Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

853 results about "Fixed carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fixed carbon is the solid combustible residue that remains after a coal particle is heated and the volatile matter is expelled. The fixed-carbon content of a coal is determined by subtracting the percentages of moisture, volatile matter, and ash from a sample. Since gas-solid combustion….

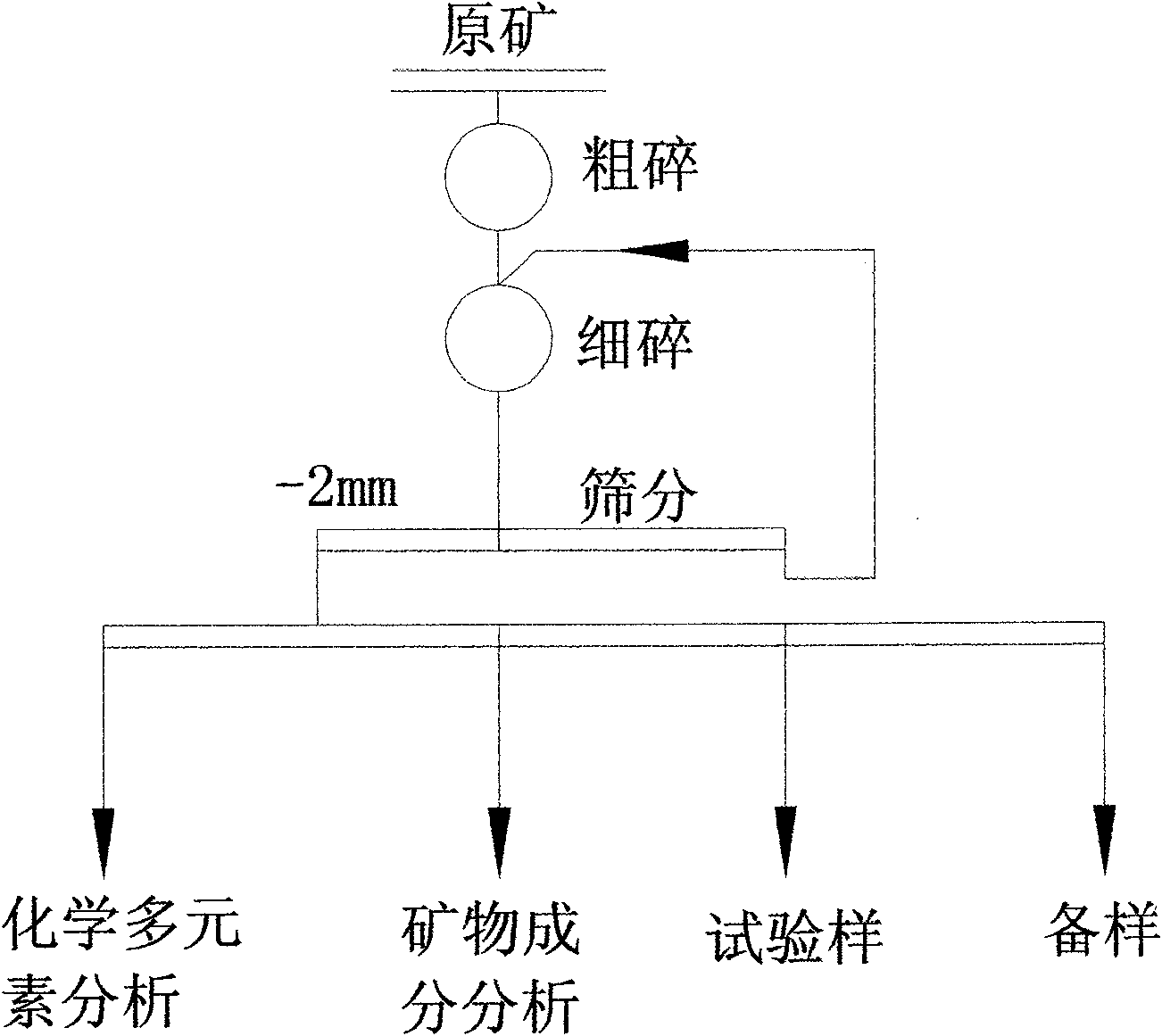

Method for purifying high-purity graphite

The invention discloses a method for purifying high-purity graphite, which aims to effectively remove impurities from the graphite and make 99.99 percent the fixed carbon content of the graphite. The method comprises the following steps of: performing the steps of crushing, ball-milling, sieving and the like on raw graphite ore and performing ore-dressing on the treated graphite ore by adopting floatation equipment or gravity dressing equipment to obtain graphite concentrate; performing alkali leaching on the graphite concentrate in a pressurized reaction kettle and then performing normal-pressure acid leaching in an ultrasonic wave field or a microwave field; and leaching treated graphite powder by using a hydrofluoric acid or fluoride salt-containing sodium fluoride to obtain the high-purity graphite product.

Owner:KUNMING METALLURGY INST

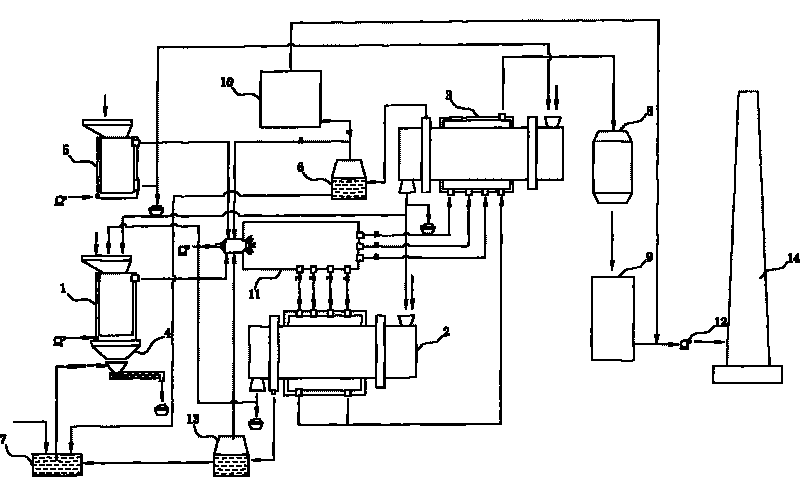

Sludge or organic garbage high-low temperature coupling themolysis method

InactiveCN101708938AFlexible to adapt to changes in natureSimple processSludge treatment by pyrolysisBiofuelsSludgeCarbonization

The invention provides a sludge or organic garbage high-low temperature coupling themolysis method which is characterized in that: the method comprises the following steps: step I: the sludge or organic garbage is fed in a low temperature drying depolymerizing furnace; material with partial carbonization is used as raw material of soil organic fertilizer; step II: the material with partial carbonization, generated in pyrolysis, is fed into a middle temperature carbonizing furnace for carrying out carbonization; the obtained bio-organic carbon is used as raw material of soil organic fertilizer or soil conditioner; step III: the material with partial carbonization, bio-organic carbon and one or more than two mixtures of the sludge, straws or organic garbage are fed in a high-temperature pyrolysis furnace for gasification; step IV: fixed carbon remained in a high-temperature depolymerizing furnace after aerogenesis is fed in a high-temperature sub-fusion activated device, and then oxygen-enriched air enters in, and then liquid in a regulating solution storage tank is prayed in for regulation, and then, compound charcoal is obtained after being cooled. The method has high efficiency, simple steps and diversified products.

Owner:SHANGHAI DISHENG ENVIRONMENTAL PROTECTION TECH CO LTD

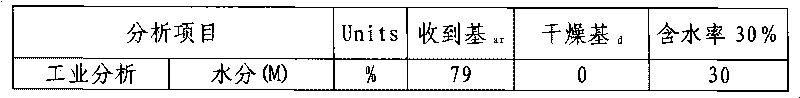

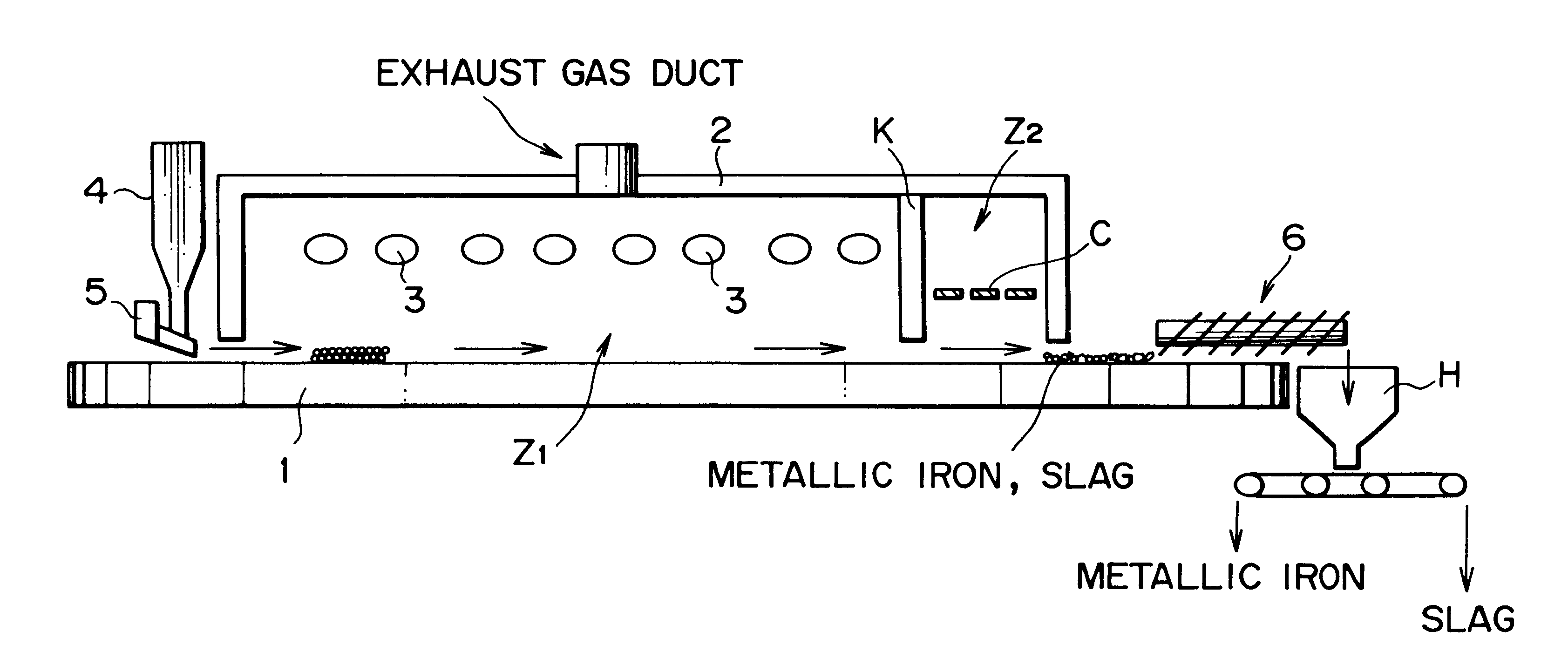

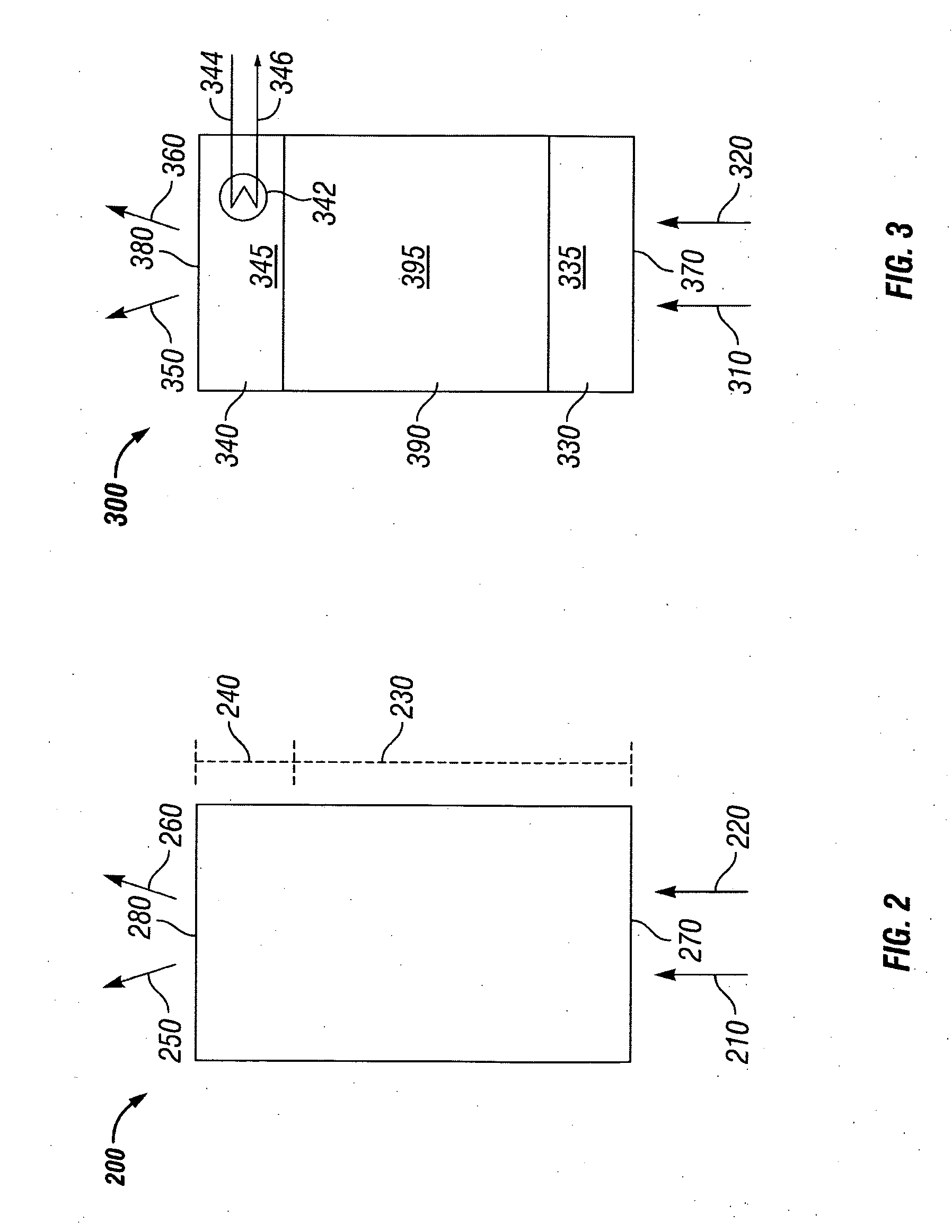

Method of producing iron nuggets

InactiveUS6592649B2Avoid smallImprove productivityProcess efficiency improvementGas emission reductionProduction rateSlag

The present invention provides a method of producing metallic iron nuggets with a high yield and good productivity, and more particularly a method which can produce metallic iron nuggets which have a high Fe purity and are excellent in transporting and handling due to a large grain diameter with a high yield and good productivity, when they are produced by reducing and melting raw material containing iron oxide such as iron ore and carbonaceous reducing agent such as coke. The method of producing metallic iron nuggets comprises steps of: heating raw material containing carbonaceous reducing agent and iron oxide-containing material in a reducing / melting furnace, reducing iron oxide in the raw material, and then heating and melting the metallic iron produced by the reduction and simultaneously making it coalesce while separating the metallic iron nuggets from slag components characterized in that the fixed carbon content ratio as the carbonaceous reducing agent is at least 73% and the volatile matter content in the raw material is not more than 3.9% are used, and the mixing content of carbonaceous reducing agent is restrained to be not more than 45% in relation to the iron oxide components, which is contained in the iron oxide-containing material of the raw material.

Owner:IDREX INT BV ROTTERDAM ZURICH BRANCH

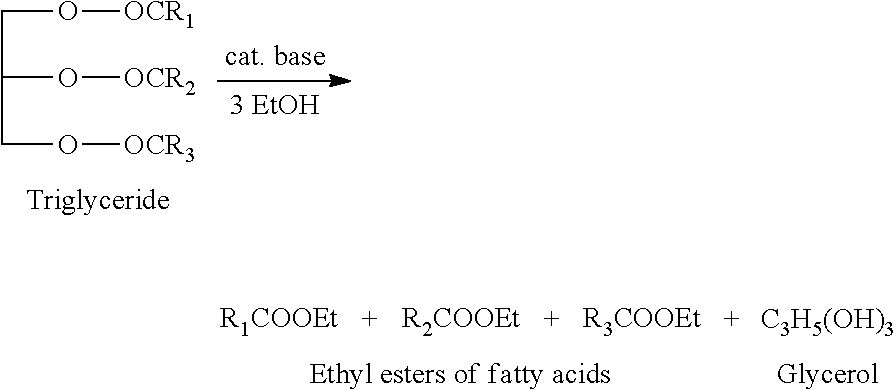

Energy utilization method of carbon dioxide zero-emission type organic waste

ActiveCN101914572AReduce the cost of trainingAvoid emissionsBio-organic fraction processingInternal combustion piston enginesNew energySludge

The invention provides an energy utilization method of carbon dioxide zero-emission type organic wastes, comprising the following steps of: (1) collecting and pretreating raw materials; (2) preparing hydrogen by anaerobic fermentation and purifying hydrogen; (3) fermenting methane and generating power by the methane; (4) treating biogas slurry and fixing carbon dioxide with microalgae; (5) processing biogas residues and planting energy grass; and (6) recycling afterheat. The method is suitable for treating various types of organic wastes, can be used for treating agricultural organic wastes, industrial organic wastes, domestic organic garbage, mud, and the like and the industries of developing new energy, and the like. The method can carry out a concrete application example of cyclic economy, eliminates environmental pollution, obtains clean energy at the same time, has no greenhouse gas emission in the process and can realize three effects of treating wastes, generating renewable clean energy and reducing carbon dioxide emission.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

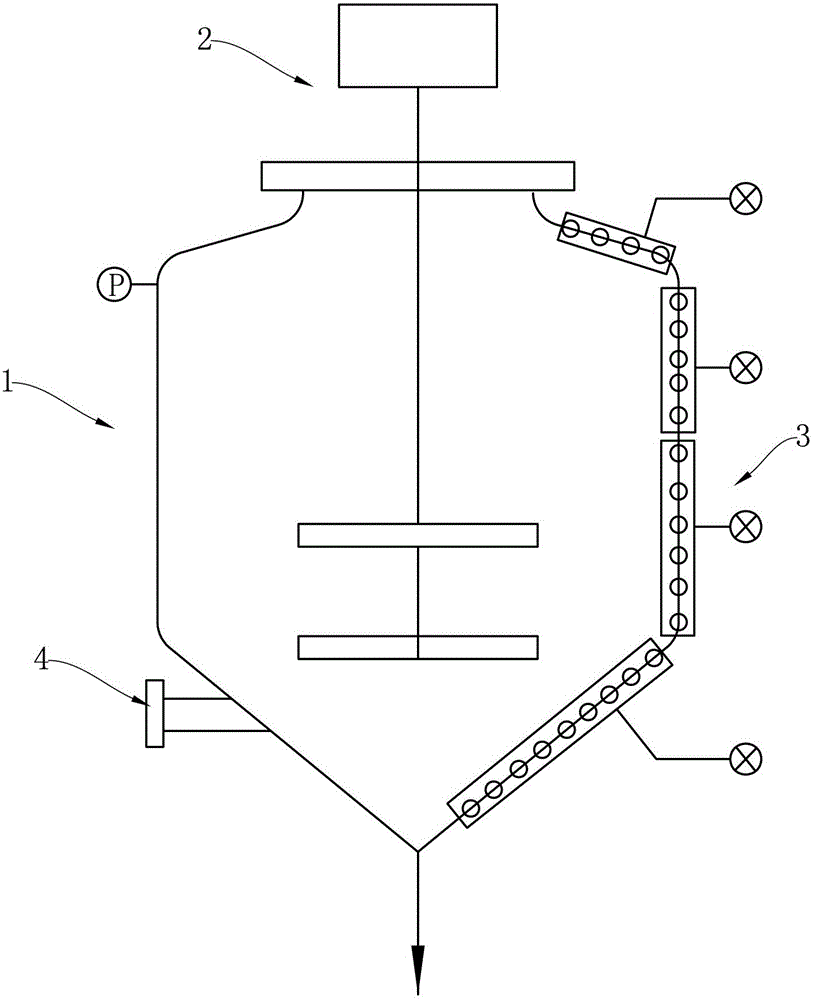

Reactor with carbon dioxide fixing material

InactiveUS20050232855A1Increase temperatureHydrogen separation using solid contactHydrogen/synthetic gas productionHydrocotyle bowlesioidesCarbon oxide

Apparatus and methods for converting hydrocarbon fuels to hydrogen-rich reformate that incorporate a carbon dioxide fixing mechanism into the initial hydrocarbon conversion process. The mechanism utilizes a carbon dioxide fixing material within the reforming catalyst bed to remove carbon dioxide from the reformate product. The removal of carbon dioxide from the product stream shifts the reforming reaction equilibrium toward higher hydrocarbon conversion with only small amounts of carbon oxides produced. Fixed carbon dioxide may be released by heating the catalyst bed to a calcination temperature. A non-uniform distribution of catalysts and carbon dioxide fixing material across catalyst bed yields higher conversion rates of hydrocarbon to hydrogen-rich reformate.

Owner:TEXACO INC & TEXACO DEV CORP

Genetically Engineered Microorganisms That Metabolize Xylose

The invention provides methods of cultivating oil-bearing microbes using xylose as a fixed carbon source. Also provided are microorganisms that have been genetically engineered to metabolize xylose as a fixed carbon source allowing them to convert xylose into oils. Particular advantages of the processes provided herein include production of oils rather than alcohols through the microbial fermentation processes utilizing xylose.

Owner:CORBION BIOTECH INC

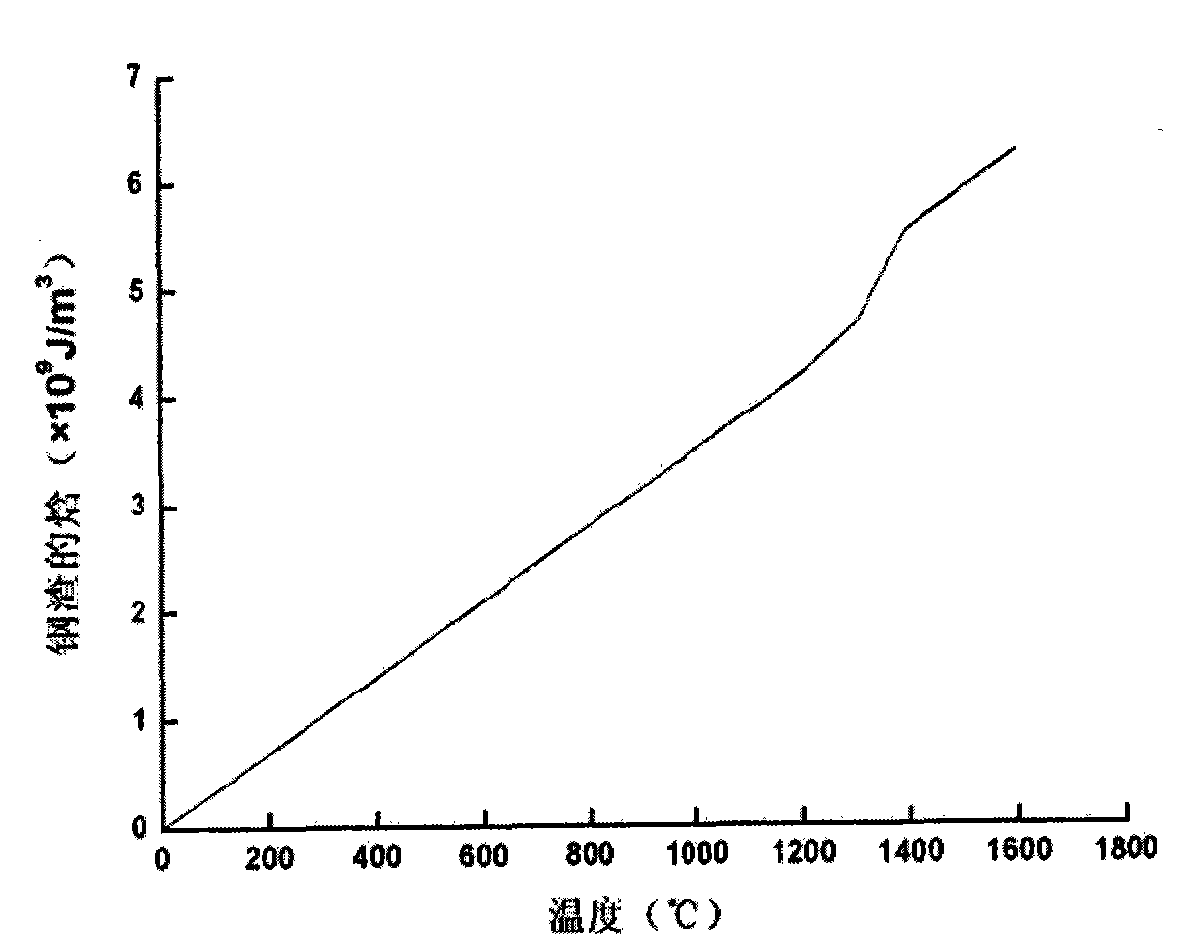

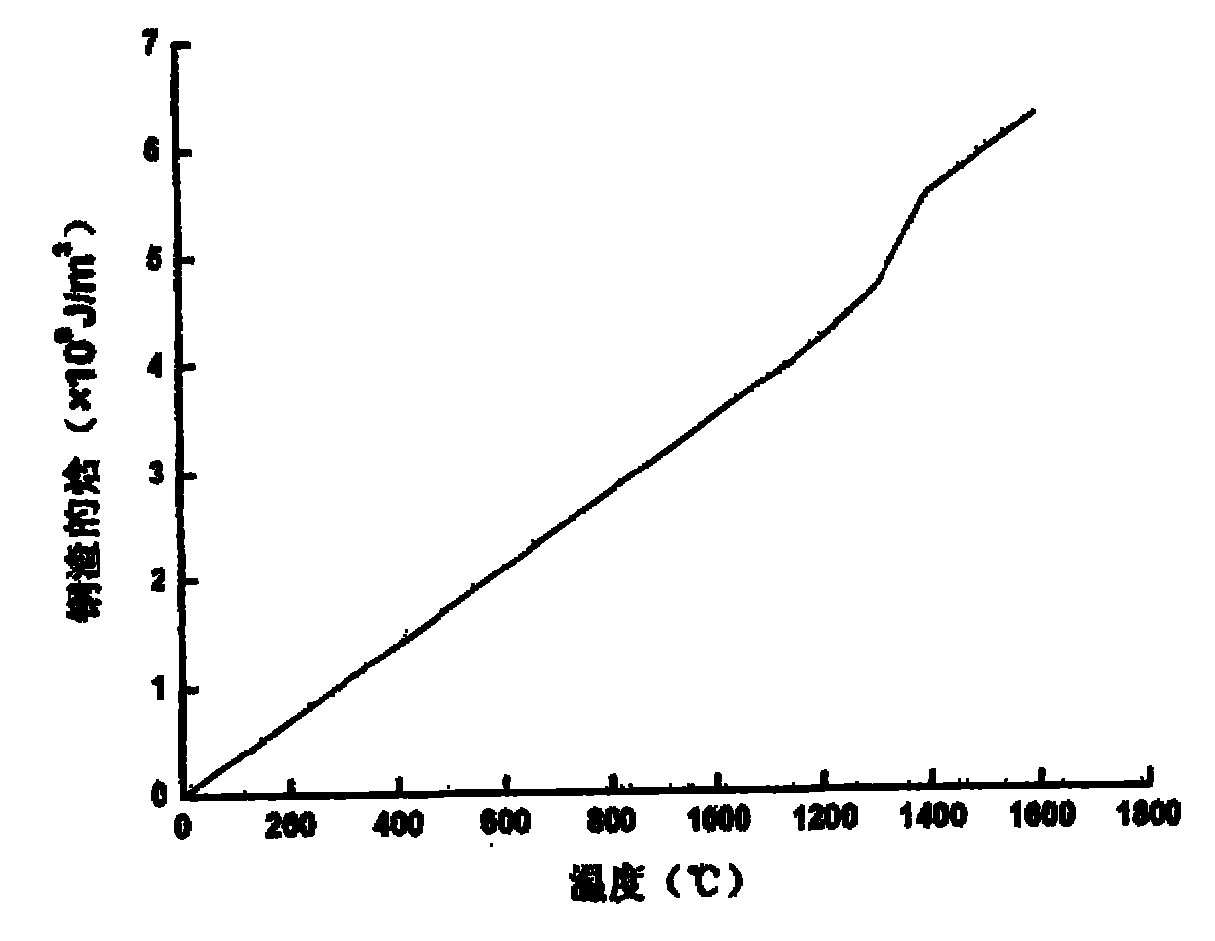

Energy-saving slag thermal insulator

InactiveCN101892332AImprove insulation effectLow raw material costRecycling and recovery technologiesChemical reactionSlag

The invention relates to an energy-saving slag thermal insulator, and belongs to the technical field of energy conservation, emission reduction and comprehensive utilization in the metallurgy industry. The thermal insulator comprises the following main chemical components in percentage by weight: 25 to 70 percent of SiO2, 1 to 25 percent of Al2O3, 1 to 40 percent of CaO, 0 to 20 percent of MgO, 0 to 10 percent of F<->, 0 to 10 percent of R2O (R is a monovalent metal ion), 0 to 10 percent of Fe2O3, 5 to 60 percent of fixed carbon with bulk density of 0.25 to 0.75g / cm<3>. The thermal insulator has high thermal insulation performance and can reduce the thermal loss of high-temperature slag; the thermal insulator contains a certain amount of fixed carbon, so heat generated in the chemical reaction of the fixed carbon can be used for further making up the thermal loss of the slag; meanwhile, the thermal insulator belongs to a silicon-aluminum material, and part or all of the thermal insulator can be dissolved in the slag finally so as to improve the chemical composition of the slag and reduce the melting point of the slag. The thermal insulator has the advantages of simple production process, low cost, and suitability for various processes for utilizing the sensible heat of the slag, increasing the fluidity of the slag or improving the performance of the slag.

Owner:UNIV OF SCI & TECH BEIJING

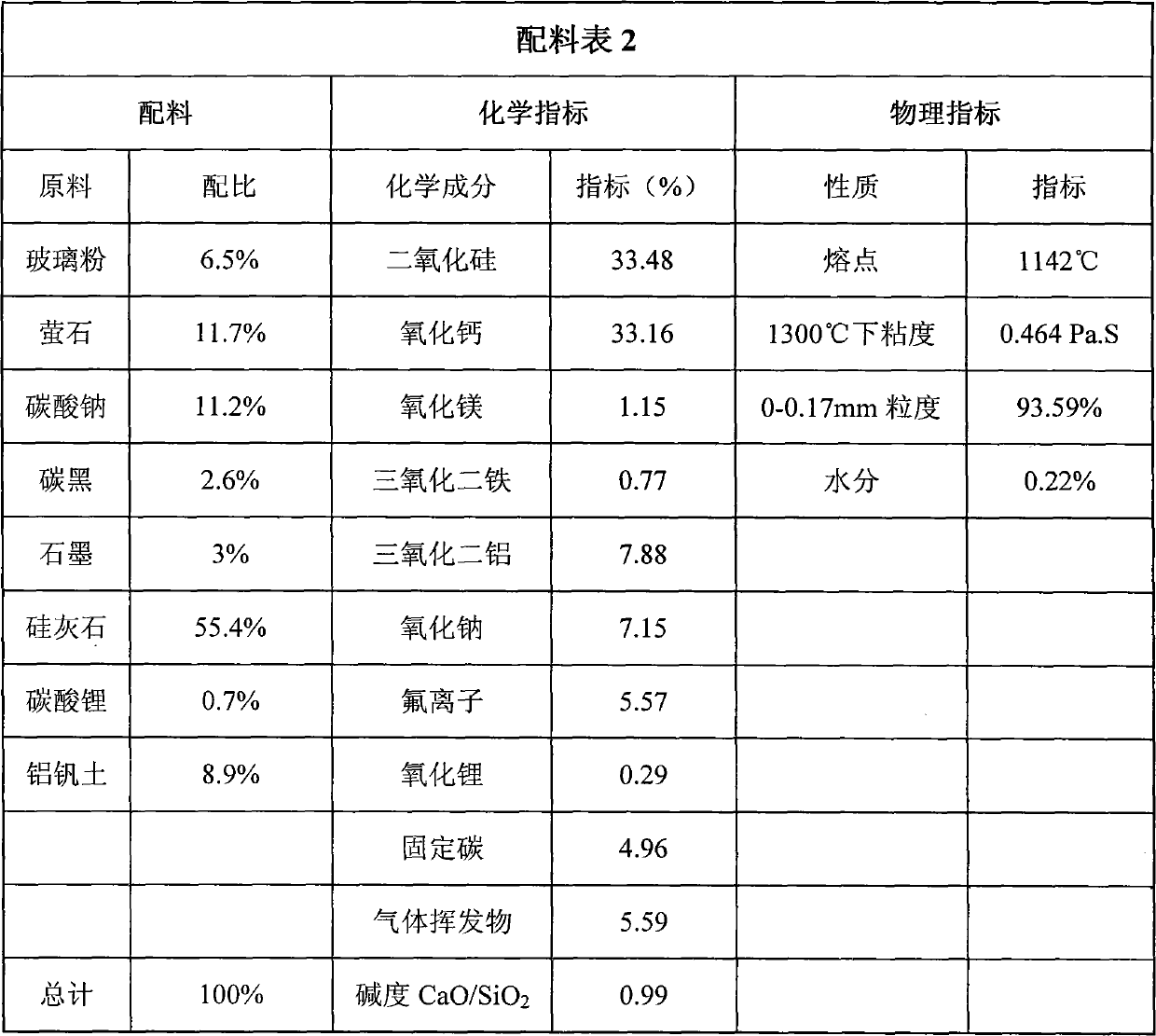

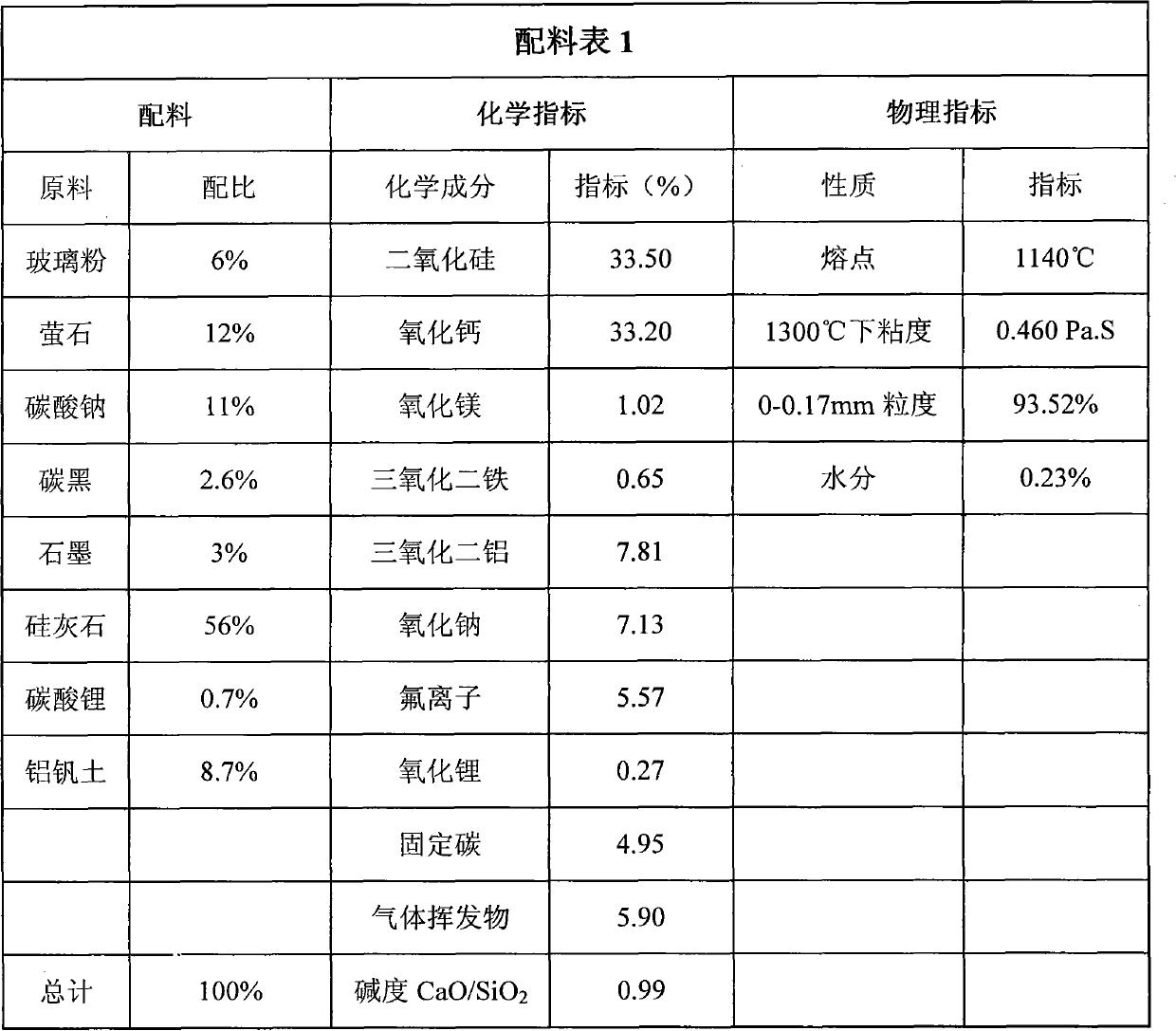

High-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag and preparation method thereof

The invention discloses high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag which comprises the following components in percentage by weight: 54-57% of wollastonite, 9-13% of fluorite, 9-13% of sodium carbonate, 0-1% of lithium carbonate, 5-7% of glass dust, 8-12% of vanadine soil, 2.5-2.7% of soot carbon and 3-3.5% of graphite, and comprises the chemical components in percentage by weight: 31.9-34.9% of calcium oxide, 32.1-35.1% of silicon dioxide, 7.3-8.3% of aluminium oxide, 0.5-1.5% of magnesium oxide, 0.5-1.4% of iron sesquioxide, 4.4-6.4% of fluorion, 6.5-7.5% of sodium oxide, 0-0.39% of lithium oxide, 4.5-6.0% of fixed carbon and 4-7% of gas volatile matters. The alkalinity of the covering slag, namely the ratio of CaO to SiO2, is 0.91 to 1.00, the melting point of the covering slag is 1100 DEG C to 1160 DEG C, and the viscosity of the covering slag is 0.3 to 0.6 Pa.s at 1300 DEG C. The invention can solve the problems of easy crusting, slag entrainment, slag inclusion, slag sticking on casting blank surfaces, bubbles under skins, cracks, deep chatter mark, felting, bleed-out, and the like of the covering slag in the crystallizer during high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting, and has the advantages of uniform and stable slagging in the crystallizer, good casting blank quality, difficult felting and bleed-out, and the like.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

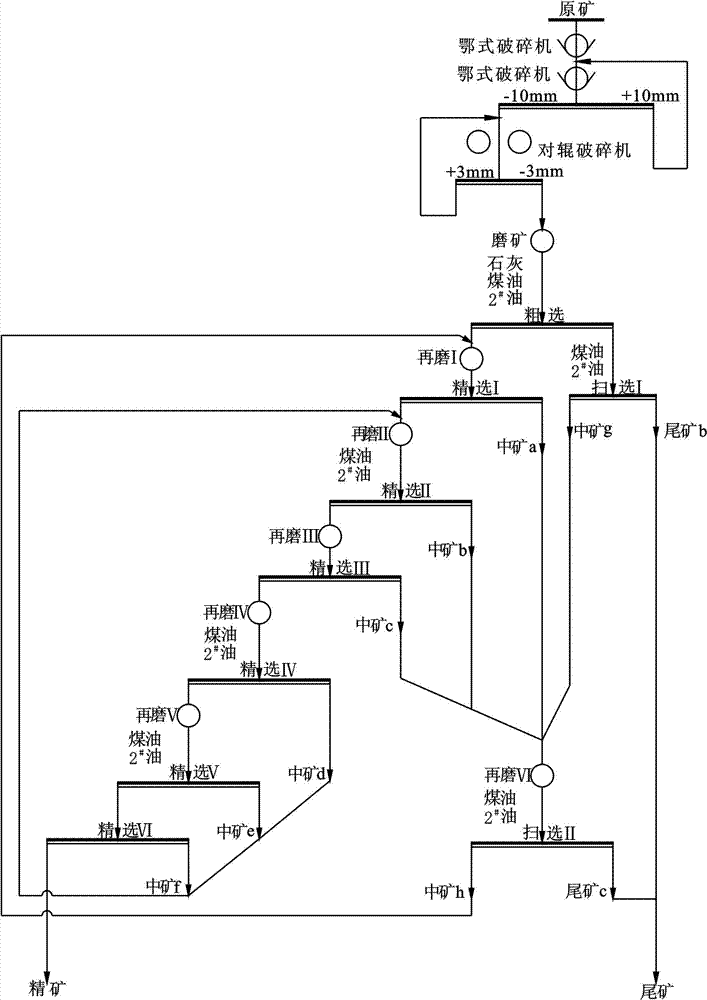

Fine flaky-cryptocrystalline mixed graphite separation technique

The invention discloses a fine flaky-cryptocrystalline mixed graphite separation technique which comprises the following steps: primary rough grinding and rough separation, quintic regrinding and sextic concentrating, and middling centralized processing. According to the technique, in the rough separation step, the grinding fineness is -0.074mm, and the content is 90-95%; in the concentrating step, the regrinding fineness is -0.045mm, and the content is 90-95%; and thus, the graphite monomer is sufficiently dissociated, thereby sufficiently ensuring the fixed carbon content and recovery rate of the concentrated concentrate. The technique adopts gradually decreased low concentrating concentrations in multiple concentrating process to ensure the dispersity of ore slurry, thereby solving thesevere problem of entrapped impurities in floatation foam; and thus, in the final concentrate, the fixed carbon content is 91.35%, and the recovery rate is 91.30%, thereby solving the problems of lowtechnical indexes, low grade, low recovery rate and high cost in the fine flaky-cryptocrystalline mixed graphite concentrate separation, so that the fine flaky-cryptocrystalline mixed graphite ores are utilized in an efficient, economical and reasonable way.

Owner:SICHUAN PILOT GRAPHITE PROD

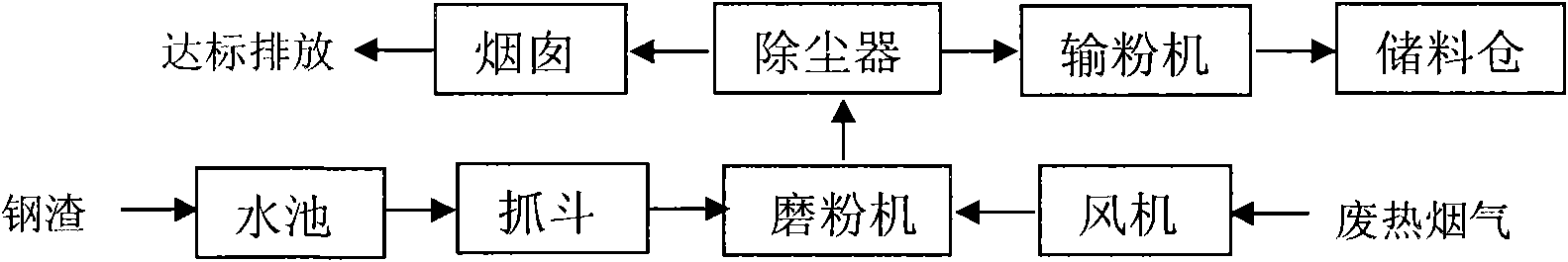

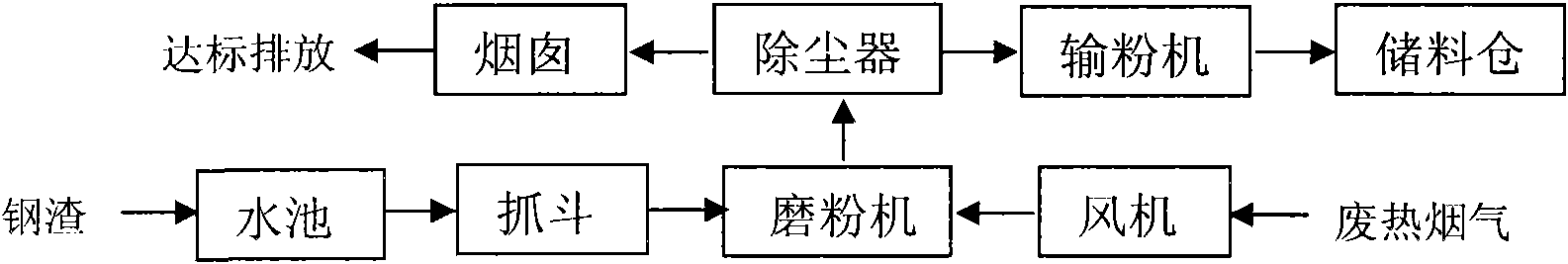

Method for fixing carbon dioxide and digesting free calcium oxide in slag micro powder

InactiveCN101851071AF-CaO content decreasedAchieve stabilizationCalcium/strontium/barium carbonatesGas treatmentSlagResource utilization

The invention relates to a method for fixing carbon dioxide and digesting free calcium oxide in slag micro powder, which belongs to the technical field of the carbon dioxide reduction and the industrial solid waste resource utilization. Converter steel slag is soaked in water, then the steel slag after being soaked in the water is added into a grinding machine, at the same time, waste heat smoke gas containing carbon dioxide is introduced into the grinding machine with the steel slag to carry out the stabilization reaction, and the steel slag is ground and dried; the waste heat smoke gas brings out the steel slag micro powder after being ground and dried from the tail section of the grinding machine to enter a power collection device, and the steel slag micro powder is discharged from the bottom part of the powder collection device; and the temperature of the waste heat smoke gas is 150 to 180 DEG C. The method has the advantages that: carbon dioxide in the waste smoke gas is used for chemically modifying the steel slag micro powder, so the content of the f-CaO is reduced, the chemical stability of the steel slag micro powder is improved, and technical requirements of the national standard GB / T 20491 - 2006 of steel slag powder for cement and concrete can be reached. The carbon dioxide also can be cured, so the exhaustion of the greenhouse gas can be reduced, and the environment-friendly carbon cycling mode can be realized.

Owner:SHOUGANG CORPORATION

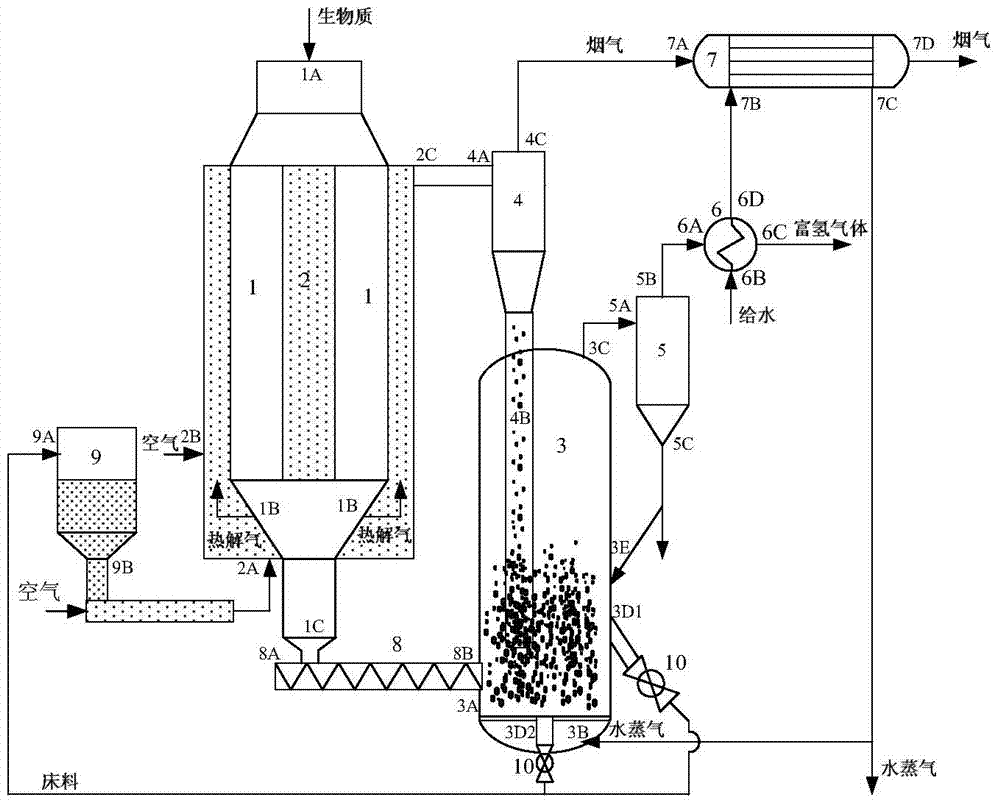

Device and method for preparing hydrogen-rich gas by gasifying biomass

ActiveCN103923705AAvoid mixingEfficient use ofEnergy inputGasification with fuel pre-distillationWater vaporGas cooler

The invention discloses device and method for preparing hydrogen-rich gas by gasifying biomass. The device mainly comprises a pyrolysis reactor, a combustion reactor, a gasification reactor, a gas-solid separator, a gas cooler and an exhaust heat boiler, wherein the pyrolysis reactor is arranged in the combustion reactor. In a process course, the biomass is firstly pyrolyzed in the pyrolysis reactor to generate pyrolysis gas and coke, the pyrolysis gas is directly combusted to provide heat for biomass pyrolysis and gasification, and the coke is subjected to gasification reaction with water vapor to obtain the hydrogen-rich gas. The device and method disclosed by the invention realize the separation of the pyrolysis process and coke gasification process of the biomass and can be used for displacing the hydrogen contained in the water vapor by sufficiently utilizing fixed carbon contained in the biomass. According to the device and method, the obtained hydrogen-rich gas mainly contains H2, CO2 and a small amount of CO, so that the conventionally gasified hydrogen-rich gas product is prevented from being mixed with low-carbon hydrocarbon gas and tar, and the subsequent decontamination and purification utilization are simple, convenient and economic.

Owner:SOUTHEAST UNIV

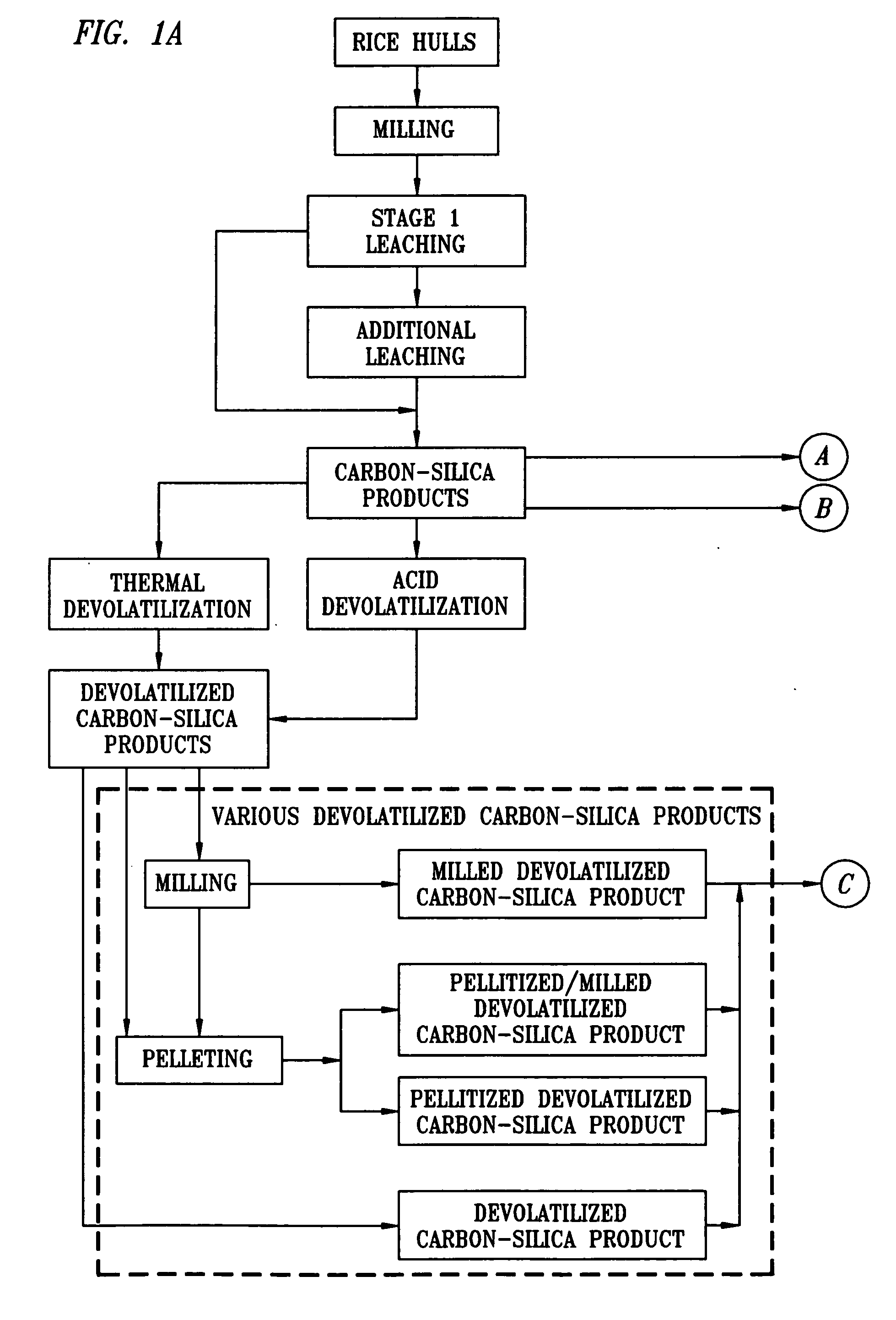

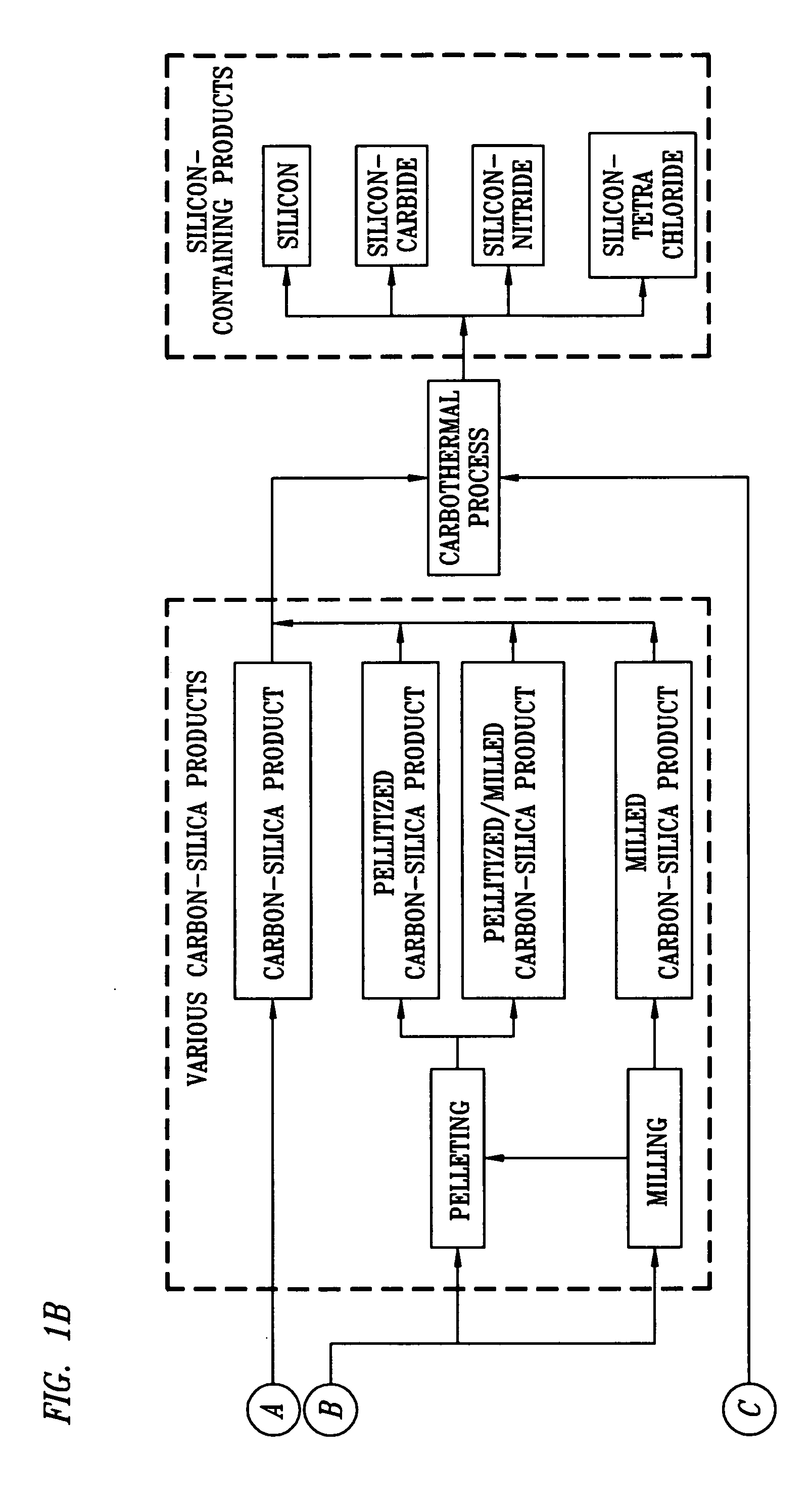

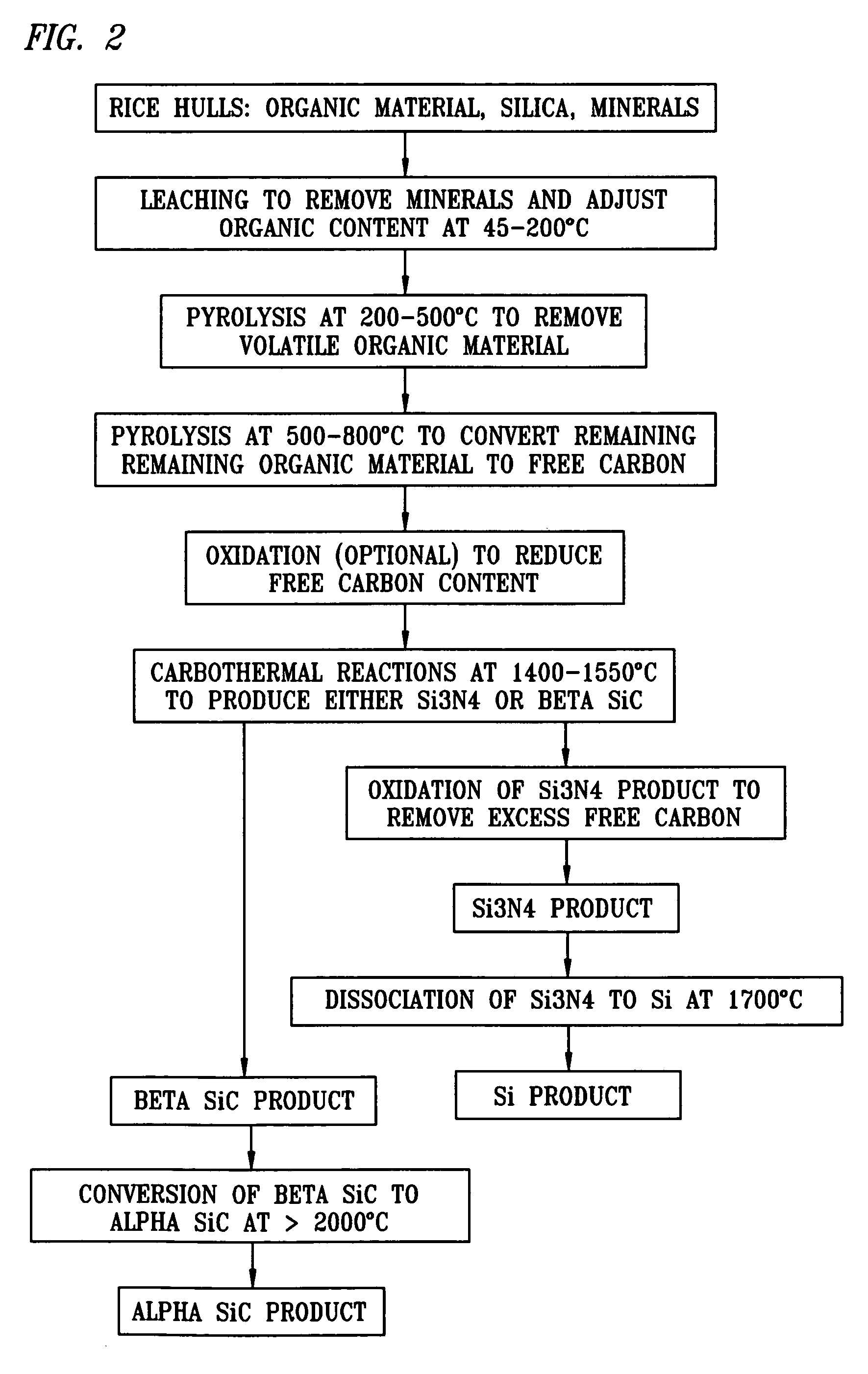

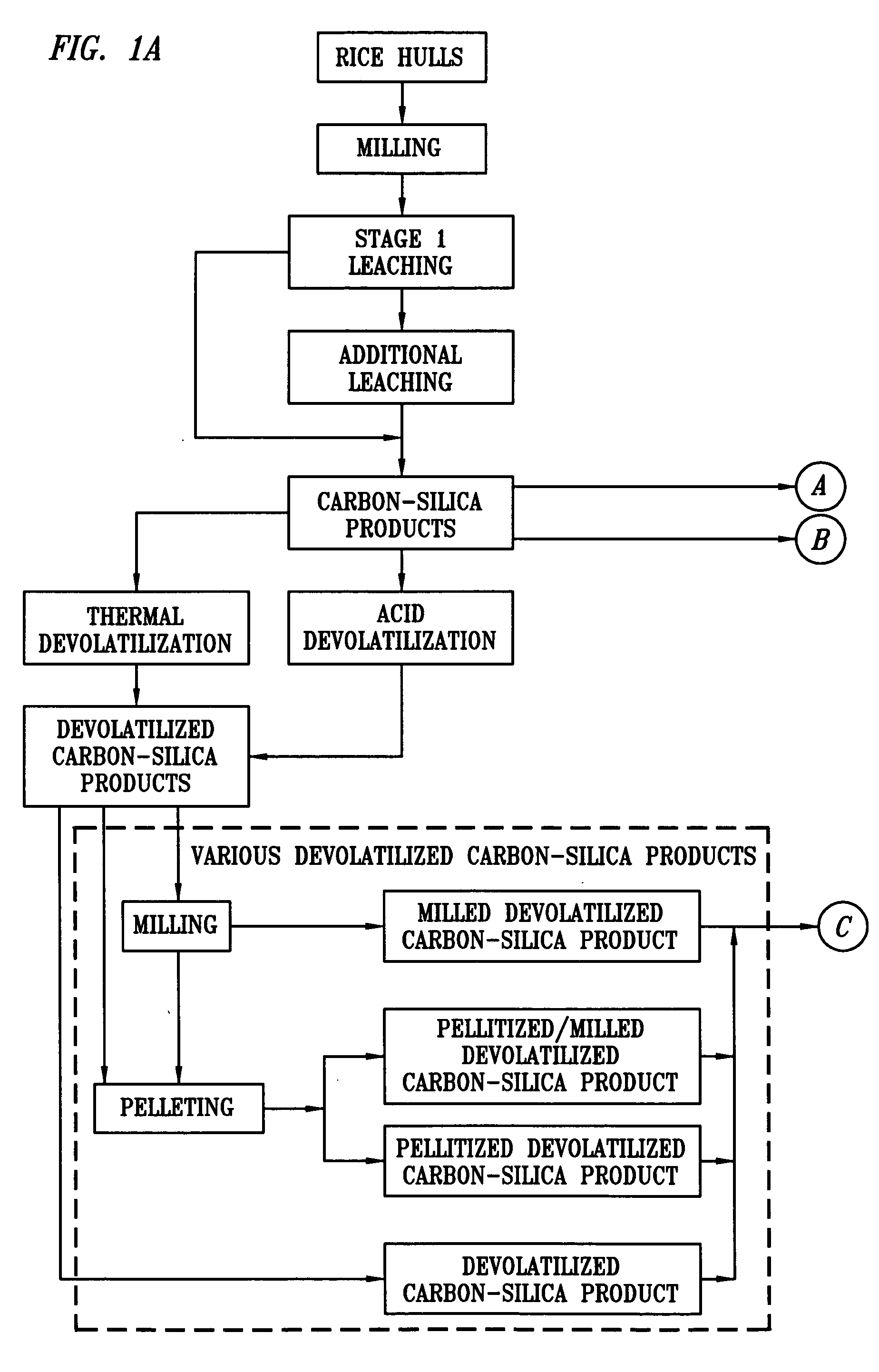

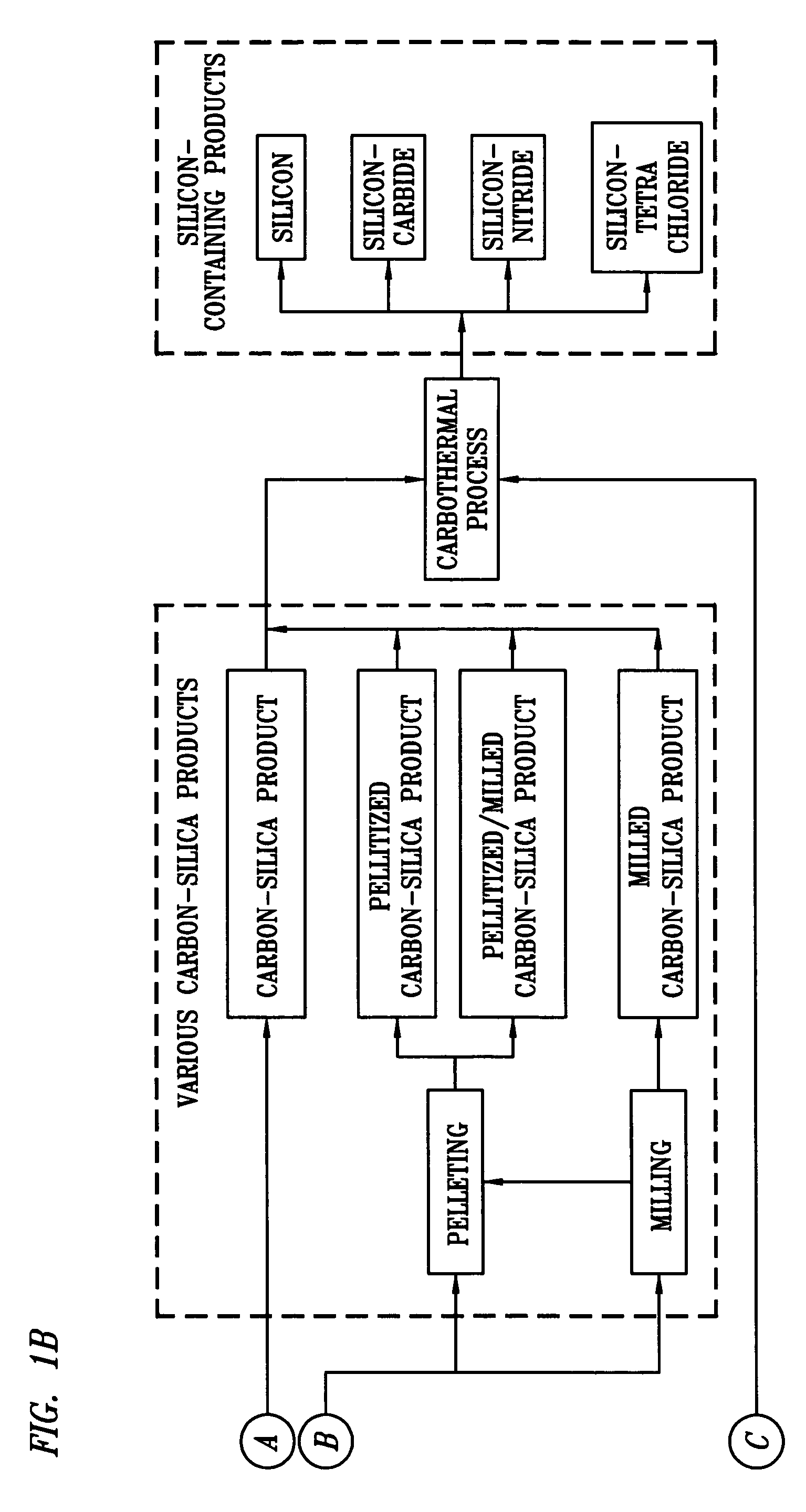

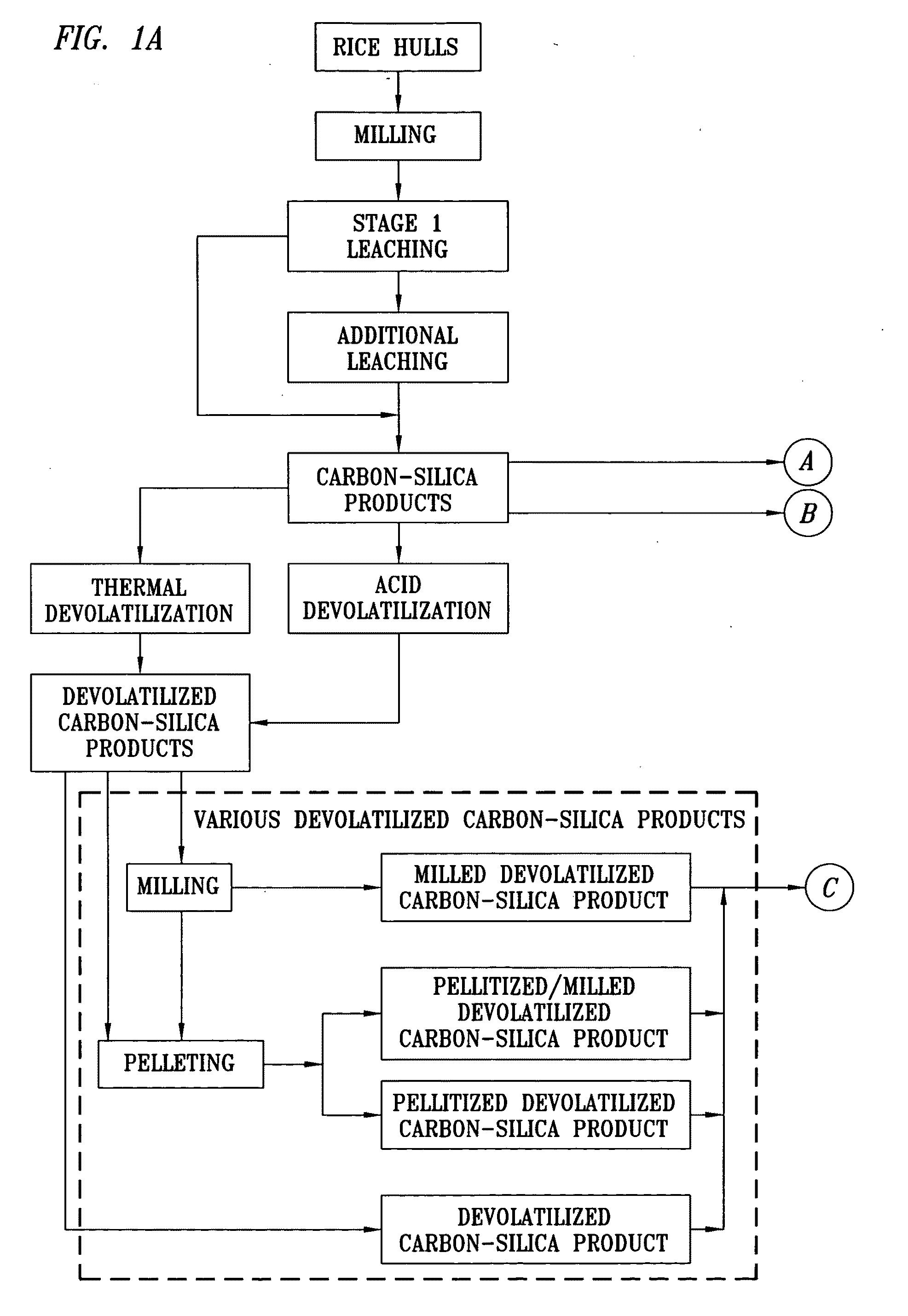

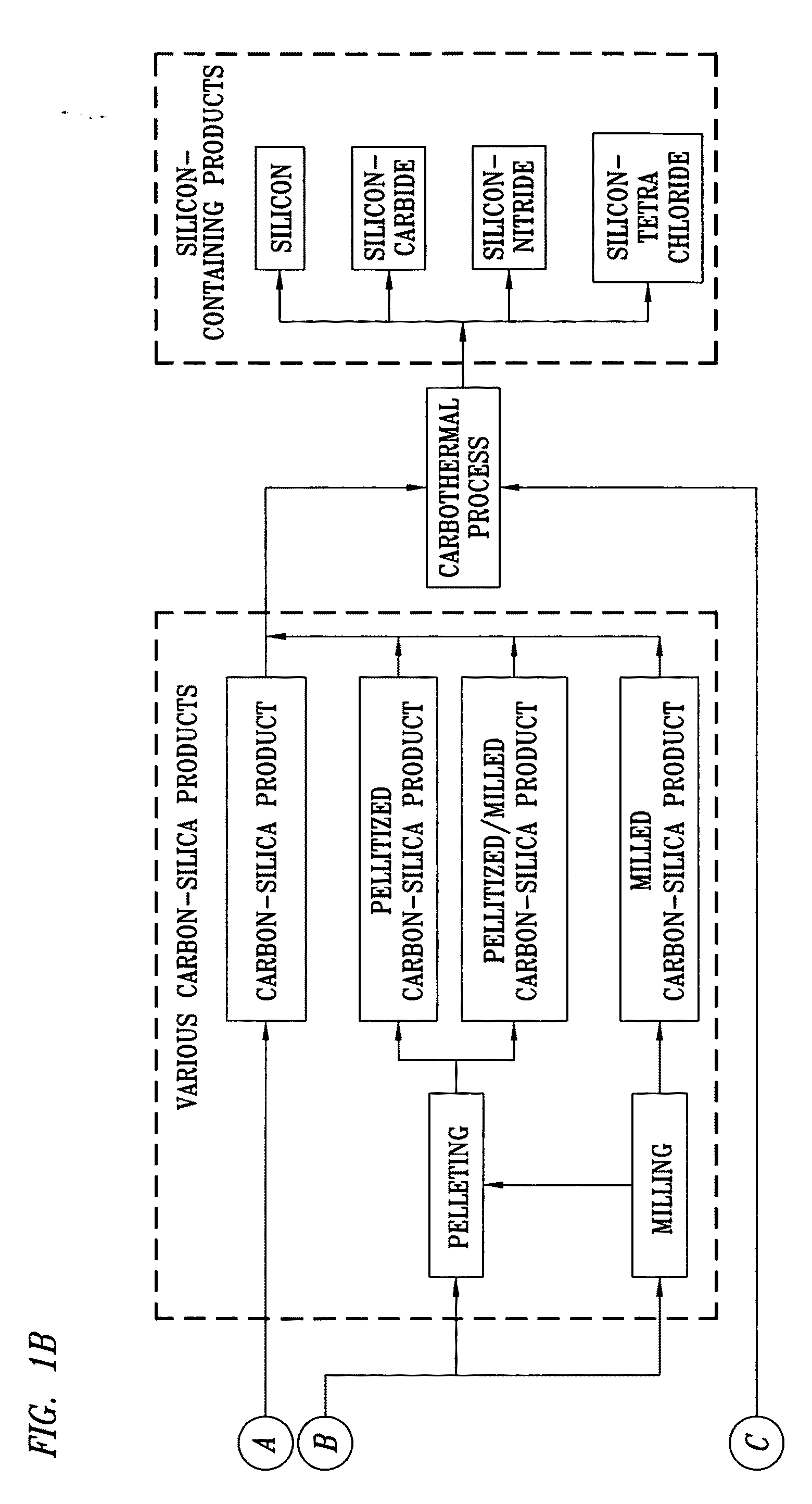

Composition and method for making silicon-containing products

Silicon-containing products, such as silicon, silicon carbide and silicon nitride, containing less than 0.01 weight percent total mineral impurities and selectively determined carbon-to-silicon ratios. The products are derived from plant matter, such as rice hulls and rice straw, containing at least three weight percent silica. Methods are provided for making such high purity silicon-containing products by leaching silica-containing plant matter with aqueous sulfuric acid under controlled temperatures, pressures and reaction times to remove minerals and metals while adjusting the mole ratio of fixed carbon to silica, and then thermally treating under controlled conditions to produce the desired product.

Owner:SI OPTIONS LLC

Composition and method for making silicon-containing products

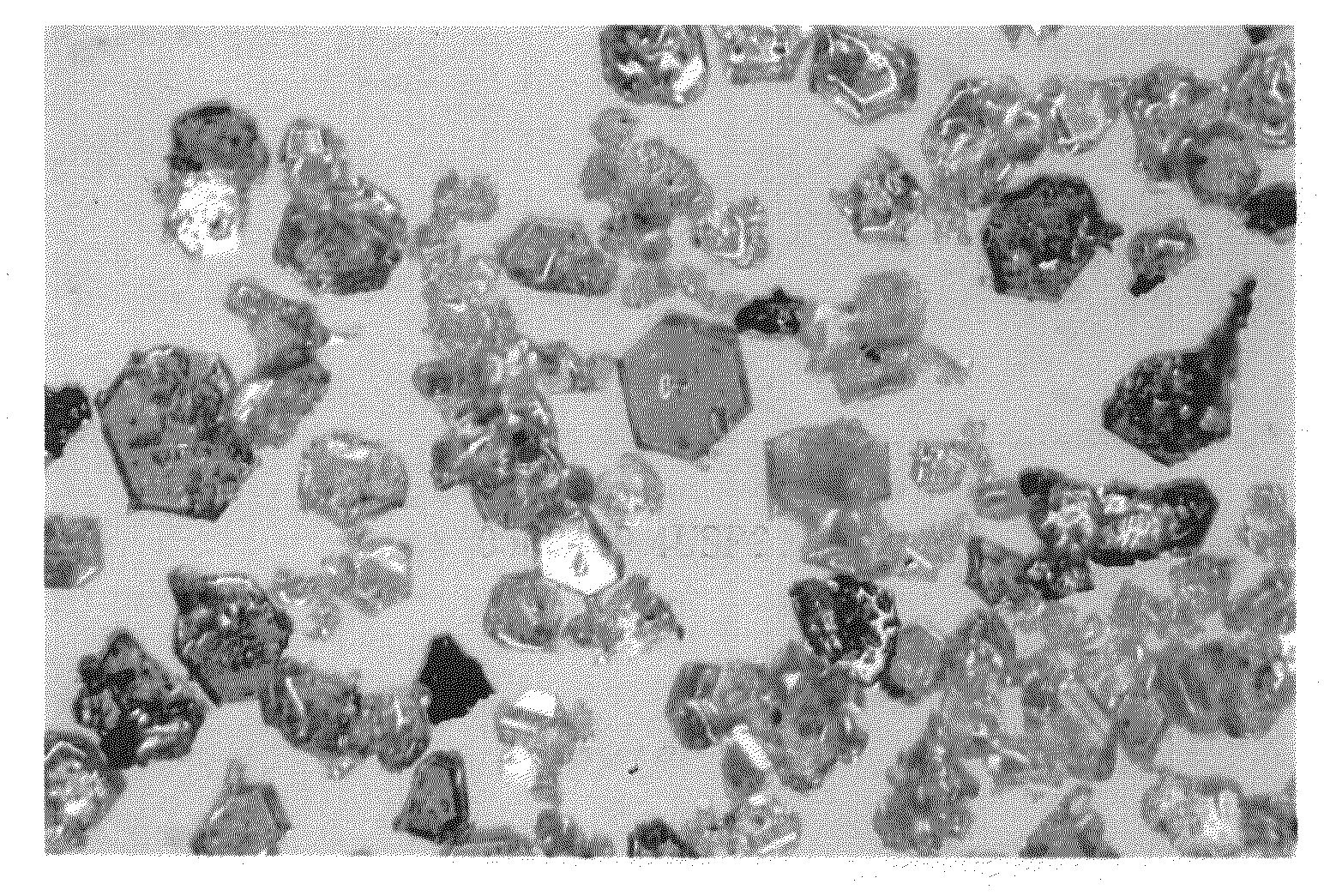

ActiveUS20050227868A1Increase throughputSave energyNitrogen compoundsOther chemical processesPorositySilicon dioxide

A method for producing carbon-silica products from silica-containing plant matter such as rice hulls or straw by leaching with sulfuric acid to remove non-silica minerals and metal while adjusting the mole ratio of fixed carbon to silica in the resultant product. The carbon and silica are intimately mixed on a micron or submicron scale and are characterized by high purity and reactivity, small particle size, high porosity, and contain volatile carbon that can be used as a source of energy for the production of silicon-containing products from the carbon-silica products. High purity silicon-containing products made from the carbon-silica products of the invention are also disclosed.

Owner:SI OPTIONS LLC

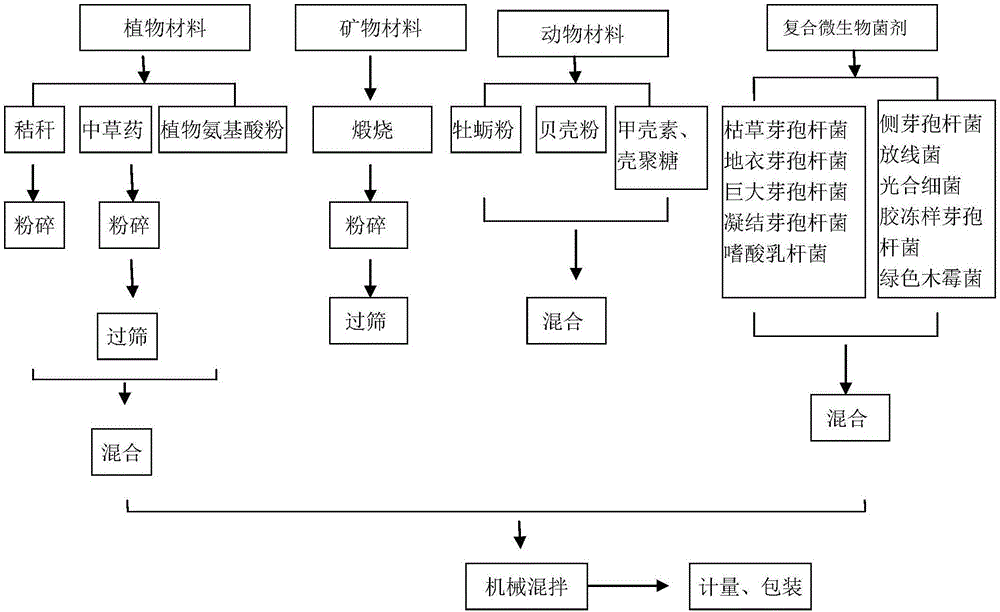

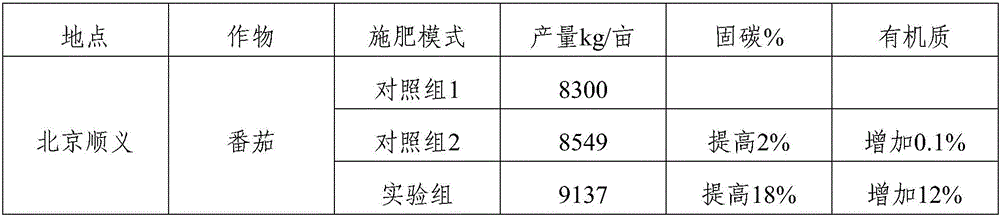

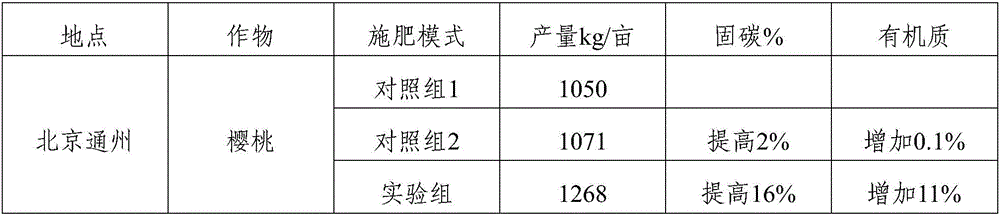

Soil-structure conditioner capable of stabilizing yield and fixing carbon and preparation method and application thereof

InactiveCN106316685AMultiple benefitsAvoid luxuryCalcareous fertilisersMagnesium fertilisersCation-exchange capacityAlkali soil

The invention relates to a soil-structure conditioner capable of stabilizing yield and fixing carbon and a preparation method and application thereof. The soil-structure conditioner comprises, by weight, 30-90 parts of plant materials, 1-40 parts of mineral materials, 1-30 parts of animal materials and 1-10 parts of compound microbial agent. The soil-structure conditioner has the advantages that carbon fixing and emission reduction of soil can be promoted, the formation of granular structures can be promoted, the water retention ability of the soil can be increased, and effective water supply is increased; the soil-structure conditioner can regulate soil pH and lower or reduce aluminum toxicity; saline-alkali soil can be improved, and base saturation degree and cation exchange capacity of the soil can be regulated; an imbalanced soil nutrition system can be conditioned, and effective nutrition supply is promoted.

Owner:仲元(北京)绿色生物技术开发有限公司 +2

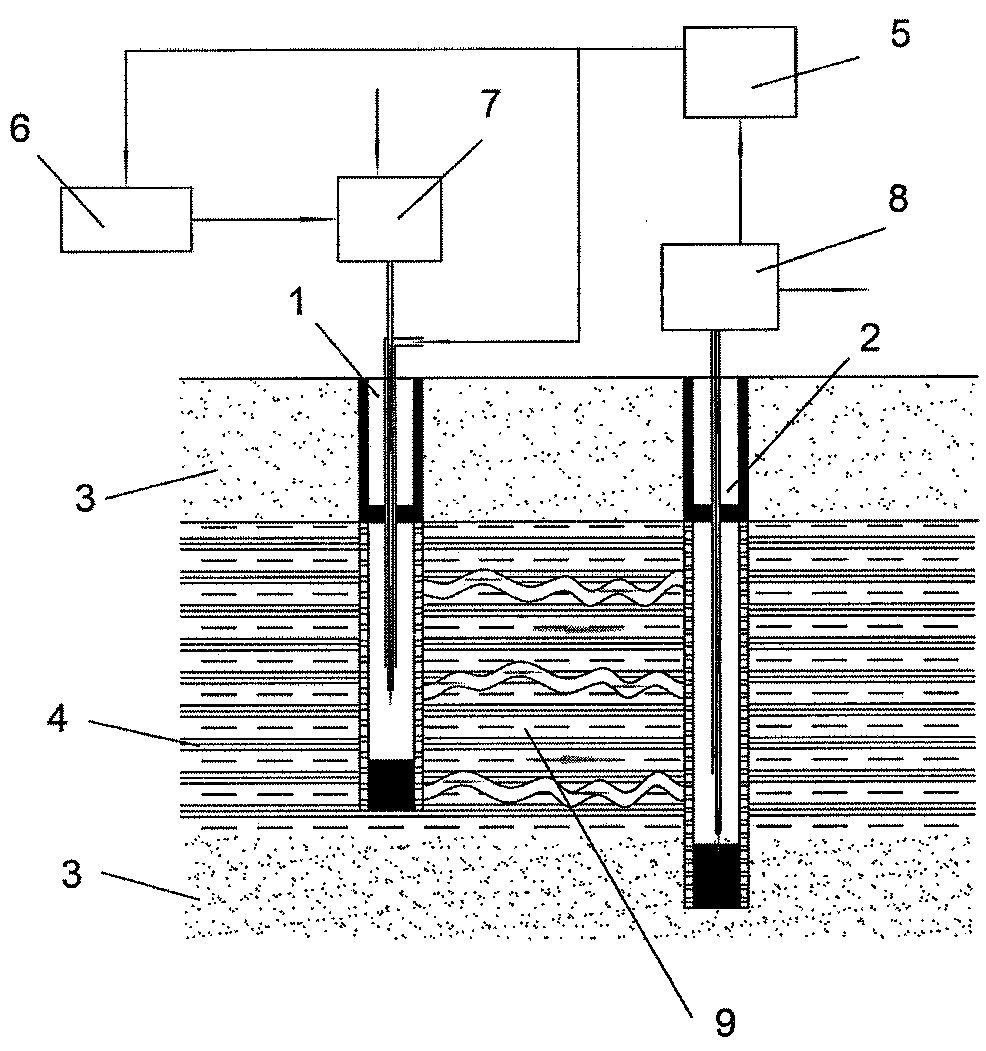

Method for extracting shale oil gas by oil shale in-situ topochemical method

The invention discloses a method for extracting shale oil gas by an oil shale in-situ topochemical method. The method includes: a partial chemical reaction area is formed in an underground oil shale stratum via hot mixed gas; in the whole process, a series of 'chain reactions' are induced by means of controlling concentrations of injected hot mixed gas and recovered hot mixed gas, and along with gradual temperature rising and range widening of the reaction area, porosity and permeability of the oil shale stratum increase continuously, heat strengthening reaction processing is realized finally, and self catalytic cracking of the oil shale stratum from inner to outer is achieved to generate shale oil and fuel gas. After the chain reactions are over, fixed carbon in the oil shale stratum is continuously enabled to react to generate low-heating-value gas via the hot mixed gas, high-temperature waste heat in the area finished in cracking reaction is recycled, and self-supporting and maximal utilization of energy for the oil shale stratum cracking are realized. By the aid of the method, exploring method, environmental harms and commercial risks can be reduced.

Owner:JILIN UNIV +1

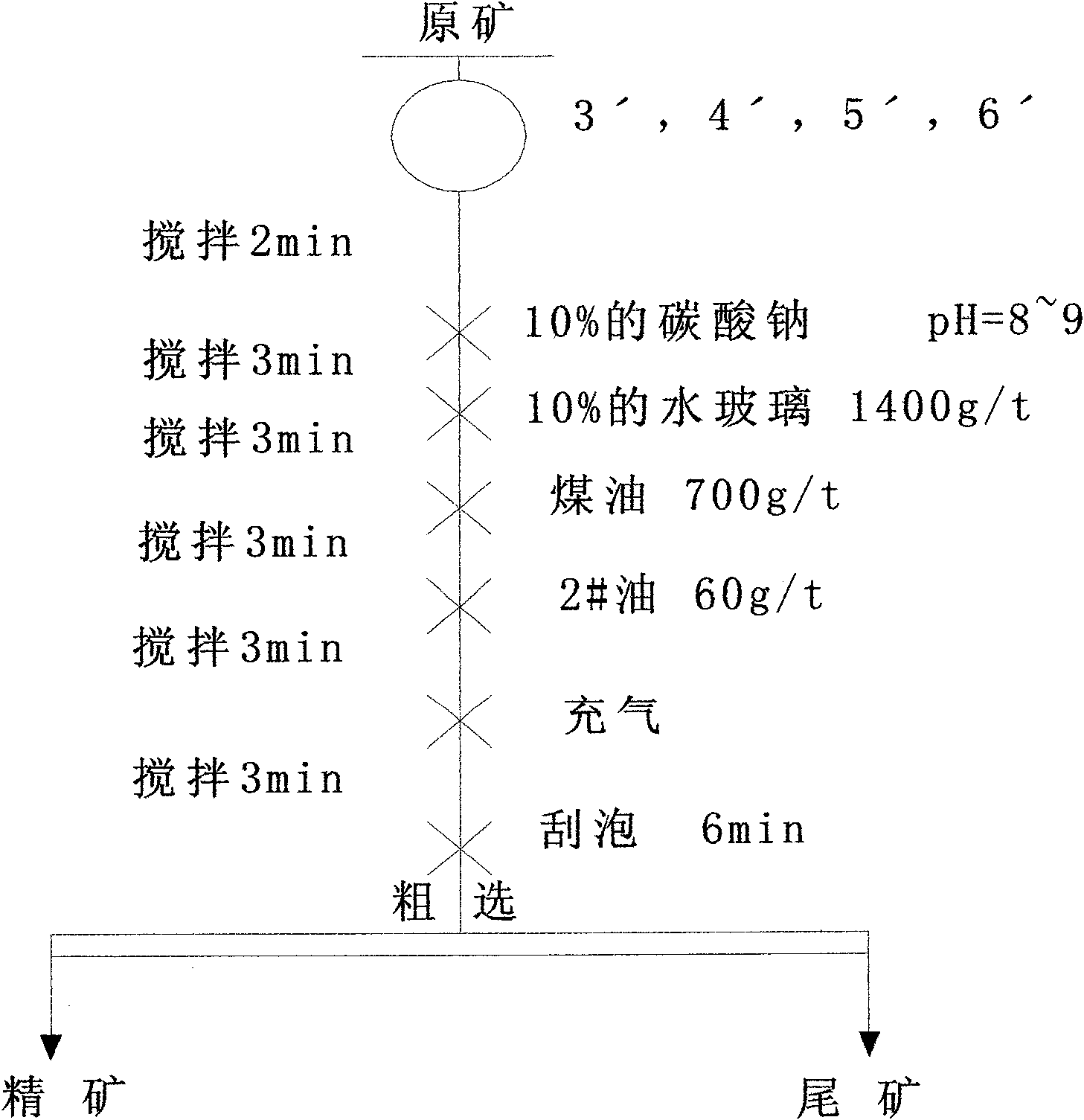

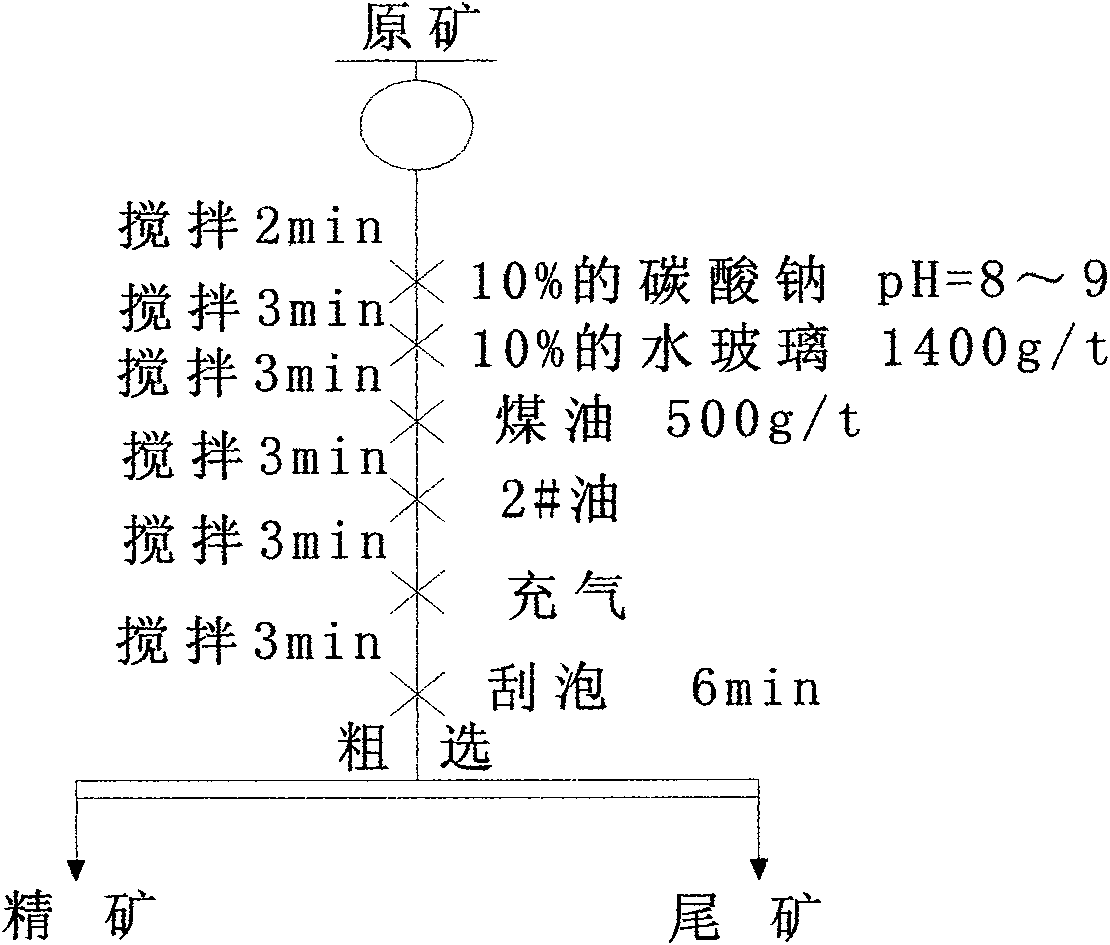

New process for purifying and manufacturing microcrystalline graphite product

The invention discloses a new process for purifying and manufacturing a microcrystalline graphite product, which comprises the following steps: adding calcined lime and water into graphite ore of which the grinding fineness is -200 meshes and the pass rate is above 90 percent after fine grinding, stirring uniformly and making pH of graphite ore slurry containing the calcined lime above 9; adding water glass to stir, adding kerosene to stir, finally adding pine oil to stir, inflating and scraping to perform rough concentration, and collecting roughly concentrated fine ore and tail ore of graphite; adding water glass into the roughly concentrated fine ore to stir, adding kerosene to stir, adding pine oil to stir, inflating and scraping to perform primary fine concentration, and collecting finely concentrated fine ore; adding water glass into the primarily finely concentrated fine ore to stir, adding kerosene to stir, adding pine oil to stir, inflating and scraping to perform secondary fine concentration, and collecting flotation graphite fine ore; adding NaOH solution into the flotation graphite fine ore for mixing, roasting, washing with water to neutral, performing acid leaching with hydrochloric acid, washing with water, dewatering and drying to obtain a high-carbon graphite product with the fixed carbon content in the graphite up to 98.74 percent.

Owner:FUJIAN FUYOU GRAPHITE TECH

High Purity Silicon-Containing Products and Method of Manufacture

InactiveUS20110008236A1Lower energy requirementsImprove throughputSilicaNitrogen compoundsSilicon dioxideImpurity

Silicon-containing products, such as silicon, silicon carbide and silicon nitride, containing less than 0.01 weight percent total mineral impurities and selectively determined carbon-to-silicon ratios. The products are derived from plant matter, such as rice hulls and rice straw, containing at least three weight percent silica. Methods are provided for making such high purity silicon-containing products by leaching silica-containing plant matter with aqueous sulfuric acid under controlled temperatures, pressures and reaction times to remove minerals and metals while adjusting the mole ratio of fixed carbon to silica, and then thermally treating under controlled conditions to produce the desired product.

Owner:SI OPTIONS LLC

Reactor and apparatus for hydrogen generation

Apparatus and methods for converting hydrocarbon fuels to hydrogen-rich reformate that incorporate a carbon dioxide fixing mechanism into the initial hydrocarbon conversion process. The mechanism utilizes a carbon dioxide fixing material within the reforming catalyst bed to remove carbon dioxide from the reformate product. The removal of carbon dioxide from the product stream shifts the reforming reaction equilibrium toward higher hydrocarbon conversion with only small amounts of carbon oxides produced. Fixed carbon dioxide may be released by heating the catalyst bed to a calcination temperature. Heat for releasing fixed carbon dioxide from the catalyst bed is generated internally within the reactor through oxidation. A non-uniform distribution of catalysts and carbon dioxide fixing material across catalyst bed can be utilized to achieve higher conversion rates of hydrocarbon to hydrogen-rich reformate.

Owner:TEXACO INC +1

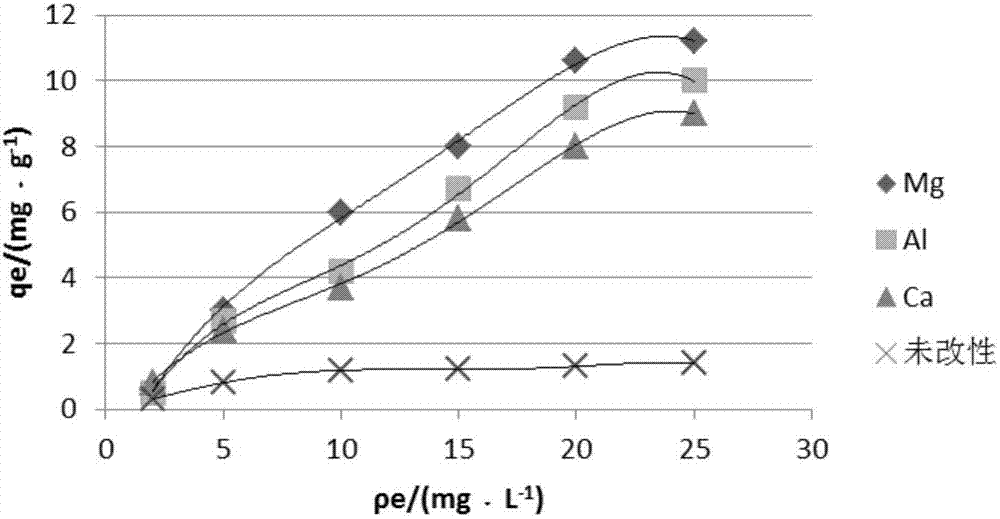

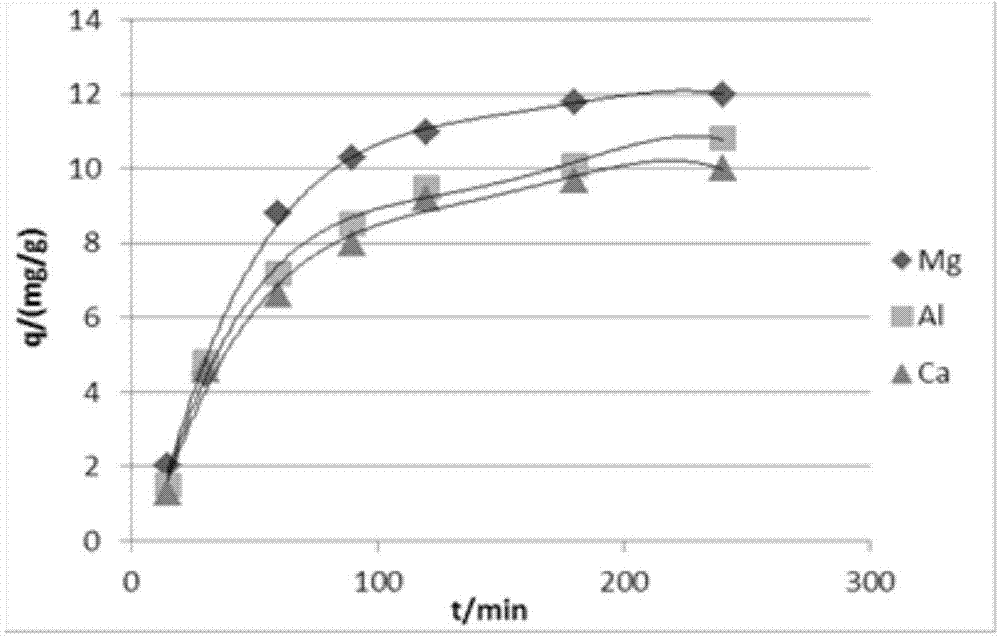

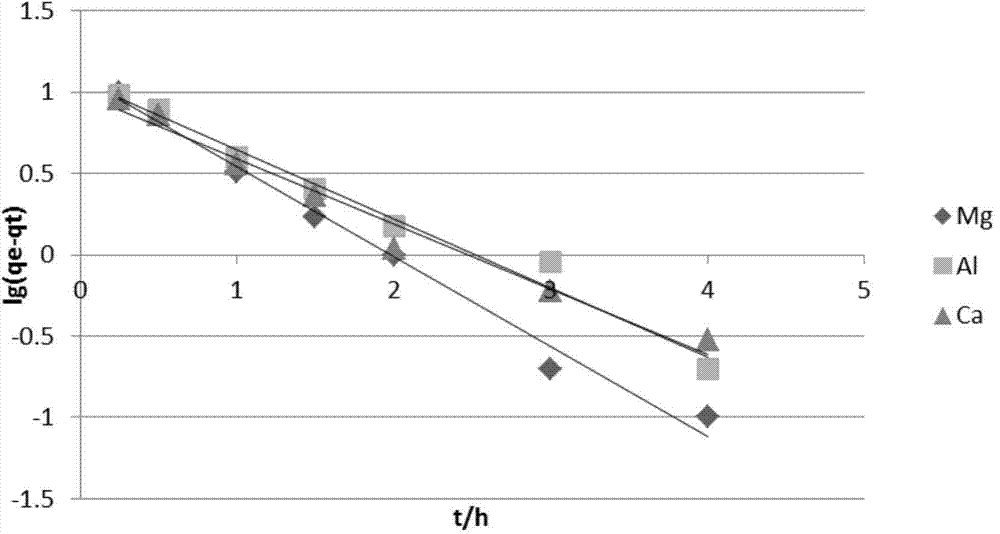

Metal element improved biochar-based nitrate radical adsorbent and preparation method thereof

InactiveCN104258812AEfficient removalReduce pollutionOther chemical processesWater contaminantsAdsorption equilibriumSorbent

The invention discloses a metal element improved biochar-based nitrate radical adsorbent and a preparation method thereof. Straws are used as raw materials, and metal ions are impregnated, pyrolyzed and washed under certain conditions, so a metal ion improved cbiochar is prepared. According to the metal element improved biochar-based nitrate radical adsorbent and the preparation method thereof disclosed by the invention, by using adsorption research on nitrate radical waste water and comparing the adsorption effect of the biochar before and after improvement, the improved biochar prepared by the preparation method disclosed by the invention has good adsorption effect for potassium nitrate, wherein Mg<2+> improved wheat straw biochar has optimal adsorption effect for nitrate nitrogen; compared with the unmodified biochar, the Mg<2+> improved biochar prepared under the optimizing conditions has the advantages that the adsorption performance is improved by 10 times, and the adsorption equilibrium can be realized in a shorter time. The modified biochar adsorbent is a green adsorbent with application potential and can be used for effectively removing the nitrate nitrogen in a water body; besides, the effects of fixing carbon, reducing discharge and relieving the non-point source pollution are achieved.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Low-grade aphanitic graphite dressing and purifying method

The invention relates to a low-grade aphanitic graphite dressing and purifying method, belonging to the technical field of graphite purification. The method comprises the following steps: firstly, crushing and grinding aphanitic graphite ores with fixed carbon content of 45-80%; adding a slime flocculant, an inhibitor, a collector and a foamer into the ore pulp, separating by flotation in a mechanical flotation machine, re-grinding and re-separating the flotation concentrate to remove most gangue mineral in the ores, thus obtaining final flotation concentrate; removing iron-contained gangue mineral in the final flotation concentrate by high-gradient magnetic separation, thus being capable of obtaining a product II satisfying the requirements of number WT88 or more. And a product II satisfying the requirements of number W80 can be obtained by re-grinding and re-separating the middling product and concentratedly re-separating the magnetically separated middling product. The total recovery is more than 80%. The low-grade aphanitic graphite dressing and purifying method is low in requirement on fixed carbon content of the ores, capable of effectively reducing iron-contained impurities, large in processing amount, low in production cost and environmental-friendly.

Owner:CENT SOUTH UNIV

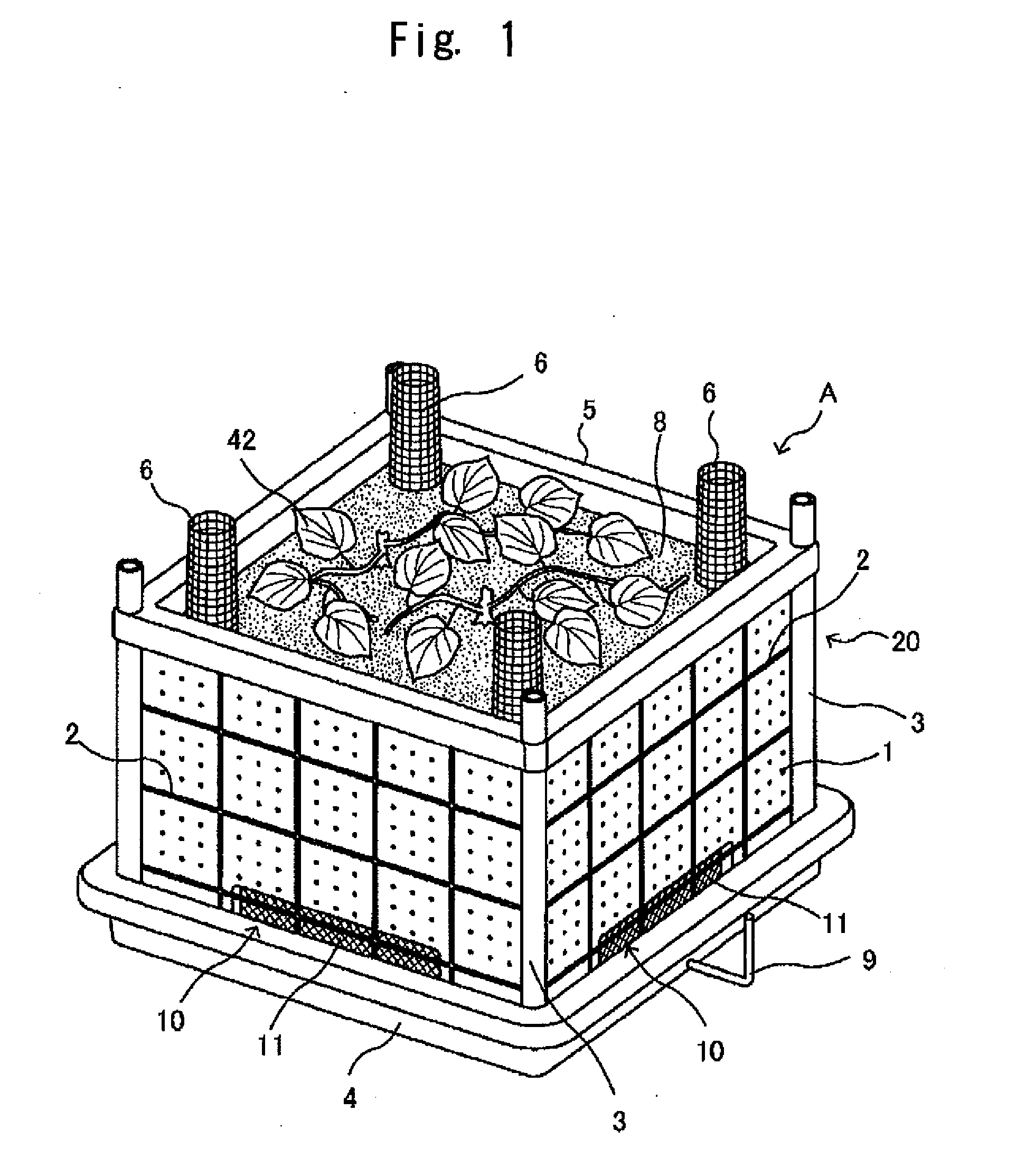

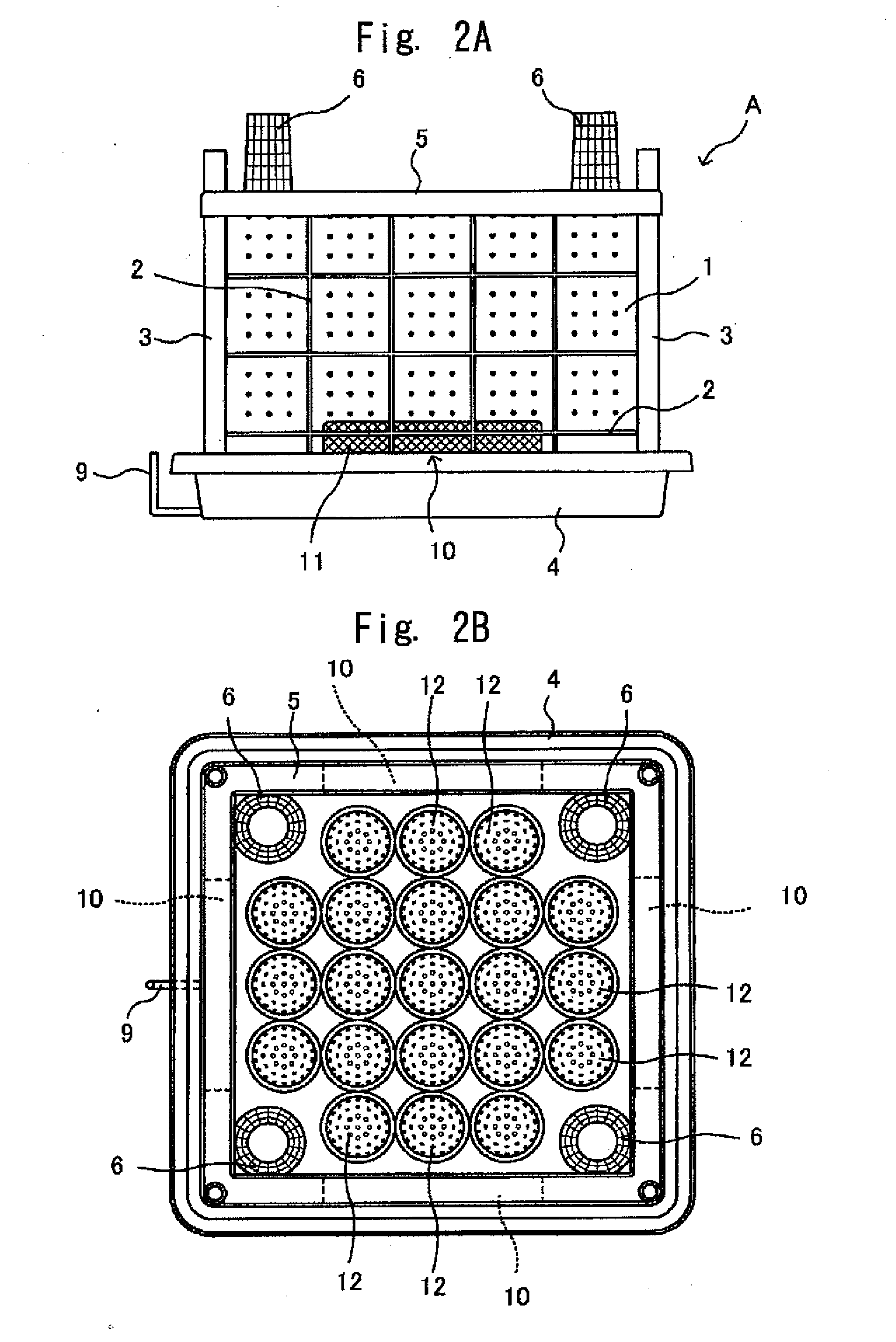

Device for fixing biomass-based solar heat and carbon dioxide gas, and house equipped with same fixing device

InactiveUS20110148124A1Increase ion concentrationPrecise changeMachines/enginesMechanical energy handlingProduction rateWater flow

Owner:PLUS KAKEN INNOVATE LABO

Preparation method and device of high-softening-point asphalt, high-softening-point asphalt, and binding agent prepared from high-softening-point asphalt

ActiveCN102876344AAvoid uncontrollableShort reaction timeWorking-up pitch/asphalt/bitumen by chemical meansBituminous material adhesivesNarrow rangeAsphalt

The invention provides a preparation method of high-softening-point asphalt, which comprises the following steps: introducing modified asphalt into a single container, and introducing inert gas into the single container, wherein the single container is sequentially provided with at least three independent heating zones from top to bottom, an independent heater is arranged in each heating zone, the heating temperatures gradually increase, and the reaction pressure is 0.03-0.05 MPa; and after heating the modified asphalt to the target temperature, keeping the temperature for 6-18 hours, thereby obtaining the high-softening-point asphalt. The invention also provides a preparation device, a prepared high-softening-point asphalt and a binding agent prepared from the high-softening-point asphalt. The invention can control the softening point of the modified asphalt within a narrow range, so that the modified asphalt has more stable quality, and the high-softening-point asphalt and binding agent with high softening point and high fixed carbon content can be prepared.

Owner:山东杰富意振兴化工有限公司

Sludge based activated carbon and production method thereof, and application of sludge based activated carbon in electroplating of chromate-containing waste water

InactiveCN103908949ARealize resourcesSolving Disposal ProblemsSludge treatment by de-watering/drying/thickeningOther chemical processesActivated carbonActivated sludge

The invention discloses sludge based activated carbon and a production method thereof, and application of the sludge based activated carbon in electroplating of chromate-containing waste water. The sludge based activated carbon is characterized by being prepared by the following steps: drying and activating sludge, performing microwave treatment, washing, and baking, wherein the sludge activated carbon comprises 13-29% of volatile component, 32-50.1% of ash content and 28.79-43.56% of fixed carbon, the specific surface area is 260-450m<2> / g, and the mean pore size is 3.179nm. The sludge activated carbon is used as an adsorbent in electroplating treatment of the chromate-containing waste water; the production method is simple, the superficial area of the sludge based activated carbon produced by micro-wave heating and steam activating methods is significantly enlarged, the sludge based activated carbon is good in adsorptive property, is low in cost, changes waste into treasures, the problem of sludge disposal is solved, and reclamation of the sludge is achieved.

Owner:HUNAN CITY UNIV

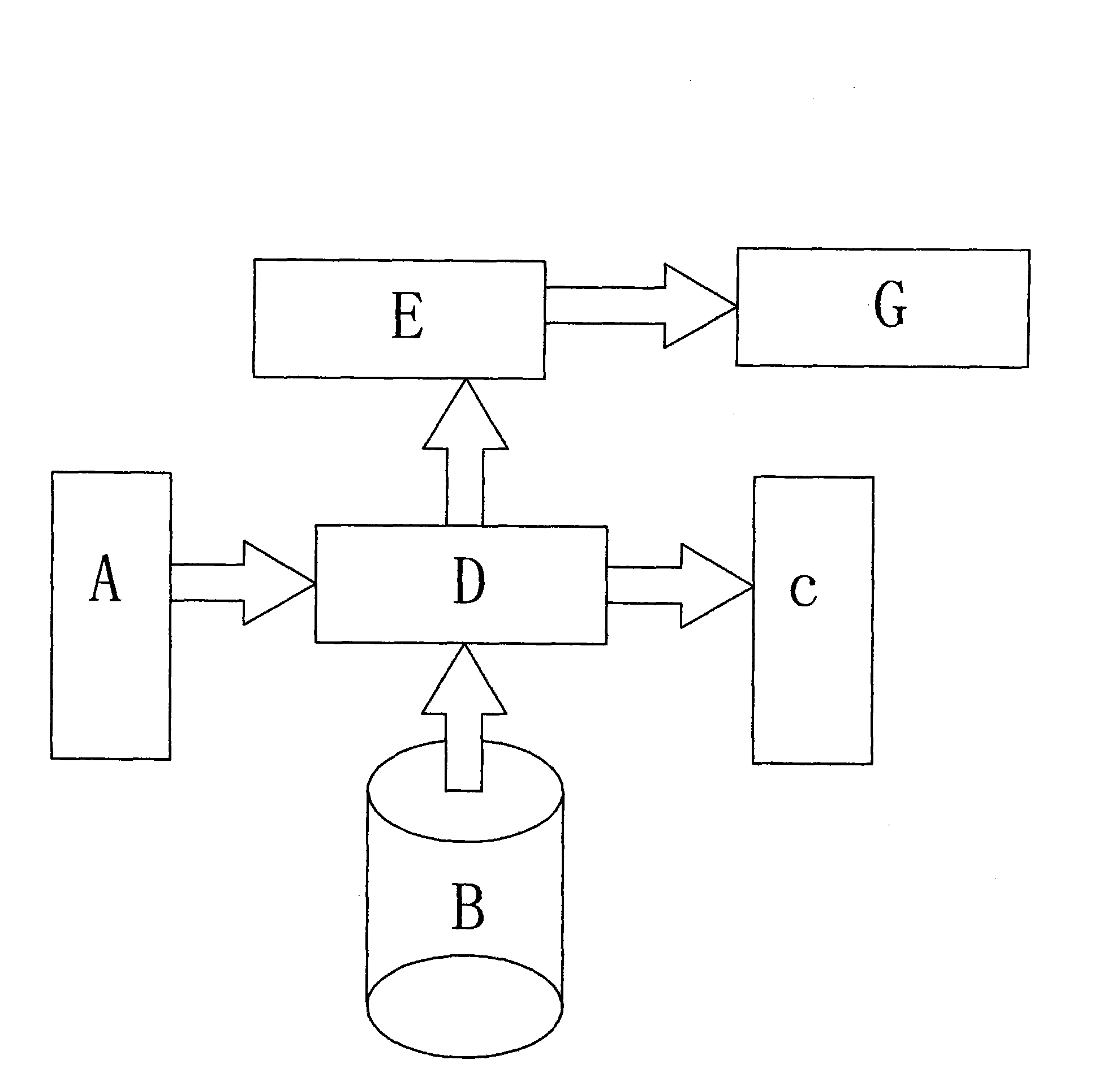

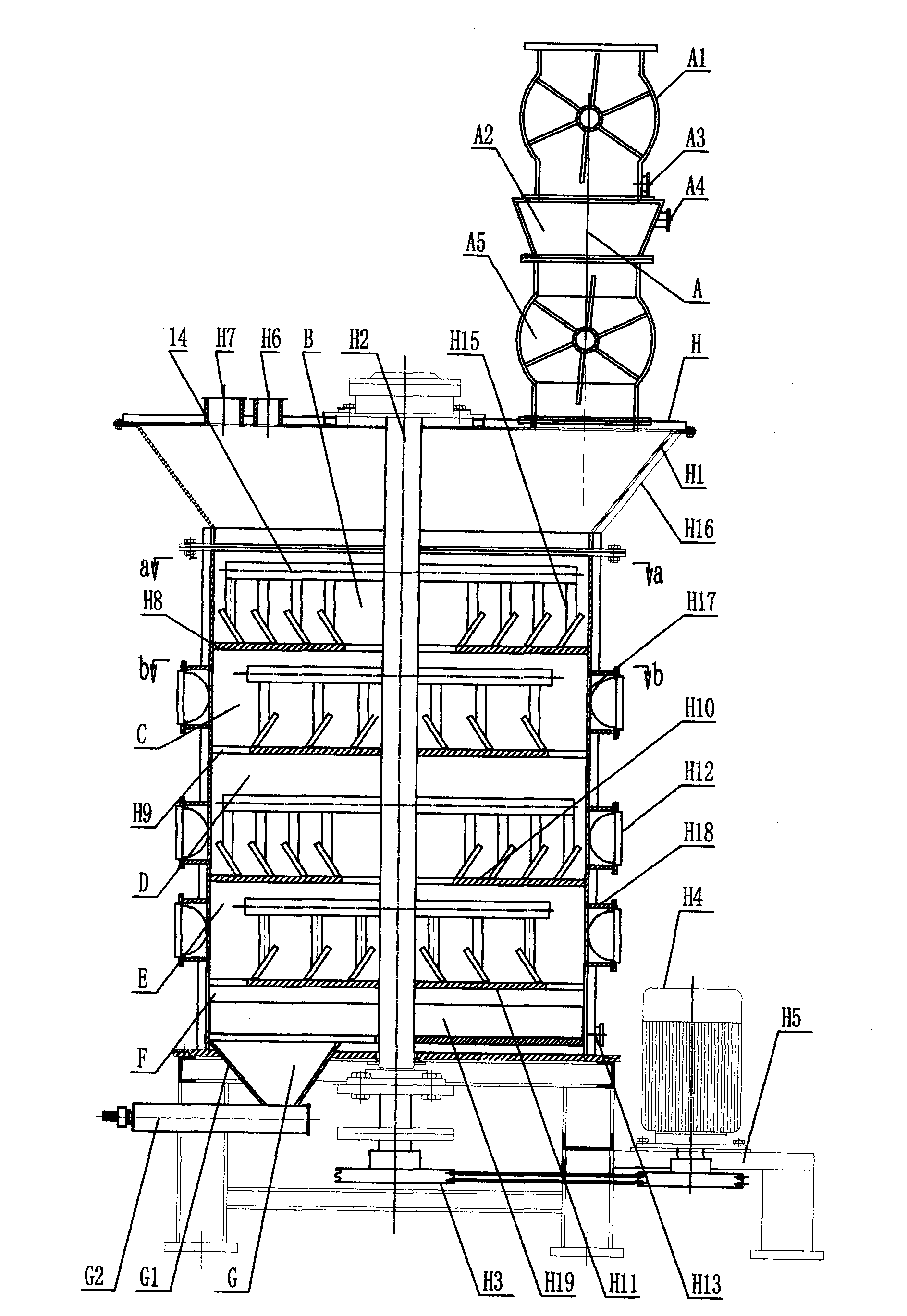

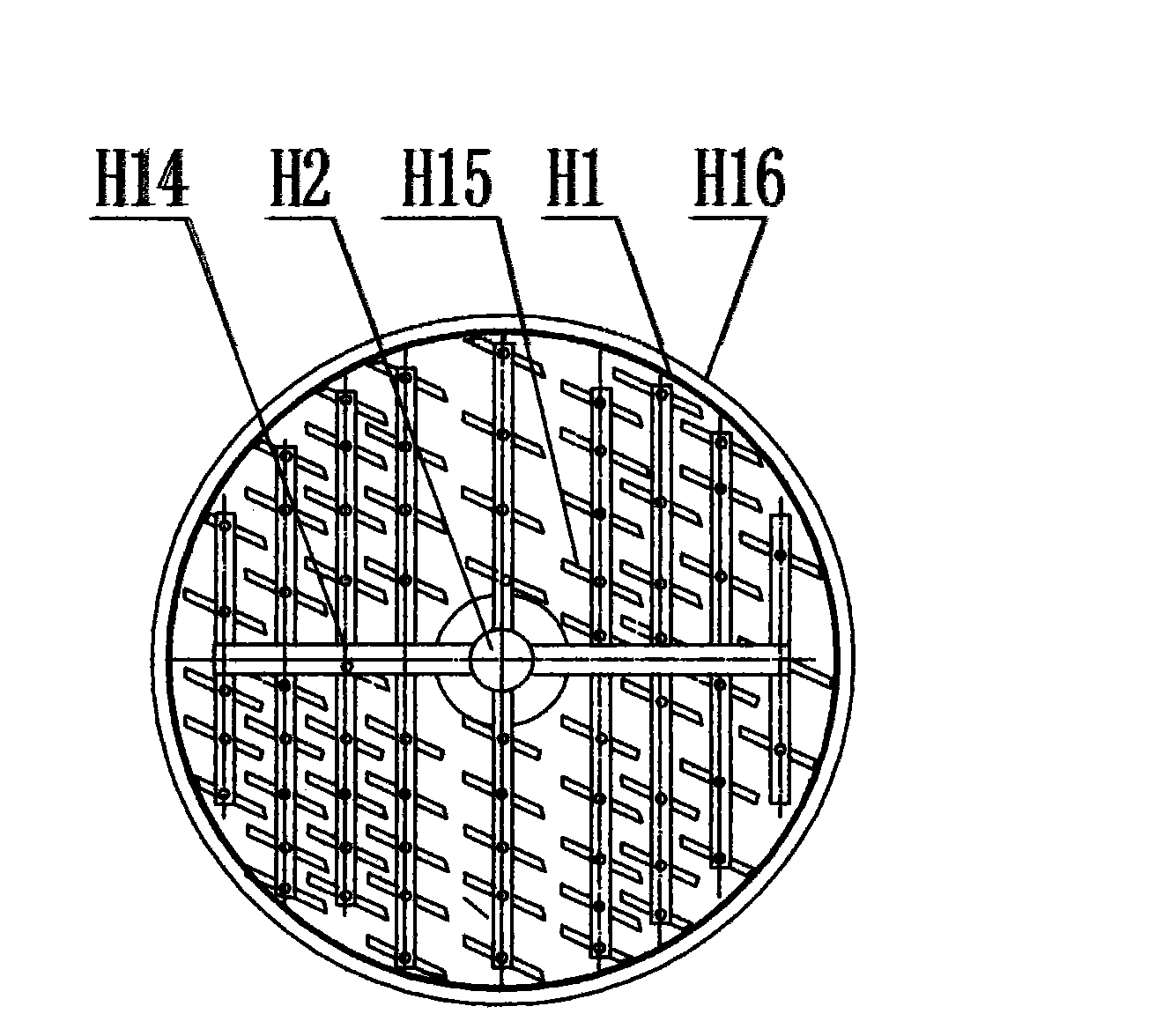

Garbage microwave pyrolysis comprehensive treatment system and method and equipment used by same

InactiveCN101797578AReduce oxygen contentLower operating temperatureSolid waste disposalHydrocarbon distillationLiquid productFuel oil

The invention discloses a garbage microwave pyrolysis comprehensive treatment system and a method and equipment used by the same, aiming to solve the problems of microwave pyrolysis treatment, and the method and equipment used by the system. The comprehensive treatment system comprises a municipal solid waste (MSW) preprocessing system A, a vertical garbage continuous microwave heating low temperature cracking furnace B, a solid product activated carbon production system C, a pyrolysis gas preparation fuel gas system D, a liquid product distilled extraction light oil and fuel oil system F and a matched sewage treatment system G, wherein the MSW preprocessing system A, the solid product activated carbon production system C and the pyrolysis gas preparation fuel gas system D are respectively connected with the vertical garbage continuous microwave heating low temperature cracking furnace B; and the liquid product distilled extraction light oil and fuel oil system F is connected with the oil recovery pipeline of the pyrolysis gas preparation fuel gas system D. The invention has the advantage that: low carbon emission is realized in the treatment process under the reducing atmosphere, fixed carbon in the garbage is emitted without violent toxicity like dioxin and heavy metal solid powder, the treated wastewater can be recycled and max garbage resource recycling is realized.

Owner:深圳市兖能环保科技有限公司

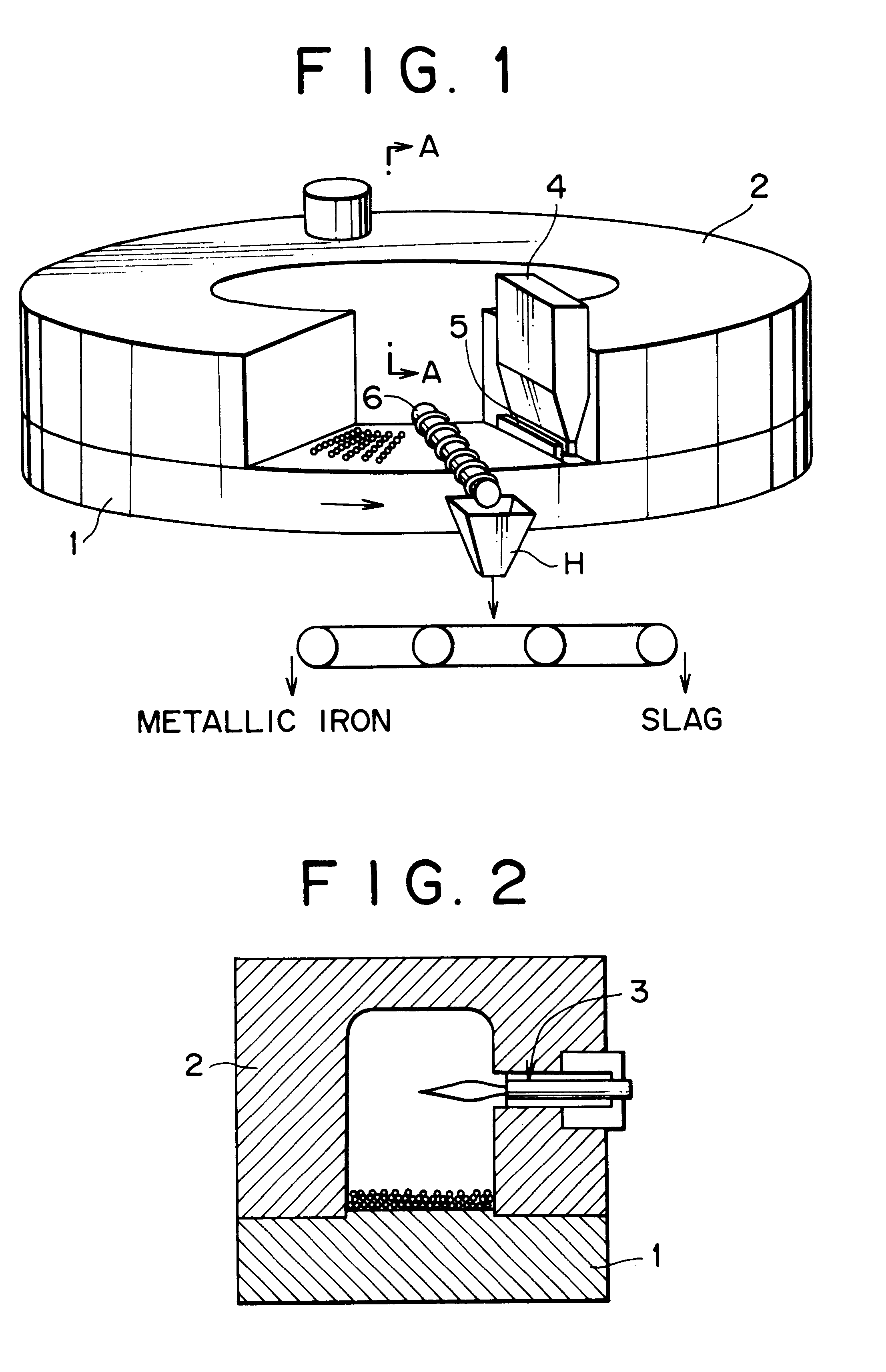

Rapid technical analysis method of coal

ActiveCN101377483AReduce total time for industrial analysis testingEliminate experimental errorWeighing by removing componentFuel testingTested timeEngineering

Owner:HUNAN SUNDY SCI & TECH DEV

Genetically Engineered Microorganisms that Metabolize Xylose

The invention provides methods of cultivating oil-bearing microbes using xylose as a fixed carbon source. Also provided are microorganisms that have been genetically engineered to metabolize xylose as a fixed carbon source allowing them to convert xylose into oils. Particular advantages of the processes provided herein include production of oils rather than alcohols through the microbial fermentation processes utilizing xylose.

Owner:CORBION BIOTECH INC

Genetically engineered microorganisms that metabolize xylose

The invention provides methods of cultivating oil-bearing microbes using xylose as a fixed carbon source. Also provided are microorganisms that have been genetically engineered to metabolize xylose as a fixed carbon source allowing them to convert xylose into oils. Particular advantages of the processes provided herein include production of oils rather than alcohols through the microbial fermentation processes utilizing xylose.

Owner:CORBION BIOTECH INC

Double-layered alkali grain covering agent for middle ladle

The present invention relates to a double-layered alkali grain heat-insulting covering agent for middle ladle. The heat-insulting covering agent consists of top slag in 10-50 wt% and bottom slag in 50-90 wt%. The bottom slag consists of SiO2 8-15 wt%, CaO 50-60 wt%, MgO 10-20 wt%, Al2O3 1-5 wt%, Fe2O3 1-3 wt%, and fixed carbon 0.01-1 wt%. The top slag consists of SiO2 85-93 wt%, CaO 0.001-3 wt%, MgO 0.001-3 wt%, Al2O3 0.001-3 wt%, Fe2O3 0.003-0.5 wt%, and fixed carbon 0.01-1 wt%. The heat-insulting covering agent forms two layers of slag, the bottom layer covers molten steel to prevent secondary oxidation, reduce carbon content in molten steel and adsorb alumina floating to the surface of molten steel, and the top layer in porous and loose structure covers molten steel to prevent incrusting and carburization.

Owner:上海宝谊保温材料有限公司

Multifunctional bio-charcoal and preparation method thereof

The invention relates to a multifunctional bio-charcoal and a preparation method thereof. According to the technical scheme, the preparation method comprises the steps of dipping biomass into 1-15wt% caustic alkali solution for 1-50h, washing with water to be neutral, and drying to obtain treated biomass; then charring the treated biomass in a tube furnace in mixed gas at 300-900 DEG for 1-130h to obtain the multifunctional bio-charcoal. The biomass is one of rice straw, wheat straw, sawdust, wood, green grass, fruit peel and animal tissue waste; the biomass contains 30-60wt% of volatile organic carbon of charcoal, 10-40wt% of fixed carbon, 1-30wt% of ash and 10-60wt% of water. The preparation method disclosed by the invention has the characteristics of low production cost, high yield, simple process, controllable production process and environment friendliness, and the prepared multifunctional bio-charcoal has a good adsorption effect on heavy metals and high stability and can be used for repairing water bodies, solid matrixes and soil which are polluted by heavy metals.

Owner:WUHAN UNIV OF SCI & TECH

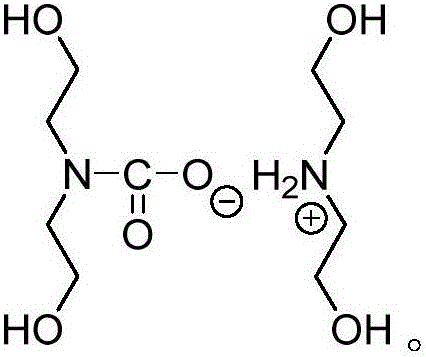

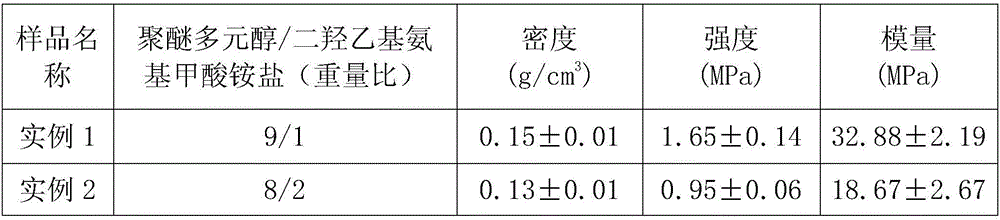

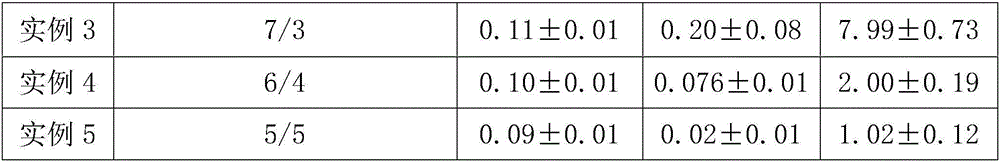

Polyurethane foam material with carbon dioxide as environment-friendly latent foaming agent and preparing method thereof

The invention relates to a polyurethane foam material with carbon dioxide as an environment-friendly latent foaming agent. The latent foaming agent is prepared from, by weight, 50-90 parts of polyether polyol, 10-50 parts of dihydroxyethyl ammonium carbamate, 125-212 parts of isocyanate, 2-5 parts of foam stabilizer and 0.5-1 part of catalyst. The preparing method of the polyurethane foam material includes the following steps that dihydroxyethyl ammonium carbamate is prepared; polyether polyol, dihydroxyethyl ammonium carbamate, foam stabilizer and catalyst are added into a plastic beaker to obtain a uniform mixture; isocyanate is added, and foaming is carried out freely at the normal temperature. The preparing method has the advantages that diethanol amine reacts with carbon dioxide to fix carbon dioxide so as to prepare dihydroxyethyl ammonium carbamate, the dihydroxyethyl ammonium carbamate serves as the environment-friendly latent foaming agent to prepare rigid polyurethane foam, which achieves environment protection and environment friendliness, and the rigid polyurethane foam is good in performance.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com