Downhole oil shale stratum combusting and heating system

A technology for heating systems and oil shale formations, which is applied to wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of underground heating efficiency, low heat utilization rate, inconvenient installation and operation, etc. The effect of polluting the environment and increasing the heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

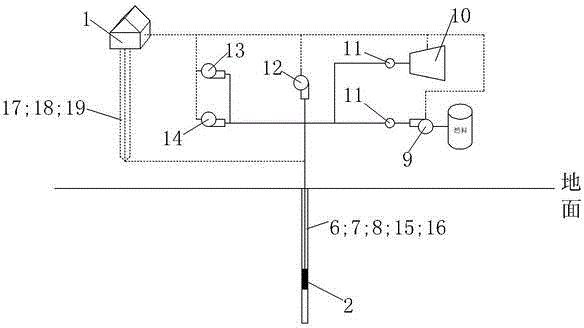

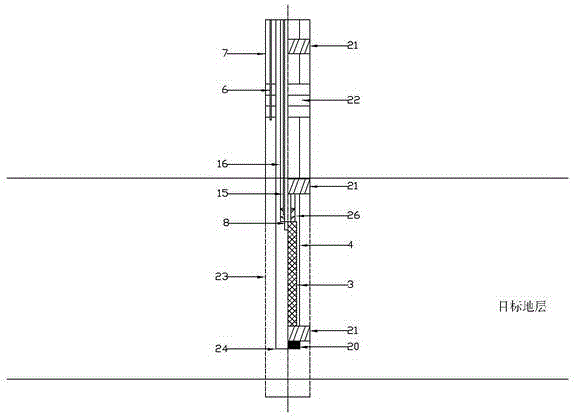

[0060] see Figure 1 to Figure 13 As shown, the purpose of the present invention is to provide a kind of oil shale formation combustion heating system in the well. The present invention can realize the heating range of 50-800°C.

[0061] The invention includes a ground monitoring and control system (1), an internal combustion and tail gas countercurrent heat exchange system (2), an external fluid injection pipe (6) and an external casing (7);

[0062] In-well combustion and exhaust gas countercurrent heat exchange system 2 includes burner 3, exhaust gas countercurrent heat exchange sleeve assembly 4, water collection and pumping system 5; burner 3 includes igniter 18, flame detection electrode 19, fuel and air / oxygen sleeve 25. Burner nozzle 28 and mixed combustion chamber 29; tail gas counterflow heat exchange sleeve assembly 4 includes exhaust gas return heat exchange sleeve 31, lower orifice plate 32, upper orifice plate 33, turbulent flow heat exchange device 30 and exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com