Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

525results about How to "Increase heating rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

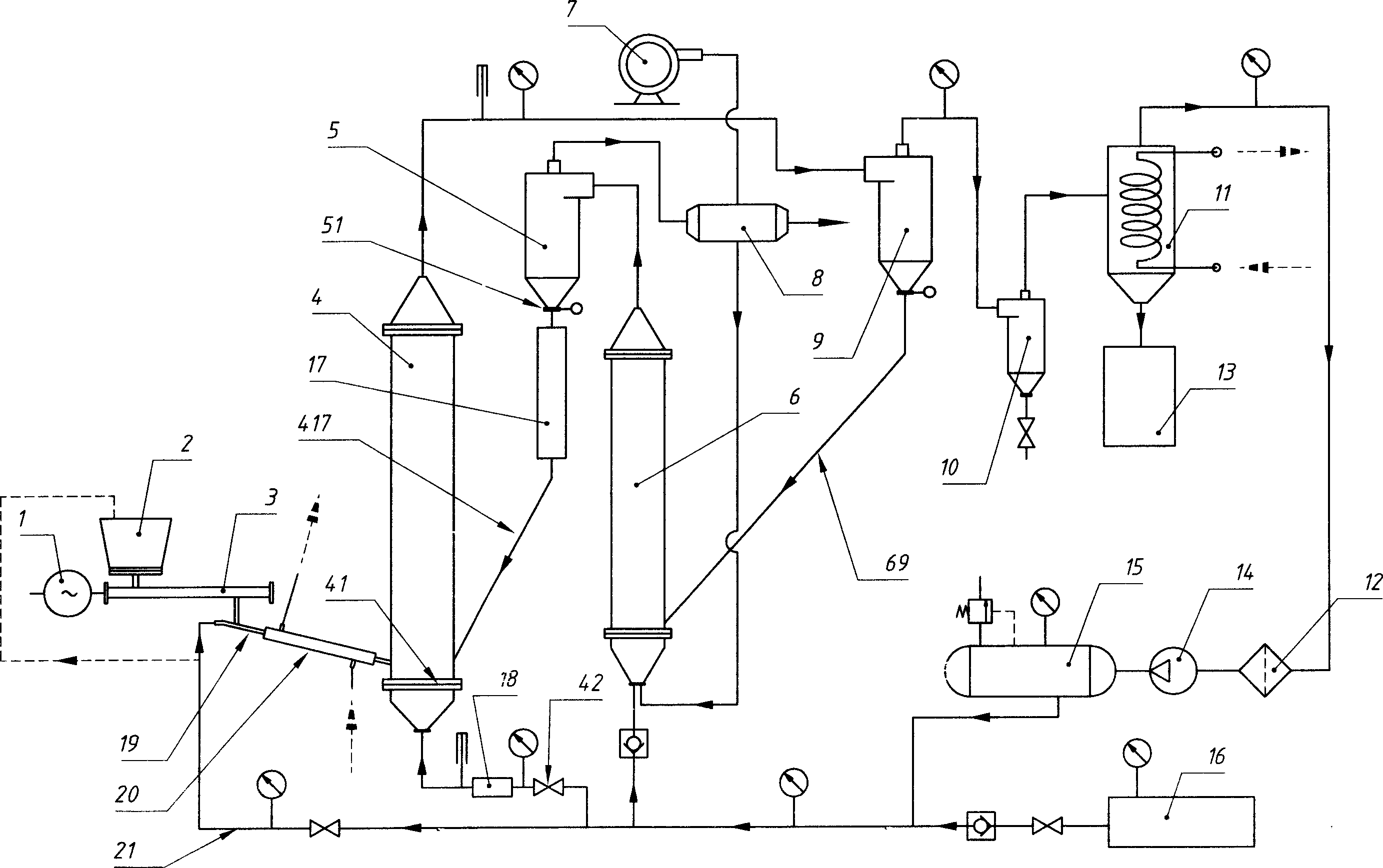

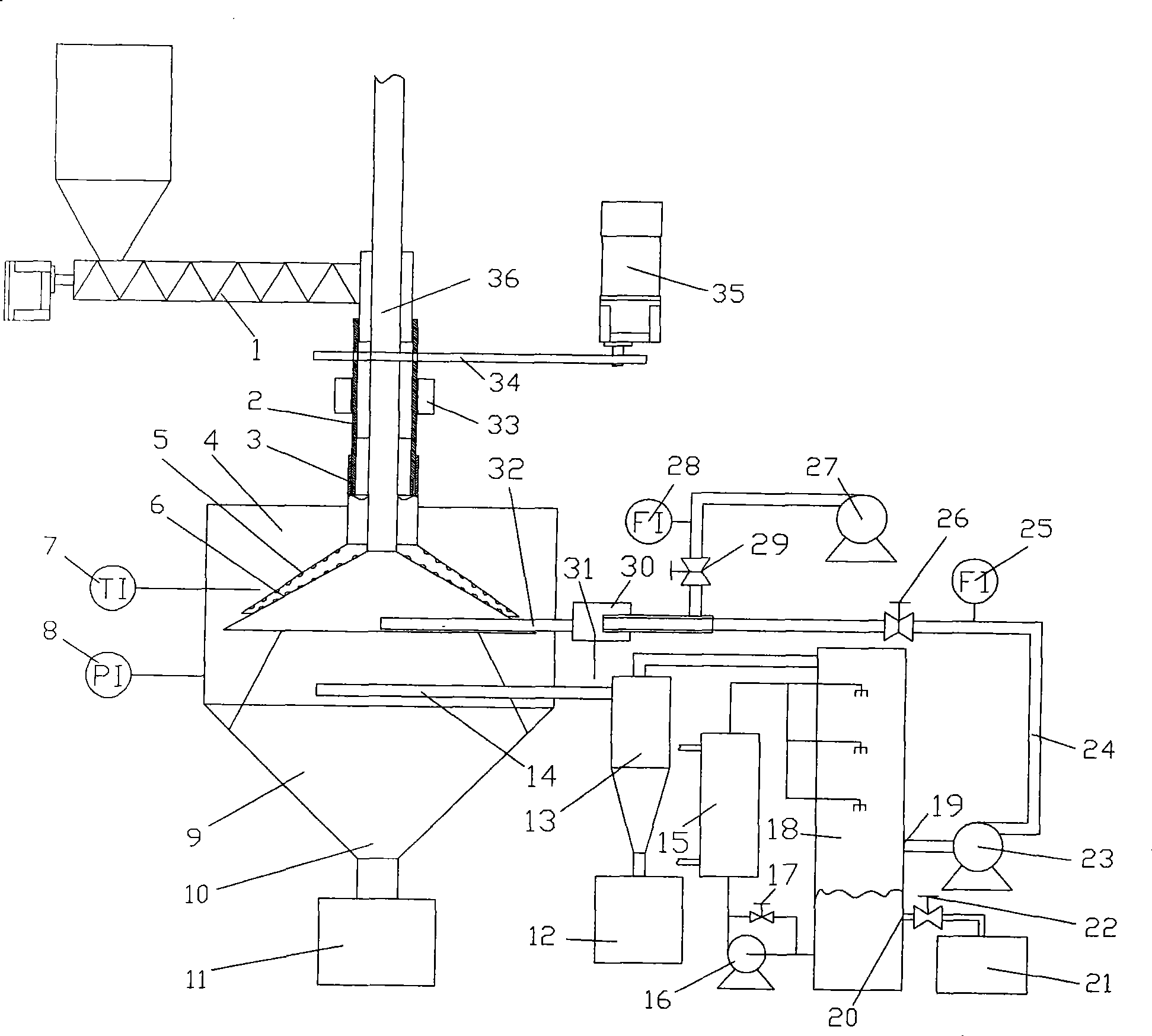

Biomass pyrolysis liquefied technique and double tower apparatus system thereof

InactiveCN1730177AImprove pyrolysis efficiencyWell mixedSolid waste disposalGas phaseProcess engineering

The invention relates to a biomass analgesic liquidation method and its twin-tower set system, the processes of which comprise the following steps: sending biomass to pyrolytic reaction tower and blending it with high-heat fluidized gas to subject biomass to pyrolytic cracking; separating thermal cracking gas with carbon residue and ash content in separator; and condensing thermal cracking gas to biological oil in condenser. In the process, heat-carrying agent is exported from pyrolytic reaction tower along with thermal cracking gas, carbon residue and so on, and carbon residue is used to preheat heat-carrying agent. The invention is special for heat-carrying agent heating tower to burn carbon residue and primary separator to separate heat-carrying agent, carbon residue and other materials. The invention can not only increase circulation rate to ensure uniform and stable temperature field in pyrolytic reaction tower, higher heating rates and shorter detention period of gas phase, but also make use of carbon residue as heat source by using existing apparatus.

Owner:CHONGQING UNIV

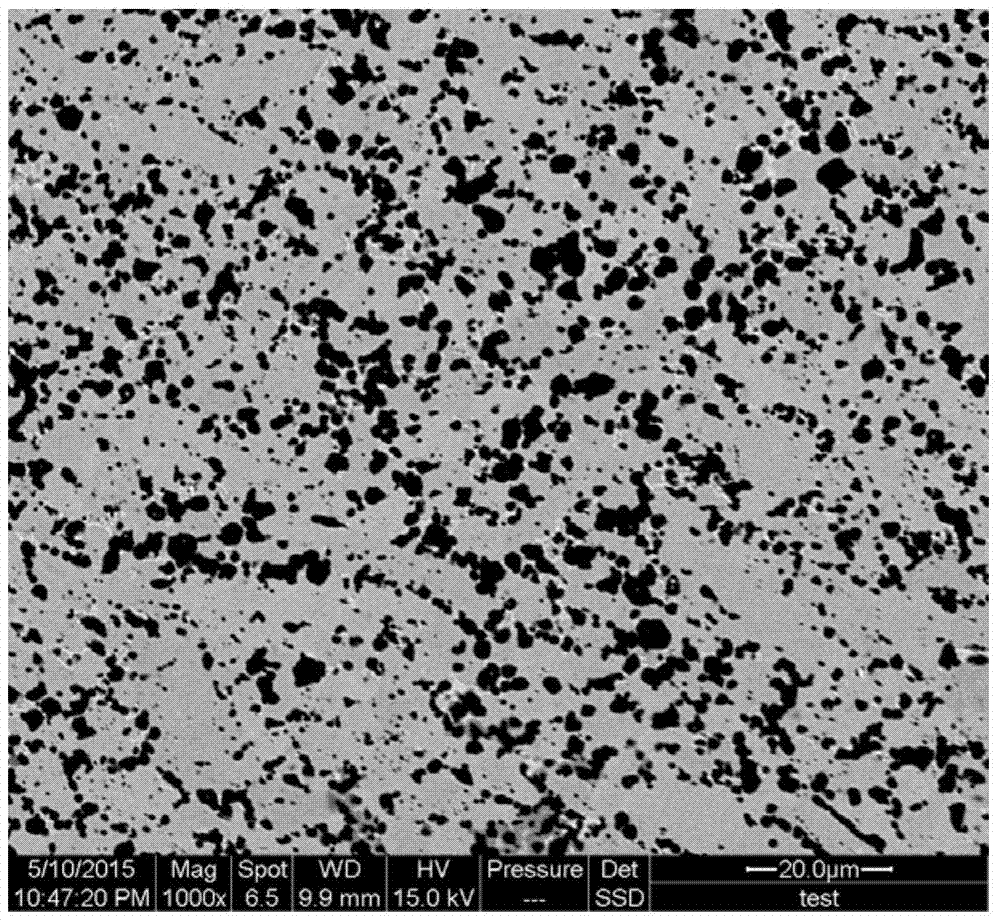

High-entropy alloy powder for 3D (three-dimensional) printing and method for preparing high-entropy alloy coating by using high-entropy alloy powder

ActiveCN104841930AImprove performanceScientifically optimize the ratioIncreasing energy efficiencySelective laser sinteringHigh entropy alloys

The invention provides high-entropy alloy powder for 3D (three-dimensional) printing and a method for preparing a high-entropy alloy coating by using the high-entropy alloy powder, and belongs to the technical field of coating preparation. By the high-entropy alloy powder, the wear resistance of the existing powder materials for 3D printing is improved. The high-entropy alloy powder is prepared by using the following ingredients in atomic percentage by weight: 16%-25% of Ni, 16%-25% of Co, 16%-25% of Cr, 16%-25% of Ti and 16%-25% of V. The preparation method comprises the following steps of (1) performing ball-mill mixing on raw materials to obtain mixed powder; (2) grinding and cleaning a matrix; and (3) placing the mixed powder in a powder feeder of 3D printing equipment and sintering the mixed powder on the surface of the matrix to form the high-entropy alloy coating by using selective laser. The NiCoCrTiV coating is prepared by selective laser sintering and has the advantages of high hardness, wear resistance, corrosion resistance and the like. The high-entropy alloy powder for 3D printing and the method for preparing the high-entropy alloy coating by using the high-entropy alloy powder can be widely used in the field of 3D printing.

Owner:HARBIN ENG UNIV

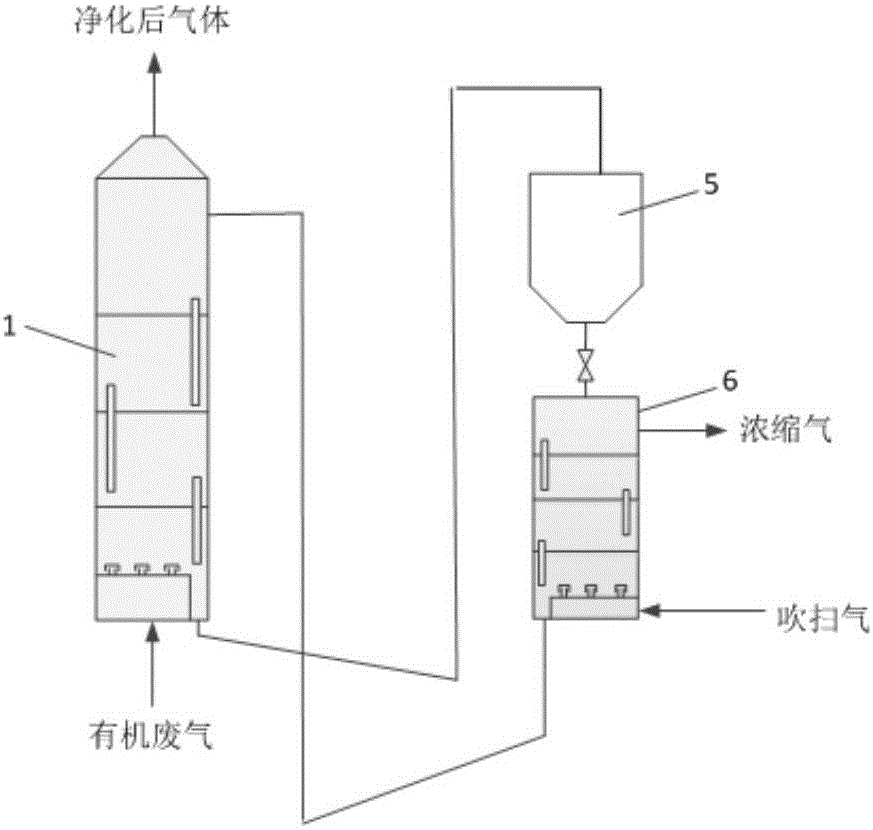

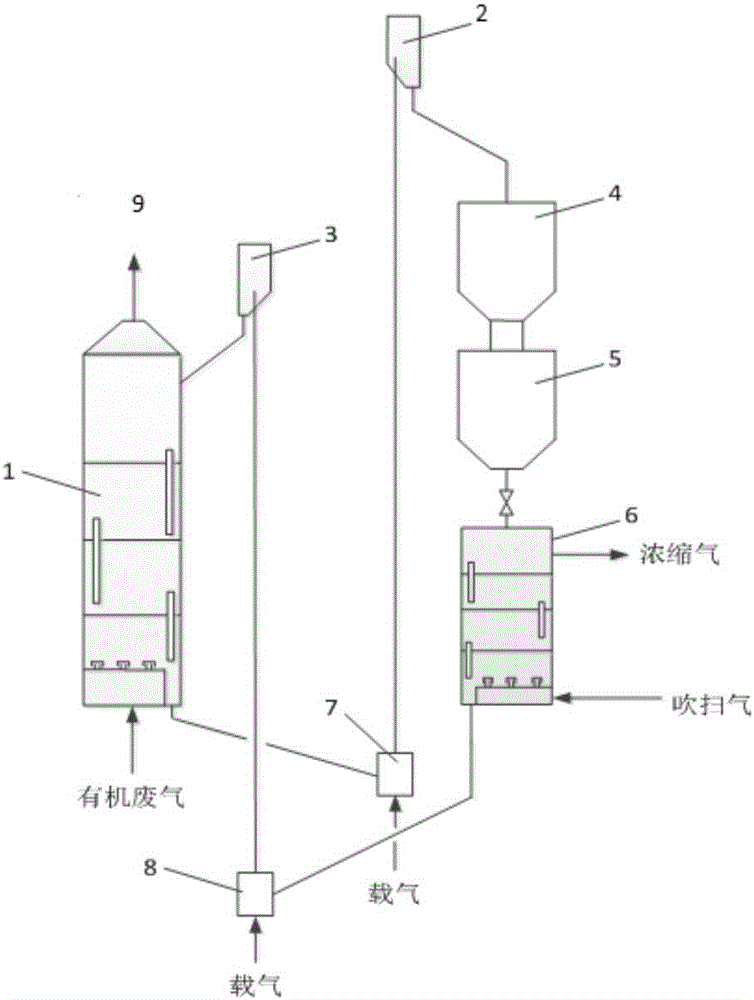

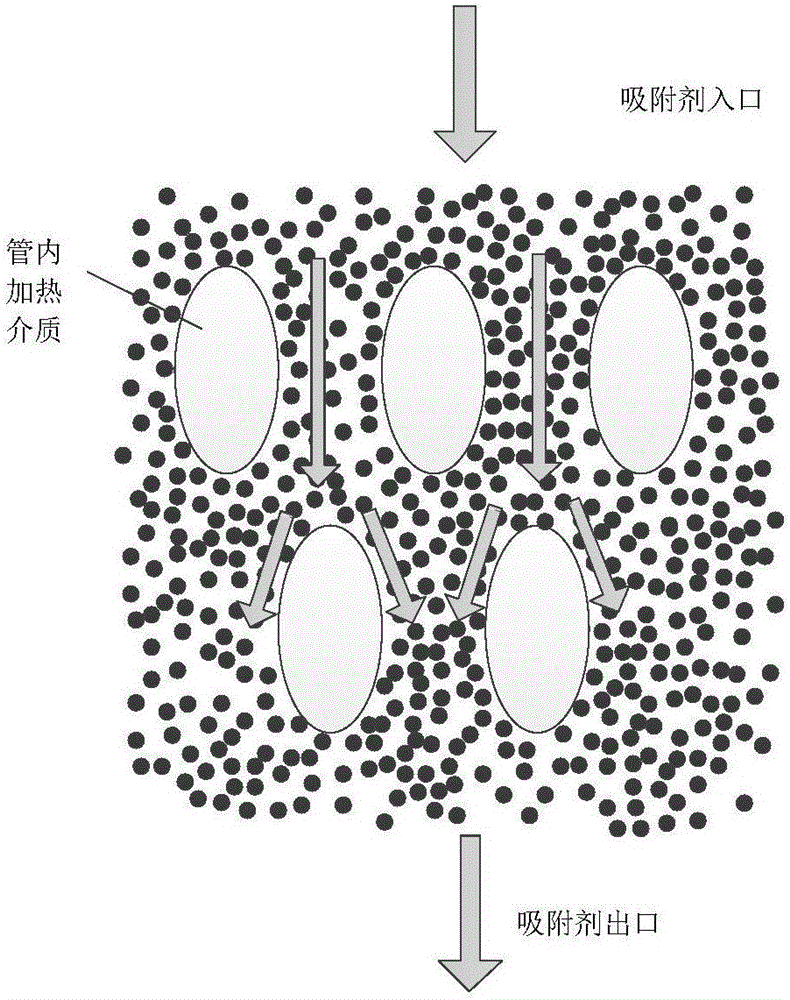

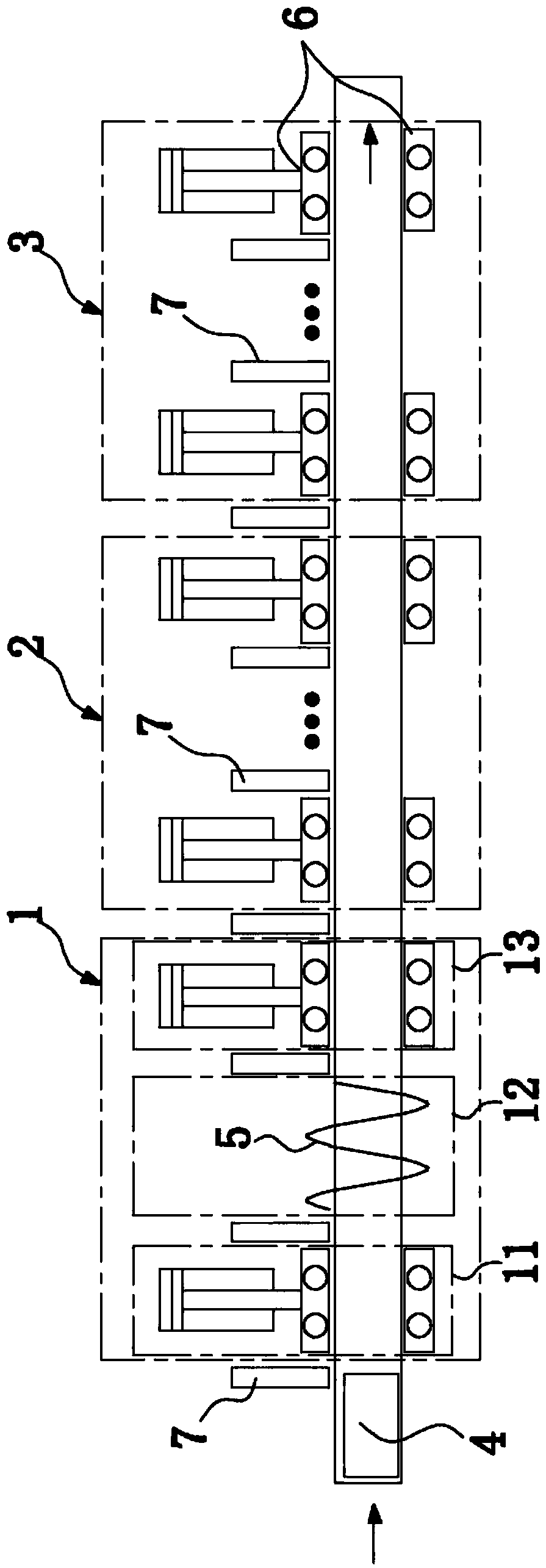

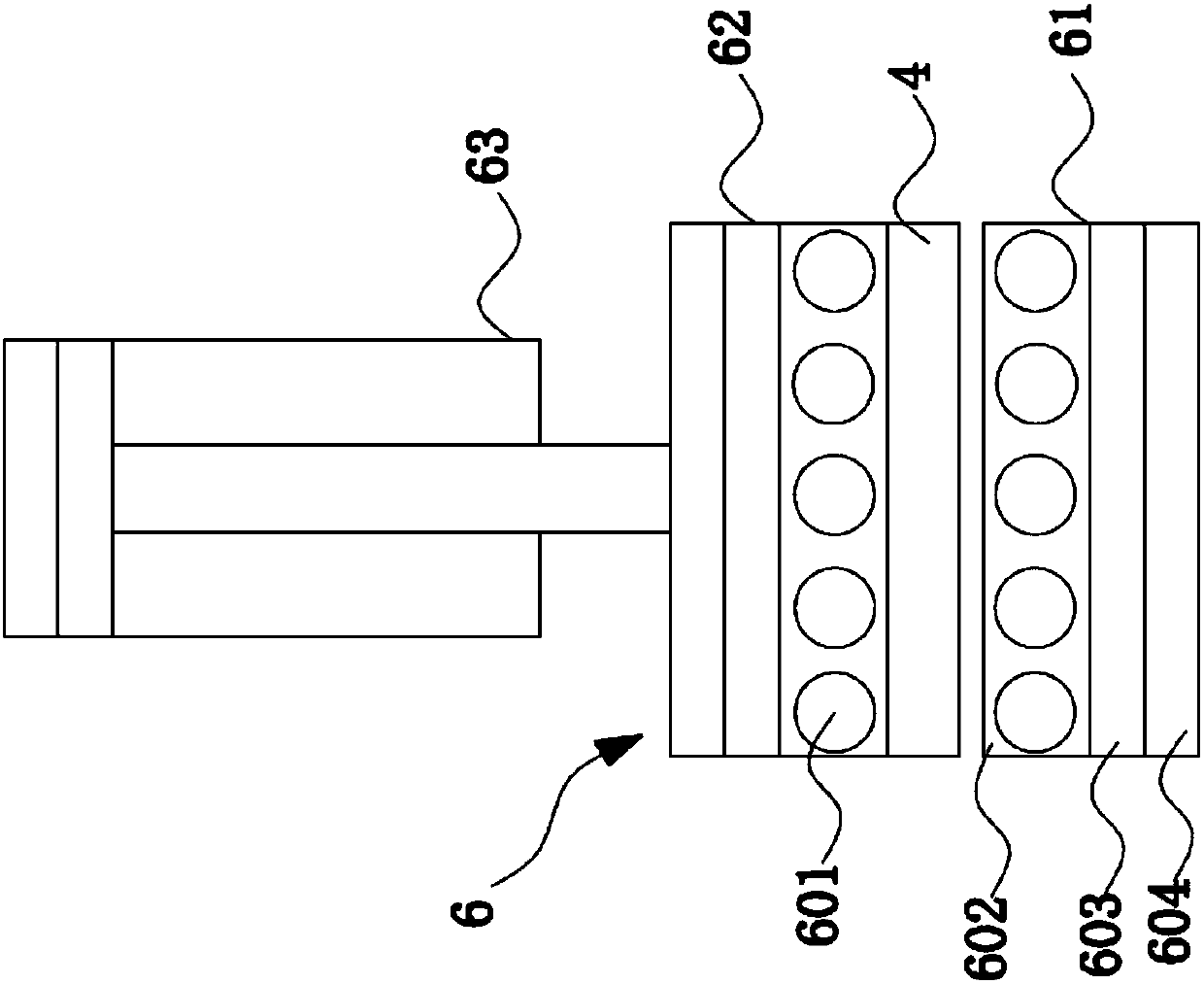

Double-fluidized bed adsorption and desorption device and method for continuous treatment of organic waste gas

InactiveCN106390681AEnhance heat and mass transferAvoid heat buildupGas treatmentDispersed particle separationHigh concentrationDesorption

The invention relates to the field of organic waste gas treatment and resource utilization and particularly relates to a double-fluidized bed adsorption and desorption device and a method for continuous treatment of organic waste gas. The device provided by the invention comprises a fluidized bed adsorption device (1), a preheater (5) and a fluidized bed desorption device (6), wherein an adsorbent outlet at the bottom of the fluidized bed adsorption device (1) is connected with a feed port of the preheater (5); a discharge port of the preheater (5) is connected with a feed port of the fluidized bed desorption device (6); and a solid outlet of the fluidized bed desorption device (6) is connected with a solid inlet of the fluidized bed adsorption device (1). In the invention, continuous treatment of high-concentration organic waste gas can be realized, heat accumulation can be prevented, and the problems such as bed fire and explosion caused by the dissipation failure of the reaction heat due to the excessively high concentration of the high-concentration organic waste gas are avoided; and moreover, the desorption effect of the adsorbent and the exit concentration of concentrated VOC gas are improved, and the catalytic combustion or solvent recycling is facilitated.

Owner:东莞市佳明环保科技有限公司 +1

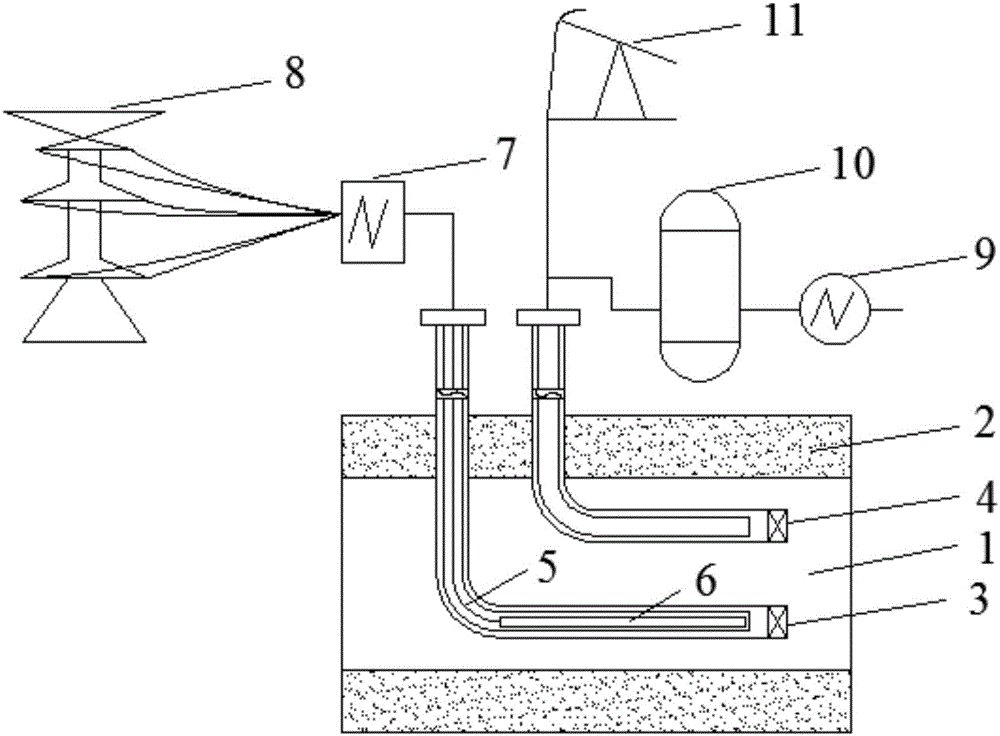

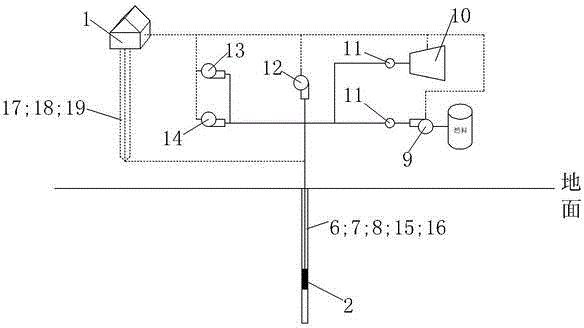

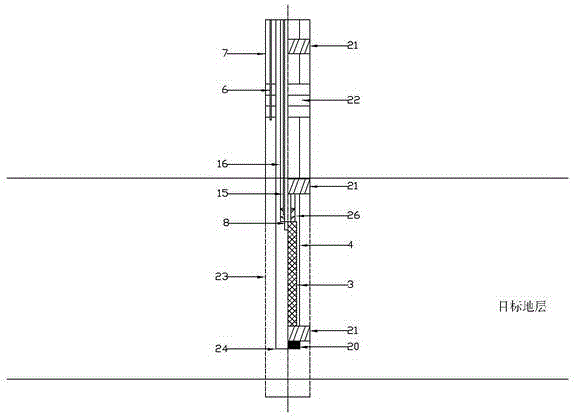

Air injection-assisted super heavy oil underground cracking improvement technology based on shaft heating modes

InactiveCN106499376AEmission reductionAchieve emissionsConstructionsFluid removalReaction rateHeater Rod

The invention provides a technology method for comprehensive oil production and in-situ improvement of super heavy oil, oil shale, kerogen and medium and low-maturity shale oil reservoirs. The technology method is characterized in that a novel shaft electric heating in-situ cracking improvement technology is adopted, and is assisted by an air injection technology; by drilling a production well group into an oil bearing reservoir or adjusting the existing well network, a heating well, an air injection well and a production well are reasonably arranged; air is injected into the reservoir, and a heating cable in a heating well shaft is connected with an electric heating bar to heat the oil bearing reservoir, so as to realize the improvement of underground cracking of crude oil. The technology method has the advantages that by combining the advantages of shaft electric heating and air injection technologies, the problems of single heat transfer type, insufficient driving energy and the like in a single shaft electric heating mode are solved; by utilizing the heat effect of crude oil and oil oxidizing reaction, the stratum temperature is increased, the cracking temperature of the crude oil is decreased, the reaction rate of in-situ cracking is accelerated, the recovery efficient of the crude oil is improved, and the consumption of water resources and carbon emission are decreased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

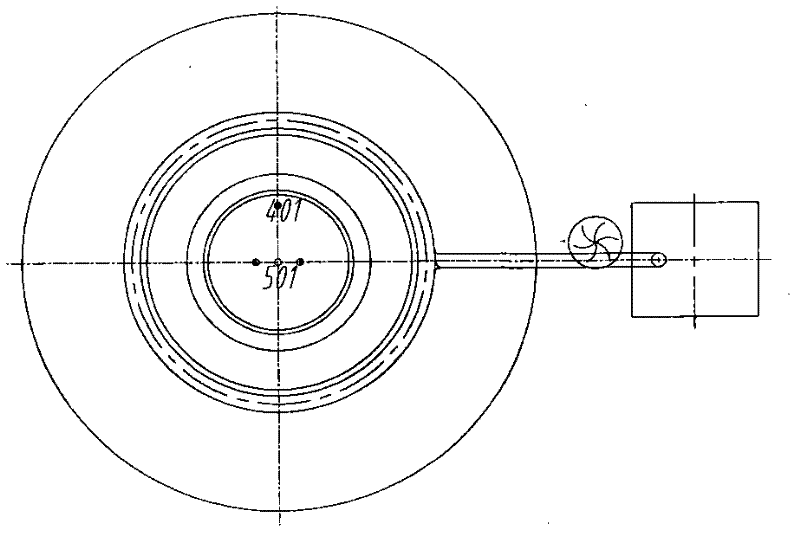

Internal combustion type heating rotating cone type biomass pyrolysis liquefaction device

ActiveCN101445737ARealize inverse motionImprove heat transfer effectBiofuelsSpecial form destructive distillationFlue gasFuel tank

The invention relates to an internal combustion type heating rotating cone type biomass pyrolysis liquefaction device. The device is characterized in that two concentric cones are arranged in a reactor, the outer cone is a rotating cone, and the inner cone is a fixed cone; a charging barrel is sectionally arranged into an upper section charging barrel and a lower section charging barrel, the upper part of the rotating cone is connected with the lower section charging barrel, and the upper section charging barrel is communicated with a spiral feeding mechanism; the upper part of the fixed cone is communicated with a flue gas pipeline; the end surface at the bottom part of the fixed cone is closed, and the lower part of the fixed cone is tangentially connected with a burning pipeline; a porous filter tube is arranged in the reactor, a reactor is led out form the other end of the porous filter tube, and the reactor is communicated with a cyclone dust collector positioned outside the reactor, the output end of the bottom part of the cyclone dust collector is connected with a carbon collecting box, and a gas outlet opening at the top part is connected with a condenser through a pyrolysis gas pipeline; an oil outlet opening on the condenser is communicated with an oil collecting tank, the air outlet opening of the condenser is accessed into a pyrolysis gas burner through a pyrolysis gas return pipeline. The invention realizes biomass self-heating type pyrolysis liquefaction, effectively improves the utilization ratio of the pyrolysis byproduct and reduces the total cost for biomass liquefaction.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

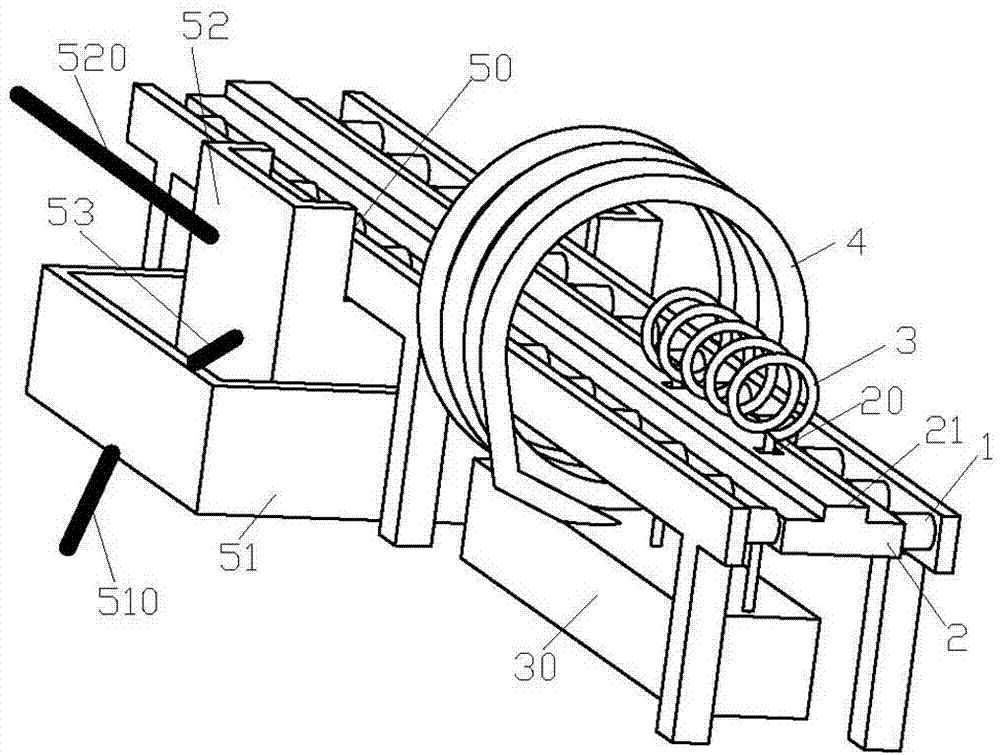

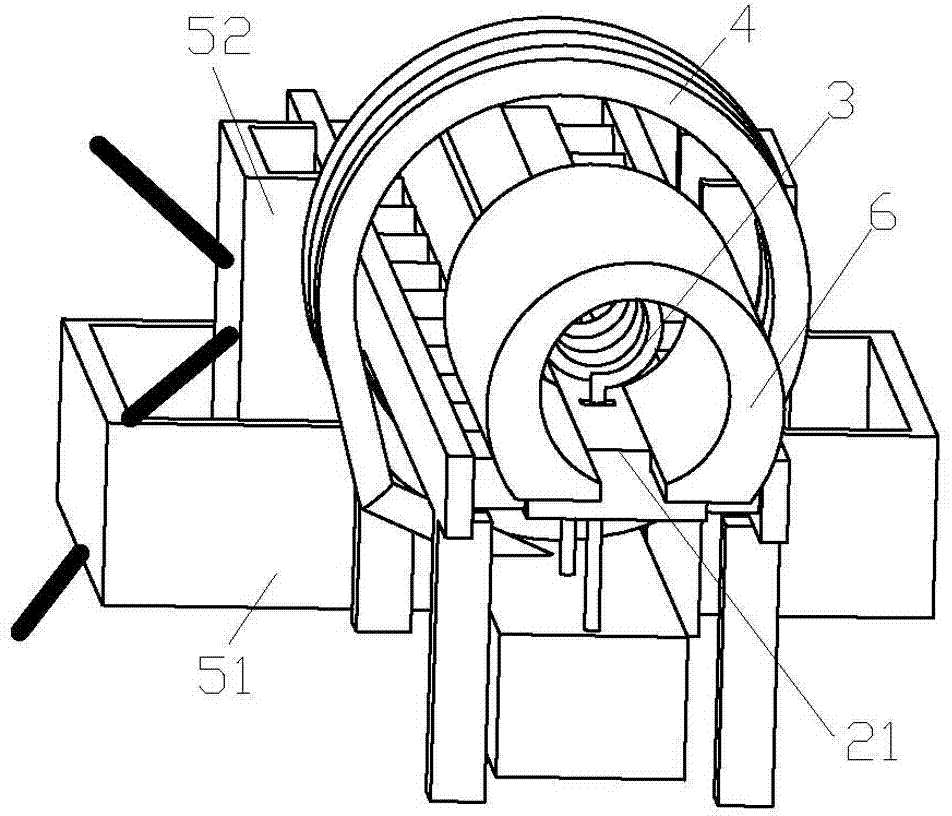

Heat treatment device for semi-closed tubular aluminum profiles

InactiveCN103882352AImprove physical performanceImprove stabilityFurnace typesHeat treatment furnacesMaterials scienceHeat treating

The invention relates to the technical field of aluminum profile production and particularly relates to a heat treatment device for semi-closed tubular aluminum profiles. The heat treatment device comprises an aluminum profile conveying track, wherein a locating track is fixed at a position, which is parallel to a conveying direction and is close to the middle of the aluminum profile conveying track, of the aluminum profile conveying track, and an internal aluminum profile heating device, an external aluminum profile heating device and a cooling device are arranged at one side of the conveying direction of the aluminum profile conveying track. According to the heat treatment device, various physical properties and internal structural stability of the aluminum profiles can be effectively improved.

Owner:HUZHOU JULI ALUMINUM

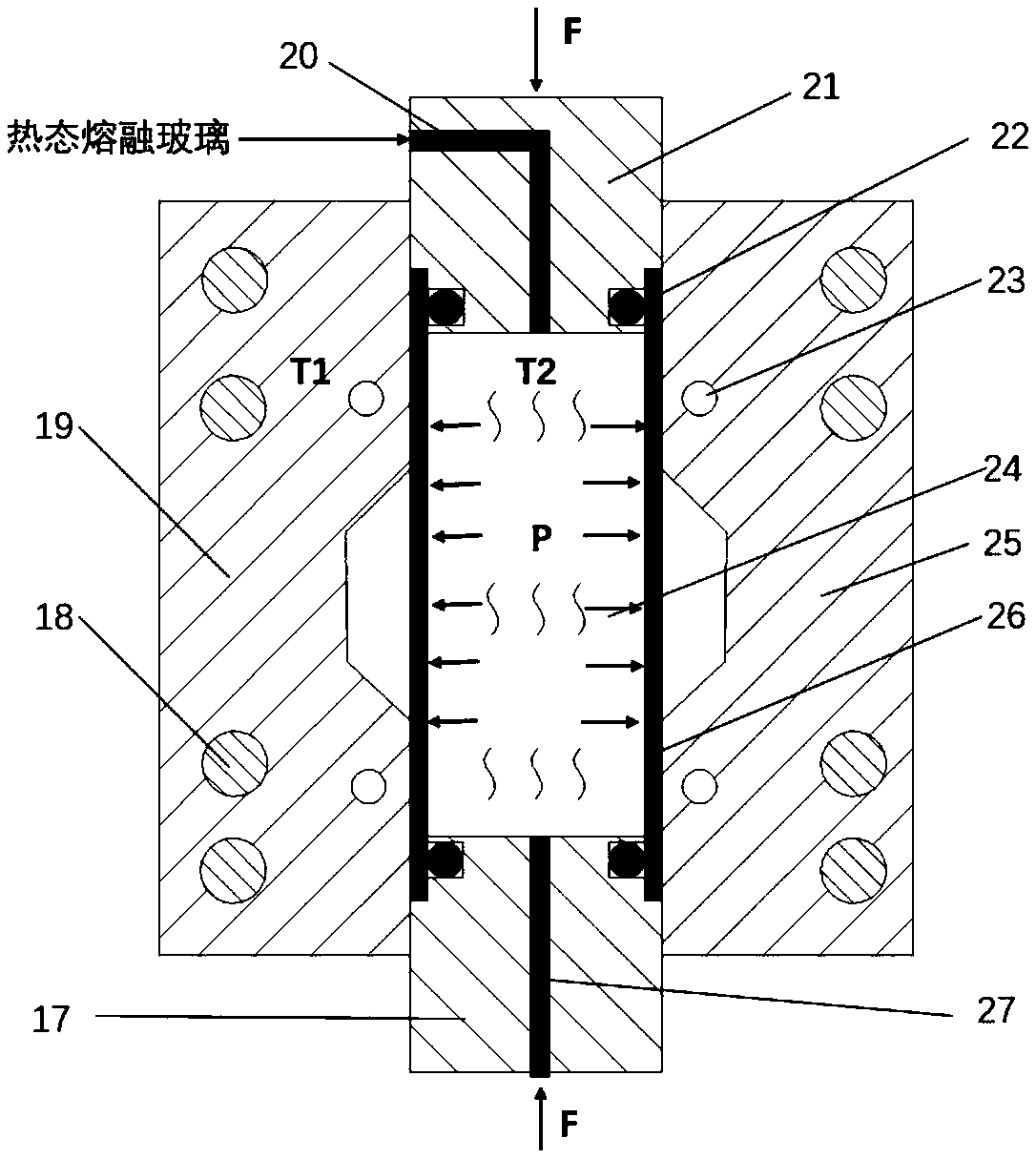

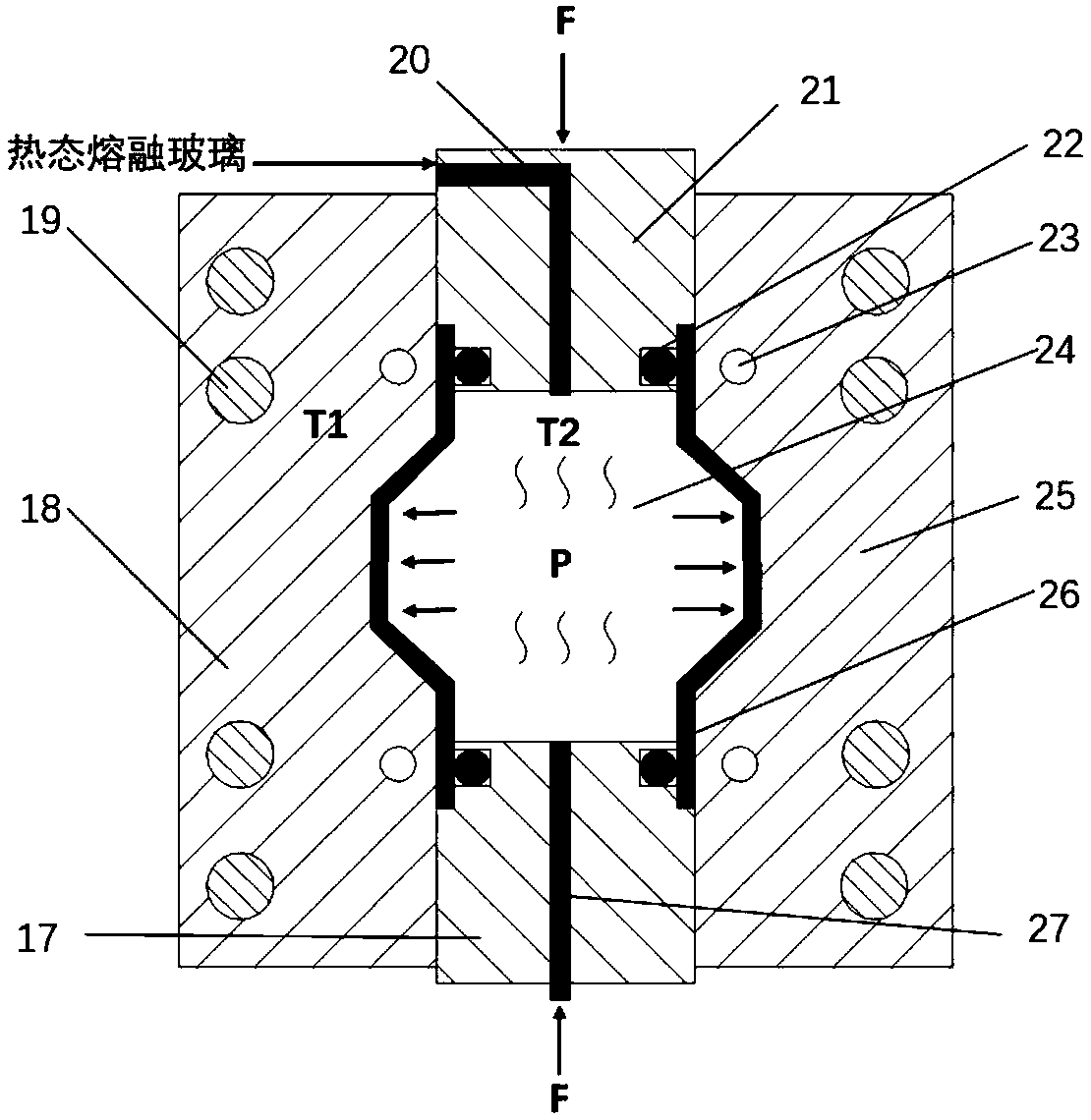

Pipe hot medium internal pressure forming method based on molten glass

ActiveCN108856441AMeet the forming temperature process requirementsReduce compressionInternal pressureHeat conducting

The invention discloses a pipe hot medium internal pressure forming method based on molten glass, and relates to a metal pipe forming method. The problems that according to existing hot medium internal high pressure forming methods, the heating speed is low, heat conducting coefficients are low, sealing is difficult, and forming pressure only can reach about 0-50MPa are solved. The method comprises the steps that 1, a pipe internal high pressure forming temperature interval is determined according to the pipe variety; 2, according to the pipe internal high pressure forming temperature, glass materials are selected; 3, a pipe to be formed is preheated; 4, a pipe blank is vertically placed into a forming die, and die closing and sealing are carried out; 5, the glass materials are heated to obtain molten glass; 6, the glass media are injected into the sealed pipe blank; 7, the pipe blank is heated to internal high pressure forming temperature under high-temperature filling; and 8, material supplementing is carried out; and 9, pressure maintaining is carried out, the molten glass flows out through an overflow valve, die opening is carried out, and the formed deformed-section pipe partis obtained. The pipe hot medium internal pressure forming method is used in the field of internal high pressure forming.

Owner:HARBIN INST OF TECH

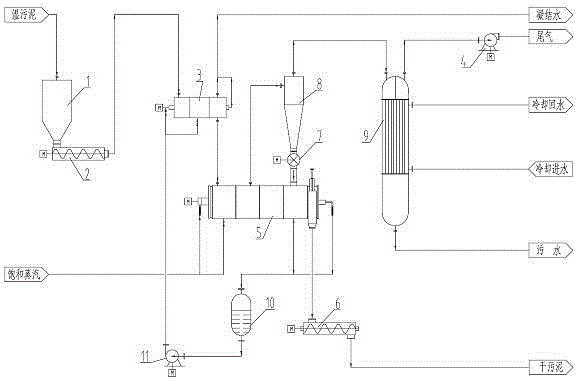

Steam condensate preheating and steam drying two-stage energy-saving sludge drying method

InactiveCN104671633AHigh steam heat utilization rateHigh heat usageSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesHigh humiditySludge

The invention relates to a steam condensate preheating and steam drying two-stage energy-saving sludge drying method. The method comprises the following steps: (1) driving wet sludge into a sludge preheater to be indirectly contacted with steam condensate obtained by steam drying to form preheated wet sludge and condensation water respectively, (2) continuously and uniformly adding the preheated wet sludge into a drier, allowing saturated steam or superheated steam to enter the drier at the same time to form dry sludge, high-temperature condensate and smelly high-humidity tail gas, (3) allowing the high-temperature condensate to enter a condensate tank, and enter the sludge preheater through a condensate pump to preheat the wet sludge, (4) after dedusting the smelly high-humidity tail gas with a duster, obtaining sludge powder and high-humidity tail gas respectively, allowing the sludge powder to return to the drier through a rotary discharger, and (5) allowing the high-humidity tail gas to enter a condenser for cooling and condensation, and obtaining cooling return water, sewage and tail gas respectively after heat exchange. The method can effectively improve steam heat utilization efficiency.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

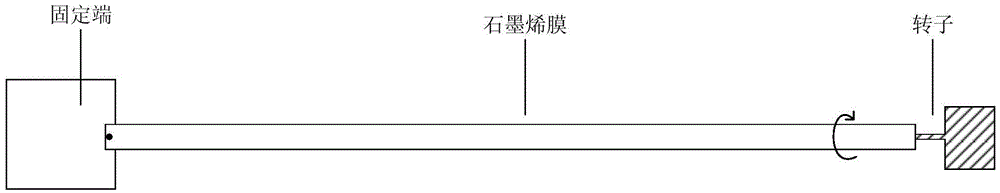

Super-stretchable graphene electro-thermal film and preparation method thereof

ActiveCN105657877ARaw materials are widely availableLow costFibre chemical featuresHeating element materialsFiberTemperature response

The invention discloses a super-stretchable graphene electro-thermal film and a preparation method thereof. The electro-thermal film is formed through knitting graphene fibers with a spiral structure; the fibers not only have ultrahigh elongation at break, and can realize rapid response on a high temperature of 30-420 DEG C under safety voltage of 0.5-5V. The preparation method is simple and specifically comprises the following steps: after chemically reducing graphene oxide, carrying out heat treatment in a high-temperature furnace at 500-3000 DEG C to obtain a graphene film; after uniformly winding, obtaining graphene fibers; and knitting the graphene fibers to obtain the graphene electro-thermal film. The graphene electro-thermal film has ultrahigh heating speed and cooling speed, and ultrahigh temperature response; the working voltage is relatively low so that the graphene electro-thermal film can be used for human bodies and is used as human body heating cloth; and the graphene electro-thermal film has a stretchable property so that the graphene electro-thermal film can be adaptive to the movement of the human bodies, such as muscle stretching, in a utilization process, and furthermore, the graphene electro-thermal film can be widely applied as an intelligent electro-thermal material.

Owner:杭州德烯科技集团有限公司

Downhole oil shale stratum combusting and heating system

The invention discloses a downhole oil shale stratum combusting and heating system which can realize a heating range of 50-800 DEG C. The downhole oil shale stratum combusting and heating system comprises a ground monitoring and control system, a downhole combusting and tail gas countercurrent flow heat exchanging system, an external flow injection pipe and an external sleeve. When the downhole oil shale stratum combusting and heating system operates, fuel combusts in a sealed combustion cavity through a burner sleeve and does not directly contact with downhole external stratum environments. The downhole oil shale stratum combusting and heating system has the advantages that the system can be used as a heating body to directly heat downhole stratums and can also heats external fluid media under a well and then perform permeation heat and mass transmission on the stratums, and stratum hot gas exploitation, overheat steam exploitation and near / super critical fluid exploitation can be achieved. In addition, the downhole oil shale stratum combusting and heating system is applicable to in-situ conversion and exploitation of organic matters in oil shale reservoirs.

Owner:JILIN UNIV

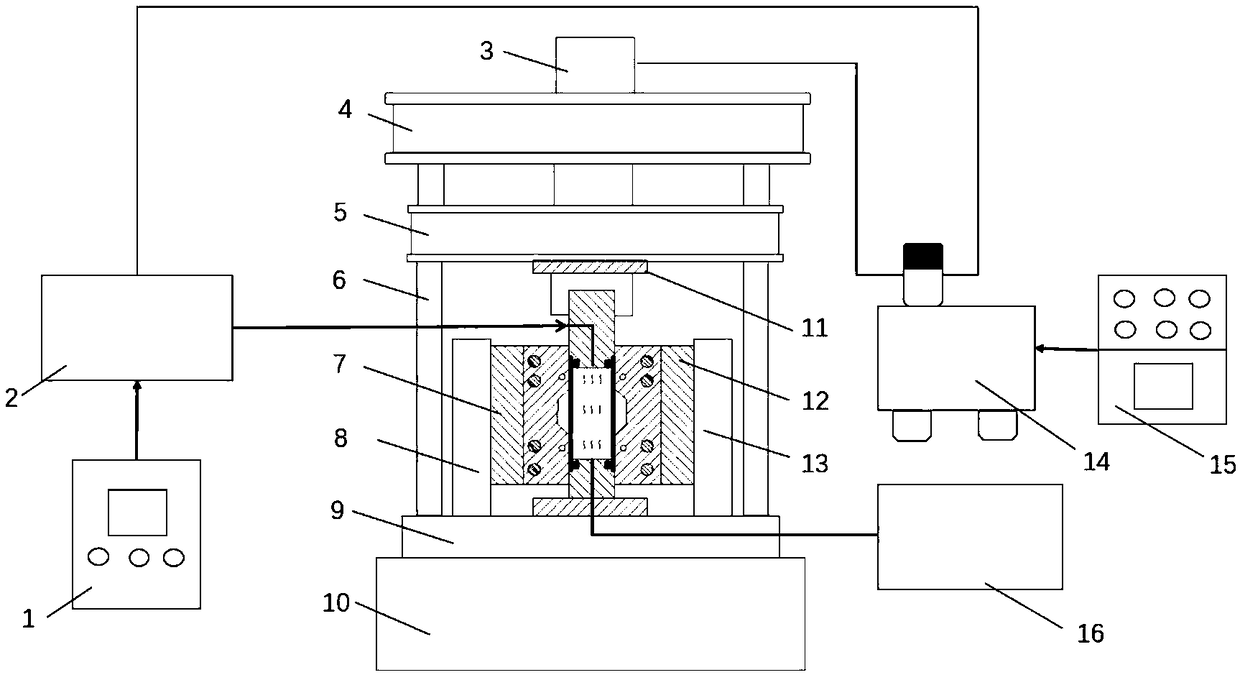

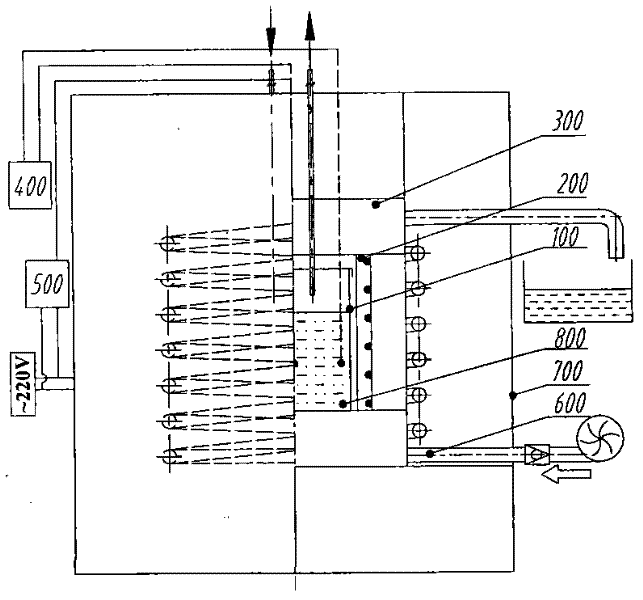

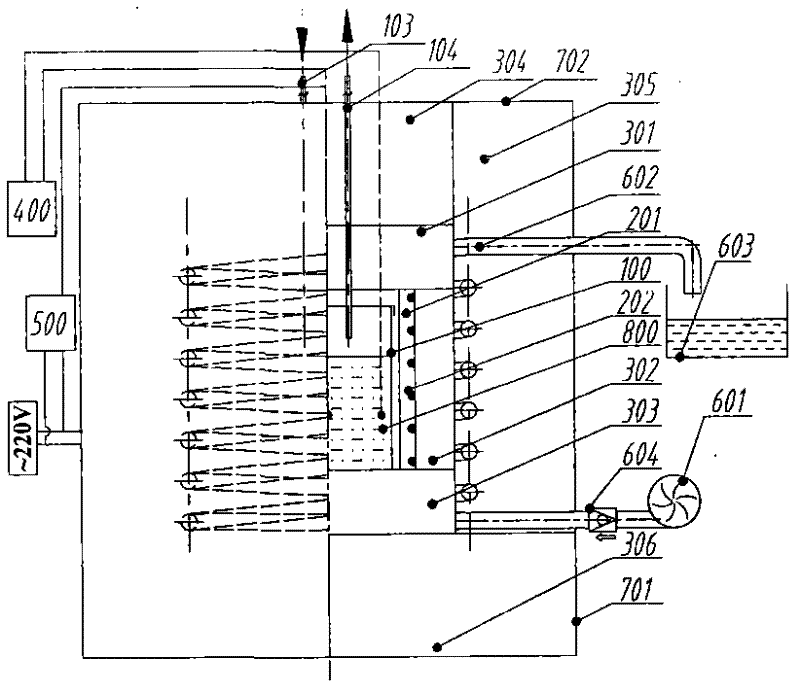

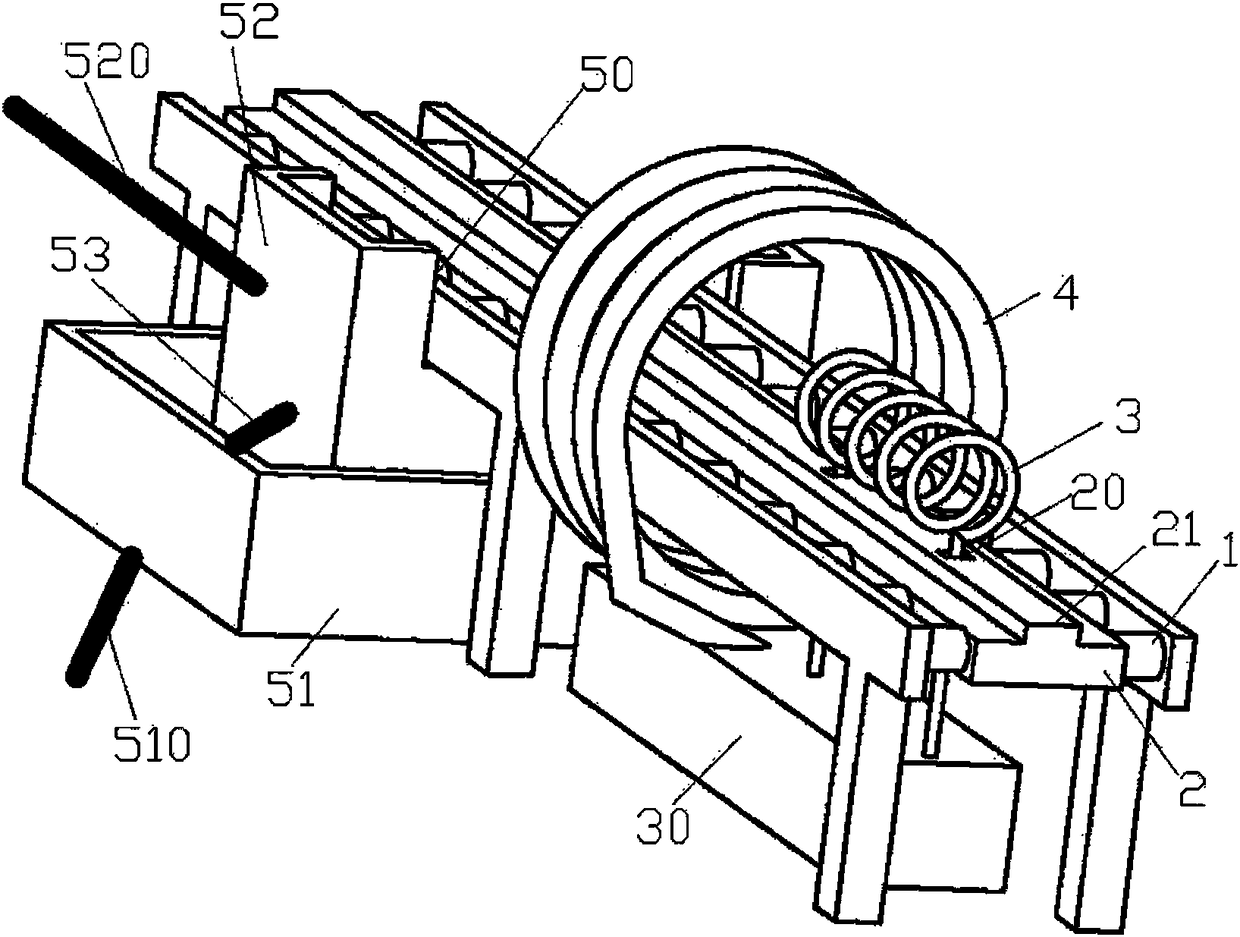

Automatic control device of material cold and hot circulation performance and operating method thereof

InactiveCN102495095AReduce labor intensityRealize the goal of intelligent controlInvestigating phase/state changeAutomatic controlThermal insulation

The invention discloses an automatic control device of material cold and hot circulation performance. The device includes a sample chamber in a resistance wire heating cylindrical heating cavity, wherein a spiral cooling water pipe is wound outside the heating cavity; the whole heating cavity is arranged in a thermal insulation device; a high-low limit PID intelligent temperature controller and a relay module control the heating temperature and the on / off of a cooling system; a thermocouple and a data acquisition instrument are adopted to measure temperature and record data; and the device comprises simple structure, efficient experiment and can reduces the labour intensity of experimenter.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

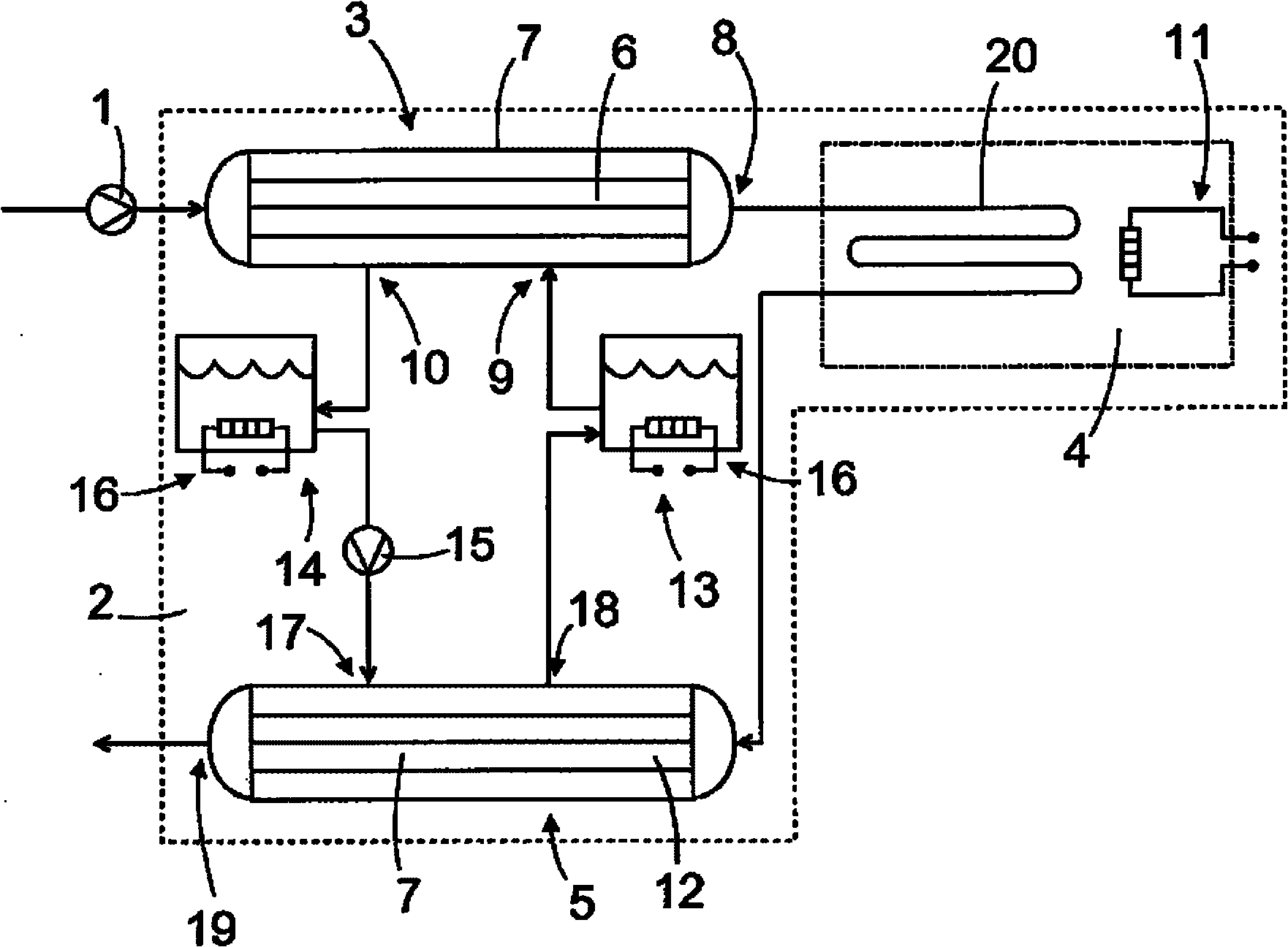

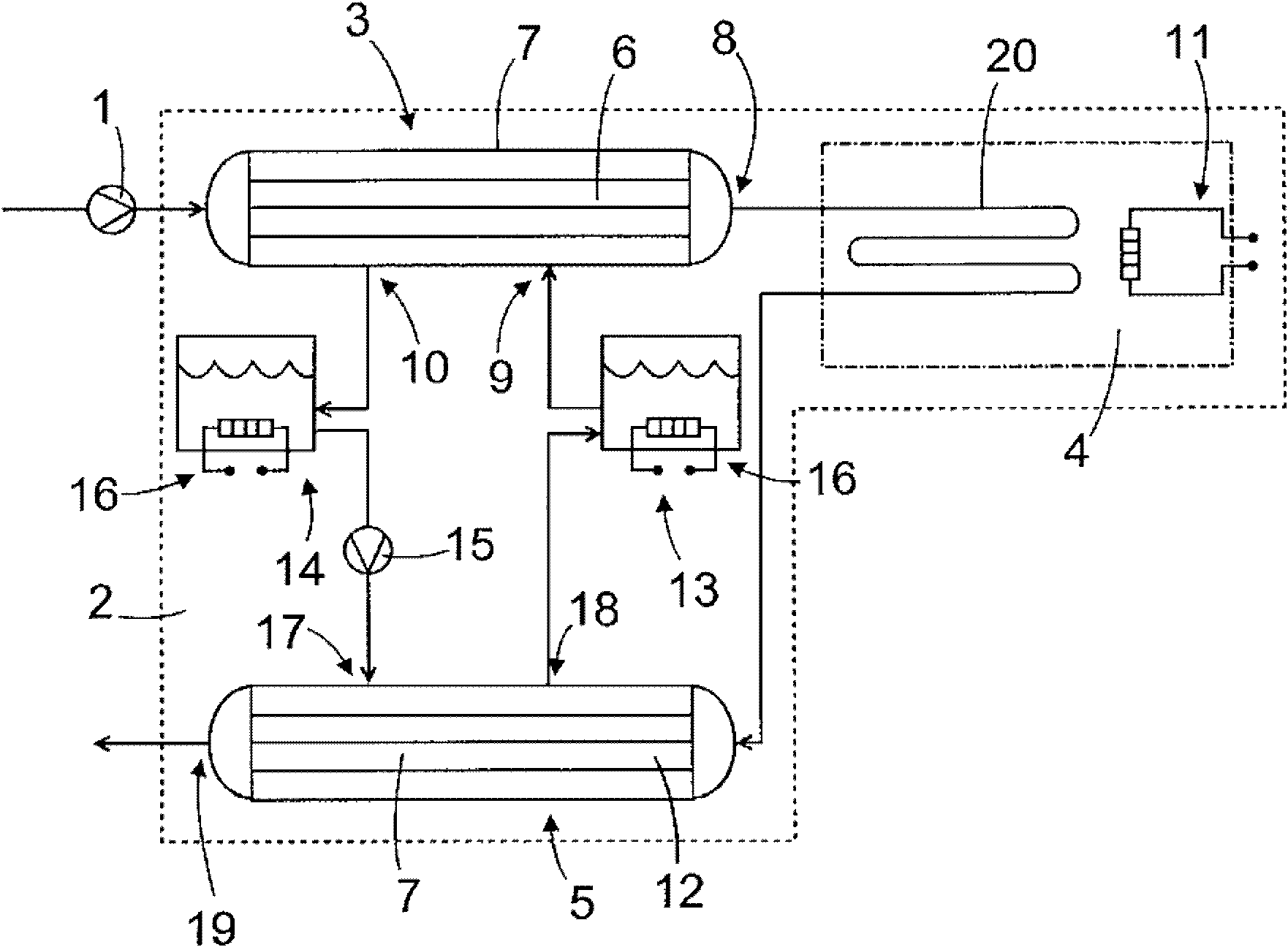

Methods, systems and applications for heat exchange

InactiveCN102264873AImprove heat exchange performanceAvoid accumulationPulp liquor regenerationHeat storage plantsThermal energyMolten salt

Disclosed are a method, a system and use for heat exchange in super-critical or near-critical water gasification process of biomass. The method comprises the steps of: heating a biomass in a first heat exchanger (6) by thermal energy of a heat transfer medium, reacting the biomass in said super-critical or near-critical water gasification process and producing reaction products, cooling the reaction products of the biomass in a second heat exchanger (12) by absorbing the thermal energy of the reaction products to said heat transfer medium, and circulating said heat transfer medium between the first heat exchanger (6) and the second heat exchanger (12), wherein molten salt is used as the heat transfer medium.

Owner:UPM-KYMMENE OYJ

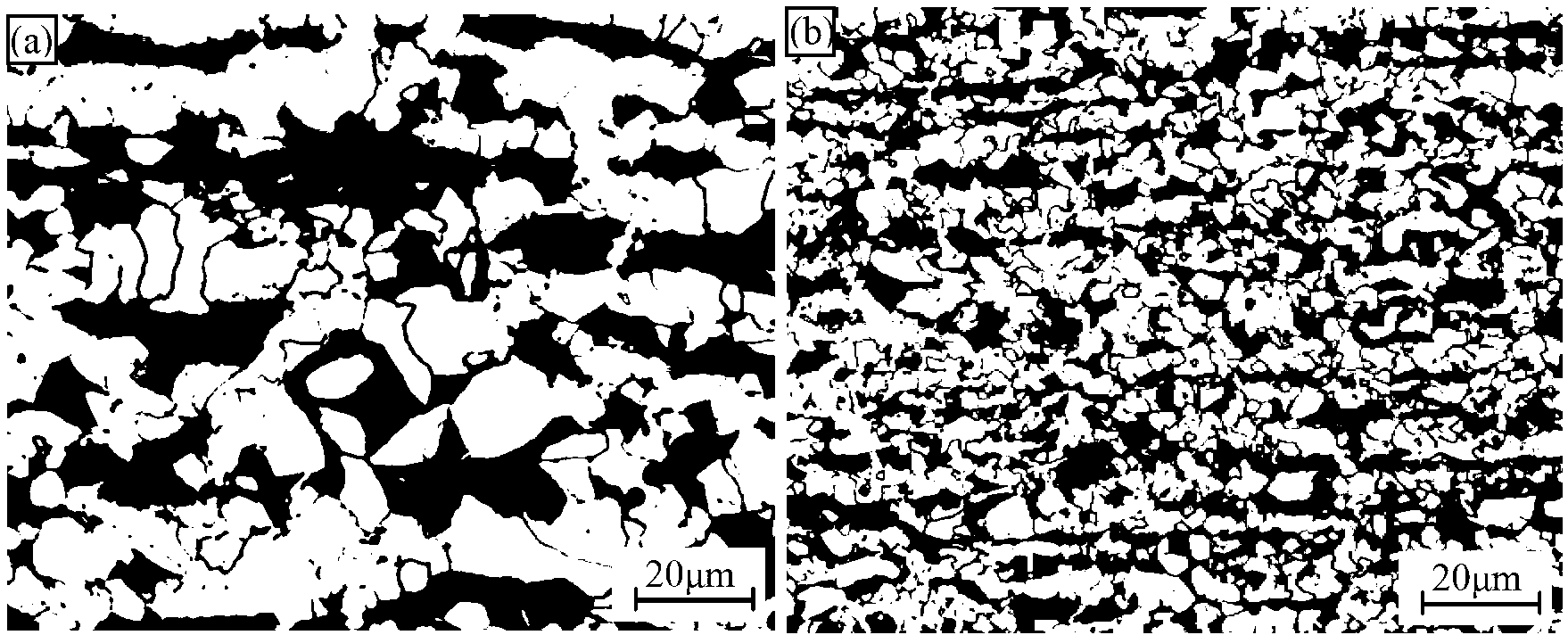

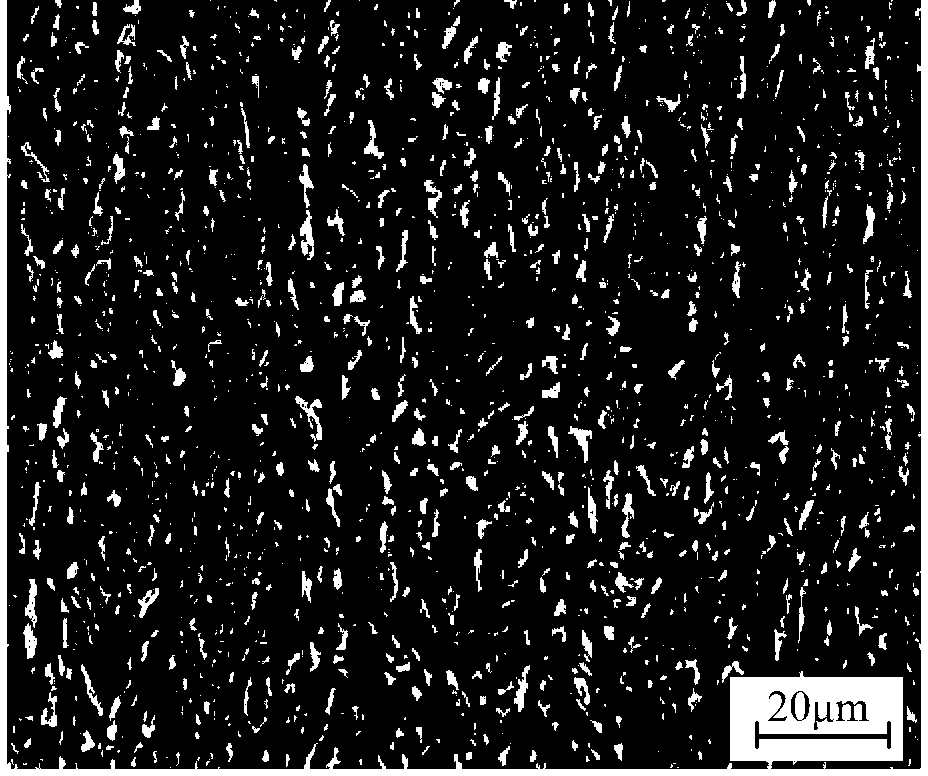

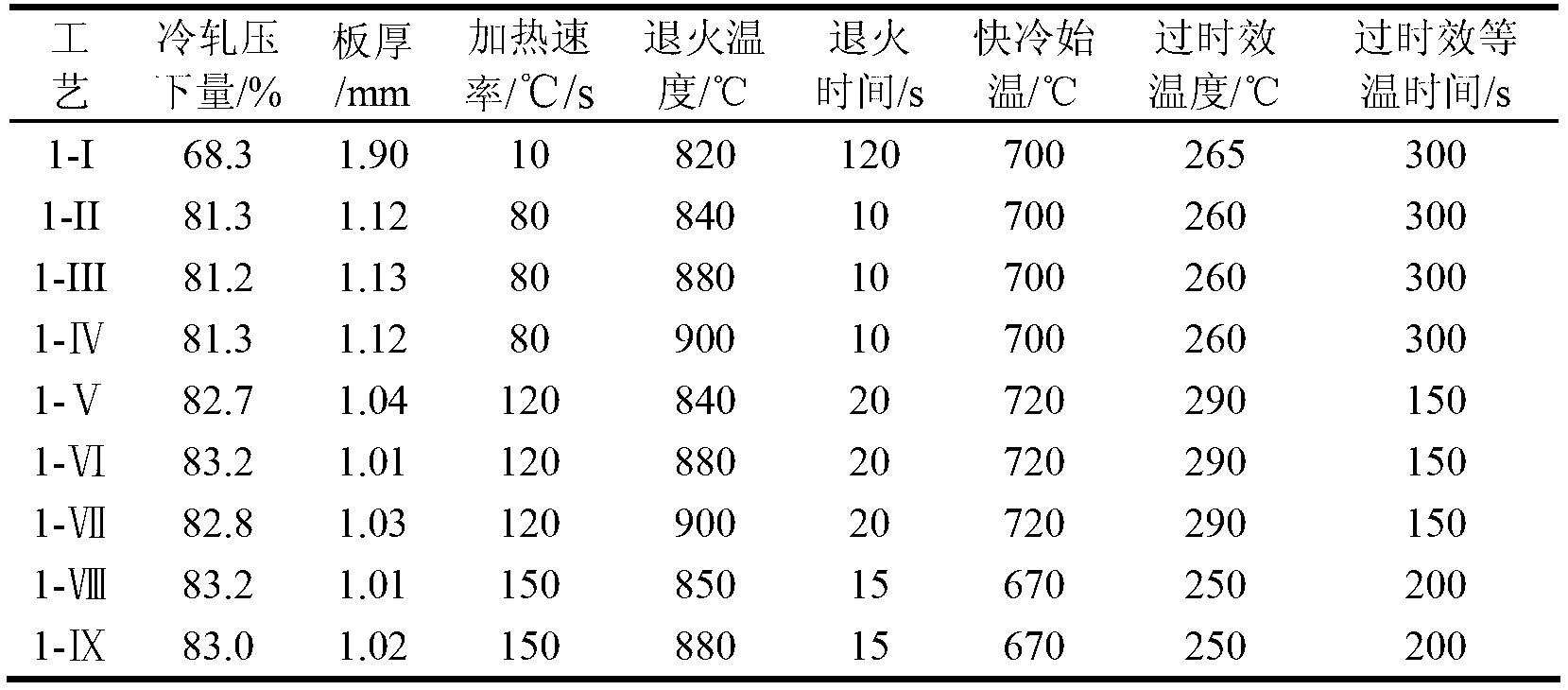

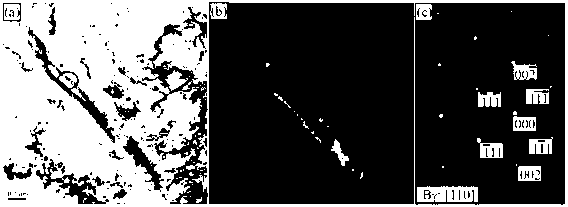

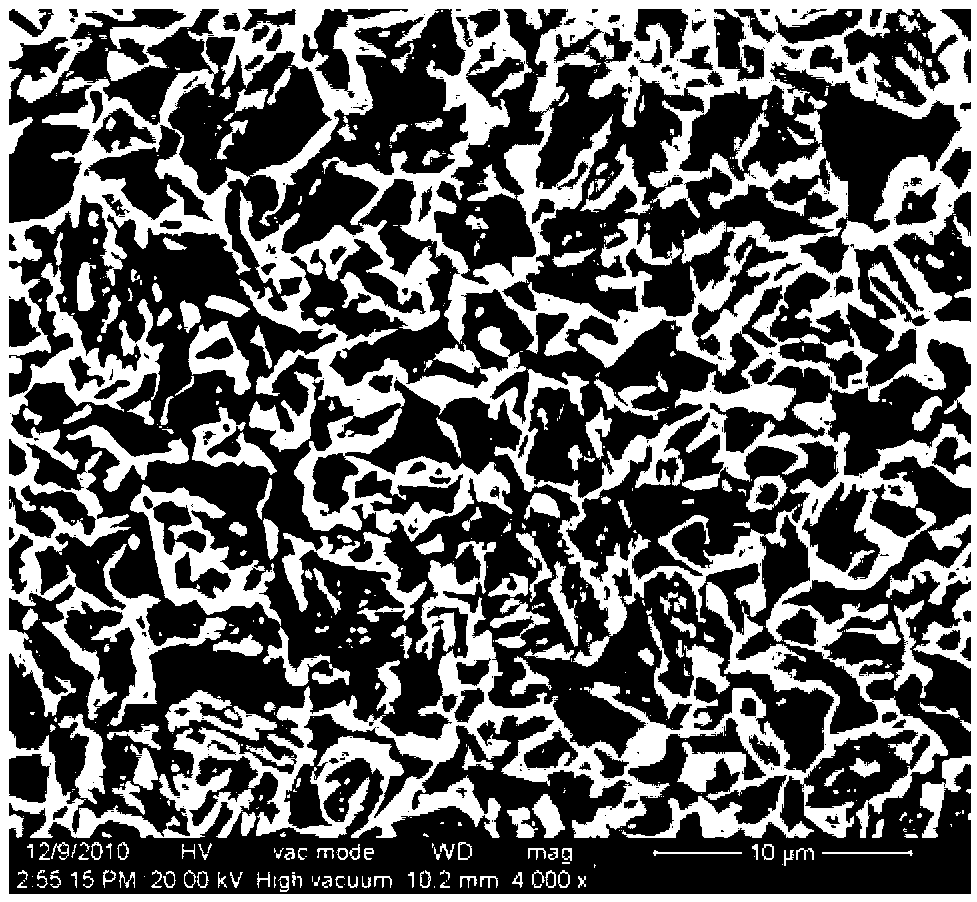

Method for improving mechanical property of low-carbon silicomanganese series cold rolling dual-phase steel

The invention belongs to the technical field of roll steel and relates to a method for improving the mechanical property of low-carbon silicomanganese series cold rolling dual-phase steel. The method comprises the following steps of: smelting and forging the low-carbon silicomanganese series cold rolling dual-phase steel to manufacture a plate blank, heating to 1100-1250 DEG C, carrying out heat preservation, carrying out rough rolling and finish rolling at 820-1100 DEG C, wherein the hot rolling and finish rolling temperature is (Ar3+30) DEG C-(Ar3+100) DEG C, then carrying out laminar cooling to (Ar3-50) DEG C-(Ar3-100) DEG C at cooling rate of 20 DEG C, and carrying out air cooling to room temperature; pickling, heating to (Ac3-50 DEG C)-(Ac3+100 DEG C) after cold rolling by adopting higher than or equal to 80% of rolling reduction, carrying out annealing treatment for 10-20s, carrying out slow cooling to 600-720 DEG C at rate of 5-8 DEG C / s, cooling to 250-300 DEG C at rate of higher than or equal to 30 DEG C / s for isothermal treatment, and carrying out air cooling and water-cooling or naturally cooling to room temperature. A cold rolling dual-phase steel plate with excellent mechanical property can be obtained by adopting the preparation method; the strength, the total percentage elongation after fracture and the work-hardening index of the cold rolling dual-phase steel plate are improved; and the strength of the cold rolling dual-phase steel plate is obviously improved.

Owner:LAIWU IRON & STEEL GRP

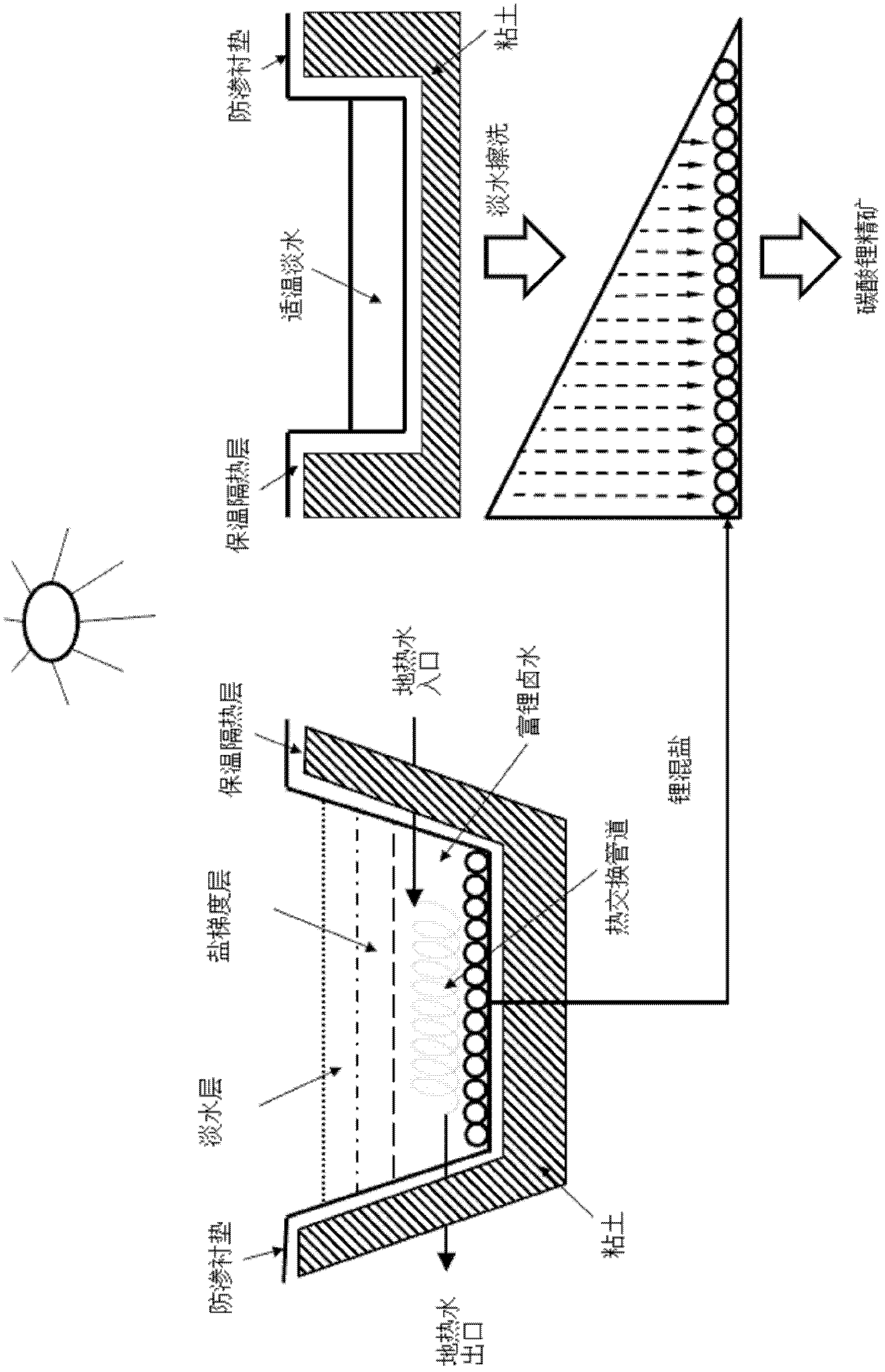

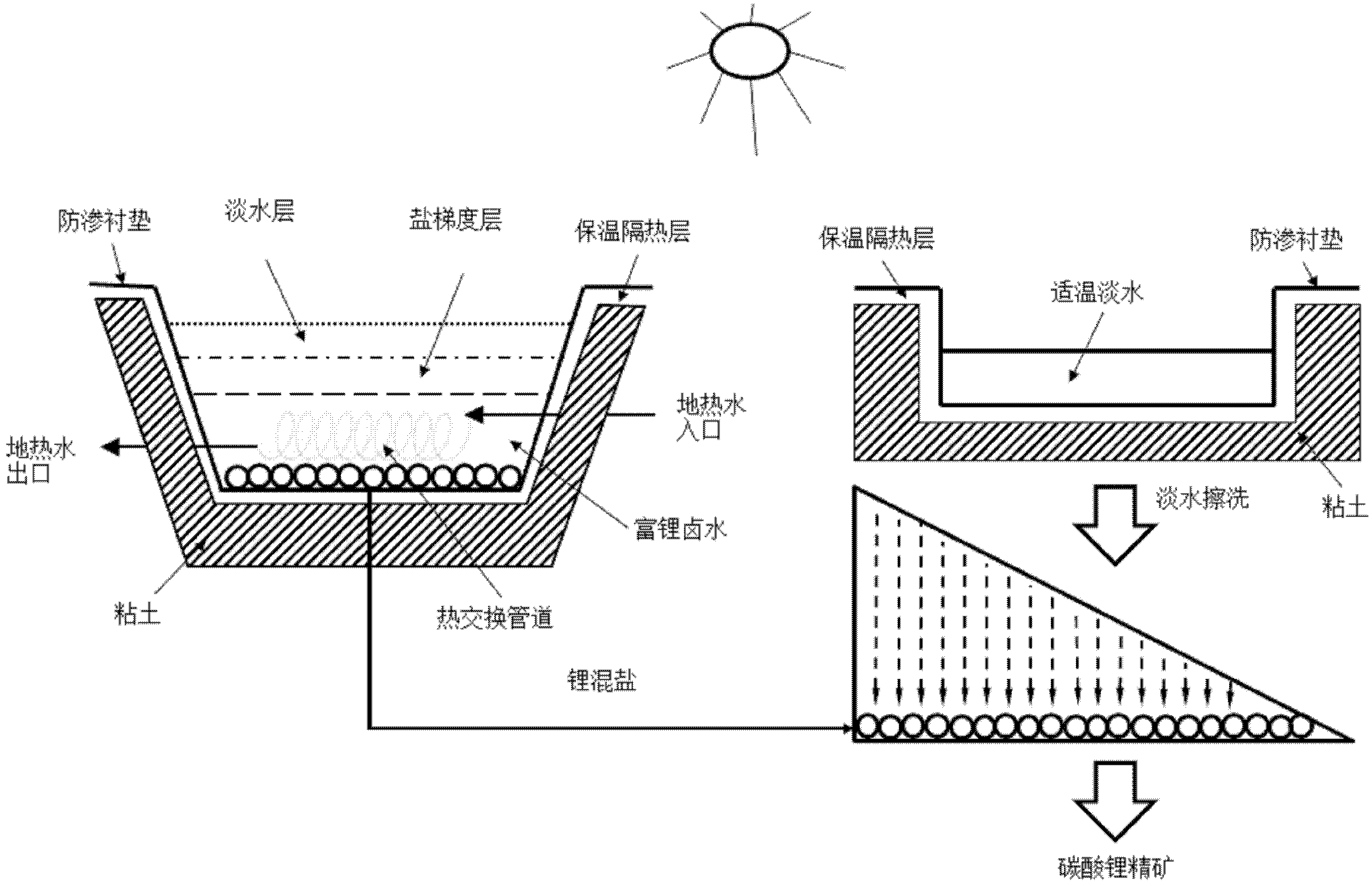

Method for extracting lithium carbonate from carbonate brine

InactiveCN102583454AImprove production efficiency and product yieldShorten the production cycleSolar heating energySolar heat collectors with working fluidsChemistryDual function

The invention discloses a method for extracting lithium carbonate from carbonate brine. A salt-gradient thermal-insulation solar pond is made of clay, a black ethylene-propylene-diene monomer (EPDM) waterproof roll, a geomembrane or high-density polyethylene plastic spraying canvas and the like are paved on the surface of the bottom of the pond to serve as liners, and a heat exchange pipeline is paved at the position 0.5-1m higher than the pond bottom. Lithium-rich brine prepared by freezing and solarization is directly injected into the salt-gradient thermal-insulation solar pond, a layer of fresh water is paved on the surface layer of the brine, the brine is warmed under the dual functions of solar radiation and geothermal water-heat exchange, lithium carbonate is separated out in a concentrated mode, and finally lithium-mixed salt obtained in the salt-gradient thermal-insulation solar pond is scrubbed through appropriate-temperature fresh water. The methods of the salt-gradient thermal-insulation solar pond, the geothermal water-heat exchange, scrubbing of the appropriate-temperature fresh water and the like are combined and applied to extraction of lithium carbonate from carbonate brine, the production efficiency and product quality are greatly improved, the production cycle is shortened, the production cost is reduced, and lithium carbonate ore concentrate can be obtained directly locally.

Owner:SALT LAKE & HOT WATER RESOURCE RES DEV CENT CHINESE ACAD OF GEOLOGICAL SCI

Temperature tactile representation device with variable heat capacity

InactiveCN101799694ARealize recurrenceRapid temperatureTemperature control using electric meansControl signalTwo temperature

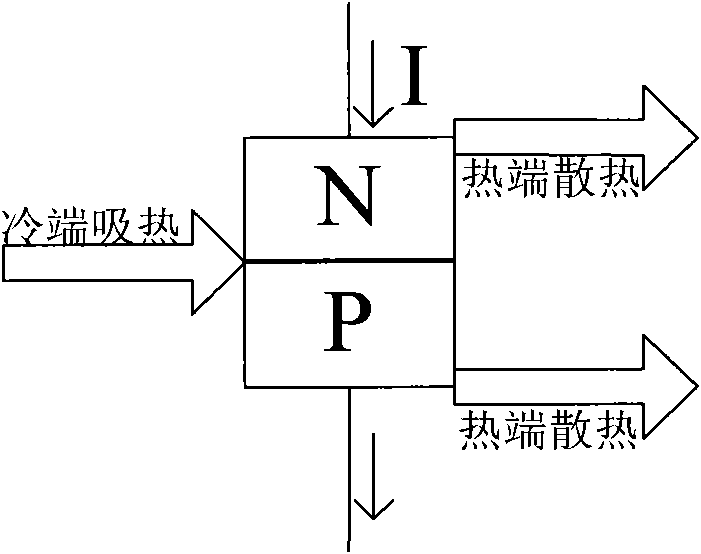

The invention provides a temperature tactile representation device with variable heat capacity, which is provided with a semiconductor cooler, a radiator, two temperature sensors and a measurement and control circuit, wherein the semiconductor cooler is used as a core of temperature control and hand perception, and consists of a P-N structure which is energized with direct current and is provided a cold end surface and a hot end surface; the radiator comprises a switch chamber with a cavity and a cooling liquid-gas two-path switching system, the cooling liquid switching system feeds cooling liquid to the cavity of the switch chamber by a cooling liquid groove via pipelines, and the switch chamber is communicated with the cooling liquid groove via a cooling liquid outlet pipeline; the gas path switching system switches air by an air inlet pipeline and an air outlet pipeline which are communicated with the cavity of the switch chamber; the pipelines of the cooling liquid-gas two-path switching system are respectively provided with an electromagnetic valve and a pump which are in connection with output control signal of the measurement and control circuit; the measurement and control circuit has a well-known power supply circuit, an analog-to-digital conversion circuit, a signal conditioning circuit and a control chip; and the two temperature sensors are respectively used for collecting temperatures of hand and the semiconductor cooler and outputs the temperatures to the measurement and control circuit.

Owner:SOUTHEAST UNIV

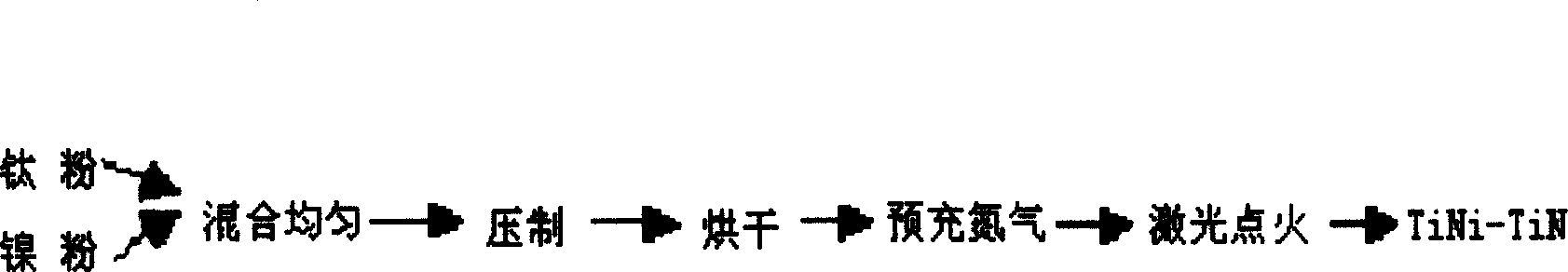

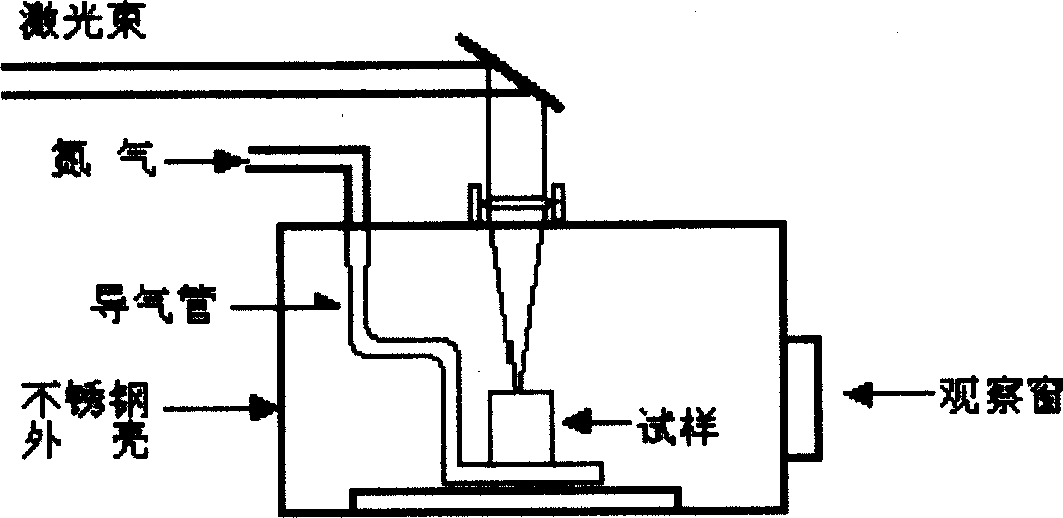

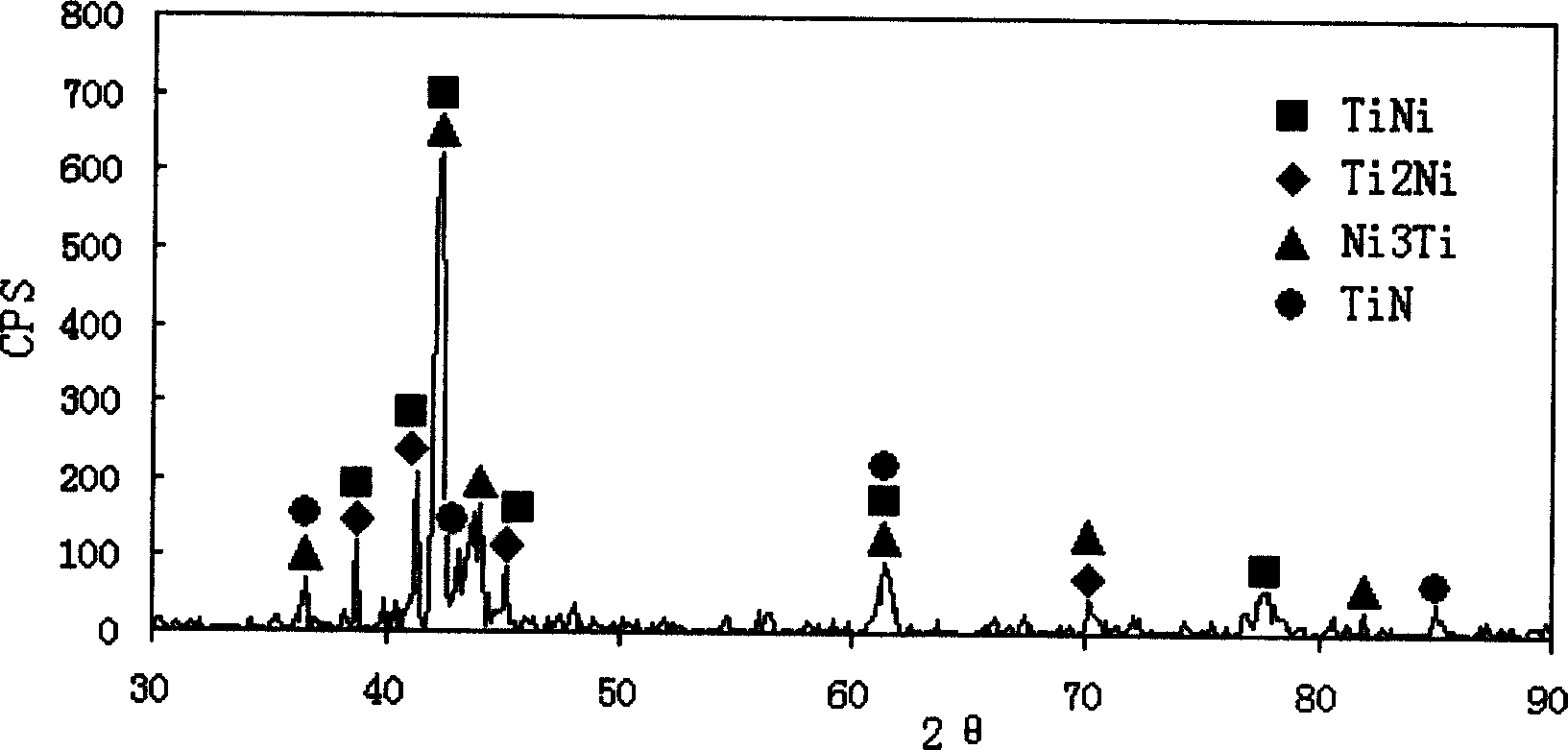

Method for synthesizing TiNi-TiN gradient material by laser-induction self-spreading under high temperature

InactiveCN1605413AEasy to synthesizeEfficient responseSelf-propagating high-temperature synthesisGradient material

The laser induced self-spreading high temperature gradient TiNi-TiN material synthesizing process includes the following steps: weighing and mixing metal Ti and Ni powder in the same molar ratio; pressing the mixture into cylindrical sample via maintaining the pressure of 20-50 KN for 1-4 min; keeping the sample at 80-150 deg.c for 1-3 min to eliminate water and partial gas; setting the sample on sample stage inside reaction container, sealing the container, introducing nitrogen in the flow rate of 5-10 L / min for over 2 min, and igniting with CO2 laser and Nd:YAG laser to induce self-spreading high temperature reaction.

Owner:SOUTH CHINA UNIV OF TECH

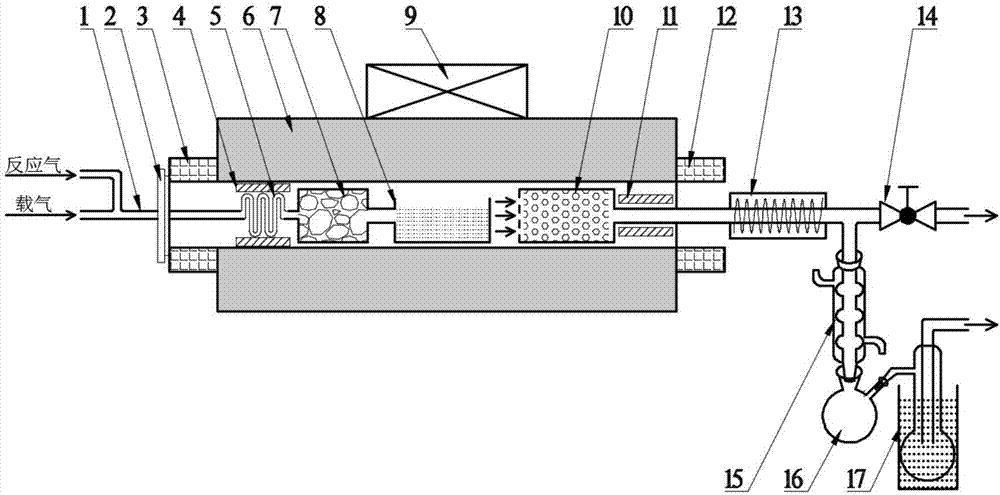

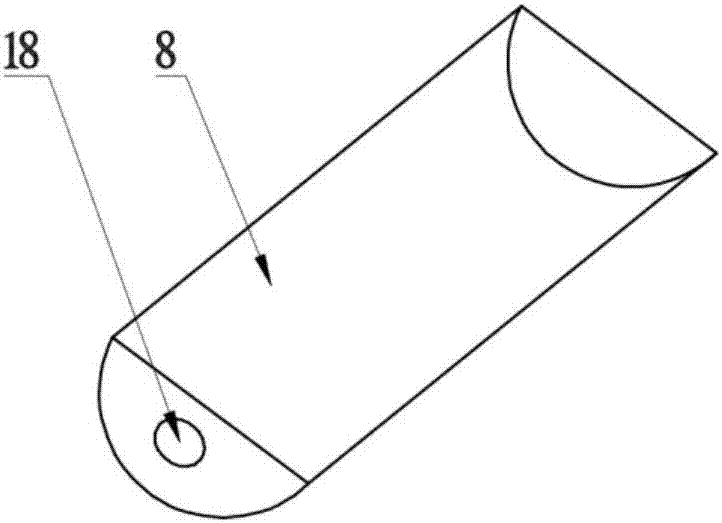

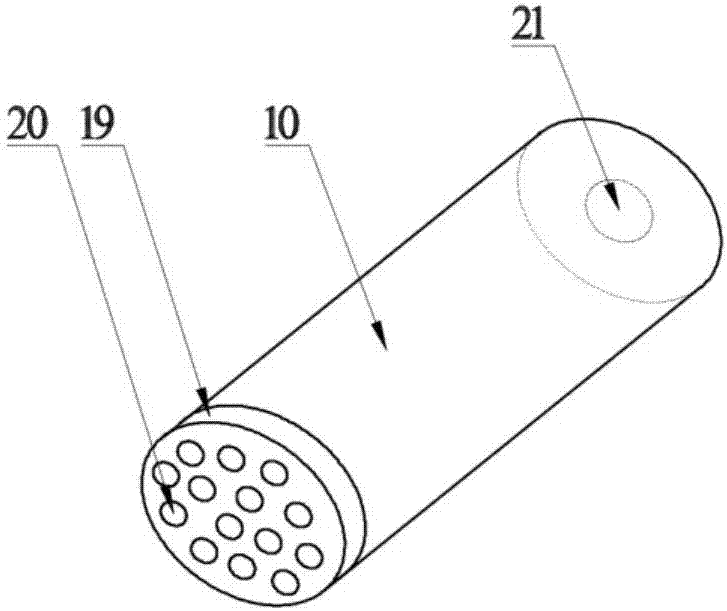

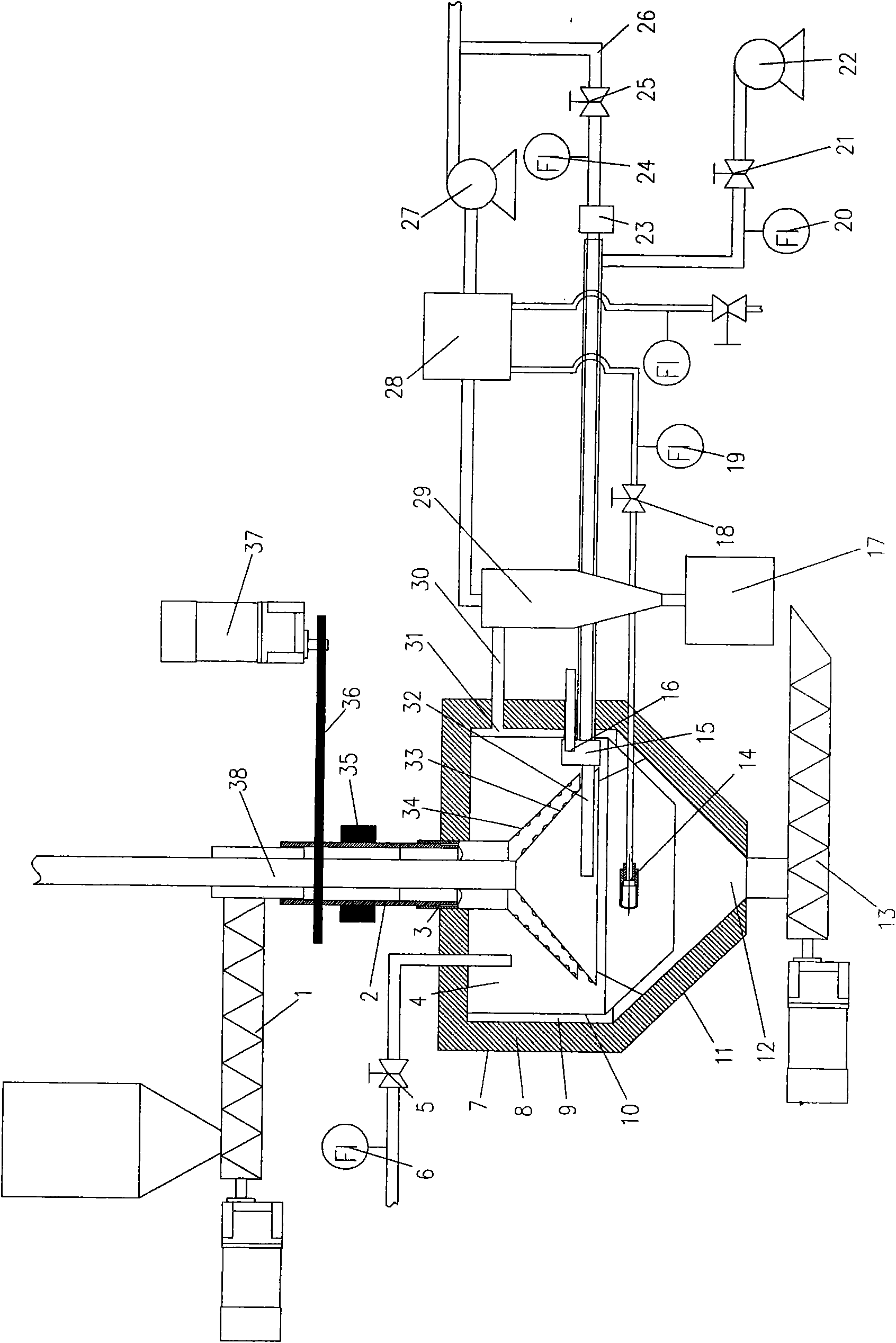

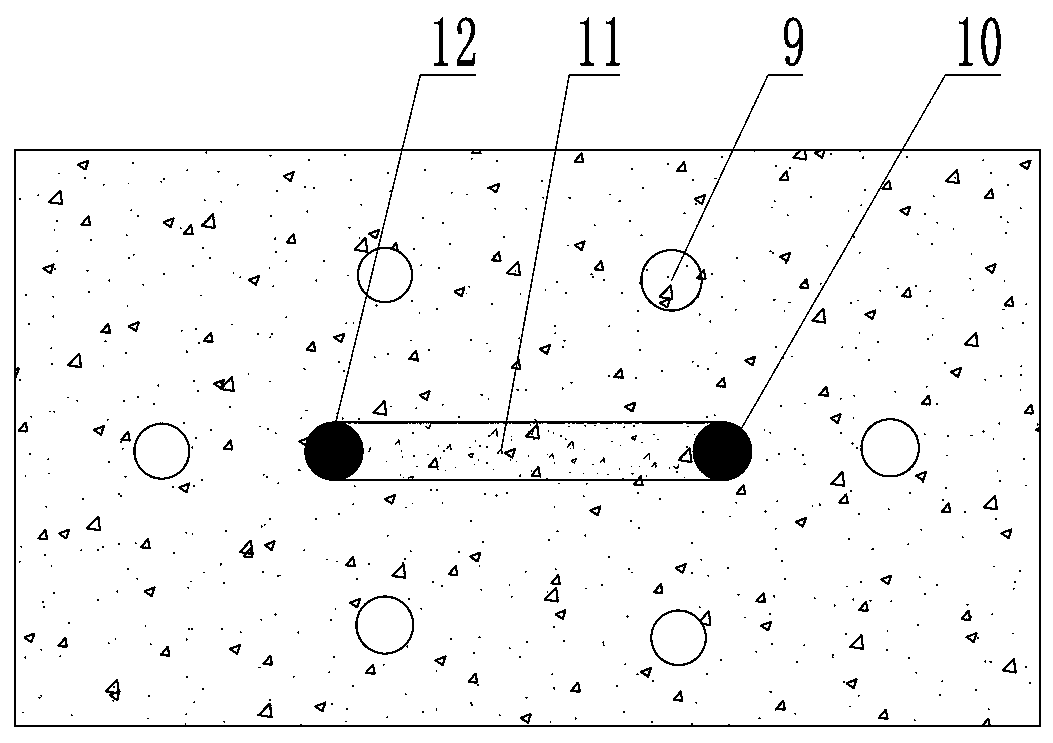

Device and method for coproducing bio-oil and biochar from solid waste through efficient microwave depolymerization

ActiveCN107987866ARealize online catalytic reformingAchieve hierarchical enrichmentLiquid hydrocarbon mixture productionCatalytic pyrolysisLiquid product

The invention discloses a device and a method for coproducing bio-oil and biochar from solid waste through efficient microwave depolymerization. The device comprises a gas inlet system for providing reaction gas and carrier gar, wherein an outlet end of the gas inlet system is connected with a preheating system, an outlet end of the preheating system is connected with a thermal-insulation filtration system, an outlet end of the thermal-insulation filtration system is connected with a reaction system, an outlet end of the reaction system is connected with a product collecting system, a productthermal insulation system is arranged on a pipeline between the reaction system and the product collecting system, and the outer sides of the preheating system, the thermal-insulation filtration system and the reaction system are sleeved with a microwave generation system. Solid waste can be converted into high-value liquid product bio-oil and solid product pyrolytic carbon in an efficient reduction, harmless and recycling manner with a two-stage conversion method of microwave depolymerization and catalytic pyrolysis.

Owner:临沂市新大环保科技有限公司

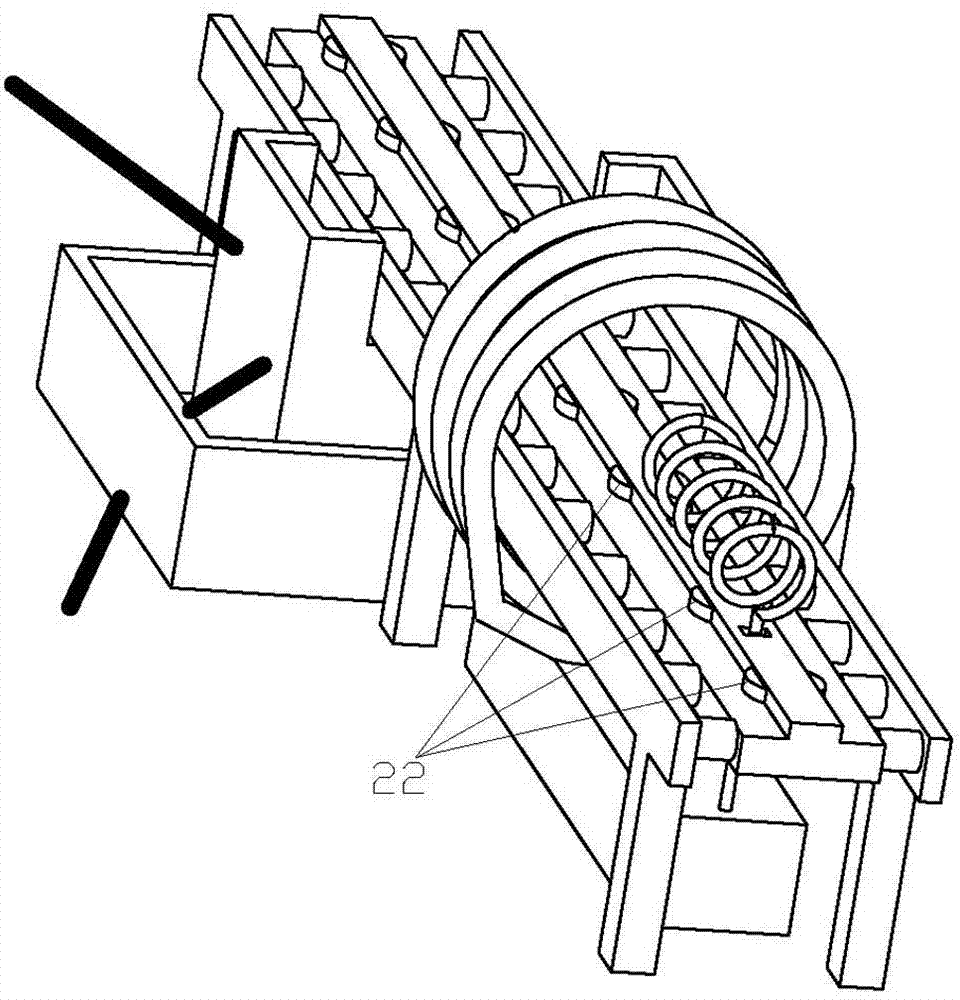

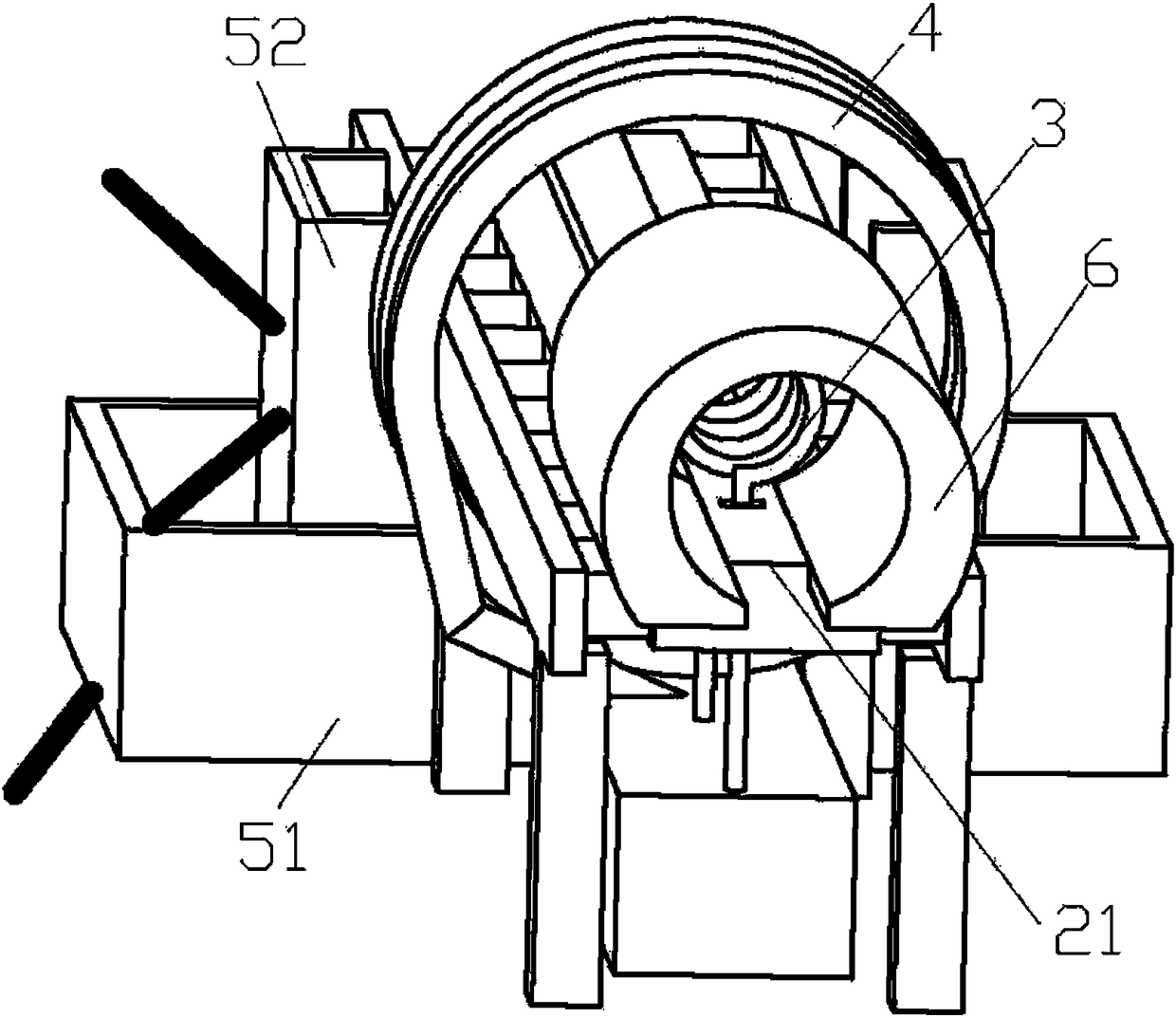

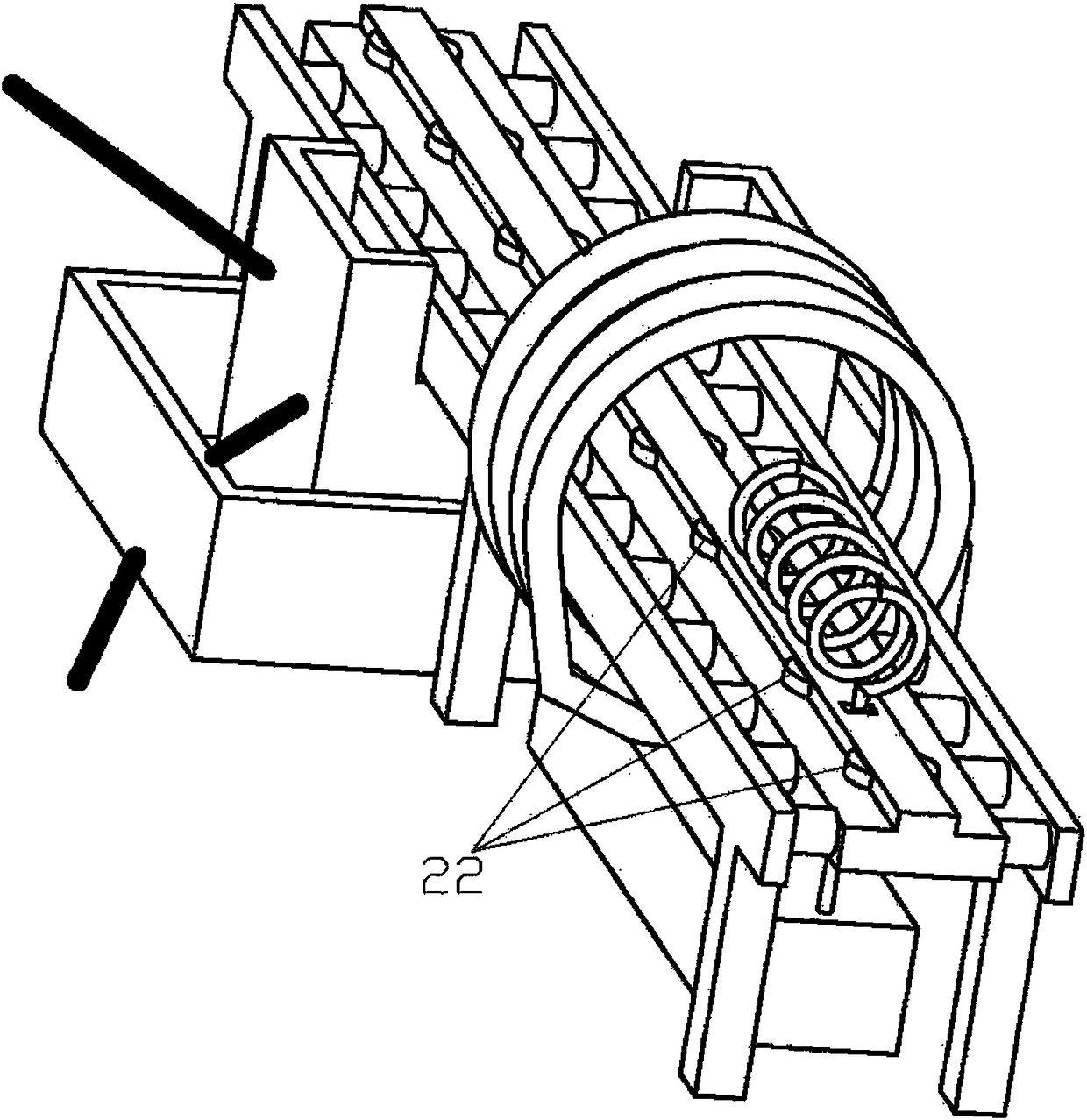

Semi-closed tubular aluminium profile heat treatment device

InactiveCN108148984AIncrease heating rateImprove battery saving performanceCoil arrangementsFurnace typesEngineeringStructural stability

The invention relates to the technical field of aluminium profile production, in particular to a semi-closed tubular aluminium profile heat treatment device. The semi-closed tubular aluminium profileheat treatment device comprises an aluminium profile conveying channel; a locating track is fixed on a middle position, parallel to the conveying direction, of the aluminium profile conveying channel;and one side of the conveying direction of the aluminium profile conveying channel is provided with an aluminium profile internal heating device, an aluminium profile external heating device, and a cooling device, and various physical properties and internal structural stability of the aluminium profile can be effectively improved.

Owner:陈卫

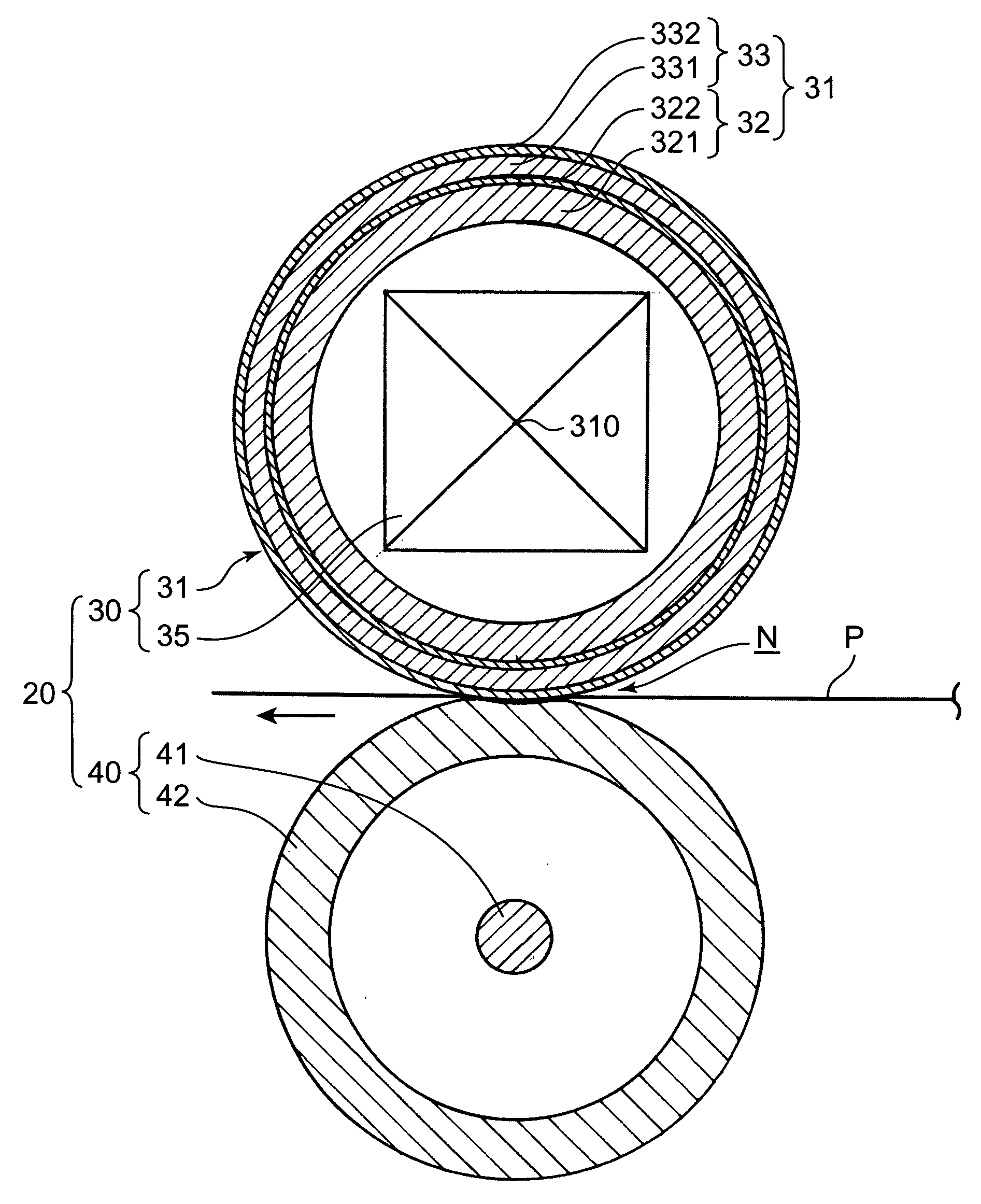

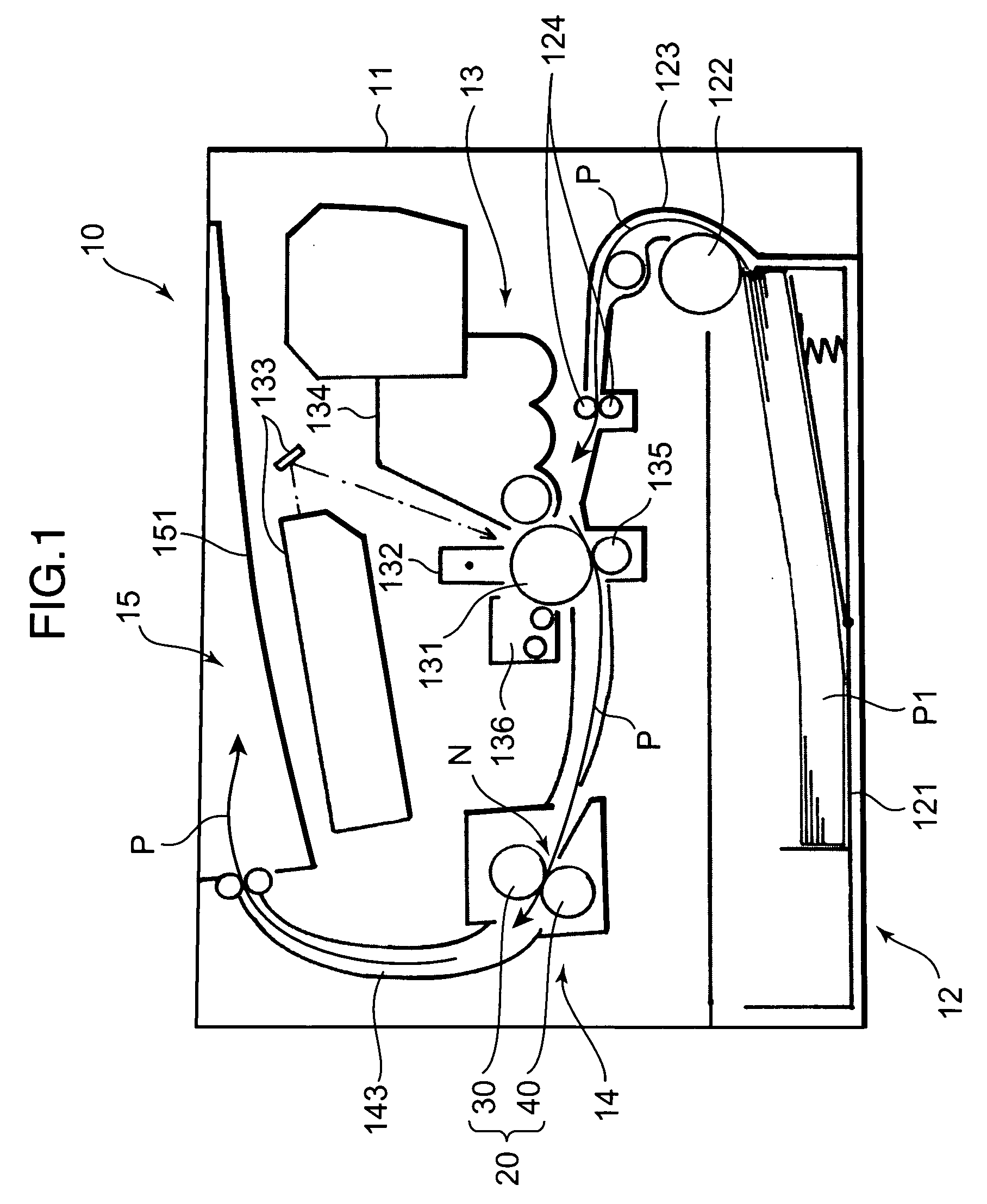

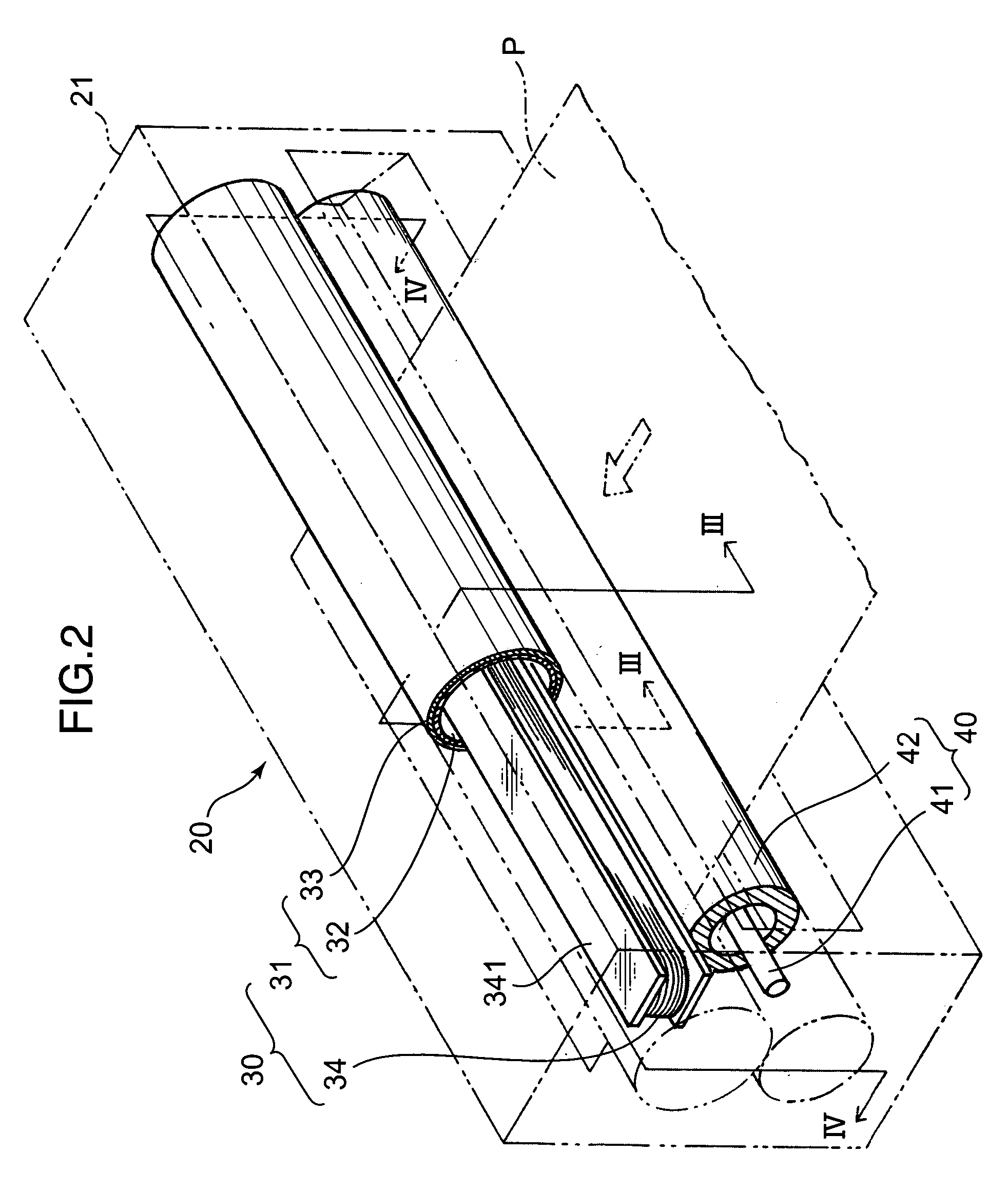

Fixing device and image forming apparatus

InactiveUS20060216080A1Reduce generationInhibit temperature riseElectrographic process apparatusElectrical resistance and conductanceImage formation

A fixing device (30) has a fixing member (30) adapted to be heated by induction heating based on a magnetic field from an induction coil (34). A pressing member (40) is disposed in contact with the fixing member (30) to define therebetween a nip zone (N) for passing a sheet (P) therethrough. The fixing member includes a heating layer (32). The heating layer (32) has a temperature-sensitive metal layer (321) formed on the side of the induction coil (34), and a nonmagnetic-metal layer (322) laminated onto the temperature-sensitive metal layer (321). The nonmagnetic metal layer (321) is made of a metal (copper (Cu)) having a specific resistance less than that of aluminum, and formed to have a thickness (30 μm) allowing the nonmagnetic metal layer to be substantially free from a temperature rise due to the induction heating.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

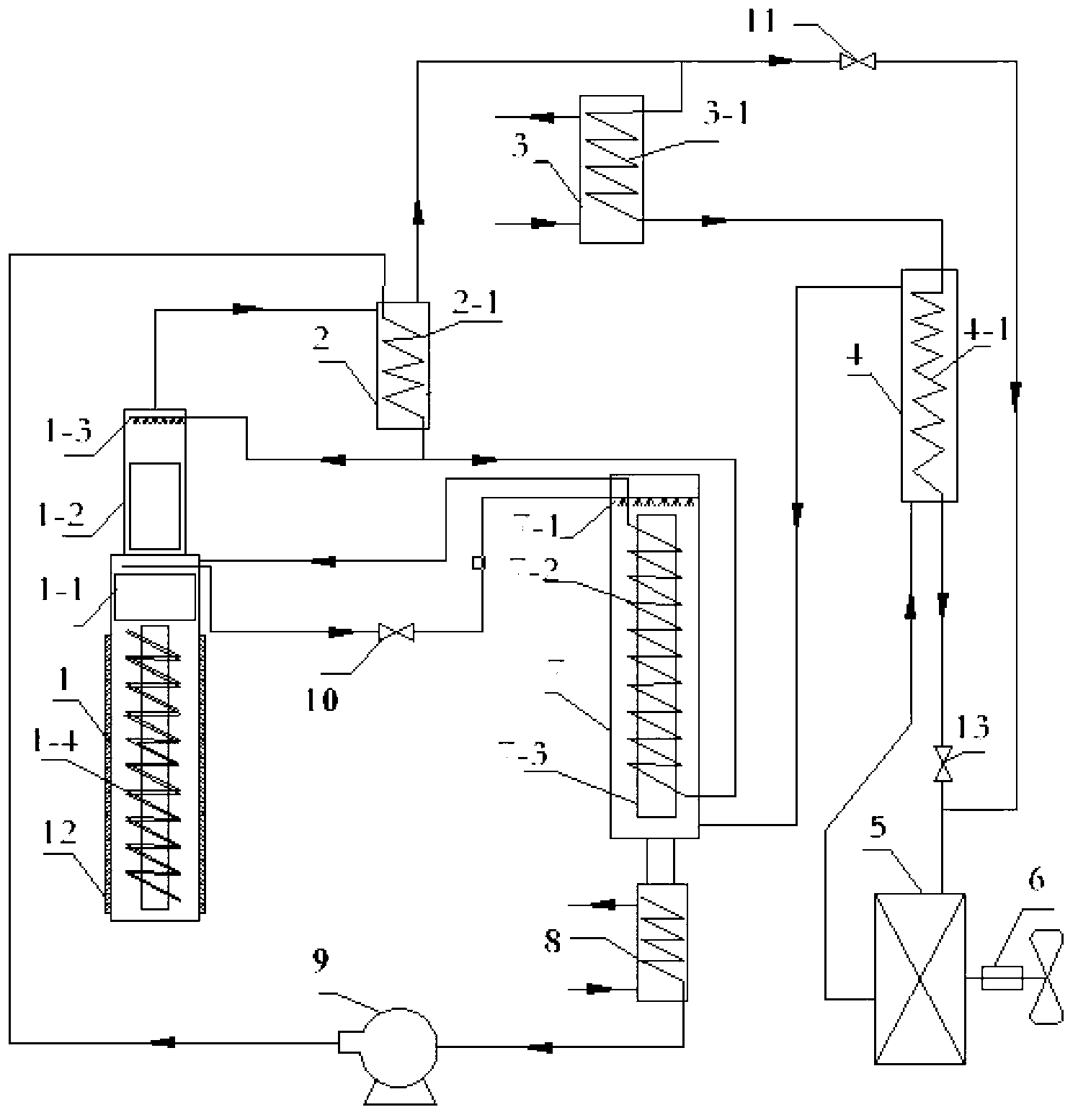

Solar energy air source absorption heat pump device

ActiveCN102840719AImprove Primary UtilizationImprove efficiencyHeat pumpsRefrigeration safety arrangementUnit operationEngineering

The invention discloses a solar energy air source absorption heat pump device. The solar energy air source absorption heat pump device is characterized in that natural energy source solar energy is taken as the driving energy of the unit, and the solar energy is input by a heating exchanger in a generator to the solar heat pump device to provide power for unit operation; energy in the air is absorbed through an air source heat exchanger coil; and the two parts of energy are released through condensation of refrigerant vapor and fusion heat of the refrigerant vapor and dilute solution, and transferred to hot water, thus the energy utilization rate is improved.

Owner:SHANDONG QIWEITE SOLAR TECH CO LTD

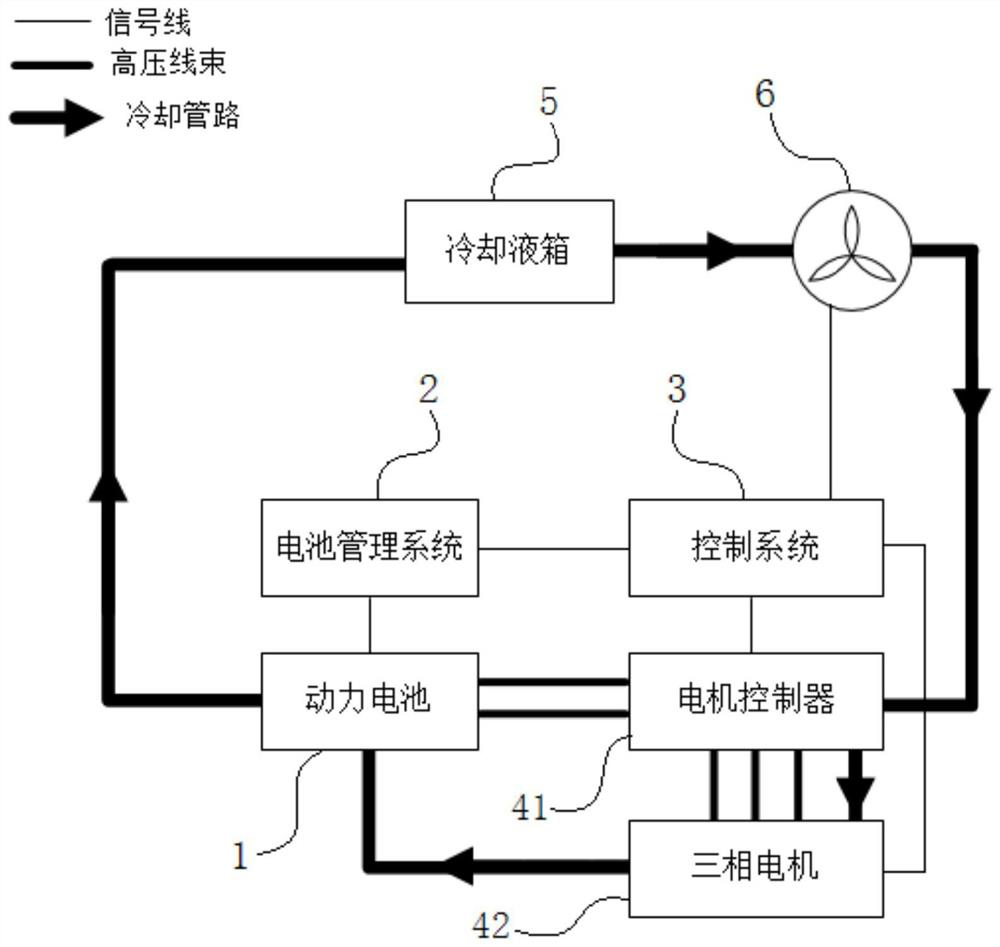

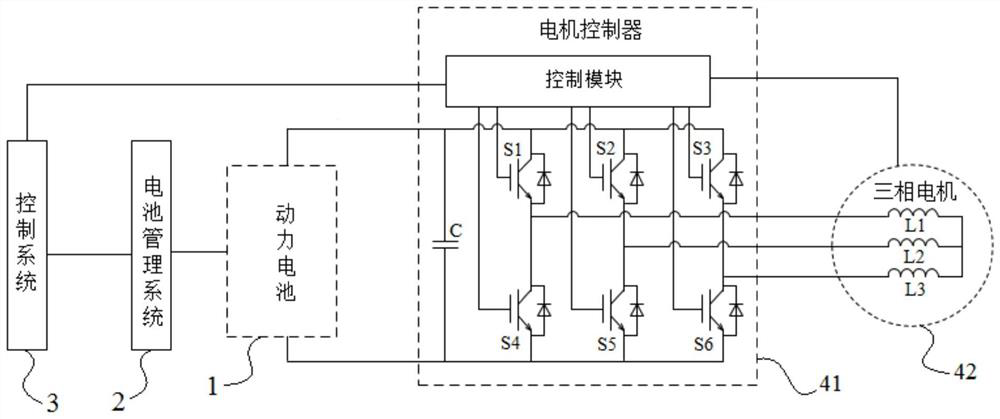

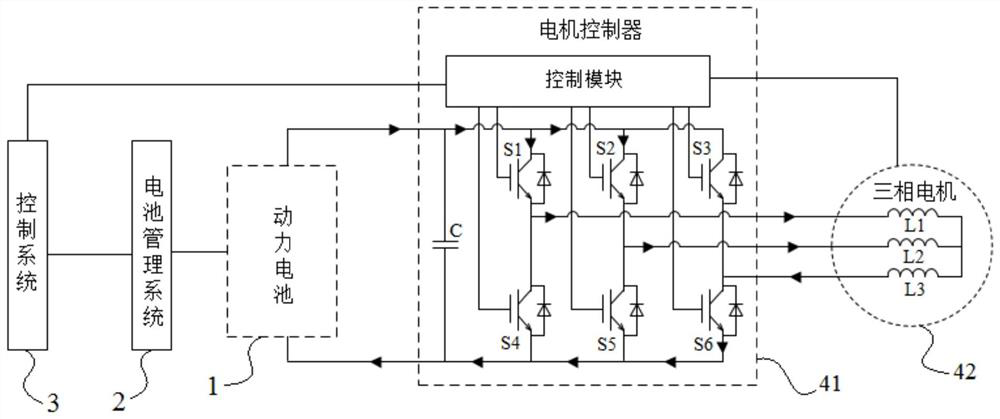

Electric automobile and power battery heating system and heating method thereof

ActiveCN113002366AIncrease speedImprove charge and discharge performanceAC motor controlCircuit monitoring/indicationAutomotive engineeringThree-phase electric power

The invention discloses an electric vehicle and a power battery heating system and method, and the method comprises the steps: enabling a motor system to enter a pulse heating mode when a pulse heating entering condition is met, carrying out the pulse heating of a power battery, and enabling a cooling liquid absorbing the heat of the motor system to enter a cooling pipeline of the power battery to heat the power battery; when the pulse heating quit condition is met, enabling the motor system to quit the pulse heating mode, stopping pulse heating of the power battery, and enabling the cooling liquid in the cooling pipeline of the power battery to stop flowing; in a pulse heating mode, enabling quadrature-axis voltage to be equal to zero, adjusting the magnitude of pulse current by controlling direct-axis voltage, generating actual pulse width modulation signals of the six power switches by superposing pulse signals. Three-phase current feedback quantity is not needed, the output pulse current is stable and small in fluctuation, the pulse heating effect of the power battery can be improved, and unexpected driving or shaking of a vehicle in the pulse heating process of the power battery is avoided.

Owner:重庆长安新能源汽车科技有限公司

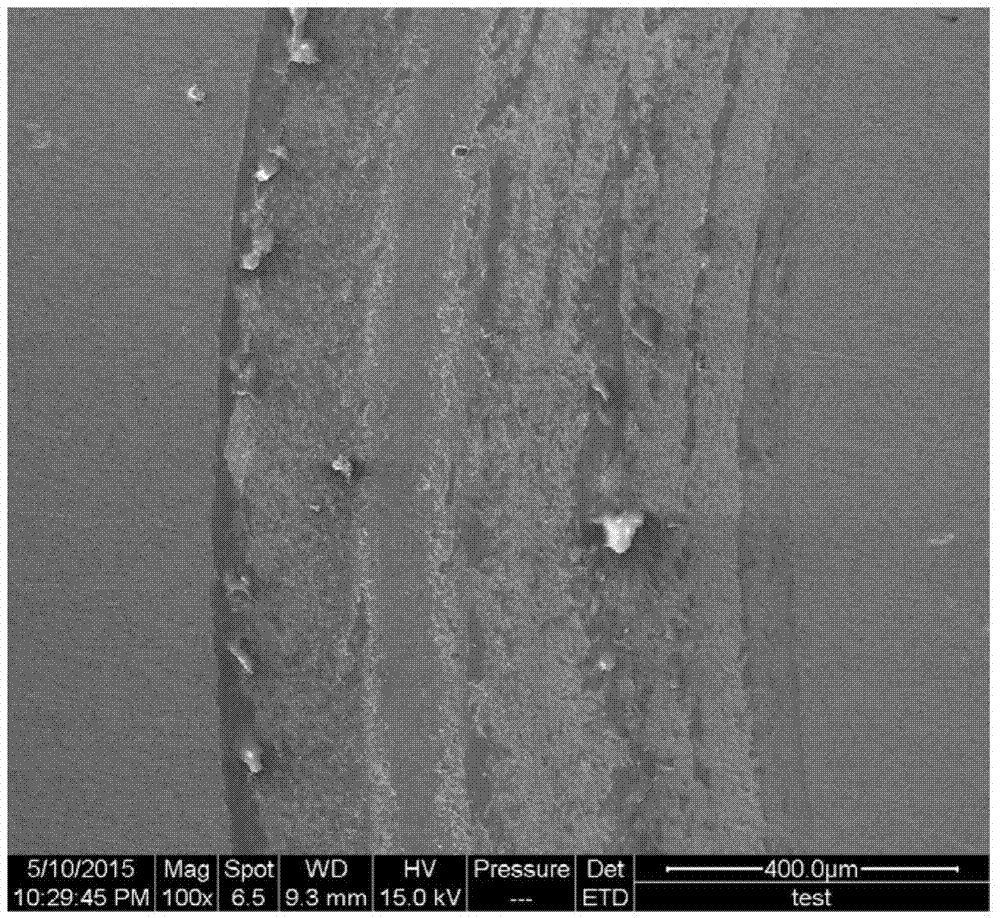

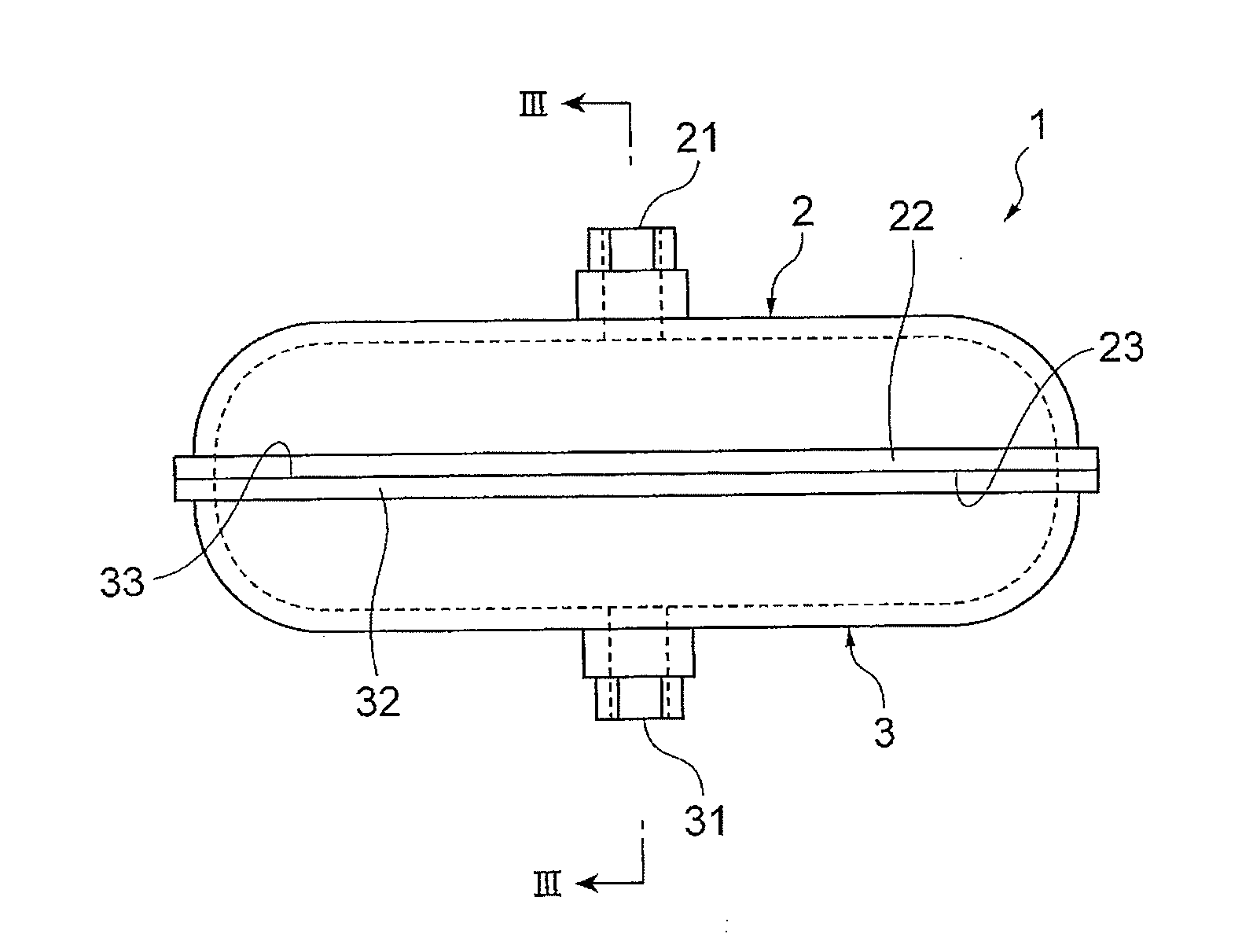

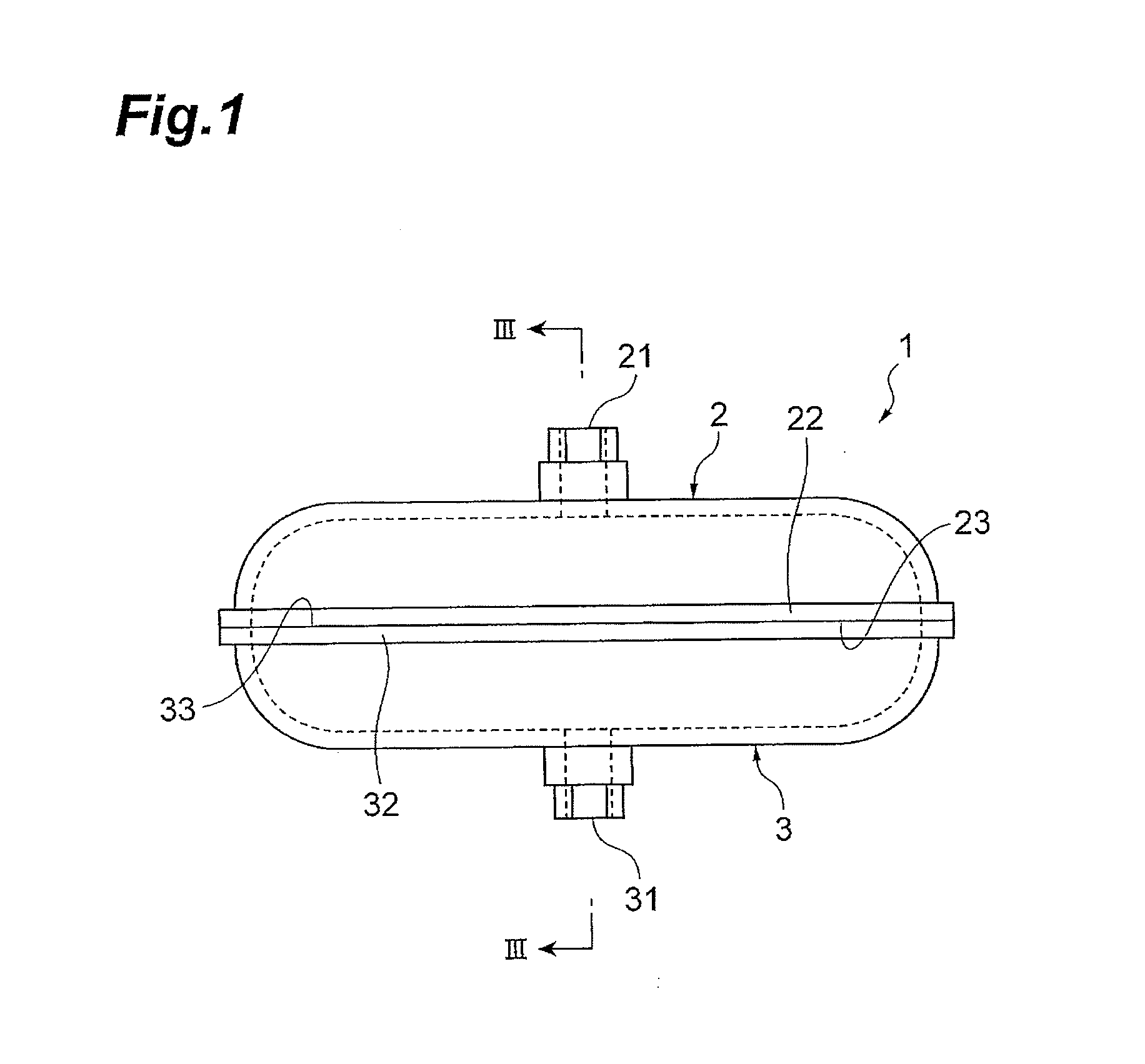

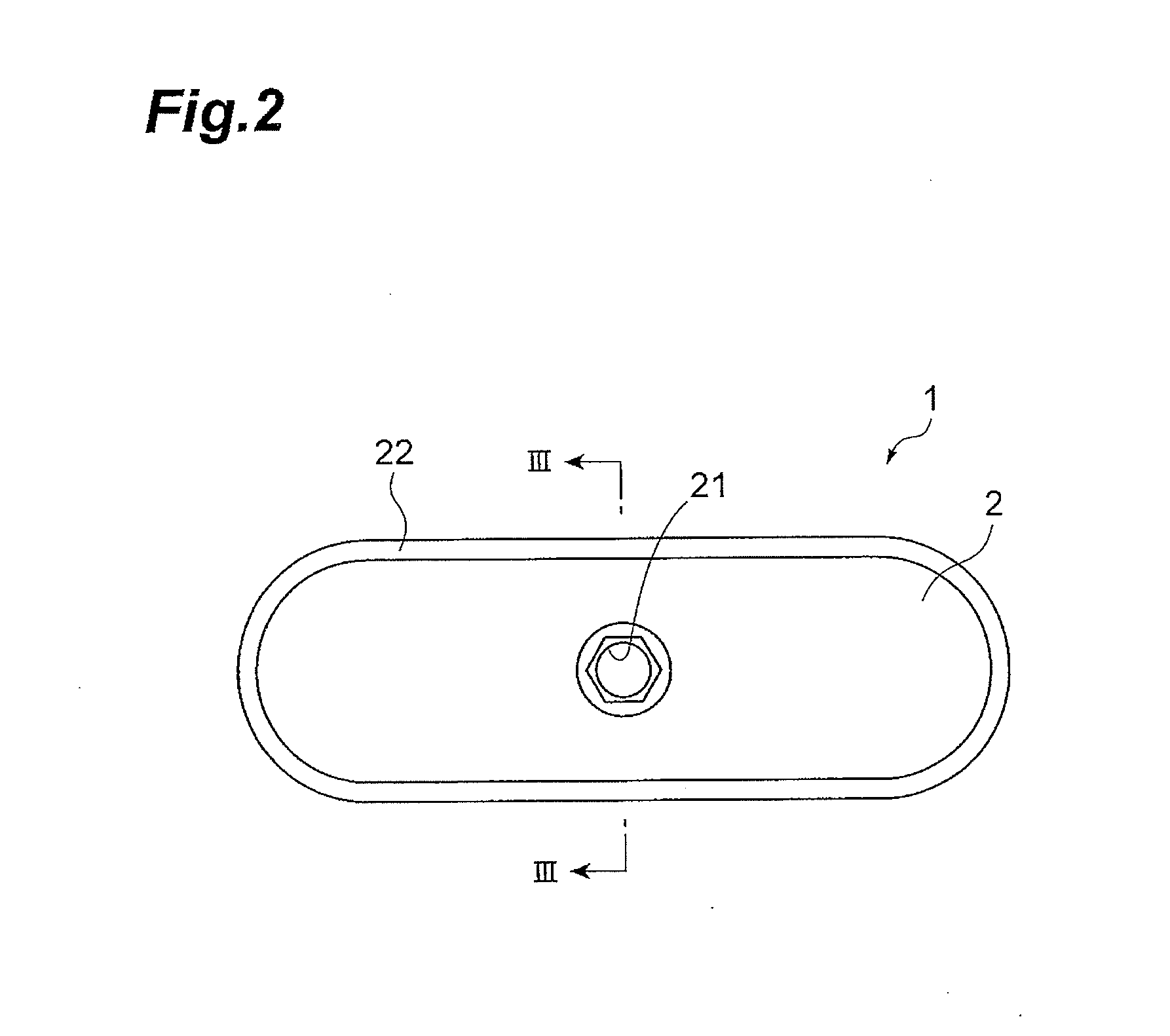

Welding method and weld

InactiveUS20150183155A1Fast welding speedEnhance layeringLamination ancillary operationsLaminationLaser lightWeld seam

Provided is a welding method for welding a first resin layer and a second resin layer, the method including interposing a metal layer having pores formed therein, between the first resin layer and the second resin layer; irradiating at least one of the first resin layer and the second resin layer with laser light; thereby causing the melted resin to penetrate through the metal layer; and thus welding the first resin layer and the second resin layer.

Owner:ASAHI KASEI CHEM CORP

Method for improving high plasticity of low-carbon silicomanganese cold-rolling transformation induced plasticity steels

The invention belongs to the technical field of rolled steel, and in particular relates to a method for improving high plasticity of low-carbon silicomanganese cold-rolling phase-change induced plasticity steel. The method comprises the following steps of: selecting the low-carbon silicomanganese cold-rolling transformation induced plasticity steels, smelting and forging so as to manufacture plate blanks, heating the plate blanks to be 1100-1250 DEG C, keeping the temperature, rough-rolling and finish-rolling the plate blanks and air-cooling the hot rolled plates to be 600-750 DEGC, coiling, and subsequently pickling so as to obtain steel plates for cold rolling; cold-rolling in a rolling reduction greater than or equal to 80%; heating the cold-rolled steel plates to be (Ac3-40 DEG C) to (Ac3+30 DEG C) at a heating velocity of at least 80 DEG C / s, carrying out annealing treatment for 5-15 seconds, subsequently cooling to a bainite area of 380-450 DEG C at a velocity of 40-80 DEG C / s, carrying out isothermal treatment for 10-50 seconds, and finally cooling to the room temperature. By utilizing the preparation method, cold-rolling transformation induced plasticity steels with high and strong plasticity is obtained, and the strength of the low-carbon silicomanganese cold-rolling transformation induced plasticity steels is greatly improved on the premise that the plasticity is not lost.

Owner:LAIWU IRON & STEEL GRP

Method and special equipment for preparing granular silicon belt

InactiveCN1469495AFlat surfaceReduce manufacturing costFinal product manufactureSemiconductor devicesSolar cellChemical stability

The present invention is the method and special equipment for preparing granular silicon belt capable of being used as the substrate material of polysilicon film solar cell. The technological process includes making silicon powder spread on quartz plate or graphite plate pass through preheating area, linear focusing heating area and natural cooling area successively. The linear focusing heatingarea is one optical heating area comprising two halogen tungsten lamp assemblies with optical linear focusing reflector on the upper and the lower sides separately. In the linear focusing heating area silicon powder layer is zone molten and the molten silicon solution flows into the gaps between silicon powder grains to form so-called granular silicon belt after being cooled. The granular silicon belt has molten crystallized surface with certain mechanical strength and chemical stability and low cost and is suitable for use as the substrate material of solar cell.

Owner:SUN YAT SEN UNIV

Preheating device, preheating method, hot bending machine and machining method of high-efficiency 3D (Three-Dimensional) cover glass

PendingCN107857466AImprove yieldAvoid damageGlass reforming apparatusGlass productionElectrical resistance and conductanceEngineering

The invention discloses a preheating device, a preheating method, a hot bending machine and a machining method of high-efficiency 3D (Three-Dimensional) cover glass. The preheating device of the high-efficiency 3D cover glass at least comprises a second preheating workstation which adopts electromagnetic induction heating equipment to heat and a third preheating workstation which is located behindthe second preheating workstation and adopts resistance heating equipment to heat. In the scheme, preheating of a molding die is carried out by combining resistance heating with electromagnetic induction heating, so that the heating efficiency can be greatly accelerated; compared with independent resistance heating preheating, half preheating time can be reduced, the preheating time can be shortened to be 10 to 20 seconds, and the preheating speed is increased; compared with independent electromagnetic induction heating, temperature homogenization can be realized by the molding die and coverglass after temperature rising through the electromagnetic induction heating, and the damage to the cover plate during a pressing process due to non-uniform heating temperature can be avoided, so thatthe yield of a 3D cover glass finished product can be increased, and effective combination of efficiency improvement and yield improvement is realized.

Owner:苏州赛万玉山智能科技有限公司

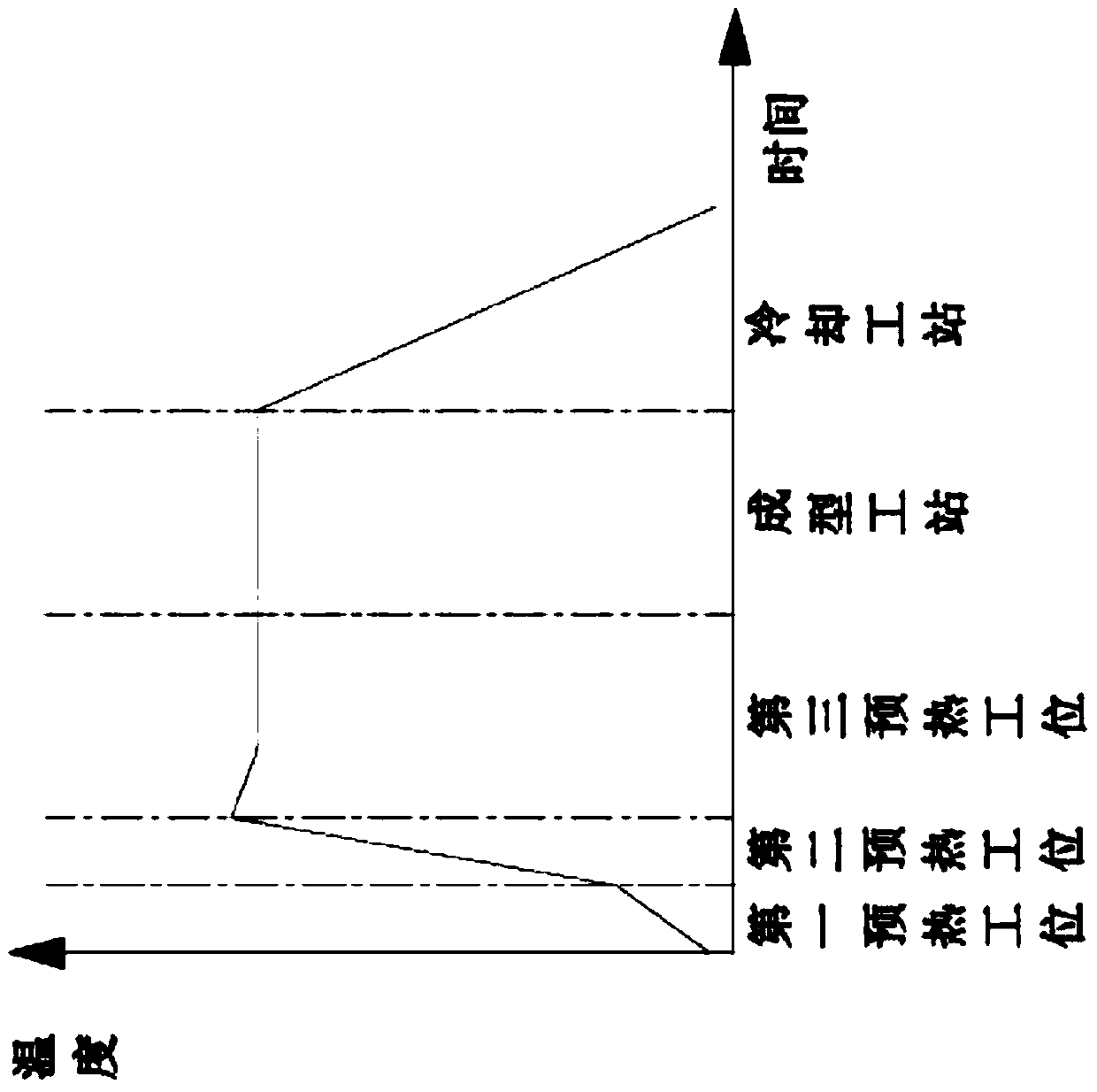

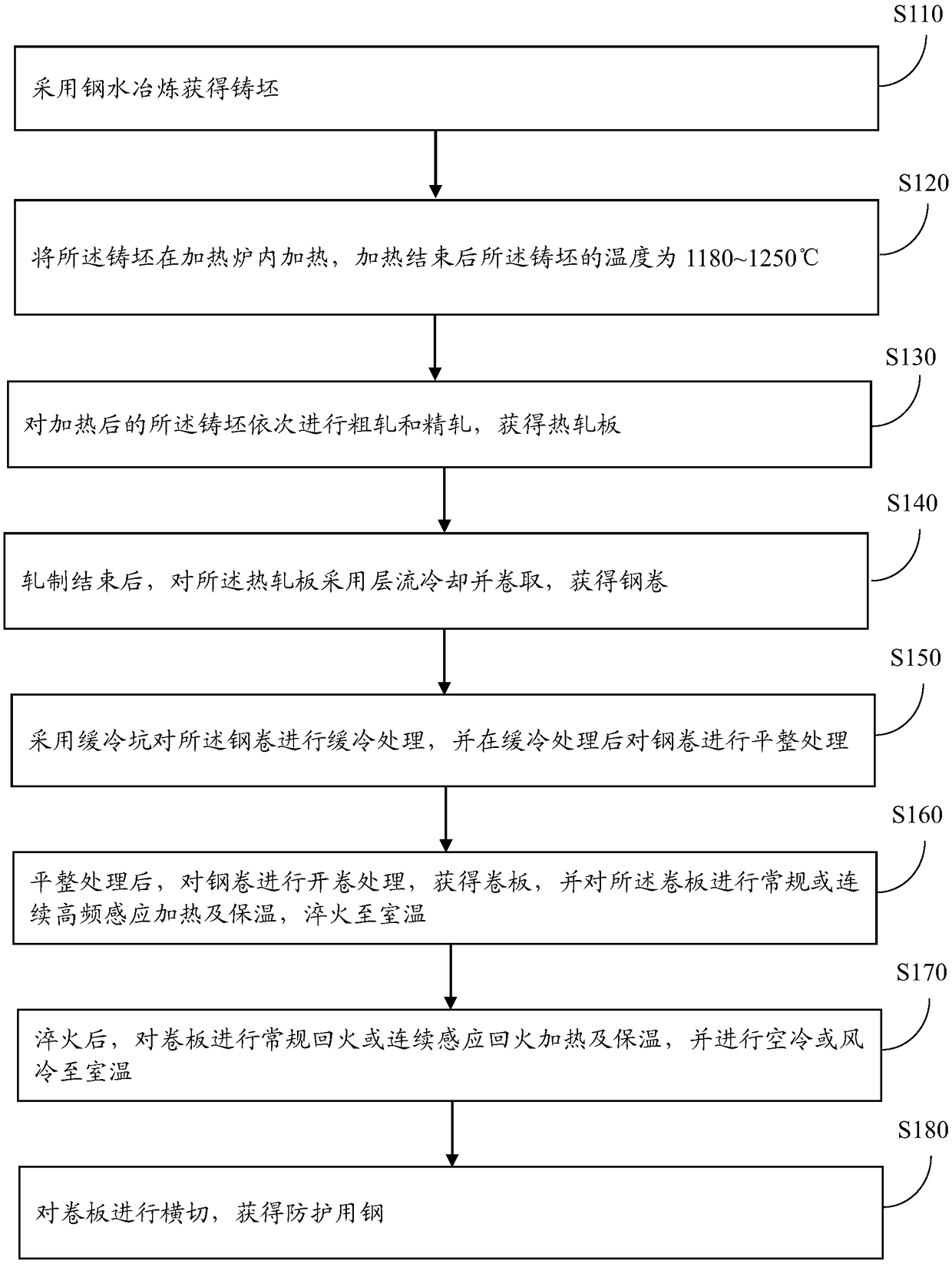

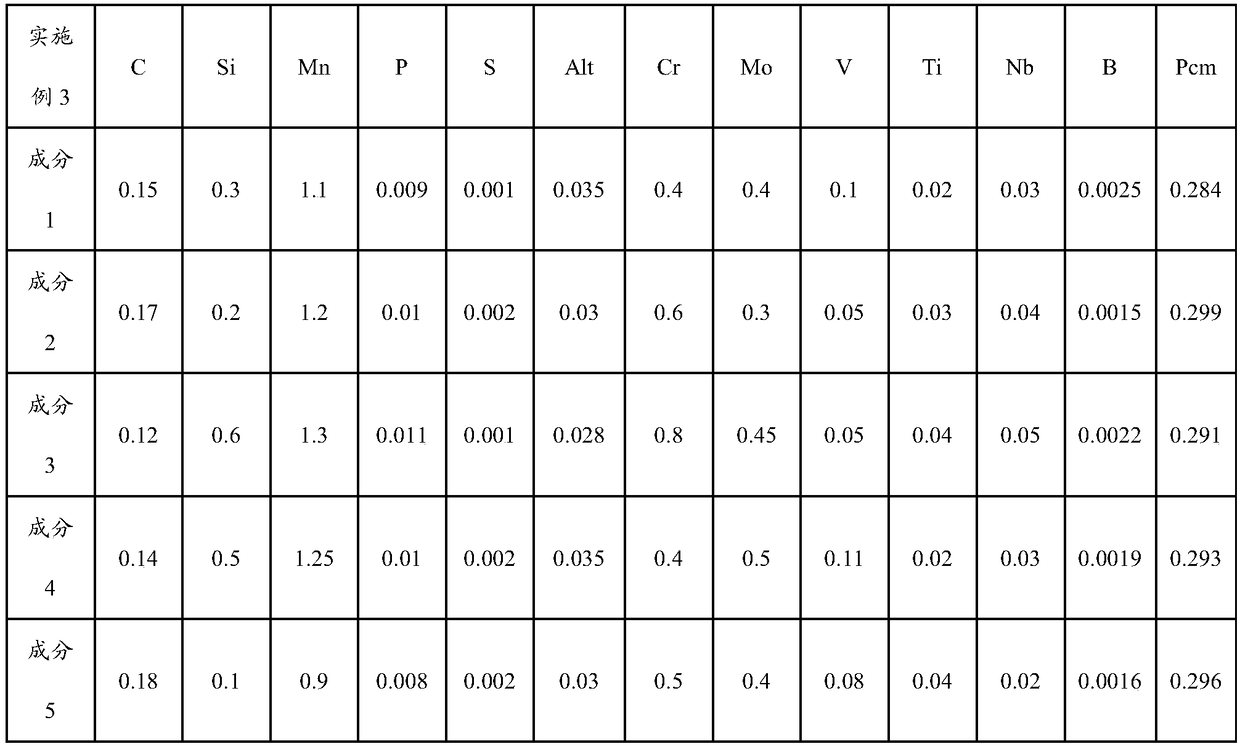

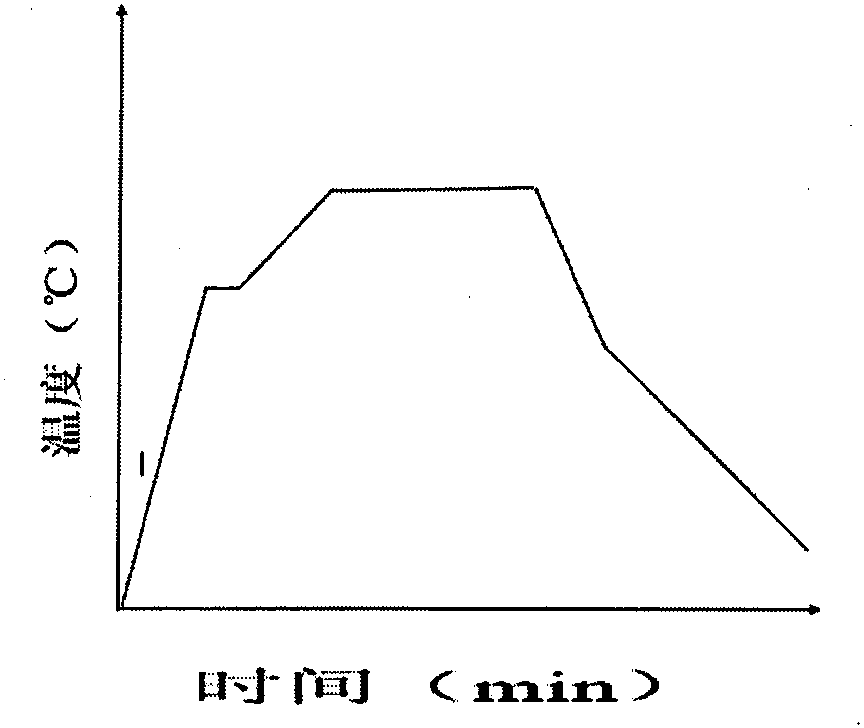

Protective steel and production method thereof

The invention discloses protective steel and a production method thereof. The protective steel is prepared from the following components in percentage by mass: 0.10-0.20% of C, 0.10-0.60% of Si, 0.8-1.65% of Mn, 0.02-0.05% of Nb, 0.3-0.8% of Mo, 0.05-0.15% of V, 0.01-0.05% of Ti, 0.01-0.06% of Al, 0.4-1.0% of Cr, 0.0015-0.0025% of B, no more than 0.02% of P, no more than 0.01% of S, no more than 0.008% of N, and the balance of Fe and unavoidable impurities. The problems that in the prior art, high-content C and high-content Mn are added into protective steel, Pcm is designed to be excessivelyhigh, consequently welding performance is lowered, and welding cold cracks and weld joint fatigue cracking are caused are solved, the technical problems of poor cold forming performance and poor low-temperature impact toughness are solved, and the technical effects that the protective steel has good cold forming performance and good low-temperature impact toughness, and safety performance of protected products is improved are achieved.

Owner:SHOUGANG CORPORATION

Production process for obtaining copper alloy strip with uniform and small grains

InactiveCN104233136ASimple production processFlexible and diverse process parameter controlThermal insulationMetal machining

The invention discloses a production process for obtaining a copper alloy strip with uniform and small grains, and belongs to the metal machining industry. According to the process, an alloy ingot is subjected to hot rolling after high-temperature heating to obtain a slab, the slab is subjected to intermediate annealing, technological parameters of a heating section, a thermal insulation section and a cooling section are controlled in the annealing process, and the copper alloy strip with the uniform and small grains is obtained. The production process is simple and has the greatest characteristic that the copper strip with the uniform and small grains can be obtained on the basis of conventional equipment, thereby having excellent popularization and application values.

Owner:CNMC ALBETTER ALBRONZE

Internal combustion heating rotation conical biomass gasification furnace

InactiveCN101538484AIncrease temperatureImprove efficiencyCombined combustion mitigationCombustible gas productionProcess engineeringBiomass gasifier

The invention provides an internal combustion heating rotation conical biomass gasification furnace which is characterized in that the furnace body is internally provided with two concentric cones, wherein the external cone is a rotation cone and the internal cone is a fixed cone; the top of the rotation cone is connected with a material cylinder at the lower section; the top of the fixed cone is communicated with a smoke gas pipeline; the bottom end surface of the fixed cone is closed and the lower part thereof is tangentially connected with a combustion pipeline; the side wall of the furnace body is arranged as jacket structure; the jacket comprises a high-temperature resistance furnace wall, a combustion gas pipeline, a heat preservation layer and an external wall of the gasification furnace sequentially from inside to outside; the airflow passage in which the combustion gas is led out from the gasification furnace is that the combustion gas is led to the bottom port of the combustion gas pipeline from the bottom of the gasification furnace along the inclined surface of the conical furnace bottom; the delivery outlet of the combustion gas is arranged at the upper part of the combustion gas passage; and a gas transmission pipeline connected on the delivery outlet of the combustion gas outside the gasification furnace is connected with a gas storage cabinet by an induced draft fan. The gasification furnace greatly improves the biomass gasification rate and the heat value of the combustion gas.

Owner:HEFEI UNIV OF TECH

Preparation method for asphalt mixture capable of rapidly warming

The invention discloses a preparation method for an asphalt mixture capable of rapidly warming. The preparation method is characterized by comprising the following steps: placing pyrite cinder and a reducer in a ball mill and carrying out ball-milling, uniformly mixing the powder after the ball-milling with a mineralizer, then carrying out compression forming, drying, and calcining for 150-200min at 1250-1450 DEG C to prepare a wave-absorbing aggregate; proportioning heavy-duty road asphalt and the aggregate in the mass percentages of 4.6-6% and 94-95.4%, breaking the aggregate and then preheating at 180-200 DEG C, heating the heavy-duty road asphalt at 160-170 DEG C, and stirring and mixing the preheated aggregate with the heated heavy-duty road asphalt at 165-180 DEG C to prepare the asphalt mixture, wherein the aggregate is composed of, 75-100wt% of the wave-absorbing aggregate and 0-25wt% of a natural aggregate. The asphalt mixture prepared by the invention is good in microwave heating effect, and suitable for road de-icing, and road bituminous pavement maintenance and rapid repair.

Owner:SOUTHWEAT UNIV OF SCI & TECH

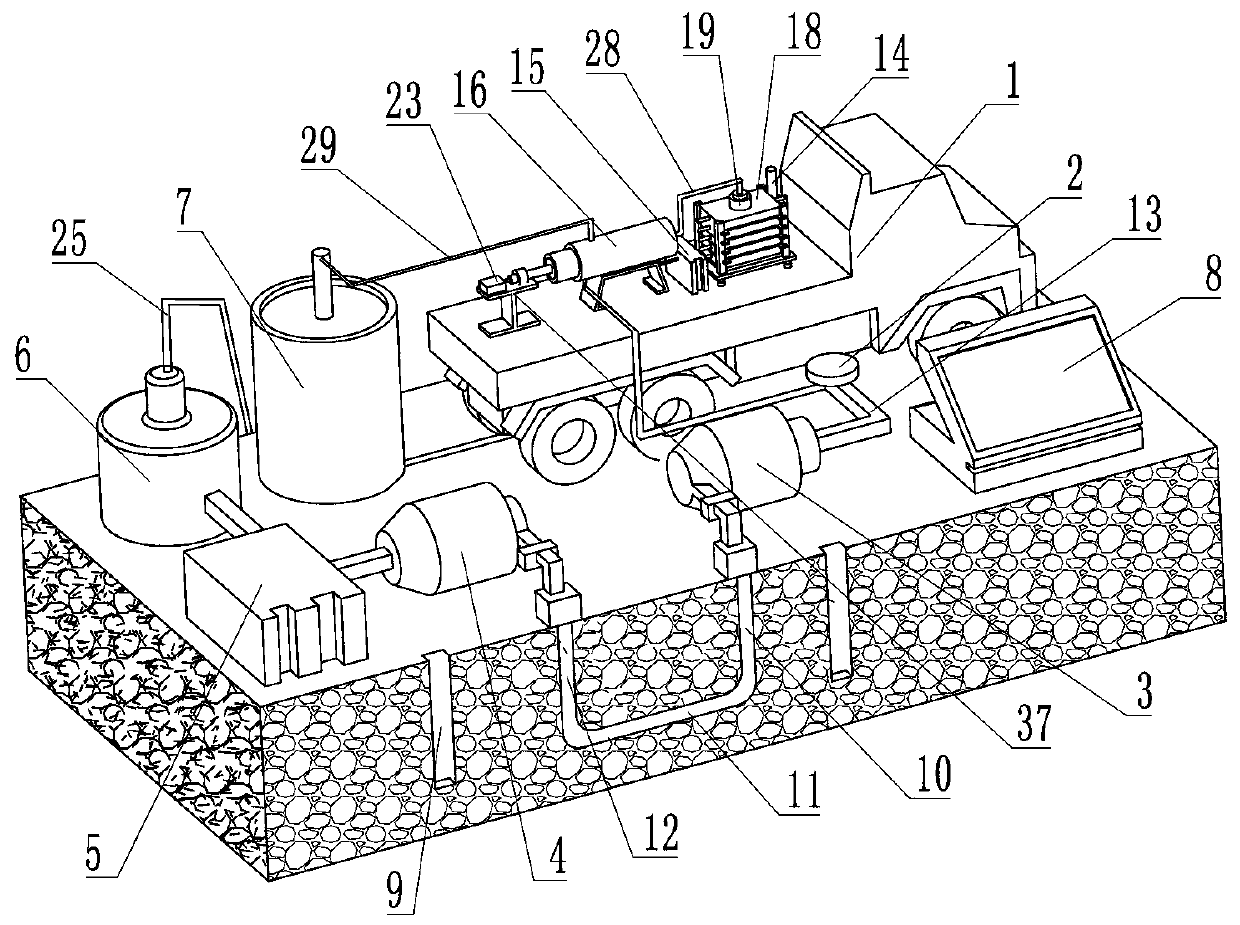

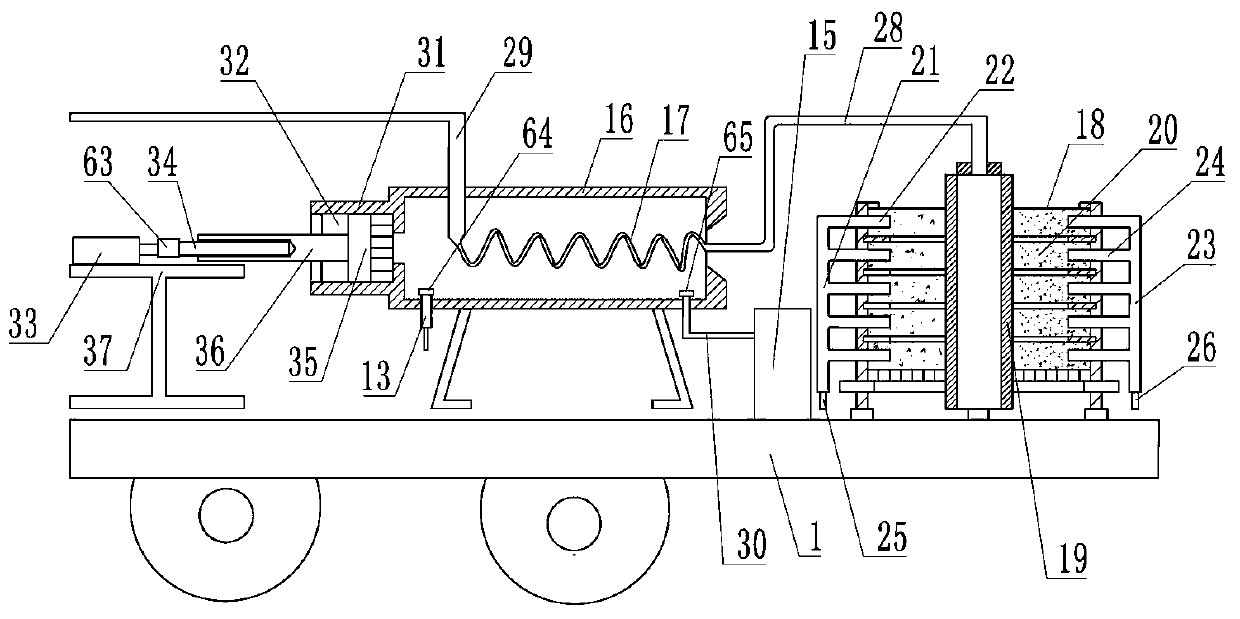

Device and method capable of heating coal reservoir to improve low-coal-rank coal bed gas yield

InactiveCN111561303AImprove conversion efficiencyRealize the supplyFuel cell heat exchangeFinal product manufactureFuel cellsHorizontal wells

The invention discloses a device capable of heating a coal reservoir to improve a low-coal-rank coal bed gas yield. The device comprises a truck, a flowmeter, a first gas booster, a second gas booster, a mixed gas separating device, a methane storage tank, a water collecting box and a control system. A U well and multiple exploited wells are drilled in the coal reservoir on the ground, the U wellis composed of a first vertical well segment, a horizontal well segment and a second vertical well segment, a fuel battery air heat exchange system is mounted on the truck, a gas outlet of the fuel battery air heat exchange system is connected with a gas inlet of the first gas booster, a gas outlet of the first gas booster is connected with a well opening of the first vertical well segment, a wellopening of the second vertical well segment is connected with a gas inlet of the second gas booster, a gas outlet of the second gas booster is connected with a gas inlet of the mixed gas separating device, and the exploited wells are connected with an extraction device. Water in a low-coal-rank reservoir is effectively removed, desorption of methane molecules is promoted, and the low-coal-rank coal bed gas yield is improved.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com