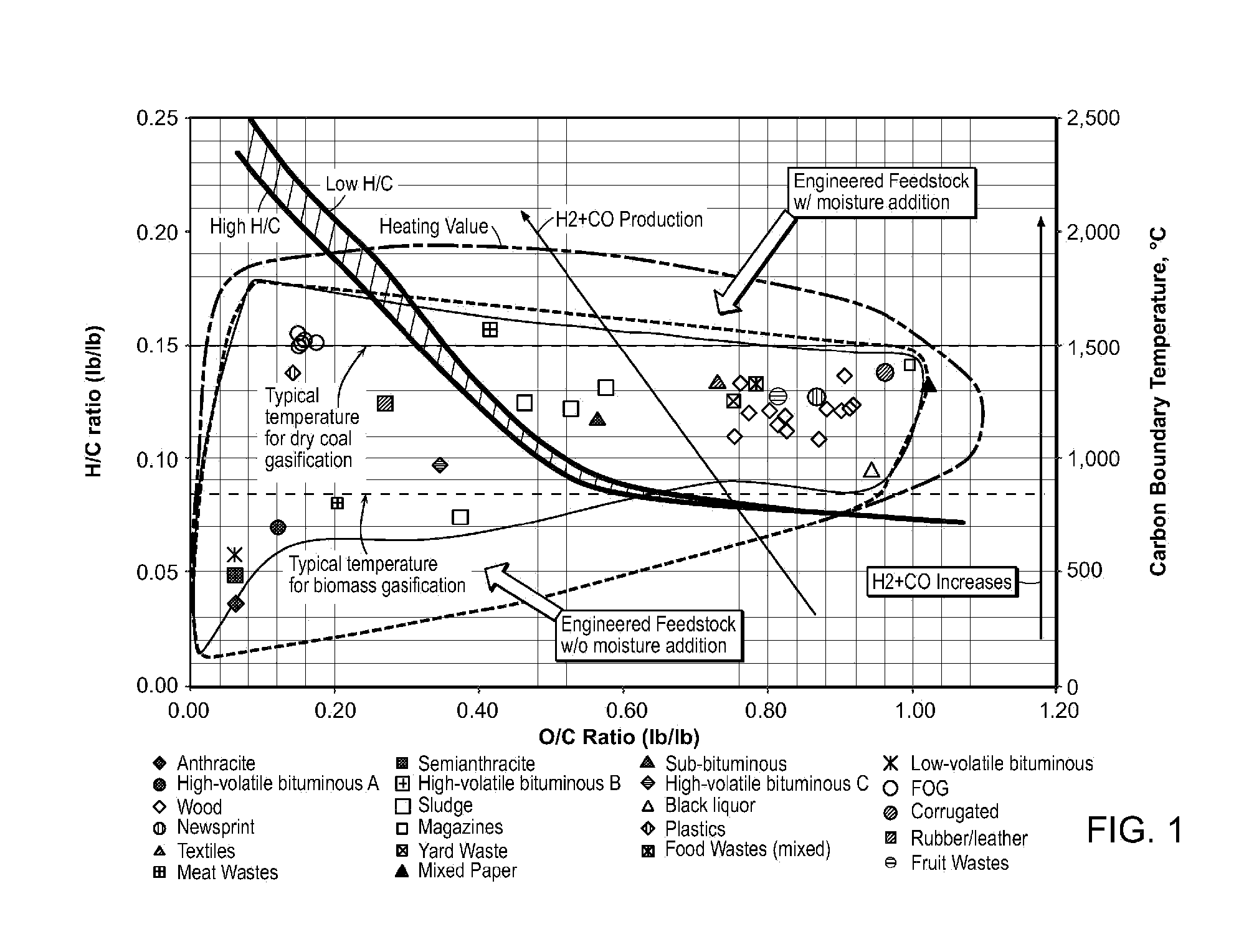

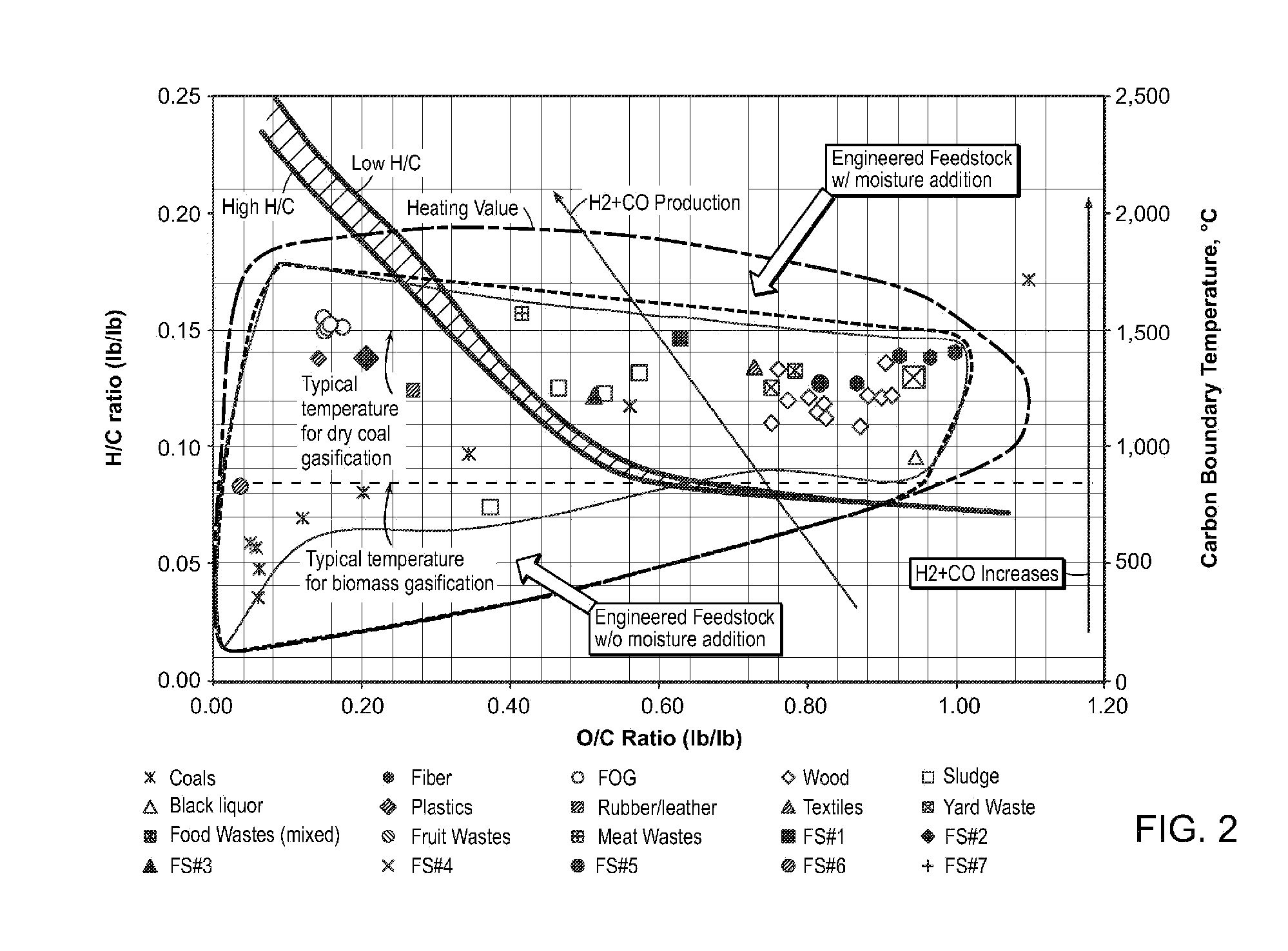

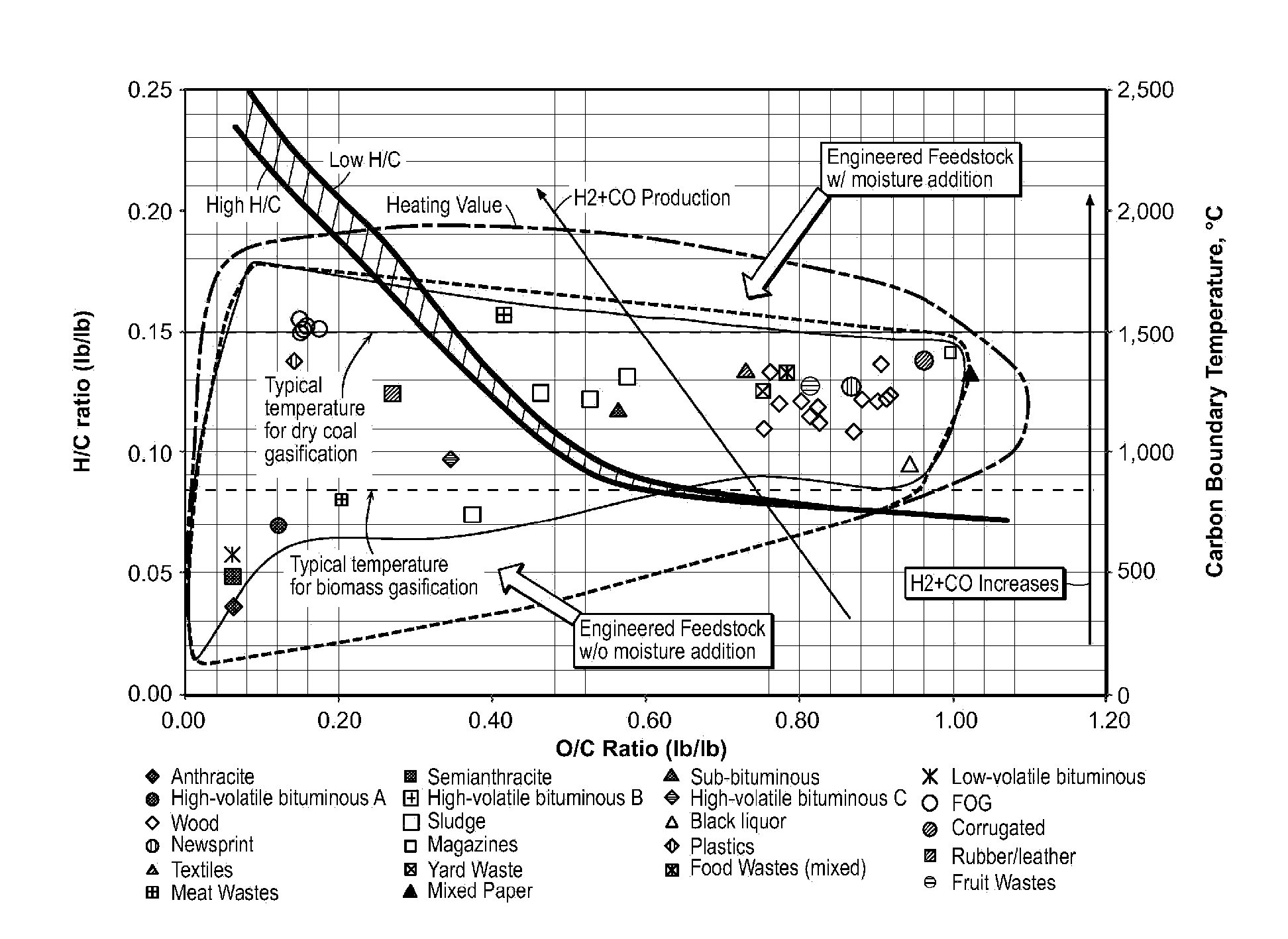

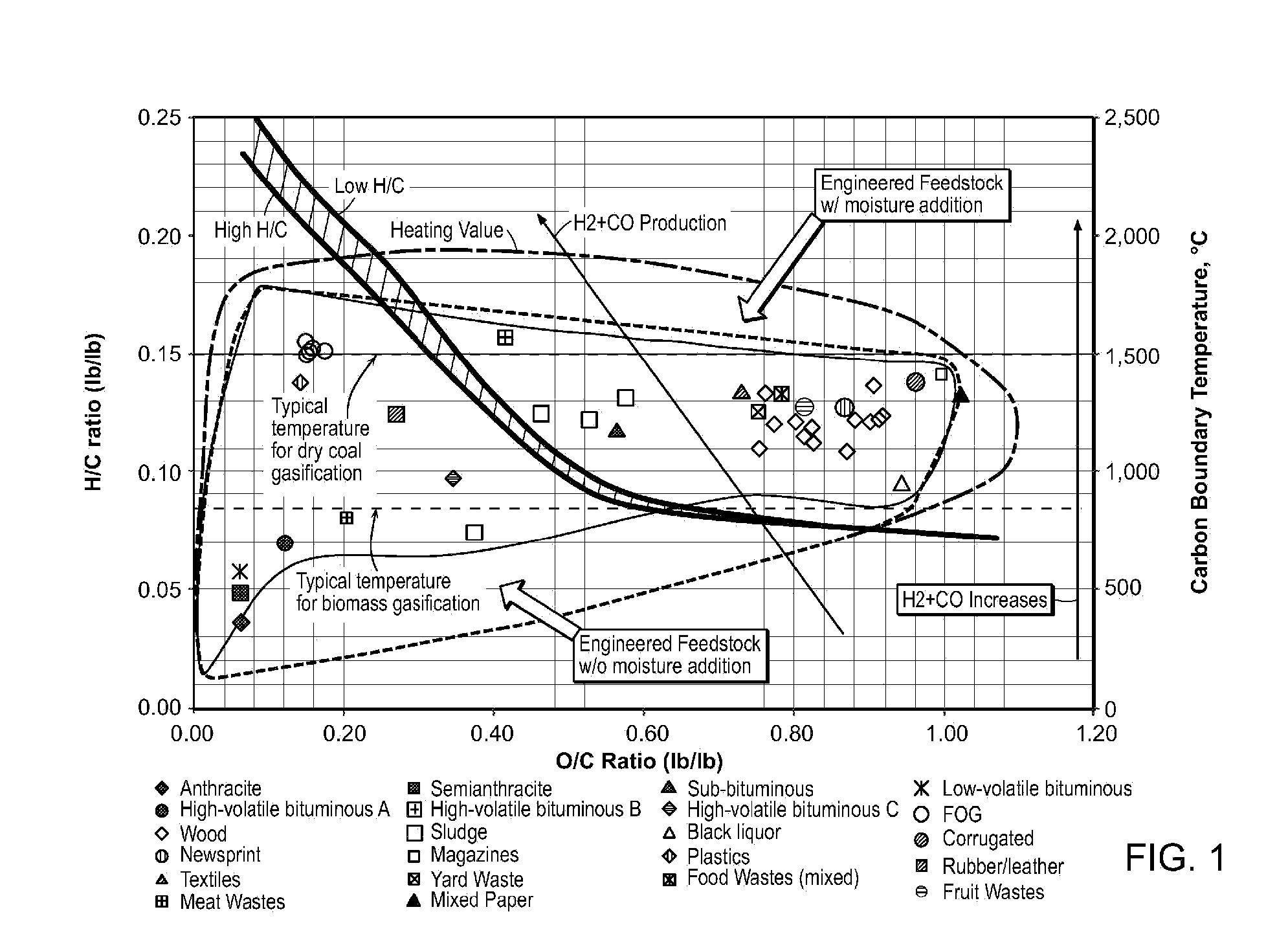

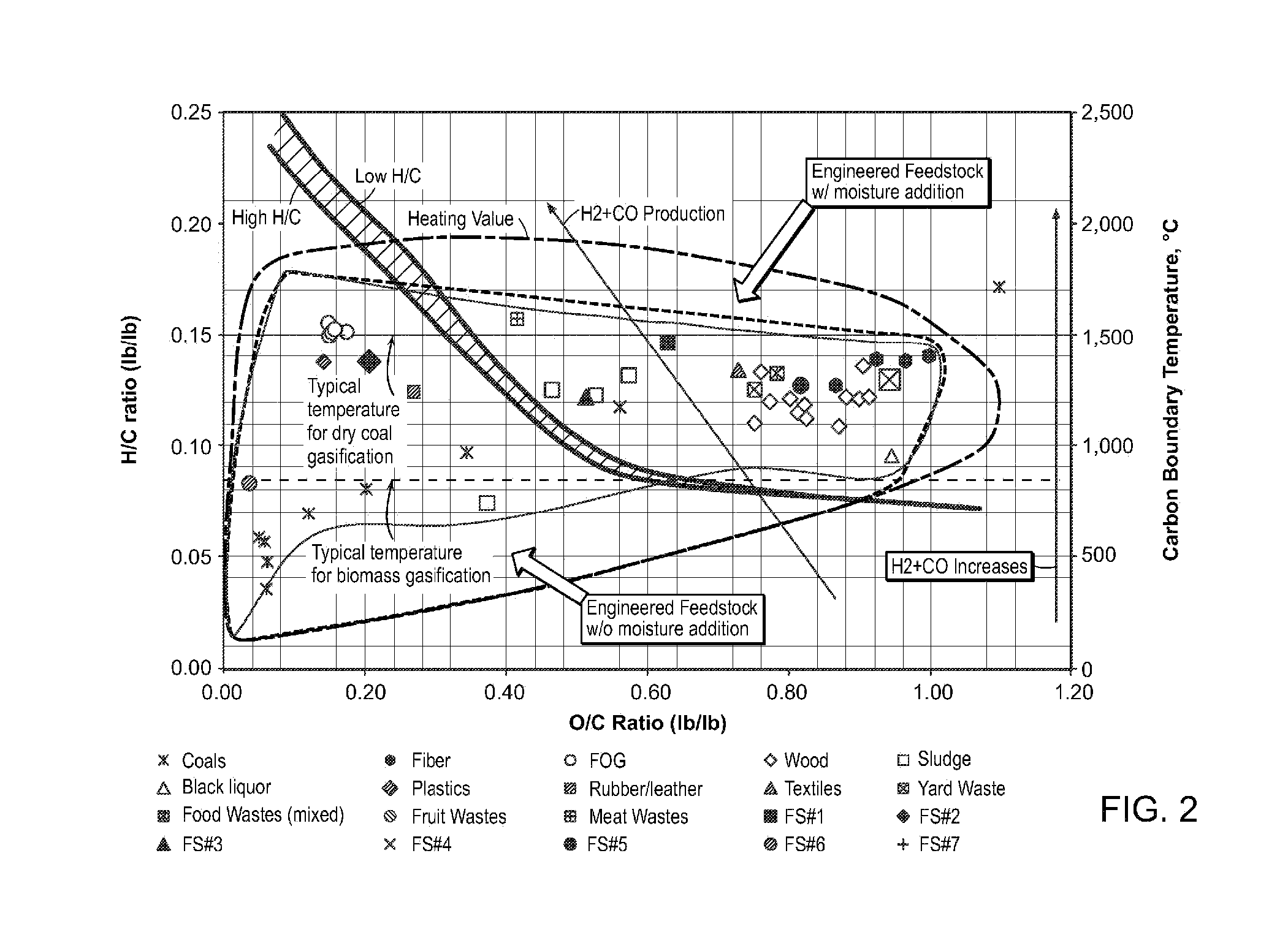

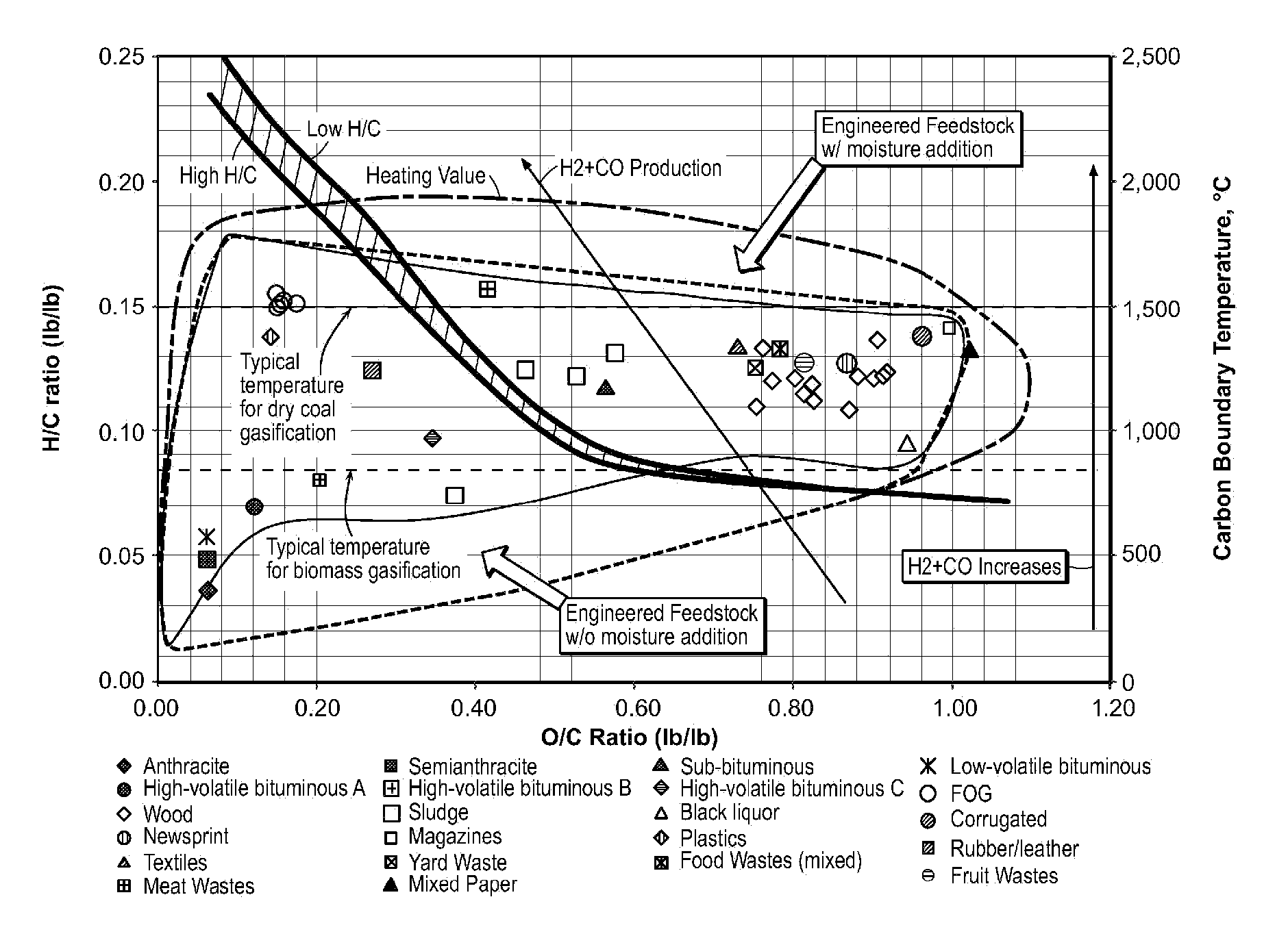

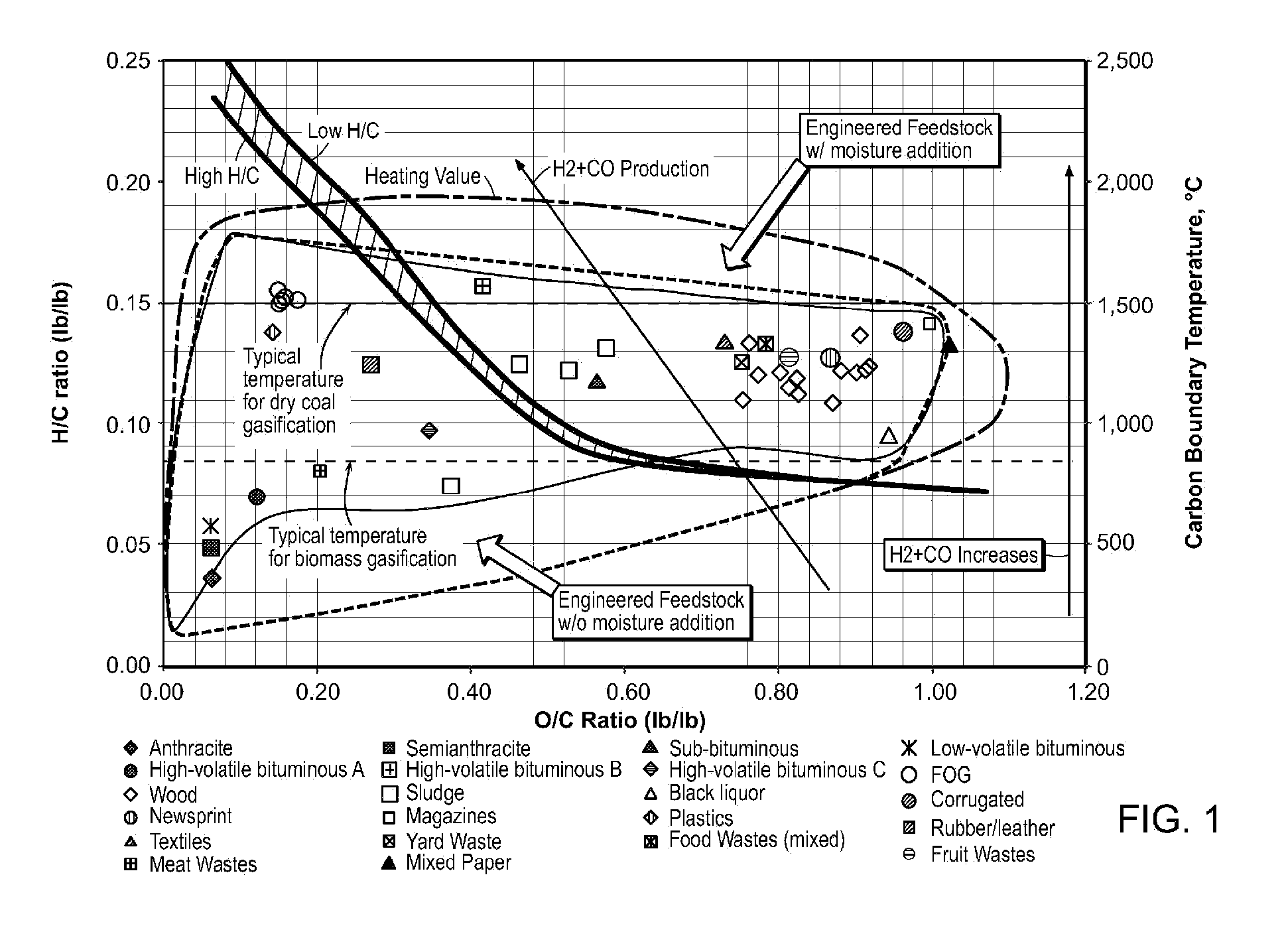

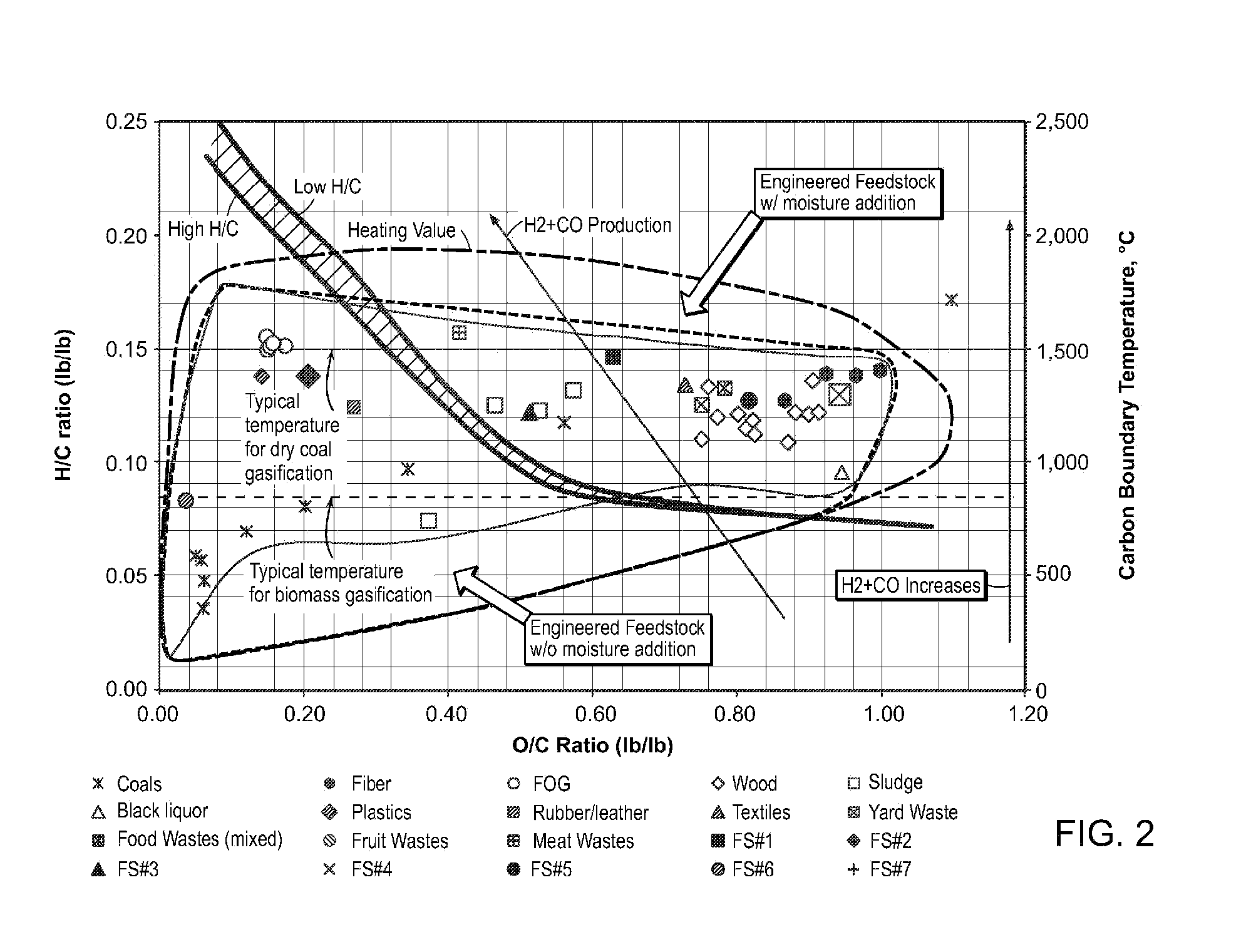

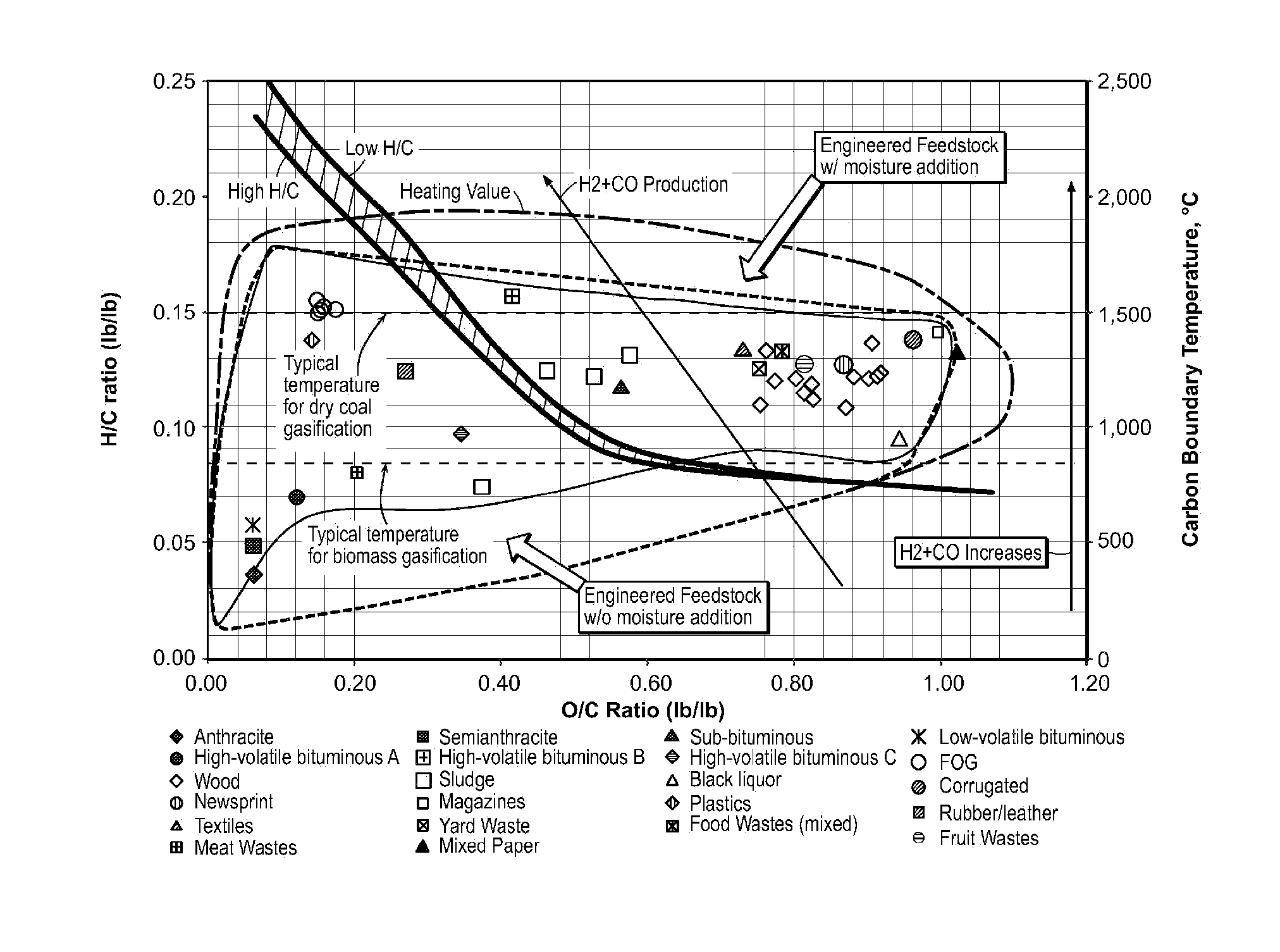

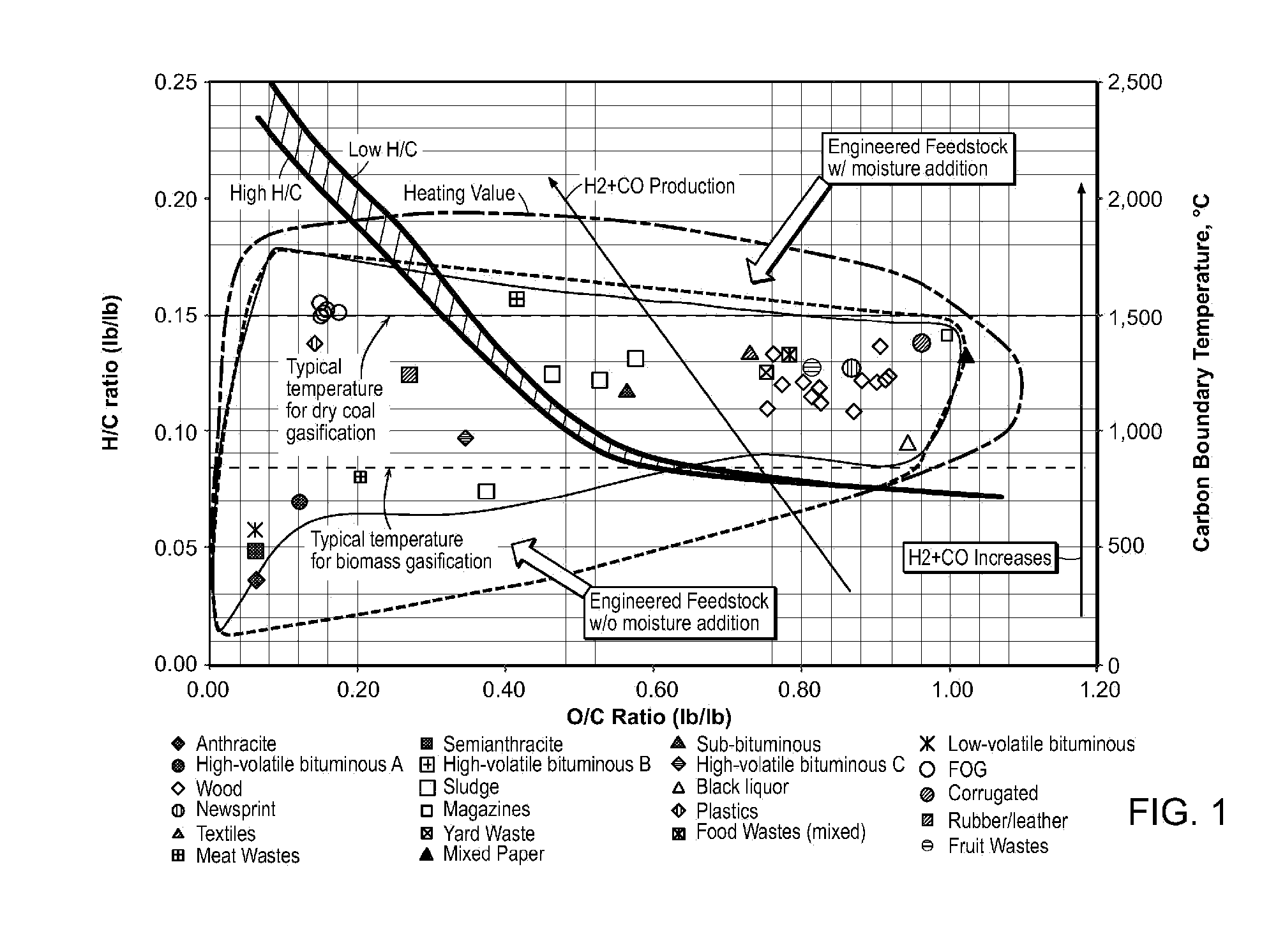

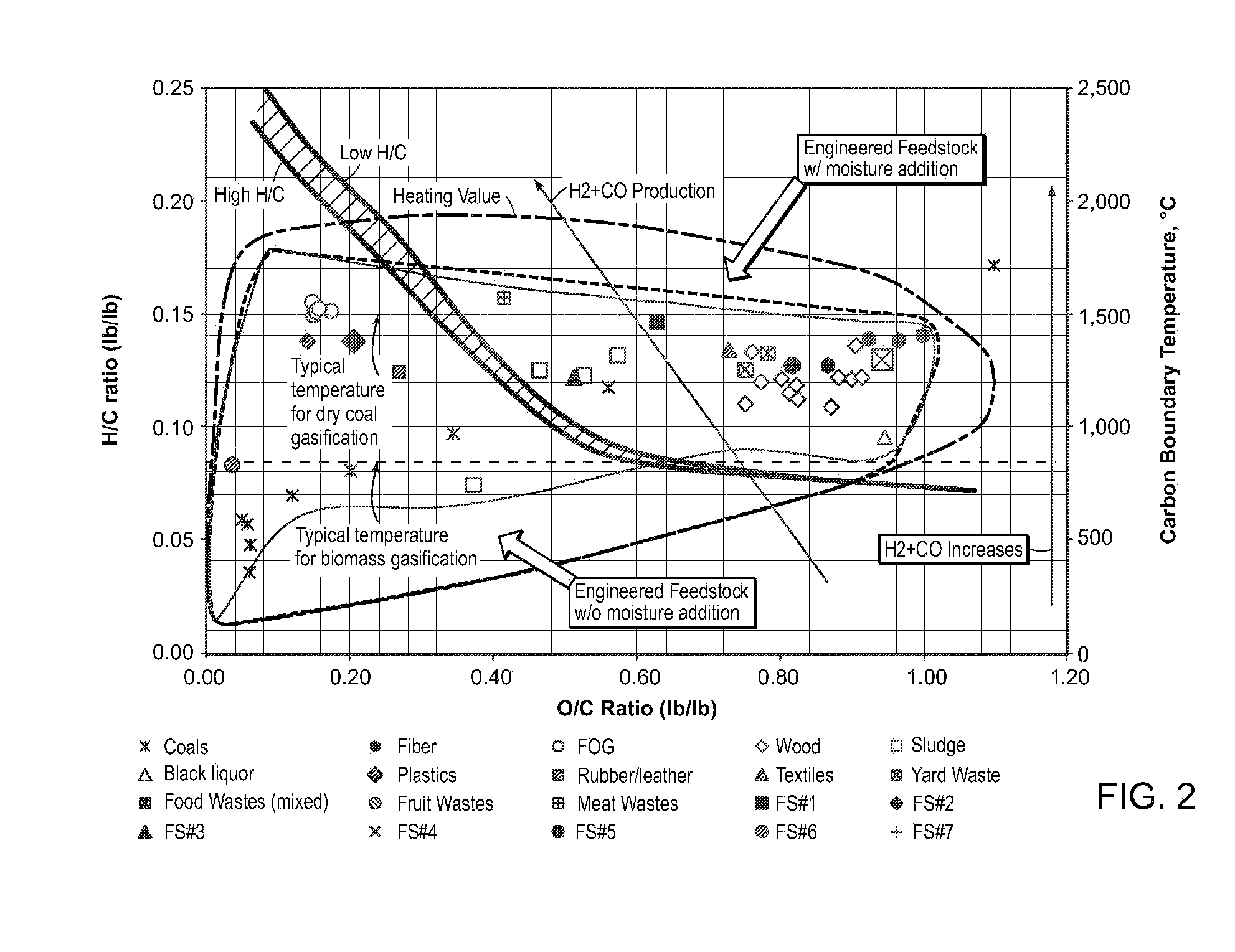

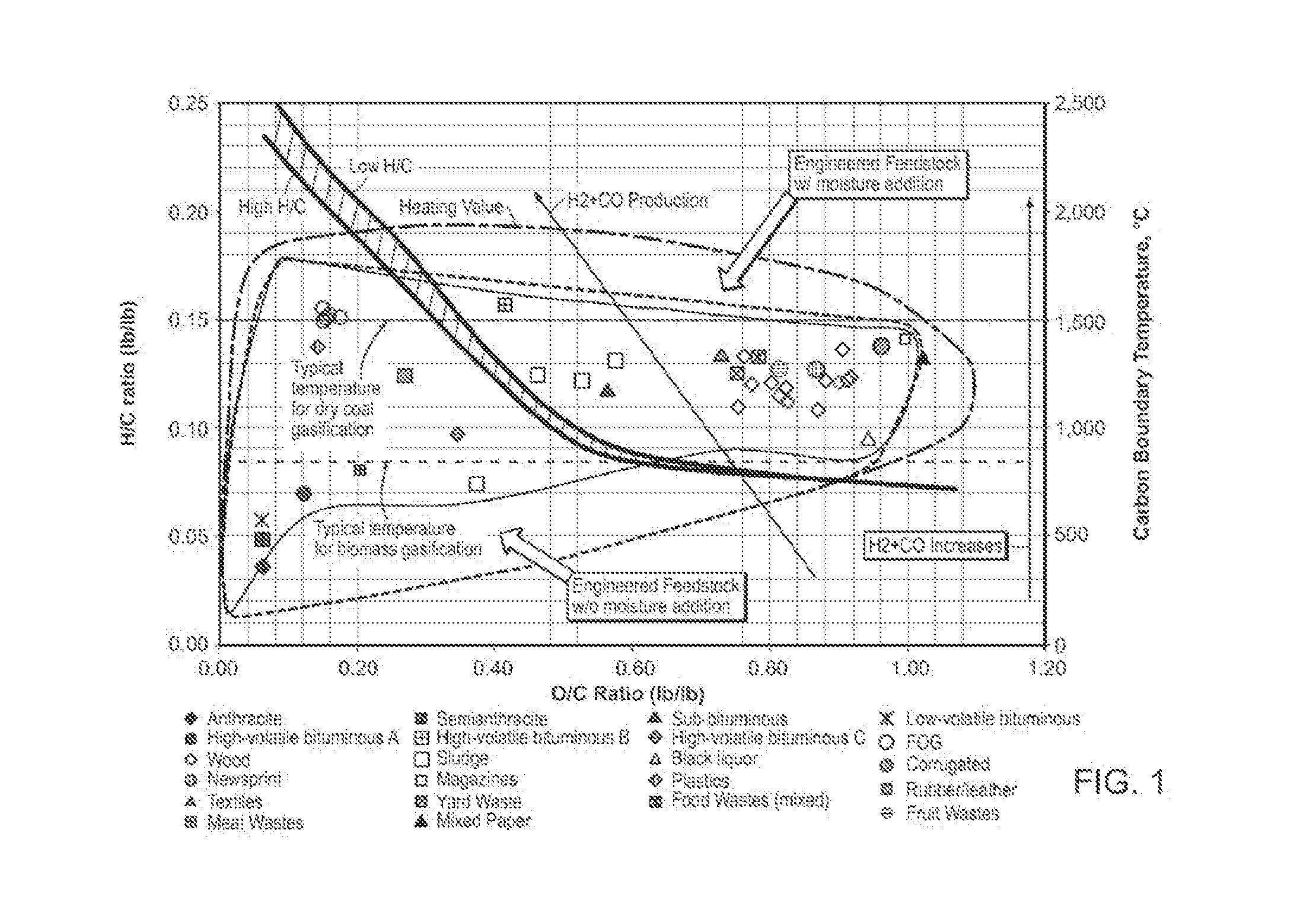

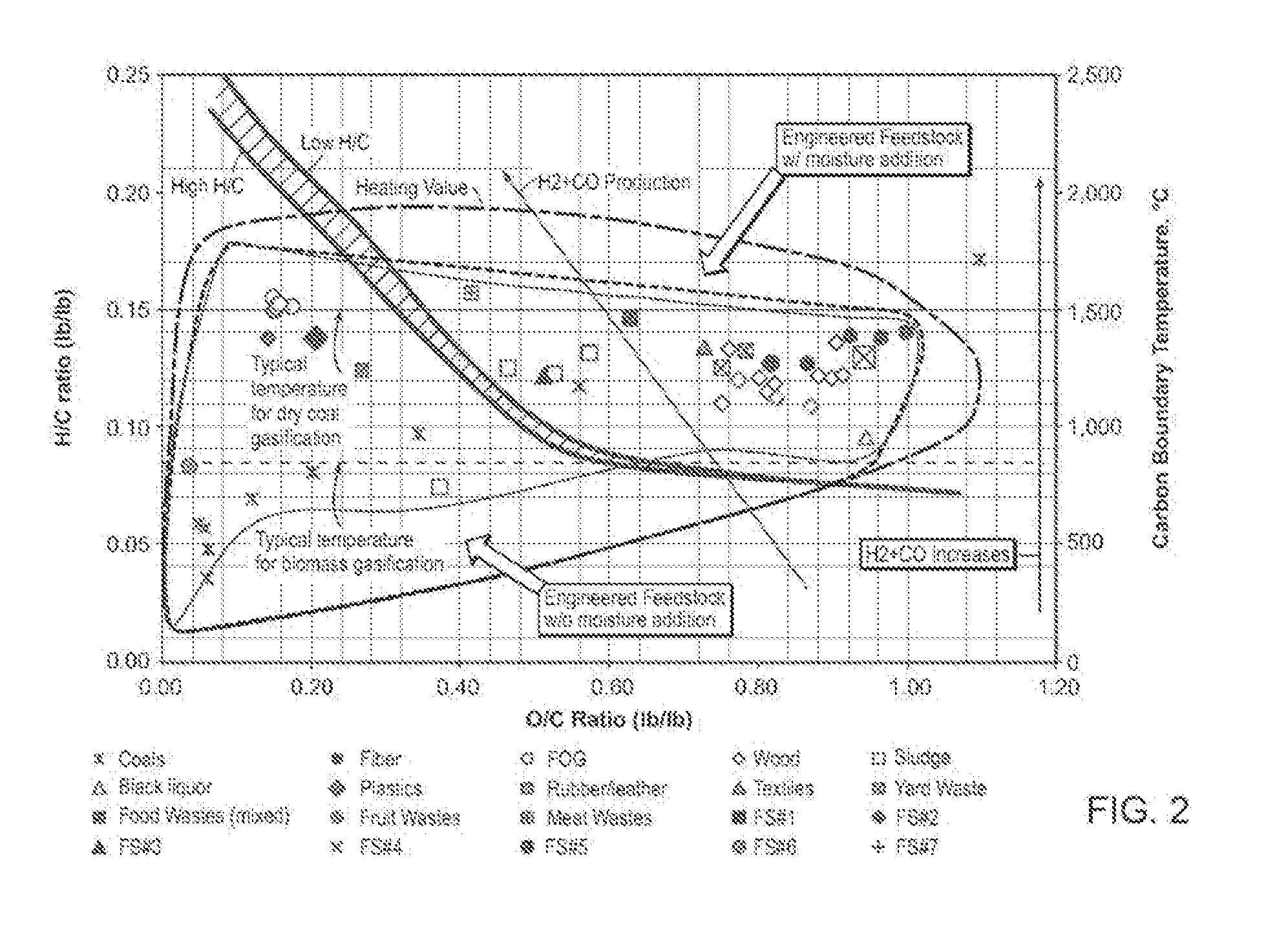

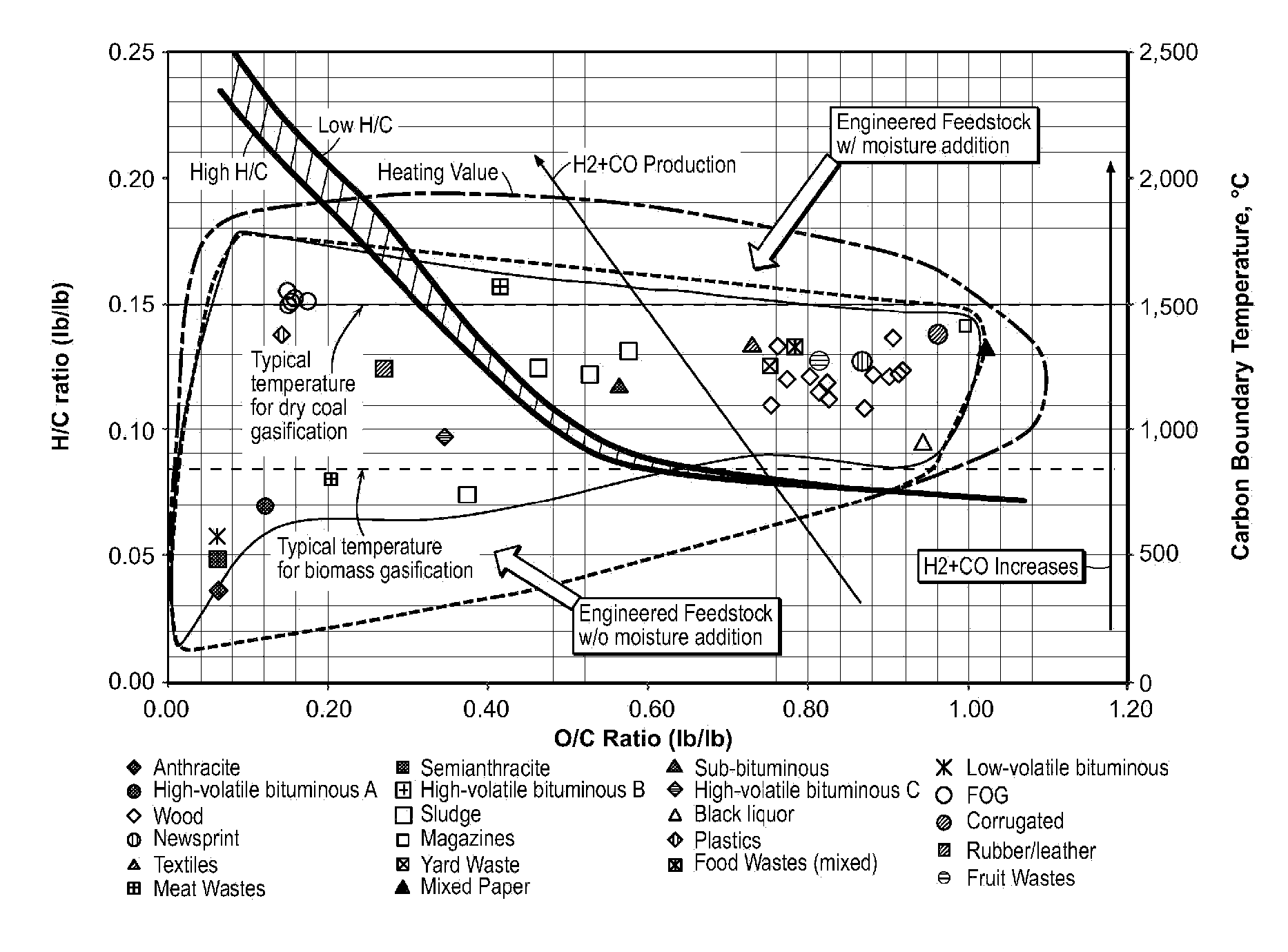

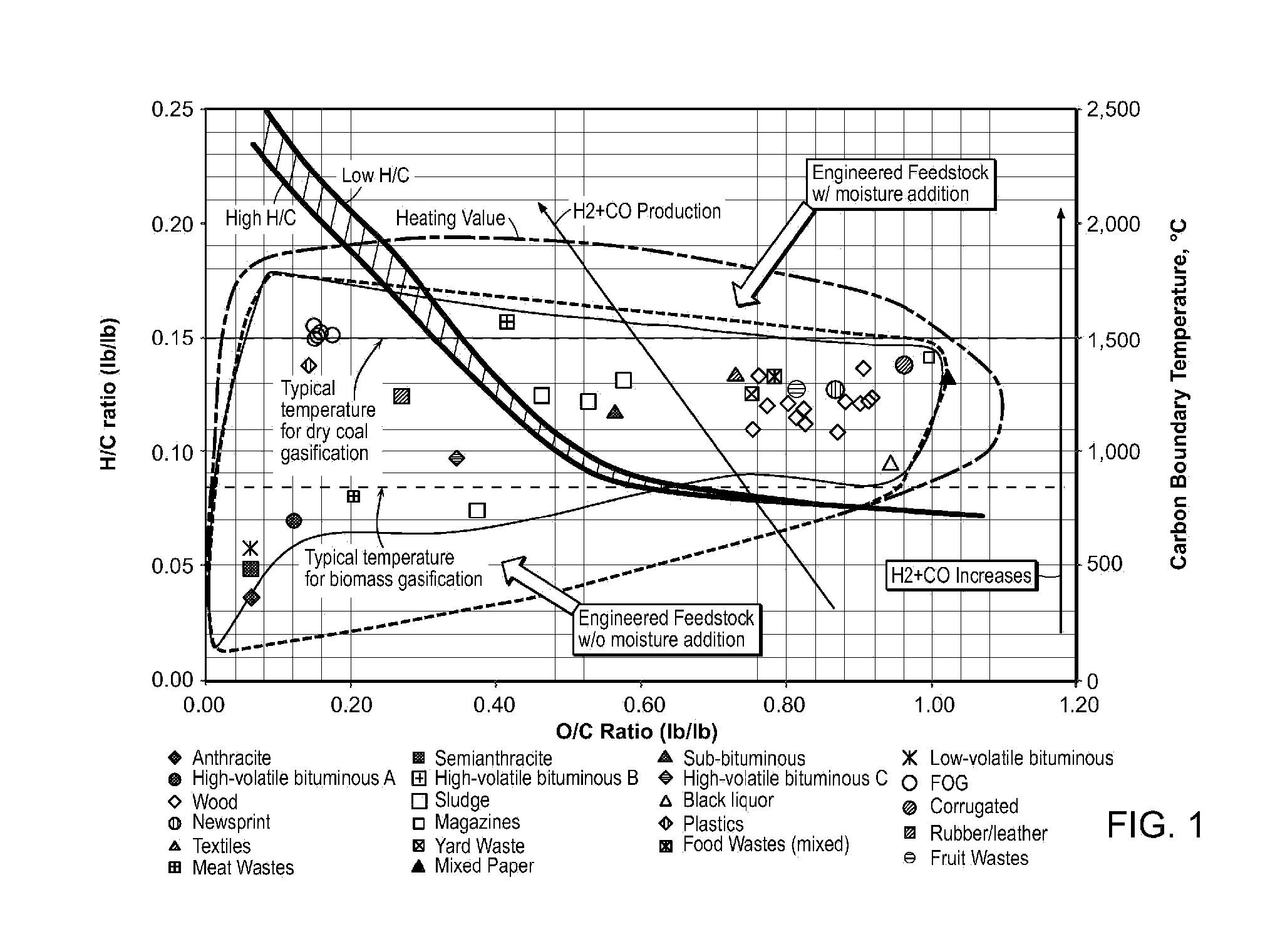

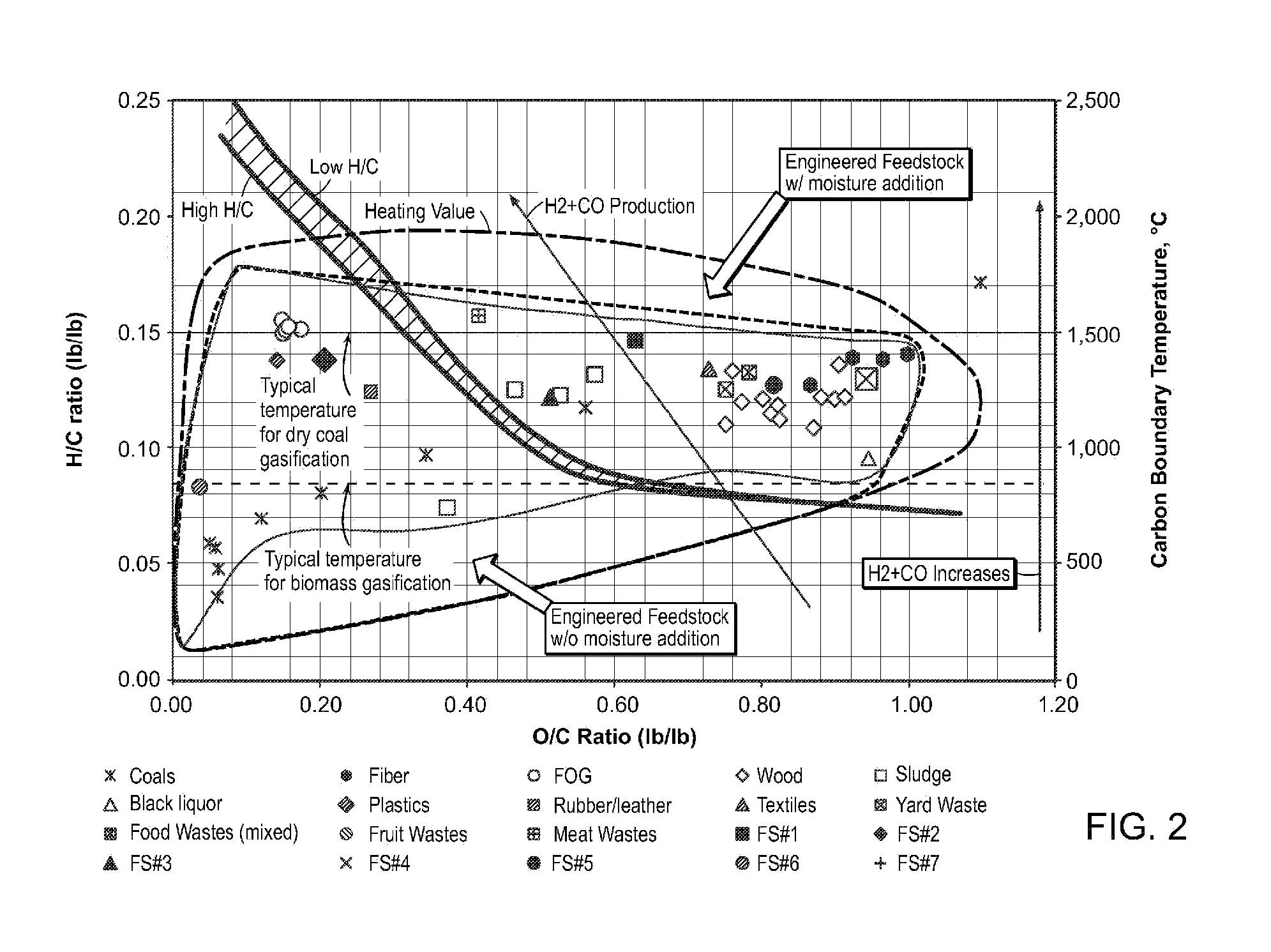

Engineered fuel feed stock useful for displacement of coal in coal firing plants

ActiveUS20100031560A1Reduce harm to the environmentQuality improvementMechanical working/deformationBiofuelsEngineeringCoal fired

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including co-firing with coal and as substitutes for coal.

Owner:REPOWER IP LLC

Engineered fuel feed stock

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including as gasification and combustion fuels.

Owner:REPOWER IP LLC

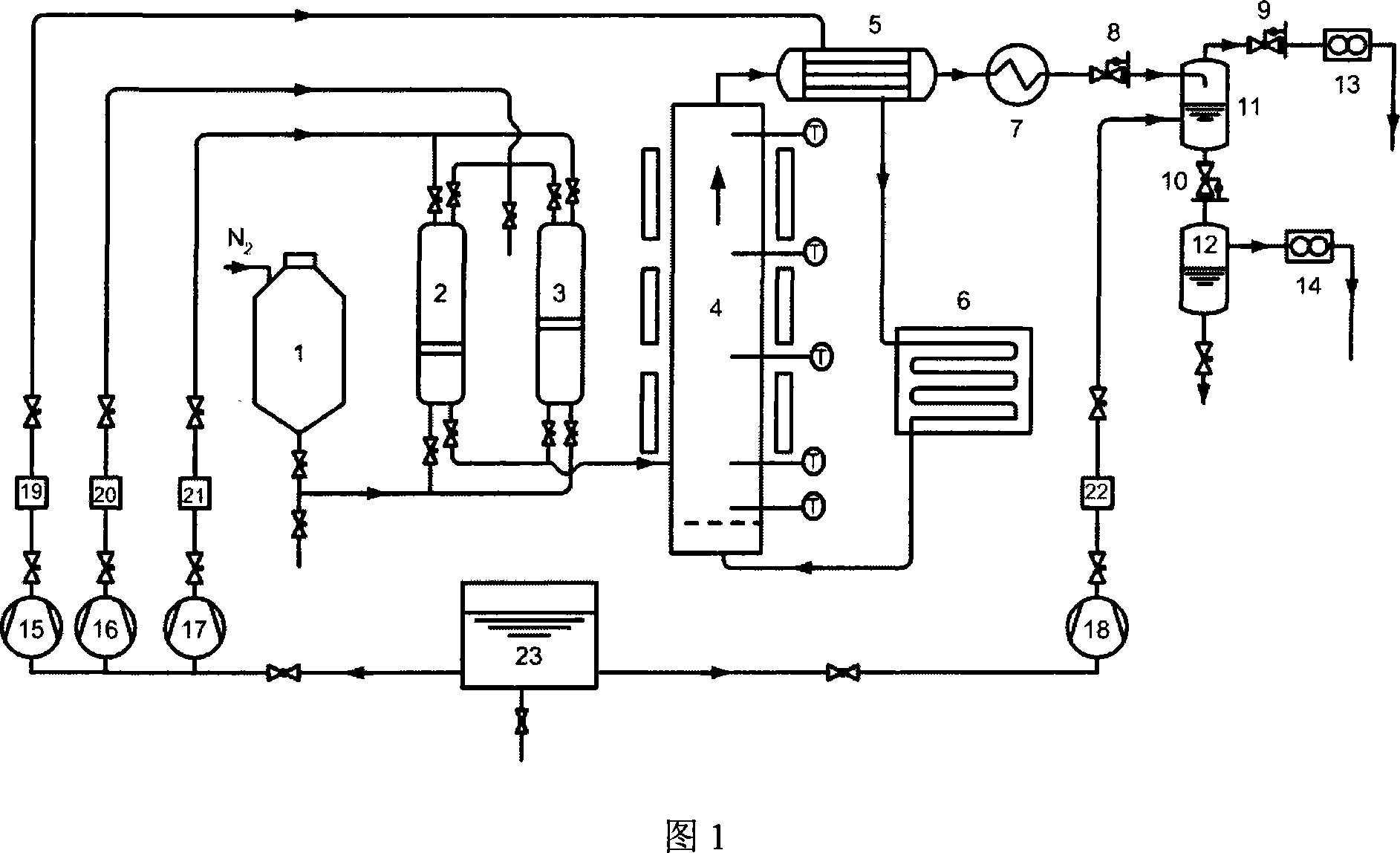

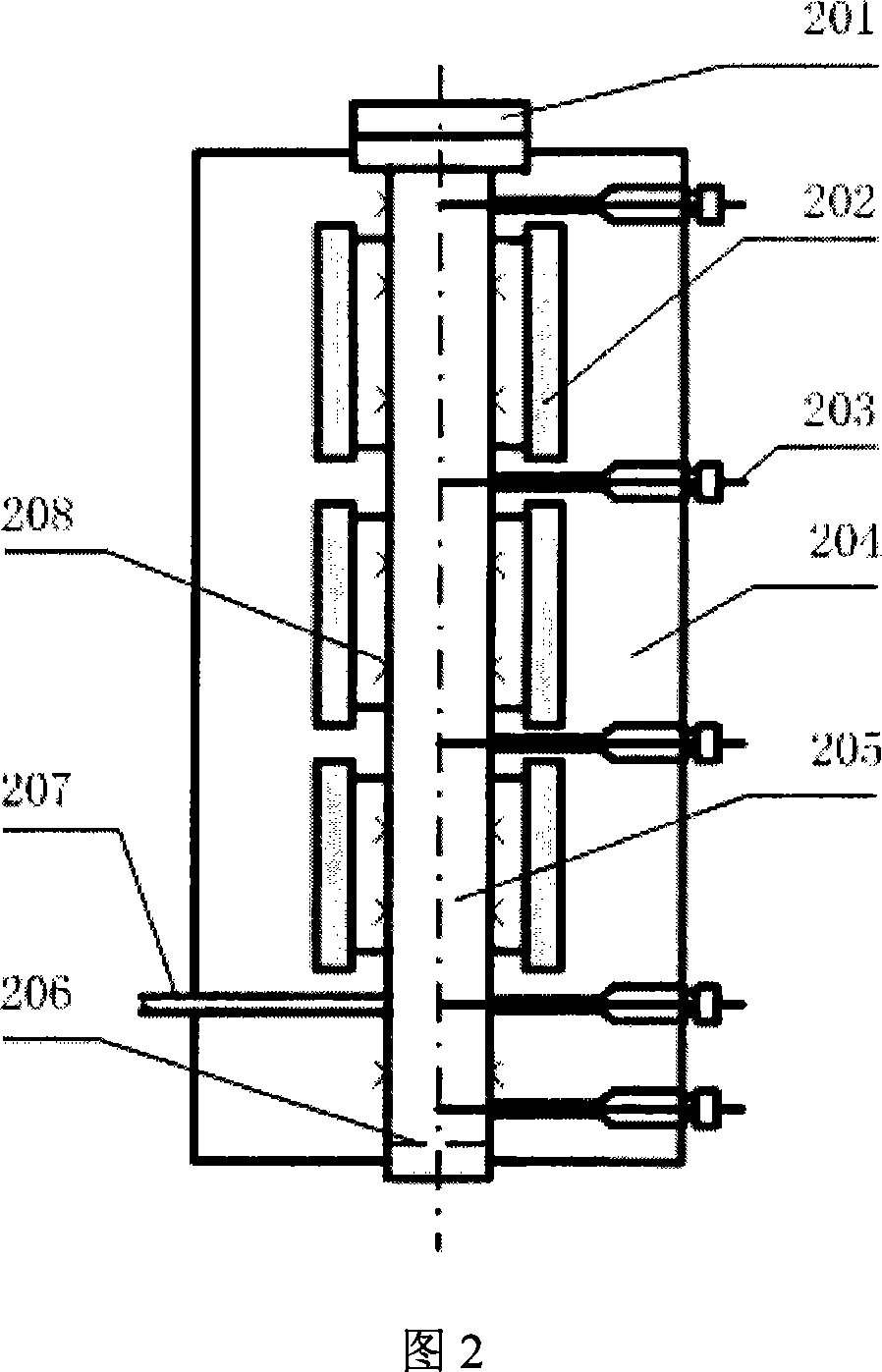

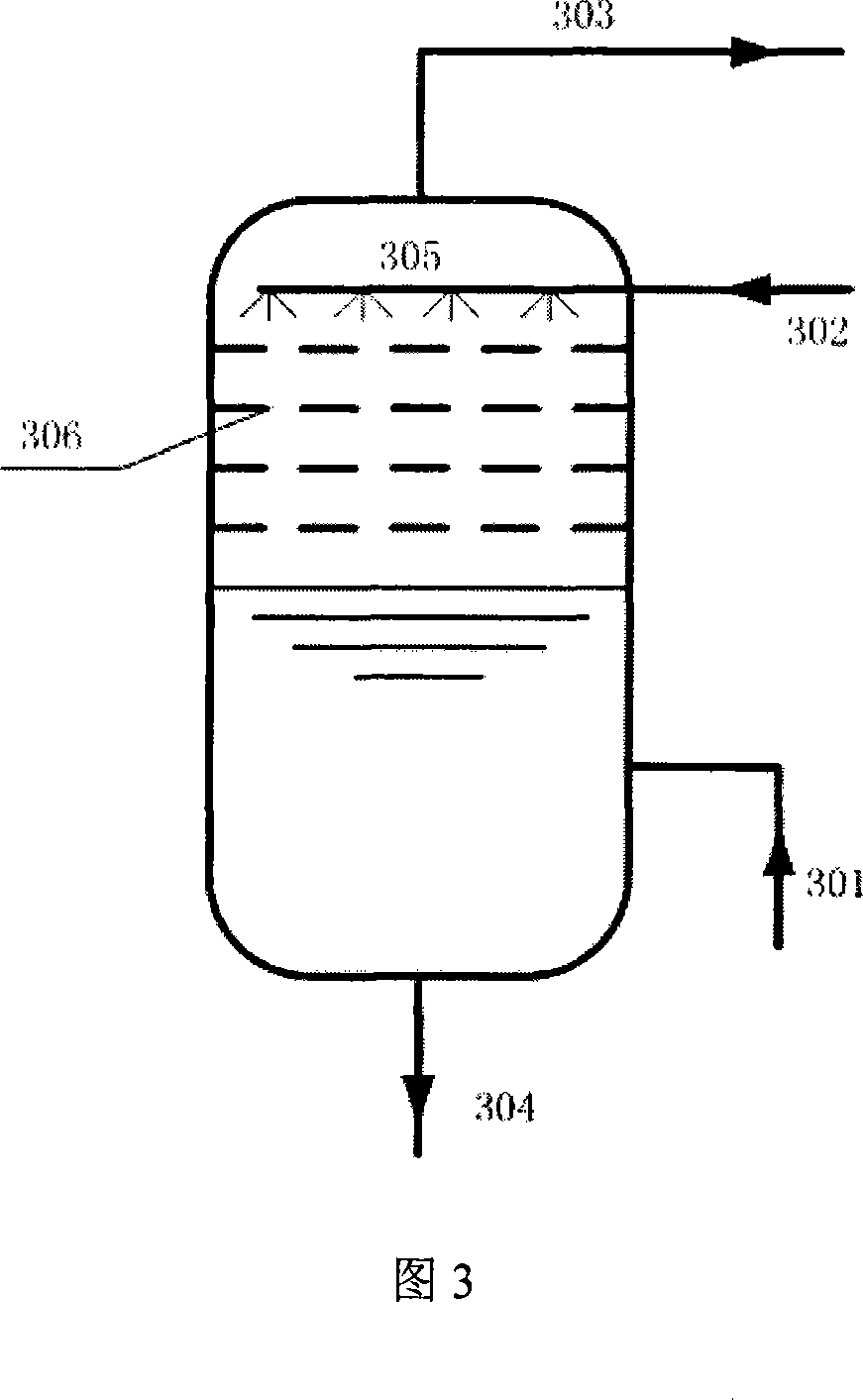

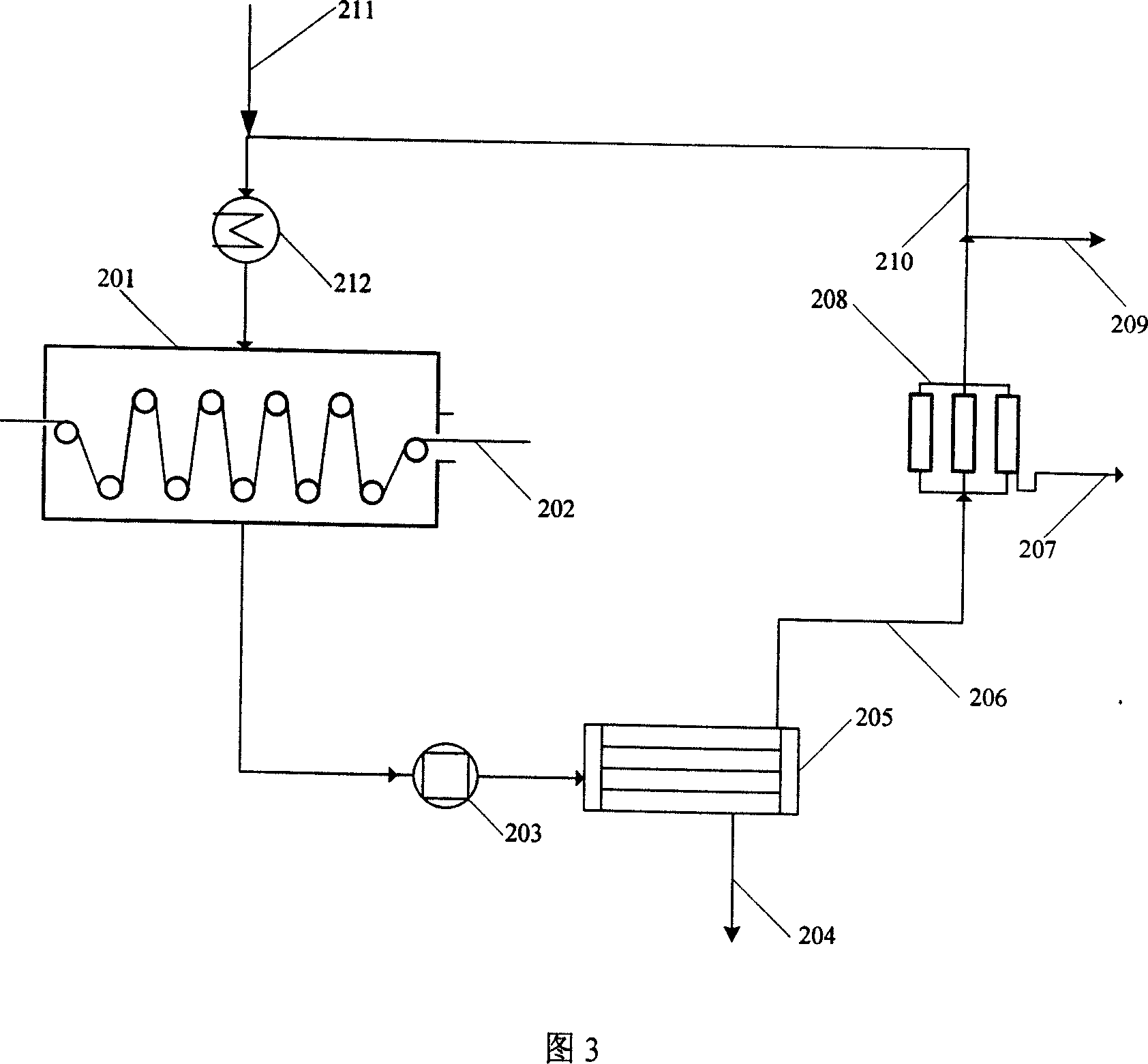

Biomass castoff supercritical water fluid bed partial oxidation hydrogen-preparation device and method

ActiveCN101058404AImprove heat transfer efficiencyConducive to centralized processing and resource utilizationSolid waste disposalHydrogen productionBiomassChemistry

The invention discloses an oxidizing and gasifying hydrogen-making device and method of hypercritical water fluid-bed part of the biological waste, which is characterized by the following: adopting hypercritical water fluid-bed reactor to prevent slagging and blocking problem in the pipe flow reactor; using high-pressure separator to generate high-pressure water to adsorb carbon dioxide in the gas product; realizing the separation of the hydrogen from the carbon dioxide; making the separated high-density carbon dioxide concentrate to be disposed and do resoursing usage conveniently; compacting the device structure; simplifying and conveniencing the operation; improving the gasifying rate of the biological waste with less pollution in the liquid product; realizing the oxidizing and gasifying fusion in the reactor; improving the biological mass transmitting rate and system energy transmitting efficiency; transmitting the biological waste into high-quality hydrogen through the method; reducing the environmental pollution; realizing the dual goals to harness pollution and make hydrogen.

Owner:陕西中核交大超洁能源技术有限公司

Engineered fuel feed stock useful for displacement of coal in coal firing plants

ActiveUS8349034B2Less-harmful emissionEmission reductionMechanical working/deformationBiofuelsWaste streamEngineering

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including co-firing with coal and as substitutes for coal.

Owner:REPOWER IP LLC

Engineered fuel feed stock

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including as gasification and combustion fuels.

Owner:REPOWER IP LLC +1

Method and apparatus to produce synthetic gas

ActiveUS20110036011A1Easy to operateEasy to evaporateValve members for heating/coolingPipe heating/coolingSyngasForming gas

A method of producing a synthetic gas (syngas) includes injecting a plurality of reactant streams into a gasification reactor via at least one injection device having a plurality of injection annuli, an inner portion that extends annularly about a centerline extending through the at least one injection device, and an outer portion extending substantially annularly about the inner portion. At least a portion of the outer portion is oriented obliquely with respect to the at least one injection device centerline. The method also includes mixing at least a portion of each of the streams together such that a plurality of recirculation zones is defined by the streams. The method further includes producing a syngas within the recirculation zones via mixing at least a portion of each of the streams. The injection device includes an inner portion that extends annularly about a centerline extending through the injection device. The device also includes an outer portion extending substantially annularly about the inner portion that includes at least one of at least one carbonaceous reactant injection port oriented obliquely with respect to the injection device centerline and at least one outer face oriented obliquely with respect to the injection device centerline.

Owner:AIR PROD & CHEM INC

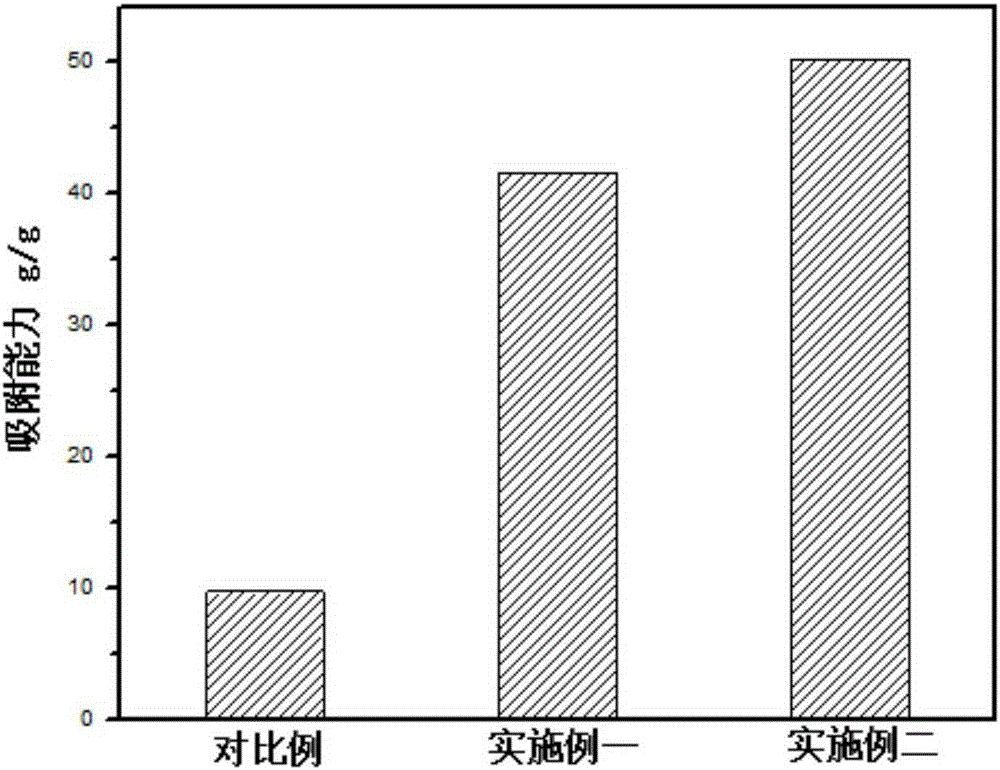

Preparation method for oxidized graphene-poly-dopamine composite aerogel

InactiveCN105254916AIntegrity guaranteedGuaranteed stabilityOther chemical processesAlkali metal oxides/hydroxidesPorosityFreeze-drying

The invention provides a preparation method for oxidized graphene-poly-dopamine composite aerogel. The preparation method comprises the following steps that 1, 0.15-0.7 g of dopamine powder is dissolved in 10-18 ml of distilled water, the dopamine aqueous solutions are mixed with 50-60 ml of oxidized graphene aqueous solutions with the concentration of 5-6 mg / ml, and stirring is performed to obtain oxidized graphene-dopamine mixed solutions; 2, 3-9 ml of tris aminomethane buffer solutions with the concentration of 0.1-0.12 mol / L are dropwise added into the mixed solutions while stirring is performed, stirring is continuously performed for 2-2.5 h, and standing is performed to enable the dopamine to be fully polymerized to obtain oxidized graphene-poly-dopamine composite aquogel; 3, after being placed in an environment with the temperature ranging from minus 20 DEG C to minus 10 DEG C to be frozen for 24-30 h, the composite aquogel is processed through freeze drying, and then the oxidized graphene-poly-dopamine composite aerogel is obtained. The method is simple in technology, and the prepared composite aerogel has the advantages of being high in porosity, excellent in adsorptivity, high in strength and the like.

Owner:SOUTHWEST JIAOTONG UNIV

Engineered fuel feed stock

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including as gasification and combustion fuels.

Owner:REPOWER IP LLC +1

Engineered fuel feed stock

InactiveUS20110209397A1Less-harmful emissionEmission reductionProductsReagentsCombustionWaste stream

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including as gasification and combustion fuels.

Owner:REPOWER IP LLC

Preparation method of graphene oxide/silicon dioxide hybrid aerogel

A preparation method of graphene oxide / silicon dioxide hybrid aerogel comprises the following steps: A, adding 0.05-0.1 mol of a precursor into 9-18 ml of distilled water and dropwise adding a hydrolyst with its concentration of 0.2-0.6 mol / L into the precursor aqueous solution, wherein molar ratio of the hydrolyst to the precursor is 1:20-1:100; stirring at 20-30 DEG C for 5-8 h; adjusting pH value to 6-7 and stirring for 5-45 min so as to obtain a dispersion containing silicon dioxide microspheres; B, adding water to dilute the silicon dioxide microsphere dispersion by 5-50 times, carrying out iso-volume mixing on the diluted silicon dioxide microsphere dispersion and a graphene oxide dispersion with its concentration being 0.6-2 mg / ml, stirring for 10-30 min, carrying out ultrasonic treatment for 10-30 min so as to obtain graphene oxide / silicon dioxide hybrid aerogel; and C, freezing the hybrid aerogel under liquid nitrogen for 5-10 min, freeze-drying and dewatering to obtain the graphene oxide / silicon dioxide hybrid aerogel. The method is environmentally friendly, and the technology is simple. The prepared hybrid aerogel has advantages of complete gel network structure, high porosity, good adsorptivity, high strength, low density and the like.

Owner:SOUTHWEST JIAOTONG UNIV

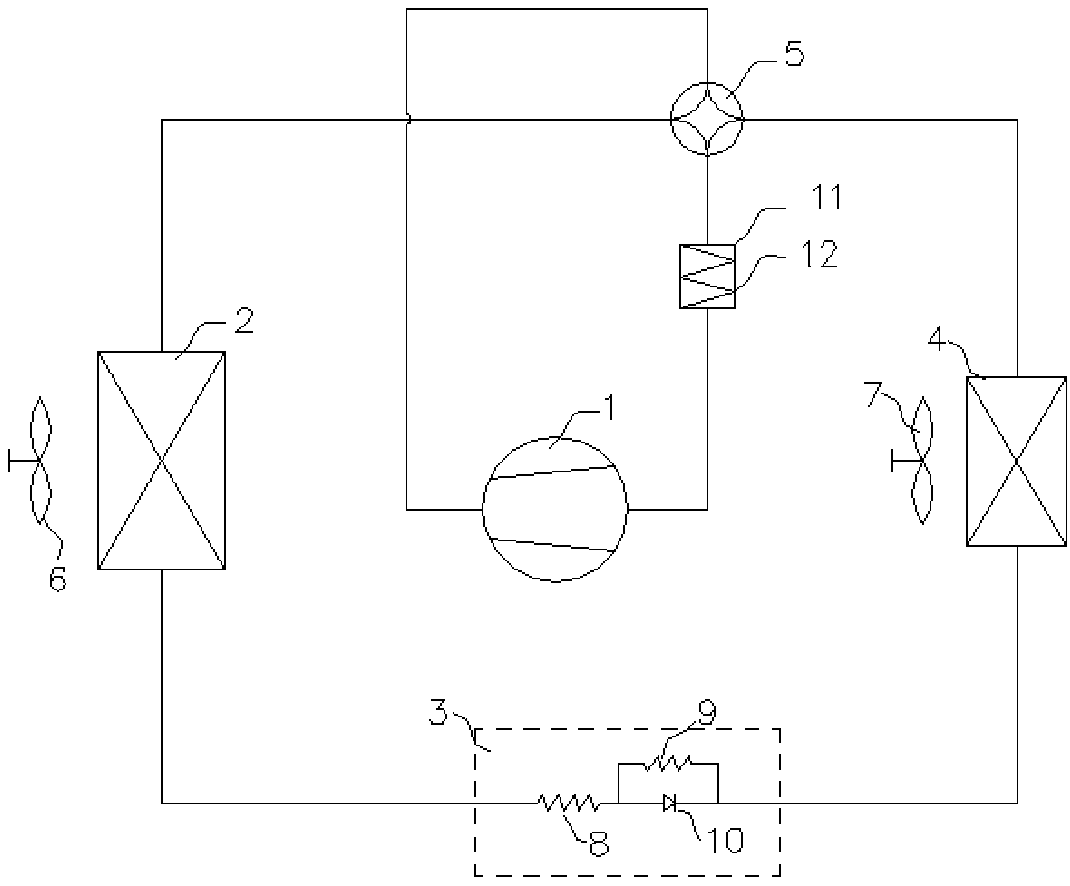

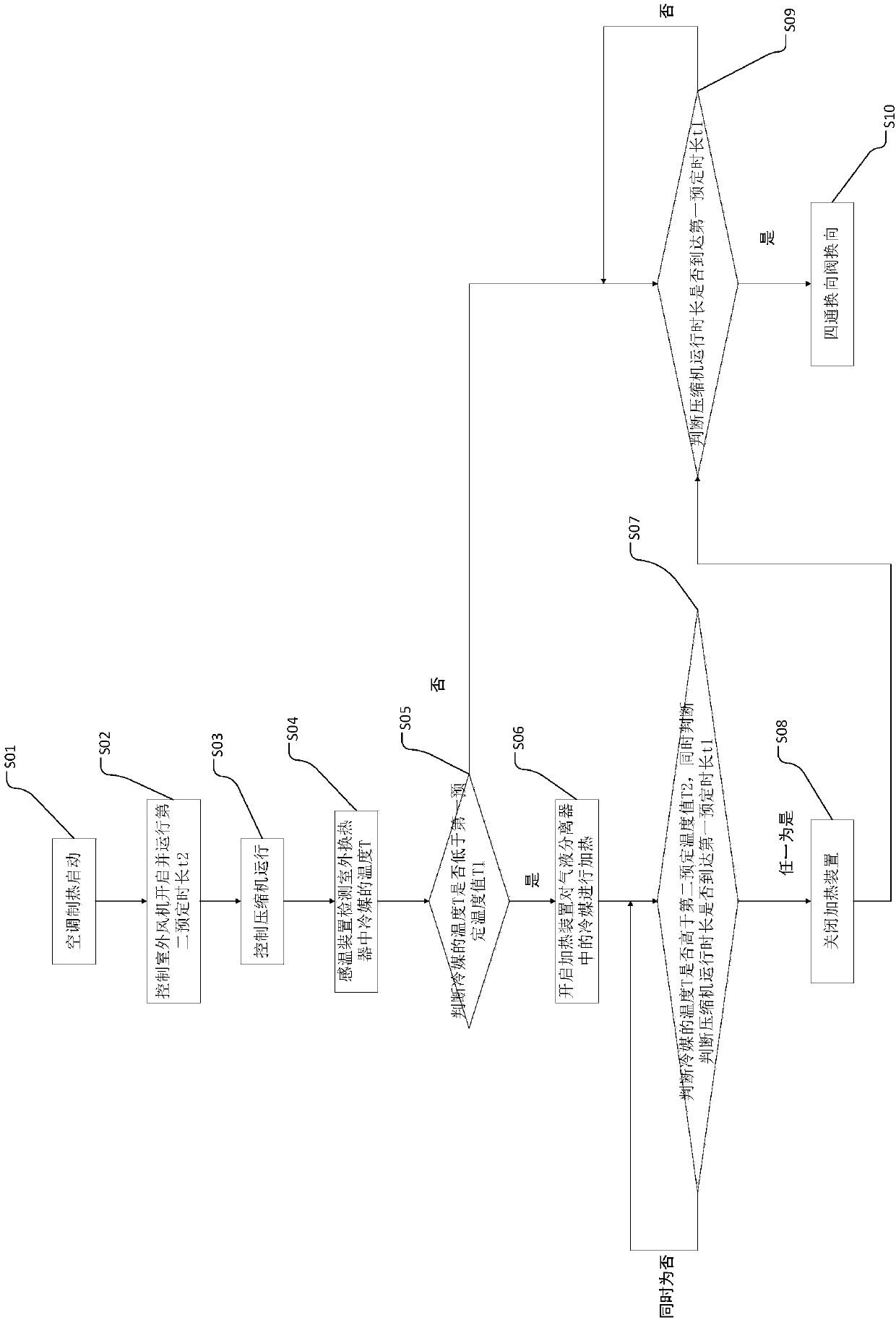

Heat pump system control method and heat pump system

InactiveCN107917548AExtended service lifeReduce floodbackCompression machines with reversible cycleRefrigeration safety arrangementVapor–liquid separatorLiquid state

The invention provides a heat pump system control method and a heat pump system. The heat pump system comprises a compressor, an outdoor heat exchanger, a four-way reversing valve, a gas-liquid separator, and a heating device for heating the gas-liquid separator. The four-way reversing valve has a first state when the heat pump system is in refrigeration operation and a second state when the heatpump system is in heating operation. The control method comprises the step of after switching on the compressor, and before switching the first state of the four-way reversing value to the second state, controlling the heating device according to a state parameter of a refrigerant in the outdoor heat exchanger. The heating device is used for heating a refrigerant in the gas-liquid separator so asto promote refrigerant gasification, the refrigerant entering the four-way reversing valve from a gas outlet of the compressor is at a gas state, and a liquid-state refrigerant cannot be accumulated in the four-way reversing valve, so that the occurrence of the phenomenon of liquid impact caused when the four-way reversing valve reverses after starting up at a heating mode is avoided, and the four-way reversing valve is prevented from being damaged by liquid impact.

Owner:GREE ELECTRIC APPLIANCES INC

Engineered fuel feed stock

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including as gasification and combustion fuels.

Owner:REPOWER IP LLC +1

Engineered fuel feed stock

ActiveUS20110209395A1Less-harmful emissionEmission reductionProductsReagentsWaste streamProcess engineering

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including as gasification and combustion fuels.

Owner:REPOWER IP LLC +1

Engineered fuel feed stock

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including as gasification and combustion fuels.

Owner:CASELLA WASTE SYSTEMS +1

Engineered fuel feed stock

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including as gasification and combustion fuels.

Owner:CASELLA WASTE SYSTEMS +1

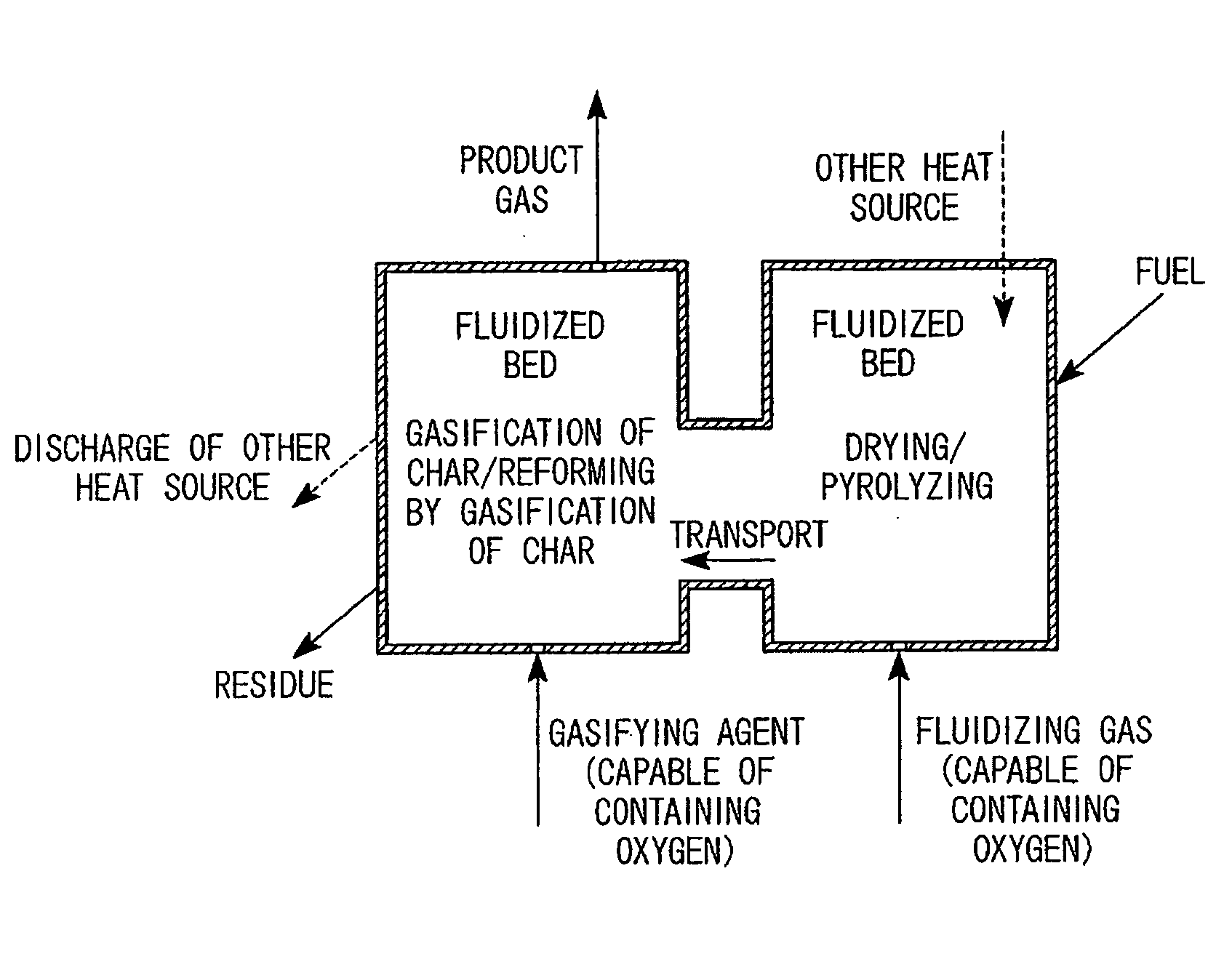

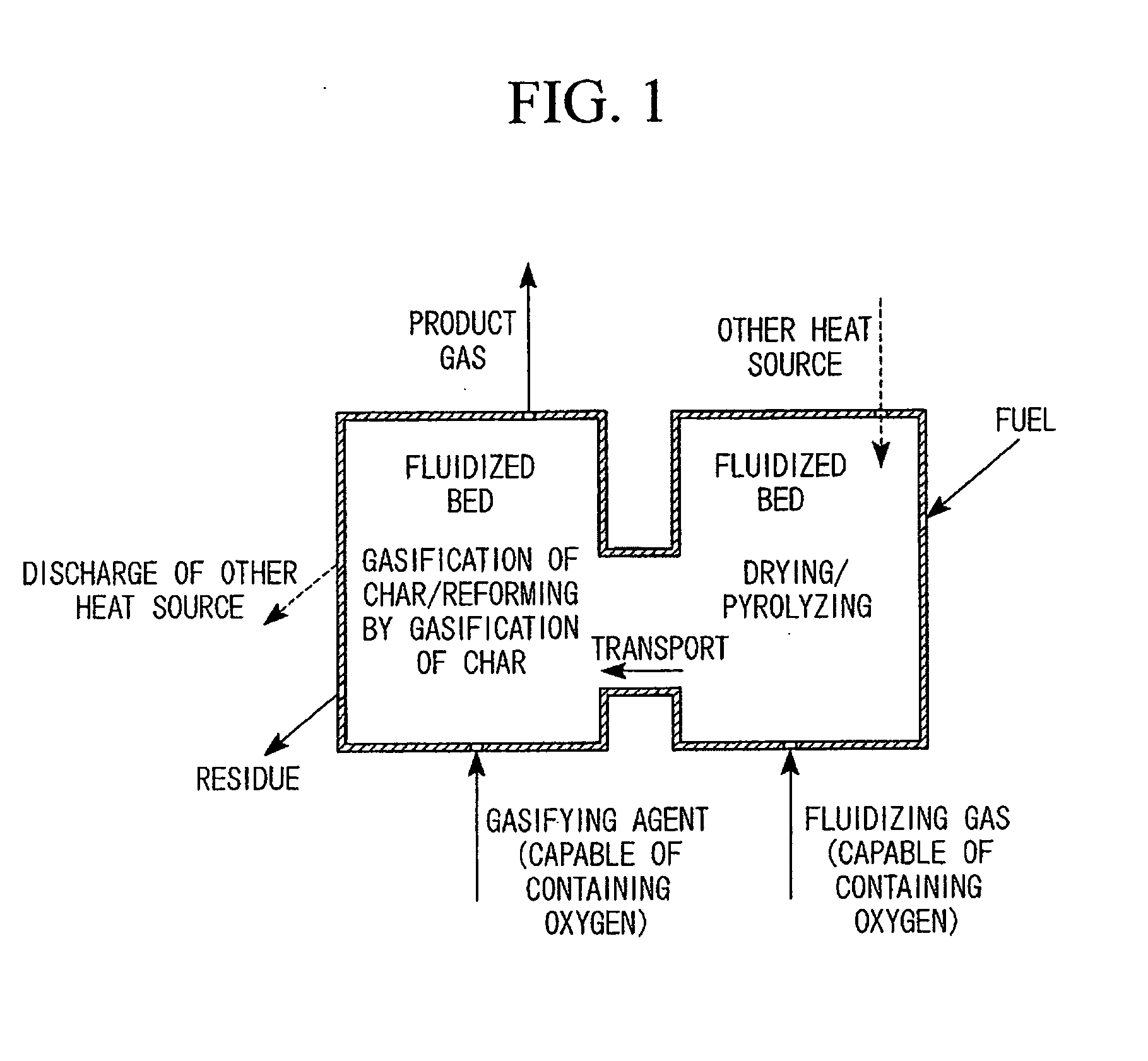

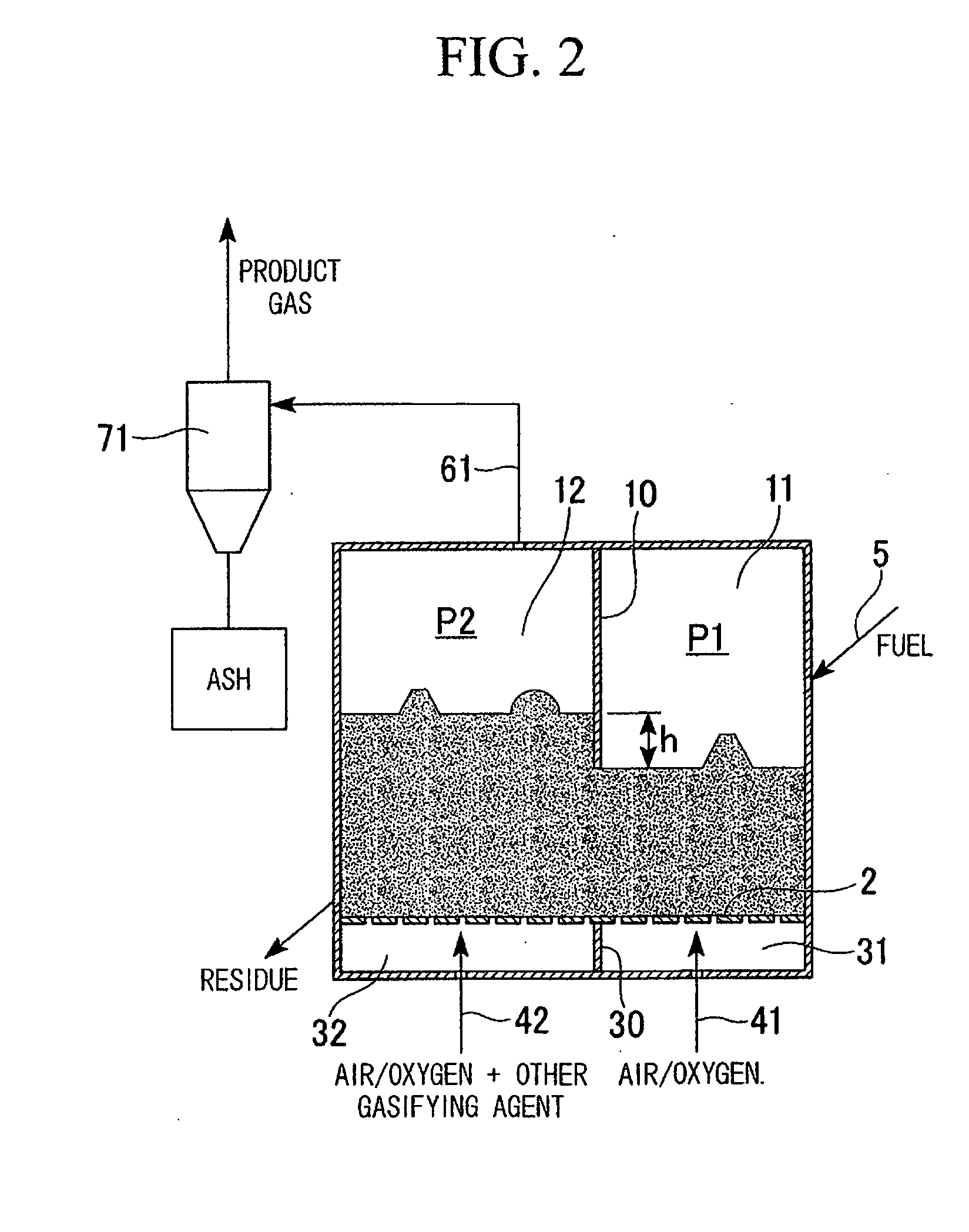

Decoupled fluidized bed gasifying method and gasifying apparatus of solid fuel

The invention relates to a solid fuel decoupled fluidized bed gasifying method and a gasifying apparatus. By physically separately performing drying and pyrolyzing of fuel, gasification of char, and tar / hydrocarbon reforming, the interactions between the separated chemical reactions and physical processes during fluidized bed gasification can be utilized. Specifically, in a fluidized bed reactor having two reaction chambers, drying and pyrolyzing of fuel, gasification of char, and tar / hydrocarbon reforming are performed, respectively, the reforming of tar / hydrocarbon is promoted through the catalytic effect of the char, and the evaporated fuel moisture is provided to the char gasification and tar / hydrocarbon reforming as an effective reaction agent. Accordingly, the tar content in product gas can be reduced, the use amount of external steam can be reduced, the overall efficiency of gasification can be improved, and this technique can also be applied to the processing of high water-containing fuel. This gasifying method not only can be applied to individual fluidized bed gasification, but can contribute to the design of a combustor that combusts unreacted char, and to advanced decoupled fluidized bed gasification.

Owner:IHI CORP

Engineered fuel feed stock

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including as gasification and combustion fuels.

Owner:CASELLA WASTE SYSTEMS +1

Engineered fuel feed stock

ActiveUS20110209396A1Less-harmful emissionEmission reductionProductsReagentsWaste streamProcess engineering

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including as gasification and combustion fuels.

Owner:CASELLA WASTE SYSTEMS +1

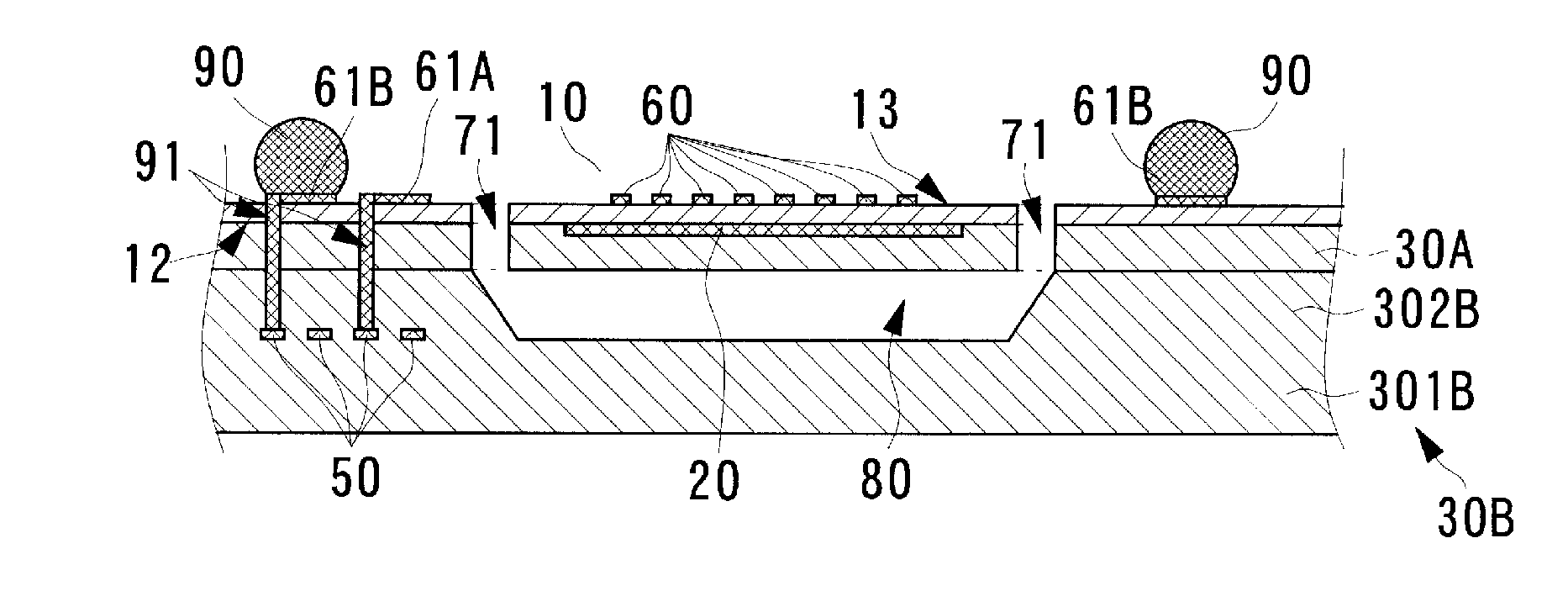

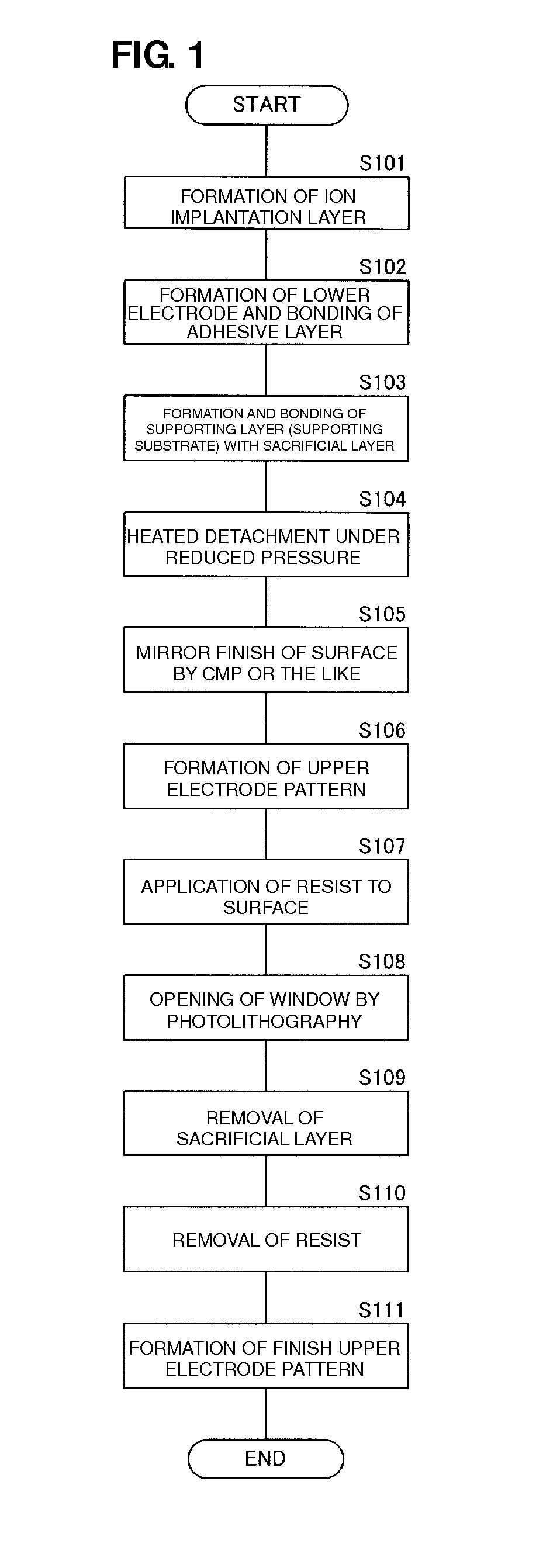

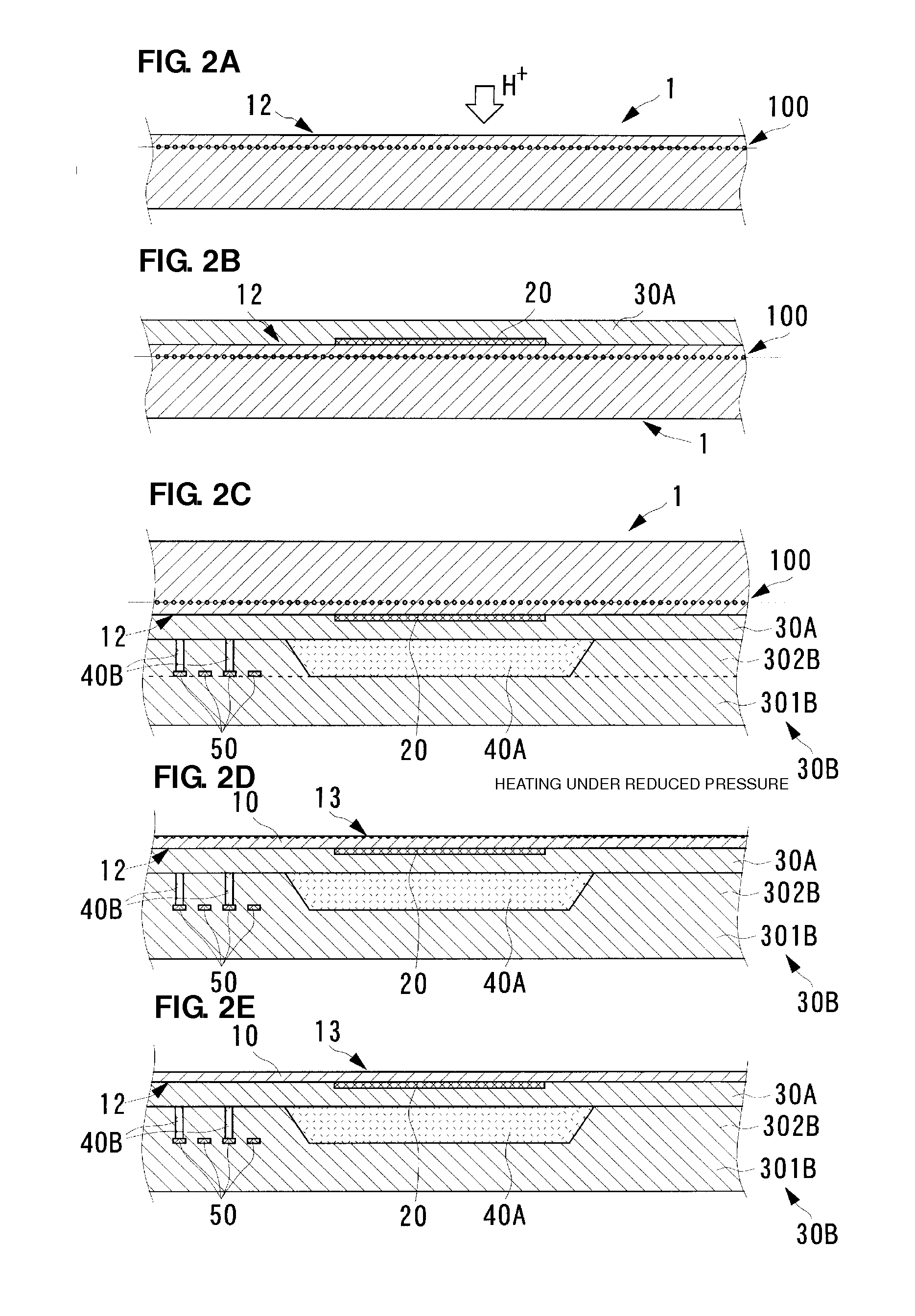

Method for manufacturing electronic device and method for manufacturing piezoelectric device

ActiveUS20100107388A1Promote gasificationReduced characteristicsPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksHydrogenMetallurgy

In a method for manufacturing an electronic device, an ion implantation layer is formed at a desired depth from one principal surface of a piezoelectric single crystal substrate by implanting hydrogen ions into the piezoelectric single crystal substrate under desired conditions. The piezoelectric single crystal substrate in which the ion implantation layer has been formed is bonded to a supporting substrate, and a piezoelectric thin film is then formed by the application of heat using the ion implantation layer as a detaching interface. This heated detachment is performed at a reduced pressure less than atmospheric pressure and at a heating temperature determined in accordance with the reduced pressure.

Owner:MURATA MFG CO LTD

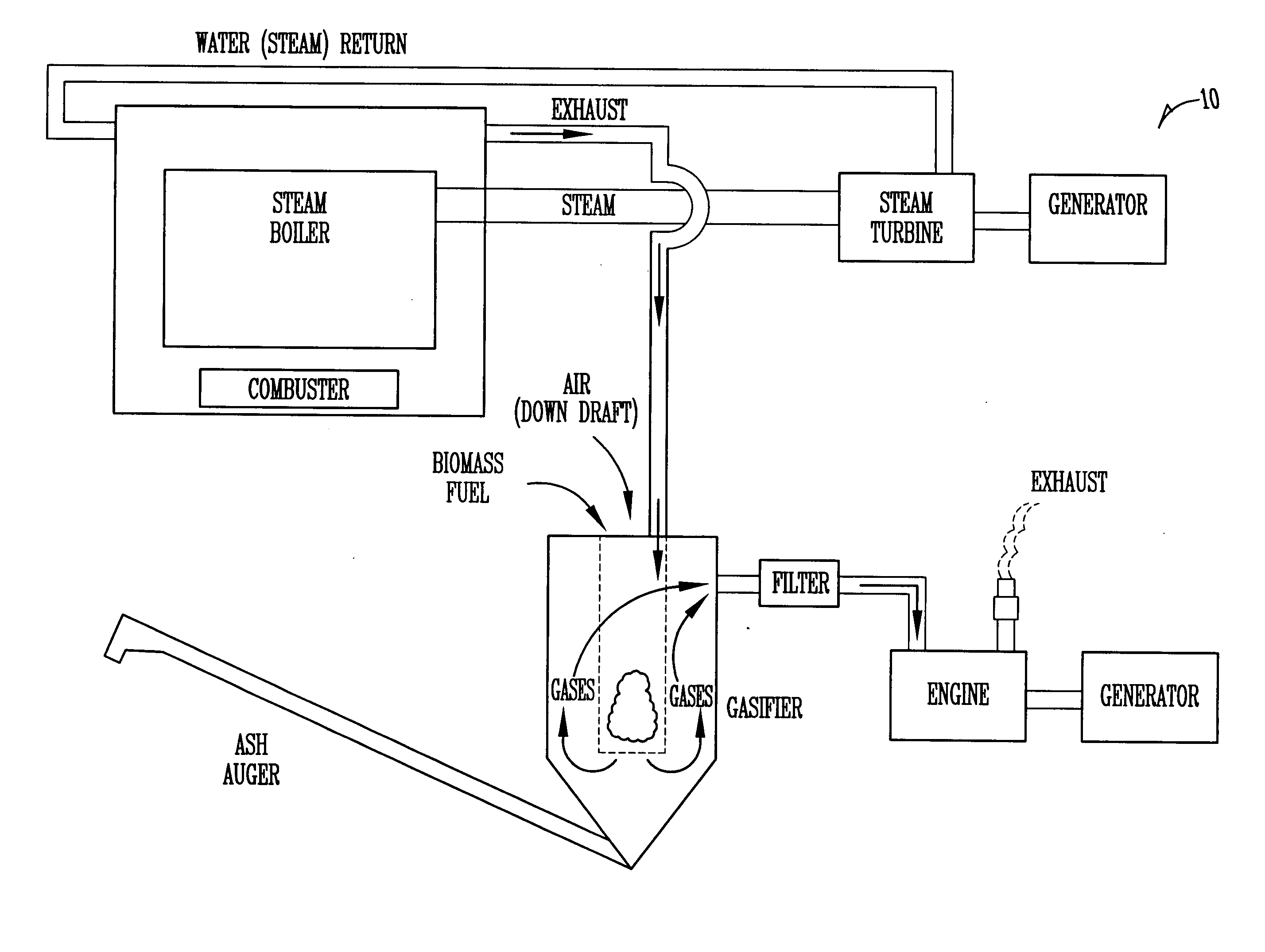

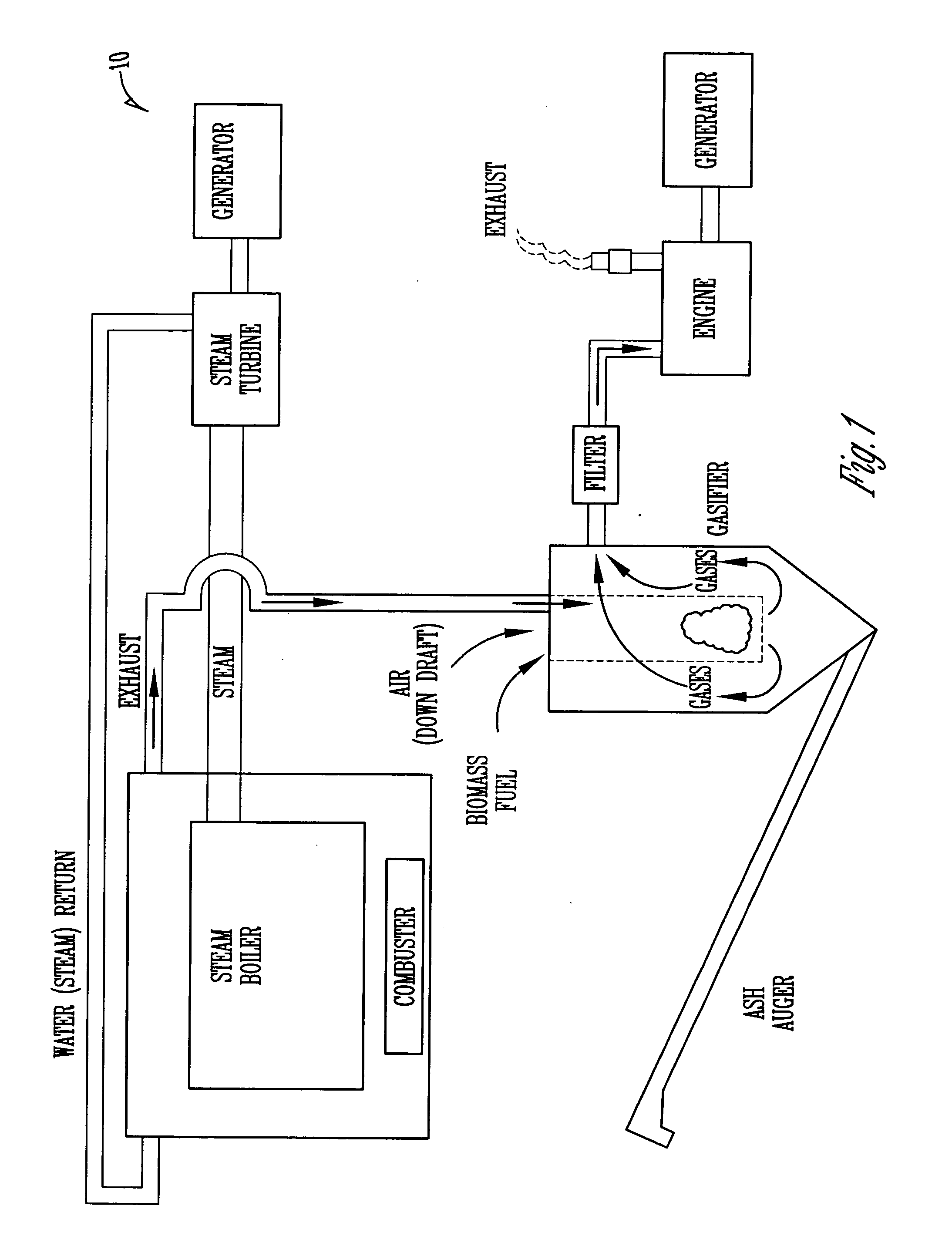

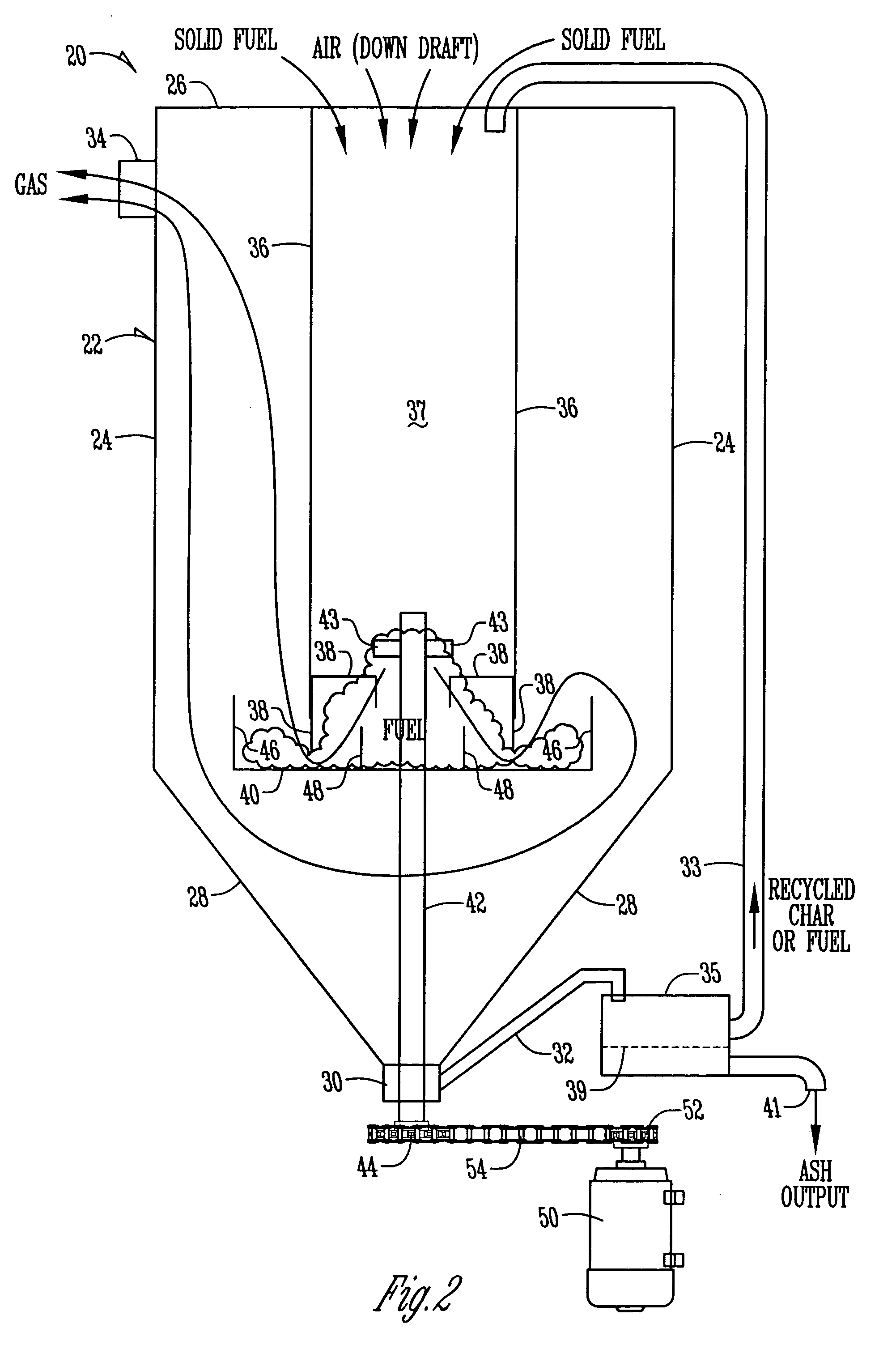

Rotating bed gasifier

InactiveUS20070169411A1Size limitImprove efficiencyGasifier mechanical detailsGasification processes detailsEngineeringMechanical engineering

The present invention includes a gasifier for gasifying fuels having a container with a top, sidewalls and a bottom for facilitating the gasifying process. One or more open vertical shafts extend downward inside the container for allowing a downdraft or updraft of air and fuel for the gasifying process. A rotating bed is preferably included inside the container and below the one or more shafts for receiving the fuel. The bed rotates essentially perpendicular to the shaft to facilitate even heating and gasifying of the fuel.

Owner:THIESSEN RANDALL J +1

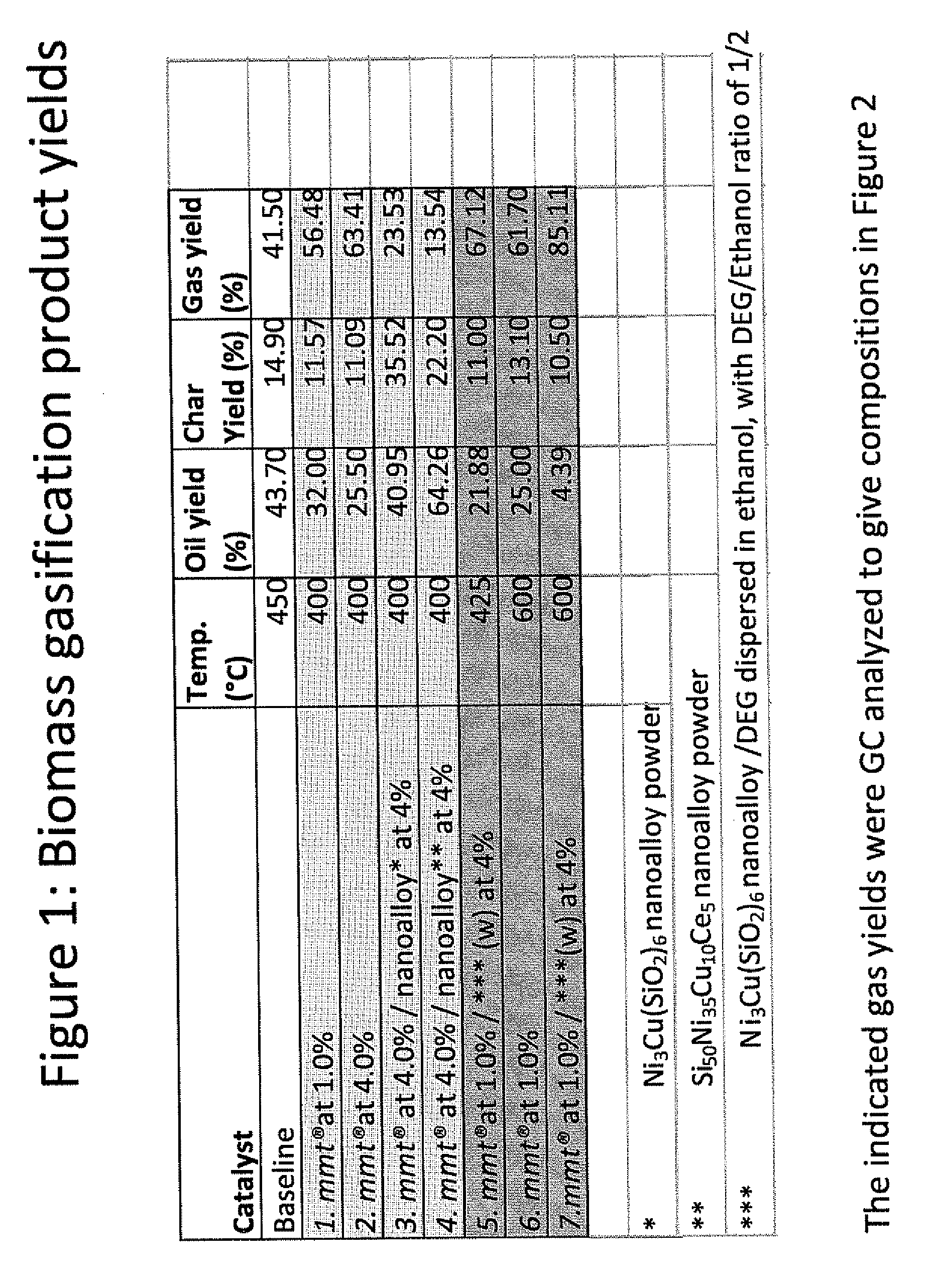

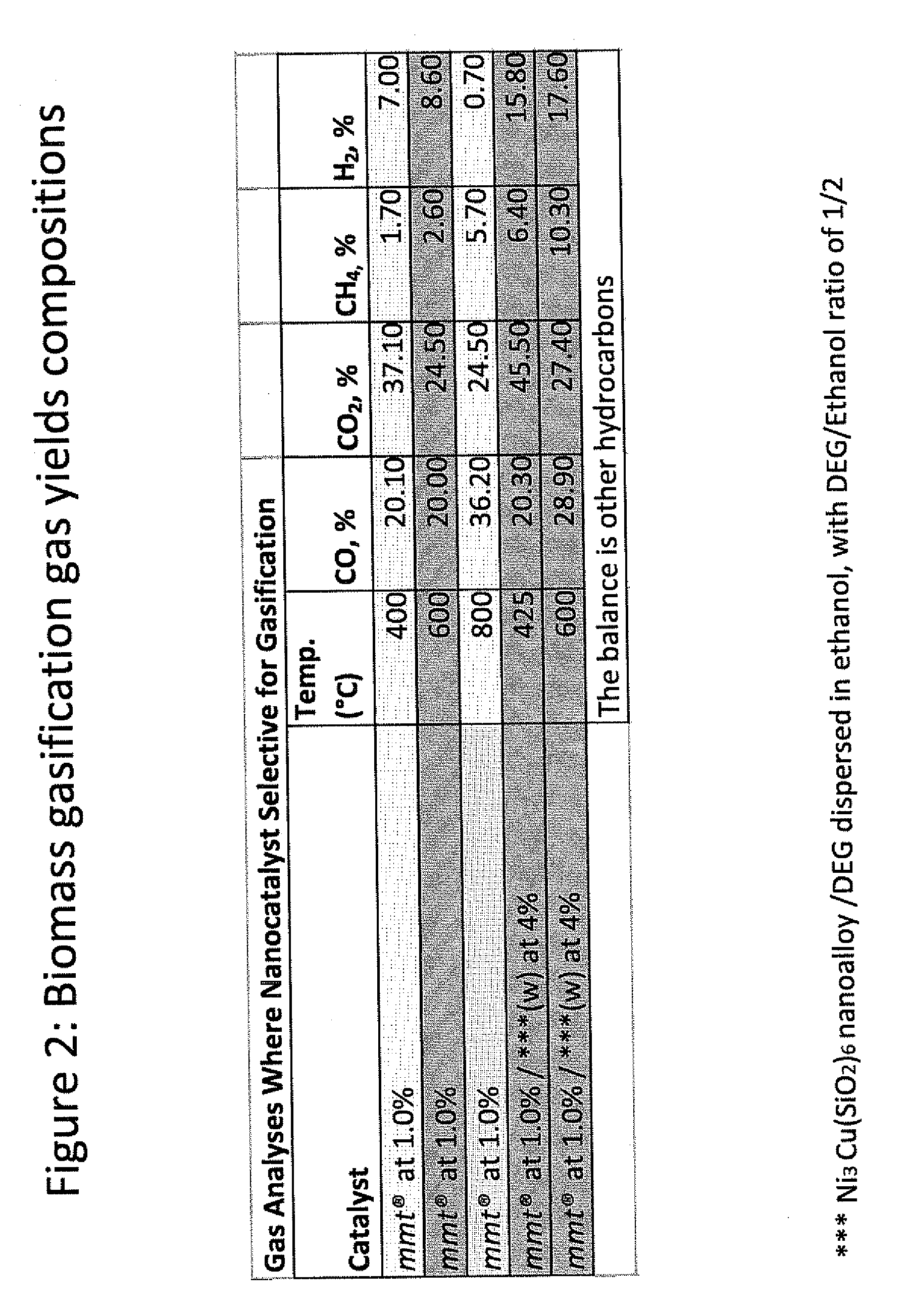

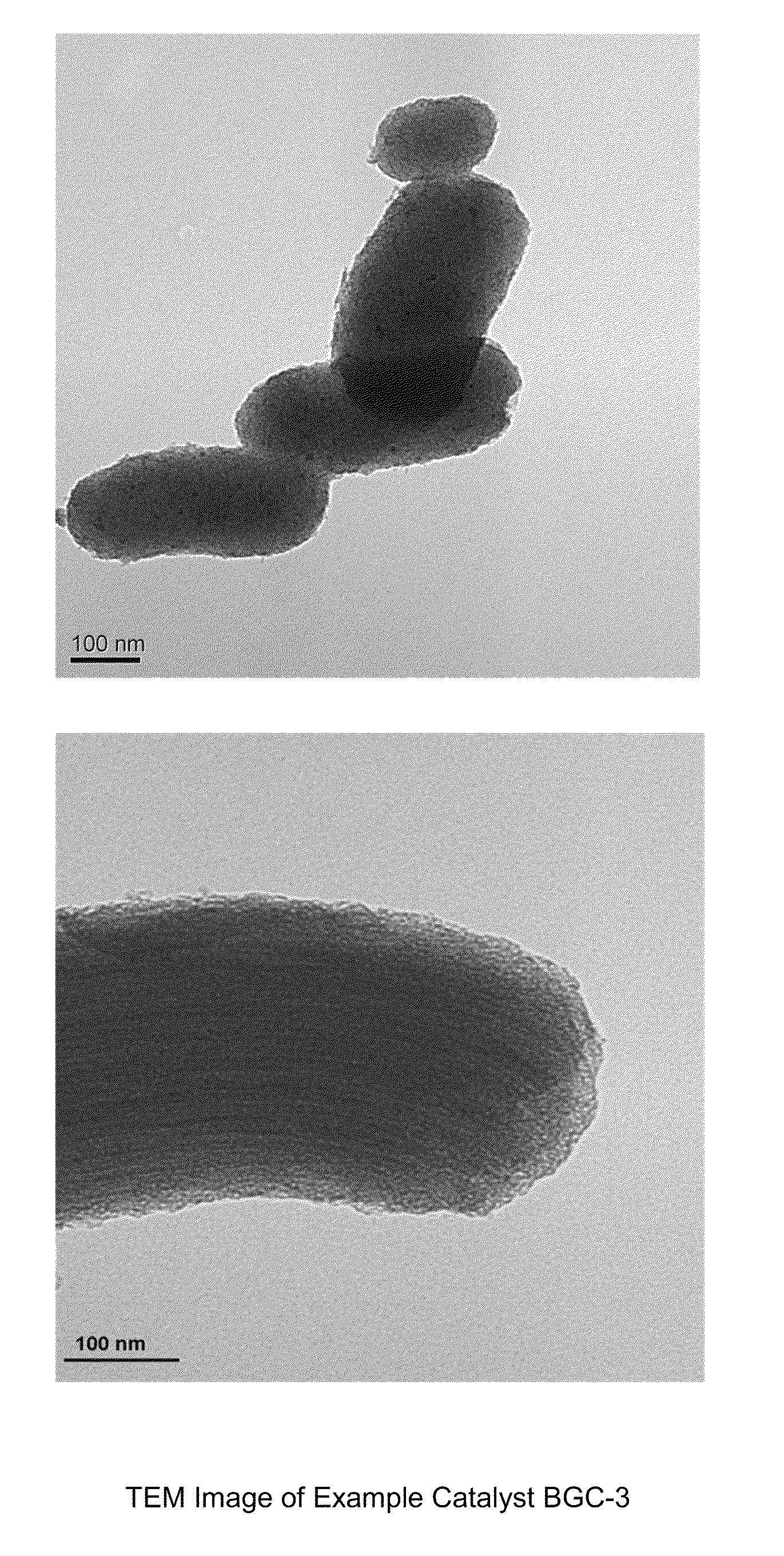

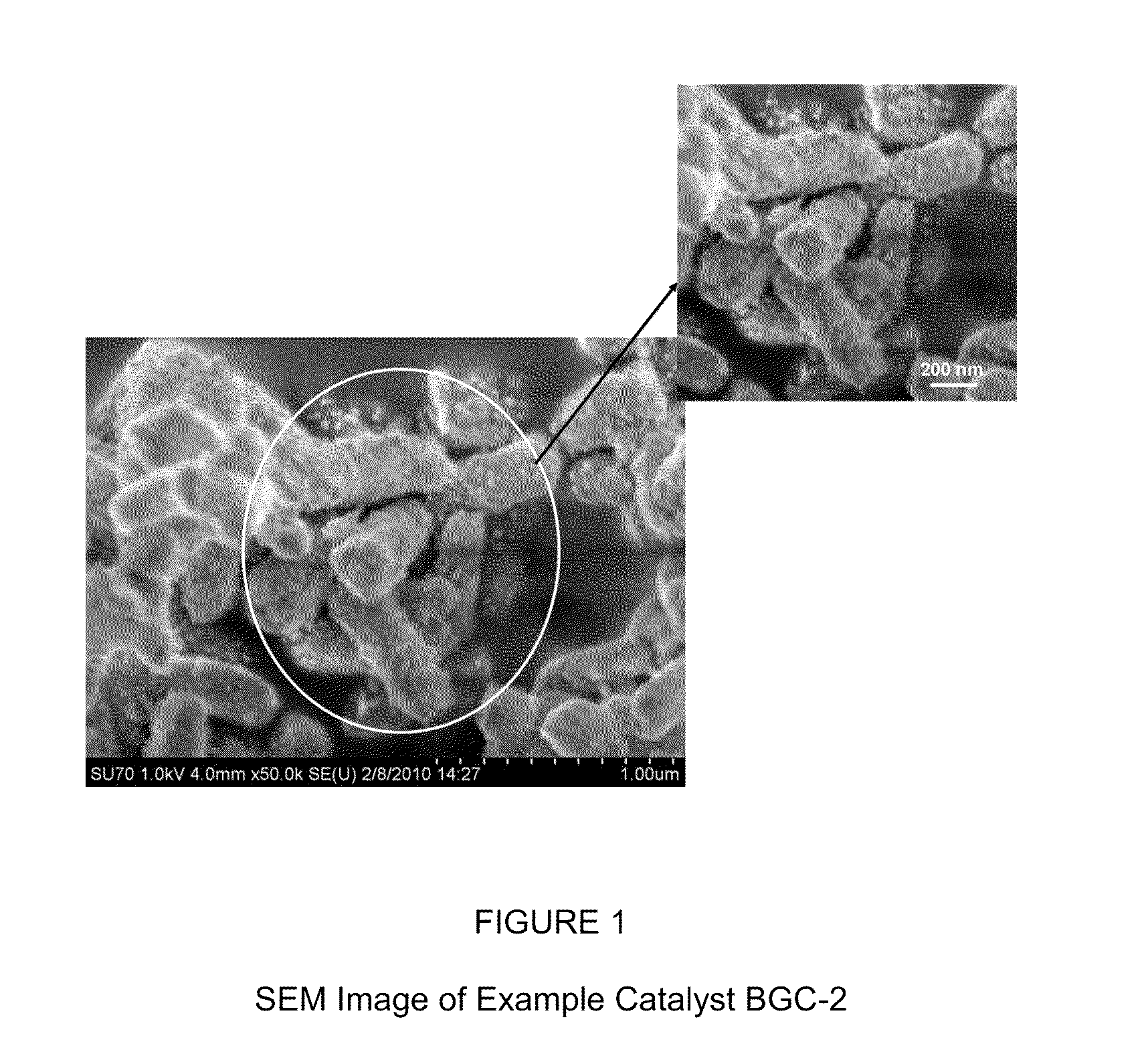

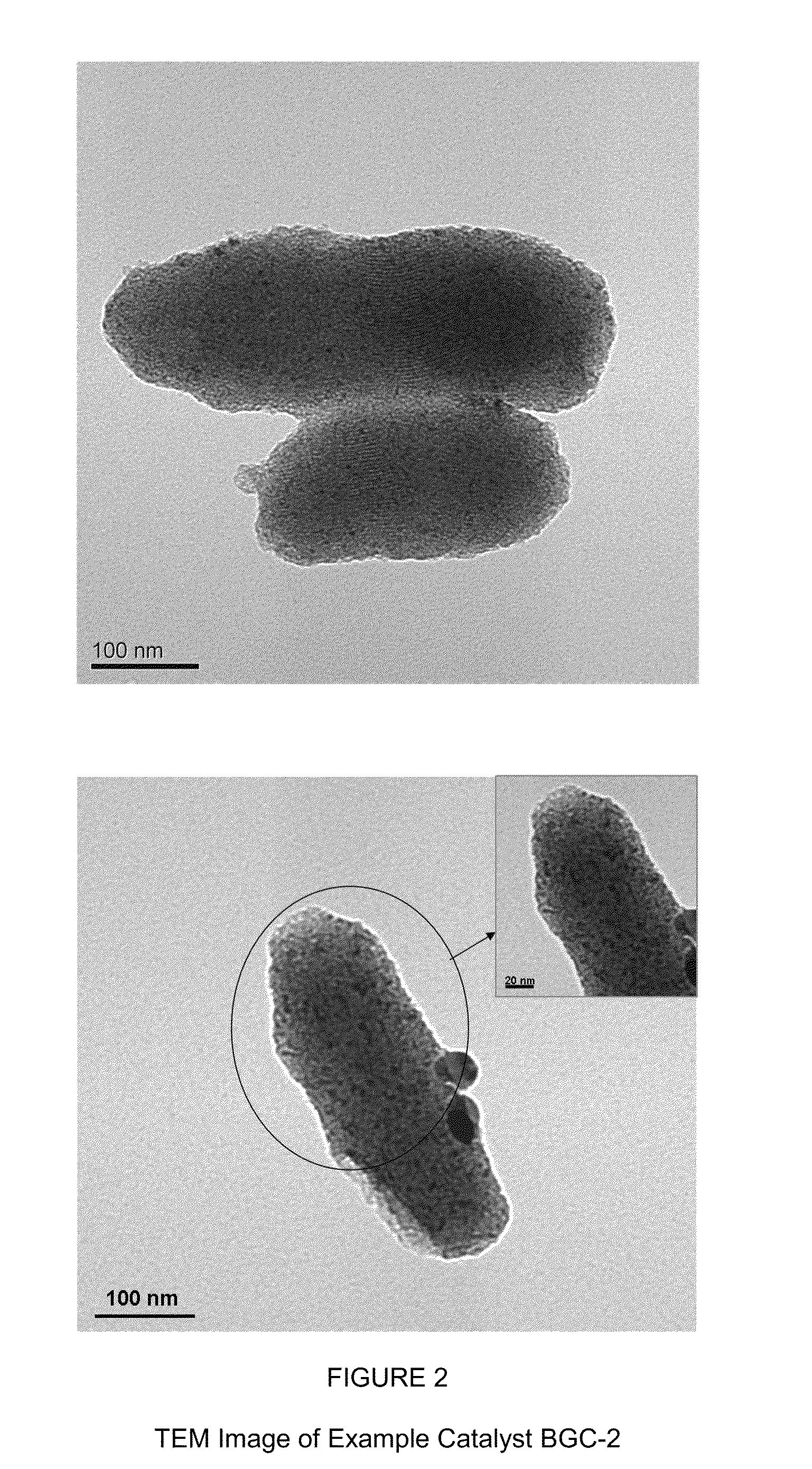

Nanoparticle Catalyst Compounds and/or Volatile Organometallic Compounds and Method of Using the Same for Biomass Gasification

InactiveUS20100299990A1Improve gasificationHigh gas yieldBiofuelsWaste based fuelNano catalystOil production

A nanocatalyst, dual catalyst and methods for improving the efficiency and output of a biomass gasification process are provided where the catalysts comprise a volatile organometallic compound(s) and / or a nanoalloy catalyst. By the catalyst and method, a very high biomass gasification conversion efficiency of over 85% can be achieved. The subject nanocatalyst cracks and gasifies lignin, which is generally inert in conventional gasification, at relatively low gasification temperatures. The subject disclosure also provides a means to increase gas yields and lower lignin content in the resulting product relative to conventional gasification. Alternatively, oil production may be increased, if desired. Moreover, the resulting gas may achieve a Fischer-Tropsch reactor favorable H2:CO ratio of about 9:1. The energy input to the gasification is correspondingly reduced to reduce costs and the environmental impact associated with the gasification process.

Owner:AFTON CHEMICAL

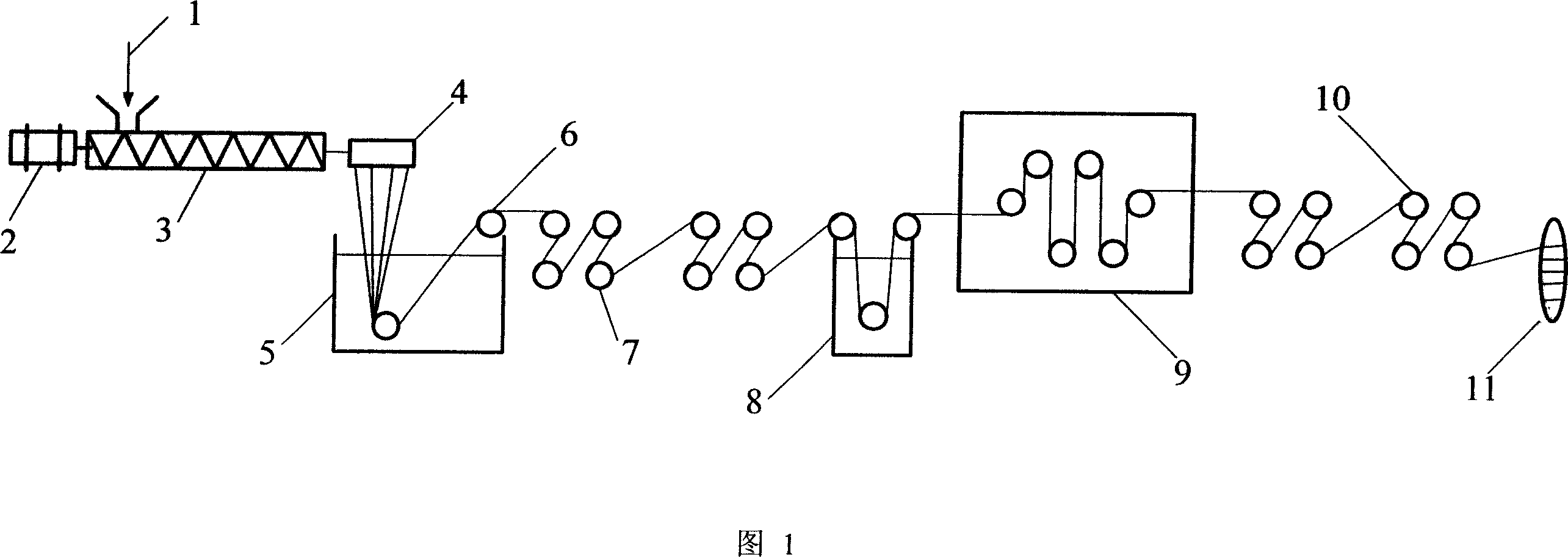

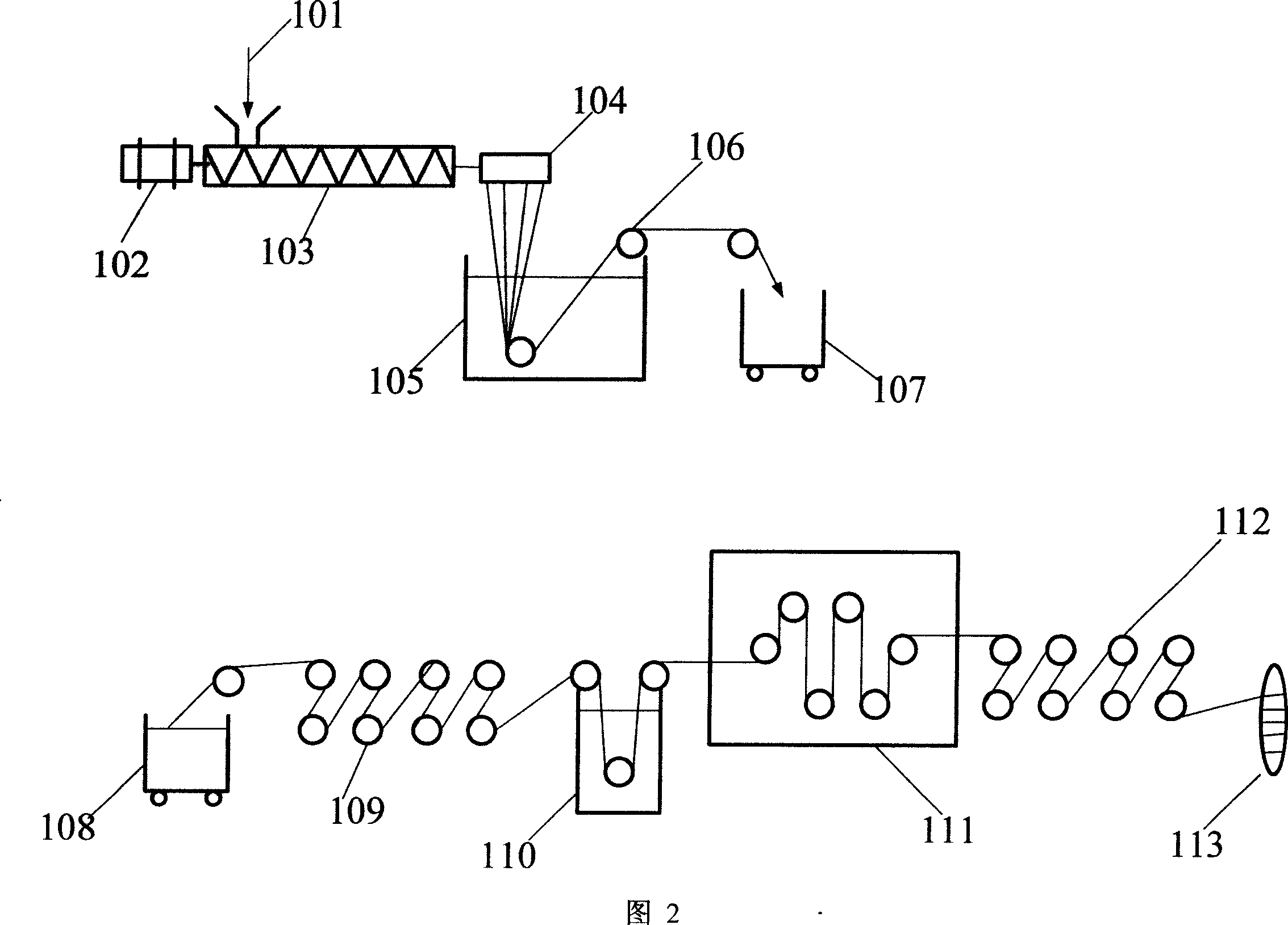

Extraction and desiccation method in preparing process of polyvinyl fibre with super high molecular weight

ActiveCN101012577AReduce oil contentHigh strengthArtificial filament washing/dryingMonocomponent polyolefin artificial filamentFiberPolymer science

The invention relates to extracting and drying methods in the process for preparing uhmwpe fiber, belonging to the field for polymers preparing technology. The method comprises that the uhmwpe powder, assistant and solvent is solidified by extruding after they are mixed in uniformity and solved sufficiently; the solvent is eliminated in extracting process and the extraction agent is eliminated by drying technology; the final product is formed by heat drawing. It is characterized in that because dichloromethane is used as the extraction agent, there is good safety, low boiling point and it is eliminated easily. Because countercurrent extraction operation is adopted in the extracting process and there is no ultrasonic wave, it is provided with low drying temperature, simple technology, high intensity of fiber product, high modulus and low oil percentage of fiber.

Owner:安徽威亚新材料技术有限公司

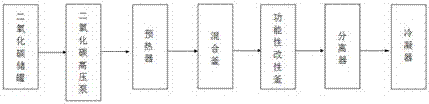

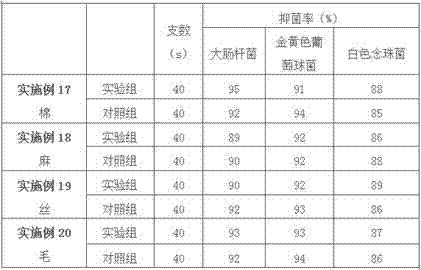

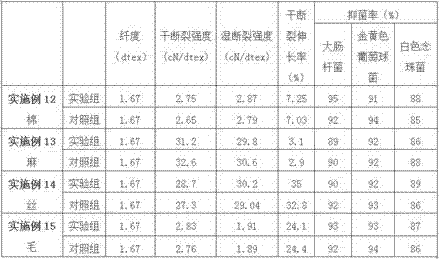

Natural fiber product modified by adopting supercritical carbon dioxide technology and modification method

The invention provides a natural fiber product modified by adopting a supercritical carbon dioxide technology. The modified natural fiber product is a cotton, hemp, silk or wool natural fiber or a yarn, fabric or clothing prepared from the natural fiber. The invention further provides a method for modifying the natural fiber product by adopting the supercritical carbon dioxide technology. The method comprises the step of adding the natural fiber and a vegetable dye and a natural plant extract; the natural fiber is modified by innovatively adopting the supercritical carbon dioxide technology; water or other reagent is not utilized as a solvent, no wastewater or waste is generated or discharged, and the method has the characteristics of ecological environment protection and wide adaptability of fabric varieties and belongs to an environment-friendly functional modification technology. The natural fiber which is functionally modified by adopting the supercritical carbon dioxide technology is uniform in color and luster, extremely good in reproducibility and free of an injury to the natural fiber.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Nanoparticle catalysts and method of using the same for biomass gasification

InactiveUS20110315931A1Accelerated pyrolysisImprove gasificationMaterial nanotechnologyBiofuelsEnvironmental effectNanoparticle

A nanoalloy catalyst, dual catalyst and methods for improving the efficiency and output of a biomass gasification process are provided where the catalysts comprise a volatile organometallic compound(s) and / or a nanoalloy catalyst. The subject nanoalloy catalyst cracks and gasifies lignin, which is generally inert in conventional gasification, at relatively low gasification temperatures. The subject disclosure also provides a means to increase gas yields and lower lignin content in the resulting product relative to conventional gasification. Alternatively, oil production may be increased, if desired. Moreover, the resulting gas may achieve a Fischer-Tropsch reactor favorable H2:CO ratio of up to about 9:1. The energy input to the gasification is correspondingly reduced to reduce costs and the environmental impact associated with the gasification process.

Owner:AFTON CHEMICAL

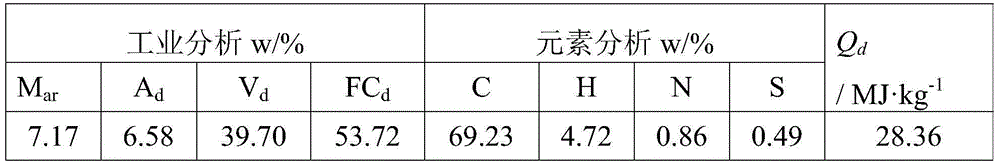

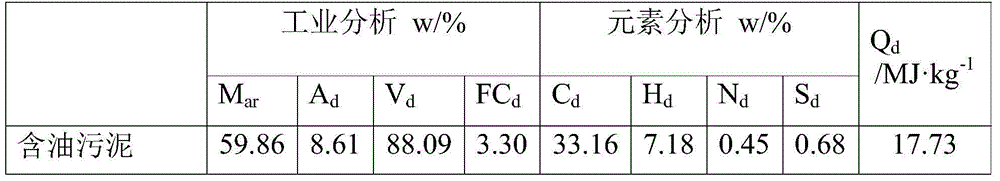

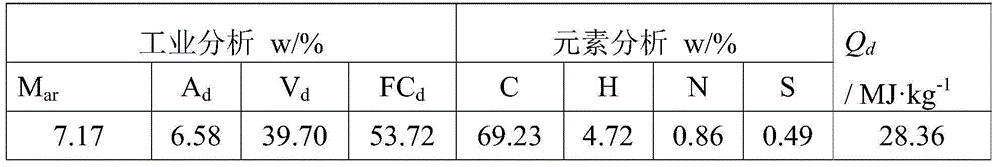

Oil-containing sludge coal slurry and preparation method thereof

ActiveCN103980968AHigh slurry concentrationTake advantage ofLiquid carbonaceous fuelsCombustionSludge

The invention discloses oil-containing sludge coal slurry and a preparation method thereof. The oil-containing sludge coal slurry comprises the following components in percentage by mass: 57-62% of coal powder, 3-14.3% of oil-containing sludge, 0.2-0.7% of a dispersing agent and water, totaling 100%. The method comprises the following steps: uniformly mixing the oil-containing sludge and the coal powder to obtain a mixture A; and uniformly mixing the mixture A, the water and the dispersing agent to obtain the oil-containing sludge coal slurry. The oil-containing sludge coal slurry disclosed by the invention is easily available in raw material, good in fluidity, high in slurry concentration, and quite high in conversion rate when being applied to combustion and gasification.

Owner:EAST CHINA UNIV OF SCI & TECH +1

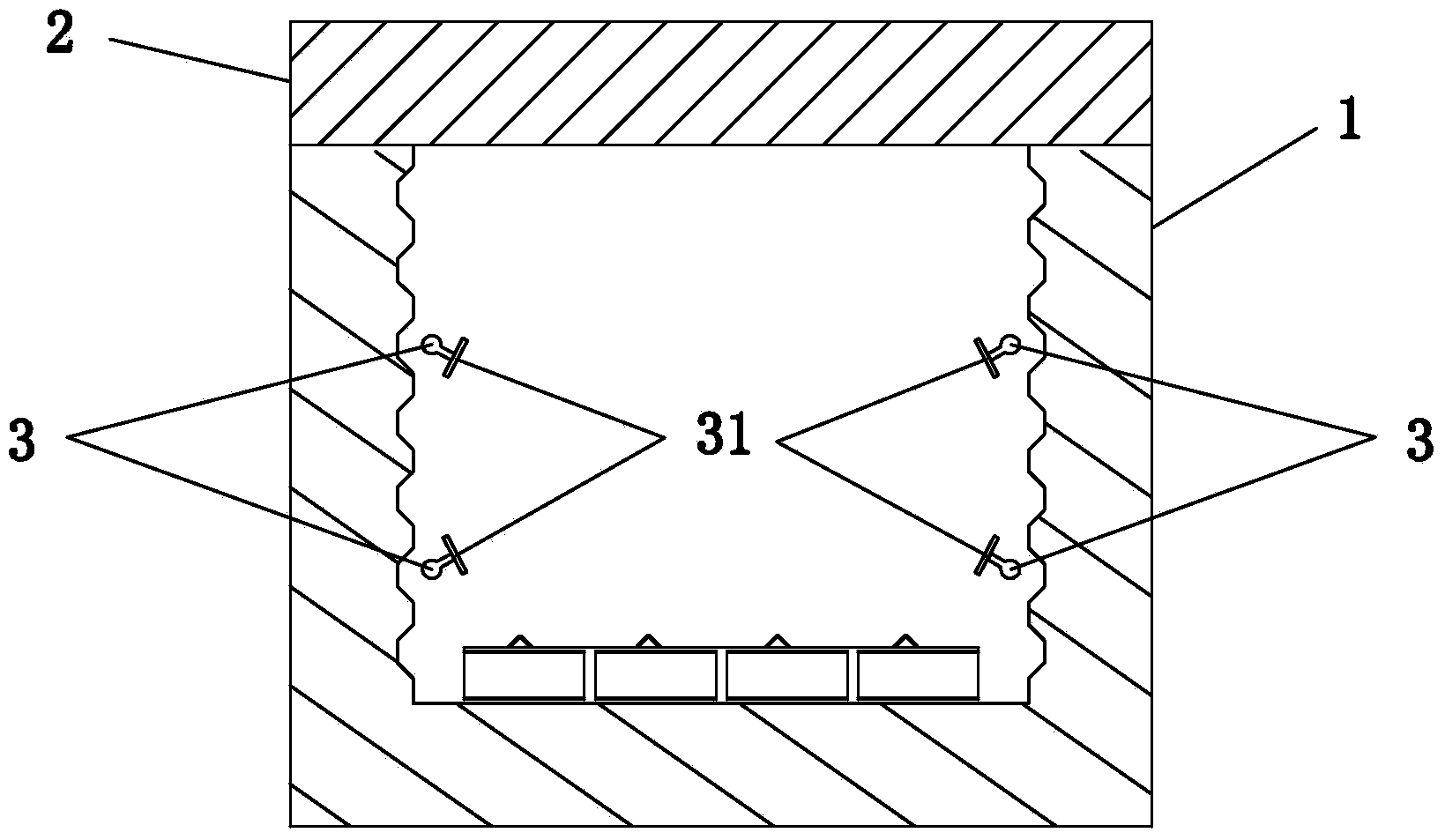

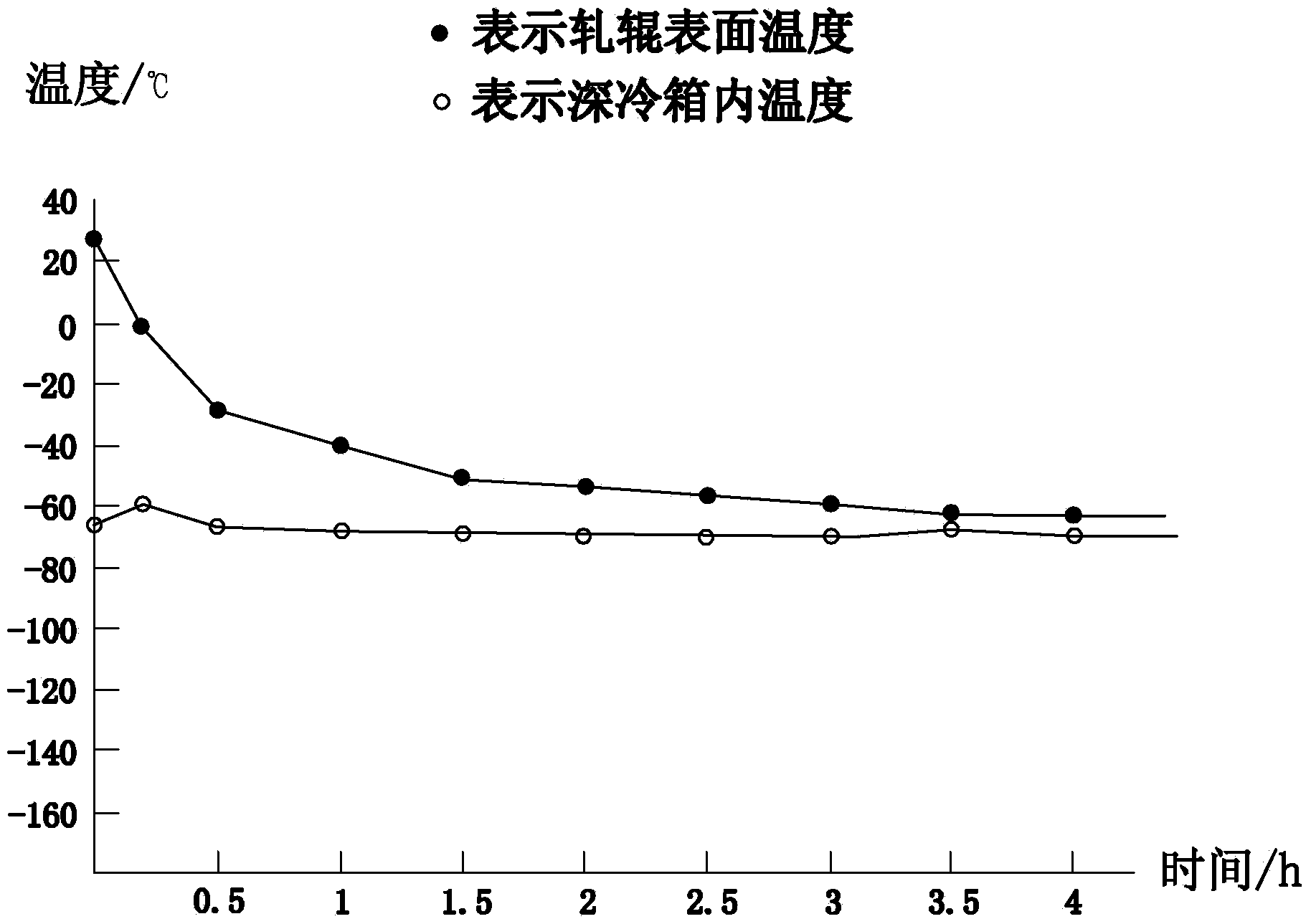

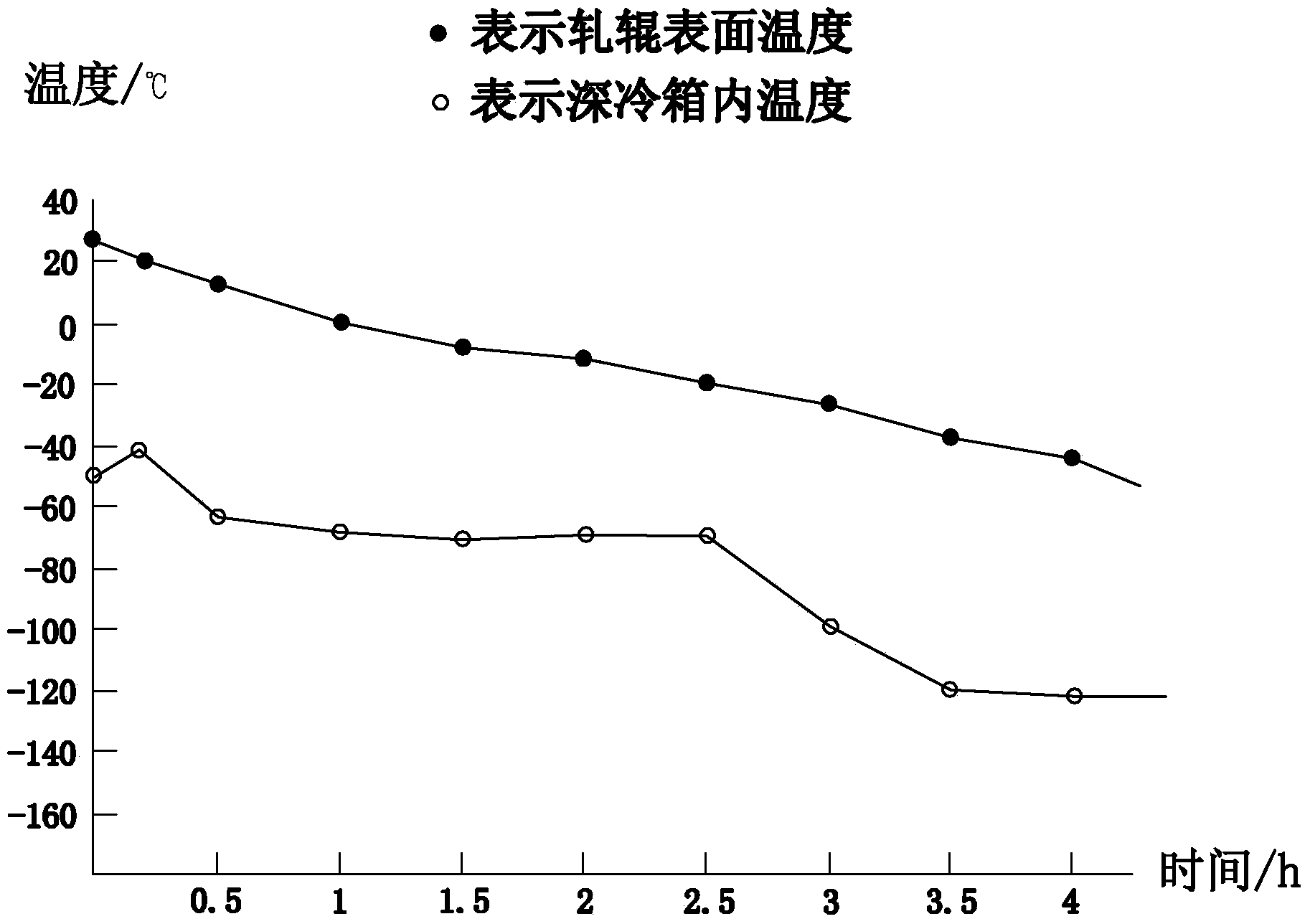

Subzero treatment method for large-diameter cold rolling work roller and copious cooling box thereof

ActiveCN103468918AReduce the temperatureImprove work efficiencyFurnace typesHeat treatment furnacesEngineeringElectromagnetic valve

The invention discloses a subzero treatment method for a large-diameter cold rolling work roller and a copious cooling box thereof. The copious cooling box comprises a box body with an insulating layer, an insulating box cover and liquid nitrogen spray pipes arranged in the box body. Two liquid nitrogen spray pipes are respectively arranged on the upper side and the lower side, nozzles of the two liquid nitrogen spray pipes on the upper side are inclined downwards, nozzles of the liquid nitrogen spray pipes on the lower side are inclined upwards, and net covers are arranged at the nozzles of the liquid nitrogen spray pipes. The subzero treatment method comprises the steps of enabling the temperature in the copious cooling box to fall to -80 DEG C to -120 DEG C and insulating for 1h-3h, then arranging the large-diameter cold rolling work roller in the copious cooling box, and controlling ultralow temperature electromagnetic valves on pipelines between the liquid nitrogen spray pipes and a liquid nitrogen storage tank to enable liquid nitrogen to be sprayed out of liquid nitrogen spray pipes to cool the large-diameter cold rolling work roller. The subzero treatment method achieves low temperature cooling, enables the low temperature limitation to be about -180 DEG C, can quickly reduce the surface temperature of the roller and improves cooling efficiency.

Owner:BAOSTEEL ROLL SCI & TECH

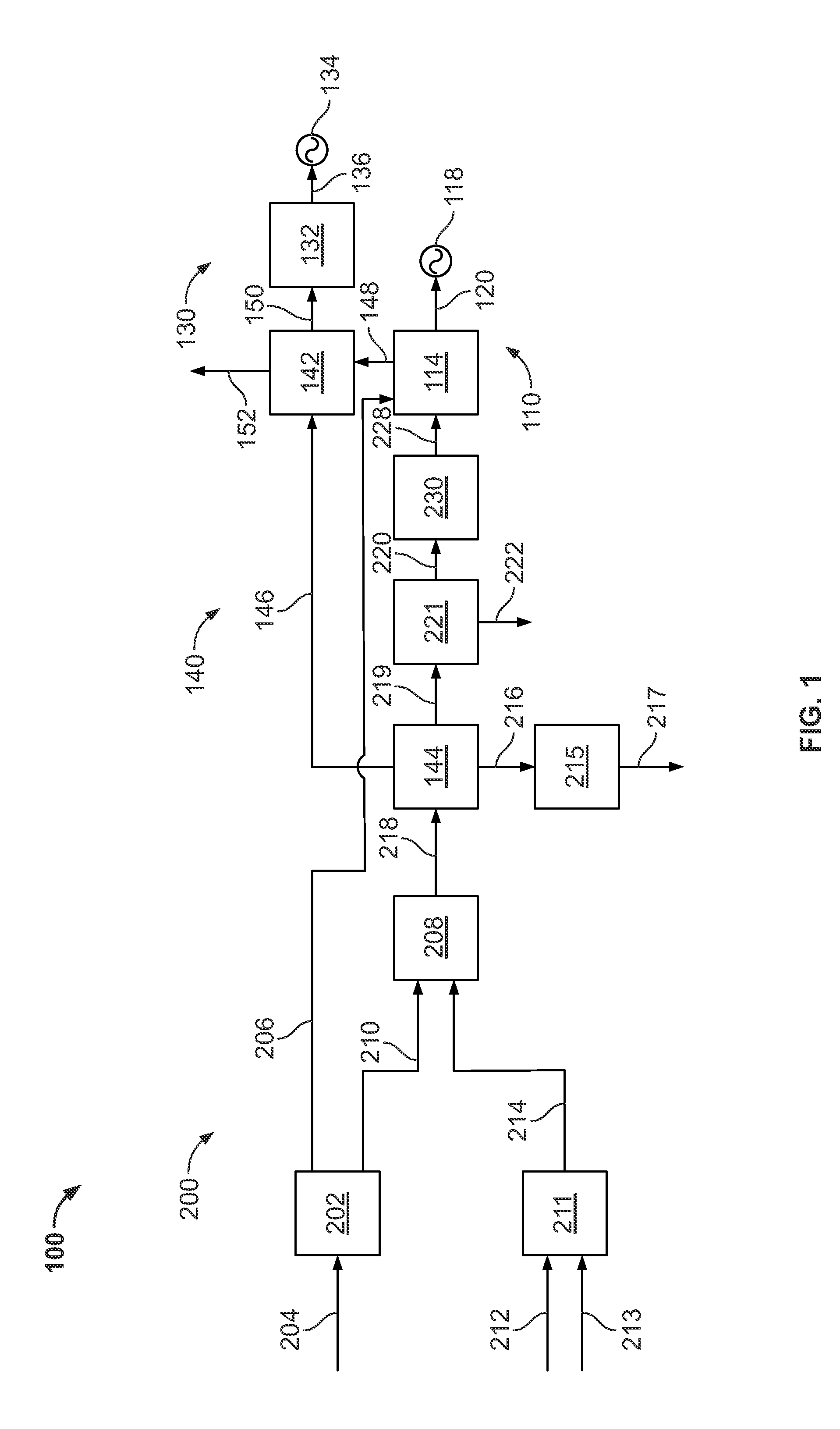

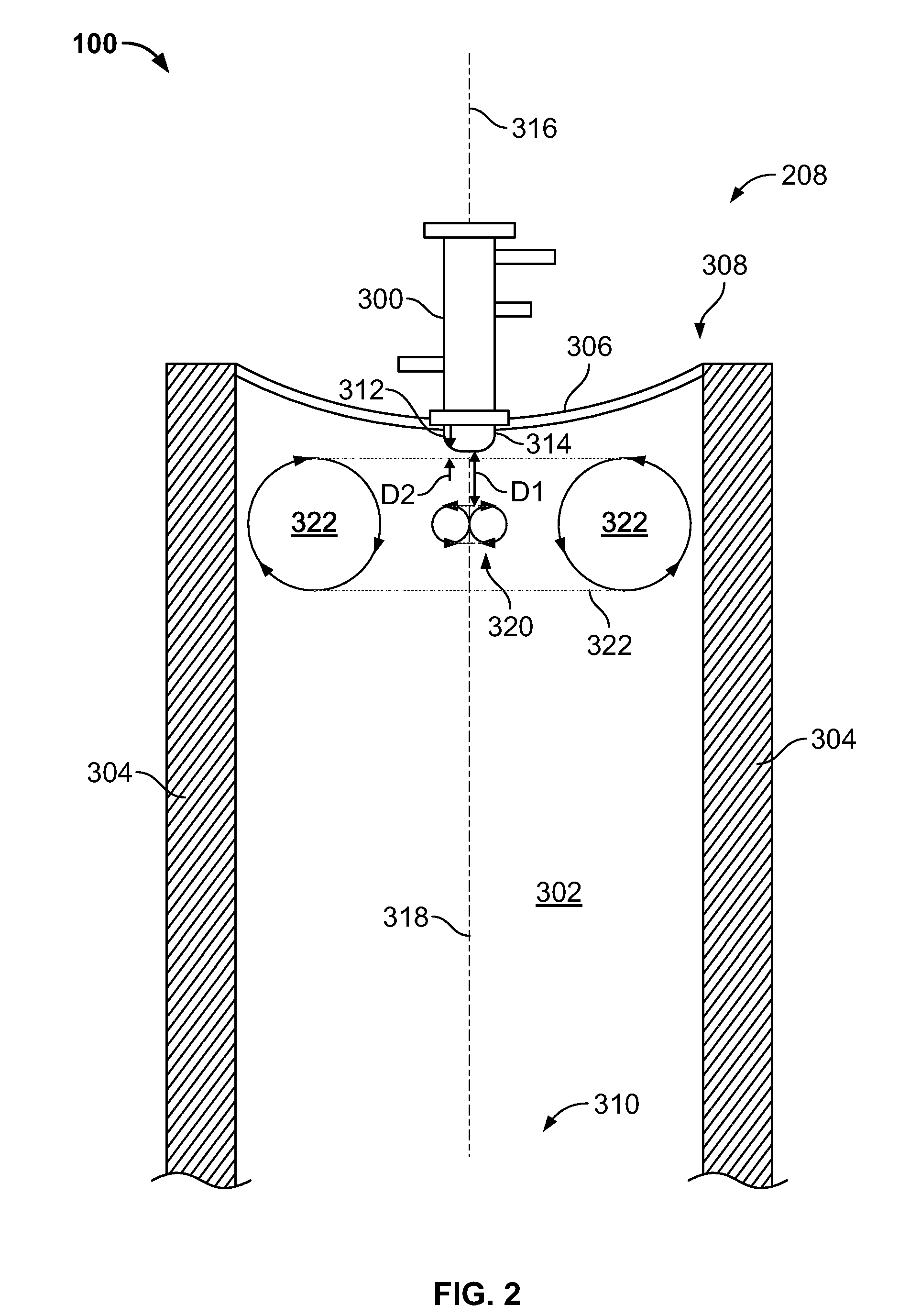

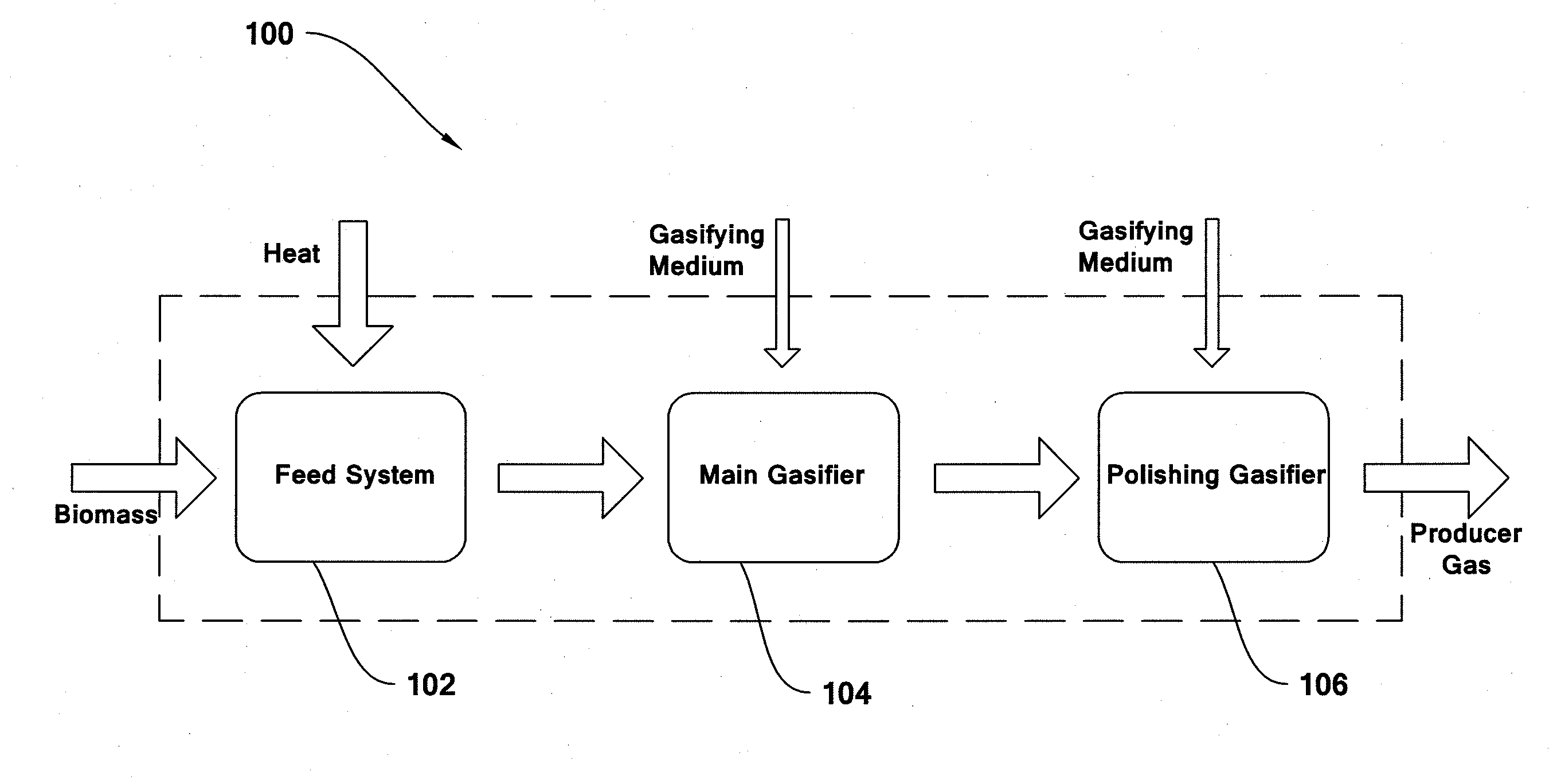

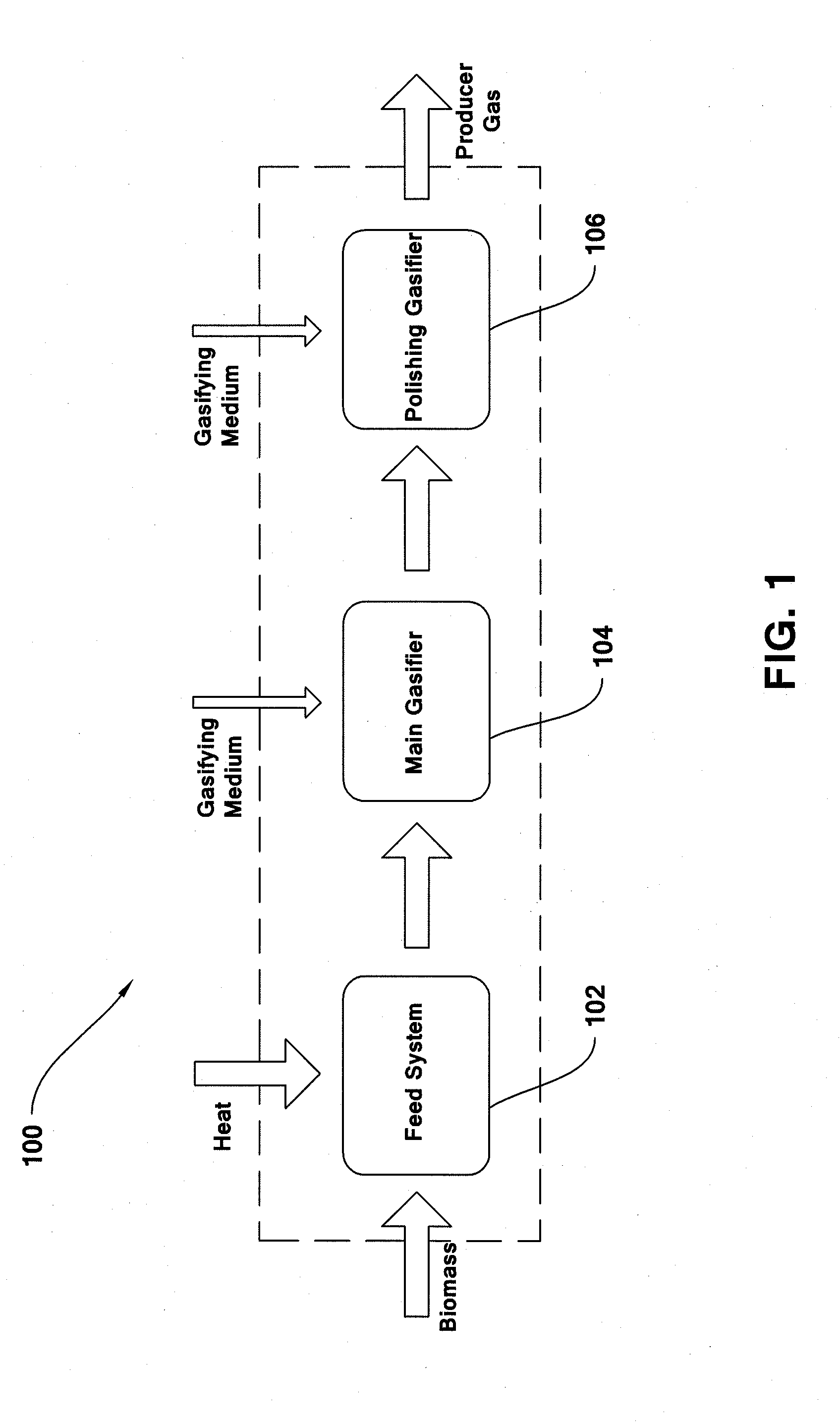

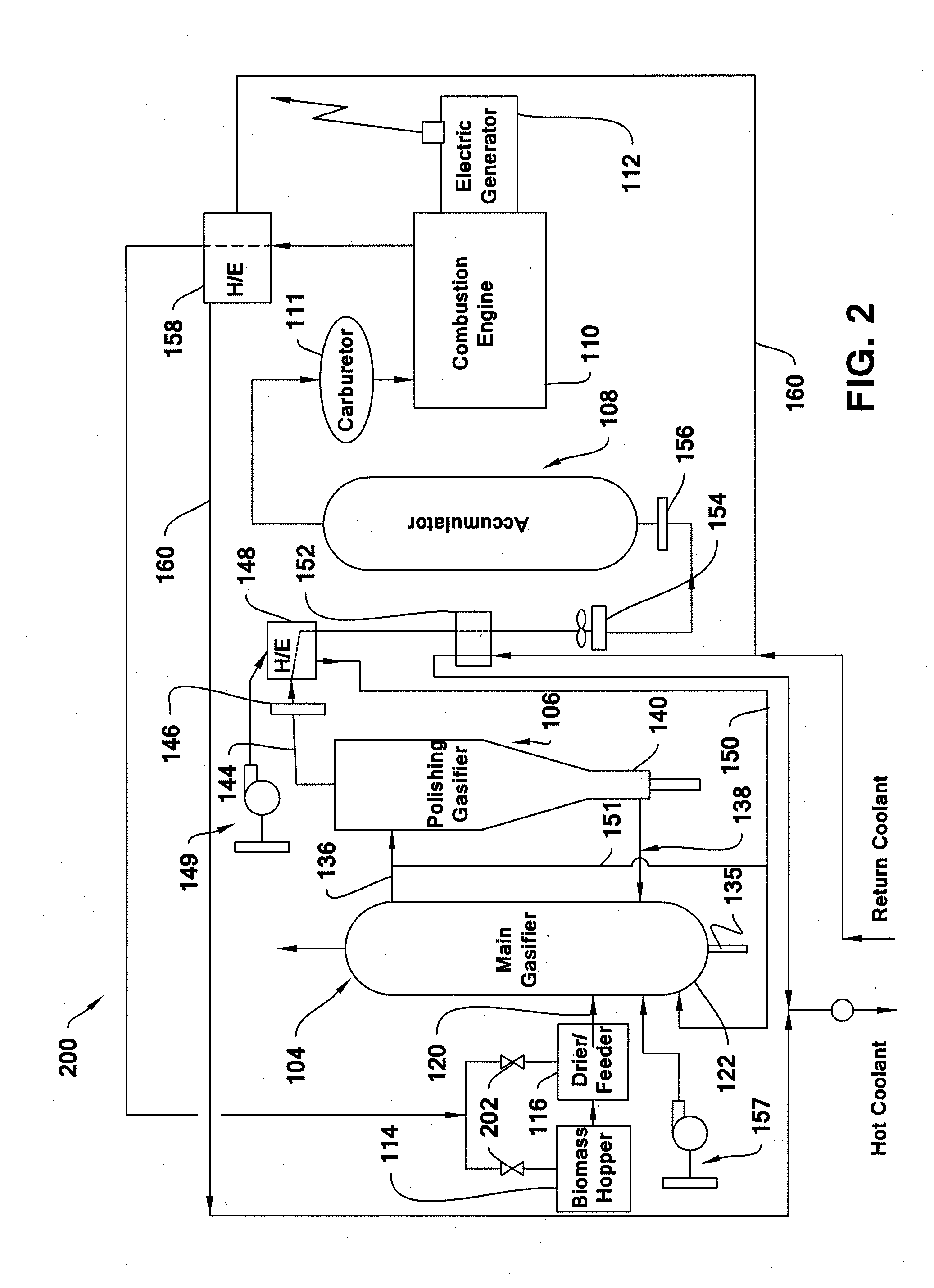

System and process for gasifying biomass products

A system for gasifying biomass materials is provided. The system includes a gasifying unit for converting the biomass materials into a gas and a feeder mechanism for introducing the biomass materials into the gasifying unit. The gasifying unit includes a plurality of gasifying medium and biomass injection ports distributed along a vertical length of the gasifying unit, and each of the plurality of injection ports has a corresponding injection angle. The injection angles include at least one of an upward tangential angle and a downward tangential angle.

Owner:STARLIGHT ENERGY HLDG

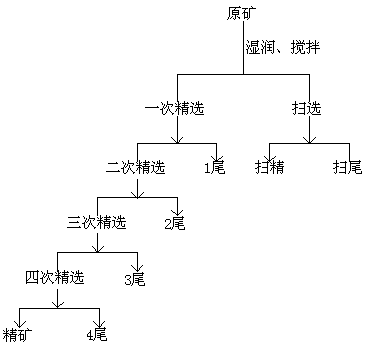

A process for preparing high-purity microcrystalline graphite with low energy consumption and in a large scale, and the high-purity microcrystalline graphite

InactiveCN107555426ALarge specific surface areaHigh purityCarbon compoundsPurification methodsGraphite

The invention relates to the technical field of microcrystalline graphite purification, and discloses a process for preparing high-purity microcrystalline graphite with low energy consumption and in alarge scale, and the high-purity microcrystalline graphite. According to the process, microcrystalline graphite raw ore is firstly crushed and ground, and flotation including one time of roughing, four times of cleaning and one time of scavenging is performed in match to increase the purity of the raw ore to the utmost through a physical method; an improved acid leaching purification method is adopted, the alkali leaching efficiency is increased, energy consumption is reduced, and the graphite recovery yield is increased; and finally a high-temperature purification method adopting a step-by-step heating manner is utilized to further reduce energy consumption for graphite purification, and the high-purity microcrystalline graphite the fixed carbon content of which is 99.993% or above can be finally obtained. The process overcomes a problem that microcrystalline graphite in the prior art is not high in purity, high in energy consumption and high in cost. Through improvements on the prior art, the process achieves an objective of reducing energy consumption and the cost, and achieves industrial production.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com