Preparation method for oxidized graphene-poly-dopamine composite aerogel

A technology of composite airgel and polydopamine, which is applied in the direction of chemical instruments and methods, alkali metal oxides/hydroxides, alkali metal compounds, etc., can solve the problem of affecting the adsorption capacity of airgel materials and cannot be applied to the field of sewage treatment, Structural stability is difficult to guarantee and other problems, to achieve the effect of environmental friendliness, integrity and stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

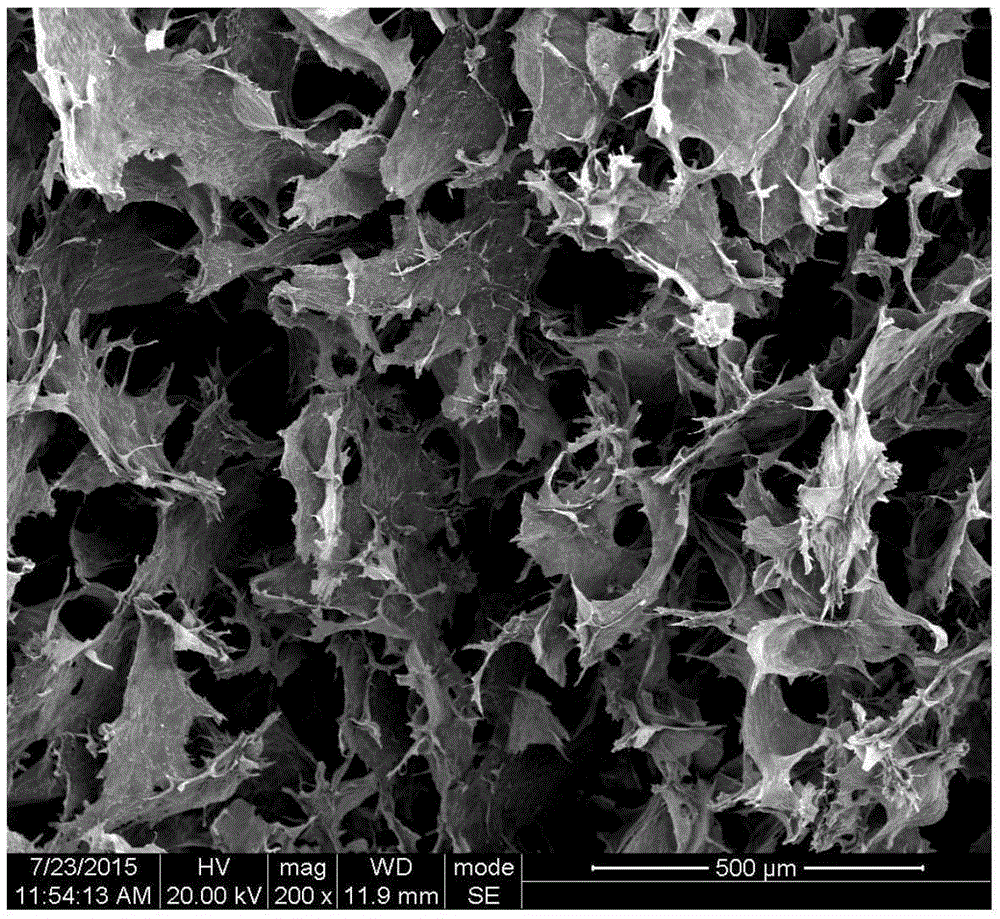

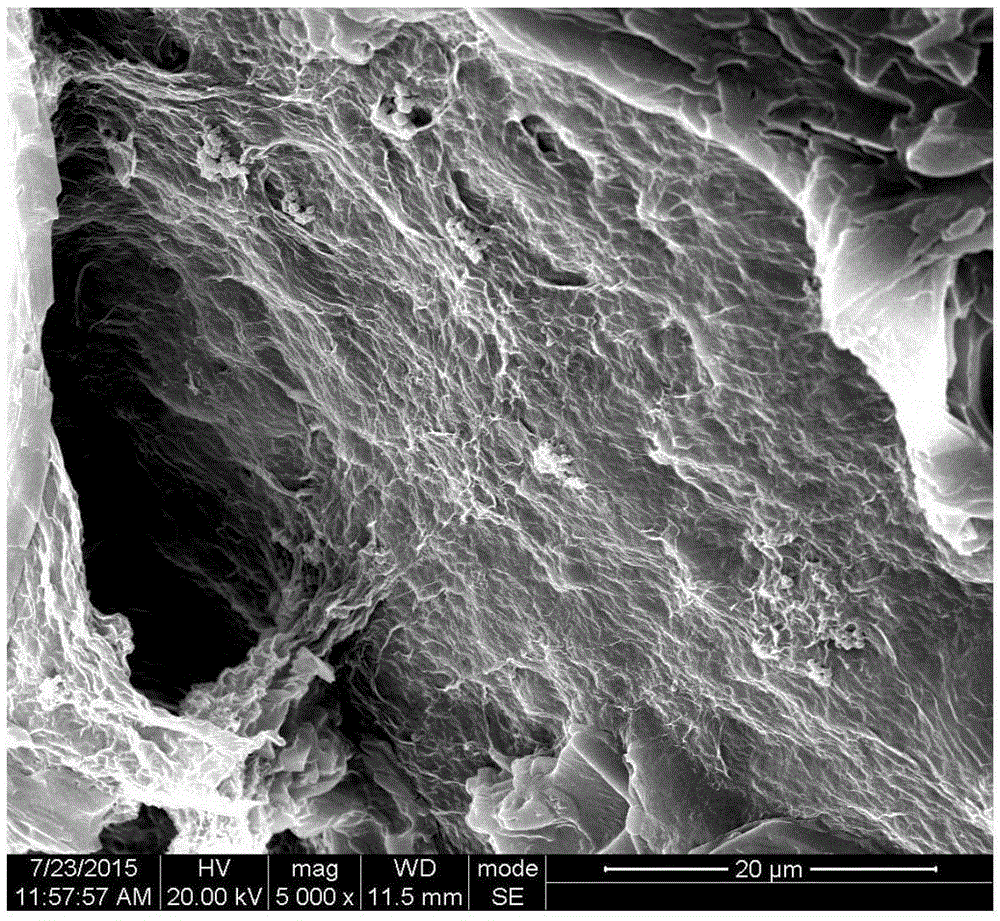

[0034] A preparation method of graphene oxide / polydopamine composite airgel, the steps are as follows:

[0035] A. Dissolve 0.6g of dopamine powder in 10ml of distilled water, mix it with 50ml of graphene oxide aqueous solution whose concentration is 6mg / ml at room temperature, stir for 30min, and the stirring speed is 60r / min to obtain graphene oxide / dopamine mixed solution;

[0036] B. While stirring, add 3mL of tris buffer solution with a concentration of 0.1mol / L dropwise in the graphene oxide / dopamine mixed solution, continue stirring for 2h after the addition is completed, and the stirring speed is 60r / min; Then stand still for 24 hours to fully polymerize dopamine to obtain graphene oxide / polydopamine composite hydrogel;

[0037] C. After freezing the graphene oxide / polydopamine composite hydrogel at -20°C for 24h, freeze-drying at a pressure of 20Pa and -50°C for 48h, the graphene oxide / polydopamine composite airgel was obtained .

[0038] The graphene oxide in the gra...

Embodiment 2

[0042] A preparation method of graphene oxide / polydopamine composite airgel, the steps are as follows:

[0043] A. Dissolve 0.3g of dopamine powder in 10ml of distilled water, mix it with 50ml of graphene oxide aqueous solution whose concentration is 6mg / ml at room temperature, stir for 30min, and the stirring speed is 60r / min to obtain graphene oxide / dopamine mixed solution;

[0044] B. While stirring, add 9mL of tris buffer solution with a concentration of 0.1mol / L dropwise in the graphene oxide / dopamine mixed solution, continue stirring for 2h after the addition is completed, and the stirring speed is 60r / min; Then stand still for 24 hours to fully polymerize dopamine to obtain graphene oxide / polydopamine composite hydrogel;

[0045] C. After freezing the graphene oxide / polydopamine composite hydrogel at -20°C for 24 hours, freeze-drying at a pressure of 20Pa and -50°C for 48 hours, the graphene oxide / polydopamine composite airgel was obtained .

[0046] The graphene oxid...

Embodiment 3

[0048] A preparation method of graphene oxide / polydopamine composite airgel, the steps are as follows:

[0049] A. Dissolve 0.7g of dopamine powder in 18ml of distilled water, compound and mix with 60ml of graphene oxide aqueous solution whose concentration is 5mg / ml at room temperature, stir for 40min, and the stirring speed is 80r / min to obtain graphene oxide / dopamine mixed solution;

[0050] B. Add 6mL tris buffer solution with a concentration of 0.12mol / L to the graphene oxide / dopamine mixed solution dropwise while stirring, and continue stirring for 2.5h after the addition is completed, at a stirring speed of 80r / min ; Then let it stand for 30 hours to fully polymerize dopamine to obtain graphene oxide / polydopamine composite hydrogel;

[0051] C. After freezing the graphene oxide / polydopamine composite hydrogel at -10°C for 30h, freeze-drying at a pressure of 30Pa and -60°C for 50h, the graphene oxide / polydopamine composite airgel was obtained .

[0052] The graphene ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com