Internal combustion heating rotation conical biomass gasification furnace

A technology for heating and rotating biomass, applied in the production of combustible gas, joint combustion mitigation, petroleum industry, etc., can solve the problems of affecting the operation of the blower, high tar yield, waste of resources, etc. The effect of calorific value, reducing tar yield and improving gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

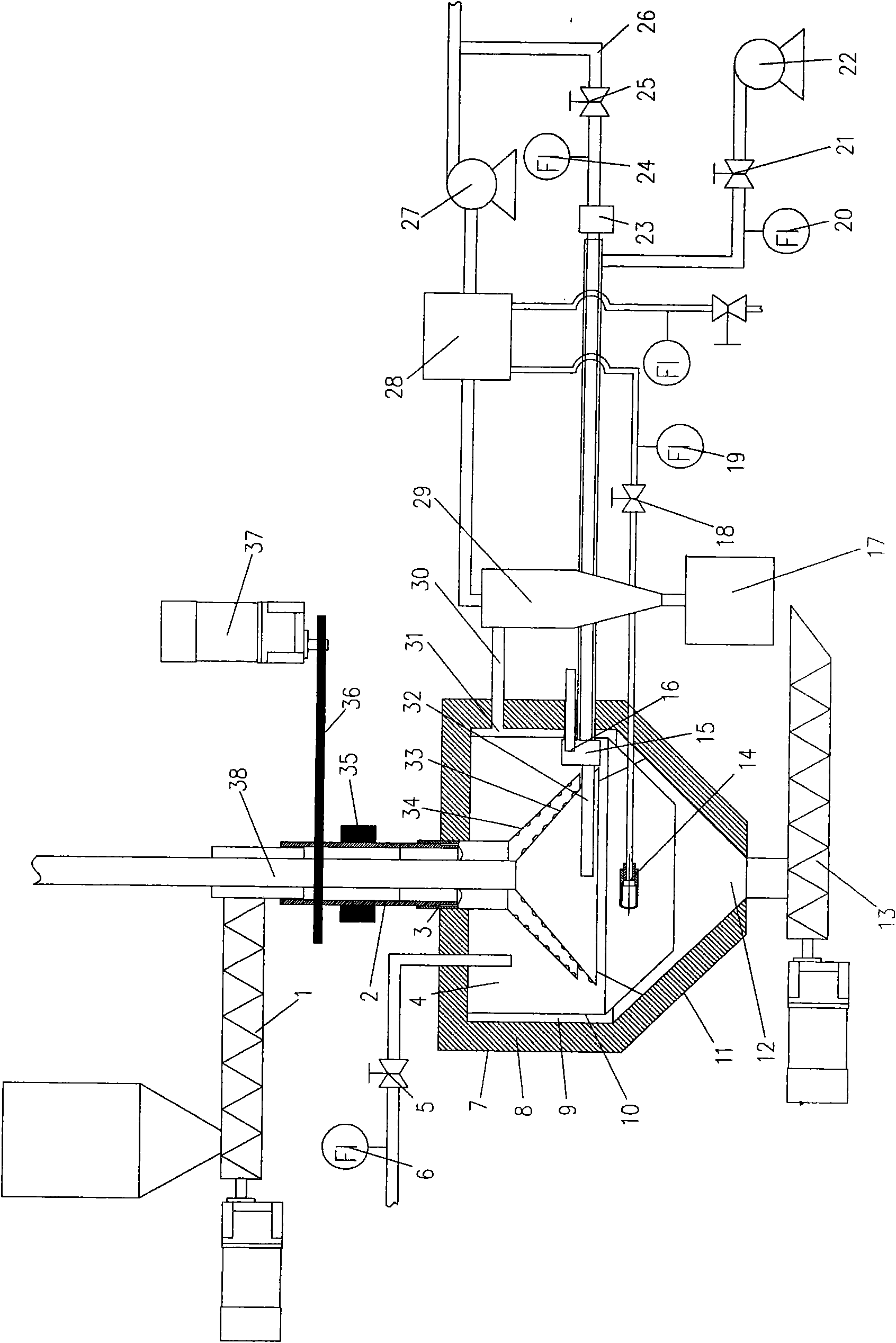

[0036] see figure 1, the furnace body 4 of rectangular or cylindrical shape is adopted, two concentric cones are arranged inside the furnace body 4, the outer cone is a rotating cone 34 that rotates around the axis, and the inner cone is a fixed fixed cone 33; The section is set as the upper barrel 2 and the lower barrel 3, the upper part of the rotating cone 34 is connected with the lower barrel 3, the upper barrel 2 is connected with the screw feeding mechanism 1; the upper part of the fixed cone 33 is connected with the flue gas pipe 38 The bottom end face of the fixed cone 33 is closed, and its lower part is connected tangentially with the combustion pipe 32; the combustion-supporting air inlet is arranged on the top of the furnace body 4; The atomizer 14, the slagging port 12 is located at the bottom of the cone, and the spiral slagging mechanism 13 is set on the slagging port 12; the side wall of the furnace body 4 is set as a jacket structure, and the jacket is a high t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com