Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

208results about "Electrical coke oven heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

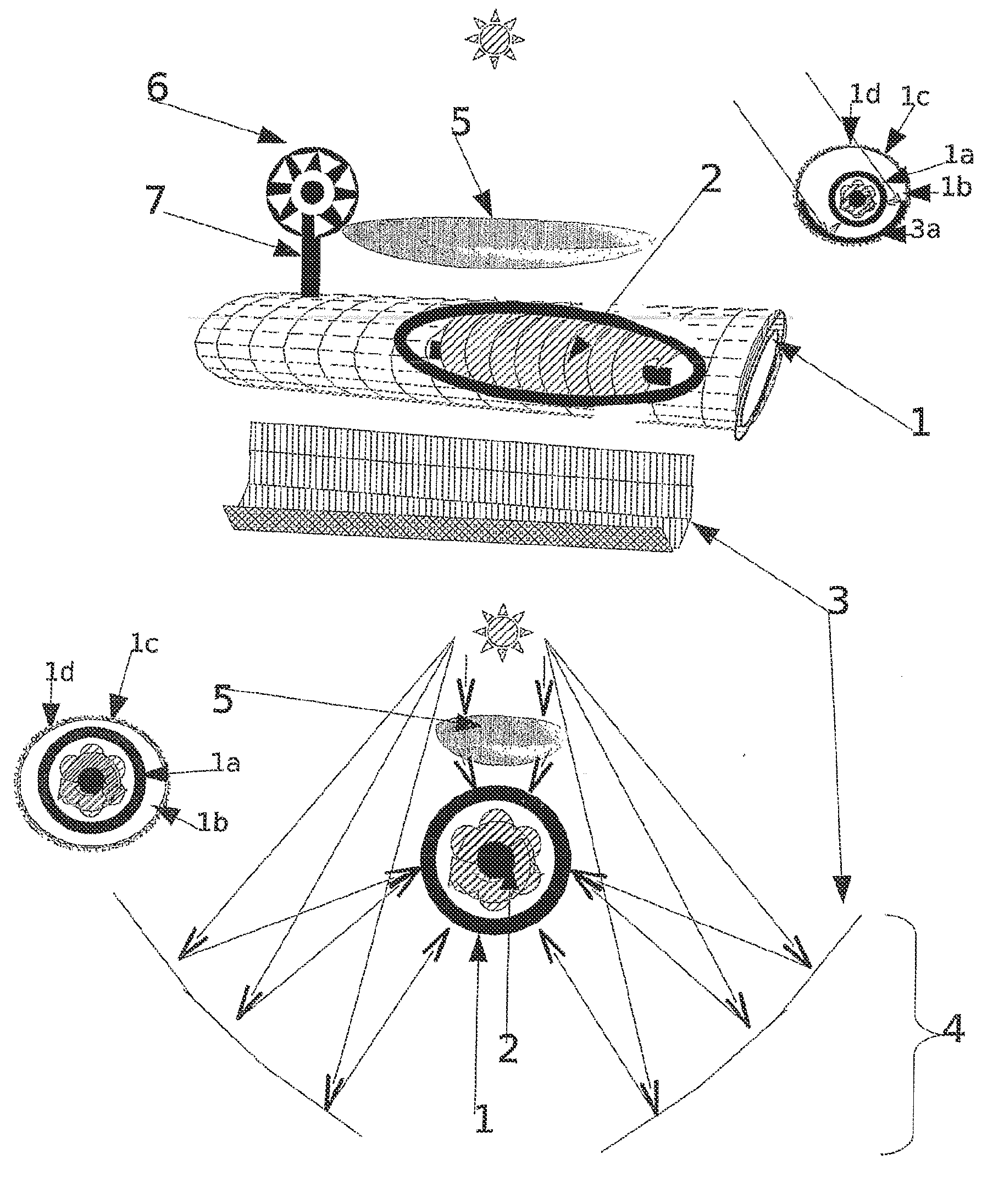

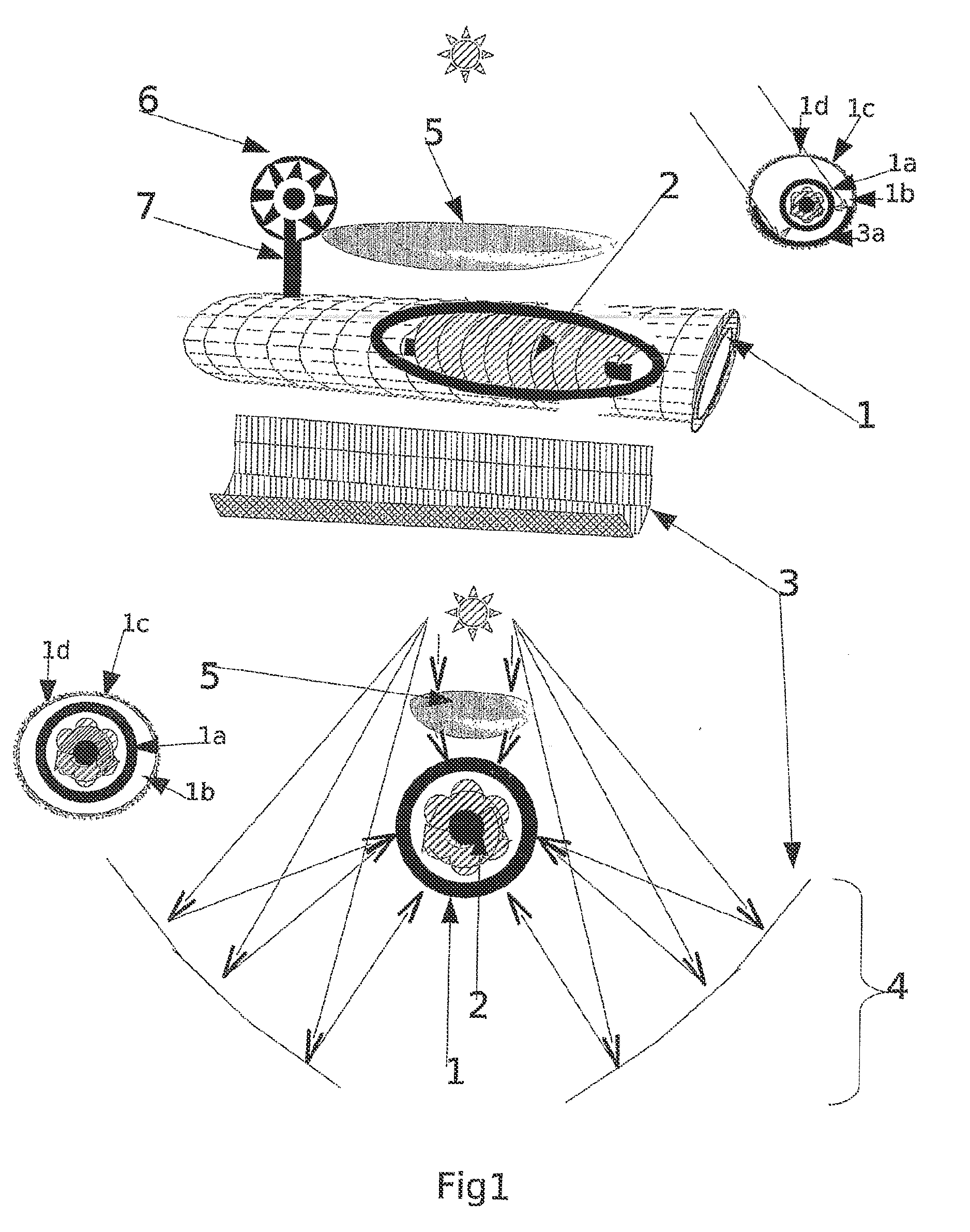

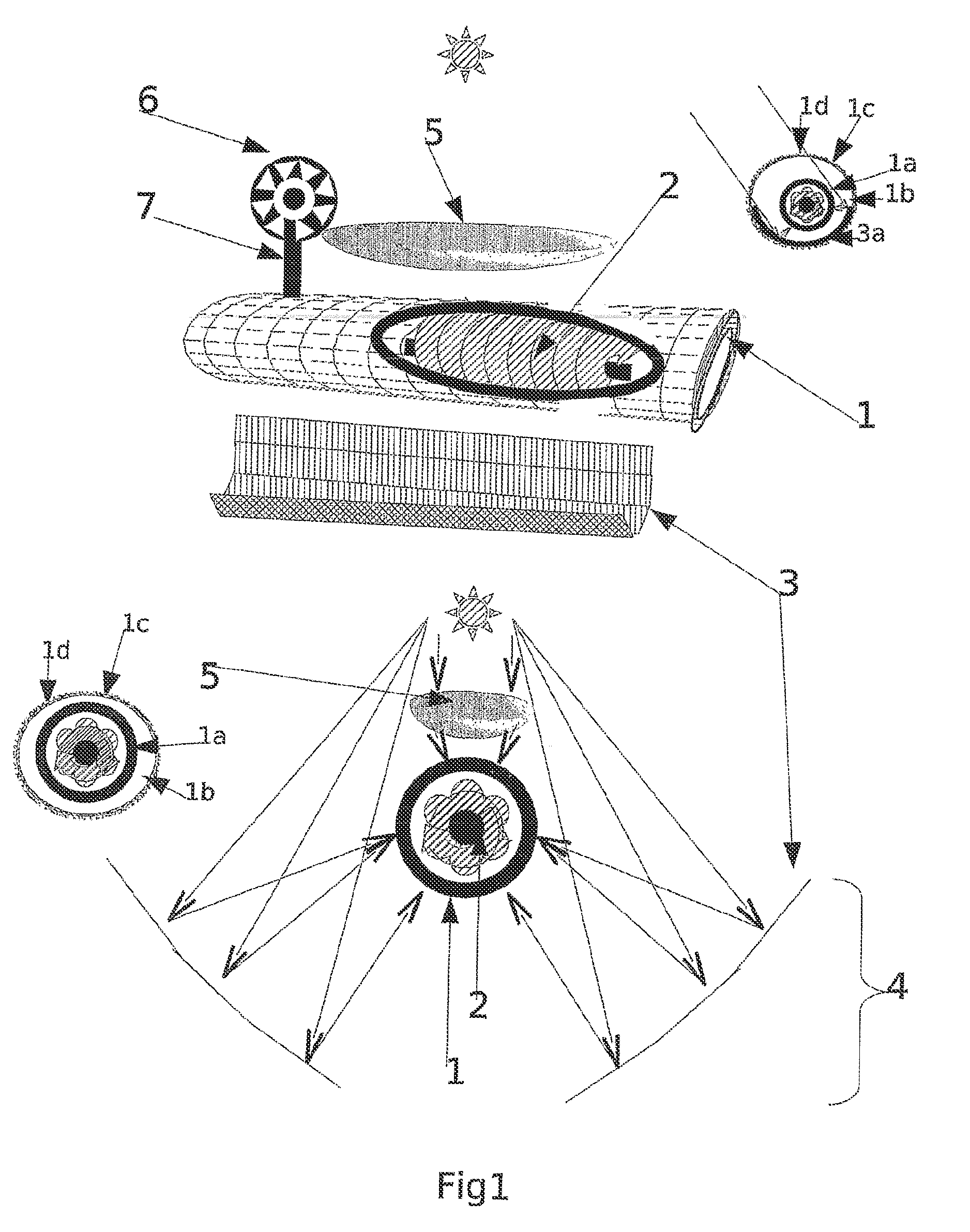

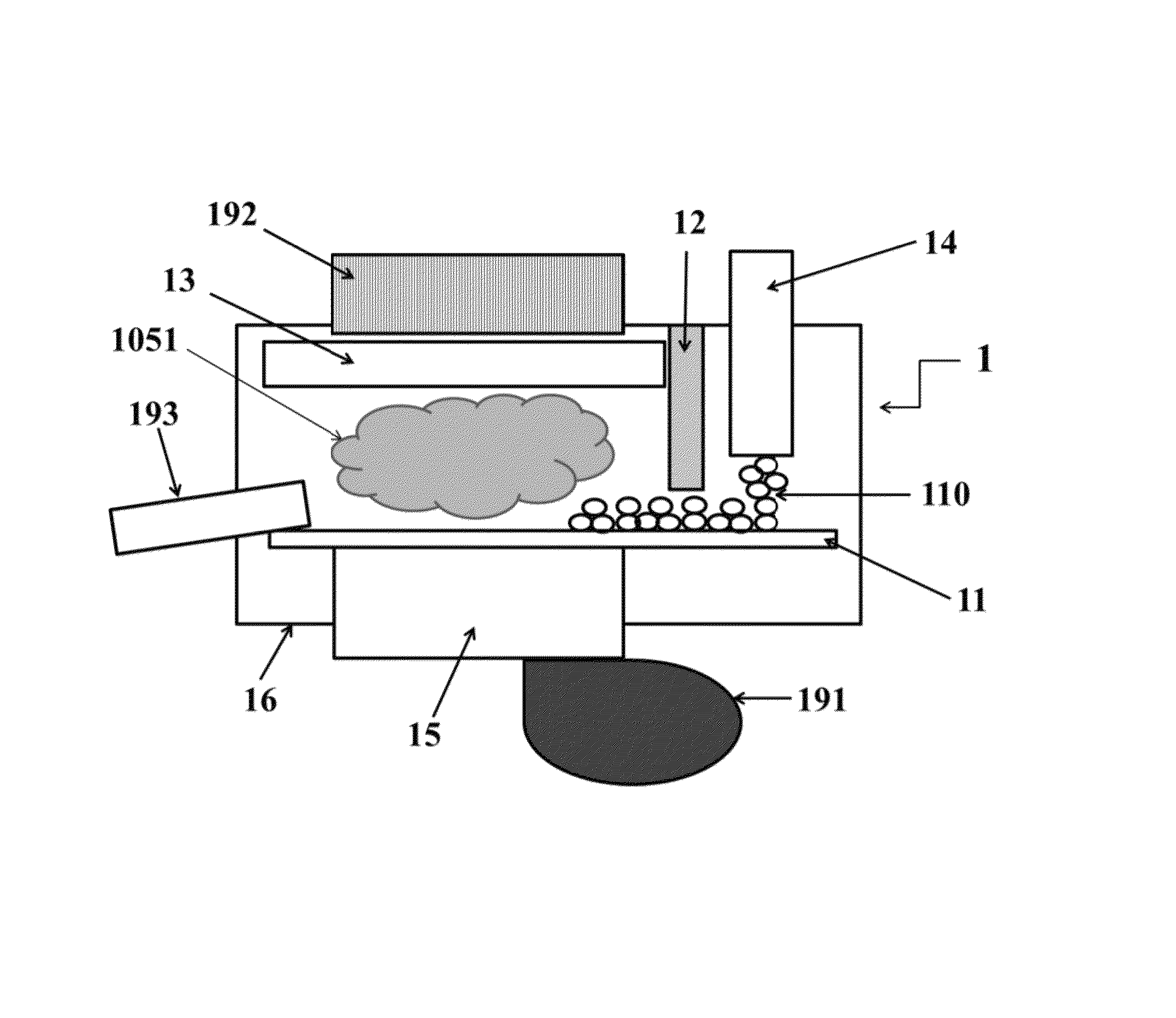

Rapid solar-thermal conversion of biomass to syngas

ActiveUS20080086946A1Improve reaction kineticsWide rangeElectrical coke oven heatingSolar heating energySyngasReactor design

Methods for carrying out high temperature reactions such as biomass pyrolysis or gasification using solar energy. The biomass particles are rapidly heated in a solar thermal entrainment reactor. The residence time of the particles in the reactor can be 5 seconds or less. The biomass particles may be directly or indirectly heated depending on the reactor design. Metal oxide particles can be fed into the reactor concurrently with the biomass particles, allowing carbothermic reduction of the metal oxide particles by biomass pyrolysis products. The reduced metal oxide particles can be reacted with steam to produce hydrogen in a subsequent process step.

Owner:UNIV OF COLORADO THE REGENTS OF

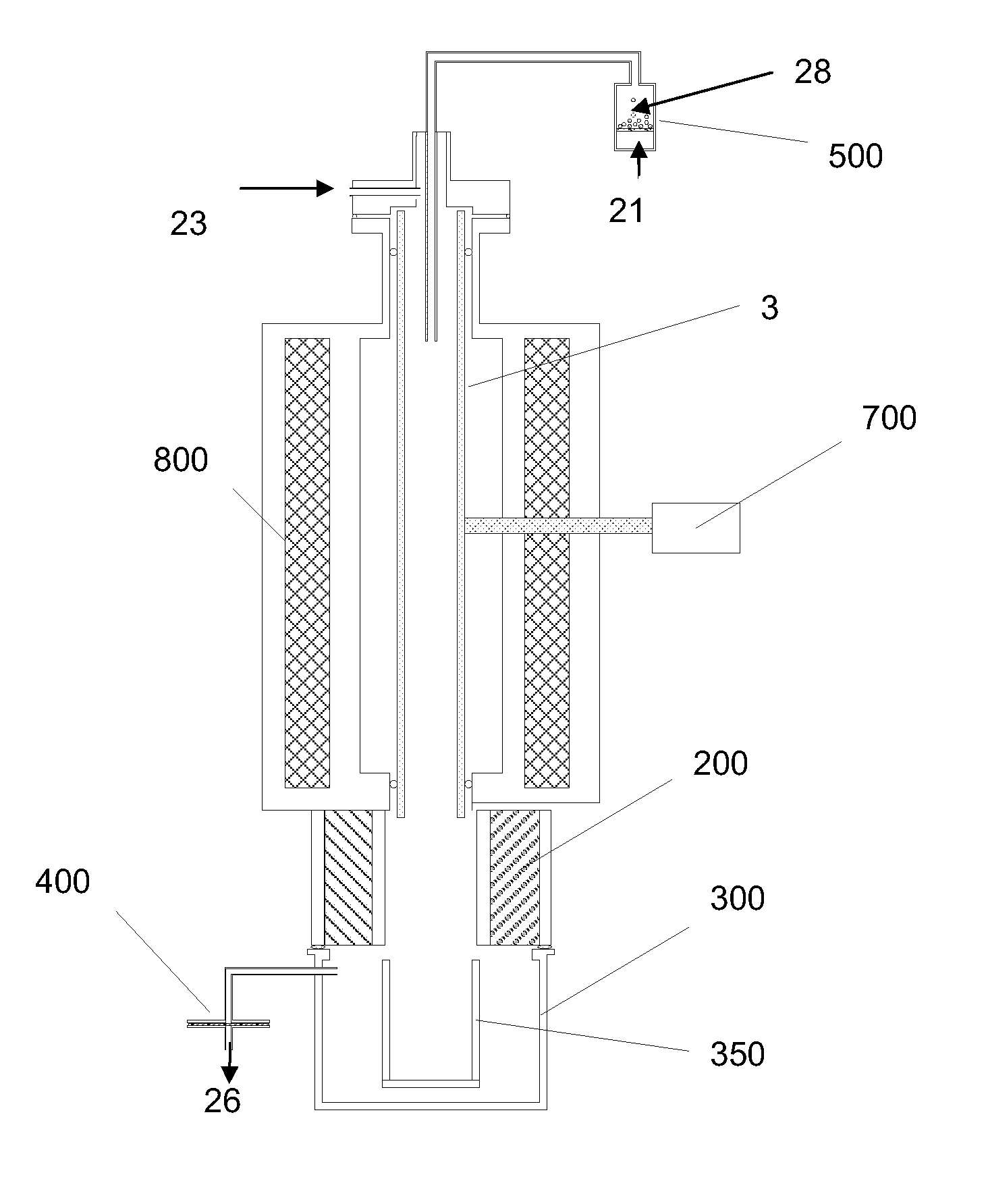

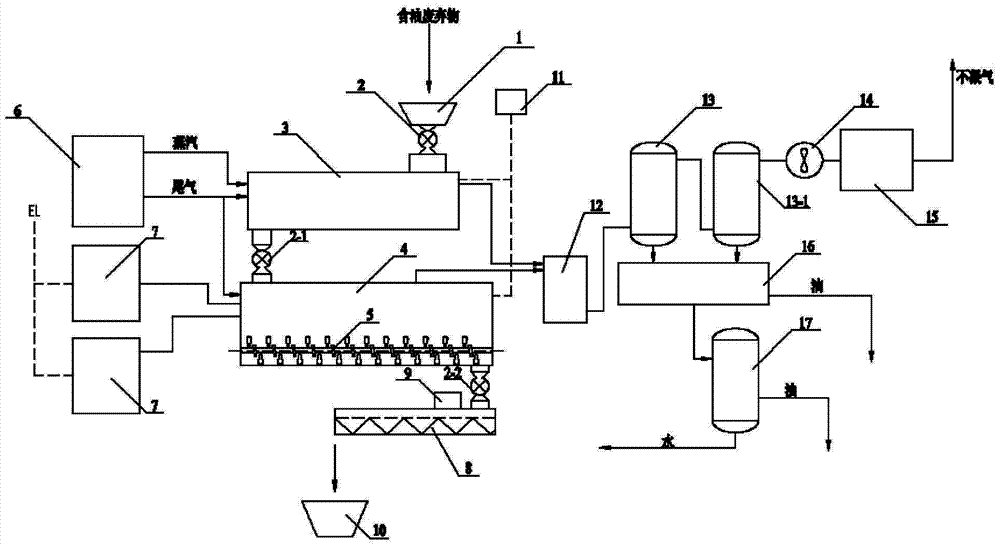

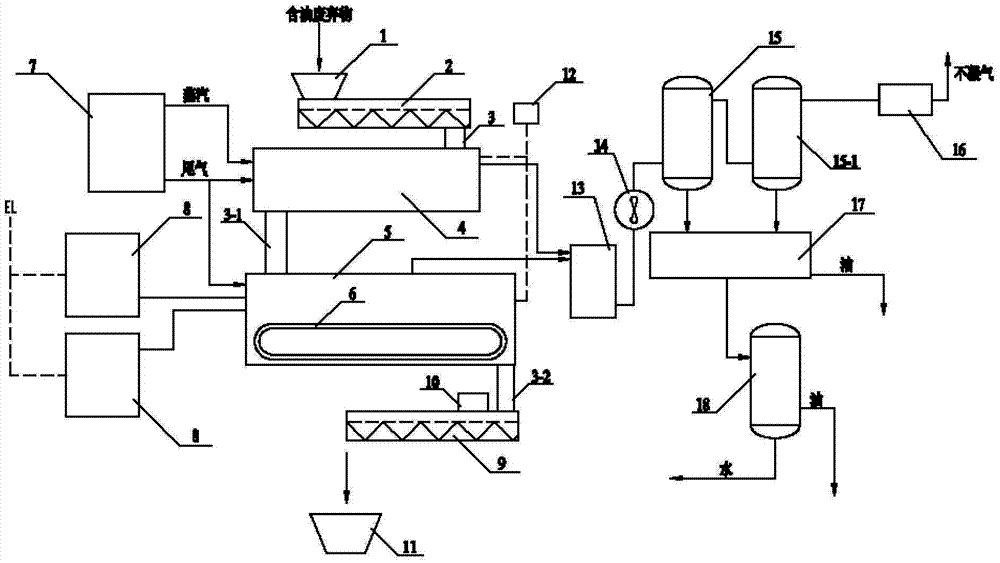

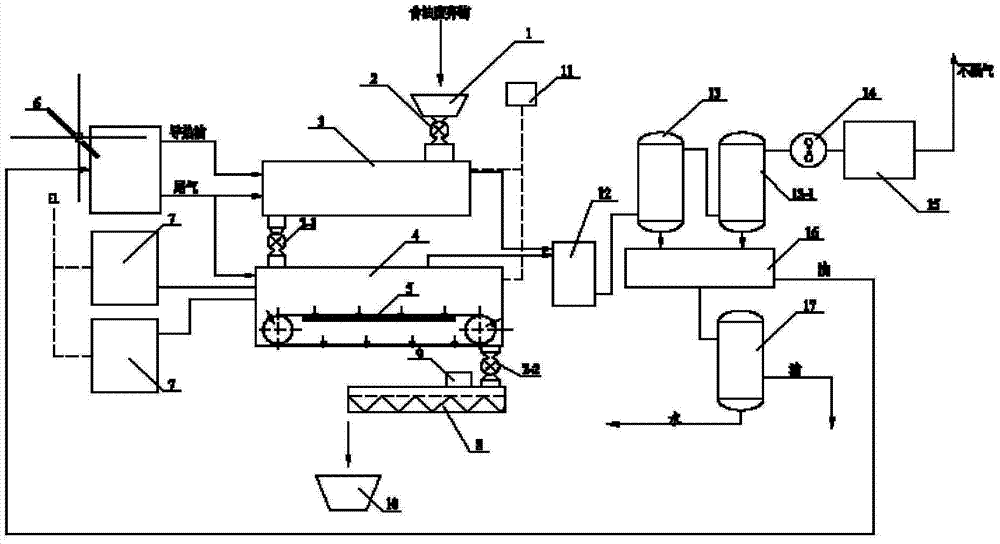

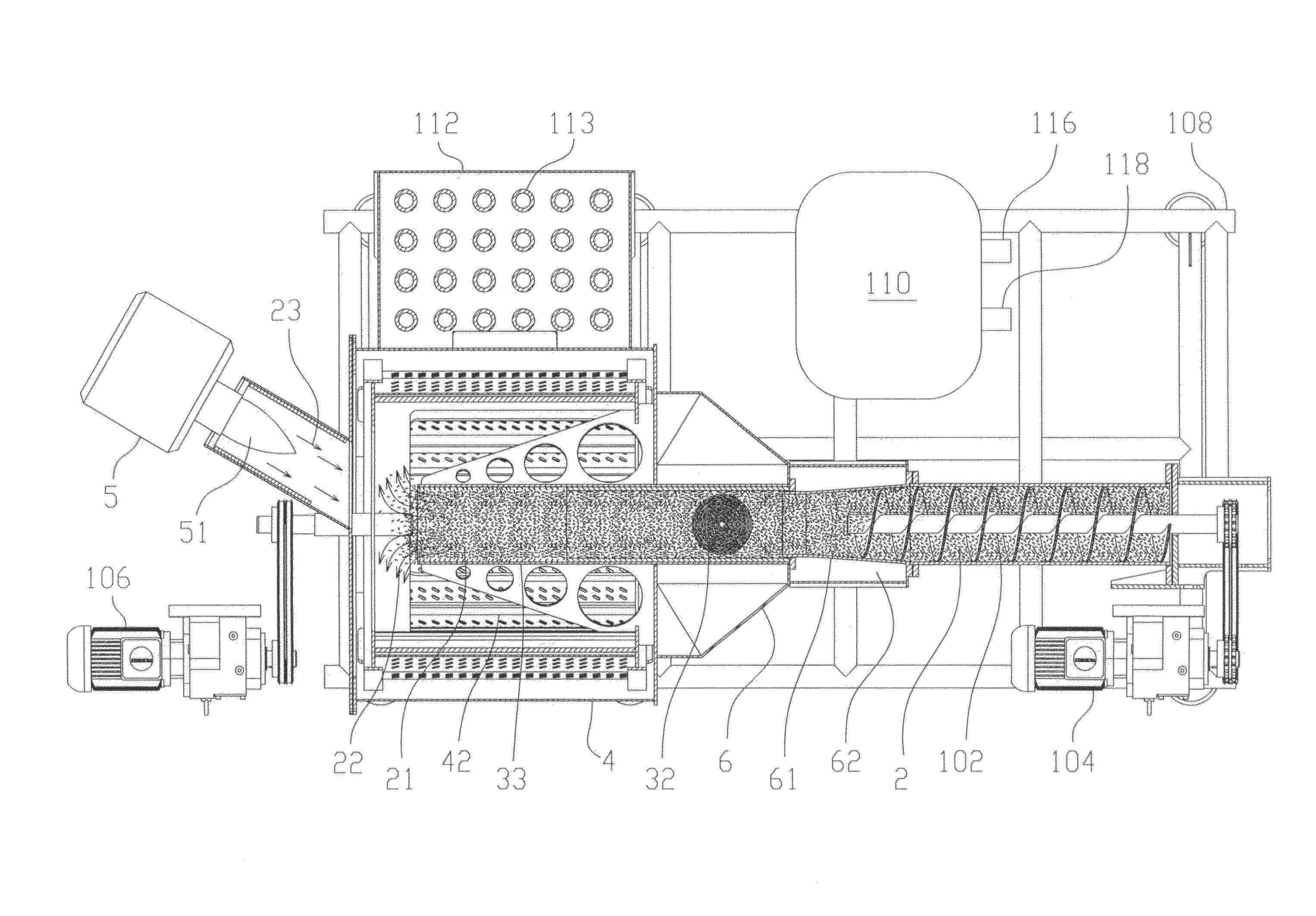

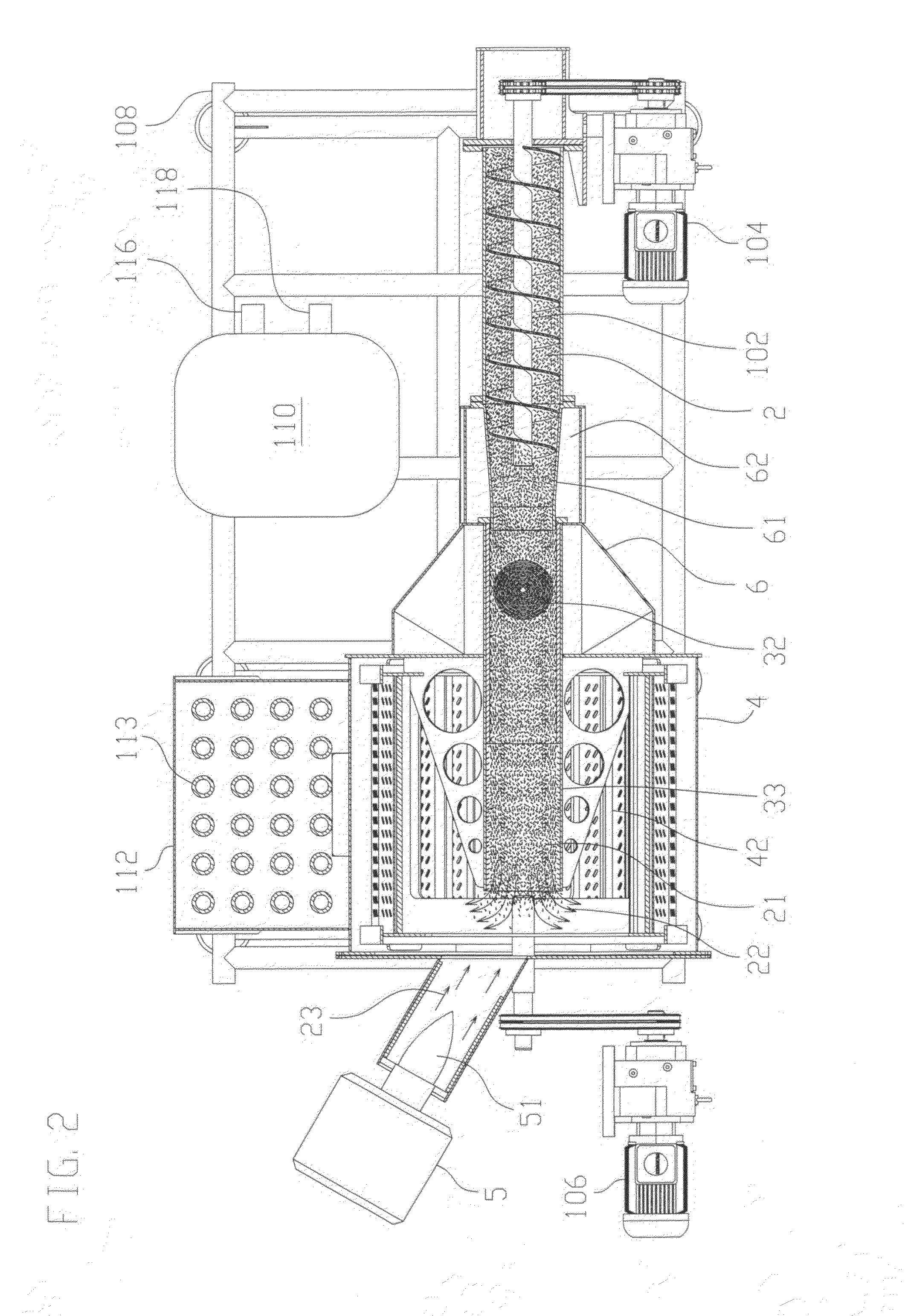

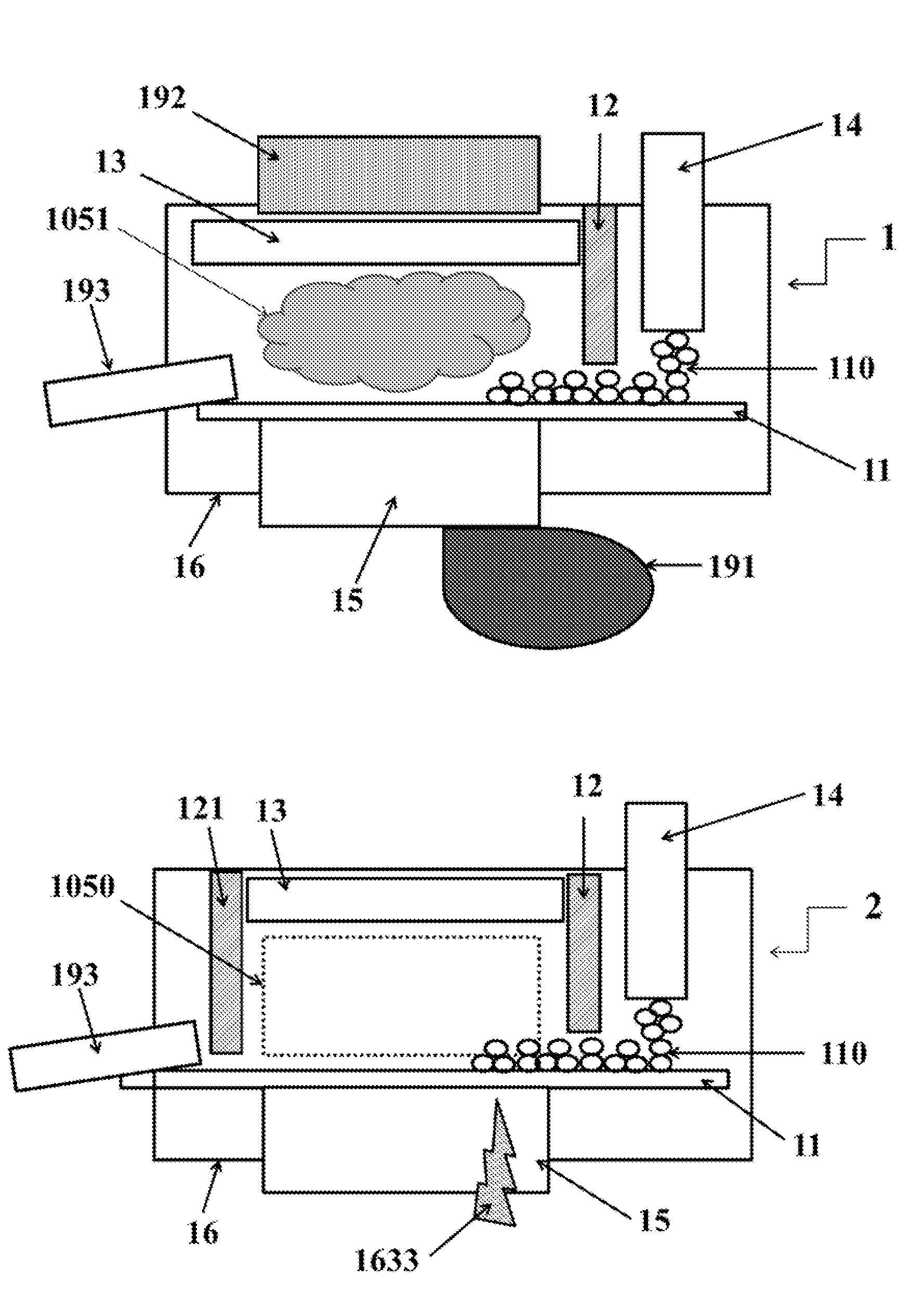

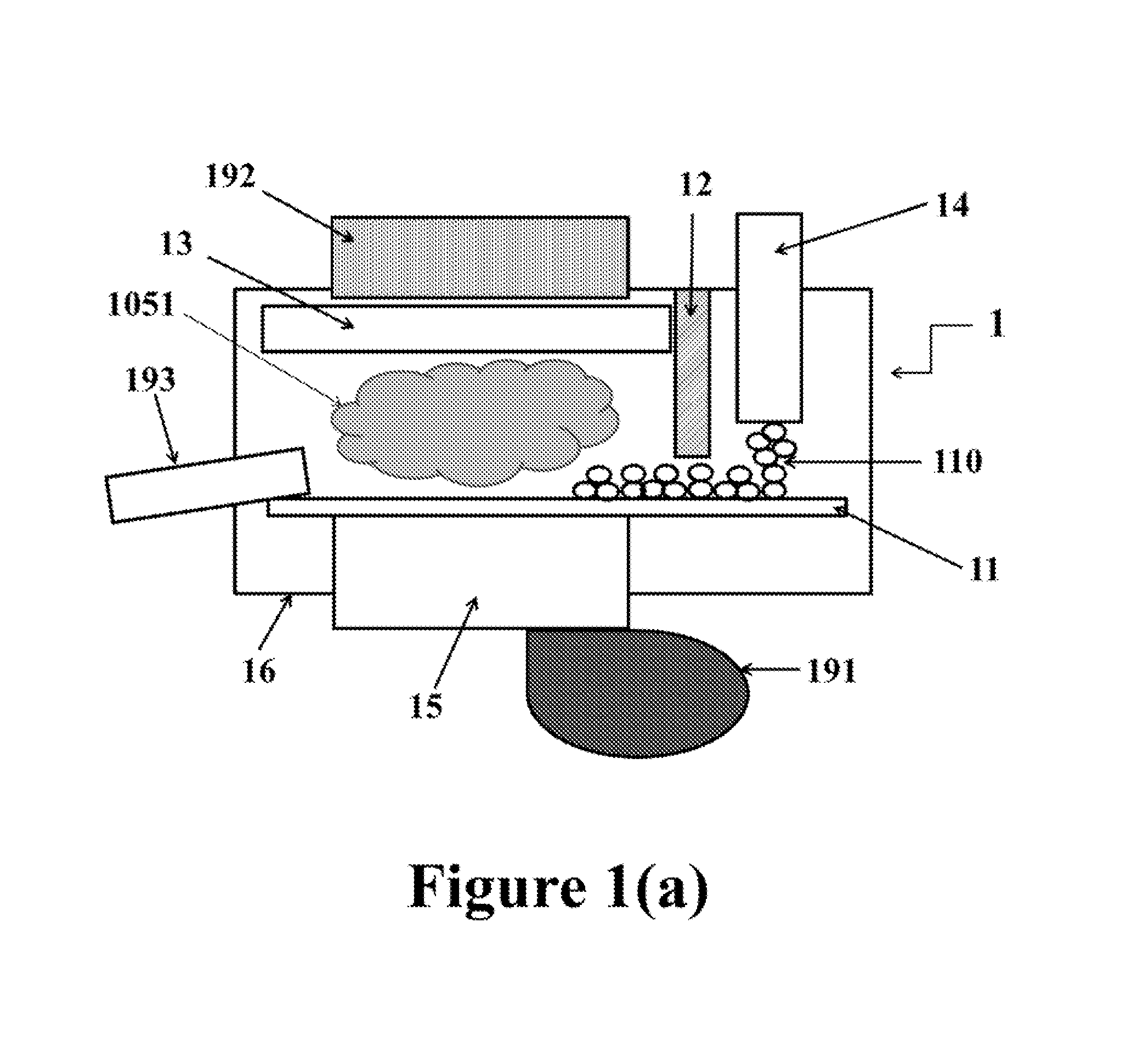

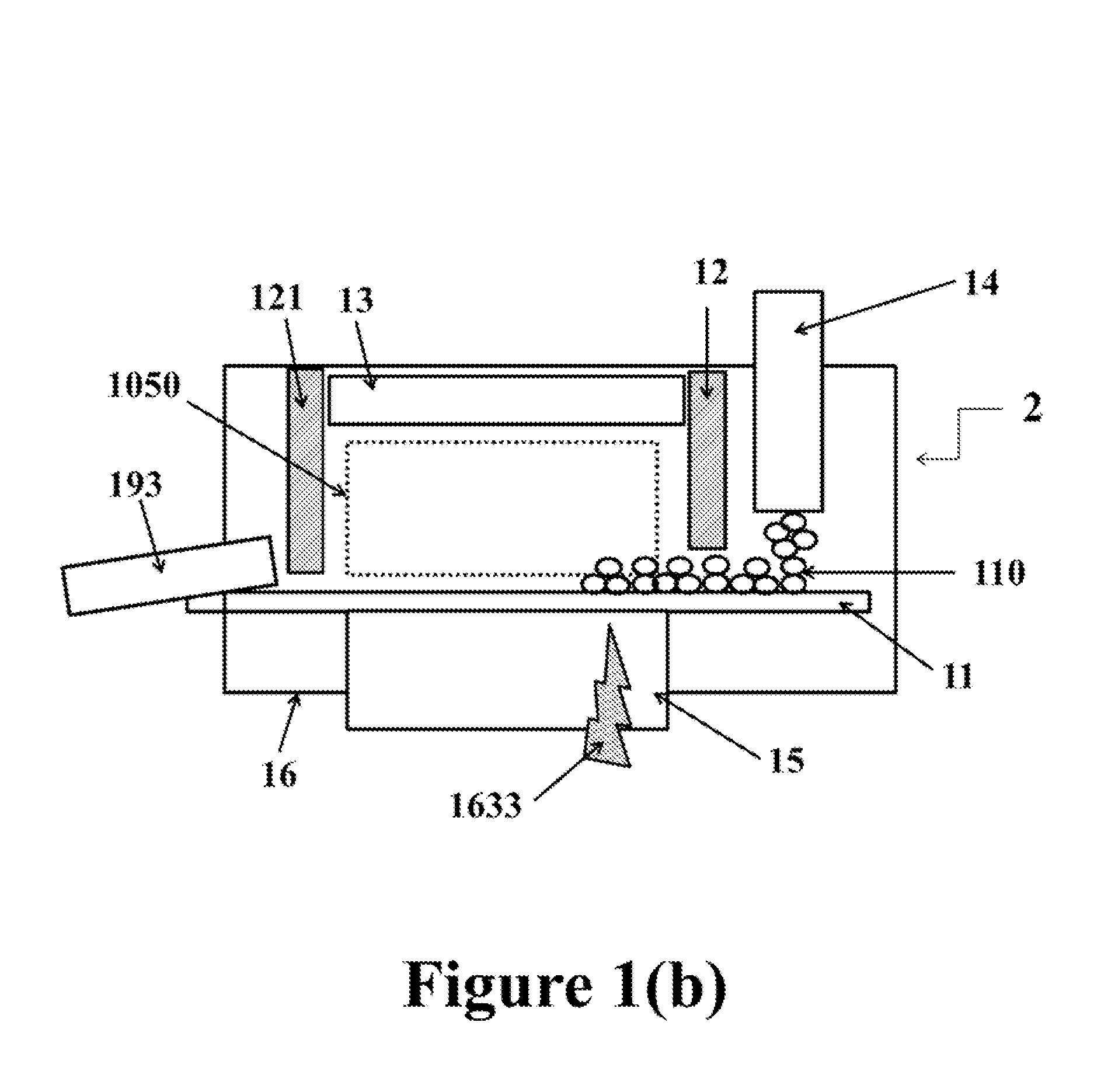

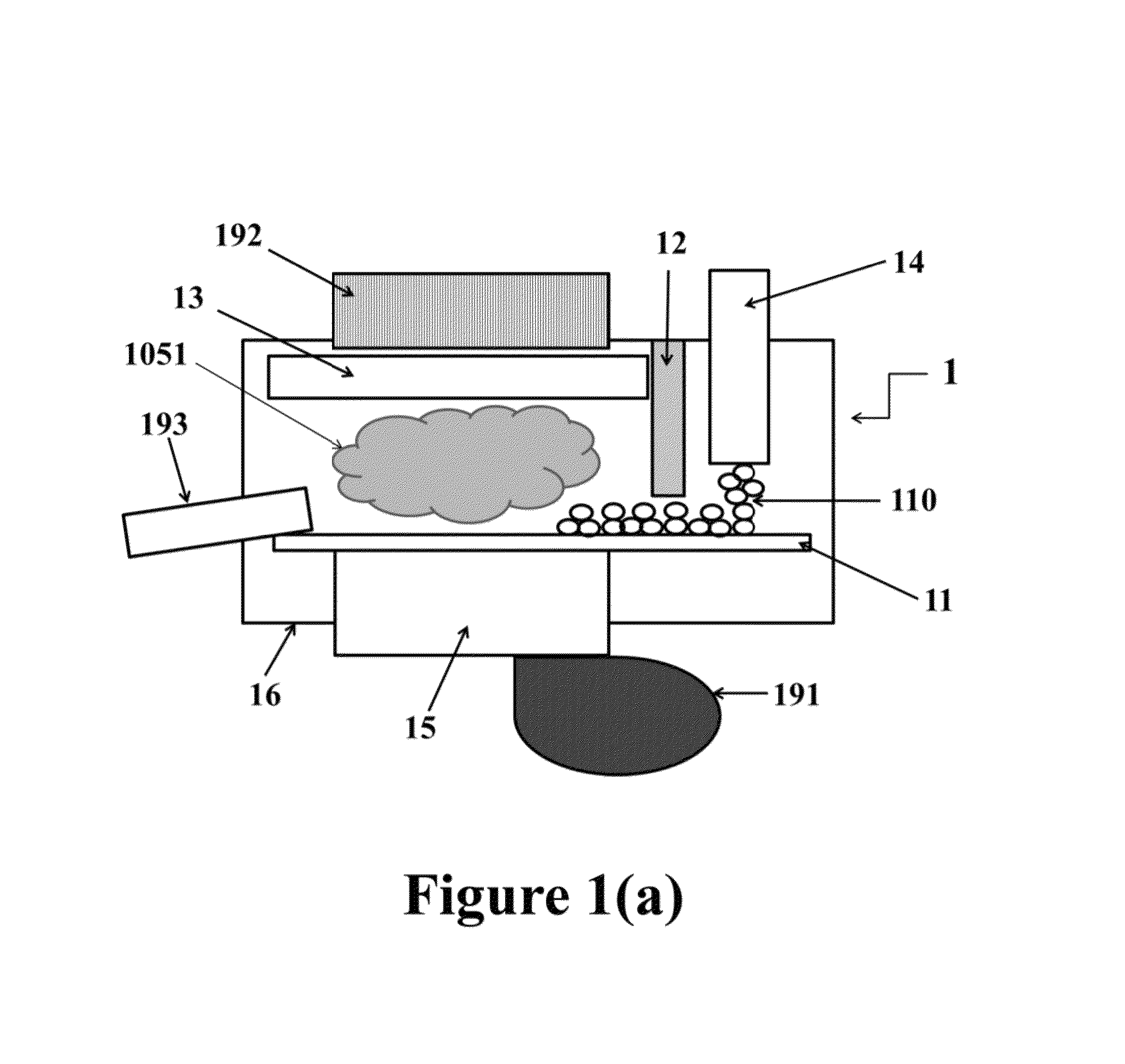

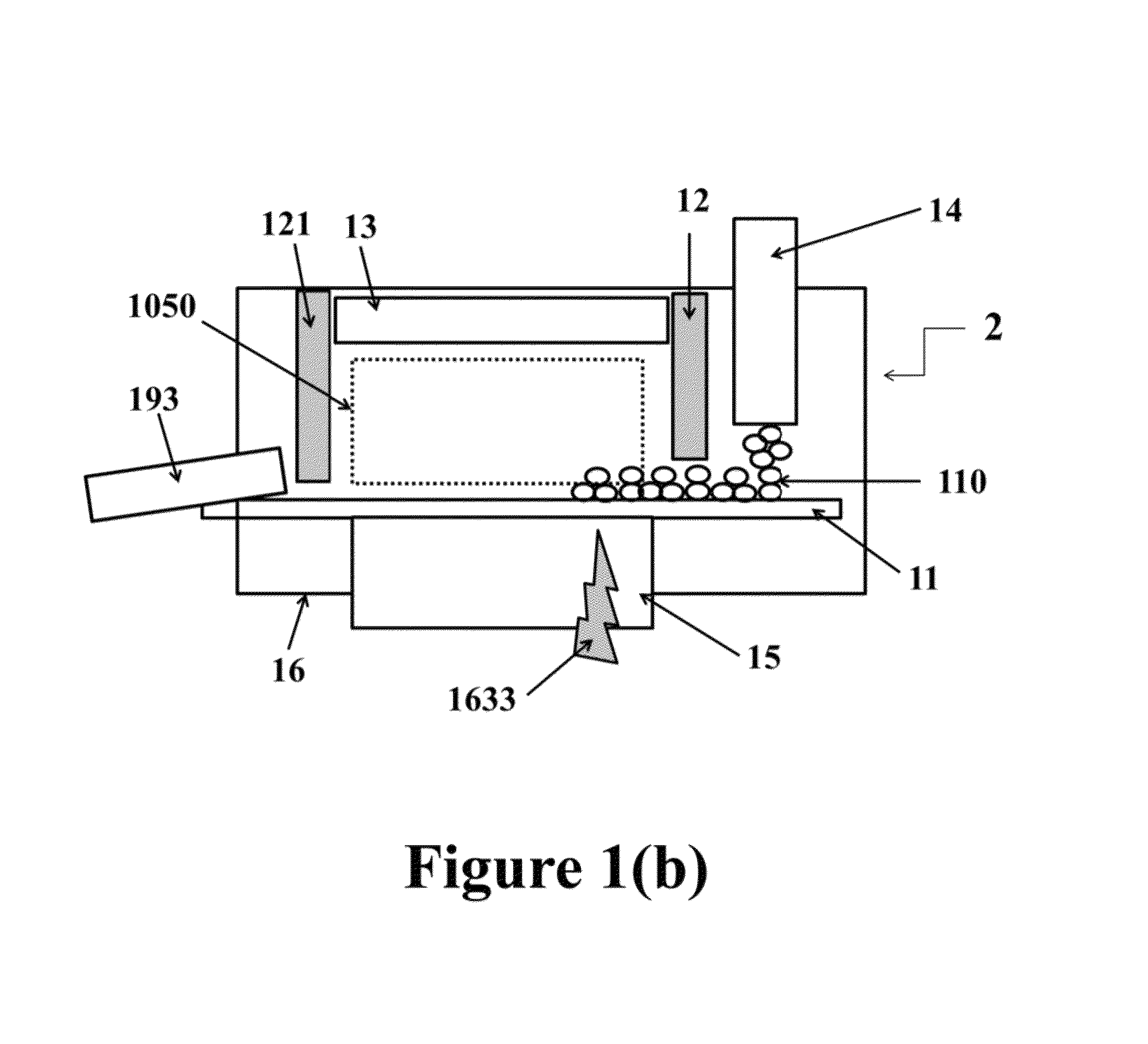

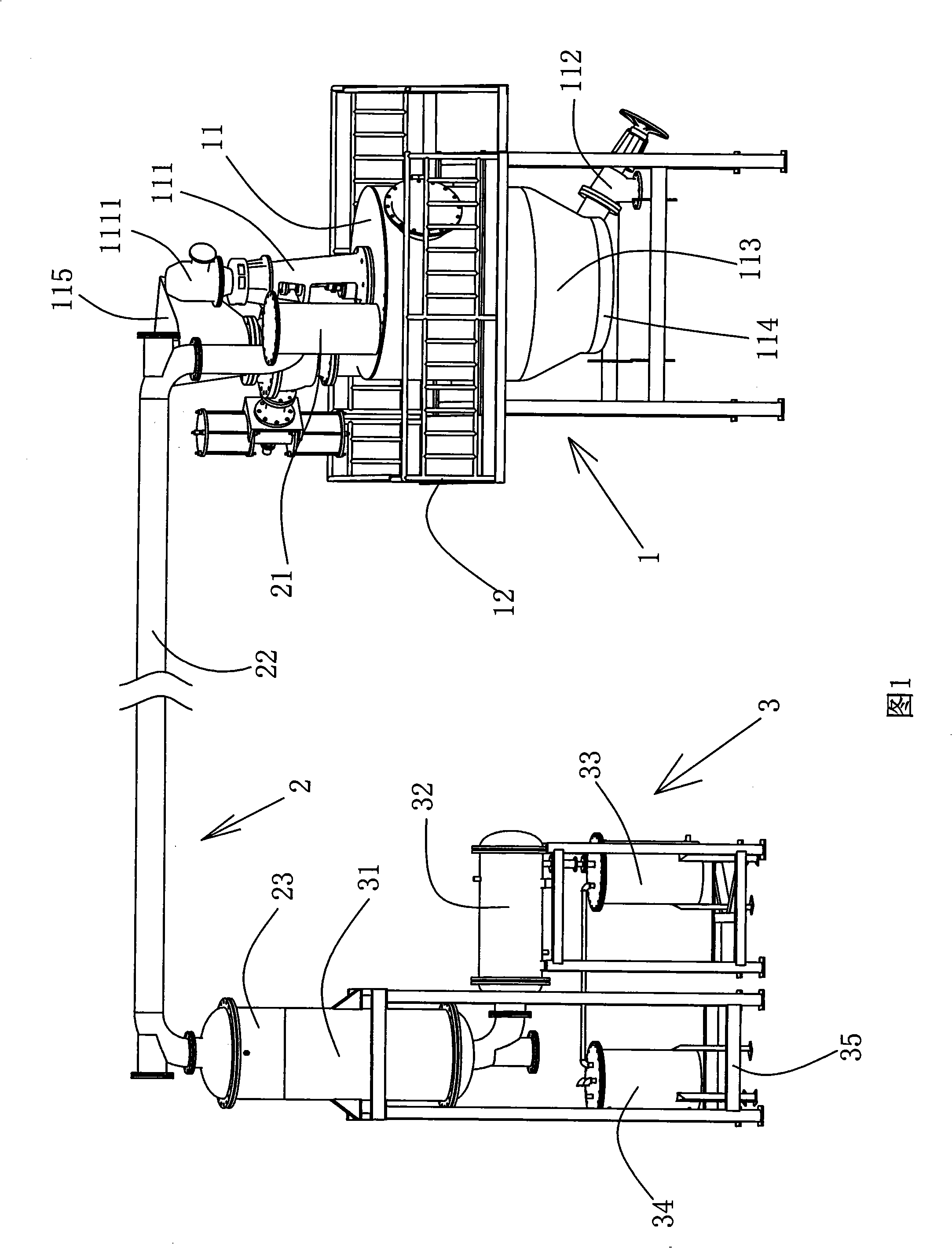

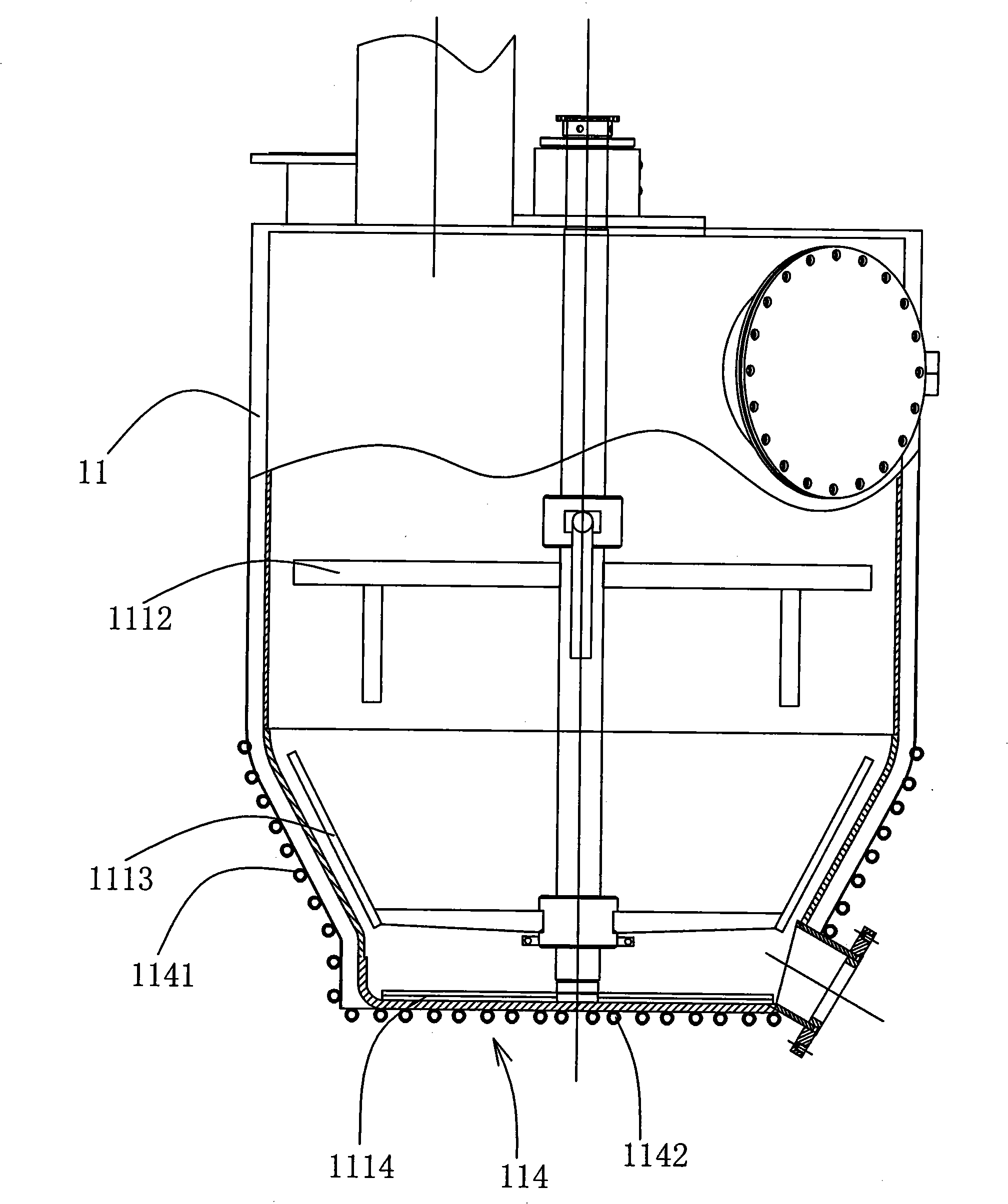

Industrial treatment method and industrial treatment device for oil field waste

ActiveCN103923670ALow boiling pointIncrease gasification rateElectrical coke oven heatingLiquid hydrocarbon mixture productionMicrowave pyrolysisEnvironmental engineering

The invention provides an industrial treatment method for oil field waste. The industrial treatment method for oil field waste comprises the following steps: carrying out sampling analysis on the oil field waste, preheating to 80-300 DEG C by using high-temperature steam or conduction oil, then carrying out microwave pyrolysis treatment, controlling pressure at minus 5000 to minus 100 Pa, thus obtaining solid treatment substances and gas, condensing, separating and purifying the gas, and finally recycling so as to obtain water, oil and non-condensable gas. An industrial treatment device for oil field waste comprises a feed hopper, a dryer, a microwave heating cavity, a microwave generator, a heating device and a condensation separation purification device, wherein the feed hopper is connected to the dryer which is connected to the microwave heating cavity, a steam or conduction oil outlet of the heating device is connected to a steam or conduction oil outlet of the dryer; gas outlets of the dryer and the microwave heating cavity are connected to the condensation separation purification device; the microwave generator is connected to the microwave heating cavity. The industrial treatment method and the industrial treatment device have good treatment effects, high utilization rate of energy sources and good economical efficiency.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

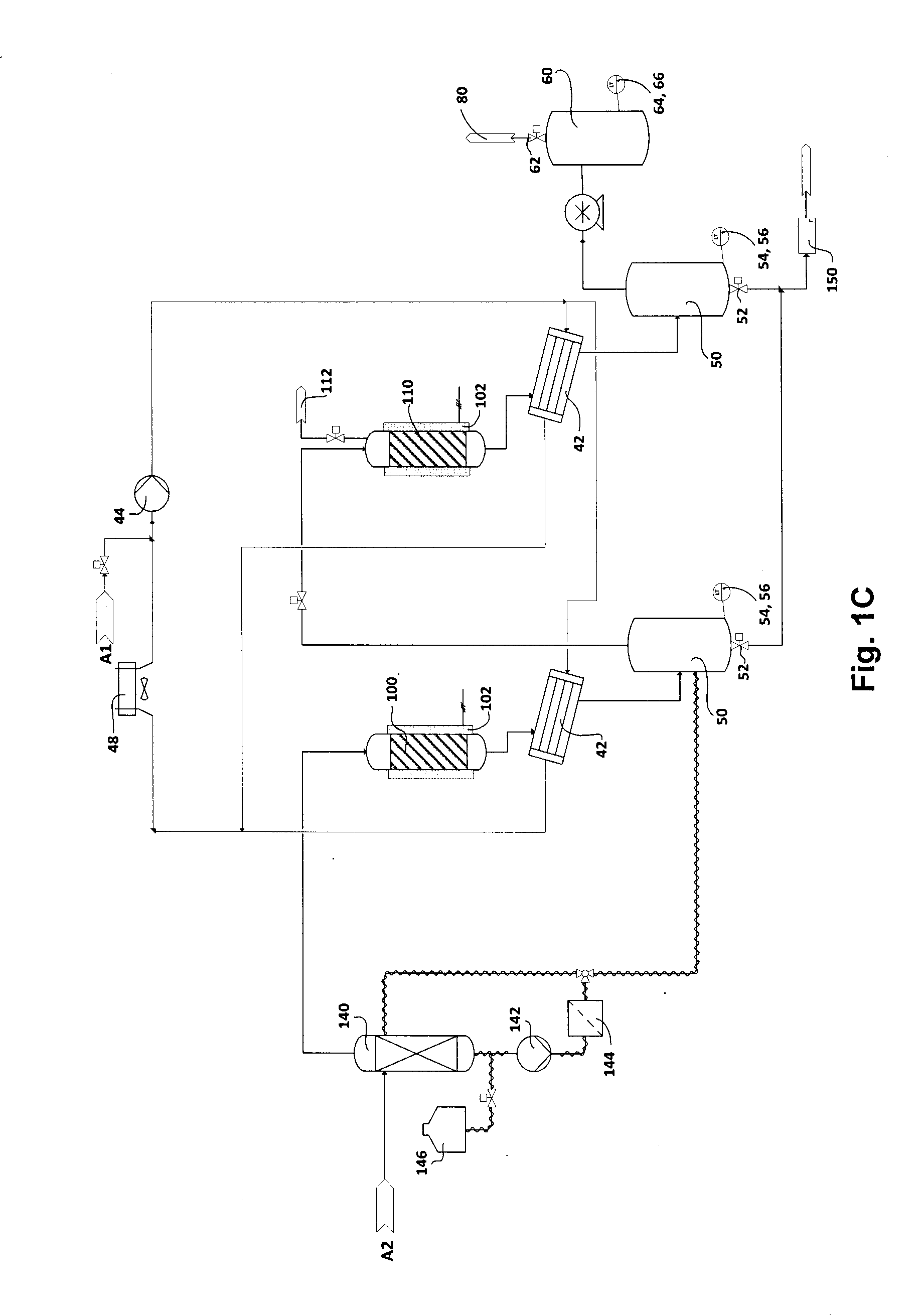

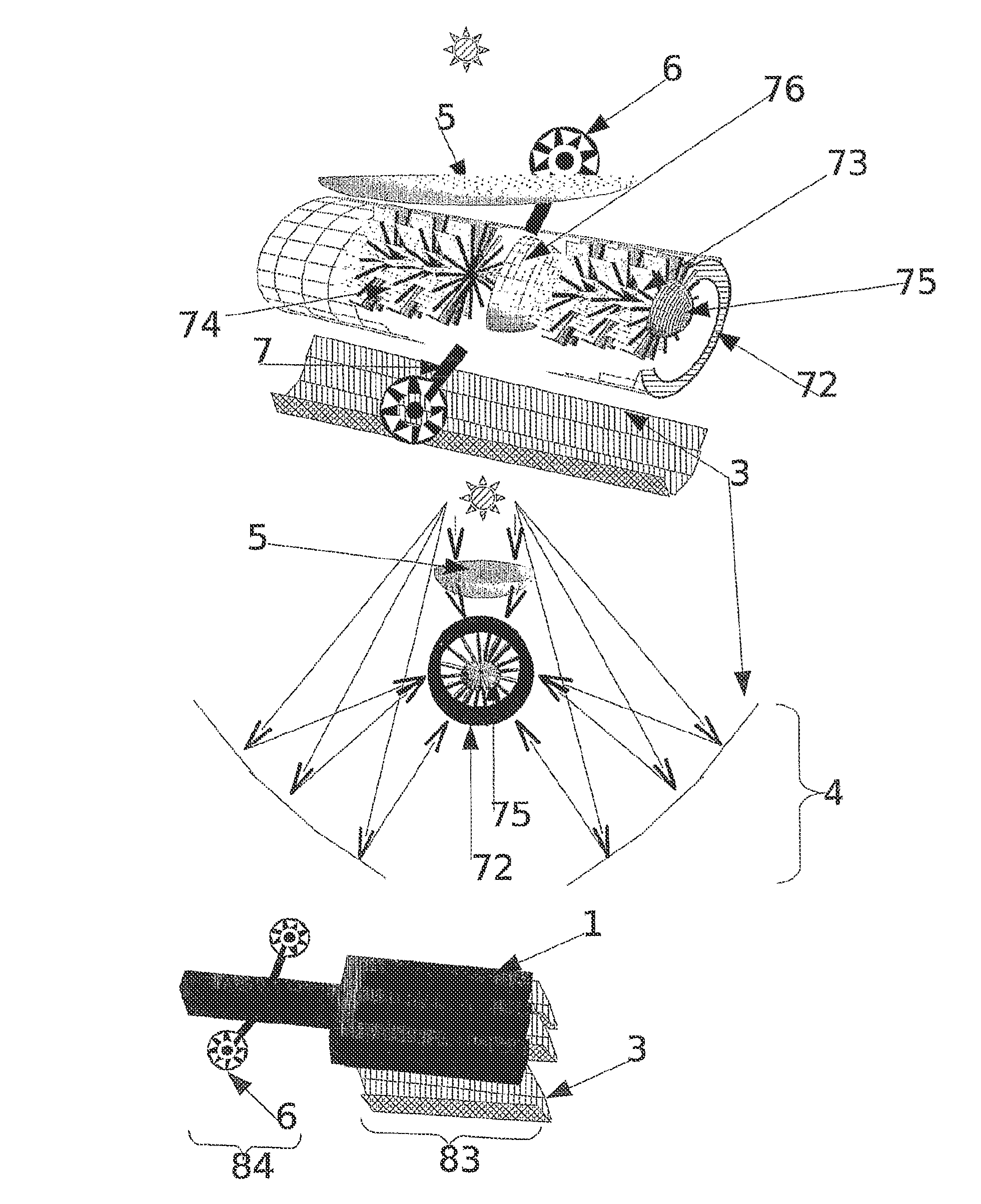

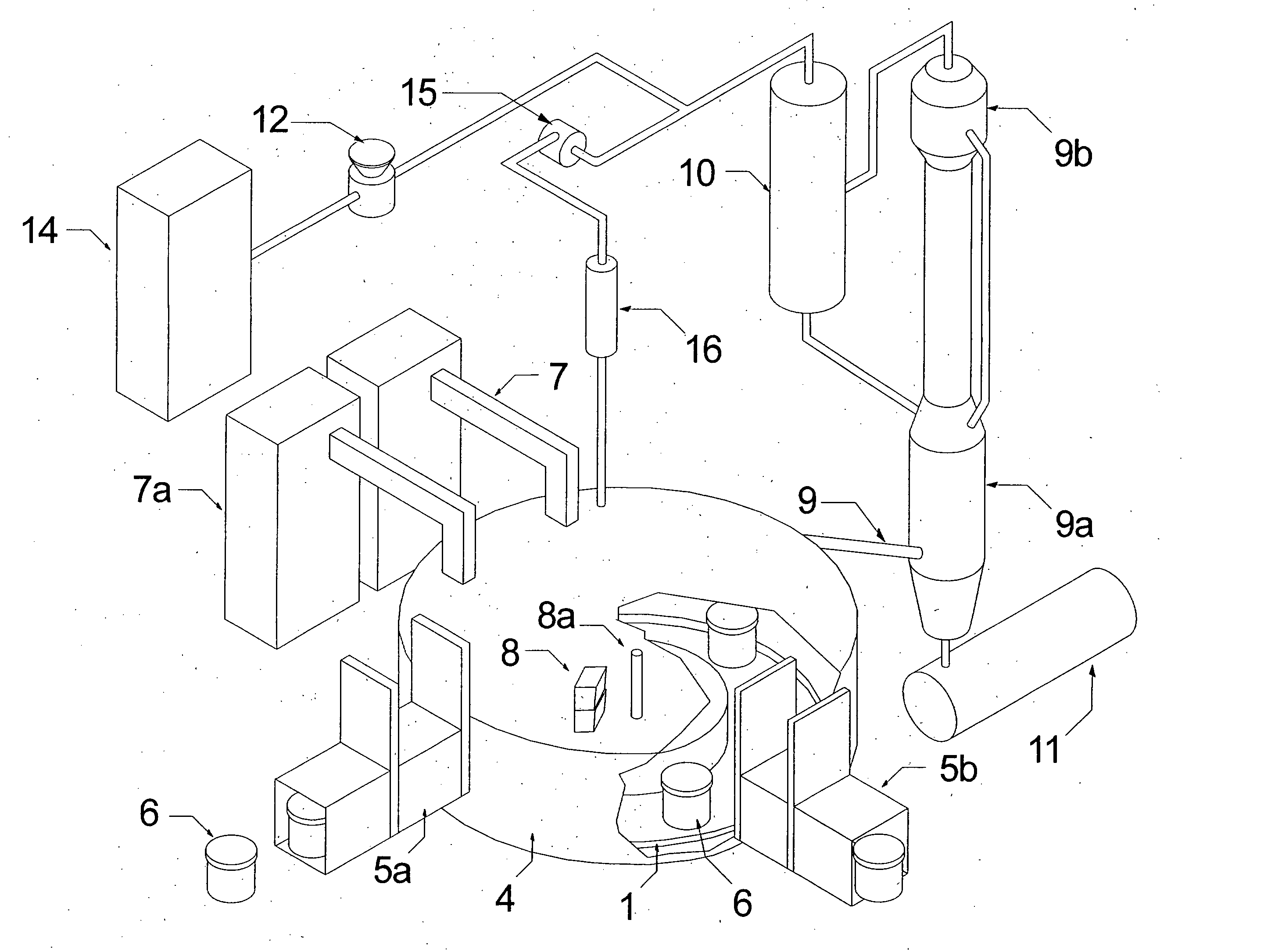

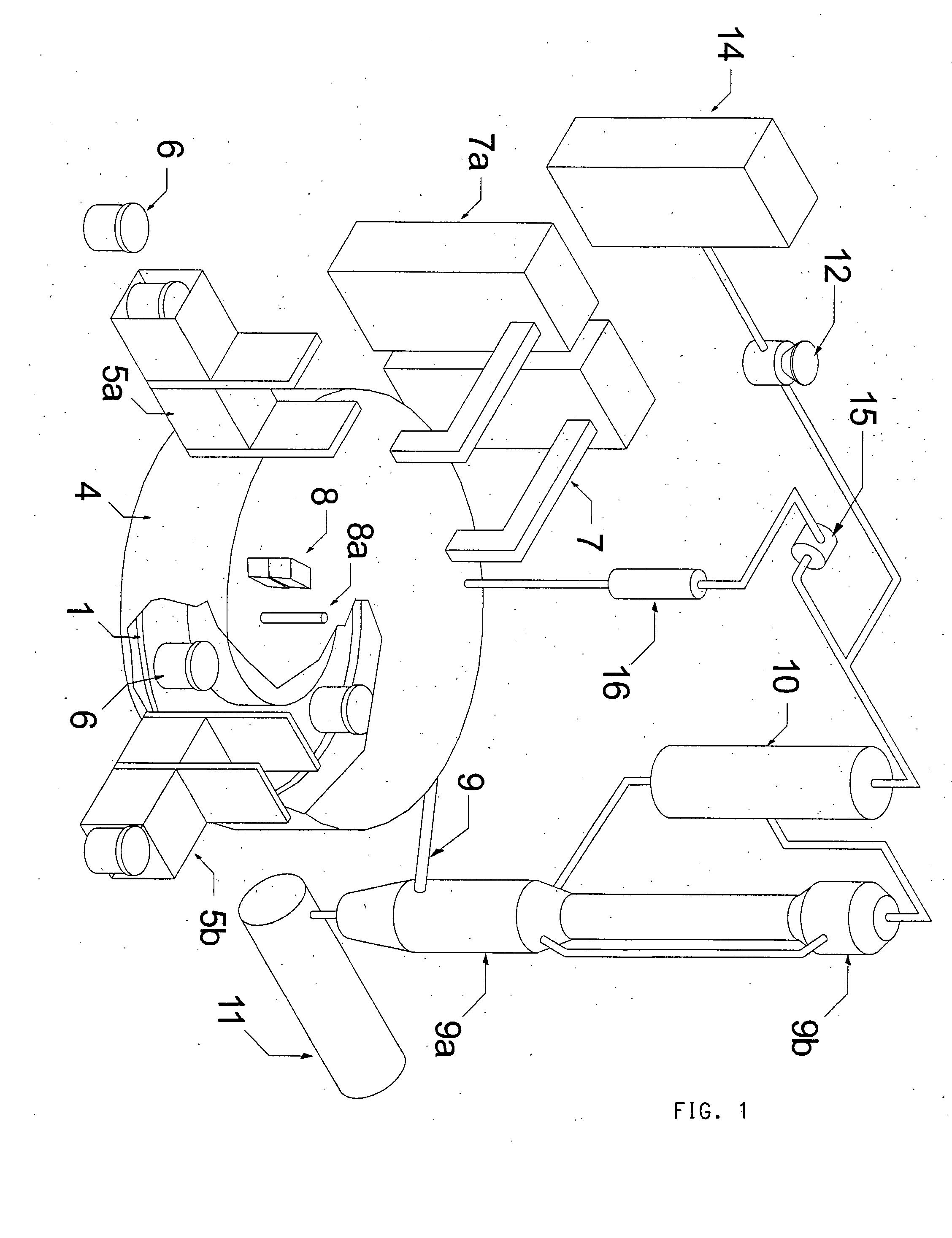

Method using solar energy, microwaves and plasmas to produce a liquid fuel and hydrogen from biomass or fossil coal

ActiveUS20100258429A1Promote gasificationImproving thermal inertiaElectrical coke oven heatingSolar heating energySludgeFractionating column

A system uses thermal solar energy coupled with microwaves and plasma for producing carbon monoxide (CO) and dihydrogen (H2) from carbonated compounds (biomass, domestic waste, sludge from waste water, fossil coal), wherein the obtained gaseous mixture yields, amongst others, hydrocarbon fuels (olefins, paraffin), esters, and alcohols via a Fischer-Tropsch synthesis. In a first step the carbonated compounds are roasted and pyrolized to produce char and dry coal, and a mixture of superheated gases containing CO2, steam, tars and non-condensable volatile materials. The method includes in a second step, and from the pyrolyis products (char or coal, gas mixture), generating a syngas substantially containing a mixture of carbon monoxide and dihydrogen, the mixture being used in Fischer-Tropsch synthesis units. After the Fischer-Tropsch step, the synthesis products are separated in a distillation column after heating in solar furnaces of mixed furnaces (solar / microwave).

Owner:UGOLIN NICOLAS

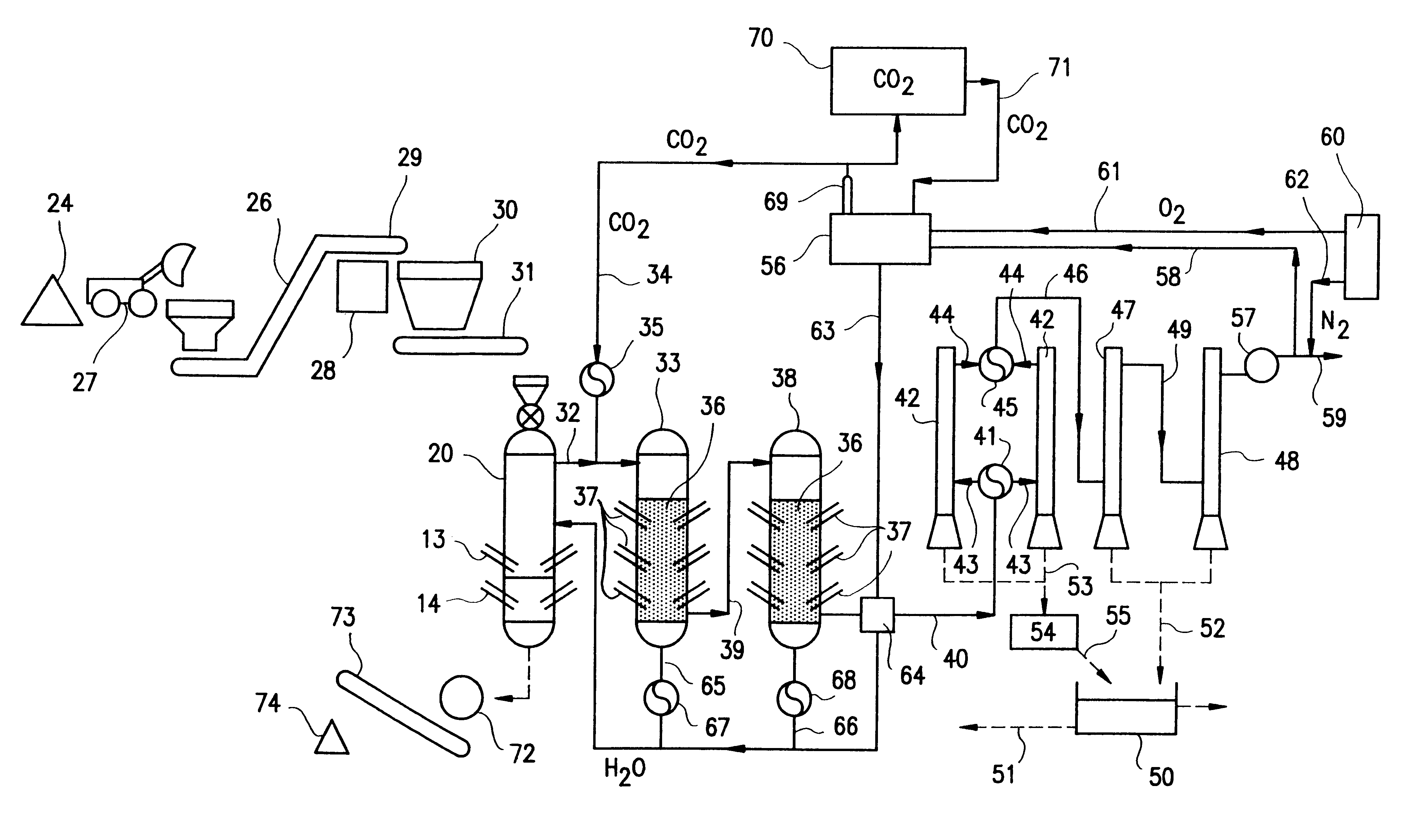

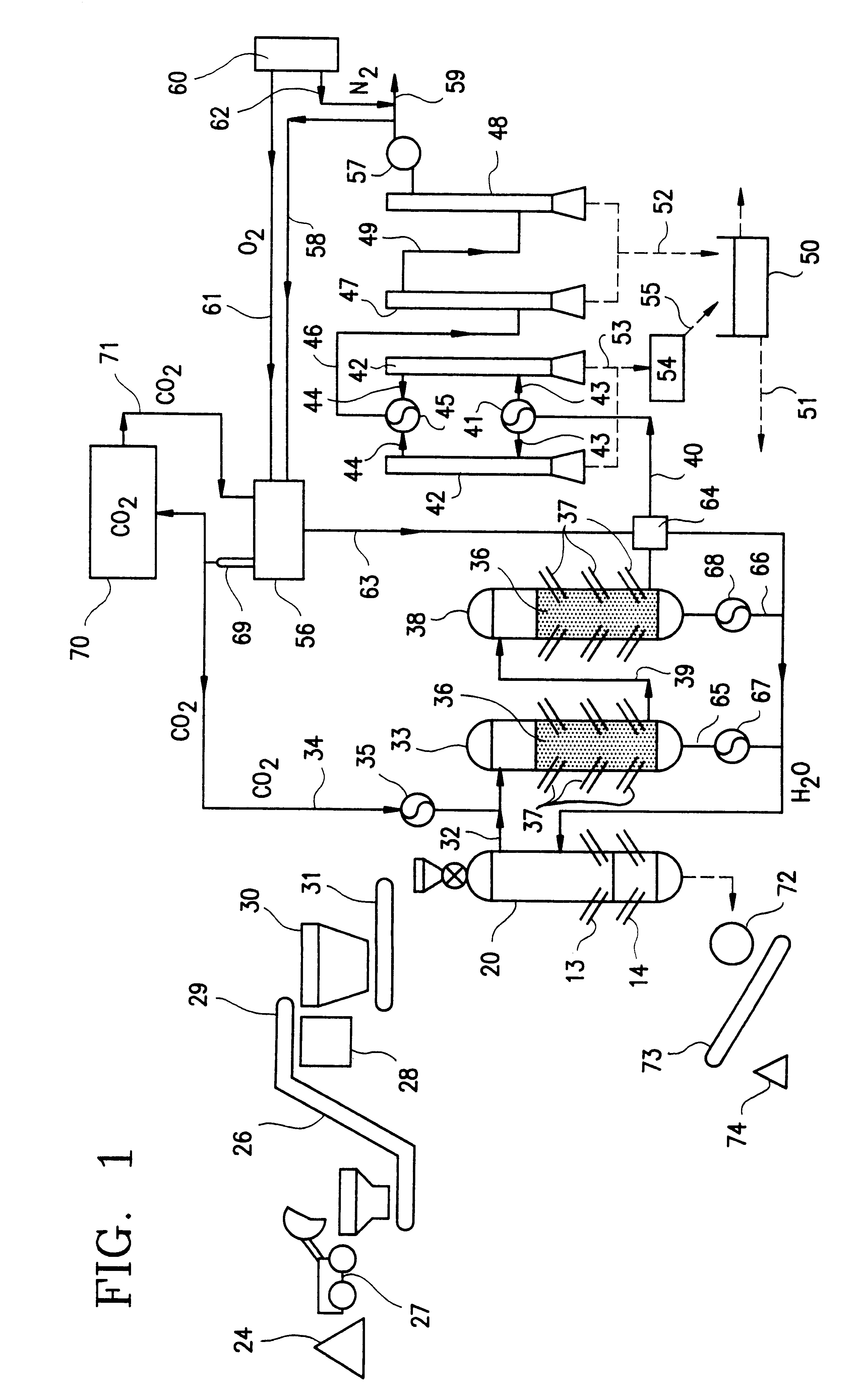

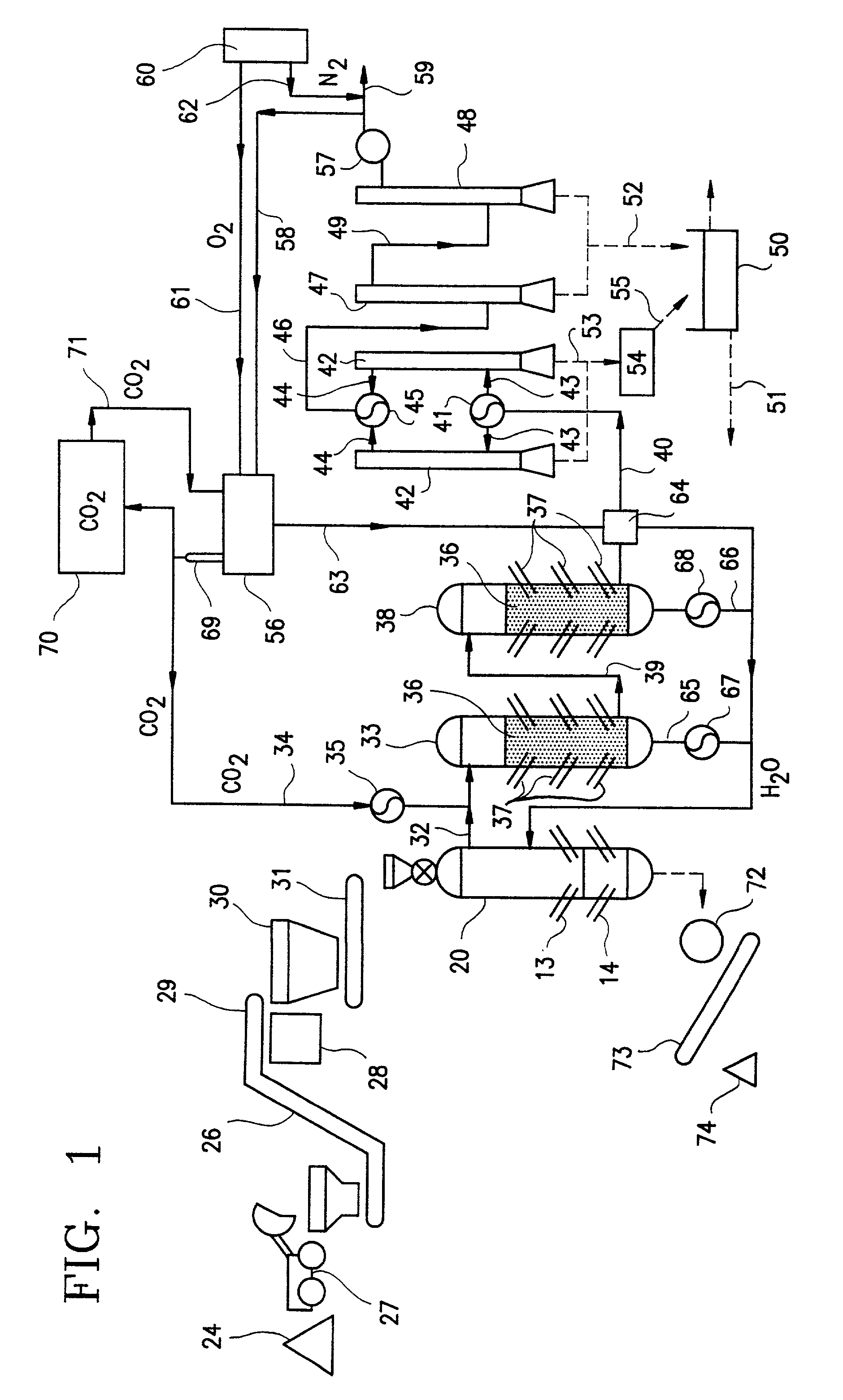

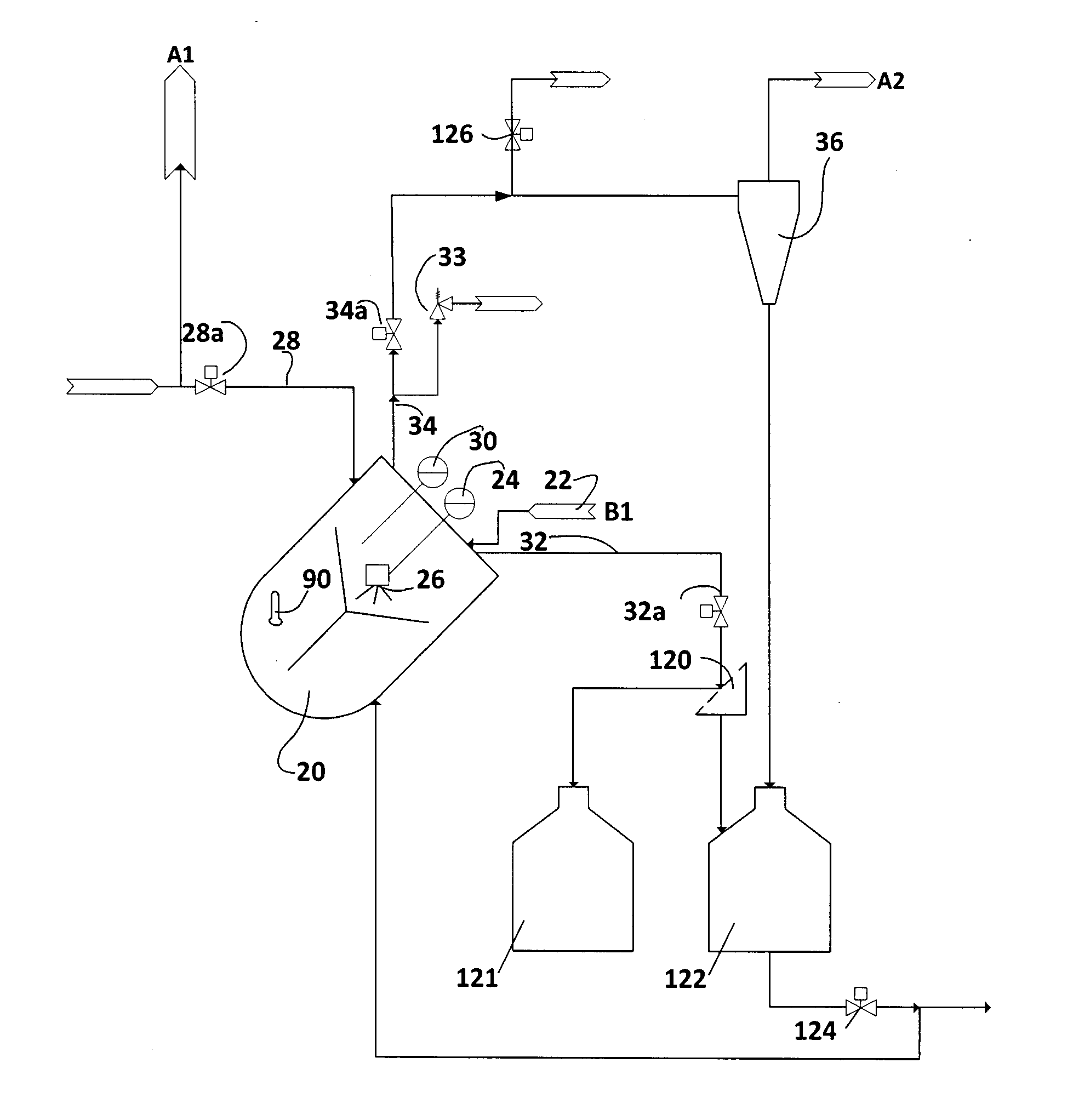

Synthesis gas production and power generation with zero emissions

InactiveUS6333015B1Avoid water pollutionEliminate needElectrical coke oven heatingGasifier electrodesClosed loopProduct gas

A process and apparatus for producing and burning synthesis gas. Carbonaceous waste material is pyrolytically decomposed in a primary reactor in the presence of steam to produce raw product gas containing H2 and CO. The raw product gas and CO2 is then introduced into a coke containing secondary reactor under pyrolyzing conditions, so that the CO2 and coke react to produce combustible gas having an increased CO content. The combustible gas is mixed with oxygen and CO2 to produce a combustible mixture which is burned as a fuel to produce heat, CO2 and H2O. A portion of the produced CO2 is recovered and used as the source of CO2 gas in the combustible mixture and as a source of CO2 gas for the secondary reactor. Preferably filters and scrubbers are used in a closed loop system to avoid undesirable emissions into the environment.

Owner:LEWIS GLORIA B

Method and Apparatus for Microwave Reduction of Organic Compounds

InactiveUS20070102279A1Maximum protectionElectrical coke oven heatingSolid waste disposalEngineeringVolumetric Mass Density

The invention described herein generally pertains to utilization of high power density microwave energy to reduce organic compounds to carbon and their constituents, primarily in a gaseous state. The process includes, but is not limited to, scrap tires, plastics, asphalt roofing shingles, computer waste, medical waste, municipal solid waste, construction waste, shale oil, and PCB / PAH / HCB-laden materials. The process includes the steps of feeding organic material into a microwave applicator and exposing the material to microwave energy fed from at least two linear polarized sources in non-parallel alignment to each other, and collecting the material. The at least two sources of microwave energy are from a bifurcated waveguide assembly, whose outputs are perpendicular to each other and fed through waveguide of proper impedance, such that the microwave sources are physically and electrically 90° out of phase to each other. The microwave frequency is between 894 and 1000 MHz, preferably approximately 915 MHz.

Owner:NOVAK JUDITH

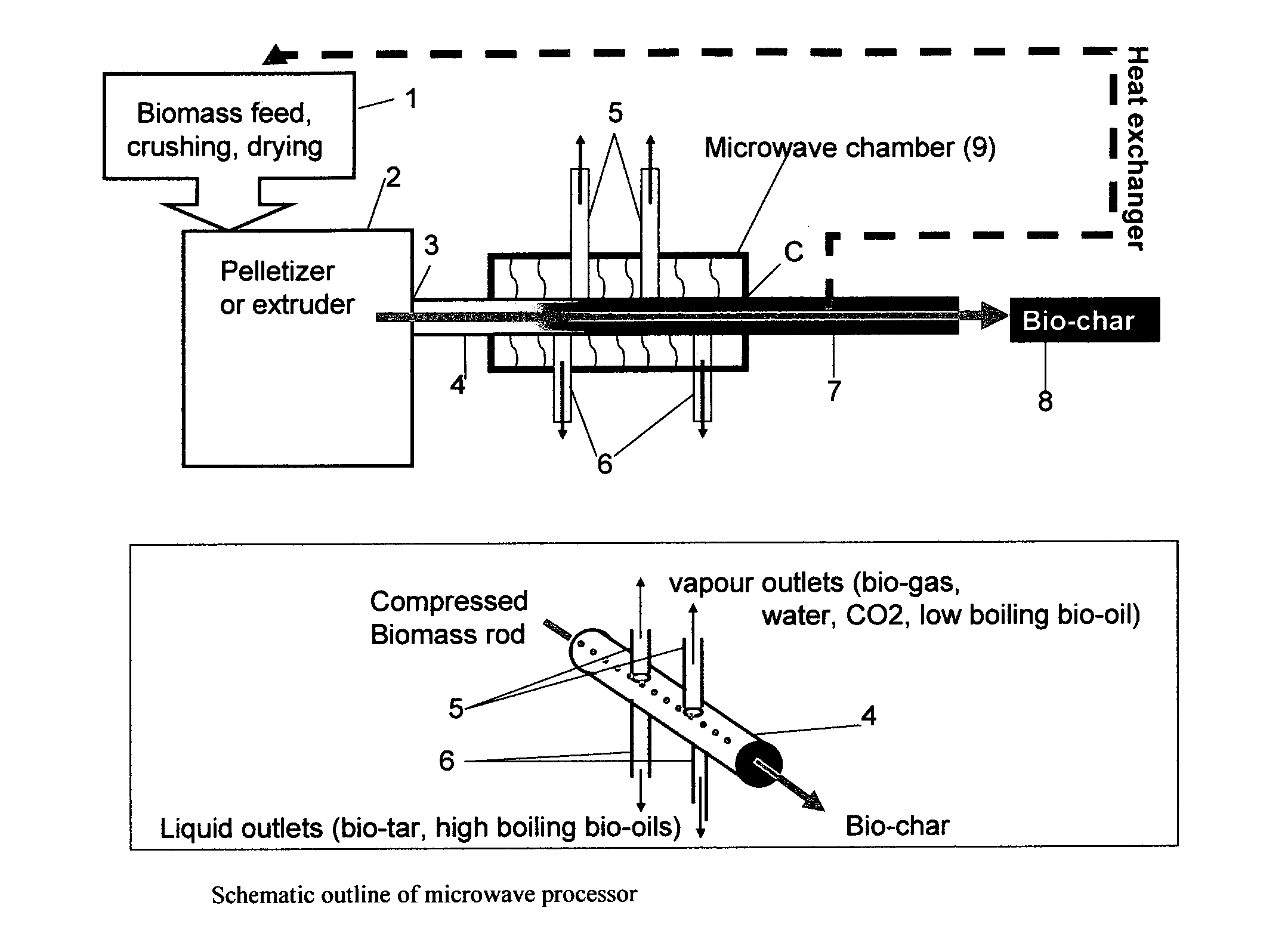

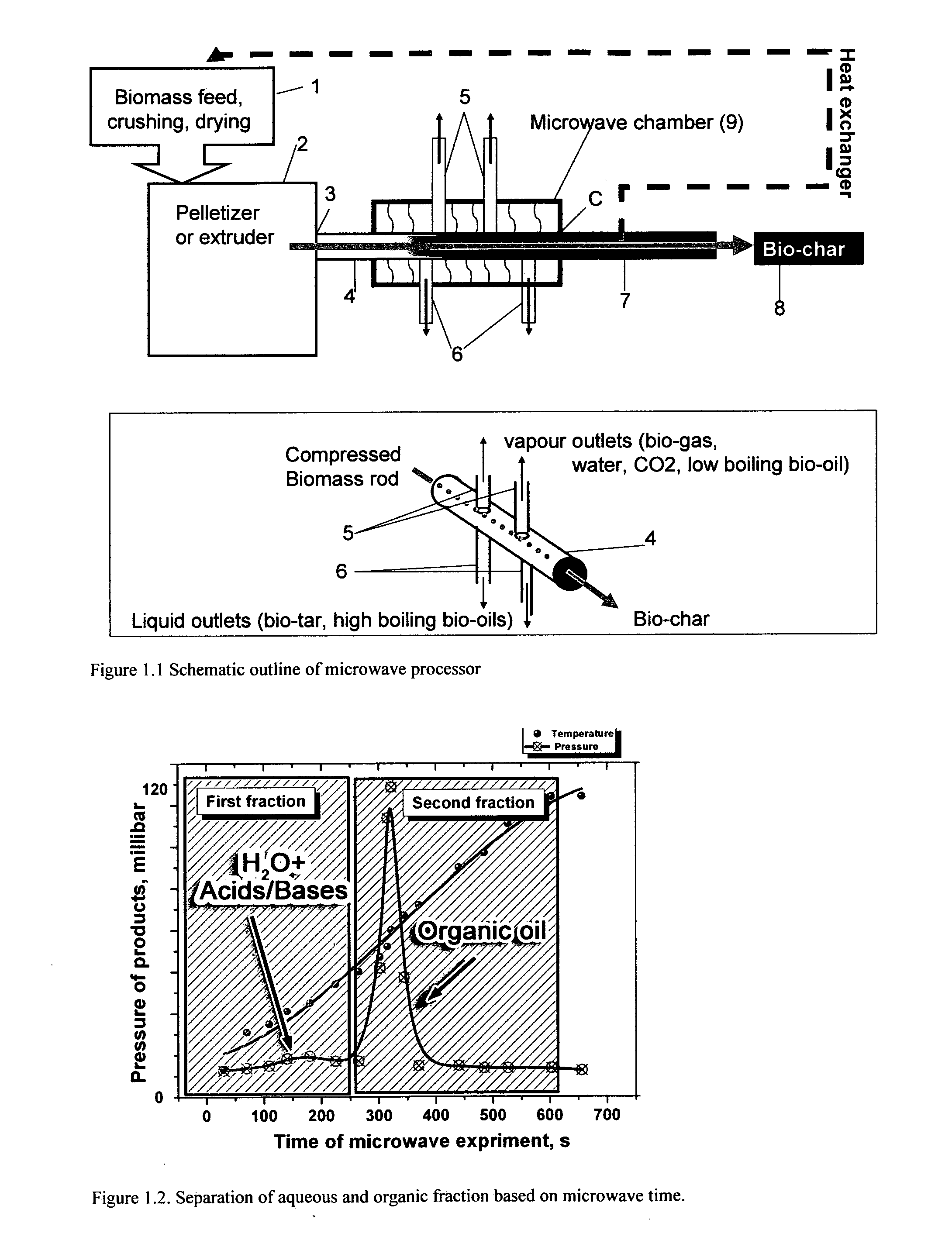

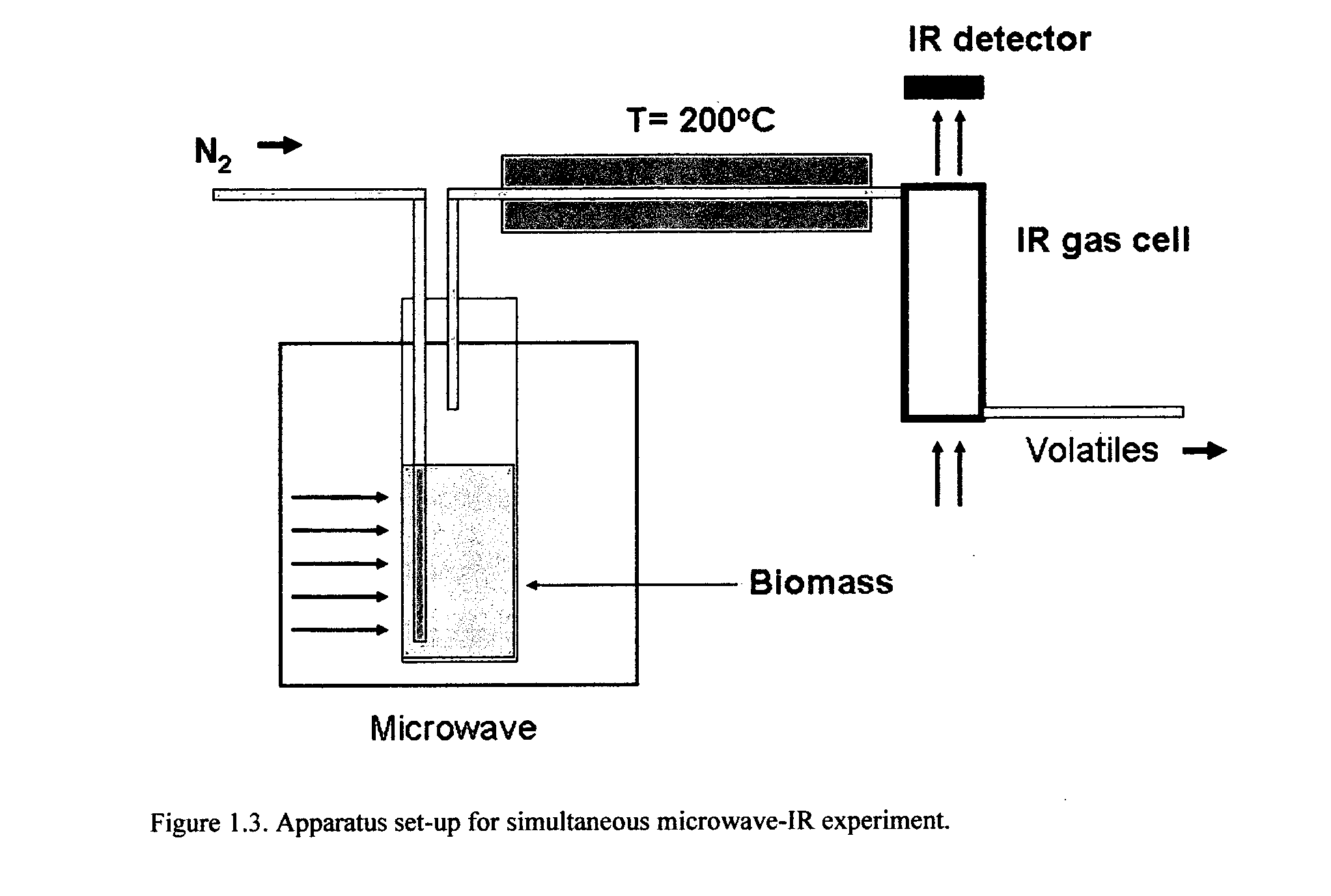

Microwave torrefaction of biomass

InactiveUS20110219679A1Increase flexibilityEasy to controlElectrical coke oven heatingBiofuelsMicrowaveTorrefaction

Owner:THE UNIV OF YORK

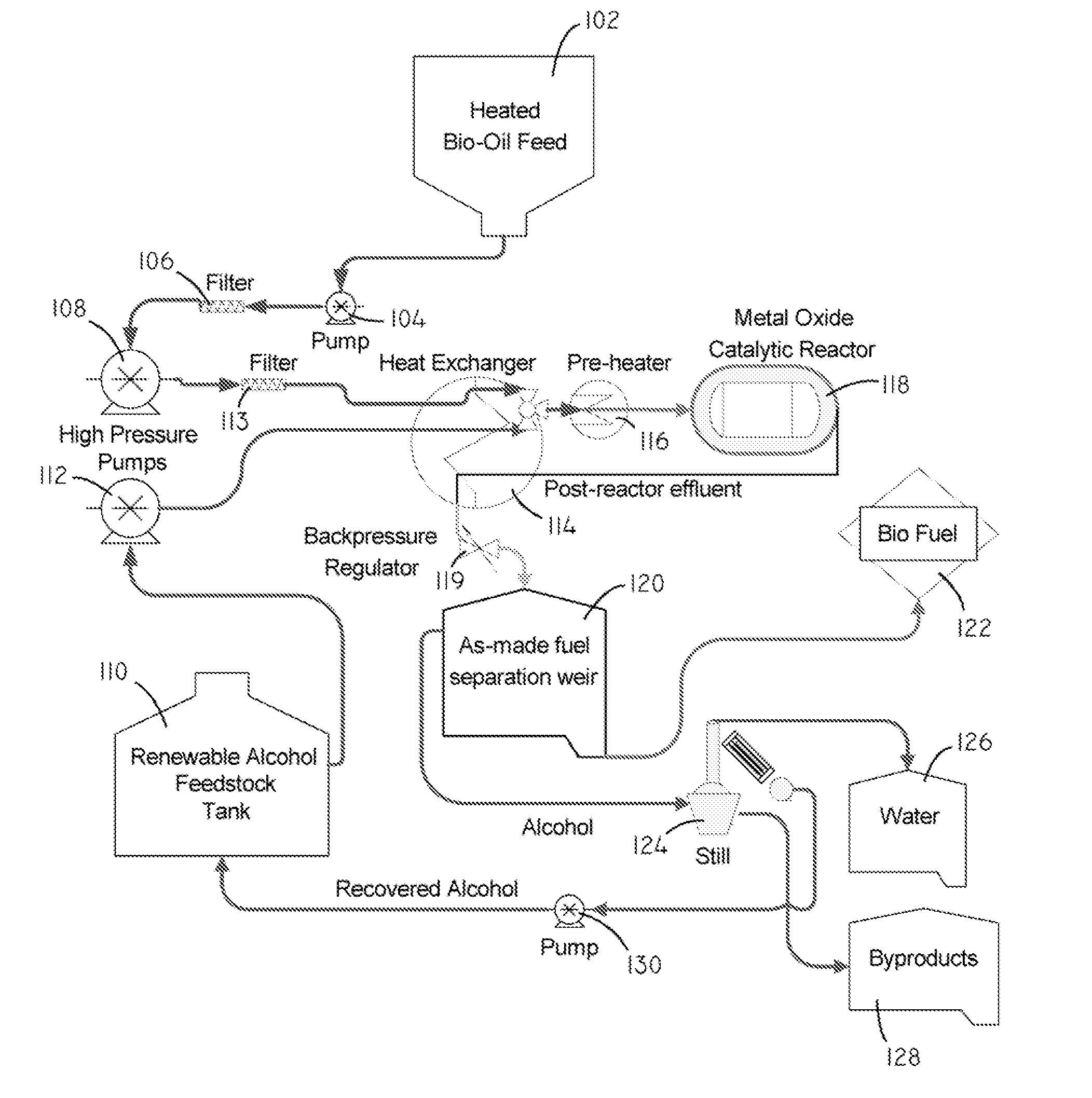

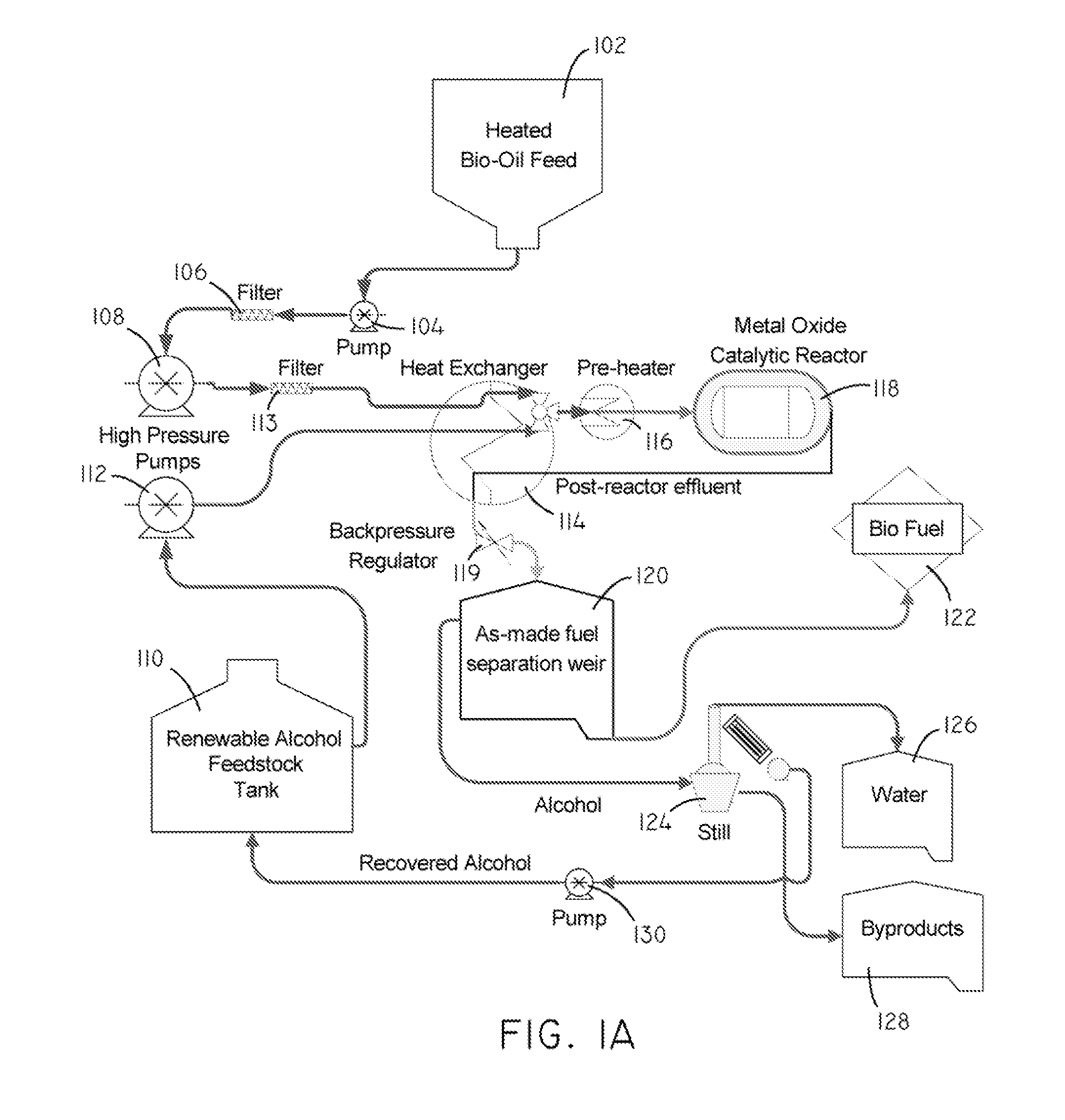

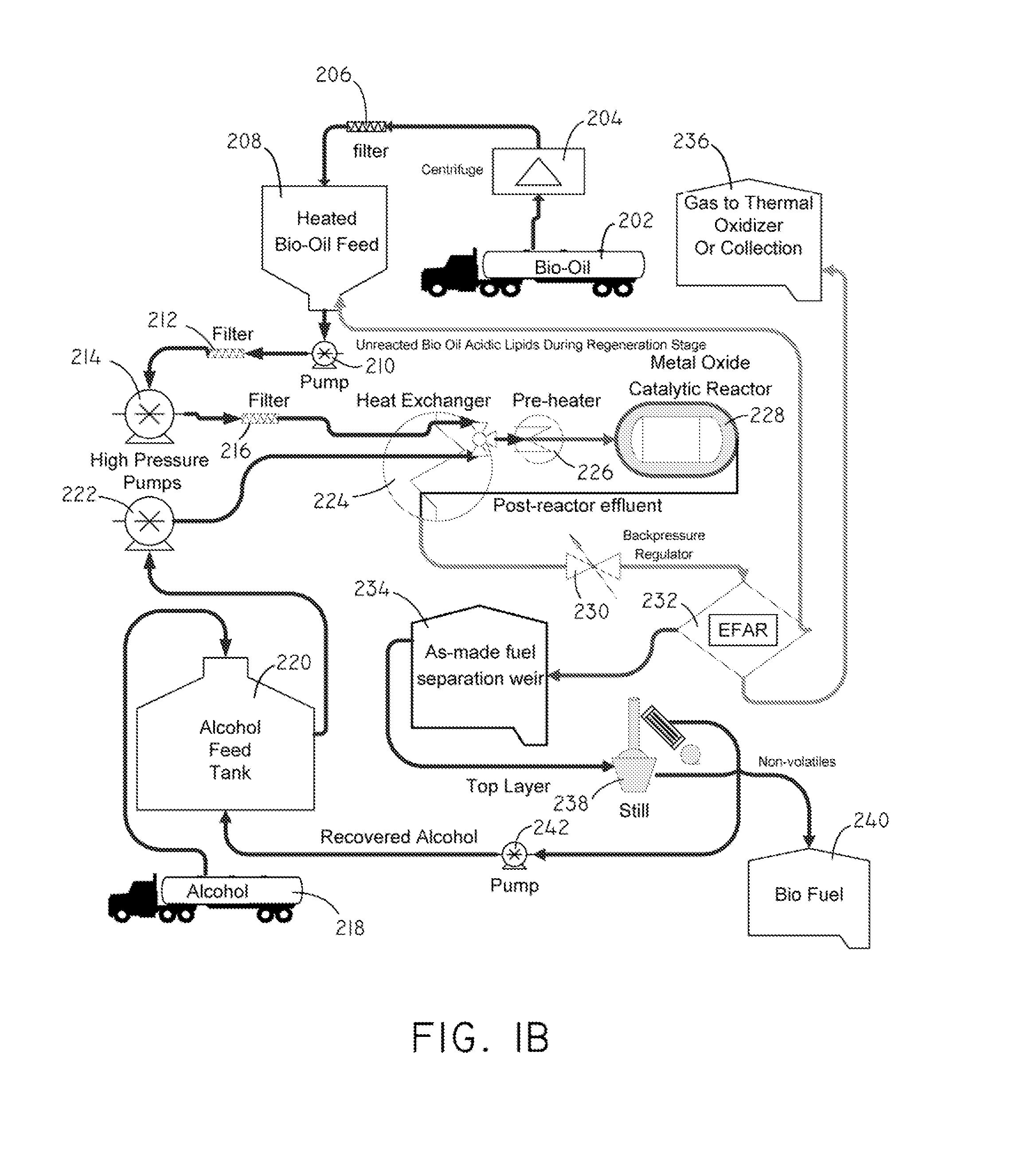

Systems and methods for producing fuels from biomass

The present invention relates to systems and methods for producing fuels. In an embodiment, the invention includes a method of producing a diesel-equivalent fuel, including pyrolyzing biomass to form a pyrolysis oil and contacting the pyrolysis oil and an alcohol with a metal oxide catalyst at a temperature of greater than about 60 degrees Celsius. In an embodiment, the invention includes a method of refining pyrolysis oil including contacting pyrolysis oil and an alcohol with a metal oxide catalyst at a temperature of greater than about 60 degrees Celsius. In an embodiment, the invention includes a system for processing biomass into fuel including a pyrolysis chamber defining an interior volume; a first heating element configured to heat the pyrolysis chamber; a refining chamber in selective fluid communication with the pyrolysis chamber, the refining chamber defining an interior volume, a metal oxide catalyst disposed within the interior volume; and a second heating element configured to heat the refining chamber. Other embodiments are also described herein.

Owner:SARTEC

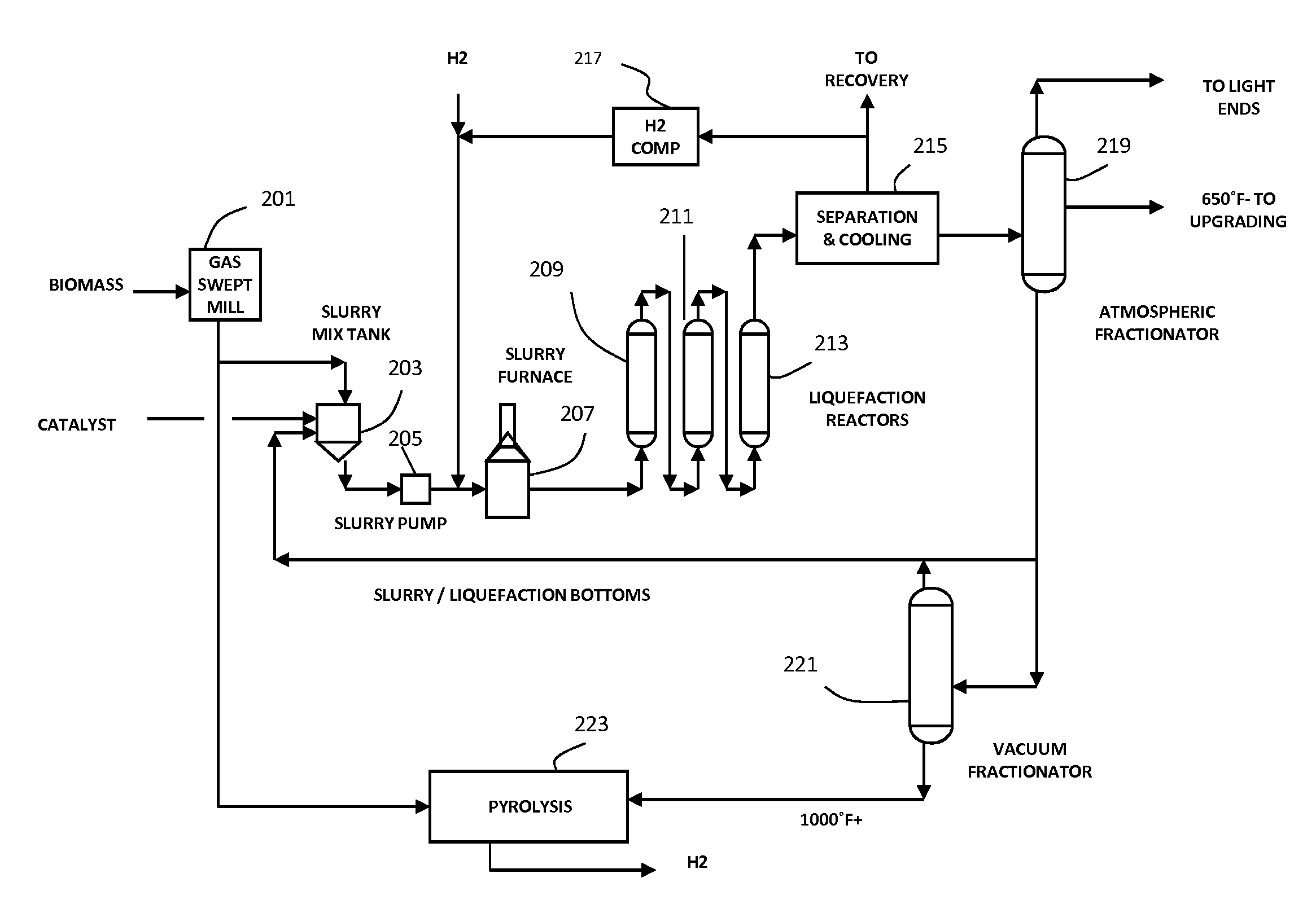

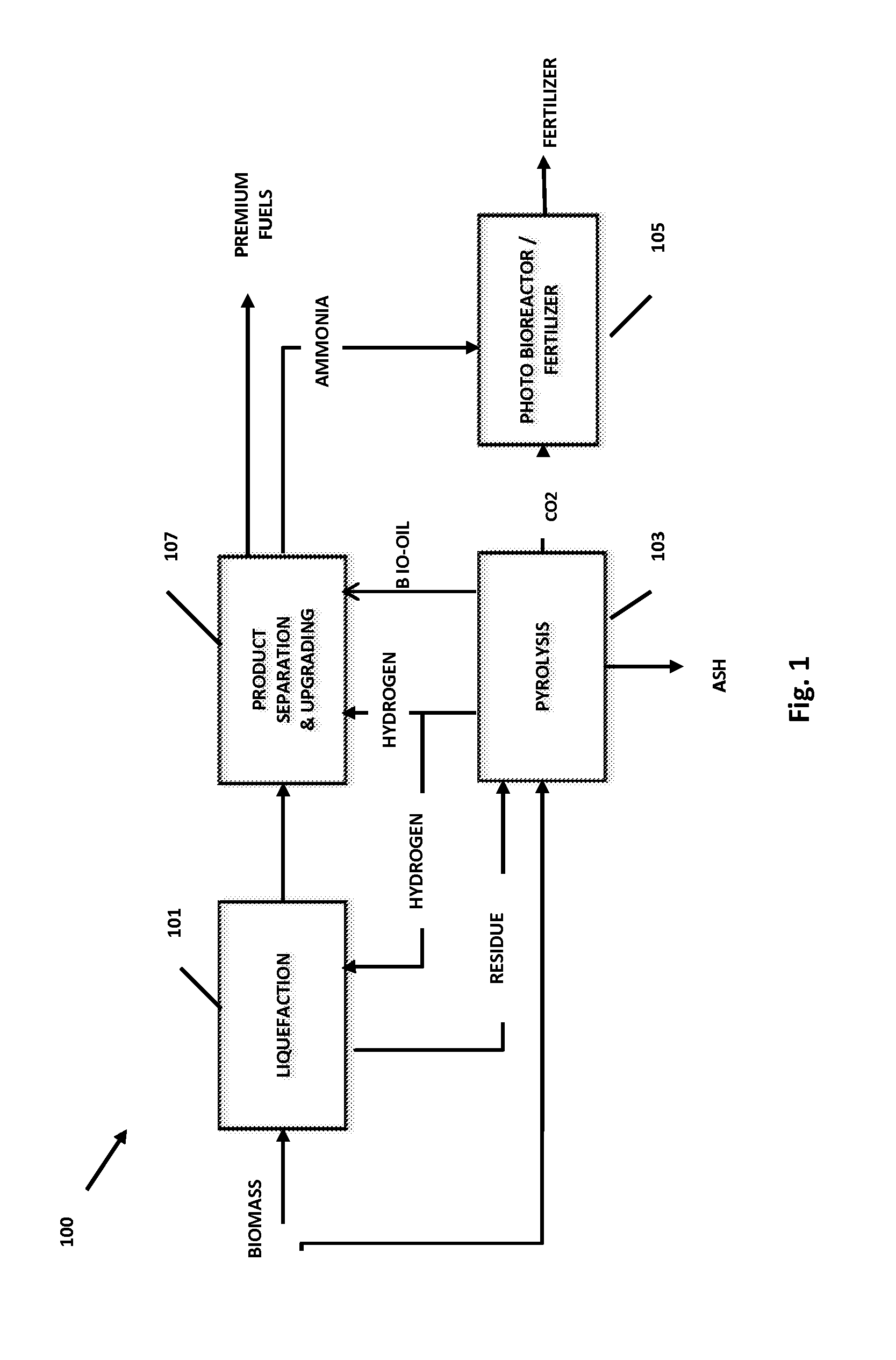

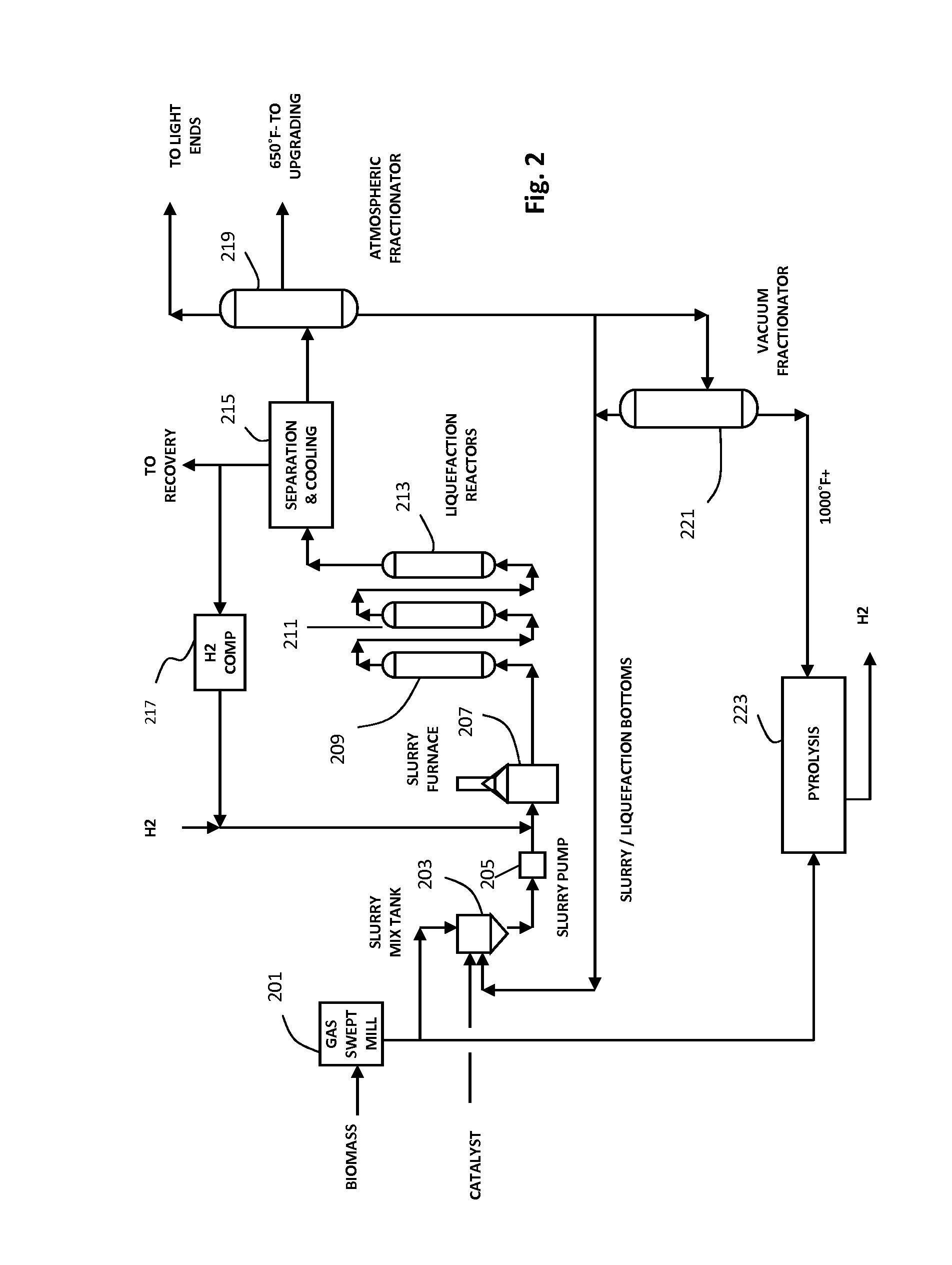

Integrated processes for producing fuels and biofertilizers from biomass and products produced

ActiveUS20140345341A1Magnifies overall carbon sequestration potentialMaximize useElectrical coke oven heatingBio-organic fraction processingLiquid fuelBiochar

An IBTL system having a low GHG footprint for converting biomass to liquid fuels in which a biomass feed is converted to liquids by direct liquefaction and the liquids are upgraded to produce premium fuels. Biomass residues from the direct liquefaction, and optionally additional biomass is pyrolyzed to produce structured biochar, hydrogen for the liquefaction and upgrading, and CO2 for conversion to algae, including blue green algae (cyanobacteria) in a photobioreactor (PBR). Produced algae and diazotrophic microorganisms are used to produce a biofertilizer that also contains structured biochar. The structured biochar acts as a nucleation agent for the algae in the PBR, as a absorption agent to absorb inorganics from the biomass feed to direct liquefaction or from the liquids produced thereby, and as a water retention agent in the biofertilizer. The ratio of cyanobacteria to diazotrophic microorganisms in the biofertilizer can be selected to optimize the so as to achieve desired total chemically active carbon and nitrogen contents in the soil for a given crop.

Owner:ACCELERGY CORP +1

Microwave pyrolysis apparatus for waste tires

InactiveUS7101464B1Electrical coke oven heatingCombustible gas coke oven heatingMicrowave pyrolysisDistillation

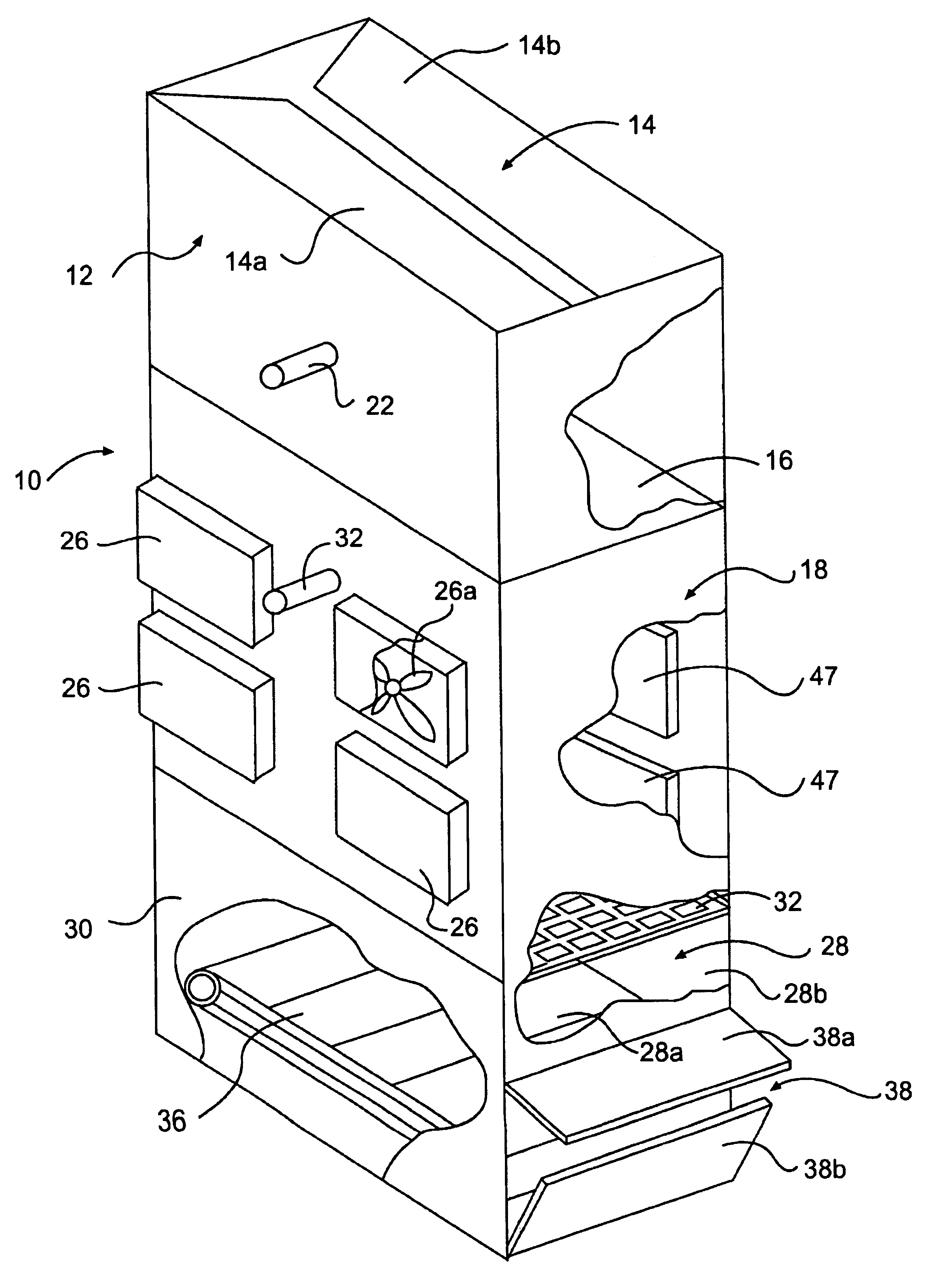

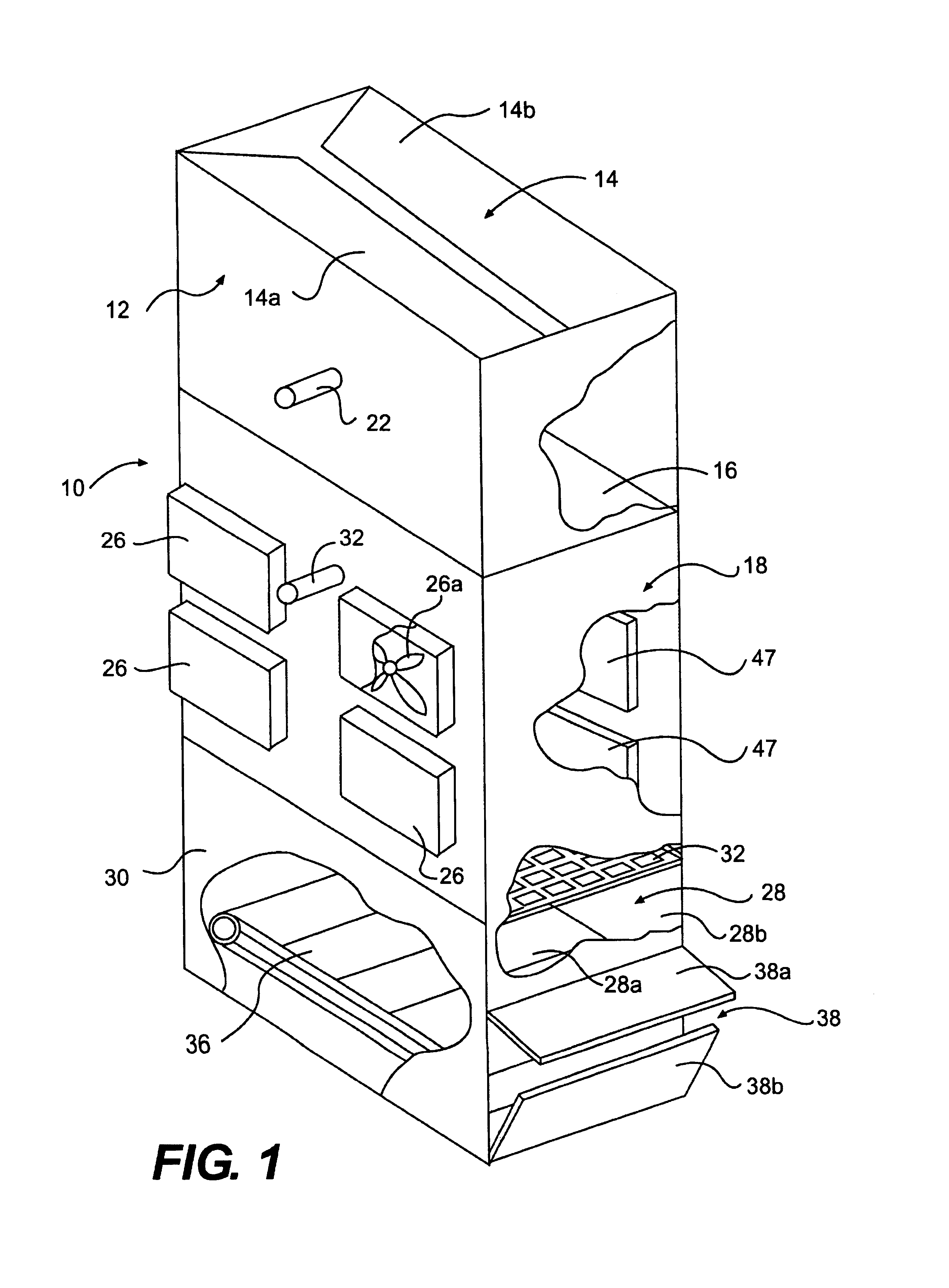

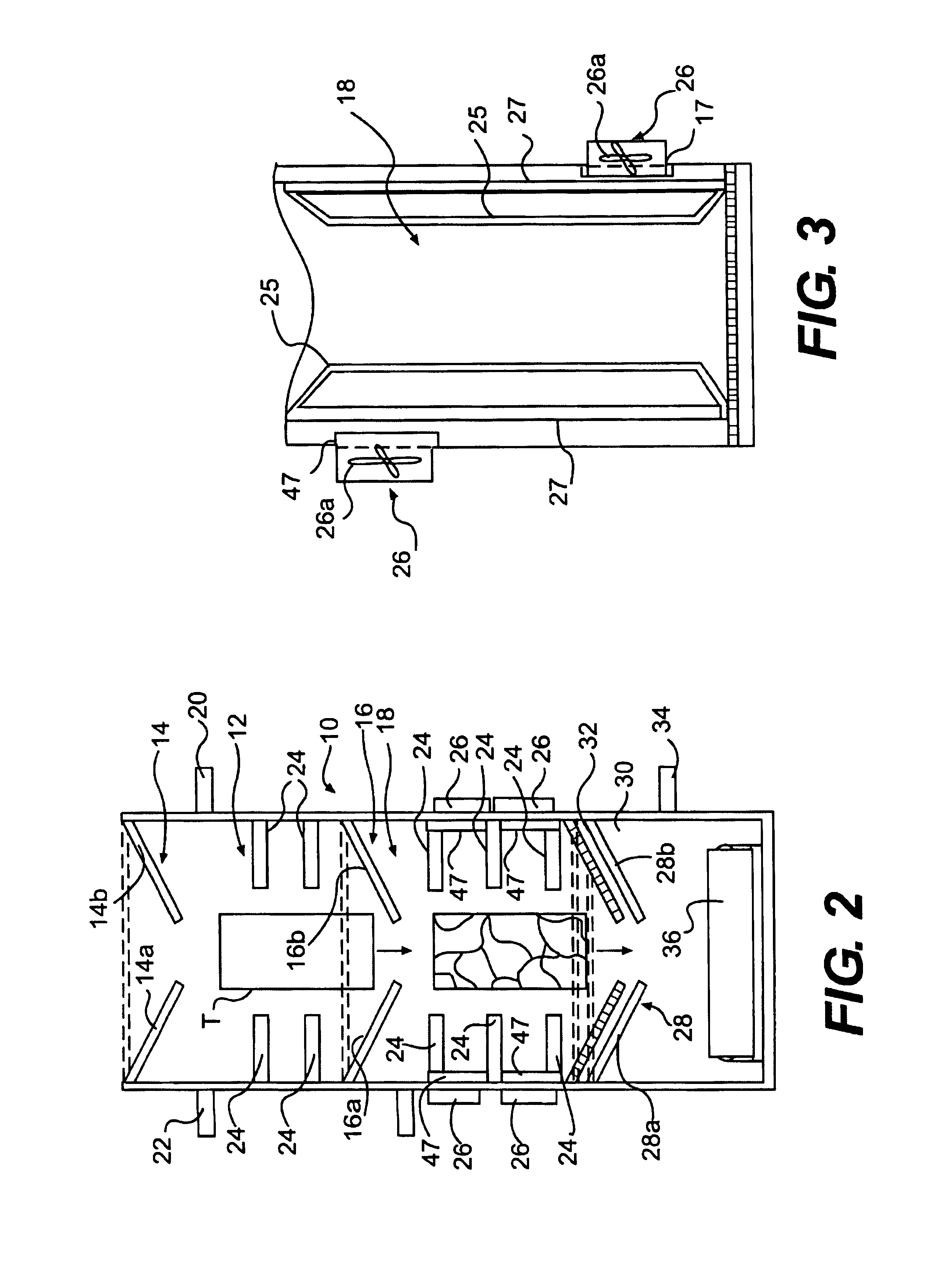

A microwave distillation apparatus provides destructive distillation of whole waste tires. The apparatus includes a housing including a plurality of vertically arranged chambers. A preheat chamber provides preheating of a whole waste tire received therein. An irradiation chamber, located below the preheat chamber and thermally coupled to the preheat chamber such that heat generated in the irradiation chamber creates heat convection currents in the preheat chamber, receives a preheated whole waste tire from the preheat chamber. A microwave energy supply supplies microwave energy to the irradiation chamber to provide destructive distillation of a tire received in that chamber. A cooling chamber, located below the irradiation chamber, receives by-products of the destructive distillation therefrom and provides delivery of the by-products from the housing.

Owner:PRINGLE JOE A MR +1

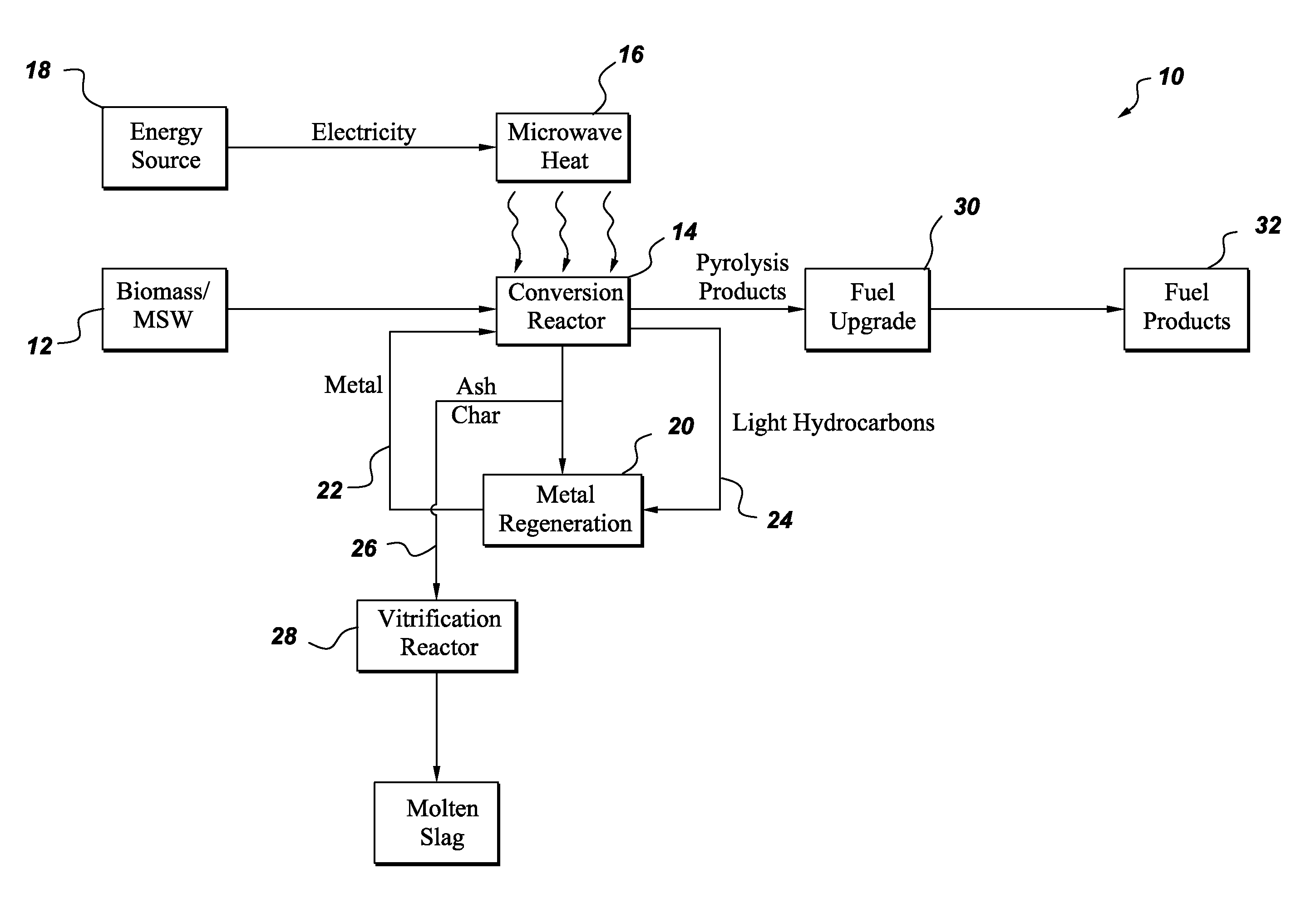

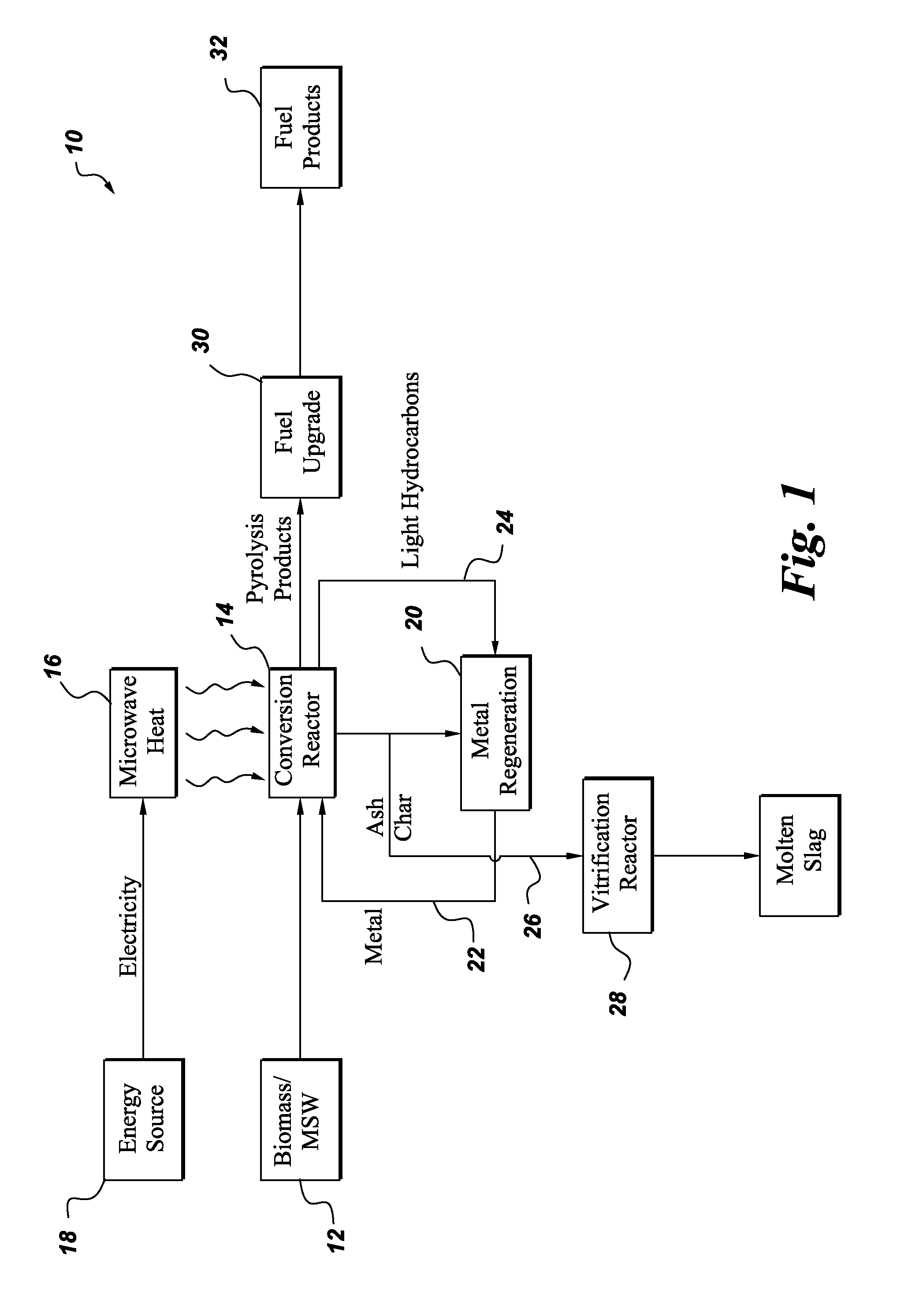

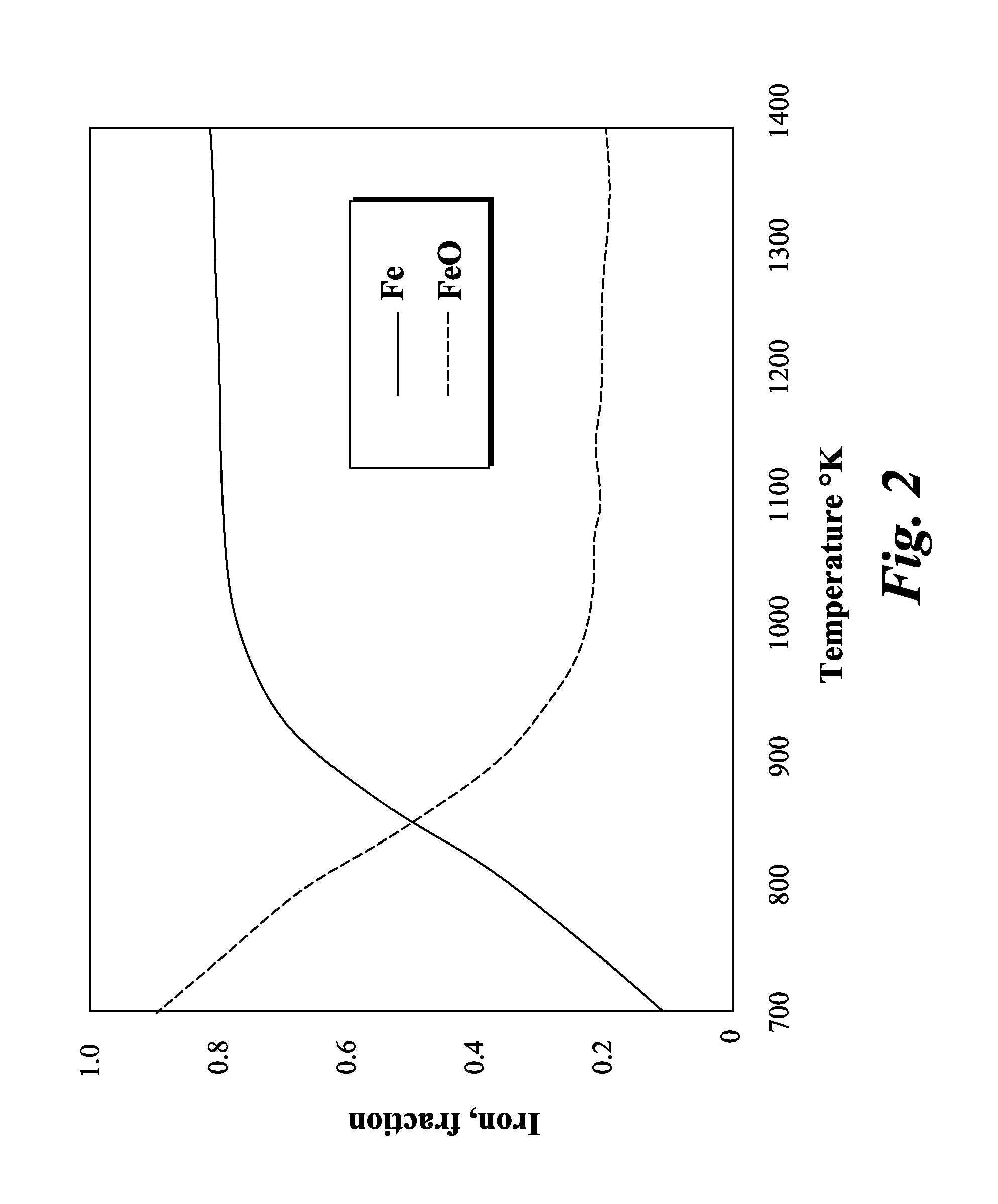

Methods for preparing fuel compositions from renewable sources, and related systems

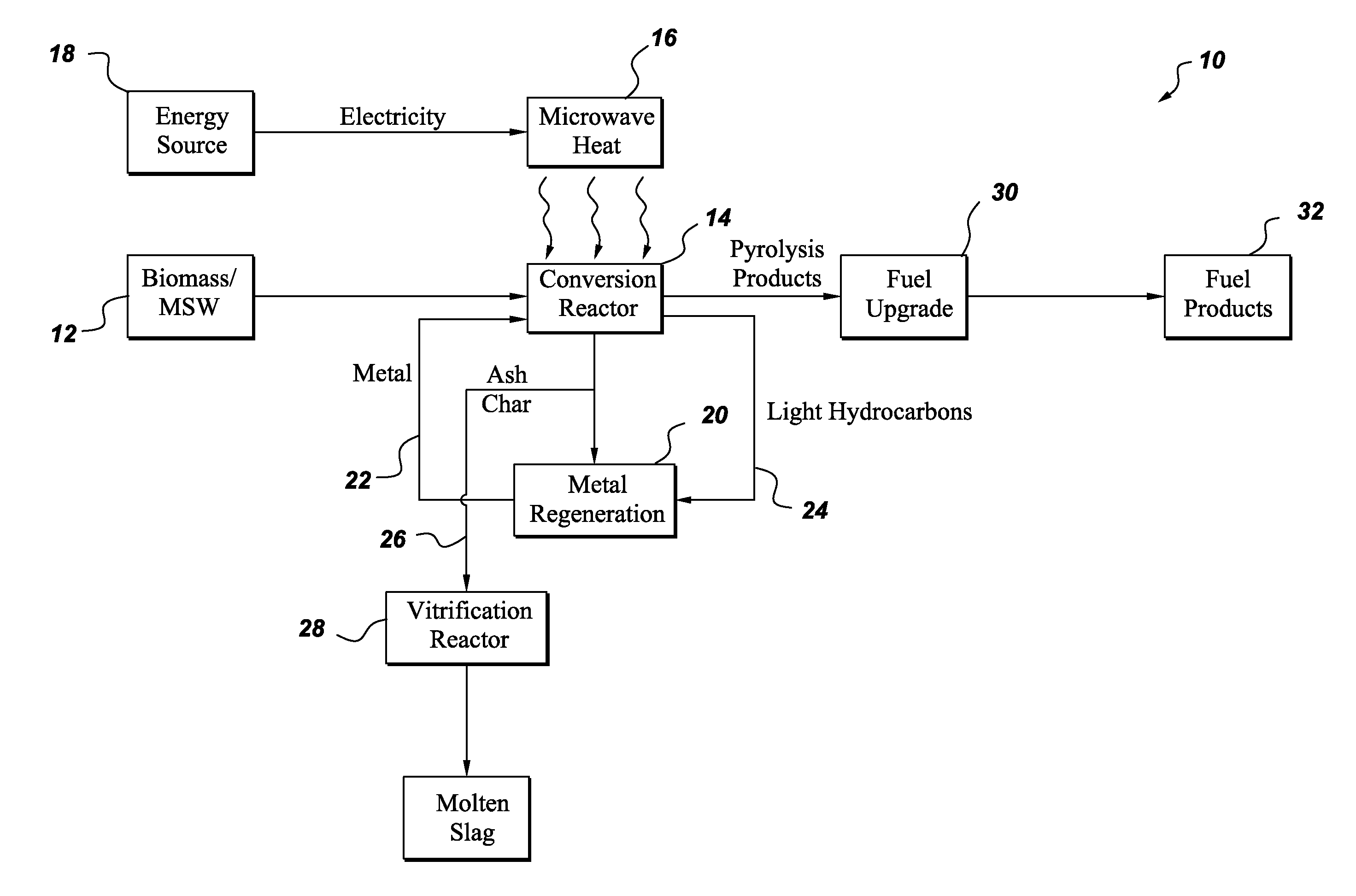

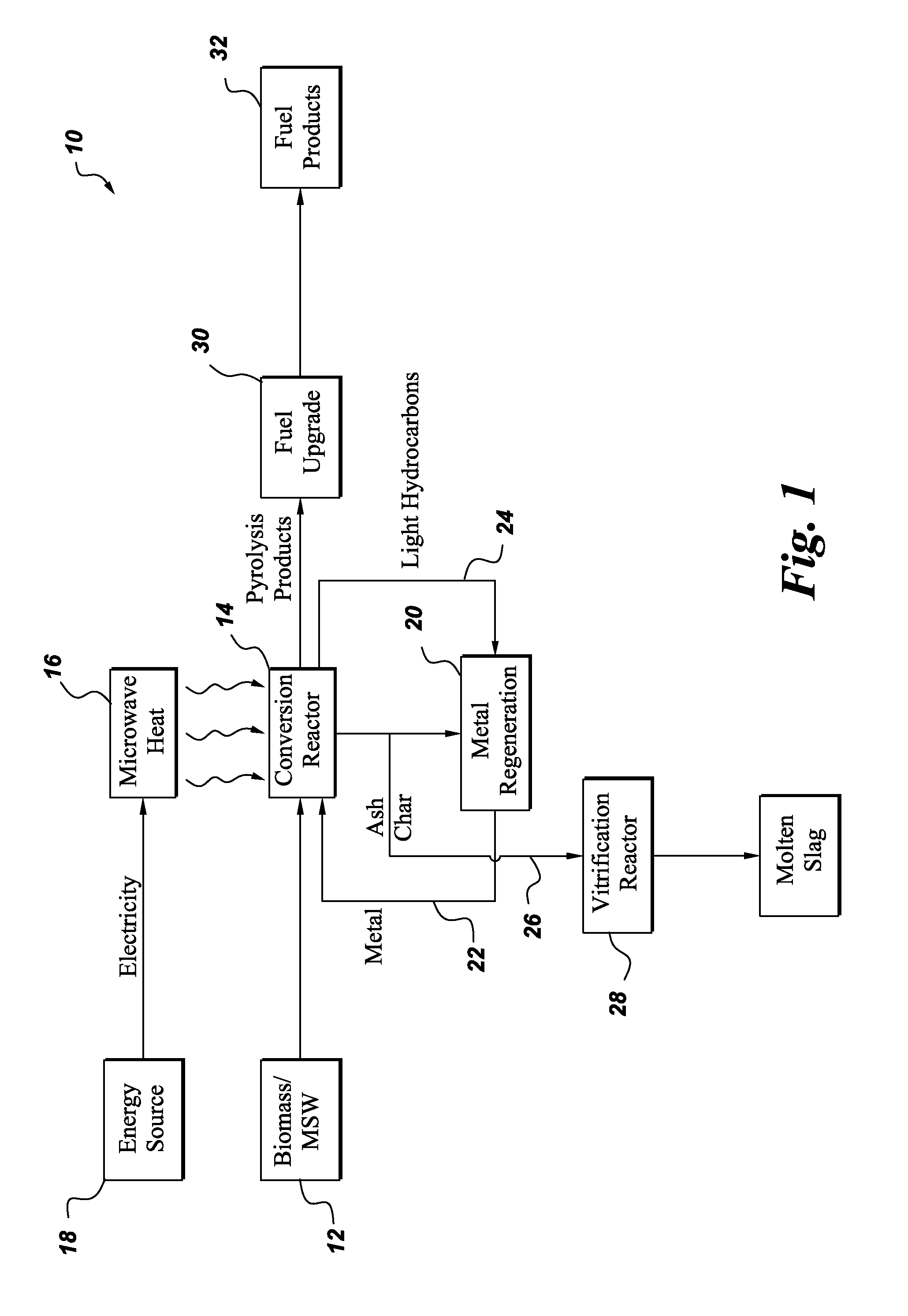

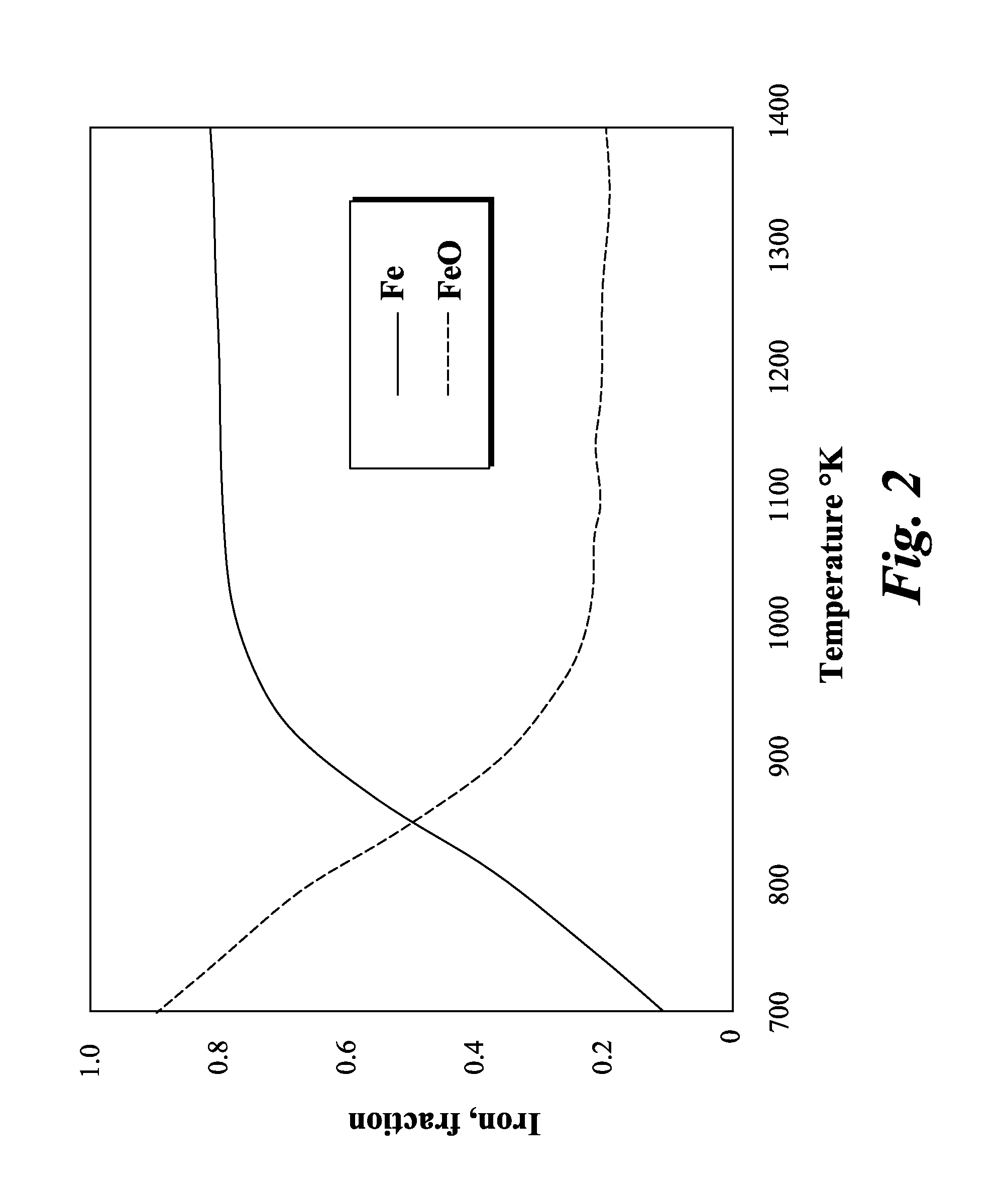

ActiveUS20120029252A1Avoid increased oxygen levelsLower Level RequirementsElectrical coke oven heatingPressurized chemical processMicrowaveLiquid fuel

A method for producing a fuel composition from a feedstock which may contain biomass and municipal solid waste is described. The method includes the step of pyrolyzing the feedstock in the presence of a transition metal, using microwave energy, so that the level of oxygen in at least one product of the pyrolysis is reduced. An integrated process is also described, in which the transition metal can be regenerated. Moreover, pyrolysis products such as bio-oils can be upgraded to liquid fuel compositions. Related systems for producing fuel compositions are also described.

Owner:AIR PROD & CHEM INC

Synthesis gas production and power generation with zero emissions

InactiveUS20020048545A1Avoid water pollutionEliminating any build-up of this productElectrical coke oven heatingGasifier electrodesClosed loopProduct gas

A process and apparatus for producing and burning synthesis gas. Carbonaceous waste material is pyrolytically decomposed in a primary reactor in the presence of steam to produce raw product gas containing H2 and CO. The raw product gas and CO2 is then introduced into a coke containing secondary reactor under pyrolyzing conditions, so that the CO2 and coke react to produce combustible gas having an increased CO content. The combustible gas is mixed with oxygen and CO2 to produce a combustible mixture which is burned as a fuel to produce heat, CO2 and H2O. A portion of the produced CO2 is recovered and used as the source of CO2 gas in the combustible mixture and as a source of CO2 gas for the secondary reactor. Preferably filters and scrubbers are used in a closed loop system to avoid undesirable emissions into the environment.

Owner:LEWIS ARLIN C

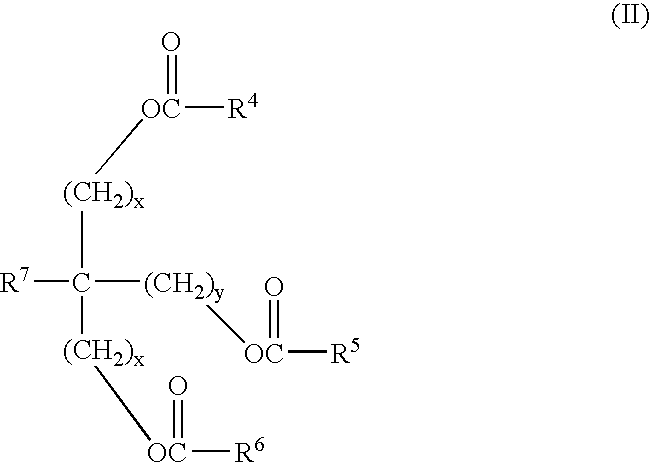

Lubricating base oil compositions and methods for improving fuel economy in an internal combustion engine using same

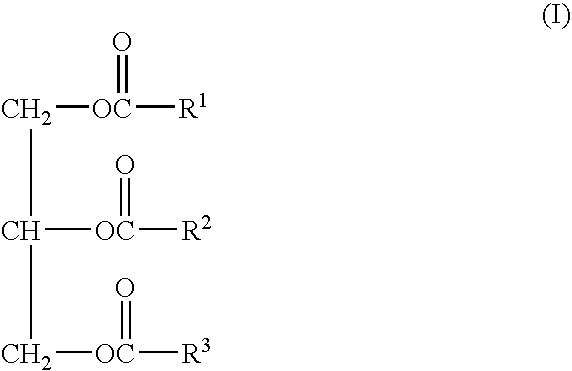

ActiveUS20060172898A1Improve stabilityImprove the lubrication effectElectrical coke oven heatingDirect heating destructive distillationPolyolInternal combustion engine

A lubricating base oil composition is provided comprising (a) at least one Fischer-Tropsch derived lubricating base oil characterized as having a kinematic viscosity of about 2 to about 5 centistoke (cSt) at 100° C.; and (b) at least one polyol ester. Methods for improving the fuel economy of an internal combustion engine are also provided.

Owner:CHEVRON ORONITE CO LLC

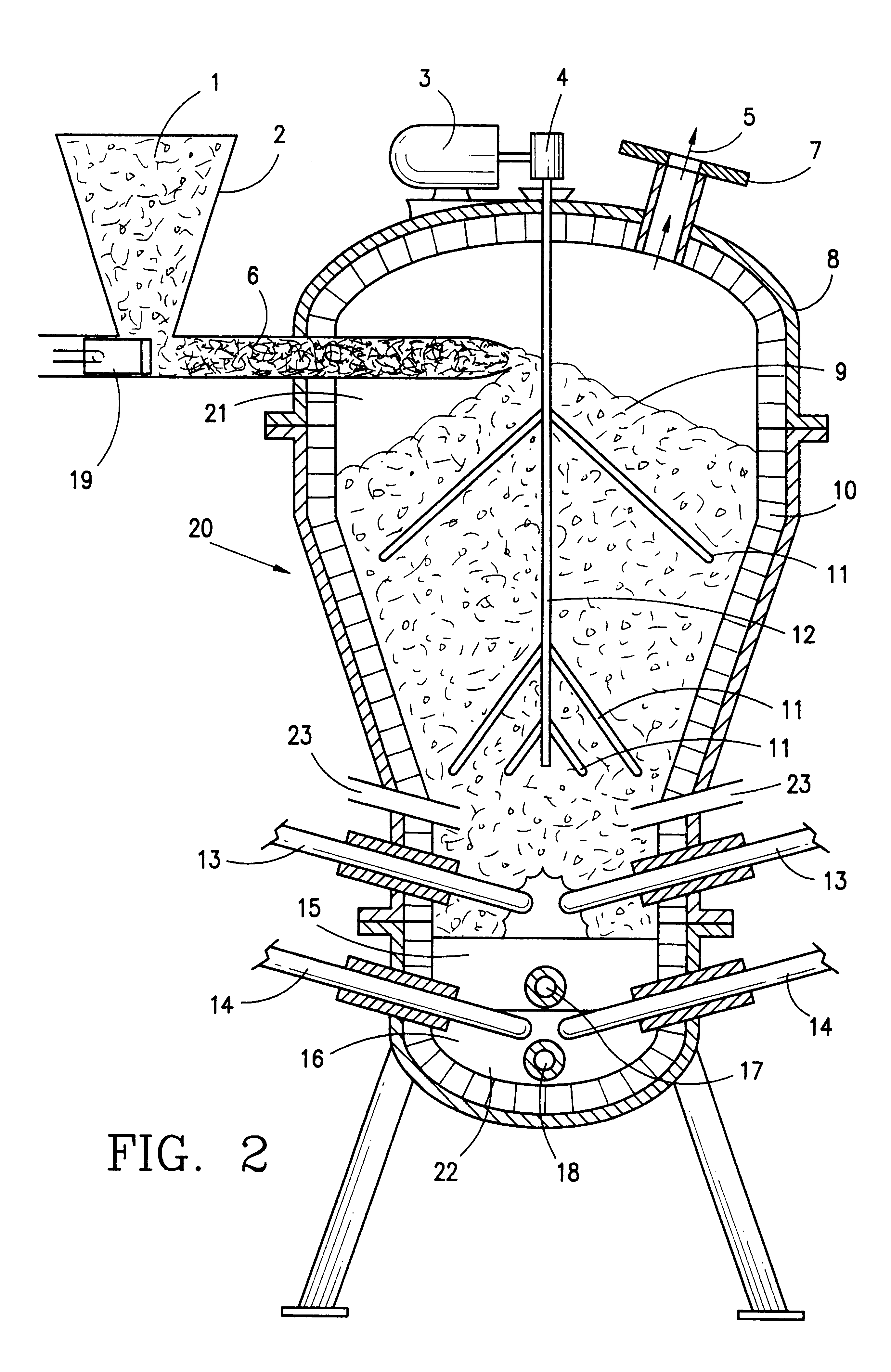

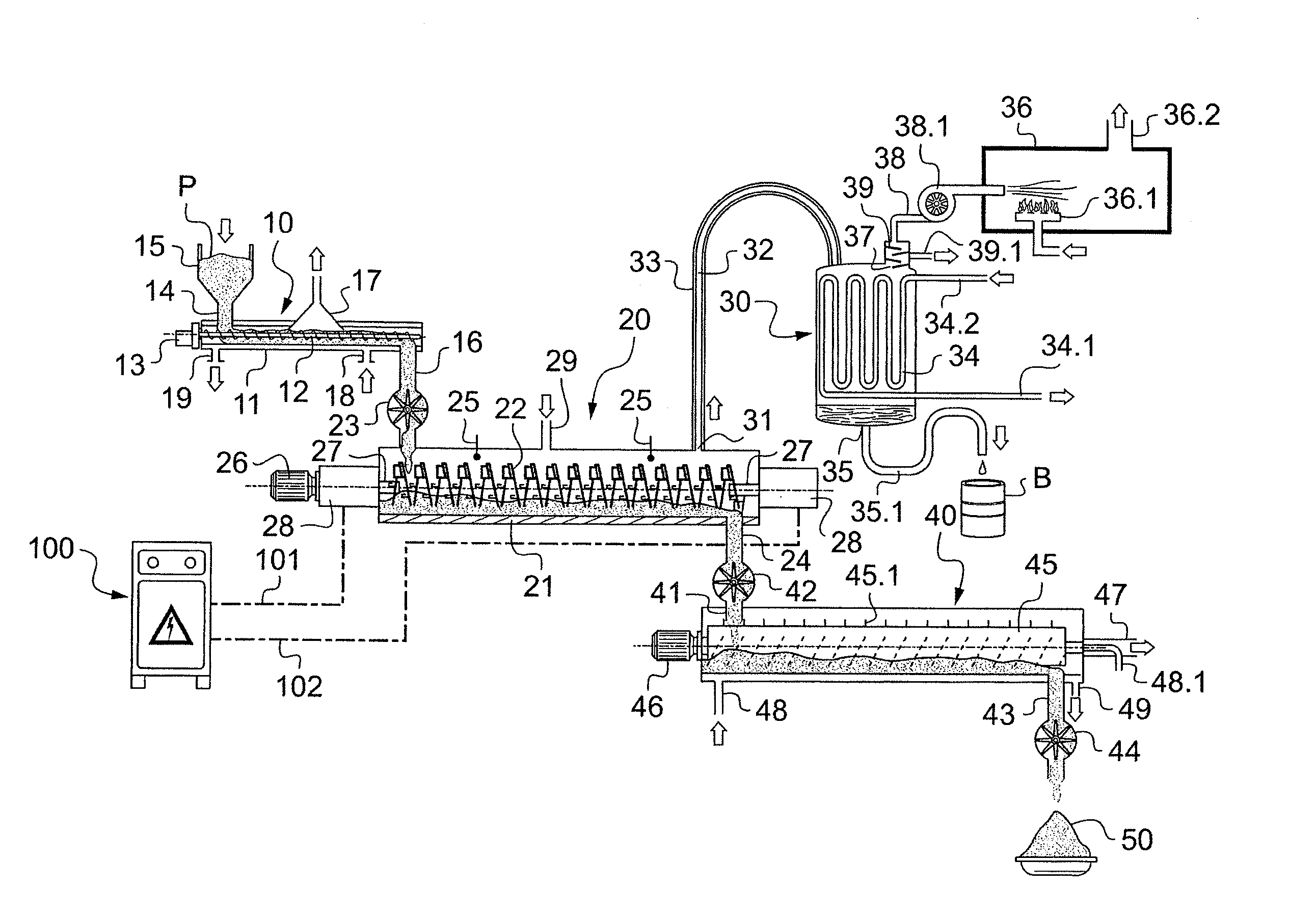

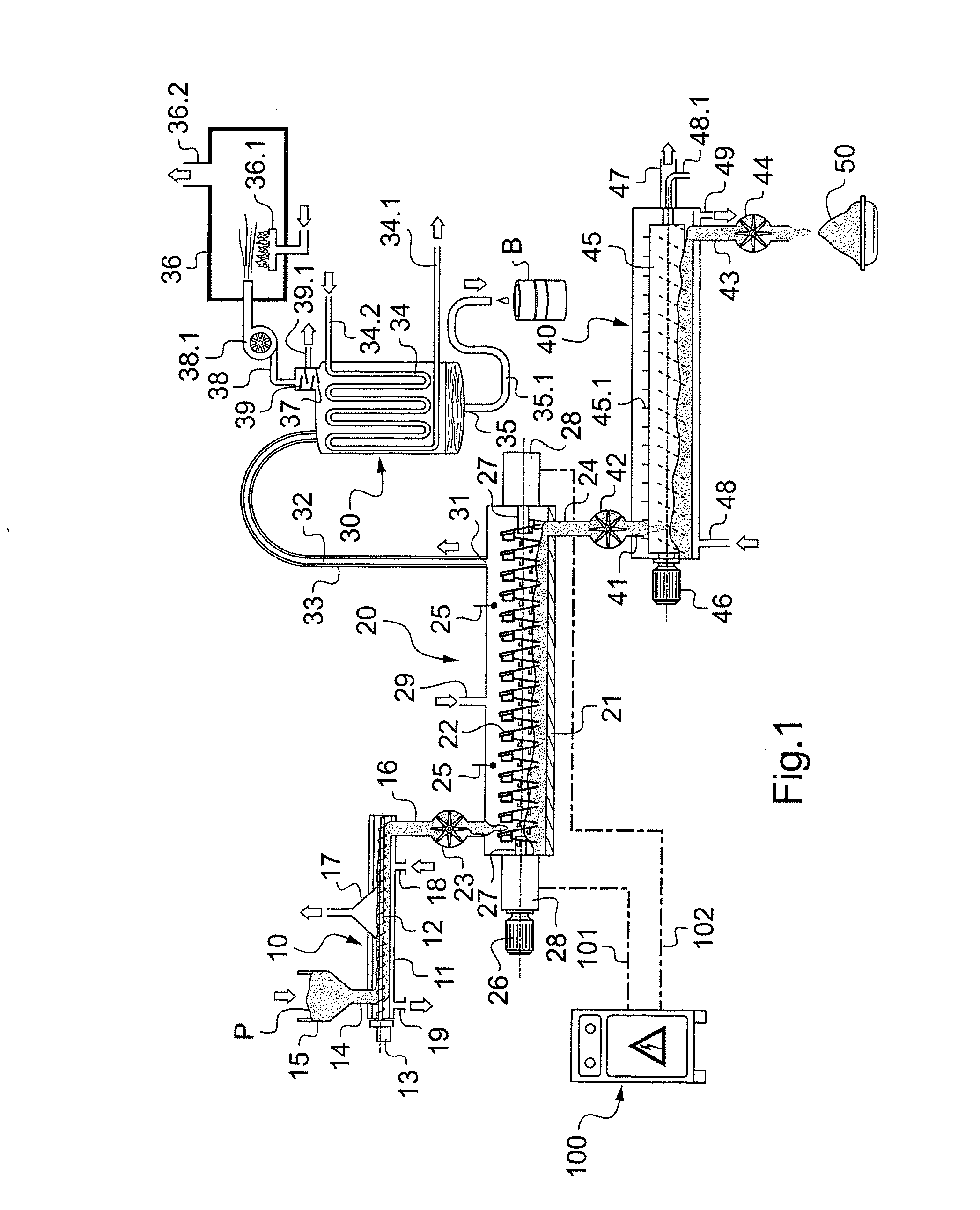

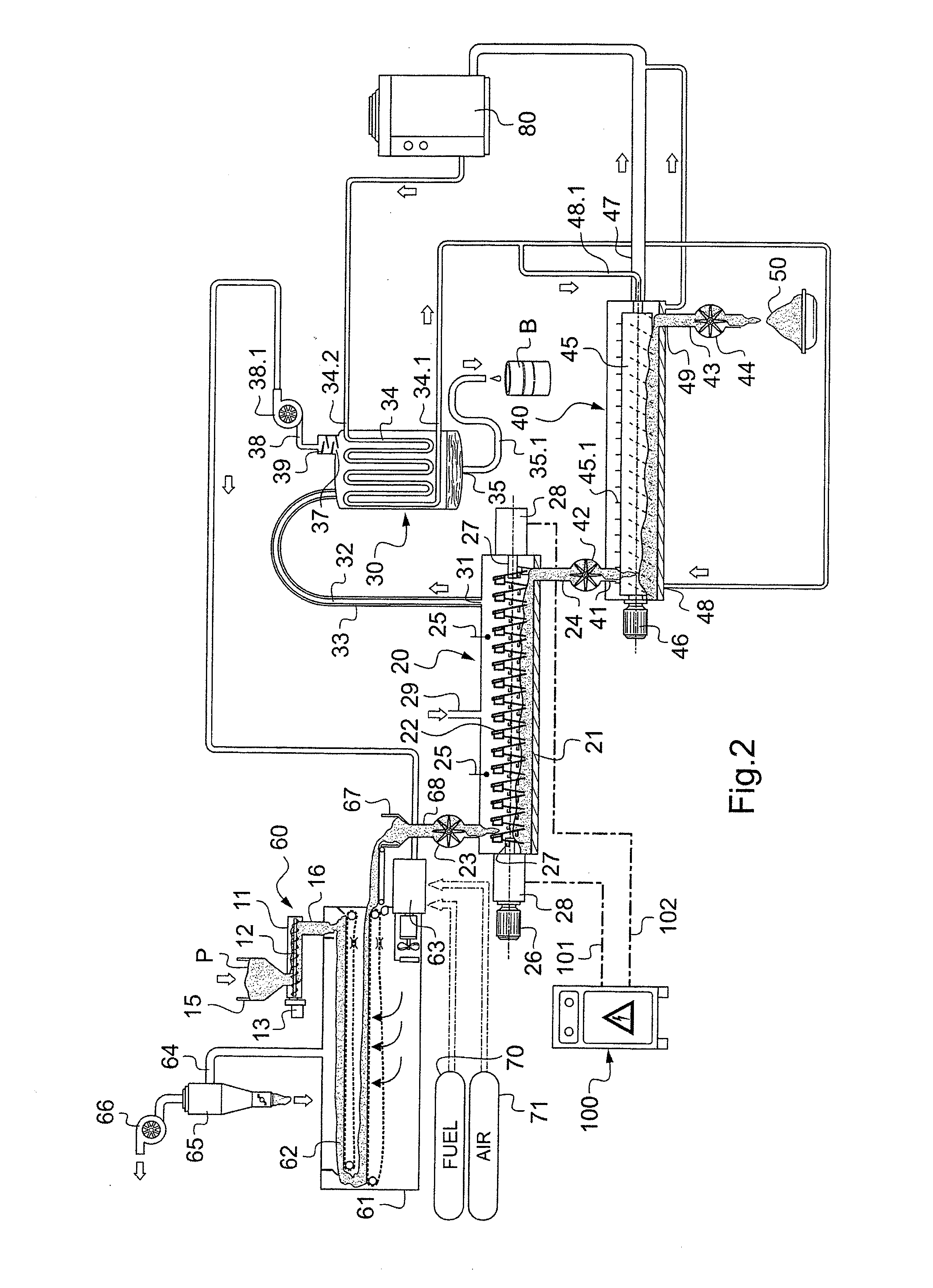

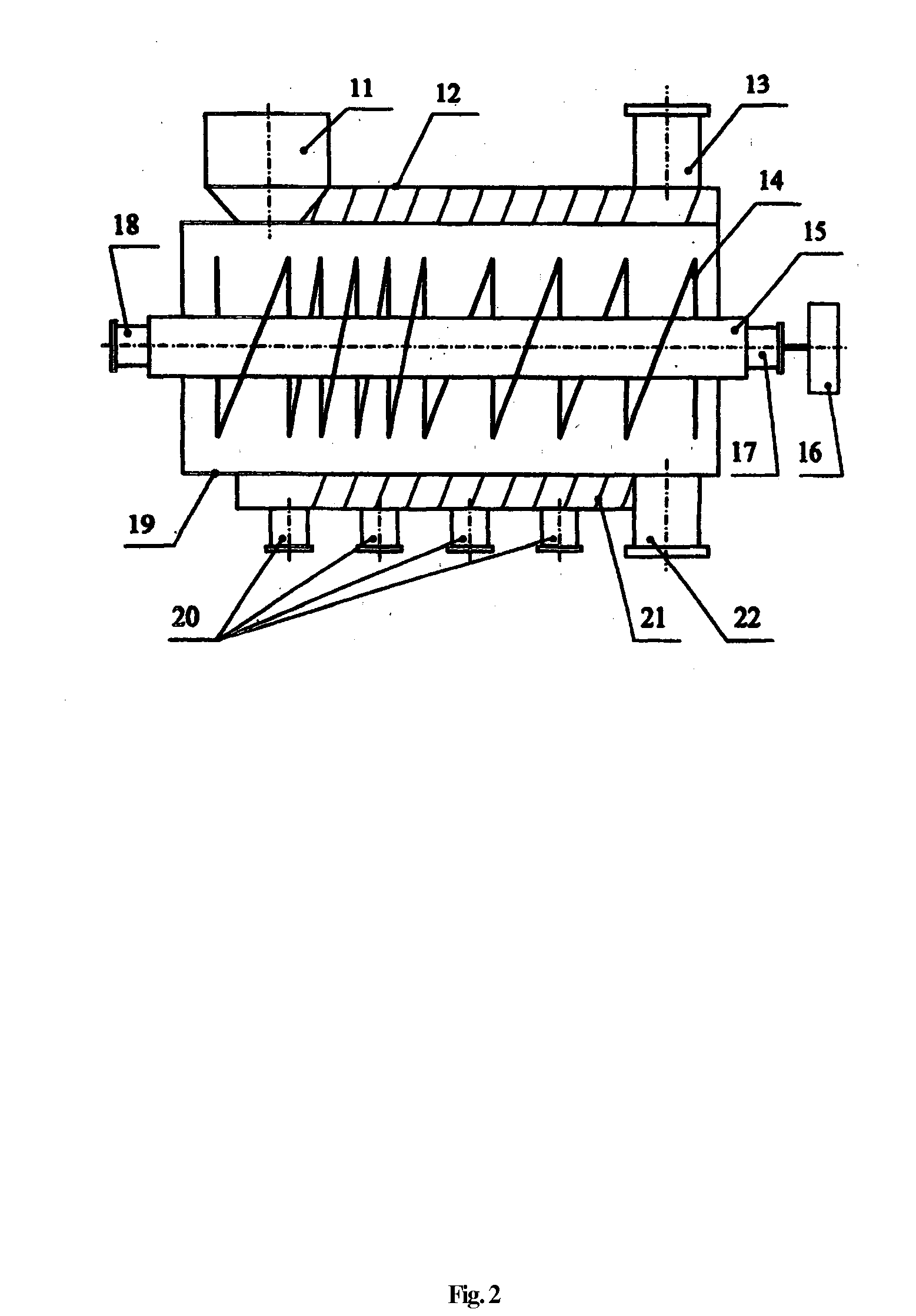

Method and apparatus for the energy densification of a material in the form of divided solids, with a view to obtaining pyrolysis oils for energy purposes

ActiveUS20120043194A1High calorific valueImprove operating conditionsMechanical conveying coke ovensElectrical coke oven heatingPre treatmentRelative humidity

A method and installation for energy densification of a material to obtain pyrolytic oils for energy. The method includes preconditioning the material by heating and drying to raise the material temperature close to 100° C. and a relative humidity not exceeding about 10%; pyrolyzing the material that is subsequently caused to flow through a substantially hermetic reactor containing at least one transfer screw or vibrating tube heated by the Joule effect, the material heated progressively in the range of 300° C. to 850° C., the electrical power passing through the transfer screw or the vibrating tube for providing heating regulated as a function of the material in order to obtain the desired temperature level during the transit time of the material through the reactor; extracting pyrolysis gas from a high portion of the reactor for rapid recondensation in a vertical condenser; and recovering pyrolytic oils from a low portion of the vertical condenser.

Owner:LEPEZ CONSEILS FINANCE INNOVATIONS LCFI +1

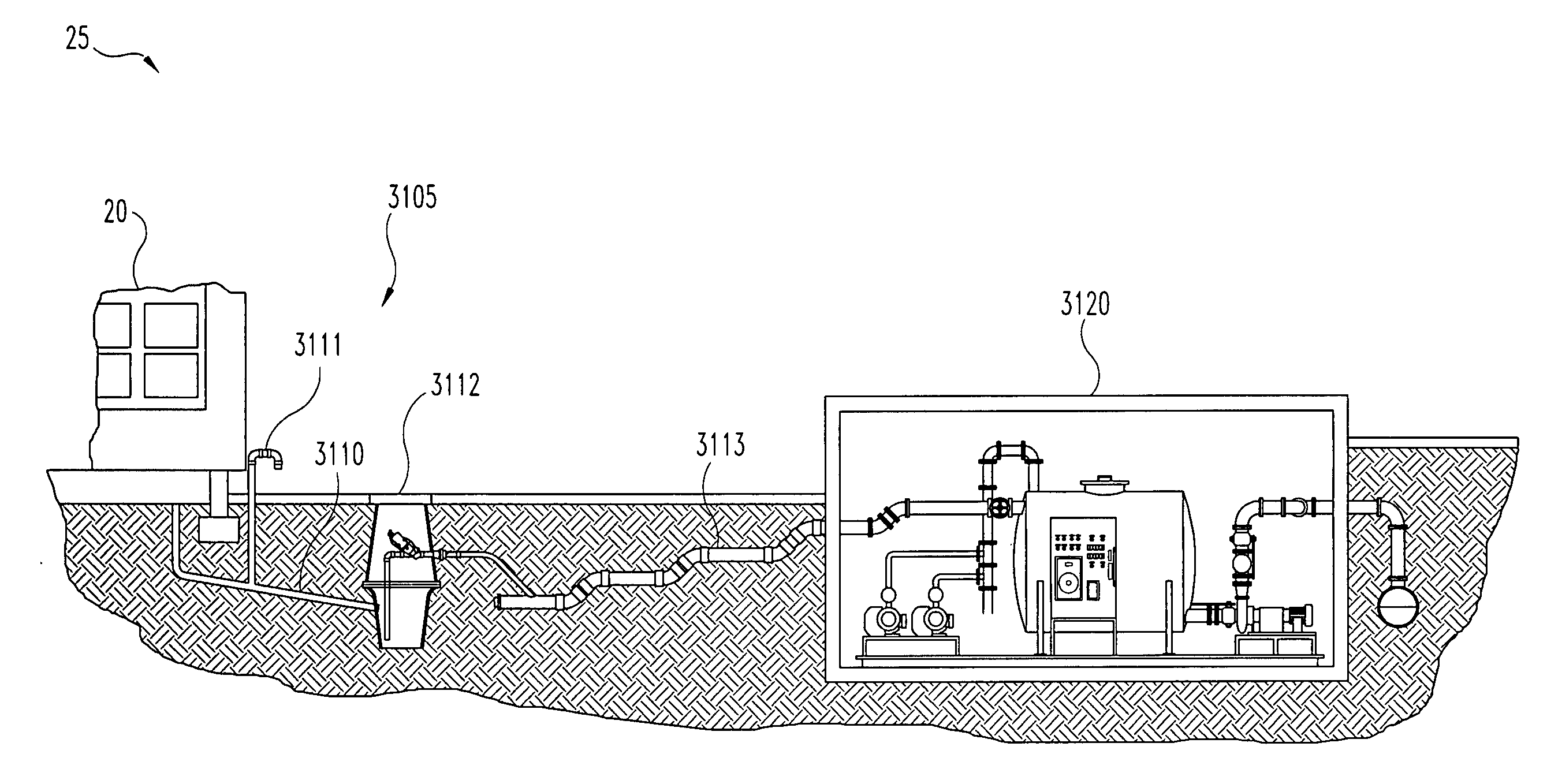

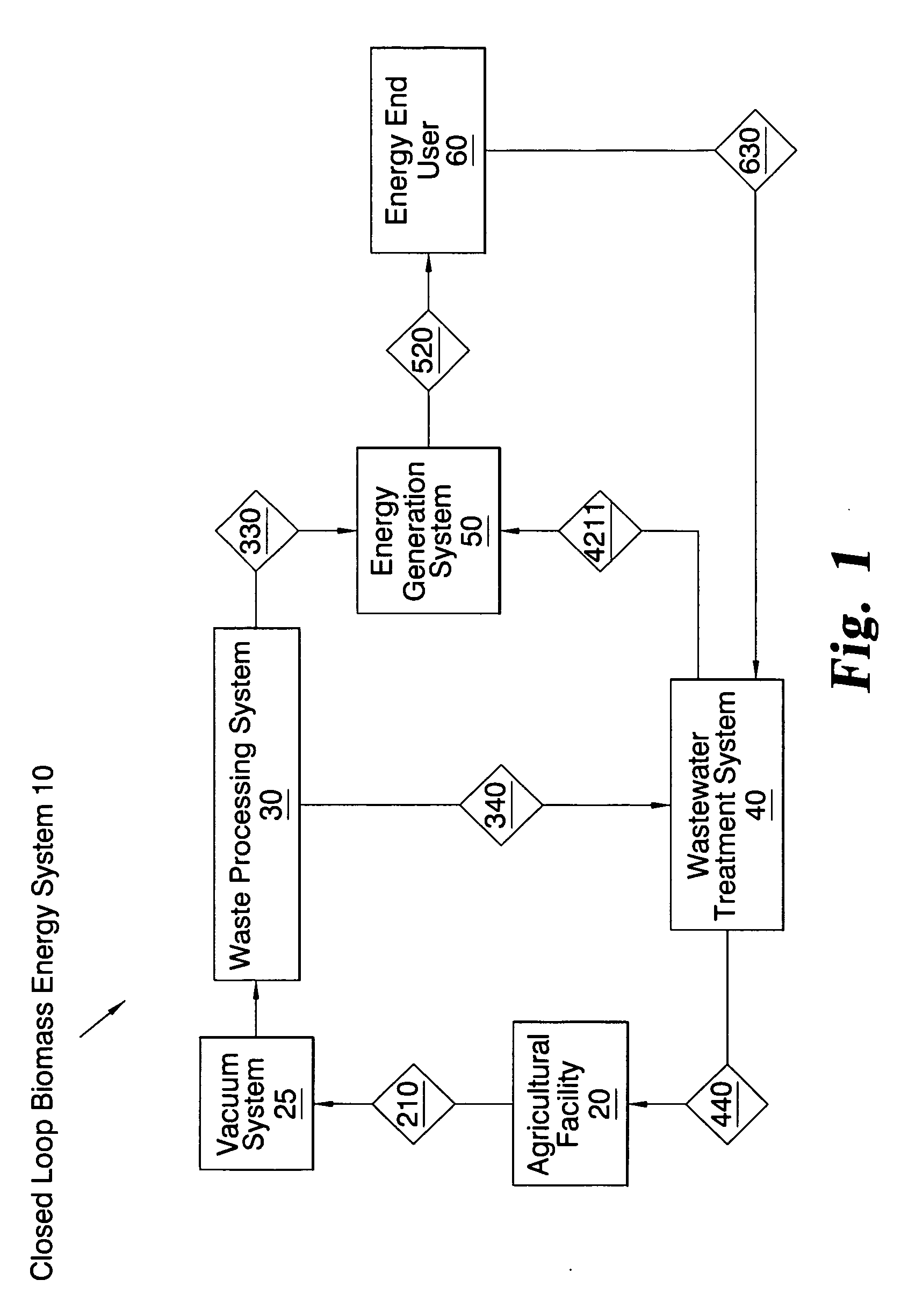

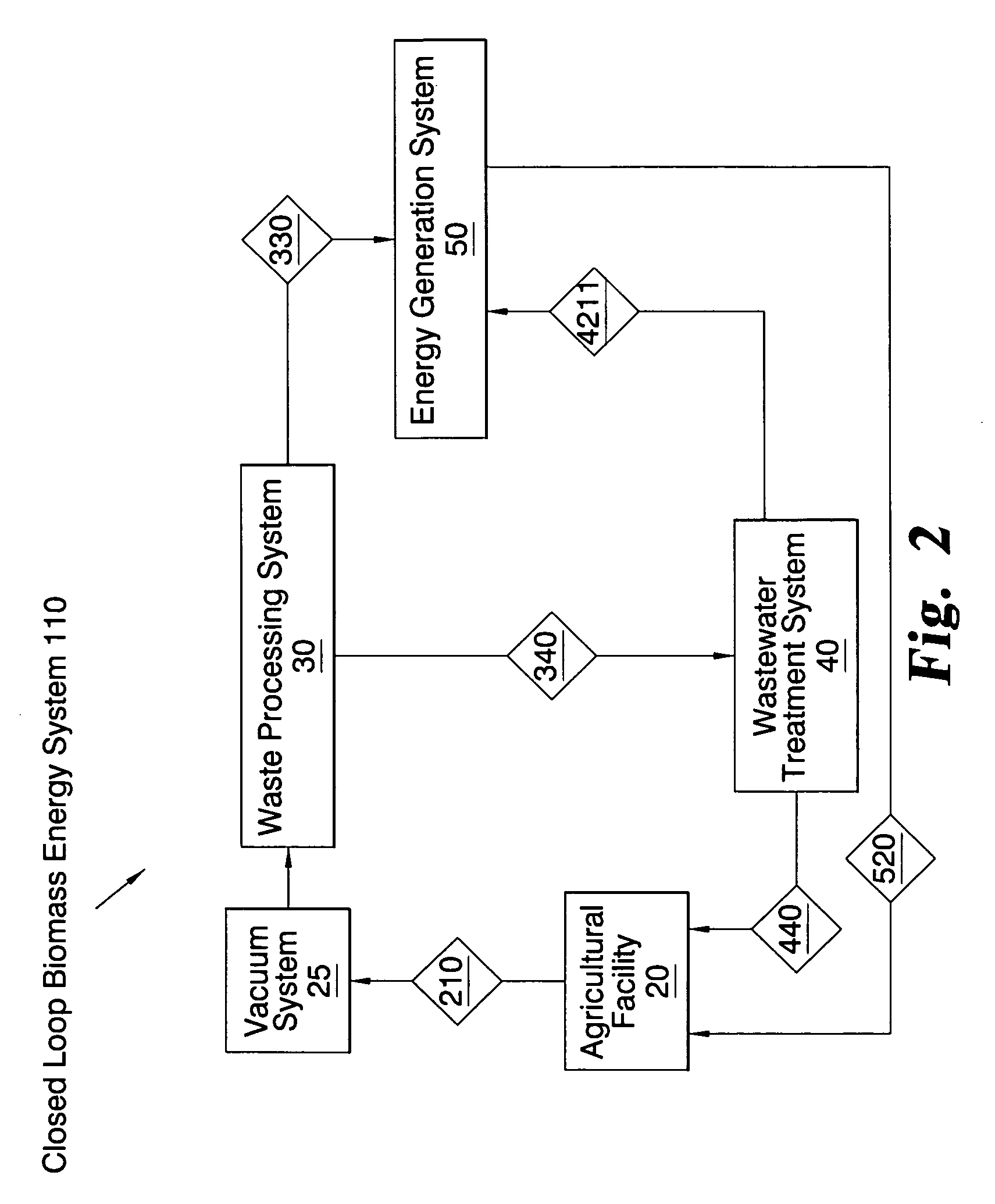

Closed loop biomass energy system

InactiveUS20090249685A1Electrical coke oven heatingFluid pressure measurement by electric/magnetic elementsBiofuelClosed loop

A closed loop biomass energy system includes at least one agricultural facility that produces agricultural waste; a waste processing system operable to convert the waste into biomass; a wastewater treatment system operable to treat wastewater created by the waste processing system and an energy production system operable to utilize the biomass to produce energy and provide the energy to an energy end-user. In one form, the energy is steam and the energy end-user is a biofuel production facility that utilizes the steam to power production of a biofuel. In a further aspect of this form, wastewater created as a byproduct of the biofuel production is transferred to and treated by the wastewater treatment system. However, additional forms, embodiments, features and aspects are contemplated as discussed in further detail in this document.

Owner:FLOWERS TROY D +2

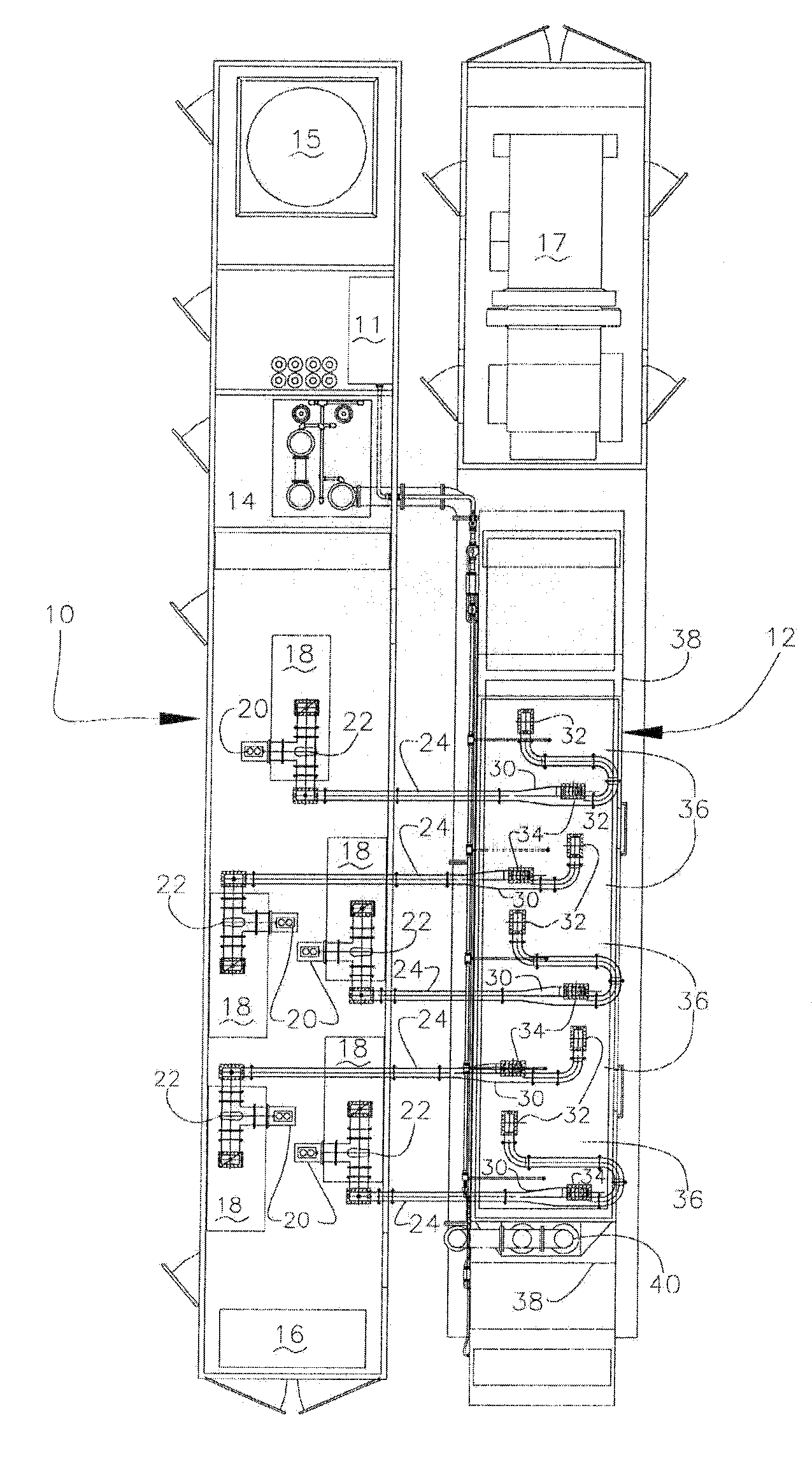

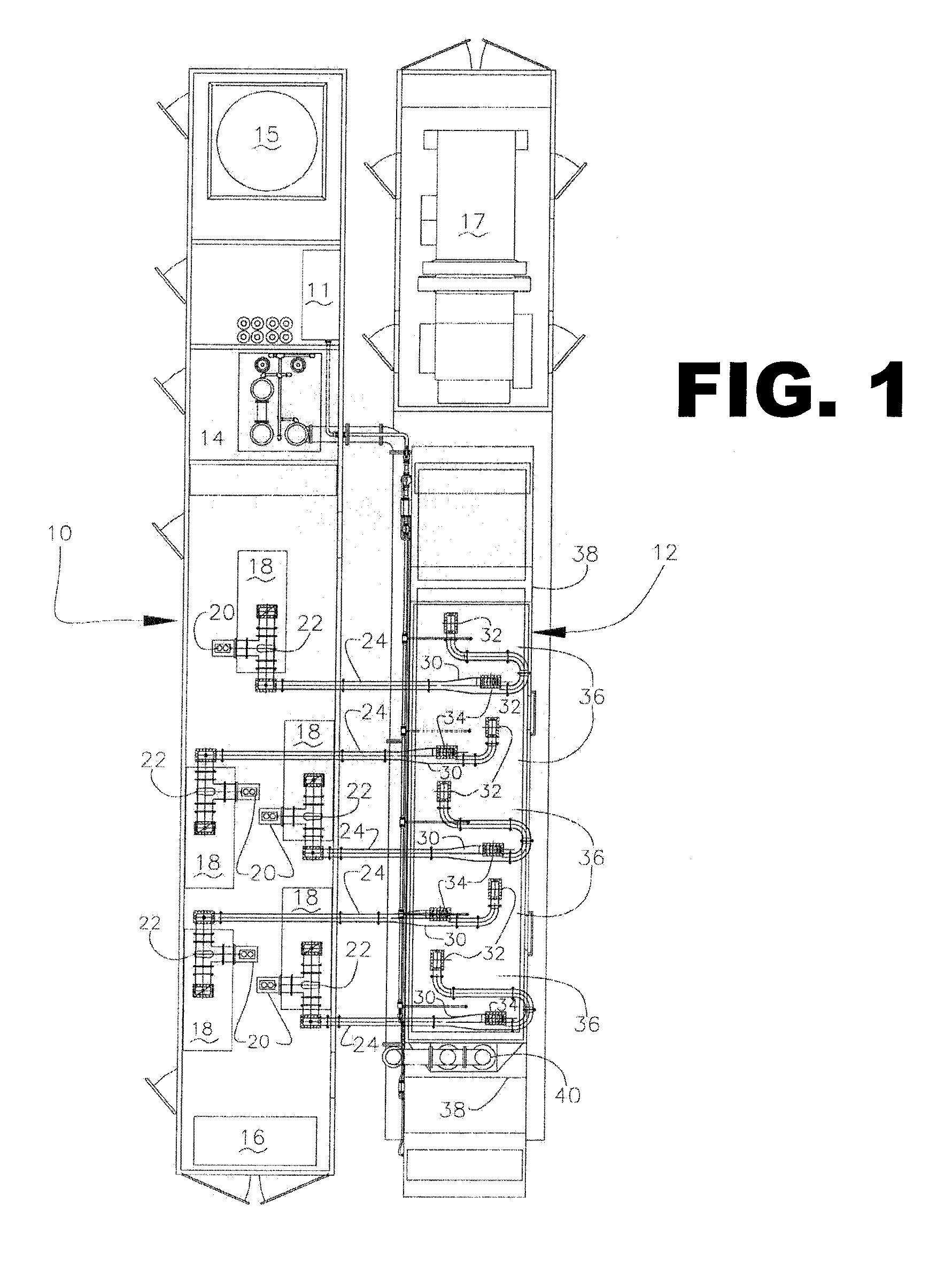

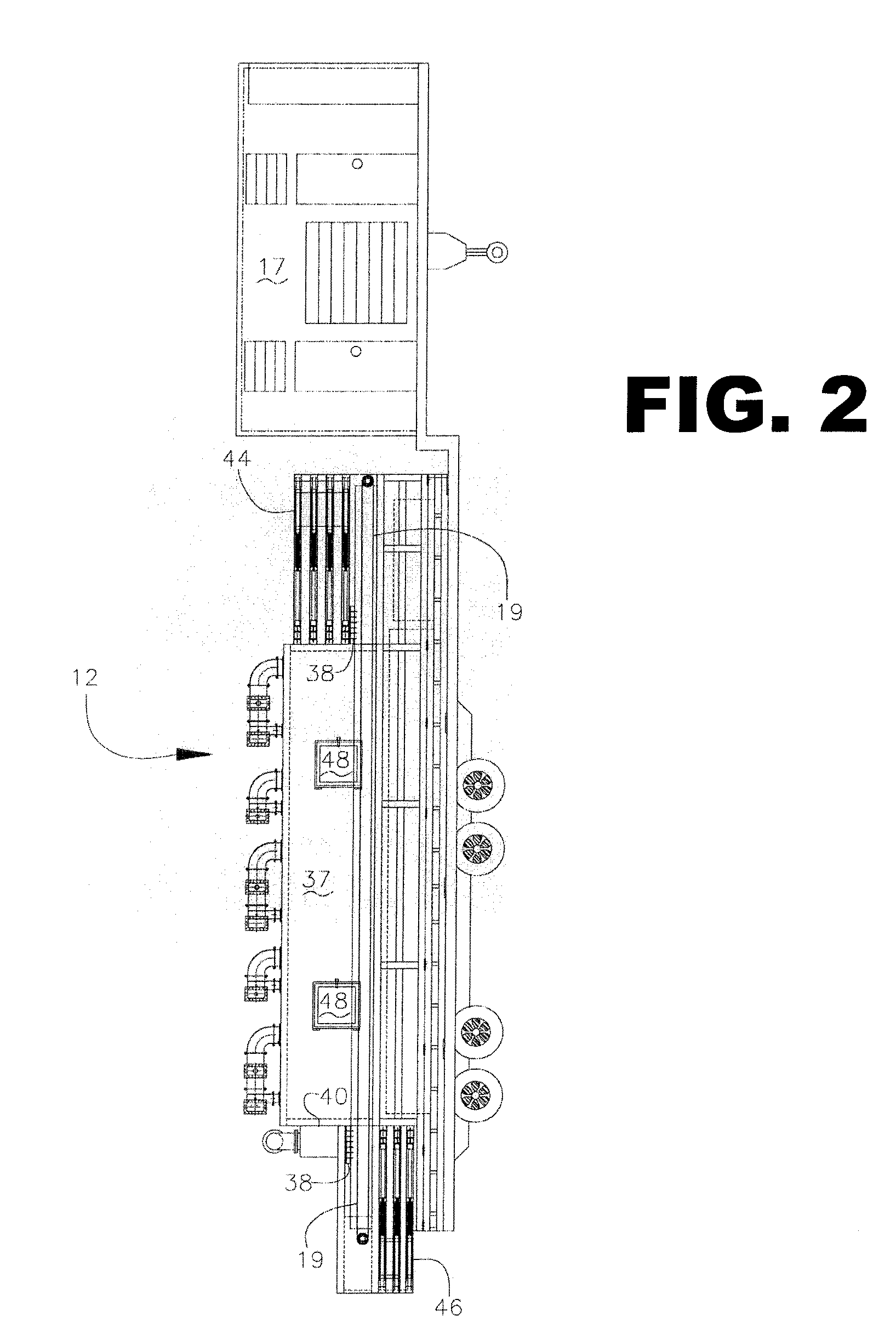

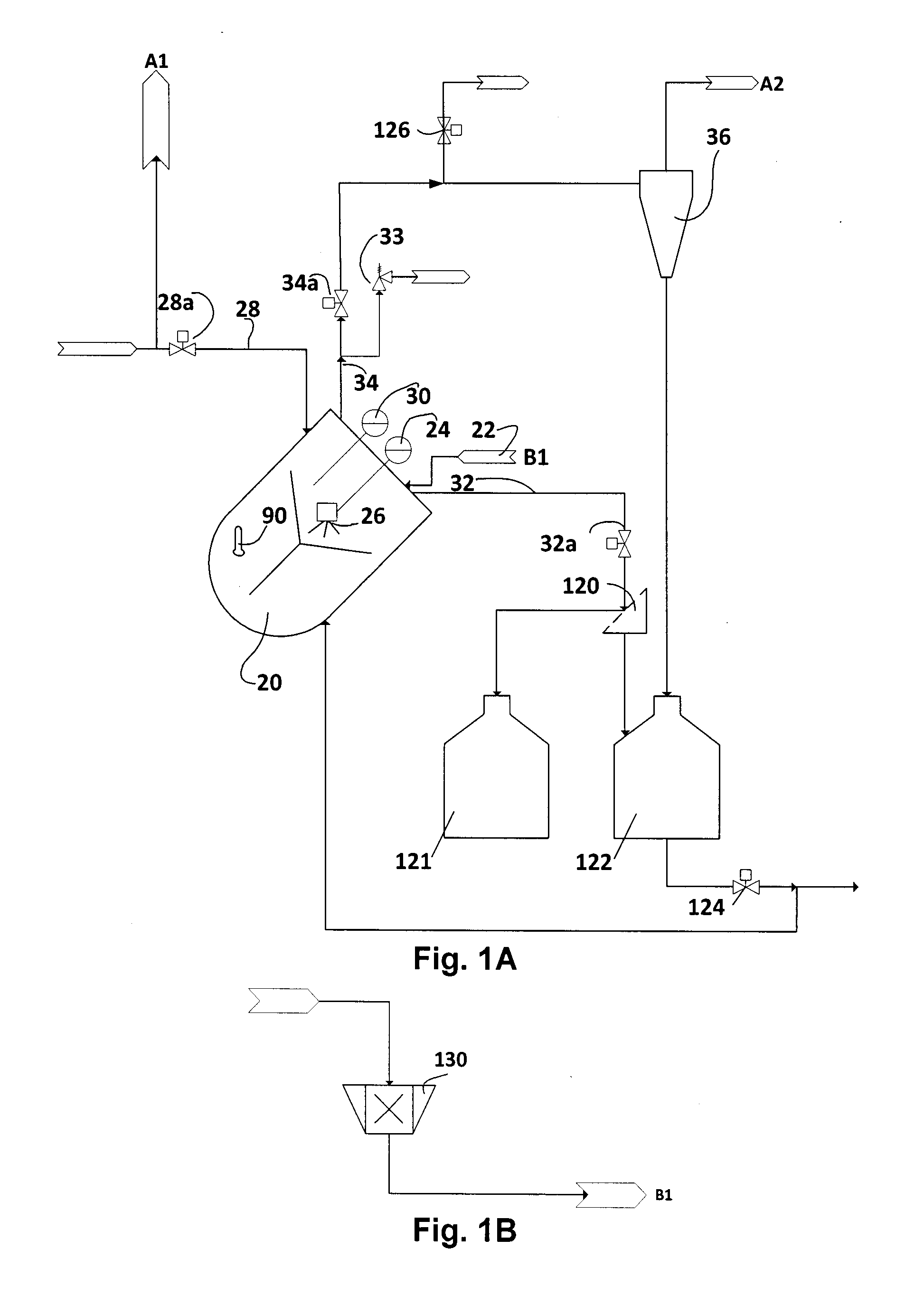

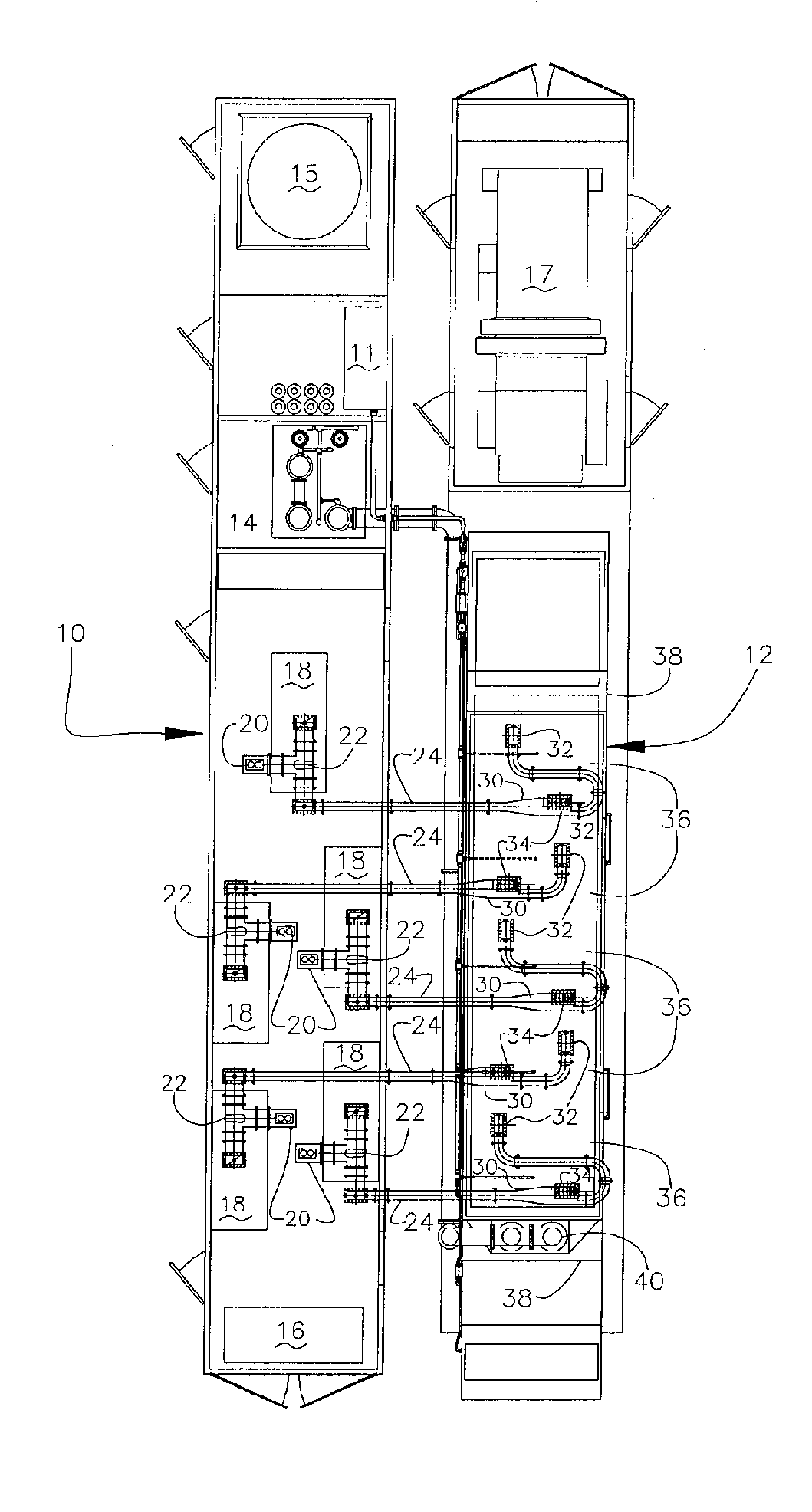

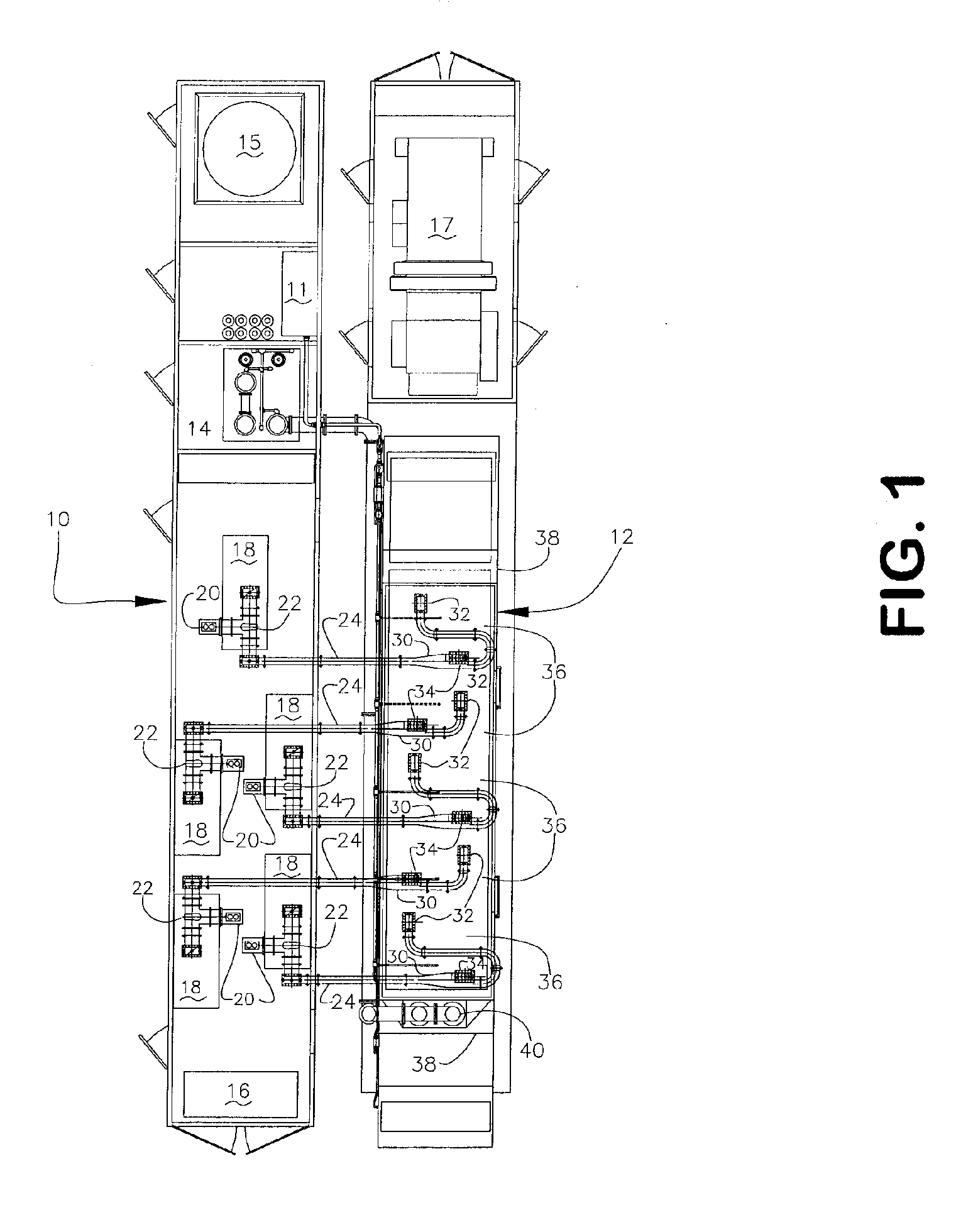

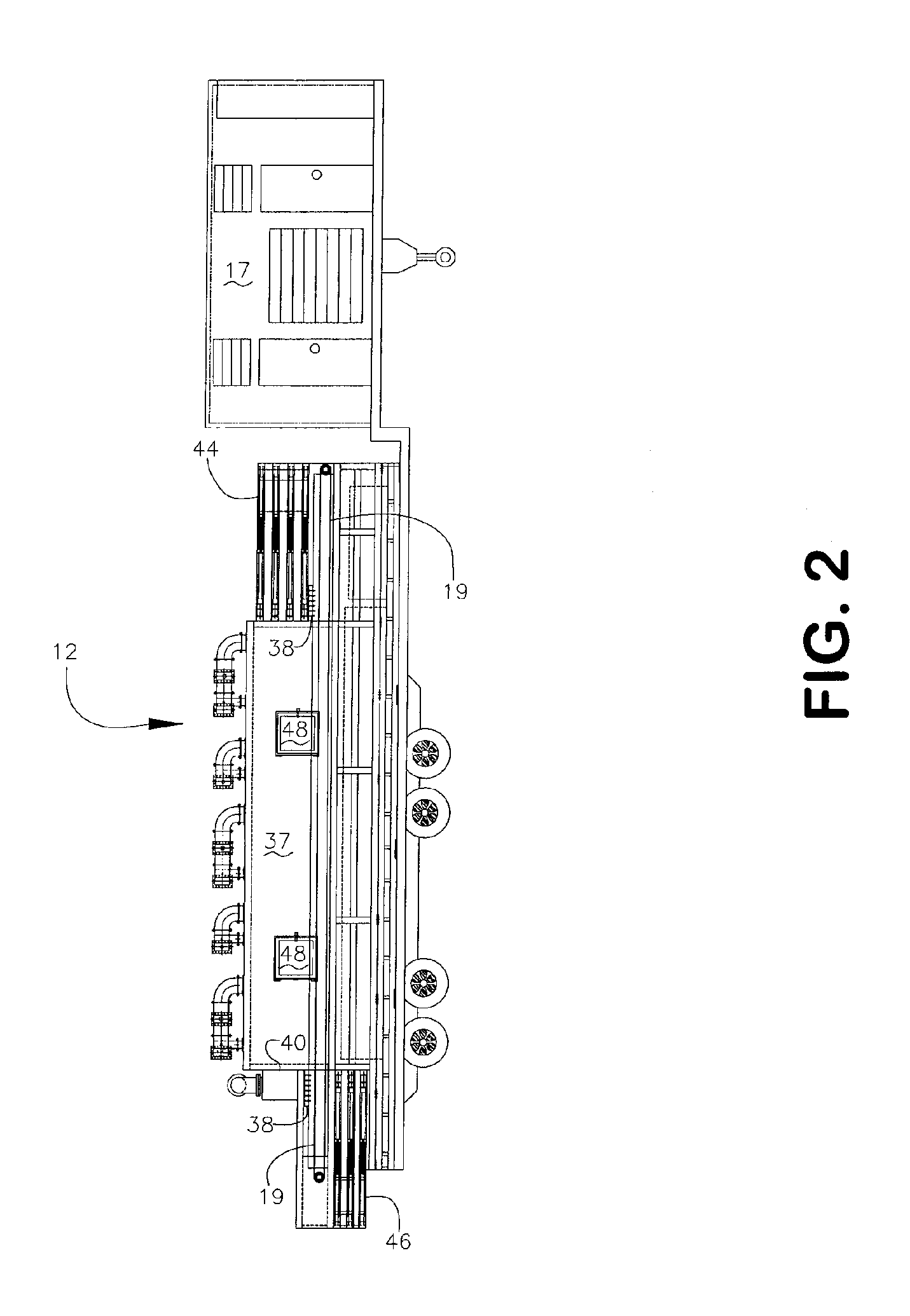

Mobile plant for thermally treating a contaminated or uncontaminated feed stream, processes thereof and uses of products thereof

InactiveUS20150368564A1Reduce transportationVolume of oilThermal non-catalytic crackingElectrical coke oven heatingPositive pressureReactor design

Mobile plant, for thermally treating a feed stream, comprising a first unit designed for heating the feed oil (Unit I); ii. a second unit comprising a rotating reactor designed to perform the thermal processing (pyrolizing) of the feed oil and a vapour solid separator (Unit II); and iii. a third unit (Unit III) that is a product separation unit and that is preferably configured for recycling at least part of the treated feed stream (heavy oil), recovered in Unit III, into Unit I. The first unit and / or the second unit is (are) configured for injecting a sweep gas in the feed oil and / or in the rotating reactor, and / or the second unit is configured in a way that the rotating reactor may work under positive pressure. The processes for thermally treating a feed material by using a mobile plant. The uses of the processes for various environmental and non-environmental applications. Processes for manufacturing the mobile plants. Uses of oil containing resins (such as cracked and / or polarized oils) for cleaning purposes and other specialty applications.

Owner:ENVIROLLEA

Process and Device for Generating Gas From Carbonaceous Material

InactiveUS20100154728A1Shorten the timeImprove energy balanceElectrical coke oven heatingGasifier mechanical detailsThermal radiationIrradiation

To gasify carbonaceous material into gas containing CO and H2, the drying and / or the heating and the pyrolysis of the carbonaceous material are performed using microwave irradiation and thermal irradiation and the pyrolysis products and / or the carbonaceous material are then gasified. For this purpose the carbonaceous material is irradiated in a microwave station with a heating unit, and then passed on into a reactor for gasification. The gasification occurs with the aid of a water-steam plasma source.

Owner:ME MUNSTERLAND ENERGY

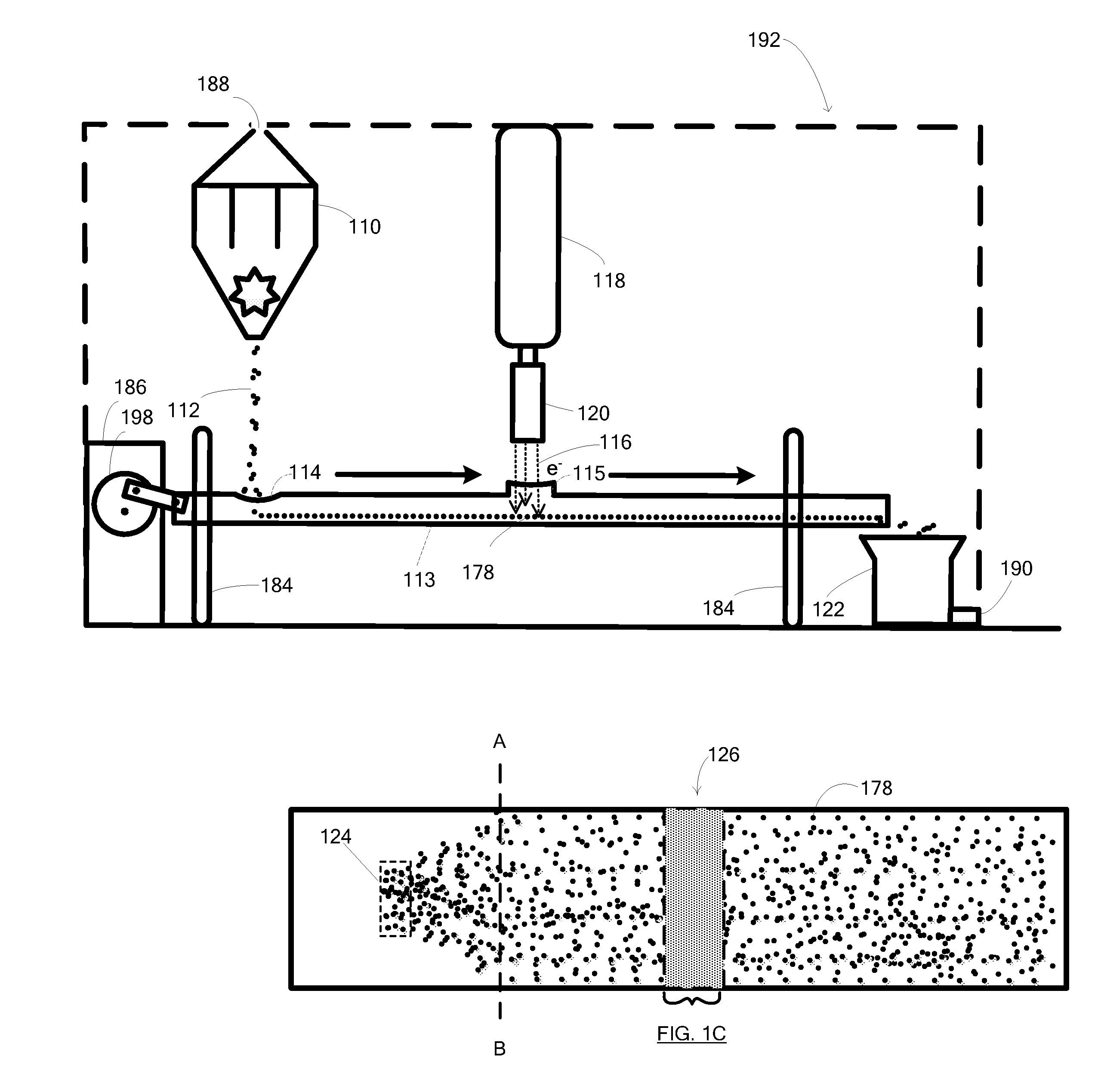

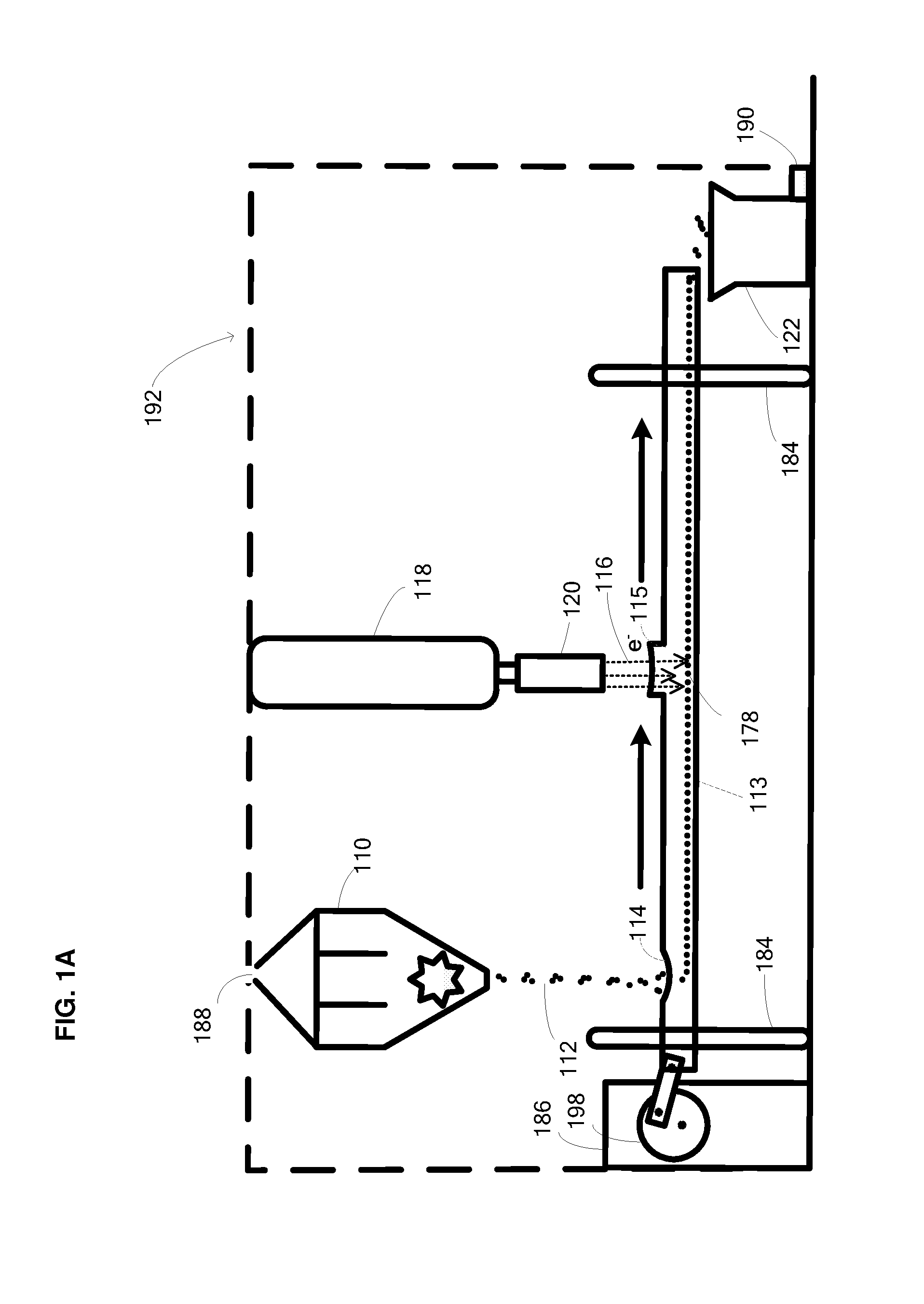

Processing biomass

Methods and systems are described for processing cellulosic and lignocellulosic materials into useful intermediates and products, such as energy and fuels. For example, conveying systems and methods, such as highly efficient vibratory conveyors, are described for the processing of the cellulosic and lignocellulosic materials.

Owner:XYLECO INC

Catalyst for distributed batch microwave pyrolysis, system and process thereof

ActiveUS20140020286A1Avoid accumulationElectrical coke oven heatingOrganic chemistryChemistryMicrowave pyrolysis

Owner:PYROWAVE

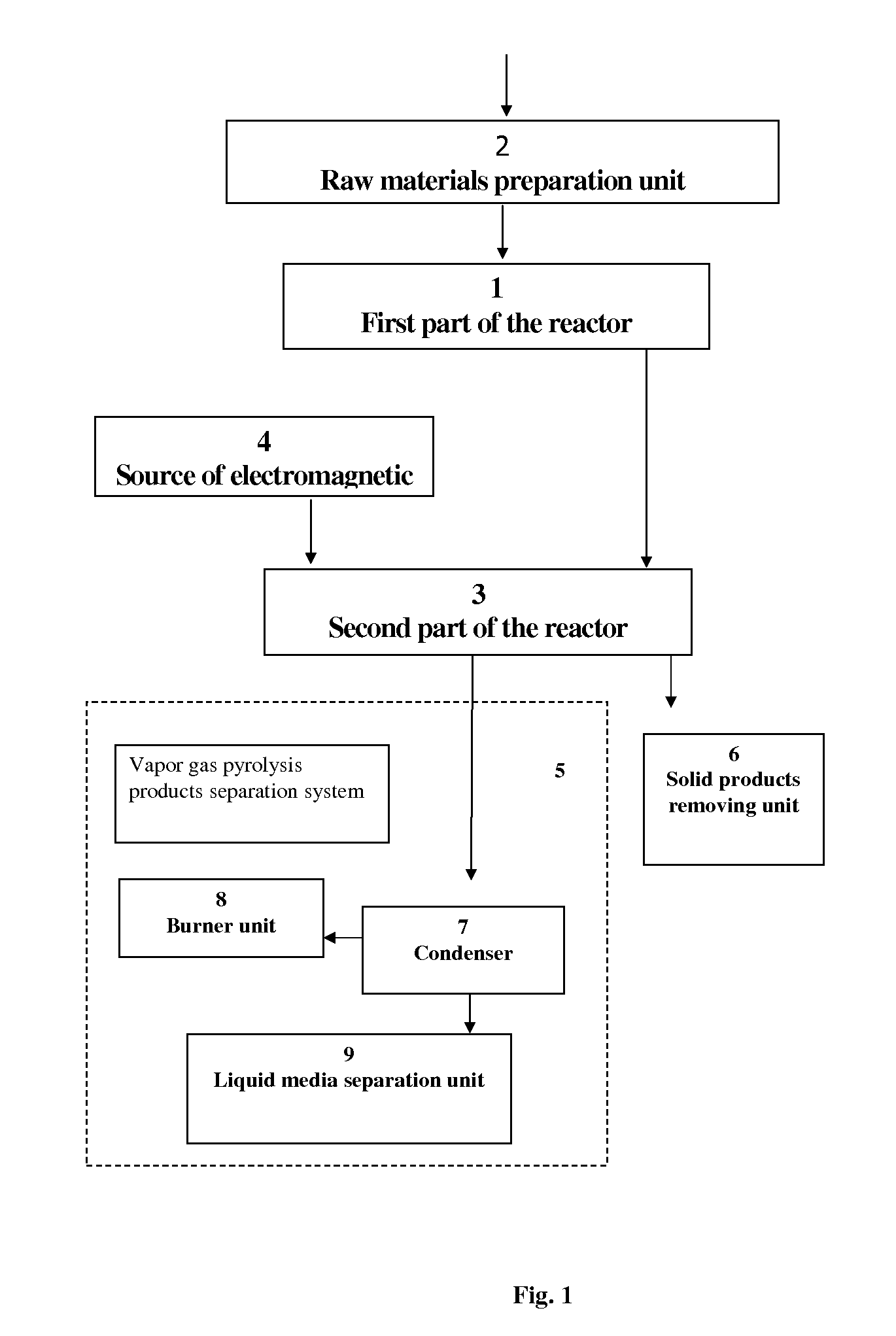

Method and Device for Processing Domestic and Industrial Organic Waste

ActiveUS20110048915A1Improve efficiencySpeed up the processElectrical coke oven heatingByproduct vaporizationWaste processingEnvironmental engineering

The invention relates to waste processing and to producing hydrocarbons from domestic and industrial organic waste by pyrolysis. The inventive waste processing method involves carrying out the first and second pyrolysis stages, fractionating pyrolysis products and processing each fraction for producing useful products. The second pyrolysis stage is carried out simultaneously with the electromagnetic action produced on the pyrolysis products. The device for carrying out said method comprises a two-sectional pyrolysis reactor. An electromagnetic source is arranged on the second section of the reactor. The output of the second section is connected to a system for dividing the vaporous pyrolysis products. The technical result consists in increasing the waste processing effectiveness and producing solid, liquid and vaporous fuel components.

Owner:ZAKRYTOE AKTSIONERNOYE OBSCHESTVO FINANSOVO PROMYSHLENNAYA GRUPPA TEZAURUM

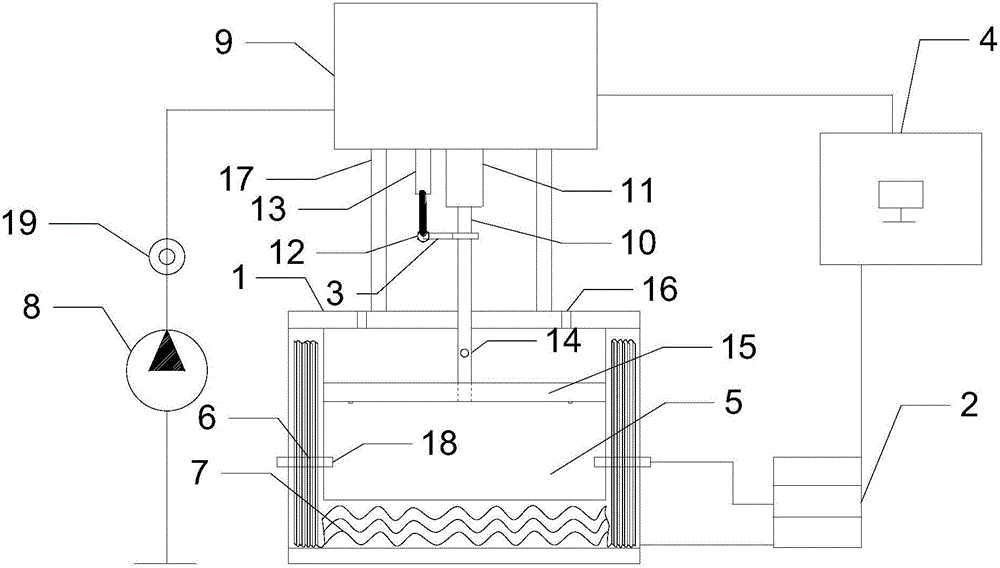

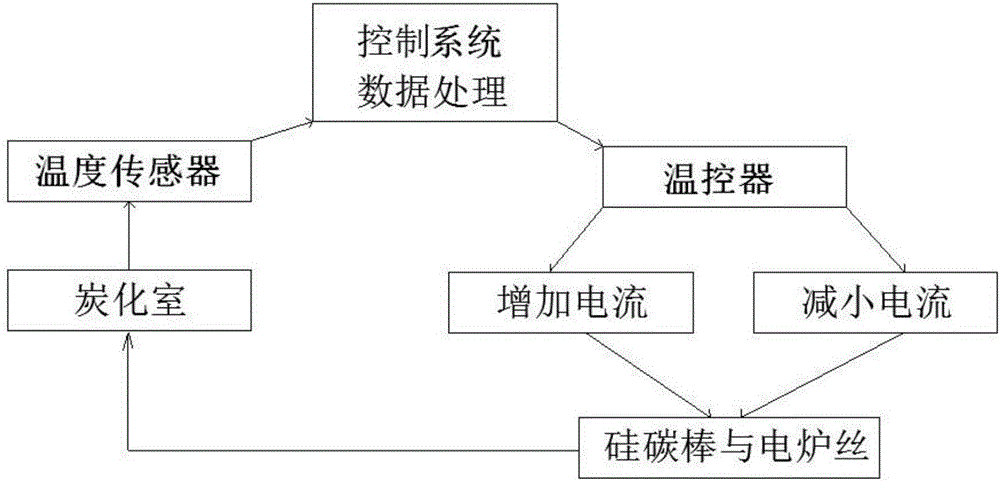

Small constant-pressure coking device and constant-pressure coking method

InactiveCN105861002AEvenly heatedIncrease heating rateElectrical coke oven heatingSpecial form destructive distillationInterior spaceControl system

The invention relates to a small constant-pressure coking device and a constant-pressure coking method. The device comprises an experiment coke oven, a temperature controller, a constant-pressure system and a control system, wherein the experiment coke oven is provided with a plurality of groups of silicon carbide rods, a resistance wire and a coking chamber, the constant-pressure system is composed of a hydraulic pump, a buffer cylinder and a movable press plate, a push rod of the buffer cylinder is connected with the movable press plate through a first hollow pipe and can drive the movable press plate to move up and down in the coking chamber, and the bottom end of the first hollow pipe penetrates through the movable press plate to be communicated with the interior space of the coking side of the coking chamber; a temperature sensor is arranged in the coking chamber, a displacement sensor is arranged on the top of the experimental coke oven, and an oil pressure regulator is arranged on a hydraulic pipeline between the hydraulic pump and the buffer cylinder. According to the device and method, coking can be conducted under the constant-pressure condition, so that the correspondence between pressure and coke quality is obtained, or comparative study is conducted on the quality of coke of different coal types under the same pressure. The device and method have great guiding significance in coal blending for coking and coking mechanism research, and the purposes of optimizing coking production process, saving coking equipment investment and effectively utilizing resources are realized.

Owner:UNIV OF SCI & TECH LIAONING

Method using solar energy, microwaves and plasmas to produce a liquid fuel and hydrogen from biomass or fossil coal

ActiveUS8388706B2Improving thermal inertiaElectrical coke oven heatingSolar heating energySludgeFractionating column

Owner:UGOLIN NICOLAS

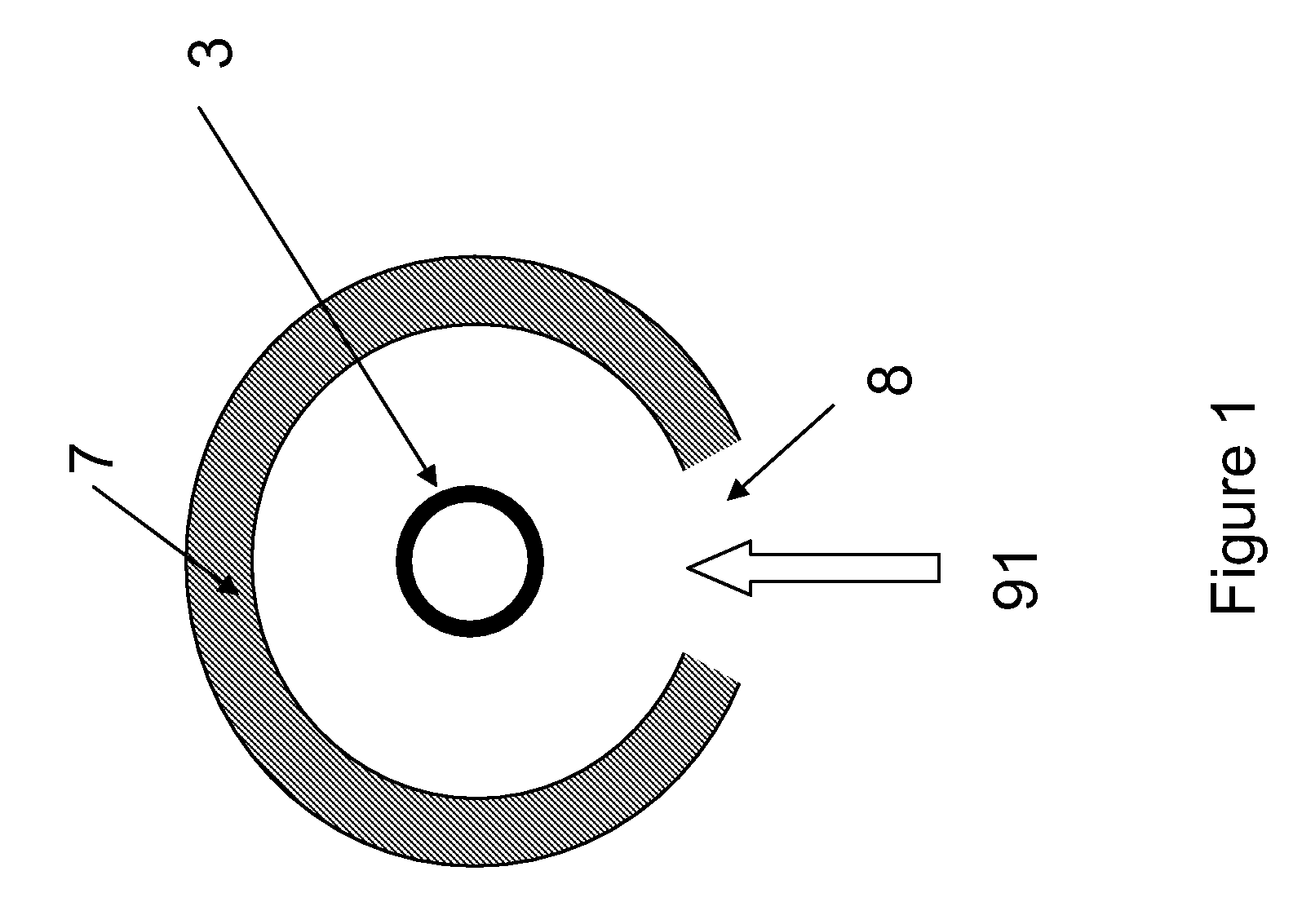

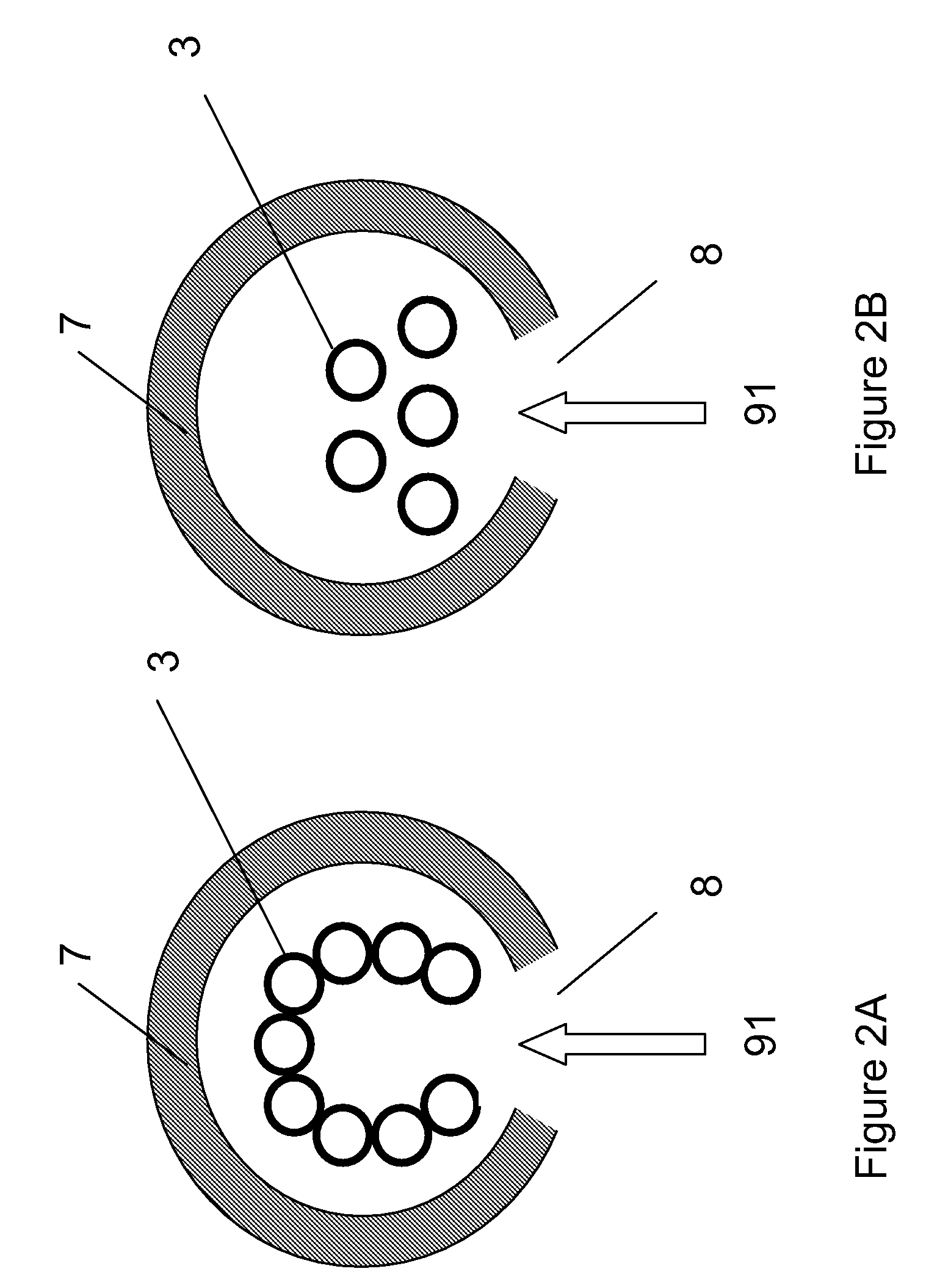

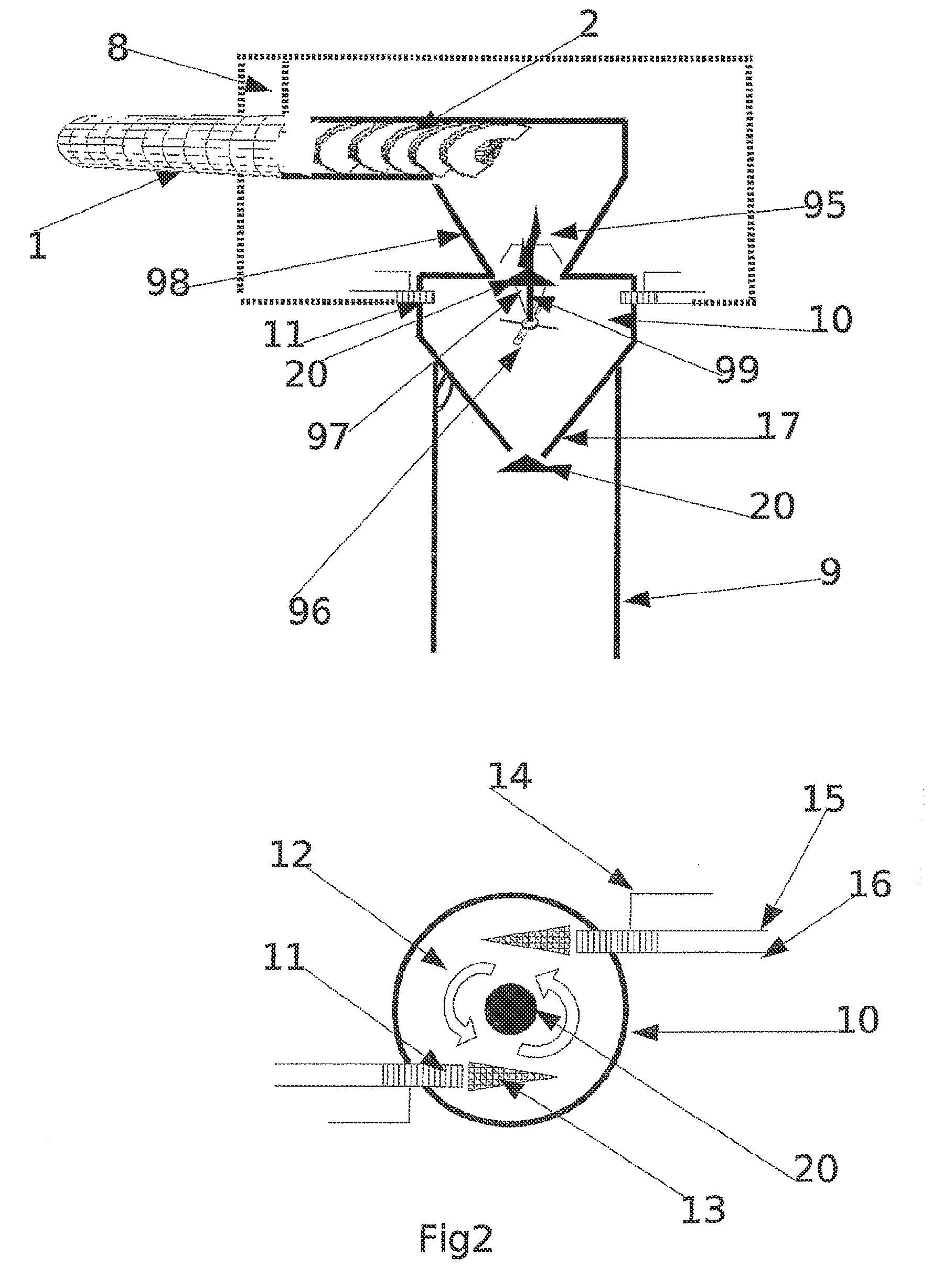

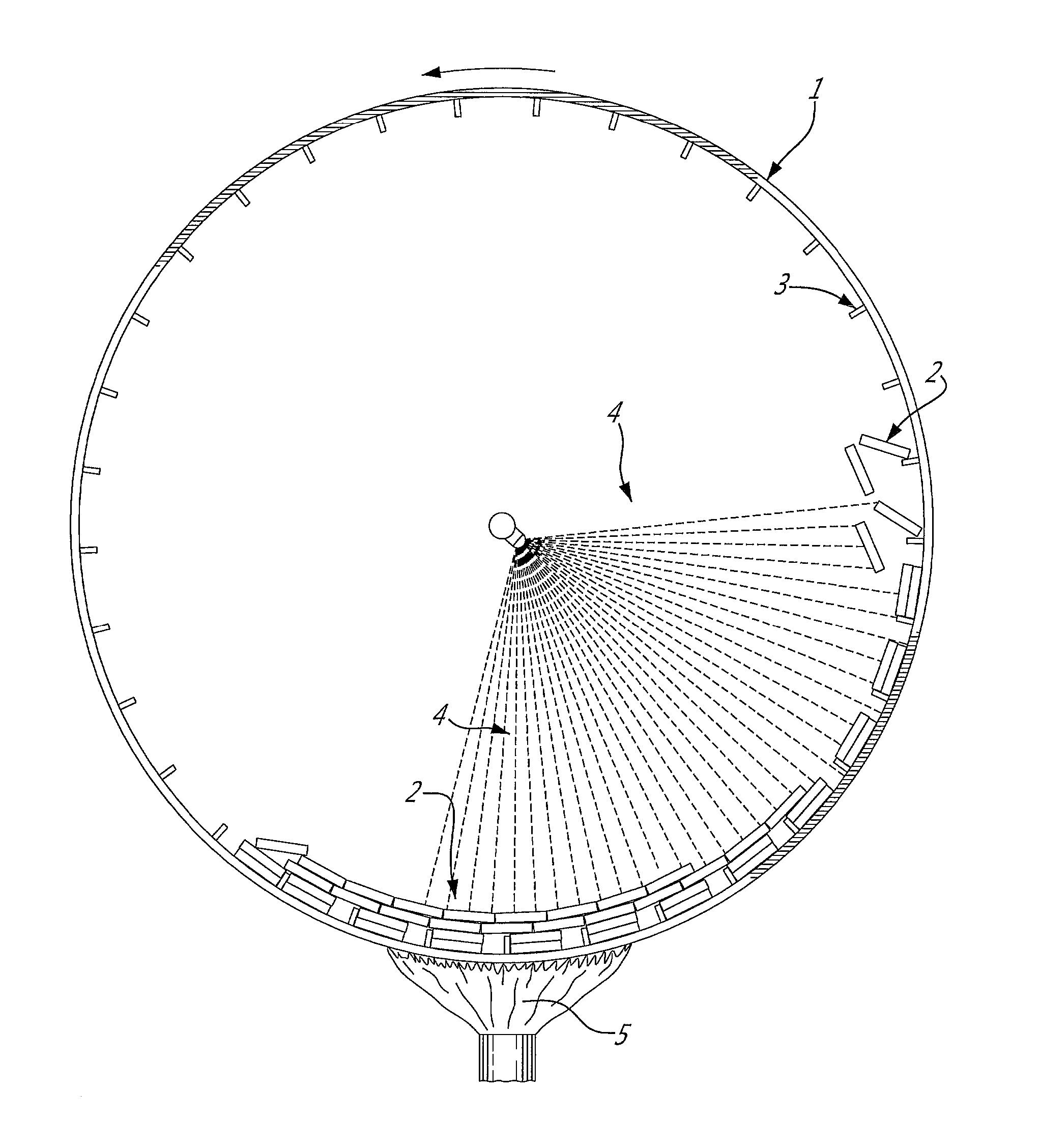

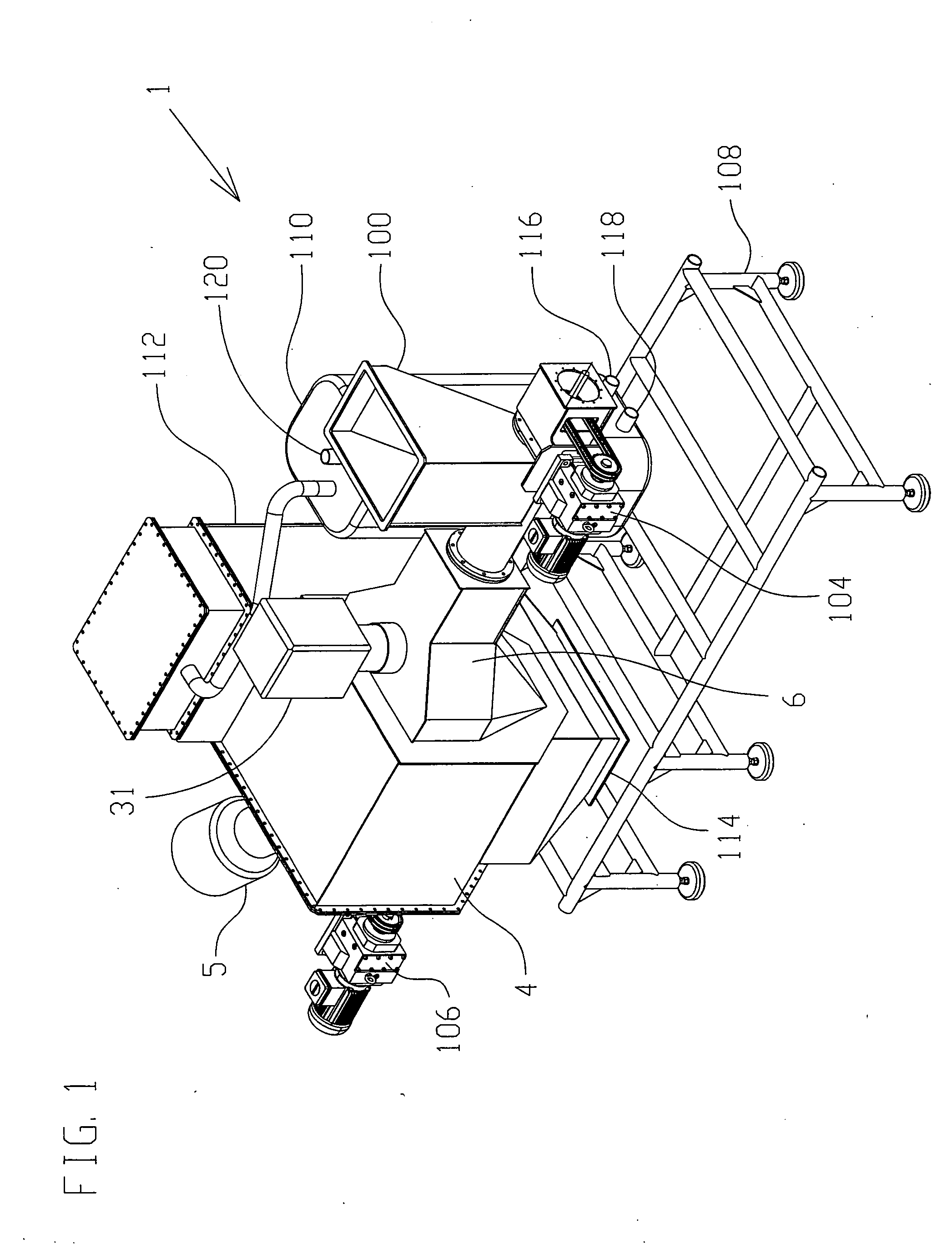

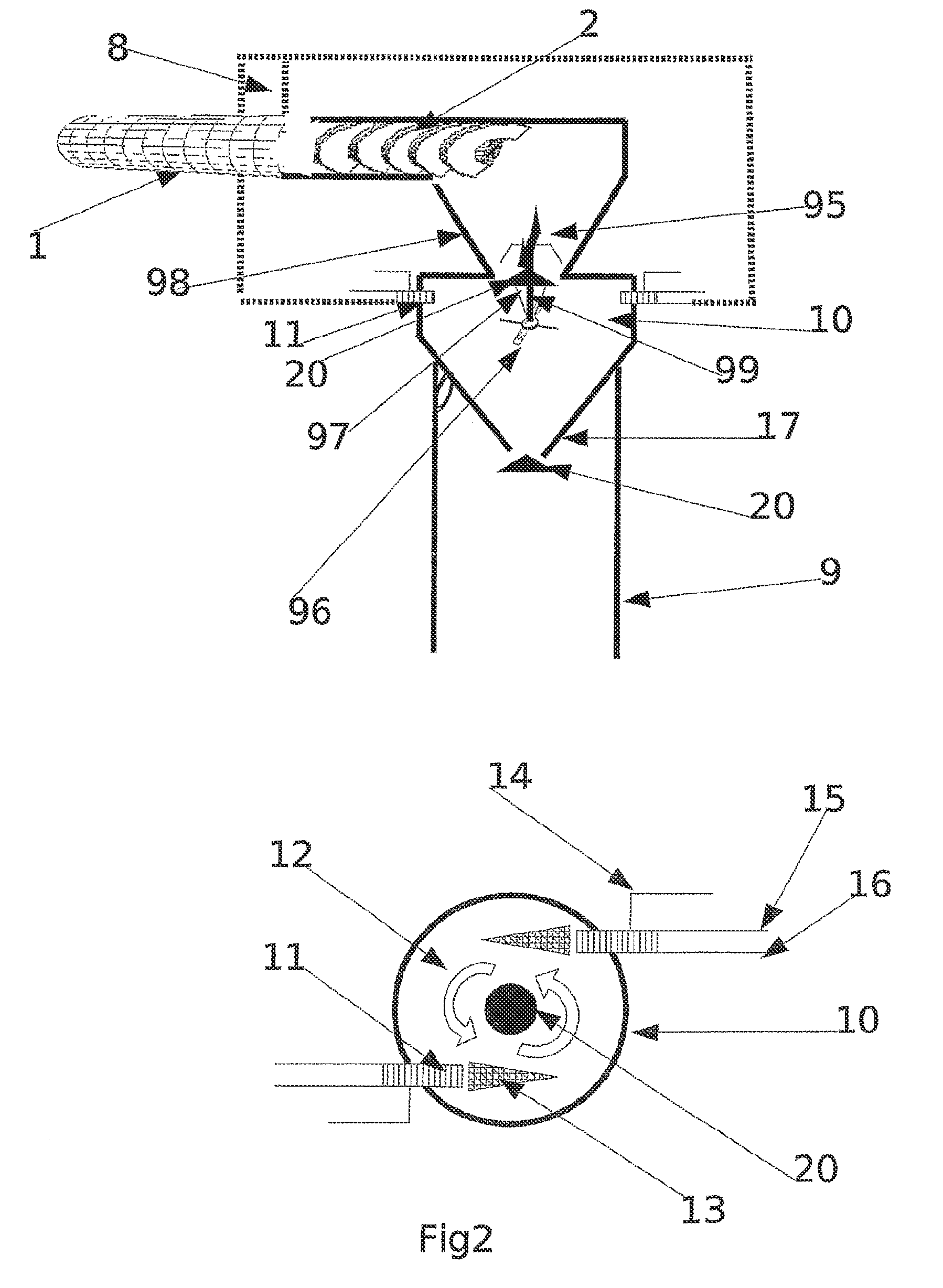

Microwave assisted flash pyrolysis system and method using the same

ActiveUS20130032464A1Strong microwave energy zoneLess carbon hydrideMechanical conveying coke ovensElectrical coke oven heatingIndustrial scaleMicrowave assisted

The present invention provides a microwave assisted flash pyrolysis system to carry out microwave assisted flash pyrolysis in an industrial scale. The microwave assisted flash pyrolysis system comprises at least one microwave generator; a chamber comprises: at least one feedstock inlet, at least one baffle plate, a microwave-transparent rotating window, and at least one microwave inlet, at least one wet gas outlet, and at least one dry end product outlet. The present invention also provides a method using the same system to carry out microwave assisted flash pyrolysis.

Owner:PHASE TRANSITION ENERGY LTD

Method and apparatus for microwave reduction of organic compounds

ActiveUS20110048916A1Electrical coke oven heatingTransportation and packagingMedical wasteEngineering

The invention described herein generally pertains to utilization of high power density microwave energy to reduce organic compounds to carbon and their constituents, primarily in a gaseous state. The process includes, but is not limited to, scrap tires, plastics, asphalt roofing shingles, computer waste, medical waste, municipal solid waste, construction waste, shale oil, and PCB / PAH / HCB-laden materials. The process includes the steps of feeding organic material into a microwave applicator and exposing the material to microwave energy fed from at least two linear polarized sources in non-parallel alignment to each other, and collecting the material. The at least two sources of microwave energy are from a bifurcated waveguide assembly, whose outputs are perpendicular to each other and fed through waveguide of proper impedance, such that the microwave sources are physically and electrically 90° out of phase to each other. The microwave frequency is between 894 and 1000 MHz, preferably approximately 915 MHz.

Owner:NOVAK JUDITH

Microwave assisted flash pyrolysis system and method using the same

ActiveUS8808507B2Strong microwave energy zoneLess carbon hydrideElectrical coke oven heatingDirect heating destructive distillationIndustrial scaleMicrowave assisted

The present invention provides a microwave assisted flash pyrolysis system to carry out microwave assisted flash pyrolysis in an industrial scale. The microwave assisted flash pyrolysis system comprises at least one microwave generator; a chamber comprises: at least one feedstock inlet, at least one baffle plate, a microwave-transparent rotating window, and at least one microwave inlet, at least one wet gas outlet, and at least one dry end product outlet. The present invention also provides a method using the same system to carry out microwave assisted flash pyrolysis.

Owner:PHASE TRANSITION ENERGY LTD

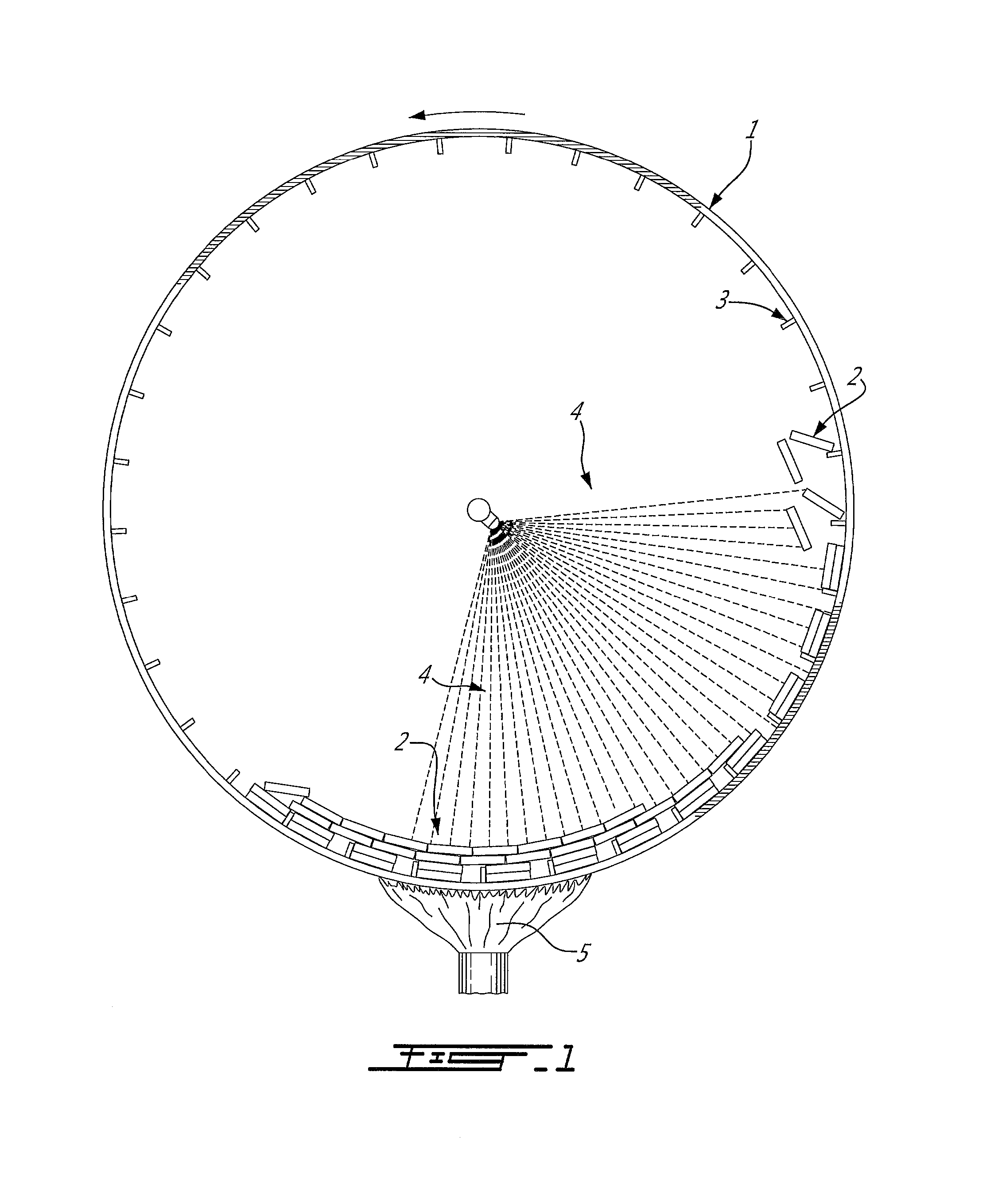

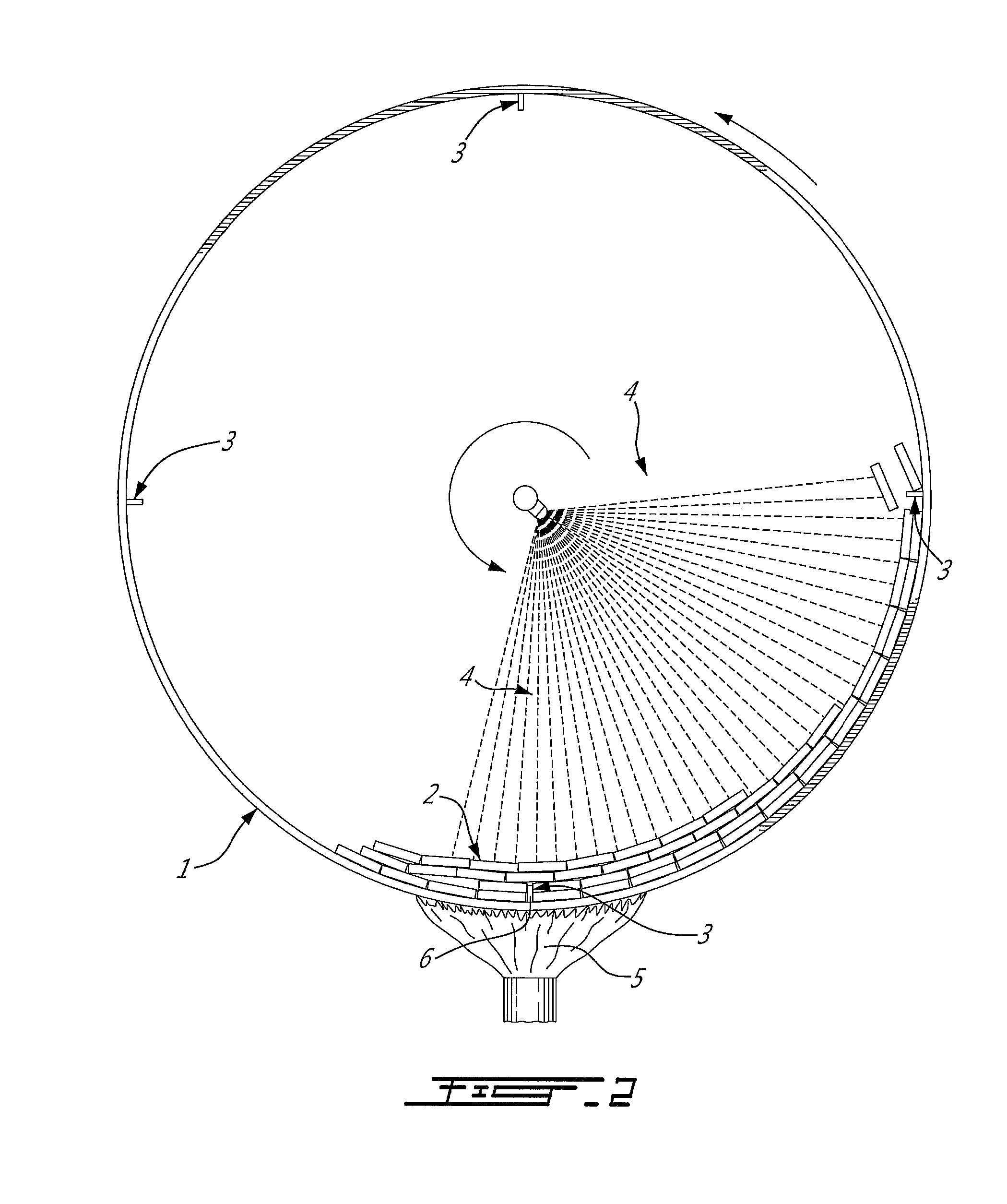

Microwave Gasification, Pyrolysis and Recycling of Waste and Other Organic Materials

Apparatus for the destructive reclamation of materials and energy from municipal wastes and other raw materials through the use of Microwave induced Gasification and Pyrolysis, where the waste or raw material may be circulated once or several times through the process thus enabling the programming of different processes to differing materials and desired end products. The form employed being linear, circulating conveyors or rotating carousels that may carry trays or crucibles, some of which may be equipped with linings that absorb microwaves to enable the early charring of materials that do not initially absorb microwaves and thus will not heat up on their own.

Owner:SCHWEITZER

Methods for preparing fuel compositions from renewable sources, and related systems

ActiveUS8657999B2Lower Level RequirementsPressurized chemical processTreatment with hydrotreatment processesMicrowaveLiquid fuel

A method for producing a fuel composition from a feedstock which may contain biomass and municipal solid waste is described. The method includes the step of pyrolyzing the feedstock in the presence of a transition metal, using microwave energy, so that the level of oxygen in at least one product of the pyrolysis is reduced. An integrated process is also described, in which the transition metal can be regenerated. Moreover, pyrolysis products such as bio-oils can be upgraded to liquid fuel compositions. Related systems for producing fuel compositions are also described.

Owner:AIR PROD & CHEM INC

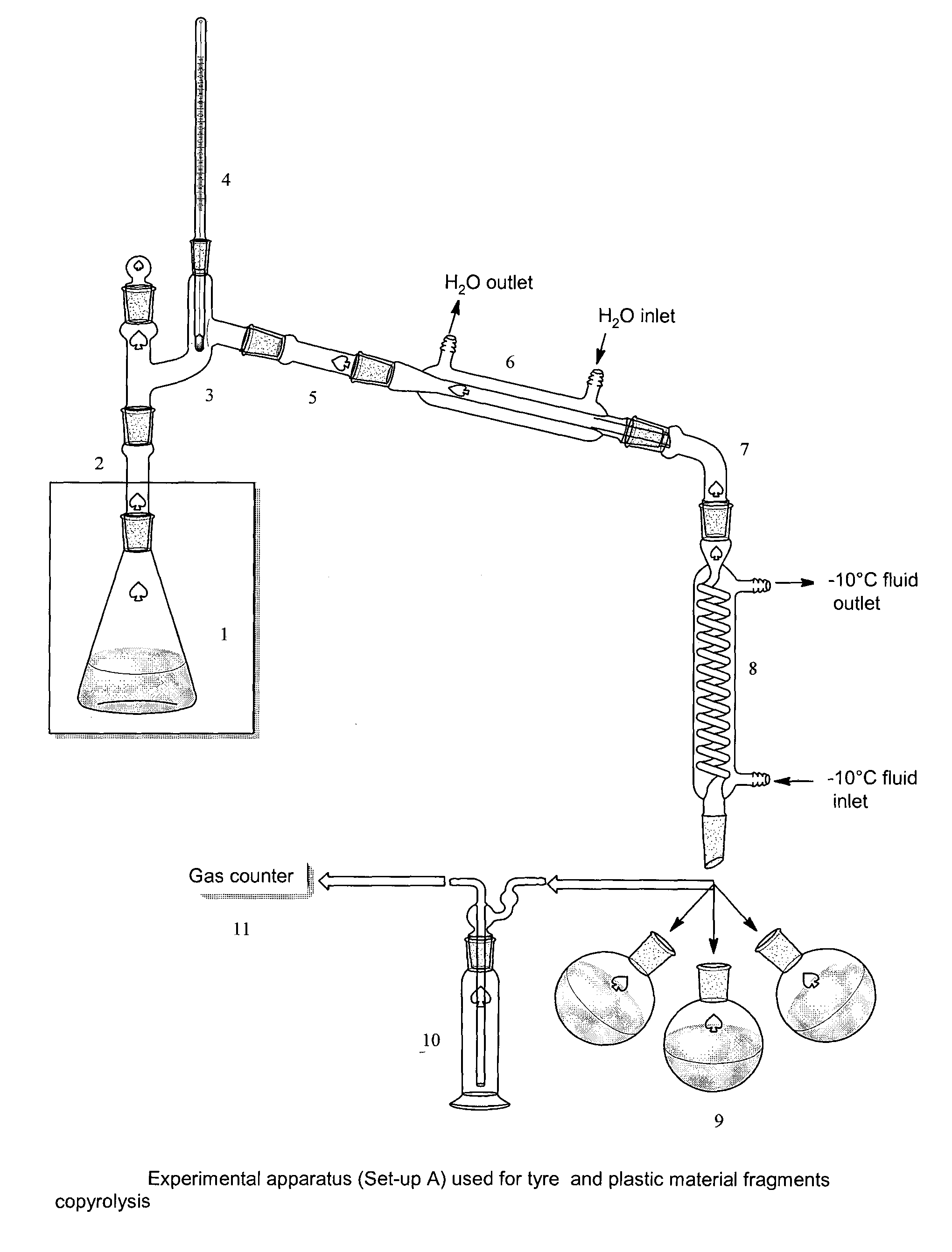

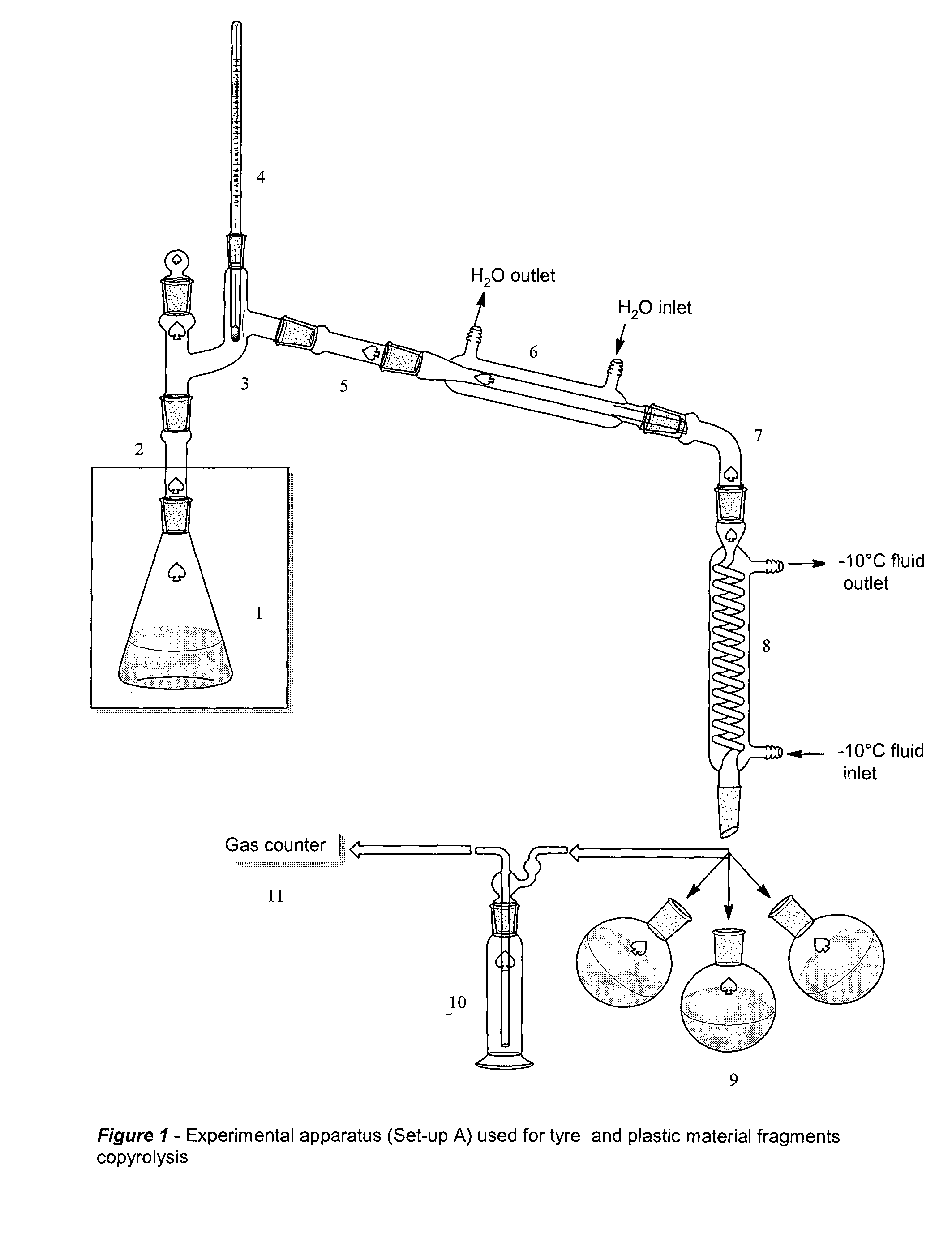

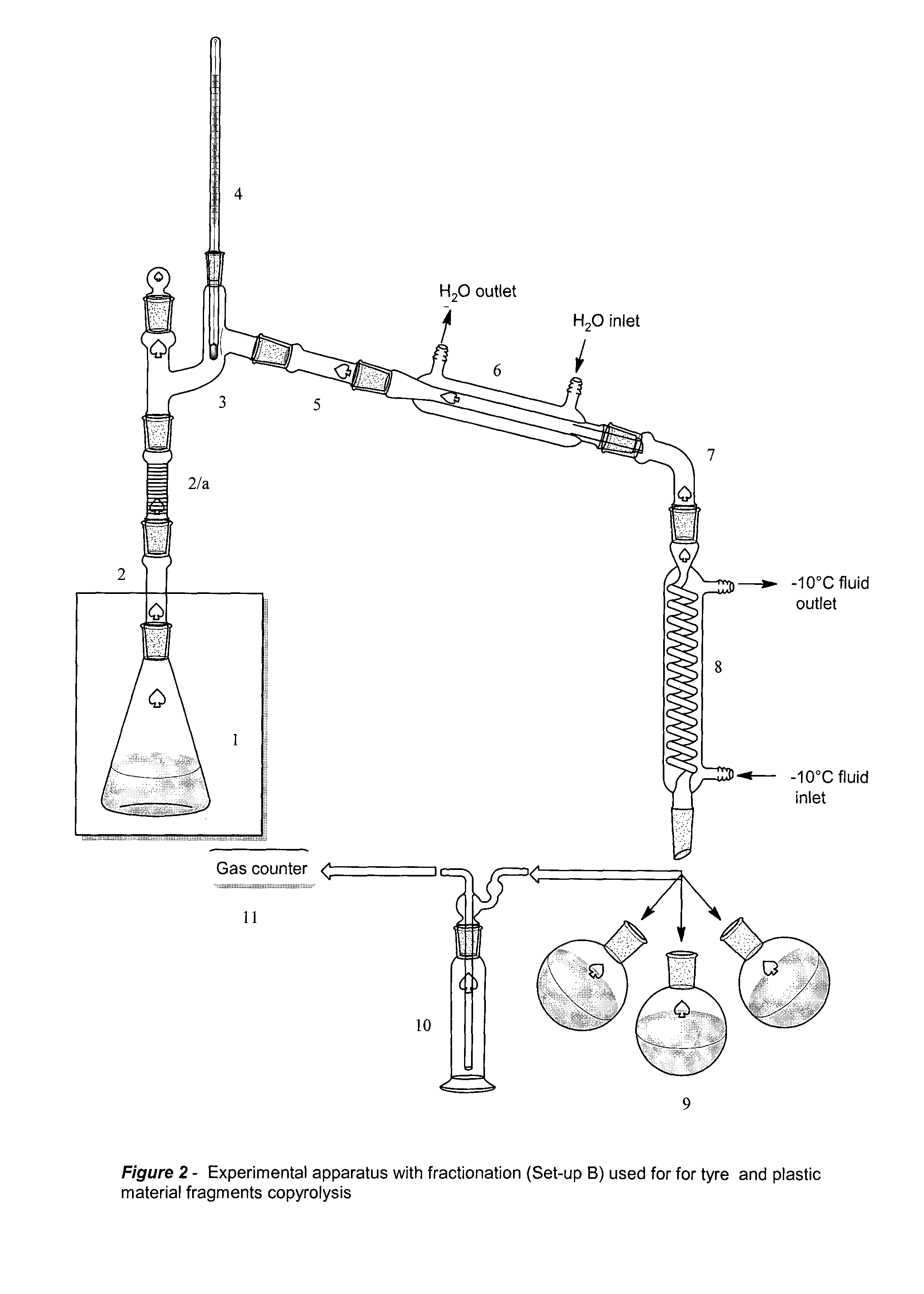

Production of hydrocarbons from copyrolysis of plastic and tyre material with microwave heating

The present invention relates to the development of a microwave pyrolysis process for plastic materials selected from PE, PP, PS, PET, PVC and mixtures thereof in the presence of end-of-life tyres, or the pyrolysis residues thereof, or other carbon materials for the production of high added value pyrolysis oils containing over 50% by weight hydrocarbons distillable between 20 and 250° C. and a sulphur content less than 1% by weight.

Owner:COOP AUTOTRASPORTATORI FIORENTINI C A F SOC COOP A R L

Reduction method for processing waste plastic and system thereof

ActiveCN101302432AGood load adaptabilityQuality improvementElectrical coke oven heatingProductsCatalytic pyrolysisLiquid fuel

The invention relates to a reduction method and a reduction system for processing waste plastics. The method and the system take an IGBT heating module as the core, and can save over 40 percent of energy compared with the prior vacuum tube high-frequency equipment and the prior thyristor induction heating equipment. The method and the system adopt the novel catalytic pyrolysis method, namely the prior mode of directly placing catalyst zeolite into the waste plastics is changed and the waste plastics are gasified into oil gas and then degraded by Y-shaped molecular sieves. Therefore, the pyrolysis effect of the method and the system is more obvious; the quality of liquid fuel gasoline and diesel fuel produced is better; and the gasoline and the diesel fuel produced reach or exceed the national standards of No.70 gasoline SHO 42-92 and No. 0 diesel fuel GB 252-94. Moreover, No. 90 to No. 93 unleaded gasoline can be modulated by utilization of the gasoline.

Owner:吴振奇

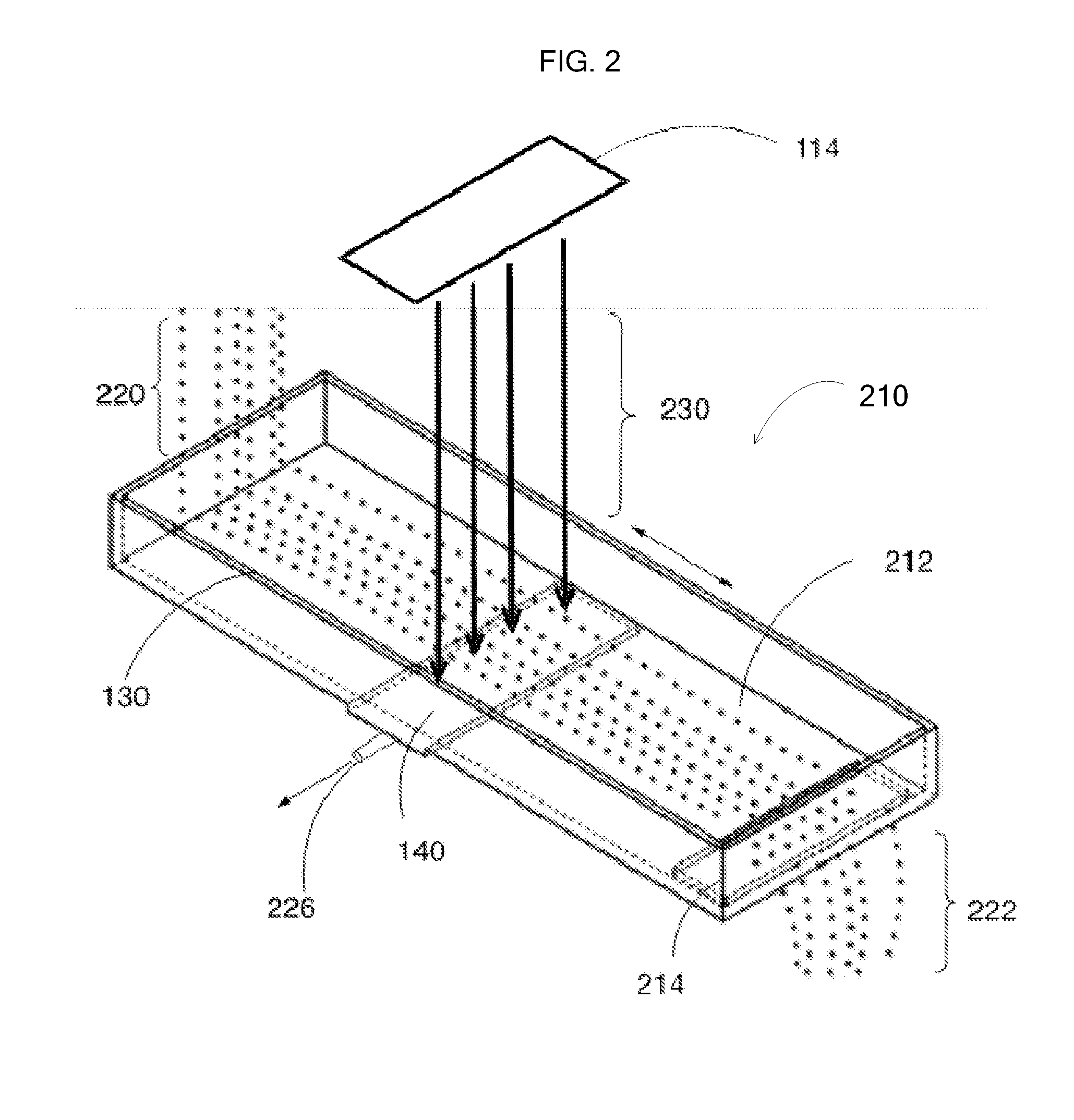

Equipment protecting enclosures

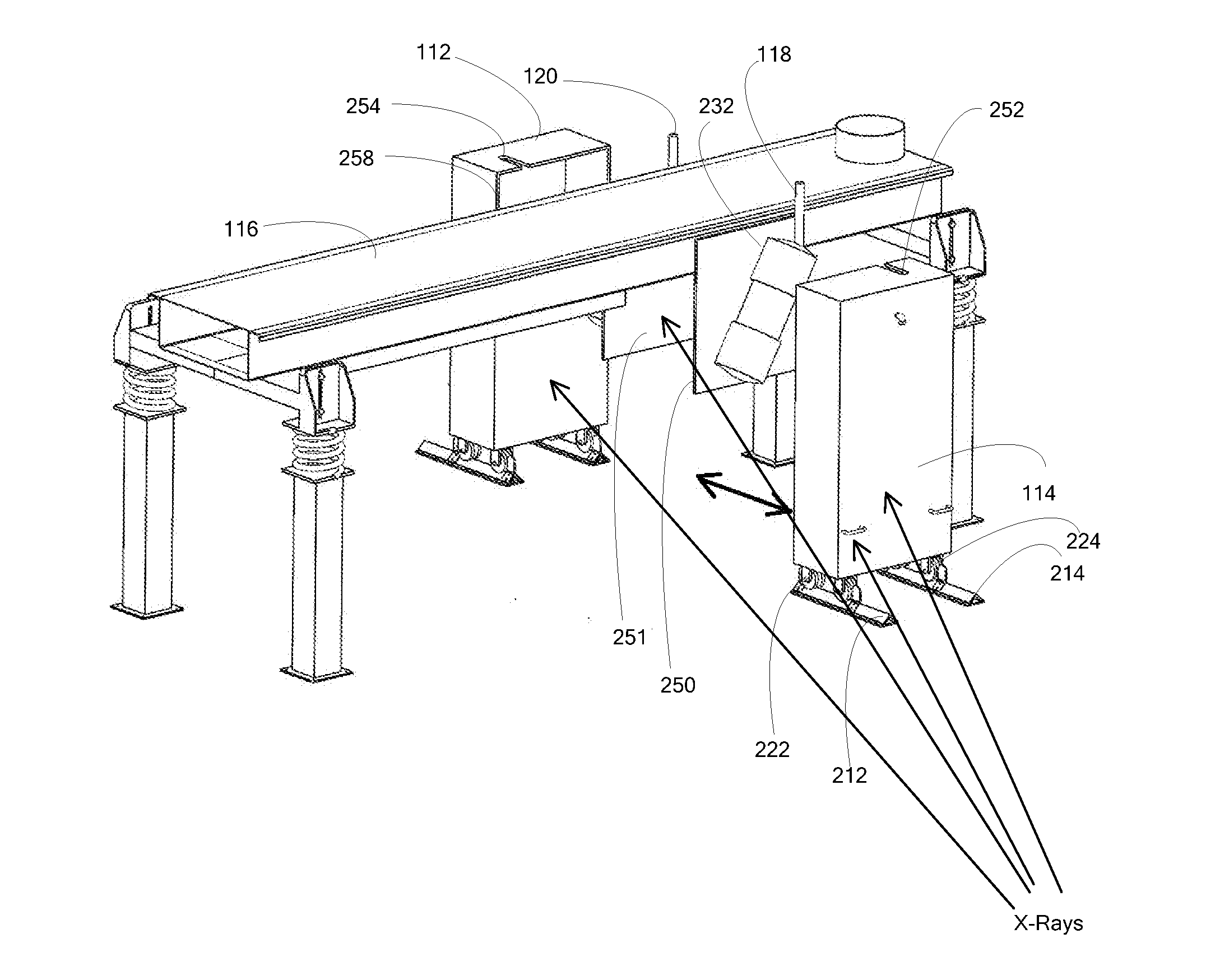

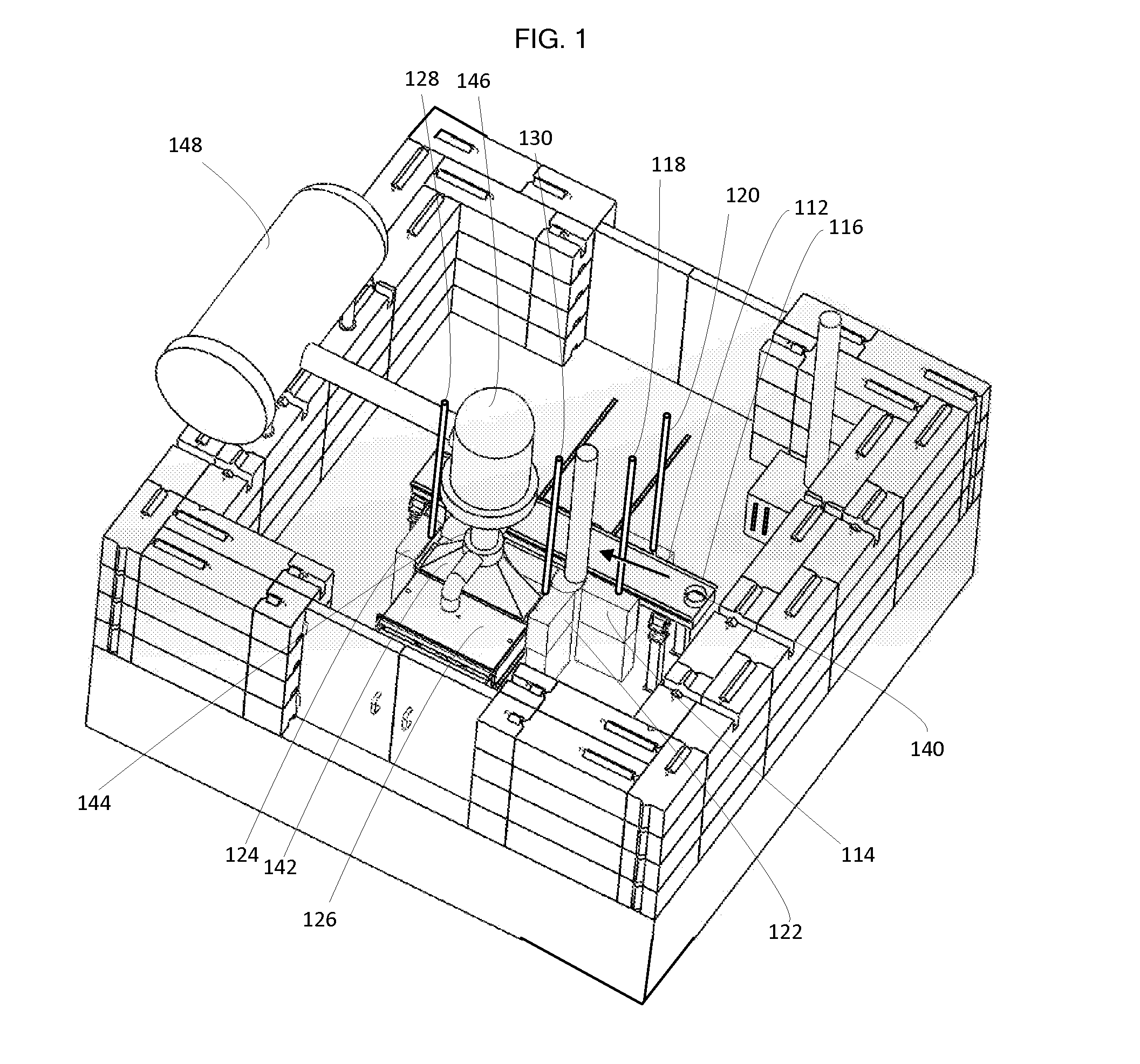

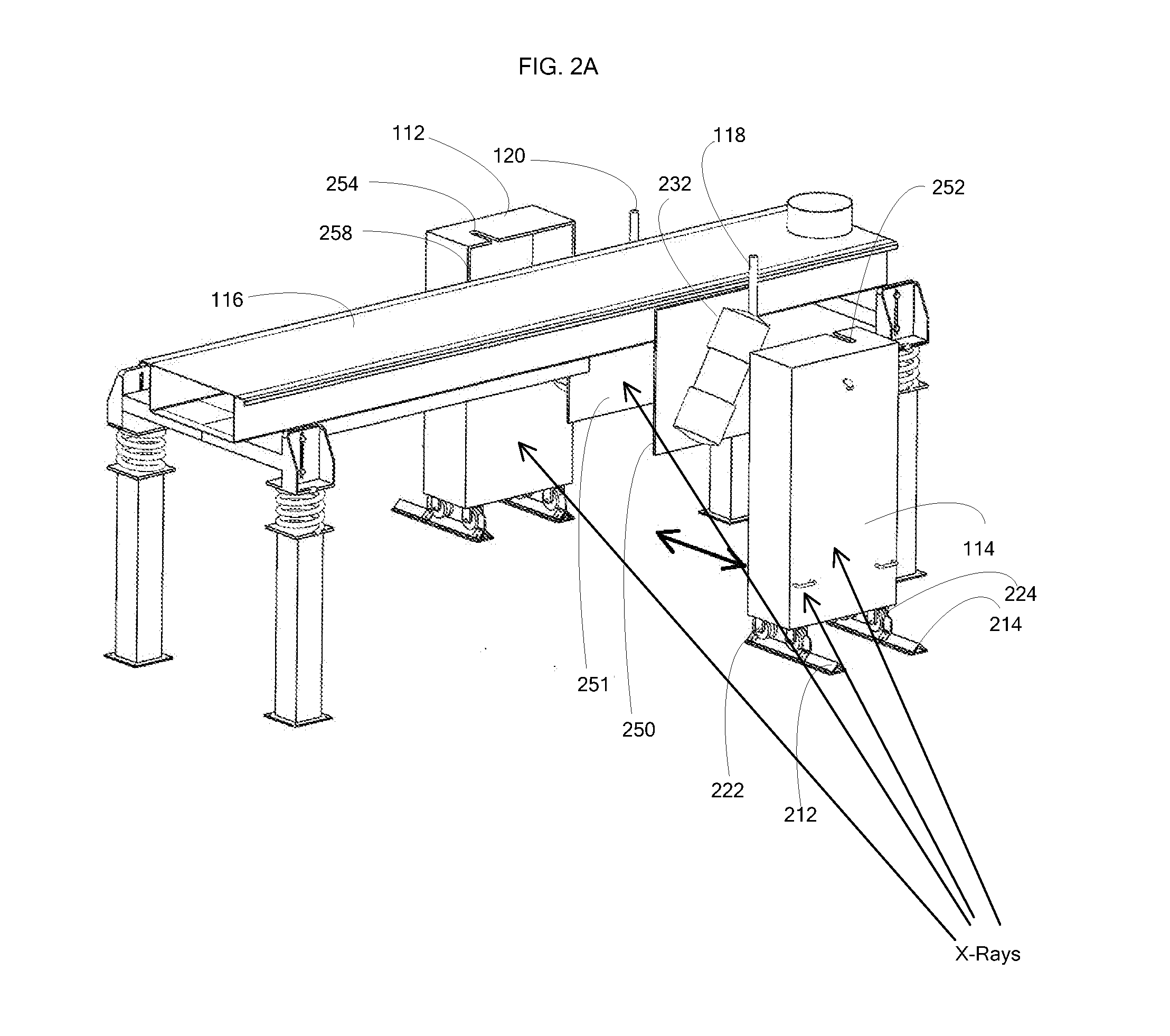

InactiveUS20150287487A1Promote sportsReduce exposureElectrical coke oven heatingBiofuelsCelluloseProduct gas

Biomass (e.g., plant biomass, animal biomass, and municipal waste biomass) is processed to produce useful intermediates and products, such as energy, fuels, foods or materials. For example, systems and methods are described that can be used to treat feedstock materials, such as cellulosic and / or lignocellulosic materials, in a vault in which the equipment is protected from radiation and hazardous gases by equipment enclosures. The equipment enclosures may be purged with gas.

Owner:XYLECO INC

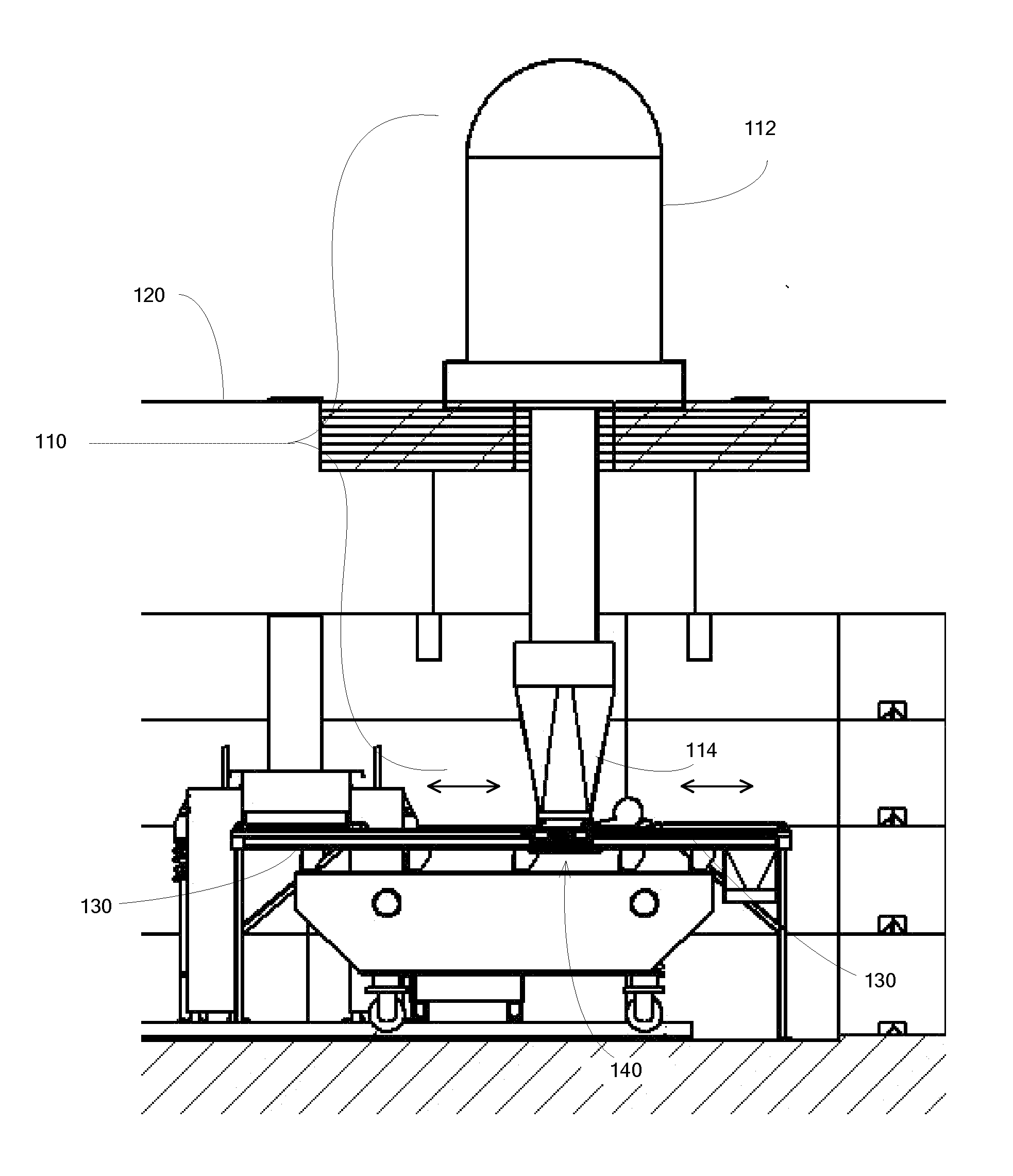

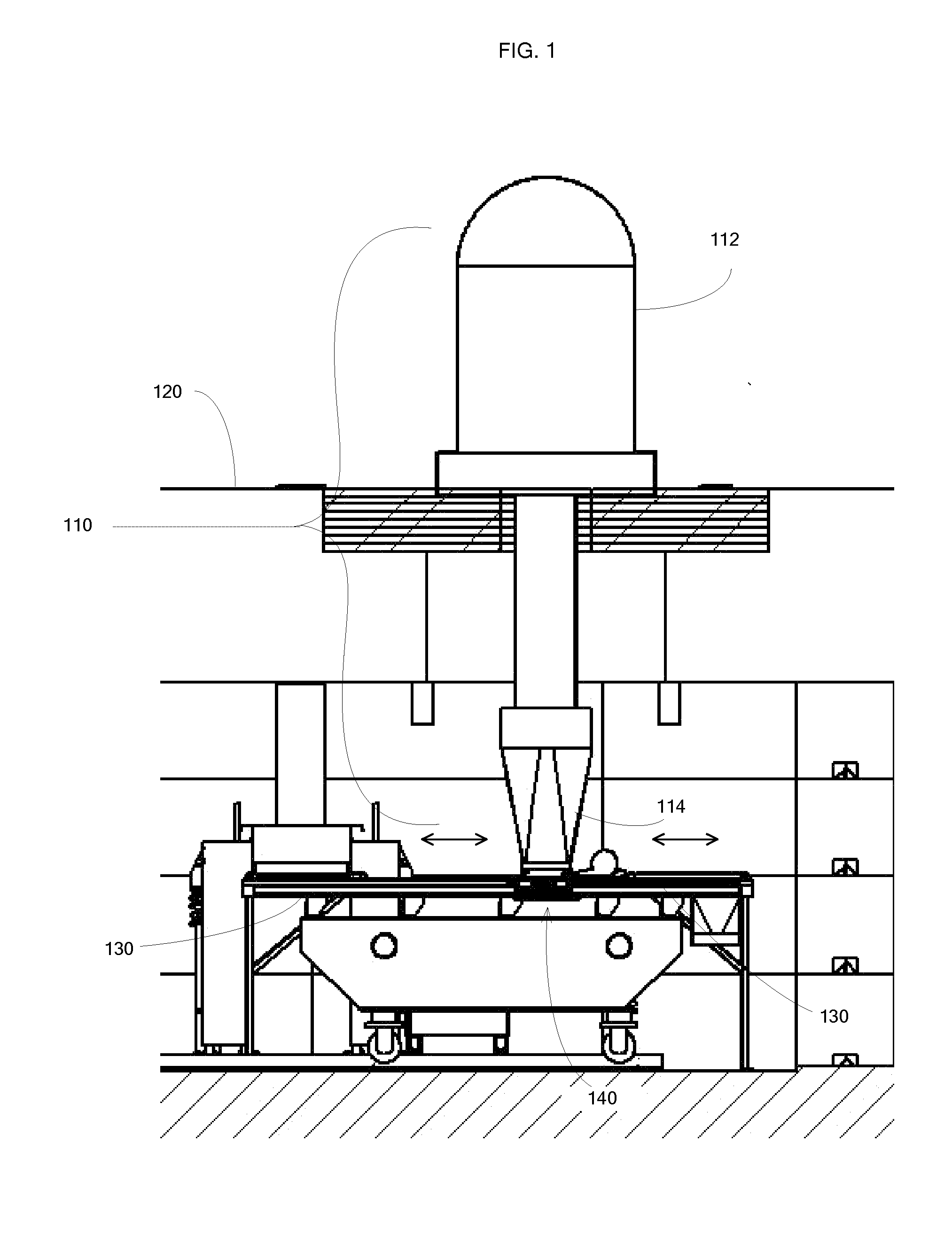

Processing materials

ActiveUS20150284907A1Avoid degradationAvoid destructionElectrical coke oven heatingBiofuelsProcess engineeringCooling fluid

Biomass (e.g., plant biomass, animal biomass, and municipal waste biomass) is processed to produce useful intermediates and products, such as energy, fuels, foods or materials. For example, systems and methods are described that can be used to treat feedstock materials, such as cellulosic and / or lignocellulosic materials, while cooling equipment and the biomass to prevent overheating and possible distortion and / or degradation. The biomass is conveyed by a conveyor, which conveys the biomass under an electron beam from an electron beam accelerator. The conveyor can be cooled with cooling fluid. The conveyor can also vibrate to facilitate exposure to the electron beam. The conveyor can be configured as a trough that can be optionally cooled.

Owner:XYLECO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com