Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1785 results about "Coal slurry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal slurry is a mixture of solids (mined coal) and liquids (water or organic) produced by a coal preparation plant.

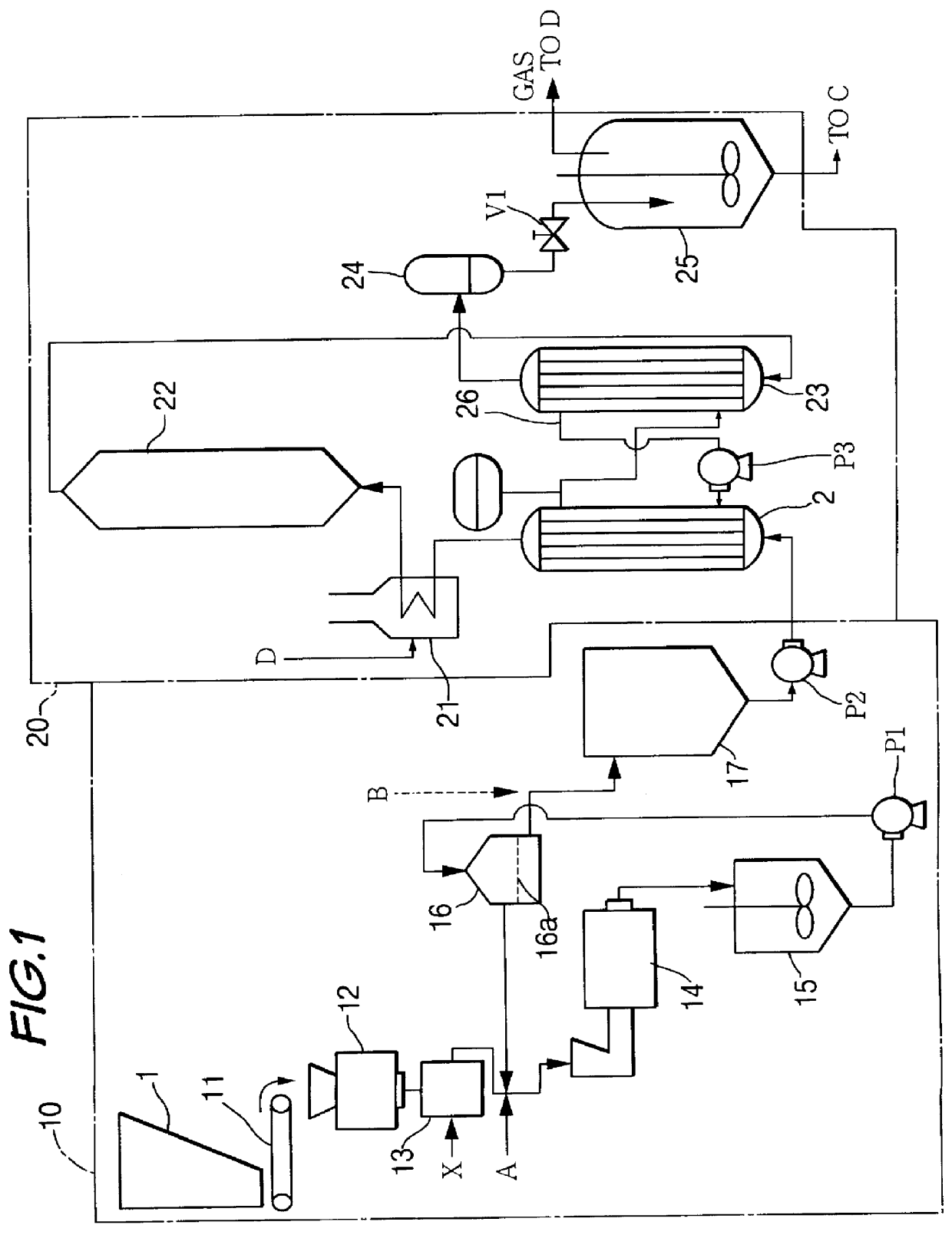

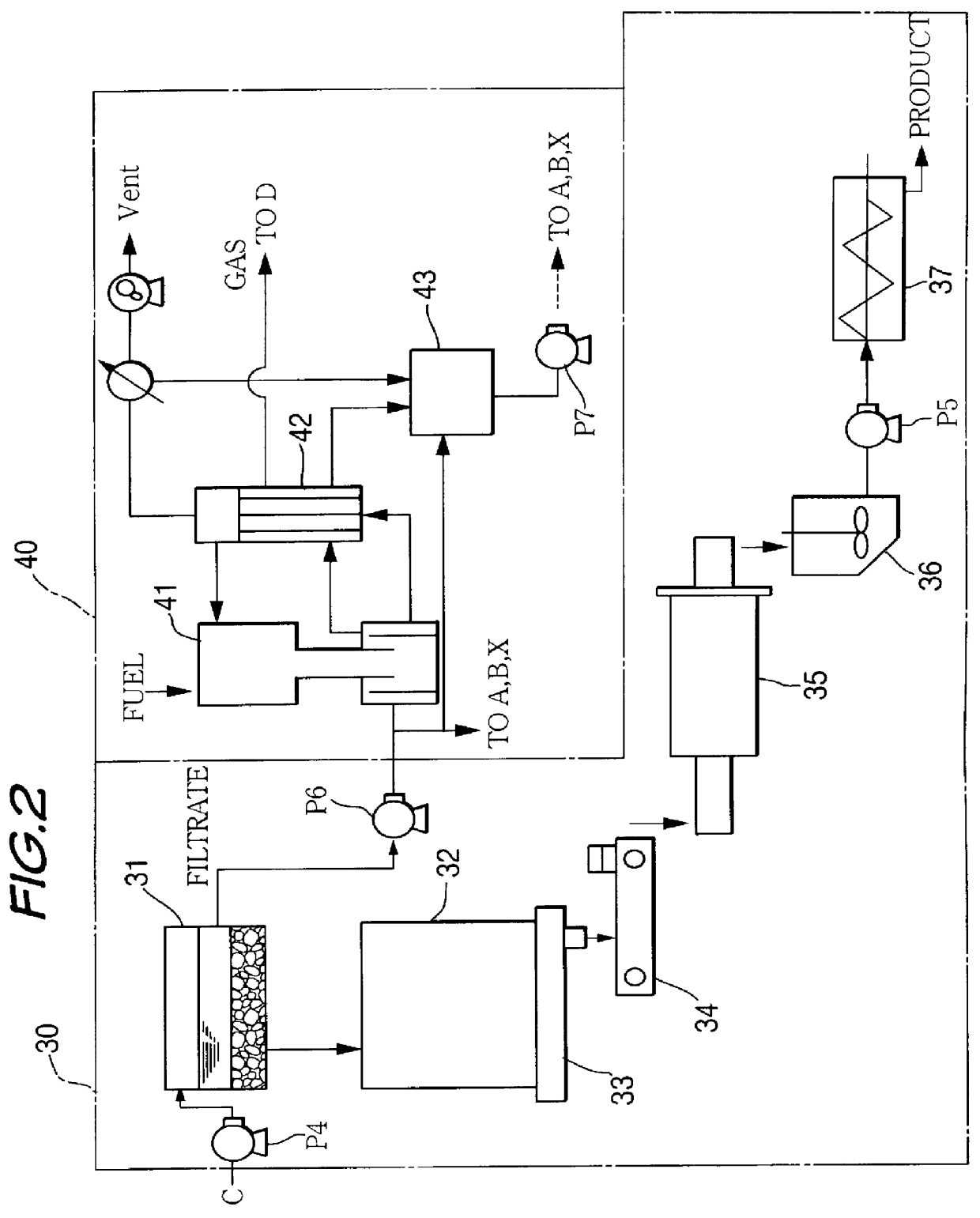

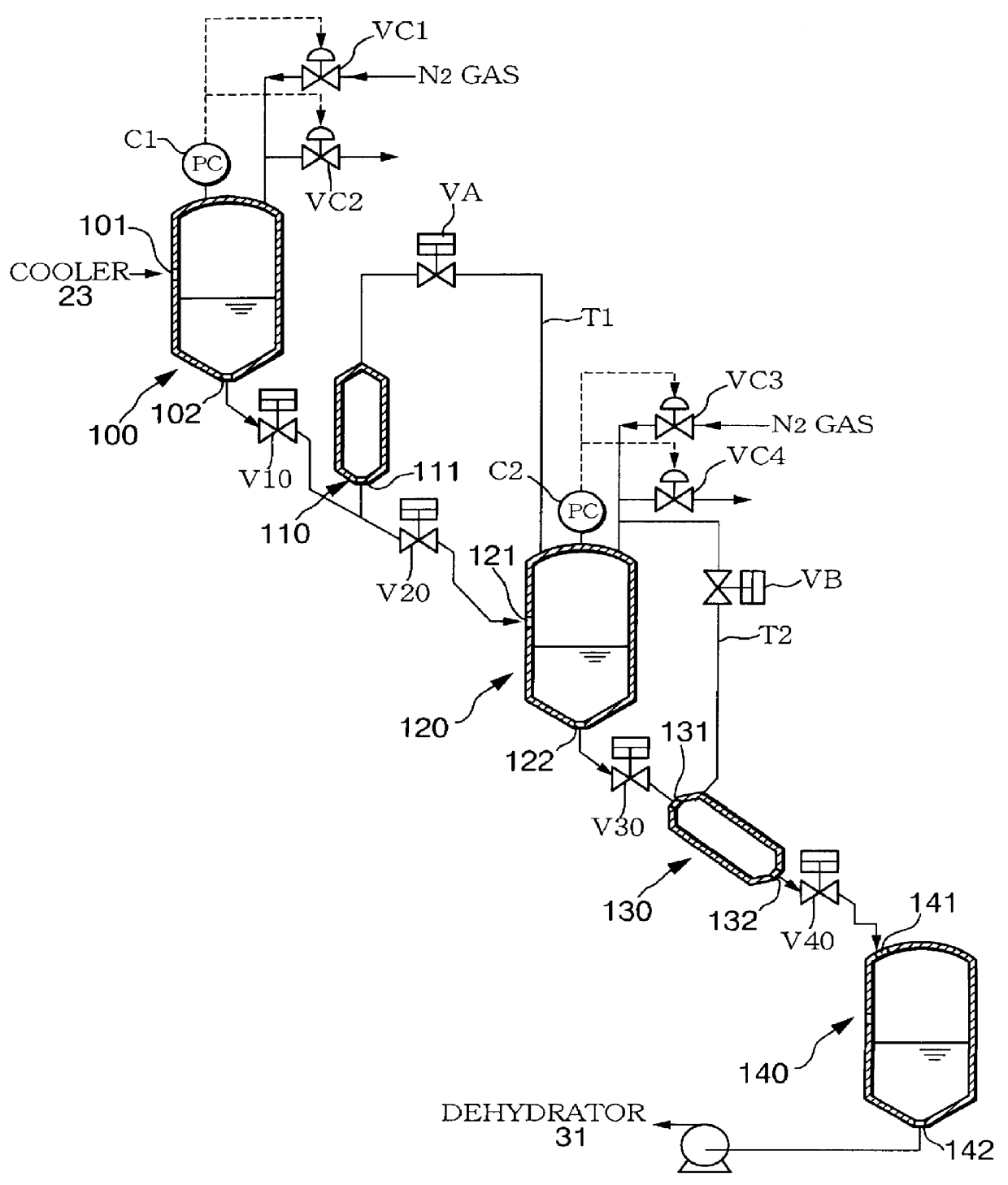

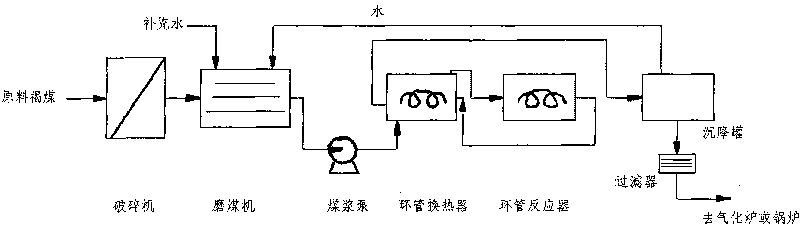

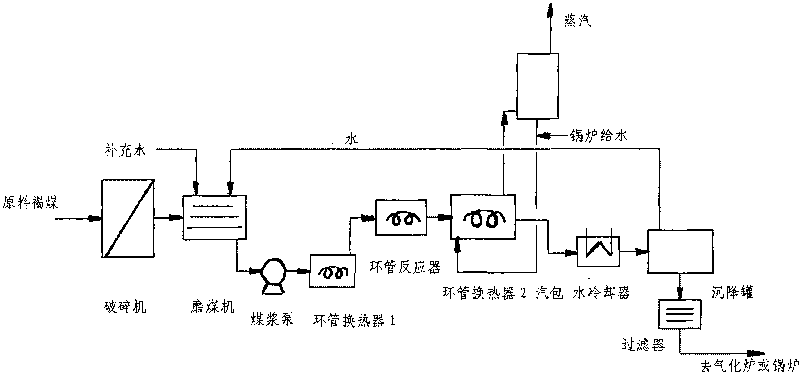

Coal-water slurry producing process, system therefor, and slurry transfer mechanism

In a coal-water slurry producing system, low grade coal is wet-ground to not greater than 3 mm in particle size to produce a ground coal slurry. An upgrading treatment is applied to the ground coal slurry under a pressurized hydrothermal atmosphere not less than 300 DEG C. to produce an upgraded coal slurry. The upgraded coal slurry is subjected to a dehydration treatment to produce an upgraded coal cake and a filtrate. A final coal-water slurry is produced from the upgraded coal cake. The filtrate is recycled for producing the ground coal slurry. A slurry transfer mechanism is provided in the coal-water slurry producing system for ensuring a stable transfer of the upgraded coal slurry from a high-pressure slurry vessel to a low-pressure slurry vessel.

Owner:JGC CORP

Fuel pellet briquettes from biomass and recovered coal slurries

The invention makes burnable renewal fuel (RF) briquettes from recovered coal from coal slurry ponds, biomass, and a binder. The briquettes may be augmented with one or more of recovered environmental burnable fraction from municipal solid waste (MSW), agricultural livestock waste, lumber processing residue, solid wood waste material, agricultural by-products and crops, and like burnable waste material. Accordingly, the method for making burnable renewal fuel (RF) briquettes includes the steps of recovering coal from coal slurry ponds; recovering biomass; adding a binder to said recovered coal and said biomass; and forming solid burnable RF fuel briquettes therefrom.

Owner:NEW ENERGY USA

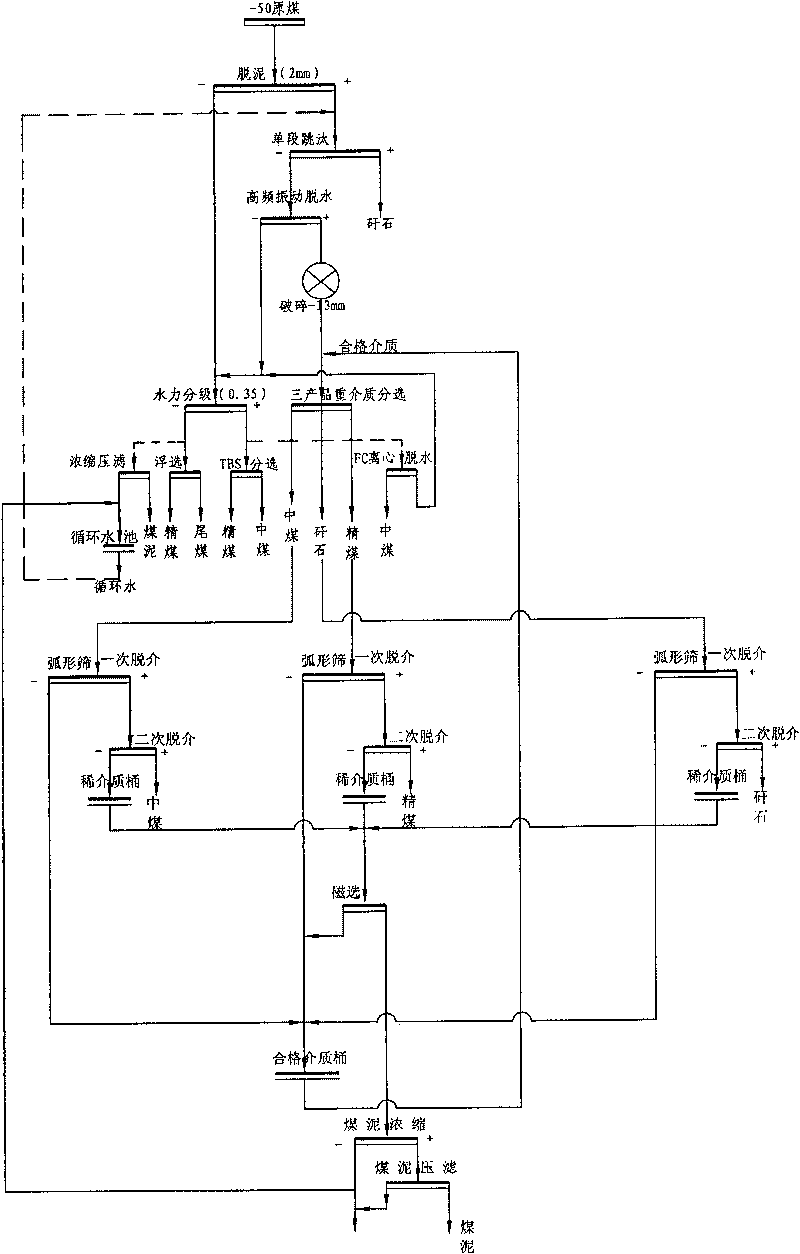

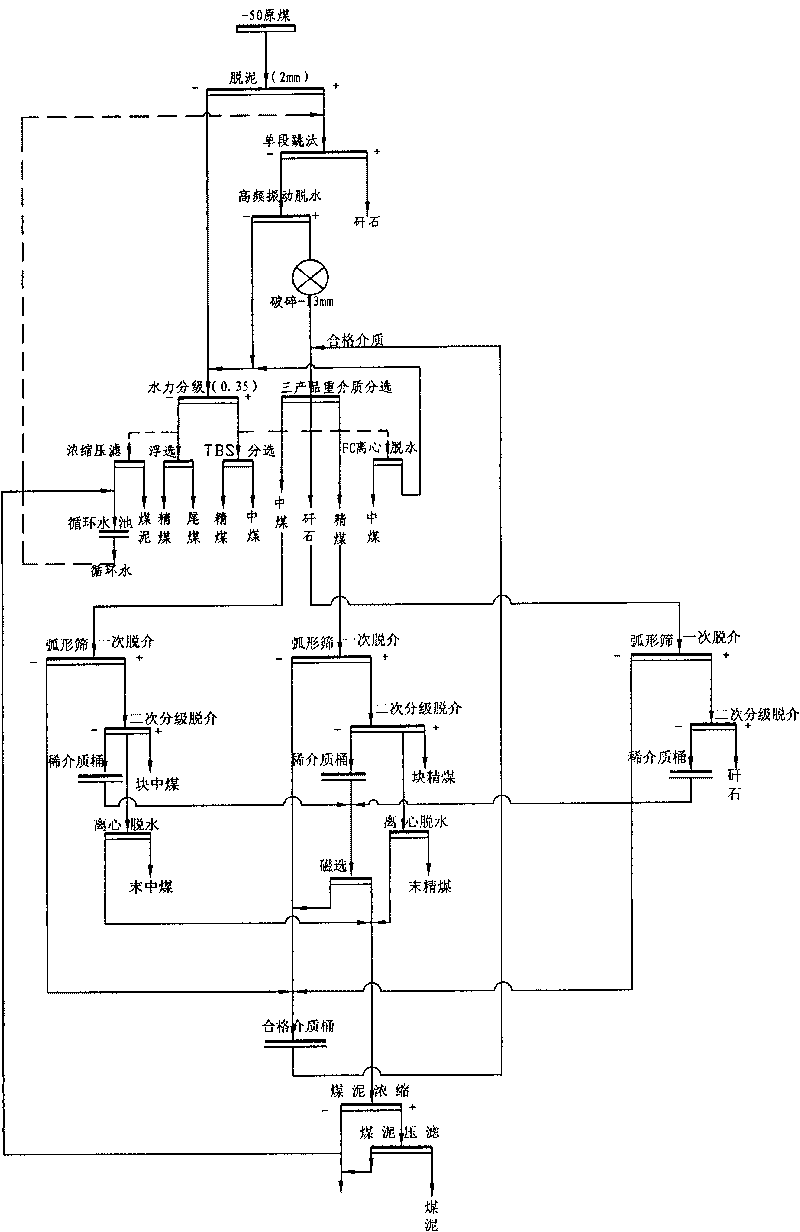

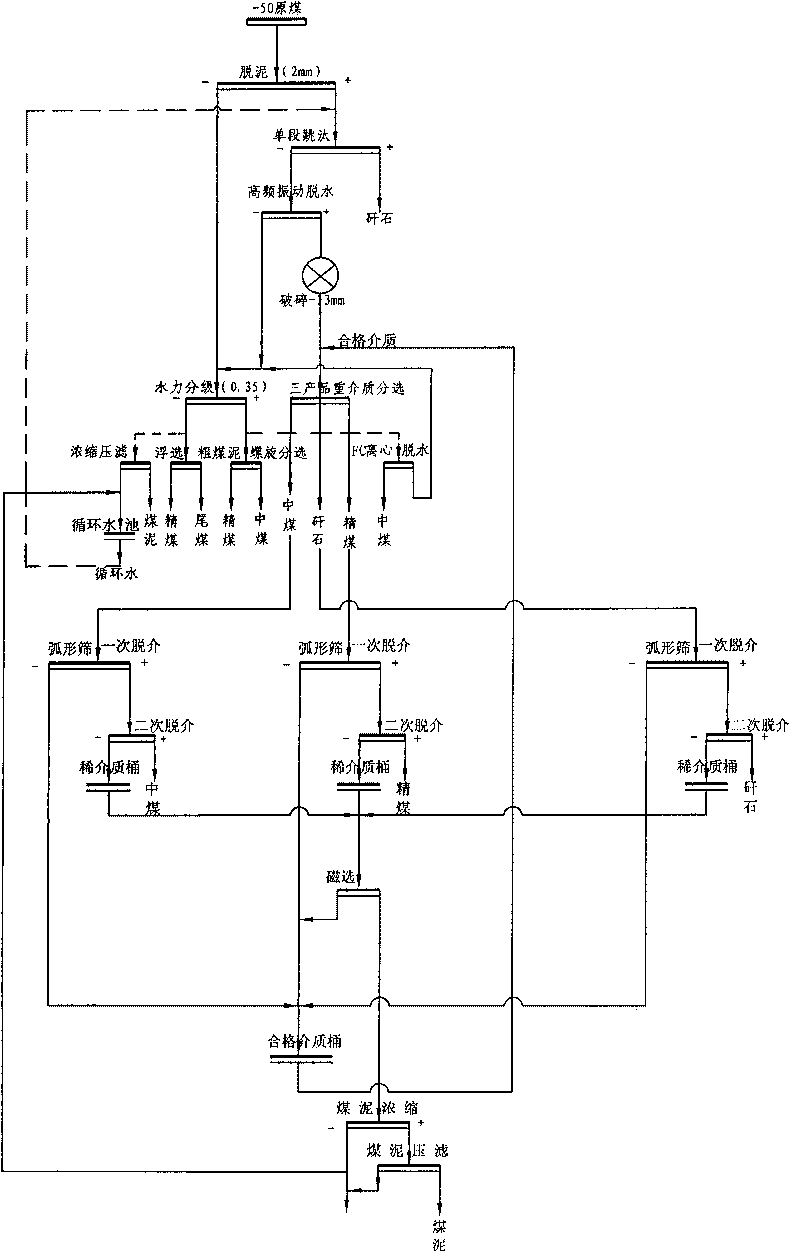

Raw coal washing process capable of realizing non-polar ash conditioning

InactiveCN101716552AReduce the amount of re-insertionReduce manufacturing costWet separationCycloneSingle stage

The invention provides a raw coal washing process capable of realizing non-polar ash conditioning. The process comprises the following steps: a, desliming and screening the part of raw coal with granularity less than 50 to 100mm; b, carrying out single stage jigging separation on screen products on a desliming screen; c, crushing lump coal obtained from the step b, namely screen products on an oscillating screen, by a crushing machine; d, feeding the crushed products from the step c into a three-product heavy medium cyclone for separation; e, respectively treating underflows and overflows obtained from a hydroclone in the step c; f, carrying out TBS separation or centrifugal dehydration treatment on the underflows of the hydroclone from the step e; g, respectively carrying out primary medium removal on clean coal, middlings coal and gangue obtained from the step d; h, respectively carrying out secondary medium removal and dehydration on the three products from the step g; and i, carrying out magnetic separation on undersize dilute medium obtained by secondary medium removal on the coal gangue in the clean coal in the step h, feeding the separated magnetite powder into a qualified medium tank, collecting residues, and carrying out coal slurry concentration.

Owner:HENAN POLYTECHNIC UNIV

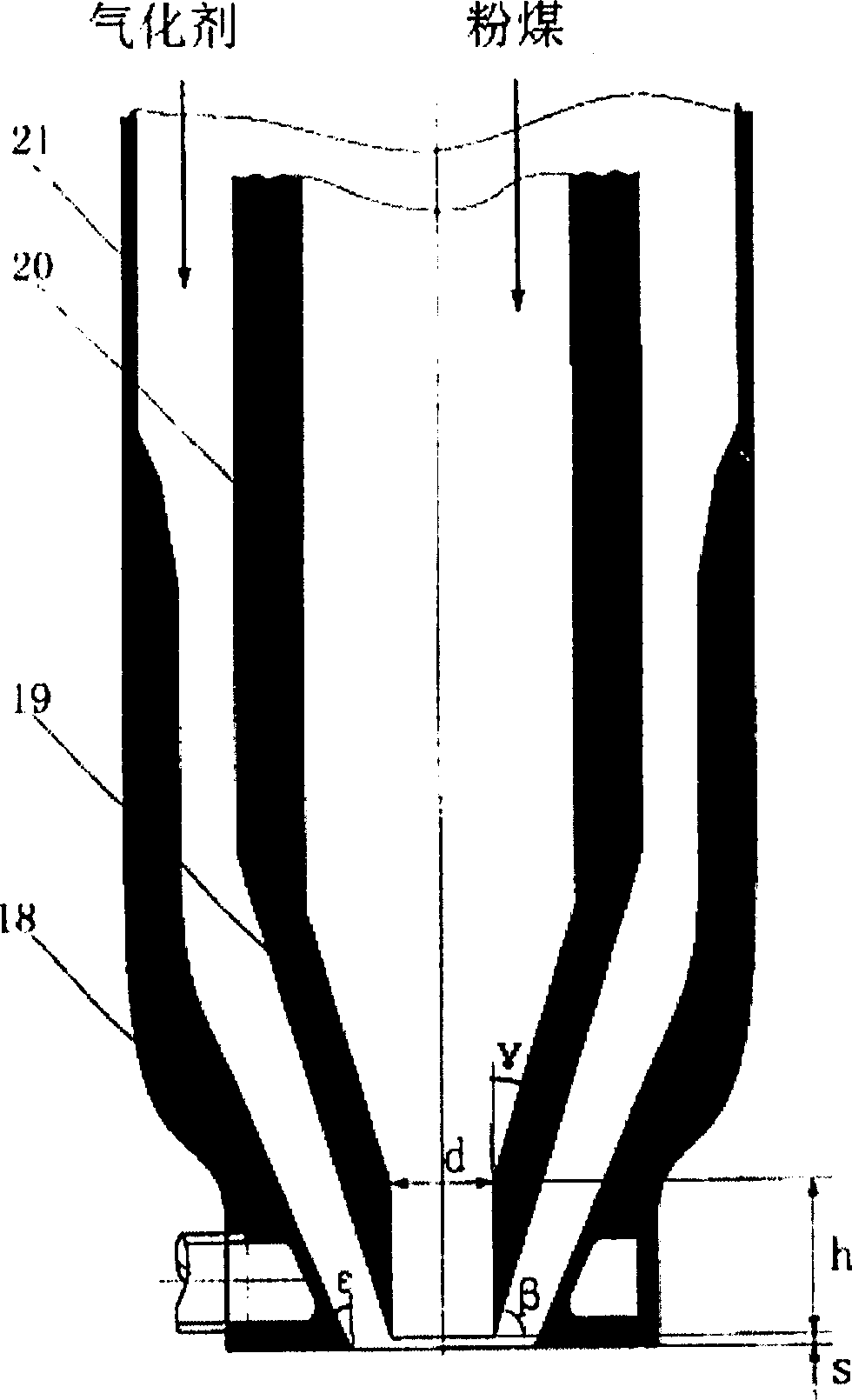

Multi-nozzle coal water mixture or fine coal gasifying furnace and its industrial application

ActiveCN1775920AUniform temperature distributionLess investmentCombined combustion mitigationGranular/pulverulent flues gasificationCoal waterSlag

The invention discloses a plural muzzles coal water slurry or fine coal gasification furnace used for gasifying coal water slurry or fine coal. The gasification room is made up of case, process muzzle room, process muzzle, preheating muzzle room, and preheating muzzle. The case has firebricks in it and washing cooling room is made up of chilling circle, down take, vesicle breaking stick and roughing slag outlet. The transforming ratio of the furnace is over 98%, and is especially suited for large scale gasification produce technology that produces 3000-5000T / day.

Owner:EAST CHINA UNIV OF SCI & TECH

Water coal slurry preparing method

The invention discloses a water coal slurry preparing method and particularly discloses a method for preparing high-concentration water coal slurry by using low-rank coal, such as brown coal. The water coal slurry is especially suitable as water coal slurry for gasification. The water coal slurry preparing method sequentially comprises the following steps of 1 smashing and drying coal, 2 extruding smashed and dried coal so as to destroy and / or seal at least one part of a pore structure of the coal and reduce water absorption of pores formed in the coal, 3 adopting a wet method or a dry method to grind the extruded coal and preparing the extruded coal into the water coal slurry, wherein a dispersing agent is added into the coal or the water coal slurry at a grinding stage or a water coal slurry preparing stage.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

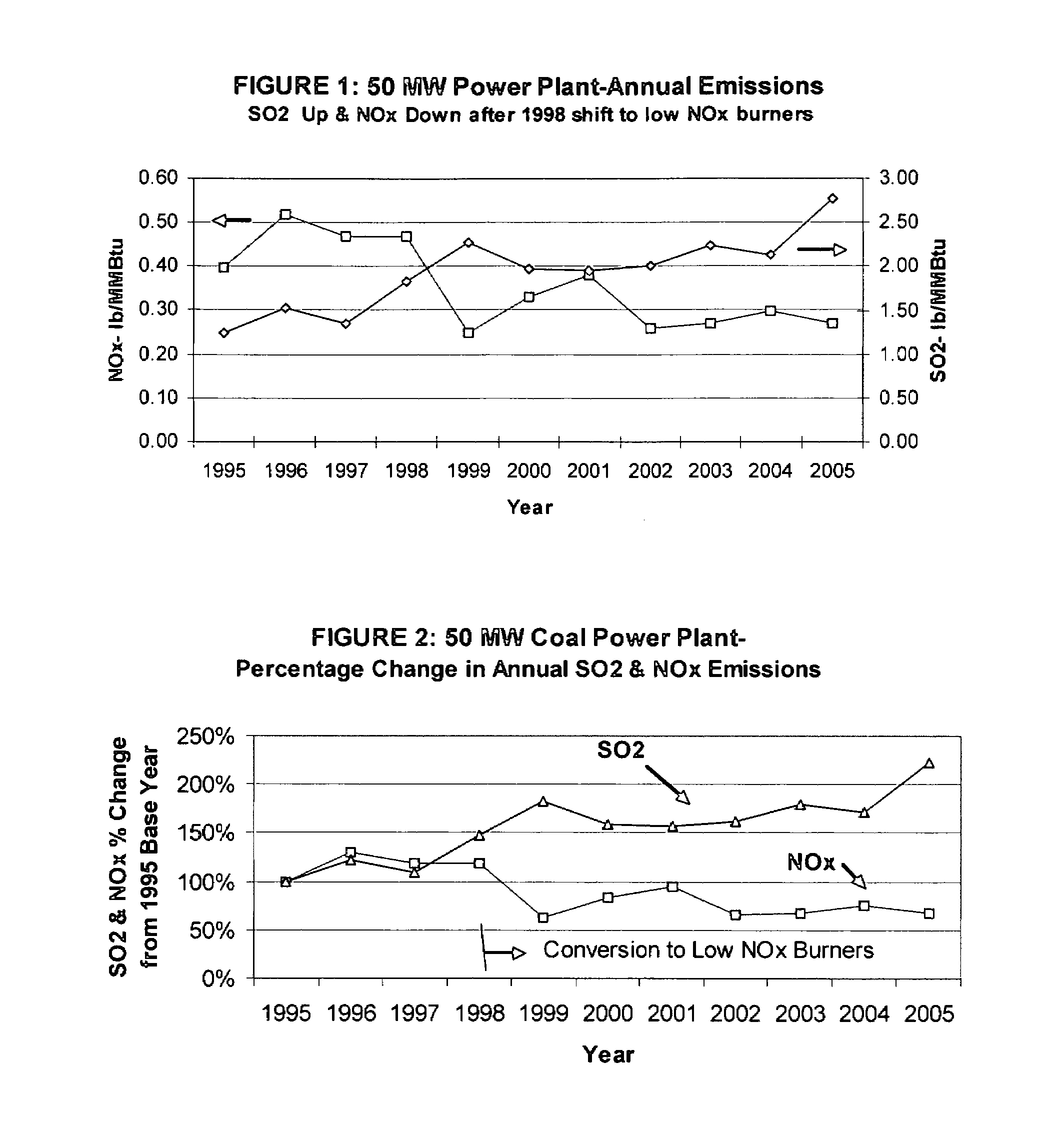

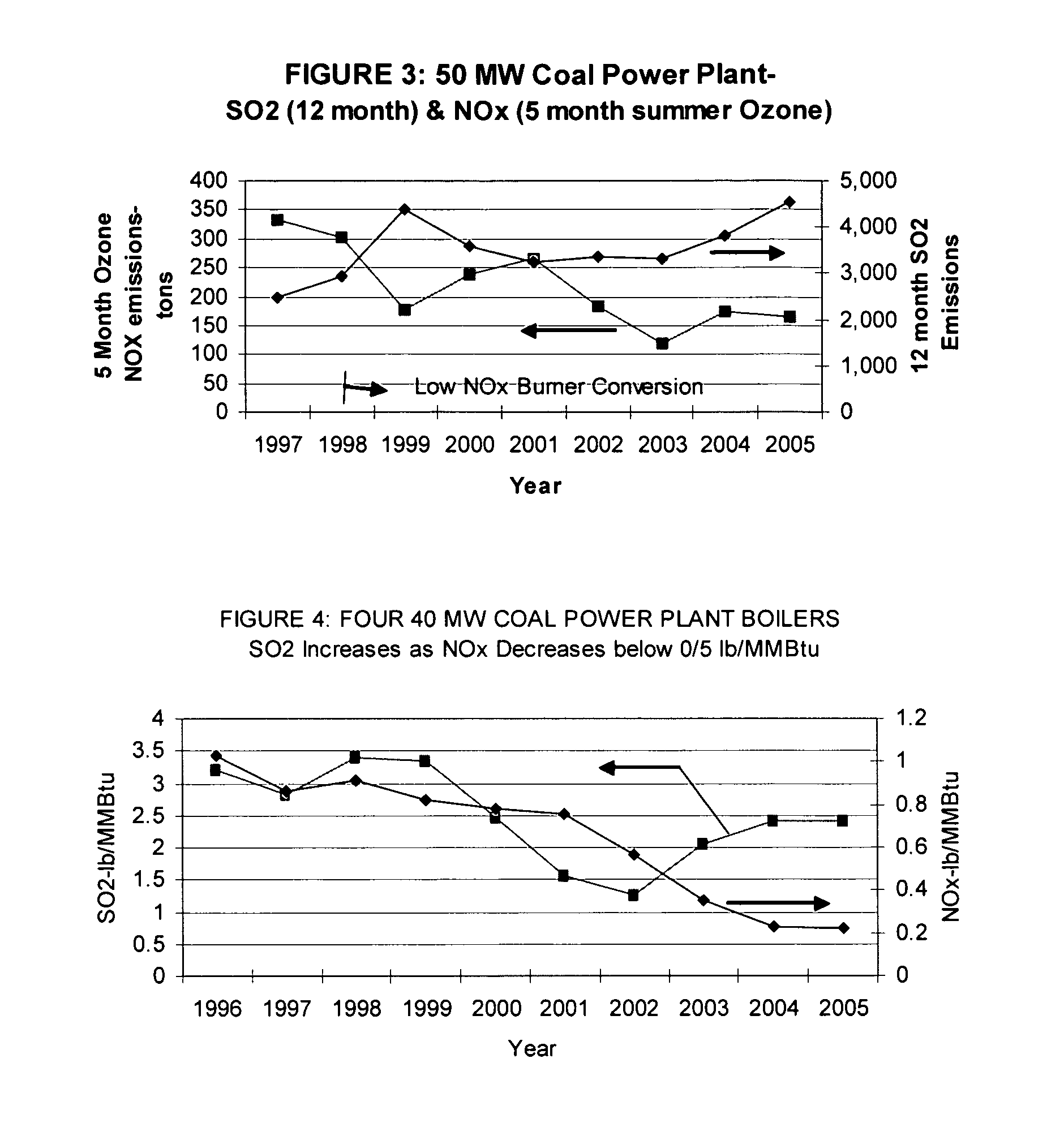

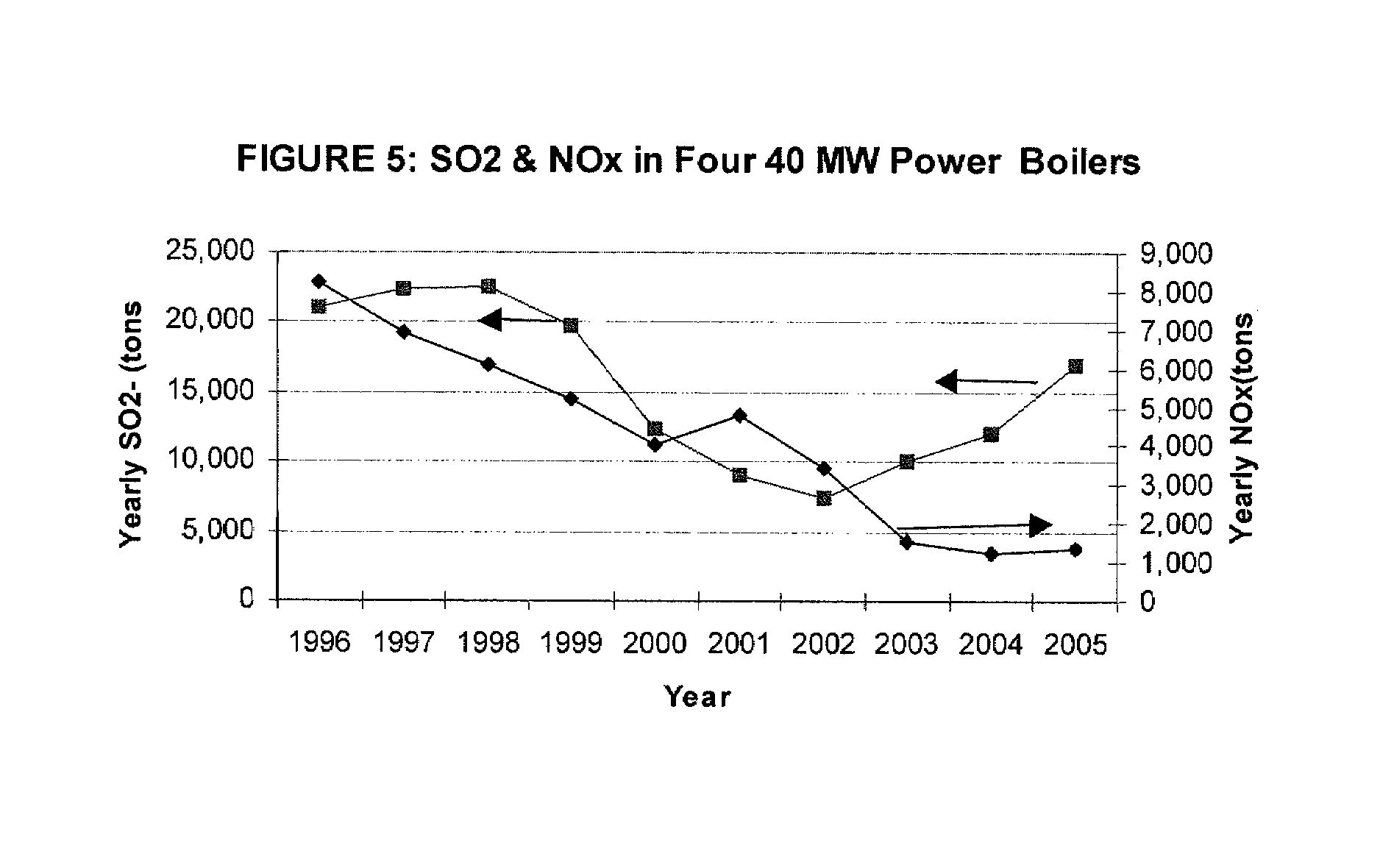

Technical and economic optimization of combustion, nitrogen oxides, sulfur dioxide, mercury, carbon dioxide, coal ash and slag and coal slurry use in coal fired furnaces/boilers

InactiveUS7553463B2Minimal equipment costLow costNitrogen compoundsUsing liquid separation agentParticulatesWater use

Methods by which new or used boilers or furnaces ranging from small industrial to the largest utility units that are designed for coal or oil or natural gas or shredded waste or shredded biomass firing can substantially improve their technical operation and sharply reduce their capital and operating costs by implementing component modifications and process steps that (a) minimize the adverse impacts of coal ash and slag on boiler surfaces and particulate emissions thereby also facilitating the use of oil or gas designed boilers for coal firing, (b) drastically reduce the loss of water used to transport coal in slurry form to power plants, (c) essentially eliminate the combined total nitrogen oxides (NOx), sulfur dioxide (SO2), mercury (Hg), trace metals, and carbon dioxide (CO2) emissions, (d) separate and permanently sequester carbon dioxide released during combustion and (e) improve the coal and solid fuel combustion efficiency.

Owner:ZAUDERER BERT

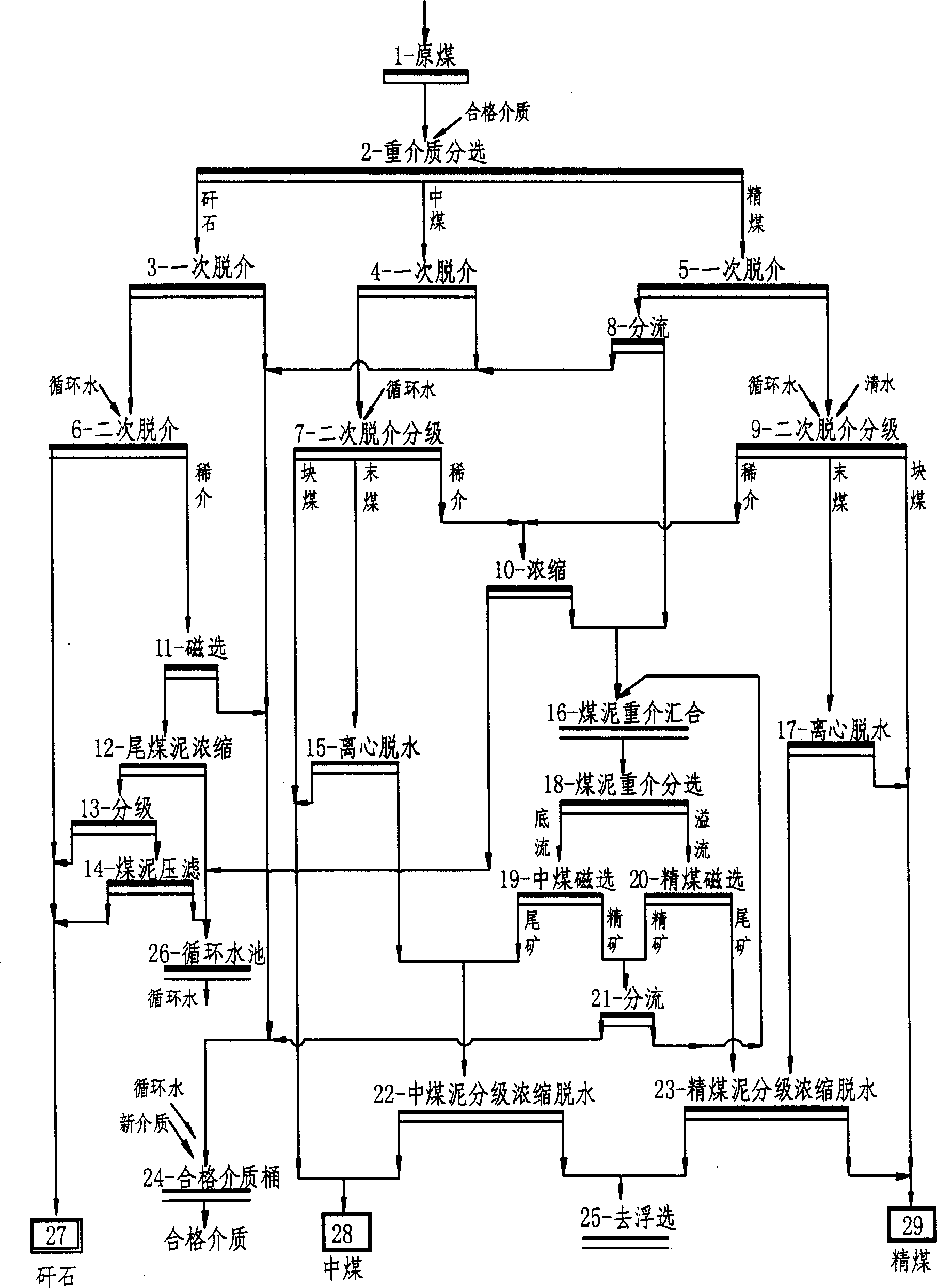

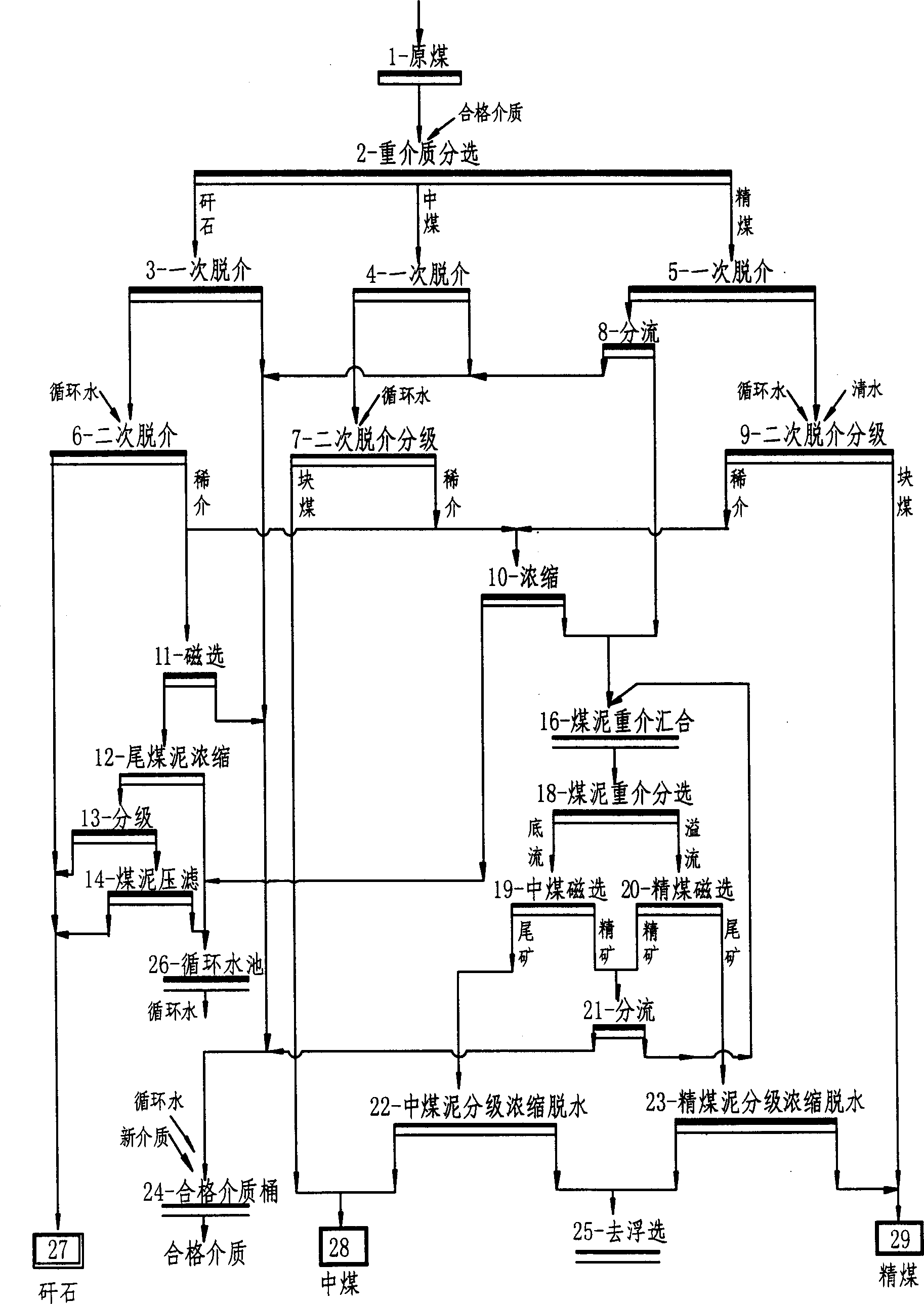

Process for heavy media separation of coarse coal slurry

InactiveCN1424151ALess investmentReduce the lower limit of heavy media sortingReversed direction vortexMagnetic separationCycloneRecovery method

A heavy medium coal-dressing process for recovering all the coarse slime is based on the simplifier JZJ technology and features its additional technological steps such as concentrating the suspension of diluted medium, mixing it with suspension of clean coal, regulating the dressing density, separating by small-diameter cyclone equipment, removing medium and recovering product. Its advnatages are simple system, high outupt rate of clean coal, and low cost.

Owner:天地科技股份有限公司唐山分公司

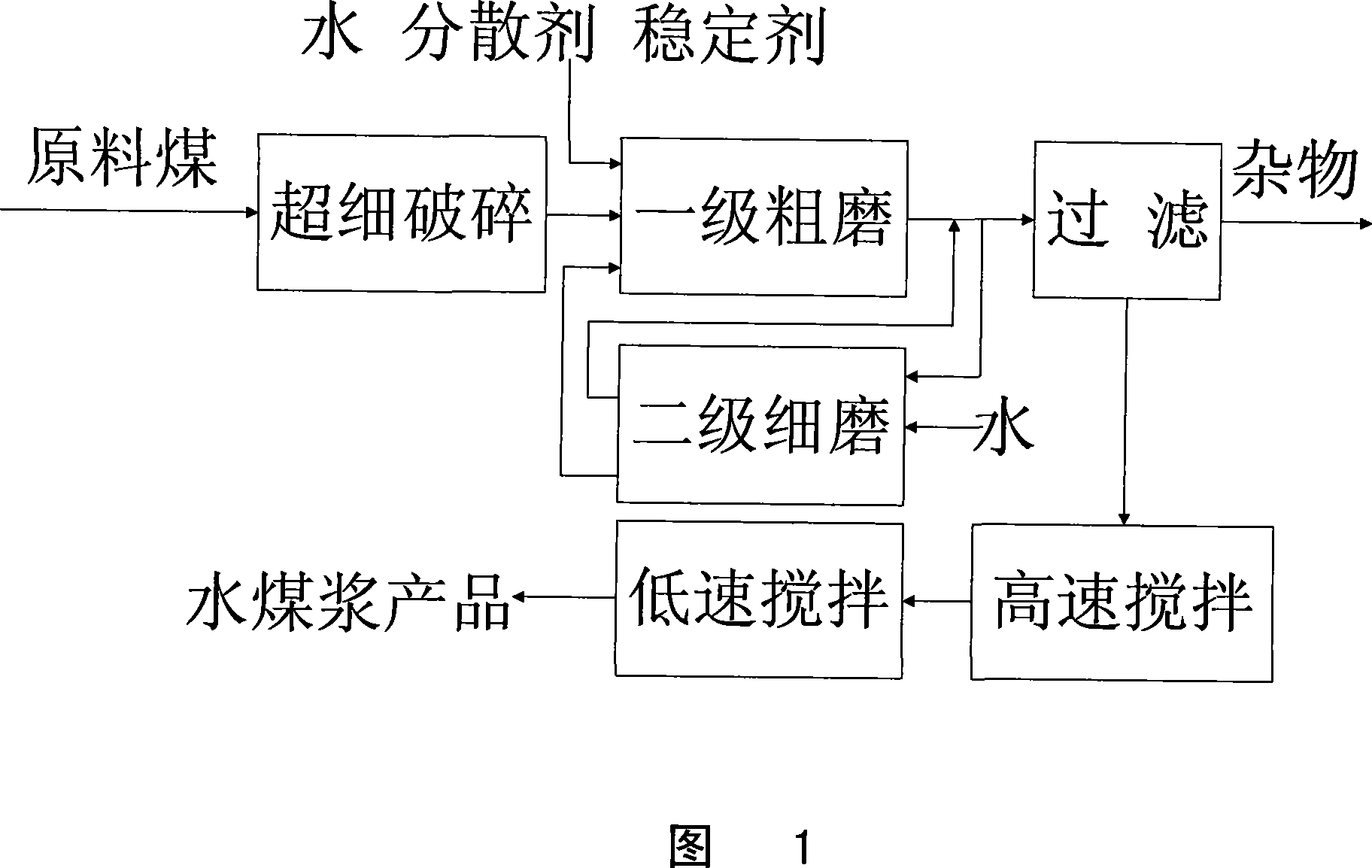

Method for preparing high concentration water-coal-slurry by low-rank coal

ActiveCN101173765AImprove particle size distributionReduce preparation energy consumptionLump/pulverulent fuel preparationHigh concentrationCoal water

The invention relates to a method for preparing high-concentration coal-water slurry by using low-rank coal. The steps include: 1) ultrafine crushing of low-rank coal; 2; 3) wet coarse grinding of the mixture; 4) ① mix 10% to 30% of the total amount of coal slurry after coarse grinding with water in a mass ratio of 5:1 to 2, and then carry out Wet fine grinding; ②The coal slurry after wet coarse grinding other than wet fine grinding is directly sent to the filter device; 5) The coal slurry after step 4) ① fine grinding is processed in the following way: ①Return all the coal slurry to step 3 ) for circulating coarse grinding; or ② return part of the coal slurry to step 3) for circulating coarse grinding, and send another part of finely ground coal slurry directly into the filter device; or ③ directly send all the coal slurry into the filter device; 6) The coal slurry sent to the filter device is filtered through a 18-20 mesh filter, and then stirred at a high speed in the stirring device, left standing, or stirred at a low speed to obtain a high-concentration coal-water slurry product.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

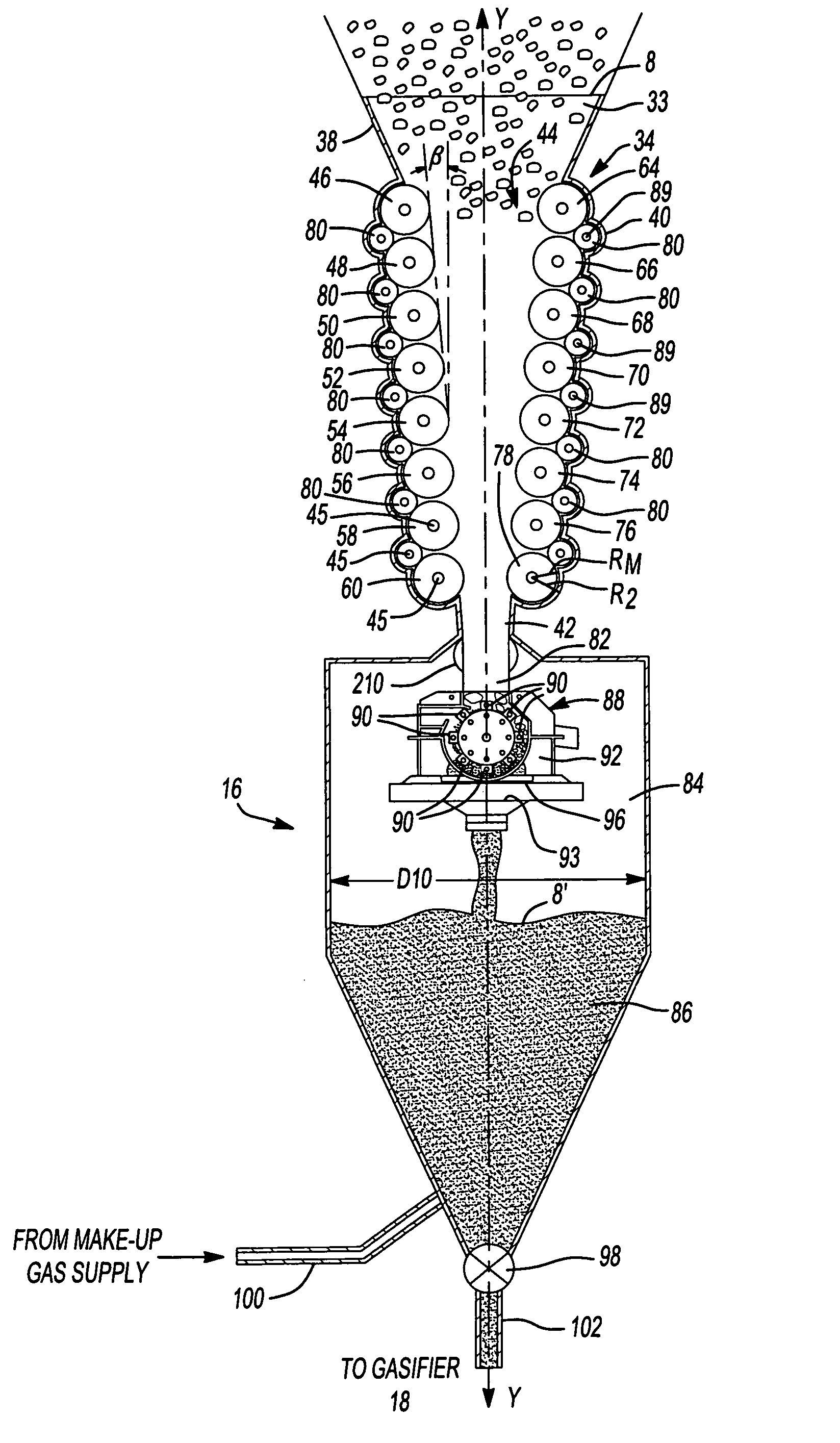

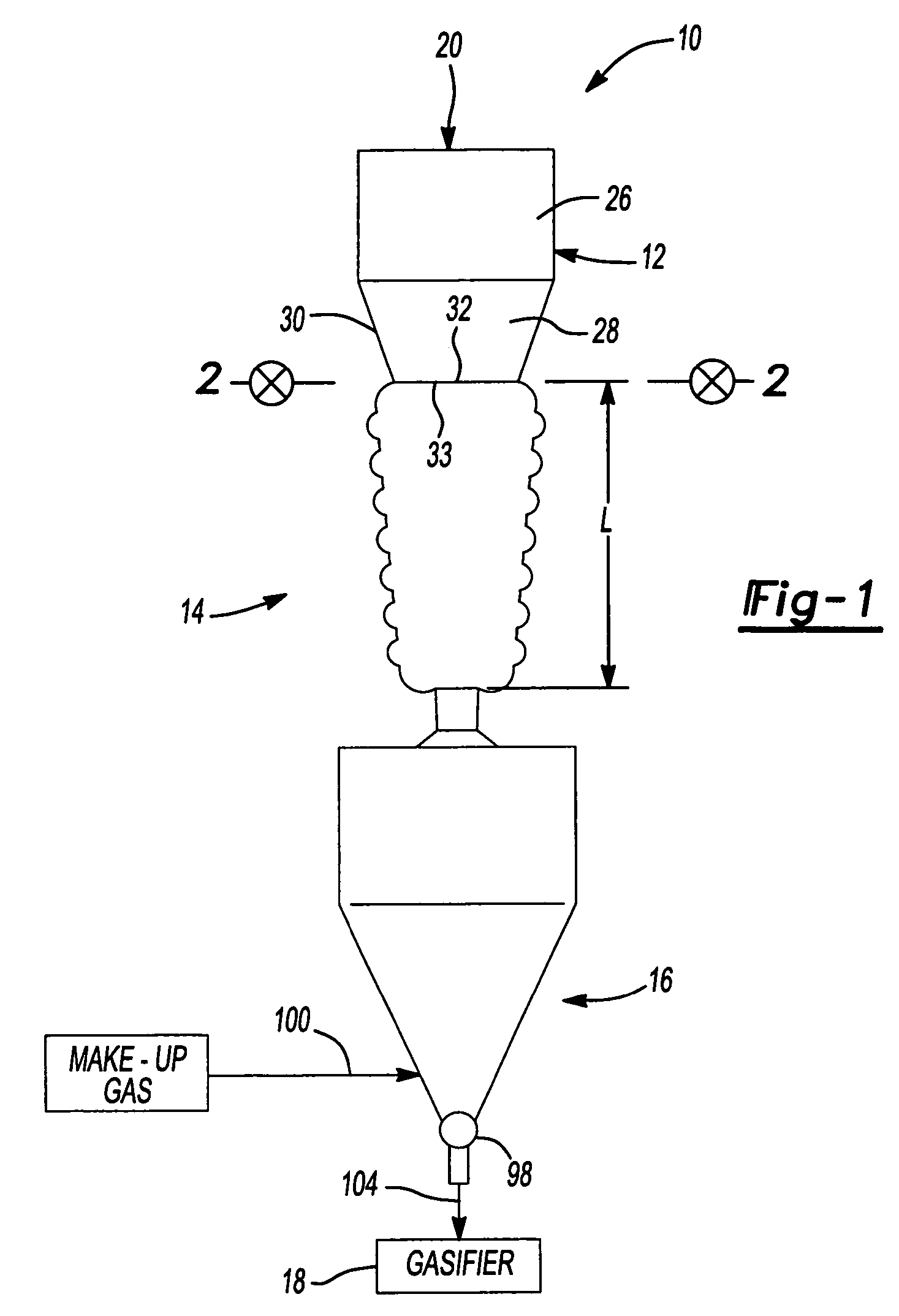

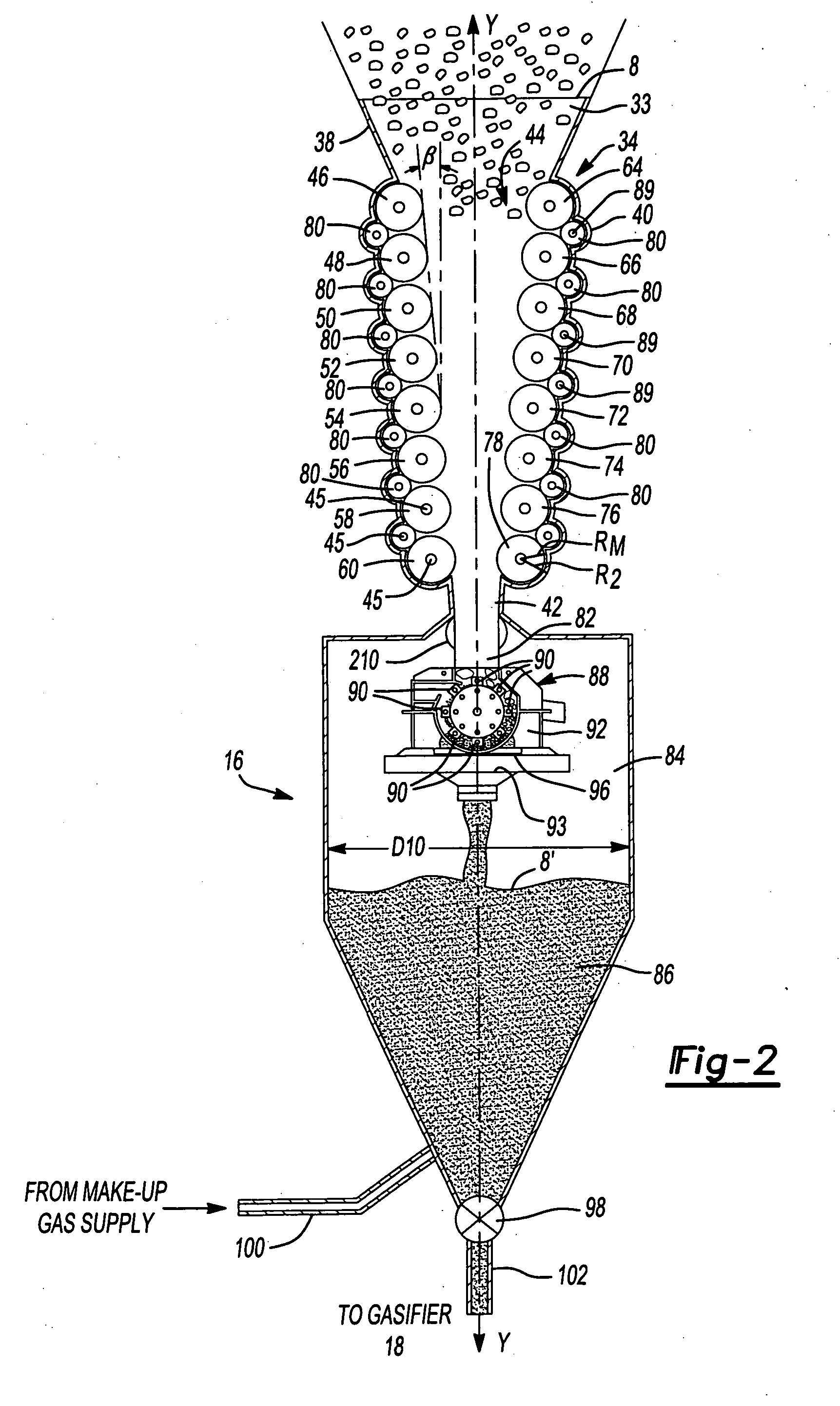

High pressure dry coal slurry extrusion pump

A system for providing highly pressurized raw fuel to a pressure reactor. The system includes an inlet for receiving the raw fuel and a roller system communicating with the inlet. The roller system includes a plurality of independent rollers arranged in two converging planes. The rollers of the roller system successively compress the raw fuel as the raw fuel passes through the roller system between the rollers, such that the fuel is highly pressurized when it reaches an output end of the roller system. An outlet is located adjacent the output end of the roller system to dispense the pressurized raw fuel to the pressure reactor.

Owner:THE BOEING CO +1

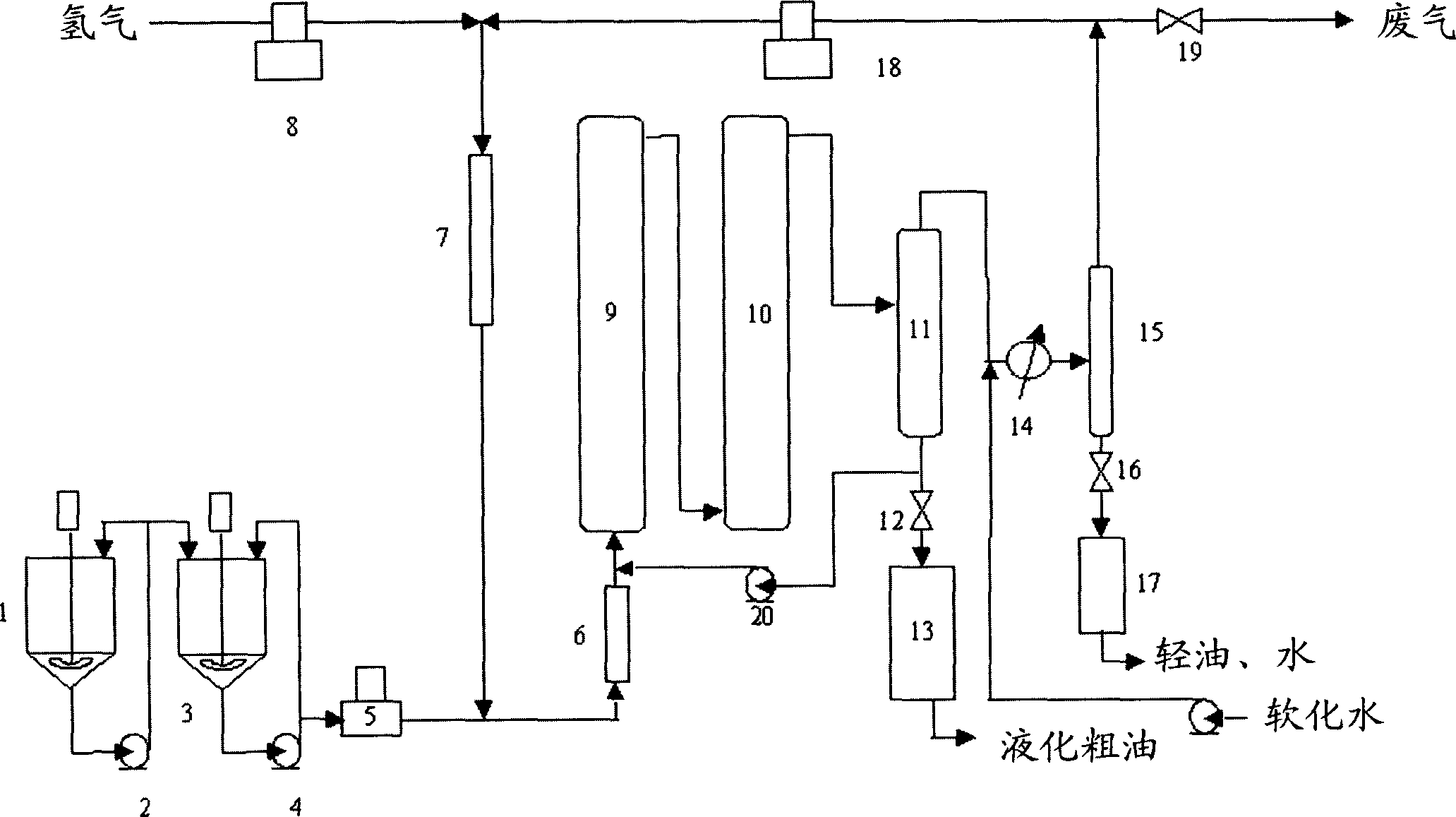

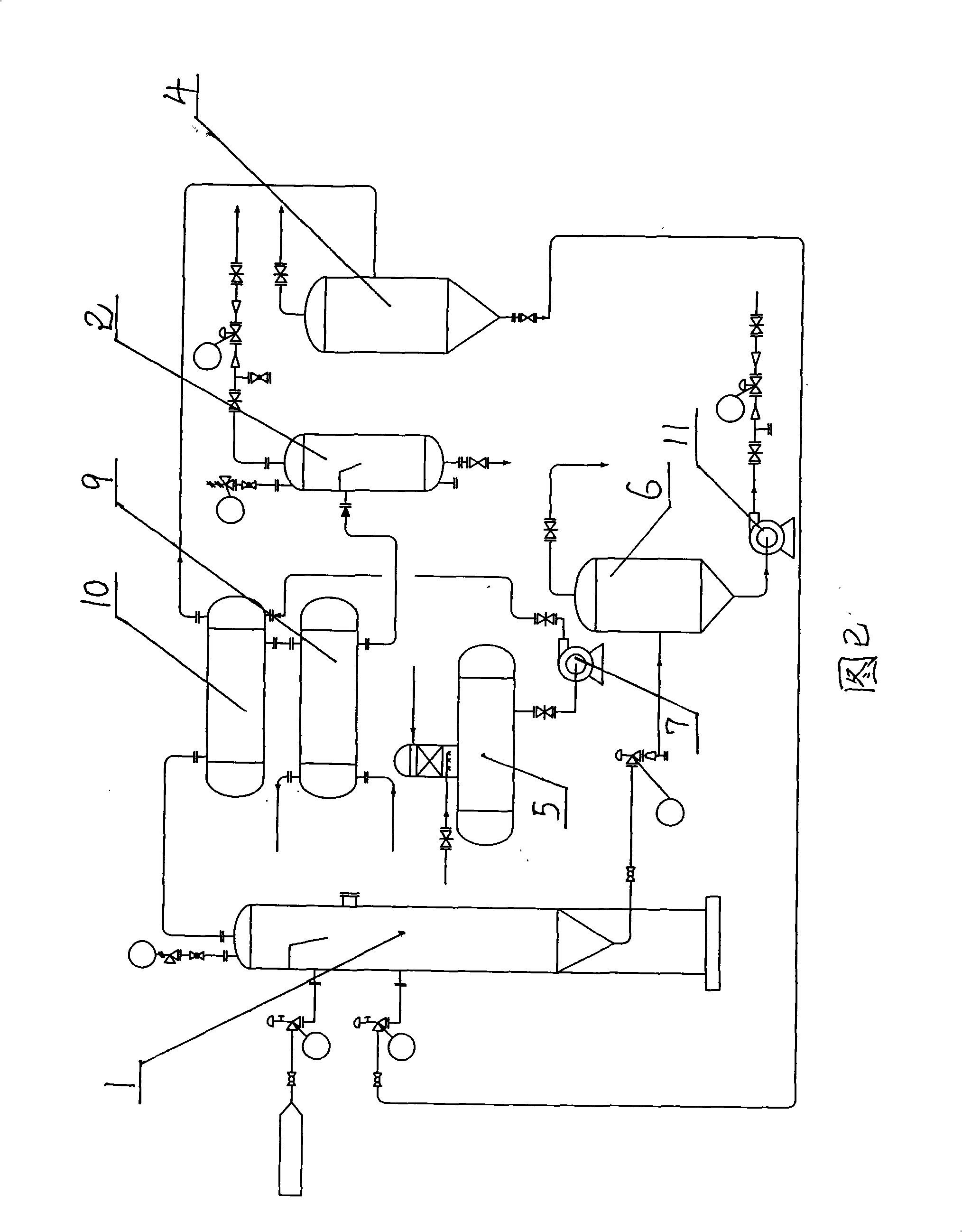

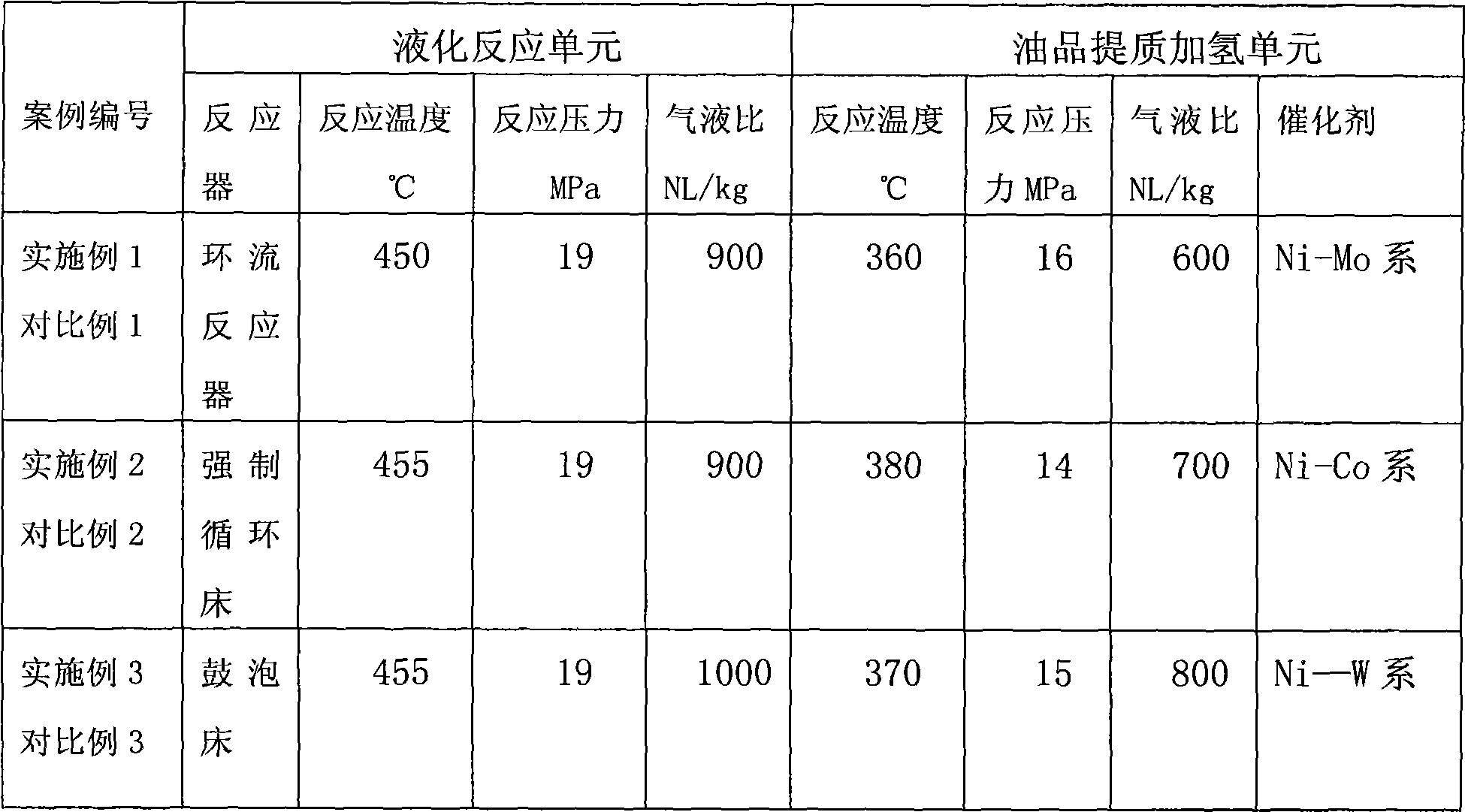

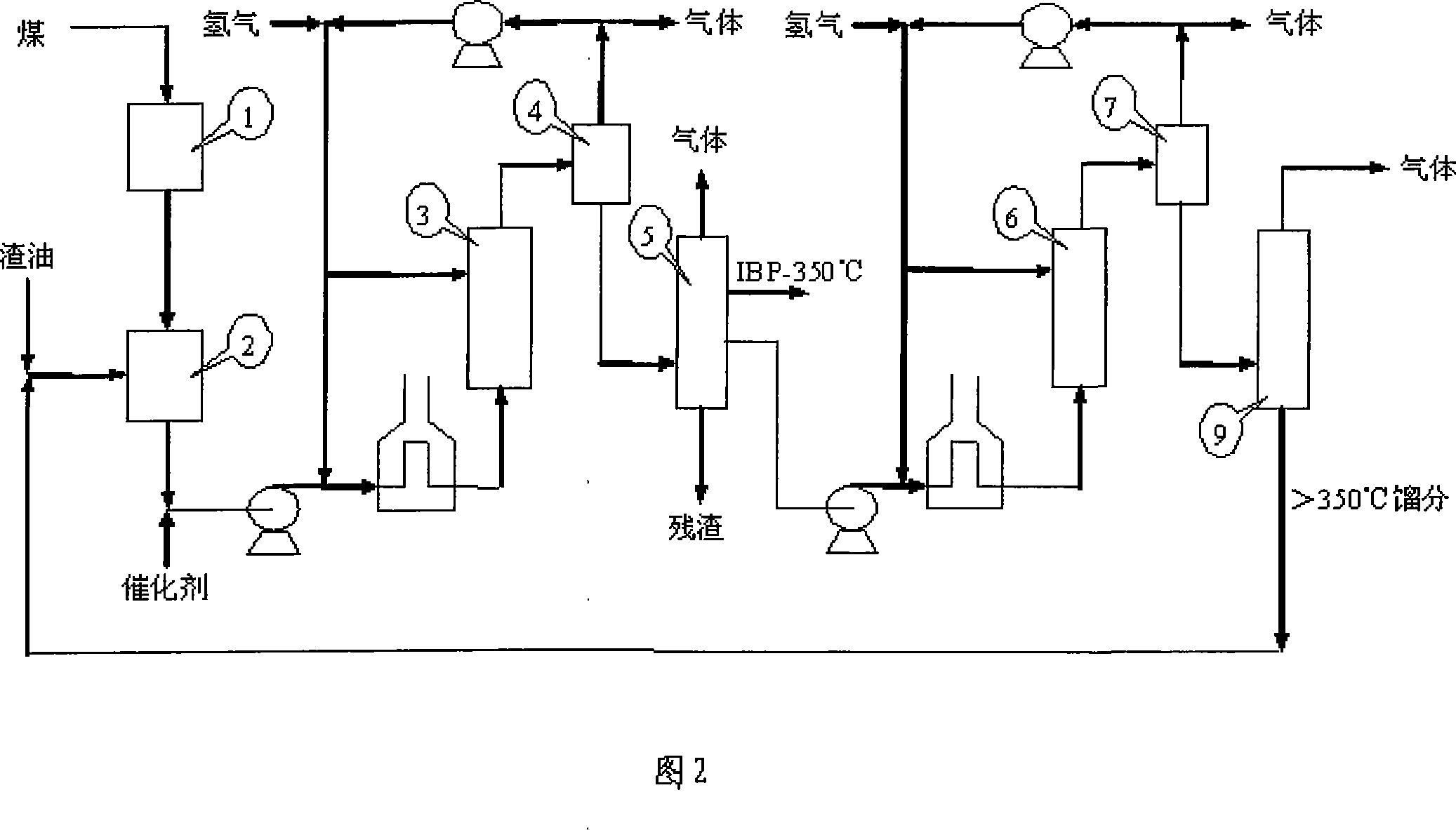

Method of directly liquifying coal

ActiveCN1869159AHigh yieldAvoid secondary decompositionLiquid hydrocarbon mixture productionCoal dustPre treatment

The invention relates to a coal direct liquefaction method. It includes the following steps: mixing coal slurry which is made up of coal dust, hydrogenation cycle solvent, and iron catalyst with freshness or cycle hydrogen; reacting by the first and second reactor; sending the product from the second reactor to high temperature separator to separate; the weight flow ratio of the recycle and freshness materials is 2-20. The method can reduce hydrogen consumption and gas yield.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

High concentration sludge coal slurry and method for preparing the same

InactiveCN1908134AImprove pulpingEasy to operateLiquid carbonaceous fuelsHigh concentrationHigh density

Owner:EAST CHINA UNIV OF SCI & TECH

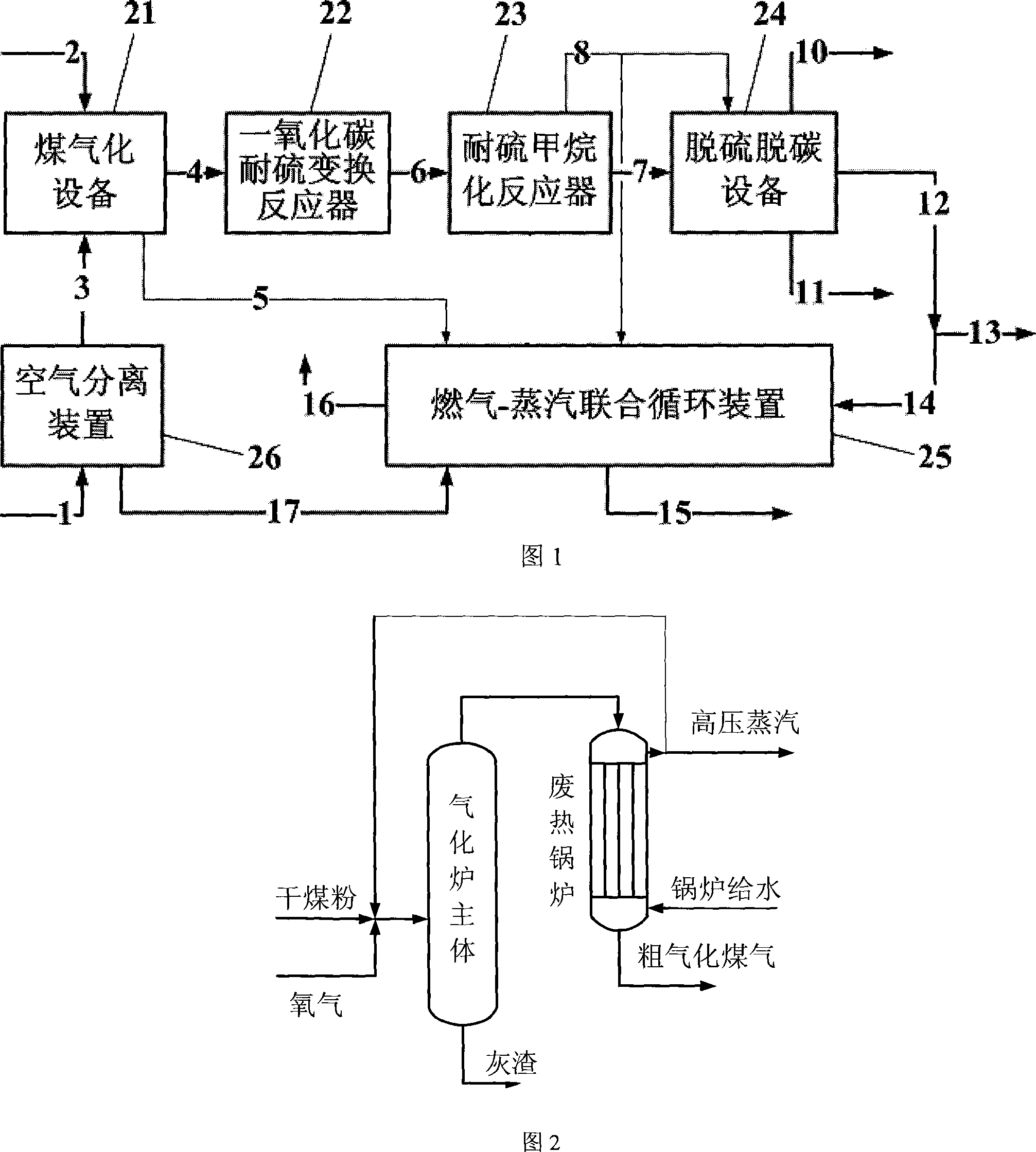

Gas-steam combined cycle system and technique based on coal gasification and methanation

ActiveCN101245262AReduce energy consumptionEasy to recycleNitrogen purification/separationCombustible gas chemical modificationMethanationSubstitute natural gas

A combined cycle system based on coal gasification and methanation gas-steam and a technique thereof, wherein, the method comprises the following steps: oxygen produced by an air separation unit and coal powder or water-coal-slurry are sent into coal gasification equipment, the produced crude gasification gas is sent to a carbon monoxide sulfur-tolerant shift reactor to adjust the ratio of hydrogen and carbon after the sensible heat recollecting, and is then sent into sulfur-tolerant methanation reactor to produce methane and carbon dioxide, then the reaction product is sent into desulfurization and decarbonization equipment so that element sulfur can be recovered and carbon dioxide can be separated so as to obtain substitute natural gas with high content of methane, part of which is sent to the gas-steam combined cycle equipment while the other part is sent to a urban gas system. The enriched CO2 density of the system can reach 50 to 60 percent, technical probability is provided for reasonably realizing low-energy-consumption reduced exhaust of CO2, no change needs to be done with gas turbines, each chemical unit operates according to established rated condition and needs not to change load owing to power conditioning so as to improve the economy of the operation of power plants; compared with the prior art, the energy utilization efficiency of the whole system is improved so as to realize the efficient clean utilization of coal.

Owner:TSINGHUA UNIV

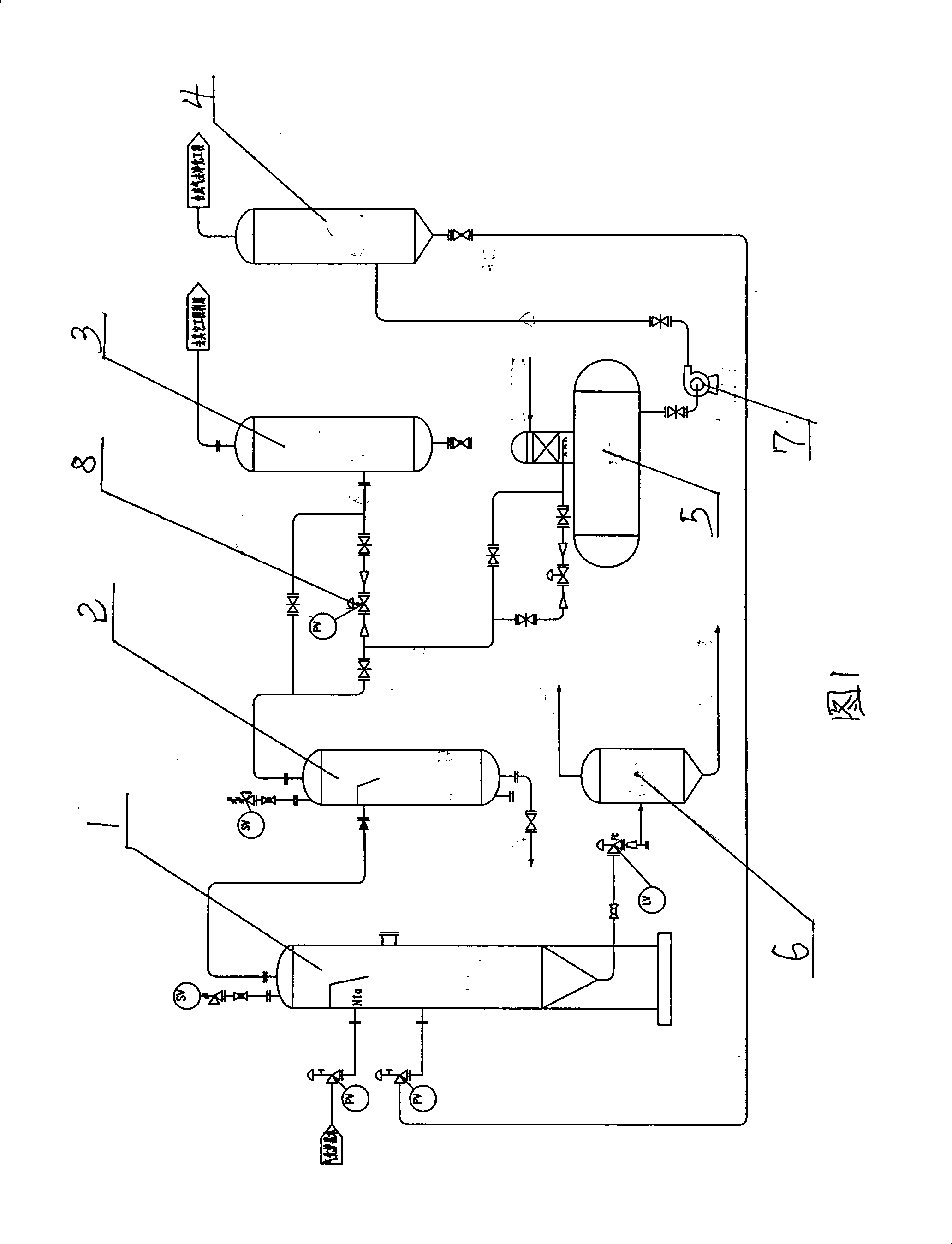

Grey water treatment technology for graded gasification furnace

InactiveCN101306899AImprove transfer efficiencyTake advantage ofMultistage water/sewage treatmentWater/sewage treatment by heatingGas phaseDeaerator

The invention belongs to the ash water processing technology for gasification of coal water slurry in gasified ash water, in particular relating to an ash water processing technique applied in a staged gasification furnace. The technique solves the problems in the prior art of complex structure, energy waste, trivial technological operation and so on. The method comprises the following steps that: black water exhausted from the staged gasification furnace and a syngas scrubber respectively enters into a high-pressure flash tank after decompressed by respective pipes; liquid phase after high-flash flash evaporation in the high-pressure flash tank passes through a pressure-reducing valve and enters into a vacuum flash tank for secondary flash evaporation; the liquid phase after vacuum flash evaporation in the vacuum flash tank enters into a settling tank the position of which is lower than that of the vacuum flash tank for settlement by means of gravity action; gas phase after high-flash flash evaporation in the high-pressure flash tank enters into a separator on the top of the high-flash tank for gas-liquid separation; and one part of separated gas phase enters into a deaerator and directly contacts the ash water for heat exchange, and the other part of the steam enters into a steam buffer tank through a pressure control valve. Compared with the prior flow, the adoption of the flow saves equipment investment by 3 million; and about 10 tons of steam is supplied in normal operation.

Owner:山西丰喜肥业(集团)股份有限公司临猗分公司

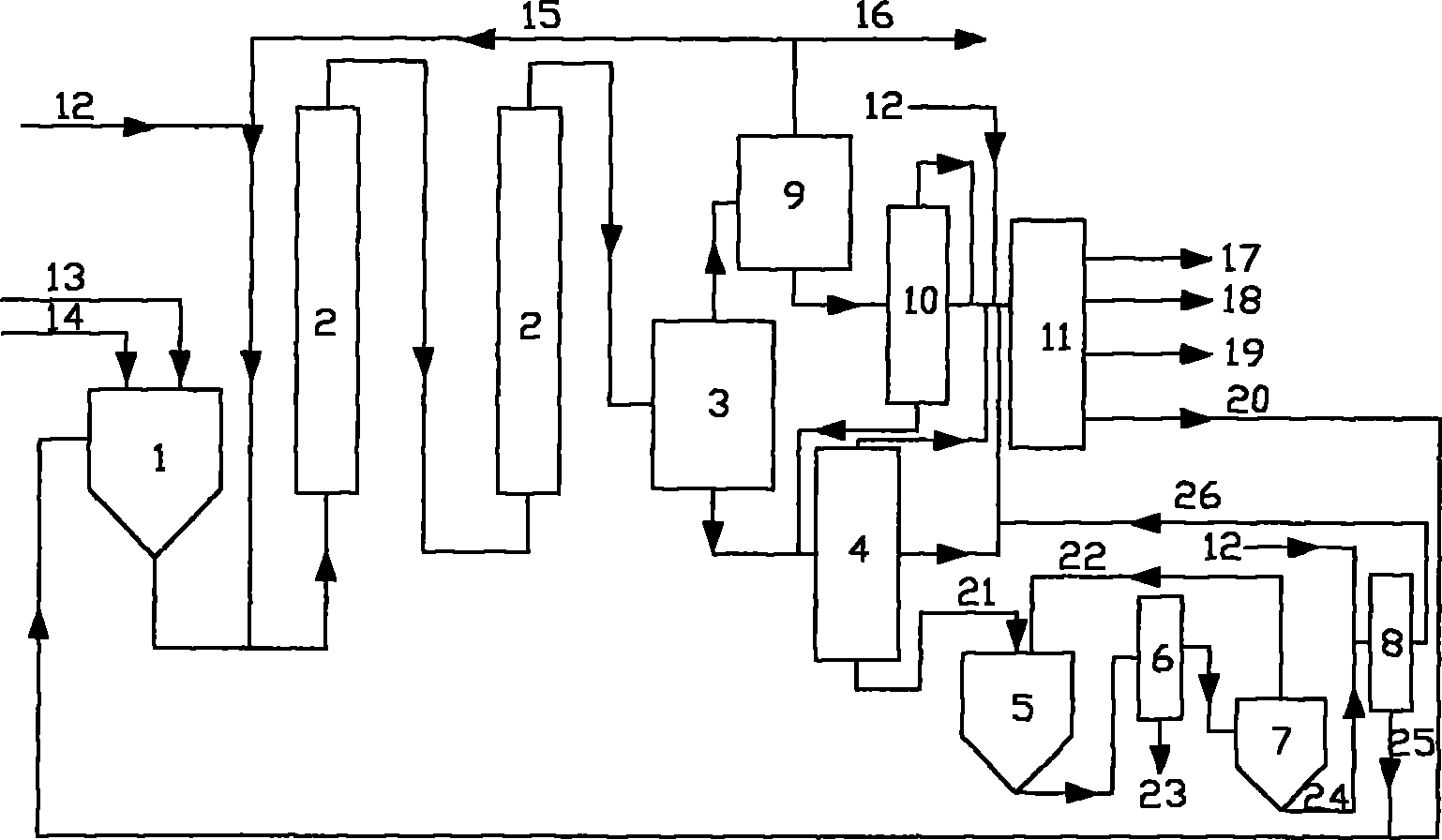

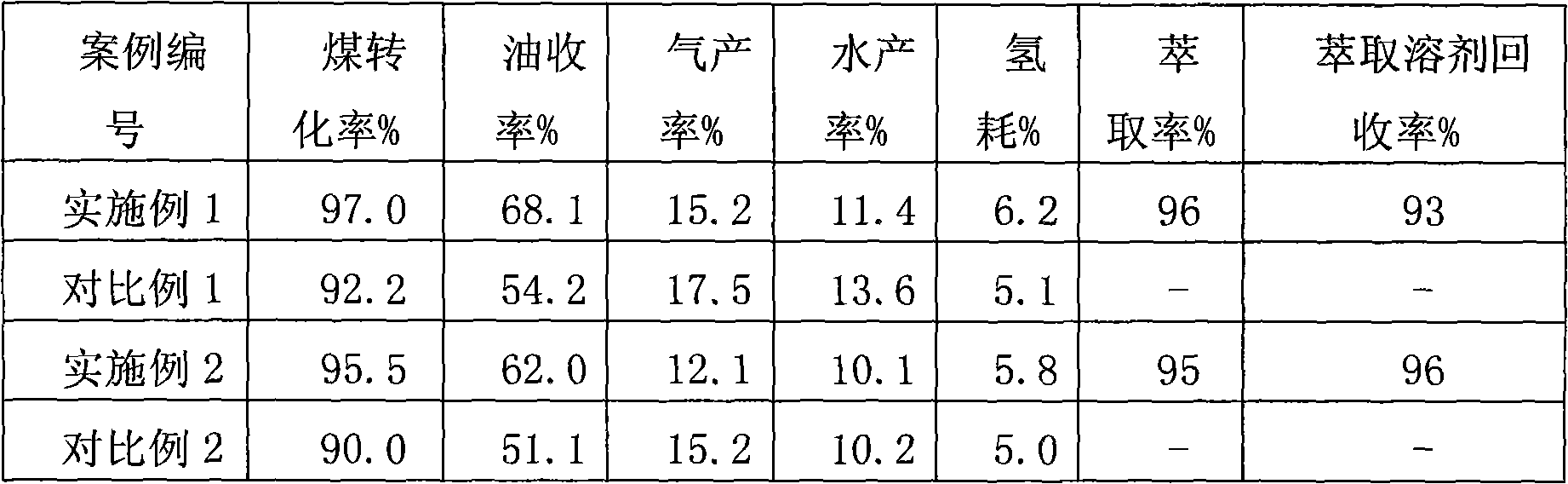

Method for directly liquefying coals with function of maximizing utilization of liquefied residues

ActiveCN102010741AGreat operating flexibilityHigh air hold-upLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesEconomic benefitsOil separation

The invention relates to a method for directly liquefying coals with a function of maximizing utilization of liquefied residues. The method comprises the following technical steps: preparing coal paste; carrying out hydrotreating and liquefaction on the coal paste; carrying out oil separation treatment on the obtained oil product; carrying out upgrading and hydrotreating on the obtained product; carrying out hot extraction on the residues and then carrying out solid-liquid separation on the residues; and recovering the solvent; and carrying out hydrotreating treatment on the mixture of heavy oils and asphalt materials so as to obtain the final product, then taking the heavy oils as recycled solvent to prepare the coal paste, and the like. The method provided by the invention has the advantages that because of organically combining the liquefaction process and the residue extraction, the utilization of liquefied residues is maximized, the conversion rate of coal is improved, the yieldsof light and middle oils subjected to coal liquefaction are improved by 10 to 60 percent, and the quality of oil is improved, thereby greatly enhancing the economic benefits of direct coal liquefaction plants and improving environment protection; and the method provided by the invention has important economic and social significances, and can widely be applied to the field of coal direct liquefaction.

Owner:CHINA COAL RES INST

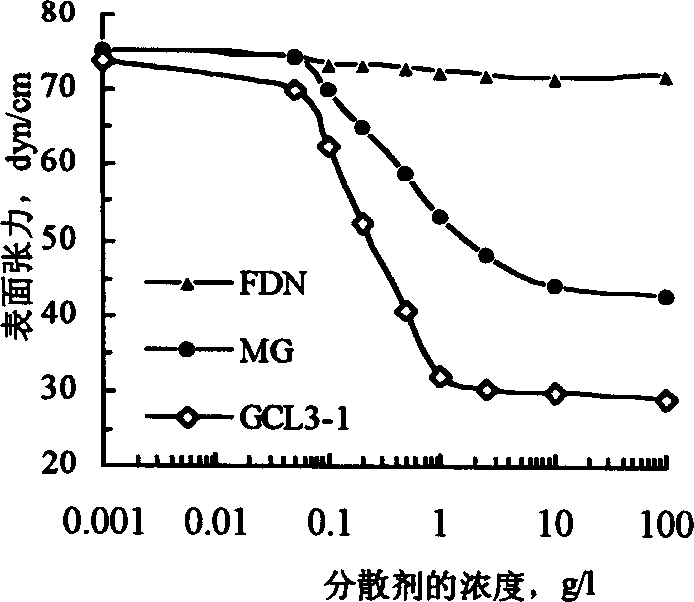

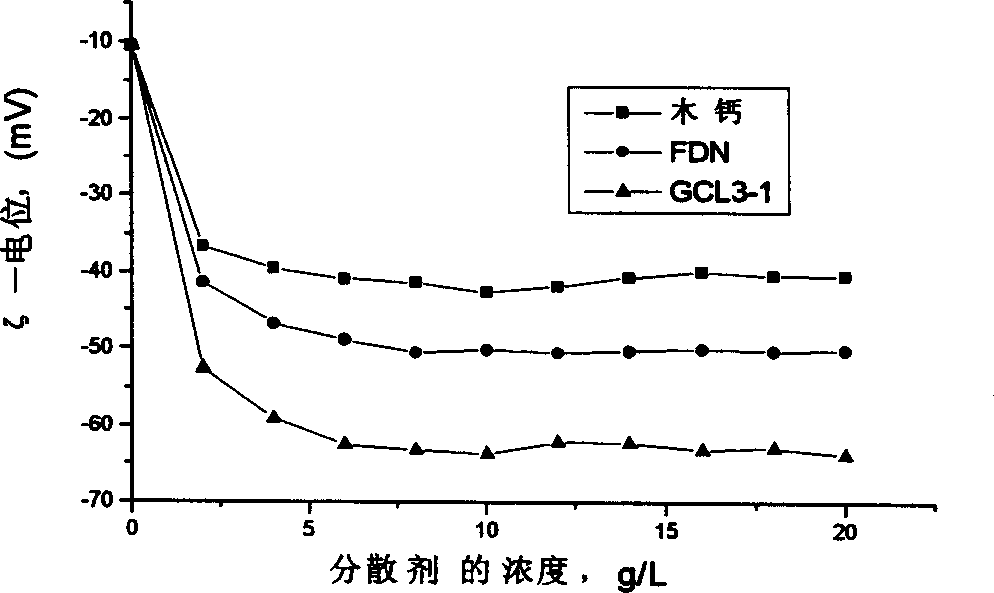

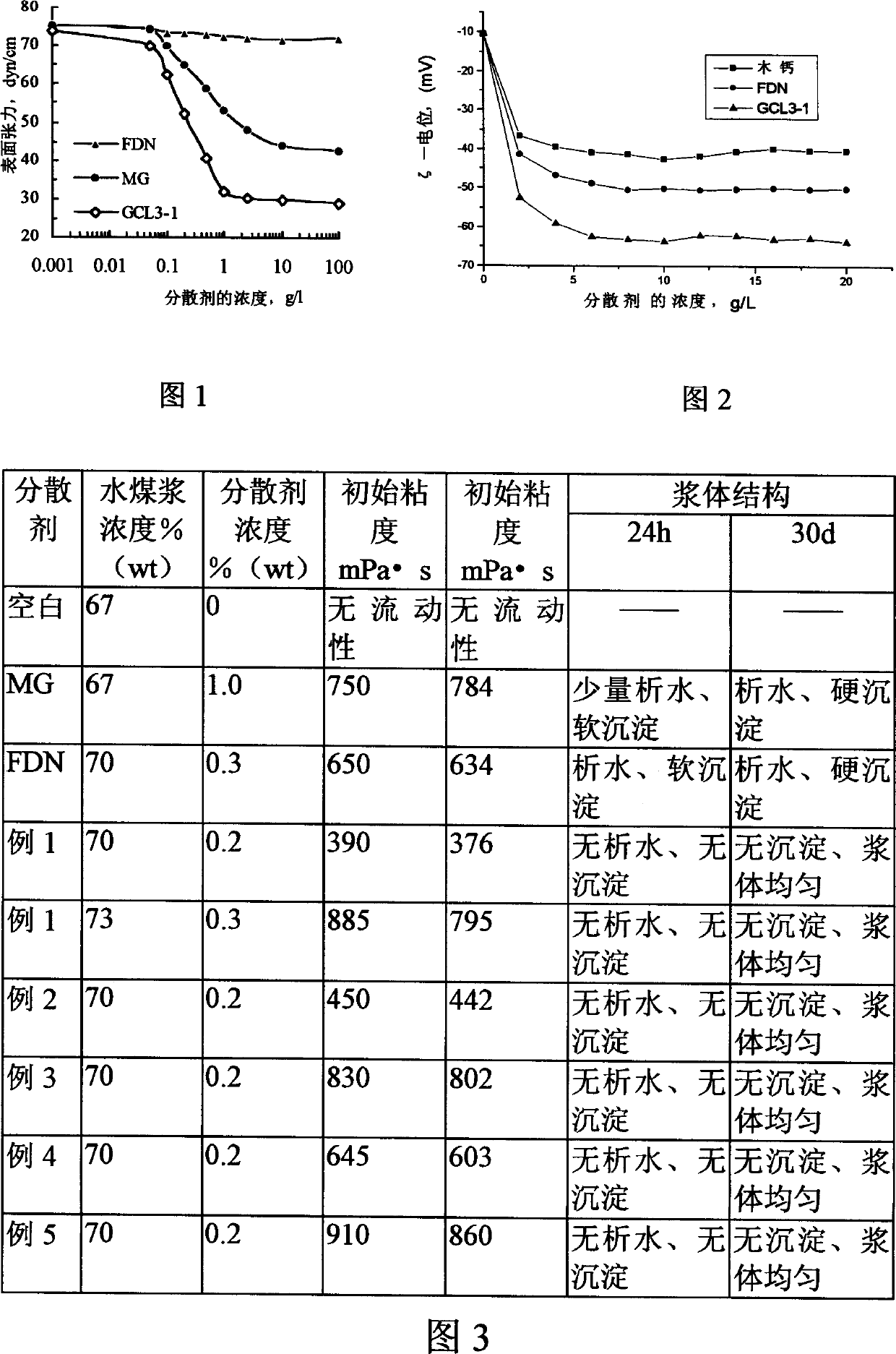

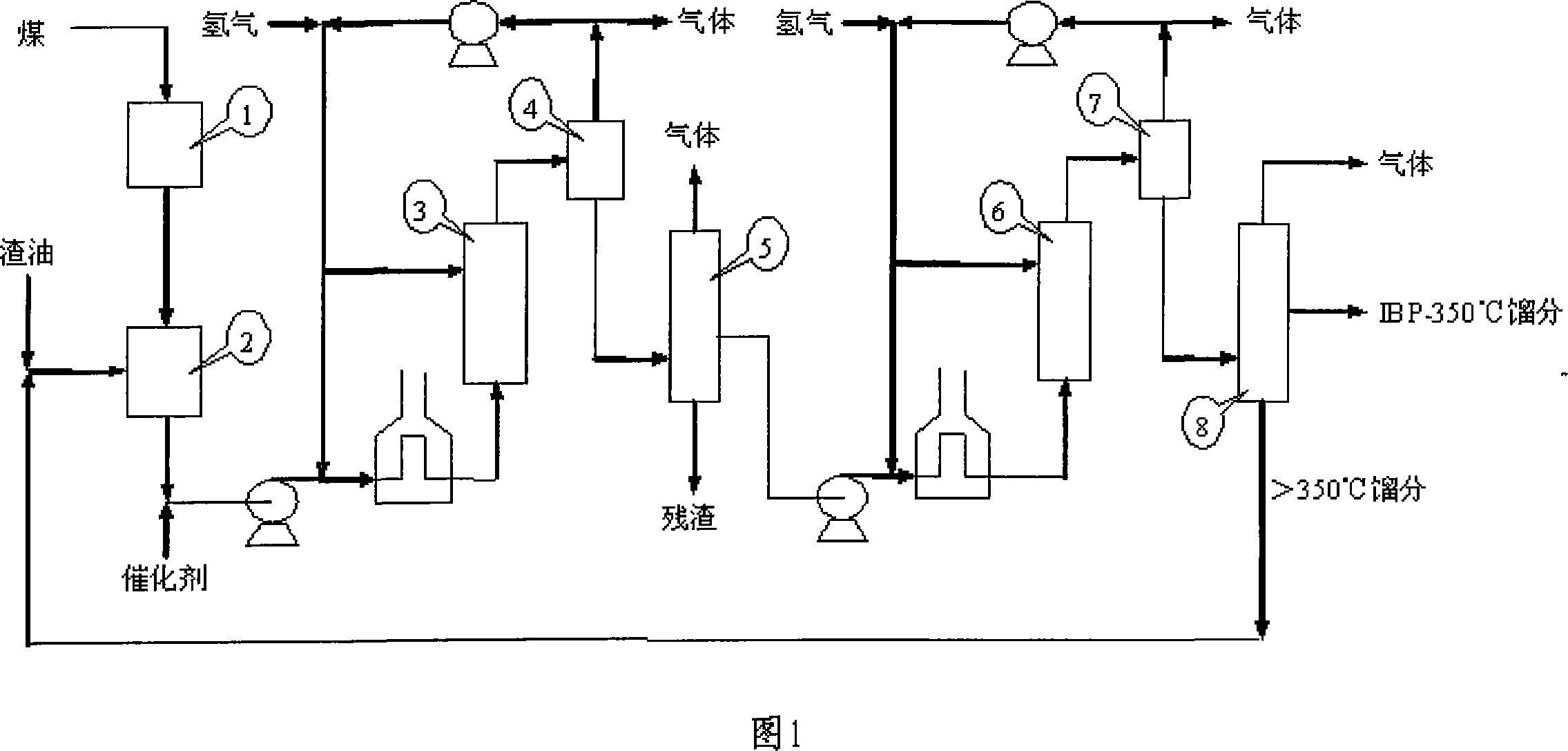

Water-coal-slurry additive and preparation method thereof

ActiveCN101550369AImprove hydrophilicityReduce viscosityLiquid carbonaceous fuelsAlkylphenolMethyl group

The invention provides a water-coal-slurry additive and a preparation method thereof. The additive is compounded by anionic surfactant naphthalene sulfonic acid formaldehyde condensation product sodium salt, lignosulphonate and non-ionic surfactant alkylphenol polyethenoxy ether (methyl) acrylic ester according to mass ratio of 8:1:1 to 1:8:1. The invention uses the naphthalene sulfonic acid formaldehyde condensation product sodium salt, lignosulphonate and alkylphenol polyethenoxy ether (methyl) acrylic ester in the preparation technology of water-coal-slurry, and the additive has wide adaptability to coal, in particular to coal with low degree of metamorphism. When ternary compound additive reaches 0.1-1wt percent of the weight (dry basis) of the coal, the water-coal-slurry with the content of coal dust being 62-70wt percent can be prepared. The slurry has good fluidity, lower apparent viscosity and favorable steady state stability. The ternary compound additive is simple in production process, excellent in performance and wide in the range of applicable coal.

Owner:ENN XINNENG BEIJING TECH

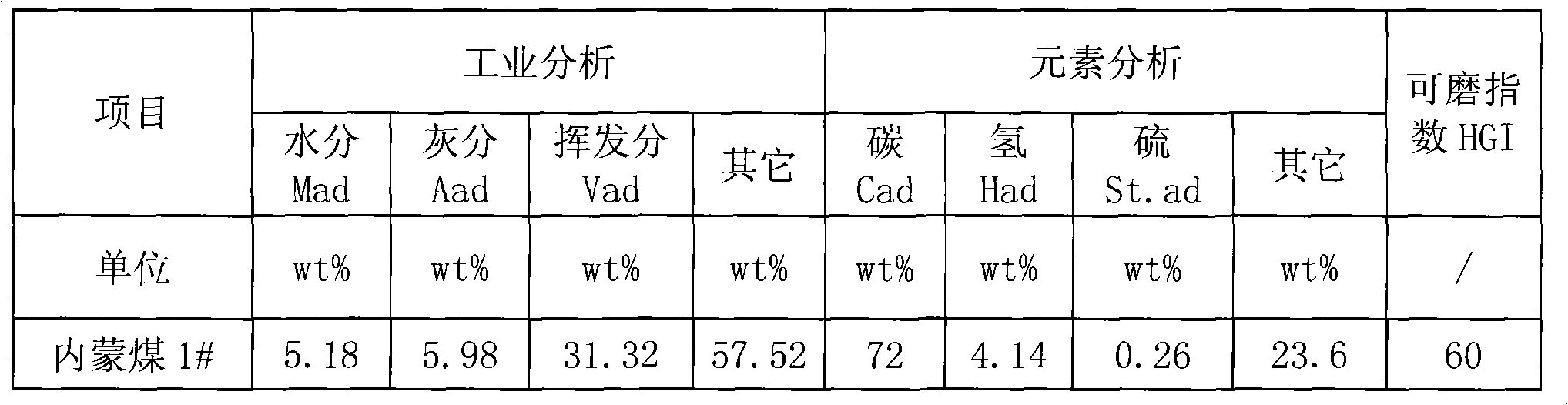

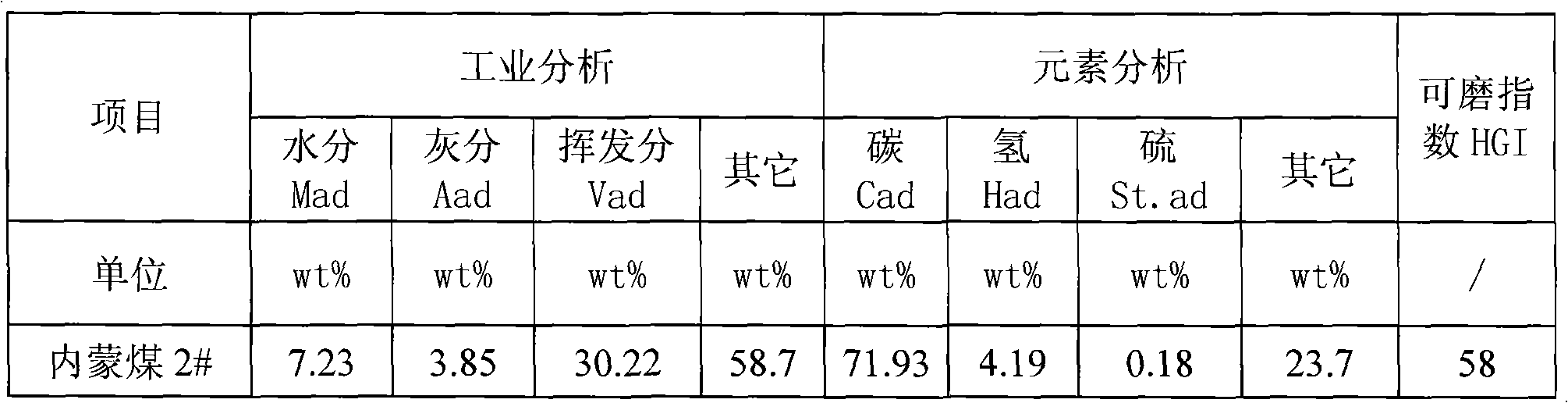

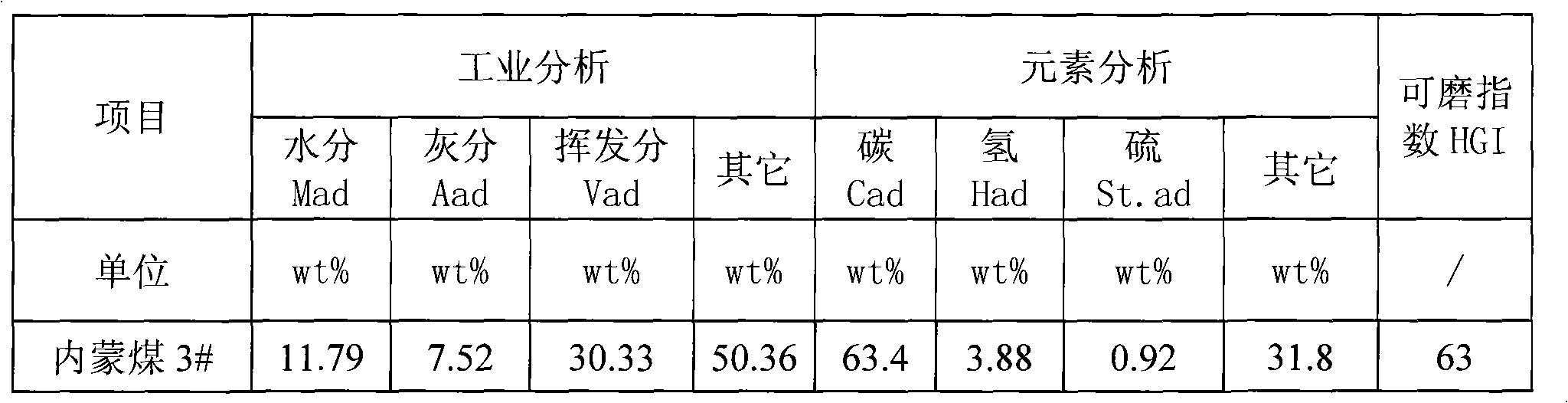

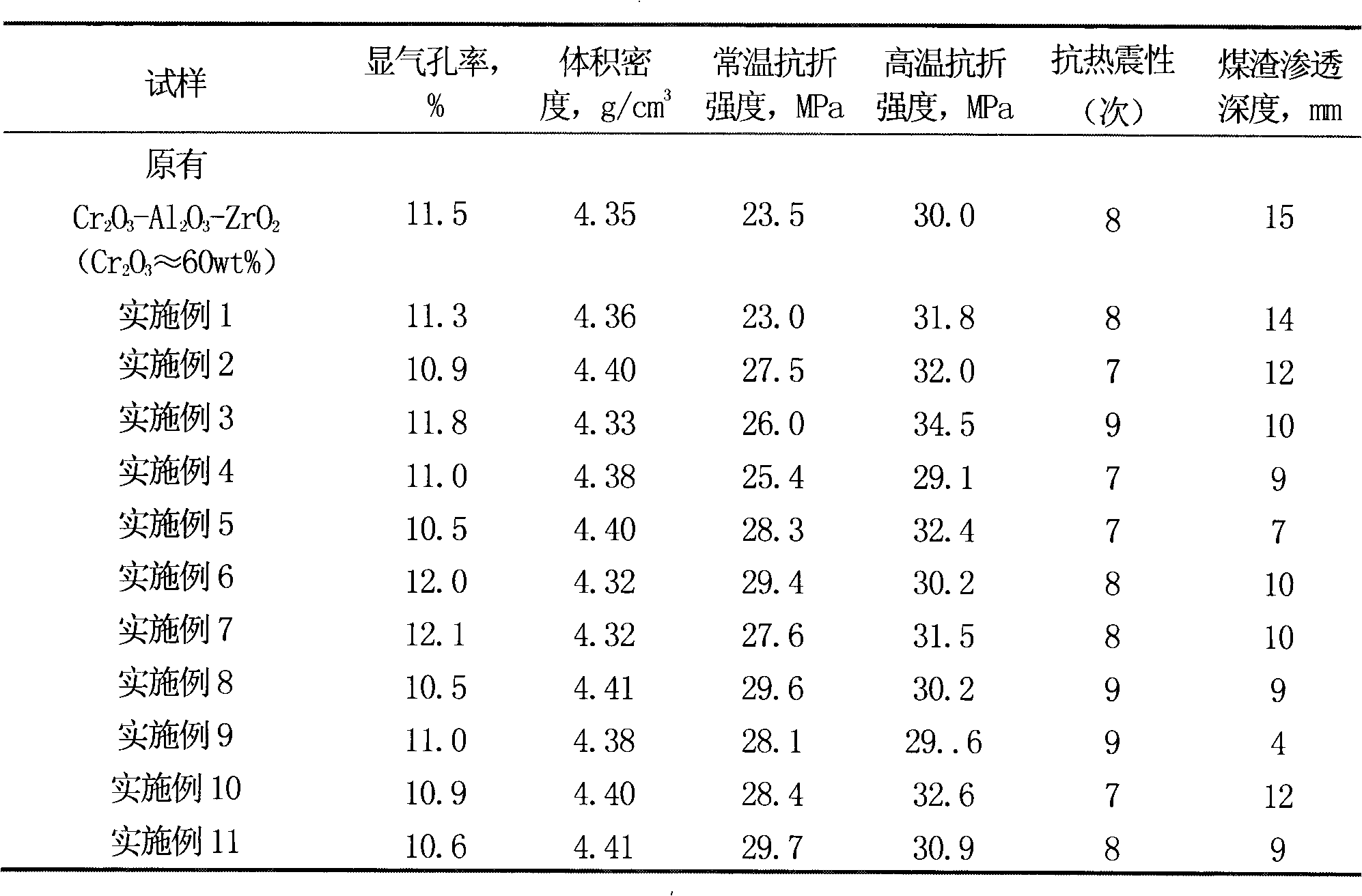

Preparation method of high-chrome brick

ActiveCN101648812AImprove thermal shock resistanceSolve the problem of reduced permeability resistancePorosityBreaking strength

The invention provides a preparation method of a high-chrome brick, belonging to the field of fireproof material. The high-chrome brick is a key lining material of a water-coal-slurry gasification furnace. Compared with the prior high-chrome brick product, the invention does not influence the apparent porosity, the breaking strength and the thermal shock resistance of the prior high-chrome brick and can obviously enhance the coal cinder permeability resistance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

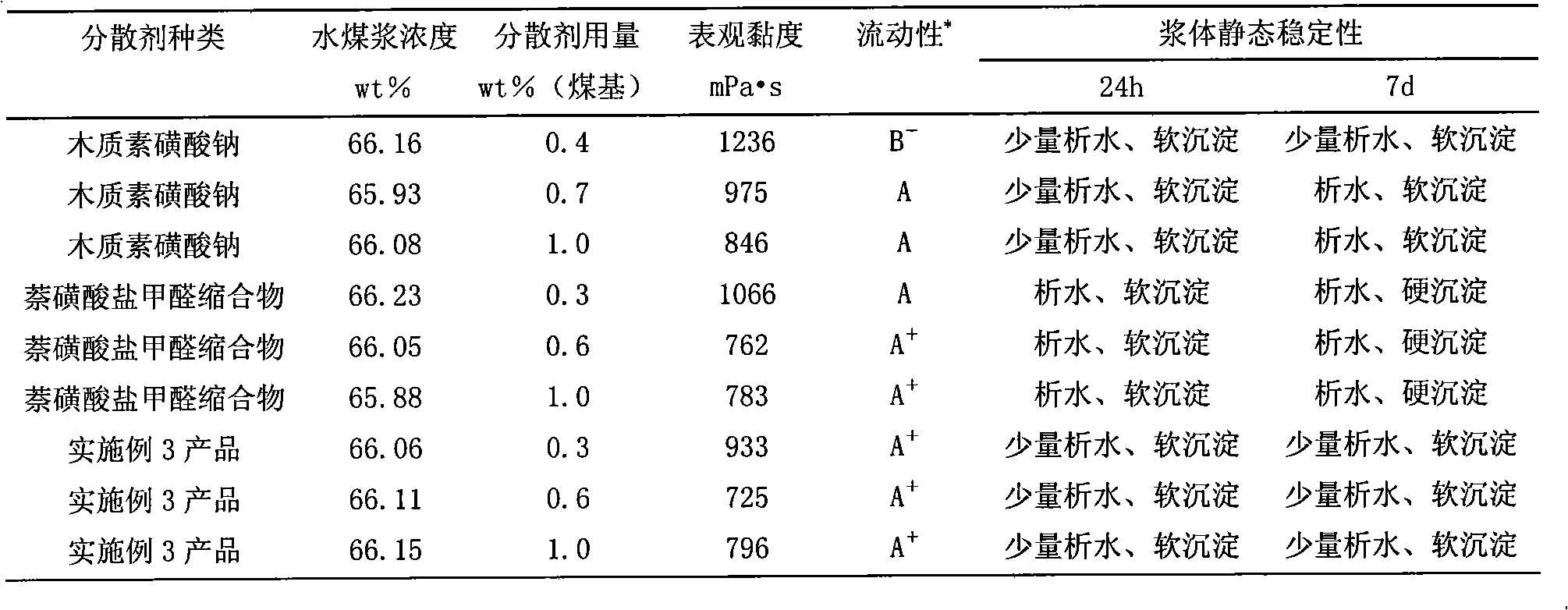

Coal water slurry additive and preparation method and application thereof

The invention discloses a coal water slurry additive and a preparation method and application thereof. The method is characterized in that the coal tar fraction wash oil is taken as the starting material, carries out sulfonation reaction with a sulfonating agent and then carries out polycondensation reaction with aminobenzene sulfonate, phenols and formaldehyde; and neutralization is carried out after reaction is completed. The method can greatly lower the production cost, and the obtained additive has the advantages of small mixing amount, excellent dispersibility, good slurry forming ability and stability and reduction of the stabilizing agent in the coal water slurry. The additive can not only be independently used for preparing the coal water slurry, but also be used by being compounded with other types of additives, such as naphthalene sulfonate-formaldehyde condensates, polycarboxylic acid additives or lignosulfonate and other anionic surfactants and synthesize the coal water slurry suitable for different types of coal by adjusting the production conditions. The coal water slurry prepared by the additive has the solid content between 63% and 70% and is easy to flow and clean. The viscosity of the coal water slurry is controlled below 1200mPa.s at the shearing rate of 100s<-1>.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD +1

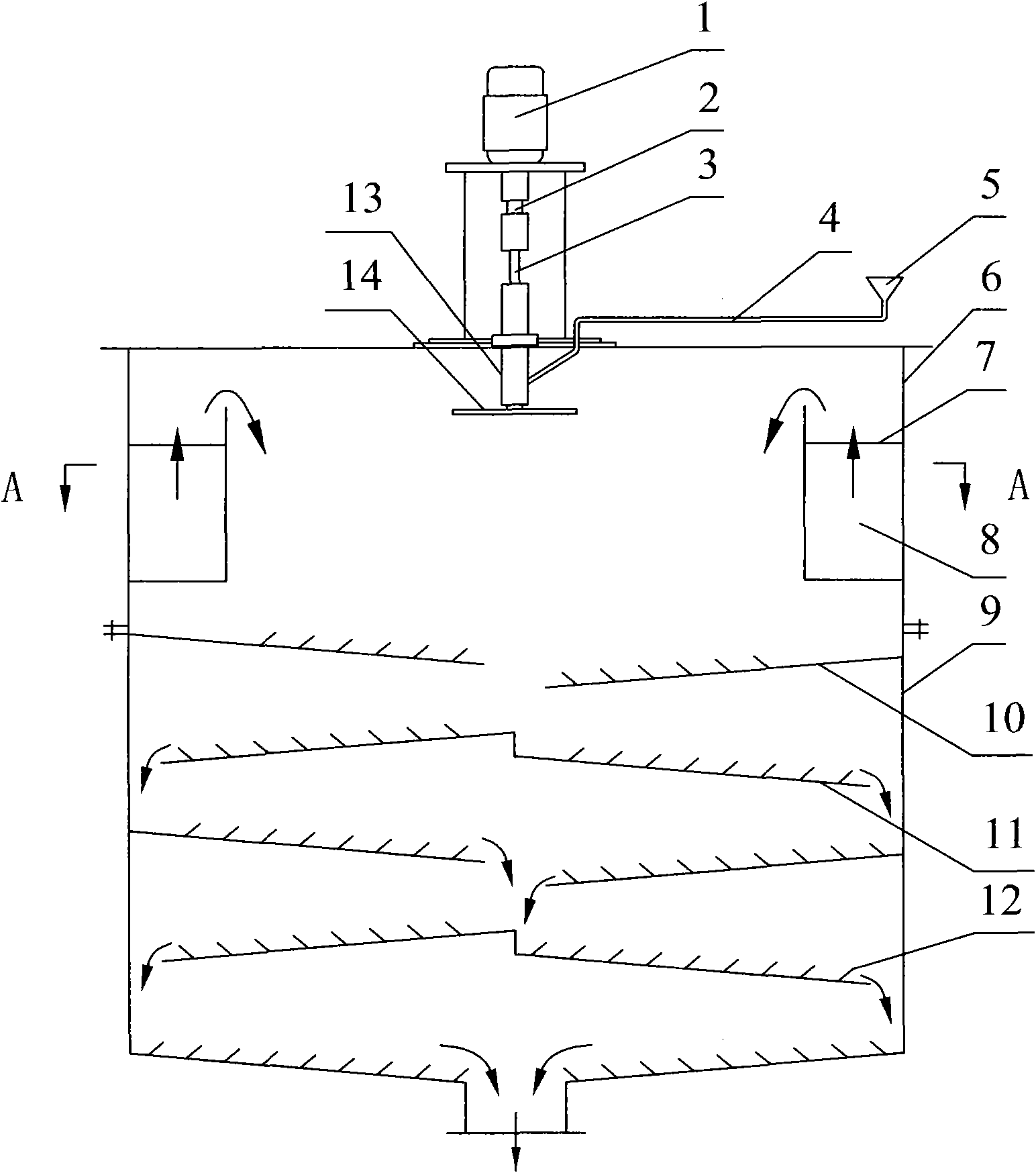

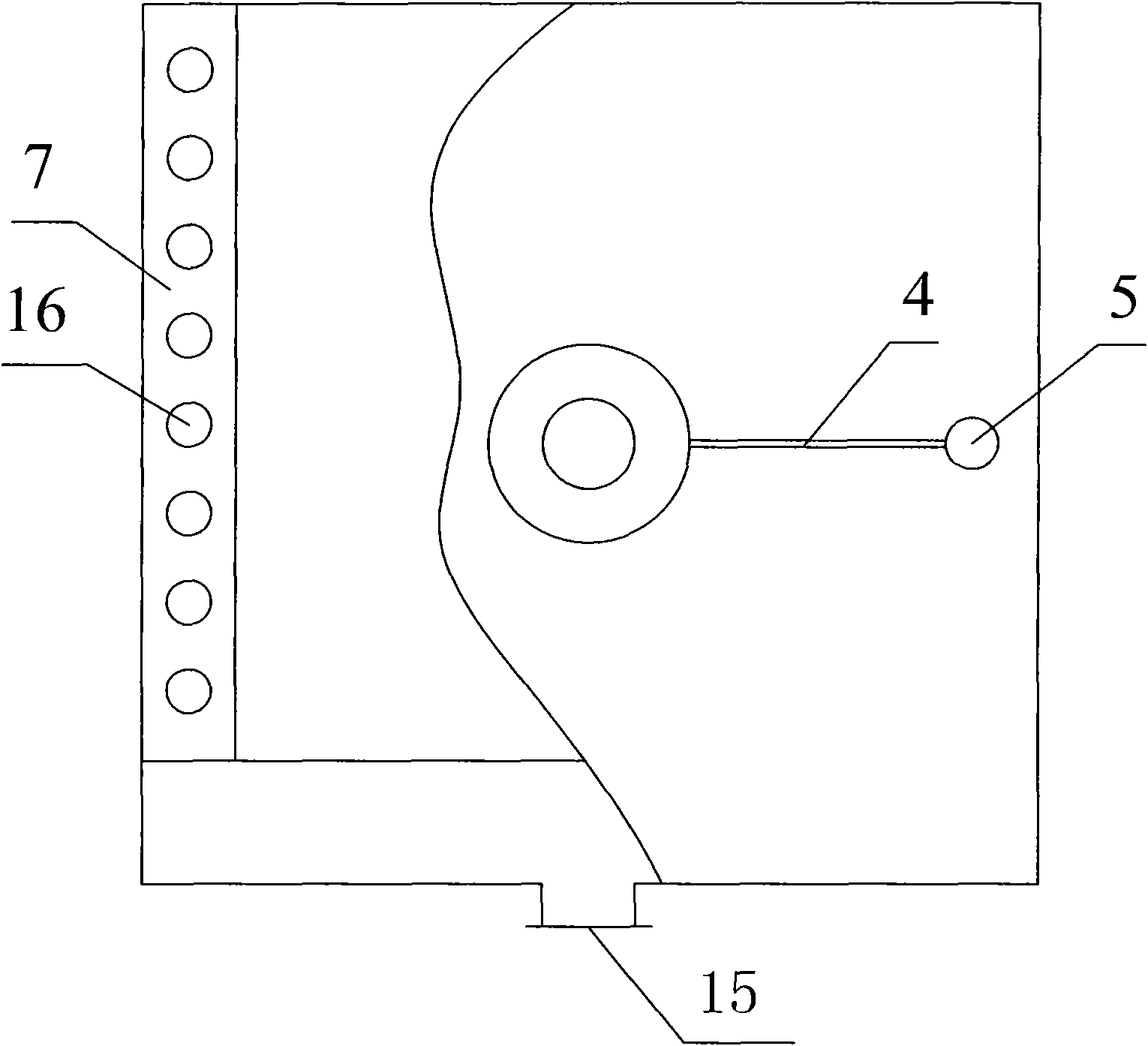

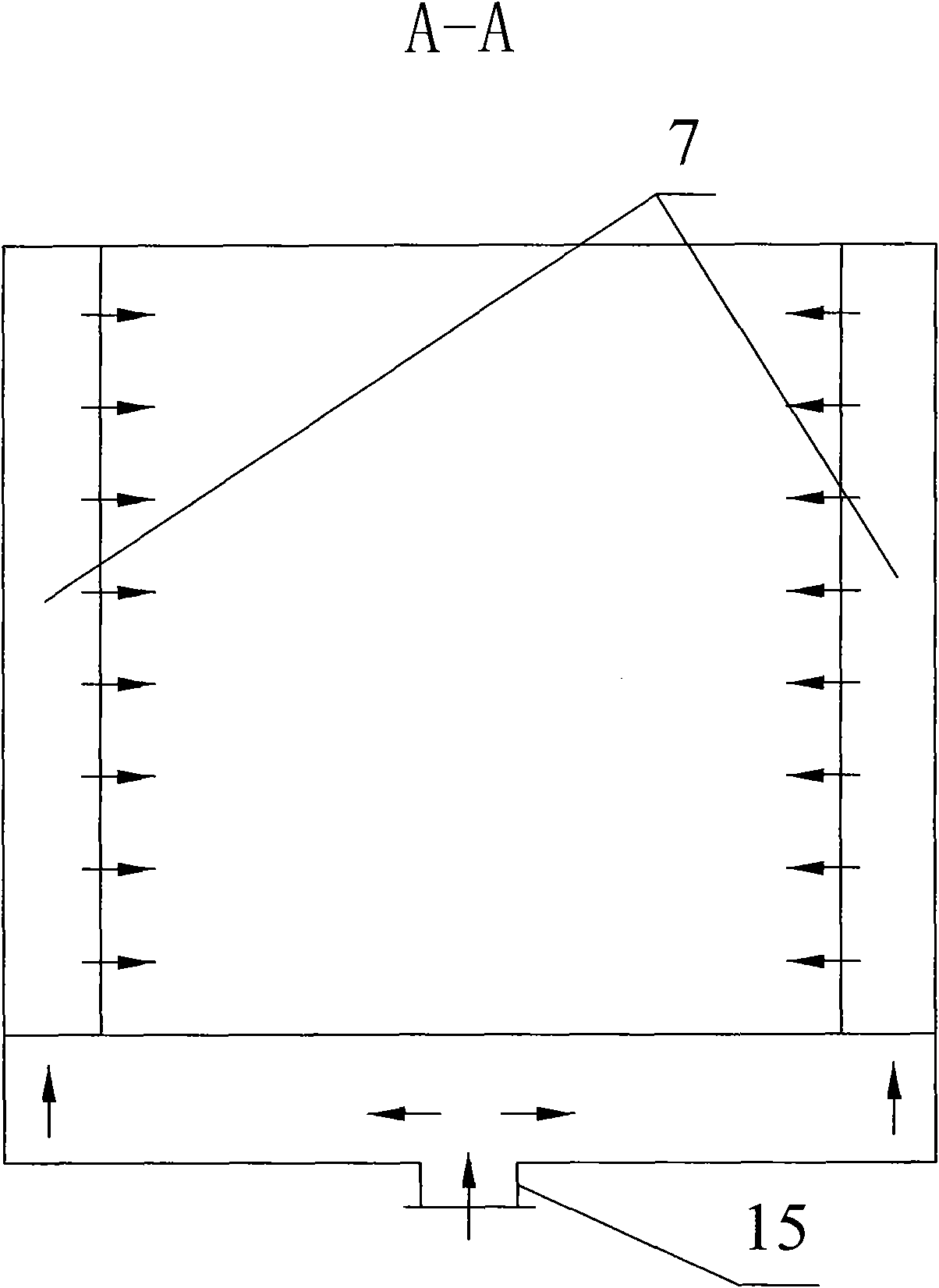

Atomized fall type coal paste preprocessor

ActiveCN101773795AAvoid cloggingAchieve repeated dropsFlow mixersTransportation and packagingProcess engineeringSlide plate

The invention relates to an atomized fall type coal paste preprocessor. A sliding plate is fixedly connected to the two sides of a lower tank body of a fall tank, a vertical shaft of a fogging disc is connected with an output shaft of an electric motor, an upper tank body of the fall tank is provided with a central feeding pipe and an overflow launder; wherein the overflow launder is internally provided with baffle plates; a slide plate comprises an upper slide plate and a lower slide plate, a ridged bar is fixedly connected on the slide plate; the vertical shaft of the fogging disc is externally sheathed with a sleeve, the lower part of the sleeve is provided with a chemical feed pipe which is communicated with a chemical feed hopper, the lower end of the chemical feed pipe is placed above the front surface of the fogging disk; a coupler is a flexible coupler. In the invention, the front surface of the fogging disk is the working surface; floating agent automatically flows to the working surface under the action of static pressure, thus avoiding blockage caused by impurities; with the fall tank, repeated fall of coal paste is realized, so that sufficient time is provided to contact and fully mix with the floating agent having gong through atomization and dispersion, thus facilitating formation of enough and stable oil film on the surface of the fogging disk; the slide plate with ridged bars is set with different contact pretreatment time for medium-thickness and fine particles of the coal paste, thus creating fine technological conditions for coal paste pretreatment.

Owner:BEIJING GUOHUA TECH GRP LTD

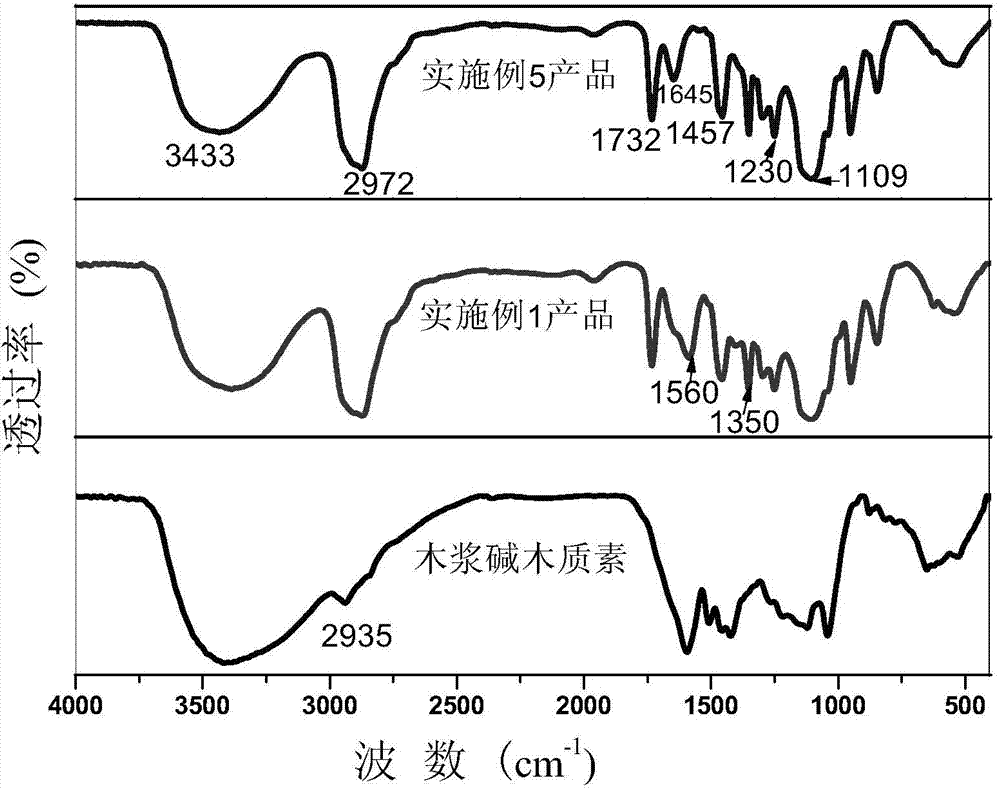

Modified lignin sulfosalt dispersant of water coal slurry

InactiveCN1404912AVersatileImprove performanceTransportation and packagingMixingLiquid productSulfonate

The preparation method of dispersing agent for water-coal slurry by using lignin sulfonate-by-product obtained by pulping for making paper includes the following steps: chemical modification, adding alkali in lignin sulfonate solution at 50-85 deg.c to regulate pH value of 8-11.5, adding catalyst, oxidant, anchor group and solvation chain and making them produce reaction for 1-10 hr., and compounding modification, adding modifying agent, stirring for 10-60 min. and cooling so as to obtain liquid product of the dispersing agent. Said invention can modify the lignin sulfonate into the additive with double action of dispersion and stabilization for water-coal slurry.

Owner:SOUTH CHINA UNIV OF TECH

Thermally dissolving and catalytic method for preparing liquid fuel by lignite as well as catalyst and solvent used therefor

ActiveCN101182421AMild operating conditionsSimple preparation equipmentOrganic-compounds/hydrides/coordination-complexes catalystsMolybdeum compoundsLiquid productForming gas

The invention belongs to the technological field of coal chemical processing and discloses a heat dissolving and catalyzing method using brown coal to prepare liquid fuel. The method comprises the following steps: 1) the brown coal is smashed and dried to prepare pulverized coal; 2) the pulverized coal, solvent and catalyst are stirred and mixed well to prepare coal slurry; wherein, the weight percent of the pulverized coal is 30 percent to 40 percent; the weight percent of the solvent is 60 percent to 70 percent; the quantity of the added catalyst is 0.5 percent to 1 percent of the weight of the pulverized coal; 3) the coal slurry is dissolved by heat and catalyzed to prepare heat dissolved and liquefied products; wherein, the temperature is 390 DEG C to 450 DEG C; the pressure is 5.0MPa to 9.0MPa; the reaction time is 30 minutes to 60 minutes; 4) the heat dissolved and liquefied products are separated to form gas-phase, liquid-phase and solid-phase products; 5) the liquid products are extracted and processed to form liquid fuel. The invention also discloses catalyst and solvent used in the method. The operation condition of the method of the invention is mild; the conversion ratio of the organic substances in the brown coal can achieve a higher level; after being processed, the liquid fuel product can be used for preparing engine fuel suiting national standards; and the preparation equipment is simple; the investment is small; the cost is low; and the invention is a coal liquefaction method suiting the national conditions of China.

Owner:ZHAOQING SHUNXIN COAL CHEM TECH

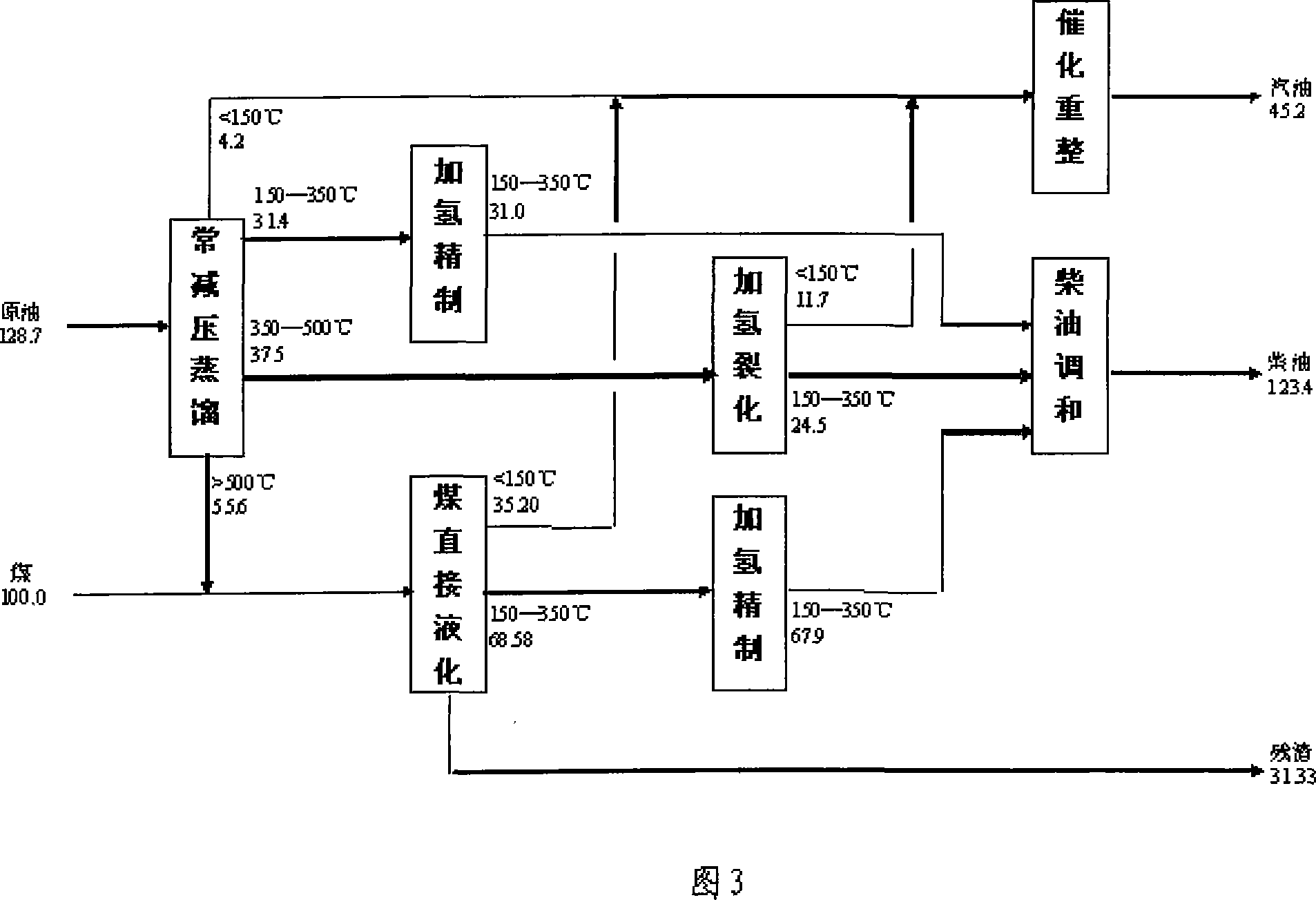

Joint processing technique for coal and stone oil

ActiveCN101220286ALow viscosityGuaranteed viscosityLiquid hydrocarbon mixture productionRefining to eliminate hetero atomsProduction rateHydrogenation reaction

The invention relates to a method for processing coal and petroleum together and comprises the following steps: (1) coal power and solvent oil are prepared into coal slurry; (2) the coal slurry is done with hydrogenation reaction and lytic reaction; (3) petroleum products are done with the hydrogenation reaction after the products in the step (2) are done with solid-removing; (4) fraction with the temperature of 350-520 DEG C in the fraction of the step (3) products is taken as the solvent oil circularly; wherein, the solvent oil of the step (1) further comprises residual oil from the petroleum and the naphthenic base residual oil is the best. By adopting the method of the invention, the residual oil can be transformed fully, the density of the coal slurry keeps high and the fuel production rate of high quality engines can be improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

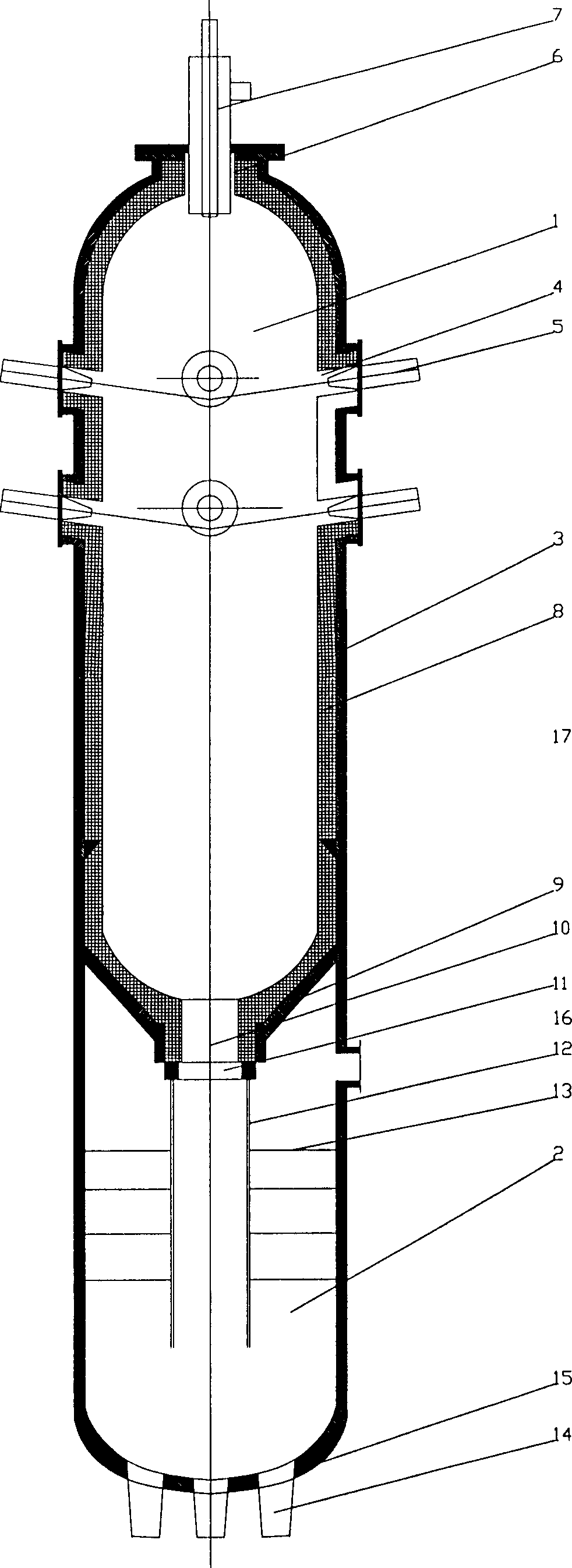

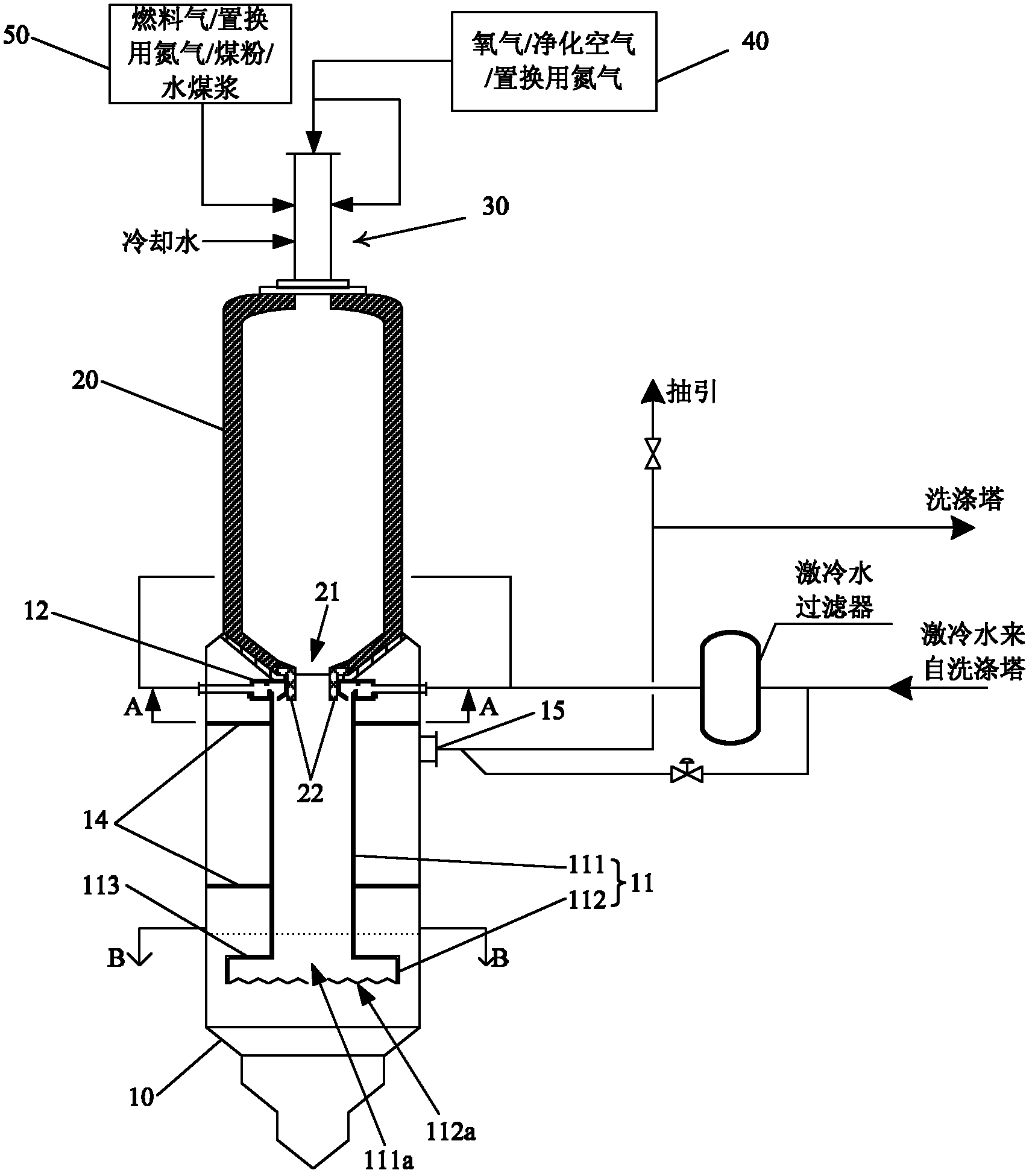

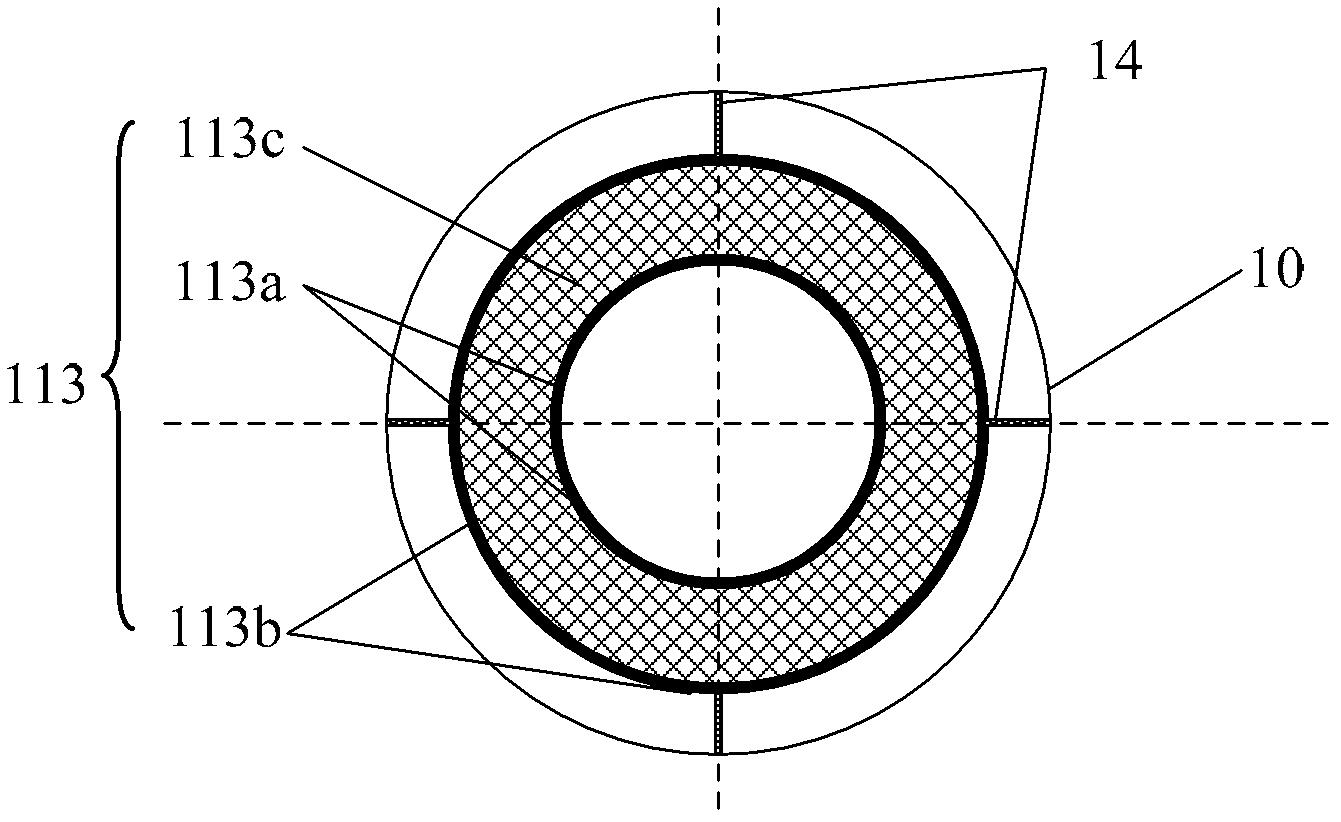

Pulverized coal or water coal slurry gasification furnace system

ActiveCN102643678AExtended operating cycleAvoid enteringGranular/pulverulent flues gasificationSyngasCombustor

The invention discloses a pulverized coal or water coal slurry gasification furnace system which comprises a gasification furnace, a feeding system for feeding the gasification furnace and a follow-up treatment system of a discharge compound gas, wherein the gasification furnace comprises a combustor and a quench chamber positioned below the combustor; the quench chamber is provided with a downcomer and a quench ring; the quench ring is arranged at the top part of the downcomer and provides quench water; the downcomer comprises an air reduction barrel and an air distribution barrel; the lower end of the air reduction barrel extends to the air distribution barrel; an air diffusion mesh is arranged on a ring-shaped cross section between the air distribution barrel and the air reduction barrel; and the lower edge of the air reduction barrel is in a sawtooth shape. According to the pulverized coal or water coal slurry gasification furnace system, water and ash containing in a synthetic gas in the quench chamber are lightened; the service lives of the quench ring and the downcomer are prolonged; the stable production is kept; the operation period of the gasification furnace is prolonged; and the continuous operation of over baking and chemical engineering feeding.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

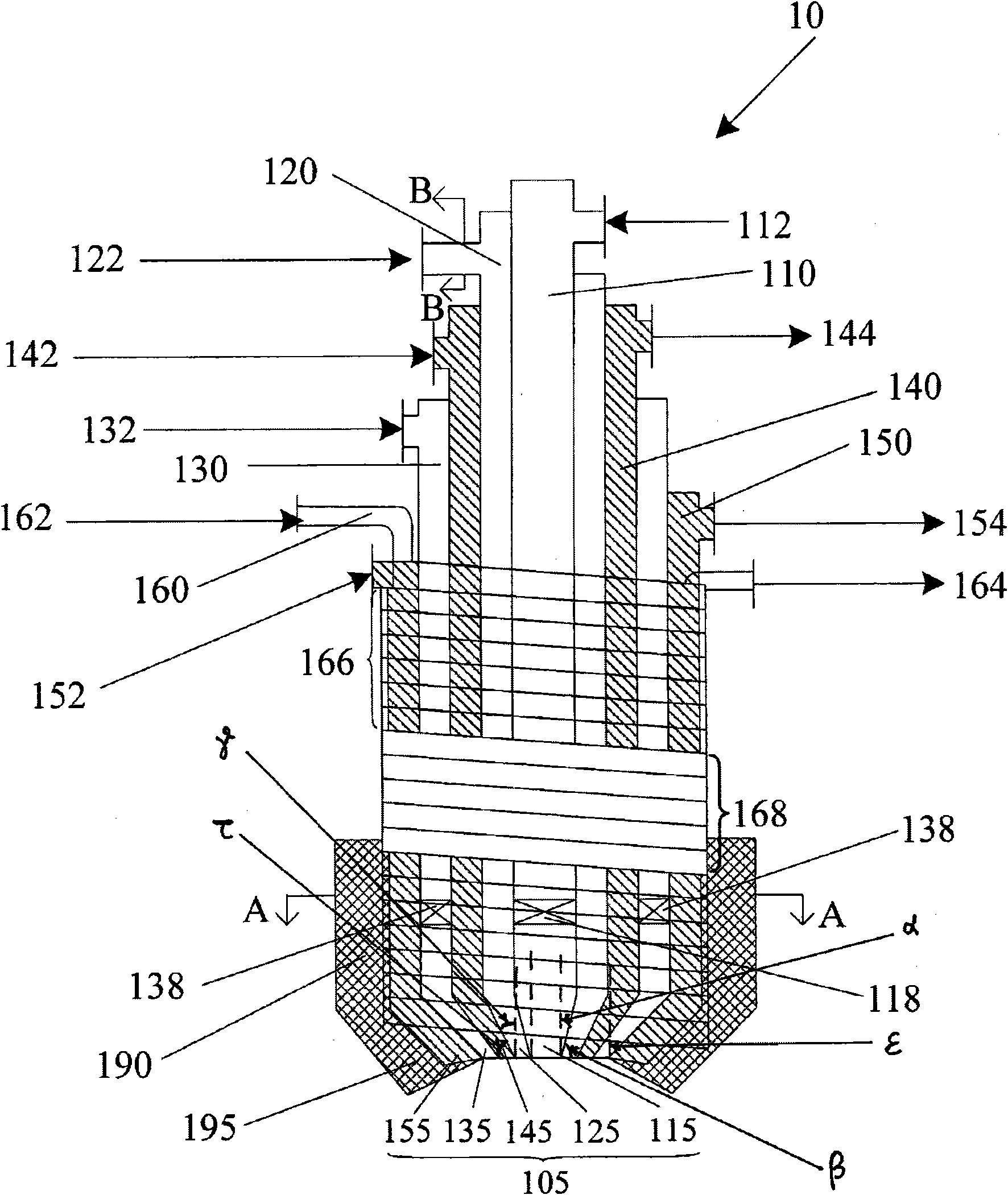

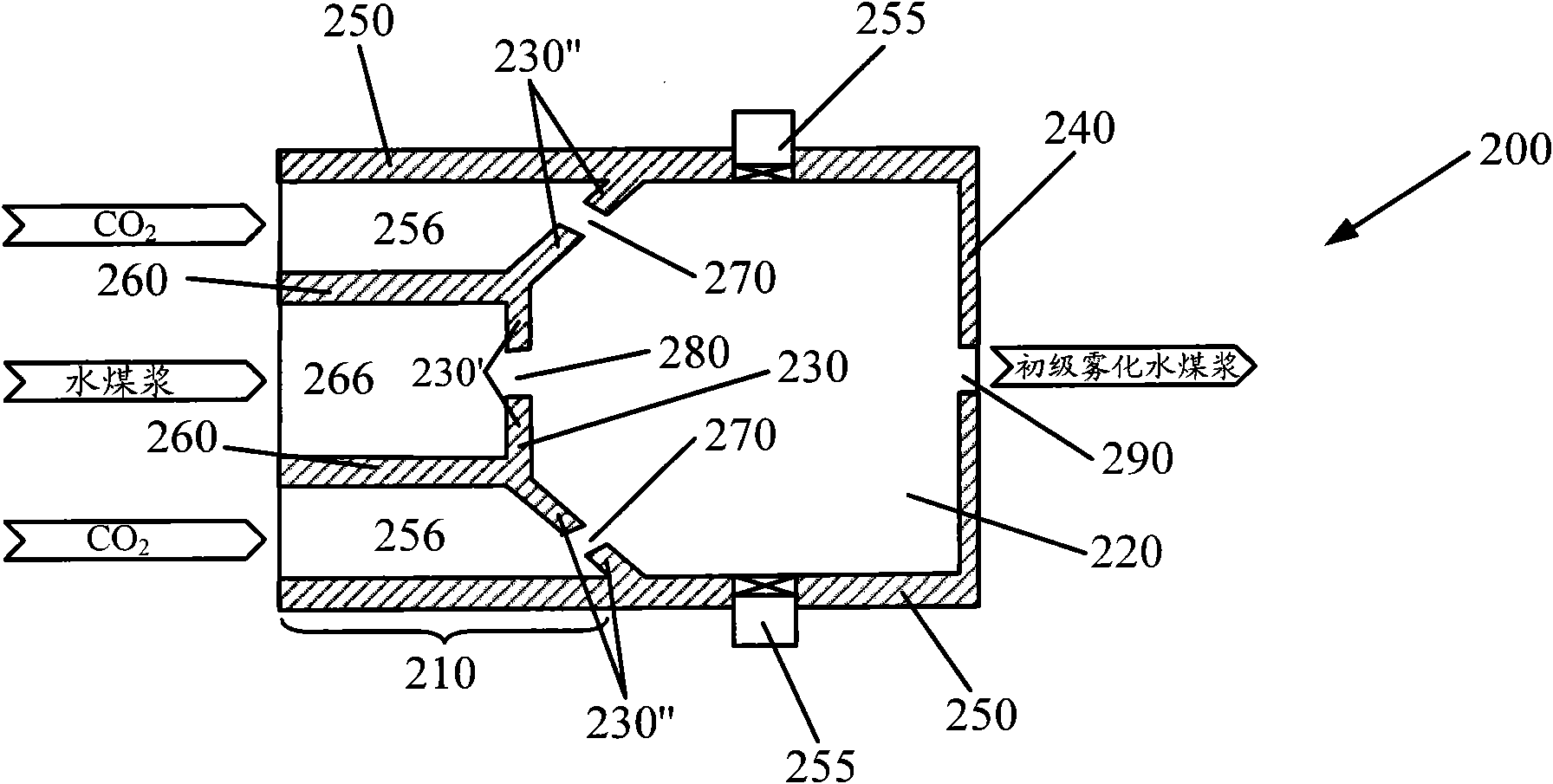

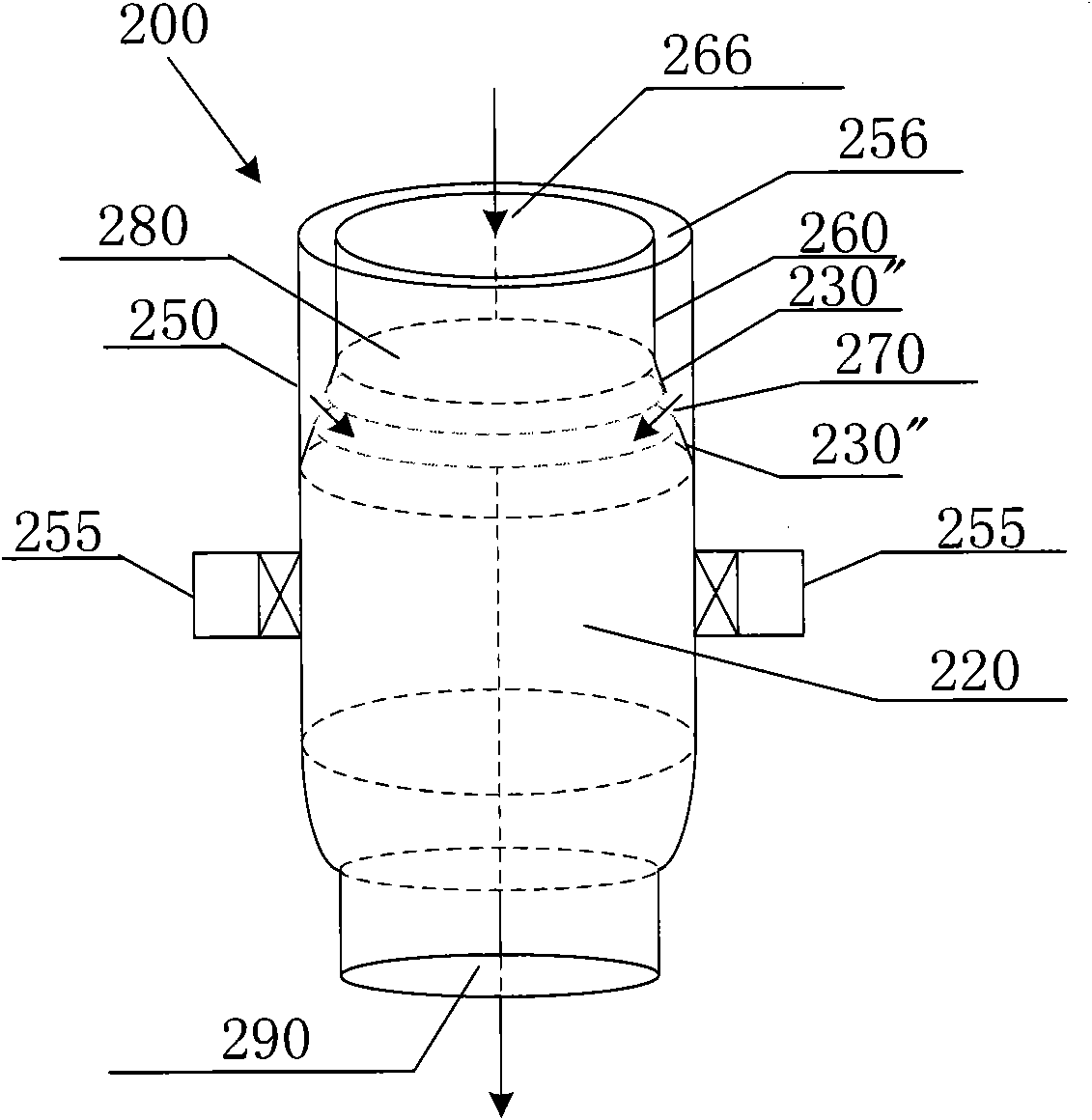

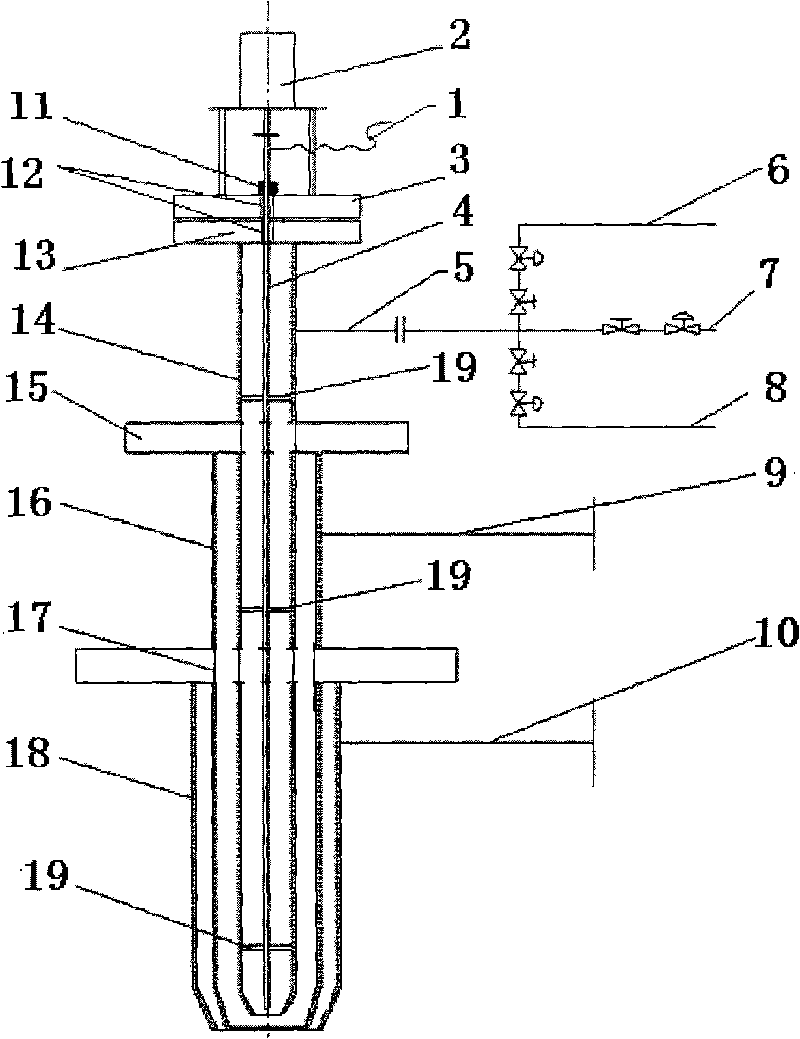

Process nozzle and system for gasifying water coal slurry and application thereof

ActiveCN102031152AEffective protectionImprove cooling effectLiquid spraying apparatusGranular/pulverulent flues gasificationCoal slurryWater jacket

The invention provides a process nozzle and a system for gasifying water coal slurry. The process nozzle comprises a first oxygen channel, a water coal slurry channel, a second oxygen channel, a first cooling water jacket and a cooling water coil, wherein the first oxygen channel comprises a first oxygen channel inlet and a first oxygen channel outlet; the water coal slurry channel comprises at least one water coal slurry channel inlet and a water coal slurry channel outlet; the second oxygen channel comprises a second oxygen channel inlet and a second oxygen channel outlet; the first cooling water jacket comprises a first cooling water jacket inlet and a first cooling water jacket outlet; and the cooling water coil comprises a cooling water coil inlet and a cooling water coil outlet. The process nozzle is characterized in that: the first oxygen channel is positioned at the central position of the process nozzle; the water coal slurry channel is positioned between the first oxygen channel and the second oxygen channel and surrounds the periphery of the first oxygen channel; and the second oxygen channel surrounds the periphery of the water coal slurry channel. The process nozzle reduces the length of combustion flame more effectively, reduces the ablation of flame on a refractory brick, promotes the mixing and atomization of water coal slurry and oxygen and improves gasification efficiency.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

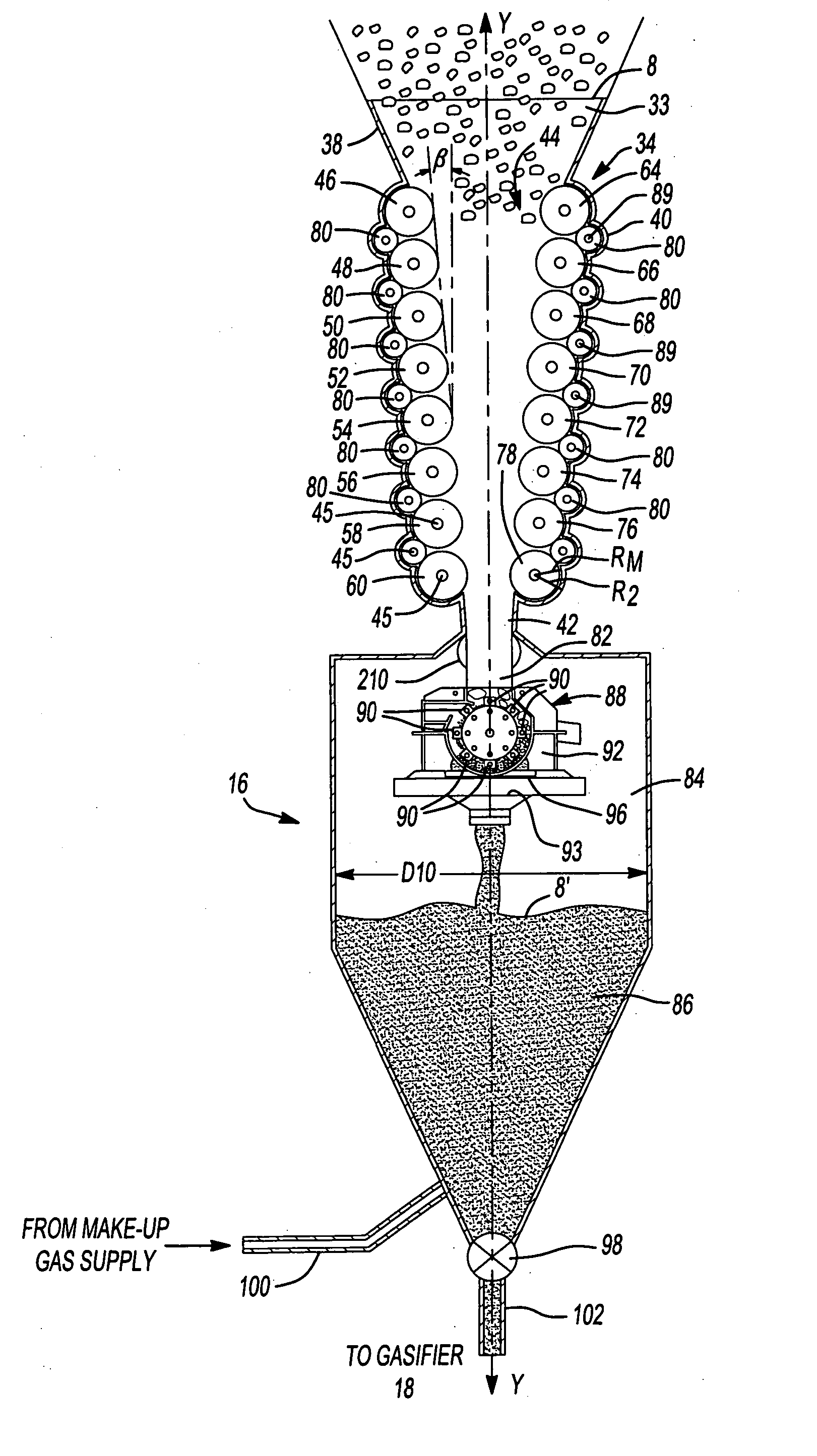

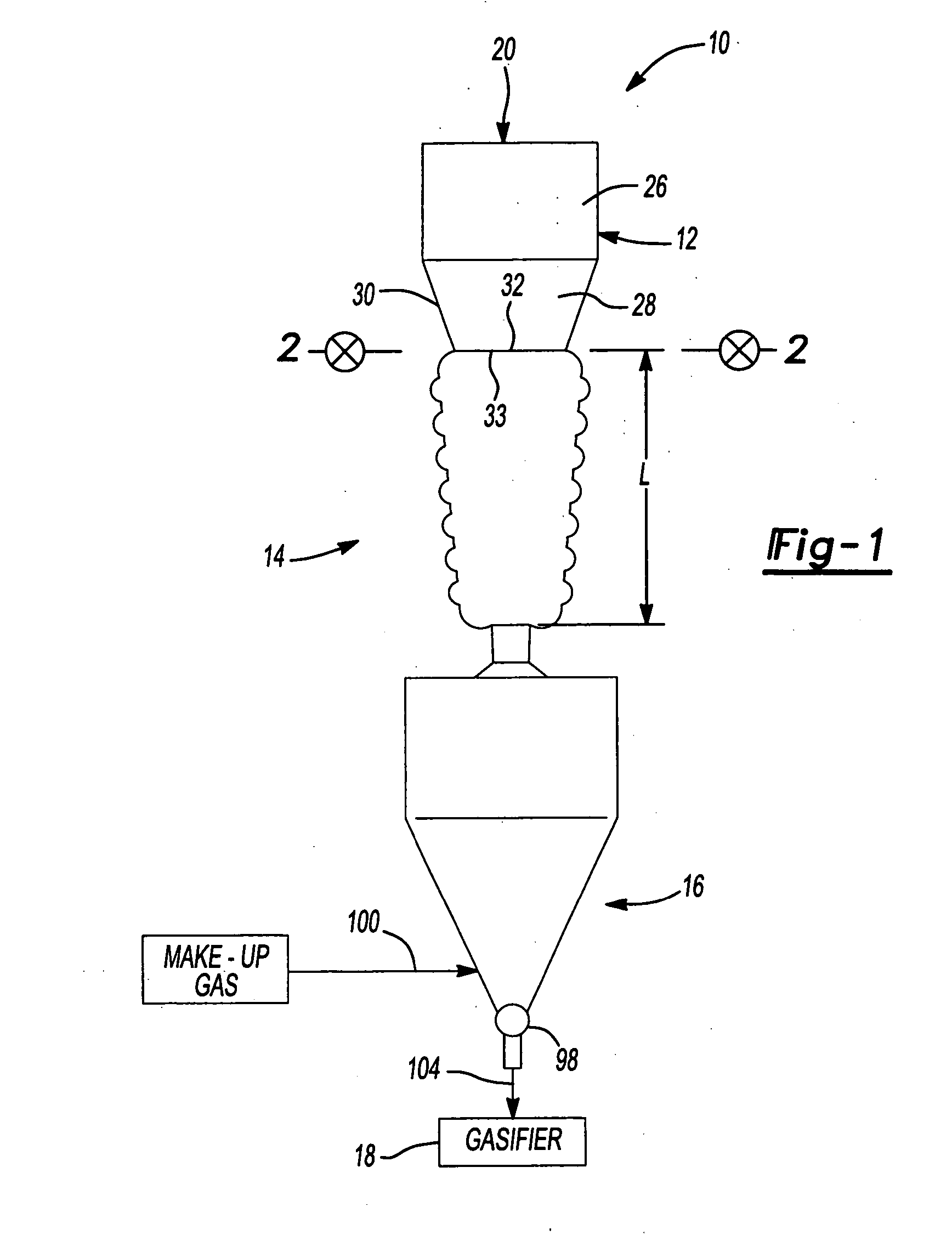

High pressure dry coal slurry extrusion pump

A system for providing highly pressurized raw fuel to a pressure reactor. The system includes an inlet for receiving the raw fuel and a roller system communicating with the inlet. The roller system includes a plurality of independent rollers arranged in two converging planes. The rollers of the roller system successively compress the raw fuel as the raw fuel passes through the roller system between the rollers, such that the fuel is highly pressurized when it reaches an output end of the roller system. An outlet is located adjacent the output end of the roller system to dispense the pressurized raw fuel to the pressure reactor.

Owner:THE BOEING CO +1

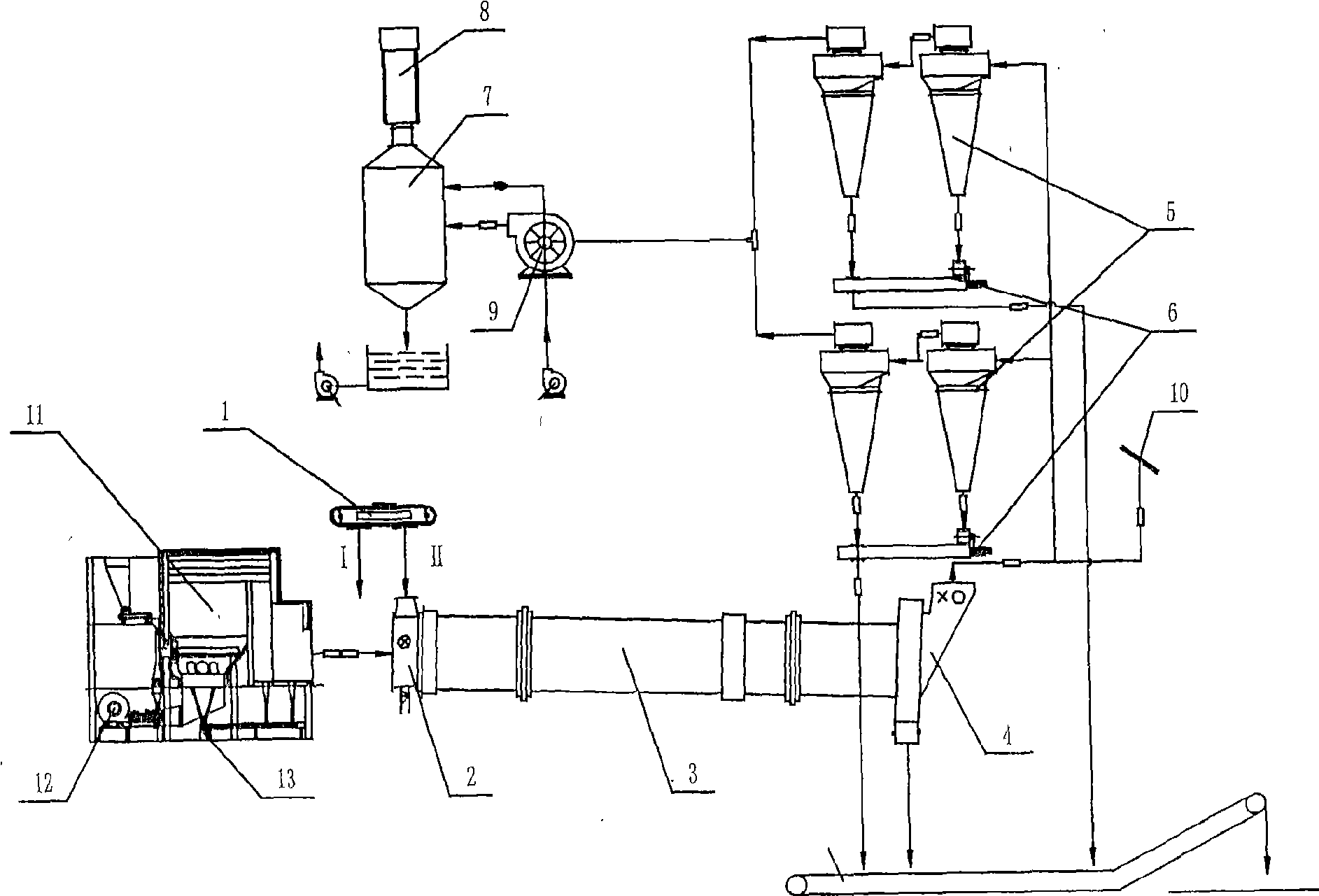

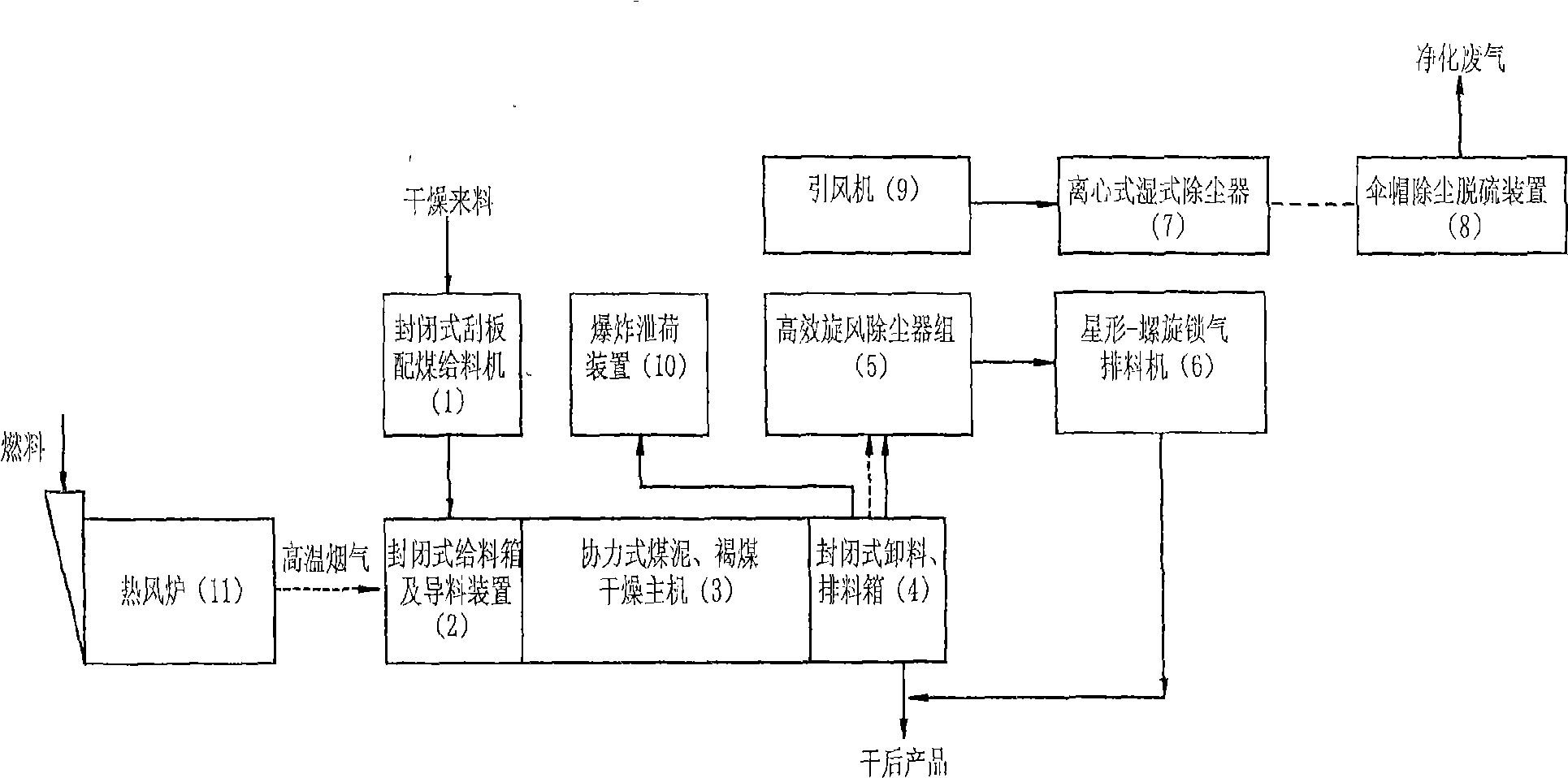

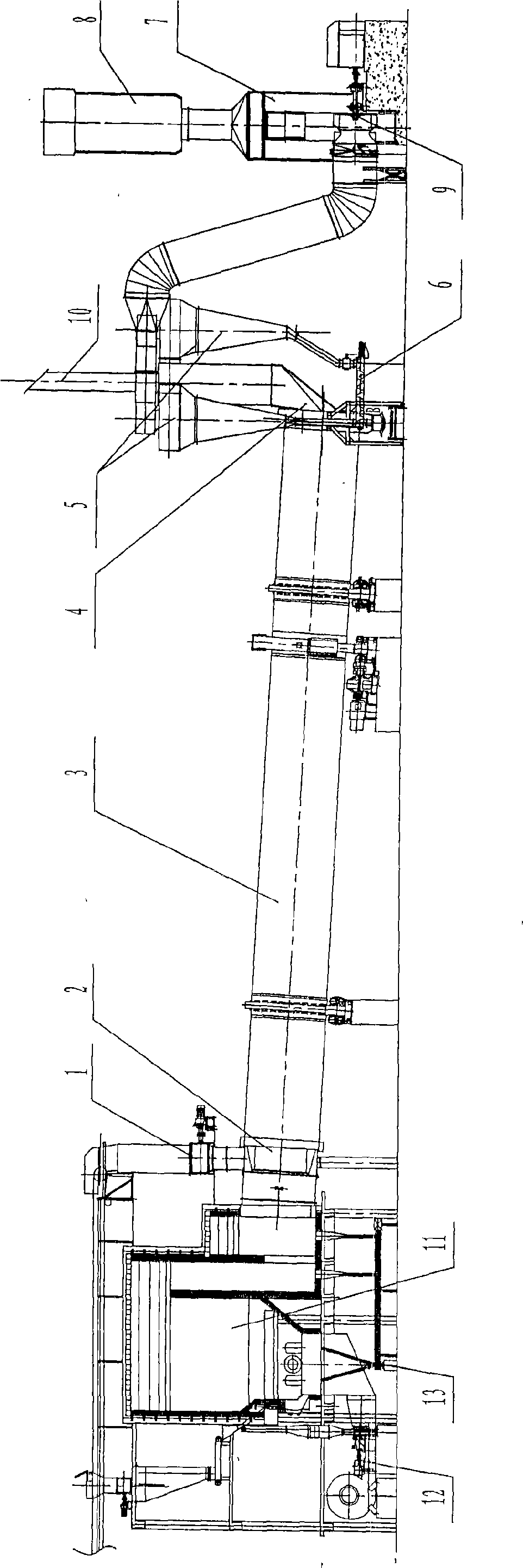

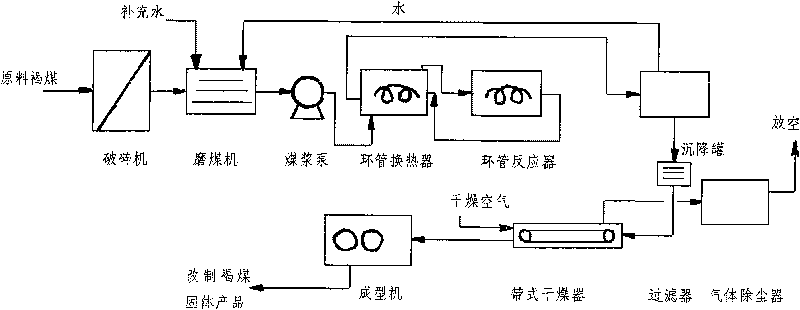

Process and equipment for improving the quality of coal slurry and lignite through drying same

InactiveCN101519617ASolve frequent blockagesSolve the burning problemSolid fuelsDrying peatEconomic benefitsProcess engineering

The invention relates to process and equipment for improving the quality of coal slurry and lignite through drying the same. The process comprises the following steps: (1) the coal slurry and the lignite are predried and then quantitatively fed to a drying system; (2) the coal slurry and the lignite are dried to be improved in quality by a material drying system; and (3) products are produced from the dried coal slurry and lignite of improved quality. The coal slurry and the lignite are dried and dewatered according to the physical and chemical properties of the same and the coal slurry and the lignite can not adhered to the wall of a cylinder of the equipment and can be cleaned automatically; the equipment is arranged integrally lineally on a plane so that the height of a factory building is lowered and the investment on the equipment is reduced by half compared with investment on the equipment arranged in a laminated mode; in addition, the equipment integrates feeing equipment, drying equipment and discharging equipment, has good sealing performance and high thermal efficiency which is increased to over 70 percent from the original 30-40 percent, saves energy to be consumed by one third, is environmentally friendly, can efficiently dewater the coal slurry and the lignite to improve the quality thereof and can be used safely and reliably so as to obtain obvious economic benefits.

Owner:张兆奇

Water coal slurry pressure gasification process burner device with ignition device

ActiveCN101691924AImprove securityBurnersGranular/pulverulent flues gasificationOxygen systemElectric ignition

The invention relates to the field of coalification process of water coal slurry pressure gasification, in particular to a water coal slurry pressure gasification process burner device with an ignition device. The burner device comprises a flange cover, a water coal slurry supply pipe, an external oxygen supply pipe, a water coal slurry pipe, a mounting flange, an external oxygen pipe and a middle flange, and also comprises a high-pressure electric igniter, execution mechanisms, an electric ignition bar, a central oxygen system and a combined seal, wherein the upper parts of an end face flange, a central oxygen pipe and the flange cover are provided with the execution mechanisms. The water coal slurry pressure gasification process burner device with the ignition device enables a water coal slurry gasification furnace with a water-cooling wall coil type inner wall to be used.

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Sewage sludge biomass coal liquid and producing process

The invention relates to sludge biomass coal slurry and a manufacturing process thereof. The invention is characterized in that the manufacturing process comprises the following steps: (1) 10-50 parts of sludge and 0.01-5 parts of sludge modifier are mixed by part by weight to form modified sludge after full reaction; (2) the modified sludge obtained in the step (1) and 40-70 parts of coal dust, 1-50 parts of water, 1-60 parts of fuel oil and 0.01-2 parts of dispersant are mixed by part by weight and ground fully, so that the average grain diameter of solid particles in the mixture is less than 300 micron, thus obtaining the sludge biomass coal slurry. Compared with the prior art, the invention has the advantages of fully utilizing useful ingredients in the sludge and being environmentally friendly and energy-saving.

Owner:吴荣标

Method for modifying lignite

The invention relates to a method for modifying lignite, belonging to the technical field of coal processing. In the method, the lignite is broken, sent into a coal mill, and is ground into coal pulp after water is added. Due to high content of internal water of the lignite, the concentration of the water-coal-slurry is relatively low, generally 30-55%. Modified water-coal-slurry is obtained after treatment under high temperature and pressure, wherein the internal water of lignite particles in the modified water-coal-slurry is reduced, and the water used for lubrication among the particles is more than needed water content of the water-coal-slurry. Measure of settlement or / and other specific measure, is / are needed to separate the excess water, and the concentration of the water-coal-slurry is increased from 30-50% to 50-70%, thereby increasing the calorific value of the lignite.

Owner:TSINGHUA UNIV +1

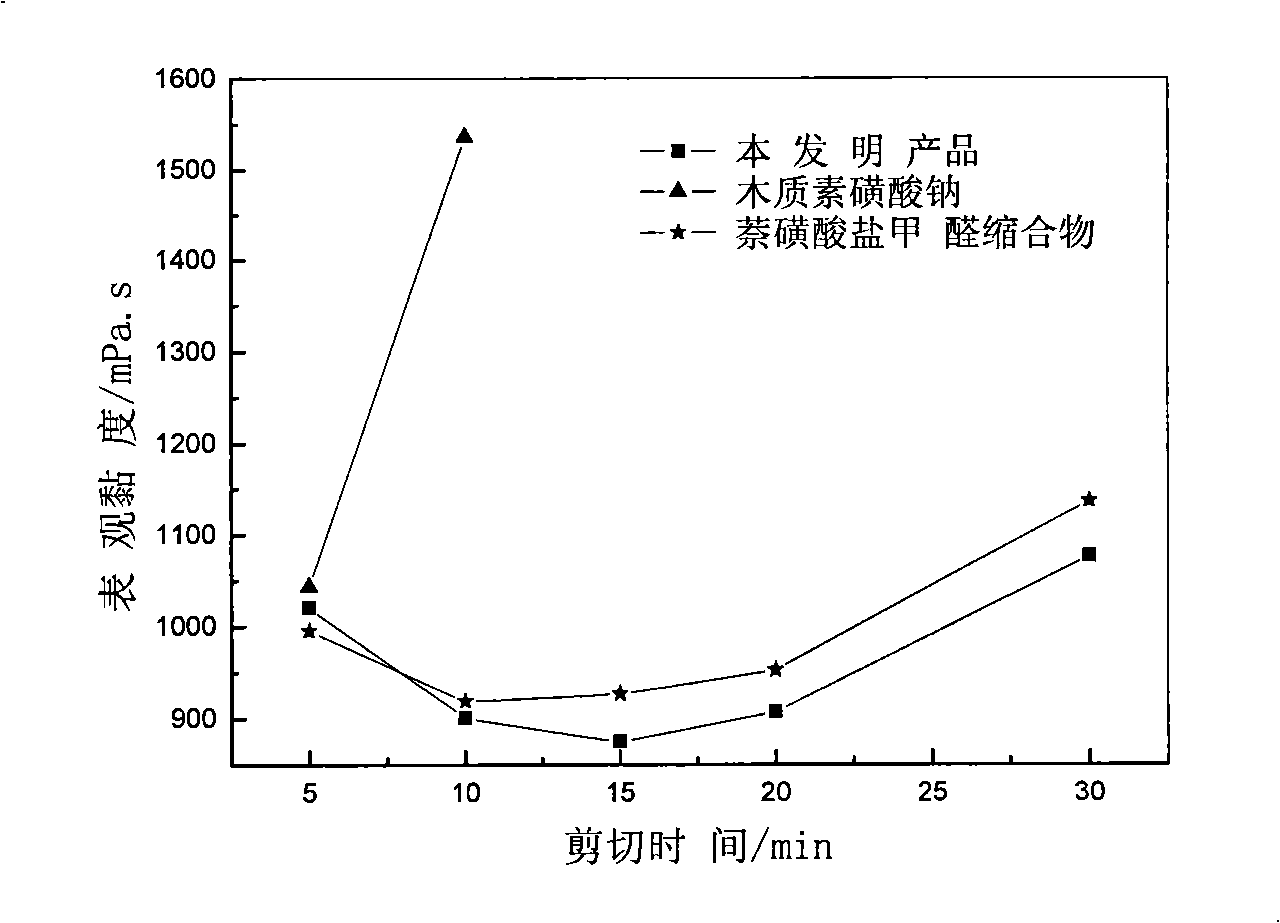

Coal water slurry dispersing agent made from black-liquor of straw pulping in paper-making and preparation thereof

InactiveCN101322927AReduce manufacturing costEasy to operate and controlTransportation and packagingMixingSolubilitySulfonate

The invention discloses a straw pulp papermaking black liquor water-coal slurry dispersant and a preparation method thereof. The prescription of the water-coal slurry dispersant is counted by mass portion and includes 20 portions of condensed straw pulp papermaking black liquor of 50 to 60 percent; 25 to 50 portions of aldehydes, 20 to 60 portions of carbonyl compounds and 25 to 50 portions of sulfonating agents. The preparation method thereof is to prepare the water-coal slurry dispersant by carrying out graft sulfonation and polycondensation on the condensed straw pulp papermaking black liquor, the aldehydes, the carbonyl compounds and a sulfonating agent. The materials of the invention have abundant sources and low cost; the production cost is low; the water-coal slurry dispersant prepared by the invention has excellent water solubility and surface activity as well as excellent slurry preparing performance to the water-coal slurry under a lower addition; the dispersing viscosity reduction performance of the water-coal slurry dispersant is far superior to lignin sulfonate; aiming at different coal varieties, the water-coal slurry dispersant achieves or exceeds the efficiency of naphthyl sulfonate formaldehyde condensate; besides, the anti-shearing performance of a slurry body is excellent; the application range to the coal varieties is broad; the water-coal slurry dispersant is novel, effective and environment-friendly.

Owner:SOUTH CHINA UNIV OF TECH

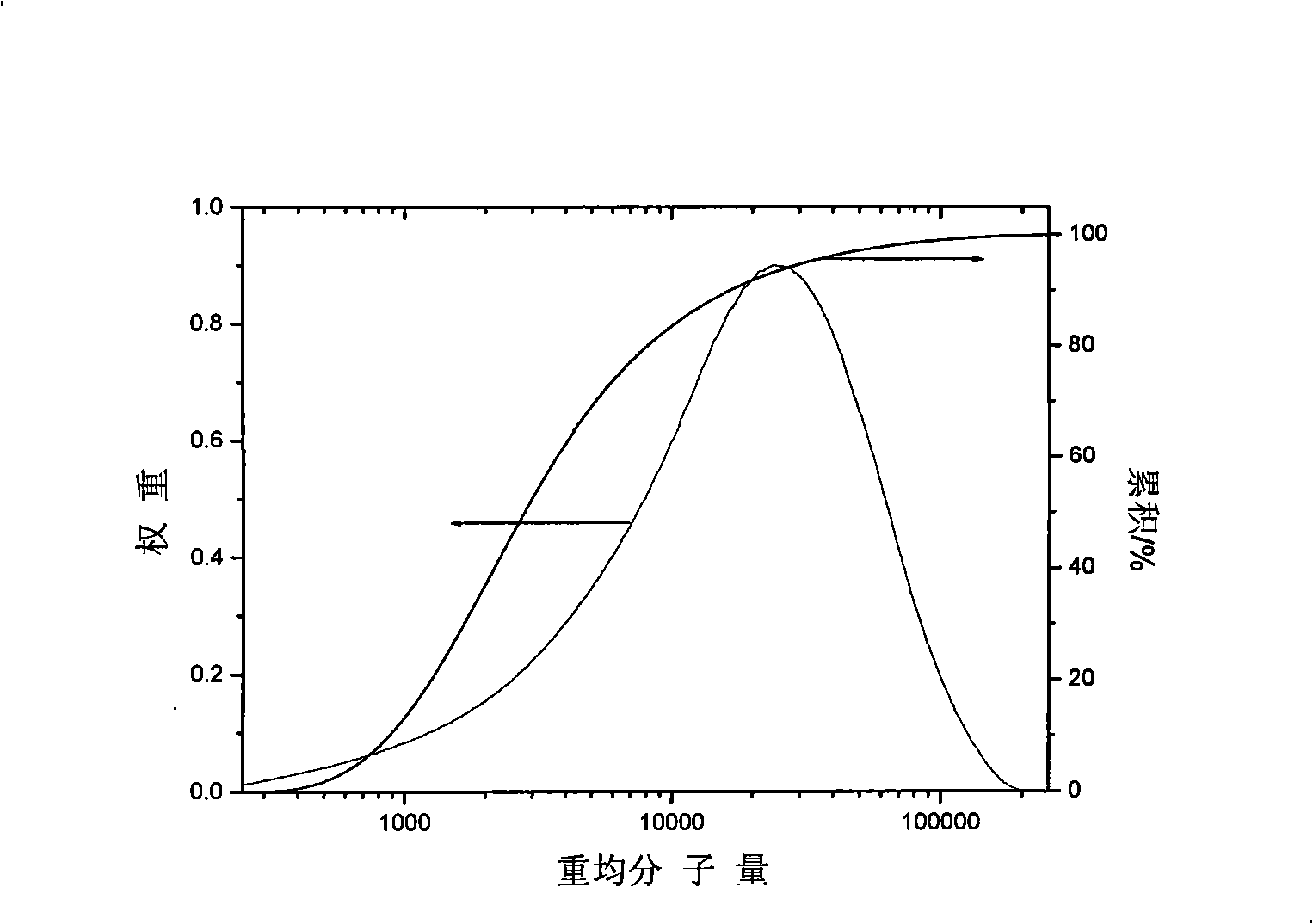

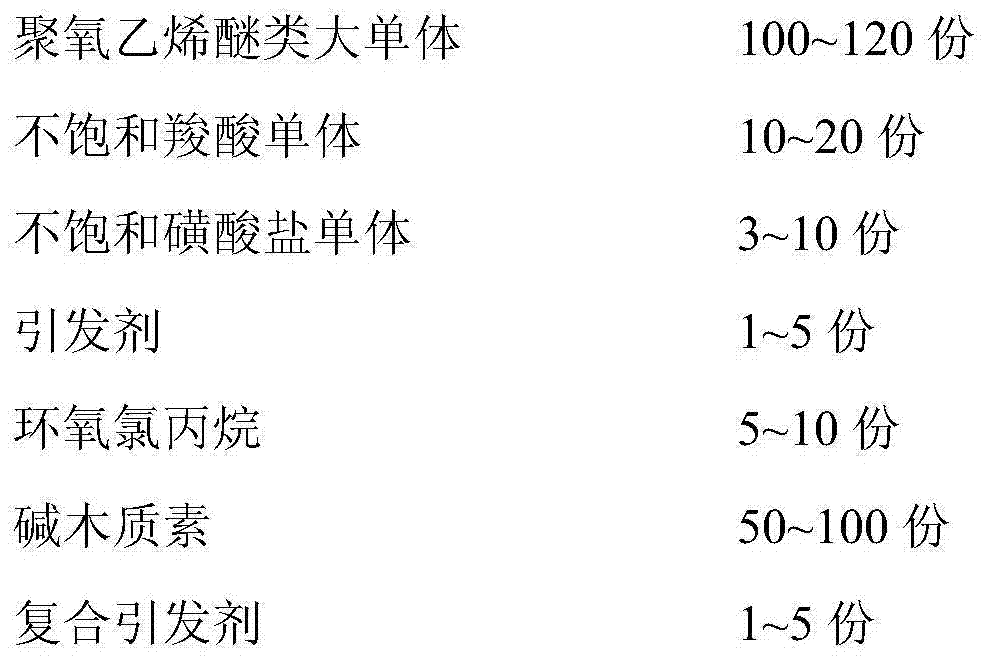

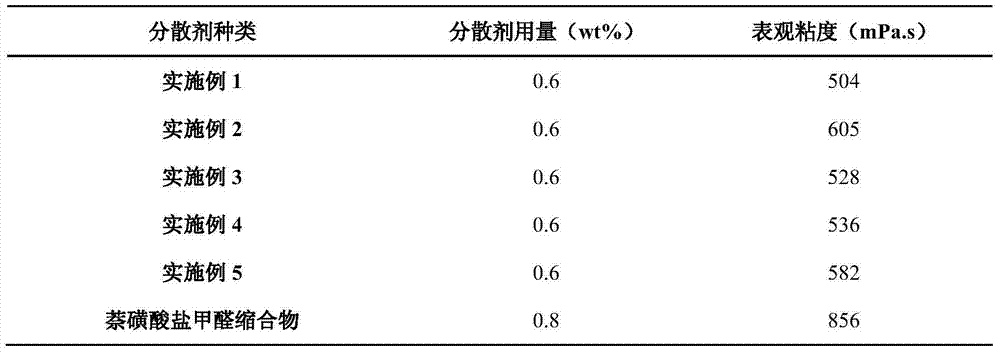

Preparation method of alkali lignin modified polycarboxylic acid-type coal water slurry dispersant

ActiveCN104327280AStay decentralizedReduce usageLiquid carbonaceous fuelsDispersion stabilityLiquid product

The invention relates to a preparation method of an alkali lignin modified polycarboxylic acid-type high-efficiency coal water slurry dispersant. The method comprises the steps: at the temperature of 50-80 DEG C, carrying out a copolymerization reaction of a polyoxyethylene ether macromonomer, an unsaturated carboxylic acid monomer, an unsaturated sulfonate monomer and an initiator for 2-3 h in an aqueous solution, adjusting the temperature to 30-50 DEG C, adding epoxy chloropropane, carrying out a reaction for 0.5-1 h, adding an alkaline regulator, adjusting the pH value to 10-12, adding an alkali lignin solution with the mass concentration of 20-50%, adjusting the reaction temperature to 60-80 DEG C, dropwise adding a composite initiator aqueous solution with the mass concentration of 2%, carrying out a reaction for 1-3 h, and thus obtaining a liquid product. The product has the dispersion viscosity reduction performance on coal water slurry superior to that of a naphthalenesulfonate formaldehyde condensation compound, and has good dispersion stability on coal slurry; and while original dispersive ability and other characteristics of the polycarboxylic acid-type dispersant are maintained, the production cost is reduced, and the usage amount of non-renewable resources and toxic materials is lowered.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com