Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

182results about "Drying peat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

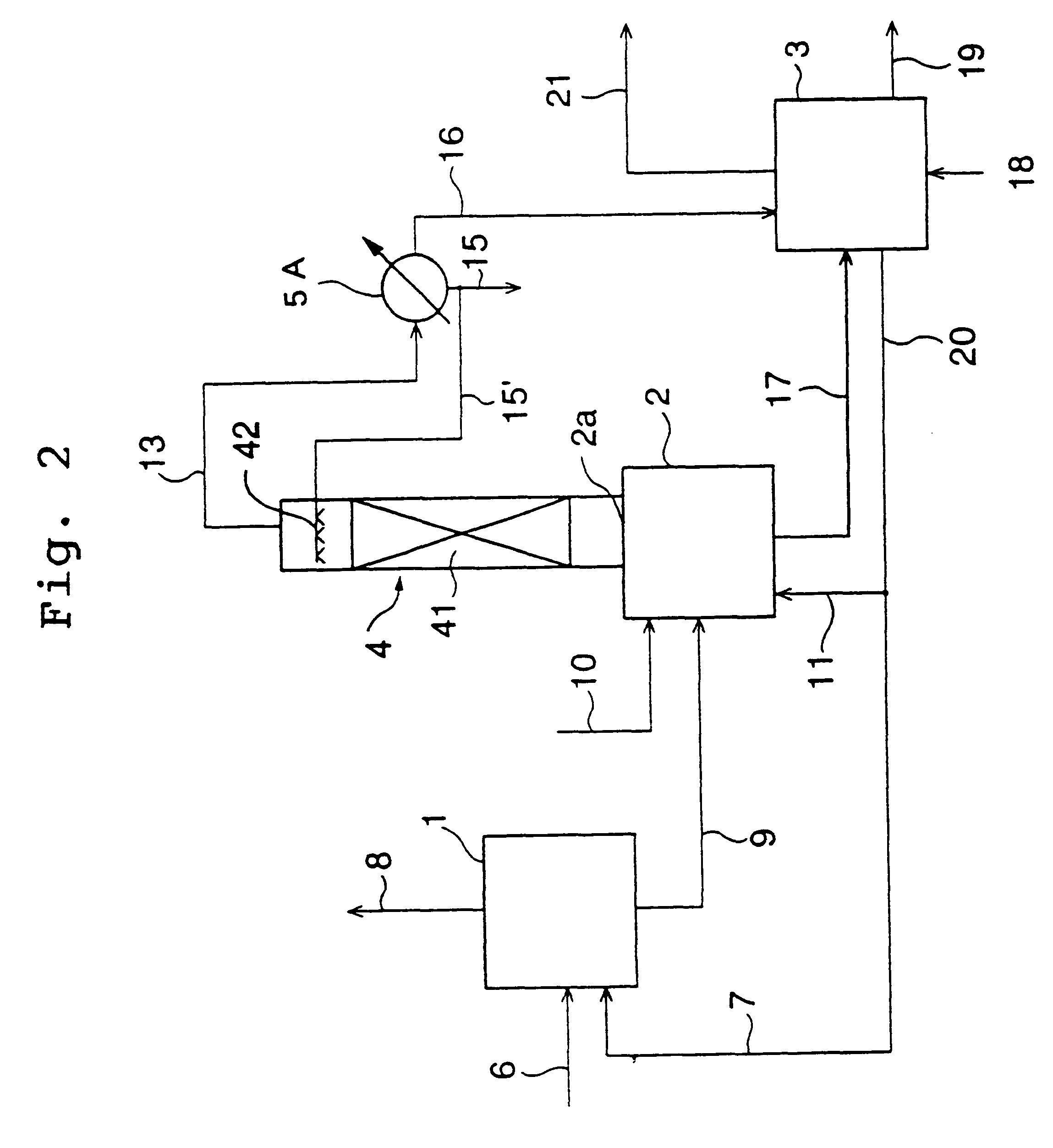

Process and reactor for microwave cracking of plastic materials

InactiveUS6184427B1Indirect and direct heating destructive distillationLiquid hydrocarbon mixture productionRadio frequency energyPlastic materials

A process of activated cracking of high molecular organic waste material which includes confining the organic waste material in a reactor space as a mixture with a pulverized electrically conducting material (sensitizer) and / or catalysts and / or "upgrading agents" and treating this mixture by microwave or radio frequency electro-magnetic radiation. Organic waste materials include hydrocarbons or their derivatives, polymers or plastic materials and shredded rubber. The shredded rubber can be the source of the sensitizer and / or catalyst material as it is rich in carbon and other metallic species. This sensitizer can also consist of pulverized coke or pyrolytically carbonized organic feedstock and / or highly dispersed metals and / or other inorganic materials with high dielectric loss which absorb microwave or radio frequency energy.

Owner:HIGHWAVE ACQUISITION

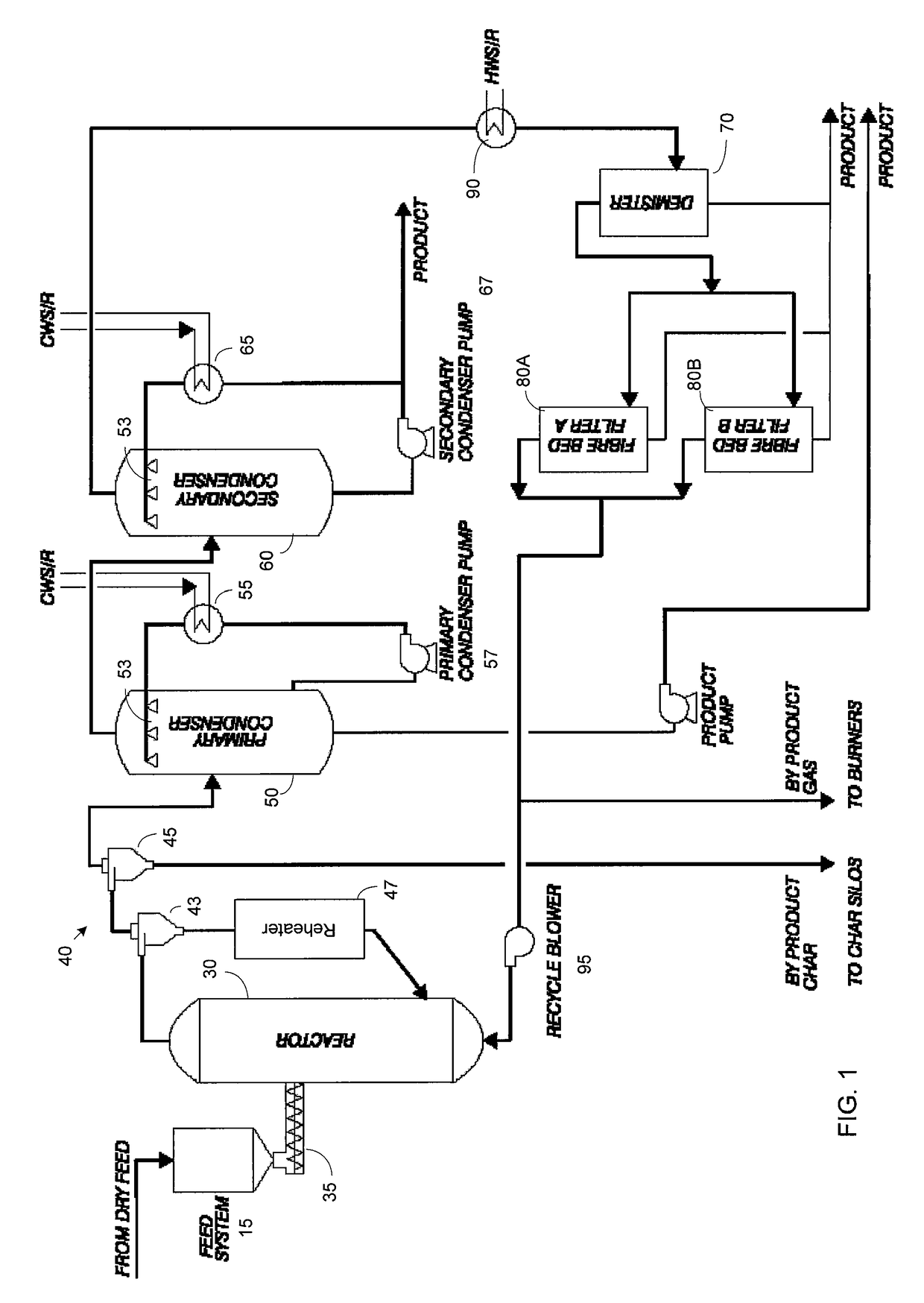

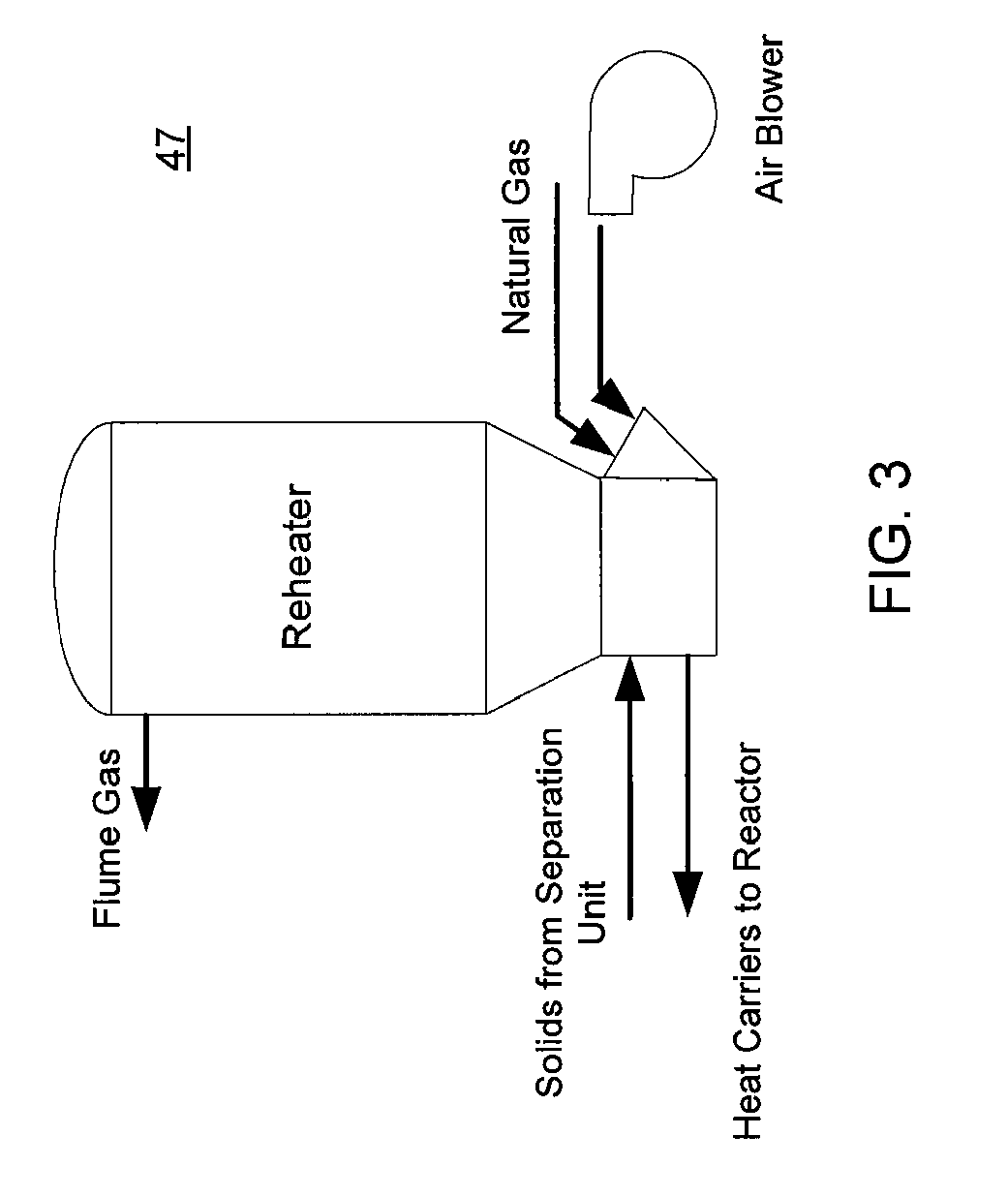

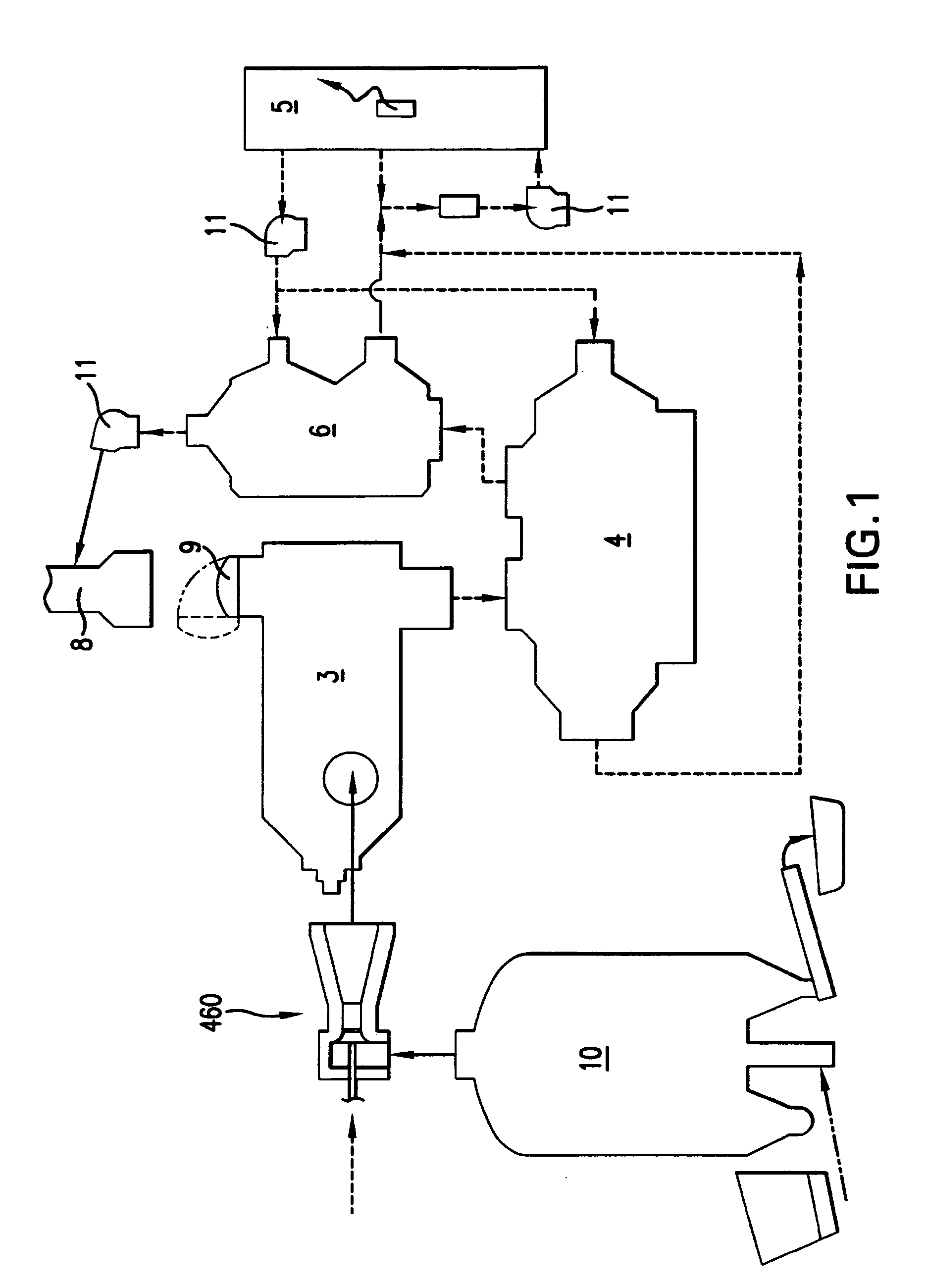

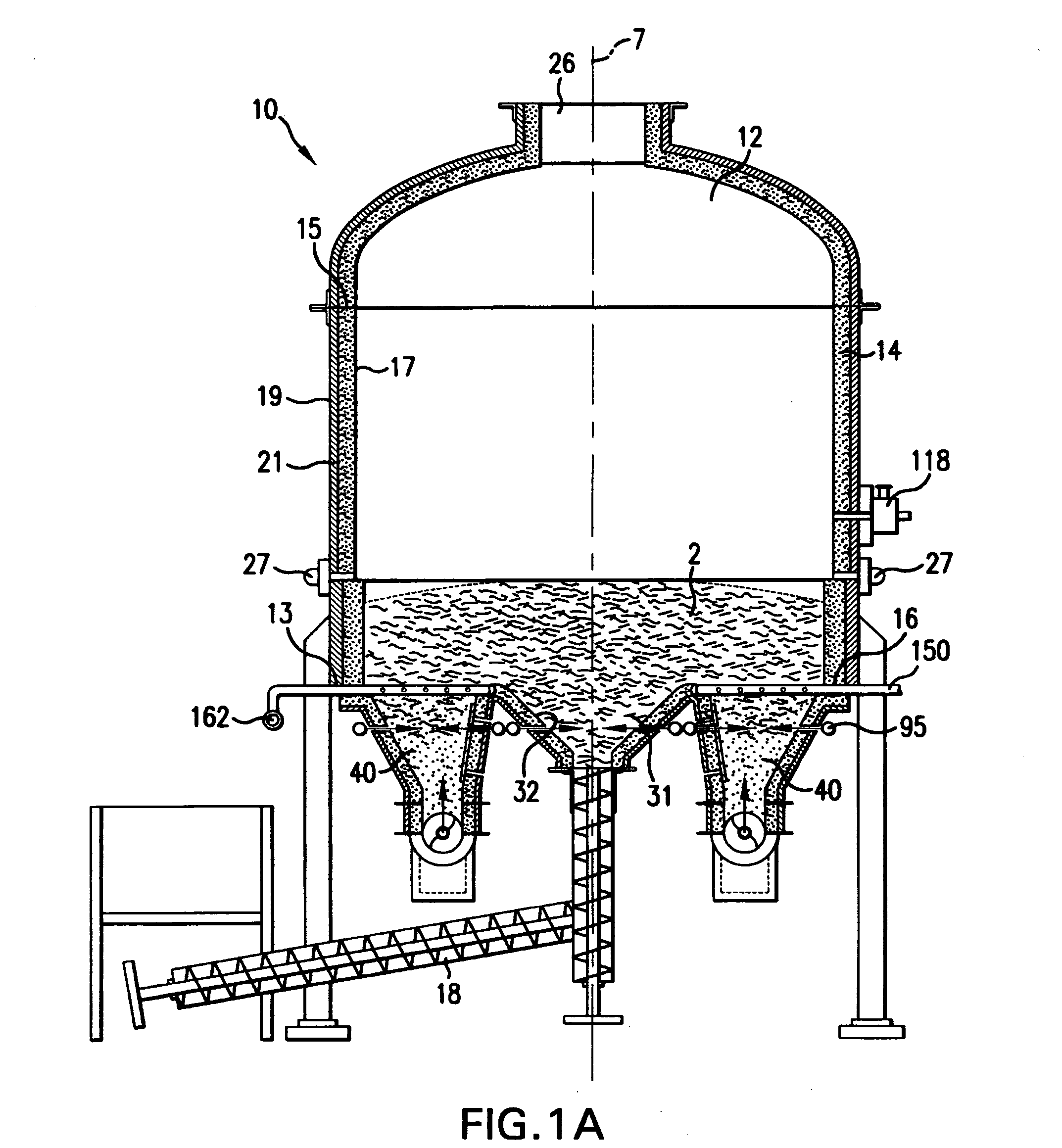

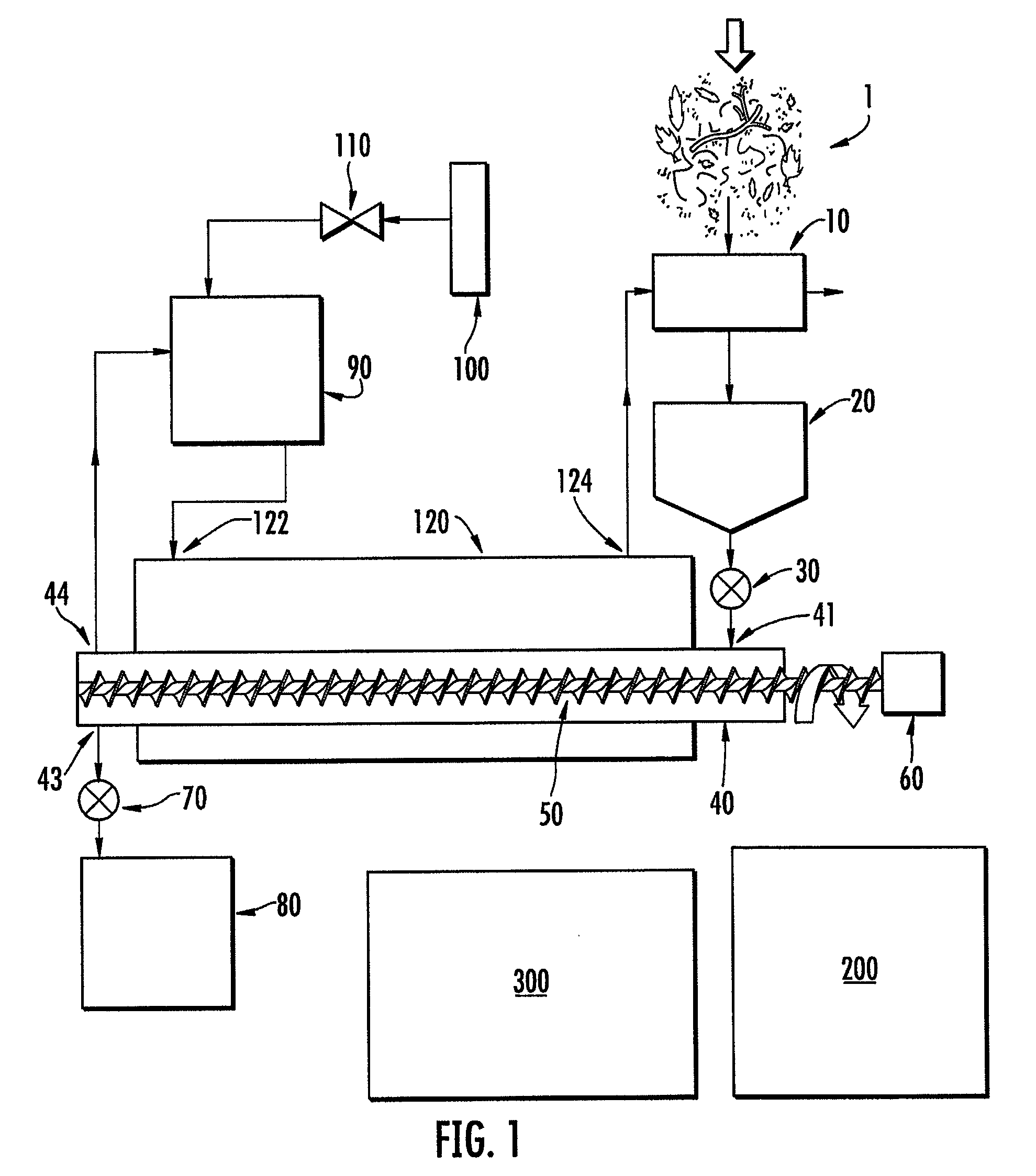

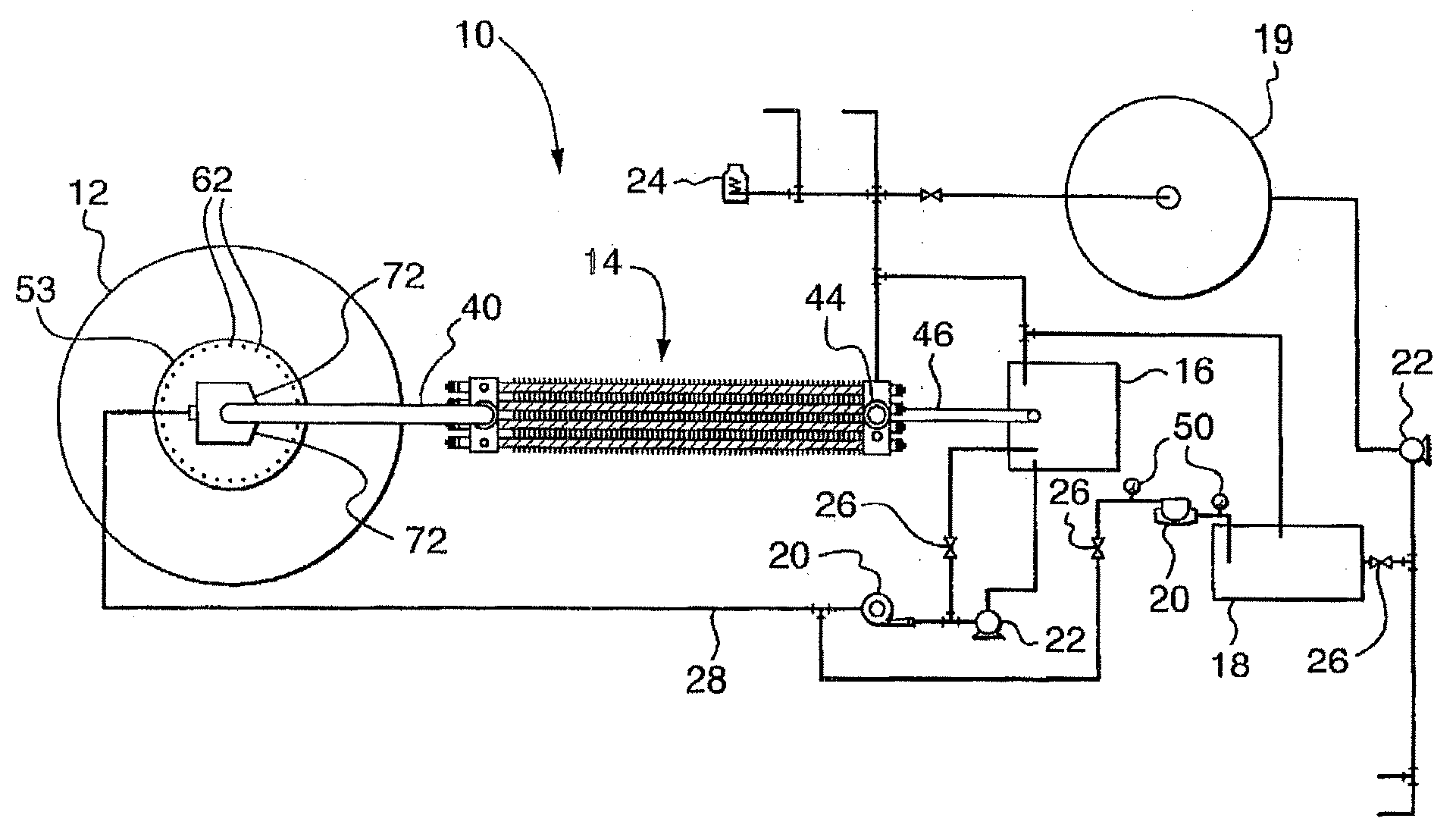

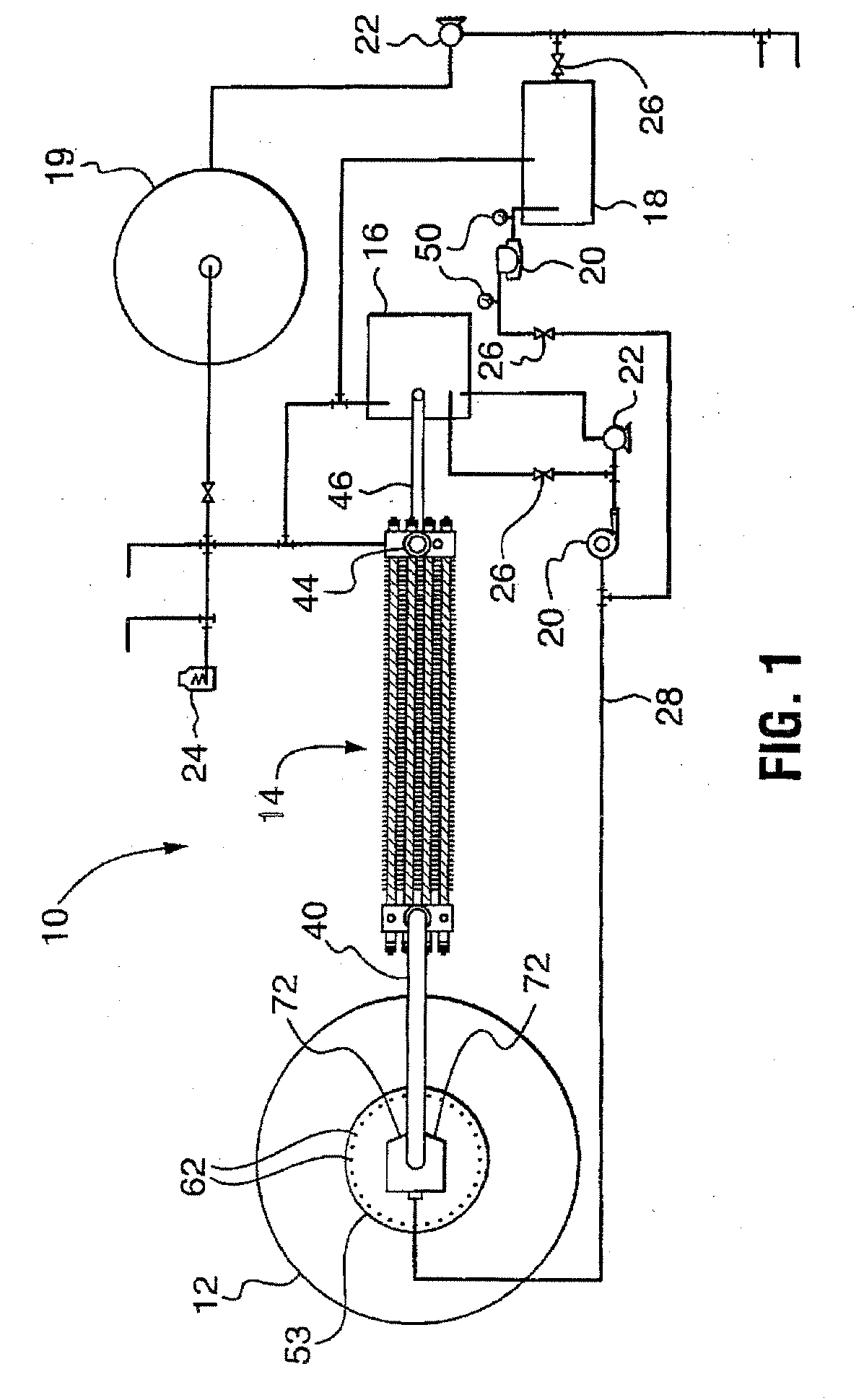

Rapid thermal conversion of biomass

ActiveUS7905990B2Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingSolid waste disposalLiquid productHeat carrier

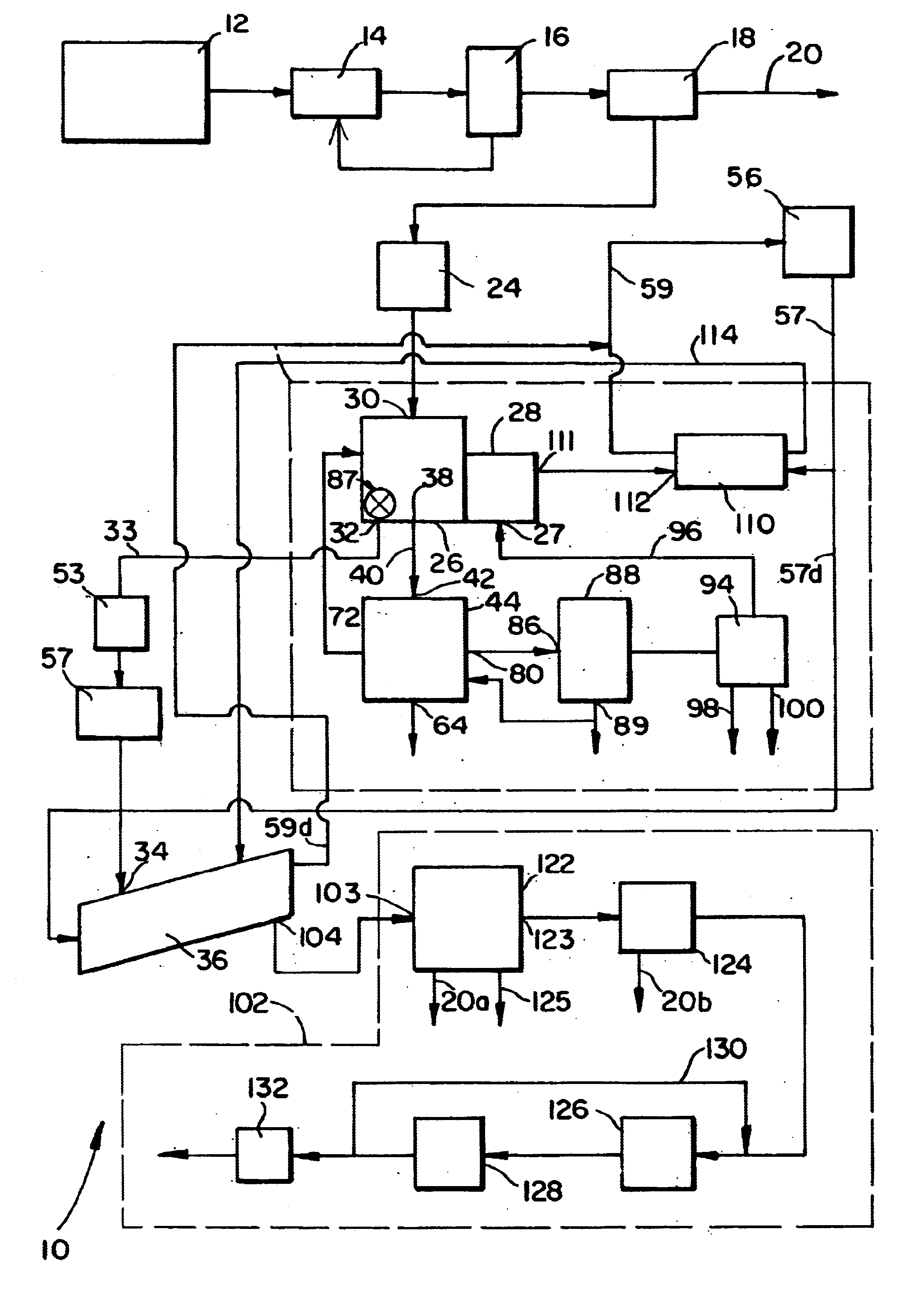

A rapid thermal conversion process for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. Biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. The liquid product may itself be used as the quench media.

Owner:ENSYN RENEWABLES

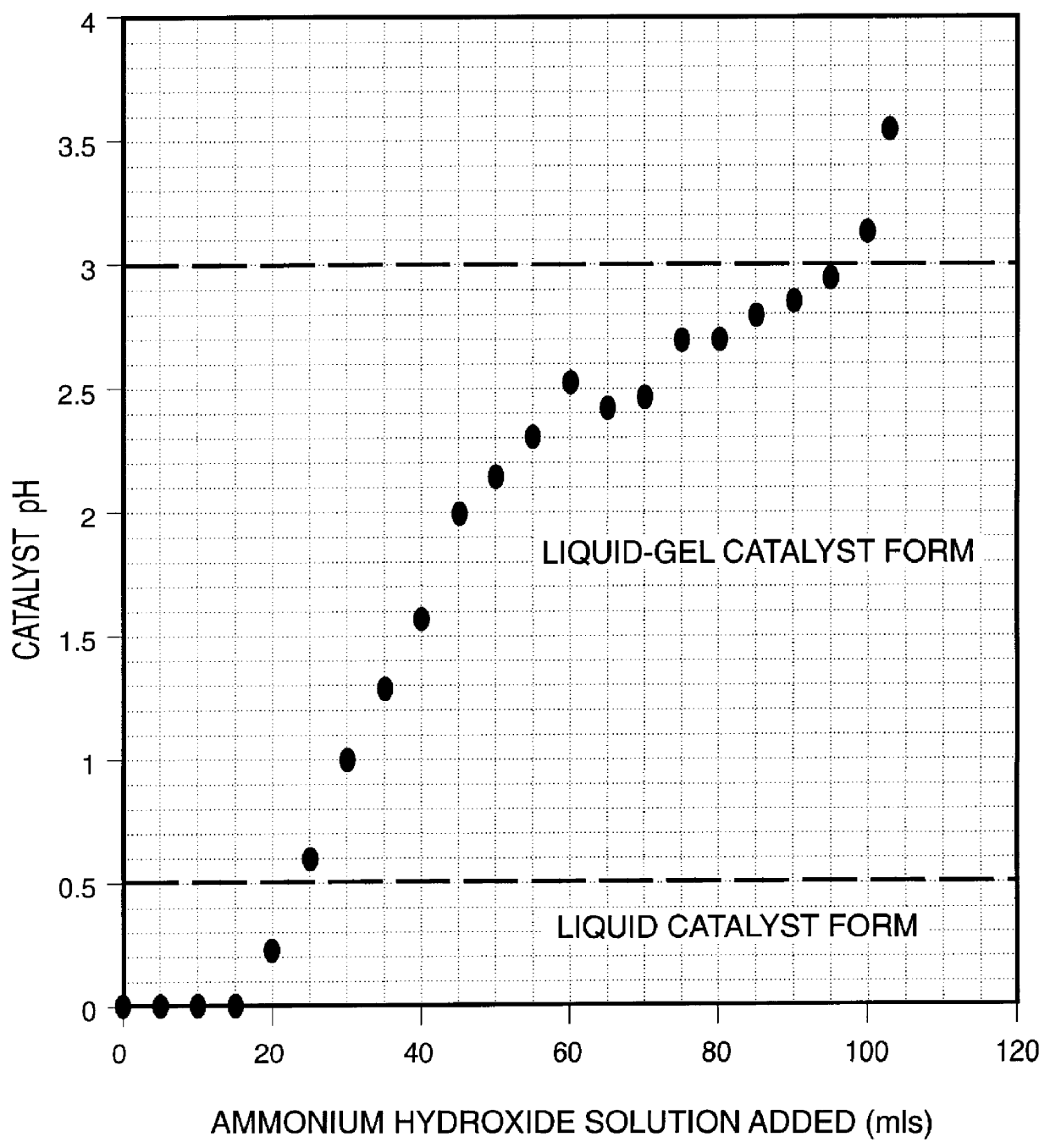

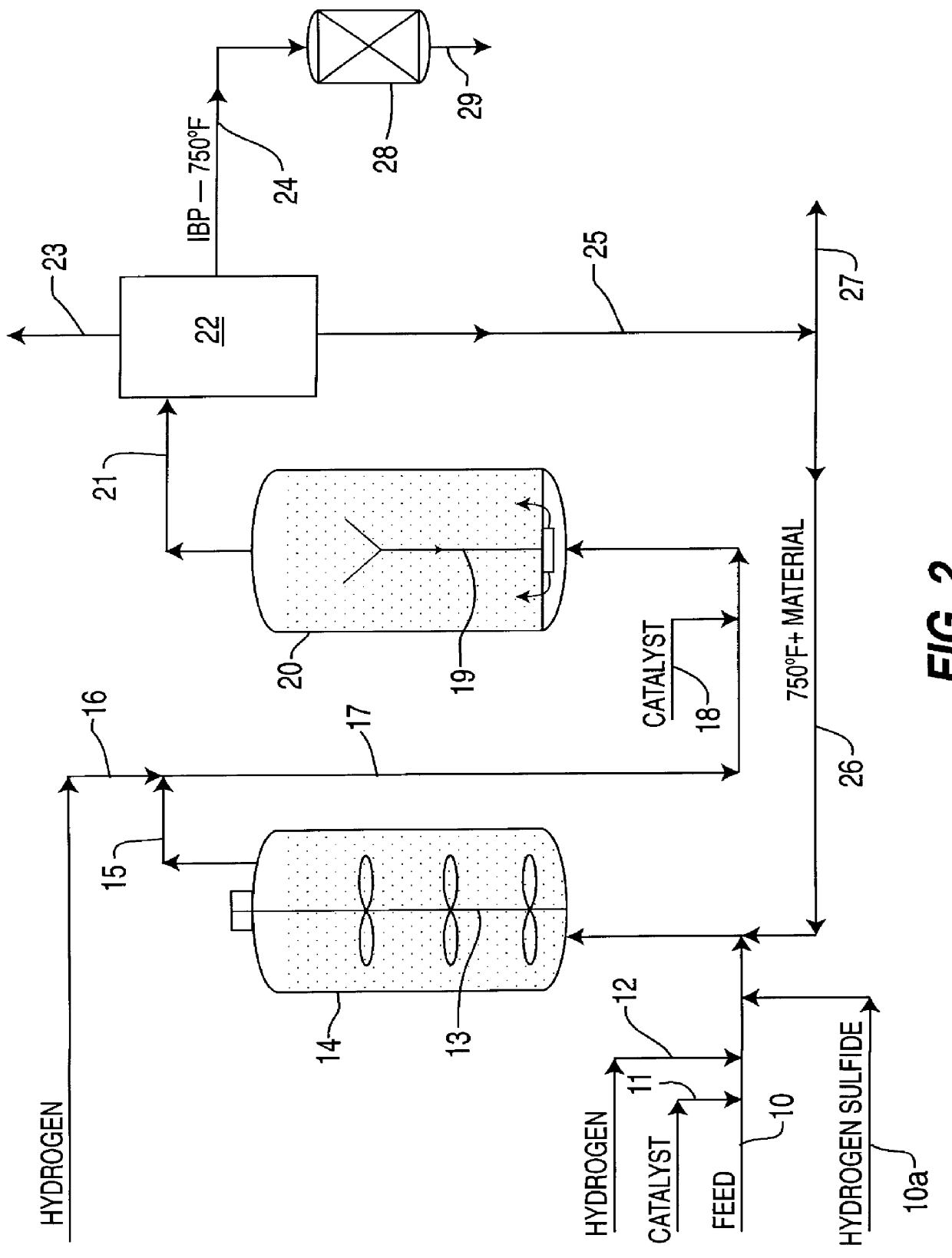

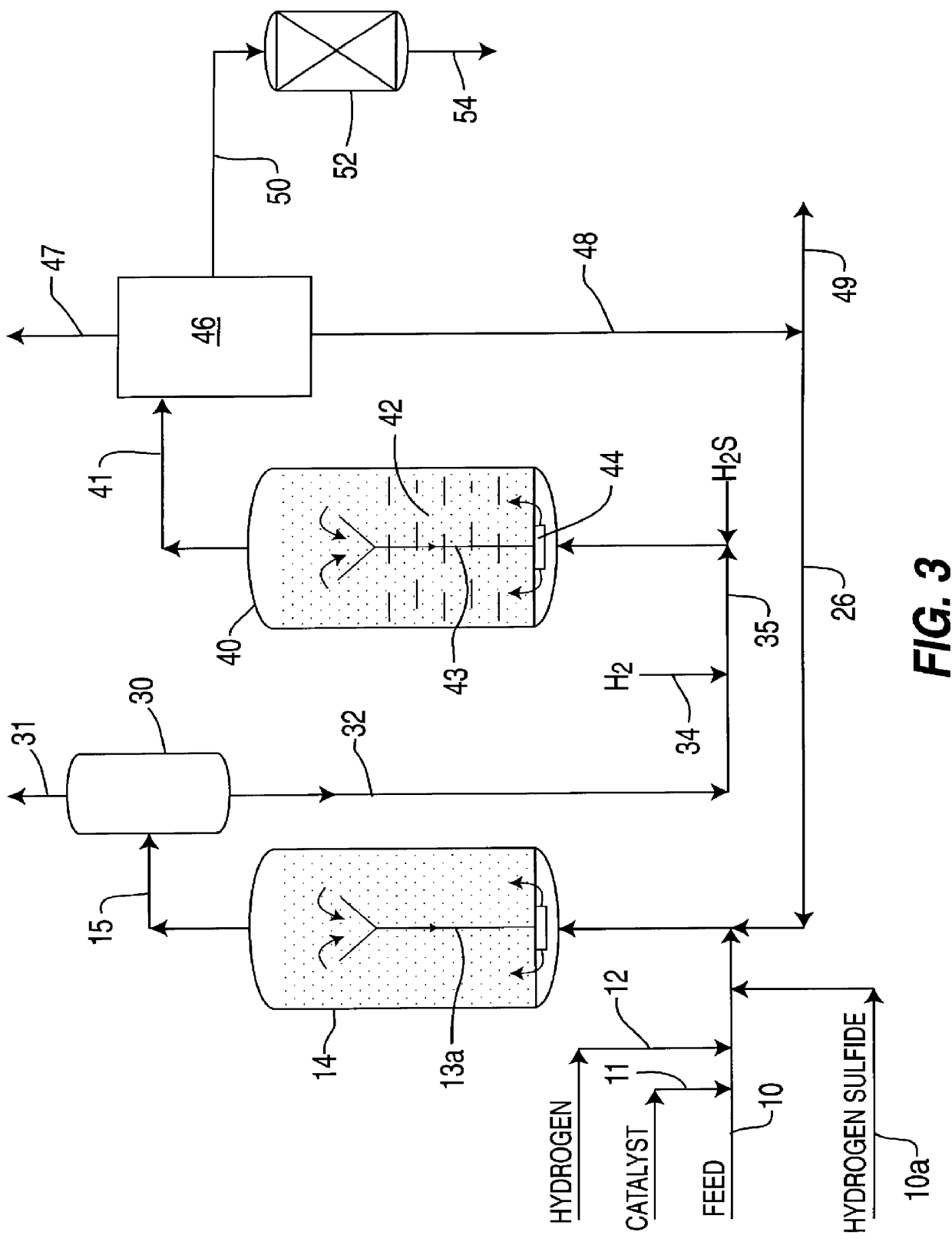

Iron-based ionic liquid catalysts for hydroprocessing carbonaceous feeds

InactiveUS6139723AIncrease hydrocracking ability of catalystIndirect and direct heating destructive distillationCatalyst activation/preparationLiquid productIron salts

A highly dispersed iron-based ionic liquid or liquid-gel catalyst which may be anion-modified and metals-promoted has high catalytic activity, and is useful for hydrocracking / hydrogenation reactions for carbonaceous feed materials. The catalyst is produced by aqueous precipitation from saturated iron salt solutions such as ferric sulfate and ferric alum, and may be modified during preparation with anionic sulfate (SO42-) and promoted with small percentages of at least one active metal such as cobalt, molybdenum, palladium, platinum, nickel, or tungsten or mixtures thereof. The resulting catalyst may be used in a preferred ionic liquid form or in a liquid-gel form, and either fluidic form can be easily mixed and reacted with carbonaceous feed materials such as coal, heavy petroleum fractions, mixed plastic waste, or mixtures thereof. The invention includes methods for making the ionic liquid or liquid-gel catalyst, and processes for using the fluidic catalysts for hydroprocessing the carbonaceous feed materials to produce desirable low-boiling hydrocarbon liquid products.

Owner:HEADWATERS CTL

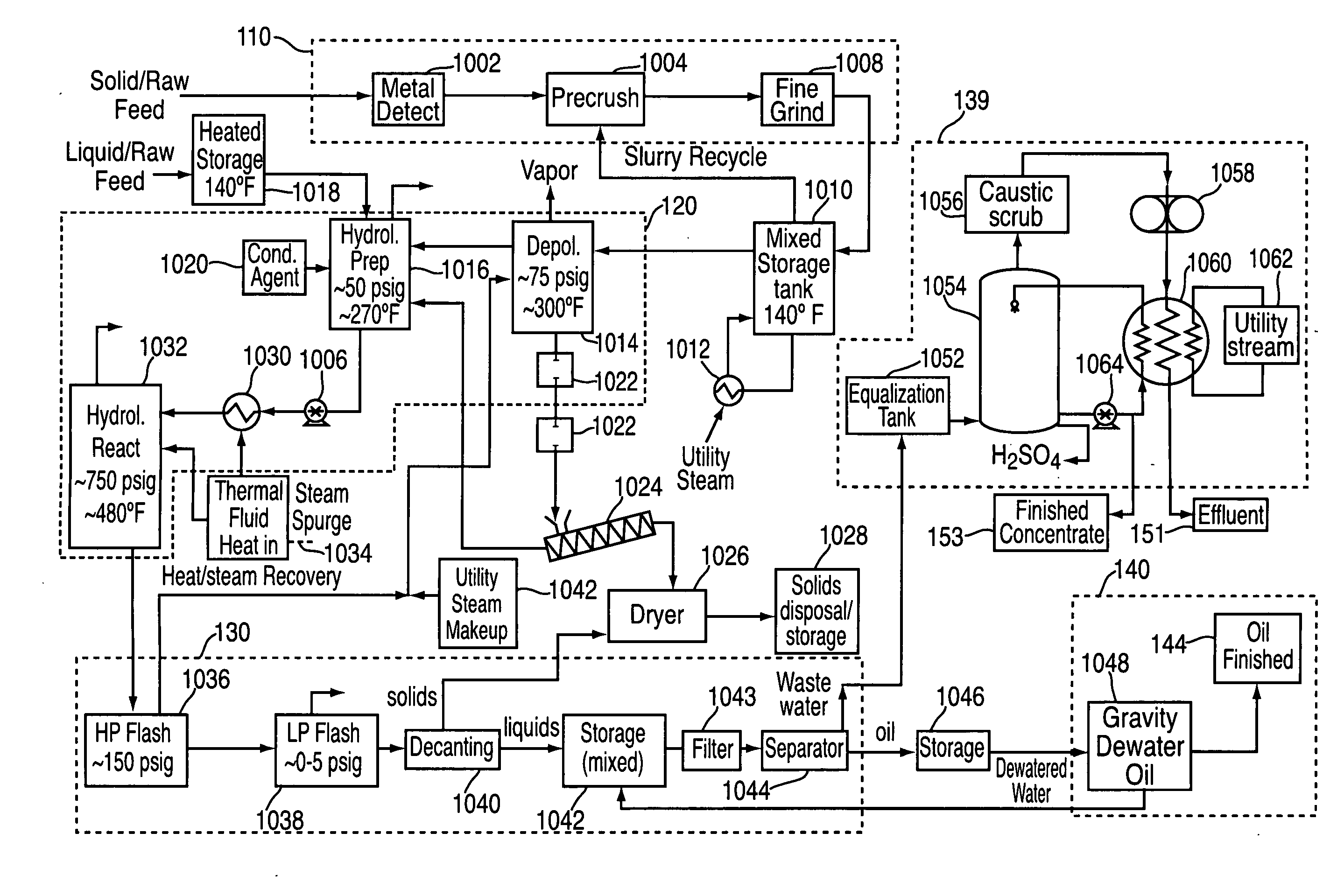

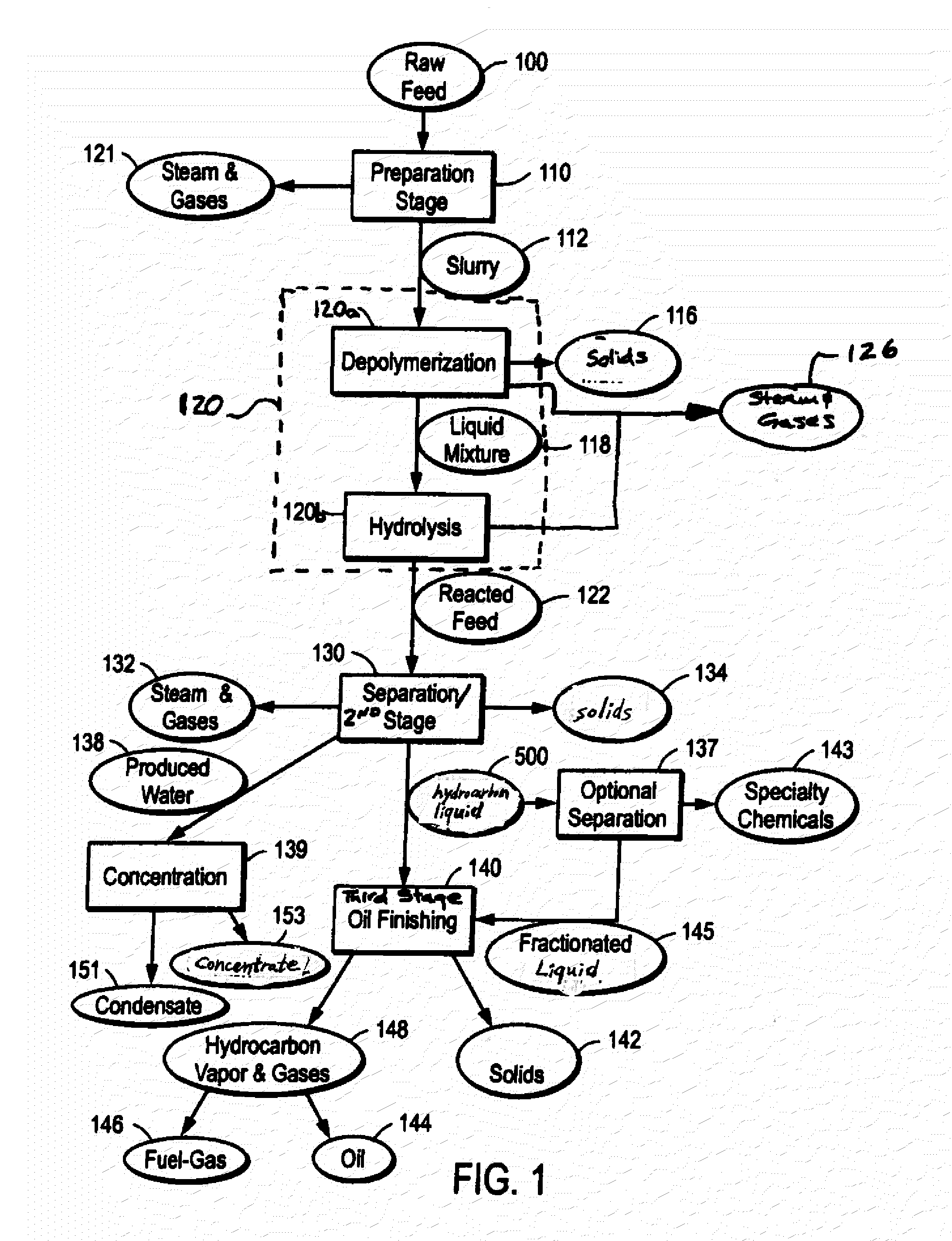

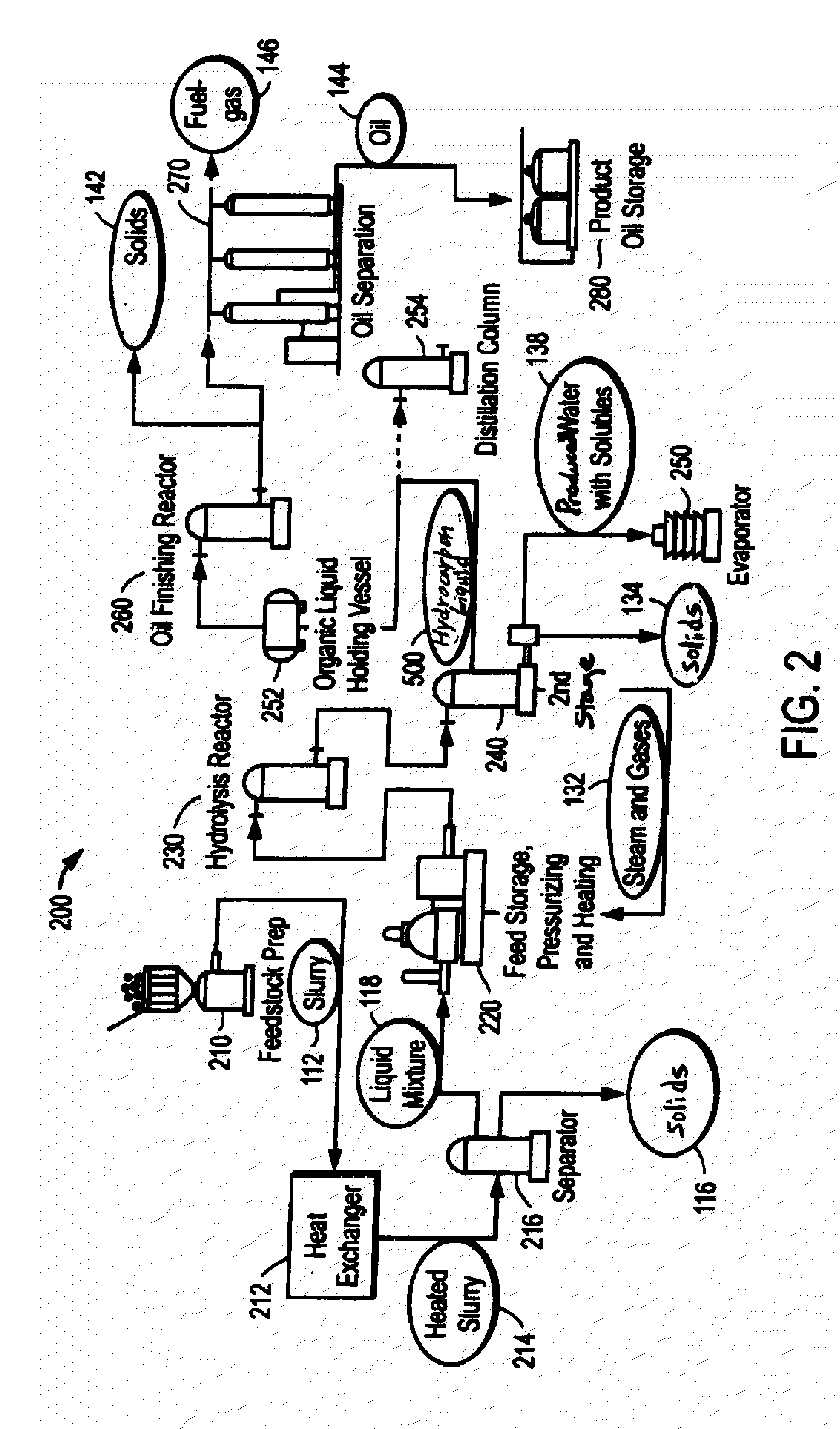

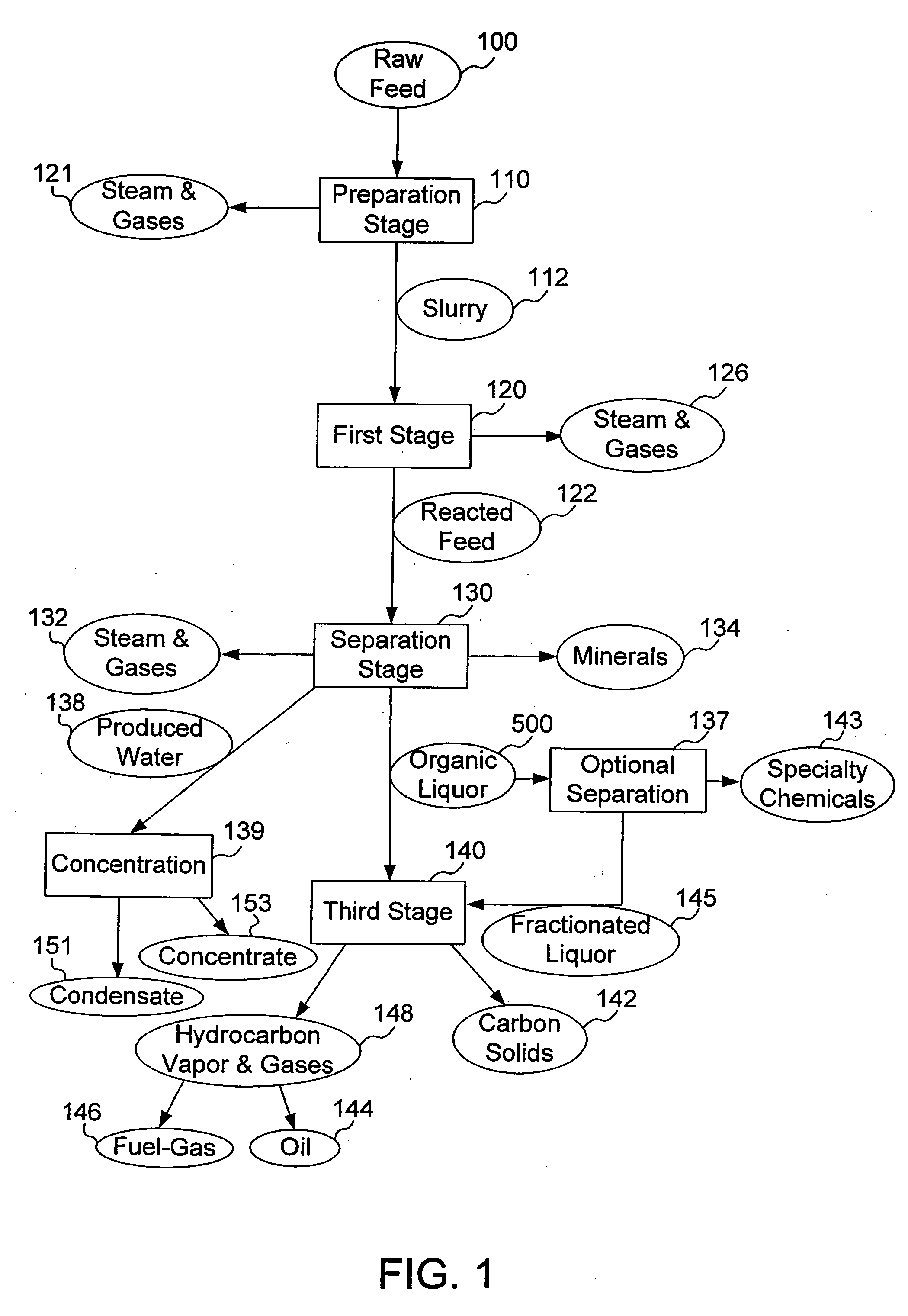

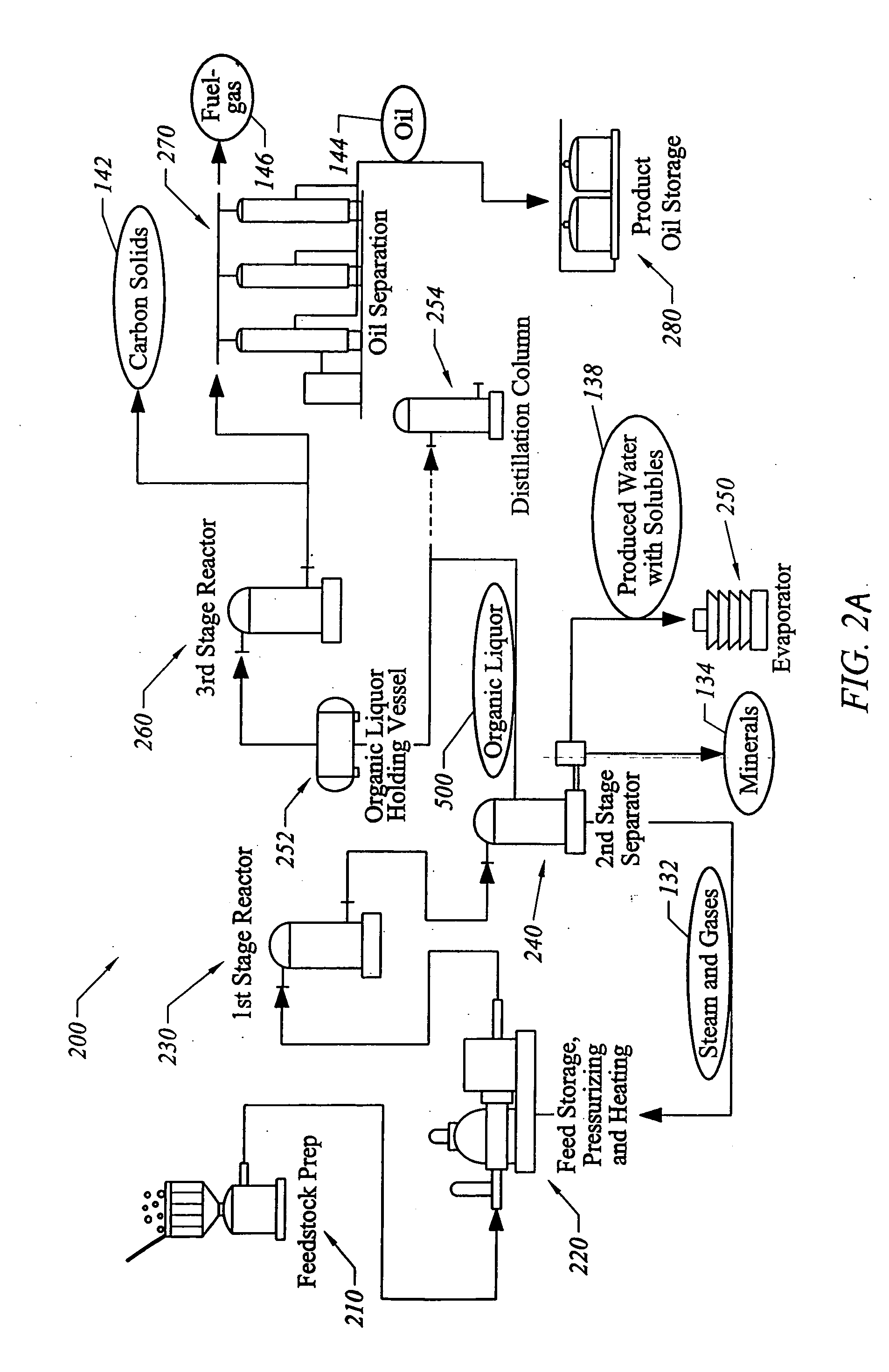

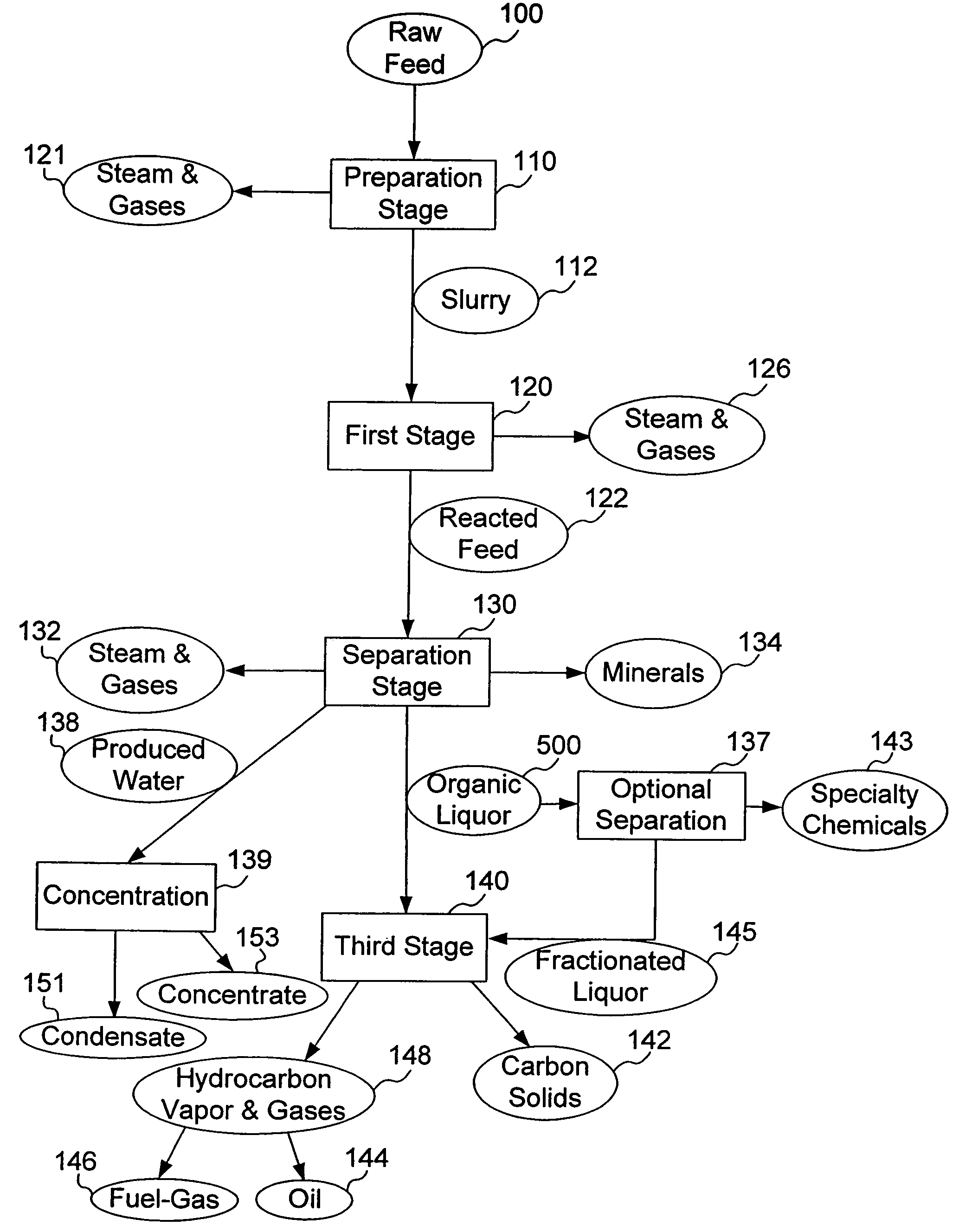

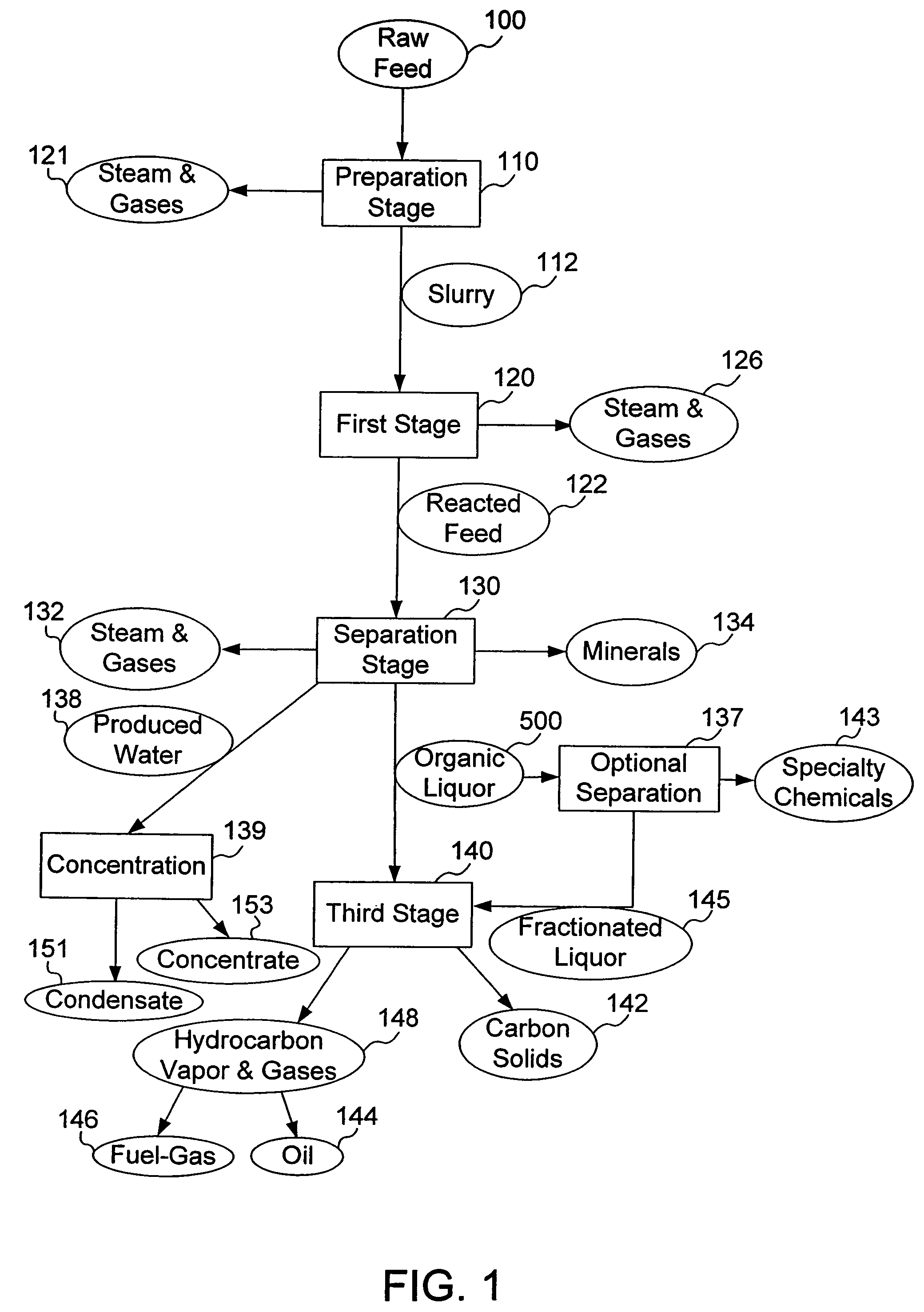

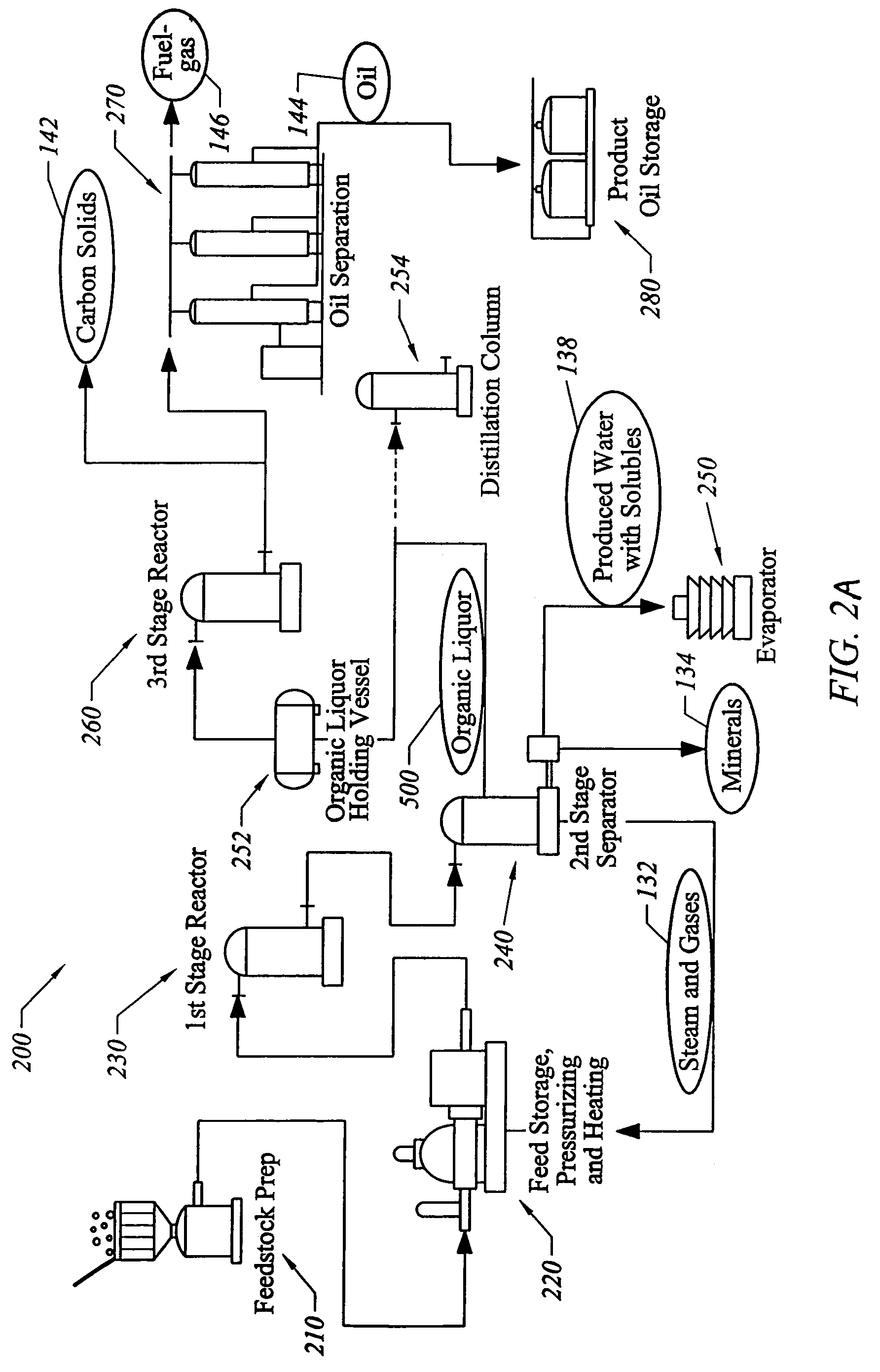

Methods and apparatus for converting waste materials into fuels and other useful products

ActiveUS20090062581A1Effectively handle problematic wasteFree of contaminantsTransportation and packagingSolid waste disposalSpeciality chemicalsBiological waste

Conversion of waste and other organic feedstock into sustainable energy, feed, fertilizer, and other useful products of reliable purities is accomplished using water, heat, and pressure. More specifically, the invention provides methods and apparatus that handle mixed streams of various feedstocks, e.g. agricultural waste, biological waste, municipal solid waste, municipal sewage sludge, and shredder residue, to yield gas, oil, specialty chemicals, and carbon solids that can be used as is or are further processed. Useful products can be diverted at various points of the process or internalized to enhance the efficiency of the system.

Owner:SYNPET TEKNOLOJI GELISTIRME

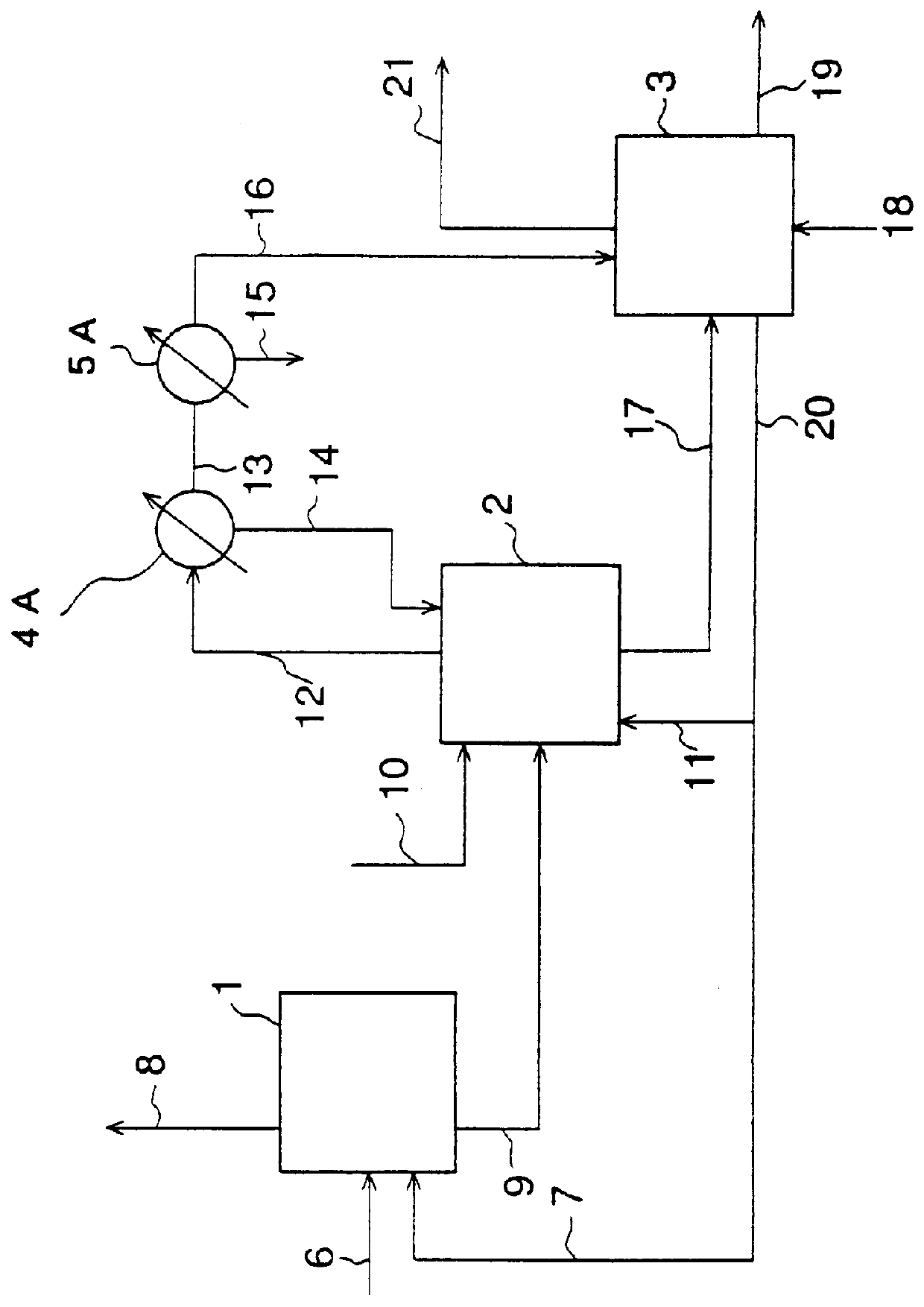

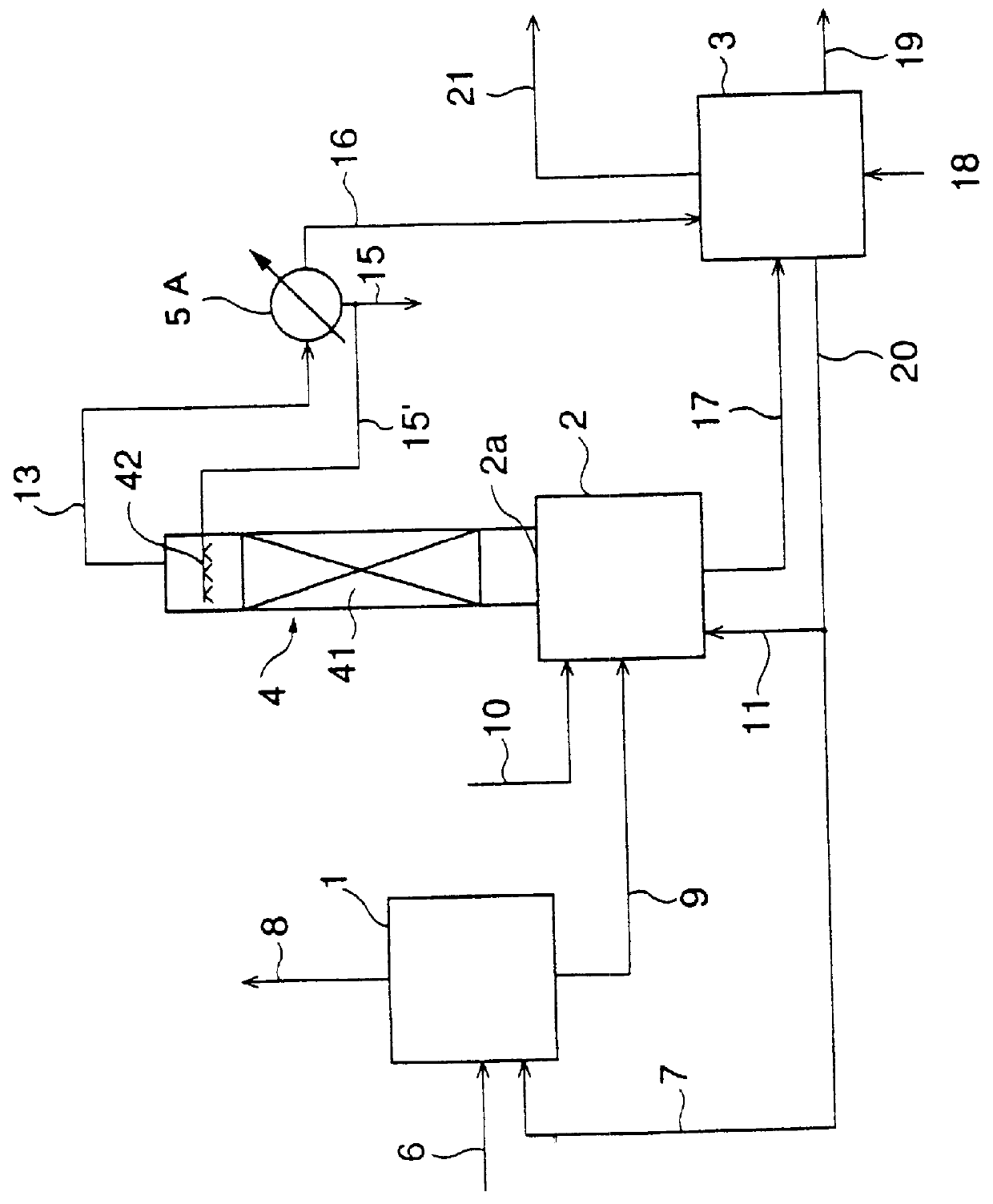

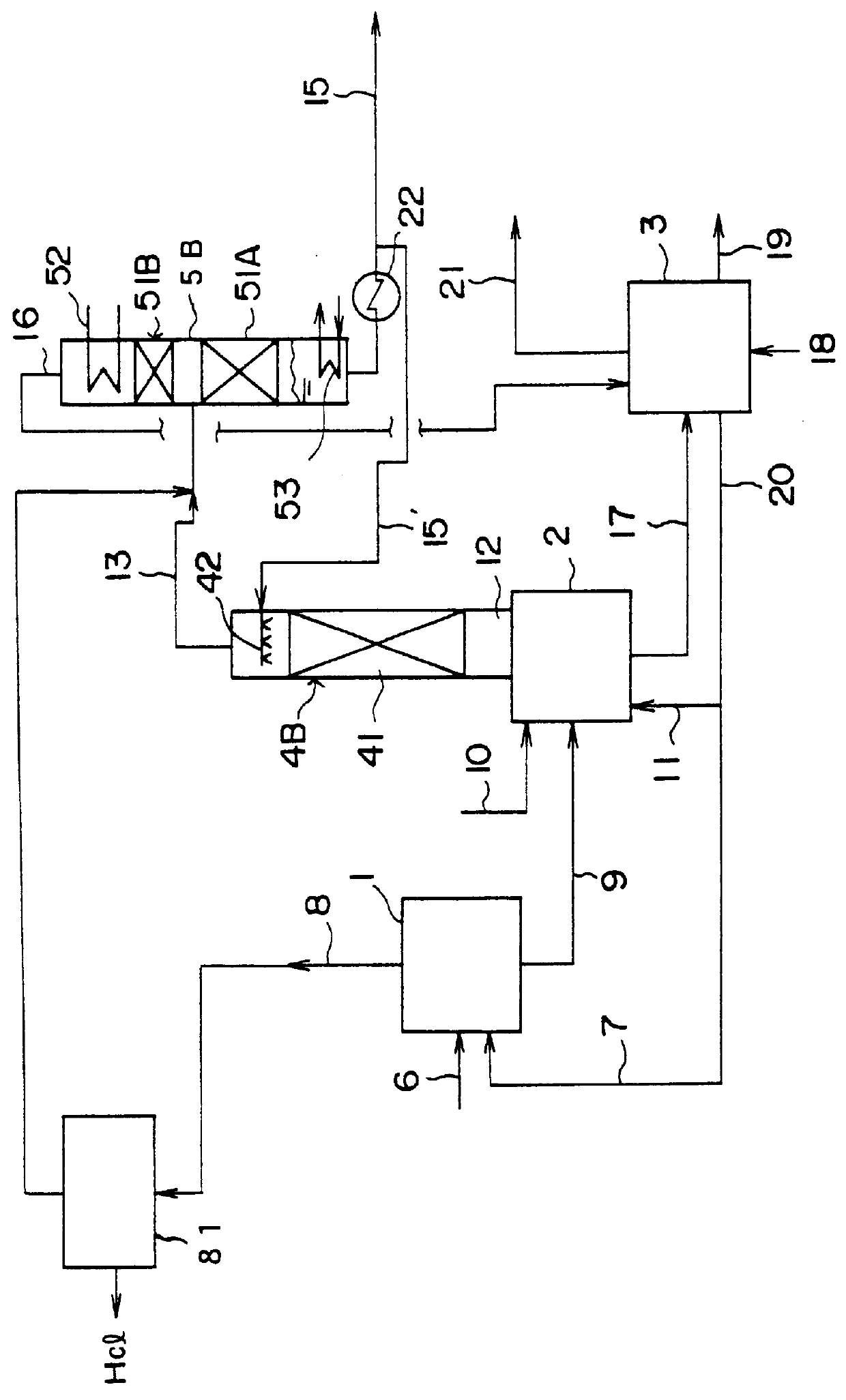

Method and apparatus for reclaiming oil from waste plastic

InactiveUS6011187AIncrease productionContinuous operationPlastic recyclingIndirect and direct heating destructive distillationForeign matterBoiling point

PCT No. PCT / JP97 / 00572 Sec. 371 Date Jan. 8, 1998 Sec. 102(e) Date Jan. 8, 1998 PCT Filed Feb. 27, 1997 PCT Pub. No. WO97 / 31990 PCT Pub. Date Sep. 4, 1997This invention provides a method for reclaiming oil from waste plastic in such a way that thermosetting resins and solid foreign matter in the plastic will not pose a problem. This method greatly reduces the burden of presorting the garbage or industrial waste. To achieve this objective when oil is to be reclaimed from a waste plastic containing chlorine compounds, such as vinyl chloride, the plastic must first be stripped of chlorine. Prior to pyrolysis, while being conveyed forward in a continuous stream, the plastic is mixed with heated sand and / or an additive agent to raise its temperature to 250-350 DEG C. This creates a product which is comprised of a mixture of sand and substantially dechlorinated plastic. The product is mixed with heated sand to heat it directly to a temperature of 350-500 DEG C. It is maintained at this temperature until pyrolysis occurs. In order to obtain high-quality oil with a low boiling point, a first gas / liquid separation process separates the product obtained from the aforesaid pyrolysis into liquid high-boiling point oil, gaseous low-boiling point oil and low molecular-weight gases, and recirculates the liquid high-boiling point oil to the pyrolysis process, and a second gas / liquid separation process separates the gaseous low-boiling point oil and low molecular-weight gases into liquid low-boiling point oil and low molecular-weight gases. The first and second gas / liquid separation process are connected in sequence.

Owner:MITSUBISHI HEAVY IND LTD

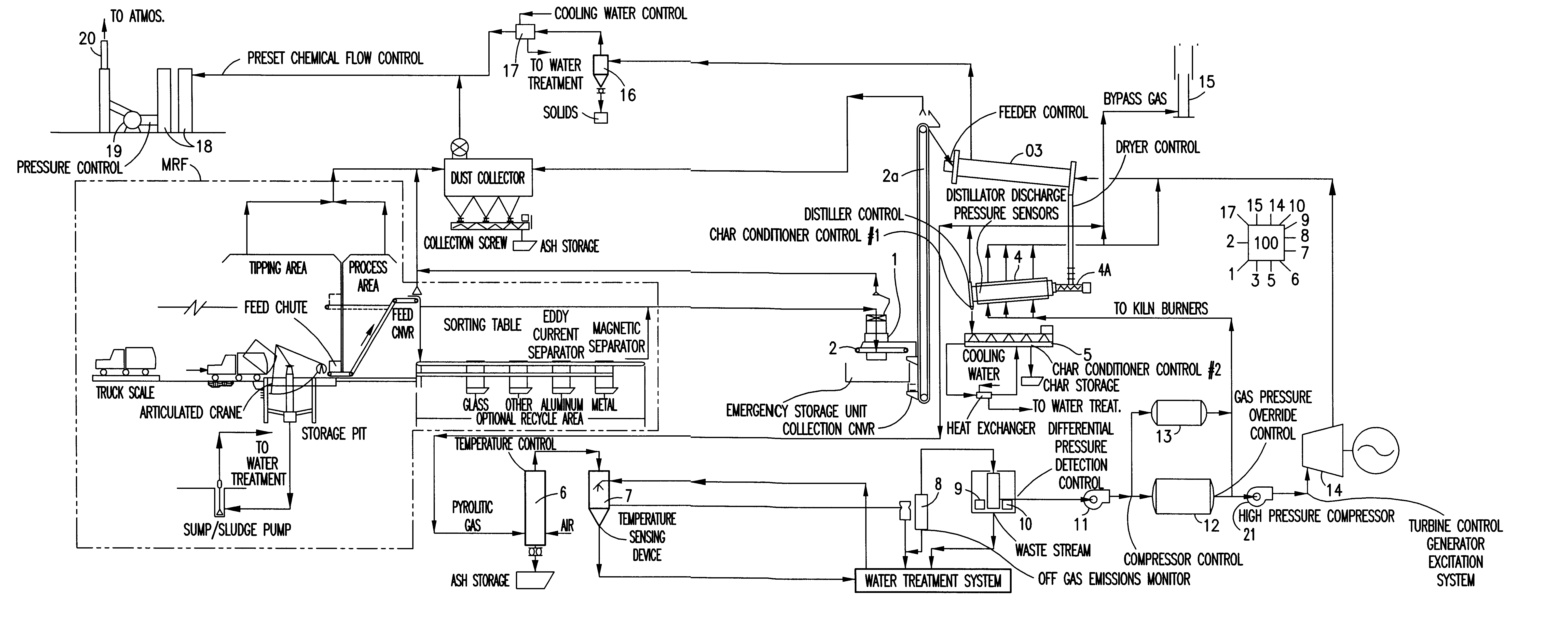

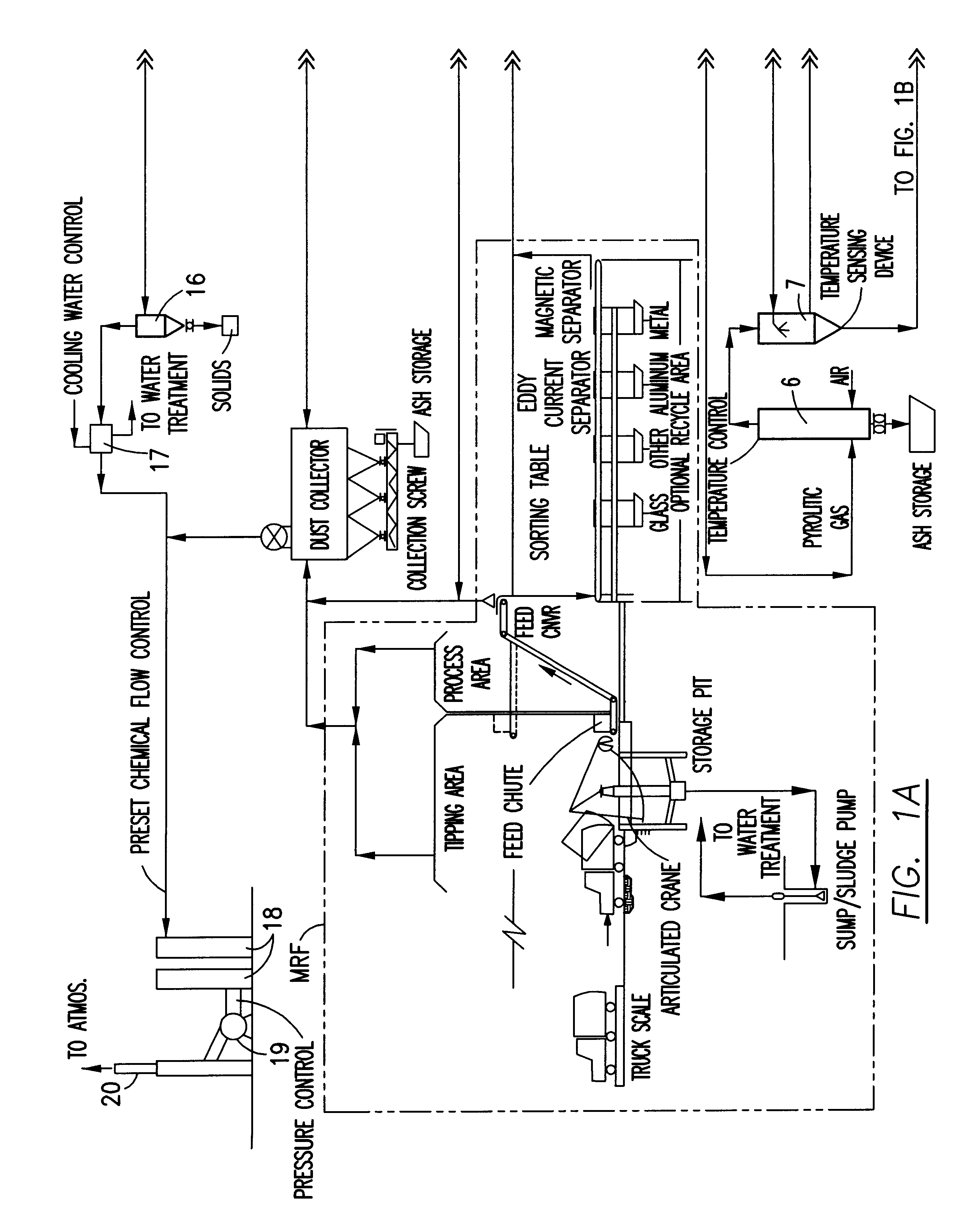

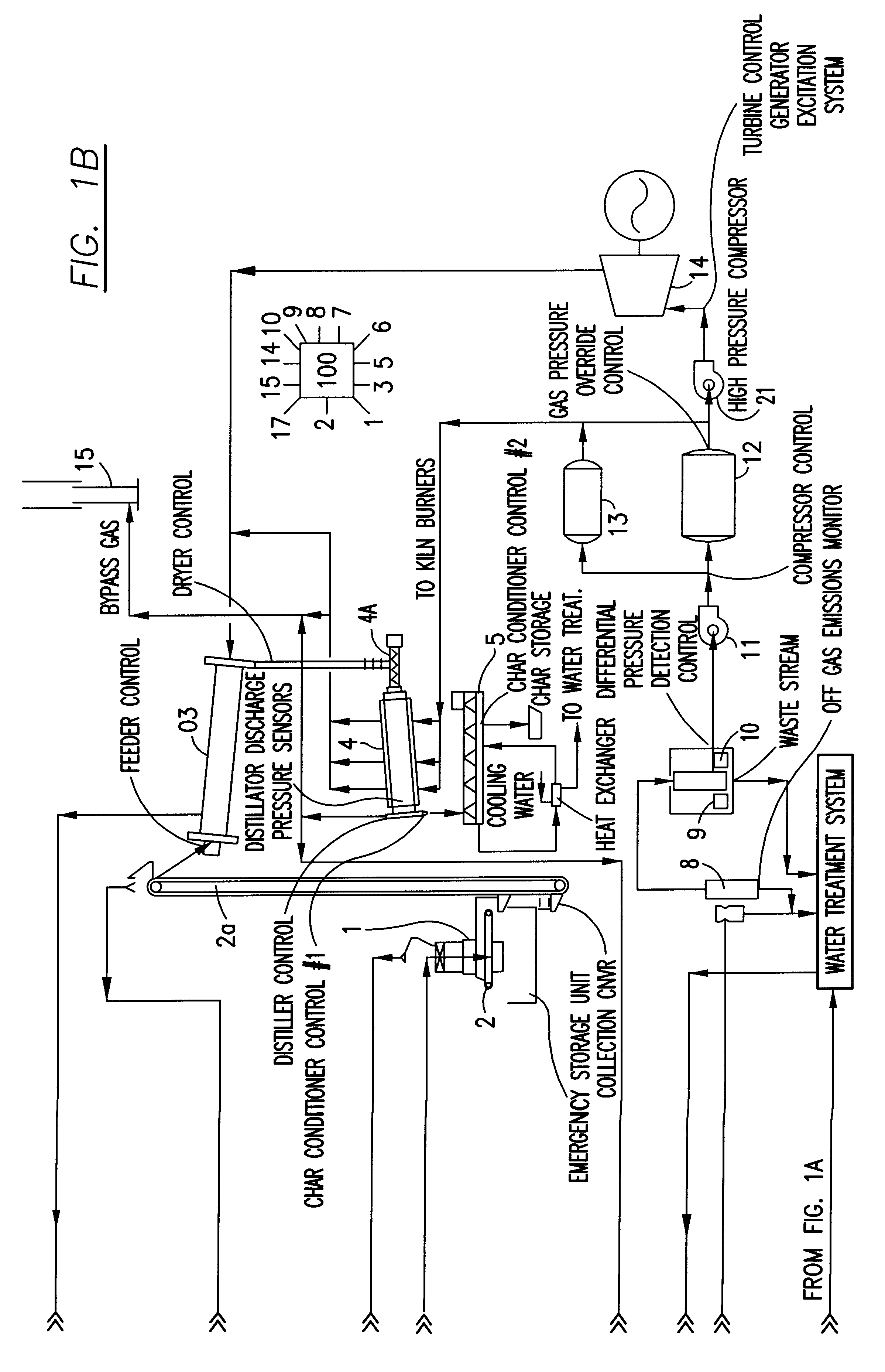

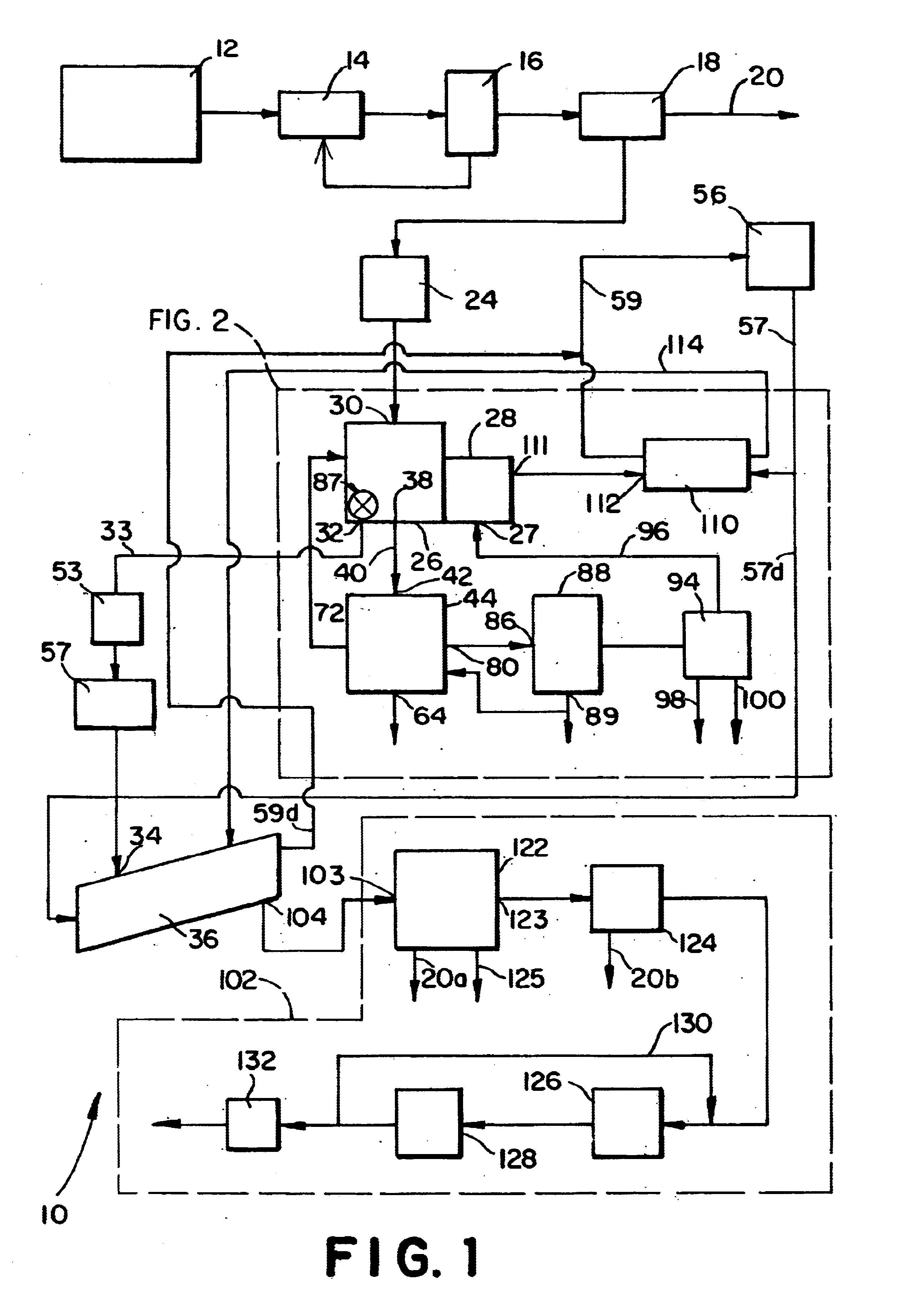

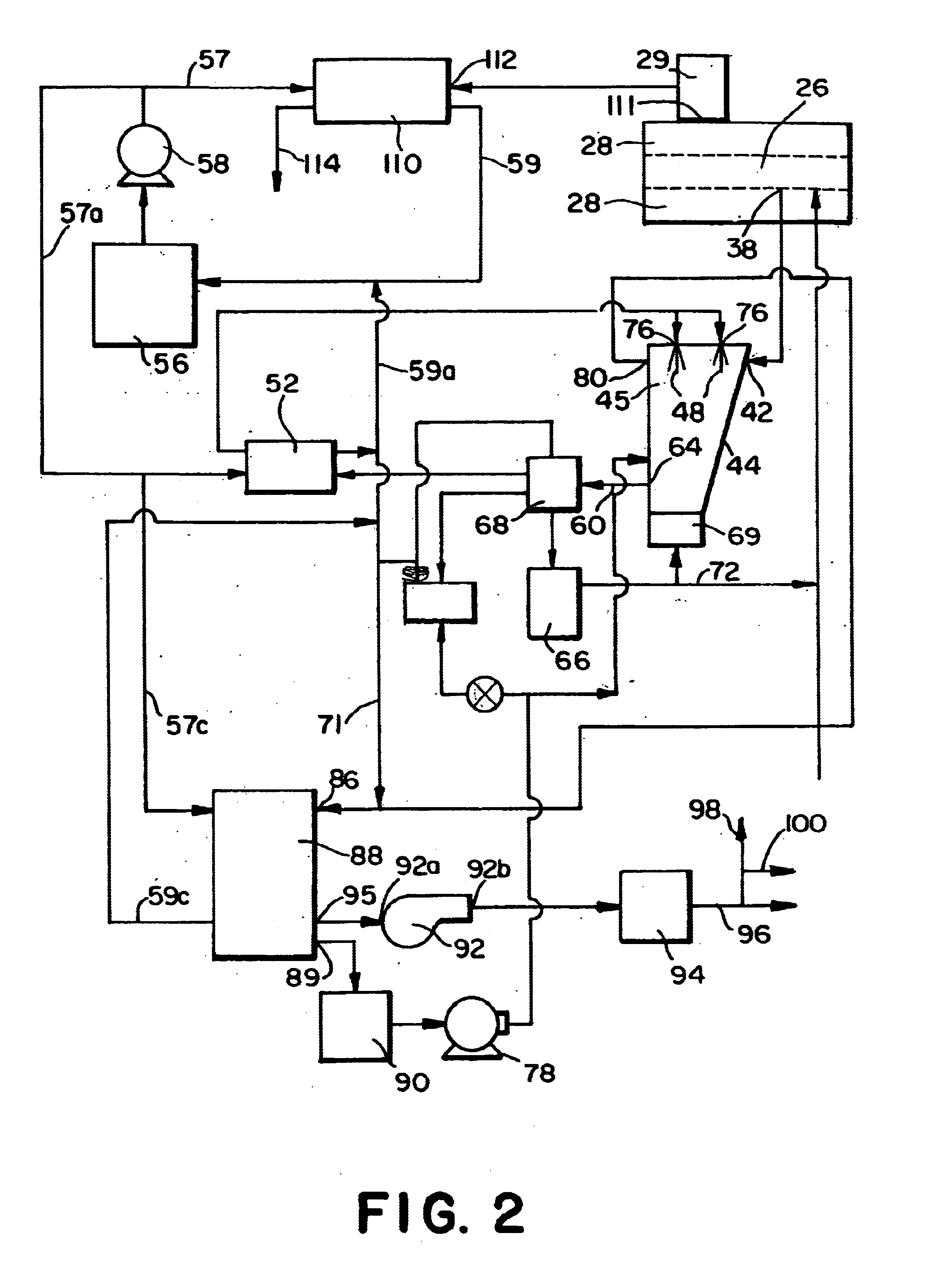

Integrated control and destructive distillation of carbonaceous waste

InactiveUS6182584B1High quantity and qualityEnhanced yield quantity and qualityHorizontal chamber coke ovensEmission preventionComputer control systemWaste stream

A system and process to provide integrated control for the pyrolytic composition of organic (biomass) waste products especially for municipal solid waste systems. The system includes integrated control that monitors biomass waste stream throughout the entire system and the products produced therefrom and includes presorting, controlling the amount of material processed in a continuous manner, shredding, removing moisture in a continuous process that is controlled and providing the waste stream to the distillation unit for pyrolytic action where it is converted into gaseous fuel and a char residue. The gaseous fuel is scrubbed clean and monitored and stored and reused to provide heat to the system. The entire system may be self-sustaining and continuous with very little or no human intervention. An integrated real time computer control system includes sensors and measuring devices with all the major components to ensure integrated efficiency.

Owner:ENVIRONMENTAL SOLUTIONS & TECH

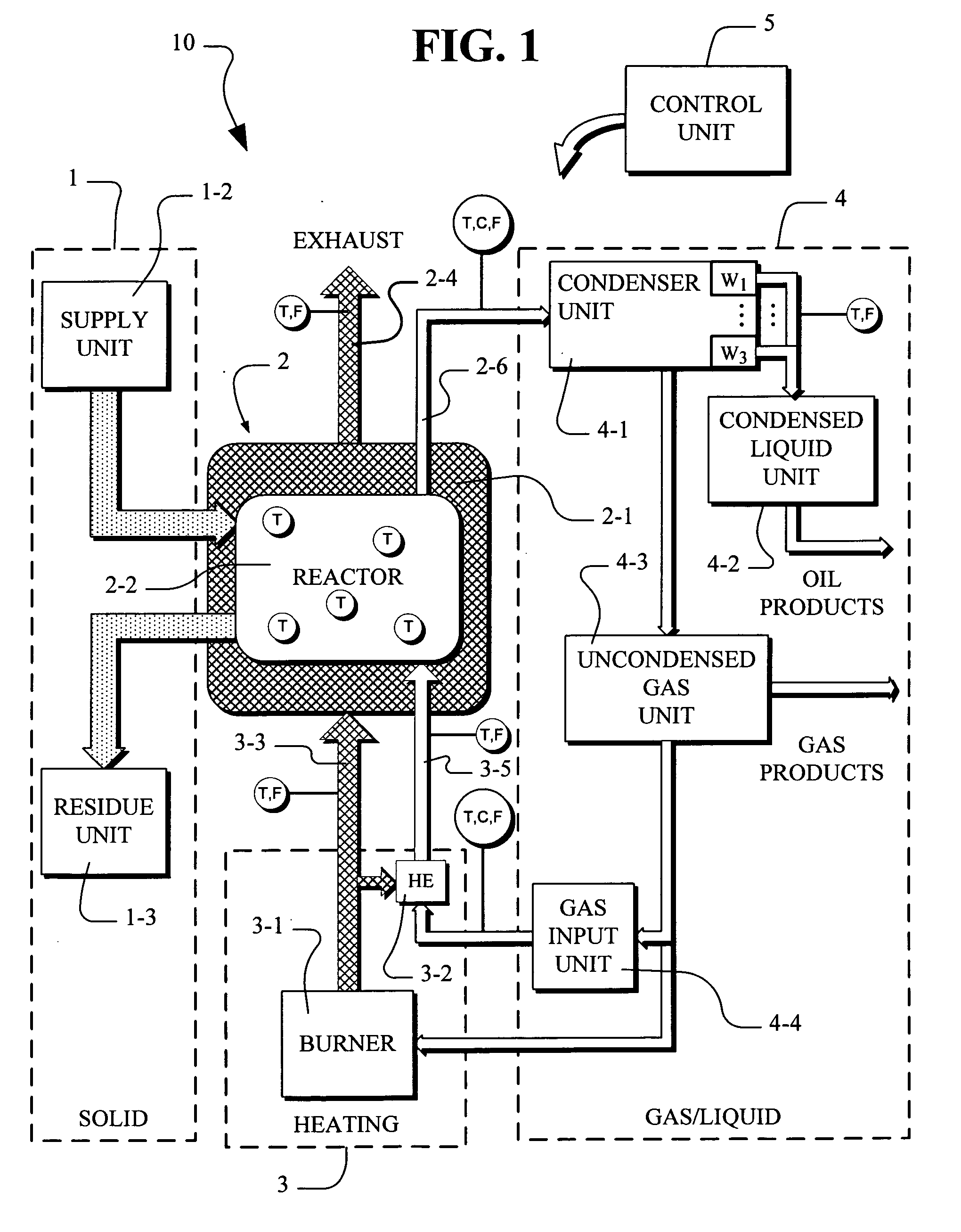

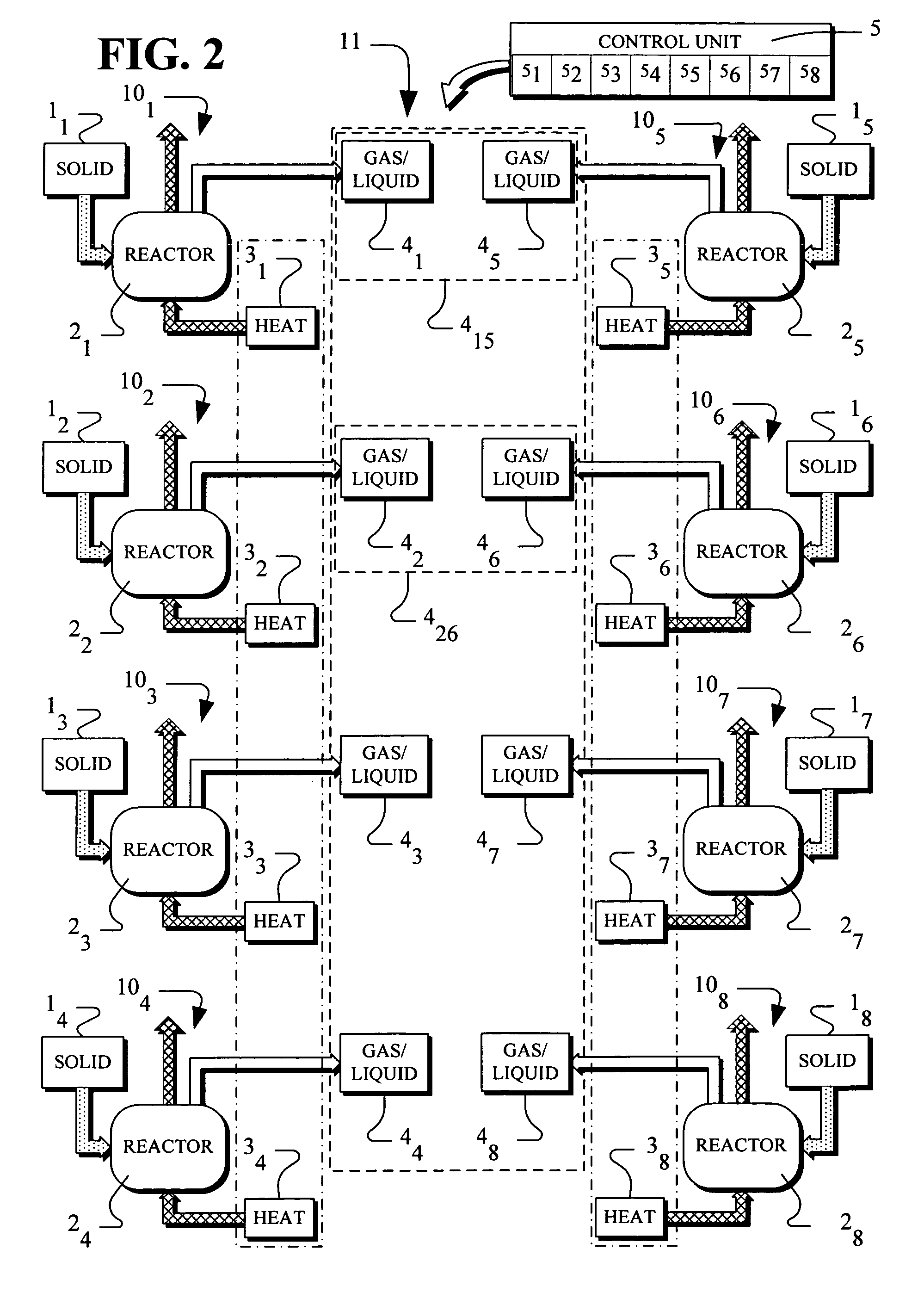

Batch pyrolysis system

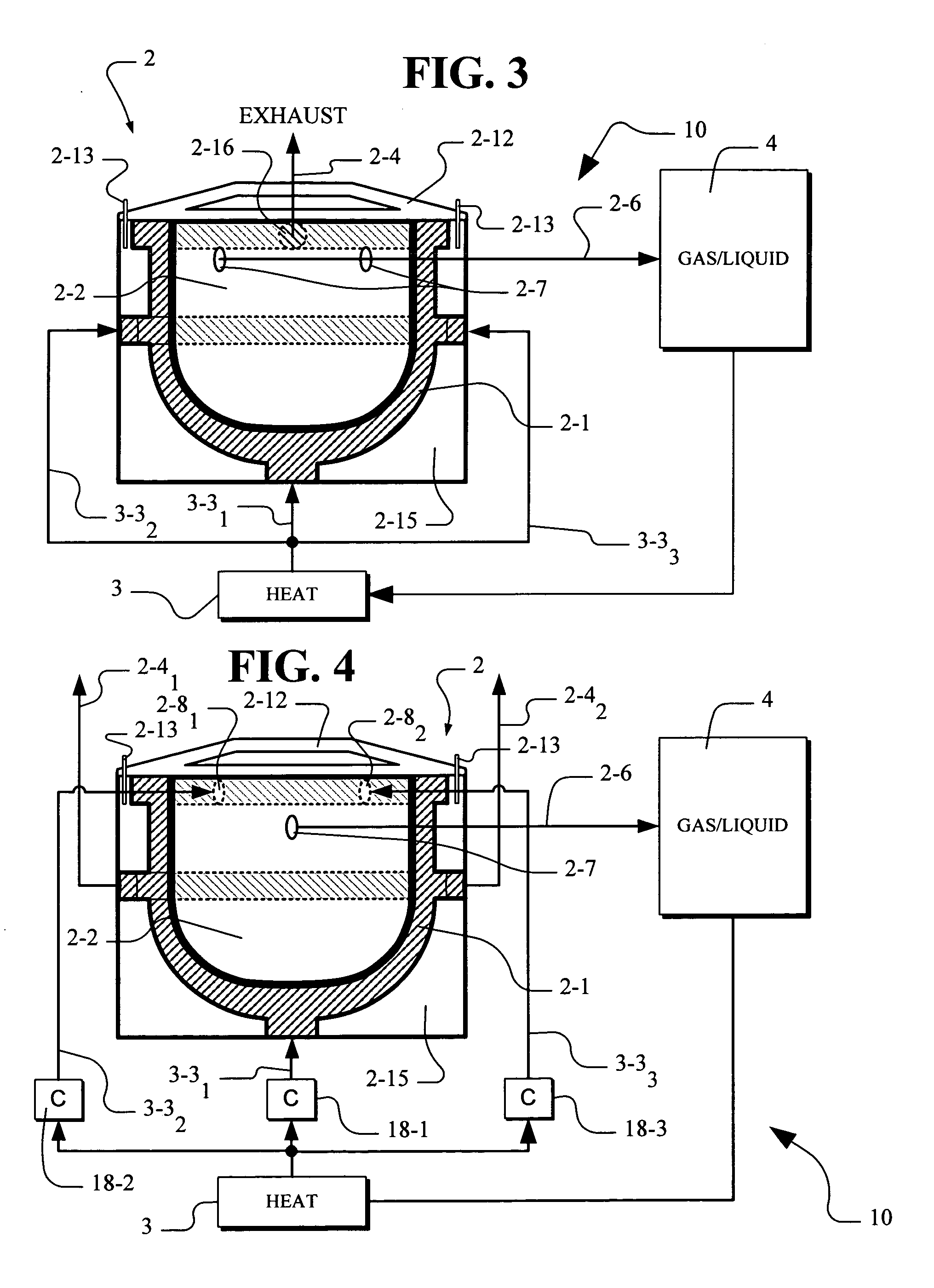

InactiveUS20060163053A1Quality improvementImprove throughputProductsBeehive ovensBatch processingProcess engineering

Disclosed is a scaleable pyrolysis system for batch processing of waste vehicle tires and other waste to provide pyrolysis products. The core pyrolysis system includes one or more batch reactors, heating units, solids processing units, gas / liquid processing units and control units. In operation, the temperature gradients internal to the reactor are controlled by preferential channeling of heat to provide pyrolysis products that are of high quality, and hence commercially advantageous, while facilitating high throughput.

Owner:ERSHAG BENGT STURE

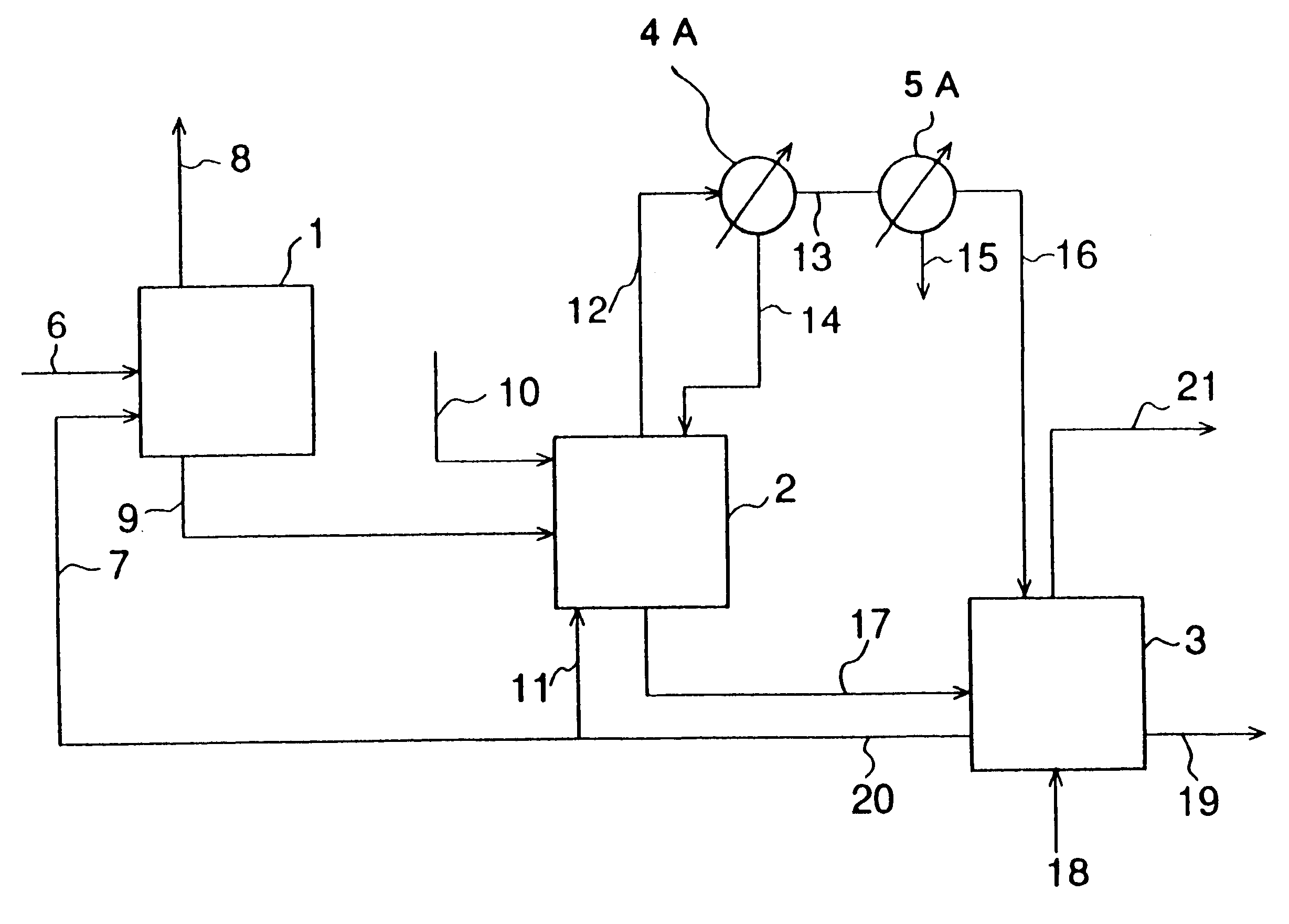

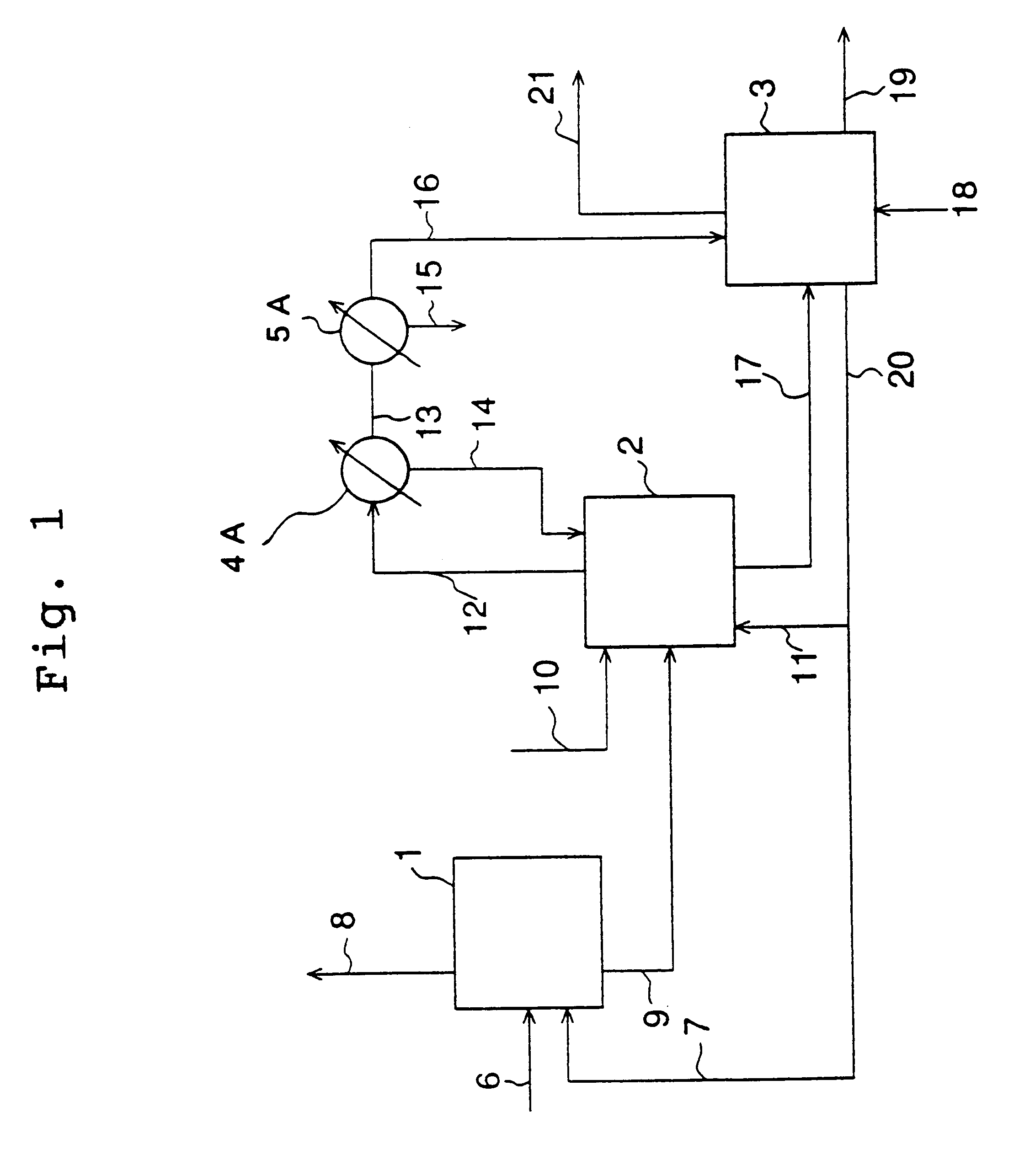

Process and plant for conversion of waste material to liquid fuel

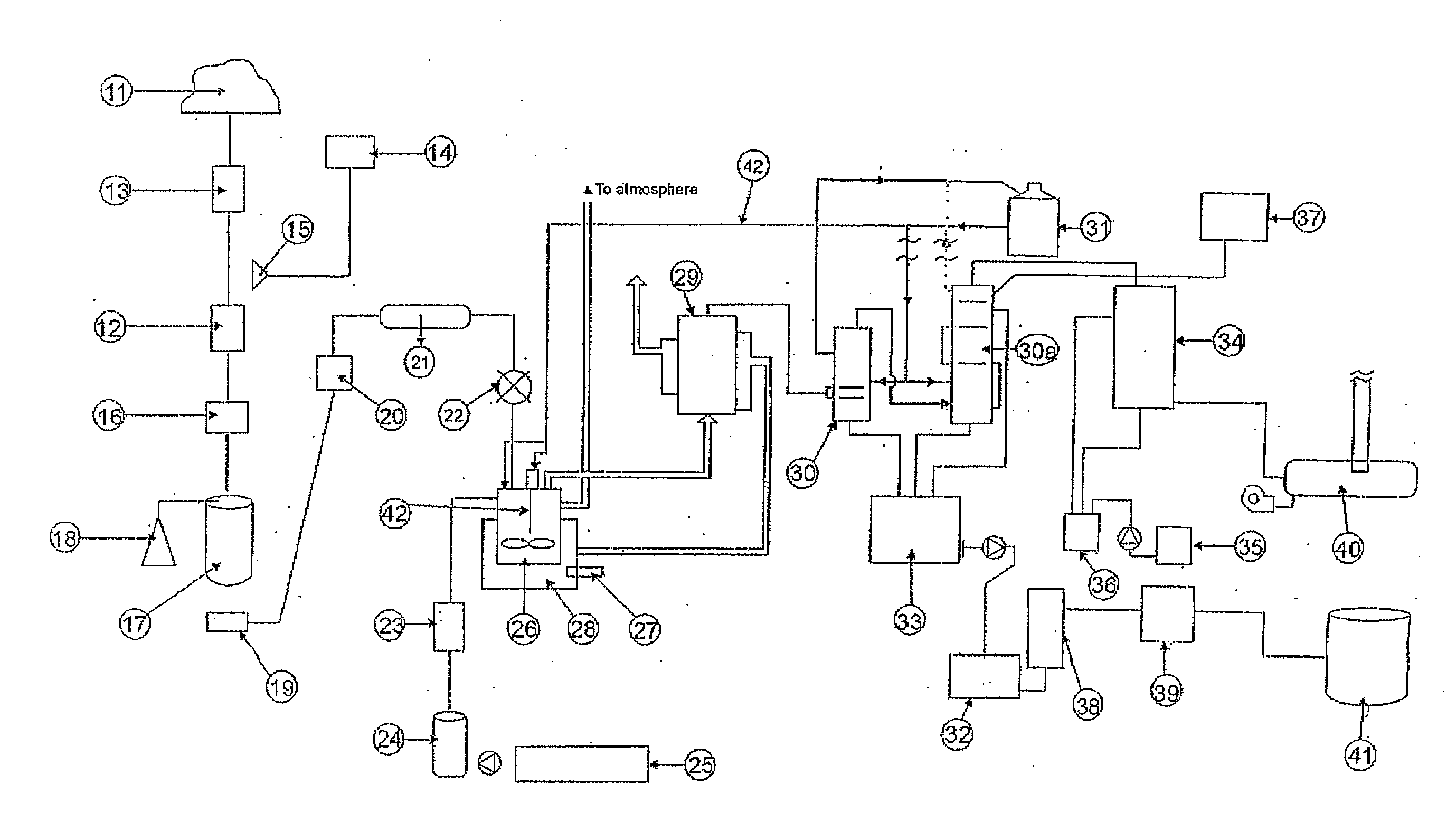

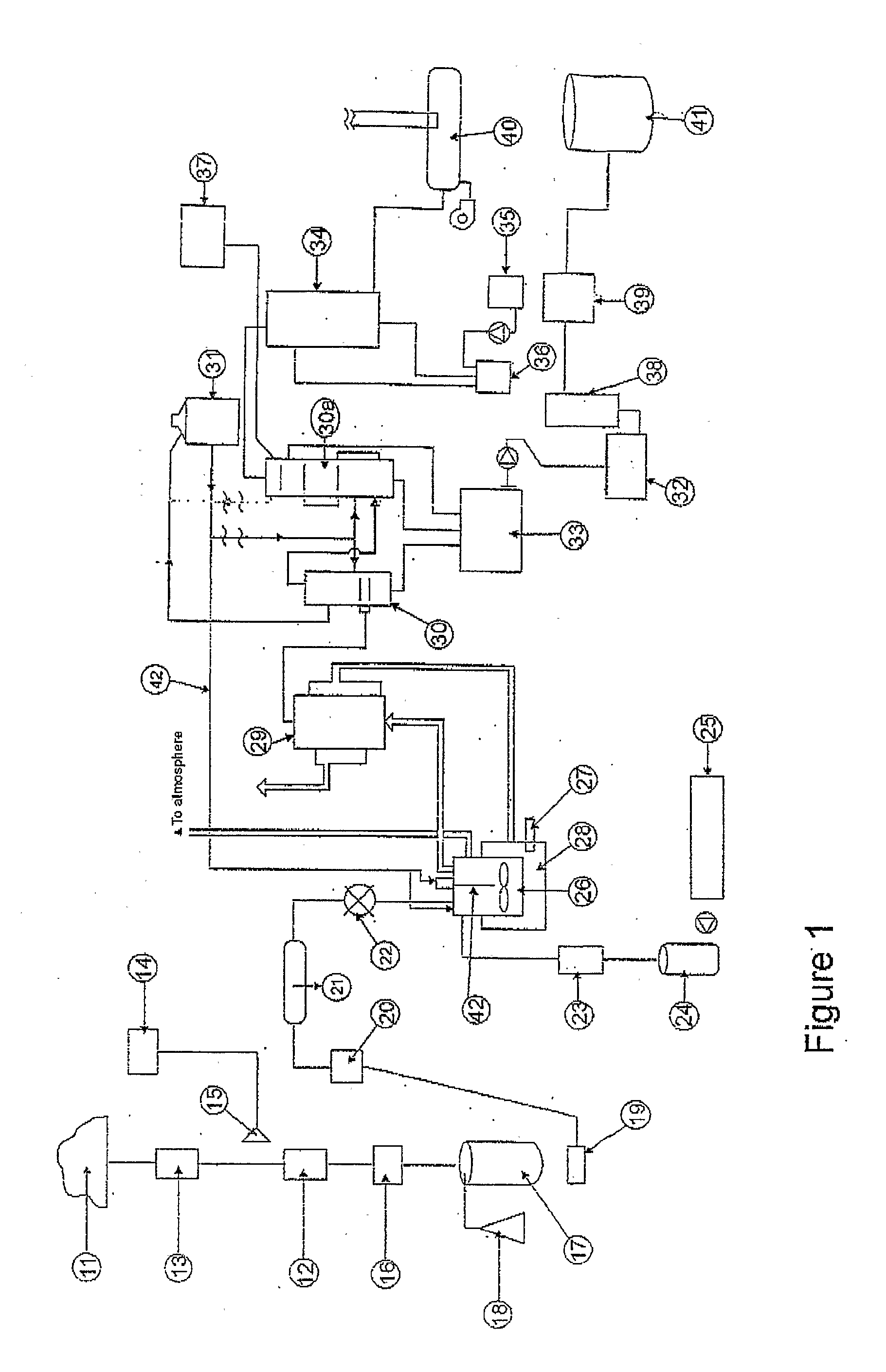

ActiveUS20070179326A1Easy to wasteEasy feedingCatalytic crackingIndirect and direct heating destructive distillationEnvironmental engineeringLiquid fuel

A process and plant for the thermocatalytic conversion of waste materials into reusable fuels and a fuel produced by the process, involving the steps of delivering melted waste material (11) to one or more pyrolysis chambers (26) via heated and valved manifolds (22) and effecting pyrolysis of the waste material into a gascous state in an oxygen purged and pressure controlled environment. Pyrolytic gases are, then transferred to a catalytic converter (29) where the molecular structure of the gaseous material is altered in structure and form, with gases then transferred to one or more condensers (30a) to distil and cool gases in to their respective fractions. After post pyrolysis treatment, fuel fractions thon form a useable fuel. Includes the melting of waste (plastic) material (11) before delivery into any of the pyrolysis chambers (26), making the movement of material into the catalytic tower (29) a semi-continuous operation, directing melted waste material into one or more, but preferably four, pyrolysis chambers (26a, b, c, d), making each chamber capable of independent operation, optionally mechanically removing waste char from the pyrolysis chamber (107) by use of an internet auger (112) or other suitable means.

Owner:FUTURE ENERGY INVESTMENTS PTY LTD

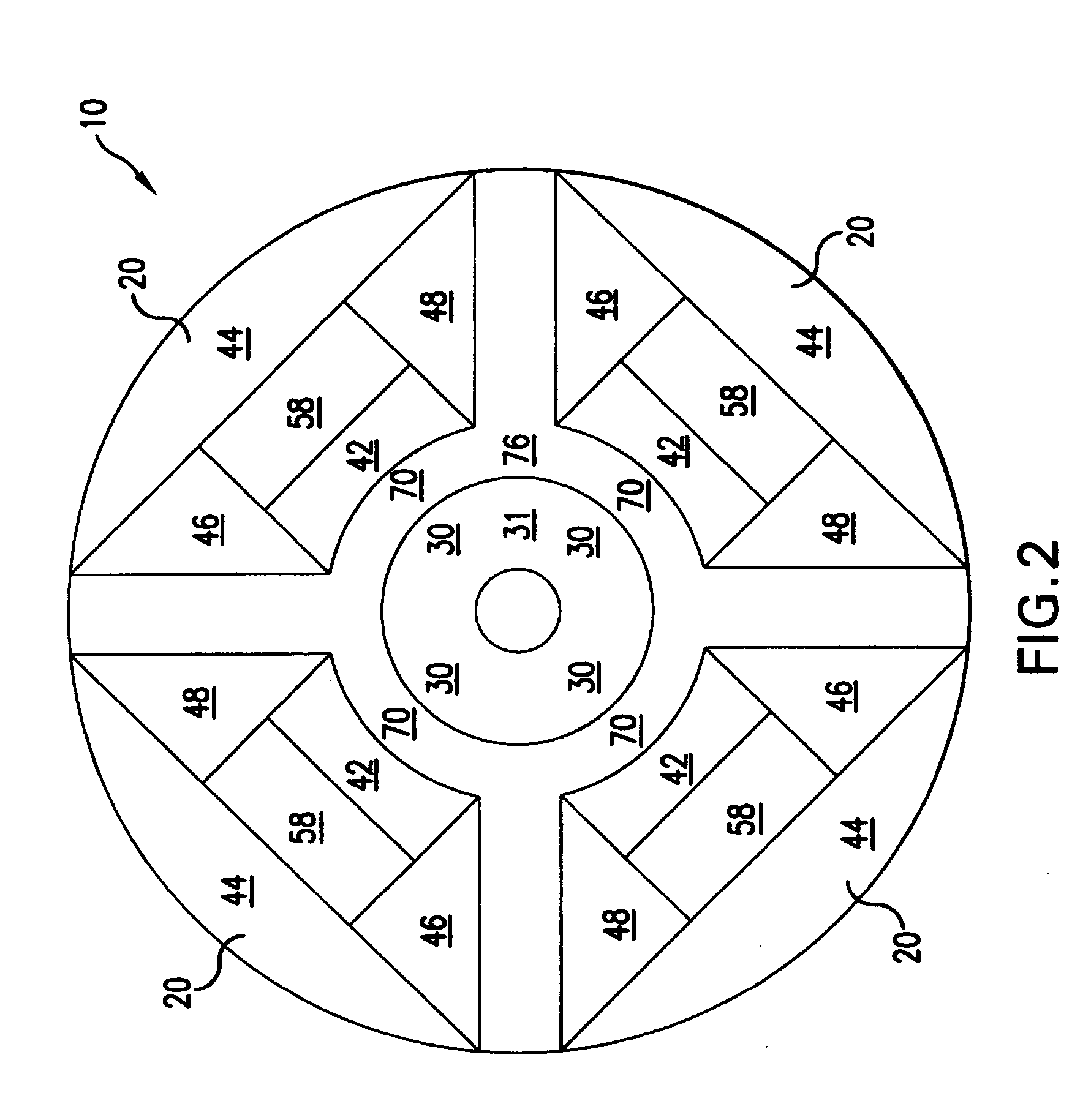

Pyrolyzing gasification system and method of use

InactiveUS20050109603A1High gasifier discharge temperatureEfficient processGasifier mechanical detailsBiofuelsHydrocotyle bowlesioidesExternal combustion engine

Pyrolyzing gasification system and method of use including primary combustion of non-uniform solid fuels such as biomass and solid wastes within a refractory lined gasifier, secondary combustion of primary combustion gas within a staged, cyclonic, refractory lined oxidizer, and heat energy recovery from the oxidized flue gas within an indirect air-to-air all-ceramic heat exchanger or external combustion engine. Primary combustion occurs at low substoichoimetric air percentages of 10-30 percent and at temperatures below 1000 degrees F. Secondary combustion is staged and controlled for low NOx formation and prevention of formation of CO, hydrocarbons, and VOCs. The gasifier includes a furnace bed segmented into individual cells, each cell is independently monitored using a ramp temperature probe, and provided with controlled air injection. Gasifier air injection includes tuyere arrays, lances, or both. The oxidizer includes three serially aligned stages separated by air injecting baffles, and ability to adjust the exit air temperature.

Owner:HEAT TRANSFER INT

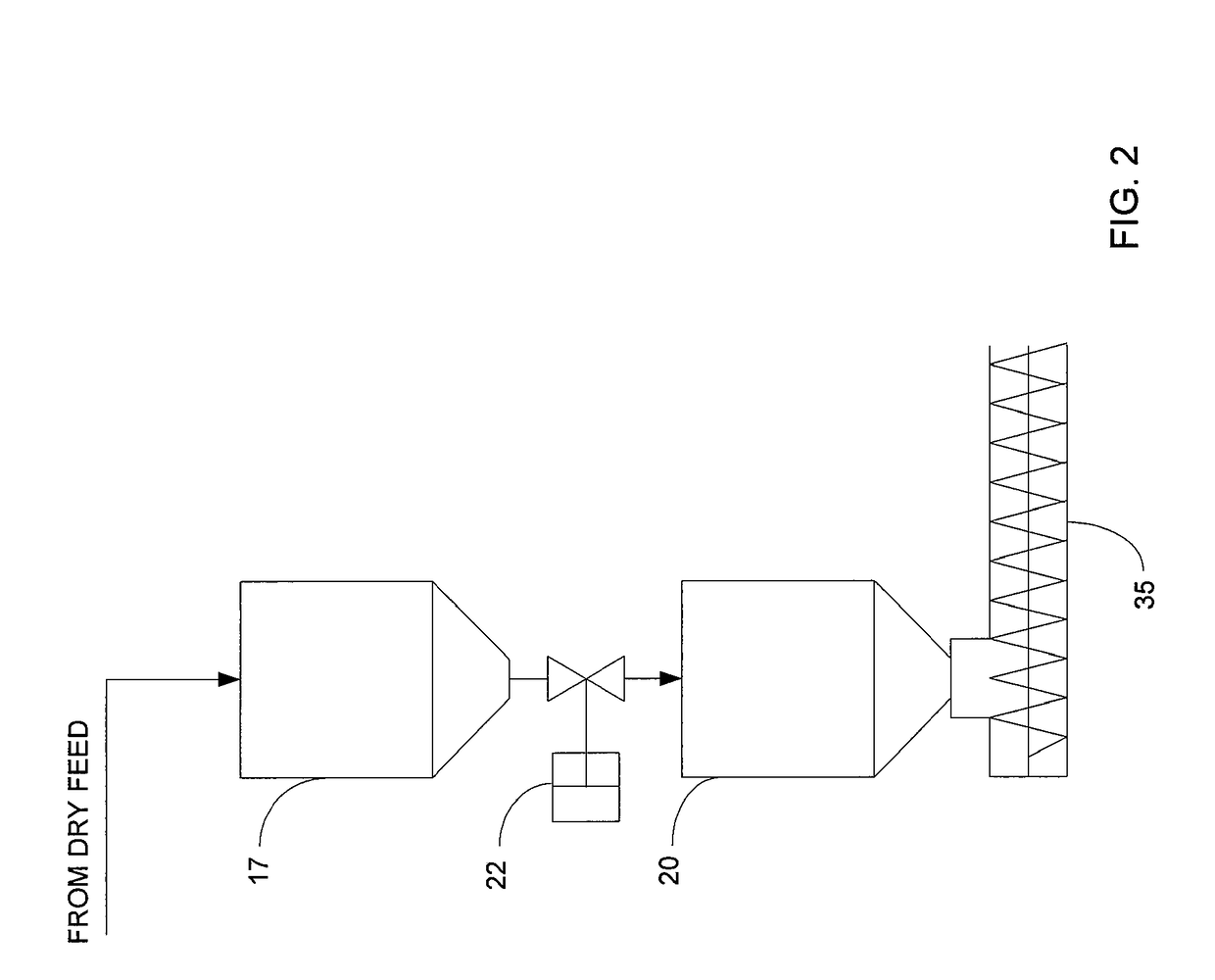

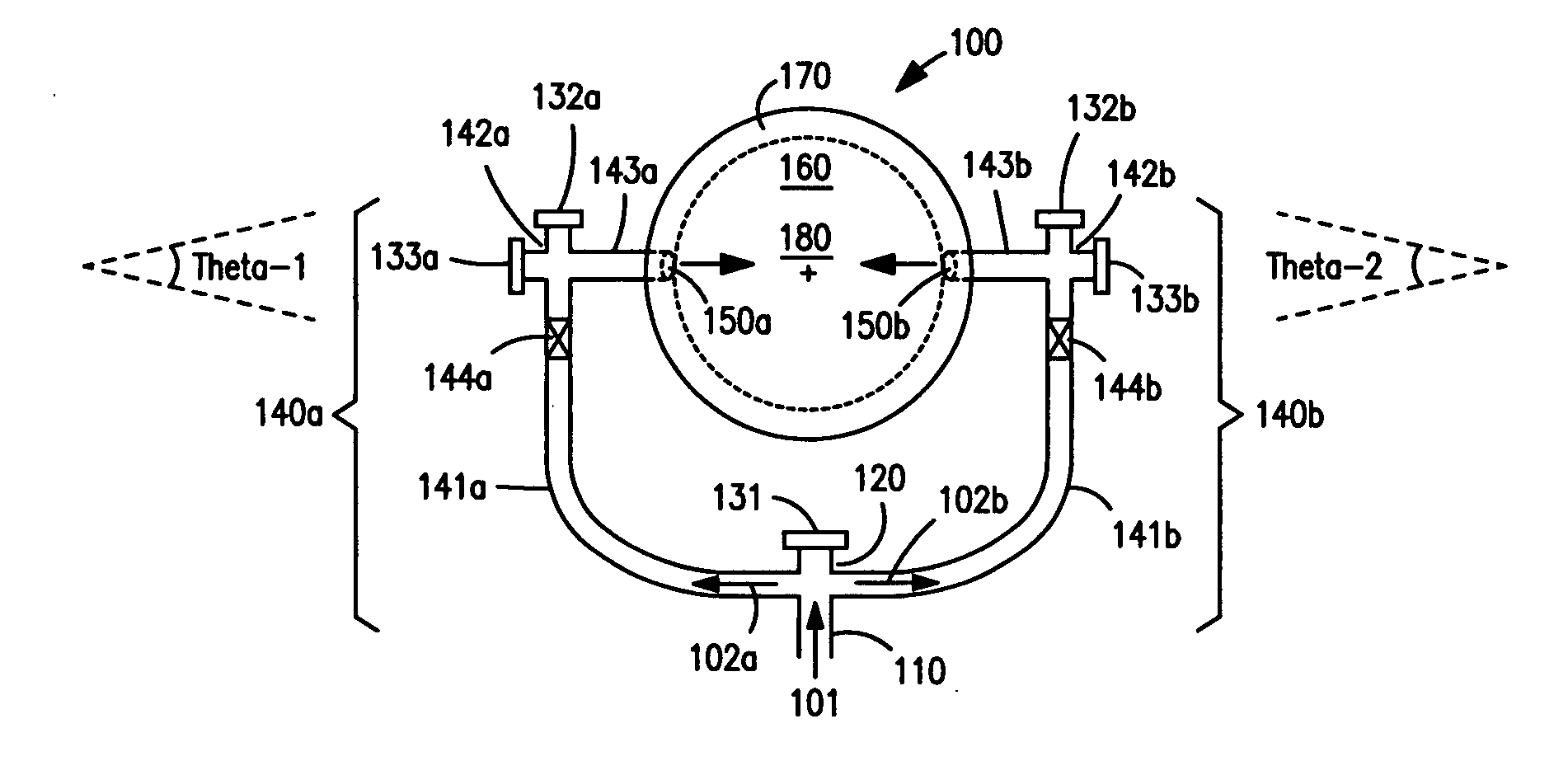

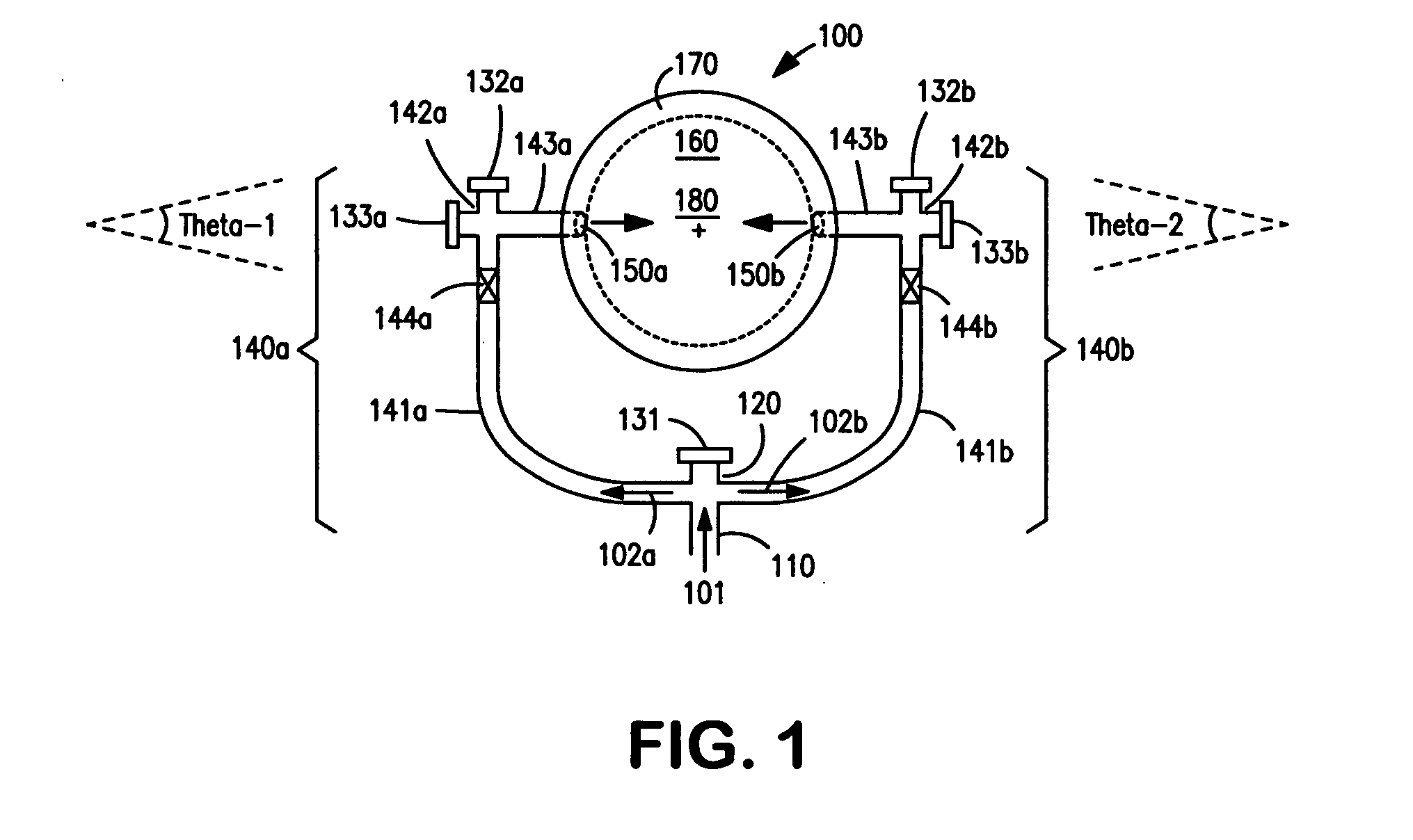

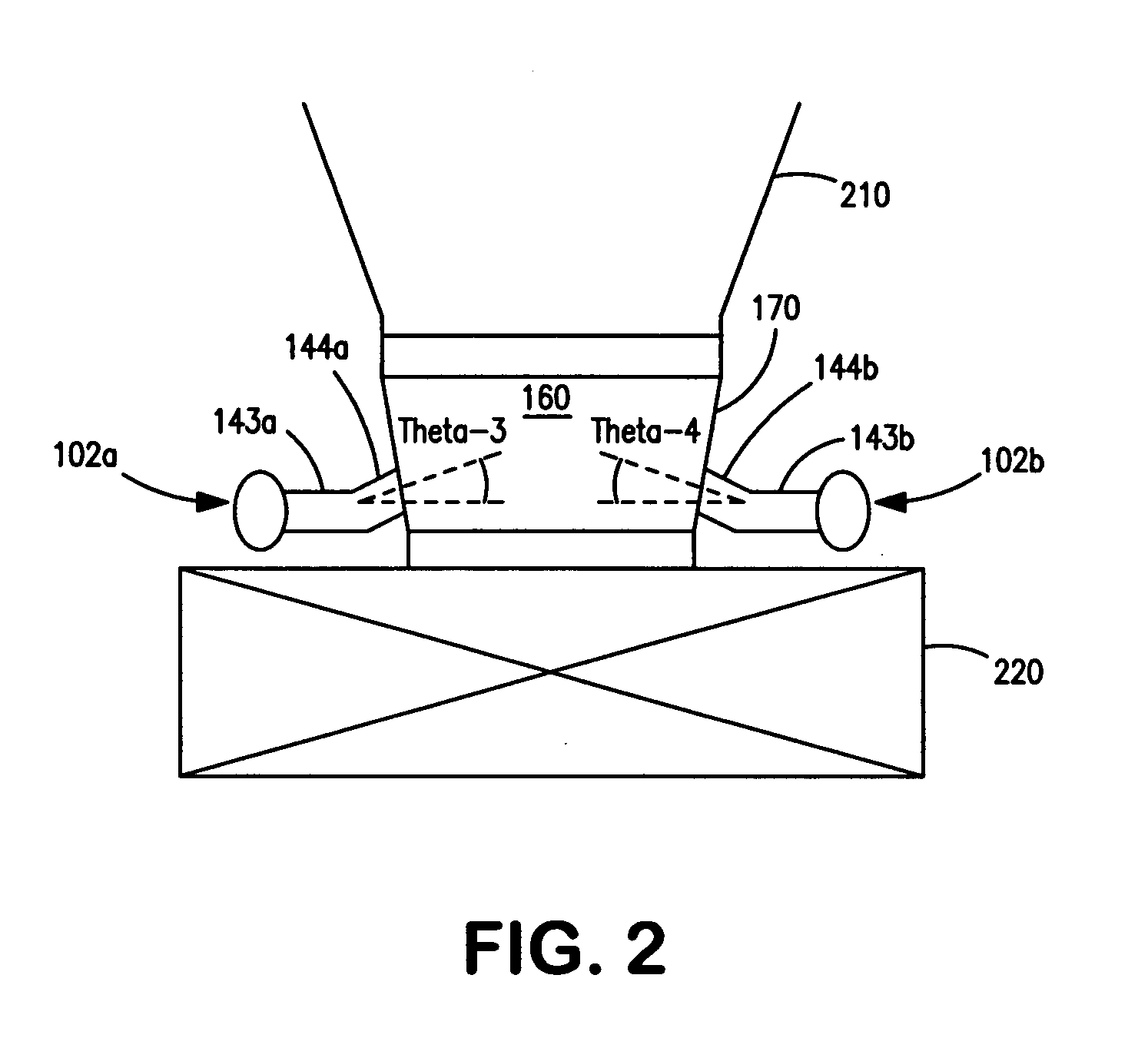

Coker feed method and apparatus

InactiveUS20080179165A1Reduces drum/vessel thermal stressReduce thermal stressThermal non-catalytic crackingCombustible gas coke oven heatingEngineeringVertical axis

Described herein are methods and mechanisms for laterally dispensing fluid to a coke drum in a predictable and maintainable manner that alleviates thermal stress. In one embodiment, the methods and mechanisms utilize a split piping system to dispense fluid through two or more inlets into a spool that is connected to a coke drum and a coke drum bottom deheader valve. A combination of block valves and clean out ports provides a more effective means to clean the lines and allows fluid to be laterally dispensed in a controllable and predictable manner. The fluid is preferably introduced to the spool in opposing directions toward a central vertical axis of the spool at equal but opposing angles ranging from minus thirty (−30) to thirty (30) degrees relative to a horizontal line laterally bisecting the spool. Alternatively, however, fluid can be introduced to the spool tangentially.

Owner:EXXON RES & ENG CO

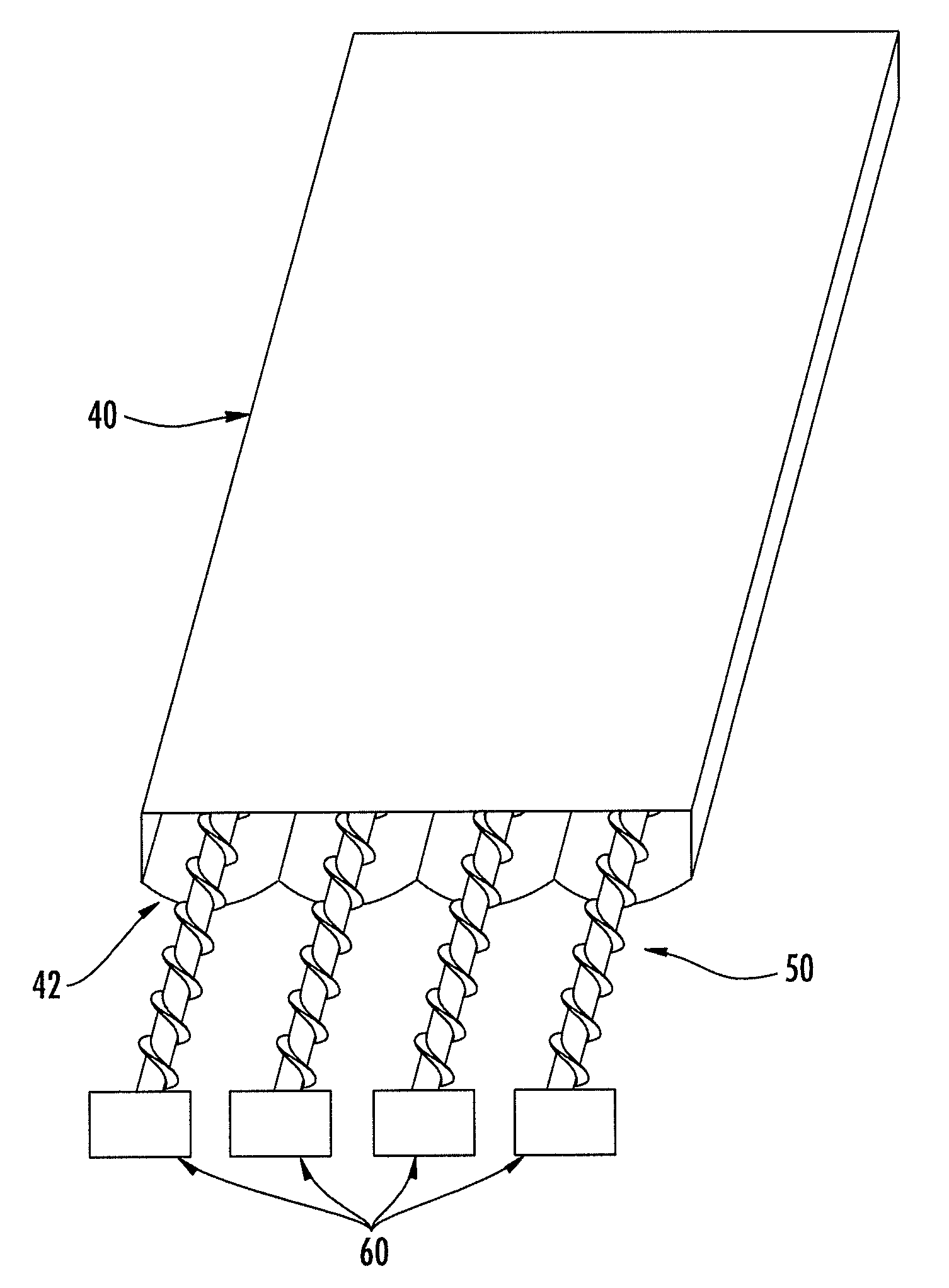

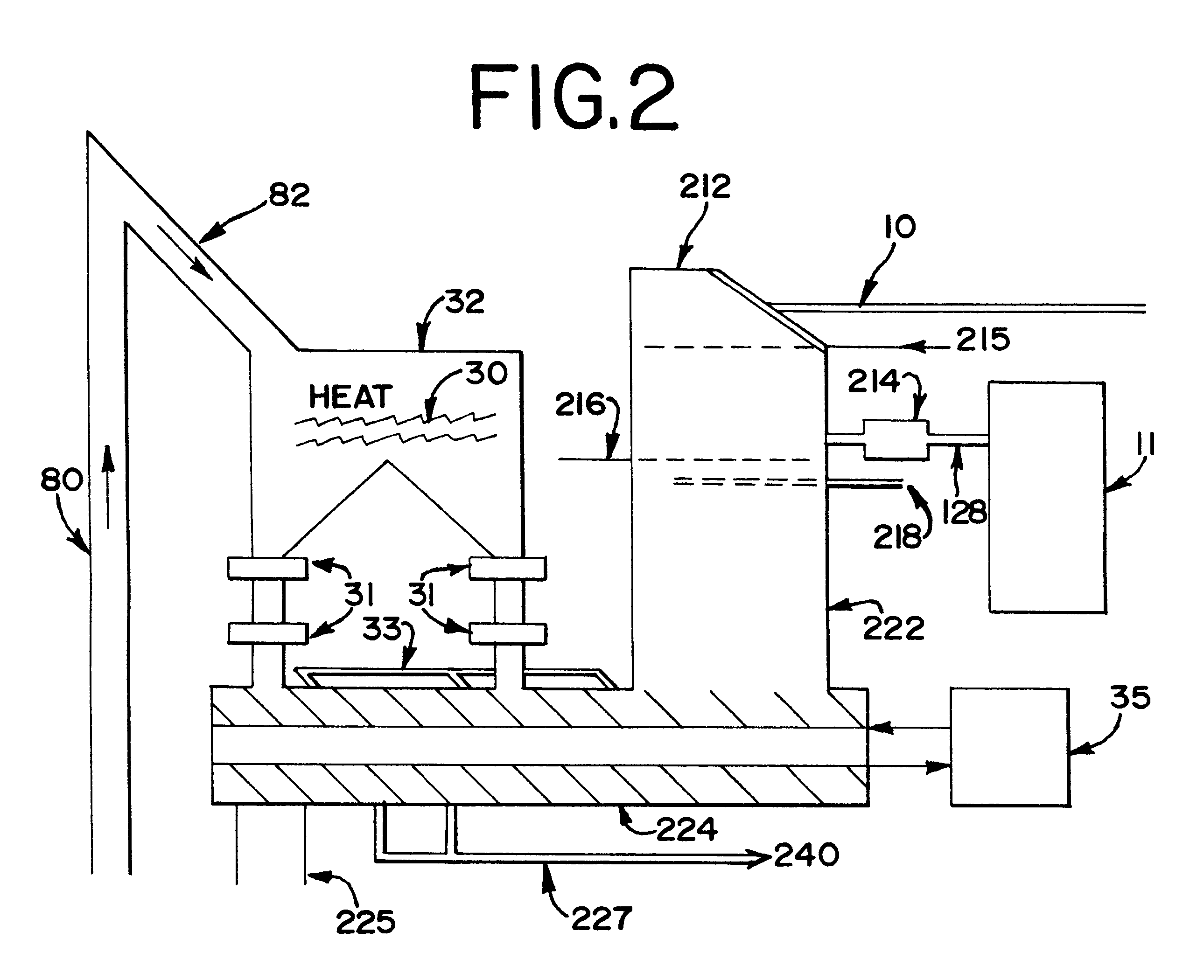

Autothermal and mobile torrefaction devices

ActiveUS20090250331A1Increased cost-effectivenessLow costCombustible gas coke oven heatingCharging-discharging device combinationsCombustorEngineering

The present invention provides an autothermal torrefaction device, which can be either stationary of mobile. Embodiments of the present invention include a torrefaction chamber having a chamber inlet for receiving biomass and at least one chamber outlet. The torrefaction chamber can be substantially surrounded by an exterior housing defining an outer jacket and having a jacket inlet and a jacket outlet. The outer jacket and torrefaction chamber define a space therebetween such that a burner unit including an inlet operatively connected to the chamber outlet and an outlet operatively connected to the jacket inlet allows vapors produced or released from within the torrefaction chamber to travel into the burner unit for combustion of at least a portion of the vapors and subsequently travel through the space between the jacket and the torrefaction chamber to provide heat necessary for autothermal torrefaction of biomass.

Owner:NORTH CAROLINA STATE UNIV

Method of storing solar energy

InactiveUS7458999B2Reduction in the atmospheric CODrawback can be obviatedCombustible gas catalytic treatmentBiofuelsEnvironmental engineeringPhotosynthetic organism

An amount of photosynthetic biomass such as wood is converted into coal such as charcoal and a substantial amount thereof is permanently stored until the atmospheric CO2 level is reduced to an extent which is unable to cause a greenhouse effect. While a main portion of the charcoal remains in permanent storage, a fraction thereof may be retained prior to or retrieved during or after achievement of the reduction in the atmospheric CO2 level. Such fraction is converted into energy or an energy source, for example hydrogen, in a manner such that thereby the atmospheric CO2 is maintained at a level which does not cause an undesired greenhouse effect.

Owner:SCHENCK LEGAL REPRESENTATIVE GUNTER EDWIN +1

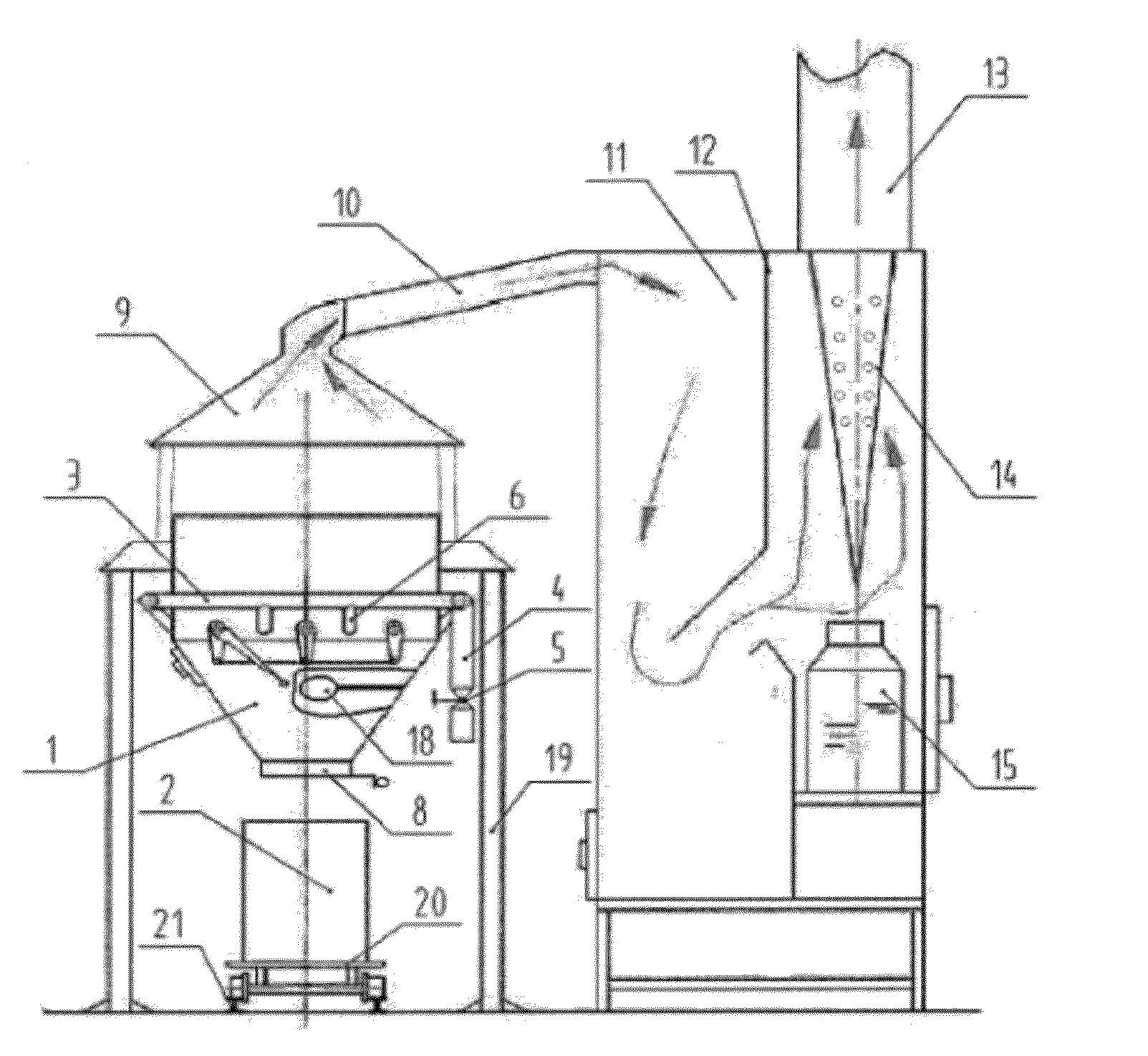

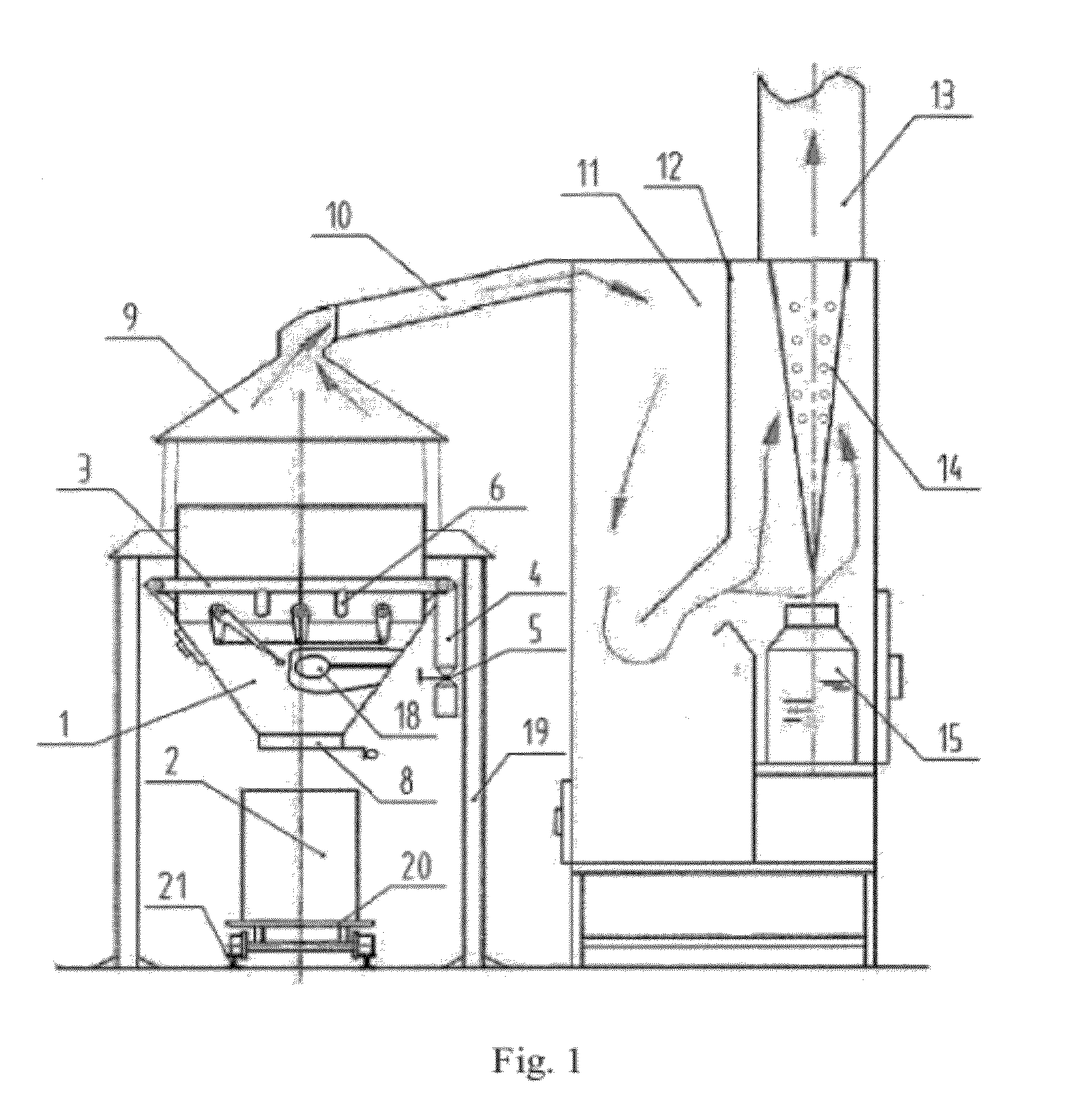

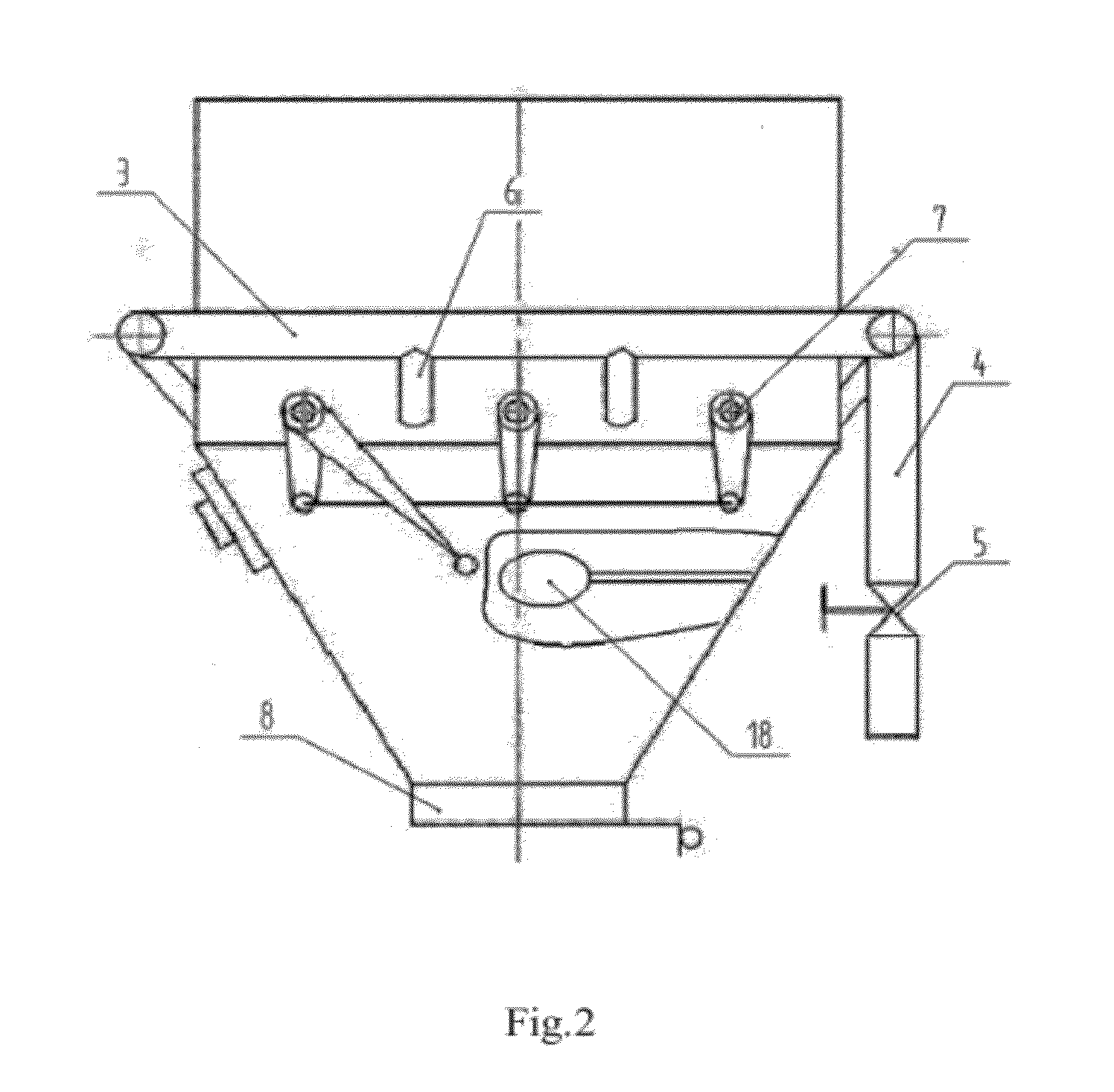

Method and device for carbonification of crop straws

ActiveUS20120305380A1SpeedReduce the temperatureCombustible gas coke oven heatingDirect heating destructive distillationEngineeringOxygen

The present invention is to provide a method for carbonification of crop straws and a device thereof. Pyrolysis process is controlled by regulating the feeding of oxygen during said pyrolysis process, and pyrolysis and carbonification are respectively conducted in separate pyrolysis and carbonification pools, wherein the straws are pyrolyzed in said pyrolysis pool and entered into said carbonification pool to be carbonified. The present invention can quickly raise the temperature of the pyrolysis process, shorten the time of the pyrolysis process, and improve the pyrolysis carbonification efficiency.

Owner:SHANXI SUPPLY & MARKETING COOP

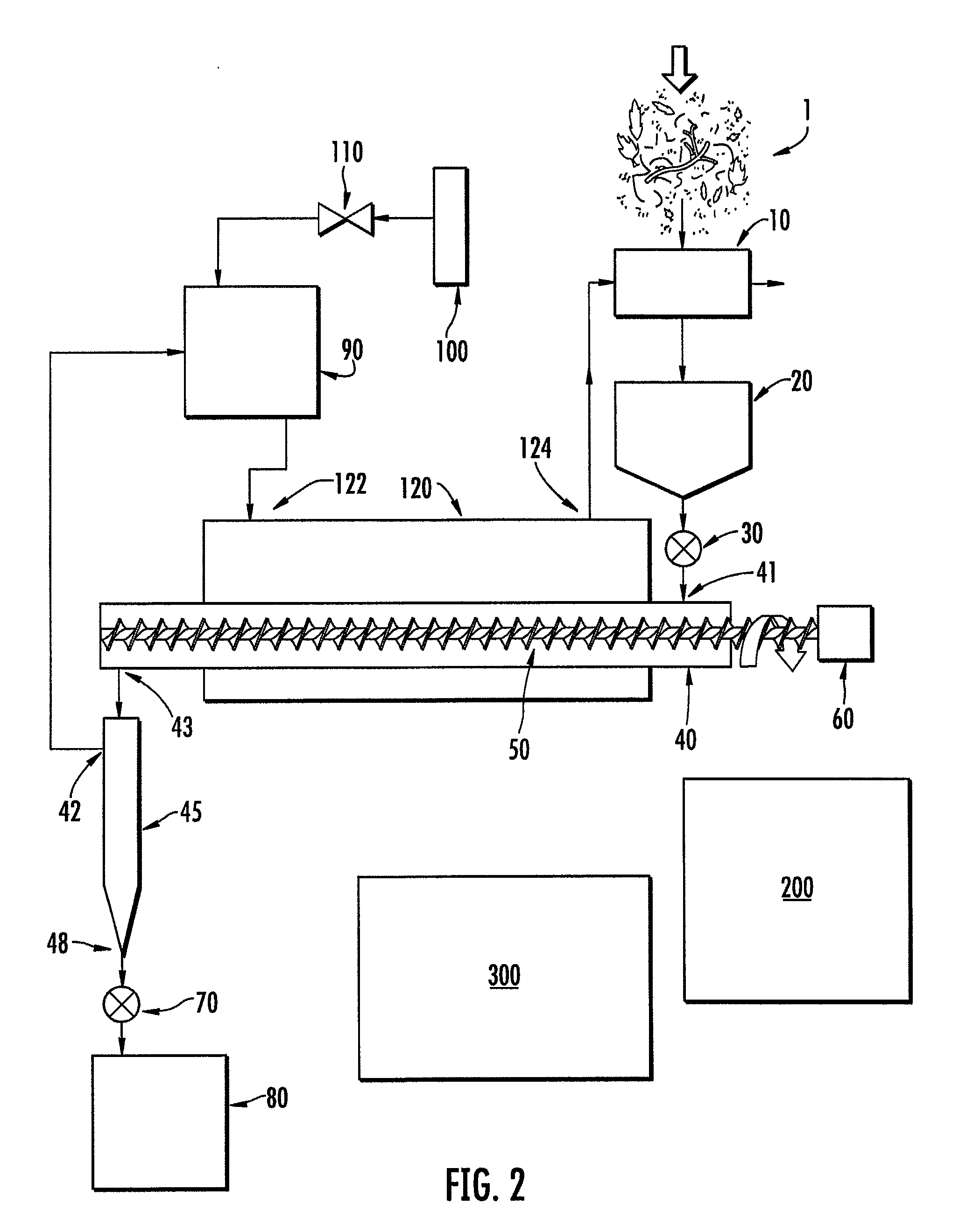

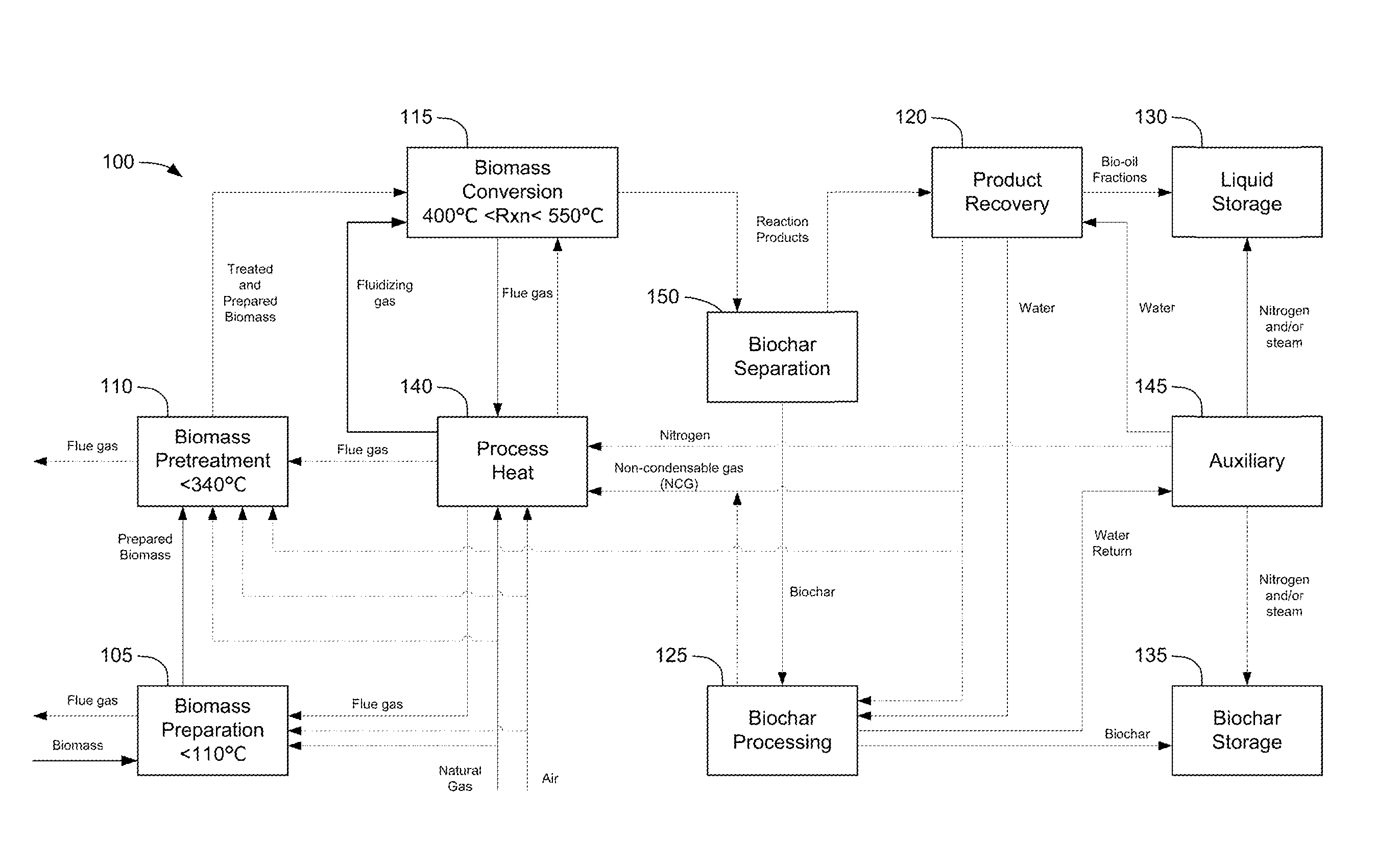

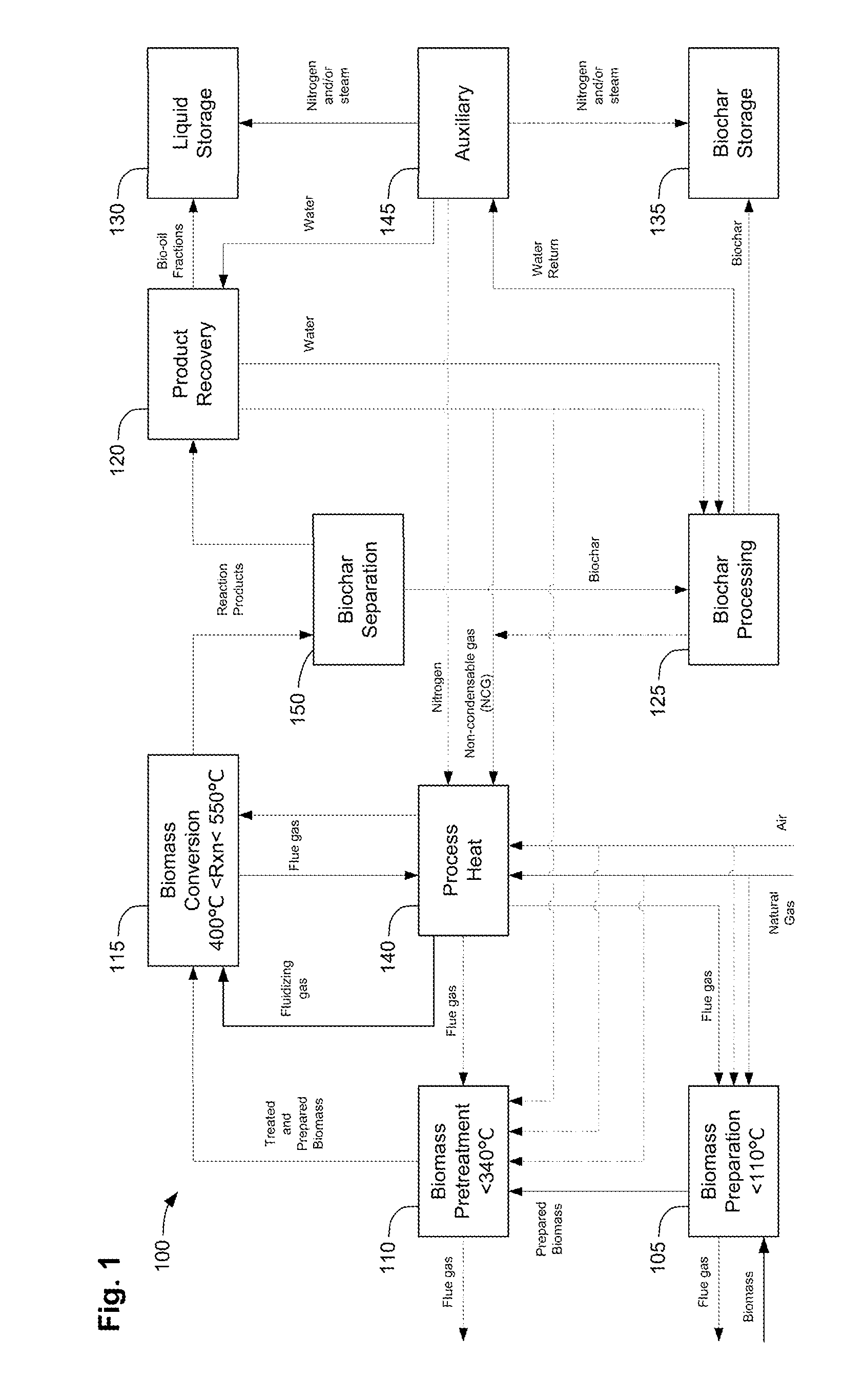

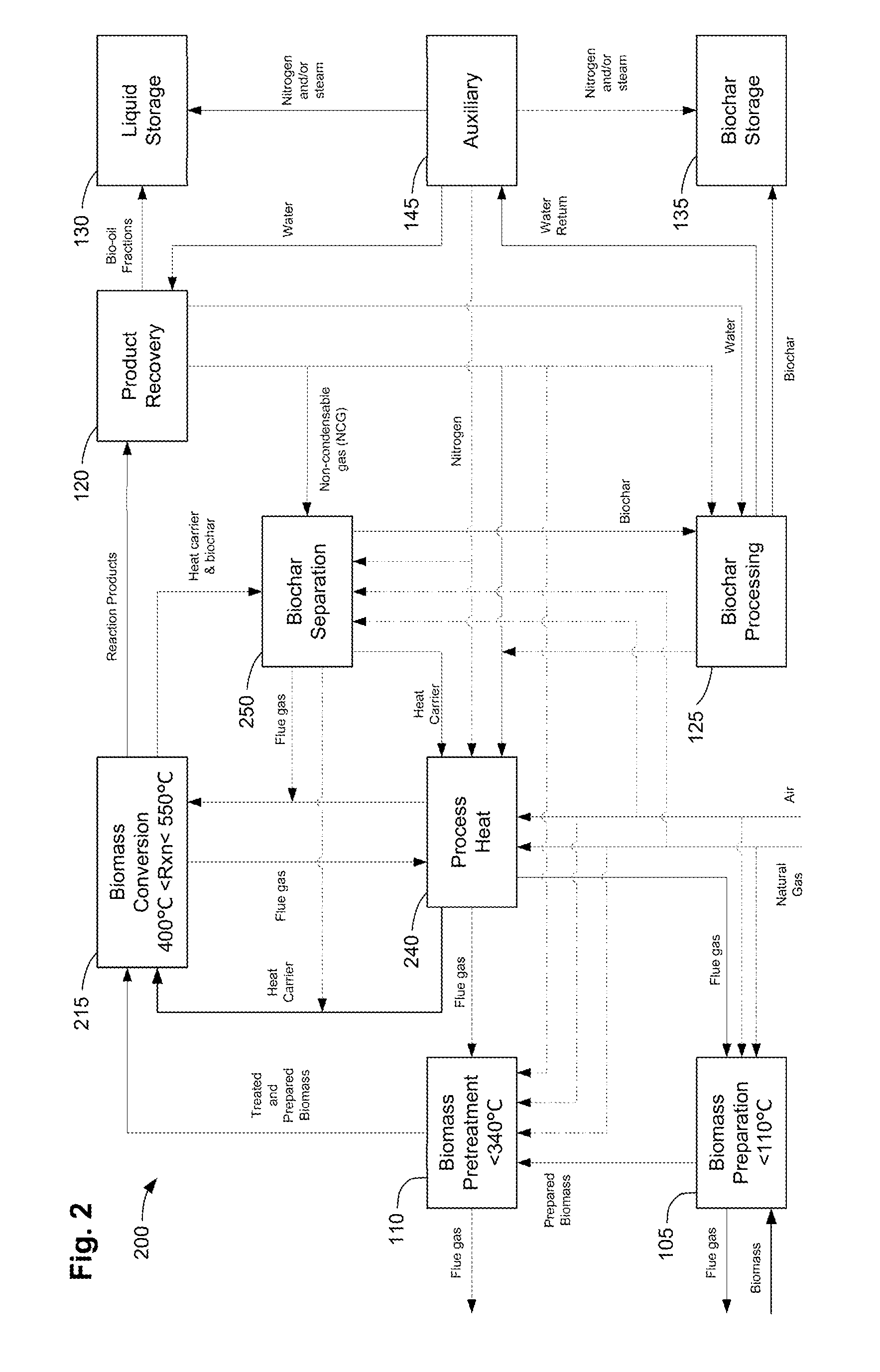

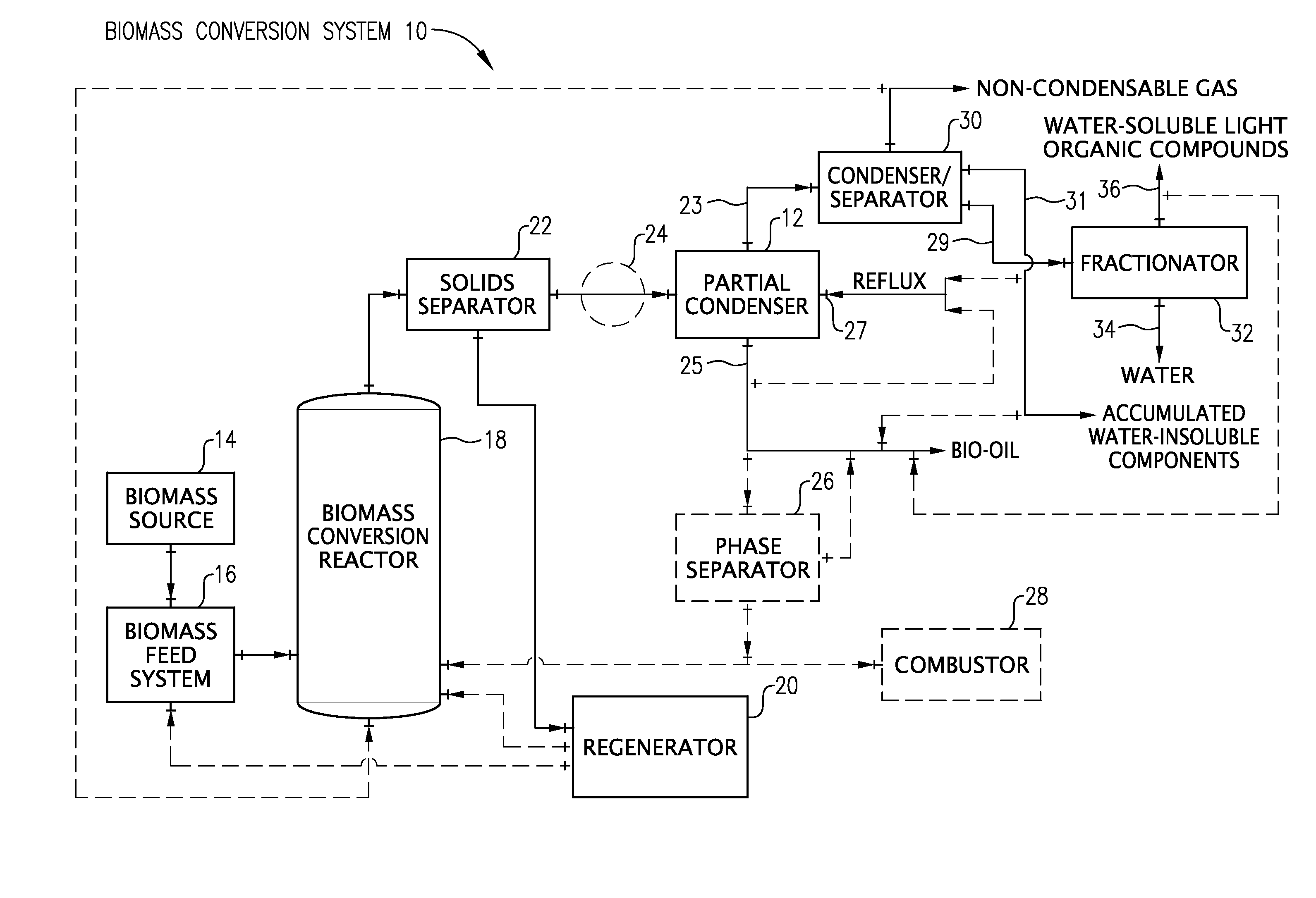

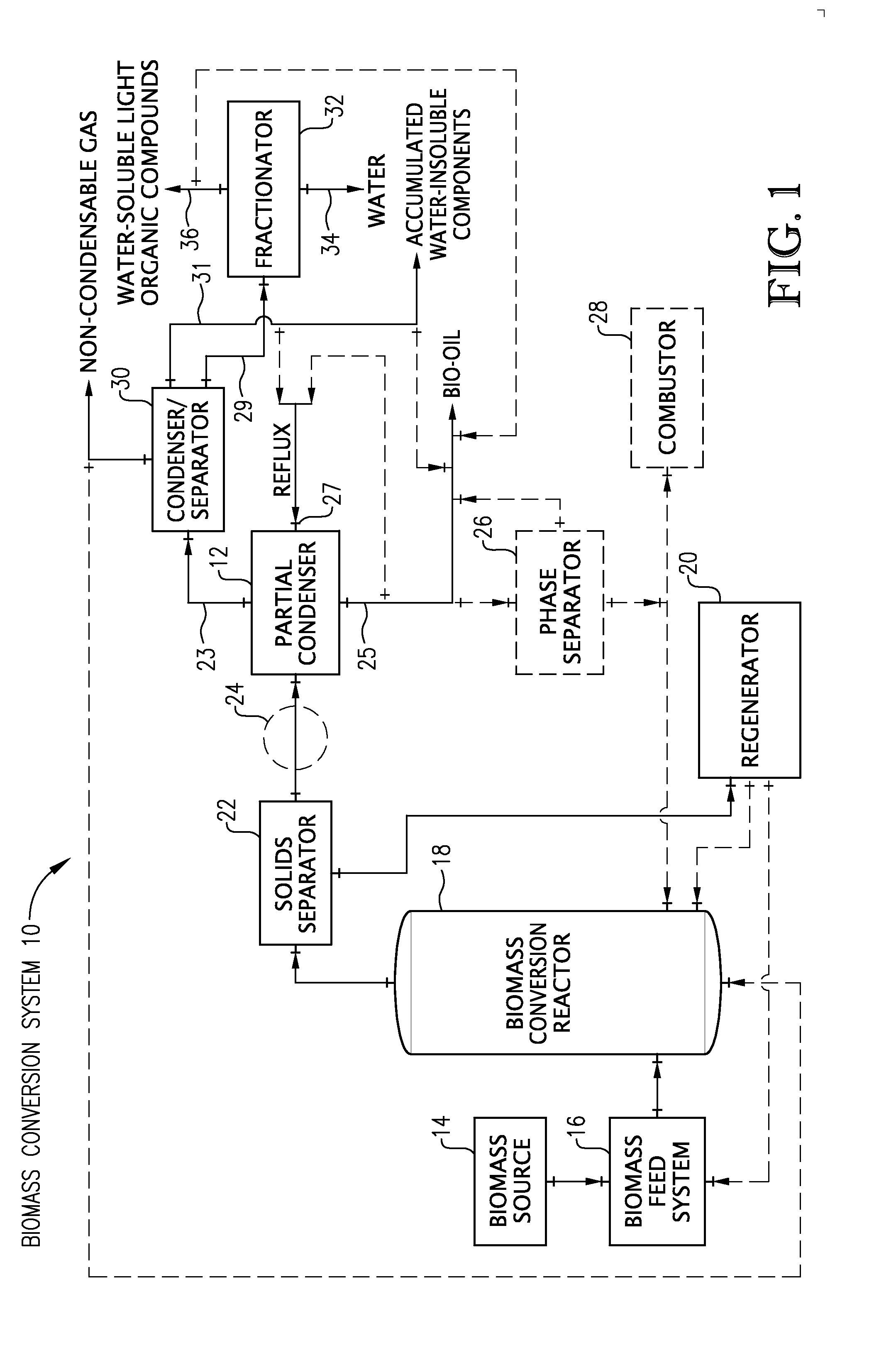

Methods for integrated fast pyrolysis processing of biomass

ActiveUS8100990B2Minimizes water contentImprove collection efficiencyDirect heating destructive distillationBiofuelsPre treatmentSafe handling

Methods, process, apparatus, equipment, and systems are disclosed for converting biomass into bio-oil fractions for chemicals, materials, feedstocks and fuels using a low-cost, integrated fast pyrolysis system. The system improves upon prior art by creating stable, bio-oil fractions which have unique properties that make them individually superior to conventional bio-oil. The invention enables water and low-molecular weight compounds to be separated into a final value-added fraction suitable for upgrading or extracting into value-added chemicals, fuels and water. Initial bio-oil fractions from the process are chemically distinct, have low-water content and acidity which reduces processing costs normally associated with conventional bio-oil post-production upgrading since fewer separation steps, milder processing conditions and lower auxiliary inputs are required. Biochar is stabilized so that it can be handled safely. The integrated fast pyrolysis process includes biomass storage, preparation, pretreatment, and conversion, product recovery and processing to create and store stable biochar and bio-oil fractions.

Owner:AVELLO BIOENERGY

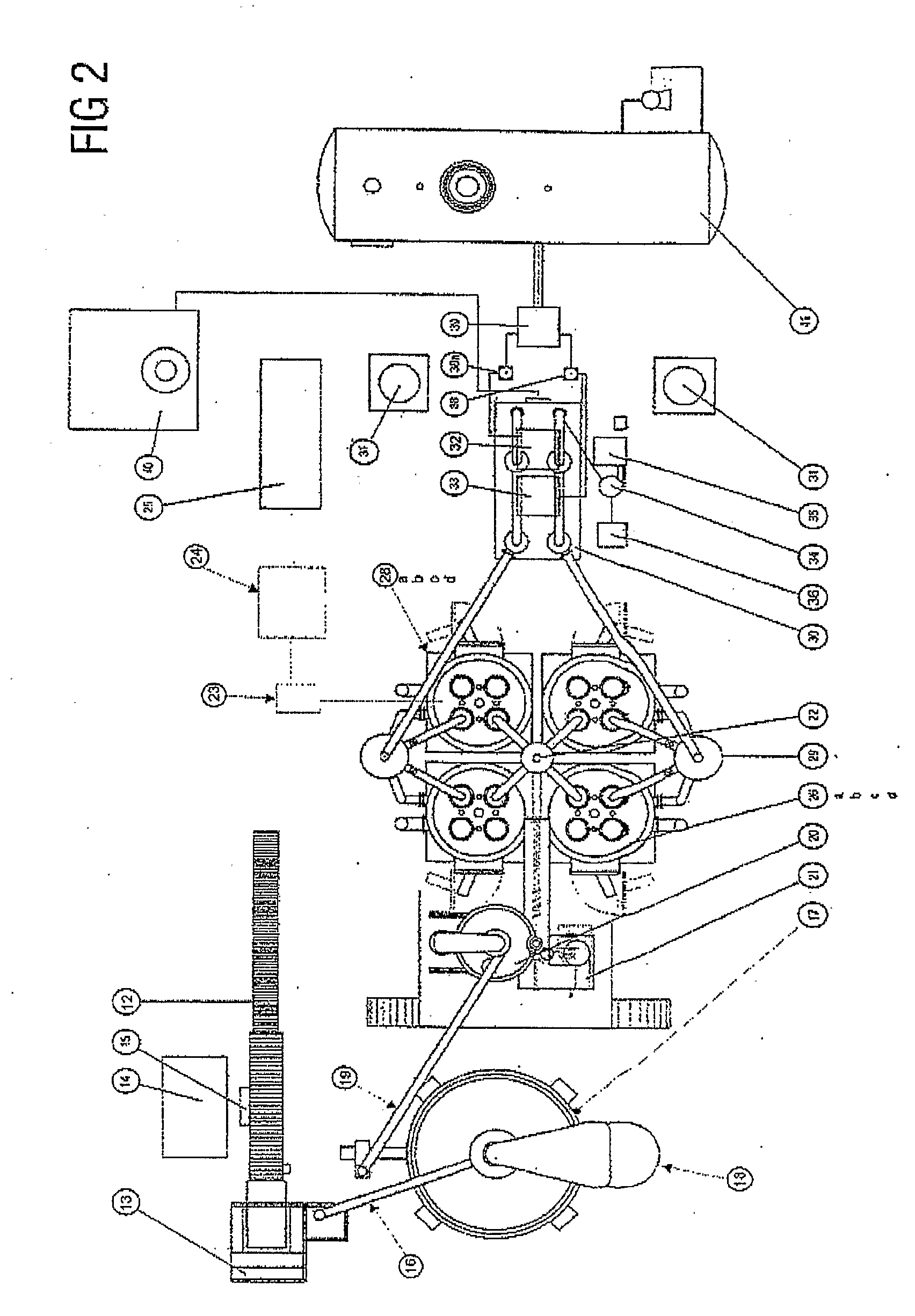

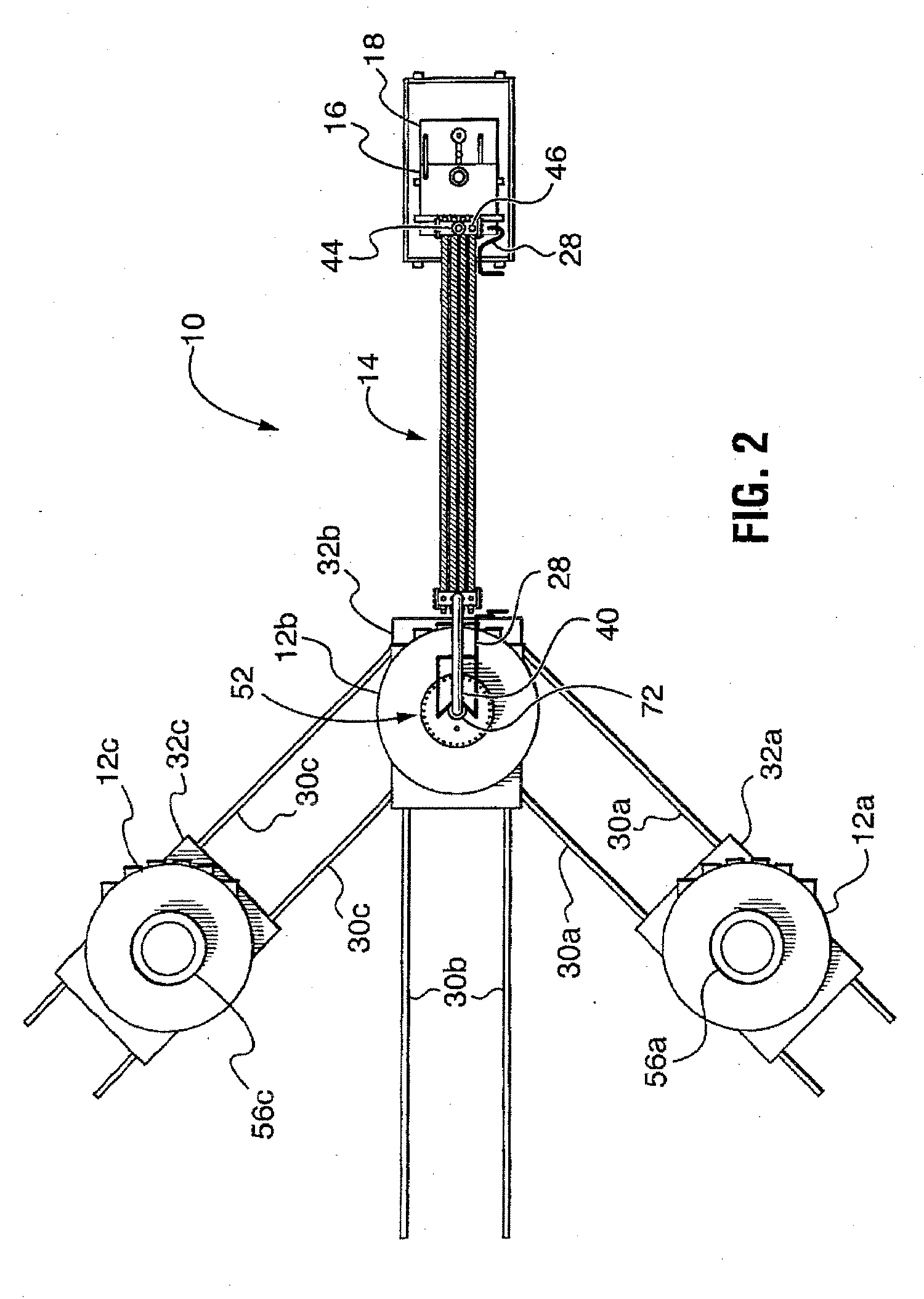

Process for pyrolyzing tire shreds and tire pyrolysis systems

Tire pyrolysis systems and processes are provided which include feeding tire shreds to a pyrolysis reactor, pyrolyzing the shreds in a pyrolysis reactor to produce a hydrocarbon-containing gas stream and carbon-containing solid, removing the carbon-containing solid from the reactor, directing the hydrocarbon-containing gas stream into a separator, contacting the hydrocarbon-containing gas stream with an oil spray in the separator thereby washing particulate from the hydrocarbon-containing gas stream and condensing a portion of the gas stream to oil, removing and cooling the oil from the separator, directing non-condensed gas from the gas stream away from the separator, and directing a portion of the cooled oil removed from the separator to an inlet of the separator for use as the separator oil spray. A process is also provided in which solids from the pyrolysis reactor are directed to an auger having a pressure which is greater than the pressure in the pyrolysis reactor, and in which non-condensed gas from the gas stream after condensing a portion of the gas is directed to at least one burner in heat exchange relation with the pyrolysis reactor, and burned to heat the reactor and generate an effluent flue gas, a portion of which effluent flue gas is cooled and injected into the auger which is a trough auger in one embodiment.

Owner:RENAISSANCE ENERGY GROUP

Method and apparatus for reclaiming oil from waste plastic

InactiveUS6172271B1Increase productionContinuous operationThermal non-catalytic crackingHydrocarbon distillationForeign matterBoiling point

Owner:MITSUBISHI HEAVY IND LTD

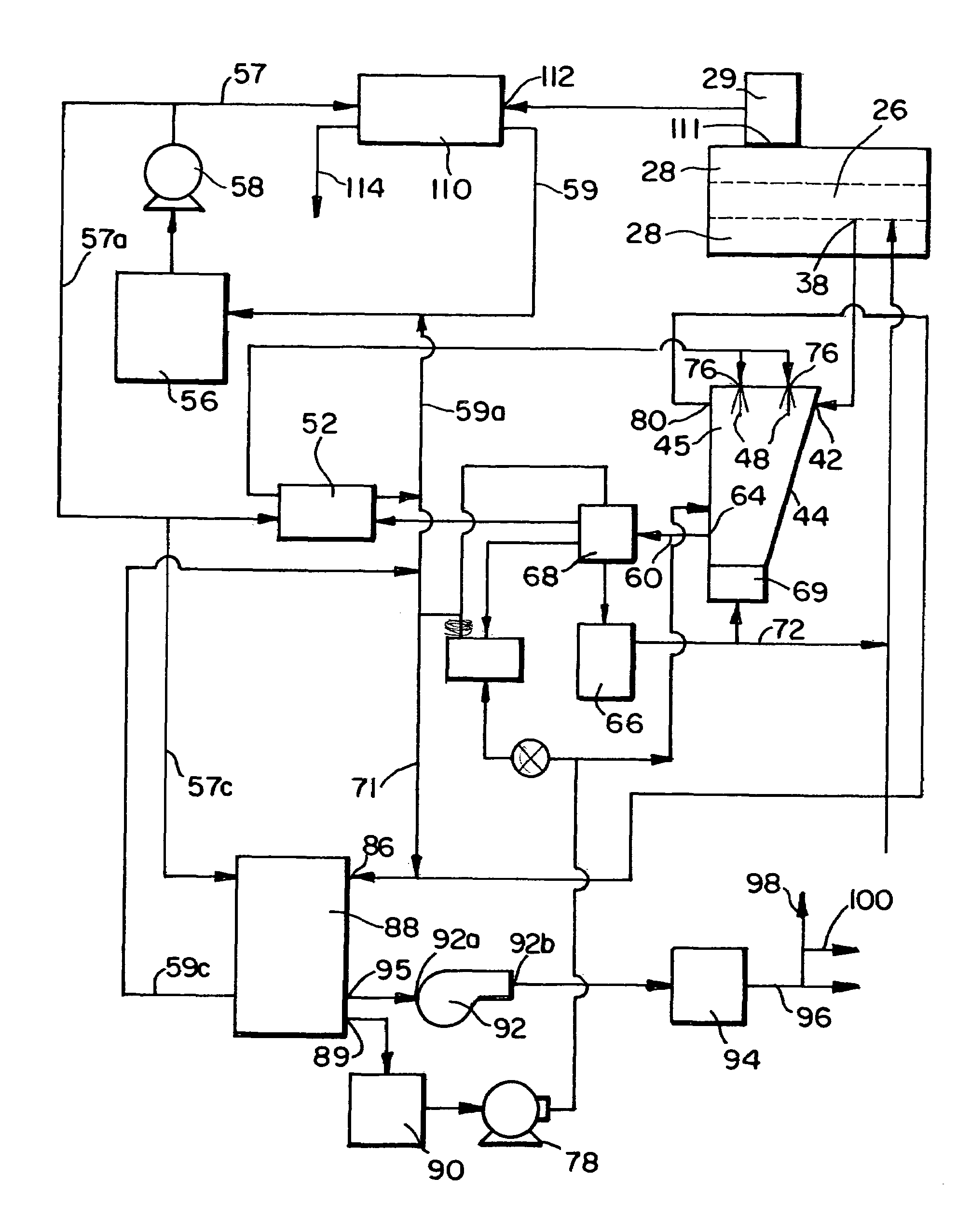

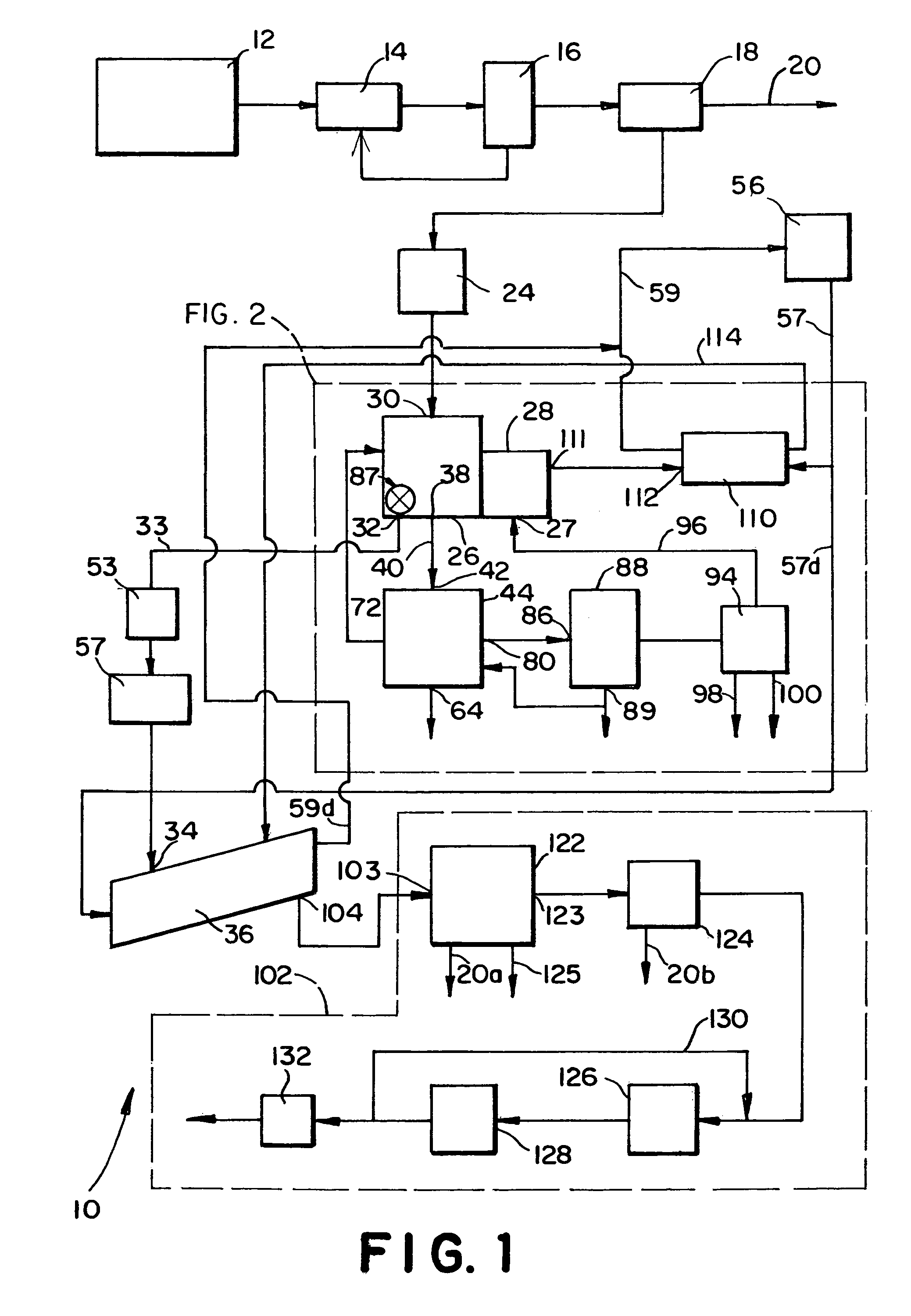

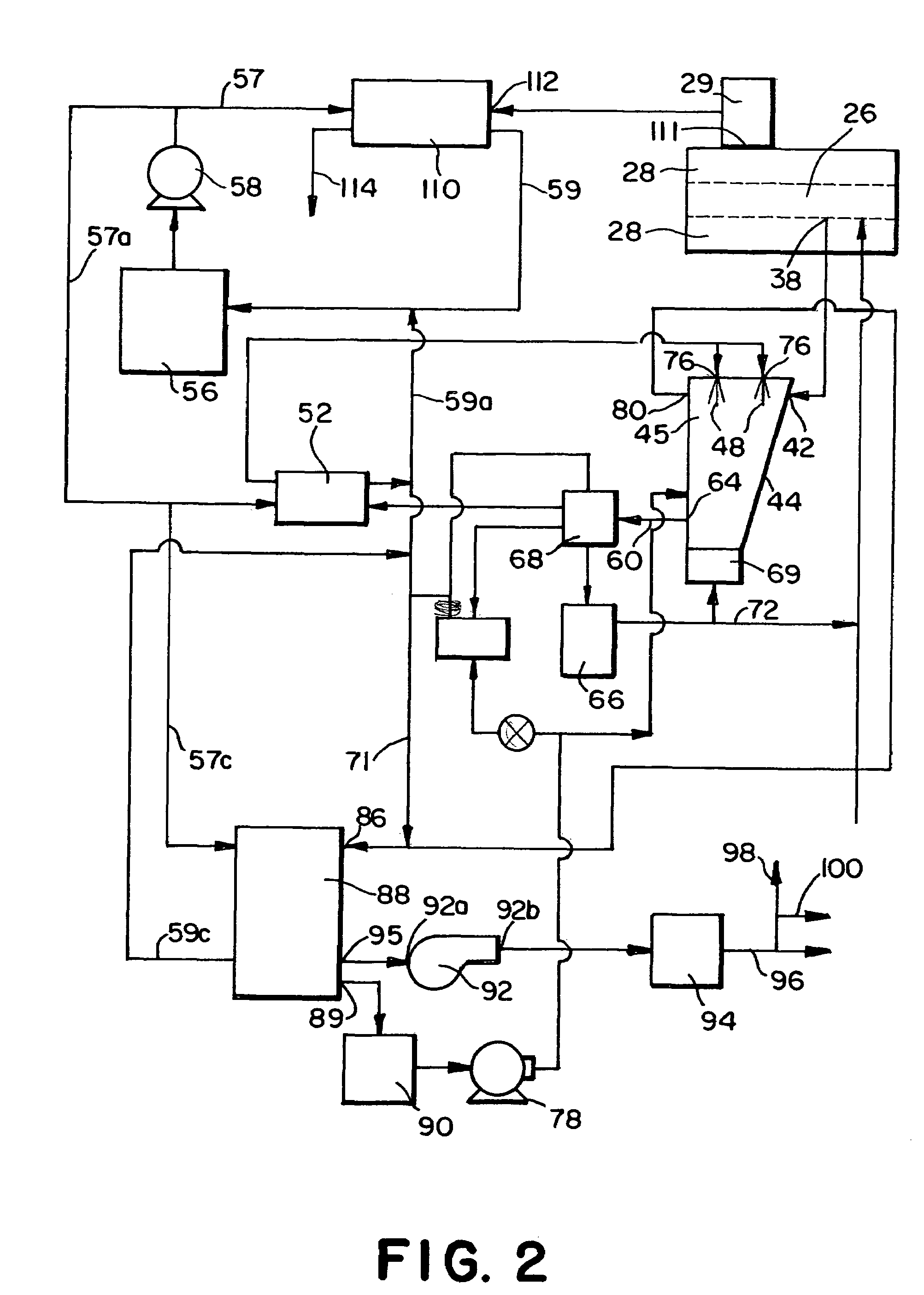

Process for conversion of organic, waste, or low-value materials into useful products

ActiveUS20060004237A1Low viscosityHydrocarbon purification/separationIndirect and direct heating destructive distillationHigh energySulfur

The present invention addresses the processing of waste and low-value products to produce useful materials in reliable purities and compositions, at acceptable cost, and with high energy efficiency. In particular, the invention comprises a multi-stage process that converts various feedstocks such as offal, animal manures, municipal sewage sludge, that otherwise have little commercial value, to useful materials including gas, oil, specialty chemicals, and carbon solids. The process subjects the feedstock to heat and pressure in a reducing environment accomplished by controlled addition of sulfur and sodium, separates out various components, then further applies heat and pressure to one or more of those components. The invention further comprises an apparatus for performing a multi-stage process of converting waste products into useful materials, and at least one oil product that arises from the process.

Owner:SYNPET TEKNOLOJI GELISTIRME

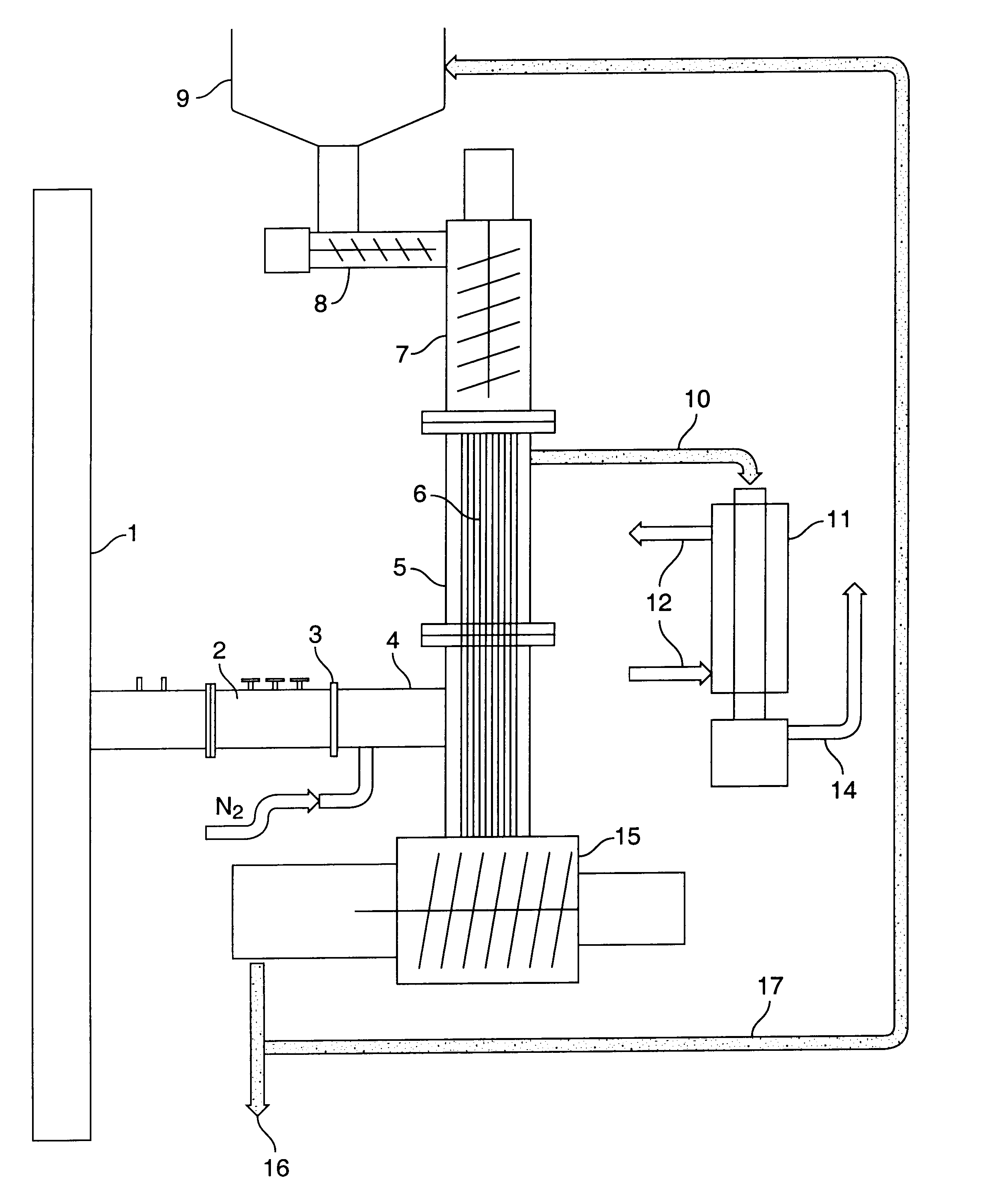

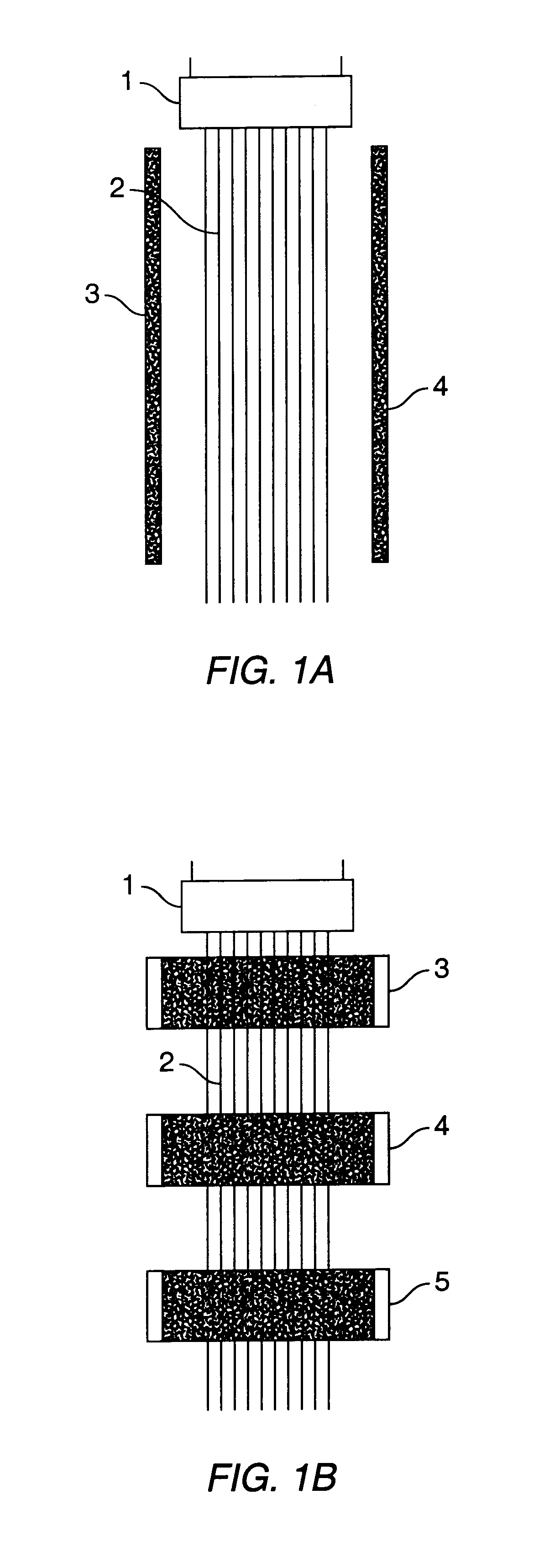

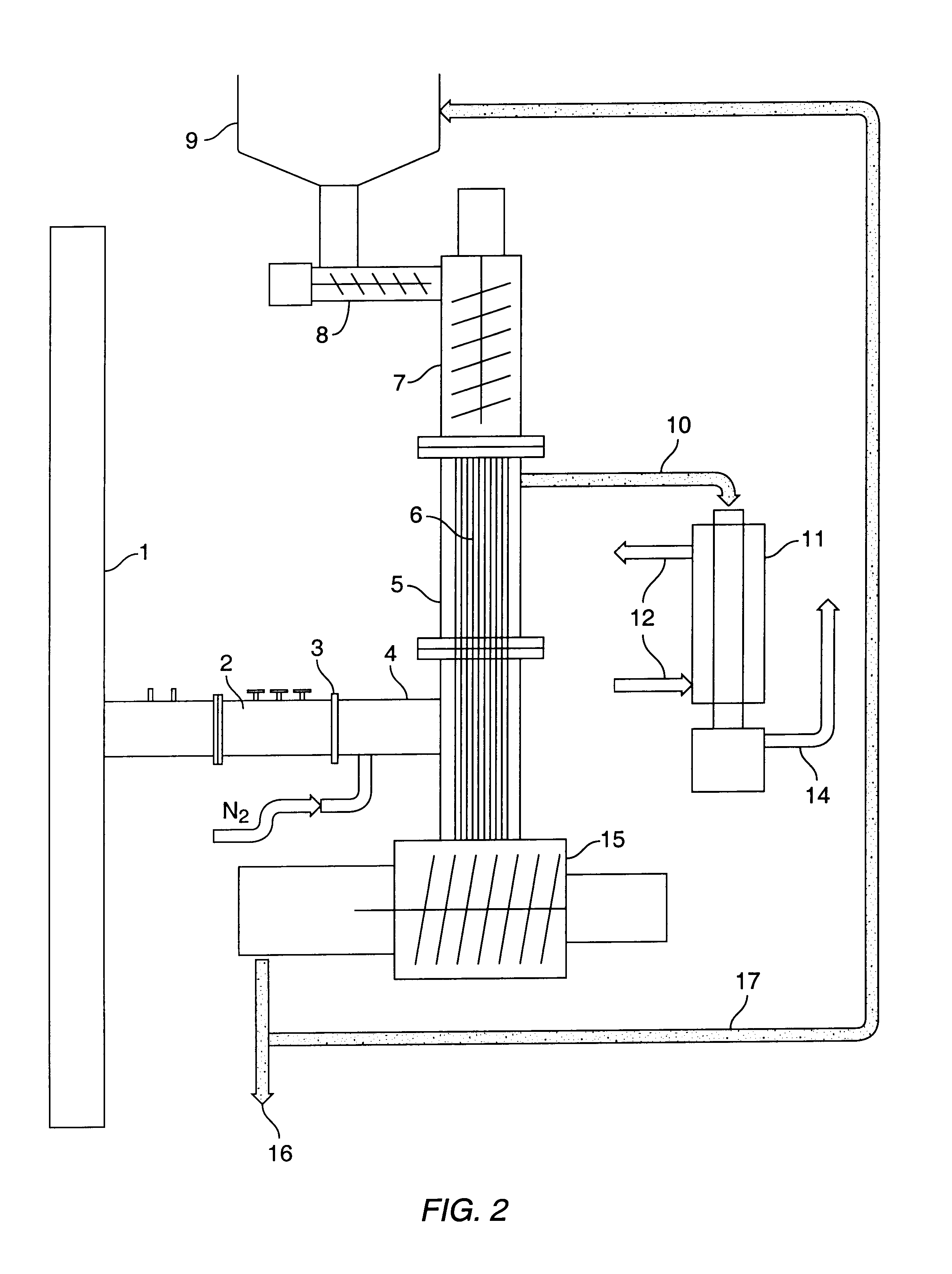

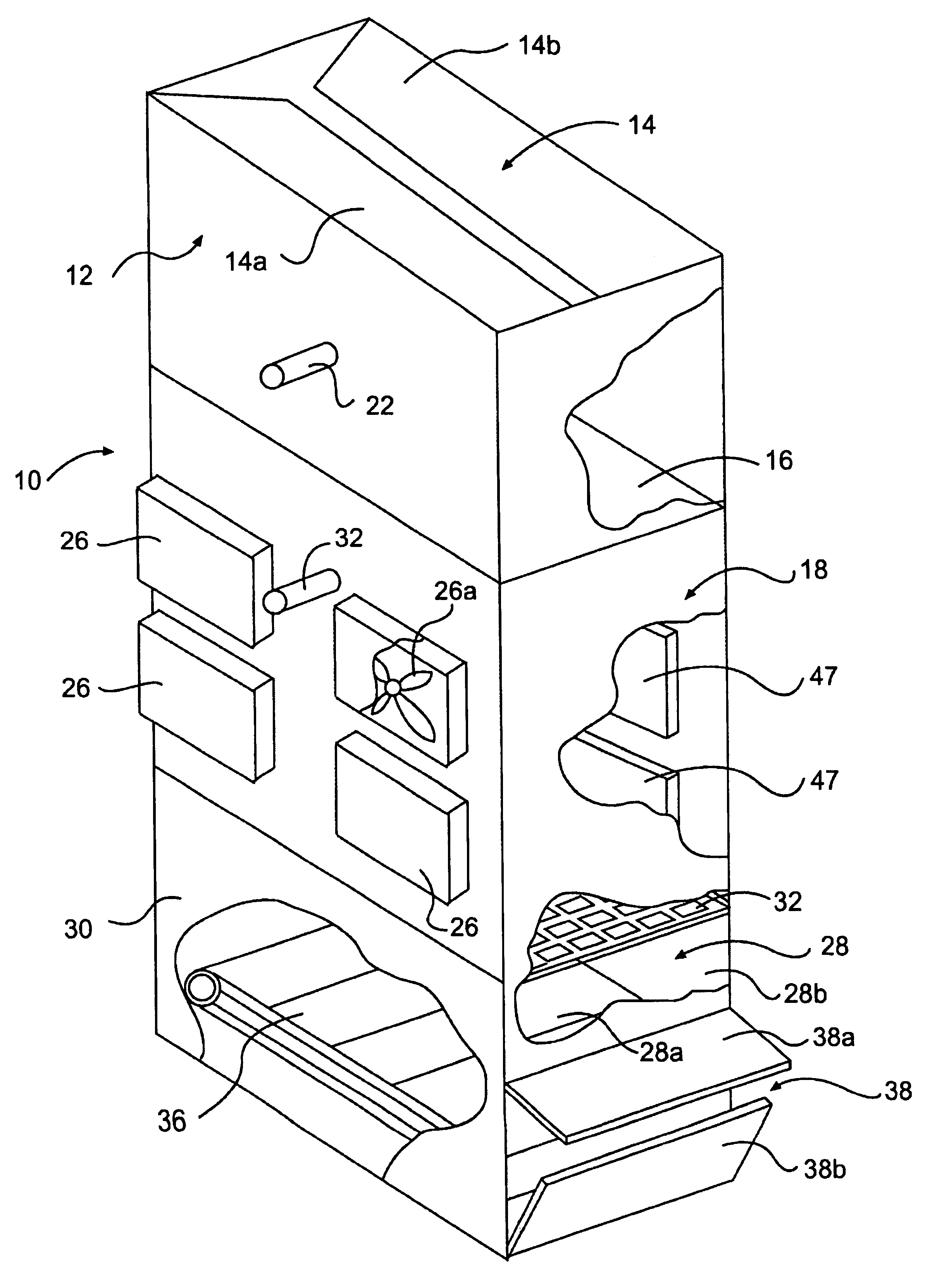

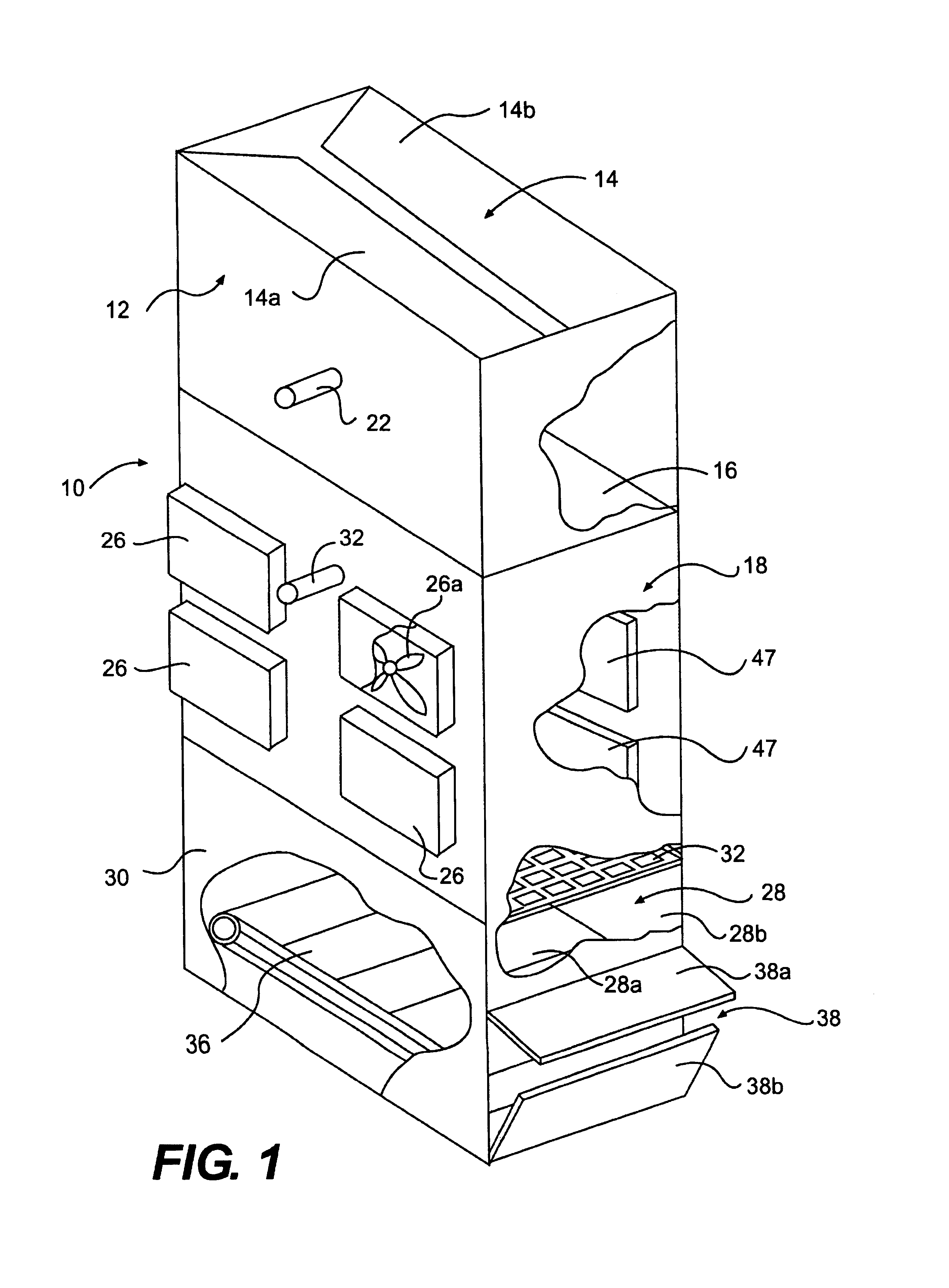

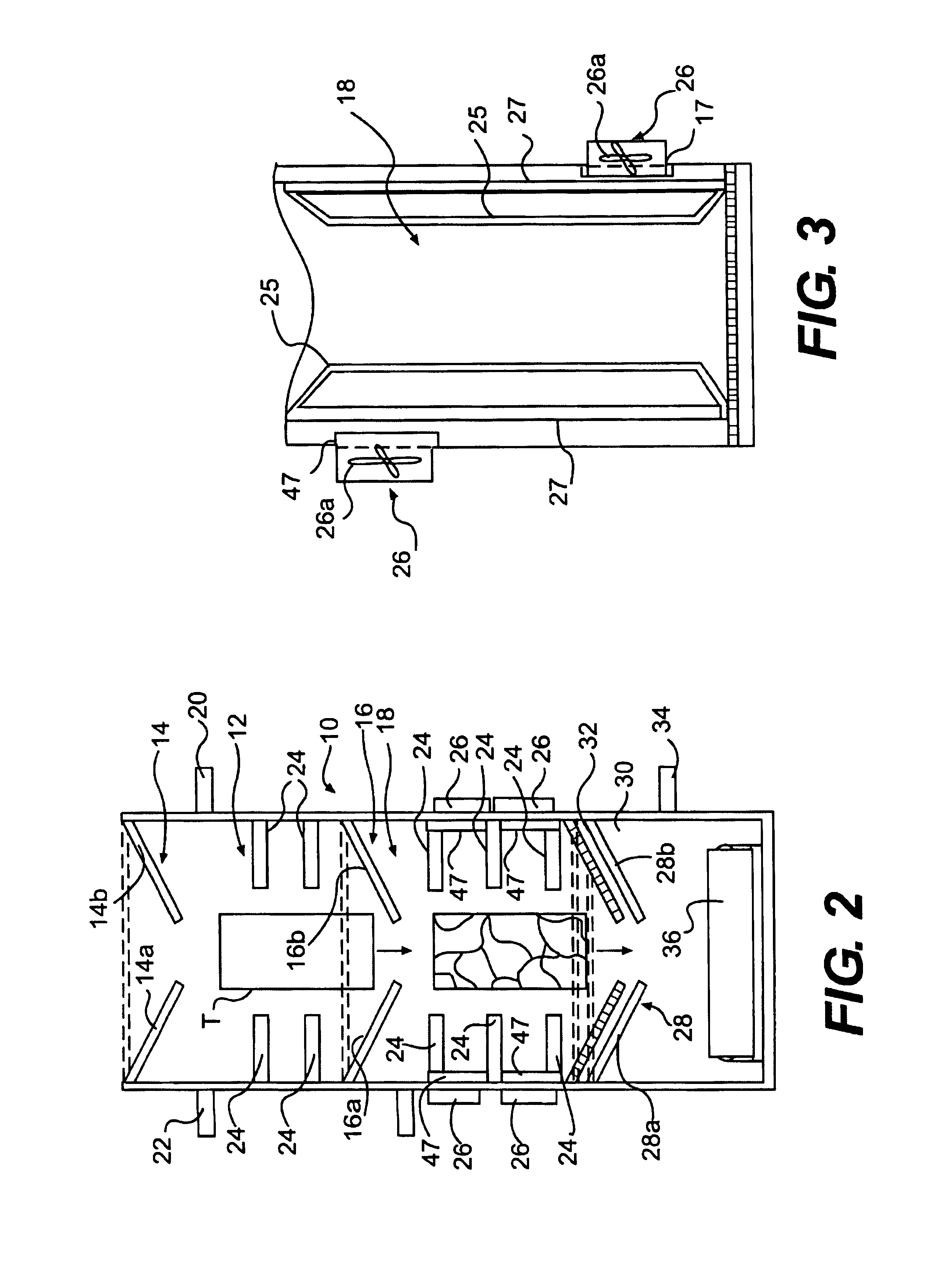

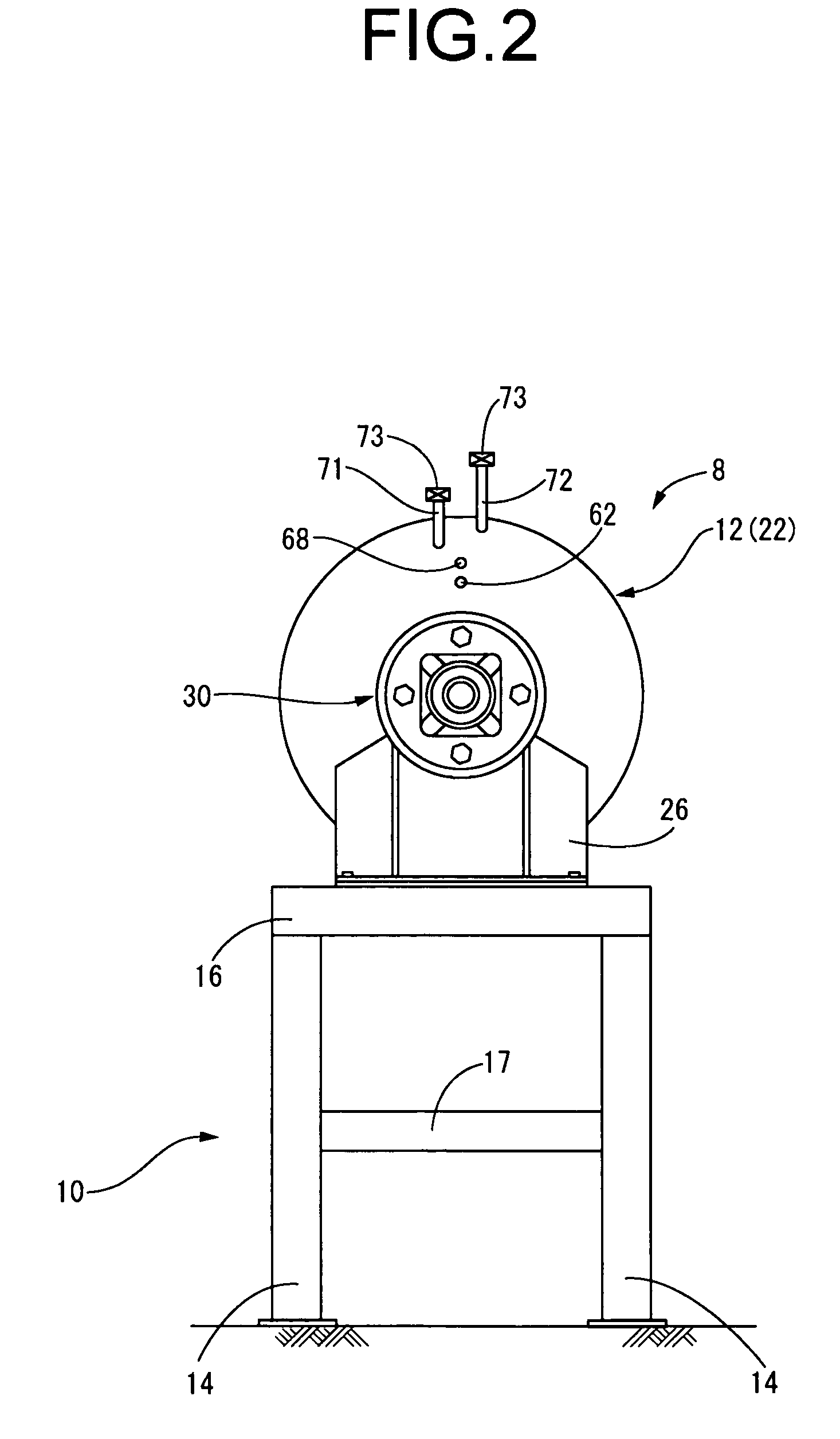

Microwave pyrolysis apparatus for waste tires

InactiveUS7101464B1Electrical coke oven heatingCombustible gas coke oven heatingMicrowave pyrolysisDistillation

A microwave distillation apparatus provides destructive distillation of whole waste tires. The apparatus includes a housing including a plurality of vertically arranged chambers. A preheat chamber provides preheating of a whole waste tire received therein. An irradiation chamber, located below the preheat chamber and thermally coupled to the preheat chamber such that heat generated in the irradiation chamber creates heat convection currents in the preheat chamber, receives a preheated whole waste tire from the preheat chamber. A microwave energy supply supplies microwave energy to the irradiation chamber to provide destructive distillation of a tire received in that chamber. A cooling chamber, located below the irradiation chamber, receives by-products of the destructive distillation therefrom and provides delivery of the by-products from the housing.

Owner:PRINGLE JOE A MR +1

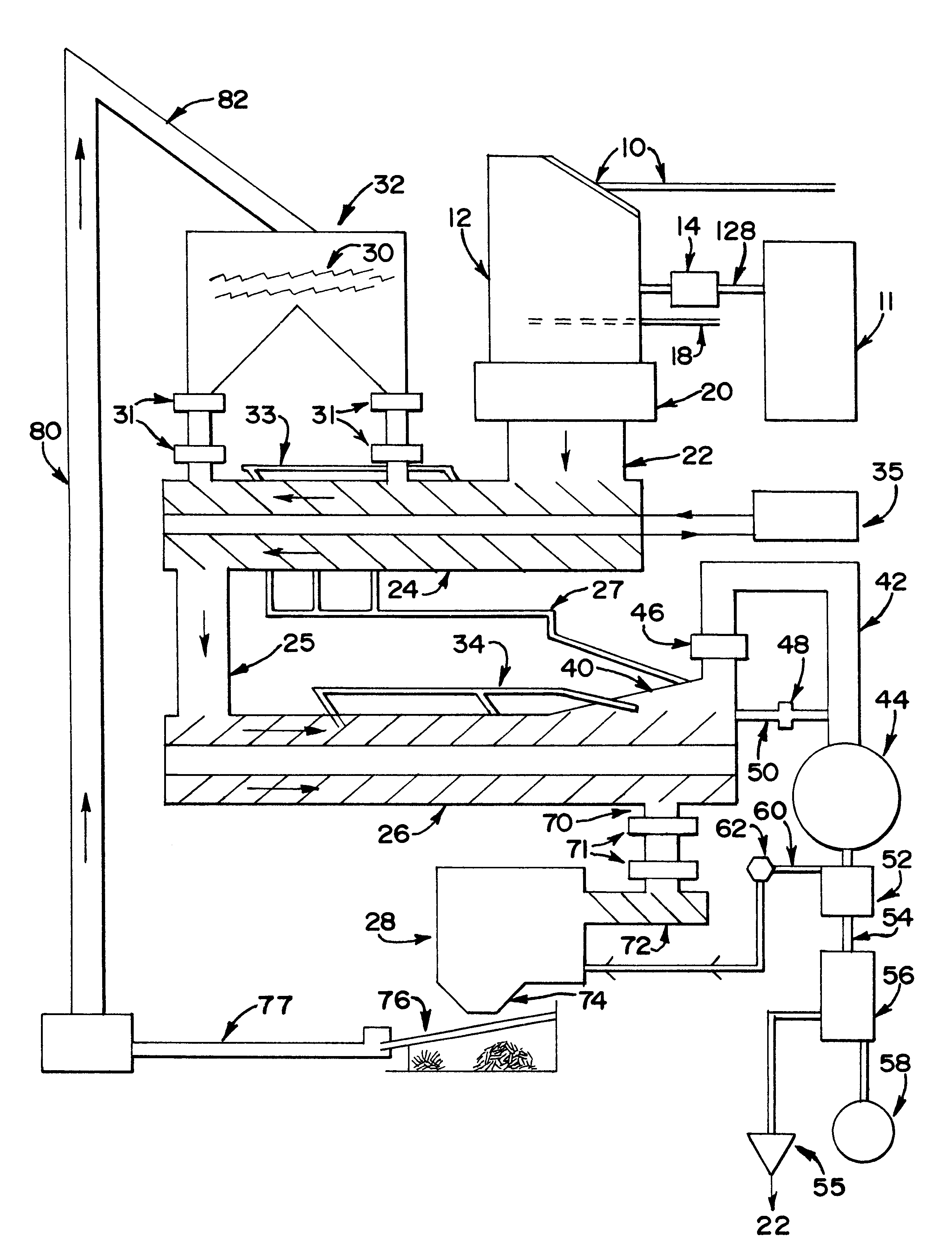

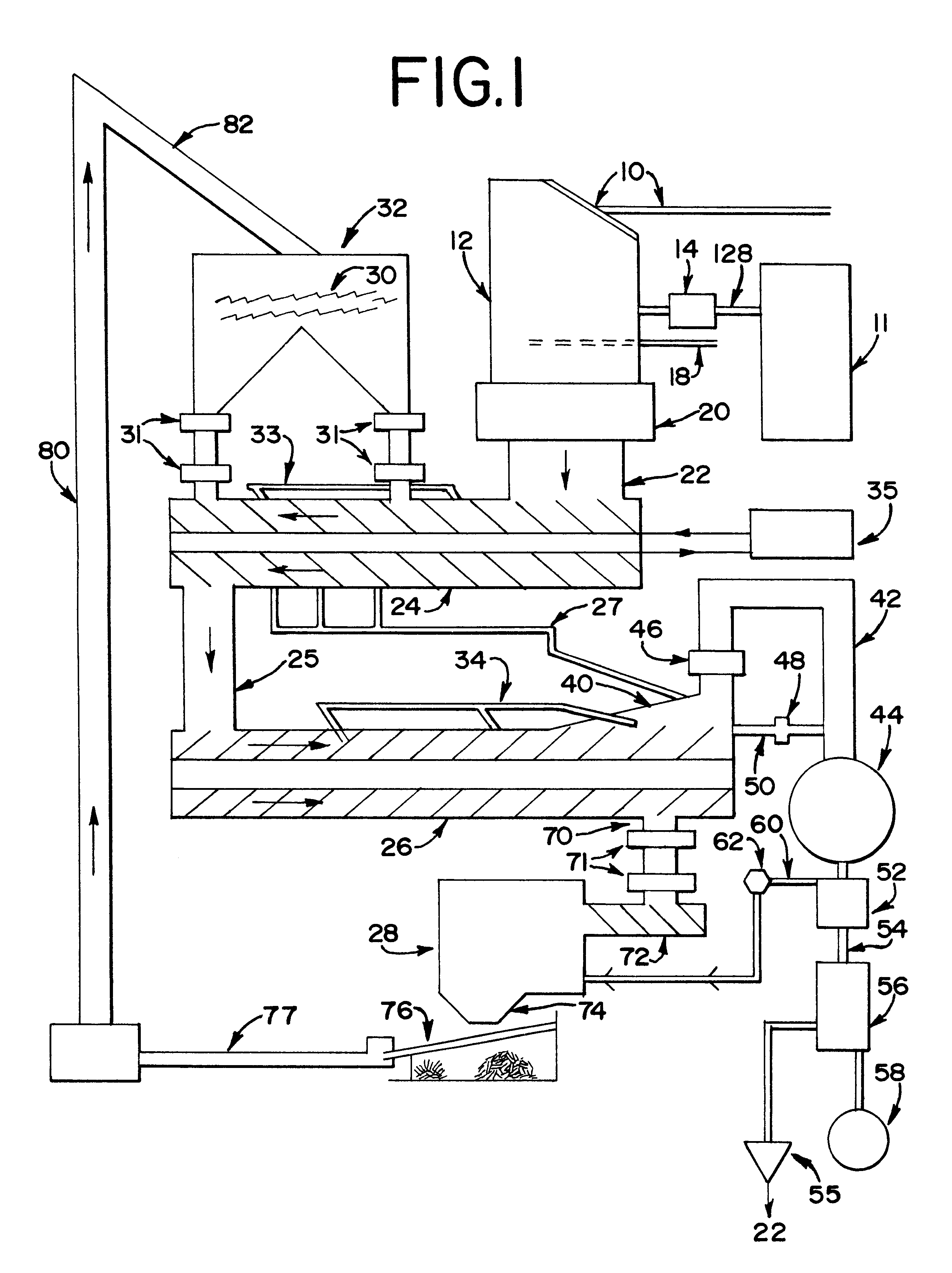

Processing method and system to convert garbage to oil

InactiveUS6387221B1Improve rendering capabilitiesIncrease speedCombustible gas coke oven heatingDirect heating destructive distillationPetroleum productHydrocotyle bowlesioides

Garbage and waste of all types that includes or comprises organic matter, particularly including medical waste, plastics, paper, food waste, animal by-products, and the like, can be economically recycled into petroleum products, including oil. Machinery performs a method that mimics natural processes but accomplishes the task in minutes, at rates of about 15 tons per day in a typical processing machine, rather than taking hundreds of thousands of years in nature. The process and apparatus of the invention may chop the waste into small pieces, under negative pressure if appropriate, and then pass the waste into first and then second augers for compression and heating. Destructive distillation occurs, in which large molecular weight hydrocarbons and petrochemicals are heated by hot oil passing through the hollow shaft and by circulating hot, dense, hard material, such as steel balls or fragments or hard rock pieces and such, under pressure with steam, to produce low molecular weight hydrocarbons. The volatile hydrocarbons are released through a pressure relief valve, into a column of catalyst material, and then to a heat exchanger, which cools the gases to condensation temperatures of water and oil. Gases remaining, such as methane, are passed to a furnace or other use, and the water and oil are separated. The hot items used to put heat into the compressed material in the first stage auger are retrieved after processing is completed and then reheated and cycled back into the first stage auger.

Owner:WASTE PROCESSORS INC TOM BECVAR TRACEY MUSGROVE & HIMSELF

Removal of water from bio-oil

A process and system for separating water from bio-oil by using a partial condenser. The process comprises partially condensing vapor conversion products from a biomass conversion reaction to produce a water-rich overhead stream and a water-depleted stream comprising condensed bio-oil. The partial condenser removes a substantial portion of the water from the bio-oil, while providing an effective and flexible process for producing bio-oil.

Owner:MARD INC

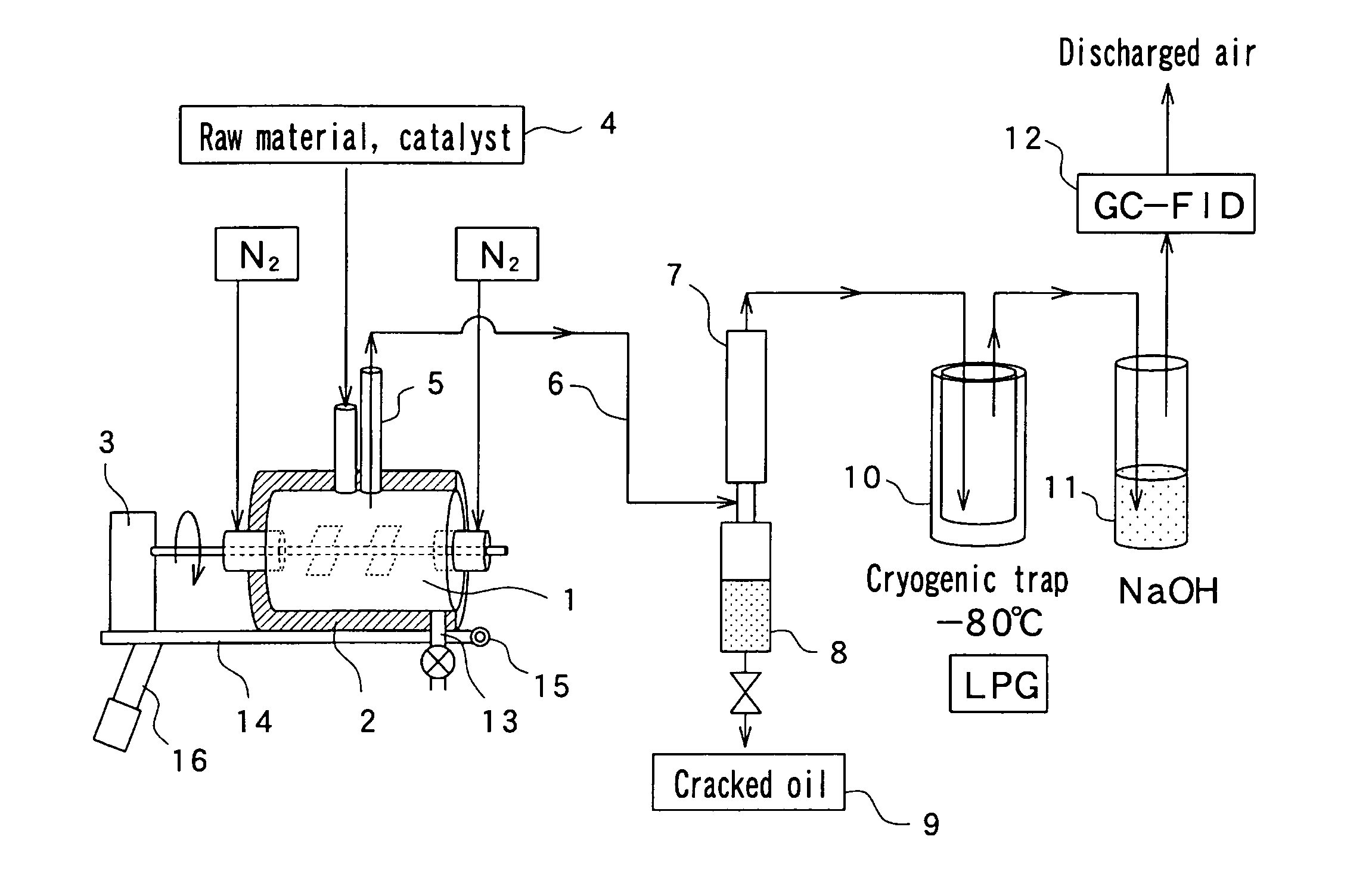

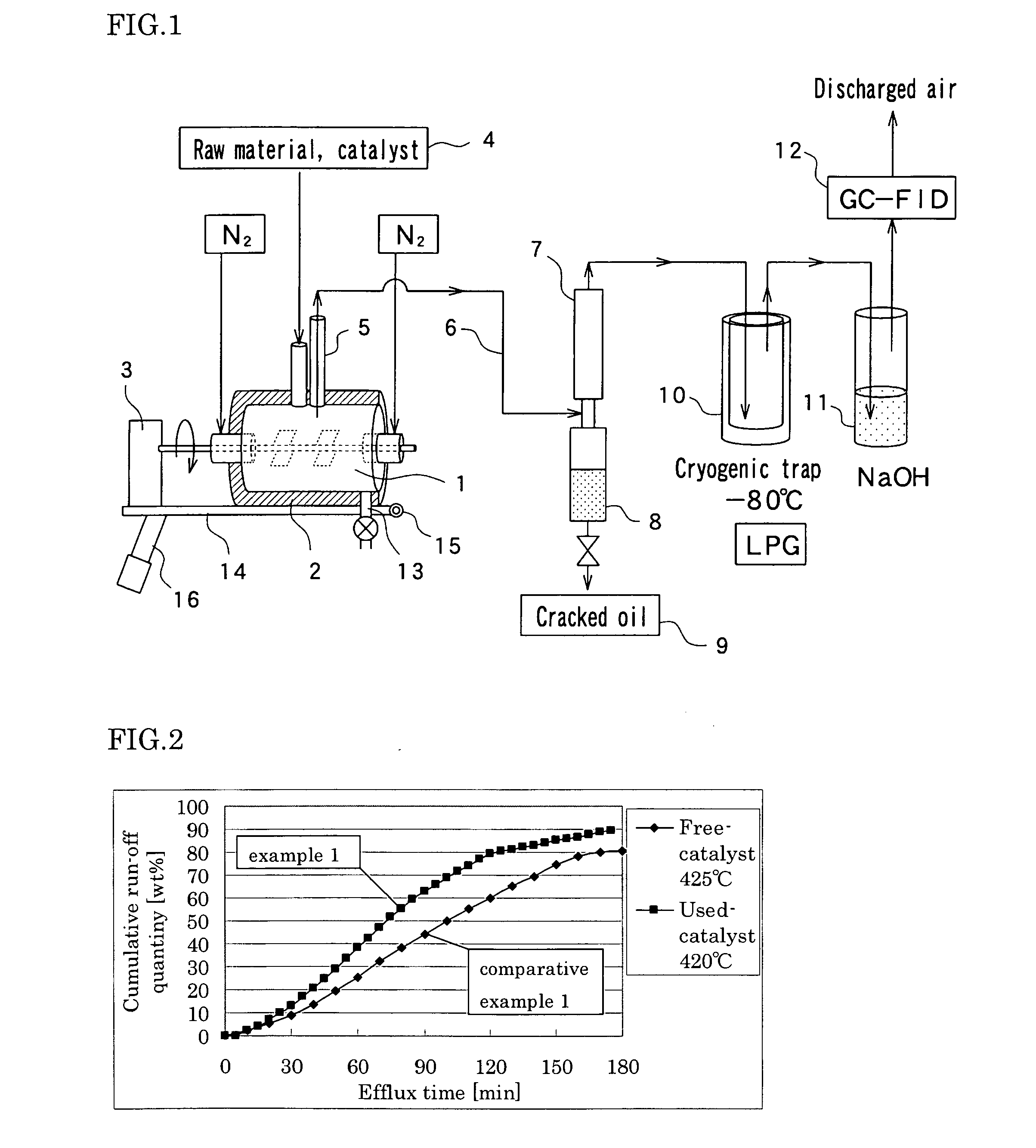

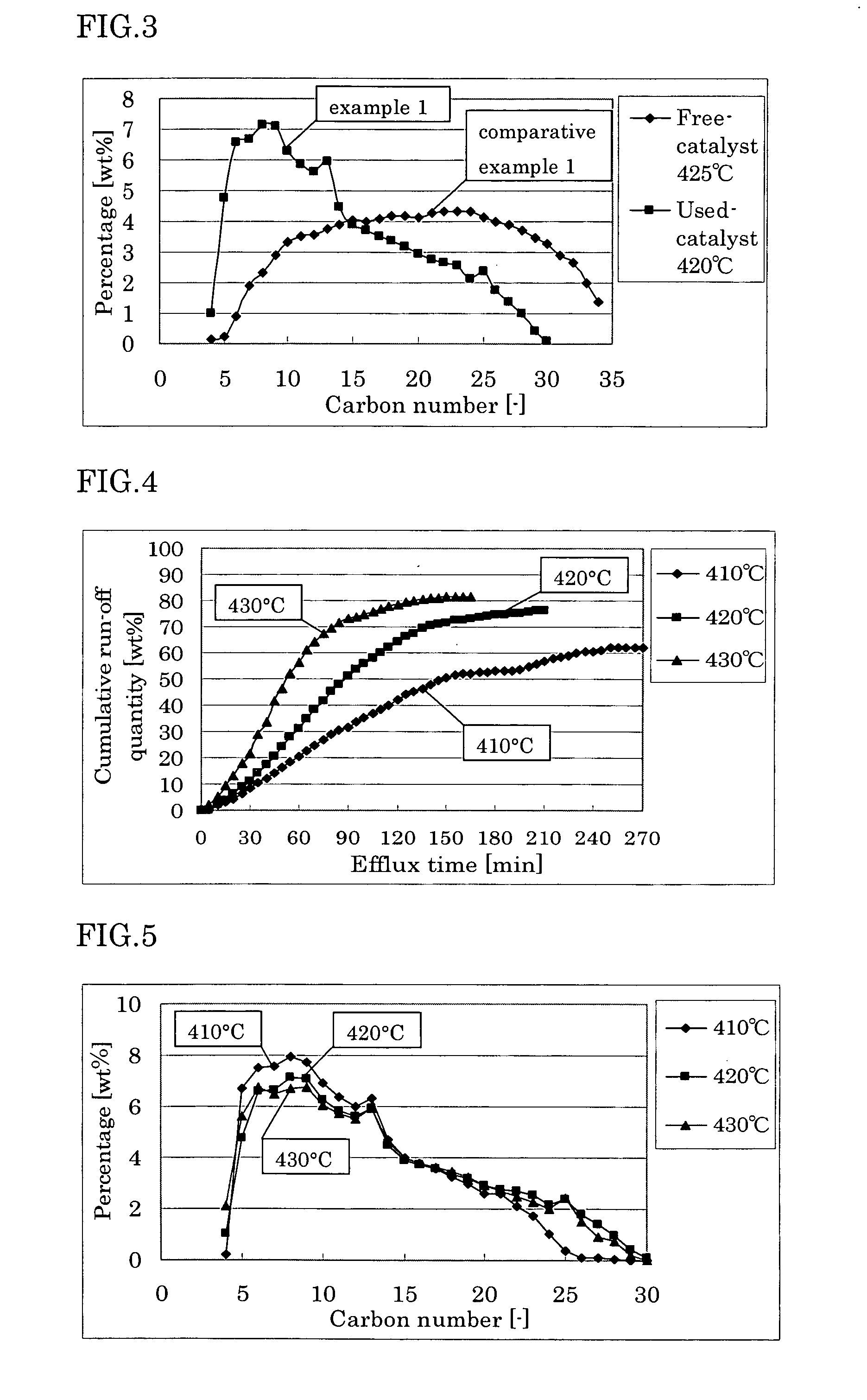

Method for catalytically cracking waste plastics and apparatus for catalytically cracking waste plastics

InactiveUS20070173673A1Improve productivityEasy to carbonizeCombustible gas coke oven heatingSolid waste disposalDecompositionChemistry

To provide a method for catalytically cracking waste plastics wherein the efficiency in decomposition is high; even polyethylene composed of linear chain molecules difficult in decomposition is decomposable at a low temperature and decomposed residue is hardly produced; the process is simple since dechlorination can be achieved at the same time with catalytically cracking waste plastics in one reaction vessel; and oil fractions can be recovered at 50% or more on a net yield basis. The method for catalytically cracking waste plastics of the present invention has a constitution in which waste plastics are loaded as a raw material into a granular FCC catalyst heated to a temperature range from 350° C. to 500° C. inside a reaction vessel, thereby decomposing and gasifying the waste plastics in contact with the FCC catalyst.

Owner:KITAKYUSHU FOUND FOR THE ADVANCEMENT OF IND

Process for conversion of organic, waste, or low-value materials into useful products

ActiveUS7301060B2Low viscosityHydrocarbon purification/separationIndirect and direct heating destructive distillationSpeciality chemicalsHigh energy

Owner:SYNPET TEKNOLOJI GELISTIRME

Apparatus for pyrolyzing tire shreds and tire pyrolysis systems

InactiveUS7329329B2Muffle furnacesIndirect and direct heating destructive distillationParticulatesCombustor

Tire pyrolysis systems and processes are provided which include feeding tire shreds to a pyrolysis reactor, pyrolyzing the shreds in a pyrolysis reactor to produce a hydrocarbon-containing gas stream and carbon-containing solid, removing the carbon-containing solid from the reactor, directing the hydrocarbon-containing gas stream into a separator, contacting the hydrocarbon-containing gas stream with an oil spray in the separator thereby washing particulate from the hydrocarbon-containing gas stream and condensing a portion of the gas stream to oil, removing and cooling the oil from the separator, directing non-condensed gas from the gas stream away from the separator, and directing a portion of the cooled oil removed from the separator to an inlet of the separator for use as the separator oil spray. A process is also provided in which solids from the pyrolysis reactor are directed to an auger having a pressure which is greater than the pressure in the pyrolysis reactor, and in which non-condensed gas from the gas stream after condensing a portion of the gas is directed to at least one burner in heat exchange relation with the pyrolysis reactor, and burned to heat the reactor and generate an effluent flue gas, a portion of which effluent flue gas is cooled and injected into the auger which is a trough auger in one embodiment.

Owner:RENAISSANCE ENERGY GROUP

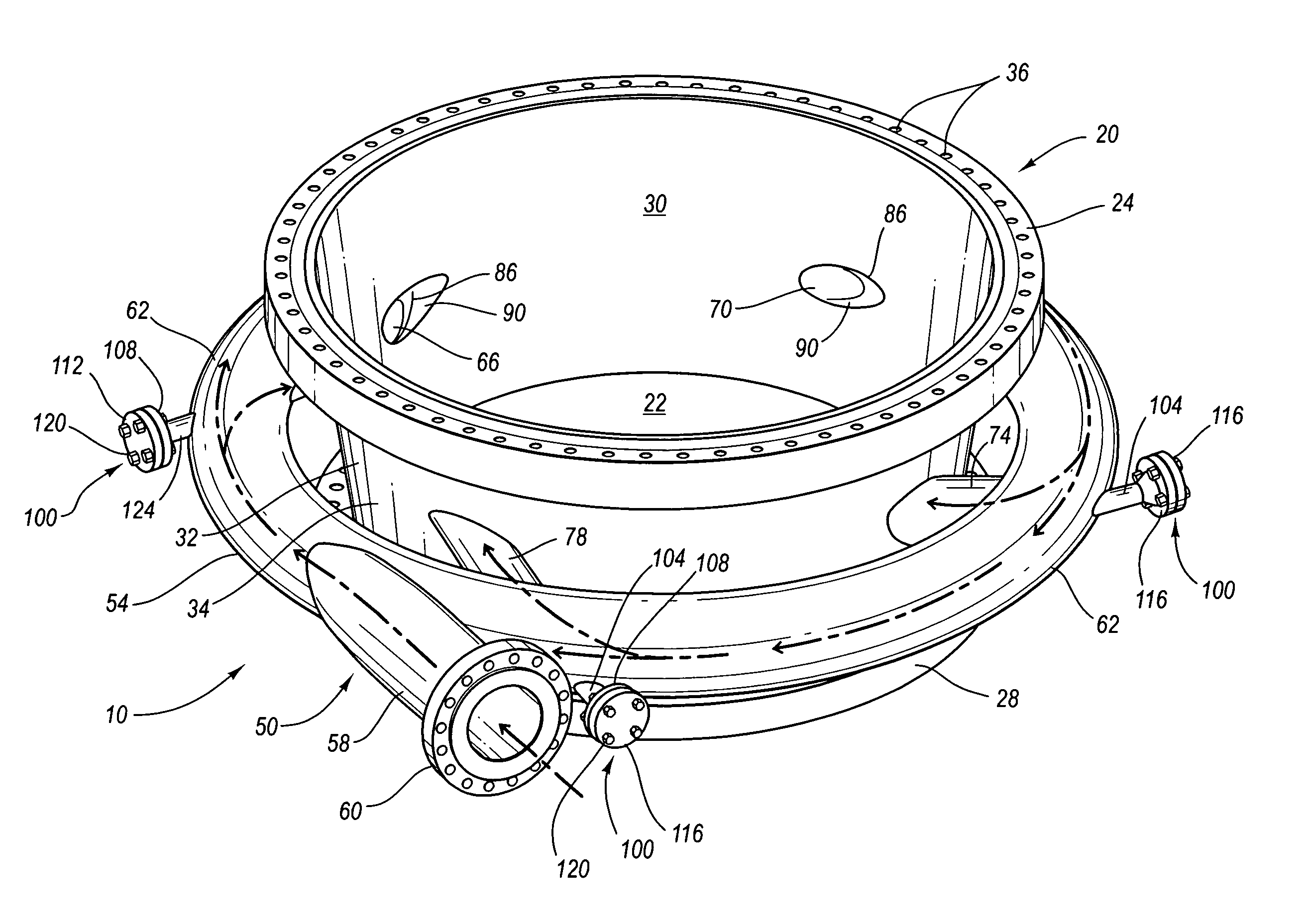

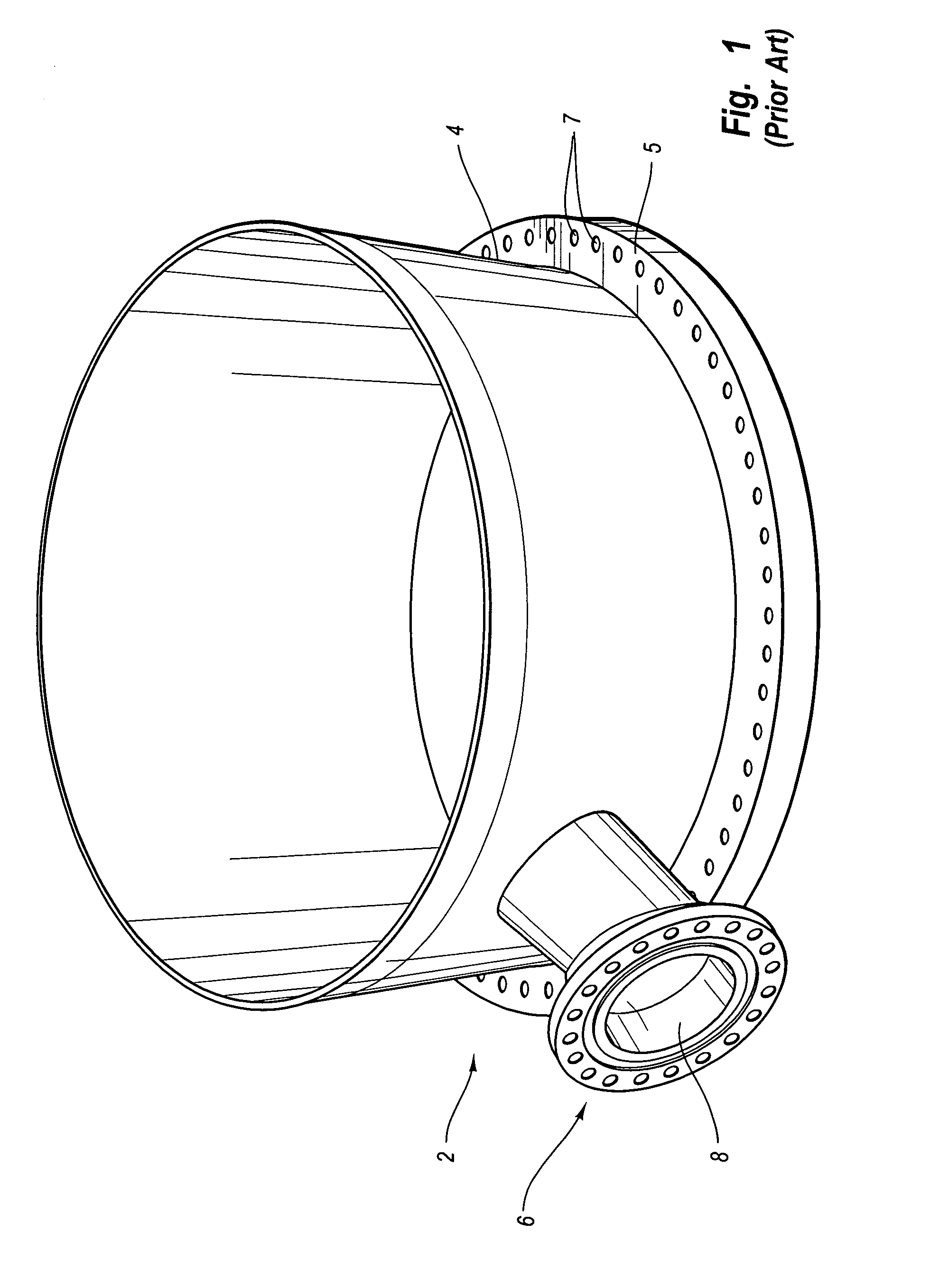

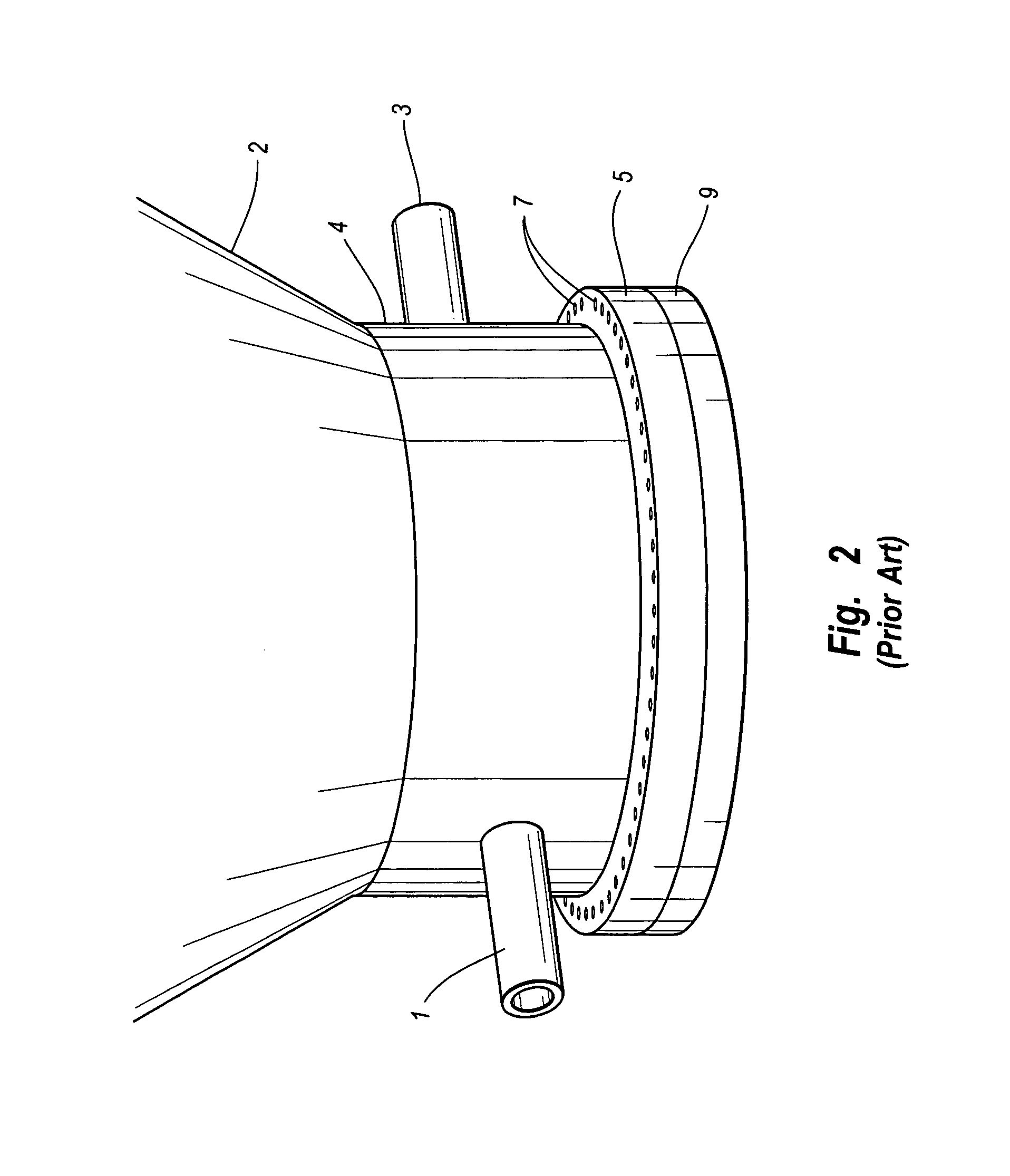

Tangential dispenser and system for use within a delayed coking system

ActiveUS7115190B2Hydrocarbon distillationLiquid hydrocarbon mixture recoveryEngineeringHeat distribution

The present invention features a tangential injection system for use within a delayed coking system, or any other similar system. The tangential injection system comprises a spool, a tangential dispenser, and a hydro blasting system, wherein the tangential dispenser comprises a delivery main surrounding the perimeter of the spool and that functions to deliver a residual byproduct or other material to a plurality of feed lines positioned at a position or at distances around the delivery main for the purpose of providing tangential dispensing of the residual byproduct into the vessel, thus effectuating or inducing even thermal distribution throughout the vessel.

Owner:DELTAVALVE

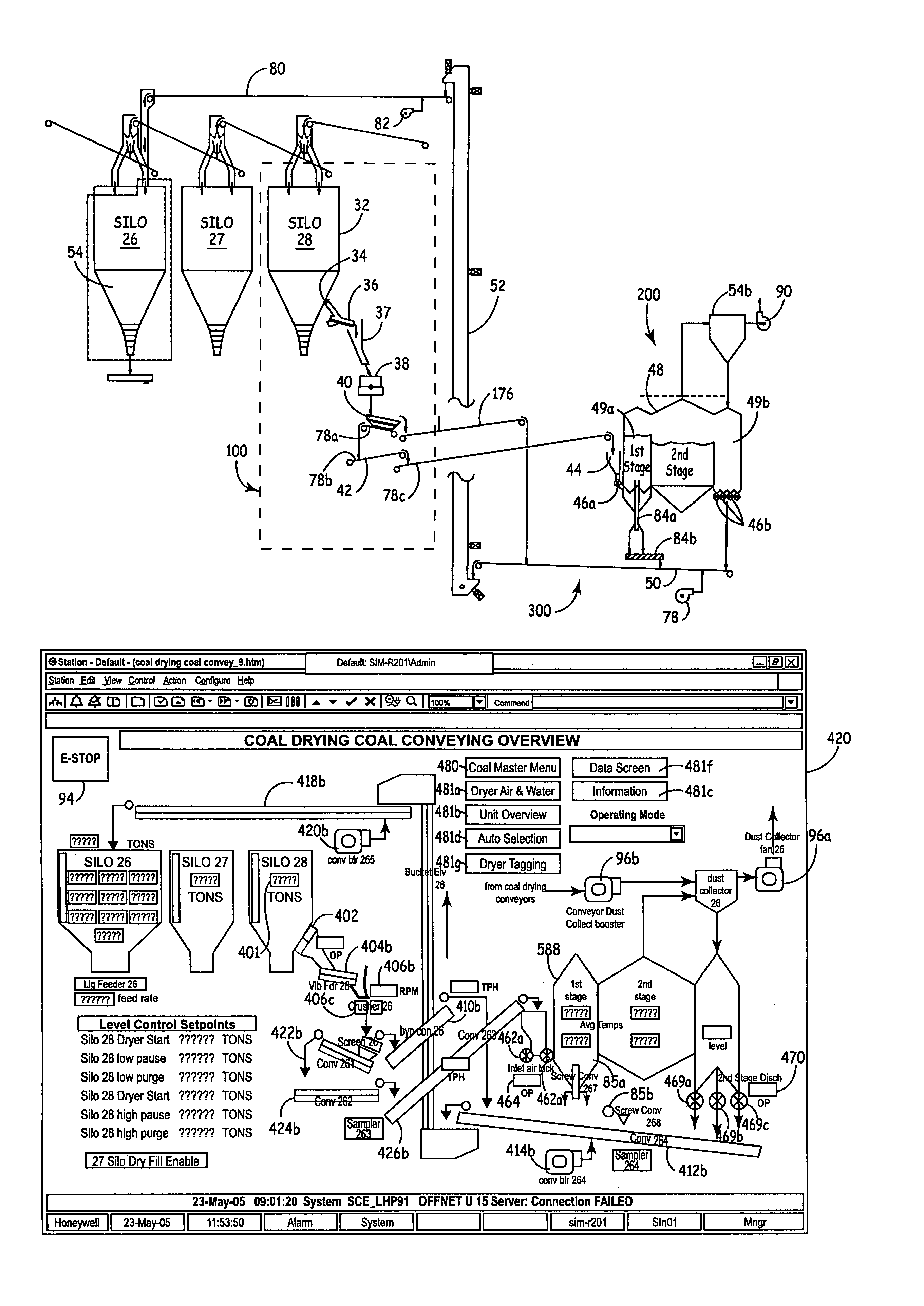

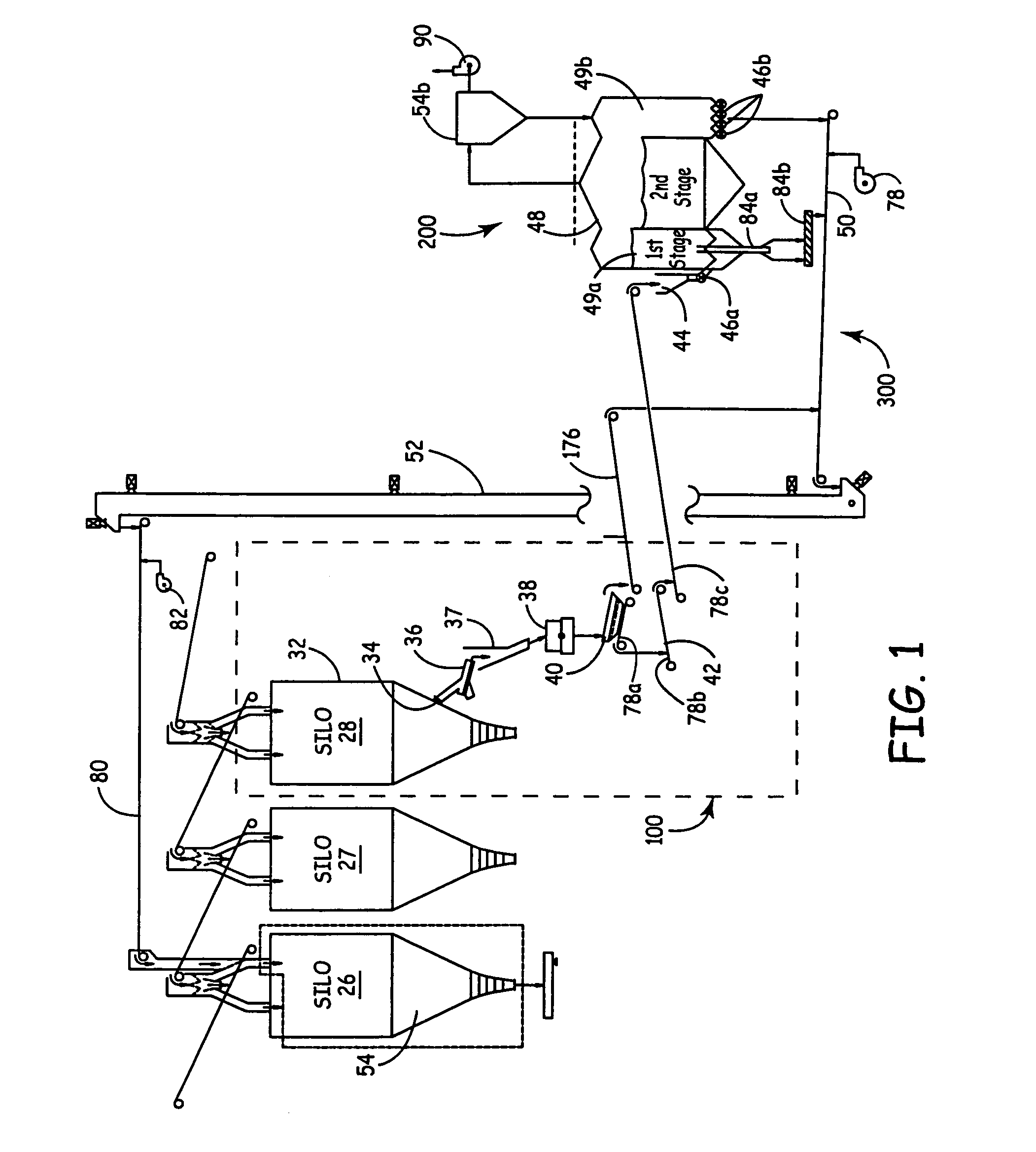

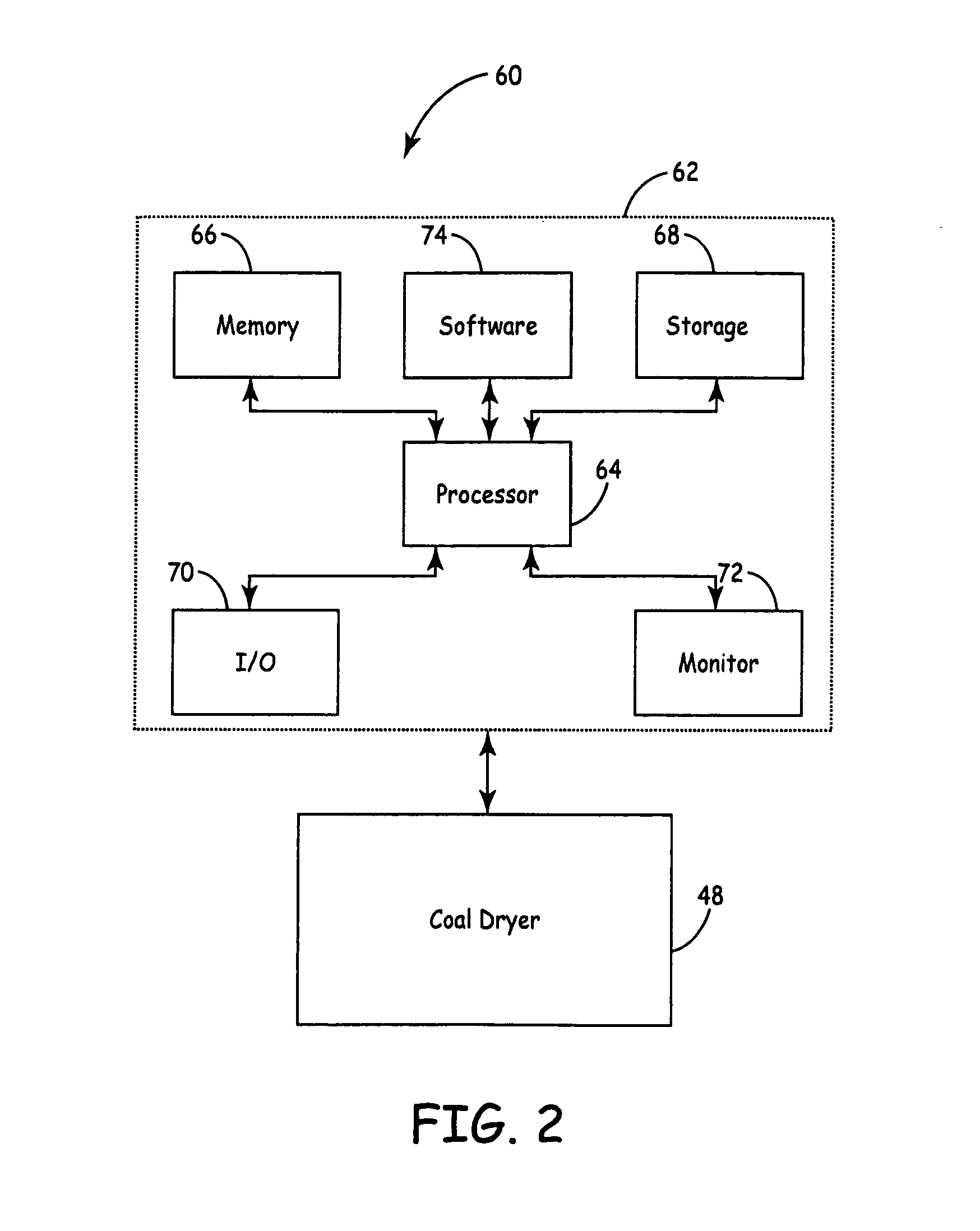

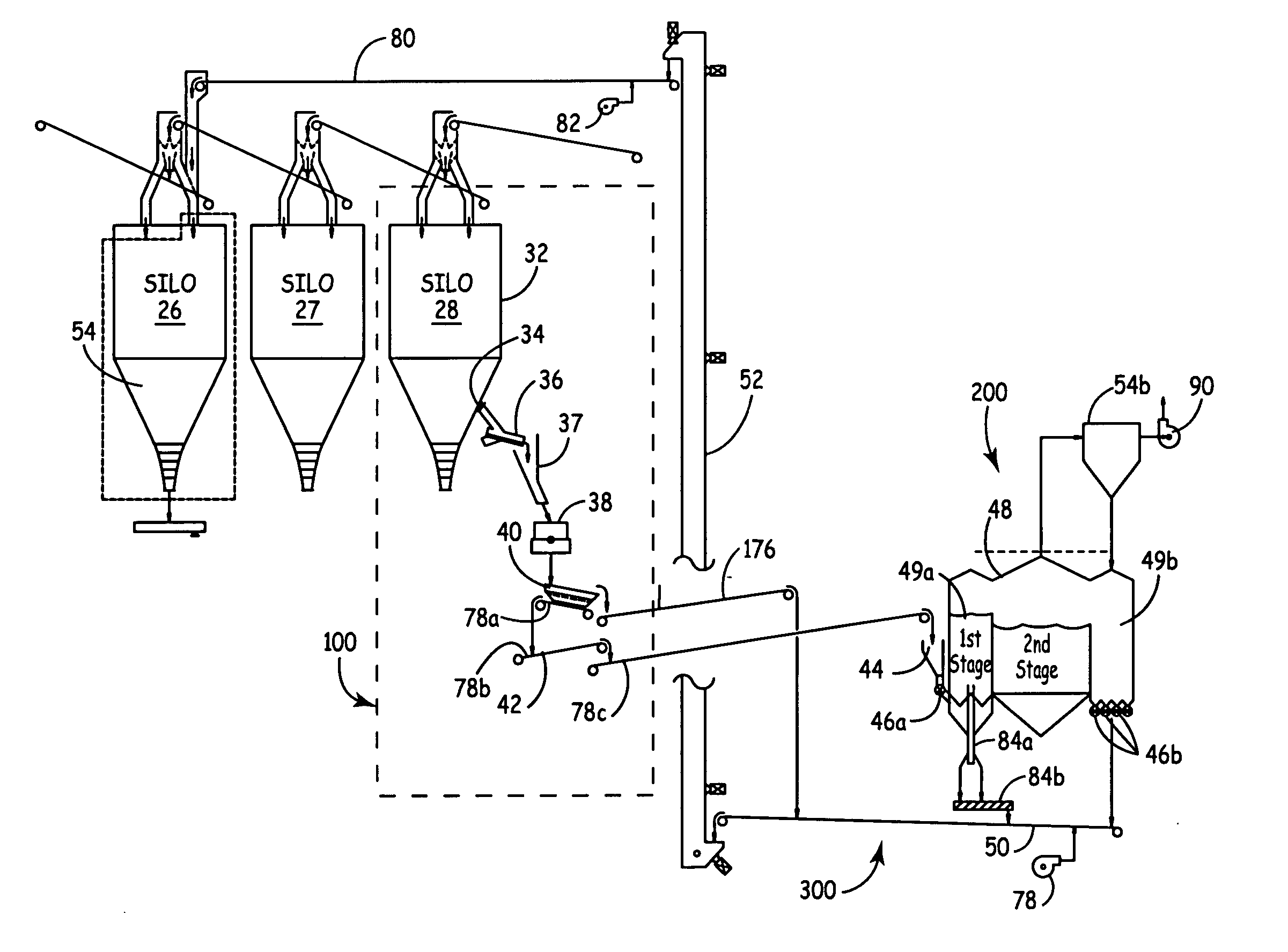

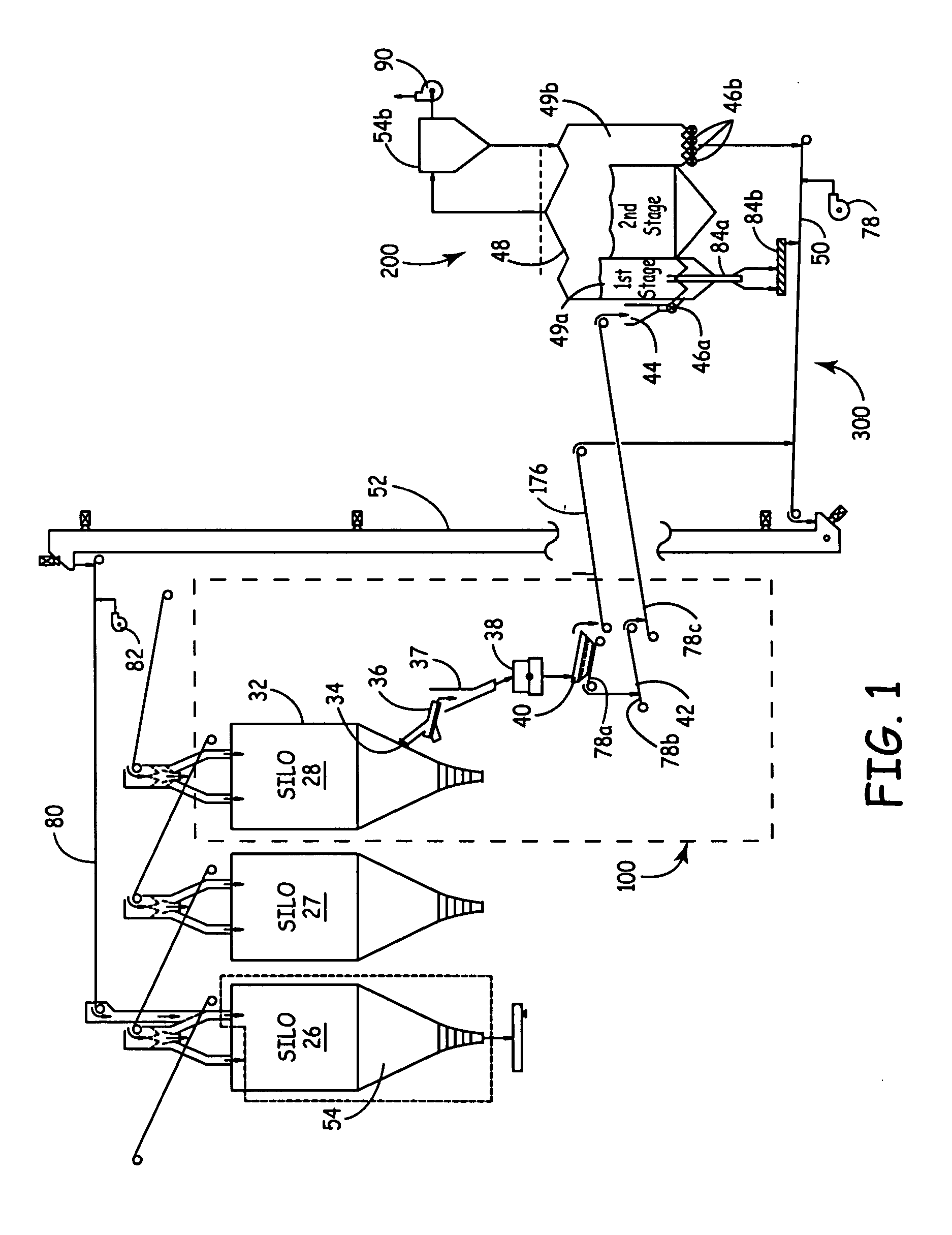

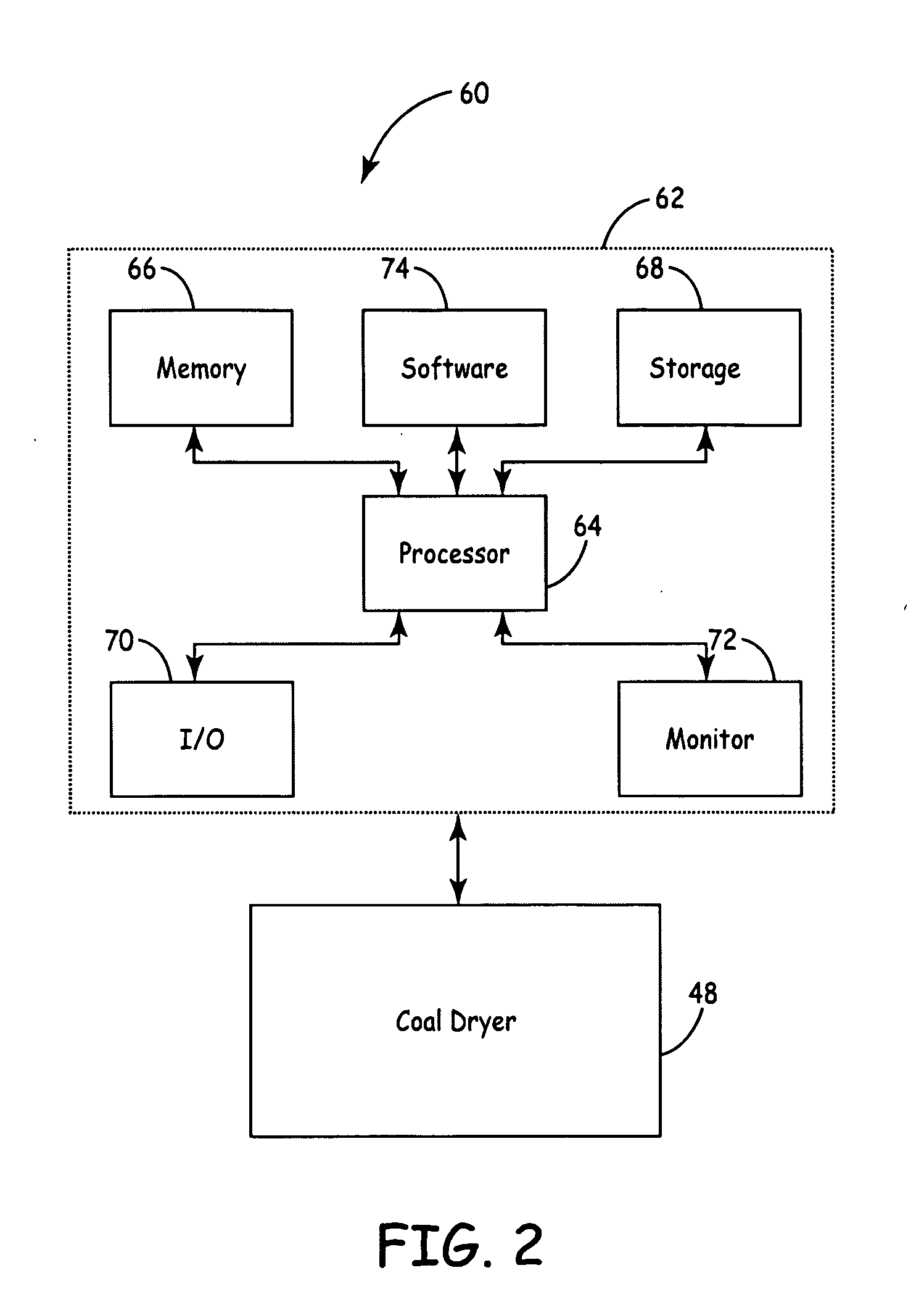

Control system for particulate material drying apparatus and process

ActiveUS7987613B2Easy to controlEasy to monitorDrying using combination processesCombustible gas coke oven heatingParticulatesFluidized bed drying

A control system for controlling the utilization of heated waste streams for fluidizing particulate matter such as coal in a fluidizing bed dryer. The control system includes a number of graphic user interfaces that allow an operator to more easily monitor and / or control the various regulator devices. The control system controls coal handling or transportation, fluid handling or flow, and the discharge of discarded or separated coal from the dryer.

Owner:RAINBOW ENERGY CENT LLC

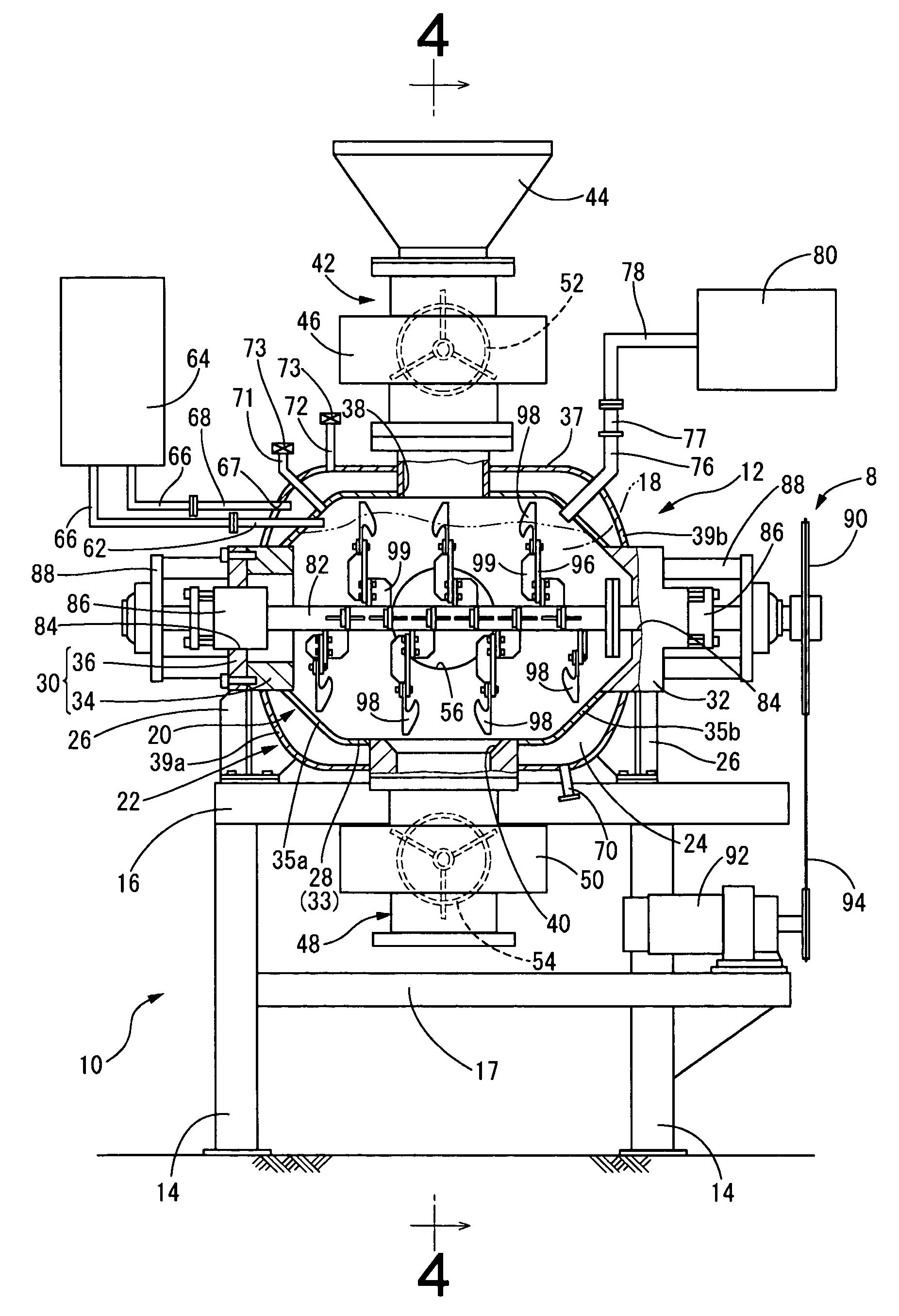

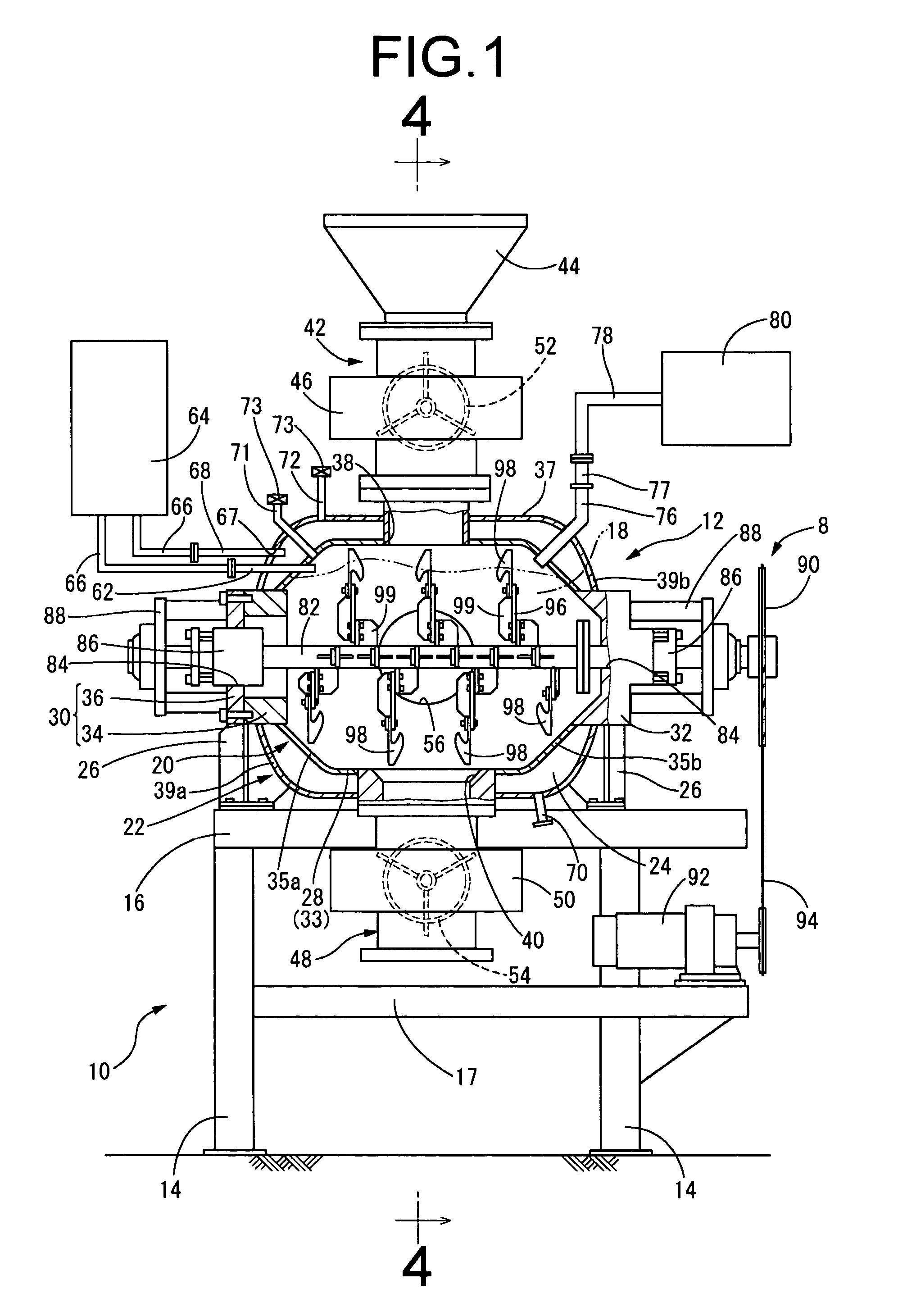

Apparatus and method for treating organic waste and organic material obtained by the treatment method

ActiveUS20100092652A1Simple procedureQuality improvementDrying solid materials with heatDrying solid materials without heatHigh pressureHydrolysis

A technique by which various types of organic waste can be easily treated so as to obtain a reusable material. An apparatus is provided which comprises a vessel (20) for introducing organic waste (18) therein, the vessel being equipped with: stirring means (82), (92), and (98) for stirring the organic waste (18); steam supply means (62), (64), and (66) which supply high-temperature high-pressure steam to the vessel (20); evacuation means (77), (78), and (80) which evacuate the vessel (20); and heating means (24), (68), (64), and (66) which heat the organic waste (18) present in the vessel (20). The apparatus has such constitution, in which the organic waste (18) in the vessel (20) is decomposed by hydrolysis and pyrolysis and vacuum dried using those means.

Owner:KUNITOMO KANKYO PLANT

Control system for particulate material drying apparatus and process

ActiveUS20060112588A1Maximize productionMaximize efficiencyCombustible gas coke oven heatingDrying solid materials with heatParticulatesFluidized bed drying

A control system for controlling the utilization of heated waste streams for fluidizing particulate matter such as coal in a fluidizing bed dryer. The control system includes a number of graphic user interfaces that allow an operator to more easily monitor and / or control the various regulator devices. The control system controls coal handling or transportation, fluid handling or flow, and the discharge of discarded or separated coal from the dryer.

Owner:RAINBOW ENERGY CENT LLC

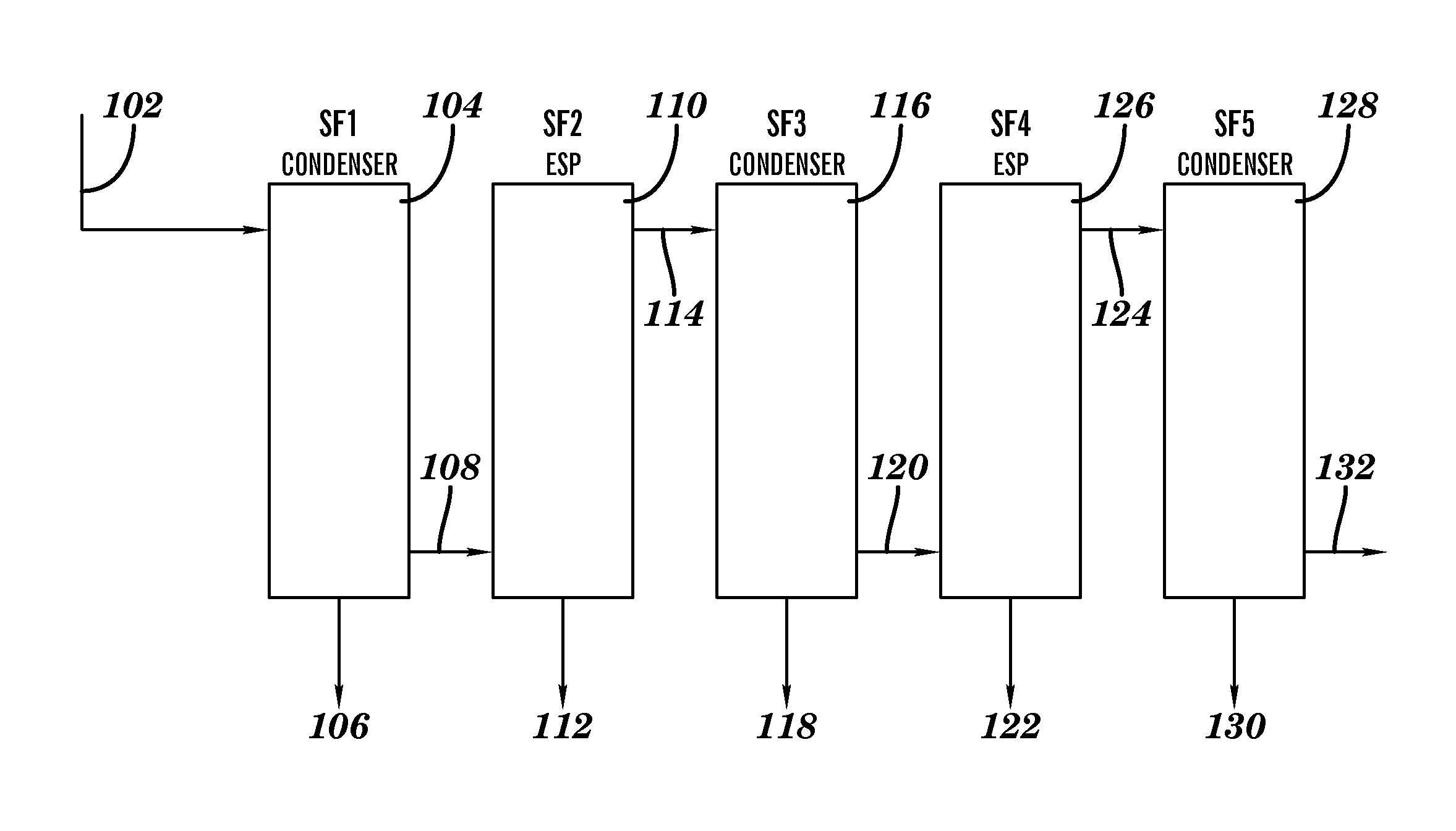

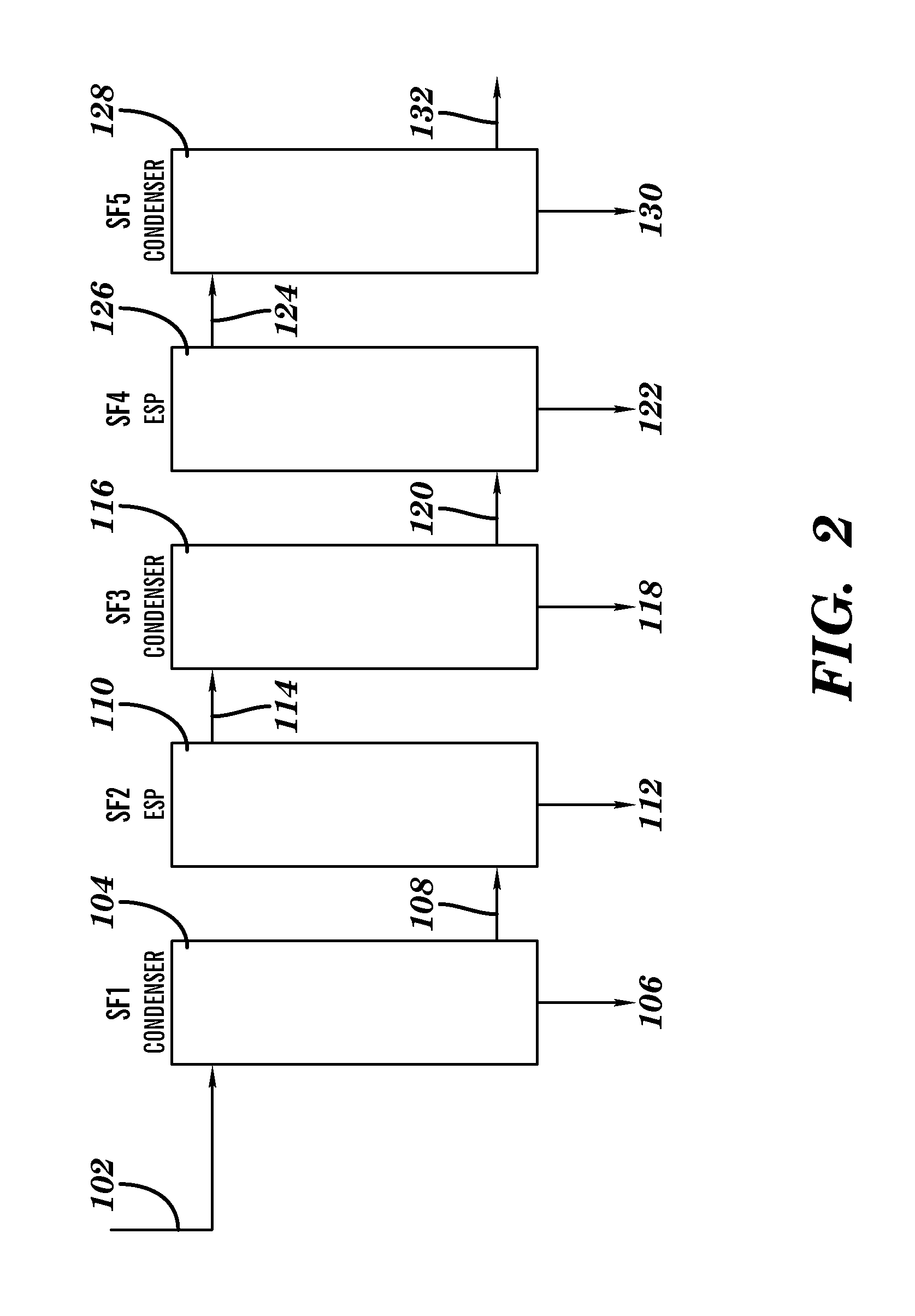

Bio-oil fractionation and condensation

ActiveUS8476480B1Reduced stabilityLower performance requirementsSolid waste disposalDirect heating destructive distillationHeat conductingFractionation

A method of fractionating bio-oil vapors which involves providing bio-oil vapors comprising bio-oil constituents is described. The bio-oil vapors are cooled in a first stage which comprises a condenser having passages for the bio-oil separated by a heat conducting wall from passages for a coolant. The coolant in the condenser of the first stage is maintained at a substantially constant temperature, set at a temperature in the range of 75 to 100° C., to condense a first liquid fraction of liquefied bio-oil constituents in the condenser of the first stage. The first liquid fraction of liquified bio-oil constituents from the condenser in the first stage is collected. Also described are steps for subsequently recovering further liquid fractions of liquefied bio-oil constituents. Particular compositions of bio-oil condensation products are also described.

Owner:IOWA STATE UNIV RES FOUND

Pyrolysis system for waste rubber

InactiveUS20090211892A1Indirect and direct heating destructive distillationHeat recoveryWaste rubberProduct gas

An apparatus for separating components of batches of waste rubber by pyrolysis comprises at least one heating chamber interconnected with a condenser by a conduit. The heating oven is provided with a plurality of cooperating heating elements, an inlet for receiving waster rubber, and an outlet for egress of pyrolyzed gaseous components. The condenser condenses and separates cooled liquid components from the gaseous components. Separated gaseous components are exhausted from the condenser. Cooled liquid components are conveyed from the condenser to a re-circulation tank. The conduit is provided with a pair of opposed injectors adjacent the outlet of the heating oven. A re-circulation line interconnects the re-circulation tank with the injectors and is provided with a pressurizing device for injecting cooled liquid components through the injectors into the conduit in the form of intersecting liquid laminar sheets thereby applying a vacuum draw on the egressing pyrolyzed gaseous components.

Owner:ANDERSEN DAN

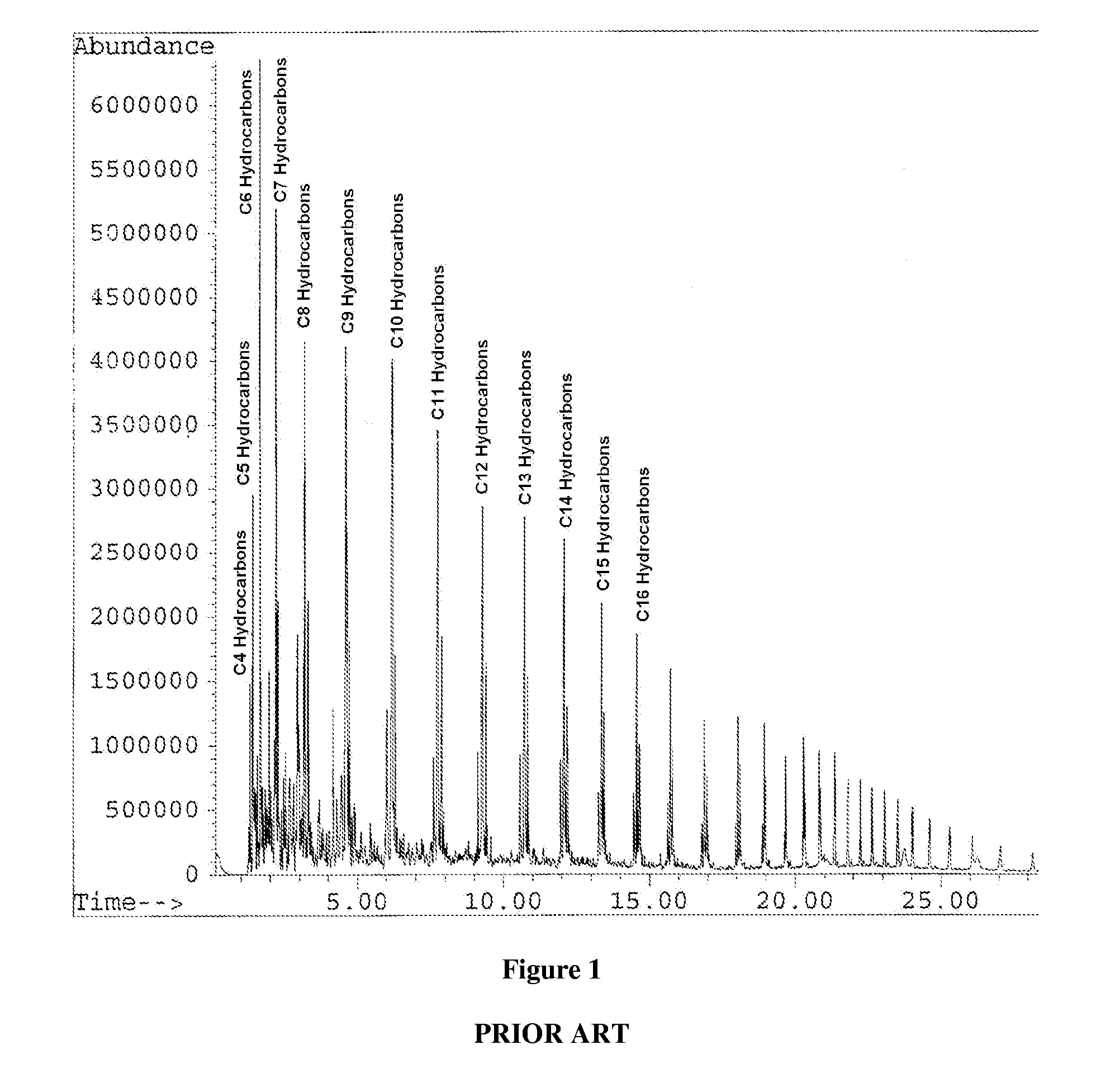

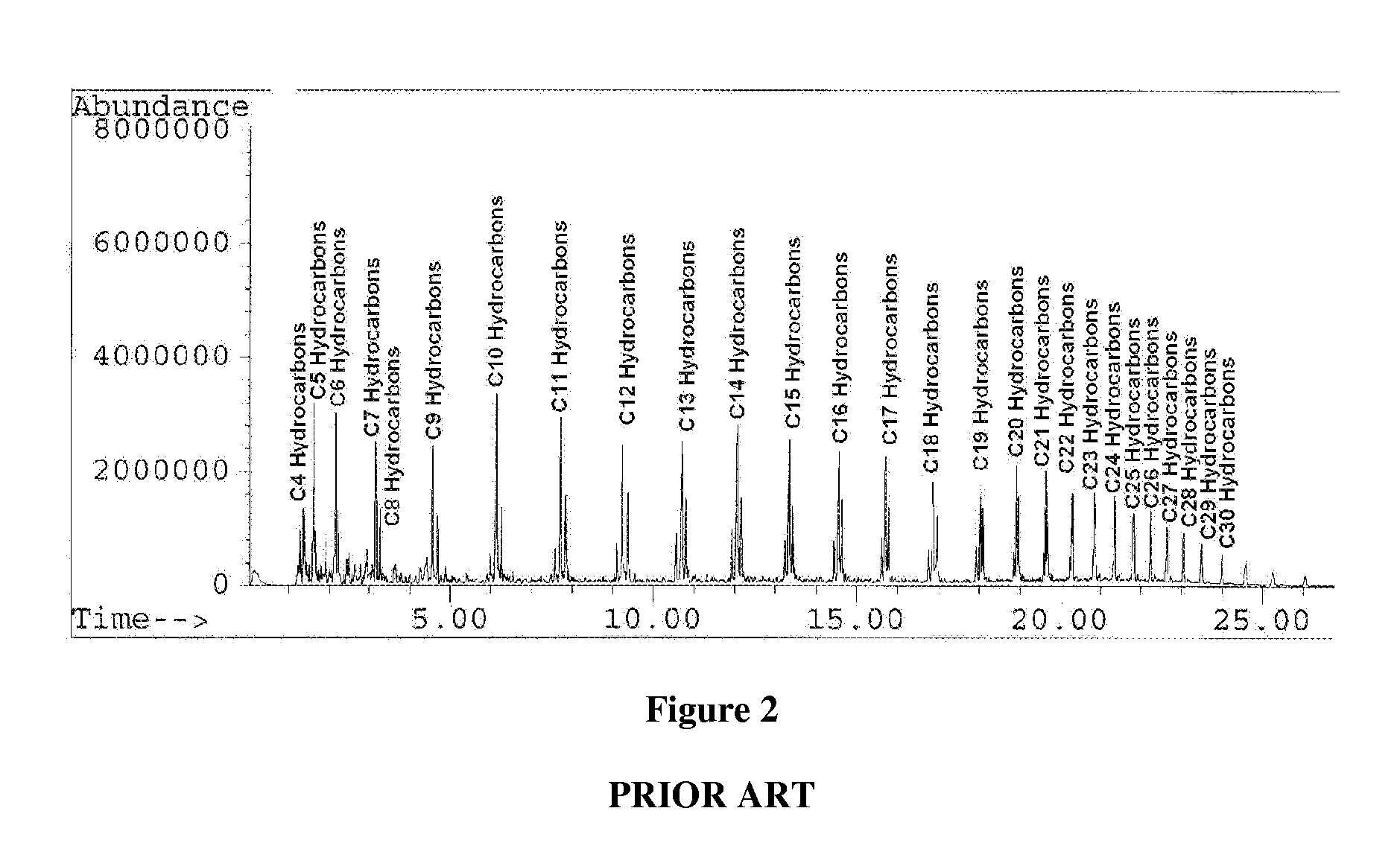

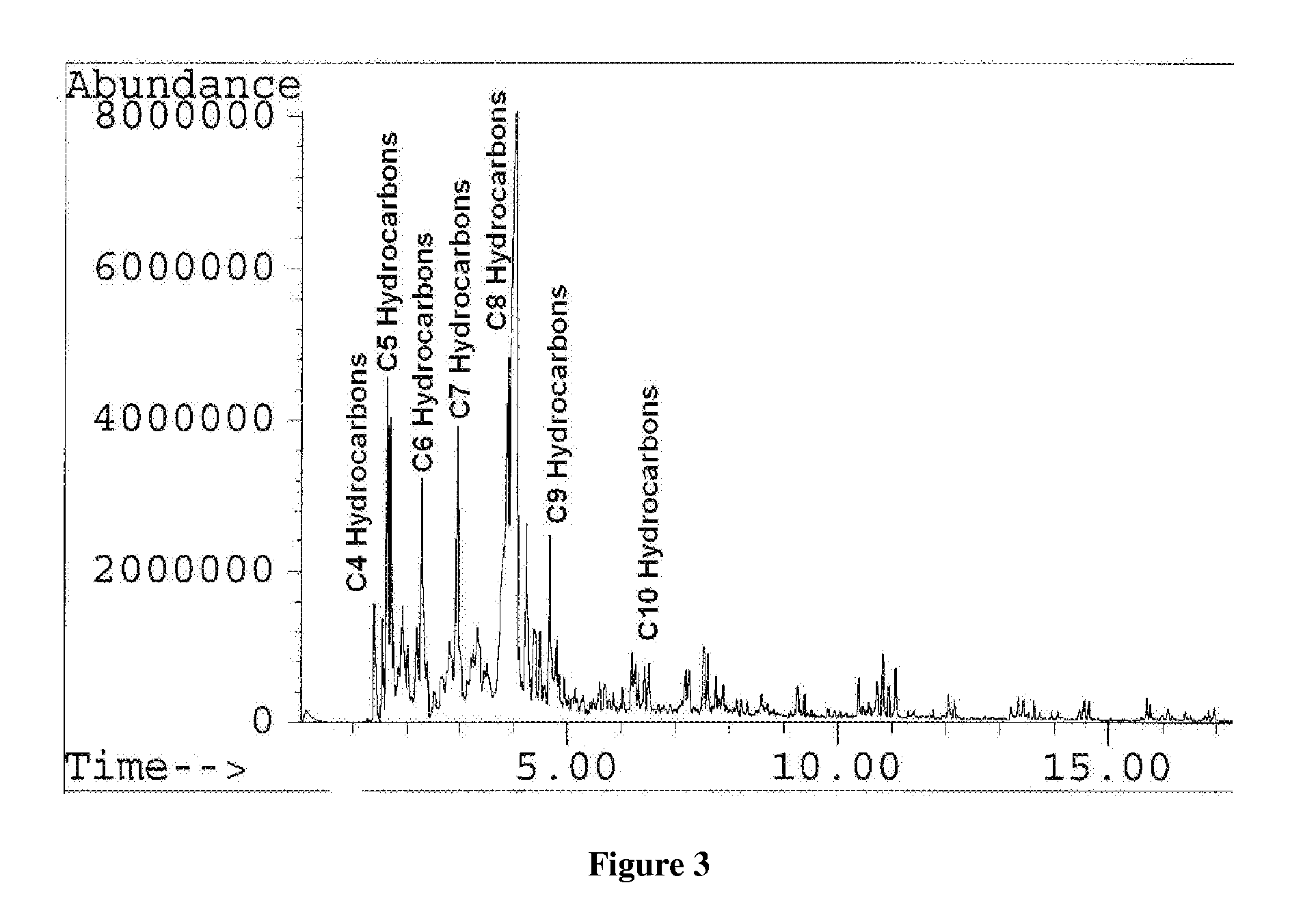

Method of Recycling A Recylable Plastic

ActiveUS20070083068A1Efficient productionEasy to recycleCombustible gas coke oven heatingSolid waste disposalPolystyreneGasoline

The present invention provides a method of recycling a plastic thereby forming a narrow spectrum of hydrocarbons having from 4 to 14 carbon atoms that can be directly used as gasoline without additional processing or refining. The method includes the step of feeding the plastic, selected from the group of polyethylene, polypropylene, polystyrene, and combinations thereof, into a heated vessel for melting. The method also includes the step of decomposing the plastic at a temperature of from 400° C. to 500° C. in the presence of a metallocene catalyst and a zeolitic catalyst thereby forming the hydrocarbons having from 4 to 14 carbon atoms. The metallocene catalyst includes dichlorobis(2-methylindenyl)zirconium (IV). The zeolitic catalyst includes ammonium Y zeolite and has a pore size of from 1 to 4 Angstroms.

Owner:ECOPLASTIFUEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com