Method of laser induction composite cladding gradient function thermal barrier coating

A technology of laser induction and thermal barrier coating, applied in coating, metal material coating process, etc., to achieve excellent thermal shock resistance, high efficiency, and improved thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of NiCrAlY / (ZrO on the surface of nickel base superalloy 2 +(6~8%)CeO 2 ) Gradient functional thermal barrier coating, the thickness of the coating is 6mm, in which ceramic phase cerium oxide stabilized zirconia (ZrO 2 +(6~8%)CeO 2 ) embedded in the bonding metal NiCrAlY, and along the thickness direction of the coating, it presents arbitrarily adjustable gradient distribution in the range of 0-90wt.%.

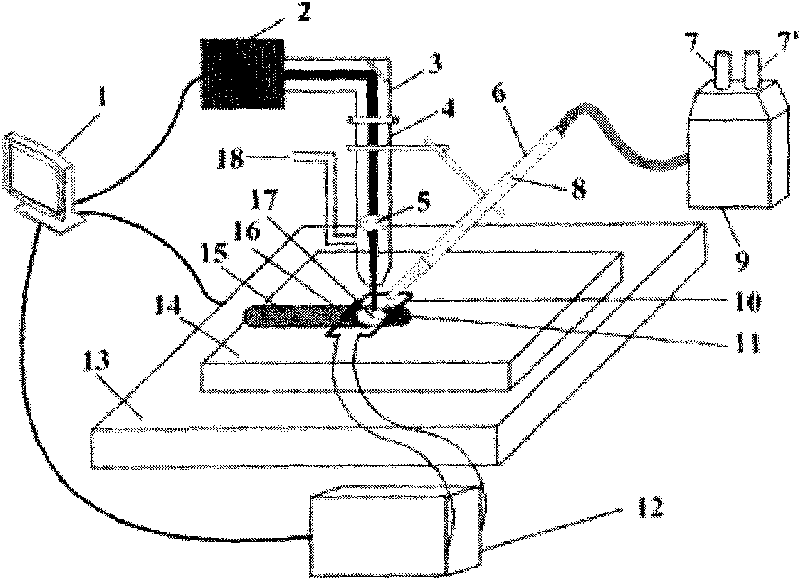

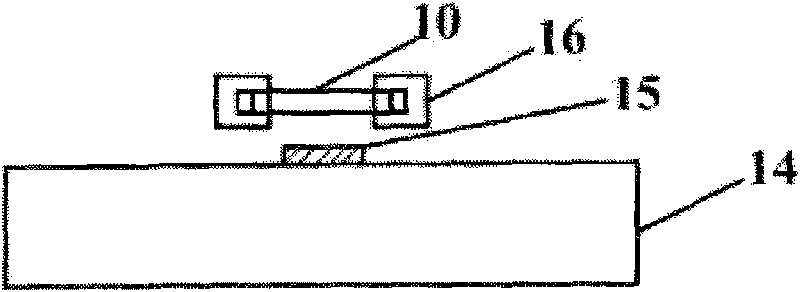

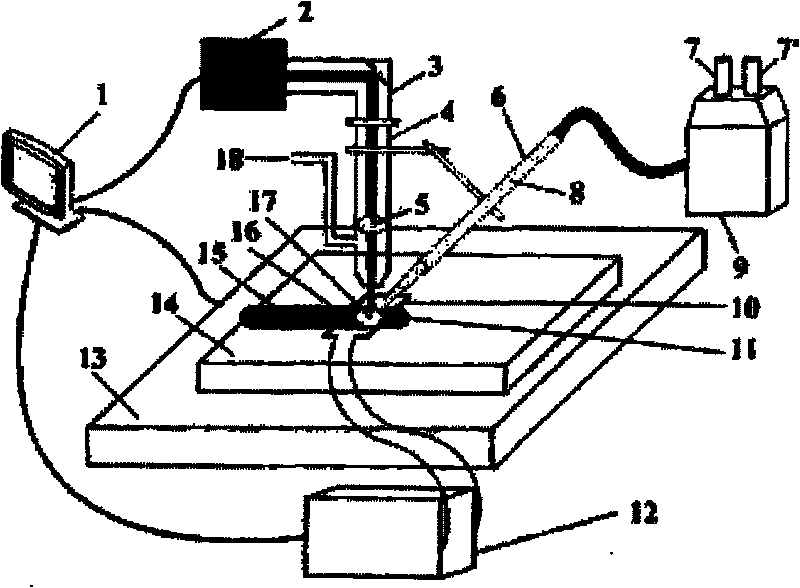

[0022] The implementation process of this embodiment is, as figure 1 and figure 2 shown.

[0023] (1) Selection and preparation of cladding materials: the bonding metal is NiCrAlY alloy powder, and its chemical composition is (mass percentage) 50-70% Ni, 19-25% Cr, 6-8% Al, 0.08-1.5% Y , the particle size is 45-90 μm, and the ceramic phase is ceria-stabilized zirconia (ZrO 2 +(6~8%)CeO 2 ), with a particle size of 20-40 μm, NiCrAlY alloy powder and ceria-stabilized zirconia (ZrO 2 +(6~8%)CeO 2 ) particles into the two loading hoppers 7, 7' of the d...

Embodiment 2

[0031] Preparation of NiCoCrAlY / Ti on the Surface of Ni-base Superalloy 3 Al gradient functional thermal barrier coating, the thickness of the coating is 3mm, in which the ceramic phase Ti 3 Al is embedded in the bonding metal NiCoCrAlY, and presents arbitrarily adjustable gradient distribution in the range of 0-90wt.% along the thickness direction of the coating.

[0032] The implementation process of this embodiment is, as figure 1 and figure 2 shown.

[0033] (1) Selection and preparation of cladding materials: the bonding metal is NiCoCrAlY alloy powder, and its chemical composition is (weight percent) 40-60% Ni, 18-22% Co, 19-25% Cr, 6-8% Al , 0.08-1.5% Y, the particle size is 45-90 μm; the ceramic phase is an intermetallic compound Ti 3 Al particles, the particle size of which is 40-60 μm, and then NiCoCrAlY alloy powder and Ti 3 The Al particles are loaded into the two loading hoppers 7 and 7' of the double-bucket automatic powder feeder 9 respectively; the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com