Method for improving mechanical property of low-carbon silicomanganese series cold rolling dual-phase steel

A carbon-silicon-manganese-based, dual-phase steel technology, applied in the field of steel rolling, can solve problems such as high equipment capacity requirements and too strict requirements, and achieve the effects of excellent mechanical properties, increased strength, and improved work hardening index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

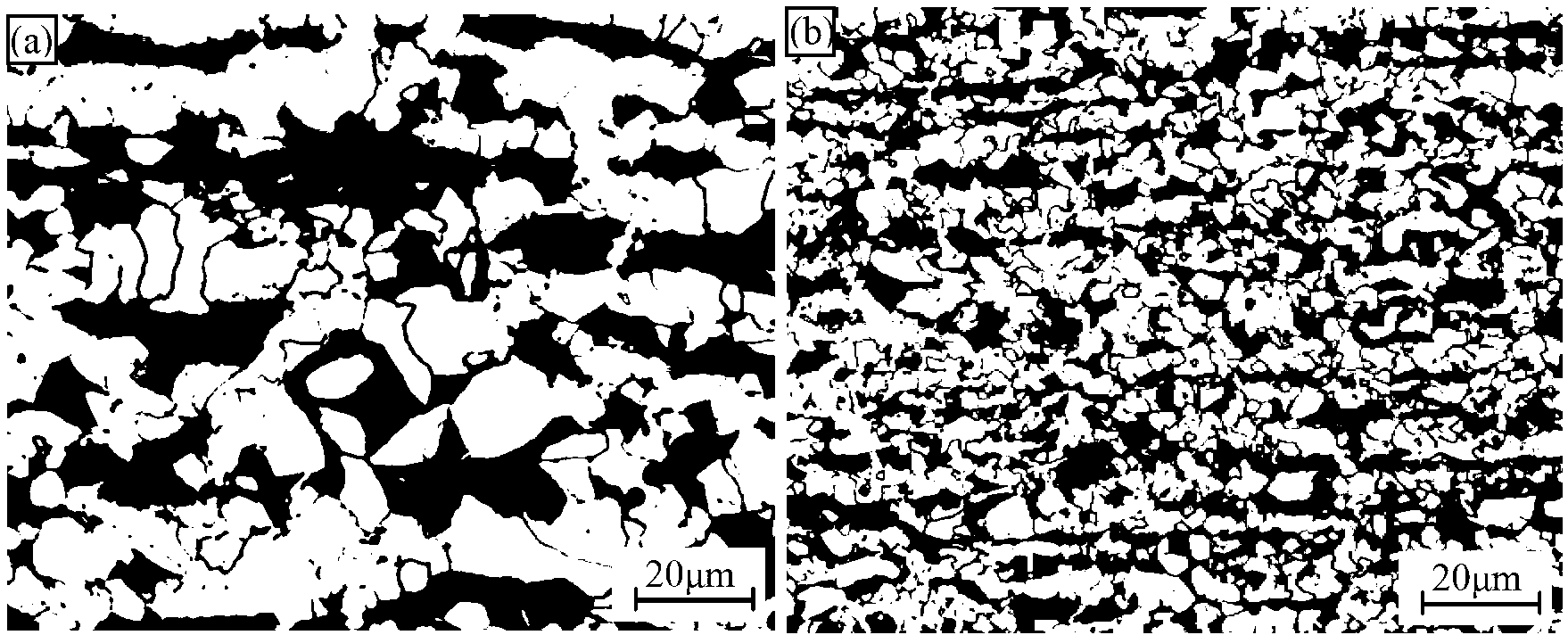

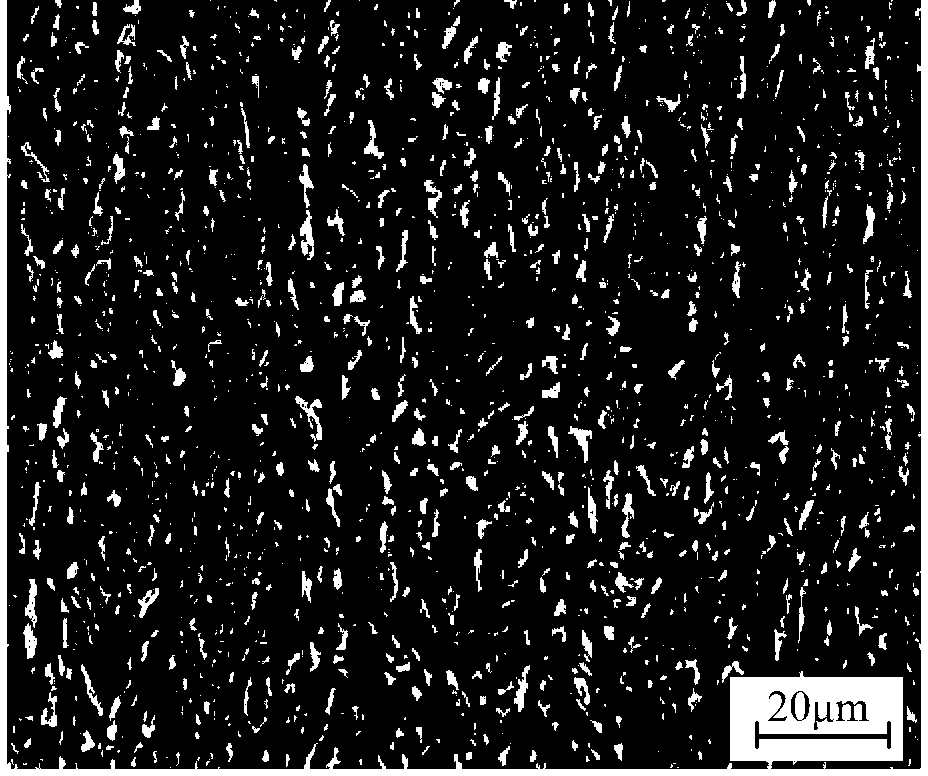

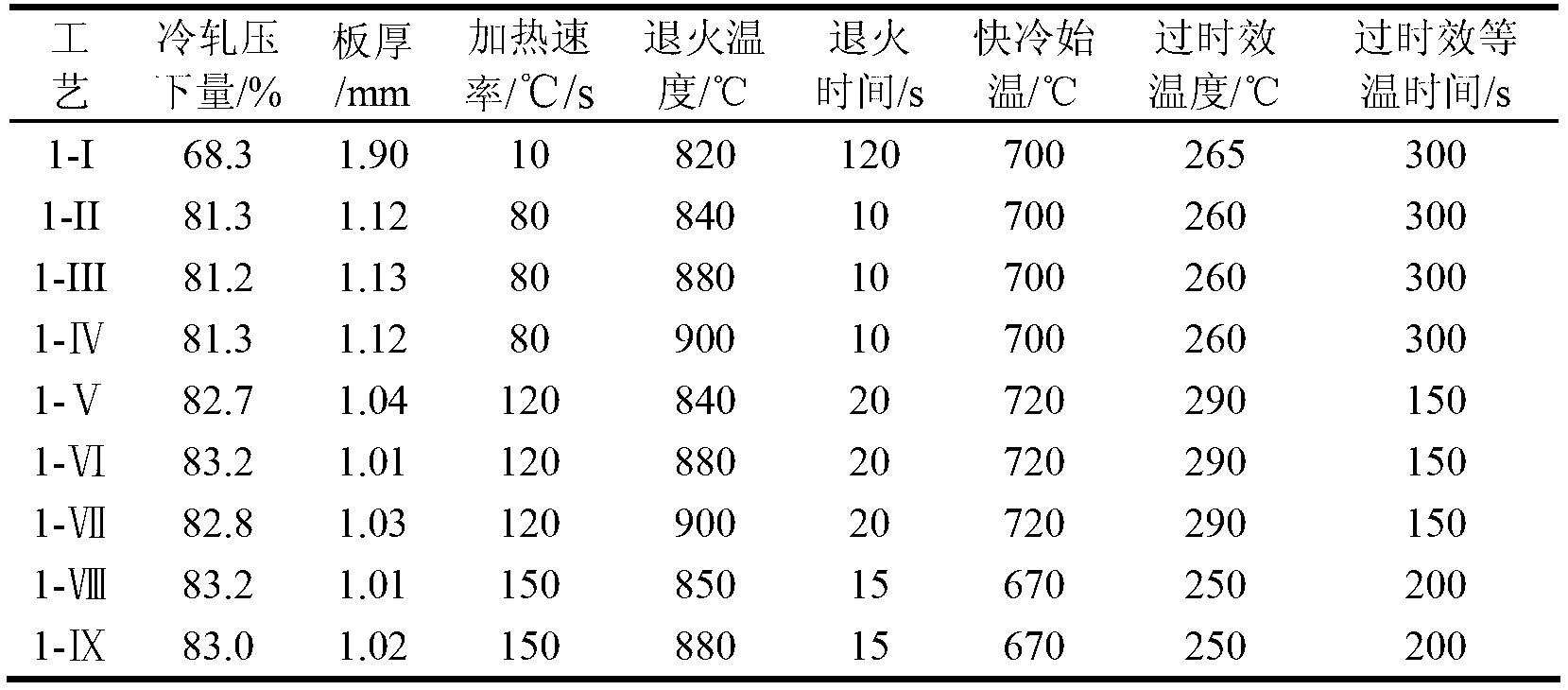

Embodiment 1

[0043] The chemical composition of the low-carbon silicon-manganese cold-rolled dual-phase steel used is C: 0.06%, Si: 0.25%, Mn: 1.71%, P: 0.003%, S: 0.016%, and the balance is Fe. Its A is measured from the thermal expansion curve c1 and A c3 759 and 890°C, respectively.

[0044] Using the above-mentioned low-carbon silicomanganese dual-phase steel, slabs with a thickness of 70 mm are made by smelting and forging, heated to 1100 ° C, kept for 1 h, and rough rolled. The rough rolling process is 4 passes, and the rough rolling start temperature is 1050 °C to obtain an intermediate billet with a thickness of 20 mm.

[0045] The intermediate billet is subjected to finish rolling, the finish rolling process is 5 passes, the finish rolling start temperature is 980°C, the finish rolling finish temperature is 840°C, and the thickness of the hot rolled plate after finish rolling is 6mm.

[0046] Process 1-I is directly air-cooled to room temperature according to the conventional p...

Embodiment 2

[0055] The chemical composition of the low-carbon silicon-manganese cold-rolled dual-phase steel used is C: 0.11%, Si: 0.14%, Mn: 1.81%, P: 0.015%, S: 0.01%, and the balance is Fe. Its A is measured from the thermal expansion curve c1 and A c3 746 and 854°C, respectively.

[0056] Using the above-mentioned low-carbon silicon-manganese dual-phase steel, slabs with a thickness of 60 mm are made by smelting and forging, heated to 1200 ° C, kept for 1 hour, and rough rolled. The rough rolling process is 4 passes, and the rough rolling start temperature is 1100 °C to obtain an intermediate billet with a thickness of 20 mm.

[0057] The intermediate billet is subjected to finish rolling, the finish rolling process is 5 passes, the finish rolling start temperature is 1000°C, the finish rolling finish temperature is 880°C, and the thickness of the hot rolled plate after finish rolling is 6mm.

[0058] Process 2-I after hot rolling and finishing rolling is directly air-cooled to roo...

Embodiment 3

[0067]The chemical composition of the low-carbon silicon-manganese cold-rolled dual-phase steel used is C: 0.16%, Si: 0.5%, Mn: 1.54%, V: 0.05%, P: 0.019%, S: 0.016%, and the rest The amount is Fe. Its A is measured from the thermal expansion curve c1 and A c3 728 and 865°C, respectively.

[0068] Using the above-mentioned low-carbon silicon-manganese dual-phase steel, slabs with a thickness of 60 mm are made by smelting and forging, heated to 1200 ° C, kept for 1 hour, and rough rolled. The rough rolling process is 4 passes, and the rough rolling start temperature is 1100 °C to obtain an intermediate billet with a thickness of 20 mm.

[0069] The intermediate billet is subjected to finish rolling, the finish rolling process is 5 passes, the finish rolling start temperature is 990°C, the finish rolling finish temperature is 876°C, and the thickness of the hot rolled plate after finish rolling is 6mm.

[0070] Process 3-I after hot rolling and finishing rolling is directly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com