Preparation method of high-chrome brick

A technology of high chromium bricks and chromium oxide particles, applied in the field of refractory materials, can solve the problems of affecting the service life of gasifiers, reducing the permeability resistance of high chrome bricks, and intensifying the penetration of cinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

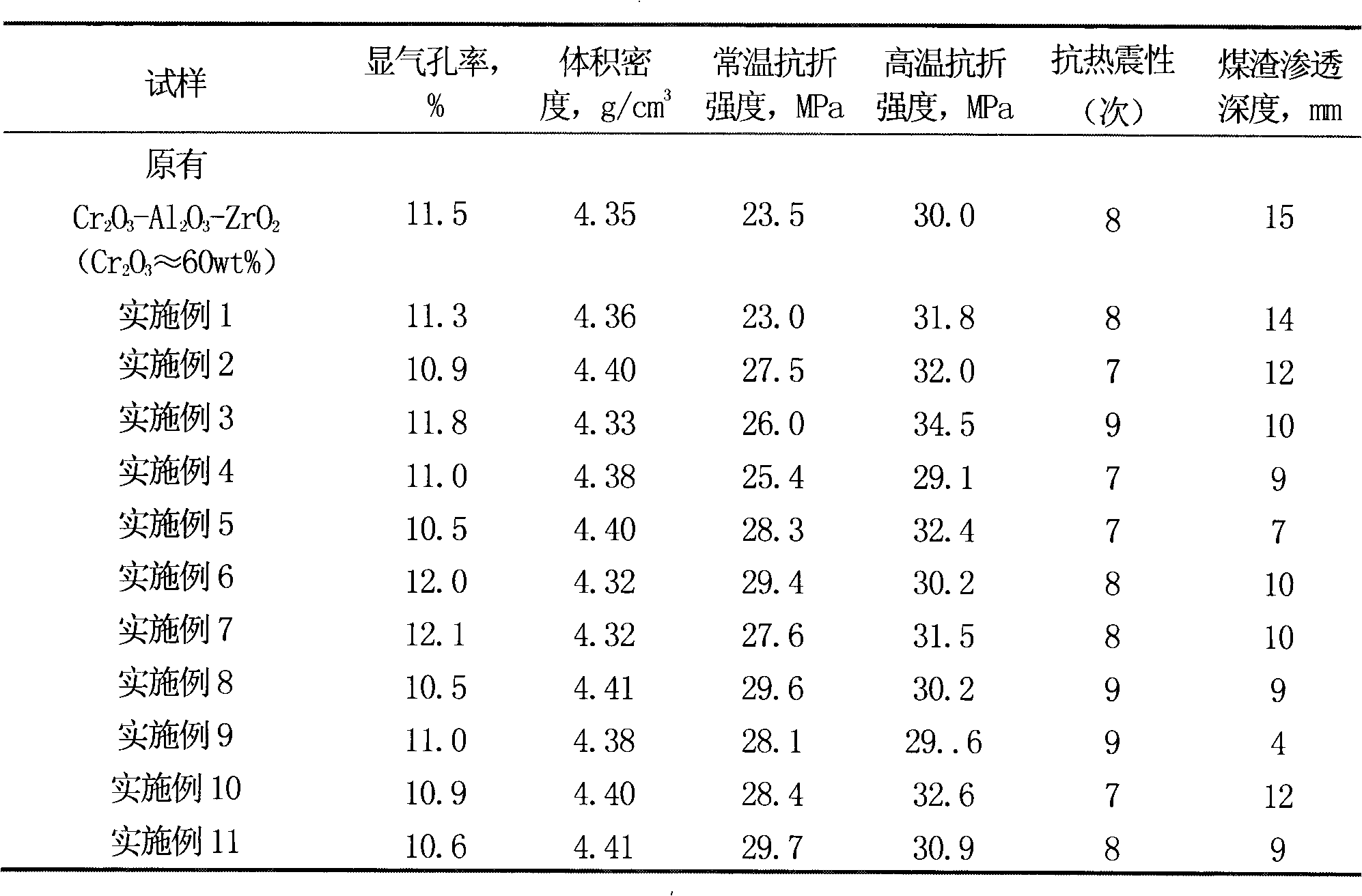

Examples

Embodiment 1

[0011] Example 1: Using 2 o 3 The matrix is magnesium oxide yttrium oxide composite stabilized zirconia powder with a particle size of 1 μm, accounting for 20%, 12%, 12%, and 1% of the total component mass respectively. The mass fraction of magnesia in the stabilized zirconia powder is 2%, the mass fraction of yttrium oxide in the stabilized zirconia powder is 1%, and the stabilization rate is 21%. Add 3% aluminum dihydrogen phosphate to the aggregate as a binder, add the matrix and mix evenly, after trapping the material, form a green body on a friction brick press, after drying, burn it in a high-temperature kiln at 1630°C to make a product.

Embodiment 2

[0012] Example 2: Using 2 o 3 powder and magnesia-stabilized zirconia powder with a particle size of 2 μm are used as the matrix, accounting for 15%, 12%, 10%, and 3% of the total component mass respectively. The mass fraction of magnesium oxide in the stabilized zirconia powder is 5%, and the stabilization rate is 33%. 4% aluminum dihydrogen phosphate is added to the aggregate as a binder, and the matrix is added to mix evenly. After the material is trapped, the green body is formed on a friction brick press, and after drying, it is fired in a high-temperature kiln at 1700°C to make a product.

Embodiment 3

[0013] Example 3: Using 2 o 3 Magnesium oxide yttrium oxide composite stabilized zirconia powder with a particle size of 4 μm is used as the matrix, accounting for 25%, 15%, 8%, 8%, and 4% of the total component mass respectively. The mass fraction of magnesia in the stabilized zirconia powder is 6%, the mass fraction of yttrium oxide in the stabilized zirconia powder is 1%, and the stabilization rate is 47%. 6% aluminum dihydrogen phosphate is added to the aggregate as a binder, and the matrix is added to mix evenly. After the material is trapped, the green body is formed on a friction brick press, and after drying, it is fired in a high-temperature kiln at 1700°C to make a product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com