Biomass pyrolysis liquefied technique and double tower apparatus system thereof

A biomass pyrolysis and process method technology, which is applied in the field of biomass regeneration and utilization and its energy utilization, achieves the effects of increasing the heating rate, being beneficial to control, and realizing energy saving and consumption reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

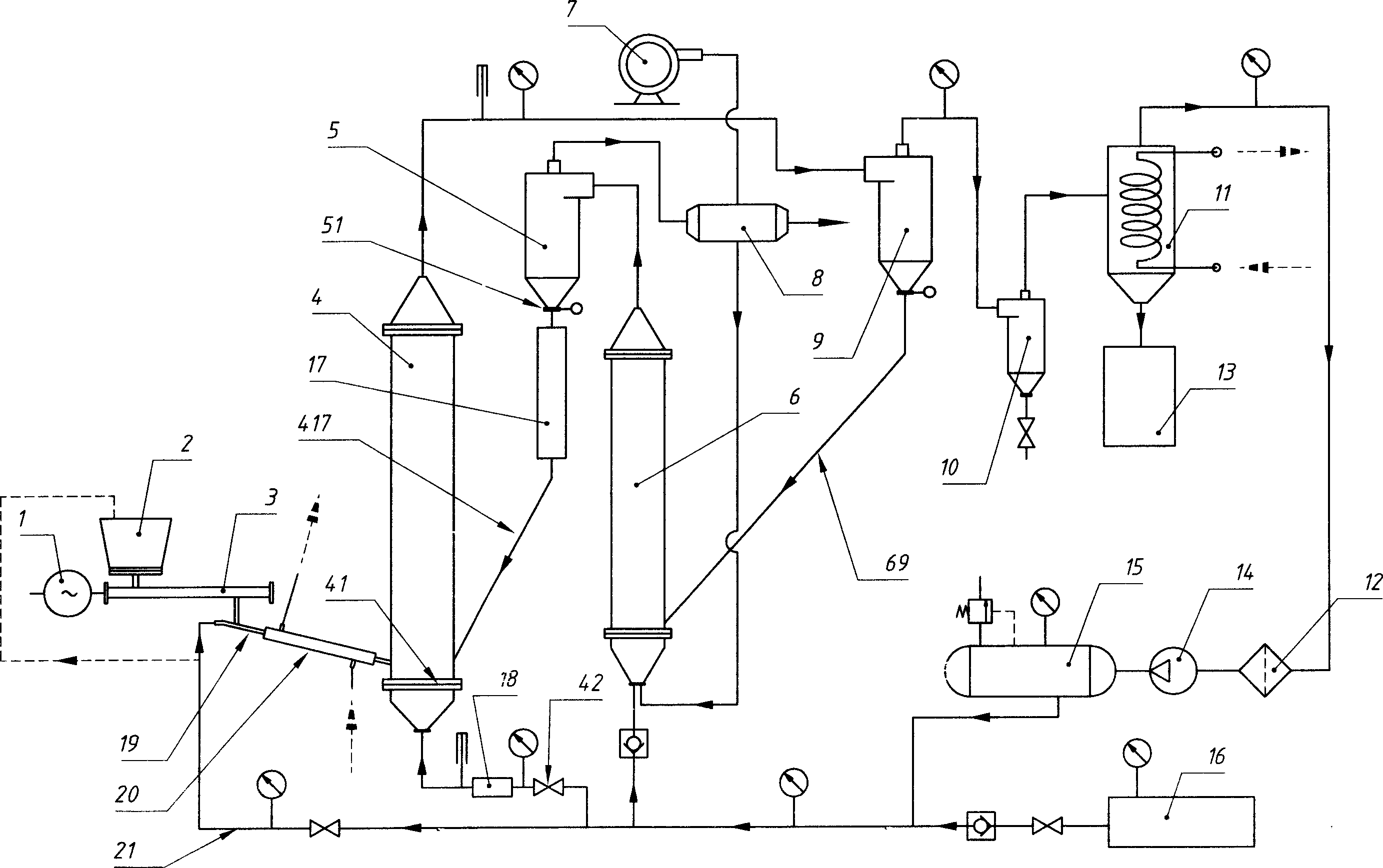

[0037] This example is based on the general description, and aims at the further specificity of the manner or structure in which the heating medium residual carbon circulation pipe 69 and the heating medium return pipe 417 transport the substances in the pipes. That is: in the device system of this example, the heating medium residual carbon circulation pipe 69 is inclined, and the inlet end of the circulation pipe 69 at the primary separator 9 is higher than the opening of the circulation pipe 69 at the heating medium heating tower 6 place. Outlet end; Similarly, heat carrier return pipe 417 is also inclined, and the inlet end of this return pipe 417 at heat carrier thermostat 17 place is higher than the outlet end of this return pipe 417 at pyrolysis reaction tower 4 places; The included angles between the inclination directions of the pipes (69, 417) and the horizontal plane are greater than 45°. That is to say, in this example, rely on the gravity of heat carrier and resid...

Embodiment 2

[0039] This example is on the basis of the general description part or embodiment 1, aiming at the further optimization of the heating rate of the pyrolysis reaction tower 4, that is: on the pipeline where the fluidization gas is imported into the pyrolysis reaction tower 4, another fluidization Gas thermostat 18. In other words, just in case the preheated heat carrier is not enough to increase the temperature rise rate in the pyrolysis reaction tower 4, the fluidizing gas thermostat 18 can be used to control the flow of the input into the pyrolysis reaction tower 4. Tempering of vaporized gas - preheating if necessary. At the same time, a corresponding thermometer should also be installed here. Of course, if conditions permit, the closer the fluidization gas thermostat 18 is to the input port at the bottom of the pyrolysis reaction tower 4, the better.

Embodiment 3

[0041] This example is based on the general description, Example 1 or Example 2, and is aimed at the further specificization of the mode or structure of auxiliary conveying of biomass powder with circulating carrier gas. That is: in the device system of this example, the feeding mechanism includes a screw conveying device 3 and a feed pipe 19 connected between the outlet of the screw conveying device 3 and the inlet of the pyrolysis reaction tower 4. The carrier gas input pipe is connected in the feed pipe 19 in the structural form of the injector, and the biomass powder is carried out auxiliary transportation in the mode of entrainment to allow the circulating carrier gas (because the structural form of the injector belongs to the technology of the field Personnel are clear, so a partially enlarged cross-sectional view is not drawn separately). Obviously, this example is an applicable structure under the condition that the dynamic pressure of the carrier gas in the carrier ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com