Foam profile control agent applicable to oil field in-depth profile control

A profile control agent and foam technology, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of low salinity, single function of profile control technology, low plugging degree, etc. The effect of not polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

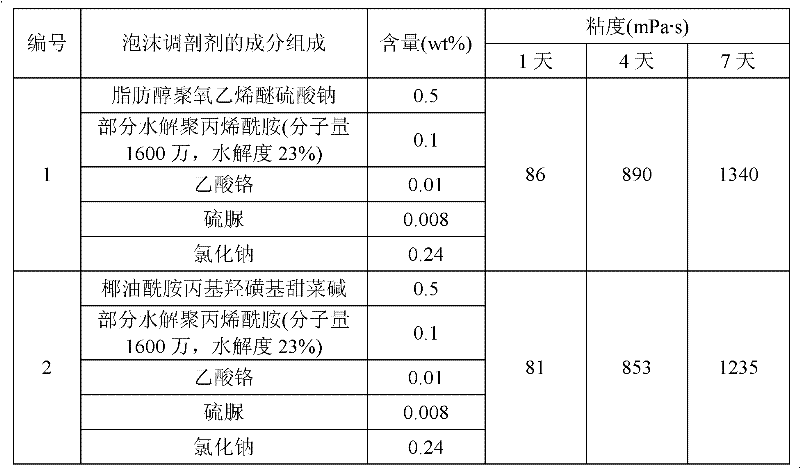

[0027] This example provides two chromium crosslinked polymer solutions, the composition of which is shown in Table 1.

[0028] These two chromium crosslinked polymer solutions were prepared according to the following steps:

[0029] At 45°C, 1 g of partially hydrolyzed polyacrylamide (molecular weight: 16 million, degree of hydrolysis: 23%) was dissolved in 991.42 g of water, and stirred with a mixer for 2 hours to completely dissolve to obtain a partially hydrolyzed polyacrylamide solution;

[0030] Repeat the above steps to prepare a partially hydrolyzed polyacrylamide solution;

[0031] To a portion of the partially hydrolyzed polyacrylamide solution, add 5g of sodium fatty alcohol polyoxyethylene ether sulfate, 2.4g of sodium chloride, 0.1g of chromium acetate, and 0.08g of thiourea in sequence, and continue stirring for 1 hour to make it evenly mixed to obtain Chromium cross-linked polymer solution numbered 1;

[0032] To another part of the partially hydrolyzed polyac...

Embodiment 2

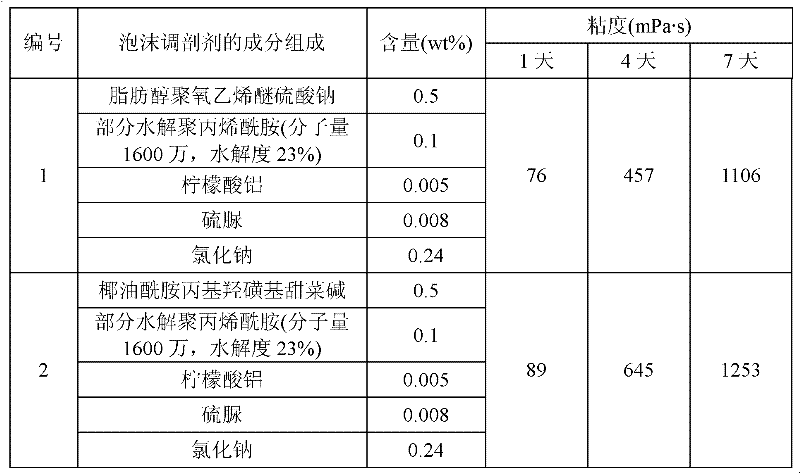

[0038] This example provides two aluminum cross-linked polymer solutions, the composition of which is shown in Table 1.

[0039] These two aluminum crosslinked polymer solutions were prepared according to the following steps:

[0040]At 45°C, 1 g of partially hydrolyzed polyacrylamide (molecular weight: 16 million, degree of hydrolysis: 23%) was dissolved in 991.47 g of water, and stirred with a mixer for 2 hours to completely dissolve it to obtain a partially hydrolyzed polyacrylamide solution;

[0041] Repeat the above steps to prepare a partially hydrolyzed polyacrylamide solution;

[0042] To a part of the hydrolyzed polyacrylamide solution, add 5g fatty alcohol polyoxyethylene ether sodium sulfate, 2.4g sodium chloride, 0.05g aluminum citrate, 0.08g thiourea in sequence, and continue to stir for 1 hour to make it evenly mixed. Obtain the aluminum cross-linked polymer solution numbered 1;

[0043] In another part of the partially hydrolyzed polyacrylamide solution, add 5...

Embodiment 3

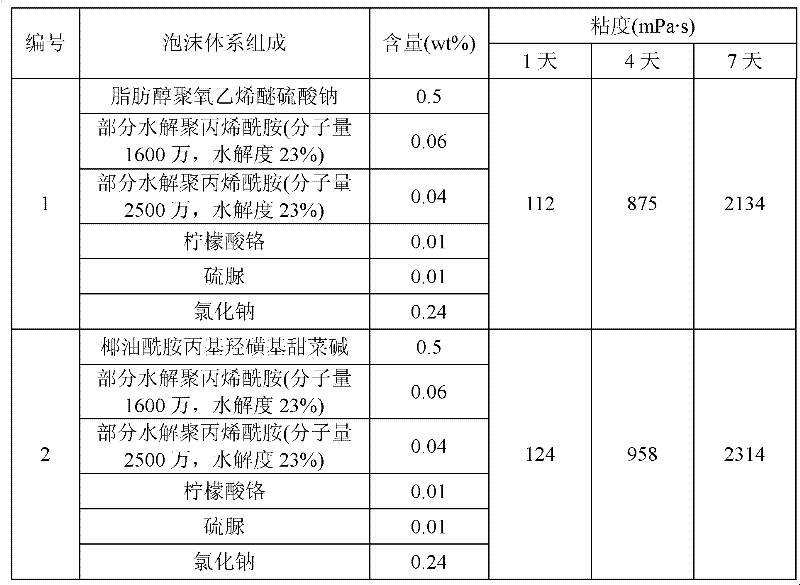

[0049] This example provides two chromium citrate cross-linked polymer solutions, the composition of which is shown in Table 1.

[0050] These two chromium citrate crosslinked polymer solutions were prepared according to the following steps:

[0051] At 45°C, dissolve 0.6g of partially hydrolyzed polyacrylamide (molecular weight: 16 million, degree of hydrolysis: 23%) and 0.4g of partially hydrolyzed polyacrylamide (molecular weight: 25 million, degree of hydrolysis: 23%) in 991.4g of water, stir with a mixer 2 hours, make it dissolve completely, obtain the partially hydrolyzed polyacrylamide solution;

[0052] Repeat the above steps to prepare a partially hydrolyzed polyacrylamide solution;

[0053] To a part of the hydrolyzed polyacrylamide solution, add 5g fatty alcohol polyoxyethylene ether sodium sulfate, 2.4g sodium chloride, 0.1g chromium citrate, 0.1g thiourea in sequence, and continue to stir for 1 hour to make it evenly mixed. Obtain the sodium dichromate cross-lin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com