Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1366results about "Gas purification by non-gaseous materials condensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

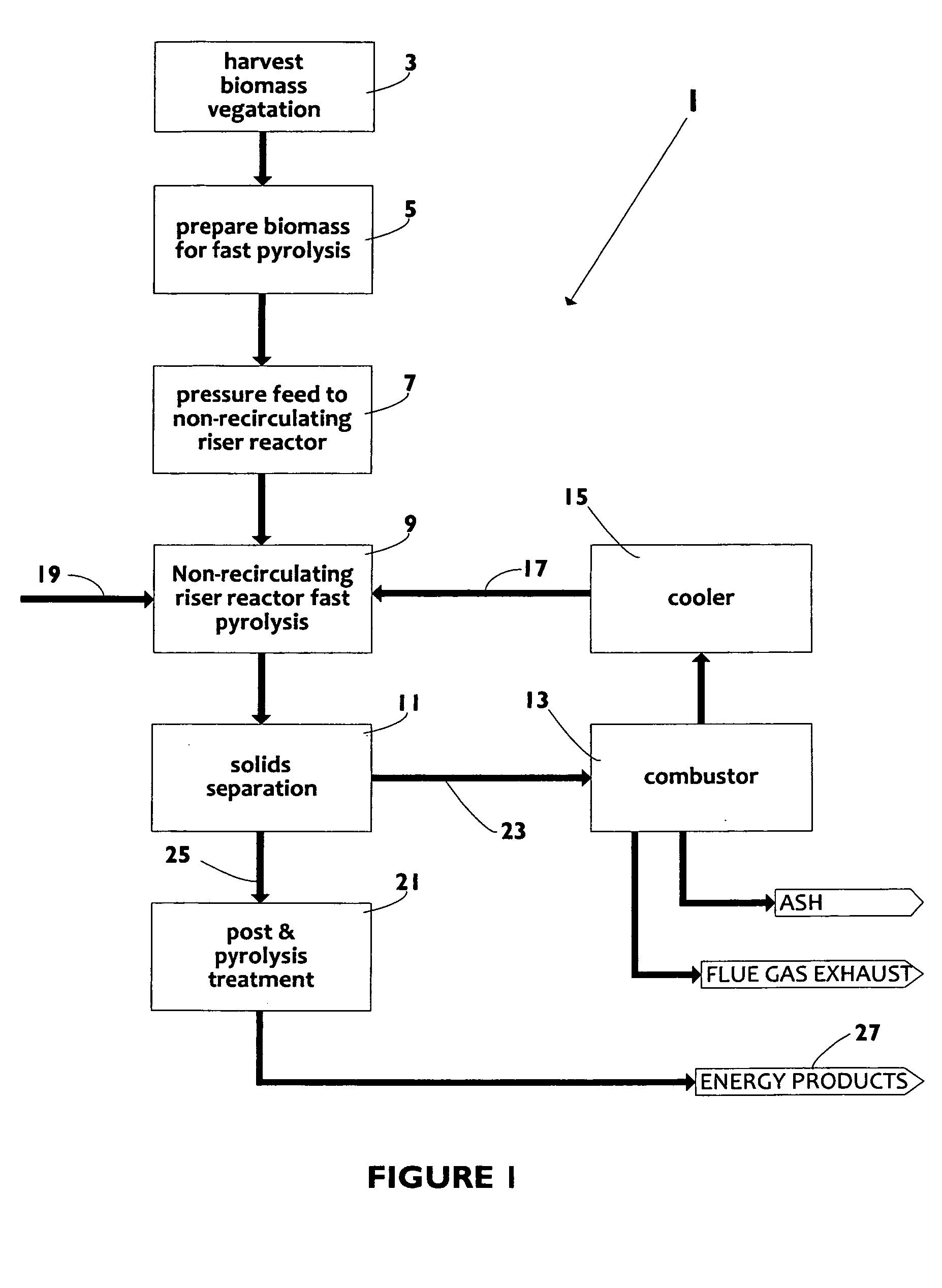

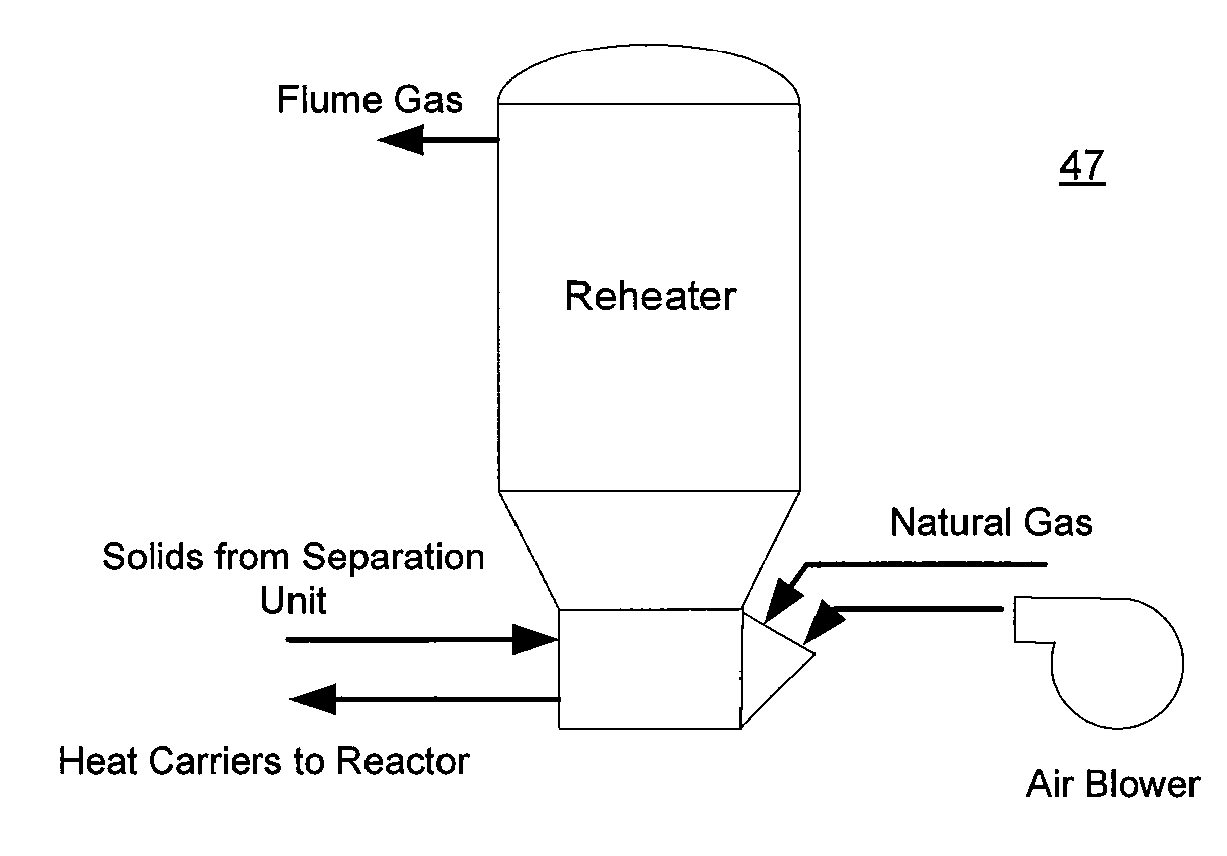

Biomass fast pyrolysis system utilizing non-circulating riser reactor

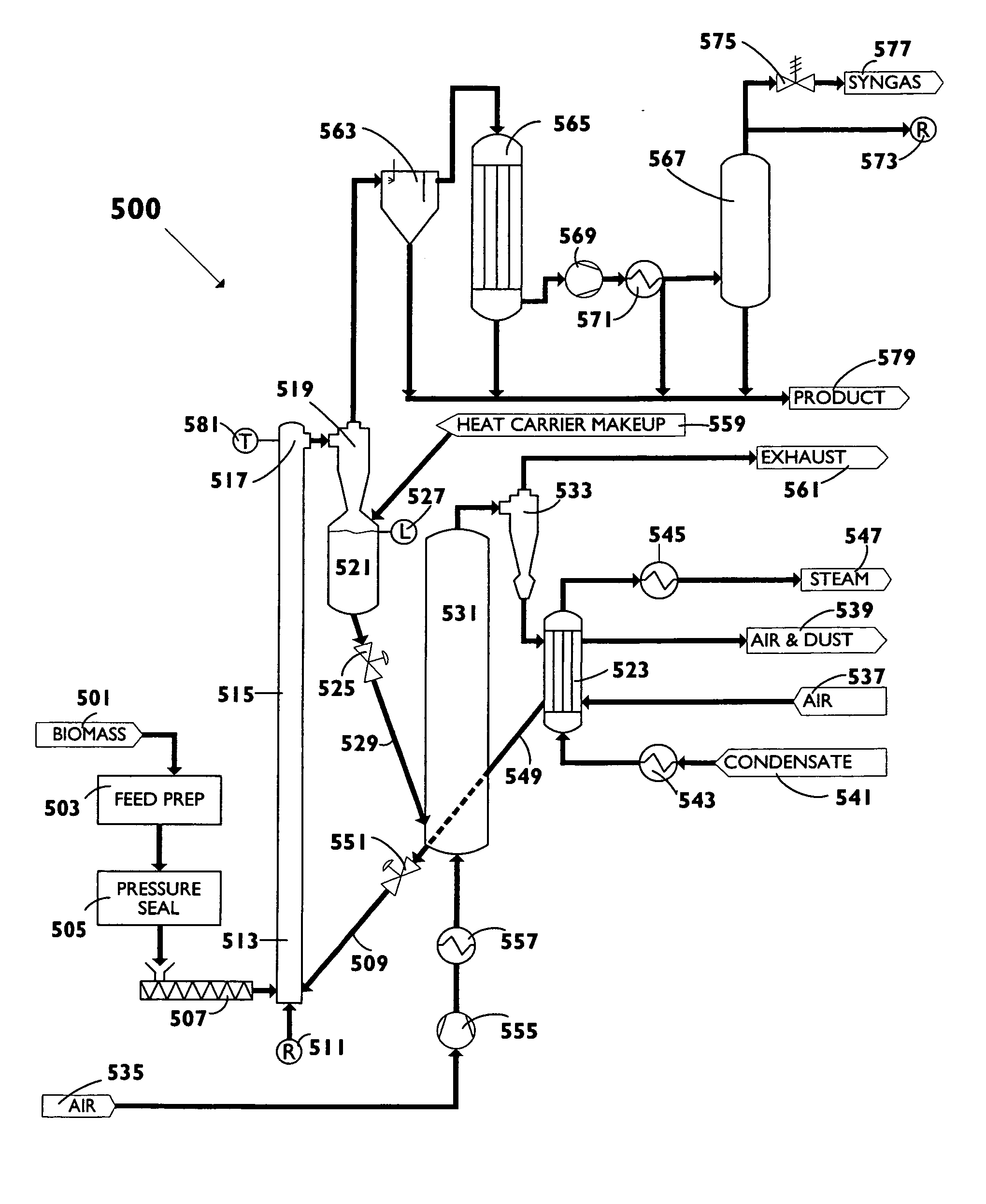

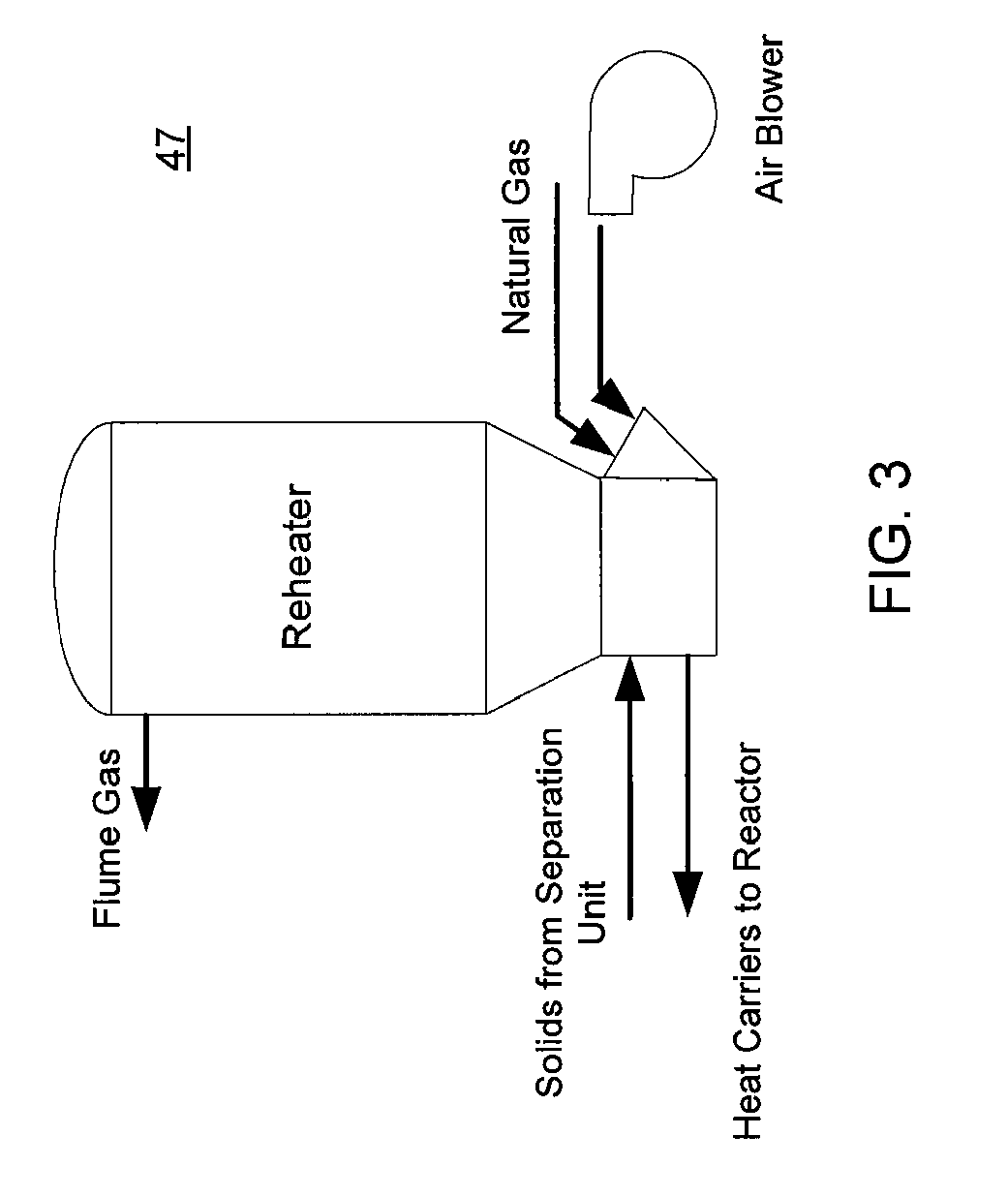

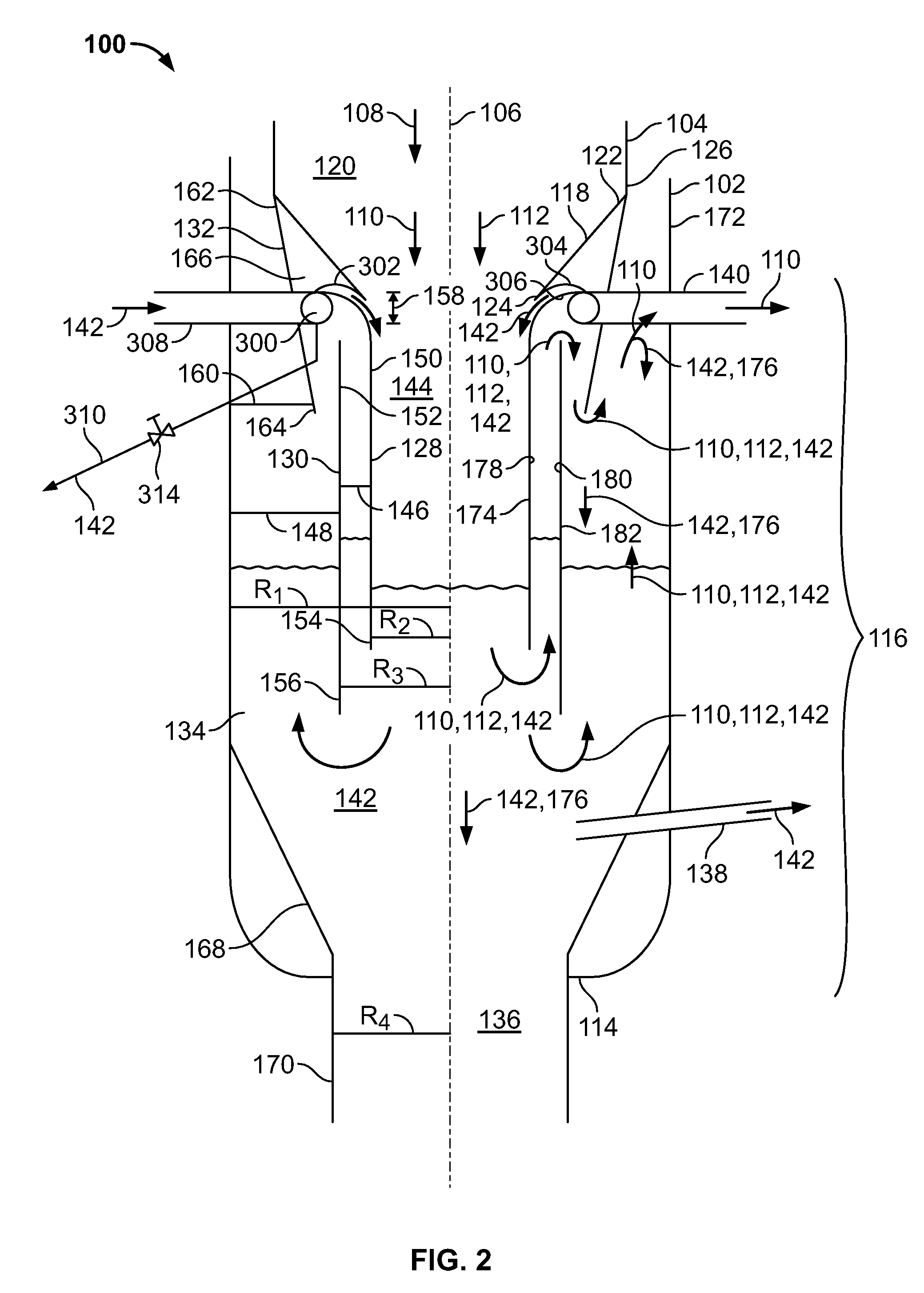

A biomass fast pyrolysis system for conversion of biomass vegetation to synthetic gas and liquid fuels includes: a) a non-circulating riser reactor for pyrolysis of biomass vegetation feedstock utilizing a heat carrier, the non-circulating riser reactor being physically structured and adapted to have a rate of reaction of at least 8,000 biomass vegetation feedstock lbs / hr / ft2, utilizing a ratio of heat carrier to biomass vegetation feedstock of about 7:1 to about 11.5:1, the riser reactor having a base input region at its bottom, a central reaction region and an output region at its top, the riser reactor including a cyclone disengager at its output region for separation of pyrolysis resulting char and heat carrier from the pyrolysis product gases, the cyclone disengager having an output downcomer and an output upcomer, the cyclone disengager output downcomer being connected to and feeding into a side combustor unit, the riser reactor being a non-circulating riser reactor in that the heat carrier is not returned directly to the riser reactor from the cyclone disengager and travels first down the cyclone disengager output downcomer to the side combustor unit; and, b) the side combustor unit for combusting pyrolysis resultant char and reheating the heat carrier the side combustor having a heat carrier downcomer connected to the base input region of the riser reactor.

Owner:INNOVATIVE ENERGY GLOBAL

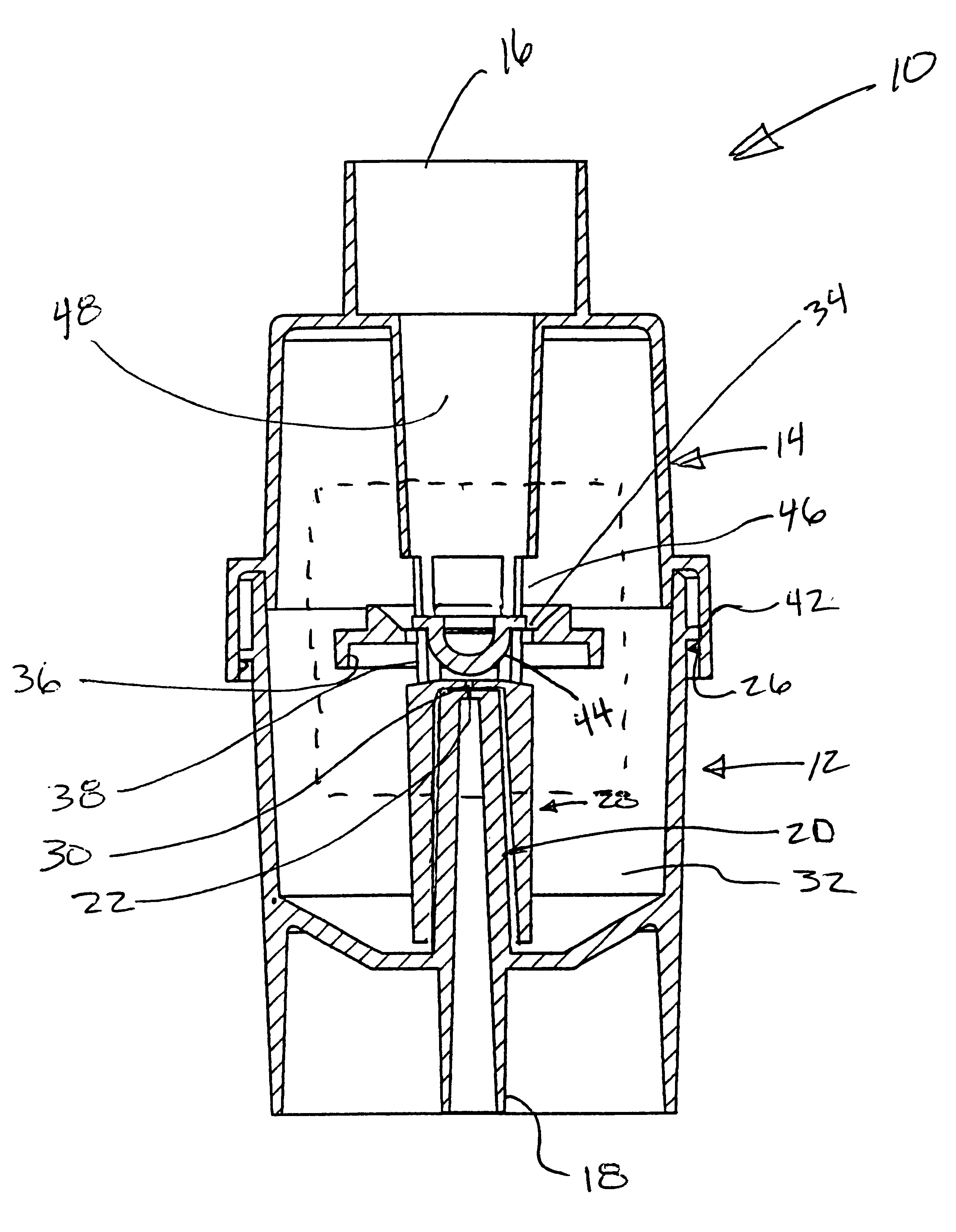

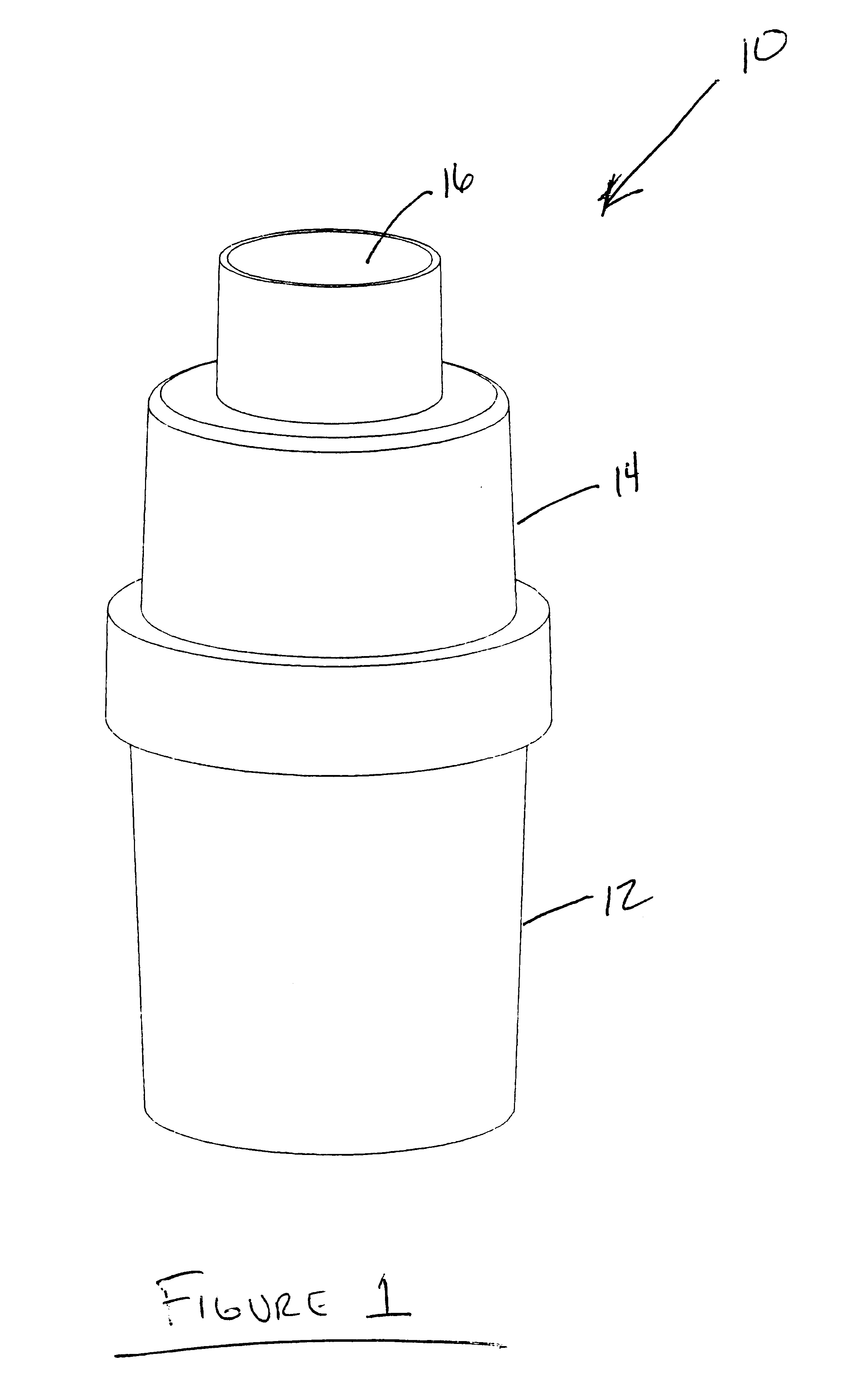

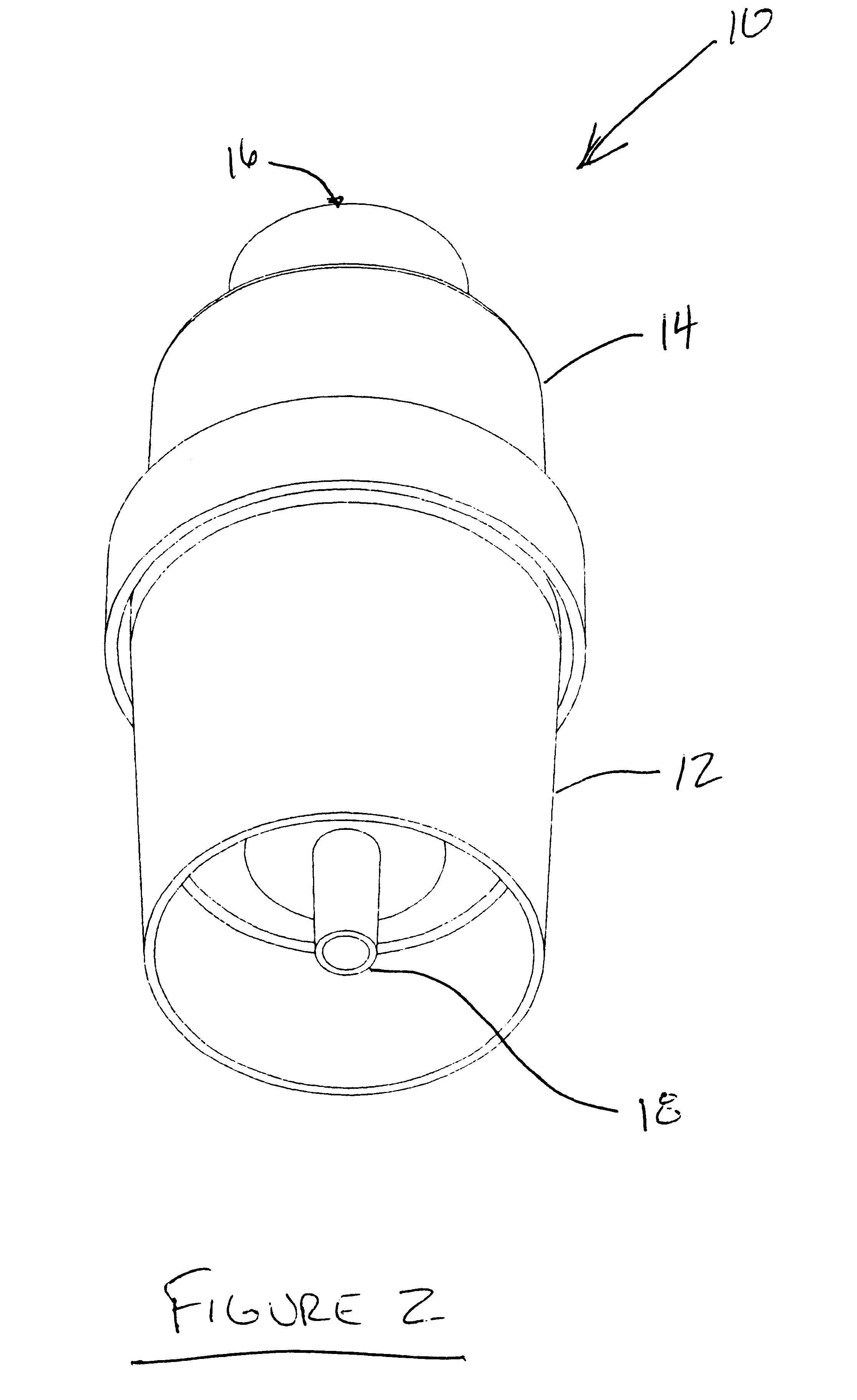

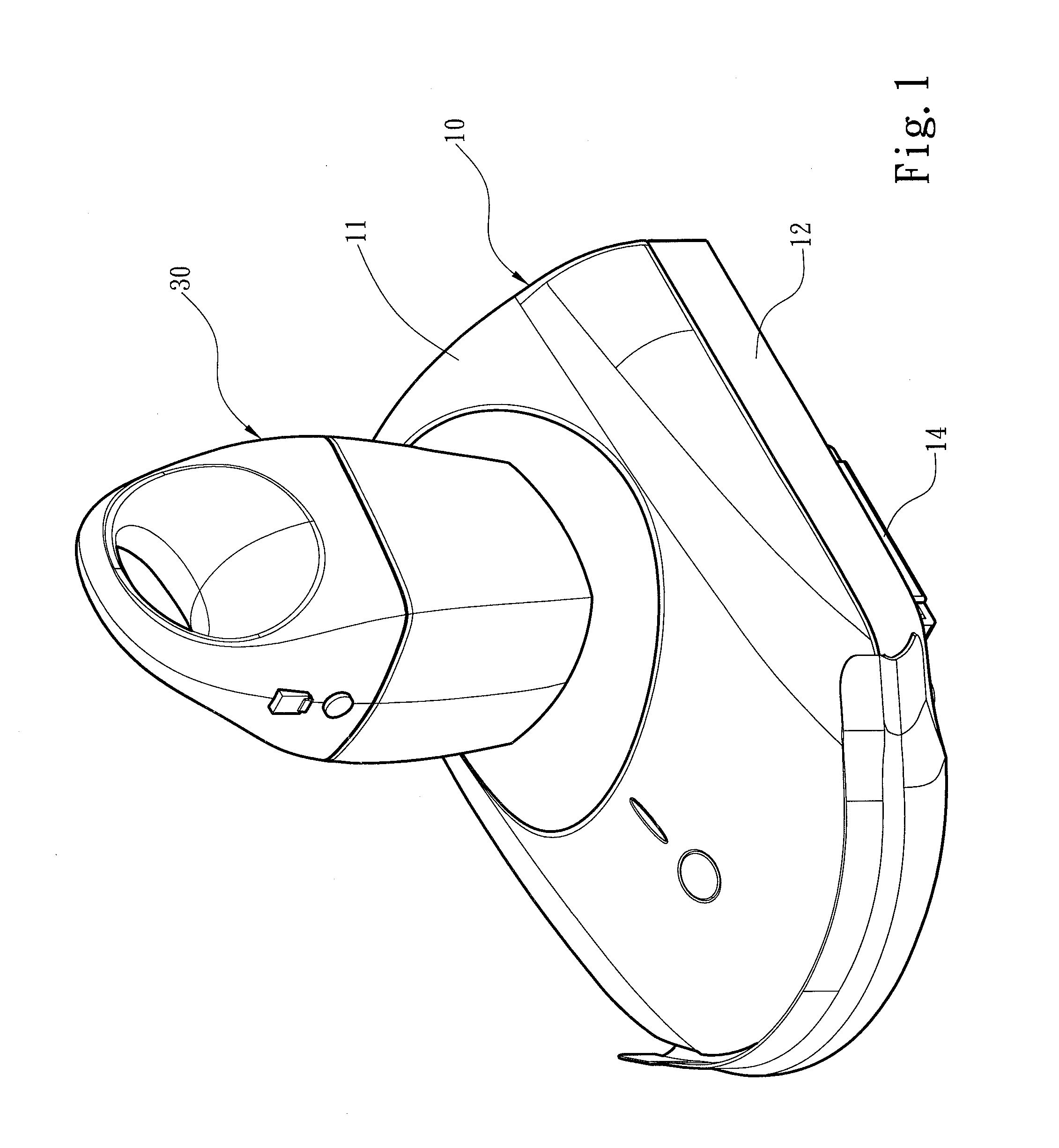

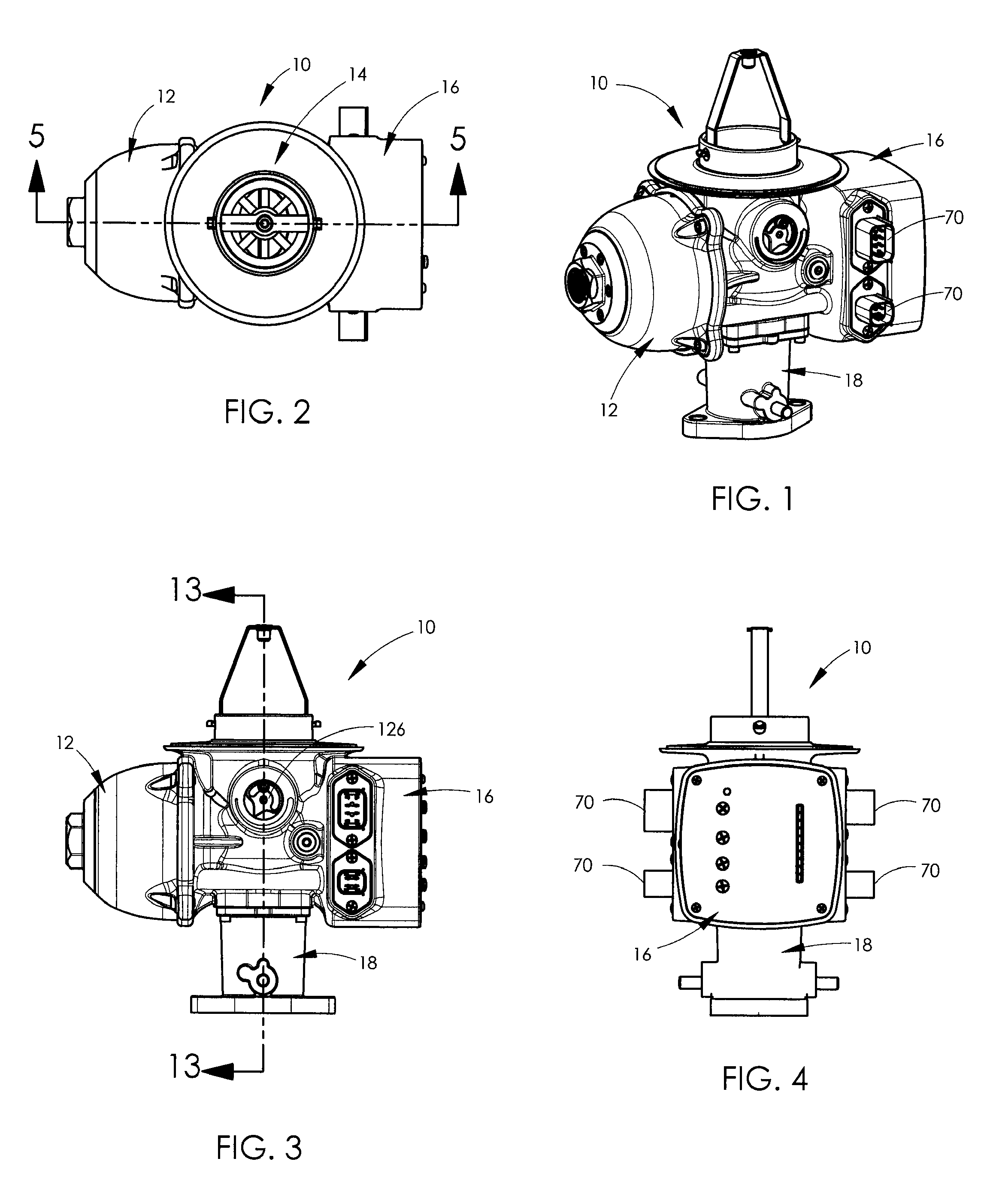

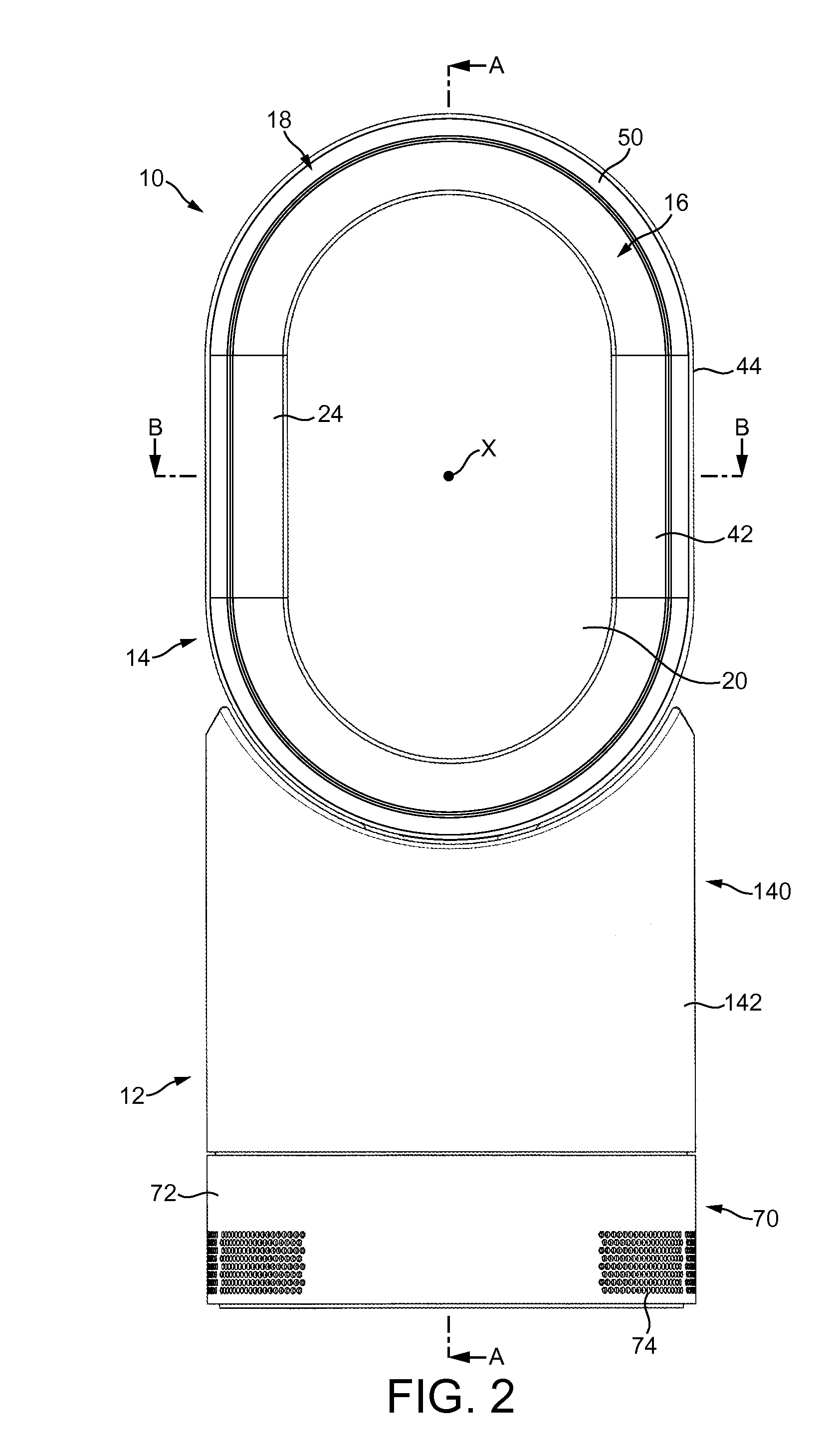

High efficiency medical nebulizer

A pneumatic nebulizer that produces a high volume of aerosols for inhalent delivery of medications and other constituencies. High pressure gas formed into a gas jet is passed through a thin choked region of fluid that is entrailed and impinged upon an aerosol amplifier which creates a spray whose aerosol components are directed up through vents to an aerosol outlet for delivery. Larger-sized liquid particles are caused to pool up in a region surrounding the aerosol amplifer and then drip down back into the liquid medication reservoir.

Owner:MERCURY ENTERPRISES

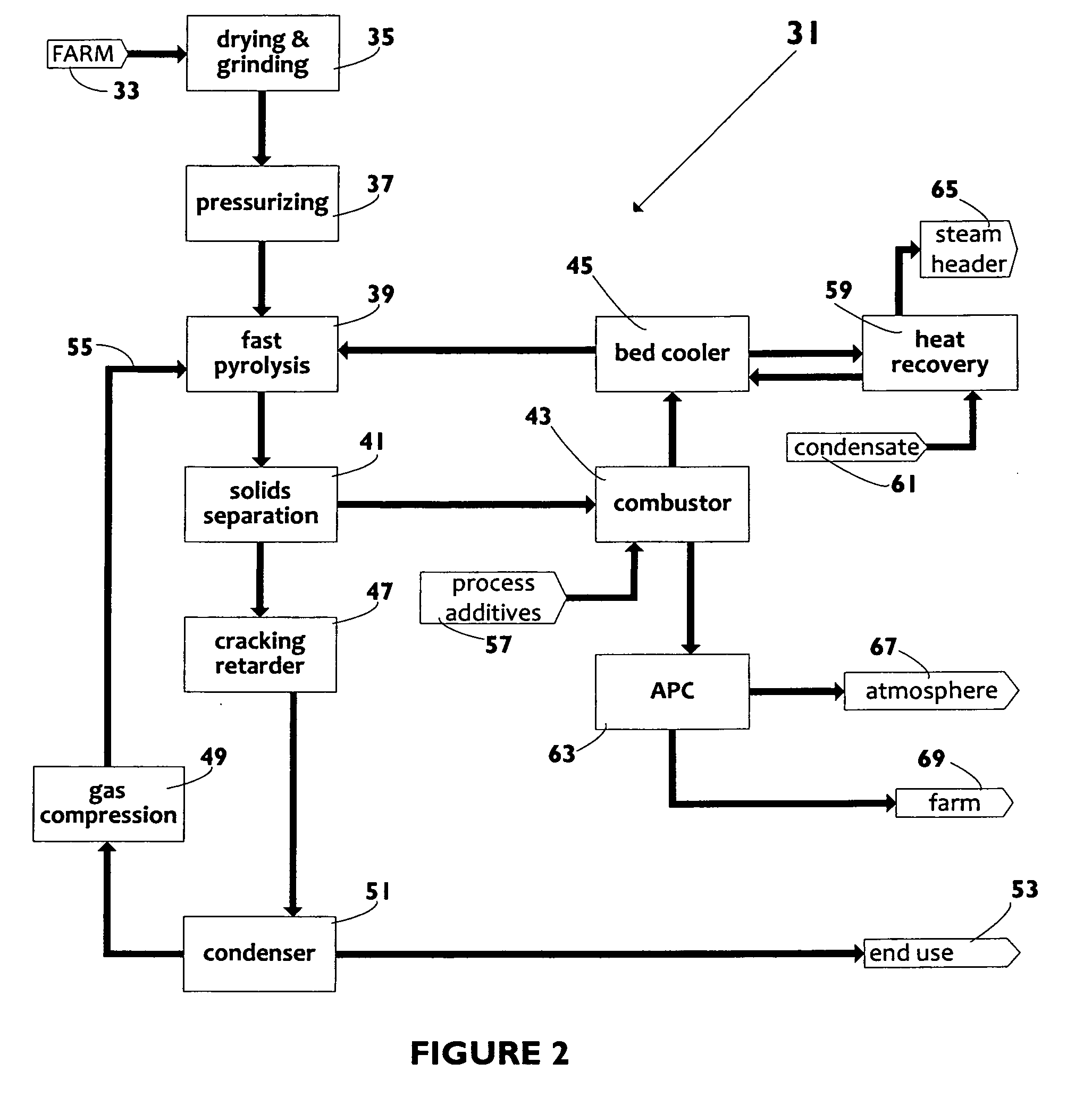

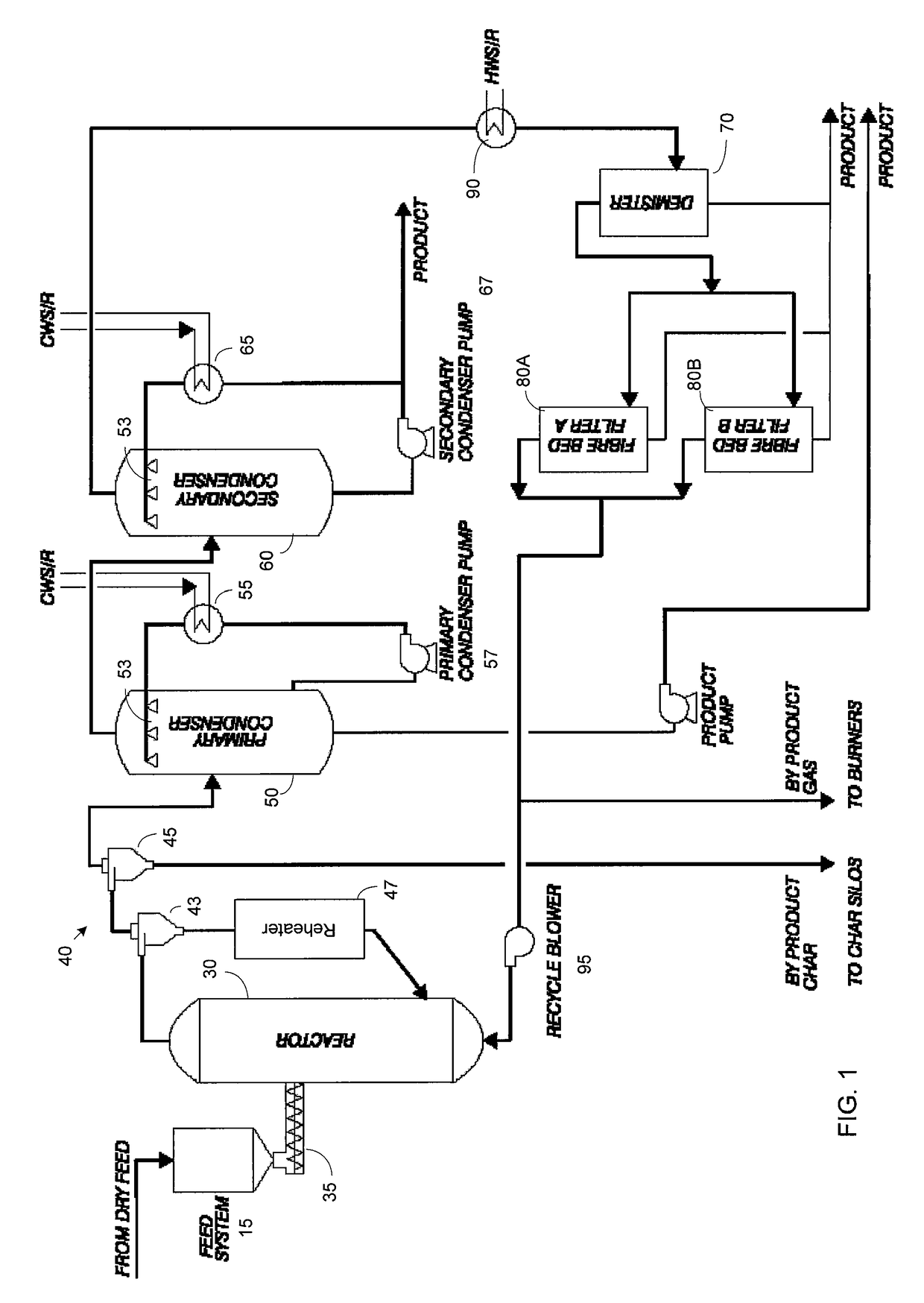

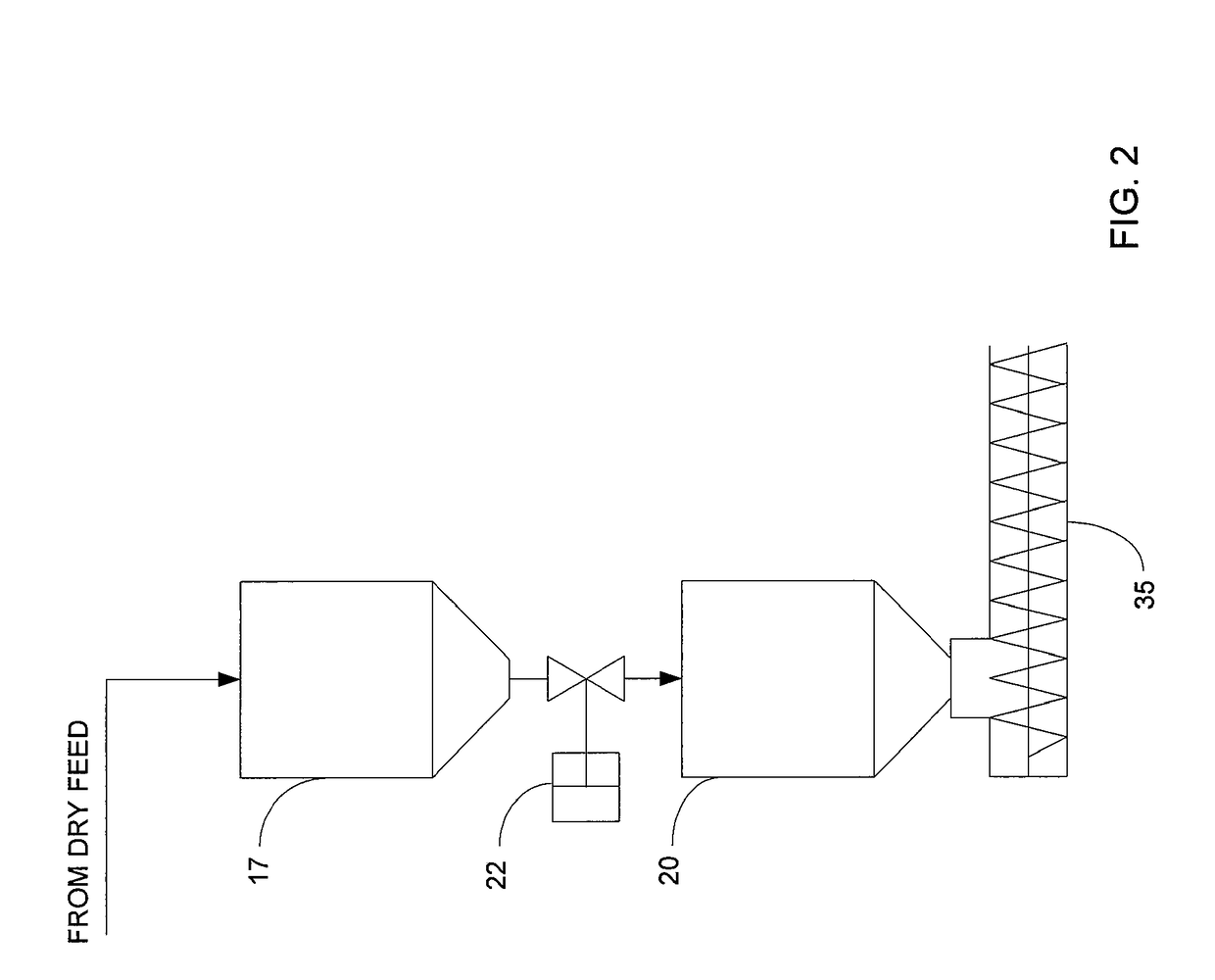

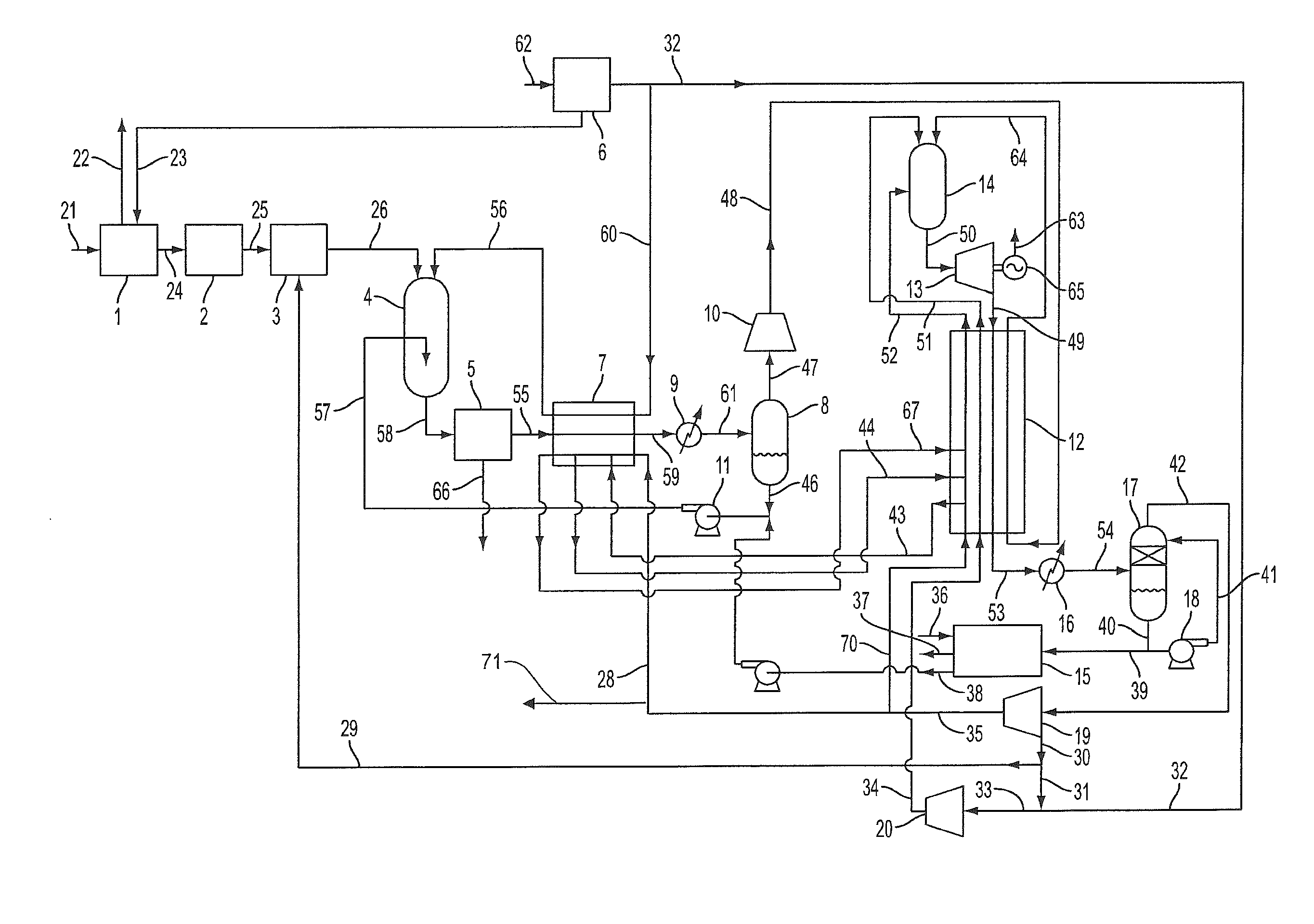

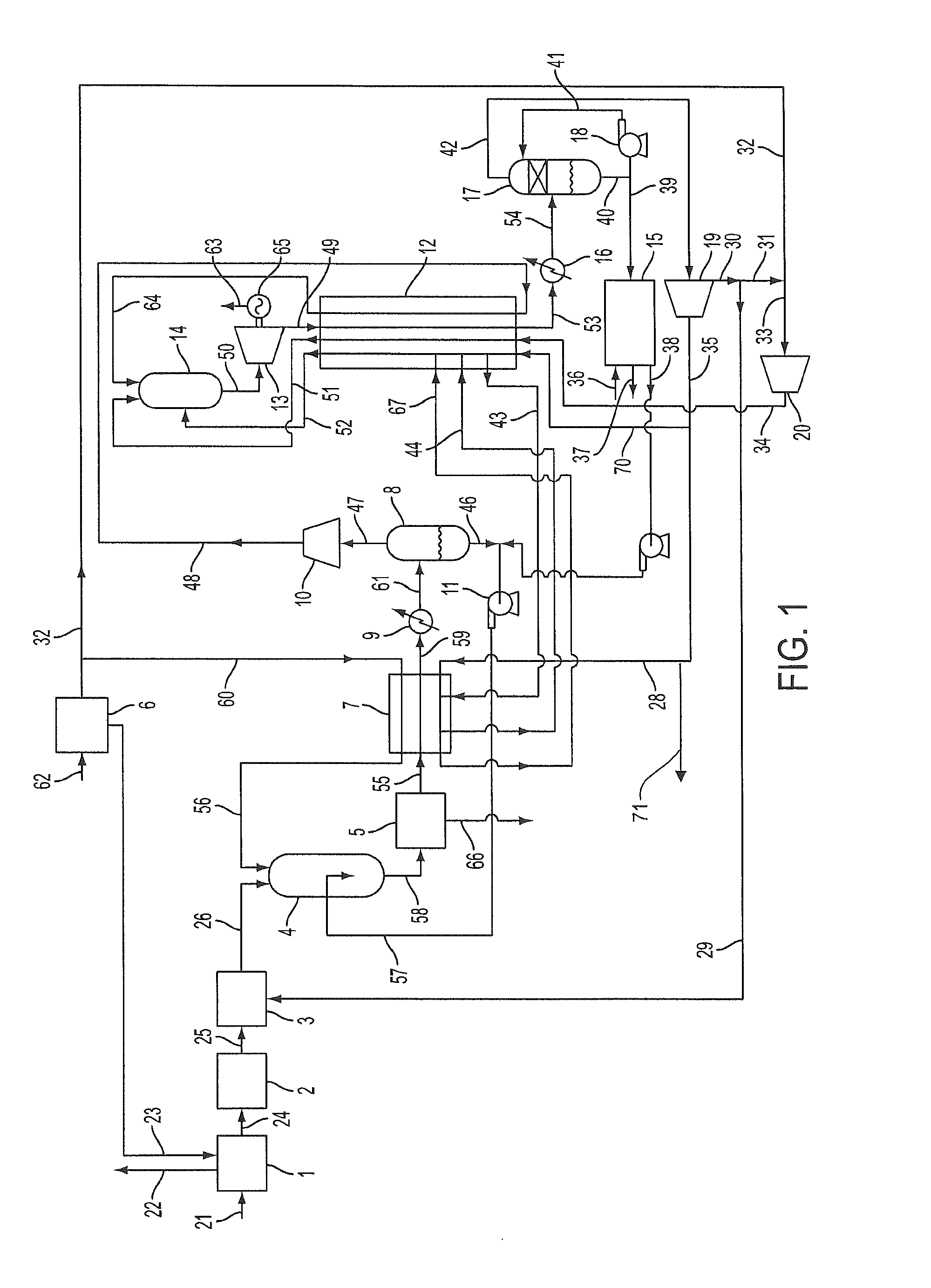

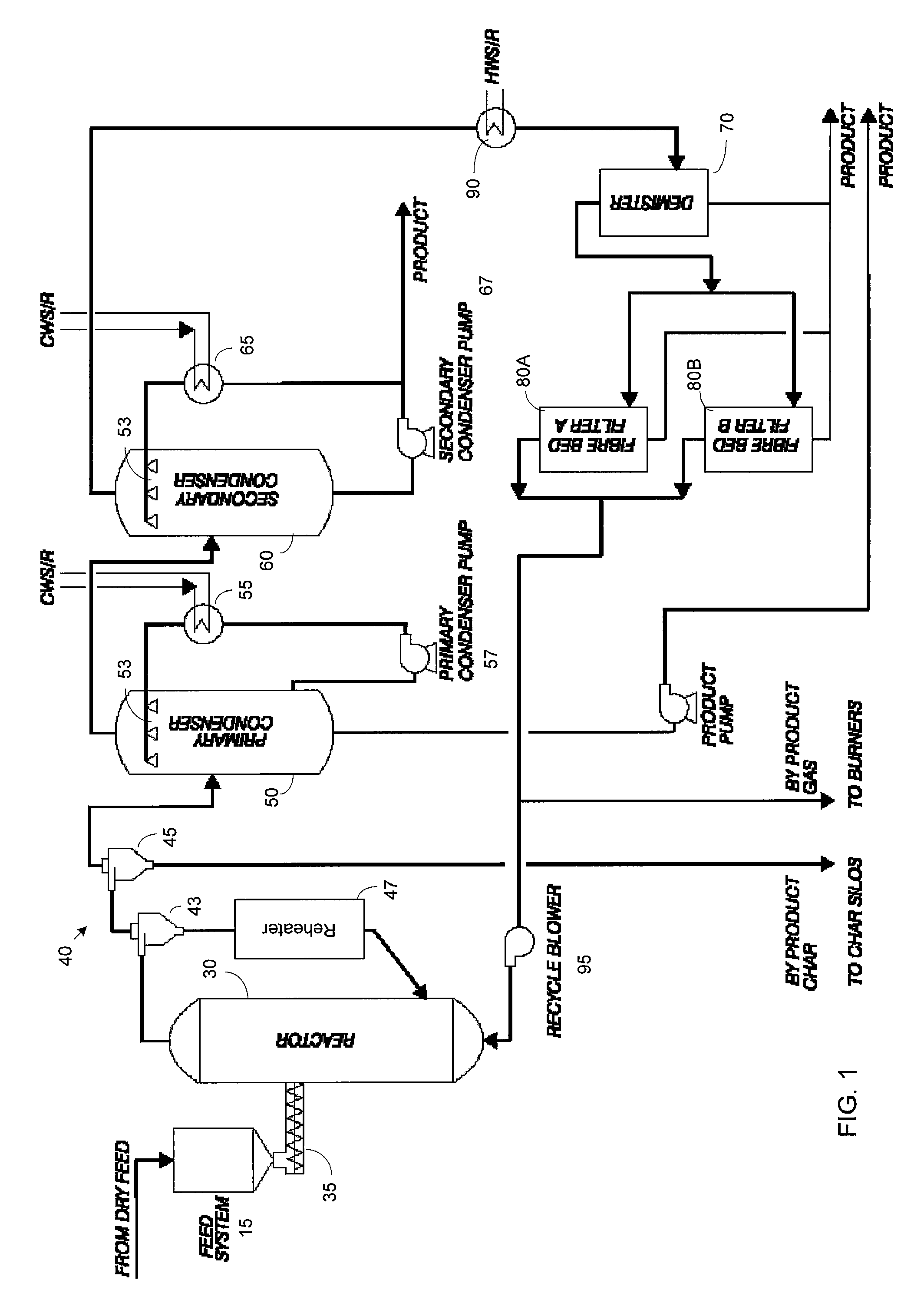

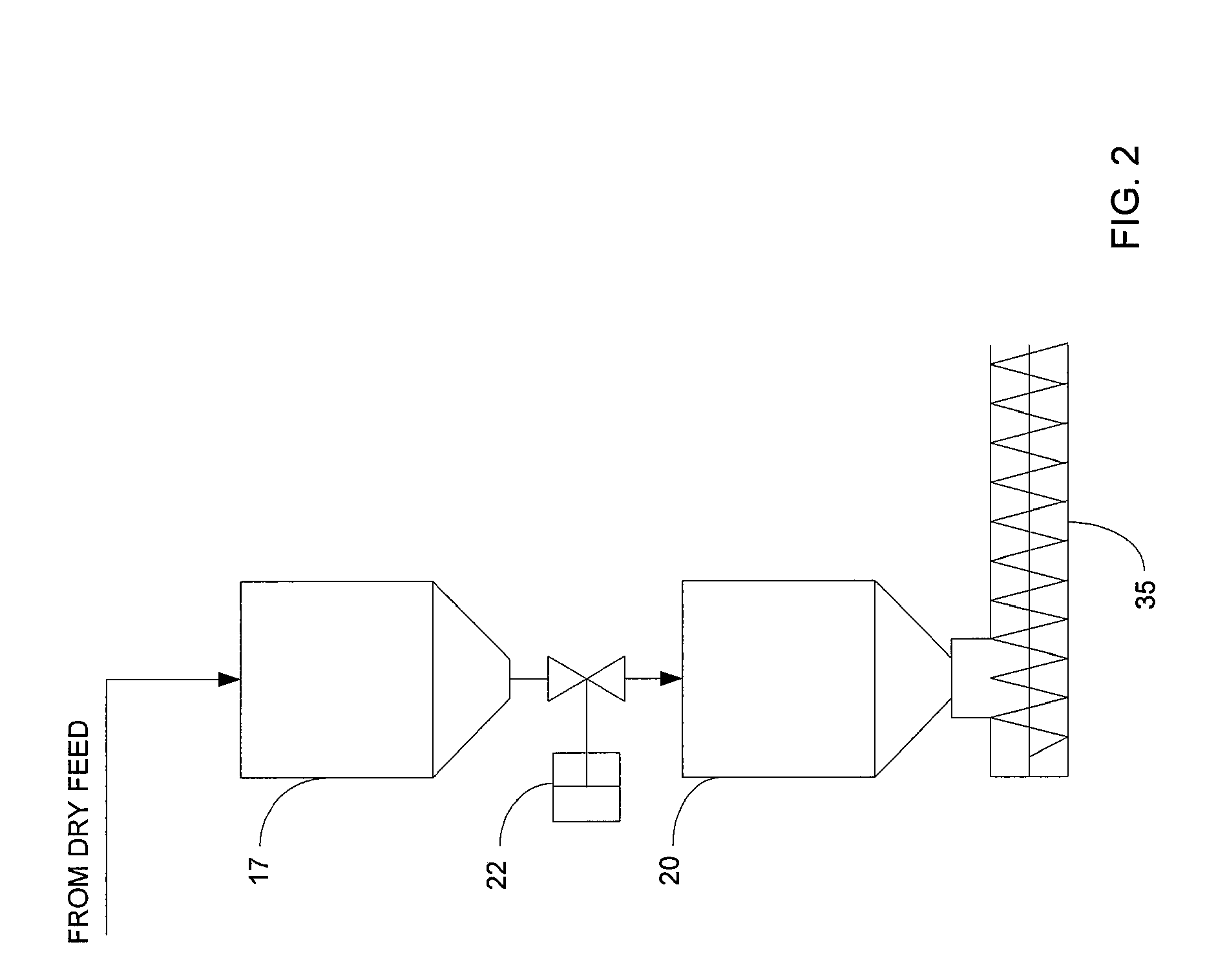

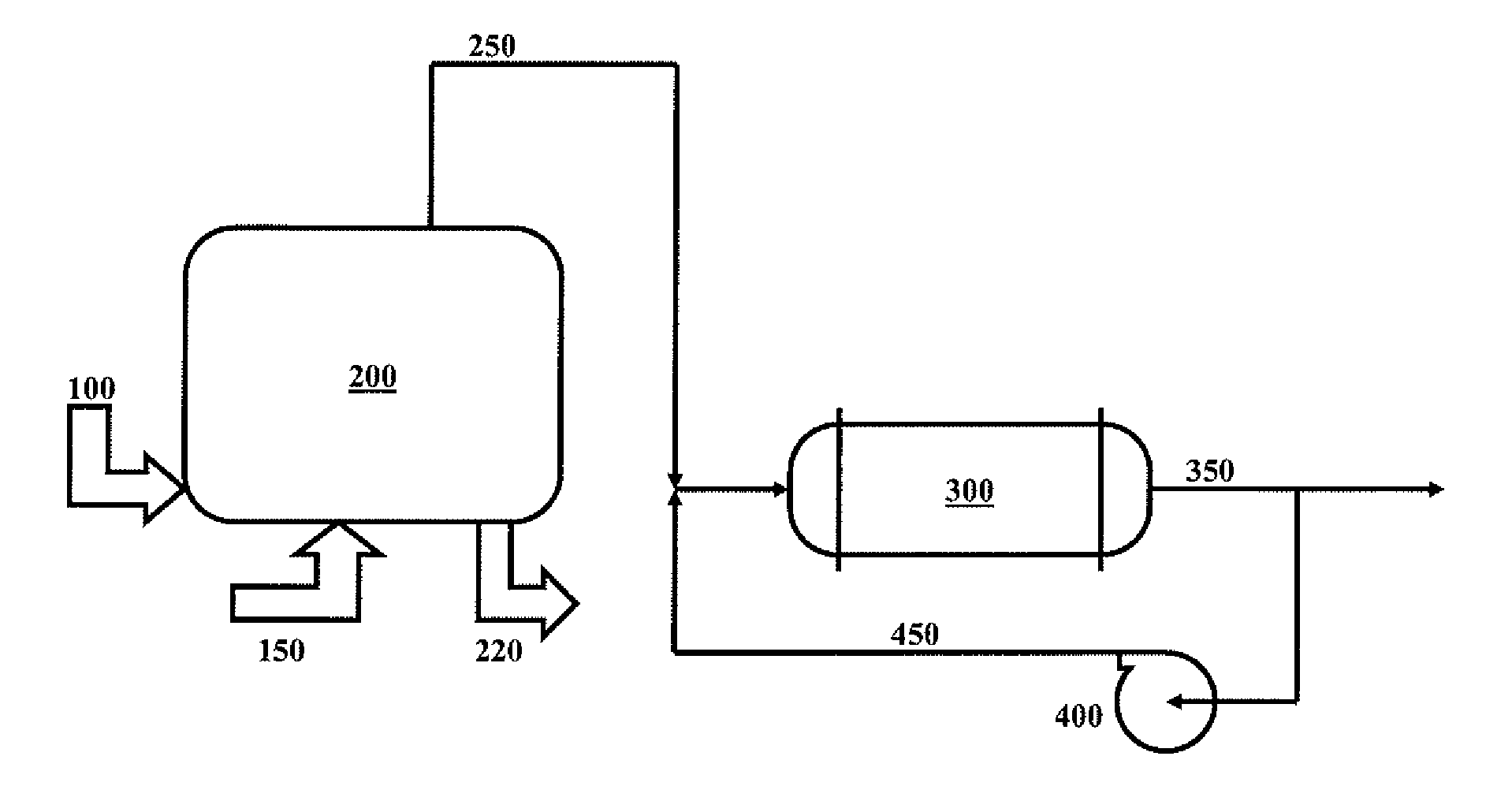

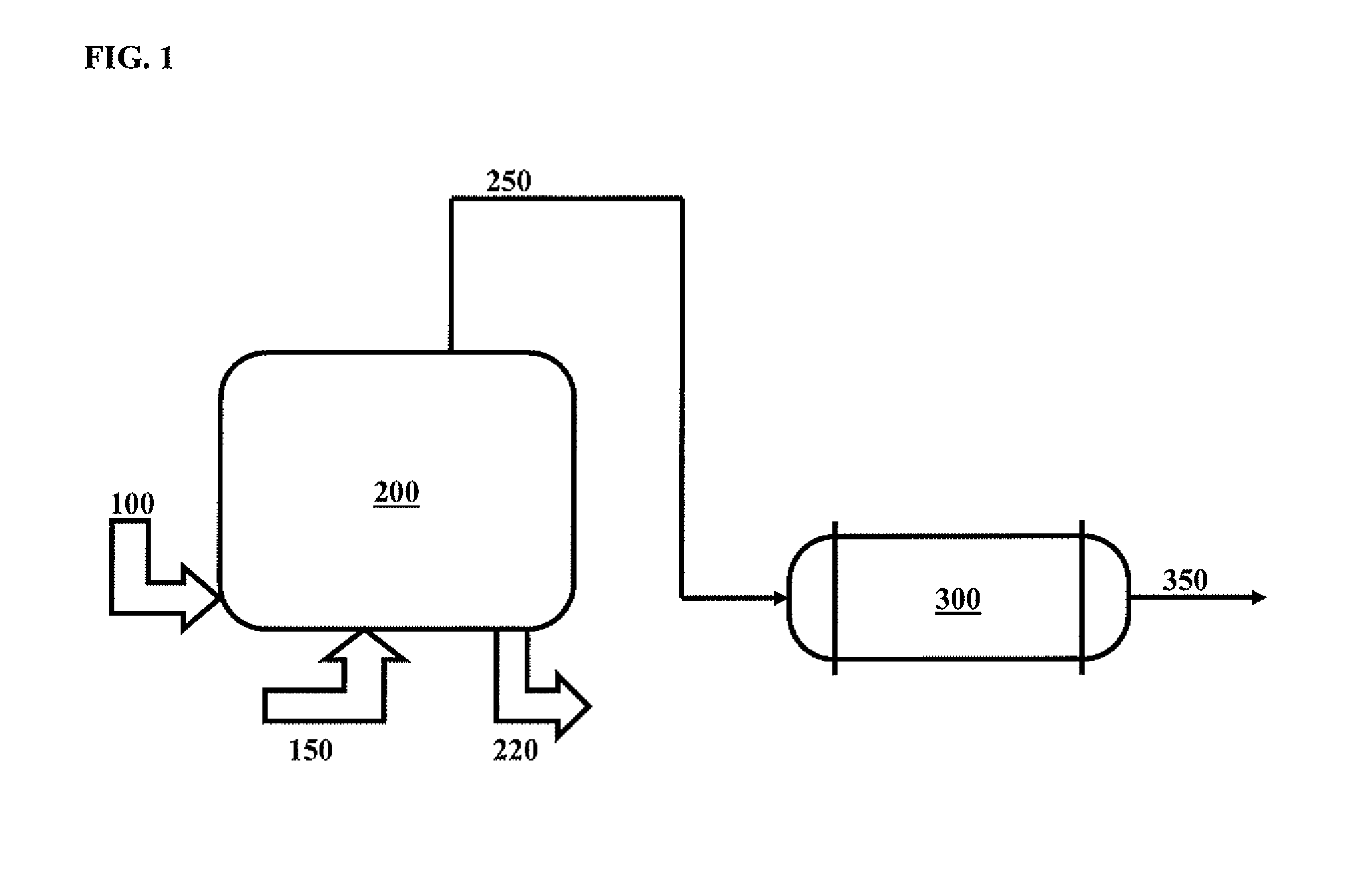

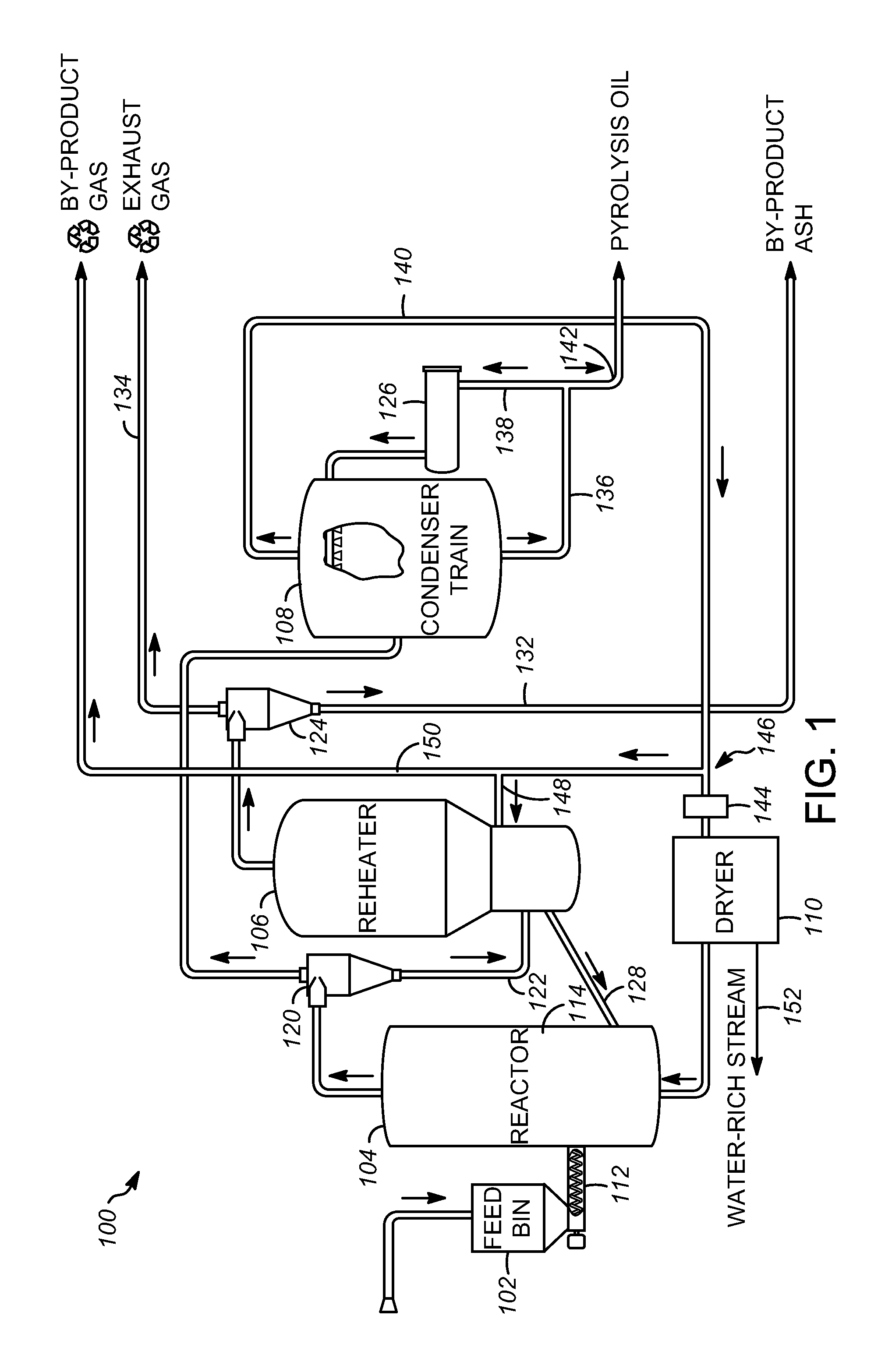

Rapid thermal conversion of biomass

ActiveUS7905990B2Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingSolid waste disposalLiquid productHeat carrier

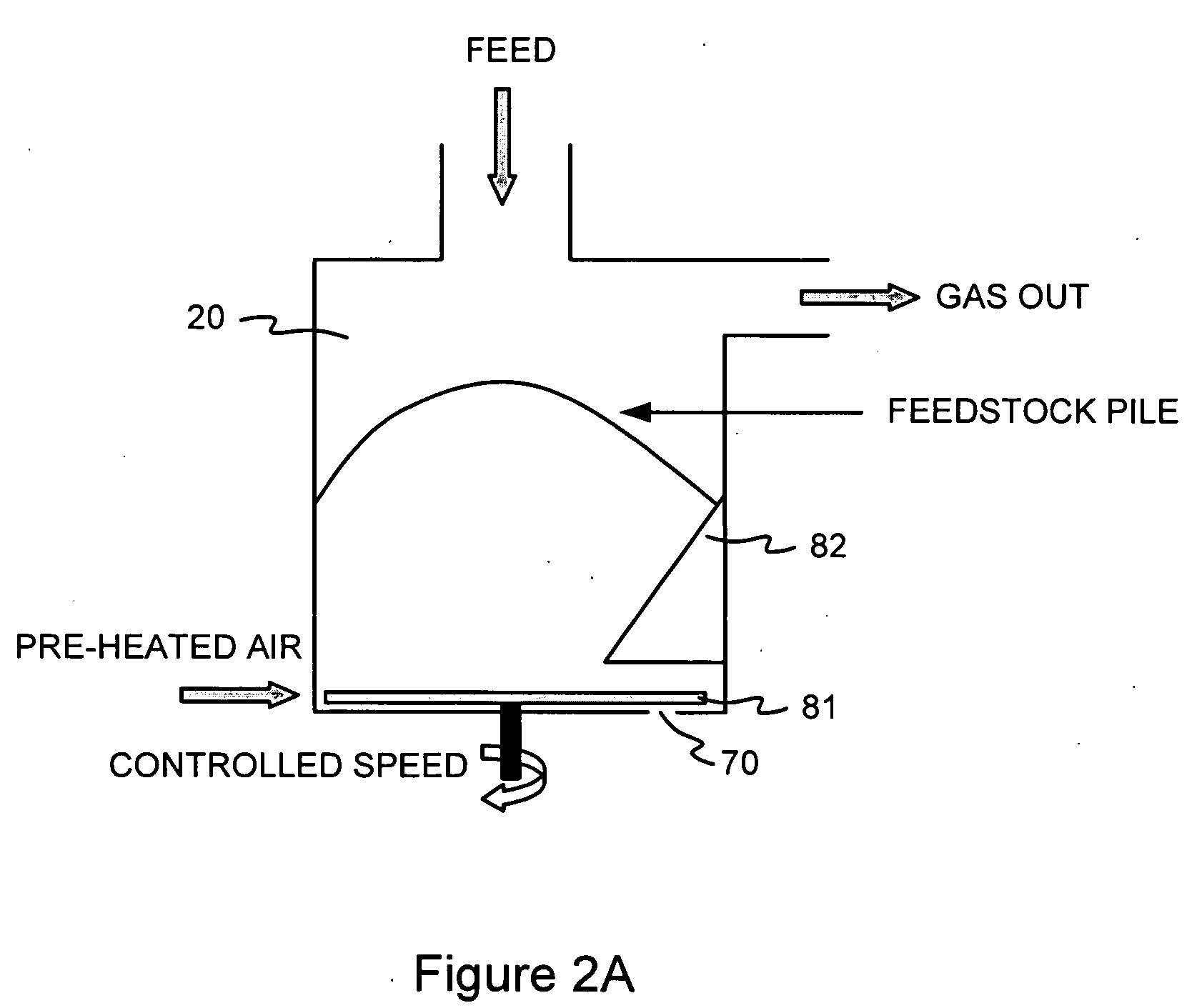

A rapid thermal conversion process for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. Biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. The liquid product may itself be used as the quench media.

Owner:ENSYN RENEWABLES

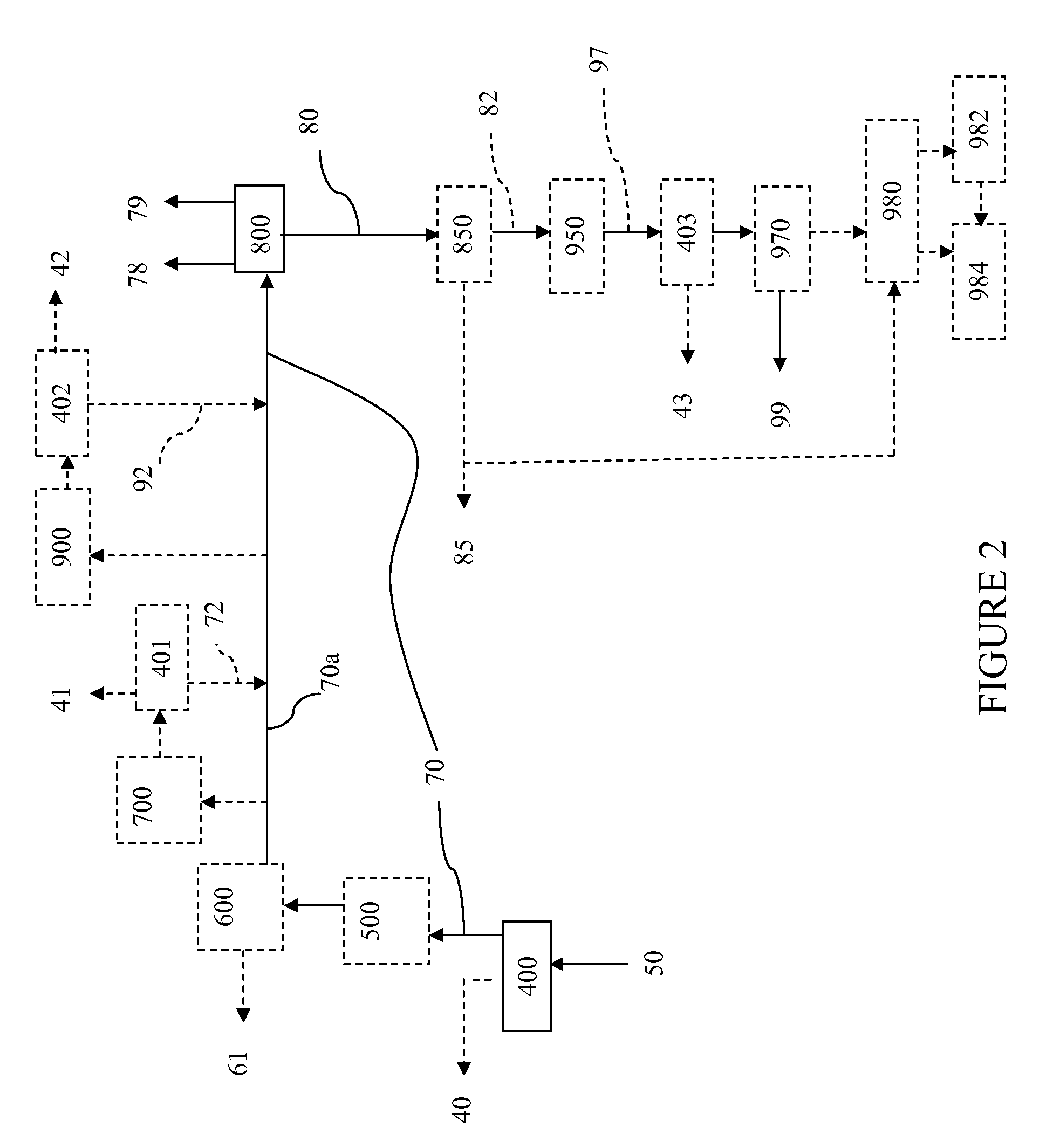

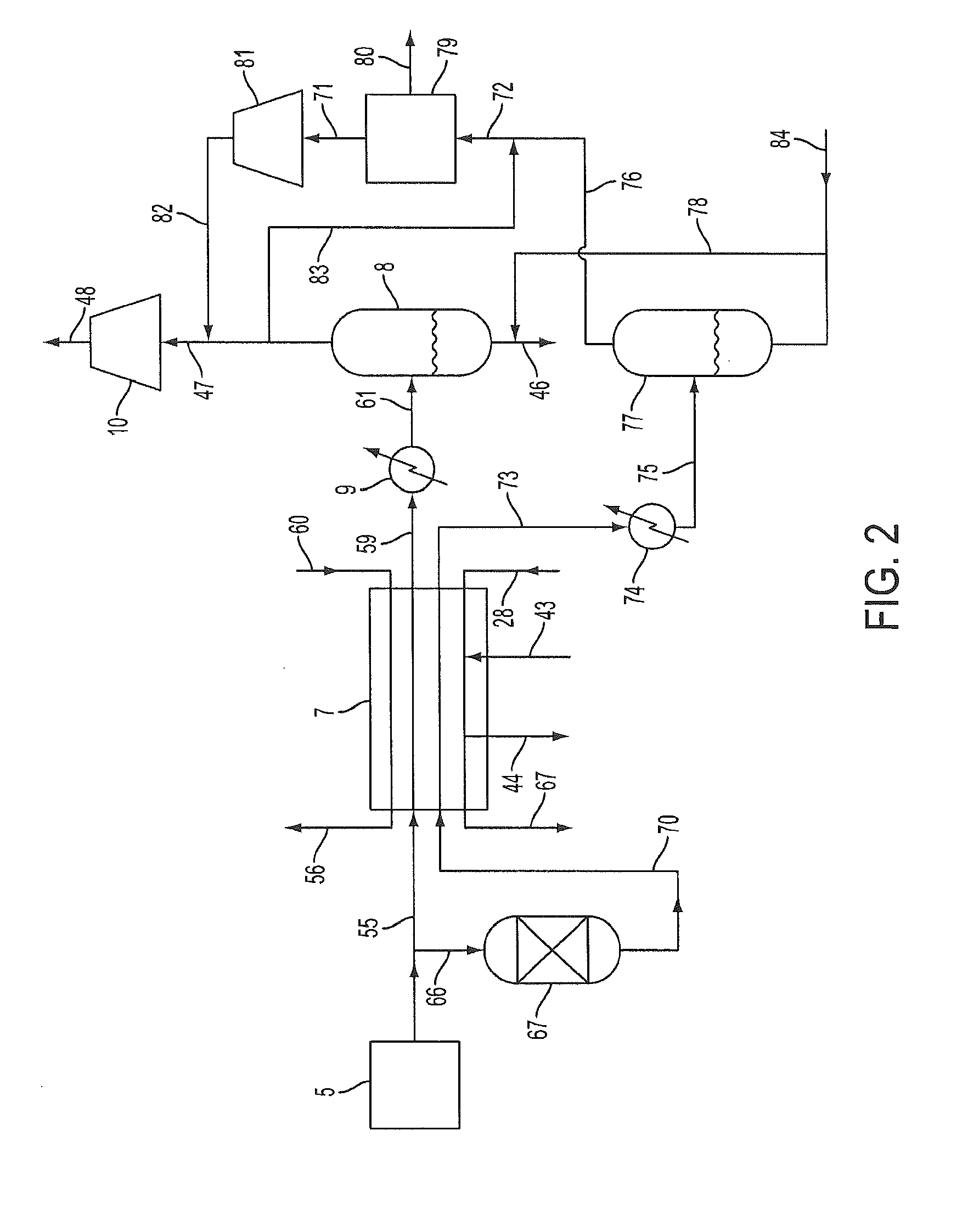

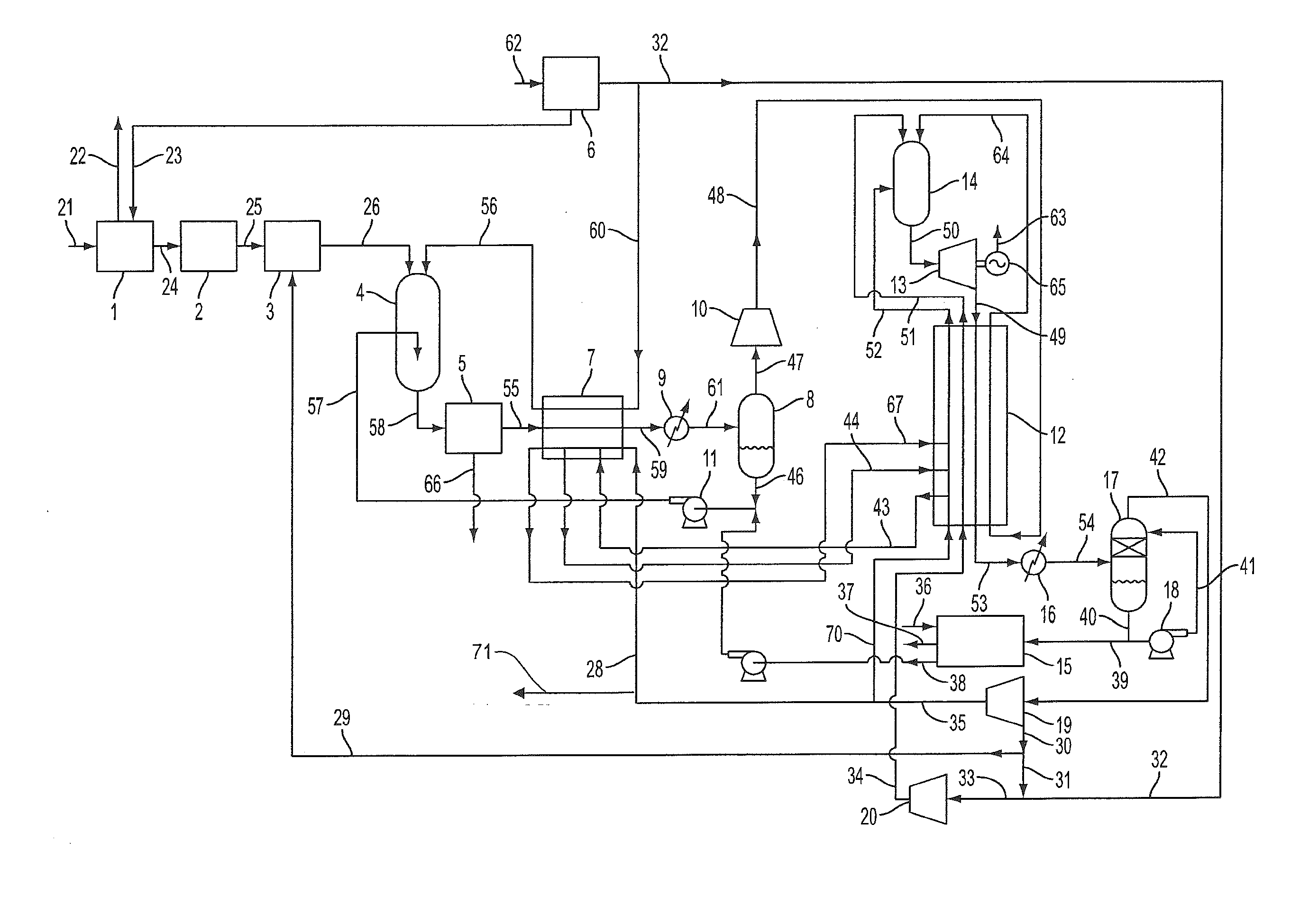

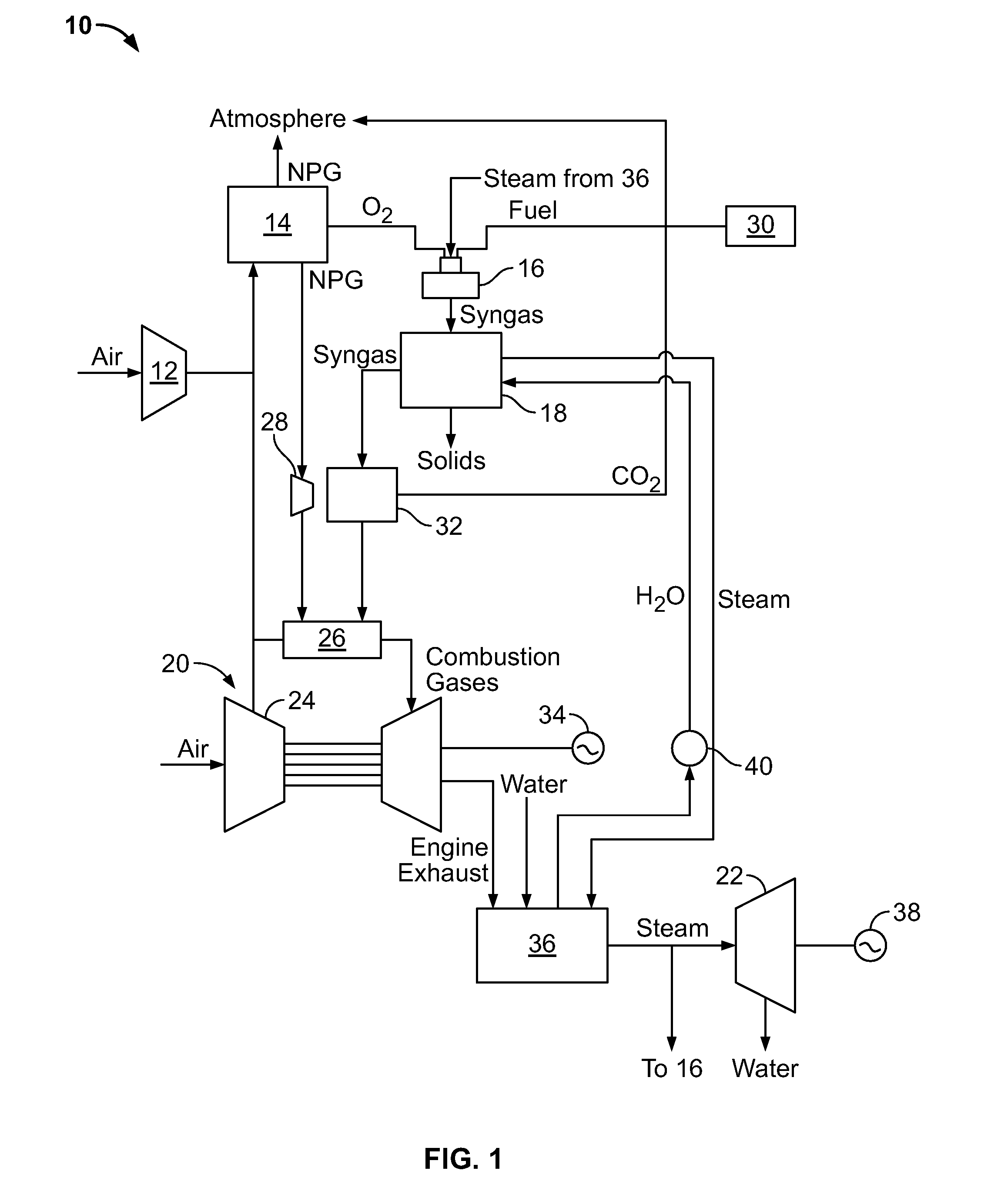

System comprising the gasification of fossil fuels to process unconventional oil sources

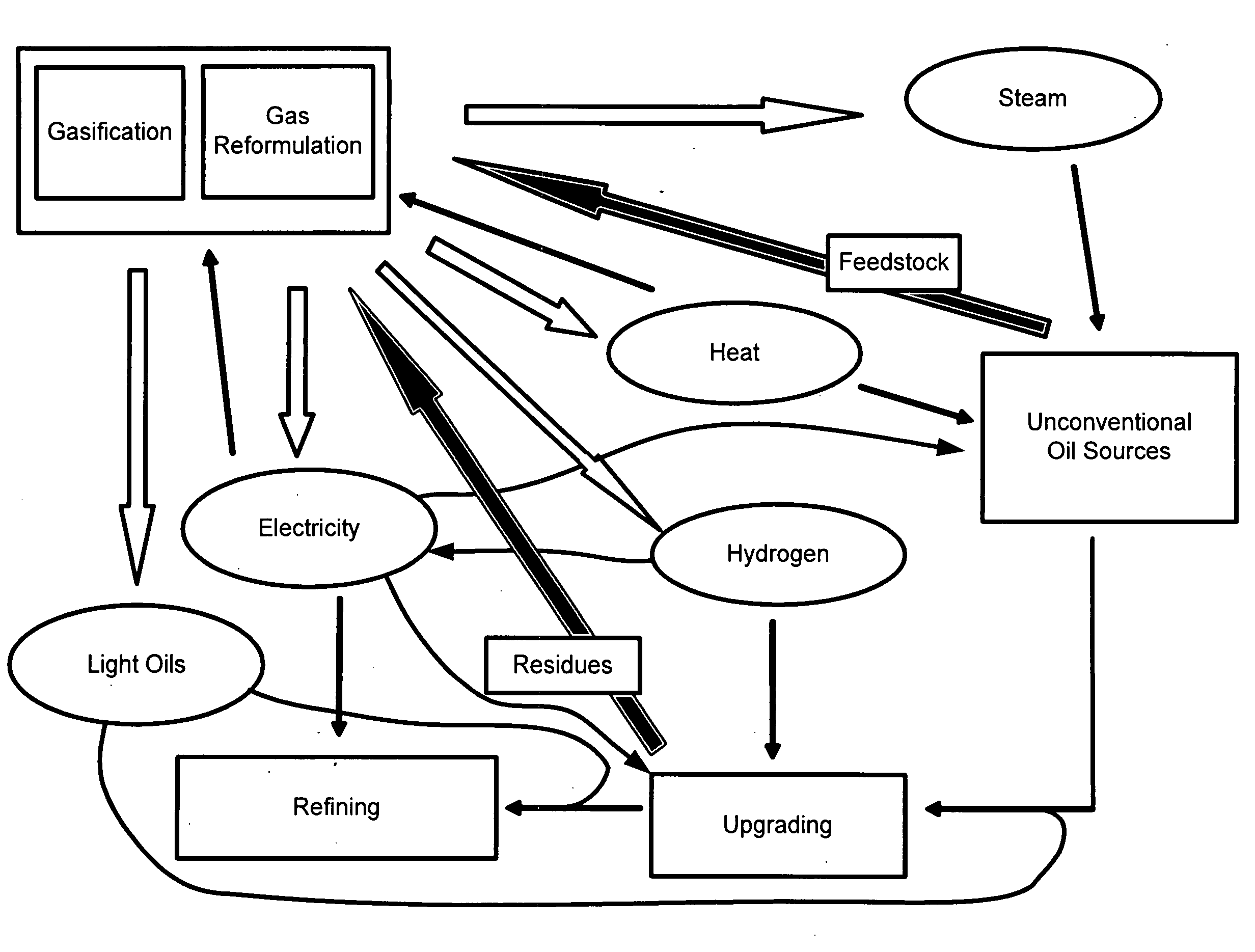

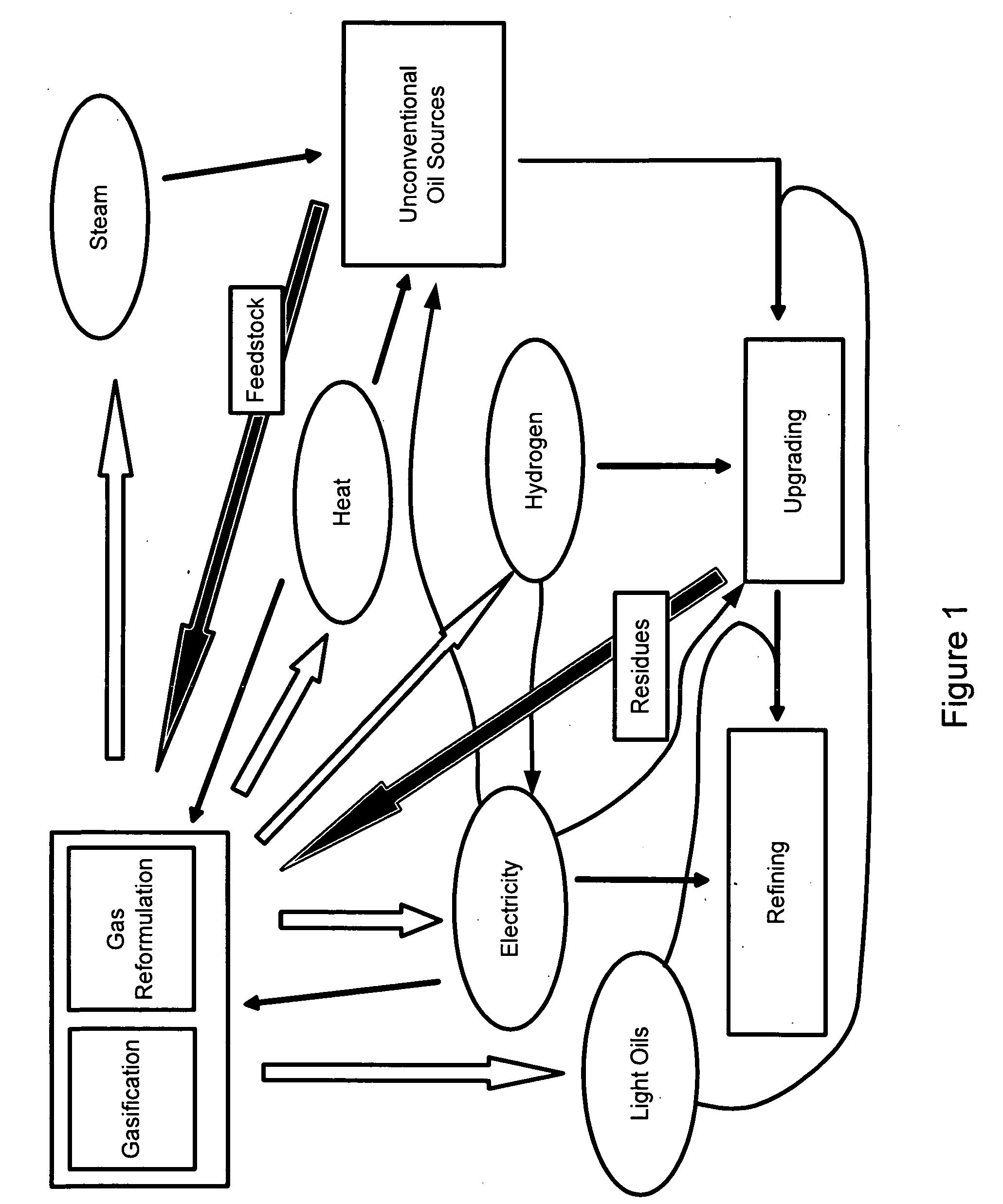

A facility comprising integrated systems for the extraction, and optionally upgrading and / or refinement, of unconventional oil sources, using fossil fuels as a primary source of energy. In particular, this facility provides a means to gasify one or more fossil fuels in an efficient manner, converting it into intermediate products such as heat, steam and electricity, which are then used by the system to obtain useful fuel products from unconventional oil sources such as tar sands and oil shale. The design of the components of this facility is optimized such that the overall costs are competitive with an equivalent unconventional oil source processing facility that uses natural gas as a source of processing energy. The facility can be used on its own, may use supplemental natural gas energy sources, or may be used in conjunction with an existing facility that uses natural gas as an energy source in order to improve the overall cost effectiveness of the processing and / or reduce the requirement for other energy sources, such as natural gas.

Owner:PLASCO ENERGY GROUP INC

Processes For Hydromethanation Of A Carbonaceous Feedstock

ActiveUS20100292350A1Increase oxygenIncrease the amount of carbonOrganic compound preparationCombustible gas catalytic treatmentPhysical chemistryProcess engineering

The present invention relates to processes for preparing gaseous products, and in particular methane, via the catalytic hydromethanation of a carbonaceous feedstock in the presence of steam, syngas and an oxygen-rich gas stream.

Owner:SURE CHAMPION INVESTMENT LTD

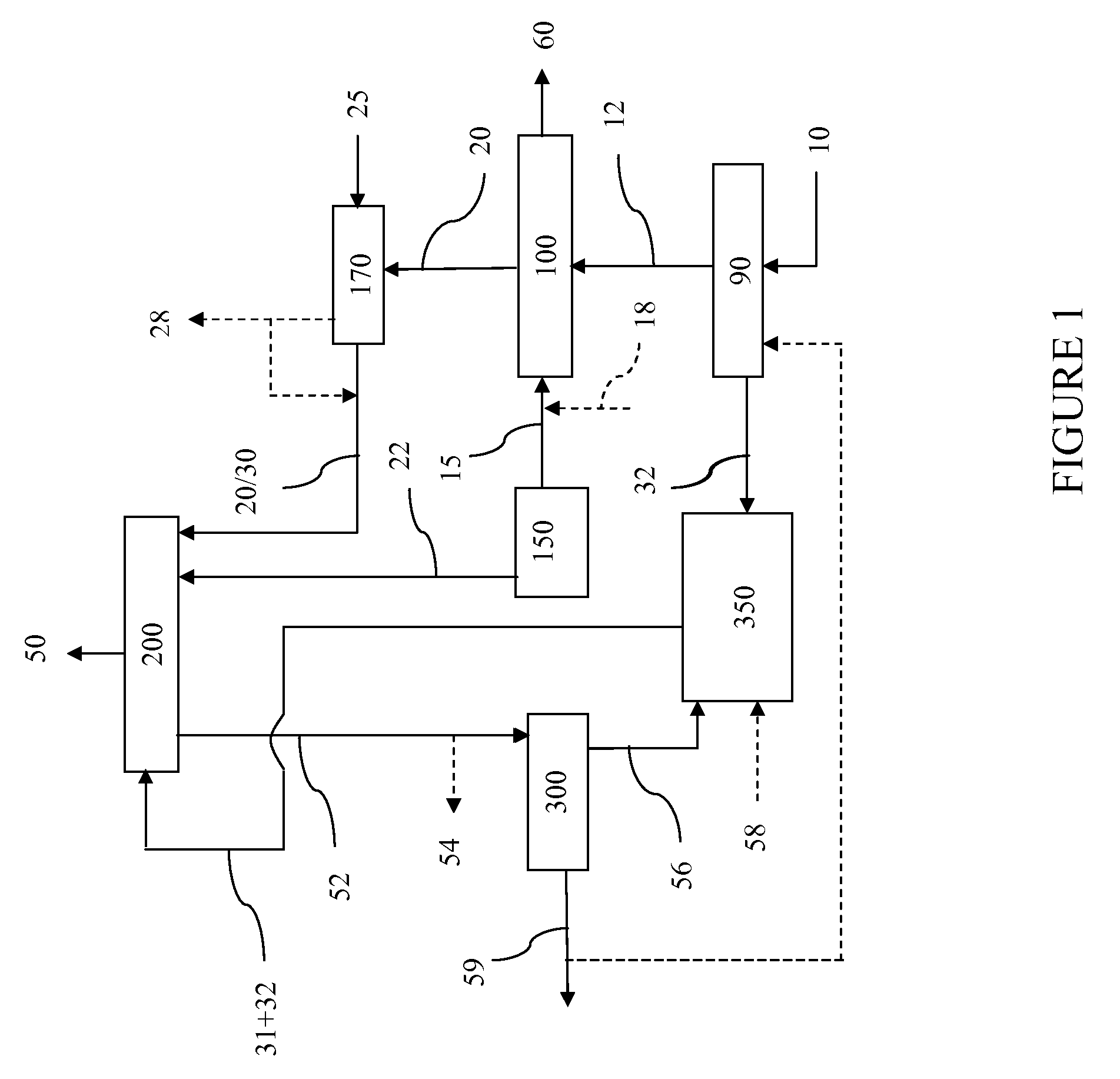

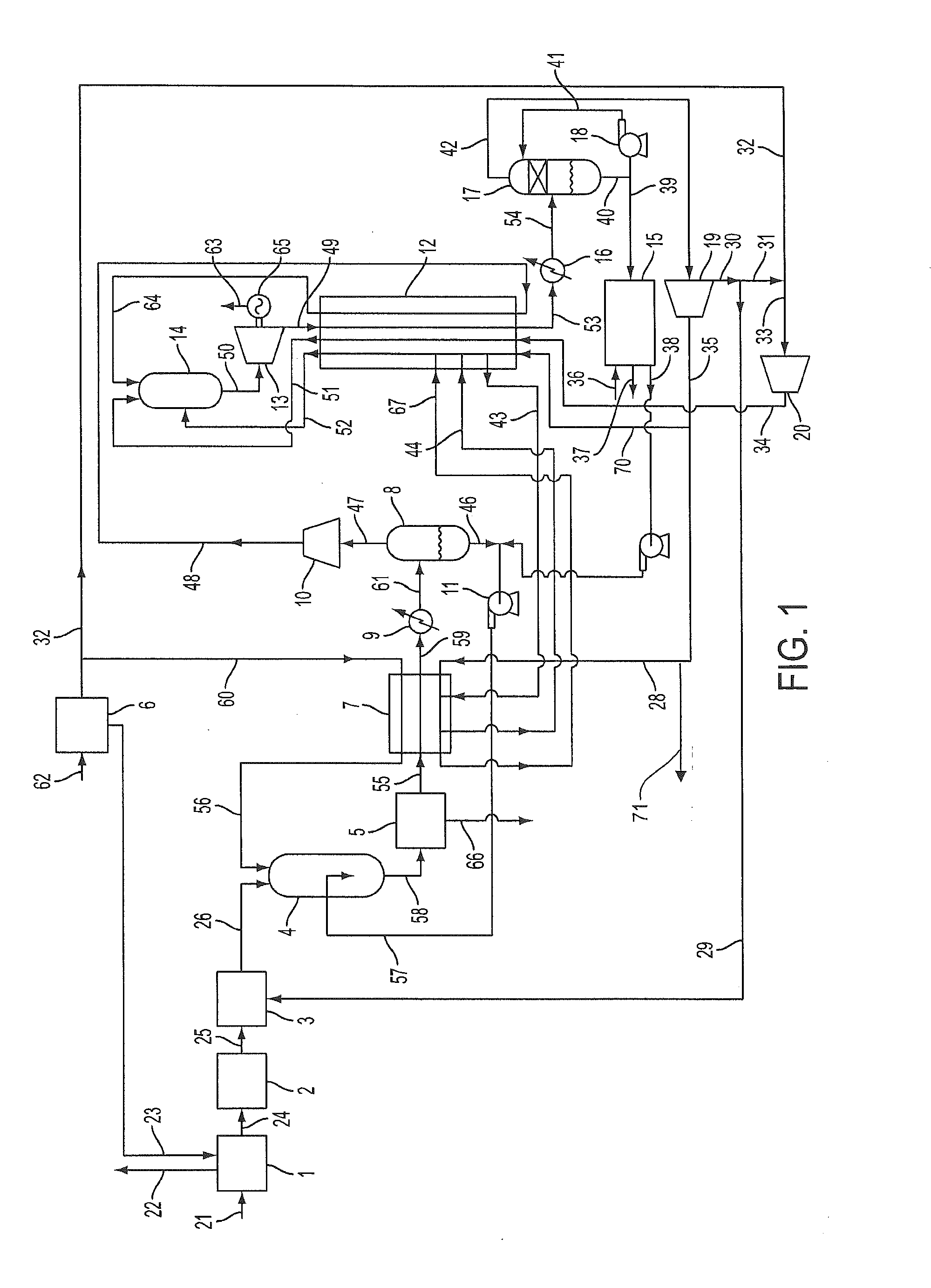

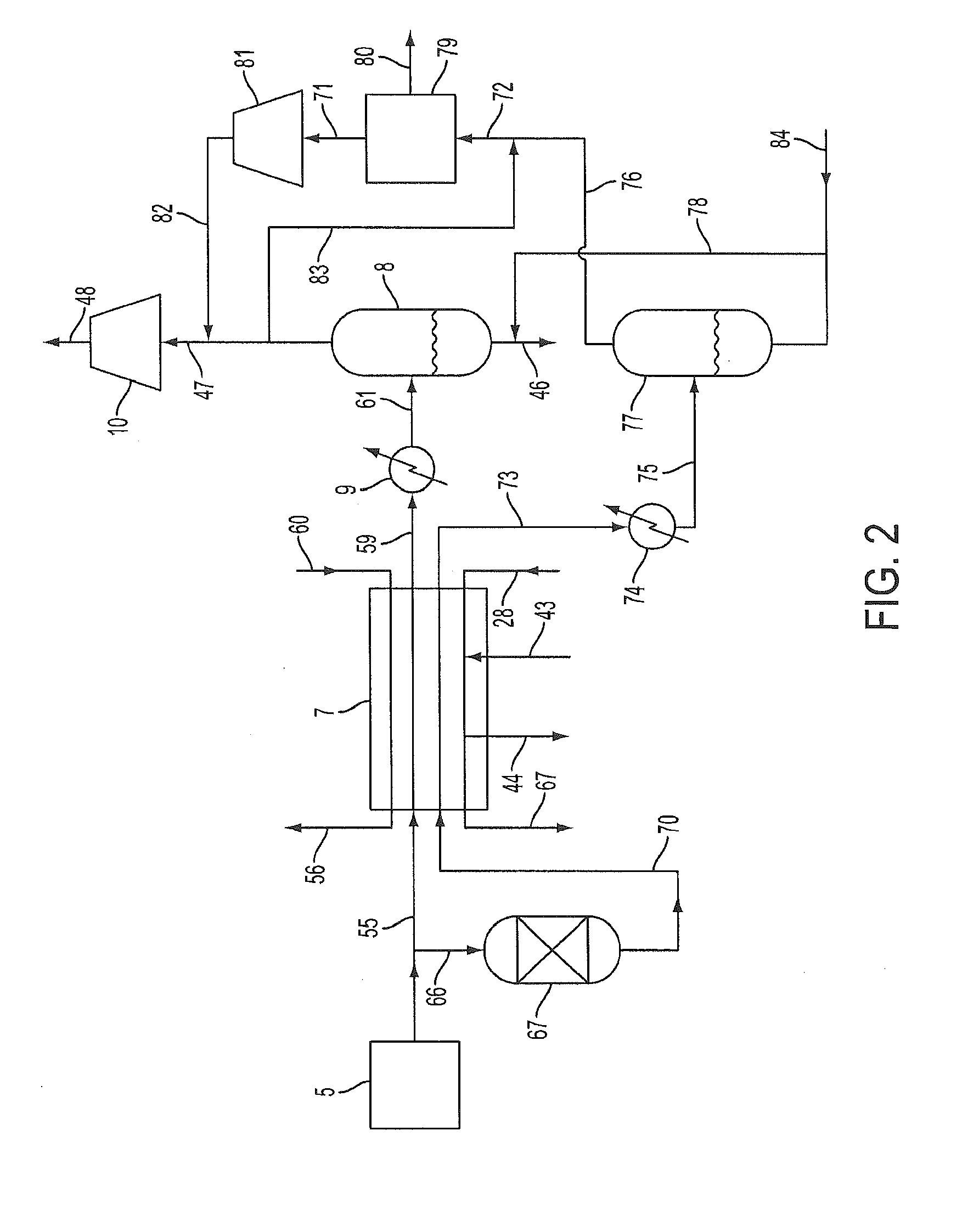

Partial oxidation reaction with closed cycle quench

ActiveUS8776532B2Prevent metal dustingReaction is slowSolidificationLiquefactionPartial oxidationCombustor

The present disclosure relates to a power production system that is adapted to achieve high efficiency power production with complete carbon capture when using a solid or liquid hydrocarbon or carbonaceous fuel. More particularly, the solid or liquid fuel first is partially oxidized in a partial oxidation reactor. The resulting partially oxidized stream that comprises a fuel gas is quenched, filtered, cooled, and then directed to a combustor of a power production system as the combustion fuel. The partially oxidized stream is combined with a compressed recycle CO2 stream and oxygen. The combustion stream is expanded across a turbine to produce power and passed through a recuperator heat exchanger. The expanded and cooled exhaust stream is scrubbed to provide the recycle CO2 stream, which is compressed and passed through the recuperator heat exchanger and the POX heat exchanger in a manner useful to provide increased efficiency to the combined systems.

Owner:8 RIVERS CAPTTAL LLC

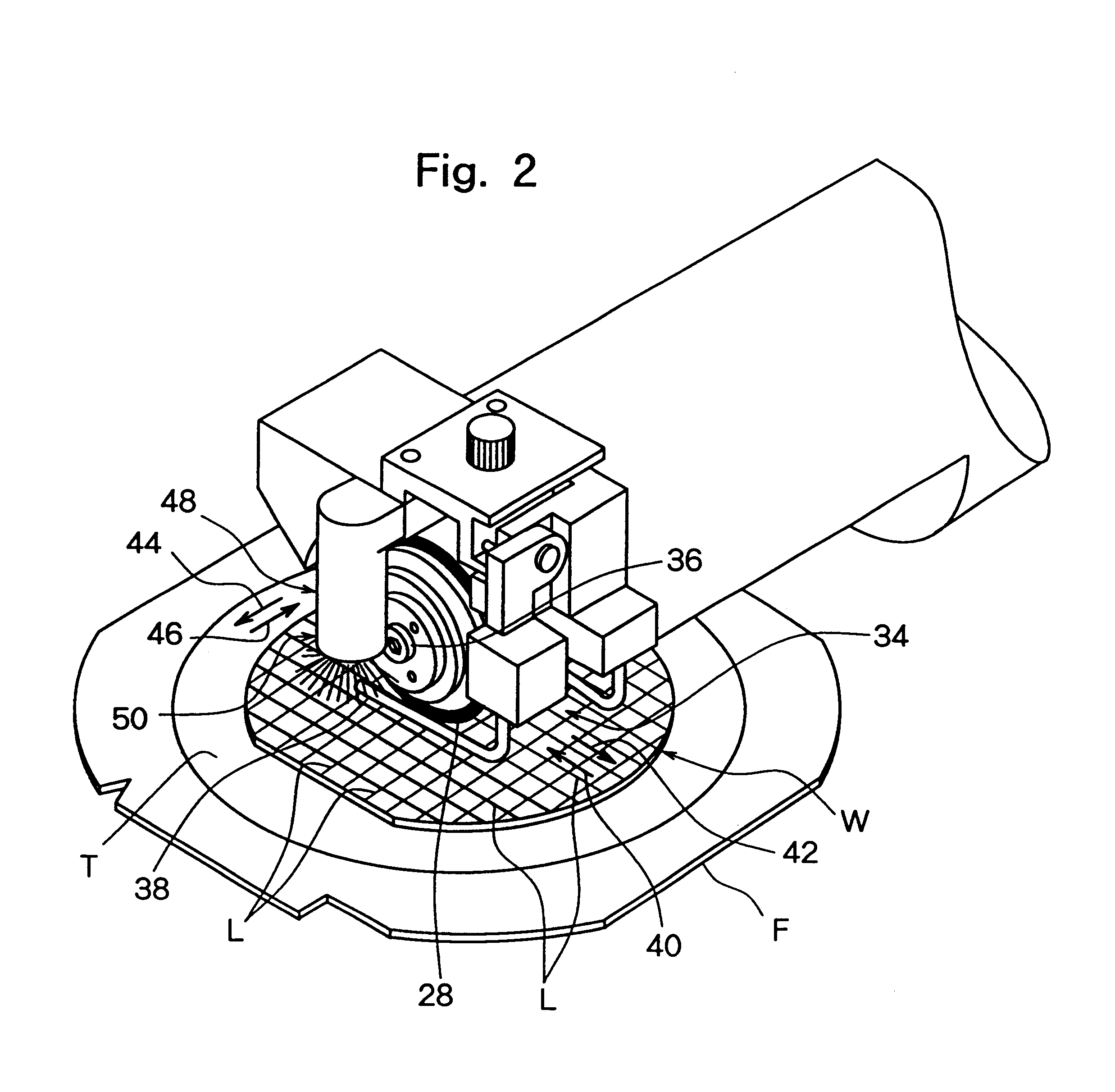

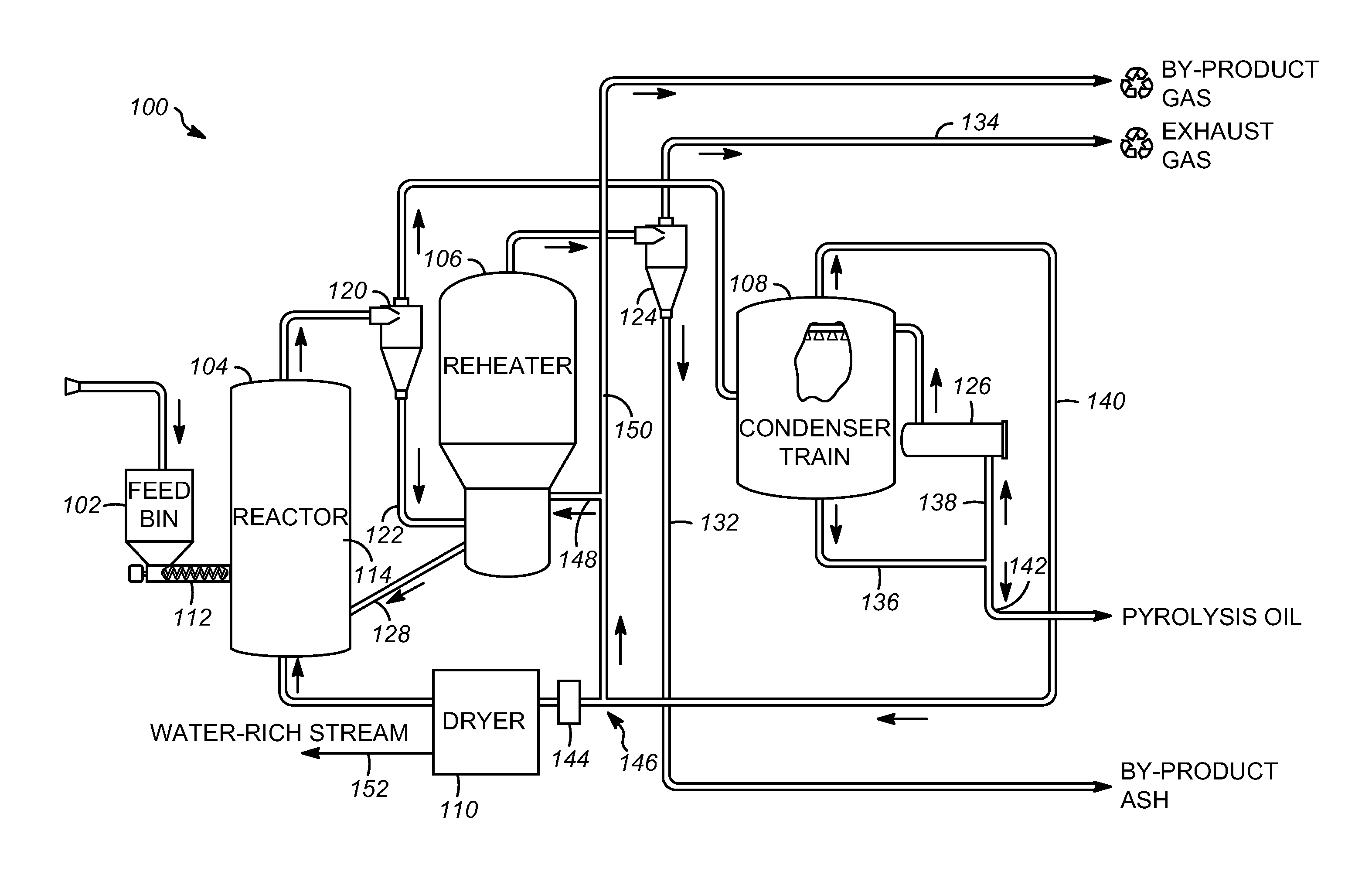

Rapid thermal conversion of biomass

ActiveUS20090139851A1Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingCoke quenchingLiquid productHeat carrier

The present invent provides improved rapid thermal conversion processes for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. In an embodiment, biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. In one embodiment, the liquid product itself is used as the quench media.

Owner:ENSYN RENEWABLES

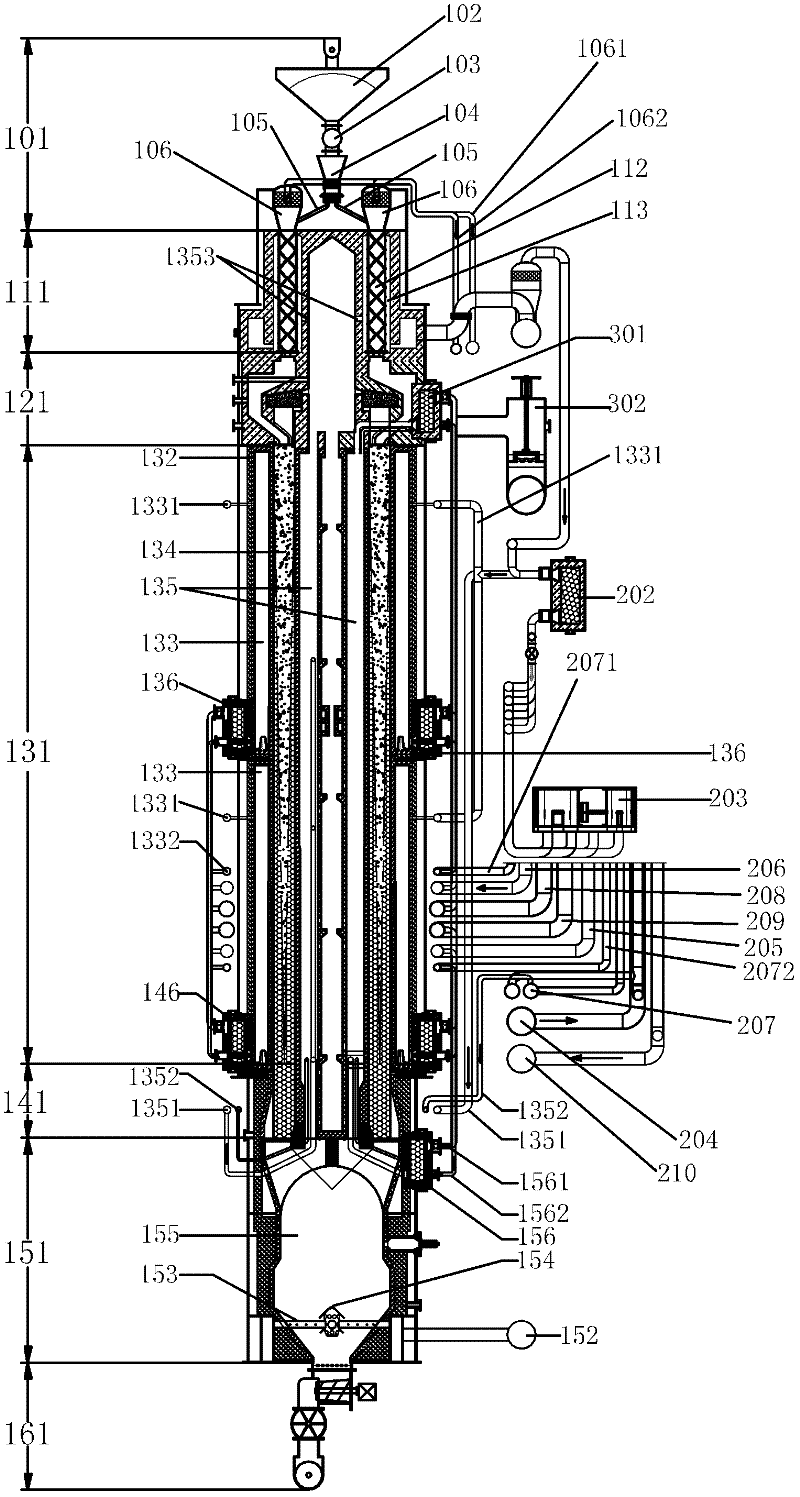

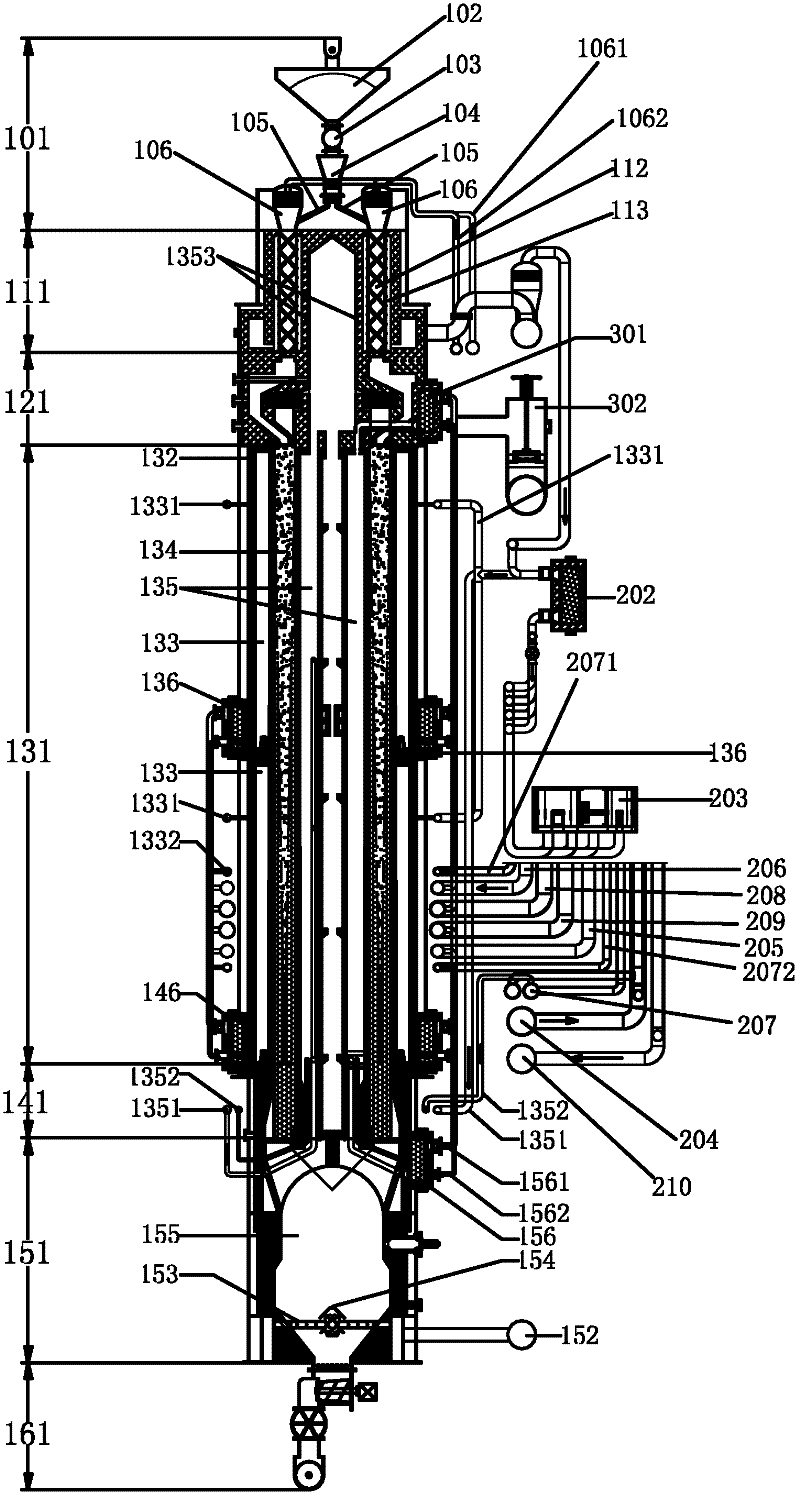

Coking furnace capable of recycling heat energy and coking method

InactiveCN102250629AExtend the industrial chainReduce pollutionCoke quenchingGas purification with selectively adsorptive solidsThermal energyCombustion

The invention discloses a coking furnace capable of recycling heat energy, and the coking furnace comprises a furnace body, an exhaust gas recycling system and a raw coal gas treatment system, wherein the furnace body sequentially comprises a coal feeding segment, a rapid coal heating segment, a raw coal gas leading-out segment, a coal carbonization coking segment, a coke quenching and tempering segment, a dry coke quenching segment and a coke discharging segment from top to bottom; the exhaust gas recycling system comprises an exhaust gas leading-out unit, an exhaust gas heat exchanger, a commutator and the like; and the raw coal gas treatment system comprises a raw coal gas leading-out unit. By using the coking furnace disclosed by the invention, continuous coal carbonization coking canbe achieved and the exhaust gas after combustion is used for dry coke quenching in the furnace; pre-dried coal can be quickly heated to 300 DEG C during entering the furnace, the coal is carbonized and coked in the furnace body, and the exhaust gas generated by self-combustion is used for dry coke quenching at the furnace bottom after the exhaust gas is cooled by heat exchange with air, thus continuously producing coke; the pollution is less in the production process; the coal industrial chain is extended, the coking cost is lowered, the coking coal types are broadened, and the product quality is improved; the profit margins are expanded in a large extent; and the maintenance cost is low.

Owner:山西华天新能源发展有限公司

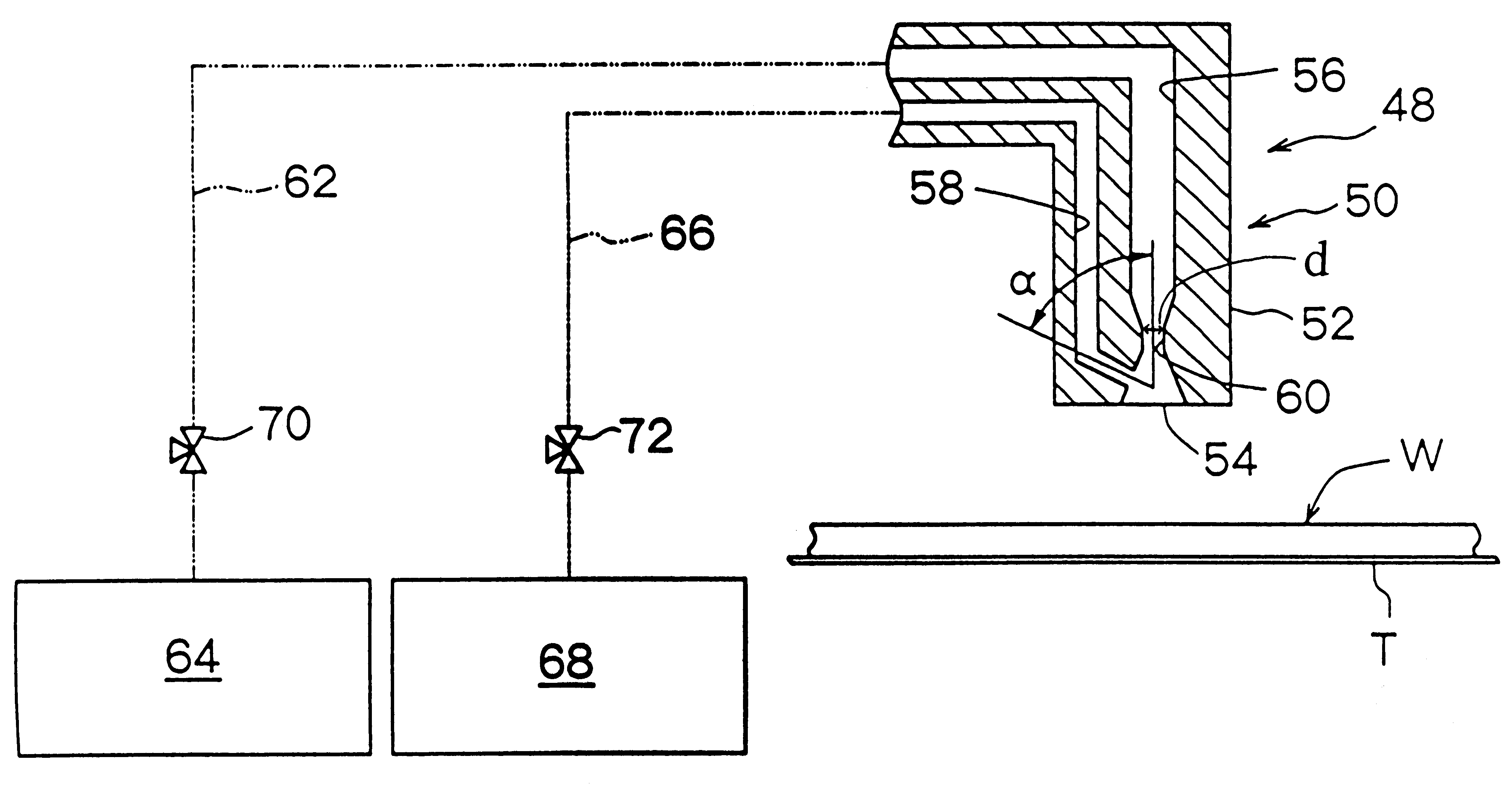

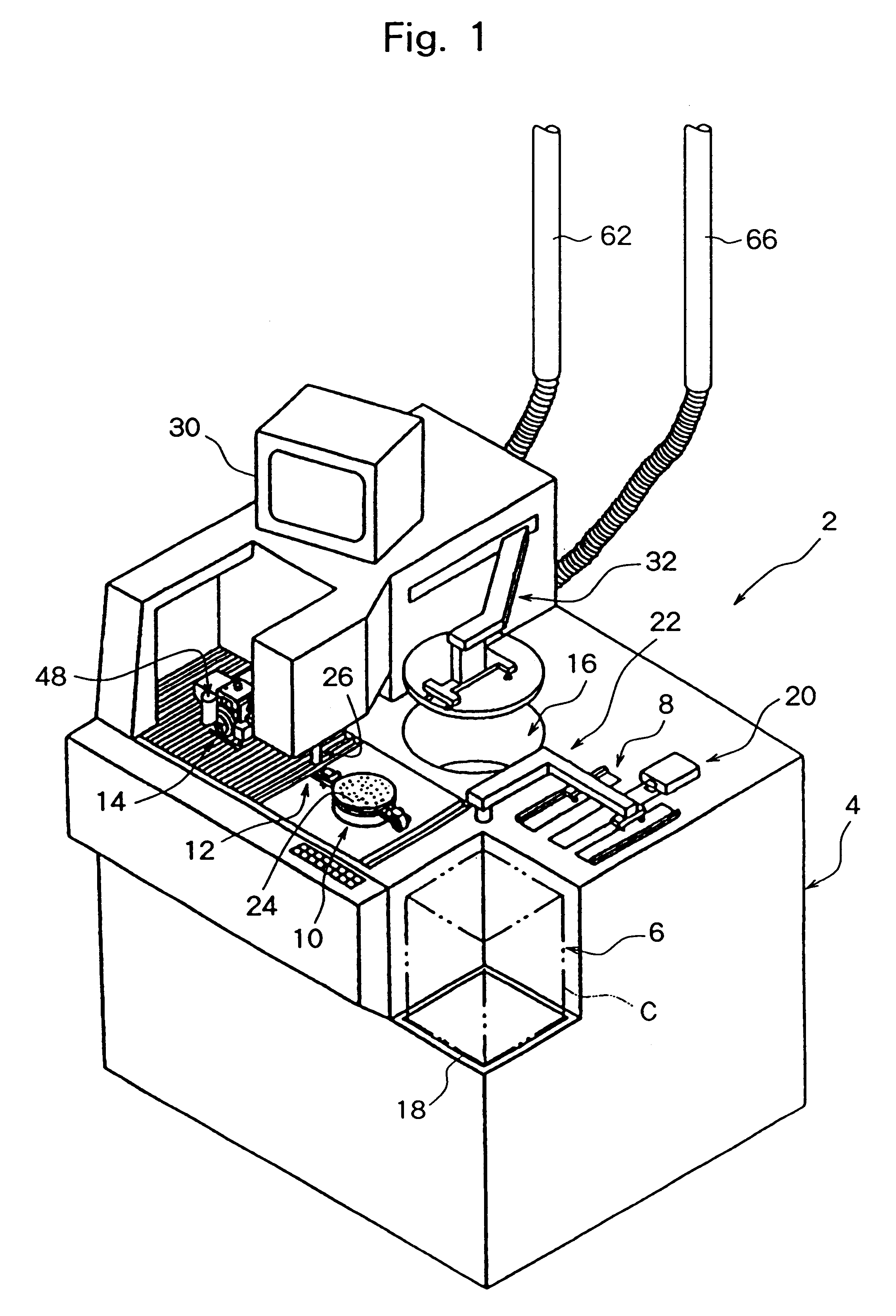

Cleaning apparatus

InactiveUS6386466B1Sufficient cleaning effectCleaning apparatus can be rendered considerably compact and inexpensiveUsing liquid separation agentMixing methodsEngineeringNozzle

A cleaning apparatus includes a nozzle having an ejection port, a cleaning liquid path communicating with the ejection port, and a compressed gas path communicating with the ejection port. The cleaning apparatus further includes a cleaning liquid feeding component for feeding a cleaning liquid to the cleaning liquid path, and a compressed gas feeding component for feeding a compressed gas to the compressed gas path. The compressed gas is ejected from the ejection port through the compressed gas path, while the cleaning liquid is ejected from the ejection port through the cleaning liquid path.

Owner:DISCO CORP

Modular automatic traveling apparatus

A modular automatic traveling apparatus includes a seat and an external coupling device mounted onto the seat. The seat includes a moving device to allow the seat to move automatically and an assembling passage which has two ends formed respectively an inlet and a holding orifice. The holding orifice has a detent portion on the perimeter thereof. The external coupling device has an installation portion which is inserted into the assembling passage through the inlet and latched on the detent portion and anchored on the holding orifice, thus is movable automatically with the seat. Users can change the external coupling devices with varying functions such as a vacuum cleaner, odorator and the like to automatically perform different types of tasks through the automatic movement of the seat.

Owner:KO JOSEPH Y

Partial oxidation reaction with closed cycle quench

ActiveUS20130205746A1Prevent metal dustingReaction is slowSolidificationLiquefactionPartial oxidationCombustor

The present disclosure relates to a power production system that is adapted to achieve high efficiency power production with complete carbon capture when using a solid or liquid hydrocarbon or carbonaceous fuel. More particularly, the solid or liquid fuel first is partially oxidized in a partial oxidation reactor. The resulting partially oxidized stream that comprises a fuel gas is quenched, filtered, cooled, and then directed to a combustor of a power production system as the combustion fuel. The partially oxidized stream is combined with a compressed recycle CO2 stream and oxygen. The combustion stream is expanded across a turbine to produce power and passed through a recuperator heat exchanger. The expanded and cooled exhaust stream is scrubbed to provide the recycle CO2 stream, which is compressed and passed through the recuperator heat exchanger and the POX heat exchanger in a manner useful to provide increased efficiency to the combined systems.

Owner:8 RIVERS CAPTTAL LLC

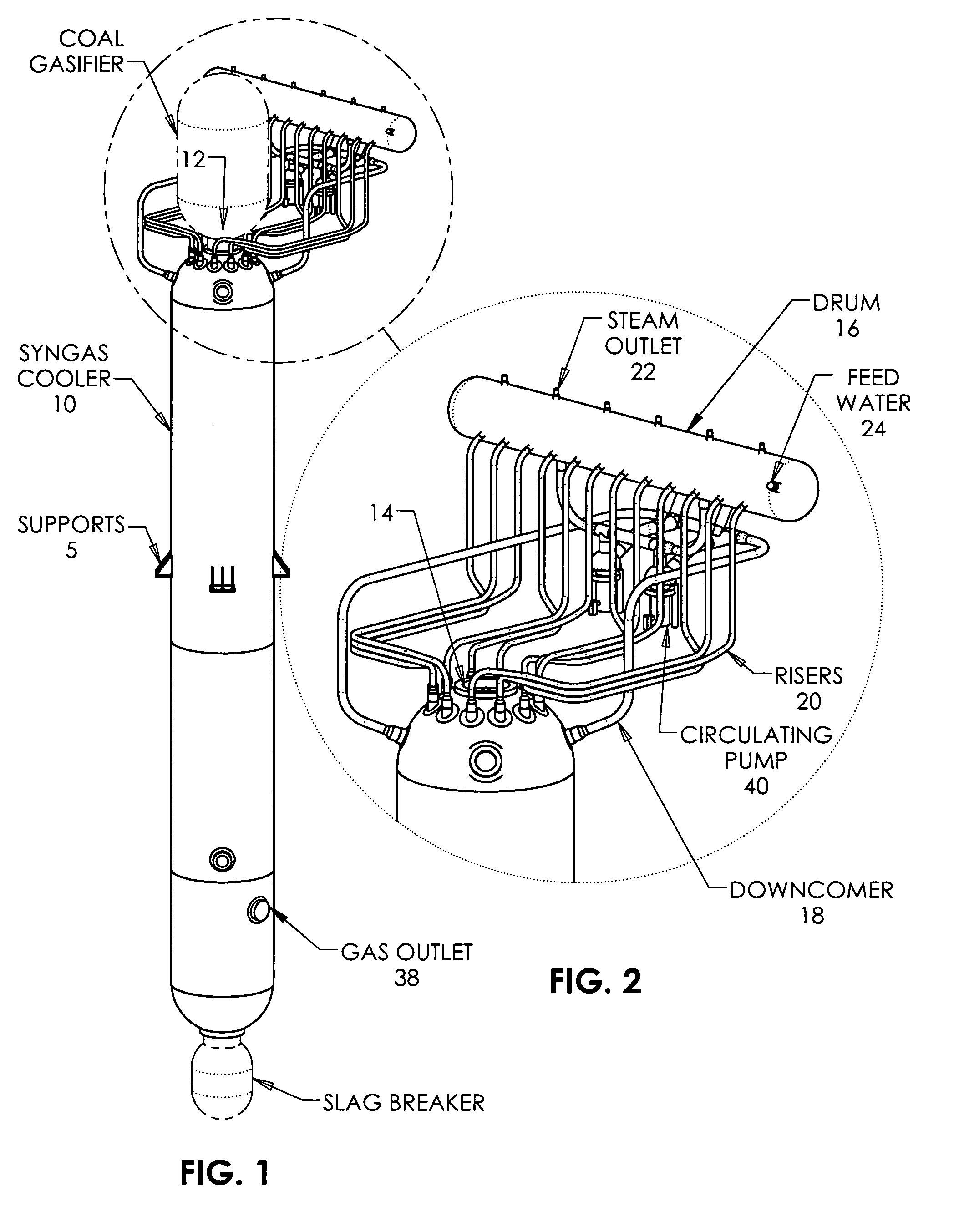

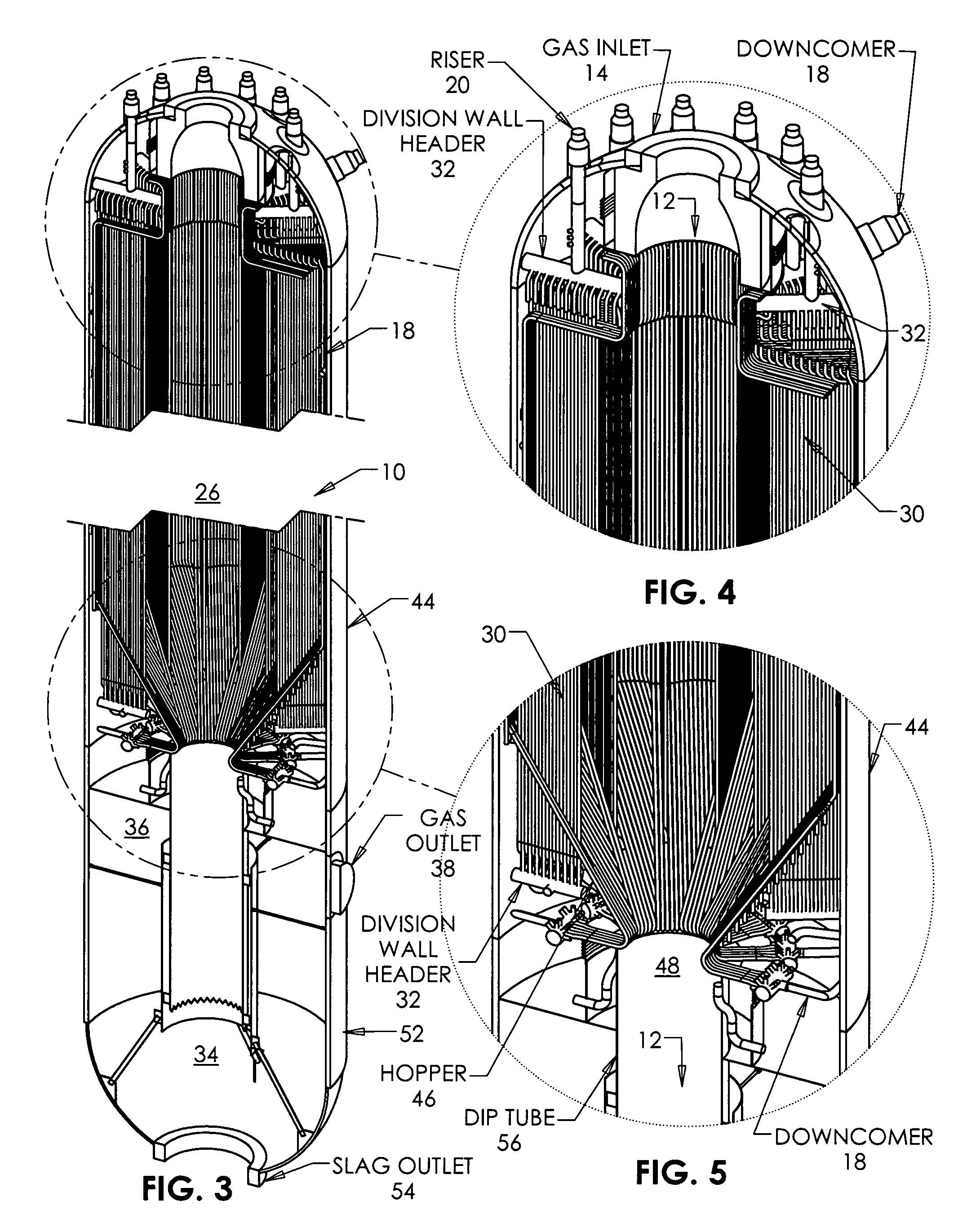

Radiant syngas cooler

A radiant syngas cooler used to contain and cool the synthesis gas produced by coal gasification processes employs radiant and convection surfaces in a specific arrangement to achieve a cost-effective, compact design.

Owner:THE BABCOCK & WILCOX CO

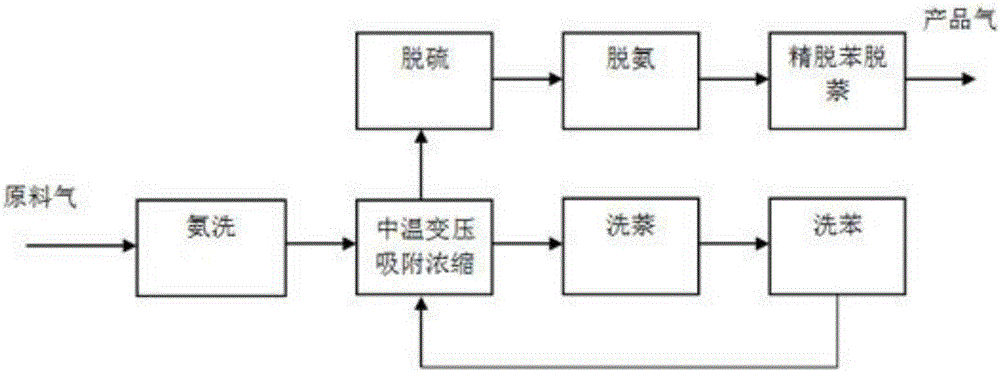

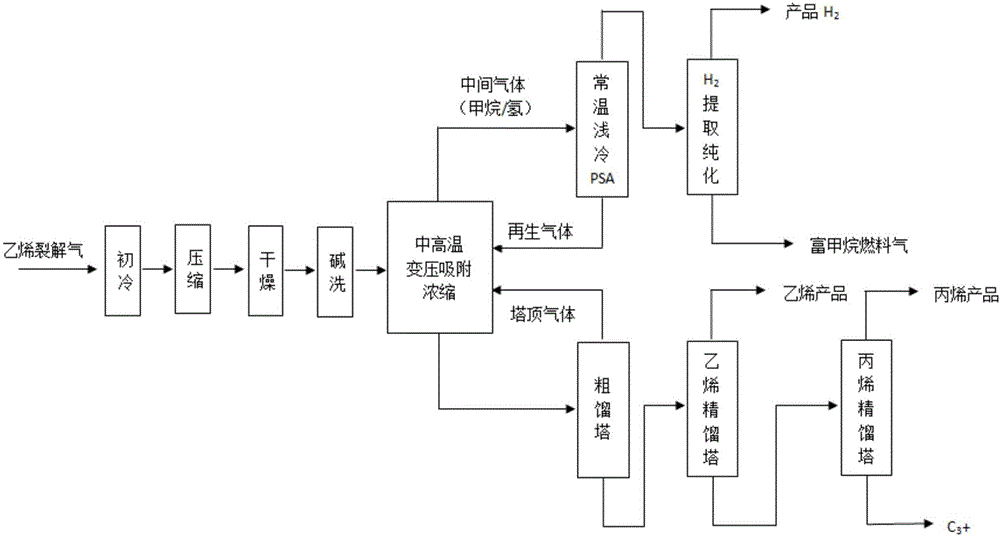

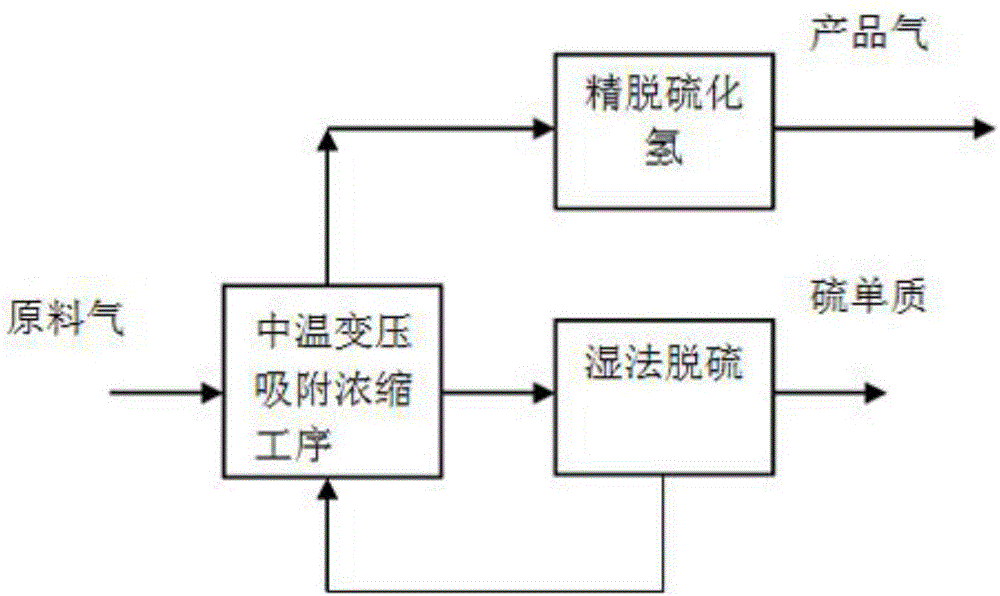

Full-temperature-range pressure swing adsorption gas separation, refinement and purification method

ActiveCN105749699AReduce energy consumptionBroaden the scope of adsorption separation applicationsSolidificationLiquefactionEnergy gradientPurification methods

The invention discloses a full-temperature-range pressure swing adsorption gas separation, refinement and purification method.By means of the difference of the temperatures and pressures of different raw material gases and the difference of the adsorption separation coefficients and physical chemistry properties of all components in the raw material gases in the temperature range of 80-200 DEG C and the pressure range of 0.03-4.0 MPa, the adsorption or desorption regeneration operation of the pressure swing adsorption circulation process is adjusted by coupling all separation methods, the adsorption theory that the pressure or temperature swing adsorption separation process is only limited to the adsorption and desorption regeneration circulation operation through pressure or temperature changes is expanded, and therefore all raw material gases are separated, refined and purified by achieving the energy gradient utilization in the gas separation, refinement and purification process and achieving the circulation operation, where adsorption, desorption and regeneration are easily matched and balanced, in the moderate to low cold and moderate to high temperature pressure swing adsorption separation process, and it is changed that a traditional adsorption method is only limited to the auxiliary effect of refinement and purification, and adsorption becomes the basic separation unit operation just as important as refinement, absorption and extraction separation.

Owner:SICHUAN TECHAIRS

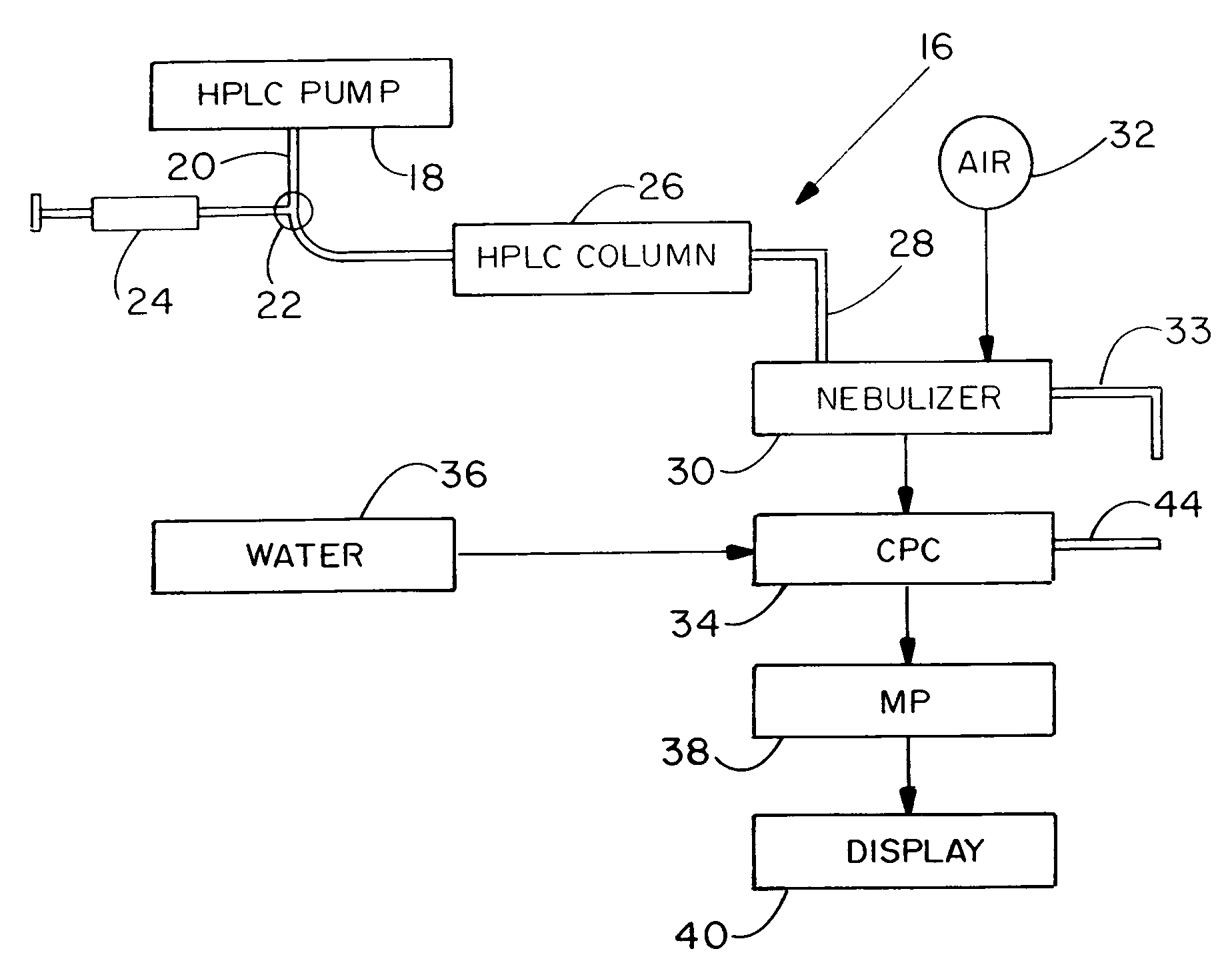

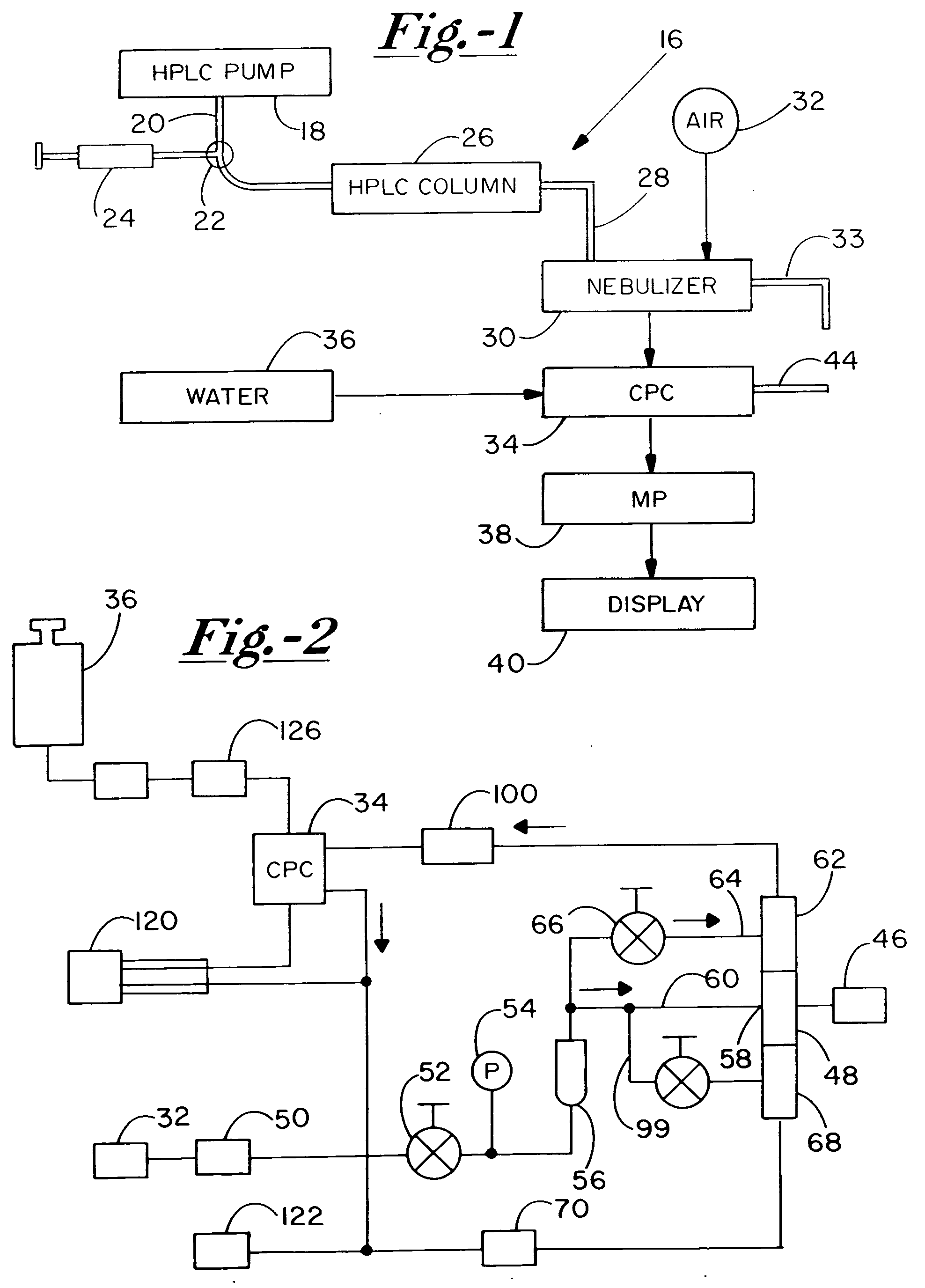

Measuring Analyte Concentrations in Liquids

InactiveUS20080137065A1Higher kinetic energy mixingSmall dropletSamplingComponent separationElectrical mobilityDroplet size

A high performance liquid chromatography system employs a nebulizer with a flow restriction at the exit of its mixing chamber to produce finer droplets, and an adjustable impactor for increased control over droplet sizes. Downstream of the mixing chamber, the nebulizer can incorporate tubing that is permeable to the sample liquid, to promote aerosol drying through perevaporation. A condensation particle counter downstream of the nebulizer uses water as the working medium, and is adjustable to control threshold nucleation sizes and droplet growth rates. A particle size selector employing diffusion, electrostatic attraction or selection based on electrical mobility, is advantageously positioned between the nebulizer and the CPC.

Owner:TSI INC

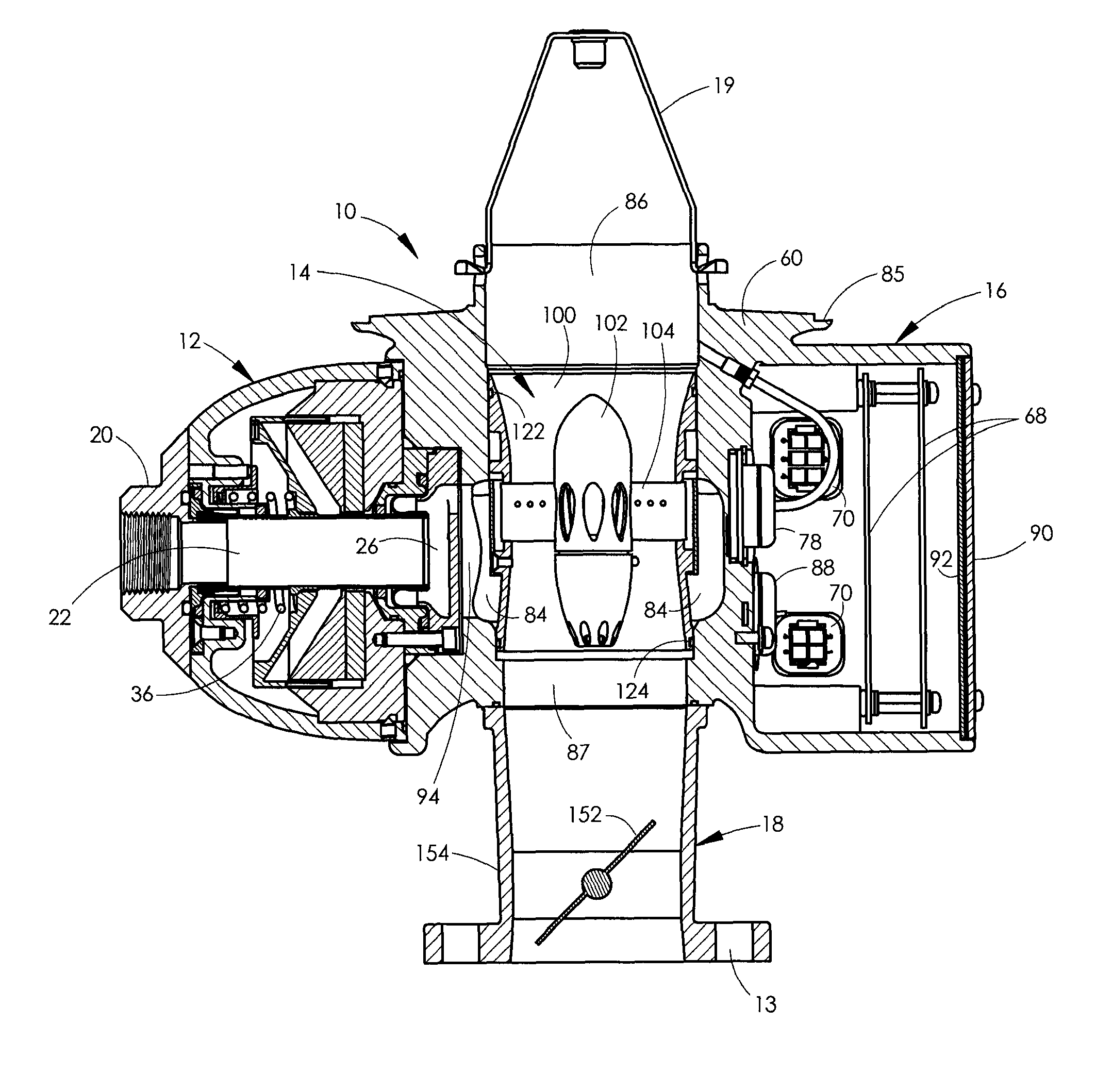

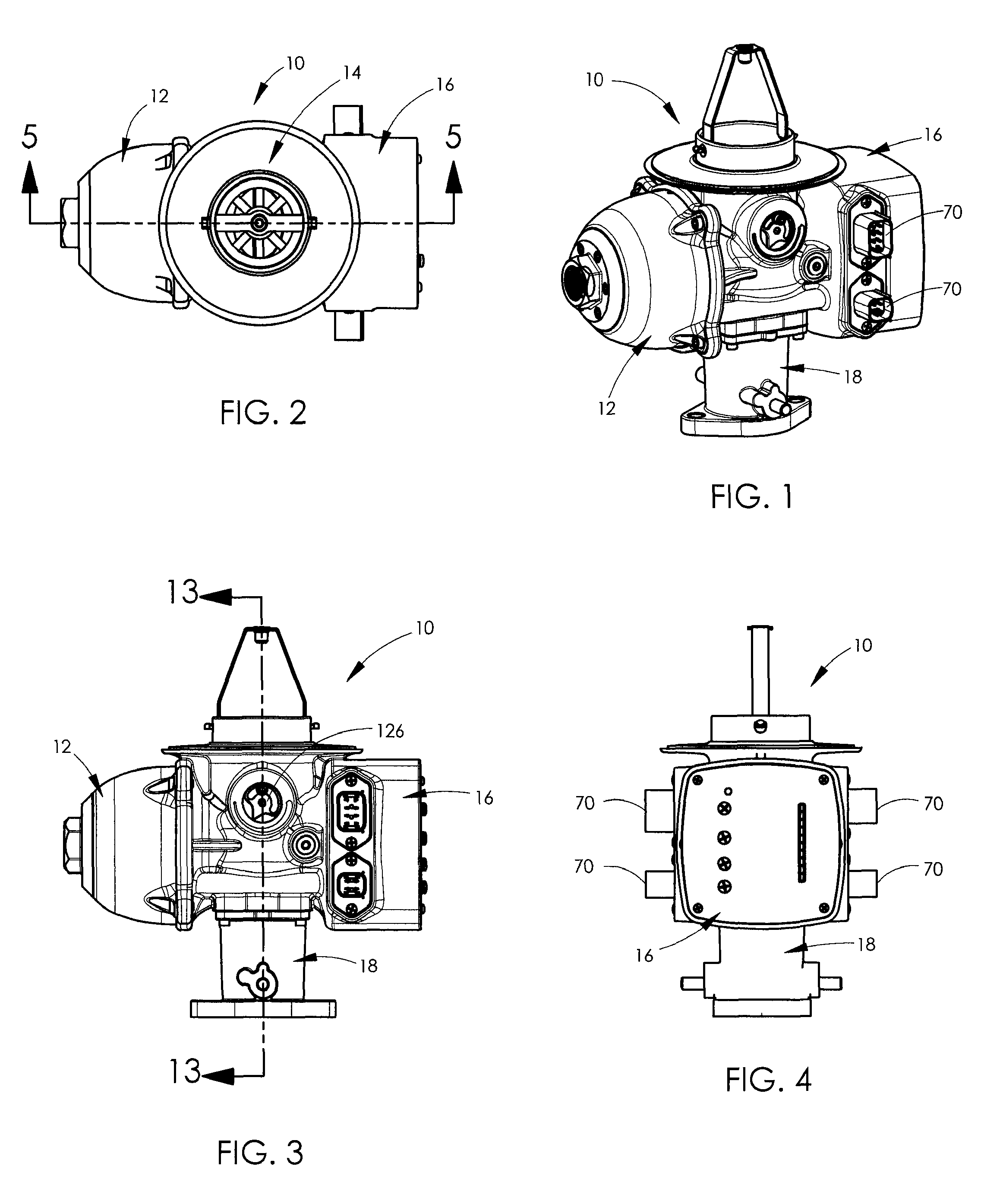

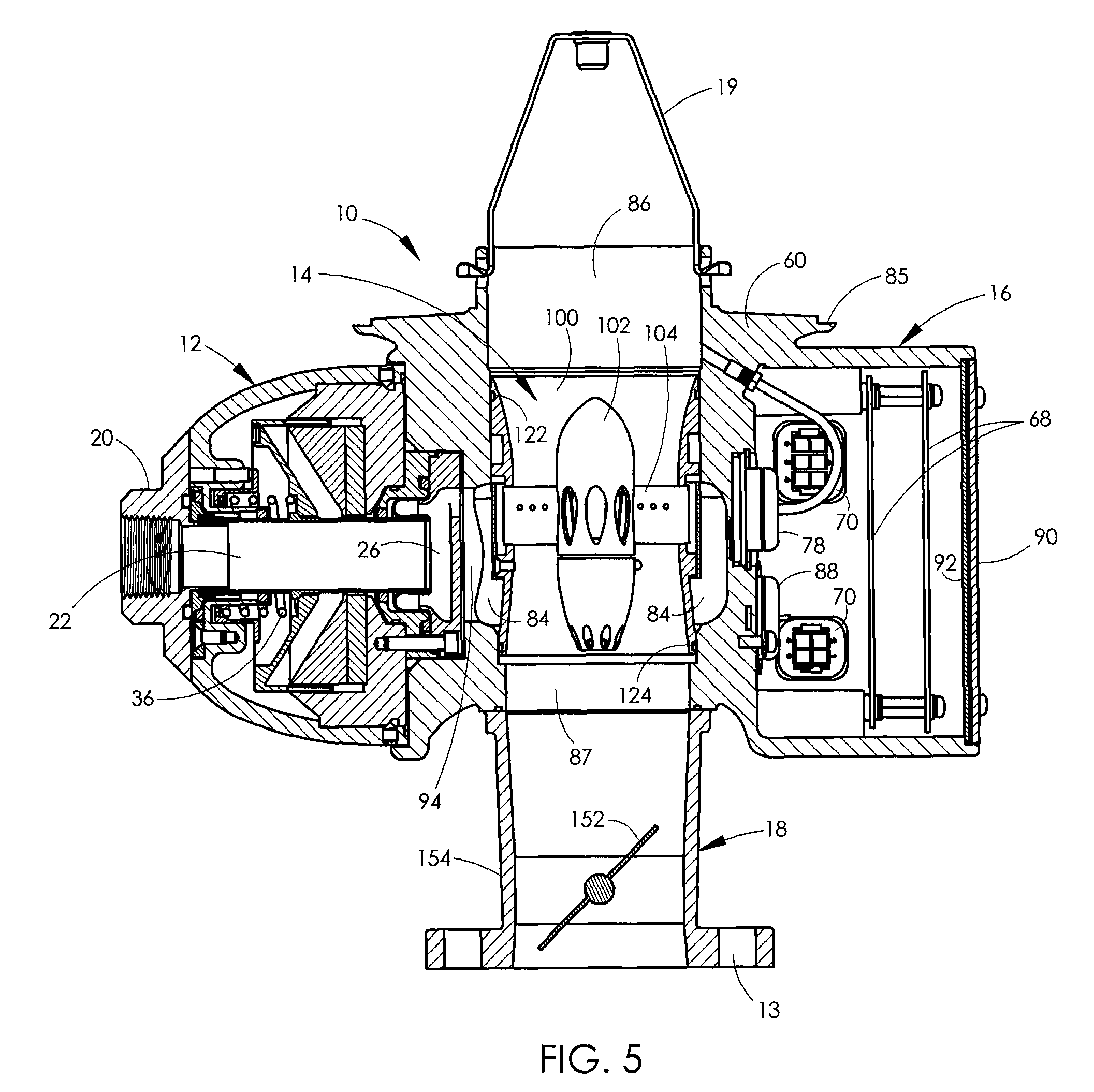

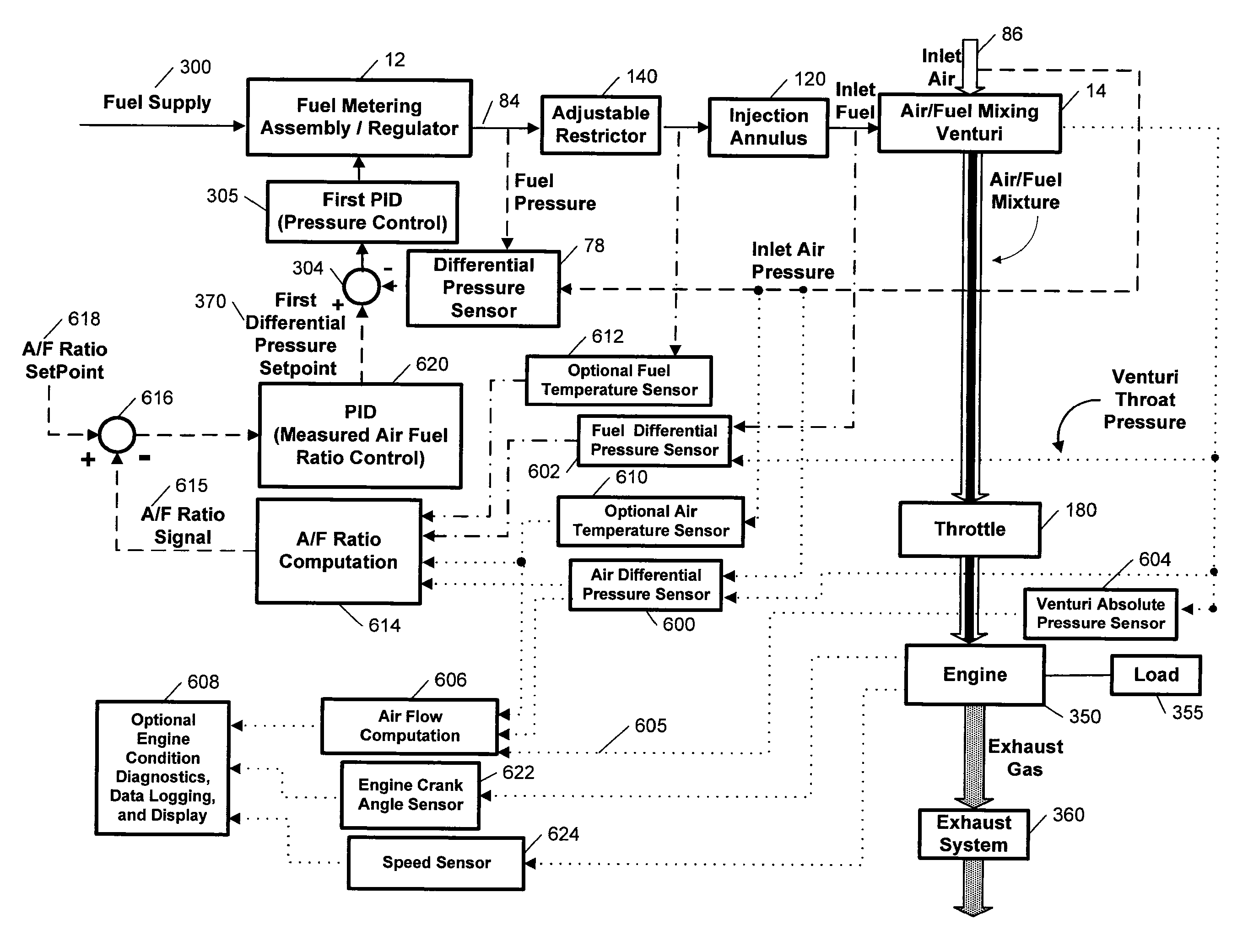

Fuel control system and method for gas engines

InactiveUS8005603B2Cost effectivePromote recoveryInternal combustion piston enginesSpace heating and ventilationControl systemClosed loop

A gaseous carburetor or fuel control system includes a fuel metering assembly, a venturi mixer assembly, a throttle assembly, and an electronic control unit. The control unit controls the fuel metering assembly in a closed loop manner based on detected gas and air pressure to an air / fuel mixing venturi. An electronic governor which controls the throttle valve may also be controlled by the same control unit which controls the fuel metering assembly, using a separate control loop.

Owner:CONTINENTAL CONTROLS CORP

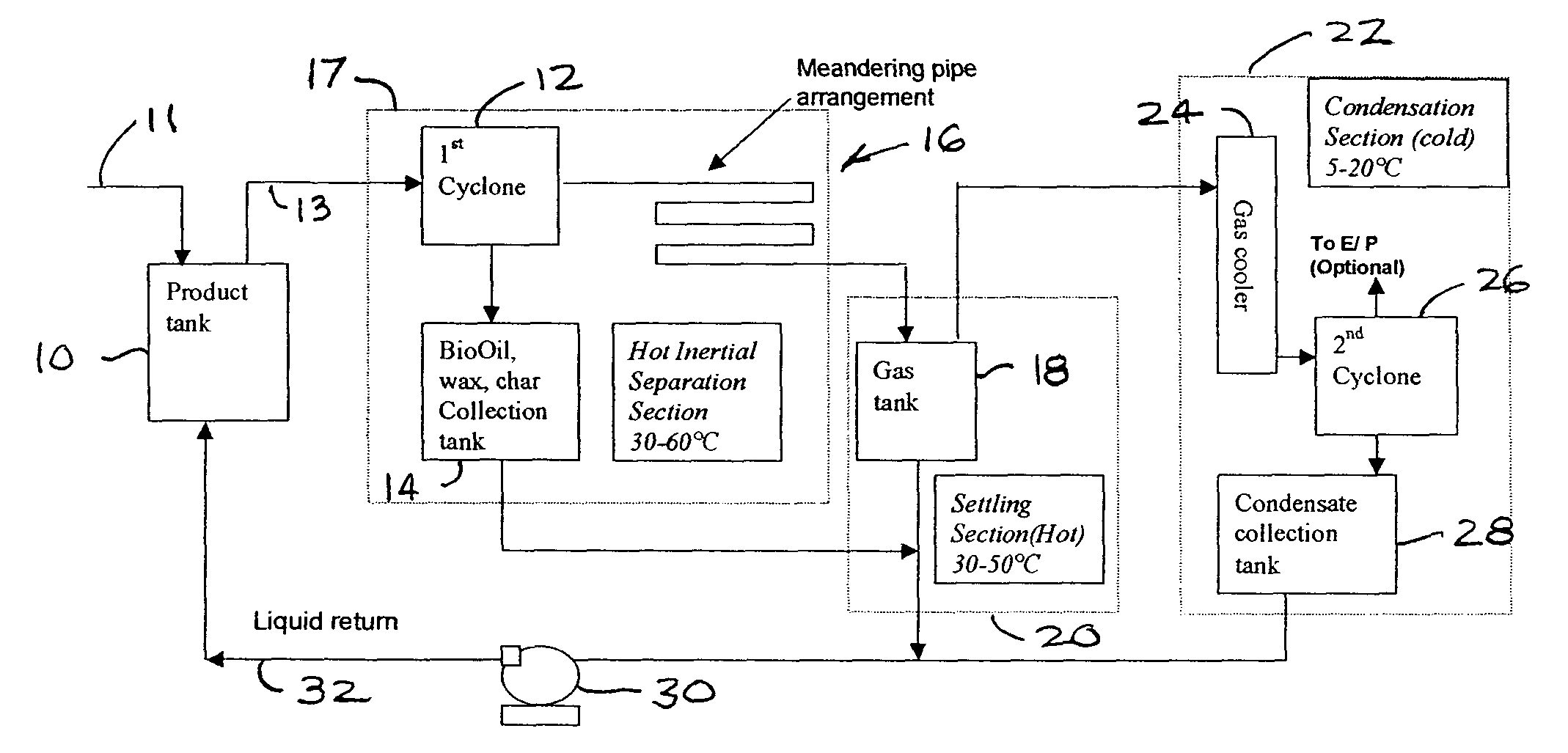

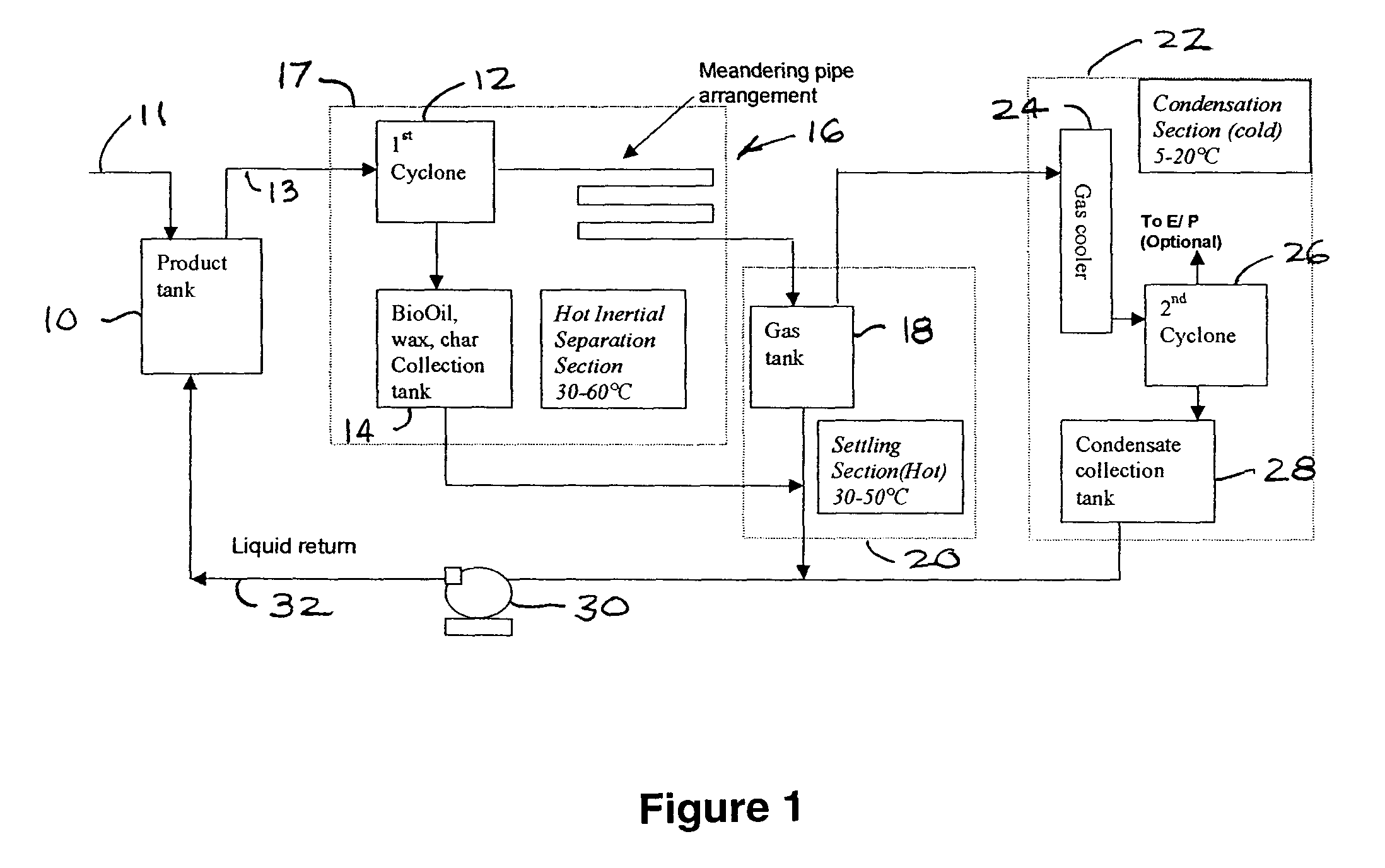

Apparatus for separating fouling contaminants from non-condensable gases at the end of a pyrolysis/thermolysis of biomass process

InactiveUS7004999B2Extended retention timeSlow downCombination devicesLiquid degasificationProduct gasComponents of crude oil

A method of continuously capturing BioOil and its constituents from a gas stream produced in a fast pyrolysis / thermolysis process, in a usable liquid form so as to produce a non-condensable gas free of fouling contaminates. The method includes separating BioOil and its constituents from a gas stream using hot inertial separation to maintain the temperature of said BioOil and its constituents above a temperature at which the thick and / or sticky constituents cause inefficient operation of the equipment but low enough so that they do not undergo rapid degradation. Next the gas velocity is reduced to a temperature sufficiently low to allow droplets in the gas stream to settle out but high enough so that a viscosity of said droplets remains low enough to avoid inefficient operation of the separation equipment. Finally, liquid is condensed out of the gas stream.

Owner:DYNAMOTIVE ENERGY SYST CORP

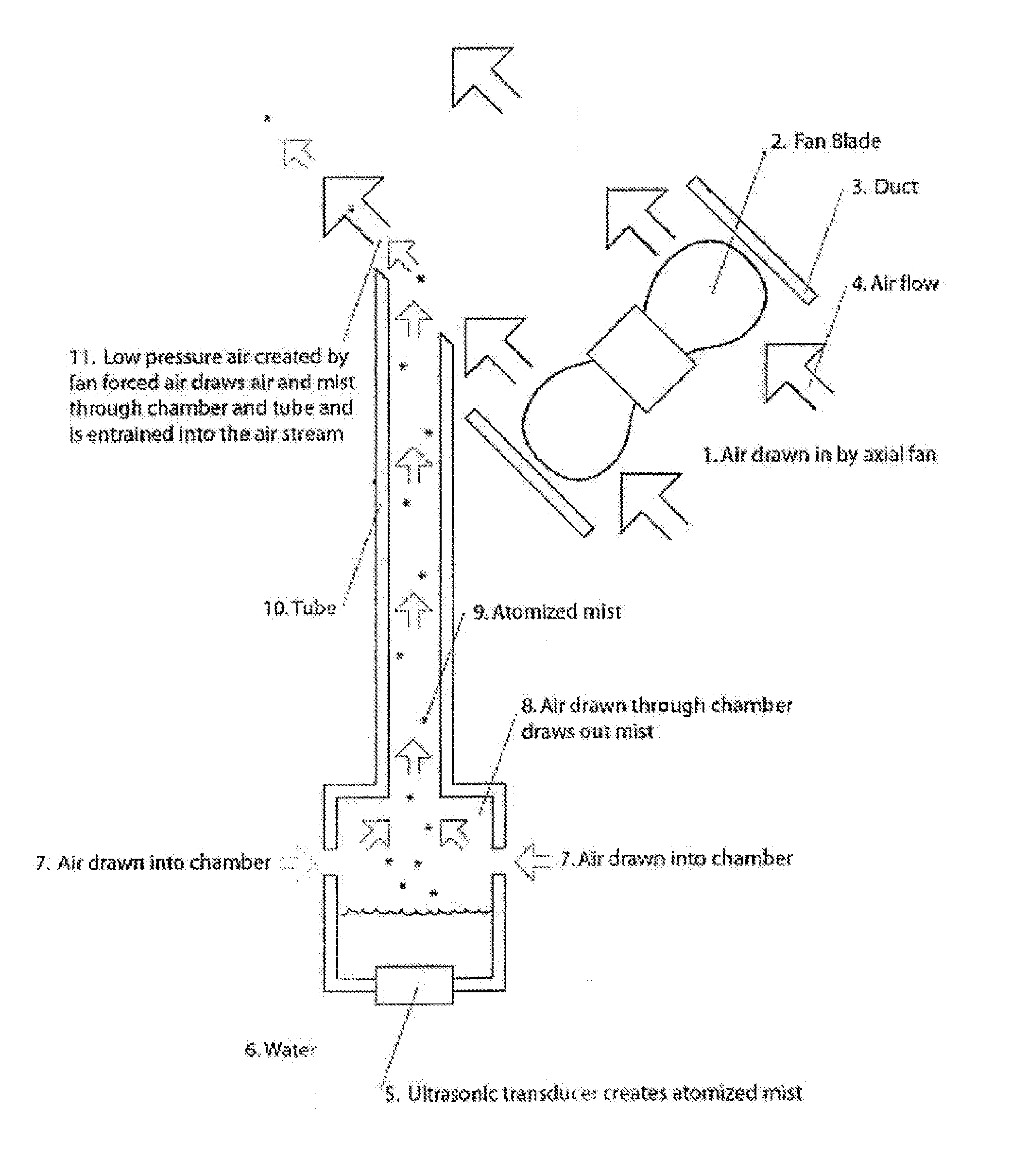

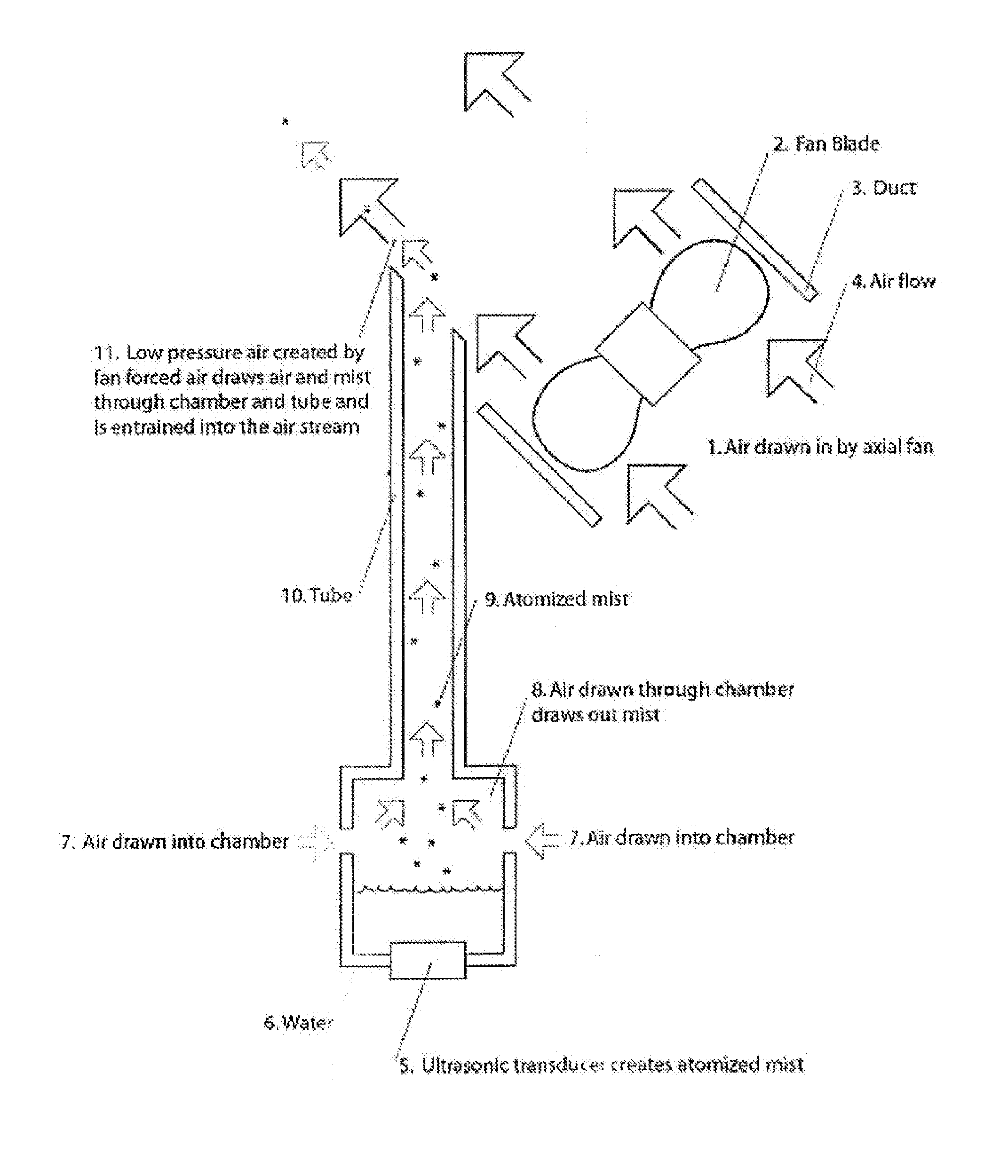

Ultrasonic humidifier

An ultrasonic humidifier is disclosed including a chamber, an ultrasonic transducer positioned at the bottom of the chamber, a passage in fluid communication with the chamber, a duct having an inlet and an outlet, the duct being in fluid communication with the passage by way of a passage outlet, a fan positioned in the duct and disposed between the duct inlet and the passage outlet. The fan is configured to propel air through the duct and over the passage outlet such that vapors in the chamber may be drawn into the duct.

Owner:VORNADO AIR LLC

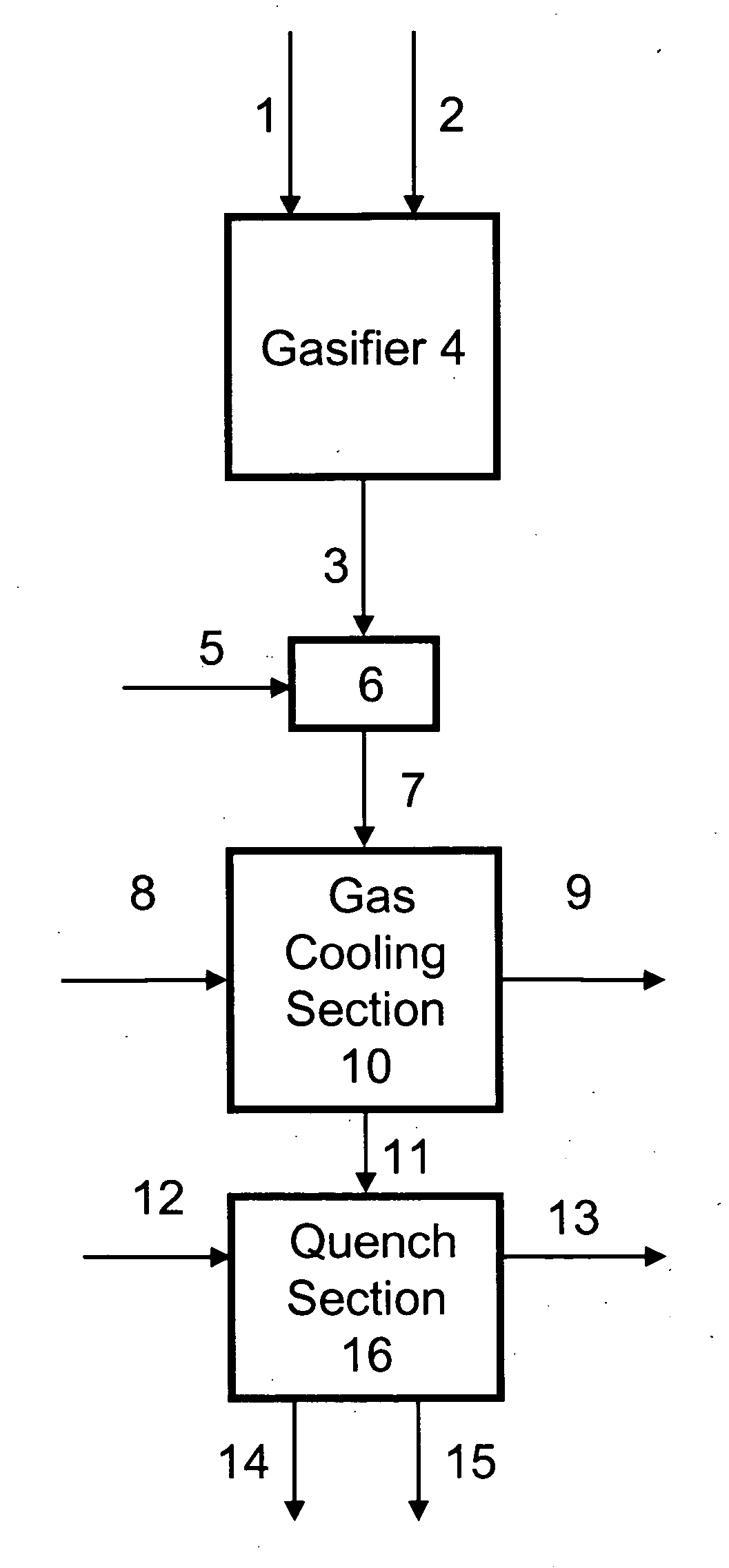

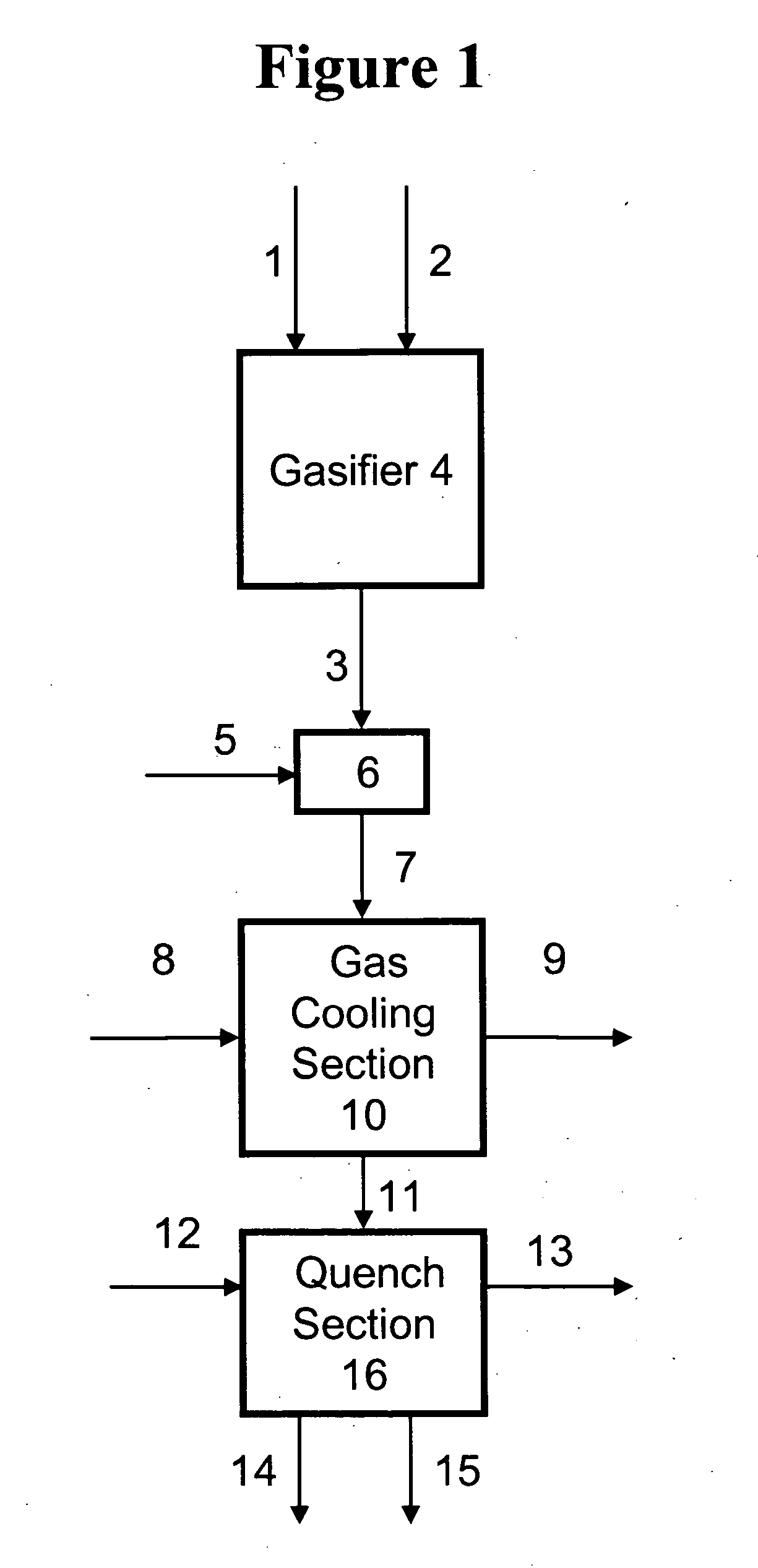

Method of Operation of Process to Produce Syngas from Carbonaceous Material

InactiveUS20120256131A1High CO/CO molar ratioEffective coolingGasifier feeding meansInternal combustion piston enginesSyngasProcess engineering

A process is provided for producing syngas that is effective for use in downstream processes. The process for producing syngas includes operating a gasification apparatus in a start-up mode until the gasification apparatus and equipment downstream of the gasification apparatus are adequately warmed up to a first target temperature. Upon reaching a first target temperature, the process is then operated in a production mode to produce a second syngas with a higher CO / CO2 molar ratio. Operation in a start-up mode until reaching a first target temperature, provides a process that is effective for reducing fouling in downstream equipment and for providing a second syngas can be more effectively cooled and cleaned.

Owner:INEOS BIO SA

Fuel control system and method for gas engines

InactiveUS20090088950A1Cost effectivePromote recoveryInternal combustion piston enginesSpace heating and ventilationControl systemEngineering

A gaseous carburetor or fuel control system includes a fuel metering assembly, a venturi mixer assembly, a throttle assembly, and an electronic control unit. The control unit controls the fuel metering assembly in a closed loop manner based on detected gas and air pressure to an air / fuel mixing venturi. An electronic governor which controls the throttle valve may also be controlled by the same control unit which controls the fuel metering assembly, using a separate control loop.

Owner:CONTINENTAL CONTROLS CORP

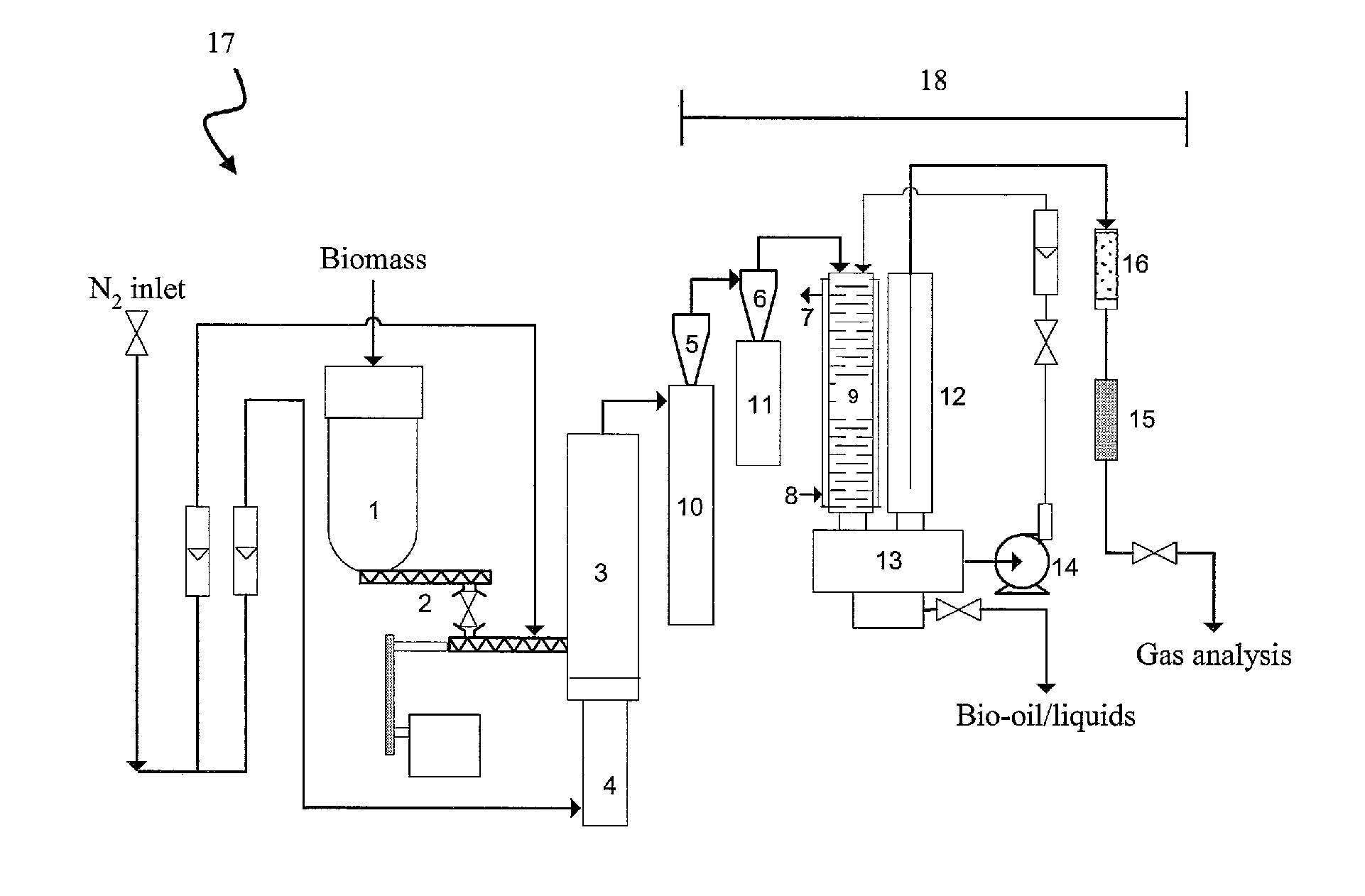

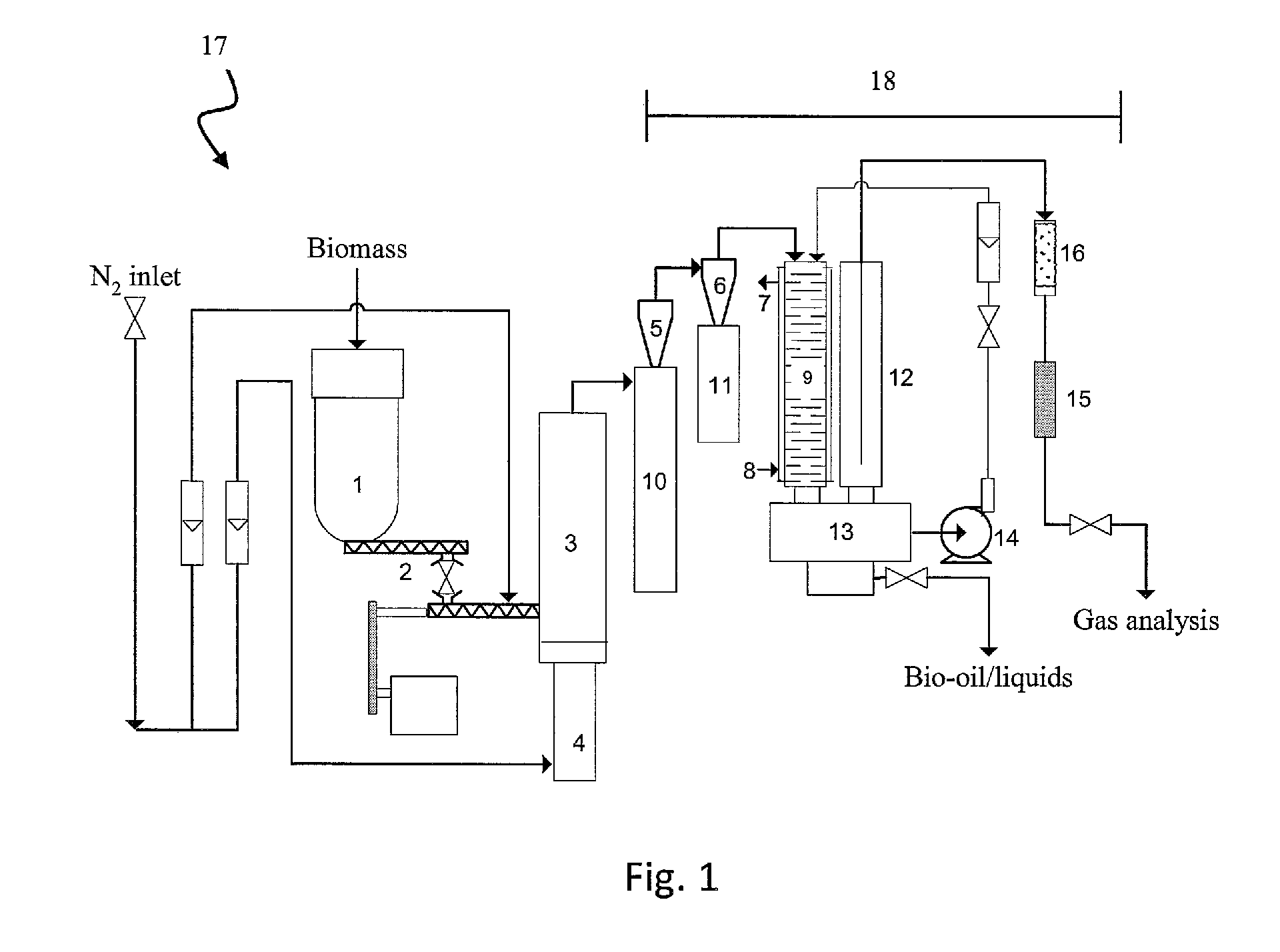

Biomass pyrolysis

InactiveUS7998315B2Reduce probabilityReduce in quantityCombustible gas coke oven heatingDirect heating destructive distillationChemistryPyrolysis

A process for pyrolyzing biomass is provided. The process comprises providing biomass to a pyrolysis reactor to produce a vapor product and condensing said vapor product to produce a condensed product, wherein a phase separation suppression agent is added during said process so as to promote the formation of a single phase condensed product.

Owner:ASTON UNIV

Process for humidifying synthesis gas

InactiveUS20070137107A1Effective recoveryEnsure adequate heatingCombustible gas catalytic treatmentBiofuelsSyngasLiquid water

Disclosed is a process for humidifying syngas to achieve a water to carbon monoxide molar ratio in the product syngas within a desired range and in which the molar ratio which can be varied over time in response to changes in downstream syngas requirements. The raw syngas is produced by reacting a carbonaceous material with oxygen, water, or carbon dioxide and can be combined with a diluent to produce a diluted syngas stream which can be cooled and contacted with liquid water to give a humidified syngas. The H2O:CO molar ratio of the humidified syngas may be adjusted in response to time-varying downstream syngas requirements by changing the amount and / or temperature of the diluent that is combined with the raw syngas stream, by adjusting quench and heat exchange conditions, or a combination thereof. The application of the process to the coproduction of chemicals and power are also disclosed.

Owner:EASTMAN CHEM CO

Radiant syngas cooler

A radiant syngas cooler used to contain and cool the synthesis gas produced by coal gasification processes employs radiant and convection surfaces in a specific arrangement to achieve a cost-effective, compact design.

Owner:THE BABCOCK & WILCOX CO

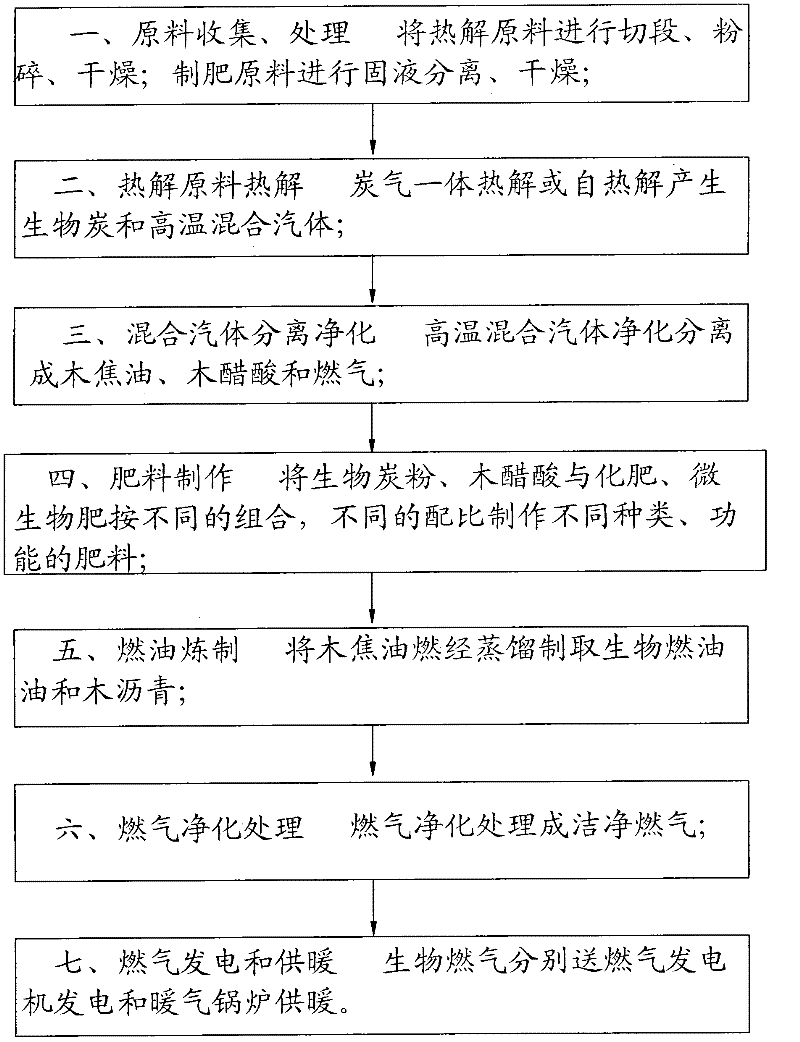

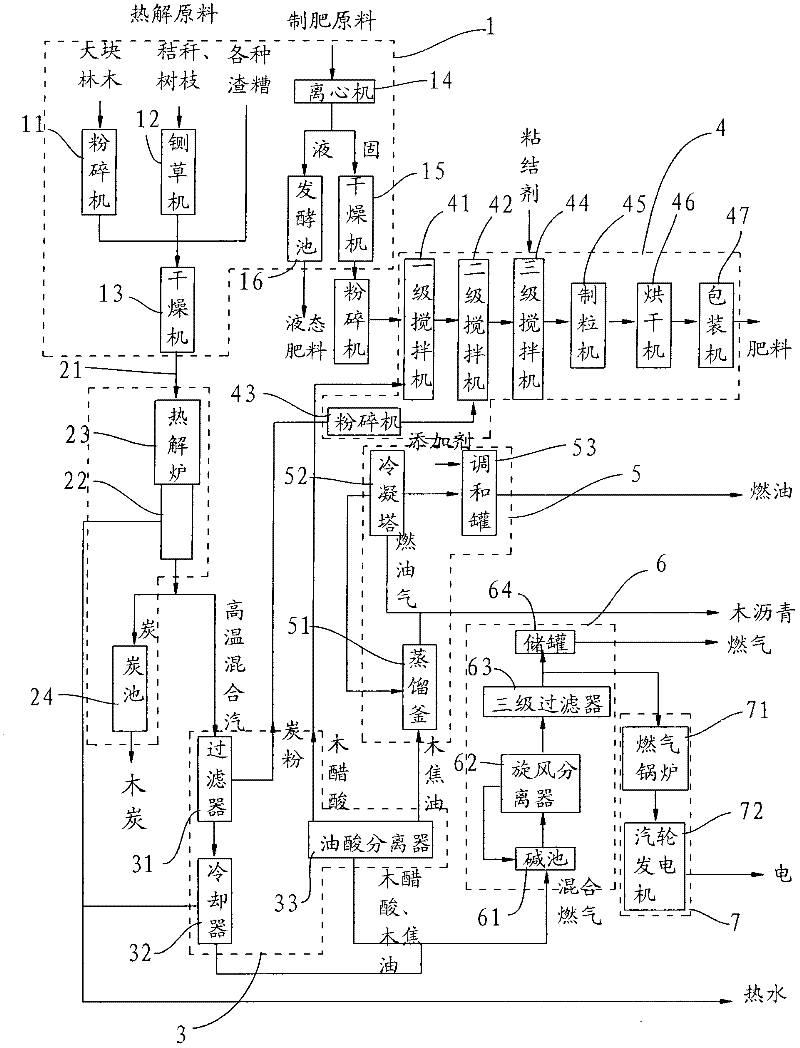

Integrated converting and utilizing co-production method for agricultural waste

InactiveCN102476129AWidely used valueAvoid secondary pollutionSolid waste disposalBiofuelsBiofuelFuel oil

The invention relates to an integrated utilizing technology for agricultural waste and in particular relates to an integrated converting and utilizing co-production method for agricultural waste. The integrated converting and utilizing co-production method comprises the following steps: 1. collecting and processing raw materials; 2. carrying out pyrolysis on the raw materials: generating biochar and high-temperature mixed gas; 3. converting the high-temperature mixed gas: converting the high-temperature mixed gas into wood tar, wood vinegar and fuel gas; 4. manufacturing fertilizers; 5. refining fuel oil: converting the wood tar into biofuel oil and wood pitch; 6. purifying the fuel gas: purifying the fuel gas into clean fuel gas; and 7. converting the fuel gas: respectively sending the biofuel gas into a gas generator, a gas supply pipe network and a heat boiler to covert the biofuel gas into heat energy and electricity energy. The agricultural waste can be converted by multiple levels and are combined to be utilized to obtain straw carbon, fuel gas, heat energy, electricity energy, fertilizers, fuel gas and the like. The use ratio of the agricultural waste reaches 100%. The problem that the agricultural waste is stacked and burnt disorderly can be solved, the pollution problem caused by using chemical fertilizers and pesticides for a long time can be solved, and the problem of utilizing energy, fertilizer and oil in rural areas also can be solved.

Owner:周仁福 +2

Methods and apparatus for cooling syngas within a gasifier system

A method for operating a syngas cooler is provided. The method includes channeling a flow of syngas into an annular cooling chamber having a longitudinal axis, injecting a cooling fluid into a manifold such that the cooling fluid is channeled substantially circumferentially about the annular cooling chamber, and discharging the cooling fluid from the manifold such that the cooling fluid contacts a surface of the cooling chamber at a predetermined angle relative to the axis of the cooling chamber.

Owner:AIR PROD & CHEM INC

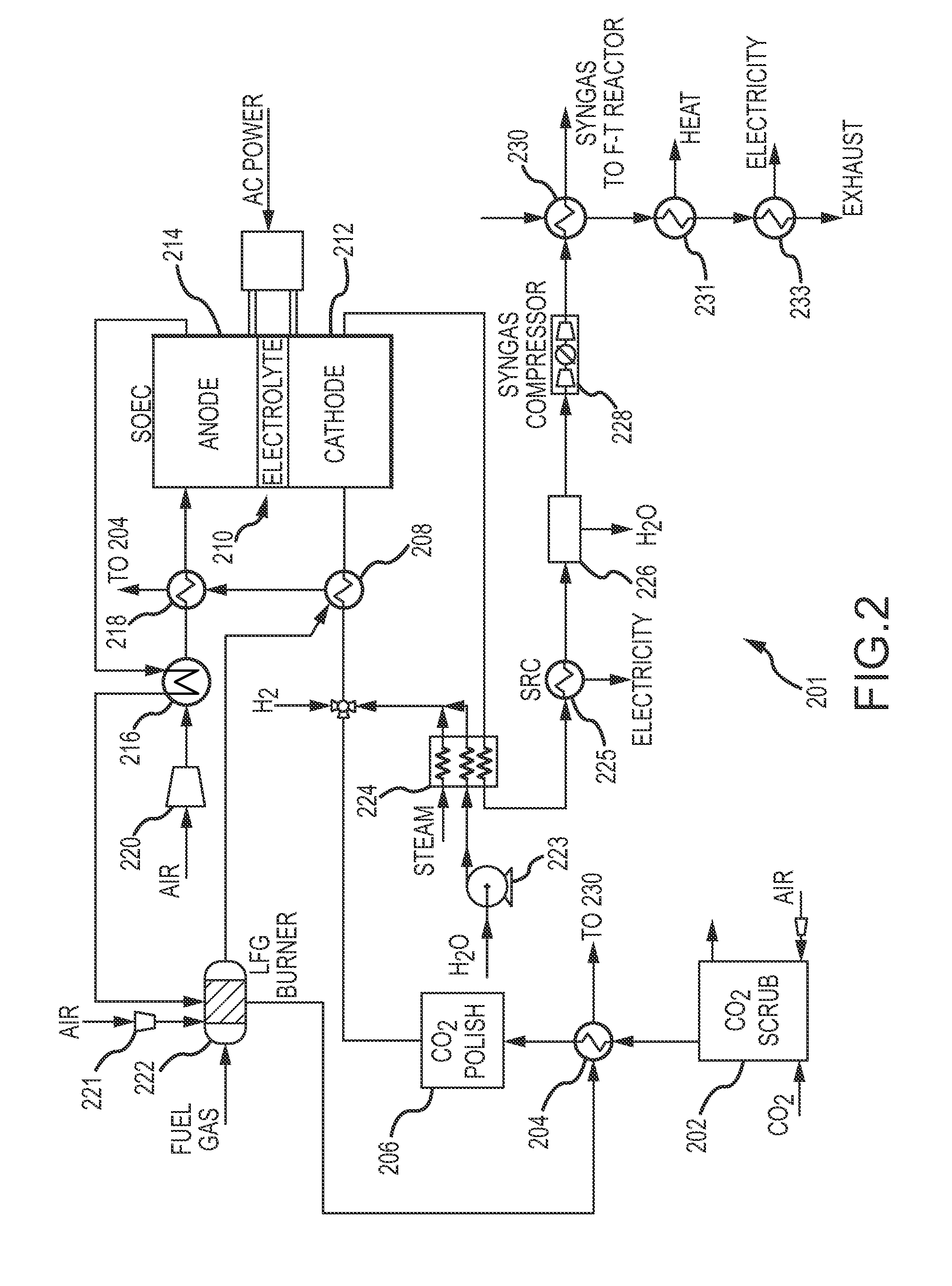

Electrochemical device for syngas and liquid fuels production

InactiveUS20140272734A1Reduces SOEC operational costUnit cost of producedBurnersCombustible gas catalytic treatmentLiquid fuelElectrolytic cell

The invention relates to methods for creating high value liquid fuels such as gasoline, diesel, jet and alcohols using carbon dioxide and water as the starting raw materials and a system for using the same. These methods combine a novel solid oxide electrolytic cell (SOEC) for the efficient and clean conversion of carbon dioxide and water to hydrogen and carbon monoxide, uniquely integrated with a gas-to-liquid fuels producing method.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

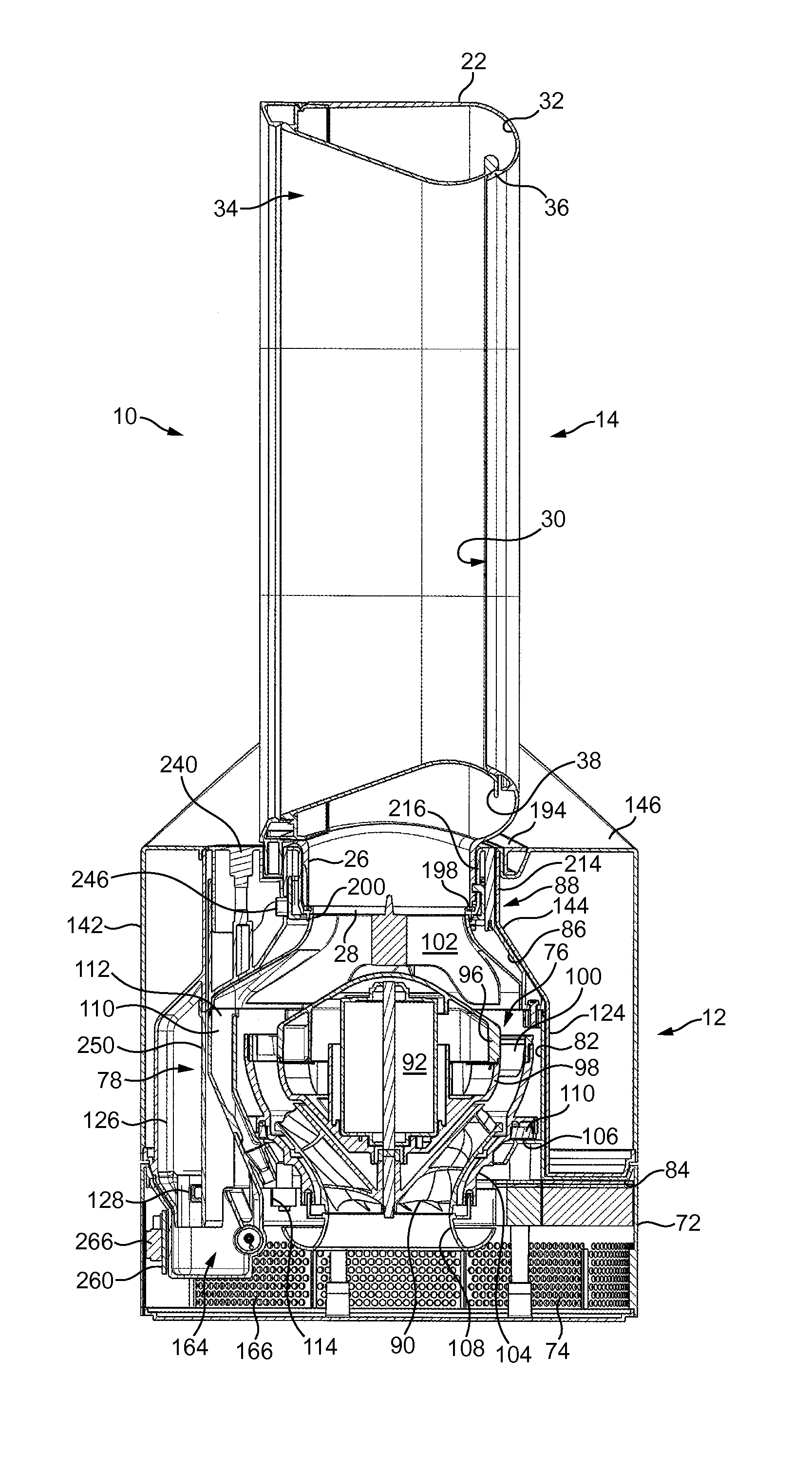

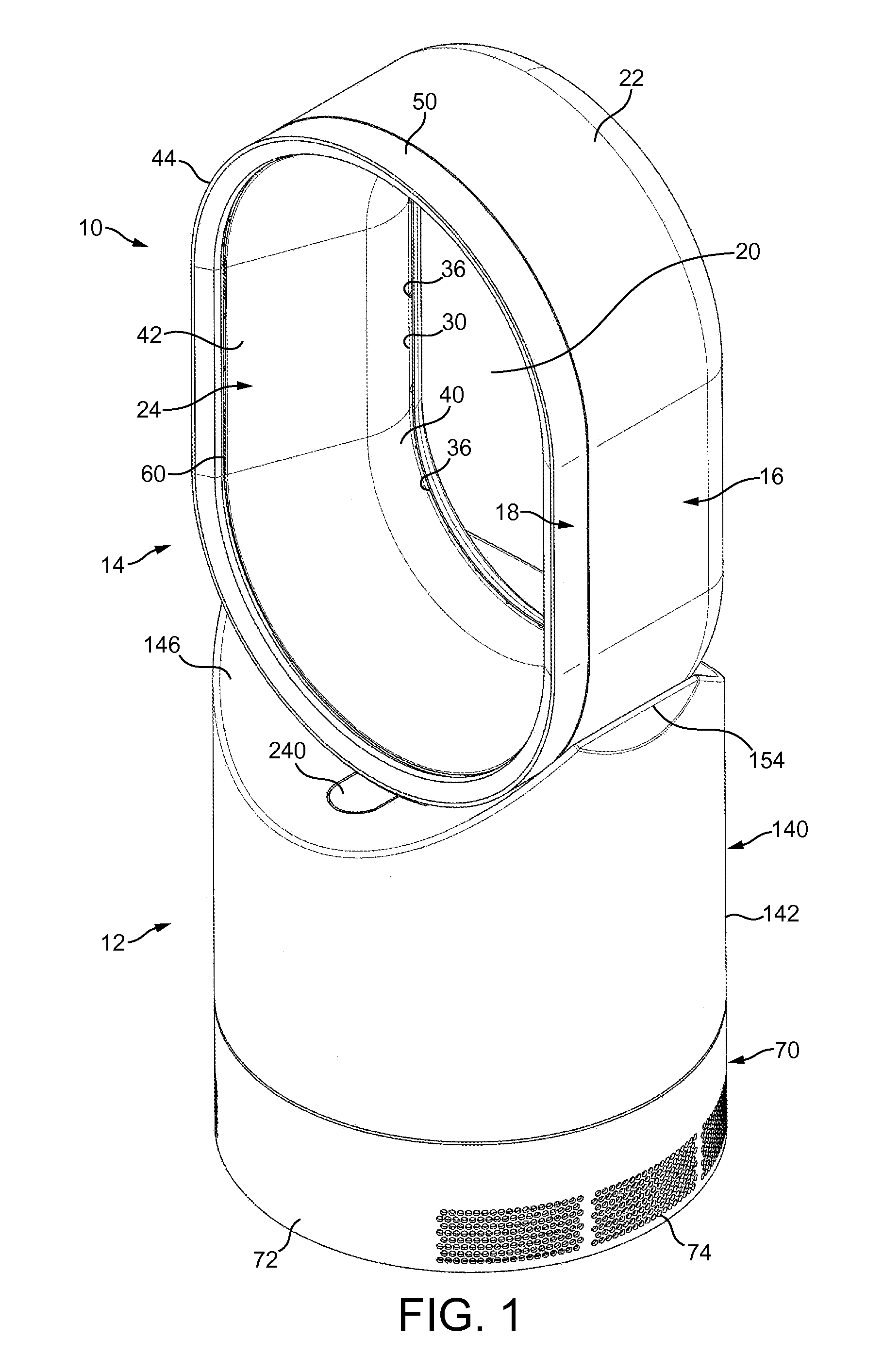

Fan assembly

ActiveUS20140210115A1Easy to cleanIncrease storage capacityLighting and heating apparatusUsing liquid separation agentUltraviolet radiationTransducer

Humidifying apparatus includes a chamber, and a water tank for supplying water to the chamber. A baffle located within the chamber divides the chamber into an inlet section and an outlet section, and guides water received from the water tank along the inlet section to the outlet section. An air flow is conveyed over water stored in the outlet section of the chamber and is emitted from the apparatus. Water within both the inlet section and the outlet section of the chamber is irradiated with ultraviolet radiation. The water within the outlet section is atomized by a transducer to humidify the air flow.

Owner:DYSON TECH LTD

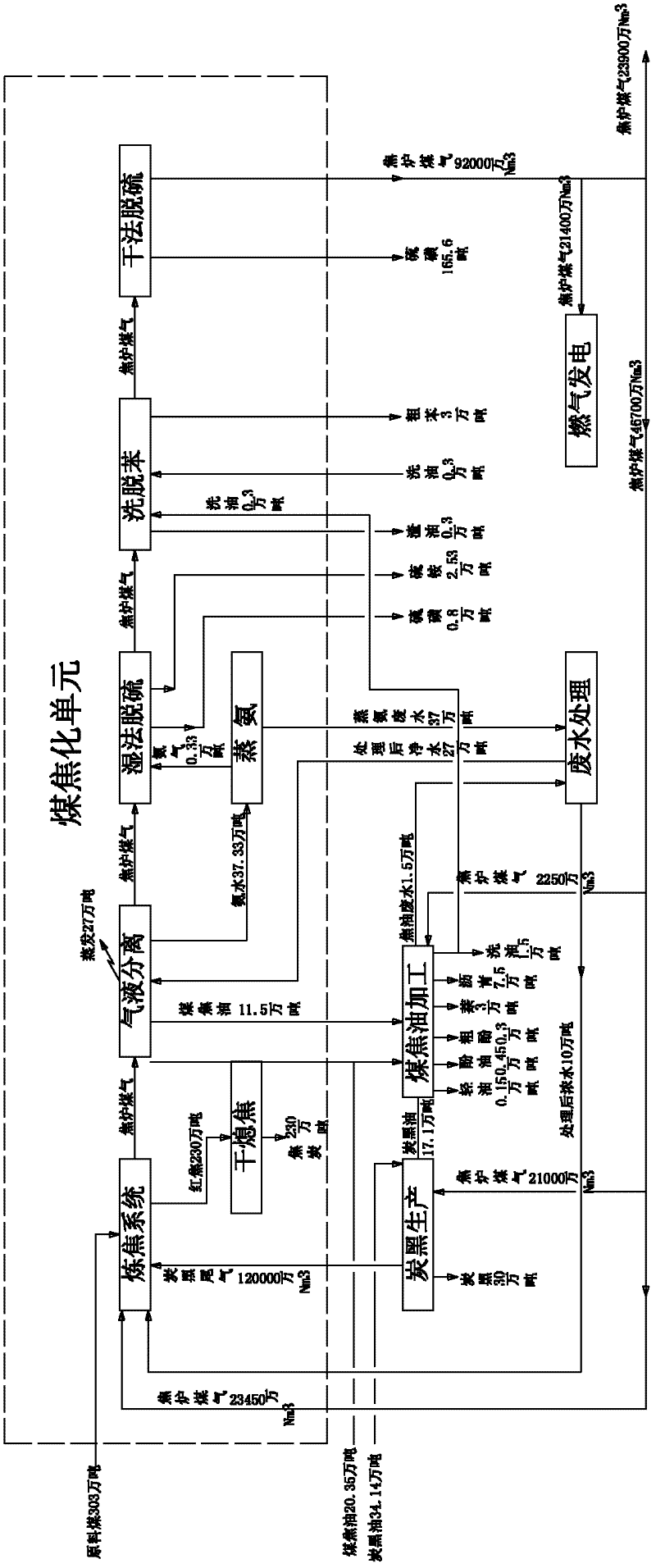

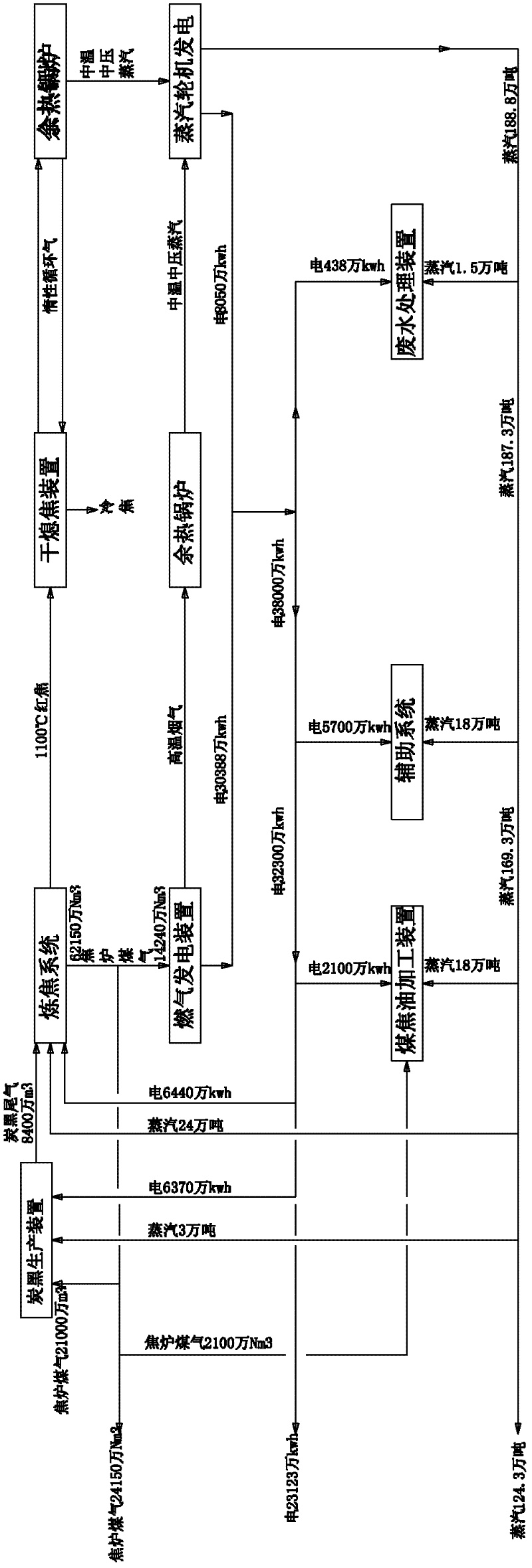

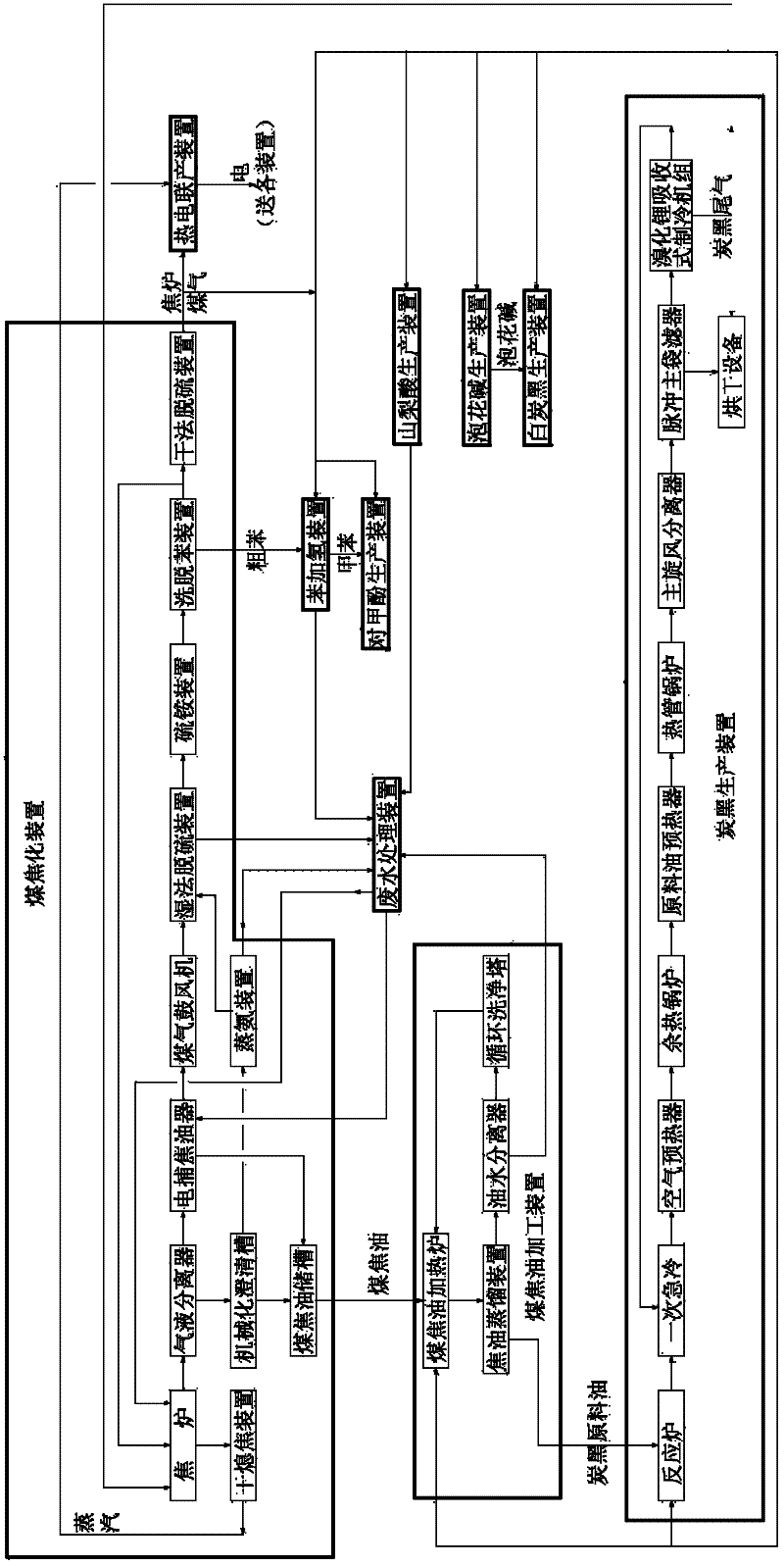

Green circular economy technology with coal coking as the main part

ActiveCN102229806AHigh aromatic contentQuality improvementPigmenting treatmentCoke quenchingCogenerationEngineering

The invention provides a green circular economy technology with coal coking as the main part. The technical scheme of the technology is as follows: a coal coking part, a coal tar processing part, a carbon black part and a part of combined power and thermoelectricity generation by coke oven gas are organically combined to form the relationship of industrial metabolism, symbiosis and coupling; suchmeasures as differentially utilizing tail gas of carbon black, recovering energy of coke drying quenching, reducing, recycling and changing the three wastes into resources, etc., enable resources to be saved, production cost to be reduced and pollution to be lessened; therefore, economic benefits of coal coking enterprises are maximized and the green circular economy technology is realized indeed. The invention also provides an apparatus for realizing the green circular economy technology with coal coking as the main part.

Owner:JINNENG SCI & TECH

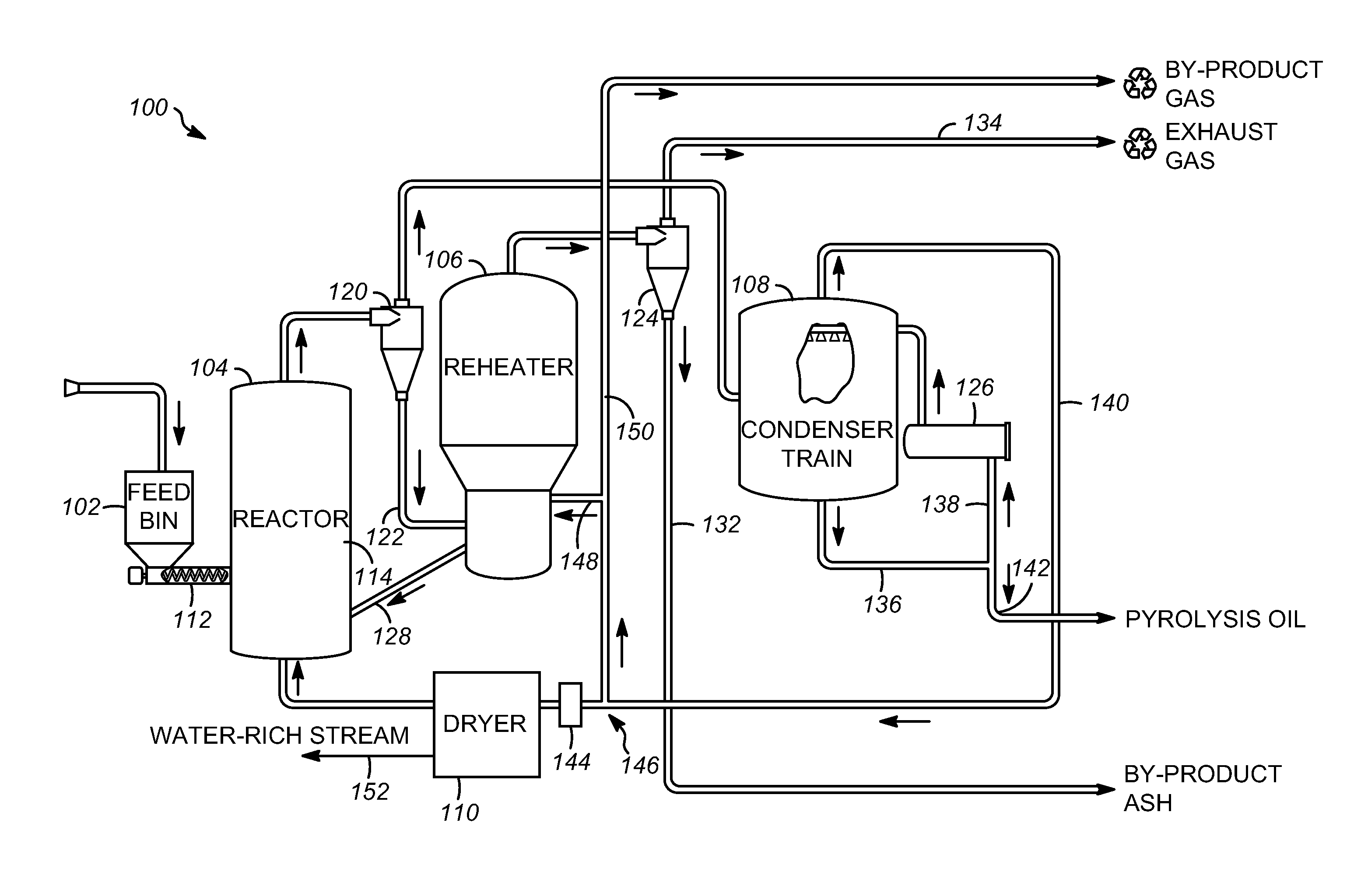

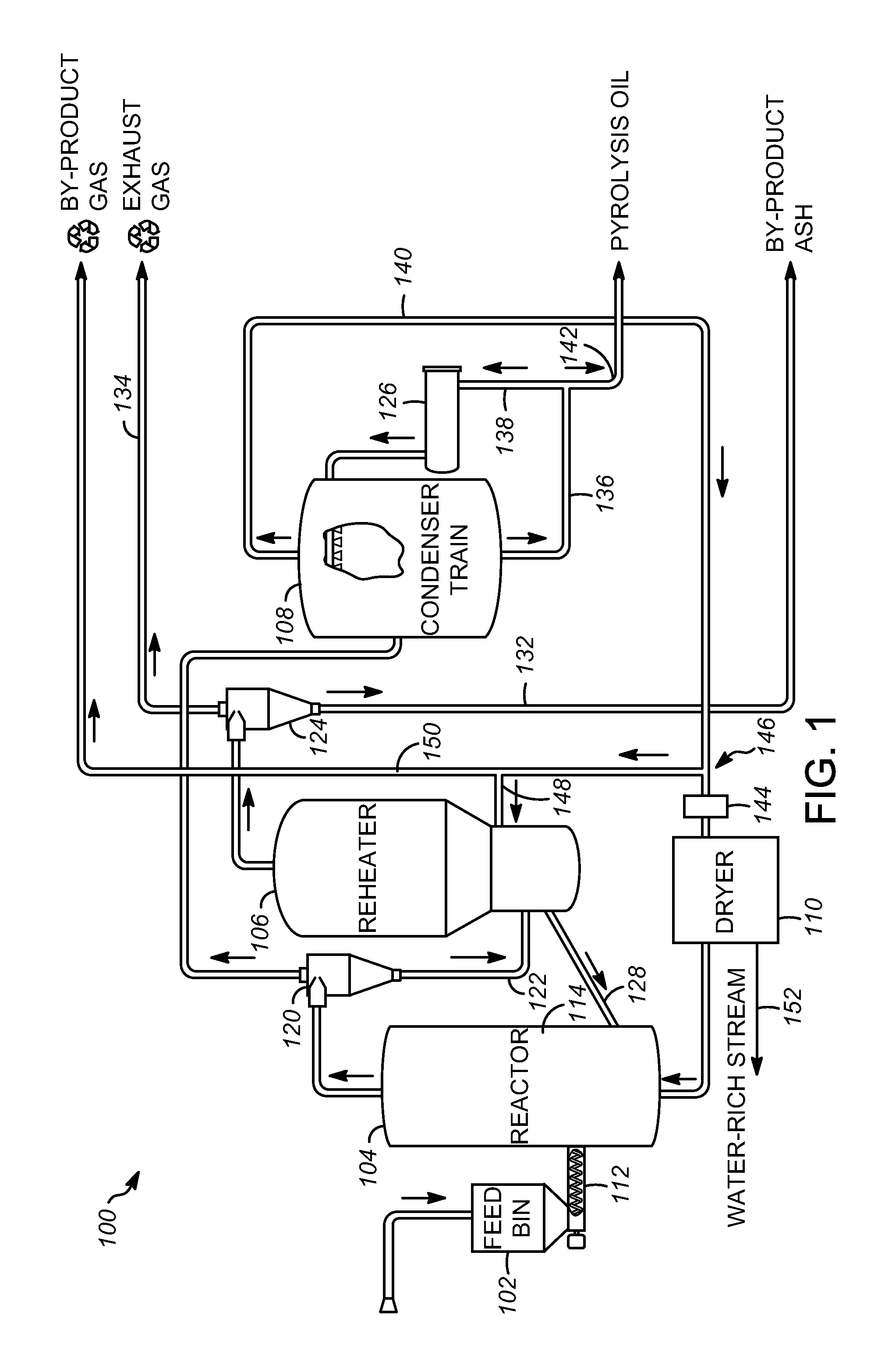

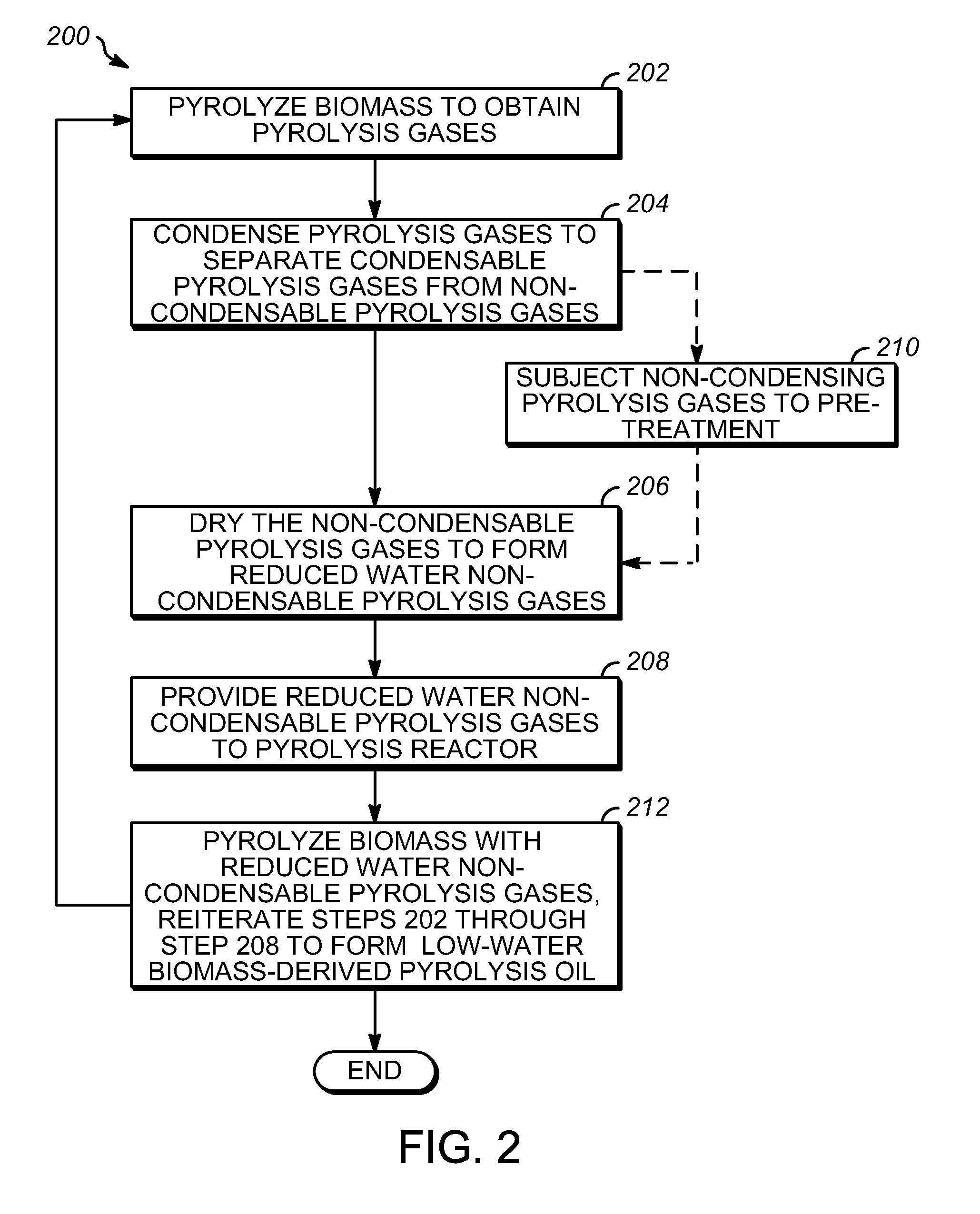

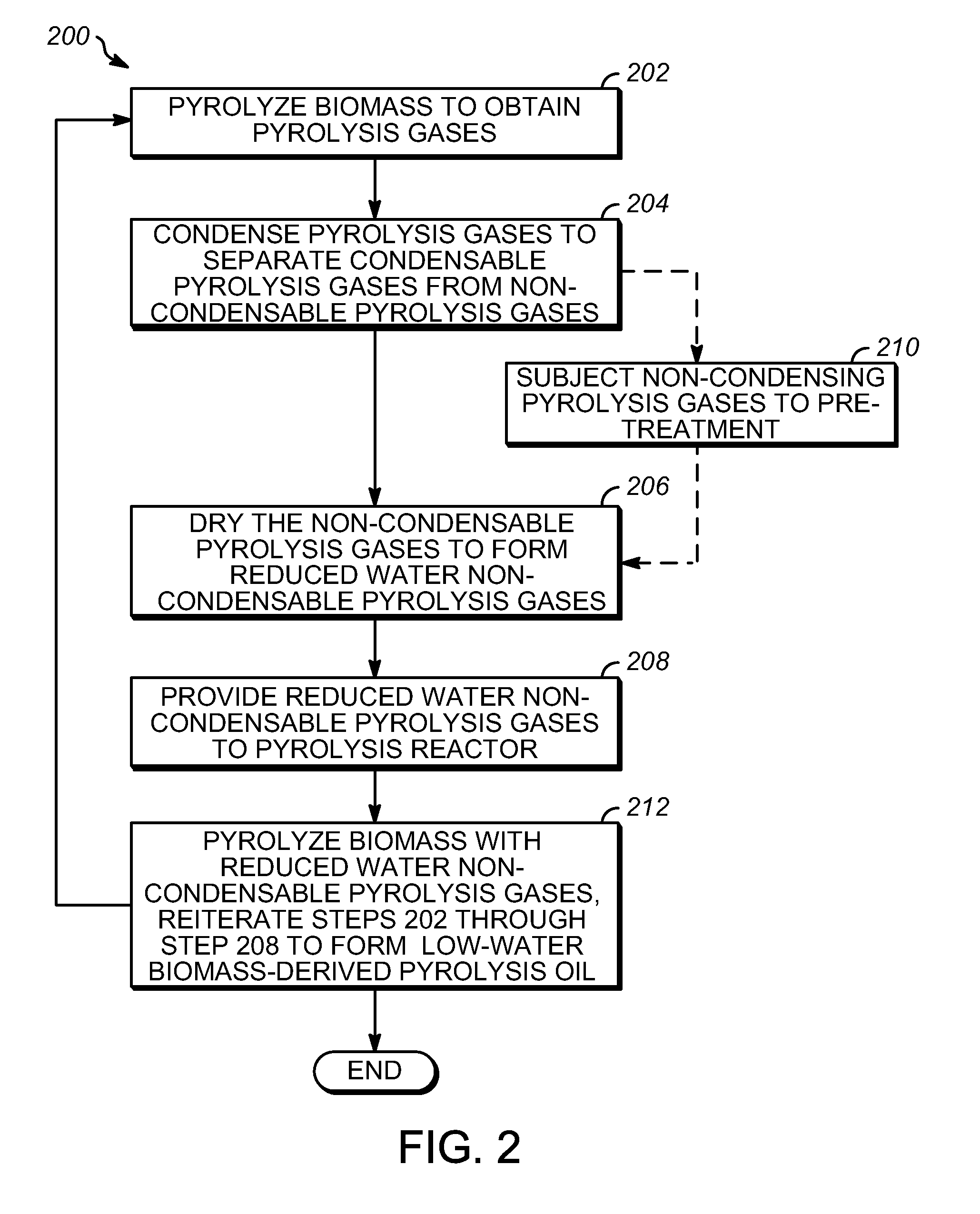

Low water biomass-derived pyrolysis oils and processes for producing the same

ActiveUS8519205B2Extensive contentReduce moistureDirect heating destructive distillationLiquid hydrocarbon mixture recoveryProduct gasWater content

Low water-containing biomass-derived pyrolysis oils and processes for producing them are provided. The process includes condensing pyrolysis gases including condensable pyrolysis gases and non-condensable gases to separate the condensable pyrolysis gases from the non-condensable gases, the non-condensable gases having a water content, drying the non-condensable pyrolysis gases to reduce the water content of the-non-condensable gases to form reduced-water non-condensable pyrolysis gases, and providing the reduced-water non-condensable pyrolysis gases to a pyrolysis reactor for forming the biomass-derived pyrolysis oil.

Owner:ENSYN RENEWABLES

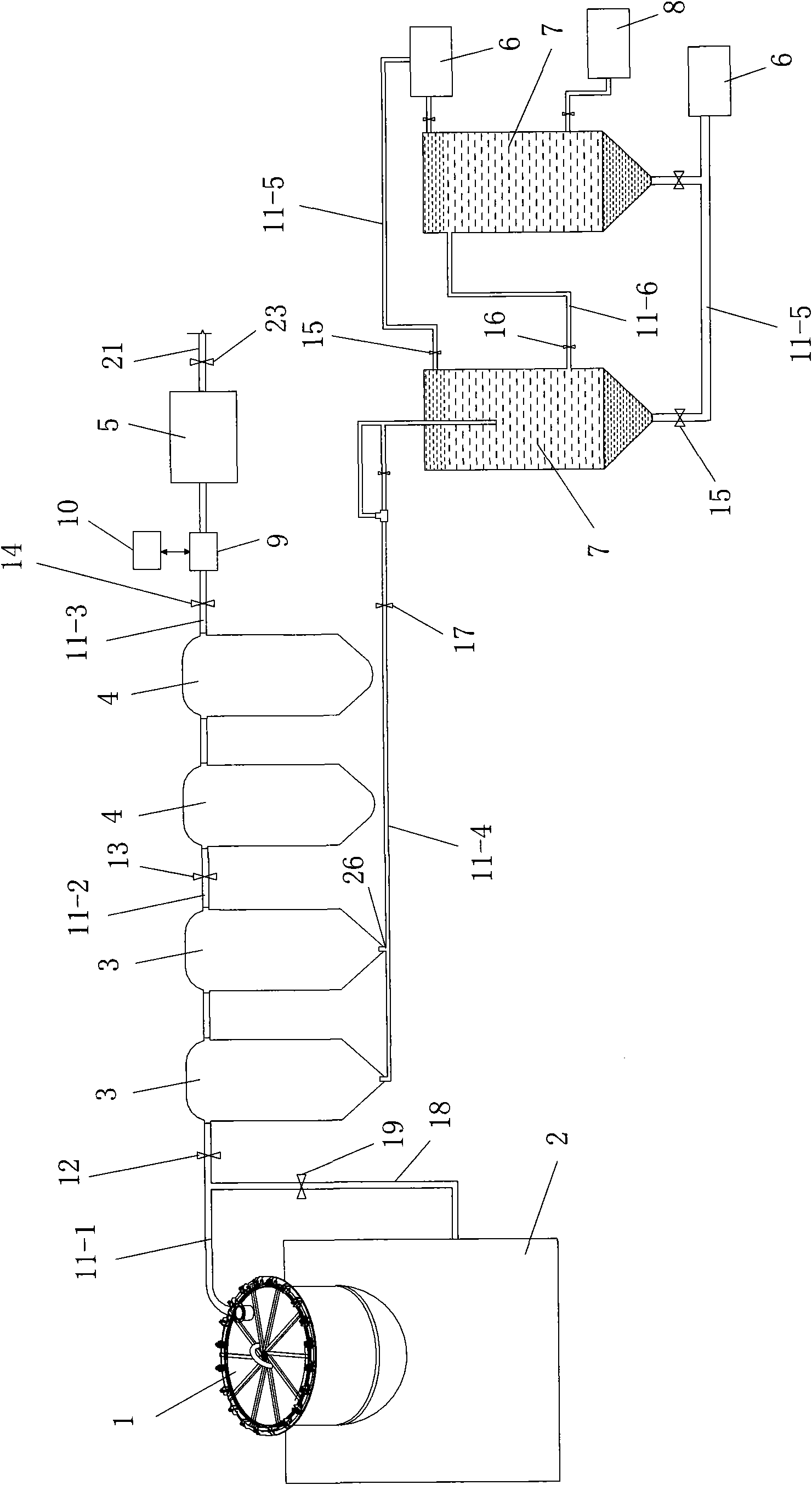

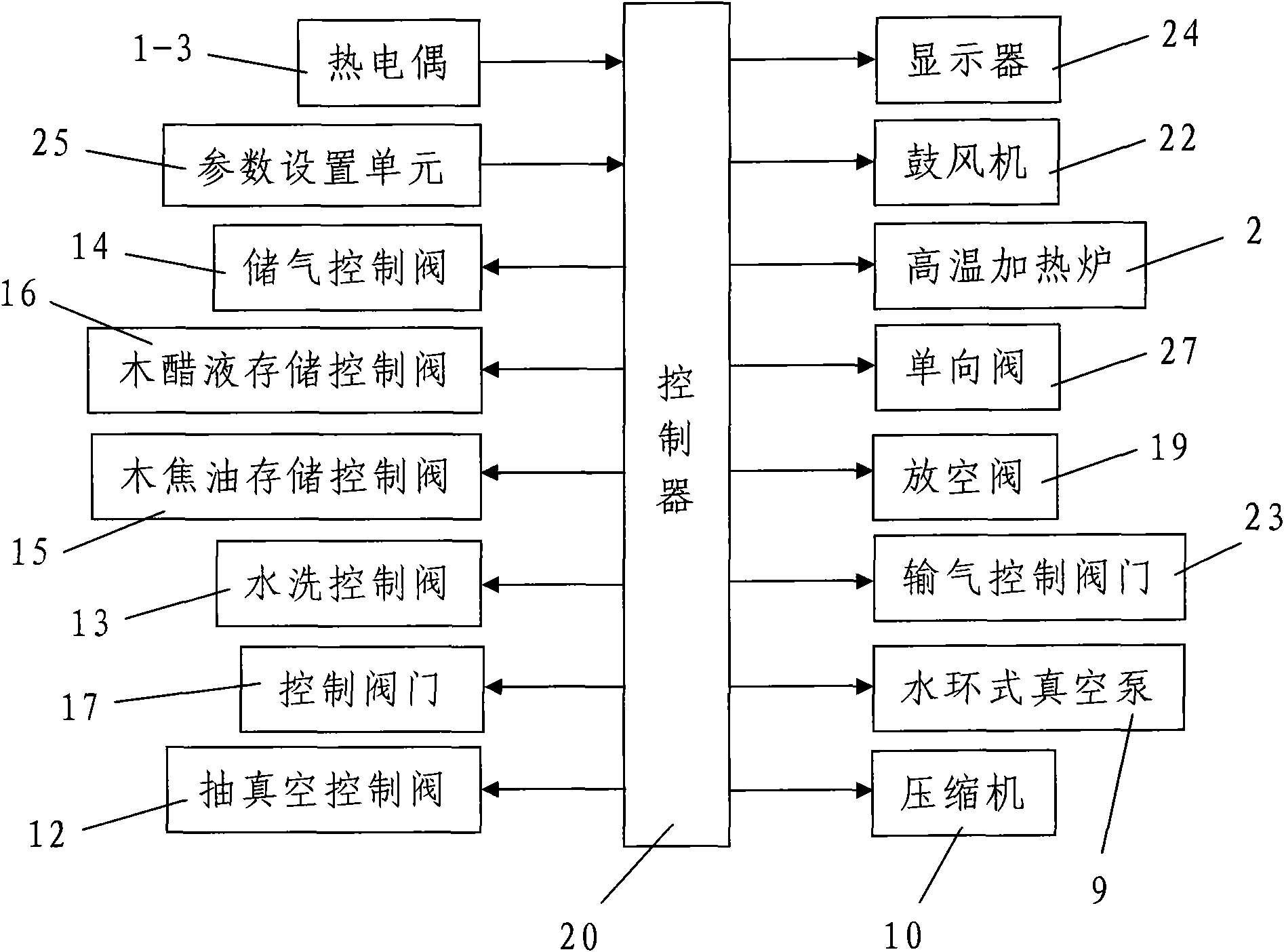

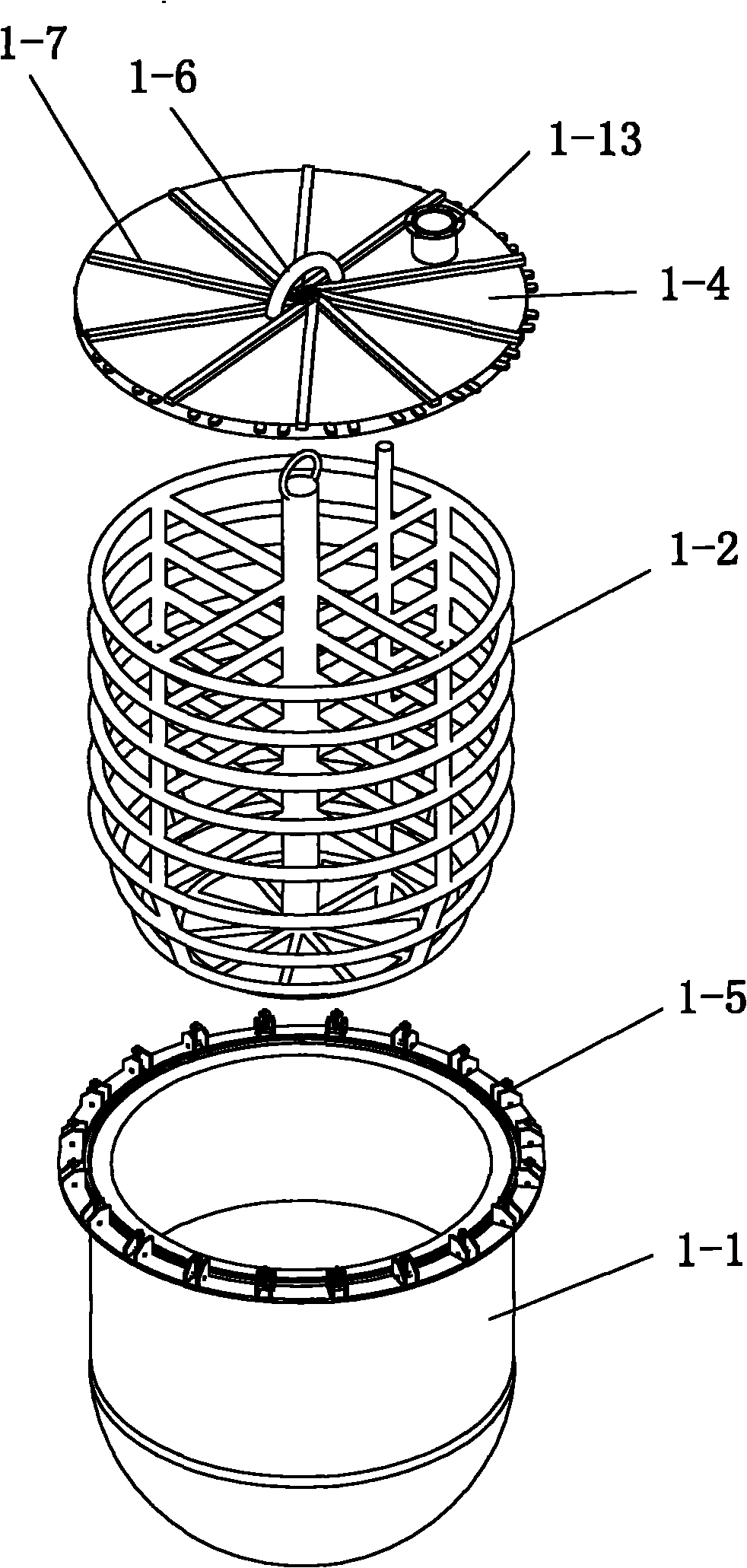

Co-production system and co-production method for biomass carbon, gas, wood tar and wood vinegar

InactiveCN101955780AFirmly connectedReasonable designBiofuelsPyroligneous acid productionSocial benefitsBiomass carbon

The invention discloses a co-production system and a co-production method for biomass carbon, gas, wood tar and wood vinegar. The co-production system comprises a biomass dry distillation kettle, a high-temperature heating furnace, a water cooling device, a washing device, a liquid separation device, a gas storage tank, a water-ring vacuum pump, a compressor, wood tar storage tank and a wood vinegar storage tank, wherein the liquid separation device separates wood vinegar and wood tar in the mixed liquid obtained by gas-liquid separation of the water cooling device; the co-production method comprises the following steps: 1, charging; 2, high-temperature carbonization: water cooling and gas-liquid separation, washing, gas storage and separation and storage of liquid matters; and 3, obtaining of the biomass carbon after the high-temperature carbonization. The co-production system for the biomass carbon, gas, wood tar and wood vinegar has the advantages of reasonable design, convenient processing, simple mounting arrangement, easy operation and good effect; and the co-production method has the advantages of convenient realization, high yield, low cost, fast co-production and relatively high production purity and has obvious economic and social benefits and wide popularization and application prospect.

Owner:陕西亿鑫生物能源科技开发有限公司

Low water biomass-derived pyrolysis oils and processes for producing the same

ActiveUS20120022171A1Large water contentReduce moistureDirect heating destructive distillationLiquid hydrocarbon mixture recoveryWater contentChemistry

Low water-containing biomass-derived pyrolysis oils and processes for producing them are provided. The process includes condensing pyrolysis gases including condensable pyrolysis gases and non-condensable gases to separate the condensable pyrolysis gases from the non-condensable gases, the non-condensable gases having a water content, drying the non-condensable pyrolysis gases to reduce the water content of the-non-condensable gases to form reduced-water non-condensable pyrolysis gases, and providing the reduced-water non-condensable pyrolysis gases to a pyrolysis reactor for forming the biomass-derived pyrolysis oil.

Owner:ENSYN RENEWABLES

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com