Ultra-high-speed laser cladding powder for repairing damaged water injection combination valve, and repairing method

A technology of laser cladding and combined valve, applied in the direction of coating, metal material coating process, etc., can solve the problems of low production efficiency, poor bonding strength, etc., to achieve extended service life, smooth surface, good wear resistance and corrosion resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in combination with specific embodiments.

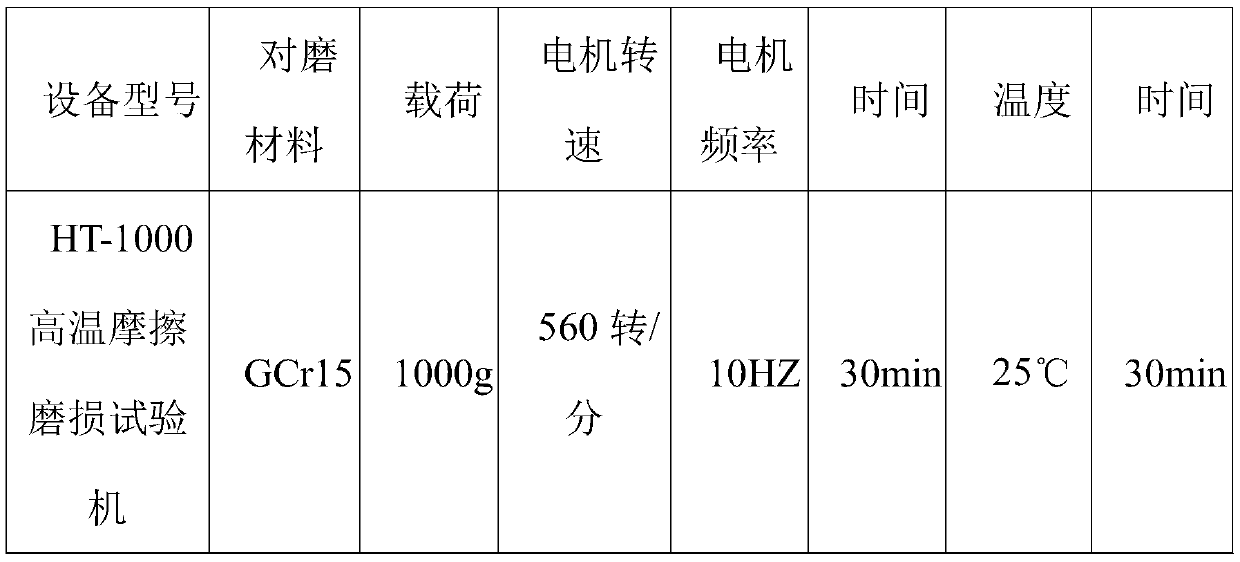

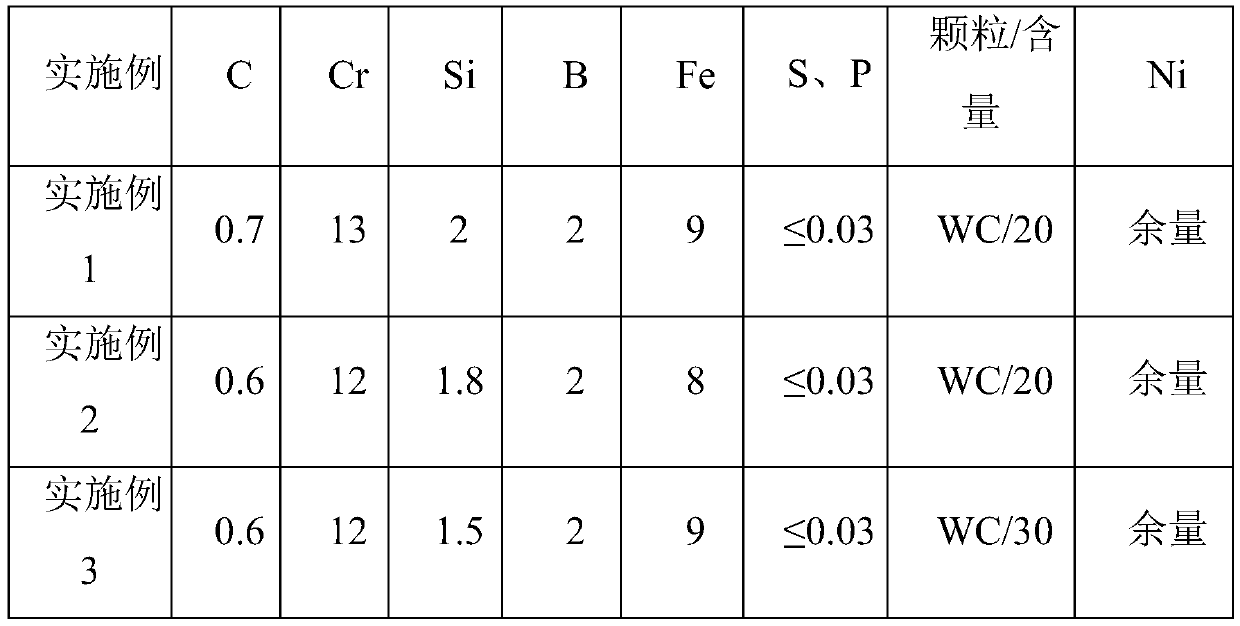

[0031] A laser cladding powder of the present invention comprises 20.0-30.0 mass percent of WC reinforced particles, 9.0-13.0 mass percent of Cr, 7-9 mass percent of Fe, 1.0-2.0 mass percent of Si, 0.5- 0.7% by mass of C, 1.0-2.0% by mass of B, and the rest being Ni; the sum of the mass percentages of the above components is 100%.

[0032] Preferably, the particle size of the cladding powder is 25-50 μm.

[0033] Preferably, the sphericity of the cladding powder is >90%.

[0034] The method of using the above-mentioned laser cladding powder and ultra-high-speed laser cladding technology to repair the combined valve is implemented according to the following steps:

[0035] Step 1. Prepare cladding powder; vacuum seal for future use;

[0036] The specific process is as follows:

[0037] First, Ni55 alloy powder and WC powder are sieved through a powder sieve to remove l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com