Coking furnace capable of recycling heat energy and coking method

A coking furnace and thermal energy technology, which is applied in coking ovens, coke cooling, combustible gas purification, etc., can solve the problems that do not meet the sustainable development plan, the coking product recovery process is complicated, and the thermal energy cannot be recycled and comprehensively utilized, etc. Coal industry chain, low maintenance cost, and the effect of expanding coking coal types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

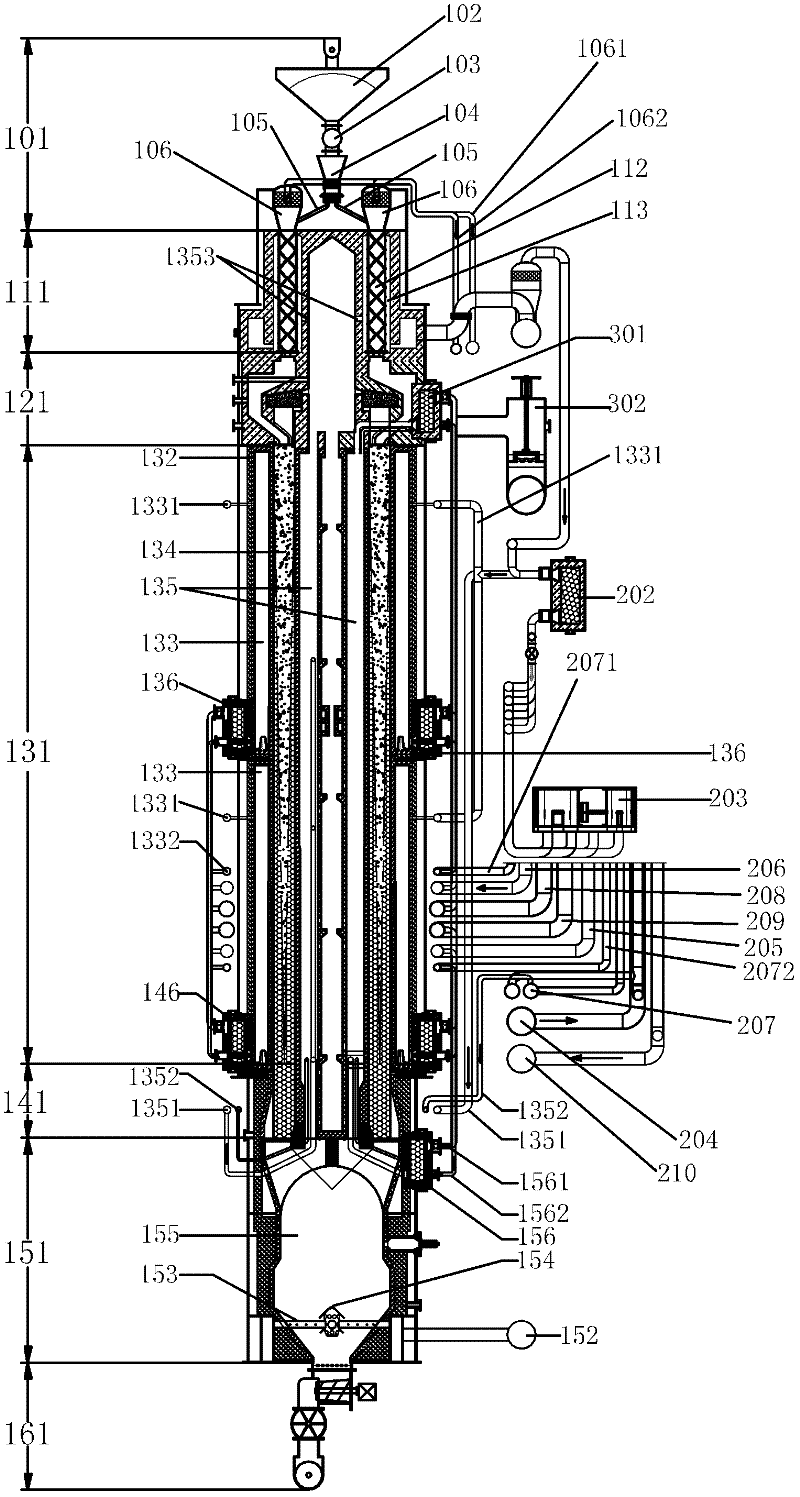

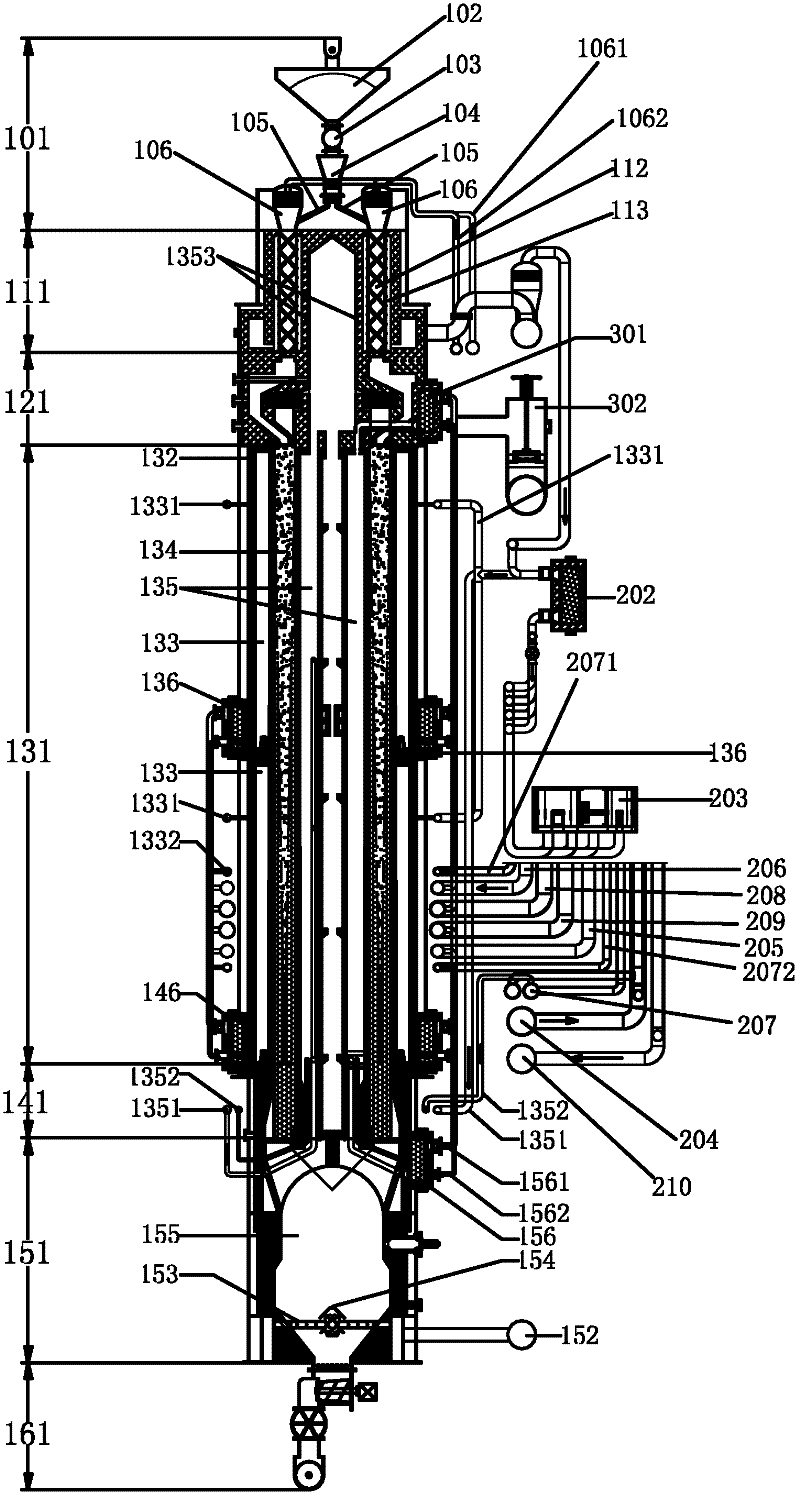

[0052] see figure 1 Shown, the present invention a kind of coking furnace of thermal energy recycling,

[0053] Including furnace body 100, exhaust gas circulation system 200, raw gas treatment system 300;

[0054] The furnace body 100 sequentially includes a coal feeding section 101, a coal rapid heating section 111, a raw coal gas export section 121, a coal dry distillation coking section 131, a coke conditioning section 141, a dry coke quenching section 151, and a coke discharge section 161 from top to bottom;

[0055] The coal feeding section 101 includes a coal feeding hopper 102, a screw feeder 103, a pulverized coal bunker 104, and a coal feeding pipe 105 from top to bottom. Below 106 is the rapid heating channel 112 of the coal rapid heating section 111. The bottom of the rapid heating channel 112 is connected to the waste gas exporting device 201 through a pipeline; a heating area 113 is arranged around the rapid heating channel 112; The gas is discharged through pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com