Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1984results about "Indirect heating destructive distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

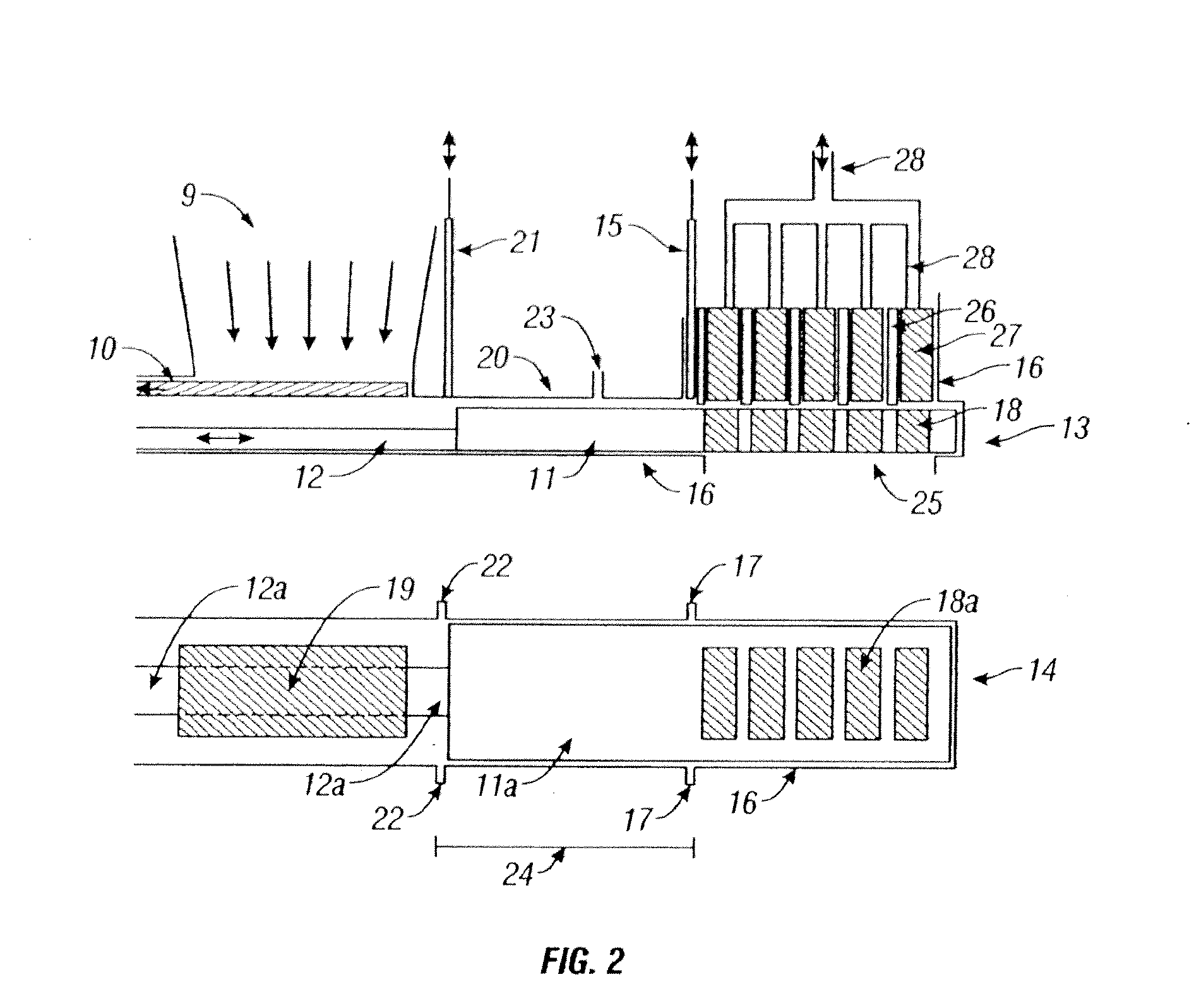

Rapid thermal conversion of biomass

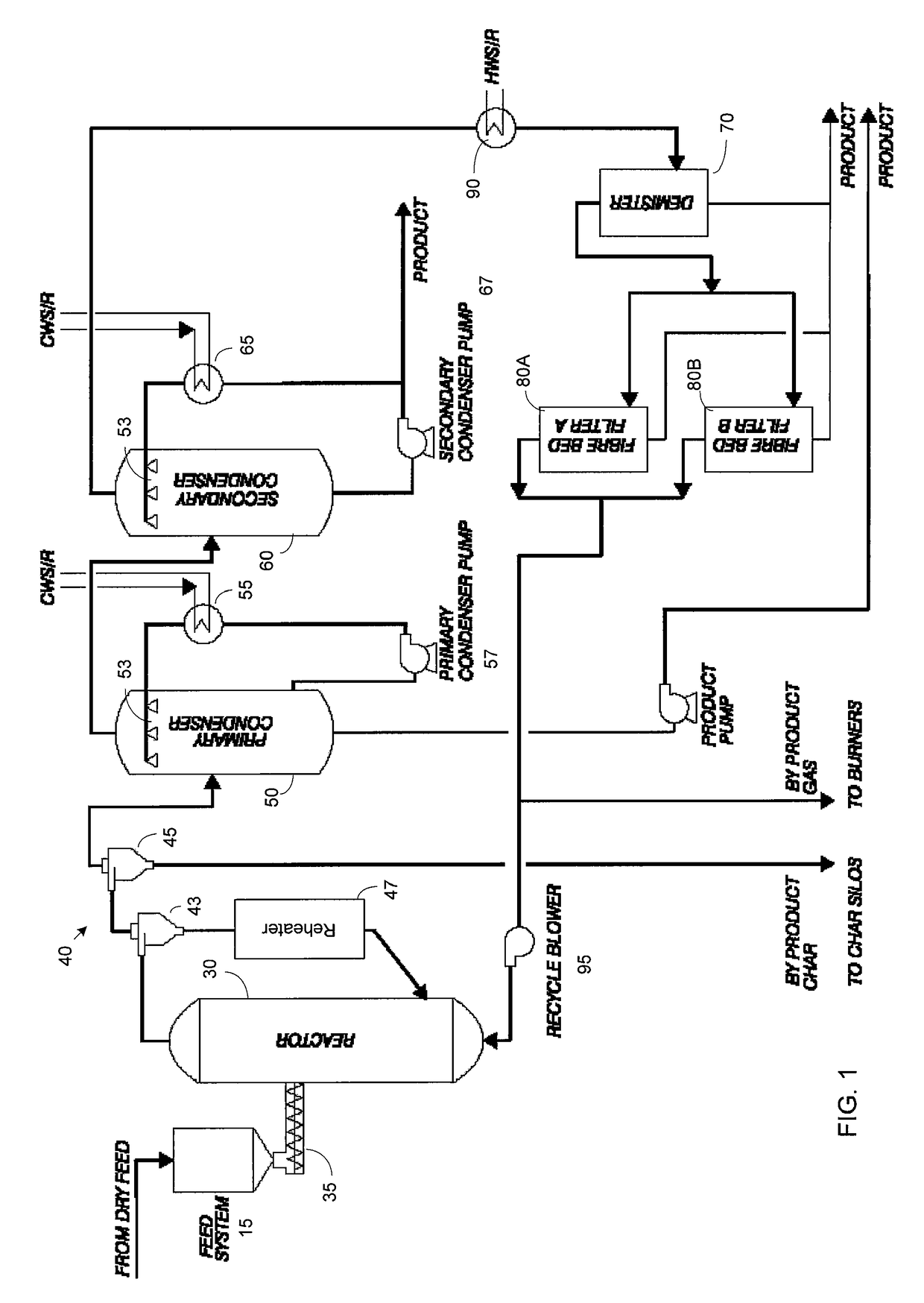

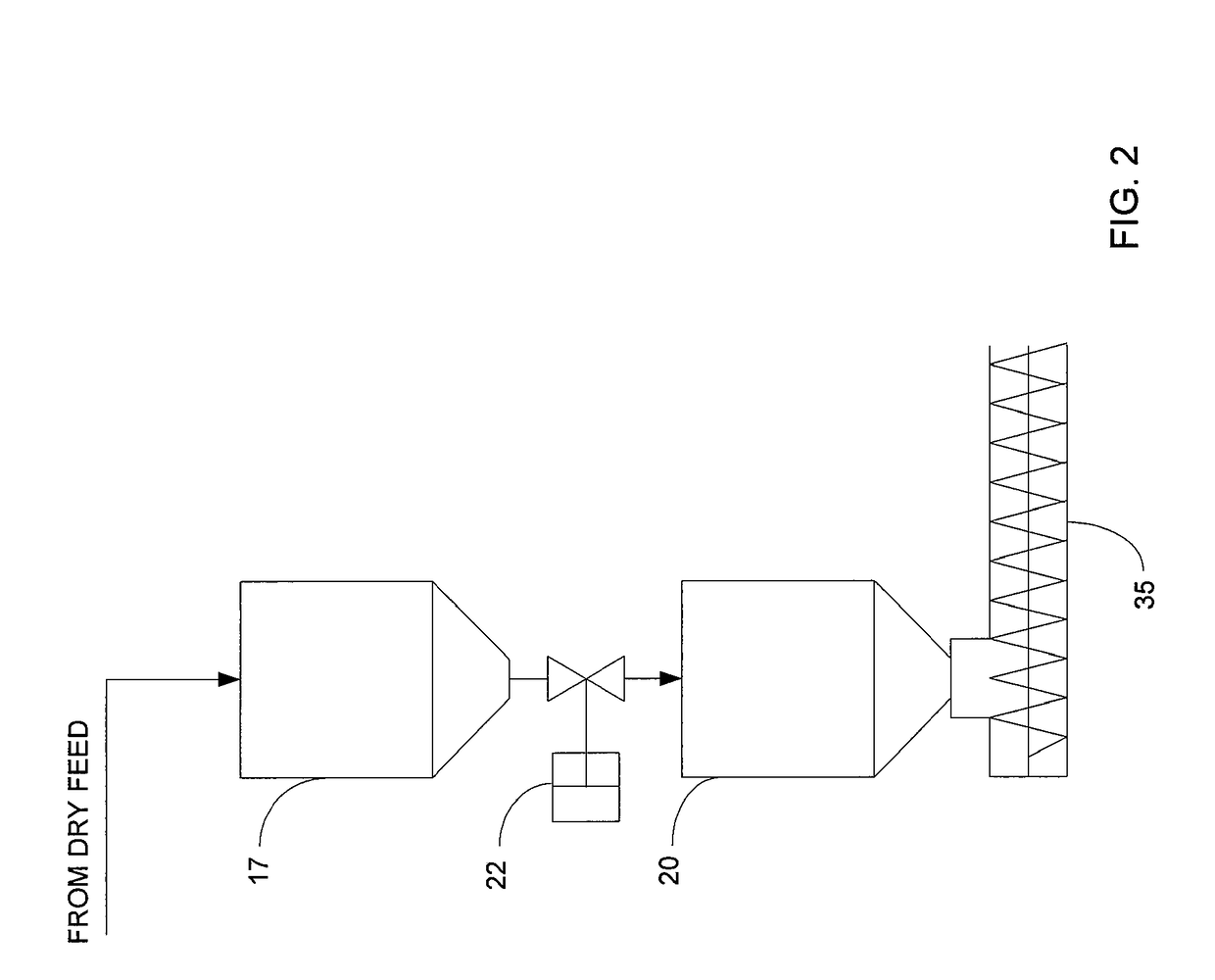

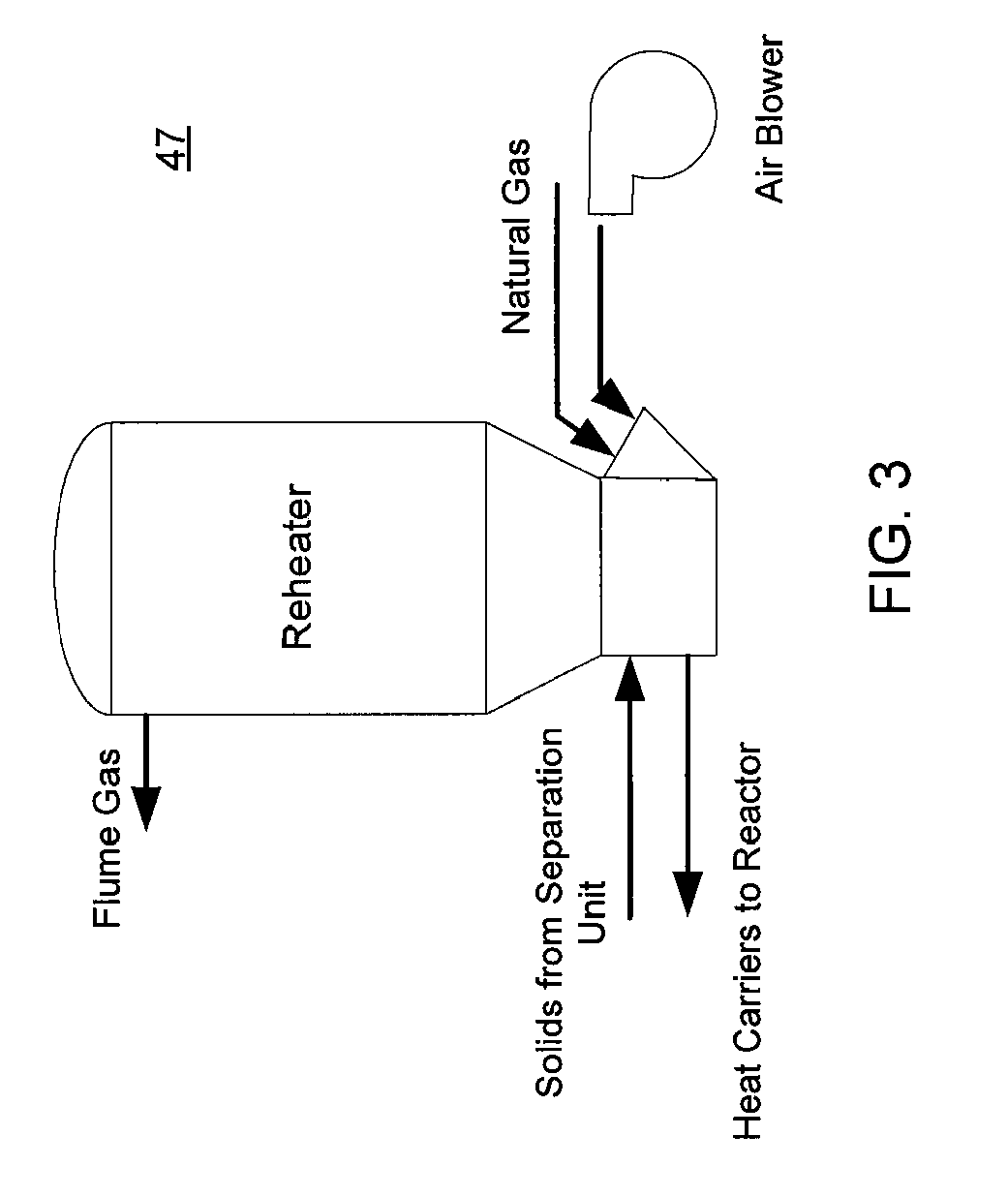

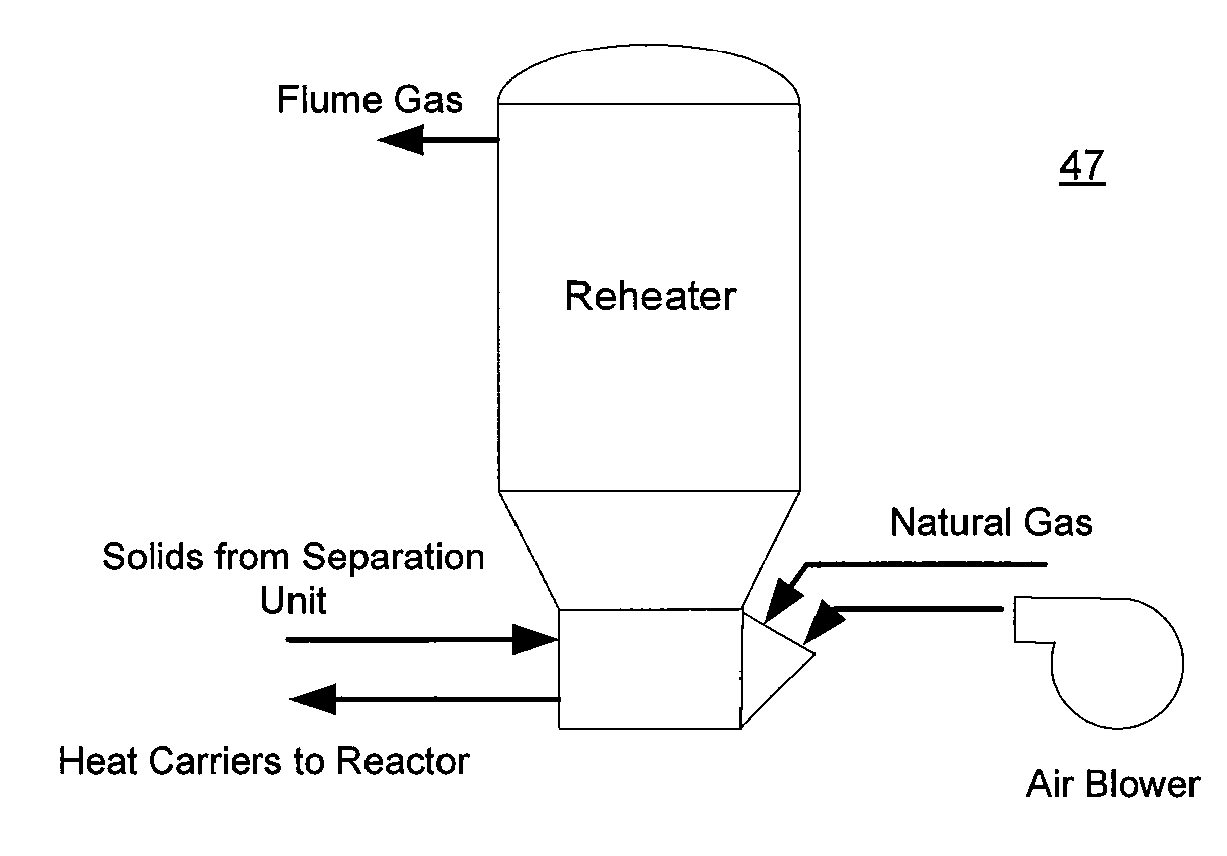

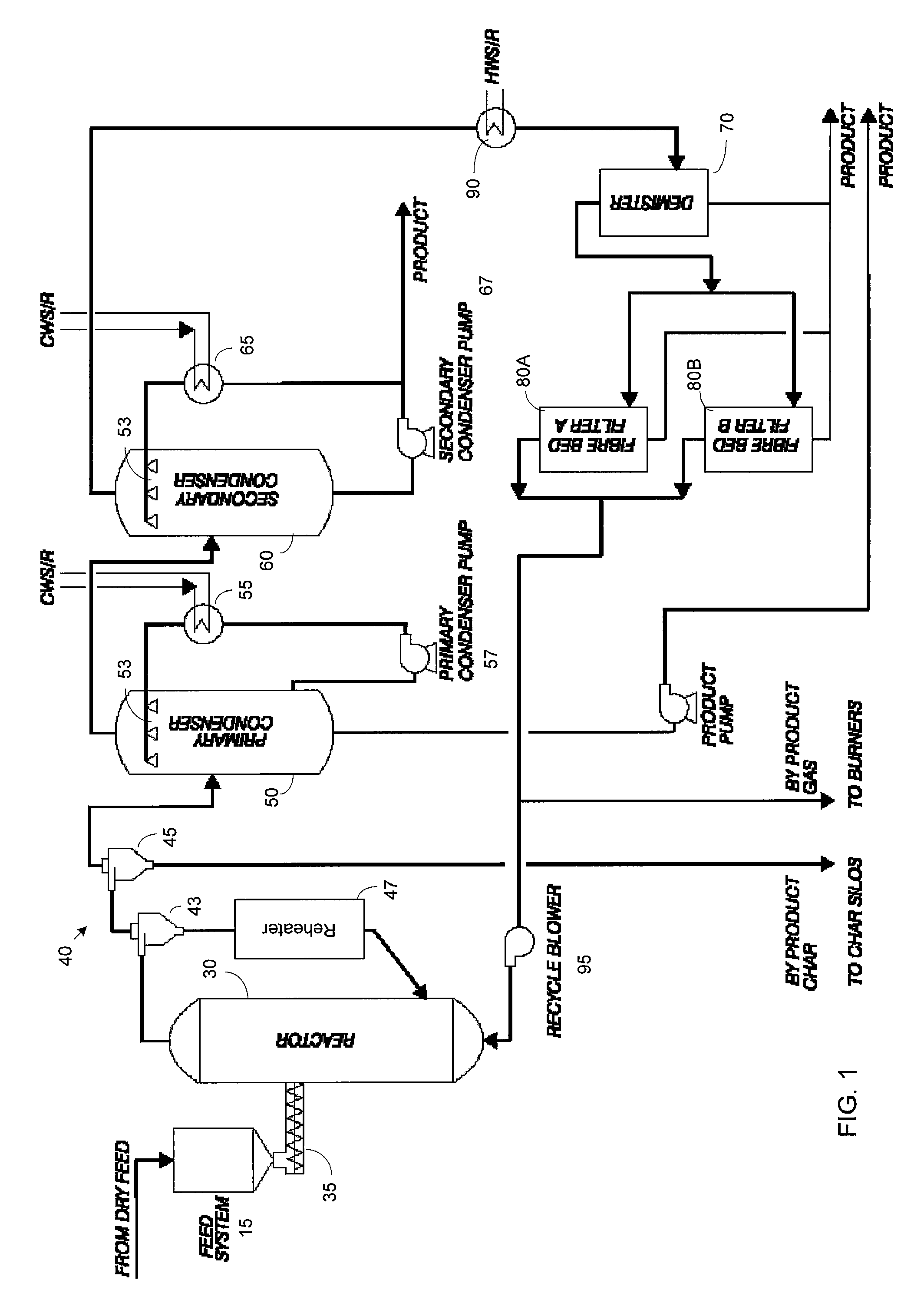

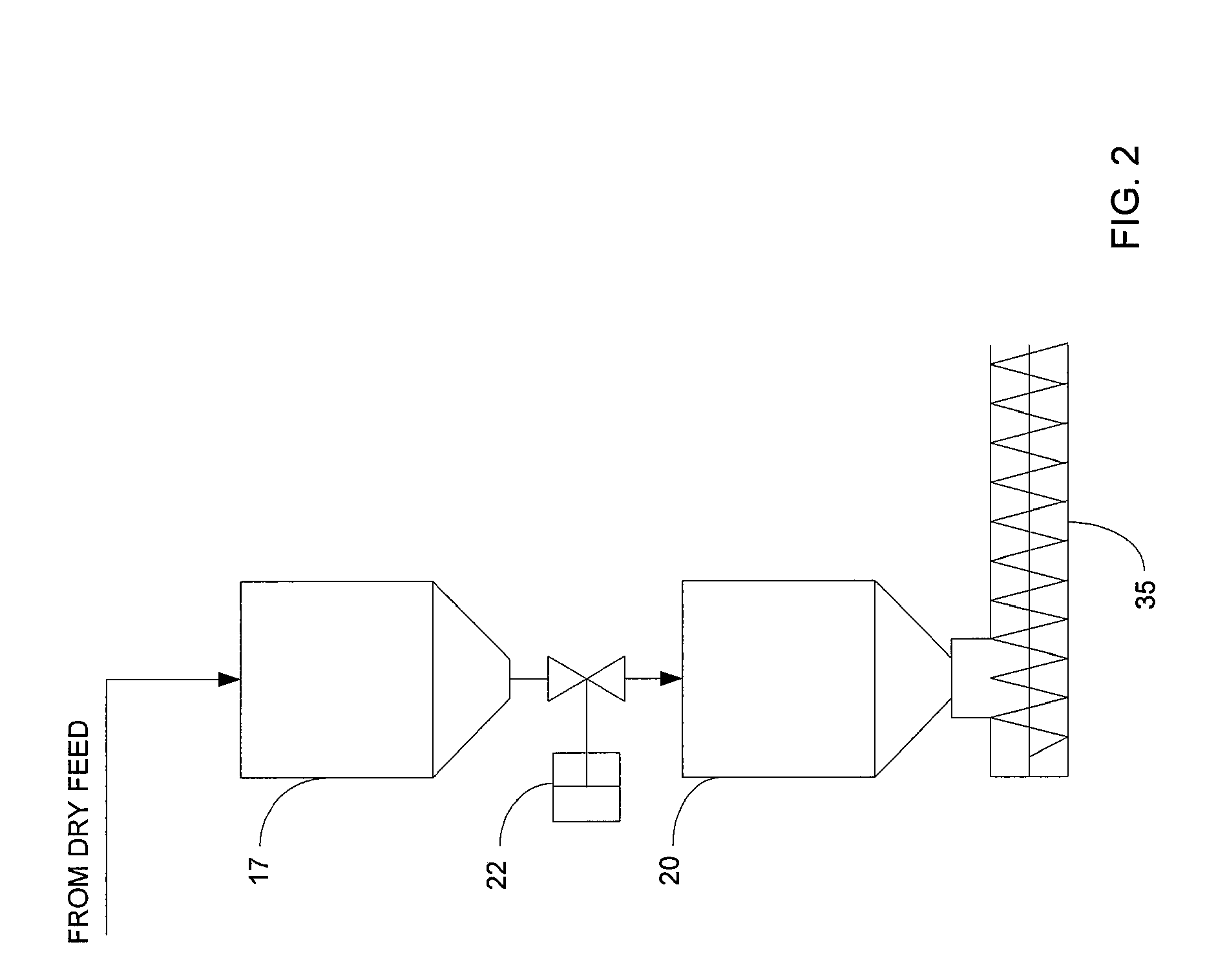

ActiveUS7905990B2Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingSolid waste disposalLiquid productHeat carrier

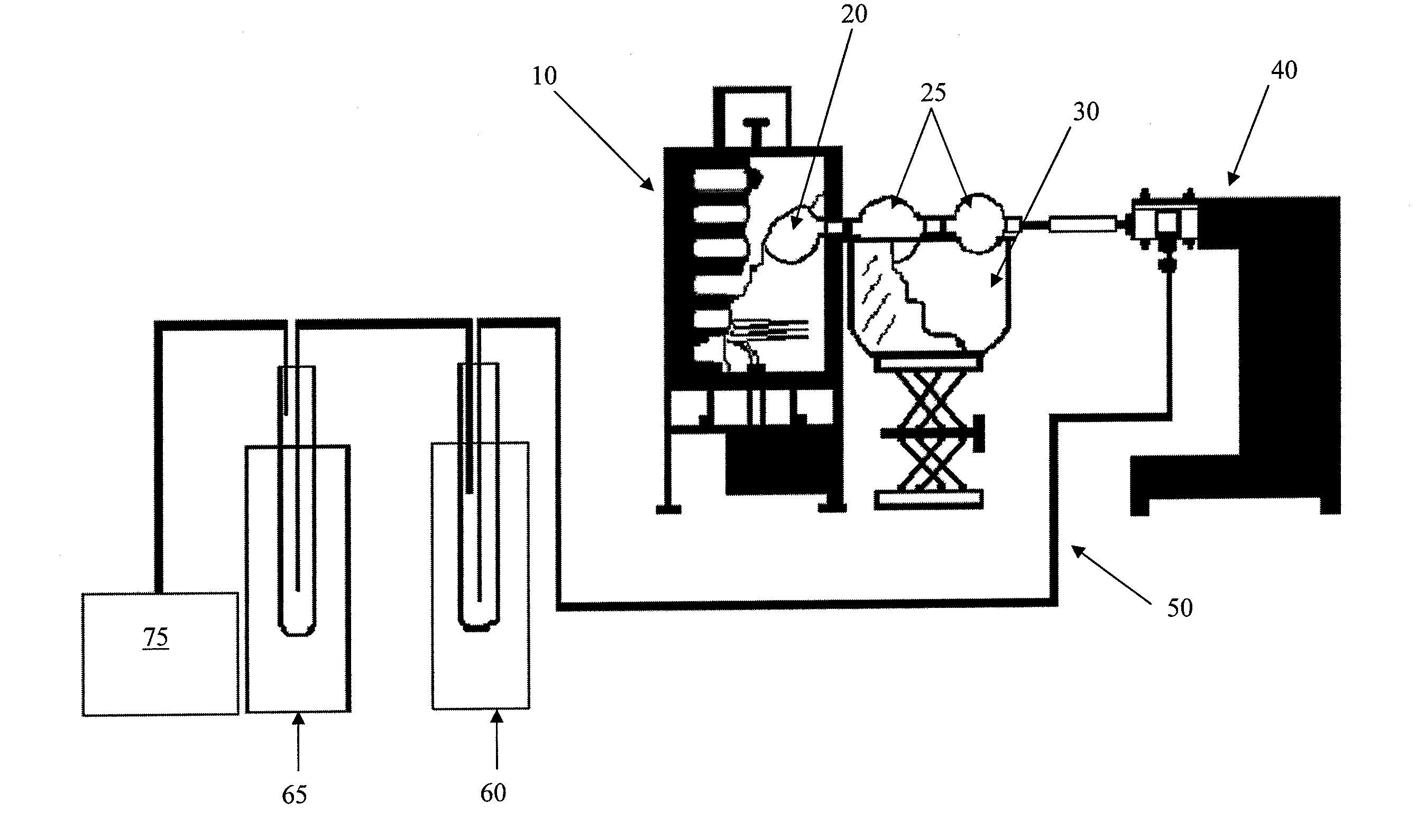

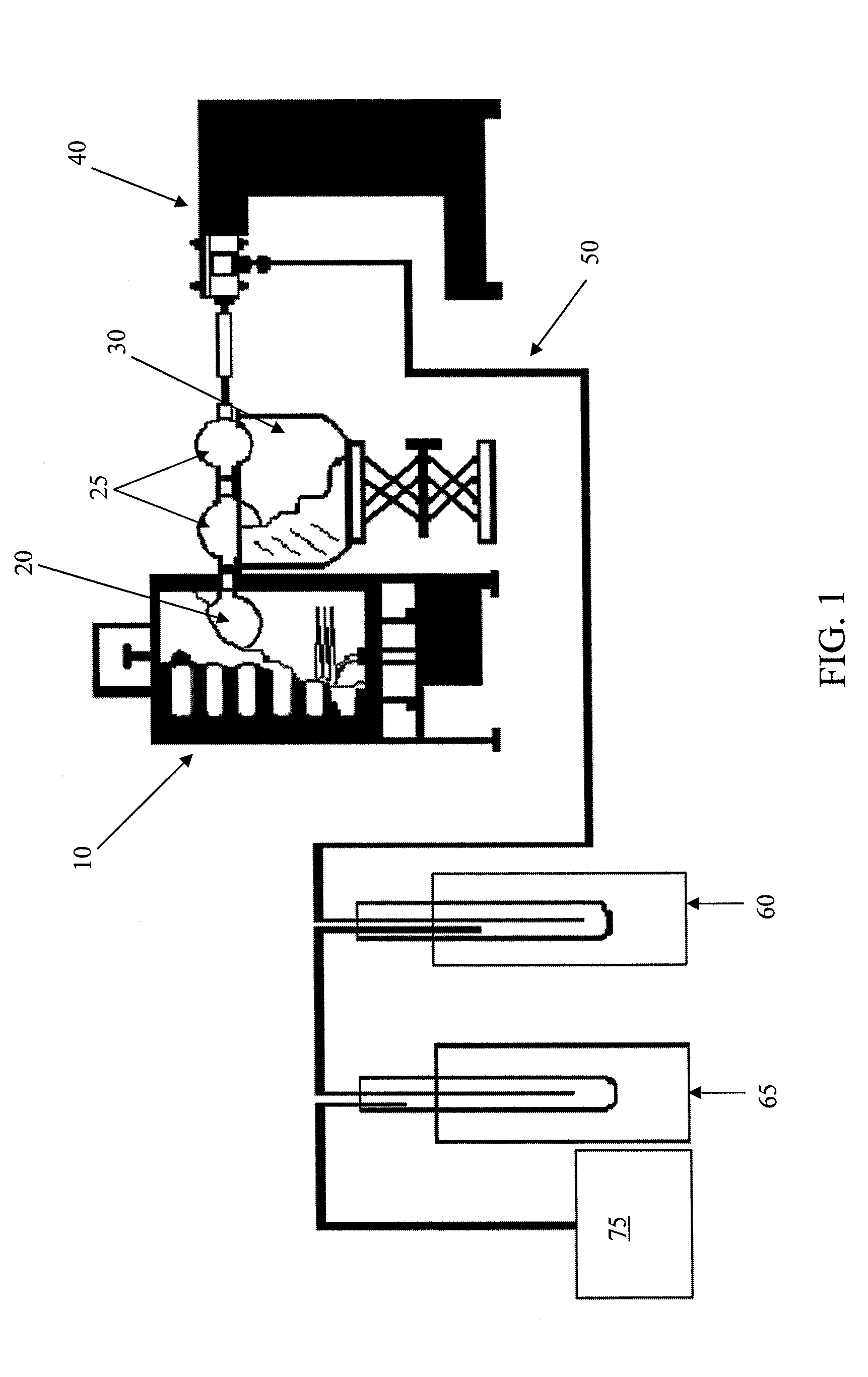

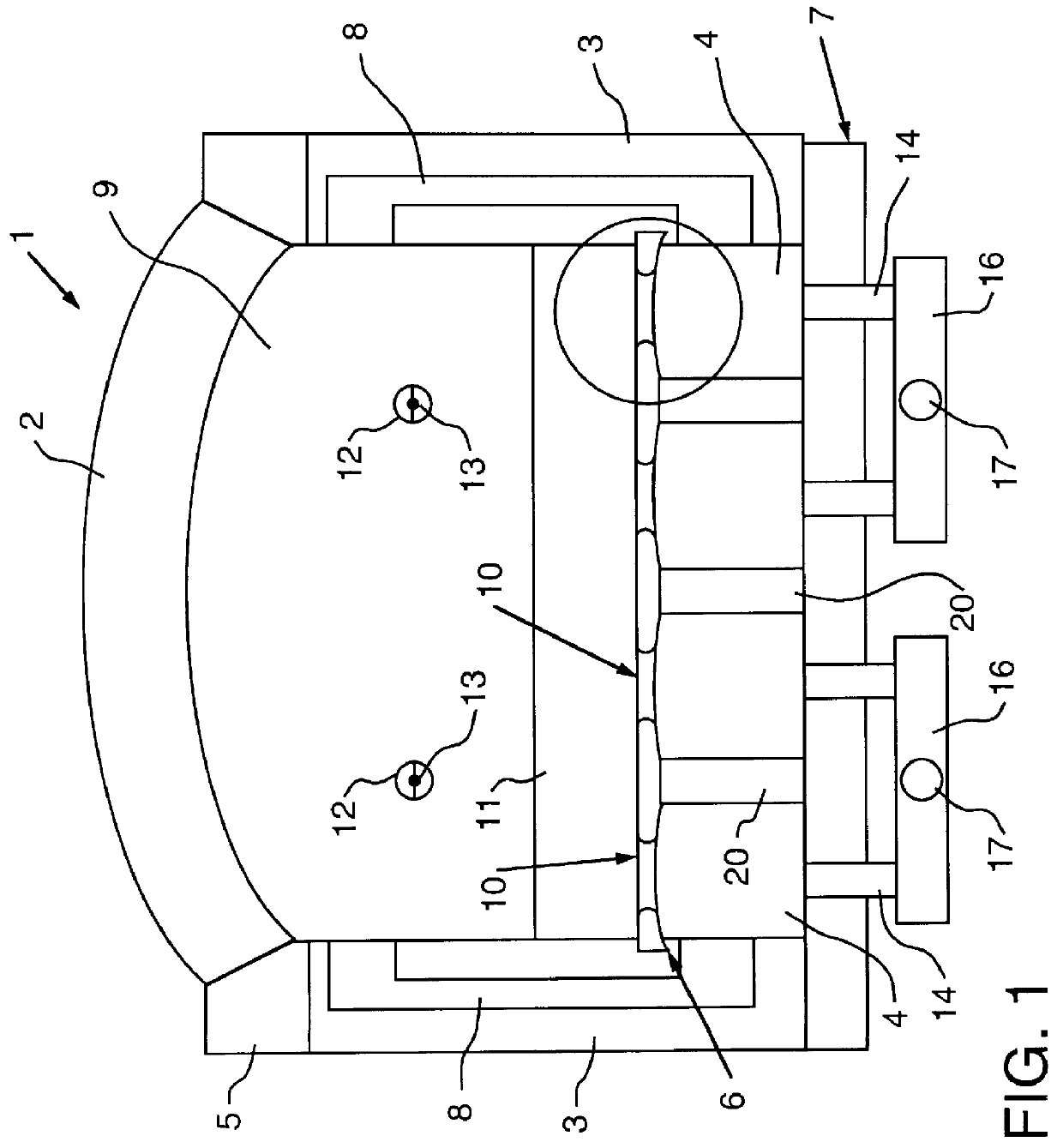

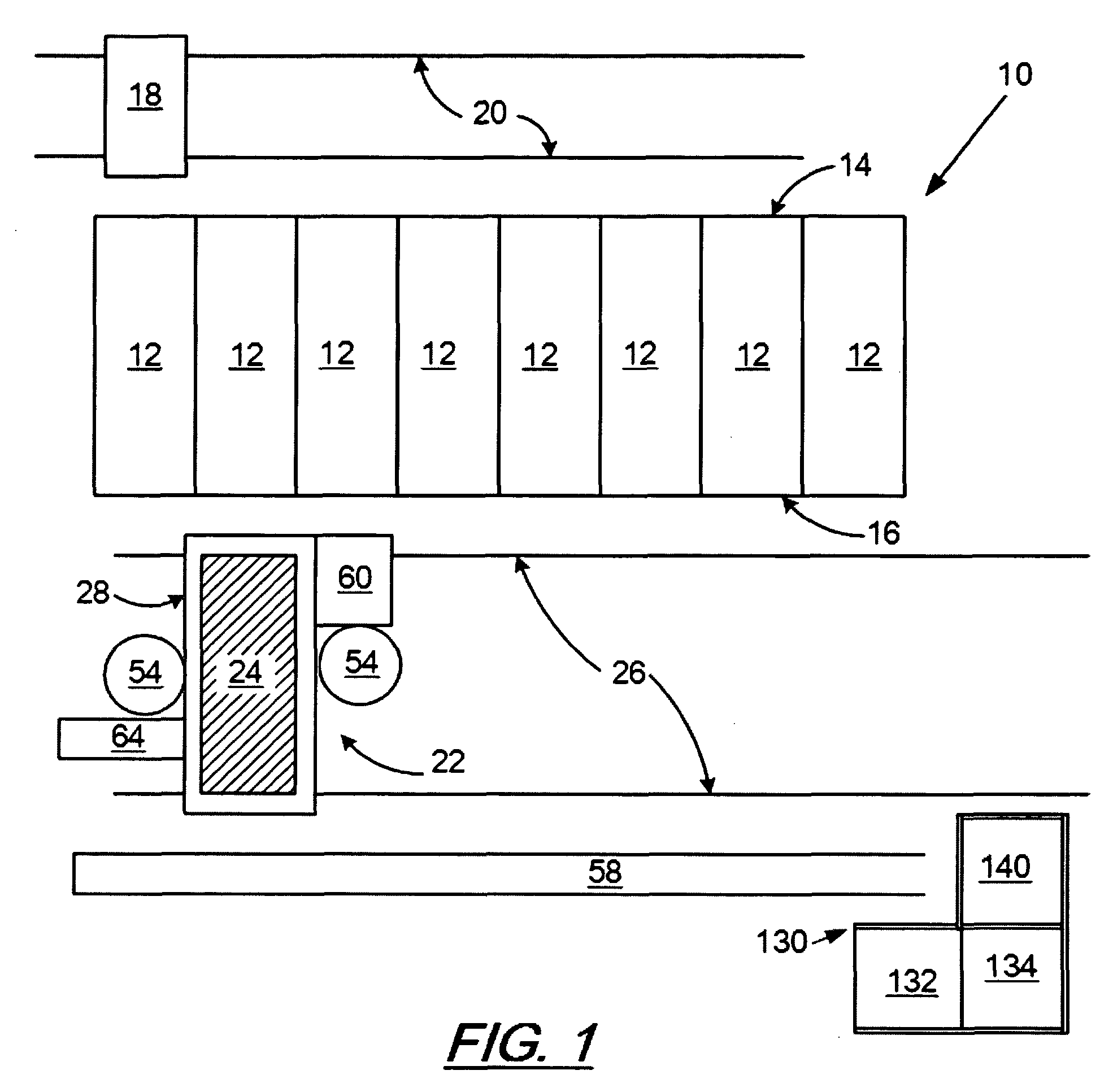

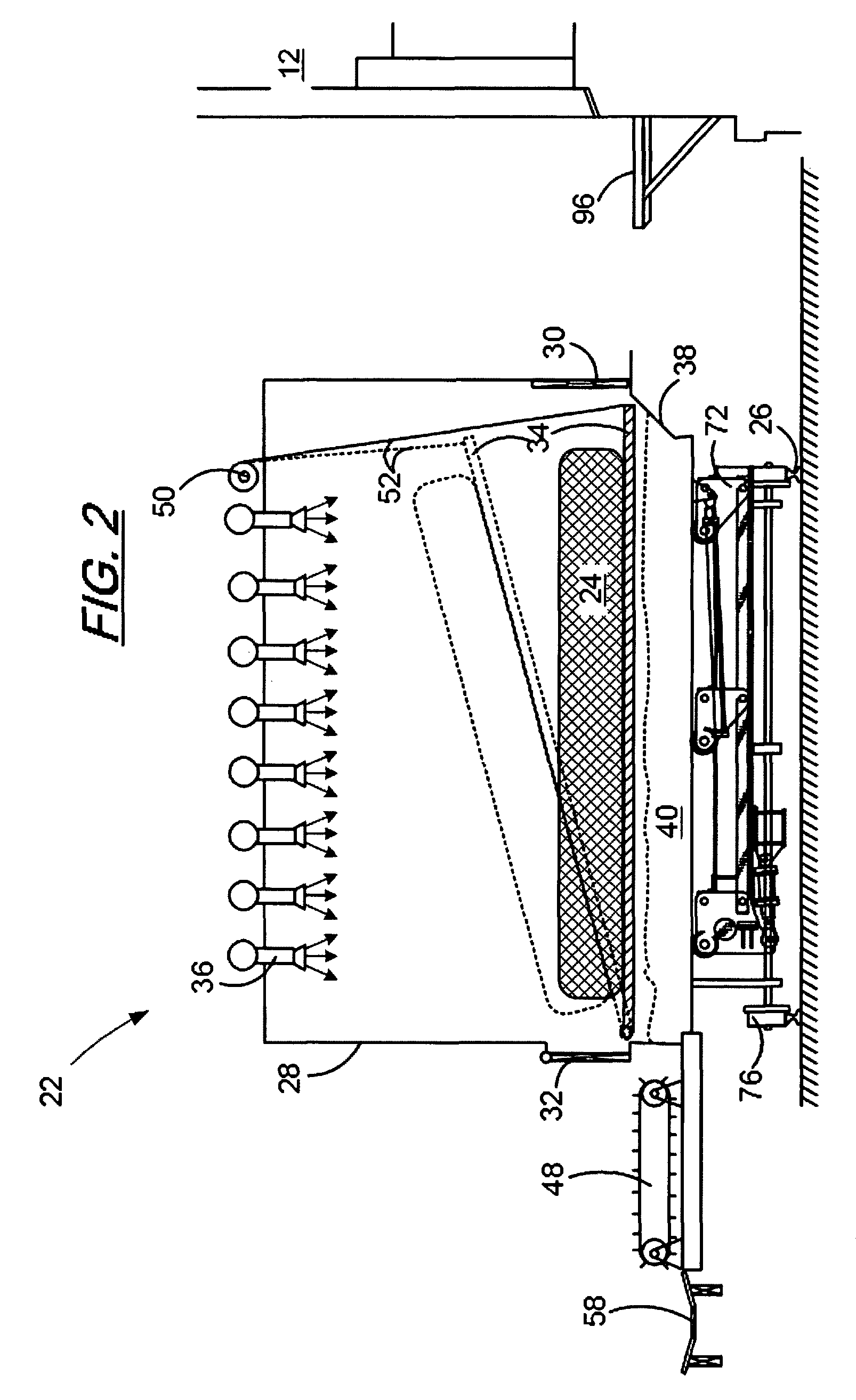

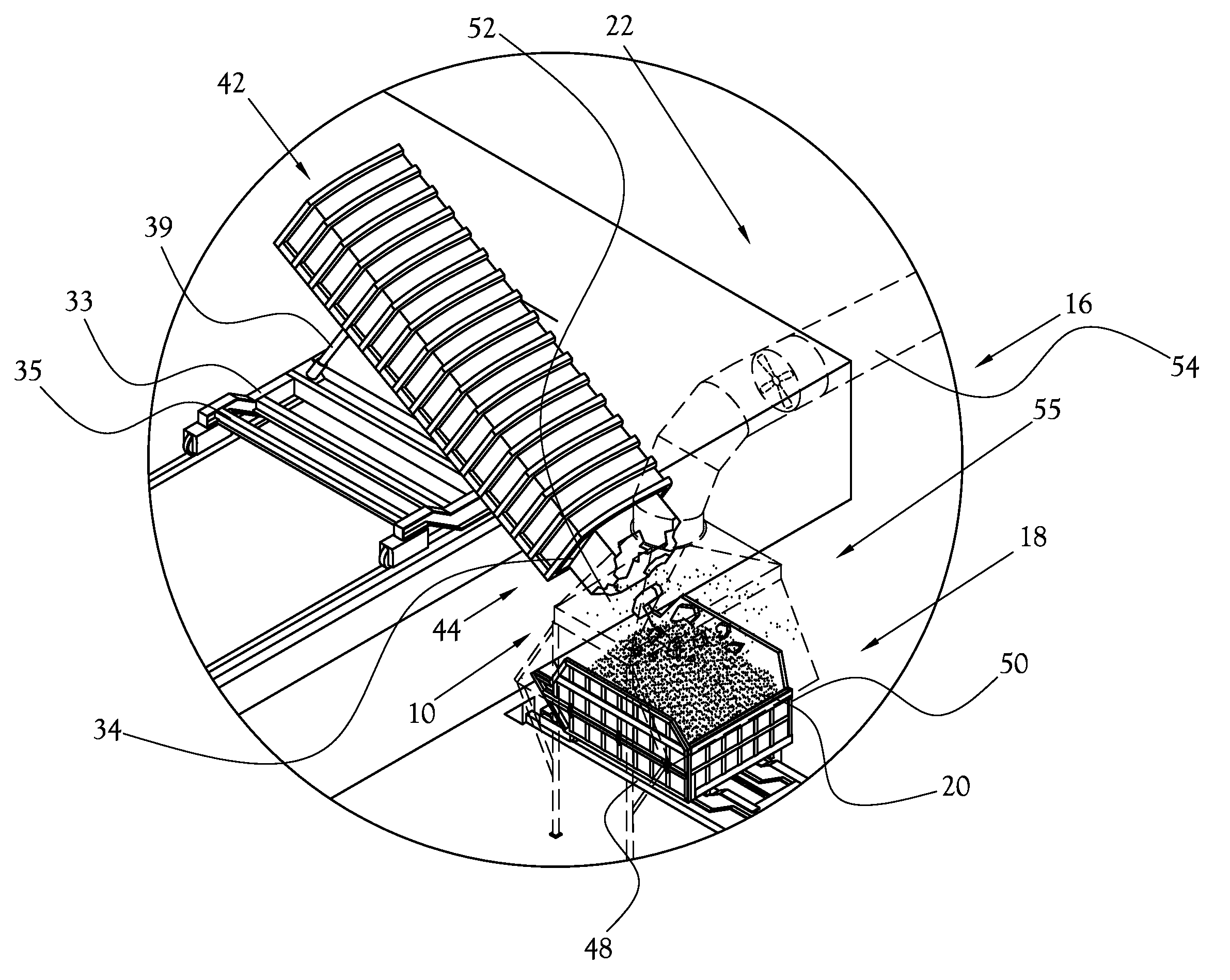

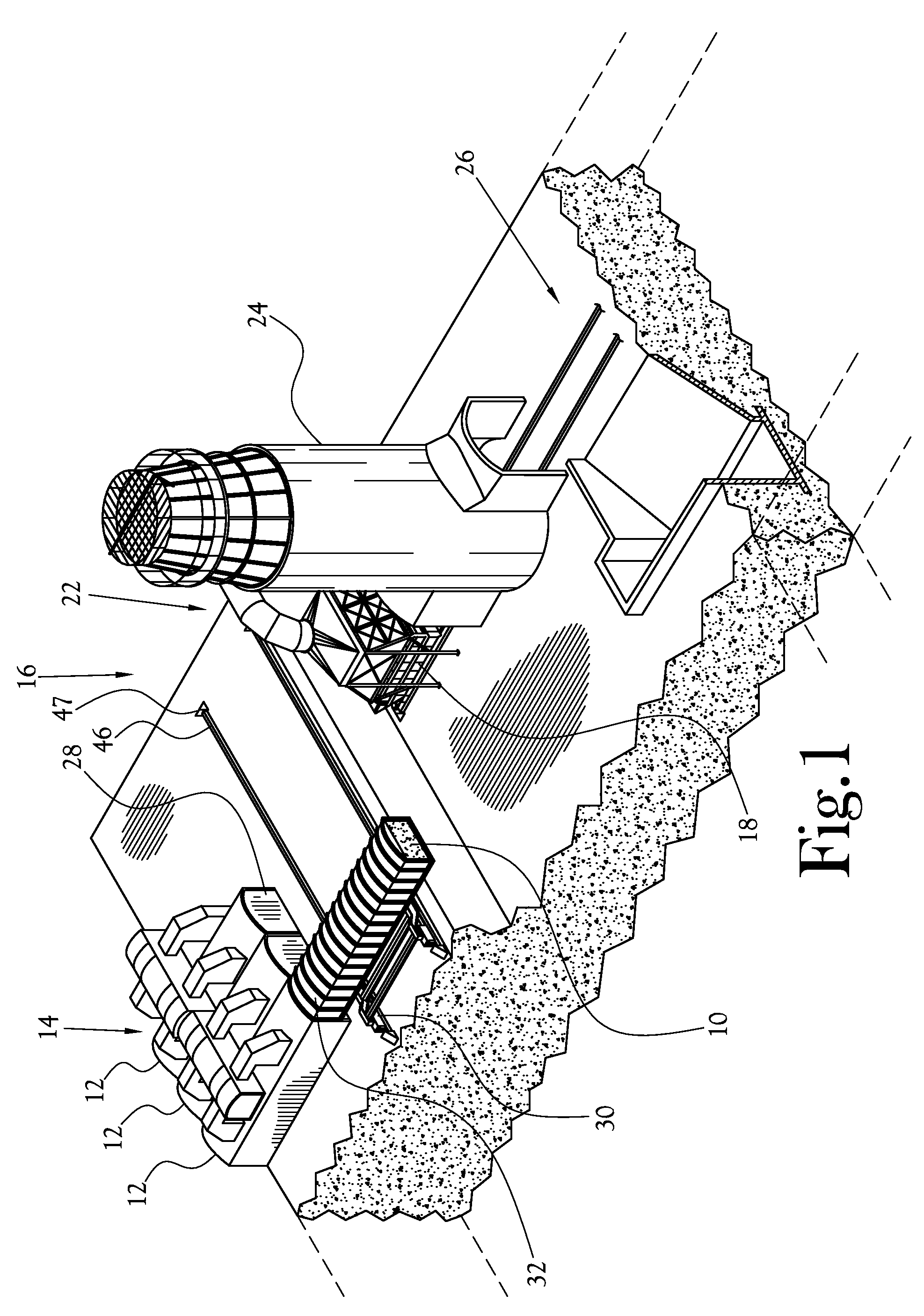

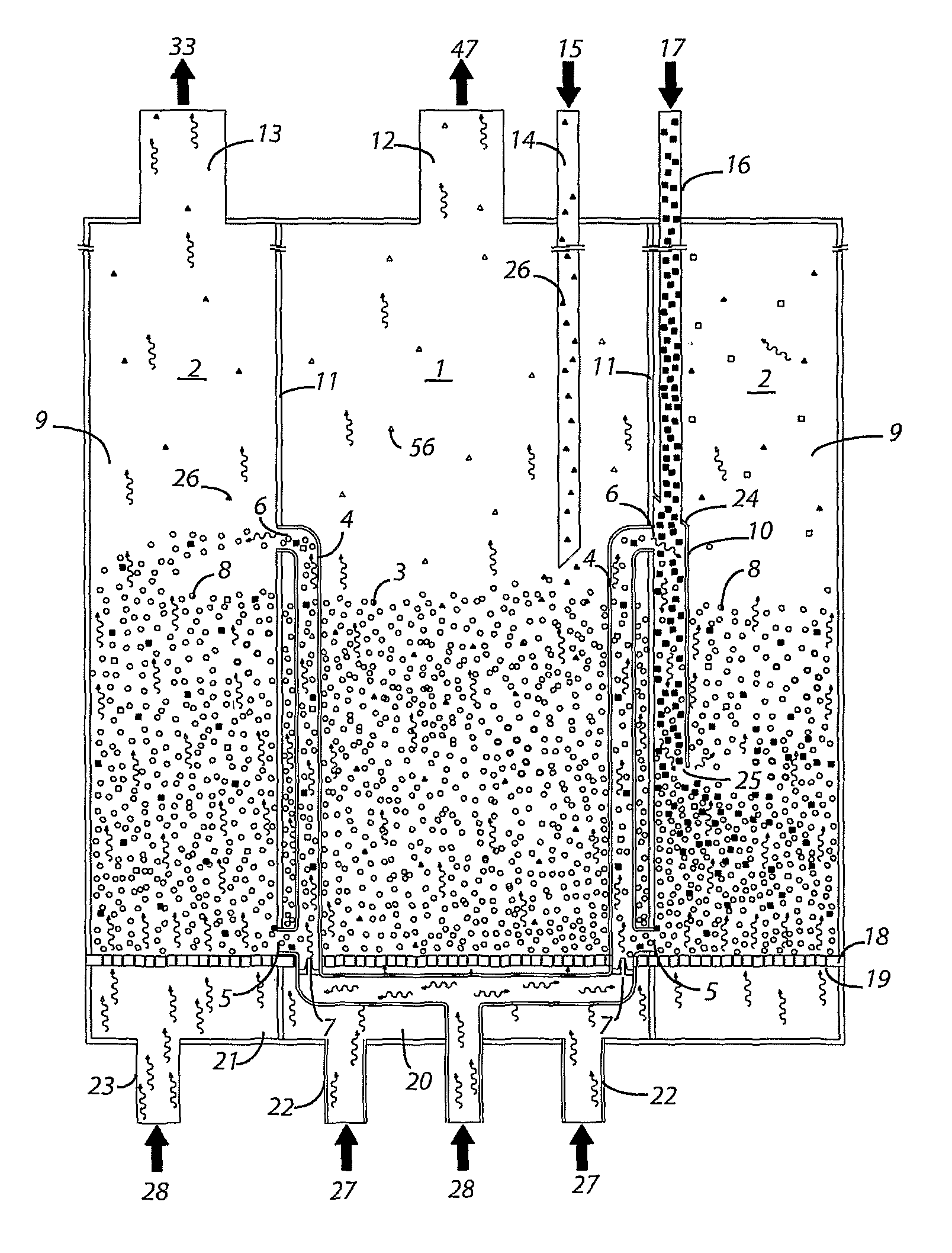

A rapid thermal conversion process for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. Biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. The liquid product may itself be used as the quench media.

Owner:ENSYN RENEWABLES

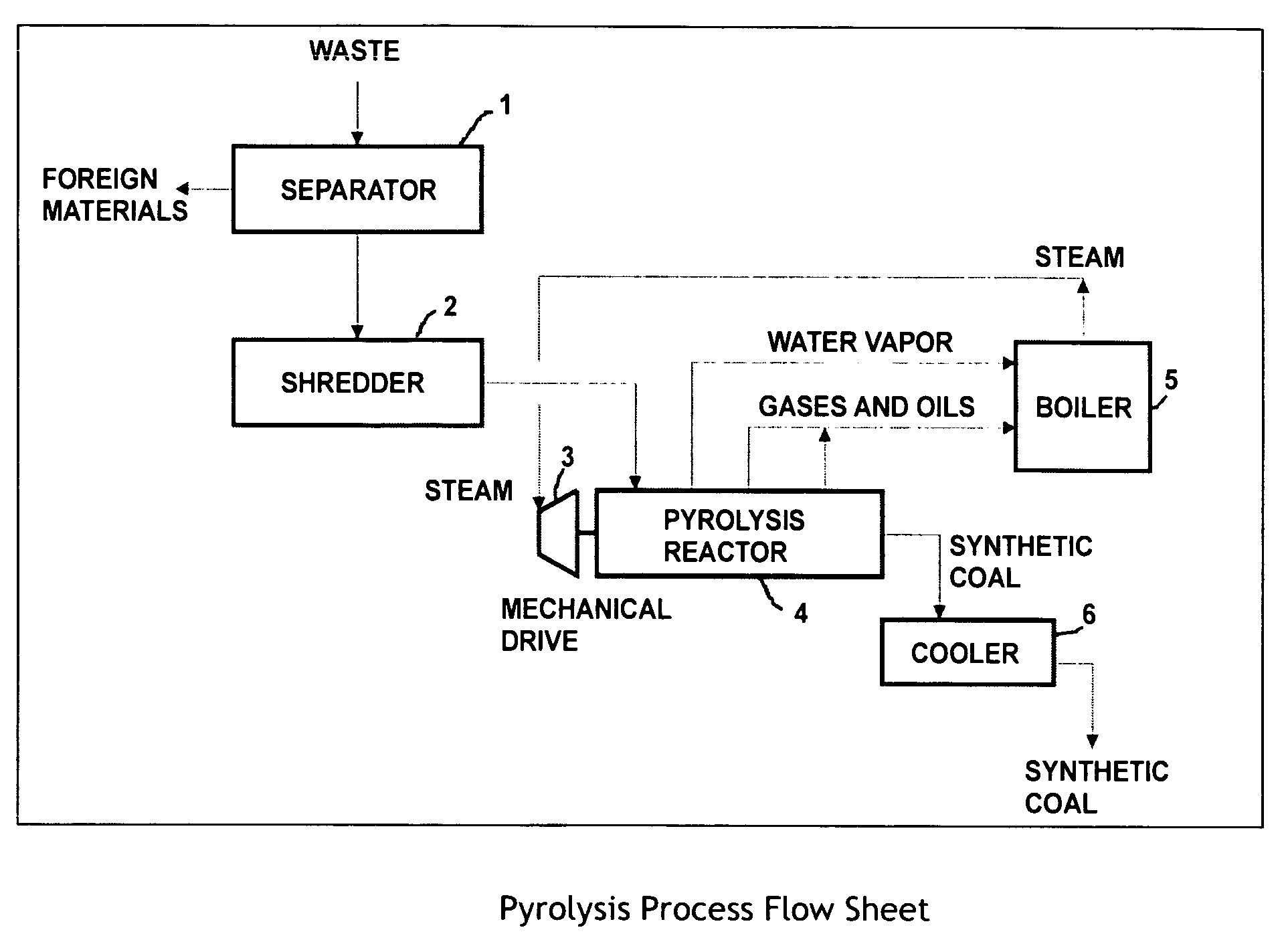

Waste conversion process

InactiveUS20060280669A1Good yieldMinimization requirementsBiofuelsIndirect and direct heating destructive distillationEnvironmental engineeringSand granules

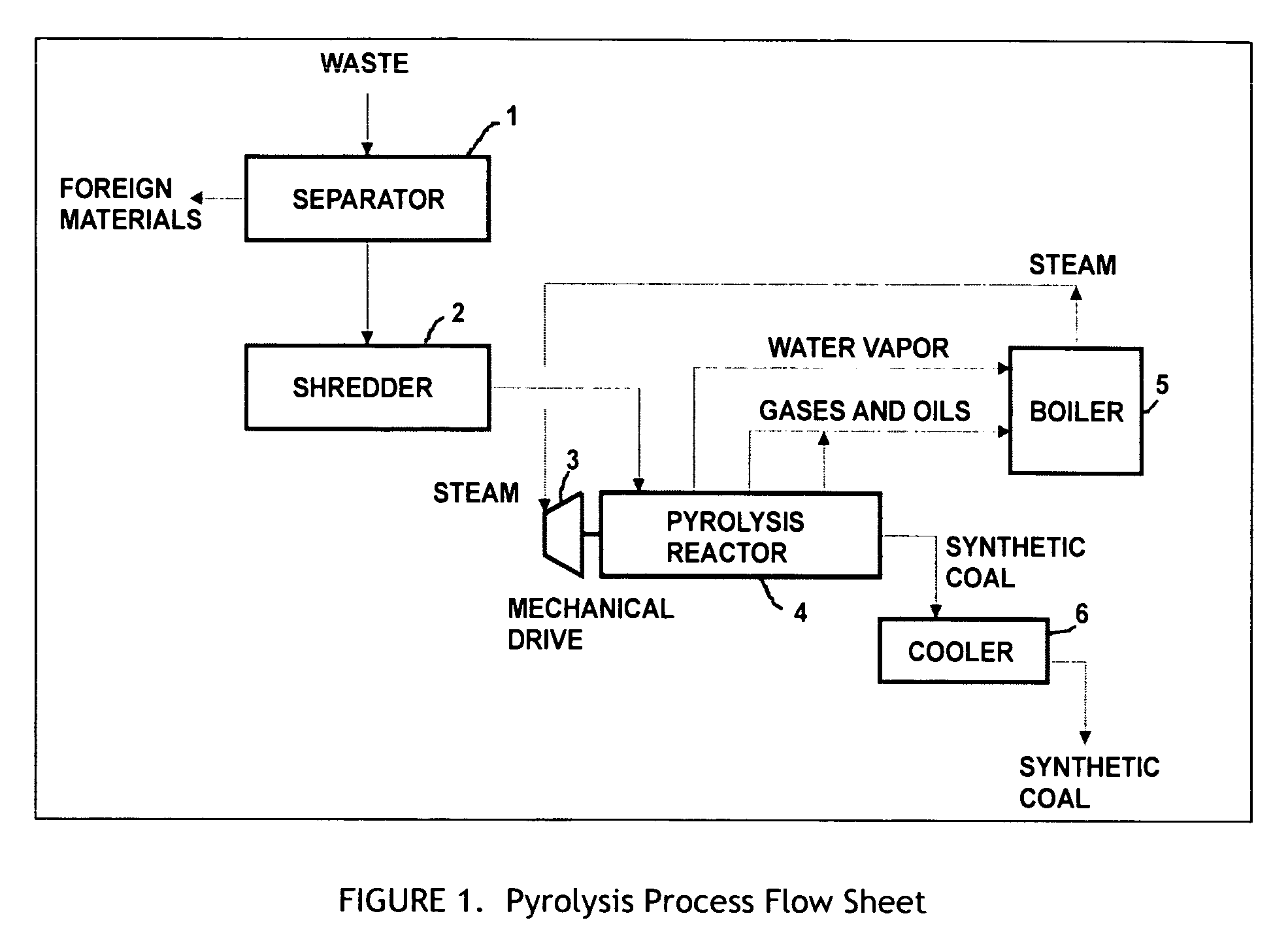

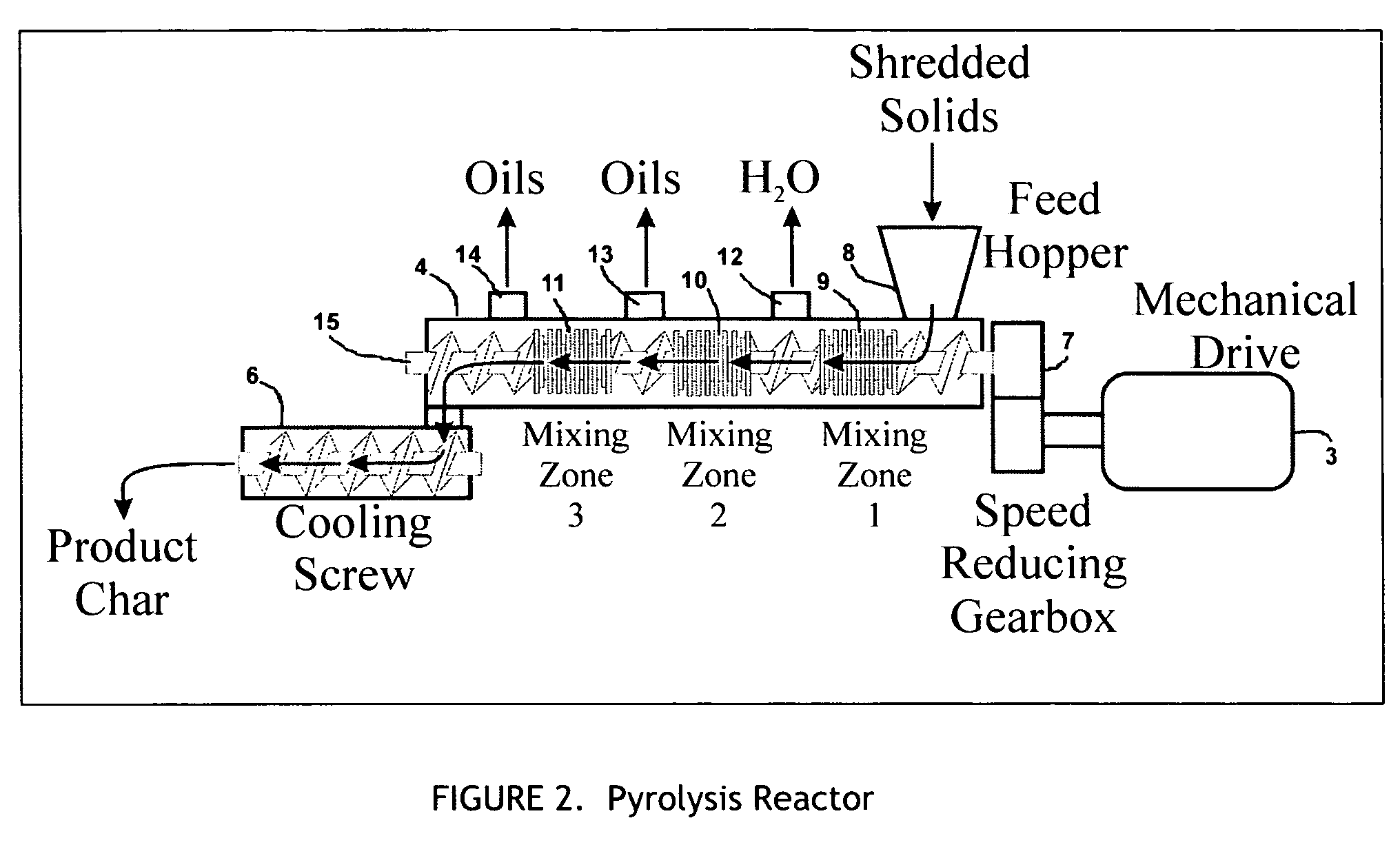

A process for the preparation of high quality char from organic waste materials. The waste is first sorted to remove recyclable inorganic materials of economic value (metals, glass) and other foreign materials that would be detrimental to the quality of the final product (stone, sand, construction debris, etc.). After size reduction, the waste is pyrolyzed at a temperature range of 250 to 600° F., in a high capacity, continuous mixer reactor, using in-situ viscous heating of the waste materials, to produce a highly uniform, granular synthetic product similar in energy content and handling characteristics to, but much cleaner burning than, natural coal.

Owner:ENTROPIC TECH CORP

Fractional catalytic pyrolysis of biomass

ActiveUS20090165378A1Eliminate needBiofuelsIndirect heating destructive distillationCatalytic pyrolysisReactive gas

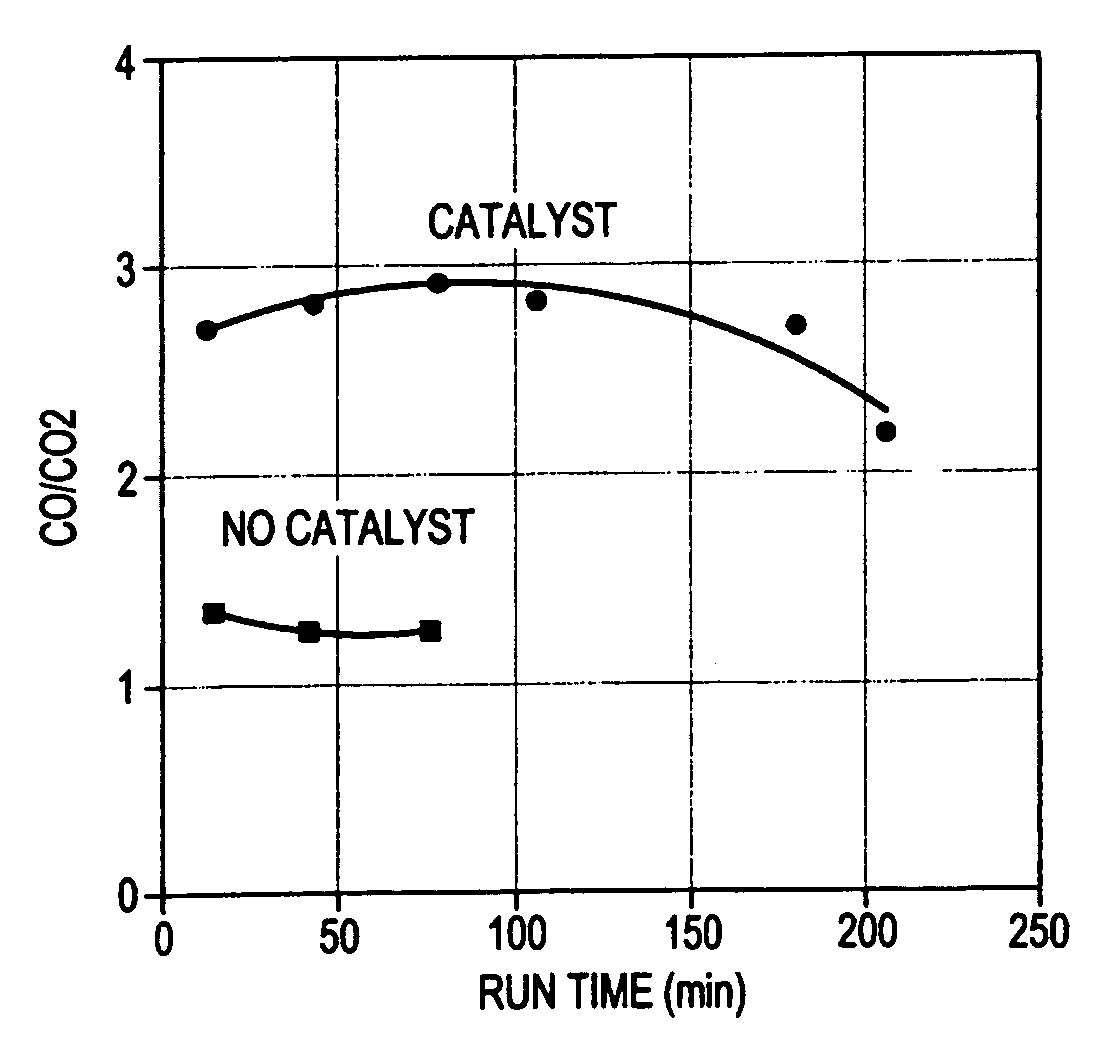

Methods for fractional catalytic pyrolysis which allow for conversion of biomass into a slate of desired products without the need for post-pyrolysis separation are described. The methods involve use of a fluid catalytic bed which is maintained at a suitable pyrolysis temperature. Biomass is added to the catalytic bed, preferably while entrained in a non-reactive gas such as nitrogen, causing the biomass to become pyrolyzed and forming the desired products in vapor and gas forms, allowing the desired products to be easily separated.

Owner:VIRGINIA TECH INTPROP INC

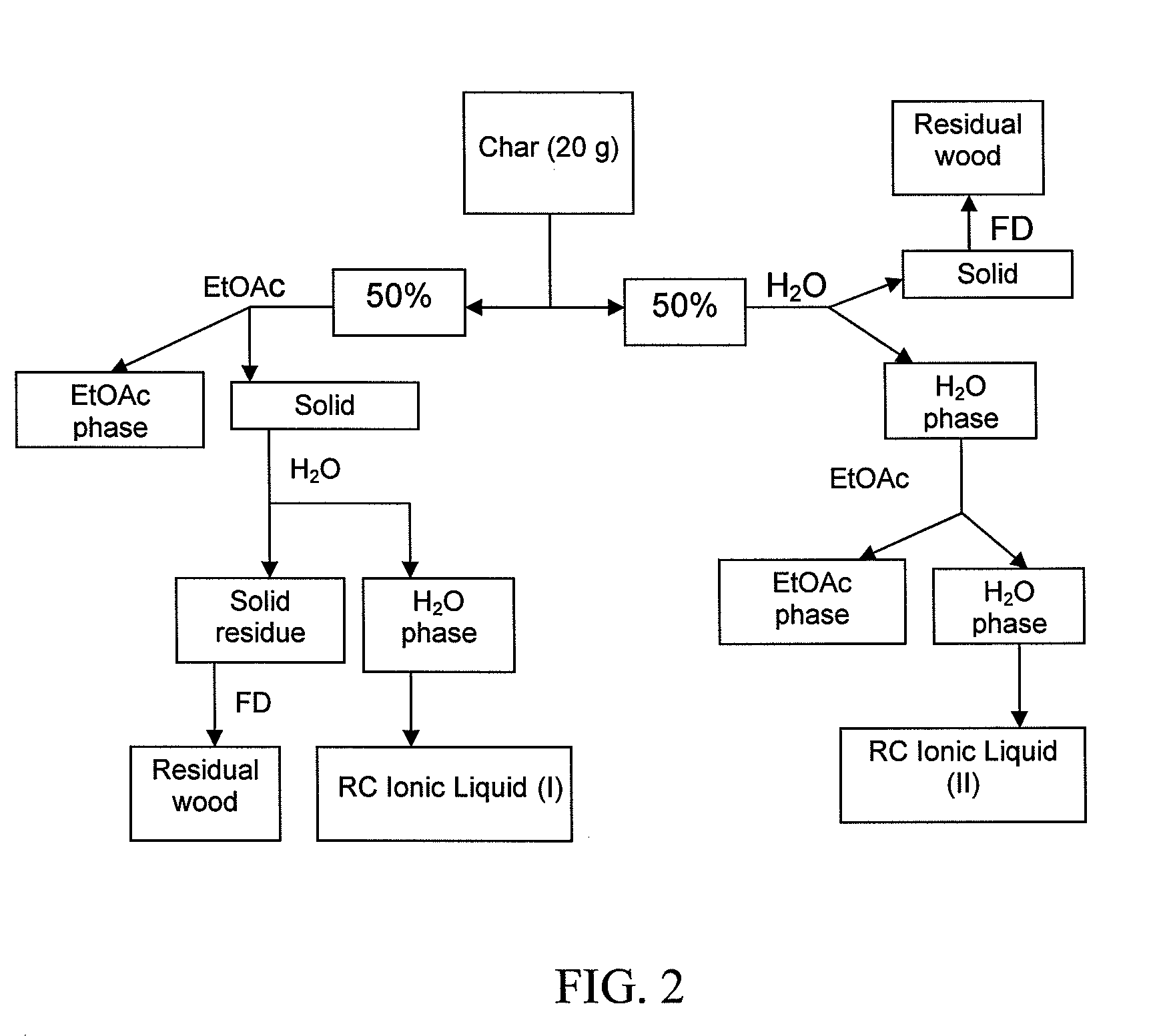

Product preparation and recovery from thermolysis of lignocellulosics in ionic liquids

InactiveUS20080185112A1Increase productionCellulosic pulp after-treatmentCoal charges mechanical treatmentCelluloseIonic liquid

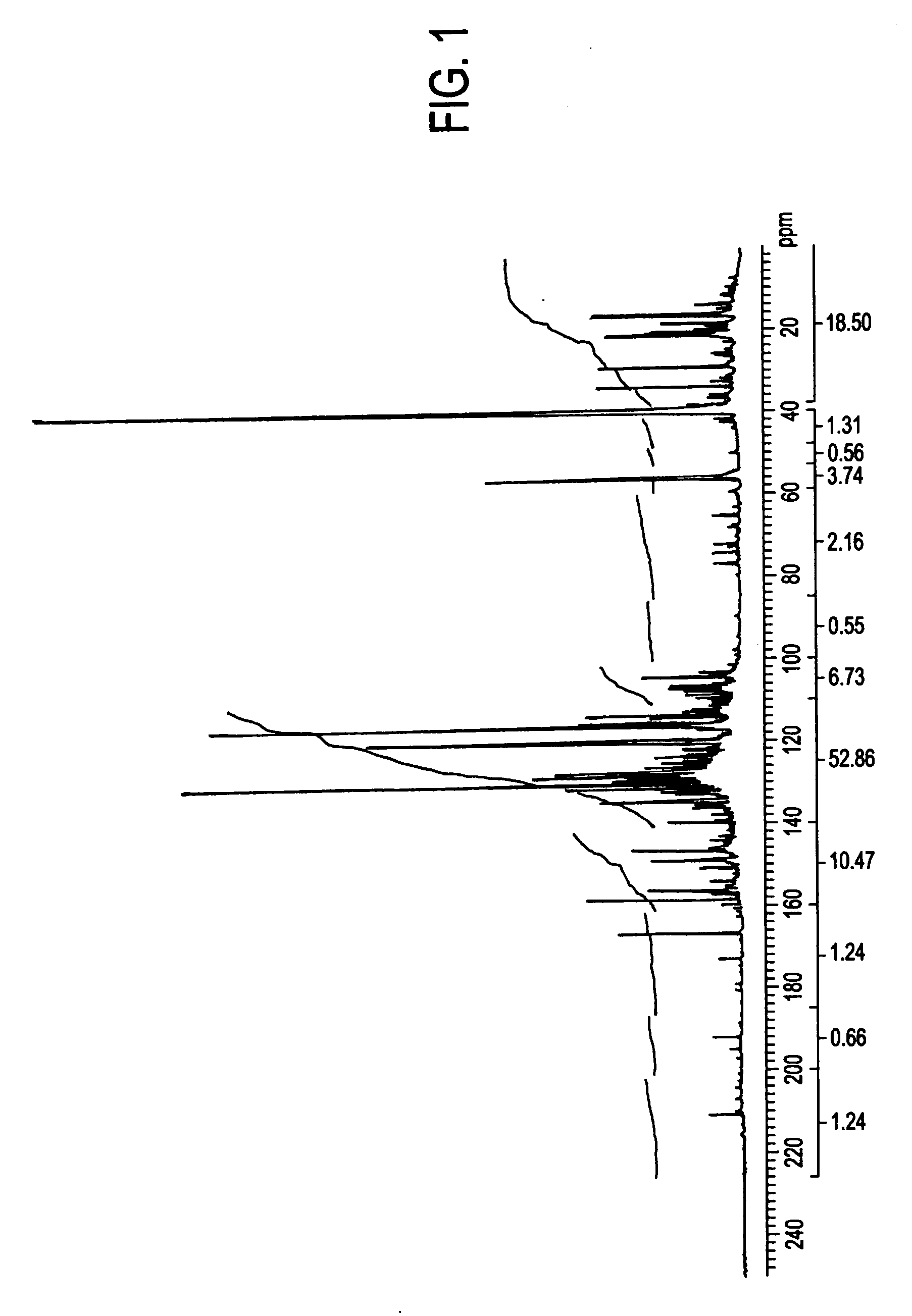

The present invention provides methods for the thermolysis of lignocellulosic materials, such as wood, cellulose, lignin, and lignocellulose. In specific embodiments, the methods comprise combining the lignocellulosic material with an ionic liquid and subjecting the mixture of the lignocellulosic material and the ionic media to pyrolytic conditions to form a recoverable product, such as a commodity chemical.

Owner:NORTH CAROLINA STATE UNIV

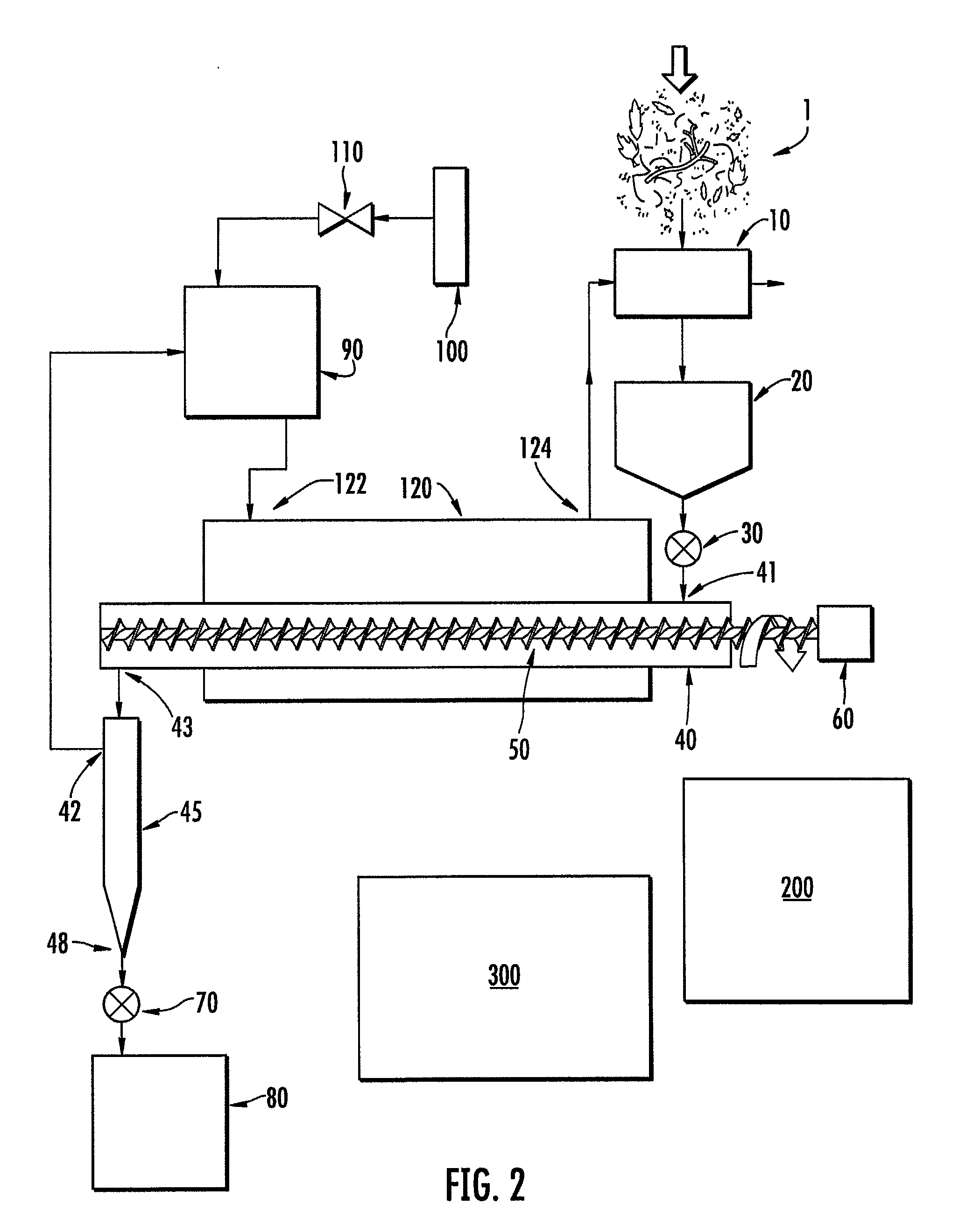

Rapid thermal conversion of biomass

ActiveUS20090139851A1Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingCoke quenchingLiquid productHeat carrier

The present invent provides improved rapid thermal conversion processes for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. In an embodiment, biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. In one embodiment, the liquid product itself is used as the quench media.

Owner:ENSYN RENEWABLES

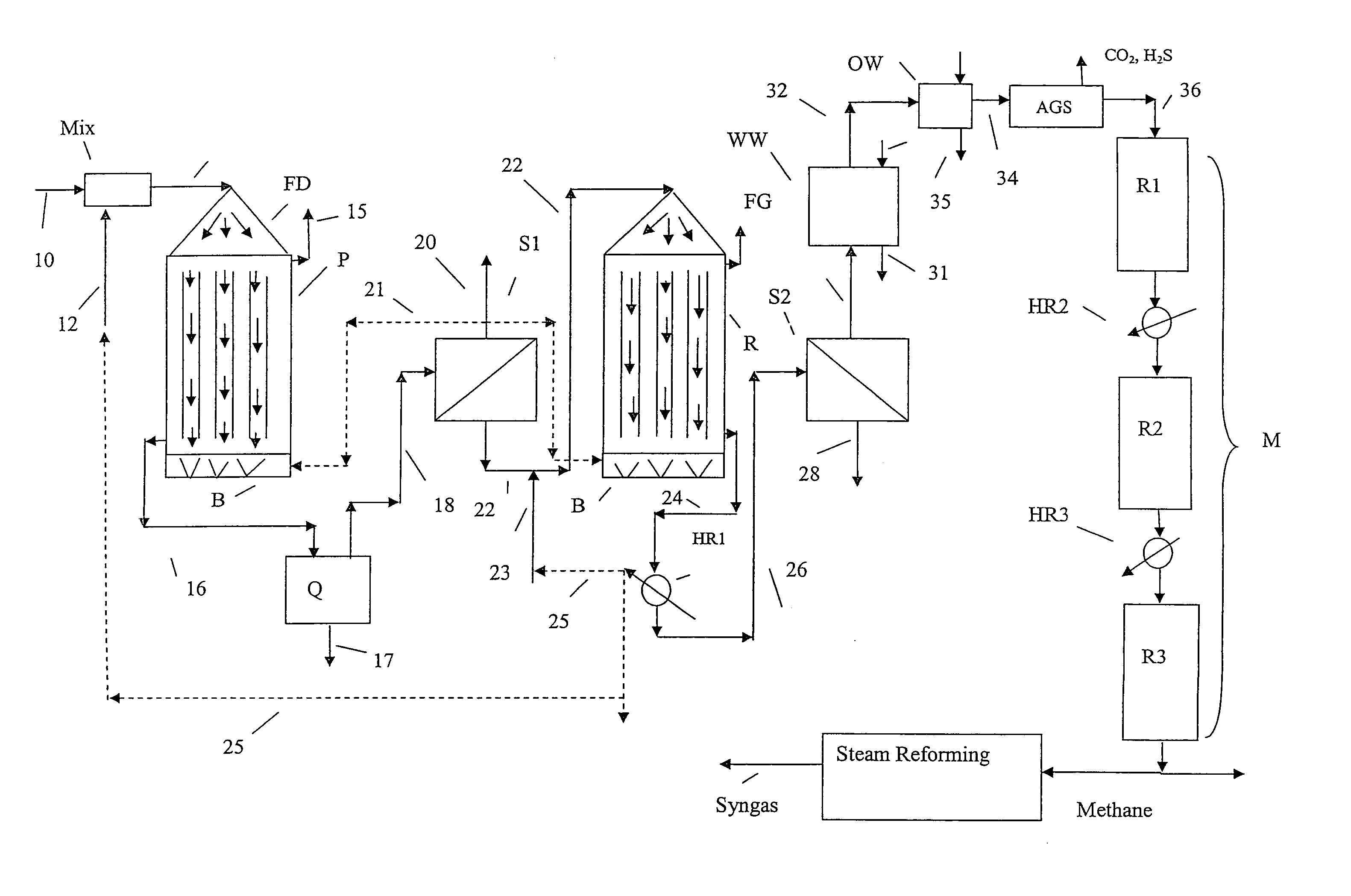

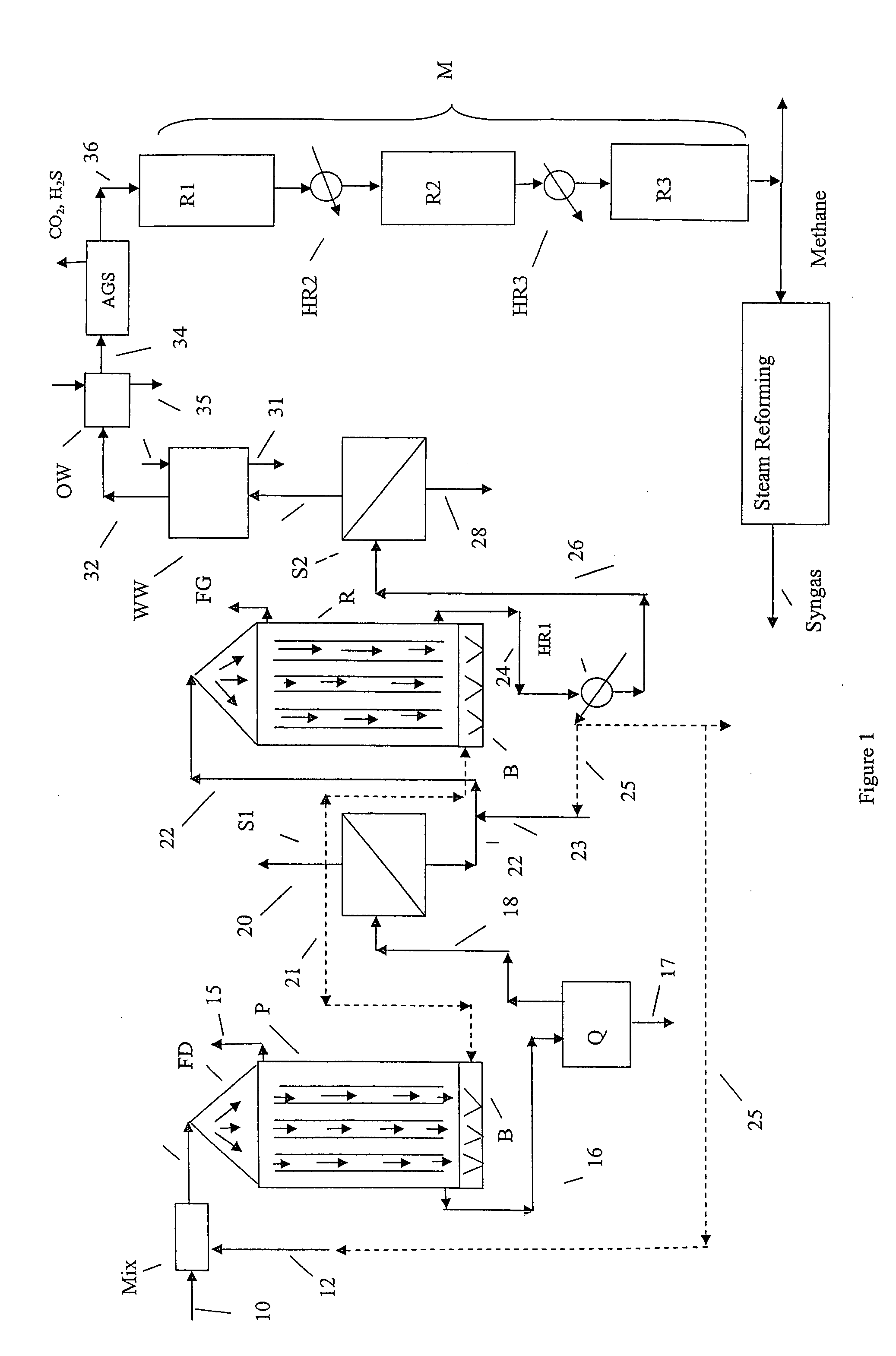

Conversion of carbonaceous materials to synthetic natural gas by pyrolysis, reforming, and methanation

InactiveUS20080016769A1Reduce the temperatureCombustible gas chemical modificationProductsSyngasSteam reforming

The production of synthetic natural gas from a carbonaceous material, preferably a biomass material, such as wood. The carbonaceous material is first pyrolyzed, then subjected to steam reforming to produce a syngas, which is then passed to several clean-up steps then to a methanation zone to produce synthetic natural gas.

Owner:CLEAN ENERGY LLC

System and method for atmospheric carbon sequestration

ActiveUS20100257775A1Increase carbon emissionsLiquid surface applicatorsSolid waste disposalCarbon sequestrationCoal

This invention relates to systems and methods for converting biomass into highly inert carbon. Specifically, some embodiments densify the carbon into anthracite-style carbon aggregations and store it in geologically stable underground deposits. The use of certain embodiments yield a net effect of removing atmospheric carbon via the process of photosynthesis and converting it into hard coal, which can be stored in underground beds that mimic existing coal deposits which are known to be stable for thousands of years.

Owner:COOL PLANET ENERGY SYST

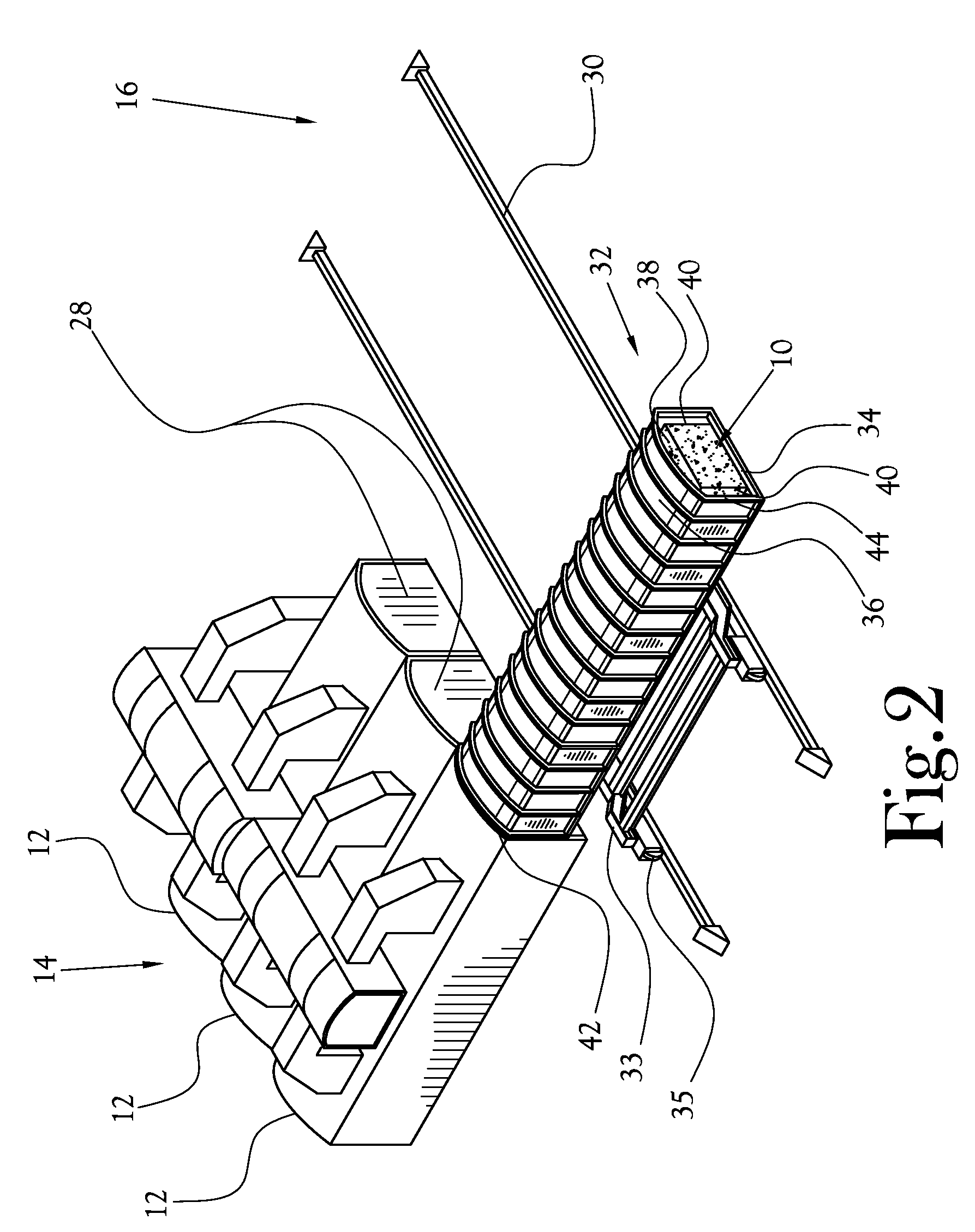

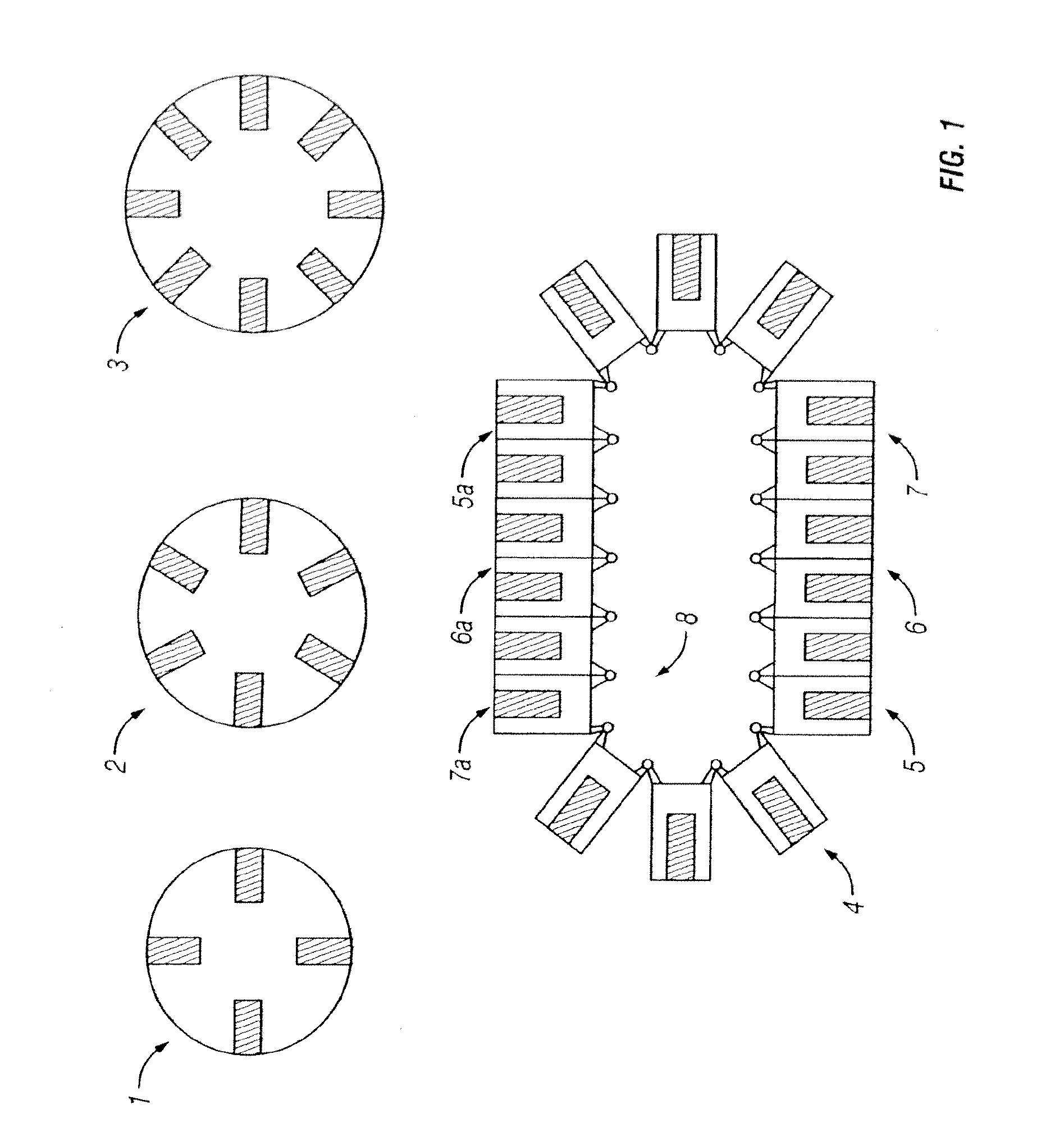

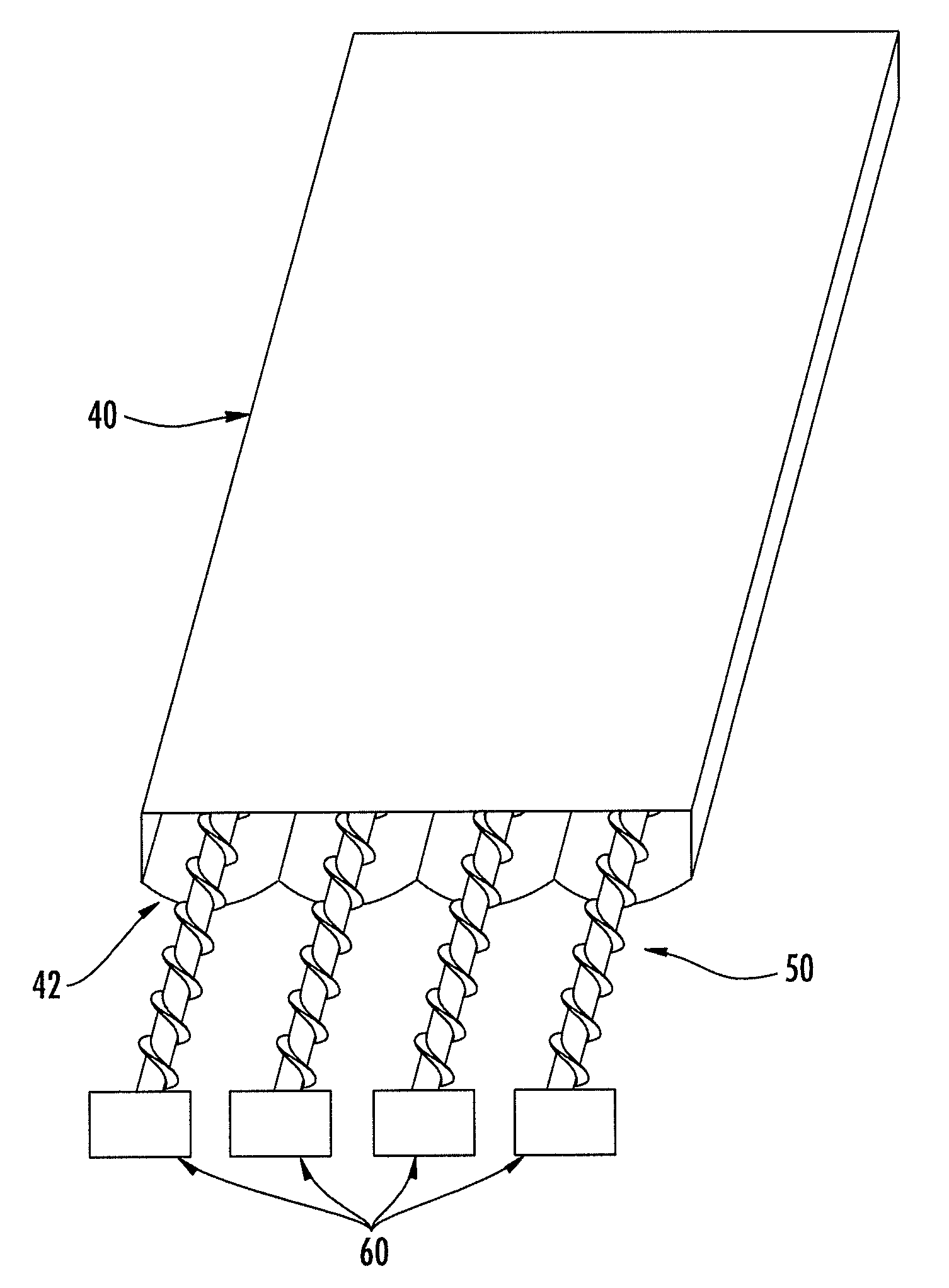

System and method for biomass fractioning

ActiveUS20100180805A1Easy inputIncrease productionDrying solid materials with heatBiofuelsSyngasThin sheet

A biomass fractionator and method are described for inputting ground biomass and outputting several vapor streams of bio-intermediate compounds along with syngas and biochar. In one embodiment, a method for biomass fractioning, comprises dispensing biomass into thin sheets of ground biomass; subjecting the thin sheets to ramps of temperature; and selectively collecting various groups of compounds as they are released from the thin sheets.

Owner:COOL PLANET ENERGY SYST

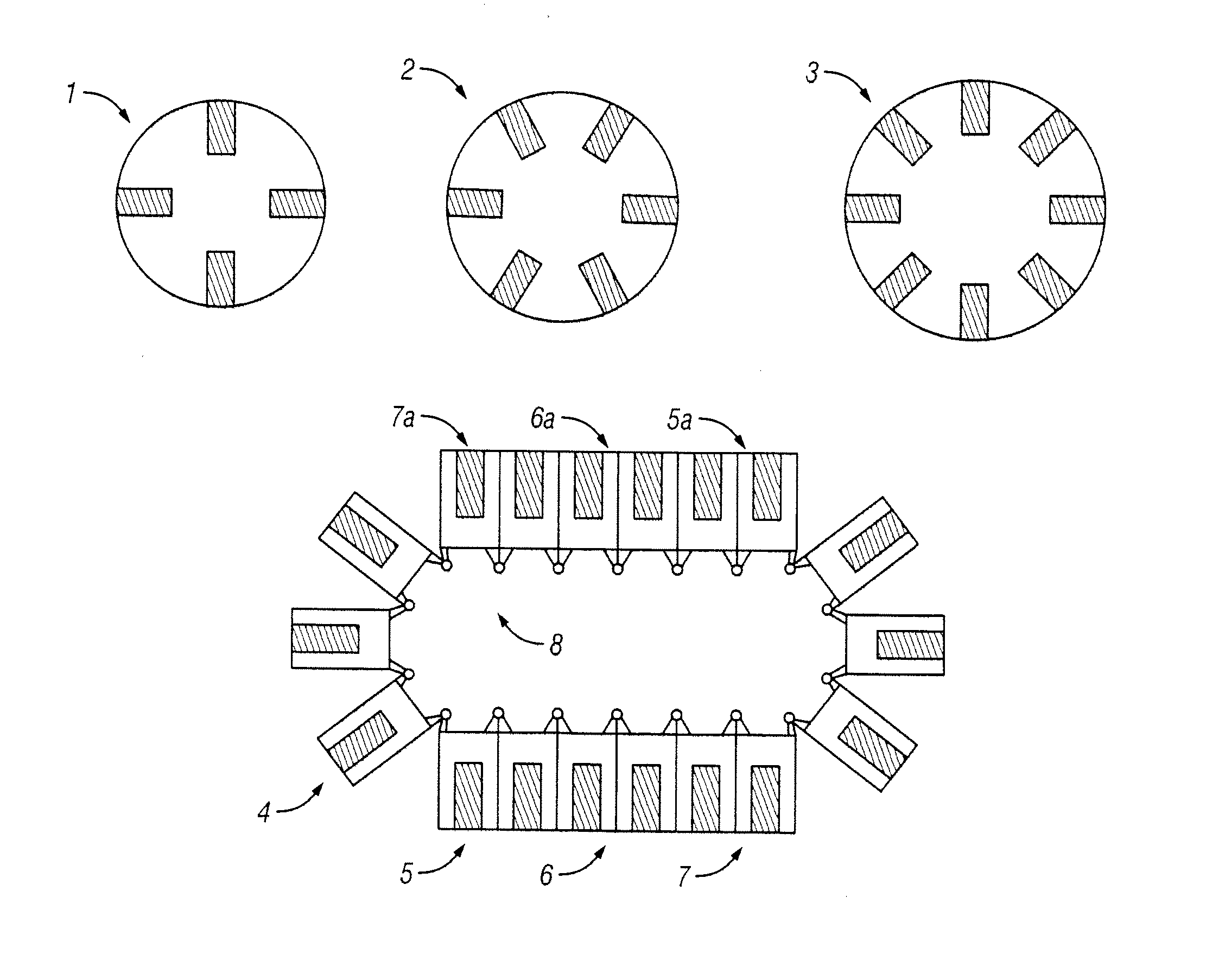

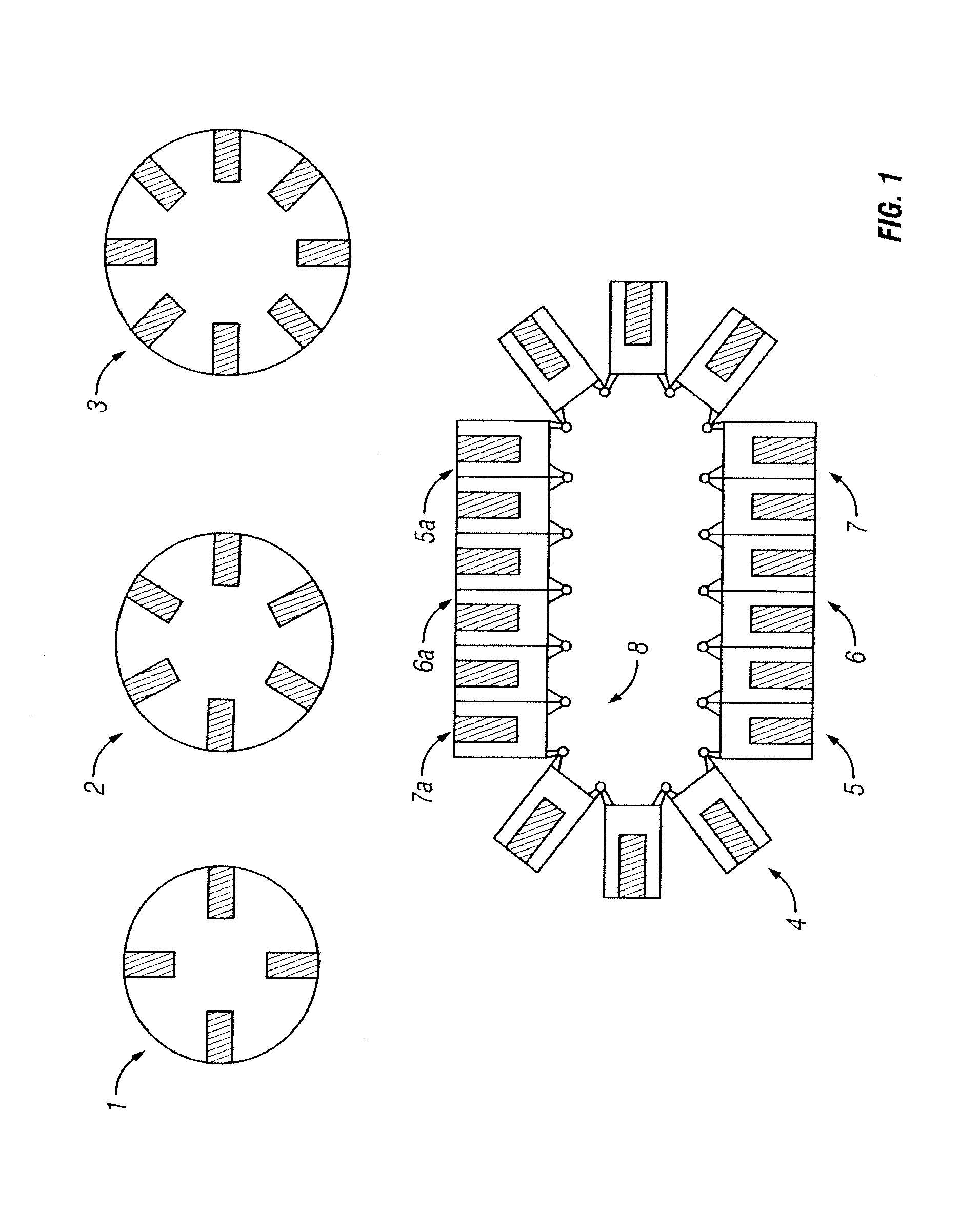

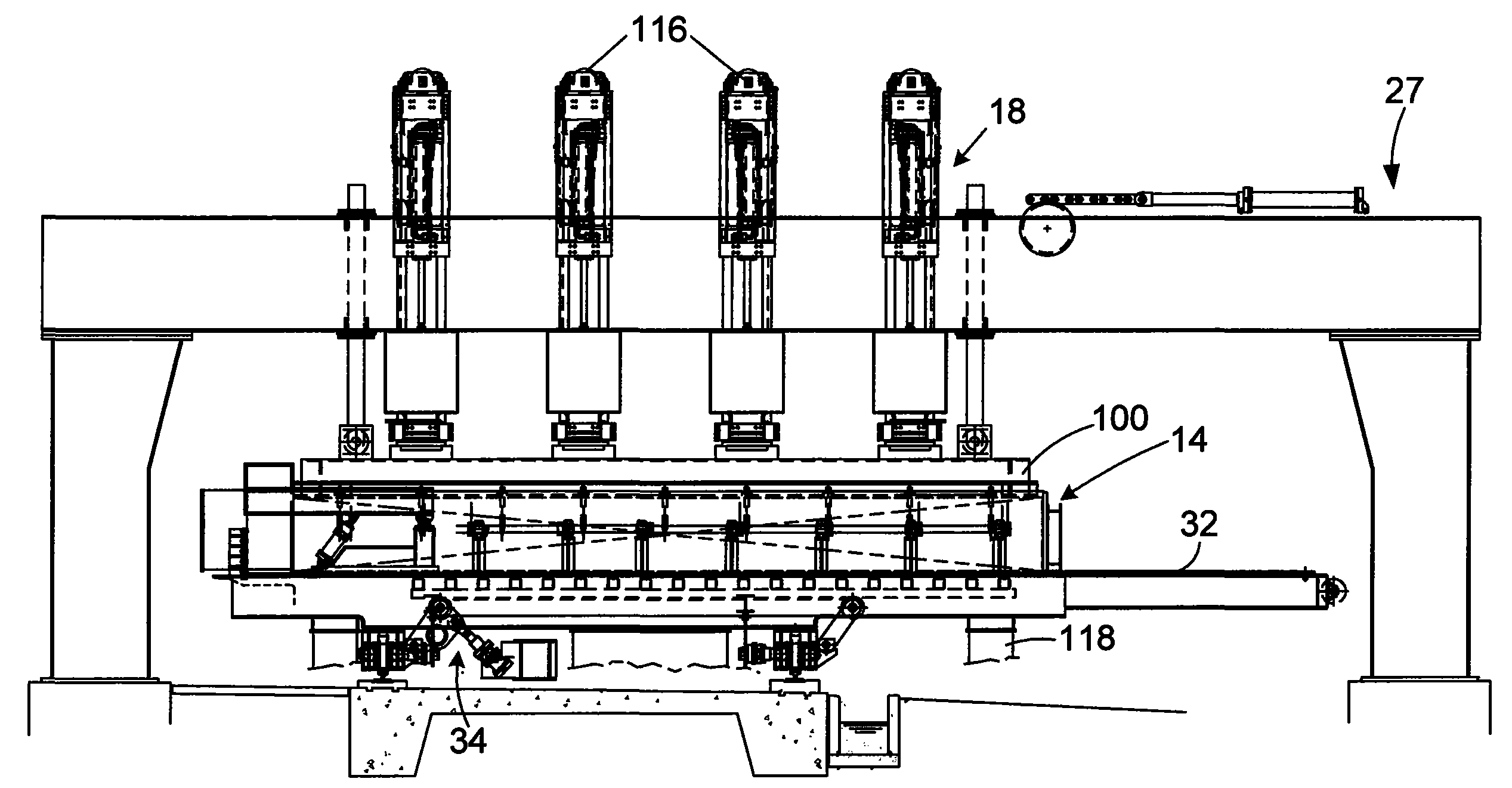

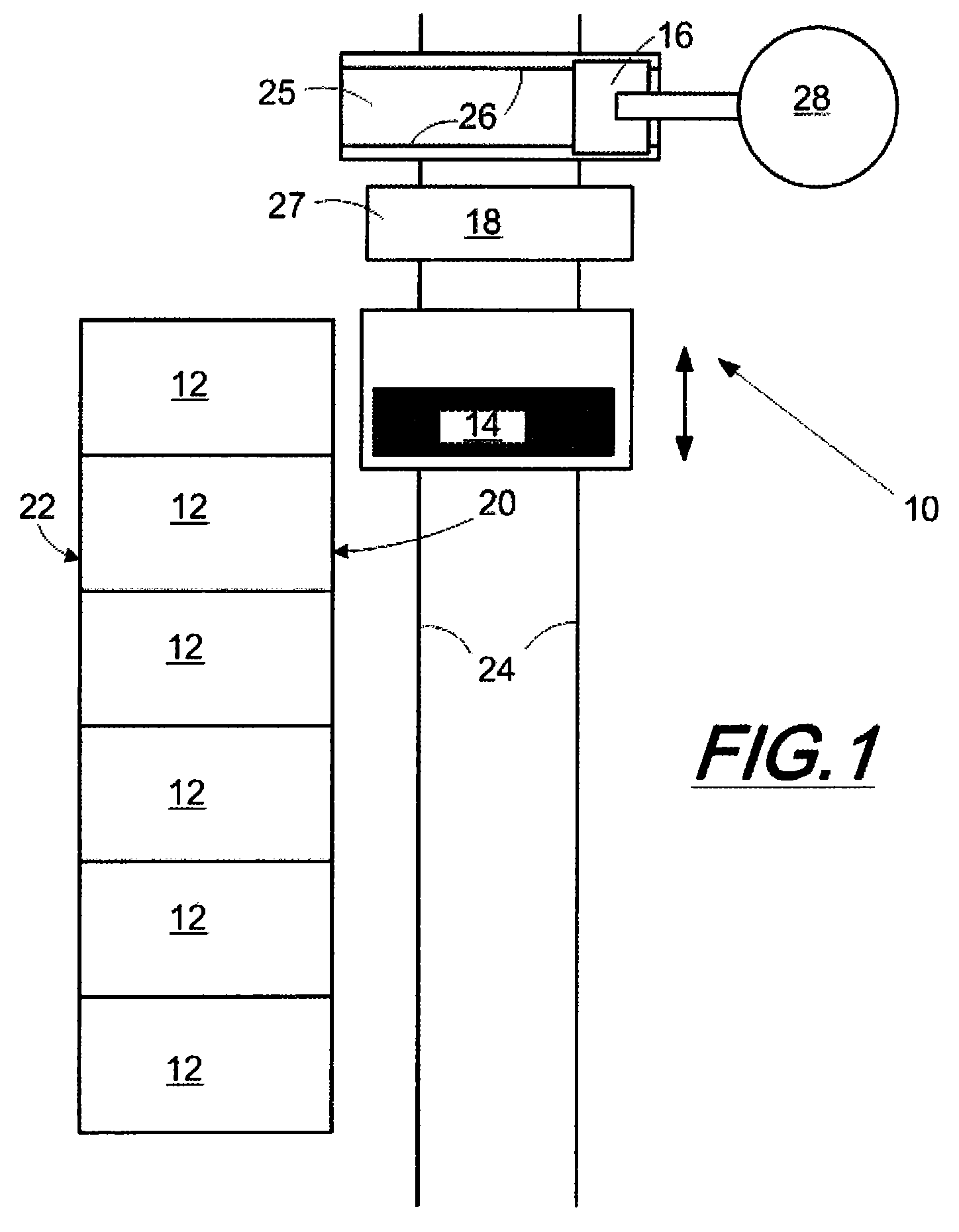

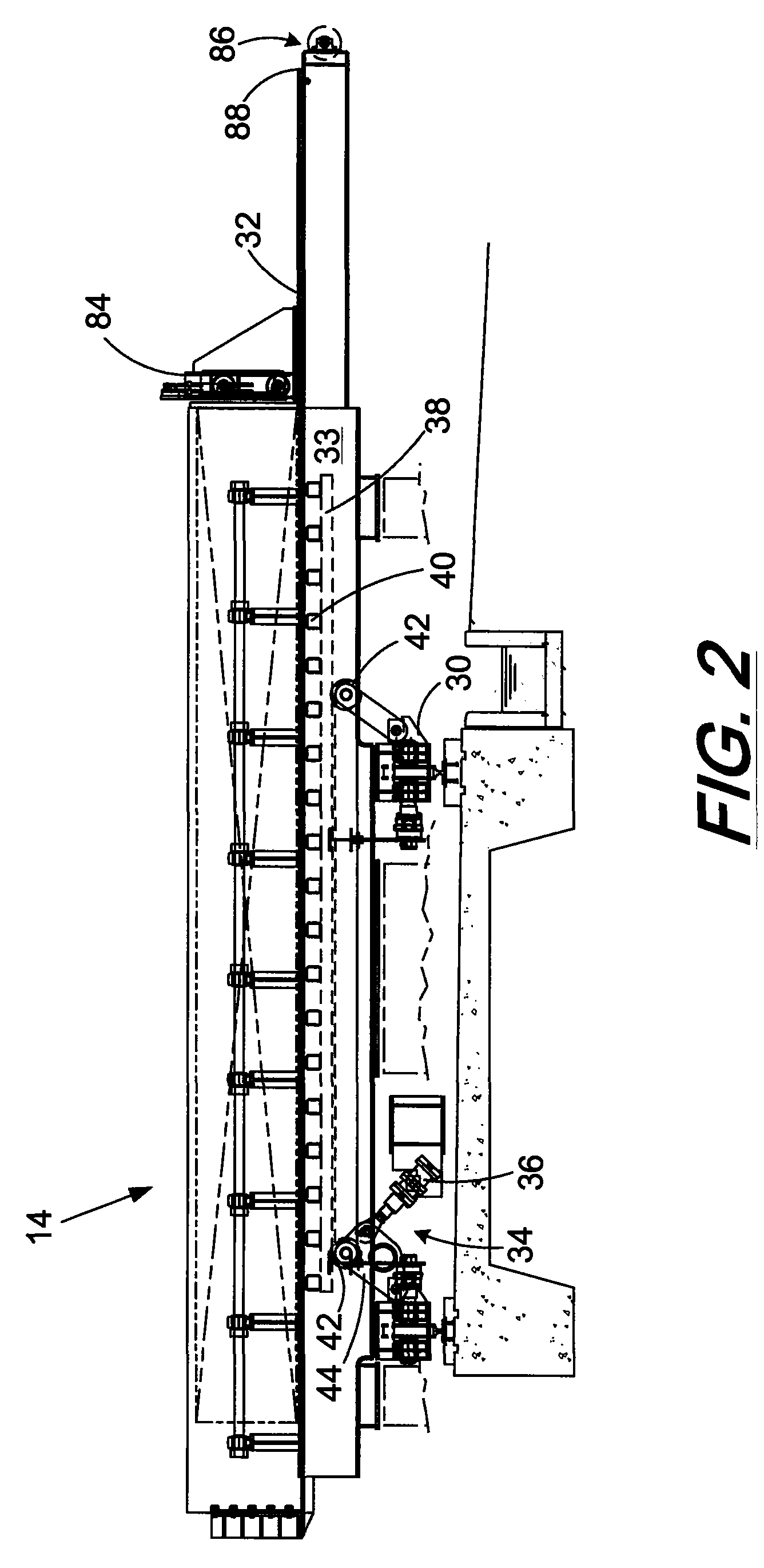

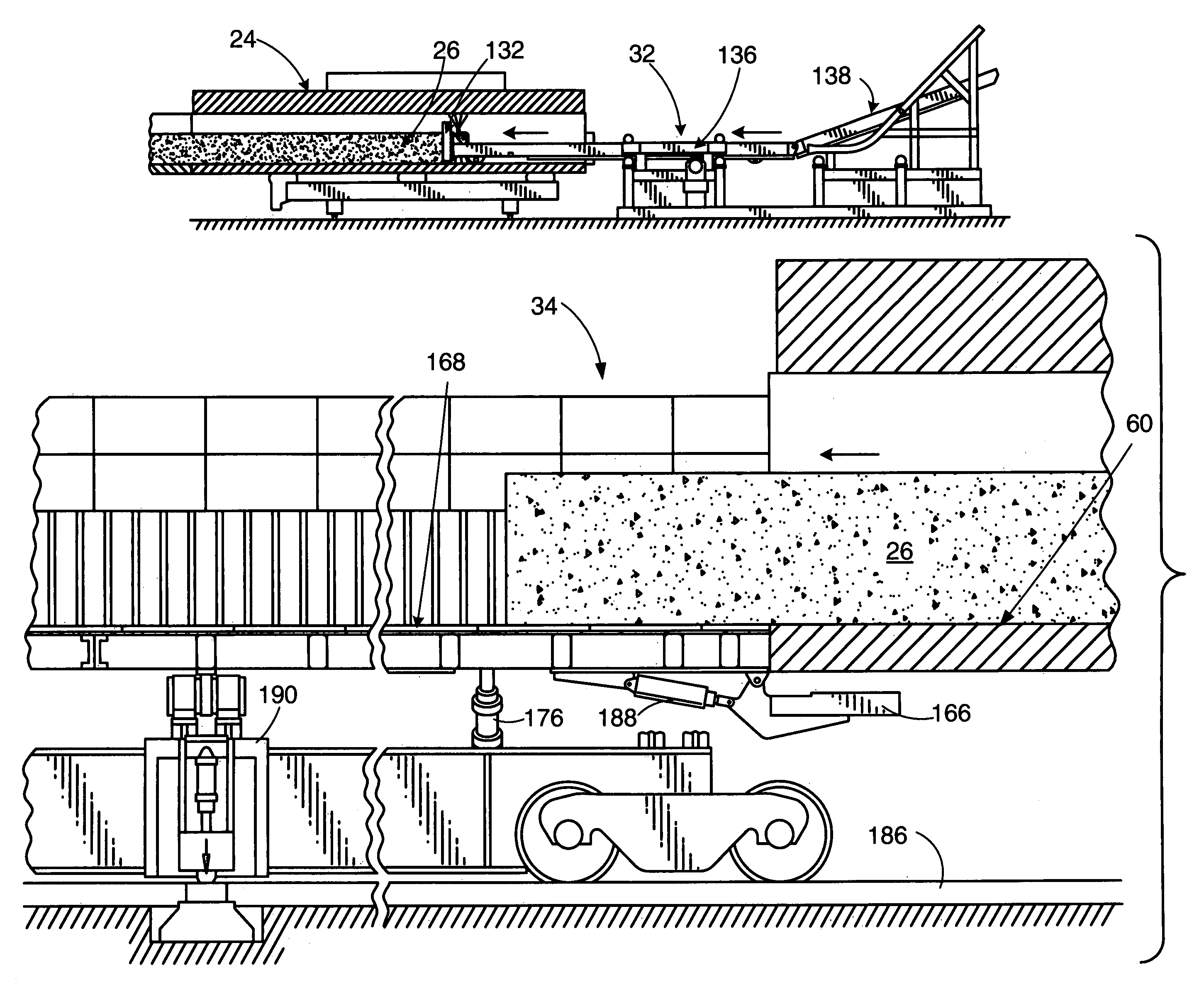

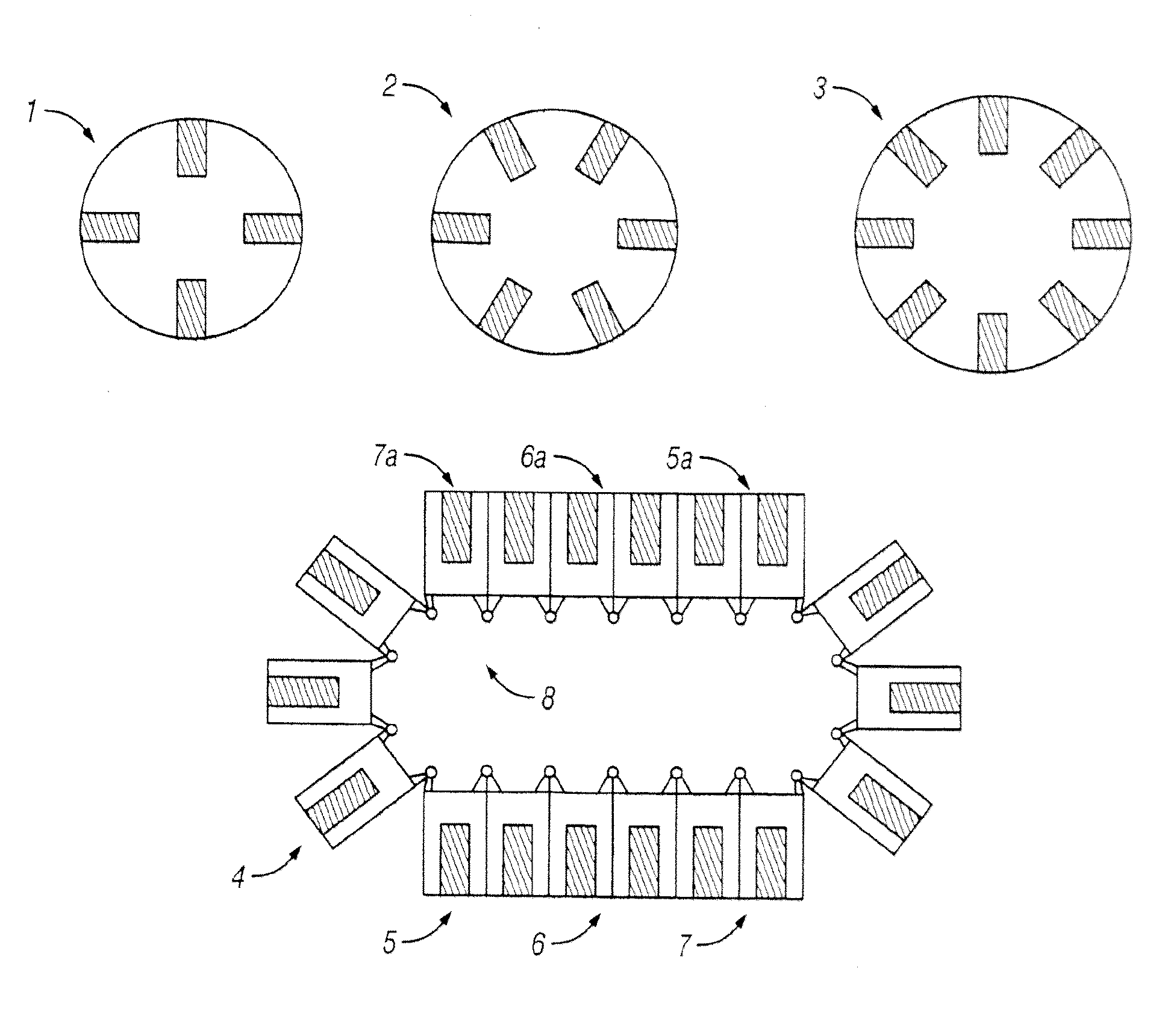

Method and apparatus for compacting coal for a coal coking process

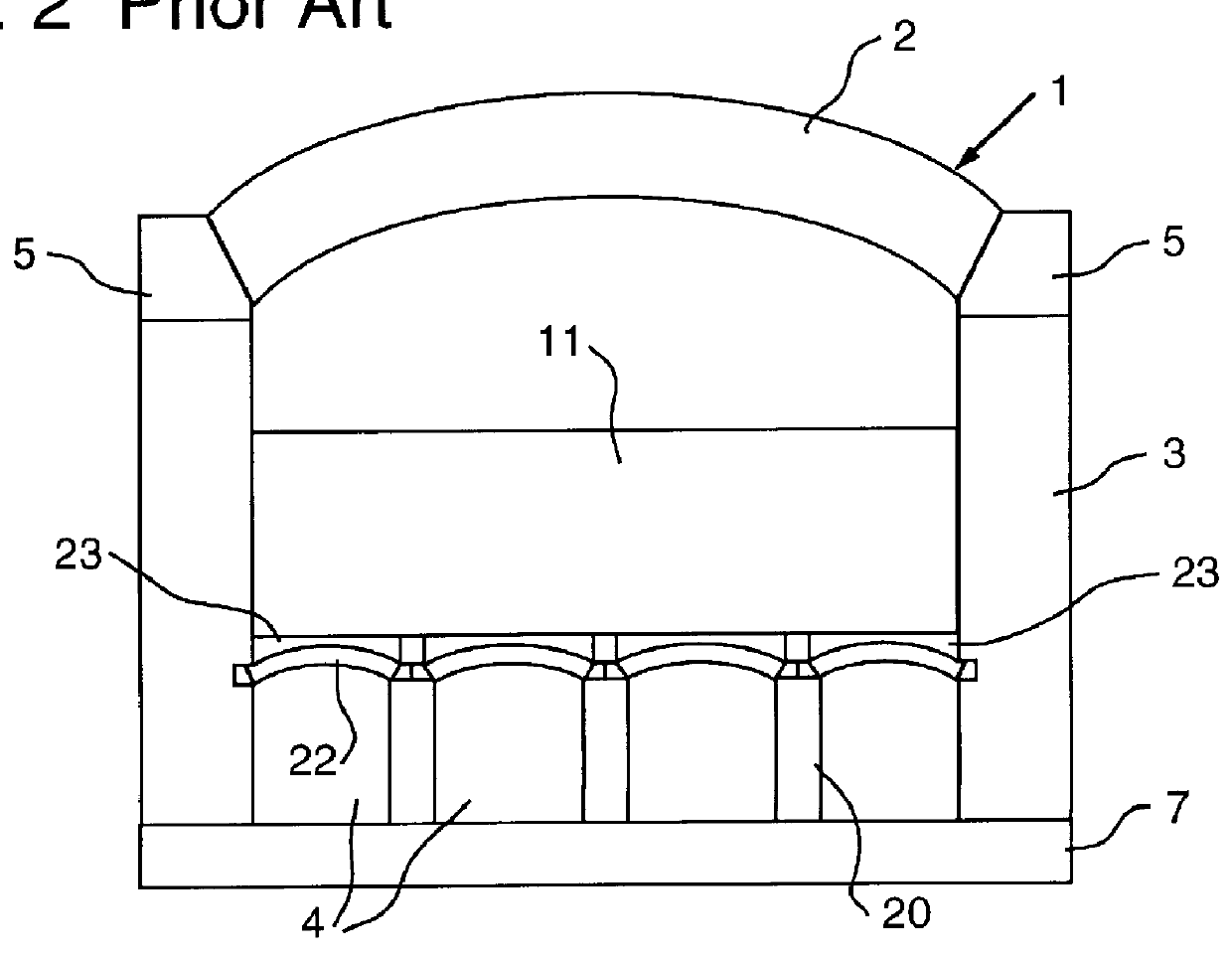

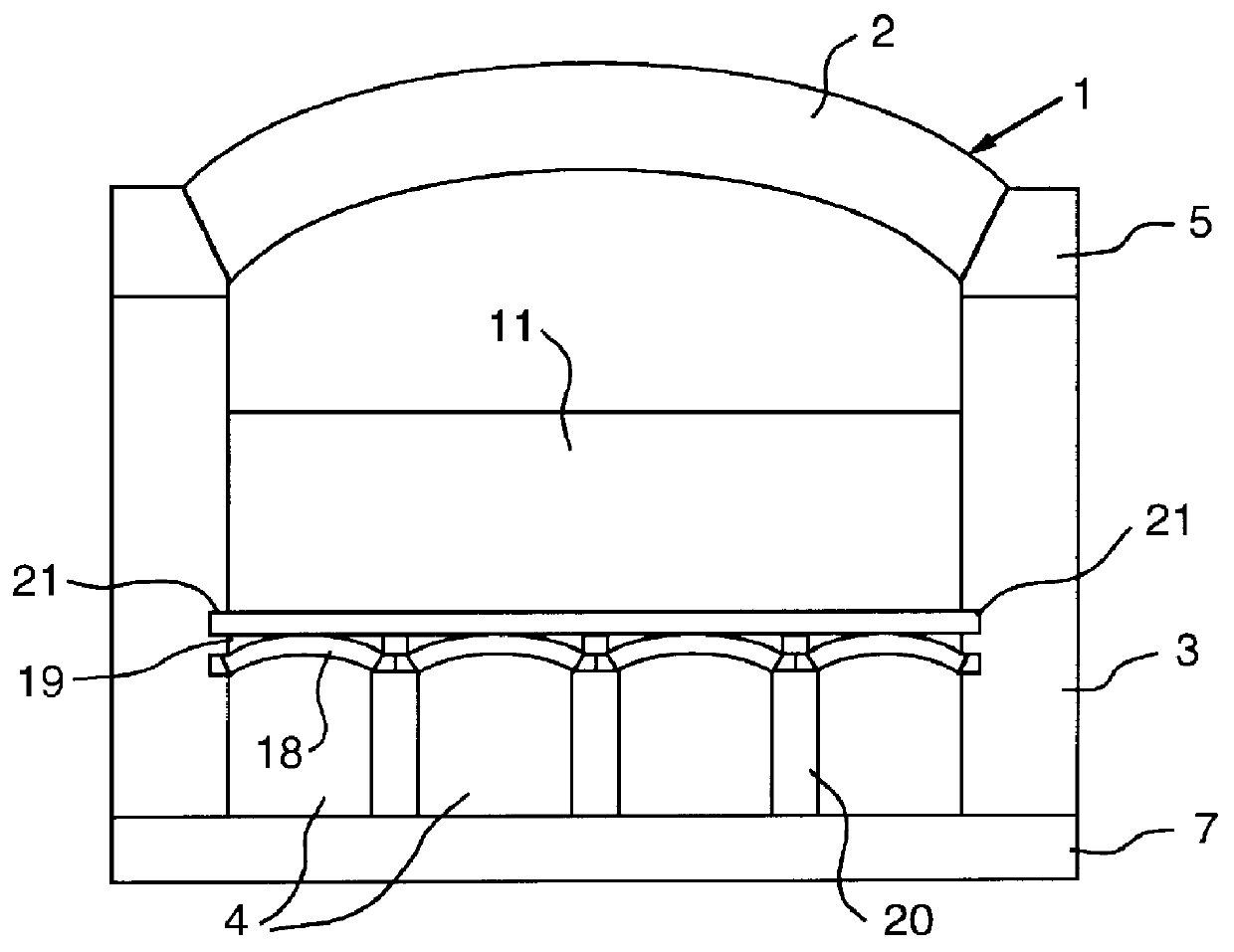

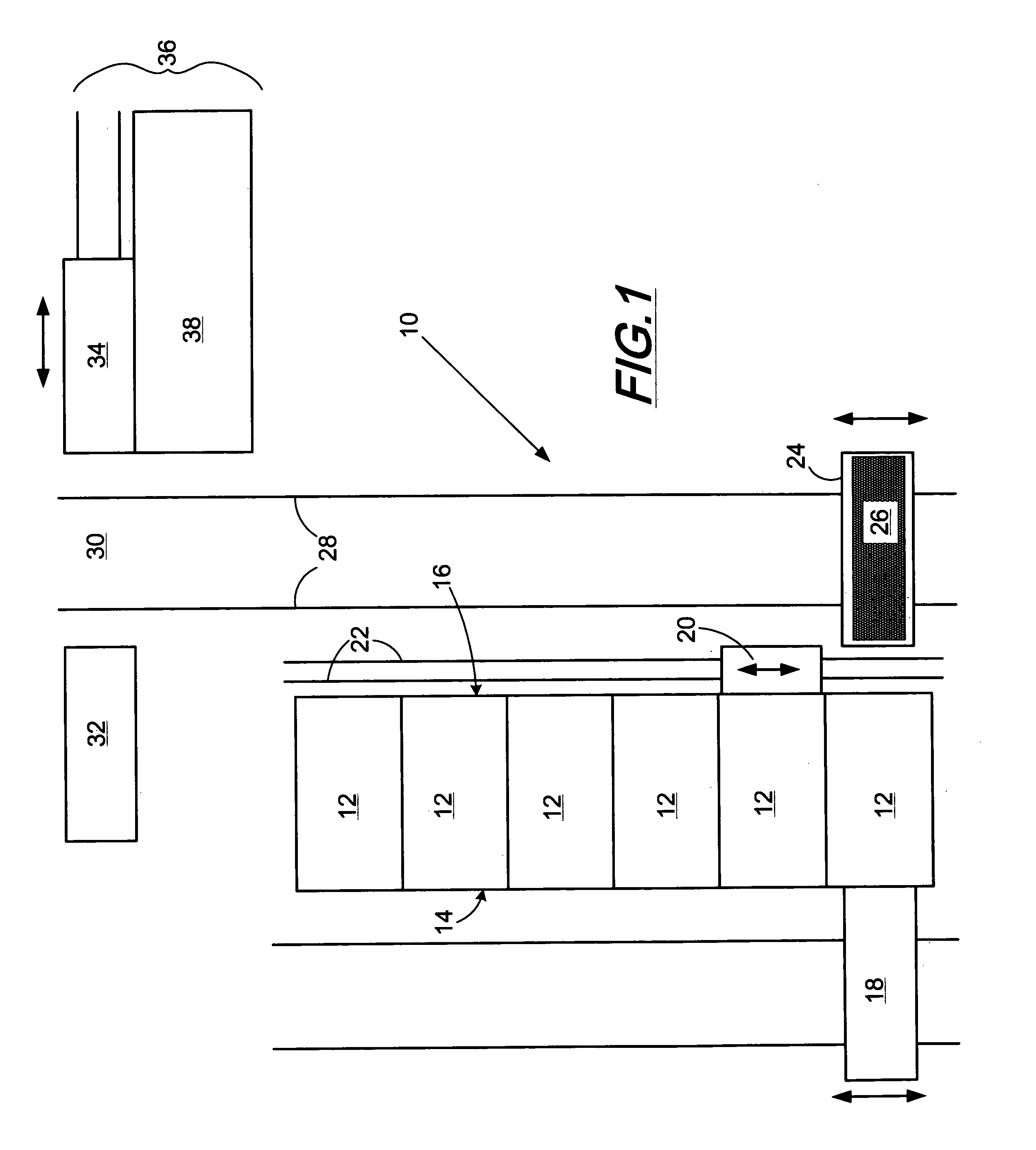

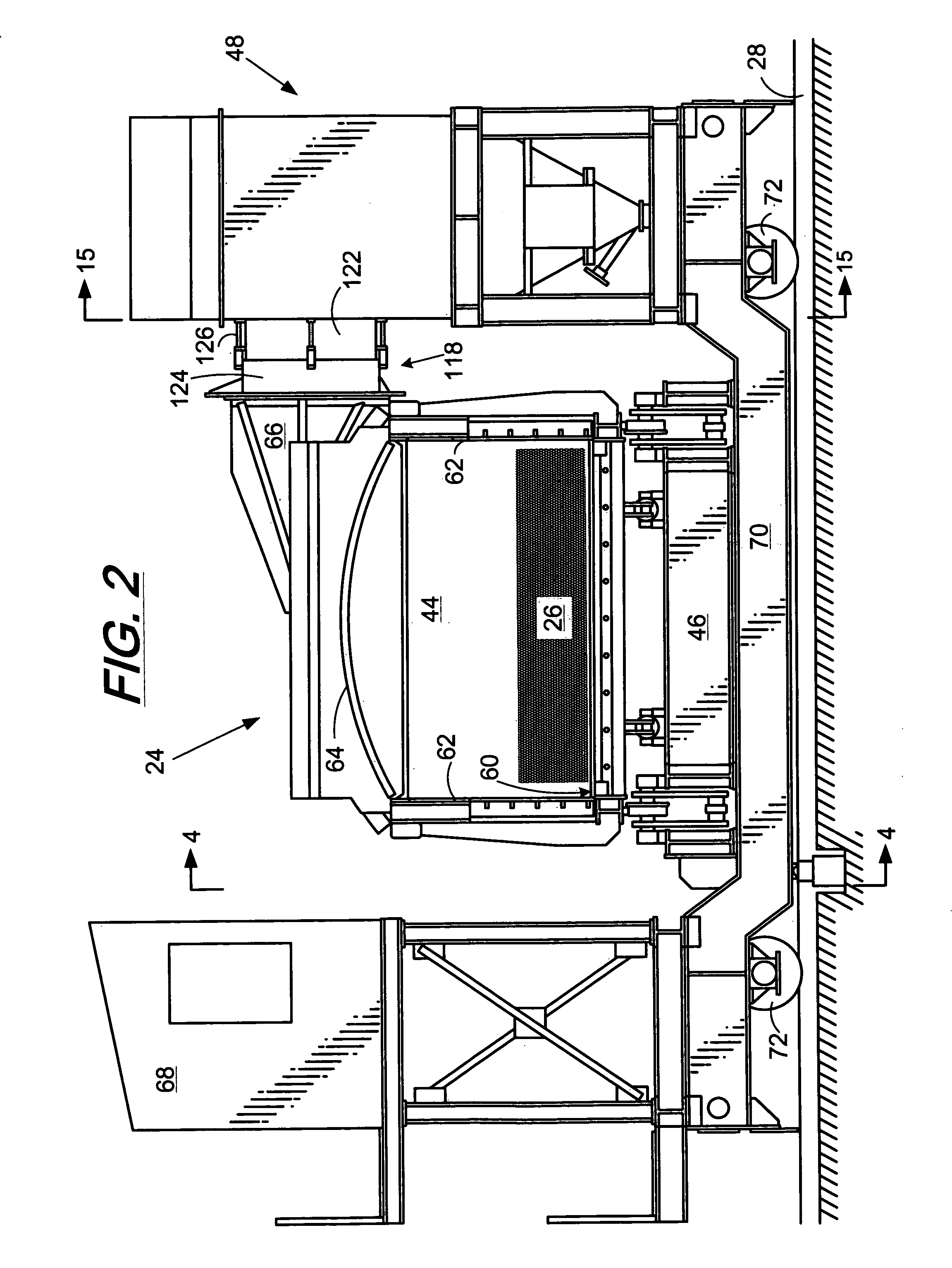

InactiveUS7497930B2Minimize amount of timeUniform bulk densityCoke quenchingCharging-discharging device combinationsEngineeringCoke oven

Relatively high speed methods for increasing the bulk density of coal particles, apparatus for increasing the bulk density of coal particles and methods for making metallurgical coke. Once such method includes depositing coal particles onto a charging plate external to a coking oven to provide an elongate bed of dry, uncompacted coal having an upper surface of the charging plate. The charging plate has side walls, and at least one movable end wall An impact pressure is applied to the upper surface of the bed of dry, uncompacted coal while degassing the coal to provide a dry, compacted coal bed having a bulk density ranging from about 960 to about 1200 kilograms per cubic meter.

Owner:SUNCOKE TECH & DEV LLC

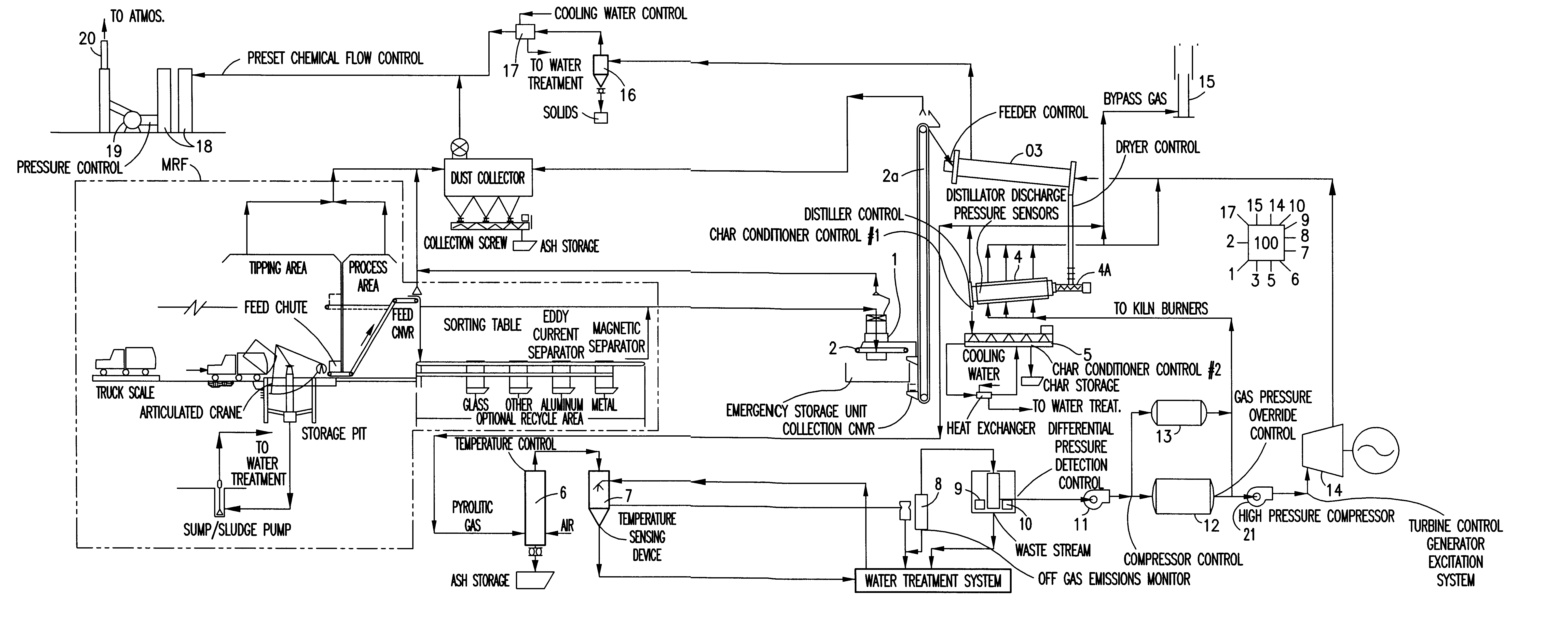

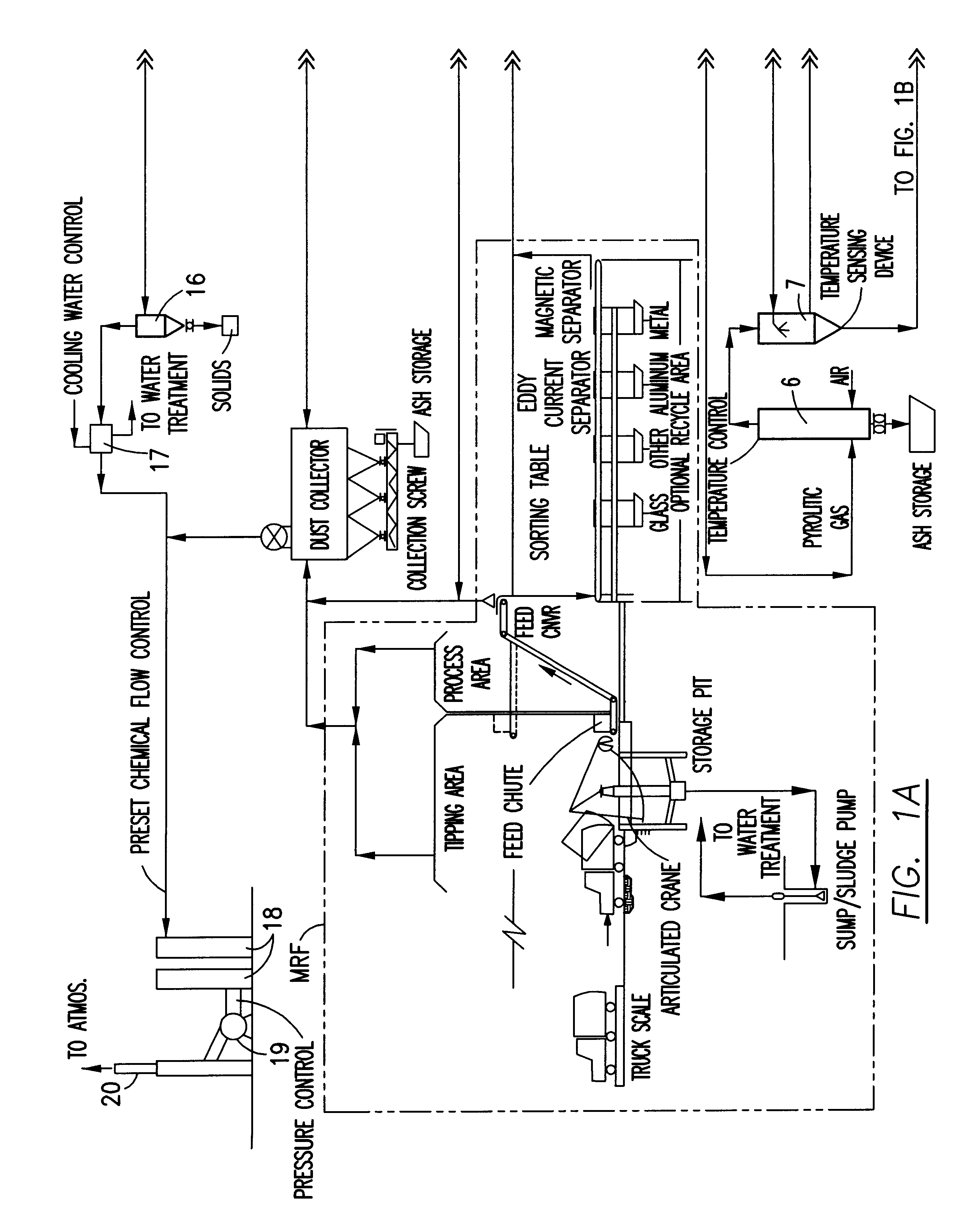

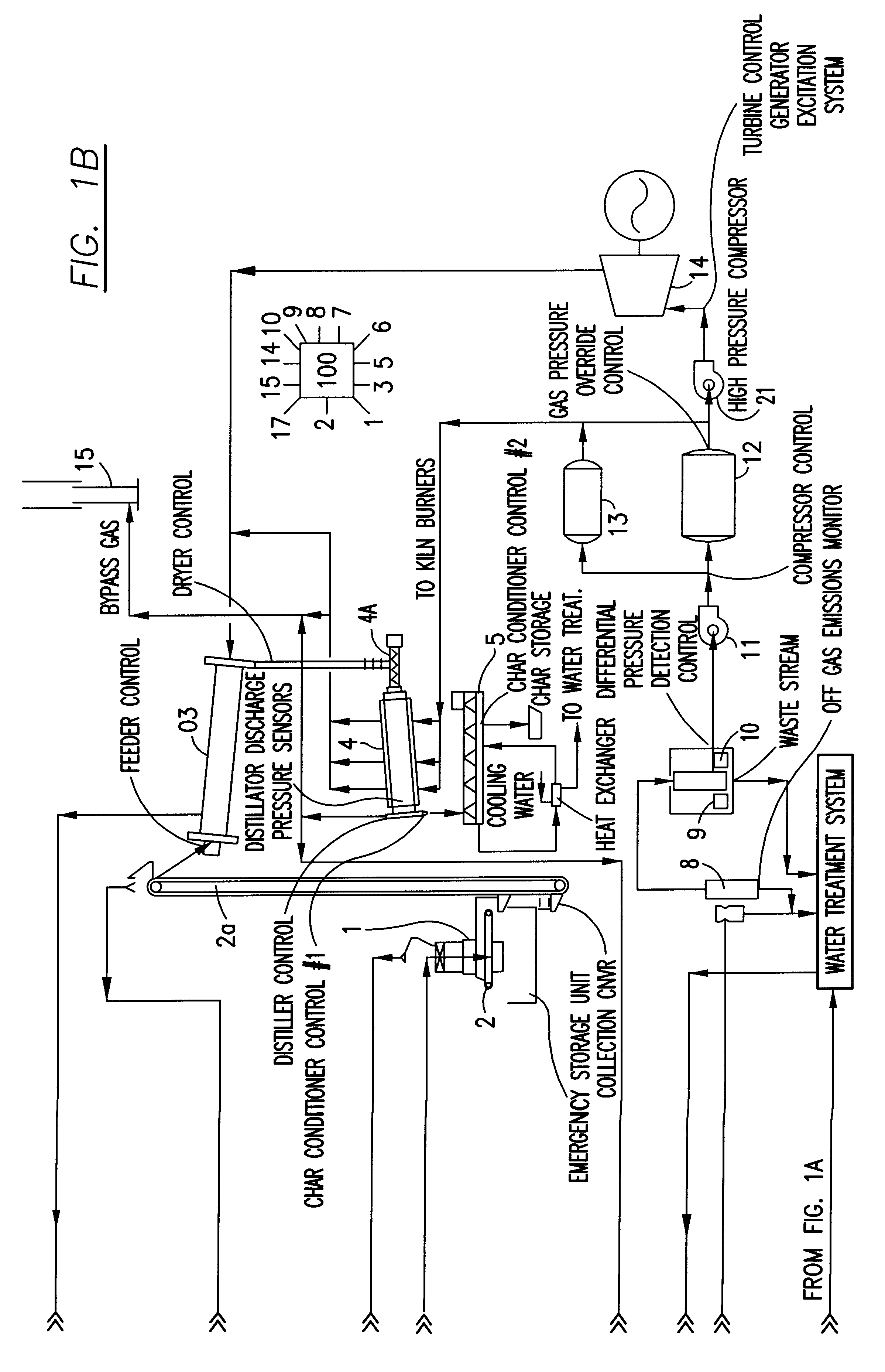

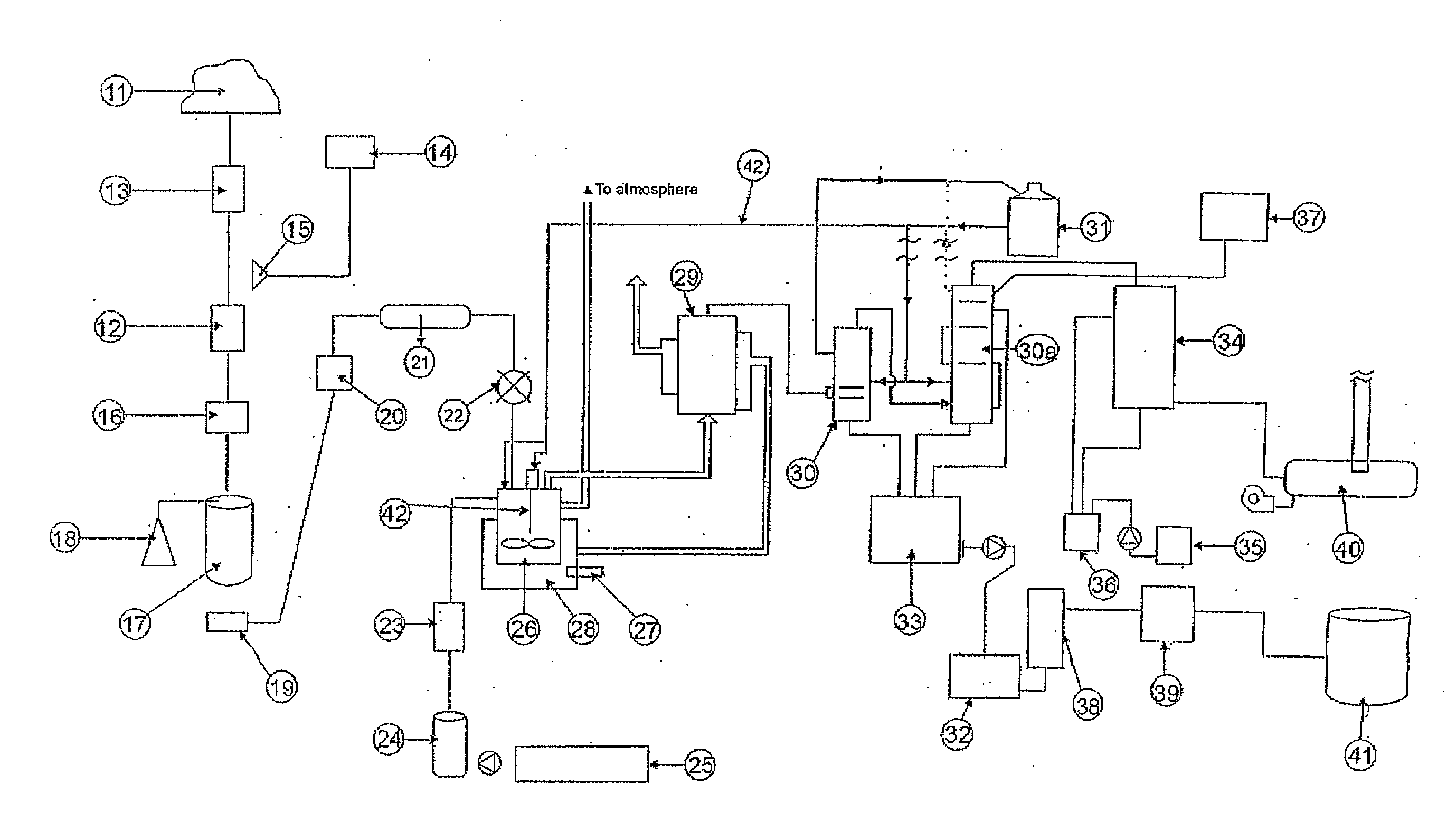

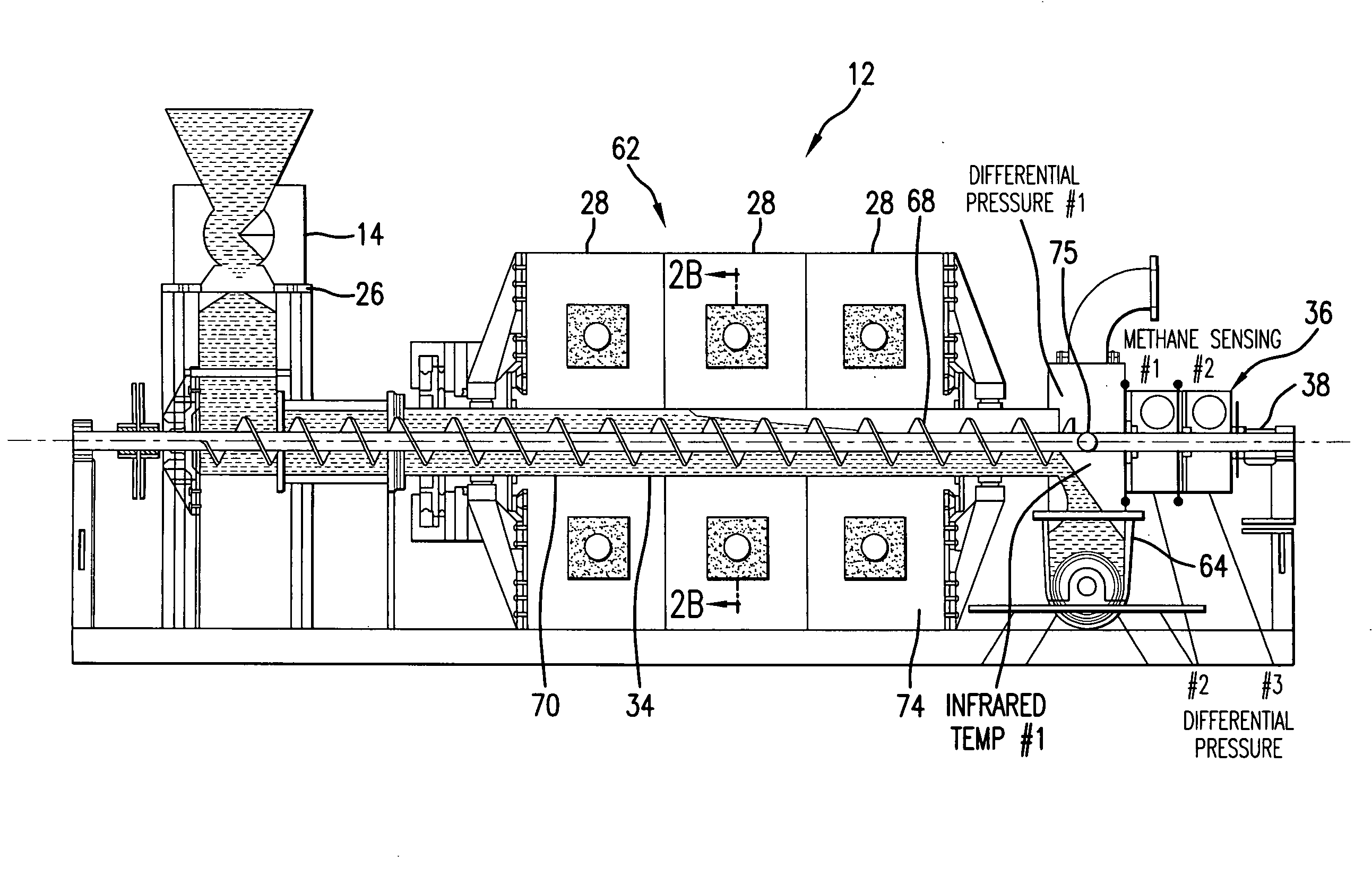

Integrated control and destructive distillation of carbonaceous waste

InactiveUS6182584B1High quantity and qualityEnhanced yield quantity and qualityHorizontal chamber coke ovensEmission preventionComputer control systemWaste stream

A system and process to provide integrated control for the pyrolytic composition of organic (biomass) waste products especially for municipal solid waste systems. The system includes integrated control that monitors biomass waste stream throughout the entire system and the products produced therefrom and includes presorting, controlling the amount of material processed in a continuous manner, shredding, removing moisture in a continuous process that is controlled and providing the waste stream to the distillation unit for pyrolytic action where it is converted into gaseous fuel and a char residue. The gaseous fuel is scrubbed clean and monitored and stored and reused to provide heat to the system. The entire system may be self-sustaining and continuous with very little or no human intervention. An integrated real time computer control system includes sensors and measuring devices with all the major components to ensure integrated efficiency.

Owner:ENVIRONMENTAL SOLUTIONS & TECH

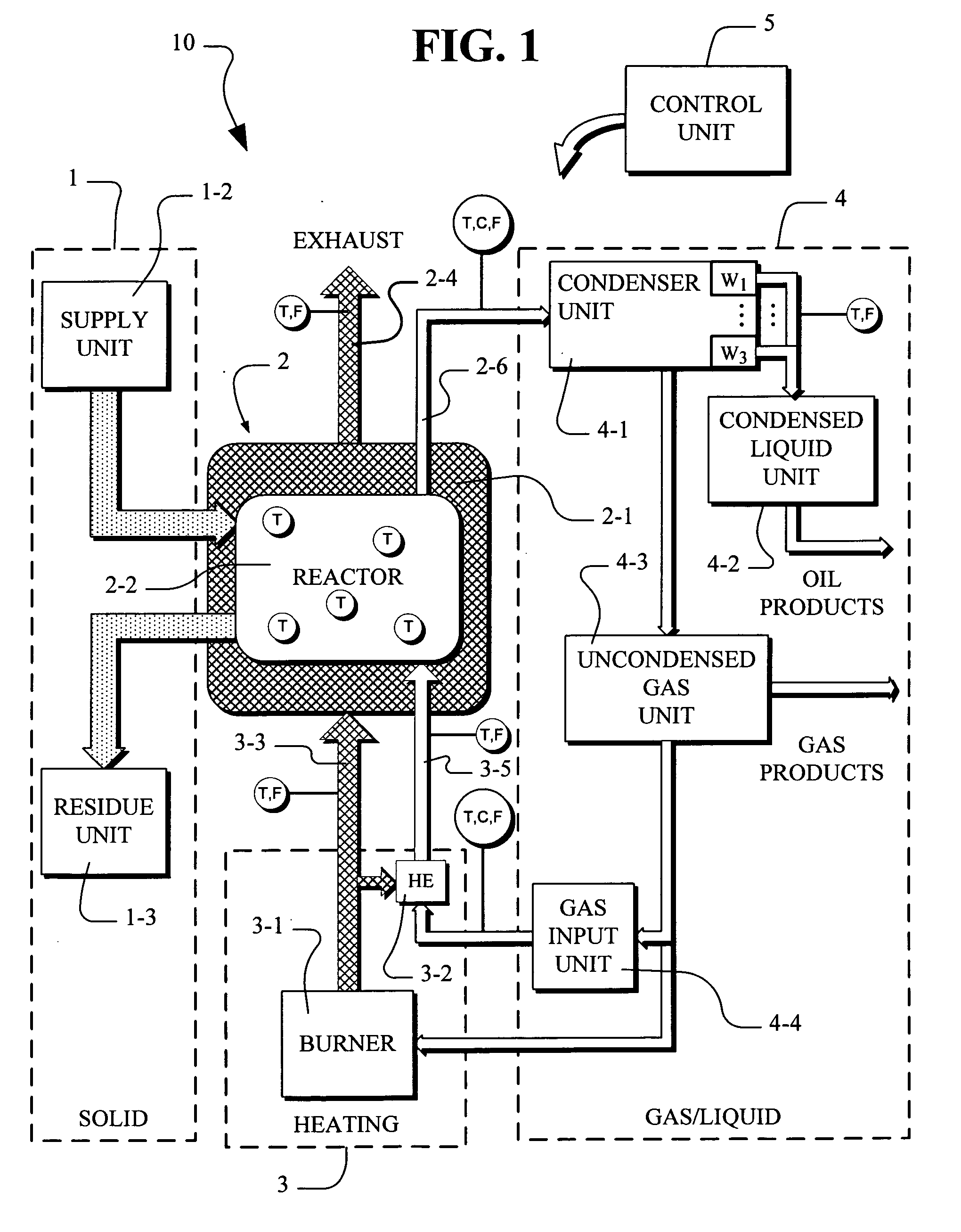

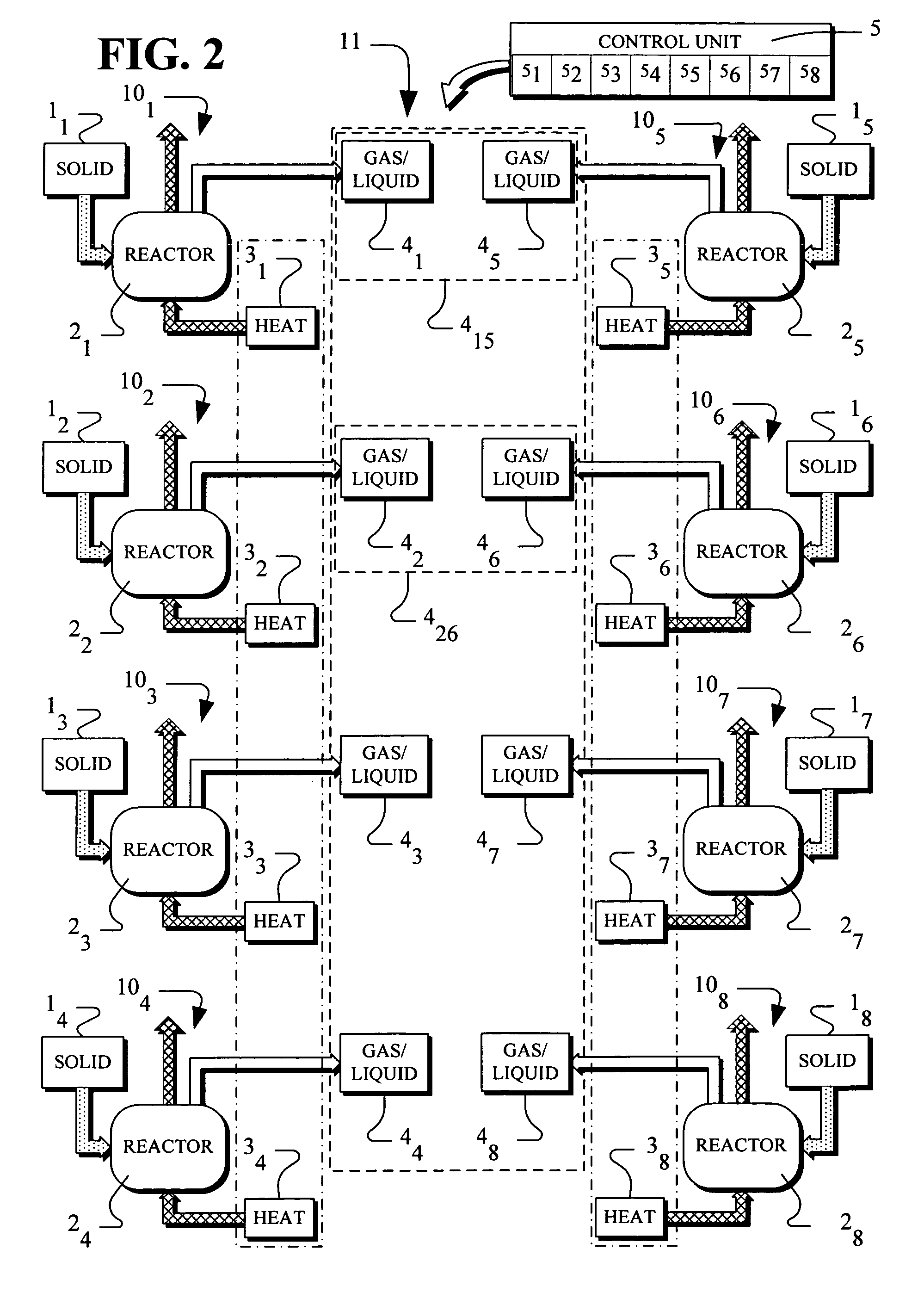

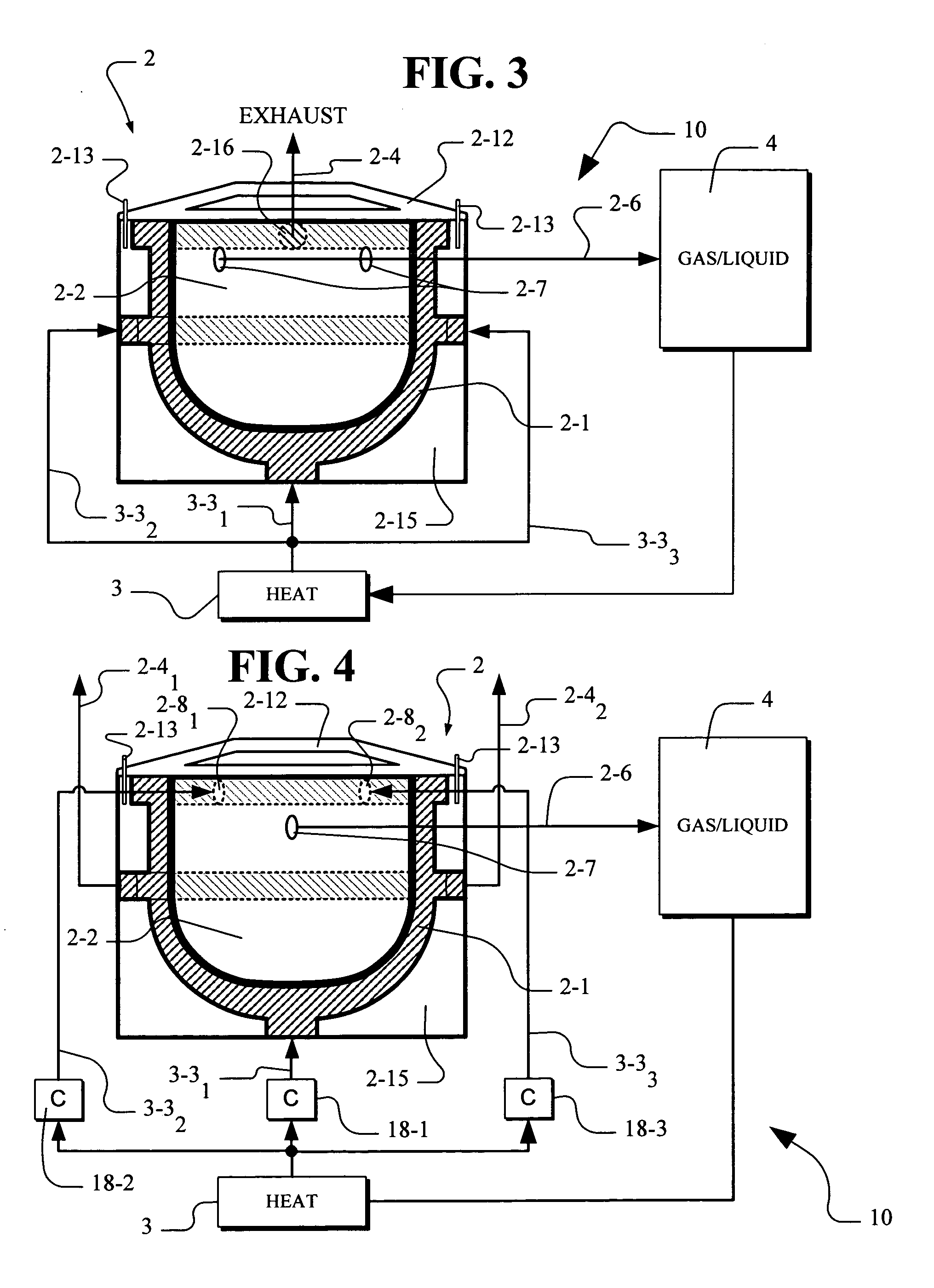

Batch pyrolysis system

InactiveUS20060163053A1Quality improvementImprove throughputProductsBeehive ovensBatch processingProcess engineering

Disclosed is a scaleable pyrolysis system for batch processing of waste vehicle tires and other waste to provide pyrolysis products. The core pyrolysis system includes one or more batch reactors, heating units, solids processing units, gas / liquid processing units and control units. In operation, the temperature gradients internal to the reactor are controlled by preferential channeling of heat to provide pyrolysis products that are of high quality, and hence commercially advantageous, while facilitating high throughput.

Owner:ERSHAG BENGT STURE

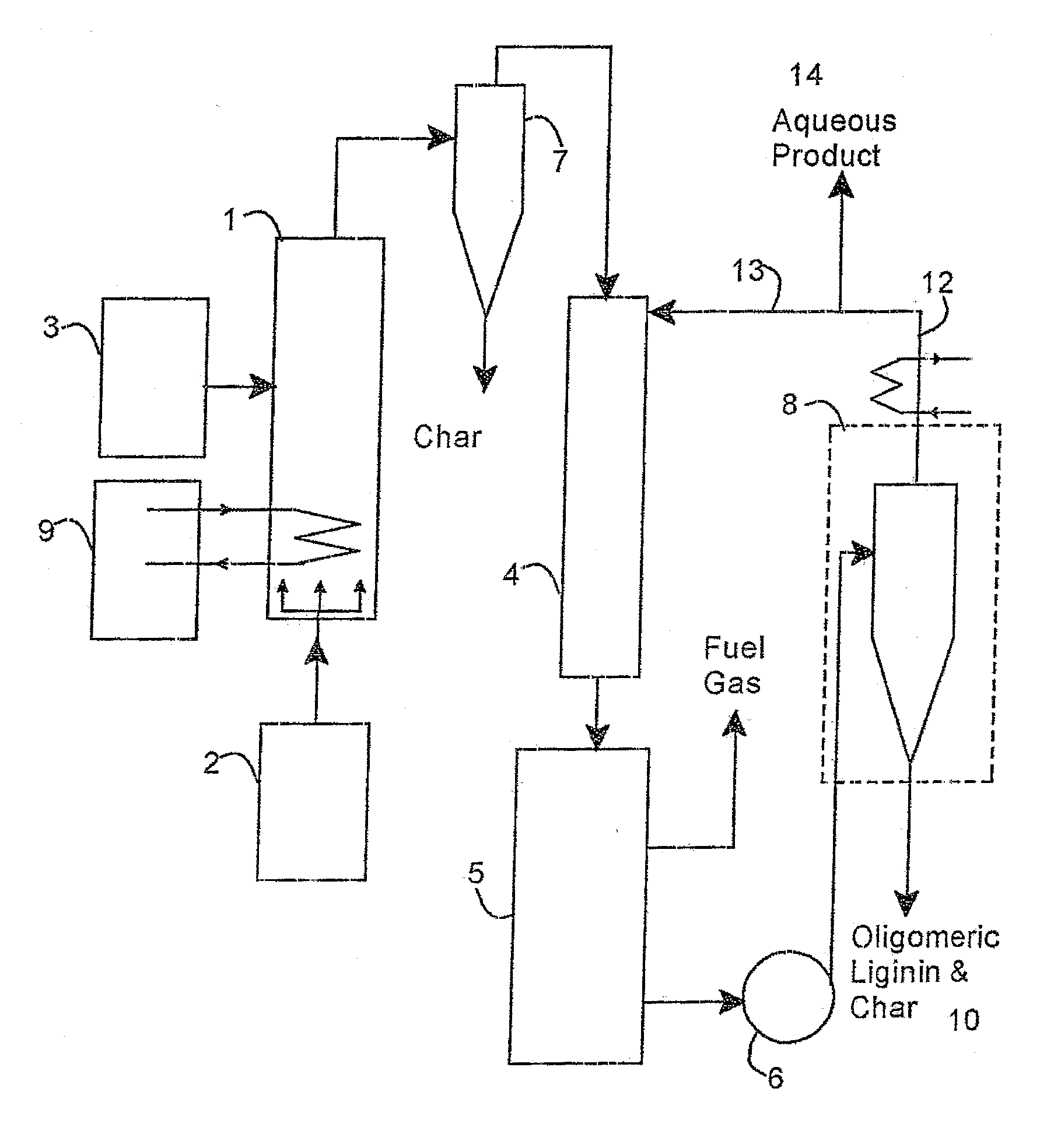

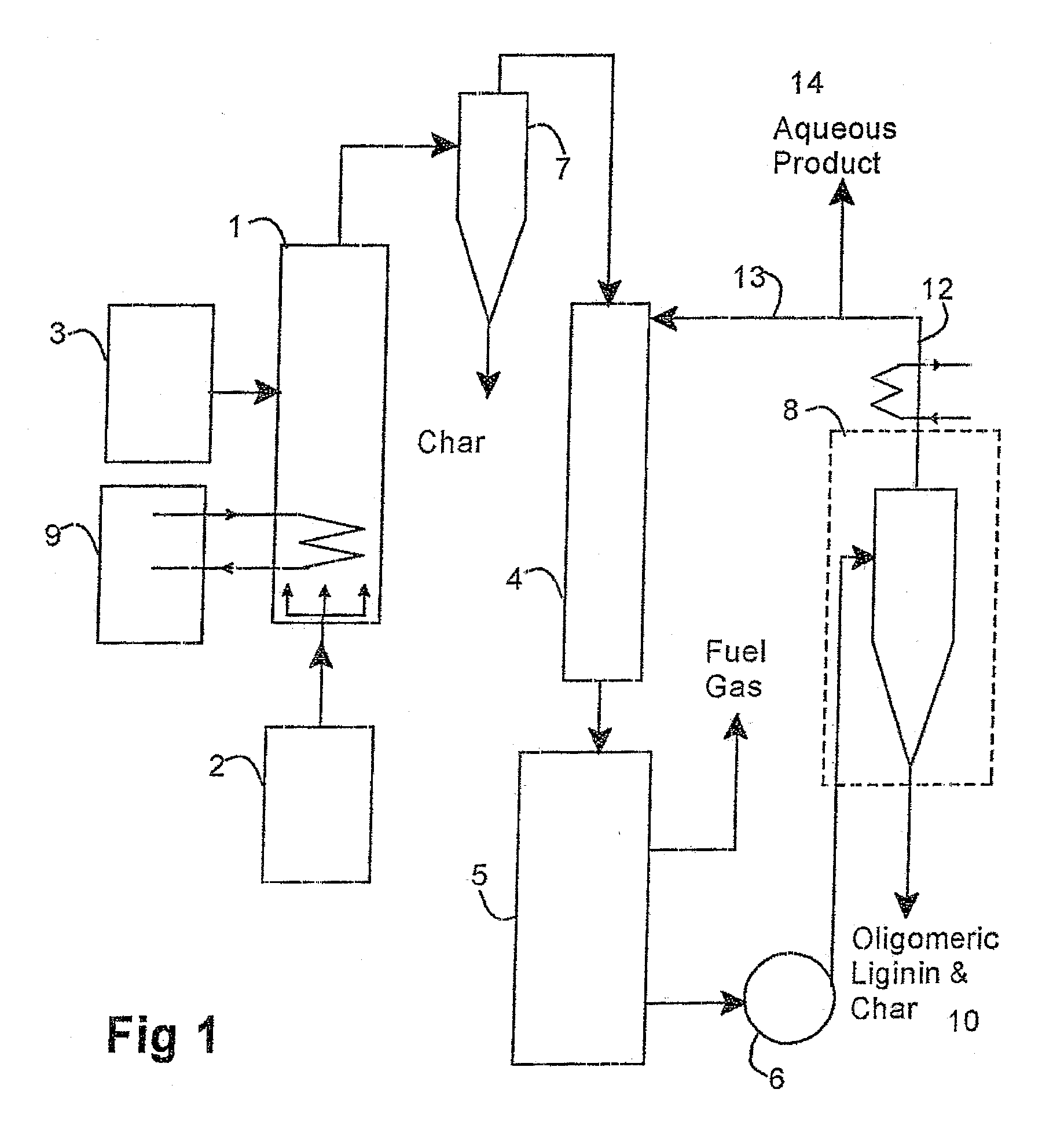

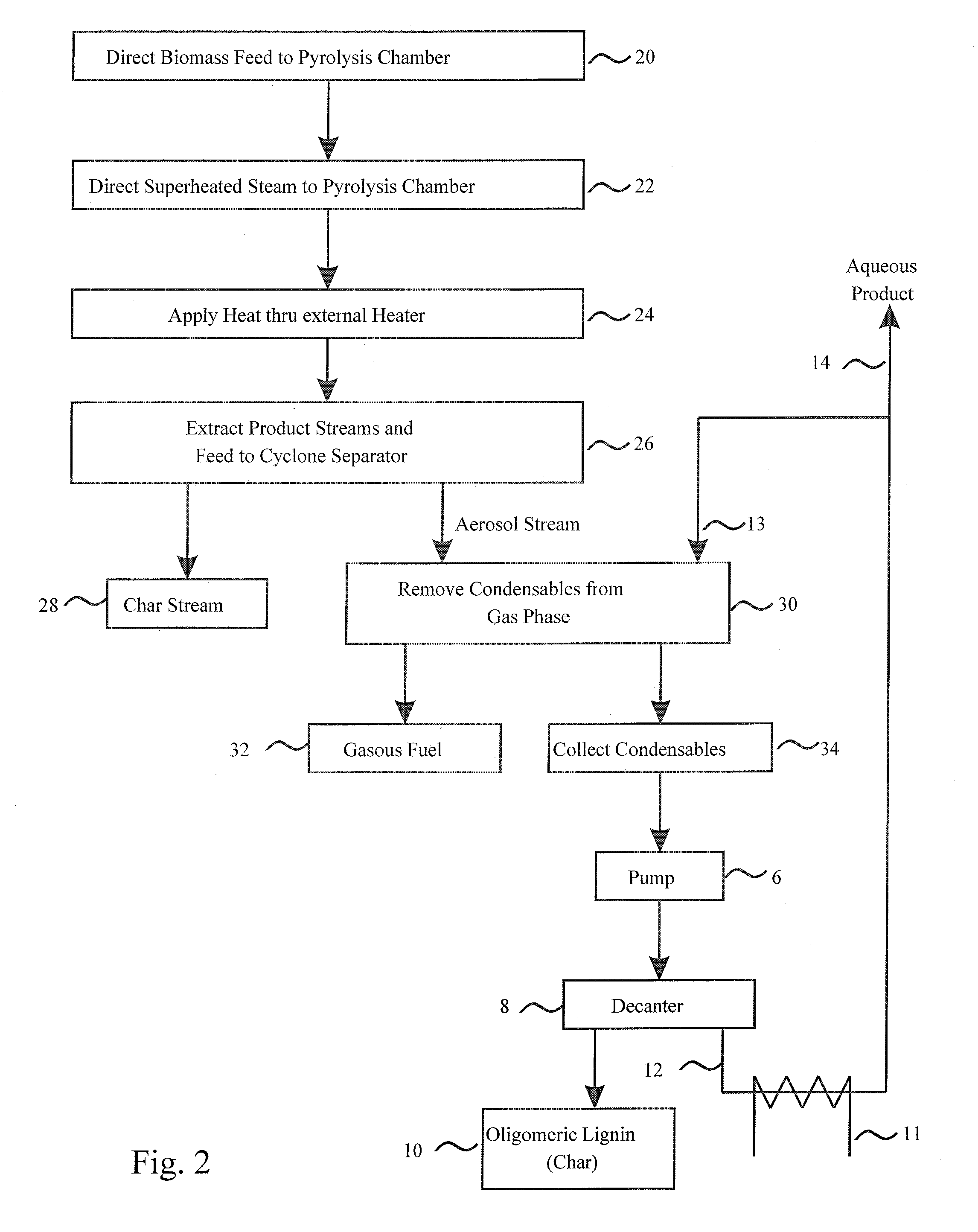

Method of producing hodge carbonyls and oligomeric lignin

ActiveUS20090126433A1Low lignin contentBiofuelsIndirect and direct heating destructive distillationSufficient timeProcess engineering

A method of treating biomass feed by pyrolyzing it in the presence of superheated steam at a selected temperature for a sufficient time to produce at least one product stream.

Owner:KERRY GRP SERVICES INT

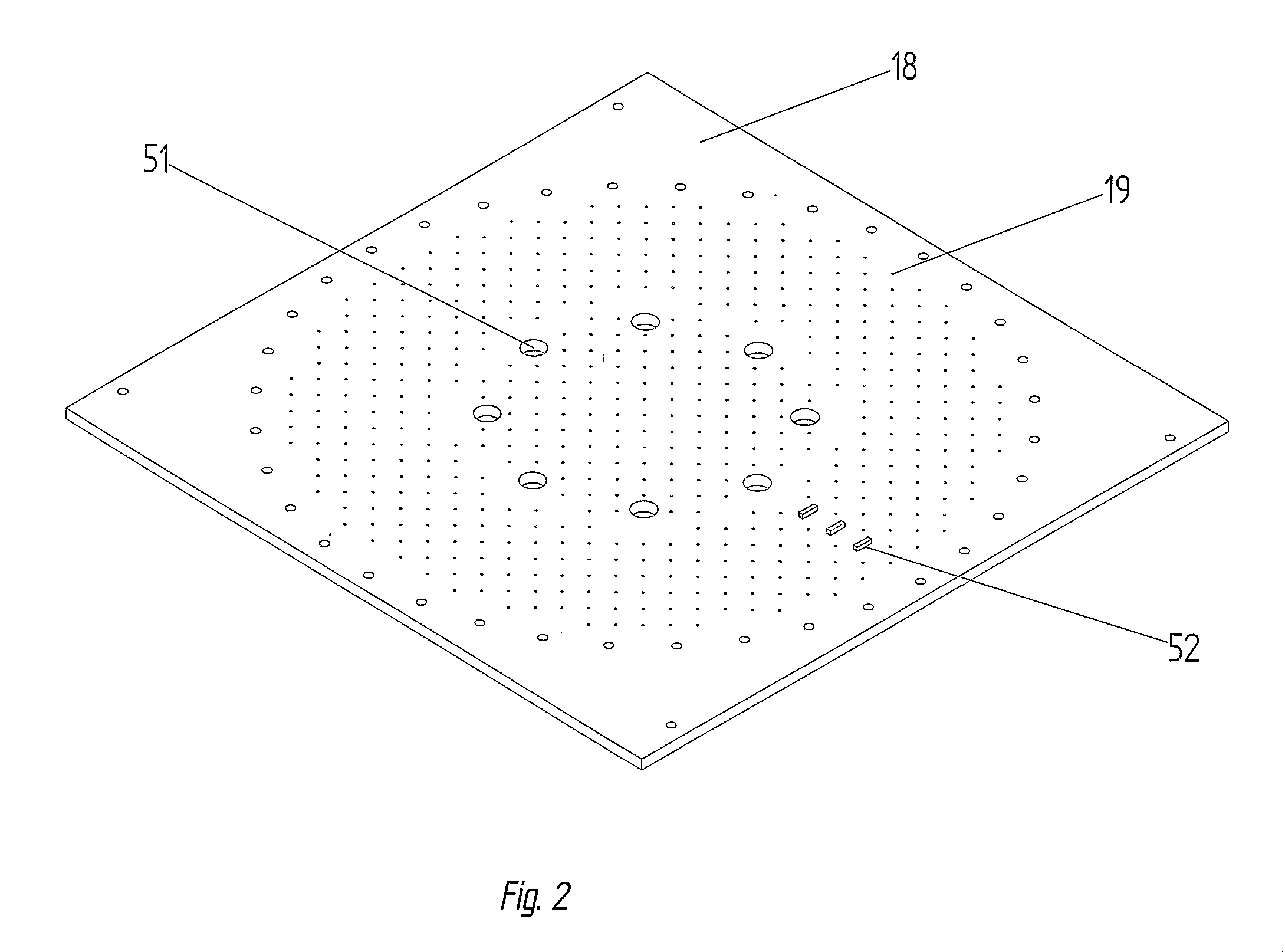

Interlocking floor brick for non-recovery coke oven

An improved non-recovery coke oven floor constructed of a single layer of refractory bricks including, for each oven sole flue, a pair of trunnion bricks and a center bridge brick spanning the width of the flue, having lower brick surfaces in the form of an arch, and joined end-to-end by a tapered tongue-and-groove joint disposed approximately perpendicular to the direction of a compression load transmitted by the center bridge brick to the trunnion bricks.

Owner:PENNSYLVANIA COKE TECH

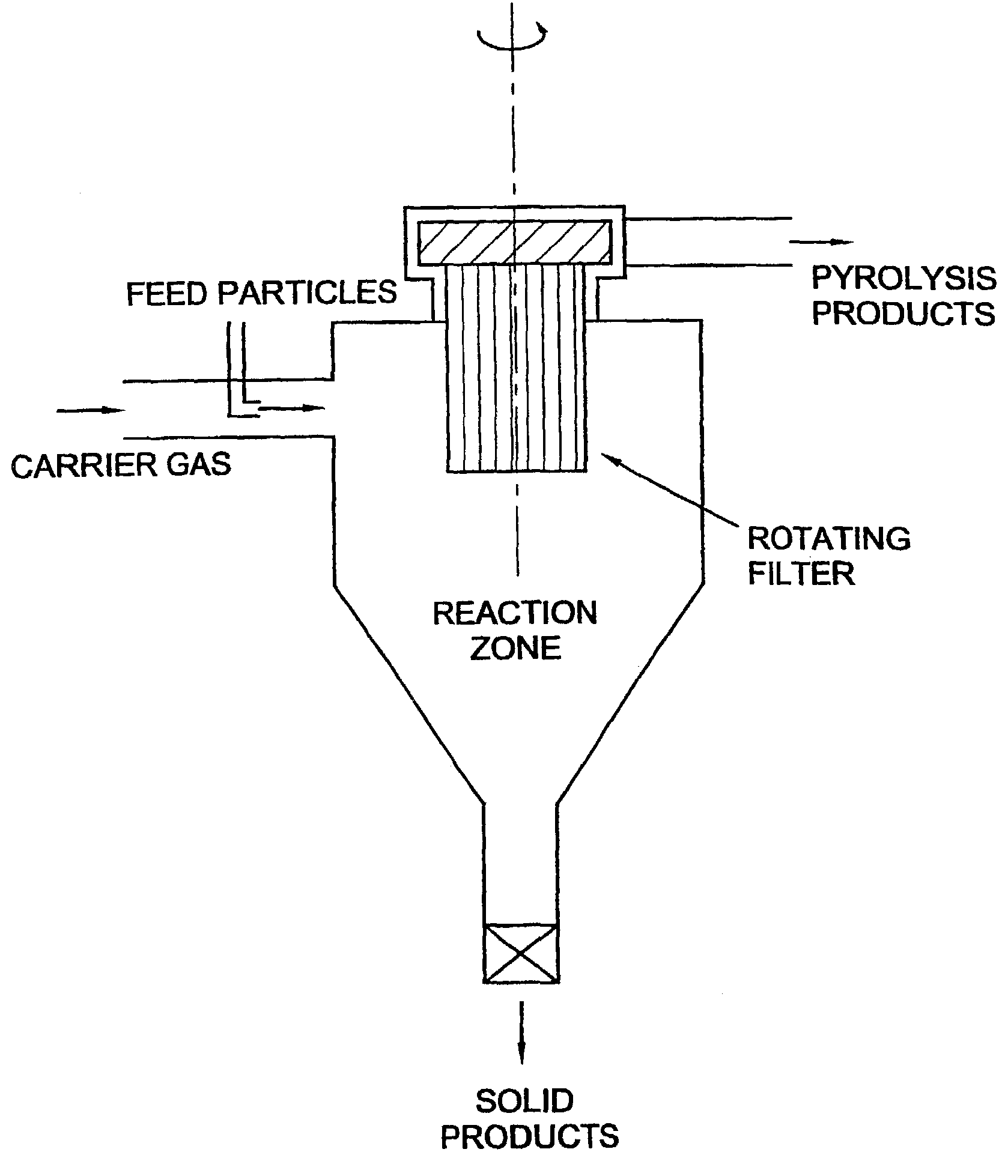

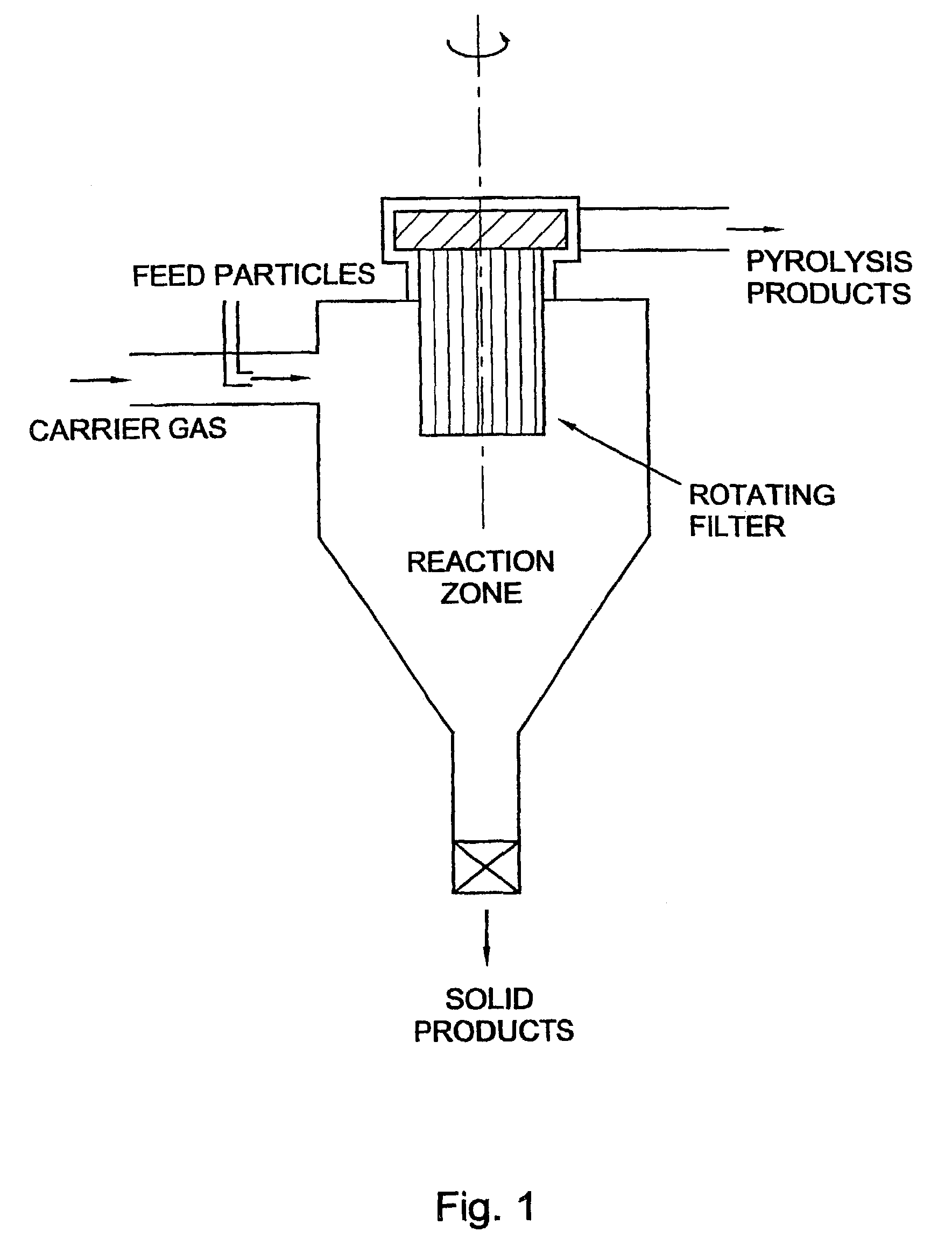

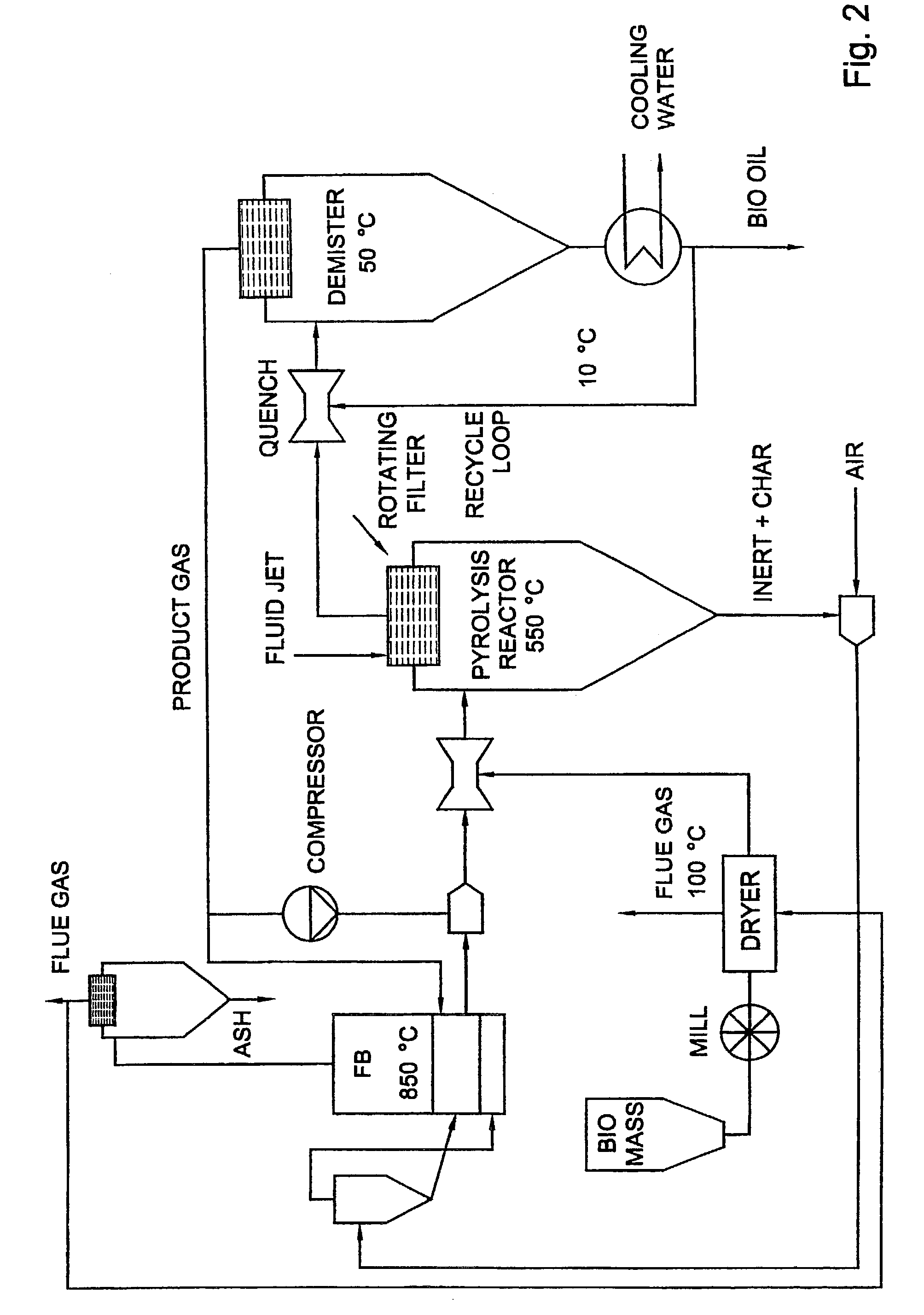

Flash-pyrolysis in a cyclone

InactiveUS7202389B1Excessive crackingCombination devicesDispersed particle filtrationParticulatesCyclone

A process for the pyrolysis of carbonaceous material is carried out in a cyclone reactor which is fitted with enhanced filtering equipment. In addition the invention relates to the use of a cyclone fitted with a rotating filter as a pyrolysis reactor. By using a cyclone of the rotating separator type as a pyrolysis reactor, carbonaceous material, such as biomass, can effectively be converted in a product having excellent chemical properties and which product is free from particulate matter.

Owner:UNIVERSITY OF TWENTE

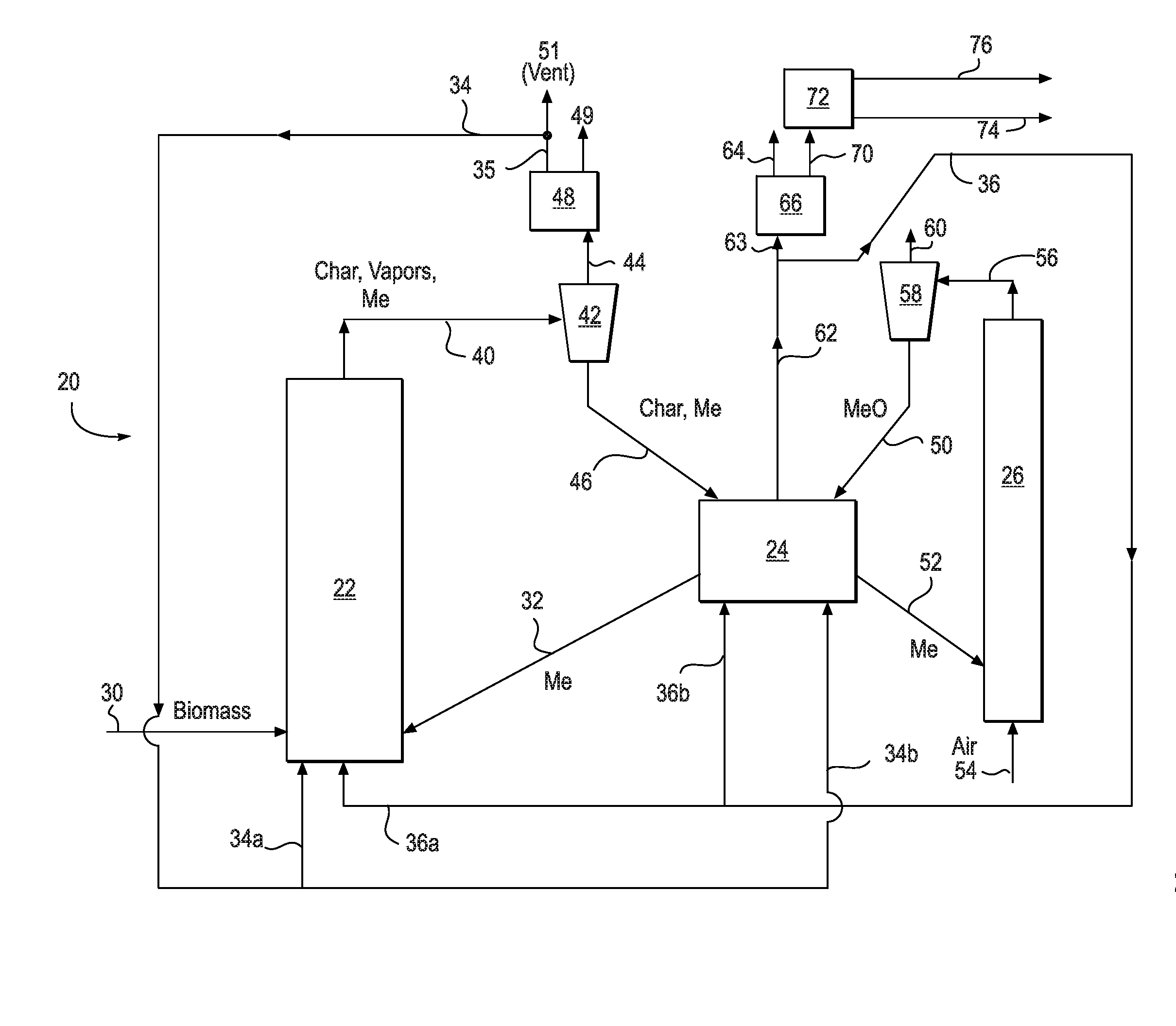

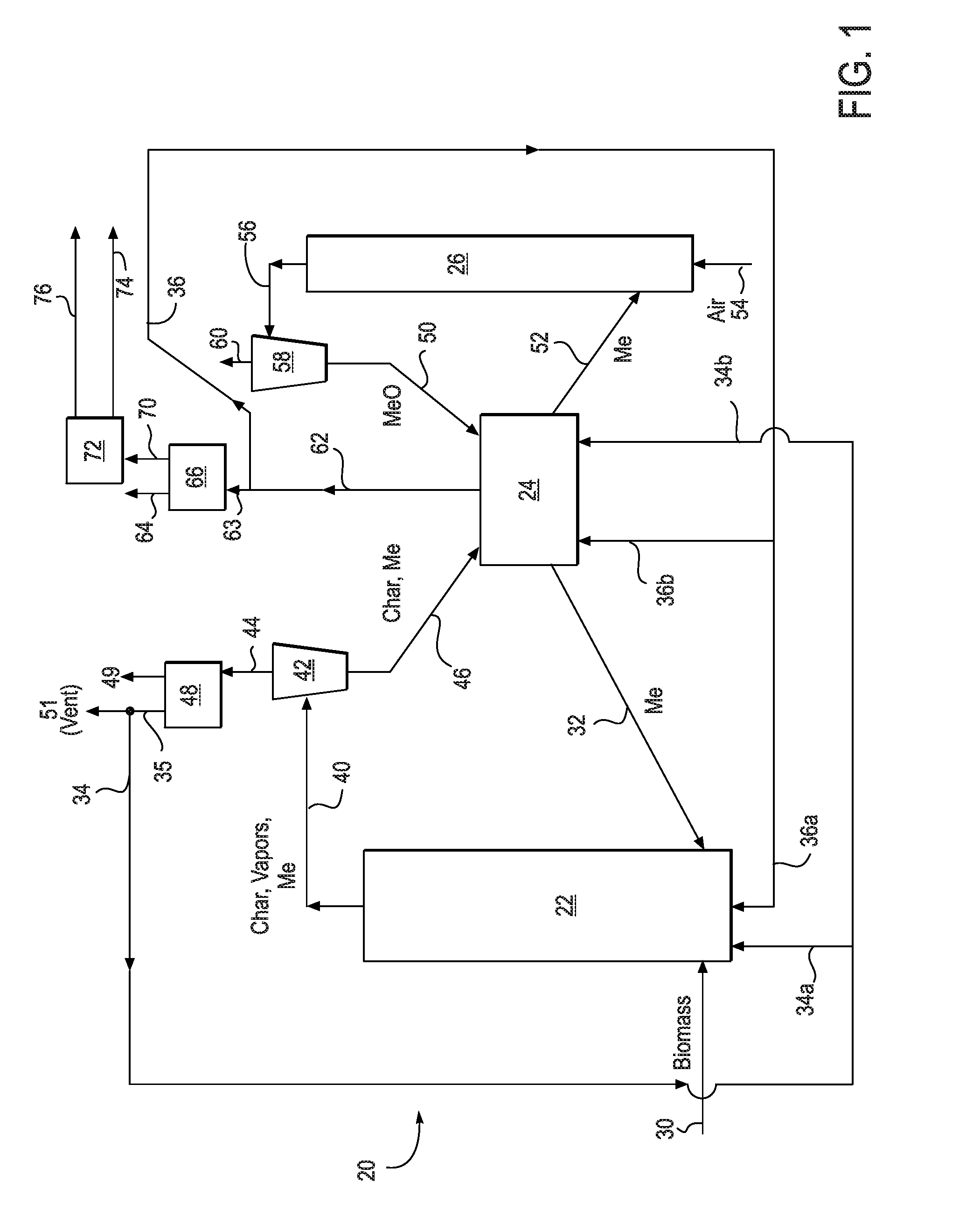

Method and system for capturing carbon dioxide from biomass pyrolysis process

A system and method for biomass pyrolysis utilizing chemical looping combustion of a produced char to capture carbon dioxide is disclosed. The system includes a biomass pyrolysis reactor, a char combustor, and oxidation reactor and a separator for separating carbon dioxide from flue gas produced by the char combustion. The pyrolysis reactor pyrolyzes biomass in the presence of reduced metal oxide sorbents producing char and pyrolysis oil vapor. The char is separated and combusted in the char combustor, in the presence of oxidized metal oxide sorbents, into a gaseous stream of carbon dioxide and water vapor. The carbon dioxide and water are separated so that a stream of carbon dioxide may be captured. The oxidation reactor oxidizes, in the presence of air, a portion of reduced metal oxide sorbents into oxidized metal oxide sorbents that are looped back to the char combustor to provide oxygen for combustion. A second portion of the reduced metal oxide sorbents is recycled from the char combustor to the pyrolysis reactor to provide heat to drive the pyrolysis. Pyrolysis oil upgrading catalyst particles may be used in addition to the metal oxide sorbents as heat energy carrier particles to improve the quality of the pyrolysis oil vapors produced in the pyrolysis reactor. Also, the metal oxide sorbents may have metals incorporated therein which serve to upgrade the pyrolysis vapors produced during pyrolysis. Non-limiting examples of such metals include Ni, Mo, Co, Cr, W, Rh, Ir, Re, and Ru.

Owner:CHEVROU USA INC

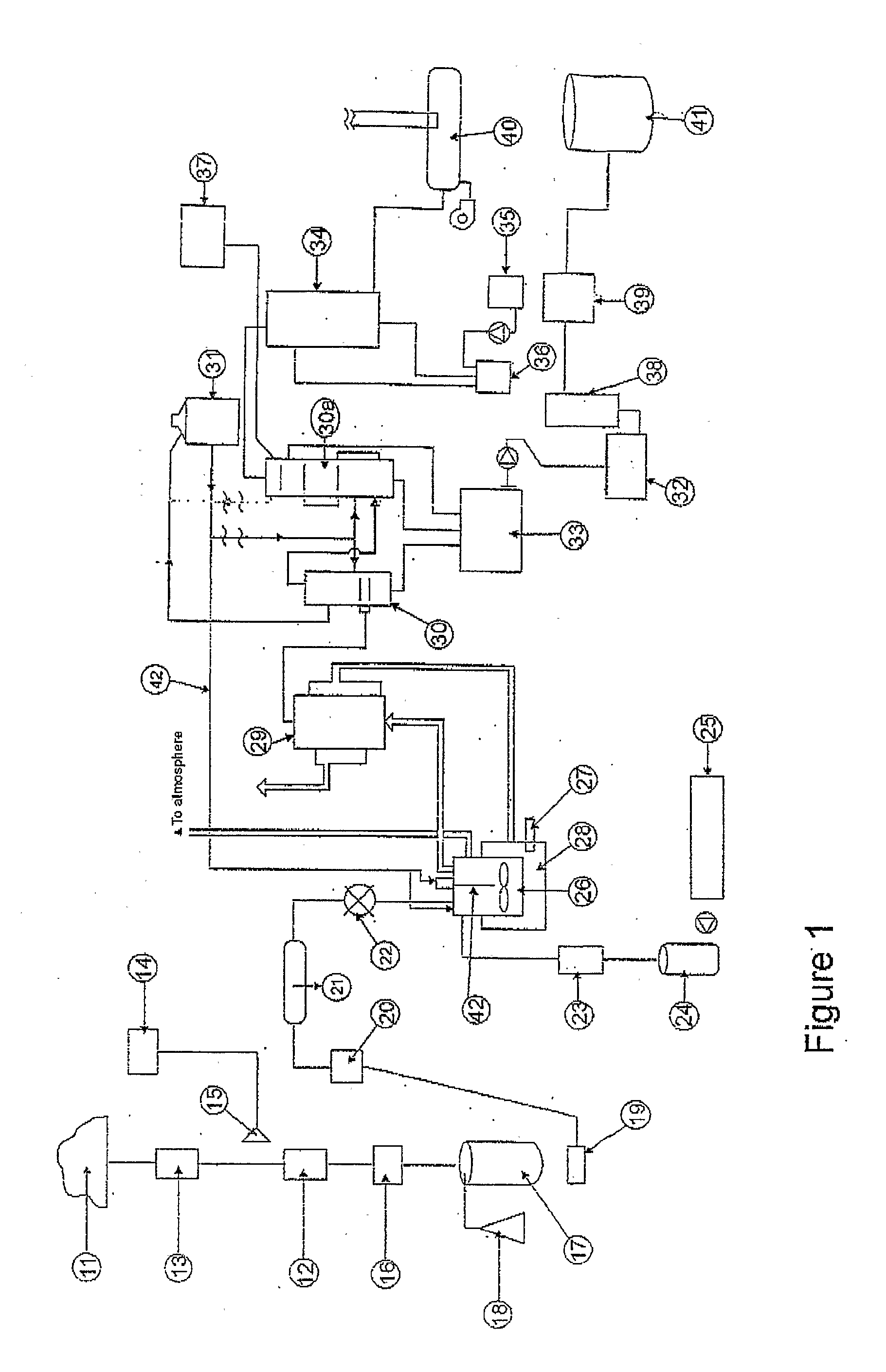

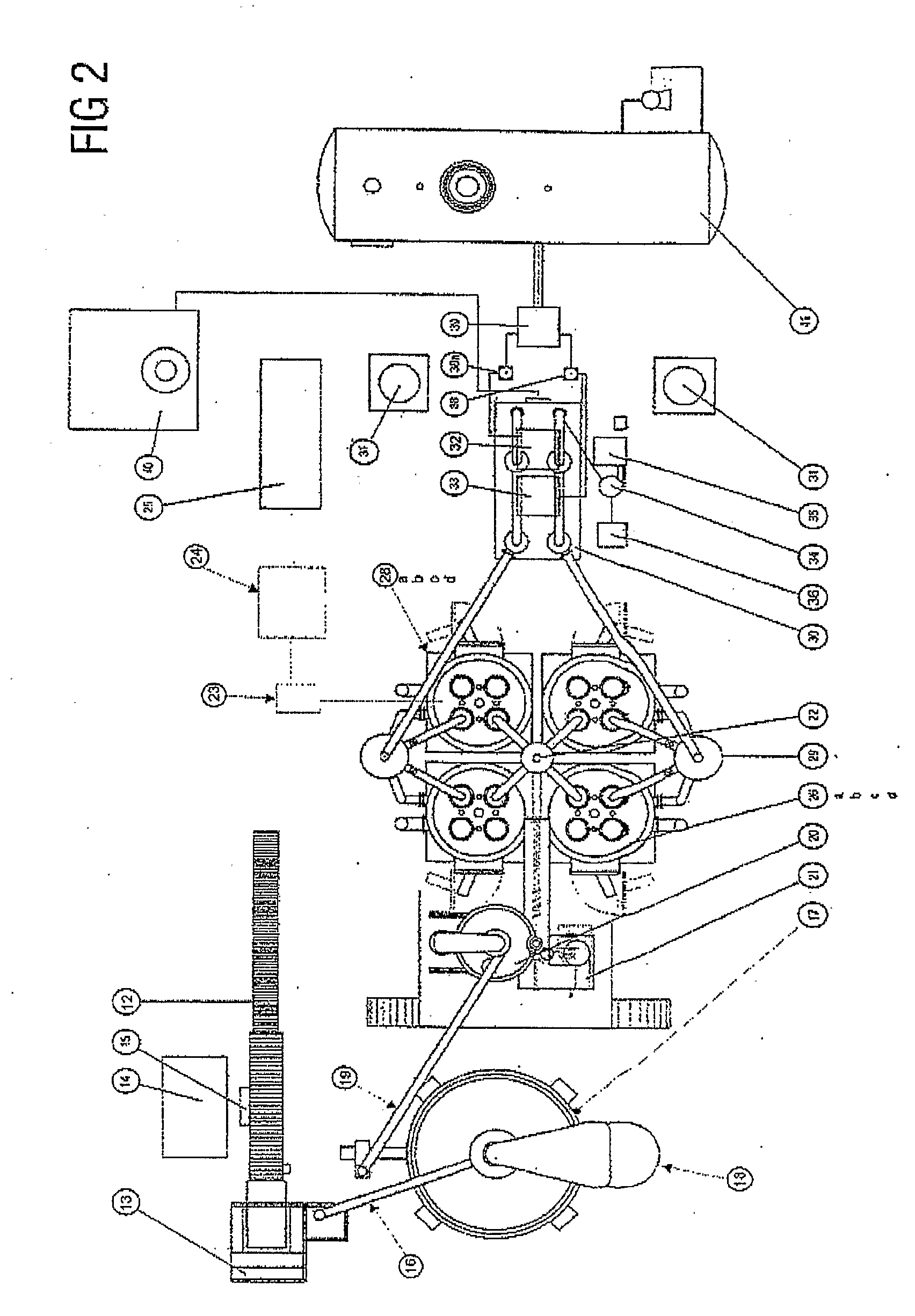

Process and plant for conversion of waste material to liquid fuel

ActiveUS20070179326A1Easy to wasteEasy feedingCatalytic crackingIndirect and direct heating destructive distillationEnvironmental engineeringLiquid fuel

A process and plant for the thermocatalytic conversion of waste materials into reusable fuels and a fuel produced by the process, involving the steps of delivering melted waste material (11) to one or more pyrolysis chambers (26) via heated and valved manifolds (22) and effecting pyrolysis of the waste material into a gascous state in an oxygen purged and pressure controlled environment. Pyrolytic gases are, then transferred to a catalytic converter (29) where the molecular structure of the gaseous material is altered in structure and form, with gases then transferred to one or more condensers (30a) to distil and cool gases in to their respective fractions. After post pyrolysis treatment, fuel fractions thon form a useable fuel. Includes the melting of waste (plastic) material (11) before delivery into any of the pyrolysis chambers (26), making the movement of material into the catalytic tower (29) a semi-continuous operation, directing melted waste material into one or more, but preferably four, pyrolysis chambers (26a, b, c, d), making each chamber capable of independent operation, optionally mechanically removing waste char from the pyrolysis chamber (107) by use of an internet auger (112) or other suitable means.

Owner:FUTURE ENERGY INVESTMENTS PTY LTD

Method and apparatus for producing coke

ActiveUS8152970B2Reduce the amount requiredReduce moisture contentSpeed controllerCoke quenchingMetallurgyMetallurgical coke

A method and apparatus for quenching metallurgical coke made in a coking oven. The method includes pushing a unitary slab of hot coke onto a substantially planar receiving surface of a hot car. The hot car containing the coke is then transported to a quench car station. The unitary slab of hot coke is pushed onto a substantially planar receiving surface of a quench car at the quench car station. Quenching of the slab of hot coke is conducted in the quench car with a predetermine amount of water. After quenching, the quenched coke is dumped onto a receiving pad for collection thereof.

Owner:SUNCOKE TECH & DEV LLC

Methods of recovering hydrocarbons from hydrocarbonaceous material using a constructed infrastructure and associated systems

ActiveUS20080190818A1Reduce processing costsIncrease volume outputThermal non-catalytic crackingSolid waste disposalEngineeringHydrocarbon

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a constructed permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

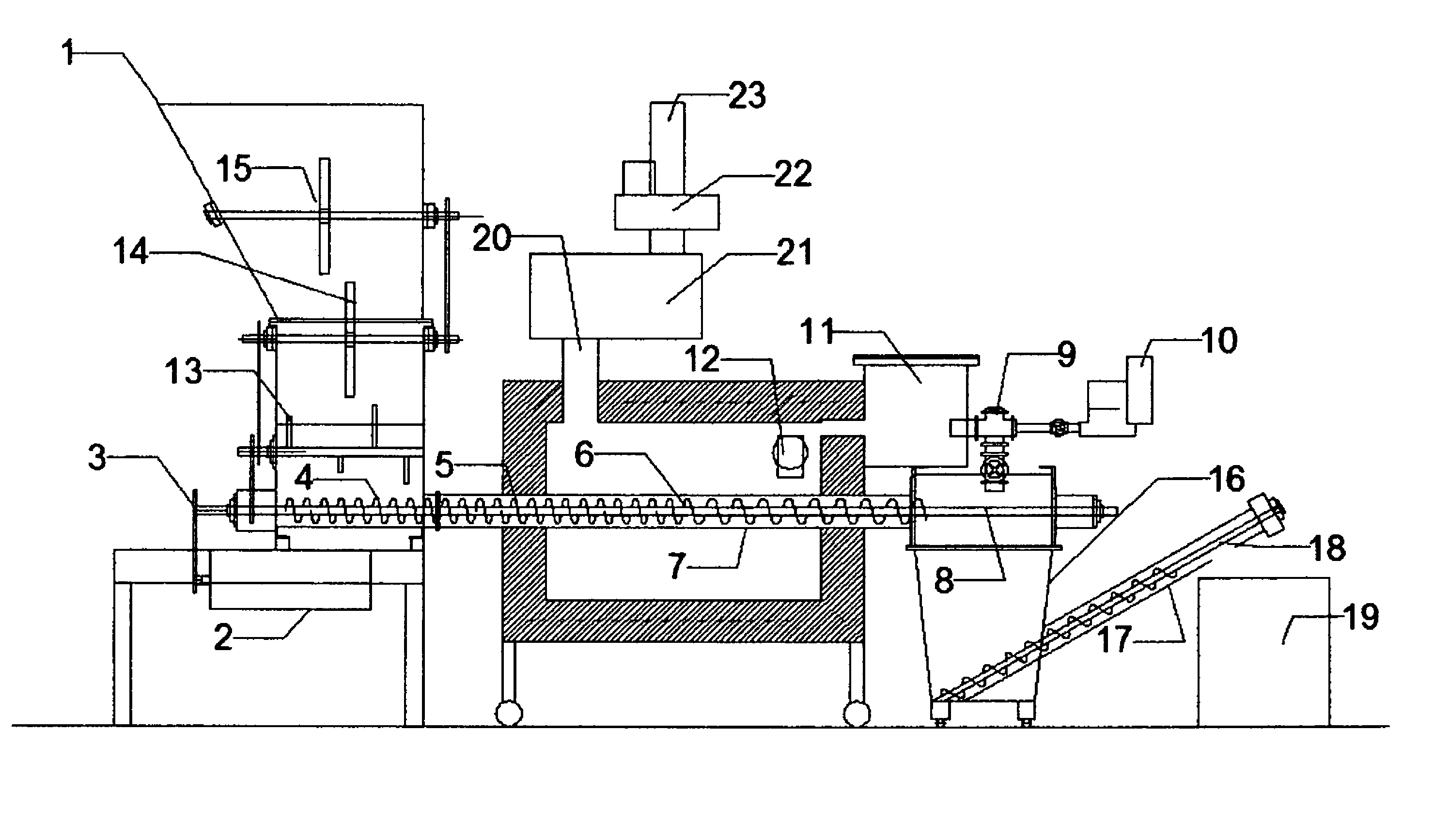

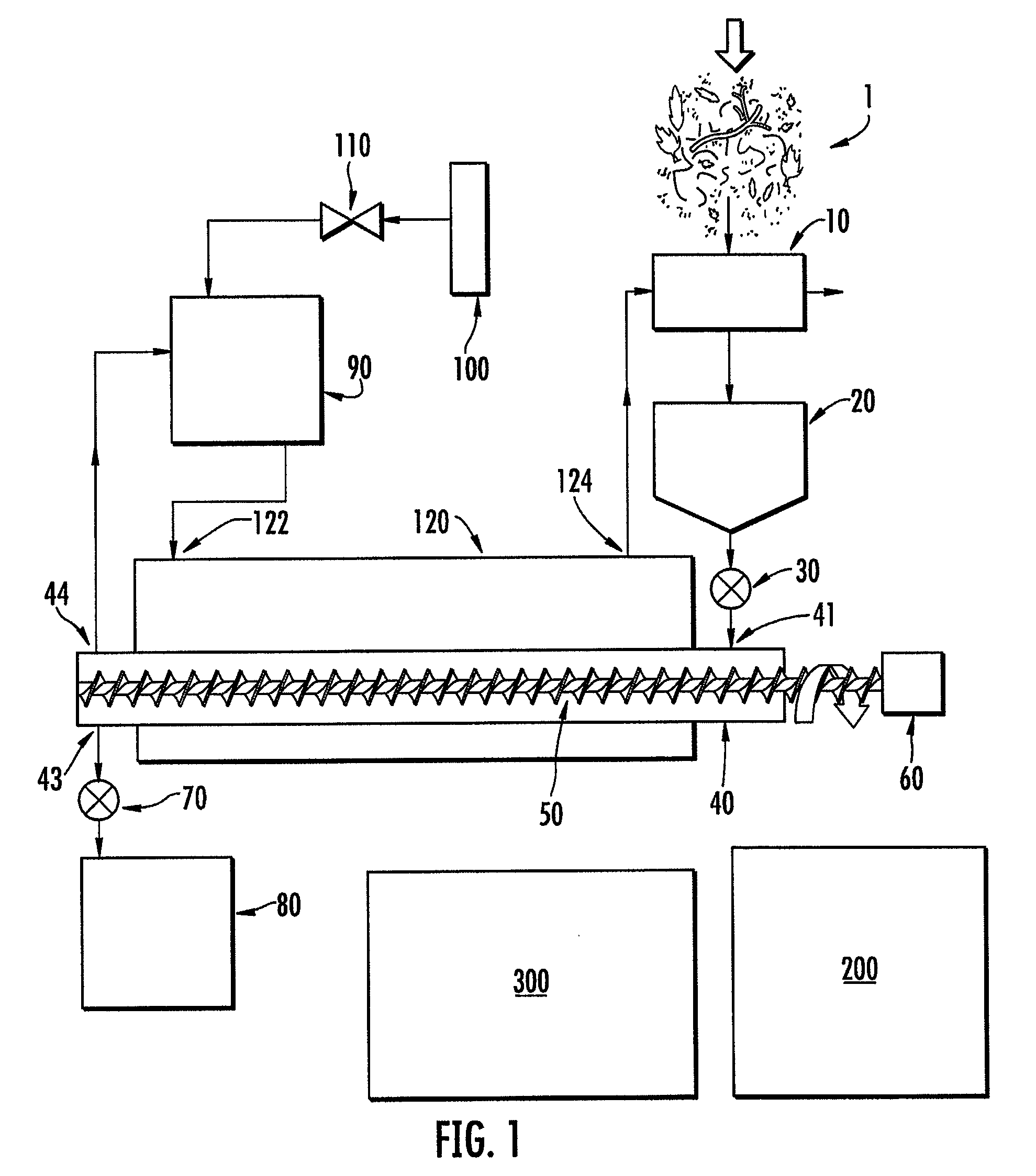

Process and device for the pyrolysis of feedstock

InactiveUS7947155B1Thermal non-catalytic crackingCombustible gas coke oven heatingVolatilesEngineering

This invention involves pyrolysis of feedstock by introducing carbonaceous feedstock, into a hopper and moving it into a reactor tube enclosed in an oven, generating heat within the oven that is in part transferred to the feedstock, heating it to sufficient temperature to pyrolyze the feedstock into useful volatiles and char. A Venturi system produces a negative pressure directing volatiles into a pyro-gas oven producing heat necessary for pyrolysis and generating useful excess heat. The extruded pyrolysis char has uses including charcoal fuel, soil amendments, and activated charcoal while liquids can be produced for processing into fuels. Excess heat may be used to heat water, steam, and air, may be used in air heating and cooling systems, perform mechanical work with a Stirling engine or generate electricity on the order of 100 kW and higher. The system may be operated in a carbon neutral or even carbon negative manner, allowing sequestration of atmospheric carbon dioxide.

Owner:GREEN LIQUID & GAS TECH

Coker feed method and apparatus

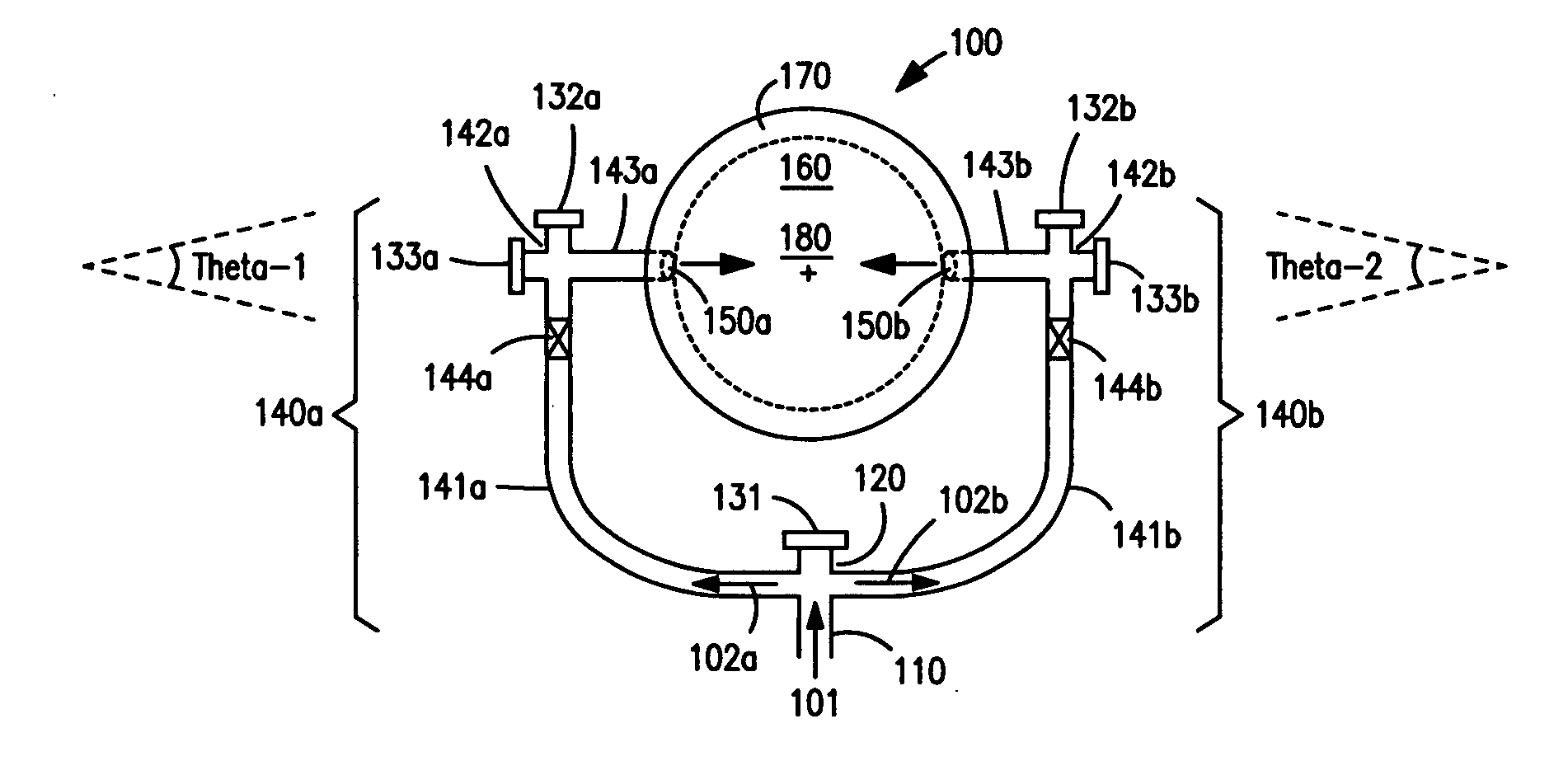

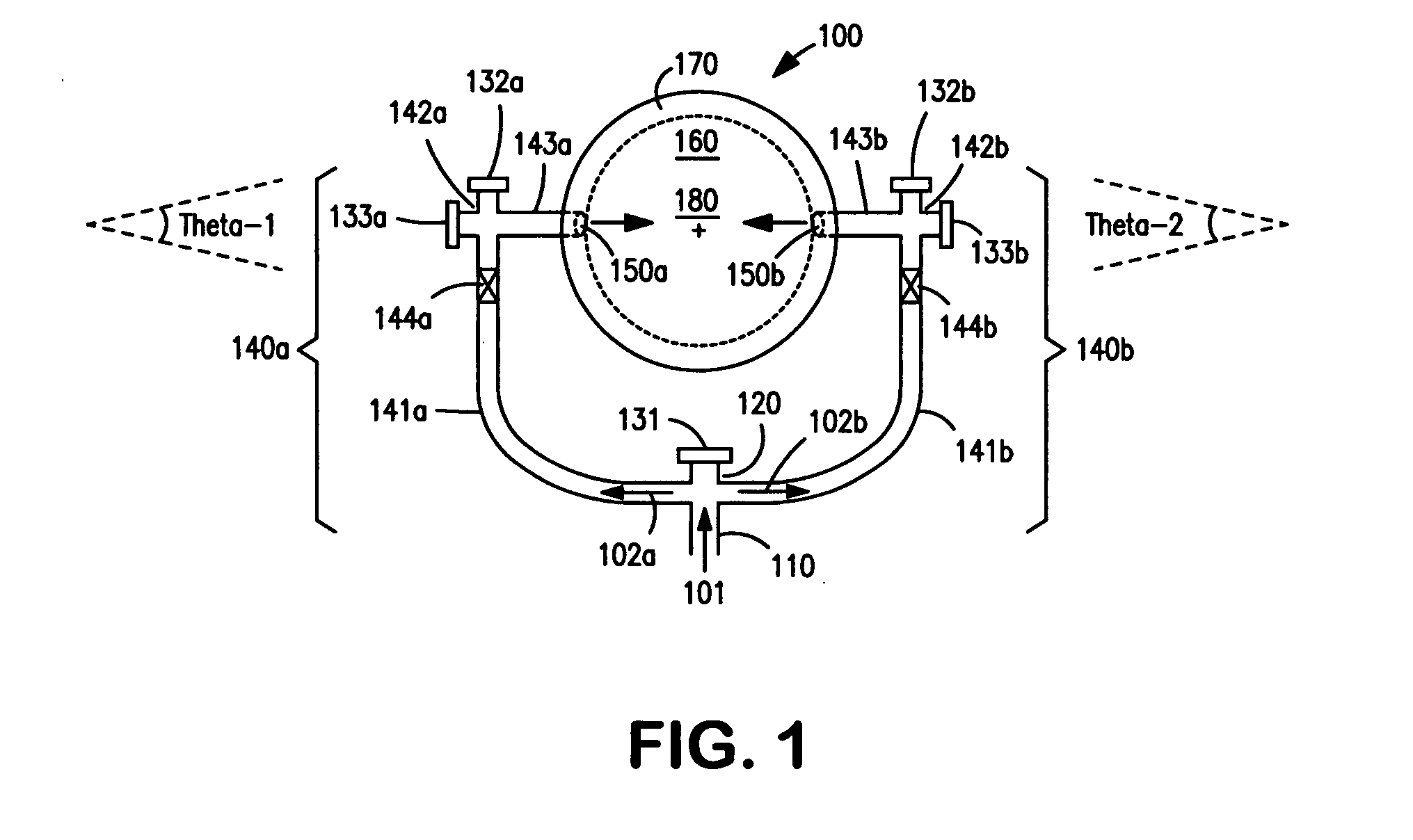

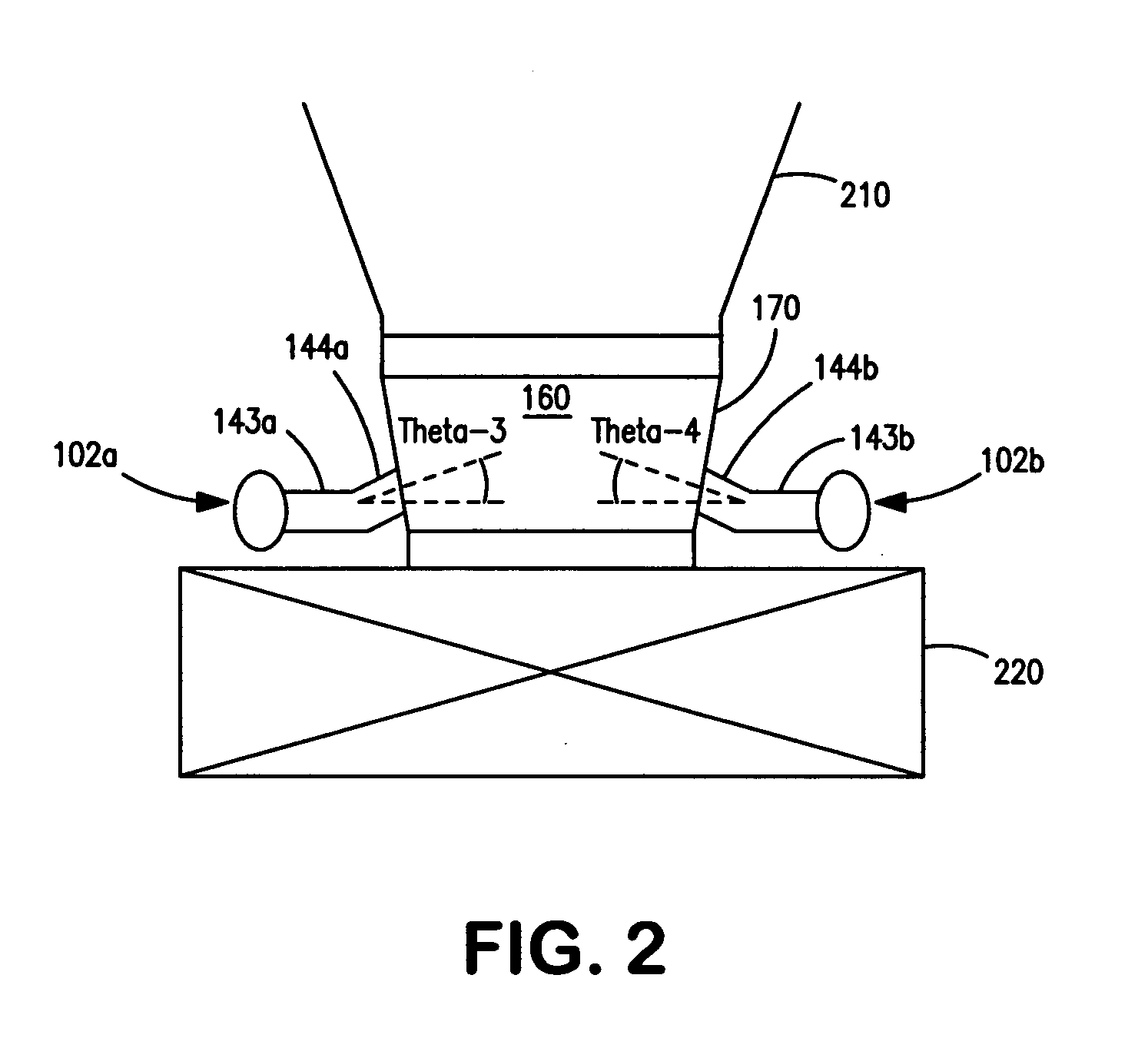

InactiveUS20080179165A1Reduces drum/vessel thermal stressReduce thermal stressThermal non-catalytic crackingCombustible gas coke oven heatingEngineeringVertical axis

Described herein are methods and mechanisms for laterally dispensing fluid to a coke drum in a predictable and maintainable manner that alleviates thermal stress. In one embodiment, the methods and mechanisms utilize a split piping system to dispense fluid through two or more inlets into a spool that is connected to a coke drum and a coke drum bottom deheader valve. A combination of block valves and clean out ports provides a more effective means to clean the lines and allows fluid to be laterally dispensed in a controllable and predictable manner. The fluid is preferably introduced to the spool in opposing directions toward a central vertical axis of the spool at equal but opposing angles ranging from minus thirty (−30) to thirty (30) degrees relative to a horizontal line laterally bisecting the spool. Alternatively, however, fluid can be introduced to the spool tangentially.

Owner:EXXON RES & ENG CO

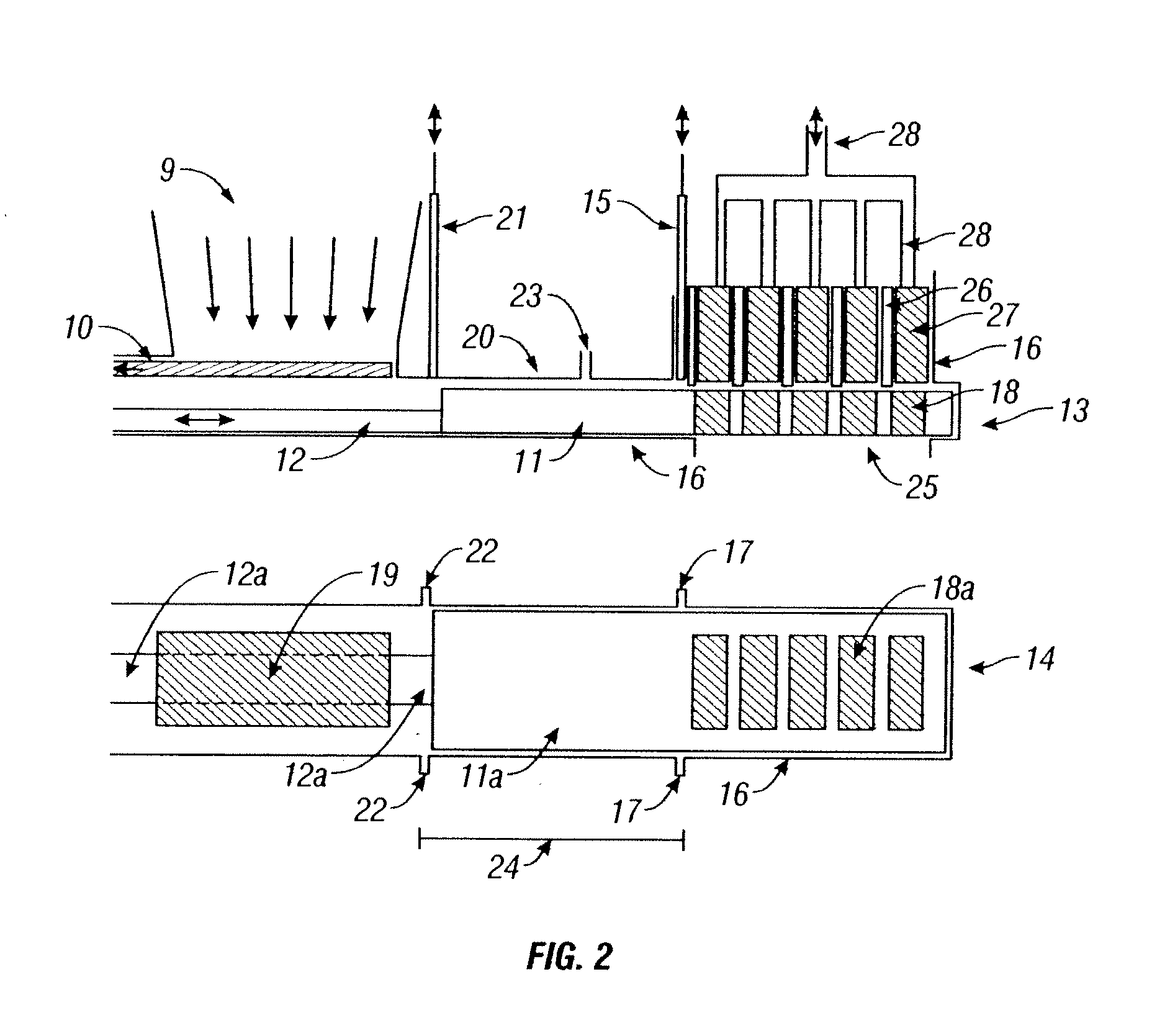

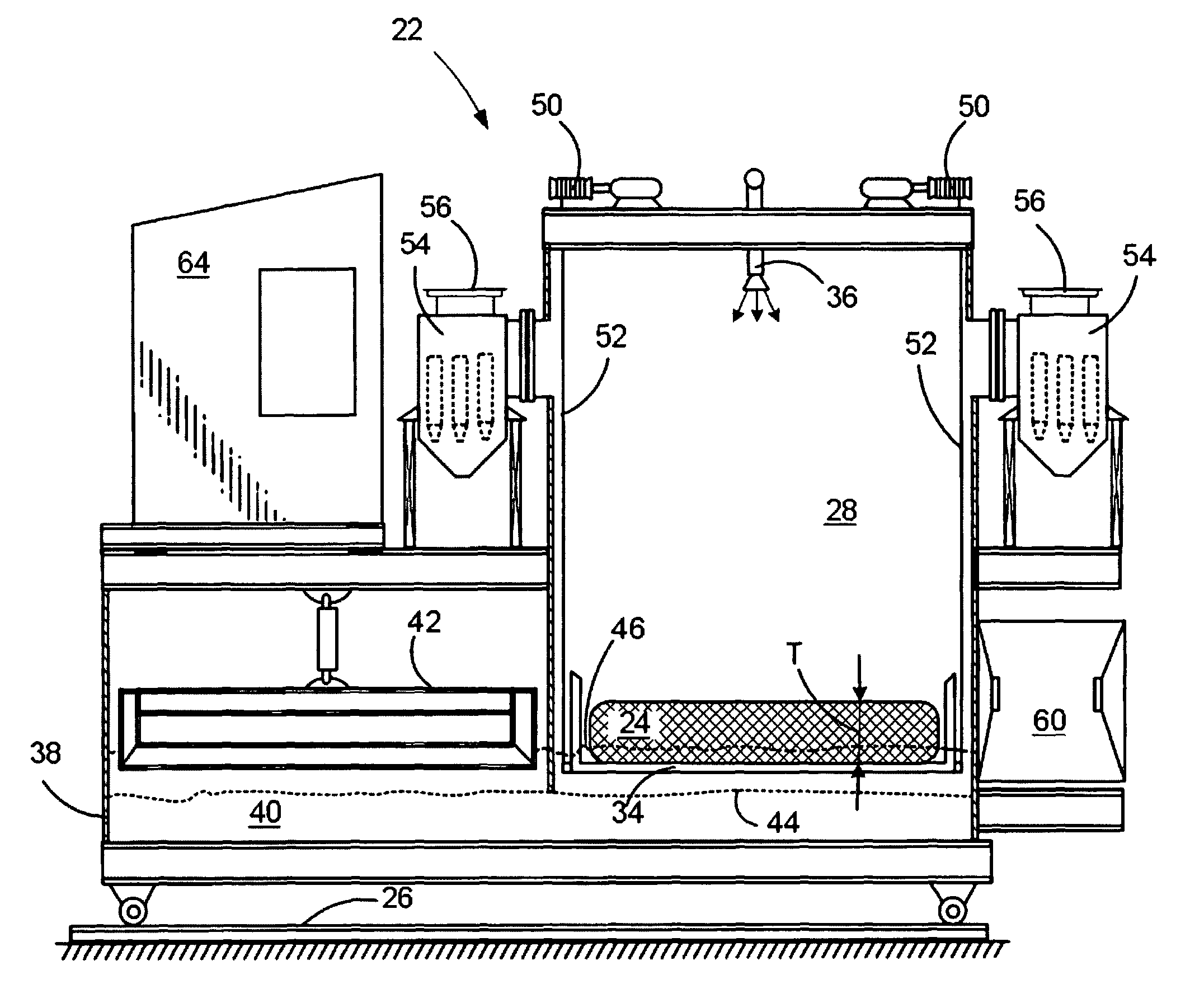

Flat push coke wet quenching apparatus and process

InactiveUS7998316B2Reduce the amount requiredImprove efficiencyCoke quenchingDirect heating destructive distillationCoke ovenWater level

A method and apparatus for quenching metallurgical coke made in a coking oven. The method includes pushing a unitary slab of incandescent coke onto a substantially planar receiving surface of an enclosed quenching car so that substantially all of the coke from the coking oven is pushed as a unitary slab onto the receiving surface of the quenching car. The slab of incandescent coke is quenched in an enclosed environment within the quenching car with a plurality of water quench nozzles while submerging at least a portion of the slab of incandescent coke by raising a water level in the quenching car. Subsequent to quenching the coke, the planar receiving surface is tilted to an angle sufficient to slide the quenched coke off of the planar receiving surface and onto a product collection conveyer and sufficient to drain water from the quenched coke.

Owner:SUNCOKE TECH & DEV LLC

Process for transporting and quenching coke

ActiveUS8236142B2Emission minimizationMinimize timeCoke quenchingDirect heating destructive distillationDust controlProcess engineering

A method and apparatus for transporting and quenching coke, useful in quenching a batch of coke produced in one of a plurality of coke ovens forming a coke oven battery, is disclosed. A hot car defining a substantially planar receiving surface is positioned adjacent a coke oven of the coke oven battery, and a unitary cake of unquenched coke is placed onto the hot car receiving surface. The hot car and unquenched coke are transported to a transfer station having a dust collection system. A quenching car is positioned at the transfer station adjacent the hot car, under the dust collection system. The unitary cake of unquenched coke is dumped into the quenching car receptacle, thereby separating the unitary cake. At least a portion of the dust generated by separation is collected. The quench car is then transported to a quenching station, where the separated coke is quenched.

Owner:WESTBROOK THERMAL TECH

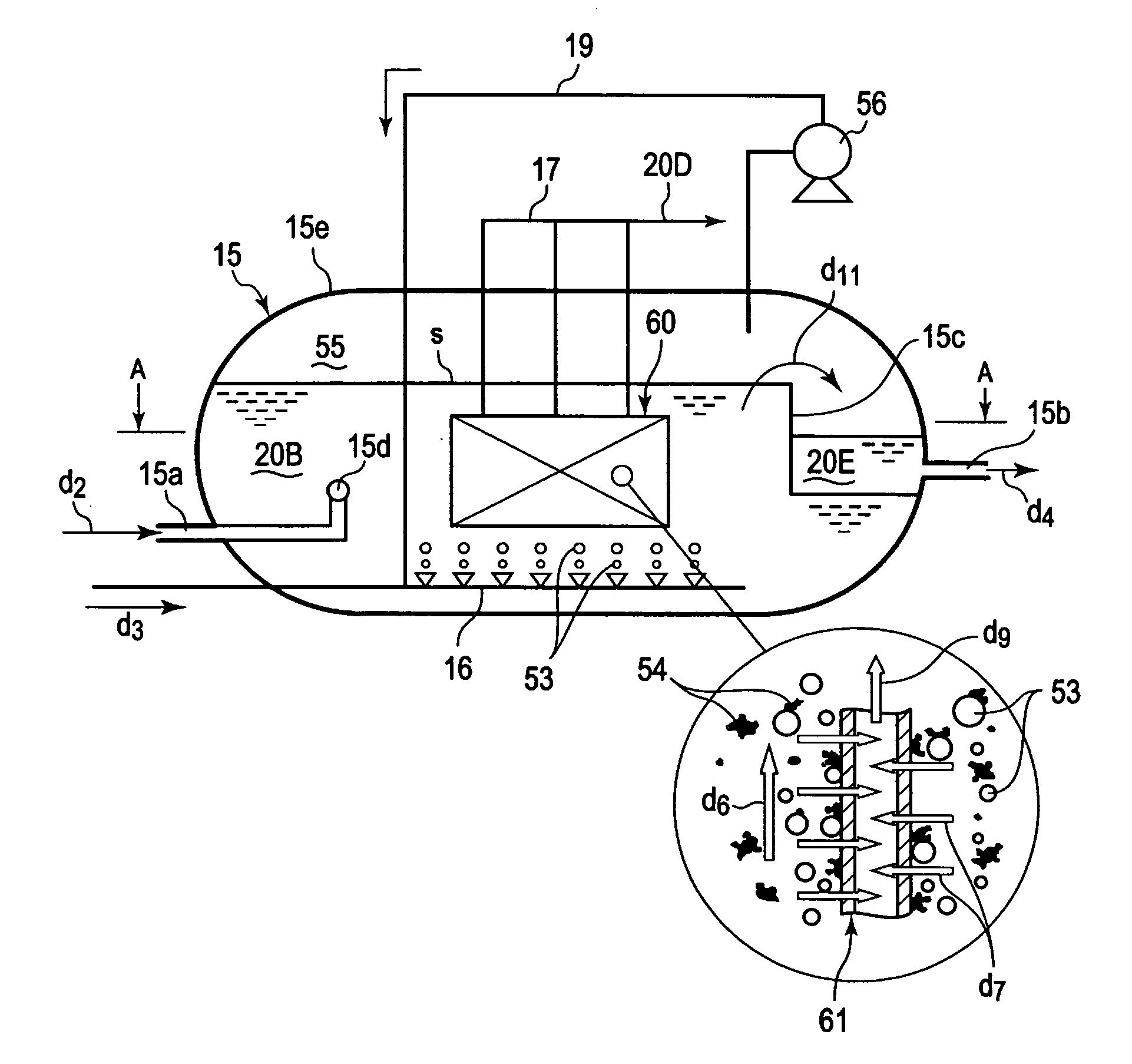

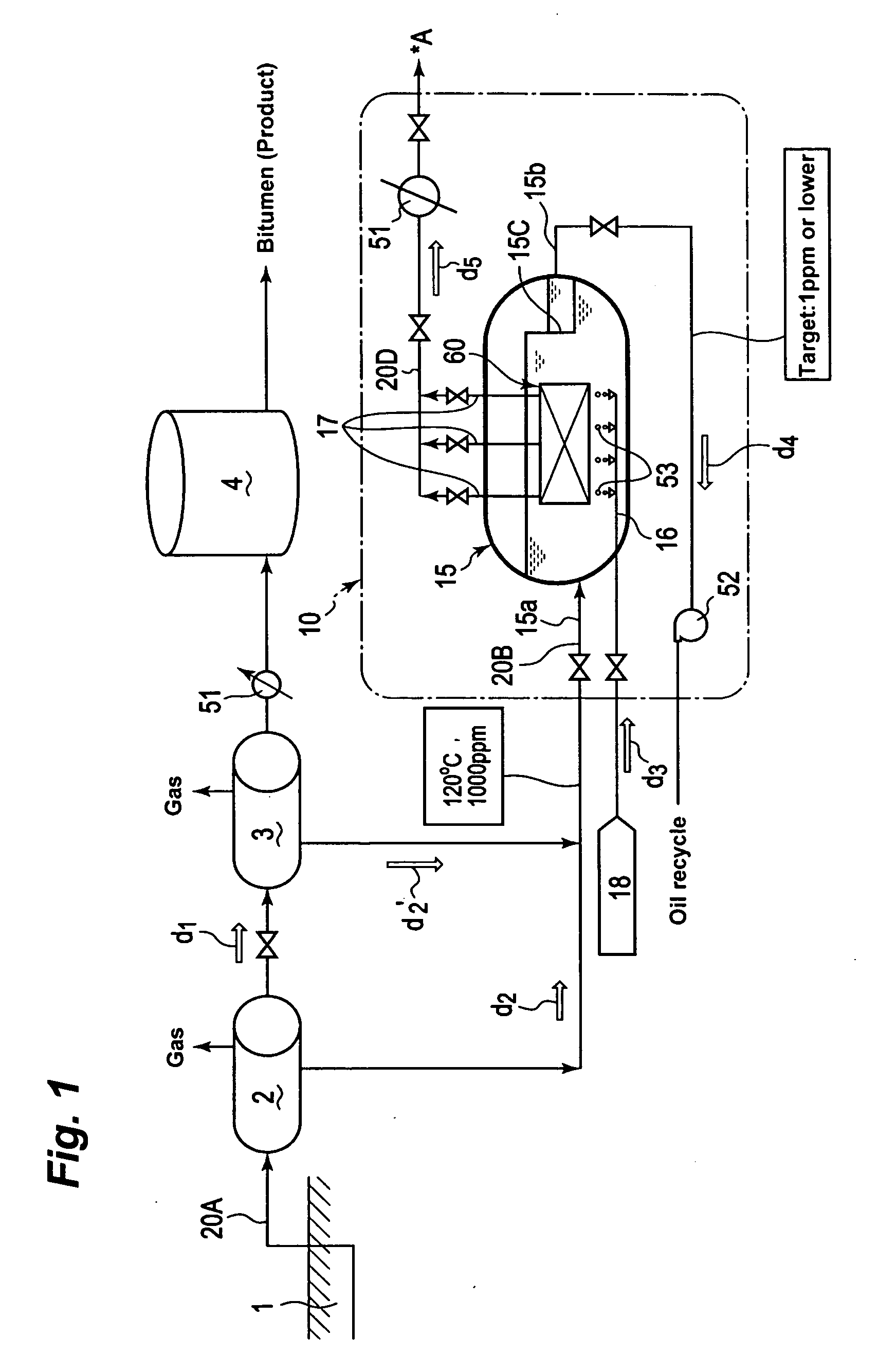

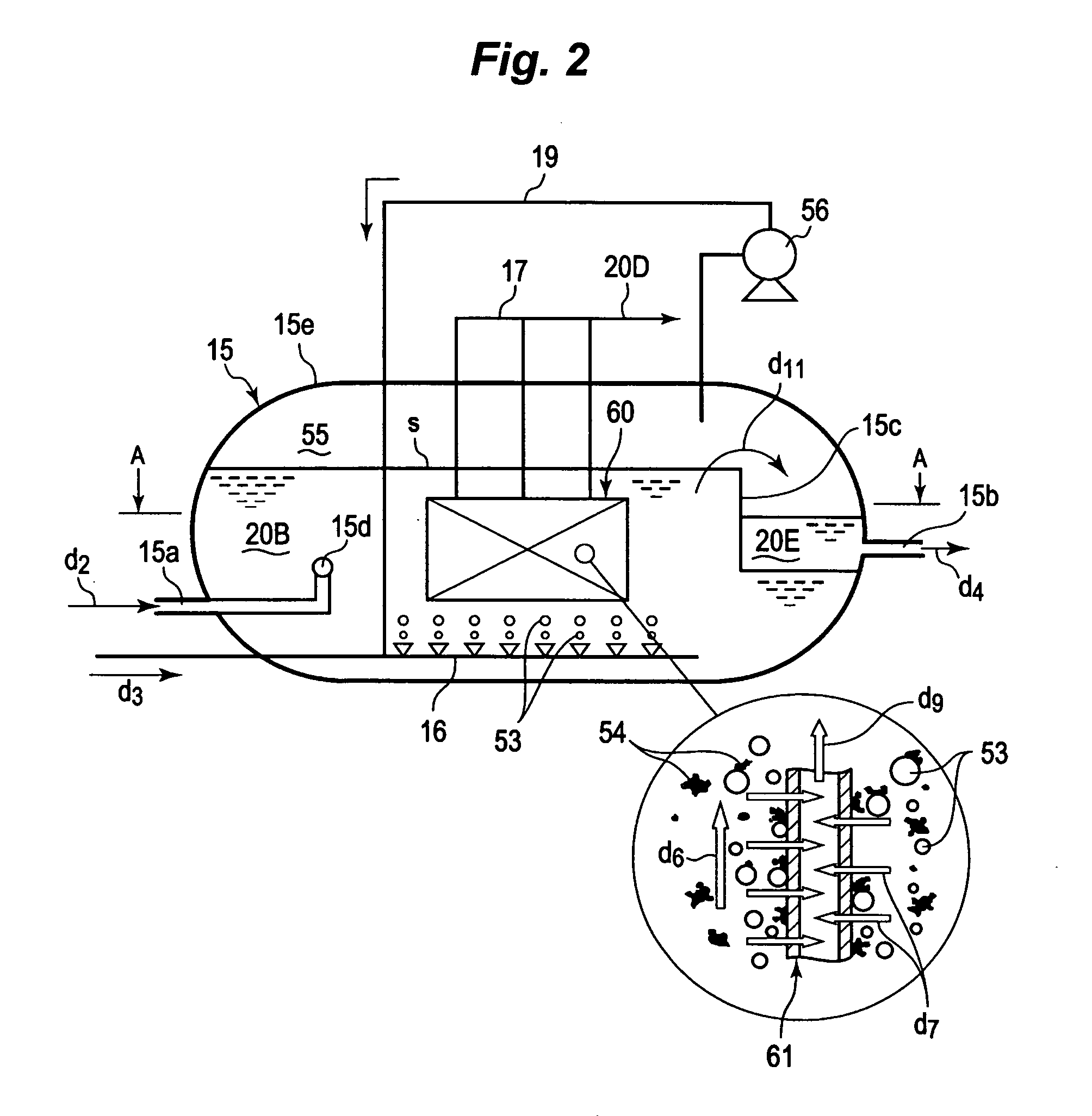

Apparatus of produced water treatment, system and method of using the apparatus, and method of water reuse by using the same

An apparatus of produced water treatment, to be adopted in an in-situ recovery method of producing bitumen from oil sand, the apparatus capable of removing the oil from produced water, the produced water of being left by separating the bitumen from bitumen-mixed fluid having been recovered from the oil sand, the apparatus having: a vessel for receiving the produced water; a submerge type filtration membrane module, installed in the vessel, for filtering the produced water in the condition of the membrane being submerged in the produced water; and a bubble generator for generating bubbles to be forwarded toward the submerged filtration membrane in the produced water.

Owner:TOYO ENG CORP +1

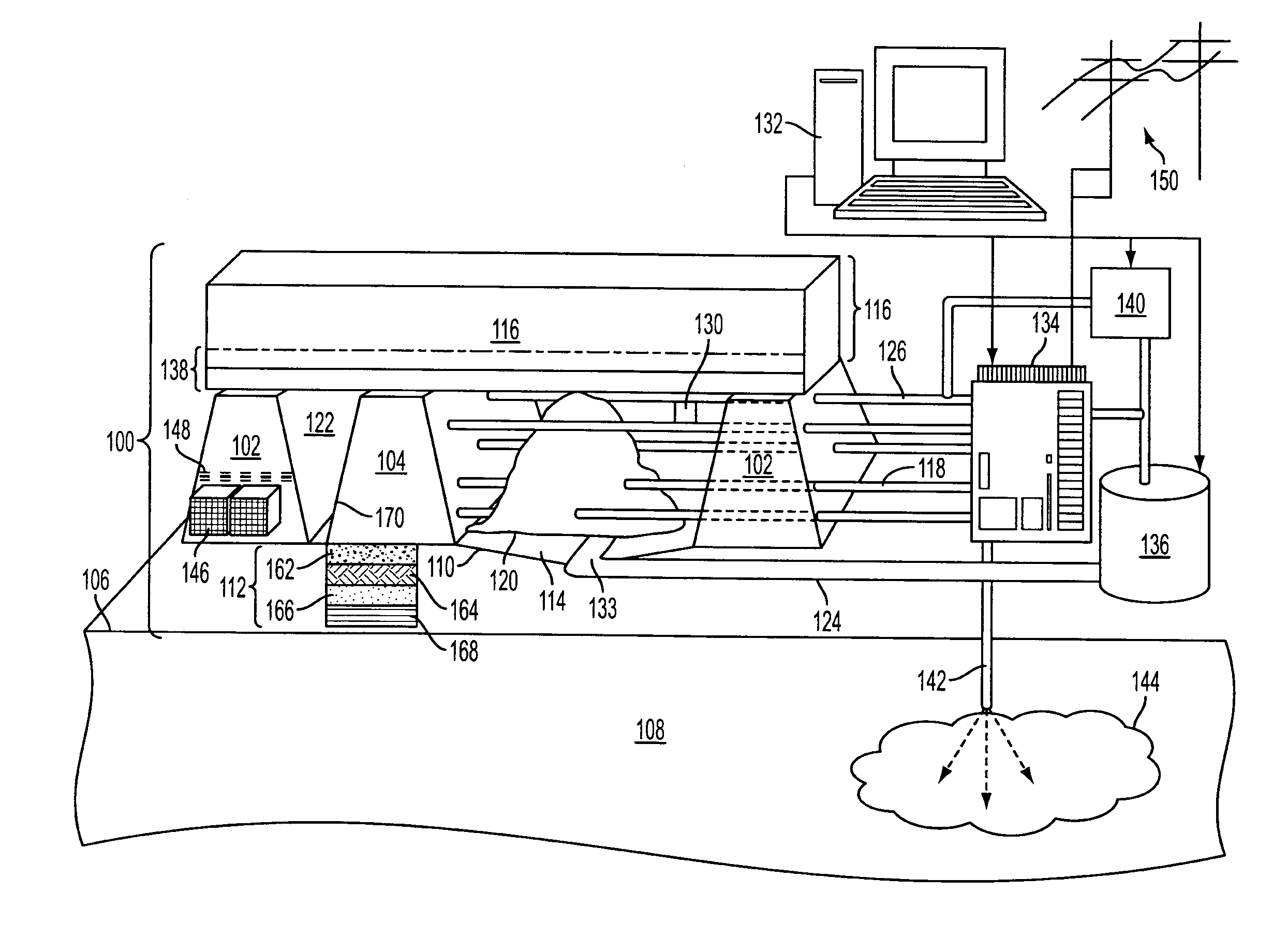

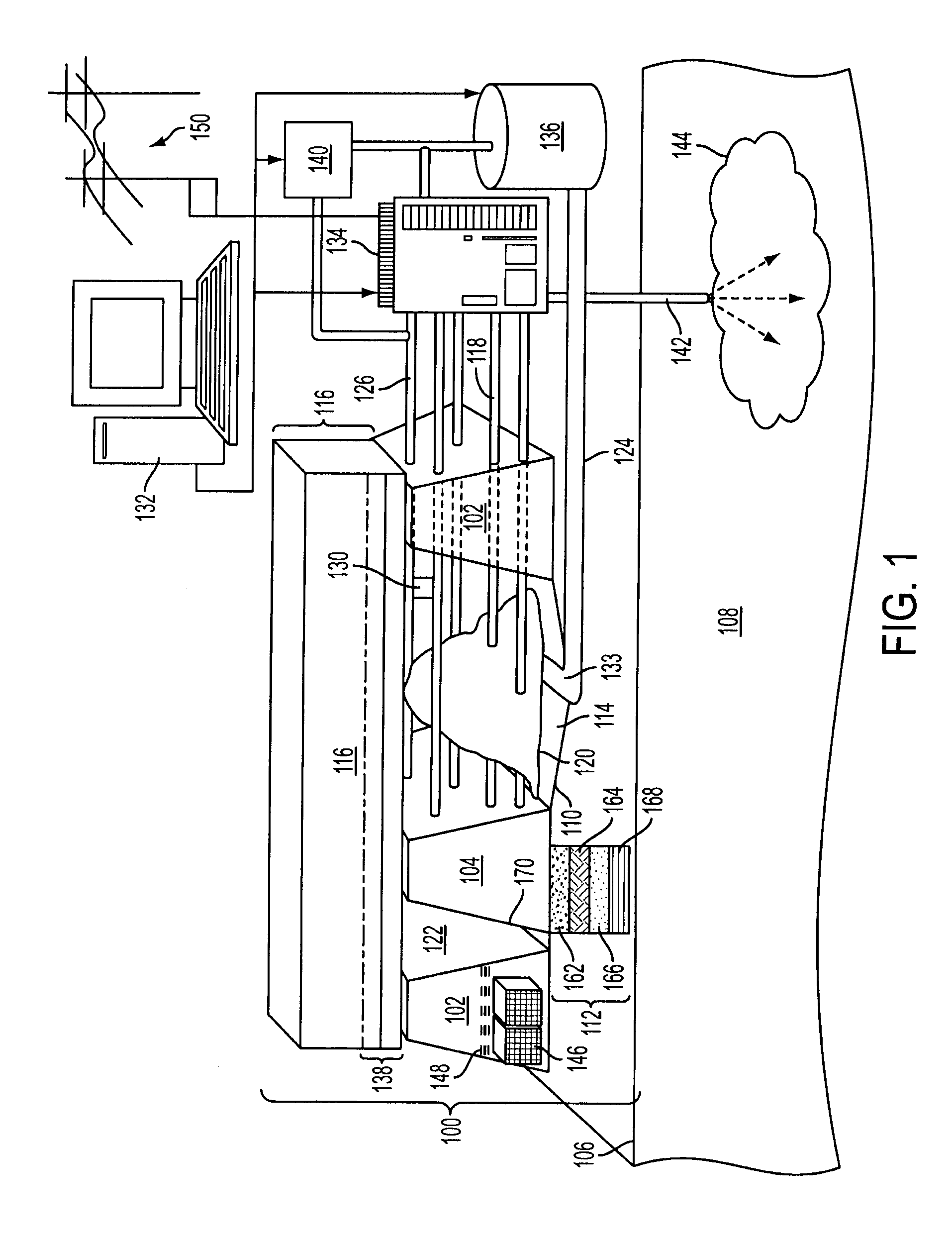

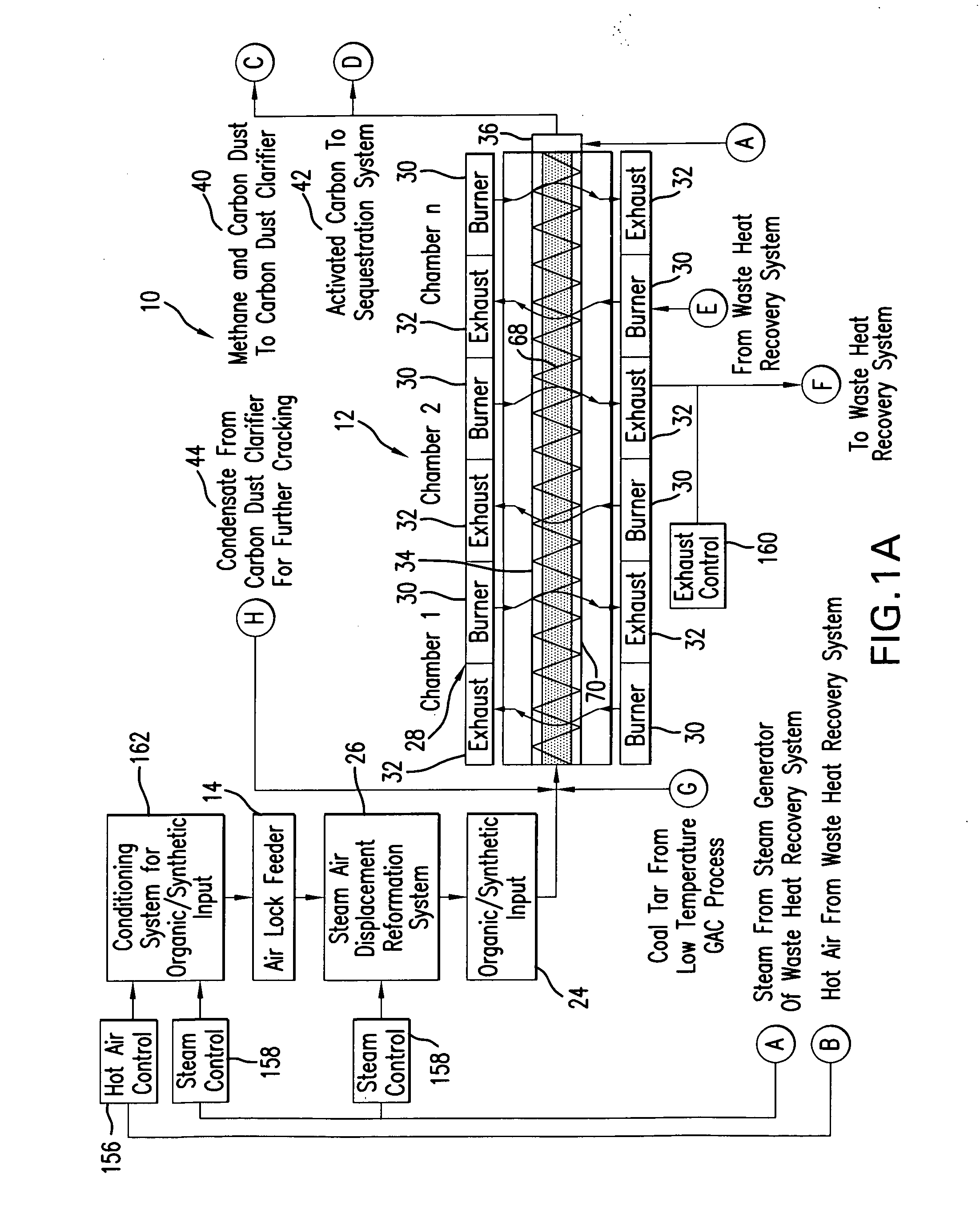

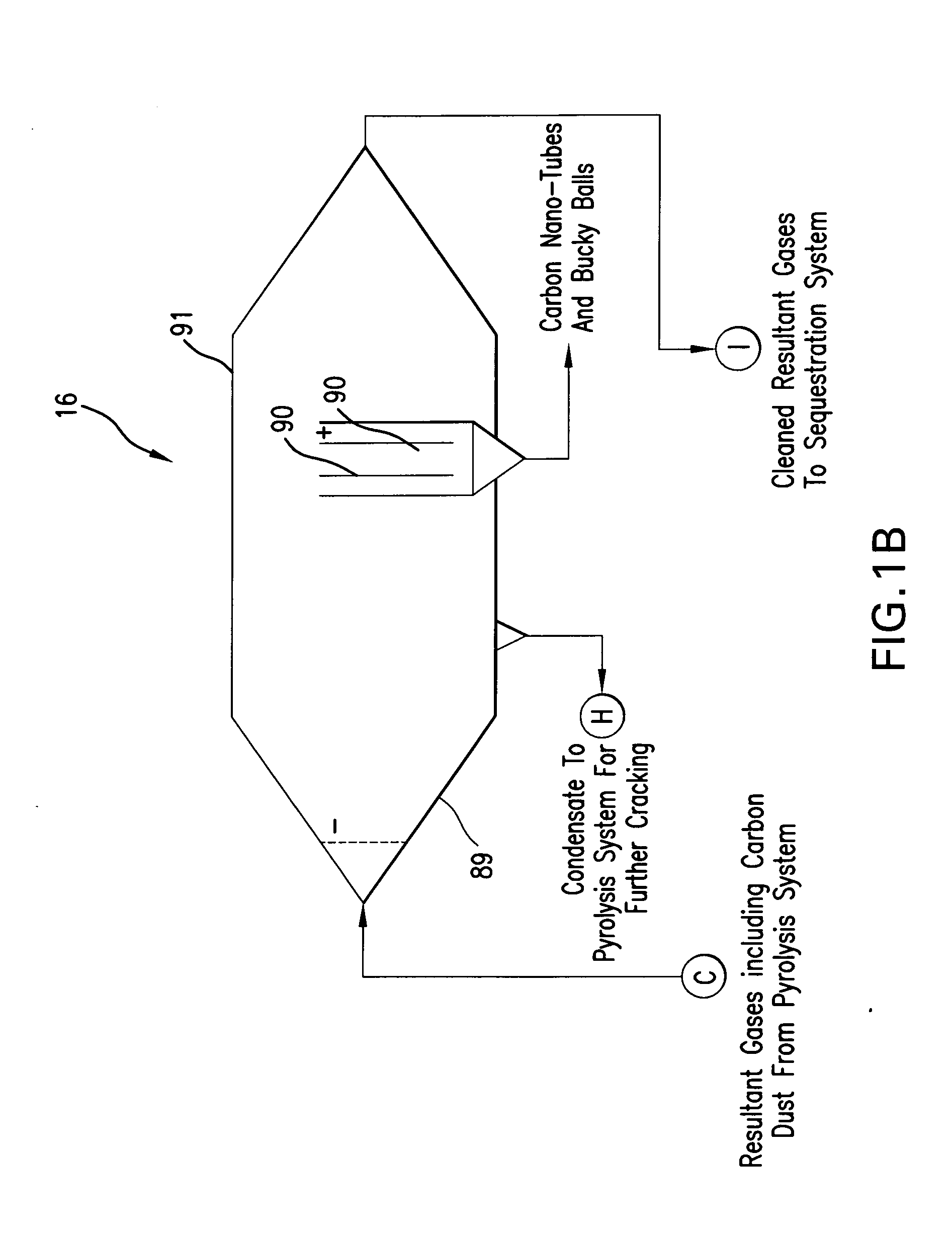

Pyrolysis Systems, Methods, and Resultants Derived Therefrom

ActiveUS20080286557A1Fit closelyWithout undesired degradation of communication system performanceLayered productsUsing liquid separation agentActivated carbon filtrationSilicon dioxide

A system and process for gasification of a carbonaceous feedstock uses pyrolysis to produce a gas product, which may include methane, ethane, and other desirable hydrocarbon gases, and a solids product, which includes activated carbon or carbon. The gas product may then be filtered using at least a portion of the activated carbon from the solids product as a filtering medium. In an embodiment, at least some of the noxious chemicals are sequestered or removed from the gas product in one or more filtering steps using the activated carbon as a filtering medium. In a further embodiment, the filtering steps are performed in stages using activated carbon at different temperatures. A high-temperature pyrolysis system that produces activated carbon may be combined with another high-temperature pyrolysis system that does not produce activated carbon to provide filtering of noxious compounds using activated carbon from the first high-temperature pyrolysis system. A high-temperature pyrolysis system may be combined with one or more low-temperature feedstock conversion processes such that waste heat from the high-temperature pyrolysis system is used to operate the low-temperature process. A novel non-wetting carbon having pores fused with silica can be produced from using the system and process.

Owner:TUCKER RICHARD D

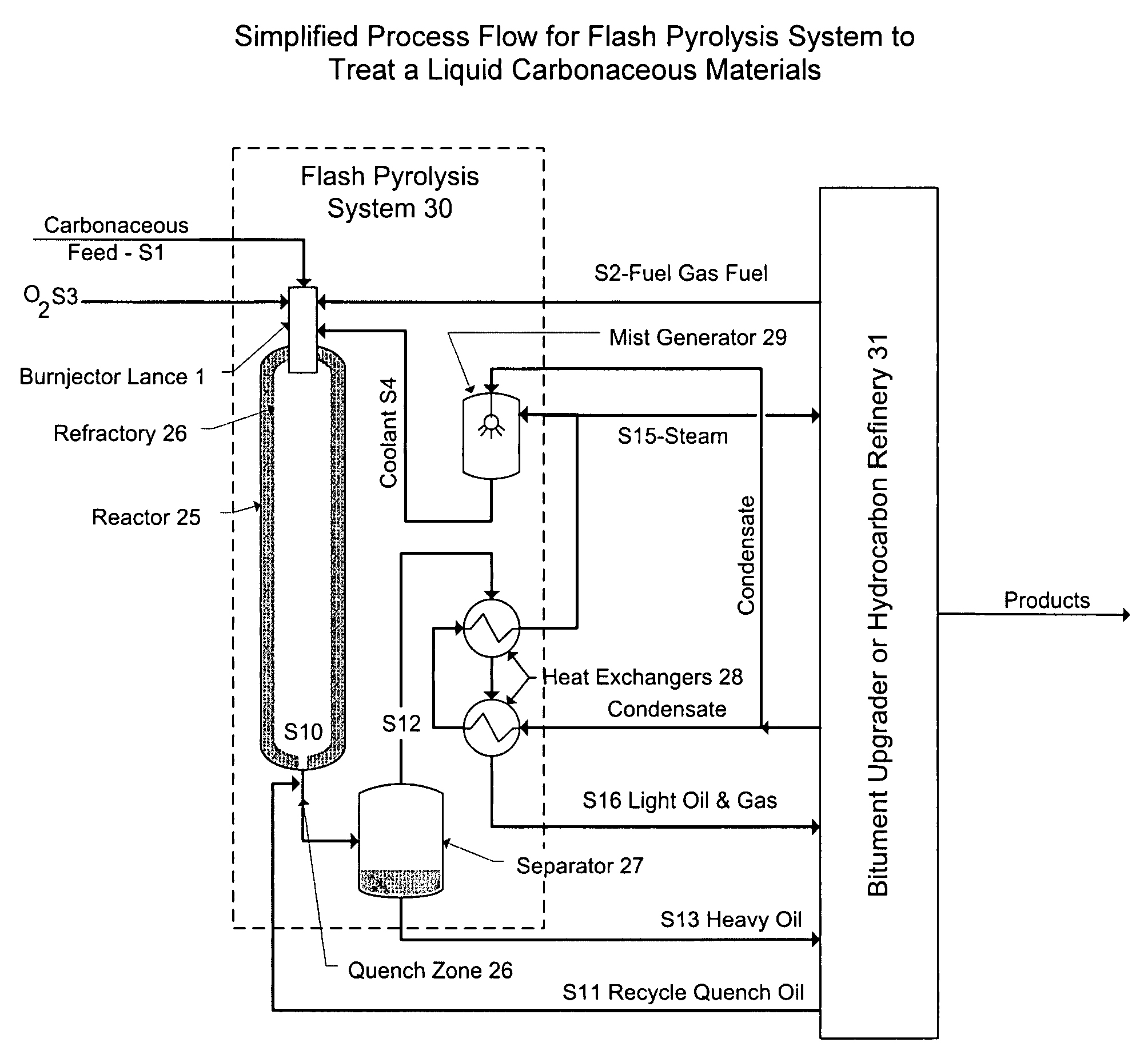

Flash pyrolosis method for carbonaceous materials

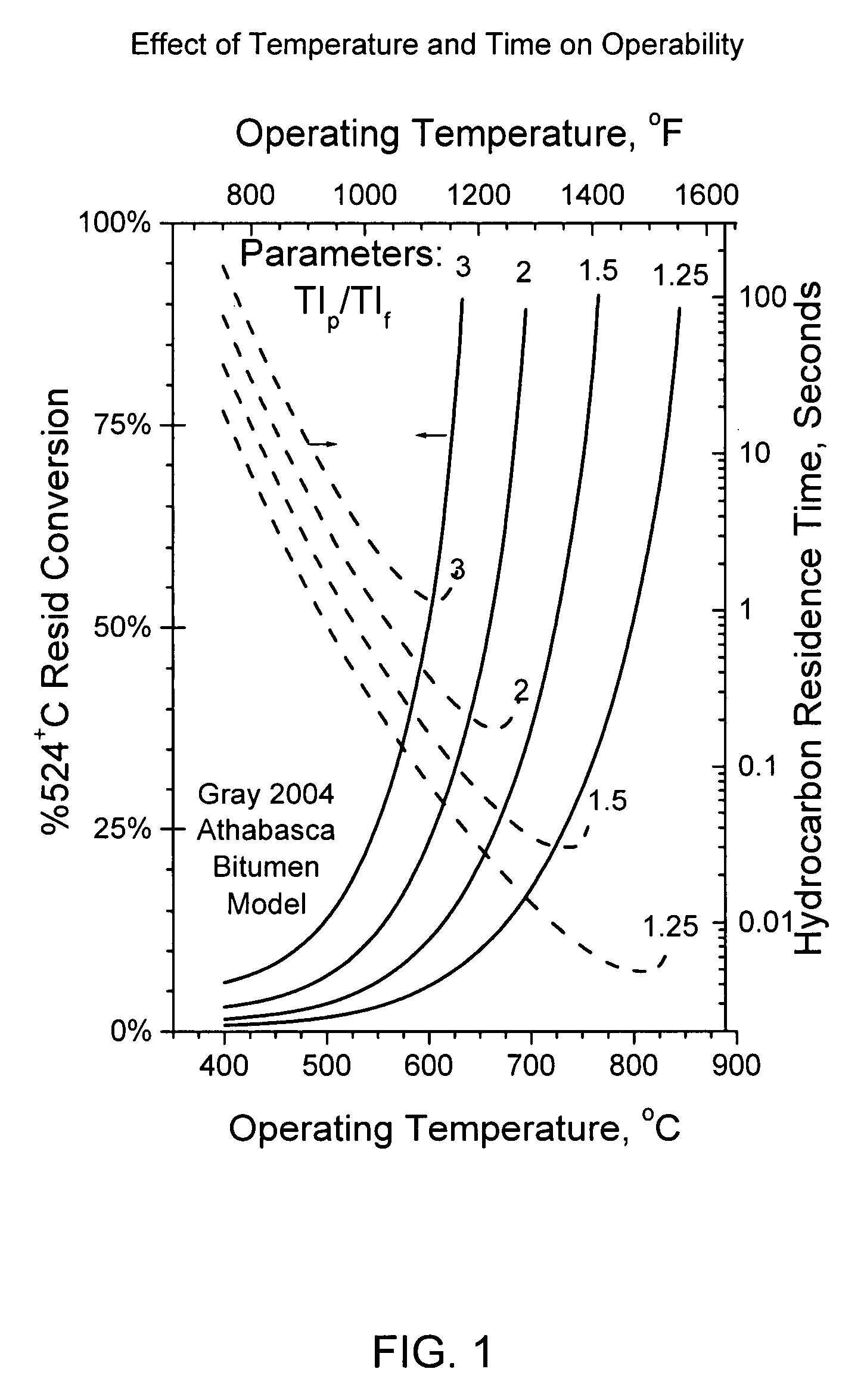

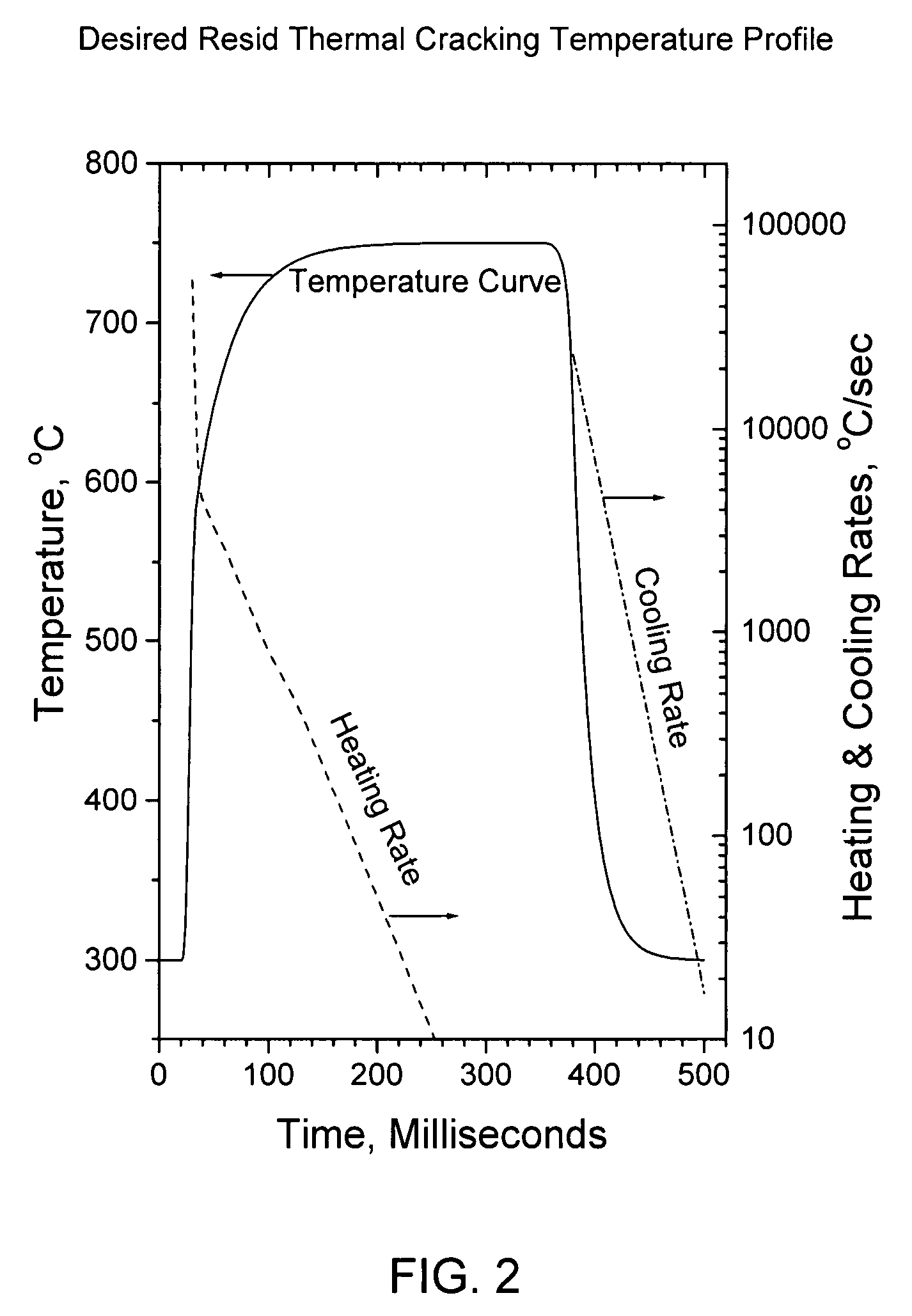

InactiveUS20070272538A1Efficient transferFast heatingThermal non-catalytic crackingDirect heating destructive distillationSufficient timeBoiling point

Methods are disclosed for pyrolizing carbonaceous materials to carbonaceous materials having lower boiling points by heating the carbonaceous material to a desired reaction temperature and holding the carbonaceous material in contact with the heat for a sufficient time to achieve the desired reaction to a lower boiling point carbonaceous materials, then rapidly cooling the desired reaction products. The heating source is a jet which will provide hot and high velocity gas streams to the carbonaceous material to be heated.

Owner:BOC GRP INC

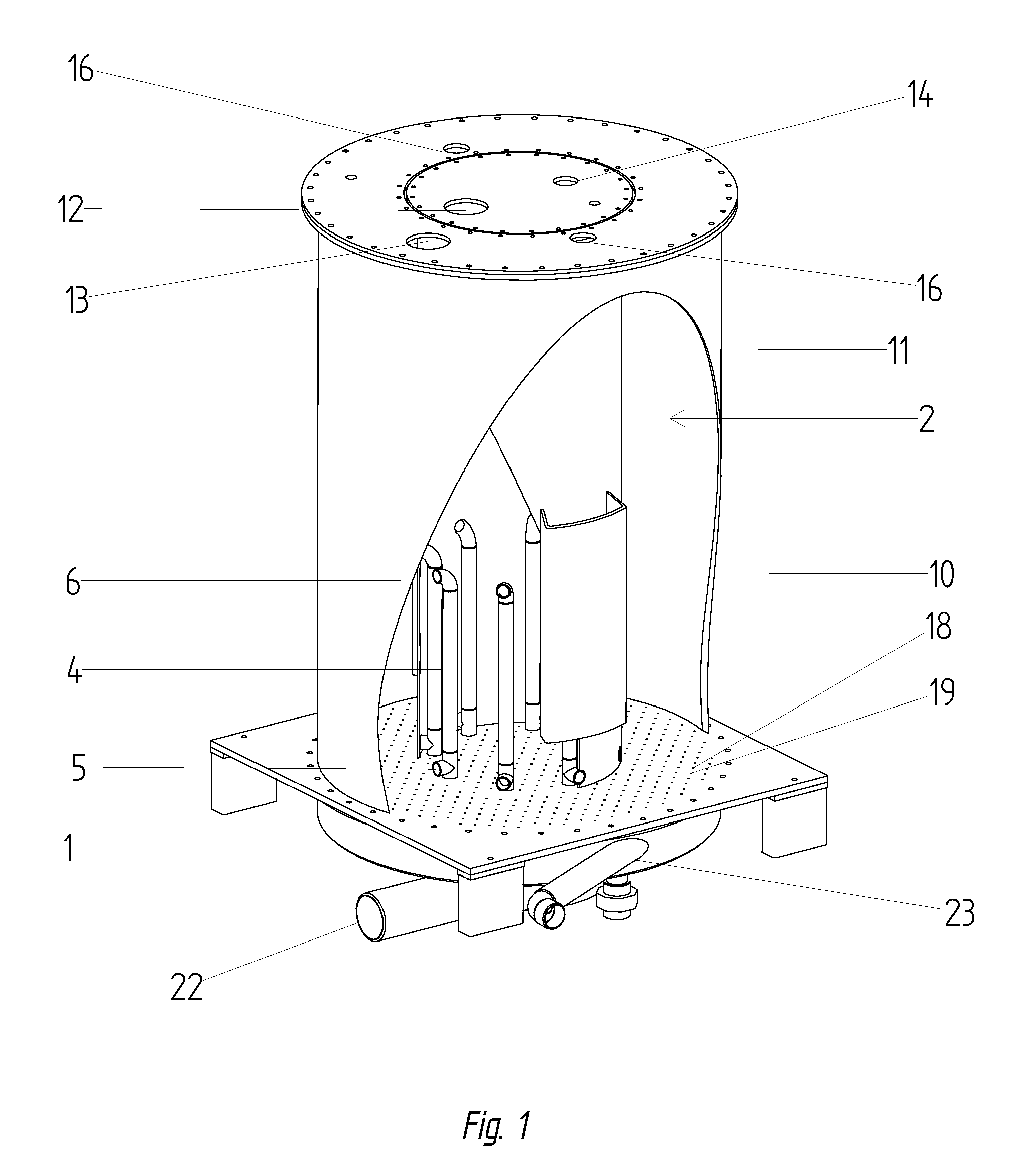

Apparatus and process for the pyrolysis of agricultural biomass

InactiveUS7943014B2Avoid cloggingPrevent escapeFluidized bed combustionCombustible gas coke oven heatingCombustion chamberFluidized bed

An integrated combustion chamber and fluidized bed pyrolysis reactor. In one embodiment, the combustion chamber is cylindrical and the pyrolysis reactor is provided annularly about the combustion chamber with an annular wall that provides a common surface for heat transfer. A lift tube in fluid communication with the pyrolysis reactor is provided within the combustion chamber for circulating biomass and an inert fluidizable media upwardly through the lift tube; this advantageously increases heat transfer and leads to more rapid pyrolysis. The media and biomass exit the lift tube into either a freeboard area of the pyrolysis reactor or into a low density region of the fluidized bed. A condensable gaseous product is produced during pyrolysis that has economic value. The apparatus and process are especially well suited to the pyrolysis of low density agricultural biomass. The apparatus is compact and particularly well suited to mobile operation.

Owner:AGRI THERM

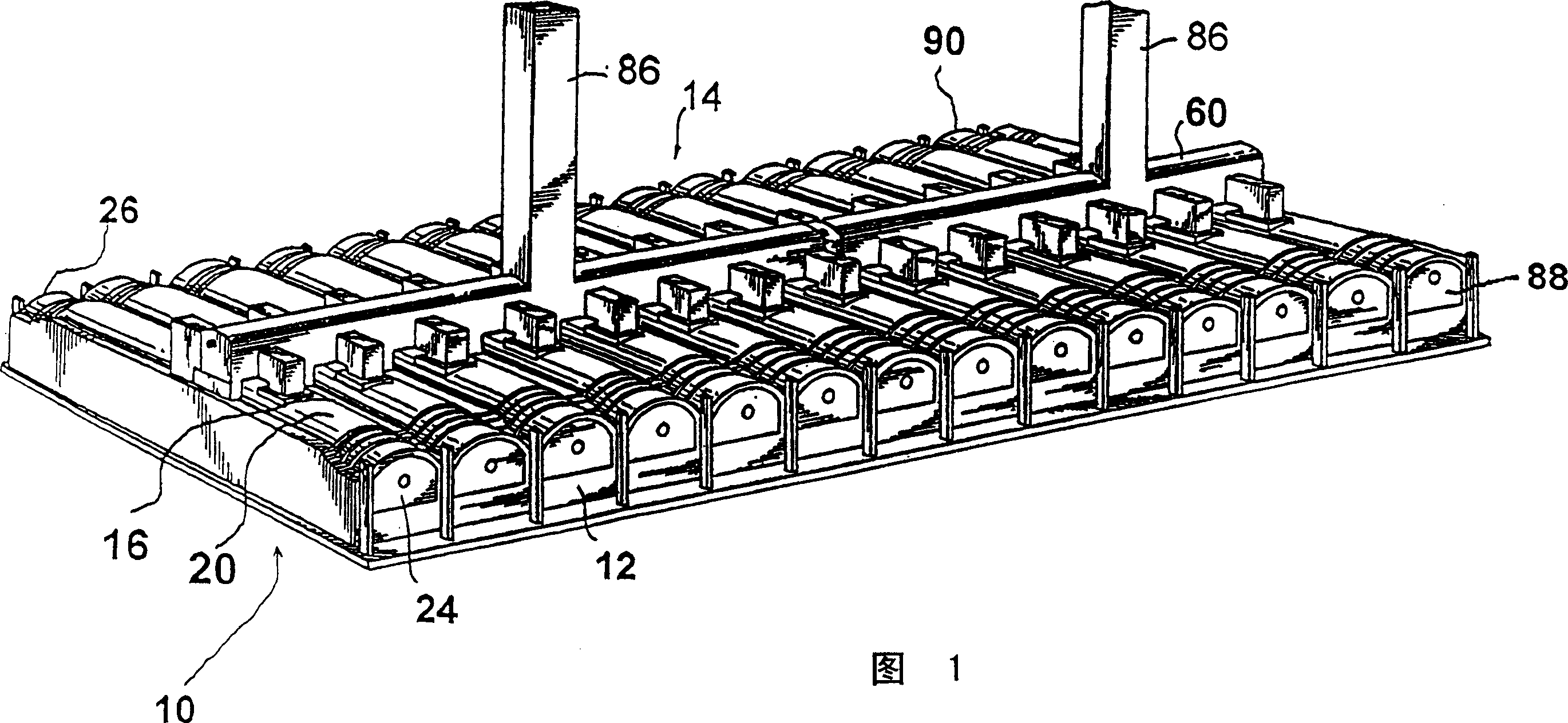

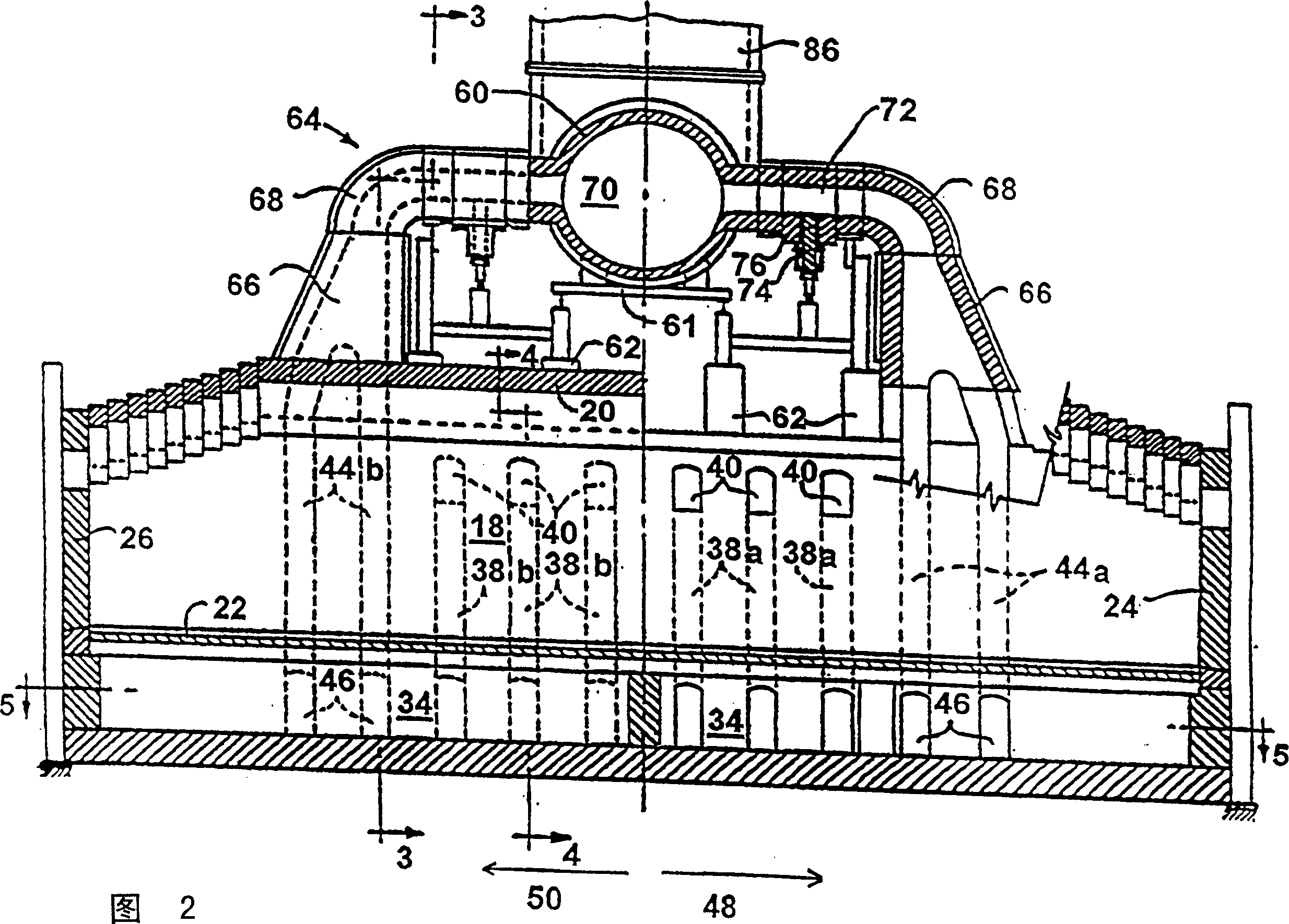

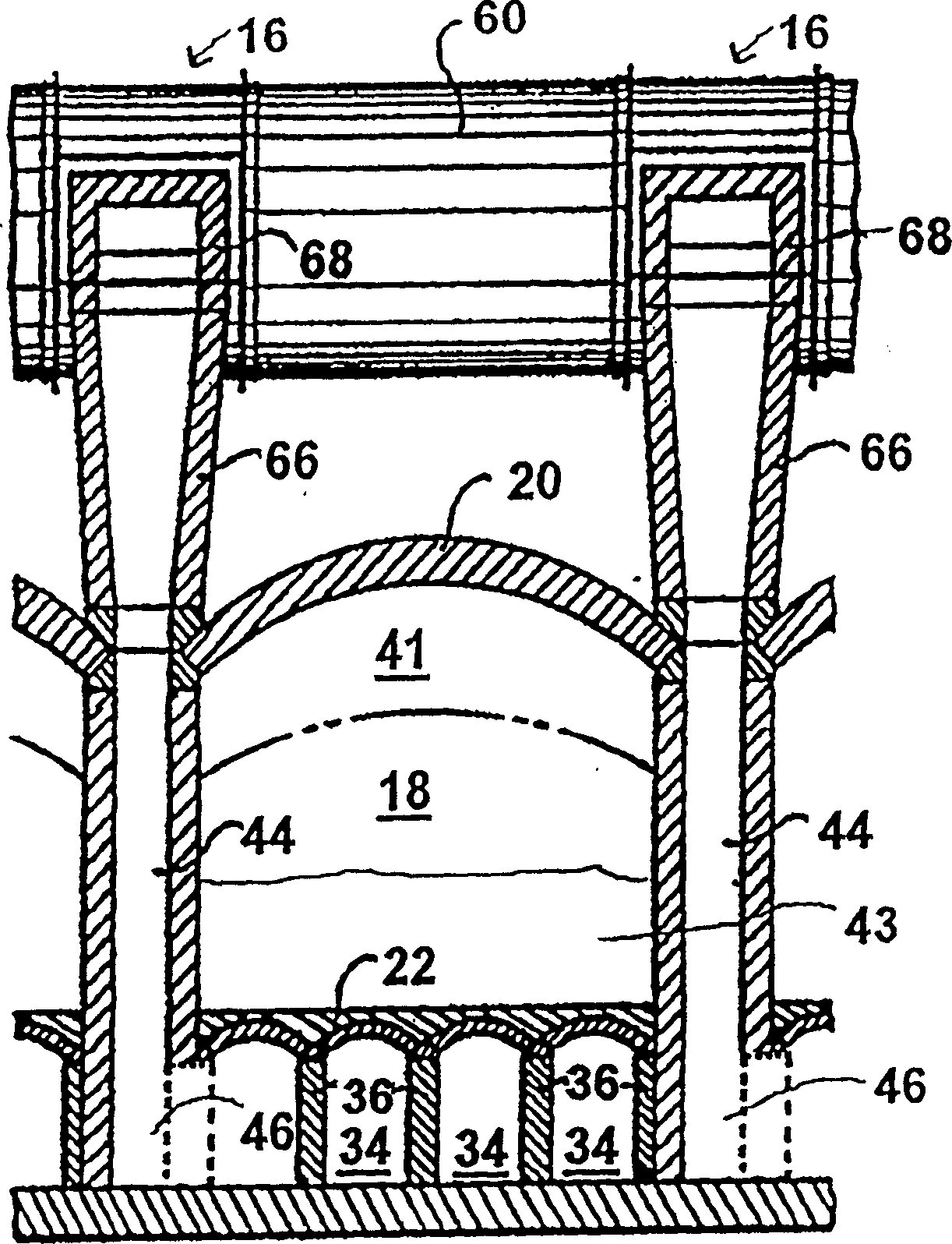

Coke oven flue gas sharing

InactiveCN1527872AExtend your lifeReduce the gas flow rateCombustible gas coke oven heatingBeehive ovensFlue gasProduct gas

The invention provide a method and apparatus for decreasing gas flow rates in a sole flue gas system for a coke oven during at least an initial coking operation after charging a coking oven with coal (43). The method includes providing a duct system (96, 98) between a first coke oven having a first coking chamber (18) and a second coke oven having a second coking chamber (18) to direct at least a portion of gas from a gas space (41) in first coking chamber (18) to the second coke oven thereby reducing a gas flow rate in the first sole flue gas system of the first coke oven. Reduction in sole flue gas flow rates has a beneficial effect on product throughput, the life of the coke oven and environmental control of volatile emissions from coke ovens.

Owner:SUNCOKE TECH & DEV LLC

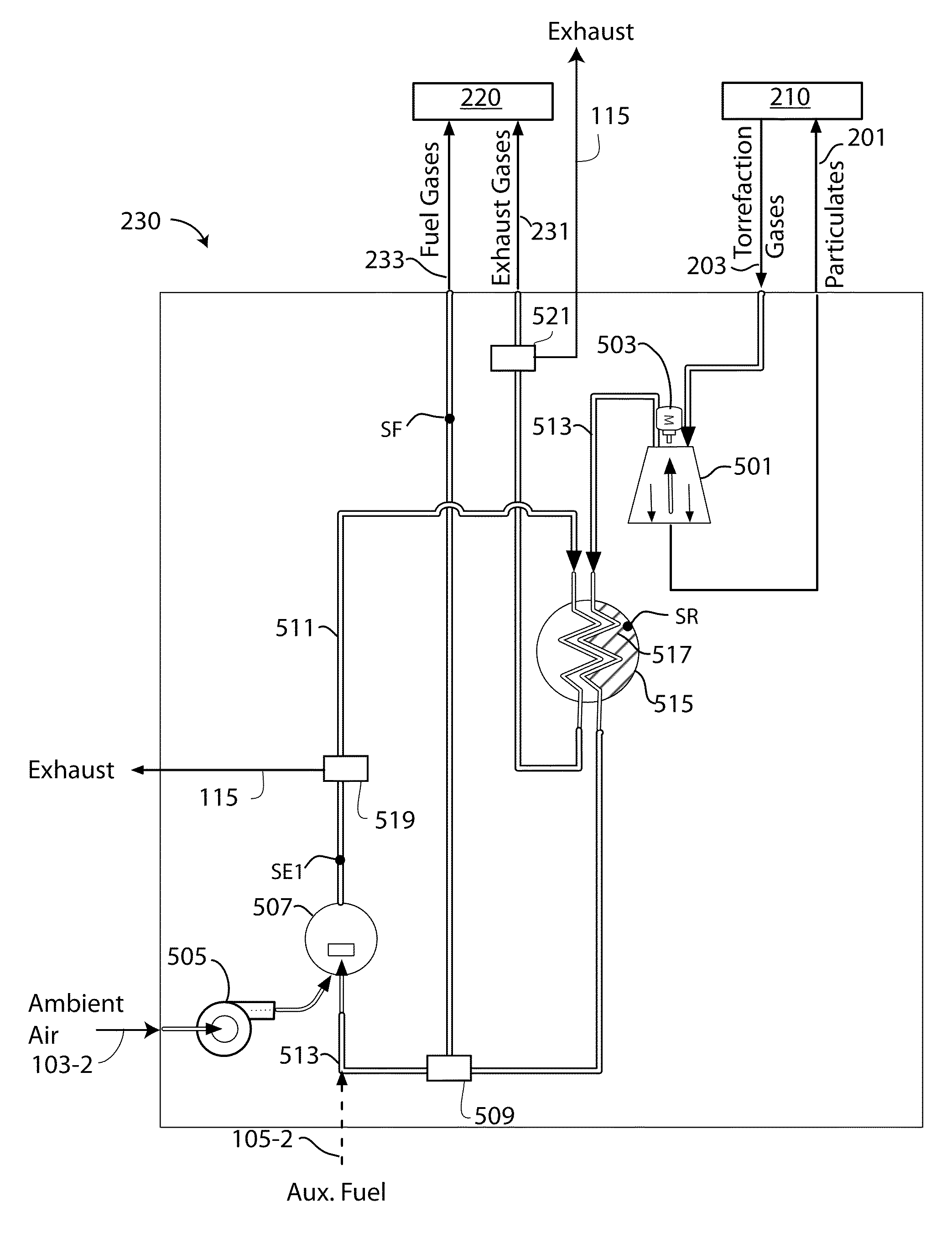

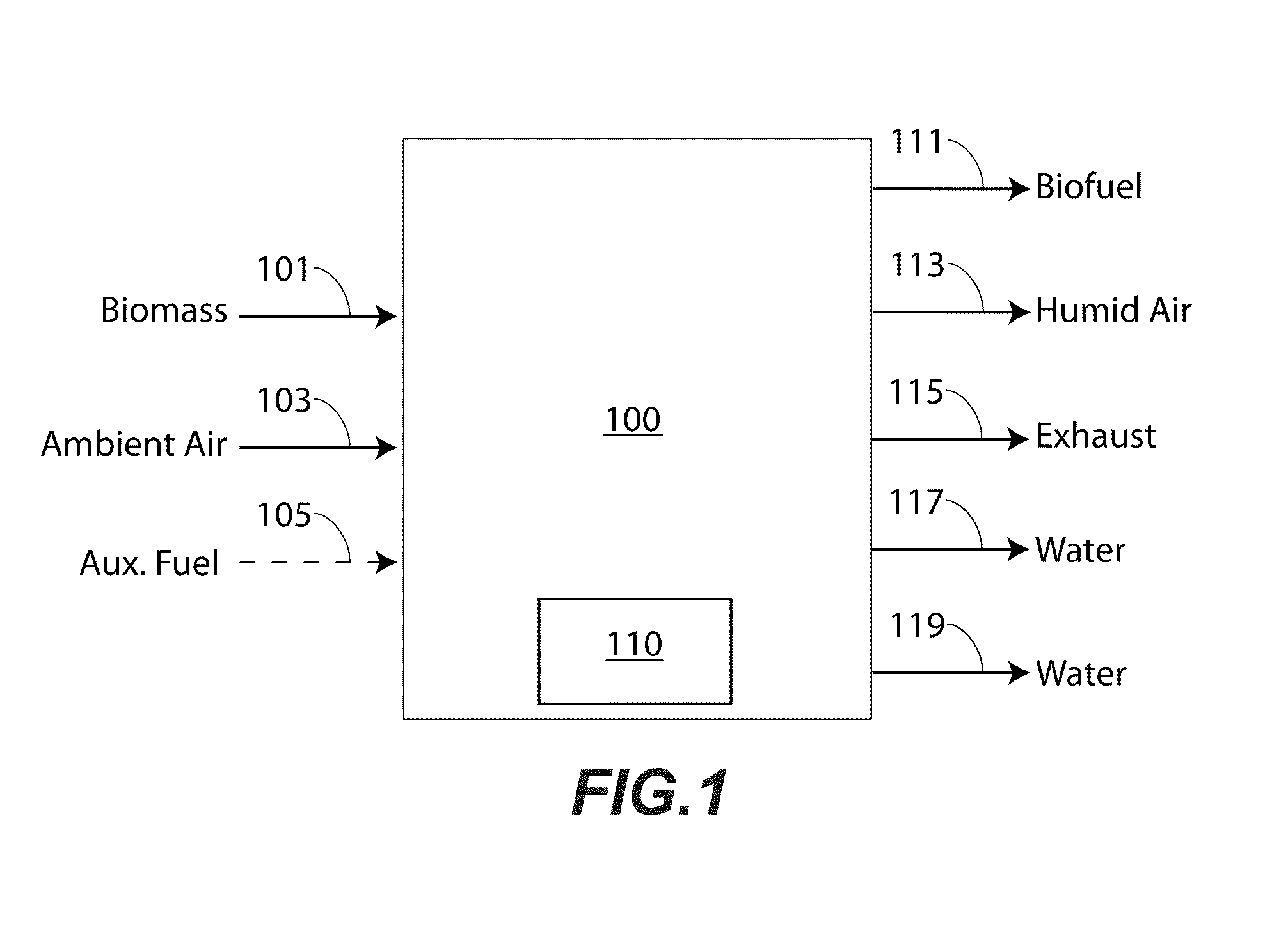

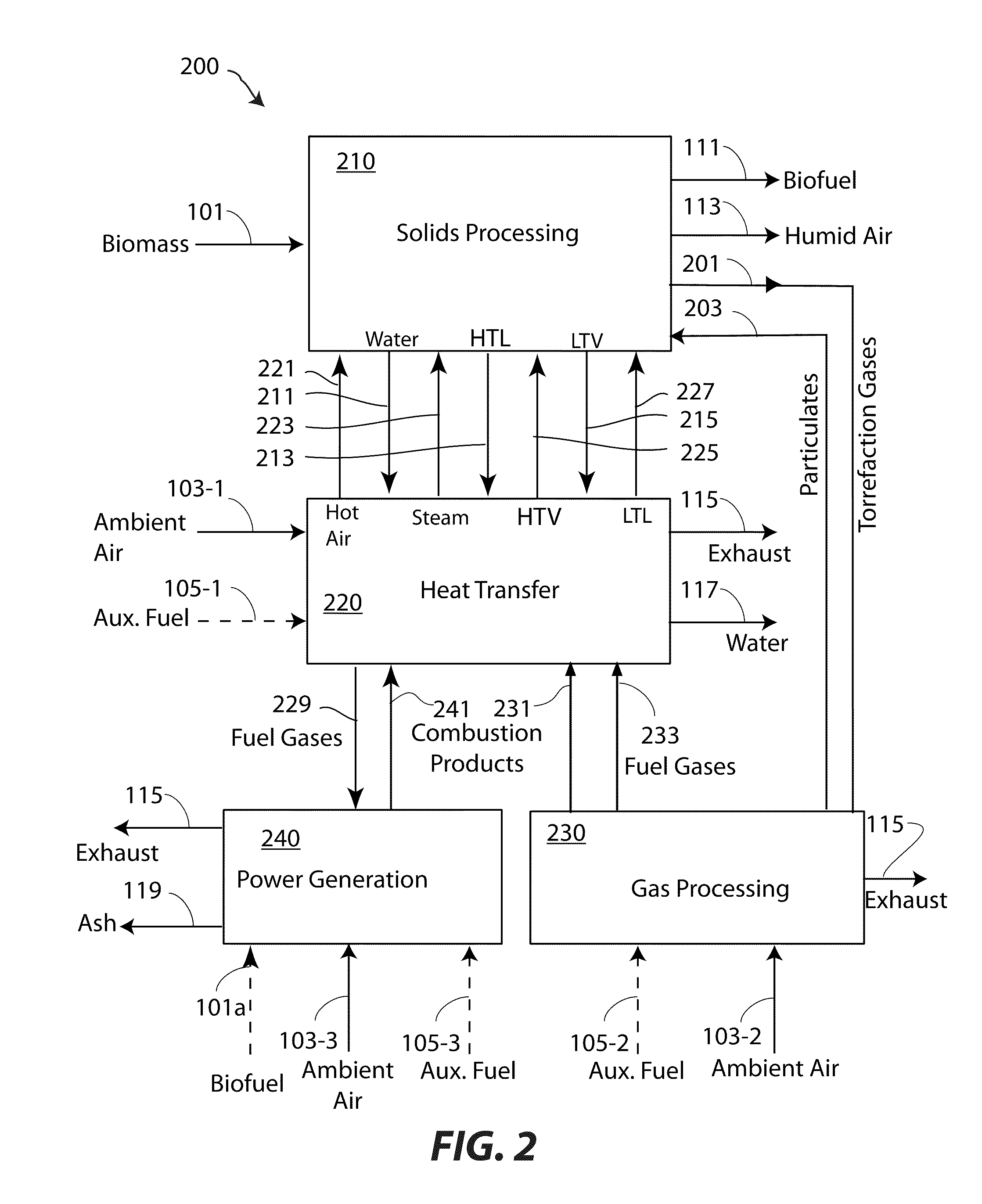

Device and method for conversion of biomass to biofuel

Embodiments presented herein describe an apparatus and method to convert carbonaceous materials, particularly biomass and those biomass resources which are remotely located, into a high performance solid fuel. This method, and the apparatus described as the means to accomplish this method, provides a continuous process which can be completely powered by the energy contained in the biomass. The heat, mechanical power and electrical power are provided from the energy in the biomass, through the methods described. In this way, the apparatus is free to operate in remote locations, where no power or auxiliary fuel sources are available.

Owner:RENEWABLE FUEL TECH

System and method for biomass fractioning

ActiveUS20110177466A1Easy inputIncrease productionDrying solid materials with heatOther heat production devicesSyngasThin sheet

A biomass fractionator and method are described for inputting ground biomass and outputting several vapor streams of bio-intermediate compounds along with syngas and biochar. In one embodiment, a method for biomass fractioning, comprises dispensing biomass into thin sheets of ground biomass; subjecting the thin sheets to ramps of temperature; and selectively collecting various groups of compounds as they are released from the thin sheets.

Owner:COOL PLANET ENERGY SYST

Autothermal and mobile torrefaction devices

ActiveUS20090250331A1Increased cost-effectivenessLow costCombustible gas coke oven heatingCharging-discharging device combinationsCombustorEngineering

The present invention provides an autothermal torrefaction device, which can be either stationary of mobile. Embodiments of the present invention include a torrefaction chamber having a chamber inlet for receiving biomass and at least one chamber outlet. The torrefaction chamber can be substantially surrounded by an exterior housing defining an outer jacket and having a jacket inlet and a jacket outlet. The outer jacket and torrefaction chamber define a space therebetween such that a burner unit including an inlet operatively connected to the chamber outlet and an outlet operatively connected to the jacket inlet allows vapors produced or released from within the torrefaction chamber to travel into the burner unit for combustion of at least a portion of the vapors and subsequently travel through the space between the jacket and the torrefaction chamber to provide heat necessary for autothermal torrefaction of biomass.

Owner:NORTH CAROLINA STATE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com