Method for producing naphthenic base transformer oil base oil by using coal tar oil

A transformer oil and naphthene production technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of preparing liquid paraffin, which is not yet available, and achieve the effects of reducing density, rational utilization, and increasing utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

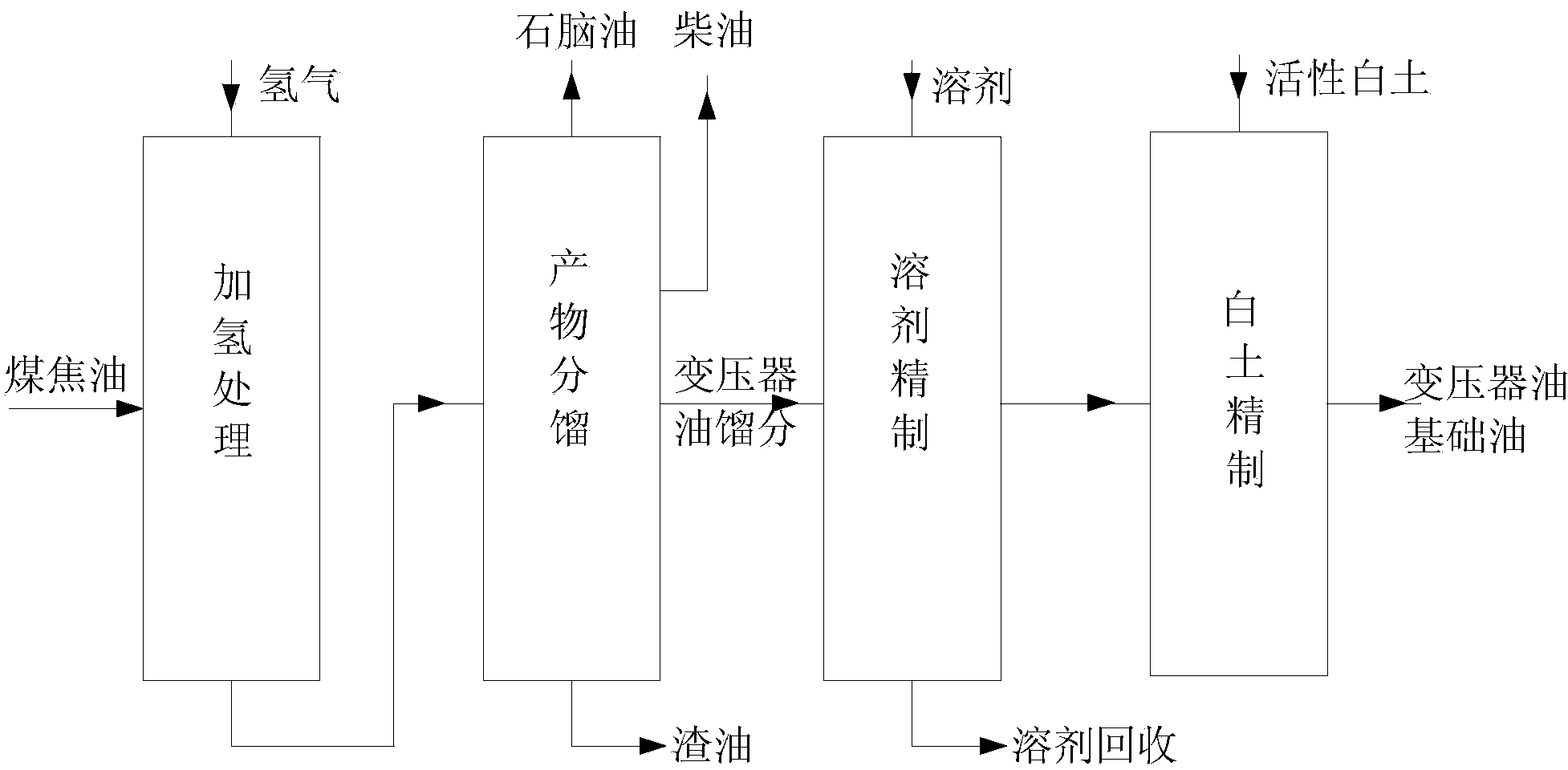

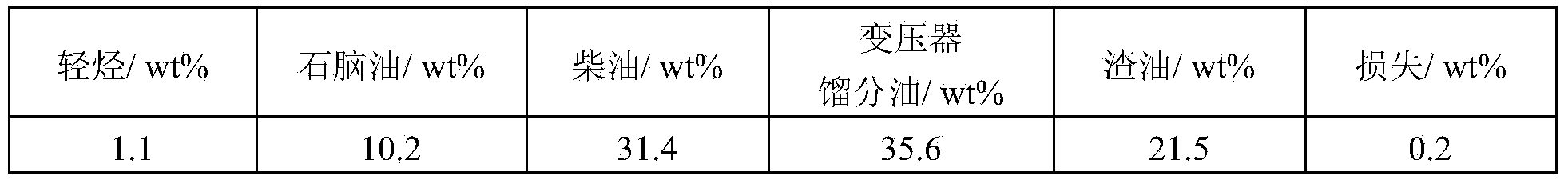

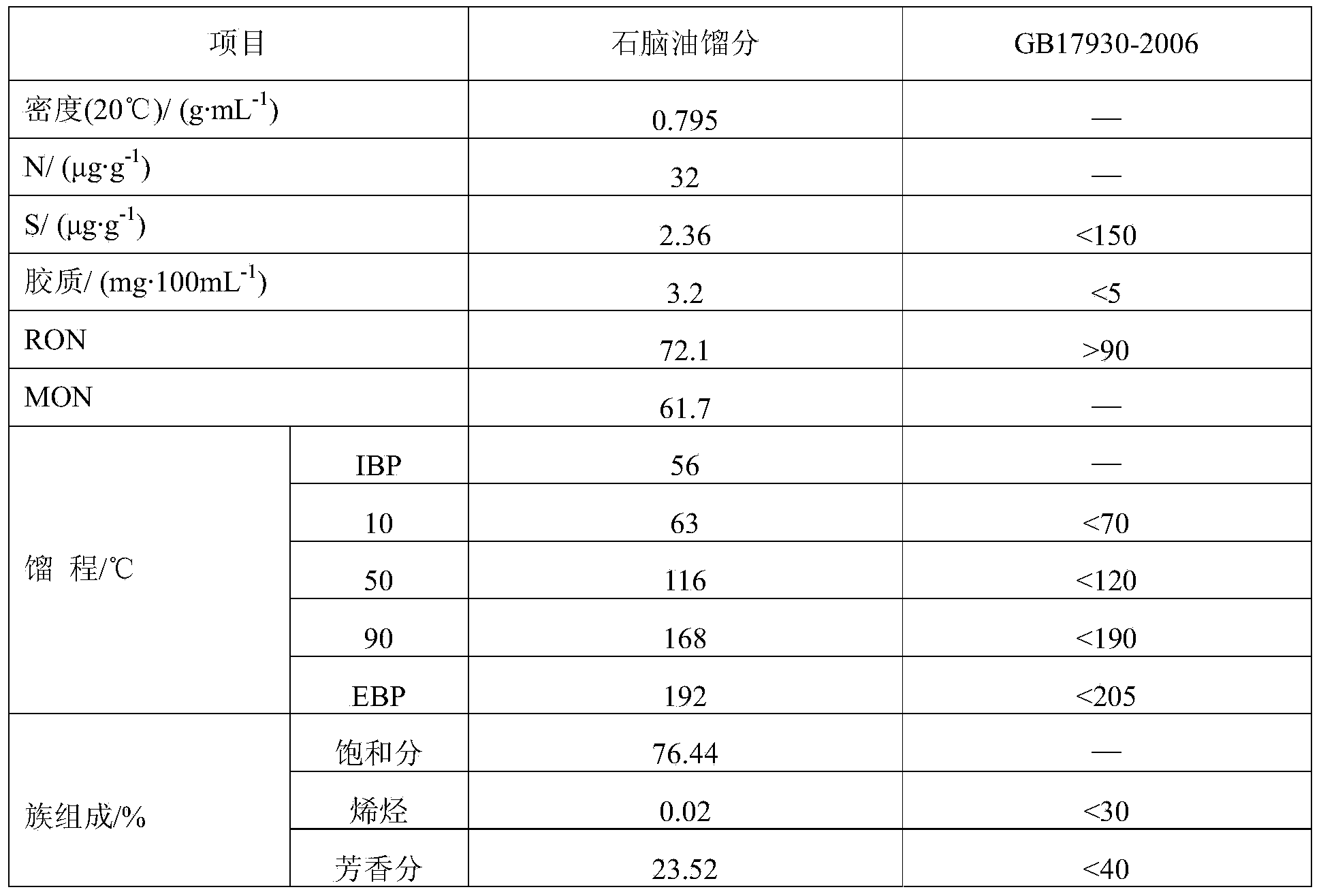

[0029] The method for producing naphthenic transformer oil base oil is realized by the following steps by using 500-700°C low-temperature coal tar produced in the coal pyrolysis process as raw material. figure 1 :

[0030] (1) Hydrotreating of coal tar

[0031] Coal tar and hydrogen are mixed and fed into the hydrogenation reactor, which is successively catalyzed by the molybdenum-nickel hydrofinishing catalyst supported by aluminum oxide and the ZSM-5 zeolite catalytic dewaxing catalyst supported by nickel. For hydrotreating, the reaction temperature is 380°C, the pressure is 14MPa, the volume ratio of hydrogen to oil is 1000:1, and the liquid volume space velocity relative to the hydrofining catalyst is 0.4h -1 , relative to the liquid volume space velocity of the catalytic dewaxing catalyst is 0.8h -1 , to obtain hydrogenated oil;

[0032] The above-mentioned molybdenum-nickel type hydrofining catalyst with aluminum oxide as the carrier is the TK-561 catalyst developed b...

Embodiment 2

[0053] In this example, in step (1), coal tar and hydrogen are mixed and fed into the hydrogenation reactor, followed by the molybdenum-nickel type hydrorefining catalyst with aluminum oxide as the carrier and the ZSM-5 zeolite with nickel as the carrier. Under the catalytic action of catalytic dewaxing catalyst, hydrotreating is carried out, the reaction temperature is 350°C, the pressure is 13MPa, the volume ratio of hydrogen to oil is 900:1, and the liquid volume space velocity relative to the hydrofining catalyst is 0.5h -1 , relative to the liquid volume space velocity of the catalytic dewaxing catalyst is 0.9h -1 , to obtain hydrogenated oil. Step (3) Use N-methyl pyrrolidone to extract the transformer oil fraction in the extraction tower by countercurrent mass flow and heat transfer, and the extracted transformer oil enters the solvent recovery device for vacuum distillation to remove residual N-methyl pyrrolidone and transformer oil The volume ratio of the distillate ...

Embodiment 3

[0055] In this example, in step (1), coal tar and hydrogen are mixed and fed into the hydrogenation reactor, followed by the molybdenum-nickel type hydrorefining catalyst with aluminum oxide as the carrier and the ZSM-5 zeolite with nickel as the carrier. Under the catalytic action of catalytic dewaxing catalyst, hydrogenation treatment is carried out, the reaction temperature is 360°C, the pressure is 12MPa, the volume ratio of hydrogen to oil is 1200:1, and the liquid volume space velocity relative to the hydrofining catalyst is 0.45h -1 , relative to the liquid volume space velocity of the catalytic dewaxing catalyst is 0.85h -1 , to obtain hydrogenated oil. The molybdenum-nickel hydrorefining catalyst with alumina as the carrier used in this example is the FZC-41A catalyst produced by Shandong Gongquan Chemical Co., Ltd. (http: / / www.gqcat.com.cn / Chinese / ProductList.asp?PID=25), the nickel-supported ZSM-5 zeolite catalytic dewaxing catalyst is the MLDW-3 catalyst of EXXON...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com